Patents

Literature

52results about How to "High gasification temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

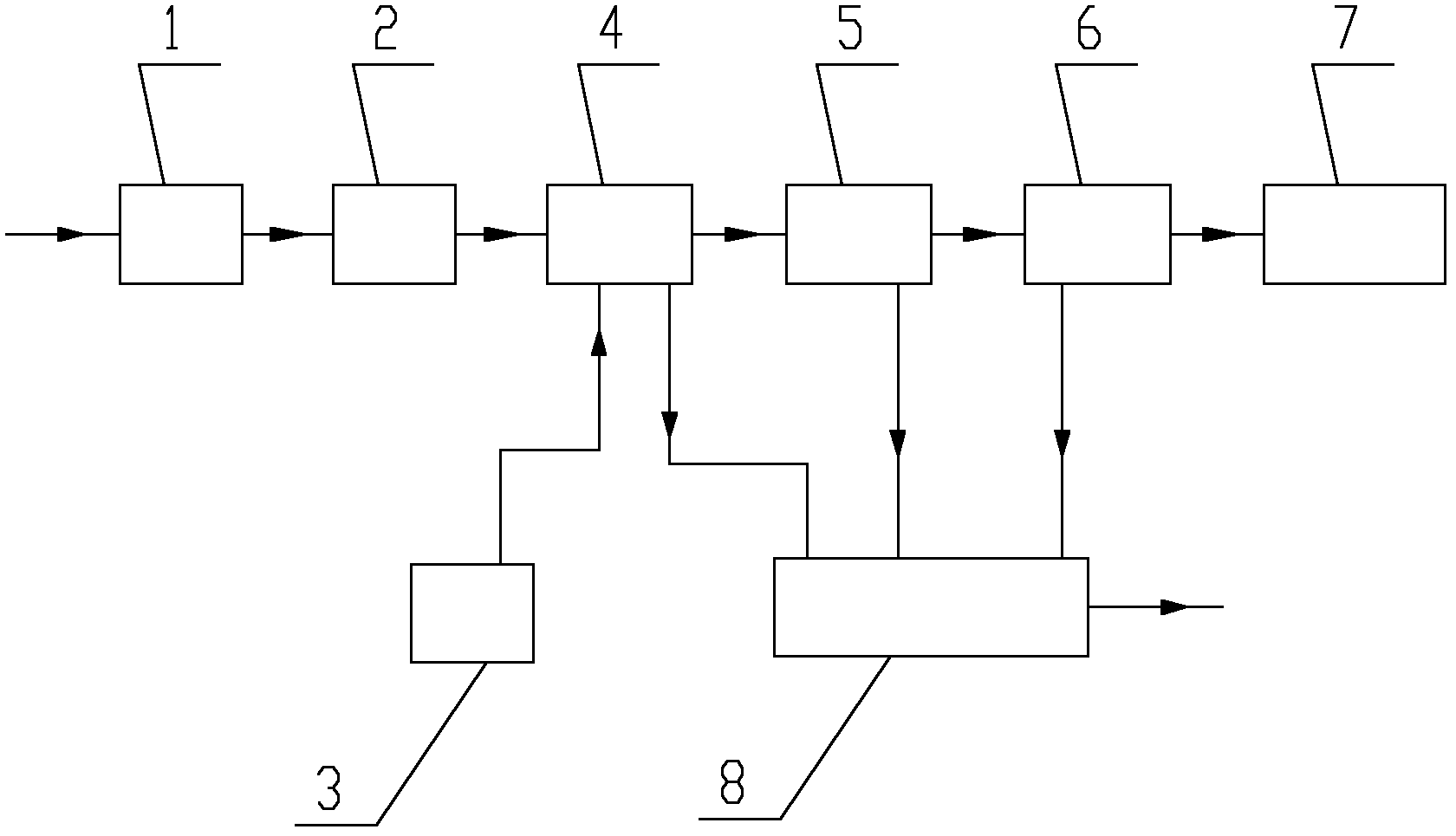

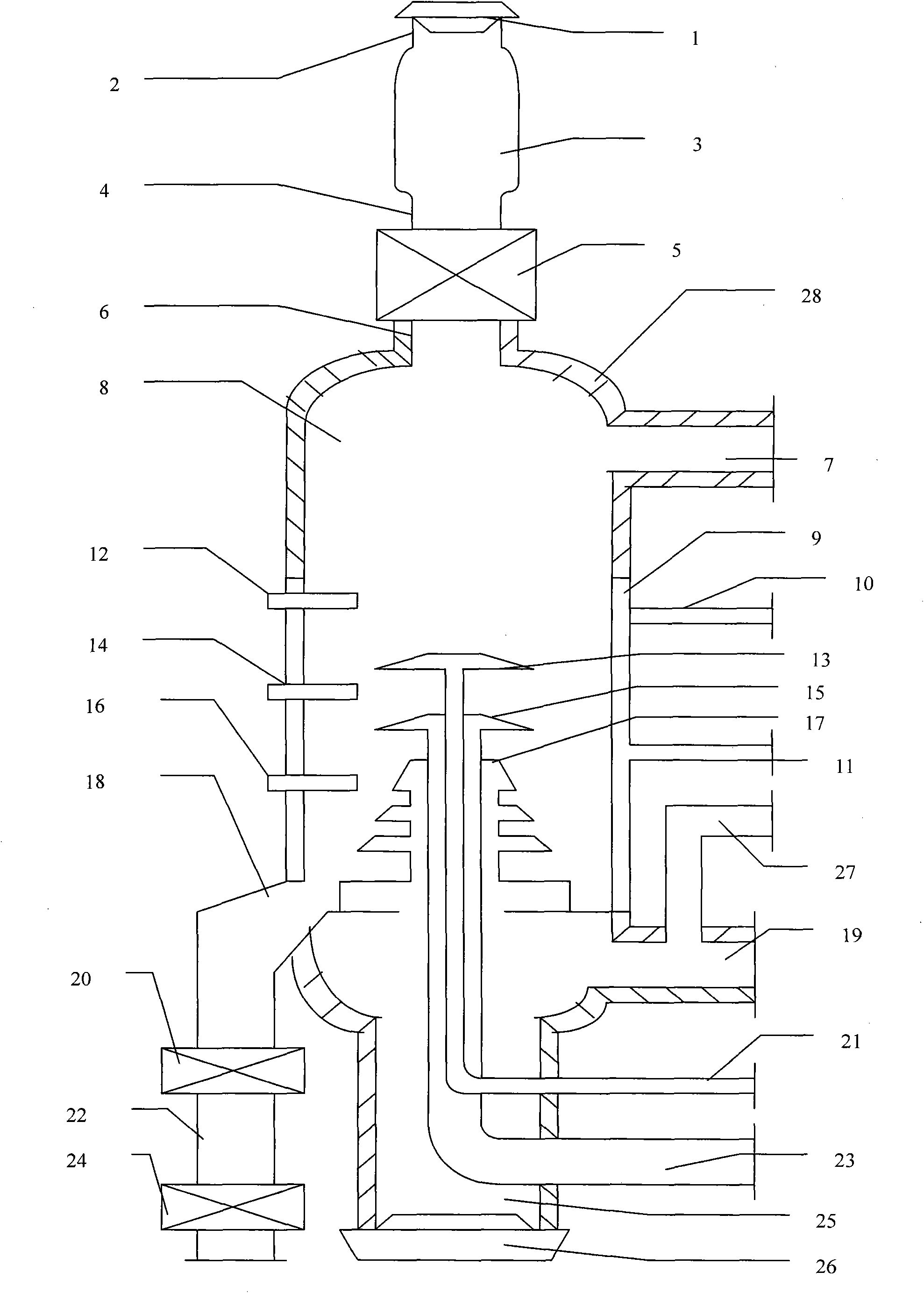

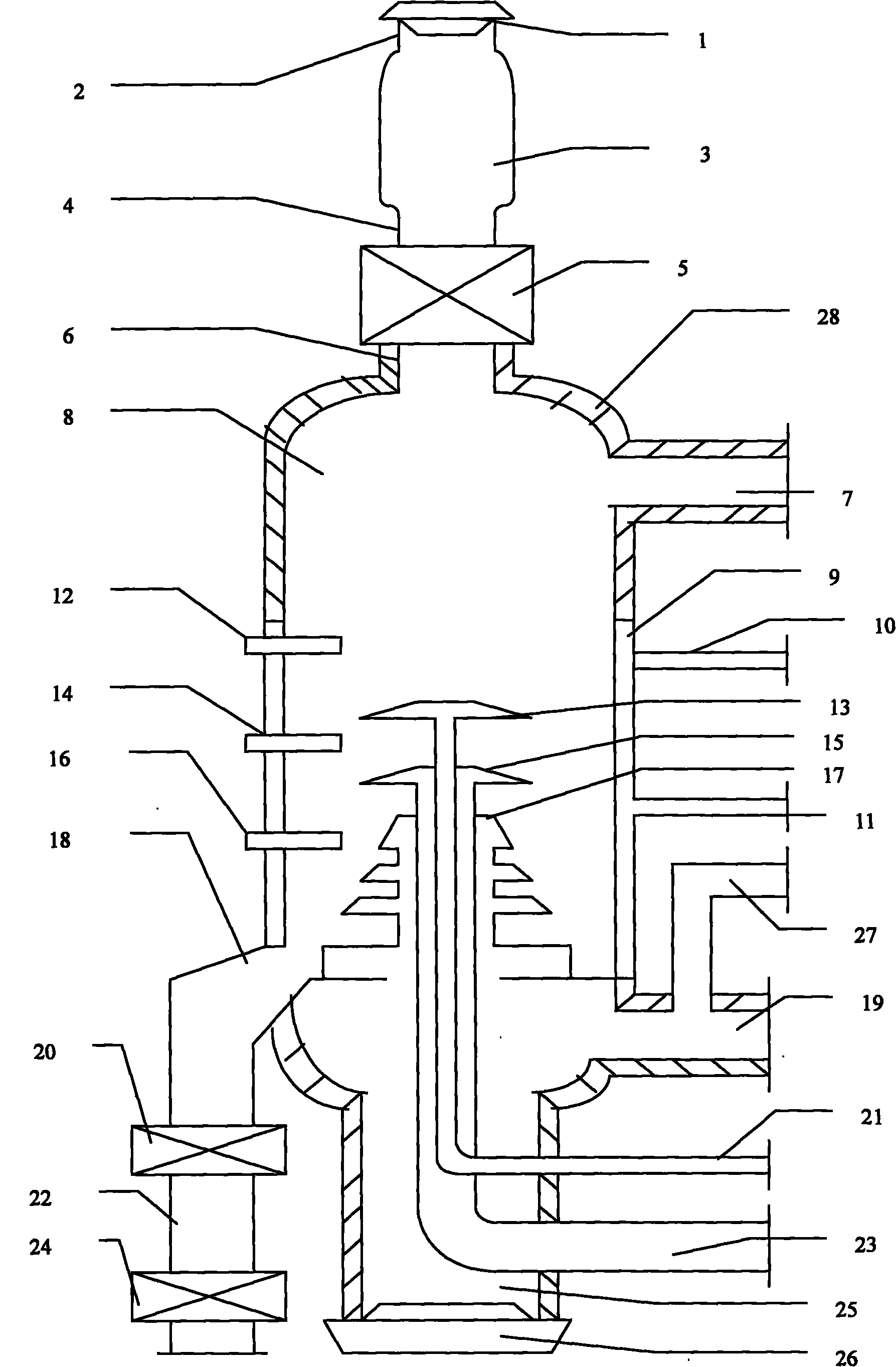

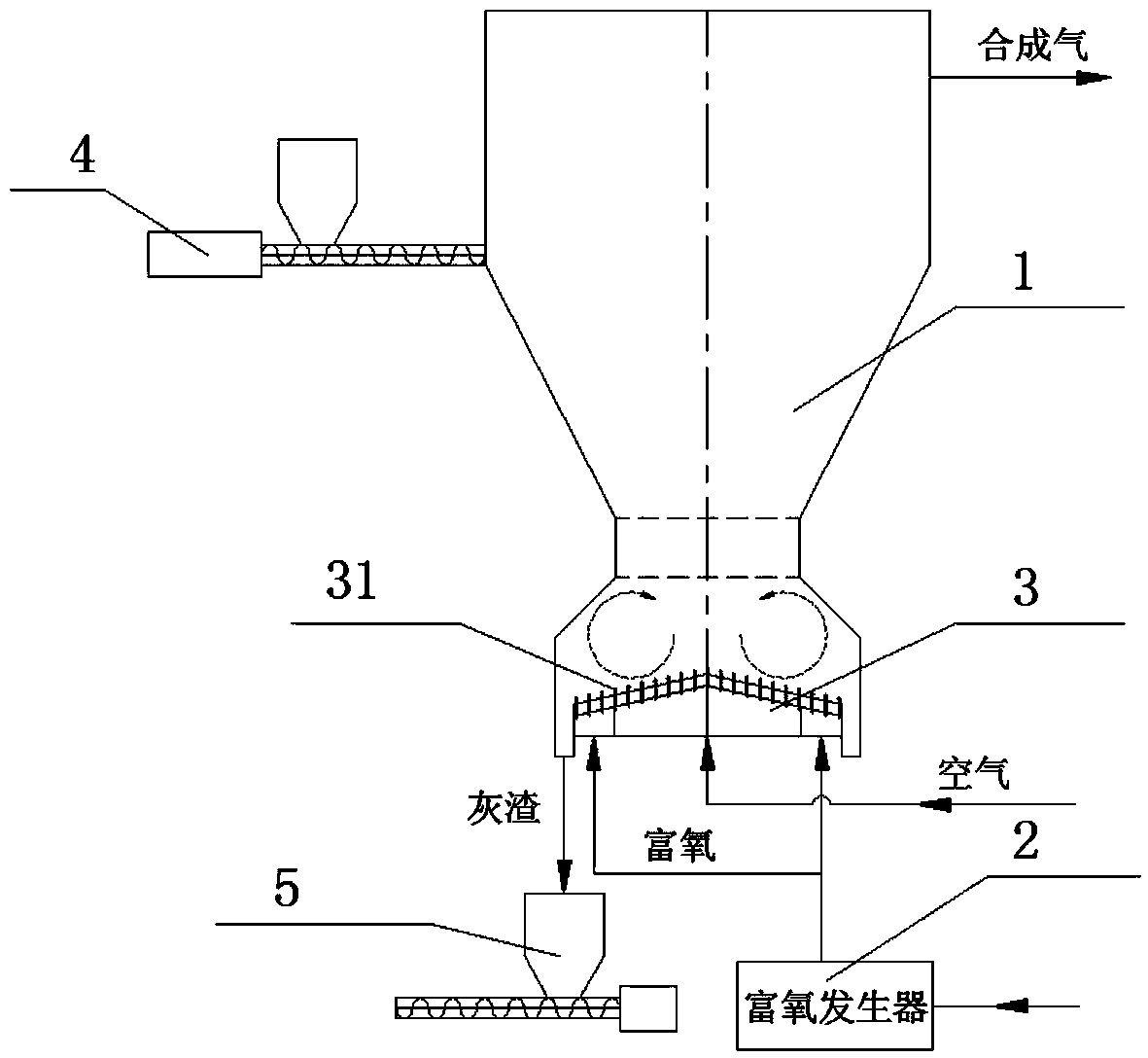

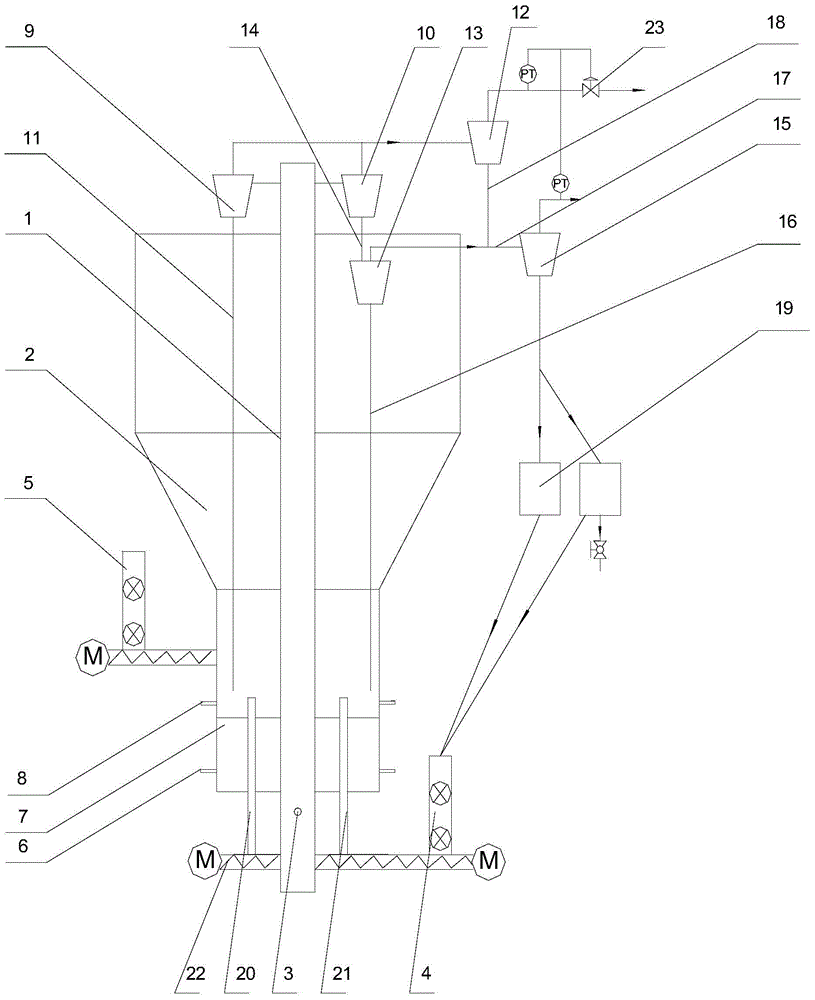

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

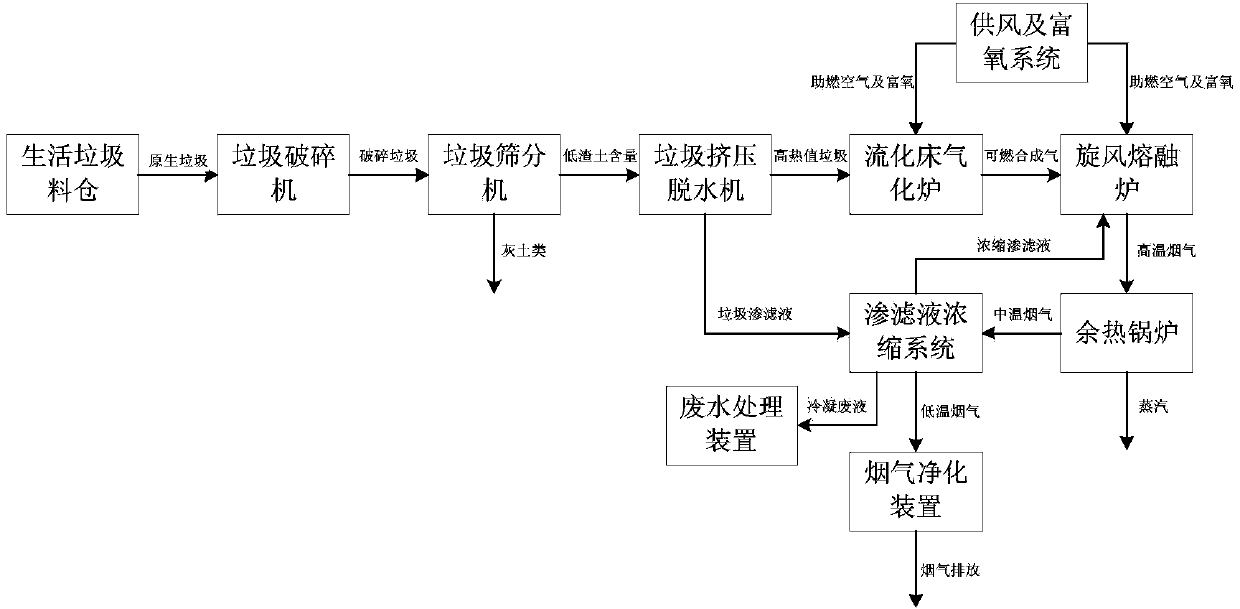

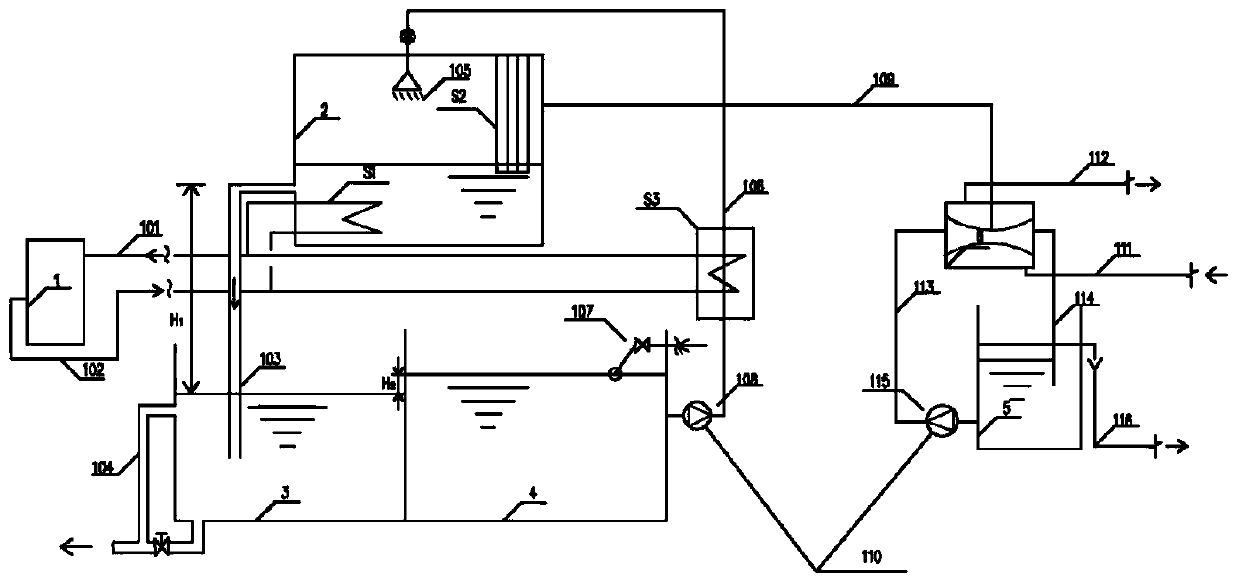

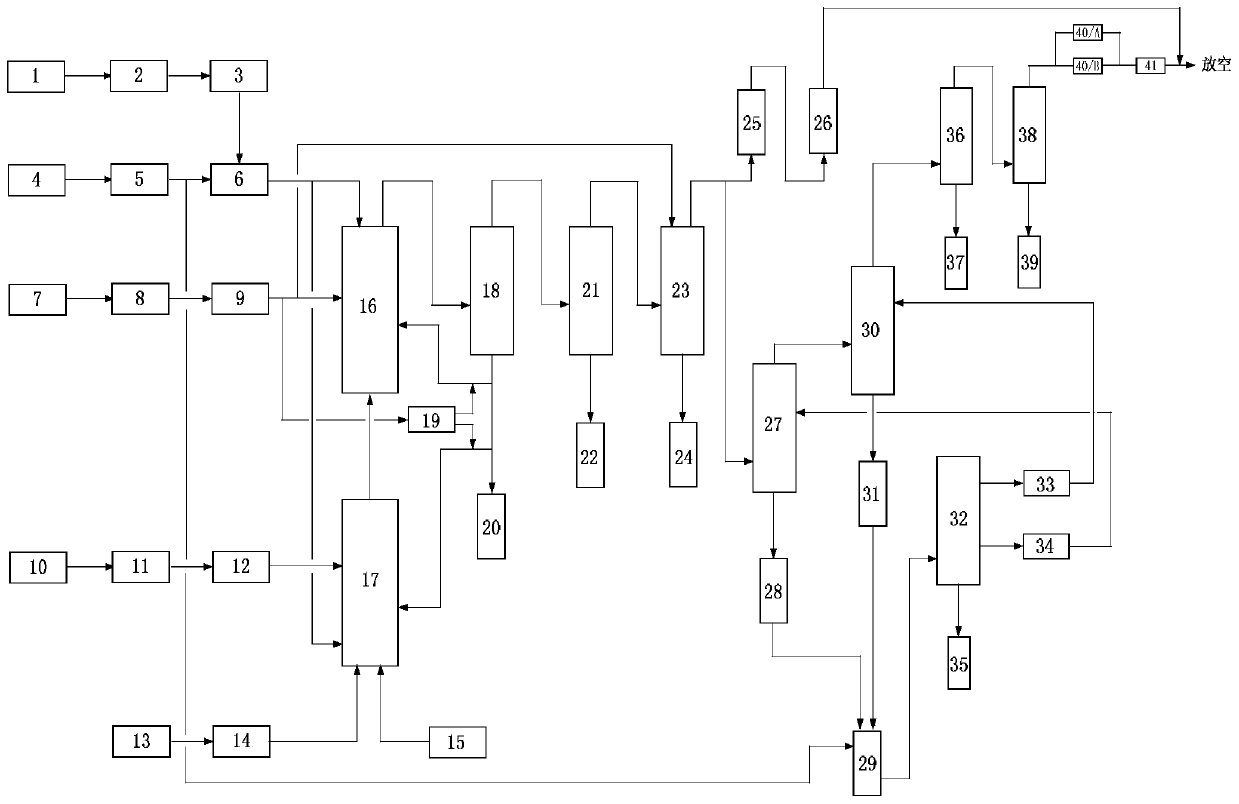

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

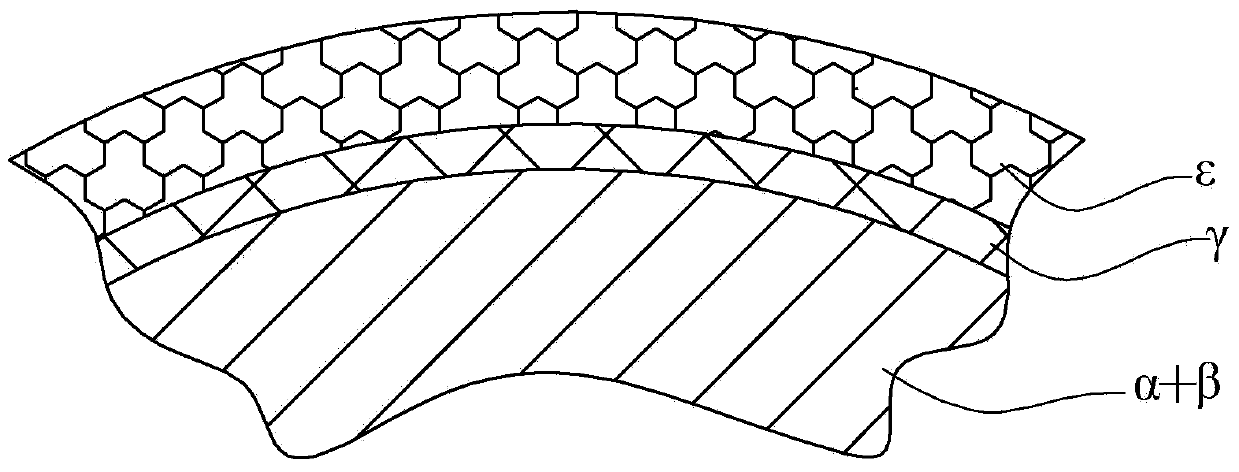

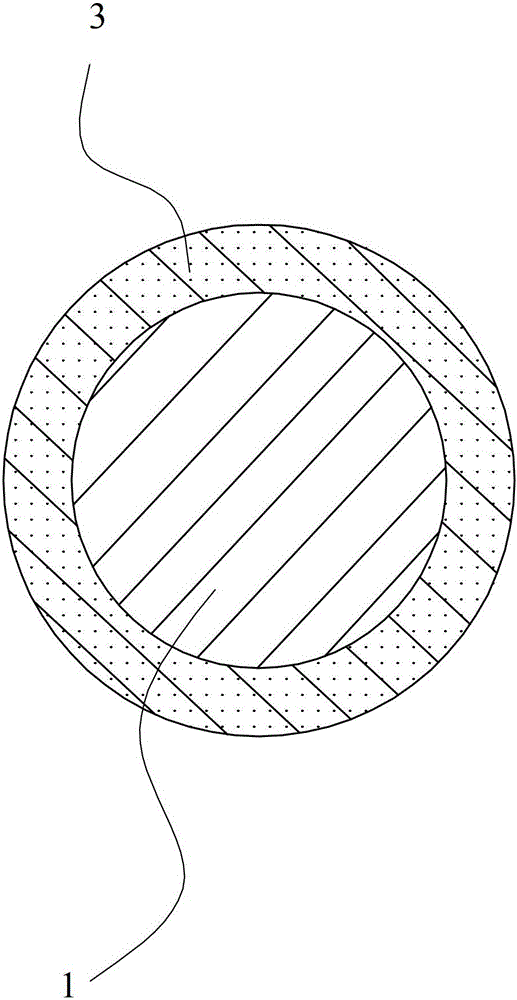

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

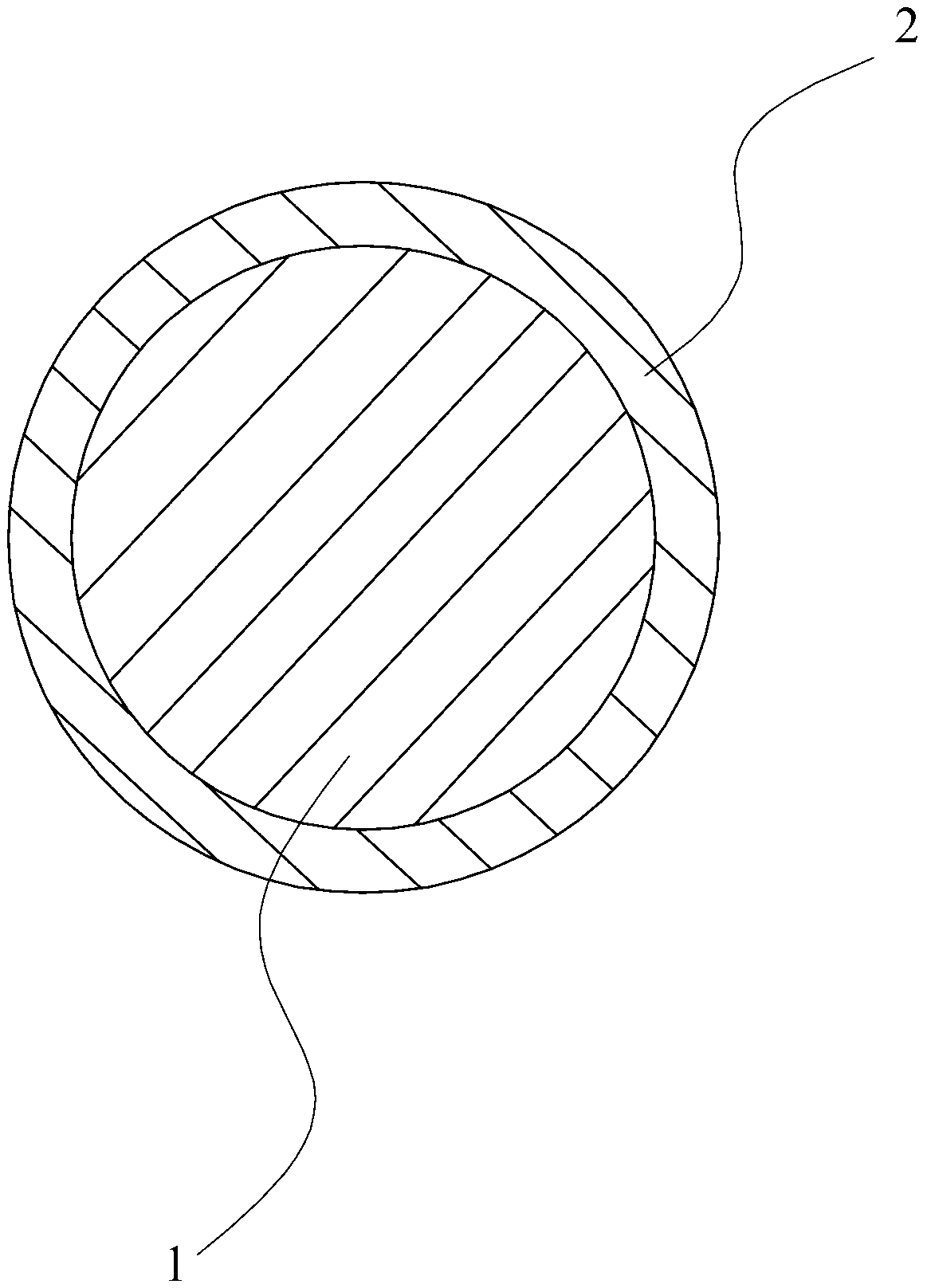

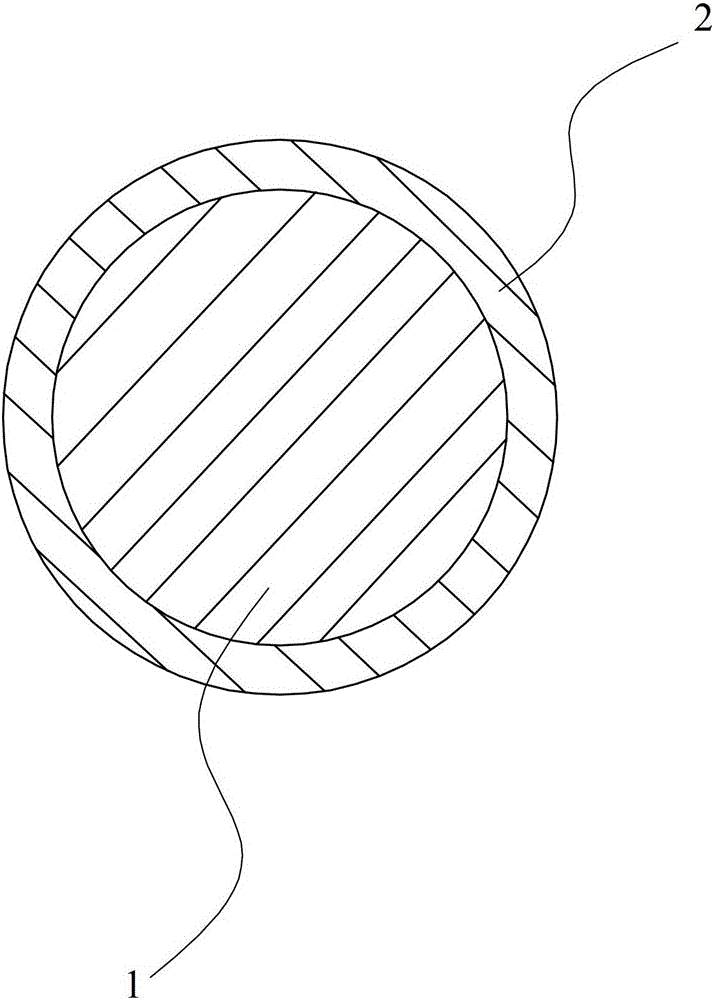

Efficient electrode wire for precision mould cutting and preparing method of efficient electrode wire

ActiveCN103273150AImprove cutting efficiencyLarge discharge energyElectrical-based machining electrodesOperabilityZinc

The invention relates to an efficient electrode wire for precision mould cutting. The efficient electrode wire comprises a core material and a shell layer wrapping the surface of the core material, the core material is made of yellow copper from the processes of smelting, casting, stretching and annealing, the shell layer is a discontinuous shell layer formed by heating, continuously drawing and continuously annealing a zinc metal plating layer plated on the yellow copper core material, and the discontinuous shell layer comprises shell particles which radially cover 40-90% of the surface of the core material and are distributed at intervals along an axial direction of the surface of the core material. The invention further relates to a preparation method of the electrode wire. The preparation method is simple in production technology, strong in operability, less in preparation steps, simple in production equipment and easy to prepare satisfactory products and realize large-scale and automated production. The efficient electrode wire is strong in universality and is particularly suitable for precision mould cutting.

