Patents

Literature

269results about How to "Improve metallurgical quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

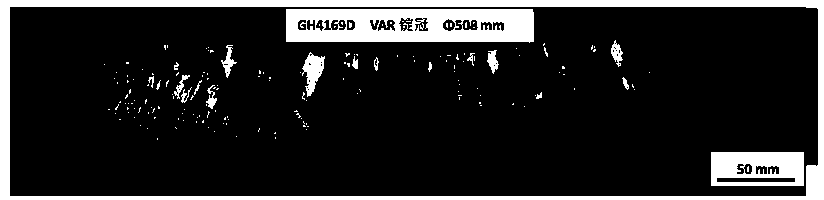

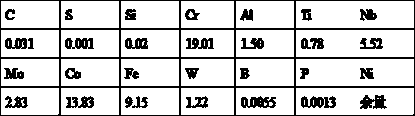

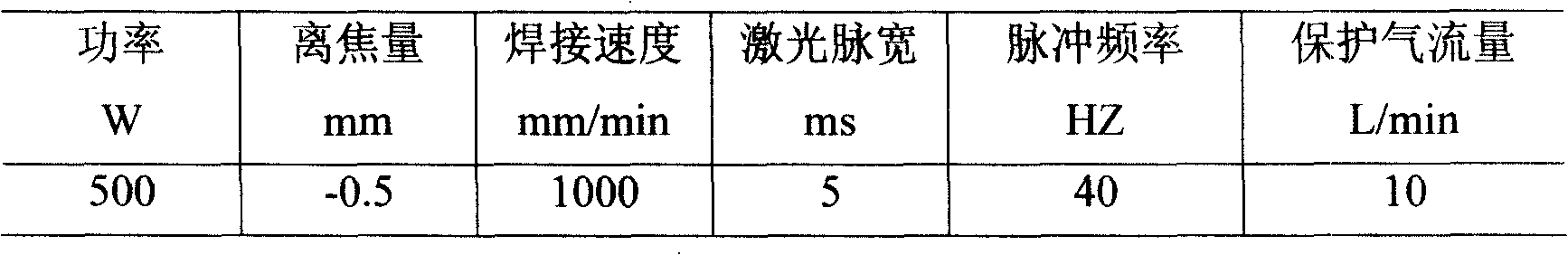

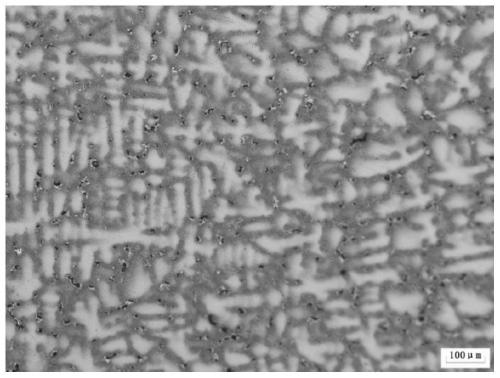

Smelting technique of novel nickel-iron-base high-temperature alloy GH4169D

The invention discloses a smelting technique of a novel nickel-iron-base high-temperature alloy GH4169D, which aims to smelt the novel high-temperature alloy GH4169D consumable ingot which has the advantages of lower raw material cost and favorable hot working properties in industrial production as well as high stability at high temperature. The scheme of the smelting technique is as follows: on the basis of the GH4169 alloy composition, the Fe content is lowered, the sum and proportion of Al and Ti are adjusted, and proper P and B are added; and by adopting a triple (VIM+PESR+VAR) smelting technique, proper slag and technological parameters are selected, and the burning loss of Al and Ti in the protective-atmosphere electroslag smelting process is controlled to obtain the precise contents of Al and Ti. The technique enhances the metallurgical quality of the high-temperature alloy, and fills up the blank of the high-temperature alloy in the aspect of the application temperature between 650 DEG C and 750 DEG C; the GH4169D alloy has the high strength, favorable hot working property and weldability of the GH4169 alloy, and has the high application temperature and other comprehensive properties of the GH4738 alloy; and the GH4169D alloy has long-term stability at 700 DEG C.

