Patents

Literature

32results about How to "Control carbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

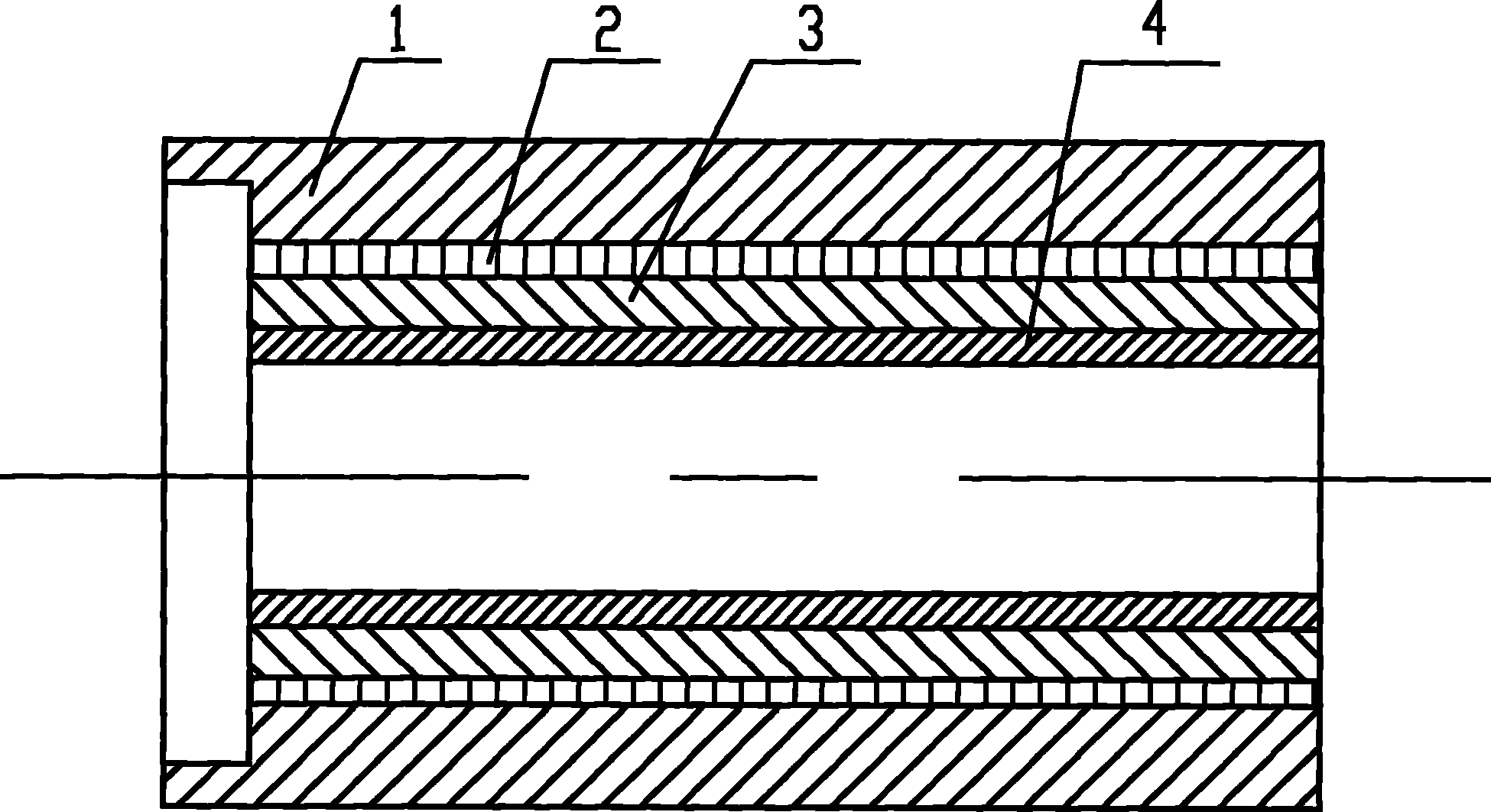

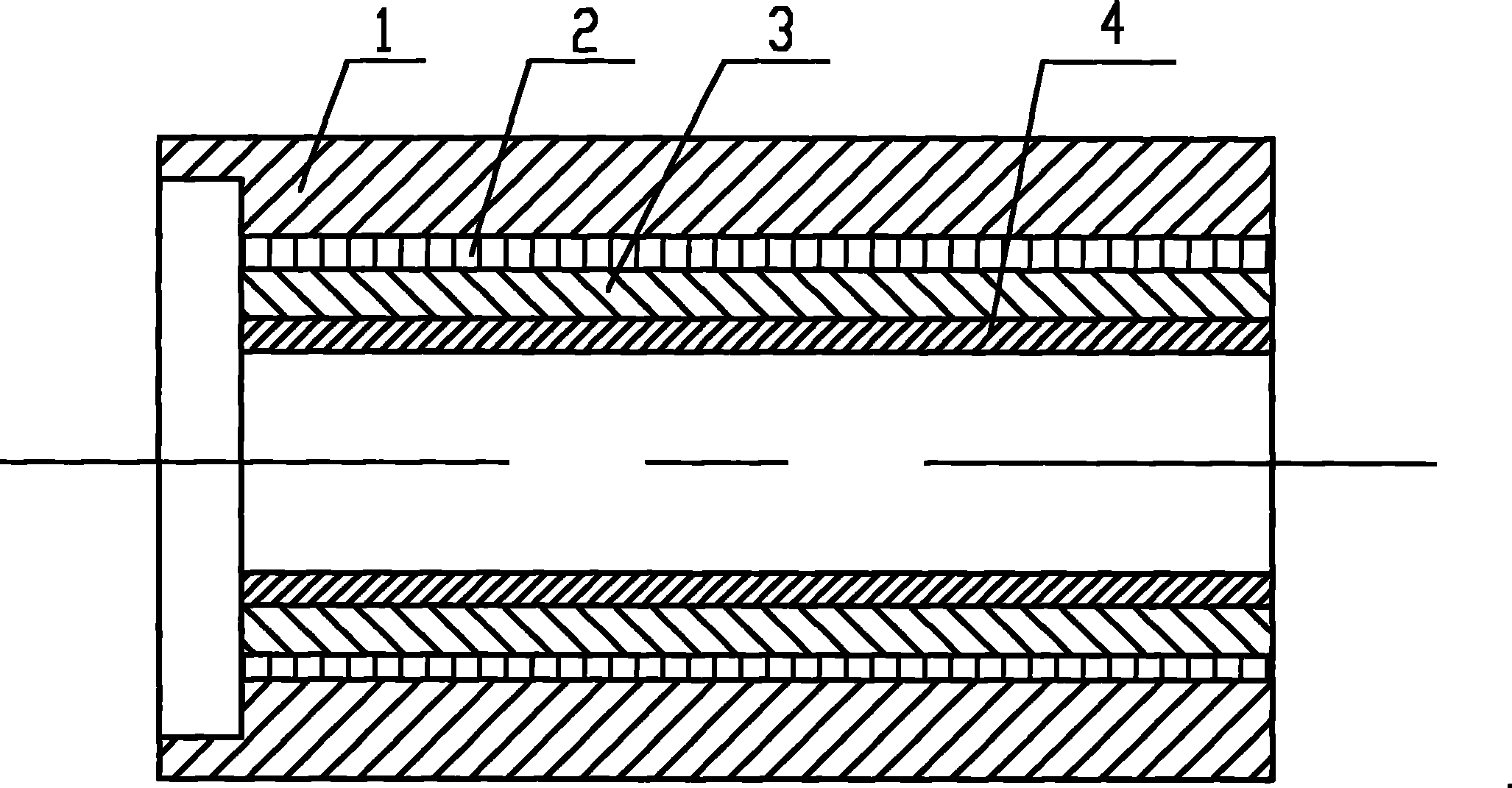

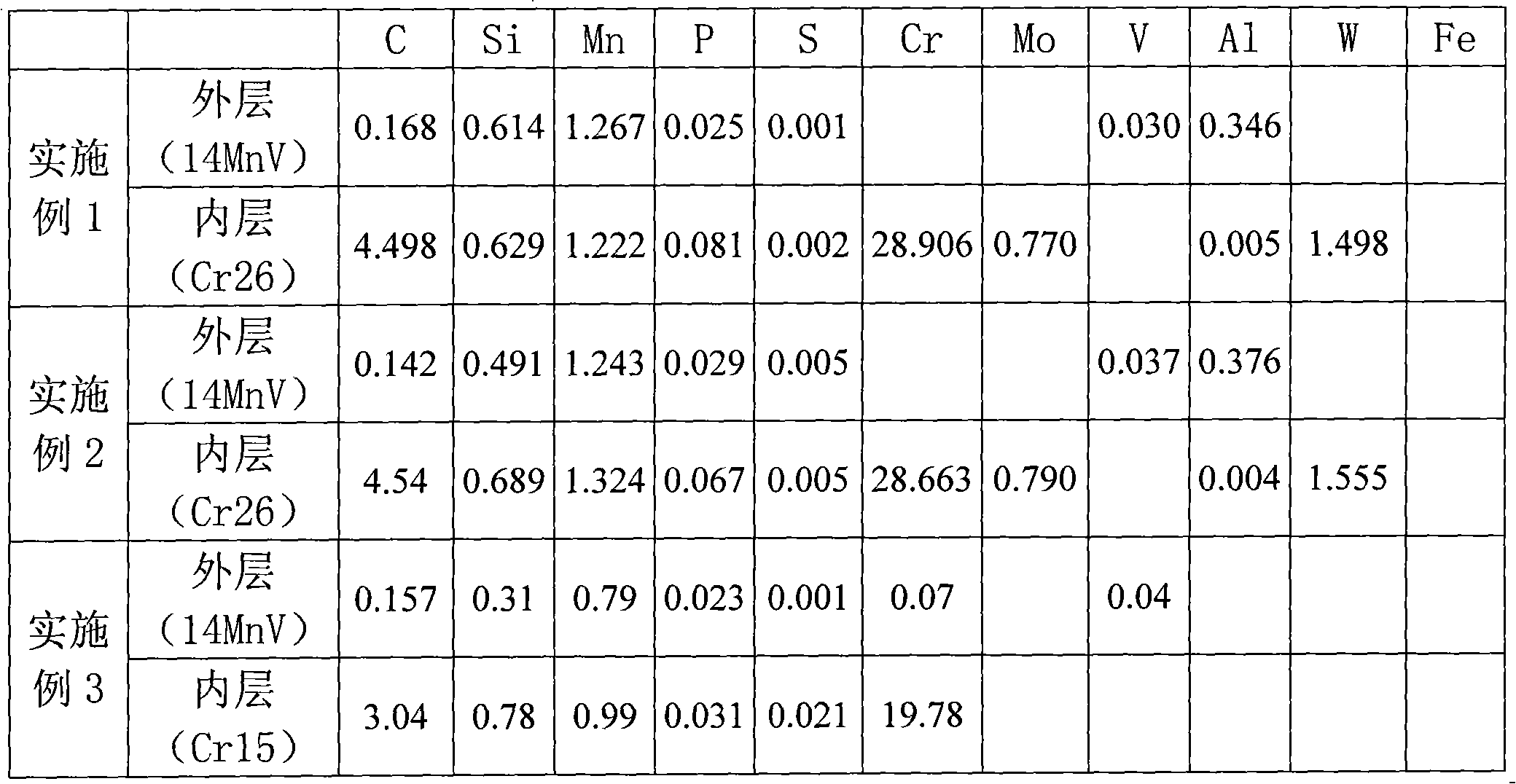

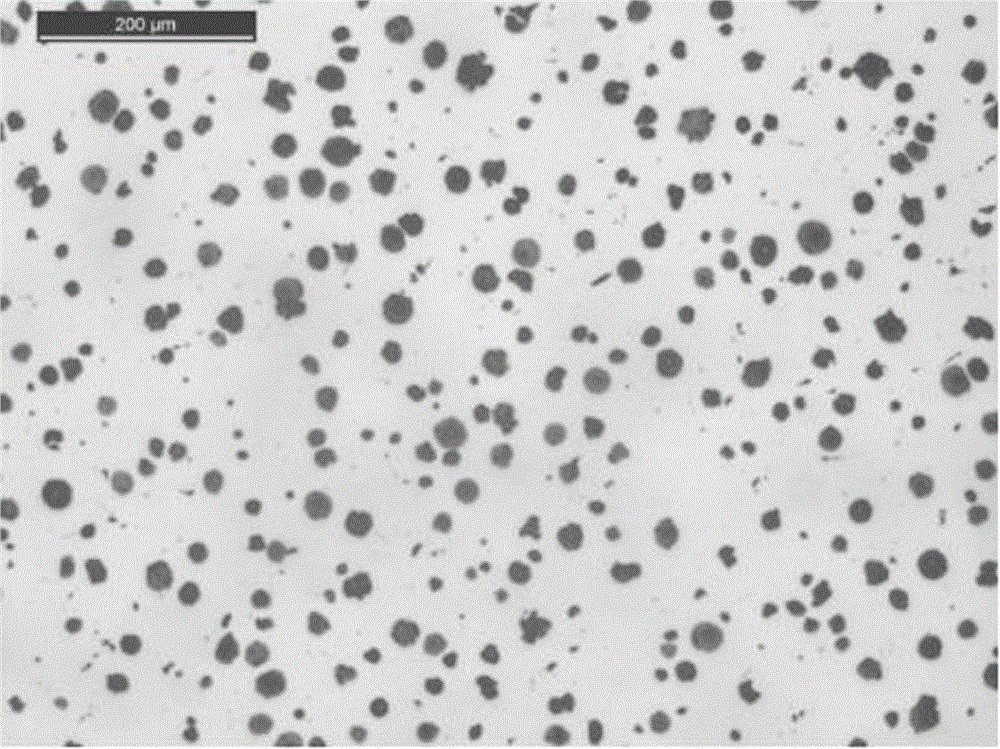

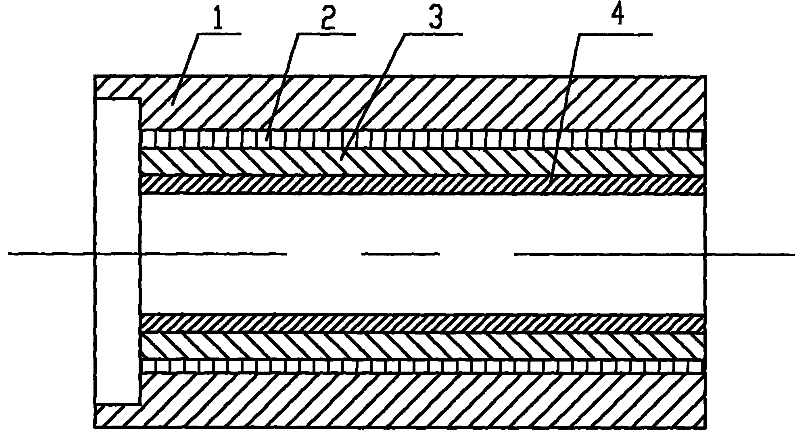

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube die after being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention also discloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method can be metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

