Patents

Literature

3295results about How to "Clamp firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

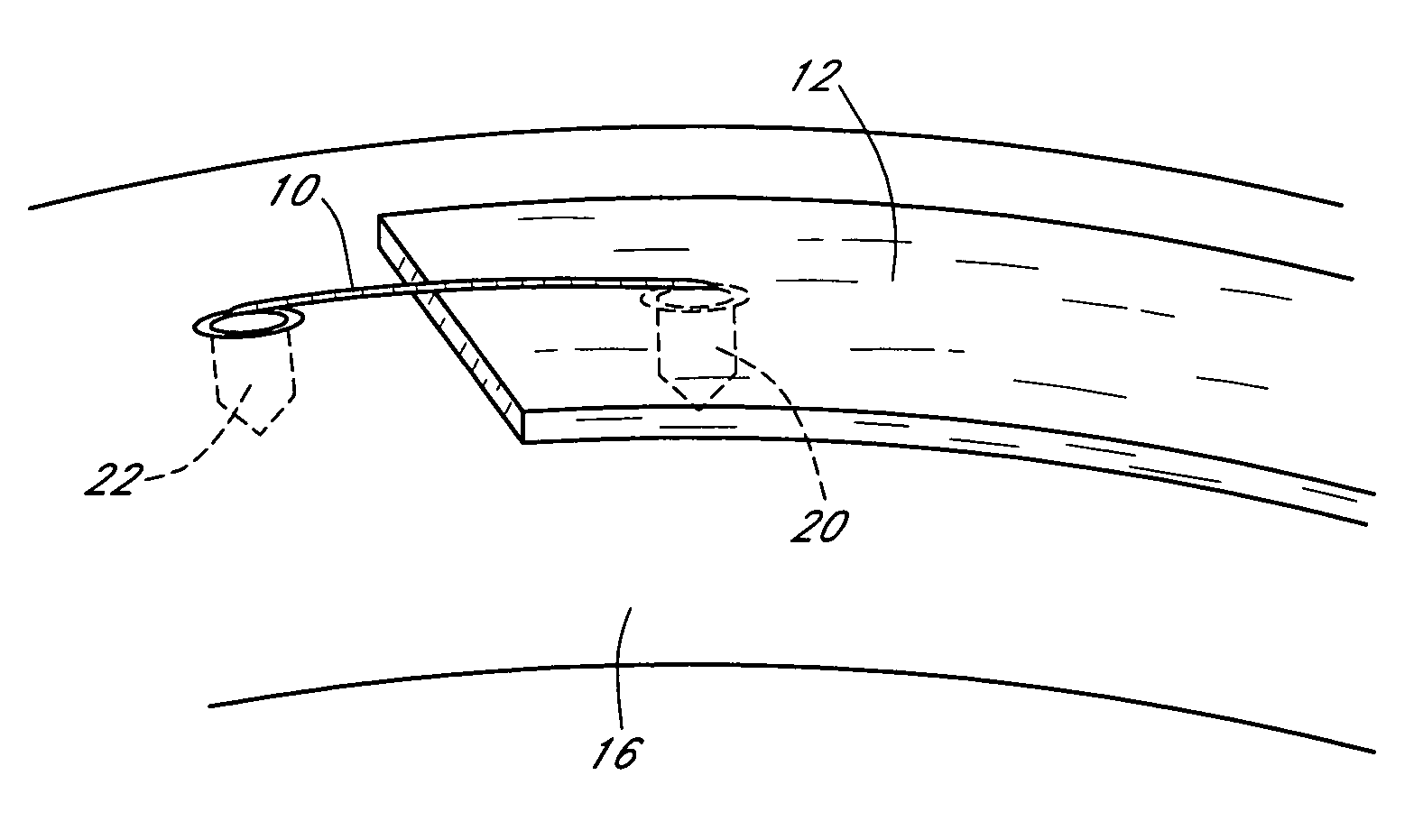

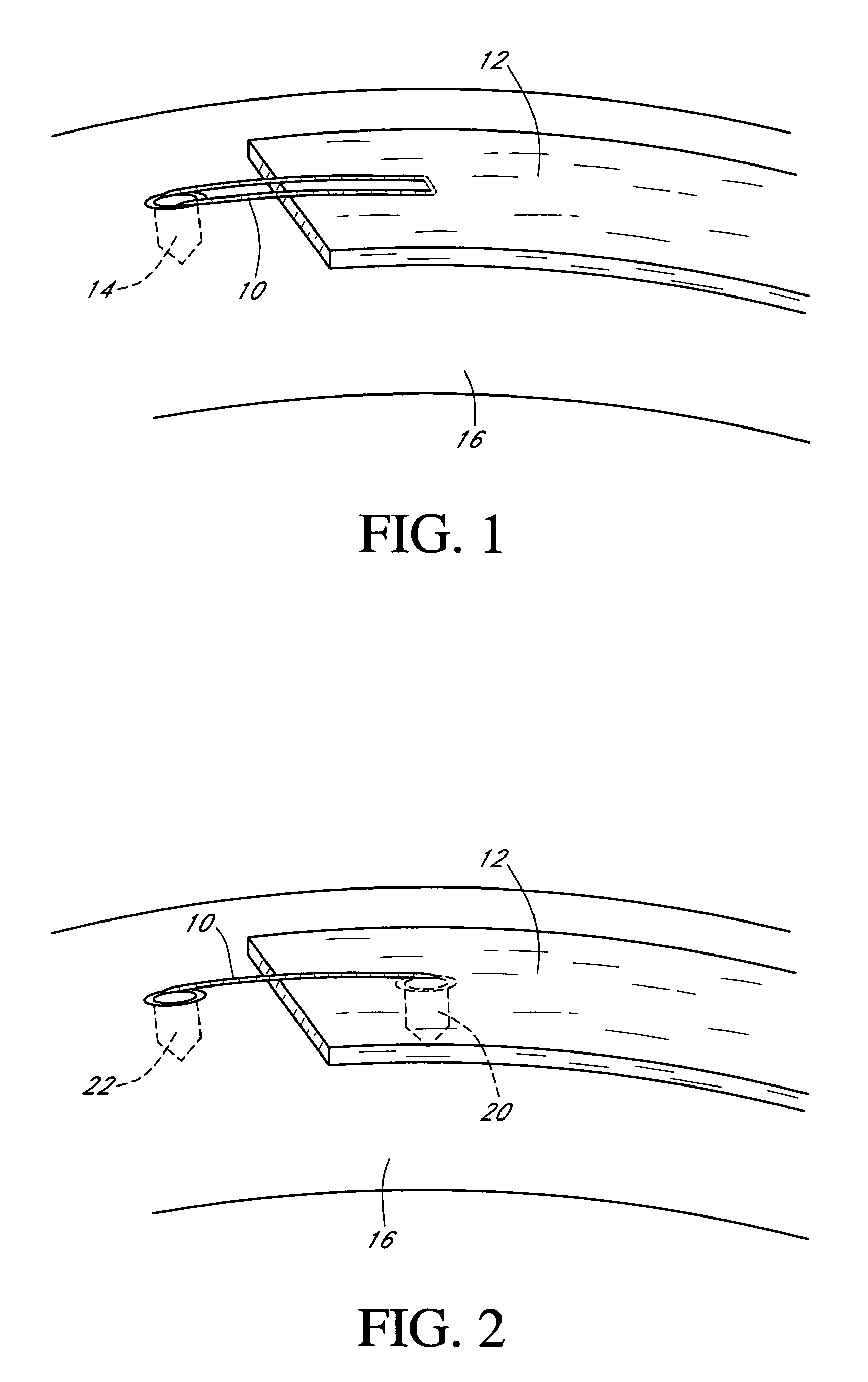

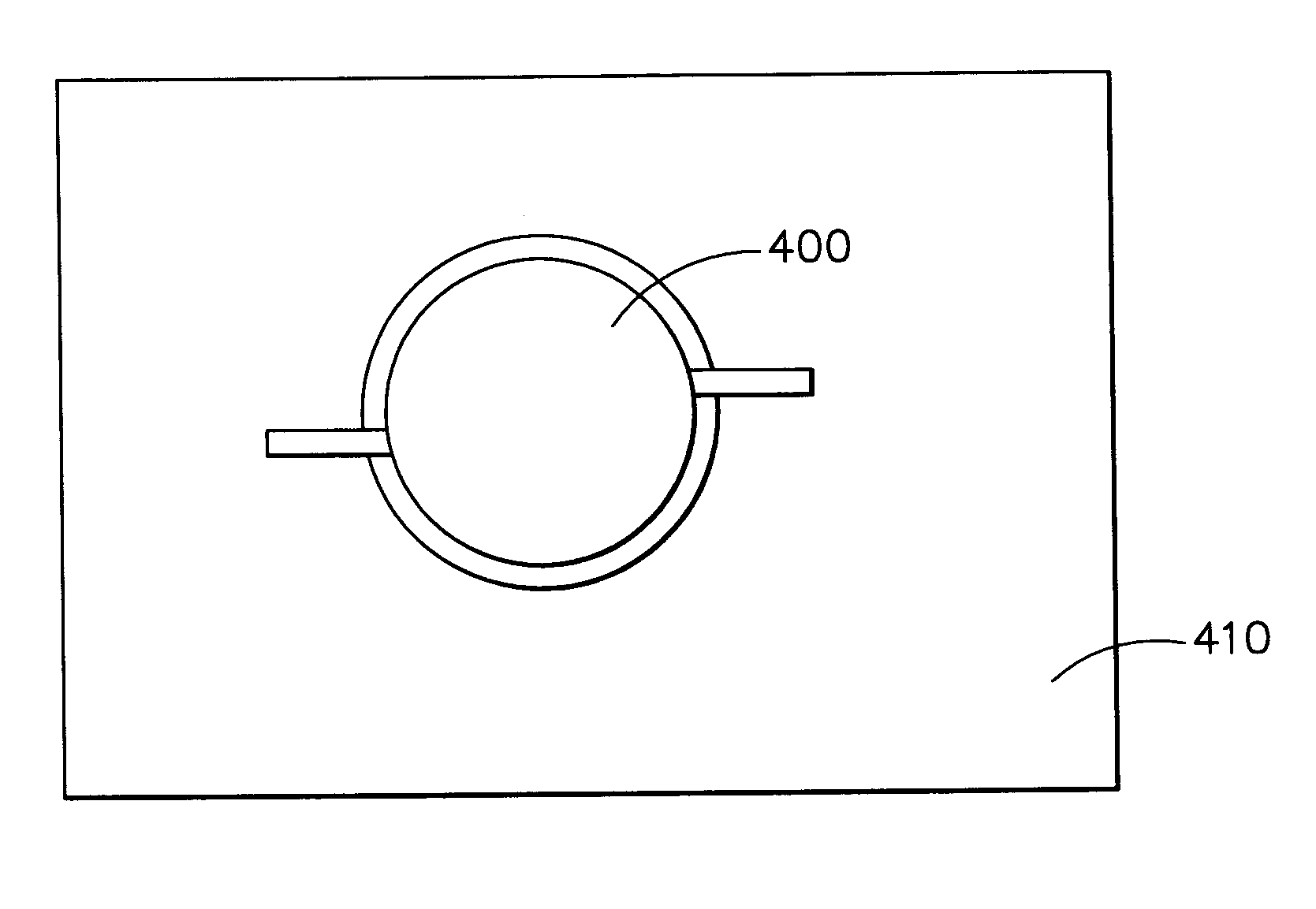

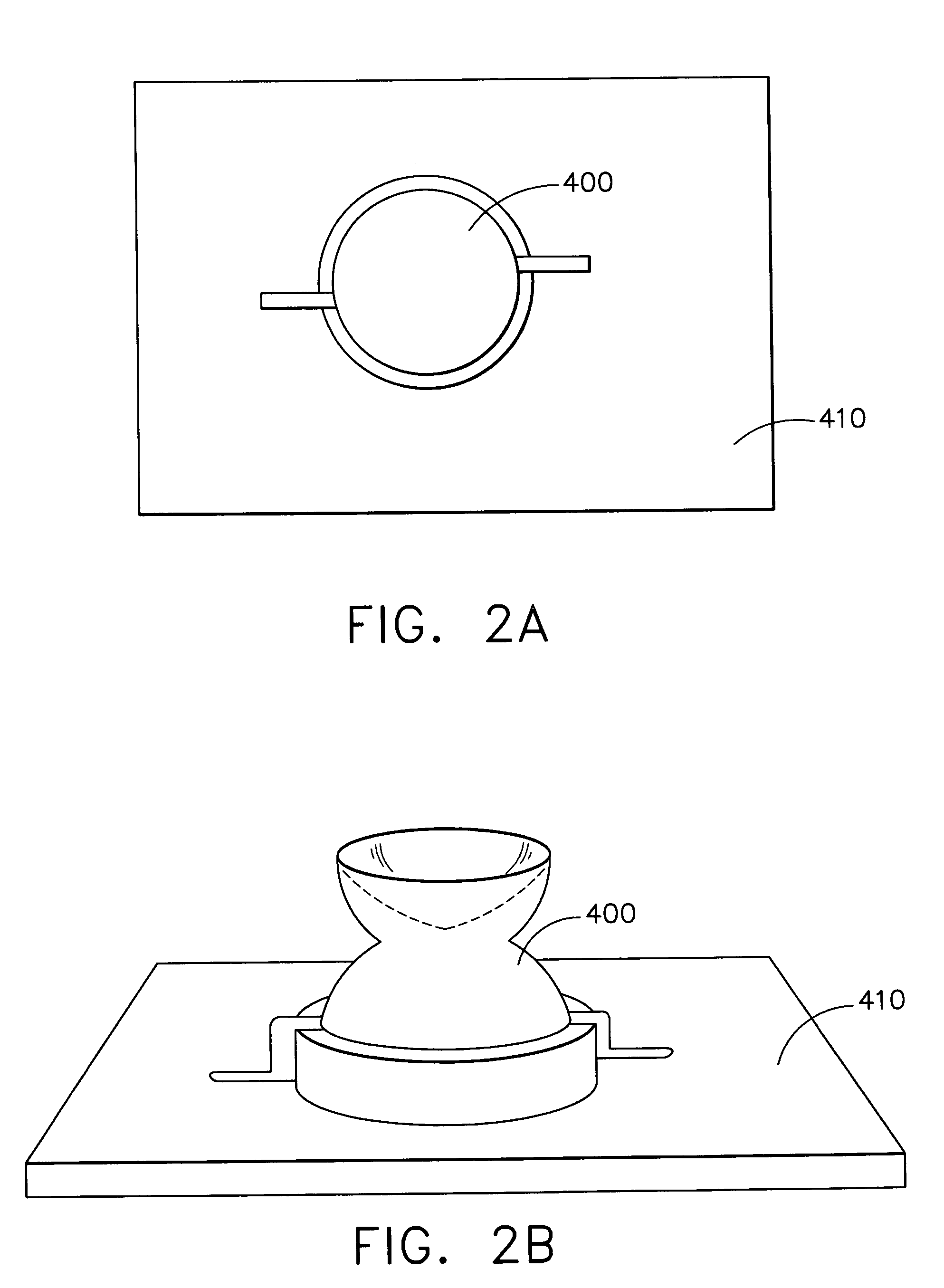

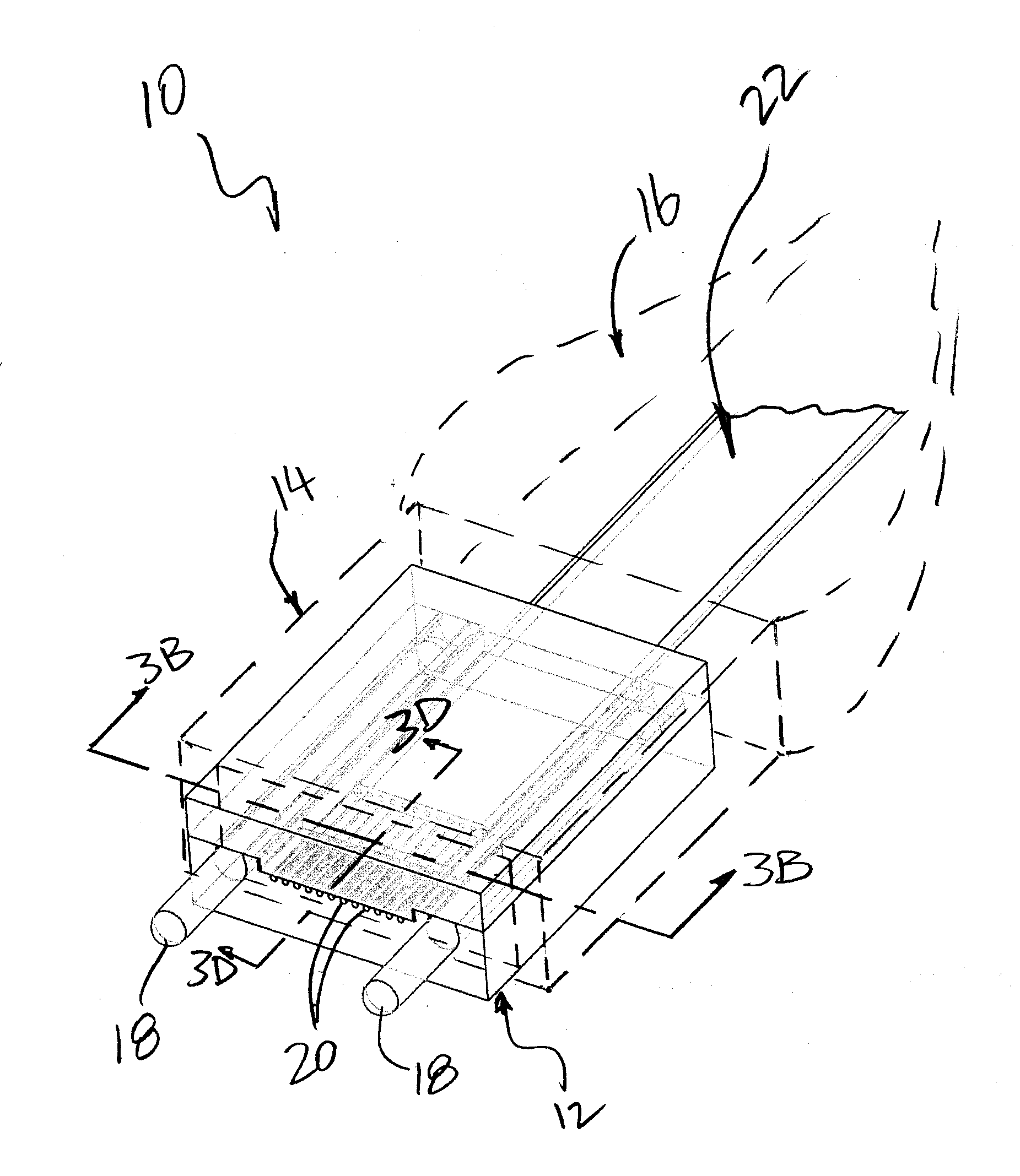

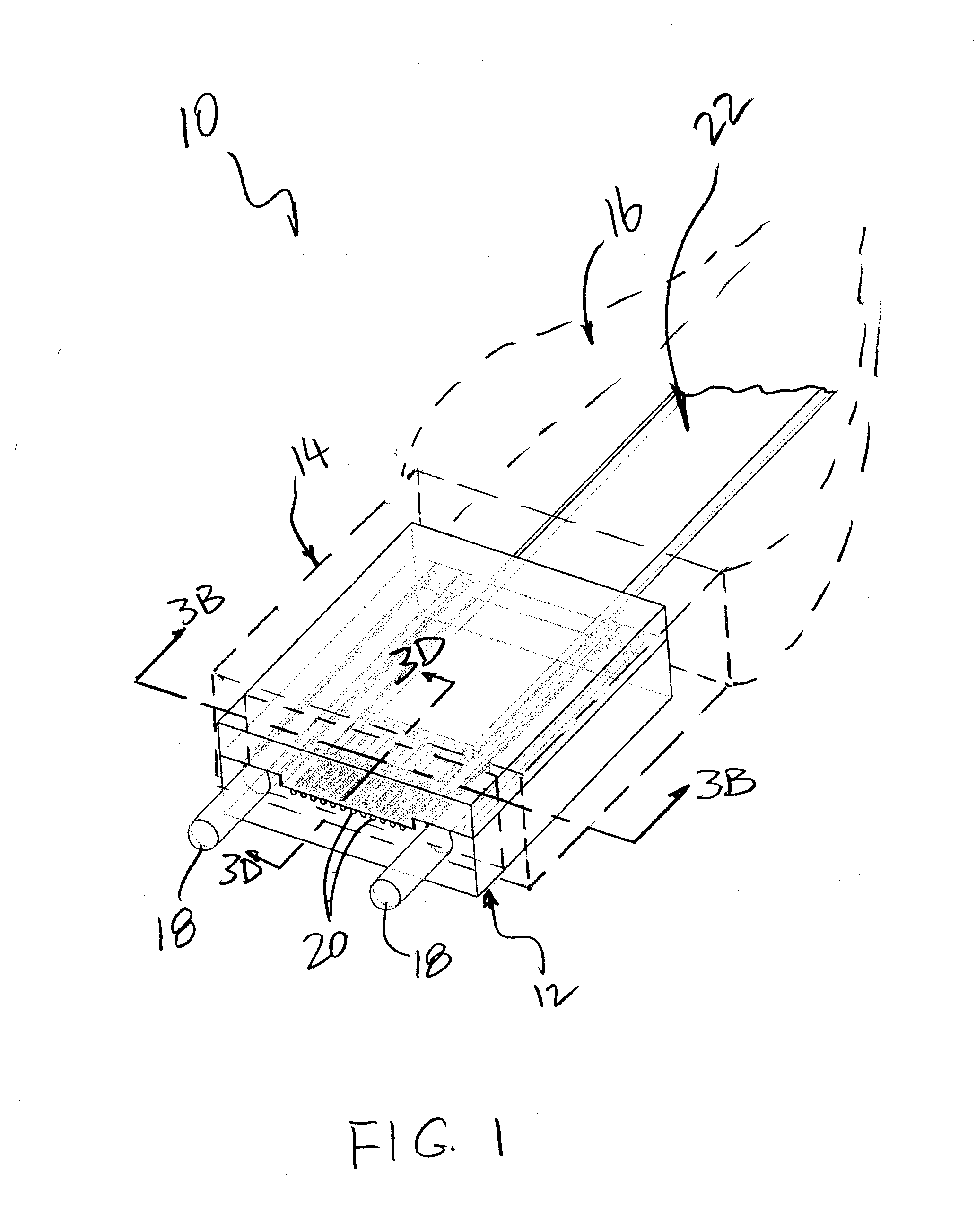

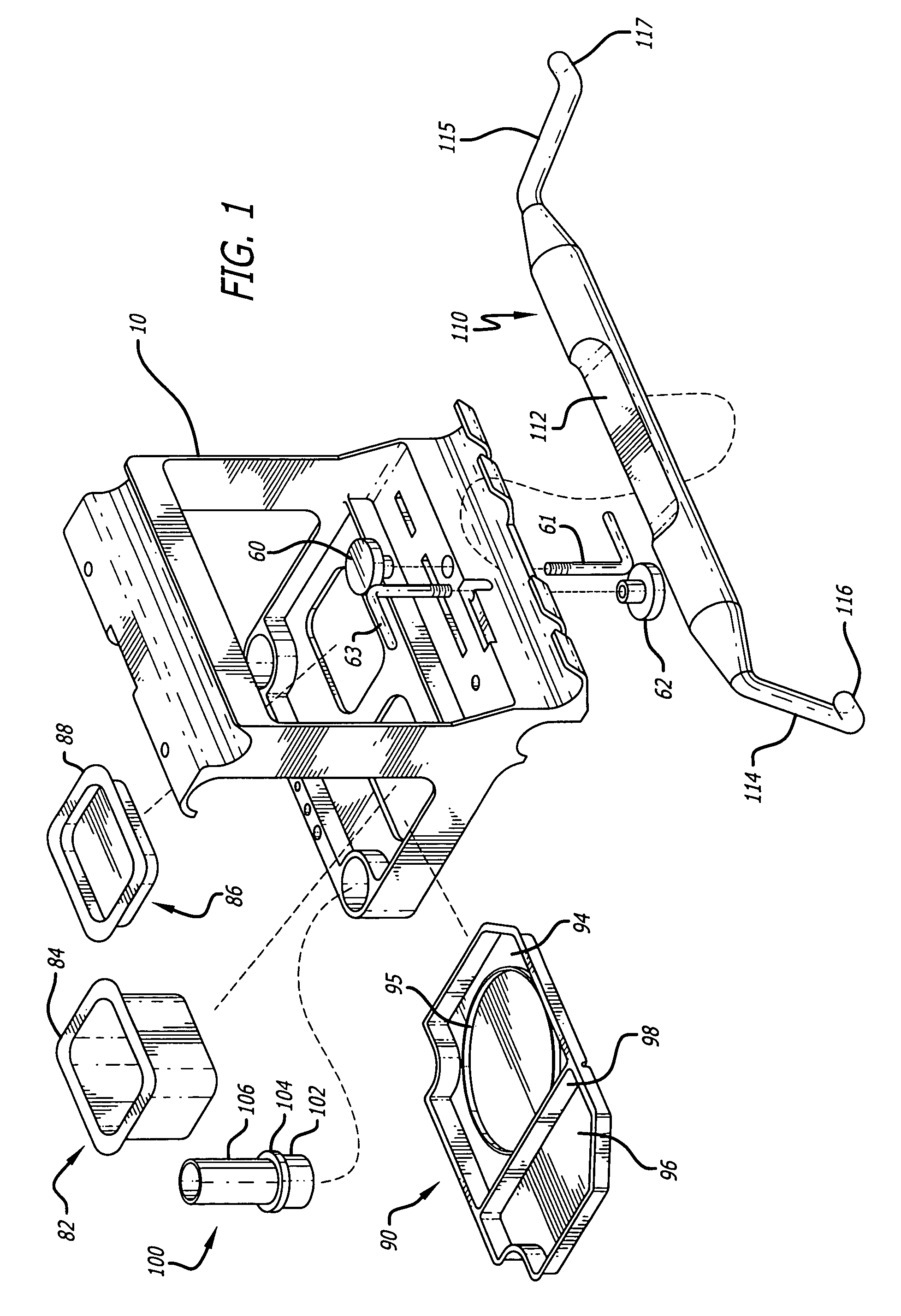

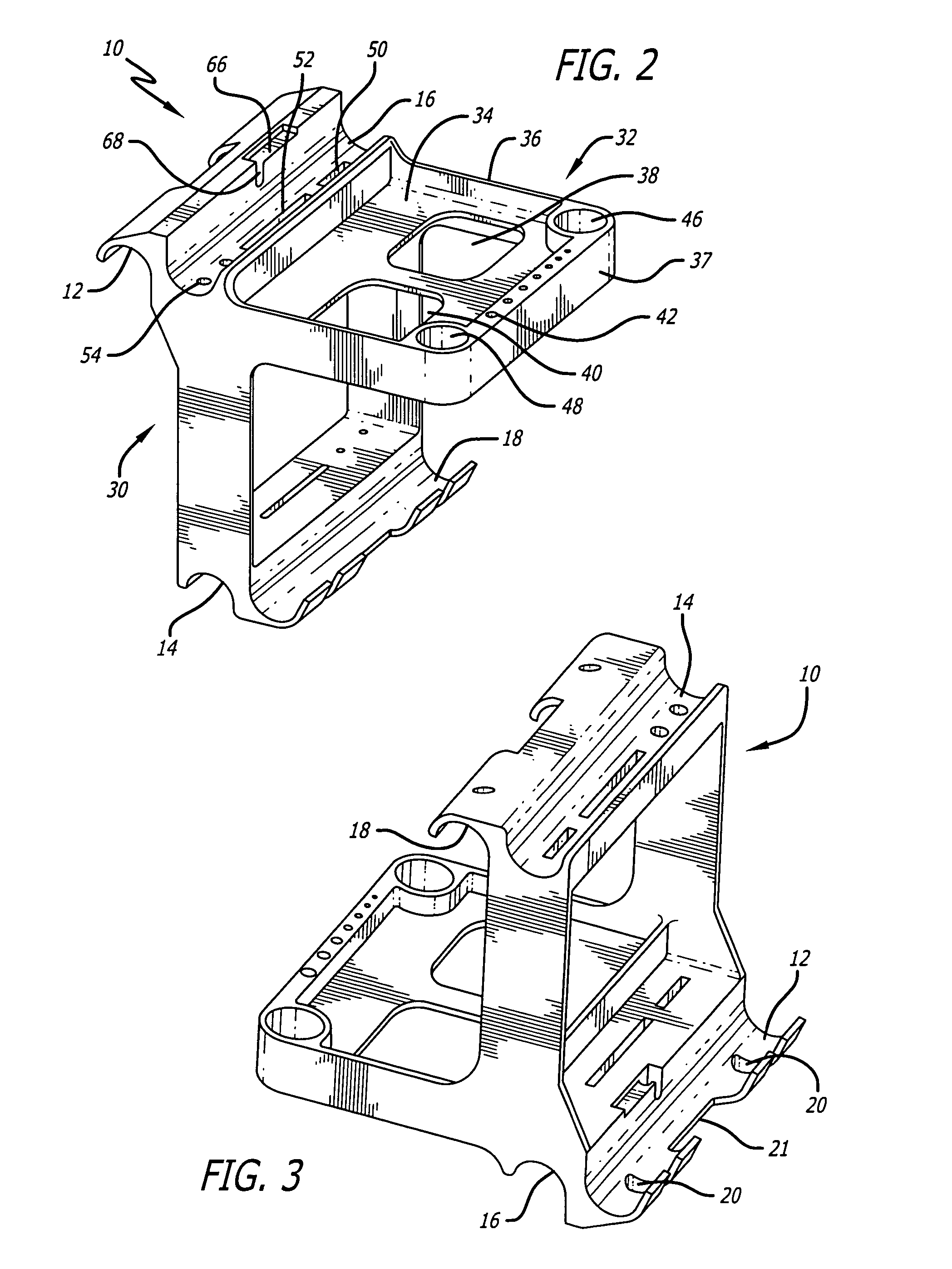

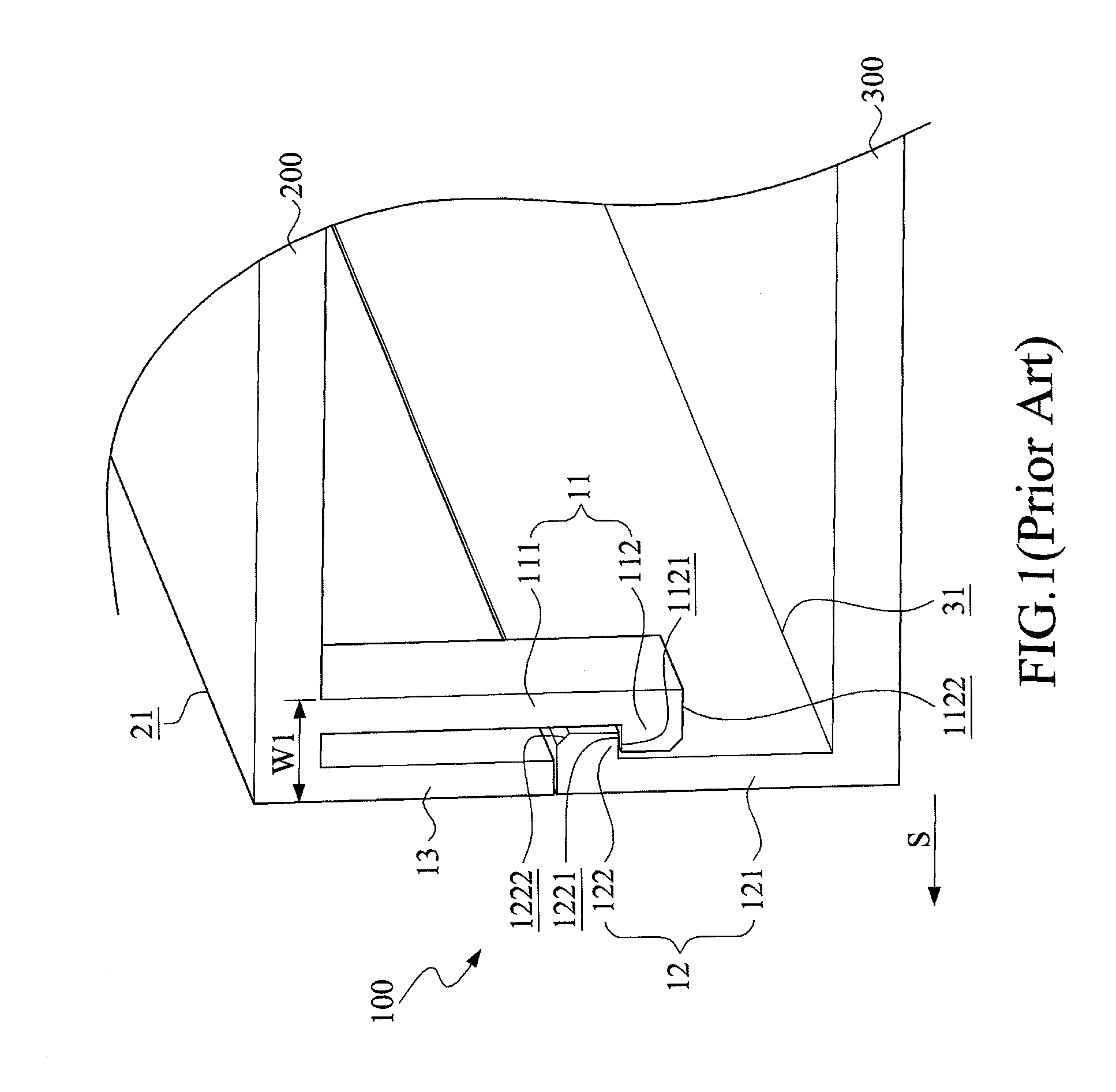

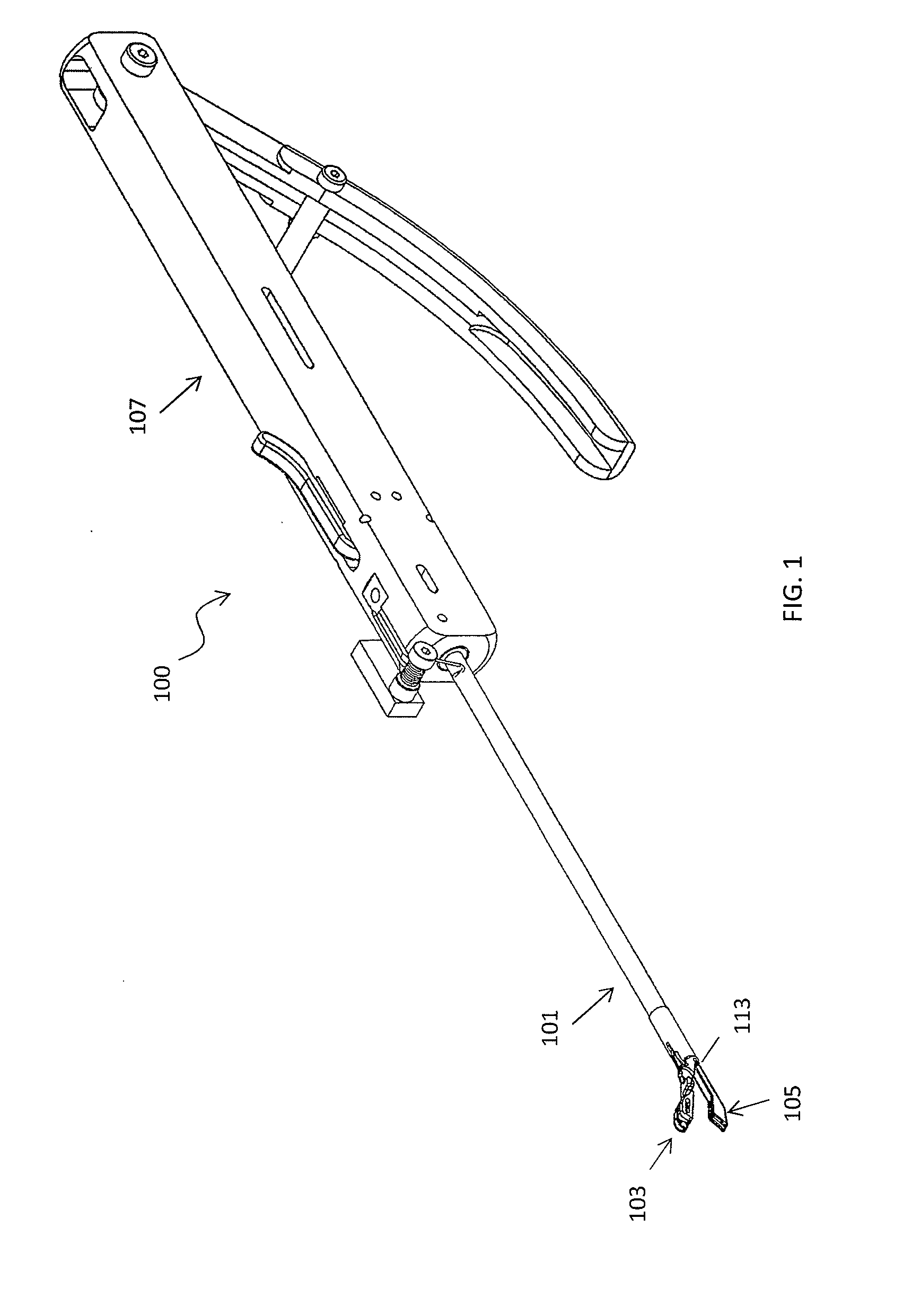

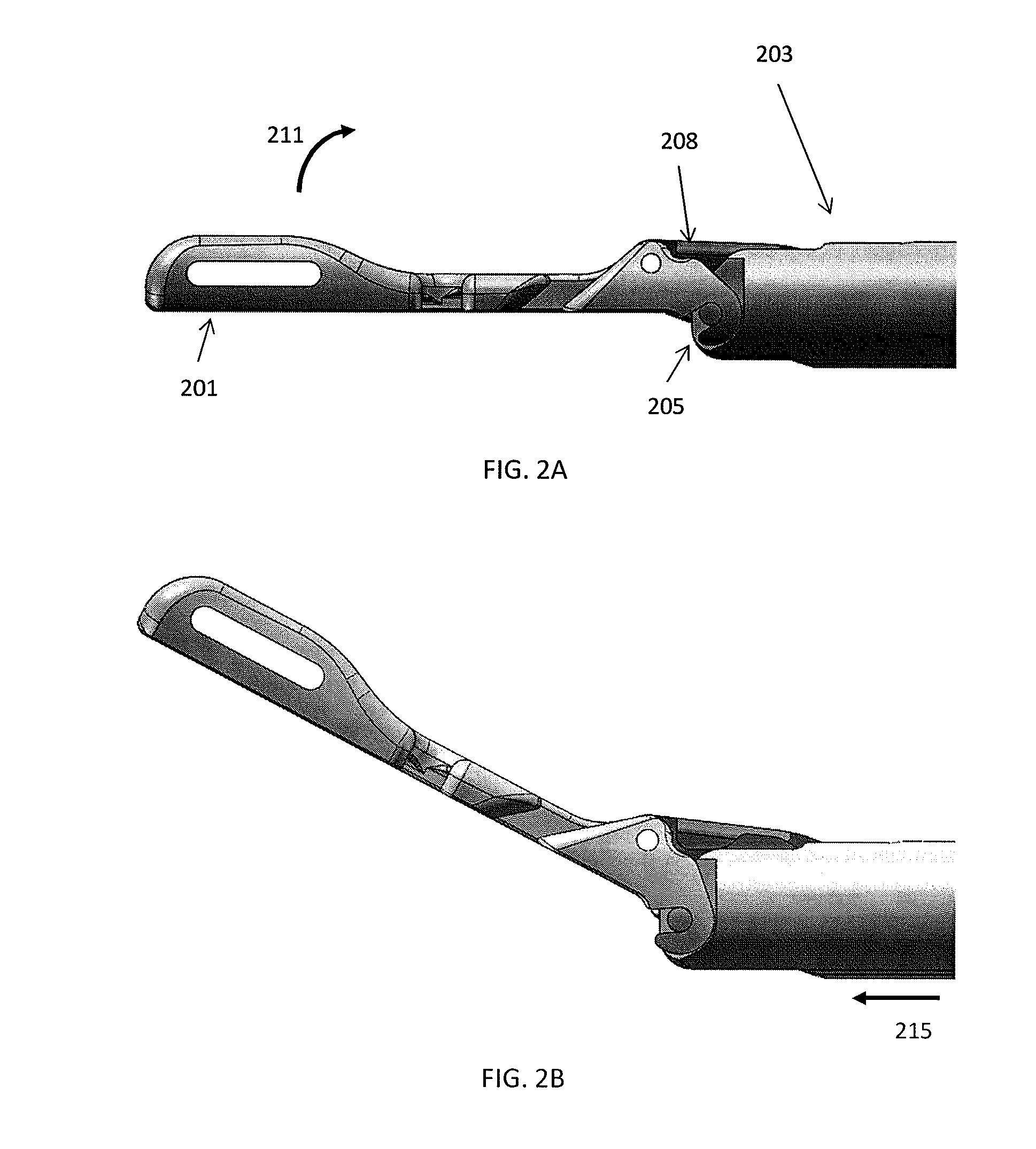

System and method for attaching soft tissue to bone

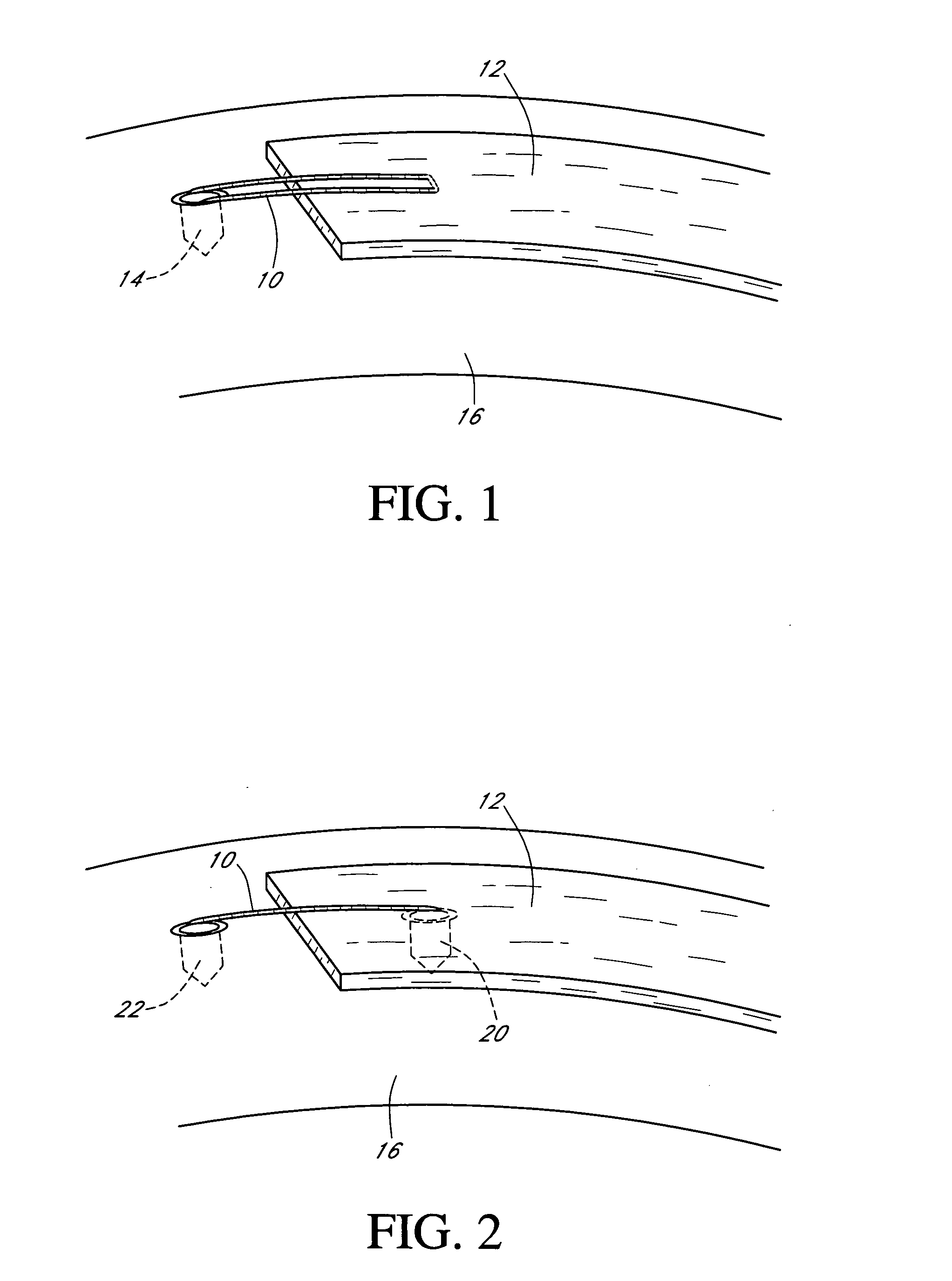

Disclosed herein are methods and devices for securing soft tissue to a rigid material such as bone. A bone anchor is described that comprises a base and a top such that suture material may be compressed between surfaces on the base and top to secure the suture to the anchor. Also described is an inserter that can be used to insert the bone anchor into bone and move the anchor top relative to the anchor base to clamp suture material there between. Also described is a soft-tissue and bone piercing anchor and associated inserter. Methods are described that allow use of the bone anchors to provide multiple lengths of suture material to compress a large area of soft tissue against bone.

Owner:SCOTT W TATE

System and method for attaching soft tissue to bone

Disclosed herein are methods and devices for securing soft tissue to a rigid material such as bone. A bone anchor is described that comprises a base and a top such that suture material may be compressed between surfaces on the base and top to secure the suture to the anchor. Also described is an inserter that can be used to insert the bone anchor into bone and move the anchor top relative to the anchor base to clamp suture material there between. Also described is a soft-tissue and bone piercing anchor and associated inserter. Methods are described that allow use of the bone anchors to provide multiple lengths of suture material to compress a large area of soft tissue against bone.

