Patents

Literature

2933results about How to "Not easy to slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

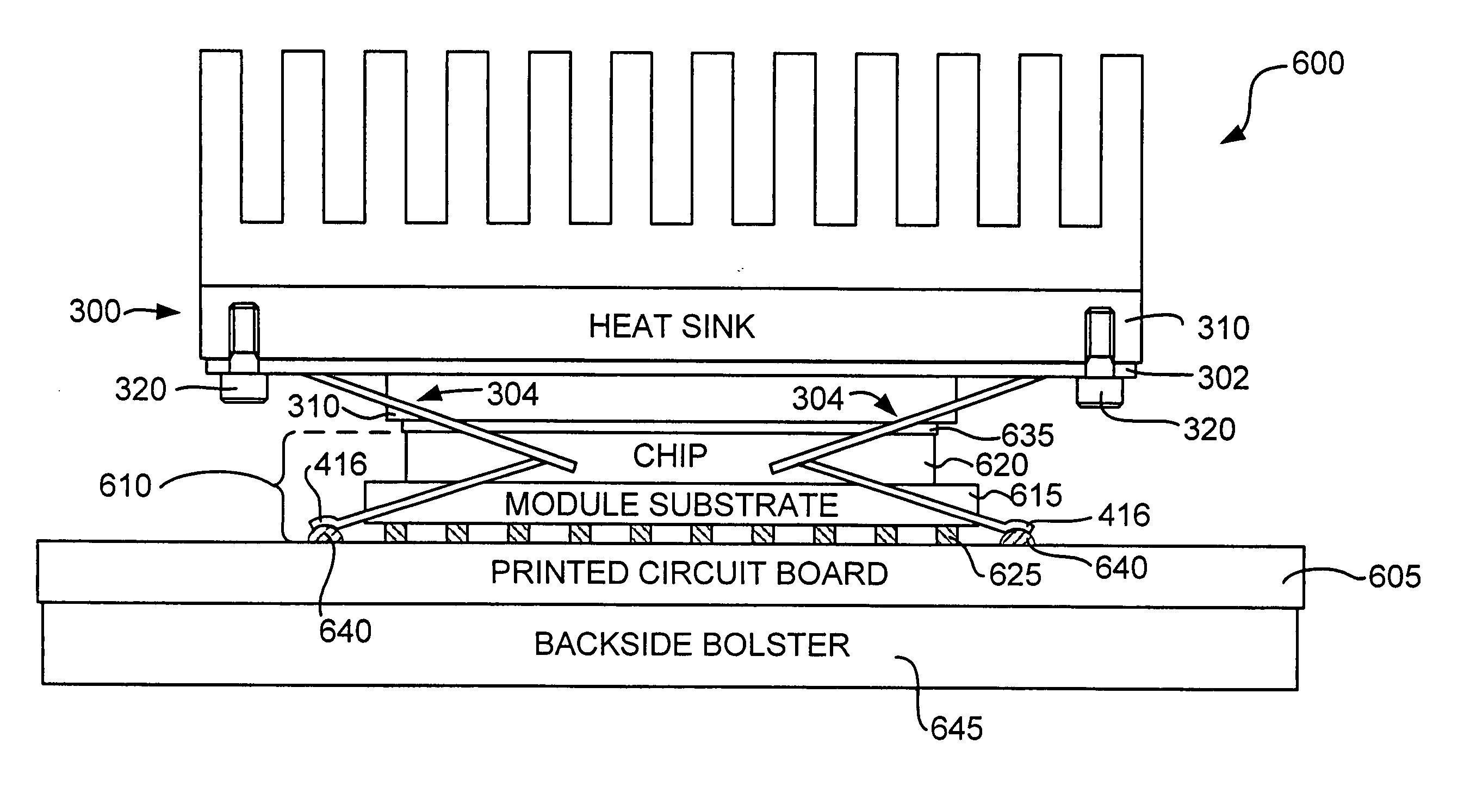

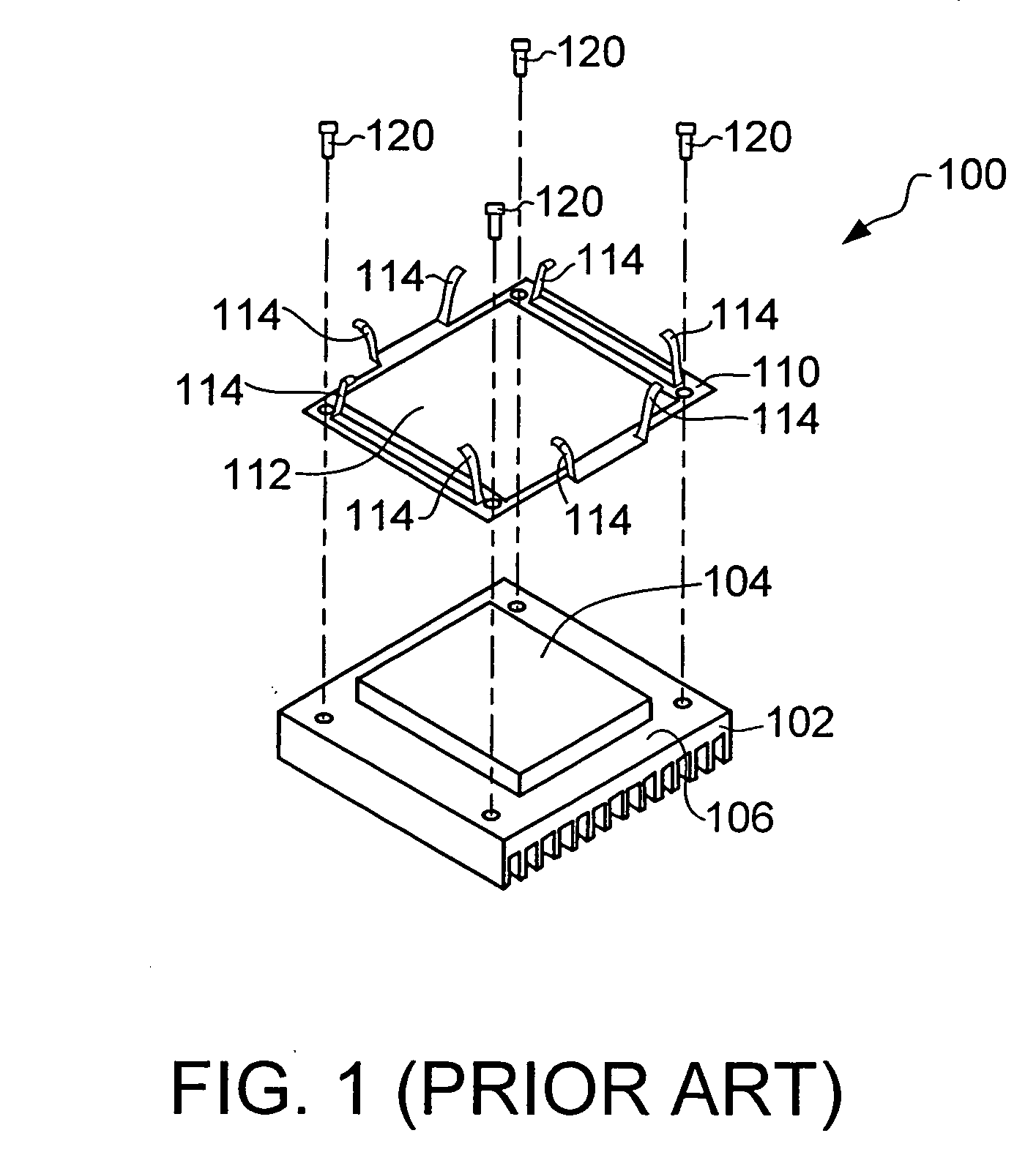

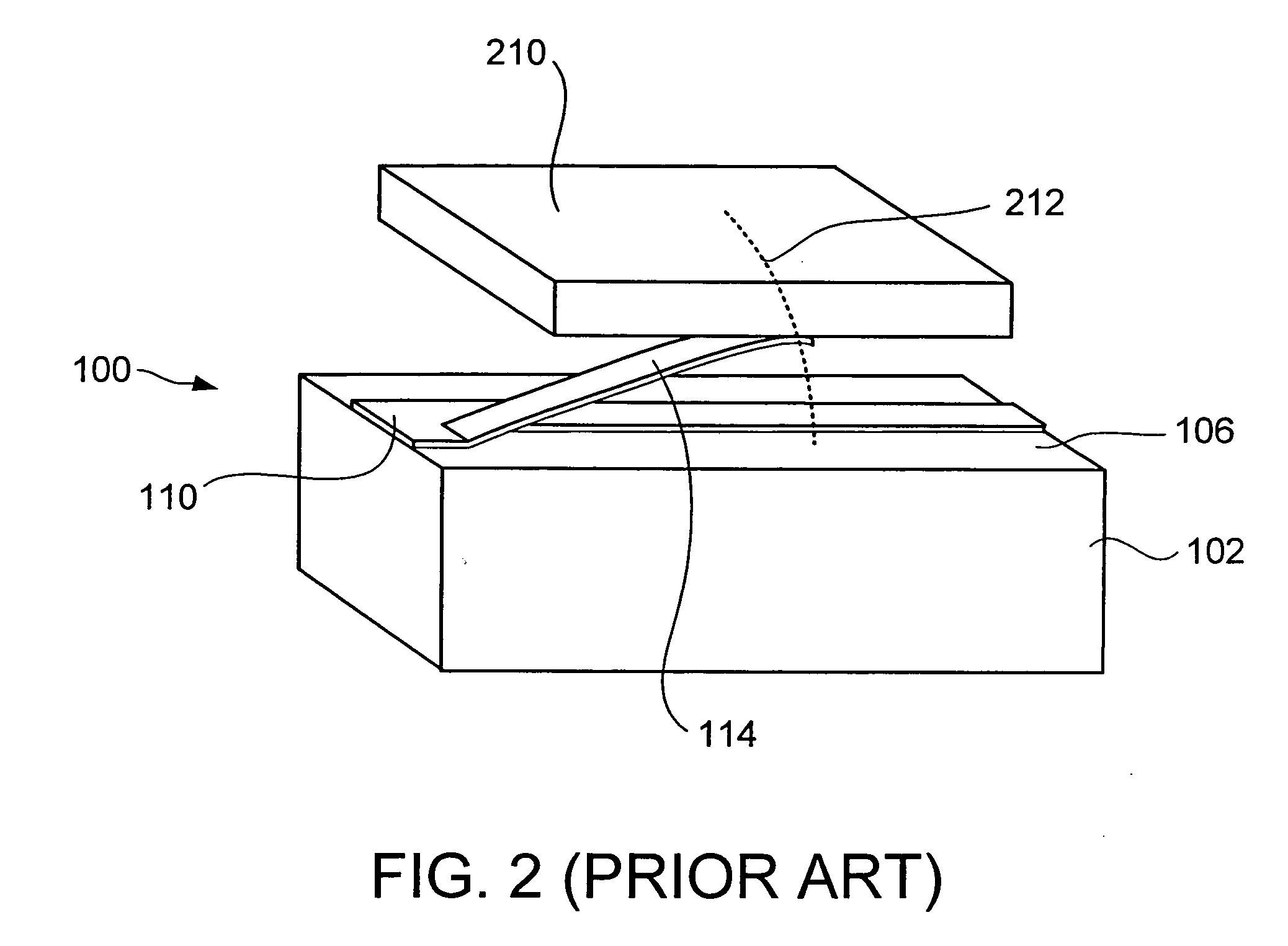

Method and apparatus for grounding a heat sink in thermal contact with an electronic component using a grounding spring having multiple-jointed spring fingers

InactiveUS20070097653A1Not easy to slipRestrict movementSemiconductor/solid-state device detailsSolid-state devicesElectricityElectromagnetic interference

A grounding spring for electromagnetic interference (EMI) suppression is interposed between a heat sink and a printed circuit board (PCB). The grounding spring comprises a conductive material having an opening formed at its base through which the heat sink makes thermal contact with an electronic module mounted on the PCB. The base makes electrical contact with a peripheral surface of the heat sink, and multiple-jointed spring fingers extend from the base to make electrical contact with conductive pads on the PCB. During compression, the movement of each spring finger's tip is substantially limited to the z-axis. Accordingly, the final installed location of the tip can be precisely controlled even when the grounding spring must accommodate a wide variety of installed heights of the heat sink relative to the PCB. Preferably, the spring fingers terminate with a concave tip that is less susceptible to sliding off the conductive pads.

Owner:IBM CORP

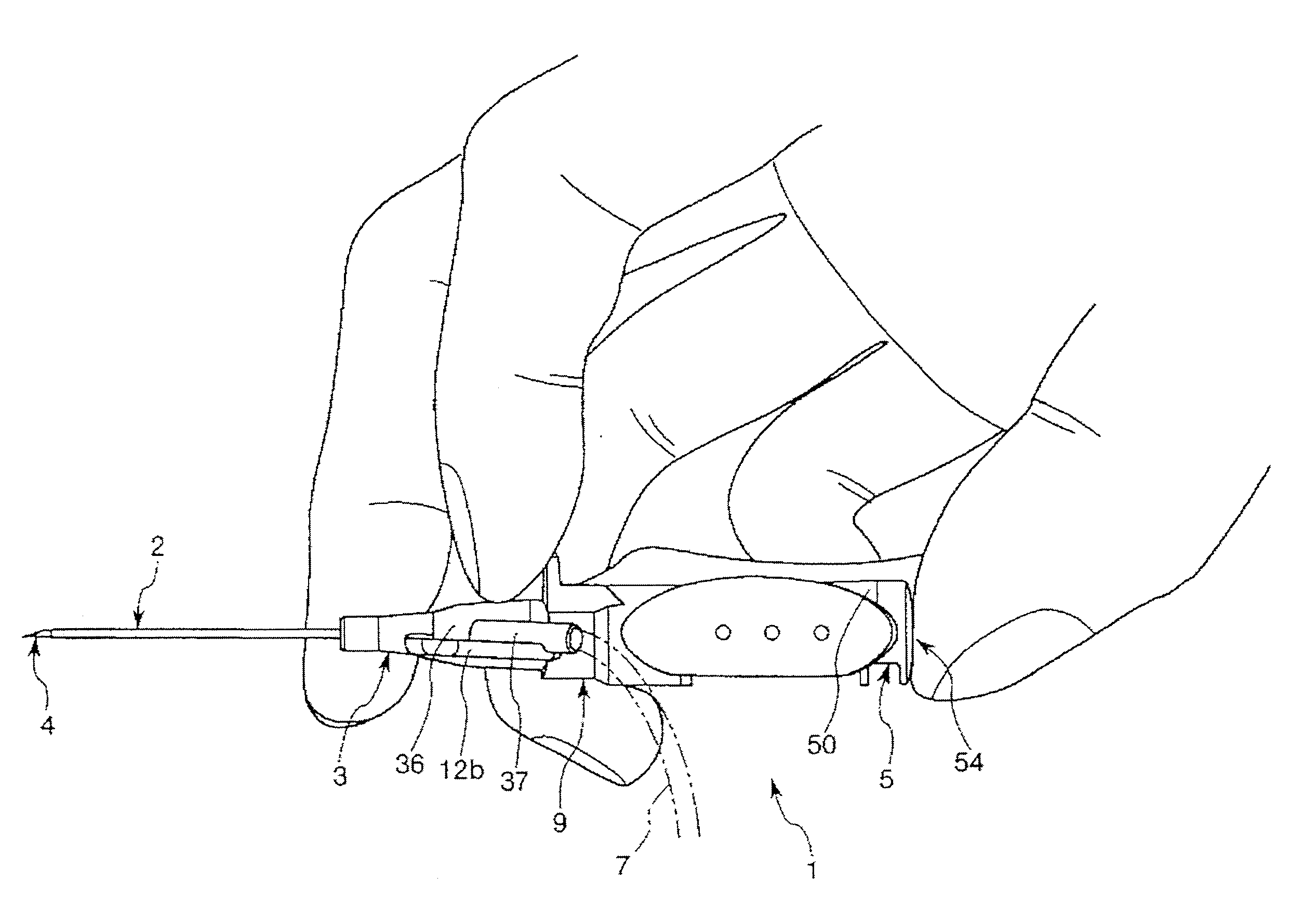

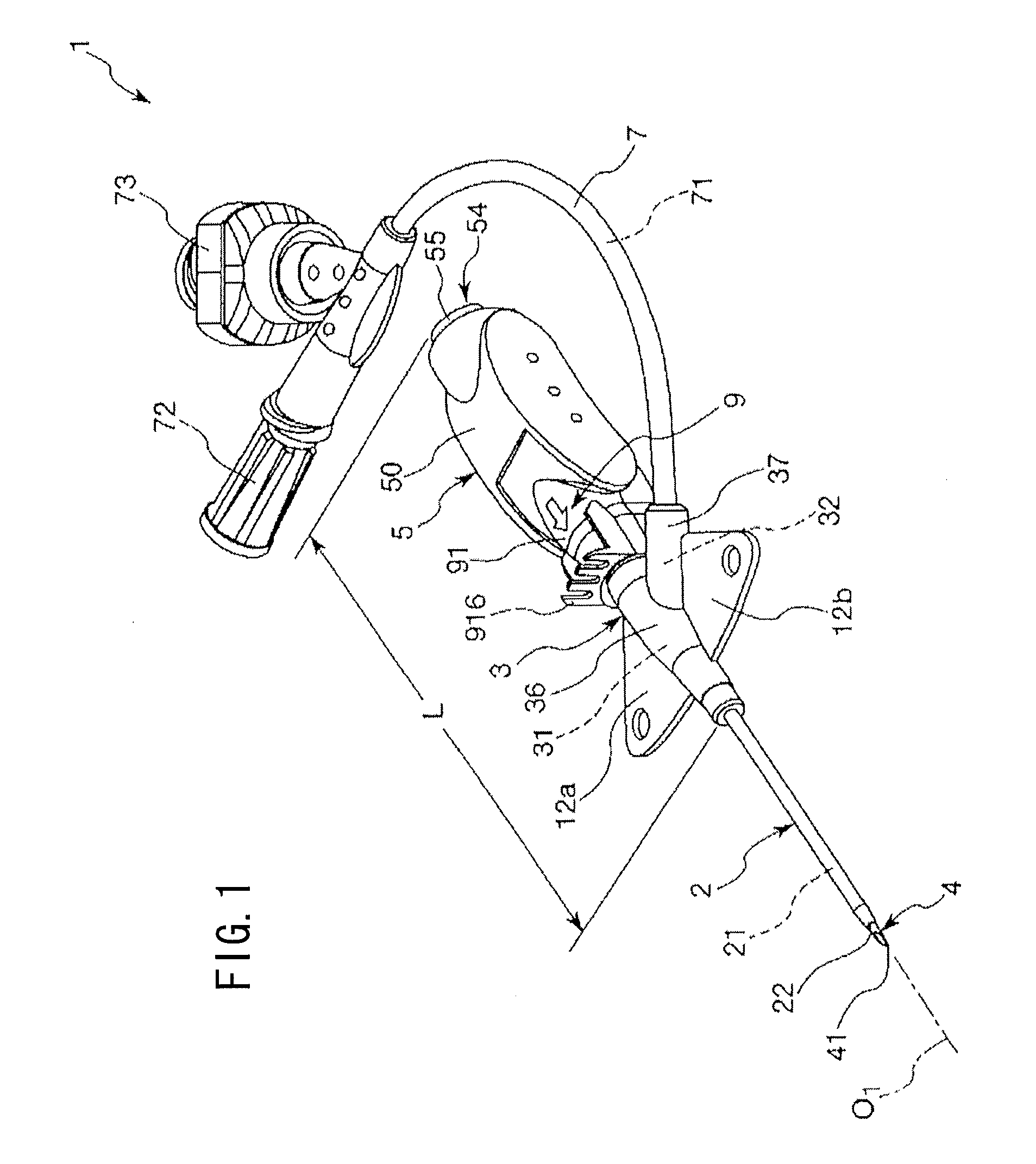

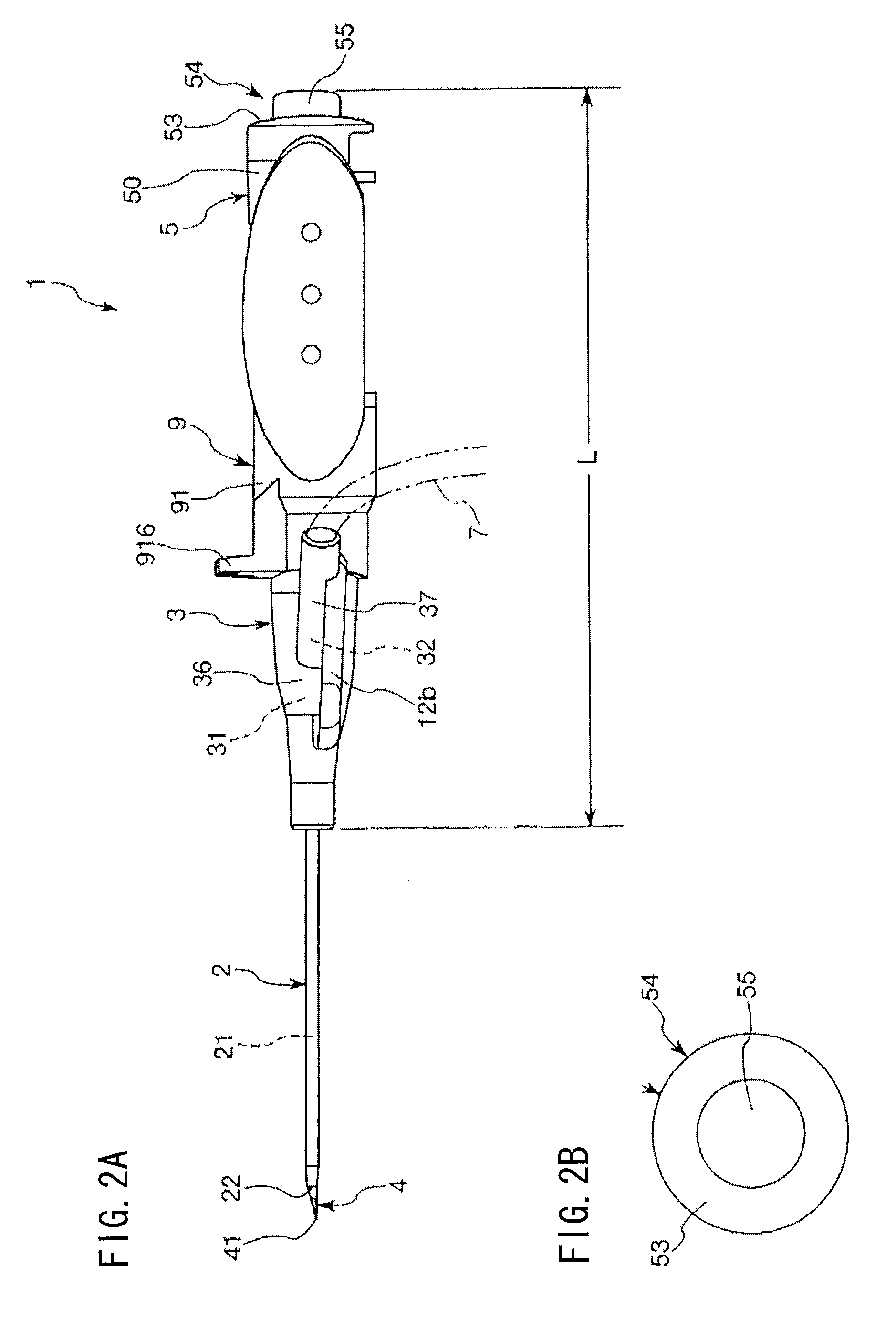

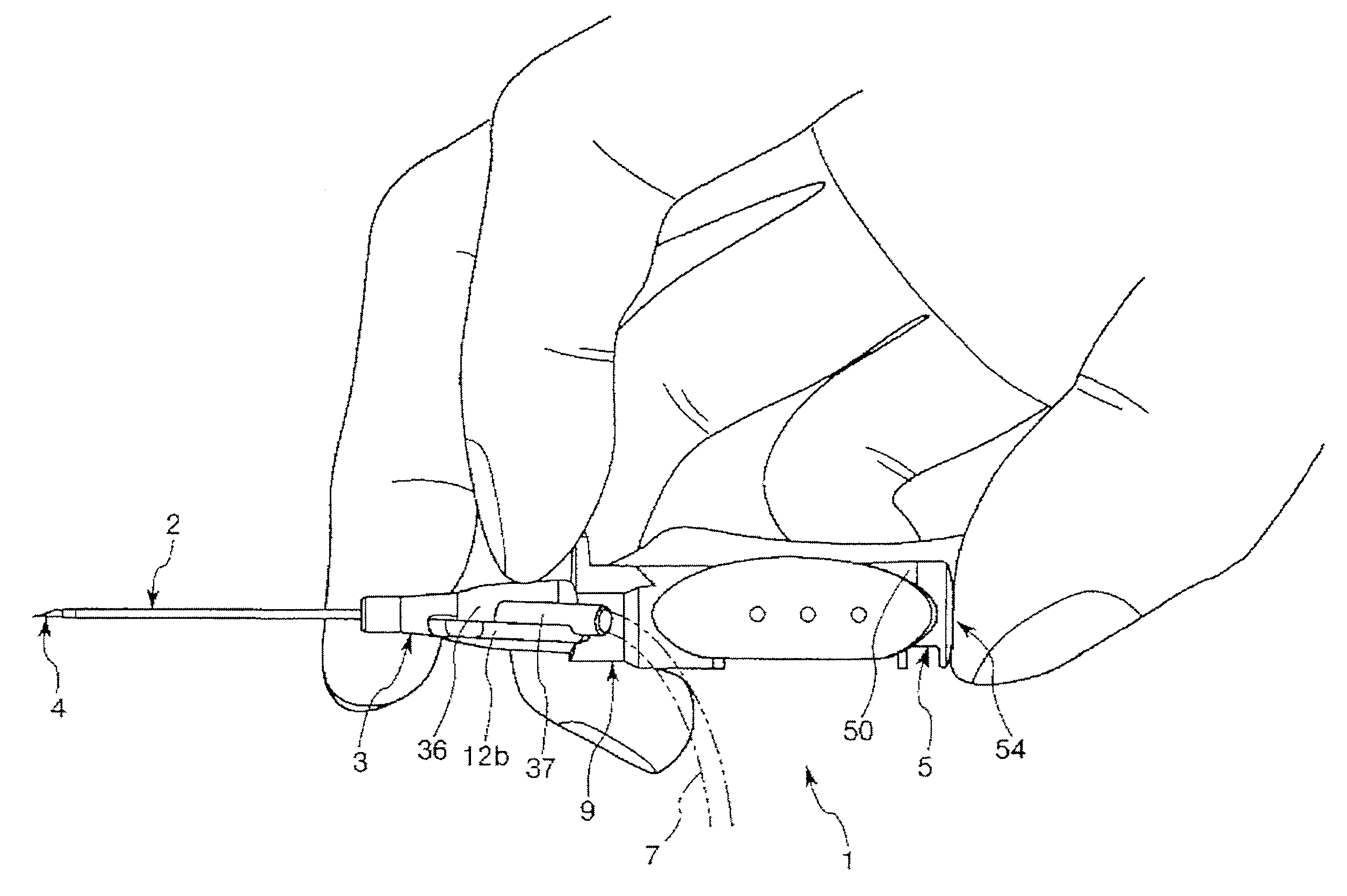

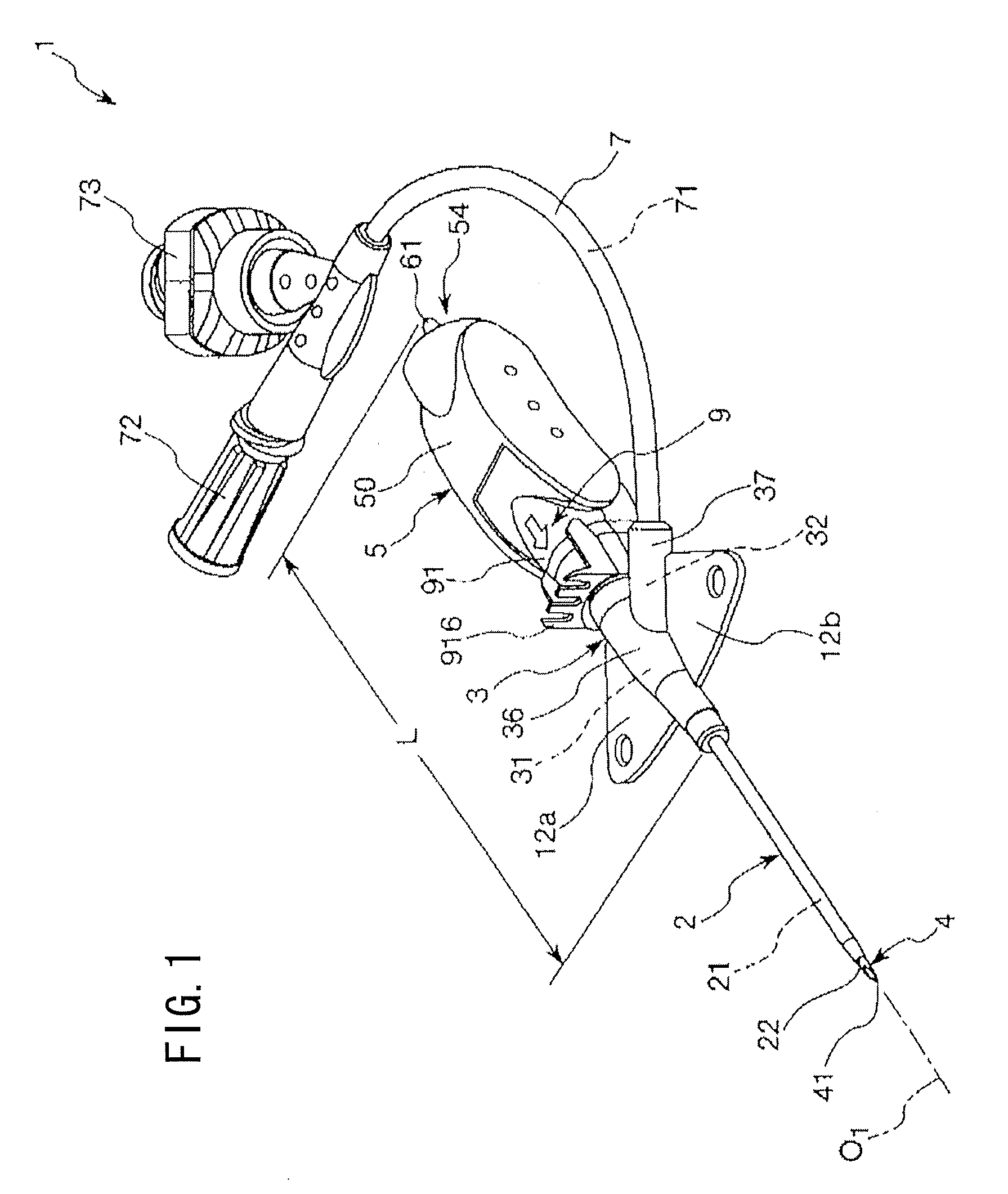

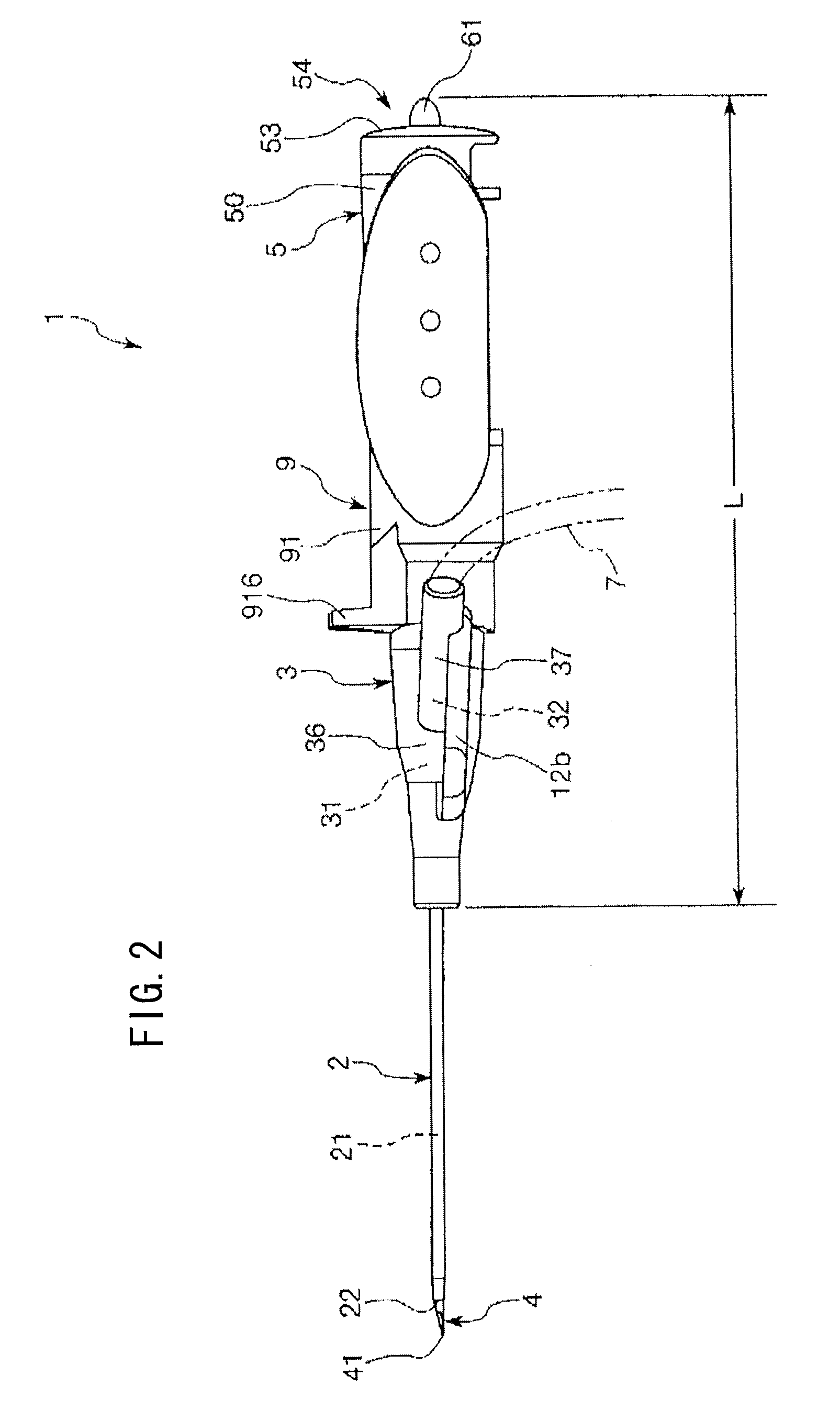

Indwelling needle assembly and method of using the same

An indwelling needle assembly, includes an inner needle having a sharp needle point at a distal end thereof, an inner needle hub fixed to a proximal portion of the inner needle, a hollow outer needle into which the inner needle is inserted, and an outer needle hub fixed to a proximal portion of the outer needle. The indwelling needle assembly is designed to be used with a thumb in contact with a proximal portion of the inner needle hub. The inner needle hub is provided with a finger hold at the proximal portion thereof. At least a part of the finger hold is formed from a material less liable to slip on a medical glove.

