Patents

Literature

917 results about "Aluminum element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nickel cobalt aluminum serving as cathodic material of lithium ion battery

ActiveCN102244239AIncrease capacityImprove cycle performanceCell electrodesNickel saltElectrical battery

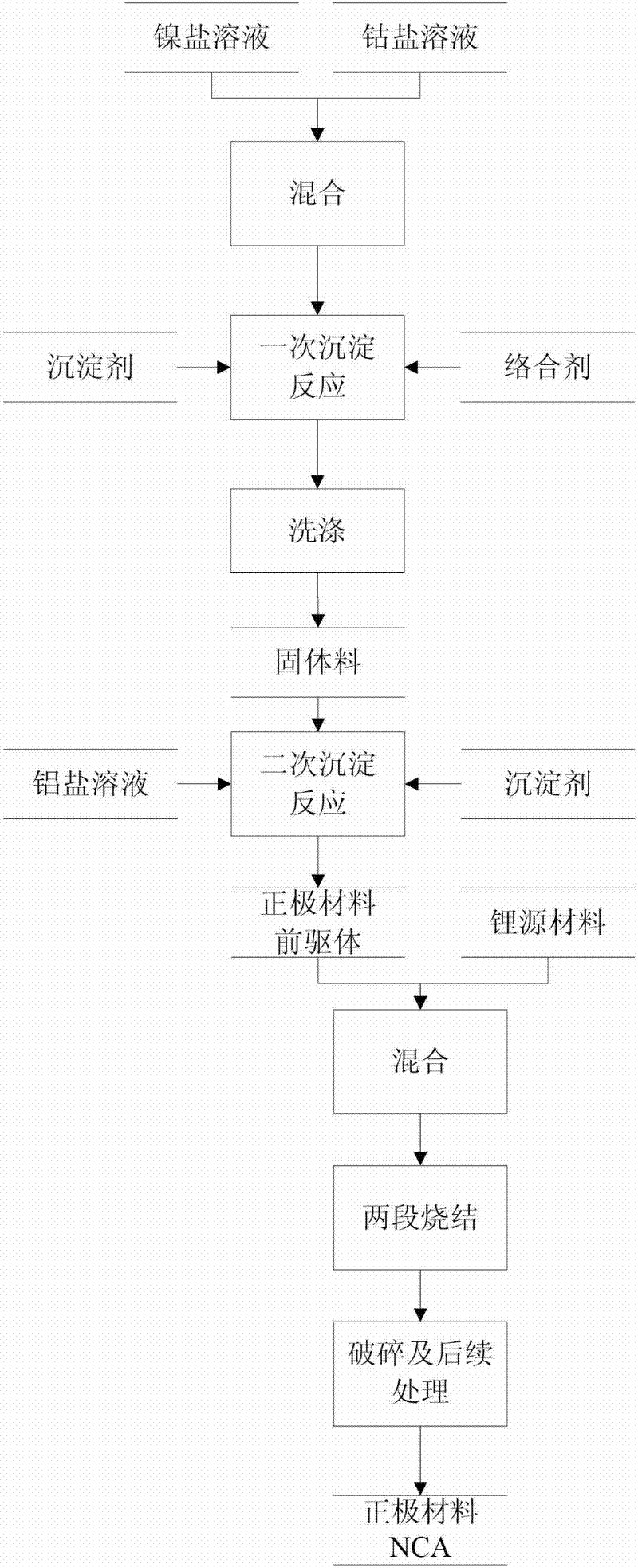

The invention discloses a method for preparing nickel cobalt aluminum serving as a cathodic material of a lithium ion battery, which comprises the following steps of: mixing nickel salt solution and cobalt salt solution uniformly, adding complexing agent solution, precipitant solution and the mixed solution into a reaction kettle with base solution in a parallel flow mode to perform precipitation reaction, performing solid-liquid separation after the reaction is performed fully, and washing; adding the washed solid material into the reaction kettle, dripping aluminum salt solution and the precipitant solution slowly to perform secondary precipitation reaction, so that an aluminum element is precipitated on the surface of the solid material gradually, stirring continuously in the integral process, performing solid-liquid separation after the reaction is finished, and washing and drying the solid material to a precursor of the cathodic material of the lithium ion battery; and mixing the precursor and a lithium source, performing two-section sintering under the condition of introducing oxygen, and crushing the calcined material which is subjected to the two-section sintering and performing subsequent processing to obtain the nickel cobalt aluminum serving as the cathodic material of the lithium ion battery. The method has the advantages of low requirement on equipment, high automation degree, environment friendliness, few wastes, high quality of products and the like and is easy to operate.

Owner:HUNAN CHANGYUAN LICO CO LTD

Carbon-coated aluminum and method for producing same

ActiveUS7327556B2Improve adhesionHybrid capacitor electrodesElectrode carriers/collectorsCarbon coatedHydrocarbon

Owner:TOYO ALUMINIUM KK

Method for preparing nickel-cobalt lithium aluminate as anode material of lithium ion battery

InactiveCN103094546AImprove electrical performanceImprove cycle performanceCell electrodesLithium aluminateOxygen

The invention discloses a method for preparing nickel-cobalt lithium aluminate as an anode material of a lithium ion battery. The method comprises the following steps: (1) mixing a nickel-cobalt metal salt water solution, a sodium metaaluminate solution, a complexing agent and a precipitant, regulating the pH value of a reaction system to be 9 to 12, and then maintaining a stirring state to carrying out a reaction at the temperature of 30 to 80 DEG C for 20 to 200 hours, thereby obtaining nickel-cobalt aluminum hydroxide precipitates; (2) washing the nickel-cobalt aluminum hydroxide precipitates by using pure water of 50 to 100 DEG C, drying, screening the part of precipitates capable of passing through a sieve being 300 meshes, adding a lithium source to the precipitates, mixing evenly, and sintering at the temperature of 600 to 1000 DEG C, wherein oxygen is filled during the sintering process; and finally sintering for 5 to 50 hours, thereby obtaining the nickel-cobalt lithium aluminate. According to the method, the sodium metaaluminate is adopted as the lithium source, so that the nickel-cobalt aluminum elements can evenly form a coprecipitation, so that the aluminum is evenly distributed in the nickel-cobalt lithium aluminate material. As a result, the electrical performance of the material is improved, and especially the cycling performance of the material is improved.

