Patents

Literature

198results about How to "Avoid backmixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

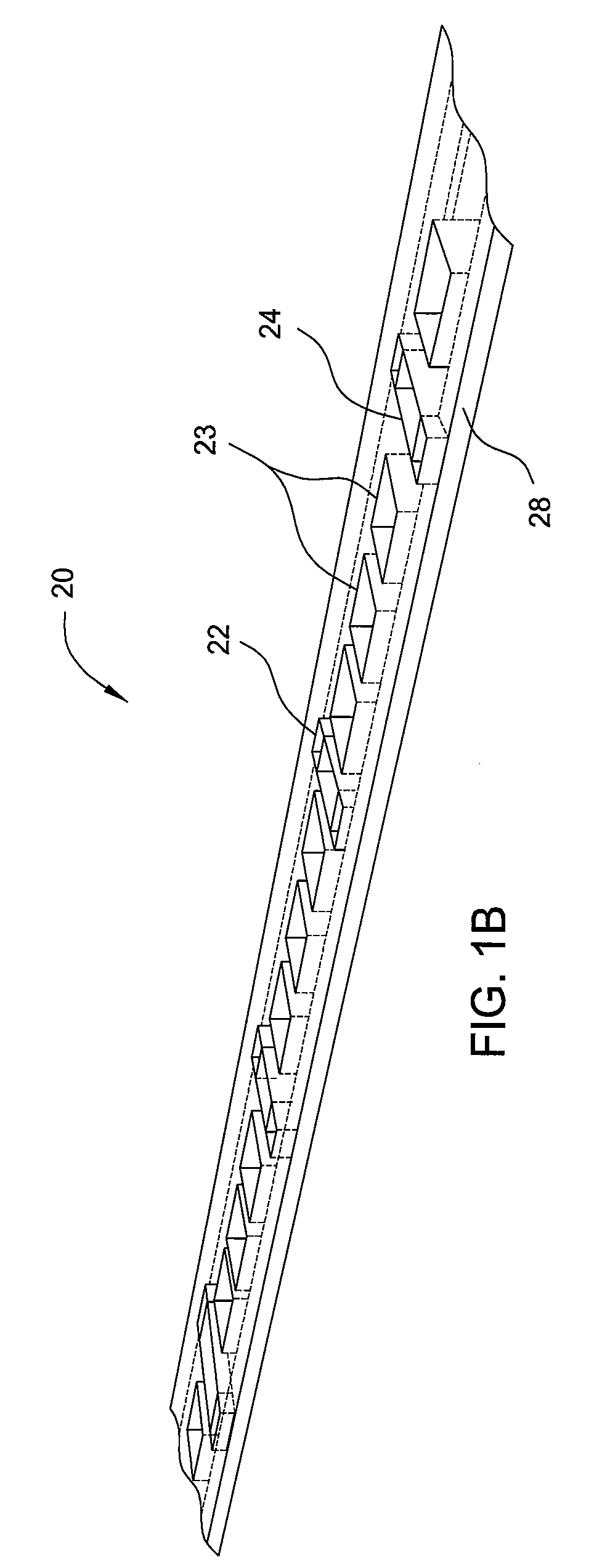

Methods and apparatus for a chemical vapor deposition reactor

ActiveUS20090324379A1Avoid enteringAvoid mixingPolycrystalline material growthLiquid surface applicatorsEngineeringChemical vapor deposition

Embodiments of the invention generally relate to a levitating substrate carrier or support. In one embodiment, a substrate carrier for supporting and carrying at least one substrate or wafer is provided which includes a substrate carrier body containing an upper surface and a lower surface, and at least one indentation pocket disposed within the lower surface. In another embodiment, the substrate carrier includes at least open indentation area within the upper surface, and at least two indentation pockets disposed within the lower surface. Each indentation pocket may be rectangular and have four side walls extending substantially perpendicular to the lower surface. In another embodiment, a method for levitating substrates disposed on a substrate carrier is provided which includes exposing the lower surface of a substrate carrier to a gas stream, forming a gas cushion under the substrate carrier, levitating the substrate carrier within a processing chamber, and moving the substrate carrier along a path within the processing chamber.

Owner:ALTA DEVICES INC

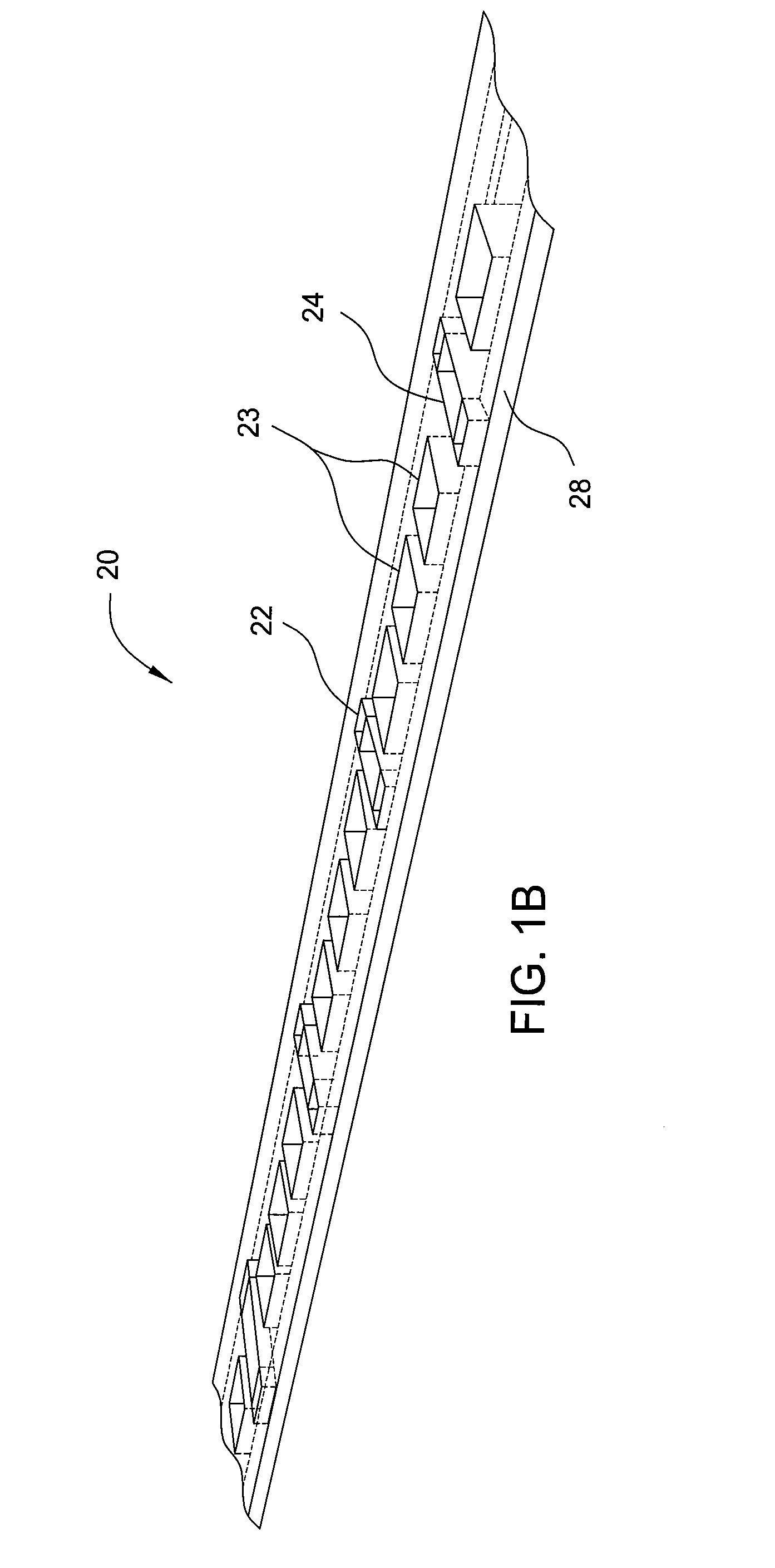

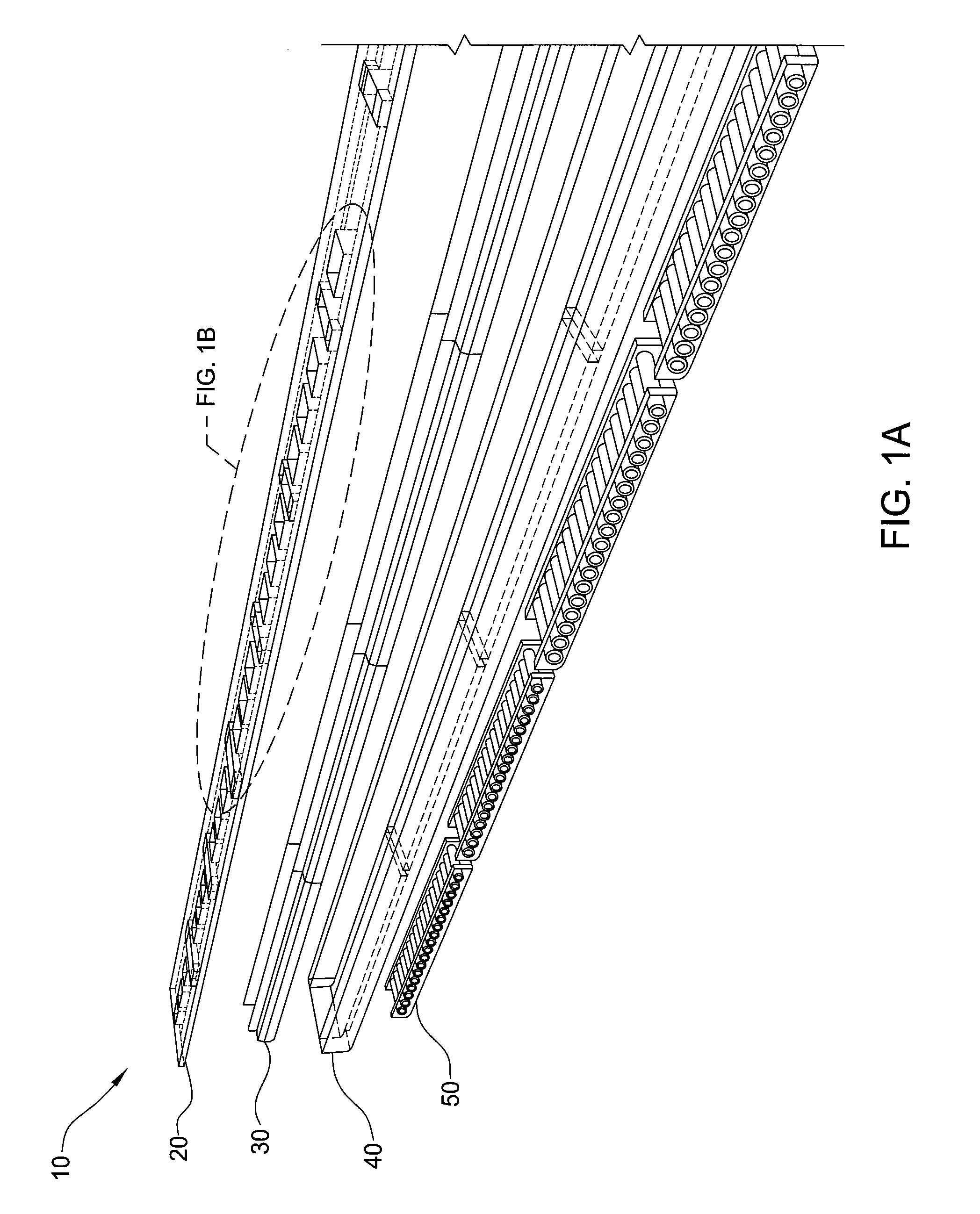

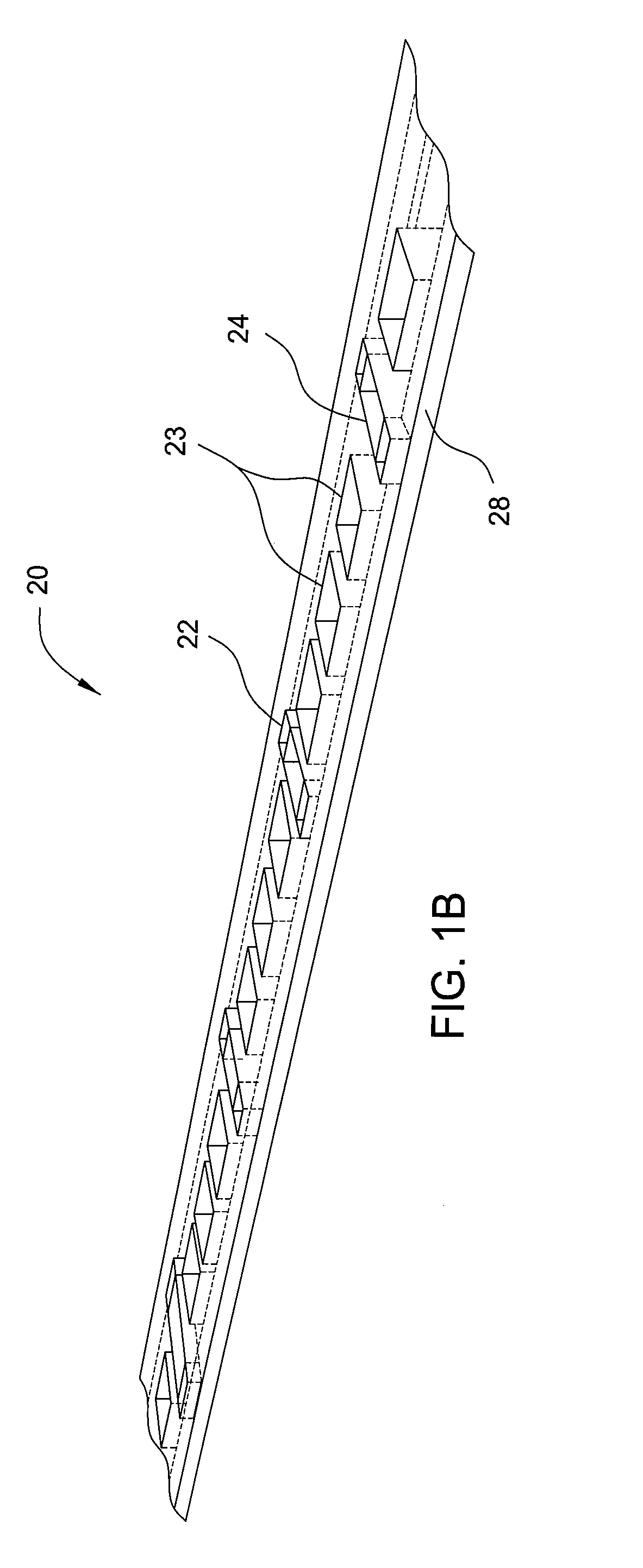

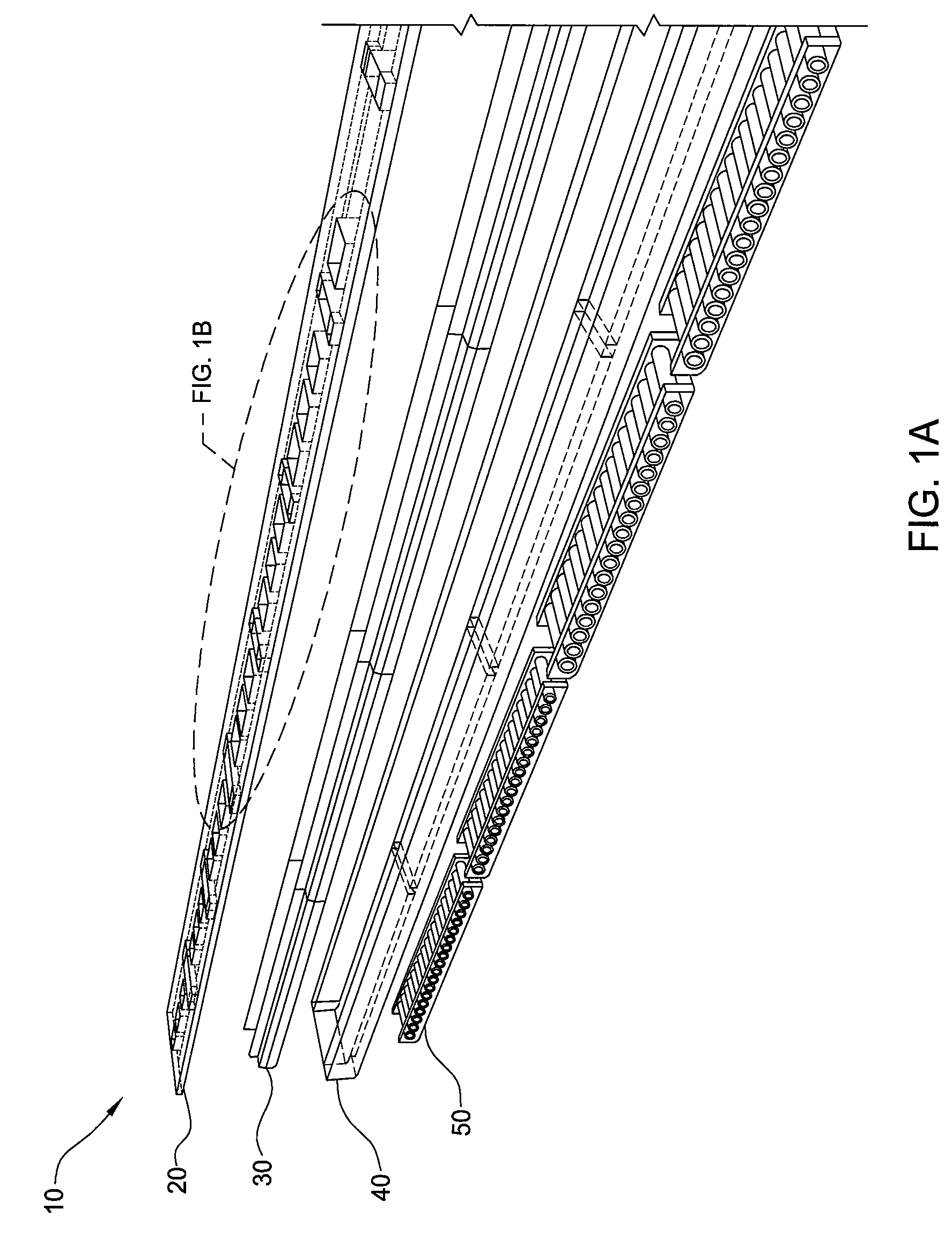

Methods and apparatus for a chemical vapor deposition reactor

InactiveUS20090325367A1Avoid enteringAvoid mixingPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseEngineering

Embodiments of the invention generally relate to a chemical vapor deposition system and related method of use. In one embodiment, the system includes a reactor lid assembly having a body, a track assembly having a body and a guide path located along the body, and a heating assembly operable to heat the substrate as the substrate moves along the guide path. The body of the lid assembly and the body of the track assembly are coupled together to form a gap that is configured to receive a substrate. In another embodiment, a method of forming layers on a substrate using the chemical vapor deposition system includes introducing the substrate into a guide path, depositing a first layer on the substrate and depositing a second layer on the substrate, while the substrate moves along the guide path; and preventing mixing of gases between the first deposition step and the second deposition step.

Owner:ALTA DEVICES INC

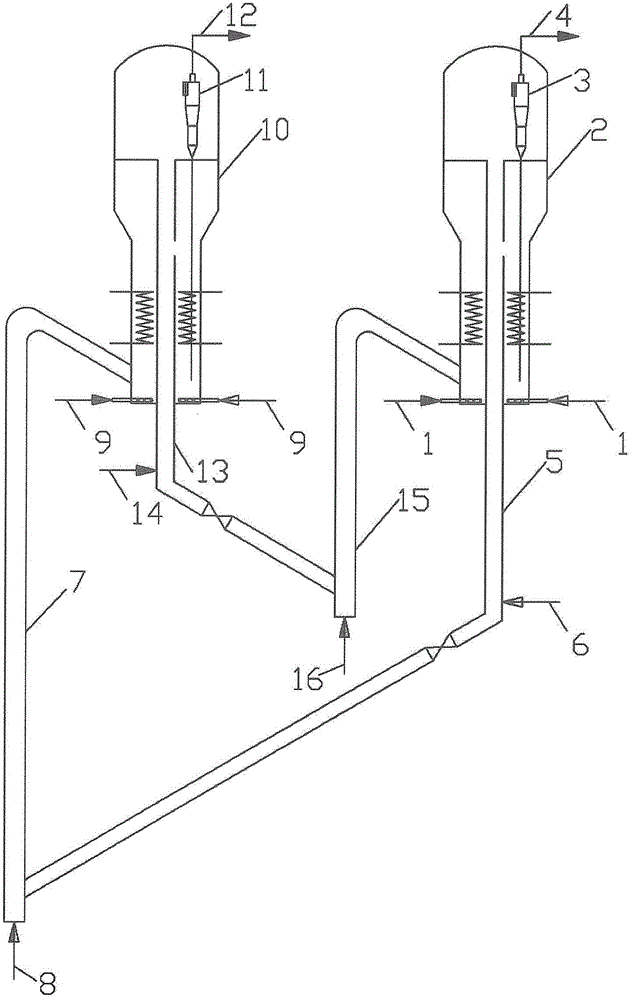

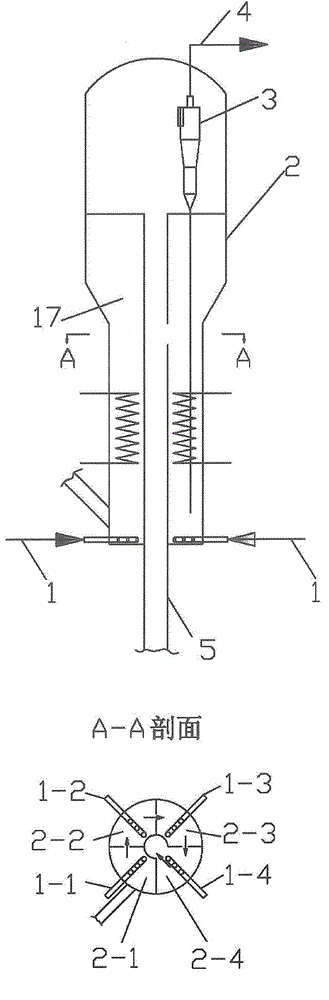

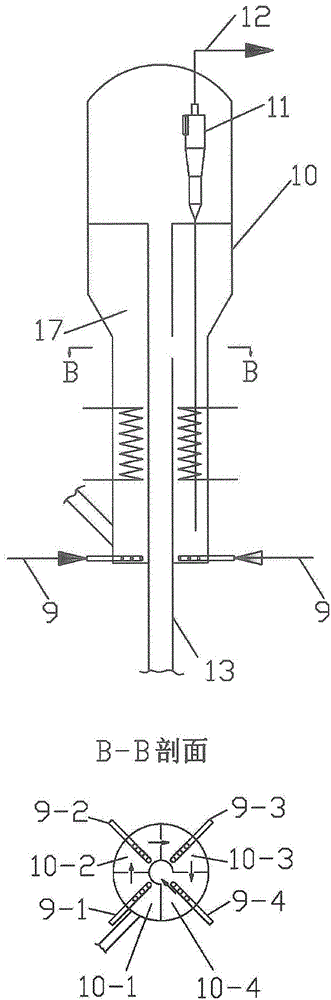

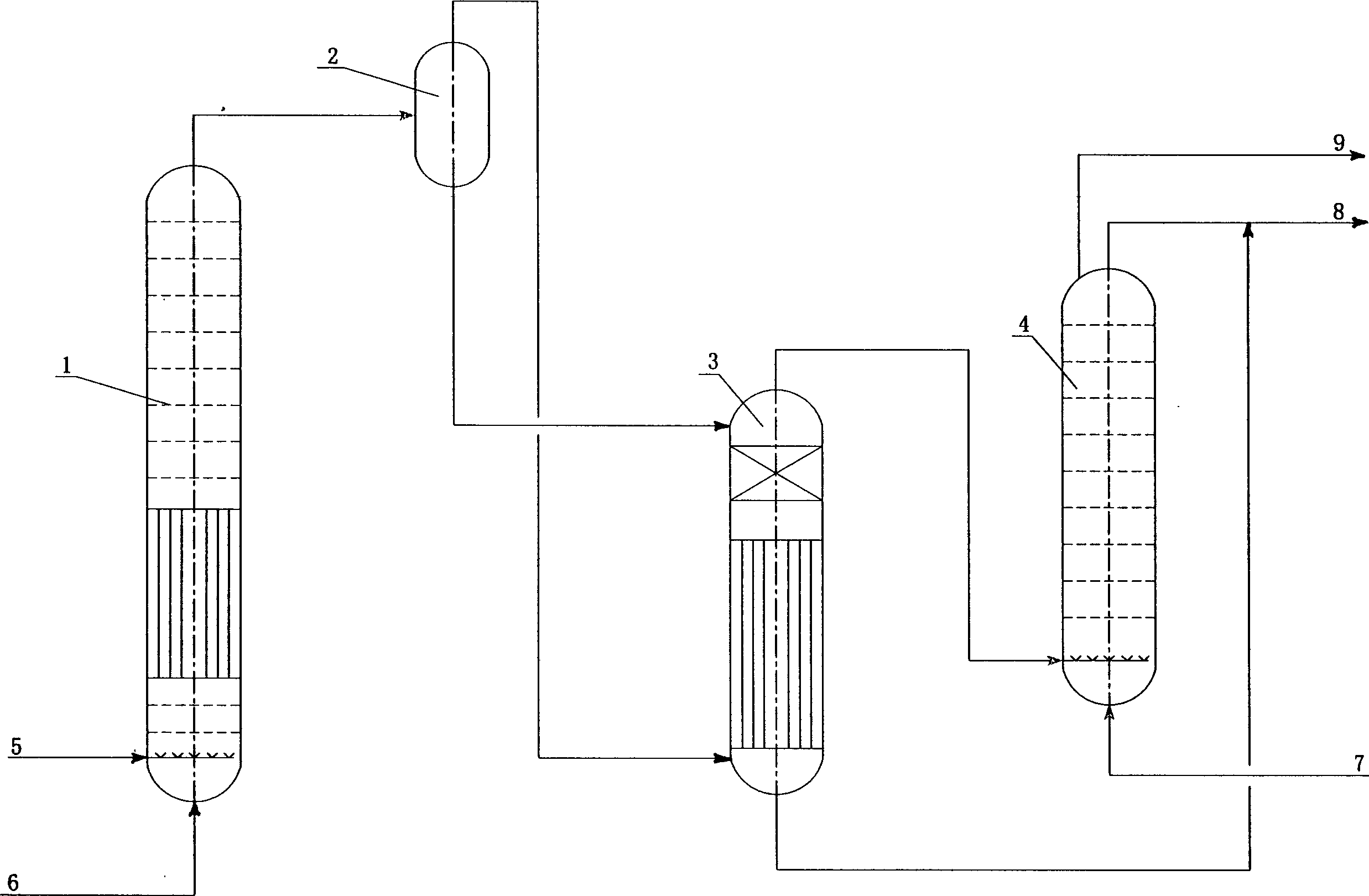

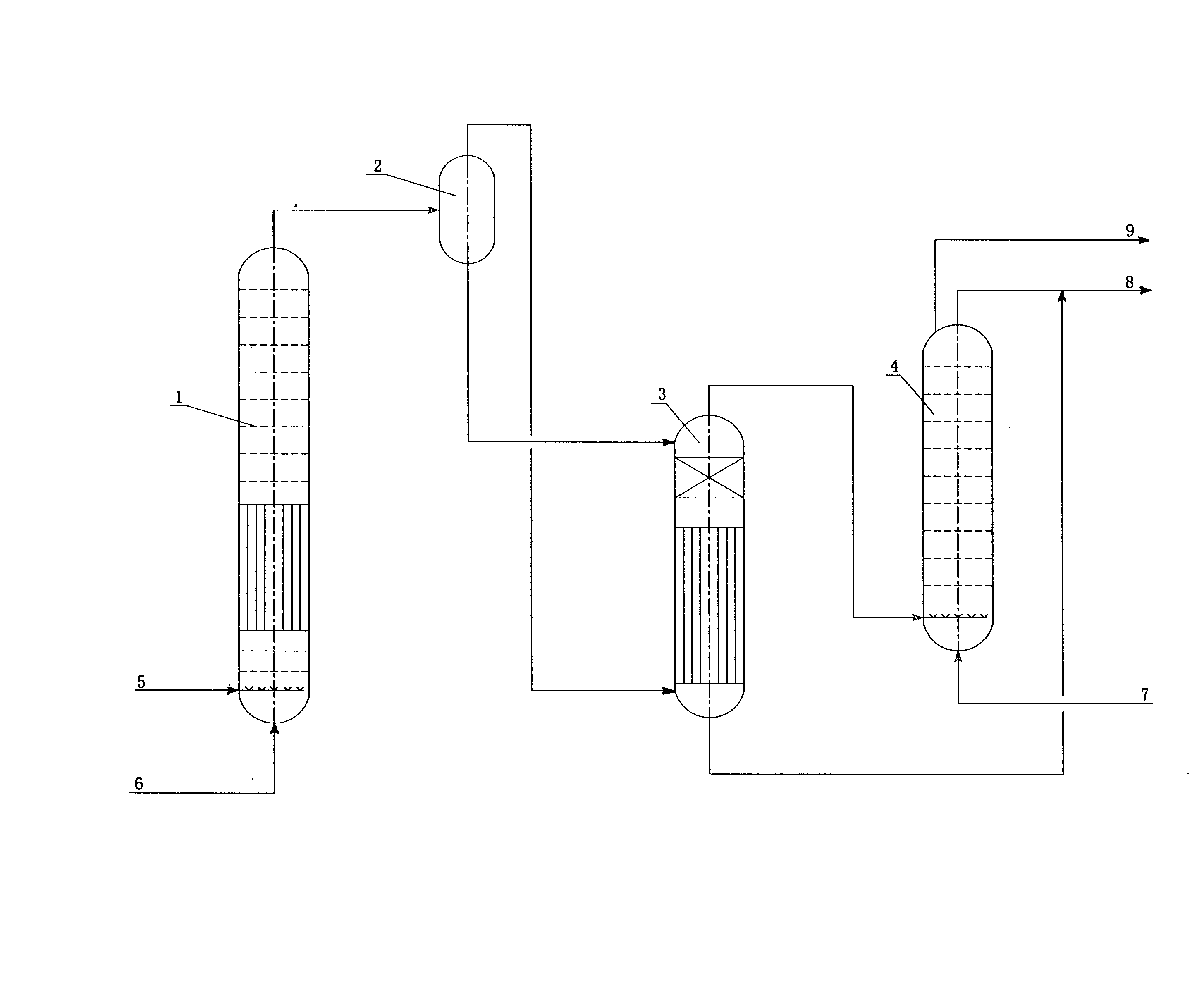

Reaction device for preparing low-carbon olefin by employing methyl alcohol and/or dimethyl ether

