Patents

Literature

63results about How to "Refining as-cast grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

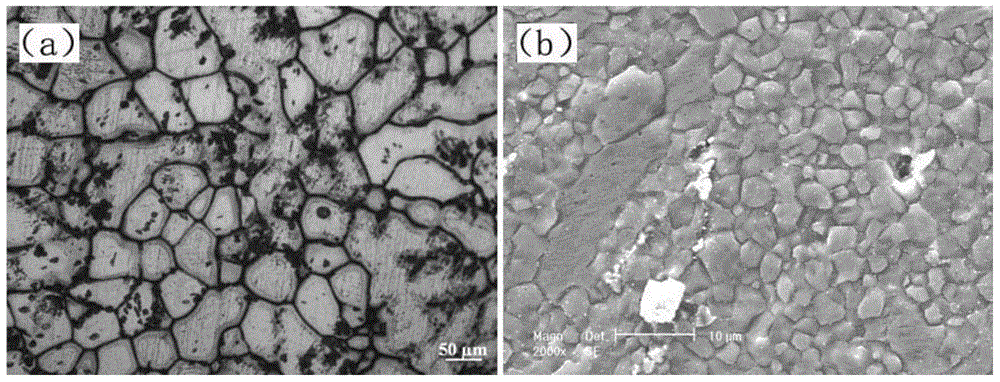

High-strength wrought magnesium alloy and preparation method thereof

ActiveCN105220041AHigh strengthImprove precipitation strengthening effectRare-earth elementCrystallite

The invention discloses high-strength wrought magnesium alloy and a preparation method thereof and belongs to the technical field of light metal materials. The high-strength wrought magnesium alloy comprises the following components in percentage by weight: 2.0-6.5% of Zn, 0.1-3.0% of RE, 0.1-2.0% of Ca and the balance of Mg and inevitable impurities; the high-strength wrought magnesium alloy also can comprise grain refiners Mn and / or Zr. Zn is a main strengthening element in the alloy, and can improve the room temperature strength of magnesium alloy through solid solution strengthening and aging precipitation strengthening; Ca is used for promoting precipitation, refining grains and improving high-temperature strength of alloy; and a small amount of RE is used for restraining recrystallization, refining deformed alloy grains, regulating texture and improving plasticity of alloy. According to the invention, by replacing expensive rare earth elements with cheap common alloying elements, a strengthening effect similar to that of rare earth is generated, the rare earth content is completely replaced or lowered and the cost of alloy is reduced while strength is guaranteed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