Owner:HUNAN BRUNP RECYCLING TECH +1

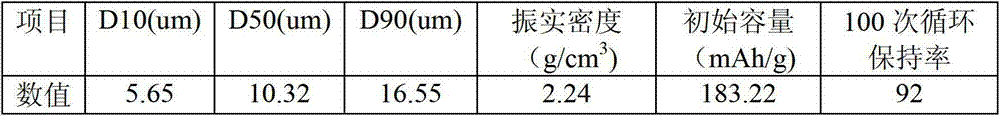

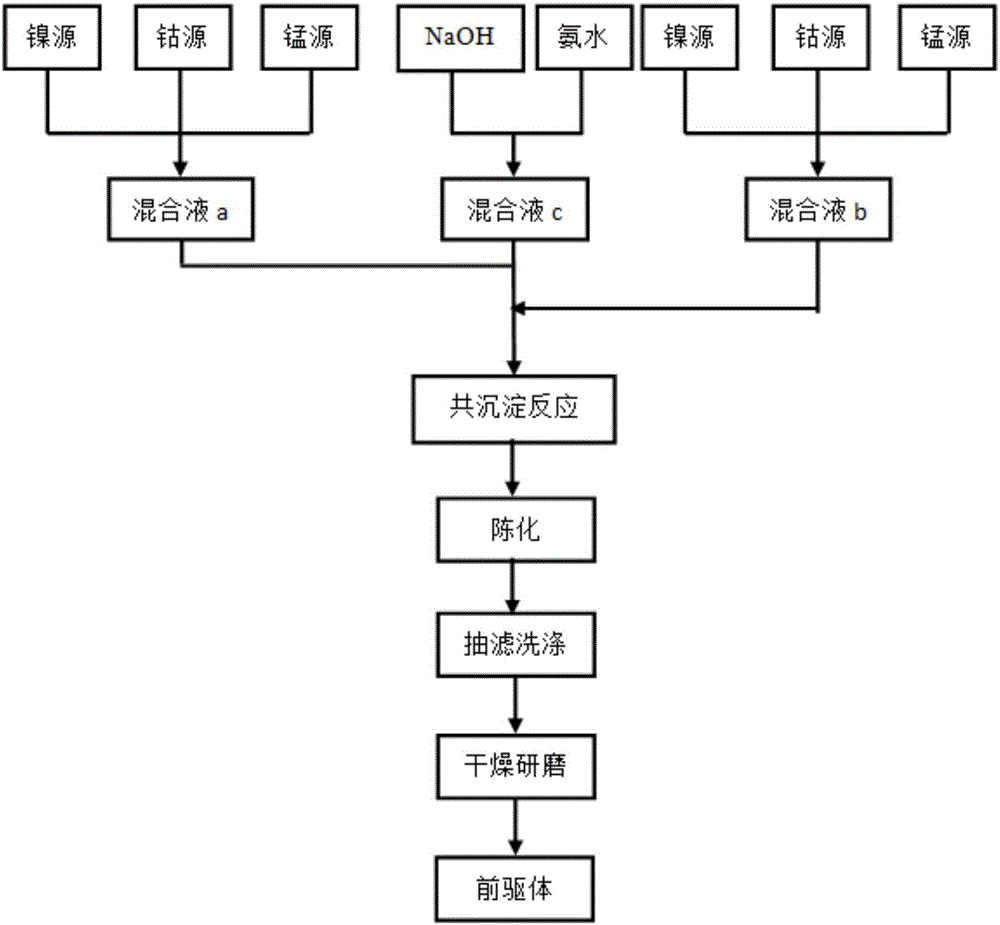

High-density spherical nickel-cobalt-aluminum precursor material and preparation method thereof

ActiveCN103553152AEffective control of coprecipitation reaction processControl the Co-precipitation Reaction ProcessCell electrodesNickel oxides/hydroxidesNickel saltHigh density

