Reaction device for preparing low-carbon olefin by employing methyl alcohol and/or dimethyl ether

A reaction device and a technology for low-carbon olefins, which are applied in the field of reaction devices, can solve the problem of low selectivity of low-carbon olefins, and achieve the effects of narrow residence time distribution, convenience for large-scale, and improved selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

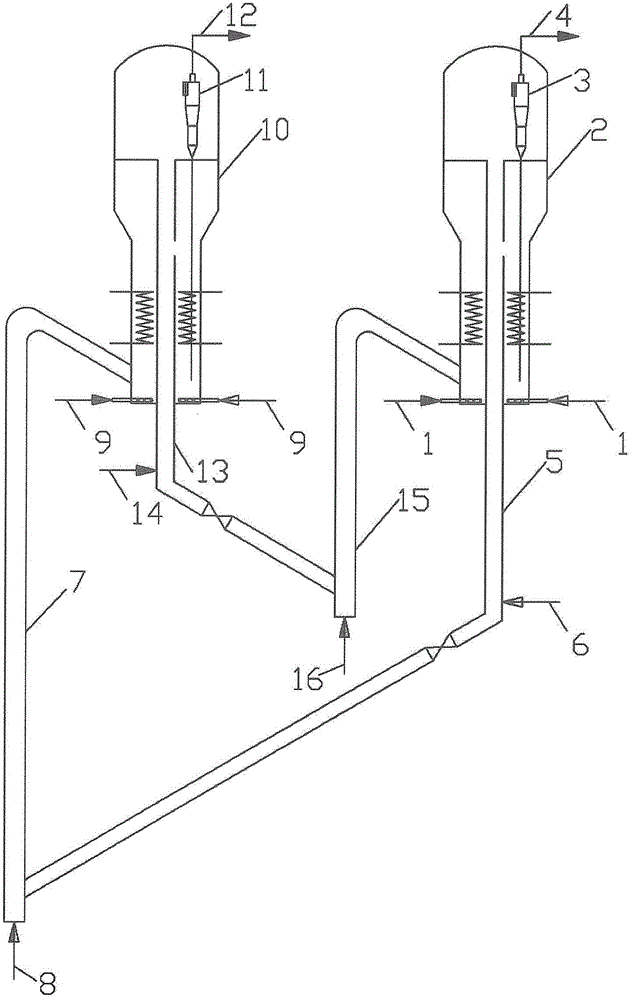

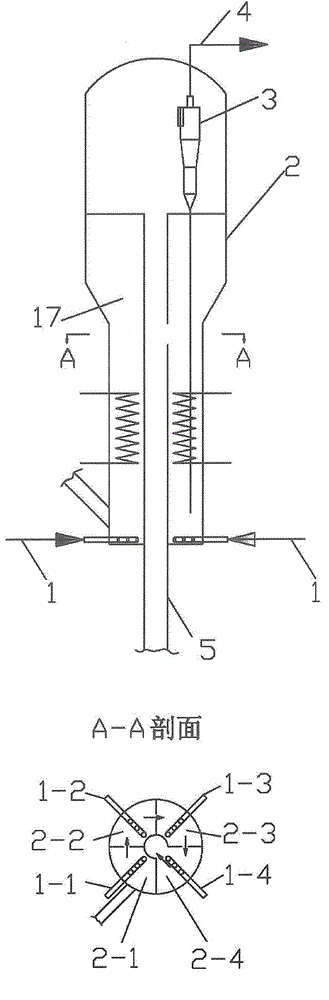

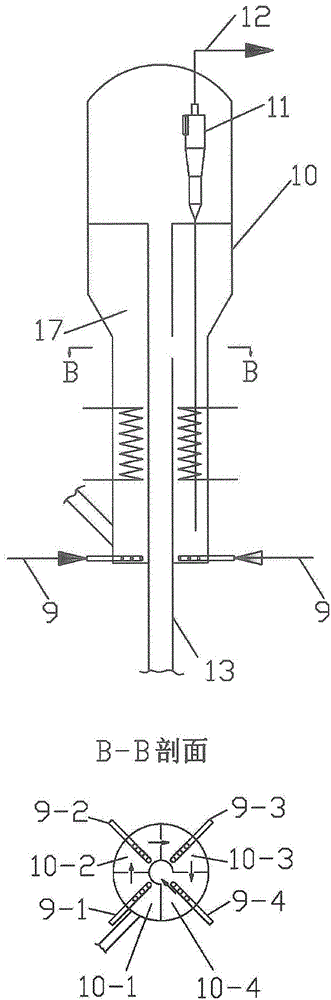

[0046] The dense-phase fluidized bed reactor is equipped with 4 secondary reaction zones, and the dense-phase fluidized bed regenerator is equipped with 4 secondary regeneration zones. The raw materials of methanol and / or dimethyl ether enter the dense-phase fluidized bed for reaction. After contacting with the catalyst including SAPO-34 molecular sieve, the generated gas phase product stream and spent catalyst, gas phase materials and entrained spent catalyst enter the cyclone separator, and the gas phase product stream enters the subsequent separation section through the outlet of the cyclone separator, and is entrained The spent catalyst enters the fourth secondary reaction zone through the feed leg of the cyclone separator. The regenerated catalyst enters the dense-phase fluidized bed reactor through the stripper and riser, and passes through the first to fourth secondary reaction zones in sequence. After carbon deposits, the catalyst is formed, which then passes through the...

Embodiment 2

[0048] Three secondary reaction zones are set in the dense-phase fluidized bed reactor, and two secondary regeneration zones are set in the dense-phase fluidized bed regenerator. The raw materials of methanol and / or dimethyl ether enter the dense-phase fluidized bed for reaction. After contacting with the catalyst including SAPO-34 molecular sieve, the generated gas phase product stream and spent catalyst, gas phase materials and entrained spent catalyst enter the cyclone separator, and the gas phase product stream enters the subsequent separation section through the outlet of the cyclone separator, and is entrained The spent catalyst enters the third secondary reaction zone through the feed leg of the cyclone separator. The regenerated catalyst enters the dense-phase fluidized bed reactor through the stripper and riser, and then passes through the first to third secondary reaction zones in sequence. After carbon deposits, the spent catalyst is formed. The spent catalyst passes ...

Embodiment 3

[0050] There are 6 secondary reaction zones in the dense-phase fluidized bed reactor, and 5 secondary regeneration zones in the dense-phase fluidized bed regenerator. The raw materials of methanol and / or dimethyl ether enter the dense-phase fluidized bed for reaction. After contacting with the catalyst including SAPO-34 molecular sieve, the generated gas phase product stream and spent catalyst, gas phase materials and entrained spent catalyst enter the cyclone separator, and the gas phase product stream enters the subsequent separation section through the outlet of the cyclone separator, and is entrained The spent catalyst enters the sixth secondary reaction zone through the feed leg of the cyclone separator. The regenerated catalyst enters the dense-phase fluidized bed reactor through the stripper and riser, and sequentially passes through the 1st to 6th secondary reaction zones. After carbon deposits, the spent catalyst is formed. The spent catalyst passes through the stripper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com