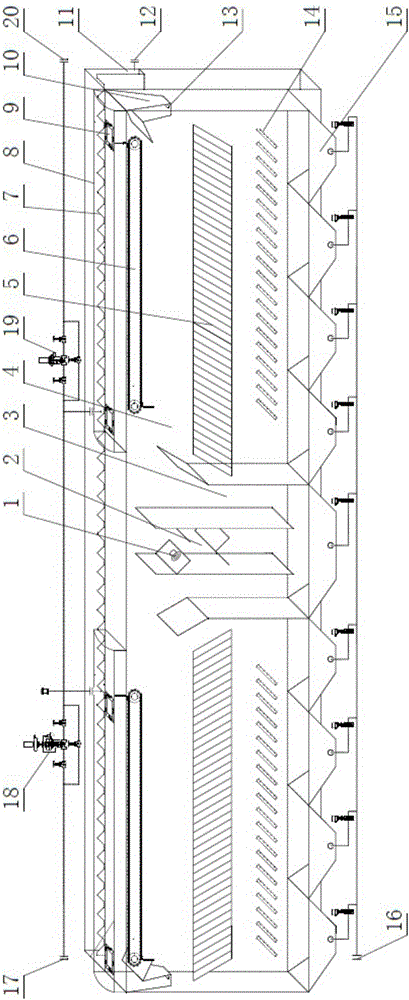

ActiveCN104672045AIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

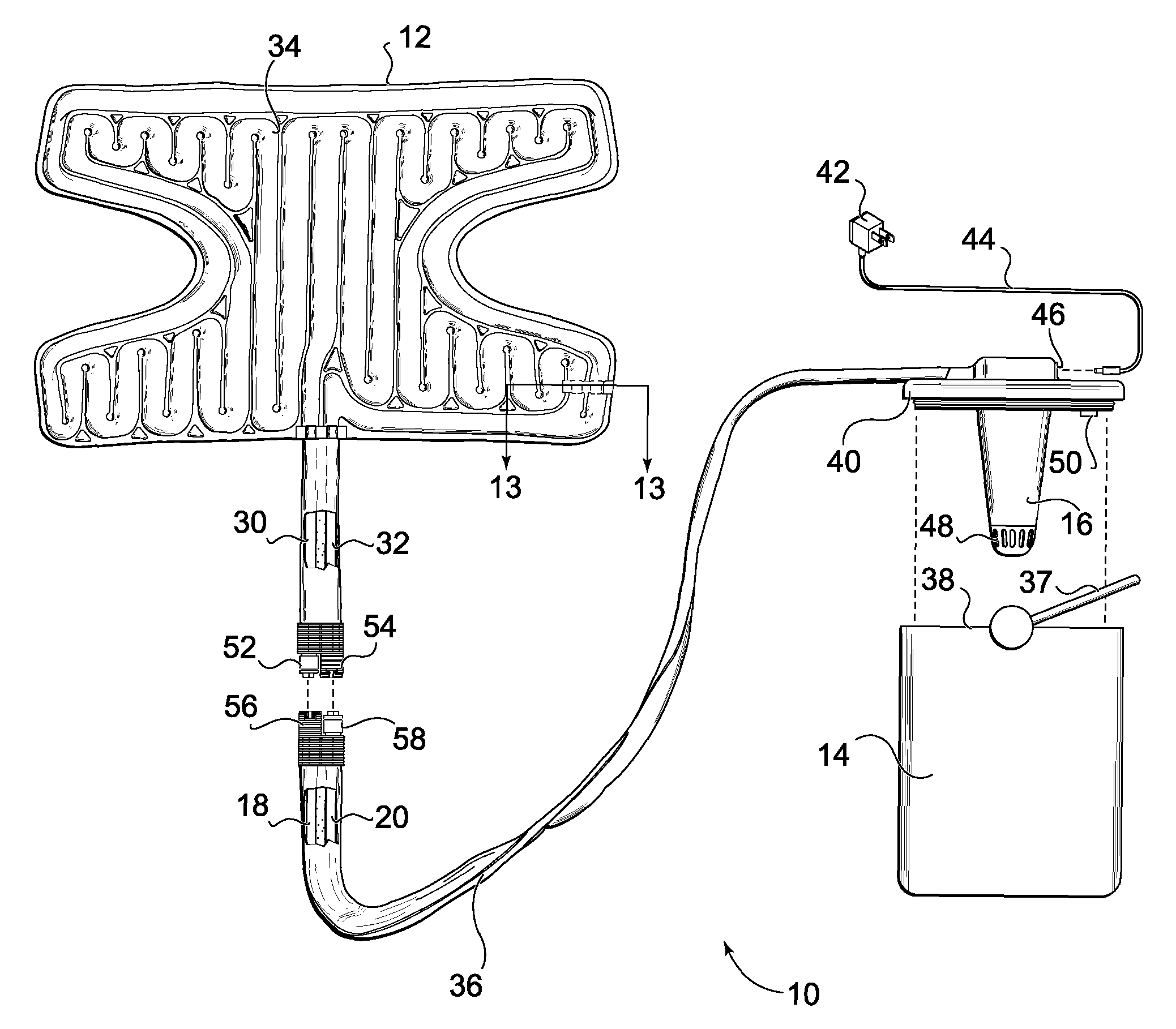

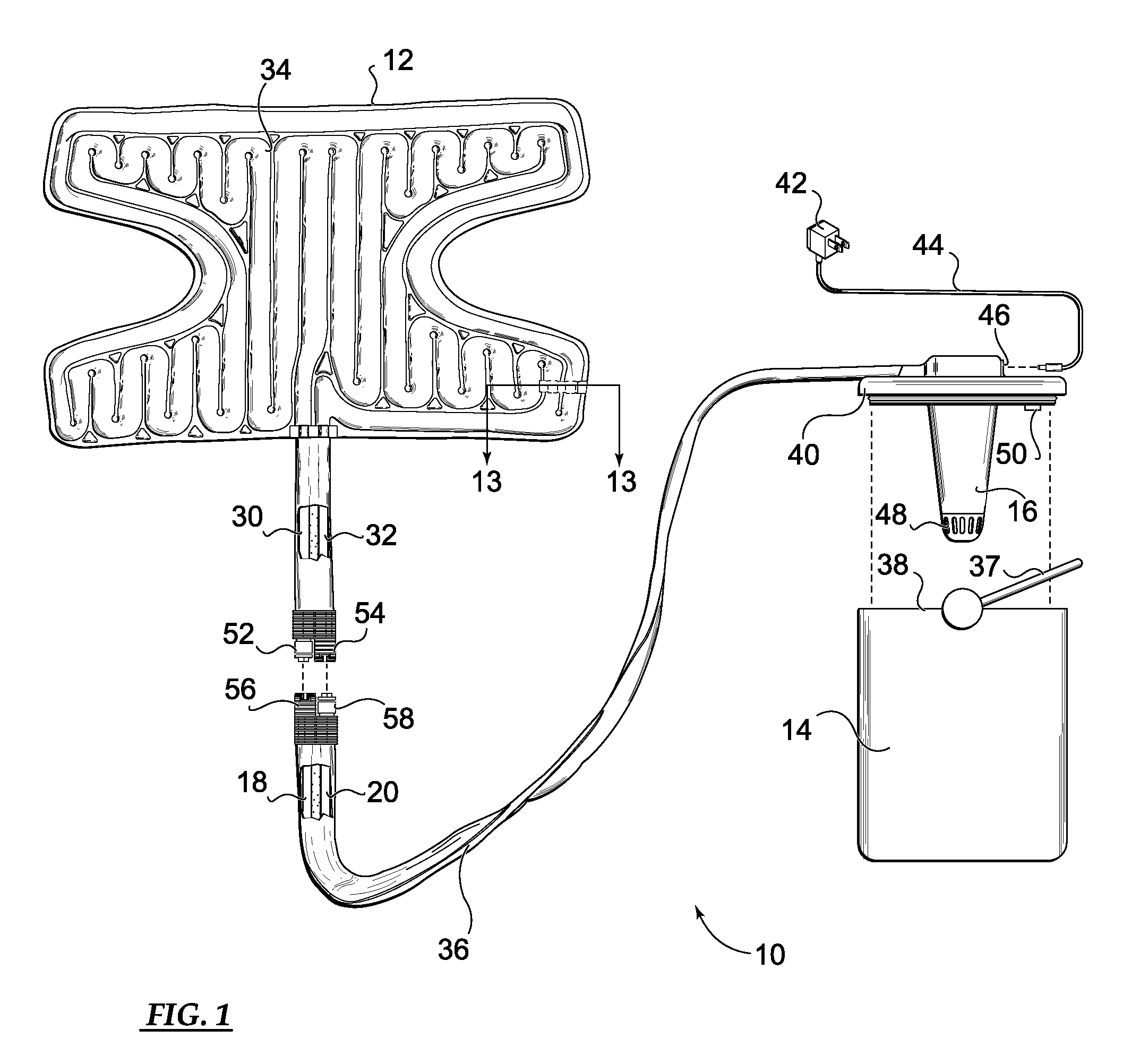

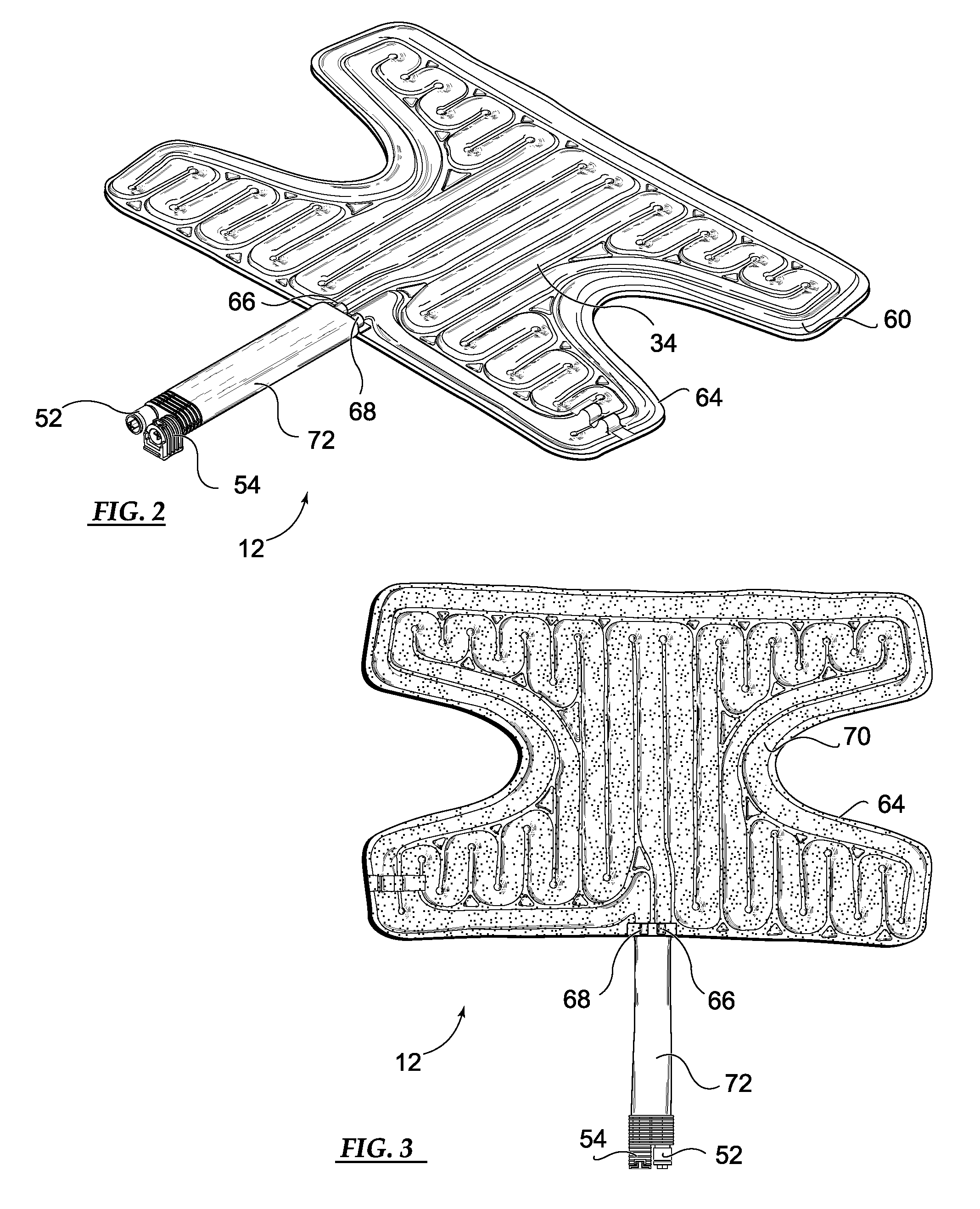

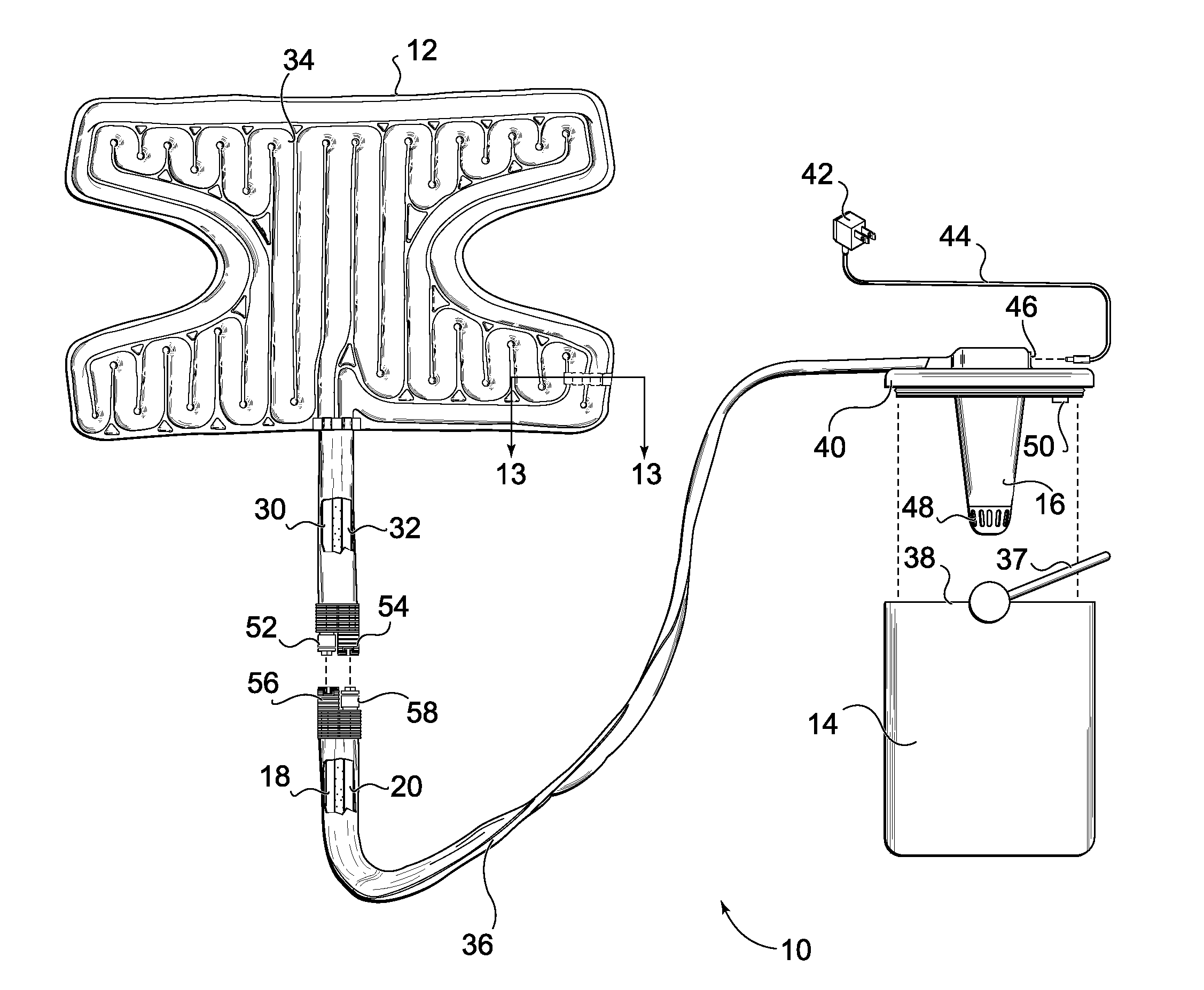

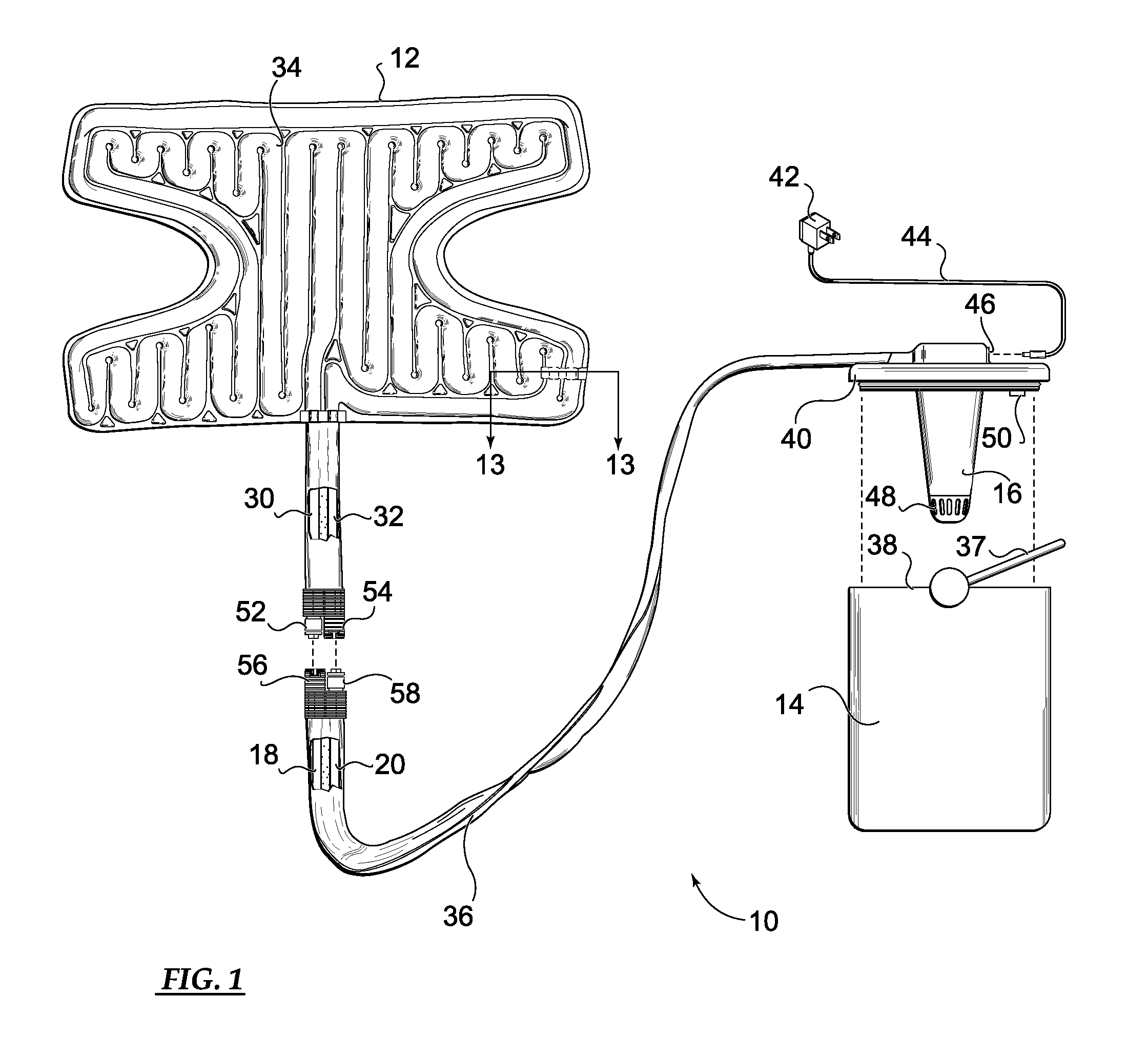

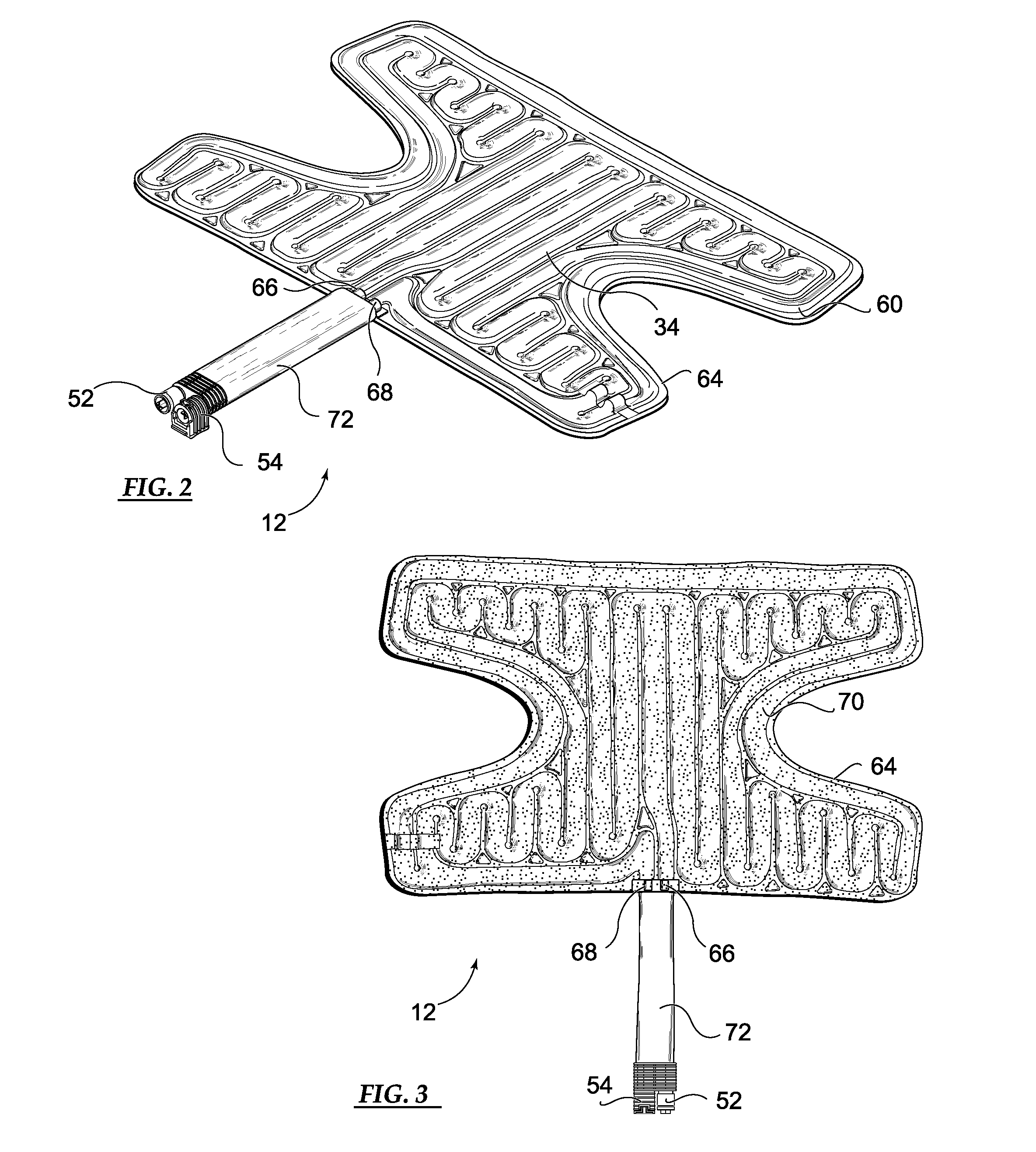

Heat transfer pad having localized treatment zones

ActiveUS9170059B2Avoid communicationAvoid backmixingTherapeutic coolingTherapeutic heatingEngineeringHeat transfer fluid

A heat transfer pad includes a pad inlet port for feeding a heat transfer fluid to the pad, a pad outlet port for discharging the heat transfer fluid from the pad and a bladder having an internal flowpath for the heat transfer fluid which extends from the pad inlet port to the pad outlet port. The internal flowpath is divided into a first flow channel and a second flow channel through which first and second flow streams of the heat transfer fluid, respectively, flow between the pad inlet and outlet ports. A first flow restrictor is positioned downstream in the first flow channel and a second flow restrictor is correspondingly positioned downstream in the second flow channel and the flow restrictors are configured to create substantial back pressures in the first and second flow channels, respectively.

