Modified graphene oxide and epoxy resin composite material and method for preparing same

An epoxy resin and composite material technology, which is applied in the field of modified graphene oxide and epoxy resin composite materials containing the modified graphene oxide, can solve problems such as incompatibility, improve tensile mechanical strength, overcome Compatibility issues, overcoming lower performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

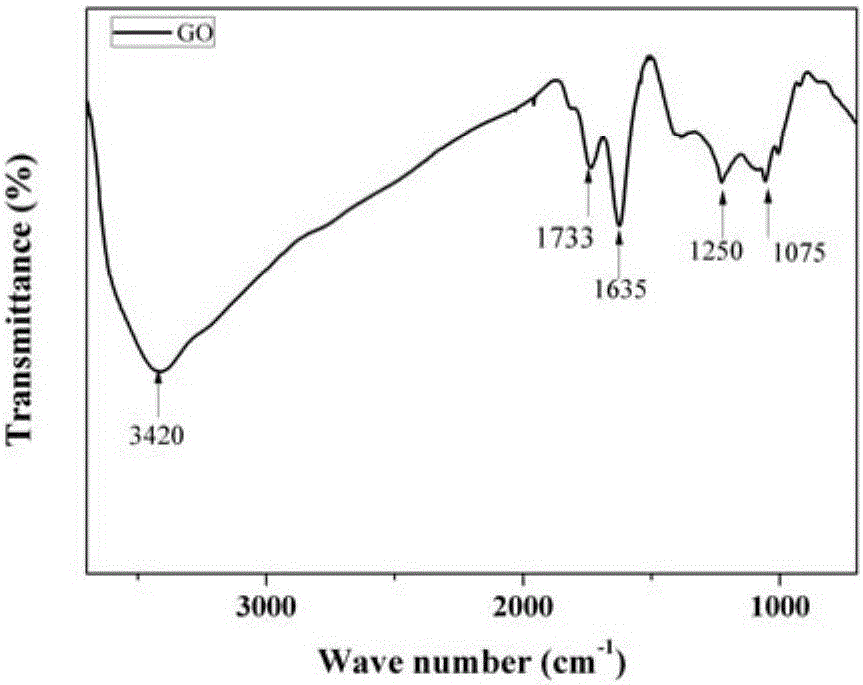

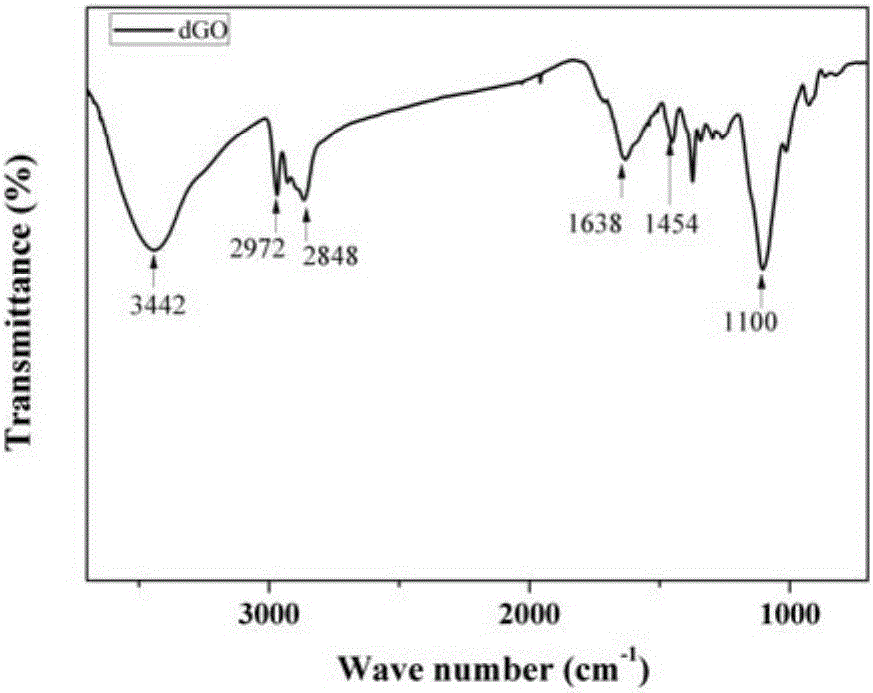

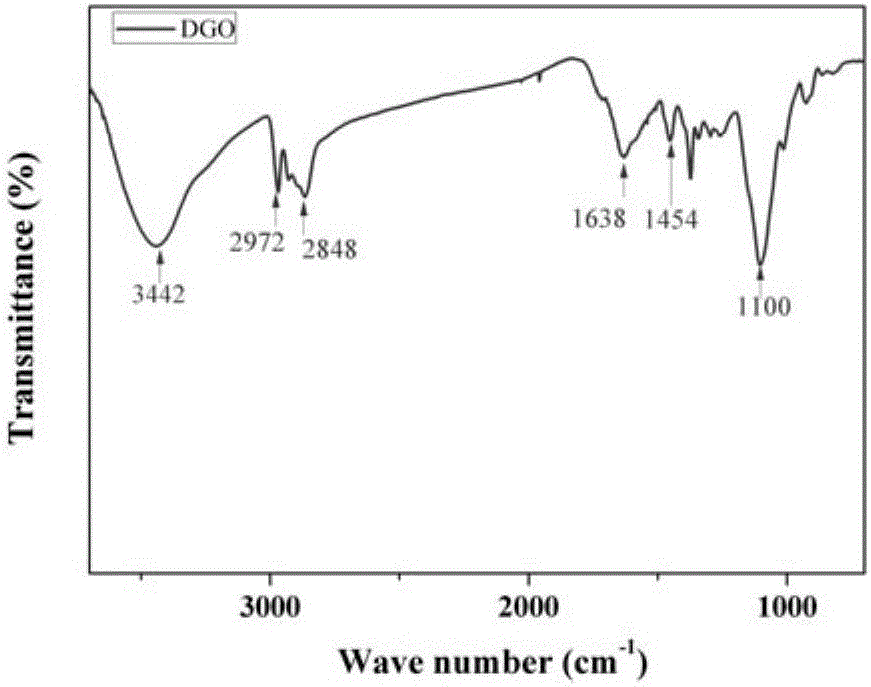

[0055] Example 1 Preparation of polyetheramine-modified graphene oxide of the present invention

[0056] 1. Preparation of graphene oxide solution (powder)

[0057] Using natural graphite powder as raw material, graphene oxide was prepared according to the Hummers method, as follows: 2g of graphite powder was added to a 250mL beaker, and 1g of NaNO 3 , slowly add 46mL concentrated sulfuric acid and stir evenly, place the beaker in an ice-water bath, slowly add 6gKMnO 4 , the process temperature should not exceed 20°C. After 5 minutes, the ice-water bath was removed, and the temperature was raised to 35°C for 30 minutes. Add 92 mL of deionized water, stir for 15 minutes, and then add 80 mL of 3% H at 60 °C 2 o 2 solution to reduce excess KMnO 4 , until there are no obvious bubbles. Finally, centrifuge at 7200rpm for 30 minutes, pour out the supernatant, wash with water and then centrifuge, repeat several times until the pH of the supernatant is 4-6, and the obtained yello...

Embodiment 2

[0066] Embodiment 2 Preparation and properties of the composite material of the present invention

[0067] 1. Preparation of composite materials

[0068] Preparation of nanocomposite EP / DGO: Weigh a certain amount (0.1phr) of modified graphene oxide DGO and disperse it in acetone solution at a ratio of 1mg / mL, ultrasonicate for 30min, add 50g of epoxy resin to the modified graphite oxide In the acetone solution of alkenes, adjust the temperature of the oil bath to 60°C, and continue electric stirring for 30min. After the graphene oxide and epoxy resin are fully mixed, put them into a vacuum oven at a temperature of 80°C for 24 hours to remove the solvent. Add 12.5g of curing agent DDM (4,4-diaminodiphenylmethane) into the beaker, continue to stir for 2-3min and then stop, then take out the beaker. Then place the beaker in a vacuum oven and vacuum to remove air bubbles. Finally, the obtained mixed liquid was poured into a polytetrafluoroethylene mold of a standard spline, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com