Owner:NINGBO BODE HIGHTECH CO LTD

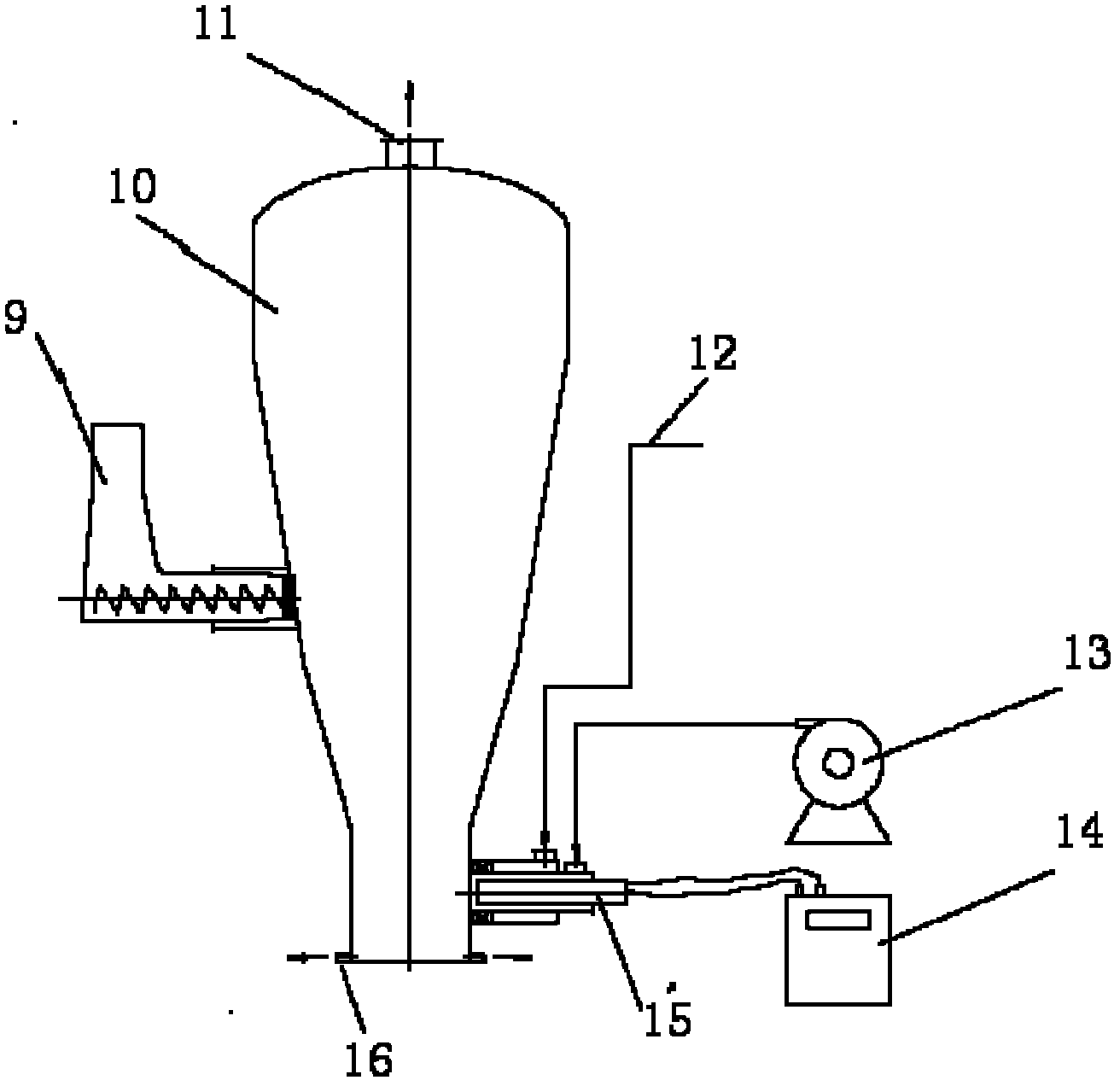

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

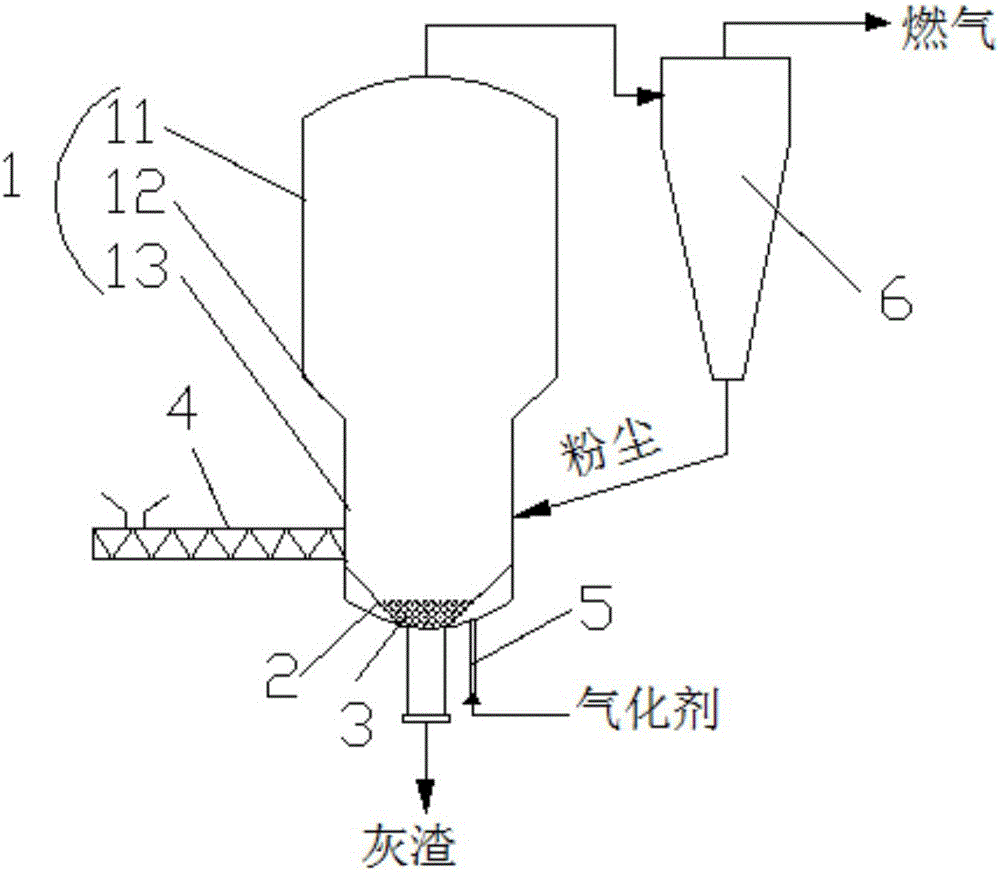

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

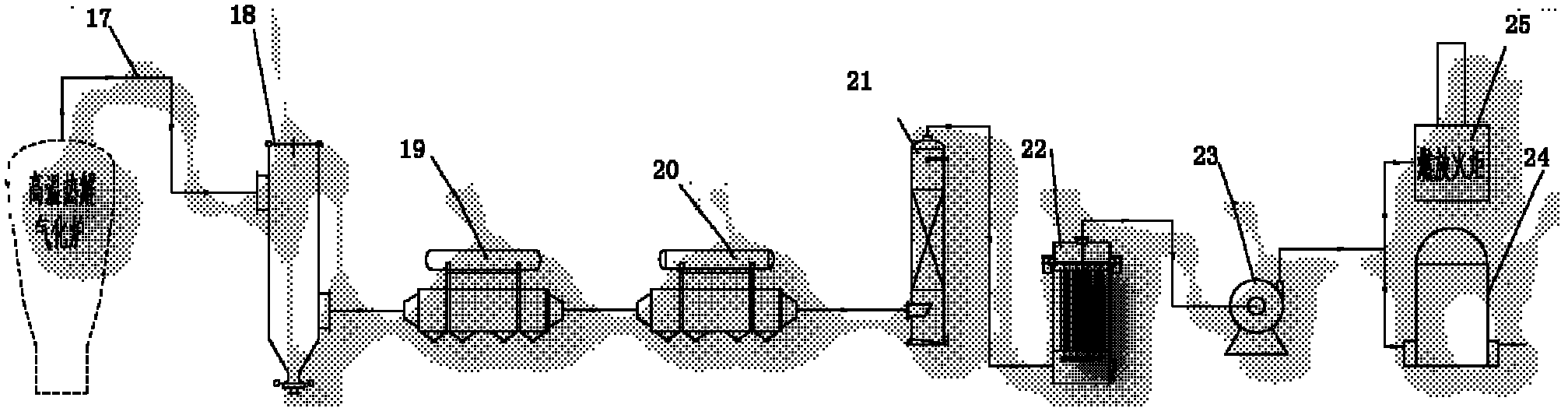

High temperature normal pressure biomass gasification island process

The invention provides a high temperature normal pressure biomass gasification island process. The process comprises the procedures of pretreatment and storage of biomass, gasification by using a biomass gasification furnace, cooling of gasified crude gasification gas, rinsing, dedusting and storage of fresh gasification gas, wherein in gasification by using the biomass gasification furnace, an external heat source is used to supply heat, reaction temperature in the gasification furnace is controlled to be 1300 to 1750 DEG C, liquid state slag removal is adopted by the gasification furnace, cooling of gasified crude gasification gas is realized through recovery of sensible heat by a quenching tower and a two-stage heat boiler, cooled crude gasification gas is subjected to rinsing and electric precipitation, fresh gasification gas is stored in a gas storage cabinet, and whole gasification island equipment operates under a negative pressure or a positive pressure of 0 to 50 KPa. According to the process, the external heat source is utilized for gasification, which enables the quality of crude gasification gas to be improved; a normal pressure fixed bed is employed for gasification, which enables the equipment of gasification furnace body to have the advantages of simpleness, small investment and easy operation; feeding, deslagging and purifying systems are simple; a wide variety of raw materials are applicable, gasification of various biomass, MSW, raw coal, sludge and the like can be realized, and blended gasification of a plurality of fuels can be realized; systems and equipment are mature, and a high localization degree is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

