Back loading high-speed computer panel saw

A computer panel saw, high-speed technology, used in circular saws, sawing components, sawing equipment, etc., can solve problems such as low work efficiency, achieve stable feeding, ensure accuracy, and ensure the effect of cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

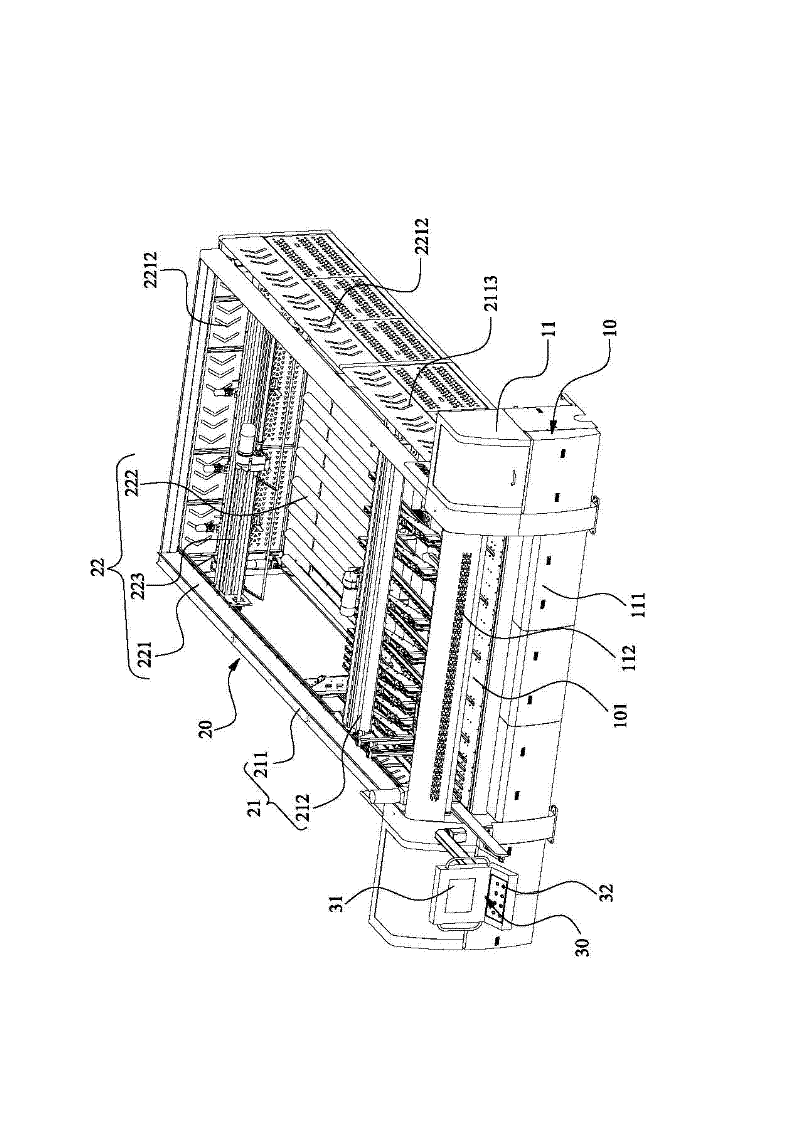

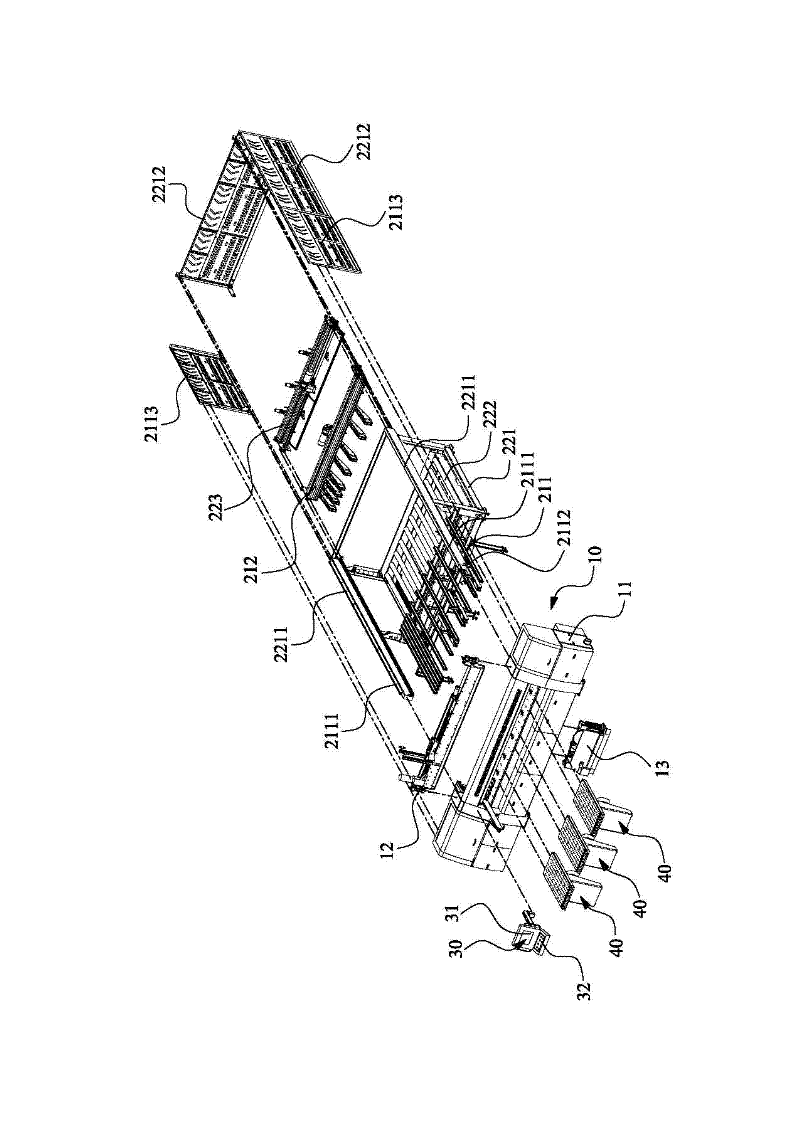

[0076] Please refer to Figure 1 to Figure 16 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a machine body 10 , a feeding unit 20 and a computer control system 30 .

[0077] Wherein, the machine body 10 includes a workbench 11, a pressing device 12 for pressing and positioning the sheet on the workbench 