Owner:BREG

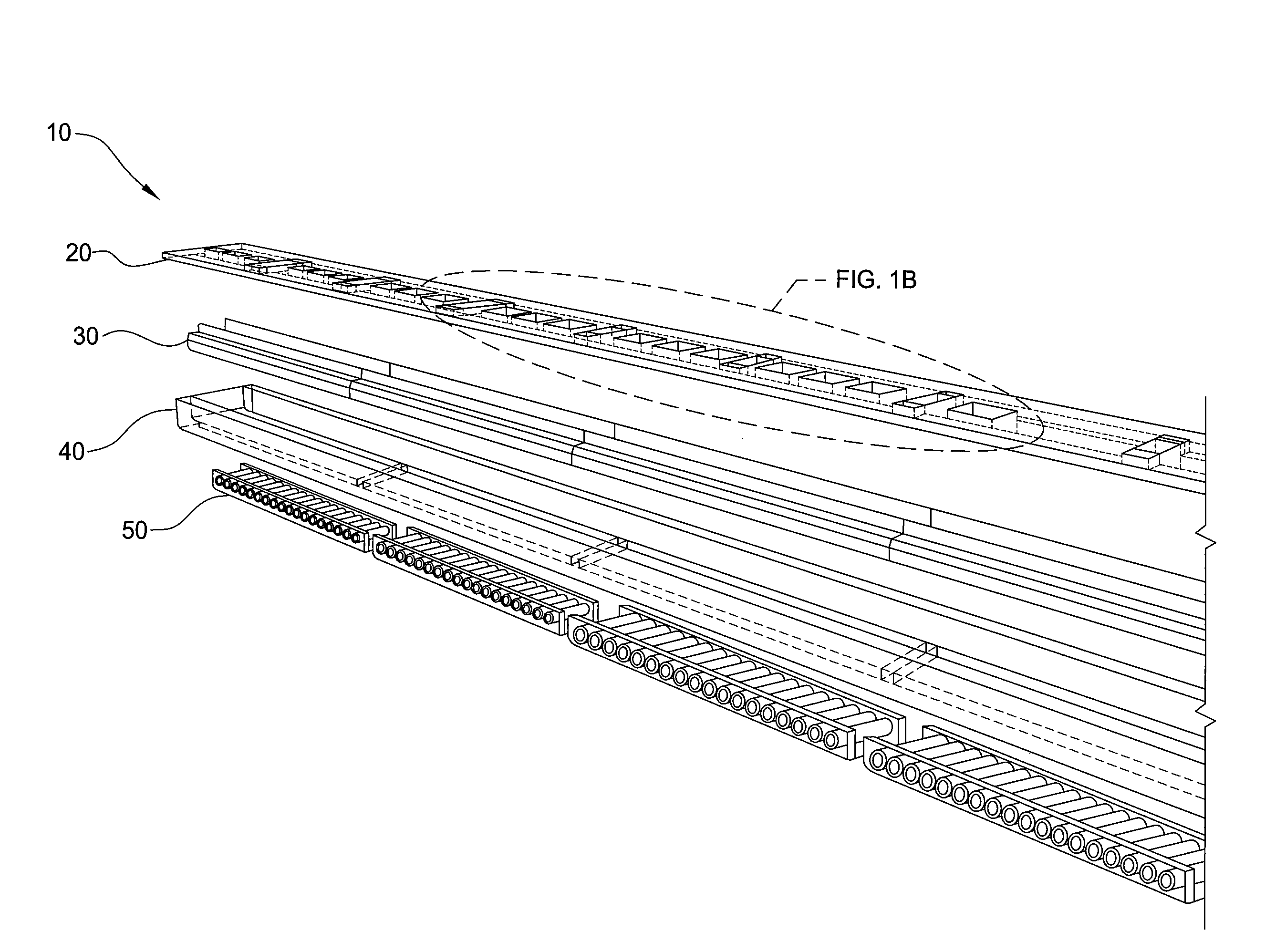

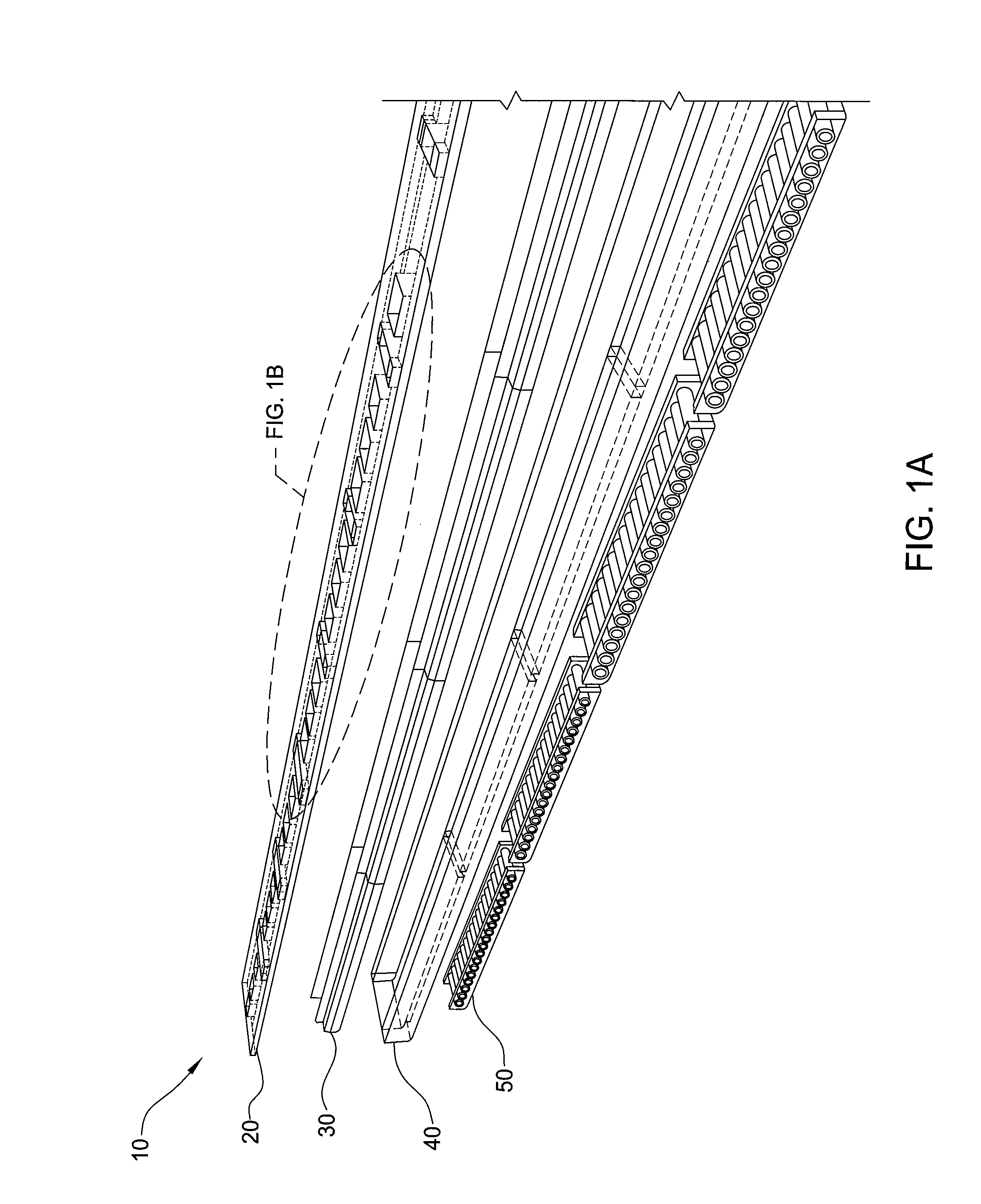

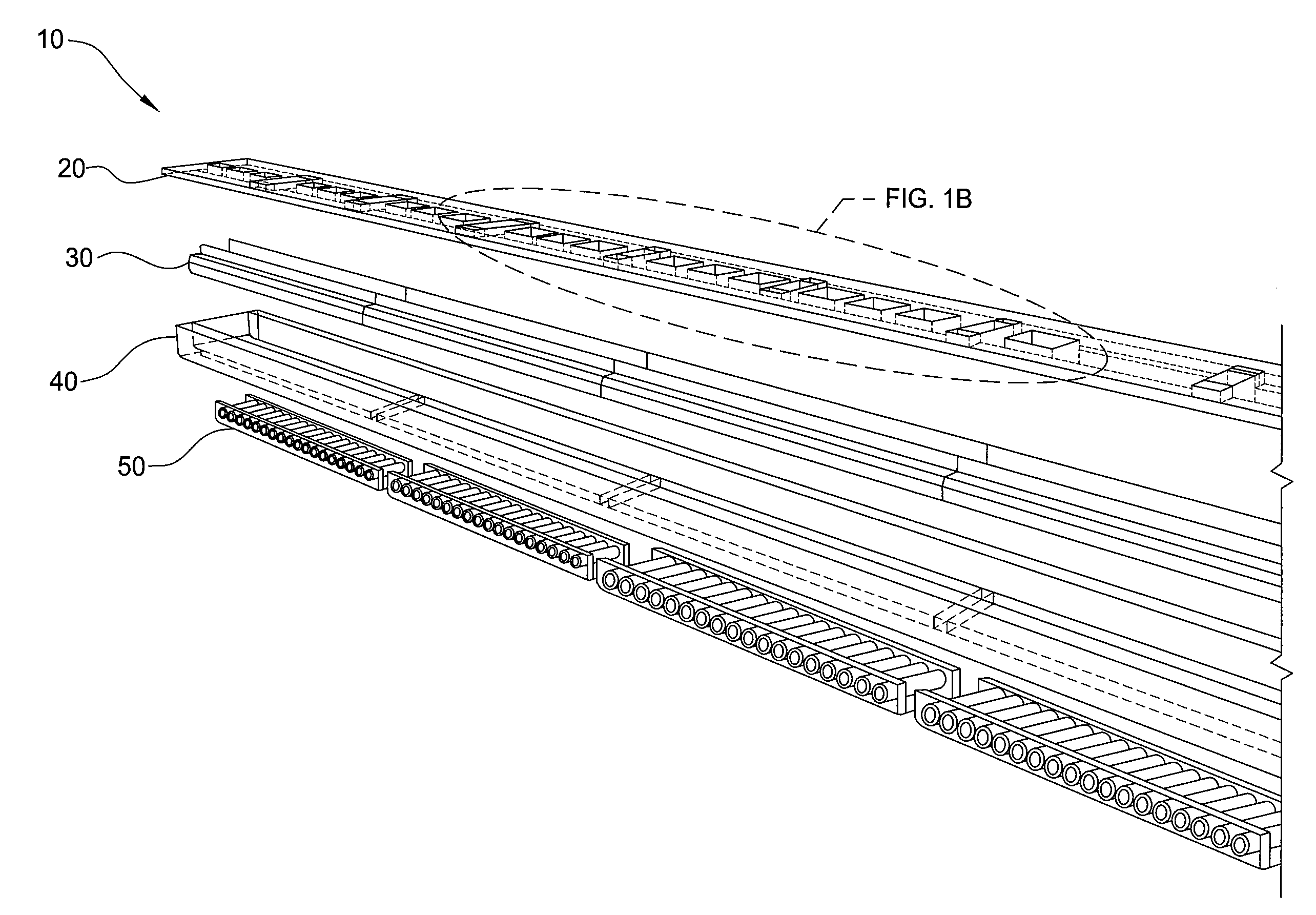

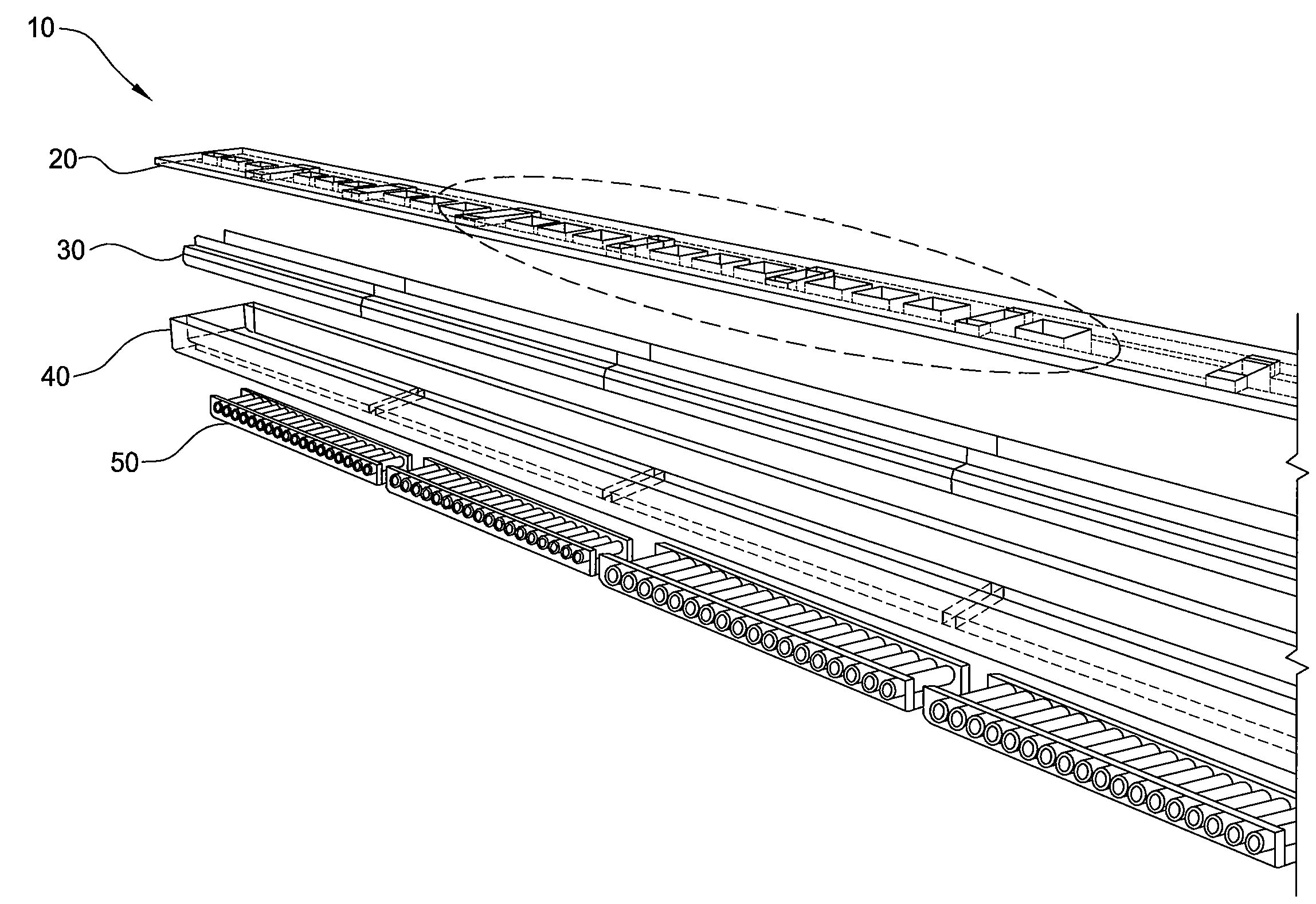

Continuous feed chemical vapor deposition

ActiveUS8008174B2Avoid enteringAvoid mixingPolycrystalline material growthSemiconductor/solid-state device manufacturingMetallurgyGas phase

Embodiments of the invention generally relate to a method for forming a multi-layered material during a continuous chemical vapor deposition (CVD) process. In one embodiment, a method for forming a multi-layered material during a continuous CVD process is provided which includes continuously advancing a plurality of wafers through a deposition system having at least four deposition zones. Multiple layers of materials are deposited on each wafer, such that one layer is deposited at each deposition zone. The methods provide advancing each wafer through each deposition zone while depositing a first layer from the first deposition zone, a second layer from the second deposition zone, a third layer from the third deposition zone, and a fourth layer from the fourth deposition zone. Embodiments described herein may be utilized to form an assortment of materials on wafers or substrates, especially for forming Group III / V materials on GaAs wafers.

Owner:ALTA DEVICES INC

Heat Transfer Pad Having Localized Treatment Zones

ActiveUS20120185021A1Avoid communicationAvoid backmixingTherapeutic coolingTherapeutic heatingTopical treatmentEngineering

A heat transfer pad includes a pad inlet port for feeding a heat transfer fluid to the pad, a pad outlet port for discharging the heat transfer fluid from the pad and a bladder having an internal flowpath for the heat transfer fluid which extends from the pad inlet port to the pad outlet port. The internal flowpath is divided into a first flow channel and a second flow channel through which first and second flow streams of the heat transfer fluid, respectively, flow between the pad inlet and outlet ports. A first flow restrictor is positioned downstream in the first flow channel and a second flow restrictor is correspondingly positioned downstream in the second flow channel and the flow restrictors are configured to create substantial back pressures in the first and second flow channels, respectively.

Owner:BREG

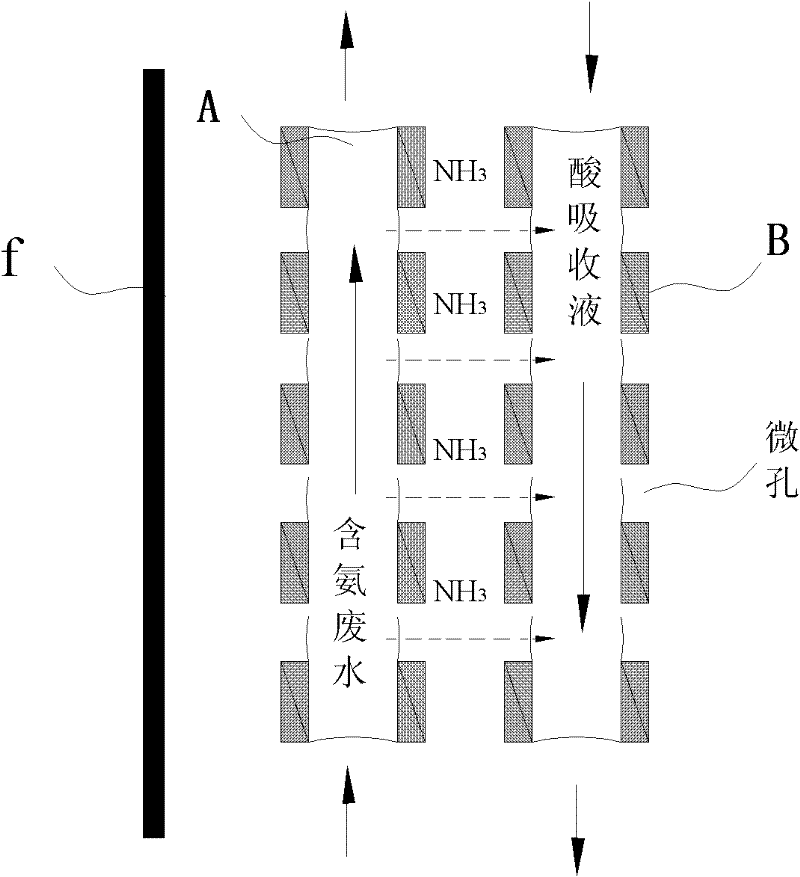

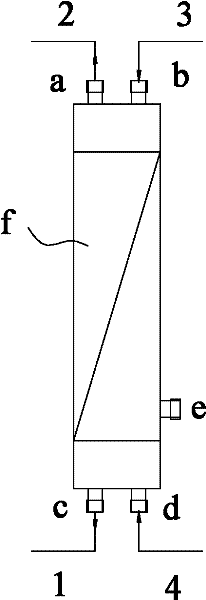

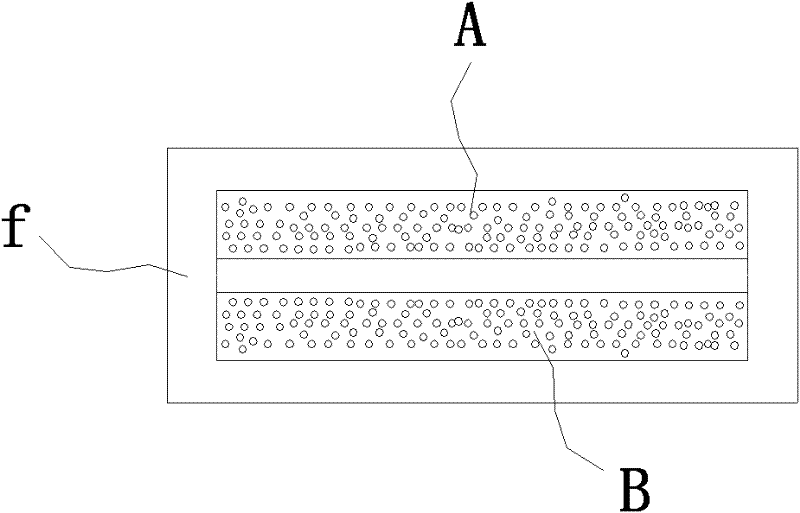

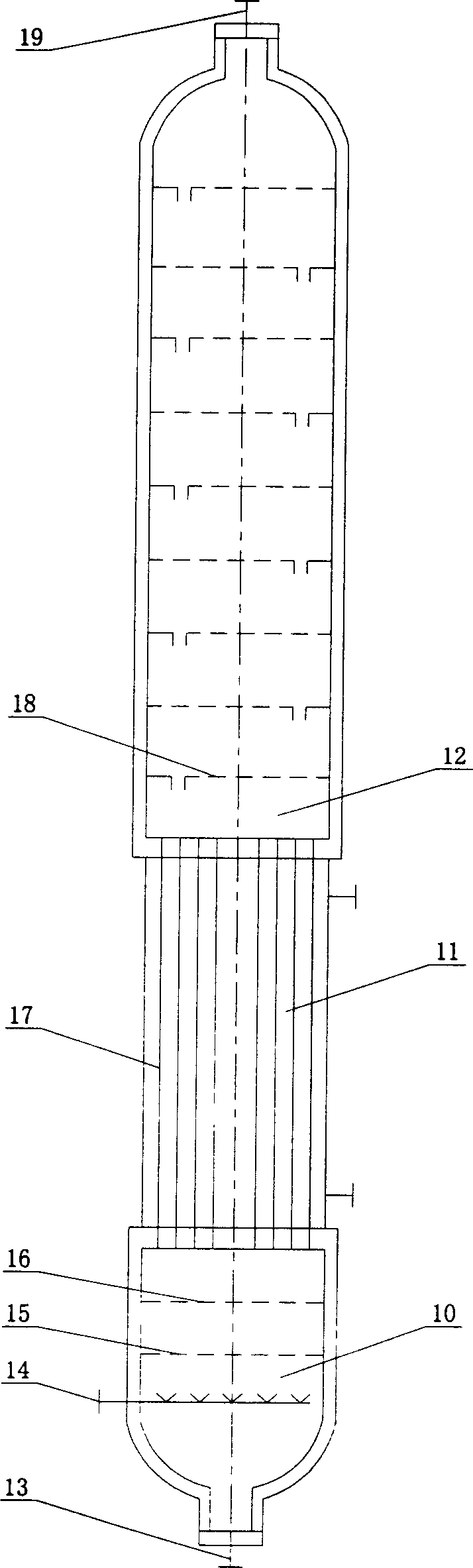

Stable gas membrane and method used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater

The invention relates to a stable gas membrane used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater. The gas membrane comprises a membrane shell, hollow fibrous membranes (A) and hollow fibrous membranes (B). A cavity is provided in the middle of the membrane shell. An inlet and an outlet are respectively arranged on each of the two ends of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are positioned in the cavity of the membrane shell. A shell pass outlet communicating with the atmosphere is arranged on a lower end of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are uniformly arranged in the membrane shell with regular spaces. Dosage liquor or wastewater containing ammonia or organic amine is delivered through the tube pass of the hollow fibrous membranes (A), and absorption liquid is delivered through the tube pass of the hollow fibrous membranes(B). With the gas membrane provided by the invention, problems of traditional gas membranes of leakage and low service life are overcome; dilution of a byproduct ammonium salt solution caused by a concomitant osmotic distillation phenomenon can be effectively inhibited; ammonium salt concentration of the byproduct ammonium salt solution can be increased from 10-20% to 20-40%; mass transfer coefficient at the acid absorption liquid side can be substantially improved; the ammonia removing efficiency is high; the ammonia removing effect is stable for a long-term; and the service life of membranesets can be improved by 3-10 times than common gas membranes.

Owner:天津凯铂能膜工程技术有限公司

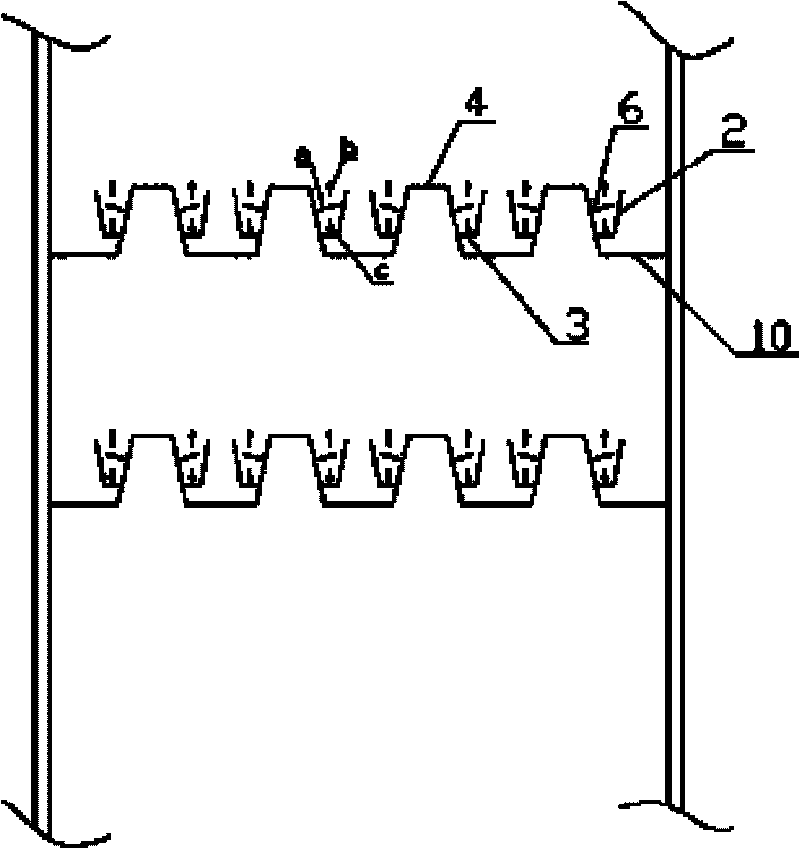

Film spray no-back mixing column plate

ActiveCN101507883AAvoid backmixingIncrease mass transfer driving forceDispersed particle separationFractional distillationEngineeringPlating efficiency

The invention relates to a film spray non-back-mixing column plate, which comprises two spray covers, a column tray ring and a down-flow plate. A column plate is provided with a raise steam hole, and a down-flow pipe is formed between the down-flow plate and the column plate, wherein a position opposite to the raise steam hole of the column plate is fixedly provided with a top cover through a supporting plate. The bottoms of the spray covers and the column plate are reserved with a gap which forms a channel for liquid to enter the spray cover, and both side walls of the spray covers are provided with spray holes. The film spray non-back-mixing column plate is characterized in that the raise steam hole on the column plate is rectangular, and the part of the raise steam hole is welded with a rectangular raise steam pipe, wherein the upper end of the raise steam pipe is provided with a nozzle; the top cover, the raise steam pipe and the supporting plate form the spray covers; and the space between the two spray covers and the outside of the edges of the spray covers are provided with a liquid guide groove, wherein three surfaces of the liquid guide groove are provided with walls, and one surface of the liquid guide groove is provided with an opening which extends into the down-flow pipe. The film spray non-back-mixing column plate can prevent the liquid from back mixing, and greatly improve mass transfer driving force and the column plate efficiency.

Owner:TIANJIN CHUANGJU TECHNOLGOY +1

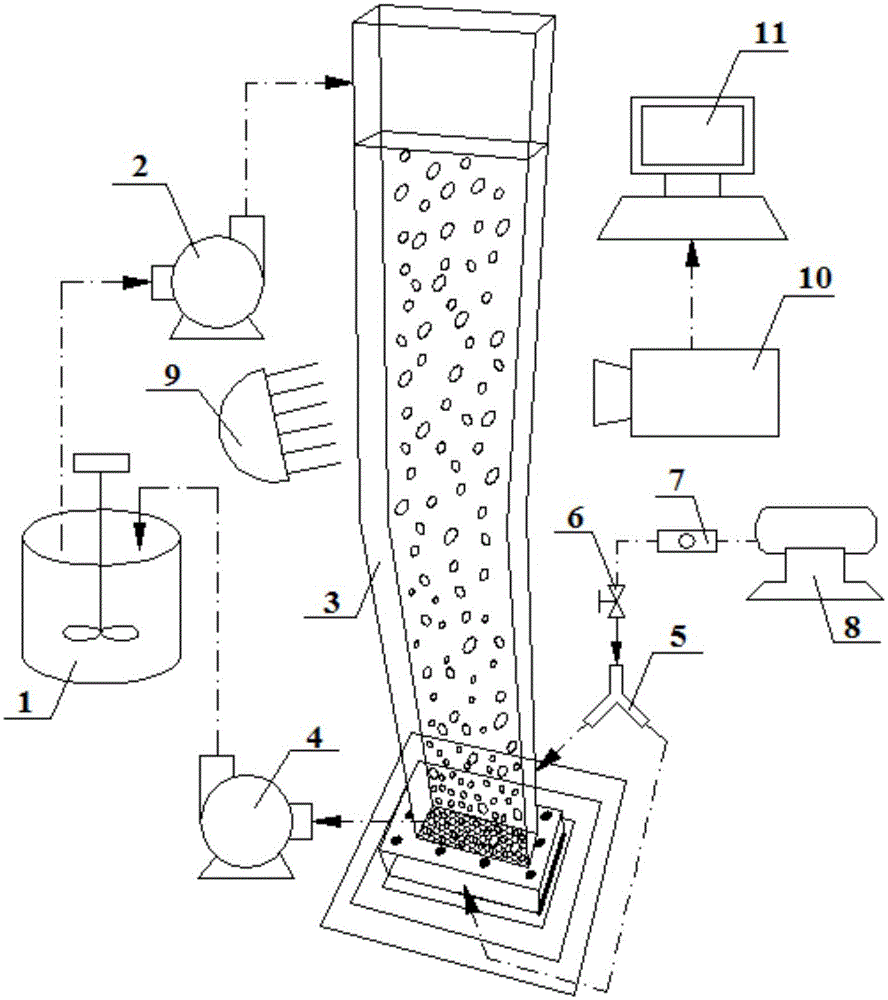

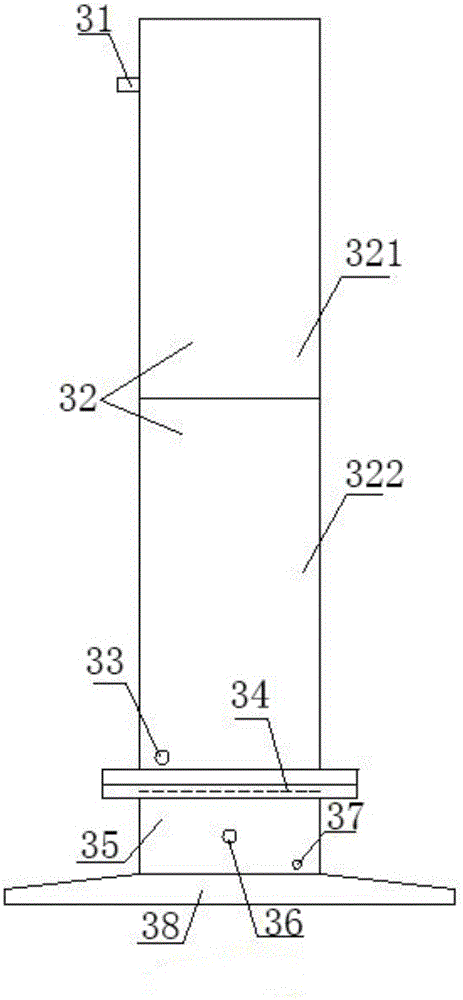

Flotation motion bubble characteristics observation experiment apparatus and method

InactiveCN105021231AEasy to addEasy to observeMeasurement devicesEducational modelsEngineeringAir compressor

The invention discloses a flotation motion bubble characteristics observation experiment apparatus and a method, wherein the apparatus comprises a transparent bubble observer and a stirring barrel; the stirring barrel is connected to the inlet at the upper part of bubble observer through a feeding pump and a pipeline, and the outlet at the lower part of the bubble observer is connected with the stirring barrel through a discharging pump and a pipeline; the bottom of the bubble observer has an air chamber with micropore ceramic; the air chamber is connected with an air compressor through a tee, a valve and an air flow meter; the two sides vertical to the bubble observer have a light source and a high speed camera respectively; the high speed camera is connected to a computer through a data line; and the computer has a bubble image analysis software. According to the invention, the problem of difficult accurate measurement because of flotation bubble motion characteristics is solved; the experiment apparatus has the advantages of visualization, simple structure, simple operation and low operation cost etc.; the experiment apparatus can be widely applied in flotation laboratory tests and can be used for flotation classroom teaching.