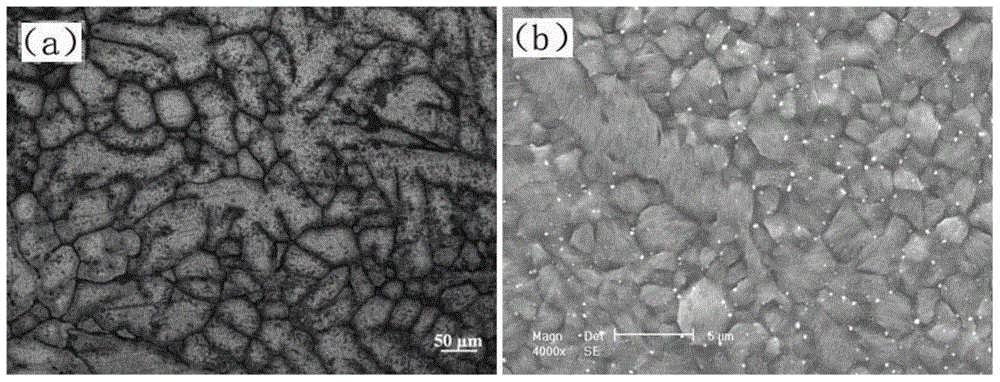

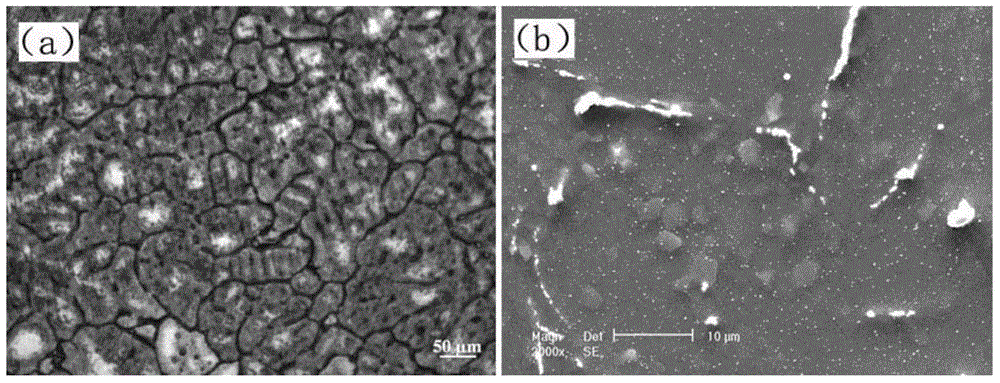

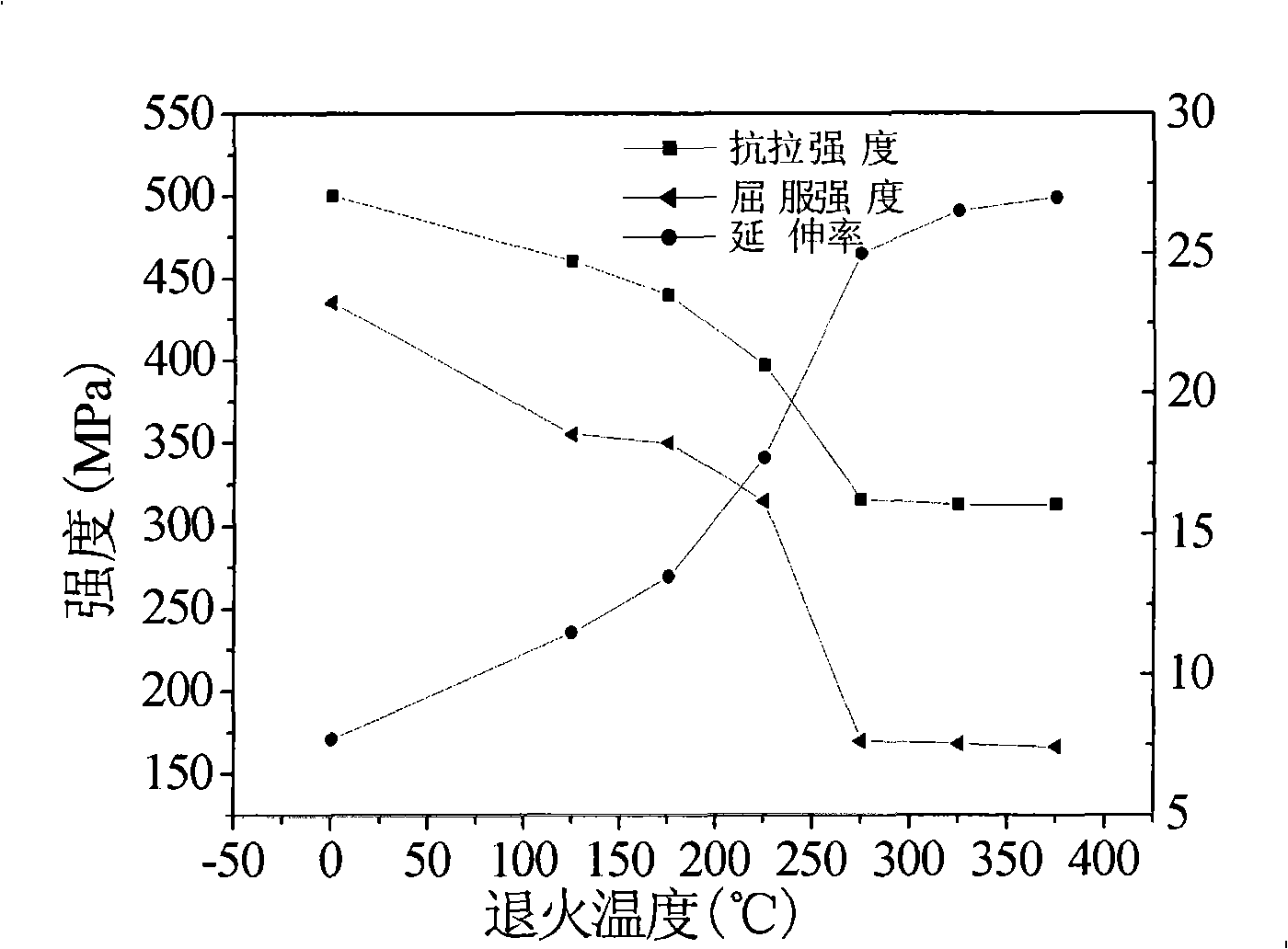

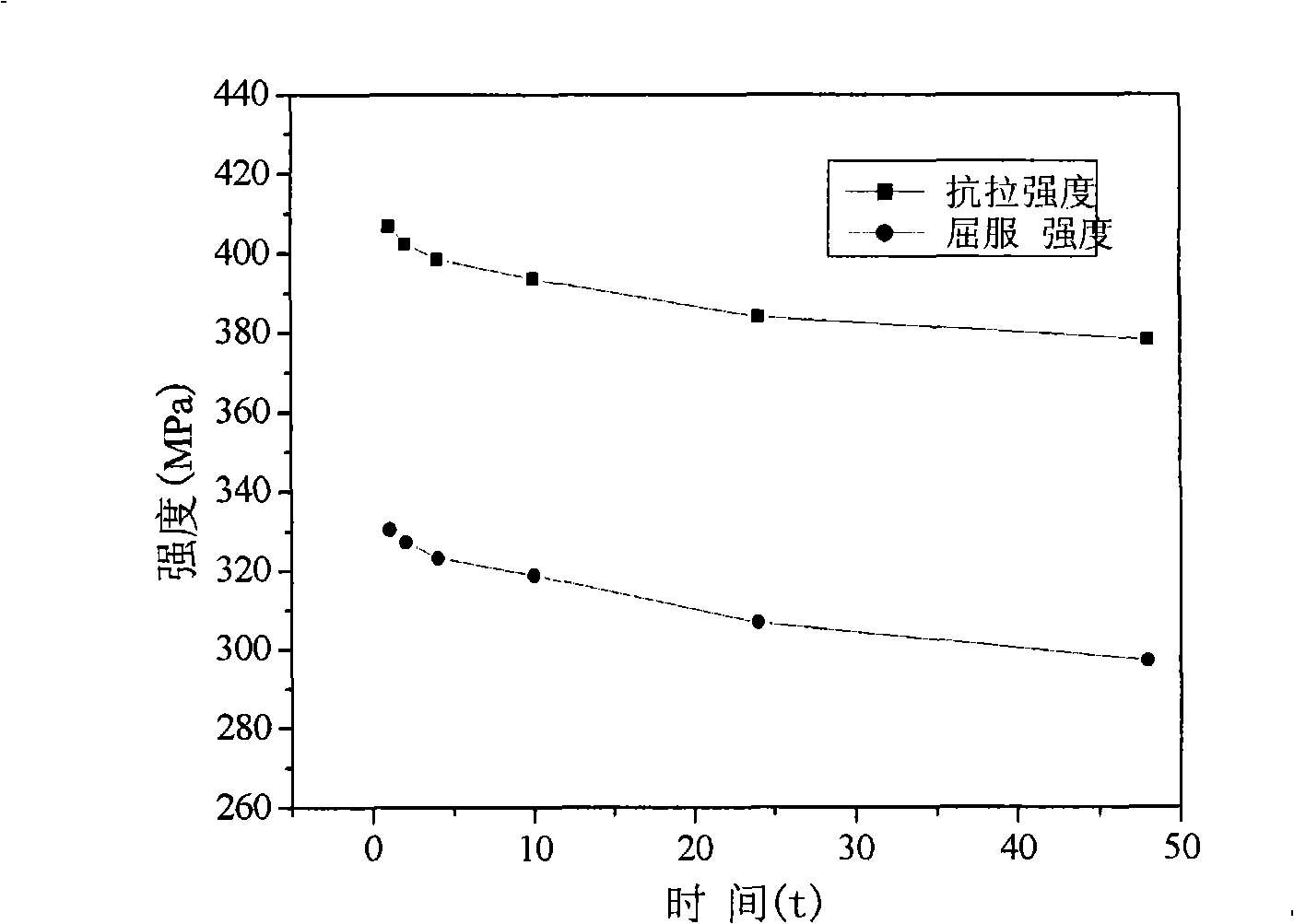

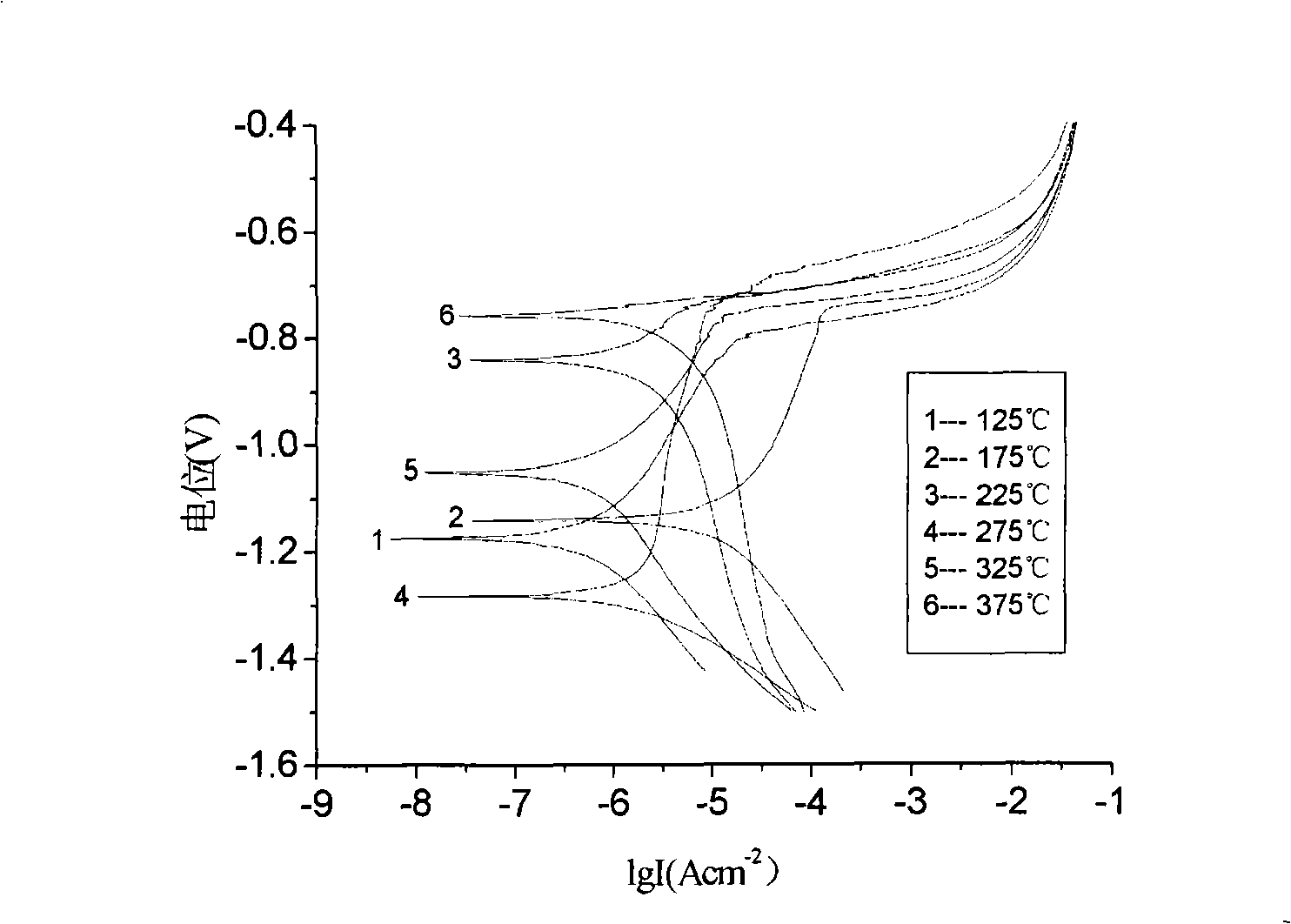

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

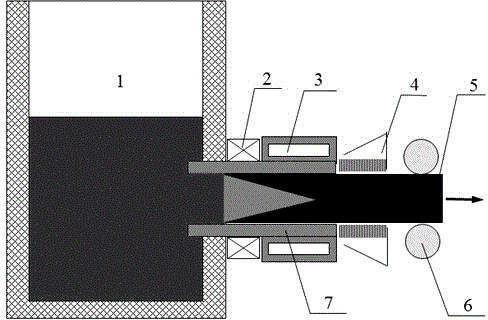

Thermo-mechanical treatment process of great-length Cu-Cr-Zr-Si alloy contact line