Owner:FUSHUN SPECIAL STEEL SHARES

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

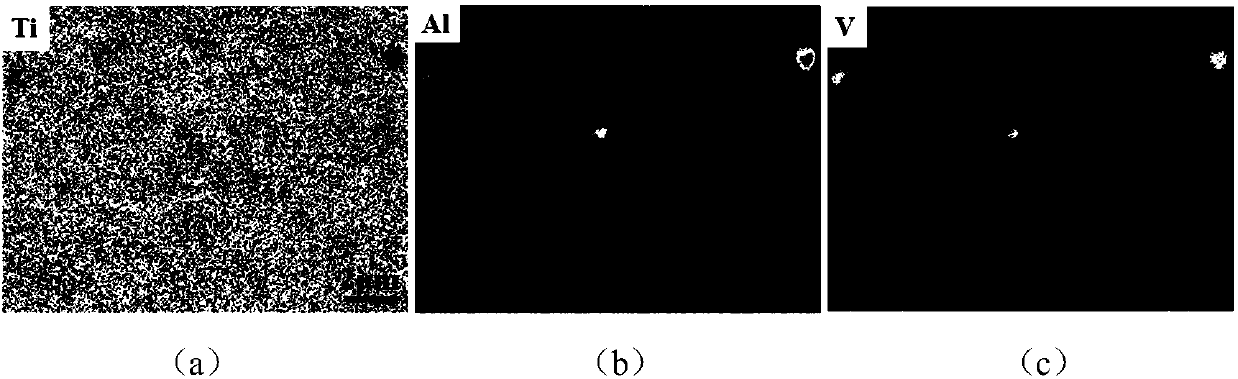

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

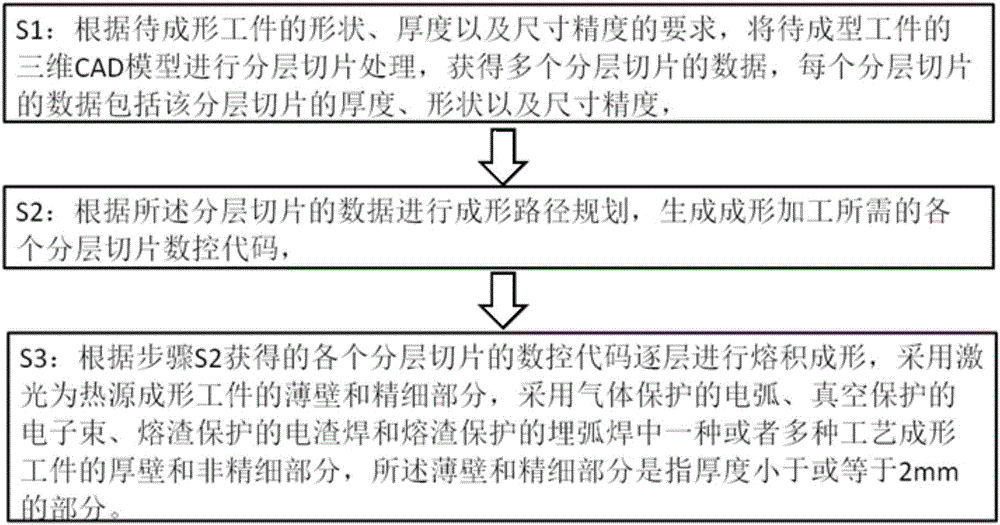

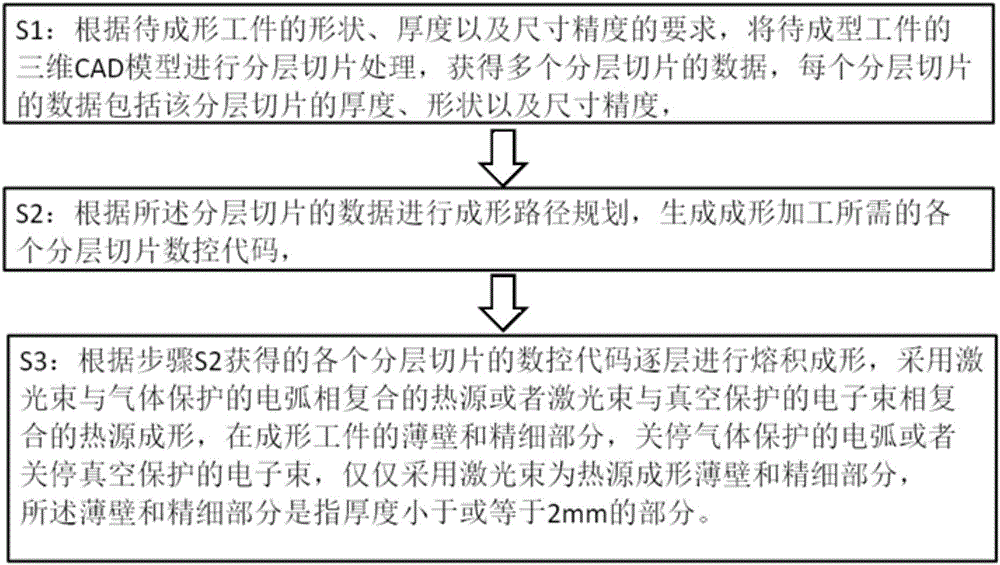

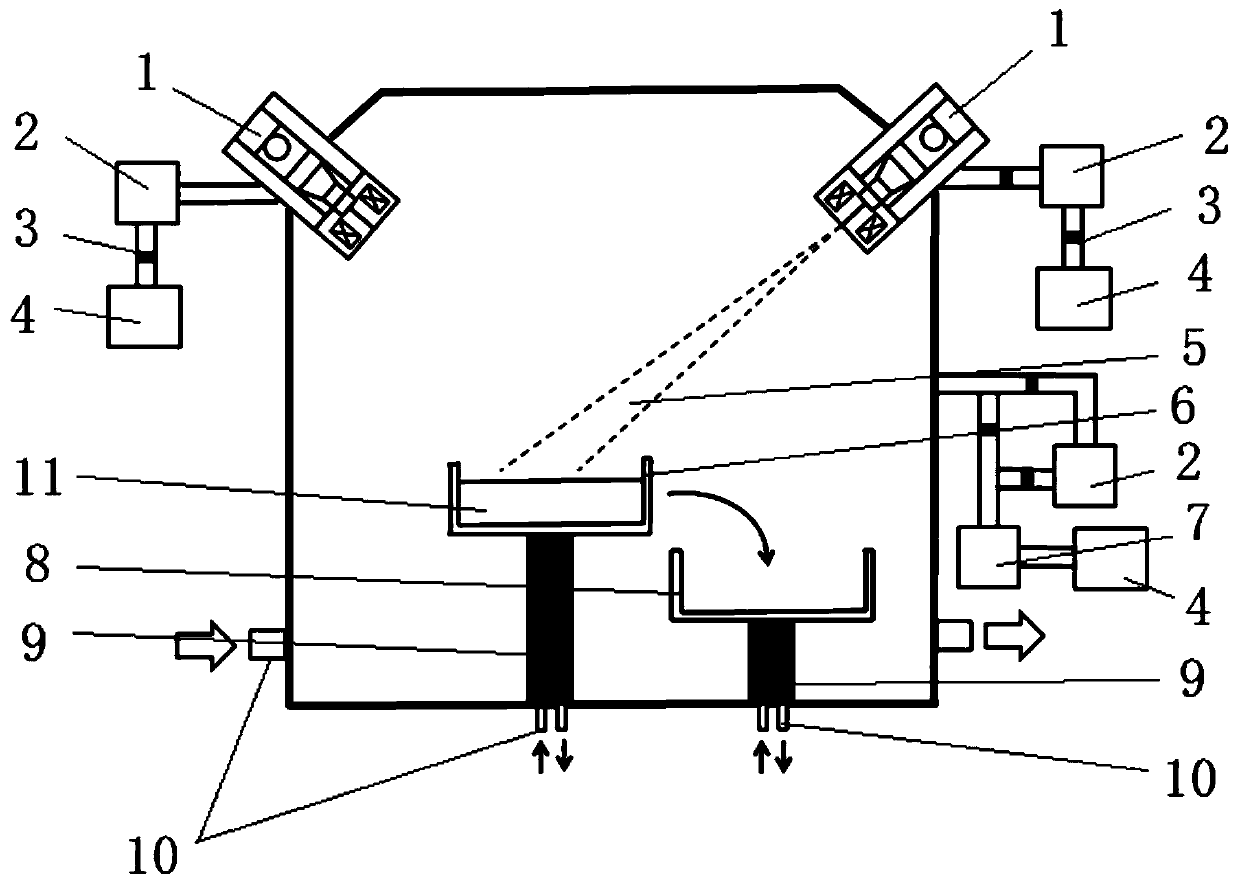

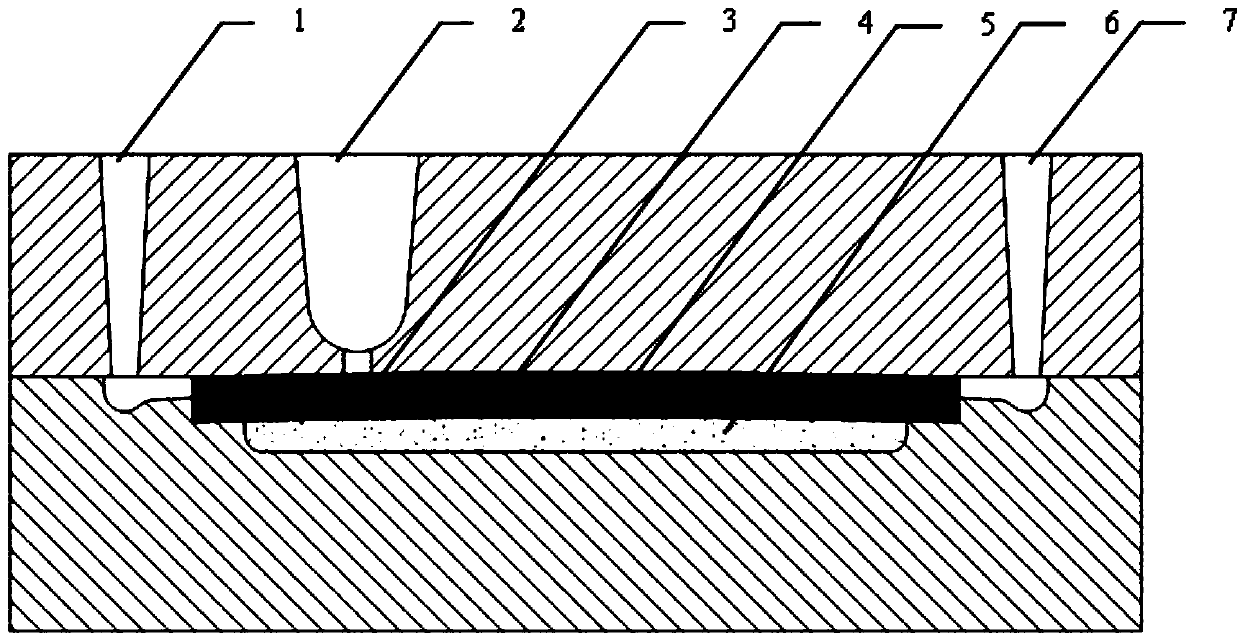

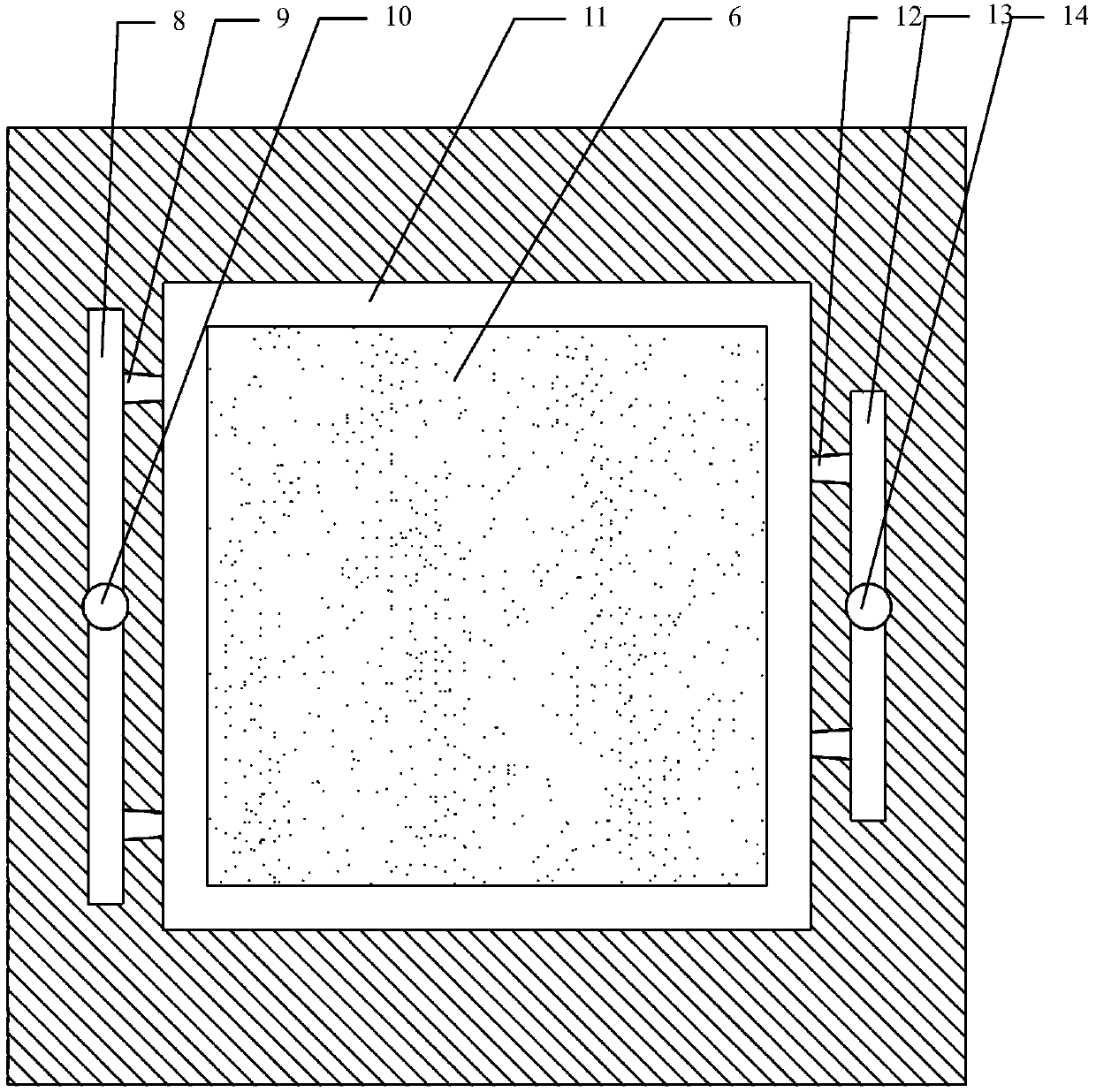

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

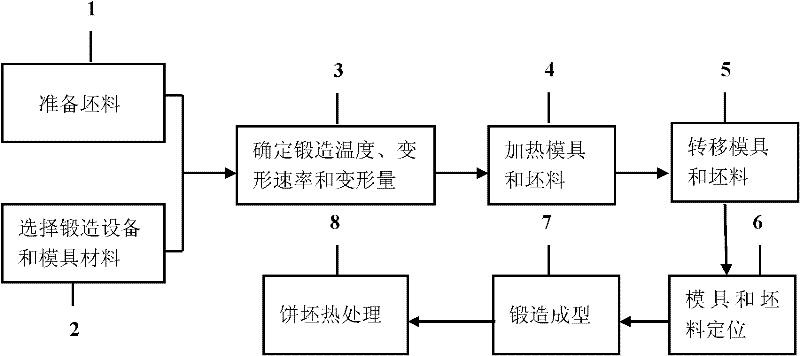

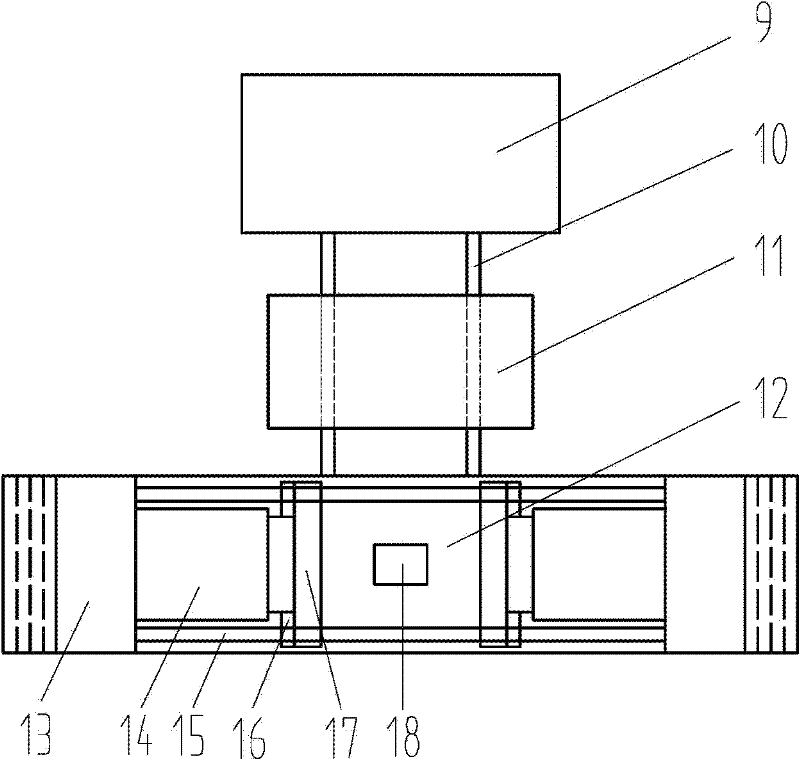

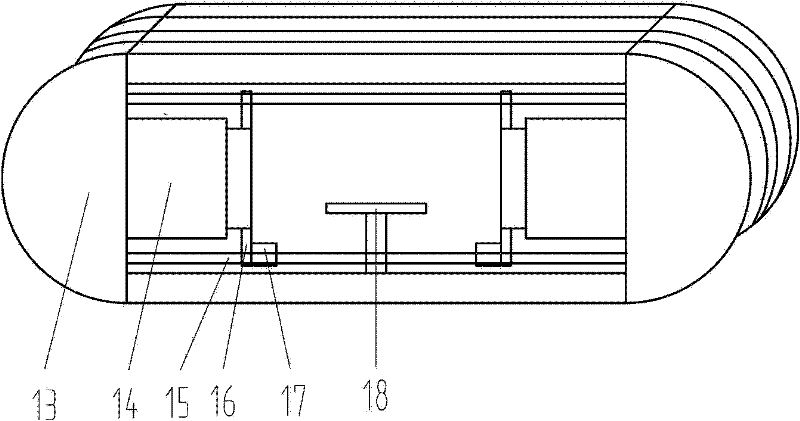

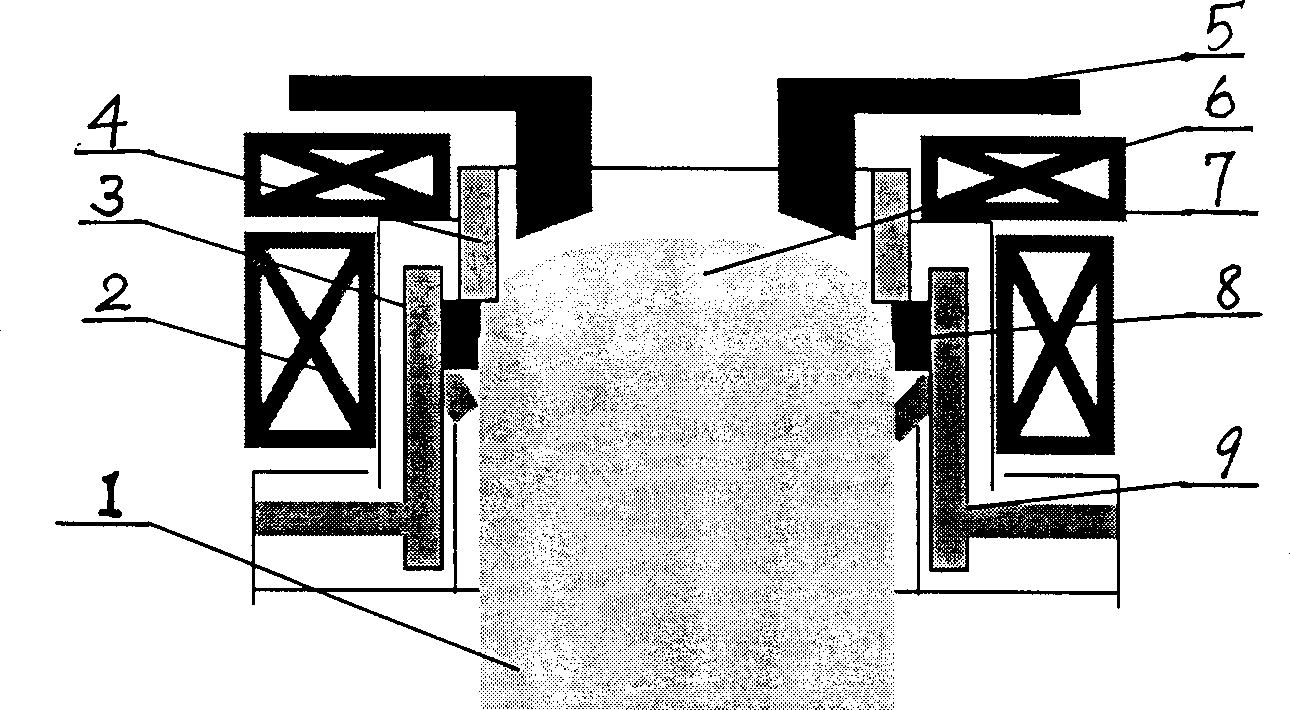

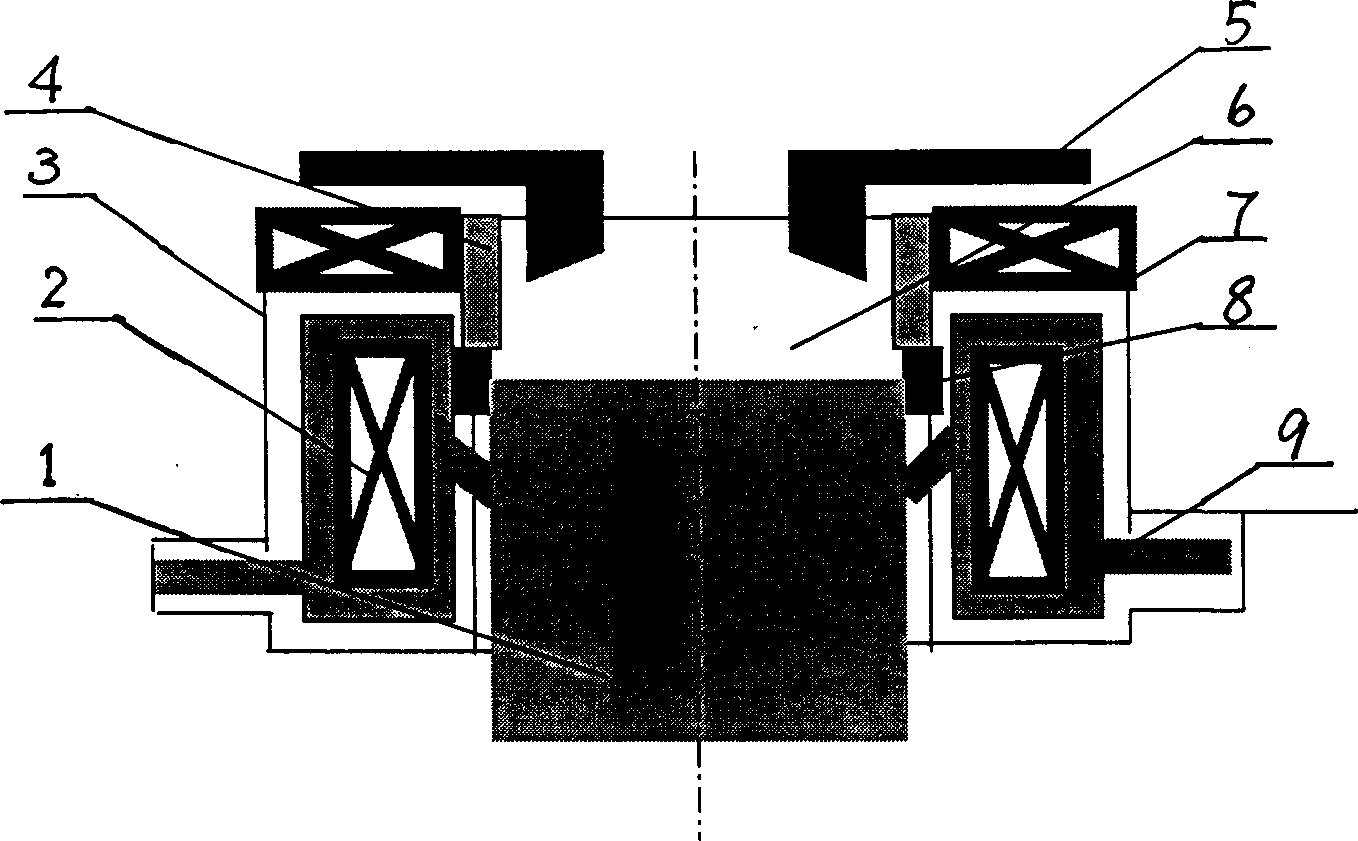

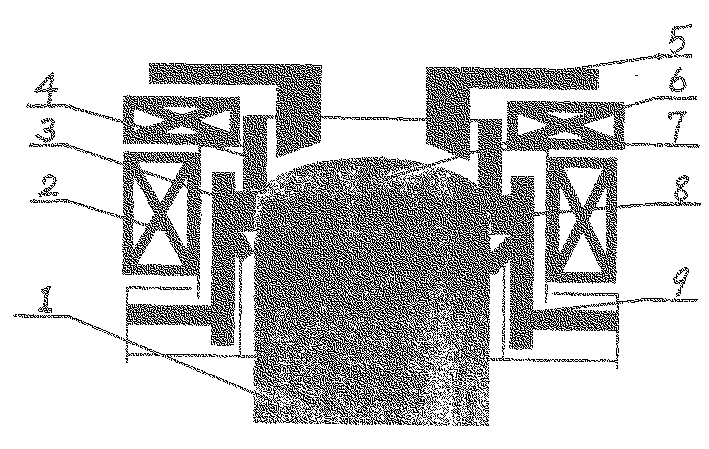

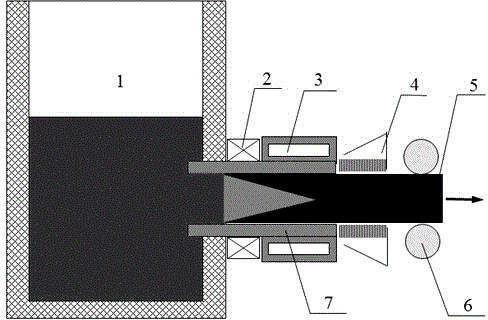

Quick isothermal forging method and device for preparing less-deformable alloy cake blank

ActiveCN102303083AReduce manufacturing costReduce the cost of forging processForging press detailsFlow stressHigh volume manufacturing

The invention discloses a quick isothermal forging method and device for preparing a less-deformable alloy cake blank. The device comprises a heating device, an automatic feeding device, a horizontal hydraulic forging device, a blank positioning device and a flame heating device. A mould material used by the device is a nickel-based alloy with creep strength which is higher than the flow stress of a forged high-temperature alloy under corresponding forging temperature and deformation rate. In the method, a homogenized electroslag remelting continuous directional solidification technology or other processes with maneuverability can be selected for preparing a high-alloyed less-deformable alloy directional solidification billet, as well as a fine grain billet prepared by adopting the processes, such as powder metallurgy and the like. The method and the device have the advantages of short production period, convenience for control and low cost, and are suitable for mass production of large-size high-clean and uniform tissue high-alloying less-deformable alloy cake blanks.