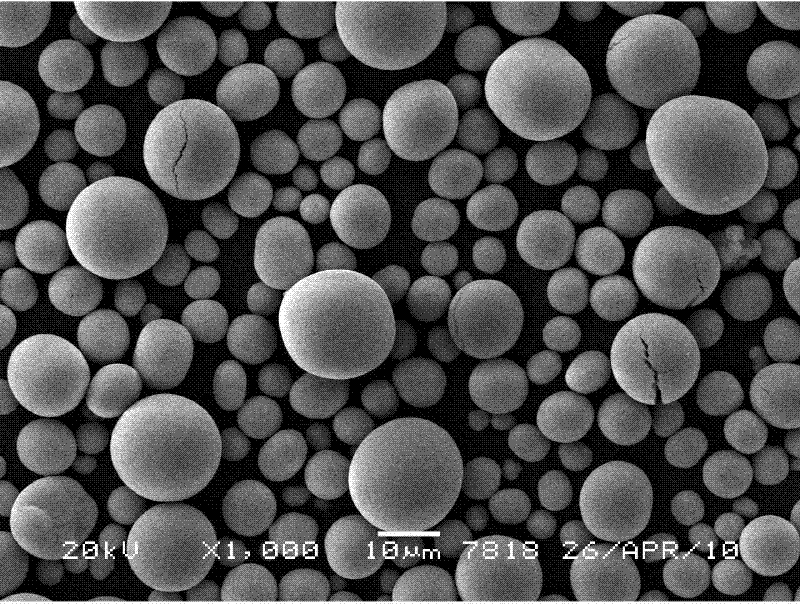

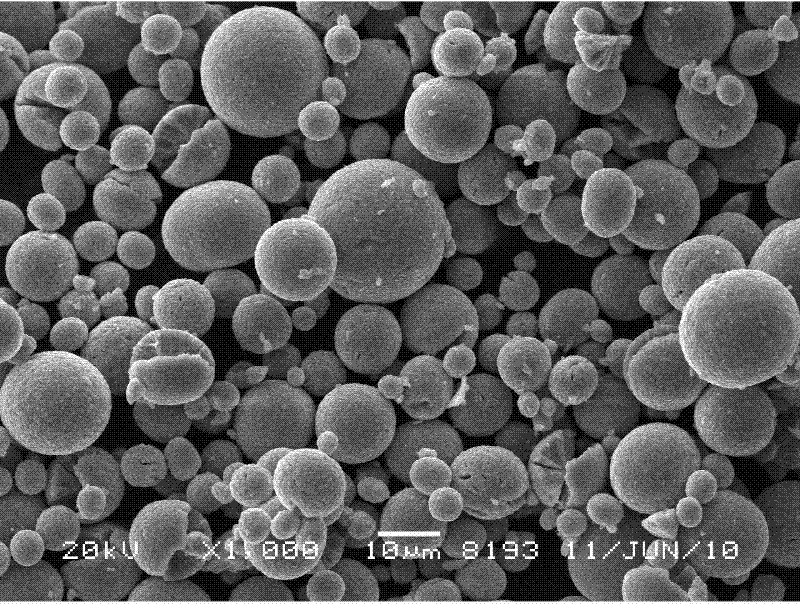

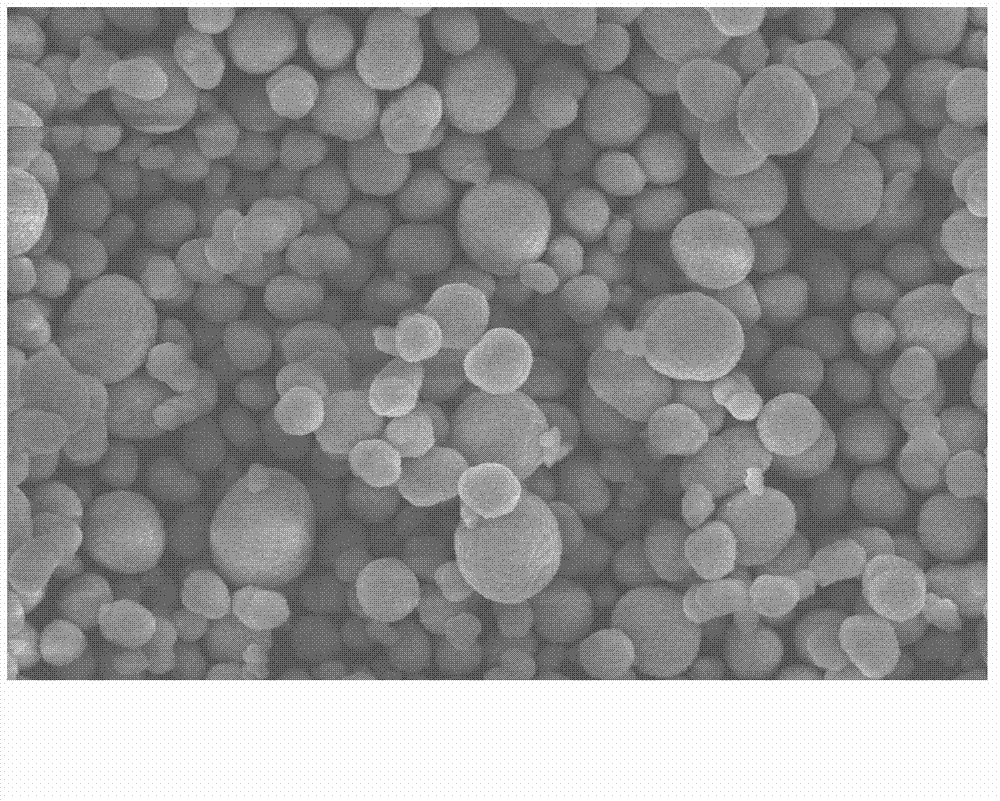

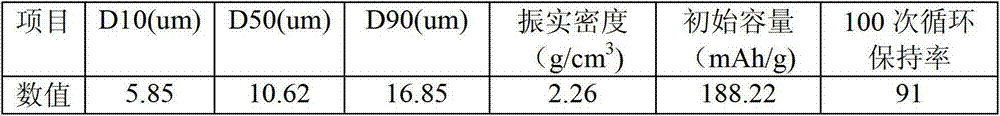

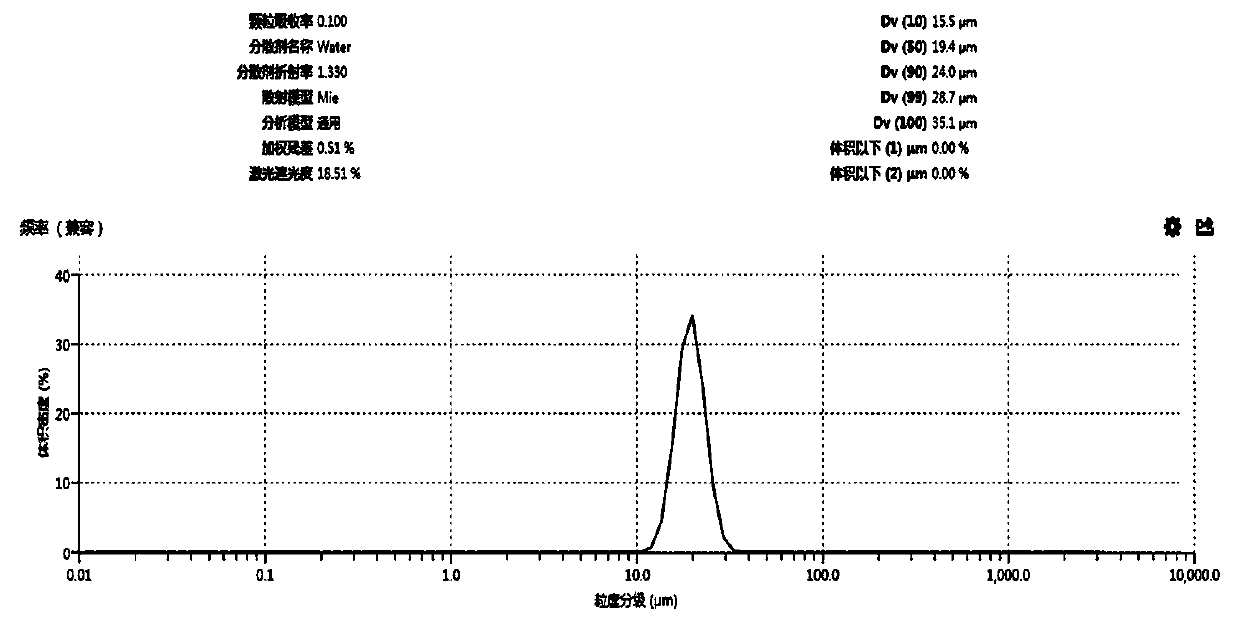

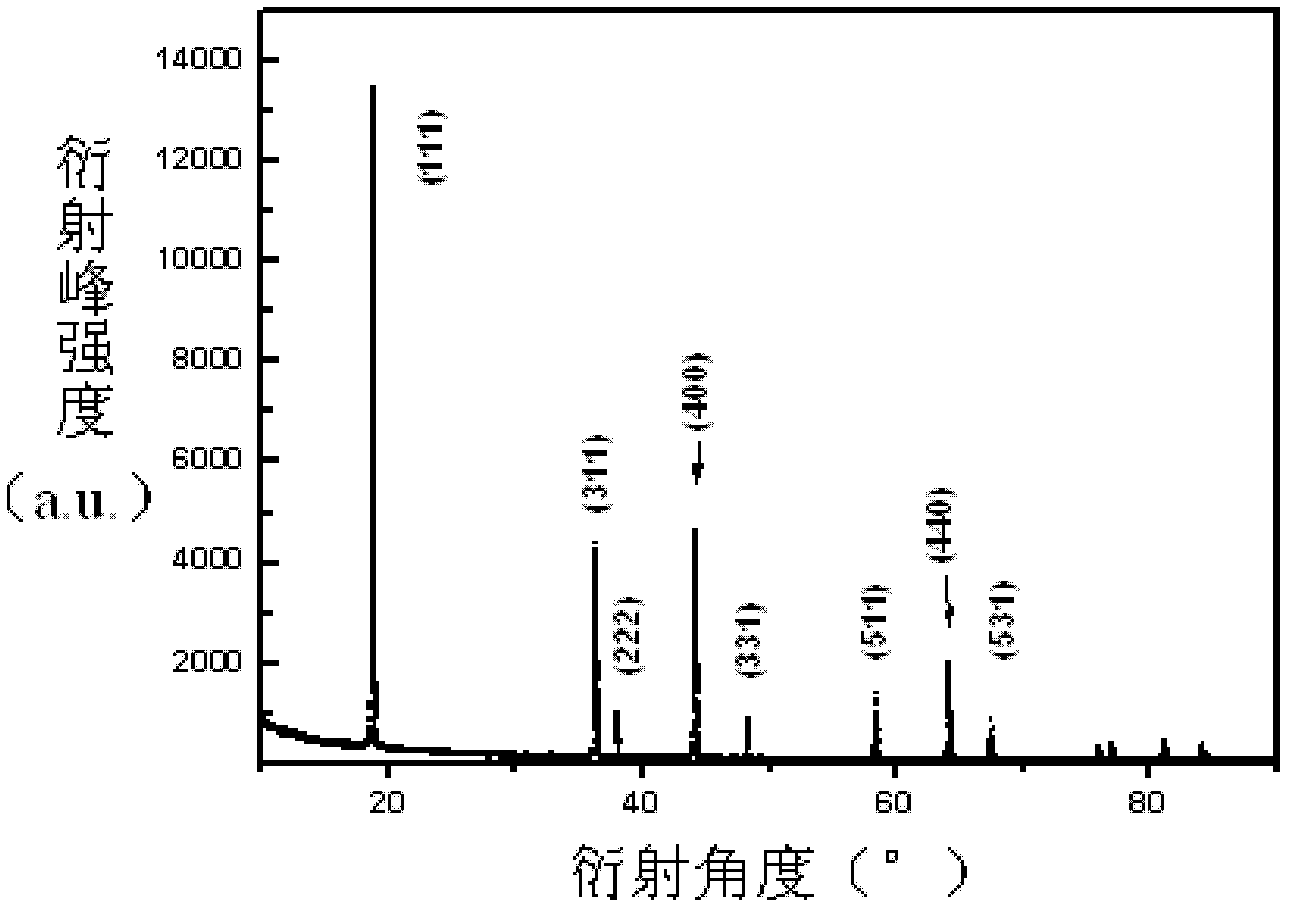

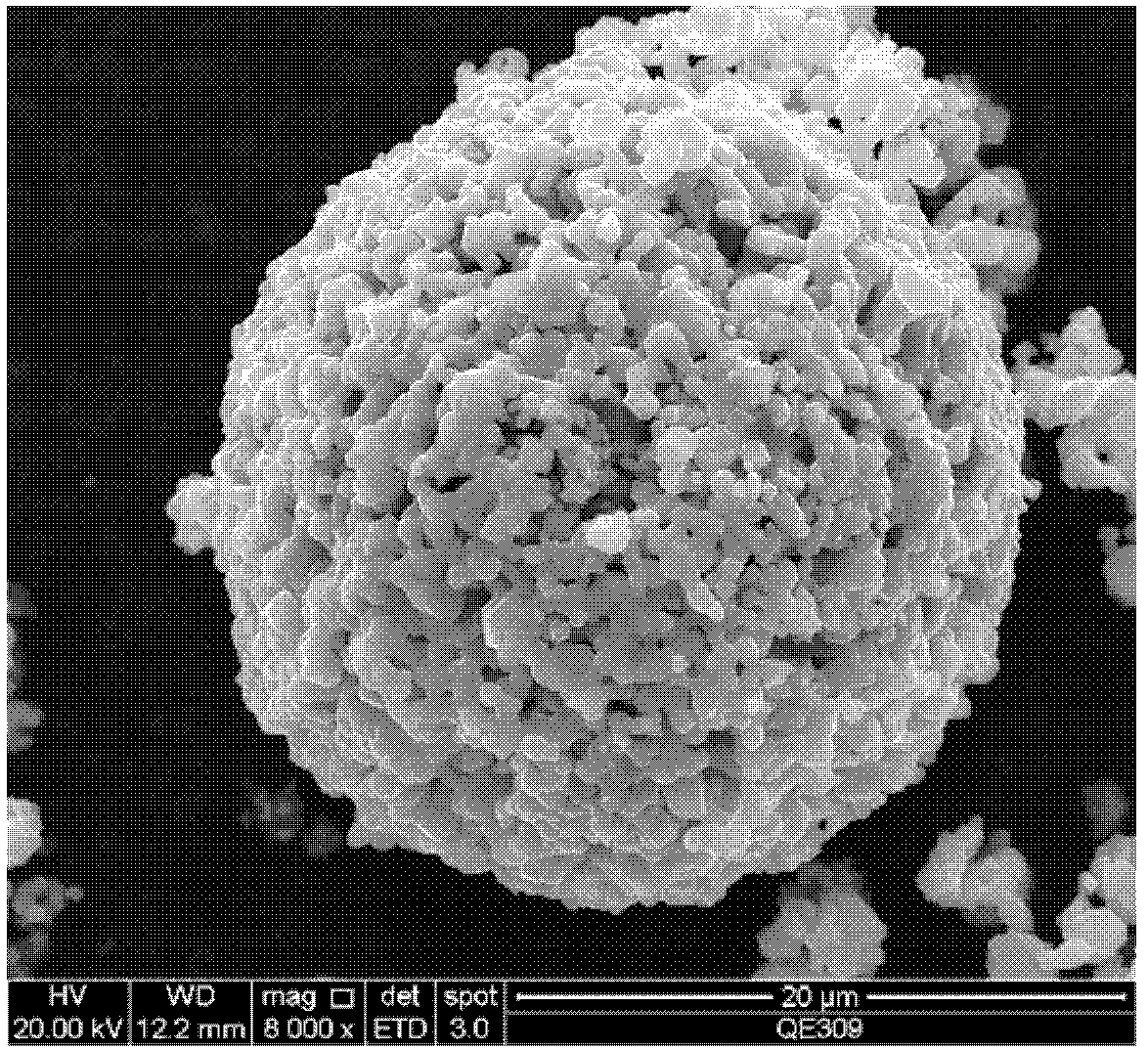

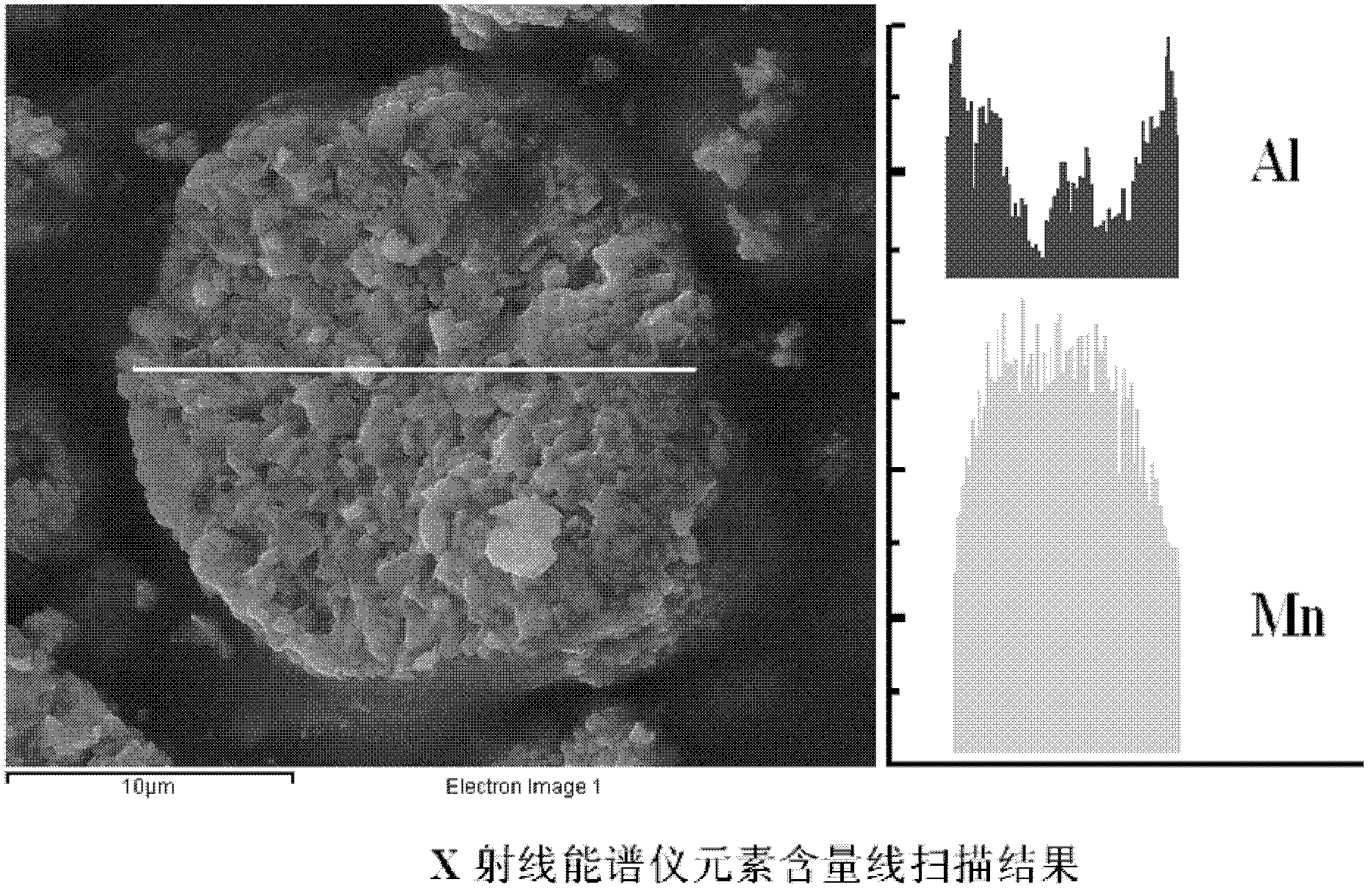

The invention discloses a high-density spherical nickel-cobalt-aluminum precursor material. The chemical molecular formula of the nickel-cobalt-aluminum precursor material is Ni(1-x-y)CoxAly(OH)(2+y); the tap density of the nickel-cobalt-aluminum precursor material is 1.8-2.4 g / cm3; the material is spherically granular; the average particle size of the material ranges from 6 to 17 microns. The invention also discloses a preparation method of the precursor material. The preparation method comprises the following steps of: firstly, evenly mixing an aluminum salt with a complexing agent; secondly, evenly mixing a nickel salt with a cobalt salt solution; adding the mixed solution, the complexing