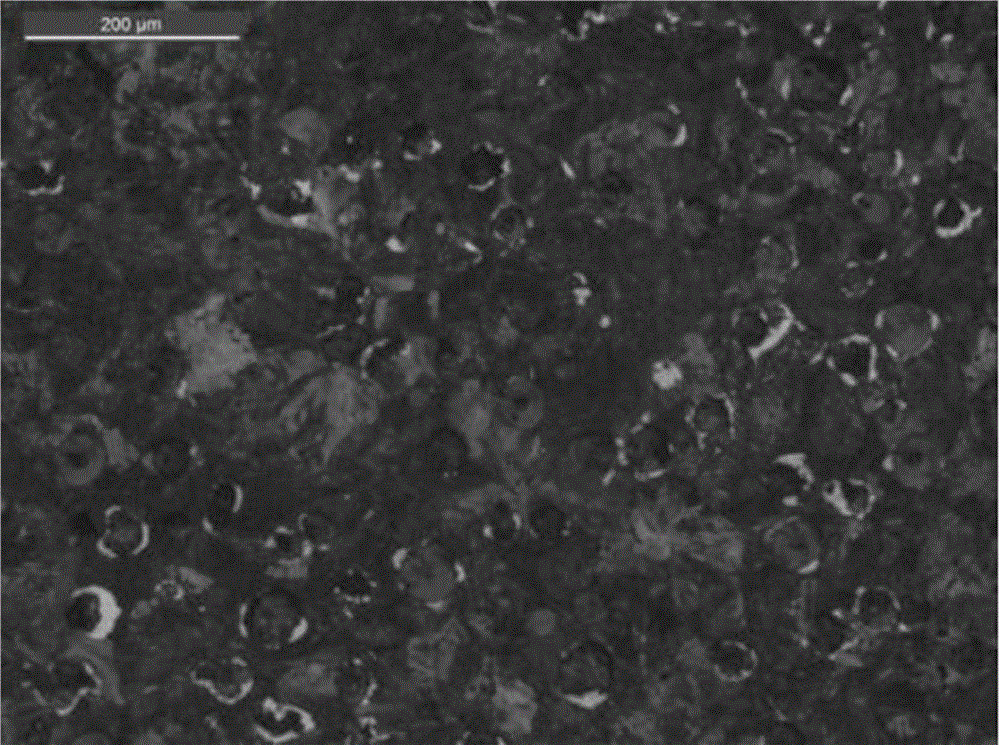

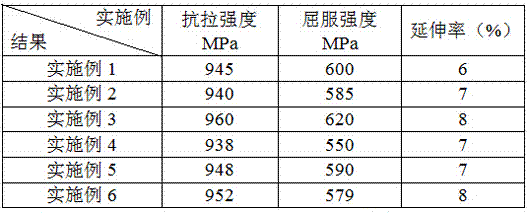

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

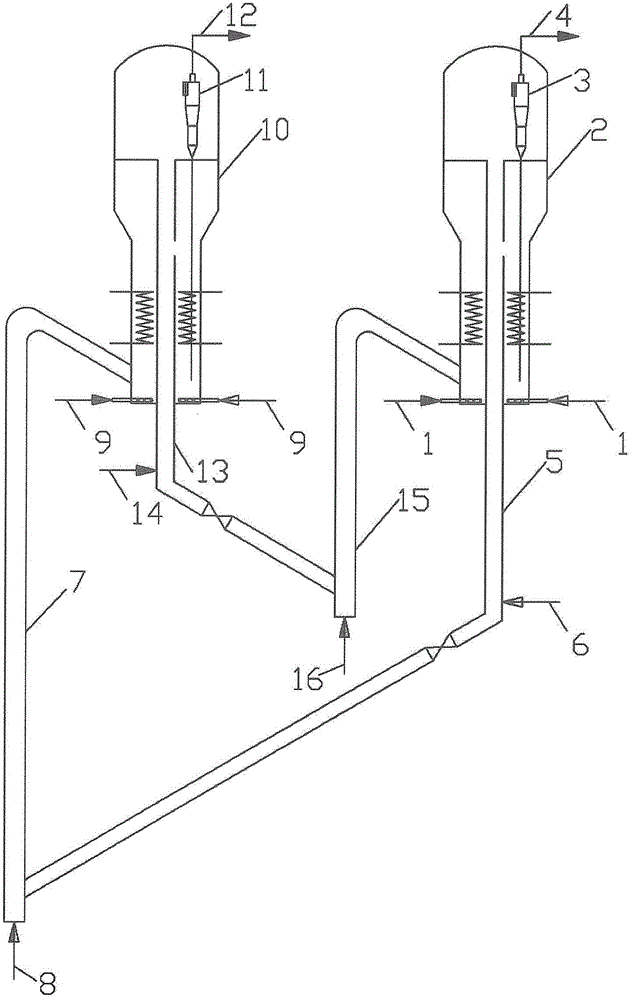

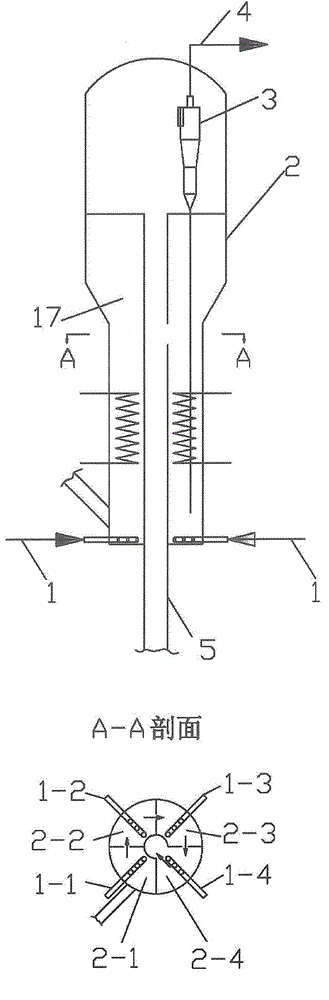

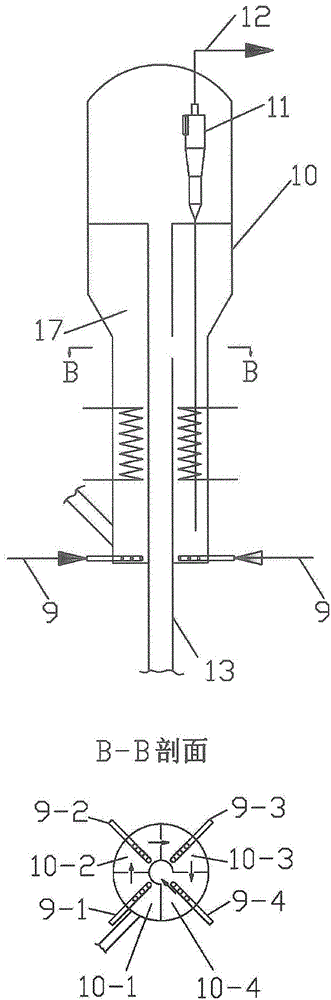

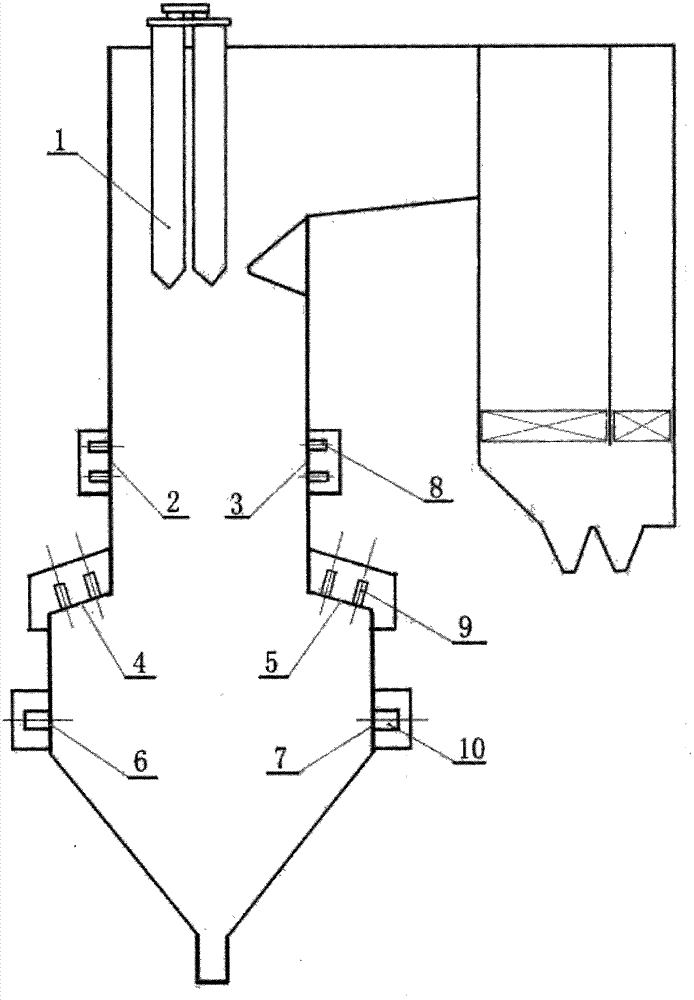

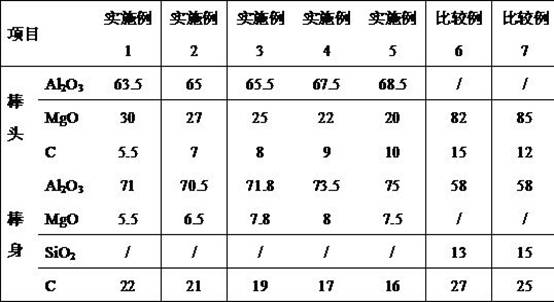

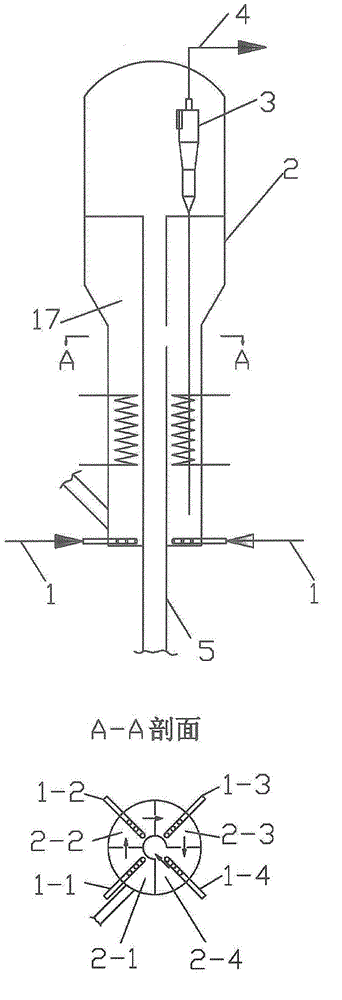

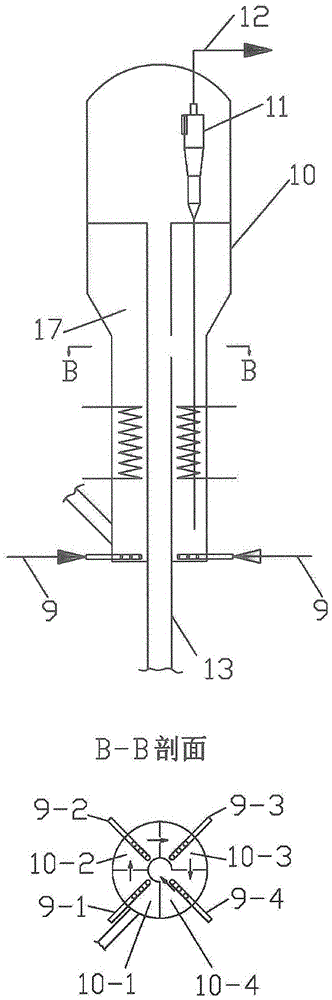

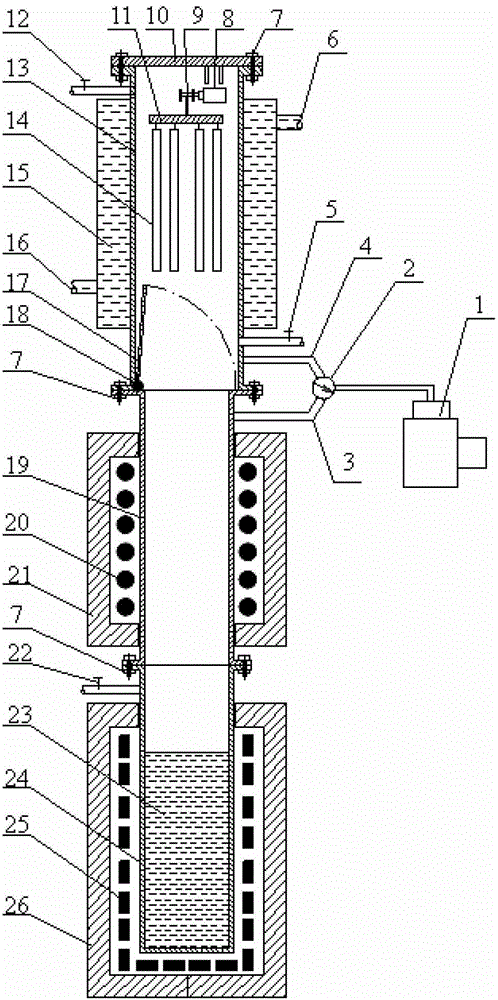

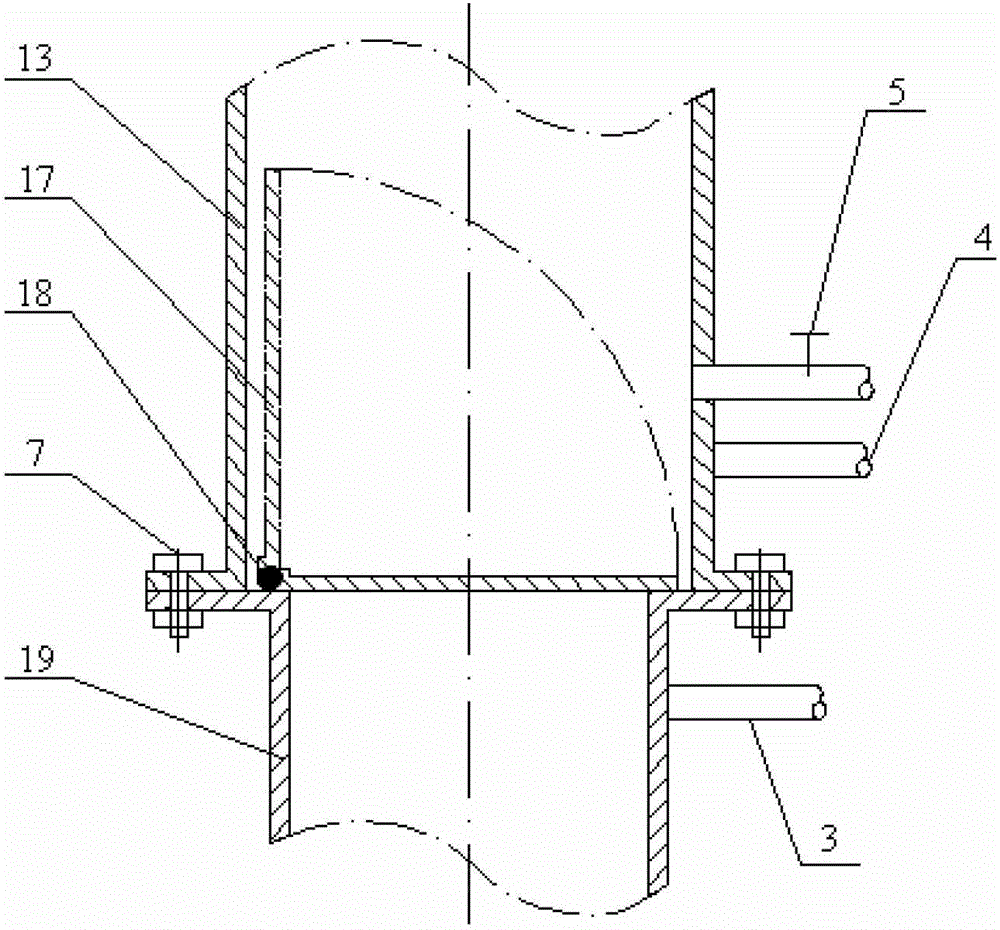

Reaction device for preparing low-carbon olefin by employing methyl alcohol and/or dimethyl ether

ActiveCN104672045AIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

Method for preparing carbon-coated lithium iron phosphate anode material of lithium ion battery

The invention relates to a method for preparing carbon-coated lithium iron phosphate anode material of a lithium ion battery, which is characterized by comprising the following steps of: putting a plurality of compounds including three elements of lithium, ferrum and phosphor and citric acid complexing agent in water to form sol; adding ethylene glycol combustion-supporting agent and ammonium nitrate oxidizing agent for dissolution; heating and boiling down to obtain gel; igniting the gel in air; wet-milling and mixing an intermediate obtained by combustion and a carbon source, finally, calcining in an inert atmosphere or reducing atmosphere to obtain lithium iron phosphate which is carbon-coated lithium iron phosphate since the outer layer of the prepared lithium iron phosphate is coated with a layer of carbon. The method not only utilizes the advantages of a sol-gel method, which mixes materials with even molecular level, but also overcomes the problems of the sol-gel method, in which all parts of the gel have uneven water loss during drying and sever expansion in calcination and the content of product carbon is difficult to control. The carbon-coated lithium iron phosphate prepared by the method has excellent large and small multiplying power performance, especially has excellent super-large multiplying power performance, and excellent cycle performance.

Owner:SOUTH CHINA UNIV OF TECH

Coarse grain hard alloy material and preparation method thereof