Owner:CENT IRON & STEEL RES INST

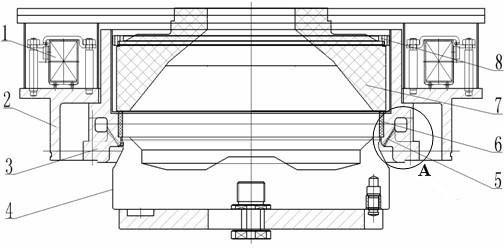

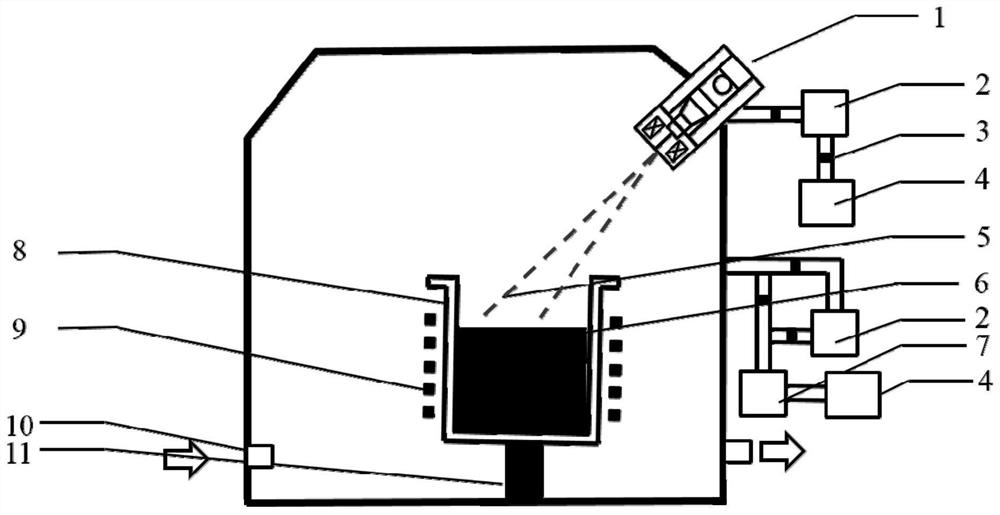

Aluminium alloy low frequency electromagnetic oscillation semicontinuous casting crystal grain fining method and device

The present invention belongs to the field of material processing technology. The equipment includes one crystallizer, one coil over the crystallizer with DC current passing through, one magnet over the DC coil to introduce the DC magnetic field into the melt in the upper part of the crystallizer, one coil outside the crystallizer with low-frequency current passing through. It has low-frequency electromagnetic field frequency of 15-30 Hz, DC magnetic field strength of 0.01-0.06 T, and AC magnetic field strength in the margin inside the crystallizer of 0.01-0.06 T. The semi-continuous low-frequency aluminium alloy casting process has casting temperature 680-750 deg.c, casting speed 50-150 mm / min and cooling water pressure 0.06-0.12 MPa. The present invention has fined cast ingot structure, isometric crystal grains, low cost internal stress, improved surface quality and hgh ingot quality.

Owner:NORTHEASTERN UNIV

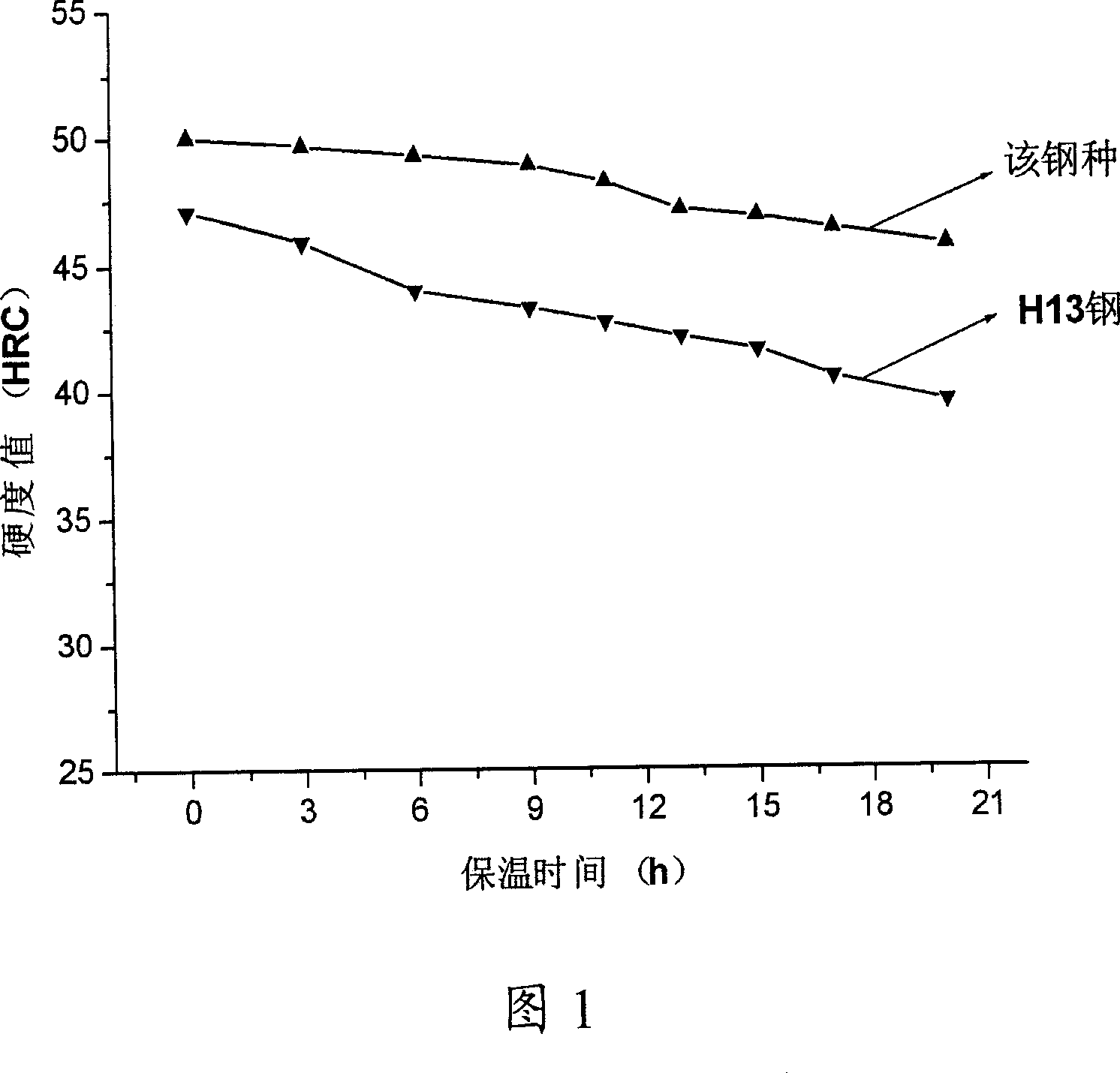

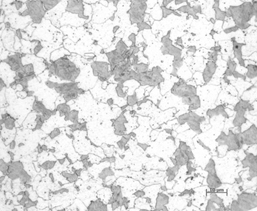

High heat-intensity hot-work die steel material

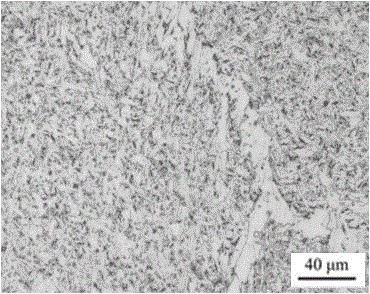

ActiveCN1924069AImprove metallurgical qualityImprove organizationHeat treatment process controlSlagHot work

The invention discloses a heat mould steel material in the alloy steel material manufacturing technological domain, which comprises the following parts: 3.5-4.0%Cr, 2.0-2.5% Mo, 1.0-1.5% V,1.0-1.5% W , 0.1-0.5% Mn, 0.1-0.25% Ni, 0.3-0.35% C, 0.1-0.5% Si, 0.005-0.01% S, 0.01-0.02% P and Fe. The preparing method comprises the following steps: (1) fusing; (2) refusing electric slag; (3) evening at high temperature; (4) forging; (5) annealing; (6) forging blank; (7) annealing to obtain the product with hardness between 48-54HRC and impaction flexibility more than 300J.

