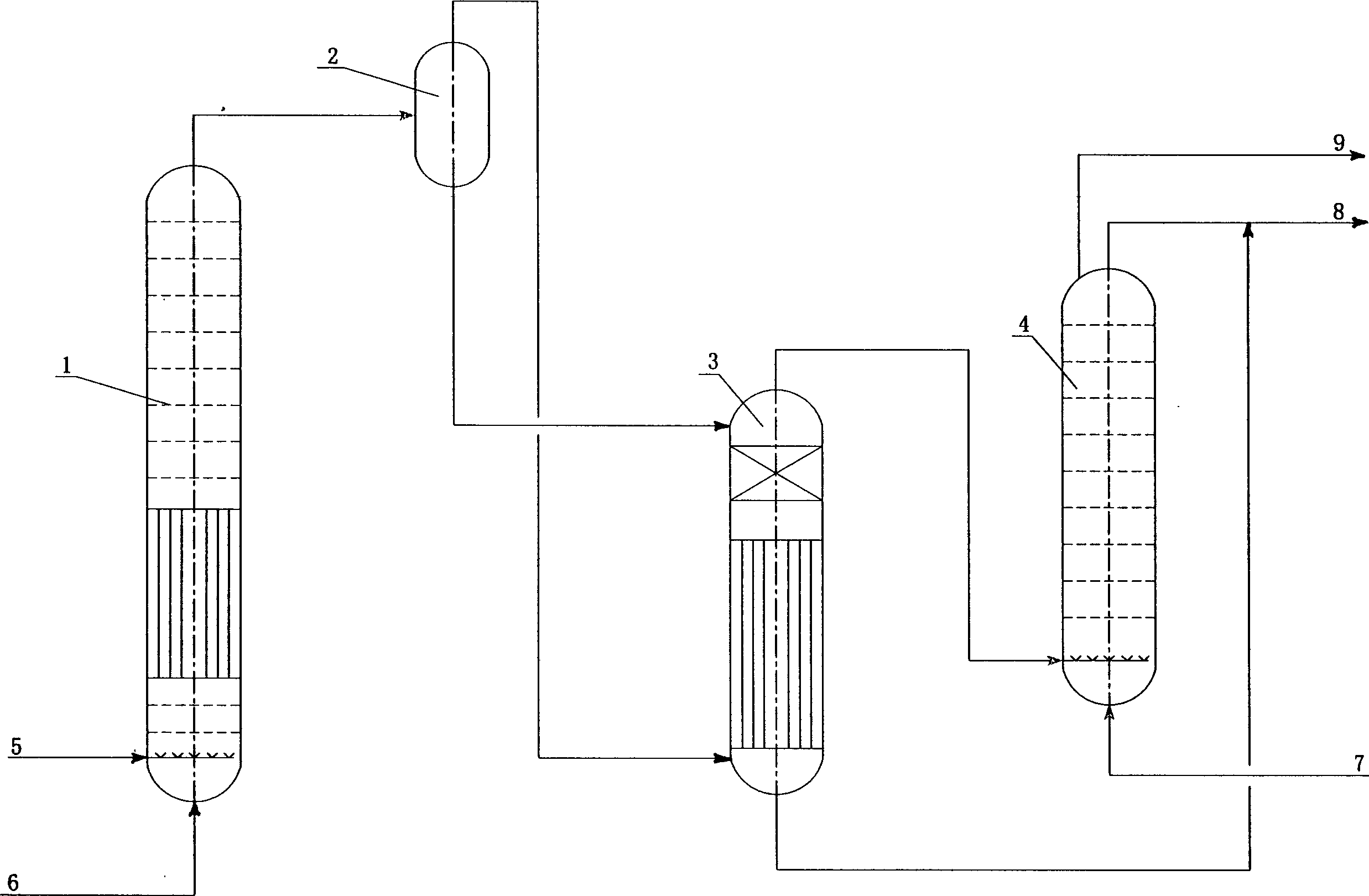

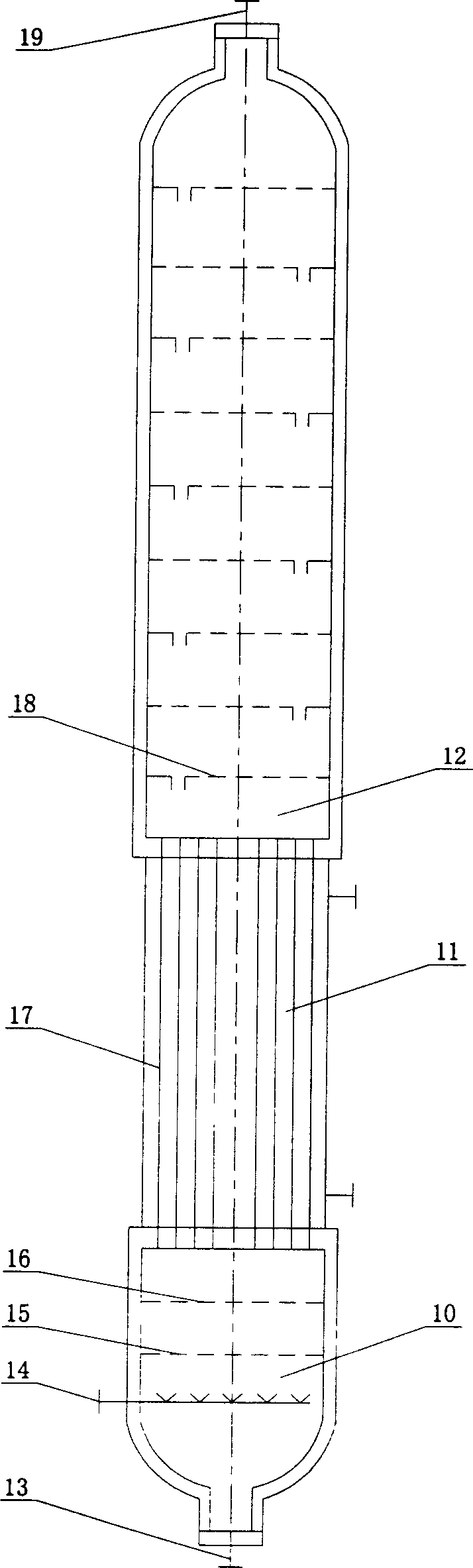

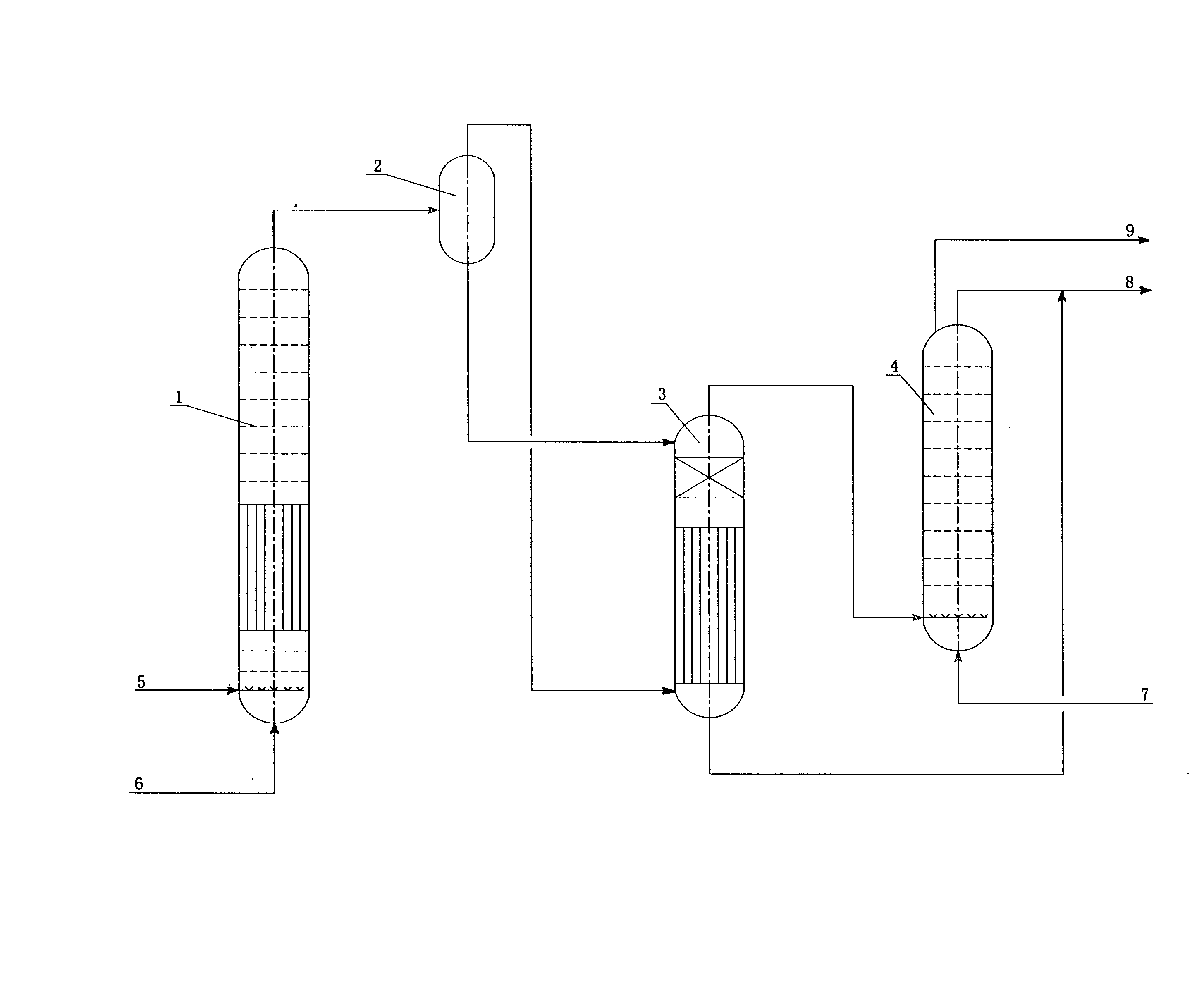

Water solution all-circulation aquadrate high pressure system energy-saving and production-increasing process

An aqueous solution full circulation, high-pressure system technology, applied in the preparation of organic compounds, preparation of urea derivatives, chemical instruments and methods, etc., can solve problems such as difficult preheating, difficult to distribute evenly, crystallization blockage of carbamate in heat exchange tubes, etc. , to achieve the effect of improving the contact interface, increasing the production significantly, and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Carry out energy-saving and production-increasing reformation to an existing medium-sized aqueous solution full-circulation urea plant with the method of the present invention, take the production capacity increase from 500 tons / day to 750 tons / day as an example, estimate the total transformation cost (including the post-process of the original high-pressure system The transformation of eliminating bottlenecks, reducing ammonia consumption and eliminating pollution) is about 18 million yuan. After the transformation, the annual output value will increase by 82.5 million yuan (according to the urea price of 1100 yuan / ton); and the energy saving and consumption reduction, only considering the reduction of ammonia, steam and electricity consumption, the urea production cost can be reduced by 61 yuan / ton, and the total annual reduction can be reduced. The cost amounted to more than 13 million yuan. Only based on the production cost of energy saving and consumption reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com