Phase change graphite powder with phase change energy storage function and preparation method thereof

A technology of phase change energy storage and graphite powder, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of low thermal conductivity, inability to fully utilize the energy storage capacity of phase change materials, and low heat release power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

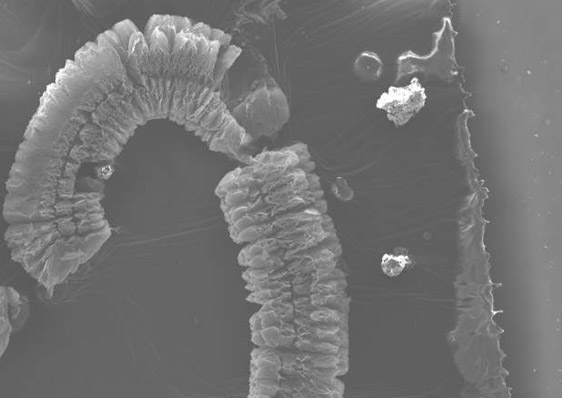

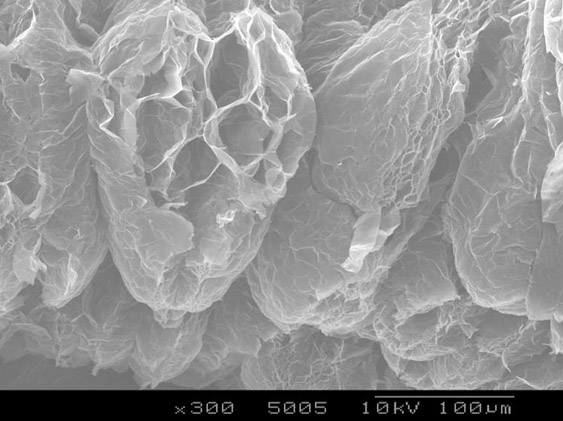

Image

Examples

Embodiment 1

[0028] Take 100 grams of flake graphite (100 mesh, 95% carbon content), 500 milliliters of concentrated sulfuric acid (98%) and 50 grams of potassium permanganate, mix them, and place them in a constant temperature water bath with a temperature of 60°C. The time is 60 minutes. After the intercalation, the mixture was filtered with a 300-mesh stainless steel filter, and washed with water, and the filtration and washing process was repeated twice, and the pH value of the water washing was 6. Finally, the filter is put into an oven for drying. The drying temperature is 110°C, and the drying time is 12 hours. Take 100 grams of the baked graphite intercalation material and put it into a high-power microwave oven for expansion. The power of the microwave oven is set to above 3000W. The microwave action time is 3 seconds. Using atmospheric pressure impregnation method, the expanded graphite is soaked in calcium chloride saturated aqueous solution for 30 hours. Remove and drain. ...

Embodiment 2

[0030] Take 100 grams of flake graphite (100 mesh, 95% carbon content), 600 milliliters of concentrated sulfuric acid (98%) and 60 grams of potassium permanganate, mix them, and place them in a constant temperature water bath with a temperature of 70 ° C. The time is 60 minutes. After the intercalation, the mixture was filtered with a 300-mesh stainless steel filter, and washed with water. The filtration and washing process was repeated twice, and the pH value of the water washing was 7. Finally, the filter is put into an oven for drying. The drying temperature is 110°C, and the drying time is 12 hours. Take 100 grams of the baked graphite intercalation material and put it into a high-power microwave oven for expansion. The power of the microwave oven is set to above 4000W. The microwave action time is 2 seconds. Using the vacuum negative pressure impregnation method, impregnate the saturated aqueous solution of sodium nitrate and calcium nitrate in the expanded graphite, ...

Embodiment 3

[0032]Take 100 grams of flake graphite (100 mesh, 95% carbon content), 1000 milliliters of concentrated sulfuric acid (98%) and 100 grams of potassium permanganate, mix them, and place them in a constant temperature water bath with a temperature of 75°C. The time is 60 minutes. After the intercalation, the mixture was filtered with a 300-mesh stainless steel filter, and washed with water. The filtration and washing process was repeated twice, and the pH value of the water washing was 7. Finally, the filter is put into an oven for drying. The drying temperature is 110°C, and the drying time is 12 hours. Take 100 grams of the baked graphite intercalation material and put it into a high-power microwave oven for expansion. The power of the microwave oven is set to above 5000W. The microwave action time is 2 seconds. Using the vacuum negative pressure impregnation method, impregnate the saturated sodium acetate aqueous solution in the expanded graphite, maintain the vacuum for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com