Owner:SHANGHAI UNIV

Method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as raw material

InactiveCN107760897AGood for controlling oxygen contentImprove compactnessTransportation and packagingMetal-working apparatusTitanium alloyTitanium powder

The invention belongs to the technical field of preparing and processing of titanium and a titanium alloy, and particularly relates to a method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as a raw material. The method comprises the following steps: hydrogenating sponge titanium; synchronously ball-milling to prepare hydrogenated titanium powder or mixed powder; pressing the powder; quickly sintering and synchronously dehydrogenizing; thermally mechanically solidifying or forming; performing complete vacuum dehydrogenizing; and obtainingan alloy product. The method realizes synchronously ball-milling to prepare mixed powder from hydrogenated sponge titanium and alloying raw materials, and the powder does not need to screen, so thatthe powder yield is greater than 96%; and under protection of inert atmosphere, pressing, quick heating and alloying, thermal mechanical solidifying and forming are completed. The method is short in process flow, is high in efficiency, can prepare the titanium and the titanium product with high compaction (greater than or equal to 99.8%) and low oxygen content (lower than or equal to 0.26%); mainmechanical properties of the alloy are higher than level of common deformed titanium alloy; and cost is obviously lower than that of conventional powder metallurgical titanium alloy.

Owner:NORTHEASTERN UNIV

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

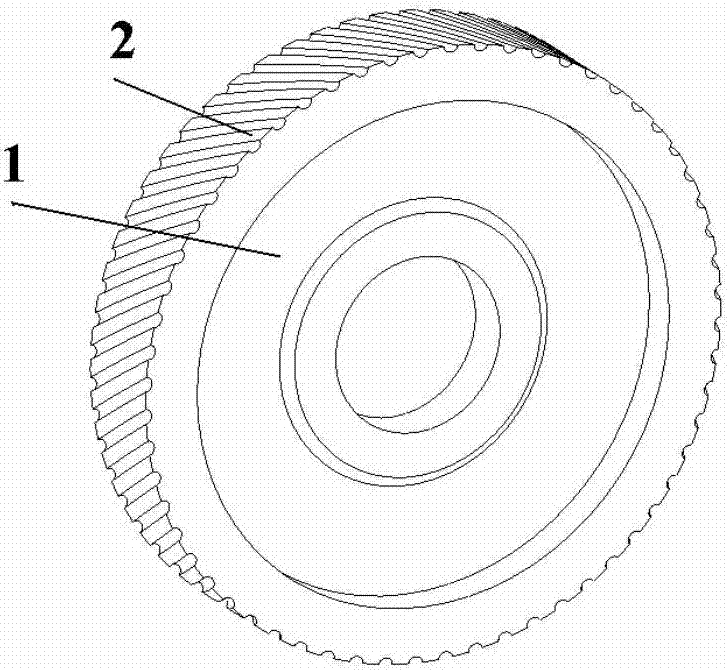

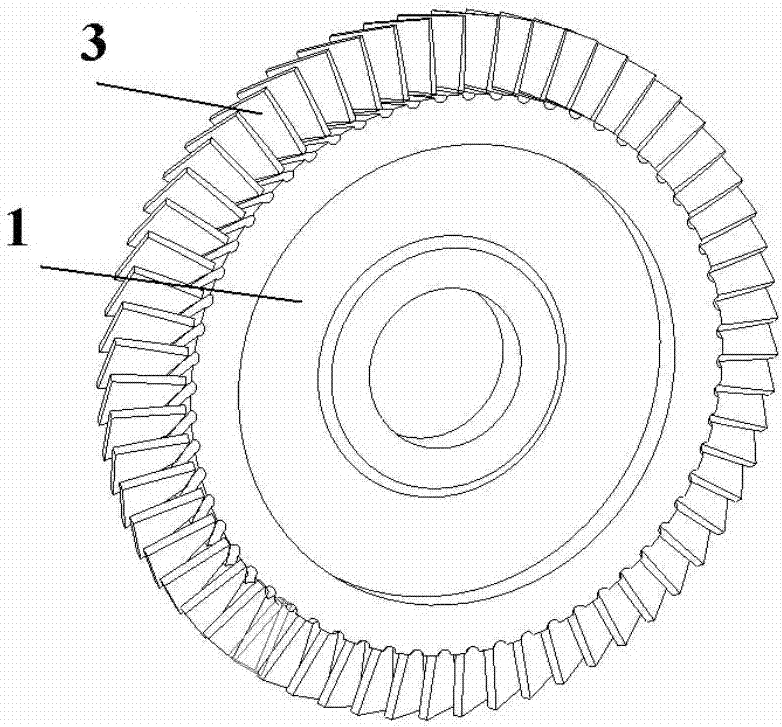

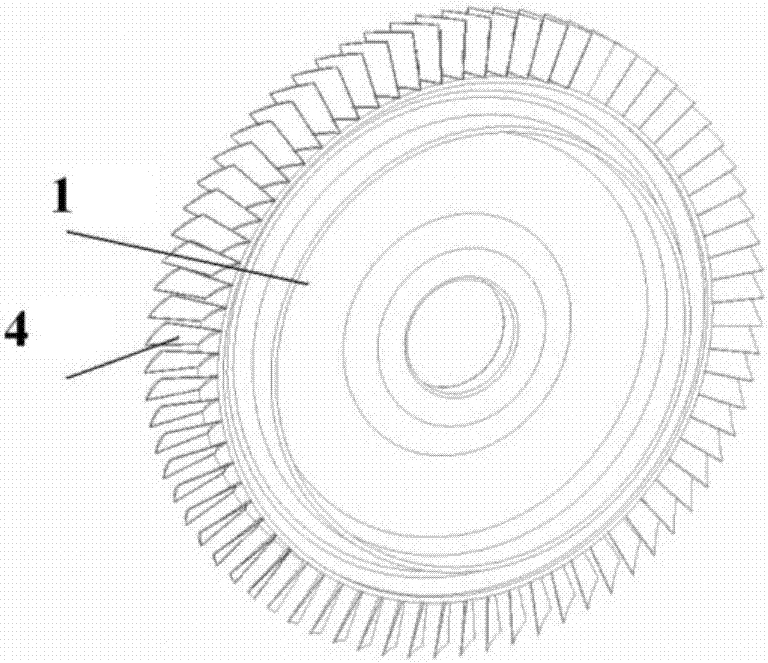

Manufacturing method for dual-metal dual-performance titanium alloy integral blade disc

The invention belongs to the technical field of engine manufacturing, and specifically discloses a manufacturing method for a dual-metal dual-performance titanium alloy integral blade disc, and a wheel disc [1] and a blade part of the integral blade disc are manufactured from different materials. The manufacturing method comprises the following steps of manufacturing titanium alloy blade blank of different materials by adopting an electron beam fused deposition additive manufacturing method on the basis of a wheel disc forged piece; then, performing mechanical processing or electrochemical machining until a designed dimension of a blade; and finally, realizing manufacturing of the dual-metal dual-performance titanium alloy integral blade disc. The manufacturing method has the characteristics of low manufacturing cost, a short period and high metallurgical quality. The blade and the wheel disc [1] are manufactured from different materials, so that mechanical property advantages of the materials can be sufficiently brought into play, the requirements, on high strength and high strain fatigue characteristics of the wheel disc [1], of the integral blade disc, and the requirements, on high stress fatigue and endurance properties, of the blade are met, and therefore, the purpose of reducing weight by enabling the whole blade disc to serve under a high temperature condition or replacing the high-temperature alloy integral blade disc is realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

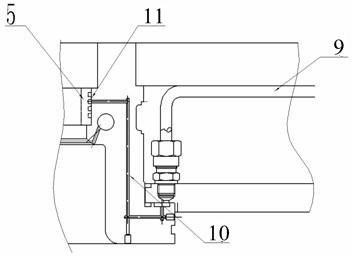

Thermo-mechanical treatment process of great-length Cu-Cr-Zr-Si alloy contact line

InactiveCN104928603ACauses a dynamic recrystallization effectRefining as-cast grainContact lineHeavy duty

The invention discloses a thermo-mechanical treatment process of a great-length Cu-Cr-Zr-Si alloy contact line. The process includes: smelting Cu-Cr-Zr-Si alloy, with Cu accounting for 0.30% to 0.50%, Cr accounting for 0.10% to 0.15% and Zr accounting for 0.01% to 0.02% in content, with a combined protective layer composed of mixed inert gas and a covering dried charcoal protective layer, in an induction furnace; and performing drag casting with a horizontal continuous casting system with electromagnetic stirring and a local heater to obtain rods 16 to 120mm in length. By high-frequency inductive thermal rolling, step heating and water-cooling solidification, cold rolling, split ageing and finish drawing or cold rolling, the alloy contact line having symmetrical grooves in two sides, 110 mm<2> to 150 mm<2> in sectional area and 1800 to 2000 m in singular length. The process has the advantages that metallurgical quality of products is high, and the performances meet the needs of various overhead line systems for modern high-speed railways and low-speed heavy duties.

Owner:YANTAI JINHUI COPPER +2

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

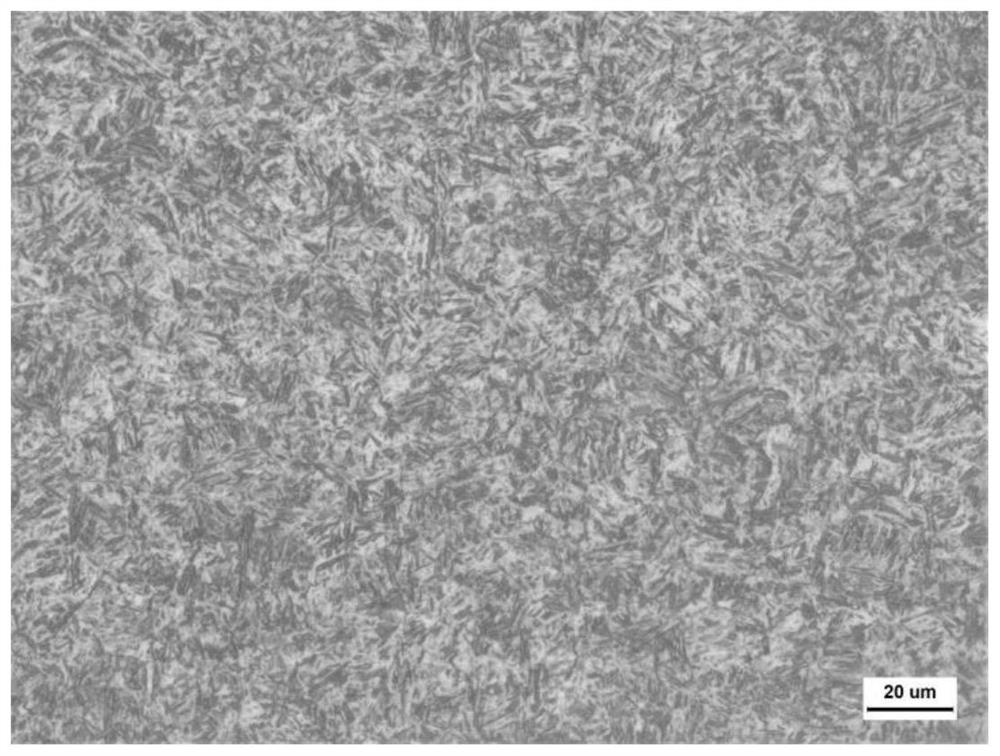

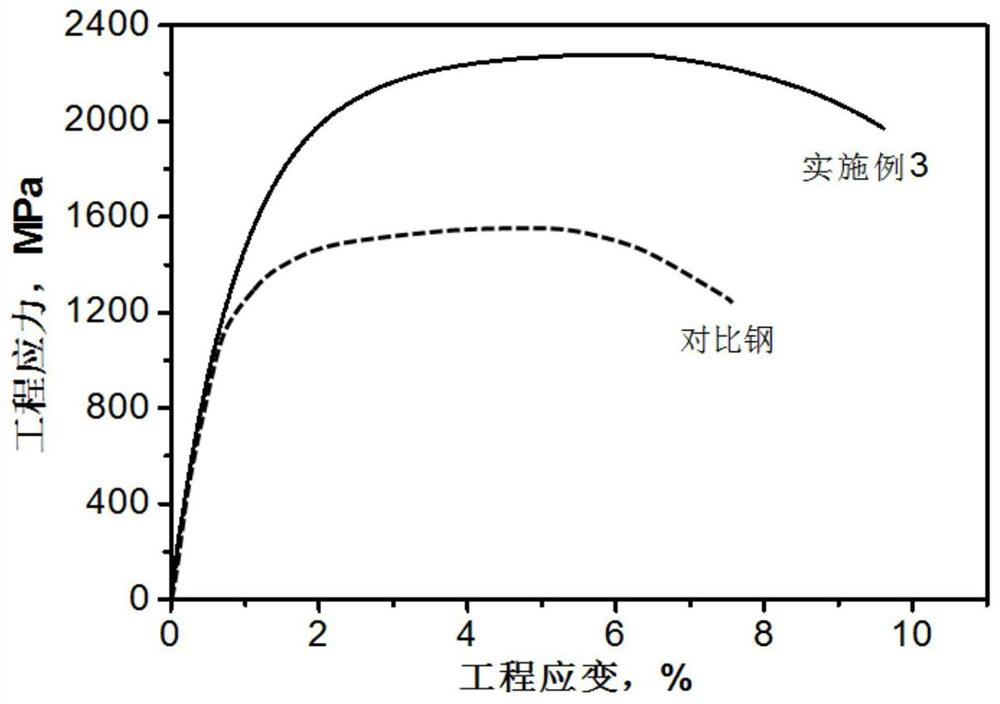

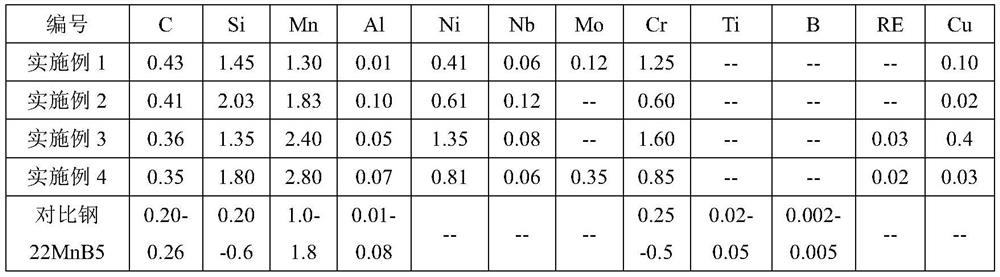

Preparation method of ultrahigh-strength high-plasticity hot stamping forming steel