Owner:SCOTT W TATE

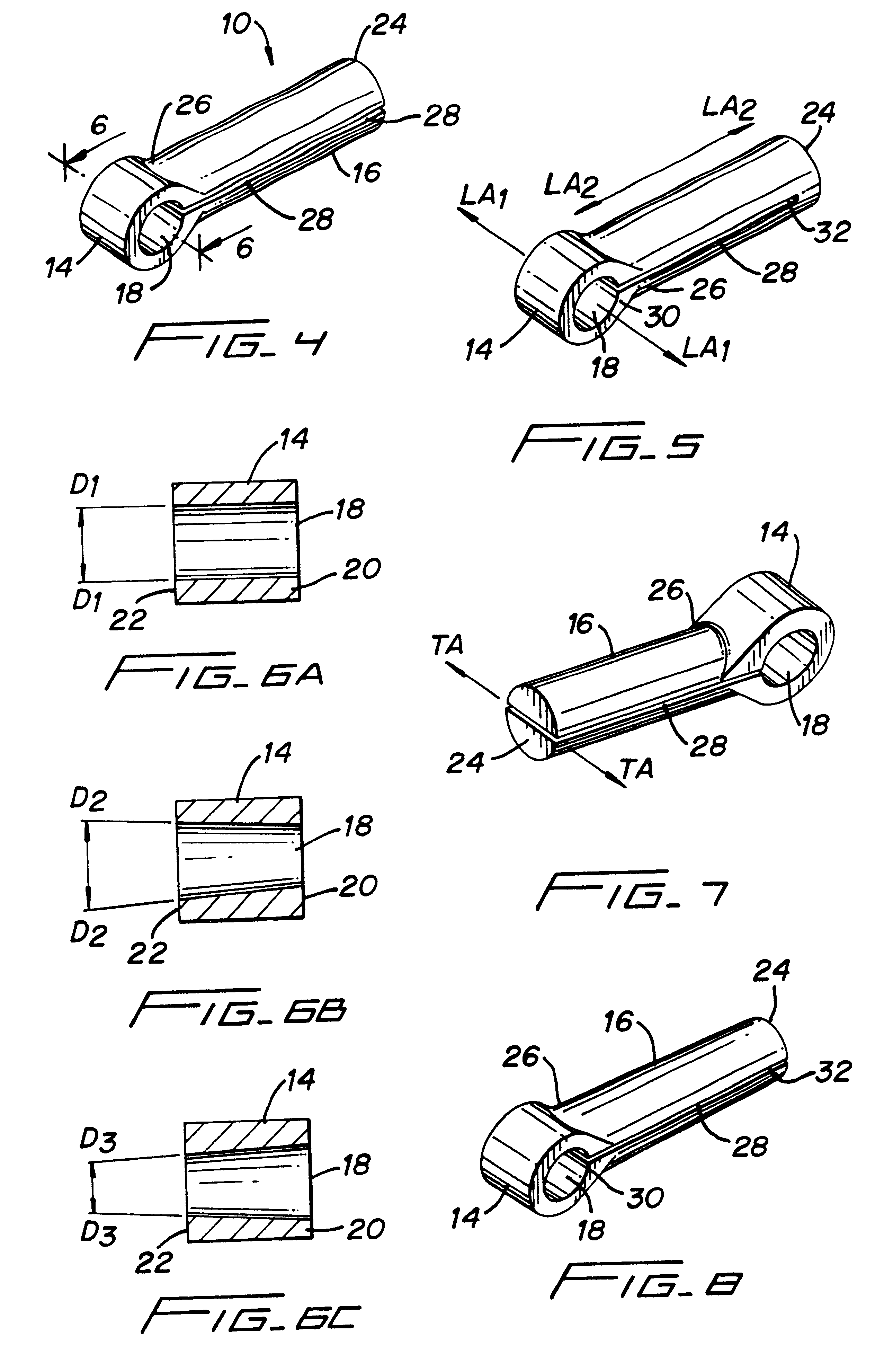

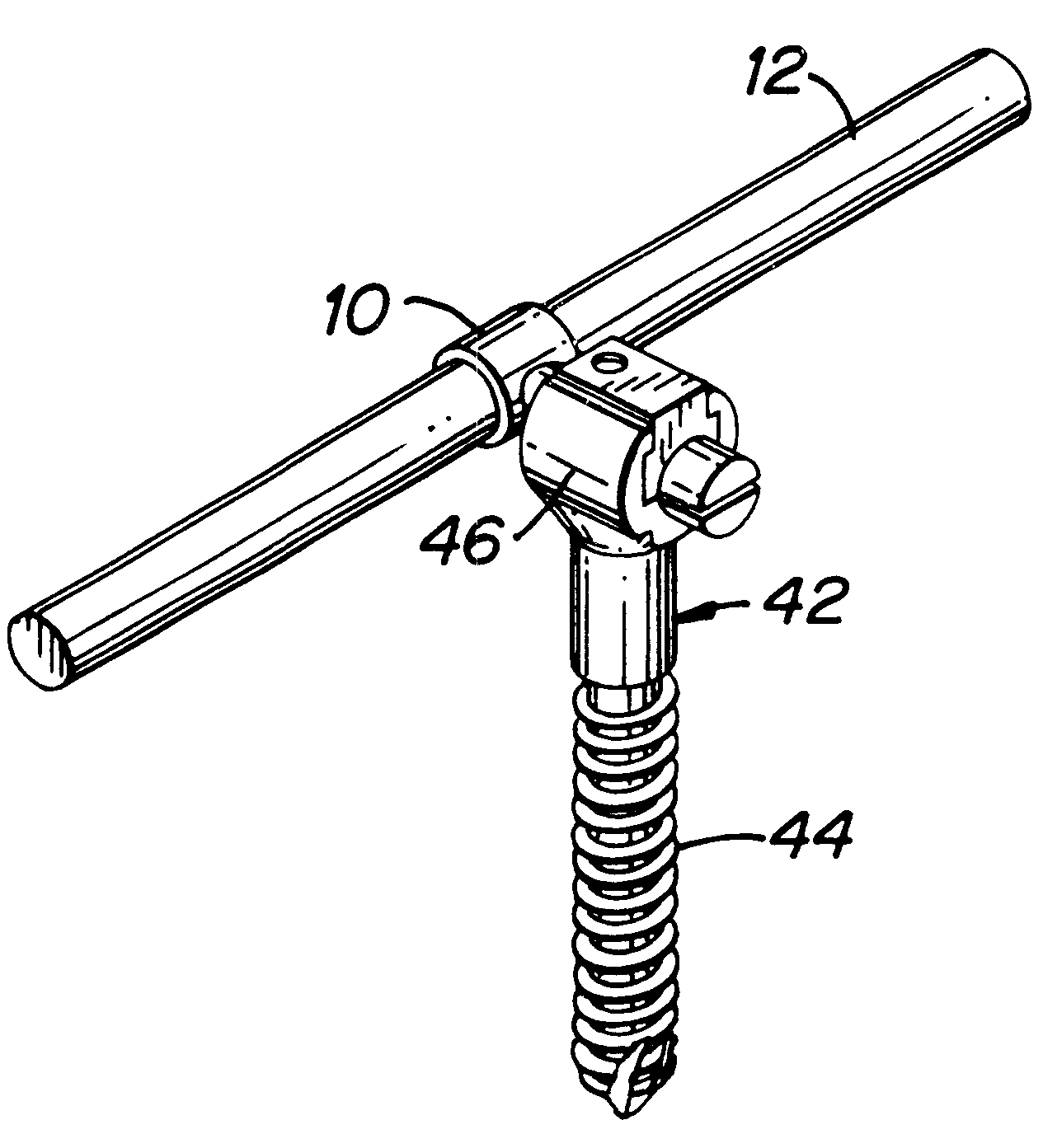

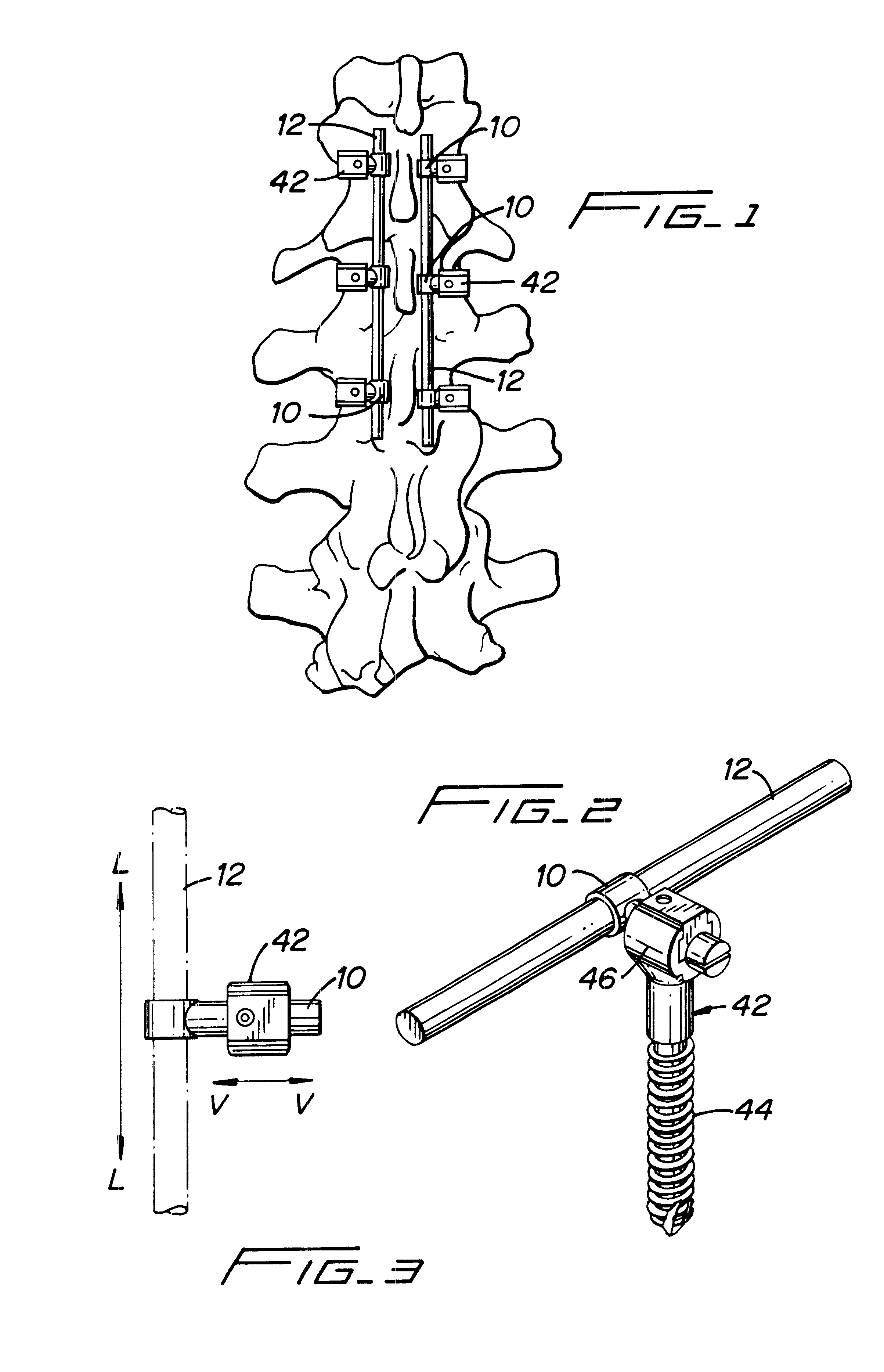

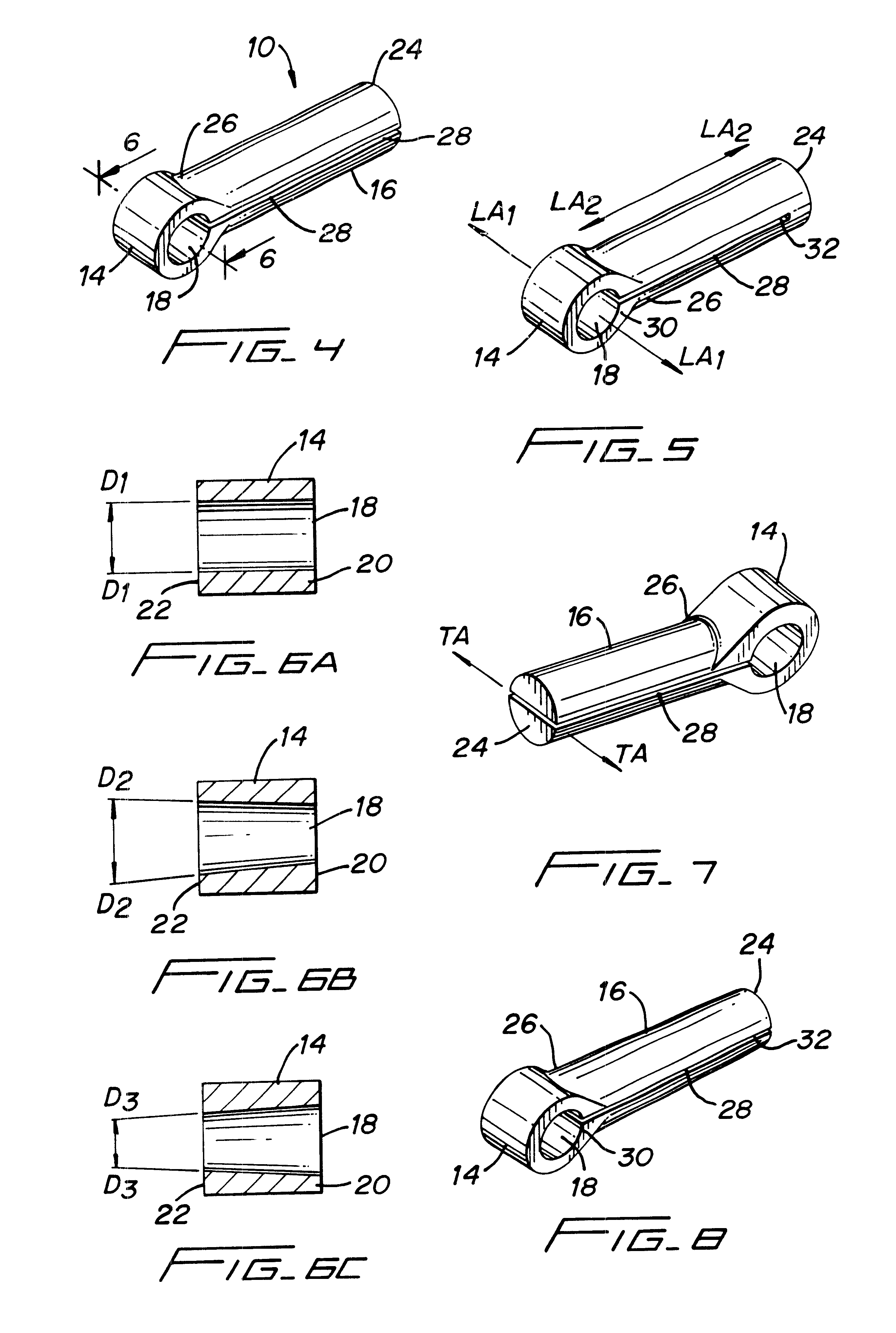

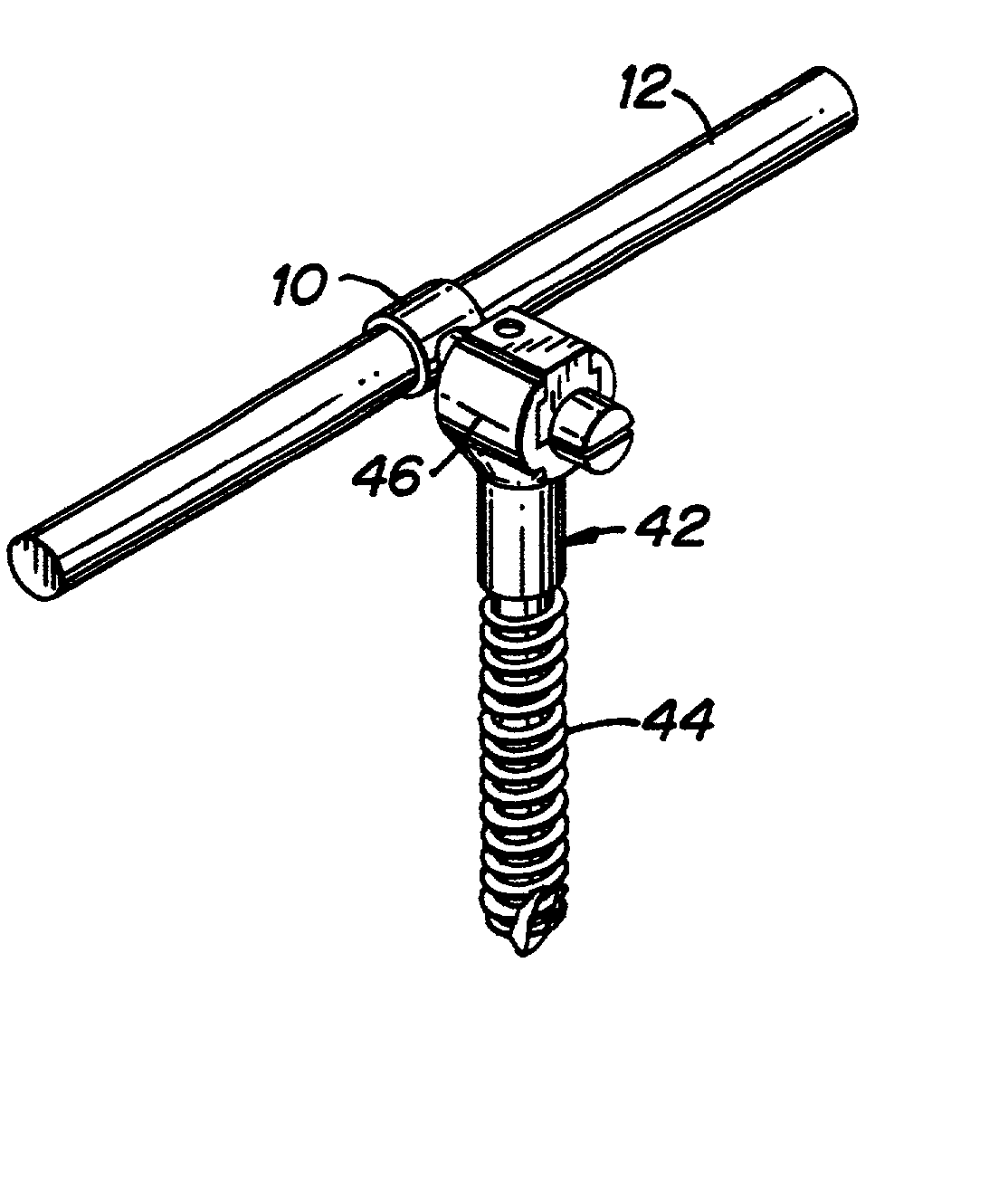

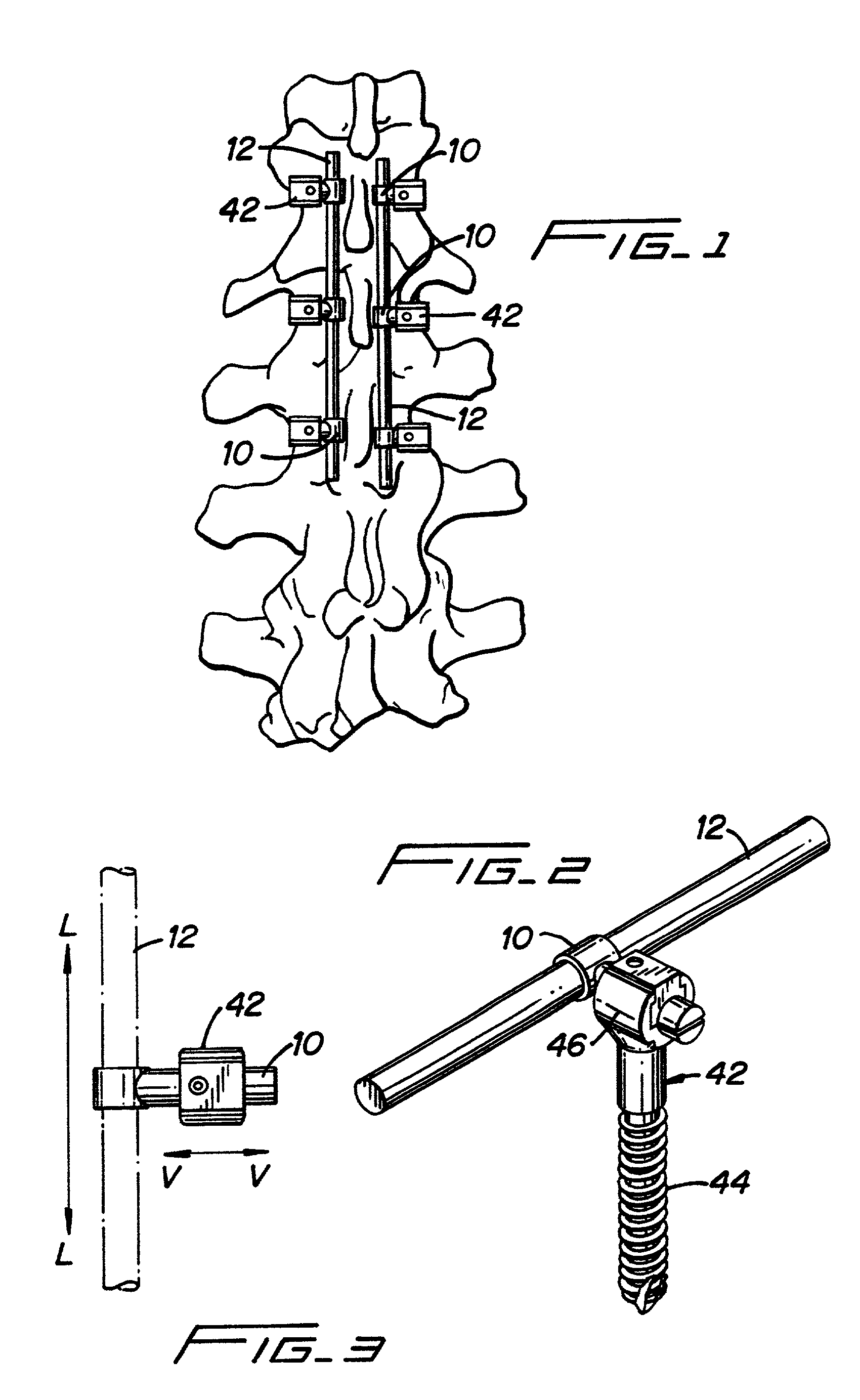

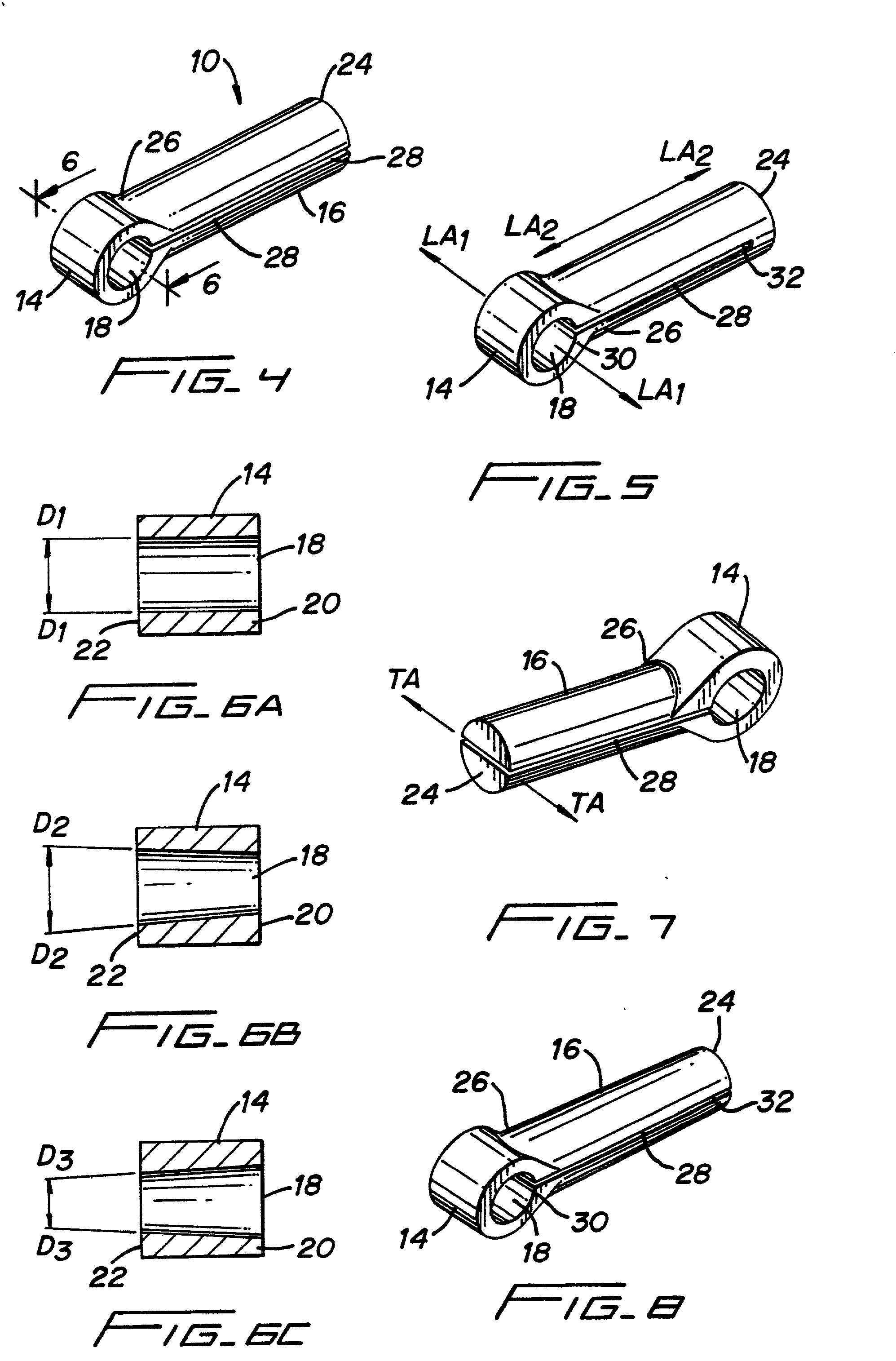

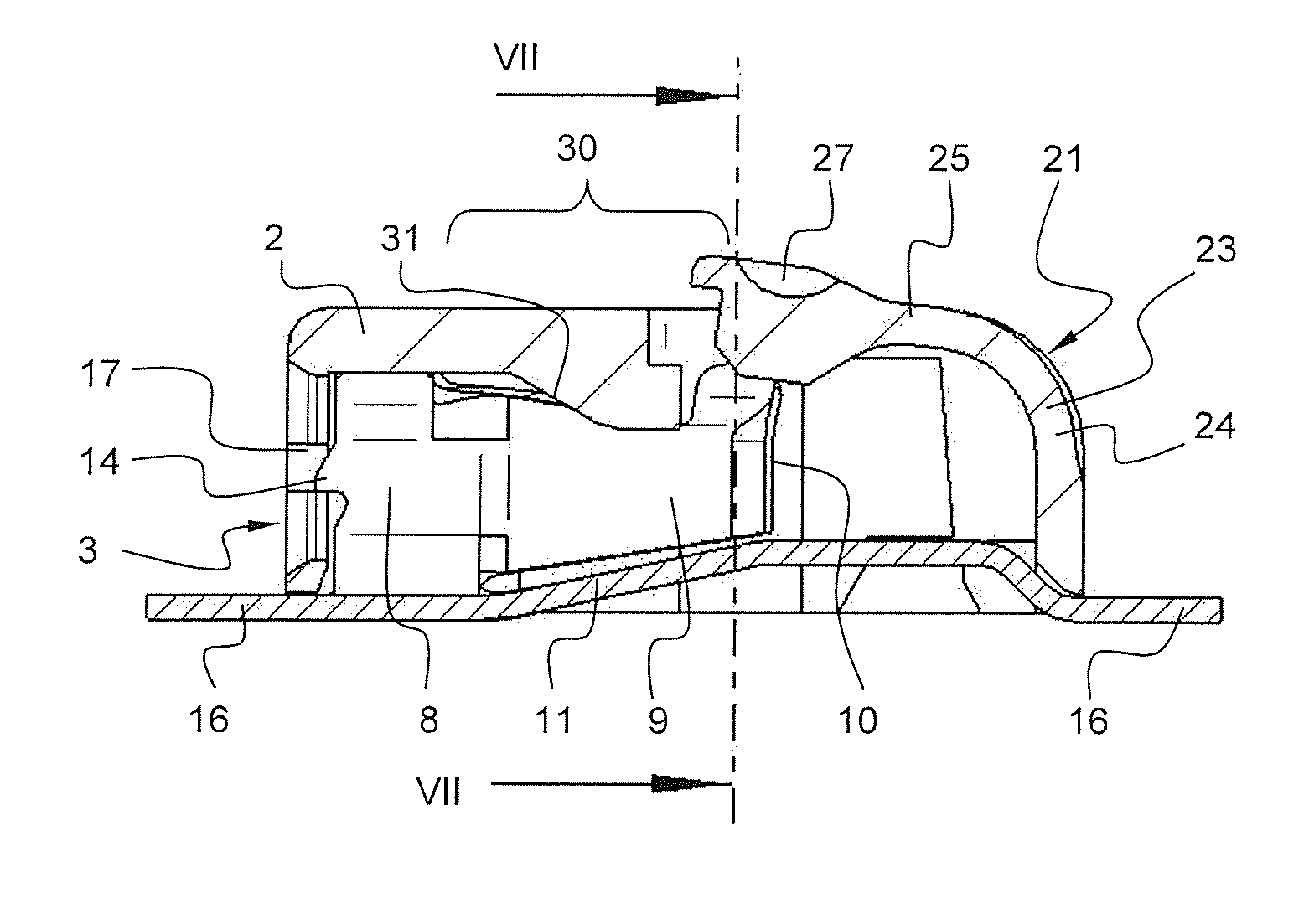

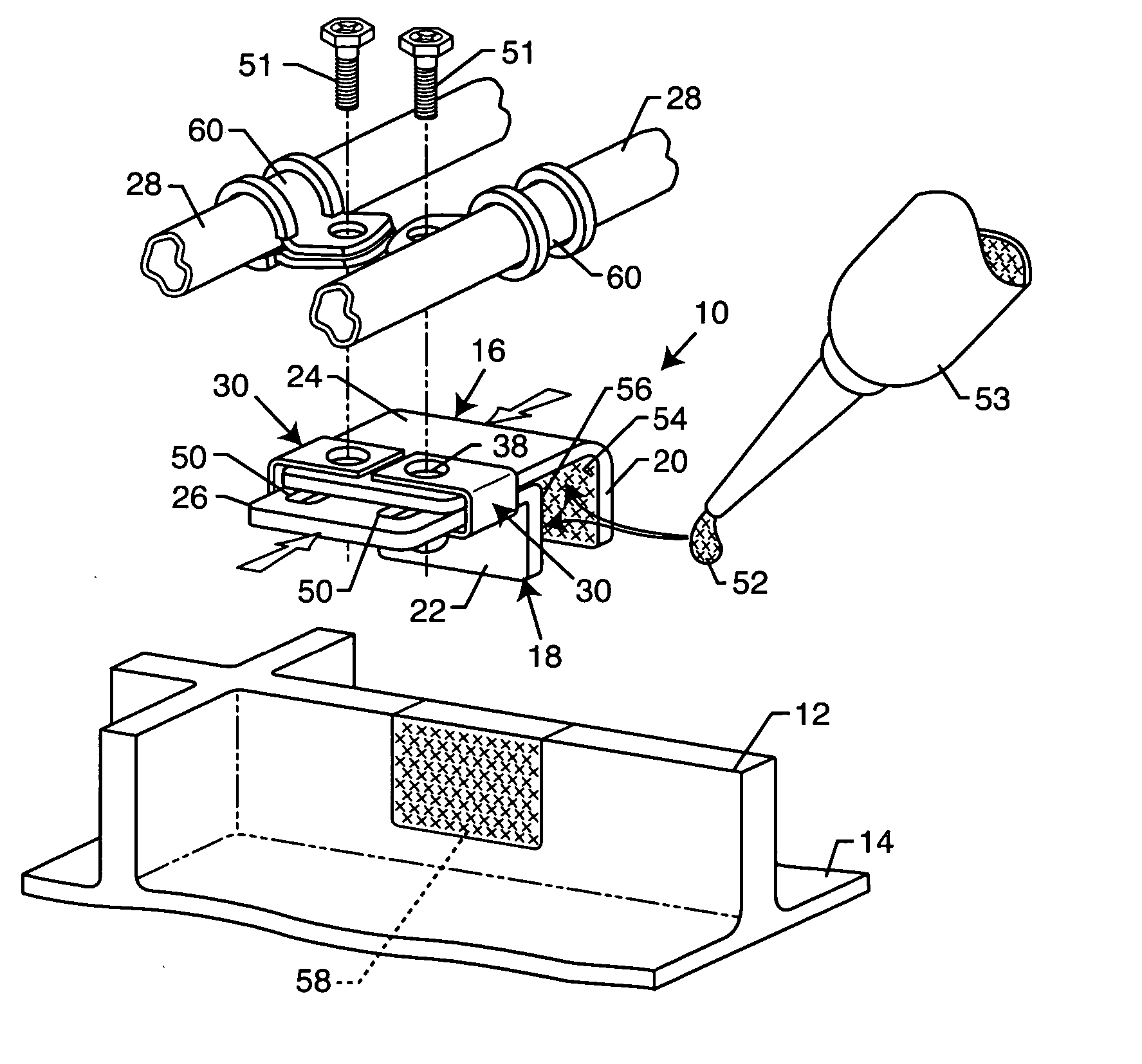

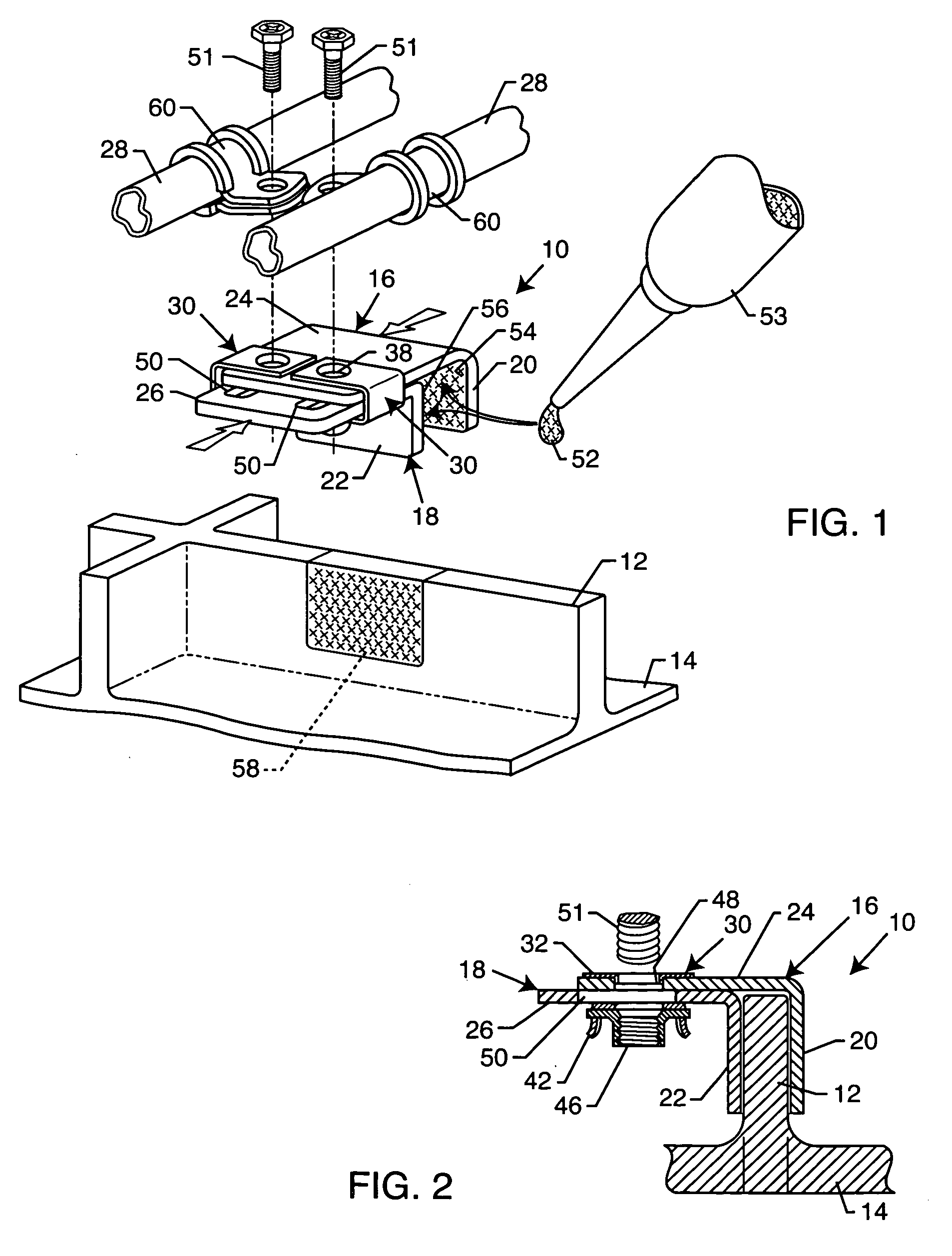

Clamping connector for spinal fixation systems

InactiveUS6706045B2Relieve pressureClamp firmlyInternal osteosythesisJoint implantsTransverse axisLocking mechanism

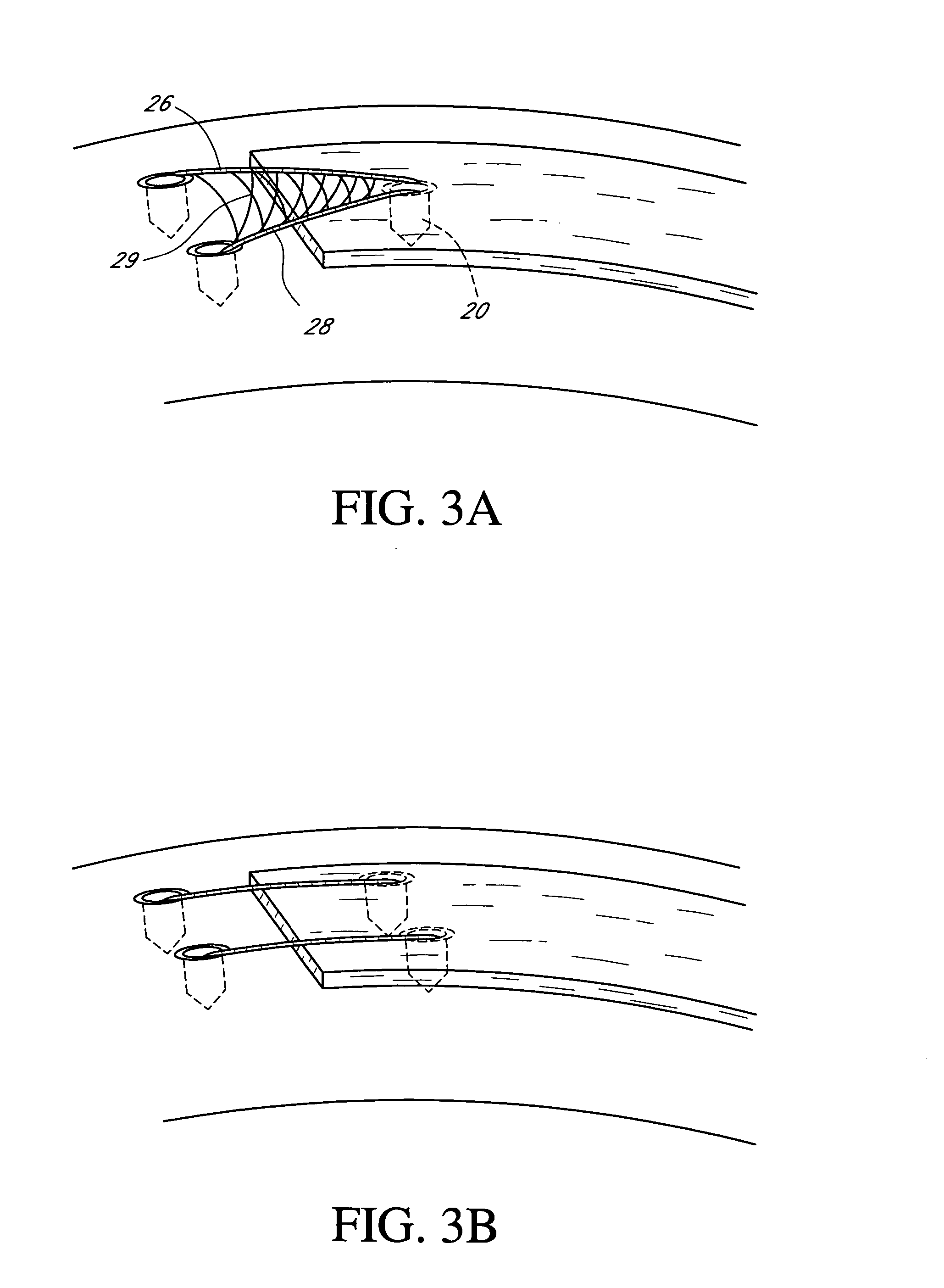

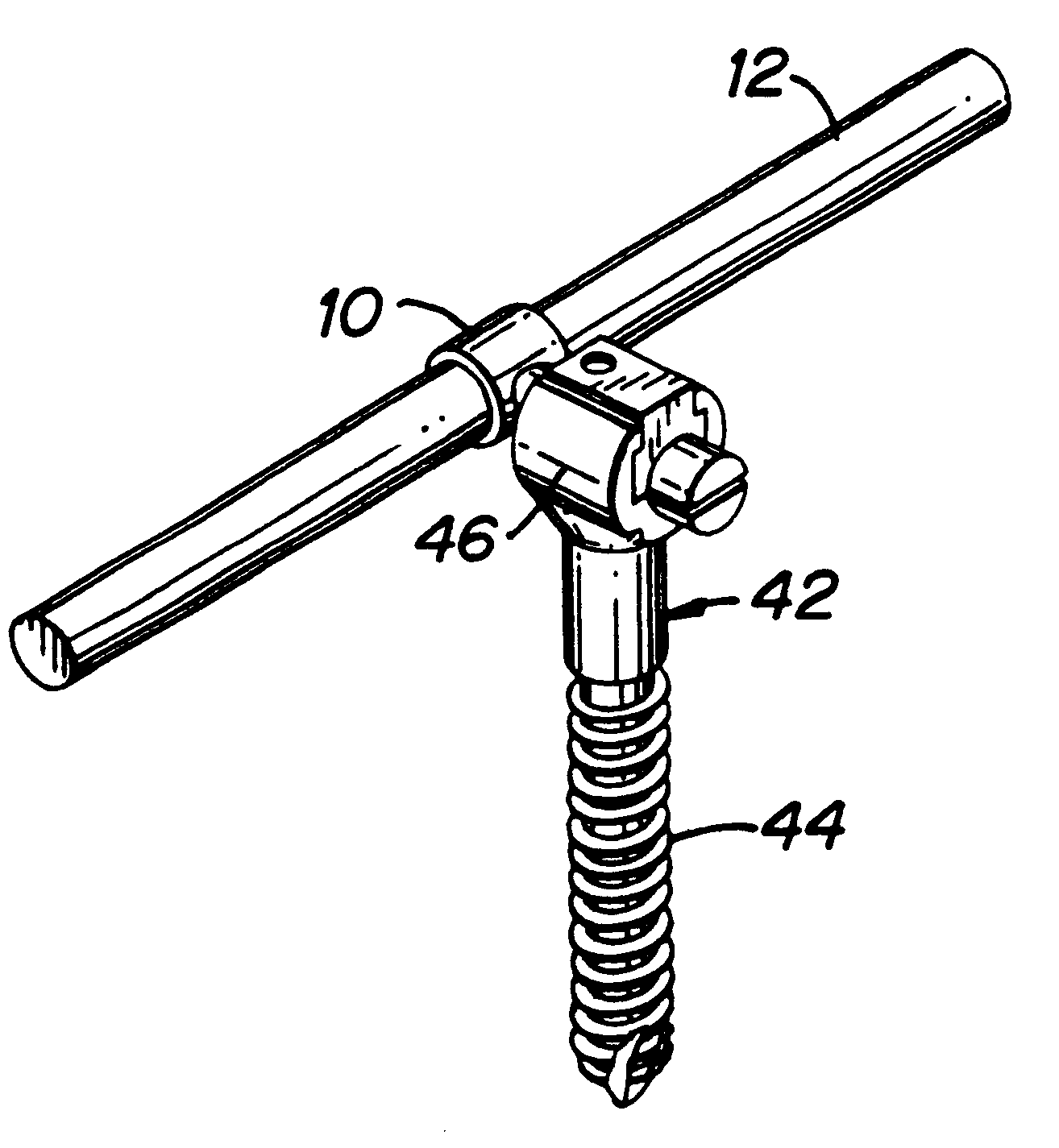

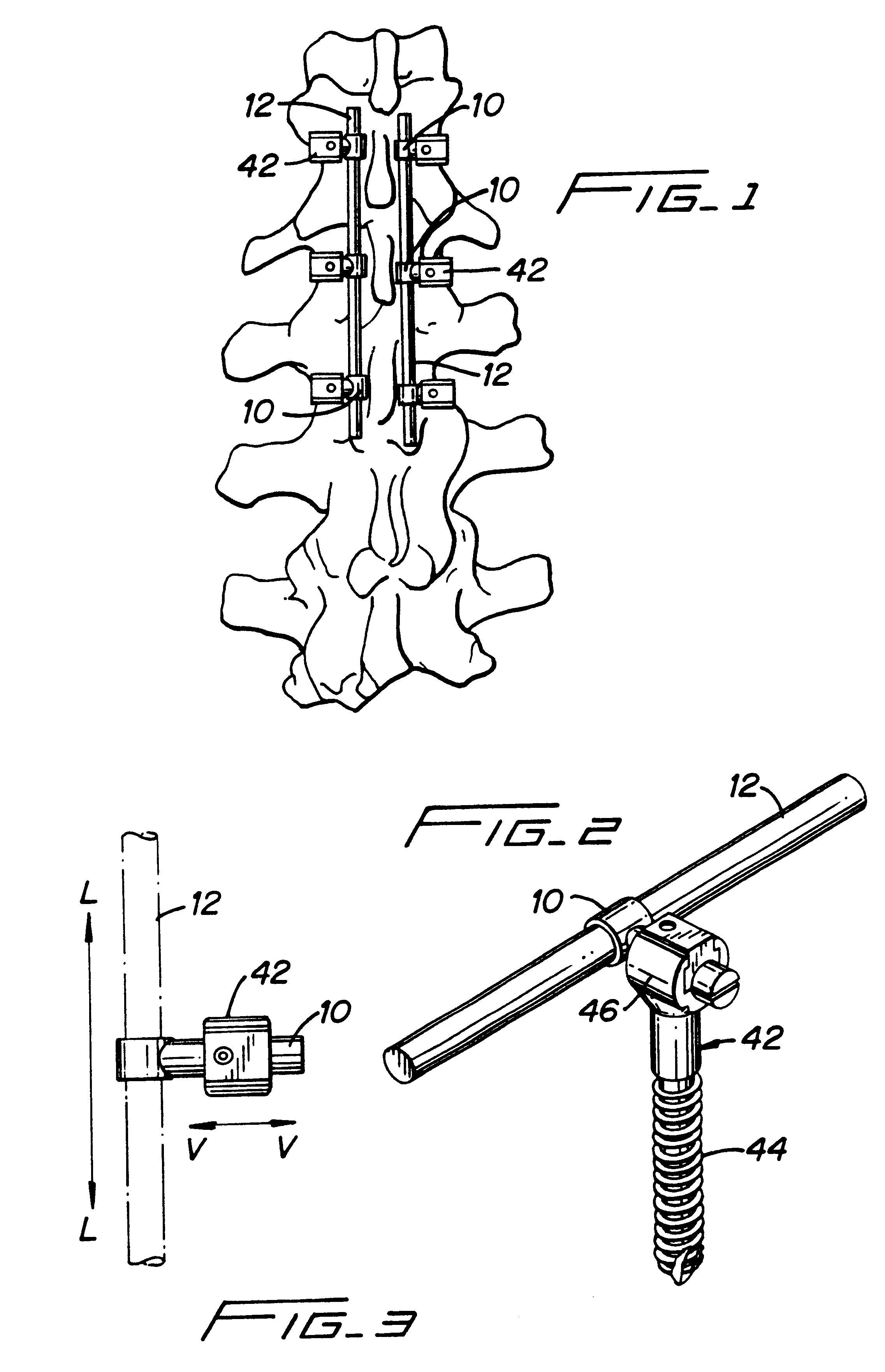

The present invention is directed to one piece connector for connecting angularly misaligned implanted pedicle screws to transverse spinal rods in spinal fixation systems. The body portion includes a bore having an inside diameter and a longitudinal axis, with the longitudinal axis of the bore being positioned perpendicular to the longitudinal axis of the leg portion. The leg portion includes a slot placed through a section of the leg portion, along the transverse axis of the leg portion and parallel to the longitudinal axis of the leg portion. The slot intersects the bore of the body portion perpendicular to the longitudinal axis of the bore. The slot allows the one piece connector to be securely clamped around a longitudinal spinal rod when a pedicle screw is implanted at variable distances from the longitudinal spinal rod. The one piece connector allows for angular misalignment of an implanted pedicle screw in relation to a longitudinal spinal rod and the one piece connector, and for the attachment of the one piece connector to both the longitudinal spinal rod and to the implanted pedicle screw with a single locking mechanism when the one piece connector is used in a spinal fixation system.

Owner:HOWMEDICA OSTEONICS CORP

Clamping connector for spinal fixation systems

InactiveUS6413257B1Relieve pressureClamp firmlyInternal osteosythesisJoint implantsTransverse axisLocking mechanism

The present invention is directed to one piece connector for connecting angularly misaligned implanted pedicle screws to transverse spinal rods in spinal fixation systems. The body portion includes a bore having an inside diameter and a longitudinal axis, with the longitudinal axis of the bore being positioned perpendicular to the longitudinal axis of the leg portion. The leg portion includes a slot placed through a section of the leg portion, along the transverse axis of the leg portion and parallel to the longitudinal axis of the leg portion. The slot intersects the bore of the body portion perpendicular to the longitudinal axis of the bore. The slot allows the one piece connector to be securely clamped around a longitudinal spinal rod when a pedicle screw is implanted at variable distances from the longitudinal spinal rod. The one piece connector allows for angular misalignment of an implanted pedicle screw in relation to a longitudinal spinal rod and the one piece connector, and for the attachment of the one piece connector to both the longitudinal spinal rod and to the implanted pedicle screw with a single locking mechanism when the one piece connector is used in a spinal fixation system.

