Patents

Literature

2774results about How to "Improve cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

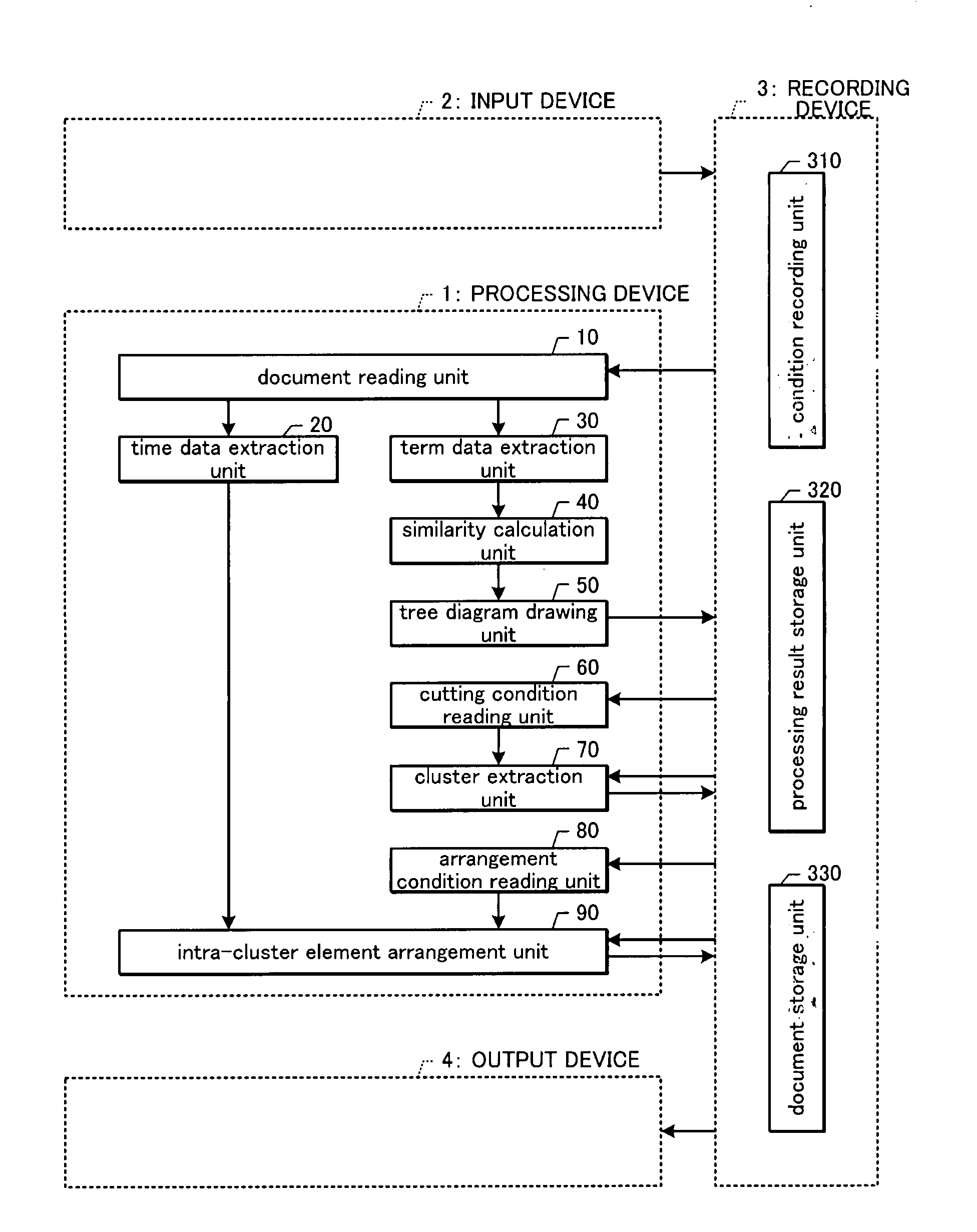

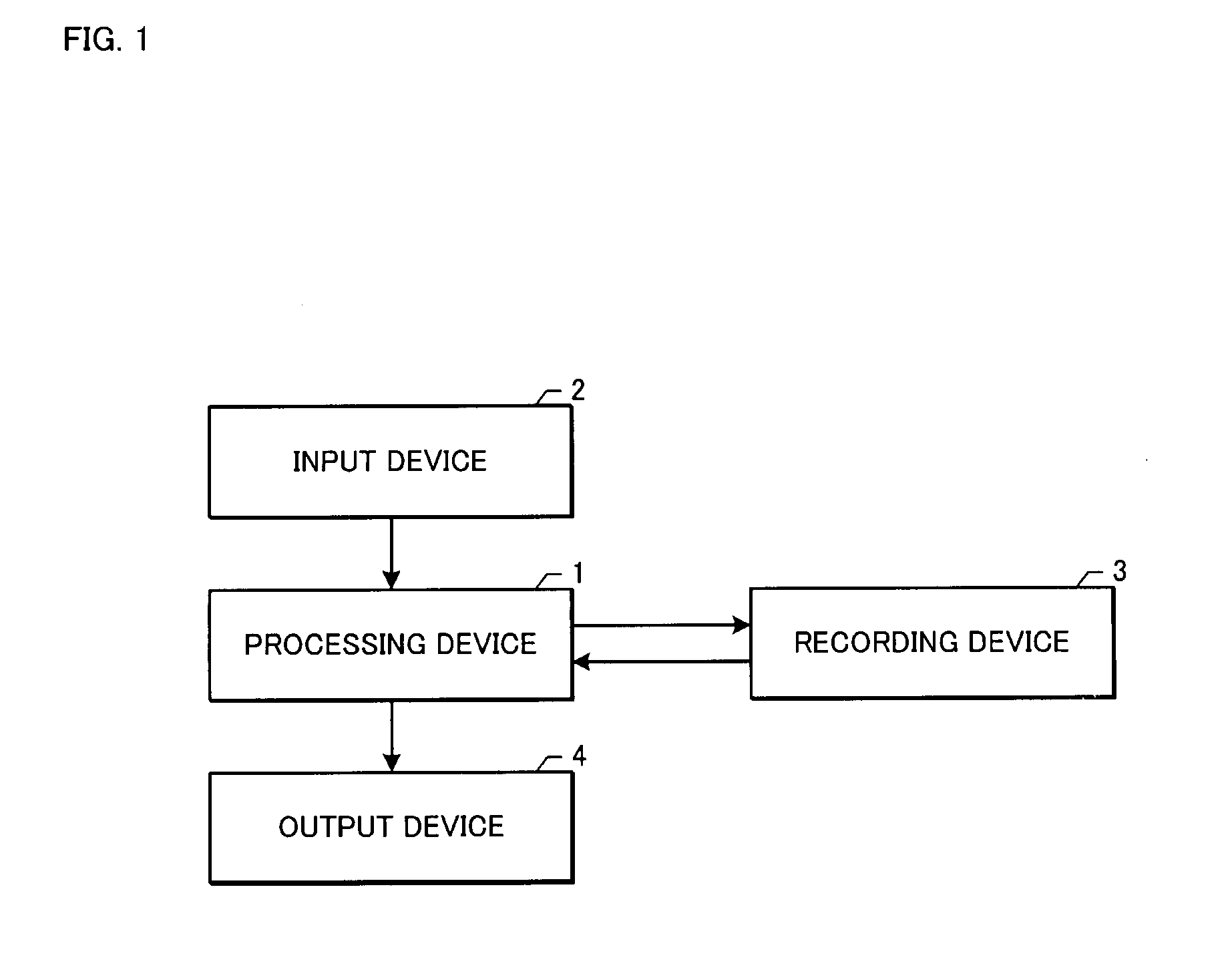

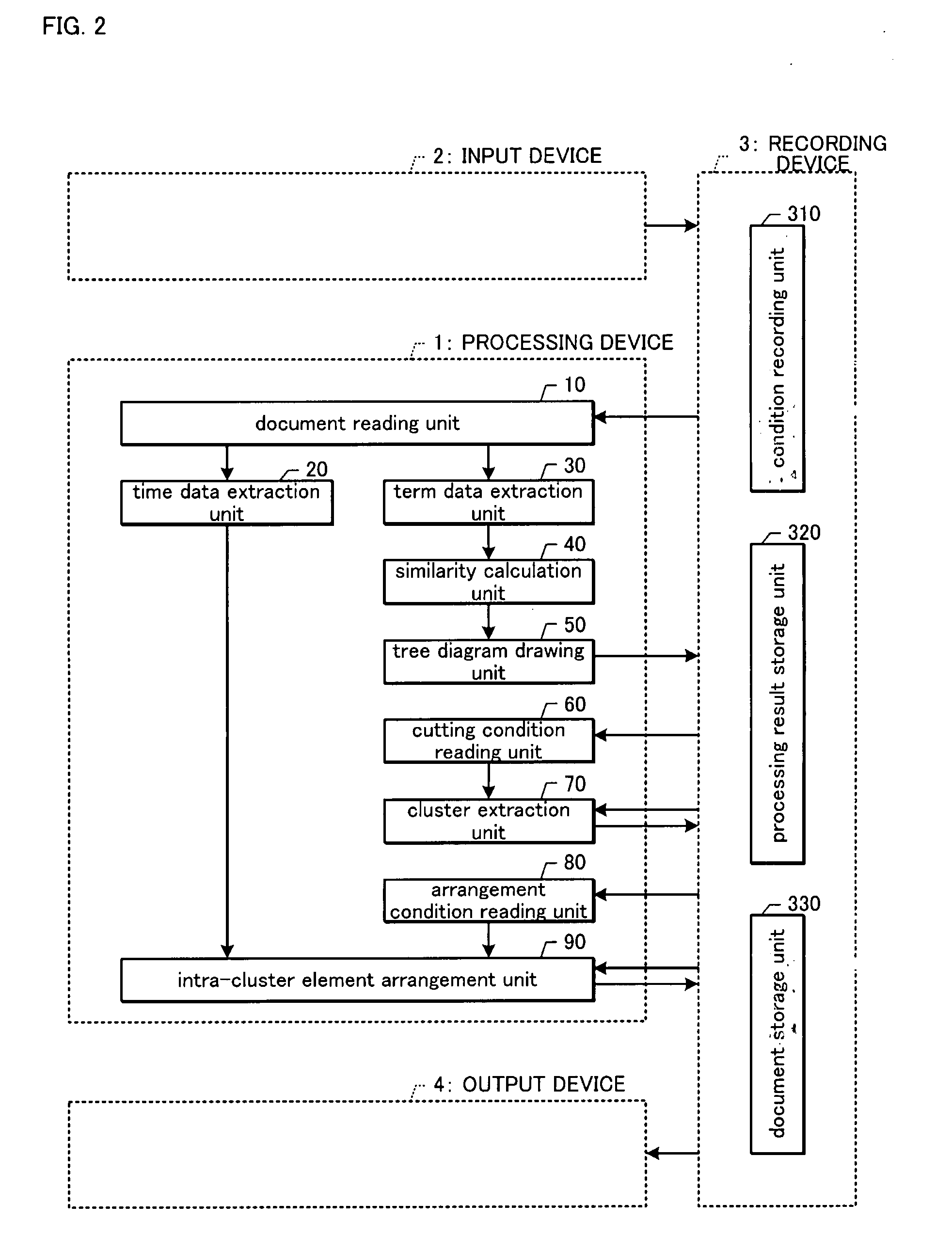

Drawing Device for Relationship Diagram of Documents Arranging the Documents in Chronolgical Order

InactiveUS20080294651A1Improve cutting accuracyImprove reliabilityCharacter and pattern recognitionText database indexingDocument preparationDendrogram

A document correlation diagram drawing device includes extracting means (20, 30) for extracting content data and time data of document elements (E) each including one or more documents, dendrogram drawing means (50) for drawing a dendrogram showing a correlation between documents on the basis of the content data of the document elements, clustering means (70) for cutting the dendrogram in accordance with a predetermined rule and extracting clusters, and intra-cluster arranging means (90) for determining an intra-cluster arrangement of the document elements belonging to each cluster on the basis of the time data of the document elements. Accordingly, a dendrogram adequately showing the chronological development in each field can be automatically drawn.

Owner:INTPROP BANK CORP (JP)