ActiveCN113106338AImprove metallurgical qualityGrain refinementFurnace typesHeat treatment furnacesHot stampingAutomobile safety

The invention discloses a preparation method of ultrahigh-strength high-plasticity hot stamping forming steel, and belongs to the technical field of automobile steel. The steel comprises the following chemical components of, in percentage by mass, 0.30%-0.55% of C, 1.0%-2.5% of Si, 1.0%-3.0% of Mn, 0.5%-2.0% of Cr, 0.05%-2.0% of Ni, 0.01%-0.10% of Al, 0.04%-0.15% of Nb, less than or equal to 0.5% of Mo, less than or equal to 0.08% of RE, less than 0.015% of P, less than 0.015% of S, less than or equal to 1.0% of Cu or less than or equal to 0.06% of V, or the combination of the two, and the balance of Fe and inevitable impurity elements, and Si+Mn+Cr is larger than or equal to 3.5% and less than or equal to 5.5%; and automobile parts are obtained through the steps of smelting, pouring solidification, hot rolling, acid pickling, cold rolling, annealing, hot stamping forming and the like. The preparation process of the hot forming steel part is simple, and the structure obtained after hot stamping forming is a martensite matrix and 1.5%-7.0% of retained austenite; and after the components are optimized, it can be guaranteed that the tensile strength of parts is larger than or equal to 2200 MPa, the yield strength is larger than or equal to 1300 MPa, the total elongation is larger than or equal to 9.0%, and the steel is suitable for automobile safety parts and other high-strength-toughness parts and has very important significance on achieving high toughness and light weight of automobiles.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing high-purity nickel-based high-temperature alloy through electron beam induced refining and casting technology

ActiveCN110423918AEfficient separationShorten the production cycleIncreasing energy efficiencyCrucibleIngot

Owner:DALIAN UNIV OF TECH

Production technology for casting wear-resistant thin plates by compounding double liquid metals

InactiveCN104174833AImprove metallurgical qualityAvoid it happening againFoundry mouldsFoundry coresThin slabLiquid metal

The invention discloses a production technology for casting wear-resistant thin plates by compounding double liquid metals, and aims to replace the conventional build-up welding abrasion-resistant plate production technology with the production technology. The production technology disclosed by the invention comprises the following steps: a gravity casting double casting system is combined with a casting technology; a special chilling material is used for adjusting the temperature fields of molten metals entering a cavity to ensure that the temperature gradient of the part I, in contact with the chilling material, of a first molten metal entering the cavity first is larger, while the temperature gradient of the part II, far away from the chilling material, of the first molten metal is smaller; pouring a second molten metal into the rest space of the cavity after the part I of the first molten metal is in a solid phase and the part II of the first molten metal is in a solid-liquid phase or a liquid phase, so as to ensure that the two molten metals are combined metallurgically but not mixed. Through the adoption of the production technology, under the premise that the metallurgical quality of a metal of a wear layer is superior, the dilution effect of a base material to the alloying constituent of the wear layer is effectively reduced.

Owner:JIAMUSI UNIVERSITY

Smelting manufacturing method for high temperature ferric alloy

A technology for smelting the refractory Fe-base alloy includes such steps as primary smelting in ordinary electric arc furnace by return oxygen blowing method and smelting the qualified refractory Fe-base alloy in AOD furnace. Said second step includes blowing the mixture of argon gas and O2 in ratio of 4:1 for decarbonizing, heating, blowing the mixture of argon gas and O2 in ratio of 1:1 when C content is 0.1%, sampling and analyzing, regulating contents of its components, blowing argon gas when C content is 0.03%, adding prereducing slags, prereducing, sampling and analyzing, adding reducing slags, blowing argon for dissolving slags, blowing argon for 3 min, adding Ti in ladle, tapping, and casting rod electrodes.

Owner:宝钢特钢有限公司

Method for reducing internal residual stress of GH4169 alloy large-size disk forge piece

The invention belongs to the technical field of preparing of a deformation high-temperature alloy GH4169 disk forge piece for an advanced aero-engine, and relates to a method for reducing the internalresidual stress of a GH4169 alloy large-size disk forge piece. The method includes the following steps of preparing a GH4169 alloy pure smelting cast ingot, conducting uniform heat treatment on the GH4169 cast ingot, cogging the cast ingot, preparing a biscuit, conducting compounding and coating, conducting gradient-speed-control constant-temperature die forging, conducting heat treatment on thedisk forge piece, conducting rough machining and conducting stress relief annealing. By means of the prepared low-stress GH4169 alloy disk forge piece, it is ensured that the internal stress of the deformation high-temperature alloy cast ingot is slowly released, the internal metallurgical quality of the alloy ingot is improved, and the disk forge piece can be used for preparing an advanced aero-engine high-pressure compressor disk, a high-pressure turbine disk, a low-pressure turbine disk and other parts.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Smelting process of nitrogenous high alloy heat-resistant steel ZG3Cr24Ni7N

InactiveCN102618795AEasy to controlInto a stableProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a smelting process of nitrogenous high alloy heat-resistant steel ZG3Cr24Ni7N, which includes preparing a steel ladle, primary smelting in an electric arc furnace, refining the steel ladle and blowing nitrogen from the bottom of the ladle. The nitrogen which is rich in sources and low-price is used as material, the nitrogen is blown to molten steel for nitrogen alloying, and accordingly production cost of nitrogenous steel is lowered greatly. Alloy recovery efficiency is improved by reasonable processes, so that the problem that chemical components are difficult to control is solved, and the metallurgical quality of molten steel is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Weather-resistant submerged arc welding wire for free-coating weather-resistant steel bridge

ActiveCN106001987AGood weld formabilityImprove metallurgical qualityArc welding apparatusWelding/cutting media/materialsChemical compositionAtmospheric corrosion

The invention discloses a weather-resistant submerged arc welding wire for a free-coating weather-resistant steel bridge, and belongs to the field of welding materials. According to the technical scheme, the weather-resistant submerged arc welding wire for the free-coating weather-resistant steel bridge comprises a basic chemical component Fe and the following chemical components in percentage by mass: 0.03 to 0.10% of C, 0.10 to 0.28% of Si, 1.15 to 1.55% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.25 to 0.55% of Cr, 0.25 to 0.55% of Ni, 0.20 to 0.50% of Cu, 0.005 to 0.025% of Ca, and 0.005 to 0.05% of Re. The welding wire is applied to the welding of Q345qENH-Q460qENH serial weather-resistant bridge steel, and is outstanding in atmospheric corrosion resistance, high in process performance, stable in quality, and suitable for large-scale popularization and application.

Owner:YANSHAN UNIV

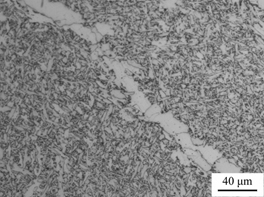

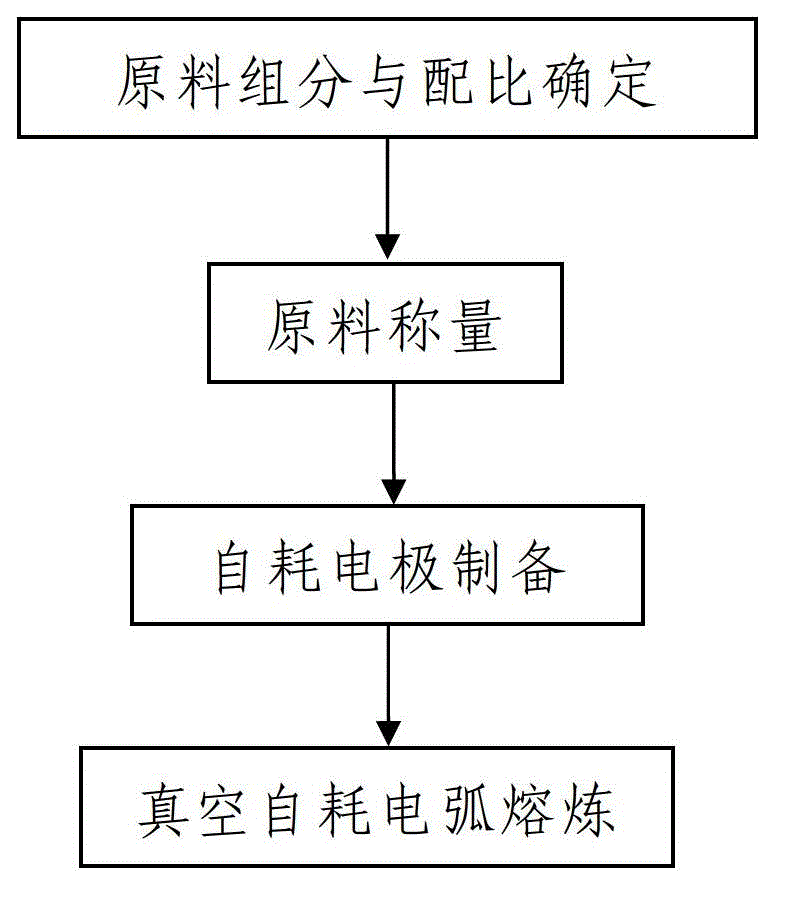

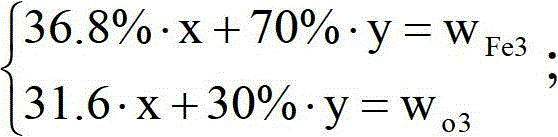

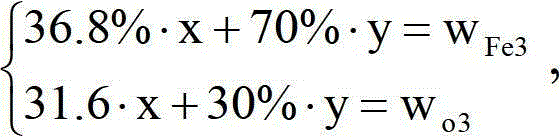

Ti-Mo-Ni alloy ingot preparation method

A Ti-Mo-Ni alloy ingot preparation method is characterized in that Ni-Mo intermediate alloy (the mass proportion content of Mo element is 20-35%) is added, the production steps of the Ti-Mo-Ni alloy ingot include that: titanium sponge, Ni-Mo intermediate alloy or Ti-Mo intermediate alloy are mixed uniformly and pressed into electrode blocks, the electrode blocks are welded into consumable electrodes through welding modes such as plasma arc, and the Ti-Mo-Ni alloy ingot is prepared through twice vacuum consumable electric arc smelting. The Ti-Mo-Ni alloy ingot produced by the preparation method has uniform and stable chemical compositions, has the chemical composition deviation of being less than 0.15%, is segregation free and overcomes the defect of high density metallurgical inclusion. The invention is applicable to producing the Ti-Mo-Ni alloy ingot with high metallurgical quality requirement.

