Thermo-mechanical treatment process of great-length Cu-Cr-Zr-Si alloy contact line

A cu-cr-zr-si, thermomechanical treatment technology, applied in the field of thermomechanical treatment production process, can solve the problems such as difficult to control the quality stability of large-length billets, high heredity of casting coarse grains, and damage to product performance, etc. , to achieve the effects of improving mechanical properties and electrical conductivity, outstanding high temperature softening resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

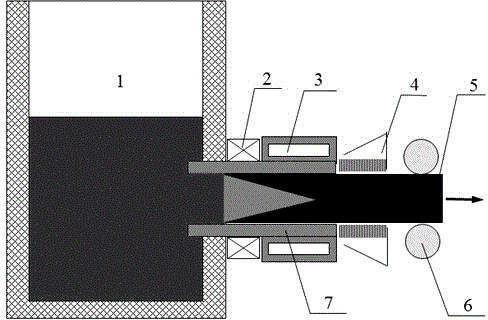

Image

Examples

Embodiment 1

[0042] The raw material is 99.96% copper cathode, Cu-Cr master alloy, Cu-Zr master alloy and Cu-Si master alloy are prepared according to the content of alloy elements (mass%): Cu-0.30%Cr-0.10%Zr-0.01%Si Smelting raw materials. The cathode Cu should be placed in the induction furnace first, and the furnace should be filled with pure Ar to 30kPa to squeeze out the air in the furnace as much as possible, and the temperature should be raised at a rate of about 10°C / min until the material melts, and then 10ml / s flow rate of pure Ar plus 15ml / s flow rate should be introduced of pure N 2 The mixed gas forms a complete protective layer of inert gas, and then covers the surface of the melt with a dry charcoal layer about 40mm thick to strengthen protection and block the thermal radiation effect of the melt. Then add Cu-Cr master alloy, then add Cu-Zr and Cu-Si master alloy after melting, and let the melt stand at 1250°C for 20 minutes evenly under electromagnetic stirring. The tight...

Embodiment 2

[0051] The raw material is 99.96% cathode copper, Cu-Cr master alloy, Cu-Zr master alloy and Cu-Si master alloy to prepare the contact wire with element content (mass%): Cu-0.60%Cr-0.15%Zr-0.02%Si smelting raw materials. First put the cathode Cu in the induction furnace and fill the furnace with pure Ar to 30kPa to squeeze out the air in the furnace as much as possible, raise the temperature at a rate of about 10°C / min until the material melts, and then feed 20ml / s flow of pure Ar plus 30ml / s flow Pure N mixed gas forms a complete protective layer of inert gas, and then covers the surface of the melt with a dry charcoal layer about 40mm thick to strengthen protection and block the thermal radiation effect of the melt. Then add Cu-Cr master alloy, then add Cu-Zr and Cu-Si master alloy after melting, and let the melt stand at 1250°C for 20 minutes evenly under electromagnetic stirring. The tightness and stability of the charcoal and mixed gas covering layer on the surface of th...

Embodiment 3

[0060] The raw material is 99.96% cathode copper, Cu-Cr master alloy, Cu-Zr master alloy and Cu-Si master alloy to prepare the contact wire with element content (mass%): Cu-0.50%Cr-0.12%Zr-0.02%Si smelting raw materials. First place the cathode Cu in the induction furnace, first place the cathode Cu in the induction furnace, fill the furnace with pure Ar to 30kPa, squeeze out the air in the furnace as much as possible, raise the temperature at a rate of about 10°C / min until the material melts, and then inject 15ml / The s flow of pure Ar plus 20ml / s flow of pure N mixed gas forms a complete protective layer of inert gas, and then covers the surface of the melt with a dry charcoal layer about 40mm thick to strengthen protection and block the heat radiation effect of the melt. Then add Cu-Cr master alloy, then add Cu-Zr and Cu-Si master alloy after melting, and let the melt stand at 1250°C for 20 minutes evenly under electromagnetic stirring. The tightness and stability of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com