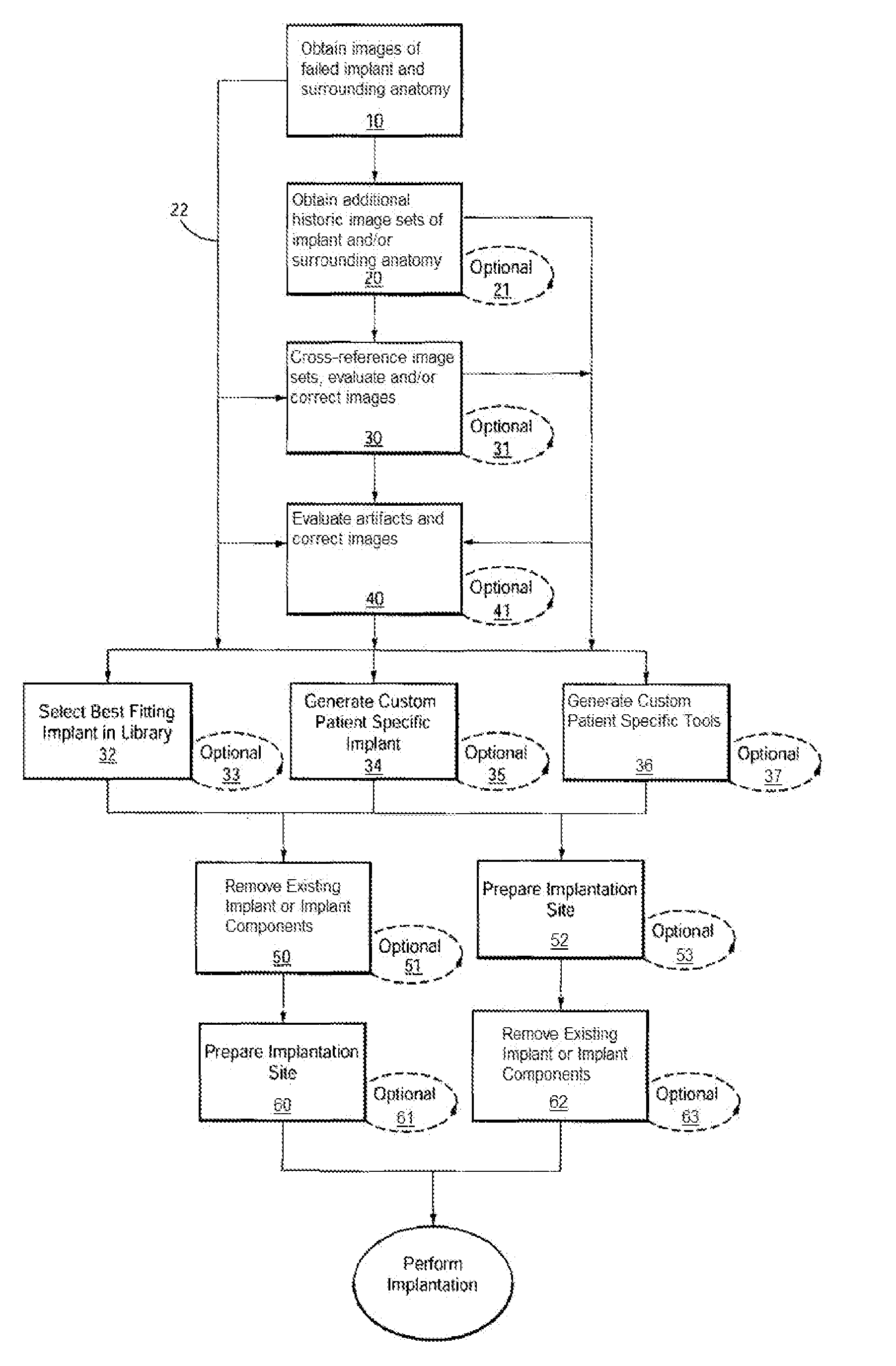

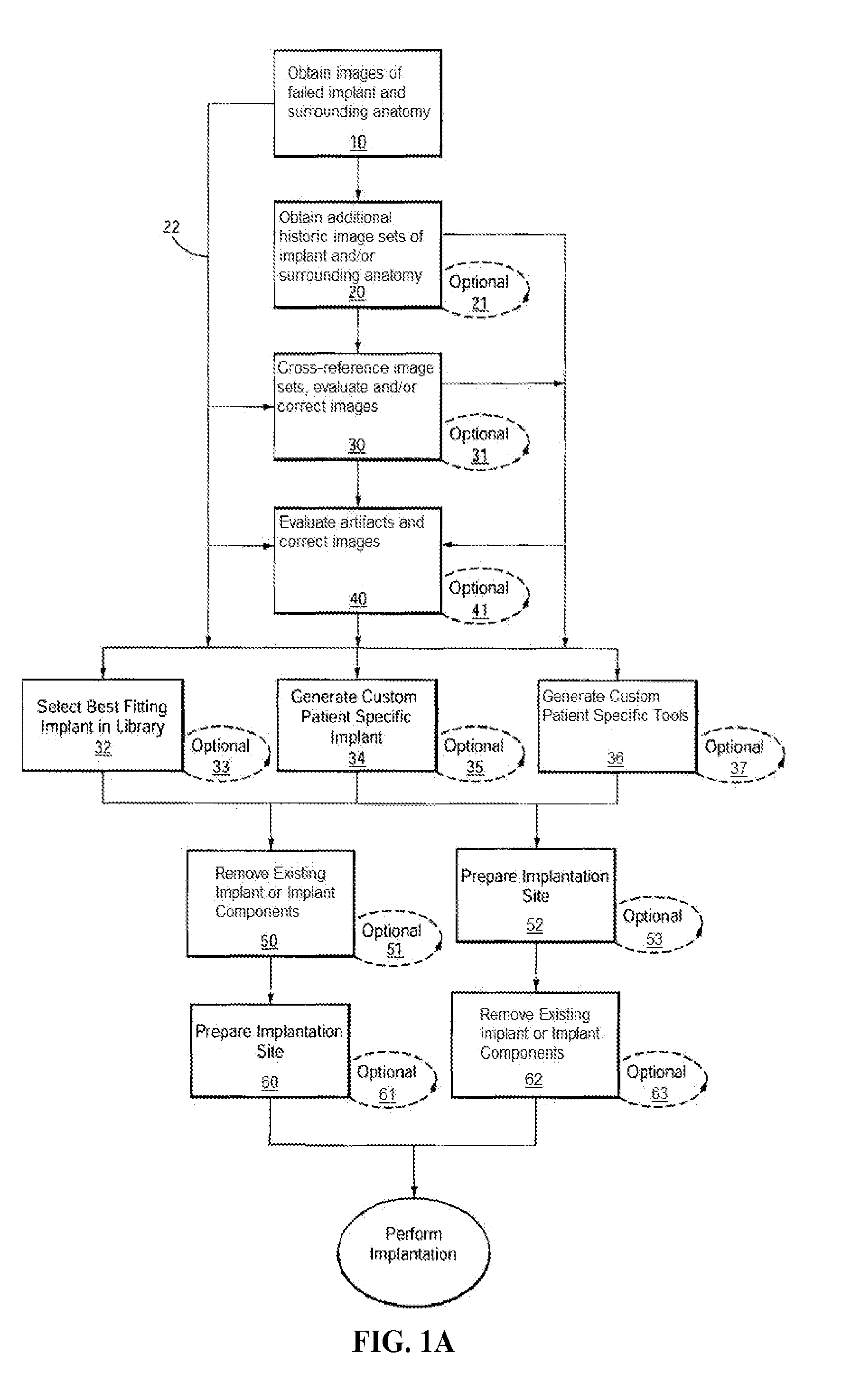

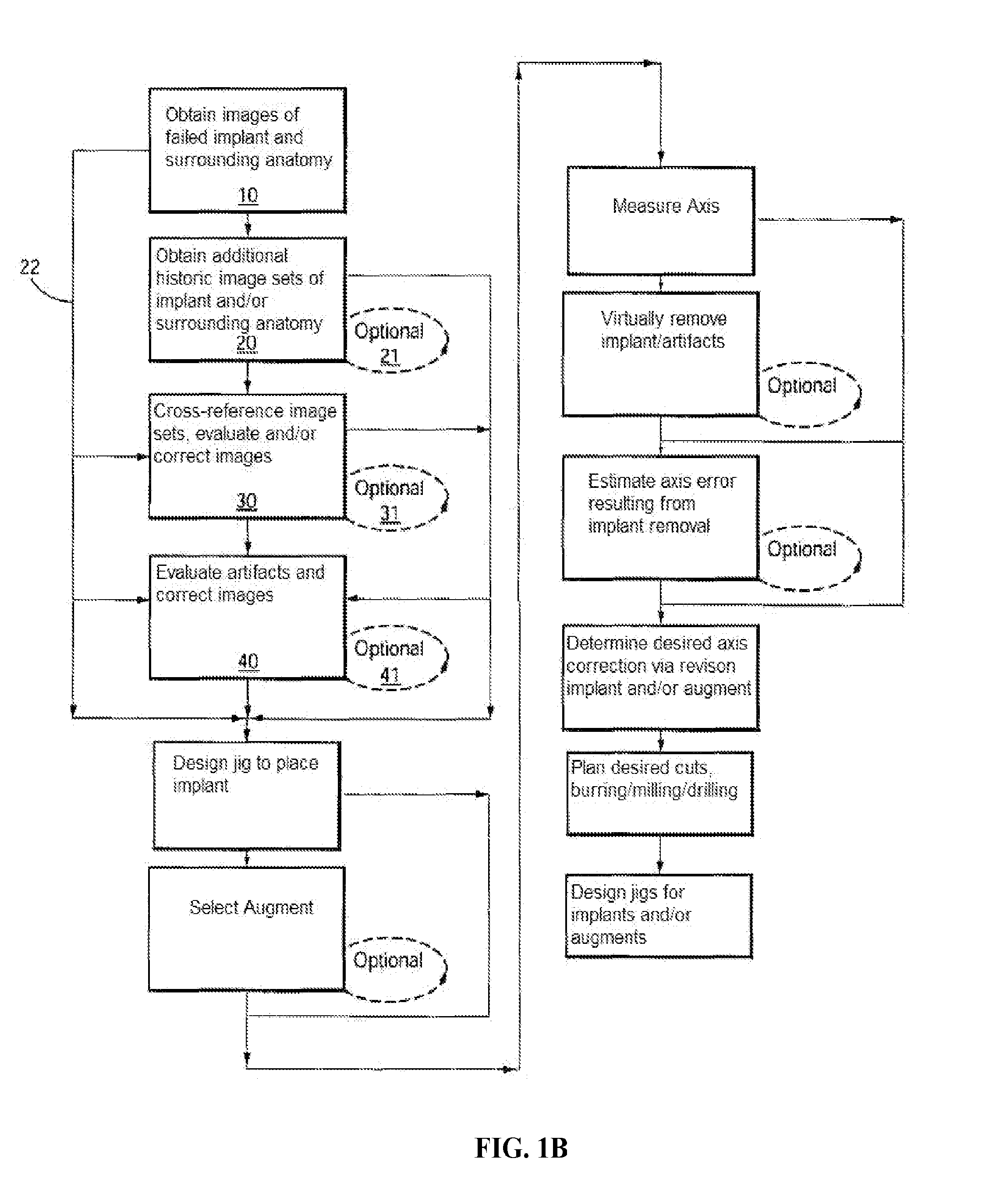

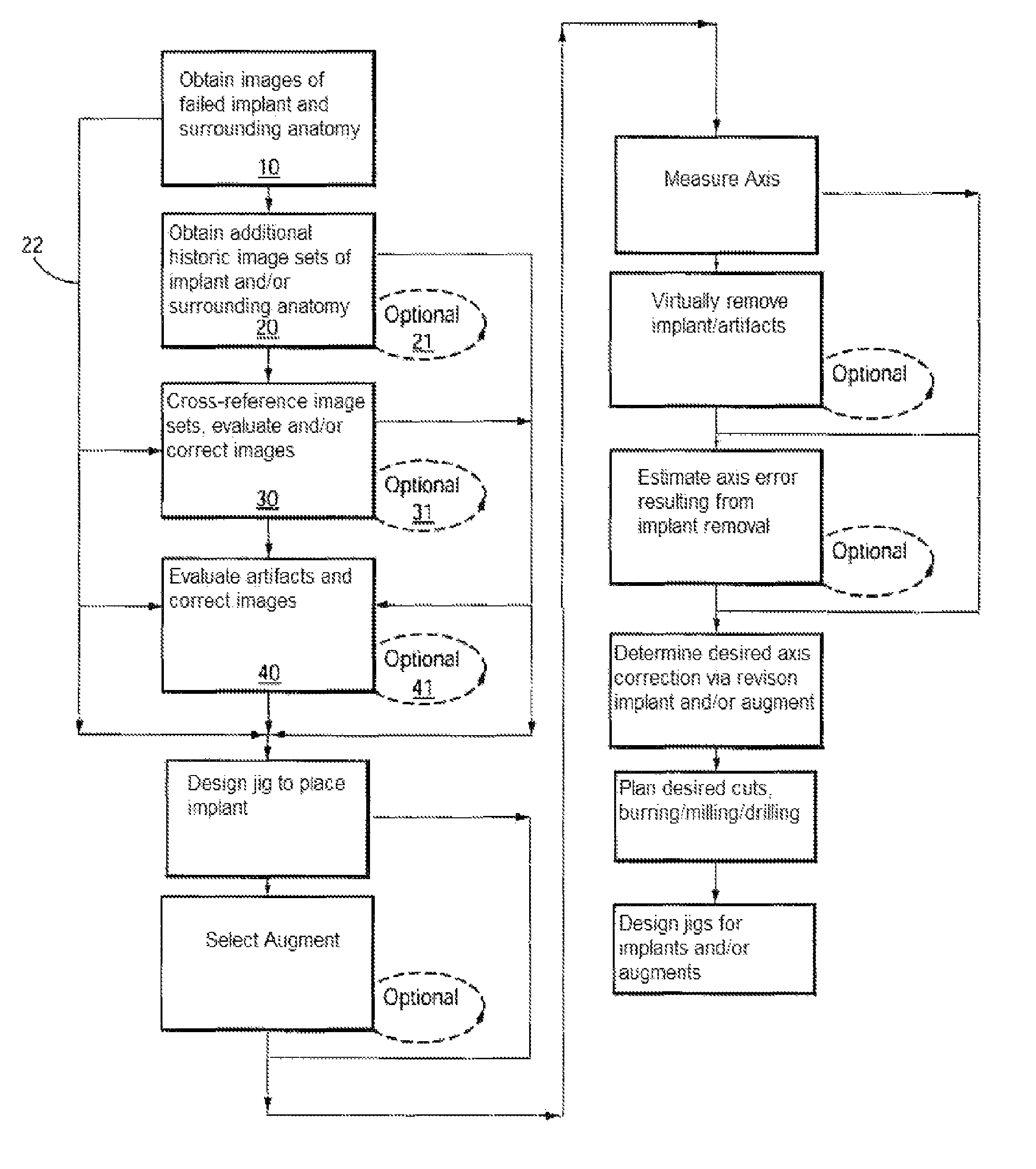

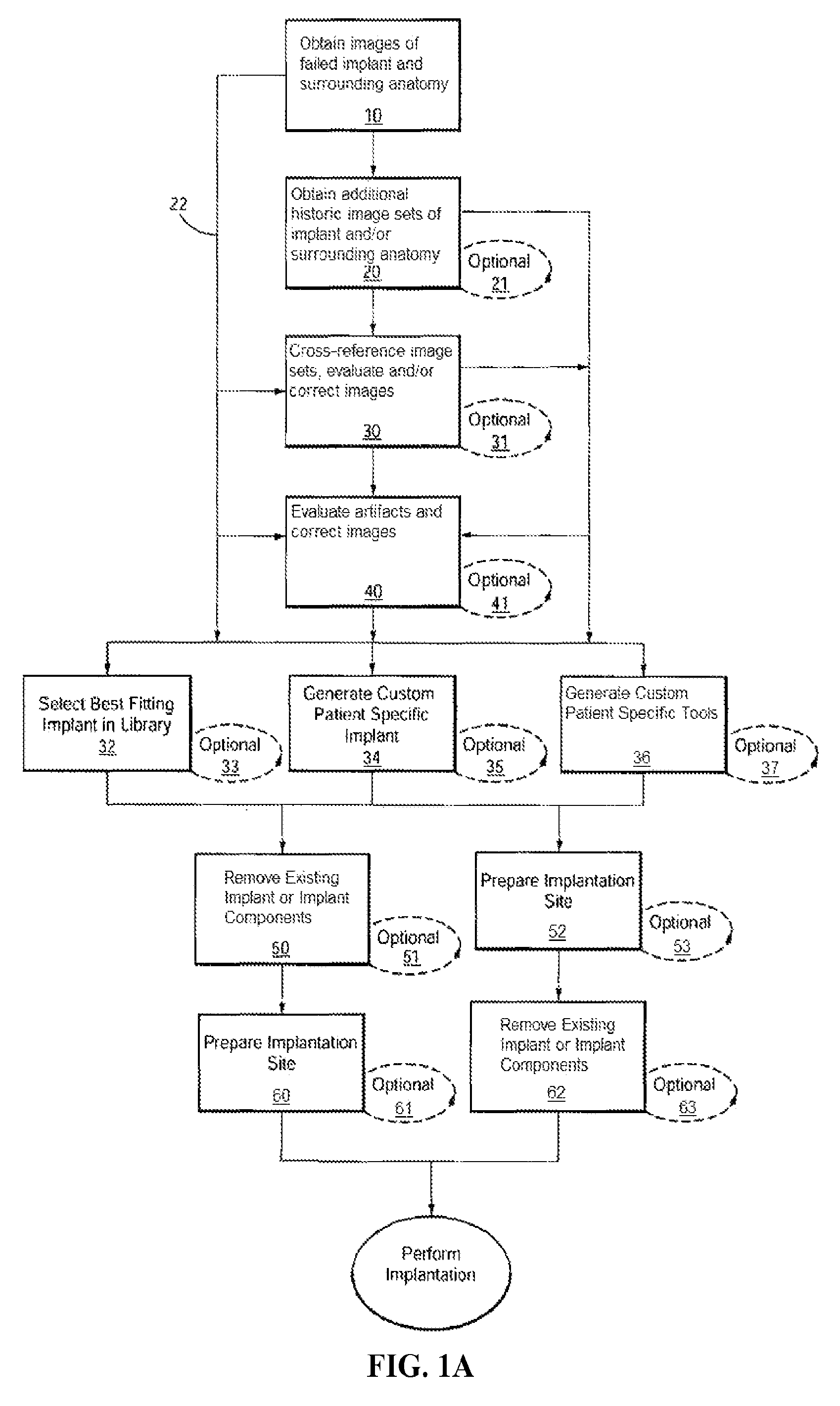

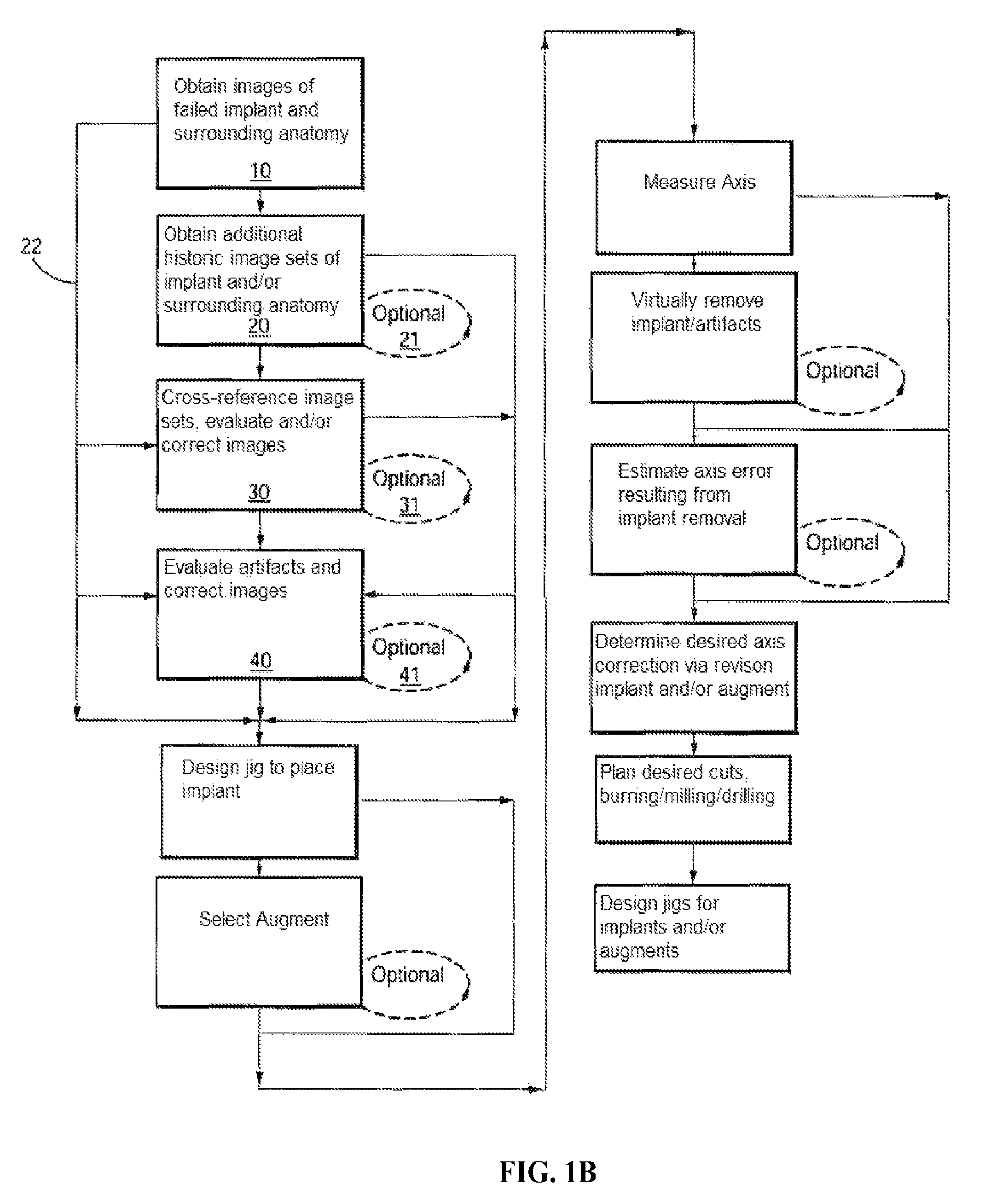

Revision Systems, Tools and Methods for Revising Joint Arthroplasty Implants

ActiveUS20140208578A1Increase accuracy of positioning of revision implantImprove cutting accuracyJoint implantsKnee jointsSacroiliac jointBiomedical engineering

Disclosed herein are methods, compositions and tools for repairing an articular joint having a failed implant. The articular repair systems are customizable or highly selectable by or adaptable to individual patients and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by or adaptable to individual patients to increase the speed, accuracy and simplicity of performing total or partial arthroplasty including revision surgeries.

Owner:CONFORMIS

Surgical suture cutter

InactiveUS20060212045A1Enhanced accuracy of cutEnhance stabilitySuture equipmentsSurgical scissorsSurgical sutureSurgical stapling

A suture cutter having a handle and a barrel with a movable cutting head on the barrel, and the barrel supporting a stationary cutting edge and a movable cutting edge. A movable support carries the movable cutting edge and includes a surface spaced from the stationary cutting edge a selected distance. An abutment wall spaced from the stationary cutting edge at the selected distance provides for snugly restricting movement of the moving cutting edge away from cutting contact with the stationary cutting edge while cutting the suture. Recesses are defined on a guiding support surface along which the movable cutting edge slides when the handle is actuated, allowing for sharpening of the moveable cutting edge when said edge is retracted proximally.

Owner:TELEFLEX MEDICAL INC

Revision systems, tools and methods for revising joint arthroplasty implants

ActiveUS9402726B2Increase accuracy of positioning of revision implantImprove cutting accuracyJoint implantsKnee jointsSacroiliac jointBiomedical engineering