Owner:TERUMO KK

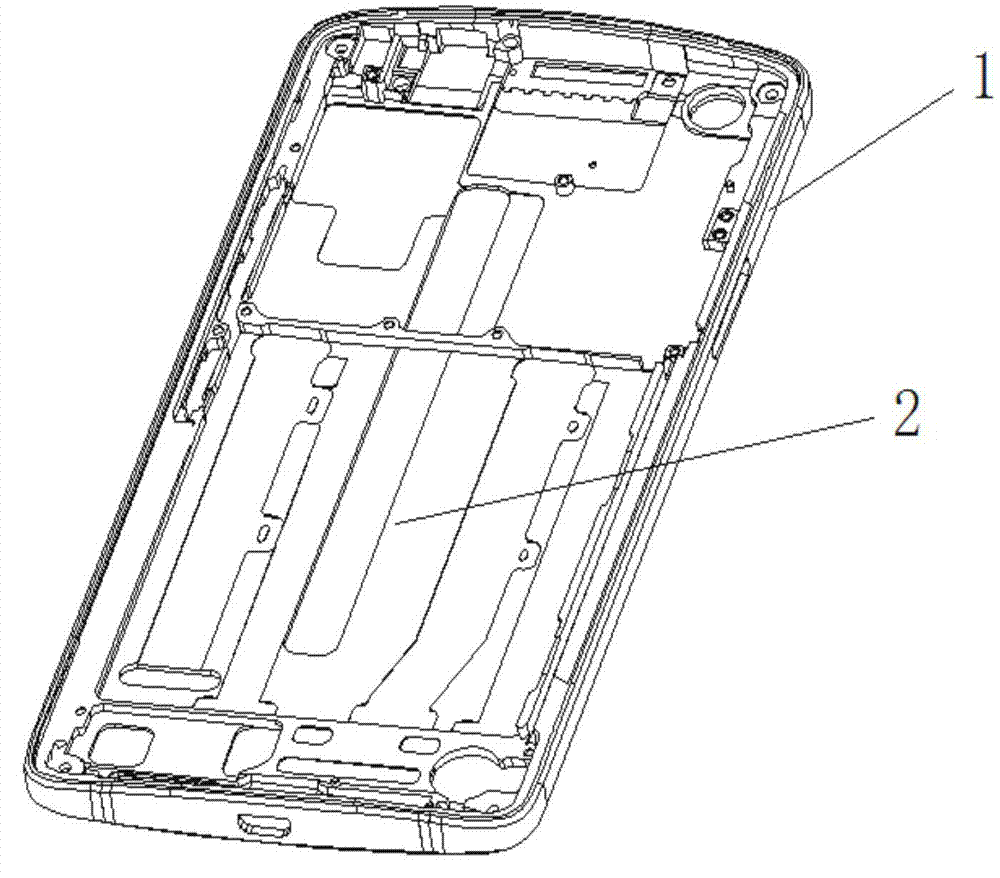

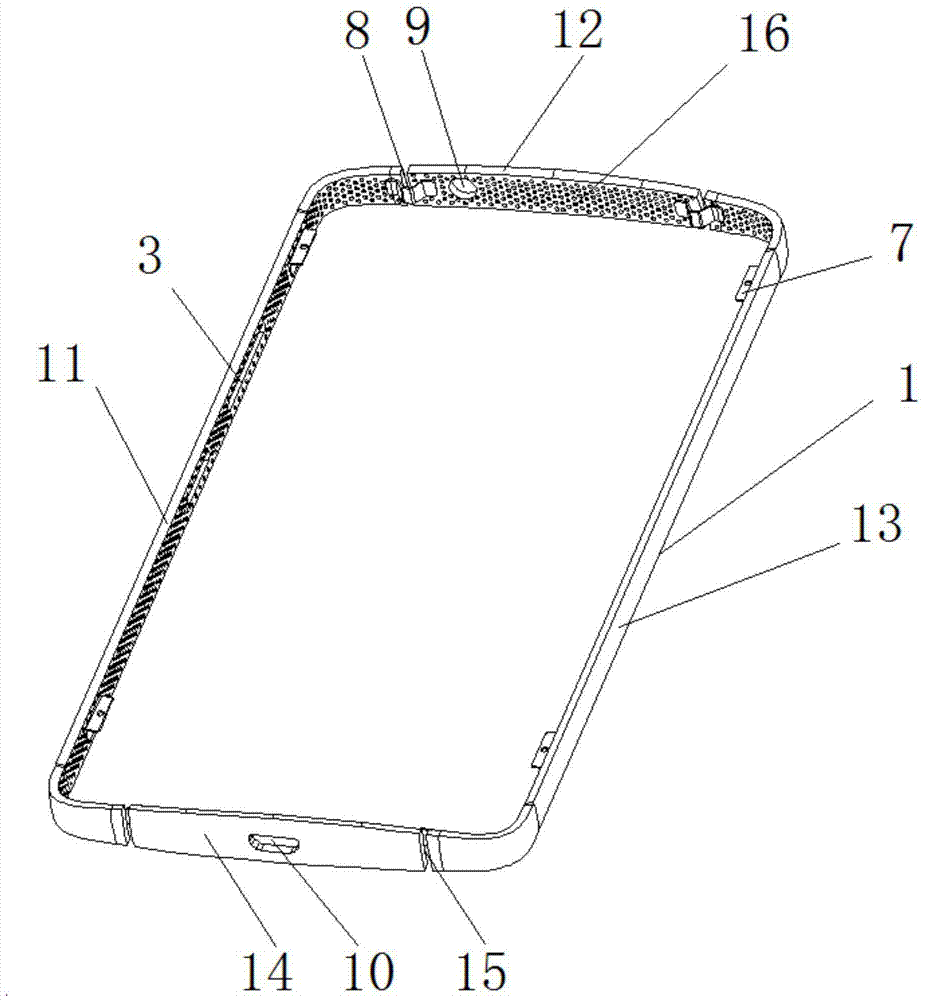

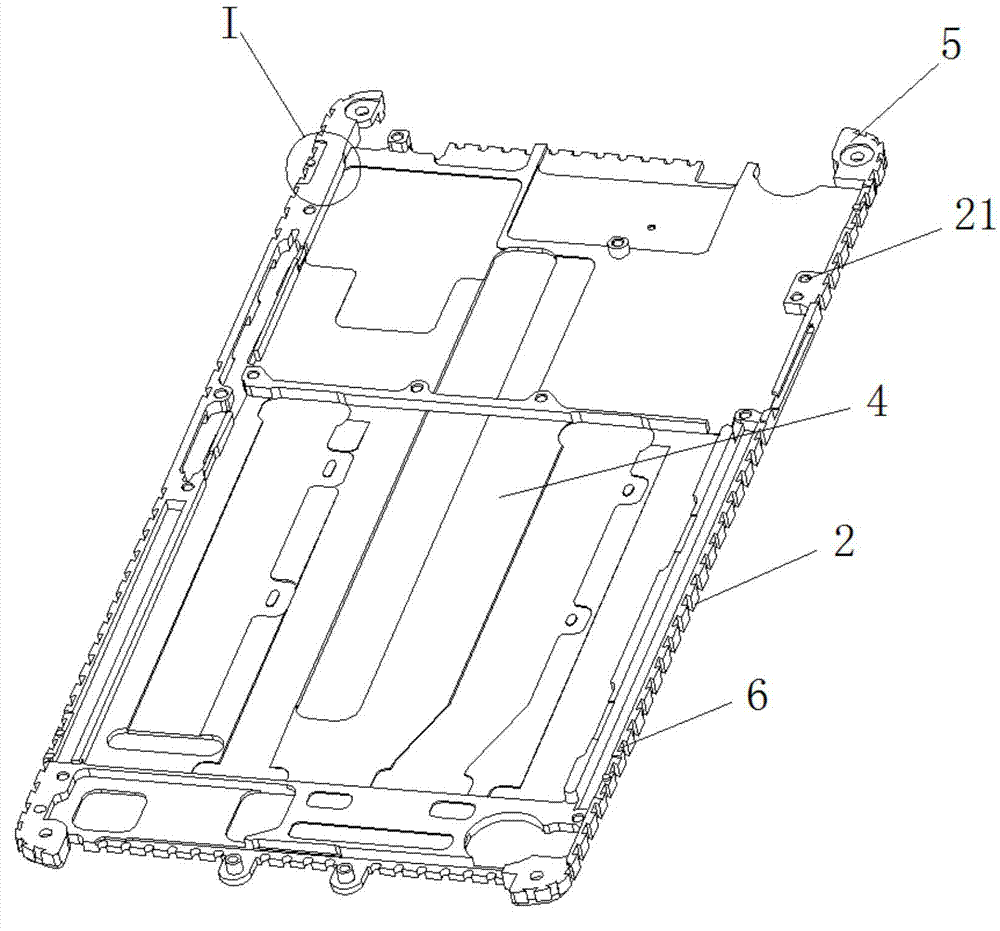

Mobile electronic product metal middle frame and processing technique thereof

InactiveCN104853549AHigh hardnessAvoid breakingCasings/cabinets/drawers detailsMetal casingsManufacturing technologyEngineering

The present invention relates to the technical field of mobile electronic product housing manufacturing, and especially relates to a mobile electronic product metal middle frame. The mobile electronic product metal middle frame comprises a side frame and a middle board, wherein the middle board is internally installed inside the side frame; the side frame comprises a first side wall, a second side wall, a third side wall and a fourth side wall which are arranged in turn; a plurality of key holes are disposed on the first side wall; the middle board comprises a middle board body and arc-shaped plates arranged at two ends of the middle board body; and a plurality of dovetail grooves are formed in the outer wall of the middle board. Through the above structure, the hardness is raised, and the structure is not easy to damage and is attractive and elegant in appearance. The present invention also relates to a processing technique for manufacturing the above mobile electronic product metal middle frame. The technique is little in processing time, and the processing time is saved.

Owner:AOJIE HARDWARE JIANGSU

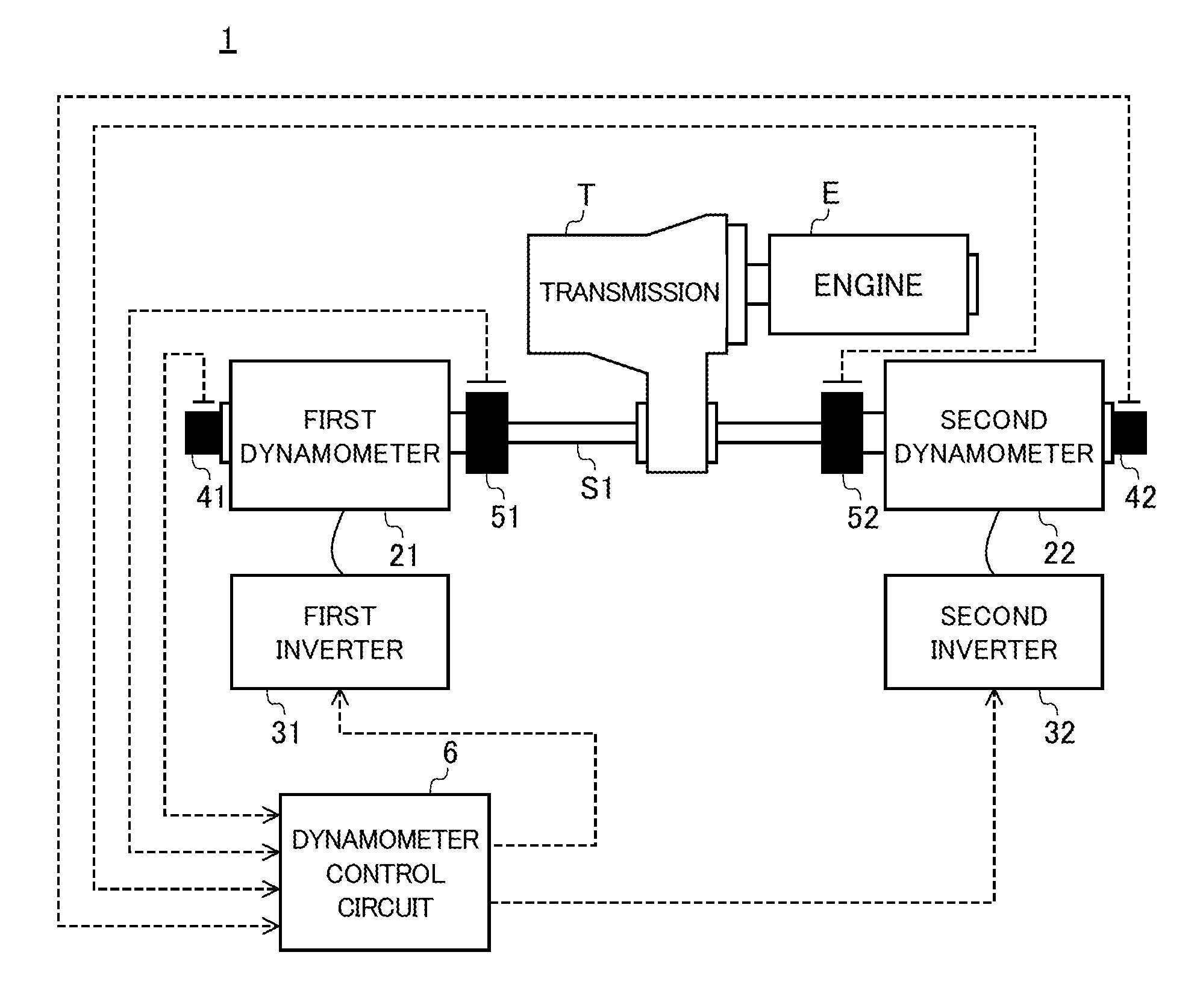

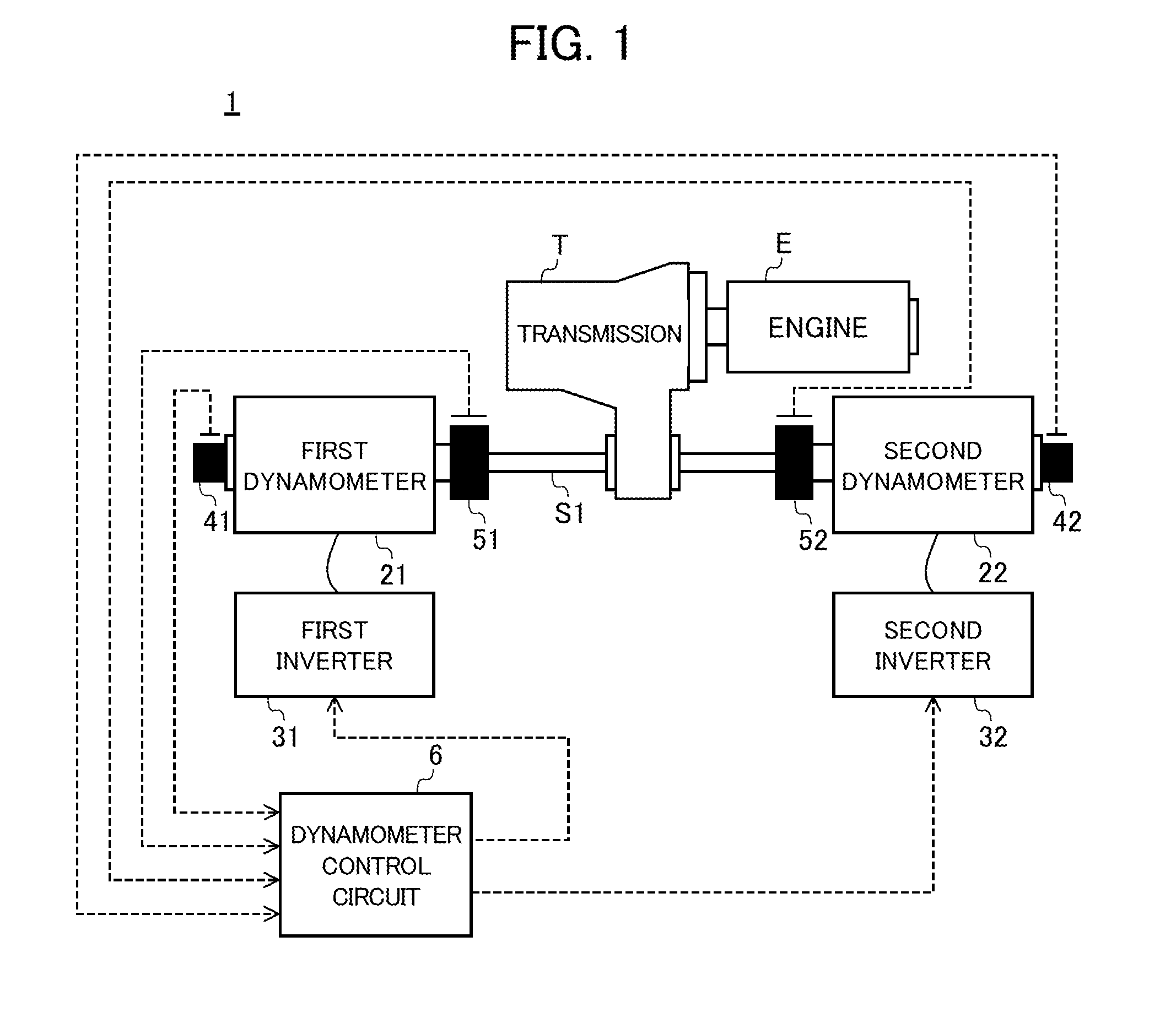

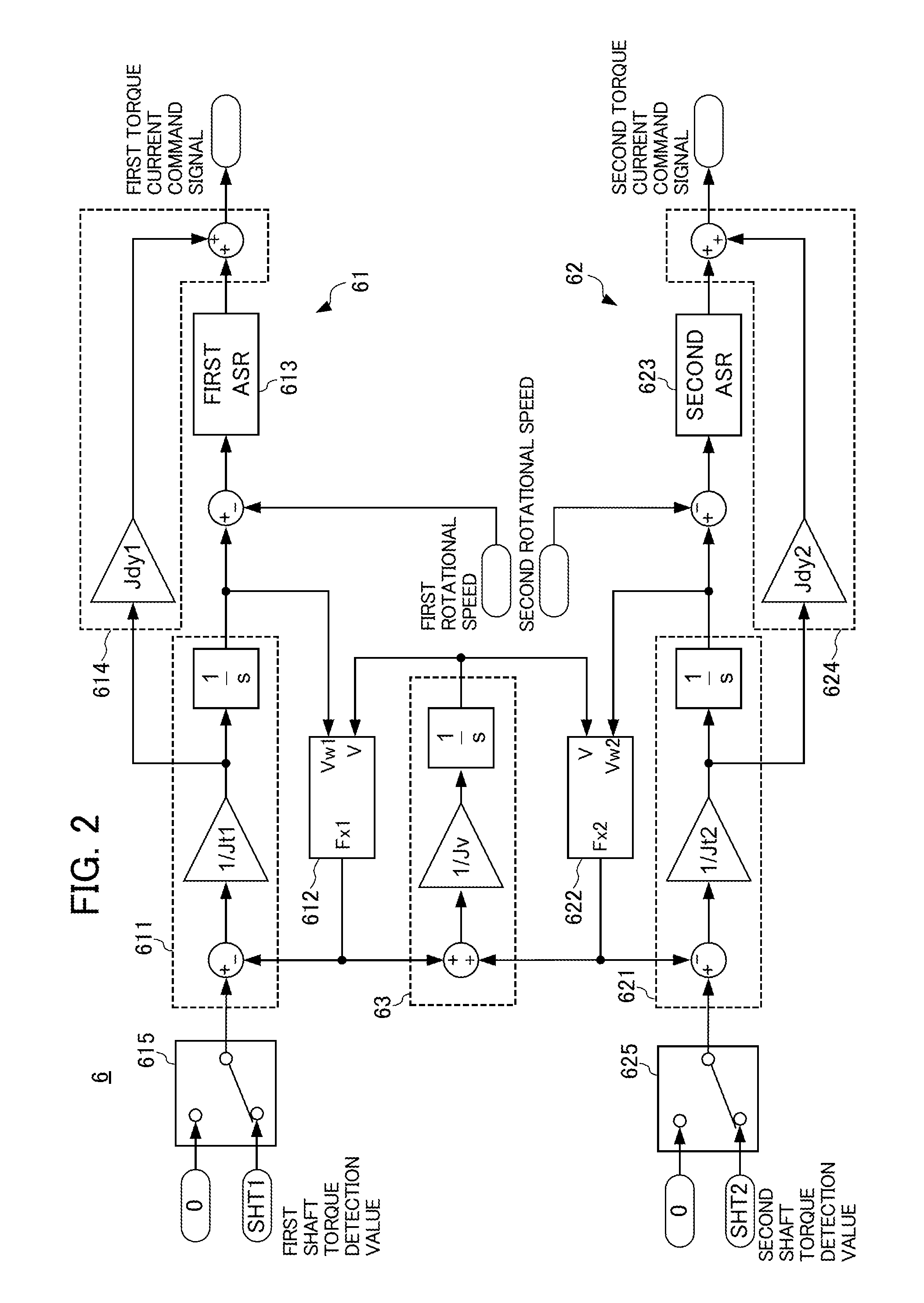

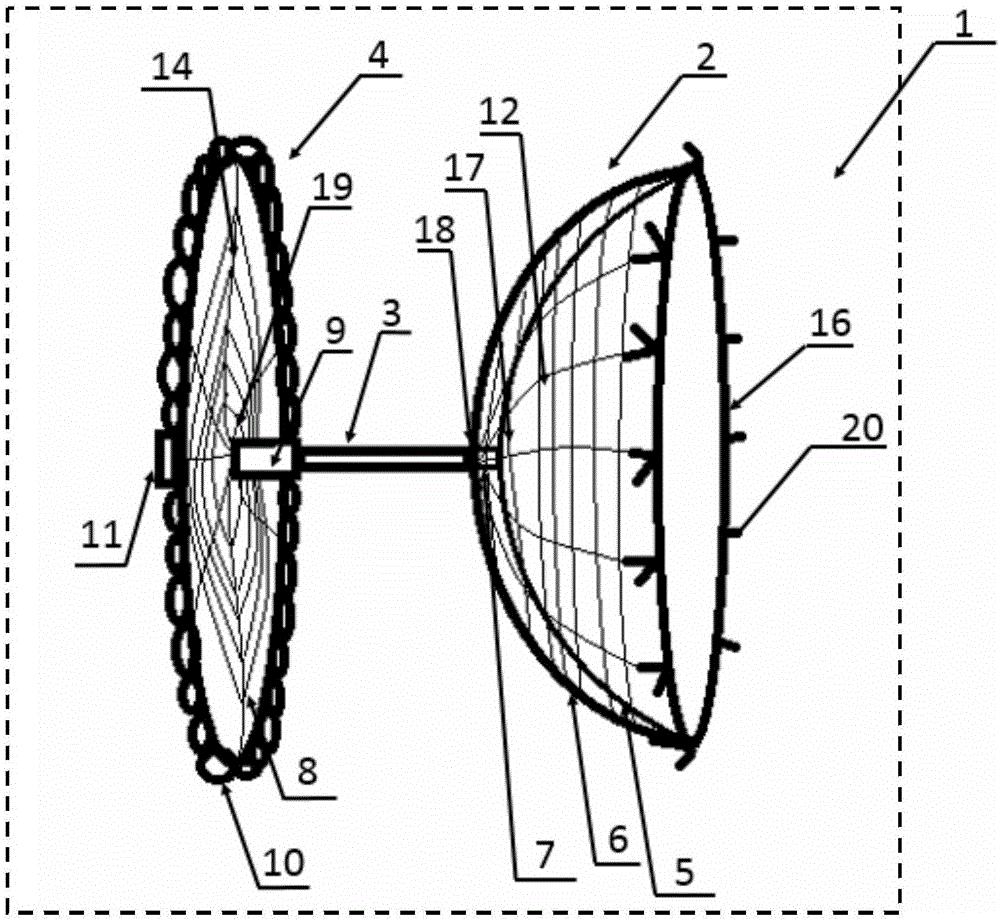

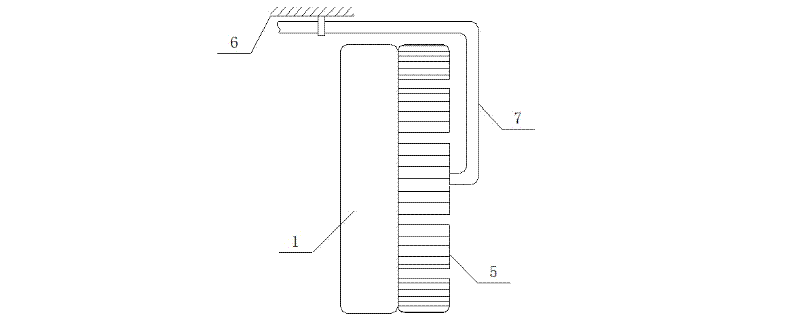

Testing system for drivetrain

ActiveUS20150219529A1High simulationEasy to carryVehicle testingMachine part testingDrivetrainVehicle driving

Provided is a testing system for a drivetrain, the testing system capable of simulating the slip behavior of a tire. A testing system is provided with: tire speed calculation units; a vehicle speed calculation unit; vehicle driving torque calculation units which calculate vehicle driving torque values; and speed control devices which output command signals such that the deviations between command values and output values from encoders are eliminated, respectively. The tire speed calculation units calculate the tire speed values on the basis of tire driving torque values obtained by subtracting the vehicle driving torque values from output values from shaft torque meters, respectively, and the vehicle speed calculation unit calculates the vehicle speed value on the basis of the vehicle driving torque values.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Electric clamping jaw

InactiveCN105922254AAutomatic calculation of clamping forceStable and reliable clampingProgramme-controlled manipulatorGripping headsIndustrial engineeringSensing system

An electric clamping jaw comprises a driving part and a clamping jaw body; the clamping jaw body is mounted on the bottom of the driving part and comprises a first clamping jaw and a second clamping jaw; the first clamping jaw and the second clamping jaw are both connected with a driving mechanism, and the clamping jaw body is provided with a slippage detection sensing system and a deformation sensing system; and according to the electric clamping jaw, clamping force can be automatically calculated and adjusted.

Owner:四川东巨自动化科技有限公司

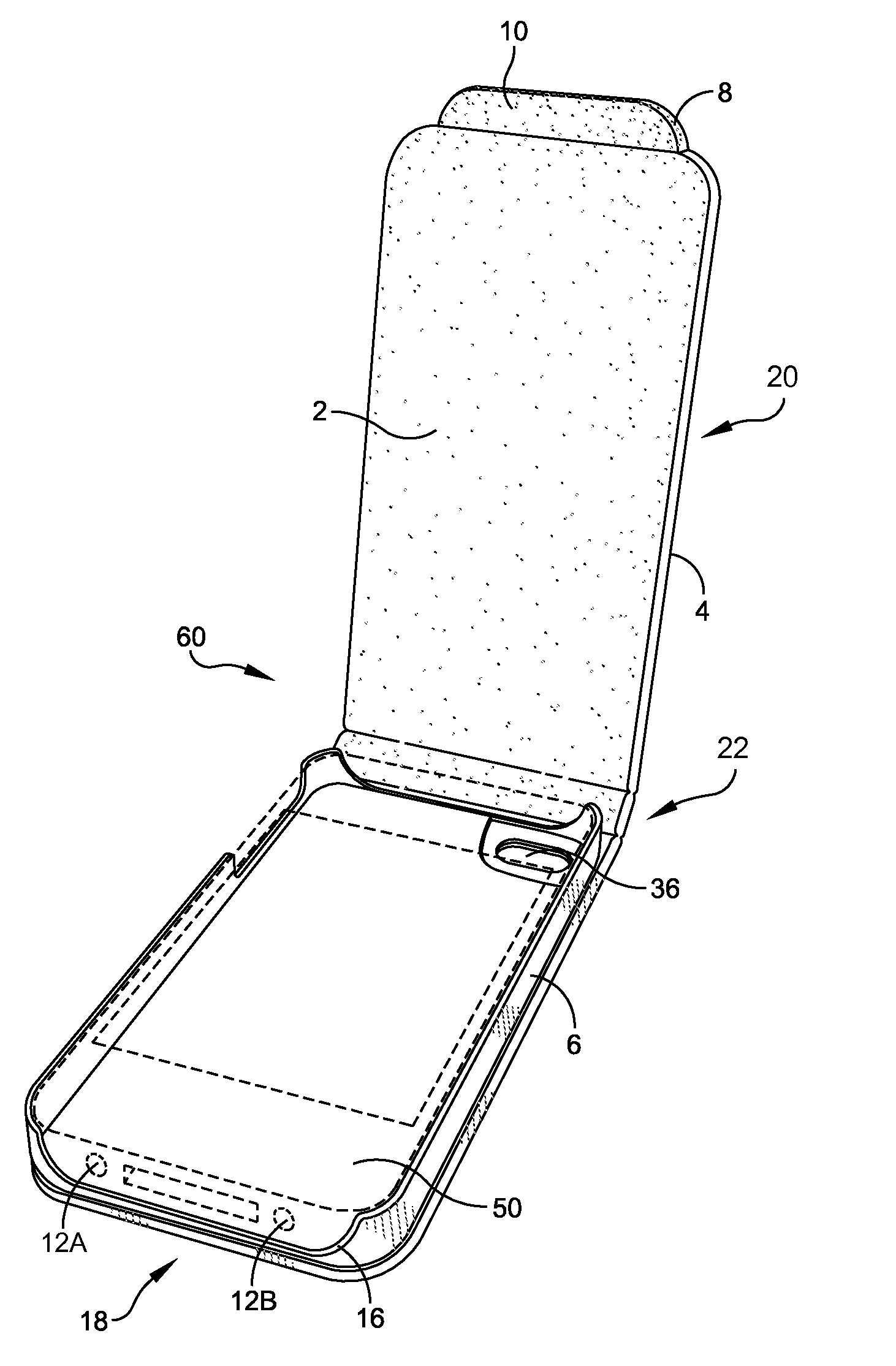

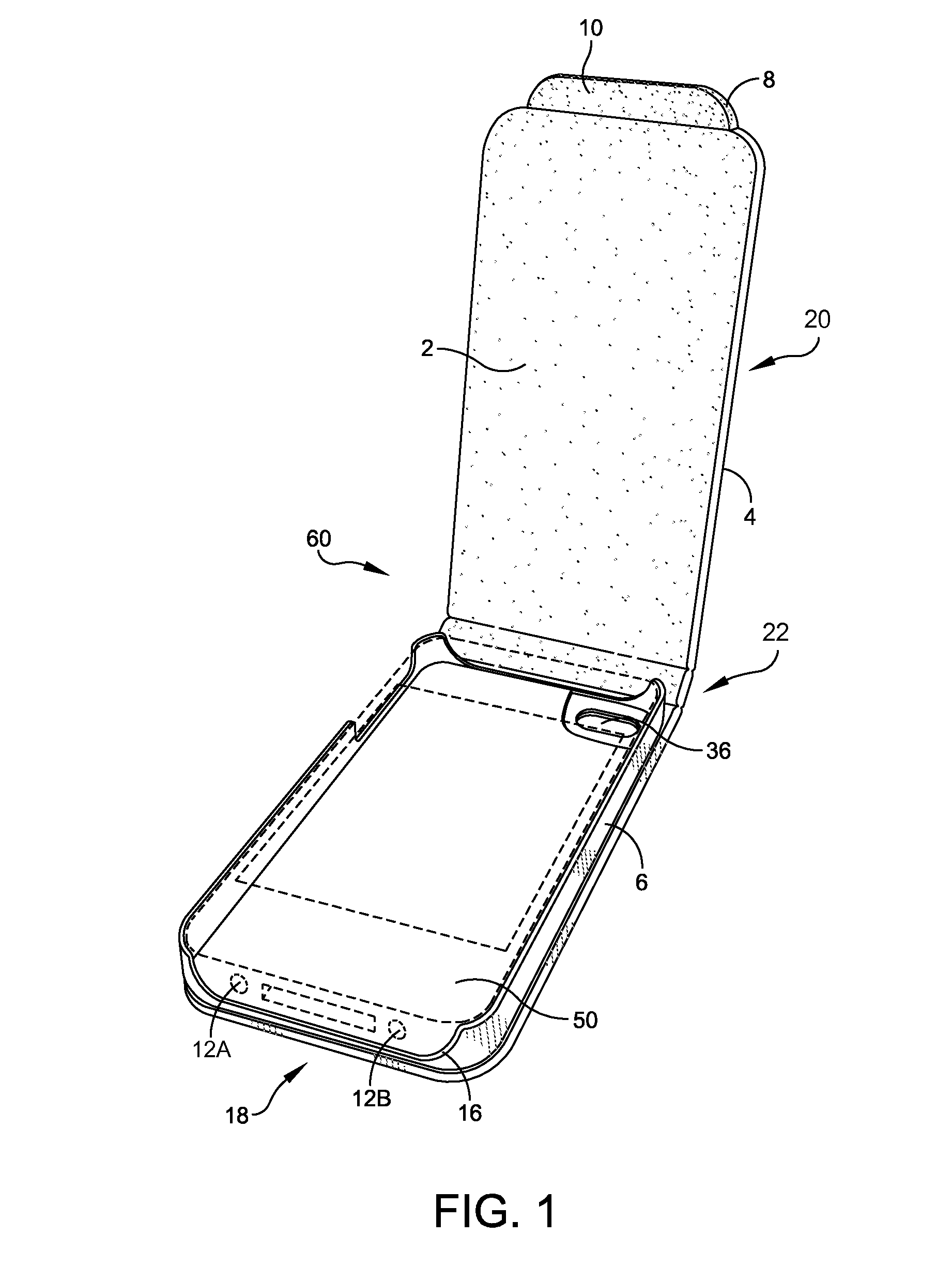

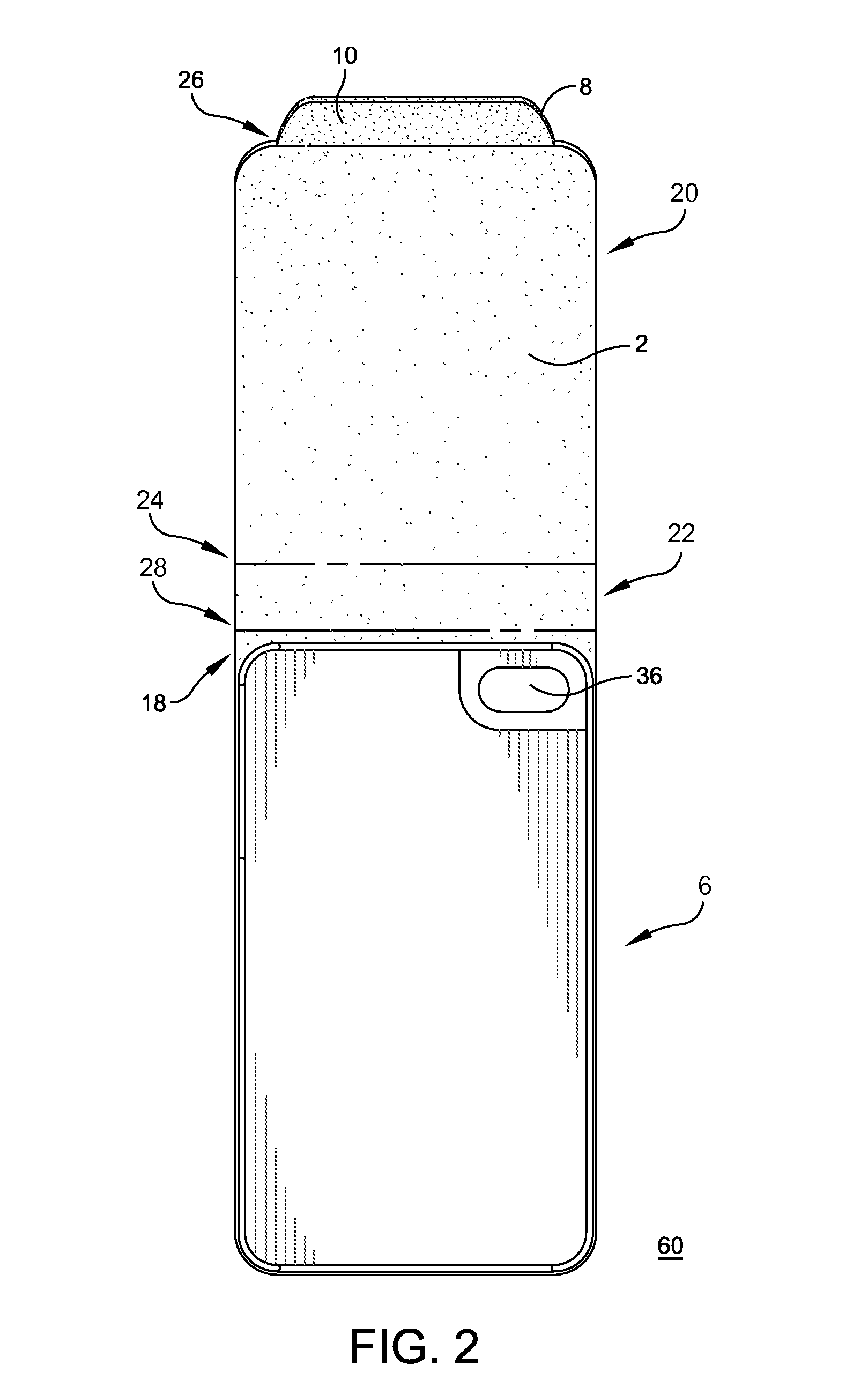

Cover for mobile telephone

InactiveUS20140183065A1Not easy to slipMeet user experienceOther accessoriesTray containersEngineeringMechanical engineering

A cover for a mobile telephone, such as a smartphone, is provided. The cover includes a front board, a back board, and a spine that hingedly attaches to the front board and the back board. These three components cooperate to cover three sides of the mobile telephone. A cradle assembly affixed to the interior surface of the back board releasably grips the mobile telephone. A flap is hingedly attached to the front board and provides attachment means for removably attaching the flap to an exposed portion of the mobile telephone. The attachment means may optionally be magnetic, and attach to a magnetic portion of the mobile telephone. A portion of the flap material may be slip-resistant to permit the cover to assume a stable, inclined configuration in which a portion of the weight of the mobile telephone on the flap material prevents slippage.