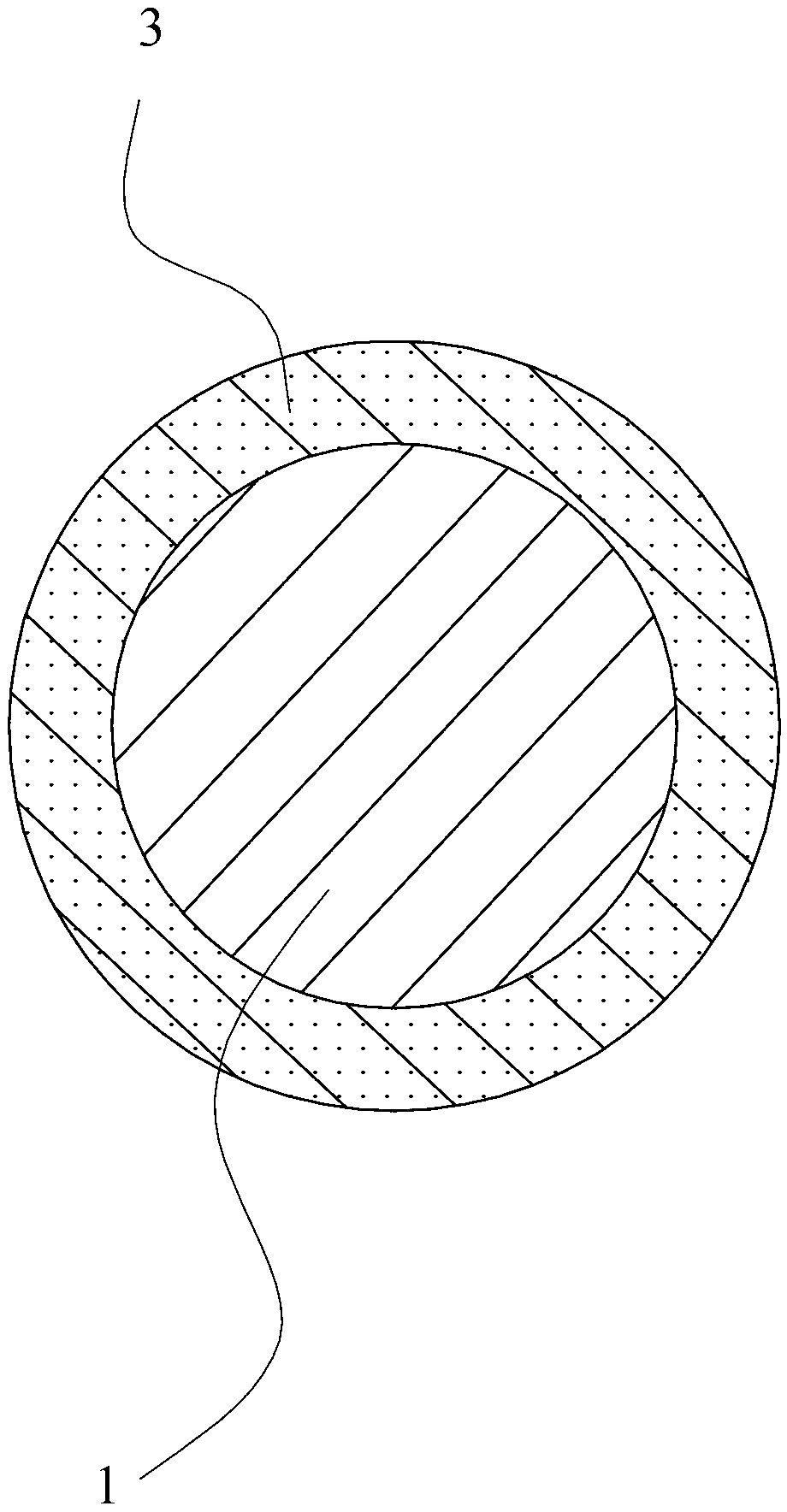

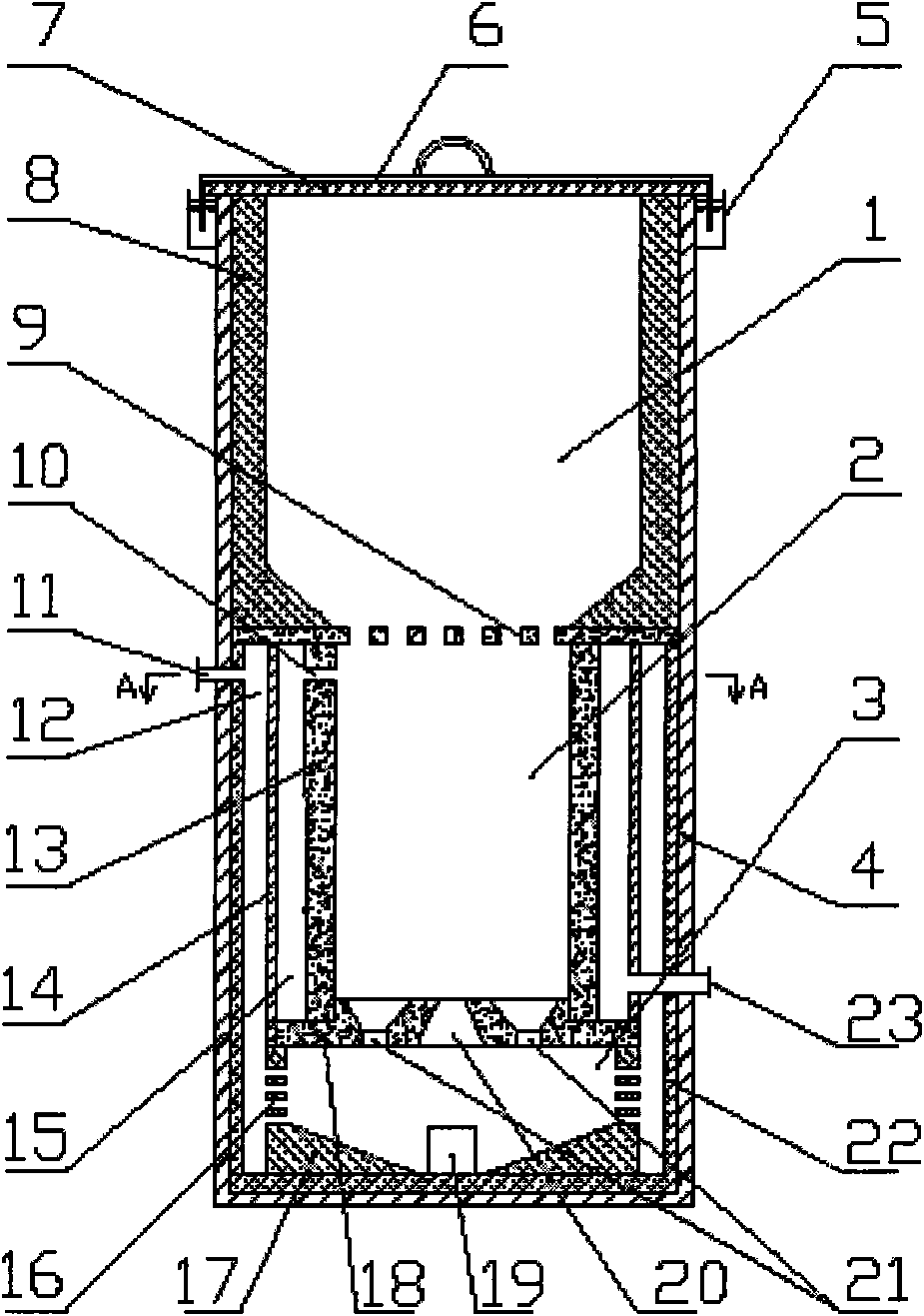

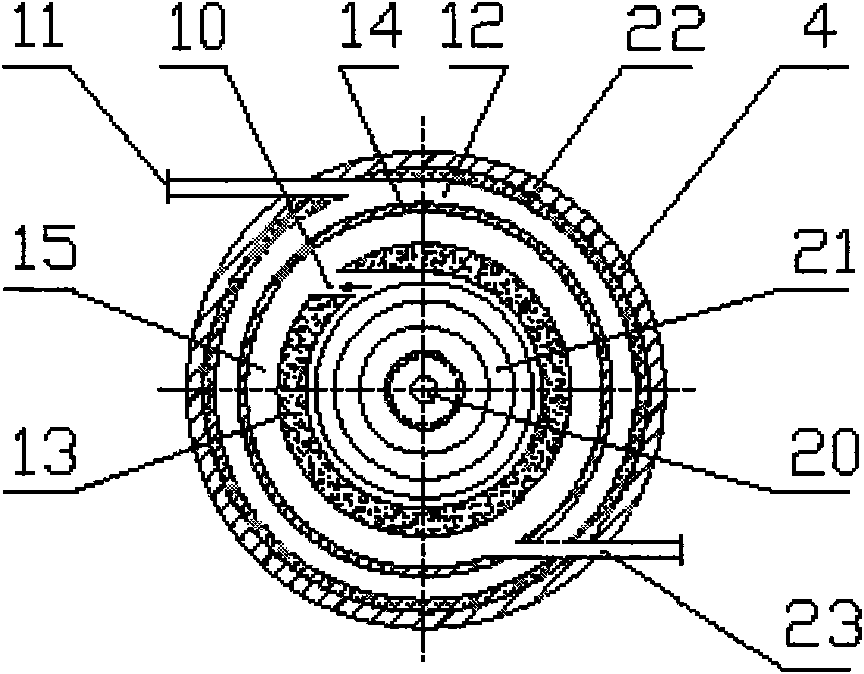

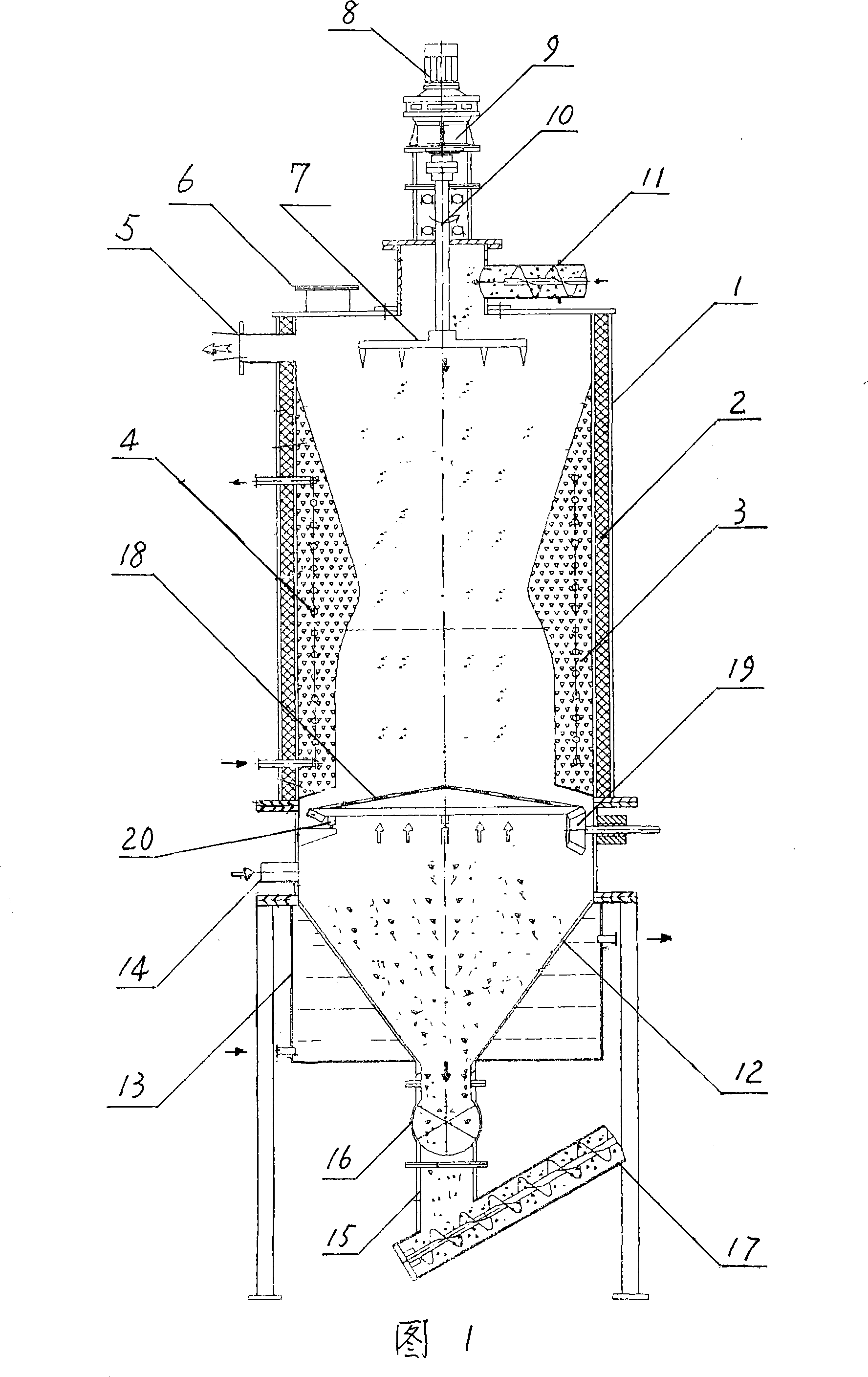

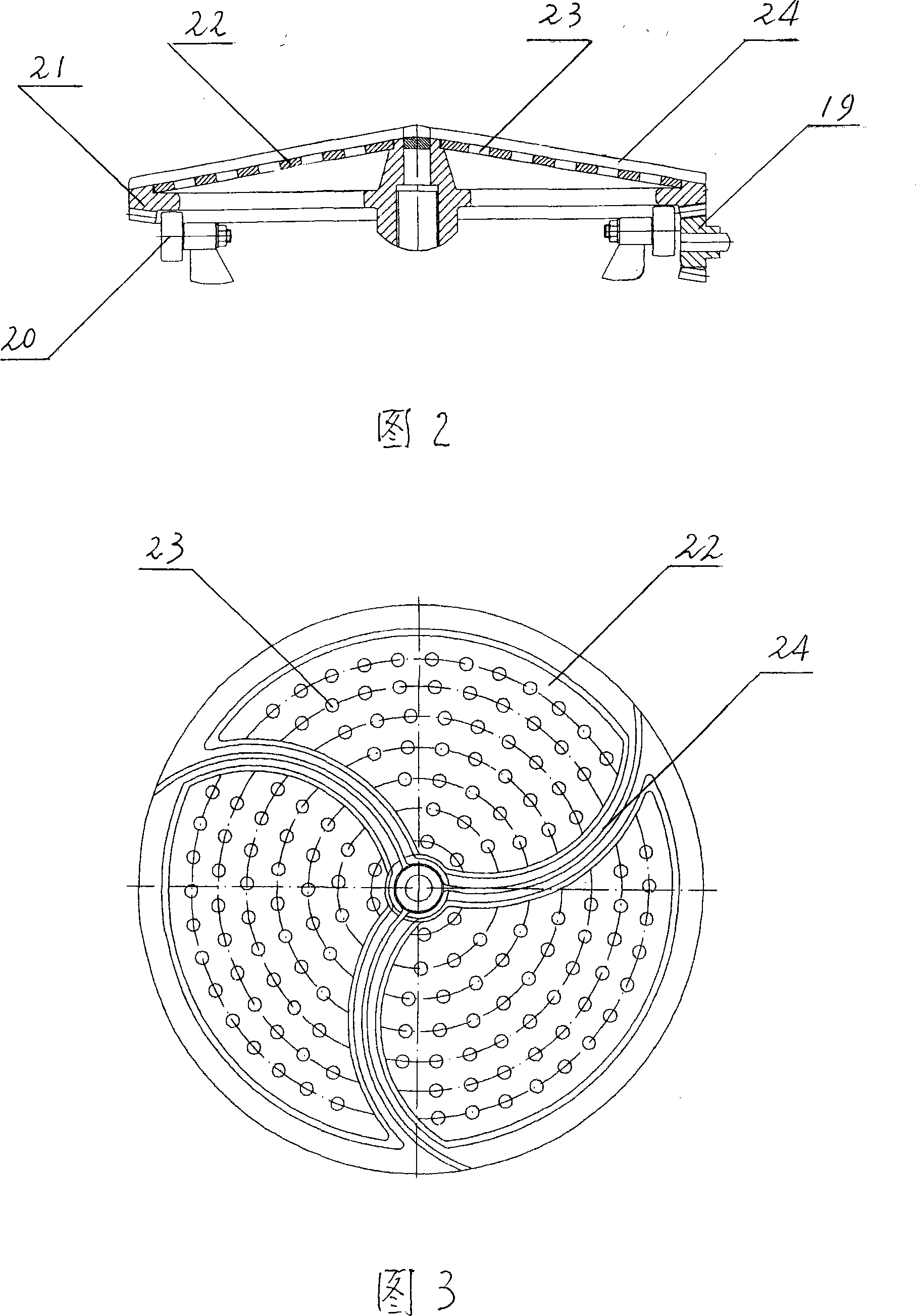

Solid biomass semi-water coal-gas producer

InactiveCN101230281AIncrease gasification rateQuality improvementSpecial form destructive distillationWater vaporCombustible gas

The invention provides a solid biomass semiwater gas generating furnace, which includes a furnace body, a transmission mechanism, a feeding mechanism and a residue discharging mechanism. A head preserving layer 2 and a fire resisting layer 3 are arranged in the furnace body, a heat exchanger pipe 4 is arranged in the fire resisting layer 3, and a material homogenizing harrow is arranged on the hearth. A clinker chamber 12 and a cooling water tank 13 are arranged on the underside of the furnace body 1, a gasification agent inlet 14 is arranged on the clinker chamber 12, and a clinker outlet 15 is arranged on the bottom of the clinker chamber which is connected with a spiral clinker discharger 17. A rotatable furnace grate is arranged on the interface of the hearth and the clinker chamber 12. The invention can feed material and discharge clinker continuously, ensures the continuous stability of the gasification process, uses the vapor generated by residual heat to participate in gasification reaction, improves the carbon utilization rate, and improves the gasification rate of the solid biomass. Compared with gasification furnace with uniform section, the gasification strength of the invention is improved by 1.5-2.0 times, and the combustible gas calorific value is doubled.