11, and a cutting device for cutting the sheet on the workbench 11. The device 13, the pressing device 12 and the cutting device 13 are all installed on the workbench 11.

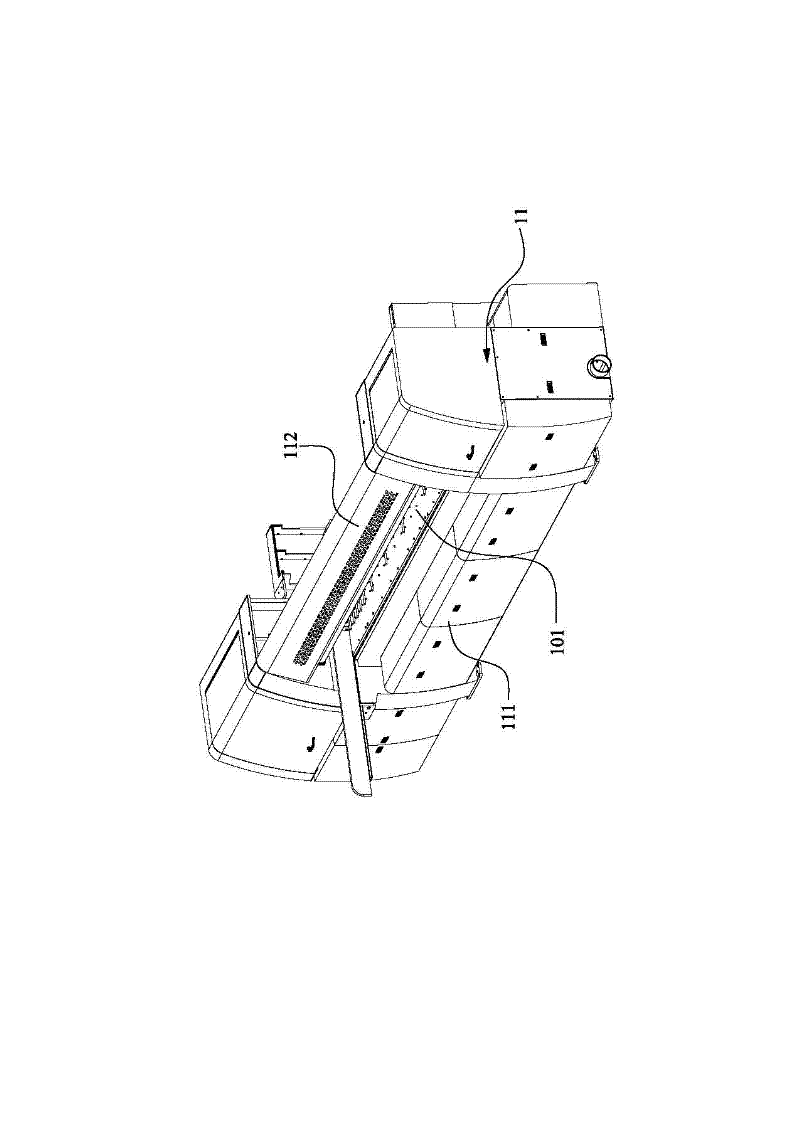

[0078] Such as image 3 As shown, the workbench 11 includes a saw base 111 and a cover 112 arranged on the saw base 111. A channel 101 for the board to pass is formed between the cover 112 and the saw base 111. The cut board The material is output forward from the channel 101; as figure 2 As shown, the front side of the workbench 11 is further provided with a discharge table 40, the discharge table 40 is used to accept the output of the channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com