High-accuracy zinc base alloy electrode wire and preparing method thereof

一种合金电极、高精度的技术,应用在电极制造、金属加工设备、电动加工设备等方向,能够解决机床的冲洗系统要求高、影响加工精度、阻碍加工精度等问题,达到降低热处理温度和热处理时间、提高切割加工精确度、提高切割精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

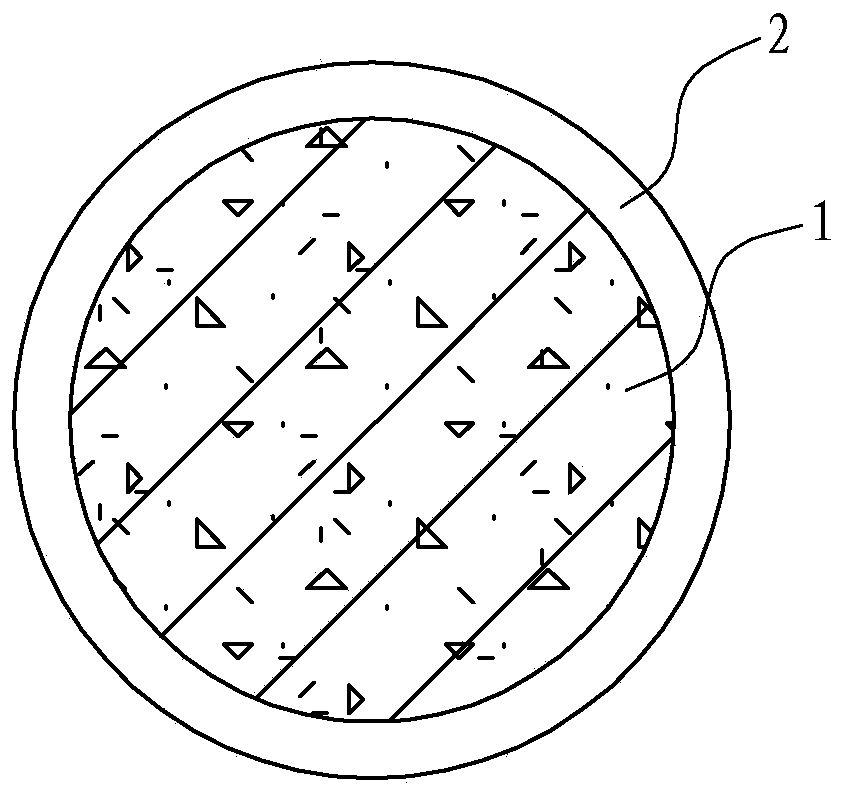

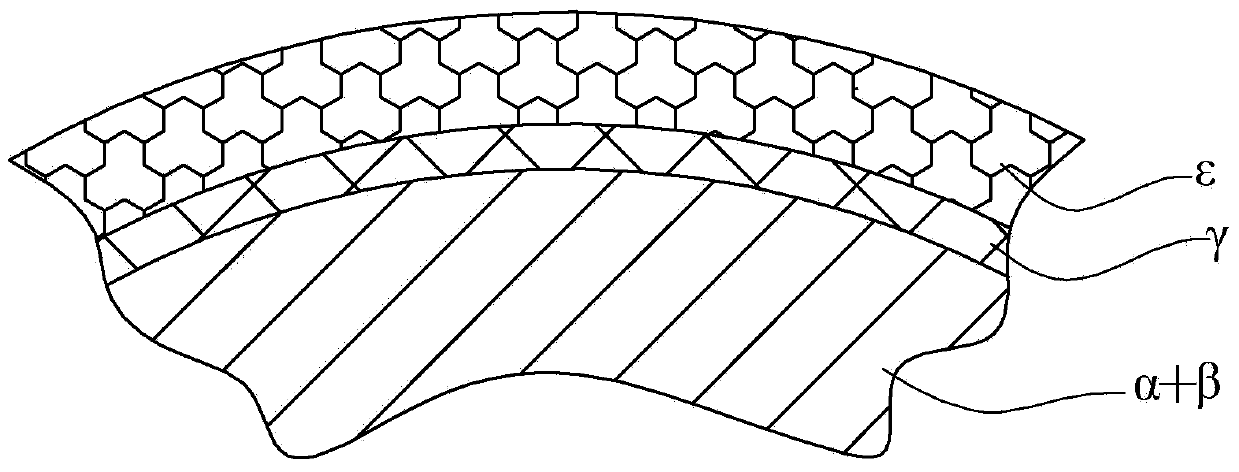

[0041] The alloy batching is carried out in proportion, and the mass percentage of the composition is: Cu: 65%, Ni: 2.0%, Si: 1.2%, Ti: 0.12%, Co: 0.2%, the rest is Zn and is brought in by raw materials and smelting The unavoidable impurities, the total content of the unavoidable impurities is 0.5%, the ingredients are mixed and poured into an induction furnace for smelting, and an alloy wire billet with a diameter of 9mm is produced through casting. Then, the prepared wire blank is extruded or stretched and annealed to form a bus bar with a diameter of 0.5 mm, and then the prepared bus bar is subjected to degreasing-pickling-water washing-galvanizing, and the thickness of the zinc coating is 0.5um, the first wire blank is produced, in which the electroplating current is 2000A, the voltage is 200V, and then the first wire blank is continuously drawn and retracted to form the second wire blank, such as figure 1 As shown, the second wire blank includes the core material 1 and the ...

Embodiment 2

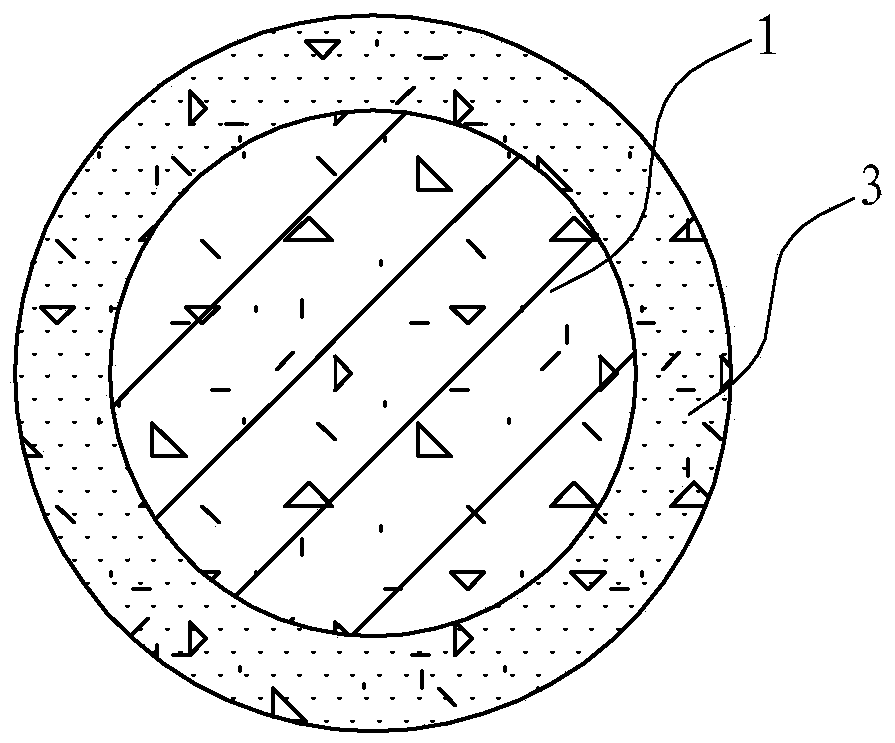

[0045] The alloy batching is carried out in proportion, and the composition of its mass percentage is: Cu: 66%, Cr: 1.5%, Zr: 1.5%, P: 0.15%, B: 0.06%, the rest is Zn and is brought in by raw materials and smelting The unavoidable impurities and the total content of unavoidable impurities are 0.3%. The ingredients are mixed and poured into