Owner:CONFORMIS

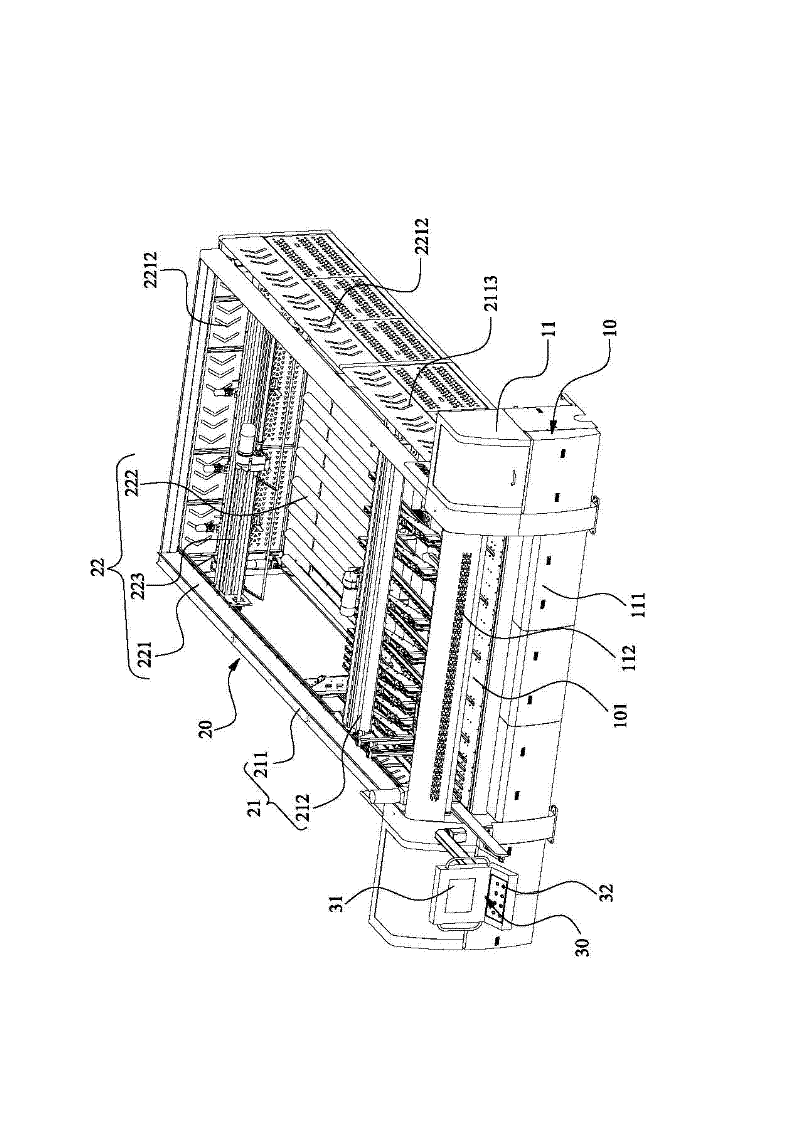

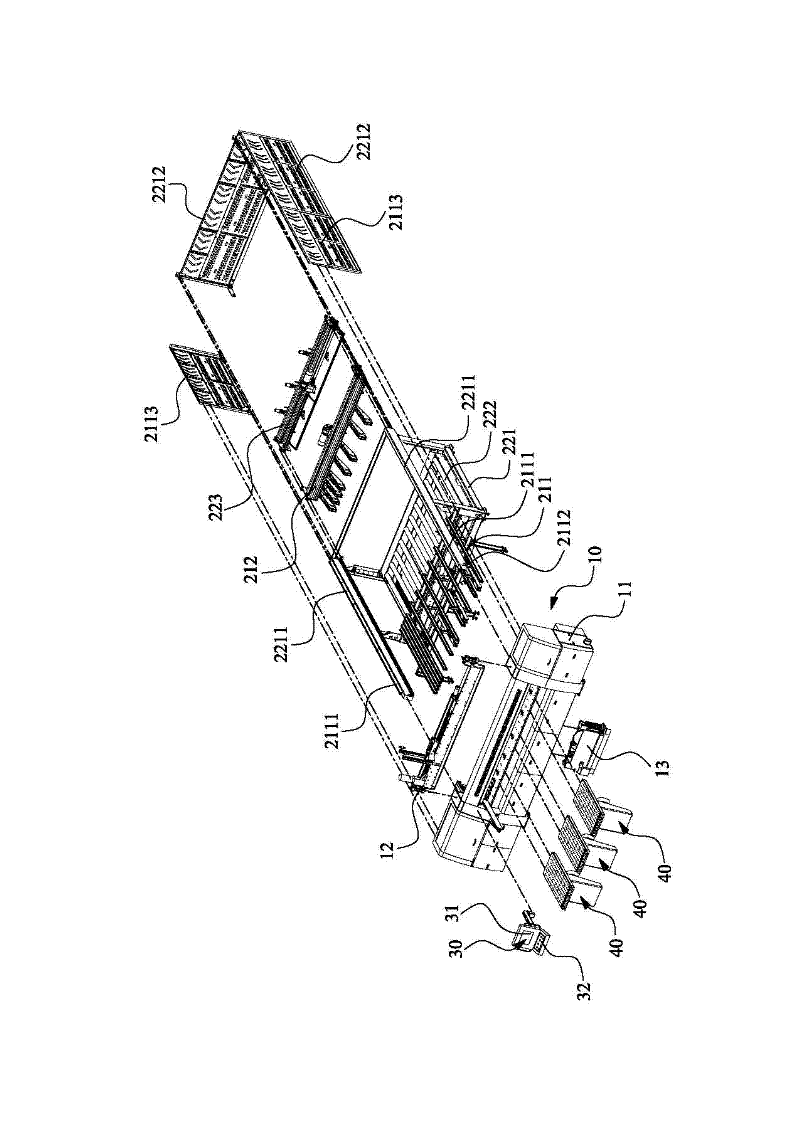

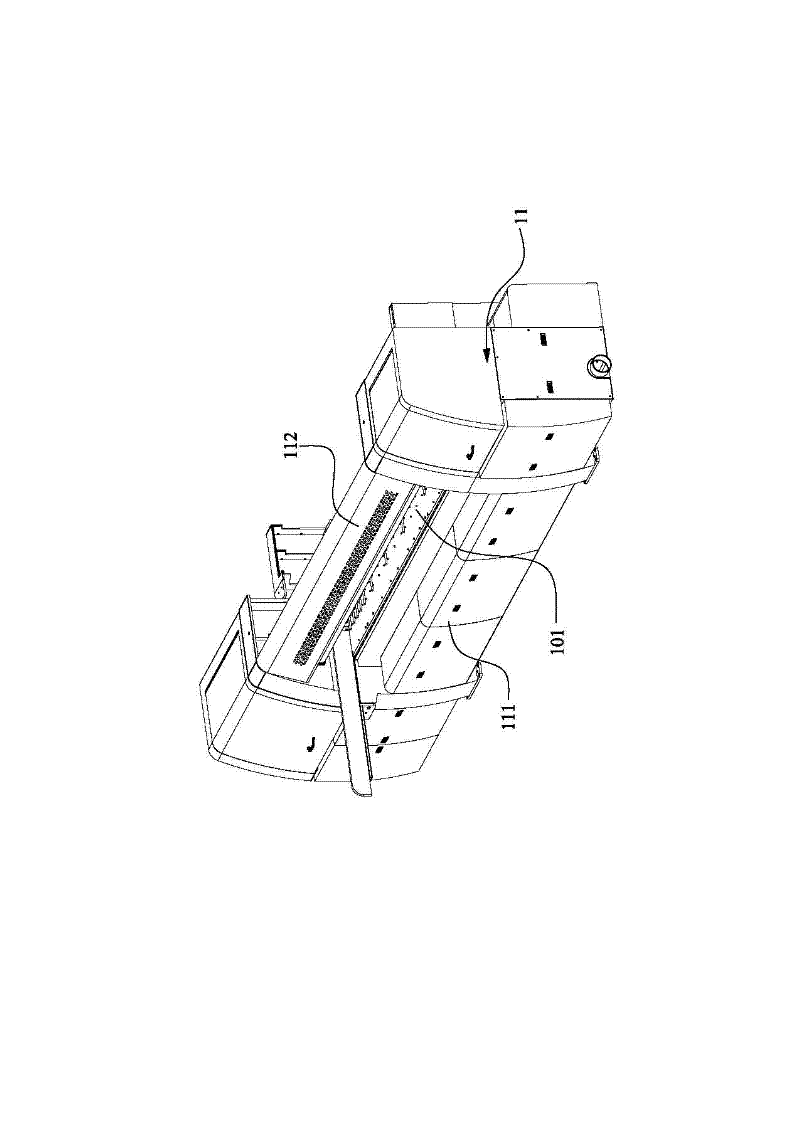

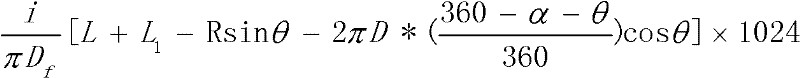

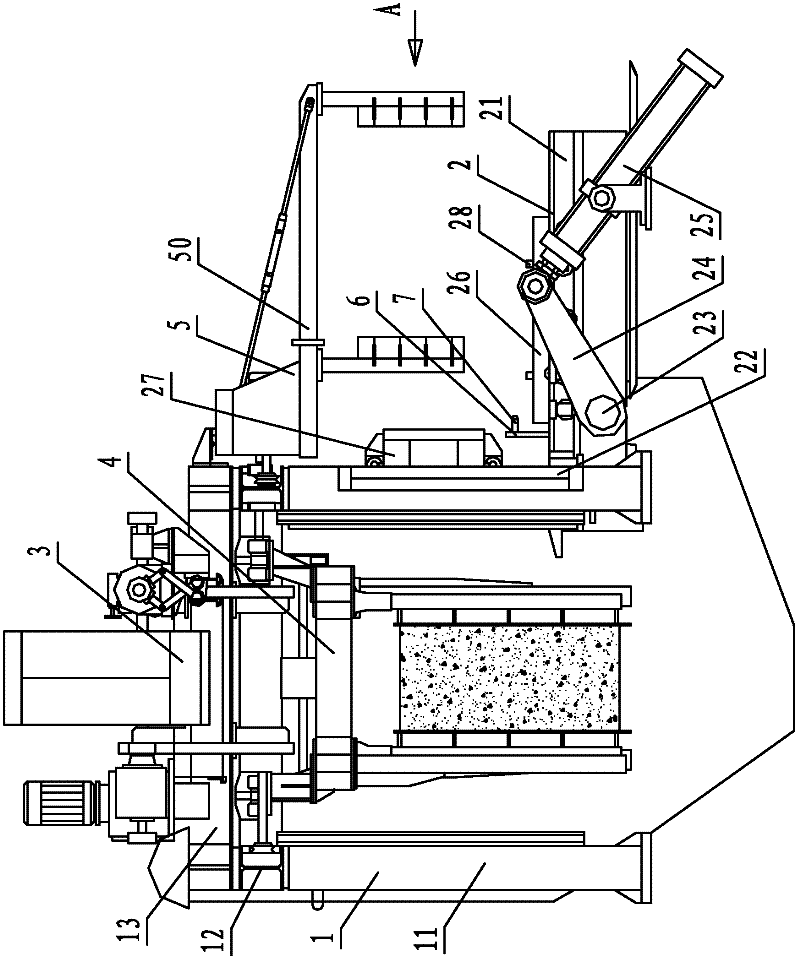

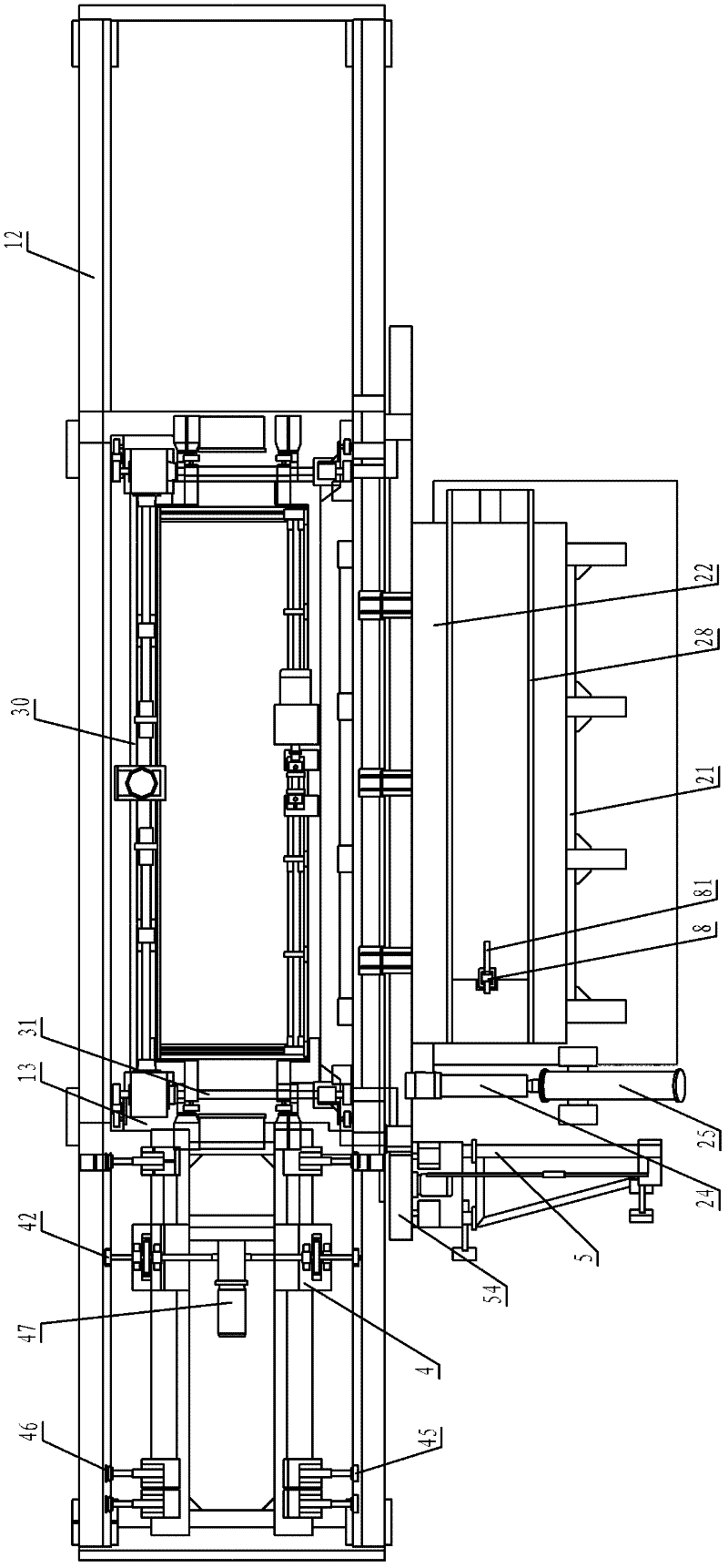

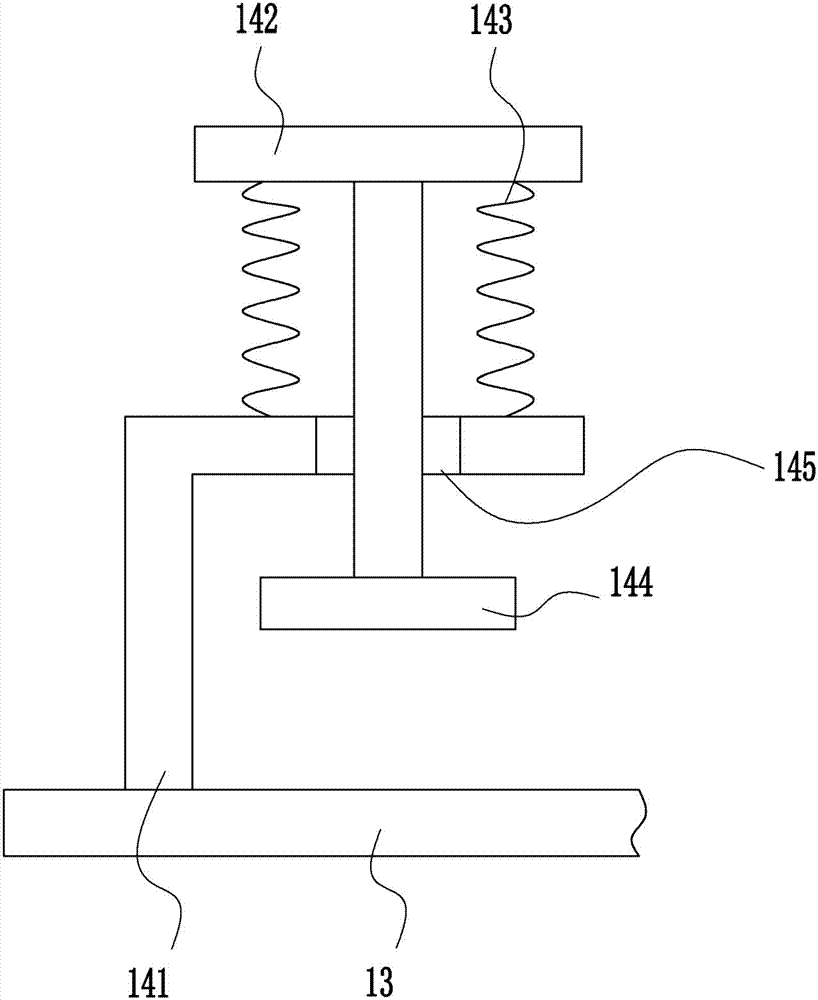

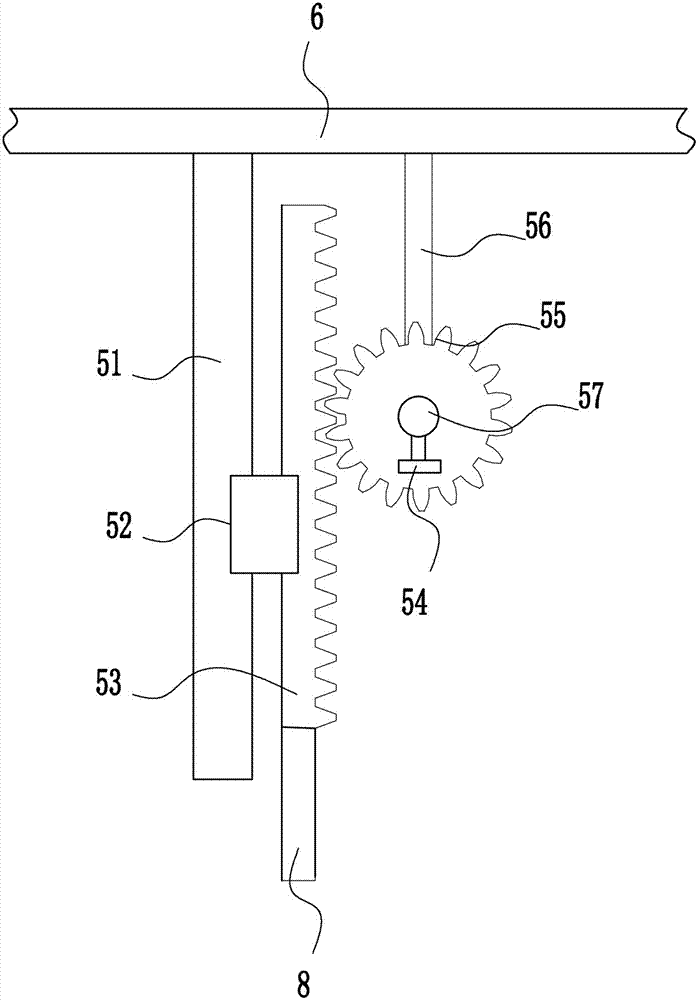

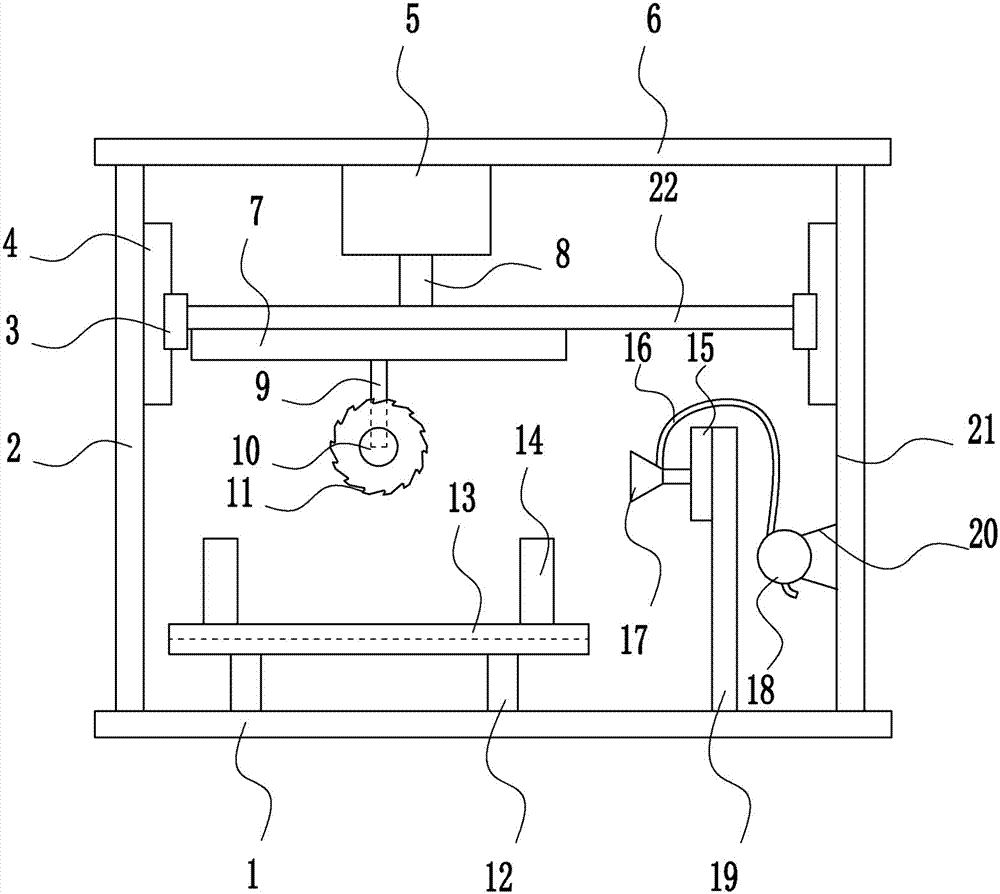

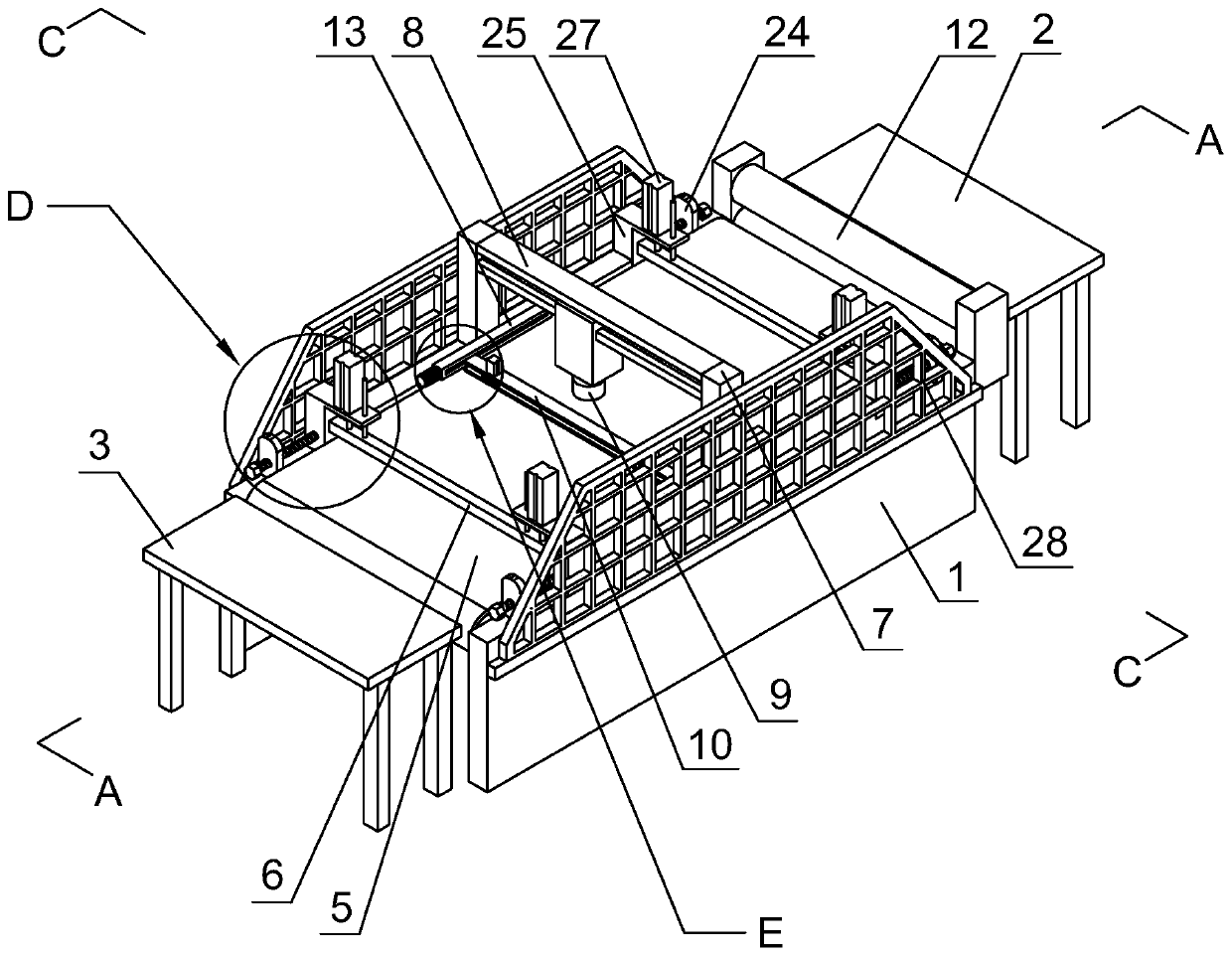

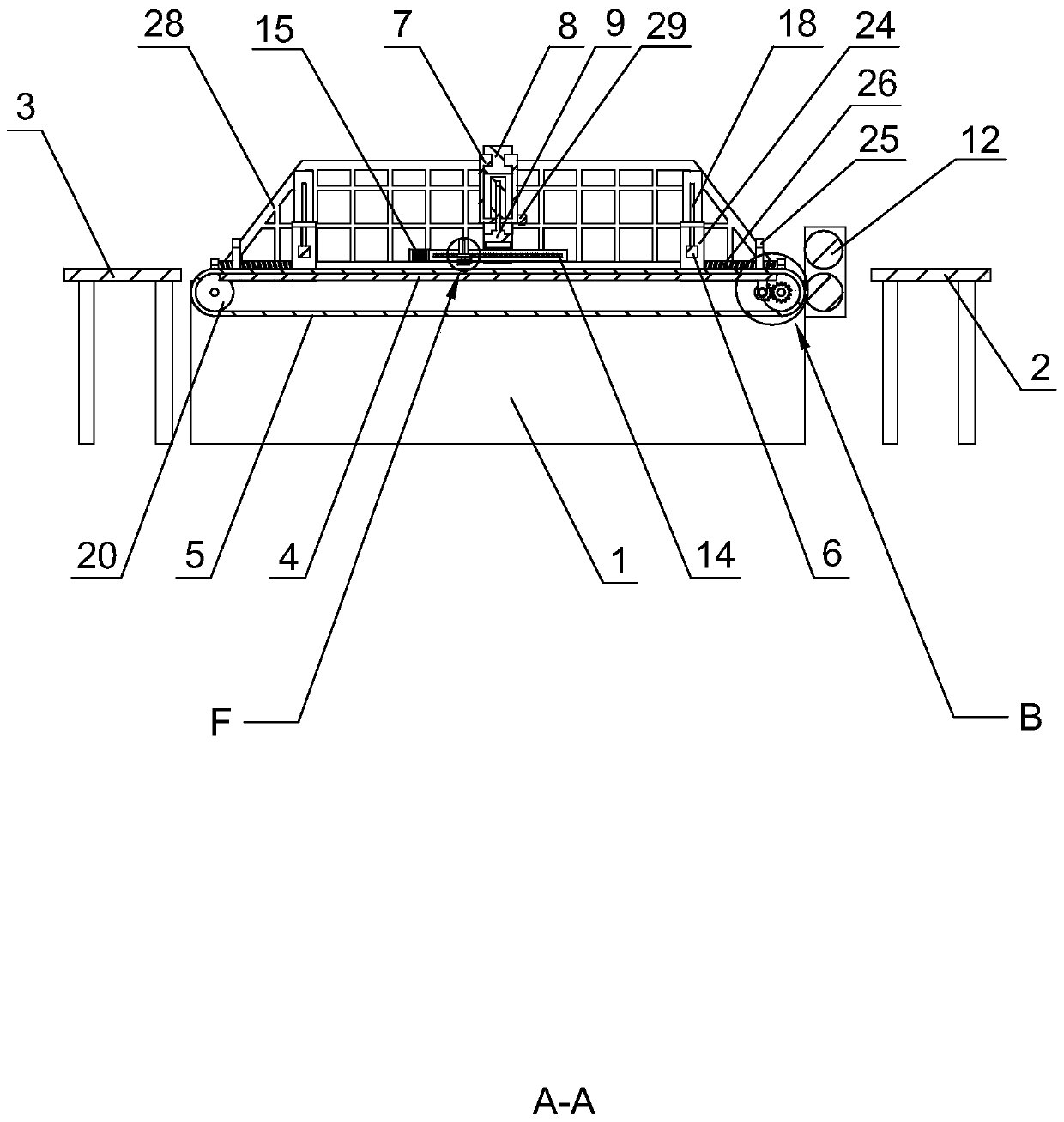

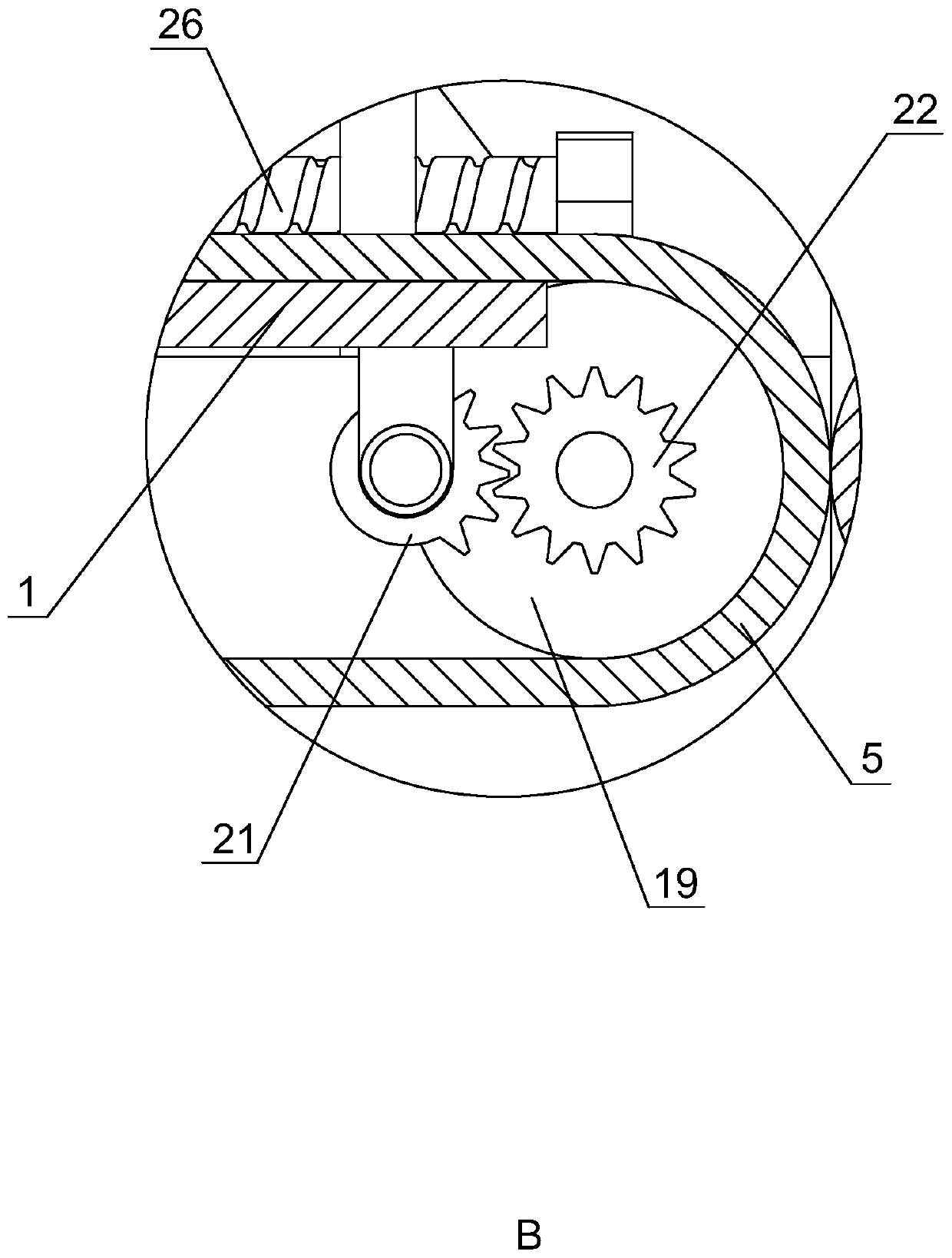

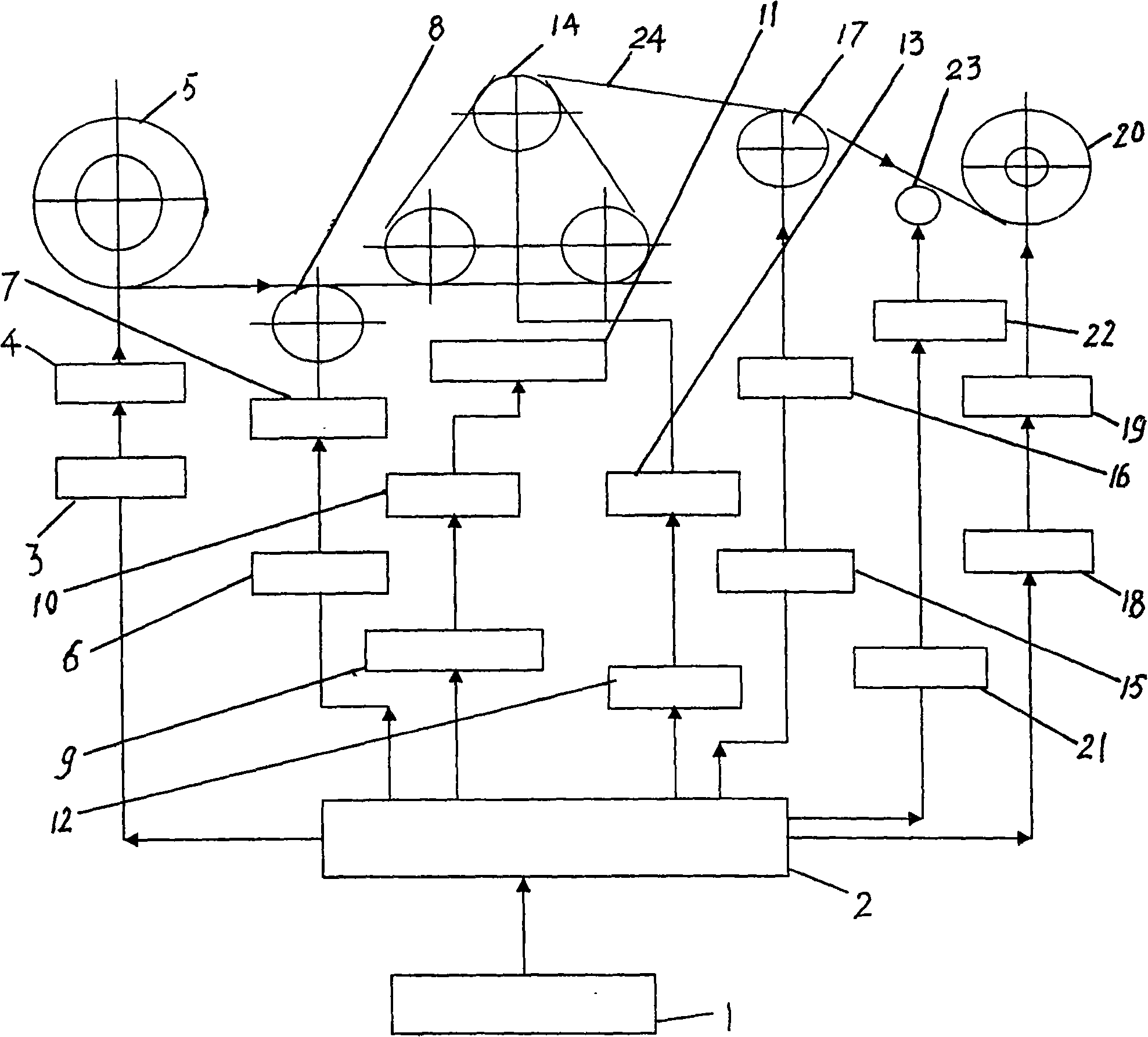

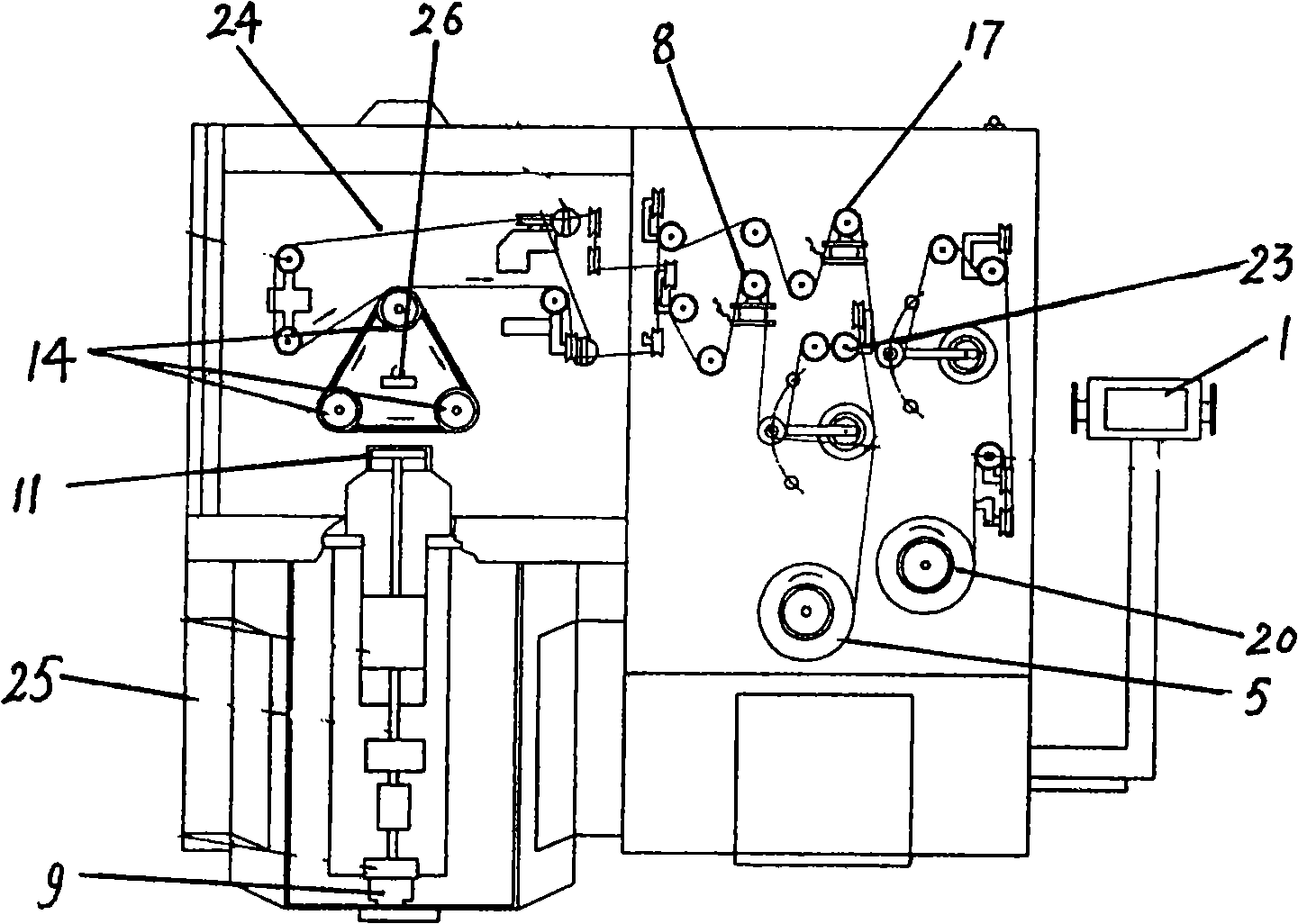

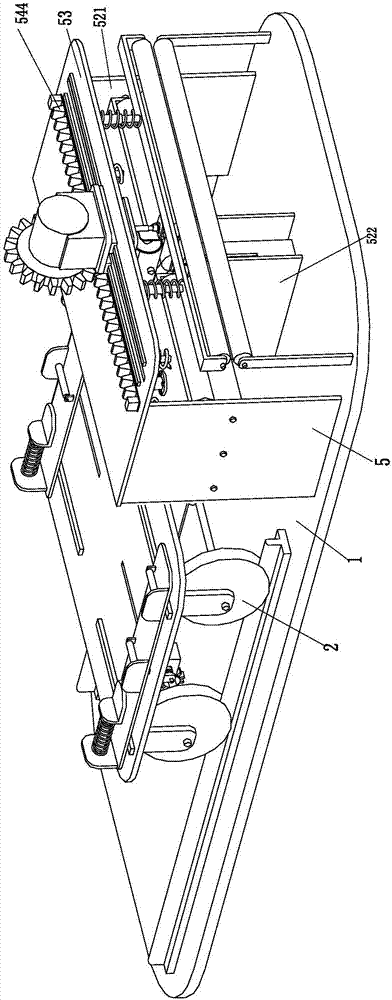

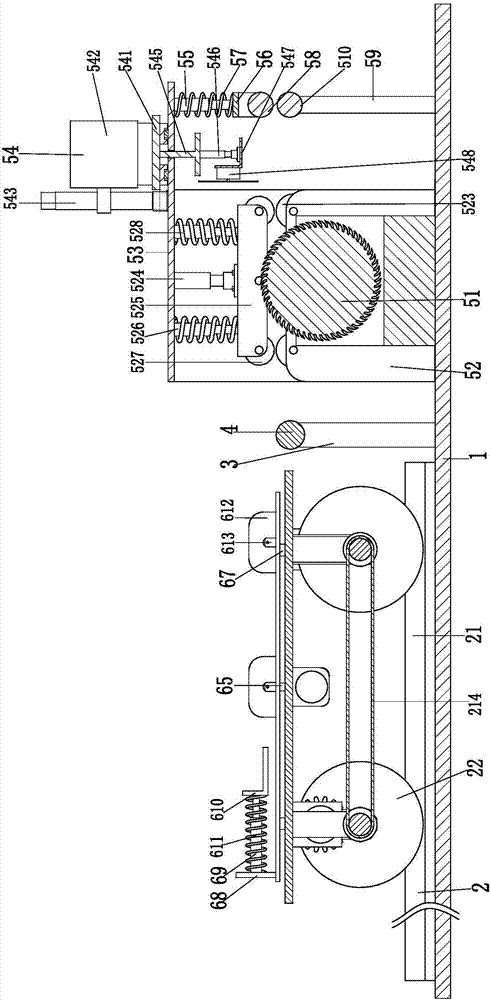

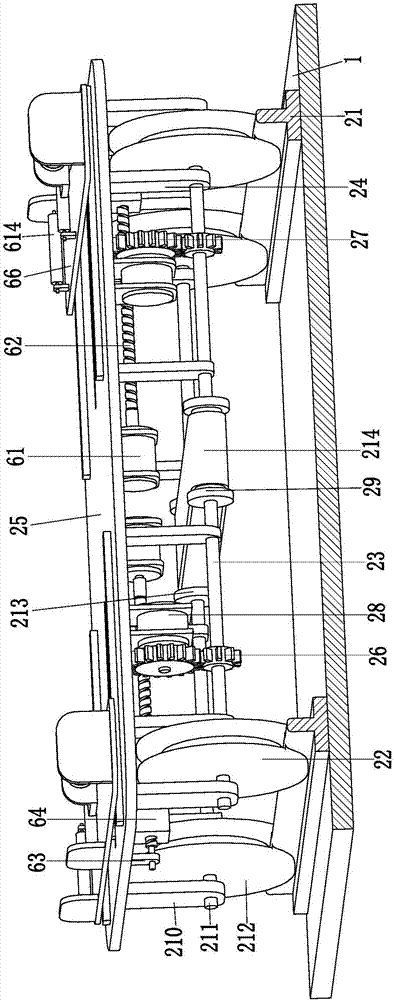

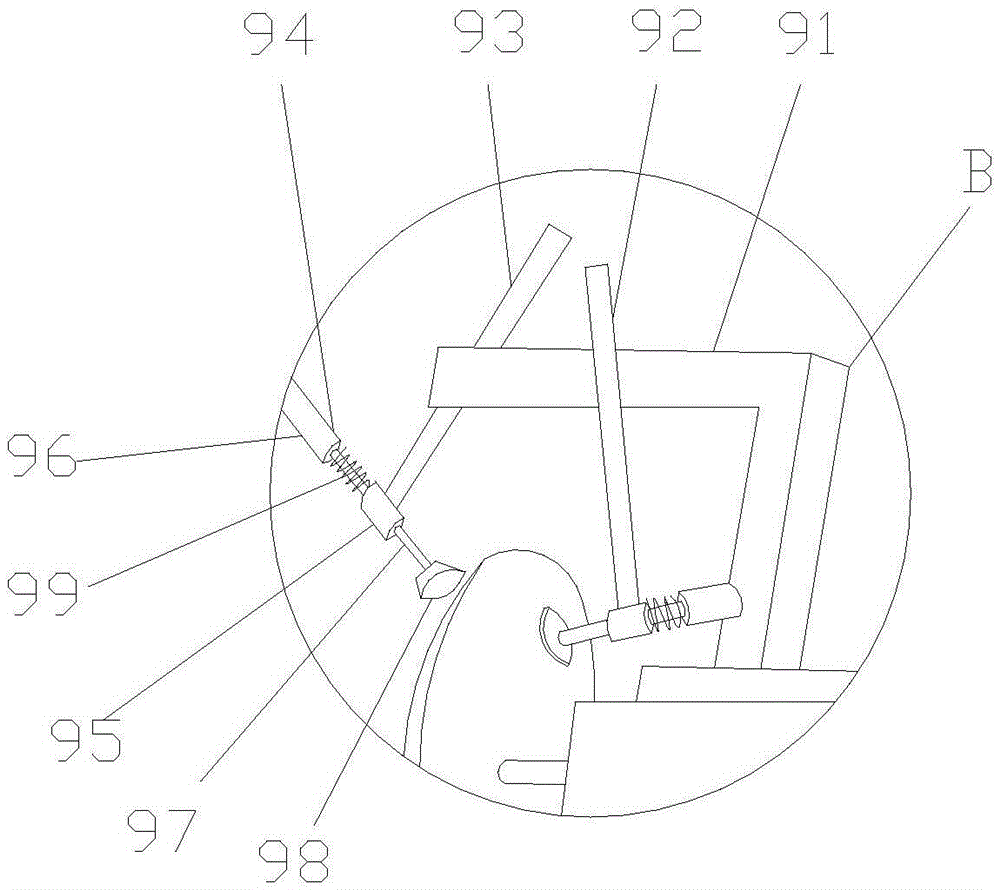

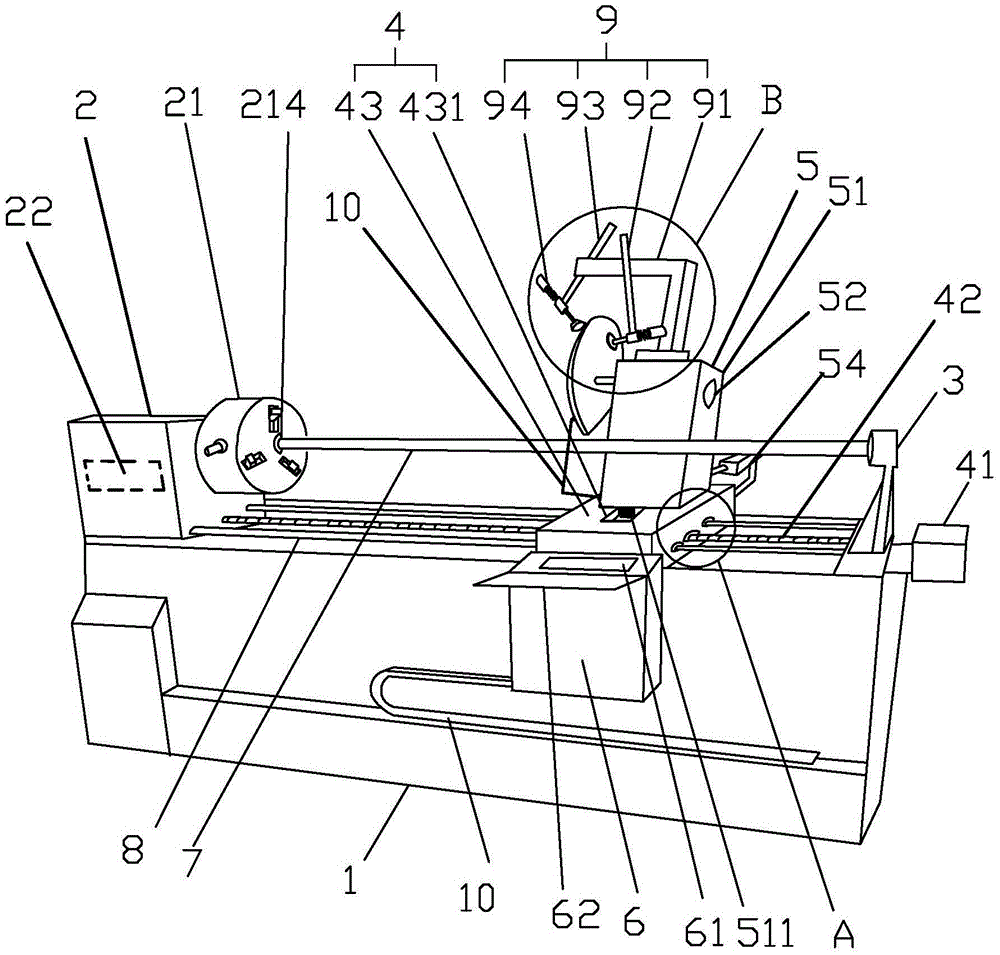

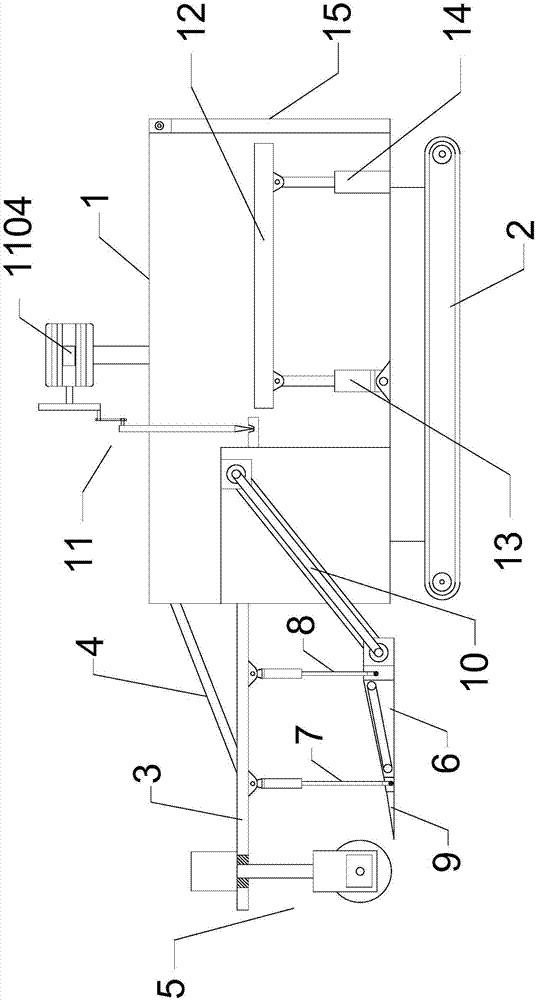

Back loading high-speed computer panel saw

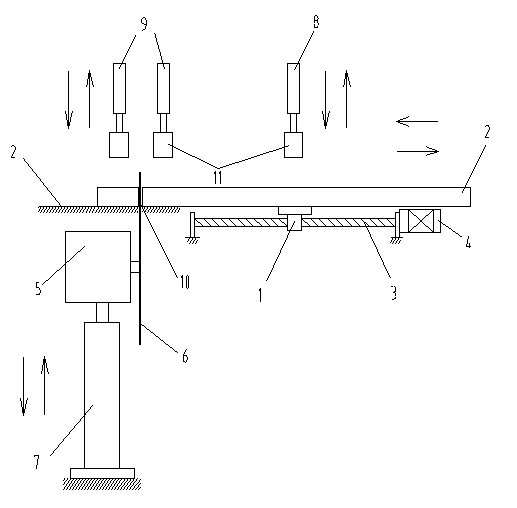

ActiveCN102390063AGuaranteed cutting accuracyConducive to survivalFeeding devicesCircular sawsComputer control systemEngineering

The invention discloses a back loading high-speed computer panel saw comprising a machine station main body, a material feeding unit and a computer control system, wherein the machine station main body comprises a worktable, a material pressing device and a cutting device; the material pressing device and the cutting device are both arranged on the worktable; the material feeding unit is arranged at the back side of the machine station main body; the material feeding unit comprises a material feeding device and a material loading device; the material feeding device is arranged between the machine station main body and the material loading device; the material feeding device comprises a material feeding bracket and a first propulsion mechanism; the material loading device comprises a material loading bracket, a lifting table and a second propulsion mechanism; the computer control system controls the work of the material pressing device, the cutting device, the material feeding device and the material loading device, thereby realizing automation operation in the overall process of panel cutting, being favorable for ensuring the cutting precision of panel material, improving the work efficiency effectively, reducing the number of operation personnel and reducing the work strength for workers, thus reducing the production cost for an enterprise and being beneficial to the survival of the enterprise.