Owner:GRAPHIQUE DE FRANCE

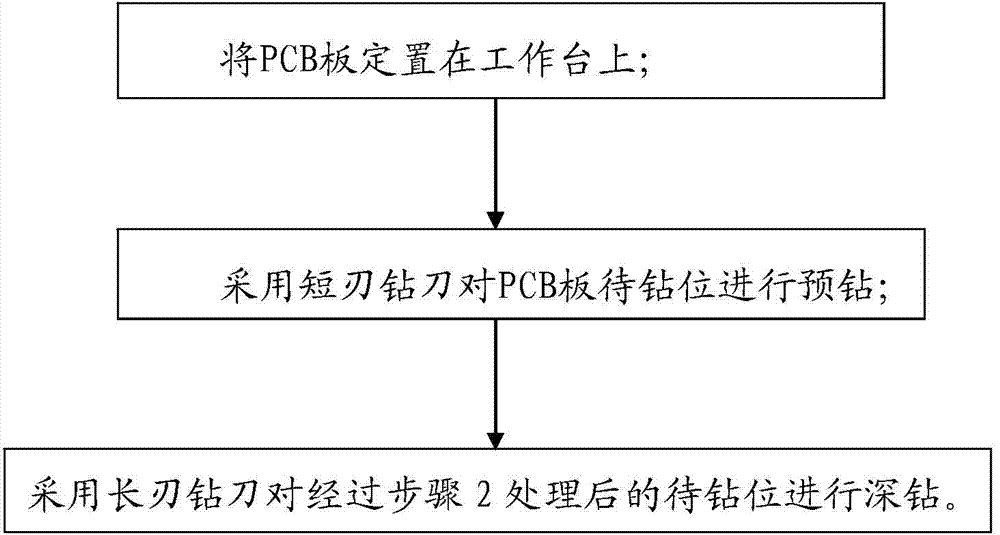

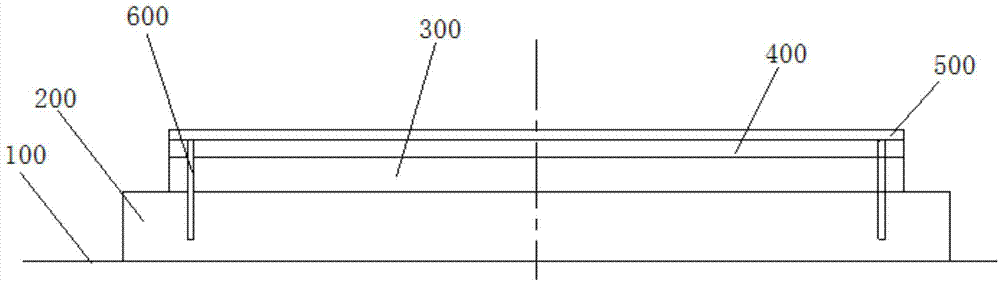

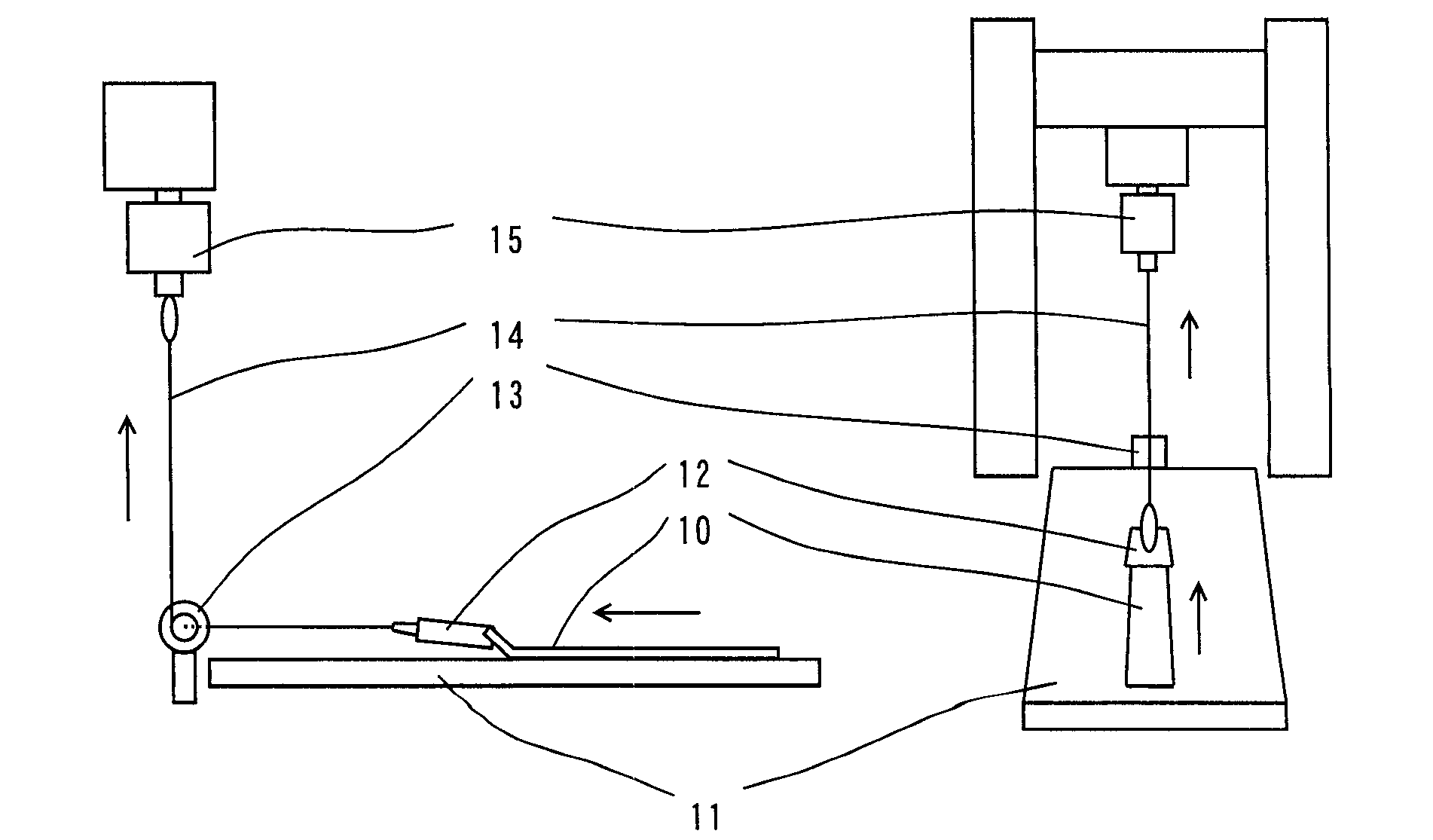

Drilling method for achieving PCB high hole-site precision

ActiveCN103786189AImprove rigidityAvoid the influence of hole position accuracyPrinted circuit manufactureMetal working apparatusHole drilling methodDeep drilling

The invention discloses a drilling method for achieving PCB high hole-site precision. The method comprises the following steps that firstly, a PCB is fixed on a workbench, secondly, the position to be drilled on the PCB is pre-drilled through a short-blade drilling tool, and thirdly, the position, to be drilled, processed in the second step is deep drilled through a long-blade drilling tool. The operation is easy and convenient and cost is low. The PCB is fixed in the first step, so that the PCB does not move during the drilling process, and the drilling precision cannot be affected. The position to be drilled on the PCB is pre-drilled through the short-blade drilling tool in the second step, and the rigidity of the short-blade drilling tool is better relative to the long-blade drilling tool, so that in the moment that the short-blade drilling tool makes contact with a PCB surface, the short-blade drilling tool is not prone to sliding. The position, to be drilled, processed in the second step is deep drilled through the long-blade drilling tool, the lateral sliding of the long-blade drilling tool during the drilling process is reduced, and therefore the drilling alignment of the long-blade drilling tool during the deep drilling process is guaranteed, and the drilled hole site can meet the requirement for the PCB high hole-site precision.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

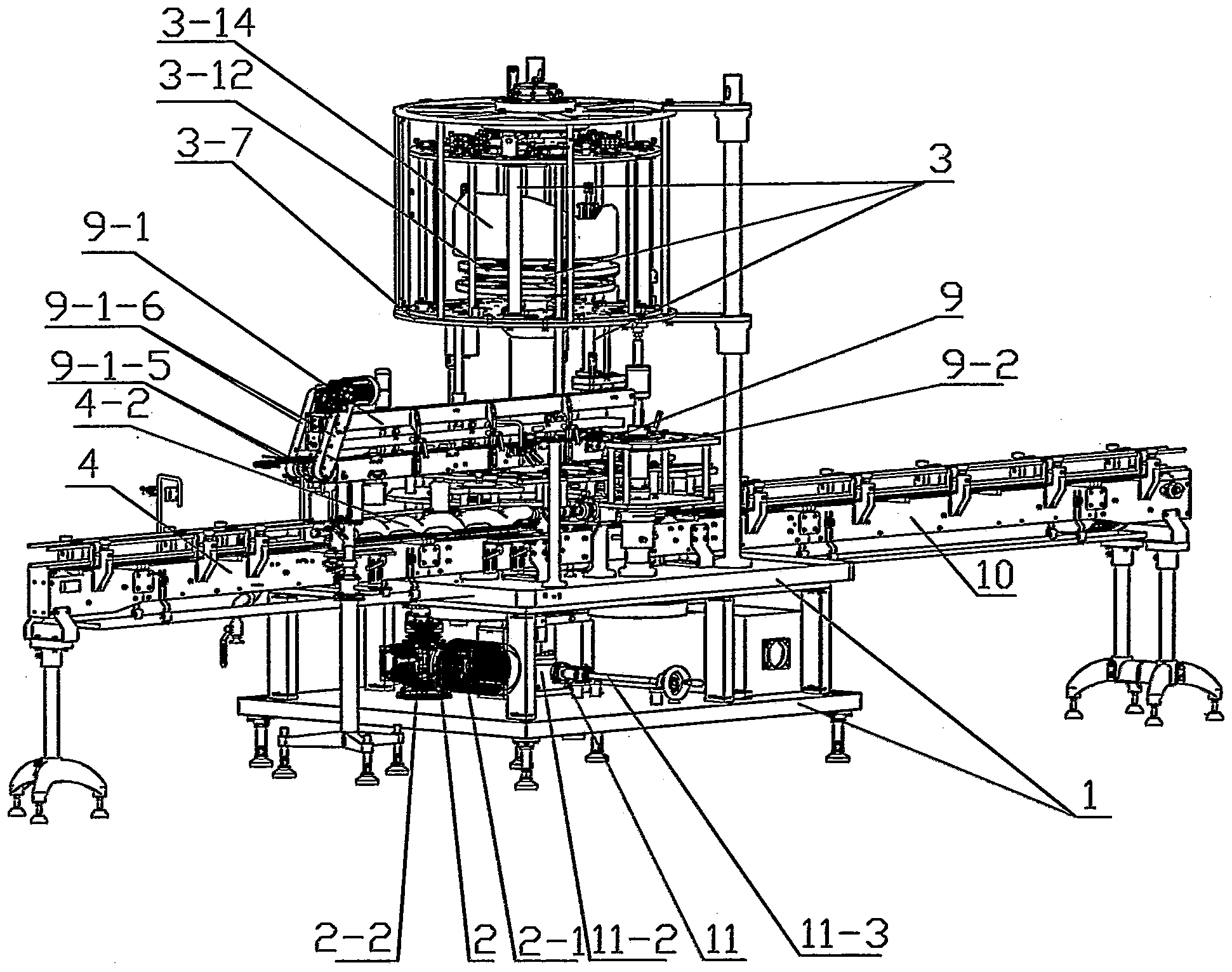

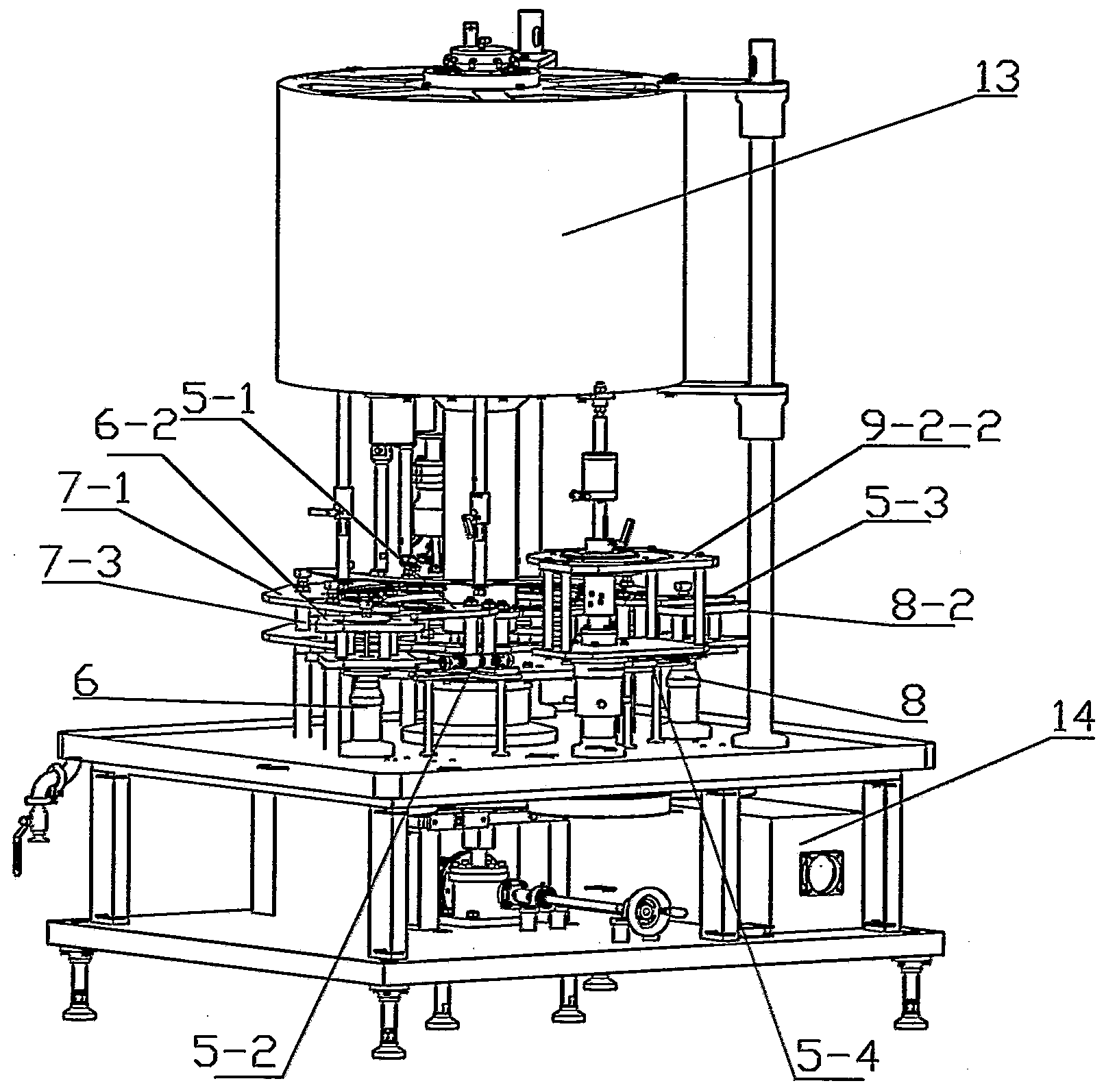

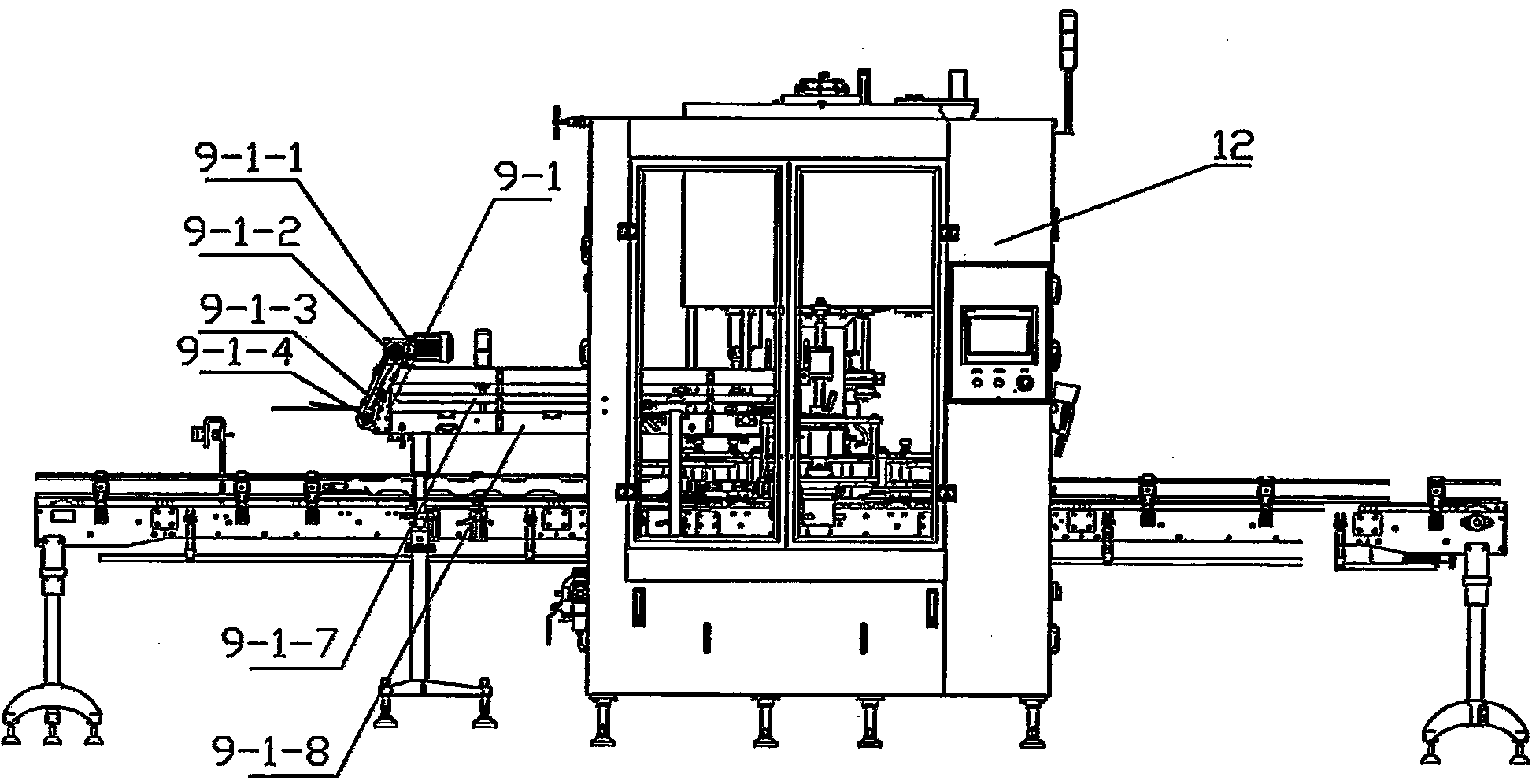

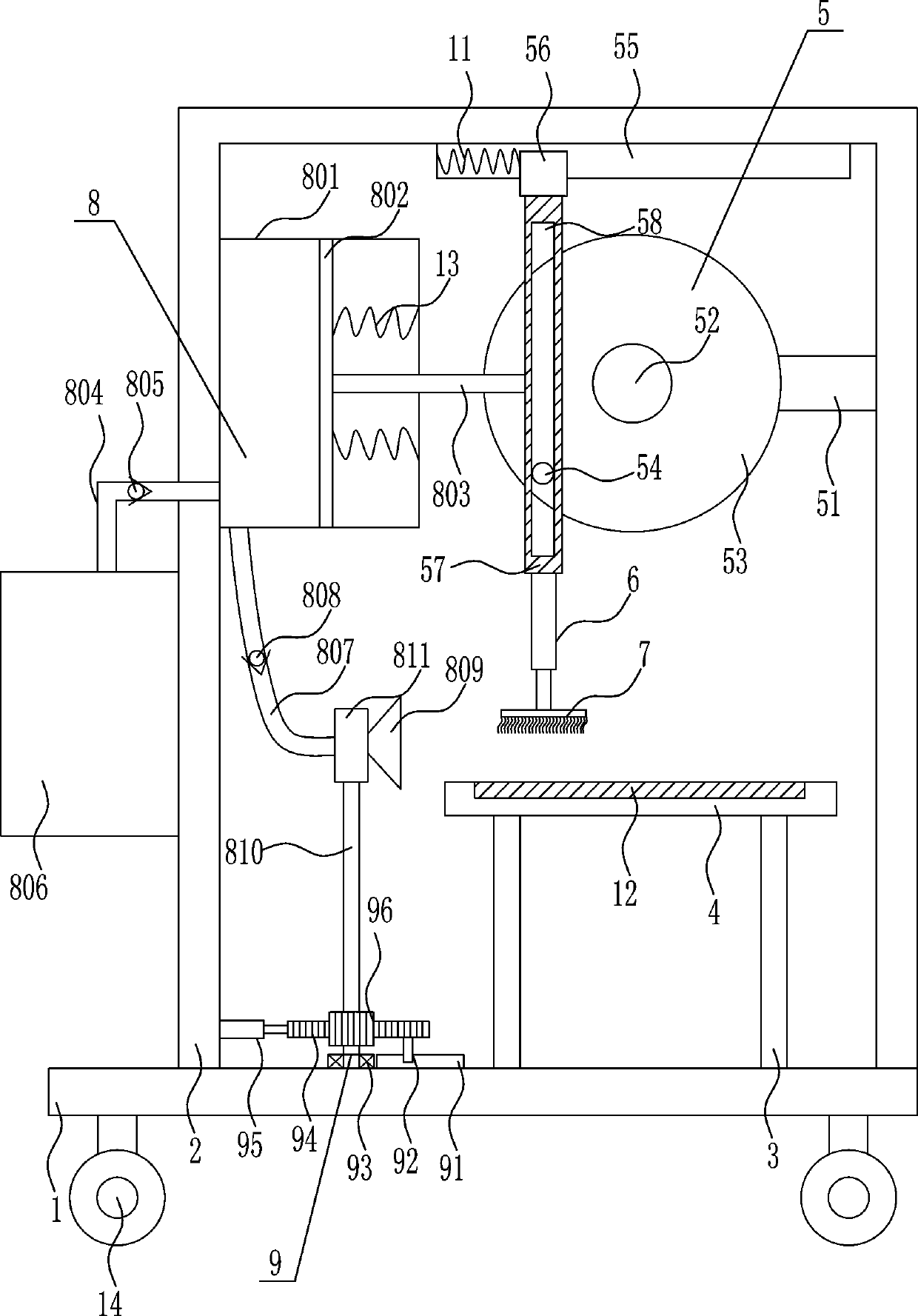

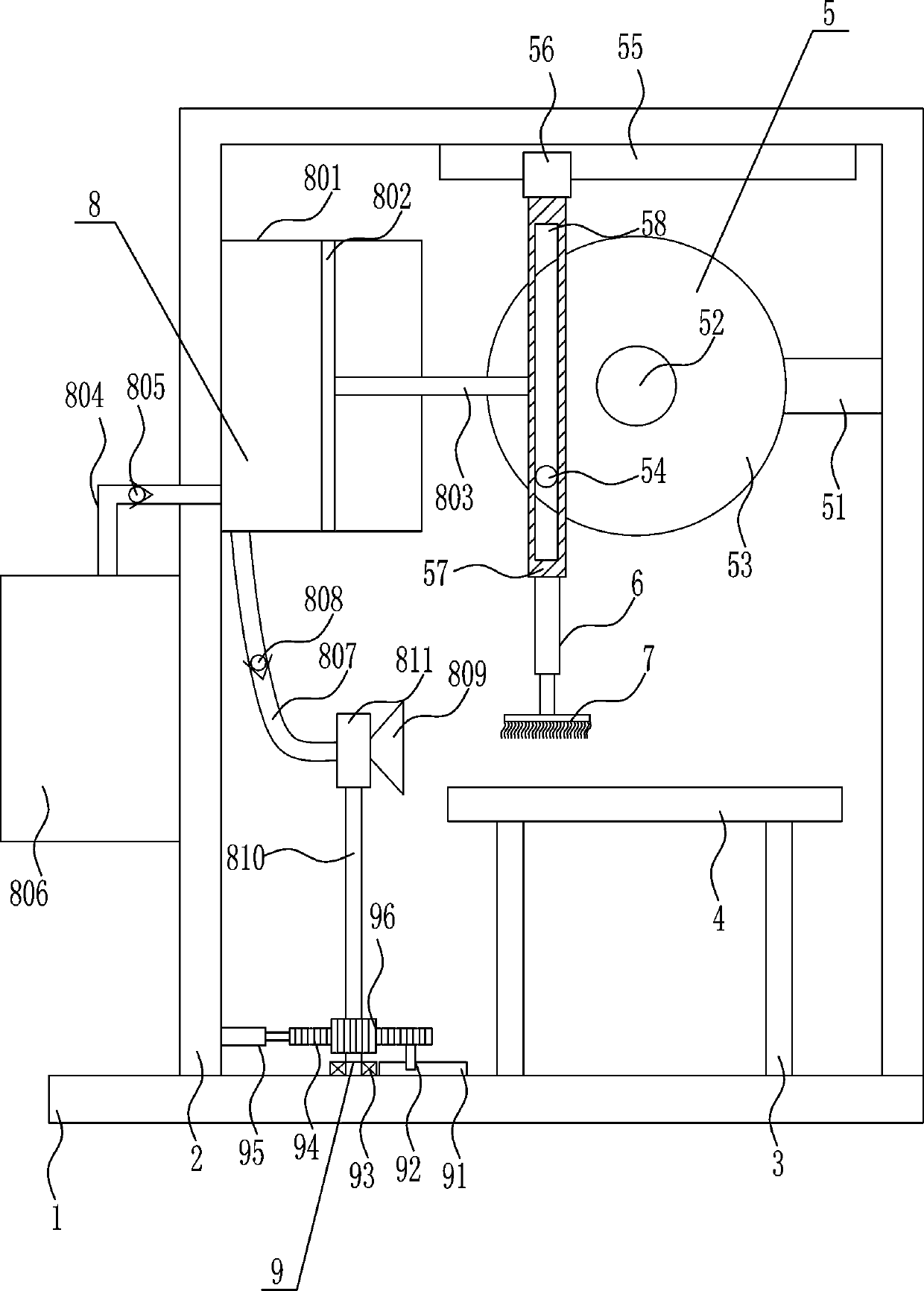

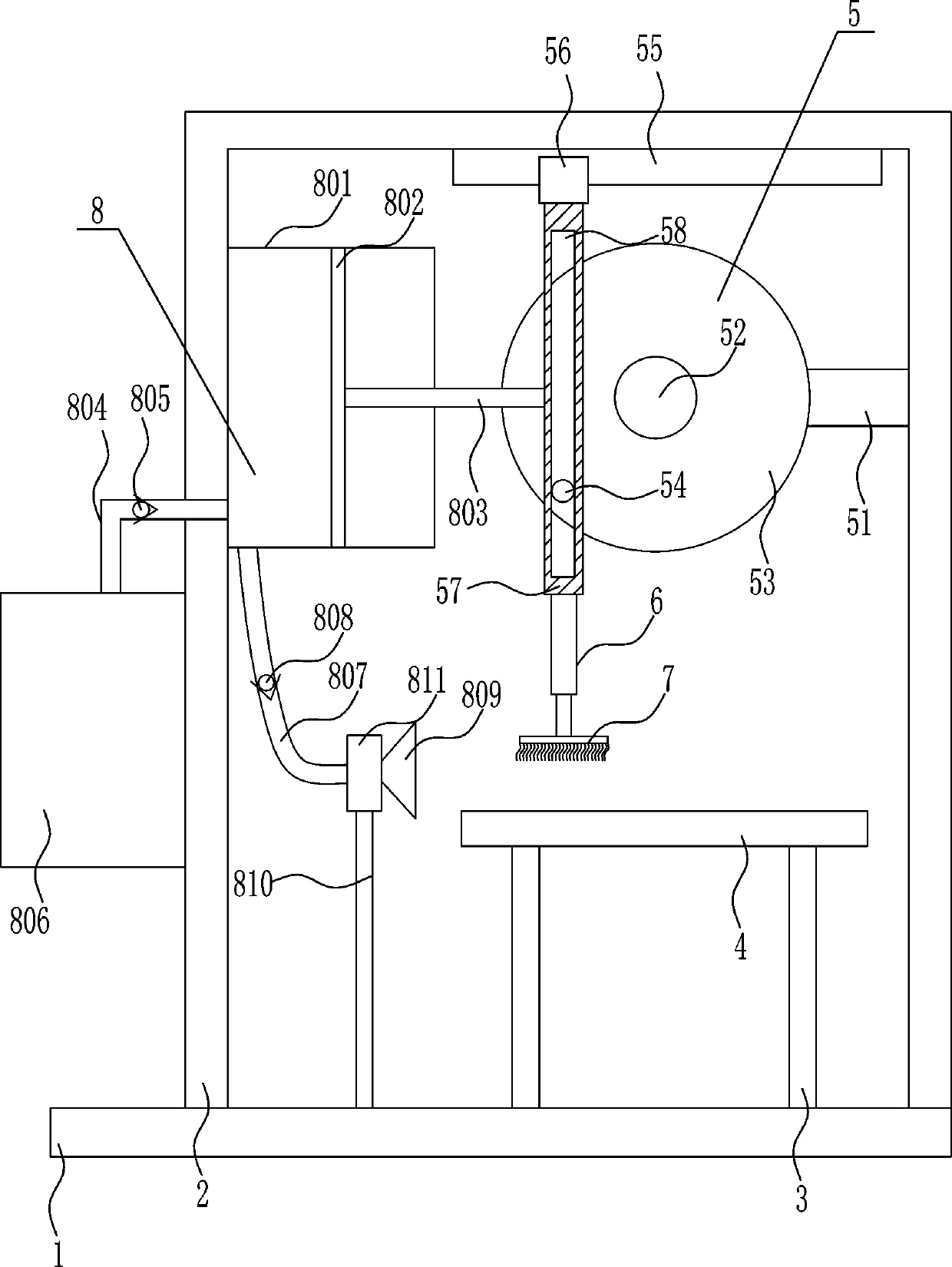

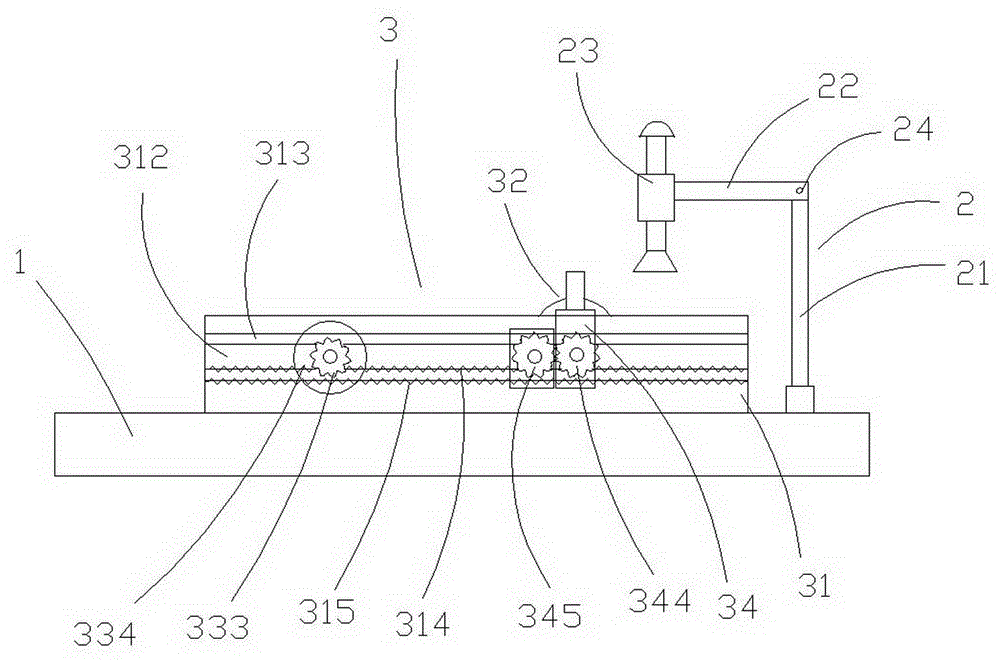

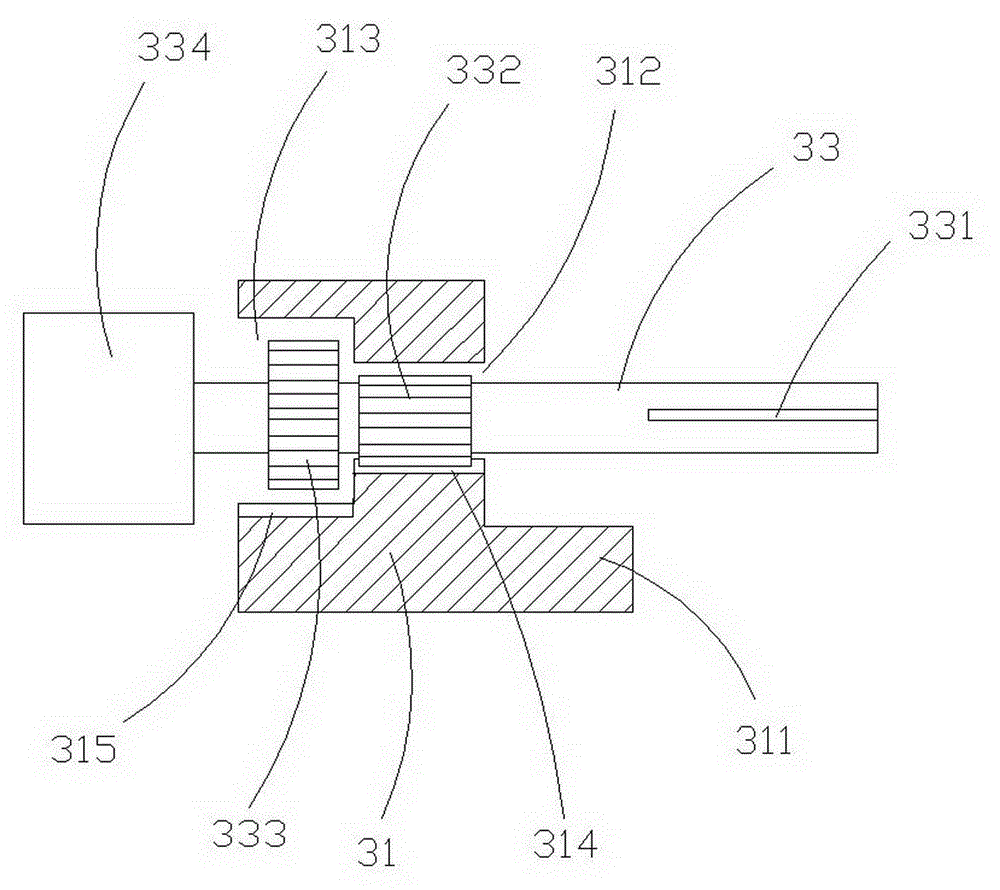

Pump cap screwing machine

ActiveCN103466523AAdjustable cap tightening forceEasy to connectThreaded caps applicationStops devicePower transmission

The invention discloses a pump cap screwing machine, which comprises a rack, a power transmission device, a cap screwing assembly, a bottle body supply device, a first bottle guide device, a second bottle guide device, a bottle feed star wheel device, a bottle stopping device, a bottle discharge star wheel device, a cap supply device, a rotating air path distribution device and a bottle output device, wherein the first bottle guide device is arranged at the tail of a screw rod and is matched with the bottle feed star wheel device, and a bottle feed inlet is formed between the first bottle guide device and the bottle feed star wheel device; the bottle feed star wheel device comprises a bottle feed turntable and a bottle feed rotating shaft which is movably connected with the power transmission device, the bottle feed turntable is provided with bottle feed clamping mounts and the bottle feed turntable is sheathed on the bottle feed rotating shaft; the second bottle guide device is matched with the bottle discharge star wheel device, a bottle discharge outlet is formed between the second bottle guide device and the bottle discharge star wheel device and the bottle stopping device is connected with the bottle discharge outlet. The pump cap screwing machine has the advantages that the structure is simple, the production efficiency is high, the processes of cap conveying, cap grabbing and cap screwing can be finished in one step, the effect of multiple products on one production line can be realized and the cap screwing effect is good.