Owner:合肥天焱绿色能源开发有限公司

Biomass and coal fluidized bed co-gasification method

InactiveCN102786990ALow costIncrease profitGranular/pulverulent flues gasificationSyngasCombustion chamber

Owner:TAIYUAN UNIV OF TECH

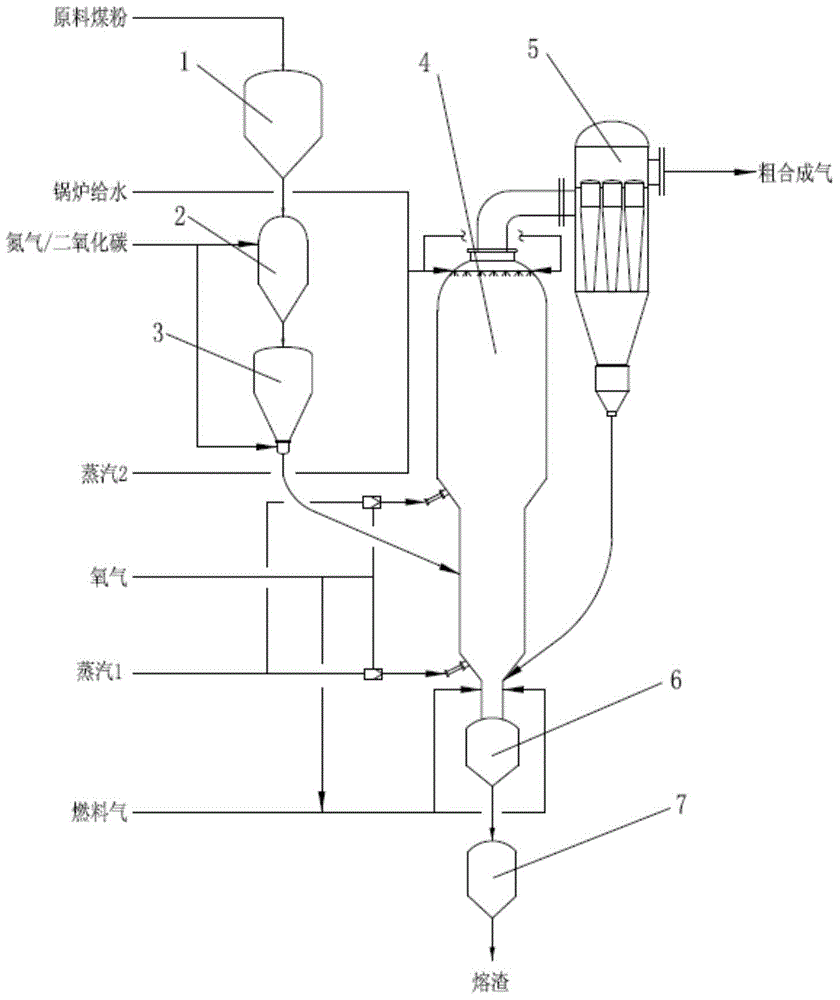

Clean coal pressurized fluidized bed slag gasification process and system

ActiveCN104531224AEffective coagulationEffective returnGasification processes detailsGasification apparatus detailsCycloneFluidized bed gasifier

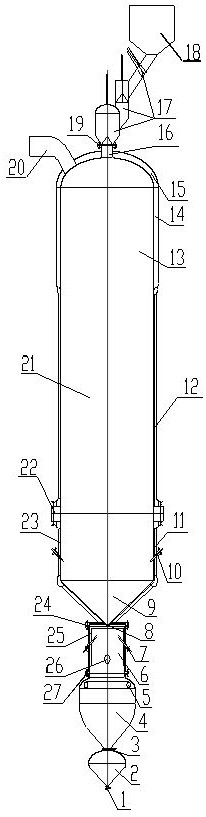

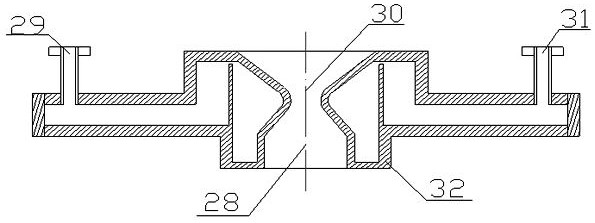

The invention discloses a clean coal pressurized fluidized bed slag gasification process and system. By means of the gasification process and system, the problems that an existing pressurized fluidized bed industrial gasification process is complex, poor in coal applicability, low in gasification pressure, small in production capacity and low in gasification efficiency, the environment is polluted are solved. According to the technical scheme, the process includes the steps that raw material coal powder is pressurized and sent to a fluidized bed gasification furnace through a material inlet to react with a gasifying agent in a gasification mode, and crude synthesis gas and coal powder ash slag are obtained; the crude synthesis gad rises and is sent to a multi-pipe type cyclone separator through a top outlet of the fluidized bed gasification furnace to be dedusted, fluidizing agents are sprayed twice through a gasification spray nozzle to improve gasification efficiency, the coal powder ash slag is melt through a slag melting device, forms melt slag and then enters a slag quenching tank through a bottom outlet of the fluidized bed gasification furnace to be quenched and discharged through a slag locking hopper. The clean coal pressurized fluidized bed slag gasification process and system are simple in process, easy and convenient to operate, wide in coal applicability, high in gasification pressure, large in production capacity, high in gasification efficiency and environmentally friendly.

Owner:WUHUAN ENG +1

Fixed-bed grading and gasifying continuous gas producing furnace

InactiveCN101942342AHigh gasification temperatureQuality improvementChemical industryCombustible gas productionThree levelSlag

The invention relates to a fixed-bed grading and gasifying continuous gas producing furnace comprising a raw material bin and a water jacket gasification furnace shell, wherein the raw material bin comprises material locking valves connected in series, the lower part of the water jacket gasification furnace shell is connected with two symmetrical slag discharging pipelines, each slag discharging pipeline is provided with the sealed material locking valves, three reaction areas are arranged in a gasification furnace, include a first reaction area, a second reaction area and a third reaction area from top to bottom and are respectively provided with a temperature monitoring device, and the three reaction areas are provided with three levels of gas distribution towers. The invention retains the integrative furnace type and the partial technical conditions of the fixed-bed intermittent gasification furnace, increases gasification temperature and gasification quality, meets the requirements on safety, environmental protection, energy saving, emission reduction and production cost reduction and provides a new route for fixed-bed gasification development.

Owner:张浩玥

Family-size updraught tar-free biomass gasification direct burn type furnace

ActiveCN101813327ASimple structureHigh gasification temperatureDomestic stoves or rangesLighting and heating apparatusTarHearth

The invention discloses a family-size updraught tar-free biomass gasification direct burn type furnace which relates to a family-size updraught biomass direct burn type furnace for thoroughly solving the problem that a biomass gasification furnace generates tar. The lower end of a gas stove is arranged in an annular water tank; the lateral wall of the gas stove is provided with a plurality of secondary air inlet holes along the circumferential direction; the bottom end face of the gas stove is provided with a plurality of gas outlet holes; a hearth is communicated with the plurality of gas outlet holes through a central hole of the annular water tank; an air preheating chamber is arranged between a flame retardant coating and an inner furnace cylinder and is formed into a spiral air preheating chamber through a spiral clapboard arranged therein, and the lower end of the spiral air preheating chamber is a preheating air outlet; the upper edge of an ash hopper tightly clings to the inner wall at the lower end of the inner furnace cylinder, and the lower end of the ash hopper is arranged in an ash chamber. Air participates in gasification after heated by the spiral air preheating chamber, and the generated gas directly burns through the gas stove for cooking without a gas output process, and tar in the gas is directly burnt, thereby solving the problem of tar treatment.