agent and a precipitator solution to a reactor in parallel for continuous coprecipitation reaction, controlling the pH value in the reaction process within the range from 11 to 12, keeping the materials stay in the reactor not more than 20 h, performing solid-liquid separation after stable reaction, and finally, aging, washing and drying the solid material to obtain the high-density spherical nickel-cobalt-aluminum precursor material. The aluminum element in the high-density spherical nickel-cobalt-aluminum precursor material provided by the invention can be combined with nickel and cobalt elements evenly; and the tap density of the high-density spherical nickel-cobalt-aluminum precursor material is higher.

Owner:JINCHI ENERGY MATERIALS CO LTD

Technique for hydro-thermal synthesis of high purity zeolite and fly ash zeolite adsorbing agent from fly ash

InactiveCN101503202AImprove adsorption capacitySimple processOther chemical processesCrystalline aluminosilicate zeolitesSorbentMaterials science

The invention provides a process for hydrothermally synthesizing fly ash into a highly-pure zeolite and a fly ash zeolite adsorbent, which comprises the following steps: adding alkali solution into fly ash, obtaining solution containing silicon elements and aluminum elements under the hydrothermal condition, adding a certain amount of base soluble Al2O3 or SiO2 in the solution containing the silicon elements and the aluminum elements, and then preparing the highly-pure zeolite after hydrothermal reaction is carried out for a certain time; and adding the fly ash or the fly ash which is not dissolved under the hydrothermal condition into sodium hydroxide or sodium carbonate to be mixed uniformly (be calcined at a certain temperature), carrying out the hydrothermal condition, and then obtaining the fly ash zeolite adsorbent. The invention has simple process; the purity of the prepared highly-pure zeolite can achieve above 90 percent; and the prepared fly ash zeolite adsorbent has stronger adsorption capacity for heavy metal ions or organic wastewater.