Owner:BAOJI TITANIUM IND CO LTD

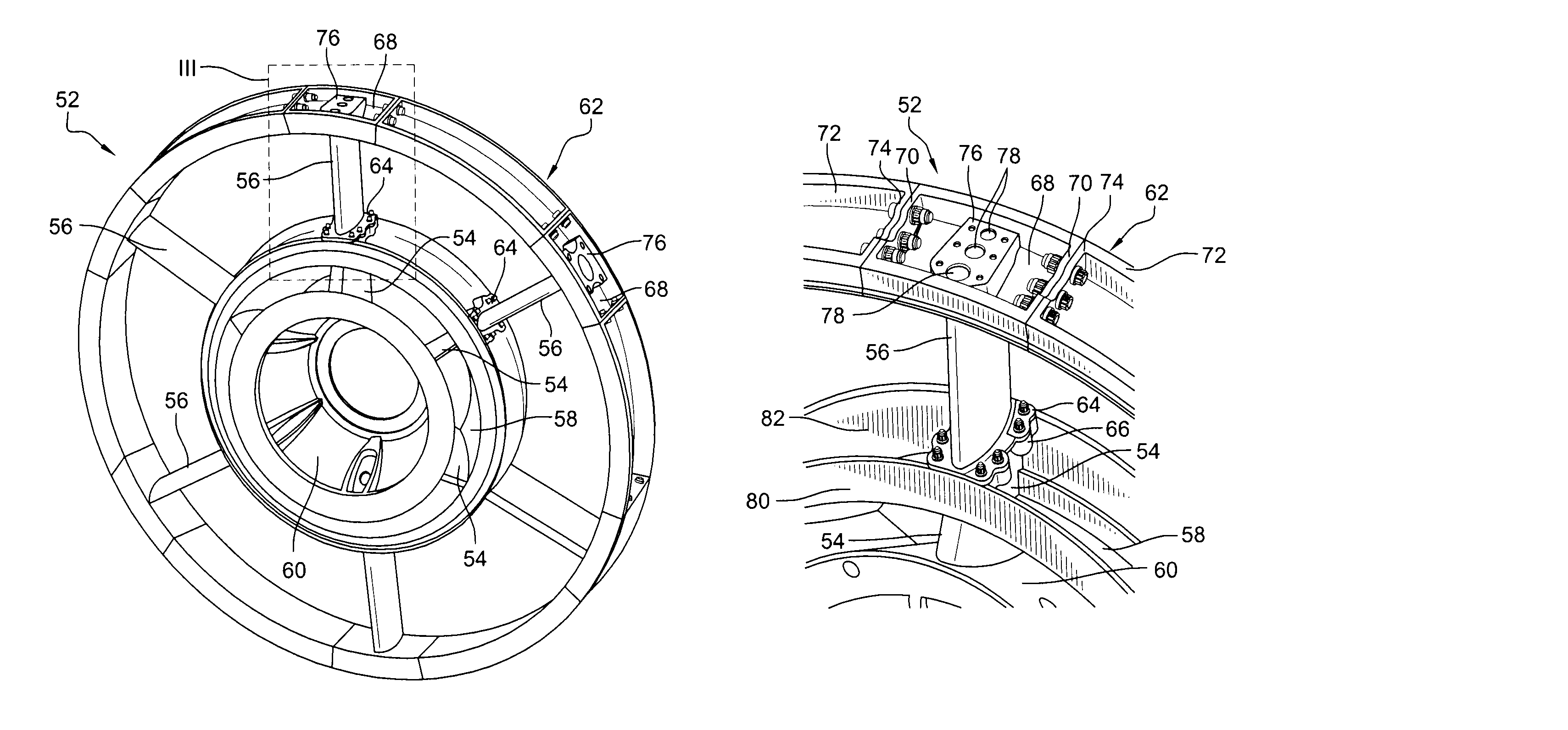

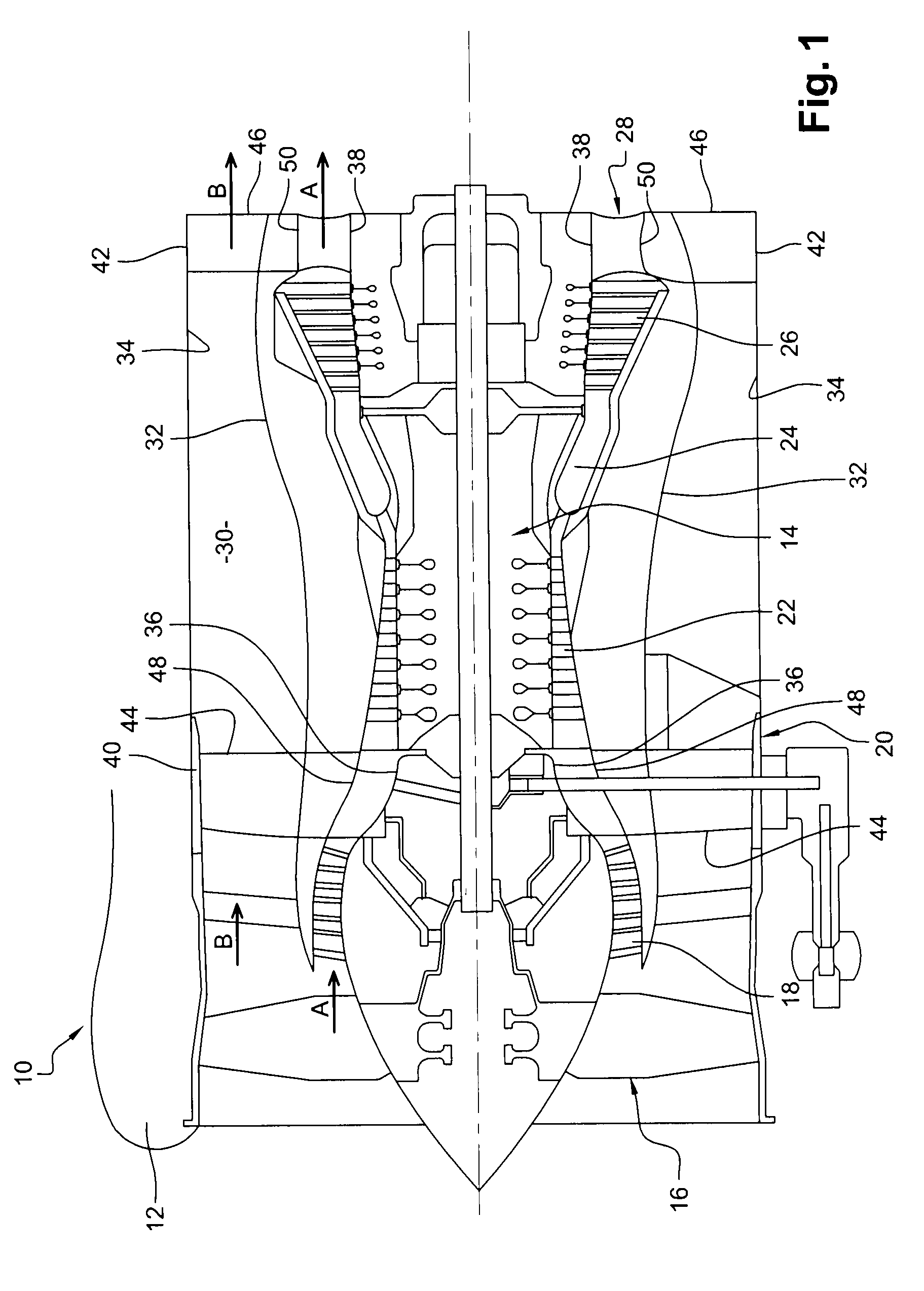

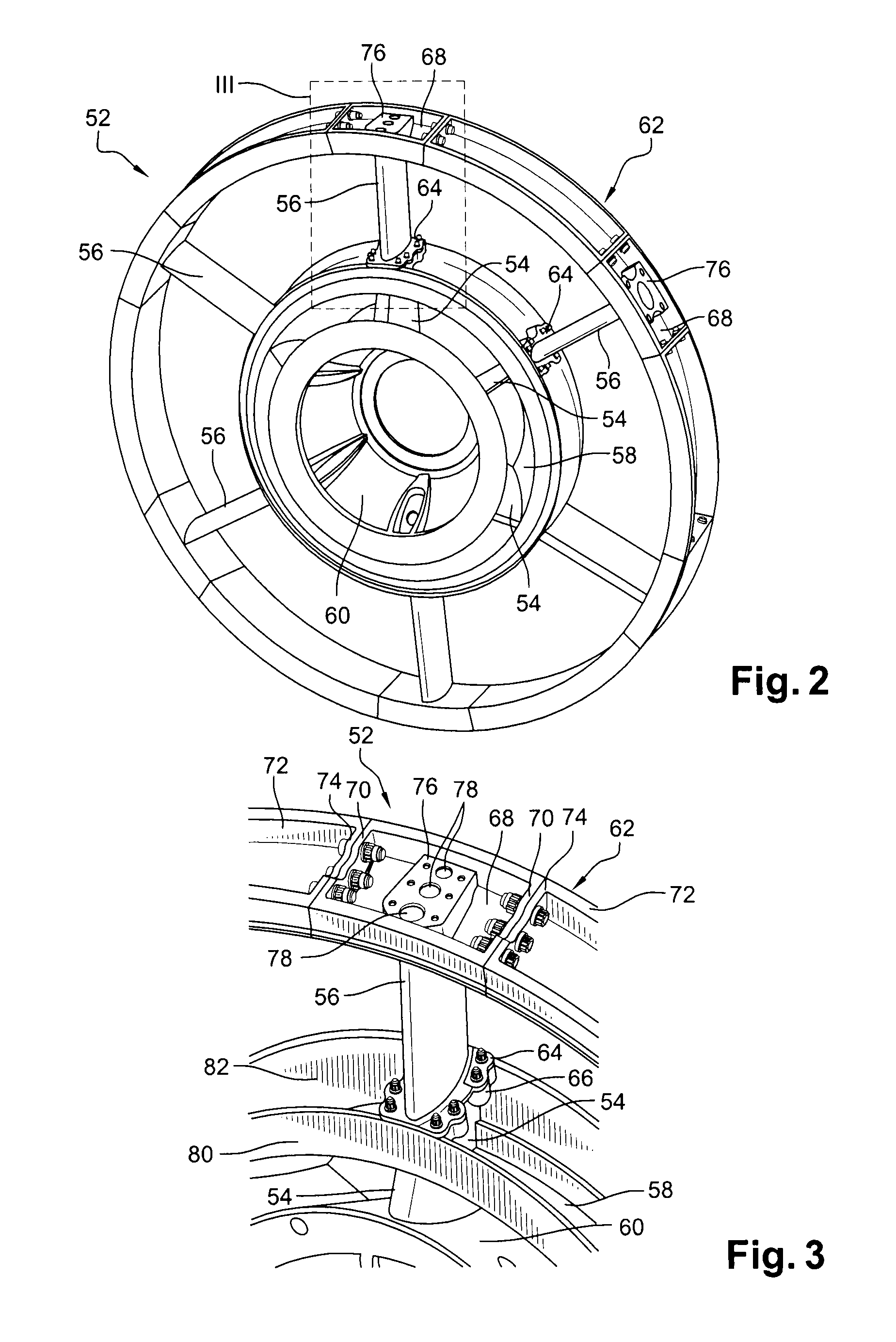

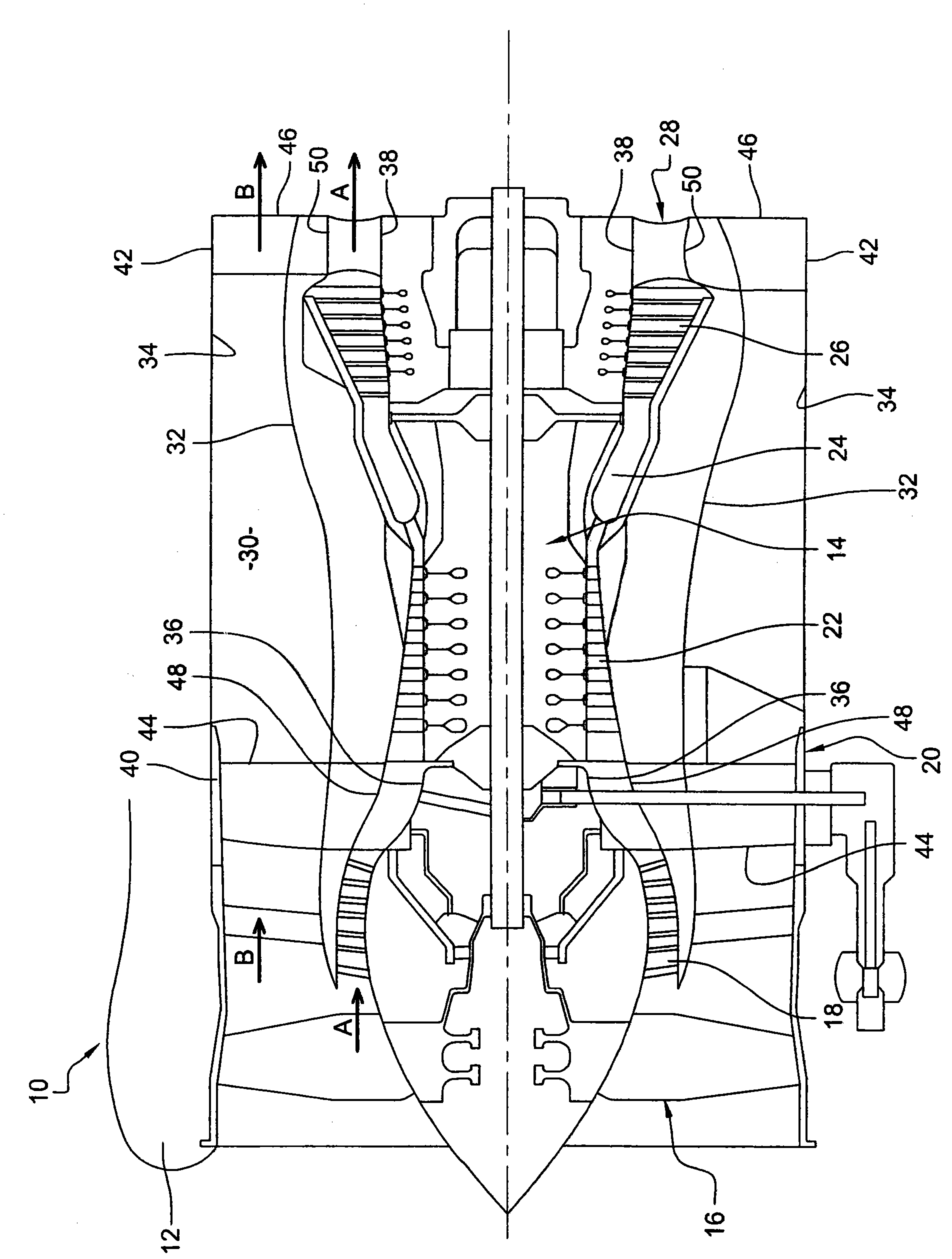

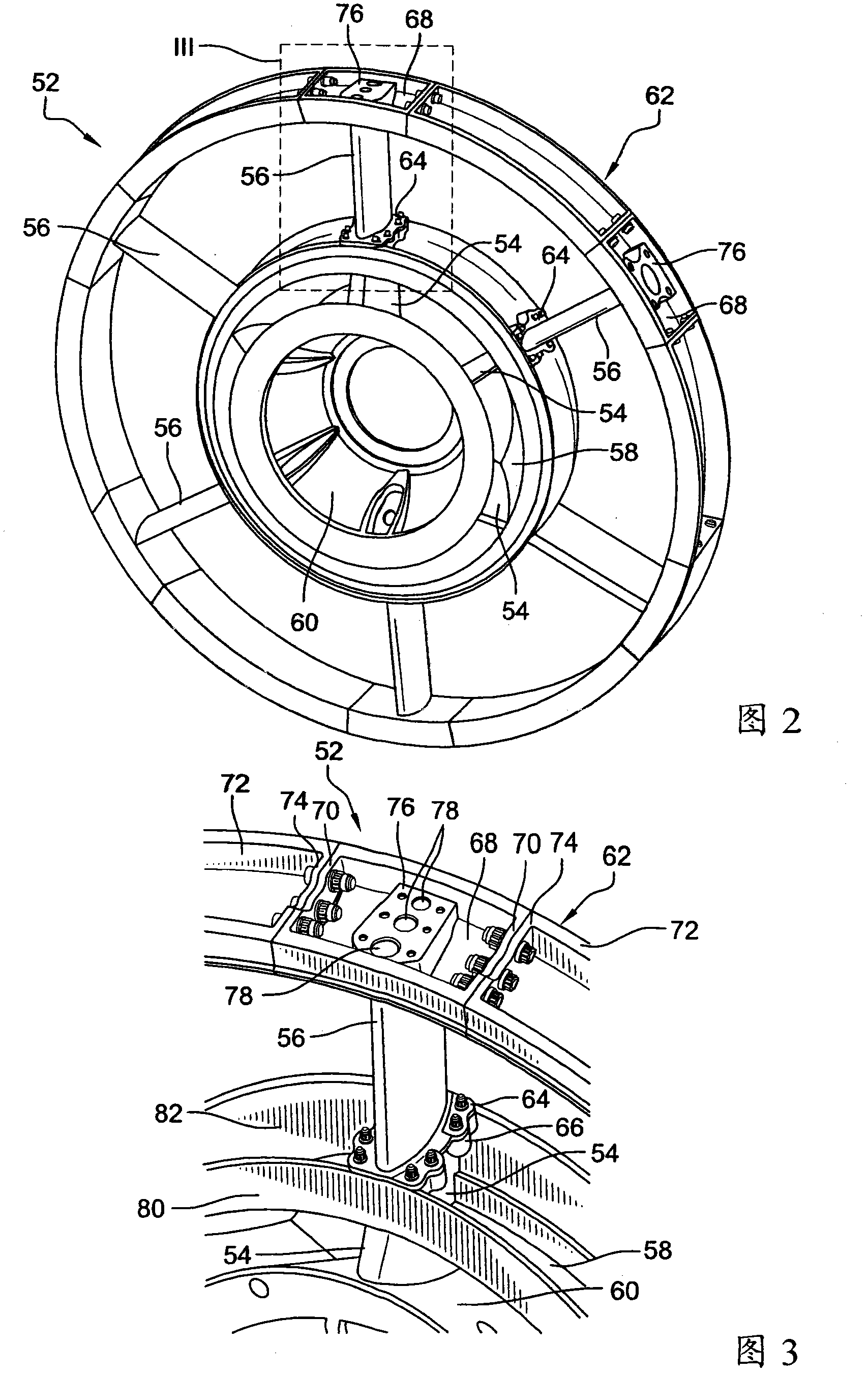

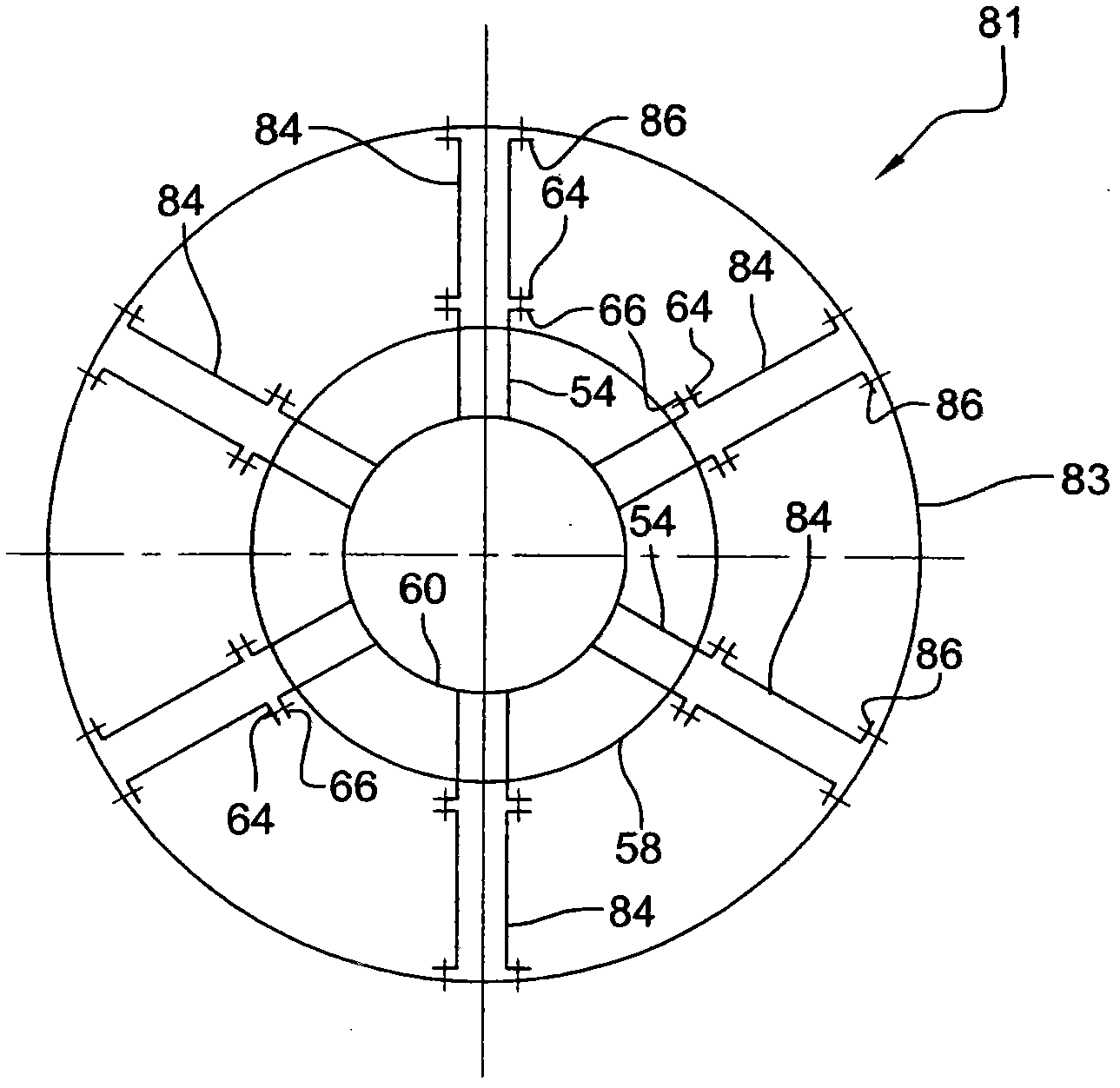

Structural frame for a turbomachine

ActiveUS8646744B2The process is simple and effectiveAvoid disadvantagesPortable framesPump componentsEngineering

A structural frame for a turbomachine, such as an intermediate frame or an exhaust frame, the frame including at least two coaxial rings, an inner ring and an outer ring, together with radial arms interconnecting the rings. At least one of these elements includes a plurality of parts that are fastened together by bolting.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

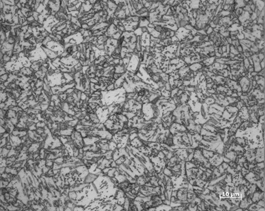

High-toughness abrasion-resistant alloy steel for excavator bucket and production process thereof

ActiveCN103014515AControl quantityReduce sizeSoil-shifting machines/dredgersExcavatorWear resistance

The invention discloses a high-toughness abrasion-resistant alloy steel for an excavator bucket, which comprises the following chemical components in percentage by weight: 0.24-0.28% of C, 0.6-1.0% of Si, 1.2-1.5% of Mn, 0.6-1.1% of Cr, 0.3-0.5% of Mo, 0.05-0.10% of V, 0.004-0.006% of B, 0.08-0.12% of Ti, 0.01-0.025% of Ce, 0.02-0.03% of La, P less than or equal to 0.03%, S less than or equal to 0.03% and the balance of iron and impurities. Compared with the traditional high-manganese steel, the high-toughness abrasion-resistant alloy steel disclosed by the invention has the advantages of higher abrasion resistance, toughness and impact resistance; and the high-toughness abrasion-resistant alloy steel can be used for ensuring that the normal working of an excavator, preventing and controlling the early brittle failure, reduces the shut-down and maintenance times, increases the labor productivity and the equipment utilization ratio and reduces the production cost.

Owner:滁州恒昌机械装备制造有限公司

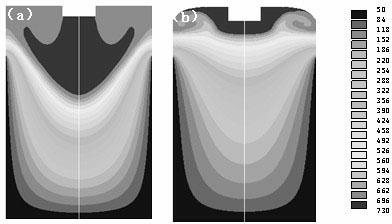

Method for casting isometric crystal turbine work blade blanks