Owner:湖南哈工机器人研究院有限公司

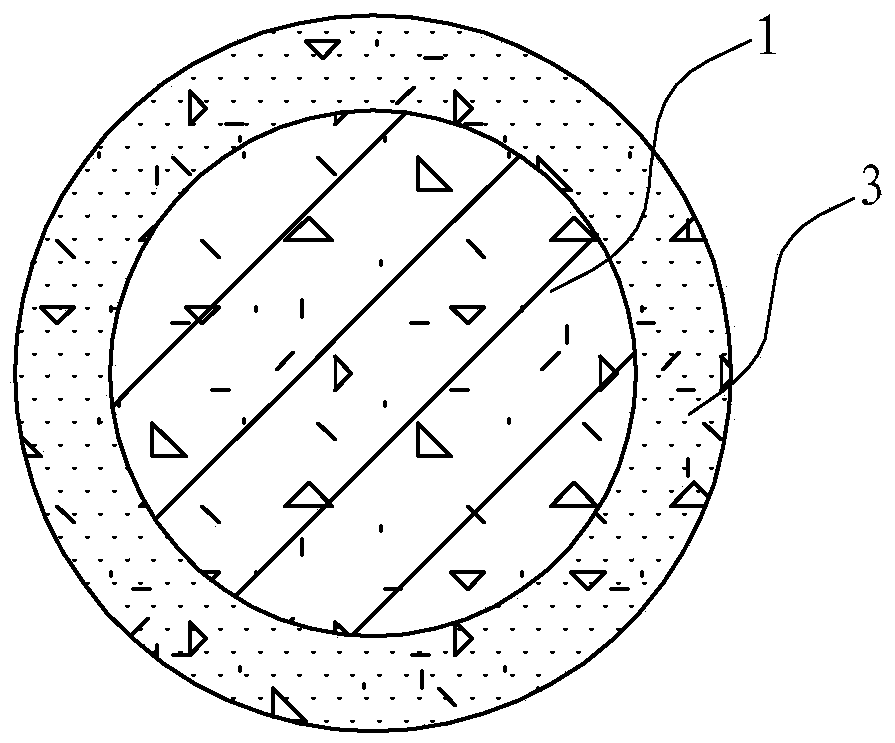

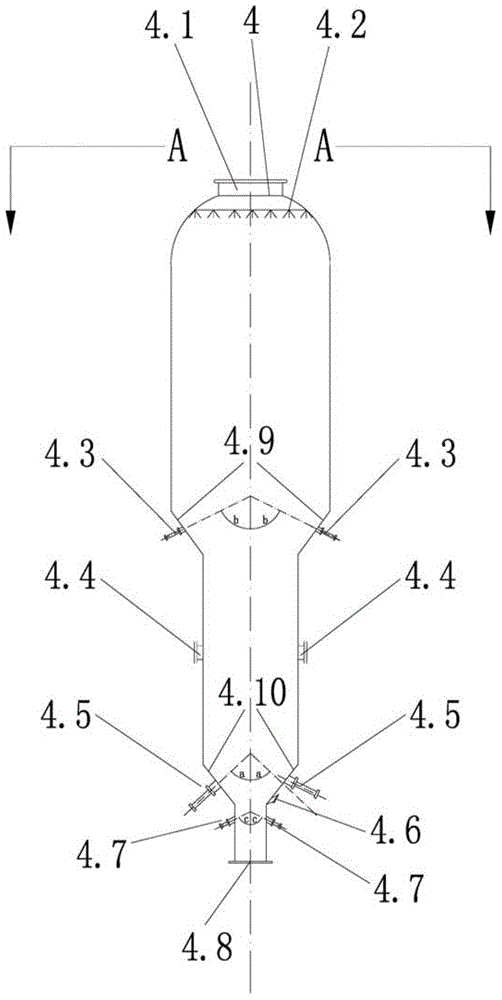

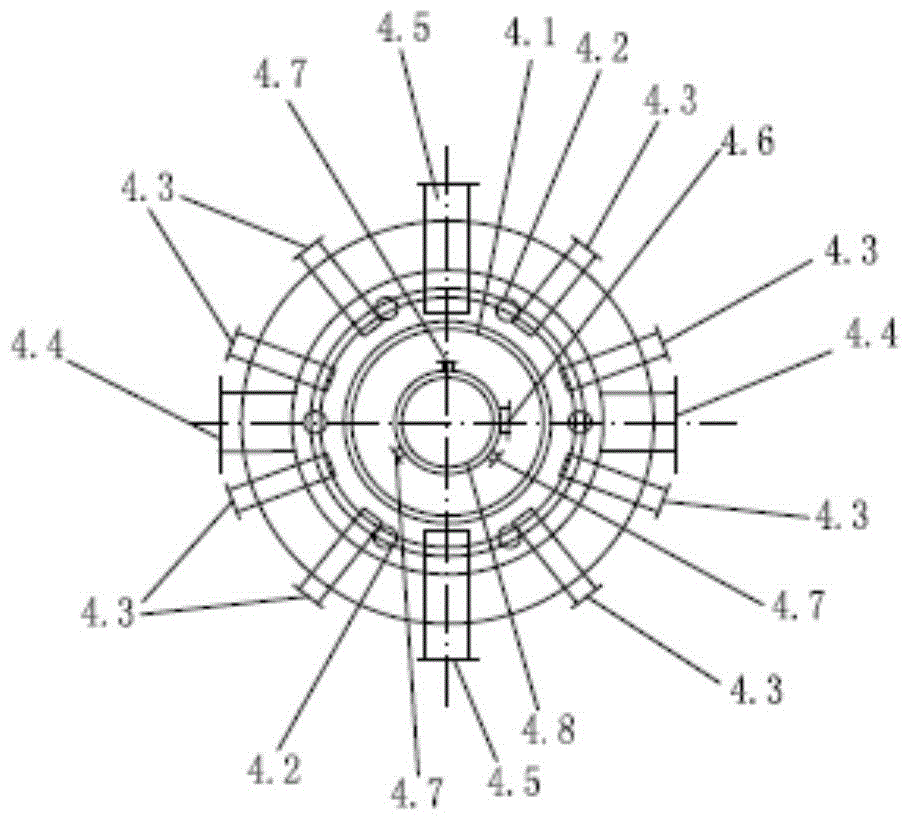

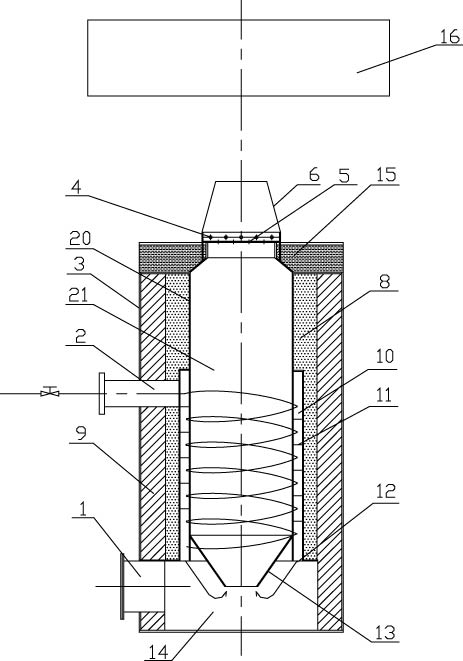

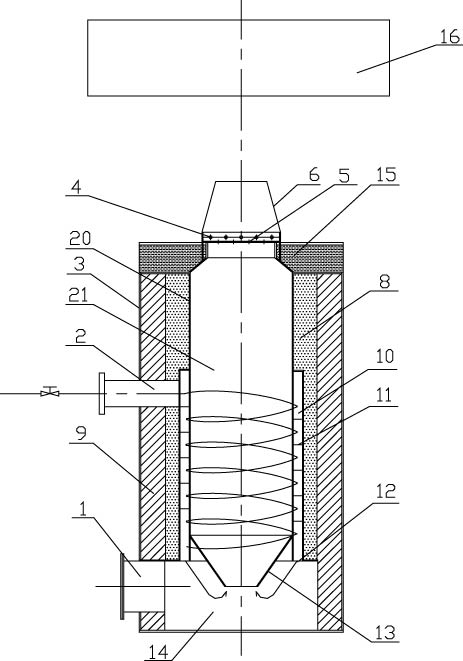

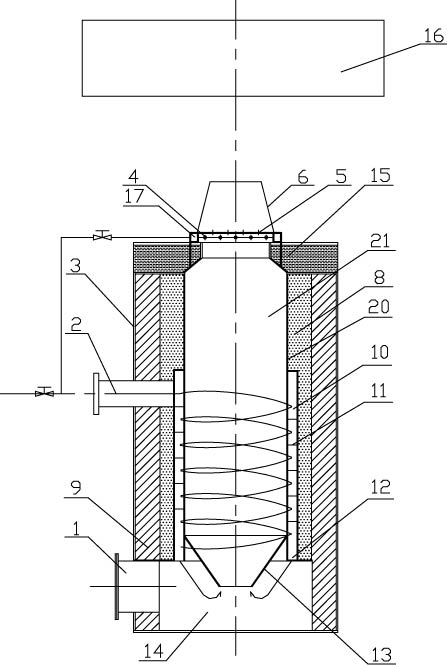

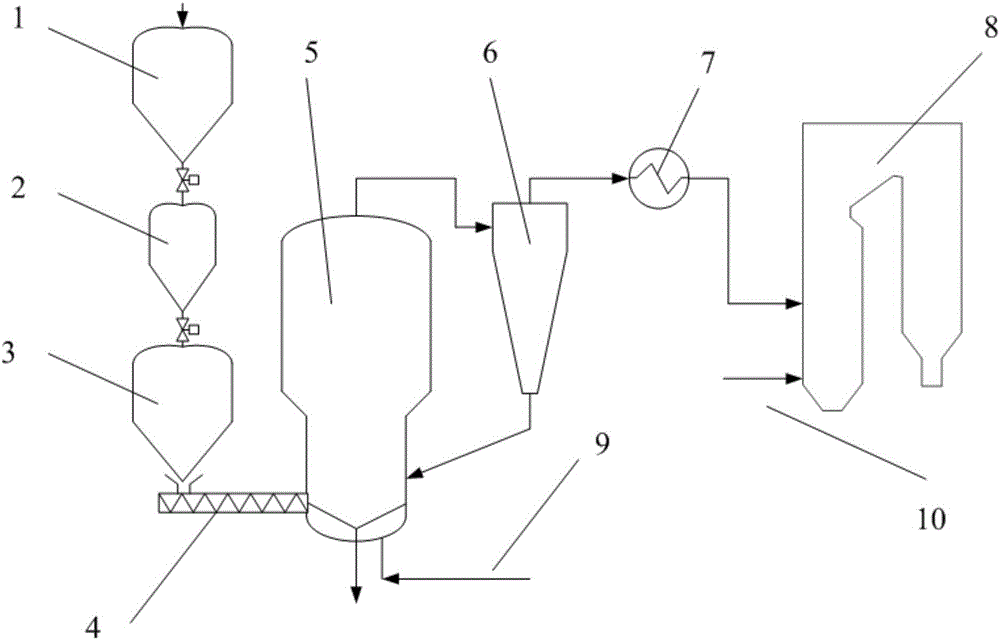

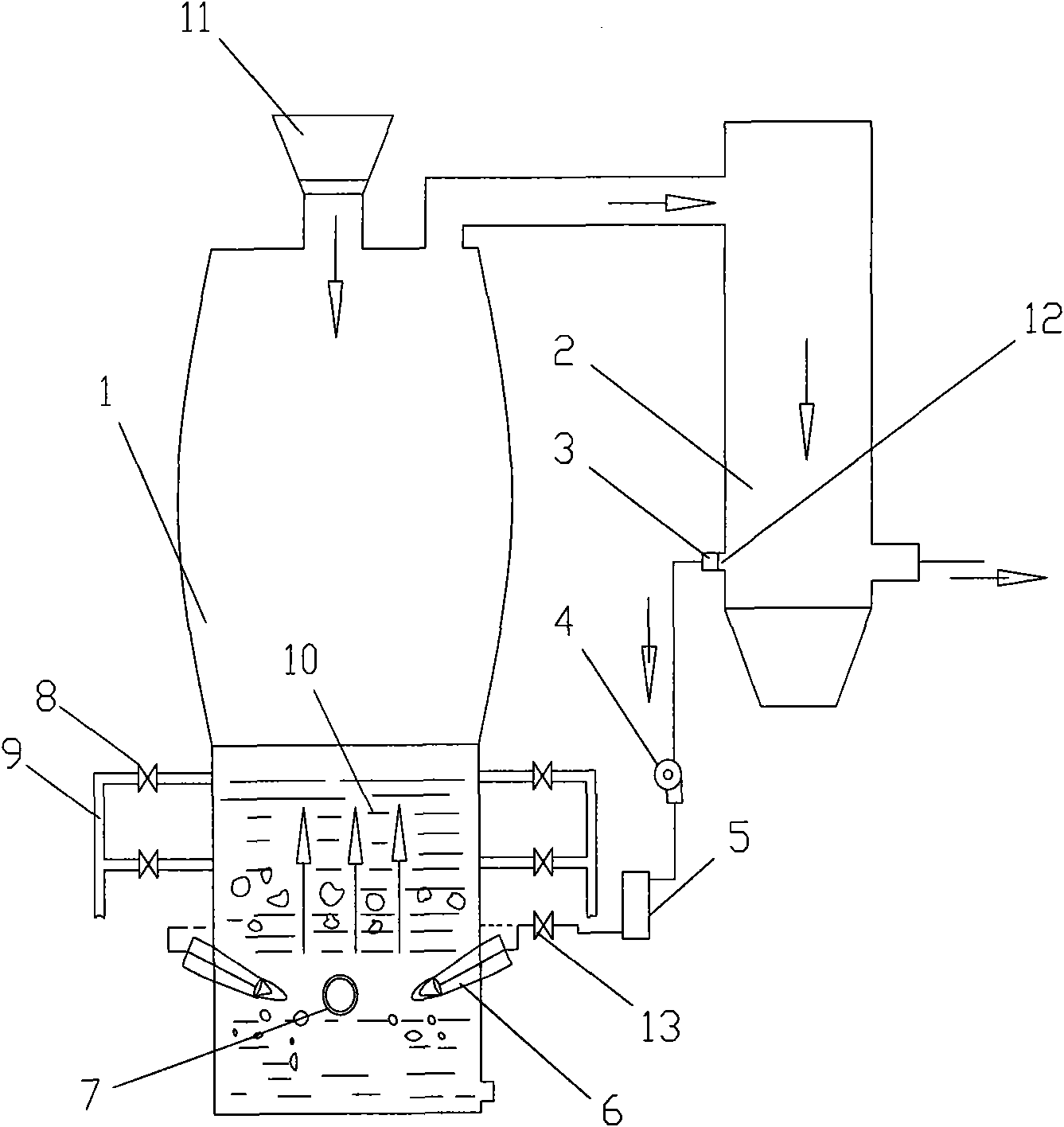

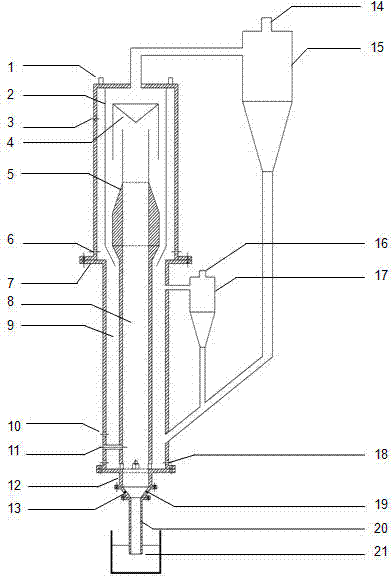

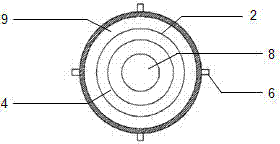

Internal circulating fluidized-bed oxygen-enriched gasification device

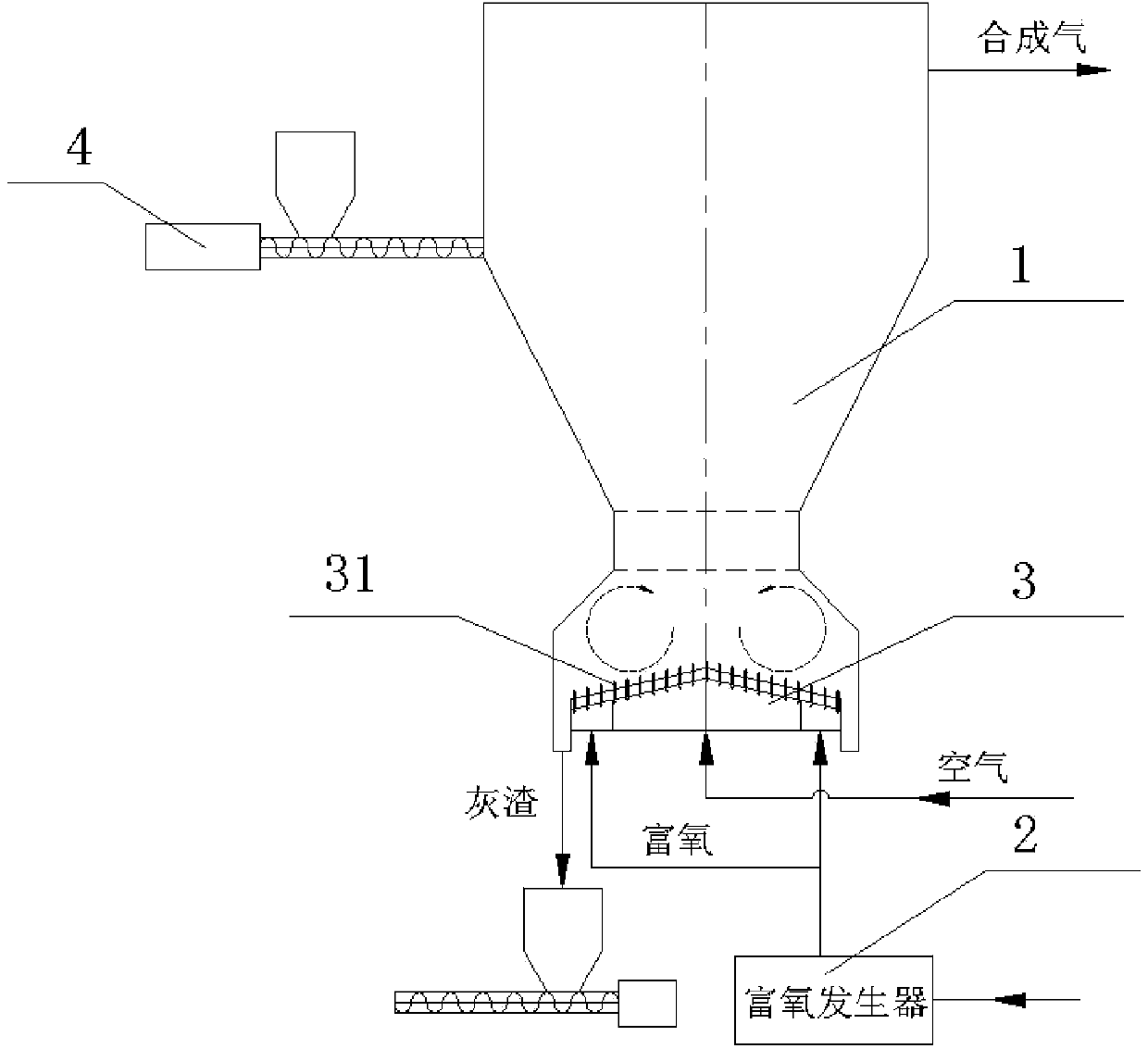

ActiveCN103471104AHigh calorific valueGood use effectIndirect carbon-dioxide mitigationIncinerator apparatusFluidized bedSlag

The invention provides an internal circulating fluidized-bed oxygen-enriched gasification device. The device comprises a gasifier body, a rich oxygen generation device, a multi-air-chamber air distribution device, a feeding device and a deslagging device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; the dense-phase region is connected with the dilute-phase region through a throat region; the multi-air-chamber air distribution device which is provided with directional wind caps is arranged at the bottom of the dense-phase region and is connected with the rich oxygen generation device; an outlet of the feeding device is arranged at the junction of the dense-phase section and the dilute-phase section; a slag outlet is arranged at a gap of the multi-air-chamber air distribution device and the gasifier body at the bottom of the dense-phase section; the deslagging device is arranged below the slag outlet. The system can efficiently realize pyrolysis and gasification of waste solid organic matters such as garbage and biomass, and has the advantages of high gasification speed, high conversion efficiency, less deslagging carbon residue, easiness in control over pollutants and the like.

Owner:XI AN JIAOTONG UNIV

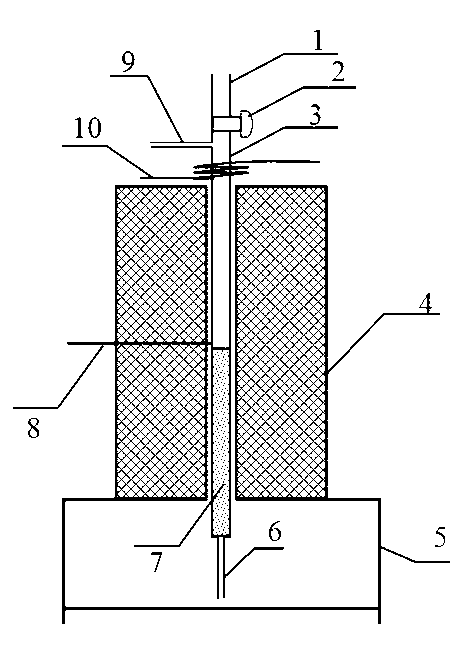

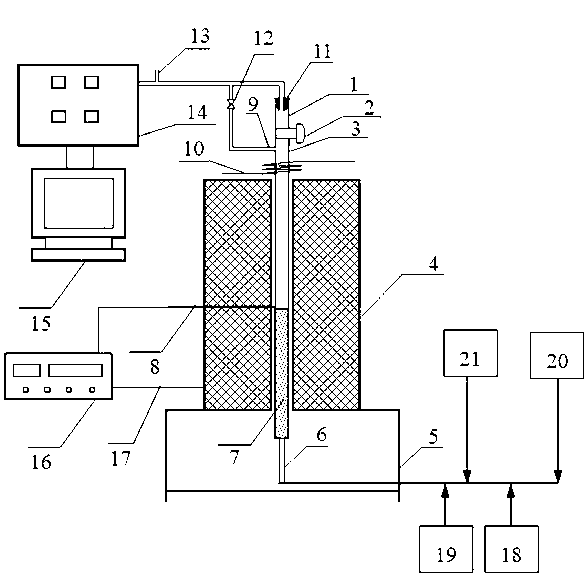

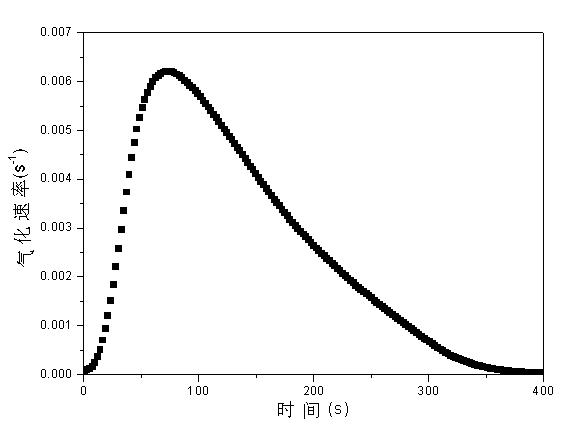

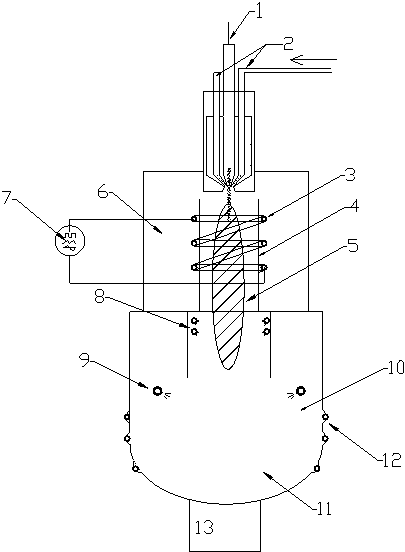

Quick heating and gasifying test device and application thereof

ActiveCN103293177AGet gasification propertiesRapid heating and gasificationInvestigating phase/state changeSolid carbonBiochemical engineering

The invention relates to a quick heating and gasifying test device; the middle part of a reaction tube (3) is positioned in a tubular electric heating furnace (4); an air inlet hole (6) is formed in the bottom end of the reaction tube (3); a filler layer (7) is arranged in the lower part of the reaction tube (3); a cooling water device (10) is arranged outside the reaction tube (3) on the tubular electric heating furnace (4); a charging valve (2) is arranged on the reaction tube (3) on the cooling water device (10); an air outlet hole (1) is formed in the charging valve (2); a side air outlet hole (9) is formed in the reaction tube (3) between the cooling water device (10) and the charging valve (2); a thermocouple (8) is arranged in the middle of the reaction tube (3) on the filler layer (7). The quick heating and gasifying test device is simple in structure, convenient to operate, and suitable for quickly heating and gasifying various solid carbon-containing matters such as coal and petroleum coke in various atmospheres at a certain temperature; the device also has the advantages of continuously measuring a gasified product and automatically recording the gasification reactivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

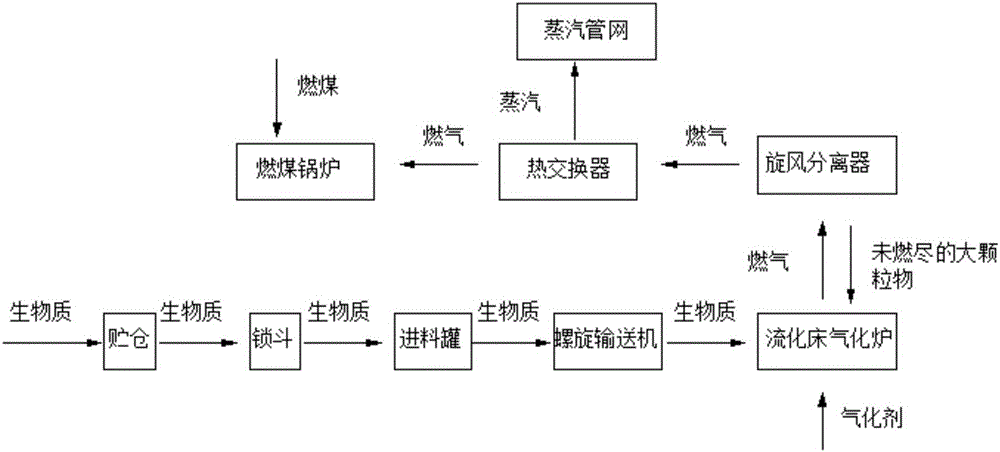

Biomass gasification power-generation process

InactiveCN106244246AHigh strengthImprove gasification efficiencyGasifier feeding meansGasification processes detailsParticulatesFood consumption

The invention discloses a biomass gasification power-generation process. The biomass gasification power-generation process comprises the following steps of step (I), pressurizing biomass granules until the gauge pressure is 0.1-4.0Mpa, then discharging materials to a charging tank, then conveying the discharged materials to a fluidized-bed gasifier, and performing a gasification reaction with a gasification agent so as to obtain fuel gas for standby application; step II, performing cyclone dust removal on the fuel gas prepared in step (I) through a cyclone separator, performing separation to obtain large particles which are not burn-out, and returning the large particles to the fluidized-bed gasifier for gasifying once again; and step (III), cooling the flue gas which is subjected to dust removal by the cyclone separator to 300-700 DEG C through a heat exchanger, and enabling the cooled flue gas to be led into a coal boiler to be subjected to mixed combustion with the coal for power generation. According to the biomass gasification power-generation process disclosed by the invention, the biomass granules are sent to a large-scale coal boiler through the fuel gas generated by gasification to be subjected to combined combustion with the coal for power generation, so that the coal consumption required for power generation is reduced, the amount of CO2 generated during combustion is reduced, greenhouse effects caused by CO2 can be alleviated, and emission of NOX by power plants is reduced.

Owner:武汉高斯生态能源技术有限公司

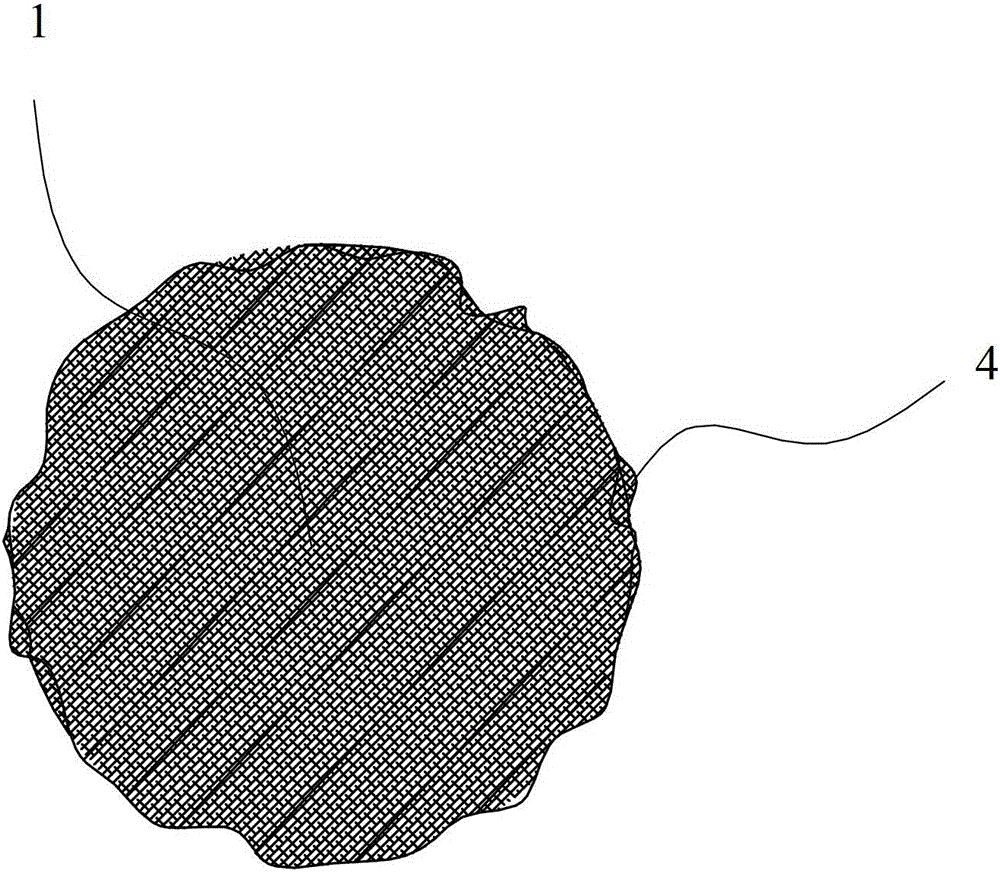

High-difficulty steel core wire electrode and manufacturing method thereof

InactiveCN105772878ALow tensile strengthImprove conductivityElectrical-based machining electrodesCopper wireHeat conducting

The invention discloses a high-difficulty steel core wire electrode and a manufacturing method thereof. The high-difficulty steel core wire electrode comprises a core material, a middle clad layer and an outer clad layer. The core material is prepared from raw materials including, by weight, 30-54 parts of iron, 30-55 parts of carbon, 1.5-2.4 parts of tin, 4-9 parts of chromium, 1-3 parts of manganese, 2-5 parts of molybdenum, 1.3-5.1 parts of nickel, 2.3-5.4 parts of silicon, 3-6 parts of tungsten, 3-4 parts of vanadium, 2-6 parts of phosphorus, 5-10 parts of sulphur and 12-15 parts of heat conducting filler. The steel core wire electrode is a composite wire and is composed of the steel core, the middle red copper clad layer and the outer brass clad layer. At the normal temperature, the steel core and a brass wire almost have the same tensile strength, but with the increase of temperature, the tensile strength of the brass wire is rapidly reduced, and the tensile strength of the steel is higher than that of the brass wire. The red copper layer is wrapped outside the steel core to improve the electric conductivity, and the outer brass layer plays a role in improving the washing performance.

Owner:尚成荣

Low-temperature high-efficiency atomization ejection seawater desalination device and method thereof

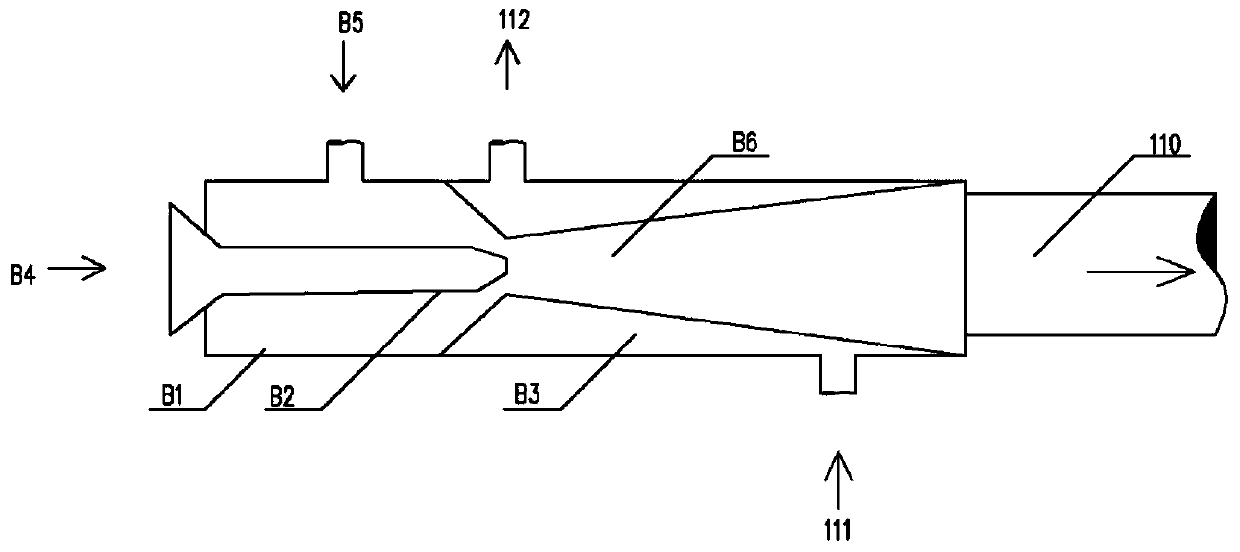

PendingCN109867317AEasy to operateLow running costGeneral water supply conservationSeawater treatmentSeawaterRenewable energy

The invention relates to a low-temperature high-efficiency atomization ejection seawater desalination device and a method thereof, and is suitable for the field of seawater desalination. The device comprises a low-pressure evaporation chamber, a solar heating device, a high-efficiency atomization device, a gas-liquid separation device, and a steam injection condensation device. The method comprises the following process flow: heated seawater is sprayed out in a mist shape through the high-efficiency atomization device, after the seawater is atomized, part of the seawater becomes water vapor and the other is seawater droplets, the seawater droplets are separated by the gas-liquid separation device, and then the water vapor is subjected to injection condensation to be turned into fresh waterfor daily use. The device provided by the invention makes full use of low-grade heat energy, has low energy consumption, reduces pollution by utilizing renewable energy, has low production costs, a high yield of the fresh water and a high salt yield, is suitable for large-scale promotion, and extremely facilitates daily life of residents in coastal areas and use by small and medium-sized fishingboats.

Owner:ANHUI UNIV OF SCI & TECH

Preparation method and application of boron-composition-cladded silicon nano paste

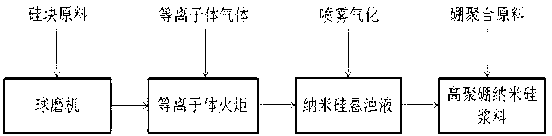

ActiveCN103280401AHigh line definitionHigh boron doping concentrationMaterial nanotechnologyFinal product manufactureHigh polymerAtmosphere

The invention discloses a preparation method and application of boron-composition-cladded silicon nano paste. The preparation method comprises the following steps: 1) preparing nano silicon suspension liquid; and 2) preparing boron-containing high polymer in the nano silicon suspension liquid prepared in the step 1), and meanwhile, stirring to prepare evenly dispersed boron-containing nano silicon paste, wherein protective atmosphere is introduced during the reaction process, and the viscosity of the boron-containing nano silicon paste is 1.0-15.0PaS. The prepared boron-containing nano silicon paste is printed on the surface of a battery silicon wafer through screen printing, the line clearness is high, and no burr is generated. The silicon wafer can be selectively doped, and high and low doped areas are formed.