an induction furnace for smelting, and an alloy wire billet with a diameter of 8mm is produced through casting. Then, the prepared wire stock is extruded or stretched and annealed to form a bus bar with a diameter of 3mm, and then the prepared bus bar is subjected to degreasing-pickling-water washing-galvanization, and the thickness of the zinc coating is 40um , The first wire blank is prepared, in which the electroplating current is 1500A, the voltage is 200V, and then the first wire blank after electroplating is continuously drawn and retreated to form the second wire blank, where the drawing speed is 500m / min, and the The post voltage is 8...

Embodiment 3

[0049] The alloy batching is carried out in proportion, and the composition of the mass percentage is: Cu: 60%, Si: 0.12%, Ag: 0.07%, Ti: 0.18%, B: 0.02%, the rest is Zn and is brought in by raw materials and smelting The unavoidable impurities, the total content of the unavoidable impurities is 0.3%, the ingredients are mixed and poured into an induction furnace for smelting, and an alloy wire billet with a diameter of 10mm is produced through casting. Then, the prepared wire blank is extruded or stretched and annealed to form a bus bar with a diameter of 4 mm, and then the prepared bus bar is subjected to degreasing-pickling-water washing-galvanizing, and the thickness of the zinc coating is 40um , The first wire blank is prepared, in which the electroplating current is 2500A, the voltage is 150V, and then the first wire blank after electroplating is continuously drawn and retreated to form the second wire blank, where the drawing speed is 1000m / min, and the The post voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com