Bar conveyer

A feeder and bar technology, applied in the field of mechanical processing, can solve the problems that cannot be solved comprehensively and effectively, failure of conveying, insufficient clamping force, etc., and achieve simple and compact machine structure, saving space and cost, and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

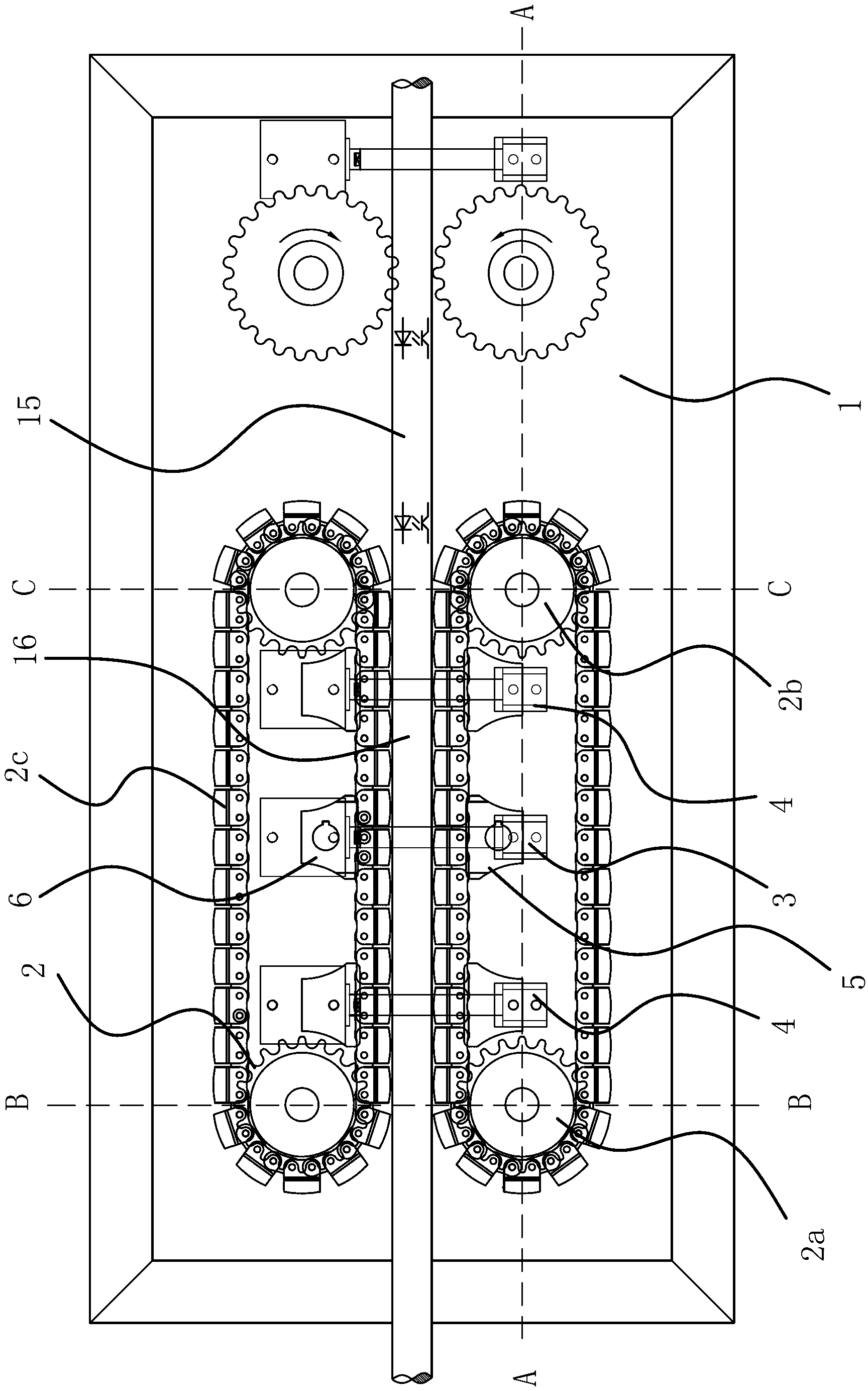

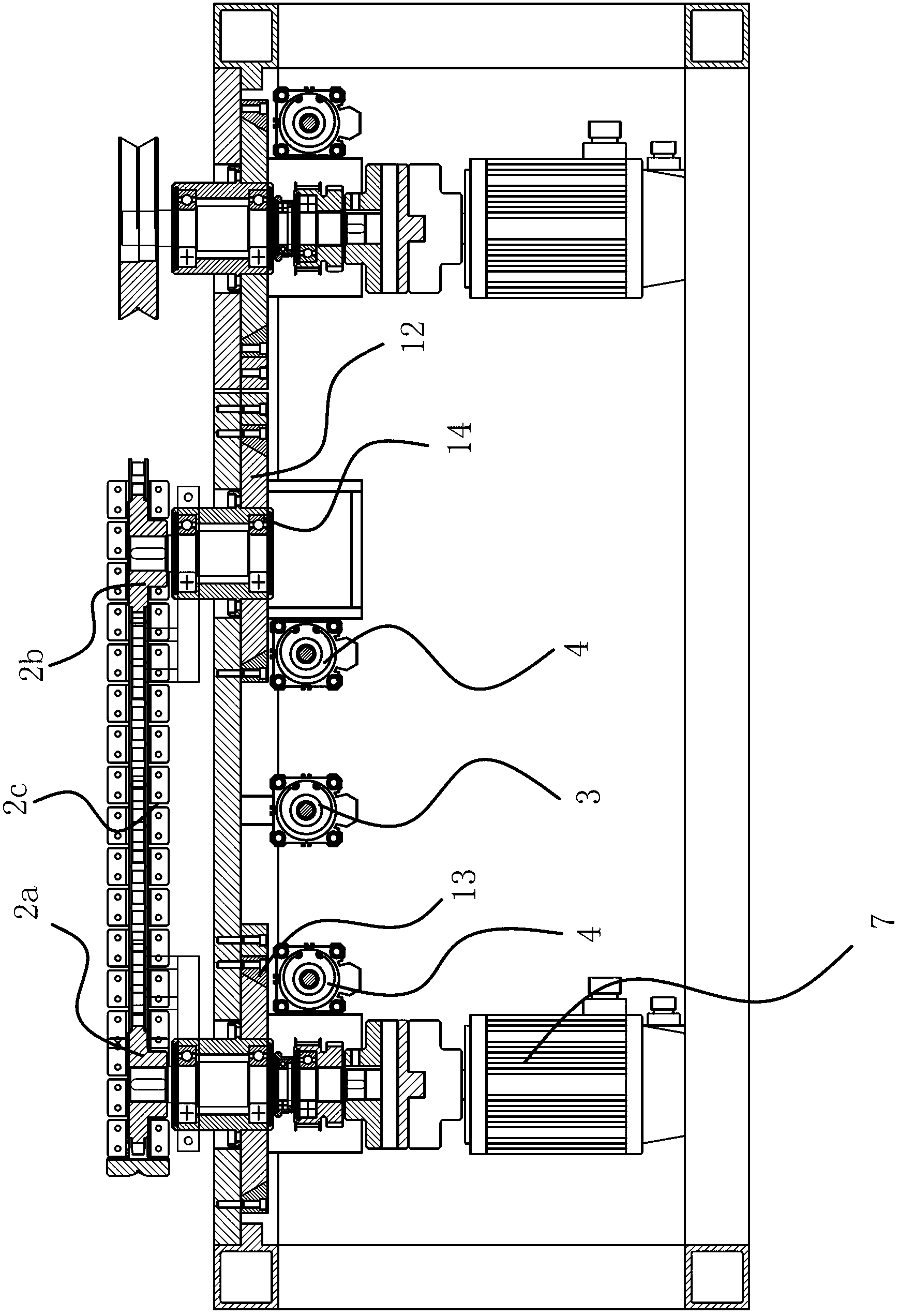

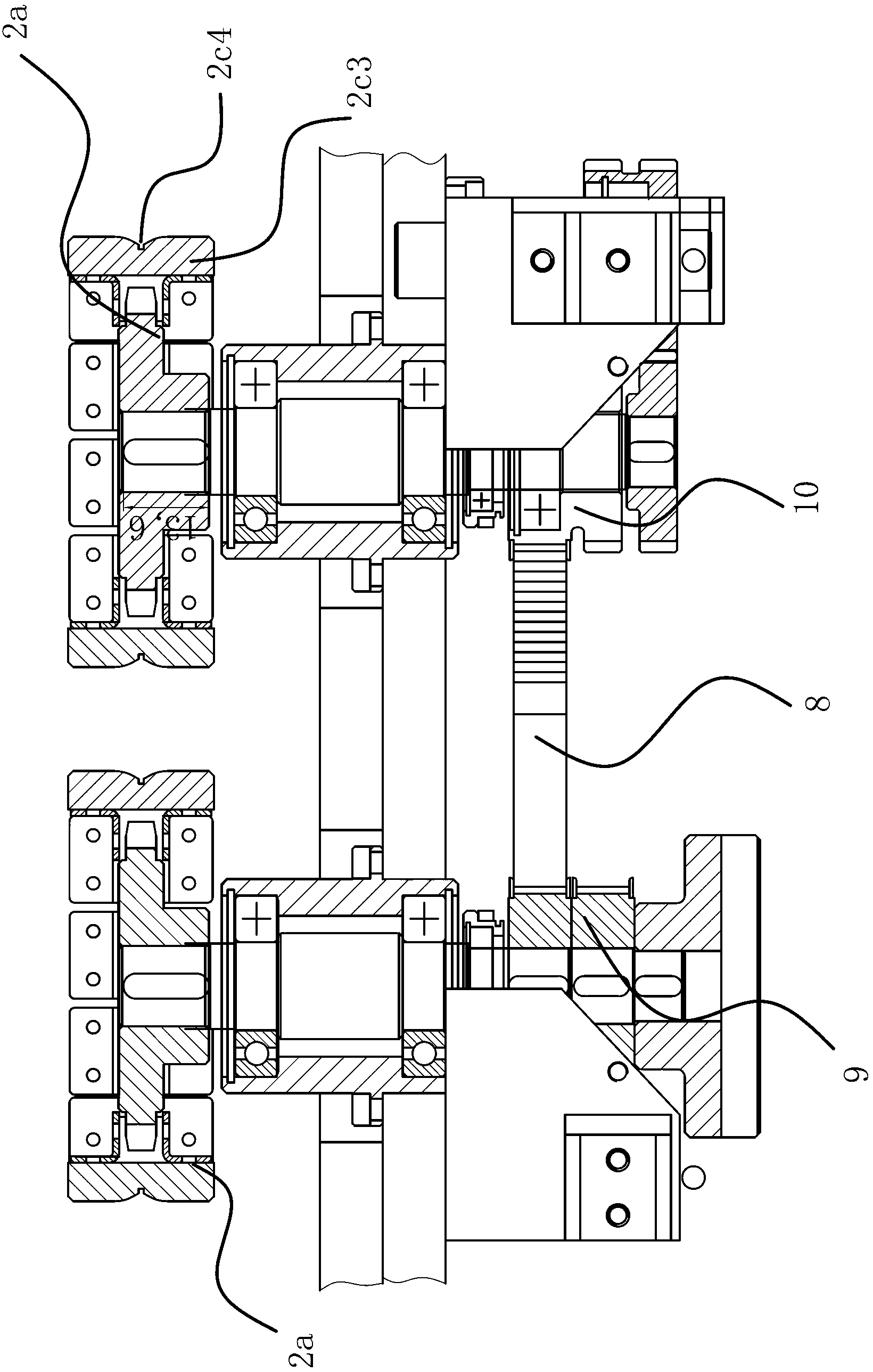

[0038] The present invention is suitable for automatic feeding of straight metal bars 15 and can be used in conjunction with punches, sawing machines, hydraulic shears, etc. to complete the automatic feeding and cutting work of straight bars 15. Such as figure 1 , figure 2 , Figure 4 As shown, the present bar feeder includes a frame 1 and two groups of horizontally opposed conveying crawler pairs 2, and a bar clamping area 16 is formed between the two groups of conveying crawler pairs 2. The conveyor pair 2 includes a driving wheel 2a, a driven wheel 2b, and a crawler 2c. The frame 1 is