Owner:宁波革鑫新能源科技有限公司

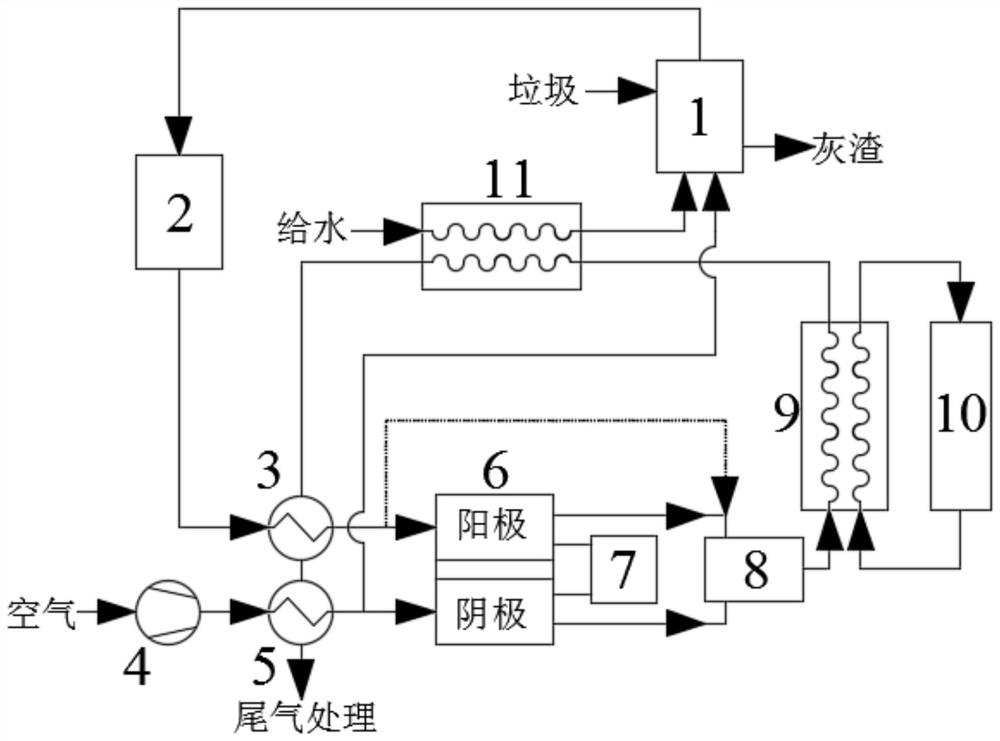

Garbage disposal system and method based on fuel cell combined power generation

PendingCN111640971AReduce the formation of dioxinsImprove efficiencyEnergy inputGasification processes detailsPhysicsChemical energy

The invention discloses a garbage disposal system and method based on fuel cell combined power generation. The system comprises a garbage gasification subsystem and a fuel cell combined power generation subsystem, wherein the garbage gasification subsystem comprises a garbage gasification furnace, a purification system and a waste heat boiler, the fuel cell combined power generation subsystem comprises a preheater, an air compressor, an air preheater, a fuel cell, an inverter, a combustion chamber, a residual heat boiler and a thermal power generation system, the garbage gasification subsystemis used for gasifying garbage to implement reduction of garbage, the fuel cell combined power generation subsystem partially converts Gibbs free energy in chemical energy of combustible gas in garbage gasified gas into electric energy, unreacted combustible gas is combusted and then generates power through the thermal power generation system, and tail gas is used for preheating the garbage gasified gas and air. The system can achieve efficient utilization of garbage.

Owner:XIAN THERMAL POWER RES INST CO LTD

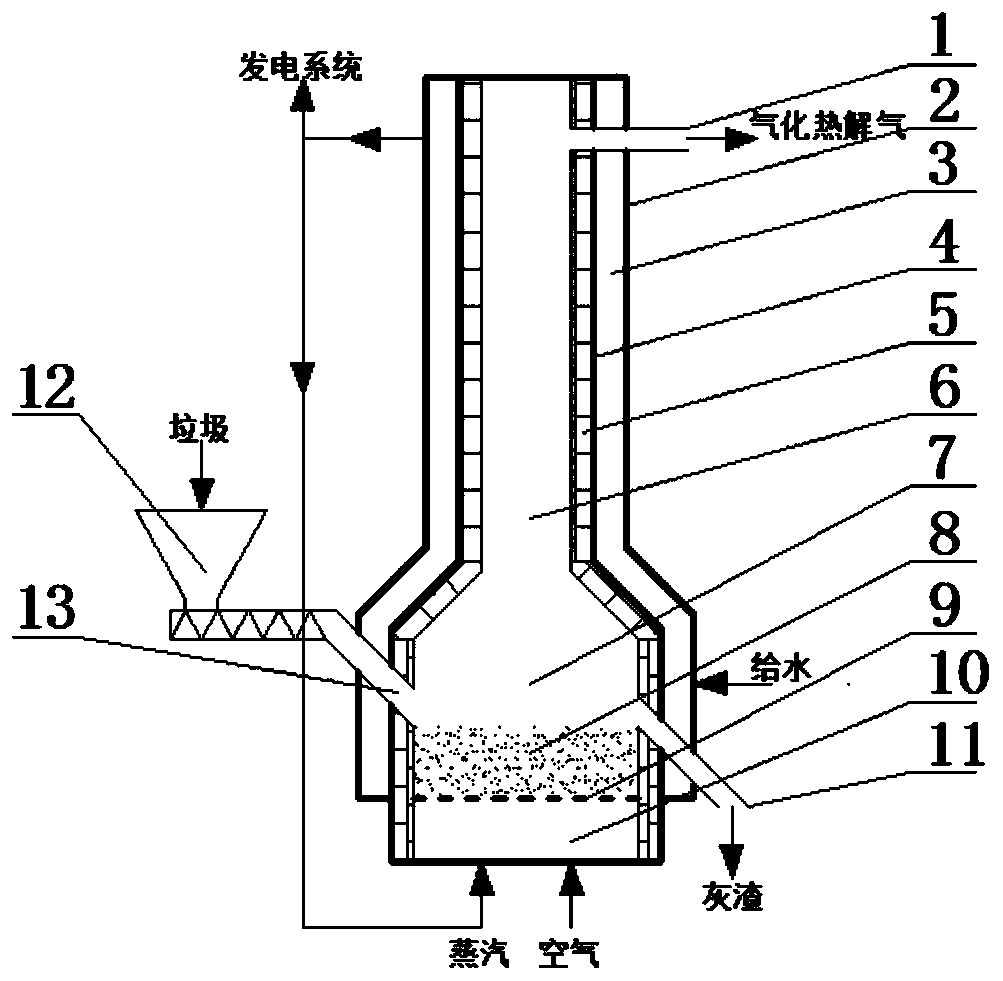

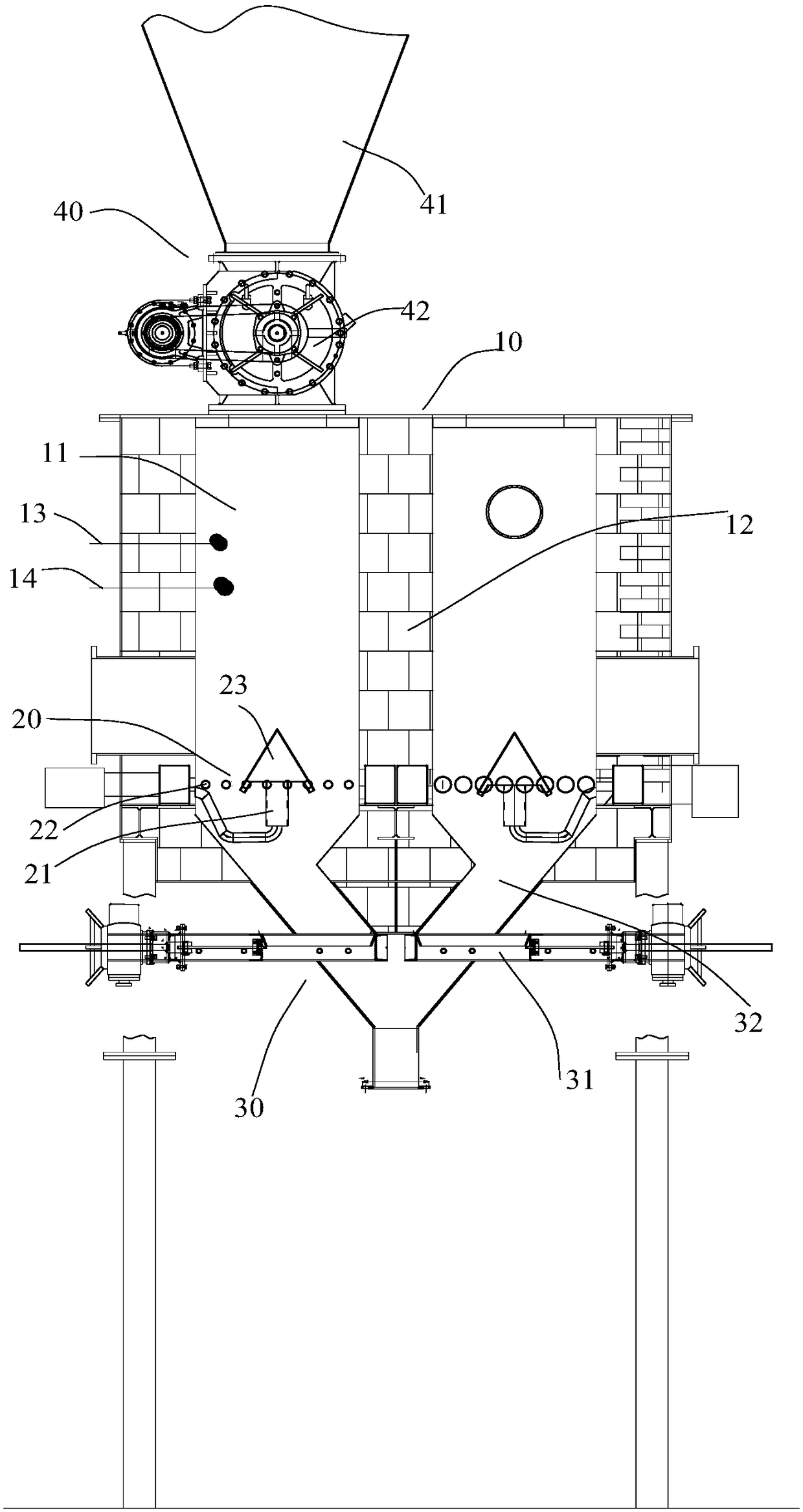

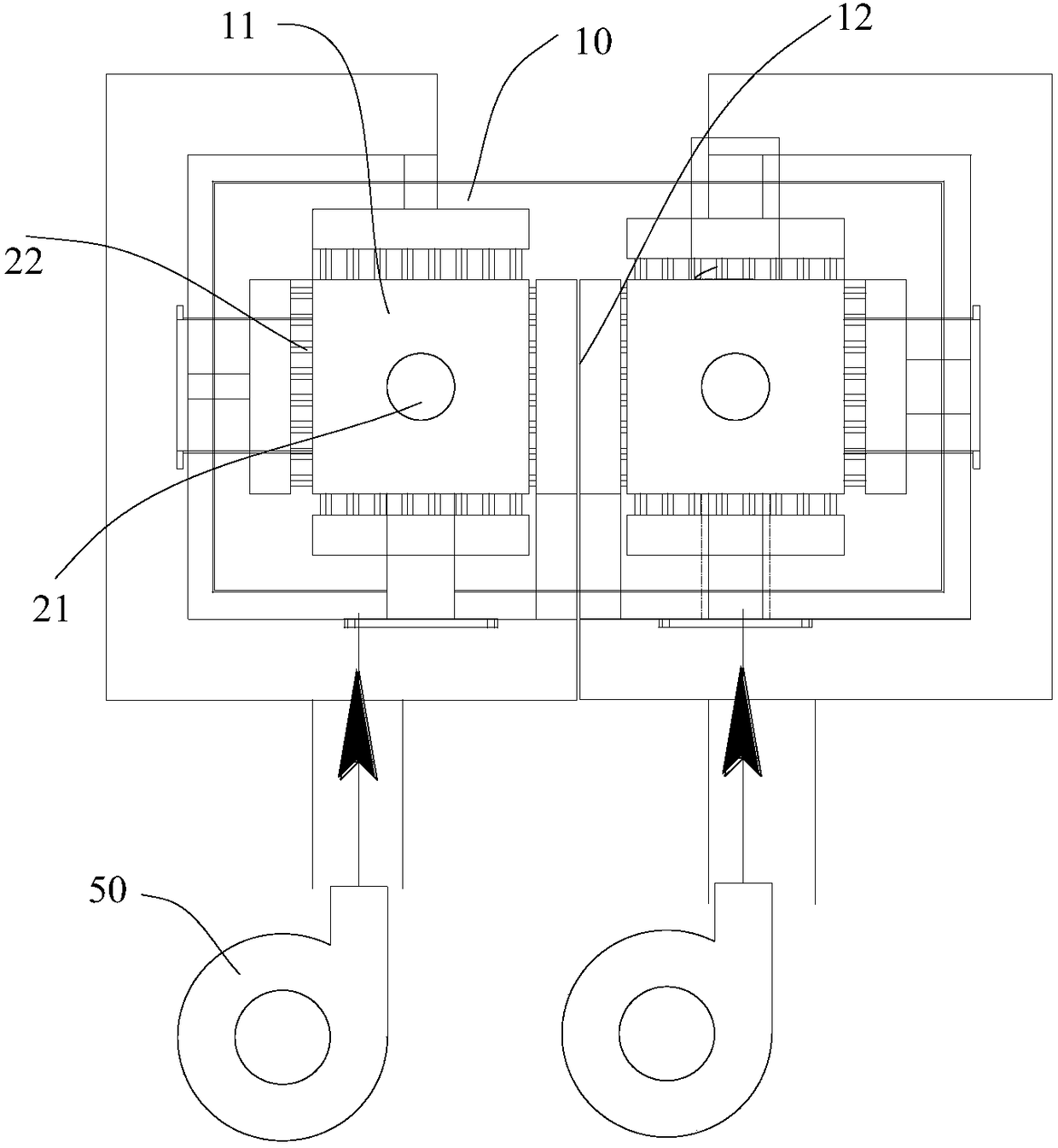

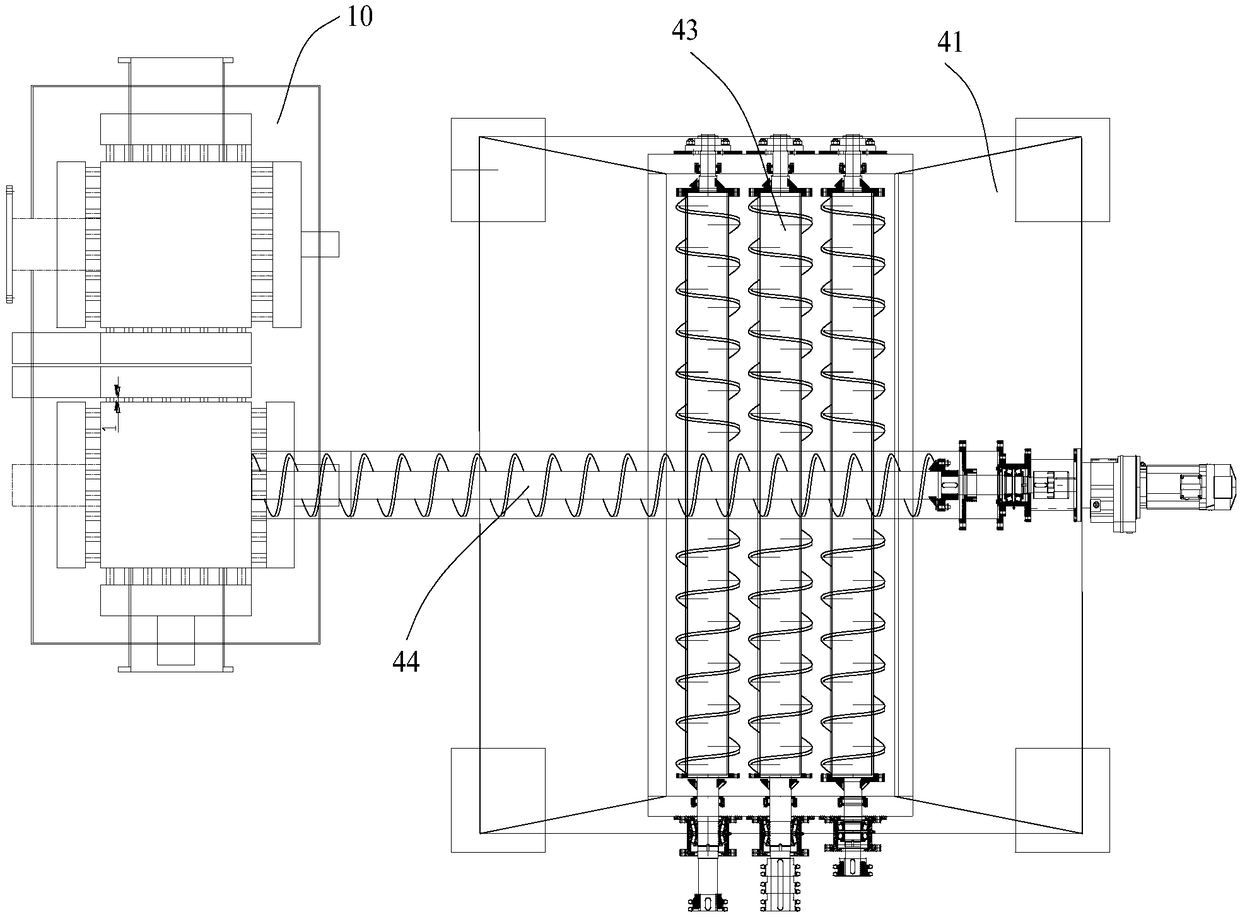

Municipal solid waste pyrolysis gasification furnace and pyrolysis gasification method

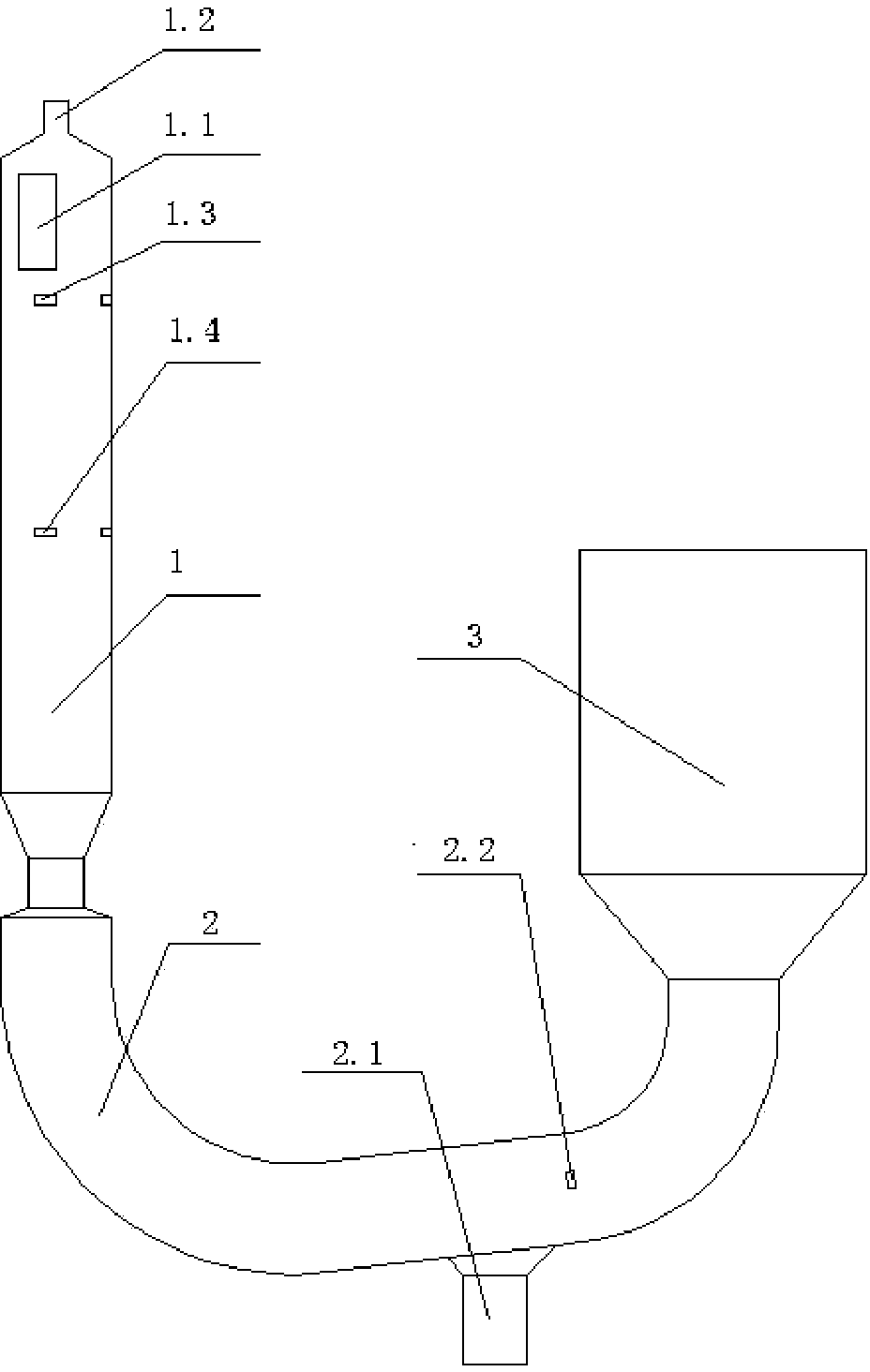

PendingCN110713849AAchieve reductionProcessing speedGasification processes detailsGranular/pulverulent flues gasificationFluidized bedFire brick

The invention discloses a municipal solid waste pyrolysis gasification furnace and a pyrolysis gasification method. The furnace includes an inner cylinder, wherein an outer cylinder is arranged outside the inner cylinder; the inner barrel comprises a lifting pipe section, a fluidized bed section and an air chamber from top to bottom; a water jacket is arranged between the outer cylinder and the inner cylinder; a refractory brick lining is arranged in the inner cylinder, a gas outlet is formed in the upper portion of the lifting pipe section, a garbage inlet and an ash outlet are formed in themiddle of the fluidized bed section, bed materials are arranged in the fluidized bed section, the garbage inlet and the ash outlet are located above the bed materials, the bed materials are located above the air chamber, and a spiral feeder is arranged on the upper portion of the garbage inlet. According to the method, the generation of dioxins can be greatly reduced, materials in the pyrolysis gasification furnace are operated in a fluidized bed manner, pyrolysis gasification can be completed in a short residence time, and the garbage treatment speed is greatly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD