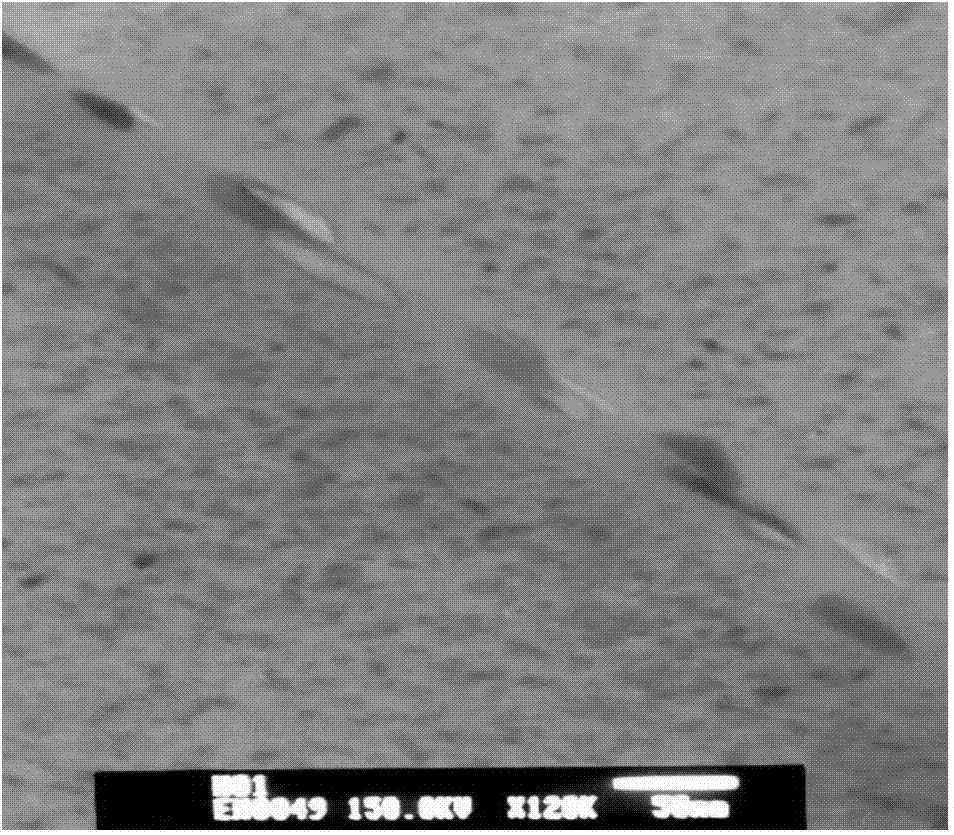

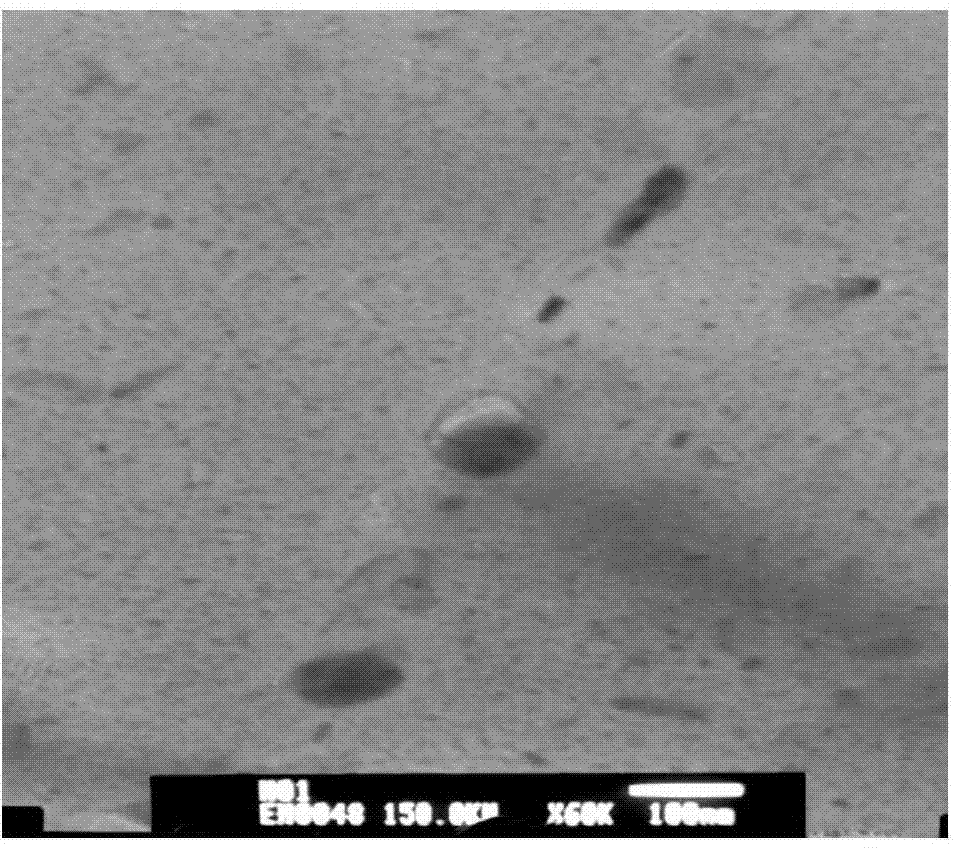

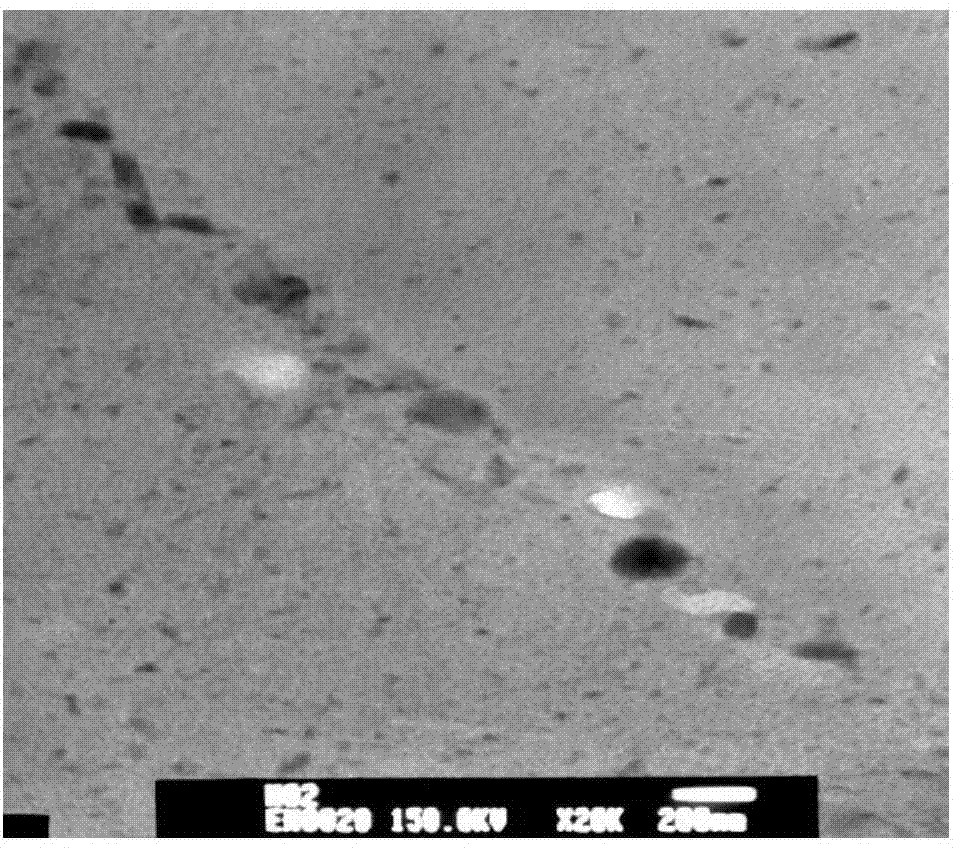

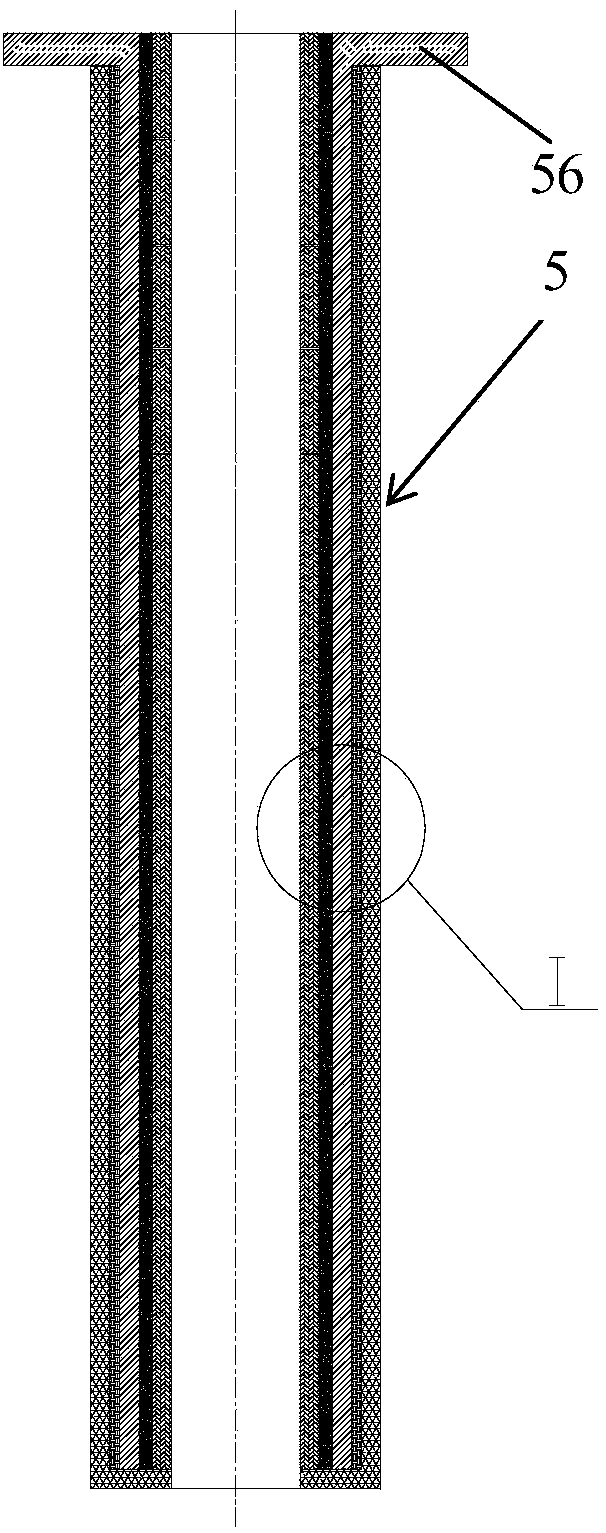

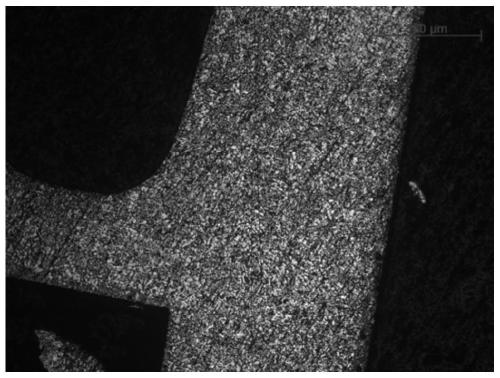

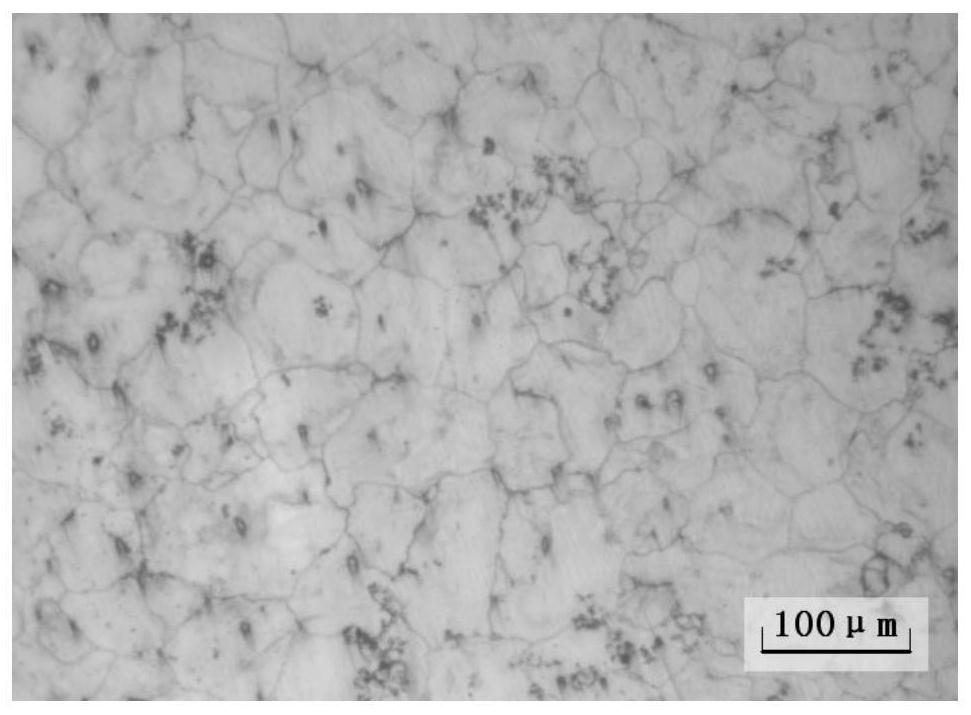

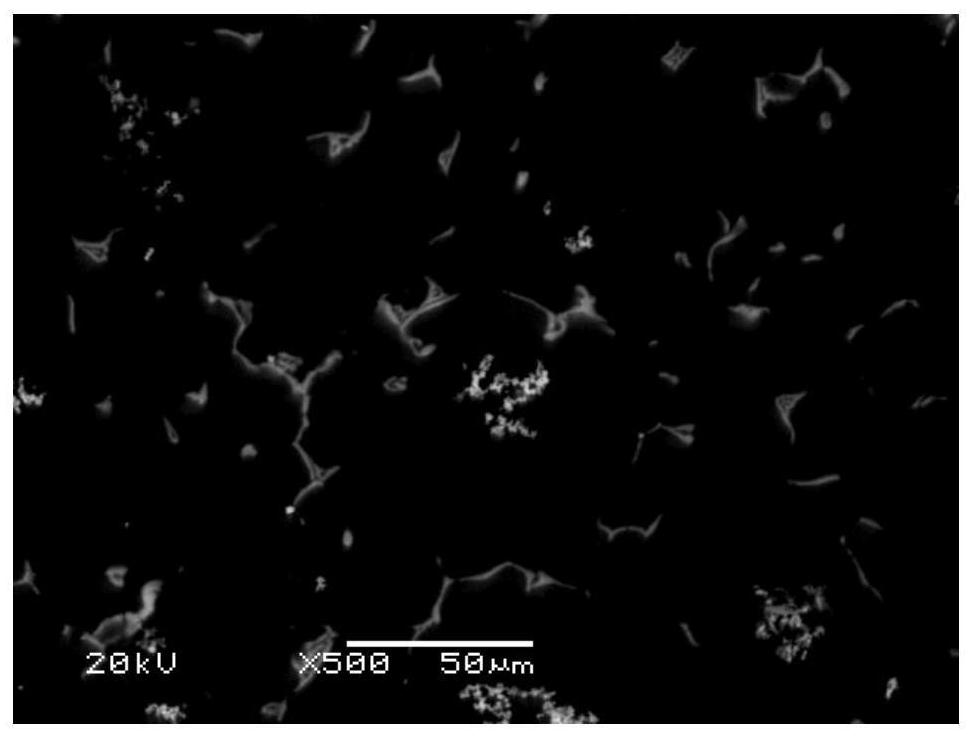

InactiveCN104928603ACauses a dynamic recrystallization effectRefining as-cast grainContact lineHeavy duty

The invention discloses a thermo-mechanical treatment process of a great-length Cu-Cr-Zr-Si alloy contact line. The process includes: smelting Cu-Cr-Zr-Si alloy, with Cu accounting for 0.30% to 0.50%, Cr accounting for 0.10% to 0.15% and Zr accounting for 0.01% to 0.02% in content, with a combined protective layer composed of mixed inert gas and a covering dried charcoal protective layer, in an induction furnace; and performing drag casting with a horizontal continuous casting system with electromagnetic stirring and a local heater to obtain rods 16 to 120mm in length. By high-frequency inductive thermal rolling, step heating and water-cooling solidification, cold rolling, split ageing and finish drawing or cold rolling, the alloy contact line having symmetrical grooves in two sides, 110 mm<2> to 150 mm<2> in sectional area and 1800 to 2000 m in singular length. The process has the advantages that metallurgical quality of products is high, and the performances meet the needs of various overhead line systems for modern high-speed railways and low-speed heavy duties.