Owner:CHANGZHOU HUITUO TECH

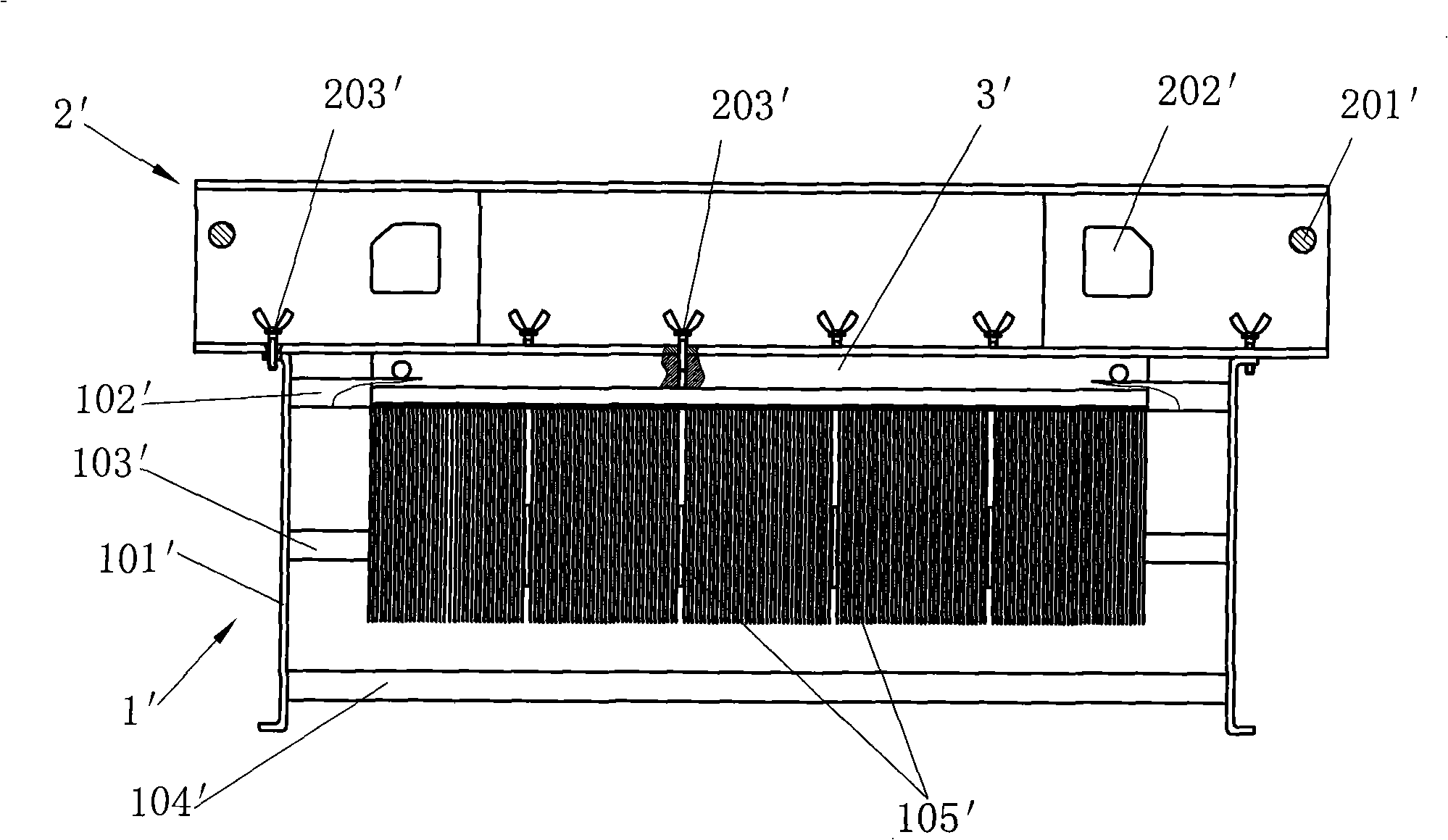

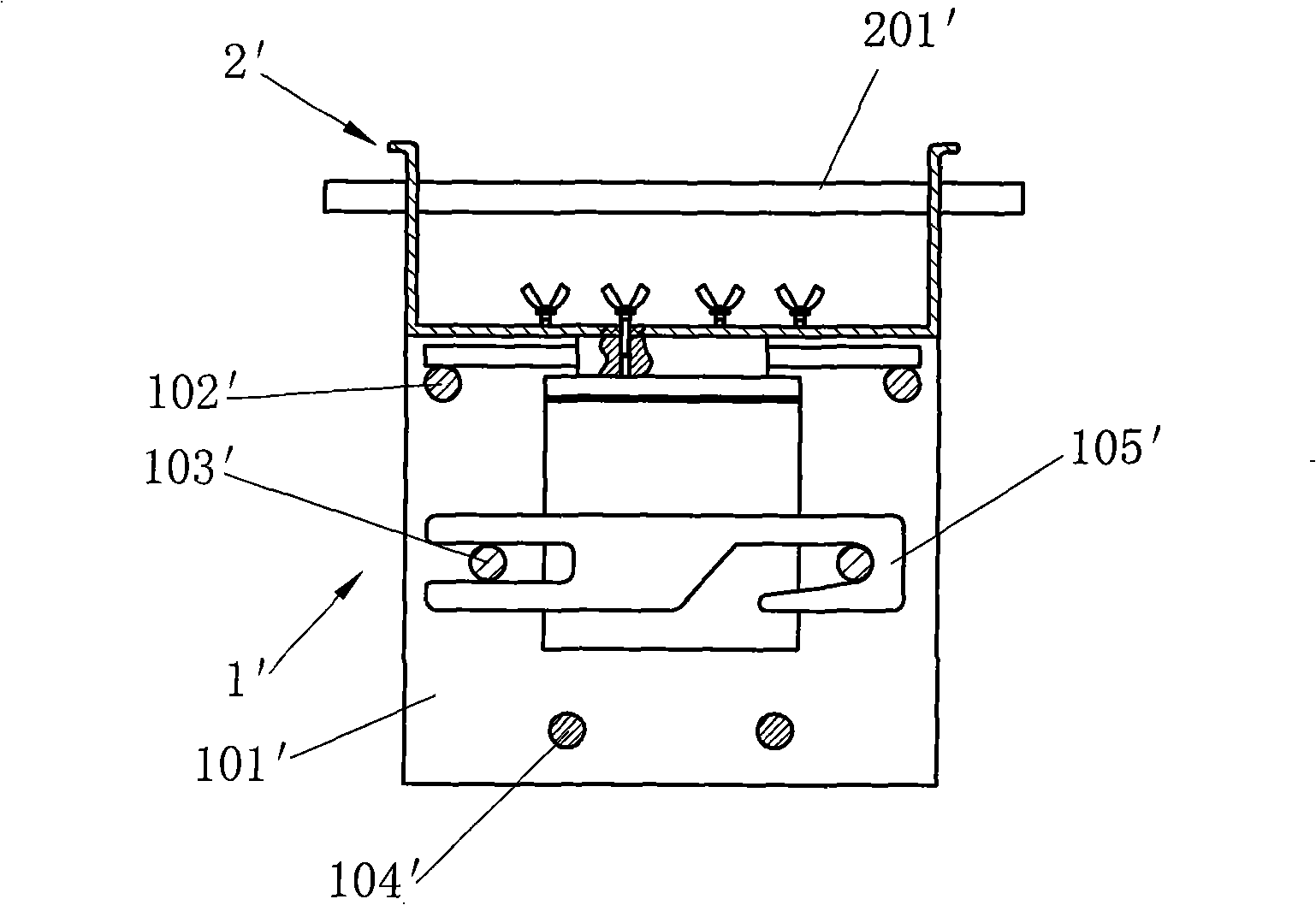

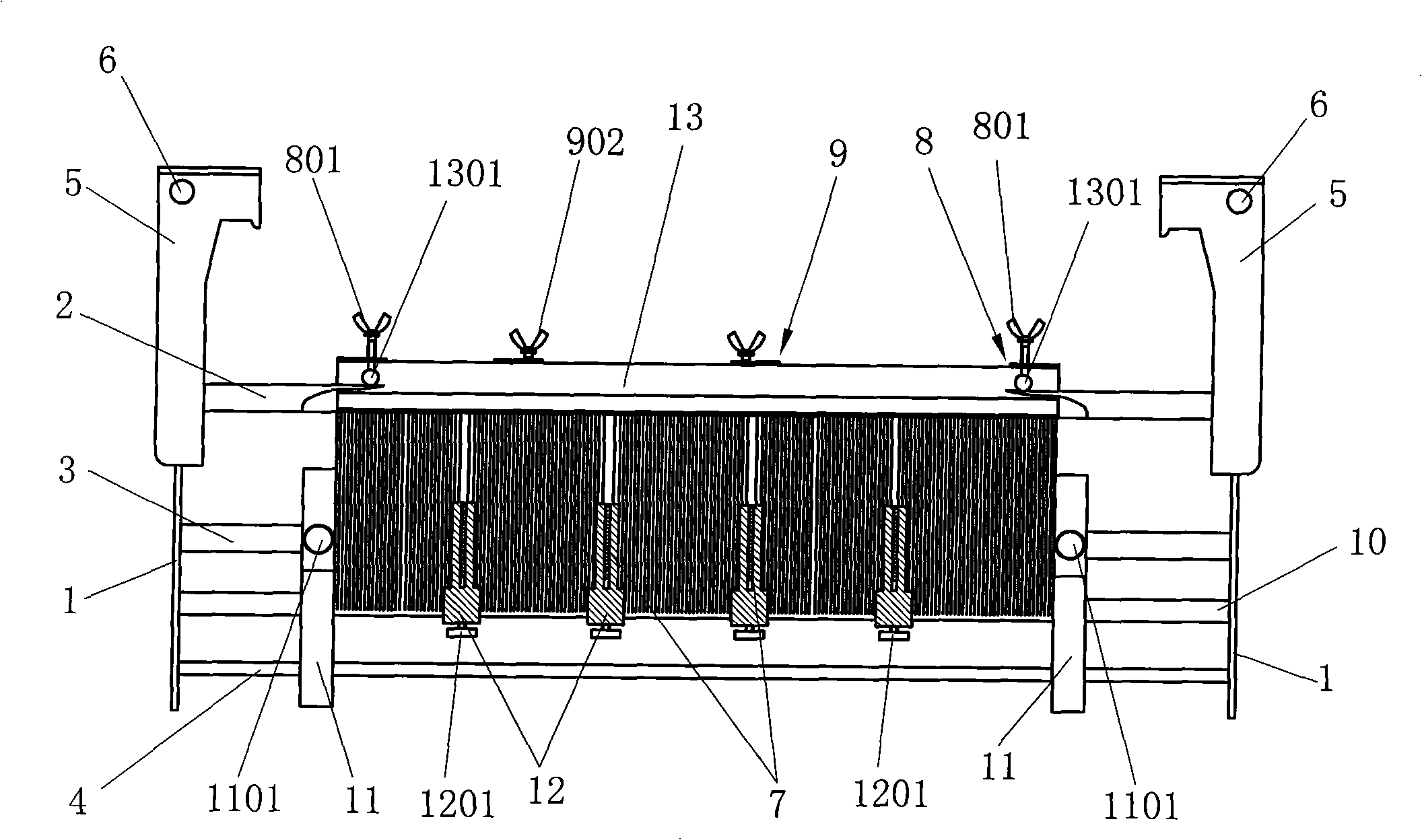

Dust removing plant for production of circuit switch

InactiveCN107694977ANot easy to moveImprove dust removal efficiencyDirt cleaningCleaning using toolsEngineering

The invention relates to a dust removing plant of a circuit switch, and particularly relates to a dust removing plant for production of a circuit switch. The technical problem to be solved is to provide the dust removing plant for production of the circuit switch, which is high in dust removing efficiency, and can treat dust in the process of removing dust, and is not easy to move the circuit switch. For solving the technical problem, the dust removing plant for production of the circuit switch is provided. The dust removing plant comprises a bottom plate, a n-shaped frame, a first supportingrod, a placing plate, and others; the top part of the bottom plate is provided with the n-shaped frame, and the upper part of the inner right side of the n-shaped frame is provided with a driving mechanism; the bottom part of the driving mechanism is provided with an air cylinder, and the bottom end of the air cylinder is connected with a soft brush; the upper part of the left side of the n-shapedframe is provided with a dust removing mechanism. The a dust removing plant reaches the effect that the dust removing efficiency is high, the dust can be treated in the process of removing dust and the circuit switch is not easy to move. Through the driving mechanism, the soft brush is driven to remove dust on the circuit switch; the dust is treated by the dust collecting mechanism, and the circuit switch is clamped by the clamping mechanism; the dust removing plant is not easy to slip.

Owner:南昌安润科技有限公司

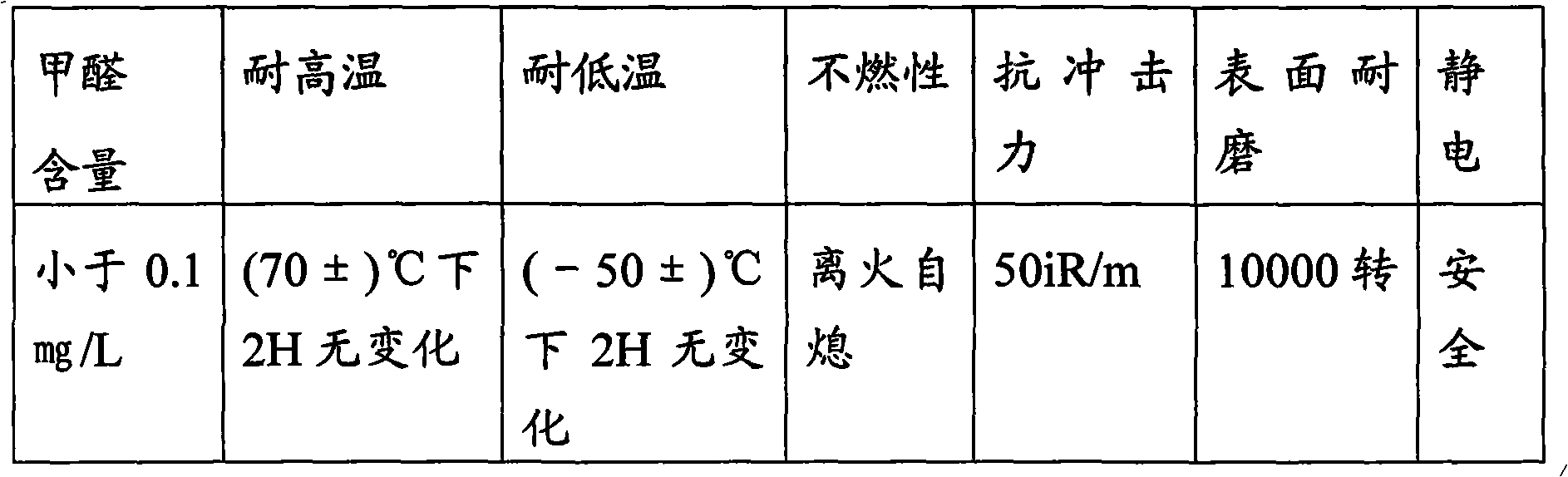

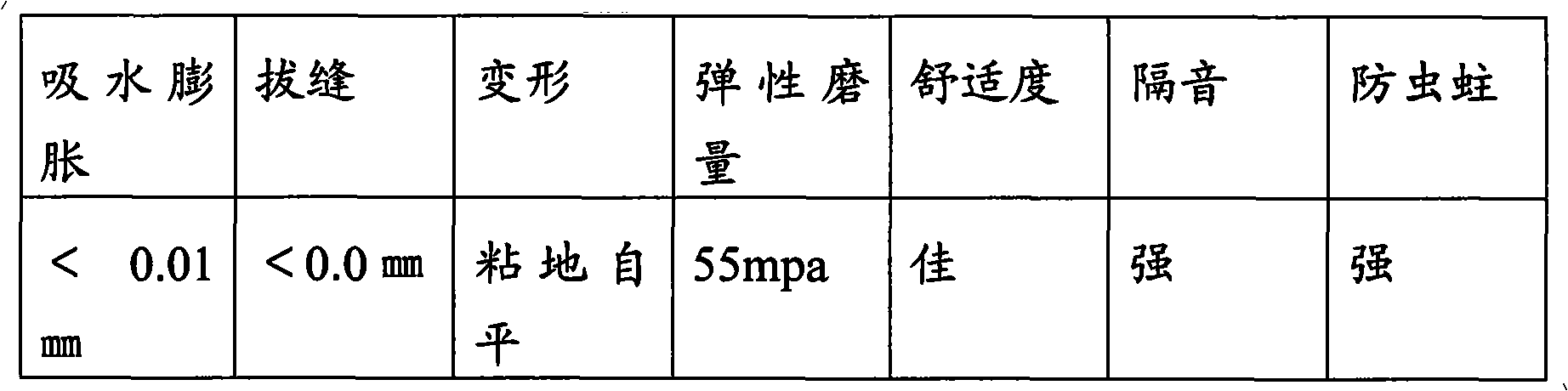

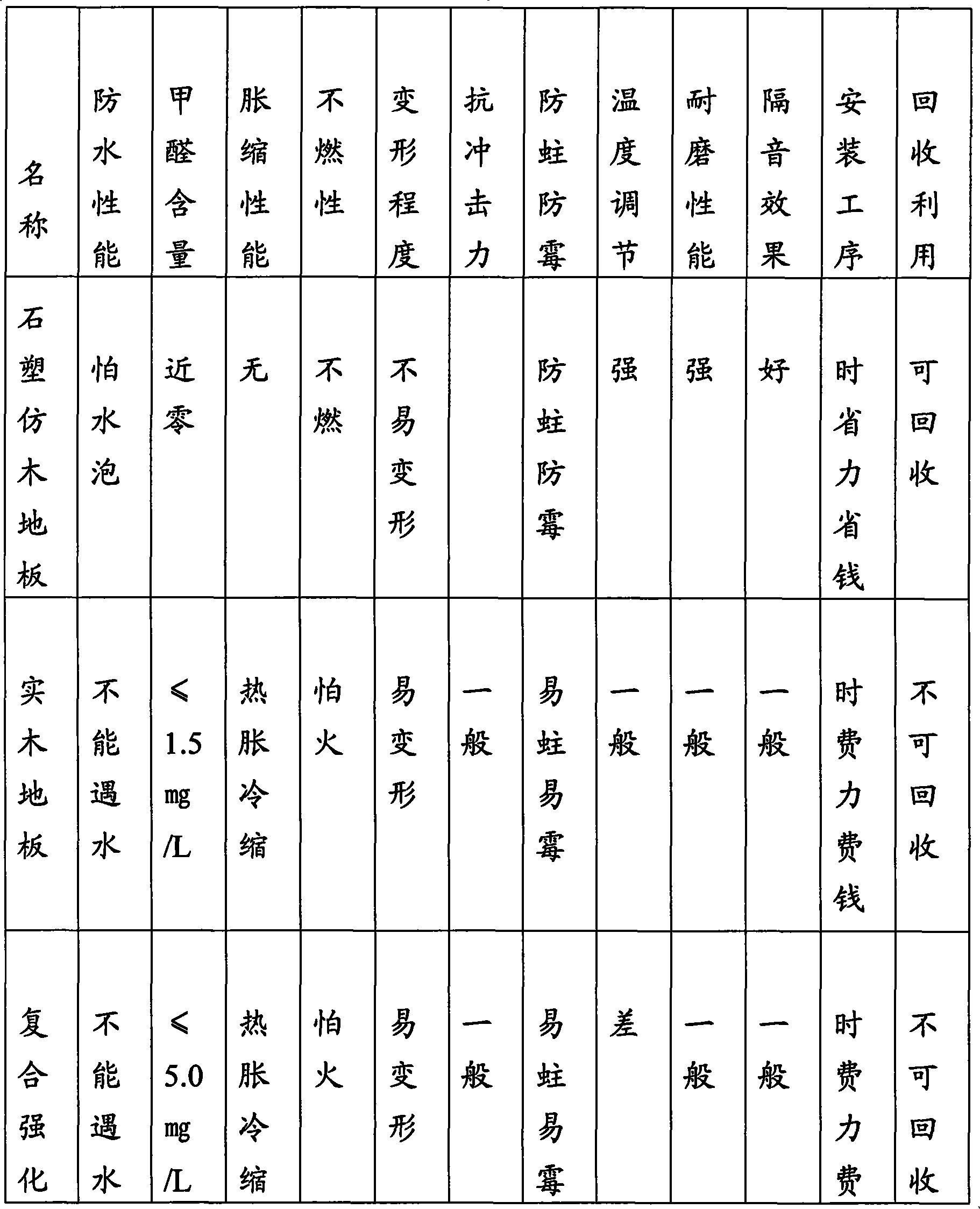

Stone-plastic simulated wood floor and manufacturing method thereof

The invention provides a stone-plastic simulated wood floor and a manufacturing method thereof. The stone-plastic simulated wood floor comprises the following components in percentage by mass: granular calcium carbonate mineral powder or tailing residue powder (containing over 50 percent of calcium carbonate), waste polyvinyl chloride (PVC) granules, polyamino modified silicone oil, polyether silicone oil, dibutyl ester, paraffin, complex stabilizers, tribasic lead sulfate, lead stearate, barium stearate and stearic acid. The stone-plastic simulated wood floor manufactured from wastes from industrial and mining enterprises and life saves resources, is insusceptible to sliding and radiation generation and solves the problems of low fire resistance, low water resistance, deformation, insect damage and troublesome maintenance and the like.

Owner:张家口德高森板业有限公司

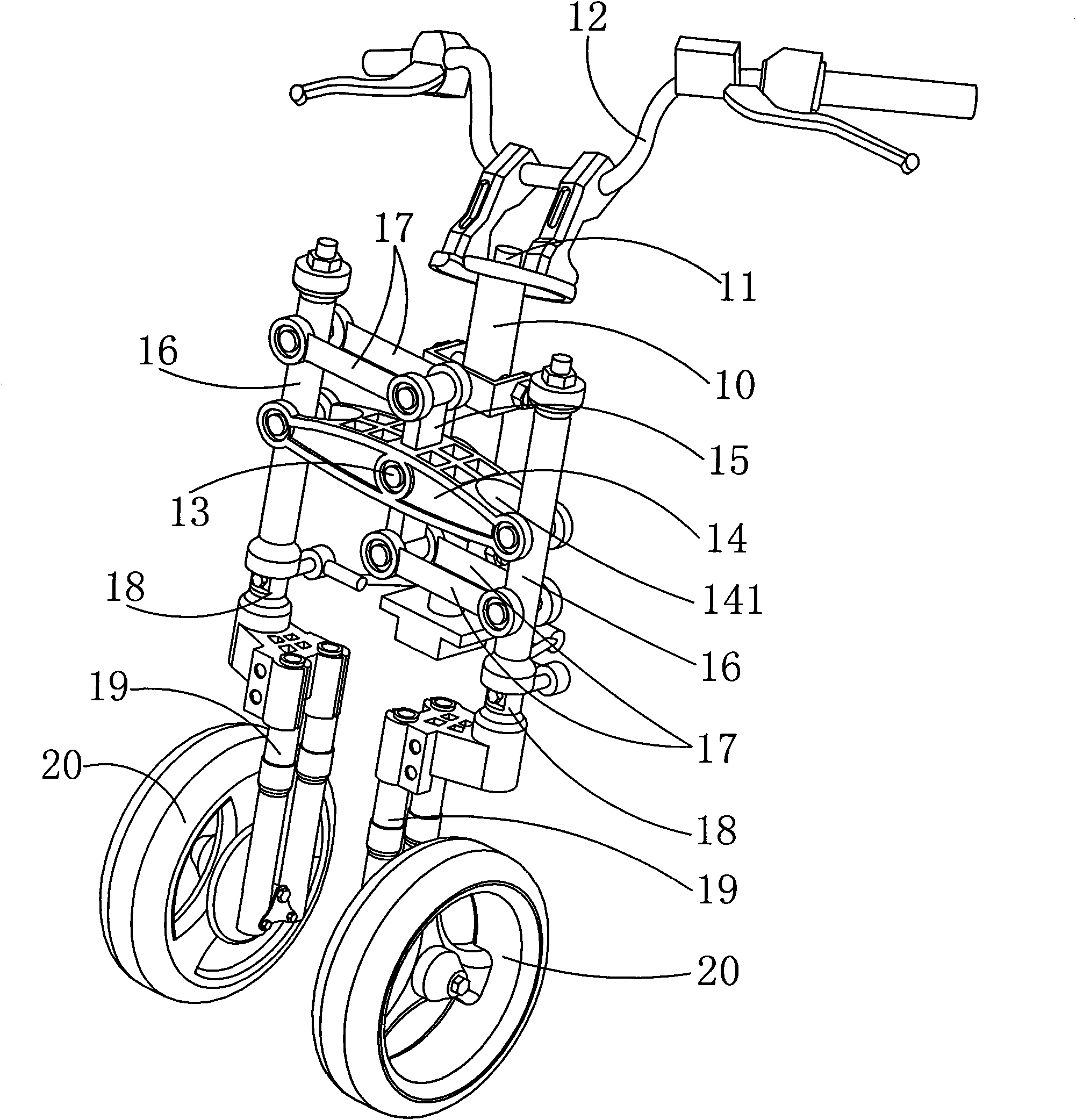

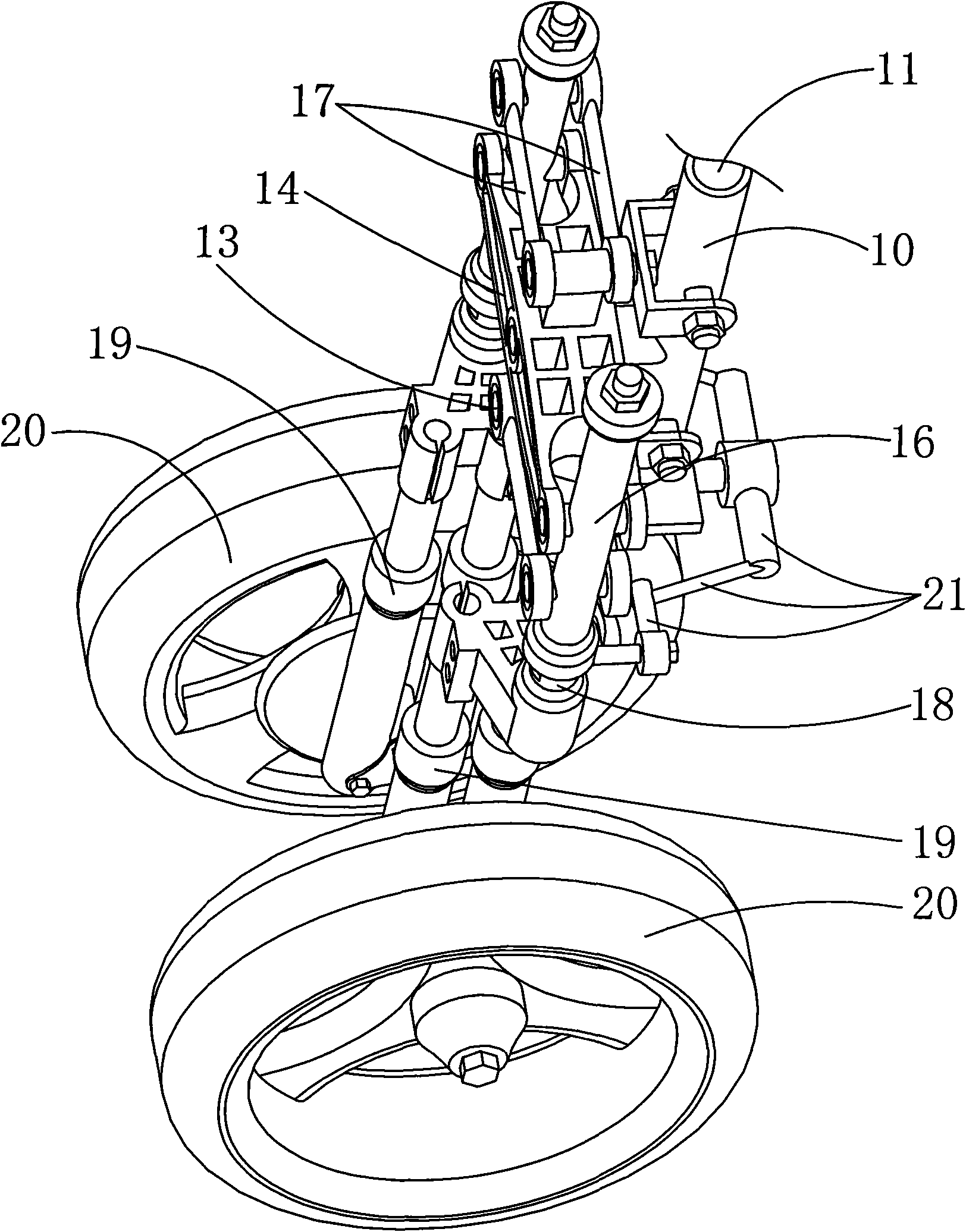

Link mechanism of double front wheels of motorcycle

InactiveCN101774414AImpact of traffic congestionNarrow areaCyclesSteering deviceVehicle frameEngineering

The invention belongs to the technical field of motorcycles and relates to a link mechanism of double front wheels of a motorcycle. A lower connecting plate is arranged in a motorcycle frame, the middle part of the motorcycle frame is provided with a positioning shaft hinged with an H-shaped balancing plate, a vertical support plate is hinged on the fixing shaft in the H-shaped balancing plate, and both sides of the H-shaped balancing plate are hinged with lateral pipes; the left side at the upper end, the right side at the lower end or right side at the upper end and the left side at the lower end of the vertical support plate are hinged with a support connecting rod parallel to the H-shaped balancing plate, and the other end of the support connecting rod is hinged with the lateral pipes respectively; and two independent suspensions are arranged in the two lateral pipes respectively, and the lower ends of the independent suspensions are connected with a shock absorber and a front wheel in sequence respectively. The link mechanism has the advantages that: the stability is high; compared with the rear two-wheeled motorcycle; the two front wheels has a small overall area; the link mechanism is narrower the use space is smaller; and the turning operation is more flexible; and compared with the conventional two-wheeled motorcycle, the motorcycle using the link mechanism is insusceptible to side skid and has a simple connecting structure and low cost.

Owner:TAIZHOU CITY KAITONG MOTORCYCLE MFG +1

Vomitus collecting device capable of preventing odor for gastroenterology department

InactiveCN107320339AAvoid distributingIncrease coefficient of frictionSpittle receiving devicesEngineeringGastroenterology department

The invention relates to a vomitus collecting device, in particular to a vomitus collecting device capable of preventing odor for a gastroenterology department. The vomitus collecting device capable of preventing odor for the gastroenterology department is convenient to use, can collect vomituses of a patient, can shield the collected vomituses and facilitates recovery of the patient. In order to solve the technical problem, the vomitus collecting device capable of preventing odor for the gastroenterology department comprises a box and the like, wherein a lifting device is arranged in the middle of the inner bottom of the box; a collecting device is arranged in the box and is positioned on the outer side of the lifting device; a collecting component of the collecting device is connected with a lifting component of the lifting device; and a through hole is transversely formed in the middle of the top of the box. The vomitus collecting device capable of preventing odor for the gastroenterology department is convenient to use, can collect the vomituses of the patient, can shield the collected vomituses to stop odor from spreading, and facilitates recovery of the patient.

Owner:赵梦洁

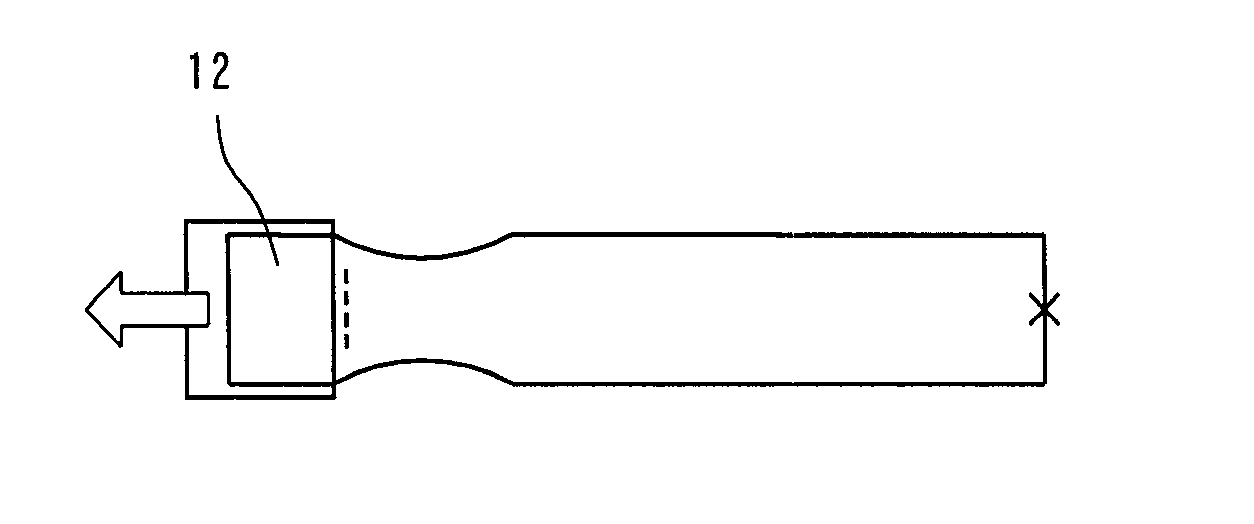

Indwelling needle assembly and method of using the same

ActiveUS20110054402A1Not easy to slipPuncturing operationInfusion syringesSurgical needlesAdhesiveSurgery

An indwelling needle assembly, including an inner needle having a sharp needle point at a distal end thereof; an inner needle hub which is fixed to a proximal portion of the inner needle and which has a proximal end face; a hollow outer needle into which the inner needle is inserted; and an outer needle hub fixed to a proximal portion of the outer needle, the inner needle is adhered and fixed to the inner needle hub with an adhesive at a proximal portion thereof, and the inner needle hub is provided with a projected part formed by projecting the adhesive toward a proximal side relative to the proximal end face.

Owner:TERUMO KK

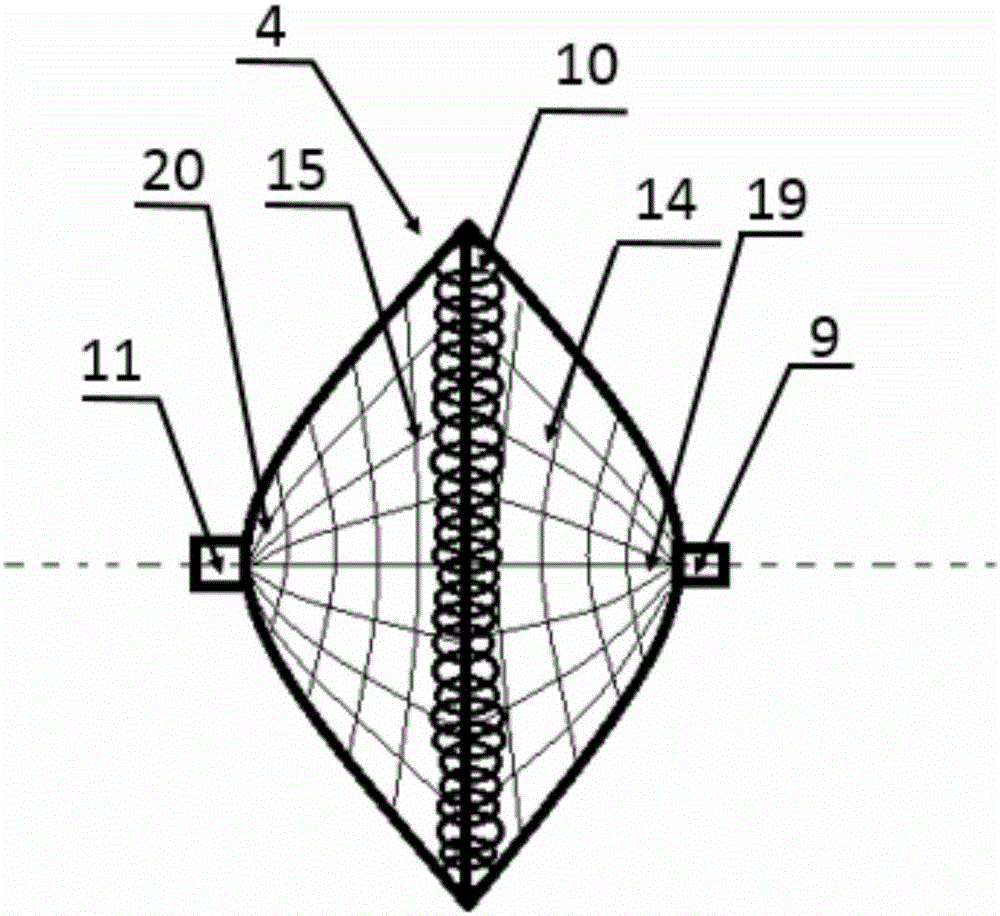

Left auricle plugging device

InactiveCN106344100ASimple positioningNot easy to fall off and slipOcculdersNickel titaniumPlate column

The invention discloses a left auricle plugging device and belongs to the field of medical apparatuses and instruments. The left auricle plugging device is provided with a plugging plate, a plugging umbrella, an elastic column, a plate-column connecting piece and a threaded connecting piece. The surfaces of the plugging umbrella and the plugging plate are covered with permeable polytetrafluoroethylene films. The plugging device is made from nickel-titanium alloy through braiding, bowl-shaped barbs are fixed to the edge of the plugging umbrella, and positioning is easy. Re-positioning of the plugging plate after plugging umbrella release can be achieved by the elastic rod of a spiral structure of the elastic column, and the function of extending and changing the direction of the plugging plate can be achieved, and the requirement relative to a left auricle opening angle of a delivery sheathing canal in operation is reduced. In addition, a thread is arranged on the edge of the plugging plate, the structure can assist the positioning of plugging plate, edge leakage caused by non-attachment between the plugging device and a left auricle wall can be also decreased, and complete plugging of the left auricle can be achieved. The errors caused by subjective judgment of an operator on the plugging device release device are decreased. Furthermore, the left auricle plugging device is suitable for left auricles of different shapes and provides convenience for operating instrument and material selection.

Owner:BEIJING UNIV OF TECH

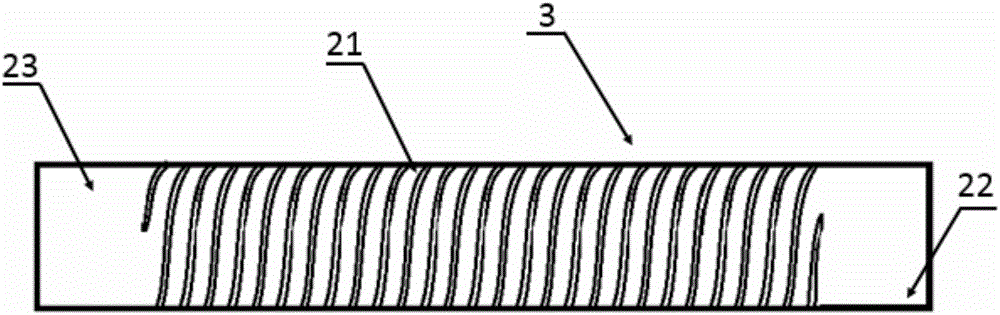

Manufacturing method for fibrous membrane for oil-water separation

ActiveCN104313796ANot easy to slipHigh breaking strengthElectro-spinningNon-woven fabricsFiberPorosity

The invention discloses a manufacturing method for a fibrous membrane of an extremely hydrophobic organic macromolecule chemical compound with an oil-water separation function in the technical field of fibrous membrane manufacturing. The manufacturing method comprises the following steps: synthetizing a copolymer with excellent electrostatic spinnability by regulating the compounding ratio of a monomer and controlling the condition of a suspension polymerization technology and by adjusting and controlling the compositions of a solution, processing parameters and the temperature and humidity conditions of environment, and spinning a copolymer solution into the fibrous membrane with the advantages of uniform and small bore diameters, high porosity, large flux and extremely hydrophobic and oleophylic properties by using an electrostatic spinning technique. The obtained fibrous membrane has the advantages that the specific surface area is large, the patterns are large, the stacking structure is proper, and the fibrous membrane is in a three-dimensional bore channel structure. Compared with an existing polymer-based oil-water separation member, the fibrous membrane has the advantages that the bore channel structure is more reasonable, the separation capacity is stronger, the separation efficiency is higher, the anti-pollution capacity is stronger, the membrane bores are not easy to block, the oil-water selectivity is stronger, the mechanical strength is higher, the flexibility and the temperature resistance are better, the preparation process is shorter, the consumed energy is little, the filtering rate is higher, and the cost is lower, so that the fibrous membrane can better satisfy the requirements of industrial practicality.