The invention discloses a coarse grain hard alloy material and a preparation method thereof. The coarse grain hard alloy material is characterized in that high-carbon WC (wolfram carbide) of 6.0-10.0 microns is adopted, and a total carbon content of WC is controlled to a mass percentage of 6.13 wt%-(1-9)%*mass percentage content of Co, meanwhile, 0.4-1.0 wt% of nano-TiC is added. By utilizing free carbon distributed in the high-carbon WC in situ and nano-TiC dispersed nearby the high-carbon WC as dual inducer, a (0001) basal plane of WC grain in the hard alloy is preferentially grown in a sintering process. According to the preparation method of the coarse grain hard alloy material provided by the invention, independence on the crude particle WC raw materials can be avoided, the process is simple to control, the coarse grain hard alloy with good intensity, hardness and wear resistance is obtained by preferential growth of the WC grain, and the preparation method can be used in the field of geological and mining tools, wear-resistant parts and the like.

Owner:SICHUAN UNIV

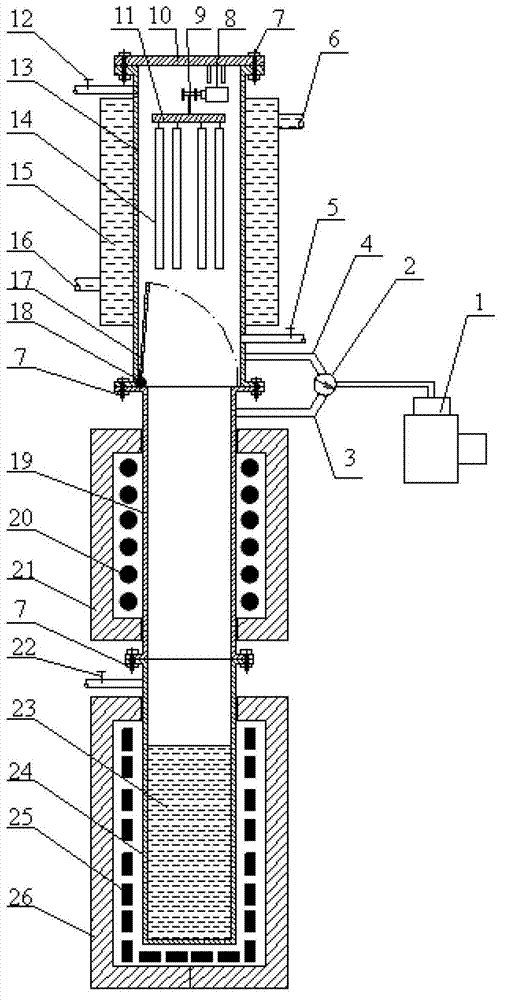

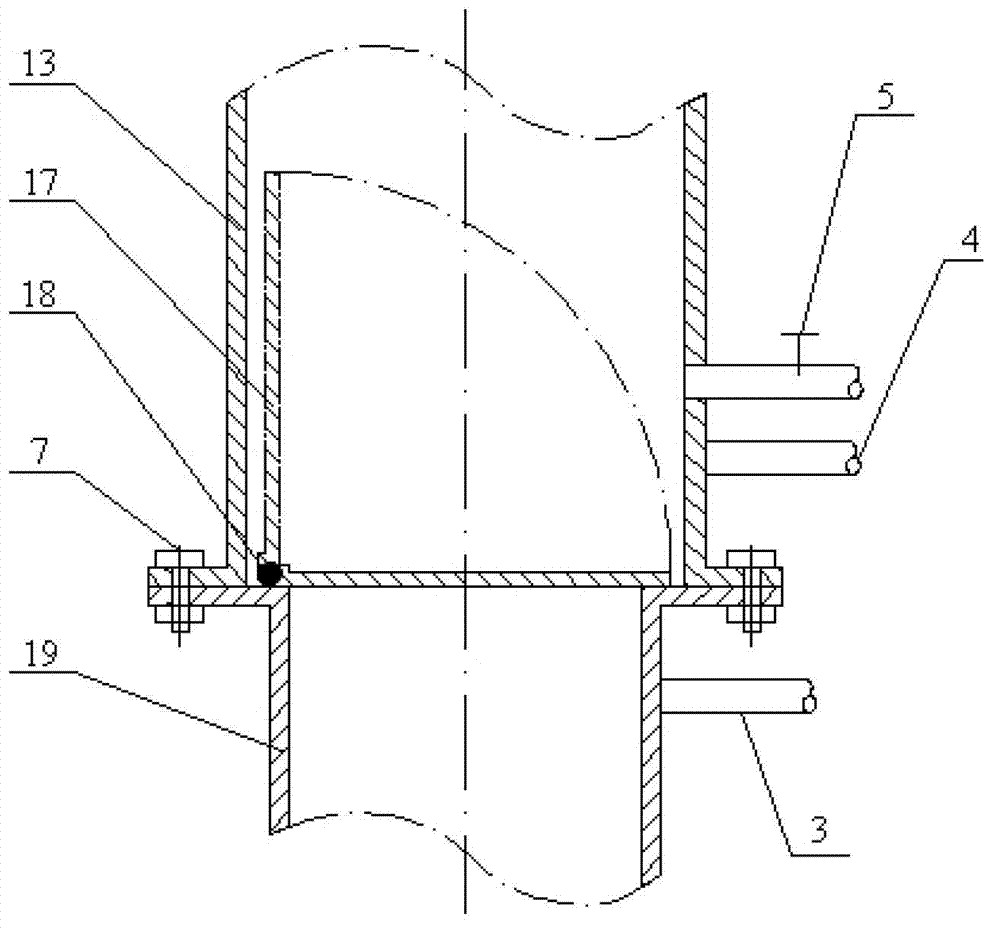

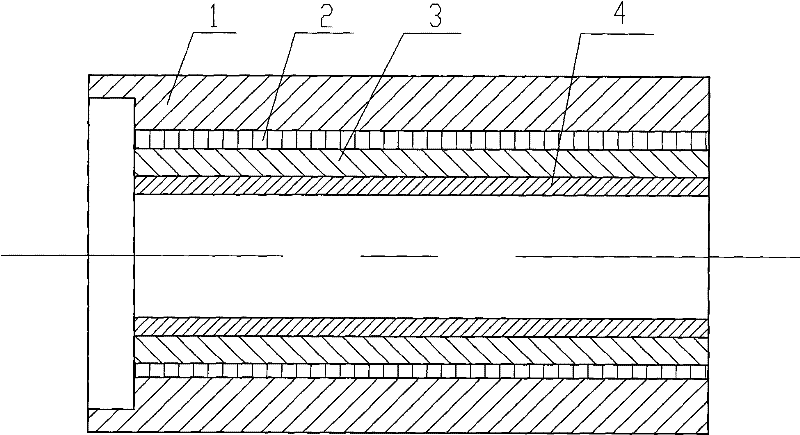

Method and device for vacuum hot dip aluminum or aluminum alloy plating for metal workpiece

InactiveCN103243286AReduce gasImprove the interface binding forceHot-dipping/immersion processesInlet valveConductor Coil

The invention discloses a method and a device for vacuum hot dip aluminum or aluminum alloy plating for a metal workpiece, which can effectively prolong the service life of the metal workpiece. The method comprises the following steps of: loading, vacuumizing for furnace sweeping, carrying out metal workpiece reduction, melting molten aluminum, carrying out hot dip aluminum or aluminum alloy plating, cooling the metal workpiece and taking out the metal workpiece. The device comprises a vacuum pump, a reversing valve, a reduction furnace exhaust pipe, a cooling furnace exhaust pipe, an inlet valve, a cooling water outlet, connection bolts, a winding motor, a steel wire rope, a feeding mechanism, a charging tray, an upper vent valve, a cooling furnace, a cooling wall, a cooling water inlet, a sealing valve cover, a driving rotation shaft, a reduction furnace, a heating element, a reduction furnace insulating layer, a lower vent valve, molten aluminum, an aluminum melting furnace, a heater and an molten aluminum melting furnace insulating layer. By the method and the device provided by the invention, the defect of plating omission can be removed, and the dip plating speed is increased; in the dip plating process, anti-oxidation treatment and degassing treatment can be carried out for the plating solution in vacuum condition, the defects, such as a pin hole and accretion, are eliminated, and the dip plating quality is improved.