Owner:HOWMEDICA OSTEONICS CORP

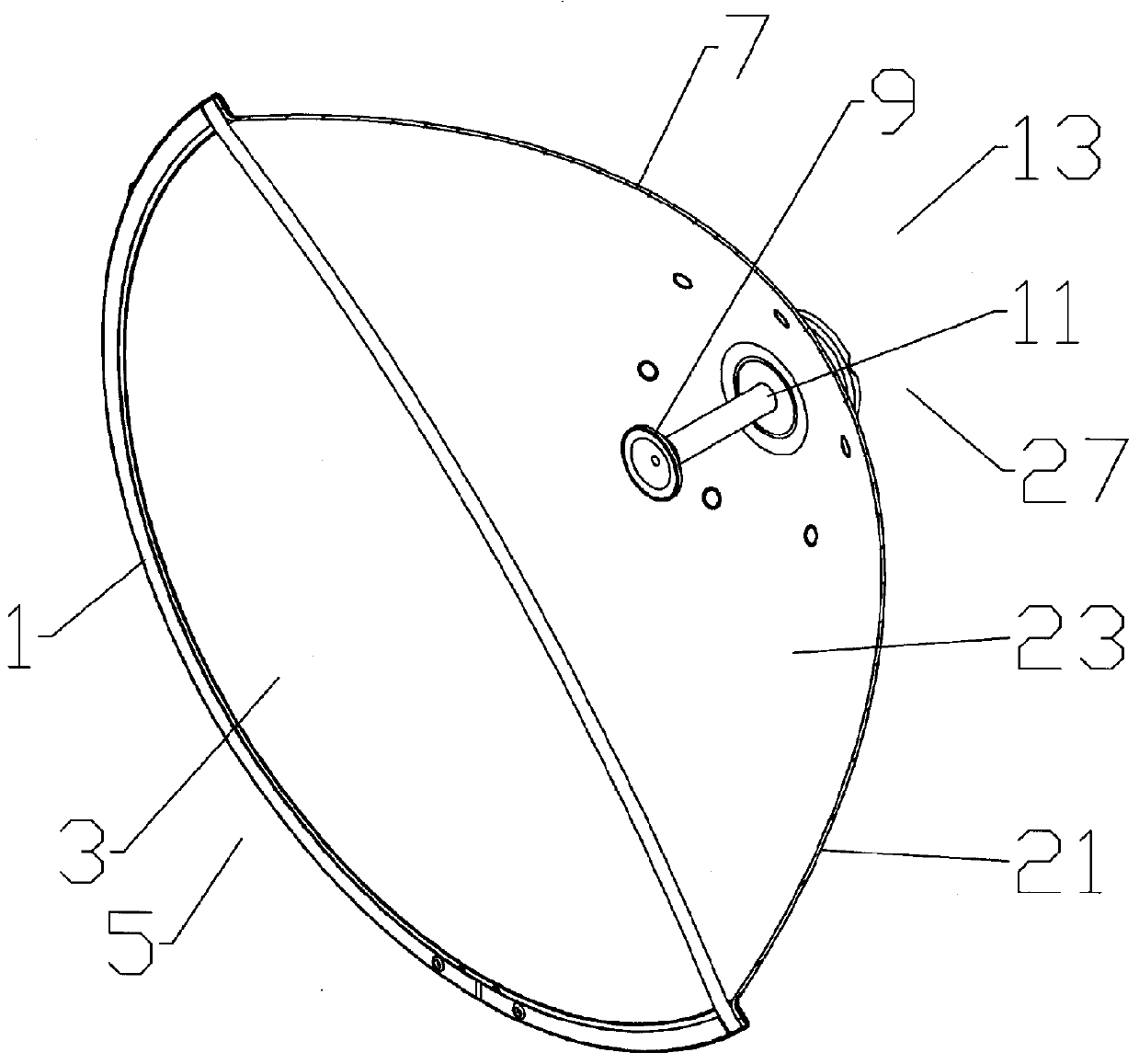

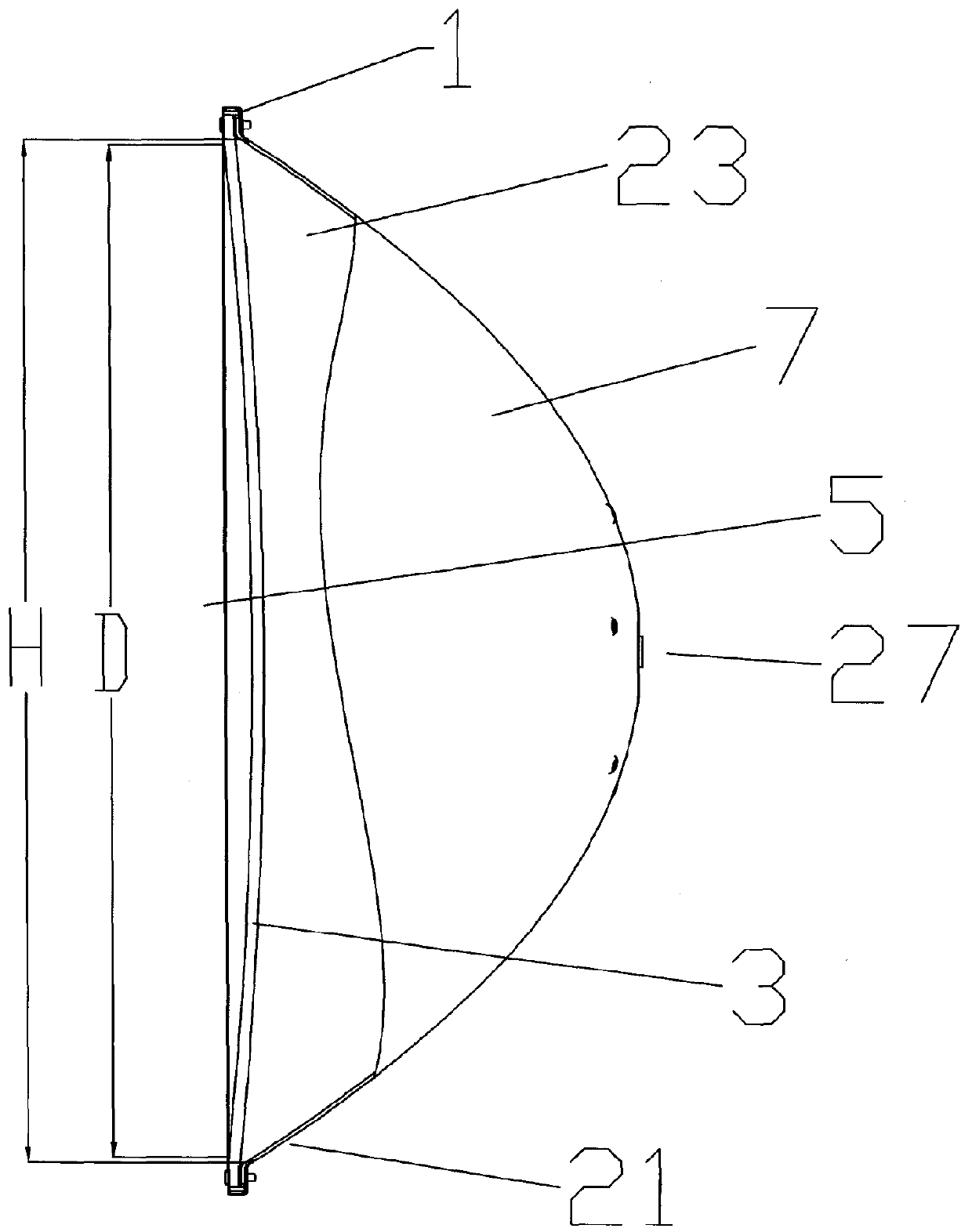

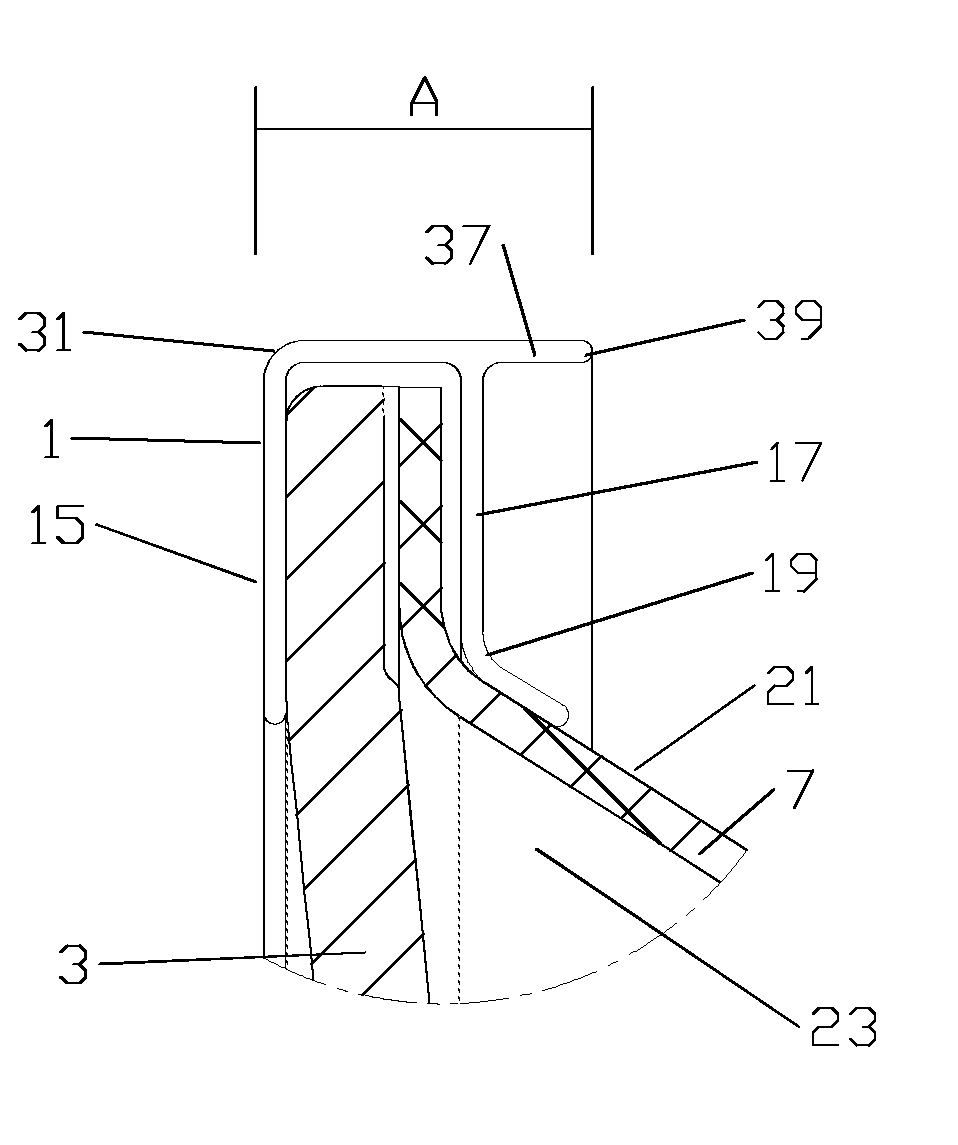

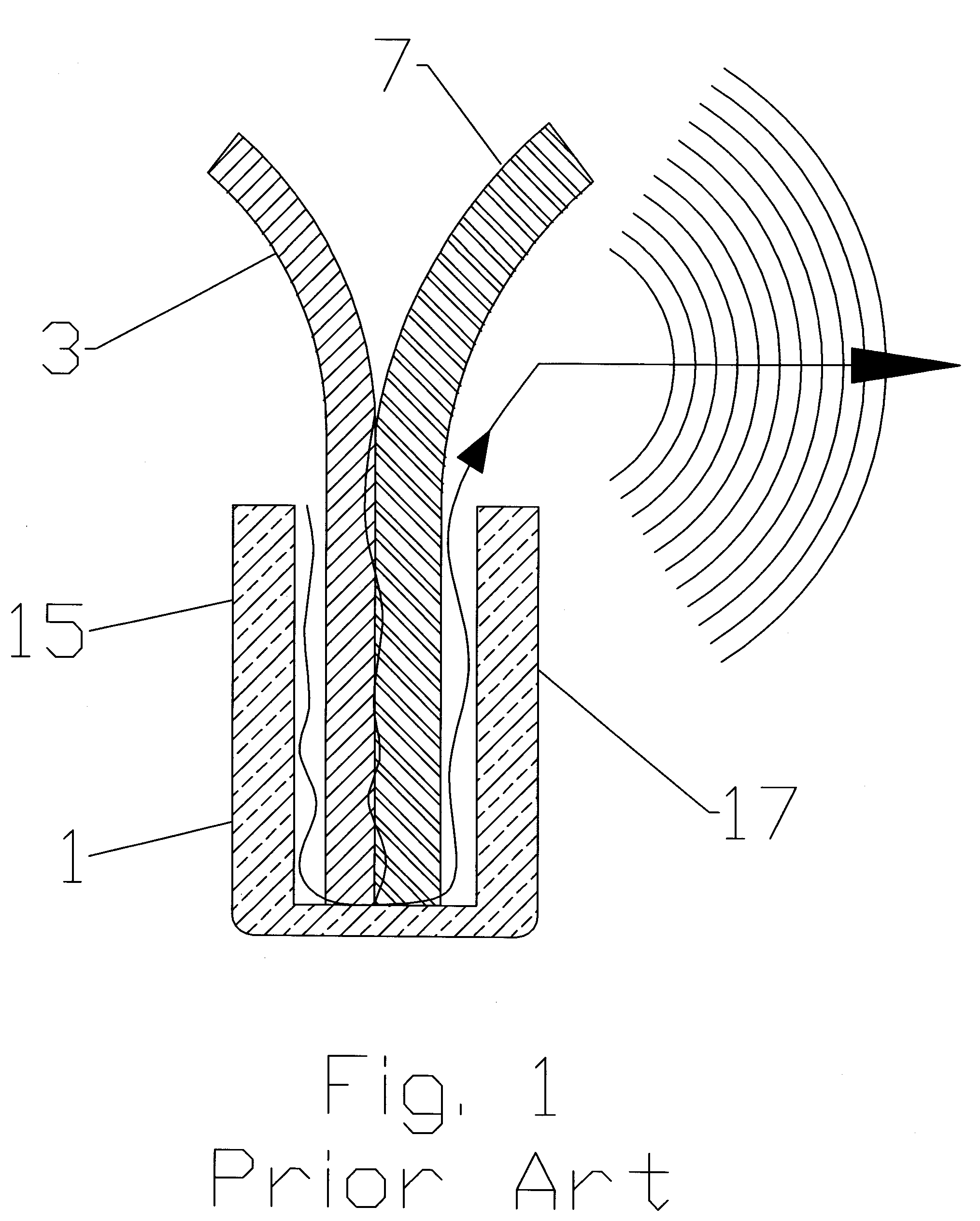

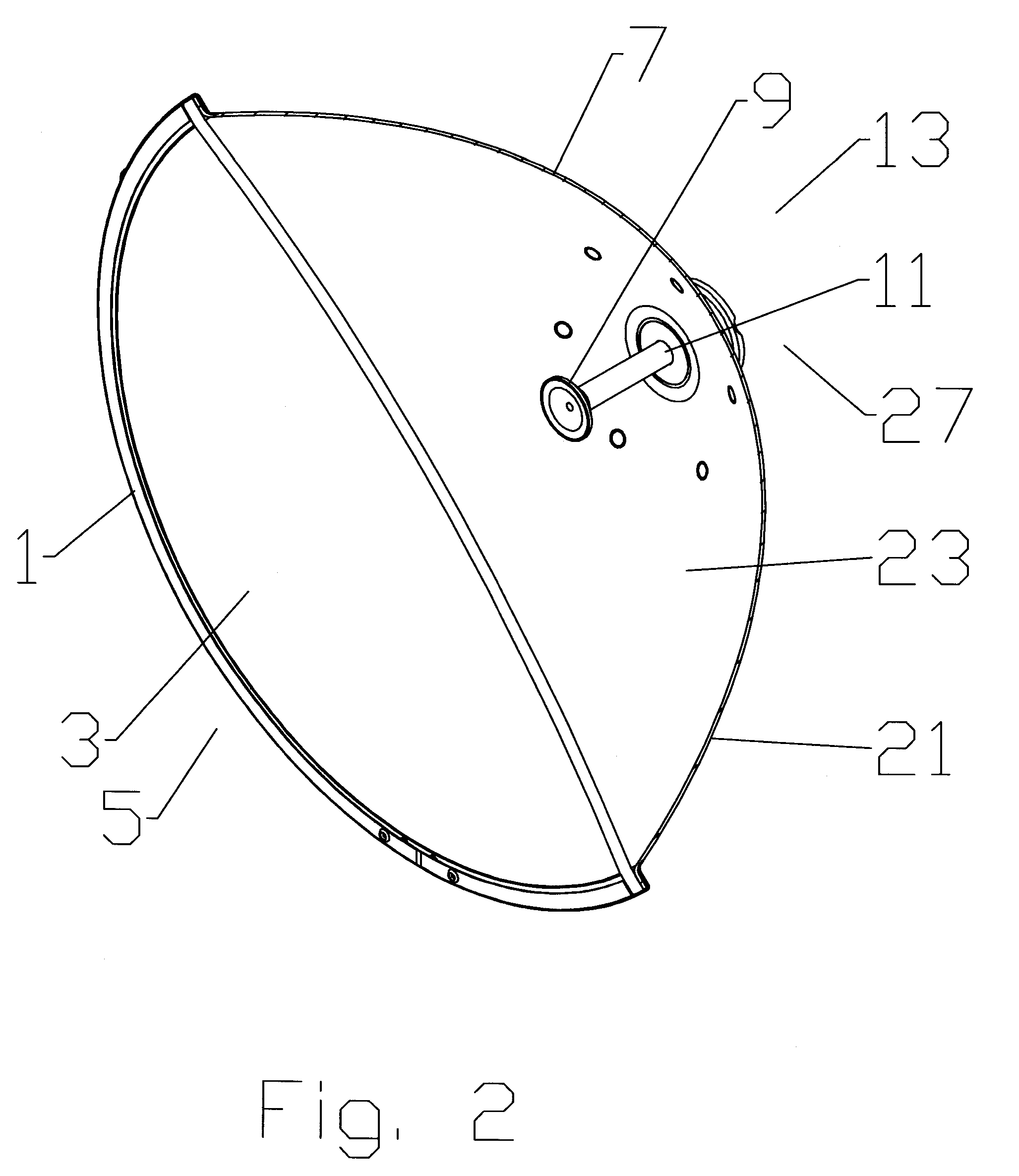

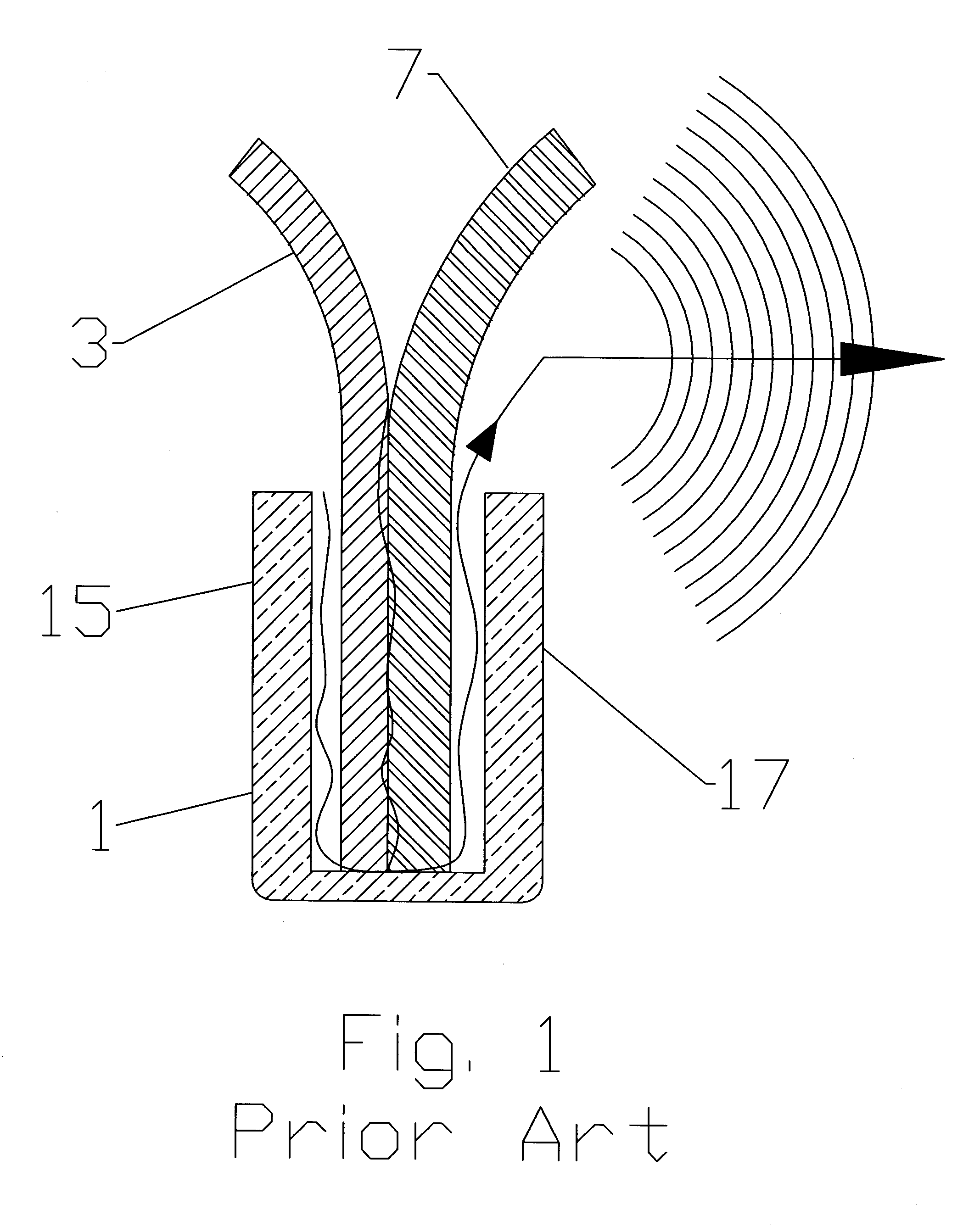

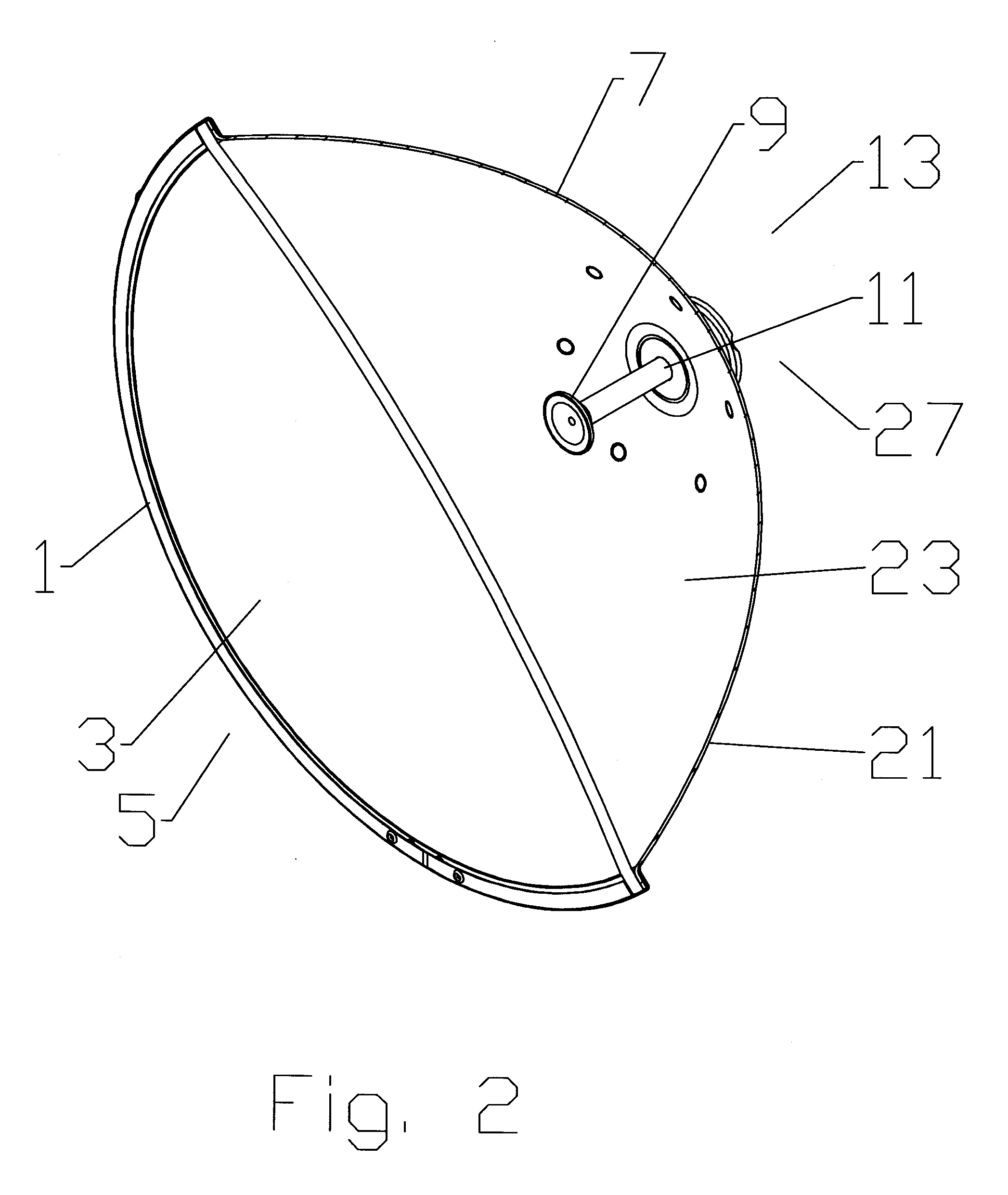

Reflector antenna radome attachment band clamp

A band clamp for coupling a radome to a distal end of a reflector dish for improving the front to back ratio of a reflector antenna, the band clamp provided with an inward projecting proximal lip and an inward projecting distal lip. The distal lip dimensioned with an inner diameter equal to or less than a reflector aperture of the reflector dish. The proximal lip provided with a turnback region dimensioned to engage an outer surface of a signal area of the reflector dish in an interference fit. A width of the band clamp may be dimensioned, for example, between 0.8 and 1.5 wavelengths of an operating frequency.

Owner:COMMSCOPE TECH LLC

Radome attachment band clamp

ActiveUS9083083B2RF leakageClamp firmlyPretreated surfacesRadiating element housingsInterference fitElectrical performance

Owner:COMMSCOPE TECH LLC

Clamping connector for spinal fixation systems

InactiveUS20020143332A1Relieve pressureClamp firmlyInternal osteosythesisJoint implantsTransverse axisLocking mechanism

Owner:HOWMEDICA OSTEONICS CORP

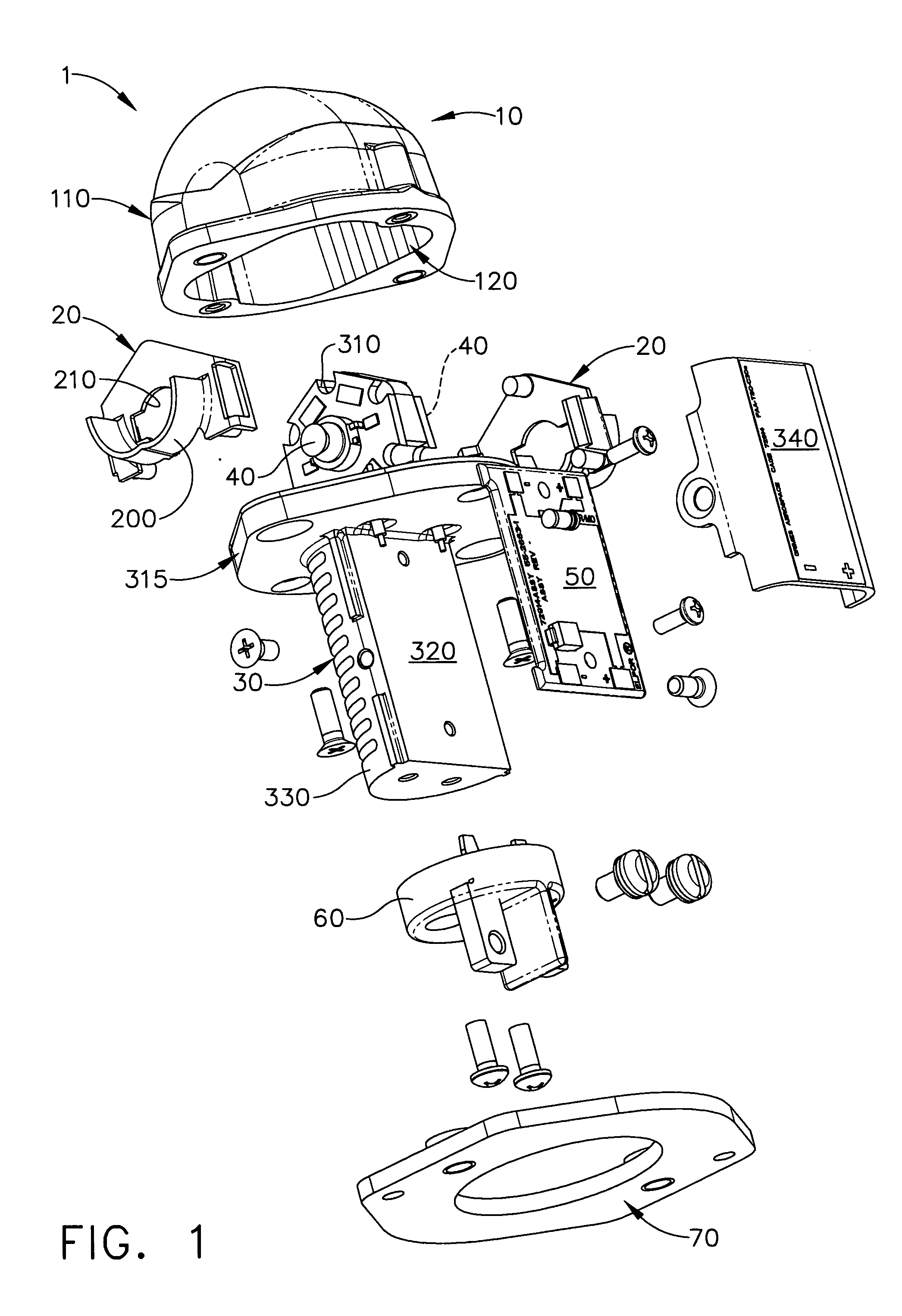

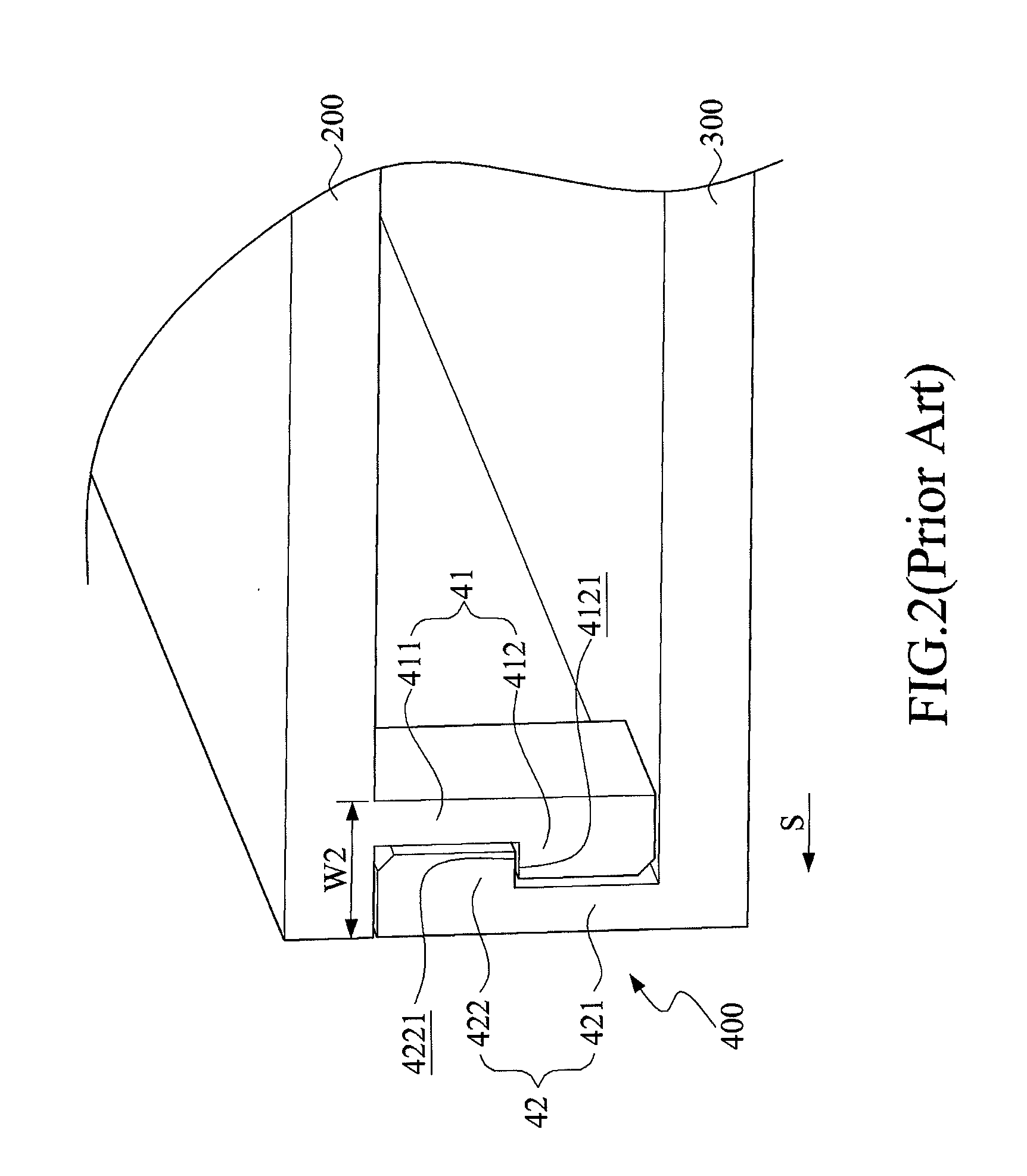

Multi-platform LED-based aircraft rear position light

InactiveUS20050201112A1Clamp firmlyFacilitate manufacture and assemblyPoint-like light sourceLighting support devicesMulti platformEngineering

An aircraft rear position light device (1) has a modular configuration. The device utilizes solid-state light sources. In an exemplary embodiment, the light sources are side-emitting light-emitting diodes (LEDs) (40), which are attached to a heat sink (30). A reflector (200) is positioned next to each of the LEDs. The device further includes an outer lens (10) with an integrated cut-off shield (110) and optical treatments (120). The configuration of LEDs and reflectors, in conjunction with the cut-off shield and optical treatments, allows the emitted light to satisfy predetermined minimum and maximum angular intensity requirements. An electronics module (50) is also attached to the heat sink to connect the LEDs to a power source in the aircraft. Electronic updates may be made by replacing the electronics module.