Owner:TIANJIN POLYTECHNIC UNIV

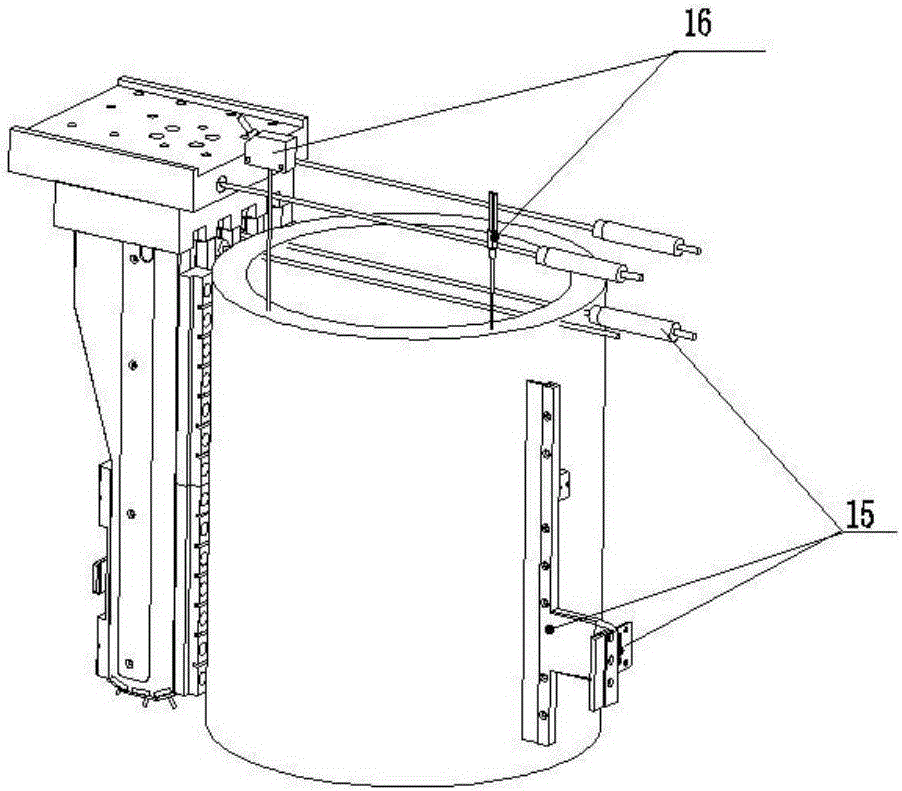

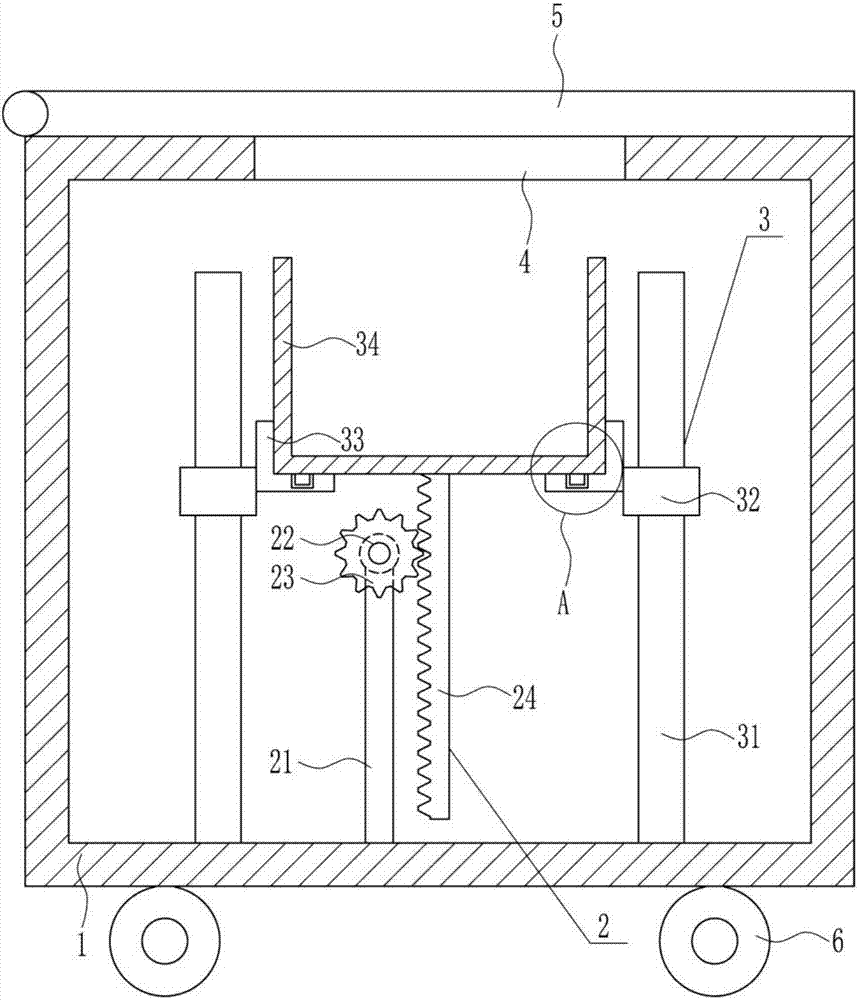

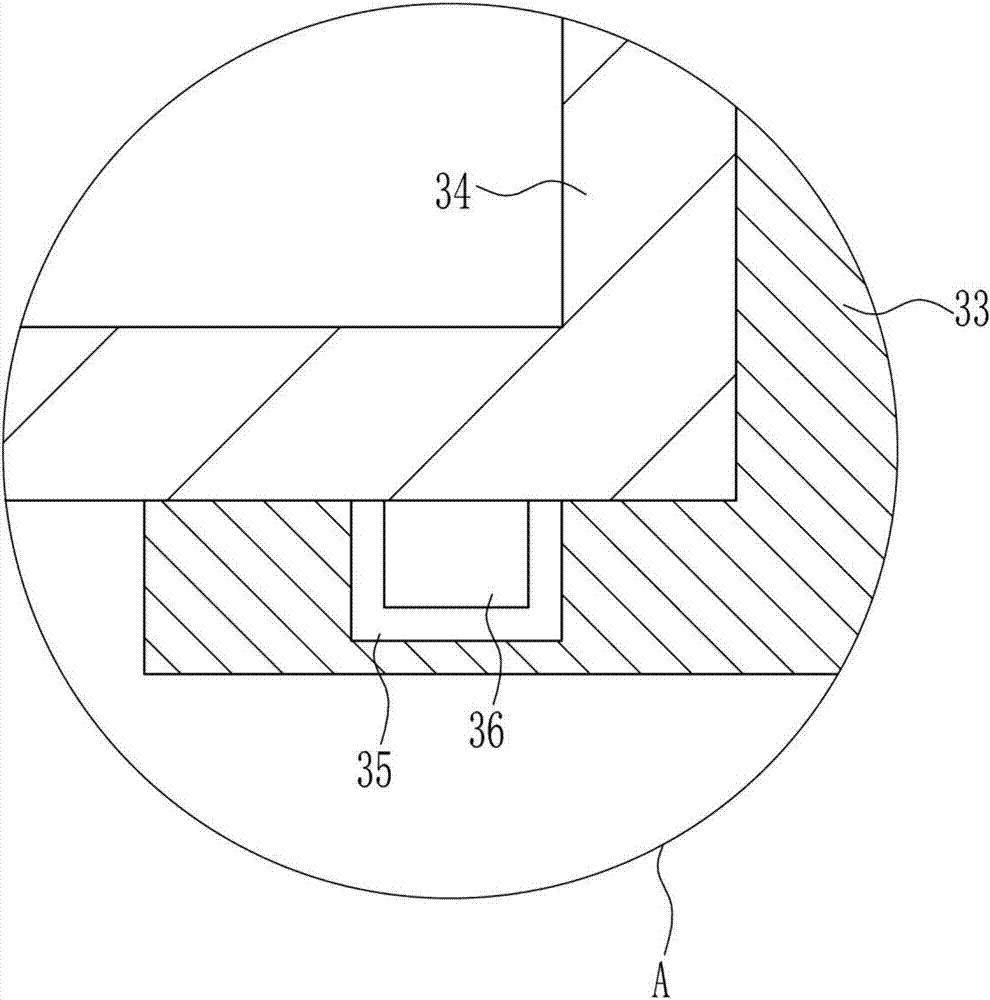

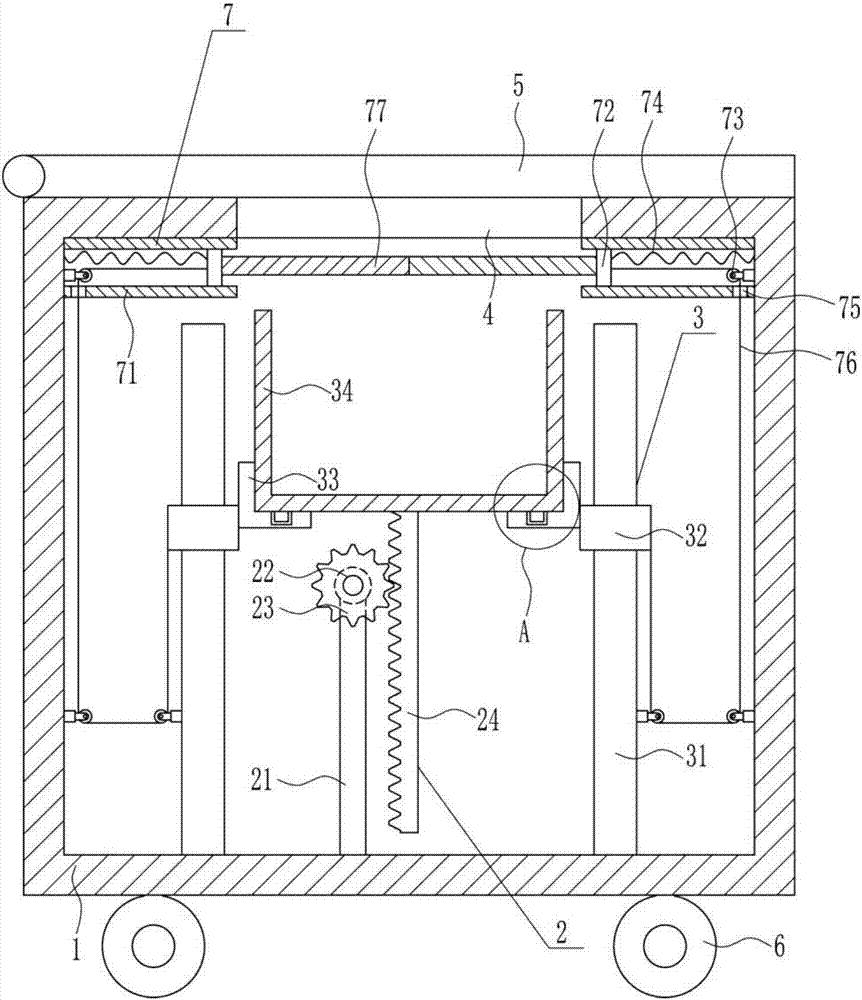

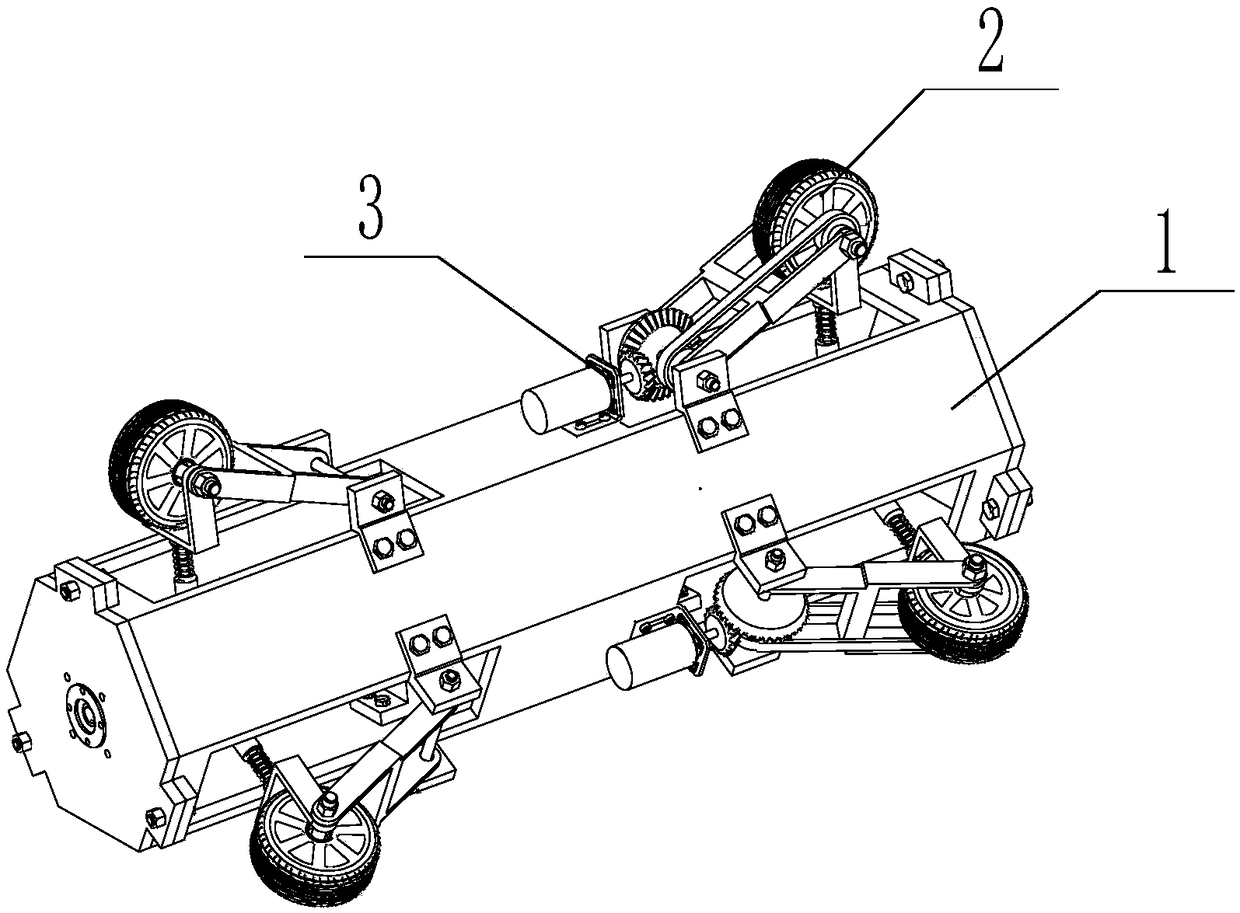

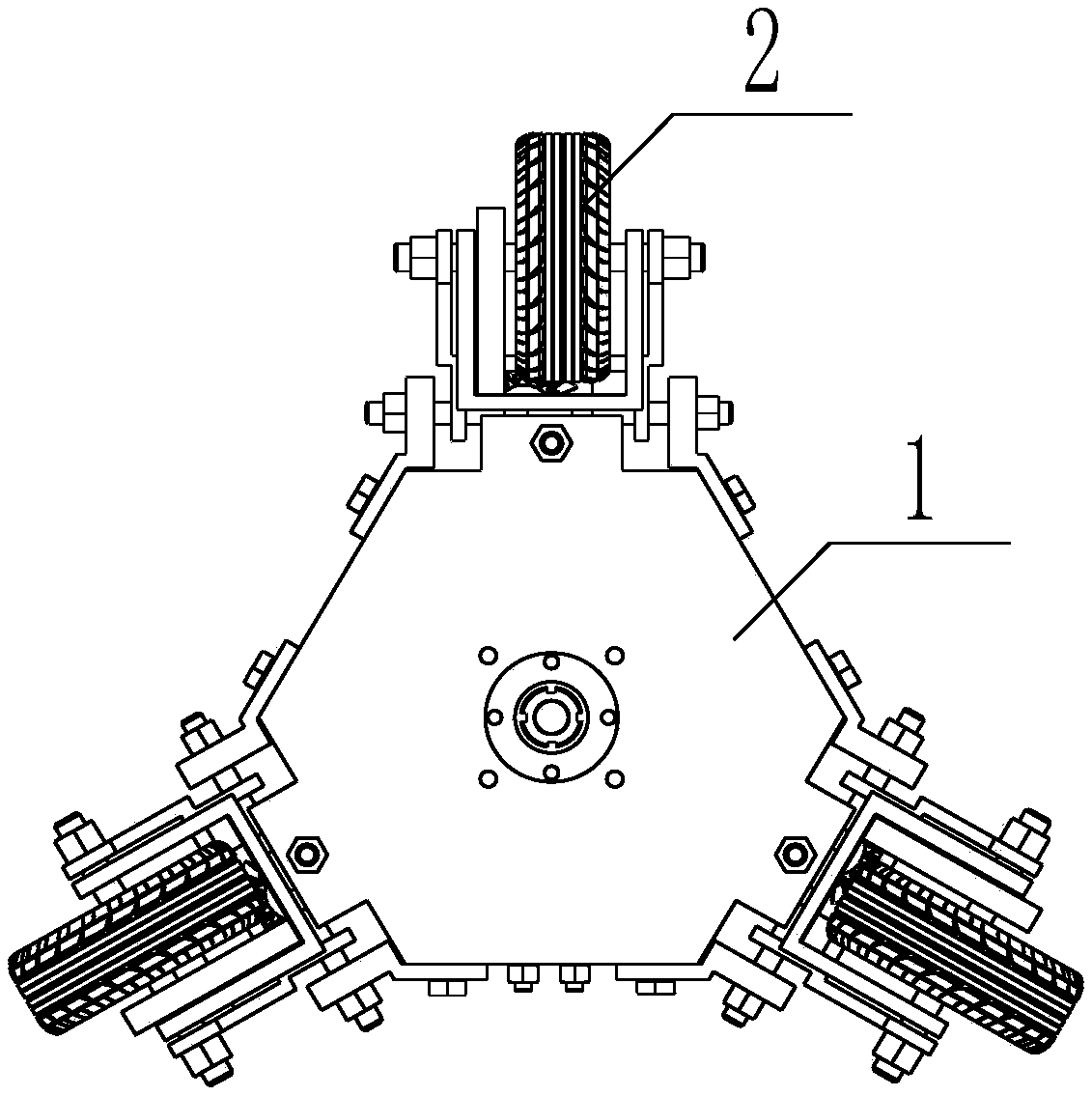

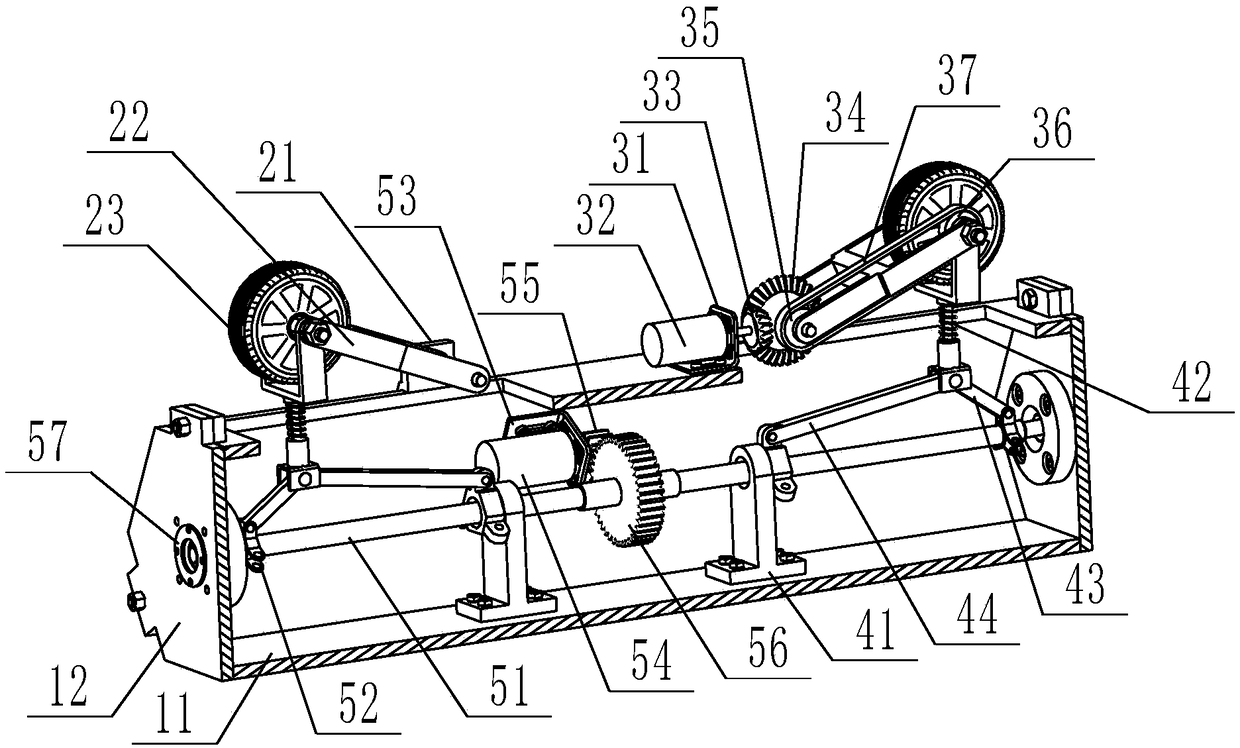

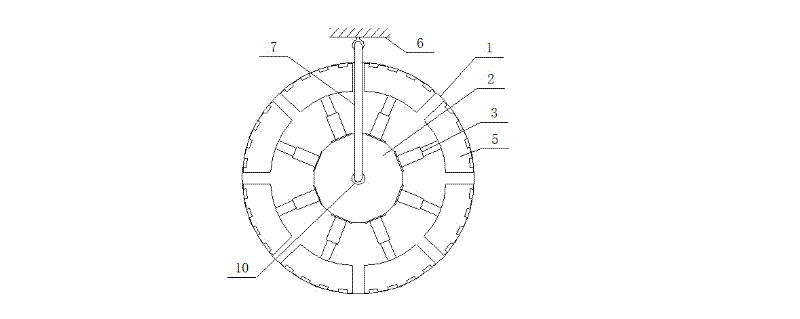

Pipeline crawling robot

The invention discloses a pipeline crawling robot, comprising a frame component, traveling devices, traveling driving devices, a radial support component, and a screw driving device. The screw drivingdevice is positioned inside; the traveling devices are positioned at the outer side of a frame; the screw driving device may drive the radial support component such that the traveling device expandsor contracts radially to adapt to pipelines of different diameters; spring supports can prevent robot or pipeline damage due to excessive pressure of traveling wheels upon the inner wall of a pipelinecaused by over-adjustment; the traveling driving device can drive the three traveling devices in the rear respectively so that the robot herein has better driving power. The pipeline crawling robot has the advantages of good pipeline adaptability, high traction force, good reliability and the like.

Owner:ANHUI UNIV OF SCI & TECH

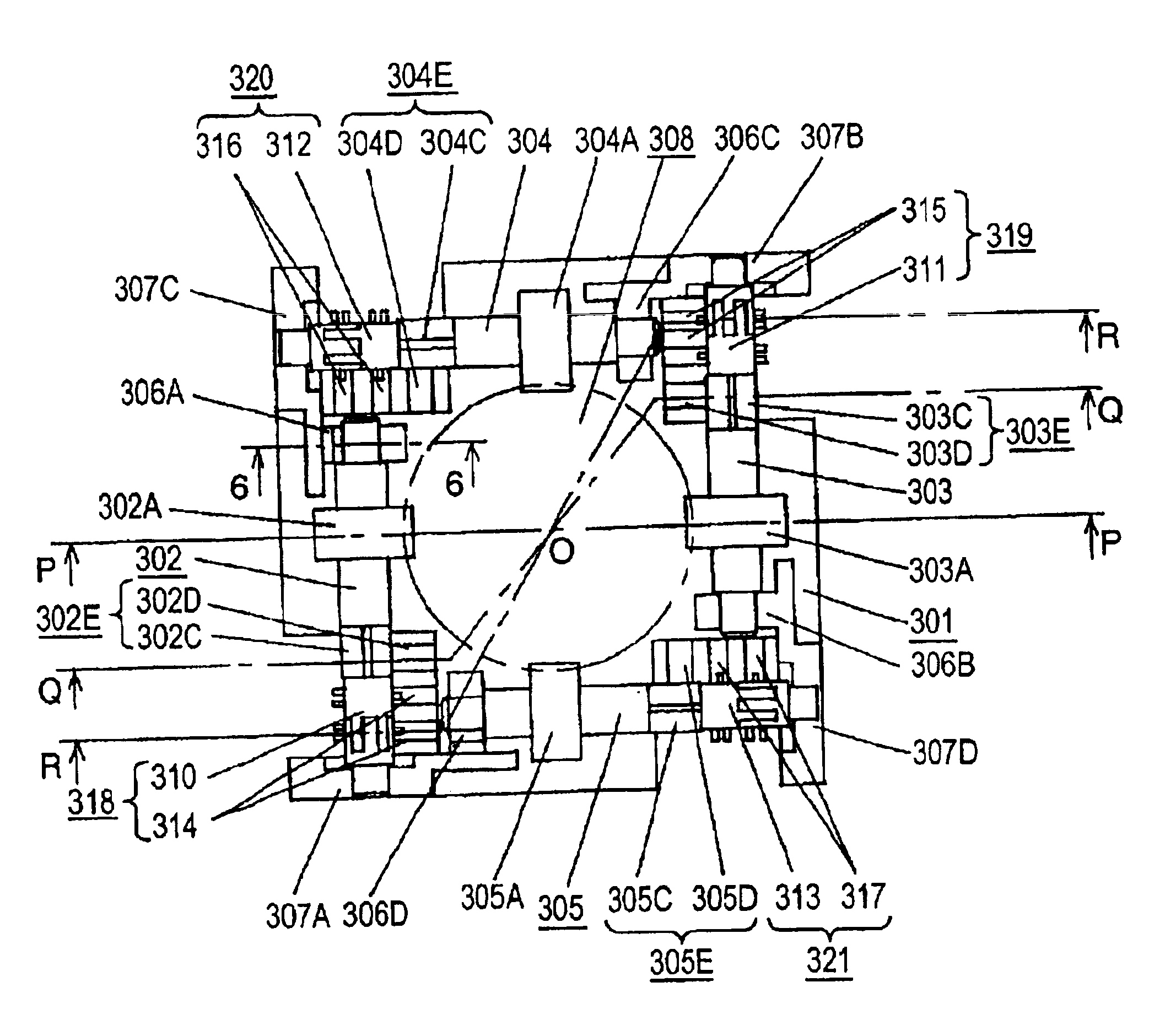

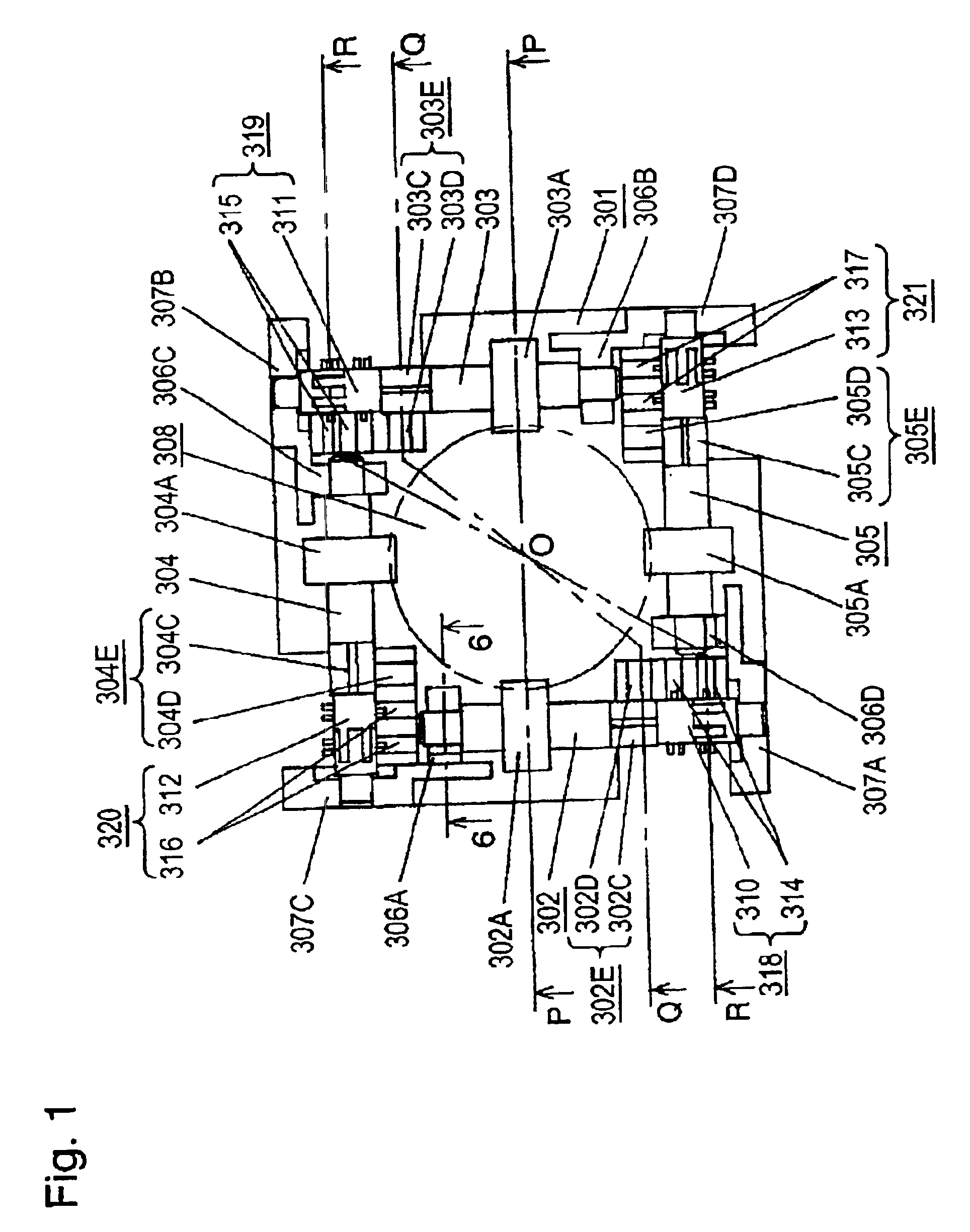

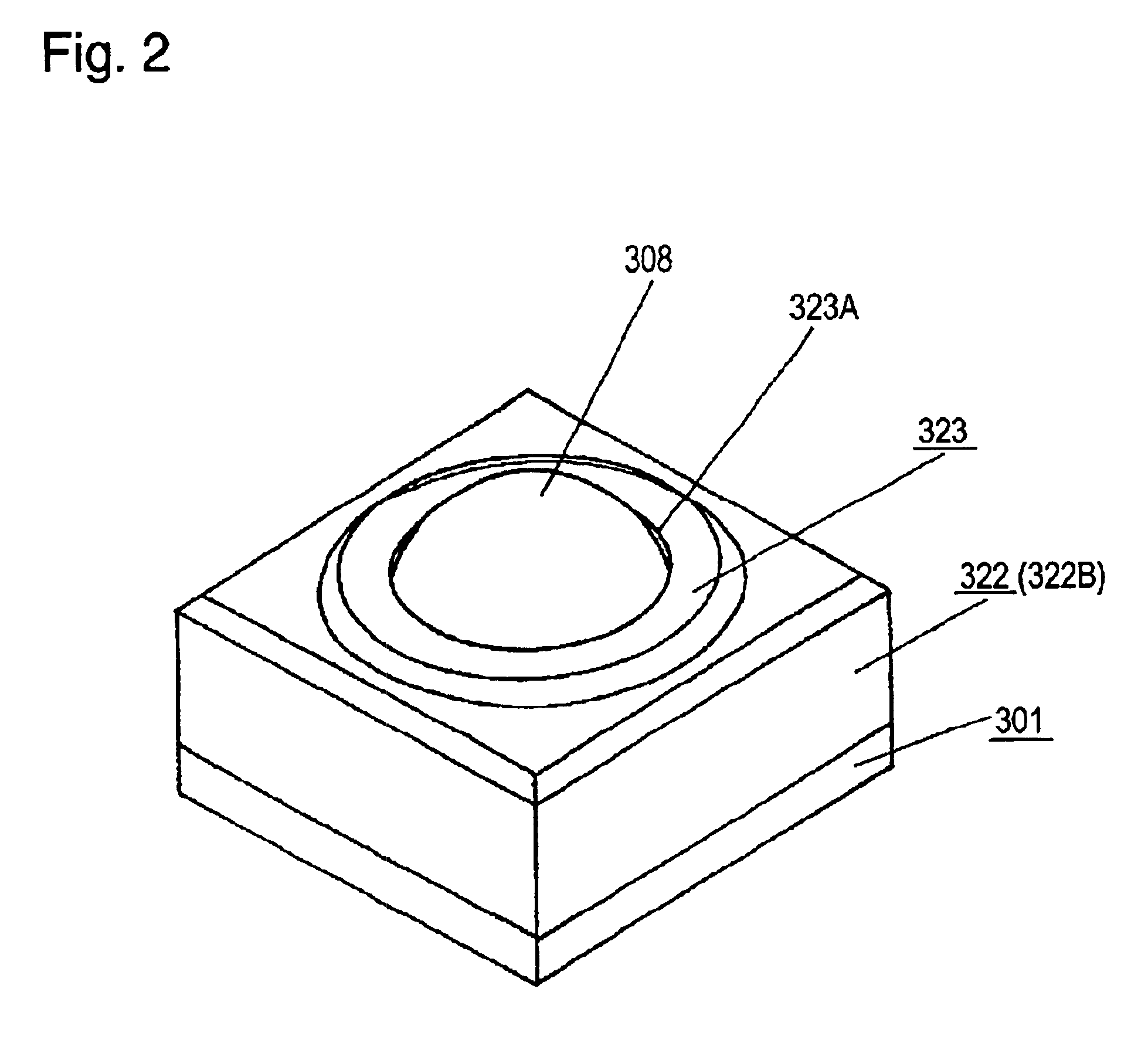

Track ball device and electronic apparatus using the same

InactiveUS6909422B2Reduce projected areaGuaranteed uptimeCathode-ray tube indicatorsInput/output processes for data processingMechanical engineeringSerration

Relating to a track ball device for manipulating a cursor moving on a display screen of an electronic apparatus, a track ball device being manipulated precisely while generating a click feel when a ball is rotated, having a small play angle and small size is presented. Beneath the center of the ball, the ball is rotatably supported by four rollers. The section of a contacting portion of the rollers contacting with the ball is a circular sawtooth profile, and the directions of the sawtooth serrations of opposite rollers are reverse to each other. Rollers 2 to 5 have switches as rotation amount detecting units. Further, X roller and Y roller contacting with the outer circumference in the orthogonal direction as seen from above the ball, and third roller hold the ball rotatably. Plural undulations are formed on the outer circumference of large-diameter contacting portions of the X roller and Y roller 3 of circular shaft shape. Rotary encoders are coupled to individual rollers.