Owner:NANXING MACHINERY CO LTD

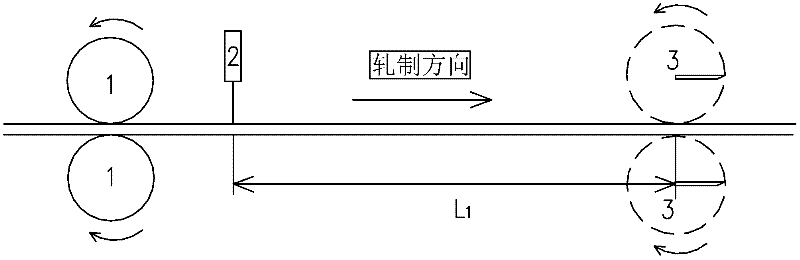

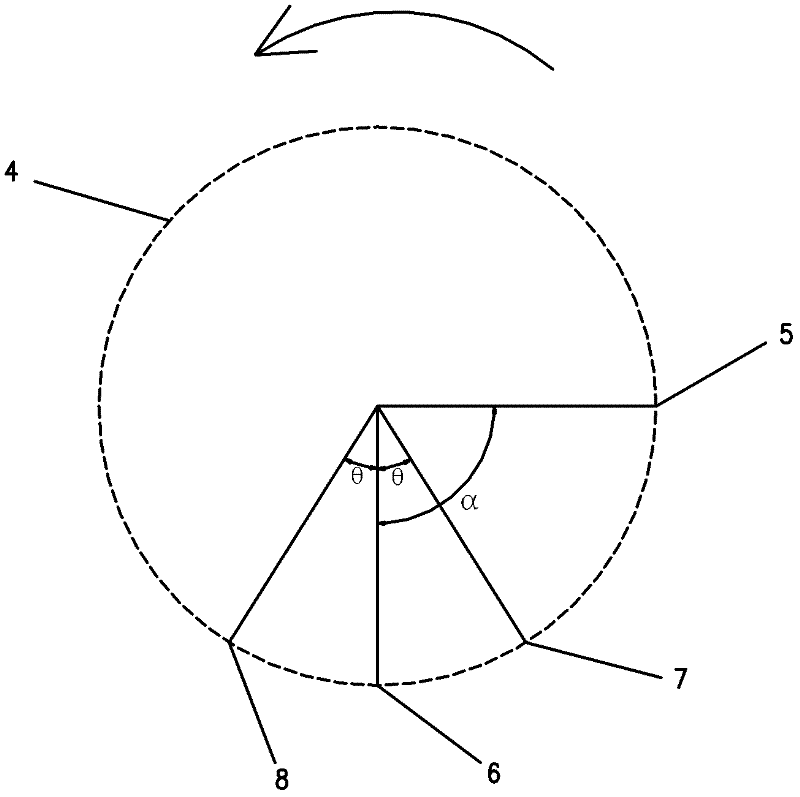

New method for controlling flying shears for bars and wires based on T400

InactiveCN102441569ASimple control structureImprove cut qualityRoll mill control devicesMetal rolling arrangementsWire rodStart stop

The invention provides a new method for controlling flying shears for bars and wires based on T400, which is an advanced electrical control method for start-stop type flying shears for bars and wires. The method comprises the steps of accurate shearing-blade position control, shearing length control and automatic shearing optimization, and the like; in the process of production, when an upstream rolling mill has an accident, or the quality of a section of a rolled piece is poor, a fragmentation function can be started on line so as to carry out partial fragmentation or complete fragmentation on the rolled piece, and the fragmentation and shearing speed is in step with the running speed of the rolled piece automatically; and when the fragmentation operation is stopped, a flying shear is automatically positioned to a start position and enters into a standby state of the normal shear mode. In the invention, the powerful computation function of the T400 is fully used, core control parts of the flying shear are completely integrated into the T400, and high-speed counters, shaft positioning modules and touch screens are not required, therefore, the cost is reduced, and high accuracy is obtained; and when the flying shear carries out double-length shearing at a speed of 21 m / s, the double-length error is basically within 75 mm, and partial double-length error can be within 30 mm.

Owner:WISDRI WUHAN AUTOMATION

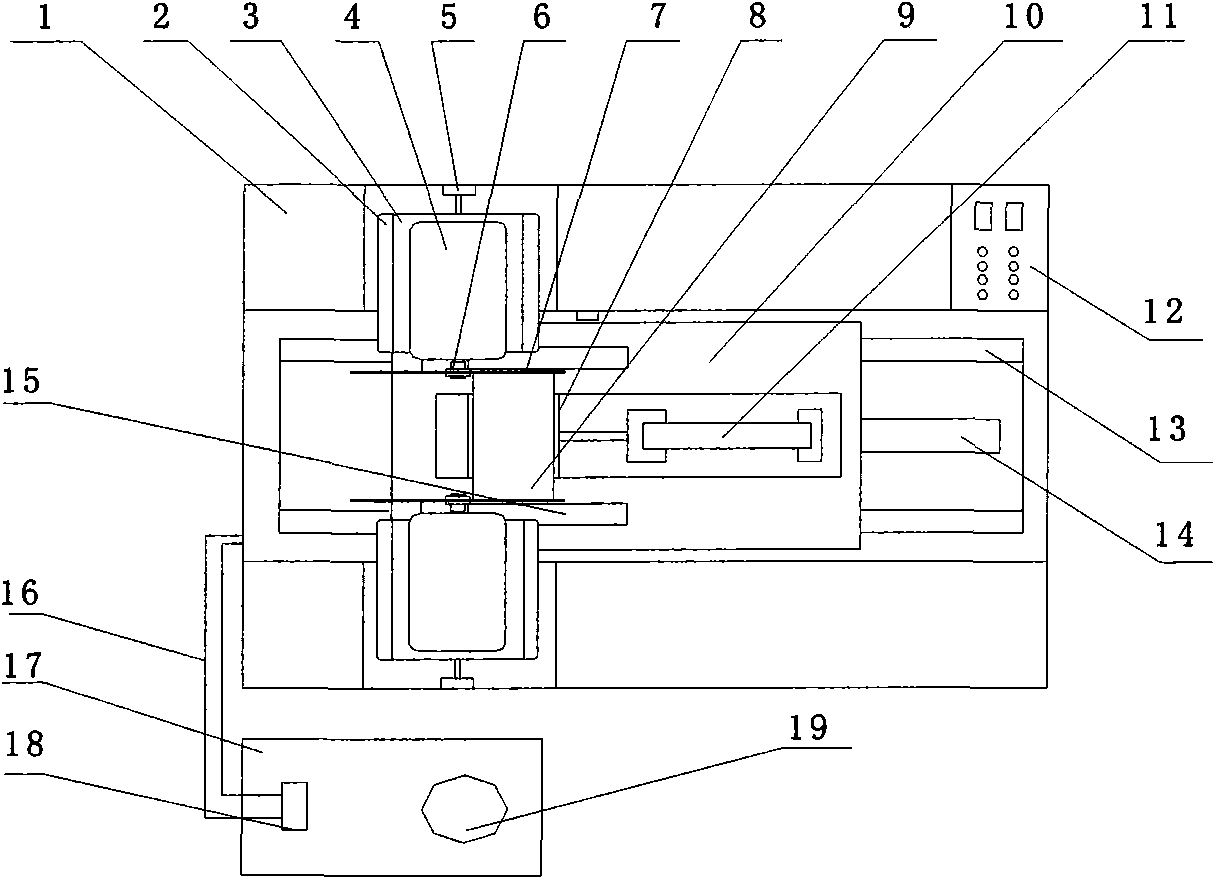

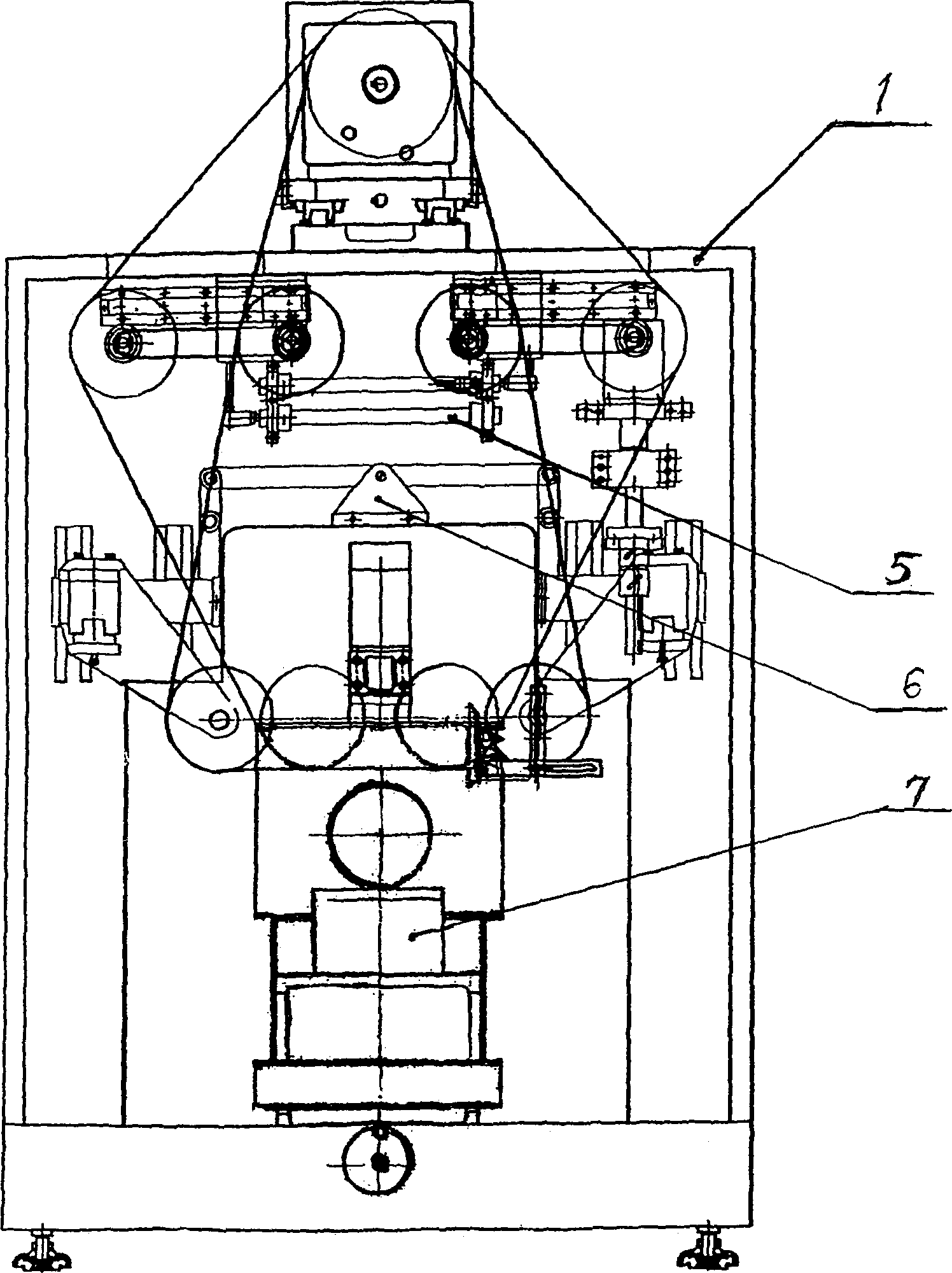

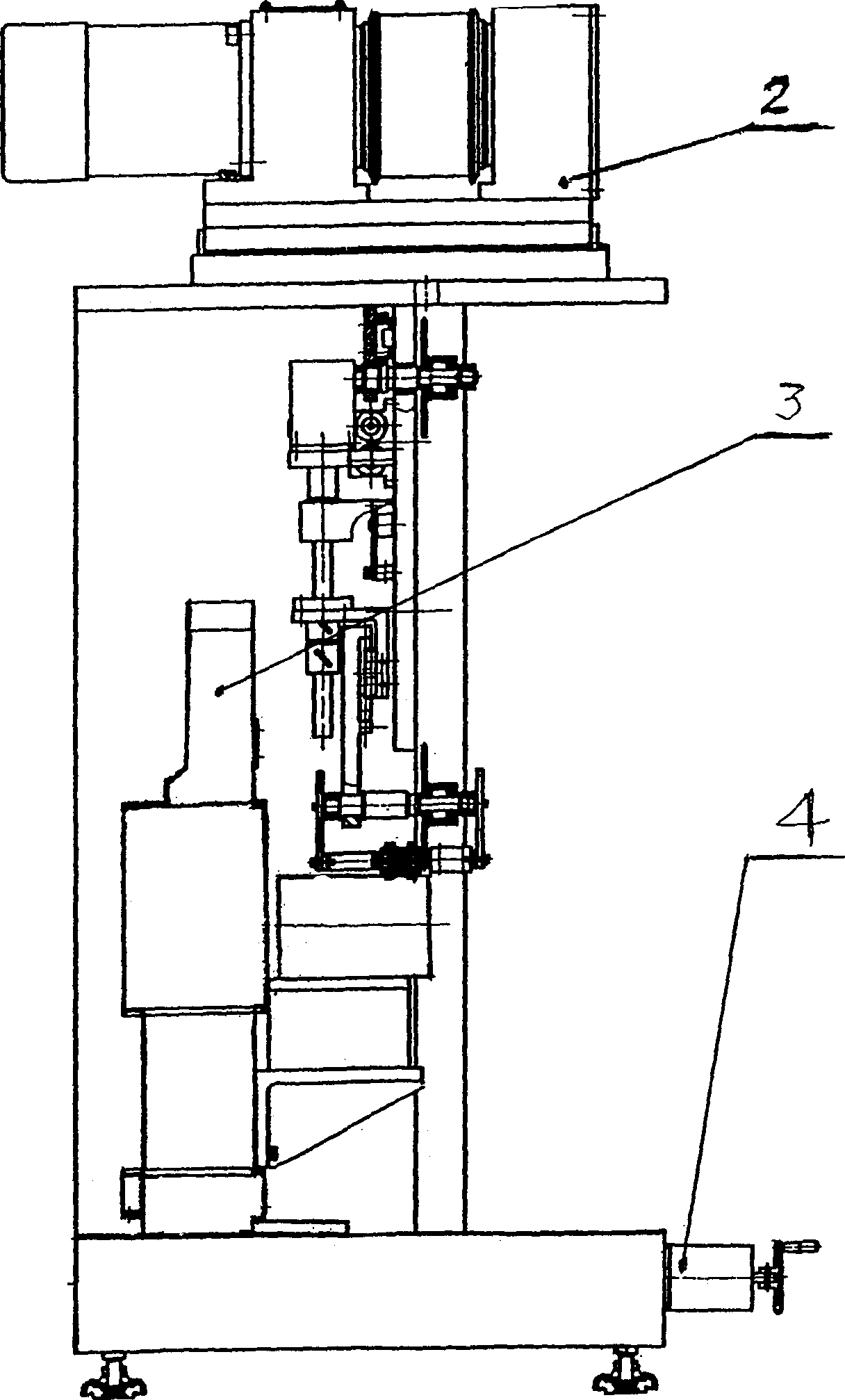

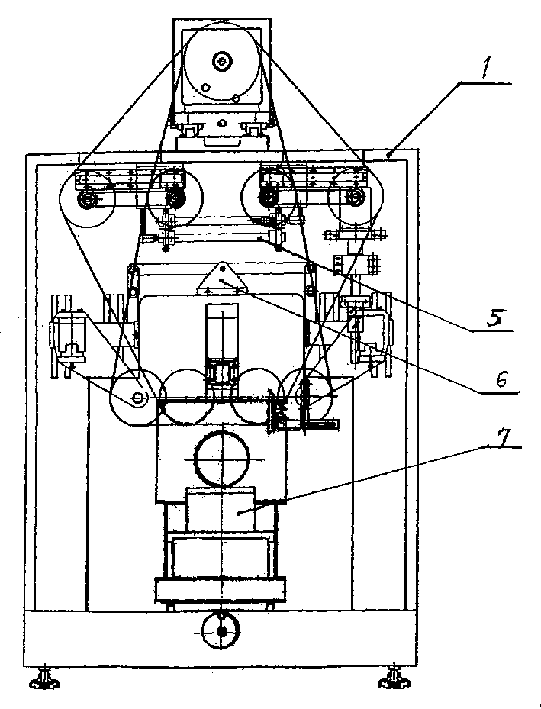

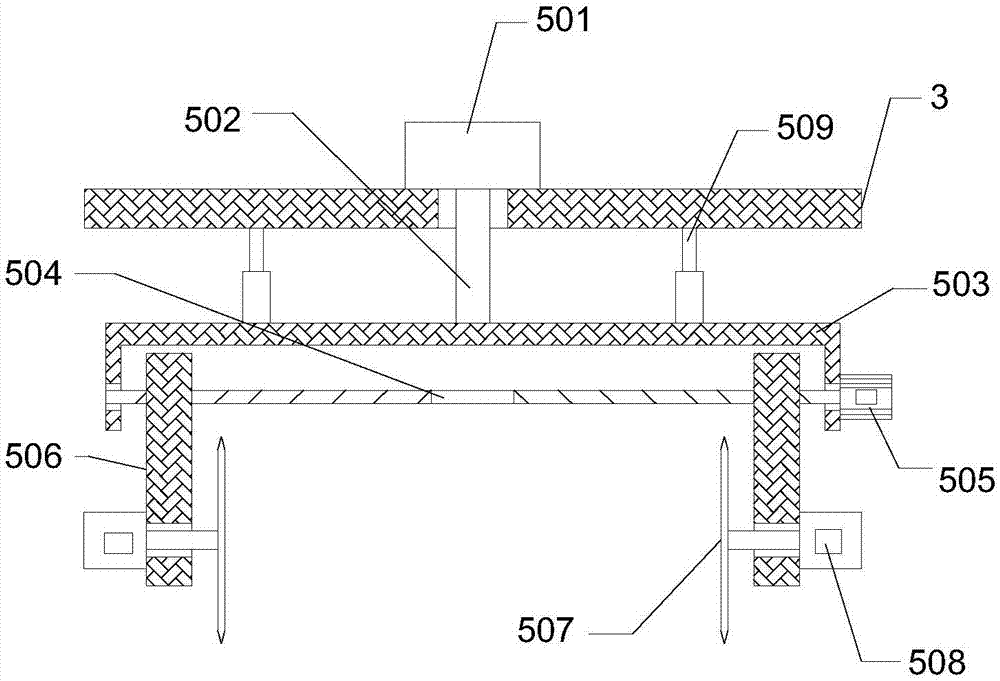

Aerated concrete cutting machine

InactiveCN102241059AMeet the requirements of automated operationsResolve mutual interferenceCeramic shaping apparatusElectricityBrick

The invention discloses an aerated concrete cutting machine. The machine comprises vertical posts, I-shaped girders and a frame, wherein the I-shaped girders are erected on the vertical posts; the frame consists of a cross beam which is positioned above the vertical posts and is fixed with the girders; an overturning platform is arranged at the middle position of the frame; a vertical cutting device which does up-and-down lifting motion is arranged between the two vertical posts in the middle of the frame; a horizontal cutting device which moves along the longitudinal direction of a blank body is arranged between the two girders; and a scrap edge cleaning device is arranged beside the overturning platform. The cutting machine integrates machines, electricity and liquid, has a compact structure, small occupied space, complete functions, high cutting accuracy and a clean and tidy operation field environment, has various functions of automatically longitudinal cutting, transverse cutting, hexahedral cutting, tetrahedral scalping, two-sided peeling, automatic scrap edge cleaning, specially-shaped brick cutting and the like, makes cutting dimensions conveniently adjusted, and reduces the labor intensity of operators due to humanized designs.

Owner:常州力顿机械科技有限公司

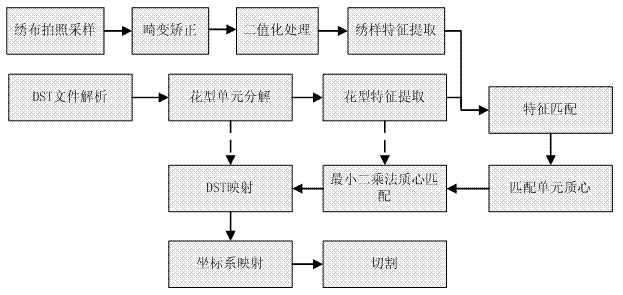

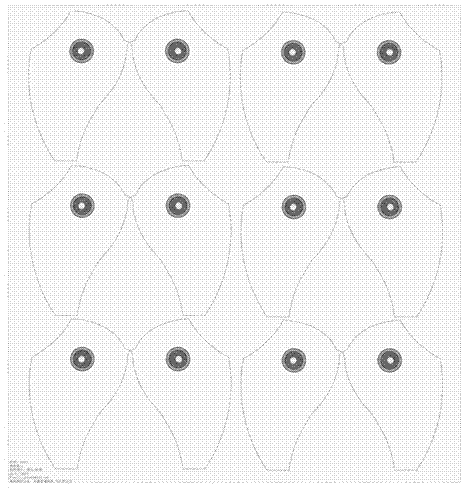

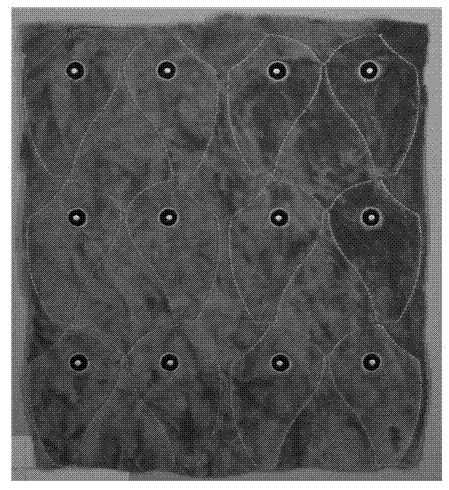

Automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision

InactiveCN102704215AIncrease profitReduce dependencyCharacter and pattern recognitionAutomatic machinesMachine visionLaser cutting

The invention discloses an automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision. In wool toy manufacturing industry, the profile and pattern of the wool toy are processed by adopting an embroidery machine, and the whole embroidery piece is cut one by one by adopting a laser cutter. The method comprises the steps of: firstly parsing a DST file (embroidery file) into an image file, selecting cutting units from the image file, and extracting the information of the cutting units to obtain the inside parameter of the unit; and carrying out correlated processing according to the image of cut sample obtained by camera shooting, matching the obtained cutting unit information with the processed sample, finally determining the cutting line position, generating a PLT file and cutting by a cutter. Different from other laser cutting methods based on machine vision, the method can finish cutting of the whole embroidery sample just by once shooting; and the method has the characteristics of high working efficiency and low unqualified rate, and has very strong cutting capability on the complicated embroidery sample.

Owner:SOUTHEAST UNIV

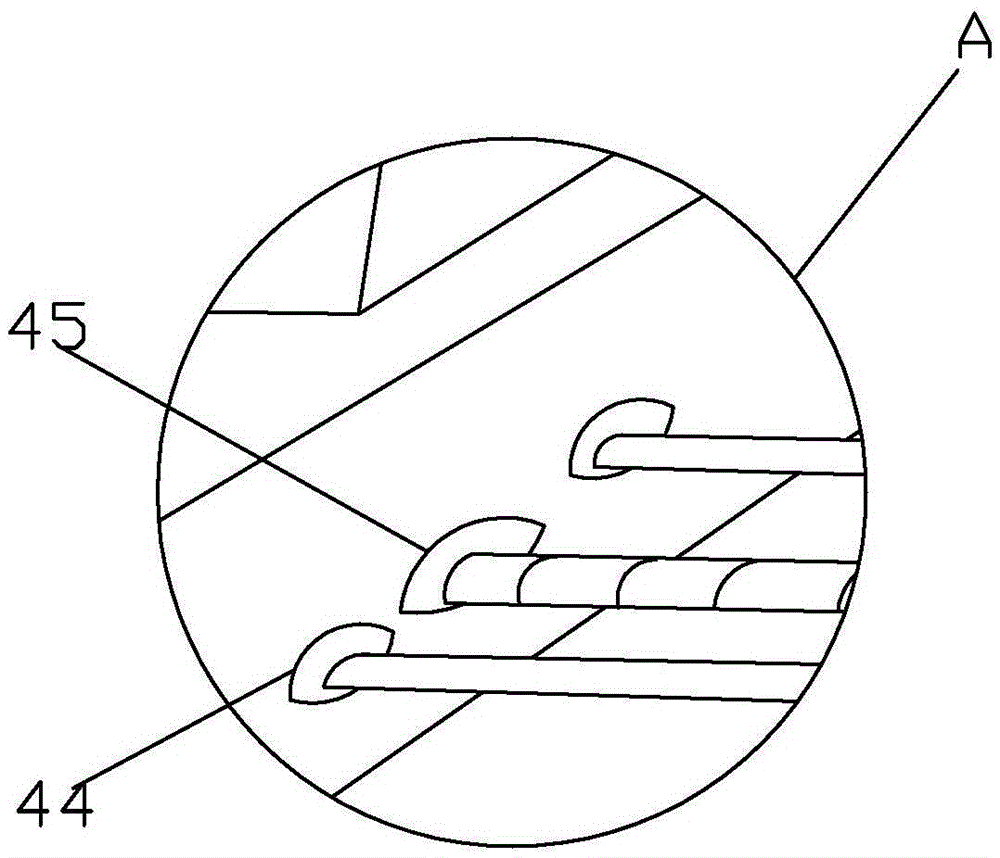

Full-automatic corner connector cutting device

ActiveCN102554343AReduce coefficient of frictionReduce noiseMetal sawing devicesBall screwEngineering

The invention relates to a full-automatic corner connector cutting device, comprising a feeding work table and a cutting work table, wherein the feeding work table moves through a ball screw, and the ball screw is connected with a servo motor; a saw blade motor is arranged below the cutting work table, a saw blade is arranged at the output end of the saw blade motor, and the saw blade motor is arranged on a cutting propulsion cylinder; and a feed pressing cylinder is arranged above the feed work table, and a sawing and cutting compressing cylinder is arranged above the cutting work table. The full-automatic corner connector cutting device has simple structure, high precision and stable operation.