Owner:HONEYWELL INT INC

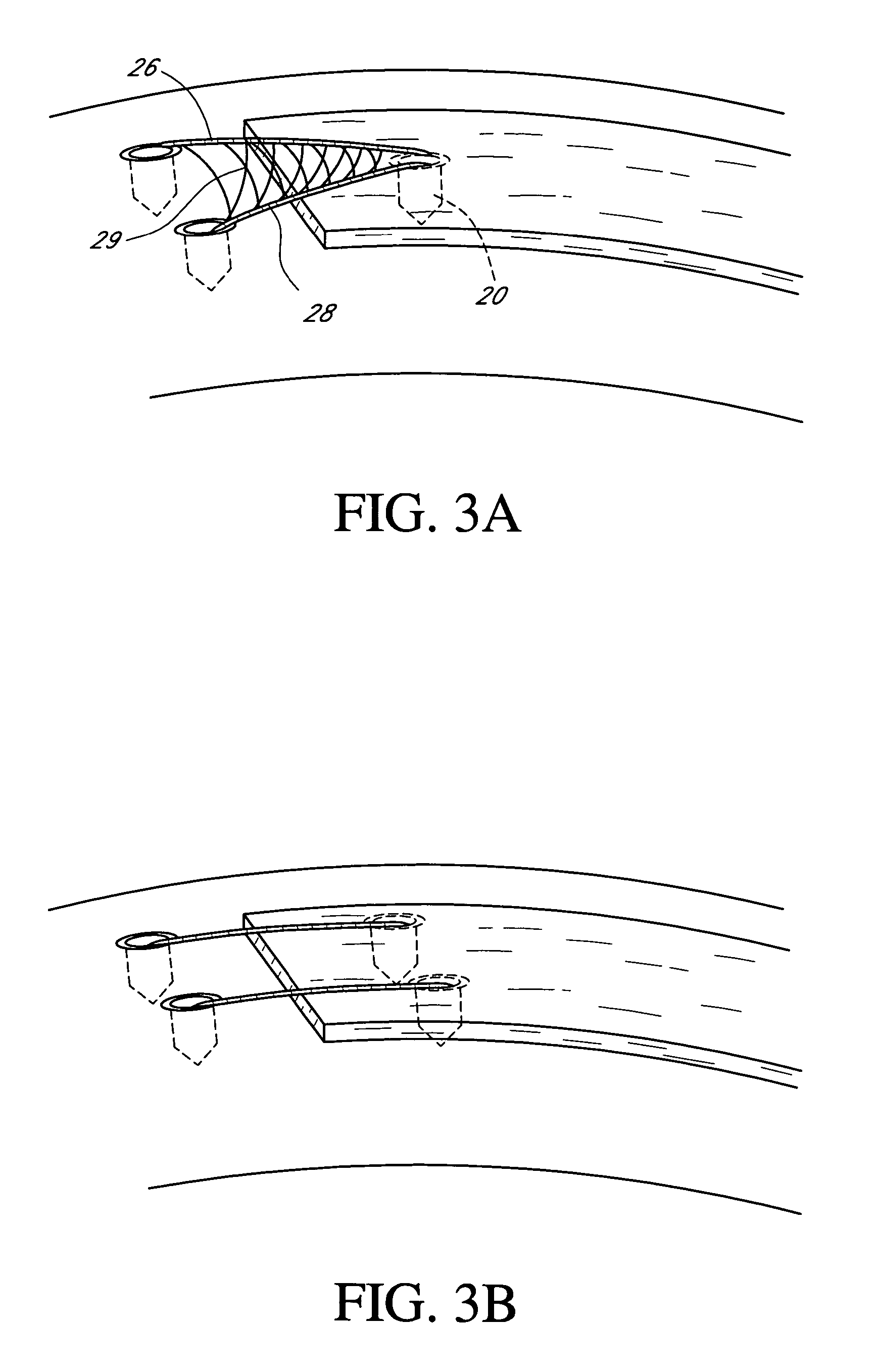

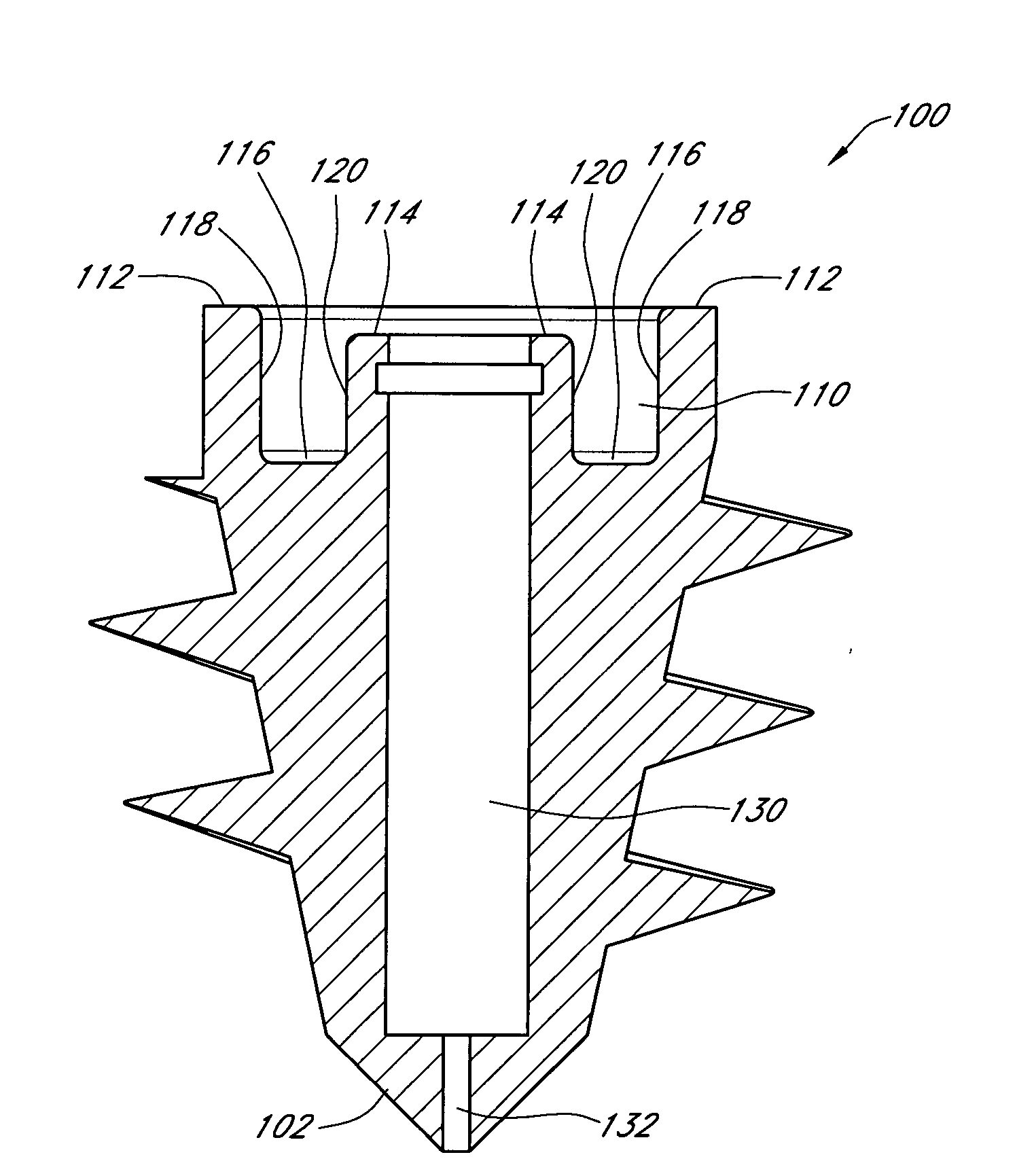

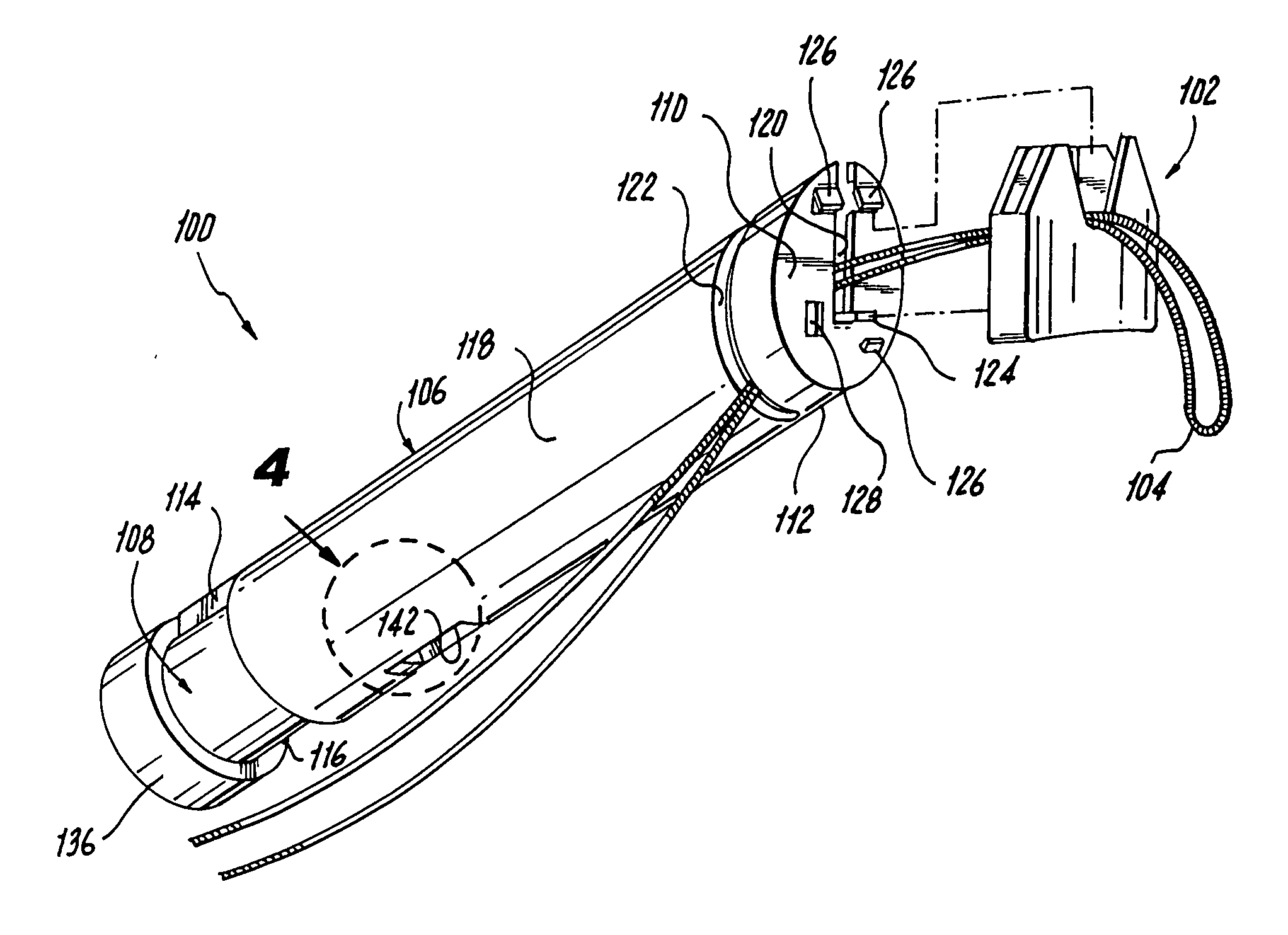

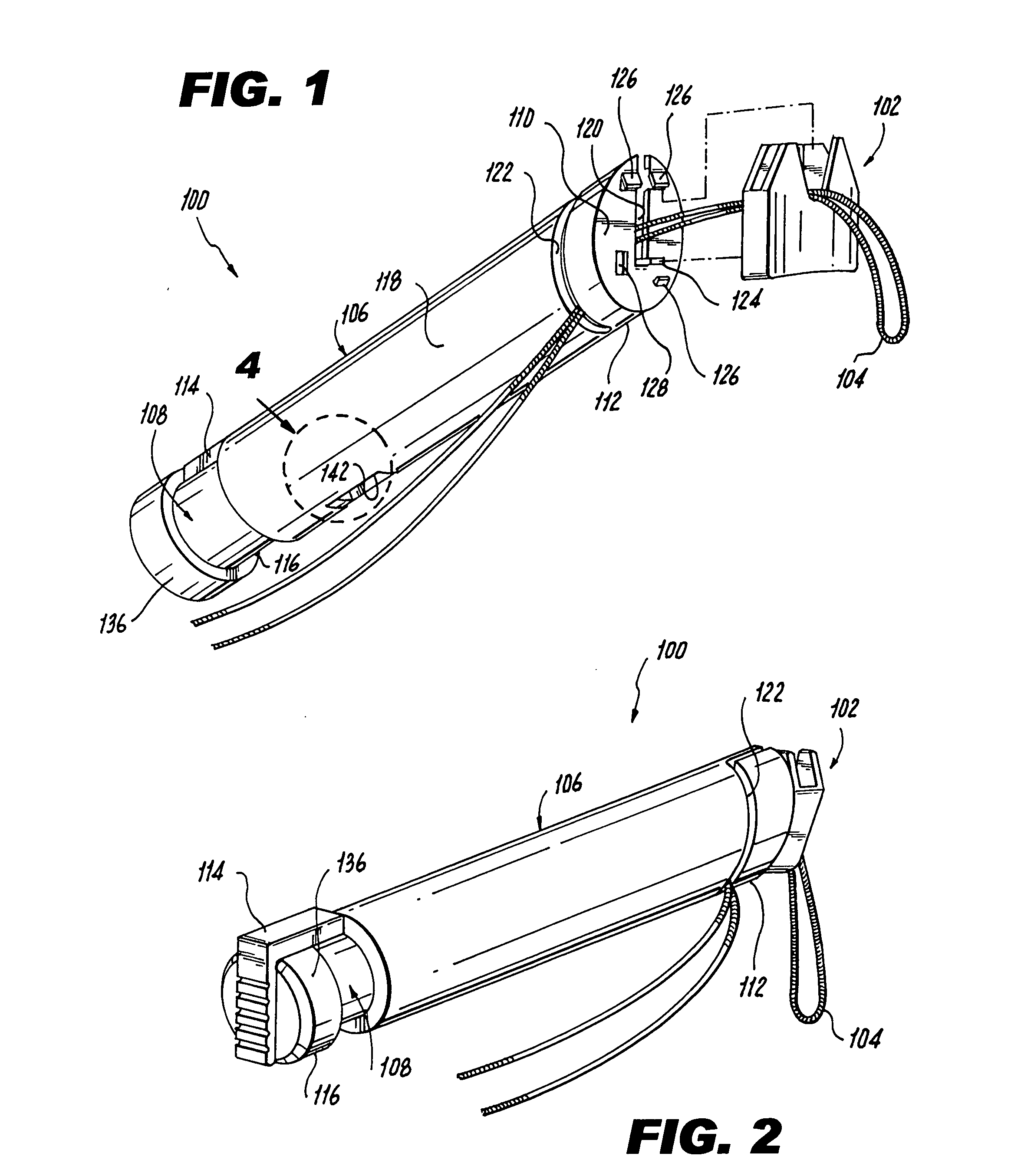

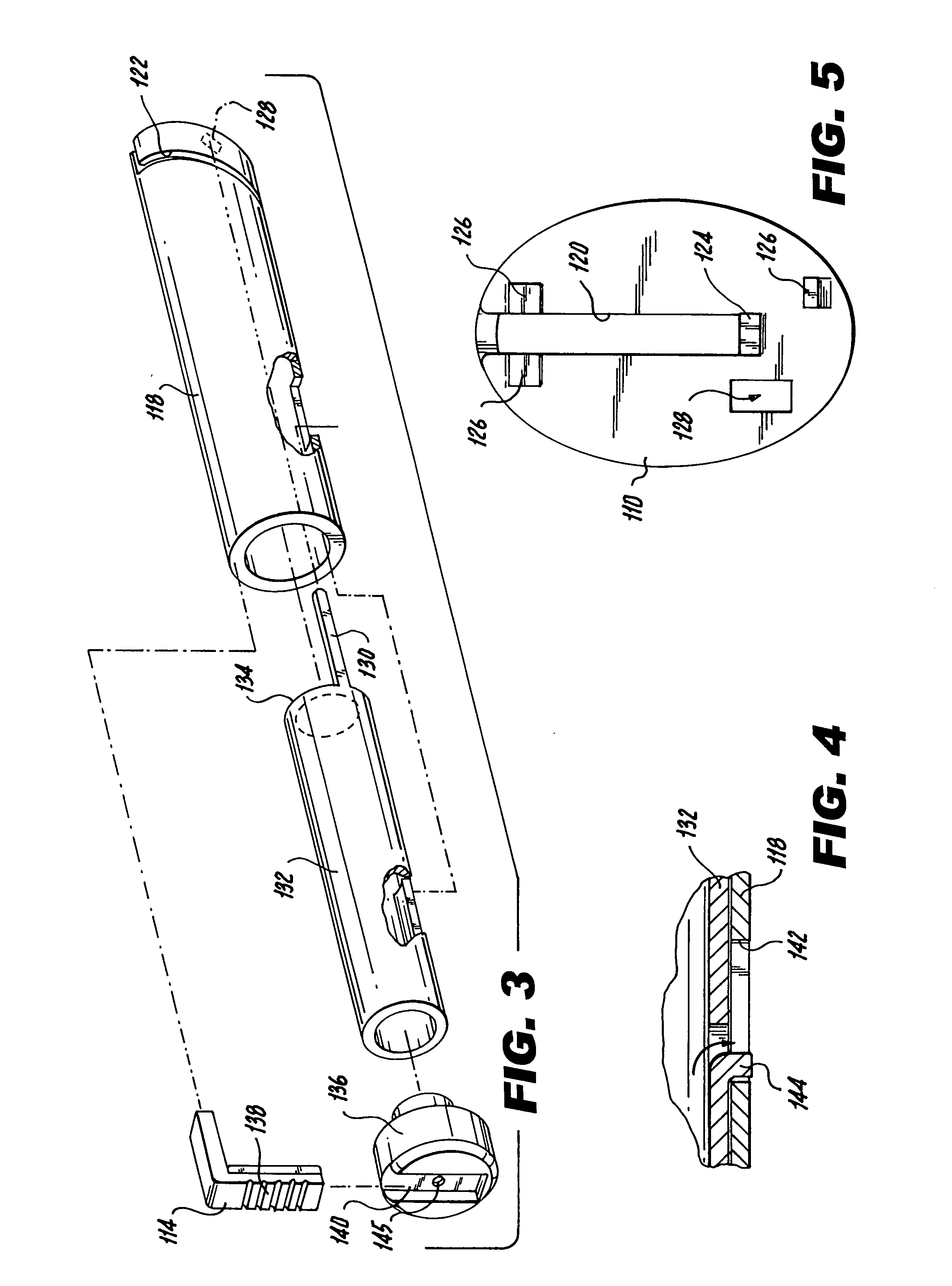

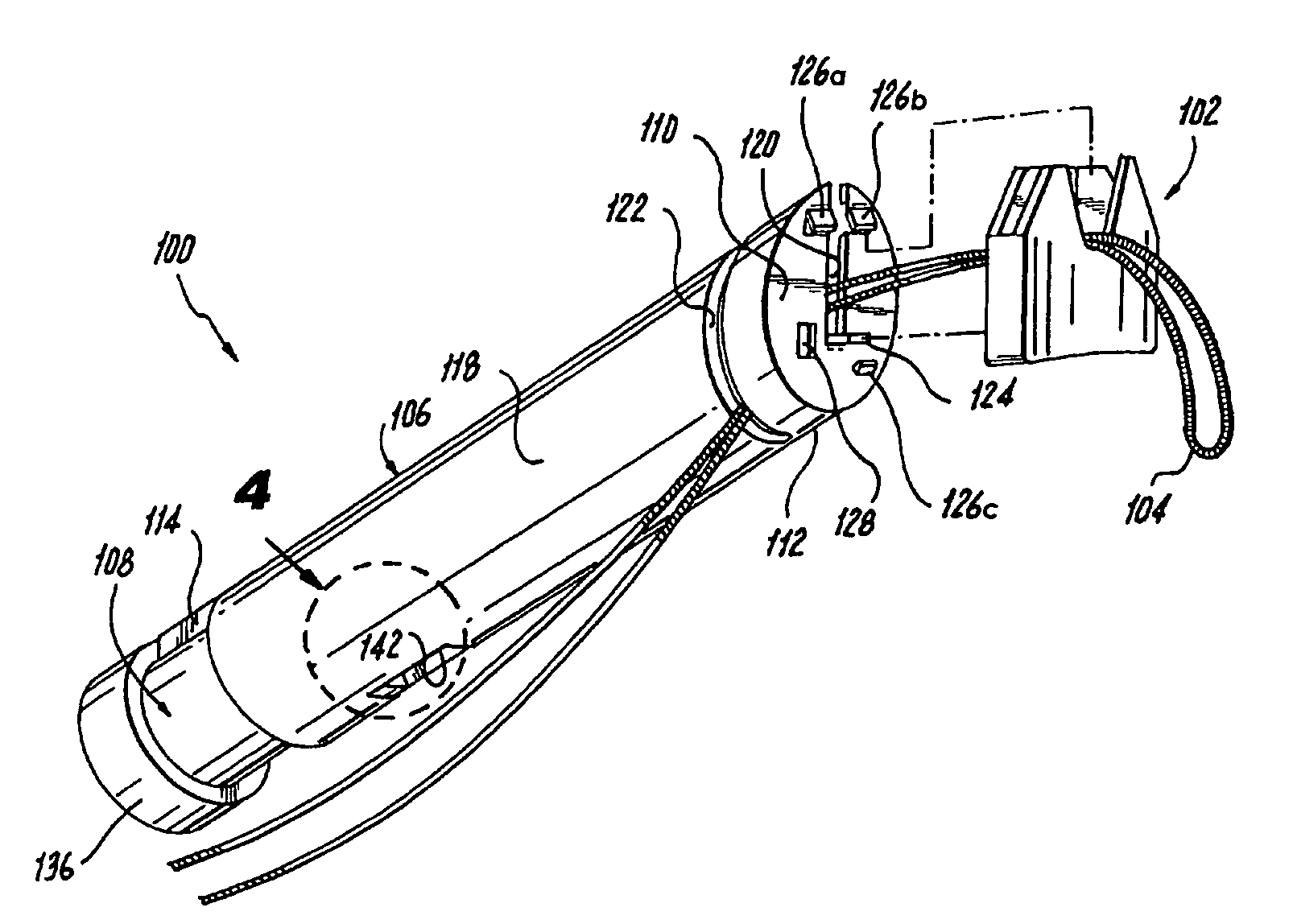

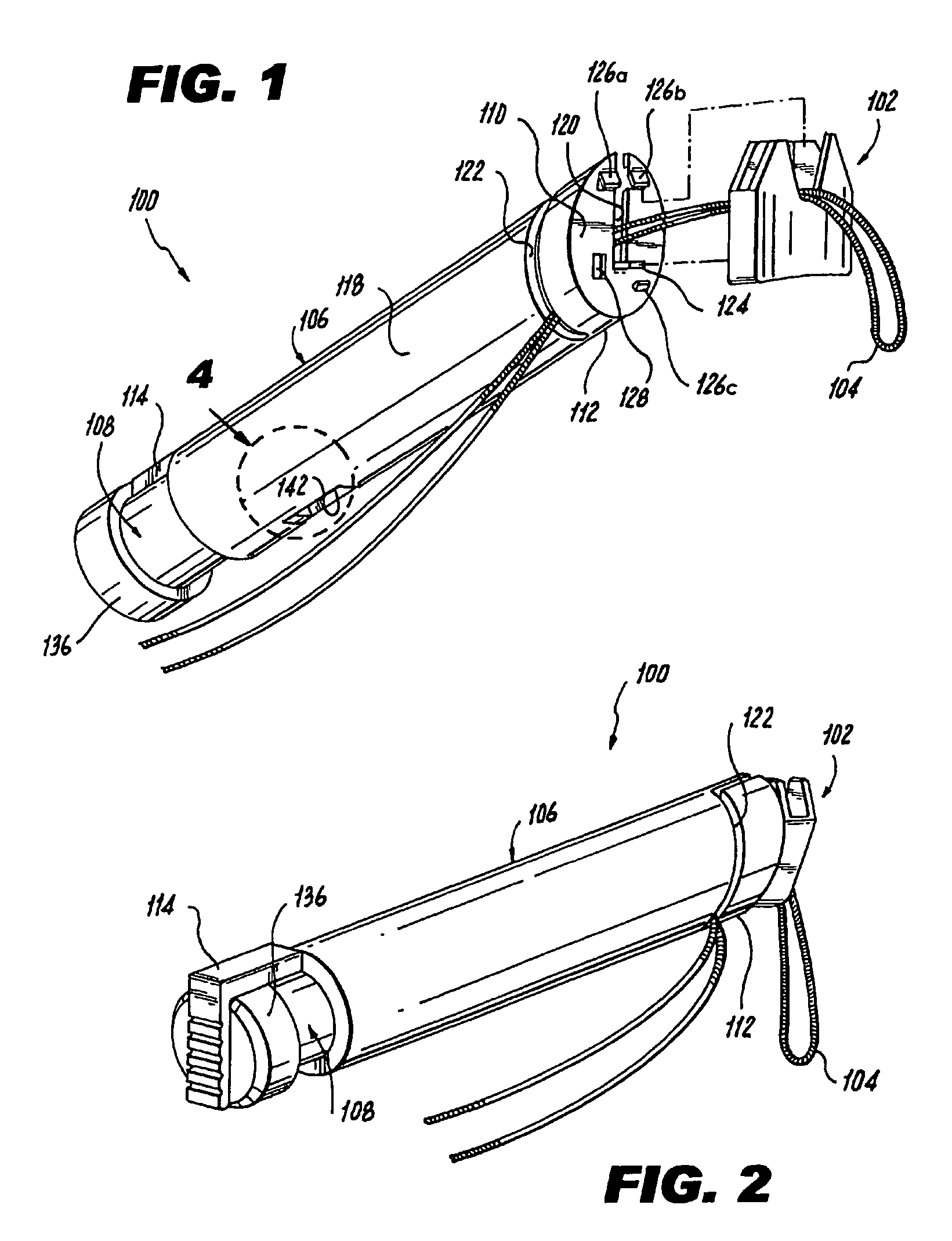

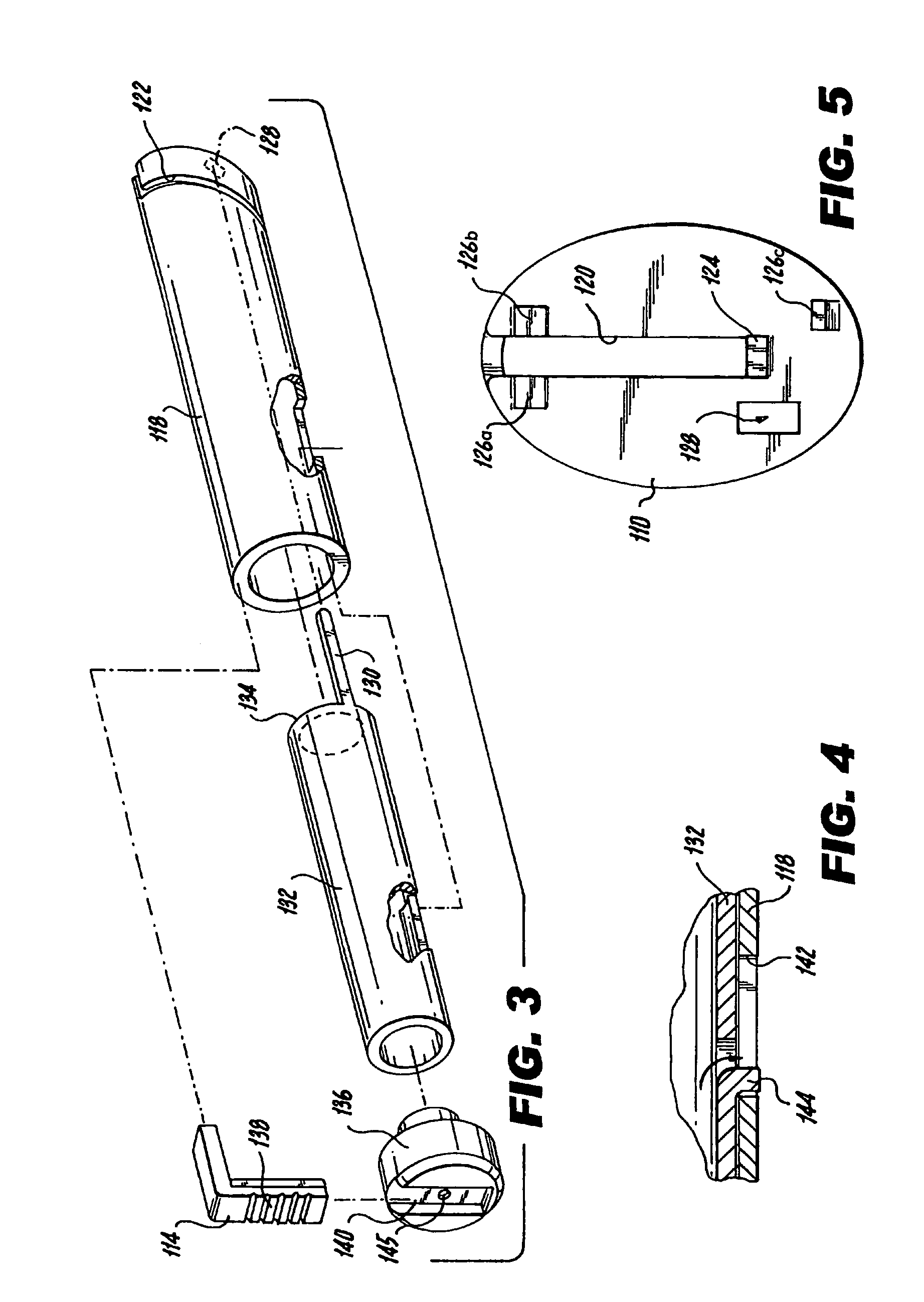

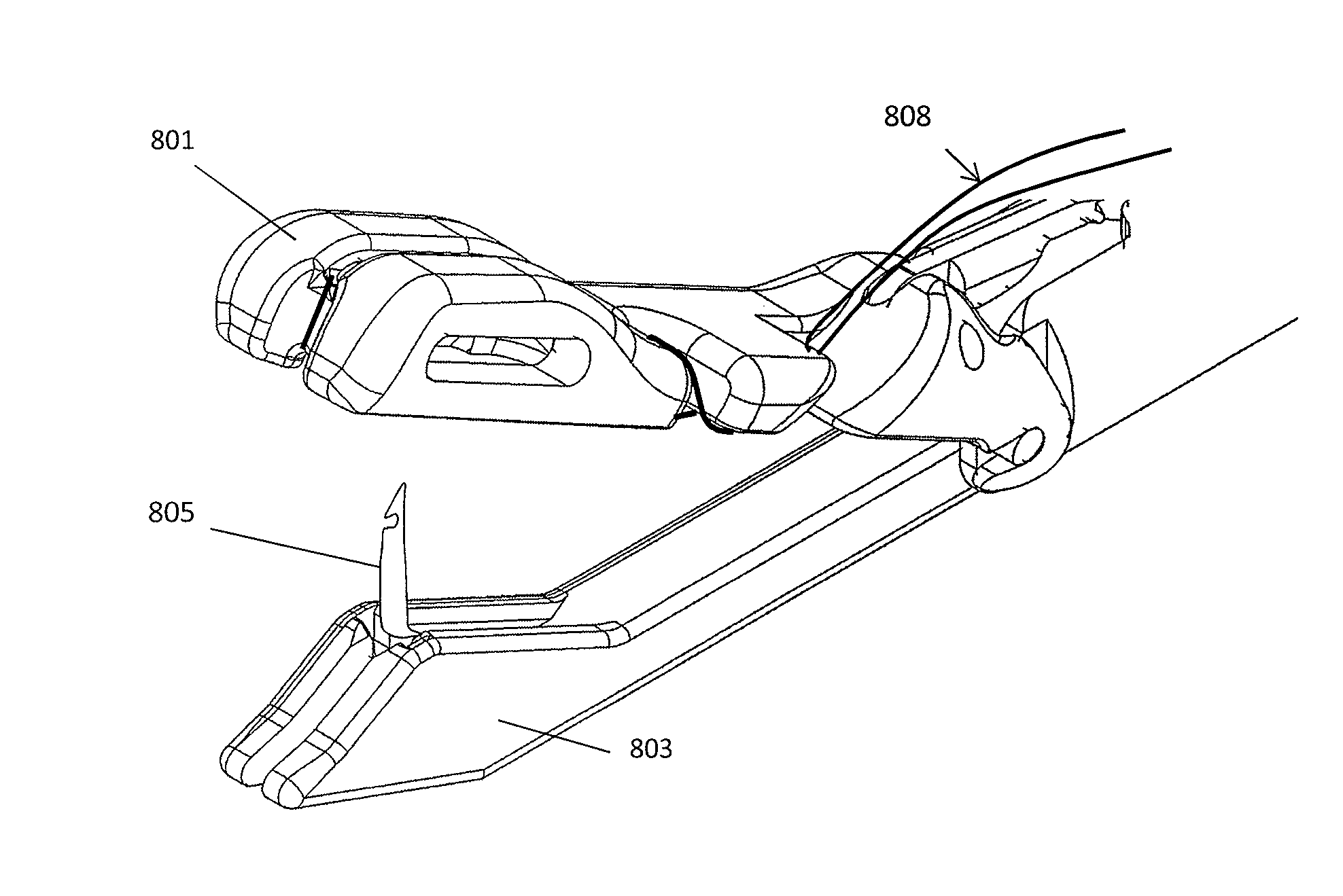

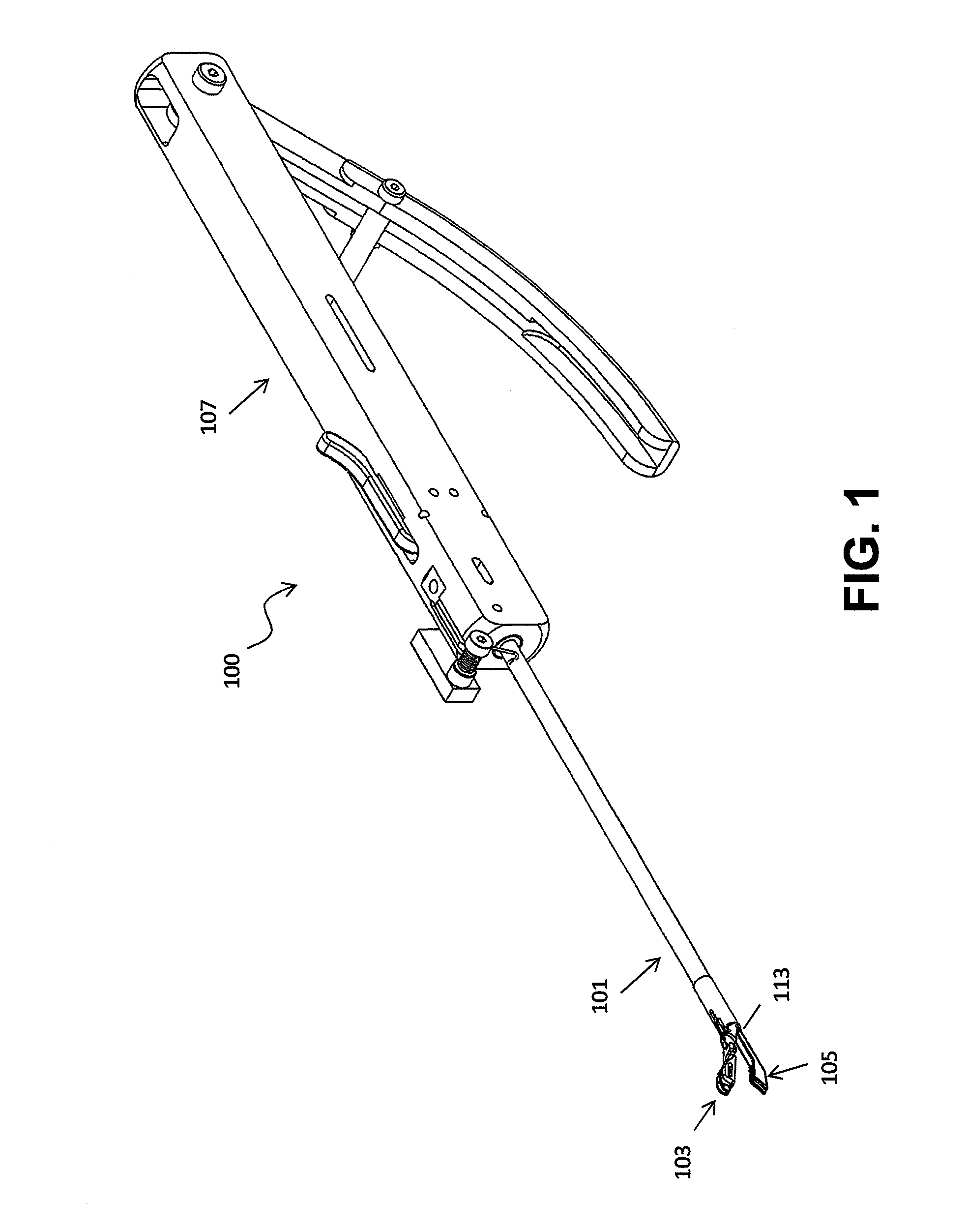

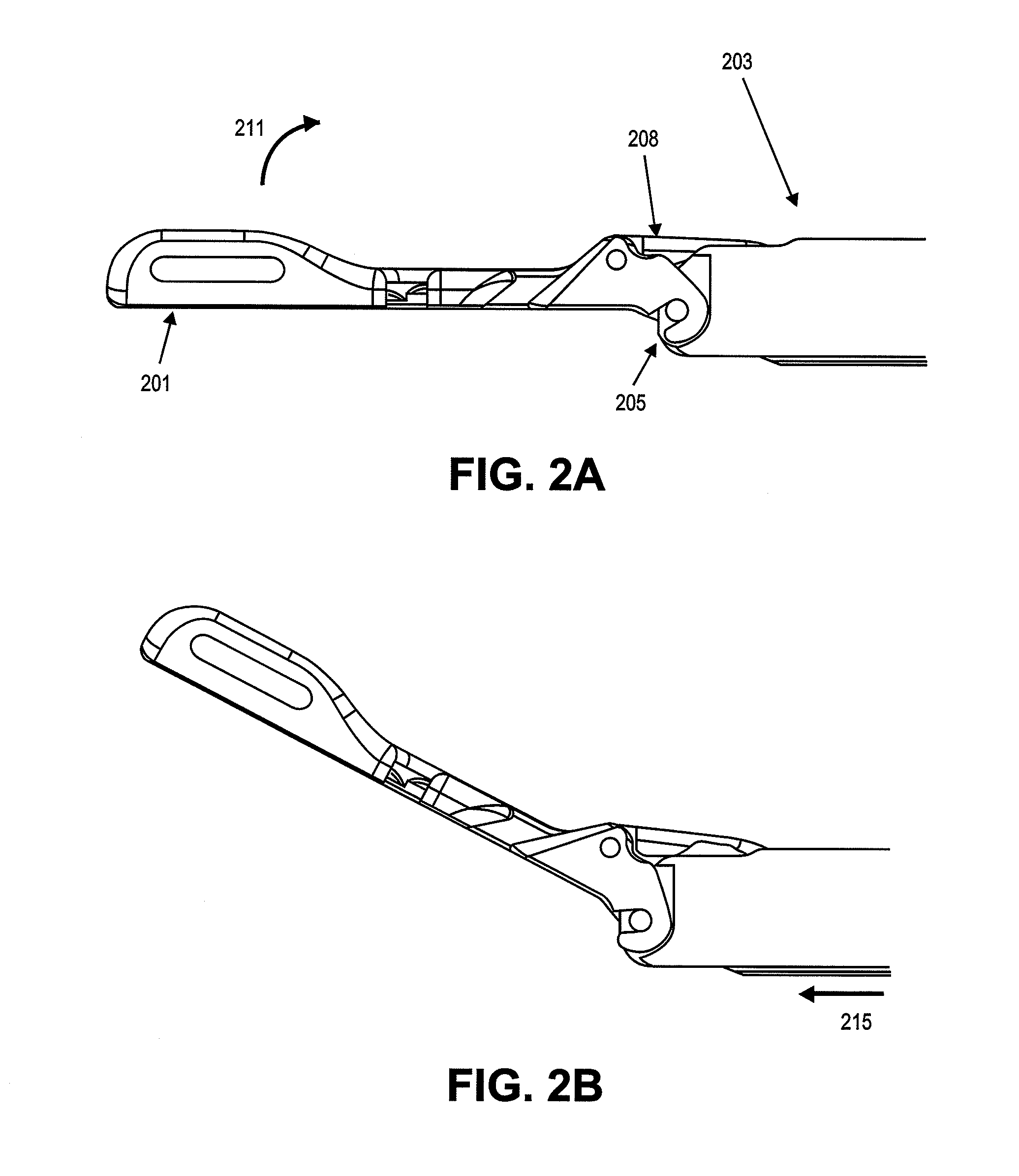

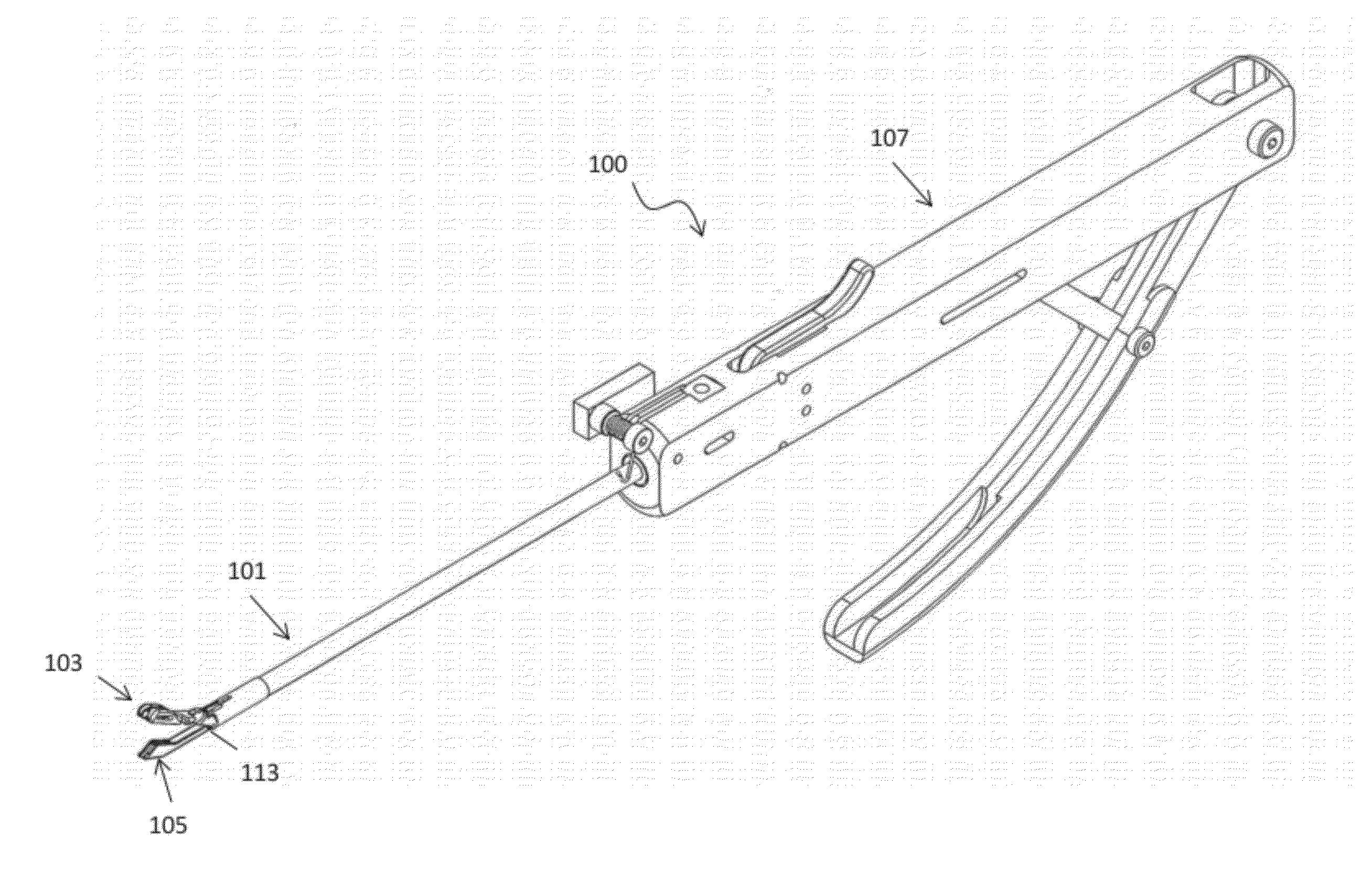

System for securing a suture

InactiveUS20060047314A1Clamp firmlyPromote sportsSuture equipmentsWound clampsEngineeringSuturing clip

A system is disclosed for securing a suture. The system includes a deformable suture clip having a pair of closely spaced panels configured for movement between an open position wherein a suture can pass between the two panels and a closed position wherein the suture can be securely clamped between the two panels. The system further includes a clip applicator having an elongated body defining opposed proximal and distal end portions. The distal end portion of the body includes a mounting fixture having structure for supporting the suture clip in an open position. The clip applicator further includes a mechanism for dislodging the suture clip from the mounting fixture, such that the panels of the clip move to the closed position to securely clamp the suture therebetween.