Owner:PANASONIC CORP

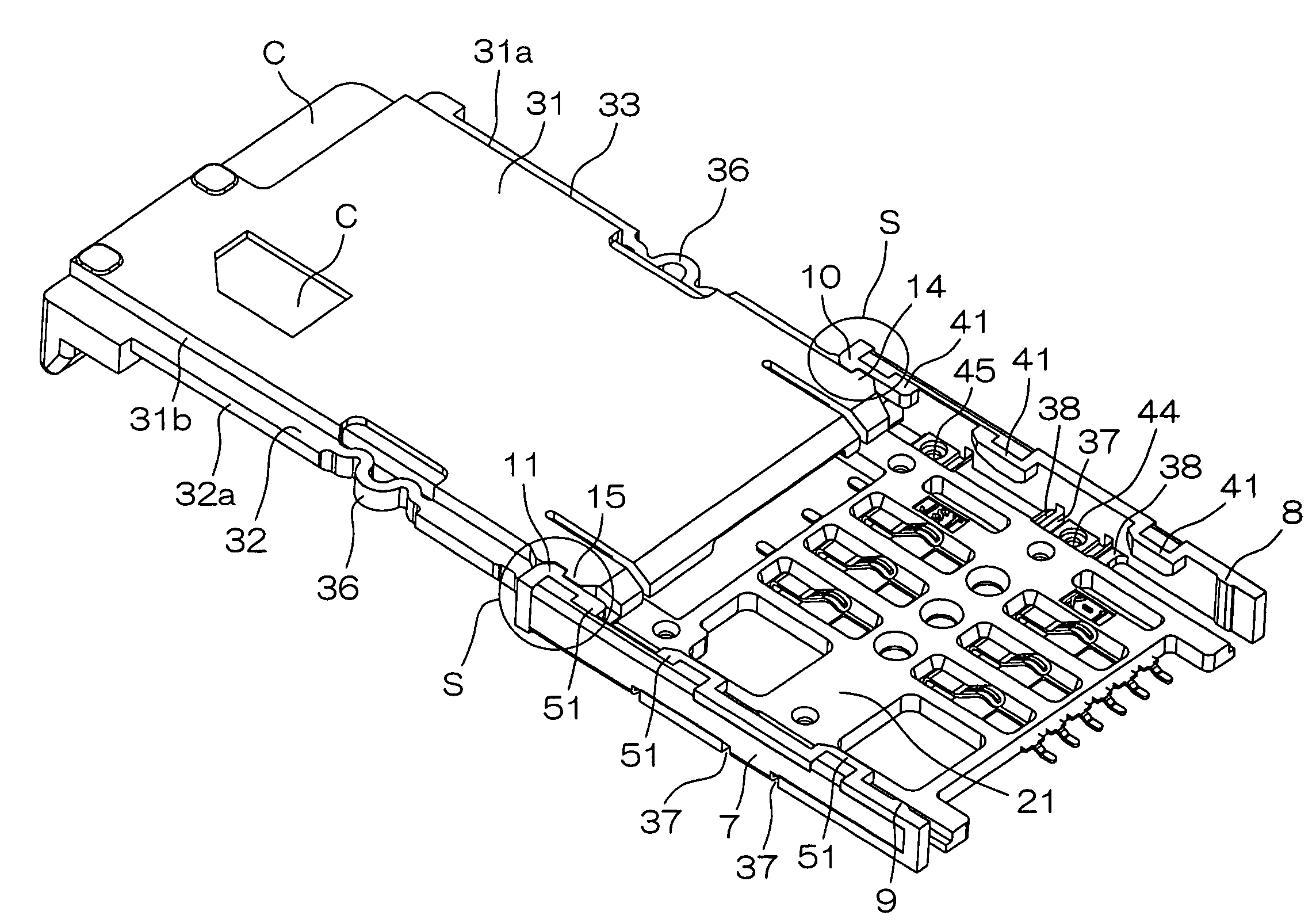

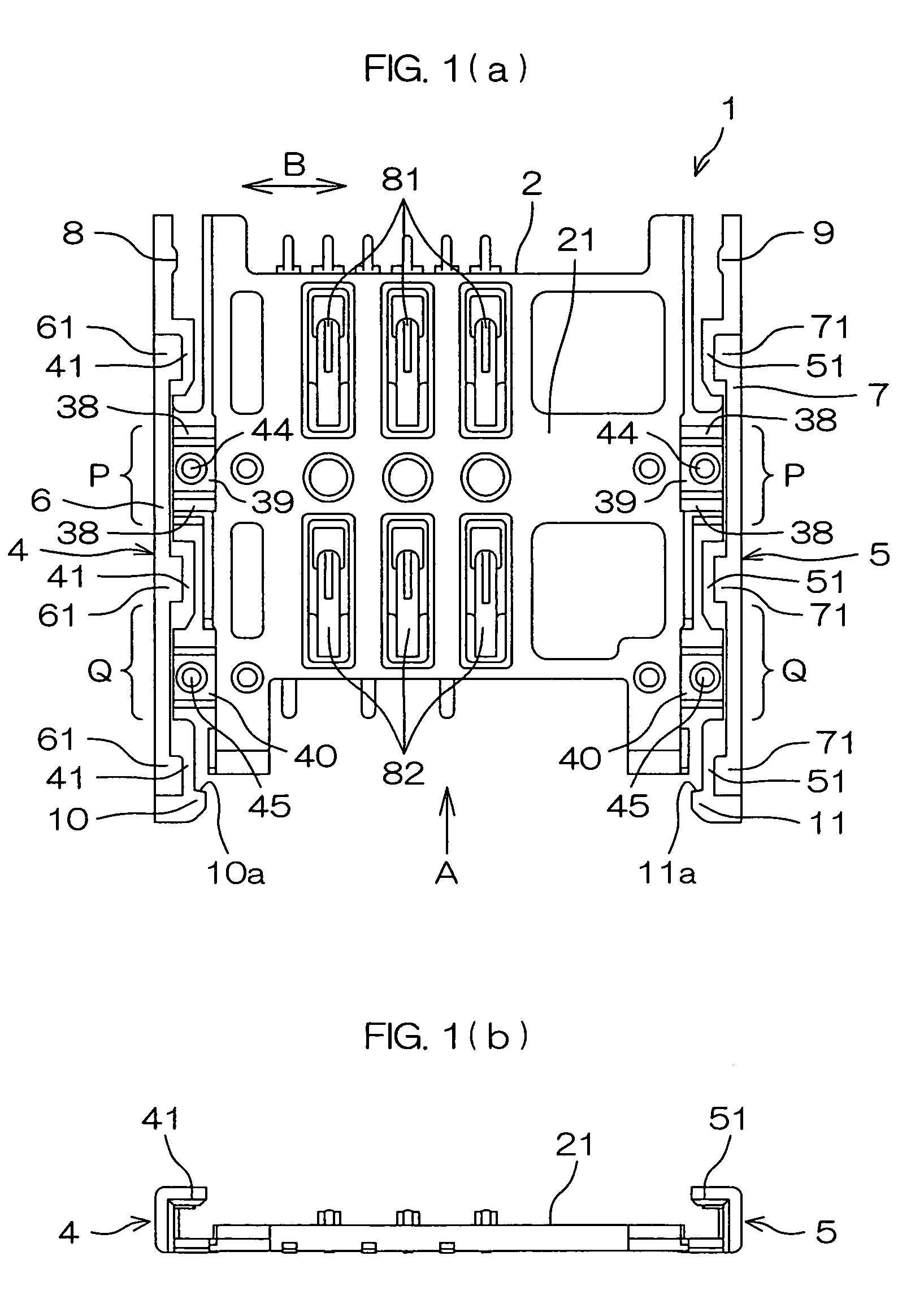

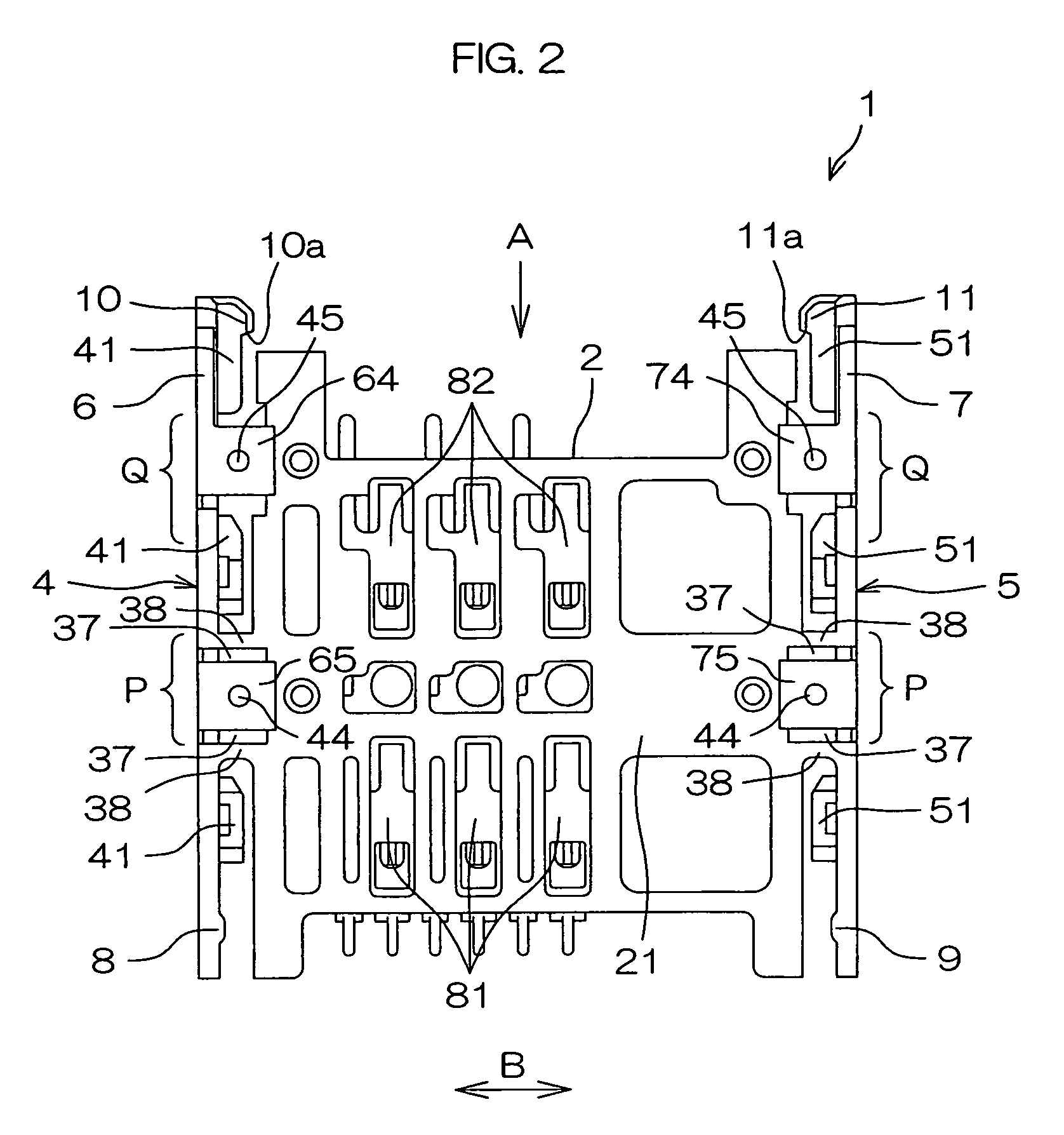

Socket for memory card

InactiveUS7438599B2Not easy to slipHold steadyTwo-part coupling devicesSensing record carriersEngineeringCard holder

In a connector housing (2), resinous guide walls (4,5) that slide and guide a card holder (3) are erected on both sides in a width direction (B) perpendicular to a direction (A) in which the card holder (3) holding a memory card (C) is inserted. The metallic guide walls (4,5) are provided with metallic reinforcement tabs (6,7) molded integrally with the guide walls (4,5) simultaneously. The metallic reinforcement tabs (6,7) can give rigidity and elasticity to the resinous guide walls (4,5). Therefore, after the card holder (3) is inserted, the card holder (3) inserted therein can be stably held so as not to easily slip off.

Owner:JST MFG CO LTD

Self-adaptive automobile wheel

InactiveCN102529567AImprove adhesionNot easy to slipAuxillary traction increasing equipmentSelf adaptiveRough surface

The invention relates to a self-adaptive automobile wheel, which is adaptable to different road conditions with the tread width increased. The self-adaptive automobile wheel comprises a tire body. An attached wheel with expandable radius is arranged at one end of the tire body, the attached wheel and the tire body are coaxially arranged, the maximum expanded radius of the attached wheel is equal to the radius of the tire body, and the tread of the attached wheel is a rough surface for increasing adhesion. The self-adaptive automobile wheel has the advantages that the integral tread of the automobile wheel is widened while the tread of the attached wheel is rough, so that adhesion of the wheel to the ground is increased greatly, the wheel is not easy to slip, drift and sideslip, and safety of an automobile is improved; and the self-adaptive automobile wheel is applicable to automobiles under poor road conditions such as icy and snowy roads, sand land, mires and the like.

Owner:LANZHOU GEELY AUTOMOBILE IND +1

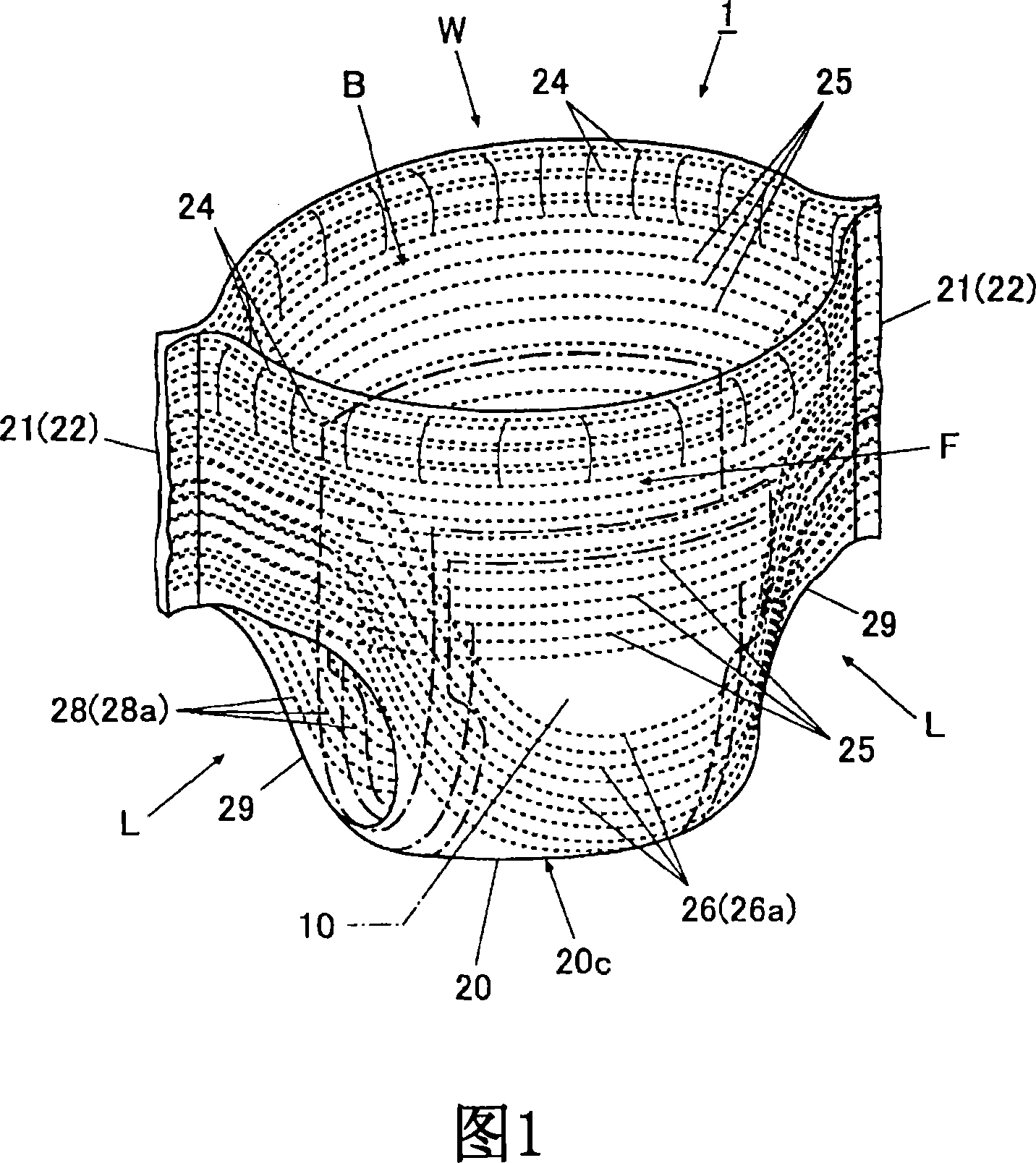

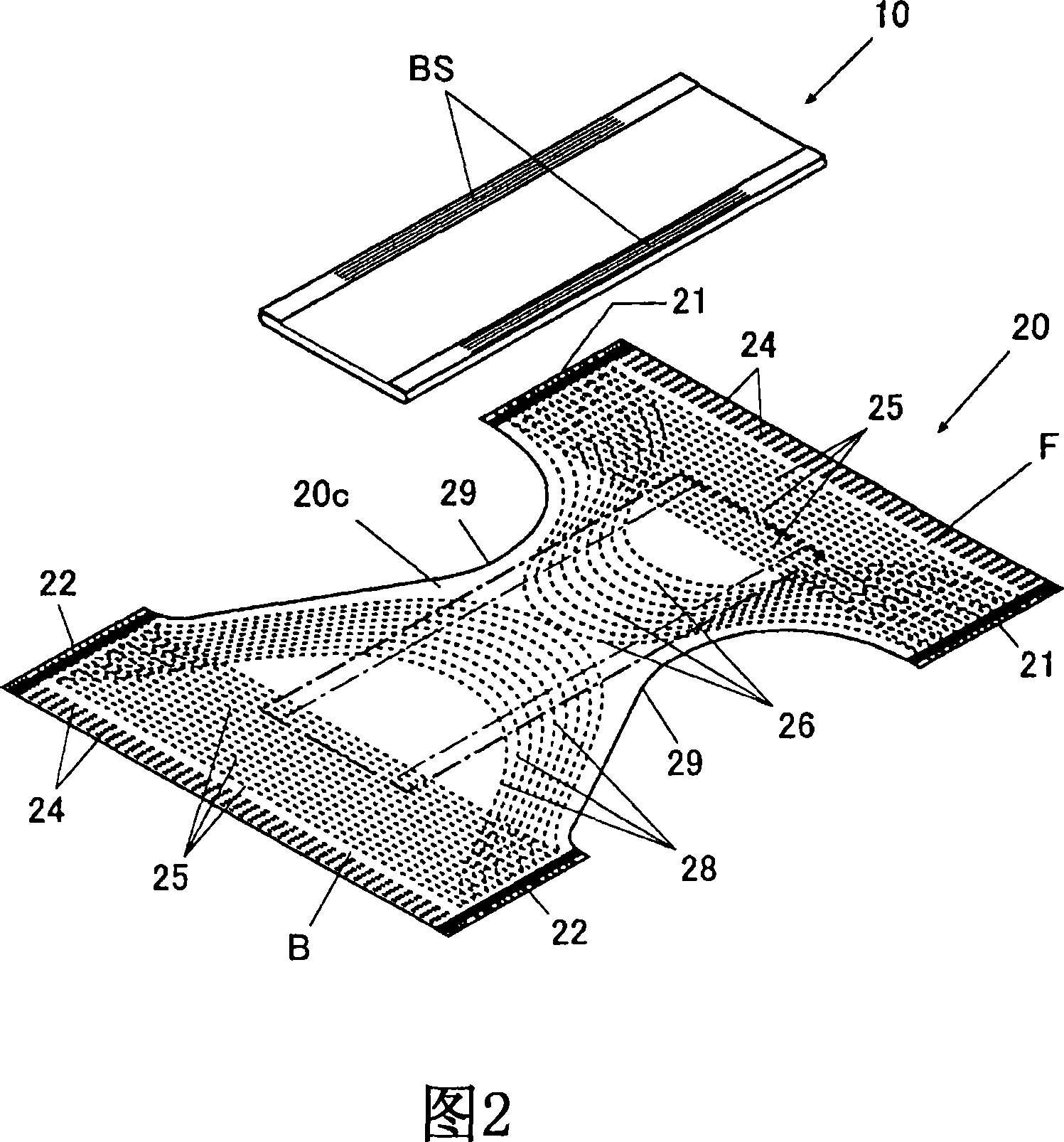

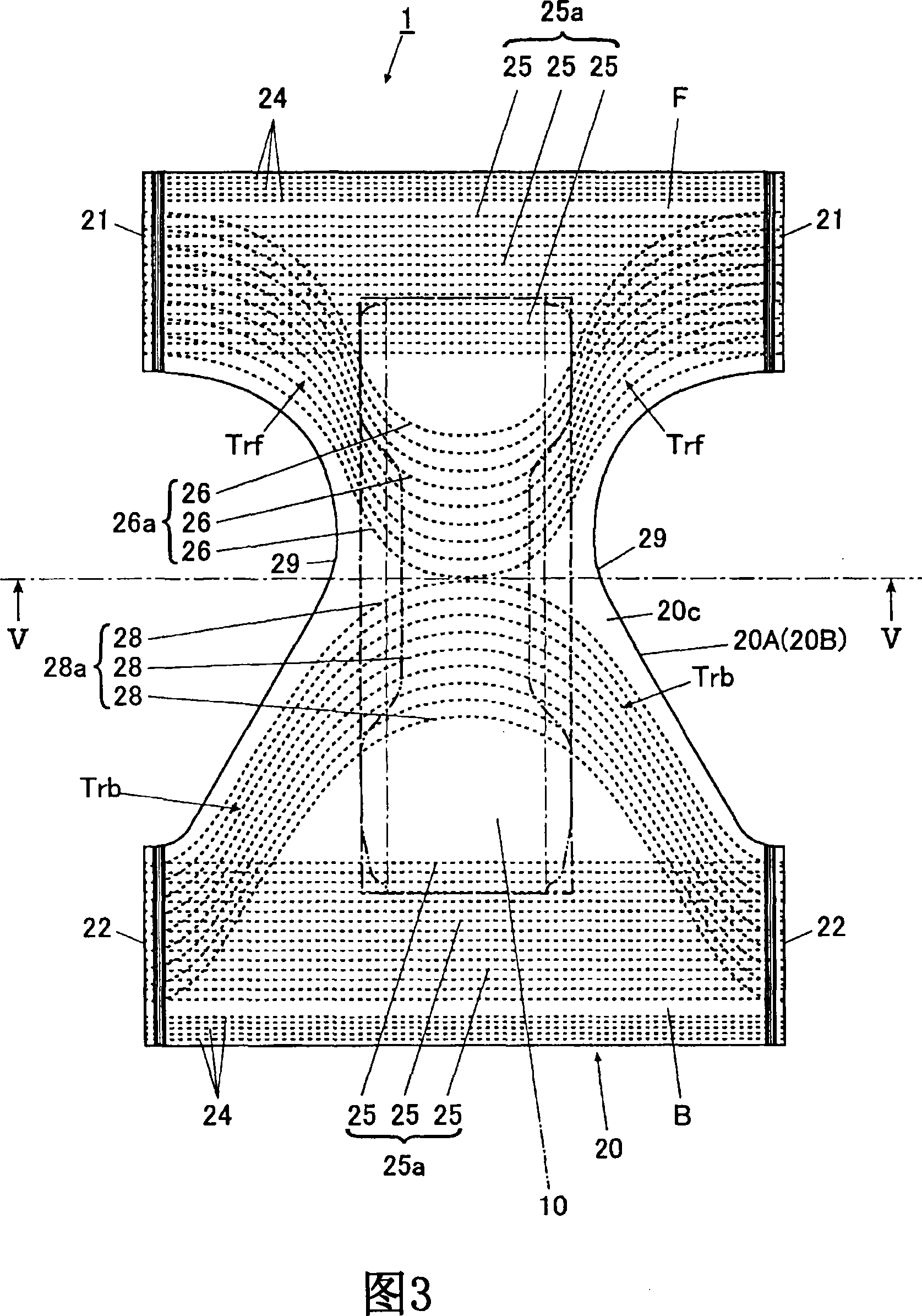

Pants-type disposable diaper

To realize a shorts type disposable diaper enabling easy putting and wearable suitably. This paper diaper (1) comprises an external sheet (20) having a waist elastic band (25a) formed of a plurality of waist elastic members (25) disposed on a front body portion (F) and a rear body portion (B) starting at one joining end parts (21, 22) thereof to the other joining end parts (21, 22) thereof, curved elastic bands (26a, 28a) formed of a plurality of curved elastic members (26, 28) disposed on the front body portion (F) and the rear body portion (B) starting at one joining end parts (21, 22) thereof to the crotch part (20c) side thereof and, after bypassing the crotch part, further to the other joining end parts (21, 22) thereof, and an absorbable body (10) disposed at the crotch part (20c). The curved elastic bands (26a, 28a) are formed to roughly cover the entire area (Trf, Trb) of the external sheet which is surrounded by the edge parts of the external sheet (20), the absorbable body (10), and the waist elastic band (25a).

Owner:DAIO PAPER CORP

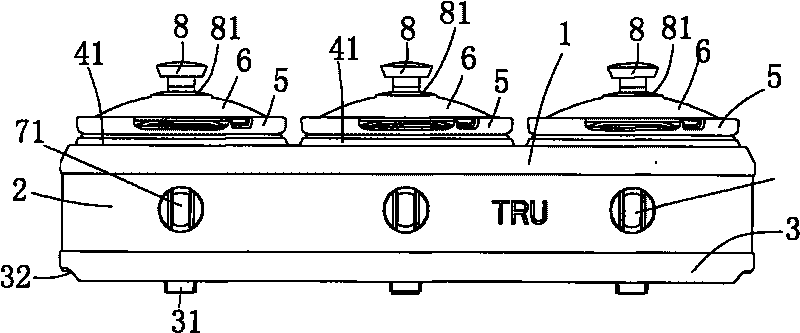

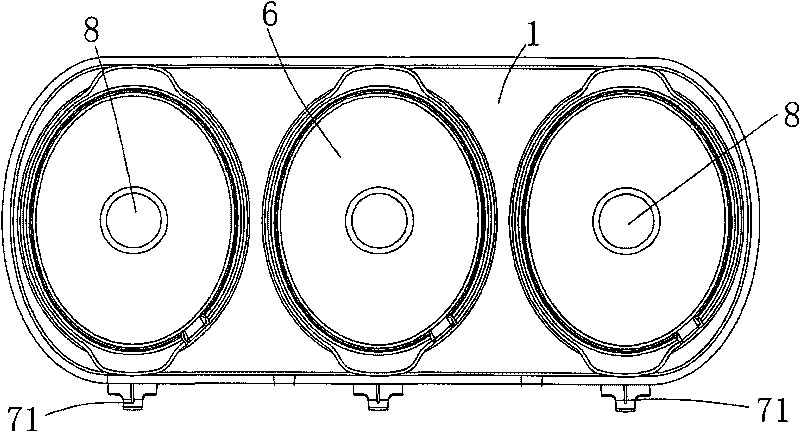

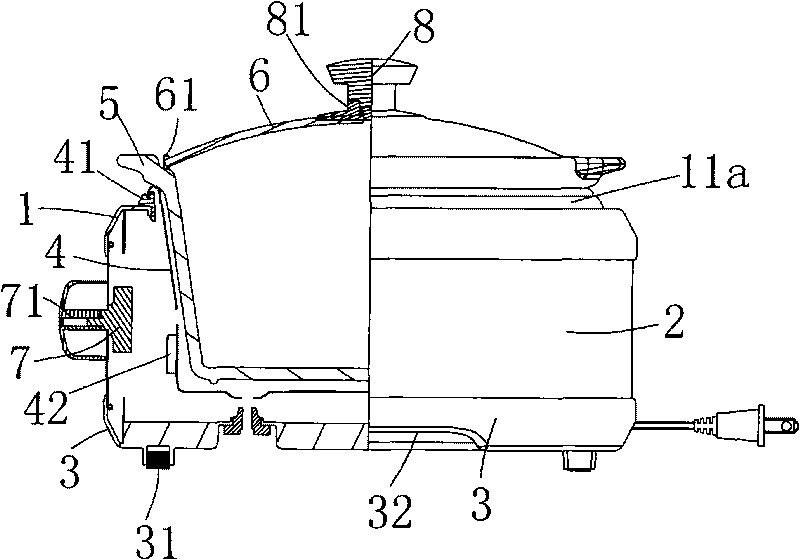

Multi-cooker site slow cooker

InactiveCN101695429AIncrease contact surfaceNot easy to burnMultiple-unit cooking vesselsPressure castingEngineering

The invention discloses a multi-cooker site slow cooker comprising an upper cover, a shell and a lower cover. Three linear parallel cooker holes running through the inner chamber of the shell are arranged on the upper cover, and a heating bladder is respectively inlaid in the cooker holes; a ceramic bladder is inlaid in each heating bladder; the cooker cover covers above the ceramic bladder; the lower ring edge of the upper cover is provided with an upper fastening edge, and the upper fastening edge and the upper ring edge of the shell are in coupling connection; the upper ring edge of the lower cover is provided with a lower fastening edge, and the lower fastening edge and the lower ring edge of the shell are in coupling connection; the side surface of the shell is provided with three linear parallel rotating switches, and the rotating switches are corresponding to the heating bladders one to one and independently control the heating operation of each heating bladder; three parallel ceramic bladders are arranged, and thereby, the cooking diversification can be realized; the upper cover and the lower cover have a plastic housing respectively, thereby having beautiful and elegant appearance and low surface temperature; the cooker cover is made of pressure casting tempering glass, thereby being safe to use and not easy to break; an operation panel has a rotating switch structure, being convenient to operate; and a right grip and a left grip are connected into a whole with a base, being durable.

Owner:浙江亿达控股集团有限公司

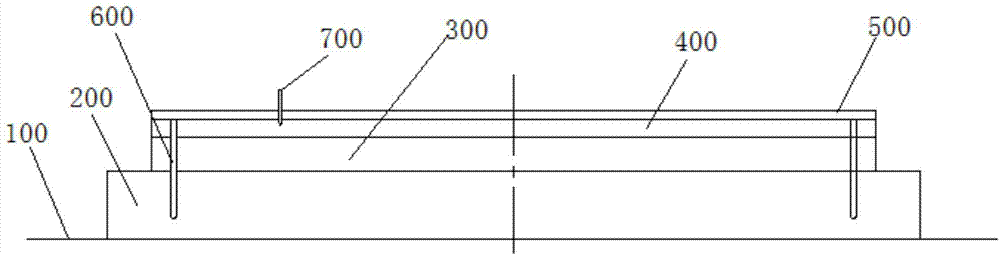

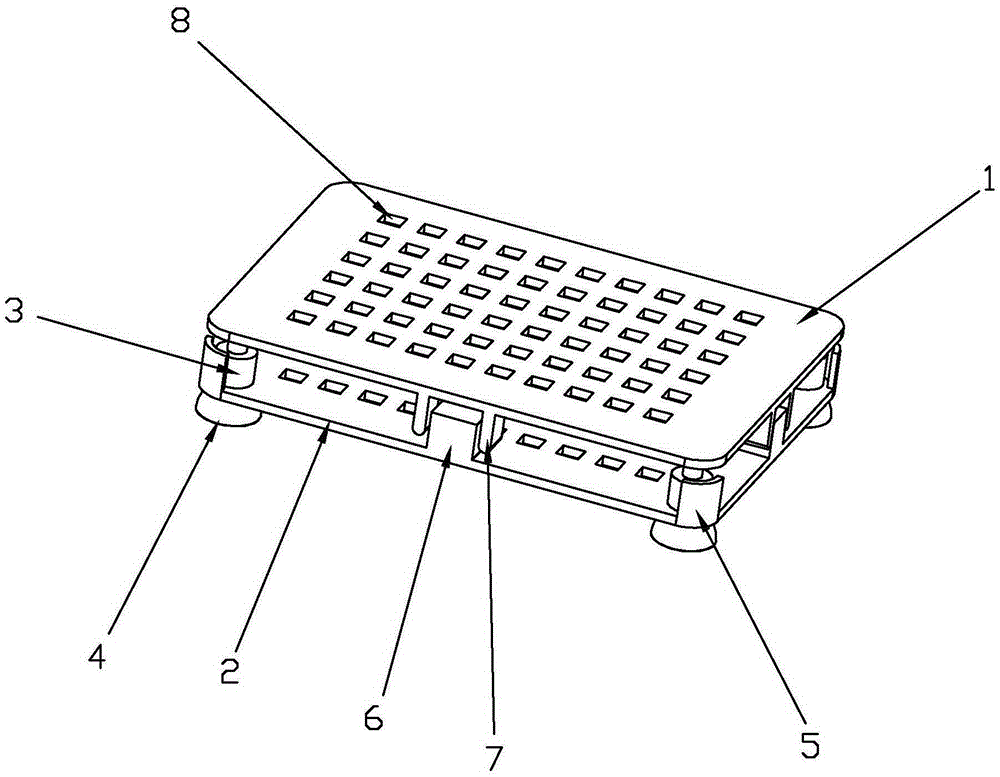

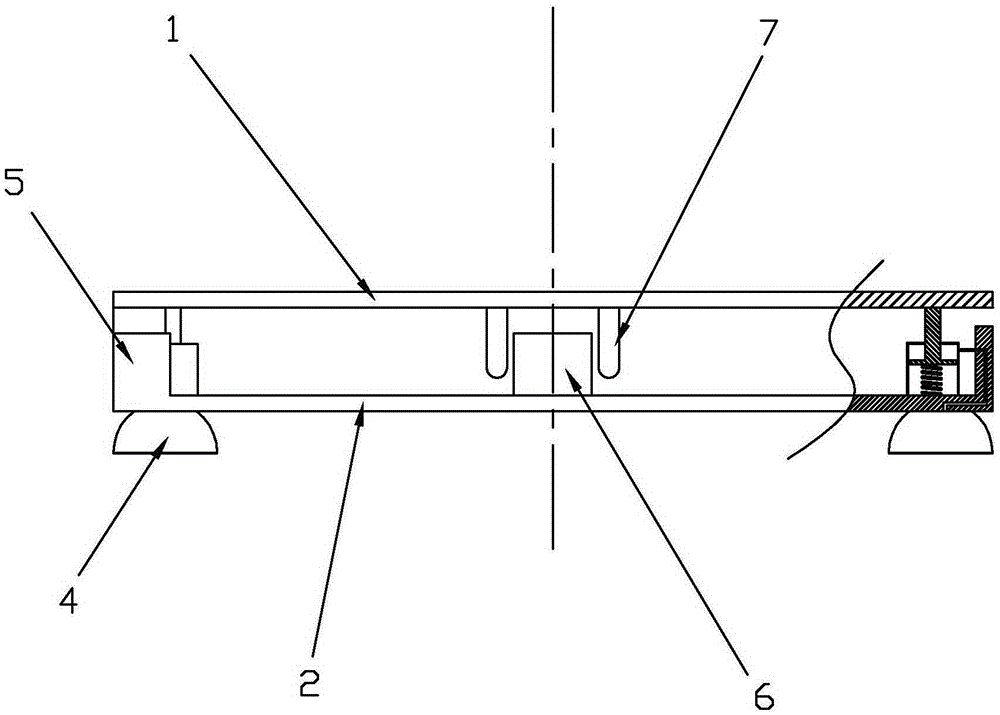

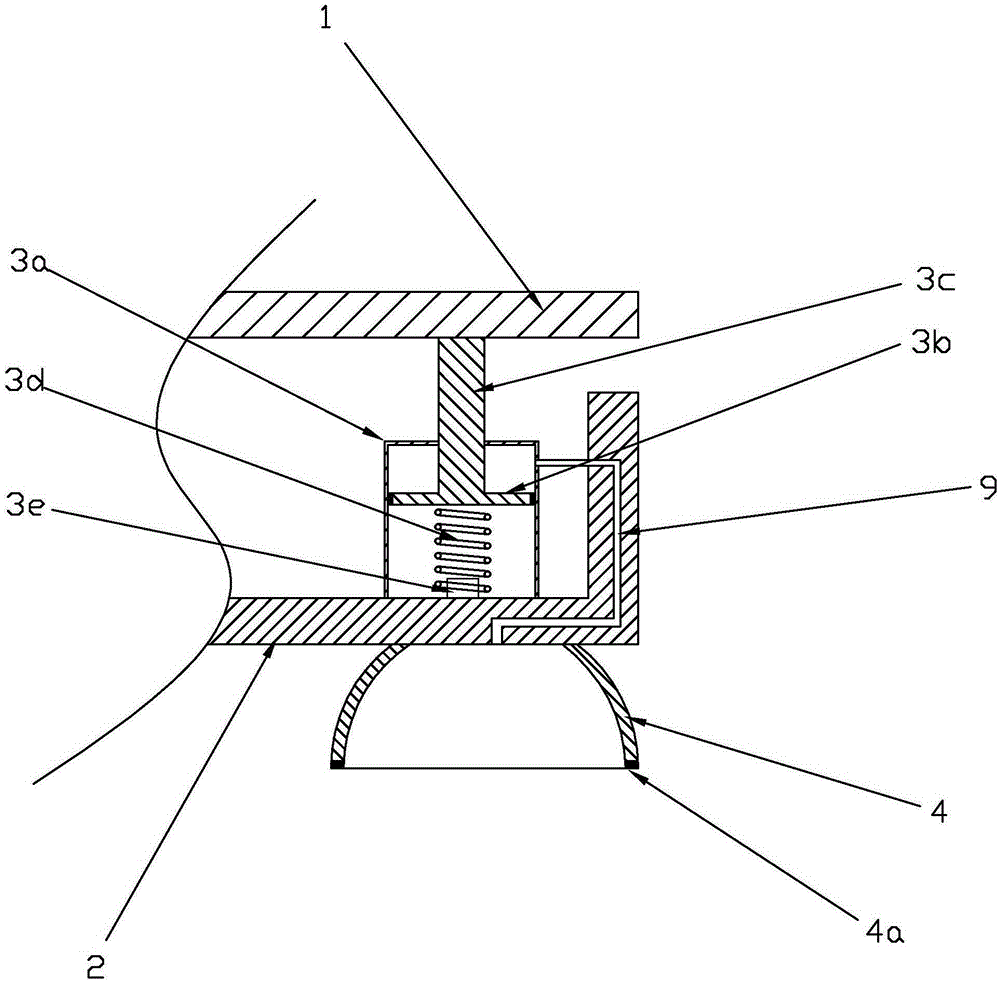

Freight pallet

The invention discloses a freight pallet. The freight pallet comprises a material storage layer and a ground contact layer. A buffer device is arranged between the material storage layer and the ground contact layer. The buffer device comprises a seal cylinder body fixed to the ground contact layer. The seal cylinder body is in slide connection with a piston disk. The cylinder body is divided into an upper containing cavity and a lower containing cavity by the piston disk. A piston rod is fixed to the piston disk. The piston rod extends out of the upper containing cavity and is fixed to the material storage layer. The bottom of the ground contact layer is provided with a suction cup. A ventilation pipeline is arranged between the upper containing cavity and the suction cup. According to the scheme, the freight pallet has a good buffer ability, meanwhile, the ground catching performance is good, and the freight pallet is not liable to sliding.