Owner:UNIV OF SCI & TECH LIAONING

Method for synthesis of lithium iron silicate/crystallized carbon composite positive electrode material

InactiveCN104009225AHigh value-added applicationsImprove conductivityCell electrodesSecondary cellsCarbon compositesAlkali metal oxide

The invention relates to a method for synthesis of a lithium iron silicate / crystallized carbon composite positive electrode material, and belongs to the technical field of lithium ion battery. The method comprises the steps: pickling rice husks, washing, filtering and drying to obtain rice husks having alkali metal oxide impurities removed; under an oxygen-free or aerobic condition, carrying out low-temperature pyrolysis of the rice husks having the alkali metal oxide impurities removed to obtain pyrolyzed rice husks; adding the obtained pyrolyzed rice husks into a transition metal M1 precursor salt solution, and then carrying out a catalytic carbonization reaction at a high temperature to obtain a catalytic carbonized product; carrying out low temperature oxidation of the catalytic carbonized product to obtain an oxidative product; adding an iron source and a lithium source into the oxidative product, carrying out wet grinding to obtain a mixed material, and then drying the mixed material; and under an inert atmosphere, baking the dried mixed material at the temperature of 500-800 DEG C for 1-20 h, and thus obtaining the lithium iron silicate / crystallized carbon composite positive electrode material. The method improves the crystallinity of carbon in the silicate / carbon composite positive electrode material prepared from the rice husks.

Owner:KUNMING UNIV OF SCI & TECH

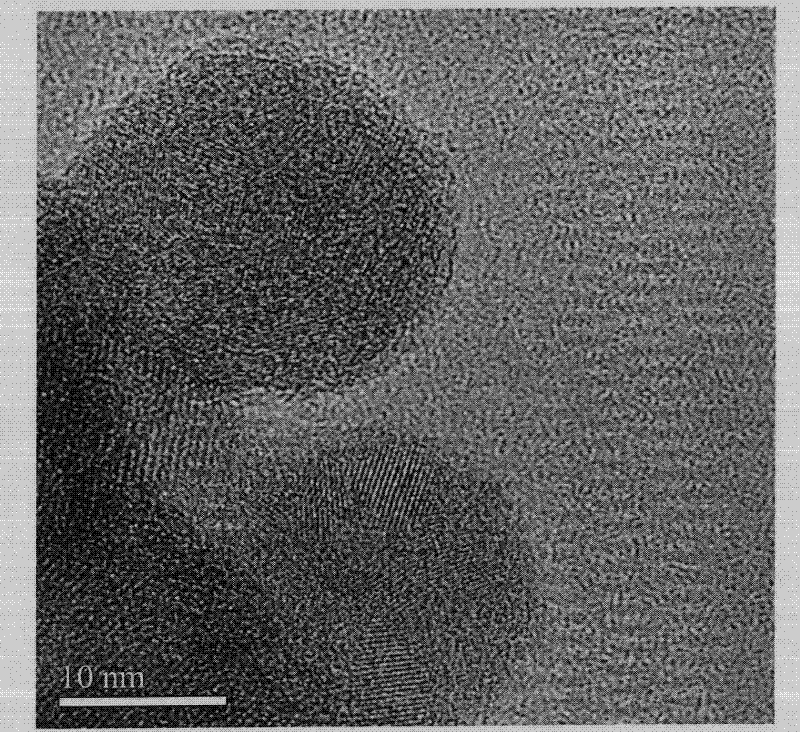

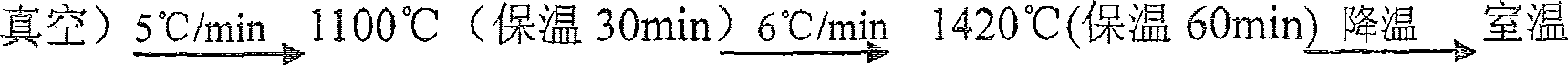

A kind of preparation method of carbon-coated Li4Ti5O12 nanometer negative electrode material

InactiveCN102299333AImprove electrochemical performanceWell mixedCell electrodesCarbon filmHigh rate

The invention discloses a preparation method of a carbon-coated Li4Ti5O12 lithium-ion battery nano negative electrode material with high rate performance. The method for preparing carbon-coated Li4Ti5O12 nanometer negative electrode material of the present invention is to use a certain amount of organolithium compound as lithium source and carbon source at the same time, and lithium source, organolithium compound and titanium source are fully mixed in a mixer according to a certain molar ratio. Mix, and then put the mixture into a sintering furnace for sintering under an inert atmosphere. The technical method of the invention has the advantages of simple process, less energy consumption, short preparation cycle and easy process control. The prepared Li4Ti5O12 nano anode material has high crystallinity, the surface is covered with a dense, uniform carbon film with a thickness of about 1nm, the average particle size is about 30nm, and the high-rate electrochemical performance is excellent. They are 136.7mAh / g and 121.1mAh / g respectively, and the cycle performance is good.

Owner:上海微纳科技有限公司

As-cast high-strength high-elongation synthetic nodular cast iron and preparation method thereof

The invention relates to the field of as-cast high-strength high-elongation synthetic nodular cast iron. The invention relates to as-cast high-strength high-elongation synthetic nodular cast iron anda preparation method thereof. The nodular cast iron is characterized in that under the as-cast condition, the nodular cast iron meets performance requirements that the tensile strength Rm is larger than or equal to 700 MPa, and the percentage elongation A after fracture is larger than or equal to 10%; the matrix is a pearlite-ferrite mixed matrix; the content of pearlite is 55%-75%, a spheroidizing grade is 1-2, a graphite size grade is 6-7, the nodular cast iron is composed of elements, by mass, 3.5%-3.7% of C, 2.9-3.3% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% ofP, less than or equal to 0.02% of S, 0.5%-0.7% of Cu, 0.55%-0.75% of Ni, 0.030%-0.065% of Mg and the balance of Fe and trace elements. The method has the beneficial effects that scrap steel and raw material pure iron are adopted for recarburization, base iron is smelted in a medium-frequency induction furnace, then pretreatment, spheroidizing treatment and inoculation treatment are conducted, final pouring is conducted, and QT700-10 is achieved under the as-cast condition.

Owner:湖北三环铸造股份有限公司

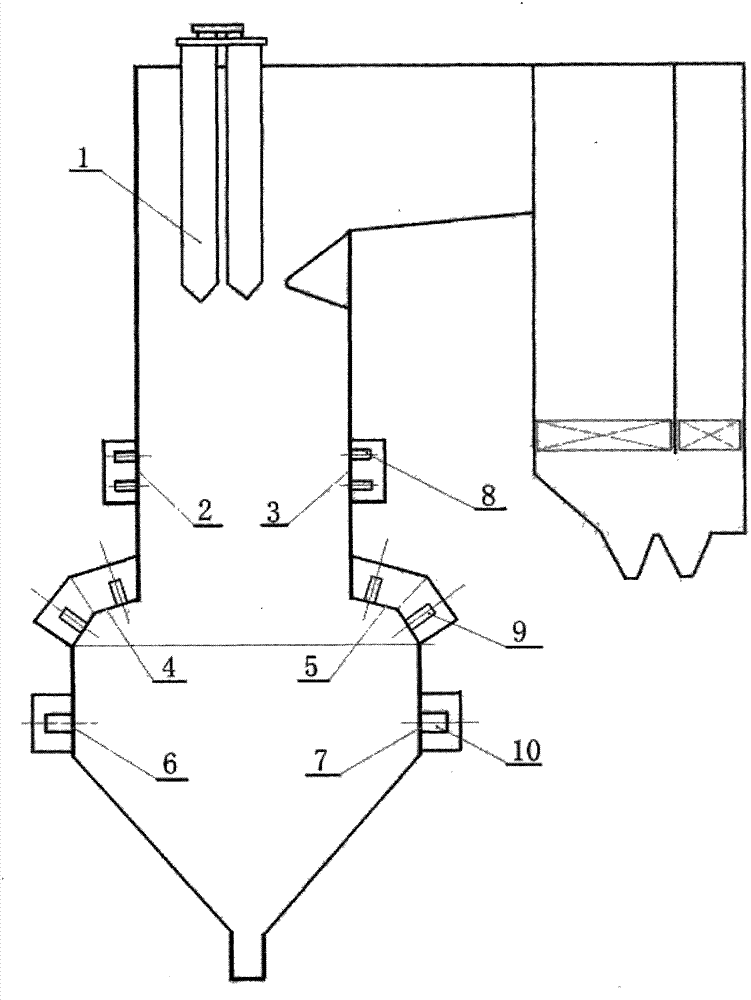

Half-W-shaped flame burning supercritical power station boiler

ActiveCN103115353AReduced thermal deviation on the furnace sideWater Cycle Reliability ImprovementsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPower station

The invention discloses a half-W-shaped flame burning supercritical power station boiler, and relates to a power station boiler which is used in a thermal power station, burns anthracites or low volatile lean coals, has a supercritical steam condition. The half-W-shaped flame burning supercritical power station boiler comprises a lower hearth with a front arch and a rear arch, the front arch and the rear arch of the lower hearth are respectively provided with two rows of weak vortex burners, and the slightly lower parts of a front wall and a rear wall of the lower hearth are respectively provided with one line of dual register burners. One layer or two layers of separated secondary air nozzles are arranged at the parts of front wall and rear wall of the upper hearth, which are away from the bottom of a platen superheater by 8m-12m. Each row of burners is arranged uniformly along the furnace width. According to the half-W-shaped flame burning supercritical power station boiler, the furnace side thermal deviation of the lower hearth water-wall tube is reduced significantly, the water circulation reliability is improved significantly, the Nox generation amount is decreased significantly, and the half-W-shaped flame burning supercritical power station boiler can adopt a less-oil or oil-free pulverized coal ignition technology easily, can be easily in large scale and can be used for designing and manufacturing the supercritical power station boiler which is in 1000MW level and burns anthracites or low volatile lean coals.

Owner:章礼道

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube dieafter being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention alsodiscloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method canbe metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