Owner:CHINA UNIV OF MINING & TECH

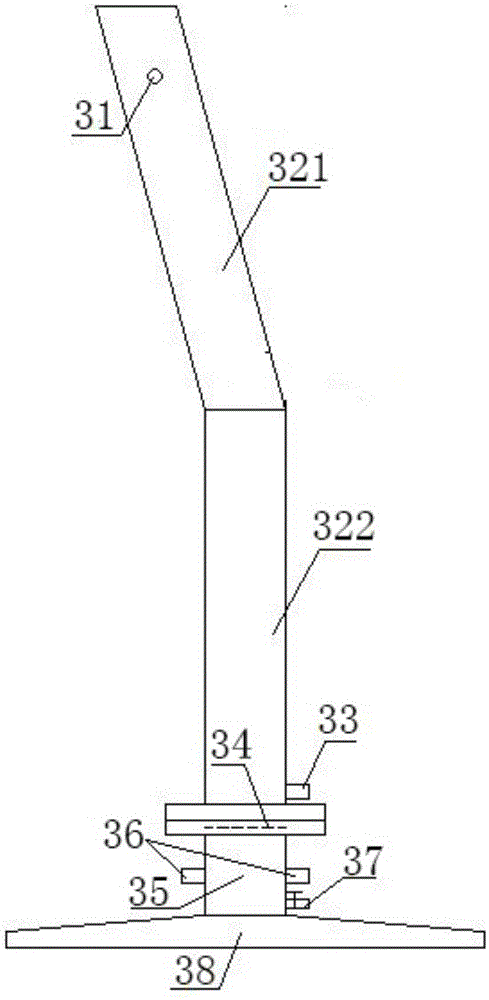

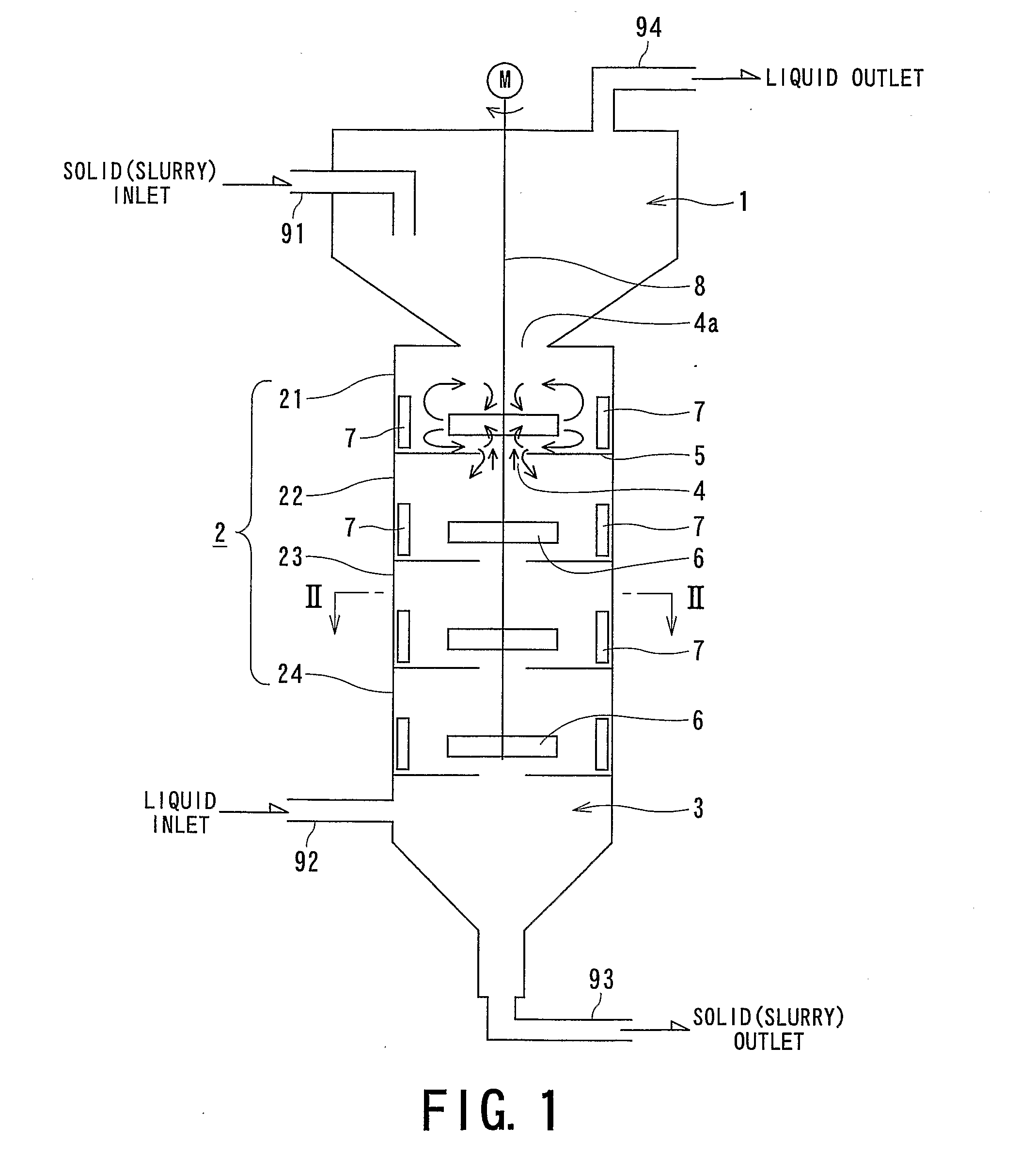

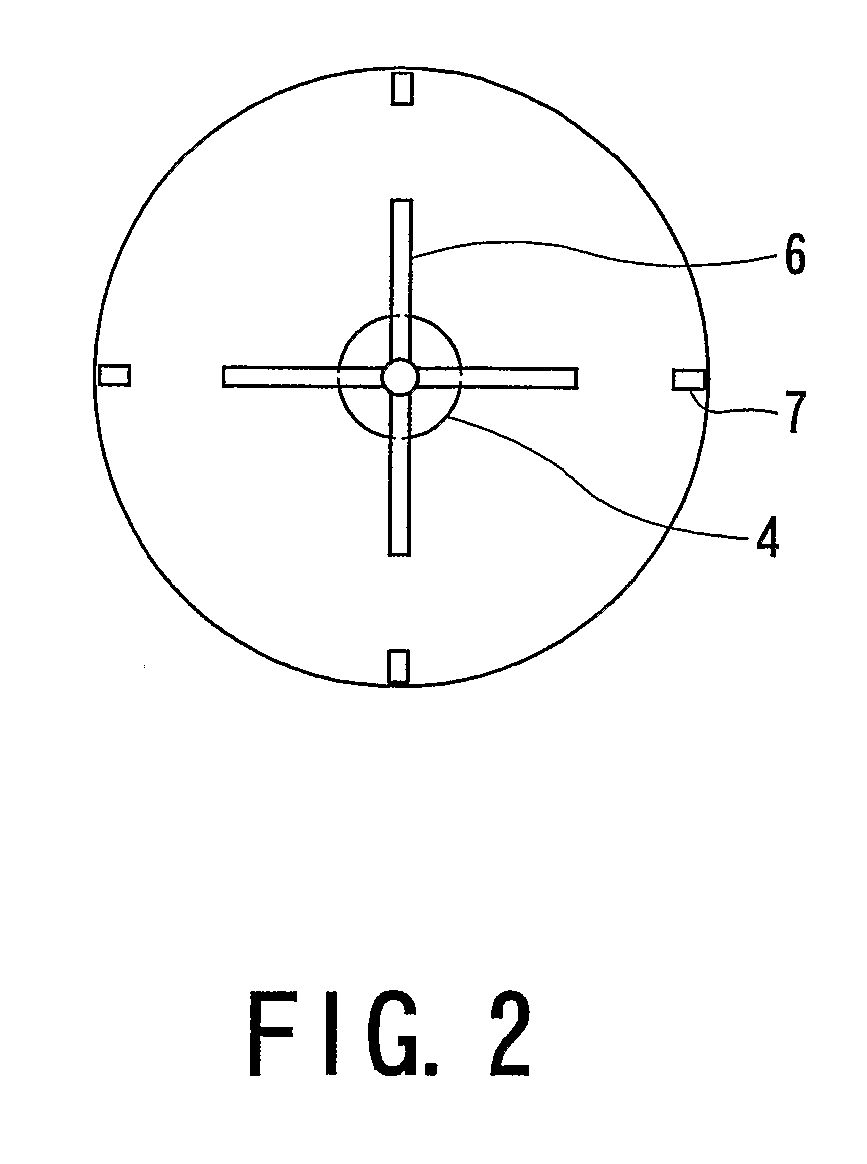

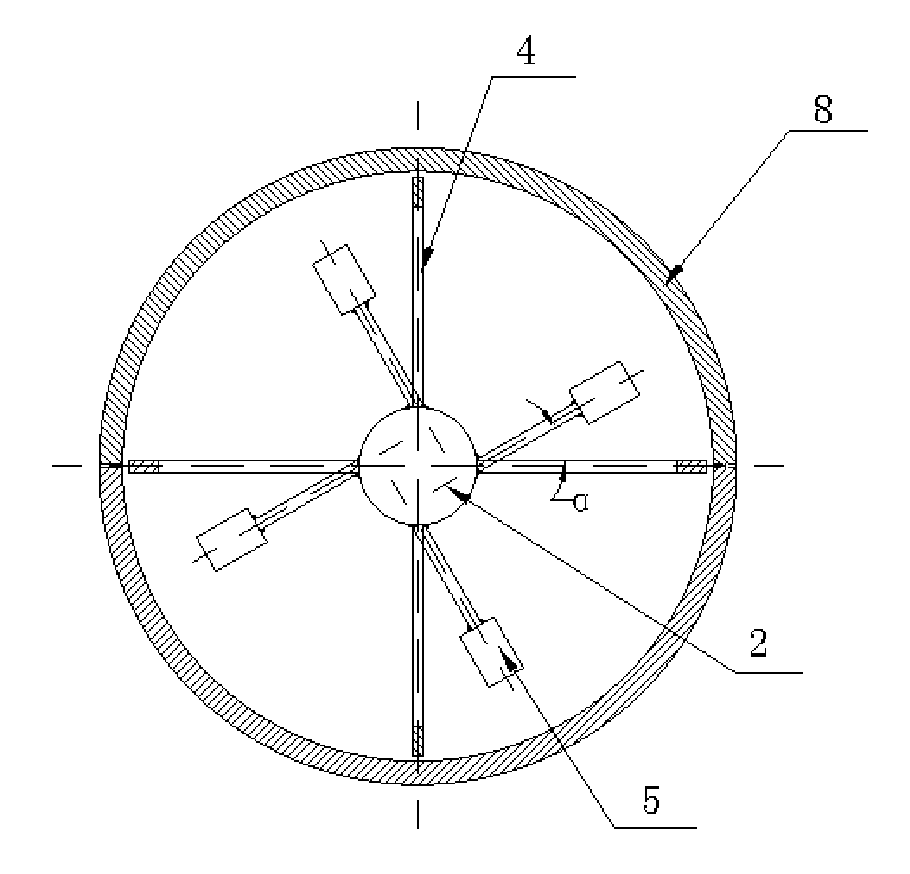

Apparatus and Method for Solid-Liquid Contact

ActiveUS20080025143A1Improve efficiencyImprove uniformityRotary stirring mixersTransportation and packagingChemical industryUnit operation

A vertical solid-liquid contact apparatus, comprising: a plurality of stirring chambers disposed vertically adjacent to each other in series, a plurality of partitioning plates each partitioning an adjacent pair of the stirring chambers and provided with a communicating hole for communication between the adjacent pair of the stirring chambers, and a liquid inlet and a solid inlet provided at an upper part and a lower part of the apparatus. Each stirring chamber has an inner side wall defining the stirring chamber, a radially ejecting stirring blade, and at least one baffle fixed on the inner side wall so as to extend vertically. The stirring blade and the baffle are positionally biased to a lower side of the stirring chamber. The apparatus exhibits a good uniformity of solid-liquid flows and a high contact efficiency, is also simple in structure and allows easy scale-up. The apparatus can be widely applied to unit operations in the chemical industry. The apparatus exhibits a particularly good solid-liquid contact efficiency when operated in the neighborhood of its maximum load.

Owner:KUREHA KAGAKU KOGYO KK

Stepped differential-velocity fluidized bed cooler

InactiveCN102435080AExtended stayGood cooling effectDirect contact heat exchangersEngineeringFluidized bed

The invention discloses a stepped differential-velocity fluidized bed cooler relating to a fluidized bed cooler. The invention aims to solve the problems of overhigh discharging temperature, poor cooling effect and non-uniform discharged grain temperature in the traditional fluidized bed cooler. A feeding pipe is communicated with the side wall at one end of a fluidized bed main body; an outer side wall at the other end of the fluidized bed main body is provided with an exhaust pipe and a first discharging pipe from the top down; a plurality of air chambers are arranged in the fluidized bed main body; the air chambers are arranged in sequence from high to low along the feeding-to-discharging direction of the fluidized bed main body; the upper end of each air chamber is provided with an air distribution plate; each air distribution plate is provided with a second discharging pipe; a plurality of air distribution holes are uniformly distributed and processed on each air distribution plate; a hood is arranged at each air distribution hole; an overflow plate is vertically arranged between every two adjacent air distribution plates; and the height of each overflow plate is sequentially and progressively reduced along the feeding-to-discharging direction of the fluidized bed main body. The stepped differential-velocity fluidized bed cooler is used for high-temperature granular materials in the cooling industry field.

Owner:HARBIN INST OF TECH

Flow-separation back-mixing-free spraying tower disc

ActiveCN102961888AStrong anti-blockingLess foamingDispersed particle separationDistillation separationSpray towerMechanical engineering

The invention discloses a flow-separation back-mixing-free spraying tower disc. The tower disc is formed by combining an upper-layer tower disc and a lower-layer tower disc; and each tower disc comprises liquid descending grooves, liquid descending pipes, liquid accepting grooves, three-dimensional spraying and mass transferring units and liquid guide grooves. The flow-separation back-mixing-free spraying tower disc is characterized in that the long-strip-shaped liquid accepting grooves are formed in the horizontal position of the center of the tower disc; each long-strip-shaped liquid descending groove is arranged between each two adjacent liquid accepting grooves; liquid descending openings are designed in the bottoms of the liquid descending grooves; each liquid descending opening corresponds to one liquid descending pipe, and each liquid descending pipe stretches and is fixed in each liquid descending groove; the three-dimensional spraying and mass transferring units are arranged among the liquid descending grooves and the liquid accepting grooves; the liquid guide grooves, which are flow-separation-plate-type liquid guide grooves, are arranged on the peripheries of cap covers of the three-dimensional spraying and mass transferring units; one liquid guide groove corresponds to one three-dimensional spraying and mass transferring unit; the shapes and the structures of the upper and lower tower discs are the same basically; and one set of liquid descending pipes on the lower edge of one liquid descending groove of the upper-layer tower disc correspond to one liquid accepting groove of the lower-layer tower disc in a staggered manner, so that the upper-layer tower disc and the lower-layer tower disc are combined into the double-layer flow-separation back-mixing-free spraying tower disc.

Owner:TIANJIN CHUANGJU TECHNOLGOY

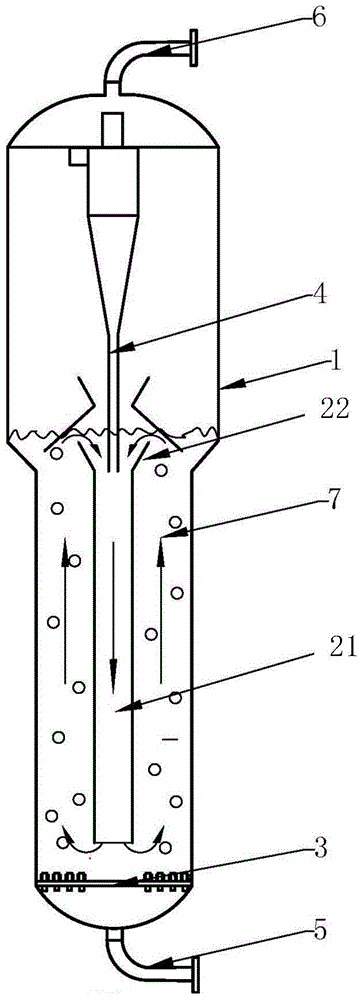

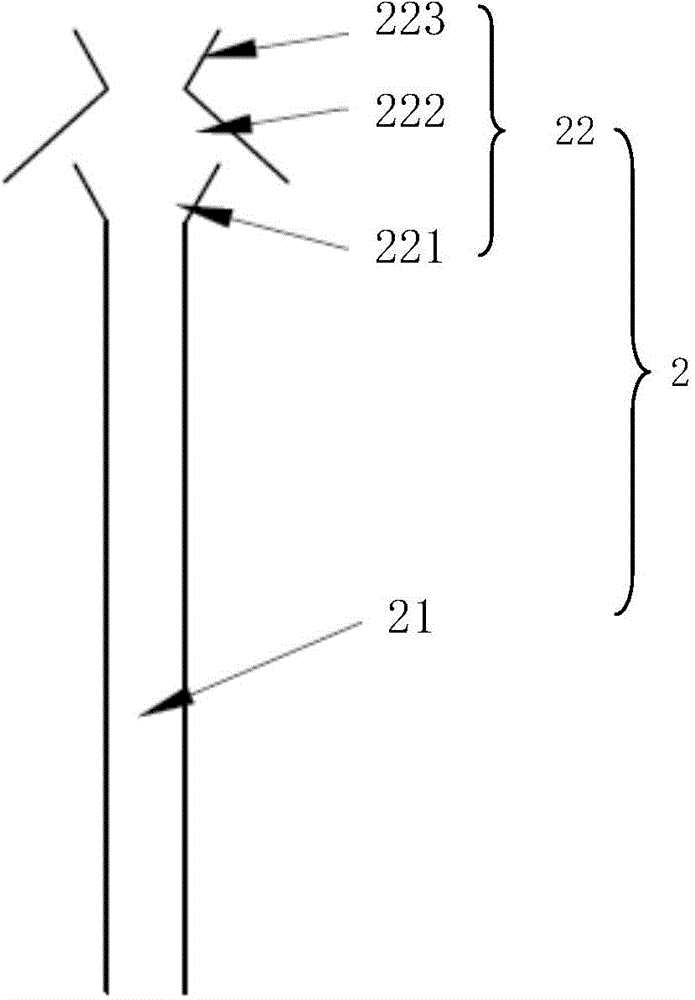

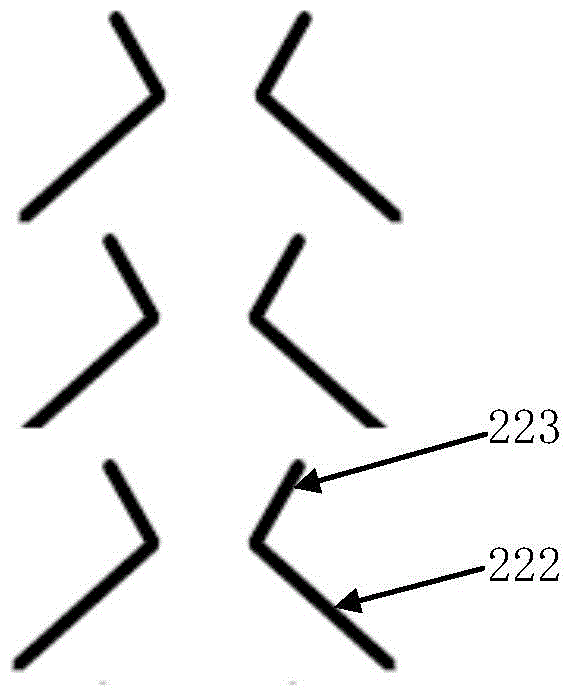

Airlift internal loop slurry-bed reactor

ActiveCN105983377ASpeed up the cyclePromote circulationChemical/physical processesPtru catalystEngineering

The invention discloses an airlift internal loop slurry-bed reactor. The airlift internal loop slurry-bed reactor comprises a shell, a guide cylinder, a gas distributor, a gas-liquid separation apparatus, a bottom inlet, a top outlet and a slurry bed layer, the gas-liquid separation apparatus, the guide cylinder and the gas distributor are arranged in the shell from up to down in order, the annular space of the guide cylinder and the inner wall of the shell are filled with the slurry bed layer, and the guide cylinder comprises an upper baffling section and a lower straight-tube enclosing section. According to the invention, the upper part of the guide cylinder is designed as a baffling communication section, the gas-liquid separation effect of the reactor is increased, circulation of a slurry in the guide cylinder and the slurry out of the guide cylinder is promoted, so that the problems that when the operating gas velocity is high, the slurry back-mixing and mist entrainment are generated can be avoided, the reaction efficiency, purity of the products and the stability of a catalyst are indirectly increased, and the energy consumption and investment of the reactor are reduced.

Owner:上海睿碳能源科技有限公司

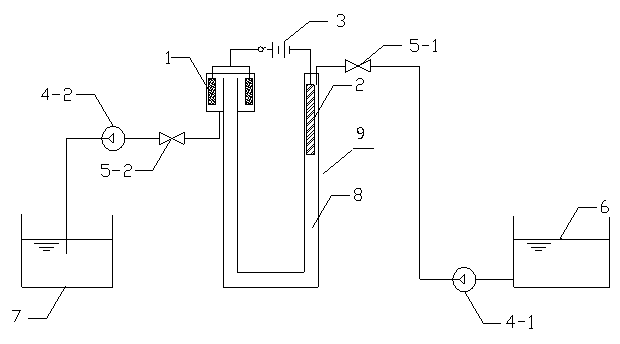

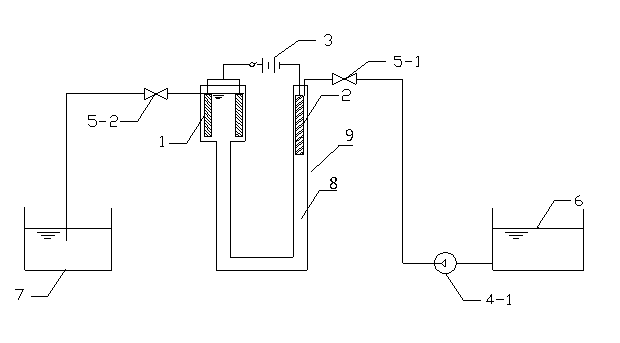

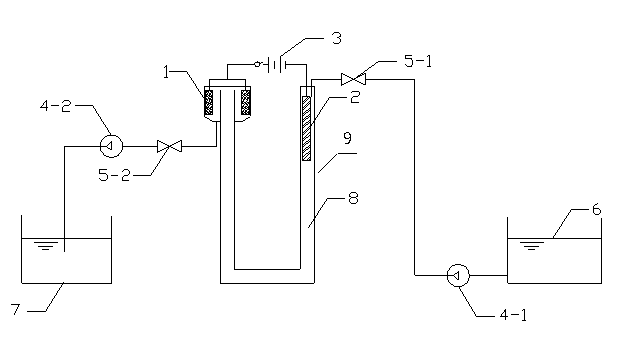

Device and process for preparing liquid ferrate through electrolysis method

The invention relates to a device for preparing liquid ferrate through an electrolysis method. The device is characterized in that an electrolyzer is a U-shaped pipe electrolyzer, an alkali liquor inlet of an alkali liquor storage tank is communicated with the alkali liquor inlet of the U-shaped pipe electrolyzer through an alkali liquor delivery pump and an alkali liquor control valve which are arranged on a pipeline, the liquid ferrate outlet of the U-shaped pipe electrolyzer is communicated with a liquid ferrate storage tank through a liquid ferrate control valve and a liquid ferrate delivery pump which are arranged on the pipeline, a side pipeline of the alkali liquor inlet of the U-shaped pipe electrolyzer is a cathode chamber, a cathode electrode is arranged in the cathode chamber of the U-shaped pipe electrolyzer, a side pipeline of the liquid ferrate outlet of the U-shaped pipe electrolyzer is an anode chamber, at least one anode electrode is arranged in an enlarged containing groove of the anode chamber of the U-shaped pipe electrolyzer, and the cathode electrode and the anode electrode are connected with a direct current power source. The device is simple in structure, economical and applicable, scientific and reasonable in technologic process, and low in operation cost, has high current efficiency and good effect, and can be widely used for interval or continuous production.