Owner:SHAANXI UNIV OF TECH

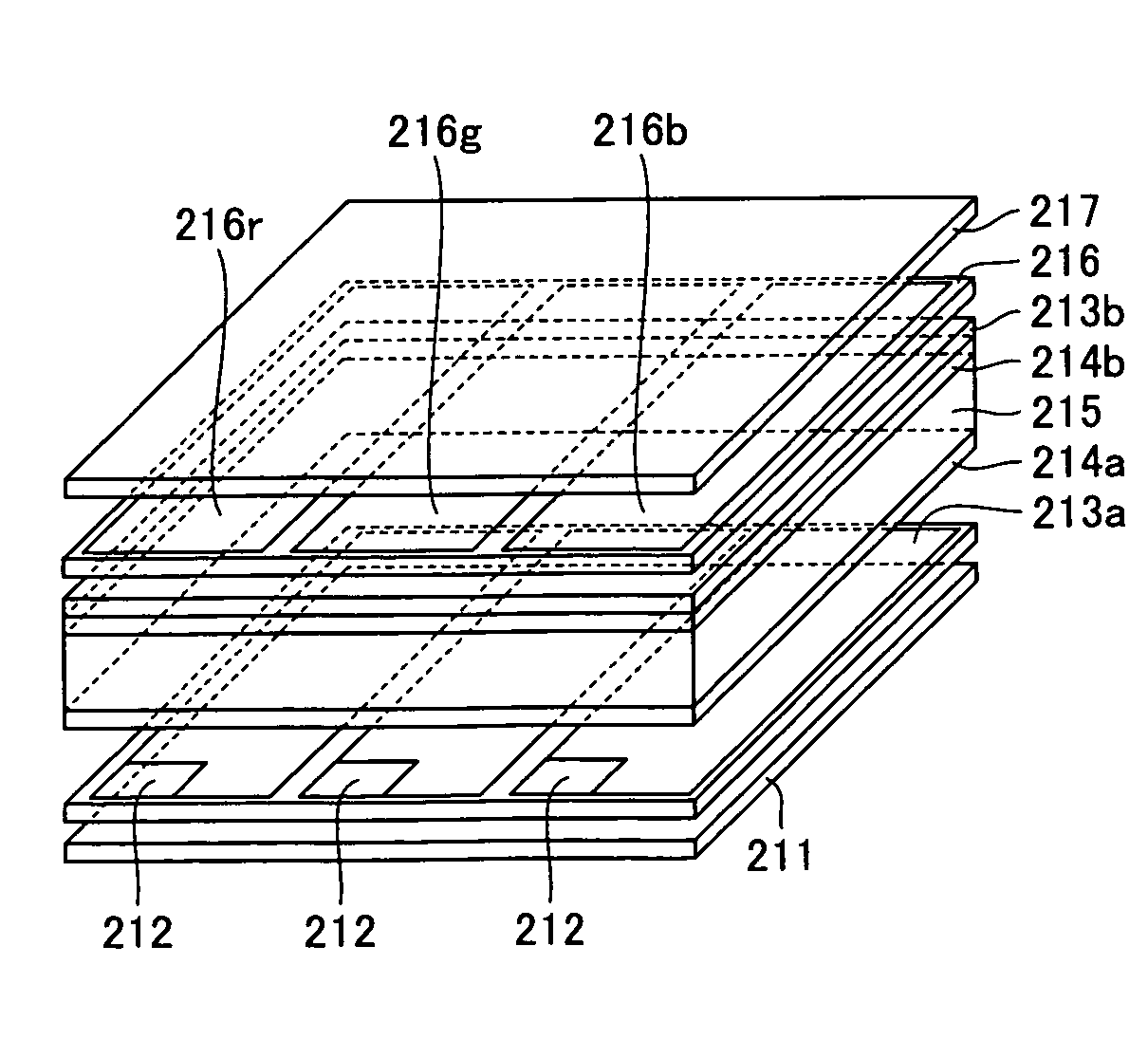

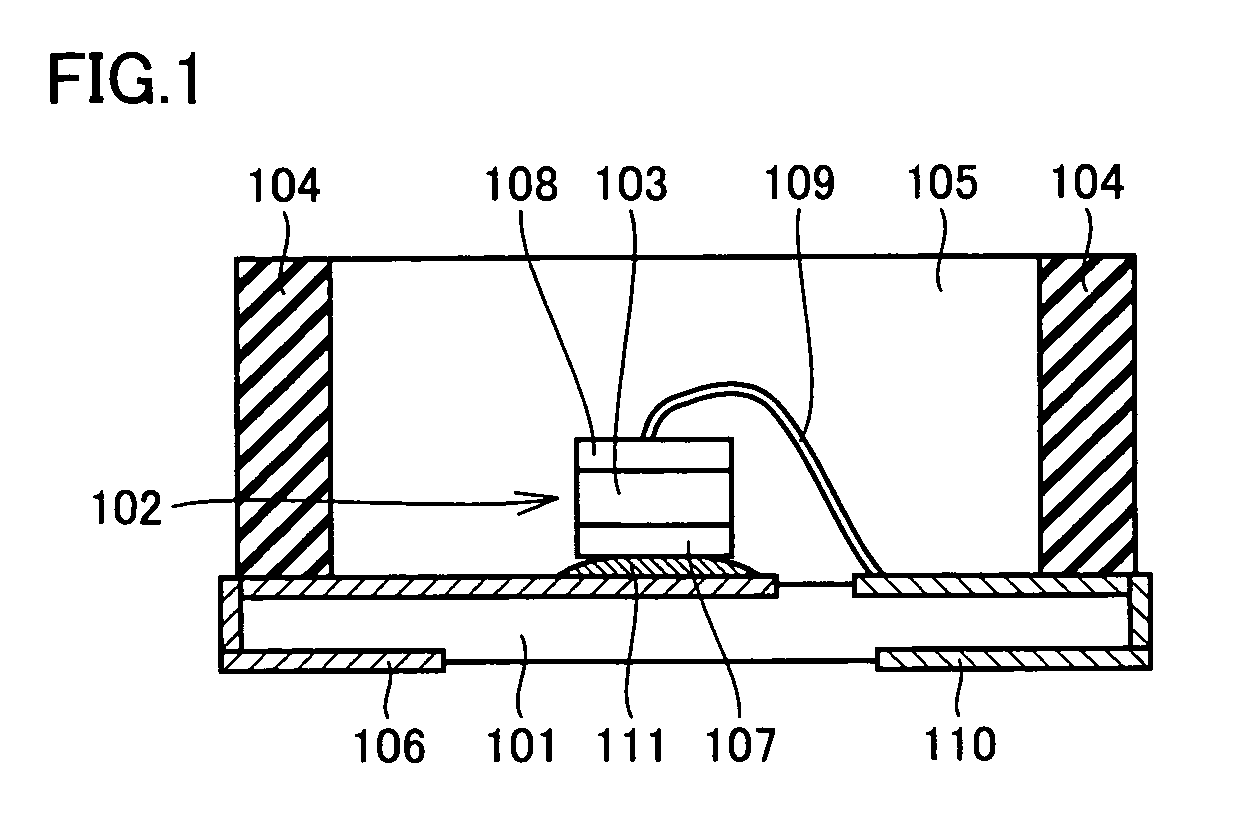

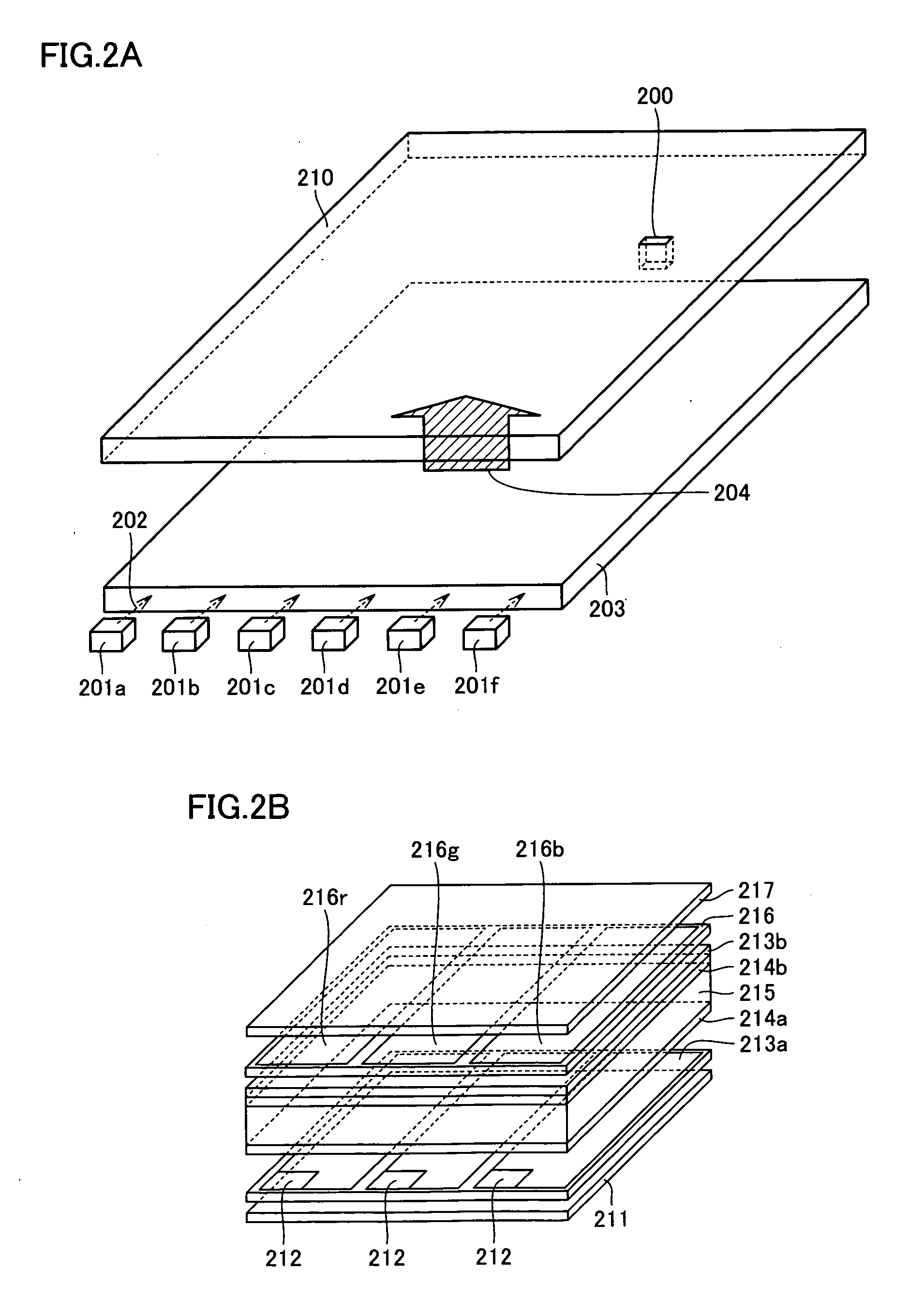