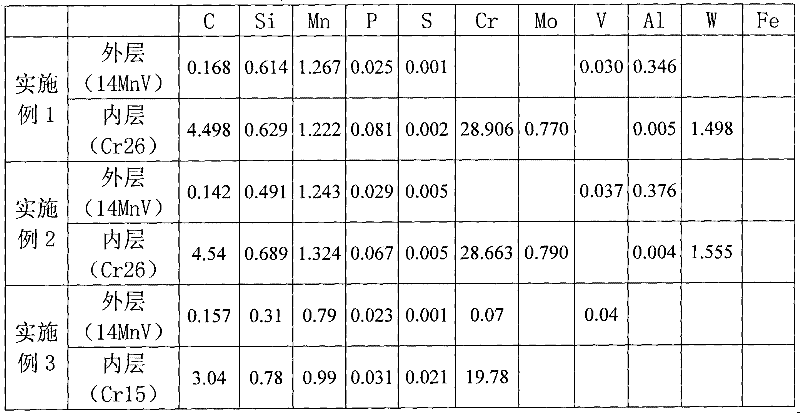

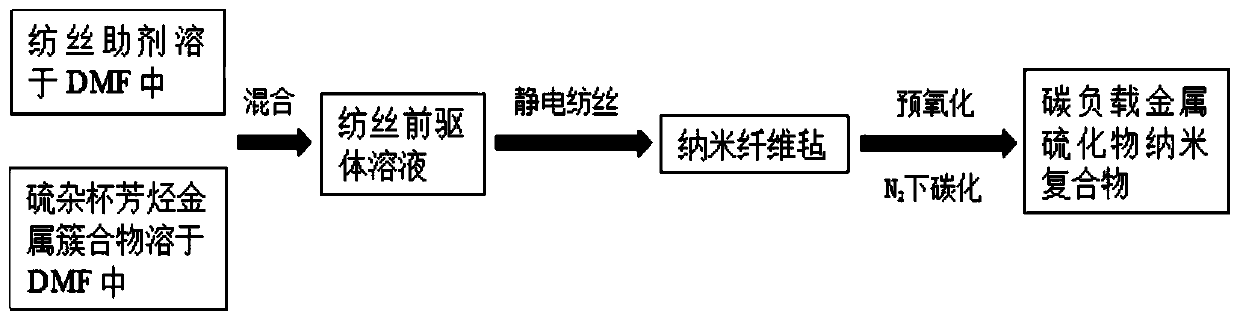

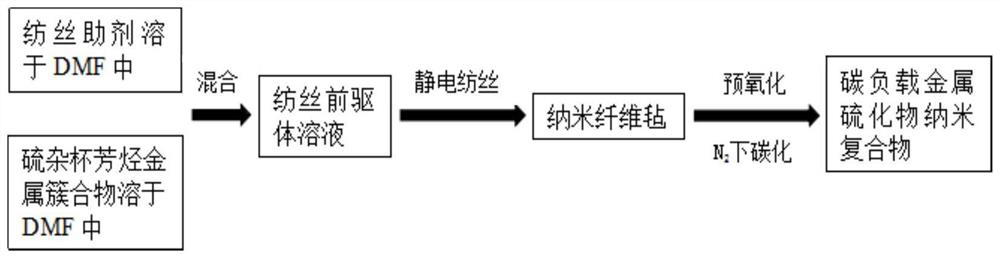

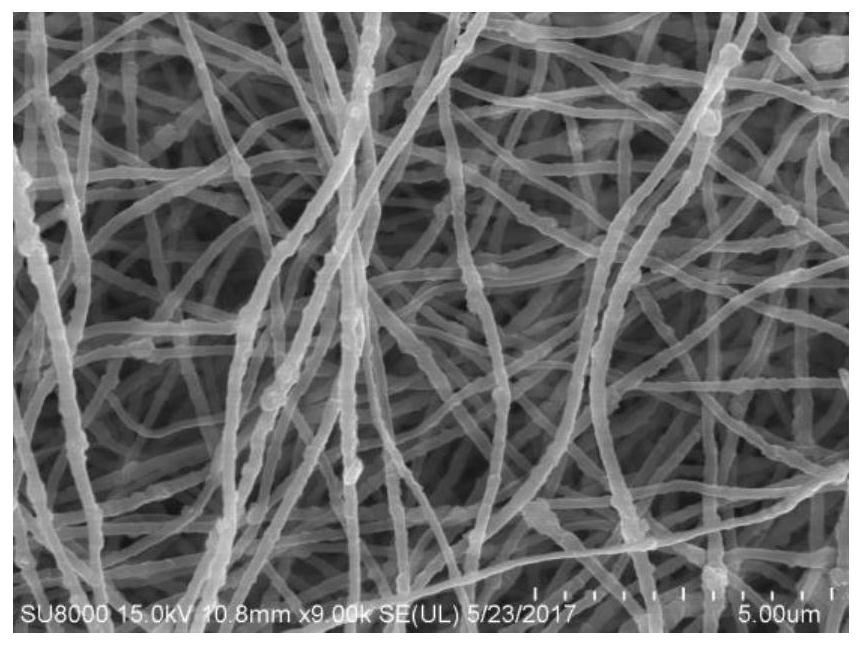

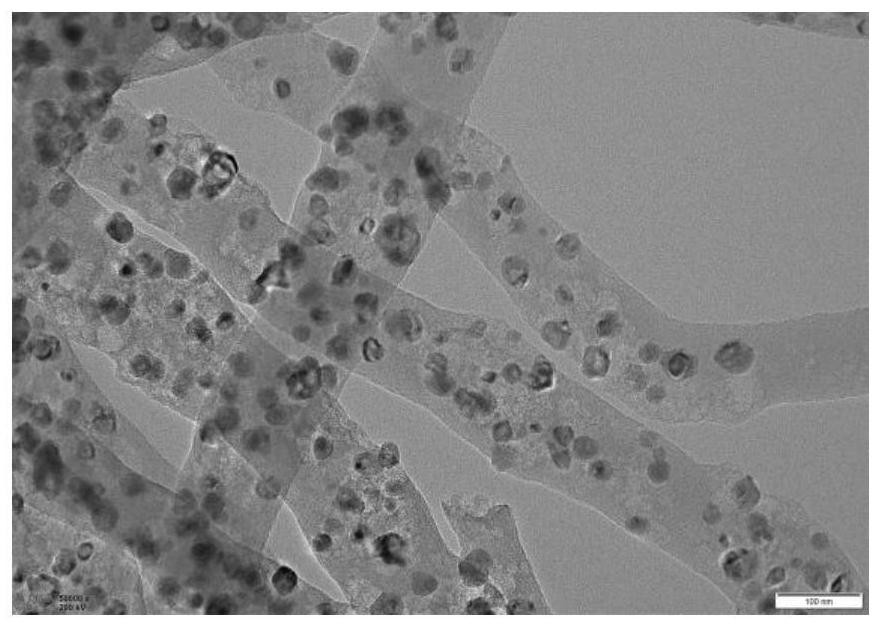

Method for preparing carbon-loaded metal sulfide nanocomposite through electrostatic spinning

ActiveCN109817936AImprove electrochemical performanceGood capacitance characteristicsCell electrodesCapacitanceFiber

The invention belongs to the field of metal sulfide nano-materials, and particularly relates to a method for preparing a carbon-loaded metal sulfide nanocomposite through electrostatic spinning, whichcomprises the following steps: (1) preparing a spinning precursor solution: respectively dissolving a thiacalixarene metal cluster compound and a spinning aid in DMF (Dimethyl Formamide), and mixing;(2) preparing nano-fibers by electrostatic spinning: sucking the obtained spinning precursor solution into an injector, adjusting the pump flow rate and voltage of the injector and the distance between a spinning needle and a receiving plate, spinning, and receiving a nano-fiber felt by the receiving plate; (3) pre-oxidizing the nano-fiber felt: pre-oxidizing the collected nano-fiber felt; and (4) carbonizing in an N2 atmosphere: carbonizing the pre-oxidized nano-fiber felt, and naturally cooling to obtain the target product. The target product is ideal in electrochemical performance and goodin capacitance characteristic, the flaky carbon material is directly used as an electrode, additives or impurities such as a binding agent can be eliminated, and the energy capacity and performance are improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