Owner:NORTHEAST DIANLI UNIVERSITY

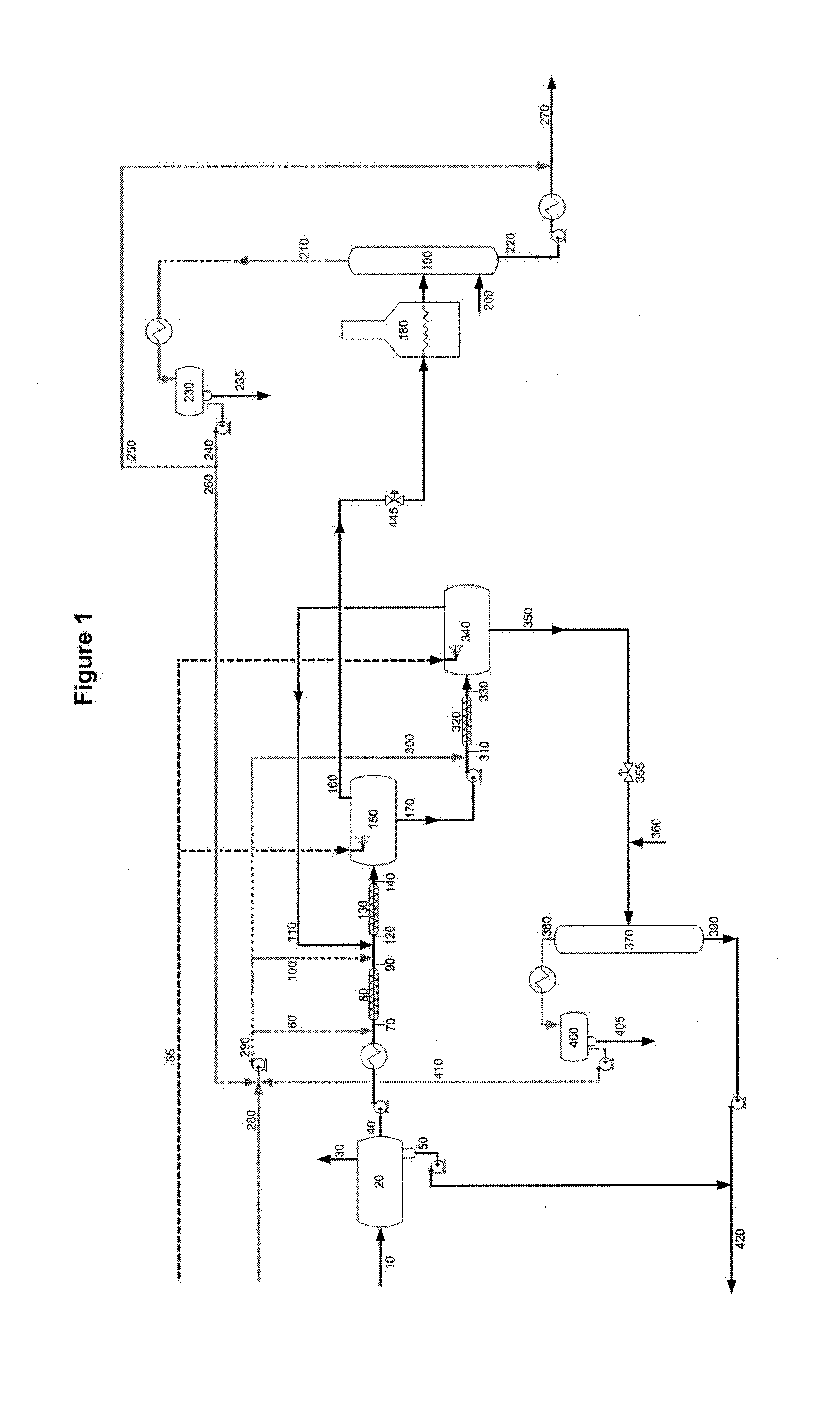

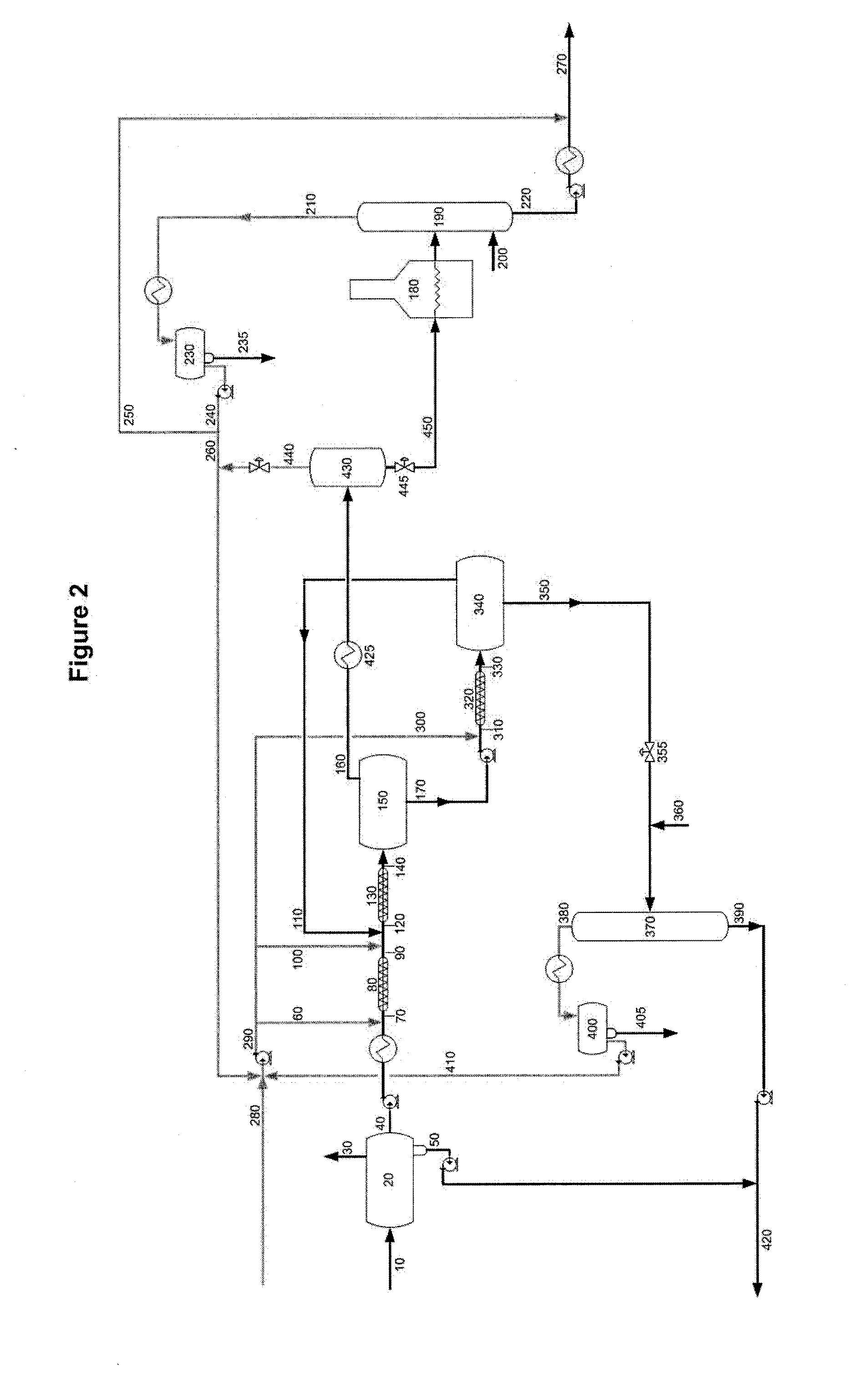

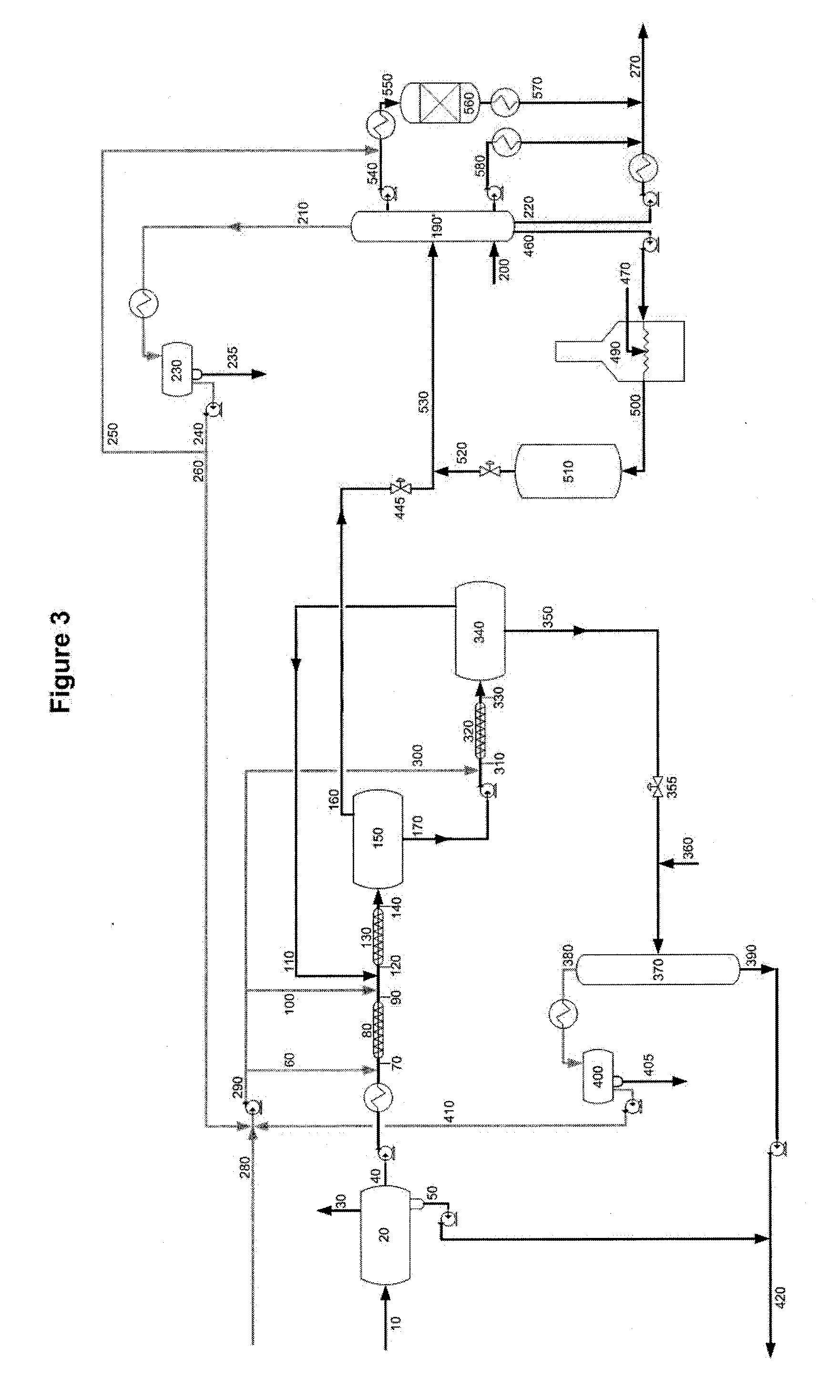

Integrated central processing facility (CPF) in oil field upgrading (OFU)

ActiveUS20140138287A1Conducive to agglomerationIncreased floc sizeThermal non-catalytic crackingTreatment with plural serial stages onlyAlkaneDiluent

A process for upgrading oil including optionally pre-treating a heavy oil including at least one dissolved gas, asphaltenes, water, and mineral solids; reducing at least one dissolved gas content from said heavy oil, optionally further reducing water content from said heavy oil; adding a paraffinic solvent to said heavy oil, at a predetermined paraffinic solvent:heavy oil ratio, facilitating separation of asphaltenes, water, and mineral solids from the heavy oil resulting in a de-asphalted or partially de-asphalted oil (“DAO”)-paraffinic solvent stream, comprising a low asphaltenes content DAO-paraffinic solvent stream and an asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the paraffinic solvent and water from the asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the DAO-paraffinic solvent stream into a paraffinic solvent rich stream and a DAO stream; and optionally adding diluent to the DAO stream resulting in transportable oil.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

Liquid guide flow type vertical sieve tray device

ActiveCN101721828ASpeed up the flowAvoid entrainmentDispersed particle separationDistillation separationGas phaseRetention time

The invention relates to a liquid guide flow type vertical sieve tray device. A mass transfer element on the tray mainly comprises a baffle and a traditional gas-liquid contact mass transfer element which are combined, wherein the baffle body comprises a bottom surface (3), a side end face (2) and a rear end face (1); a gap is formed between the rear end face (1) of the baffle and an end plate (7) of the mass transfer element or a jet plate (6) and between the bottom surface (3) of the baffle and a board of the tray (10); a part of area on the bottom surface (3) of the baffle is hollow; and the section of the hollow part is welded with the jet plate (6) of the gas-liquid contact mass transfer element. The liquid guide flow type vertical sieve tray device effectively realizes uniform flow of gas-liquid two phases and avoids back-mixing and local backflow of the liquid phase. Meanwhile, the gas-liquid two phases can be better separated under the impact action between a gas-liquid two phase mixture jetted by the mass transfer element and the baffle; the retention time of the gas phase in the liquid phase is reduced; gas entrainment is reduced; and the operation resilience and the separation efficiency of the tray are improved.

Owner:TIANJIN UNIV

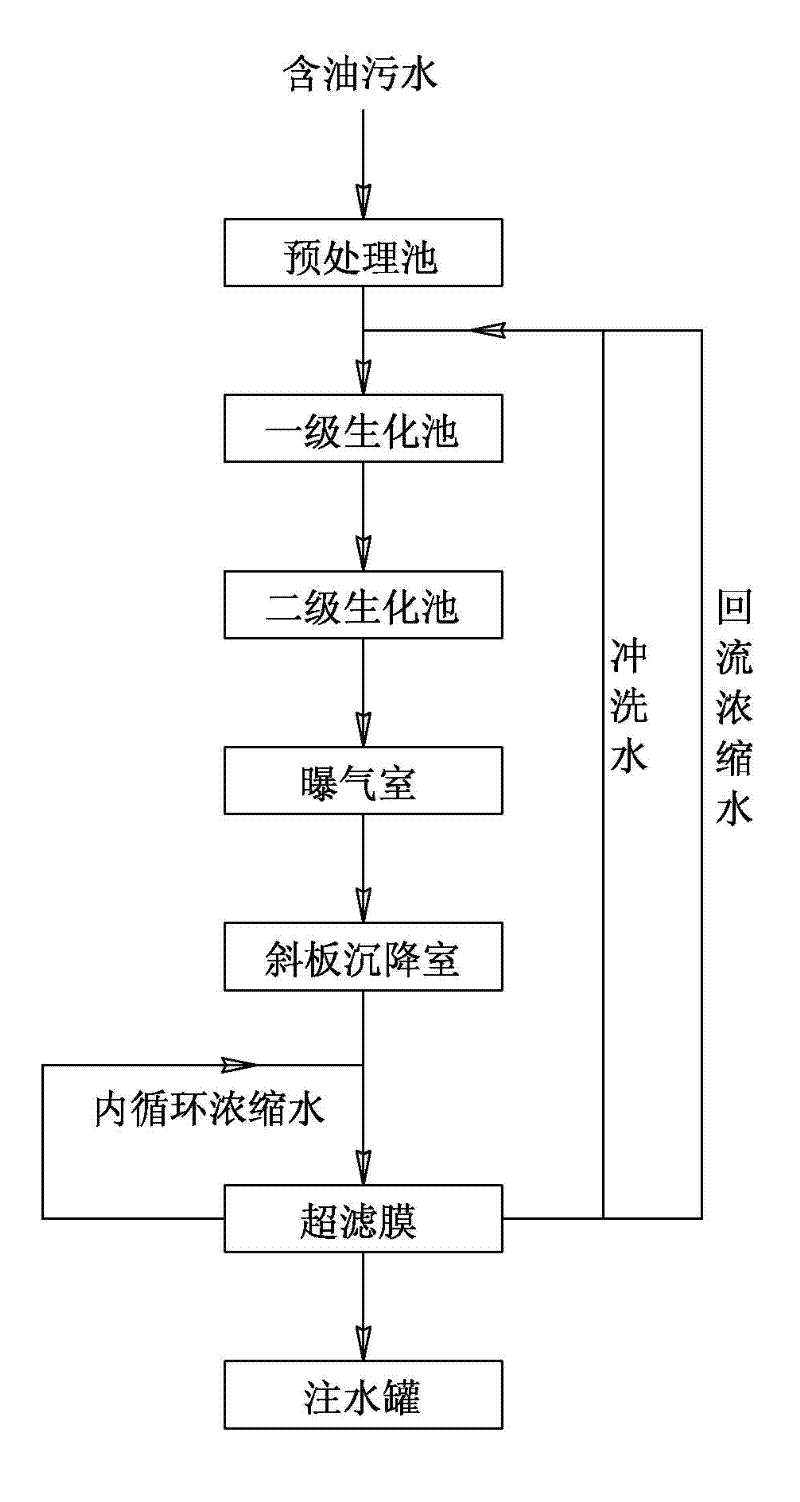

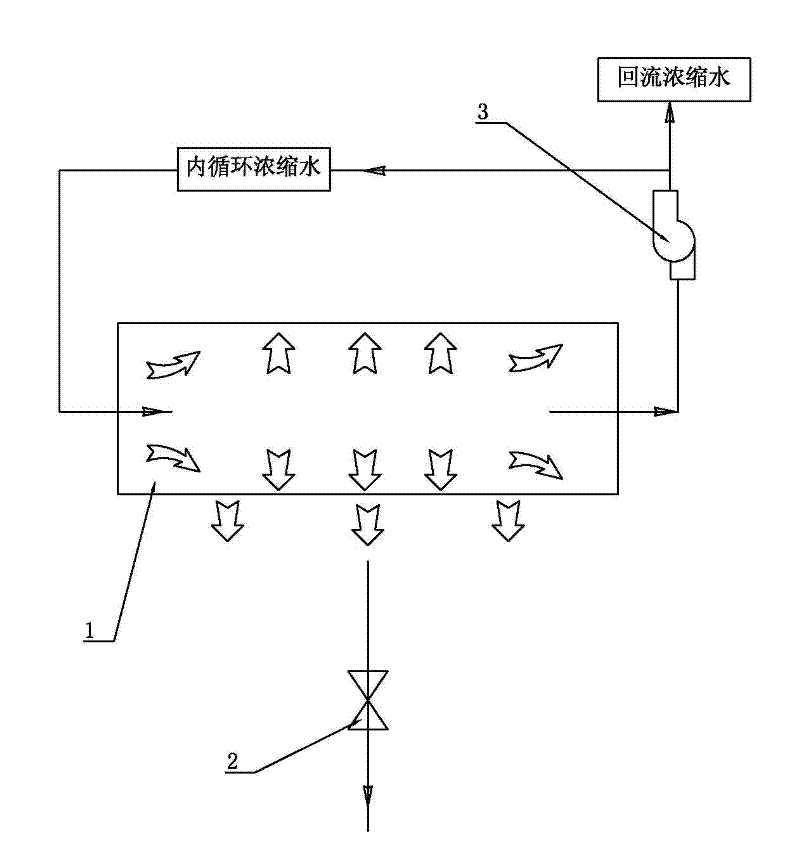

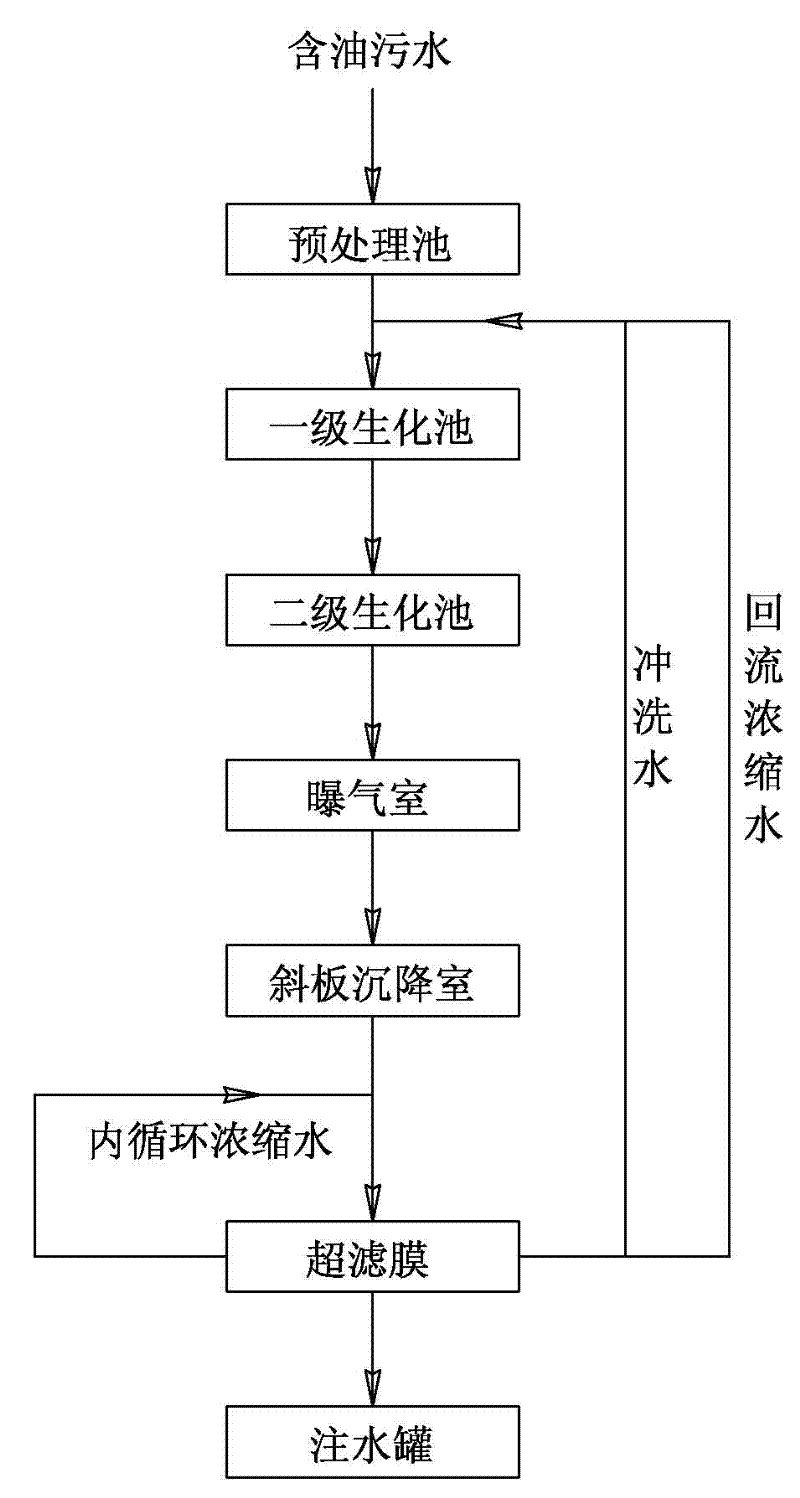

Treatment process of oil-containing sewage in low-permeability oil field

ActiveCN102372403AEfficient removalReduce pollutionWaste water treatment from quariesMultistage water/sewage treatmentUltrafiltrationFiltration

The invention discloses a treatment process of oil-containing sewage in a low-permeability oil field in the technical field of petroleum exploitation. The process comprises the following steps: firstly, carrying out aeration pretreatment to remove sulfide in the oil-containing sewage; then, entering a biological contact oxidation system to degrade crude oil in the oil-containing sewage, wherein the biological contact oxidation system comprises at least two stages of biochemical pools which are connected in series, the biochemical pool is provided with a hydrophilic combined filling material, and the pool bottom of the biochemical pool is provided with an air aeration device; putting an oil-removing microorganism agent in an initial stage of starting in the biochemical pool, and then carrying out efficient aeration sedimentation treatment on extracellular polymers and other biochemically degradable organic substances; and finally, treating by an ultrafiltration membrane filtration system and then injecting into a water tank. The process has the characteristics of small system sludge amount, less oil content in sewage at the membrane inlet, little ultrafiltration membrane pollution,stable membrane flux and long chemical cleaning period of ultrafiltration membrane, and the quality of water at the water outlet of the system reaches the grade A water quality standard of the low-permeability oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

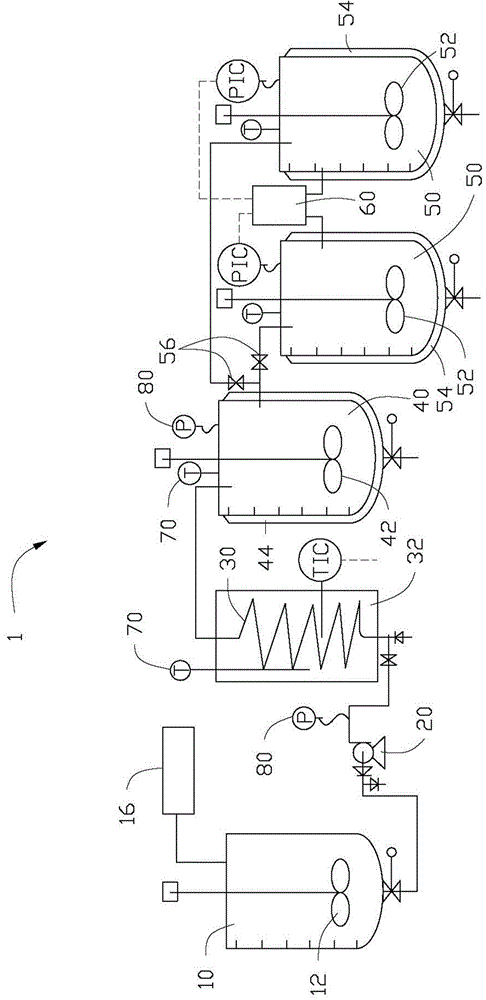

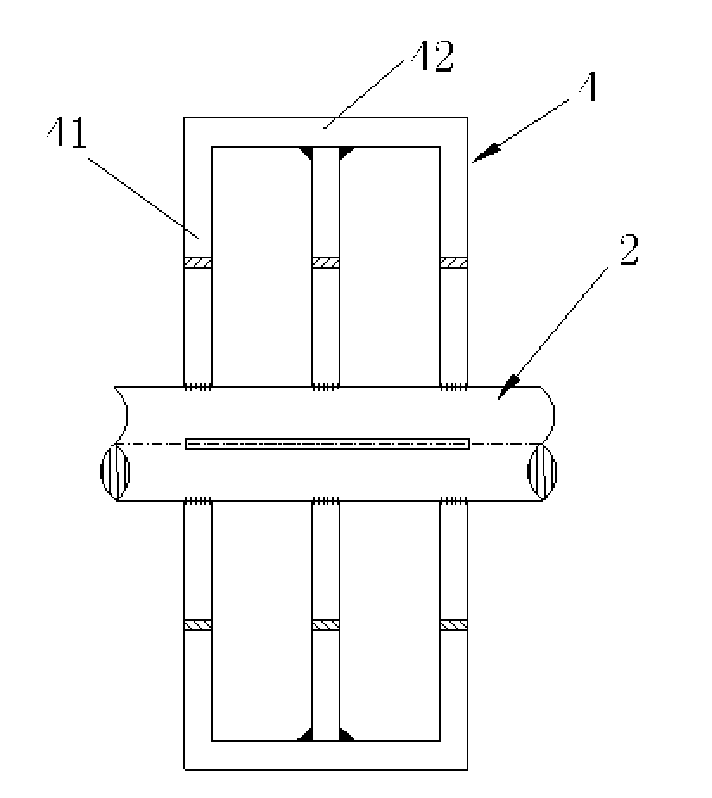

Continuous lithium iron phosphate preparation device and continuous lithium iron phosphate preparation method

ActiveCN104555975AImprove performanceAvoid backmixingElectrochemical processing of electrodesElectrode thermal treatmentLithium iron phosphateSystem pressure

The invention relates to a continuous lithium iron phosphate preparation device comprising a raw material system, a material conveying system, a pipe-type reaction device, a kettle-type reaction device, a reactions system pressure-adjusting system and a discharge system, wherein the raw material system is used for mixing a raw material solution; the material conveying system is used for continuously conveying the mixed raw material solution to the pipe-type reaction device; the pipe-type reaction device is used for enabling materials to be in plug flow conveying reaction state at the given time, the temperature and the pressure; the kettle-type reaction device is arranged at the back of the pipe-type reaction device and is used for enabling the materials to be in complete mixing flow reaction state at the given time, the temperature and the pressure and enabling the reacted product to be conveyed to the discharge system; and the reaction system pressure-adjusting system is used for adding a volatile solvent component to a reaction system to adjust system pressure so that the pipe-type reaction device and the kettle-type reaction device are maintained at the given pressure condition. The invention also relates to a continuous lithium iron phosphate preparation method.

Owner:江苏合志新能源材料技术有限公司 +1

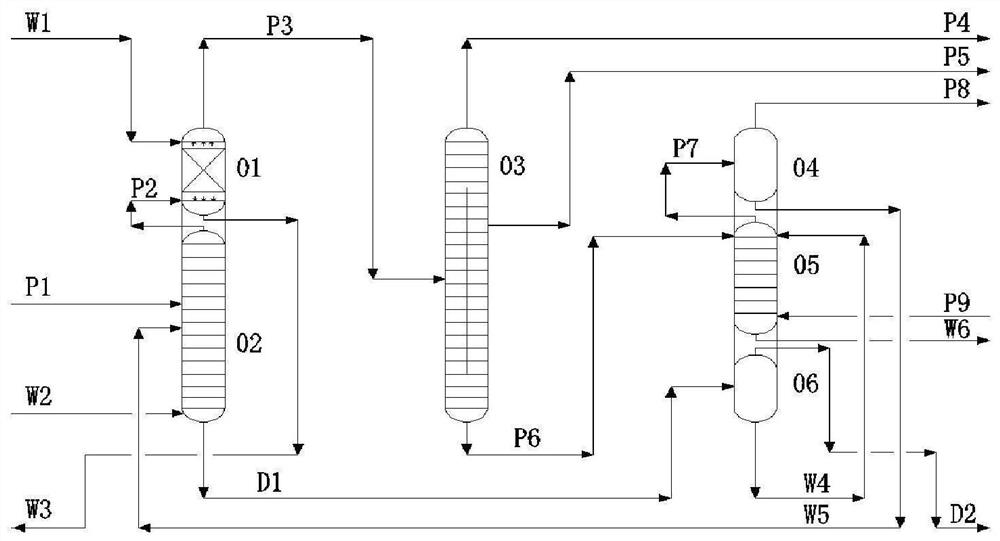

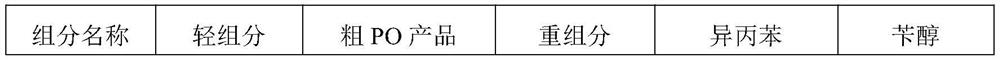

Crude separation system and crude separation method for cumene method epoxidation products

The invention discloses a crude separation system and a crude separation method for cumene method epoxidation products. The separation system comprises an alkaline washing tower, a crude PO tower, a dividing wall tower, a flash tower, an extraction tower and an oil-water separation tower, wherein the alkaline washing tower and the crude PO tower are combined into a superposition tower; the flash tower, the extraction tower and the oil-water separation tower are combined into a superposition tower, and the dividing wall tower is provided with a dividing wall in the middle; and by adopting the dividing wall tower and superposition tower technology, the occupied area of the equipment is reduced by 16.67-44.44%. According to the separation method, low-pressure steam is injected into the crude PO tower to reduce the temperature of a tower kettle, so that the temperature of the tower kettle is reduced to 85-110 DEG C, the increment of cumene is reduced to 6.8-8.6 wt%, the loss of cumene is reduced to 0.11-0.13 kg CUM / tPO, the problems of large occupied area of equipment and large loss of cumene in the prior art are well solved, and the separation method can be applied to 50000-900000 tons of CHPPO devices for producing PO.