Owner:YANTAI JINHUI COPPER +2

Aluminum alloy for anti-chloridion-corrosion type aluminum alloy oil pipe and pipe manufacturing method of aluminum alloy

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

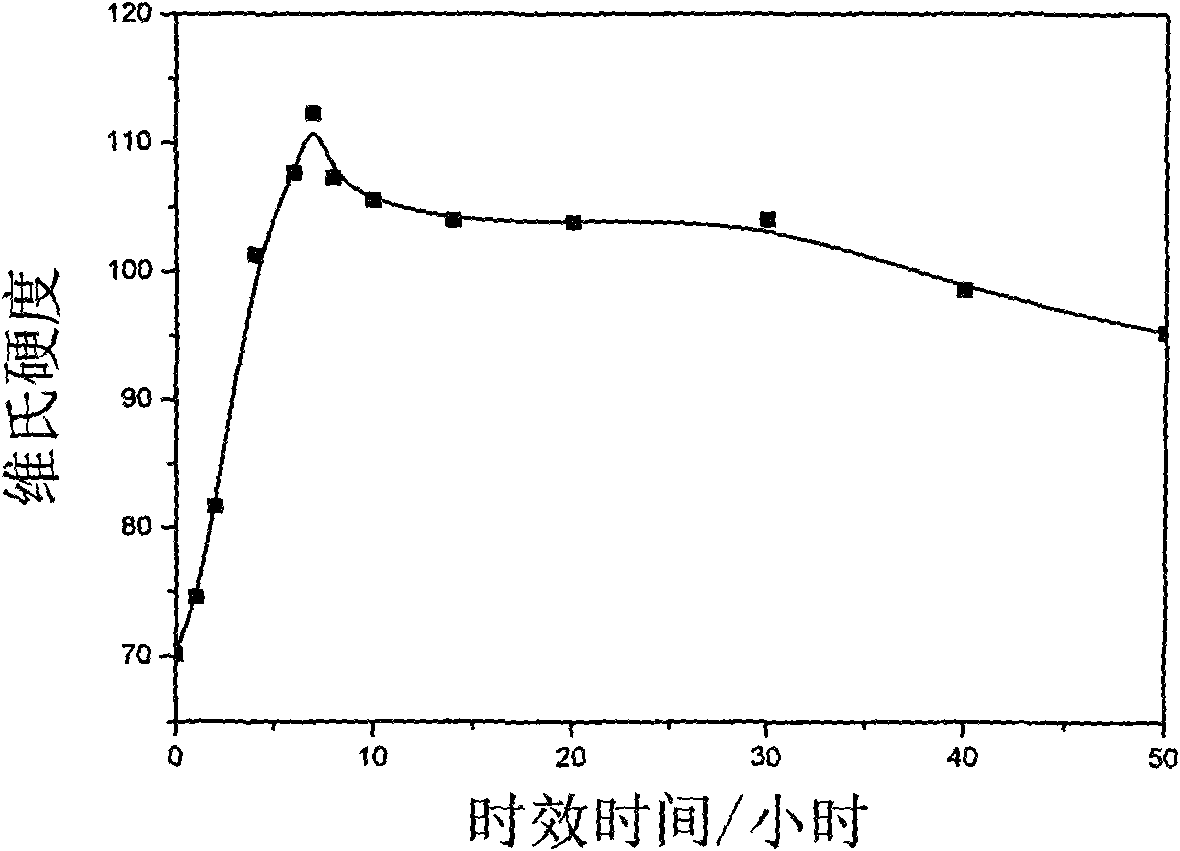

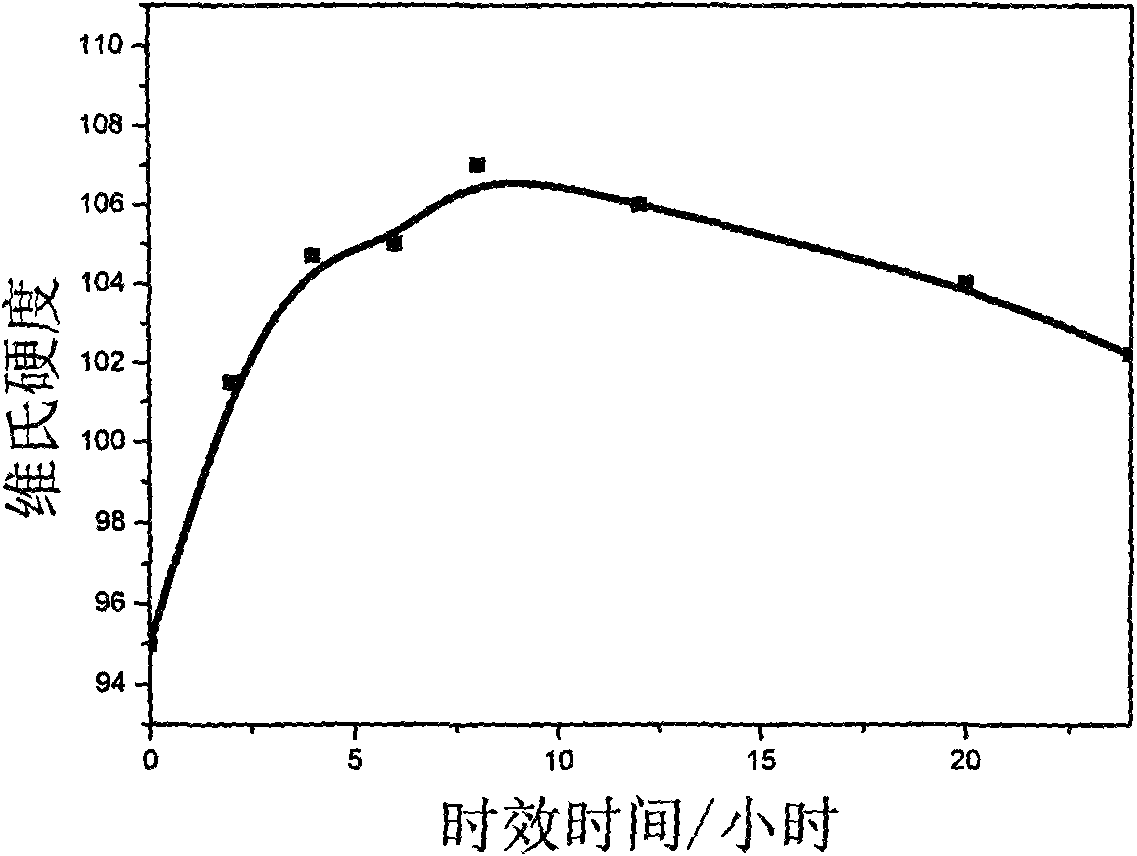

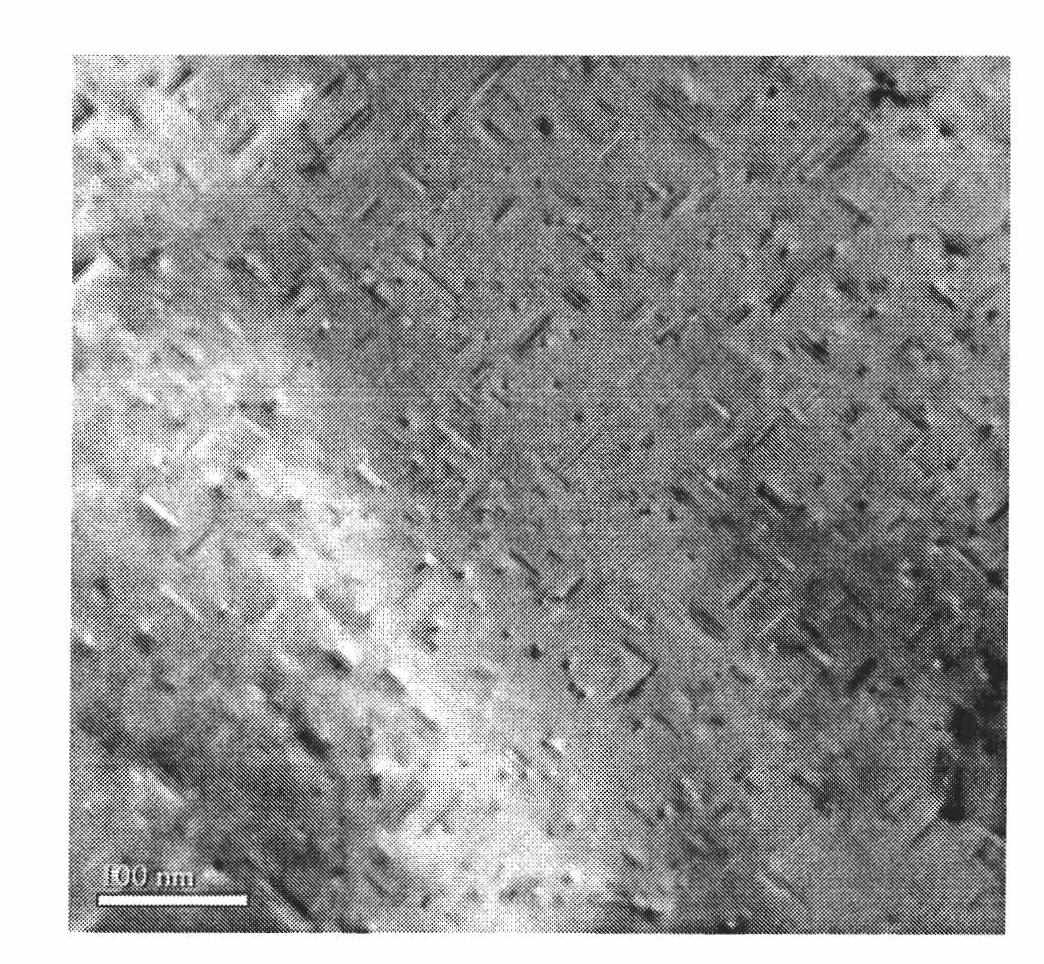

Preparation and ageing treatment process for novel Al-Mg-Si-Er aluminum alloy plate material

The invention discloses preparation and an ageing treatment process for a Al-Mg-Si-Er aluminum alloy plate material, belonging to the technical field of metal alloy. The preparation method comprises the following steps: preparing metal ingots by adopting a semi-continuous casting method; homogenizing the metal ingots; respectively performing hot rolling and cold rolling on a rolling mill of 310*480mm, wherein the heating temperature of the hot rolling is 450 DEG C; and preserving the temperature for 2 hours, wherein the final rolling thickness is about 2mm. One process condition is that: 1 to 50 hours of ageing heat treatment is performed at 180 DEG C after solution treatment; and the other process condition is that: 1 hour of regression heat treatment is performed at 220 DEG C based on 7 hours of ageing at 180 DEG C, and the alloy is re-aged for 1 to 24 hours at 150 DEG C after regression treatment. The alloy treated by the process has higher strength, the 230MPa using performance requirement of the alloy can be well fulfilled, and the corrosion resistance and plasticity of the alloy can be improved.

Owner:BEIJING UNIV OF TECH

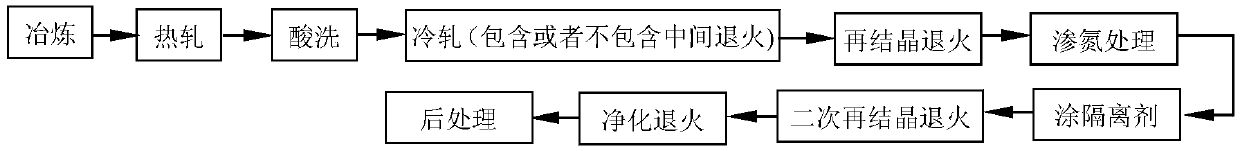

High magnetic induction orientated high-silicon steel plate thin strip and preparation method thereof

ActiveCN109097677AStrong initial inhibitionImprove uniformitySolid state diffusion coatingFurnace typesCollocationMetallurgy

The invention discloses a high magnetic induction orientated high-silicon steel plate thin strip and a preparation method thereof. The thin strip comprises the following ingredients: less than or equal to 0.04% of C, 5.0-6.7% of Si, 0.05-0.2% of Mn, 0.015-0.04% of Als, less than or equal to 0.2% of Nb, less than or equal to 0.1% of V, less than or equal to 0.5% of Cu, 0.006-0.010% of N, 0.007-0.02% of S and the balance of Fe and impurities. The method comprises the following steps that: carrying out hot rolling on a plate blank obtained by casting, carrying out acid pickling on a hot rolling plate to remove an oxidization layer, and then, carrying out warm rolling; then, carrying out decarburizing annealing on a cold rolling thin plate; carrying out nitridation processing, and coating thesurface of the steel strip with separant, and carrying out secondary recrystallization annealing and purification annealing; and finally, carrying out flattening stretching annealing. By use of the thin strip, the heating temperature of the plate blank is lowered, inhibitor behaviors and recrystallization tissues are regulated and controlled, so that the harmonious collocation of an inhibition force-tissue-texture in a secondary recrystallization process is realized, the high magnetic induction orientated high-silicon steel plate thin strip with sharp Goss ([110](001)) texture characteristicscan be produced on a large scale, production cost is greatly lowered, and the thin strip has a wide application prospect.