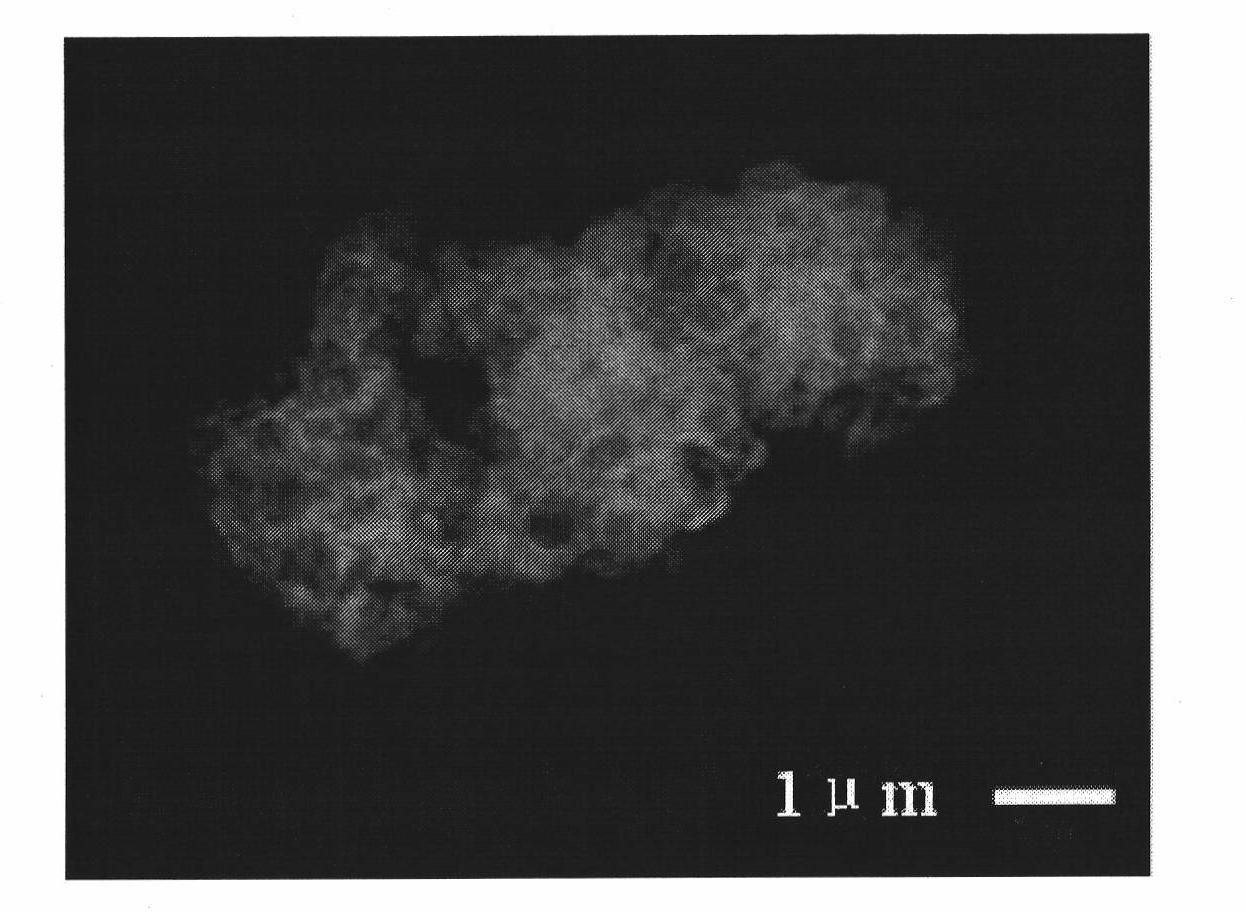

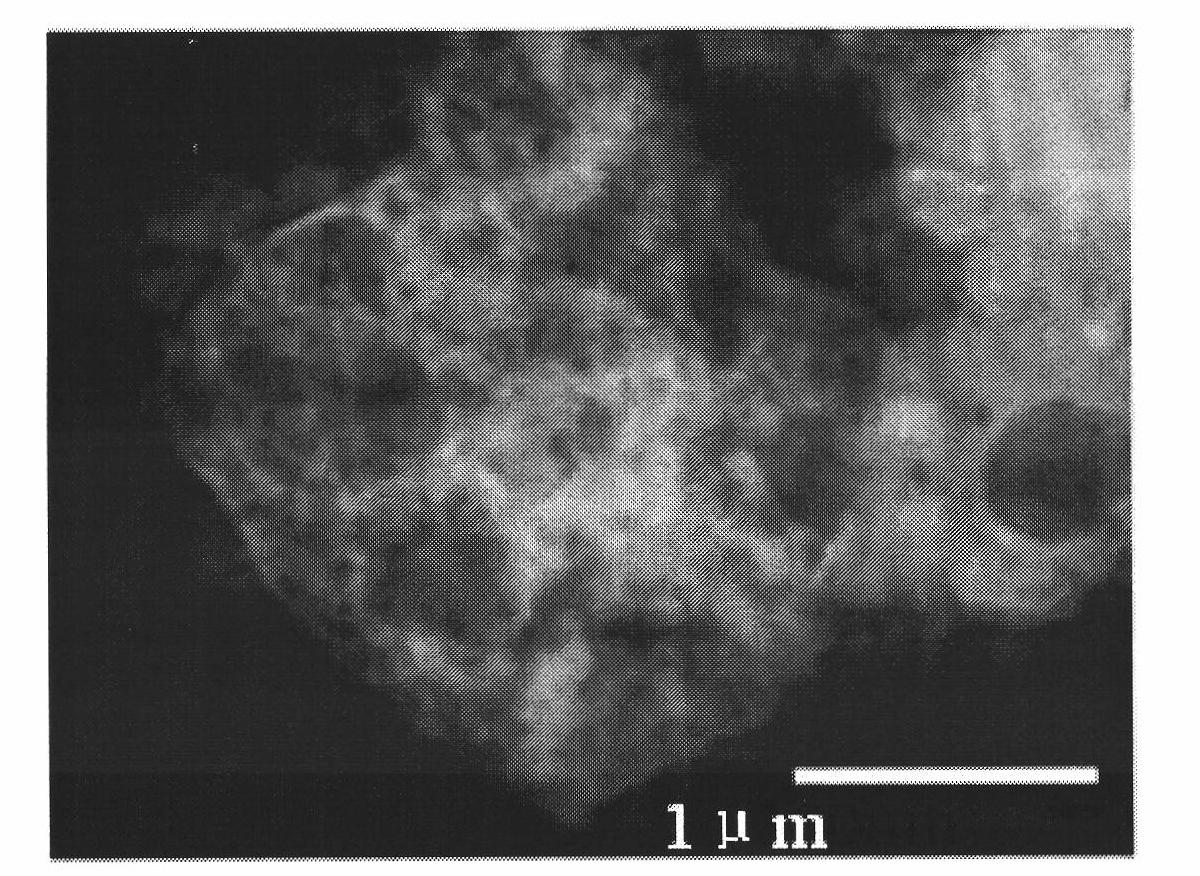

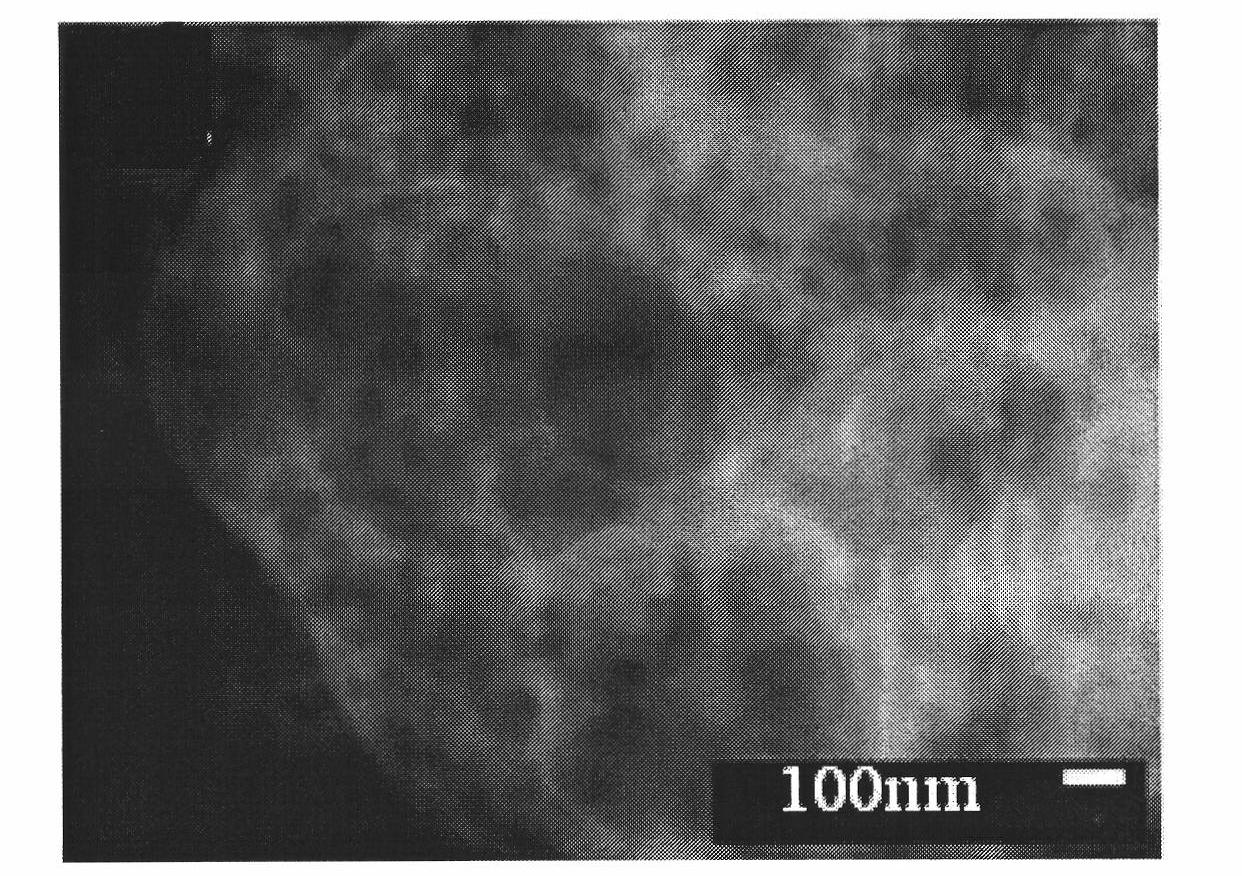

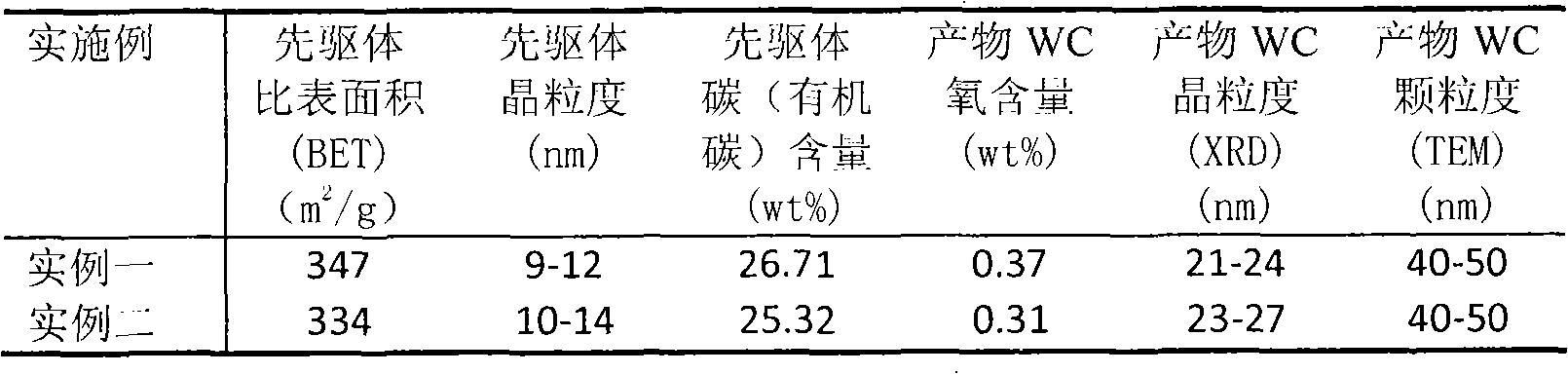

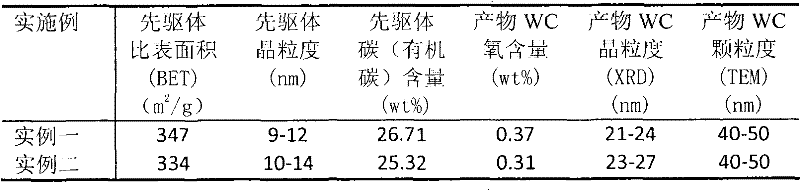

Liquid-state alkane back flow method for preparing nanometer tungsten carbide

InactiveCN101857228AHigh reactivitySmall grain sizeTungsten/molybdenum carbideAlkaneEnergy conservation

The invention relates to a method for preparing nanometer tungsten carbide powder from liquid-state alkane through back flow carbon covering. Sodium tungstate is used as a tungsten source, and a liquid-state alkane mixture (C11 to C16) is used as a carbon source. The invention has the sequential process steps of material preparation, back flow, drying, material charging, high-temperature heat treatment and sampling. The back flow time and the back flow temperature of raw materials are controlled, precursor powder with different carbon contents can be prepared, and high-purity nanometer tungsten carbide powder can be prepared through the heat treatment process. The tungsten carbide powder prepared by the method has the average granularity between 30 and 60 nm and the average grain fineness number between 20 and 30 nm. The method of the invention has simple process and lower cost. Compared with an ordinary heat reducing method, the invention saves energy sources, and can easily realize the scale preparation.

Owner:SICHUAN UNIV

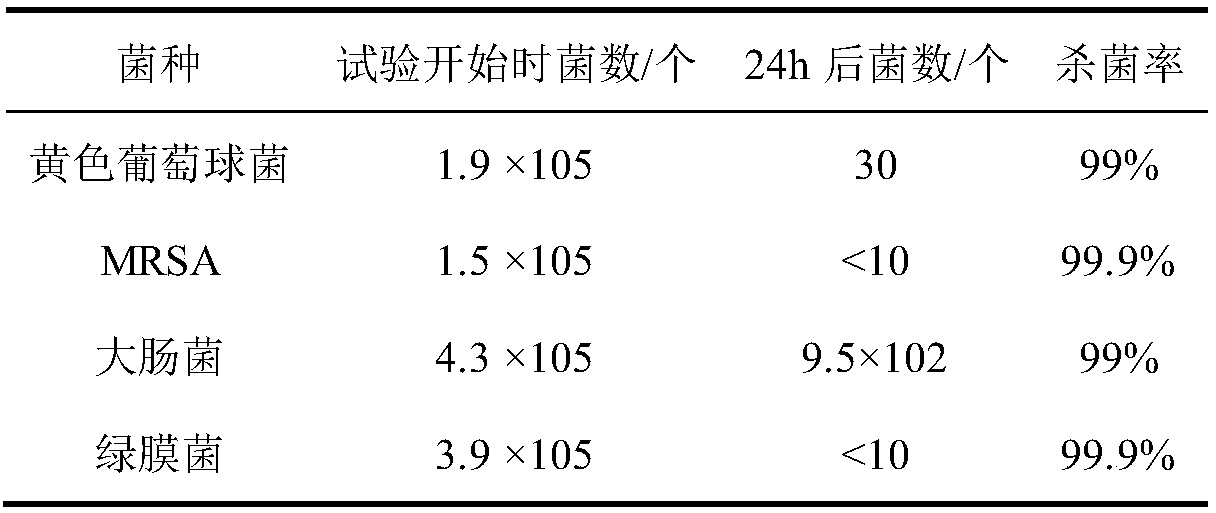

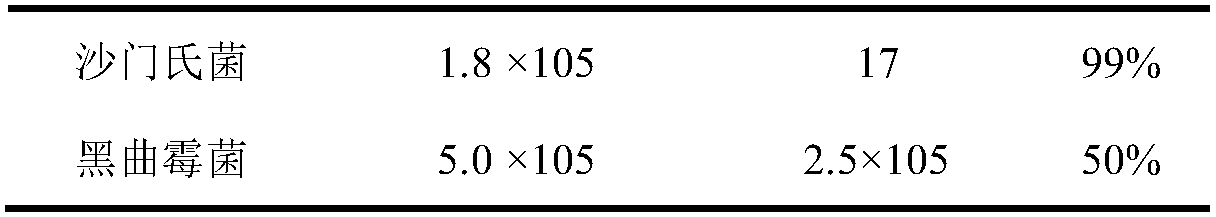

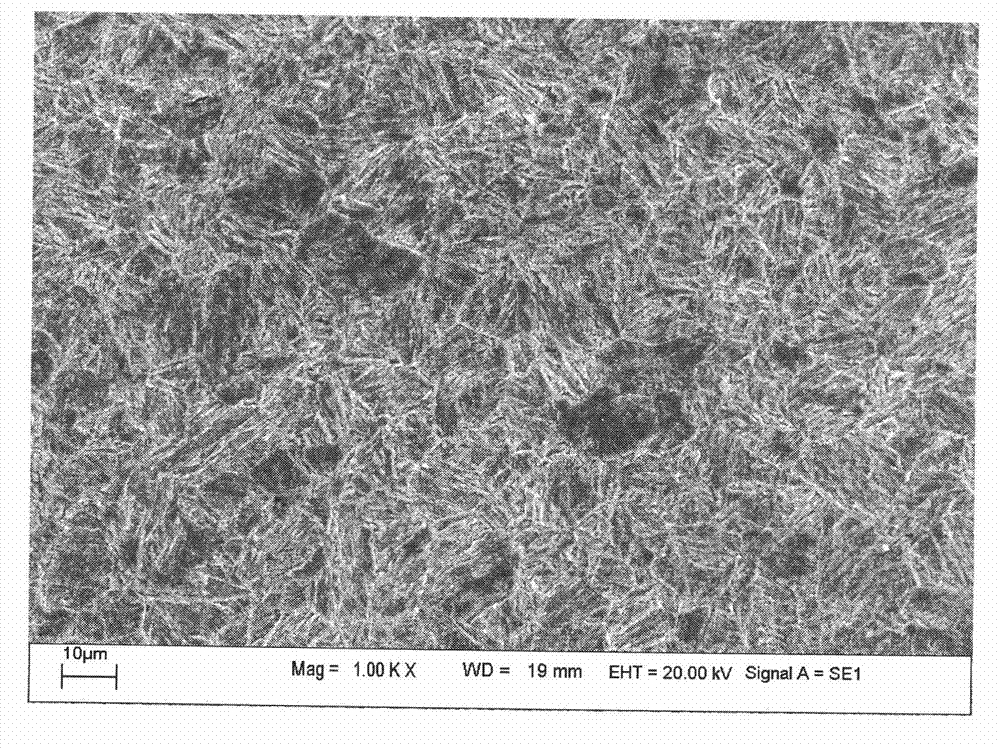

Hot-rolled 430 ferrite antibacterial stainless steel and preparation method thereof

InactiveCN109457185AHigh kill rateReduce the deterioration of corrosion resistanceProcess efficiency improvementMetallic materialsSS - Stainless steel

The invention provides hot-rolled 430 ferrite antibacterial stainless steel and a preparation method thereof and belongs to the field of metal materials. The hot-rolled 430 ferrite antibacterial stainless steel comprises less than or equal to 0.01% of C, less than or equal to 0.75% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S, 16-18% of Cr, less than or equal to 0.6% of Ni, 1.8-2.5% of Cu, and the balance Fe and impurities. The preparation method comprises the following steps of smelting, continuous casting, hot rolling and antibacterial annealing. By adding a certain content of copper into hot-rolled 430 ferrite stainless steel and through antibacterial annealing heat treatment, enough copper big enough is precipitated, and itis ensured that a certain quantity of copper ions can be released in the using process, so that a hot-rolled plate has the antibacterial performance and has the escherichia coli and staphylococcus aureus killing rate reaching up to 99%. Since the precipitated copper is uniformly distributed in the hot-rolled plate, the antibacterial performance cannot disappear along with abrasion to the material. The stainless steel is protected against corrosion resistant performance deterioration caused by long-time antibacterial annealing by controlling the carbon content. The stainless steel provided bythe invention has the advantages of the lasting antibacterial performance, wide antibacterial range and good mechanical performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

Semi-W flame combustion subcritical steam pocket furnace

InactiveCN104132322ALow investment costLow running costCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenHearth

The invention discloses a semi-W flame combustion subcritical steam pocket furnace, and relates to a low-nitrogen transformation method of a utility boiler which combusts anthracite or low-volatile-matter meager coal and has the W flame combustion method with the subcritical steam parameter. The semi-W flame combustion subcritical steam pocket furnace comprises a lower hearth with a front arch and a rear arch. The front arch of the hearth and the rear arch of the hearth are respectively provided with a line of weak vortex burners. The lower middle portion of a front wall of the lower hearth and the lower middle portion of a rear wall of the lower hearth are respectively provided with two lines of dual register burners. The portion, 8 m to 12 m away from the bottom of a screen type superheater, of a front wall of an upper hearth and the portion, 8 m to 12 m away from the bottom of the screen type superheater, of a rear wall of the upper hearth are respectively provided with one or two layers of separated secondary air nozzles. In each line, the burners are evenly distributed in the width direction of the furnace. On the lowermost layer, the dual register burners are start-up burners. All dual-inlet and dual-outlet steel ball grinding outlets are matched with dynamic and static separators. By means of the semi-W flame combustion subcritical steam pocket furnace, the thermal deviation of the furnace side of a lower hearth water-cooled wall pipe is obviously reduced, and water circulation reliability is obviously improved; the NOx production volume is obvious lowered; the less-oil or oil-free coal powder ignition technology is easily adopted.

Owner:章礼道

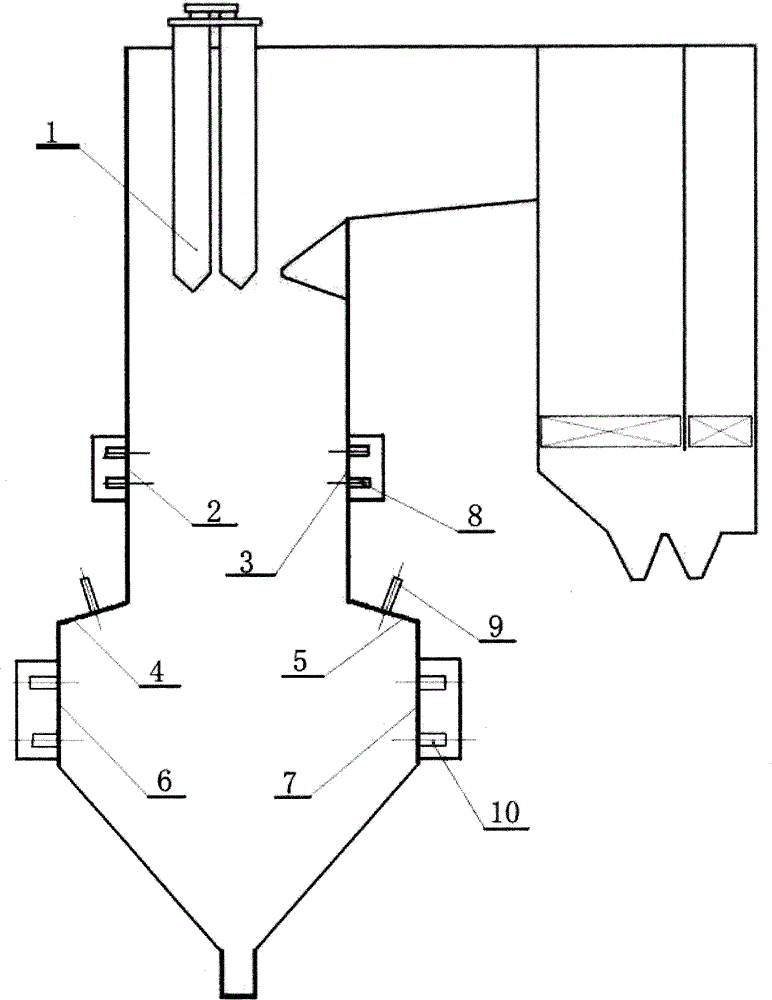

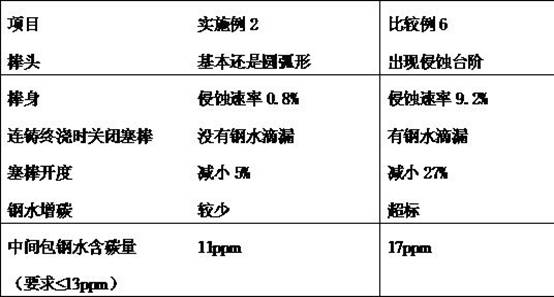

Stopper rod for continuous casting of high-oxygen steel

ActiveCN113526965AGood resistance to molten steel erosionReduce carbon increaseProcess efficiency improvementSlagMolten steel

