Fabric for making inflatable winter clothes, and production method thereof

A kind of fabric and breathable technology, applied in the field of textiles, can solve the problems of limited materials and textures, lack of tailorability, poor application flexibility, etc., to improve thermal performance, easy to carry and store, and reduce air convection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Selection of fabrics: the first layer of 30D polyester PU film knitted fabric, the second layer of 75D polyester double-sided brushed fleece, the third layer of 75D polyester film single-sided brushed polar fleece

[0025] Bonding flower pattern: choose C-shaped pattern flower sticks in combination with appearance and bonding quality

[0026] Ultrasonic bonding: 15KHZ, 6m / min, power 12kw; after that, roll the finished product for use.

[0027] The test method is as follows:

[0028] Peeling strength: refer to FZ / T80007.1-2006;

[0029] Bursting strength: refer to GB / T19976-2005;

[0030] Tear strength: refer to GB / T3917.2-2009 (2);

[0031] Seam cracks: refer to FZ / T81007;

[0032] Appearance after washing: refer to GB / T8629-2001;

[0033] Warmth test: refer to GB / T11048-2008.

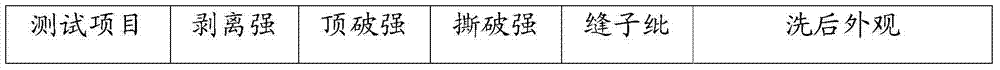

[0034] The physical index test results are shown in Table 1:

[0035] Table 1

[0036]

[0037]

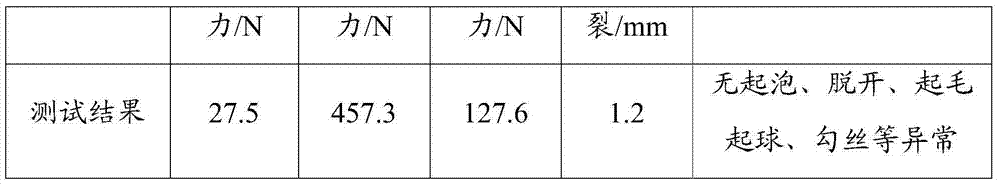

[0038] The heat retention test results are shown in Table 2:

[0039] Table 2

...

Embodiment 2

[0042] Selection of fabrics: the first layer of 75D polyester PU coated woven elastic fabric, the second layer of 60g / m2 polyester spray-bonded cotton, the third layer of 75D polyester PU coated woven single-side brushed fabric

[0043] Adhesive pattern: choose ◇-shaped patterned flower sticks in combination with appearance and bonding quality

[0044] Ultrasonic bonding: 15KHZ, 8m / min, power 12kw; after that, roll the finished product for use.

[0045] The test method is as follows:

[0046] Peeling strength: refer to FZ / T80007.1-2006;

[0047] Bursting strength: refer to GB / T19976-2005;

[0048] Tear strength: refer to GB / T3917.2-2009 (2);

[0049] Seam cracks: refer to FZ / T81007;

[0050] Appearance after washing: refer to GB / T8629-2001;

[0051] Warmth test: refer to GB / T11048-2008.

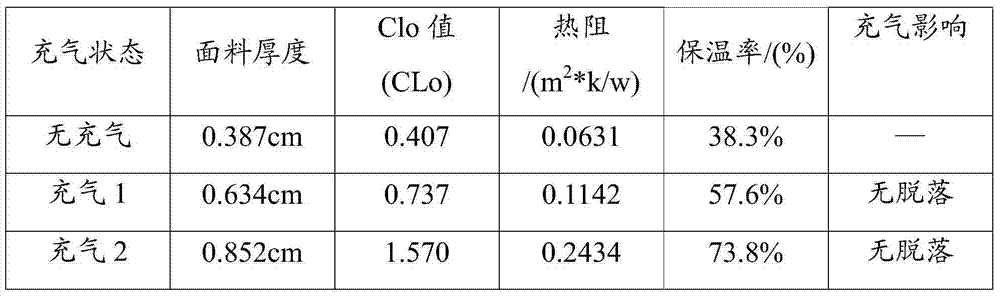

[0052] The physical test results are shown in Table 3.

[0053] table 3

[0054]

[0055] The heat retention test is shown in Table 4.

[0056] Table 4

[0057] Inflated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com