Owner:CHINA PETROLEUM & CHEM CORP +1

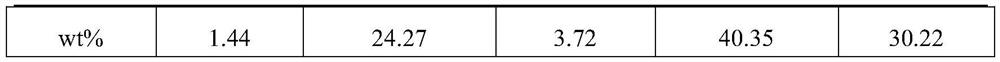

Novel flotation column

The invention relates to a novel flotation column. A main body of the novel flotation column is a column body; two-section type pore plate rolling padding is arranged in the column body; a middling circulating device is arranged on the lower portion of the column body and comprises an inverted-cone-shaped barrel, a circulating pump and an air bubble generator which are sequentially connected to one another through a pipe; the inverted-cone-shaped barrel is arranged in the column body; an opening of the inverted-cone-shaped barrel is upward; the circulating pump and the air bubble generator are arranged on the outside of the column body; the inverted-cone-shaped barrel is connected with the circulating pump through a liquid inlet pipe; and the air bubble generator is connected with the inside of the column body through a liquid outlet pipe. The novel flotation column is simple in structure and cannot be blocked easily; rising air bubbles are in contact with descending ore pulp sufficiently; and the flow state of the ore pulp is stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

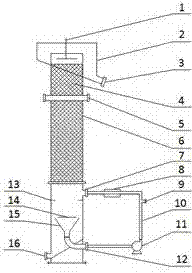

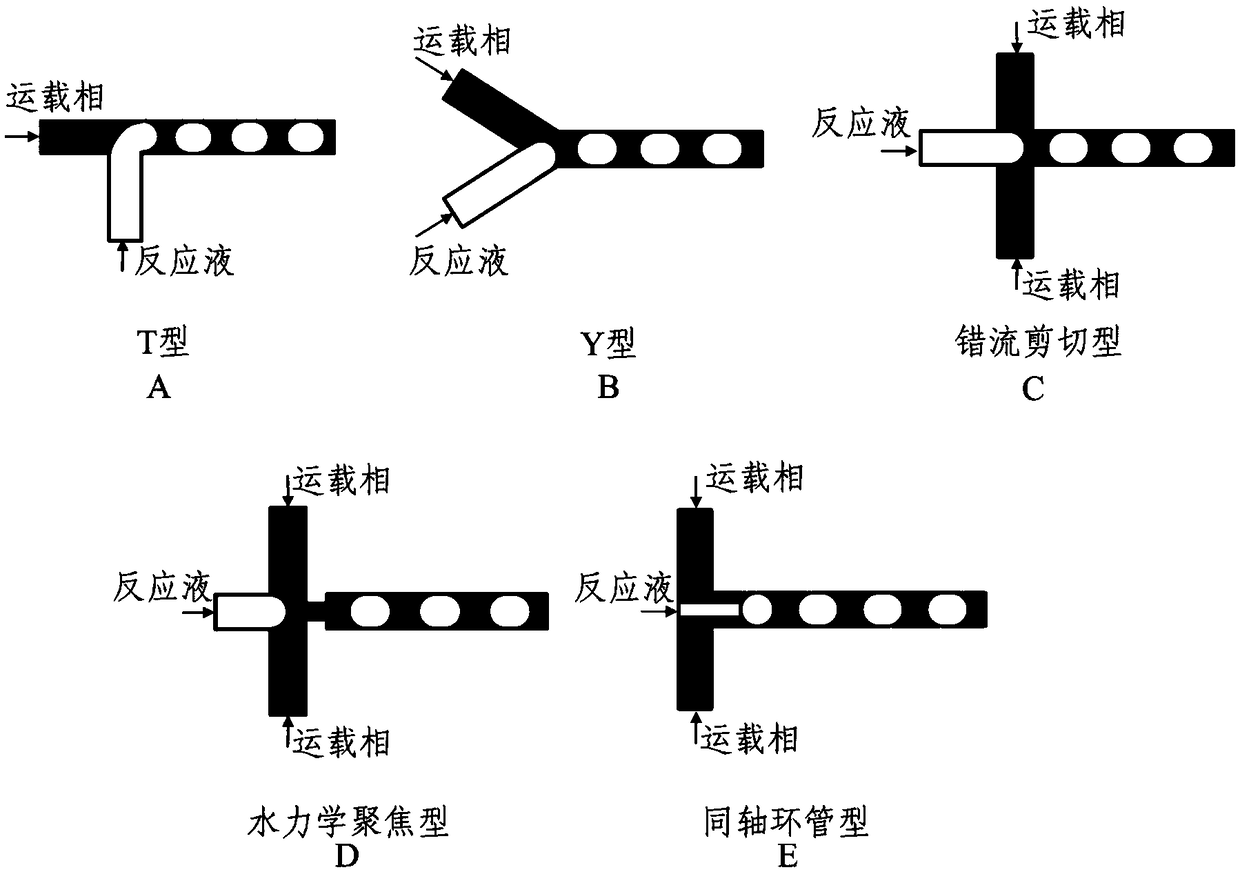

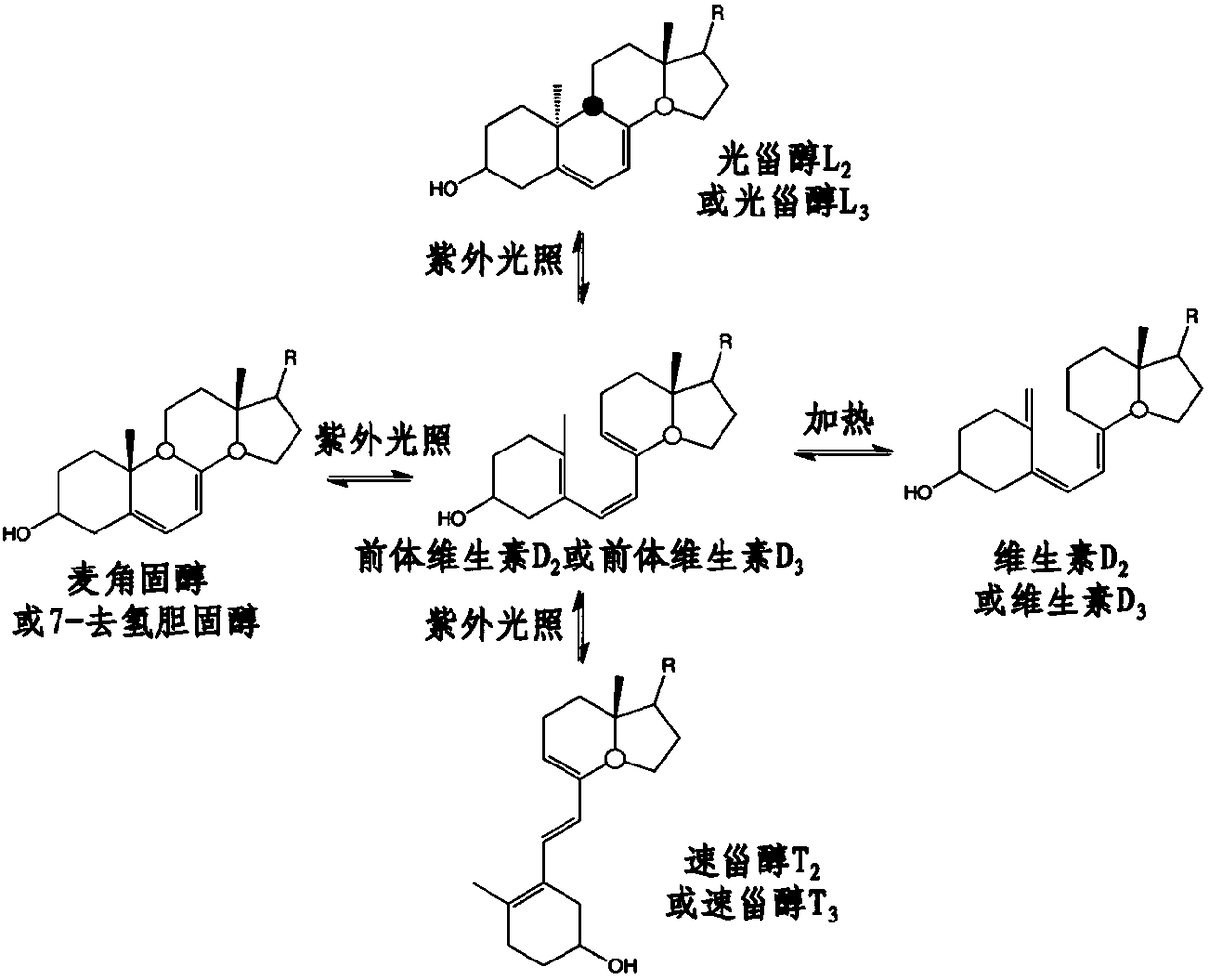

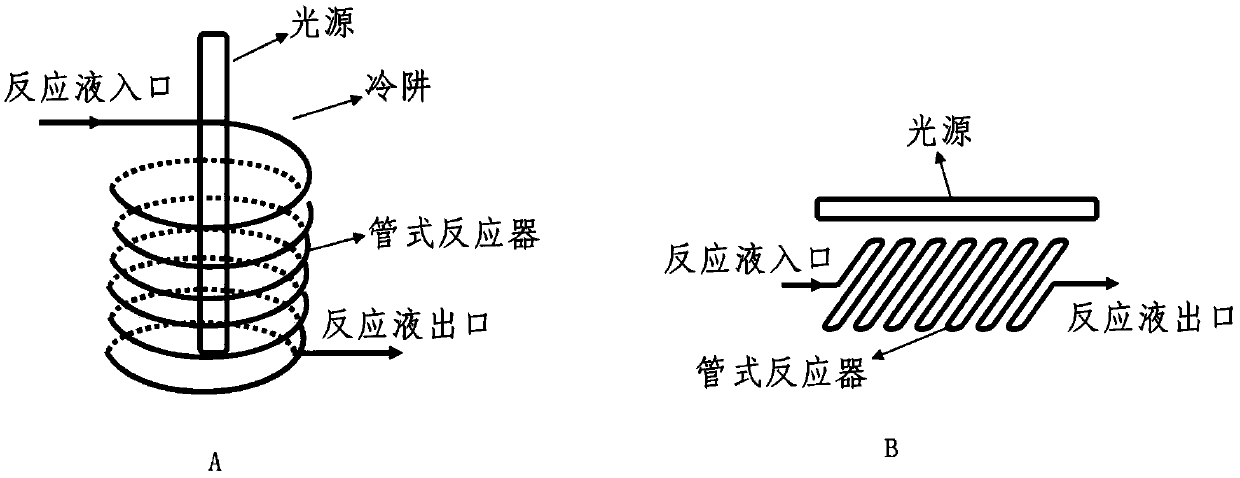

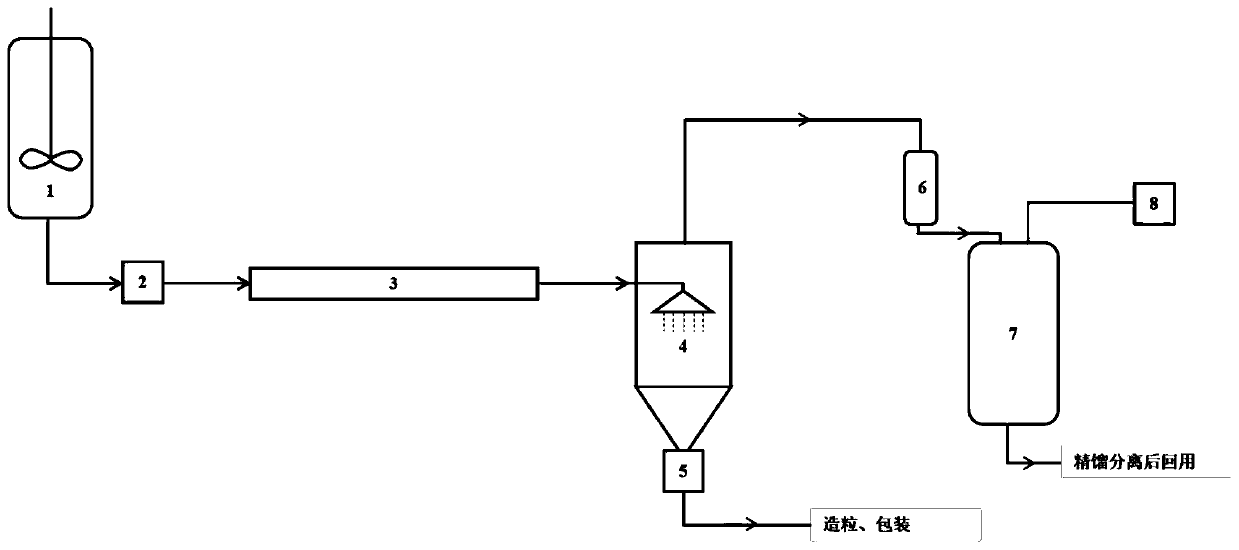

Method for photochemically synthesizing vitamin D2 and D3 in tubular reactor

The invention relates to a method for photochemically synthesizing vitamin D2 and D3 in a tubular reactor. The method is characterized in that the vitamin D2 and D3 are synthesized by ultraviolet light of different bands, the residence time of reaction liquid fed at different times in the tubular reactor is controlled to be the same by not dissolving with reaction liquid, not participating in reaction liquid separation and carrying ergosterol and 7-dehydrocholesterol reaction liquid and enhancing internal disturbance of the reaction liquid; the method has the advantages of continuous, stable and high efficiency of solar energy utilization, the operation is simple, and the process is controllable; the method has great prospect in the industrial production of the photochemically synthesizedvitamin D2 and D3.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +1