The invention relates to a stopper rod for continuous casting of high-oxygen steel. The stopper rod comprises a rod head, a rod body and a slag line section, wherein the rod head is made of Spinel-C and comprises the following chemical components in percentage by weight: 60 to 72 percent of Al2O3, 20 to 30 percent of MgO, 5 to 10 percent of C and the balance of trace impurities, and an antioxidant and a phenolic resin binding agent are additionally added; the rod body is made of Al2O3-Spinel-C and comprises the following chemical components in percentage by weight: 70 to 80 percent of Al2O3, 5 to 10 percent of MgO, 15 to 23 percent of C and the balance of trace impurities, and an antioxidant and a phenolic resin binding agent are additionally added; and the slag line segment is made of a MgO-Spinel-C material. According to the invention, when being applied to high-oxygen steel casting, the low-melting-point phase cannot be formed, good corrosion resistance is achieved, recarburization of molten steel is reduced, and the number of continuous casting furnaces is increased.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength composite solder

InactiveCN110076476AMaterial deviation is smallImprove matchWelding/cutting media/materialsSoldering mediaSlagManganese

The invention relates to high-strength composite solder. Deposited metal formed by the solder comprises, by mass percentage, 0.04%-0.08% of carbon, 0.30%-0.50% of silicon, 4%-8% of manganese, 10%-18%of nickel, 4%-8% of chromium, 2%-4% of titanium, 0.4%-0.8% of molybdenum, 60%-70% of iron and the balance impurities, specifically, the weight ratio of the nickel to the chromium is 2-3:1. The high-strength composite solder has the high strength and the high mechanical stretch performance, is stable in performance under the high temperature condition, low in cost and few in electric arc splash, and easily achieves slag removal.

Owner:HUANGSHI GAOCHAO IND & MINING MACHINERY

A reaction device for producing light olefins from methanol and/or dimethyl ether

ActiveCN104672045BIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

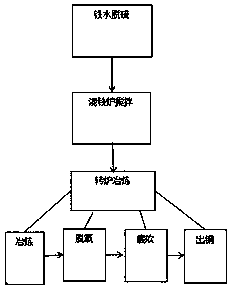

A kind of production method of low carbon and high chromium steel

The invention discloses a production method for low-carbon high-chromium steel. The production method comprises the following steps: primarily melting molten steel by adopting a converter, wherein the final tapping temperature is controlled at 1670-1690DEG C, the C content of tapping liquid steel is regulated to be 0.04-0.06wt% and the oxygen activity is regulated to be 600*10<-6> to 700*10<-6>, and ferrochrome alloy is quantitatively added according to a ratio of 40-50kg / t liquid steel in the steel tapping process; performing primary refining to the primarily molten liquid steel in a ladle refining furnace, wherein the ferrochrome alloy is added when the primary refining starts to regulate the content of Cr in the liquid steel to be 3.6-4.0wt%, and the final tapping temperature of the primary refining is controlled to be 1645-1655DEG C; carrying out decarburization treatment to the primarily refined liquid steel in an RH furnace to regulate the content of C to be 0.02% below; then carrying out secondary refining to the decarburized liquid steel in the ladle refining furnace to finally obtain the low-carbon high-chromium steel, wherein the ferrochrome alloy is added when the secondary refining starts to regulate the content of Cr in the liquid steel to be 3.8-4.2wt%, and the final tapping temperature of the secondary refining is controlled to be 1595-1605DEG C. The low-carbon high-chromium steel is obtained by adopting the method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

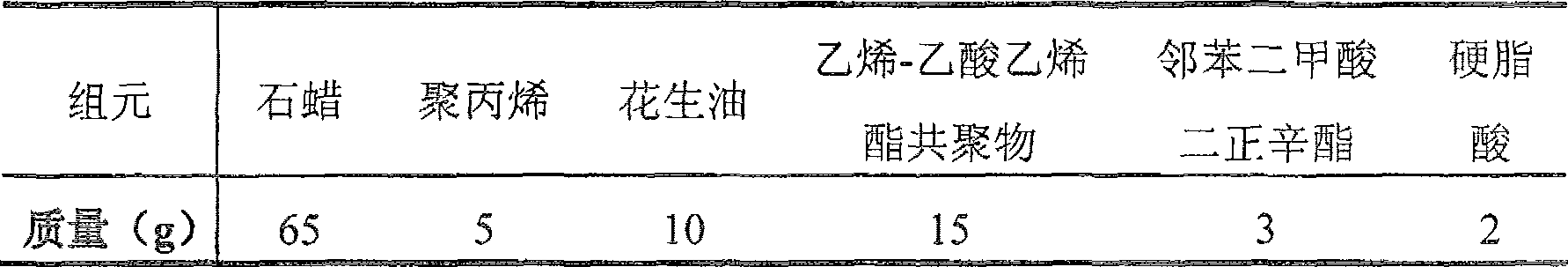

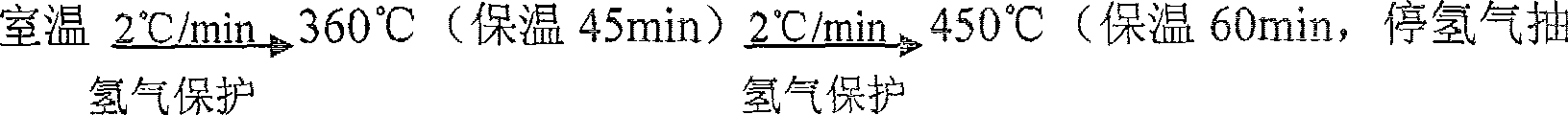

Method of producing hard alloy rotatable special-shaped blade

InactiveCN100519010CSolve the technical problem that it is impossible to directly prepare special-shaped bladesReduce subsequent processingWaxCoupling

The invention relates to a WC-Co cemented carbide indexable special-shaped blade prepared by powder injection molding, which is characterized in that WC-Co mixed powder and a wax-oil-low molecular coupling agent-high molecular polymer composition The multi-component binder is mixed to prepare a uniform feed, and the feed is injected on the injection machine to produce an indexable special-shaped blade injection blank, and the injection blank is solvent-degreased in a solvent to control the solvent degreasing rate in the range of 45% to 65%. In the end, the solvent degreasing billet is finally subjected to a one-step thermal degreasing + sintering process. The prepared indexable special-shaped insert has high mechanical properties, and its bending strength is higher than that of the alloy prepared by the ordinary molding method, which can meet the production requirements. At the same time, the size deviation of the product is within Within ±0.5%.

Owner:CENT SOUTH UNIV

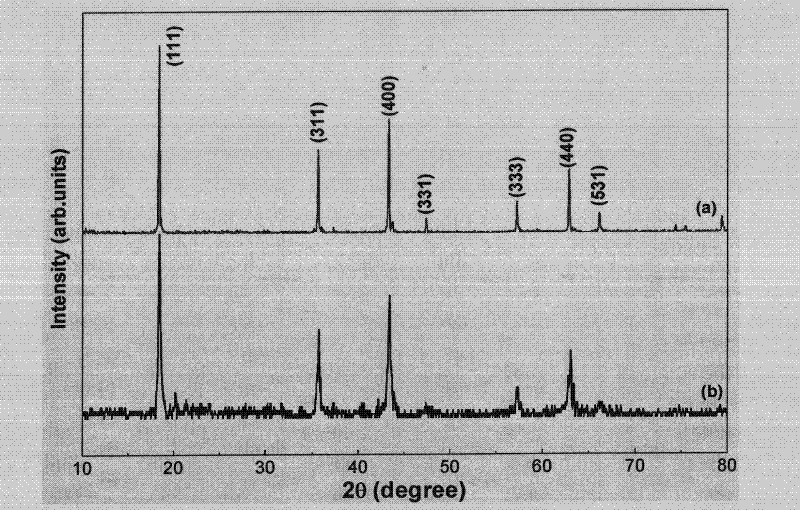

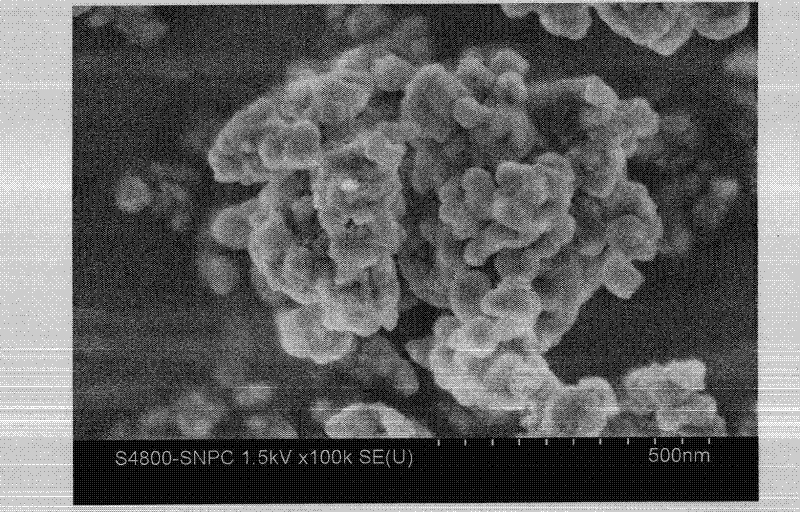

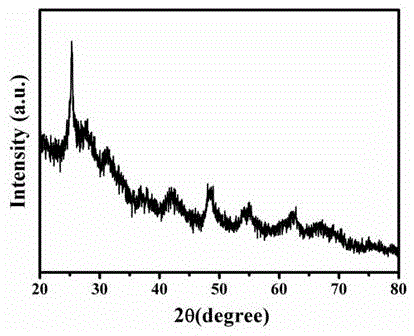

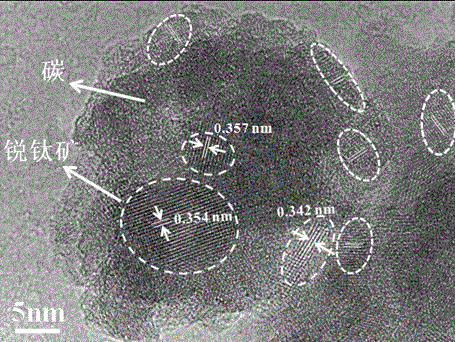

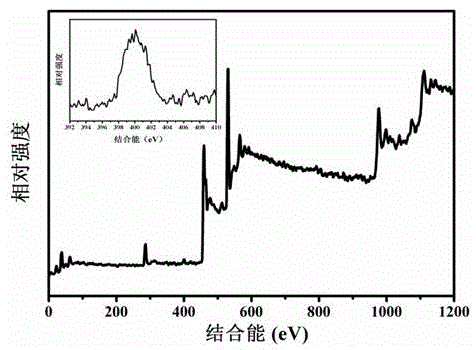

n-tio2/c and n-tio2 and preparation method thereof

InactiveCN104028292BHigh nitrogen contentVisible light photocatalytic activityCatalyst activation/preparationTetramethylammonium hydroxideTitanium tetraisopropoxide

The invention relates to N-TiO2 / C and N-TiO2 and a preparation method thereof, and specifically discloses a method for preparing nitrogen-doped titanium oxide and its nanocomposite with carbon by heat treatment in air. Its preparation method includes the following steps: (1) Mix 10wt% tetramethylammonium hydroxide aqueous solution with ethylene glycol, add titanium isopropoxide, stir well, and heat the obtained solution at 200°C for 8 hours; (2) Mix the step ( 1) The obtained hydrothermal product is centrifuged and washed in ethanol and deionized water, and dried in air at 70°C; (3) The dried product in step (2) is heat-treated in air at 250-550°C for 2 hours, that is A nitrogen-doped titanium oxide / carbon nanocomposite or nitrogen-doped titanium oxide is obtained. The nitrogen-doped titanium oxide / carbon nanocomposite and the nitrogen-doped titanium oxide obtained by the invention have the advantages of high nitrogen content, extended absorption spectrum to the light region, visible light photocatalytic activity and the like. The adopted preparation method has the advantages of simplicity, high safety factor, low cost and the like.

