Low-thermal-conductivity phase-change energy-storage thermal-insulation board as well as preparation method and application thereof

A technology of phase change energy storage and low thermal conductivity, which is applied in the direction of heat exchange materials, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of rising thermal conductivity of honeycomb panels, high thermal conductivity, and reducing Thermal insulation performance and other issues to achieve the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

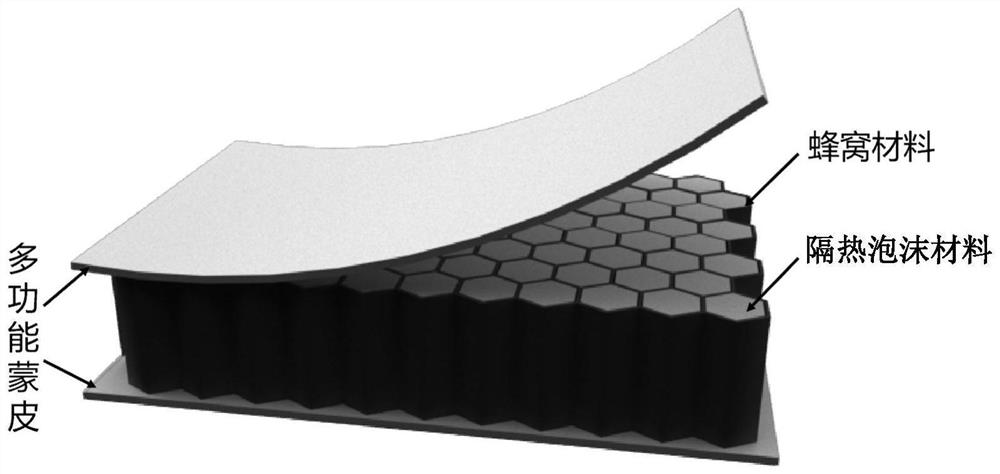

[0037] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned low thermal conductivity phase-change energy storage insulation board, including:

[0038] Encapsulate the phase change material in the cortex body with multiple cavity structures to form a multifunctional cortex structure;

[0039] Filling the heat-insulating foam material in the pores contained in the uniform porous material as a reinforcing material to obtain a core structure;

[0040] The multifunctional skin layer structure is covered on the surface of the core plate structure to obtain the low thermal conductivity phase change energy storage insulation board.

[0041] Further, the preparation method includes: using a resin adhesive to bond the multifunctional skin structure encapsulated with the phase change material to the core structure to obtain the low thermal conductivity phase change energy storage insulation board.

[0042]Another aspect of the emb...

Embodiment 1

[0049] In this embodiment, the low thermal conductivity phase-change energy storage insulation board includes: a core plate structure and a multifunctional bamboo fiber skin structure arranged on the upper and lower surfaces of the core plate structure, and the multifunctional bamboo fiber skin structure is encapsulated The phase change material paraffin is provided, and the content of the paraffin is 10wt%. The core plate structure includes a resin-impregnated glass fiber fabric honeycomb material as a reinforcement phase, and a heat-insulating polyurethane foam material filled and distributed inside the resin-impregnated glass fiber fabric honeycomb material.

[0050] The manufacturing method of the low thermal conductivity phase-change energy storage insulation board in this embodiment includes: encapsulating paraffin in a multi-functional bamboo-wood fiber skin structure with a plurality of cavity structures to form a multi-functional skin structure. The polyurethane foam ...

Embodiment 2

[0053] In this embodiment, the low thermal conductivity phase change energy storage insulation board includes: a core plate structure and a glass fiber reinforced epoxy resin skin structure arranged on the upper and lower surfaces of the core plate structure, and the glass fiber reinforced epoxy resin skin structure The inner package is provided with hexadecane, and the content of hexadecane is 15wt%. The core plate structure includes an aramid paper honeycomb material as a reinforcing phase, and a heat-insulating polystyrene foam material filled and distributed inside the aramid paper honeycomb material.

[0054] The manufacturing method of the low thermal conductivity phase-change energy storage insulation board in this embodiment includes: encapsulating hexadecane in a glass fiber reinforced epoxy resin skin structure with a plurality of cavity structures to form a multifunctional skin structure. The heat-insulating polystyrene foam material is filled in the pores contained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com