Owner:浙江志光塑料托盘有限公司

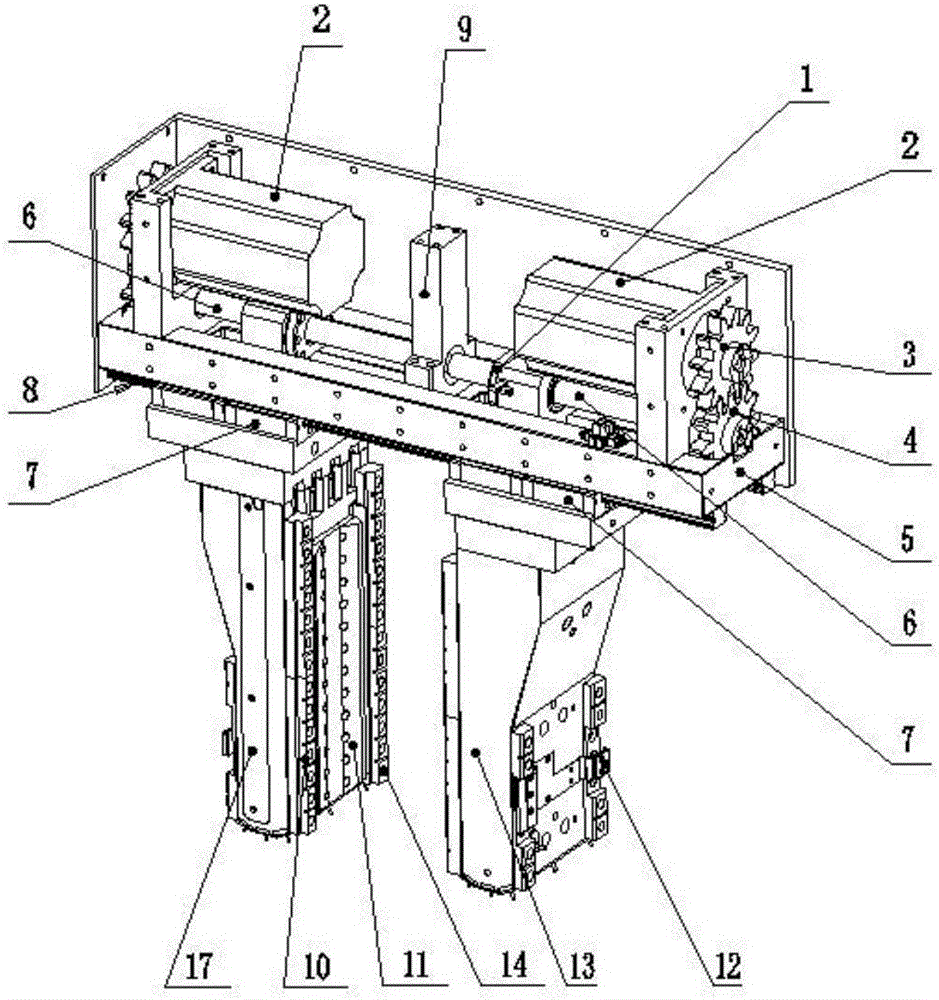

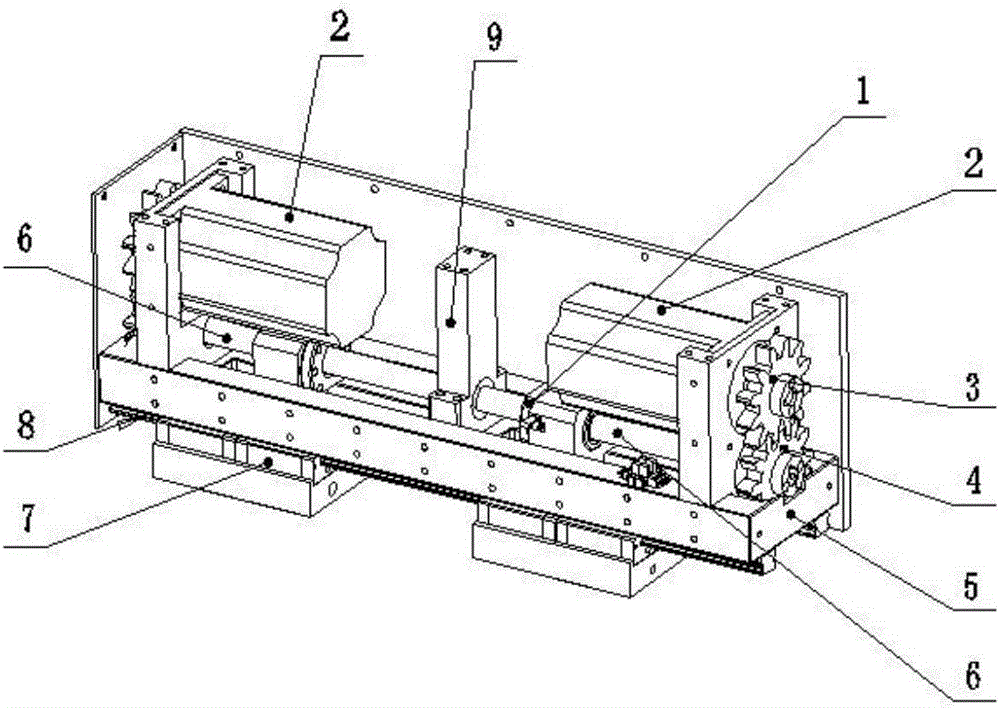

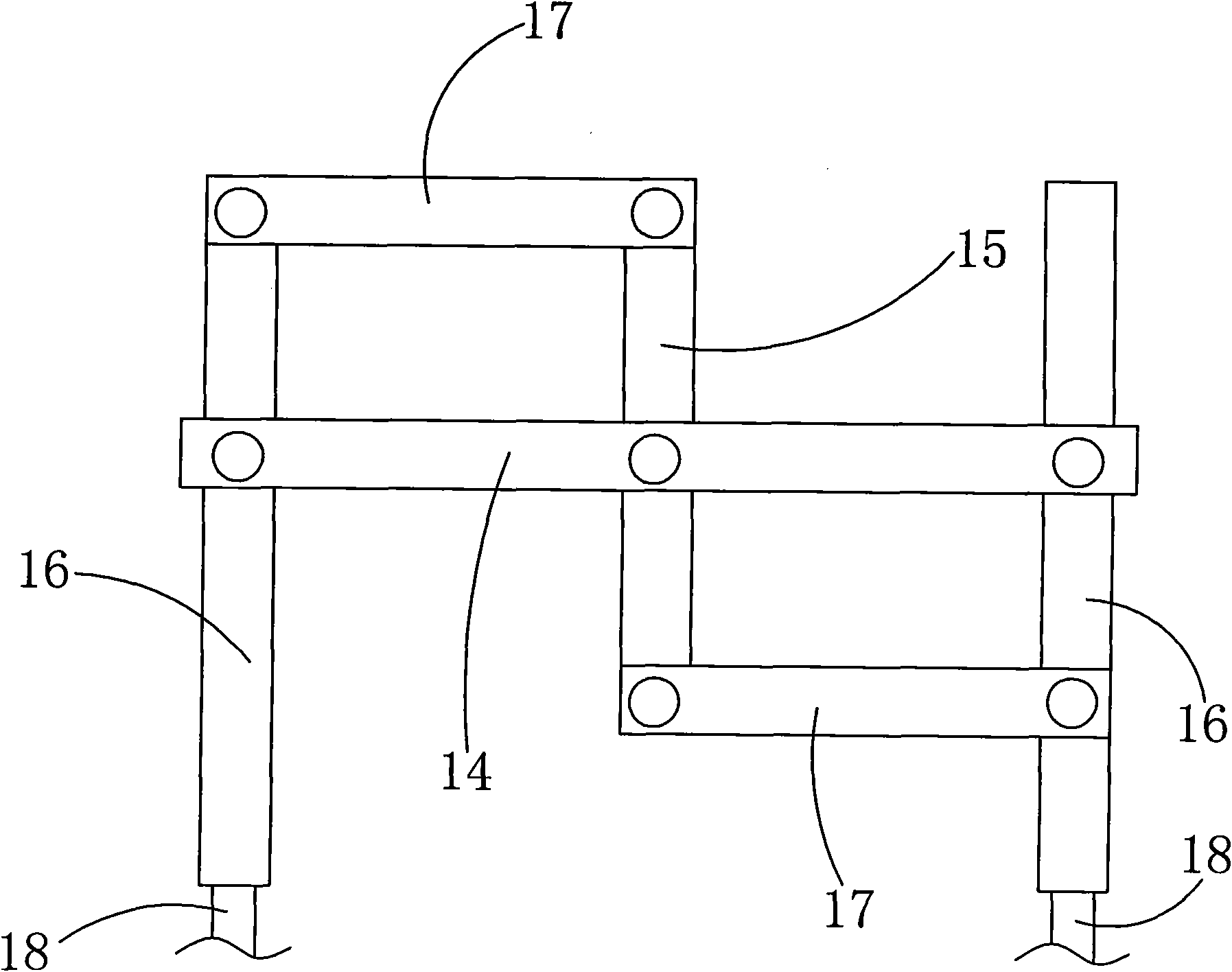

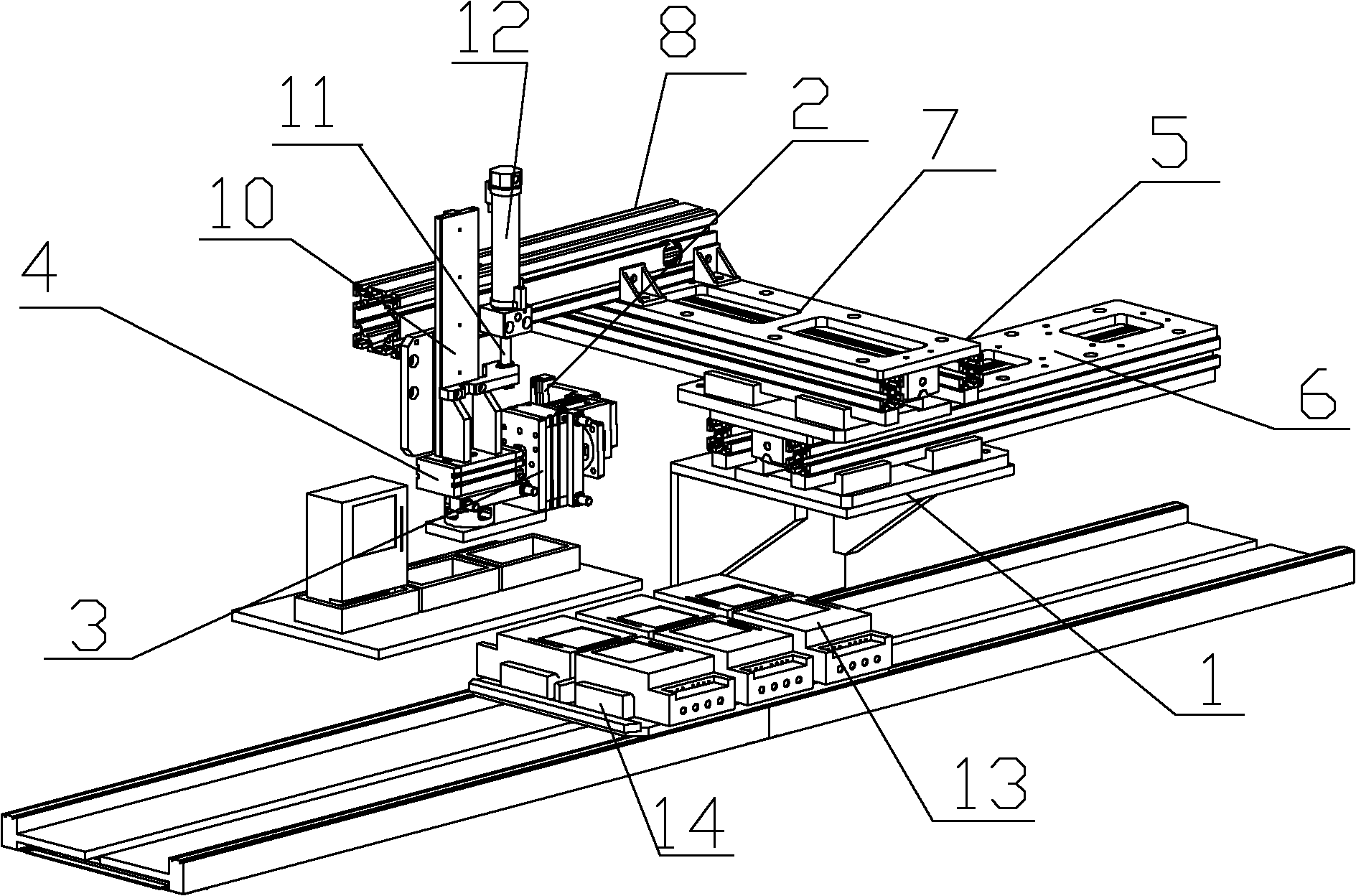

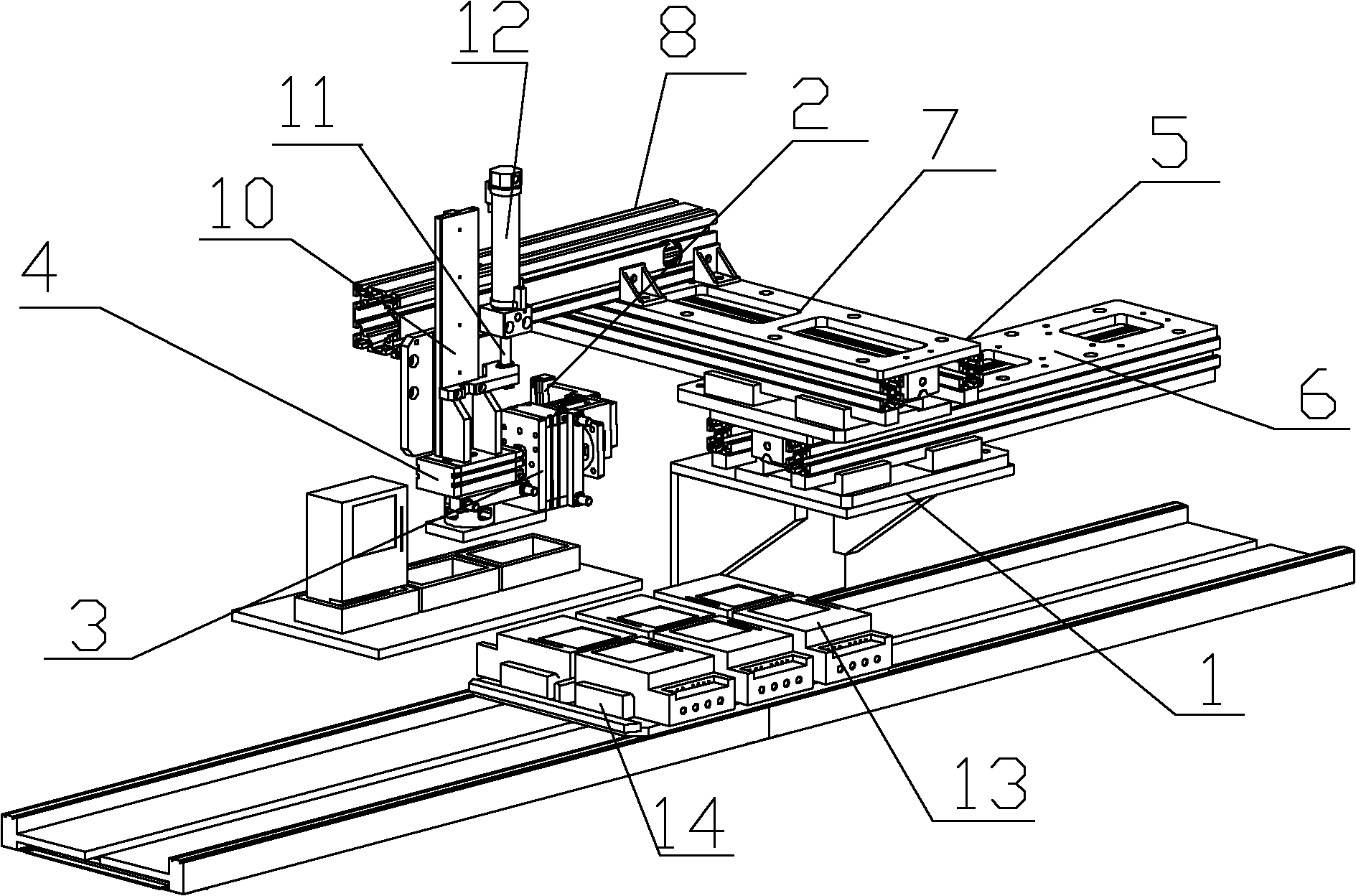

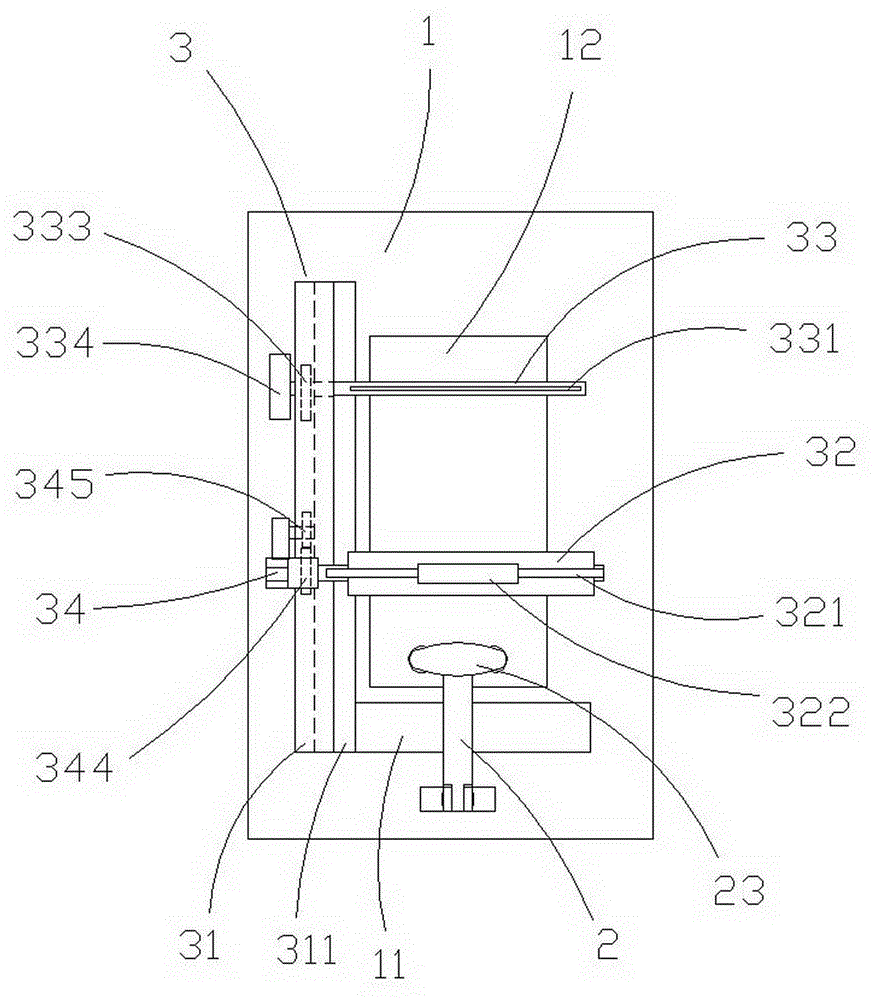

Watt-hour meter handling manipulator suitable for multi-meter-position tooling board

ActiveCN102134000AIncrease flexibilityMeet the requirements of placement orientationConveyor partsElectricity meterManipulator

The invention relates to a watt-hour meter handling manipulator suitable for a multi-meter-position tooling board, relating to watt-hour meter moving and loading equipment and solving the technical problem of low efficiency because manual operation is mostly carried out at present. The watt-hour meter handling manipulator suitable for the multi-meter-position tooling board comprises a stand and aclamp for clamping the watt-hour meter and is characterized in that the clamp is fixedly connected with a vertical turnover mechanism; the vertical turnover mechanism is connected with a horizontal rotating mechanism which is arranged on a vertical lifting mechanism; the vertical lifting mechanism is connected with a sliding block which is glidingly connected with a crossed horizontal sliding platform, and the crossed horizontal sliding platform is glidingly connected with the stand. The watt-hour meter handling manipulator provided by the invention is the mechanized equipment special for feeding and discharging on the multi-meter-position tooling board for the watt-hour meter, has the advantages of improving production efficiency, saving labor resources and meeting the requirements of the multi-meter-position tooling board for the arrangement orientation of the watt-hour meter, so that the watt-hour meter has high mounting position accuracy, and the detection result bias caused by the arrangement position can be avoided.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

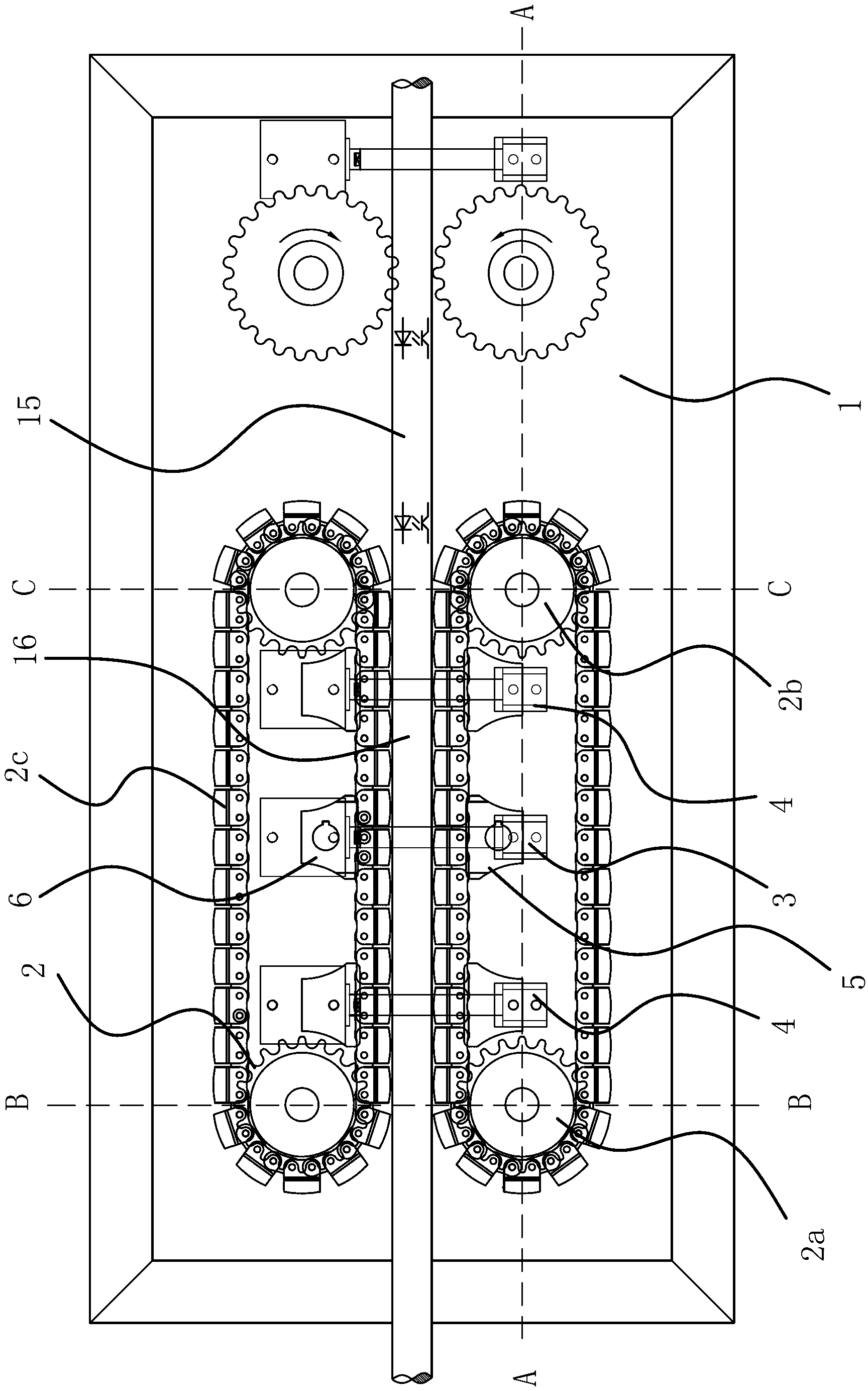

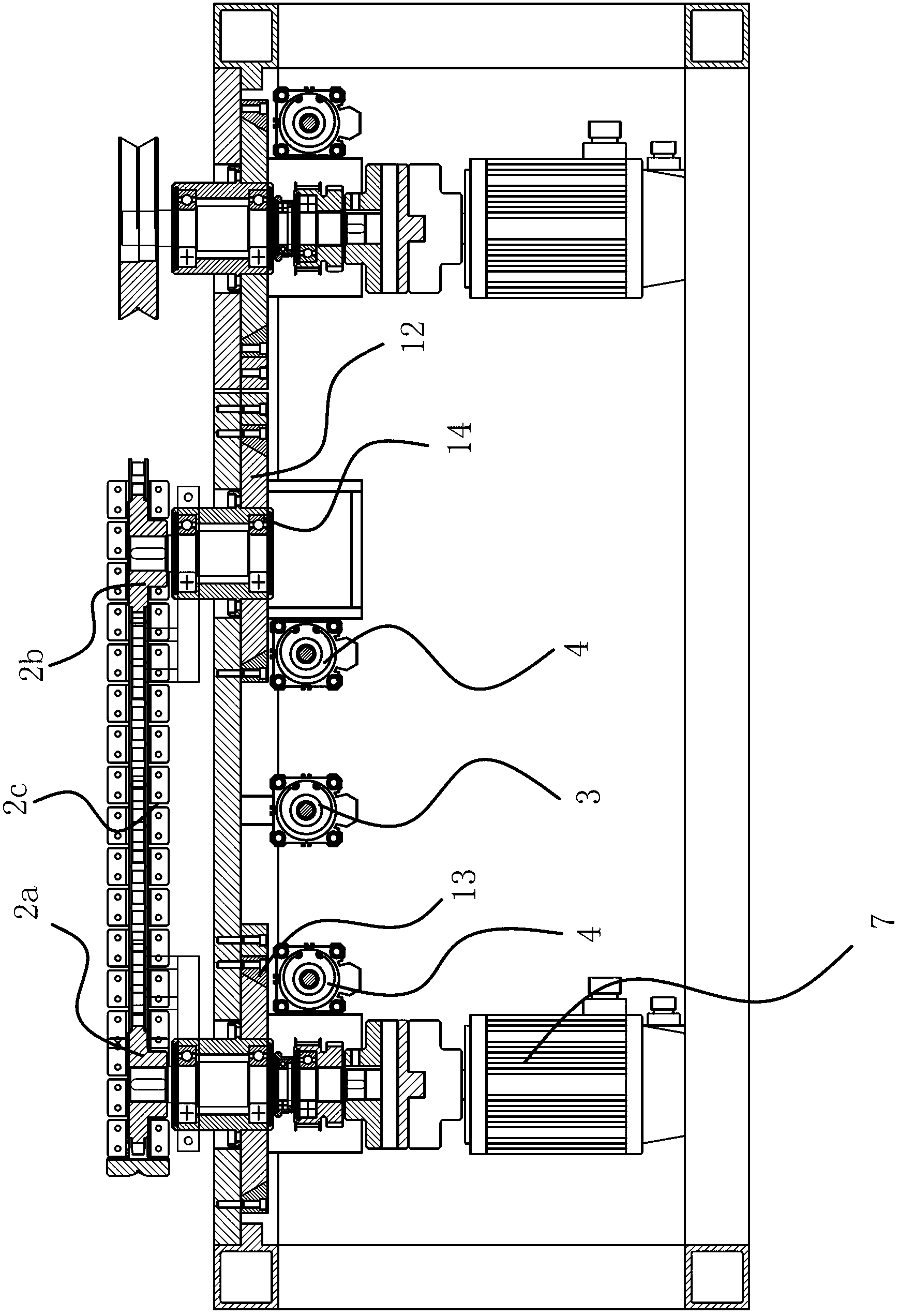

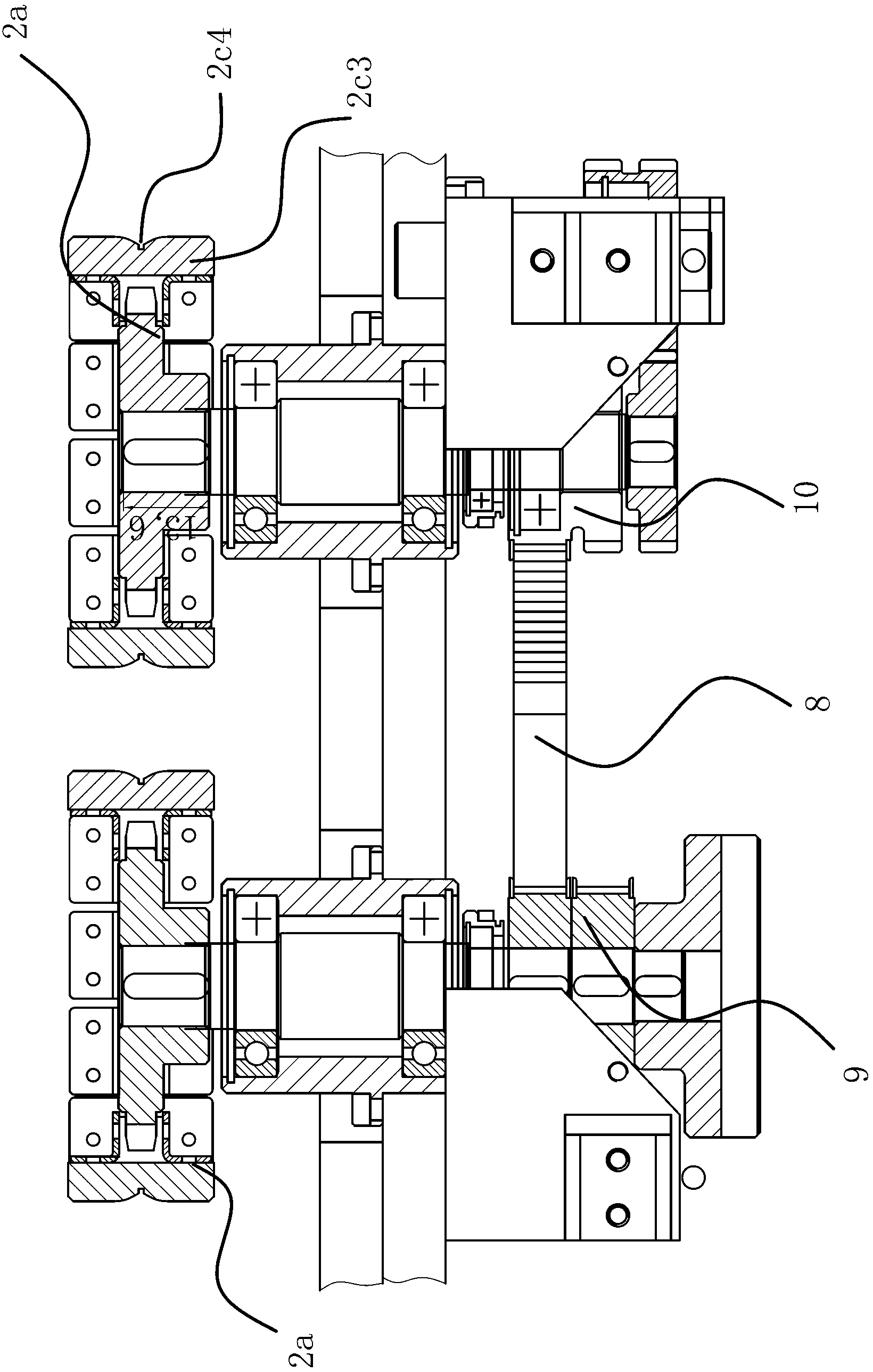

Bar conveyer

The invention provides a bar conveyer, belongs to the technical field of machining and solves the problem of insufficient and unstable clamping force of an existing crawler-type full-automatic bar feeding mechanism. The bar conveyer comprises a frame and two groups of conveyor crawler pairs, wherein the two groups of conveyer crawler pairs are oppositely arranged in parallel, and a bar clamping area is formed between the two groups of conveyer crawler pairs. Each group of the conveyor crawler pair comprises a driving wheel, a driven wheel and a crawler belt, and clamping grooves which are matched with a bar to be clamped are arranged on the surface of the crawler belt in the conveying direction of the bar. The machine frame is provided with a driving piece which can drives the driving wheel of at least one group of crawler pair to rotate. The conveyor crawler pairs are horizontally disposed and can limit and guide the bar from both sides of the bar on a horizontal plane, thereby improving the position accuracy when the bar is conveyed out.

Owner:台州市良曜成套设备有限公司

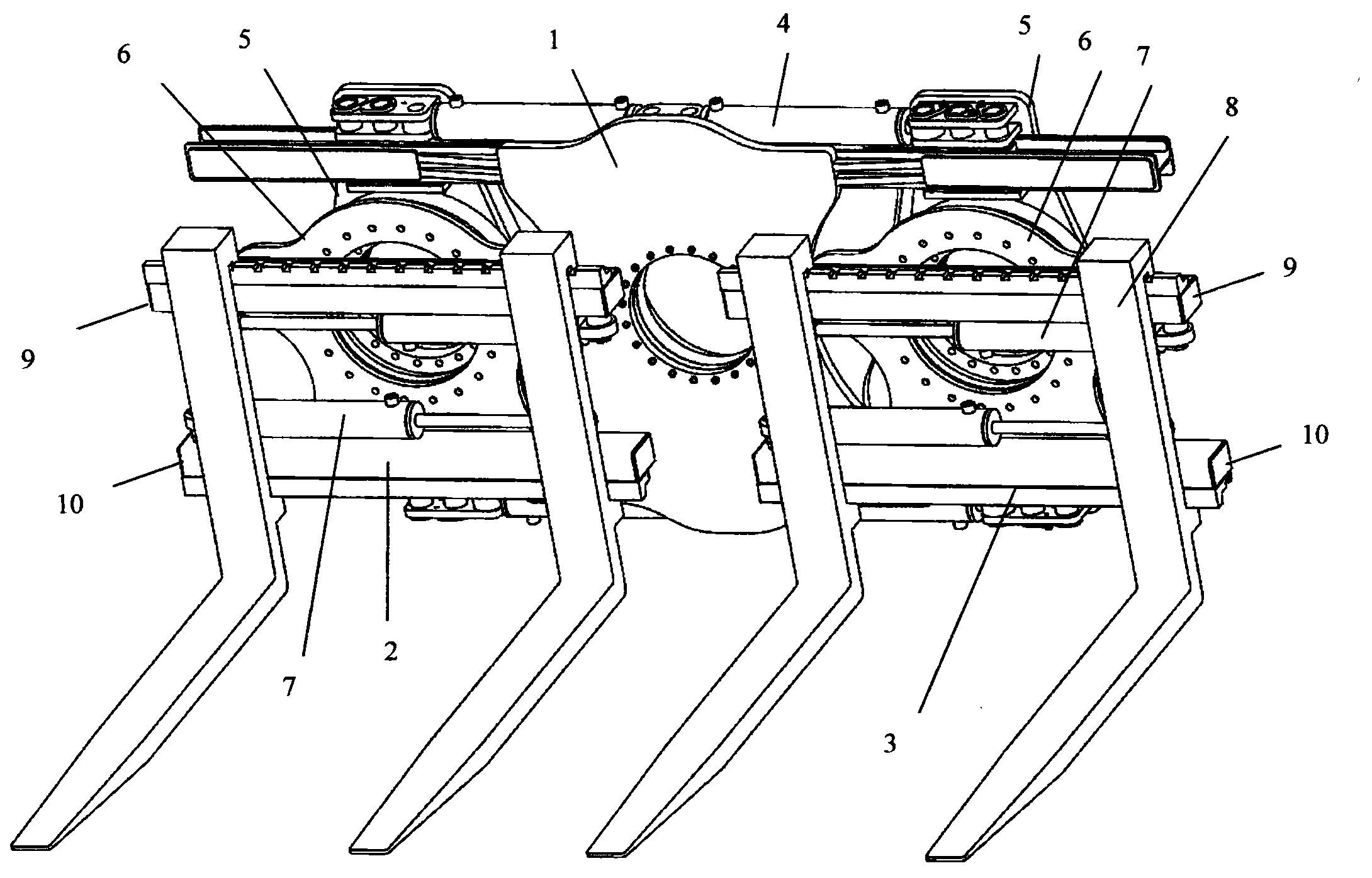

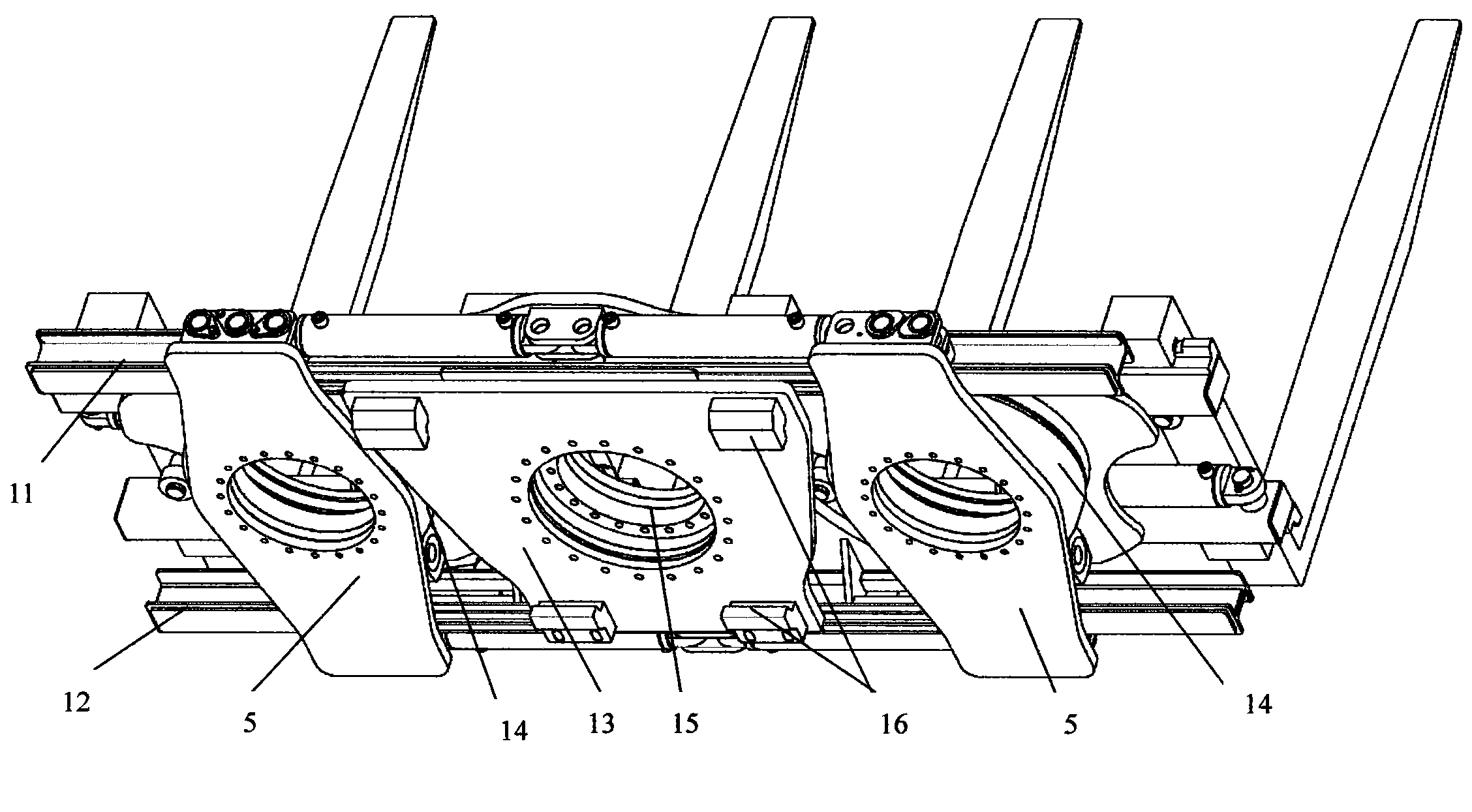

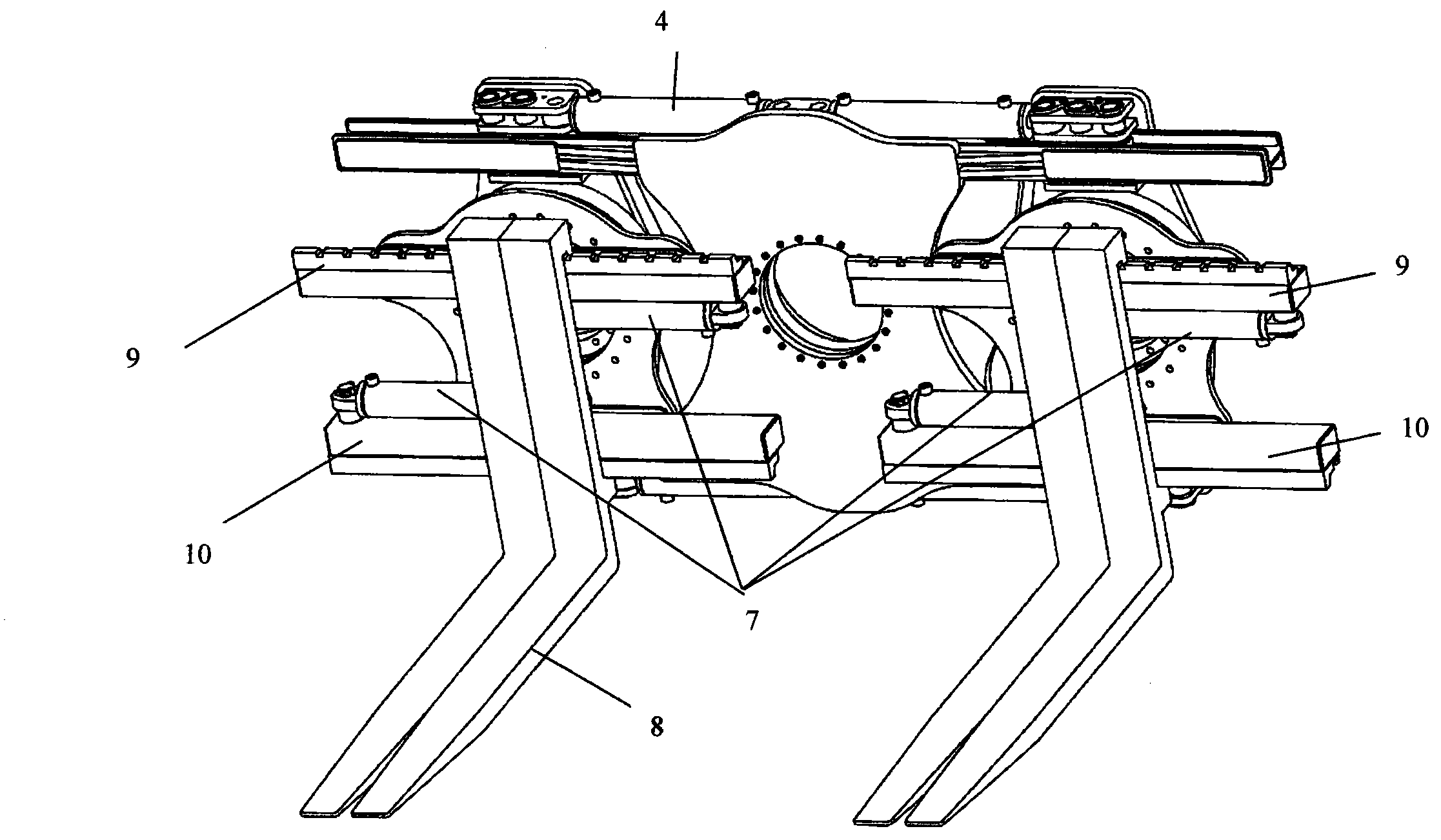

Multifunctional forklift attachment

ActiveCN104386622AIncrease productivityLow running costLifting devicesLateral movementElectrical and Electronics engineering

The invention relates to a forklift attachment designed by multiple degrees of freedom and capable of realizing such functions as distance adjustment, lateral movement, rotation, switching between single tray and double trays, clamping and double layers of double trays. The forklift attachment comprises a main driving mechanism, and a double-fork driving mechanism connected to the main driving mechanism, wherein the main driving mechanism comprises a main panel, a main baseplate, a main rotary driving mechanism, a main translation upper guide rail and a main translation lower guide rail; the main baseplate, the main rotary driving mechanism and the main panel are connected in sequence to form a rotating mechanism of the main driving mechanism; the double-fork driving mechanism comprises a secondary baseplate, a secondary rotary driving mechanism, a secondary panel, a fork translation upper guide rail, a fork translation lower guide rail, fork translation oil cylinders and two parallel forks; the secondary baseplate, the secondary rotary driving mechanism and the secondary panel are connected in sequence to form a rotating mechanism of the double-fork driving mechanism; clamping mechanisms at the upper and lower ends of the secondary base are respectively clamped with the main translation upper guide rail and the main translation lower guide rail; and the side surfaces of upper and lower clamping structures of the secondary baseplate are respectively connected with movable ends of the two translation oil cylinders of the double-fork driving mechanism.