Owner:TAICANG WEGOMA MACHINERY

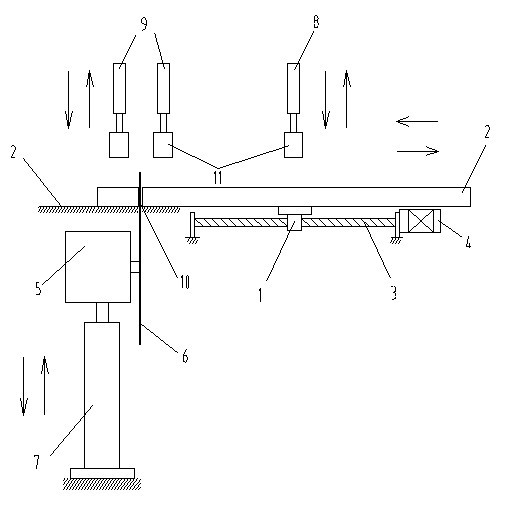

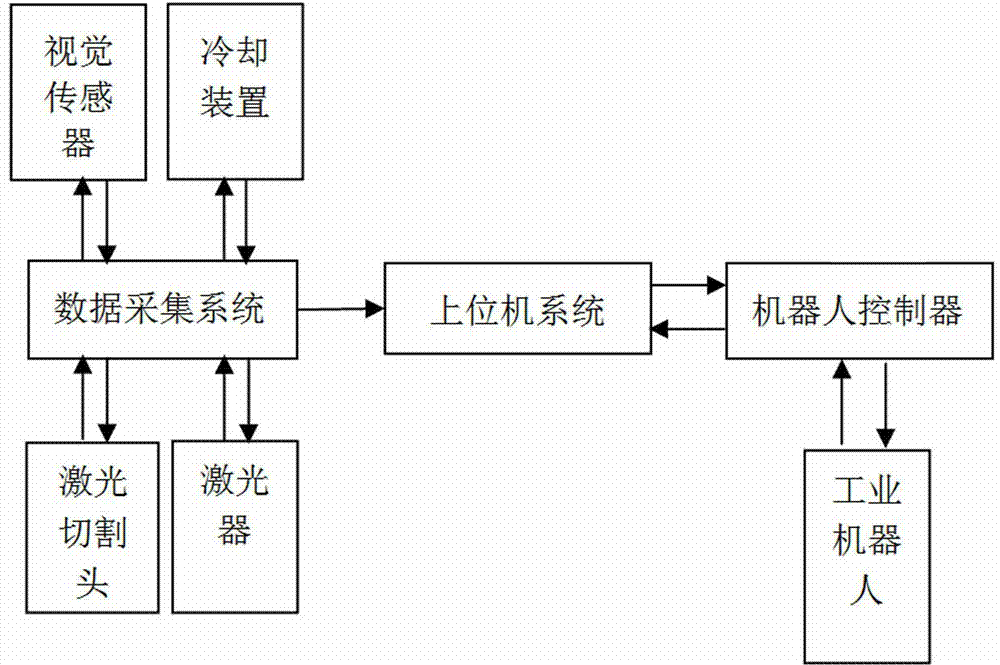

Automatic robot three-dimensional laser cutting system and thereof

InactiveCN104722926ARealize automatic three-dimensional positioningImprove cutting accuracyLaser beam welding apparatusLaser cuttingEngineering

The invention discloses an automatic robot three-dimensional laser cutting system and method. The cutting system comprises an upper computer system, a data collecting system, a visual sensor, an industrial robot, a laser device, a laser cutting head and a cooling device. The cutting method comprises the following steps that (1) offline cutting track planning; (2) offline cutting technological parameter planning; (3) cut object detecting and positioning; (4) automatic robot three-dimensional laser cutting. By means of the automatic robot three-dimensional laser cutting system and the cutting method thereof, the automatic three-dimensional positioning of a cut object can be achieved, the cutting precision and efficiency are improved, meanwhile, the transformation of the cutting track to a workpiece coordinate system from a digital analogy coordinate system is automatically achieved, the processes of automatic track planning and cutting technological parameter planning can be achieved, the cutting efficiency and precision can be effectively improved, and the automatic robot three-dimensional laser cutting system and the cutting method thereof can be used in laser cutting.

Owner:JIANGSU CHANGJIANG HEAVY TECH CO LTD

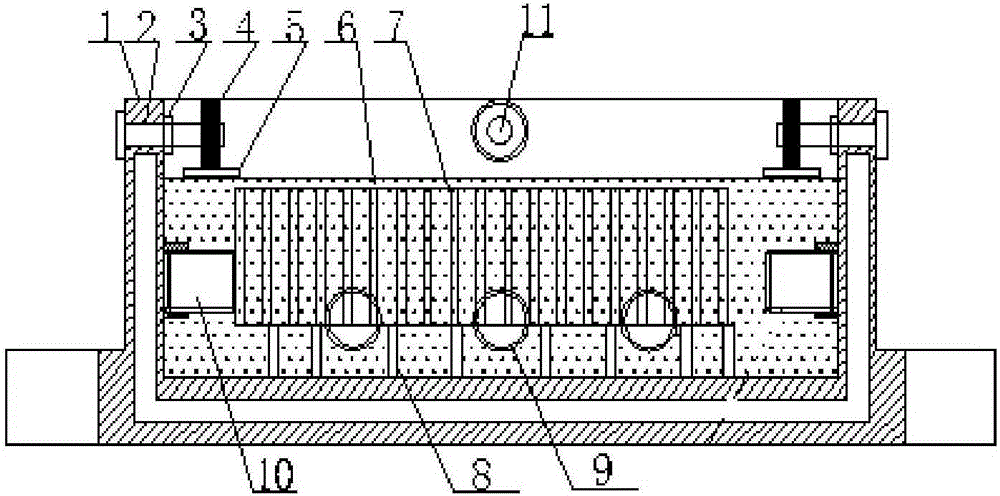

Ice immobilization machining method for metal honeycomb workpiece

ActiveCN105171460ASolve clamping problemsSuppression of processing defectsWork clamping meansMilling equipment detailsHoneycombLiquid nitrogen

The invention provides an ice immobilization machining method for a metal honeycomb workpiece, belongs to the field of machining technological methods and relates to a machine tool fixture device and a machining method for immobilizing a metal honeycomb material through an ice immobilization manner to achieve ultralow-temperature cutting. The method comprises the steps that after metal honeycomb holes arranged in a metal honeycomb ice immobilizing fixture are filled with low-temperature pure water or cutting liquid, the metal honeycomb ice immobilizing fixture is arranged in an adjustable refrigerating testing cabinet, and the freezing temperature and the refrigerating time are set; and then the metal honeycomb ice immobilizing fixture is clamped to a machine tool worktable, metal honeycombs are machined through a liquid nitrogen internal spraying cutter, and the freezing state is maintained through liquid nitrogen external spraying. The method achieves the purpose of clamping of the metal honeycomb workpiece difficult to machine, the freezing temperature of the pure water or the cutting liquid and the temperature maintaining degree are effectively controlled, the machining immobilizing effect can be better, and the cutting precision is improved; and the operation of the method is convenient, the immobilizing effect is stable, the machining efficiency is high, and the machining effect is good.