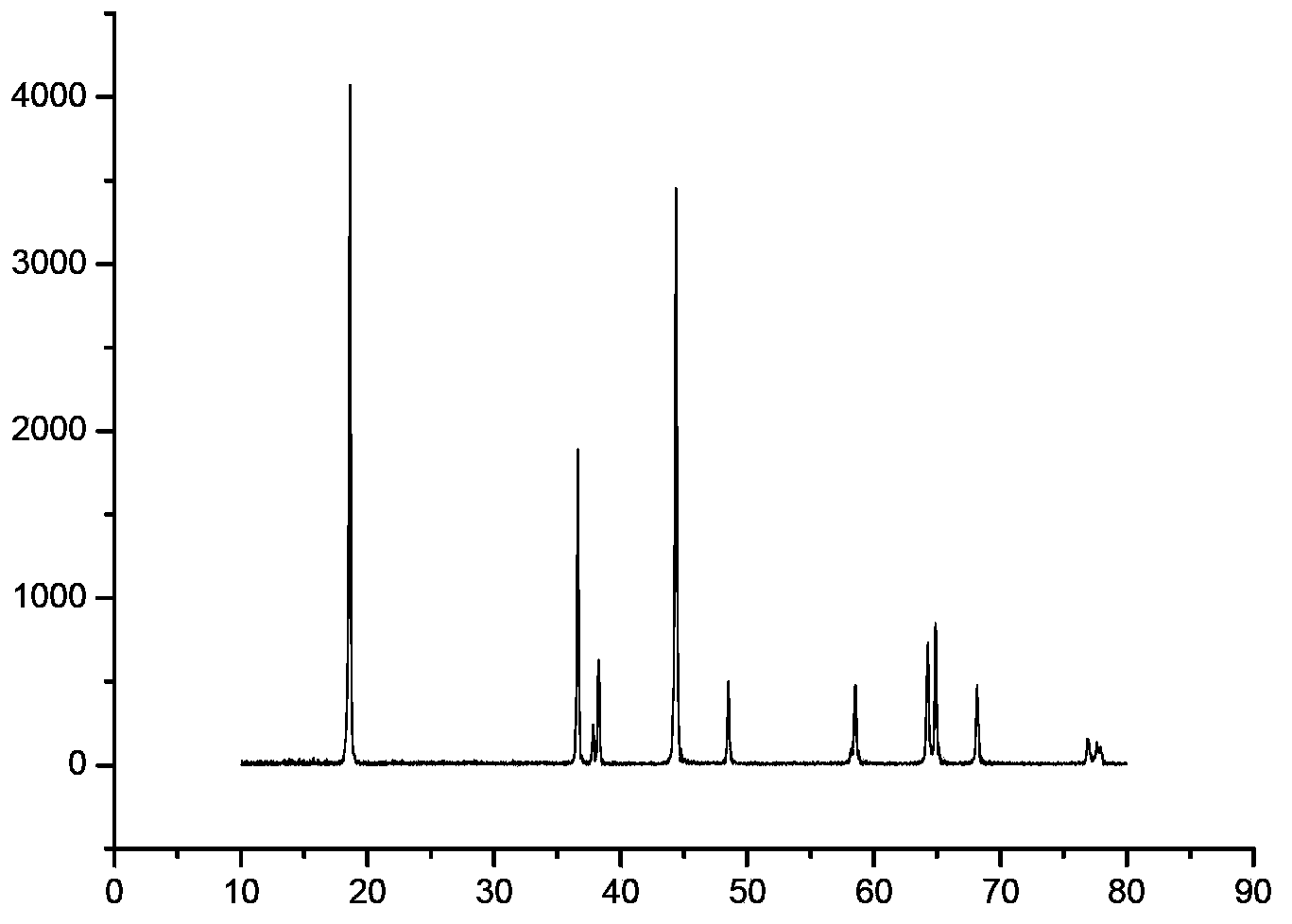

Method of manufacturing phosphor, light-emitting device, and image display apparatus