Owner:NORTHEASTERN UNIV

Aluminum alloy cast ingot for automotive bumper and production process thereof

InactiveCN102965553AStrong age hardening effectImproves resistance to stress corrosionSlagThermal deformation

The invention relates to an aluminum alloy cast ingot for an automotive bumper and a production process thereof and belongs to the technical fields of aluminum alloy and processing technique. The processing of the aluminum alloy cast ingot for the automotive bumper is finished by the following steps of: material proportioning, smelting, permanent magnetism stirring, temperature measurement, sampling, adjustment of ingredient and temperature, turning down, refining (first purification), standing, online adding of Al, Ti and B wires, online degassing and slag removal (secondary purification), double filtering, equal-level hot top casting, cast ingot homogenization, machining of the cast ingot, inspection of the cast ingot and heating of the cast ingot by an induction furnace. The hard aluminum alloy cast ingot, machined in the invention, has excellent thermal deformation performance and higher strength after being subjected to online quenching in extrusion process, the welding property and corrosion resistance of a product are excellent, and the product has certain stress-corrosion resistance and particularly has stronger shock absorption capacity and folding resistance.

Owner:CONGLIN GROUP

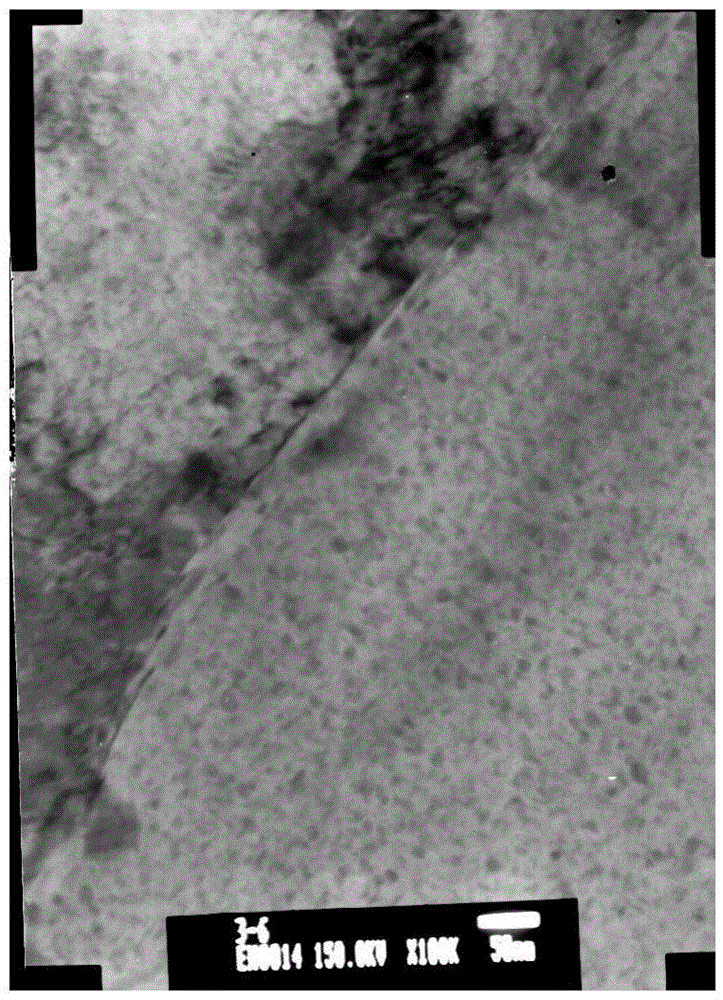

Gd-Lu-containing aluminum alloy section bar for space flight and aviation and preparation method thereof

InactiveCN104862560AIncrease the precipitation densityInhibition of recrystallizationRare-earth elementCorrosion

The invention discloses a Gd-Lu-containing aluminum alloy section bar for space flight and aviation and a preparation method thereof. The Gd-Lu-containing aluminum alloy section bar comprises, by weight, 5.2-6.4% of Zn, 1.8-2.6% of Mg, 1.5-2.0% of Cu, 0.3-0.6% of Mn, 0.25-0.35% of Cr, 0.1-0.3% of Si, 0.15-0.25% of Fe, 0.05-0.1% of Ti, 0.04-0.08% of Zr, 0.2-0.4% of Gd, 0.1-0.2% of Lu and the balance Al. Gd and Lu rare earth elements are added into an Al-Zn-Mg-Cu series aluminum alloy and through alloying, alloy as-cast grains are refined, strengthening phase precipitation density is improved, strengthening phase distribution is uniform, recrystallization is inhibited, crystal boundary movement is prevented, re-crystal grain growth is inhibited, alloy strength is substantially improved and stress corrosion resistance and welding performances of the alloy are improved. Gd and Lu replace Sc and are added in the Al-Zn-Mg-Cu series aluminum alloy so that a production cost is not greatly improved and alloy strength is greatly improved. The Gd-Lu-containing aluminum alloy section bar can be widely used in the field of space flight and aviation.

Owner:CHENGDU ZHILIDA TECH

Aluminum alloy sodium-free refining agent and application thereof

The invention provides an aluminum alloy sodium-free refining agent and belongs to the technical field of casting of aluminum alloys. The sodium-free refining agent comprises the following raw materials in parts by weight: 30-35 parts of K2CO3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 12-18 parts of LiCl, 3-5 parts of calcium oxide, 30-35 parts of BalF3, 5-10 parts of K2SiF6, 10-15 parts of C6Cl6, 5-10 parts of TiO2 and 3-8 parts of CaCl. The aluminum alloy sodium-free refining agent is free of impurity sodium; meanwhile, rare-earth metals are added into the sodium-free refining agent; the rare-earth metals have high chemical affinity with impurity elements such as H2 and S and the like; the rare-earth metals and various impurity elements form compounds; the influence of harmful impurities can be eliminated; the rare-earth metals have the functions of modifying and refining the aluminum alloy structure; the dendrite spacing of the aluminum alloy is effectively reduced; the as-cast grains are refined; the mechanical performance of the alloy is improved; meanwhile, the smelting temperature of the aluminum alloy is maintained at 710-730 DEG C in the process of using the aluminum alloy sodium-free refining agent, so that the effect of removing impurity elements such as H2 and S and the like is more significant.

Owner:贵州航天风华精密设备有限公司

High-strength corrosion-resistant aluminum alloy section bar for doors and windows

The invention discloses a high-strength corrosion-resistant aluminum alloy section bar for doors and windows. The high-strength corrosion-resistant aluminum alloy section bar consists of the following components in percentage by weight: 1.2-1.8% of Mg, 1-1.5% of Cu, 0.3-0.5% of Mn, 5-8% of Zn, 0.02-0.2% of Sc, 0.02-0.1% of Ti, 0.01-0.1% of Cr, 0.05-0.25% of Fe and 0.05-0.3% of Yb. The high-strength corrosion-resistant aluminum alloy section bar is prepared by the following process: smelting raw materials and putting the smelted raw materials on an extruder to extrude at an extrusion speed of 5-40m / min; after extrusion is ended, cooling the raw materials to a temperature lower than 50 DEG C to carry out stretching and straightening, thereby obtaining an extruded part; putting the extruded part into a heat preserving furnace to carry out thermal treatment, carrying out degreasing, chromizing, washing and drying on the extruded part after a washing process, and then carrying out powder spraying on the extruded part to obtain the high-strength corrosion-resistant aluminum alloy section bar. The high-strength corrosion-resistant aluminum alloy section bar for doors and windows disclosed by the invention is high in strength, and is good in corrosion resistance; and doors and windows manufactured by the high-strength corrosion-resistant aluminum alloy section bar are not liable to deformation and color change, and are long in service lifetime.

Owner:ANHUI XIN FA ALUMINUM PROD

Machining method of a window and door aluminium alloy

The invention discloses a machining method of a window and door aluminium alloy. The window and door aluminium alloy comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn,0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare earth element RE and the balance of Al. The window and door aluminium alloy is prepared by using the steps of melting, slagging-off, heat preservation and standing, online refining, alloying, refining, on-line degassing, casting, homogenizing annealing, extrusion forming, heat treatment, shading, sealing treatment and the like. According to the machining method of the window and door aluminium alloy, by optimizing alloy components, a mixing ratio and a machining process, a problem that the strength and the casting performance of the aluminium alloy contradict each other can be effectively solved; and problems of large hot cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminium alloy are solved.

Owner:阜阳力佳门业有限公司

Automobile corrosion-resistant die-casting aluminum alloy and preparation method thereof

The invention discloses an automobile corrosion-resistant die-casting aluminum alloy and a preparation method thereof, and belongs to the field of aluminum alloy die-casting processing. The automobilecorrosion-resistant die-casting aluminum alloy comprises, by weight, 6.5%-7.6% of Si, 1.4%-2.1% of Mg, 0.8%-1.3% of Cu, 0.05%-0.11% of Sr, 0.4%-0.9%of Zn, 0.4%-0.8% of Mn, 0.2%-0.6% of Fe, 0.2%-0.5%of Y, 0.03%-0.05% of Er, less than or equal to 0.5% of other metals and non-metals, and the balance Al. The automobile corrosion-resistant die-casting aluminum alloy is prepared by the steps of melting, refining, standing, die casting, solid solution quenching treatment, aging treatment and the like. The aluminum alloy has the advantages that the corrosion resistance is greatly improved, the tensile property at high temperature is good, the toughness is high, and the extrusion resistance is good; and the preparation method is simple and feasible in process, and has the advantages of being highin safety and low in production process cost, and the produced aluminum alloy casting meets the use requirements of the workpiece needing to bear a large dynamic load.

Owner:广西平果铝合金精密铸件有限公司

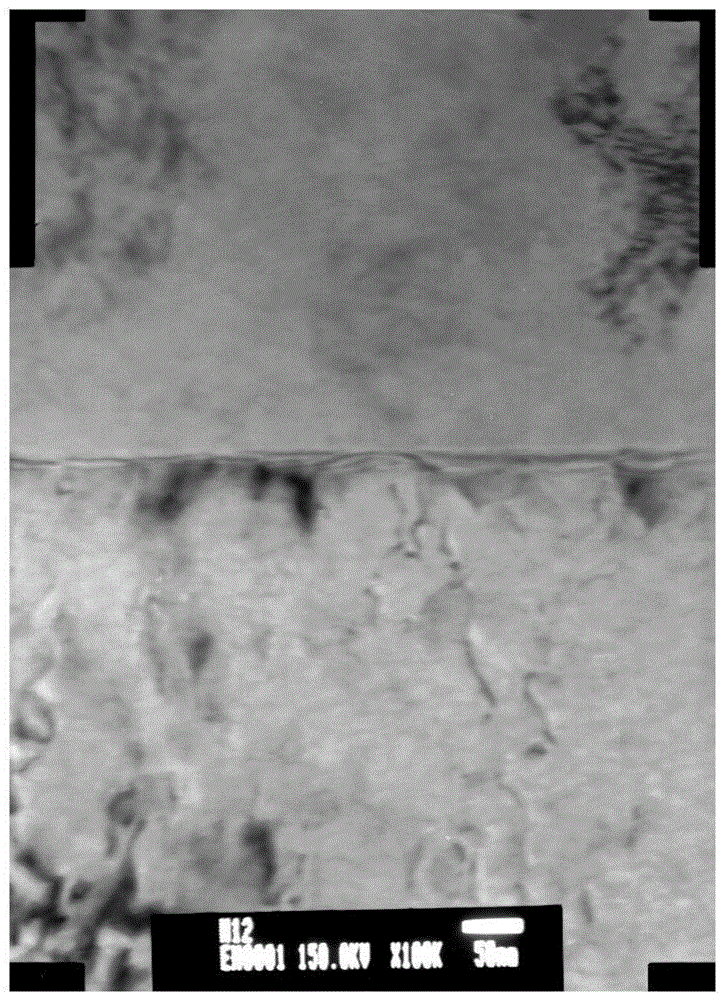

Preparation method of overlength Cu-Cr-Zr alloyed contact line

ActiveCN101531149BAvoid early precipitationAvoid direct precipitation strengthening effectsTrolley linesContact lineInduction furnace

The invention discloses a preparation method of overlength Cu-Cr-Zr alloyed contact line. The smelting content in an induction furnace is Cu-(0.30-0.60) %Cr-(0.10-0.15) %Zr-(0.01-0.02) %Si alloy. By processes of continuous casting, extrusion, heat treatment, cold drawing and rolling, a contact line with a nominal area of 110-150mm<2> is prepared, under the conditions that processes are simplified and equipment and alloying components are fairly simple, the contact line with a length of simple root of the finished product being up to 1000-1500m has fine tensile strength, electrical conductivity and high temperature softening resistance.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +2