Owner:GREEN DAVID T

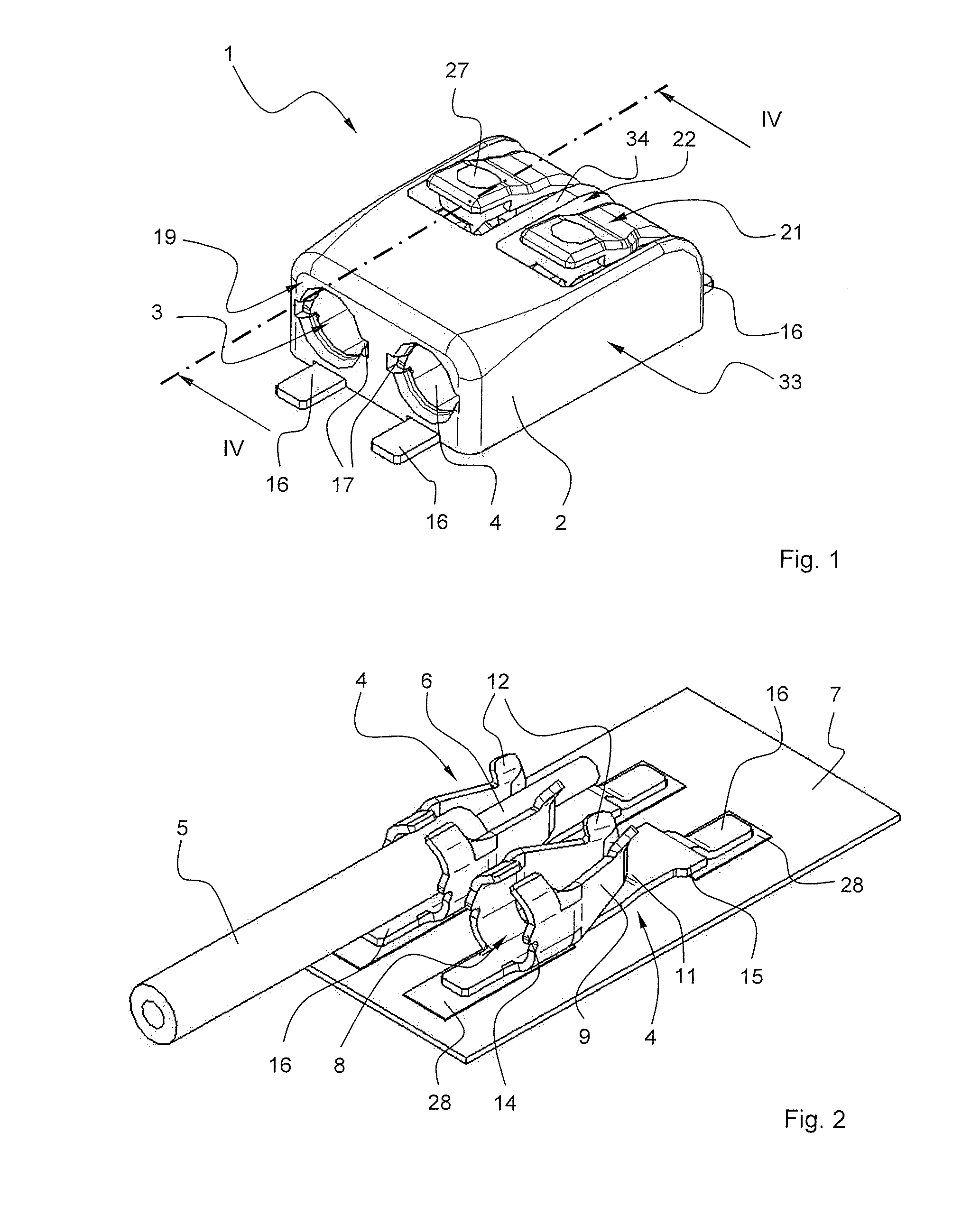

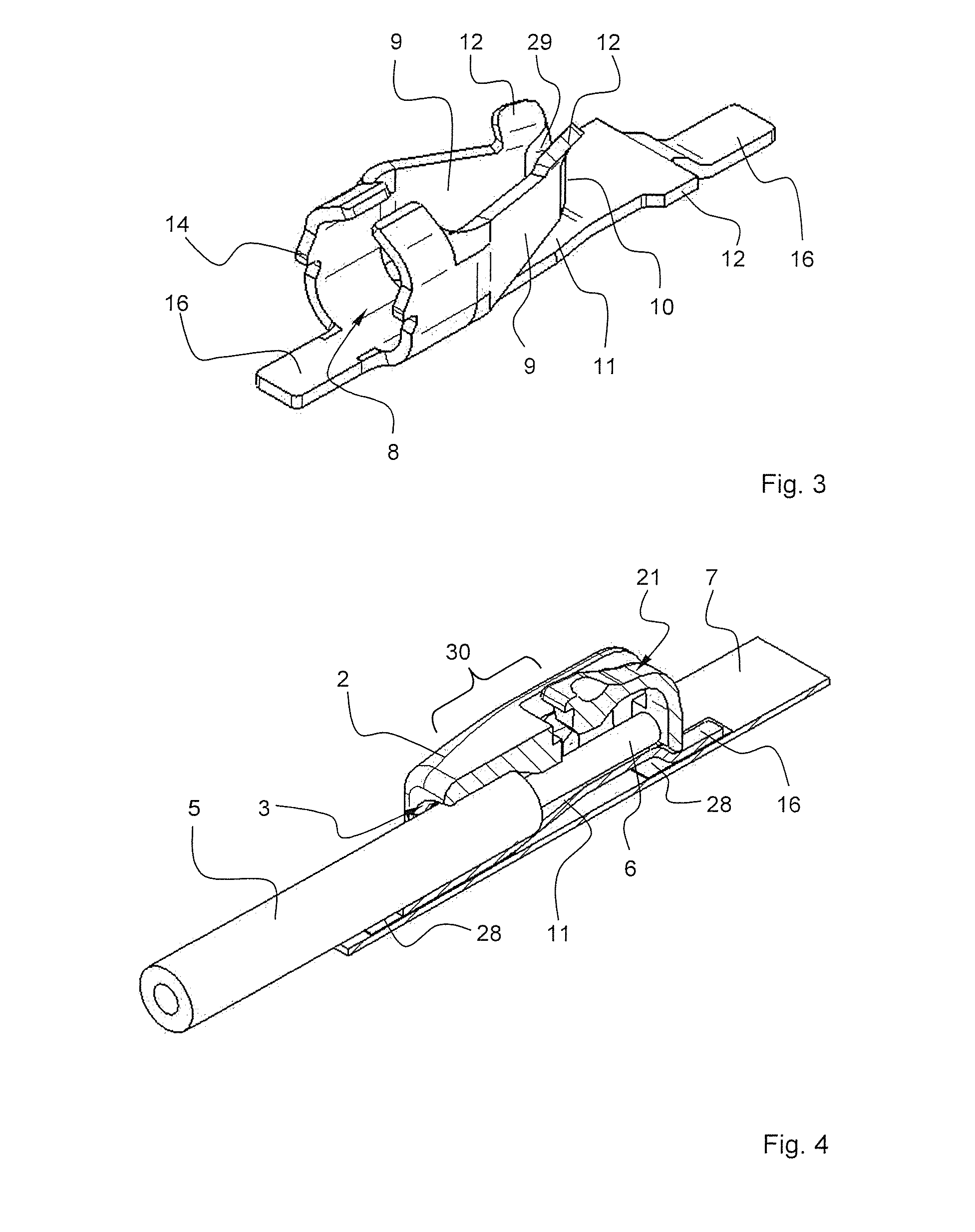

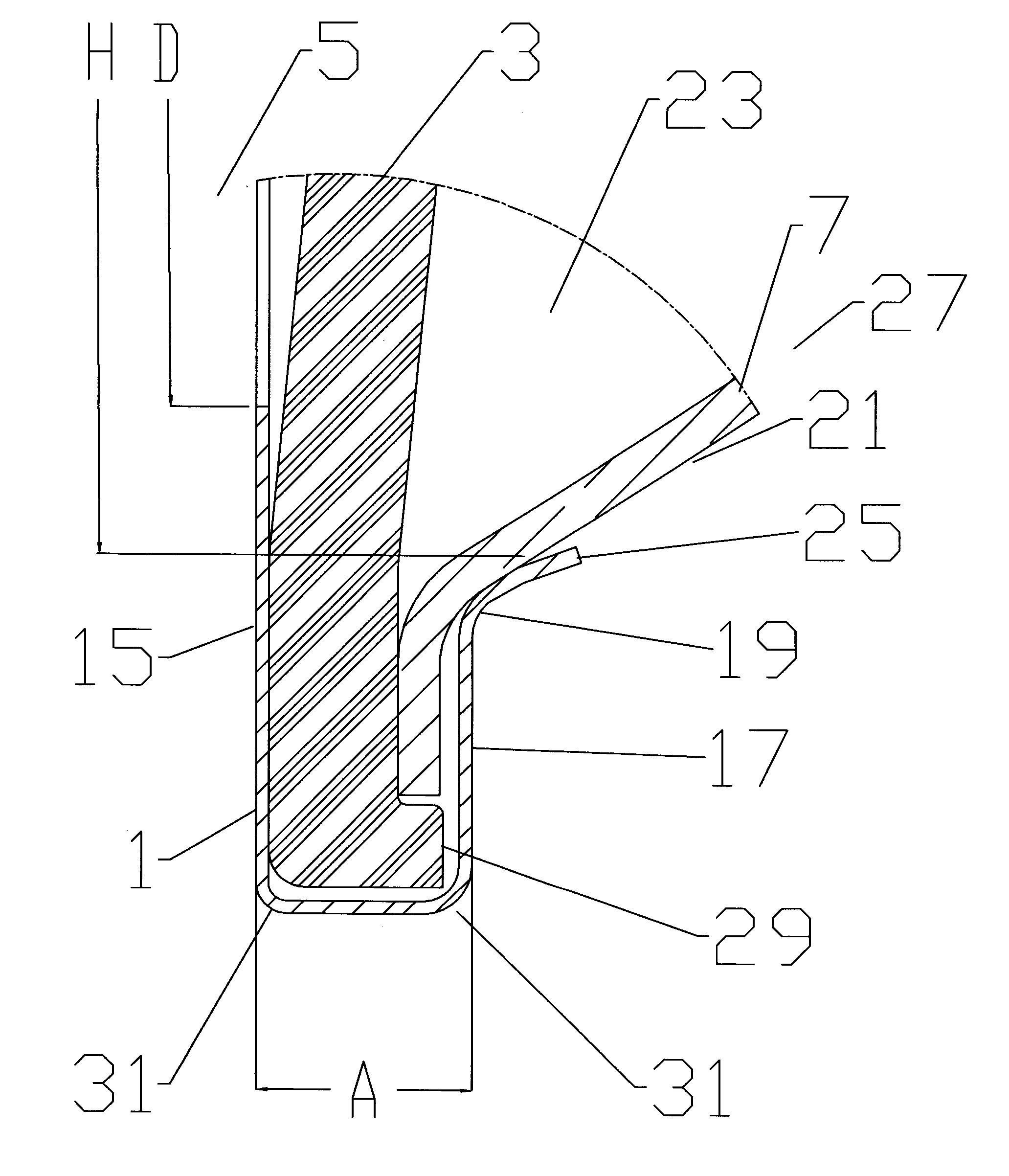

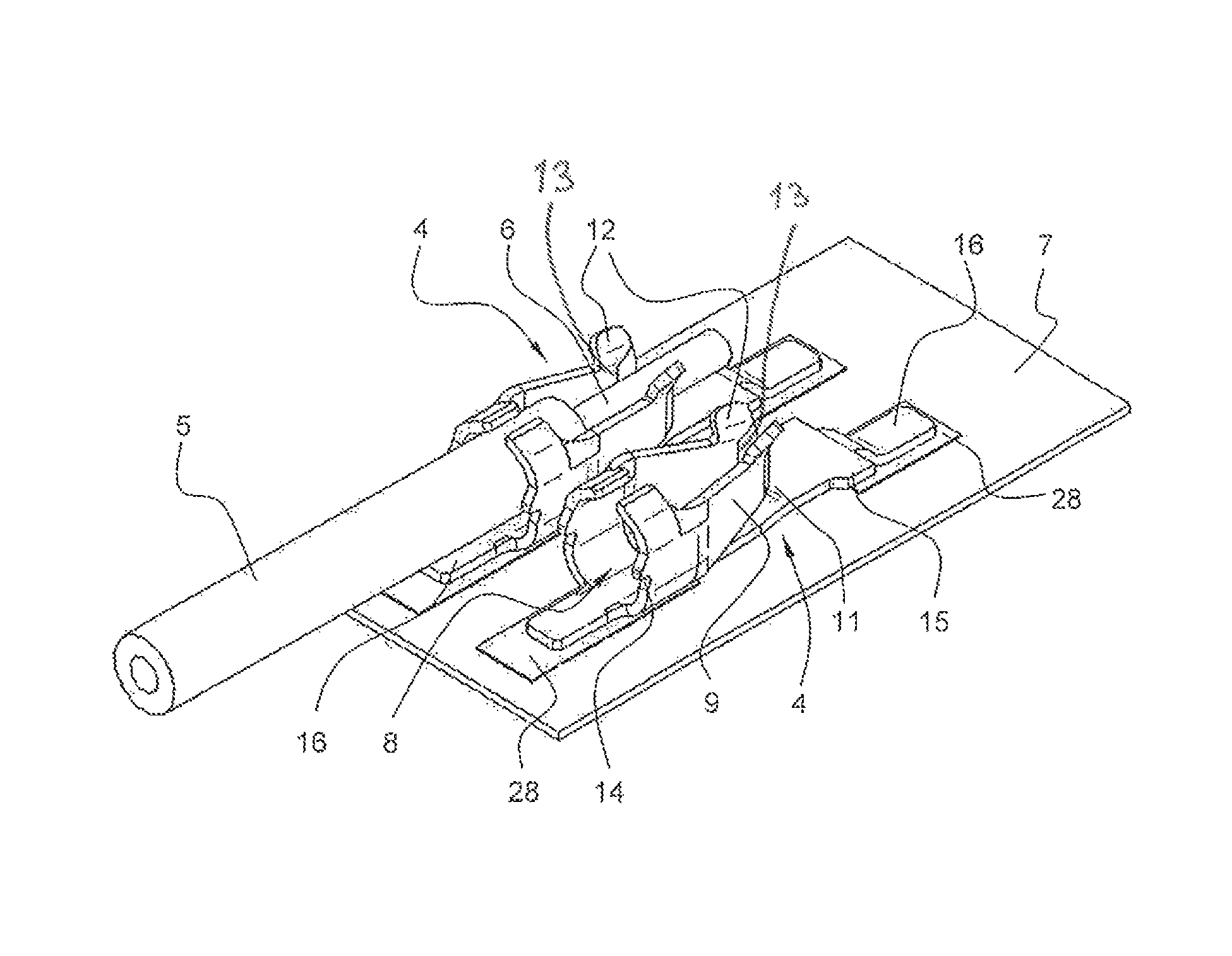

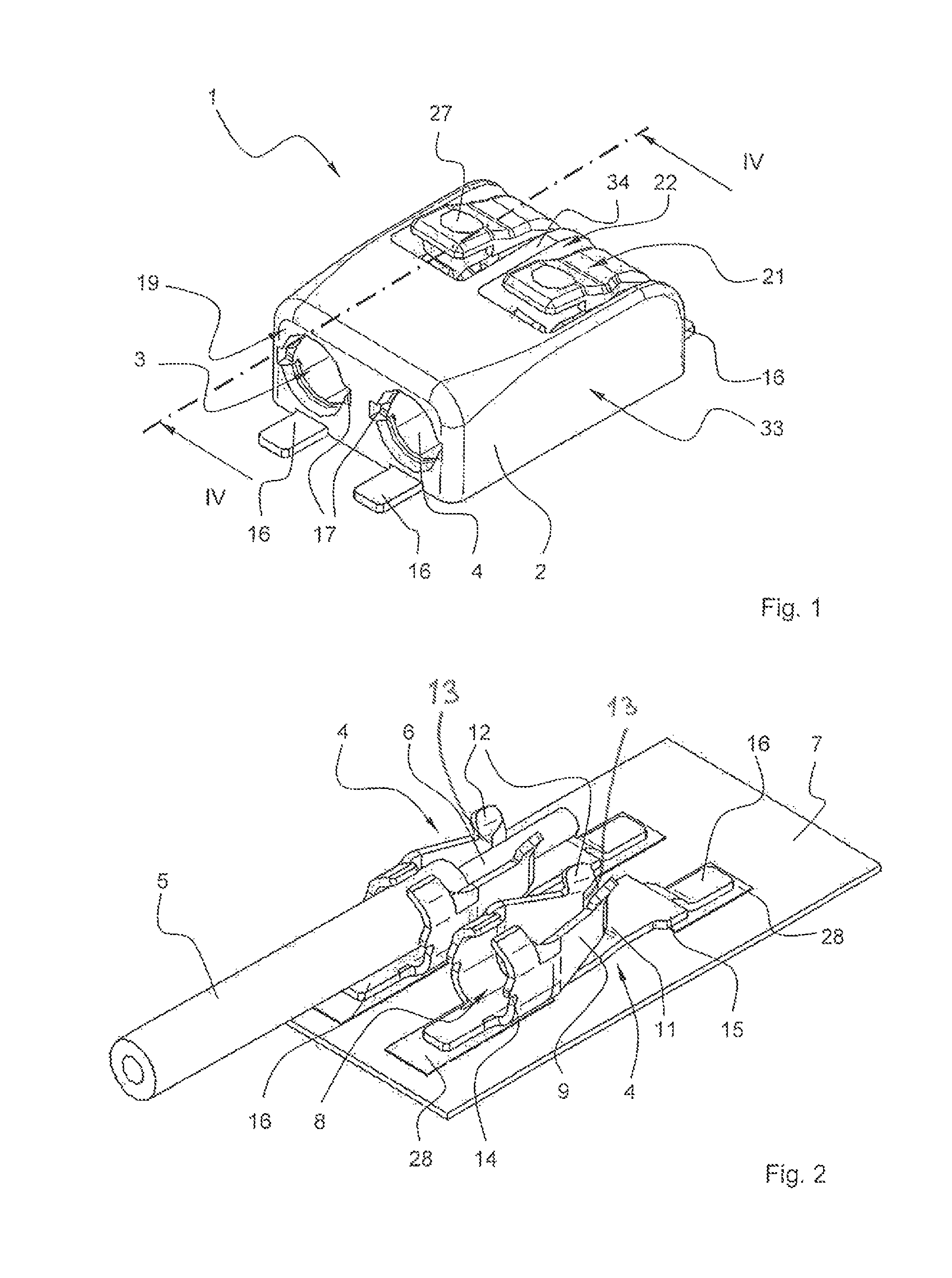

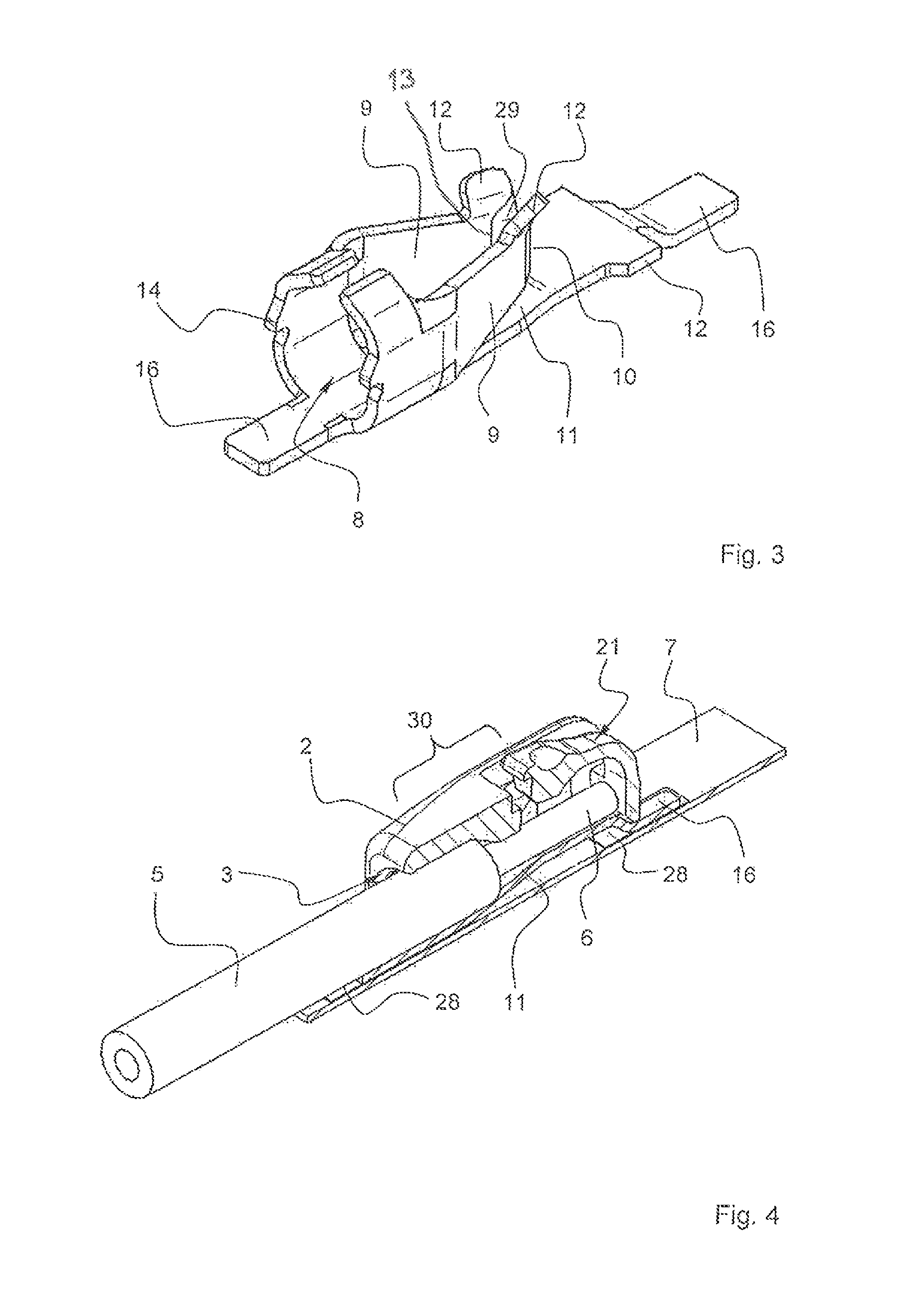

Electrical connection terminal

ActiveUS20110250803A1Simple structureClamp firmlyVehicle seatsTwo pole connectionsElectrical conductorMetallic materials

Electrical connection terminal (1) for the clamping connection of at least one electrical conductor (5), having a contact frame (4) which is accommodated in an insulating material housing (2) and is stamped out from a flat metal material and is shaped in the form of a channel with at least two side walls and a contact base (11), with the contact frame (4), for the purpose of forming a conductor clamping connection, having on each side wall in each case a leaf spring (9) in the form of a tongue which is stamped out from the flat metal part and which is bent out of the plane of the flat metal part in such a way that the free end of the leaf spring (9) forms a clamping edge (10) which is directed toward the electrical conductor (5), and having a conductor insertion region (30) which is in the form of a funnel at least in sections and tapers in the direction of a clamping point which is formed by the clamping edge (10), with the conductor insertion region (30) adjoining a conductor insertion opening (3) in the insulating material housing (2) in the conductor insertion direction. The conductor insertion region (30) which is in the form of a funnel at least in sections is at least virtually closed over the circumference, and is formed jointly from the contact frame (4) and at least in regions by the insulating material housing (2).

Owner:WAGO VERW GMBH

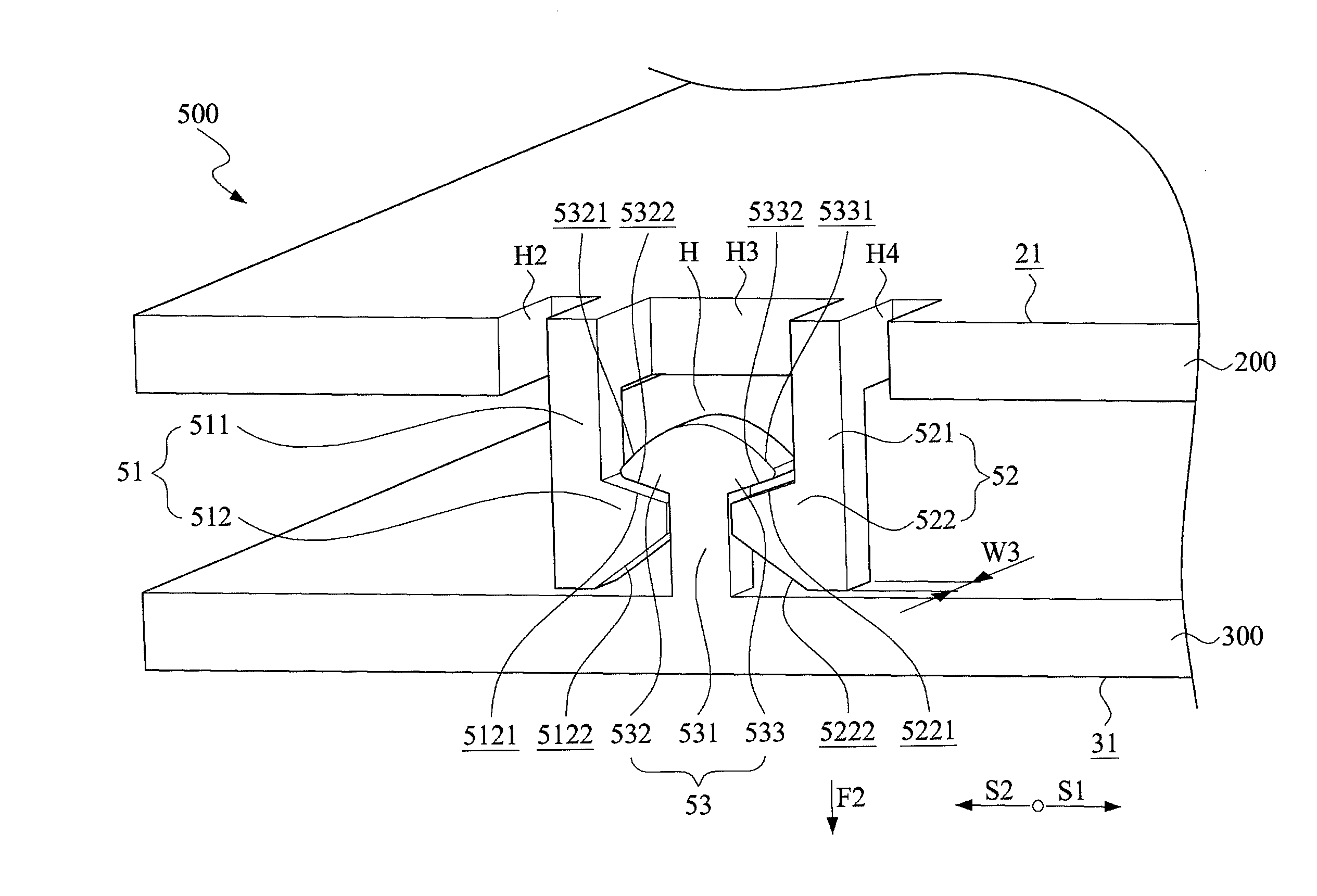

Optical fiber connector ferrule having open fiber clamping grooves

A ferrule for an optical fiber connector having open fiber clamping grooves. The ferrule has a body having a plurality of open grooves for clamping the terminating end sections of optical fibers. At least a section of the longitudinal opening of the groove is provided with opposing lips to provide a clamping effect. The width of the longitudinal opening defined between the lips along at least a section of the grooves is narrower than the diameter of the optical fibers to create a tight fit. The grooves and the width of the longitudinal groove openings are shaped and sized to retain the fibers without any clearance to allow for movement of the fiber relative to the groove. Similar grooves may be provided in the ferrule body for alignment guide pins. The grooves are precision formed by high throughput processes, such as stamping and extrusion.

Owner:SENKO ADVANCED COMPONENTS

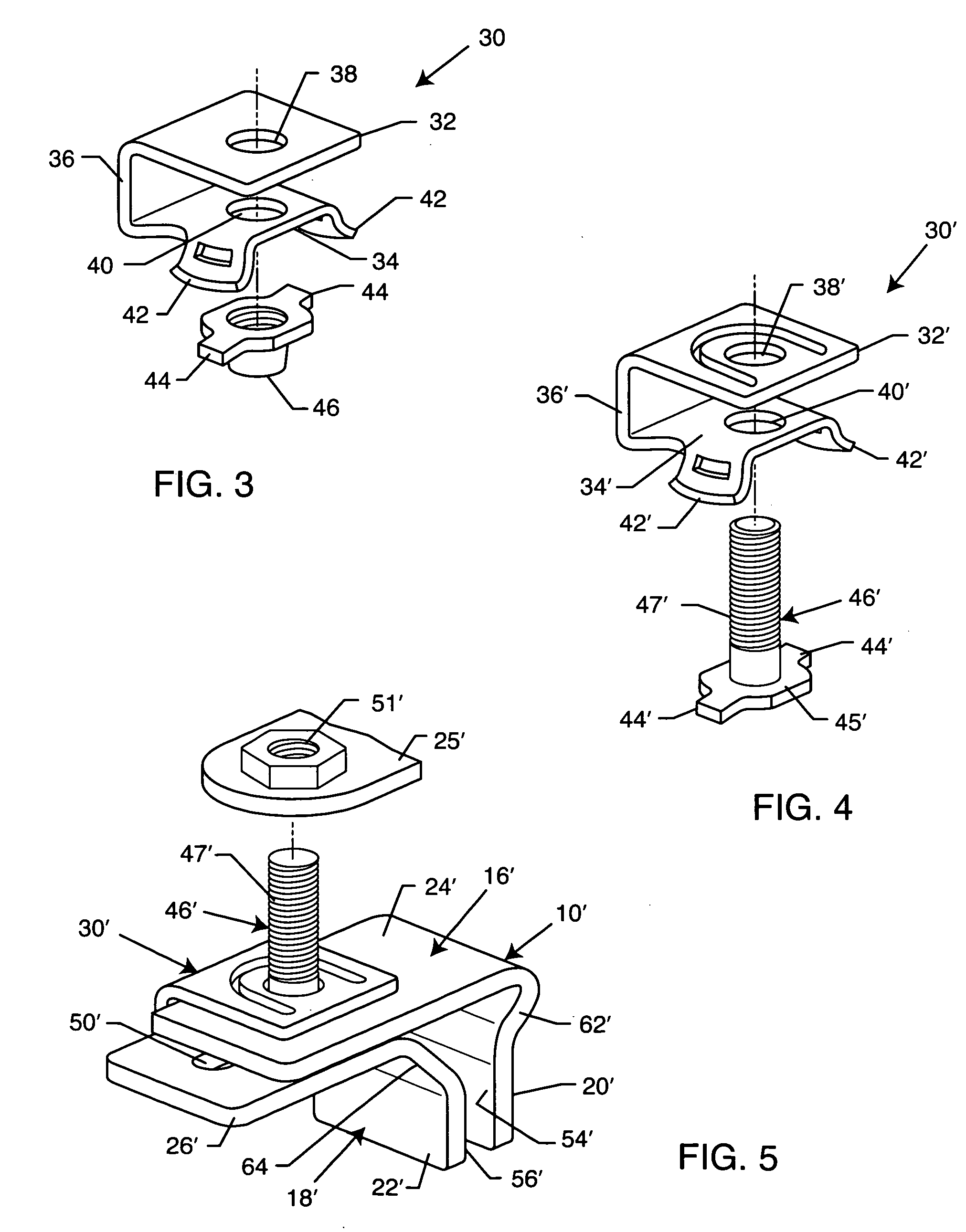

Adjustable mounting bracket

ActiveUS20050284995A1The process is convenient and fastQuick and easy subsequent mountingCandle holdersLighting support devicesEngineeringMechanical engineering

An adjustable mounting bracket for secure mounting as by adhesive attachment onto an exposed edge of a substrate, wherein the mounting bracket is adapted for quick and easy subsequent mounting of a selected structure such as tubing, wire bundles, etc., relative to the substrate. The adjustable mounting bracket includes a pair of slidably interfitting, generally L-shaped bracket members which cooperatively define a slidably overlying pair of mounting plates and an associated pair of slidably separable clamp jaw plates. The slidably interfitting mounting plates accommodate adjustable spaced-apart separation of the clamp jaw plates to seat firmly against opposed surfaces of the substrate edge, such as mounting onto a rib protruding from the substrate or mounting onto an inner diameter edge of an opening formed in the substrate.