Owner:DALIAN UNIV OF TECH

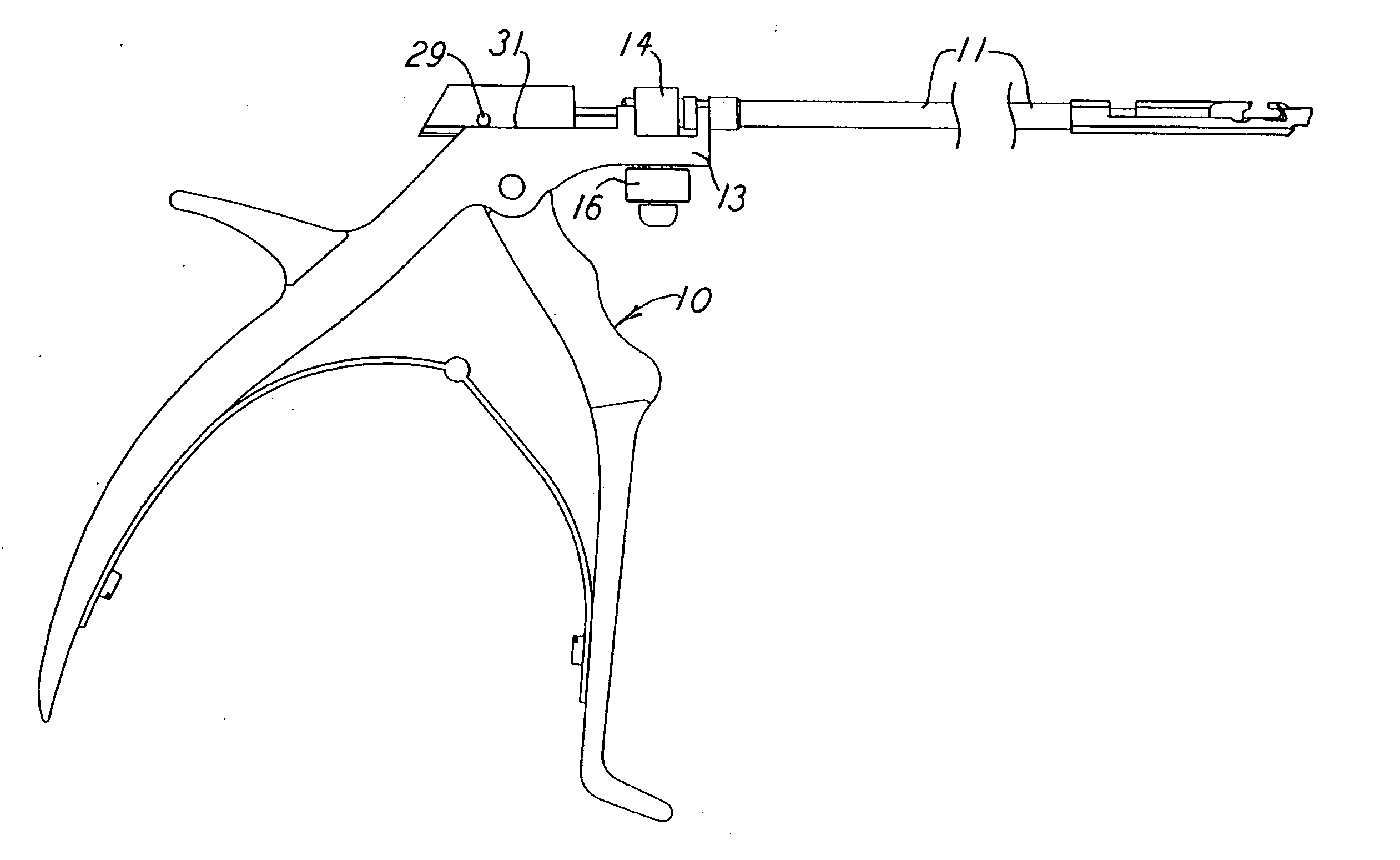

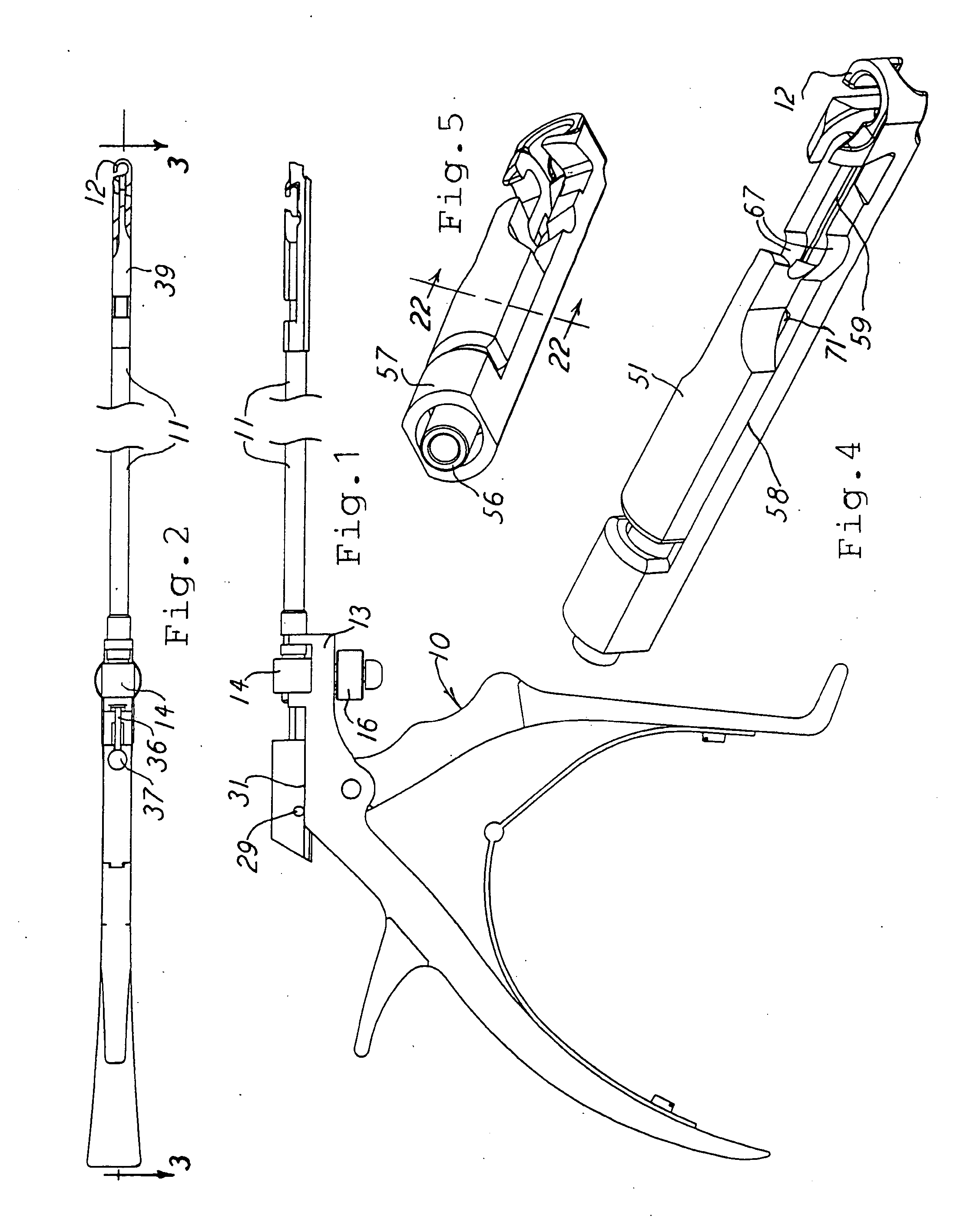

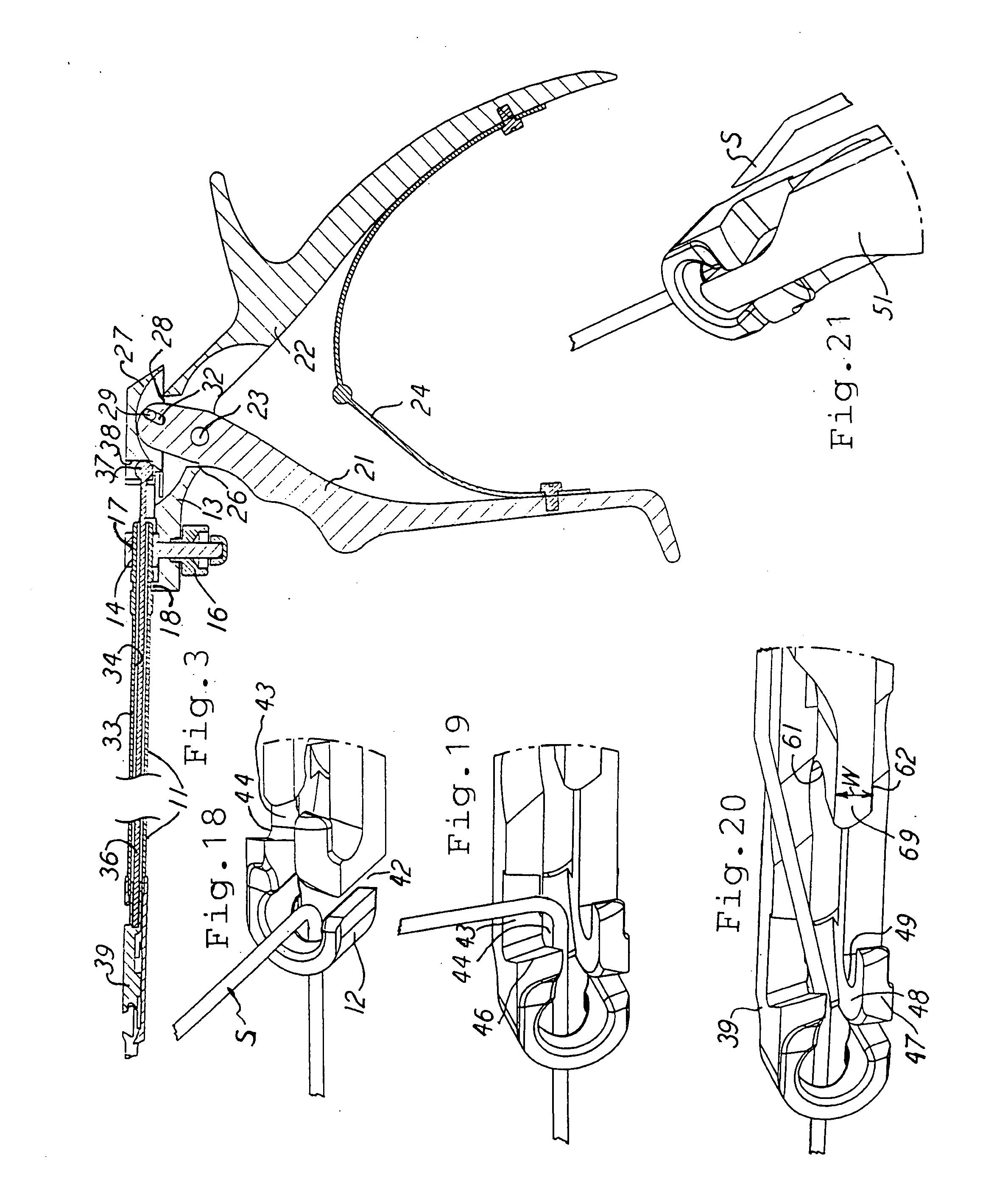

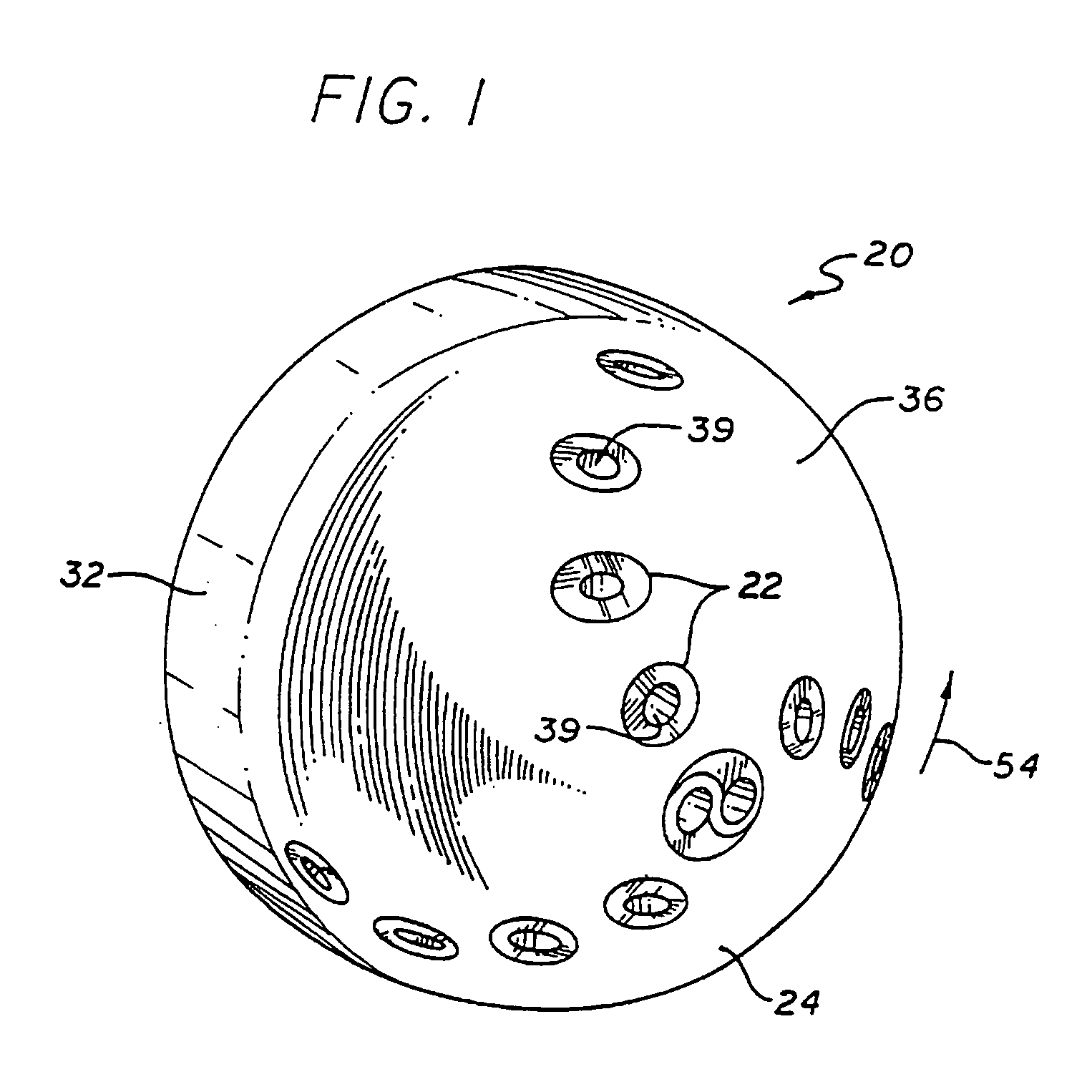

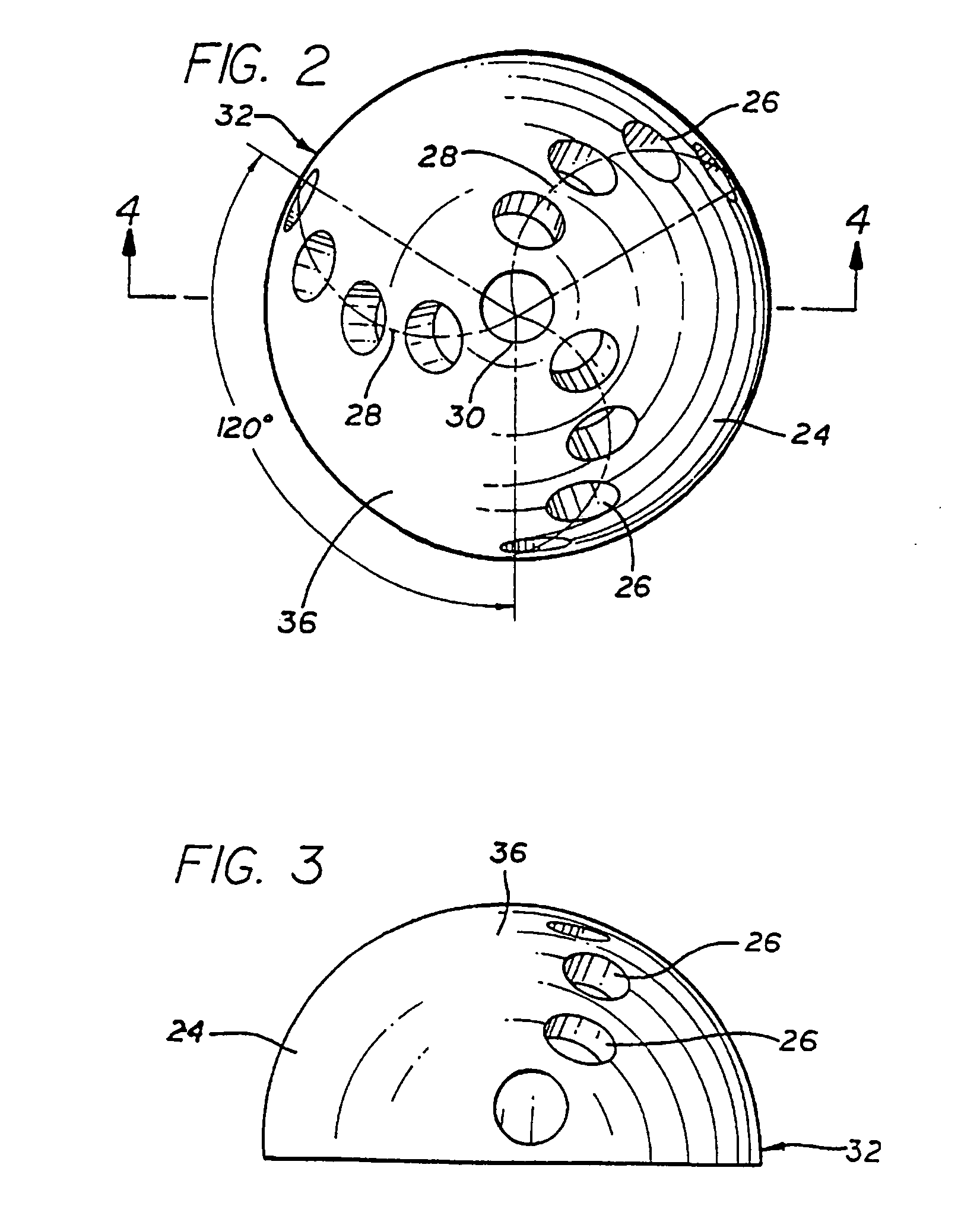

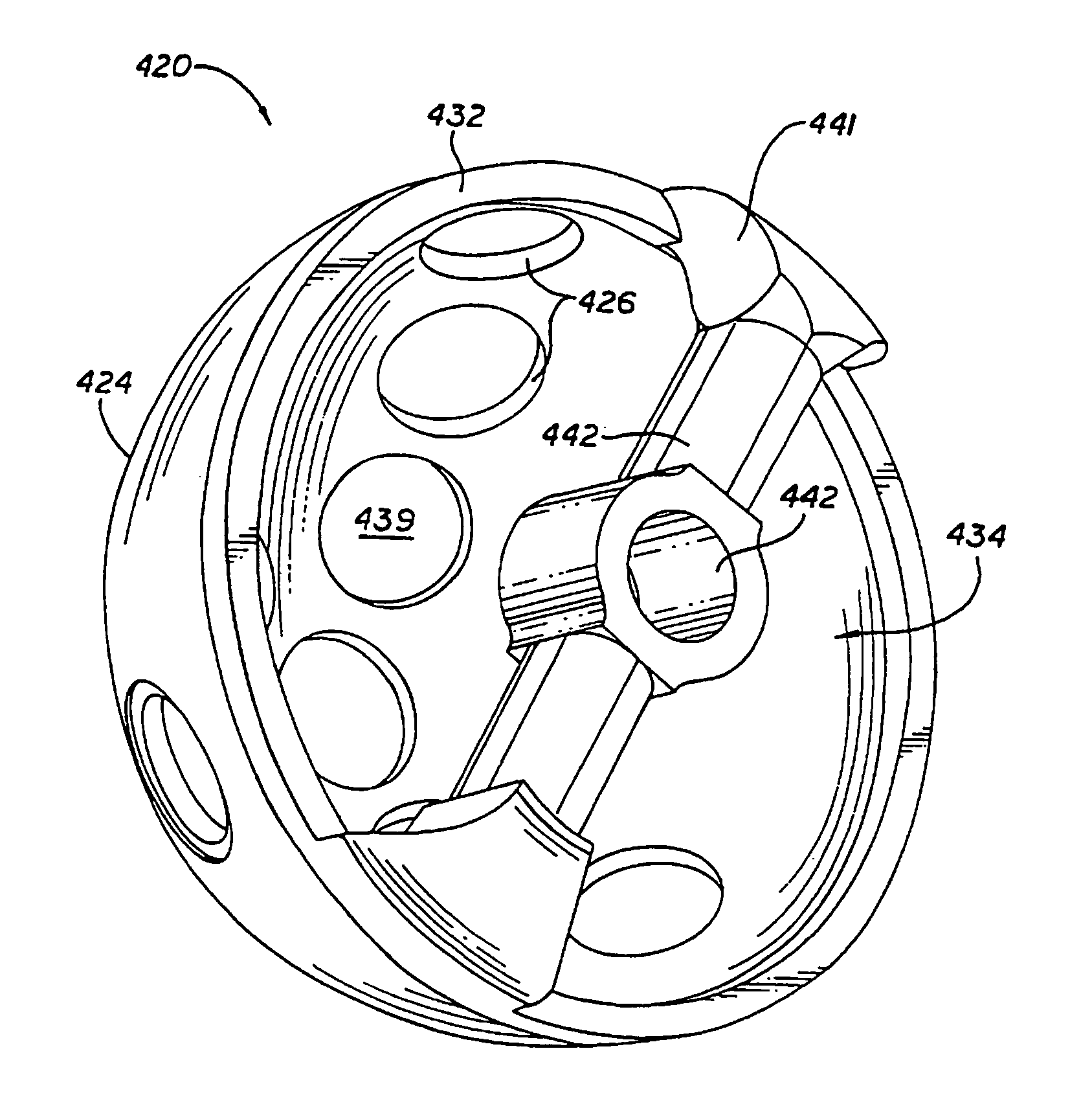

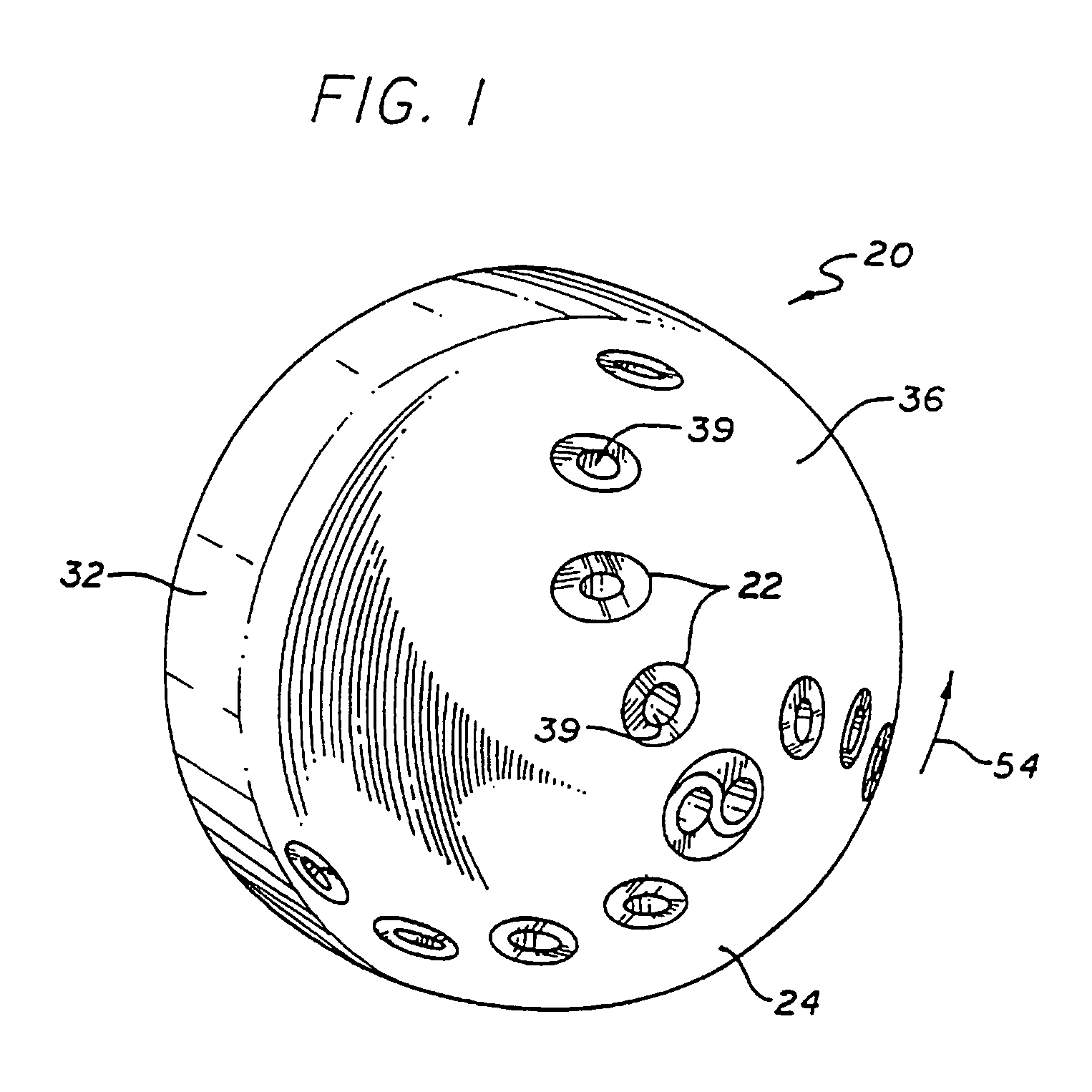

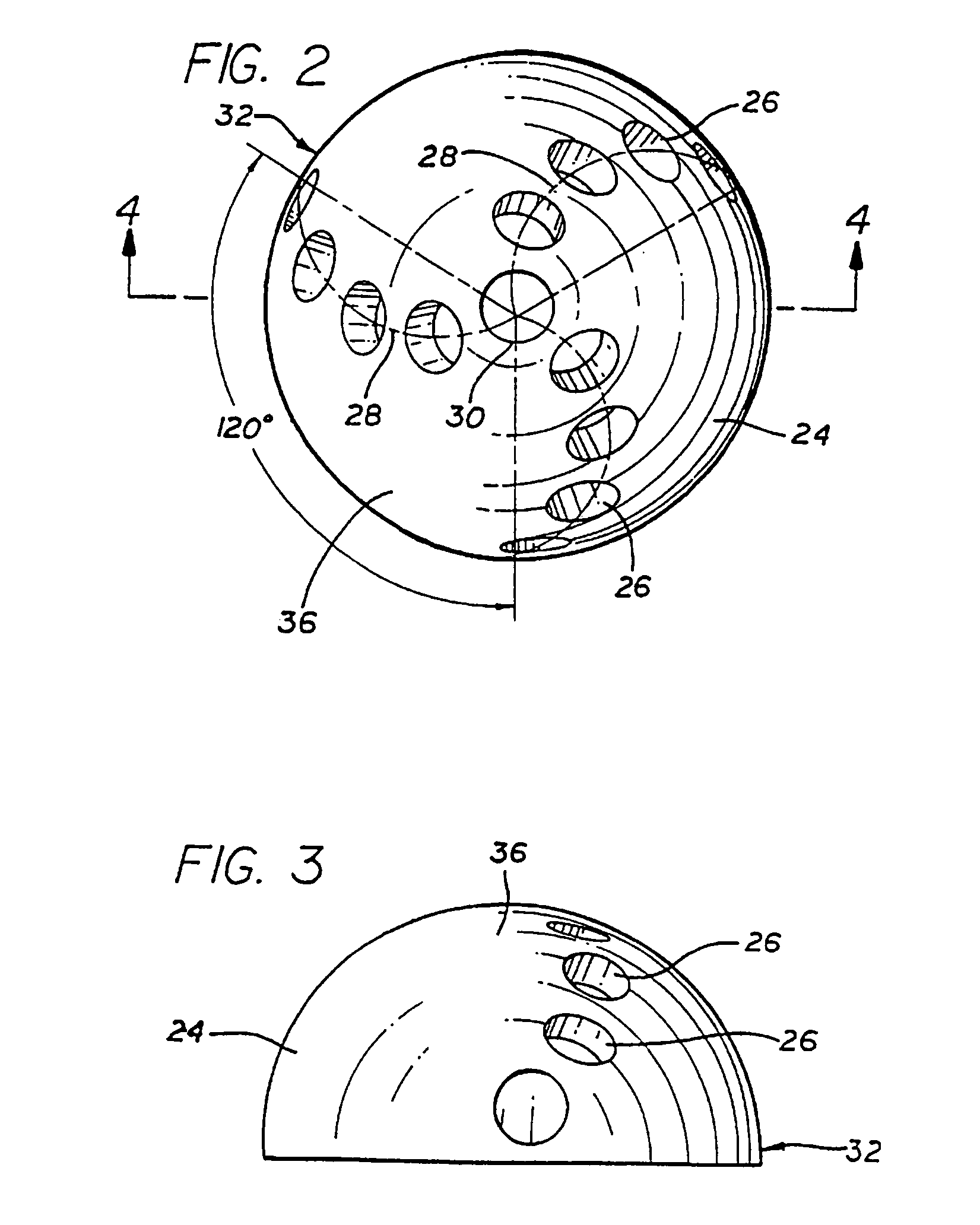

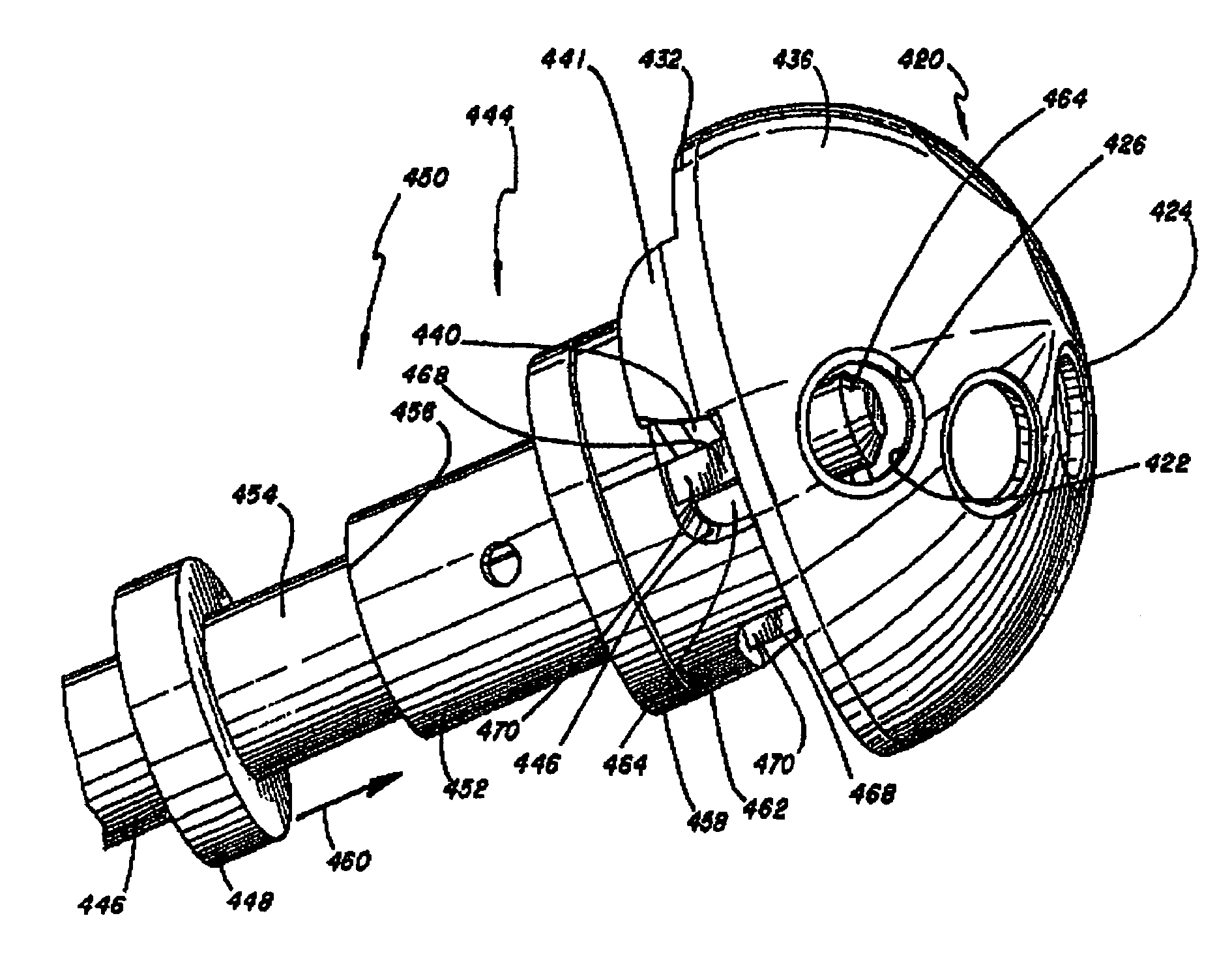

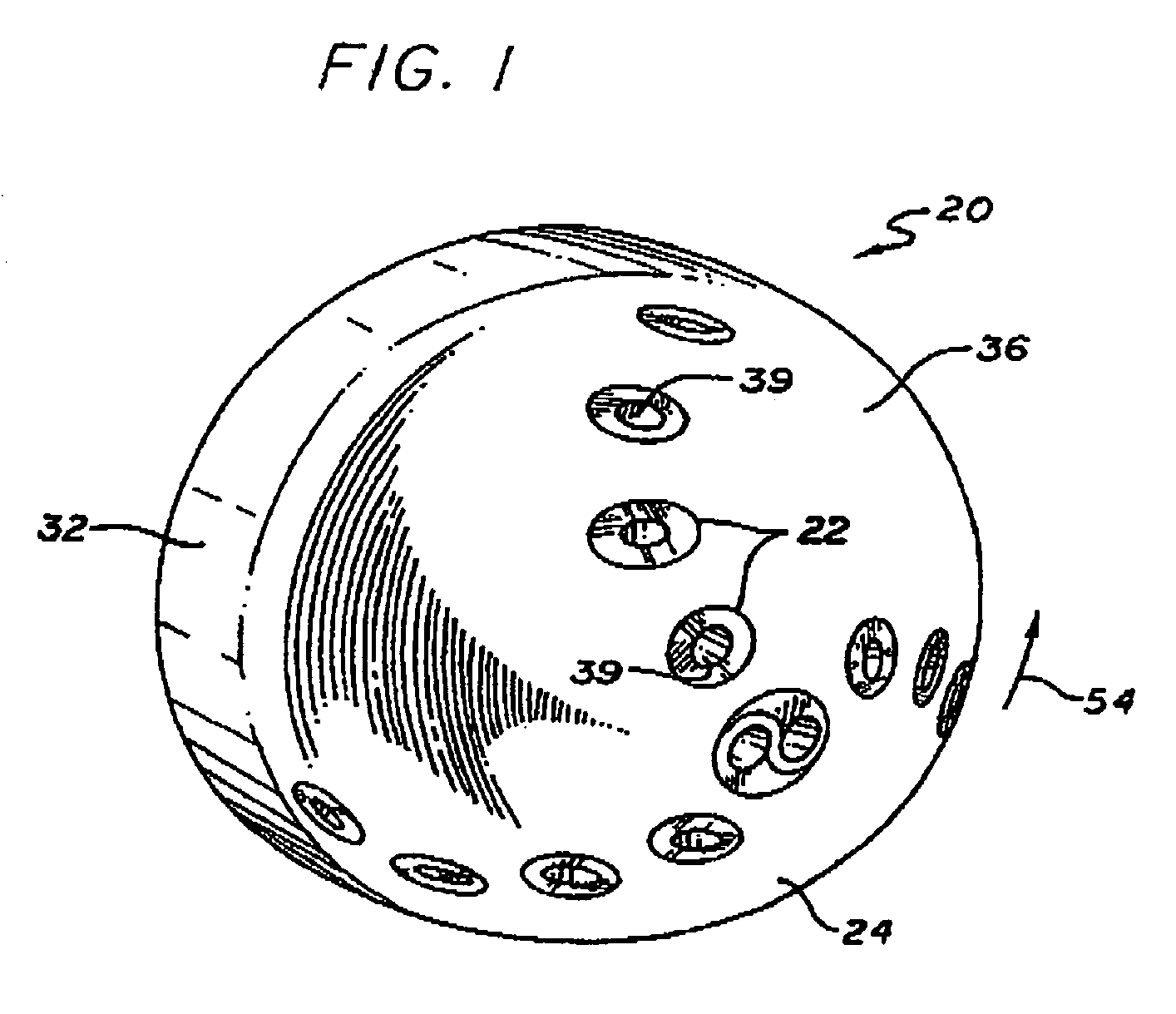

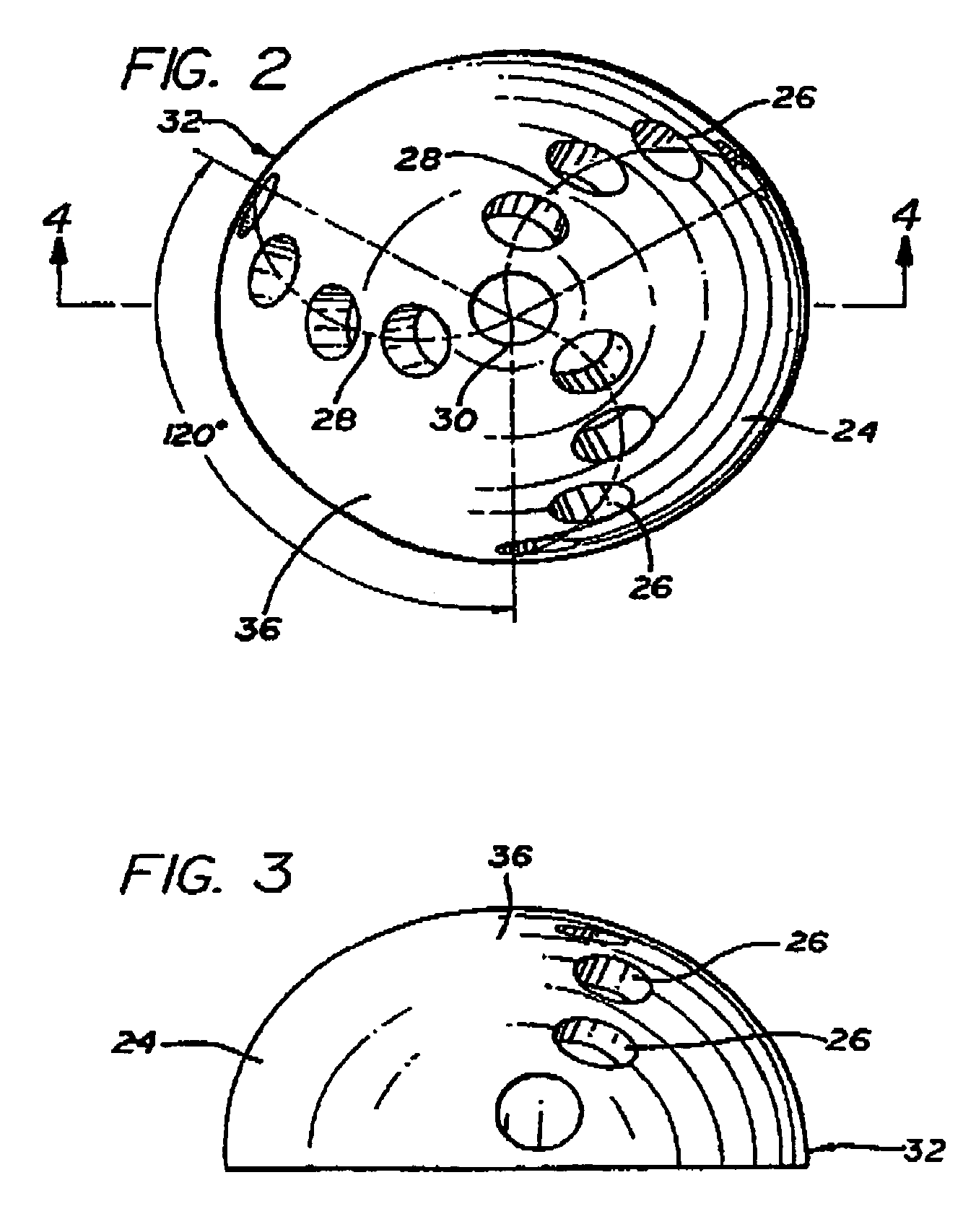

Connector for domed cutting tool

The surgical reamer has a hollow dome with apertures spaced apart arranged in arcs extending from an apex of the dome to the base portion of the dome, and removable teeth positioned in the apertures. Each cutting tooth has a flange that is aligned flush with the external surface of the dome, and a raised cutting edge extending above the flange and the external surface of the dome, and an interior passageway communicating between the outside and inside of the dome. In one embodiment, a base plate is removably secured on the base portion of the dome to provide closure of the central cavity of the dome.

Owner:VIANT AS&O HLDG LLC

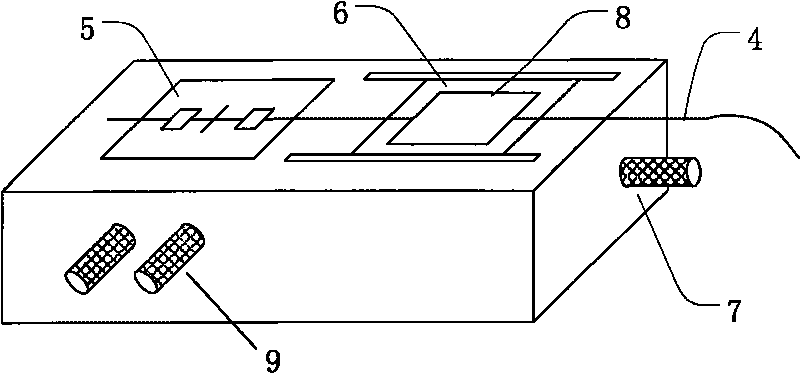

Steel plate clad cutting device for circuit board production

ActiveCN106985185AEasy accessImprove cutting effectMetal working apparatusCircuit precursor manufactureSheet steelEngineering

The invention relates to a steel plate clad cutting device, in particular to a steel plate clad cutting device for circuit board production. The steel plate clad cutting device for the circuit board production aims to achieve the technical effects of being light, handy, high in cutting precision and good in cutting effect. The steel plate clad cutting device for the circuit board production comprises a base plate, a left frame, a first sliding block, a first sliding rail, a lifting device, a top plate, a moving device, a lifting rod, an installation rod, a second motor, a blade, a first support and the like. The left frame is welded to the left side of the top of the base plate. A right frame is welded to the right side of the top of the base plate. The top plate is welded to the top ends of the left frame and the right frame. The lifting device is arranged in the middle of the bottom of the top plate. According to the steel plate clad cutting device for the circuit board production, a worker manually shakes a rocker bar, the lifting device is controlled to move up and down, the height of the blade is controlled to be more appropriate, the cutting effect is better, and the blade is driven to move leftwards and rightwards through the moving device.

Owner:秦皇岛市东旭达黏胶制品有限公司

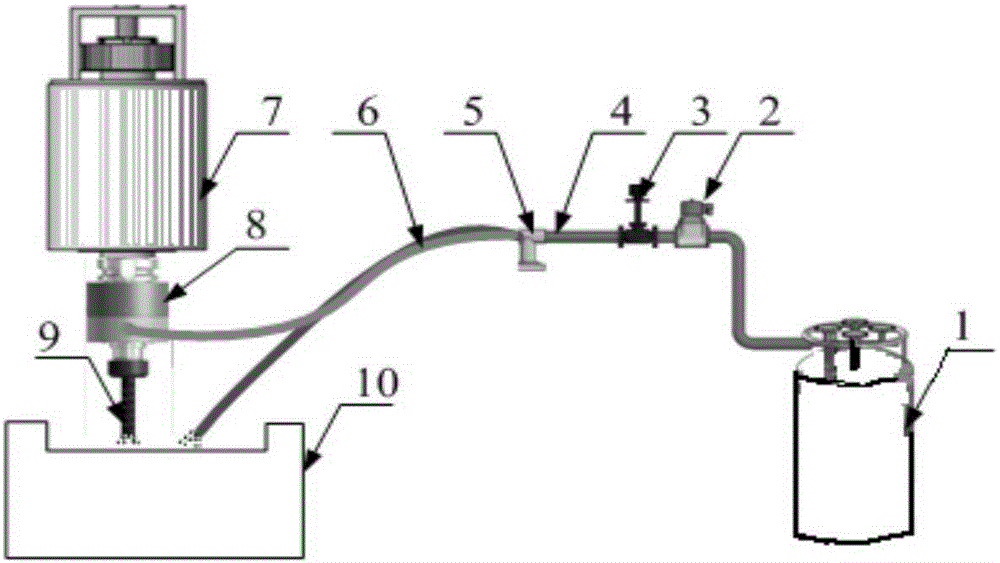

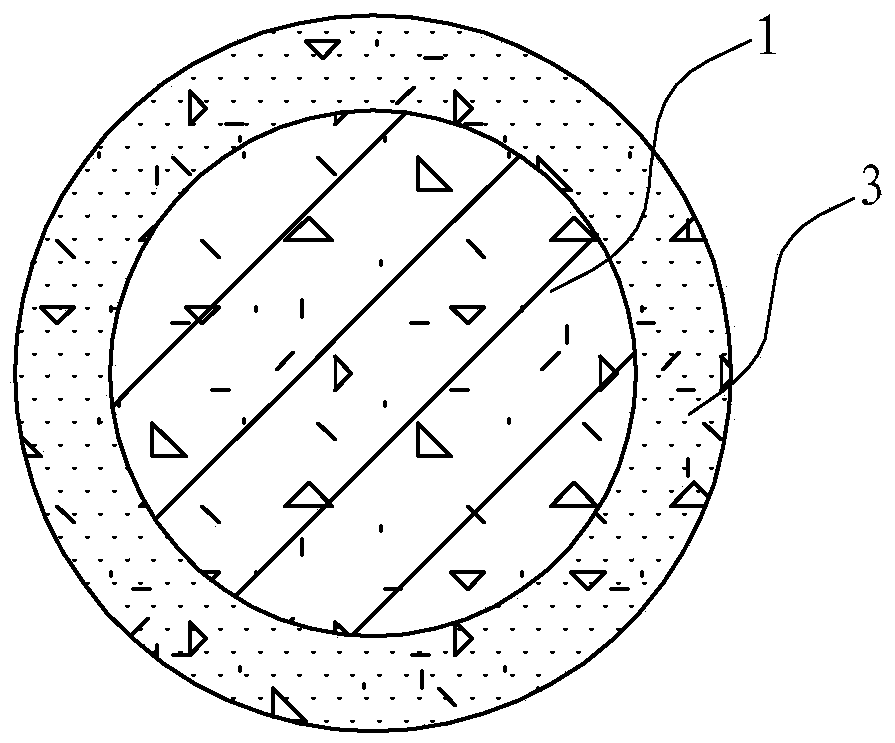

Great diameter SiC monocrystal cutting method

ActiveCN1739927ARealize continuous cuttingReduce lossesMetal working apparatusWire cuttingSingle crystal

The great diameter SiC monocrystal cutting method belongs to crystal material processing technology. SiC monocrystal is cut by means of diamond wire cutting machine with cutting wire of 150-450 micron diameter and coated with diamond grains. The diamond wire cutting wire in high speed reciprocation cuts great diameter SiC monocrystal. The present invention has the following advantages: capacity of cutting SiC monocrystal of size ove 2 in, less cutting loss, shallow cutting trace, less damage to cut chip, capacity of cutting chip with thickness as small as 200 micron, saving in cost, homogeneous thickness and less deformation of the cut chip, and simple cutting process.

Owner:SICC CO LTD

Connector for domed cutting tool

The surgical reamer has a hollow dome with apertures spaced apart arranged in arcs extending from an apex of the dome to the base portion of the dome, and removable teeth positioned in the apertures. Each cutting tooth has a flange that is aligned flush with the external surface of the dome, and a raised cutting edge extending above the flange and the external surface of the dome, and an interior passageway communicating between the outside and inside of the dome. In one embodiment, a base plate is removably secured on the base portion of the dome to provide closure of the central cavity of the dome.

Owner:VIANT AS&O HLDG LLC

Automatic cutting machine for non-woven fabric

InactiveCN109825998AImprove detection accuracyImprove cutting accuracySevering textilesMetal working apparatusWoven fabricEngineering

The invention discloses an automatic cutting machine for a non-woven fabric, and relates to the technical field of mask fabric cutting devices. The problems that non-woven fabrics are loose, and the cutting positions of the non-woven fabrics are likely to shift, so that non-woven fabrics are wasted are solved. The machine comprises a machine body, a feeding table and a discharging table; a workbench is fixedly arranged inside the machine body, and a conveyor belt is intermittently and rotationally arranged on the workbench; two pressing plates are arranged inside the machine body in a liftingmode; the two sides of the workbench are each fixedly provided with a supporting base, the two supporting bases are jointly fixedly connected with a tool rest, and a cutter is slidably arranged on thetool rest; a transverse beam is slidably arranged between the two supporting bases, a stroking plate is arranged at one side of the beam in a lifting mode; two flattening rollers are rotationally arranged at one side of the machine body. The loose non-woven fabrics are compressed through the flattening rollers, the non-woven fabrics are stroked and compressed by sliding the stroking plate, the non-woven fabric is more flat, the cutting effect of the non-woven fabric is better, the phenomenon that non-woven fabrics are not cut through is avoided, and the mask fabric yield is increased.

Owner:上海即索实业有限公司

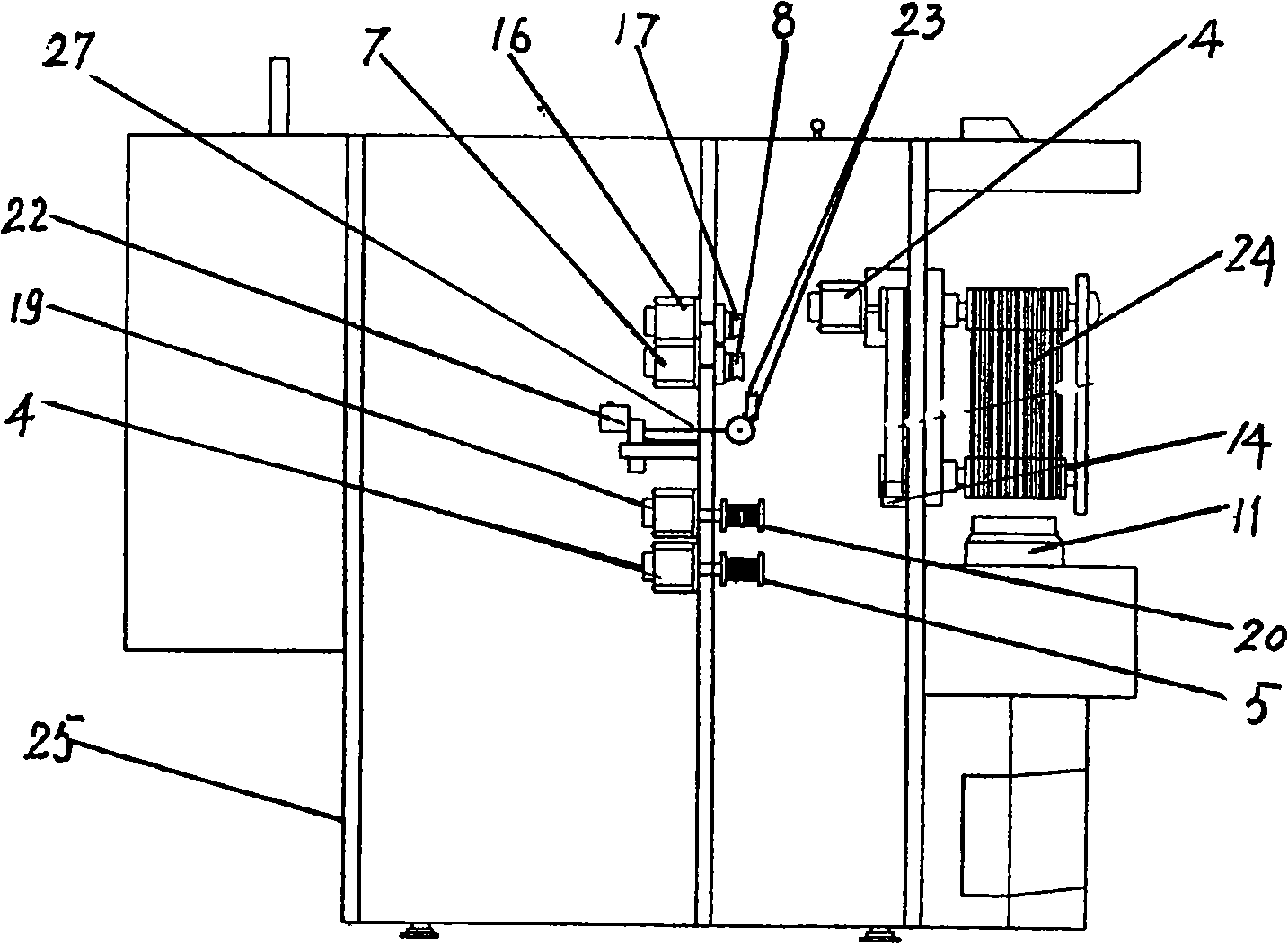

Microcomputer control multiline cutting machine

InactiveCN101301734AConstant tensionAchieve the purpose of being cutGrinding machinesFine working devicesAudio power amplifierWire wheel

The invention provides a micro-computer control multi-wire cutting machine, comprising a frame, a worktable, a metal wire, and a grinding lubricant supply mechanism; the control part of the micro-computer control multi-wire cutting machine adopts the programming of a main substrate to control a CPU module; the parameters of the CPU module are set by a touch display; furthermore, a servo amplifier is controlled by optical fibres; the servo amplifier controls a servo motor; a frame is internally provided with at least six servo amplifiers and six servo motors which respectively control the lifting of the worktable; the micro-computer control multi-wire cutting machine also comprises three rotation rollers, a wiring wheel, a wiring tensioning sensor, a stranding wheel, and a stranding tensioning sensor; the grinding lubricant supply mechanism leads out an emery liquid injection pipe; the outlet of the emery liquid injection pipe is in the middle of an isosceles triangle which is presented by three rotation rollers; the metal wire extends from wiring wheel passing through the wiring tensioning sensor and winding parallel hundreds of rounds on three rotation rollers to form a cut surface, the main substrate programming controls the CPU module so as to control the rotation / direction of the servo motors, thus leading the rotation rollers, stranding wheel and wiring wheel to reciprocate to rotate. The micro-computer multi-wire cutting machine has high cutting precision and working efficiency.