Aluminum alloy sodium-free refining agent containing rare earth

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

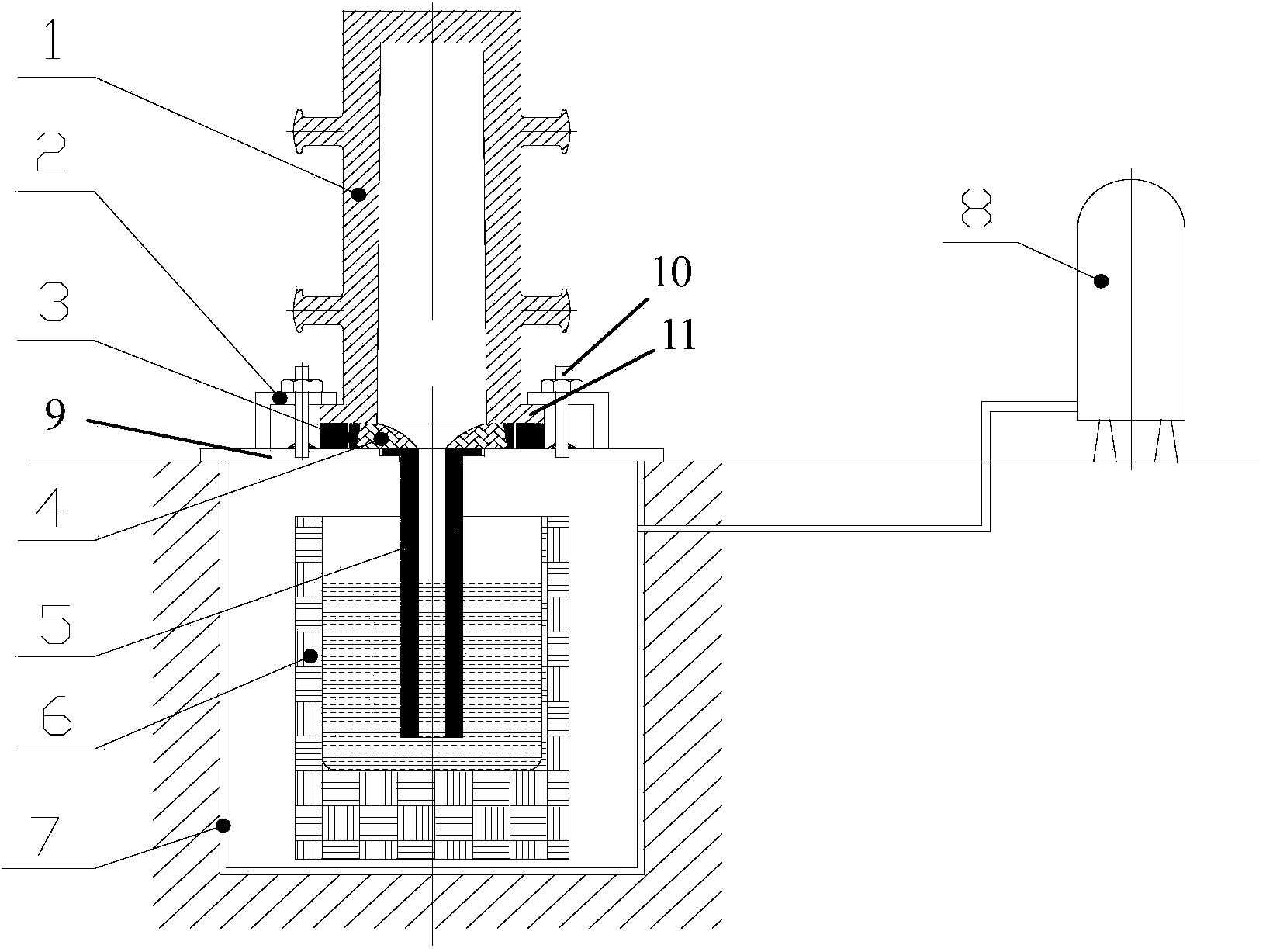

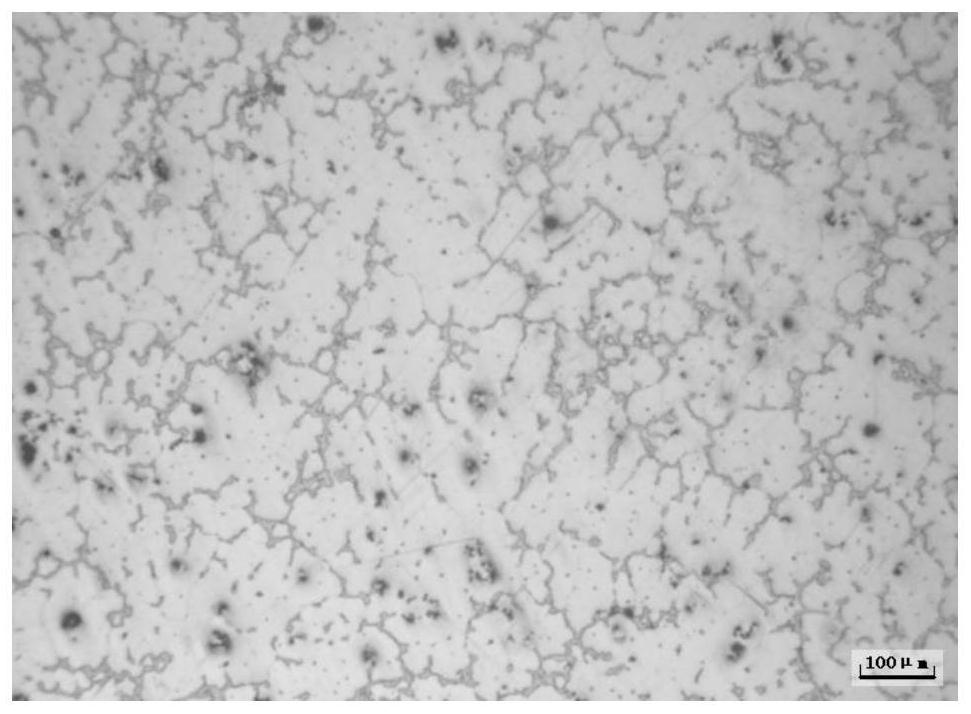

Pressure casting method of purified homogenized compacted fine-grained large steel blank

The invention relates to the field of manufacturing of large-section thick large blanks, in particular to a pressure casting method of a purified homogenized compacted fine-grained large steel blank. According to the method for improving quality of a large steel blank by pressure effect, the problems that the existing large-section blank experiences gross segregation, shrinkage cavity and porosity, inclusion and grain coarseness can be solved; the large steel blank can be purified, homogenized, compacted and fine grained during manufacturing; yield of the blank is significantly improved; on such basis, gravity riser feeding is replaced with pressure feeding to allow non-riser casting, and yield of the blank can be significantly increased. The pressure casting method is applicable to manufacturing of large-section steel blanks, including round billets, square billets and flat billets, is applicable to manufacturing of large blanks of aluminum alloy, magnesium alloy and high-temperature alloy and is also applicable to manufacturing of complex castings of ferrous metals and nonferrous metals.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