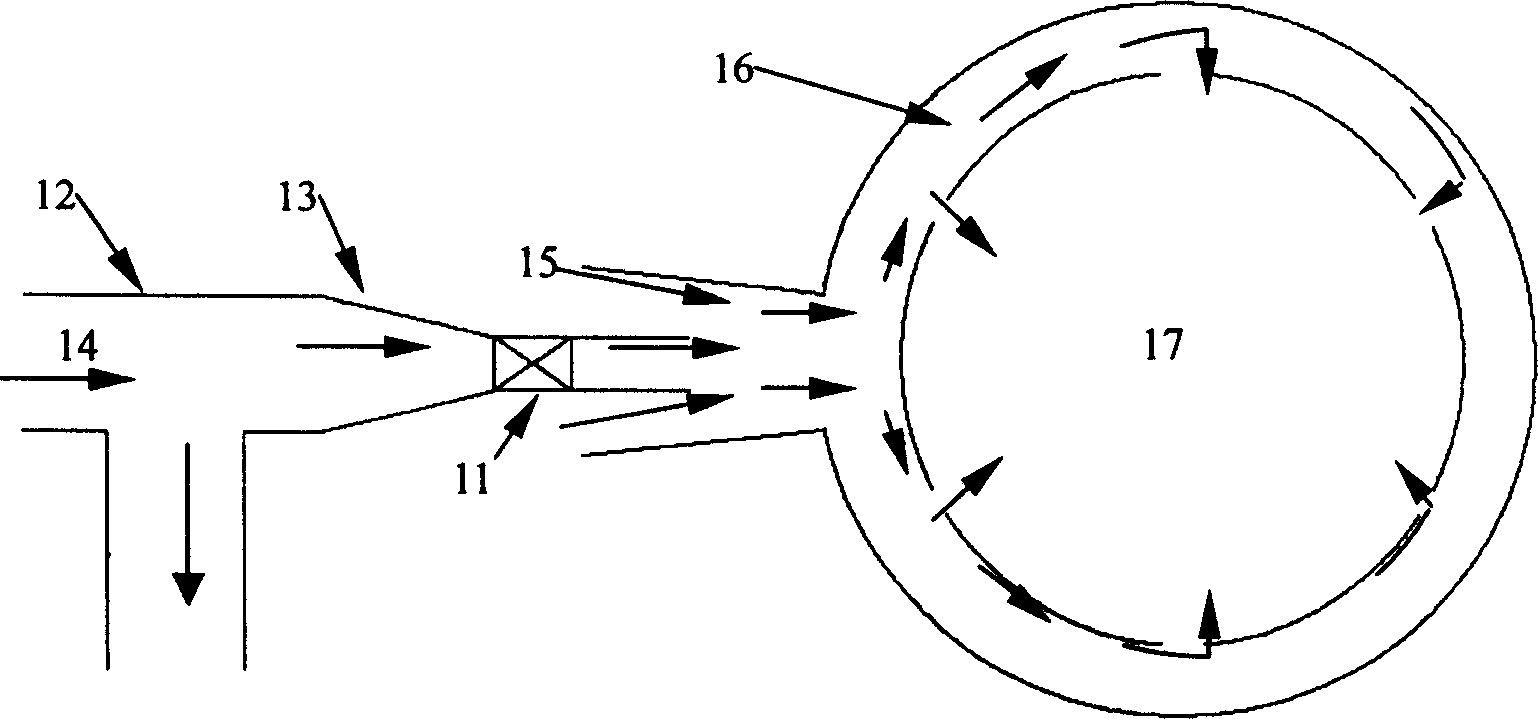

Auxiliary gasification technique using synthesis gas to burnback and equipment thereof

ActiveCN101671576AReduce outputCost-effective useCombined combustion mitigationCombustible gas productionSyngasCombustion chamber

The invention discloses an auxiliary gasification technique using synthesis gas to burnback and equipment thereof, mainly solving the difficulty that the existing gasification furnace has poorer wave adaptability to fuel characteristics. The technique comprises the following steps: one part of the output synthesis gas is extracted under the state that the gas gasification is in conventional operation and the generated synthesis gas is output from the upper part of the gasification furnace continuously, then is delivered into a burning chamber at the lower part of the gasification furnace, generates vigorous burning reaction with sprayed oxygen, and generates high-temperature and high-heat smoke so as to assist the cycle process of the fuel gasification above the burning chamber. The equipment comprises a gasification furnace and subsequent treatment equipment which is provided with a synthesis gas extracting port; the synthesis gas extracting port is connected with a synthesis gas nozzle by a pressure-stabilizing gas storage tank of a circulating fan; and the synthesis gas nozzle and an oxygen nozzle are arranged on the wall surface of the burning chamber at the lower part of the gasification furnace. The technique and the equipment are characterized by good load adjustment, good burning stability, high gasification temperature, wide fuel adaptability and high product quality.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

Fluidized bed heavy oil cracking and gasification graded conversion device and fluidized bed heavy oil cracking and gasification graded conversion method

ActiveCN110819384AImprove conversion rateImprove liquid yieldTreatment with plural serial stages onlyFluidized bedDust control

The invention discloses a fluidized bed heavy oil cracking and gasification graded conversion device and a fluidized bed heavy oil cracking and gasification graded conversion method. The device comprises a feeding unit, a carrier gas unit, a cracking-gasification unit, a cooling recovery unit, a gas-liquid separation unit and a light oil recovery unit, wherein the feeding unit comprises a heavy oil system, a steam system and a solid particle system and is used for realizing efficient atomization of heavy oil and steam and continuous and stable feeding of oil gas, the carrier gas unit comprisesa fluidized gas system and a gasifying agent system and is used for preheating fluidized gas and continuously feeding a gasifying agent, the cracking-gasification unit comprises a coupling reaction system, a solid circulating return system and a dust removal system and is used for completing heavy oil cracking, solid trapping and circulating return, the cooling recovery unit comprises an online sampling system, a washing system and a rectification system and is used for realizing the collection of cracked oil products and the recycling of light oil and heavy oil, and the gas-liquid separationand light oil recovery unit comprises a two-stage condensation gas-liquid separation system, an adsorption tank and a filter and is used for completing the efficient separation of gas and liquid phases and recovery of light tail oil.

Owner:SHAANXI YANCHANG PETROLEUM GRP

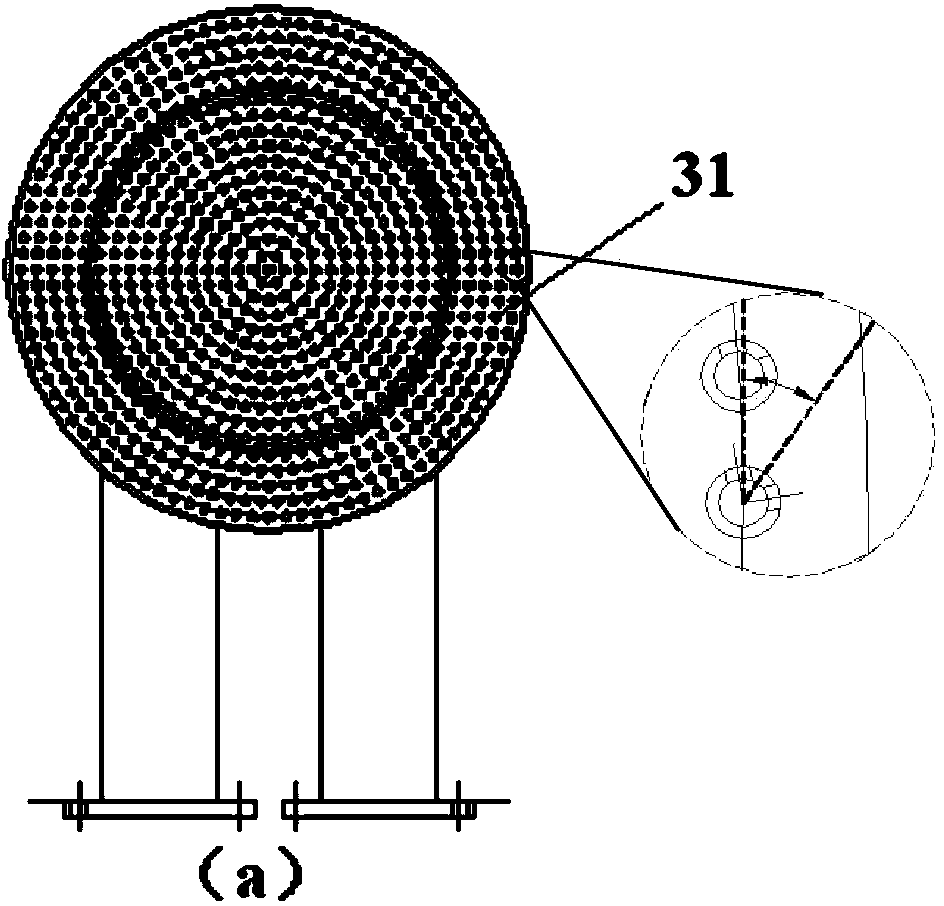

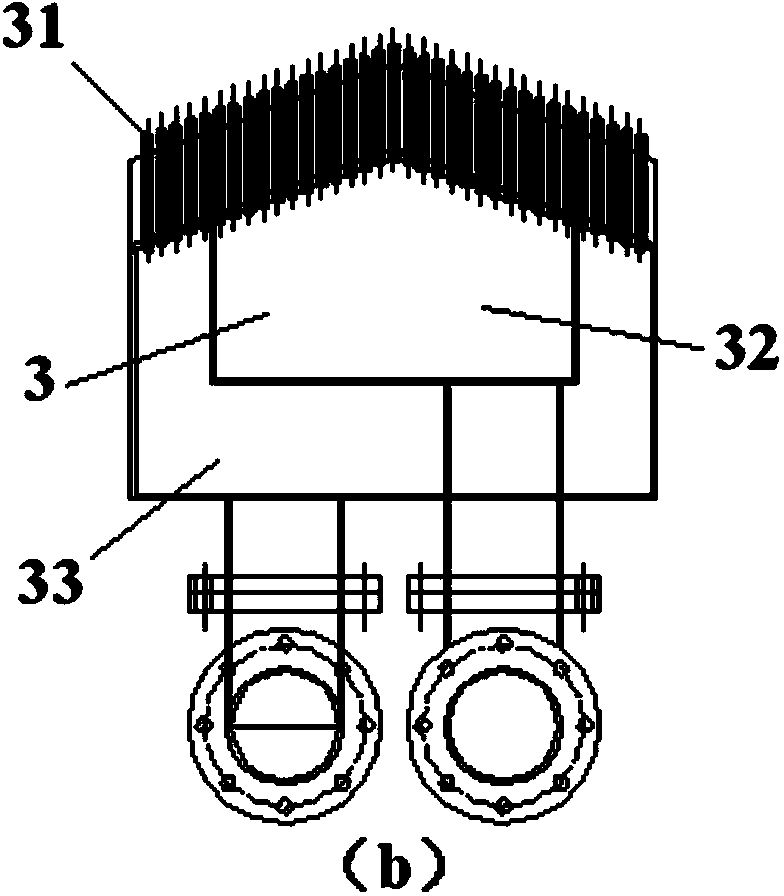

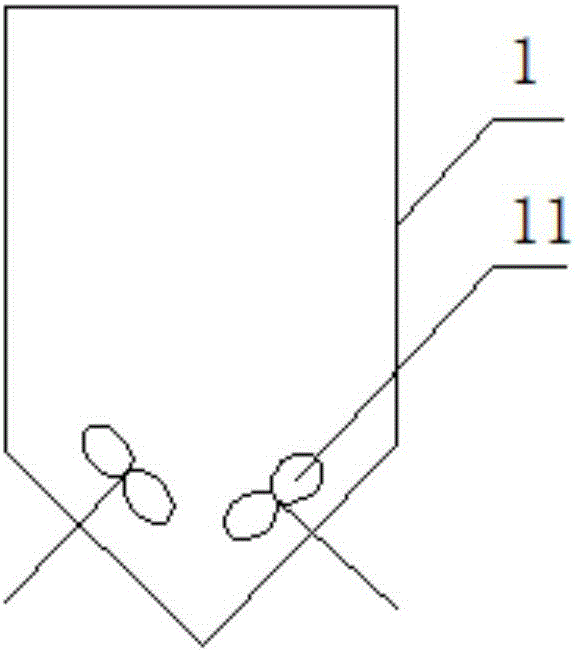

Fluidized-bed gasification furnace for treating biomass

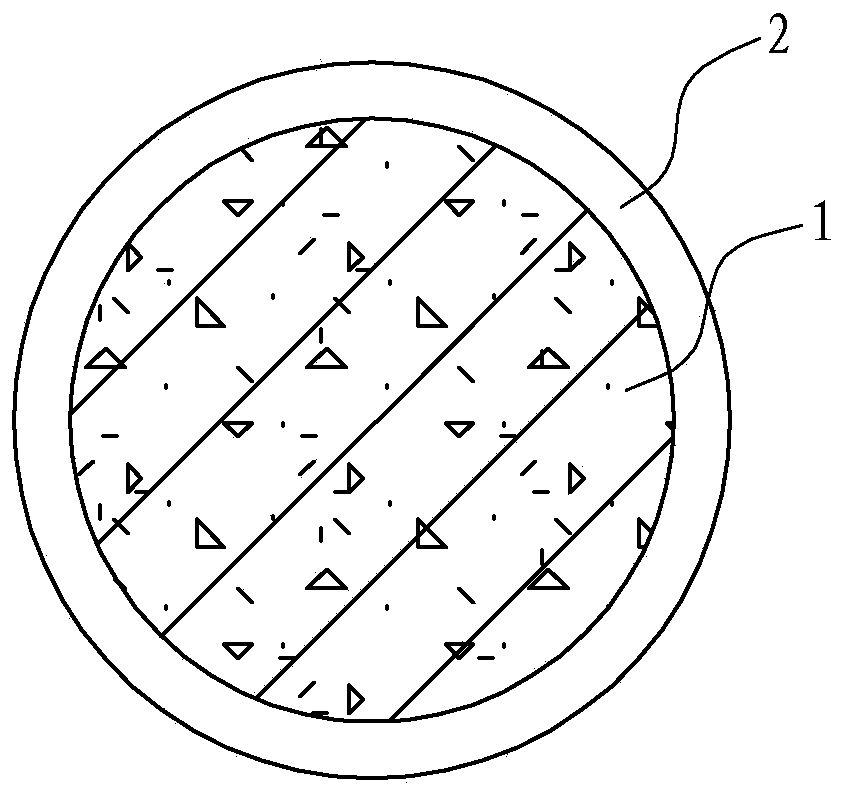

InactiveCN106336905ALight weightSmall specific surface areaGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierRound table

The present invention discloses a fluidized-bed gasification furnace for treating biomass. According to the fluidized-bed gasification furnace, the fluidized-bed gasification furnace body comprises an upper cylinder having a cylindrical structure, a lower cylinder having a cylindrical structure, and a connection section for connecting the upper cylinder and the lower cylinder; and the fluidized-bed gasification furnace is characterized in that the diameter ratio of the upper cylinder to the lower cylinder is 1.5-2:1, the connection section has a top-removing cone structure, the inclination angle of the connection section is 45-75 DEG, the bottom portion of the lower cylinder is provided with a wind distribution plate, the wind distribution plate has a hollow round table structure having the large upper portion and the small lower portion, and the included angle between the wind distribution plate and the bottom portion of the lower cylinder is 20-55 DEG. According to the present invention, the biomass raw material can be subjected to the large-scale treatment with the fluidized-bed gasification furnace, the fluidized-bed gasification furnace has the high energy conversion rate, the tar content in the produced fuel gas is low, and the secondary pollution cannot be generated.

Owner:武汉高斯生态能源技术有限公司

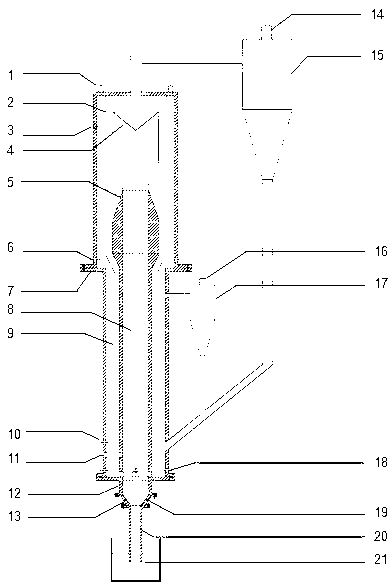

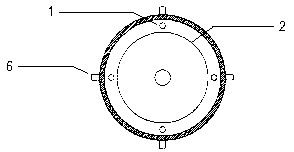

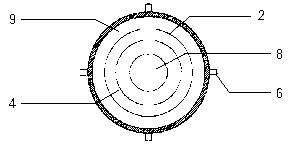

Slag gasification reaction furnace for preparing carbon monoxide, and gas preparation method thereof

PendingCN111635783ARaise the pyrolysis gasification reaction temperatureHigh gasification temperatureChemical industryGasification processes detailsWater jacketMolten slag

The invention relates to a slag gasification reaction furnace for preparing carbon monoxide, and a gas preparation method thereof, belongs to the fields of coal chemical industry, coke (containing semi-coke) gasification, fuel gas and the like, and relates to chemical engineering, a chemical process, chemical machinery, an instrument and an automation technology. The slag gasification reaction furnace comprises a gasification furnace body, a slag hole, a combustion short section, a chilling chamber and an automatic coke adding machine, wherein the gasification furnace body comprises a shell, an upper barrel, a hearth inlet, a coal gas outlet, lining refractory bricks, a water jacket, a gasifying agent nozzle, a water cooling coil pipe, a slag pool, a furnace cover and a large connecting flange. According to the invention, due to the adoption of slag gasification and liquid deslagging, the gasification temperature is high, the carbon conversion rate is improved, the effective gas content is high, the operation energy consumption is low, the cost is low, the methane content is low, the raw coal application is wide, the investment is saved, the equipment is completely domesticated, the maintenance is convenient, the operation is simple and feasible, the requirements of safety, environmental protection and energy conservation are met, and the pure oxygen continuous gasification technology is upgraded.

Owner:江西昌昱实业有限公司

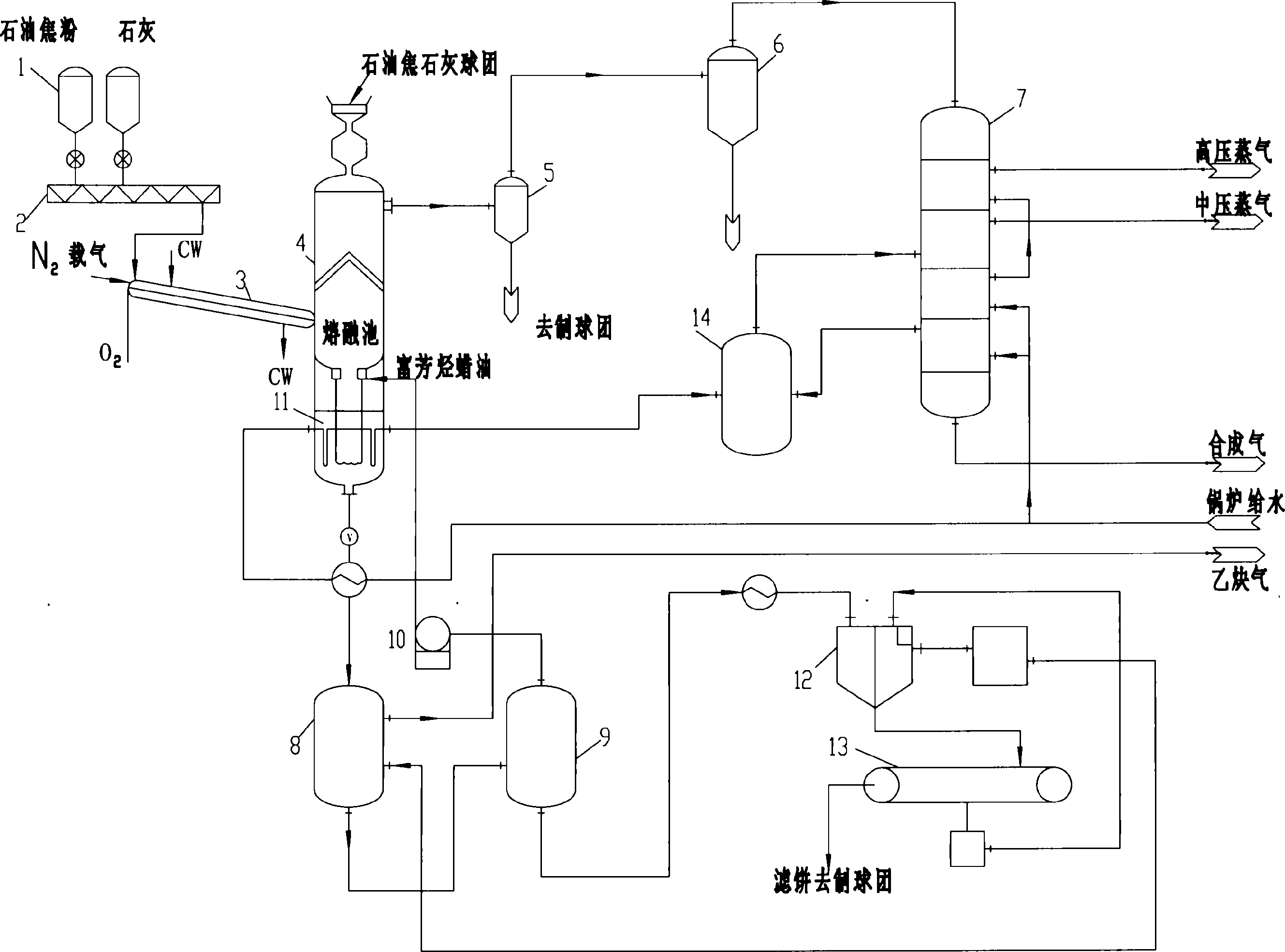

Process of co-producing acetylene and synthetic gas with petroleum coke and low ash coal

InactiveCN1887830ASave powerIncrease inputOrganic chemistryHydrogen productionCalcium hydroxideSyngas

The process of co-producing acetylene and synthetic gas includes the following steps: mixing and drying petroleum coke and lime powder and spraying to gasifying furnace together with oxygen for partial oxidation reaction to produce molten calcium carbide flowing to back reaction area of the gasifying furnace for further reaction to produce synthetic gas; exhausting the synthetic gas through the pellet filler layer in the upper part of the gasifying furnace, dedusting in the cyclonic separator and ceramic tube filter and recovering afterheat in the afterheat recovering system to generate high and medium pressure steam; chilling the reacted molten calcium carbide with the chilling agent of arene-rich wax oil in the chilling trough below the molten bath to form calcium carbide oil slurry; reducing pressure and temperature of calcium carbide oil slurry and reacting with water in the acetylene generator to produce acetylene and calcium hydroxide.