Owner:PHYSICAL SYST

System for securing a suture

InactiveUS7435251B2Precise alignmentPrecise positioningSuture equipmentsWound clampsEngineeringSuturing clip

Owner:GREEN DAVID T

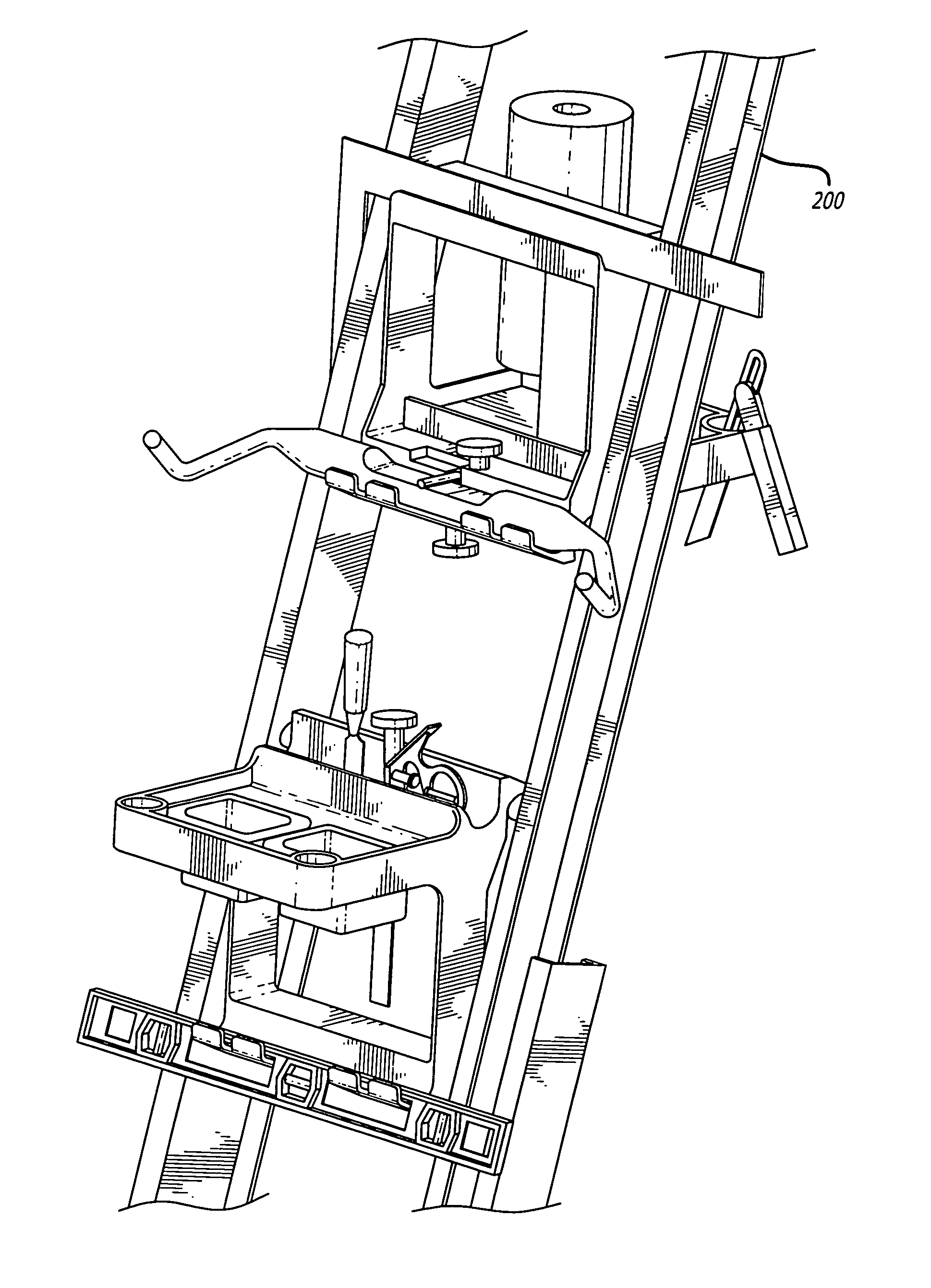

Ladder caddy

InactiveUS7077238B2Easily invertedEasily removed and reattachedOther accessoriesContainer/bottle contructionTool holderEngineering

Owner:FIRE DOME L L C

Radome Attachment Band Clamp

ActiveUS20130002515A1RF leakageClamp firmlyPretreated surfacesRadiating element housingsInterference fitElectrical performance

A band clamp for coupling a radome to a distal end of a reflector dish for improving the front to back ratio of a reflector antenna, is provided with an inward projecting proximal lip and an inward projecting distal lip. The distal lip is dimensioned with an inner diameter equal to or less than a reflector aperture of the reflector dish. The proximal lip may be provided with an inward bias dimensioned to engage the reflector dish in an interference fit and / or turnback region dimensioned to engage an outer surface of a signal area of the reflector dish in an interference fit. A variety of different configurations of protruding portions extending from the band clamp may be applied to further improve electrical performance.

Owner:COMMSCOPE TECH LLC

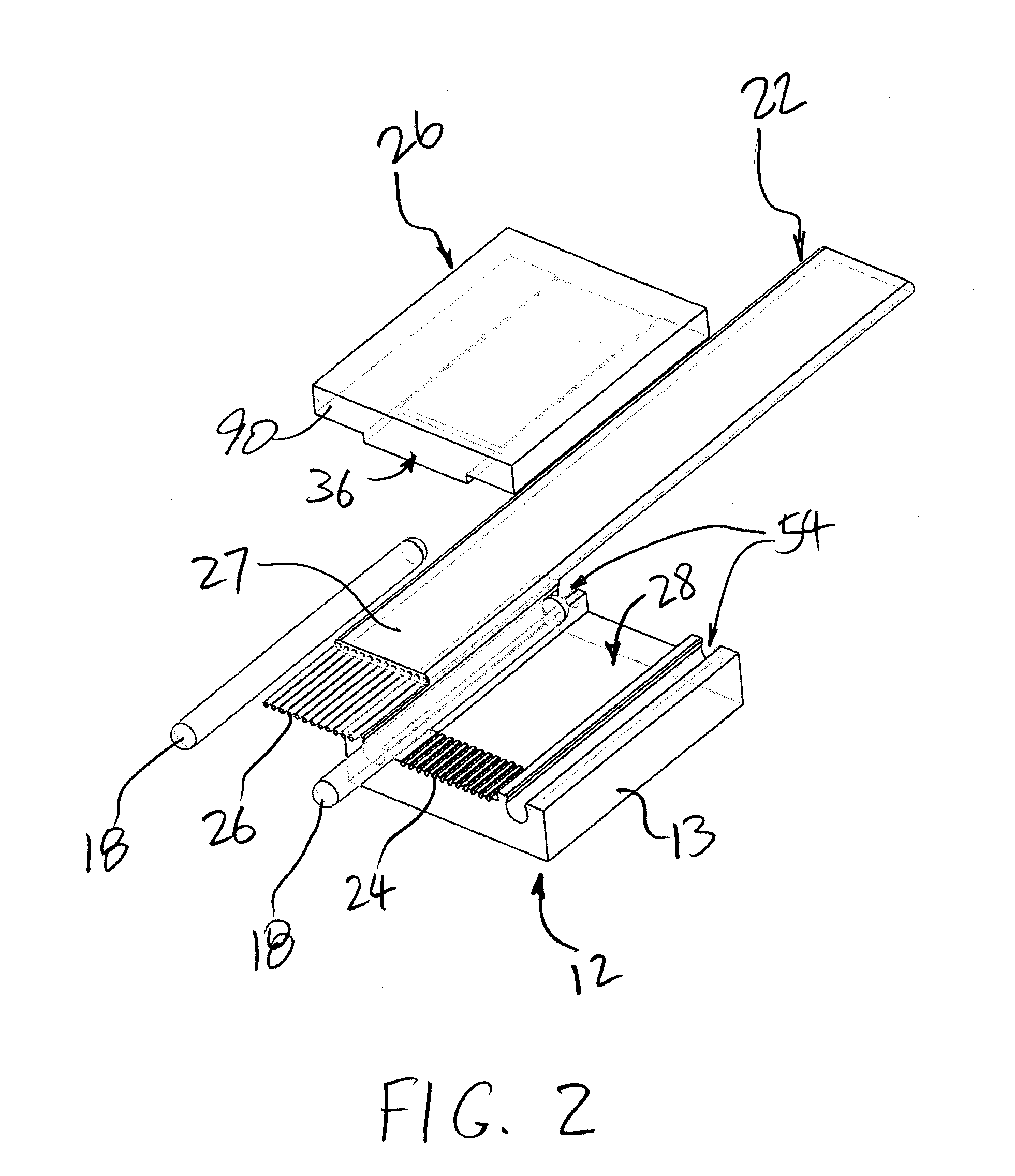

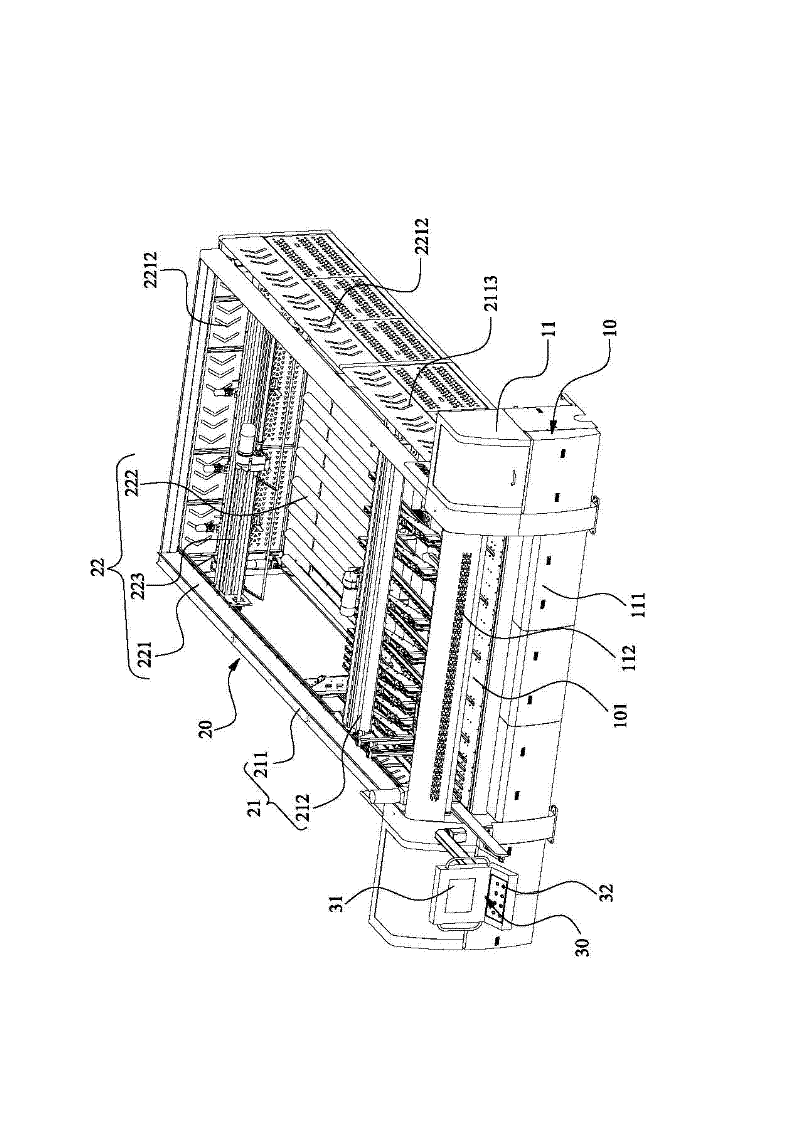

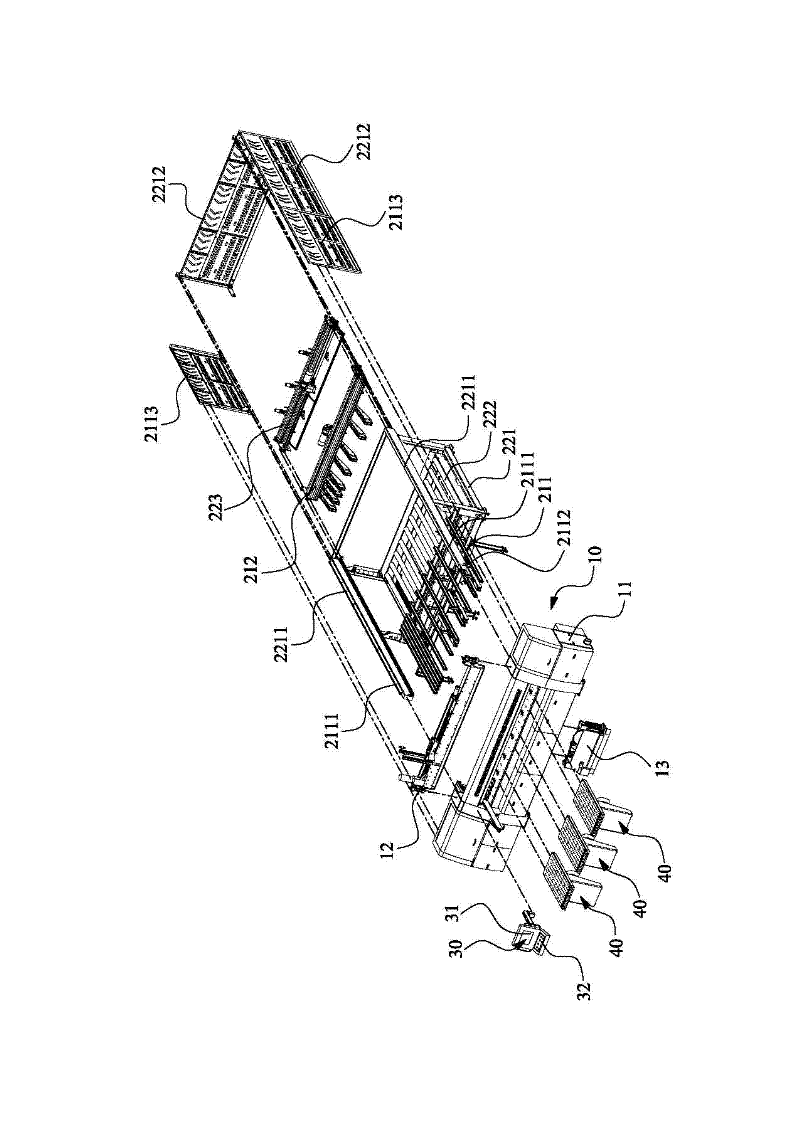

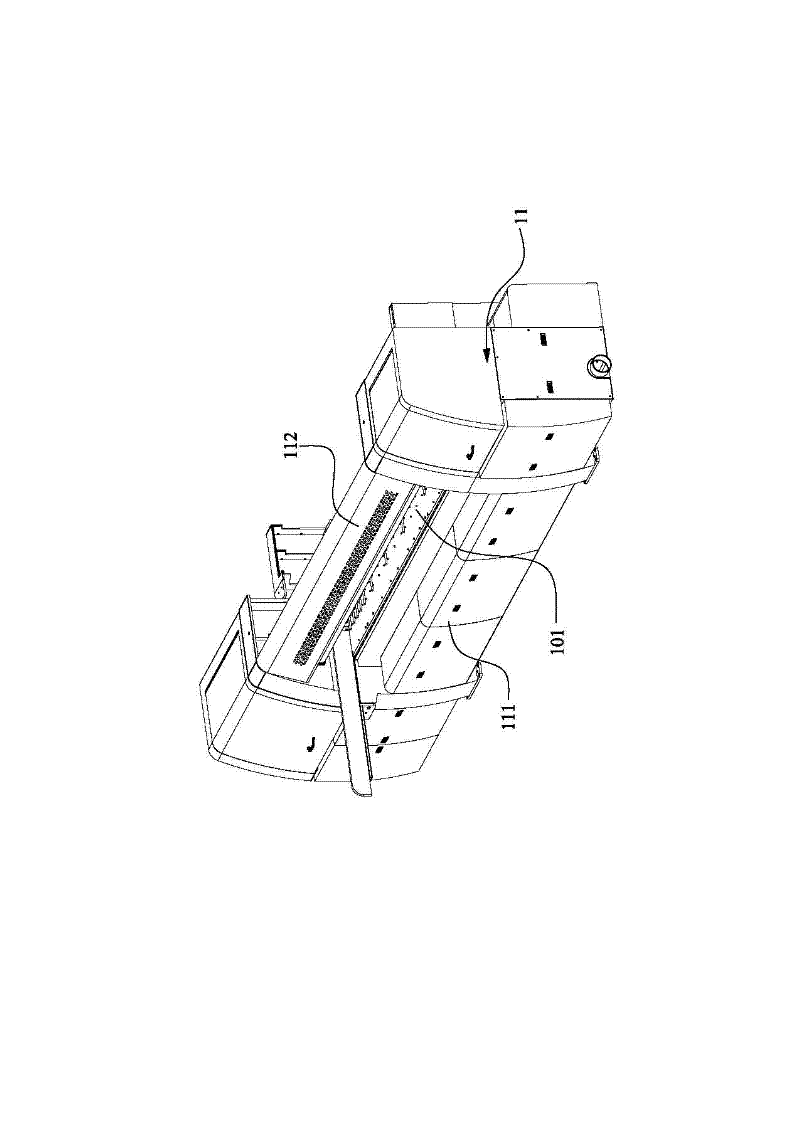

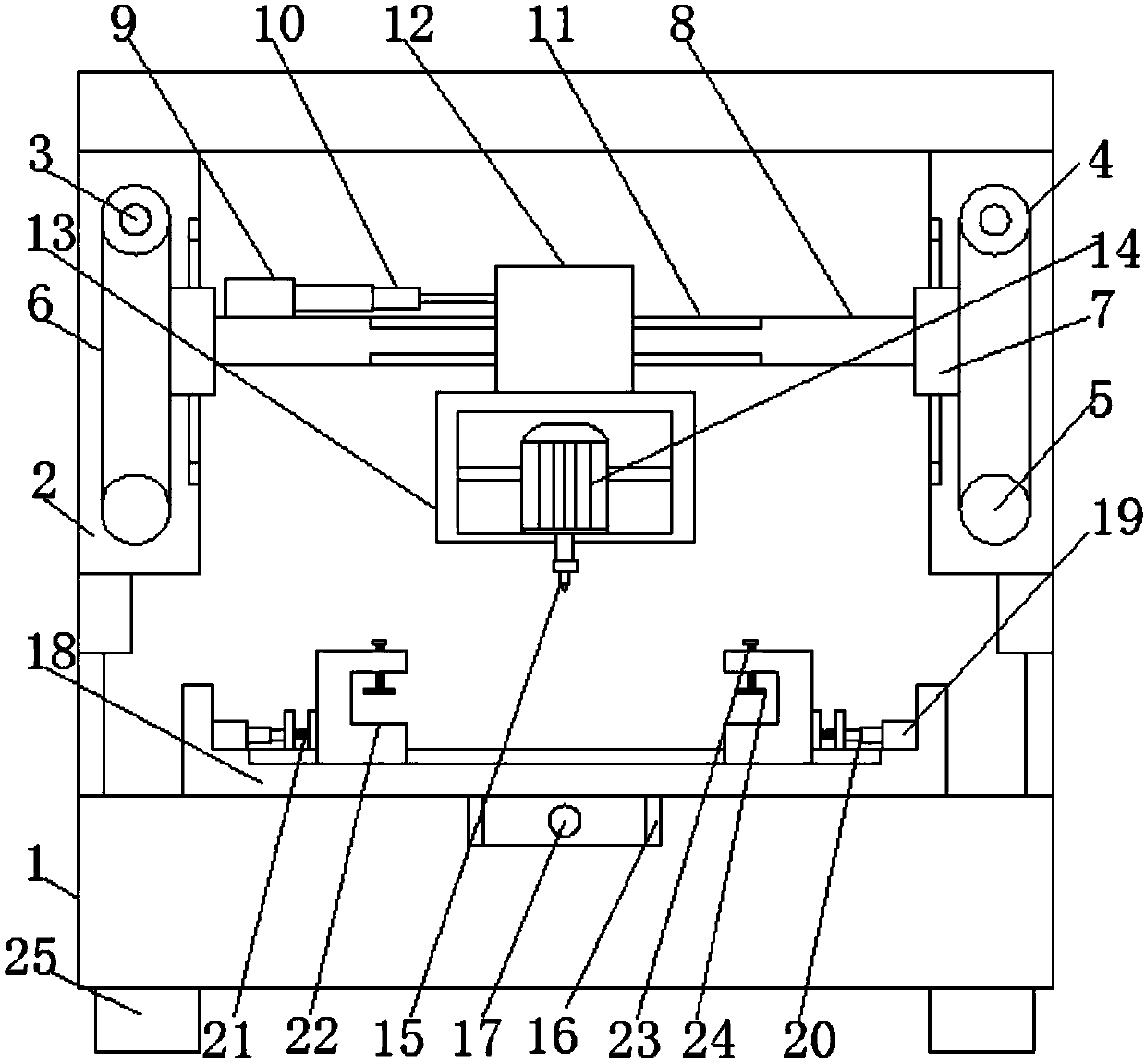

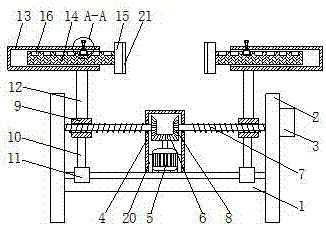

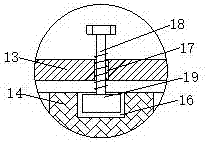

Back loading high-speed computer panel saw

ActiveCN102390063AGuaranteed cutting accuracyConducive to survivalFeeding devicesCircular sawsComputer control systemEngineering

The invention discloses a back loading high-speed computer panel saw comprising a machine station main body, a material feeding unit and a computer control system, wherein the machine station main body comprises a worktable, a material pressing device and a cutting device; the material pressing device and the cutting device are both arranged on the worktable; the material feeding unit is arranged at the back side of the machine station main body; the material feeding unit comprises a material feeding device and a material loading device; the material feeding device is arranged between the machine station main body and the material loading device; the material feeding device comprises a material feeding bracket and a first propulsion mechanism; the material loading device comprises a material loading bracket, a lifting table and a second propulsion mechanism; the computer control system controls the work of the material pressing device, the cutting device, the material feeding device and the material loading device, thereby realizing automation operation in the overall process of panel cutting, being favorable for ensuring the cutting precision of panel material, improving the work efficiency effectively, reducing the number of operation personnel and reducing the work strength for workers, thus reducing the production cost for an enterprise and being beneficial to the survival of the enterprise.