Owner:乐清市新晶电子器件有限公司 +1

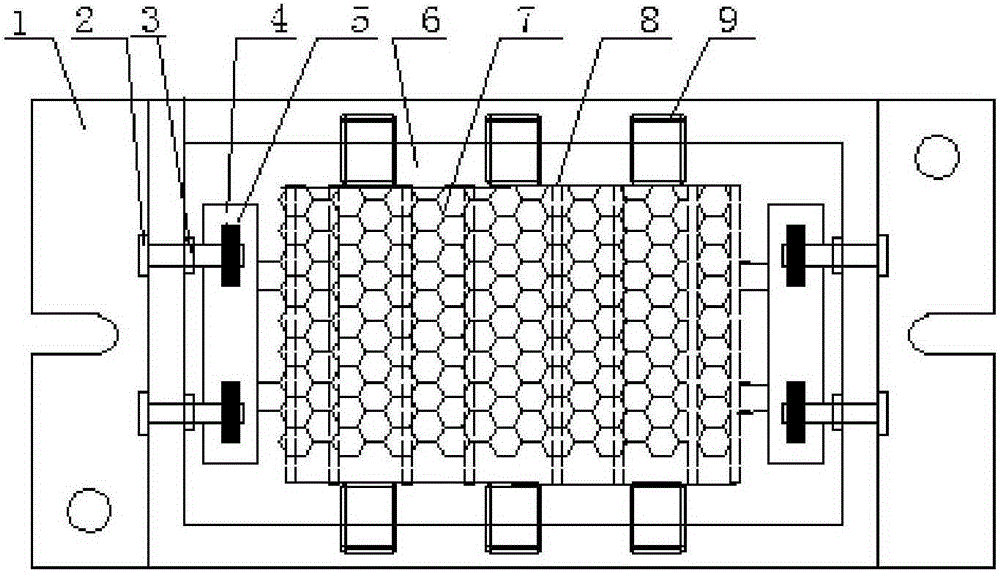

Honeycomb ceramic dry green body dual-blade cutting machine

InactiveCN101579887ANo deformationNo damageCeramic shaping apparatusWorking accessoriesControl systemElectric machinery

The invention relates to a honeycomb ceramic dry green body dual-blade cutting machine, which consists of a cutting device, a linear working table, a hydraulic system, a dust collector and a control system, wherein the cutting device adopts a dual-blade structure, and two parallel round diamond blades are connected with a main shaft driven by one or two motors respectively; and the linear working table conveys a green body to the cutting device and consists of a green body clamping device and a green body conveying device provided with a travel switch for controlling motion. The green body clamping device consists of a cylinder, a green body clamp and a green body liner plate and is used for clamping and cutting a dry green body, and the clamping degree of the green body is controlled by adjusting the pressure of compressed air with a pressure adjusting valve so that a finished product after cutting is not deformed and damaged; and the green body conveying device drives the working table to perform linear feeding motion under the control of the hydraulic system and the travel switch.

Owner:JIANGSU GAOCHUN CERAMICS +1

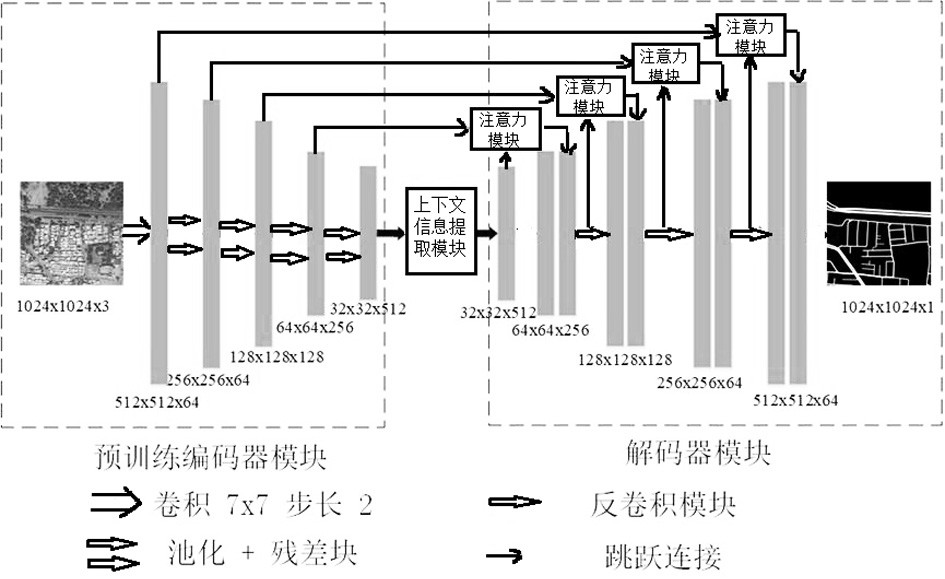

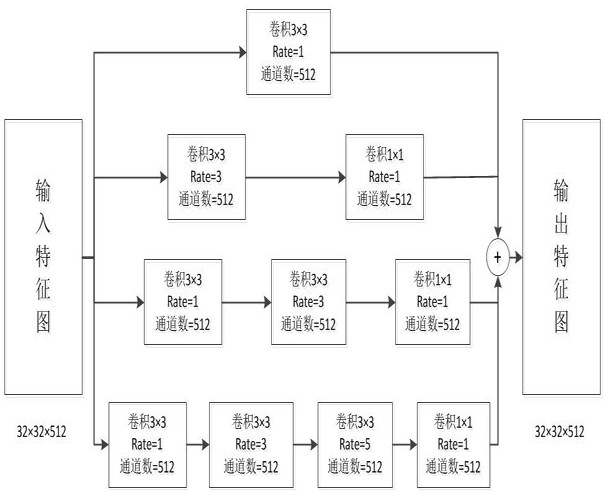

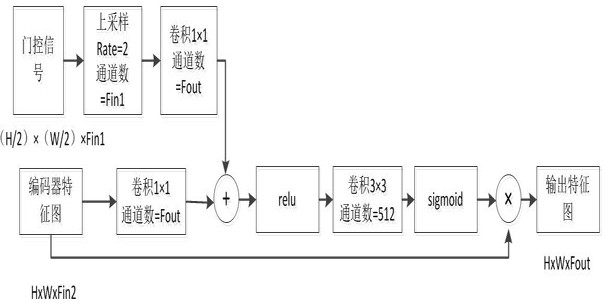

Remote sensing image road segmentation method based on context information and attention mechanism

InactiveCN112183258ARealize the downsampling effectGuaranteed segmentation effectScene recognitionNeural architecturesData setComputer vision

The invention discloses a remote sensing image road segmentation method based on context information and an attention mechanism, and belongs to the technical field of remote sensing image road segmentation methods. The technical problem to be solved is to provide an improvement of a remote sensing image road segmentation method based on context information and an attention mechanism. According tothe technical scheme, the method comprises the steps of dividing a remote sensing image data set into a training set and a test set according to a certain proportion; establishing a remote sensing image road segmentation network, wherein the remote sensing image road segmentation network comprises a context information extraction module and an attention module; inputting the preprocessed trainingset data into a remote sensing image road segmentation network, and training the remote sensing image road segmentation network; inputting the test set data into a trained remote sensing image road segmentation network, and outputting an accurate segmentation result of the image road data; the method is applied to image road segmentation.

Owner:TAIYUAN UNIV OF TECH

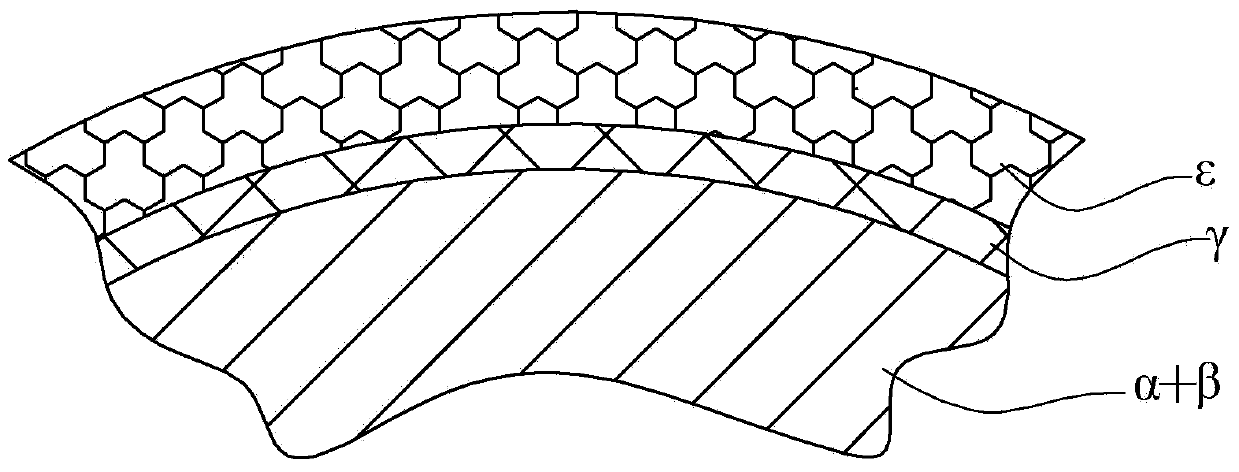

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

Automatic cutting machine for artificial wood fiber board

InactiveCN107127827ARealize the function of automatic cuttingReduce labor intensityGuide fencesGripping devicesFiberEngineering

The invention relates to an automatic cutting machine for an artificial wood fiber board. The automatic cutting machine for the artificial wood fiber board comprises a base board, a movable pushing device is mounted at the rear end of the base board, two supporting boards are symmetrically mounted in the middle of the base board, a first supporting roller is mounted between the inner walls of the upper ends of the two supporting boards through a bearing, a cutting device is mounted at the front end of the base board, and the movable pushing device and the cutting device cooperate with each other to complete the automatic processing technology of boards. The automatic cutting machine can solve the problems that workers need to use clamps to push the boards and use a disk saw to cut the boards when using a traditional cutting method to conduct cutting processing in small-sized board processing factories, the cutting precision is low, clamps need to be replaced manually according to needs of different board widths, the labor intensity is high, the traditional board cutting method can only conduct cutting in one direction, the boards need to be processed for a second time, and the working efficiency is low; and the automatic cutting machine can achieve the function that the boards are cut automatically.

Owner:广西鹿寨通用人造板有限公司

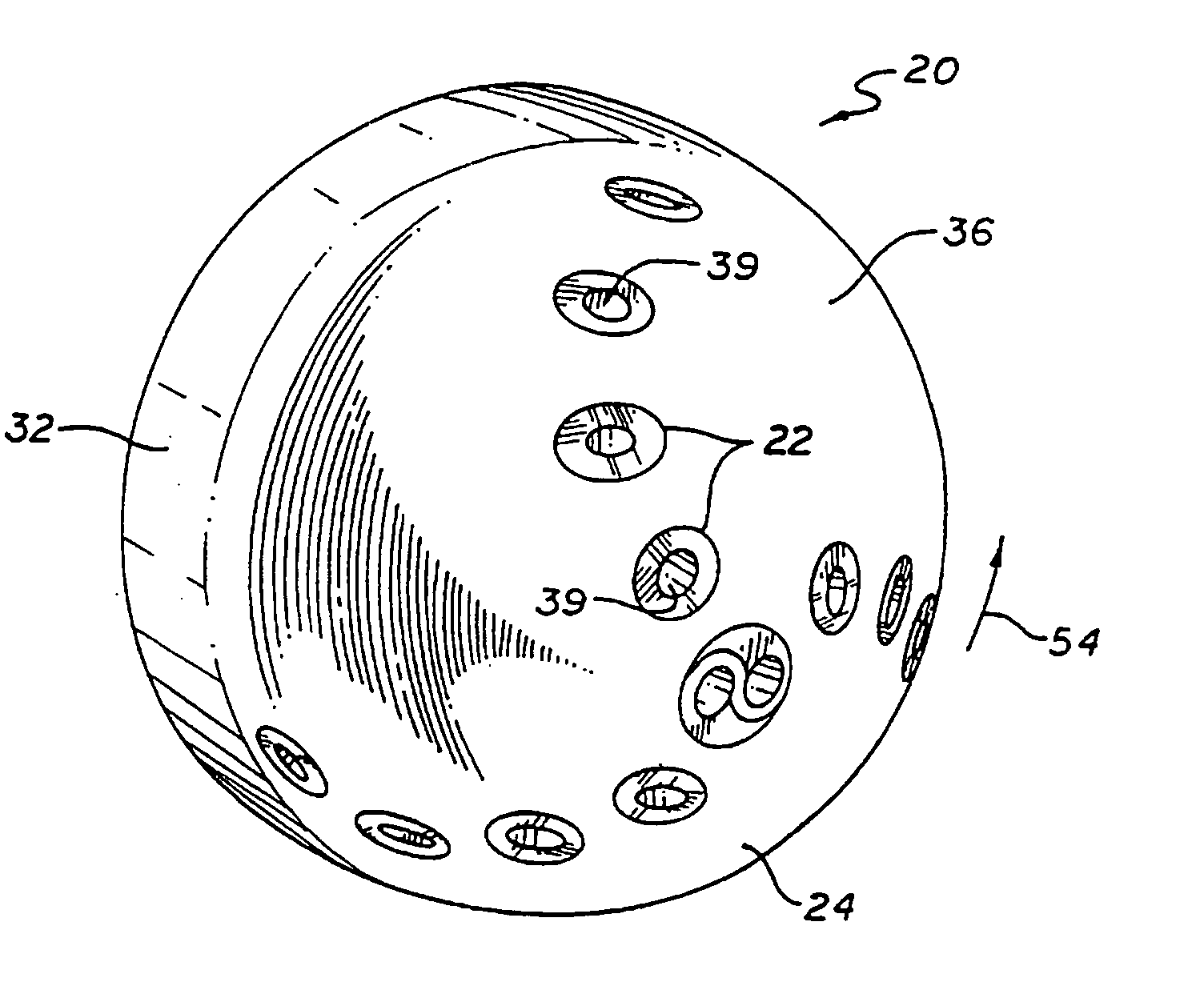

Connector for domed cutting tool

InactiveUS7048740B2Easy to remove and replaceImprove cutting accuracySurgeryPaving detailsEngineeringReamer

The surgical reamer has a hollow dome with apertures spaced apart arranged in arcs extending from an apex of the dome to the base portion of the dome, and removable teeth positioned in the apertures. Each cutting tooth has a flange that is aligned flush with the external surface of the dome, and a raised cutting edge extending above the flange and the external surface of the dome, and an interior passageway communicating between the outside and inside of the dome. In one embodiment, a base plate is removably secured on the base portion of the dome to provide closure of the central cavity of the dome.

Owner:VIANT AS&O HLDG LLC

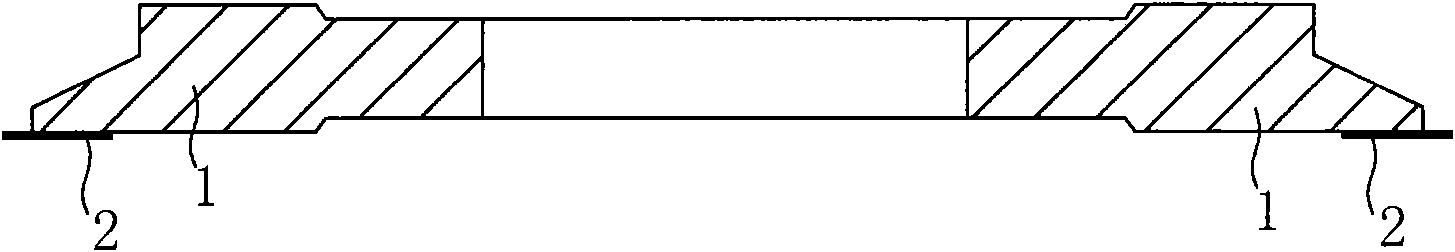

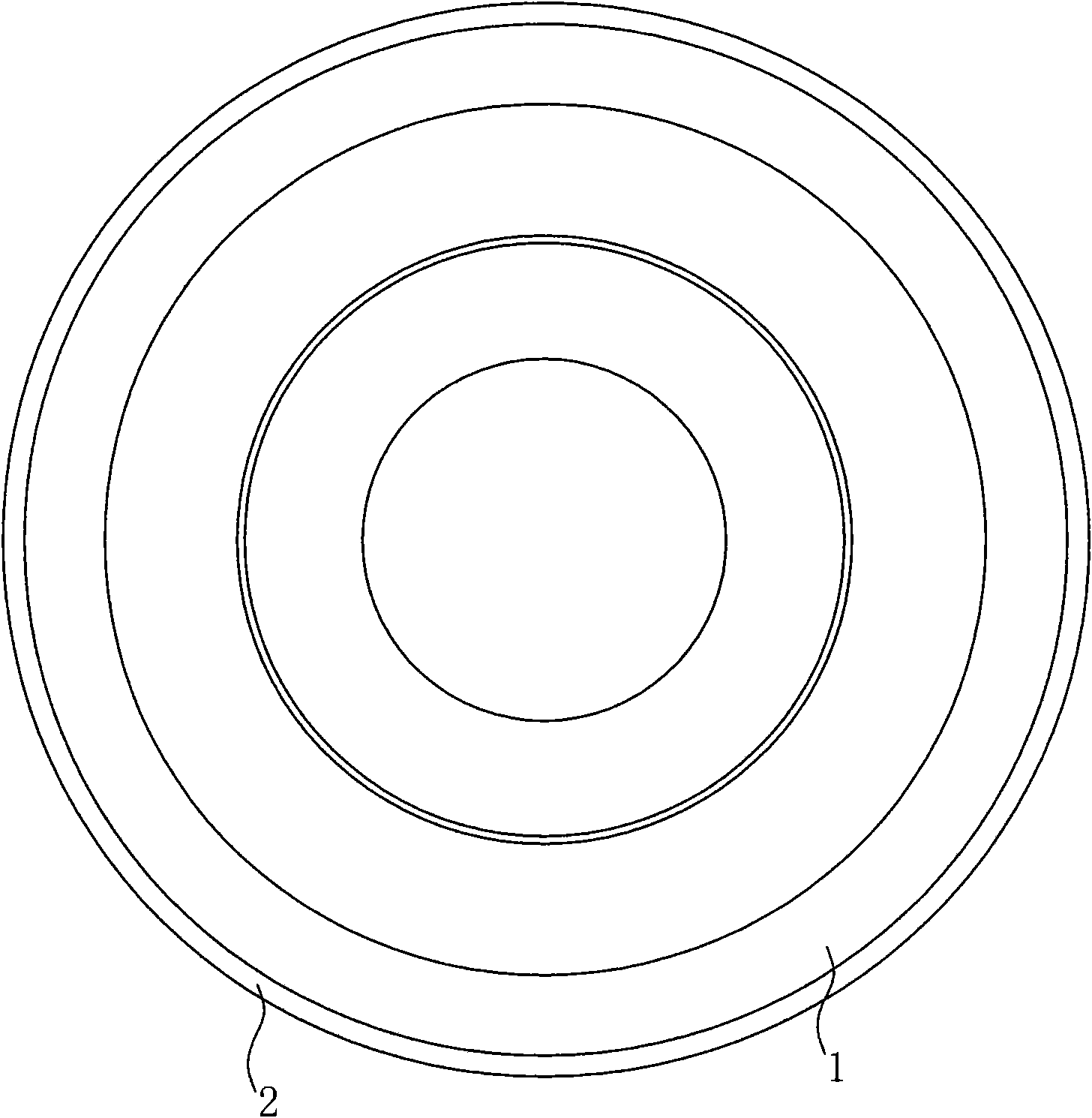

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

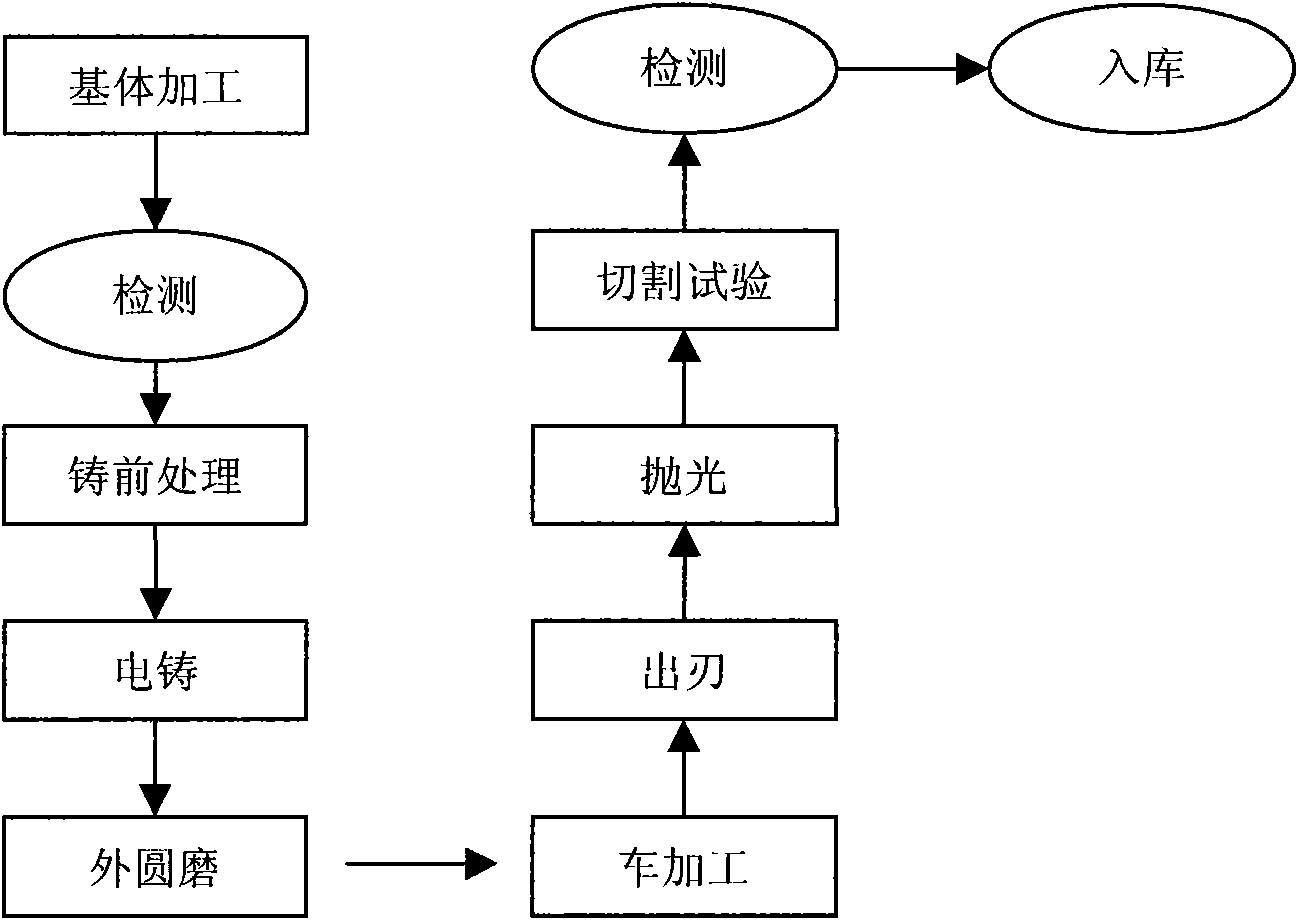

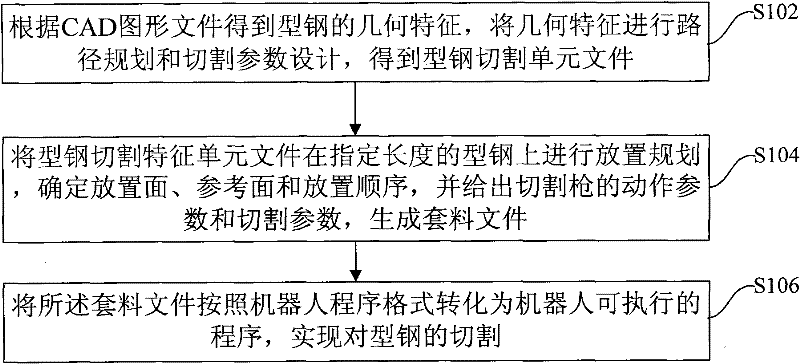

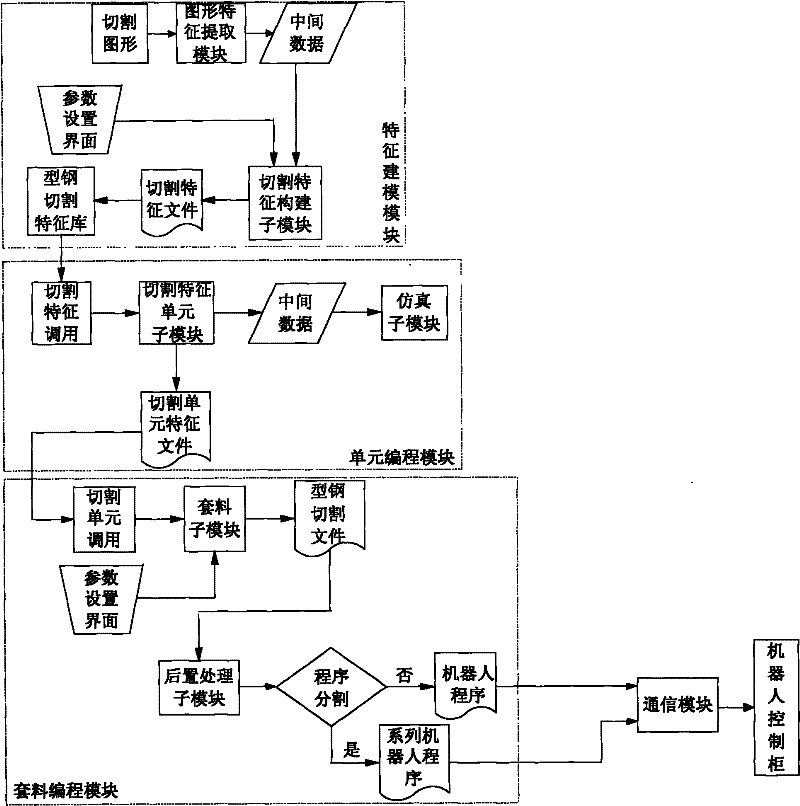

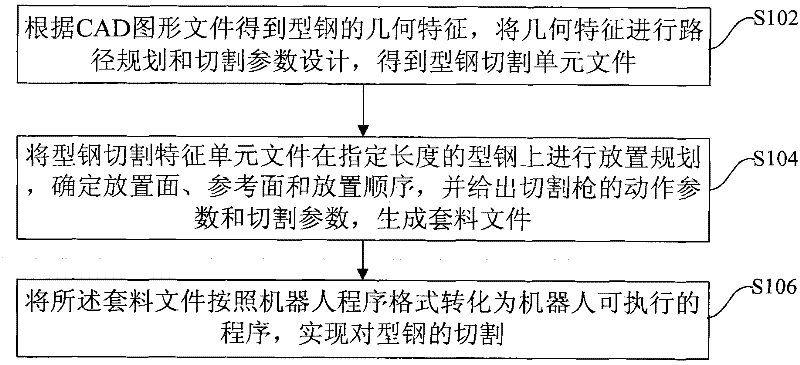

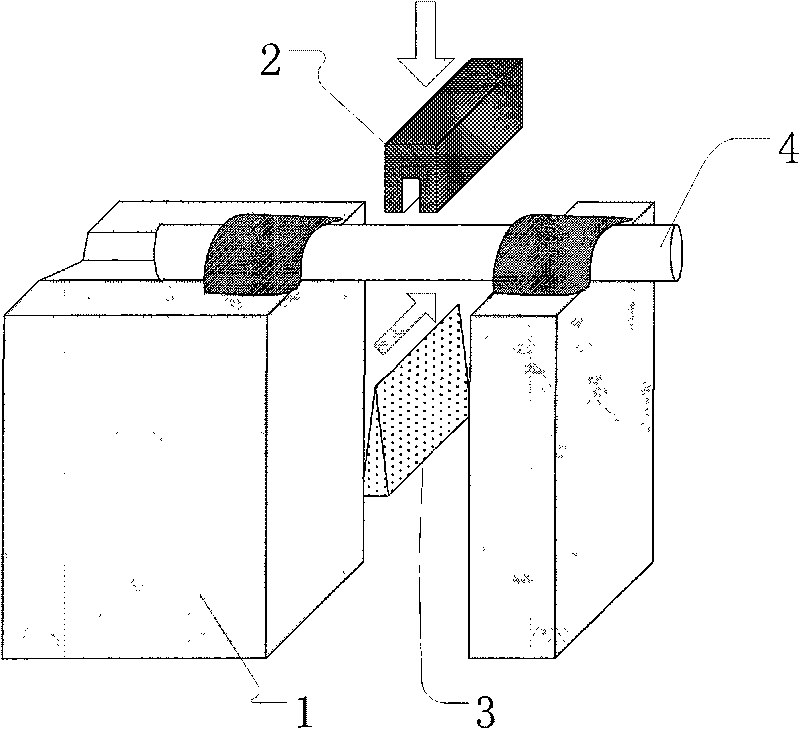

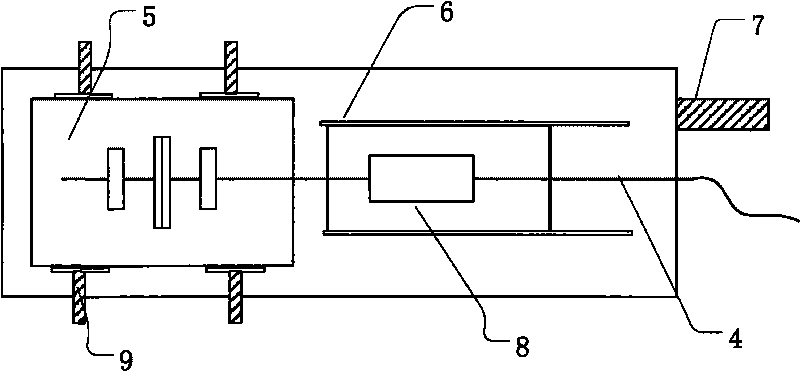

Robotic cutting method for profile steel

ActiveCN102189348AImprove cutting accuracyImprove cutting efficiencySpecial data processing applicationsWelding apparatusGraphicsDesign information

The invention discloses a robotic cutting method for profile steel, which is based on the robot offline programming. The method comprises the following steps of: reading a CAD graphics file to obtain geometrical characteristics of profile steel cutting; generating a cutting unit by a path planning and a cutting parameter design of the geometrical characteristics; determining an action parameter and a cutting parameter of a cutting gun and generating a trepanning file by a placement planning of the cutting unit on profile steel having a specific length; converting the trepanning file to be a robot executable program in accordance with the robot program format, and achieving the cutting of the profile steel. Based on the robot offline programming technology, by utilizing the designed information of CAD graphics directly, the robotic cutting precision and efficiency can be increased; the method is suitable for cutting requirements of groove-type profile steels, such as V-type, Y-type andthe like and varied-groove-type profile steel; the problem of the poor cutting quality at the edge of an angle steel or other steels is solved; the method has the characteristics of generality, flexibility, high efficiency and high precision.