InactiveCN103252452AImprove metallurgical qualityImprove mechanical propertiesFoundry mouldsFoundry coresTurbine bladeX-ray

The invention discloses a method for casting isometric crystal turbine work blade blanks. The method is characterized by firstly adopting a bottom pouring system and a top pouring system and comprising the following steps of: casting isometric crystal turbine work blades in groups, wherein each group comprises four to twenty work blades which are distributed along the blade circumference; then under the conditions of uniform and identical temperature and uniformly-distributed temperature, adhering an attachment structure to the middle of the back of each blade to be poured and connecting the attachment structure to a straight sprue to form a feeding head and eventually form a mixed pouring system of top pouring, bottom pouring and side pouring; and finally casting by using the mixed pouring system of top pouring, bottom pouring and side pouring so as to obtain the isometric crystal turbine work blade blanks. Through X-ray detection on blade cast produced by the method, the loose defect in the blades is eliminated completely and the requirements of a technical standard are met. The loose defect in the blades is eliminated and the metallurgical quality and the mechanical property of turbine blades are enhanced greatly.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for preparing high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining

The invention provides a method for preparing a high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining. The method comprises the following stepsof S1, pretreatment of raw materials; S2, charging into a furnace; S3, vacuum induction melting; and S4, electron beam refining, so that the refined alloy is obtained. By coupling vacuum induction melting and electron beam refining, a superalloy mother alloy is melted through a vacuum induction method, then the superalloy is further purified through electron beam refining, the segregation degreeis reduced, the metallurgical quality of a superalloy cast ingot is improved by fully utilizing the advantages of induction melting and electron beam refining, and finally, high-purity preparation ofthe alloy is realized.

