Magnesium alloy for notebook computer

A notebook computer and magnesium alloy technology, applied in the field of magnesium alloy, can solve the problems of poor plasticity at room temperature, flammability, galvanic corrosion, etc., and achieve the effect of good protection performance, small pores, and weakened corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

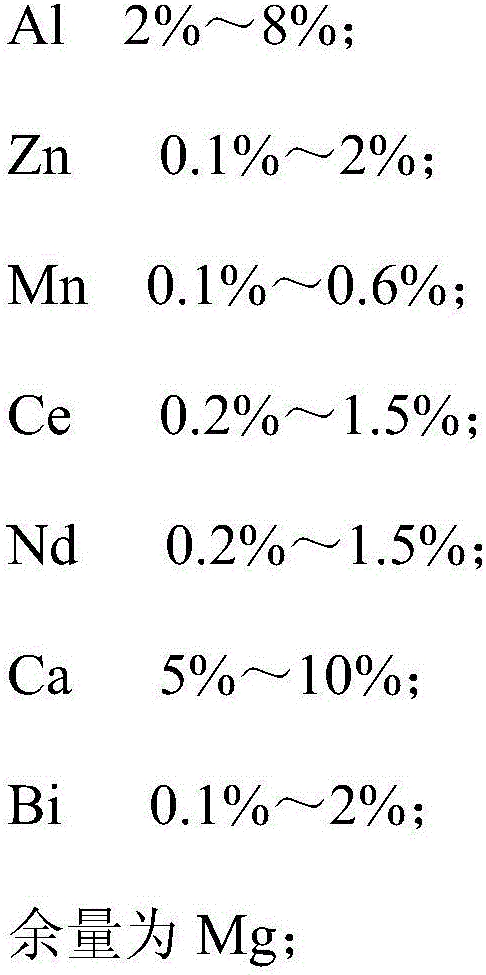

[0047] This embodiment provides a kind of magnesium alloy for notebook computer, by atomic percentage, described magnesium alloy for notebook computer comprises:

[0048]

[0049] The magnesium alloy is also filled with graphite fibers accounting for 3wt% of the total mass of the magnesium alloy;

[0050] The surface of the magnesium alloy is subjected to pickling and activation treatment. According to the mass ratio, the formula of the pickling solution is:

[0051] Na 3 PO 4 12H 2 O 70%;

[0052] h 3 PO 4 10%;

[0053] KMnO 4 20%;

[0054] The duration of pickling activation treatment is 5min.

[0055] The diameter of the graphite fiber is 1μm-5μm, the length is 10μm-1mm, the tensile modulus is 600GPa-800GPa, and the tensile strength is 1.5GPa-4.0GPa.

[0056] Its preparation method comprises the following steps:

[0057] The first step is to preheat the melting furnace and preheat the crucible to 600°C;

[0058] The second step is to pass the protective gas...

Embodiment 2

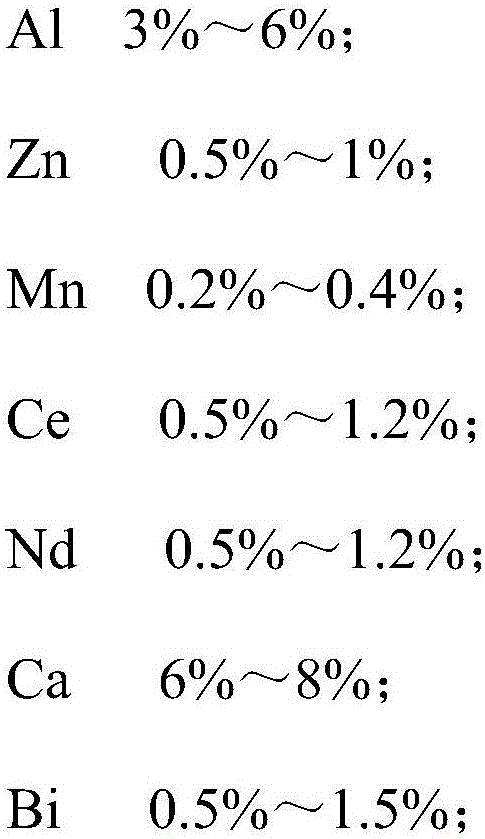

[0068] This embodiment provides a kind of magnesium alloy for notebook computer, by atomic percentage, described magnesium alloy for notebook computer comprises:

[0069]

[0070] The magnesium alloy is also filled with graphite fibers accounting for 2wt% of the total mass of the magnesium alloy;

[0071] The surface of the magnesium alloy is subjected to pickling and activation treatment. According to the mass ratio, the formula of the pickling solution is:

[0072] Na 3 PO 4 12H 2 O 60%;

[0073] h 3 PO 4 20%;

[0074] KMnO 4 20%;

[0075] The duration of pickling activation treatment is 3min.

[0076] The diameter of the graphite fiber is 1μm-5μm, the length is 10μm-1mm, the tensile modulus is 600GPa-800GPa, and the tensile strength is 1.5GPa-4.0GPa.

[0077] Its preparation method comprises the following steps:

[0078] The first step is to preheat the melting furnace and preheat the crucible to 610°C;

[0079] The second step is to pass the protective gas...

Embodiment 3

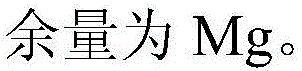

[0089] This embodiment provides a kind of magnesium alloy for notebook computer, by atomic percentage, described magnesium alloy for notebook computer comprises:

[0090]

[0091] The magnesium alloy is also filled with graphite fibers accounting for 2.5wt% of the total mass of the magnesium alloy;

[0092] The surface of the magnesium alloy is subjected to pickling and activation treatment. According to the mass ratio, the formula of the pickling solution is:

[0093] Na 3 PO 4 12H 2 O 65%;

[0094] h 3 PO 4 20%;

[0095] KMnO 4 15%;

[0096] The duration of pickling activation treatment is 9min.

[0097] The graphite fiber has a diameter of 1 μm-5 μm, a length of 10 μm-1 mm, a tensile modulus of 600 GPa-800 GPa, and a tensile strength of 1.5 GPa-4.0 GPa.

[0098] Its preparation method comprises the following steps:

[0099] The first step is to preheat the melting furnace and preheat the crucible to 620°C;

[0100]The second step is to pass the protective g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com