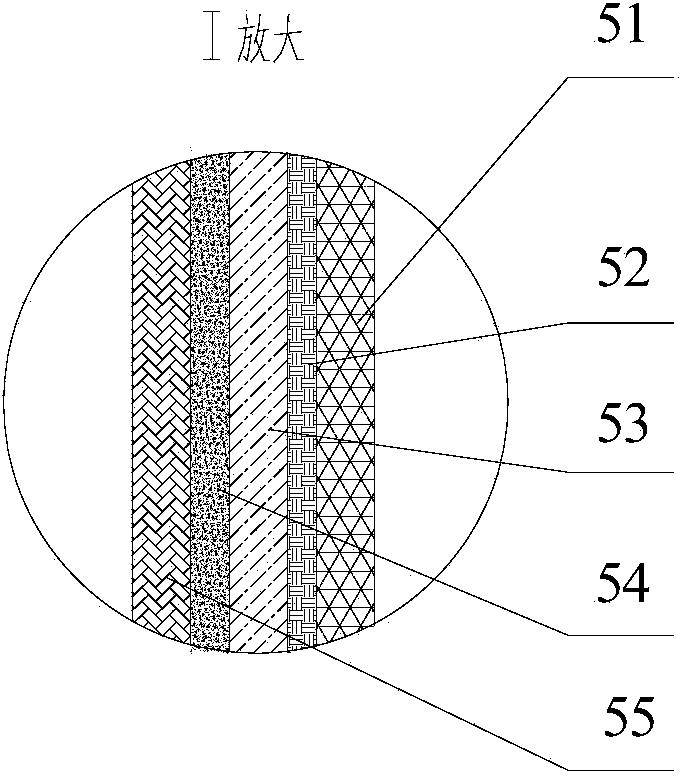

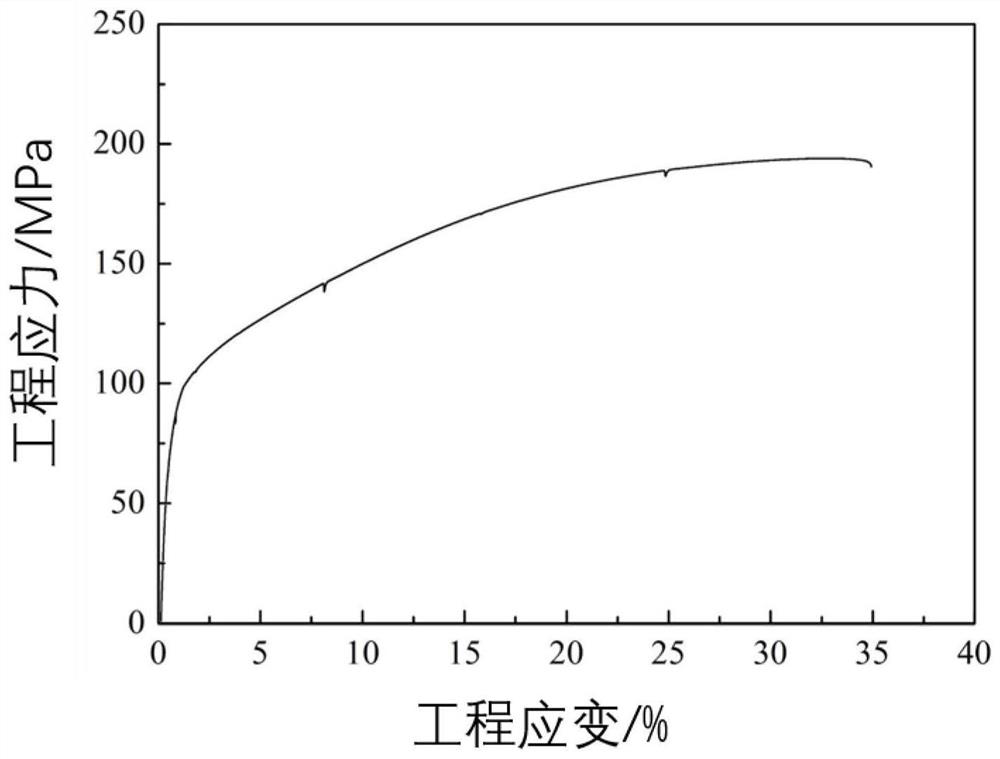

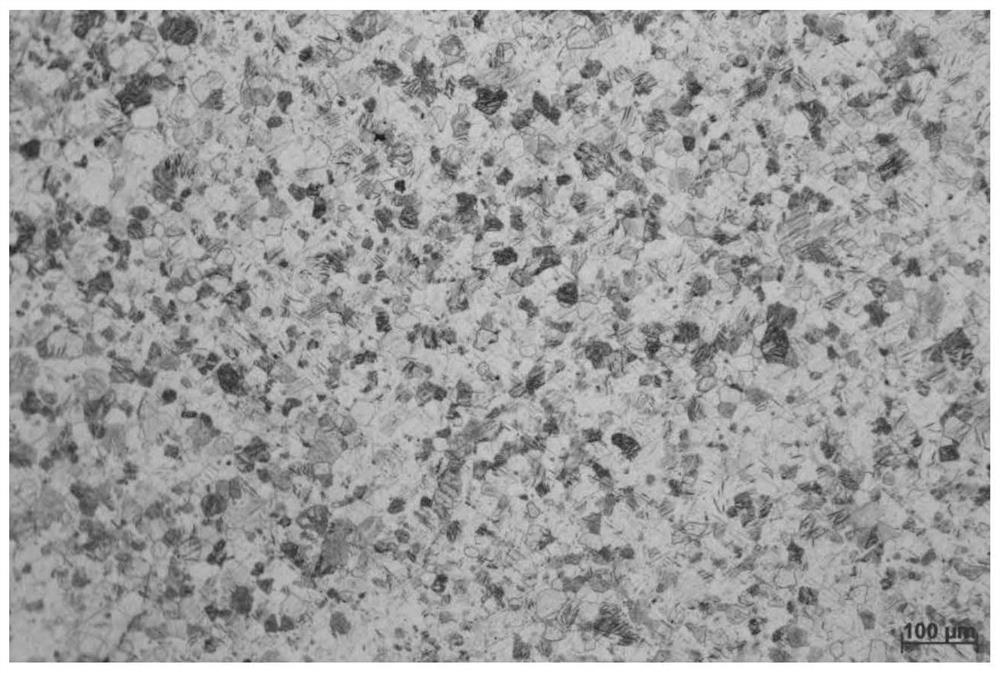

Ultrahigh-plasticity magnesium alloy and preparation method of deformation material of ultrahigh-plasticity magnesium alloy

The invention discloses an ultrahigh-plasticity magnesium alloy and a preparation method of a deformation material of the ultrahigh-plasticity magnesium alloy. The magnesium alloy comprises the following components of, by weight, 1.0%-3.0% of Gd, 0.3%-1.0% of Zr and the balance Mg. The preparation method of the deformation material of the magnesium alloy comprises the following steps that S1, alloy smelting is carried out, wherein a pure magnesium ingot, a Mg-Gd intermediate alloy and a Mg-Zr intermediate alloy are taken as raw materials, proportioning is carried out according to the magnesiumalloy components and the weight percentage, and alloy ingredients are smelted and then are cast into an alloy ingot; S2, machining is carried out, and specifically the alloy ingot prepared in the step S1 is machined into an extruded blank; and S3, extrusion forming is carried out, wherein the extruded blank prepared in the step S2 is preheated to an extrusion temperature, and primary extrusion forming is carried out by adopting a hot extrusion process so as to obtain the deformation material of the magnesium alloy. The ultrahigh-plasticity magnesium alloy shows ultrahigh room-temperature plasticity, can be conventionally and rapidly formed, is low in cost, is simple in process and can undergo large-strain forming and cold working.

Owner:CHONGQING UNIV

Welding wire matched with AI-Mg-Si series aluminum alloy during use and preparation process of welding wire

InactiveCN106271192AGuaranteed performanceQuality assuranceWelding/cutting media/materialsSoldering mediaRare-earth elementSurface oxidation

The invention discloses a welding wire matched with AI-Mg-Si series aluminum alloy during use. The welding wire is prepared from the following main chemical components in percentage by weight: 1.2-1.5 percent of Mg, 0.8-1.0 percent of Si, 0.2-0.3 percent of Cu, 0.4-0.5 percent of Fe, 0.1-0.15 percent of Cr, 0.15-0.2 percent of Ce, 0.1-0.2 percent of Er and the balance of Al. A preparation process of the welding wire comprises the following steps: mixing the raw materials in proportion, smelting by adopting a medium-frequency induction resistance furnace and casting under the protection of argon gas into a cast ingot; beheading and milling the homogenized cast ingot and then extruding to prepare an alloy wire rod; performing coarse, medium and fine wire drawing on the alloy wire rod and then performing scraping and cleaning treatment to obtain the welding wire. The welding wire prepared by the preparation process disclosed by the invention has the following advantages that a smelting process is stable and easy to realize, the drawing performance of the welding wire is good, and a drawing device is subjected to sealing treatment to prevent the surface oxidation of the welding wire; as rare earth elements are added, the welding wire structure is refined; impurities in the welding wire are less and low in content, so that the toughness of the welding wire is promoted to be improved; scraping and ultrasonic cleaning are adopted for surface treatment, so that the simplicity and no pollution are realized; the welding wire is low in burn rate, difficult to break and good in mechanical property.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

Electroslag remelting slag system for duplex stainless steel

PendingCN110029229AGood chemical stabilityHigh strengthProcess efficiency improvementSlagSS - Stainless steel

The invention discloses an electroslag remelting slag system for duplex stainless steel. The electroslag remelting slag system is prepared from the following components in percent by weight: 50.0-65.0% of CaF2, 8.0-15.0% of Al2O3, 3.0-10.0% of CeO2, 15.0-20.0% of CaO, 3.0-5.0% of MgO, 1.0-3.0% of SiO2 and the balance impurities which are not more than 1%. According to the slag system, the slag viscosity changes gently as the temperature is reduced, and the high temperature plasticity and the strength of slag can be also improved, so that bleed-out and slag leakage are prevented. The conductivity of the slag can be reduced, the chemical stability of the slag can be improved, and the system has better deoxidizing and desulfurizing effects and inclusion absorption action, thereby playing a role of purifying molten steel deeply. As-cast grains can be refined, and the strength and the toughness of steel are improved. The electroslag remelting slag system is uniform to transfer heat and goodin lubricating effect, and the slag layer is kept stable and is melted uniformly.

Owner:JIANGSU XIHU SPECIAL STEEL

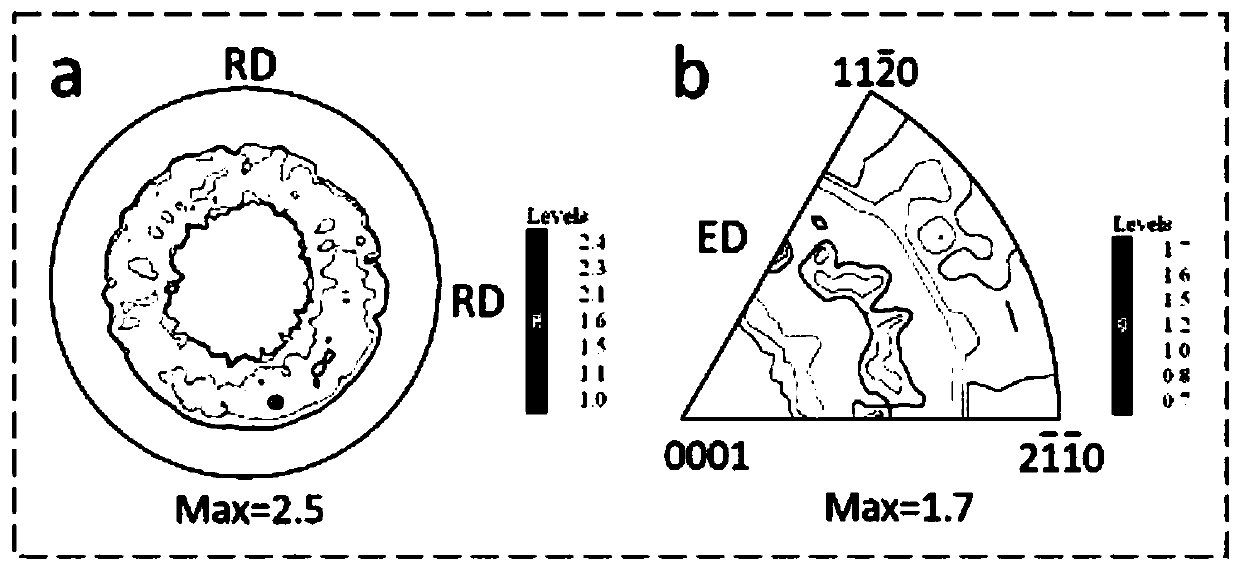

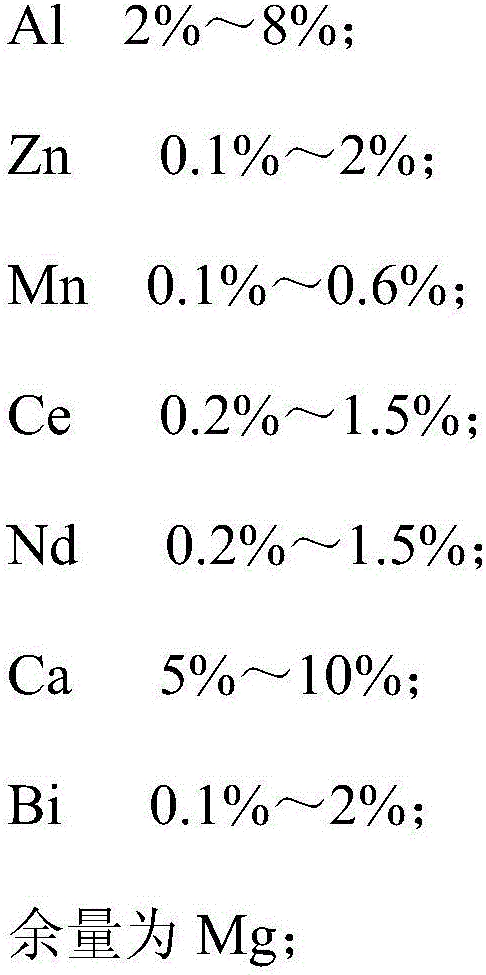

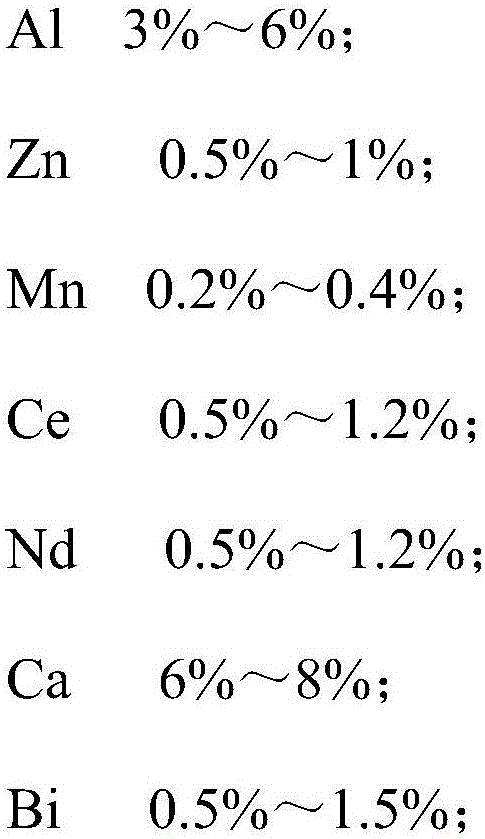

Magnesium alloy for notebook computer

The invention belongs to the technical field of magnesium alloy and particularly relates to magnesium alloy for a notebook computer. The magnesium alloy for the notebook computer comprises the following components according to atomic percent: 2-8% of Al, 0.1-2% of Zn, 0.1-0.6% of Mn, 0.2-1.5% of Ce, 0.2-1.5% of Nd, 5-10% of Ca, 0.1-2% of Bi and the balance of Mg; the magnesium alloy is also filled with graphite fiber accounting for 1-5wt% of the total mass of the magnesium alloy; the surface of the magnesium alloy is subjected to pickling and activating treatment, and a pickling solution is prepared from the following components in mass ratio according to a formula: 50-75% of Na3PO4.12H2O, 15-25% of H3PO4 and 8-25% of KMnO4; and the pickling and activating treatment lasts for 1-10 min. Compared with the prior art, the magnesium alloy is relatively high in mechanical property and corrosion resistance and relatively low in inflammability.