Owner:ZHEJIANG UNIV

A kind of high-strength ductile iron Qt900-6 and preparation method thereof

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

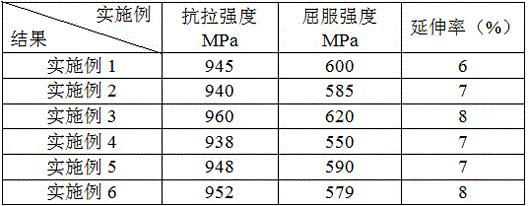

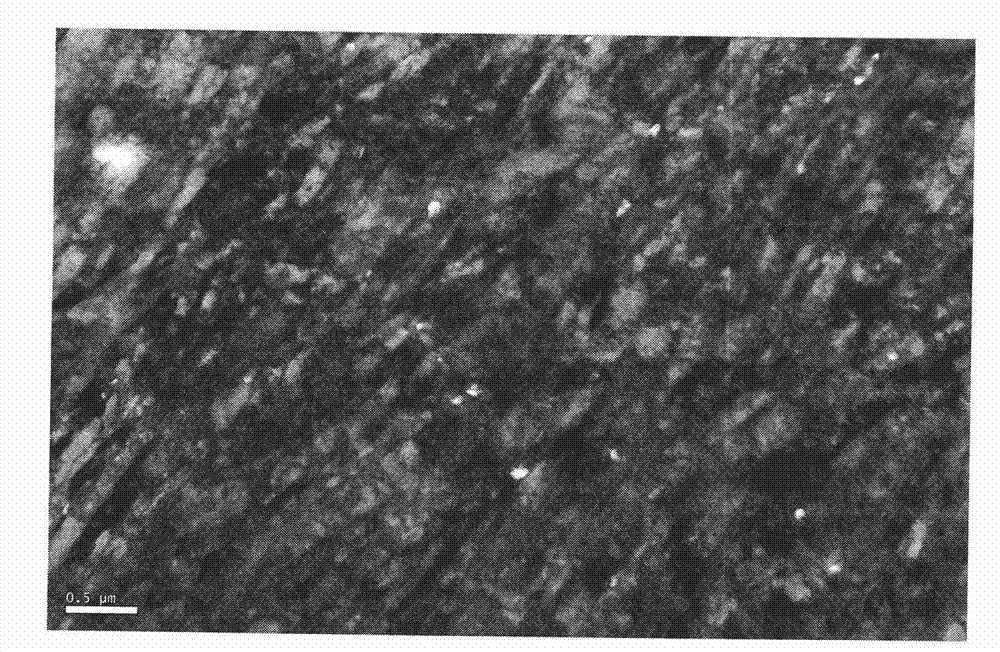

Bainite steel plate with high elongation, high strength and low carbon and production method thereof

InactiveCN101942616BReduce the amount addedControl carbon contentTemperature control deviceFurnace typesChemical compositionSheet steel

The invention discloses a bainite steel plate with high elongation, high strength and low carbon and a production method thereof. The production method can produce the steel plates with high elongation, high strength and good low-temperature toughness and welding performance, wherein the elongation is more than or equal to 20% and the yield strength is more than or equal to 1100 MPa. The steel plate comprises the following chemical compositions in percentage by mass: 0.06-0.18% of C, 0.55-1.7% of Si, 1.1-1.7% of Mn, more than or equal to 0.007% of P, more than or equal to 0.006% of S, more than or equal to 0.0040% of N, 0.02-0.06% of Nb, 0.25-0.4% of Mo, 0.01-0.02% of Ti, 0.3-0.5% of Cr, 0.3-0.8% of Ni, 0.3-0.8% of Cu, 0.025-0.05% of V, and 0.0005-0.0015% of B, optionally 0.015-0.02% of ALs, and the balance Fe and inevitable impurities. The microstructure of the steel plate is a multiphase structure and contains bainite structure, martensite structure, a small amount of residual austenite structure and carbide with dispersedly distributed Nb, V, Ti and others elements at the same time. The method for producing the bainite steel plate with high elongation, high strength and low carbon comprises the following steps of preparation of materials, converter or smelting in electric furnace, external refining, continuous casting, reheating of slabs, controlled rolling, controlled cooling, and heat treatment.

Owner:UNIV OF SCI & TECH BEIJING

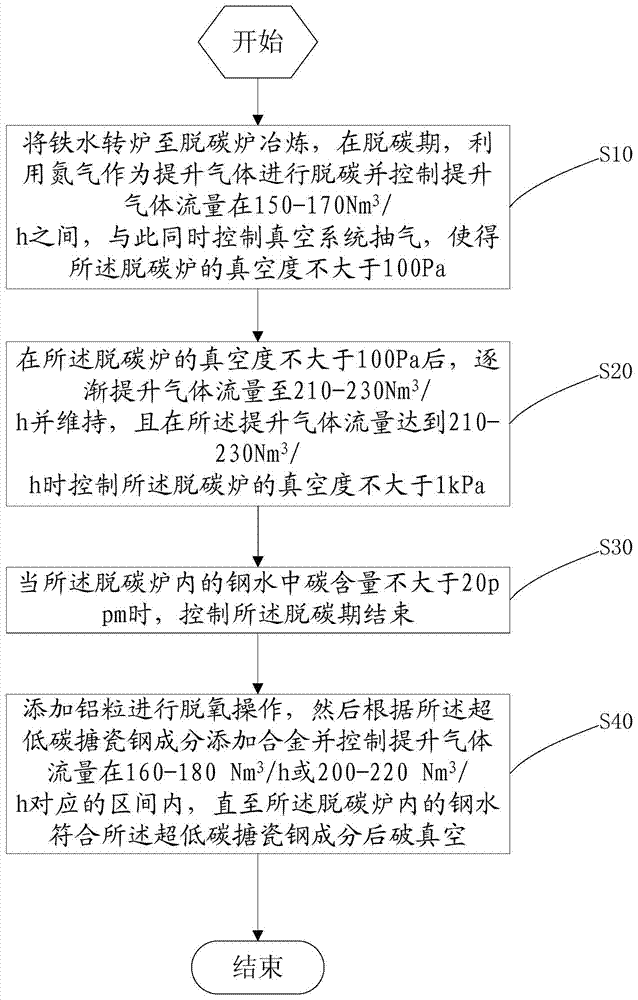

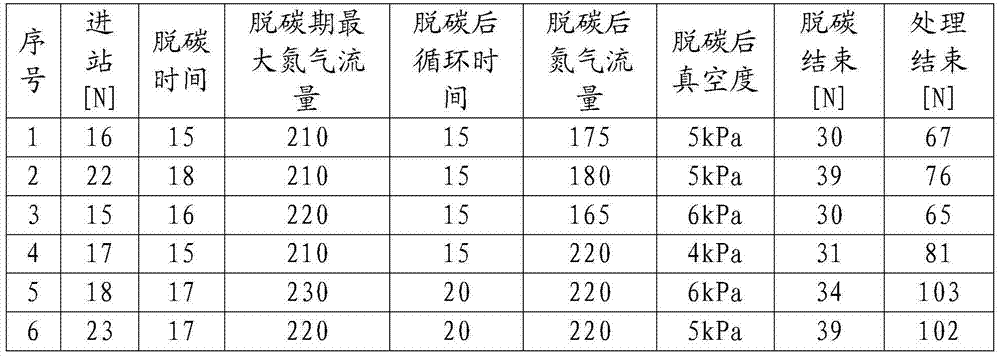

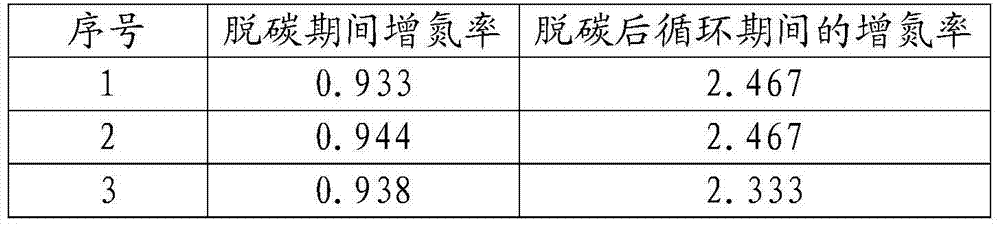

Nitrogen-increasing method for molten steel of ultra-low carbon enamel steel

ActiveCN103911490BControl nitrogen contentControlled Nitrogen Boosting Nitrogen Content in Decarburization and Deoxidation ProcessesNitrogenLifting gas

The invention belongs to the technical field of ferrous metallurgy, and particularly relates to a method for adding nitrogen to ultra-low carbon enamel molten steel. The method comprises the following steps: decarbonizing by utilizing nitrogen as a lift gas while controlling the flow of the lift gas at 150-170Nm<3> / h, and exhausting, so that the vacuum degree of a decarburization furnace is not greater than 100Pa; gradually lifting the flow of the lift gas to 210-230Nm<3> / h, and finishing the decarburization stage until the carbon content in the molten steel is not greater than 20ppm, wherein the vacuum degree of the decarburization furnace is not greater than 1kPa; carrying out a deoxidation operation; adding alloy and controlling the flow of the lift gas in an interval corresponding to 160-180Nm<3> / h or 200-220Nm<3> / h; breaking vacuum until the molten steel accords with the ultra-low carbon enamel molten steel ingredient. Nitrogen is added in decarburization by controlling the flow of the lift gas of nitrogen, the vacuum degree and the decarburization time of the decarburization furnace in the decarburization and deoxidation processes, so that the nitrogen content of a finished product can be accurately controlled, use of alloy is reduced, and the cost is reduced.

Owner:SHOUGANG CORPORATION

Method for preparing carbon-supported metal sulfide nanocomposites by electrospinning

ActiveCN109817936BImprove electrochemical performanceGood capacitance characteristicsCell electrodesCapacitancePolymer science

The invention belongs to the field of metal sulfide nanomaterials, and particularly relates to a method for preparing carbon-loaded metal sulfide nanocomposites by electrospinning, including (1) preparing a spinning precursor solution: mixing thiacalixarene metal clusters and Spinning aids were dissolved in DMF and mixed together; (2) Preparation of nanofibers by electrospinning: Inhale the obtained spinning precursor solution into the syringe, adjust the flow rate and voltage of the syringe pump, and the distance between the spinning needle and the receiving plate , for spinning, accepting the nanofiber mat with a receiving plate; (3) pre-oxidizing the nanofiber mat: pre-oxidizing the collected nanofiber mat; (4) N 2 Carbonization under atmosphere: Carbonize the pre-oxidized nanofiber mat, and then cool down naturally to obtain the target product. The target product of the present invention has ideal electrochemical performance and good capacitance characteristics. The sheet carbon material is directly used as an electrode, which can eliminate additives or impurities such as binders and improve energy capacity and performance.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Process for increasing sulfur recovery rate in steel smelting

InactiveCN109097520AIncrease profitControl carbon contentManufacturing convertersSulfurOxygen content

The invention relates to the field of steel smelting production processes, in particular to a process for increasing sulfur recovery rate in steel smelting. The process comprises steps of molten irondesulphurization, metal mixer mixing and converter smelting. With the adoption of the converter steel making process, oxygen content can be controlled effectively by controlling carbon content and final temperature of a converter, and sulfur using rate is increased.

Owner:江阴市茂昌金属新材料科技有限公司

A method and device for vacuum hot-dip aluminum or aluminum alloy plating on metal workpieces

InactiveCN103243286BReduce gasImprove the interface binding forceHot-dipping/immersion processesInlet valveAluminum metal

The invention discloses a method and a device for vacuum hot dip aluminum or aluminum alloy plating for a metal workpiece, which can effectively prolong the service life of the metal workpiece. The method comprises the following steps of: loading, vacuumizing for furnace sweeping, carrying out metal workpiece reduction, melting molten aluminum, carrying out hot dip aluminum or aluminum alloy plating, cooling the metal workpiece and taking out the metal workpiece. The device comprises a vacuum pump, a reversing valve, a reduction furnace exhaust pipe, a cooling furnace exhaust pipe, an inlet valve, a cooling water outlet, connection bolts, a winding motor, a steel wire rope, a feeding mechanism, a charging tray, an upper vent valve, a cooling furnace, a cooling wall, a cooling water inlet, a sealing valve cover, a driving rotation shaft, a reduction furnace, a heating element, a reduction furnace insulating layer, a lower vent valve, molten aluminum, an aluminum melting furnace, a heater and an molten aluminum melting furnace insulating layer. By the method and the device provided by the invention, the defect of plating omission can be removed, and the dip plating speed is increased; in the dip plating process, anti-oxidation treatment and degassing treatment can be carried out for the plating solution in vacuum condition, the defects, such as a pin hole and accretion, are eliminated, and the dip plating quality is improved.

Owner:UNIV OF SCI & TECH LIAONING

Liquid-state alkane back flow method for preparing nanometer tungsten carbide

InactiveCN101857228BHigh reactivitySmall grain sizeTungsten/molybdenum carbideAlkaneEnergy conservation

Owner:SICHUAN UNIV

Coarse grain hard alloy material and preparation method thereof

The invention discloses a coarse-grain cemented carbide material and a preparation method thereof, which is characterized in that high-carbon WC of 6.0-10.0 μm is used and the total carbon content of WC is controlled at 6.13wt%-(1-9)%*Co mass percentage, while adding 0.4-1.0wt% nano-TiC. The free carbon distributed in situ in high-carbon WC and nano-TiC dispersed near high-carbon WC are used as dual inducers to make the (0001) basal plane of WC grains in cemented carbide grow preferentially during sintering. The preparation method of the coarse-grained cemented carbide material of the present invention can avoid dependence on coarse-grained WC raw materials, the process control is simple, and the coarse-grained cemented carbide with good strength, hardness and wear resistance is obtained by utilizing the preferential growth of WC grains , can be used in geological and mining tools, wear-resistant parts and other fields.

Owner:SICHUAN UNIV

Manufacturing method of ultrahard wear-proof honing stone

The invention provides a manufacturing method of ultrahard wear-proof honing stone. The manufacturing method particularly comprises the steps of raw material melting and mixing, electron beam purification, breaking treatment, mixing treatment and sinter molding. Compared with the prior art, the method has the benefits that aluminum oxide, ferrochrome and ferrotungsten are broken to form high fineness spherical powder which is intensively mixed with diamond powder; aluminum oxide, a chromium element, a tungsten element, a ferrum element and diamond are integrated; the wear resistance of the honing stone finished product is greatly improved; an alloy is subjected to electron beam melting; harmful impurity elements such as O, N and S in an alloy melting process can be greatly reduced; the purity of the alloy is improved from an angle of reducing a harmful element content; high strength, high toughness and high corrosion resistance of a metal are guaranteed; brown aluminum oxide is adopted; an aluminum oxide content in brown aluminum oxide is 96%; and the stone is applicable to large allowance honing of most steel heavy parts under a heavy duty condition and machining of various forging parts.

Owner:ZHENJIANG N E T DIAMOND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com