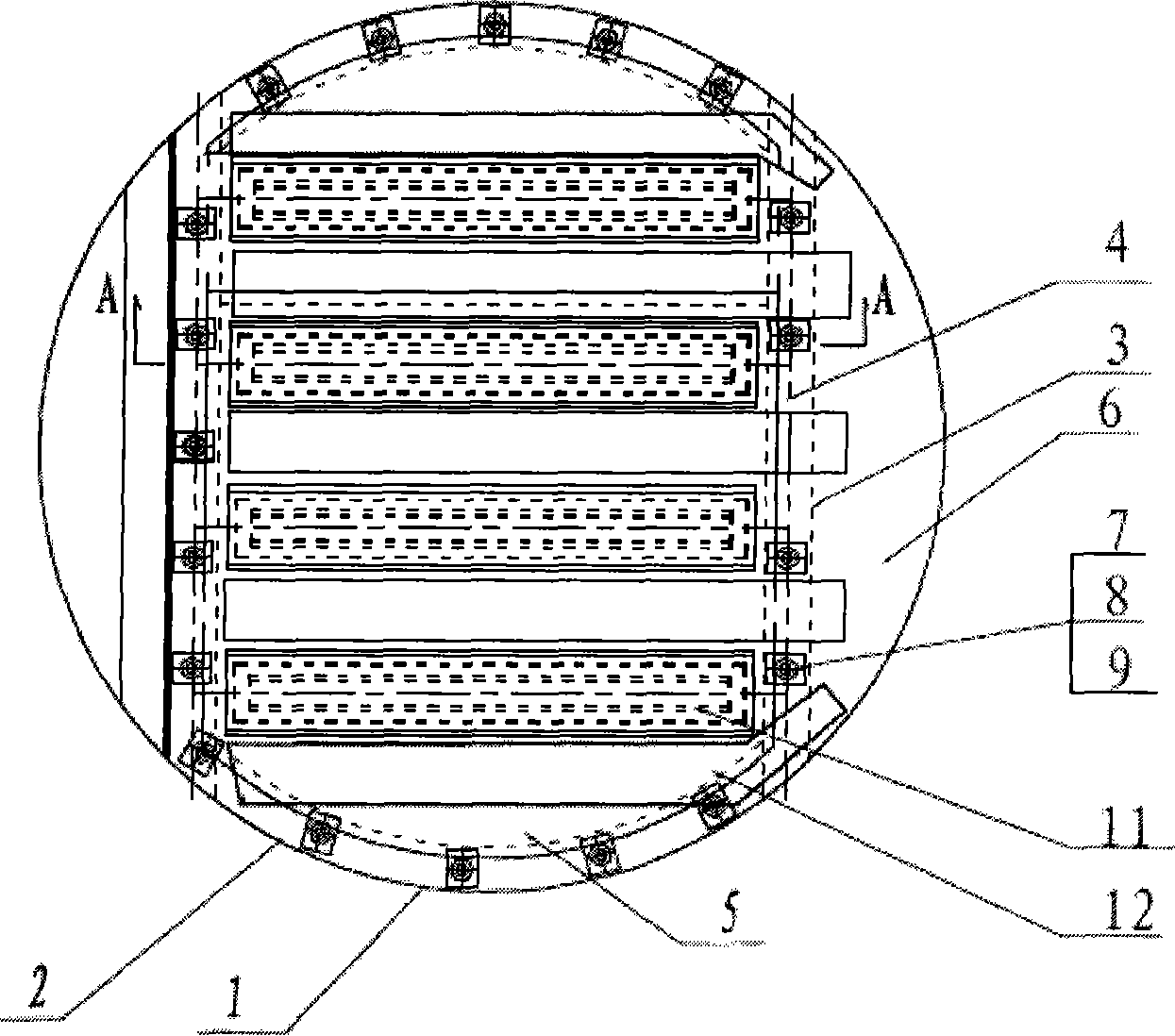

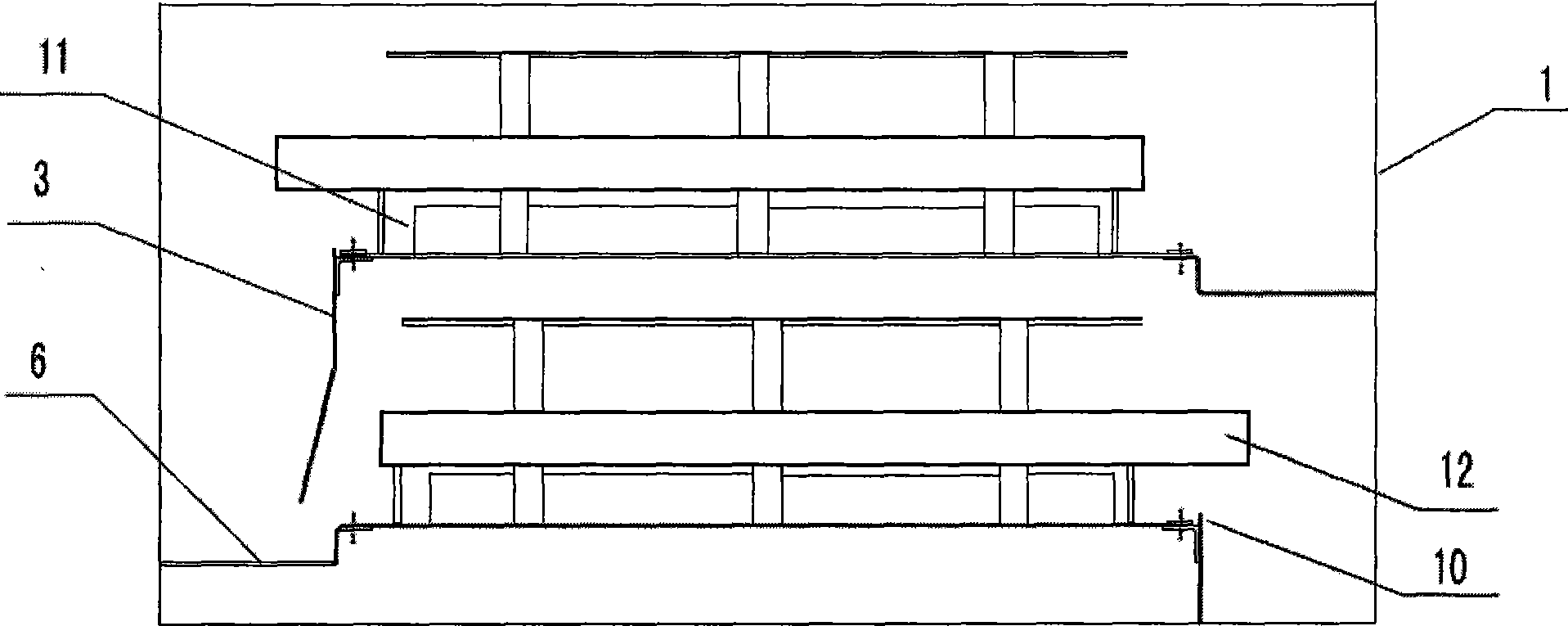

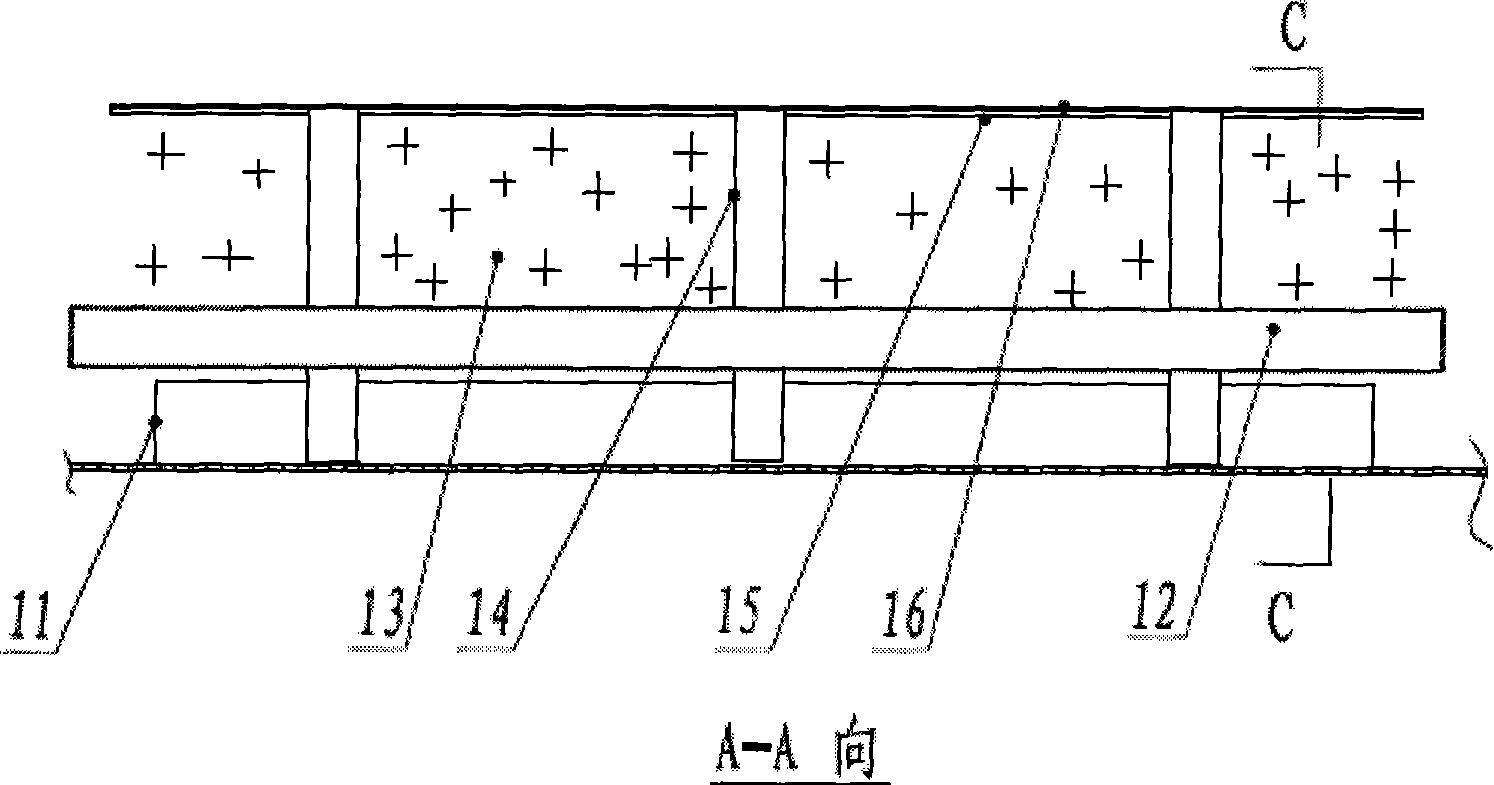

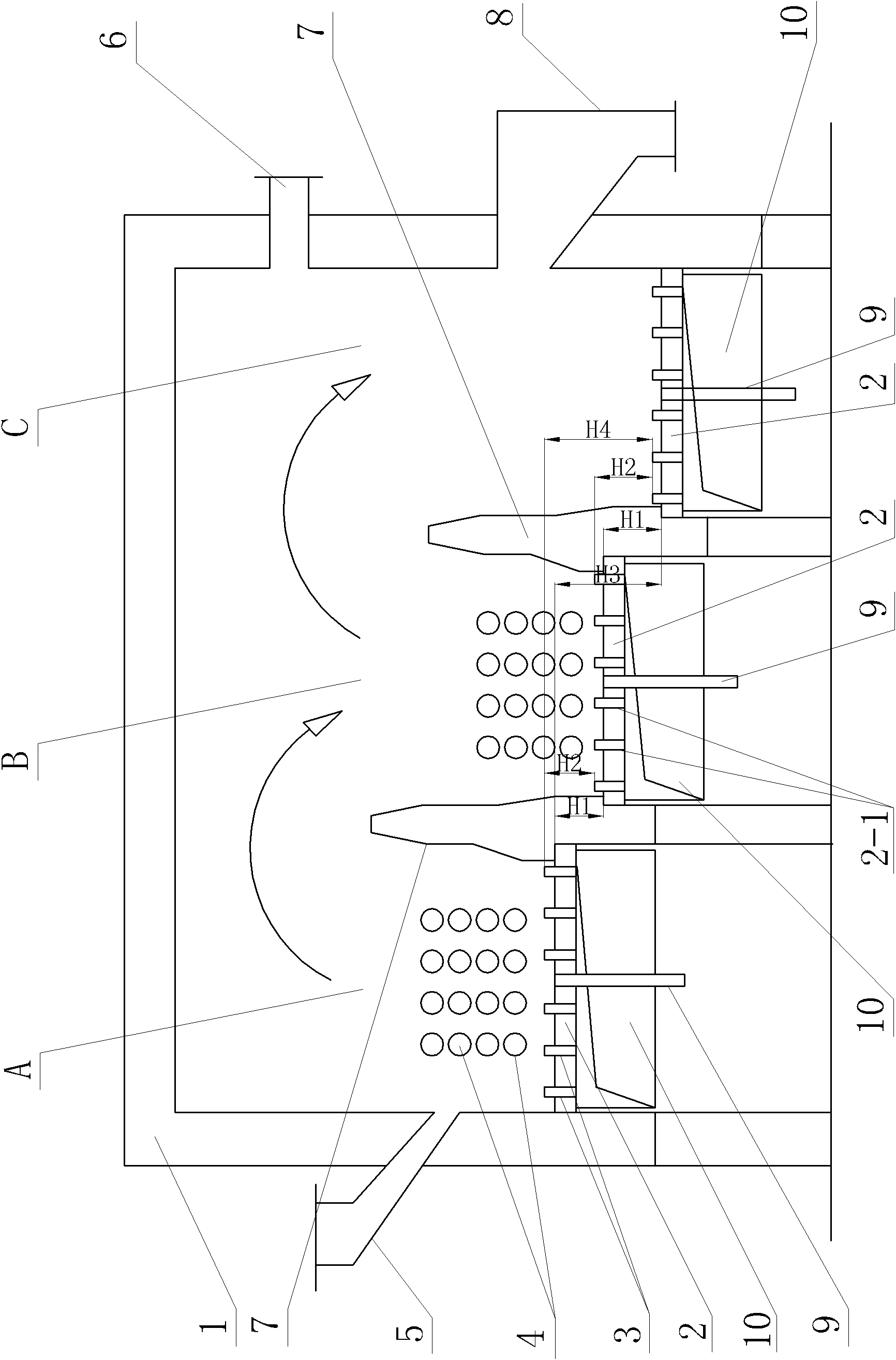

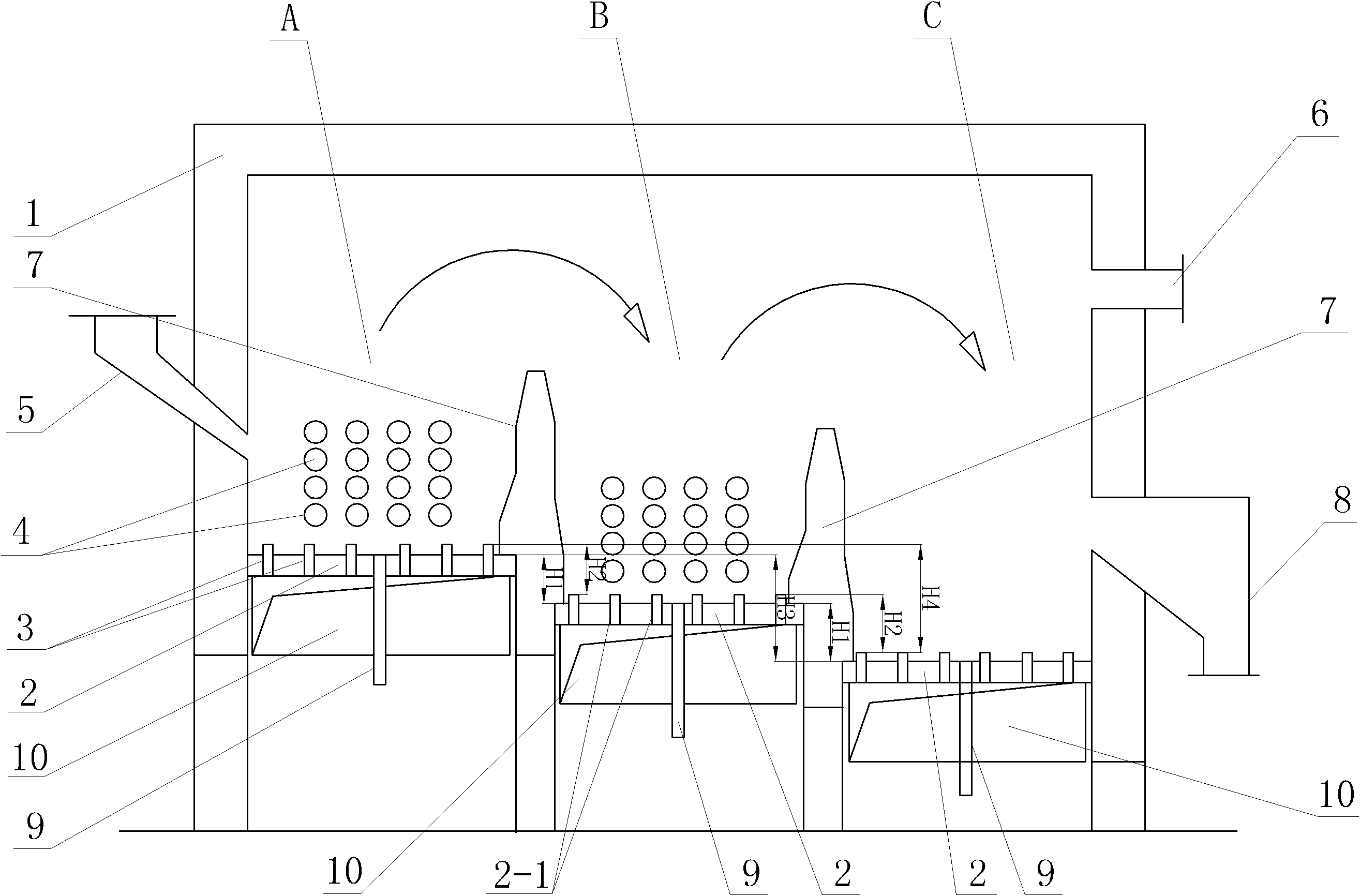

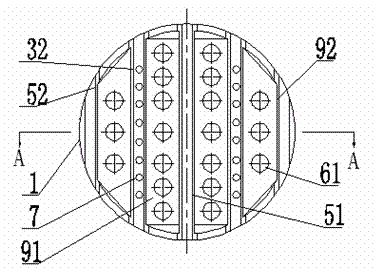

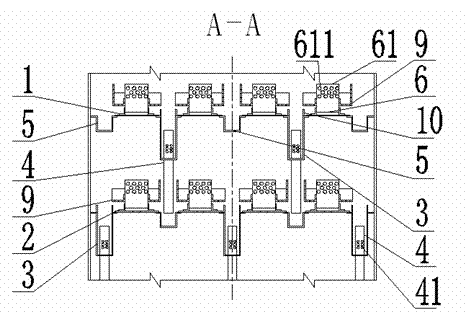

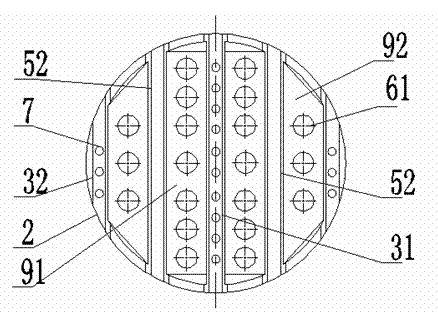

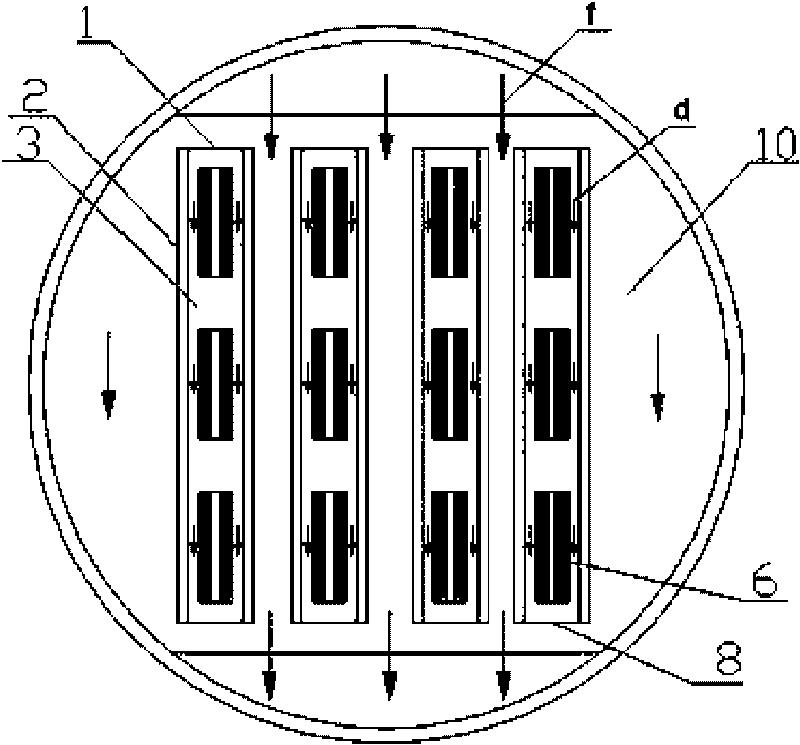

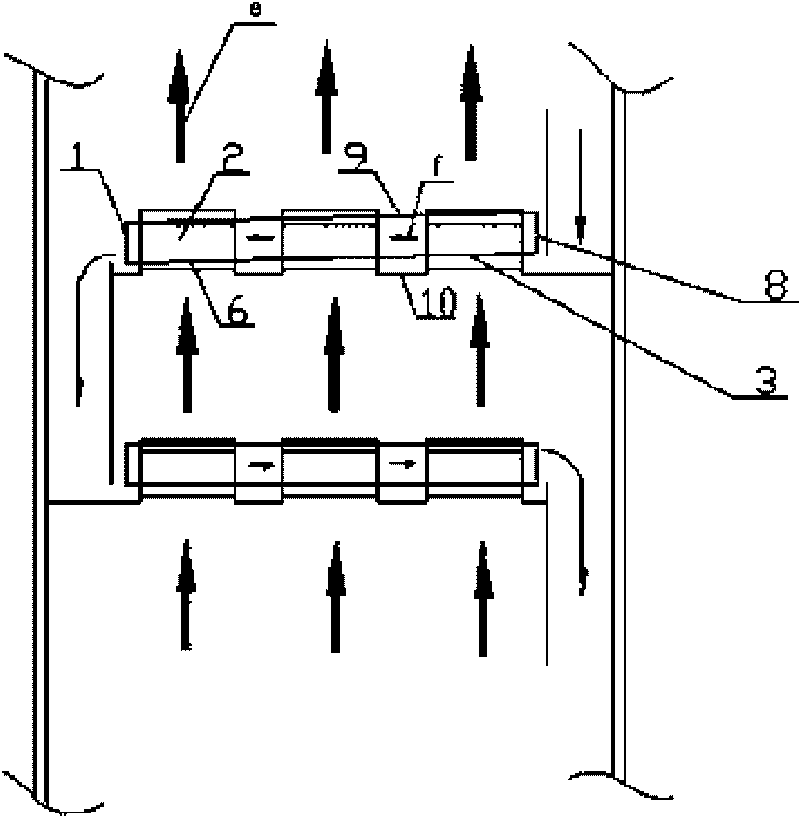

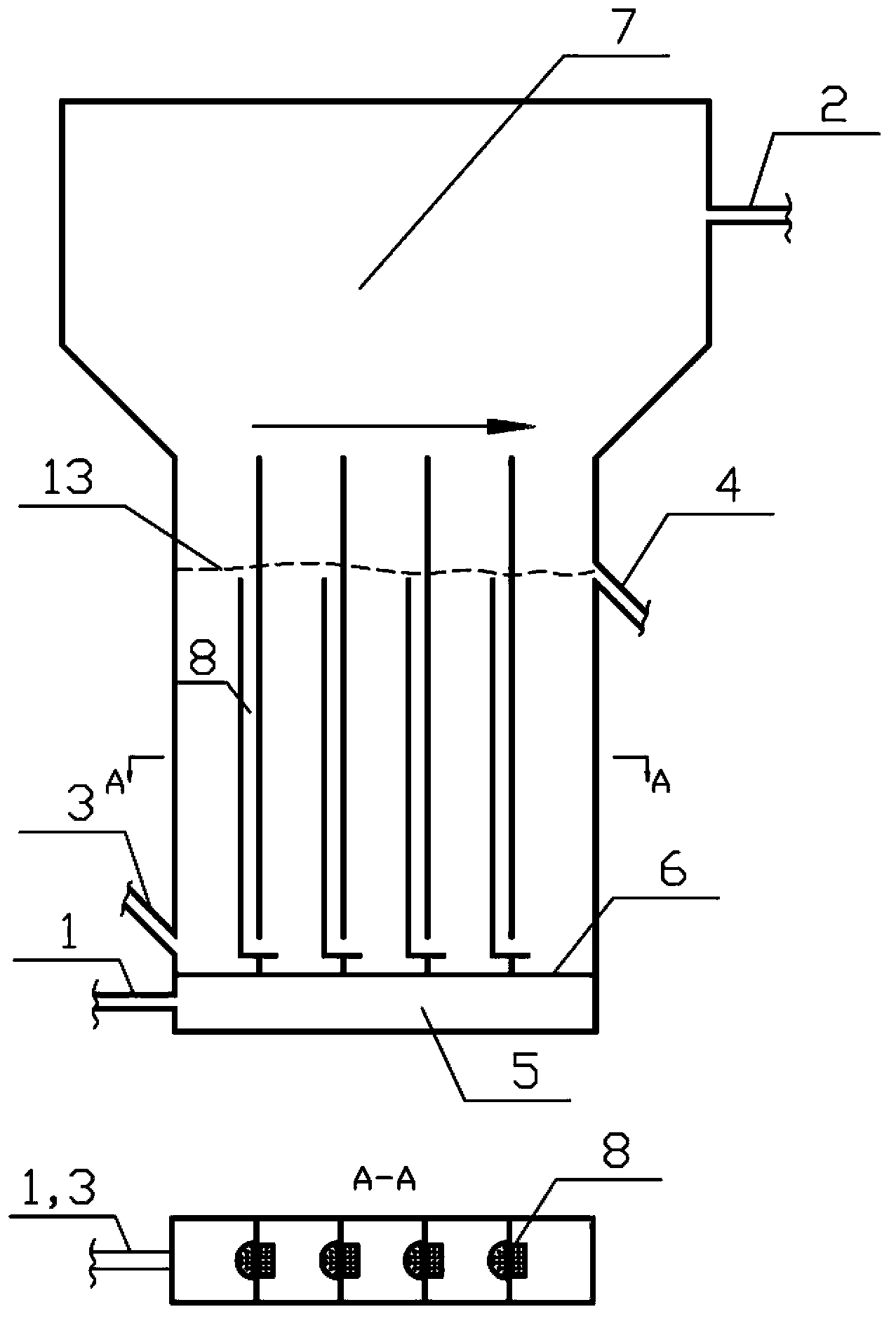

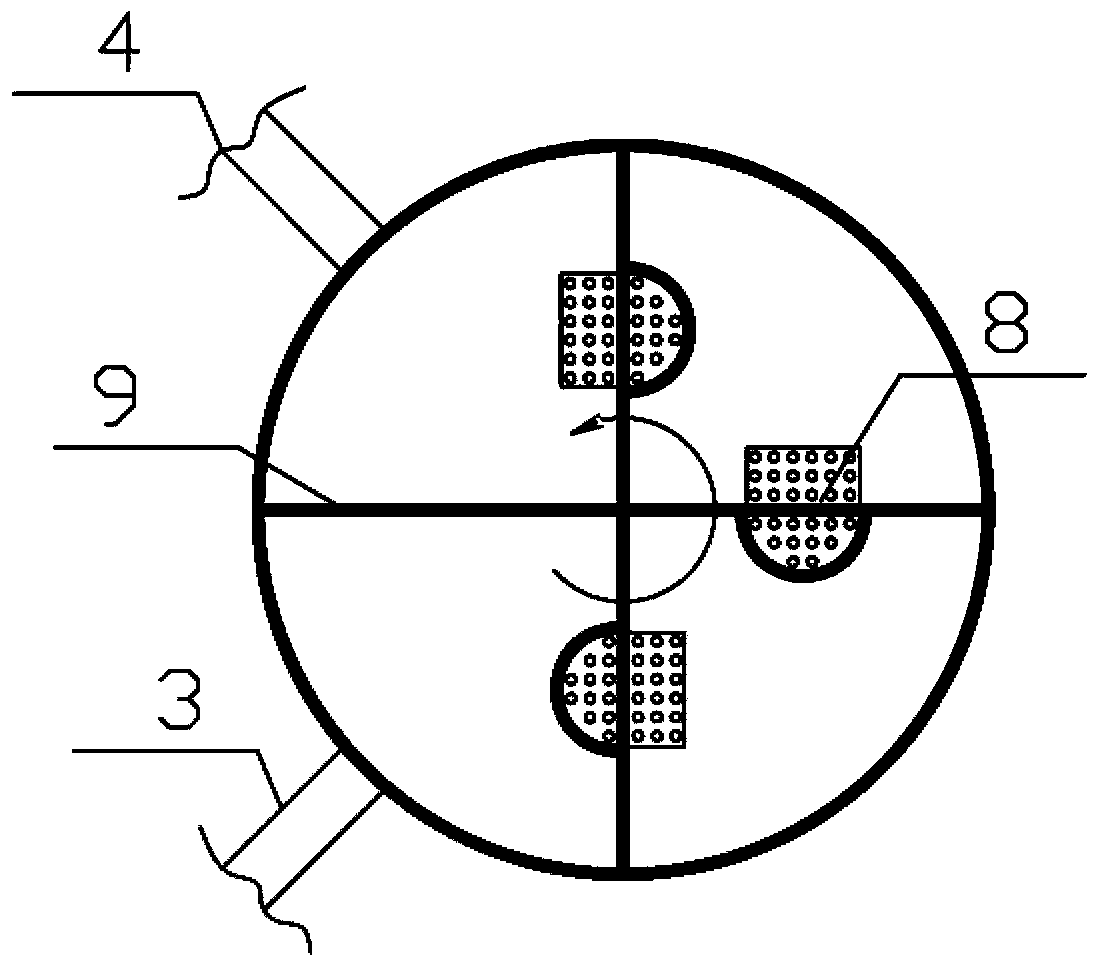

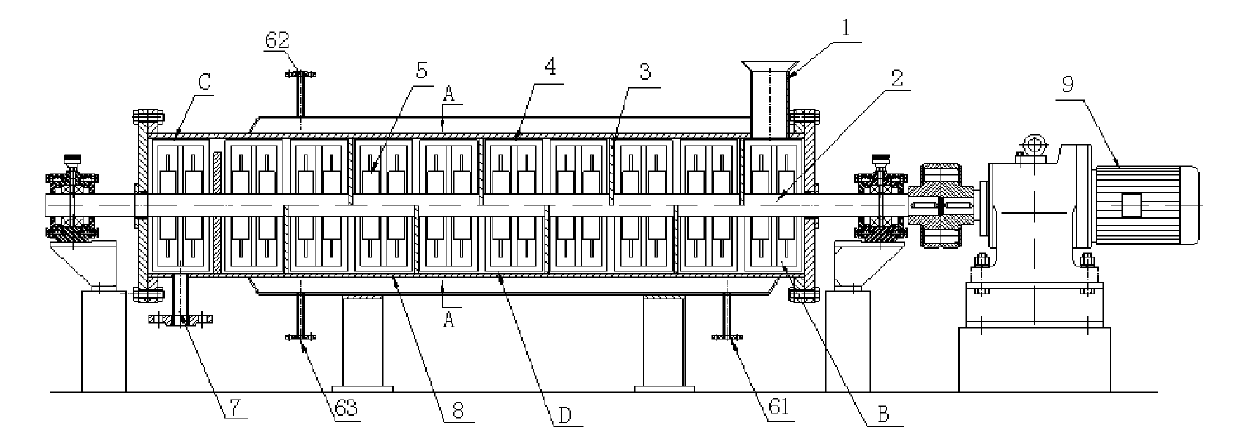

Multi-chamber fluidized bed reactor

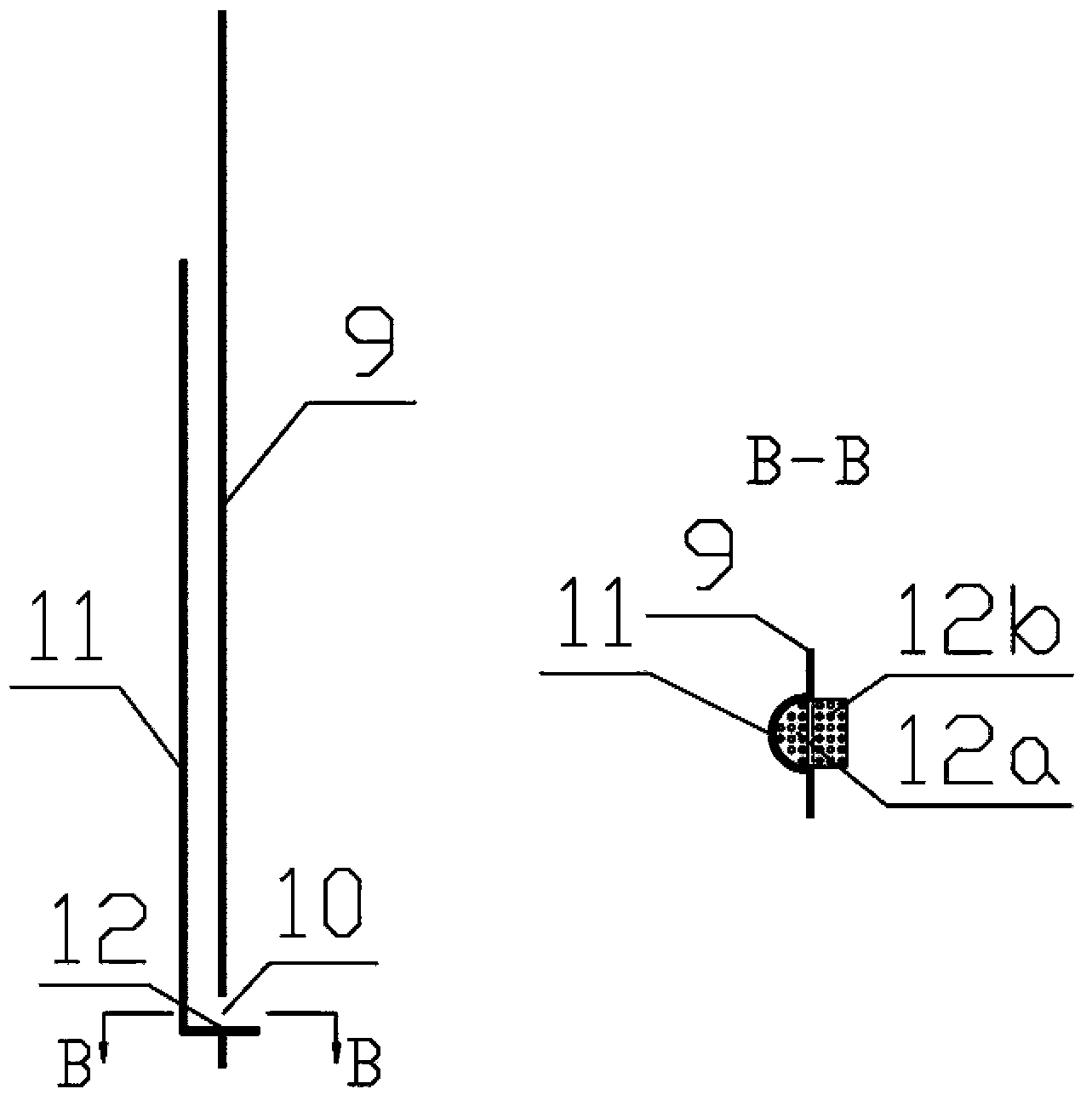

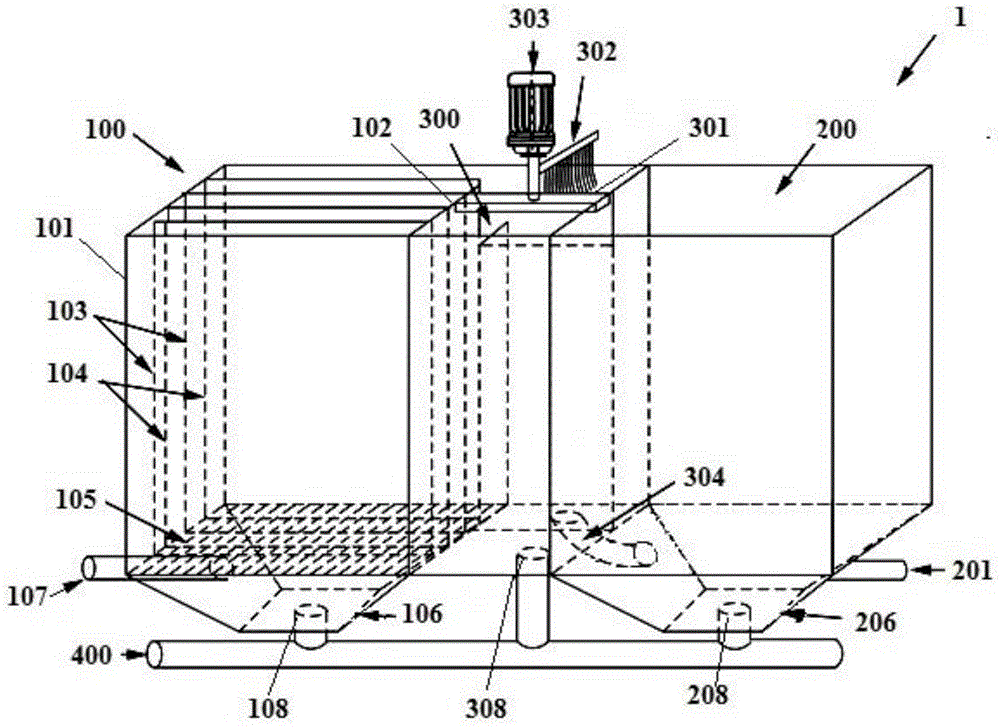

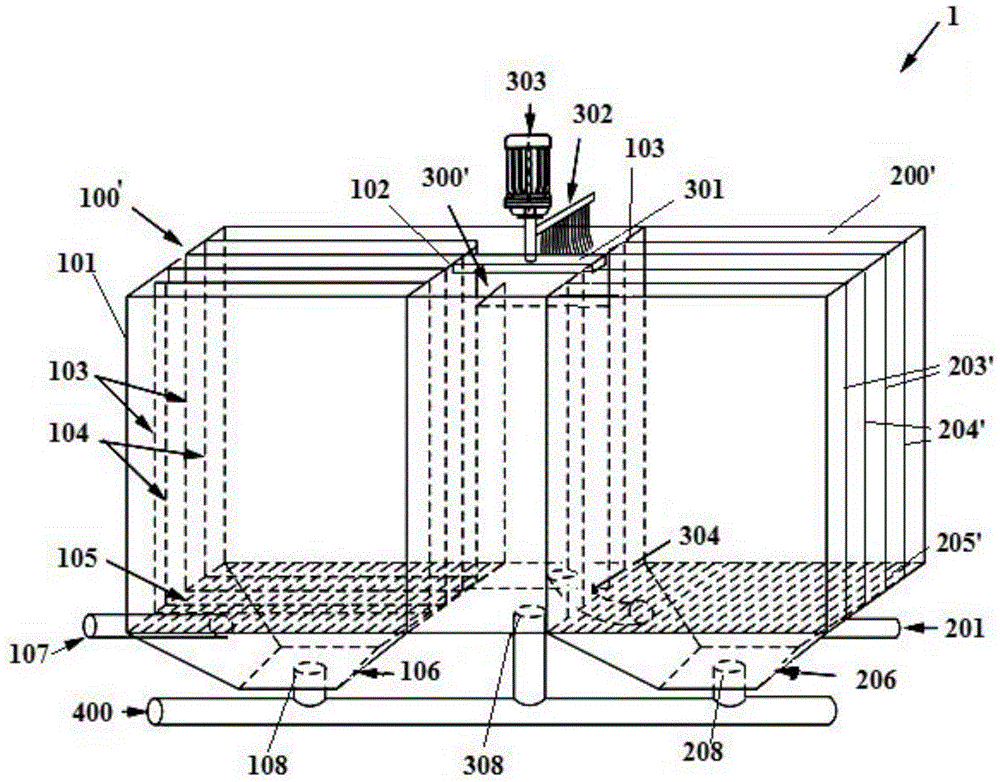

ActiveCN104096518AAvoid backmixingCrosswind suppressionChemical/physical processesFluidized bedEngineering

The invention relates to a multi-chamber fluidized bed reactor, which can realize fast and high-throughput flow of the particle material from an upstream chamber to a downstream chamber, while avoiding particulate material backmixing and back flow between adjacent chambers. The multi-chamber fluidized bed reactor is composed of an air inlet (1), an air outlet (2), a feed port (3), a discharge port (4), a wind chamber (5), an air distributor plate (6), a fluidizing chamber (7) and n material flow controllers (8), wherein n is more than or equal to 1; and each material flow controller (8) comprises a partition (9), an orifice (10), a material down flow tube (11) and a bottom baffle (12). The partition divides the fluidized bed reactor is divided into n+1 secondary fluidizing chambers, the air inlet is connected to the air chamber, the air outlet is connected to the upper part of the fluidizing chamber, the feed port is connected to the first secondary fluidizing chamber, and the discharge port is connected to the No. n+1 fluidizing chamber.

Owner:中科催化新技术(大连)股份有限公司

Up-flow electro-catalytic reactor

InactiveCN104445529AAvoid backmixingLow costWater/sewage treatment apparatusAnodic oxidationWater pipe

The invention relates to an up-flow electro-catalytic reactor. The up-flow electro-catalytic reactor comprises a reaction region and a skimming region; the following components are arranged in the reaction region: a plurality of anode shape-stable titanium plates and cathode stainless steel plates which are all arranged in parallel and used for electro-catalysis operations, a flow guide grille which is arranged perpendicular to the anode shape-stable titanium plates and the cathode stainless steel plates, a first dustpan-shaped catchment hopper which is arranged on the lower part of the flow guide grille and used for collecting residues or particles generated in the electro-catalysis process, and a water inlet pipe which is connected by use of a hole formed in the side surface of the dustpan-shaped catchment hopper; a skimming brush is arranged in the skimming region and driven by a motor to skim floating foam or dross; and the skimming region also serves as a first static settling tank. As the flow guide grille is arranged in the reaction region, backmixing between anode and cathode reaction regions is avoided, energy loss due to that an anodic oxidation product is reduced again at the cathode is prevented, and meanwhile, the cost is saved to the maximum extent. Besides, due to the arranged skimming region, floating objects such as floating foam and dross are effectively removed and prevented from going into water again to affect the effluent quality.

Owner:BEIJING NORMAL UNIVERSITY

Micro-positive pressure fully-closed large air floatation apparatus and sewage treatment method

InactiveCN106365236AImprove flotation separation efficiencyAvoid slag backmixingWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusPositive airway pressureEngineering

The invention relates to a micro-positive pressure fully-closed large air floatation apparatus. The apparatus comprises an air dissolving system and an air floatation device body, a coagulation chamber is provided with a sewage inlet, an air dissolving system release opening is arranged beside the sewage inlet in the coagulation chamber, the coagulation chamber is formed by coagulation spacing boards, micro-bubble releasing chambers formed by spacing boards are arranged beside the coagulation chamber, separation areas are arranged beside the micro-bubble releasing chambers, the separation areas are provided with inclined board groups, the upper portion of the air floatation device body is provided with an arc-shaped top cover, the arc-shaped top cover and the air floatation device body are sealed, the air floatation device body is connected with a gas supply device, a pressure release device and a pressure control device, and the pressure control device controls the gas supply device and the pressure release device to make the pressure in the air floatation device body always be a micro-positive pressure. The air flotation device is symmetric separation structure, improves the flotation separating efficiency and avoids return mixing of falling residues; and trapezoid water collecting weirs are arranged along the length direction of the tank to realize effective residue scraping and prevent overflow of residue collecting tanks, so the adjustment of a water outlet weir is not needed when the water flow greatly fluctuates.