Owner:DONGGUAN EONTEC CO LTD +1

High-strength die-casting alloy material for mobile phone middle plate and preparation method and application of high-strength die-casting alloy material

The invention relates to a high-strength die-casting alloy material for a mobile phone middle plate and a preparation method and application of the alloy material. The alloy material comprises, by weight, 4.0%-8.0% of Si, 4. %-8.0% of Mg, 0.4%-1.0% of Mn, 4.0% of Cu, 1.5% of Zn, 0.5% of Fe, 0.25% of Ti, 1.0% of Sc, 0.5% of Zr, and the balance of Al, wherein the sum of the weight percentages of other impurities is controlled to be less than 1.0 %. Compared with the prior art, the high-strength die-casting alloy material and the preparation method thereof have the advantages that the tensile strength of the obtained mobile phone middle plate can reach 350-400 MPa, the yield strength can reach 250-300 MPa, and the elongation is 2.0%-4.0%.

Owner:苏州慧金新材料科技有限公司

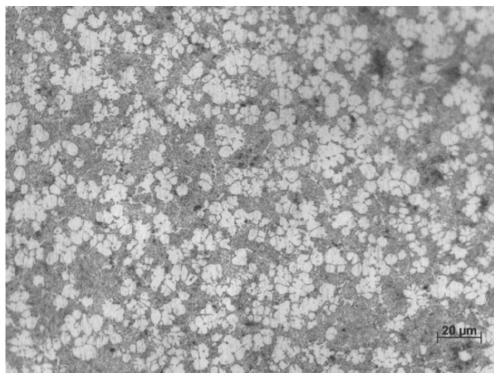

Ultrahigh-plasticity aluminum alloy and preparing method thereof

PendingCN111979457ARefining as-cast grainObtain ultra-high plasticity at room temperatureMetallic materialsToughness

The invention relates to the technical field of metal materials and machining technology of the metal materials and discloses an ultrahigh-plasticity aluminum alloy and a preparing method thereof. Thealuminum alloy comprises, by weight percent, 0.8%-1.2% of Mg, 0.4%-0.8% of Si, 0.2%-0.4% of Fe, 0.2%-0.5% of Cu, and the balance Al. The preparing method of the aluminum alloy comprises several processes of burdening, smelting, casting, homogenizing treatment and extruding deformation treatment. When the aluminum alloy is prepared, the aluminum alloy composition components and the use amounts ofall the components are reasonably controlled, a wrought aluminum alloy microstructure with the structure still being of the single phase is obtained, and in addition, the structure is uniform; and dueto a solution strengthening effect of various elements, the phenomenon that elements are excessively added, a second phase is generated, and the subsequent extruding deformation treatment process ishindered is avoided, the problem of difficult aluminum alloy extruding is solved, grain growth in the extruding process is avoided, and the high-toughness aluminum alloy with the small and uniform alloy microstructure is obtained finally. The method is simple and easy to operate, low in requirement for equipment, low in cost and suitable for large-scale production.

Owner:YANTAI NANSHAN UNIV +1

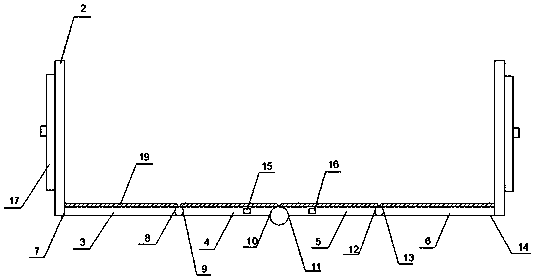

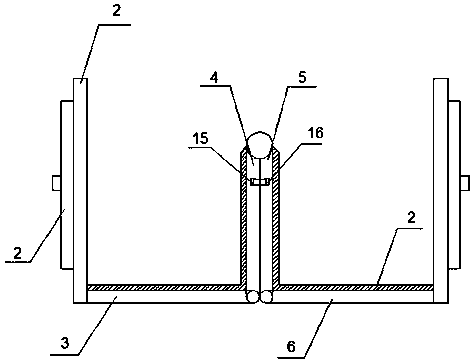

High-heat-dissipation air-ventilation tray type cable bridge

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

Processing method of improved 5052 aluminum alloy refrigerator foaming die cast

The invention discloses a processing method of an improved 5052 aluminum alloy refrigerator foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements Pr, Ce, and Y are added to the improved 5052 aluminum alloy, so that the dendritic crystal distance of the aluminum alloy can be effectively reduced, as-cast grains are refined, and the mechanical property of the aluminum alloy is improved. The processed aluminum alloy refrigerator foaming mold die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州佳诚模具制造有限公司

Aluminum alloy for high-strength corrosion-resistant doors and windows and preparation method thereof

InactiveCN109161746AImprove toughnessAccelerated corrosionSurface reaction electrolytic coatingRare-earth elementUltimate tensile strength

The invention discloses an aluminum alloy for high-strength corrosion-resistant doors and windows, which comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn, 0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare-earth element Re, and the balance of Al. The aluminum alloy is prepared by the steps of melting, slag-off, heat preservation, standing, on-line refining, proportioning, refining, on-line degassing, casting, uniform annealing, extrusion molding, heat treatment, coloring and pore sealing. By optimizing the composition, proportion and processing technology of the alloy, the contradiction between the strength and the casting performance of the aluminum alloy can be effectively solved, and the problems of large thermal cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminum alloy are solved.

Owner:阜阳力佳门业有限公司

A kind of aluminum alloy for 480mpa grade aluminum alloy oil pipe and its pipe material manufacturing method

An aluminum alloy for a 480MPa grade aluminum alloy oil pipe according to the present invention comprises Zn: 5.50-6.90%, Mg: 1.75-1.80%, Cu: 0.05%, Mn: 0.10-0.30%, Cr: 0.10-0.30% in weight percentage , Ti: 0.01-0.02%, Zr: 0.15-0.18%, and the rest are Al and unavoidable impurities; among the unavoidable impurities, the content of Si is not more than 0.15% of the total weight of the aluminum alloy, and the content of Fe is not more than the total weight of the aluminum alloy 0.15%. A method for manufacturing an aluminum alloy pipe, comprising the following steps: 1) smelting and refining the above-mentioned raw materials to obtain a pipe billet; 2) three-stage homogenization treatment; 3) extruding at high temperature; 4 ) by two-stage solution treatment and quenching and cooling; 5) pre-stretching deformation; 6) by two-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

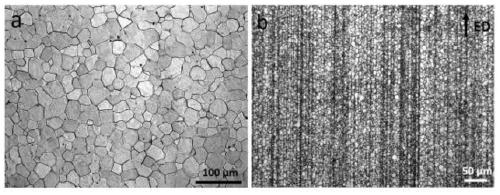

Ultrahigh-plasticity rare earth wrought magnesium alloy and preparation method of extruded plate thereof

ActiveCN114293079AEasy to startReduce the anisotropy of mechanical propertiesMetal-working apparatusPlastic propertyMagnesium alloy

The invention provides an ultrahigh-plasticity rare earth wrought magnesium alloy and a preparation method of an extruded plate of the ultrahigh-plasticity rare earth wrought magnesium alloy, and belongs to the technical field of magnesium alloy materials and molding.The ultrahigh-plasticity rare earth wrought magnesium alloy comprises, by mass, 0-4% of Gd, 0-4% of Er, 0.1-0.6% of Zr, the balance Mg and 1-4% of total rare earth, the ultrahigh-plasticity rare earth magnesium alloy is prepared by upsetting an ultrahigh-plasticity rare earth magnesium alloy material and carrying out asymmetric extrusion by using an extrusion die. The method has the two advantages that 1, in the aspect of the forming process, a die is used for upsetting, it is guaranteed that different areas of the extruded plate are fully deformed, grains are further refined, and non-uniform extrusion can greatly weaken the defect of a strong base surface texture of the extruded plate under a traditional deformation process; and 2, in the aspect of material design, the ultrahigh-plasticity magnesium alloy plate is obtained through the action of activating a non-crystal face slippage system by rare earth elements, and the percentage elongation after fracture of the plate is larger than or equal to 35%. The wrought magnesium alloy plate disclosed by the invention has the characteristics of ultrahigh plasticity and weak texture at room temperature, can be subjected to large-strain room-temperature forming and processing, and has a wide application prospect.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Aluminum alloy for chloride ion corrosion-resistant aluminum alloy oil pipe and method for manufacturing the same

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

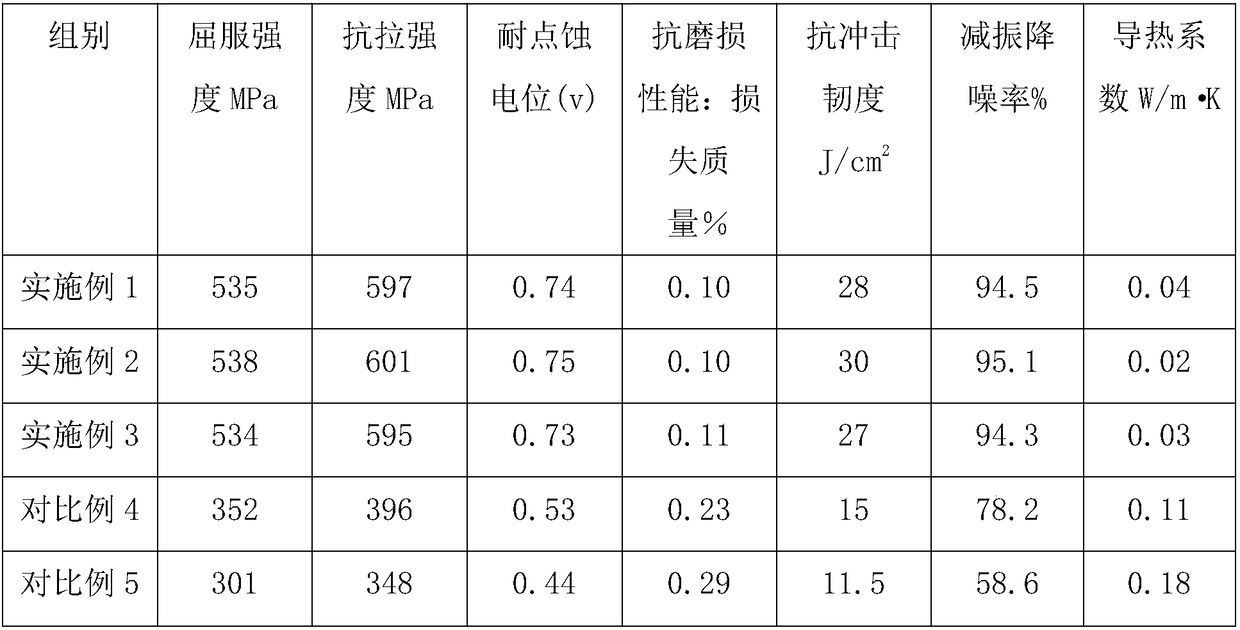

Novel aluminum alloy door and window sectional material and preparation method thereof

InactiveCN108441715AImprove internal crystal structureSimple manufacturing processAnti-corrosive paintsPolyester coatingsNoise reductionStructural stability

The invention discloses a novel aluminum alloy door and window sectional material and a preparation method of the novel aluminum alloy door and window sectional material and relates to the technical field of metal door and window materials. The sectional material comprises the following chemical ingredients of Fe, Mn, Ti, Cu, Mg, Co, Sb, Te, Mo, Zr, Nb, Sc, Ce, N and Al. The preparation method comprises the steps of smelting, refining, homogenization treatment, squeezing and aging of waste aluminum and alloy and powder raw materials. The preparation method of the aluminum alloy door and windowsectional material is simple and convenient, and a finished product of the sectional material has excellent vibration attenuation and noise reduction, mechanical strength, flame retardance and heat insulation, corrosion resistance and oxidation resistance, structural stability and the like and is wide in application and long in service life.

Owner:合肥市旺友门窗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com