Owner:NANXING MACHINERY CO LTD

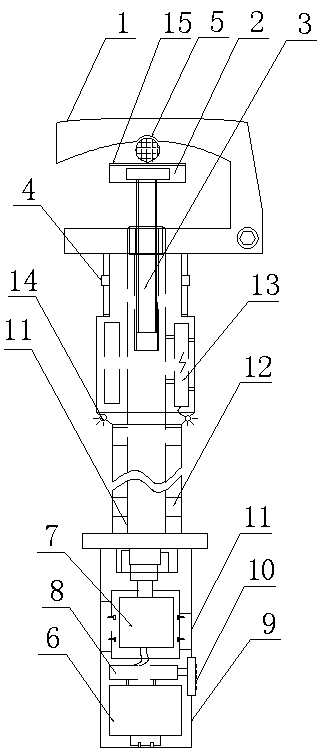

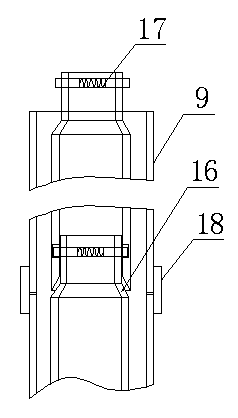

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

Coupling structure for a shell

InactiveUS20110239418A1Increase elasticityAvoid breakingClosed casingsSheet joiningCouplingBiomedical engineering

A coupling structure for coupling first and second halves includes two hooks and a two-way securing hook. The first hook includes a first resilient section extending from the first half towards the second half and a first clamping section extending laterally from the first resilient section along a first direction. The second hook includes a second resilient section extending from the first half towards the second half and a second clamping section extending laterally from the second resilient section along a second direction opposite to the first direction. The first and second hooks and the first half cooperatively define a clamping space thereamong. The securing hook includes a securing section projecting from the second half towards the first half, a first interfering section extending laterally from the securing section along the second direction and a second interfering section extending laterally from the securing section along the first direction.

Owner:GIGA BYTE TECH CO LTD

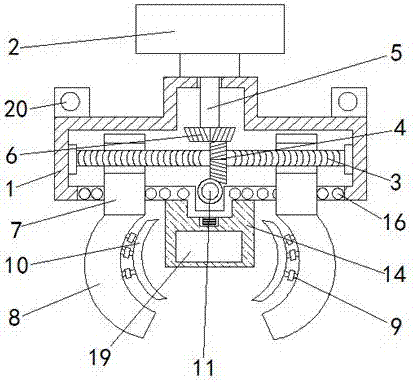

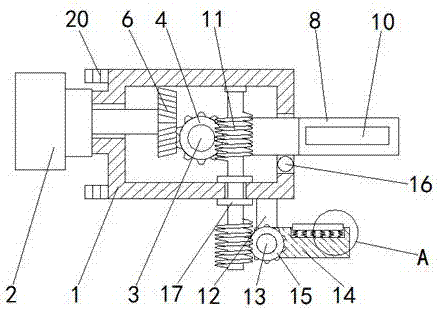

Clamping device for air conditioner production equipment

The invention discloses a clamping device for air conditioner production equipment. The clamping device comprises a sliding rail; the two sides of the sliding rail are fixedly connected with supporting plates correspondingly; controllers are fixedly connected to the sides, away from the sliding rail, of the supporting plates; the top of the sliding rail is fixedly connected with a box body; a motor is fixedly connected with the position, located in an inner cavity of the box body, at the top of the sliding rail; a rotating shaft of the motor is sleeved with a first bevel gear; a first thread rod is movably connected between the two supporting plates; and the ends, away from the supporting plates, of the first thread rod penetrate through the box body and extend to the inner cavity of the box body. According to the clamping device for the air conditioner production equipment, the motor, the first bevel gear and a second bevel gear are matched to enable the first thread rod to rotate so that a thread sleeve can transversely move, a vertical rod and a fixed plate are conveniently driven to transversely move, thus air conditioner cabinet bodies with different sizes can be clamped, operation is convenient, the applicability of the air conditioner cabinet body clamping device is improved, and using of a user is more convenient.

Owner:TAIZHOU BAOKU REFRIGERATION EQUIP MFG

Suture passer devices and methods

ActiveUS20120283754A1Travel can be limitedAvoid elevationSuture equipmentsSurgical needlesPasserGeneral surgery

Owner:CETERIX ORTHOPAEDICS

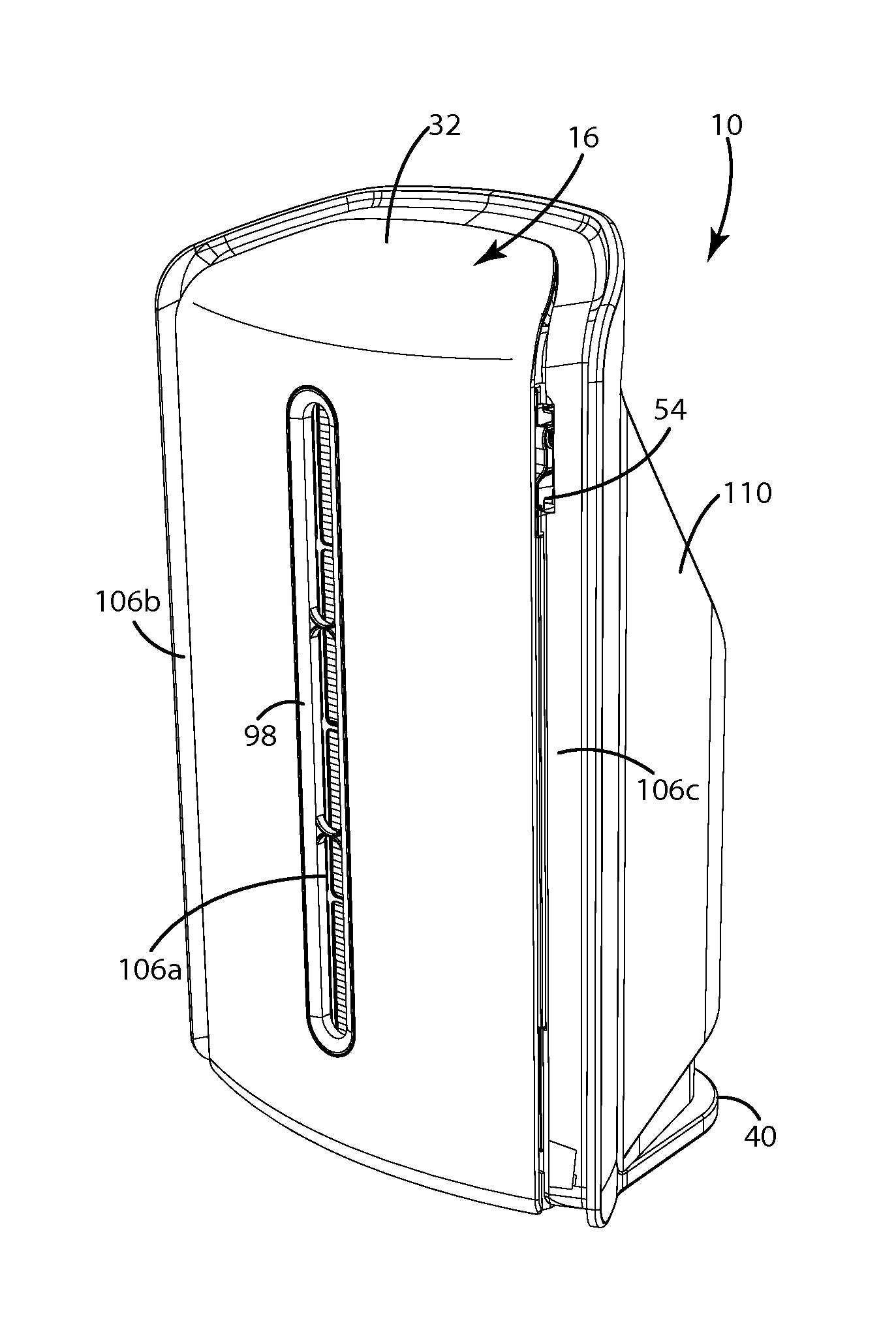

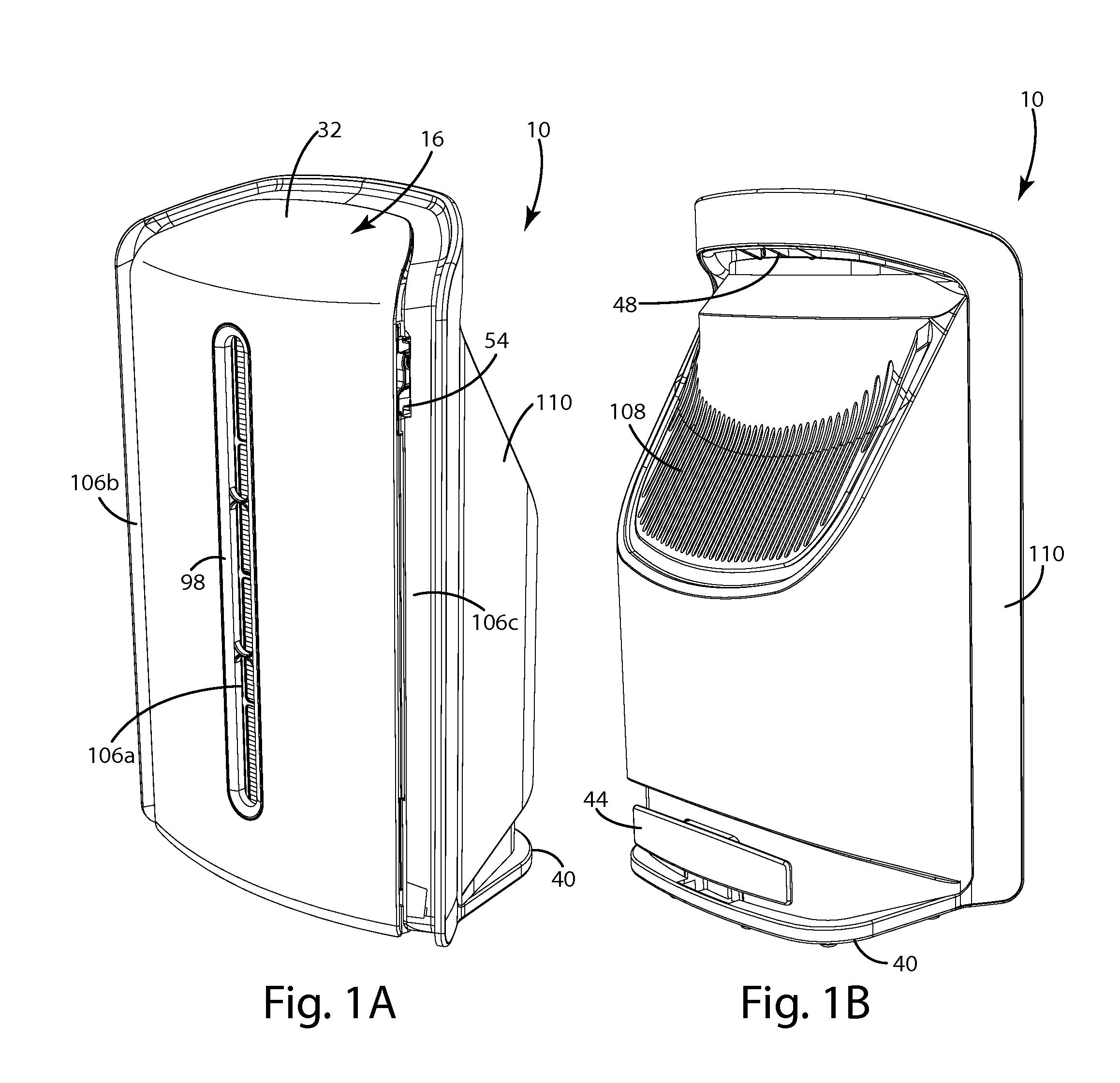

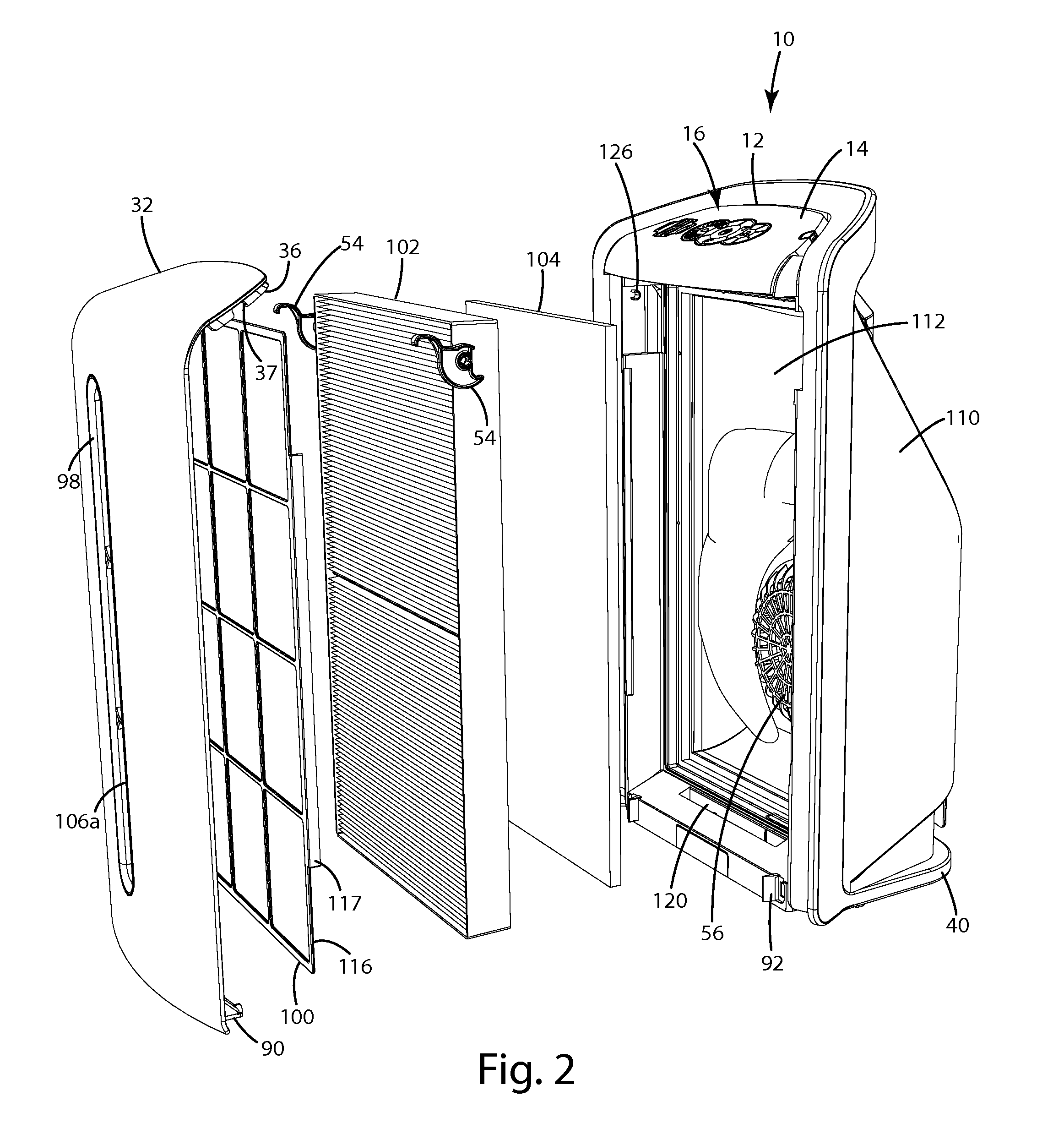

Air treatment system

ActiveUS20150273381A1Simple control systemClean and simple appearanceCombination devicesAuxillary pretreatmentParticulatesControl system

An air treatment system having an improved control system. The control system may include a dynamic “dead front” display that varies the display based on mode of operation. The display may include capacitive touch sensors and include an array of capacitive film segments or traces integrated into the display. The control system may include a self-contained electronics module that can be tested and calibrated before installation in the ATS. A dust sensor assembly may be integrated into the electronics module. The front cover may be attached with a mechanical attachment at the top and a magnetic attachment on the bottom. The ATS may include a filter retainer assembly with a rotating clip configured to perform in a cam-like manner to firmly clamp the particulate filter and carbon filter in place.

Owner:ACCESS BUSINESS GRP INT LLC

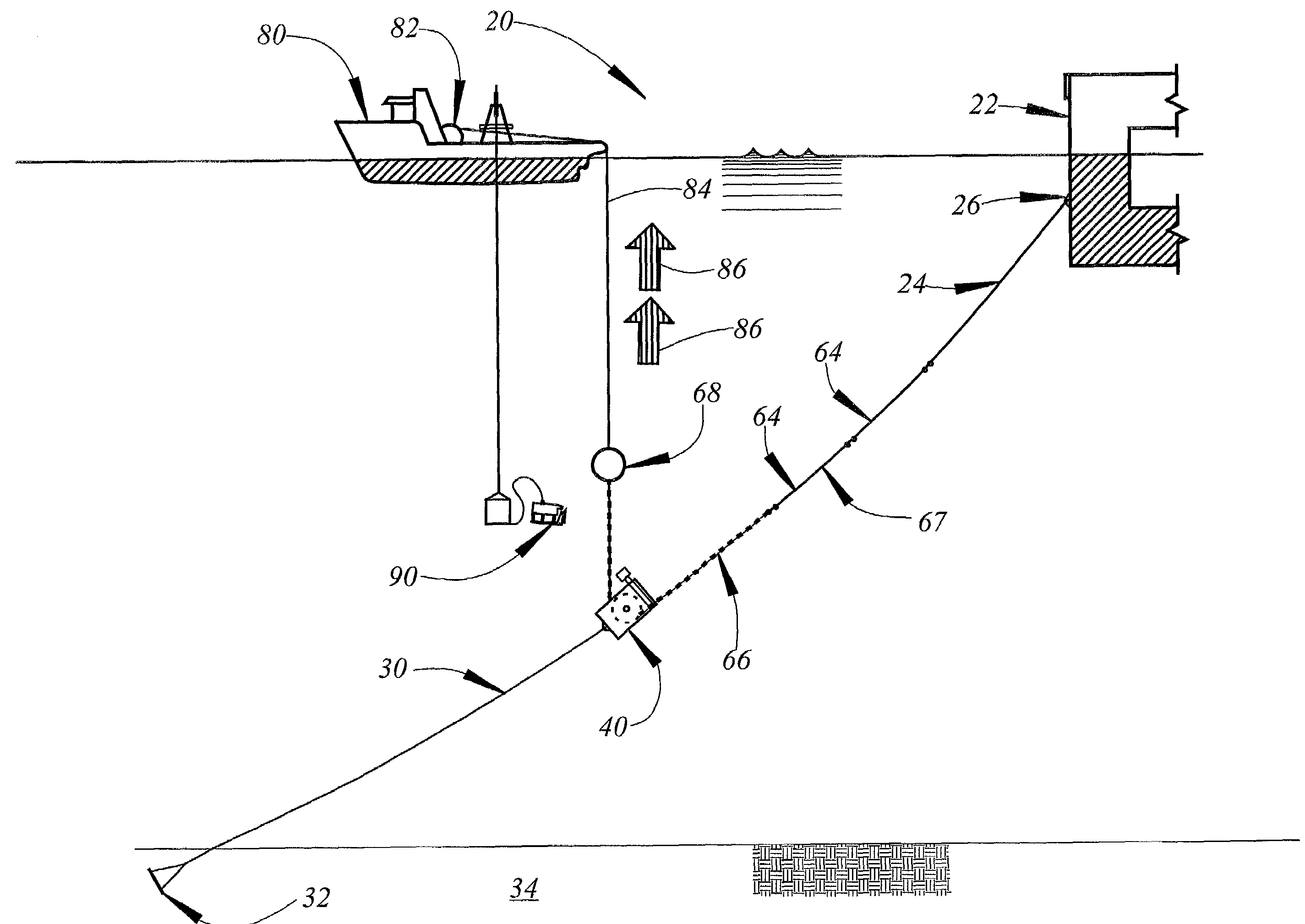

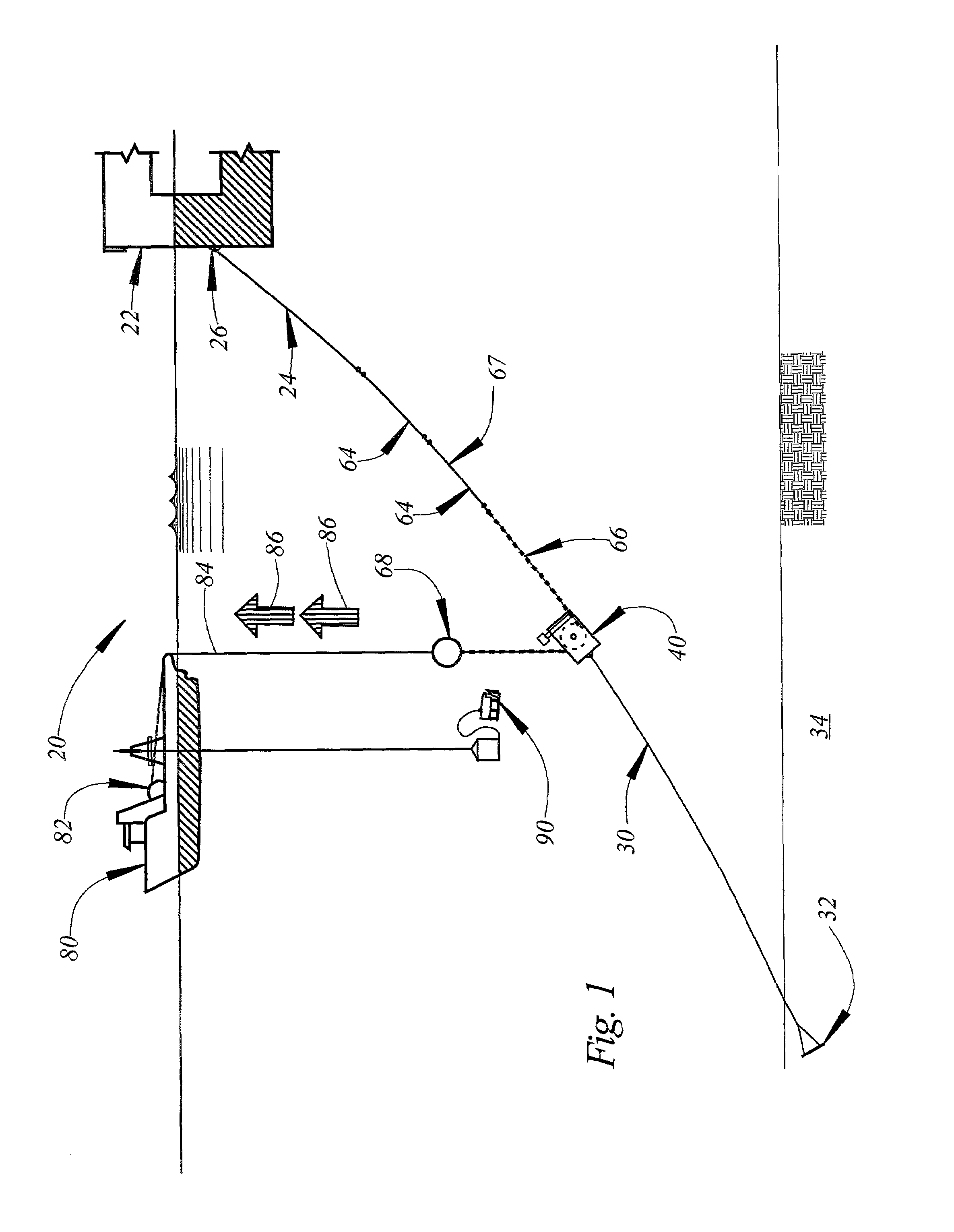

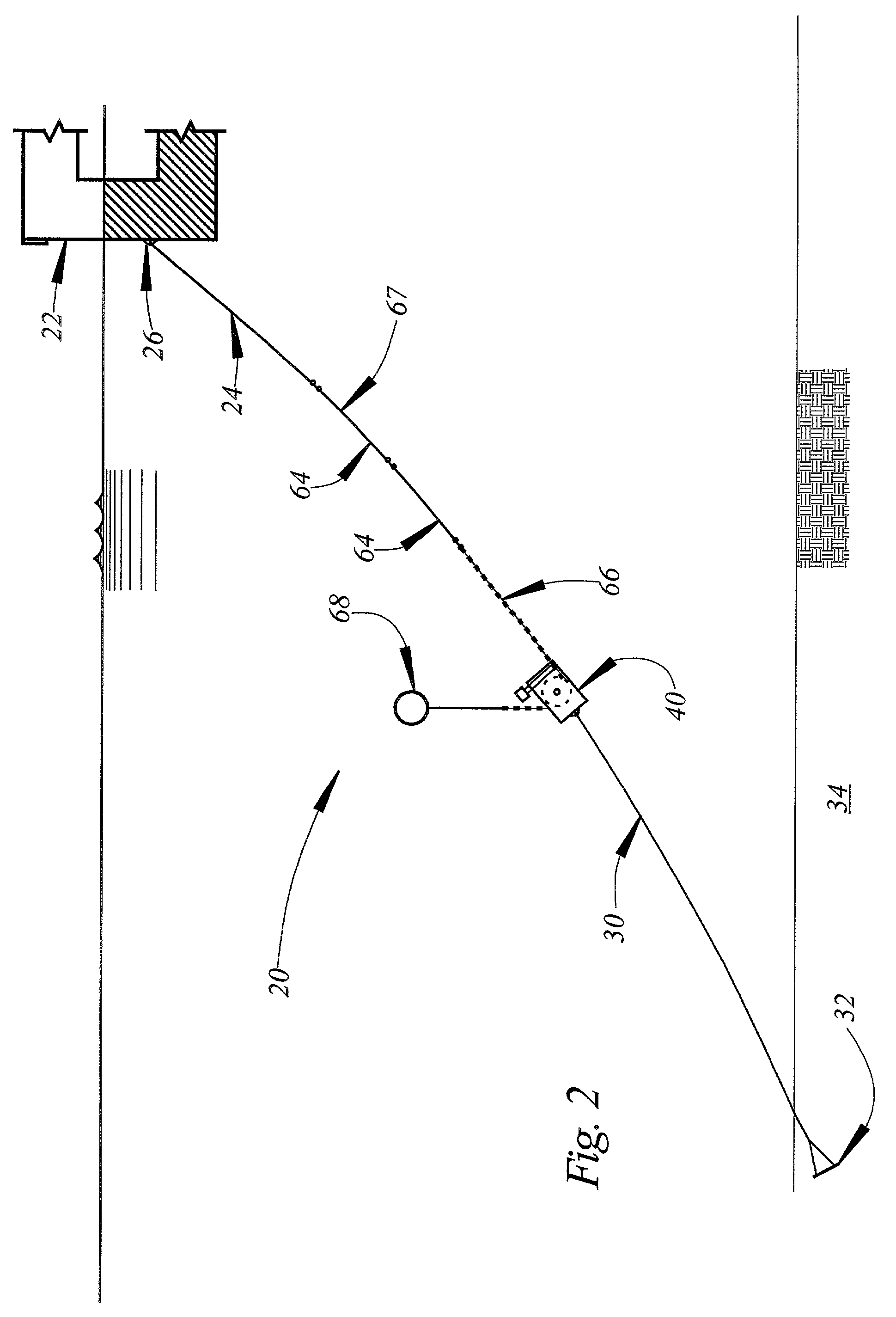

Method of and apparatus for offshore mooring

ActiveUS6983714B2Expensive to operateClamp firmlyAnchorsAnchoring arrangementsMarine engineeringPulley

In a method of and apparatus for offshore mooring, a clamping apparatus includes a clamping mechanism and a pulley. A mooring line connected to an anchor or a pendant line connected to a vessel to be moored extends through the clamping mechanism and around the pulley of the clamping apparatus. The distal end of the line extending through the clamping apparatus is connected to an anchor handling vessel. The anchor handling vessel is employed to apply a predetermined tension to the pendant line and the preset mooring line. A remote operated vehicle is then employed to actuate the clamping apparatus and to disengage the anchor handling vessel.

Owner:TECH FRANCE SA

Table arrangement for motor vehicles

InactiveUS6038983ALess dependencyClamp firmlyVehicle arrangementsPicture framesSteering wheelEngineering

PCT No. PCT / DE95 / 01773 Sec. 371 Date Aug. 25, 1997 Sec. 102(e) Date Aug. 25, 1997 PCT Filed Dec. 11, 1995 PCT Pub. No. WO96 / 18520 PCT Pub. Date Jun. 20, 1996A table arrangement for mounting on the steering wheel of a motor vehicle having a table top and a container-shaped bottom part, as well as an adjusting device for determining the angular position of the table top in relation to the bottom part. The table arrangement may be hooked on the steering wheel by an anchoring device that allows the table to slide towards the driver.

Owner:LENDL WILHELM

Suture passer devices and methods

Owner:CETERIX ORTHOPAEDICS

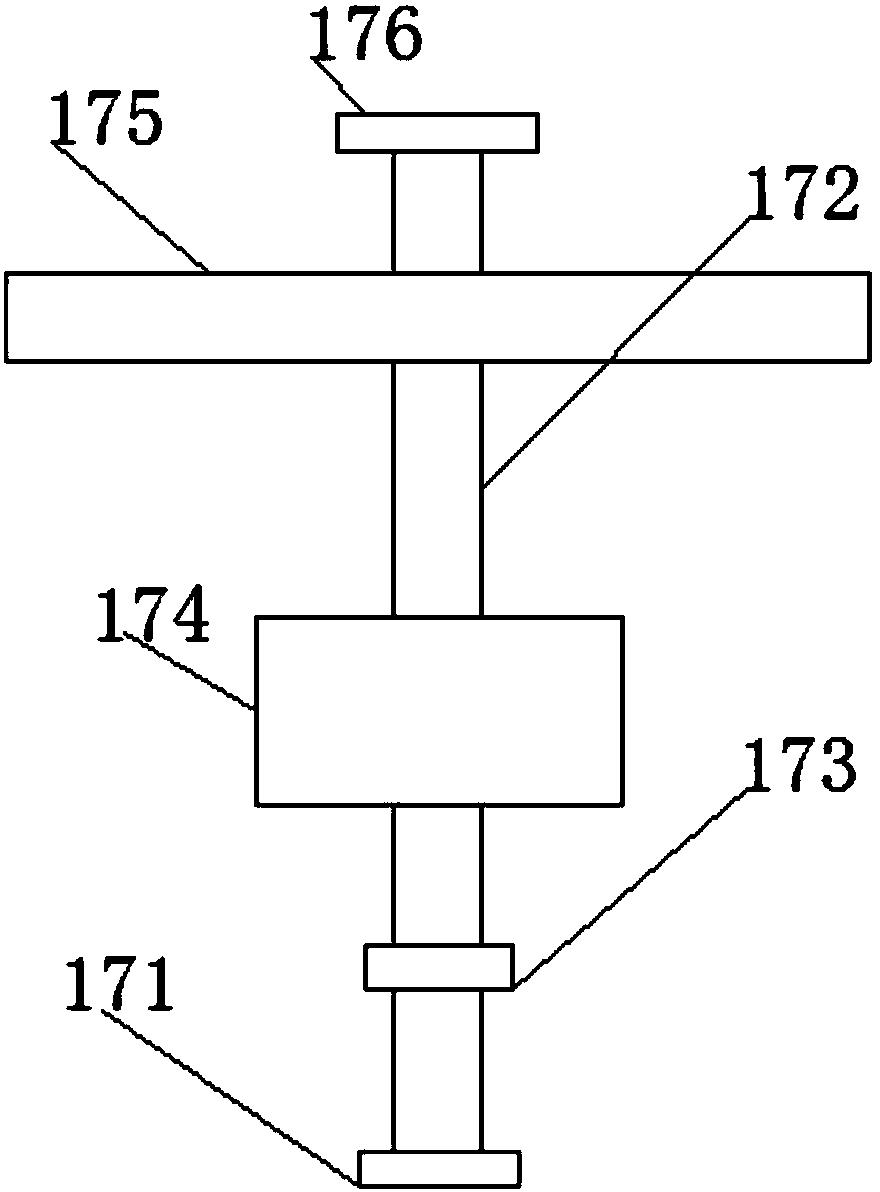

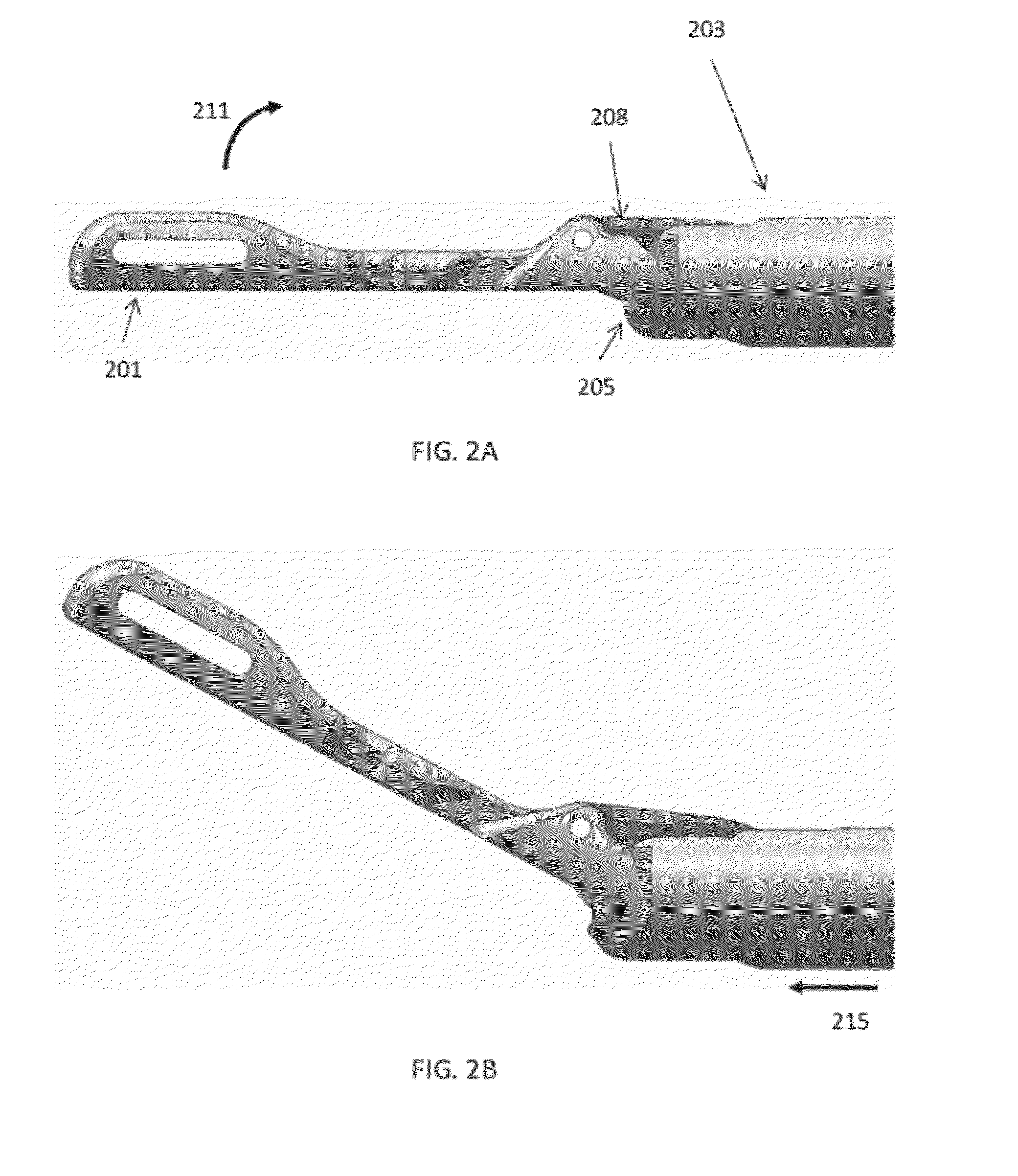

High voltage grounding tool for power maintenance

ActiveCN103531925AImprove securityAvoid safety hazardsLine/current collector detailsMulticonductor cable end piecesGround lineHigh pressure

The invention discloses a high voltage grounding tool for power maintenance, which comprises a grounding wire chuck and an operating rod, wherein the wire chuck comprises a C-shaped hanging frame, a wire clamp moving plate and a lifting rod; a connector connected with the C-shaped hanging frame is arranged at the top of the operating rod; the upper end of the lifting rod is connected with the wire clamp moving plate; a driving mechanism connected with the lifting rod is arranged in the operating rod; the operating rod is arranged in a multi-section insertion manner; locking rings are arranged among sections of the operating rod; reducer pipes are arranged among sections of a movable casing pipe; elastic pins or key structures matched with the movable casing pipe are arranged on the reducer pipes. According to the invention, the high voltage grounding tool is hung on a wire by utilizing the C-shaped hanging frame; the wire is clamped by adopting the lifting rod; the wire-off accident is prevented; the low-position safe operation is realized; the potential safety hazard caused by the climbing operation is avoided; the working difficulty is reduced; the working efficiency is improved; the sectional design concept is adopted; the flexible variation of the length of the operating rod is ensured; in the transmission link, the interchangeable connection can be carried out; the effects are obvious.