provided with a driving member that can drive at least one set of the driving wheel 2a of the conveyor pair 2 to rotate. Between the conveyor pair 2 and the frame 1 An adjustment mechanism that can increase or decrease the width of the bar clamping area 16 is provided.

[0039] Specifically, the adjustment mechanism includes a first clamping cylinder 3 and two sets of second clamping cylinders 4...

Embodiment 2

[0045] The structure of this embodiment is basically similar to that of the first embodiment. The difference is that the driving member includes two motors 7, and the two motors 7 and the two driving wheels 2a are connected in a one-to-one correspondence through universal joints. The two driving wheels 2a have their own driving parts, so there is no need for a synchronous transmission structure.

[0046] In addition, the adjustment mechanism of this embodiment includes a first abutment member 5, the first abutment member 5 is located inside a set of conveyor belt pairs 2 crawler 2c, the frame 1 is provided with the first abutment member 5 to the other The first clamping cylinder 3 that conveys the crawler pair 2 moves in the direction and makes the first abutting member 5 abut against the inner surface of the crawler 2c. One group of conveying crawler pairs 2 does not move, and the other group of conveying crawler pairs 2 move closer or away.

Embodiment 3

[0048] The structure of this embodiment is basically similar to that of the second embodiment. The difference is that the adjustment mechanism includes a first clamping cylinder 3, a set of conveyor track pairs 2 is provided with a first abutment member 5 inside the track 2c, and the other set of conveyor track pairs 2 A second abutment member 6 is provided on the inner side. The first abutment member 5, the second abutment member 6, the driving wheel 2a and the driven wheel 2b are all positioned on the frame 1 through corresponding guiding structures; the first clamping cylinder 3 The cylinder is connected with the first abutment member 5, and the piston rod is connected with the second abutment member 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com