Owner:黄鸿宁

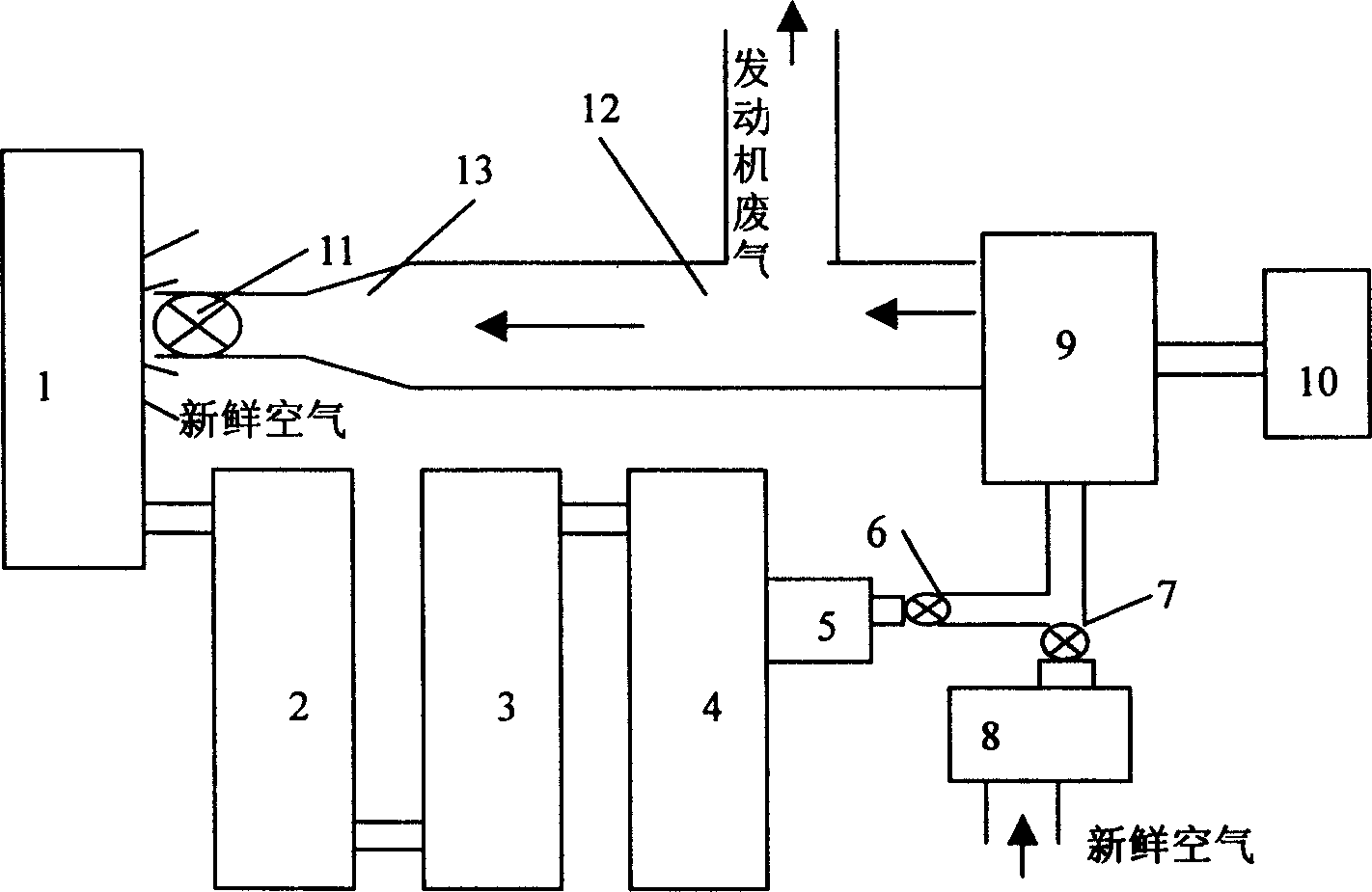

Method and device for heating down-draft biomass gasifier by exhaust gas of engine

InactiveCN102041097AHigh gasification temperatureImprove gasification efficiencyInternal combustion piston enginesExhaust apparatusWater vaporFixed bed

The invention discloses a method and device for heating a down-draft biomass gasifier by exhaust gas of an engine, comprising a biomass gasifier, a double-fuel engine, a heat exchanger and the like. In the invention, high-temperature waste gas exhausted by the double-fuel engine is partly led into a spiral tube arranged in the gasifier to heat materials in the gasifier, thereby raising the biomass gasification temperature and the temperature of a catalytic cracking chamber in the furnace and benefiting the cracking of tar in gas, in the furnace. The heat exchanger arranged at the outlet of the gasifier can supply self-production steam to the gasifier and enables the gas to be condensed and cooled to realize the purpose that the steam and the air are used as a gasification agent. Compared with a down-draft biomass gasifier usually taking air as the gasification agent, the down-draft biomass gasifier provided by the invention ensures that a heat value of the gas is enhanced by above 20 percent. The device can integrate biomass gasification and catalytic cracking of the tar in the furnace, efficiently solve the problem of purification of the tar in the gas to enable the tar content to be lowered by above 60 percent in comparison with the tar content in the gas of an ordinary fixed-bed gasifier and has the advantages of simple structure, little flowing resistance and easiness for implementation.

Owner:YANGZHOU POLYTECHNIC INST

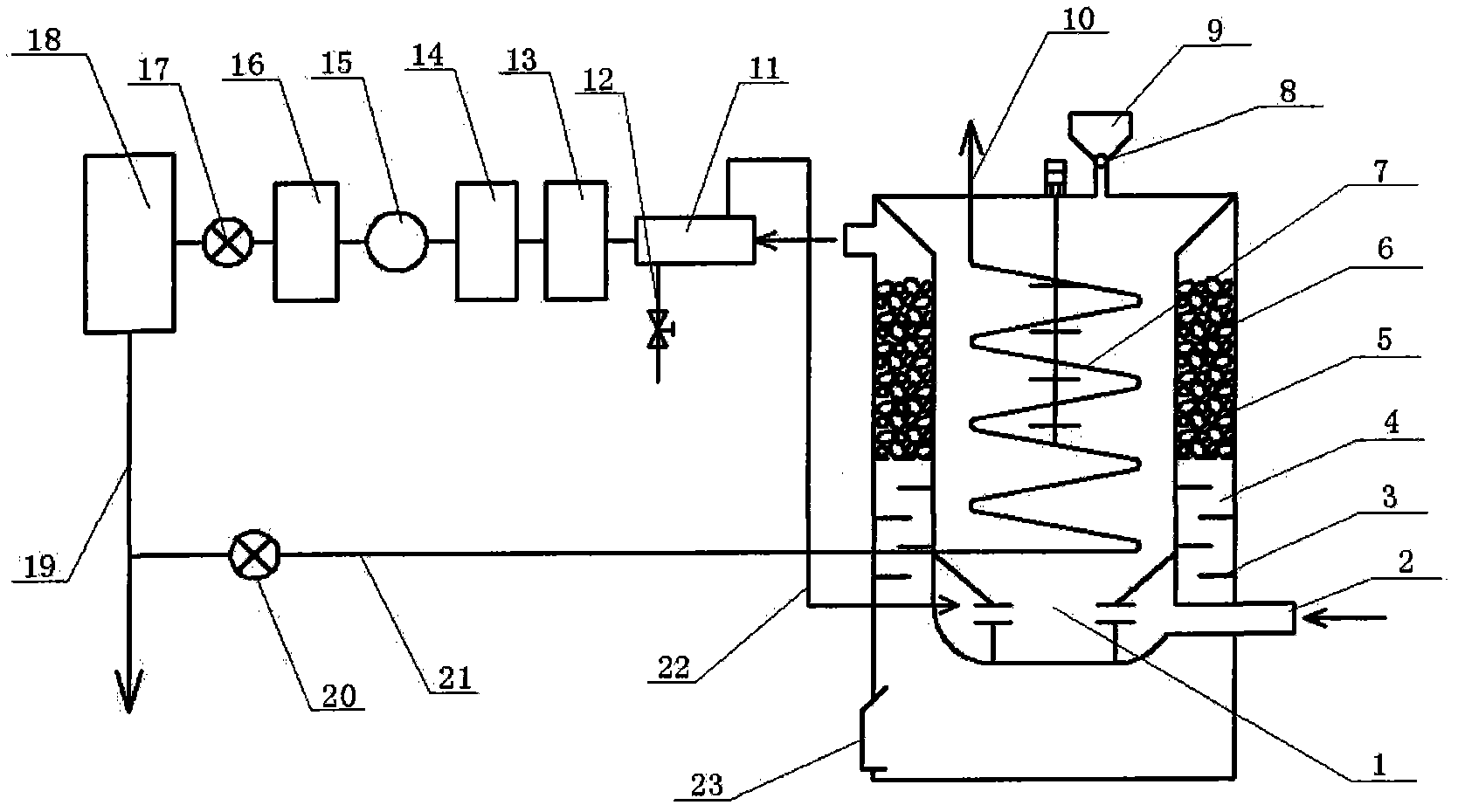

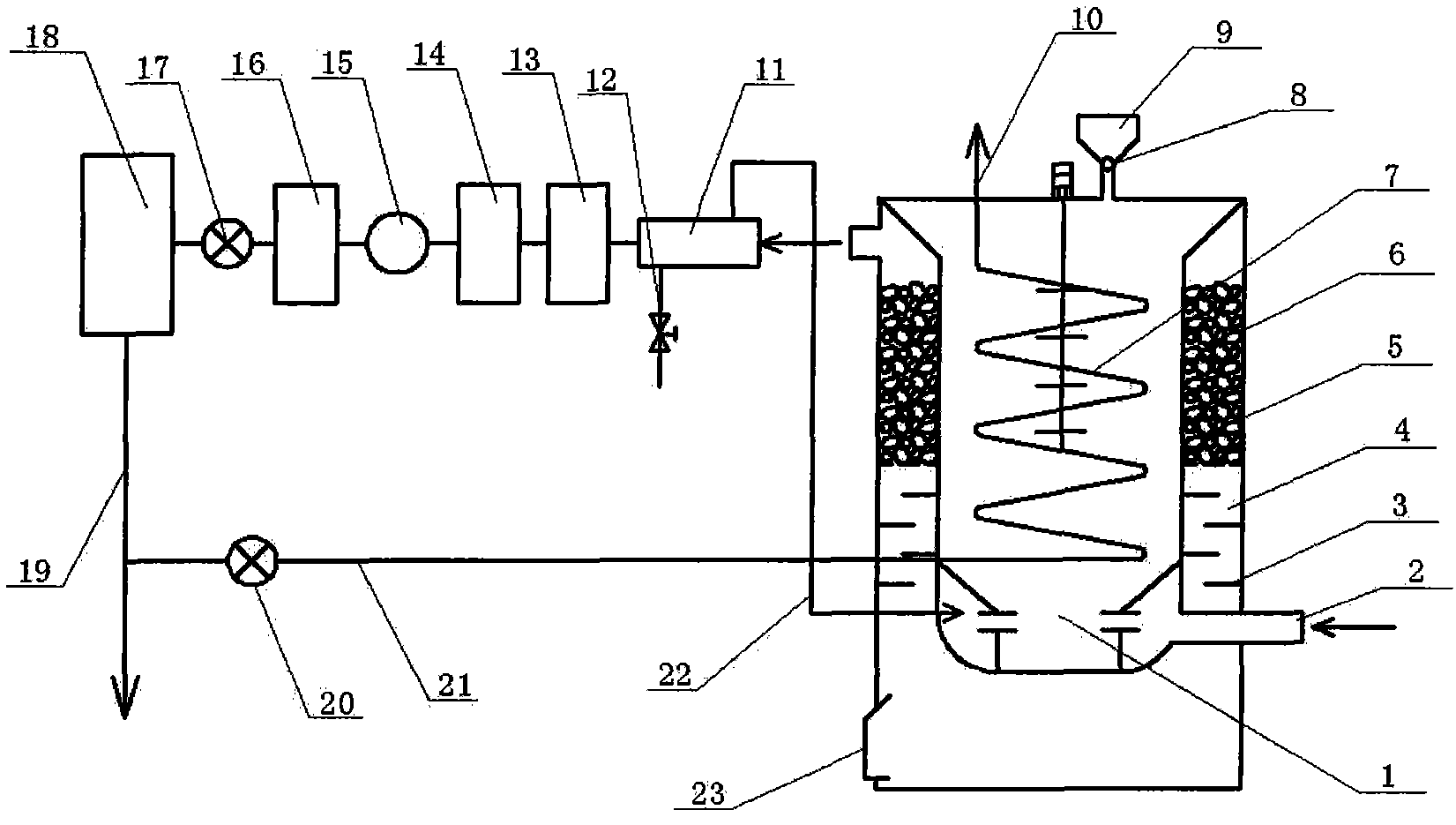

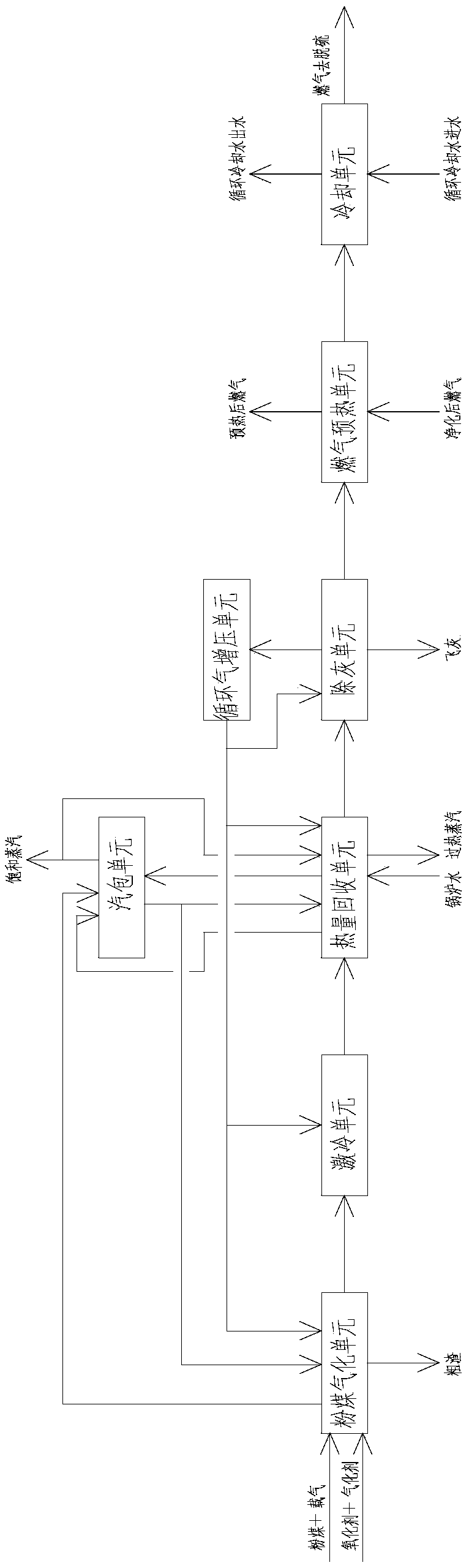

Process method for preparing fuel gas from coal

InactiveCN108977230AConcentration adjustableHigh gasification temperatureGranular/pulverulent flues gasificationEnvironmental resistanceWastewater

The invention relates to a process method for preparing fuel gas from coal. A device for preparing fuel gas from coal used in the method comprises a powdered coal gasification unit, a quenching unit,a heat recovery unit, an ash removing unit, a circulation gas pressurization unit, a steam bag unit, a fuel gas preheating unit and a cooling unit. The process method for preparing fuel gas from coalhas the advantages of high gasification temperature and high coal type applicability; the local cheap coal types can be used as raw materials for greatly reducing the gas preparation cost; the environmental-friendly performance is good; no organic waste water is generated; the fly ash content in the coal gas is low; the fuel gas pressure is from normal pressure to 0.5MPa; the heat value is 900 to2500 kcalNm<3>; the method meets the requirement of low-heat-value fuel gas need in industries of aluminum oxide, ceramics, glass and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A high-efficiency electrode wire for precision mold cutting and its preparation method

ActiveCN103273150BImprove cutting efficiencyLarge discharge energyElectrical-based machining electrodesZinc metalOperability

The invention relates to an efficient electrode wire for precision mould cutting. The efficient electrode wire comprises a core material and a shell layer wrapping the surface of the core material, the core material is made of yellow copper from the processes of smelting, casting, stretching and annealing, the shell layer is a discontinuous shell layer formed by heating, continuously drawing and continuously annealing a zinc metal plating layer plated on the yellow copper core material, and the discontinuous shell layer comprises shell particles which radially cover 40-90% of the surface of the core material and are distributed at intervals along an axial direction of the surface of the core material. The invention further relates to a preparation method of the electrode wire. The preparation method is simple in production technology, strong in operability, less in preparation steps, simple in production equipment and easy to prepare satisfactory products and realize large-scale and automated production. The efficient electrode wire is strong in universality and is particularly suitable for precision mould cutting.

Owner:NINGBO BODE HIGHTECH CO LTD

Gasifying device for recycling biomass for engine exhaust

InactiveCN1749062AHigh gasification temperatureImprove gasification efficiencyFuel supplyExhaust fumesTar

The present invention relates to engine, and is especially exhaust circulating and biomass gasifying method and device for engine. Partial high temperature exhaust with certain pressure is jetted to the gasifying furnace together with fresh air and used as gasifying agent to raise biomass gasifying temperature, raise gasifying efficiency and lower tar content in the inflammable gas. The present invention solves the problems of engine exhaust circulation and its control. The present invention can reduce NOx exhaust of double fuel engine, raise biomass gasifying efficiency and lower tar content in the biomass gas.

Owner:JIANGSU UNIV

Biomass double fluidized bed indirect gasification system and its control method

ActiveCN105018154BHigh calorific valueAvoid backmixingGranular/pulverulent flues gasificationWater vaporNitrogen gas

The invention relates to a biomass double fluidized bed indirect gasification system and its control method. Double fluidized beds interact to realize combustion and indirect gasification so as to prepare a high-quality biomass syngas. The system provided by the invention comprises a fluidized-bed combustor and its secondary cyclone separator, a fluidized-bed gasifier and a second cyclone separator, a combustor air injection system, a combustor bed material feeding system, a gasifier vapor injection system, a gasifier biomass feeding system, a gasifier and combustor bed material circulatory system, a bed material recovery system, a combustor and a gasifier pressure control system. By the internal and external circulating double fluidized bed indirect gasifier, nitrogen in the air is naturally separated from the syngas. Through improvement of structure design of a reactor, mixed use of different bed materials, a bed material circular flow system and improvement of the gas-solid mixing level, gasification efficiency is raised, calorific value of the syngas is increased, tar content is reduced, and high-quality syngas is prepared.

Owner:代建军

Biomass and coal fluidized bed co-gasification method

InactiveCN102786990BLow costIncrease profitGranular/pulverulent flues gasificationSyngasCombustion chamber

The invention discloses a biomass and coal fluidized bed co-gasification method. The method comprises the following steps: biomass and coal are crushed and mixed to form biomass-coal mixture, the biomass-coal mixture is added to a fluidized bed gasification outer barrel and is gasified under the effect of a gasifying agent, and gas generated by gasification reaction is discharged through a cyclone separator; meanwhile, the biomass-coal mixture is added to a combustion inner barrel, coal coke which is not gasified in the gasification outer barrel and the entered compressed air are subjected to combustion reaction, and then ascend along the gasification inner barrel; and the coal coke enters an inertia separator to be gasified circularly along with a combustion gas flow, high-temperature flue gas and the biomass-coal mixture are subjected to countercurrent heat exchange and are discharged by a cyclone separator, and ash residue is discharged from the bottom. According to the biomass and coal fluidized bed co-gasification method, the gasification process and the combustion process of the biomass and coal are separated, the circulation of high-temperature material provides heat for the gasification reaction, heat is also directly exchanged through the thermal radiation and convection of a combustion chamber and a gasification chamber, the heat loss is reduced, meanwhile the production efficiency is improved, and the heat value of synthesis gas is high.

Owner:TAIYUAN UNIV OF TECH

Gasification device for sludge treatment

PendingCN108503174AHigh gasification temperatureRealize harmless decompositionWater contaminantsSludge treatment by pyrolysisCombustion chamberDecomposition

The invention discloses a gasification device for sludge treatment. The gasification device comprises a combustion chamber, an ignition device, a fan, an air pipe assembly and a residue discharging device, wherein the air pipe assembly comprises a first air pipe and a plurality of second air pipes, the ignition device is arranged at the bottom end of the combustion chamber, and an air inlet end ofthe first air pipe is communicated with an air outlet of the fan; an air outlet end of the first air pipe is communicated with the bottom end of the combustion chamber; the plurality of second air pipes are uniformly distributed around the center axis of the combustion chamber at intervals; air outlet ends of the plurality of air outlet pipes are communicated with the bottom end of the combustionchamber, and air inlet ends of the plurality of the second air pipes are communicated with the air outlet of the fan; the air outlet end of the first air pipe is communicated with middles of the airoutlet ends of the plurality of second air pipes; the residue discharging device is communicated with the bottom end of the combustion chamber; a gas outlet is arranged at the top end of the combustion chamber. The gasification device for sludge treatment can distribute air uniformly, thus, the gasification temperature in the combustion chamber can be as high as 800 DEG C or above, and harmless decomposition of sludge is realized finally.

Owner:湖南省益能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com