Owner:ZHEJIANG YABO AUTOMATION EQUIP CO LTD

Film pasting device

InactiveCN104150008ANot easy to slipSolve the problem of difficult film positioningPackagingTectorial membraneEngineering

The invention discloses a film pasting device. An antiskid soft cushion and a baffle are arranged on a face plate of a base and used for locating a mobile phone, a film suction and location frame is located outside the baffle, a film suction device at the top end of the film suction and location frame is suspended above the antiskid soft cushion, a protection film sucked by the film suction device keeps opposite to a mobile phone screen in position, a sliding groove is formed in a base of a film pressing device, a rotating rod with one end inserted in the sliding groove in a penetrating mode and a rolling barrel crossing the upper portion of the corresponding base are suspended above the mobile phone in a parallel mode, the rotating rod is connected with an attaching film, the rolling barrel presses the upper portion of the protection film transversely, and the rotating rod and the rolling barrel achieve pasting of the protection film and separation of the attaching film synchronously in a rotating displacement process in the sliding groove. According to the film pasting device, the film can be pasted smoothly in order, operation speed is high, and the film pasting device is easy and convenient to use.

Owner:安徽长正升科技有限公司

Clamper for cleaning and degumming silicon chip

InactiveCN101409253ANot easy to slipImprove yield rateFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringScrew thread

The invention relates to a cleaning and degumming clamp used during the process for producing a solar electric silicon wafer. The cleaning and degumming clamp comprises two lateral plates, and a pair of upper guide poles, a pair of partition plate guide poles and a pair of lower guide poles which are arranged between two lateral plates. Partition plates are clamped and hung on the partition plate guide poles. The cleaning and degumming clamp is characterized in that two pair of machine bonding plate fixing clamps and at least a pair of machine bonding plate position limiting clamps are sheathed on the upper guide poles in a slide way; the machine bonding plate fixing clamps are provided with bolts which clamp pins on a machine bonding plate; the machine bonding plate position limiting clamps are provided with adjusting collets which resist against two sides of the machine bonding plate; the adjusting collets are connected with the machine bonding plate position limiting clamps by screw thread; and the machine bonding plate position limiting clamps are provided with the bolts which fix the machine bonding plate position limiting clamps on the upper guide poles. A silicon wafer cleaning and degumming clamp disclosed by the invention can be fit for the different types of the machine bonding plates, is convenient to use and operate with labor saving and reduces the cost investment on clamp; in addition, a cleaned and degummed silicon wafer is upright on the lower guide poles and is not slipped and bumped easily to broke the silicon wafer, and the invention improves the good yield of the cleaned and degummed silicon wafer.

Owner:KONCA SOLAR CELL

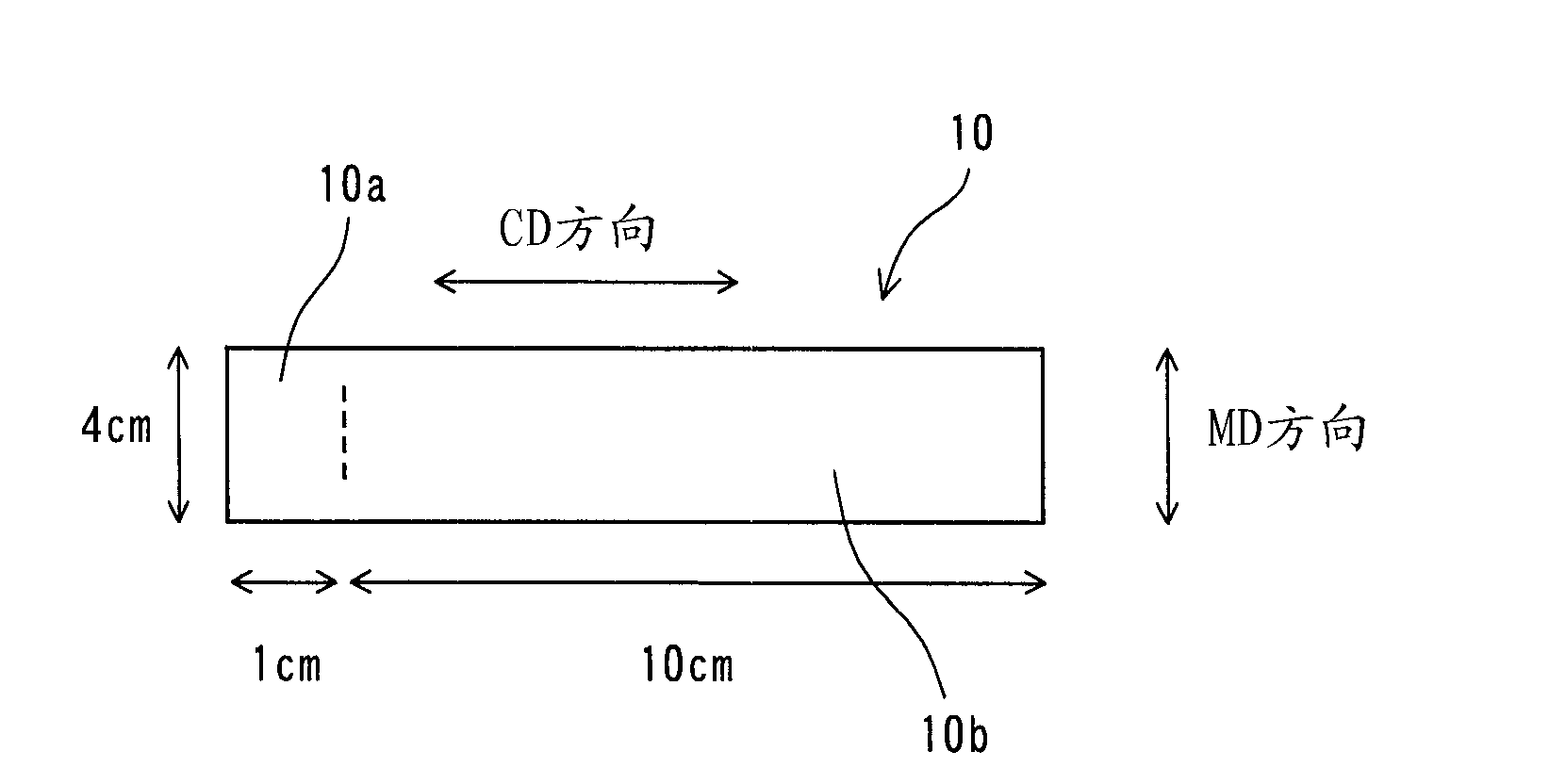

Laminated sheet, and process for production thereof

ActiveCN102482818AImprove adhesionImprove adaptabilityCosmetic preparationsToilet preparationsPolymer scienceSkin contact

A laminated sheet is produced by forming an adhesion layer permeable to a liquid component and contactable with a skin on at least one side of a liquid-retention layer comprising a nonwoven structural member and having an ability to absorb the liquid component. The adhesion layer comprises a nonwoven structural member comprising a fiber having a number-average fiber diameter of not more than 10 [mu]m, and the thickness ratio of the adhesion layer relative to the liquid-retention layer is 1 / 4 to 1 / 100 as a ratio of the adhesion layer / the liquid-retention layer. The fiber of the nonwoven structural member of the adhesion layer may have a standard deviation of fiber diameter of not more than 5. The nonwoven structural member of the liquid-retention layer may comprise a fiber having a fiber diameter larger than that of the fiber of the adhesion layer. The laminated sheet has a liquid retentivity and a liquid releasability in a well-balanced manner, and has an excellent adhesion and an excellent fit to the skin in the state where the sheet is impregnated with a liquid component.

Owner:KURARAY KURAFLEX CO LTD

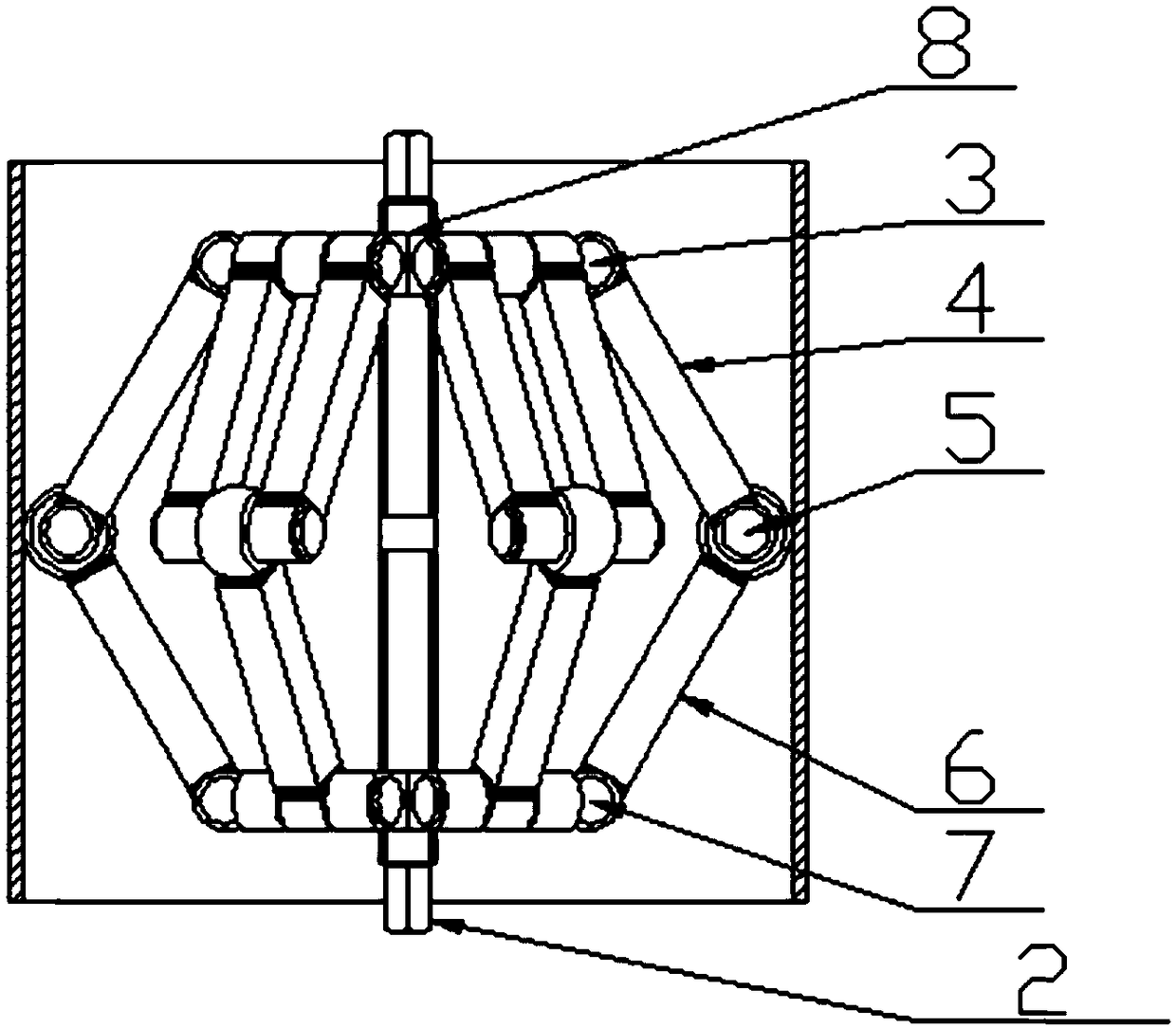

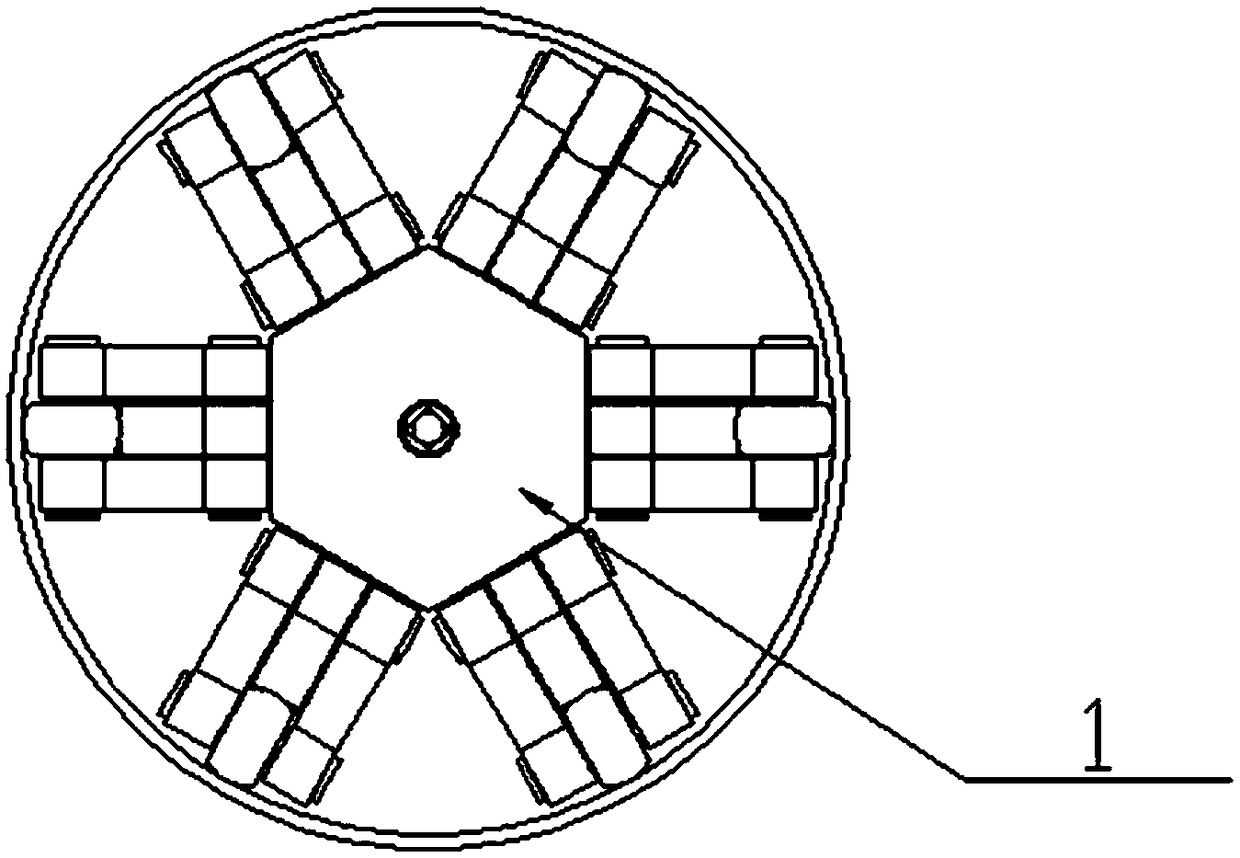

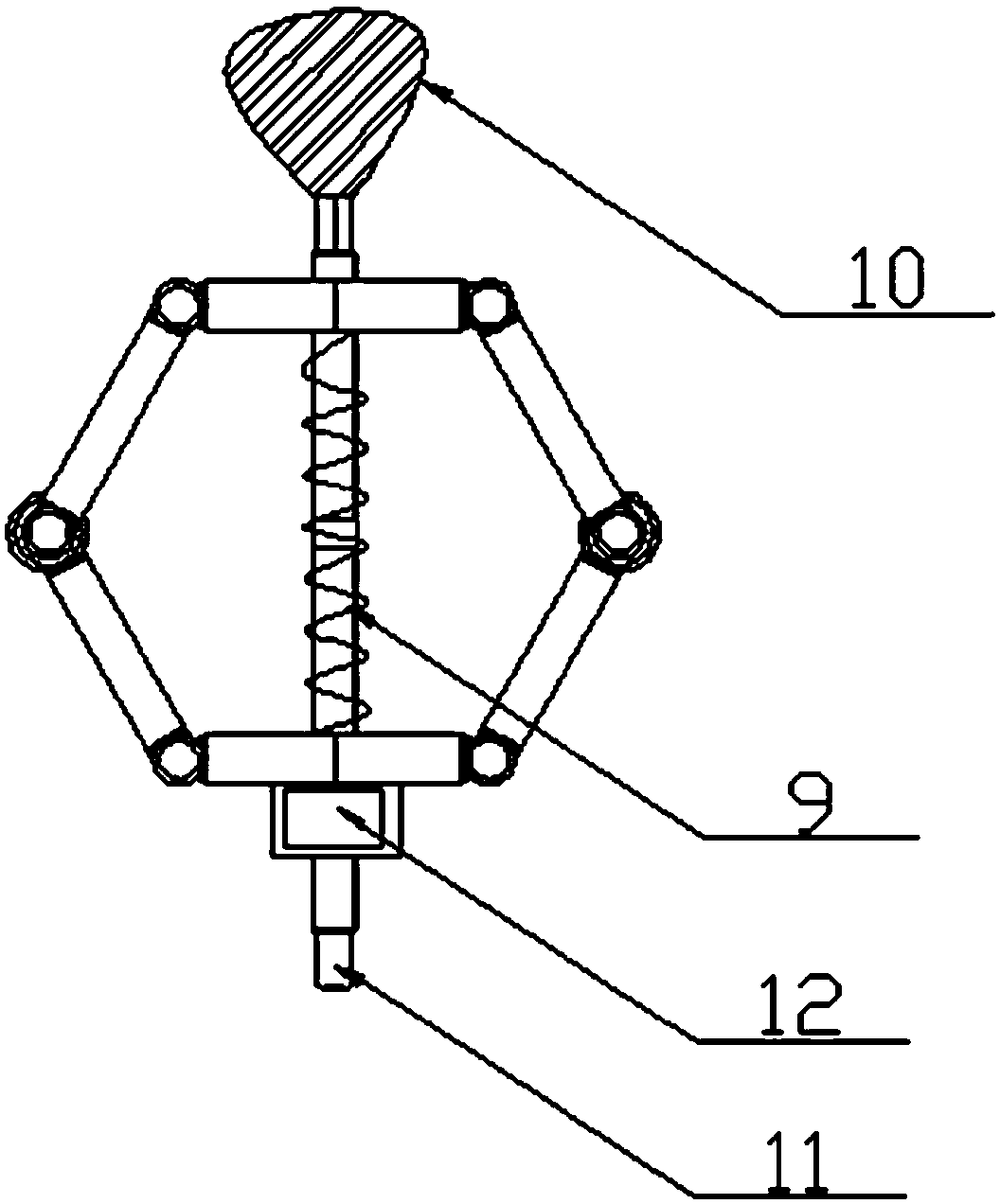

Supporting tool in thin-wall pipe

ActiveCN109277841AEasy to assemble and disassembleEasy to operateWork clamping meansPositioning apparatusEngineeringThin wall

The invention discloses a supporting tool in a thin-wall pipe. The supporting tool comprises an upper supporting plate and a corresponding lower supporting plate. The center of the upper supporting plate and the center of the lower supporting plate are connected with a lead screw through a left thread and / or a right thread, upper hinges are arranged on the edge of the upper supporting plate at equal central angles, and the upper hinges are hinged to upper supporting rods. Lower hinges are correspondingly arranged on the edge of the lower supporting plate at equal central angles, the lower hinges are hinged to lower supporting rods, and the upper supporting rods and the lower supporting rods are hinged through hinges. A locking nut is arranged between the upper supporting plate and the leadscrew, and a locking nut is arranged between the lower supporting plate and the lead screw. The supporting tool is provided with a fixing structure. The supporting tool adapts to the sizes of different pipe diameters, the roundness of the pipe is kept, grooves meeting standard requirements can be machined conveniently, the problem that when grooves are machined in the stainless steel thin-wall pipe, the pipe diameters deform is solved, the supporting tool is convenient to dismount and mount and easy to operate, and the working efficiency can be improved.

Owner:CHENGXI SHIPYARD

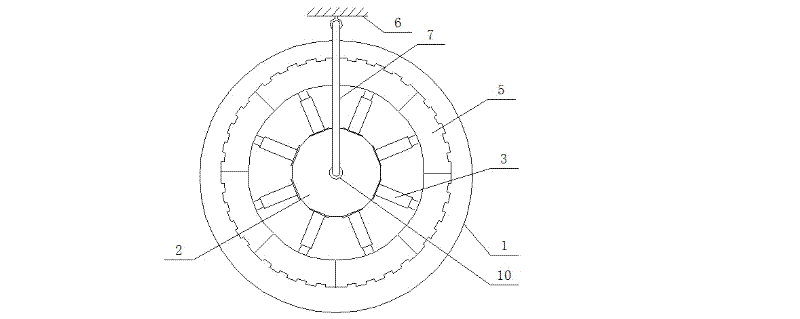

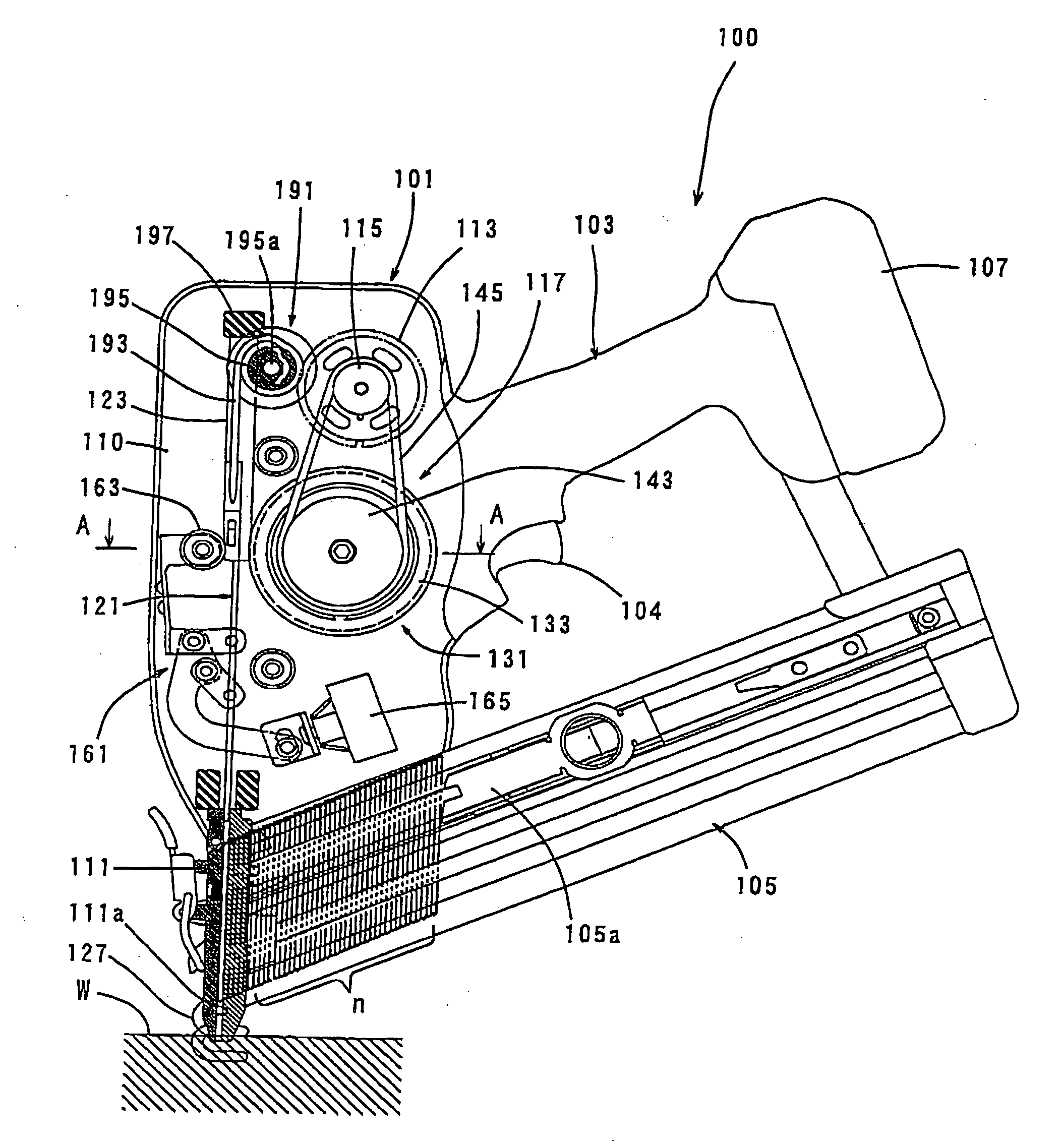

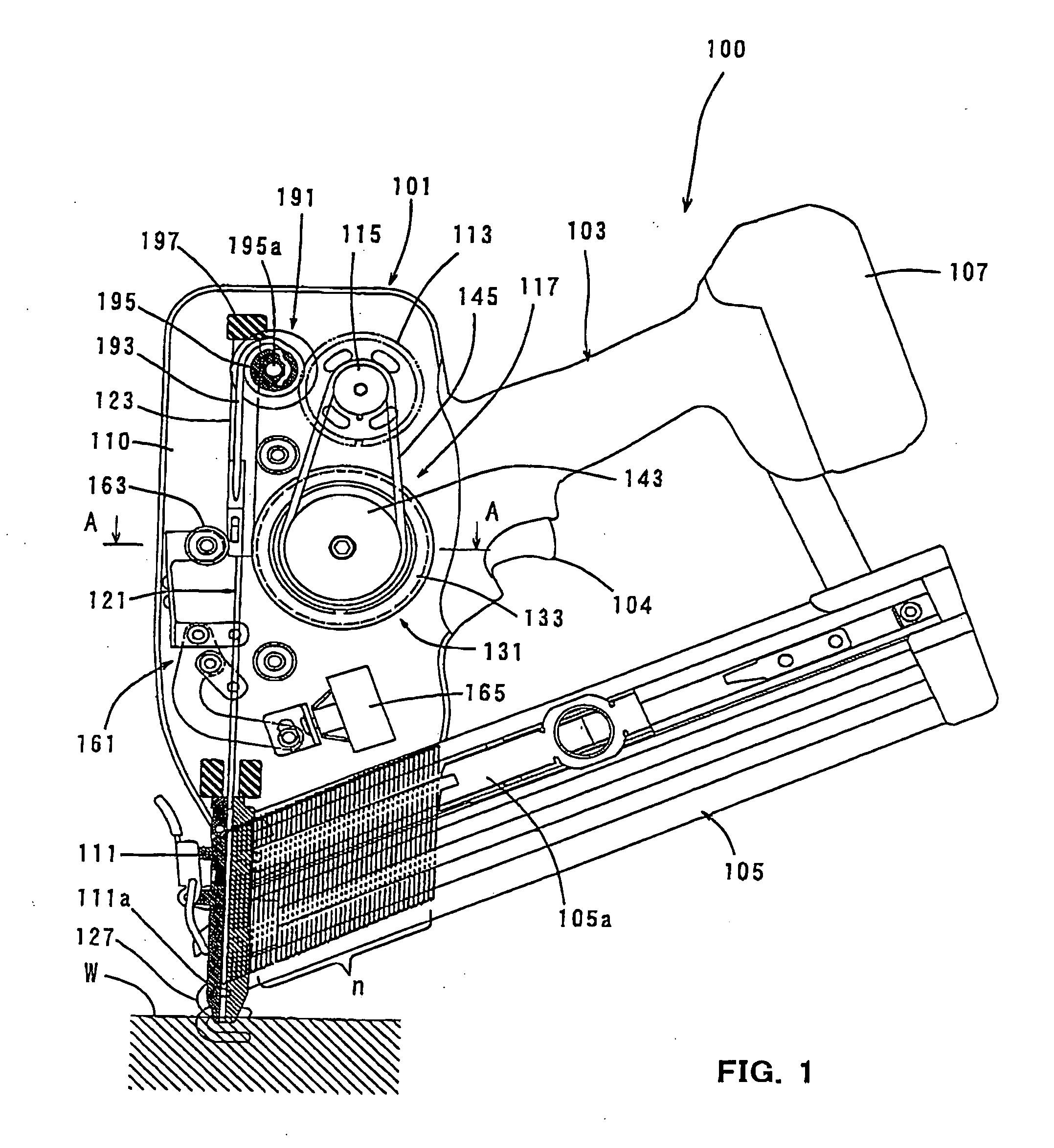

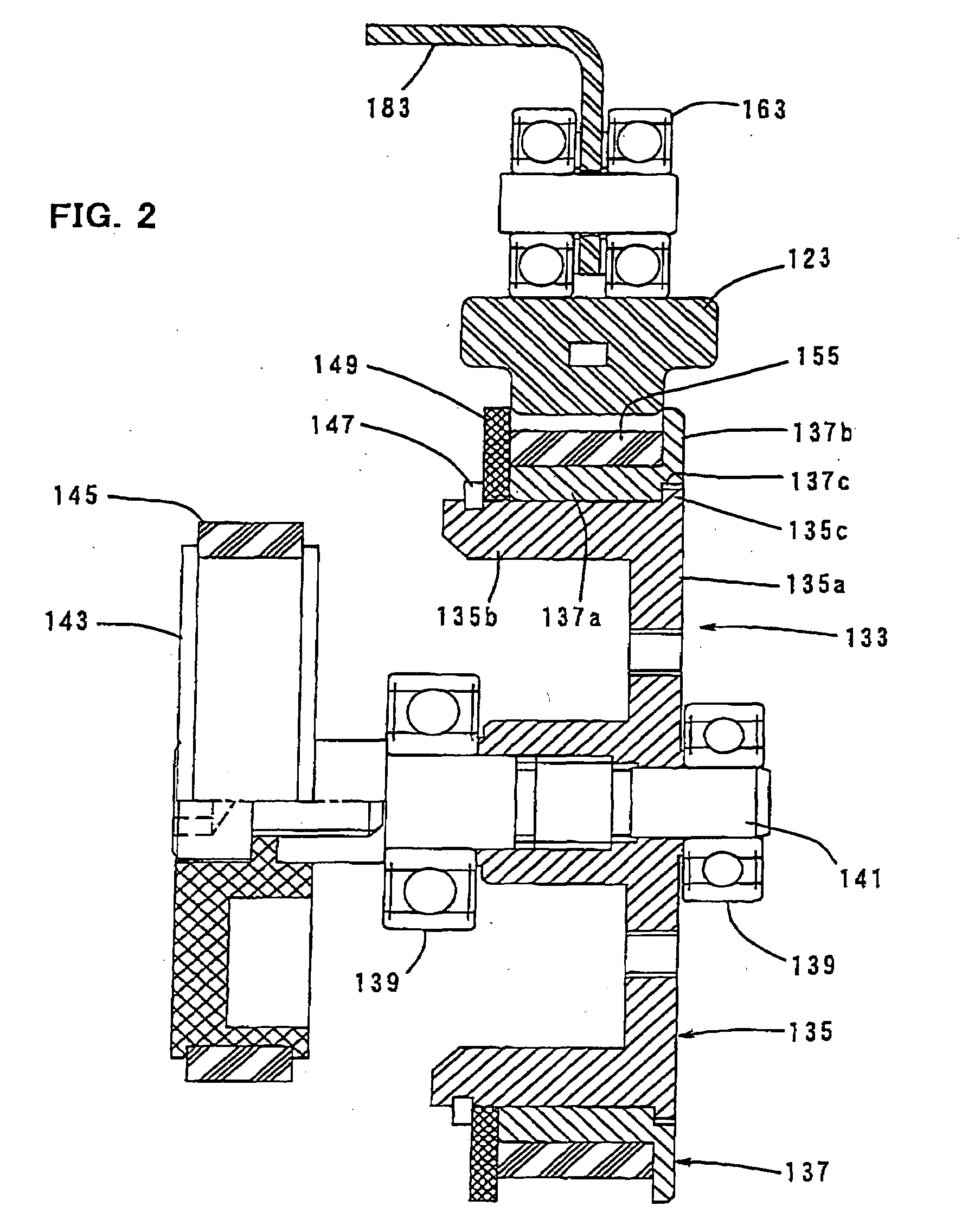

Driving tool

InactiveUS20080257933A1Increased durabilitySolve the small frictionStapling toolsNailing toolsFreewheelFlywheel

It is an object of the present invention to increase durability of a driving tool. A representative driving tool comprises an elongated operating member that drives in a driving material and a drive mechanism that drives the operating member. The drive mechanism comprises a rotating flywheel and the flywheel includes an inner wheel and an outer wheel which are concentrically disposed to each other. The inner circumferential surface of the outer wheel is fitted on an outer circumferential surface of the inner wheel. The outer circumferential surface of the outer wheel directly contacts the operating member and thus, the rotational force of the flywheel is transmitted from the inner wheel to the operating member via the outer wheel and the drive mechanism linearly moves. A frictional force between the outer circumferential surface of the inner wheel and the inner circumferential surface of the outer wheel is set to be smaller than a frictional force between the outer circumferential surface of the outer wheel and the operating member. With such construction, when the operating member contacts the rotating flywheel, slippage is caused between the inner wheel and the outer wheel such that only a smaller frictional force may be produced between the inner wheel and the outer wheel. Therefore, stress which acts upon the inner wheel and the outer wheel can be alleviated and as a result, wear of the flywheel and the operating member can be reduced to increase the durability.

Owner:MAKITA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com