High-strength die-casting alloy material for mobile phone middle plate and preparation method and application of high-strength die-casting alloy material

A technology of die-casting alloys and alloy materials, applied in the field of aluminum alloy high-pressure casting, which can solve the problems of increased wiring density, pad pitch, diameter reduction, size reduction, etc., to achieve high density, improve mechanical properties, and reduce pore content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

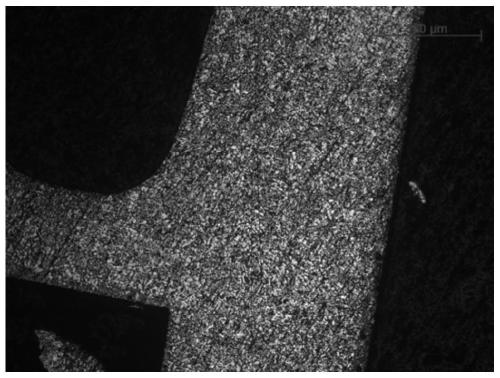

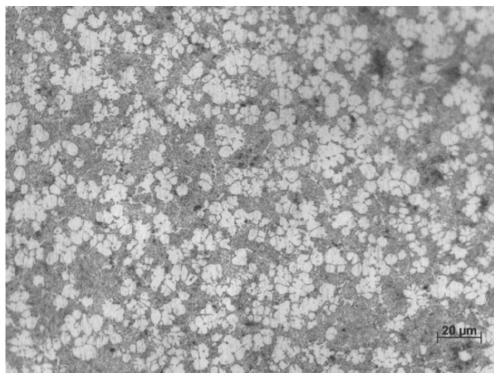

Image

Examples

Embodiment 1-9

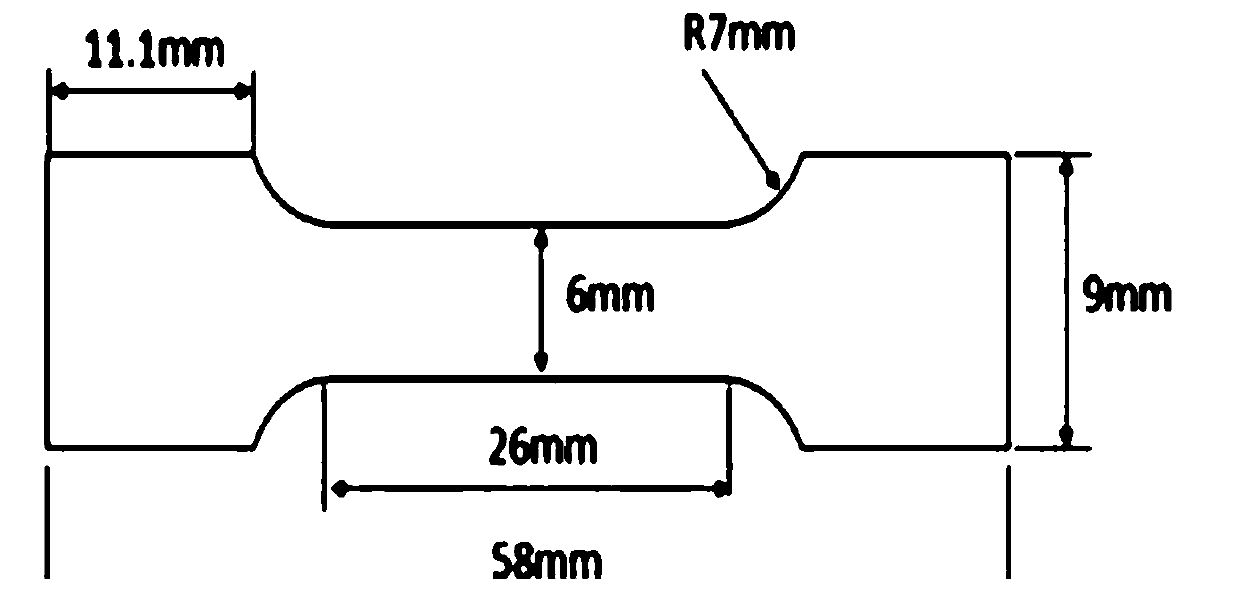

[0045] A high-strength die-casting alloy material for a mobile phone mid-plate, comprising the following components in mass percentage, and the balance being aluminum and unavoidable impurities.

[0046] Si: 4.0wt%-8.0wt%; Mg: 4.0wt%-8.0wt%; Mn: 0.4wt%-1.0wt%; Cu<4.0wt%; Zn<1.5wt%; Fe<0.5wt%; Ti< 0.25wt%; Sc<1.0wt%; Zr<0.5wt%, the sum of weight percentages of other impurities is controlled below 1.0wt%, and the balance is Al.

[0047] Table 1 is the content table of each element in the aluminum alloy of Examples 1-9 and the performance table of the middle plate of the mobile phone made therefrom

[0048]

[0049] The aluminum alloy materials described in the above embodiments are made into aluminum alloy ingots according to the following methods, and then made into the middle plate of the mobile phone. The process is as follows:

[0050] 1) Put the high-purity aluminum element into the heating furnace, heat it to 680°C, completely melt and keep it for 20 minutes;

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com