Owner:STATE GRID CORP OF CHINA +1

Clamping device for robot arm

InactiveCN107186741AStable clampingGuaranteed stabilityGripping headsThreaded rodIndustrial engineering

The invention discloses a clamping device for a robot arm. The clamping device for the robot arm comprises a rack body and a servo motor, wherein the servo motor is fixedly connected with the outer wall of one side of the rack body; a cavity is formed in the rack body, a threaded rod is rotationally connected to the interior of the cavity and fixedly sleeved with a first gear; the output end of the servo motor is fixedly connected with a rotating rod; the end, away from the servo motor, of the rotating rod penetrates through the outer wall of the rack body and extends into the cavity; the extending end of the rotating rod is fixedly sleeved with a second gear which is engaged with the first gear; the threaded rod is in threaded connection with two supporting blocks in a sleeved mode; and the inner wall of one side of the cavity is provided with sliding openings corresponding to the supporting blocks. Through arrangement of arc plates and a bearing plate, the clamping device is simple in structure and convenient to operate, and can stably clamp an object and prevent the object from falling off.

Owner:陕西舜洋电子科技有限公司

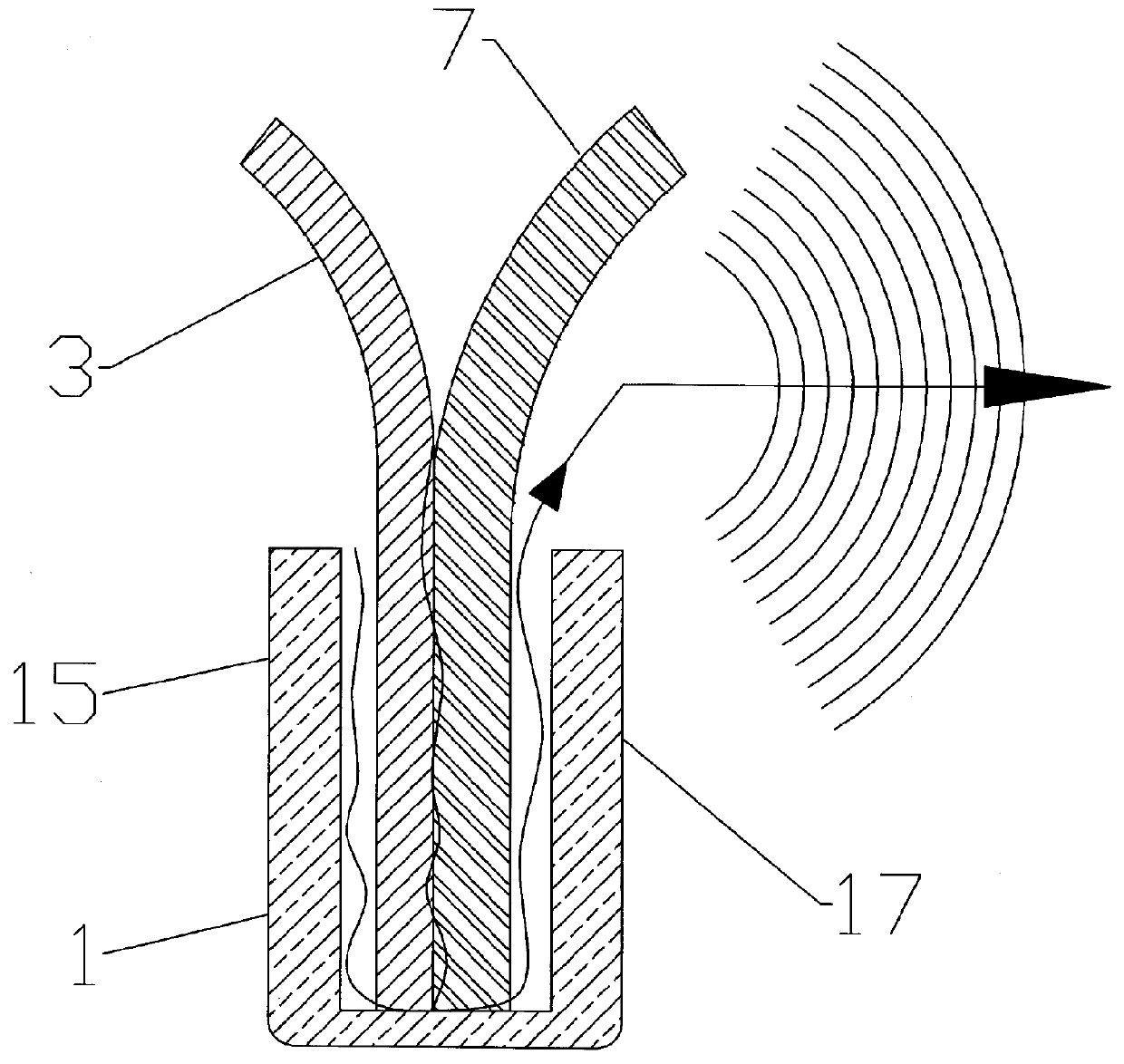

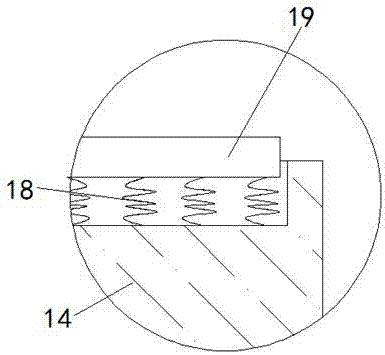

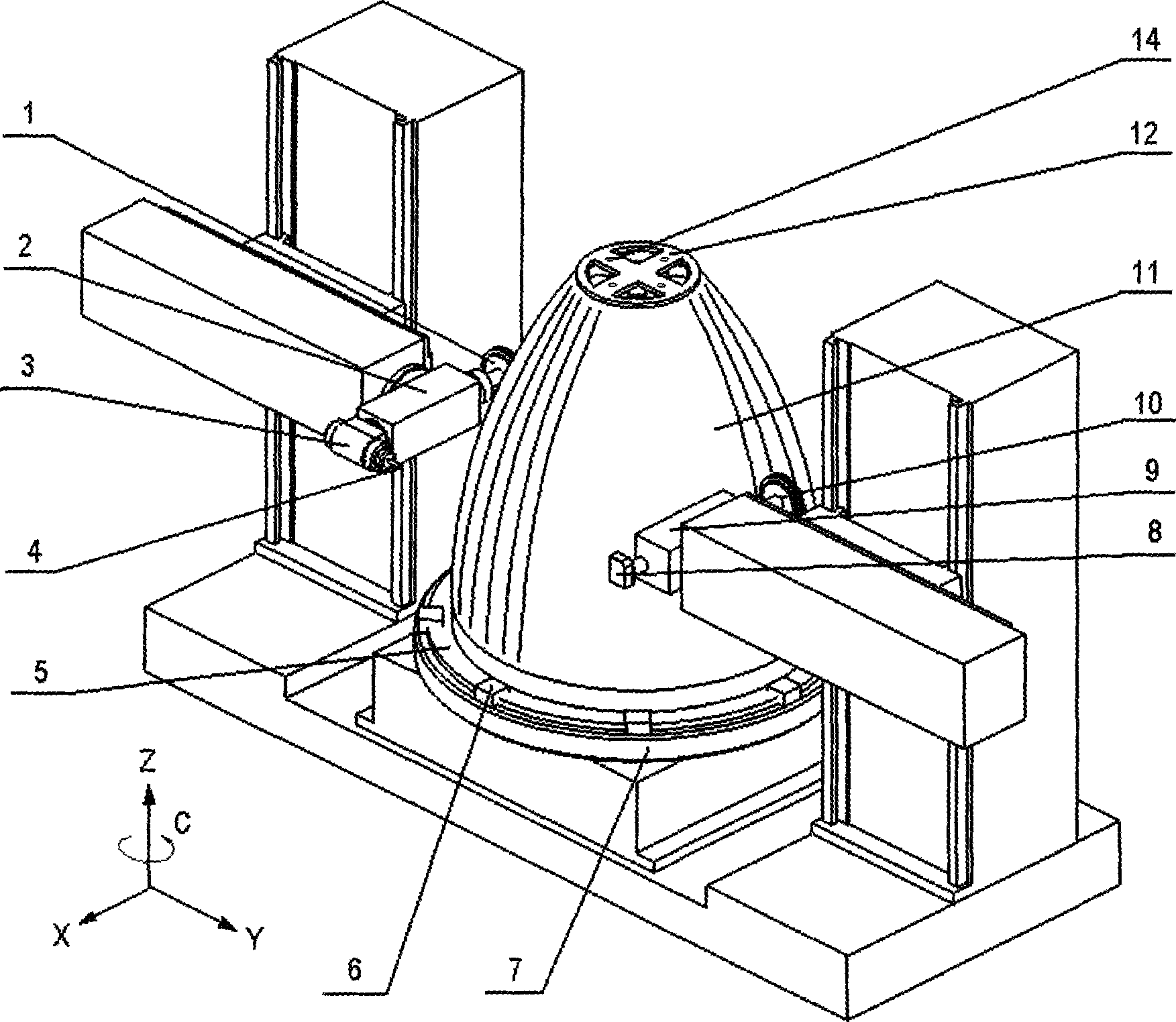

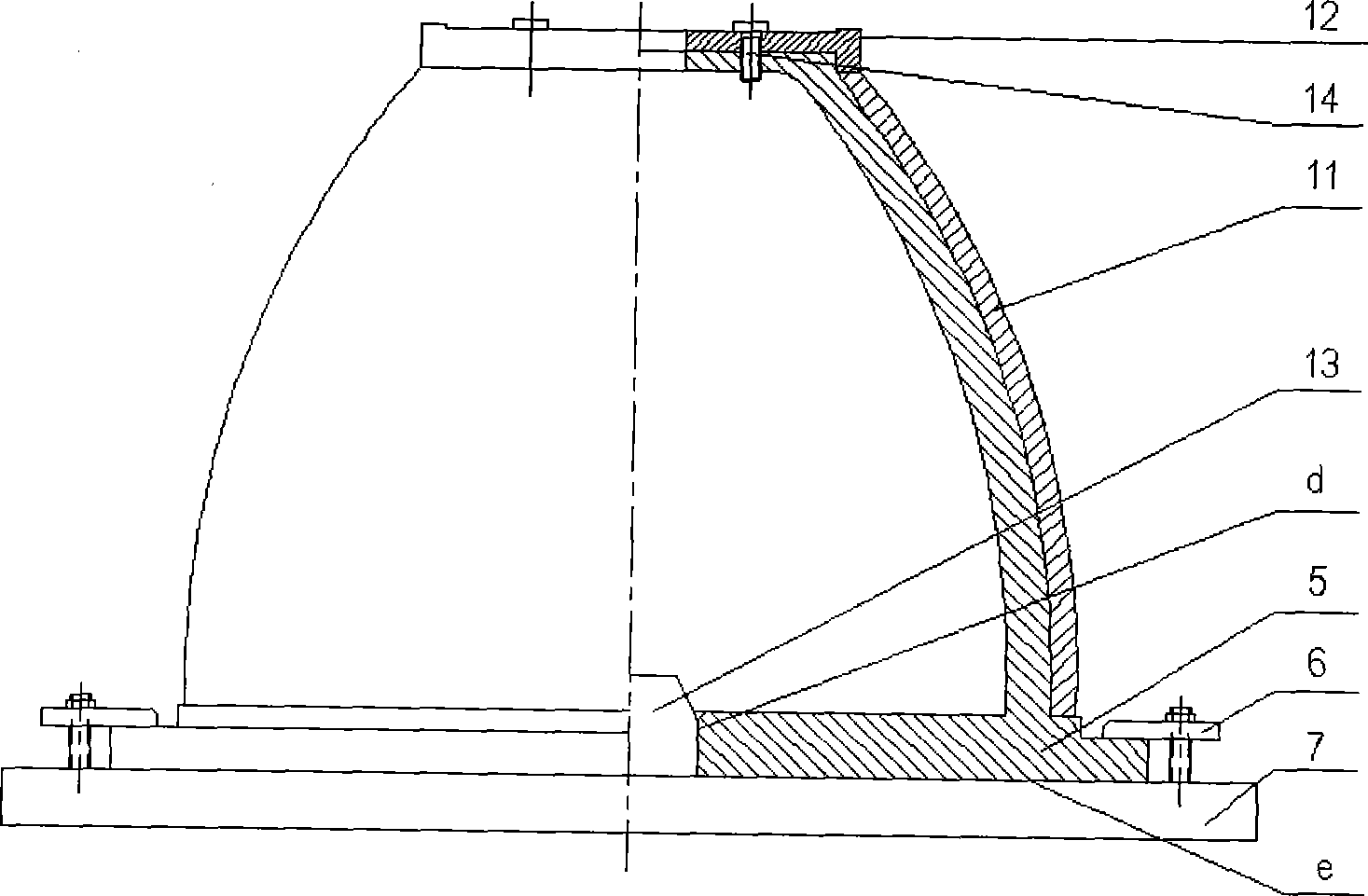

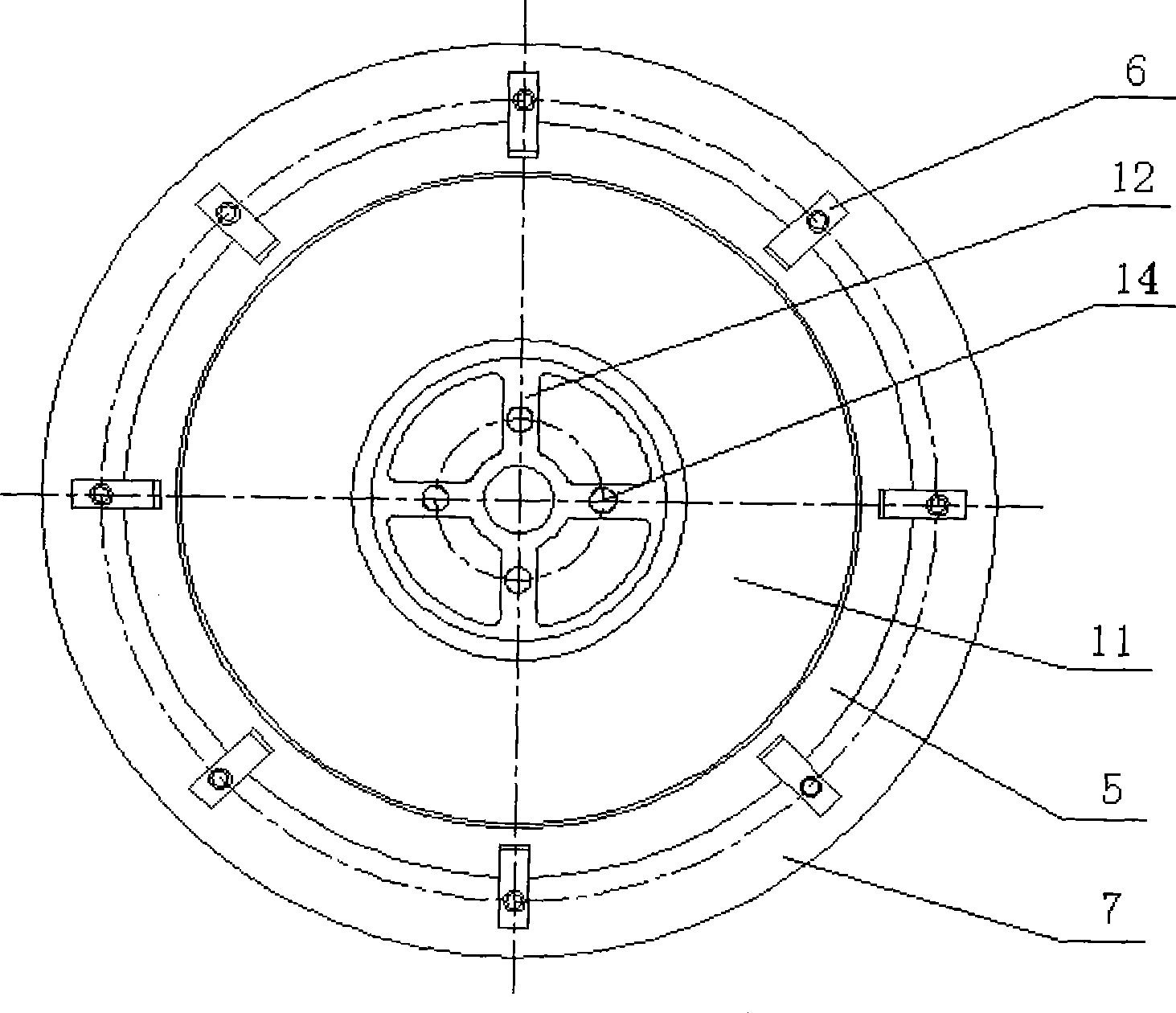

Vertical type method for processing nozzle cooling channel of liquid-propel land rocket engine

InactiveCN101412122AImprove smoothnessHigh-precision digital processingAutomatic control devicesMeasurement/indication equipmentsData setLaser sensor

The invention relates to a method for vertically processing a cooling passage of a liquid rocket engine thrust jet, which belongs to the processing method field of liquid rocket engine thrust jet. In the invention, the thrust jet adopts a vertical clamp; a single-point laser sensor scans bus bars strip by strip to acquire the actual profile of the thrust jet and a sampled data set to reconstruct the bus bars of the thrust jet strip by strip; the buses of the sampled data set are smoothed strip by strip to acquire a thrust jet smoothed data set; the data set of all the bus bars are compressed to acquire a compressed data set; and a cubic spline is used for performing interpolation to approximate the actual bus bars of the thrust jet. The milling tool position is calculated by dual milling head for symmetrical milling and high speed back chipping. The method realizes the integration of measurement and processing, finishes the treatments of profile measurement, milling groove and back chipping by one clamping, can satisfy the processing requirements on different physical dimensions and different bus bar linetypes, has high processing efficiency and good consistency, and realizes the digital processing with high efficiency and high precision of the cooling passage of the liquid rocket engine thrust jet.

Owner:DALIAN UNIV OF TECH

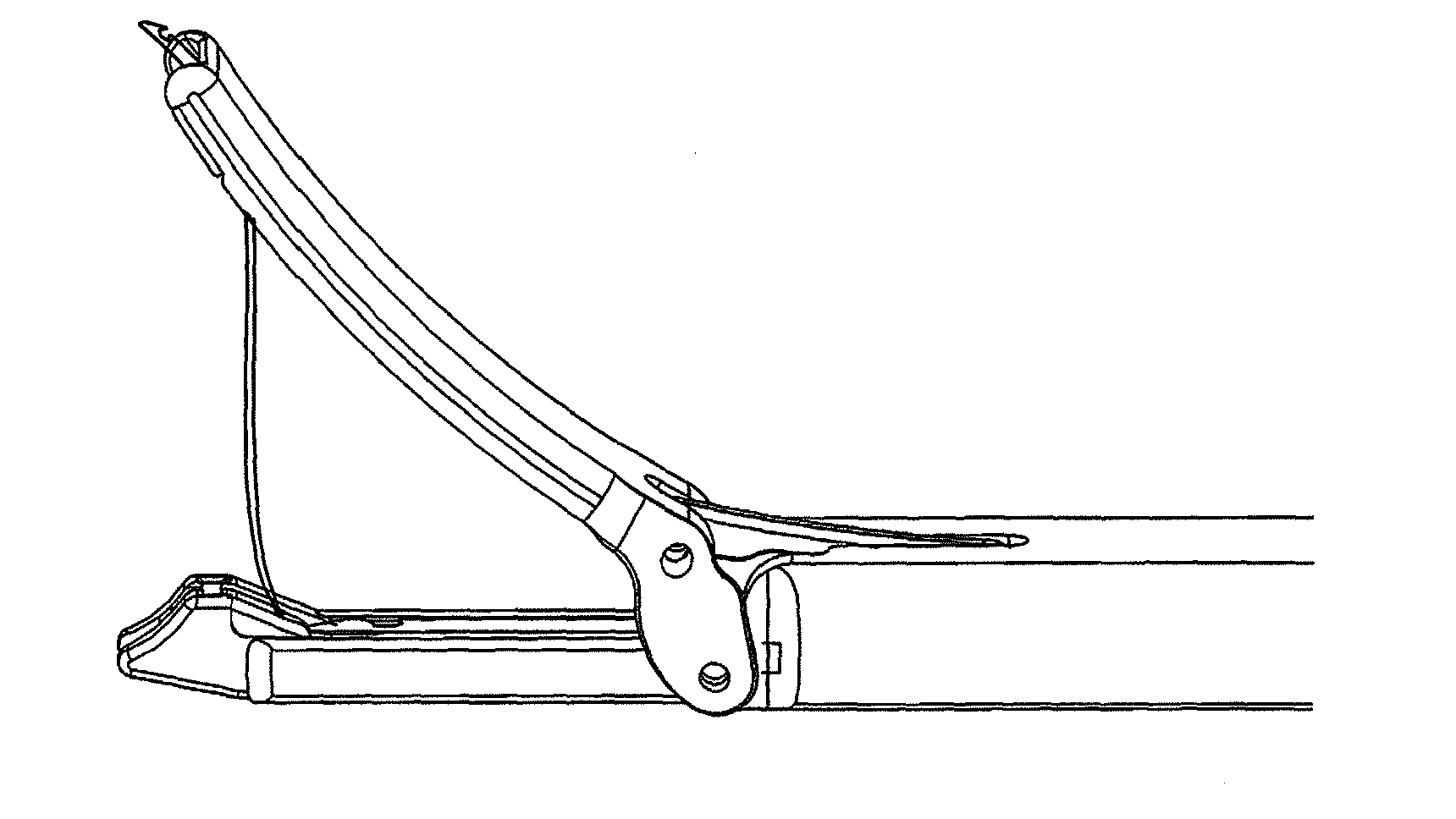

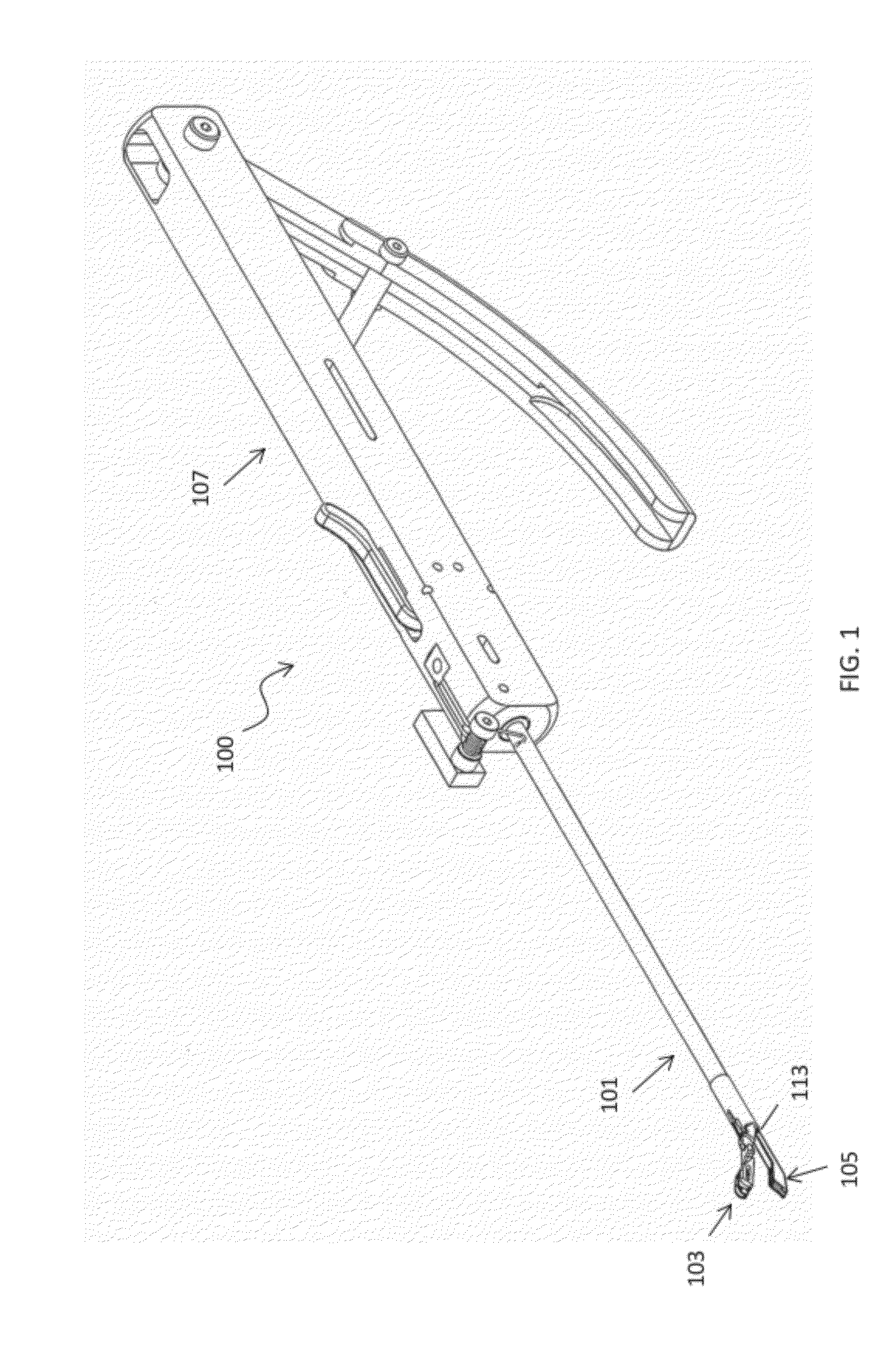

Suture passer devices and methods

ActiveUS20120283753A1Travel can be limitedAvoid elevationSuture equipmentsSurgical needlesPasserGeneral surgery

Devices, systems and methods for passing a suture. In general, described herein are suturing devices, such as suture passers, as well as methods of suturing tissue. These suture passing devices are dual deployment suture passers in which a first distal jaw member is moveable at an angle with respect to the longitudinal axis of the elongate body of the device and the second distal jaw member is retractable proximally to the distal end region of the elongate body and / or the first jaw member. Methods of suturing tissue using a dual deployment suture passer are also described.

Owner:CETERIX ORTHOPAEDICS

Electrical connection terminal

ActiveUS8591271B2Simple structureClamp firmlyVehicle seatsTwo pole connectionsElectricityElectrical conductor

An electrical connection terminal provides secure clamping of an electrical conductor and at the same time has a simple structure. Simple and effective conductor guidance is achieved on account of a funnel-like conductor insertion region being composed of an insulating material housing and a contact frame. The contact frame can be of very simple, compact and material-saving design.

Owner:WAGO VERW GMBH

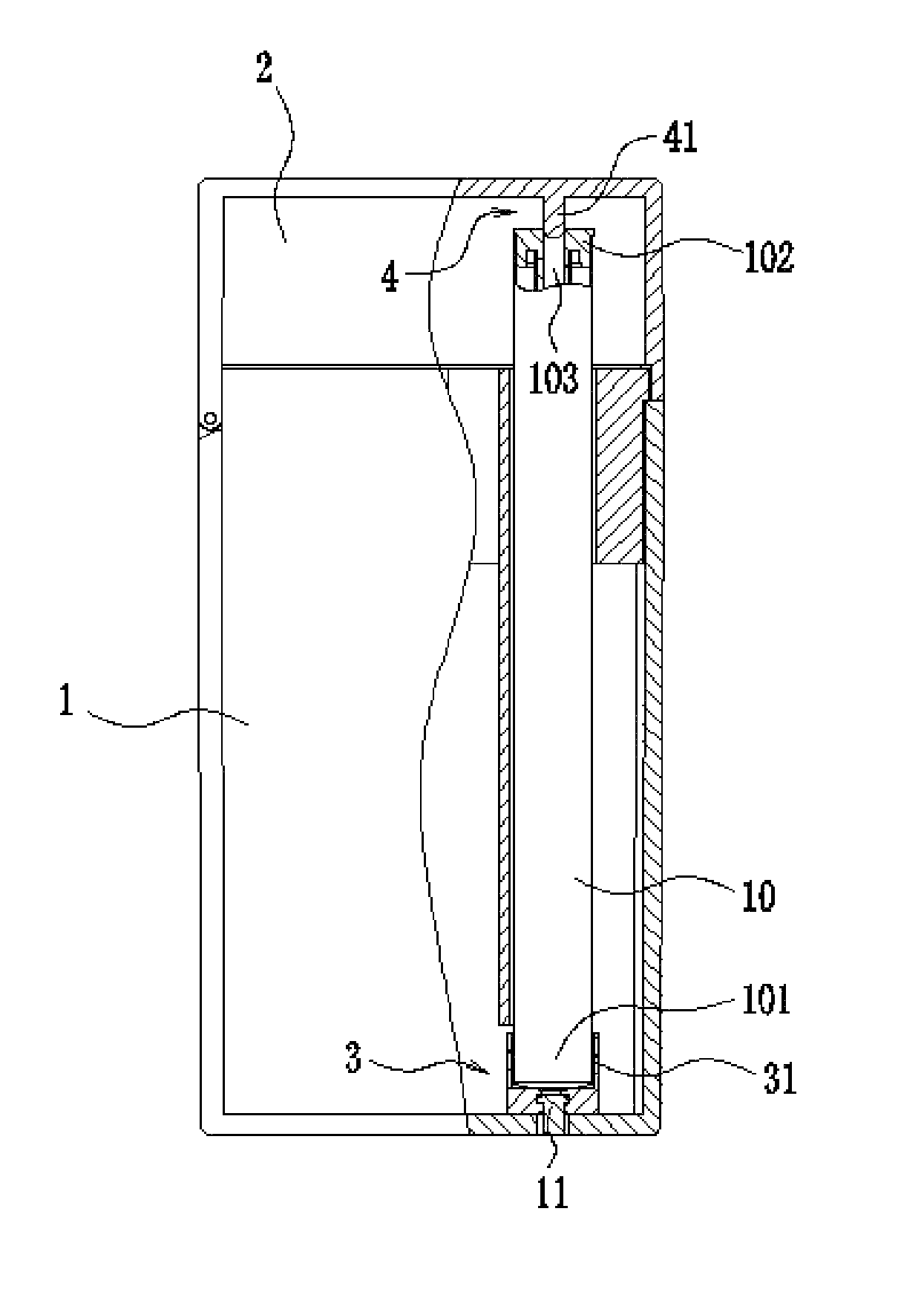

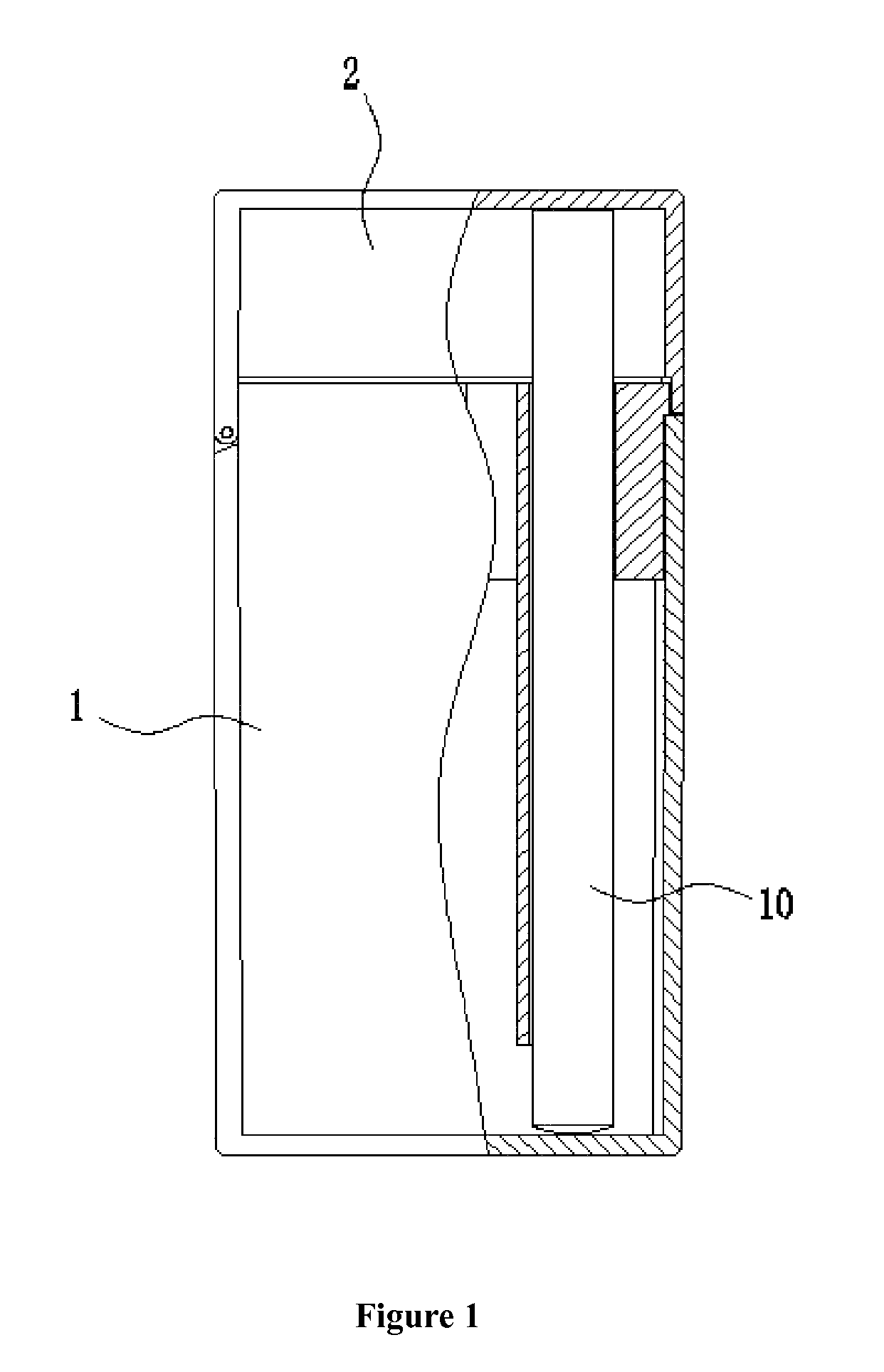

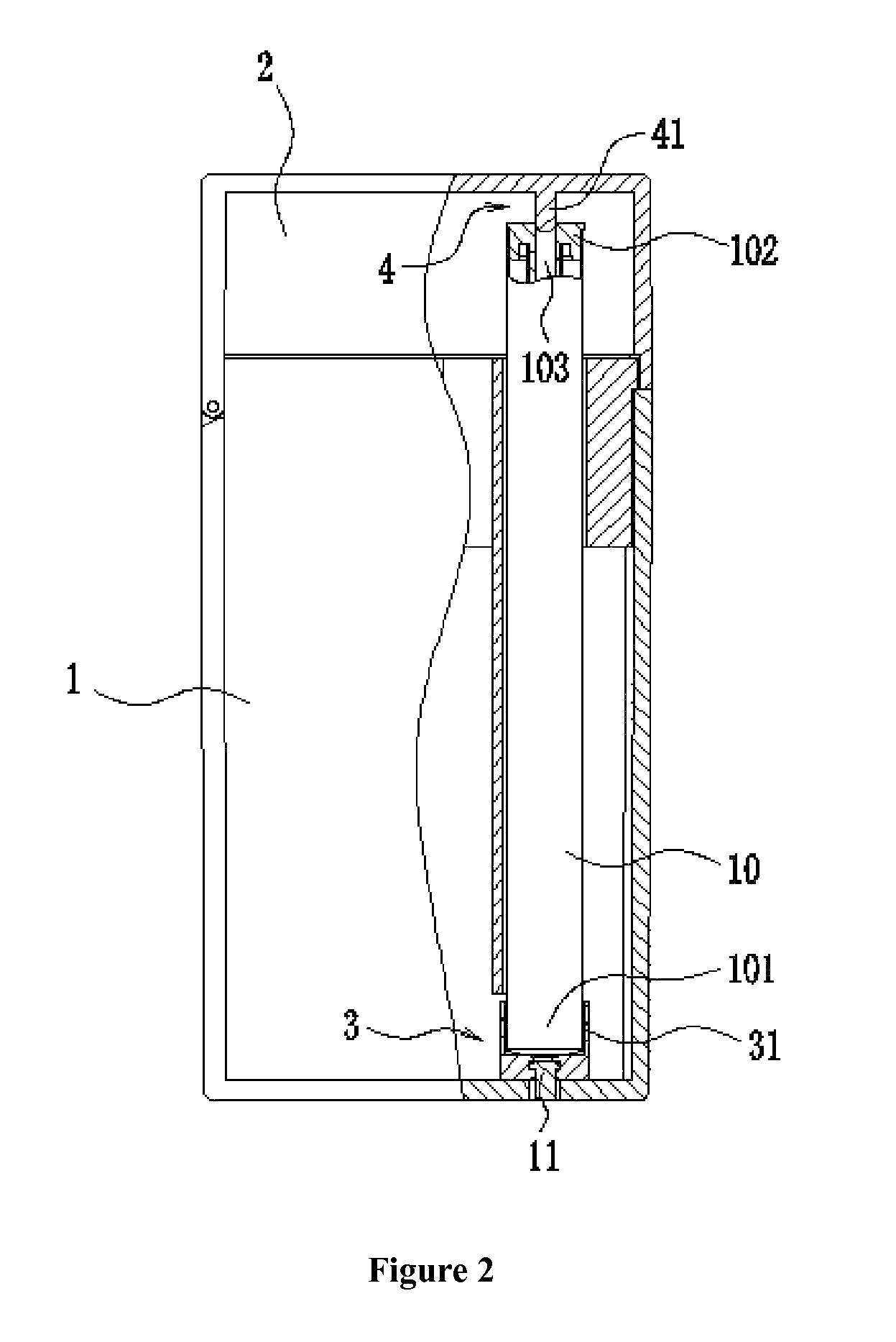

Electronic cigarette box

InactiveUS9198463B2Clamp firmlyEffectively avoid moisture in the airTobacco pipesTobacco devicesElectronic cigaretteEngineering

An electronic cigarette box is provided in the present invention. The electronic cigarette box is configured for receiving electronic cigarettes, and the electronic cigarettes define spiracles for gas circulation. The electronic cigarette box includes sealing devices corresponding to the spiracles, and the sealing devices are configured for sealing the spiracles.

Owner:HUIZHOU KIMREE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com