Owner:HARBIN INST OF TECH

Cutting device of high-precision optical fiber length and cutting method thereof

InactiveCN101726796AEasy to buildImprove cutting accuracyCoupling light guidesEngineeringOptical fiber

The invention discloses a cutting device of high-precision optical fiber length, which is characterized by comprising an optical fiber cutter and a high-precision optical fiber displacement platform which comprises an optical fiber cutter stationary fixture, an optical fiber propelling platform and a high-precision propelling reading mechanism; the optical fiber cutter is tightly fixed at the left side of the high-precision optical fiber displacement platform through the stationary fixture, and comprises a cutter blade and a pressing broken arm matched with the cutter blade to work; the optical fiber propelling platform is arranged at the right side of the high-precision optical fiber displacement platform by the high-precision propelling reading mechanism, and can drive the optical fiber which is to be cut with a fixed upper part, to precisely move to the direction of the optical fiber cutter under the action of the high-precision propelling reading mechanism. The device overcomes the defects in the prior art, and can realize cutting precision at 0.01mm magnitude.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

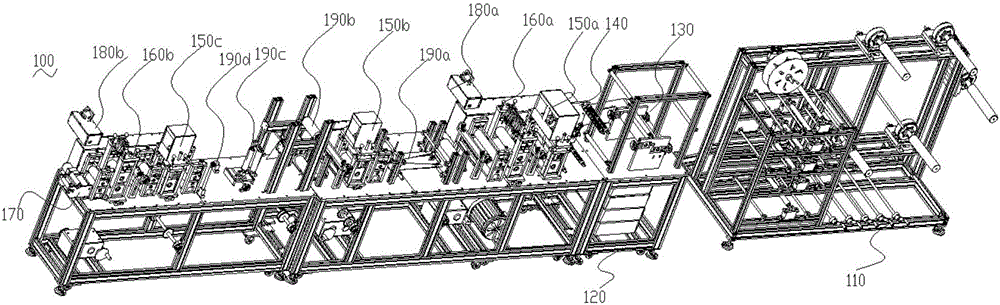

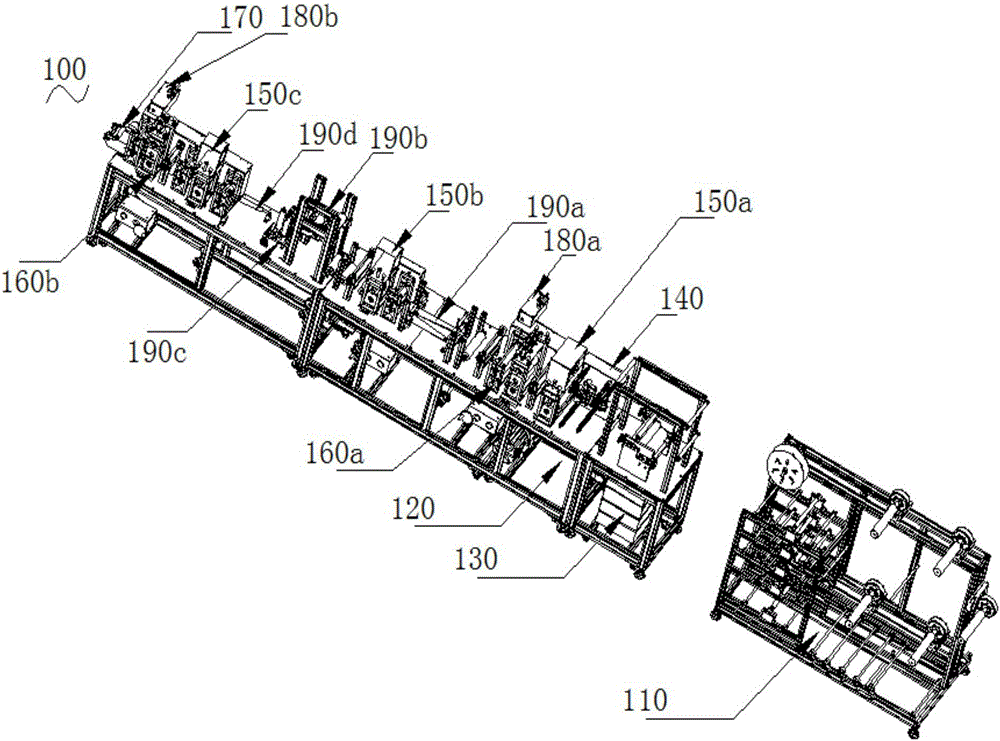

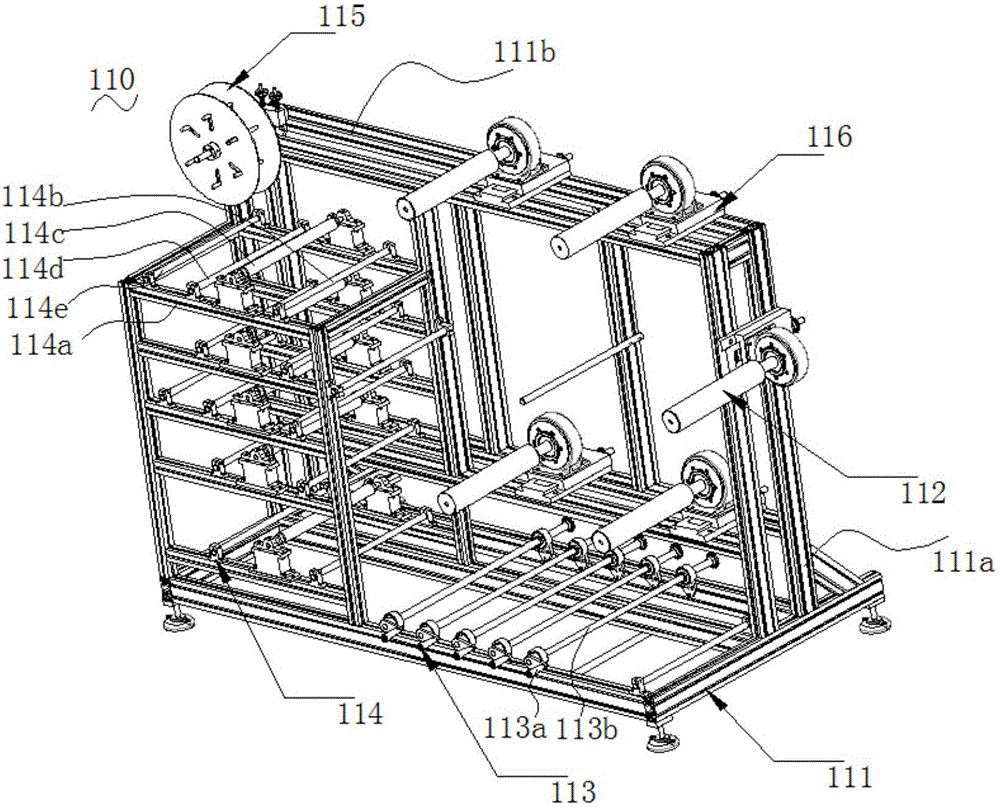

Face mask body making machine

ActiveCN105725309AHigh degree of automationImprove work efficiencyProtective garmentWoven fabricElectrical and Electronics engineering

The invention relates to the field of face mask production equipment, in particular to a face mask body making machine. The face mask body making machine comprises a feeding mechanism, a frame, a printing mechanism, a fixed nose bridge strip mechanism, a pattern mechanism, a cutting mechanism, a waste material collecting mechanism and a discharging mechanism, wherein the feeding mechanism is used for feeding non-woven fabrics and nose bridge strips; the printing mechanism is used for printing on the non-woven fabrics; the fixed nose bridge strip mechanism is used for welding the nose bridge strips on the non-woven fabrics; the pattern mechanism is used for molding patterns on the non-woven fabrics; the cutting mechanism is used for cutting corners of the non-woven fabrics on which the patterns are molded; the waste material collecting mechanism is used for recovering waste scraps; the discharging mechanism is used for discharging finished face masks; the printing mechanism, the fixed nose bridge strip mechanism, the pattern mechanism, the cutting mechanism, the waste collecting mechanism and the discharging mechanism are all arranged above the frame, and are all positioned behind the feeding mechanism. The face mask body making machine has high production efficiency, and has contribution to improvement of the face mask quality.

Owner:东莞市南方力劲机械有限公司

Automatically controlled high-precision crystal wire electrode cutting machine

InactiveCN1387979AImprove rigidityAvoid deformationFine working devicesMetal working apparatusEngineeringMechanical engineering

The present invention relates to cutting equipment and is especially one computerized efficient and high-precision wire electrode cutting machine. The cutting machine consists of frame, winding cylinder driven by one DC motor to rotate in either right direction or reverse direction, Z-axis bench, Y-axis bench, tension mechanism with one pair of tension wheels controlled by one pair of micro cylinders to support the cutting wire, oscillating mechanism with one pair of oscillating support wheels and fixture. The cutting machine is used mainly for cutting silicon wafer, quartz glass, ceramic, jewel, magnesia and other hard and fragile material.

Owner:沈阳科晶设备制造有限公司

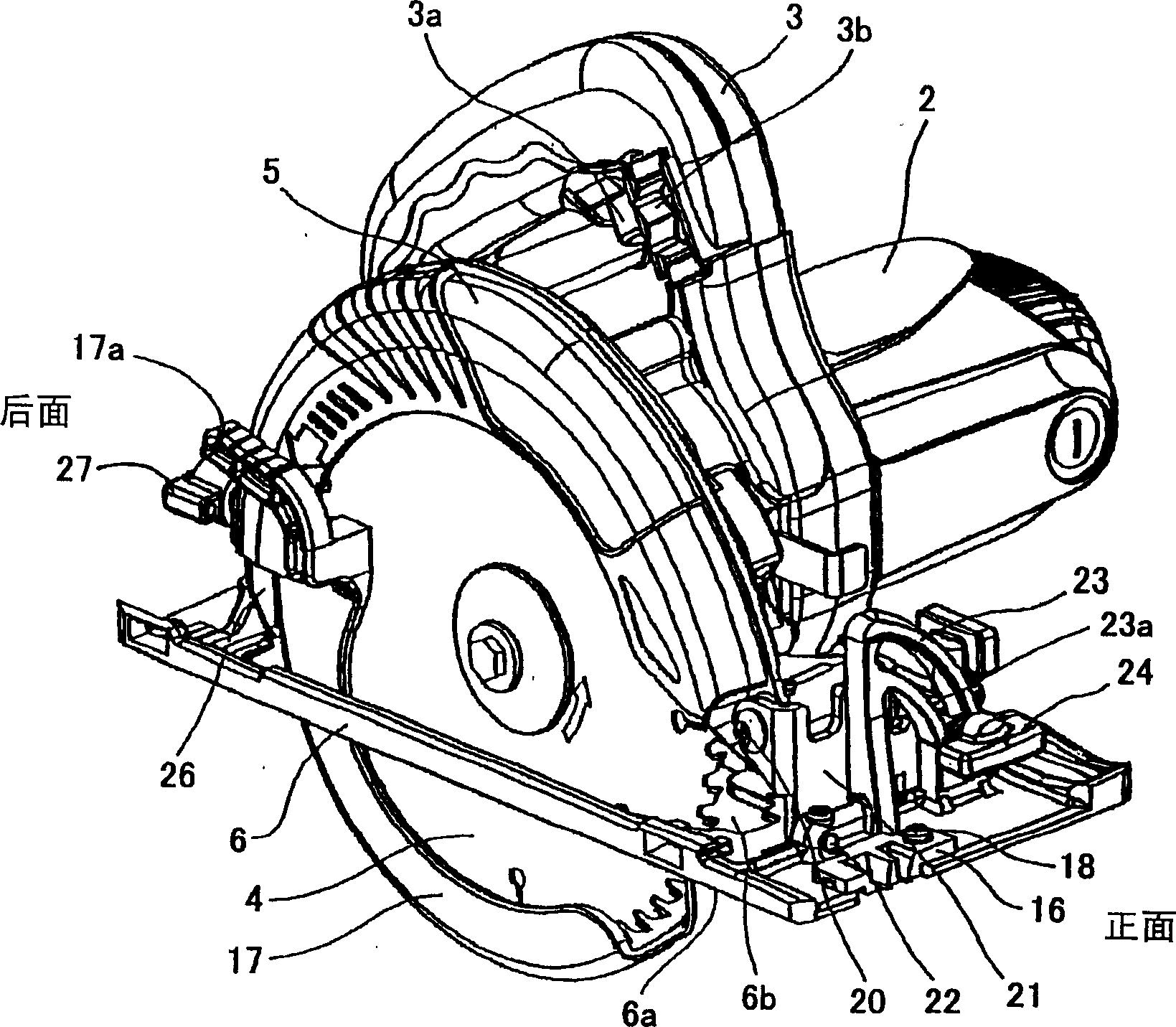

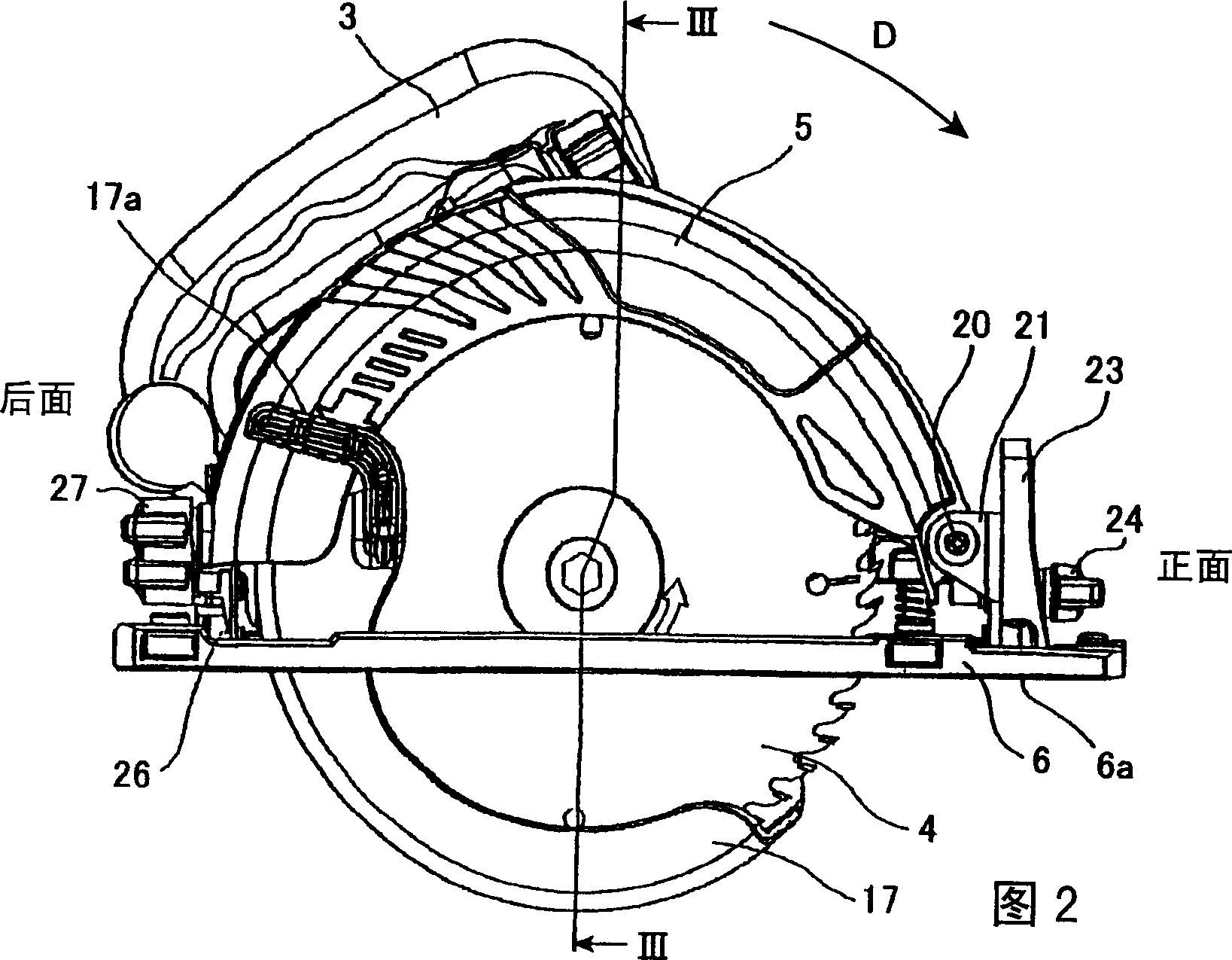

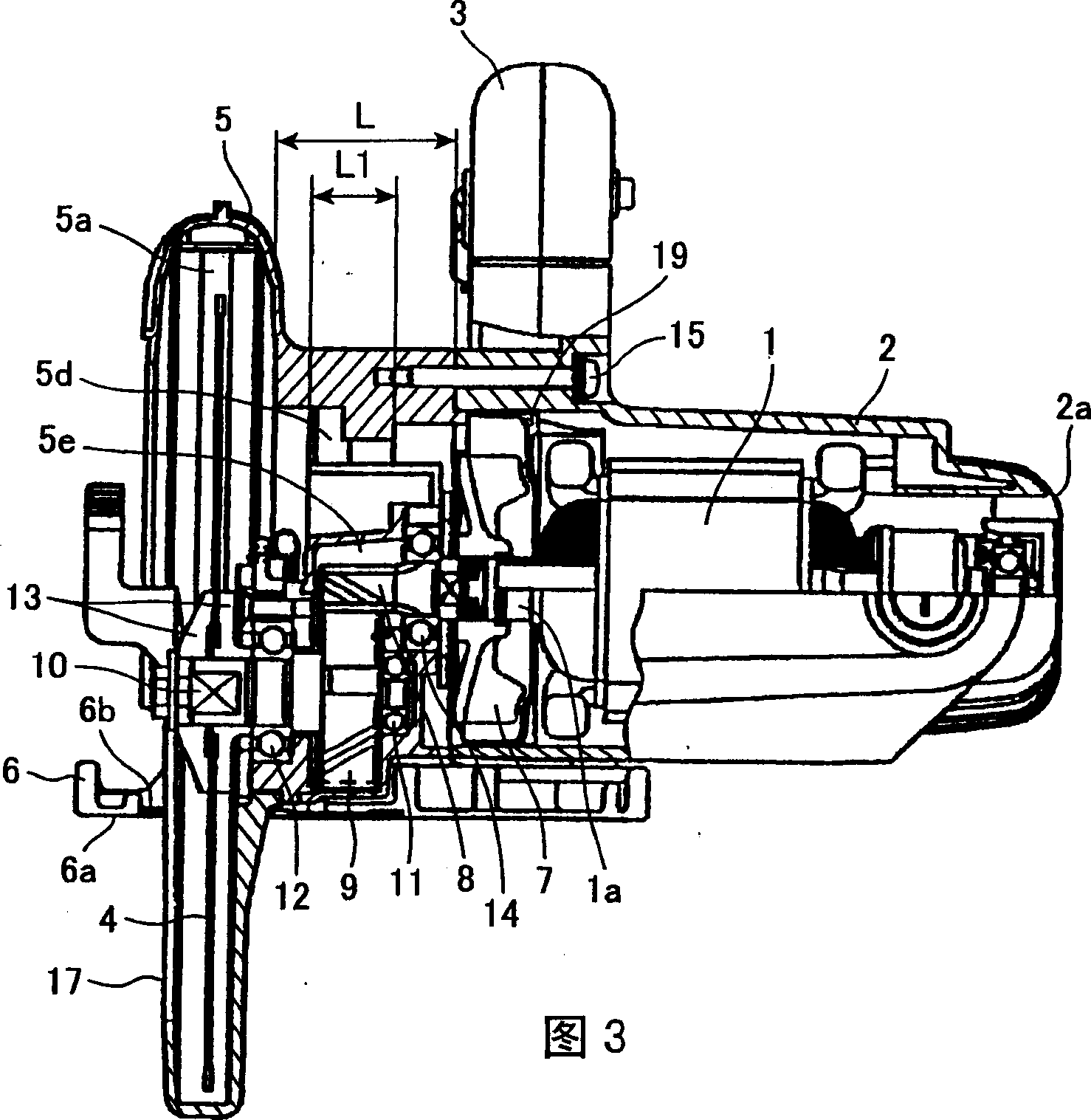

Portable electric cutting device with blower mechanism

ActiveCN1496800AAvoid accumulationImprove cutting accuracyPortable power driven sawsBark-zones/chip/dust/waste removalEngineeringMechanical engineering

Fanned air generated by a fan to cool a motor is discharged from a housing through fanned air discharge ports toward an opening formed in a base. The fanned air discharged toward the opening is then introduced into a groove in fluid communication with the opening. The groove is formed in a bottom surface of the base and has an open side at a front side of the base. The fanned air is then discharged from the front side of the base, blowing off saw dust on a cutting object so as to prevent dust from accumulating on a marking line on the cutting object.

Owner:HITACHI KOKI CO LTD

Cloth slitter

InactiveCN105619505APrevent affecting cutting accuracyGood cutting precisionSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention mainly discloses a cloth slitter. According to the technical scheme, the cloth slitter comprises a machine frame, a machine head, a machine tail, a moving device, a cutting device, a knife sharpening device and a PLC control cabinet; a loop bar is arranged between the machine head and the machine tail; the cutting device is connected to the upper side of the moving device; the PLC control cabinet controls the moving device and the cutting device; the cutting device comprises a cutting frame, a first motor, a cutting knife and an air cylinder; the knife sharpening device comprises a supporting frame, a first polishing support, a second polishing support and a pair of polishing modules, wherein the first polishing support and the second polishing support are installed on the two sides of the supporting frame respectively in an inclined mode and are connected to the respective corresponding polishing modules, and the polishing modules are located on the two sides of the cutting knife respectively. The cloth slitter has the advantages of being simple in structure, convenient to operate, accurate in cutting and capable of polishing the cutting knife.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

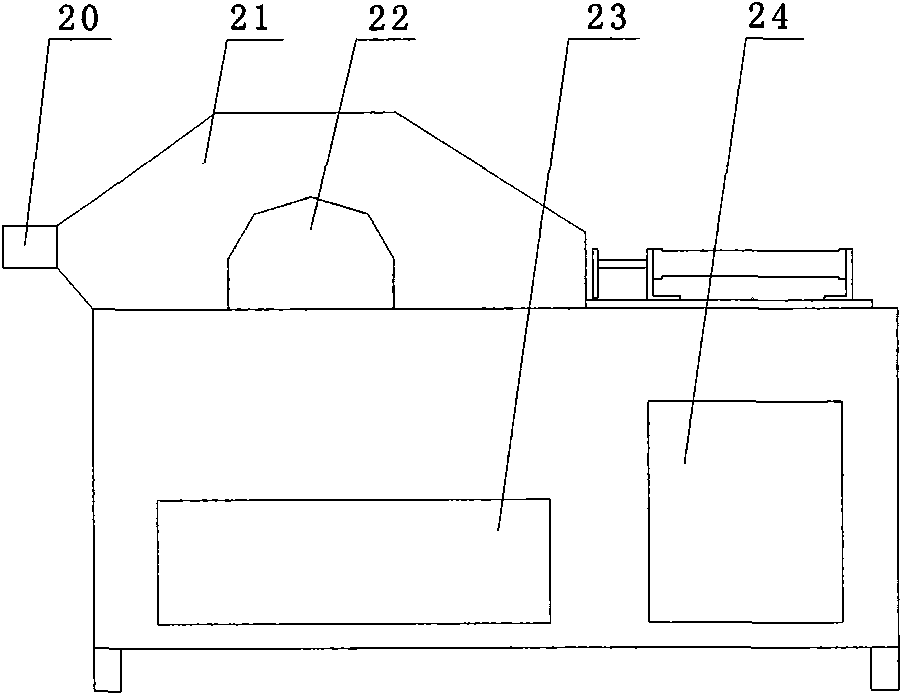

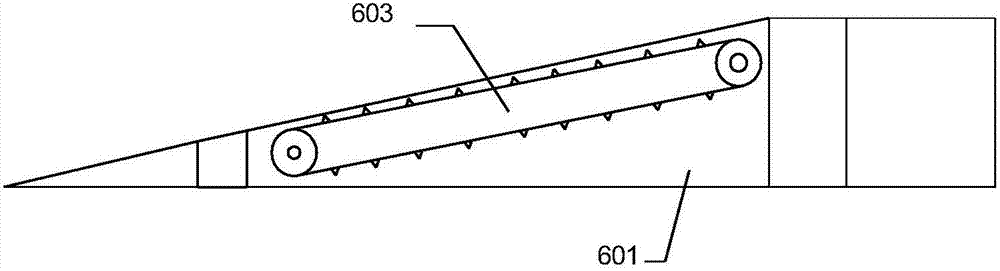

Adjustable turf harvester

InactiveCN107347274AImprove harvesting efficiencyImprove cutting accuracyHops/wine cultivationTurf growingEngineeringSoil horizon

The invention discloses an adjustable turf harvester, which comprises a car body; the left side wall of the car body is fixedly connected with a beam plate; the left side of the beam plate is provided with a turf cutting device; the right side of the turf cutting device is provided There is a shovel device. The present invention is equipped with a turf cutting device and a turf shoveling device with an adjustable width, which can cut the turf into a specified width according to the needs and efficiently shovel and collect it, greatly improving the harvesting efficiency and cutting accuracy of the turf, and ensuring the turf block The thickness of the soil layer is consistent; the invention is equipped with a turf cutting device, which can cut out a specified area of turf according to the needs, so as to realize accurate harvesting; the invention is equipped with a rotatable lifting plate, which is convenient for unloading the turf, and is convenient for shipment and subsequent laying.

Owner:ZHENGZHOU BINGTONG LIZHI ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com