Self-absorption inflated heat-insulating membrane

A thermal insulation film, self-priming technology, applied in plant protection covers, tents/canopies, building types, etc., can solve the problems of promotion and use, increase costs and other issues, achieve practical promotion value, reduce costs, installation and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

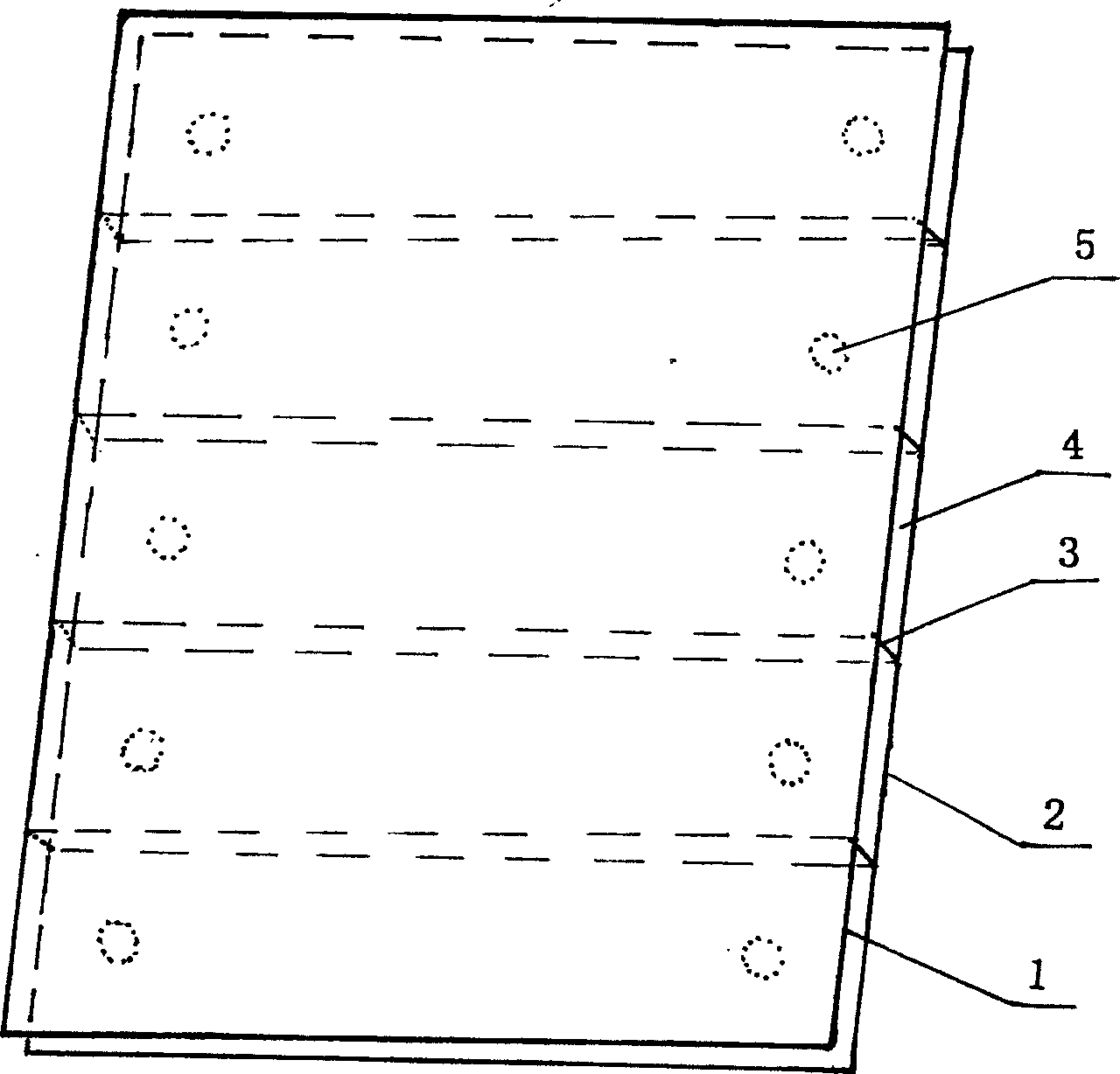

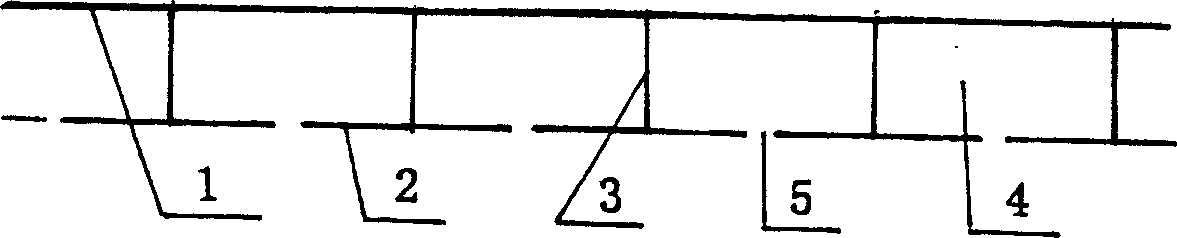

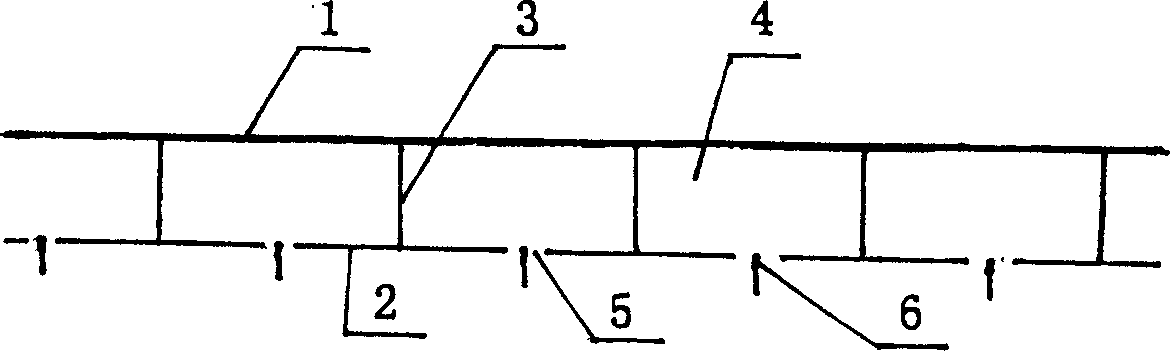

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] Such as Figure 1-2 As shown, the self-priming air-filled thermal insulation film of the present invention comprises two layers of transparent plastic films 1,2 up and down, and it is connected with vertical plastic diaphragms 3 arranged at intervals in a transverse direction between the upper and lower film layers 1,2, so that the upper and lower films Layers 1 and 2 are divided into several laterally arranged air-filled airbags 4, and an air-filled ventilation hole 5 is respectively opened on both sides of the lower film layer 2 of the airbag 4.

[0014] When the present invention is processed and produced, the upper film layer 1 adopts a thicker film so as to withstand the impact of strong wind or external force, while the lower film layer 2 adopts a thinner film, which can form an air bag filled with air and play a role of heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com