Owner:青岛海晏环境技术工程有限公司

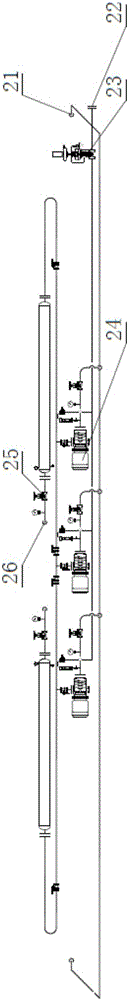

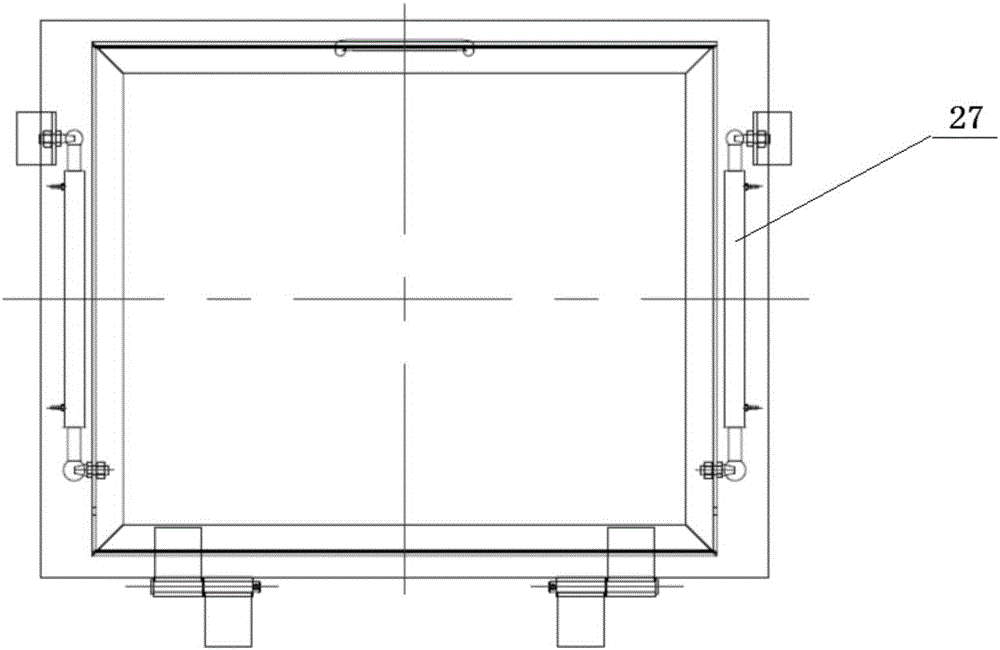

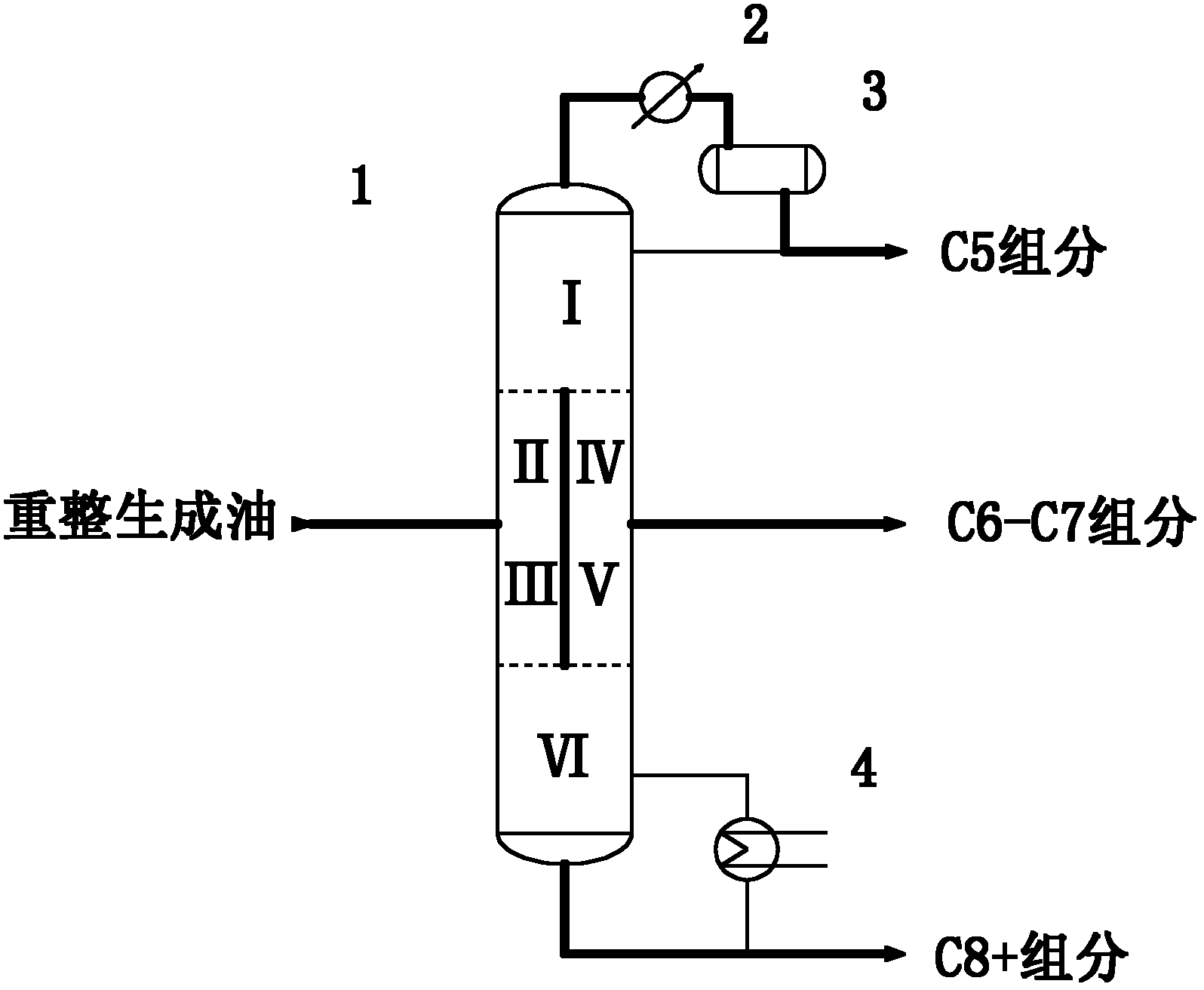

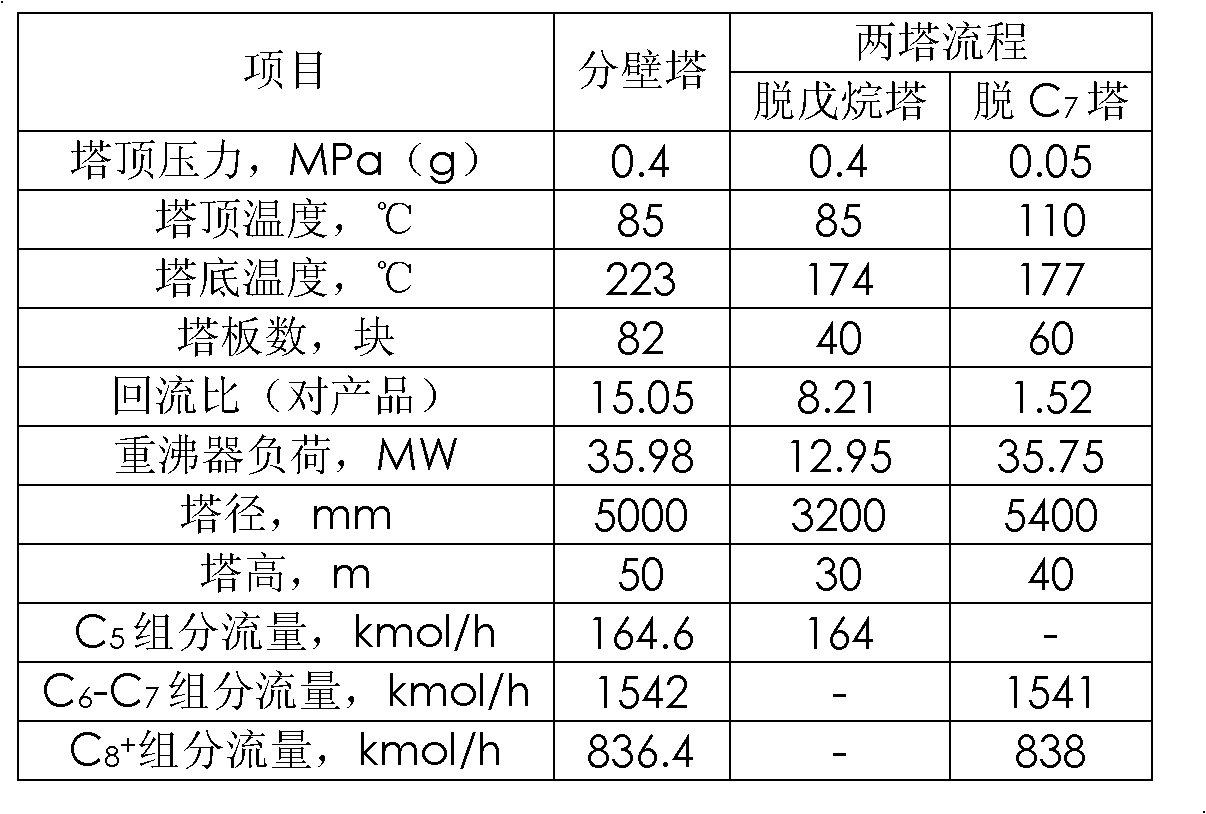

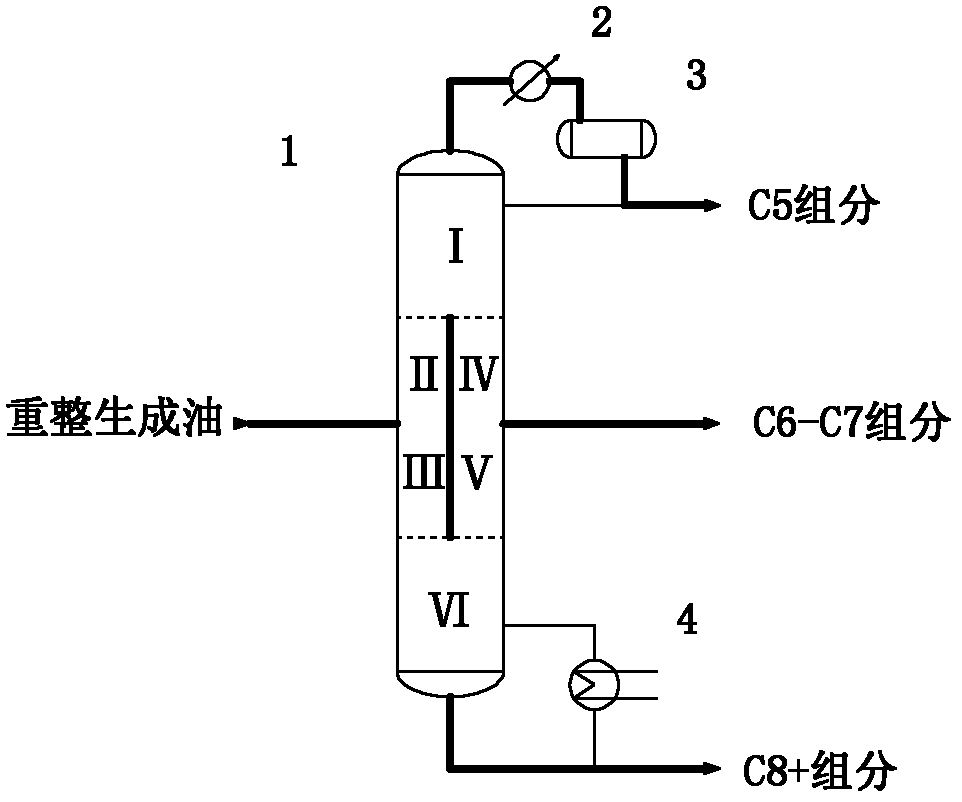

Equipment and method for separating reformed oil

ActiveCN102206504AReduce the number of devicesLow investment costHydrocarbon distillationEngineeringEnergy consumption

The invention relates to equipment and a method for separating reformed oil. The method comprises the following steps of: separating three components, namely C5, C6-C7 and C8<+> in the reformed oil by using a bulkhead rectification column; adding the reformed oil prepared in a reforming device from a rectifying section of a feeding part and the middle part of a stripping section of the feeding part into the bulkhead rectification column; cooling the C5 component on the top of the column by using a condenser, and adding the cooled C5 component into a reflux tank, wherein a liquid phase at the bottom of the reflux tank is partially used as a C5 component product, and the rest liquid phase is used as back flow and flows back to a shared rectifying section on the upper part of the bulkhead rectification column; performing gas-phase side-line extraction on the C6-C7 component from a rectifying section of an extraction part of a side line product and the middle plate of a stripping section on the extraction part of the side line product; and performing condensation cooling and then feeding to an aromatics extraction device, wherein the C8<+> component is arranged at the bottom of the column. The feeding pressure is 0.5MPa (g), the operation pressure of the bulkhead rectification column is 0.4MPa (g), the energy consumption is low, the purity of the C6-C7 component can reach 99.7 percent, floor space is reduced by 40 percent, and the total investment on the equipment is saved by 20 percent.

Owner:PETROCHINA CO LTD +1

Water solution all-circulation aquadrate high pressure system energy-saving and production-increasing process

InactiveCN1463964AIncrease production capacityEasy to installUrea derivatives preparationOrganic compound preparationTowerHigh pressure

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

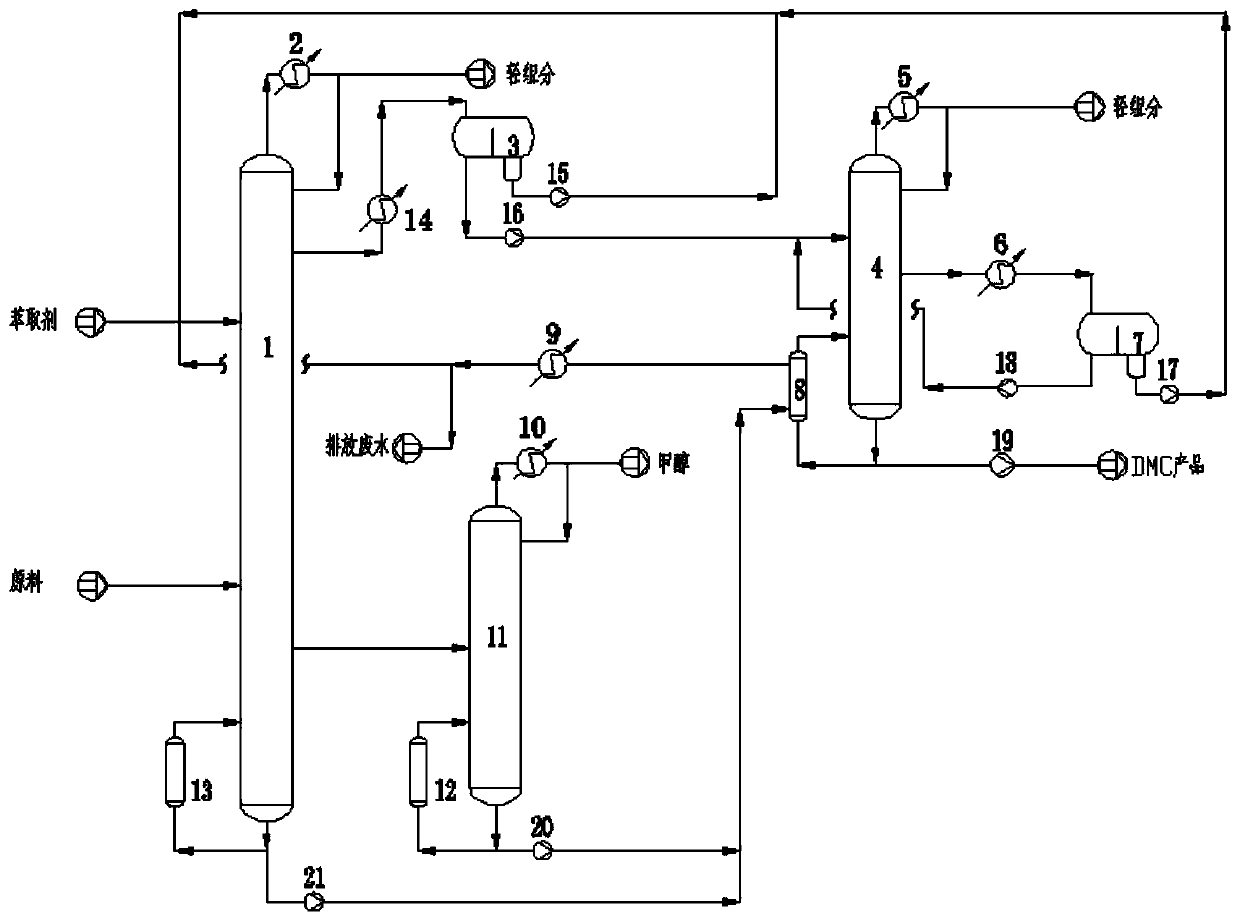

Separation purification process of dimethyl carbonate

ActiveCN110372512AImprove applicabilityAvoid backmixingOrganic compound preparationChemical industryExtractive distillationReboiler

The invention discloses a separation purification process of dimethyl carbonate. The separation purification process uses a crude product of a coal-prepared glycol by-product or a dimethyl carbonate crude product synthesized by methanol oxidative carbonyl as a raw material, and a separation device comprises an extractive distillation column with a material stream extraction side line, two phase splitters, a methanol distillation column, a dimethyl carbonate dehydration tower with a material stream extraction side line, a plurality of condensers and a plurality of reboilers; and the refined dimethyl carbonate, a light component product containing methylal and methyl formate and methanol are finally obtained through the continuous operation steps of the three separation units of extractive distillation-methanol distillation-dimethyl carbonate dehydration and an extraction agent recycling unit. The purification process of the dimethyl carbonate is high in applicability, simple in processflow and obvious in energy-saving effect through heat coupling.

Owner:TAIYUAN UNIV OF TECH

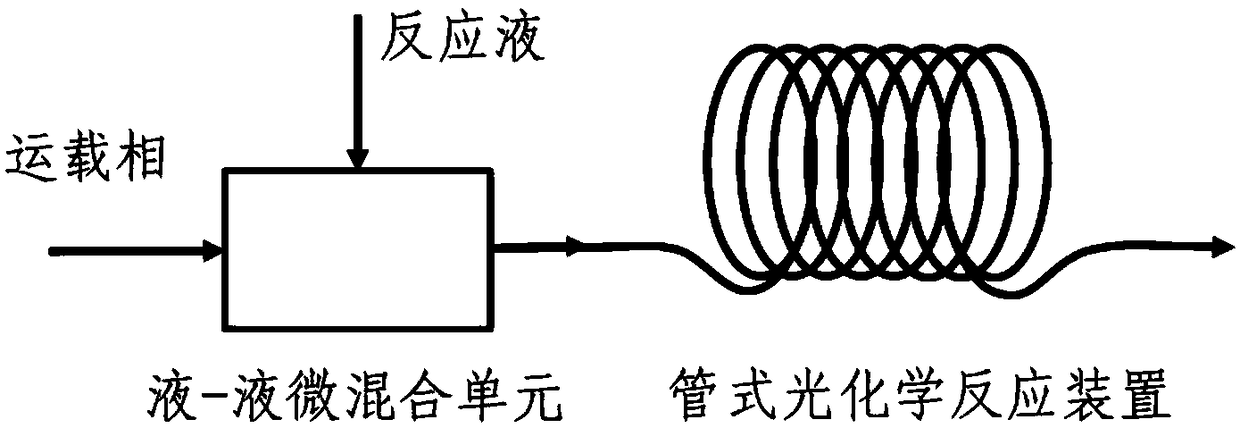

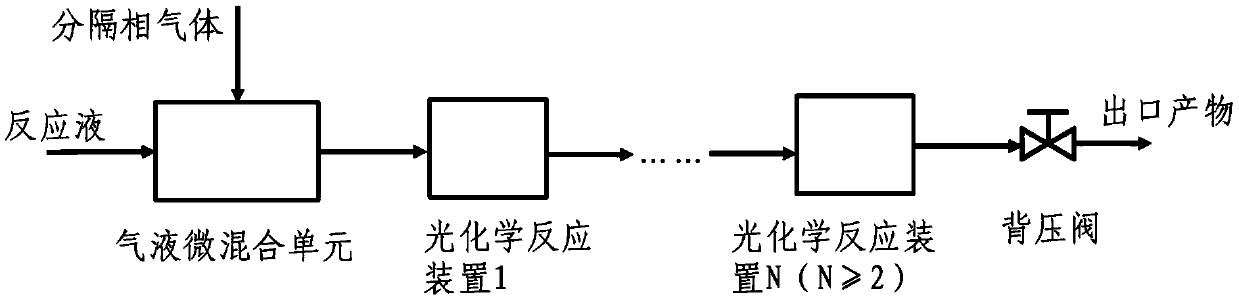

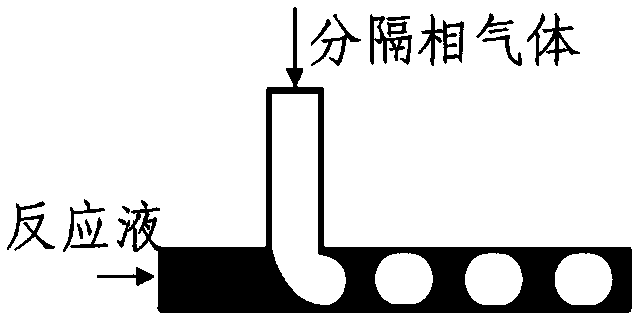

Gas separation flow system and gas separation flow method for photochemical synthesis of 9-beta,10-alpha-dehydroprogesterone ketal

The invention relates to a gas separation flow system and a gas separation flow method for photochemical synthesis of 9-beta,10-alpha-dehydroprogesterone ketal. The method is characterized in that 9-beta,10-alpha-dehydroprogesterone ketal is synthesized in one step or two steps by utilizing ultraviolet light with different wave bands, a raw material 9-alpha,10-beta-dehydroprogesterone ketal reaction solution is separated by gas doing not participate in a reaction, the internal disturbance of the reaction solution is enhanced, and the retention time of the reaction solution in a tubular reactoris ensured to be consistent. The method has the advantages of being continuous, stable, high in light energy utilization rate, low in production cost, easy and convenient to operate and controllablein process, and has huge prospect in the industrial production of 9-beta,10-alpha-dehydroprogesterone ketal through photochemical synthesis.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +2

Continuous homogenizing mixing reactor

ActiveCN102019163AWell mixedAvoid first in first outChemical/physical/physico-chemical stationary reactorsRotational axisControl system

The invention discloses a continuous homogenizing mixing reactor, which comprises a cylindrical container having a feed port and a discharge port, a mixing device arranged in the cylindrical container, a driving system in driving connection with the mixing device, and an electric apparatus control system connected to the driving system, wherein the mixing device is formed by a central rotating shaft connected to the driving system, a plurality of sets of E-shaped paddles and combined plate type paddles arranged on the central rotating shaft, and a plurality of baffle plates arranged in the cylindrical container. The baffle plates divide the cylindrical container into a feeding area at the feed port, a discharging area at the discharge port, a plurality of mixing reaction areas between thefeeding area and the discharging area, and a discharging channel for connecting each area in a bending manner formed between the baffle plates and between the baffle plates and the cylindrical container is installed from the feeding area to the discharging area. The reactor of the invention can ensure that the firstly fed materials are discharged firstly, various materials are uniformly mixed andthe material concentration fluctuation is small without any fluctuation.

Owner:CHINESE TEXTILE ACAD

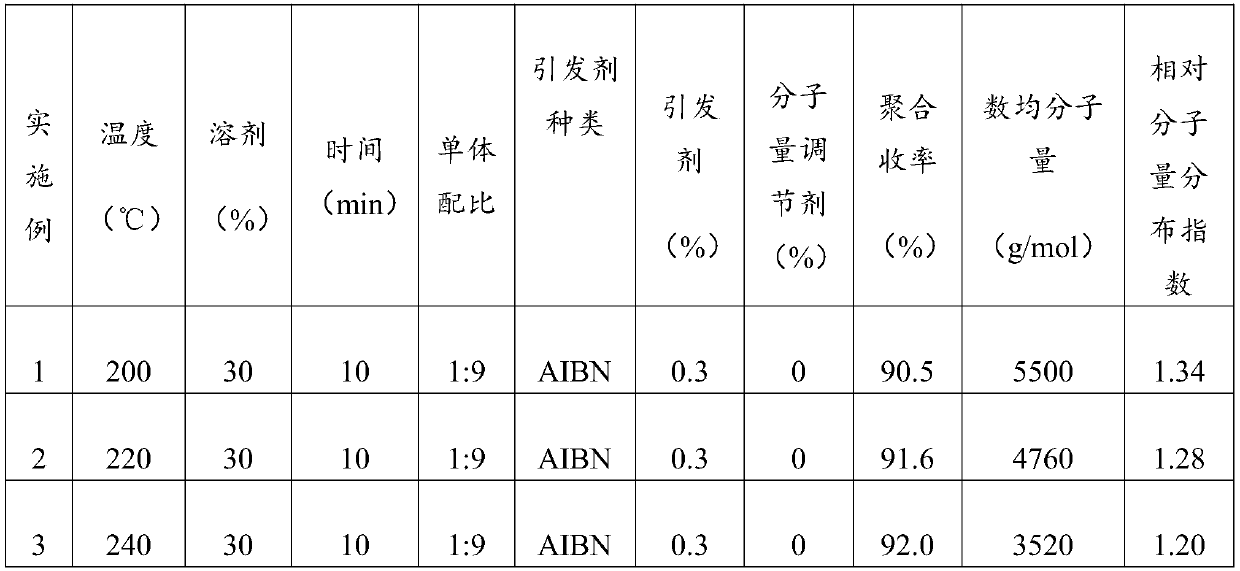

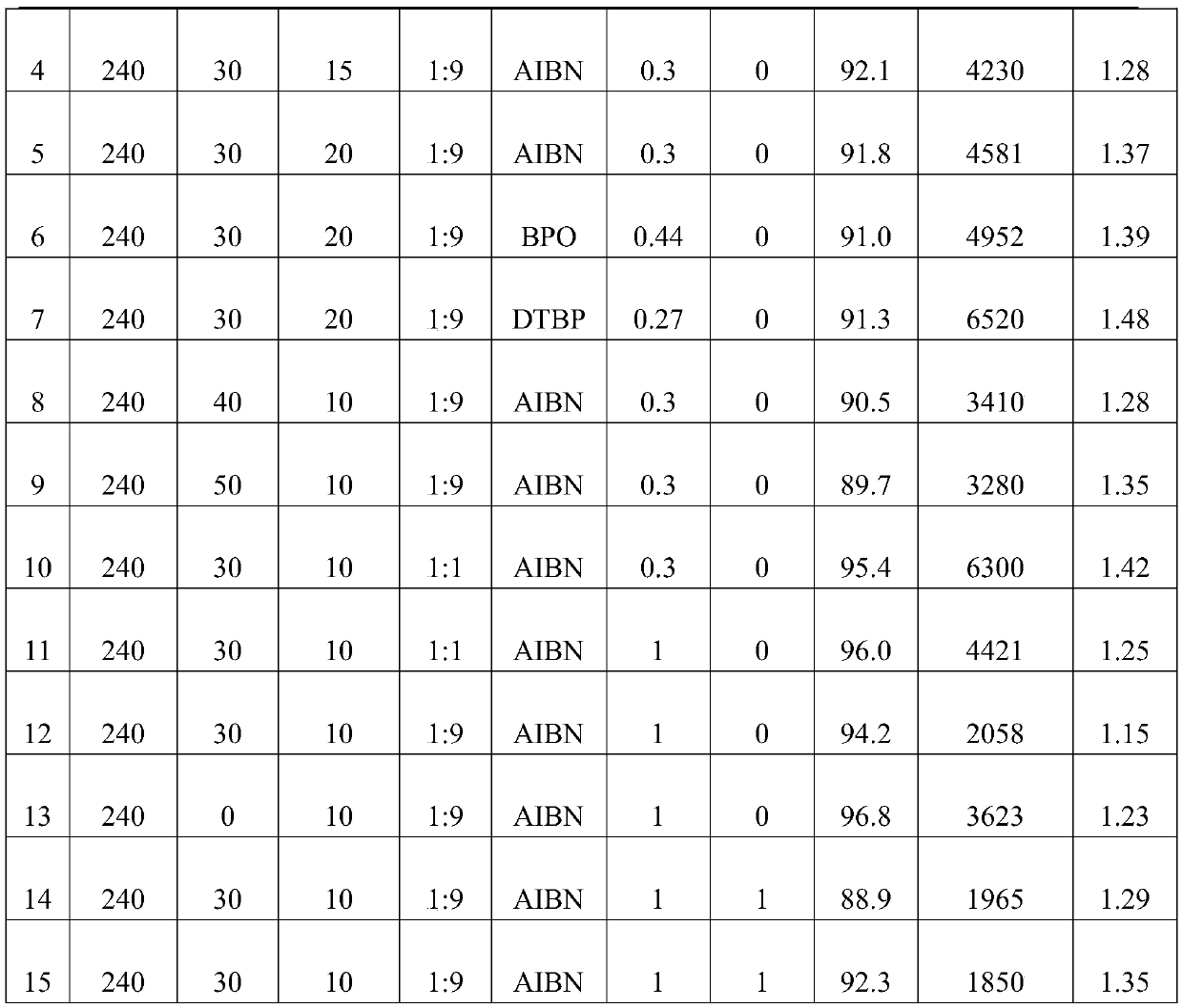

Low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and preparation method thereof

The invention provides a low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and a preparation method thereof, and belongs to the technical field of high polymer material preparation. The styrene-maleic anhydride copolymer is prepared by adopting a high-temperature continuous free radical polymerization method, the method is simple in process, low in solvent and initiator consumption, low in cost, capable of realizing continuous production, short in reaction time, high in reaction rate and high in conversion rate; and the low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer prepared by the method is small in molecular weight distribution range, more uniform in product molecular weight distribution and more stable in product performance, and has a good industrial prospect.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com