Owner:DALIAN UNIV OF TECH

Turbomachine structural casing

ActiveCN102066696ASmall sizeImprove metallurgical qualityEngine manufactureEfficient propulsion technologiesAerospace engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

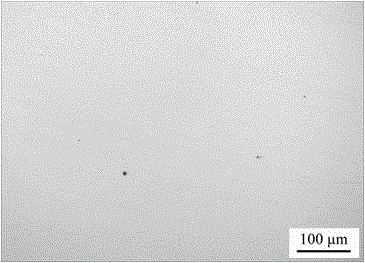

Precise laser forming method for aluminum alloy part with complex inner runner

InactiveCN105386036ADense tissueFine and uniformMetallic material coating processesLaser scanningCasting defect

The invention discloses a precise laser forming method for an aluminum alloy part with a complex inner runner. The method includes the following steps that a three-dimensional model is established and spliced layer by layer, so that a laser scanning path is obtained; a base material is fixed and aluminum alloy powder is put in a powder cylinder; argon is injected in a forming chamber and the aluminum alloy powder is laid on the base material; a laser forming device is started for scanning; a forming cylinder descends at the distance of the thickness of a layer, the powder cylinder accordingly ascends at the distance of the thickness of a layer, and the aluminum alloy powder is laid on the machined current layer through a powder laying device till the part is completely machined; and the part is annealed, so that the aluminum alloy part is obtained. The formed part manufactured through the method is dense, tiny and even in structure, free of casting defects such as shrinkage porosity, shrinkage cavities and cold laps generated in the casting process, good in metallurgy quality, free of leakage in the pressing process and barely free of the deformation phenomenon, the form and location tolerance of the side wall of the obtained thin-wall part is good, no following treatment is needed, the material use rate is increased, the work procedures are reduced, and the part manufacturing period is shortened.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

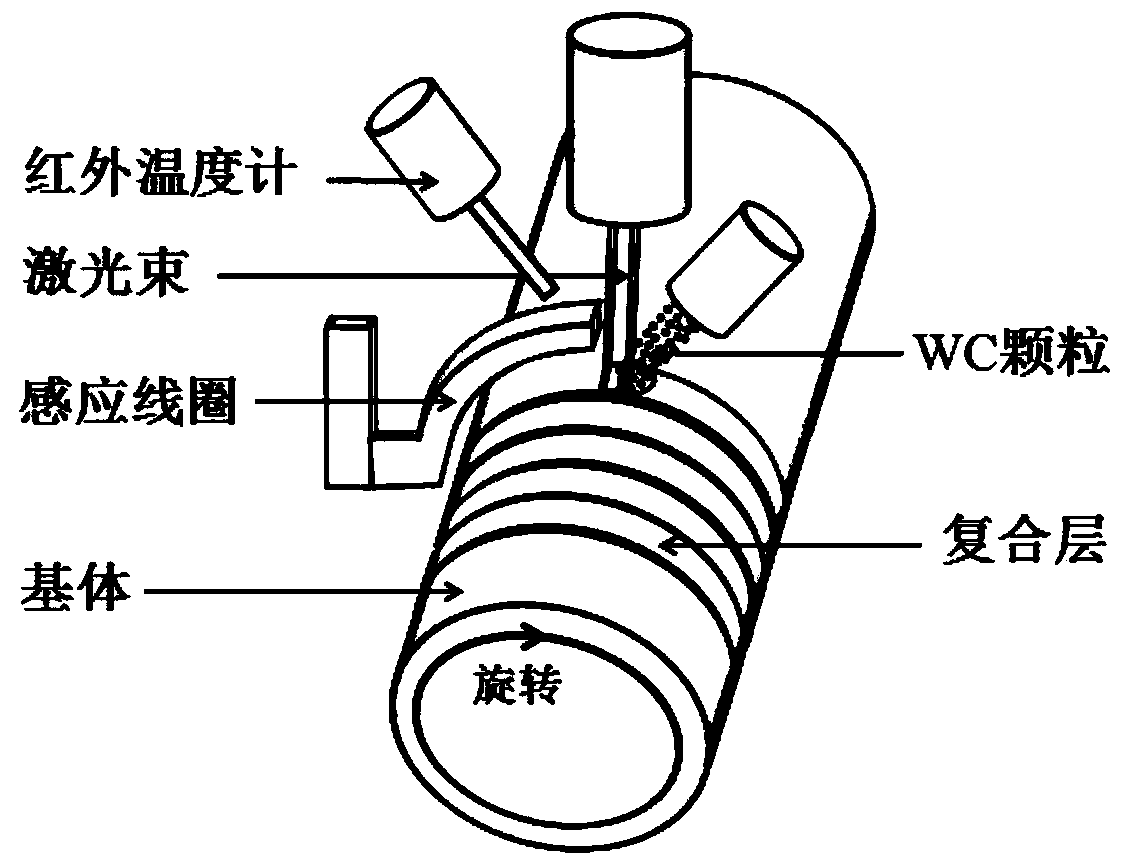

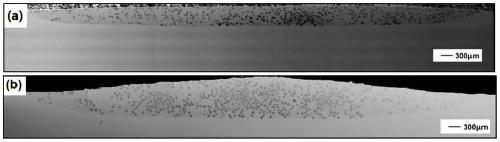

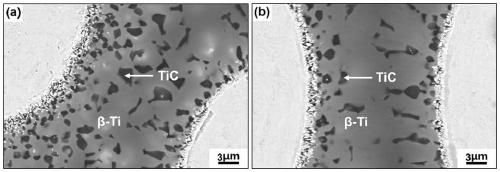

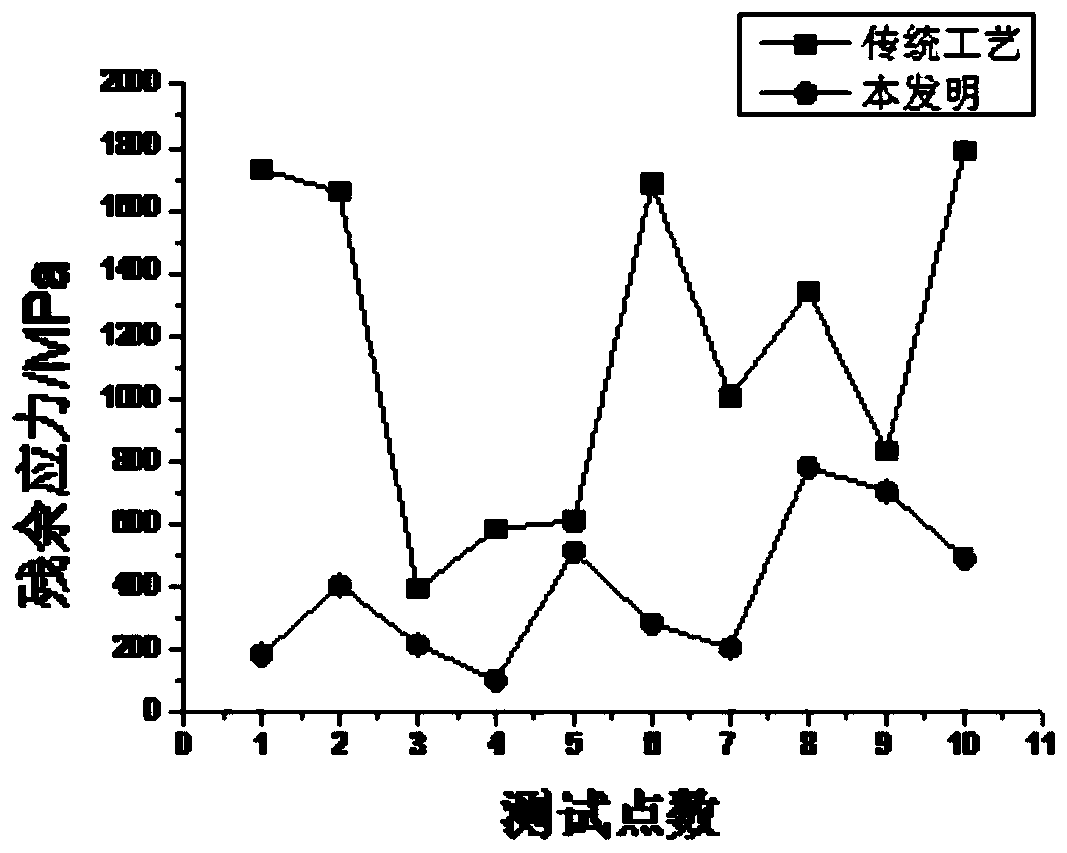

Method capable of giving consideration to laser melt injection efficiency, composite layer depth and metallurgical quality

ActiveCN110306184AReduce precipitationPrevent precipitationMetallic material coating processesInterfacial reactionNucleation

The invention belongs to the field of laser advanced manufacturing, and discloses a method capable of giving consideration to laser melt injection efficiency, composite layer depth and metallurgical quality. According to the method, a molten pool is formed on the surface of a metal base material through a laser beam, and meanwhile, a substrate is subjected to synchronous preheating through an induction coil; and then, ceramic reinforced particles are poured into the molten pool, the reinforced particles which are not completely molten are caught in the molten pool, and accordingly, and a particle-reinforced metal ceramic composite layer is formed on the surface of the metal base material. Induction preheating is synchronously introduced into the traditional laser melt injection technologytreatment process, the cooling rate of the molten pool can be properly decreased, nucleation of the brittle metal compound in the molten pool is inhibited, the problem that cracking occurs due to thefact that the precipitation amount of the brittle compound in the traditional metal ceramic composite layer laser melt injection process is too large is solved, and the intensity of interfacial reaction is effectively controlled while the laser melt injection efficiency and the composite layer depth are remarkably improved.

Owner:HUAZHONG UNIV OF SCI & TECH

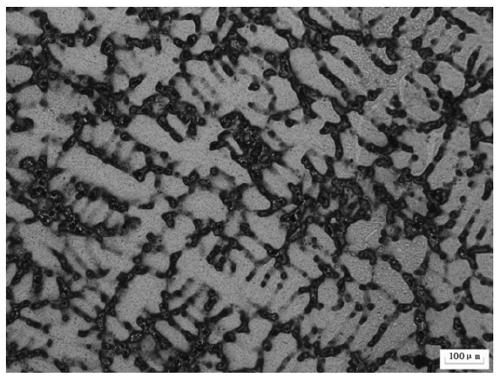

Preparation method of deformed high-temperature alloy ingot

ActiveCN110396605AReduce and reduce thermal stressAvoid crackingIncreasing energy efficiencySelf consumptionEconomic benefits

The invention discloses a preparation method of a deformed high-temperature alloy ingot. The method adopts the preparation process of raw material pretreatment, vacuum induction smelting, hot-fittingannealing, electroslag remelting, hot-fitting annealing, vacuum self-consumption and hot-fitting annealing; the cleanliness of a smelting furnace material is improved through the raw material pretreatment; electrodes with uniform components can be obtained through vacuum induction smelting; the impurities can be further reduced by electroslag remelting, so that a cast ingot is compact in structureso as to obtain an electrode ingot with more excellent quality; and vacuum self-consumption remelting further enables an alloy cast-state dendritic crystal tissues to be refined and the tissues to behomogenized so as to realize a good feeding effect, and the metallurgical defects of severe segregation, looseness, shrinkage and the like are avoided. According to the method, hot-fitting annealingafter smelting in each step is carried out, so that cracks of the electrode or the re-molten ingot in the cooling process can be prevented, and finally a high-quality cast ingot with good surface quality, no crack defect, fine cast dendritic structure, low segregation and low stress is obtained, the percent of pass of the cast ingot is improved, and the high-quality cast ingot has remarkable economic benefits.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Union melt welding wire with tensile strength of 650 MPa grade for coating-free weathering steel bridge and steel wire rod

ActiveCN111975245AGood atmospheric corrosion resistanceReasonable ratio of ingredientsWelding/cutting media/materialsSoldering mediaChemical compositionImpact energy

The invention discloses a steel wire rod for a union melt welding wire with tensile strength of 650 MPa grade for a coating-free weathering steel bridge, and belongs to the field of weathering steel welding materials. The steel wire rod is prepared from chemical composition in percentage by mass: 0.04-0.09% of C, 0.12-0.32% of Si, 1.60-2.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.25-0.55% of Cr, 0.6-1.10% of Ni, 0.20-0.35% of Cu, 0.10-0.40% of Mo, 0.02-0.15% of Ti, 0.010-0.025% of Nb, 0.005-0.030% of Ca, less than or equal to 0.030% of Zr, less than or equal to 0.025% of Ce, less than or equal to 0.0010% of B and the balance of Fe and other unavoidable impurities. Based on the steel wire rod for the union melt welding wire, the invention further provides the union melt welding wire with the tensile strength of 650MPa grade for the coating-free weathering steel bridge. The welding wire and the steel wire rod are suitable for the welding of the coating-free steel bridge with tensile strength of 650 MPa, wherein the tensile strength of deposited metal is greater than or equal to 650 MPa; the yield strength is greater than or equal to 500 MPa; the elongation is greater than or equal to 22%; and the low-temperature impact energy KV2 of the deposited metal at -40 DEG C is greater than or equal to 80 J.

Owner:YANSHAN UNIV

Method for adding oxygen and iron in titanium alloy

The invention discloses a method for adding oxygen and iron in titanium alloy. According to the method, an oxygen element and an iron element contained in the titanium alloy required to be prepared are added in the form of mixed powder, the mixed powder is formed by uniformly mixing a component A and a component B, the component A is FeTiO3 powder, and the component B is Fe2O3 powder or TiO2 powder. The method is simple in step, reasonable in design, low in investment cost, easy and convenient to operate and good in using effect, and can effectively avoid the phenomena of micro-cell non-uniformity and unfused TiO2 caused when industrial iron and TiO2 powder serve as intermediate alloys are added.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Laser additive manufacturing method for multihole micro-channel structure

InactiveCN107855522AShorten the manufacturing cycleIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningOptoelectronics

The invention discloses a laser additive manufacturing method for a multihole micro-channel structure. The laser additive manufacturing method for the mulithole micro-channel structure comprises the following steps that a three-dimensional model is established and subjected to layered slicing, and a laser scanning path is acquired; a base material is fixed, and stainless steel / titanium alloy powder is put into a powder cylinder; argon is fed into a forming chamber, and the base material is paved with the powder; laser additive manufacturing equipment is started to conduct scanning machining; aforming cylinder is lowered by a distance of the thickness of a layer, a powder laying device lays a layer of powder on the current machined layer until the structure machining is completed; and a part is subjected to annealing treatment, and the multihole micro-channel structure is obtained. After being formed, the multihole micro-channel structure manufactured through the laser additive manufacturing method is compact, fine and uniform in texture, the metallurgical quality is good, leakage does not occur in the pressing process, the complex inner channel structure is high in size precision,the cross section shape and the distribution limitation of an inner channel are reduced, and the product performance is high; and after the complex multihole inner channel structure is formed, the welding working procedure is not needed, the material utilization rate is increased, working procedures are reduced, and the part manufacturing period is shortened.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com