ActiveUS20080297031A1Range of color reproductionMaximum color reproduction rangeDischarge tube luminescnet screensLamp detailsGreen-lightOxygen

A method of manufacturing a first phosphor of which emission spectrum shape well matches with a color filter of three primary colors of light, a light-emitting device including the first phosphor, and an image display apparatus including the light-emitting device are provided. The light-emitting device includes a semiconductor light-emitting element emitting excitation light and the first phosphor absorbing the excitation light and emitting green light. The first phosphor contains a solid solution of aluminum element and a metal element M selected from the group consisting of Mn, Ce and Eu in crystals of an oxynitride having a β-type Si3N4 crystal structure, an amount of oxygen in the crystals being not higher than 0.8 mass %.

Owner:NAT INST FOR MATERIALS SCI +1

Nickel-cobalt lithium aluminate and preparation method of precursor thereof

ActiveCN103400973AHigh crystallinityHigh charge and discharge capacityCell electrodesHigh densityCobalt salt

The invention relates to a preparation method of a nickel cobalt aluminum material precursor. The method used in the invention comprises the steps: carrying out a complexation reaction of an aluminum salt and a complexing agent to form a stable aluminum complex, then injecting the aluminum complex simultaneously with a nickel-cobalt salt solution into a reaction kettle for carrying out a co-precipitation reaction to prepare a high-density precursor of nickel-cobalt lithium aluminate, and then carrying out a lithium mixed roasting to form a high-density spherical nickel-cobalt lithium aluminate material. At the same time, the invention also discloses an application of the nickel-cobalt lithium aluminate material used in a cathode material of a lithium ion battery. The high-density spherical nickel-cobalt lithium aluminate material which has atomic level mixture of nickel cobalt aluminum elements and good crystallinity can be produced under a premise without mass increase of cost, and the charge and discharge capacity and the first time efficiency have a certain improvement compared with those of current products. The process is simple and easy to implement, and can be used in large-scale industrialized production.

Owner:郭建

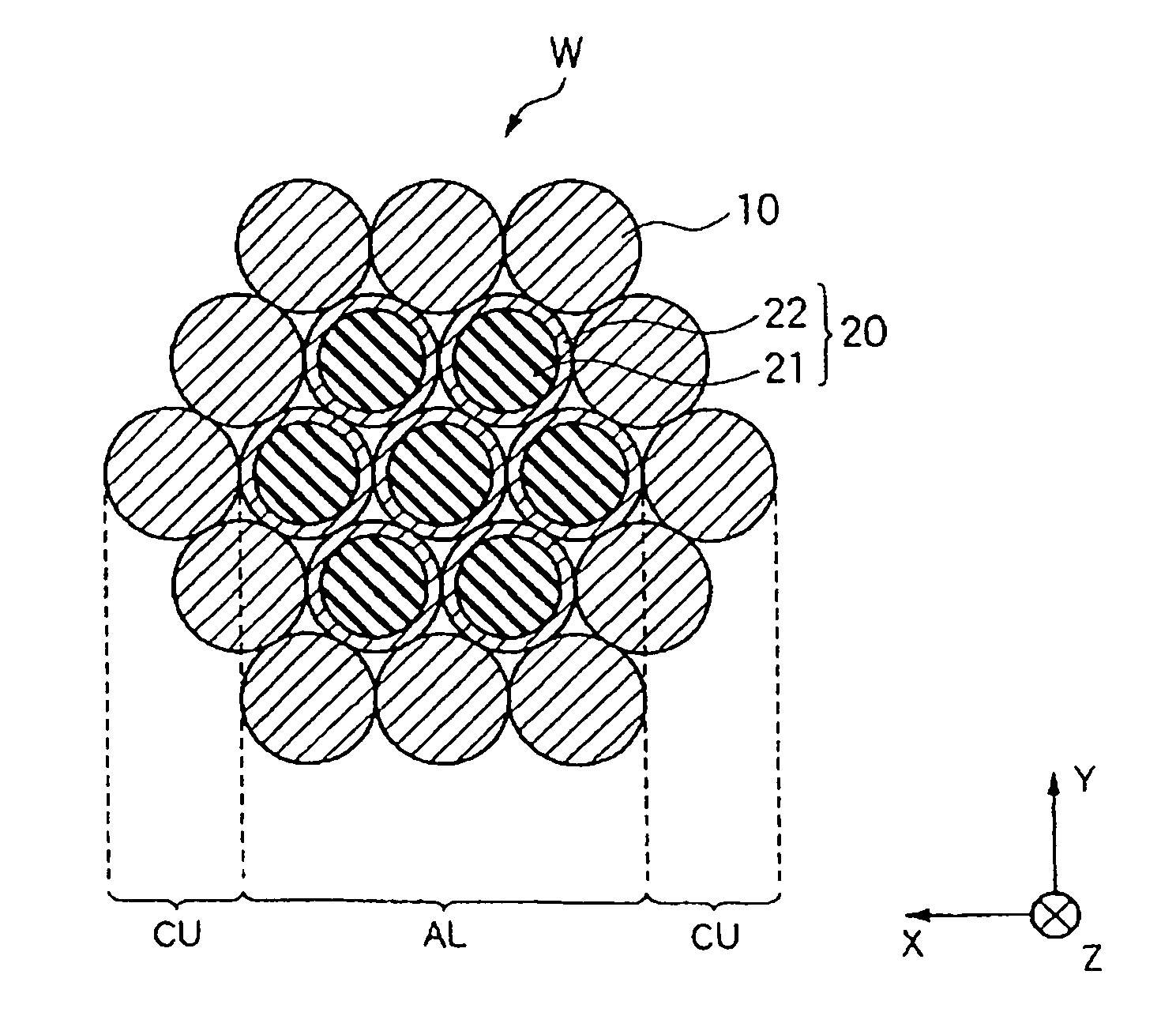

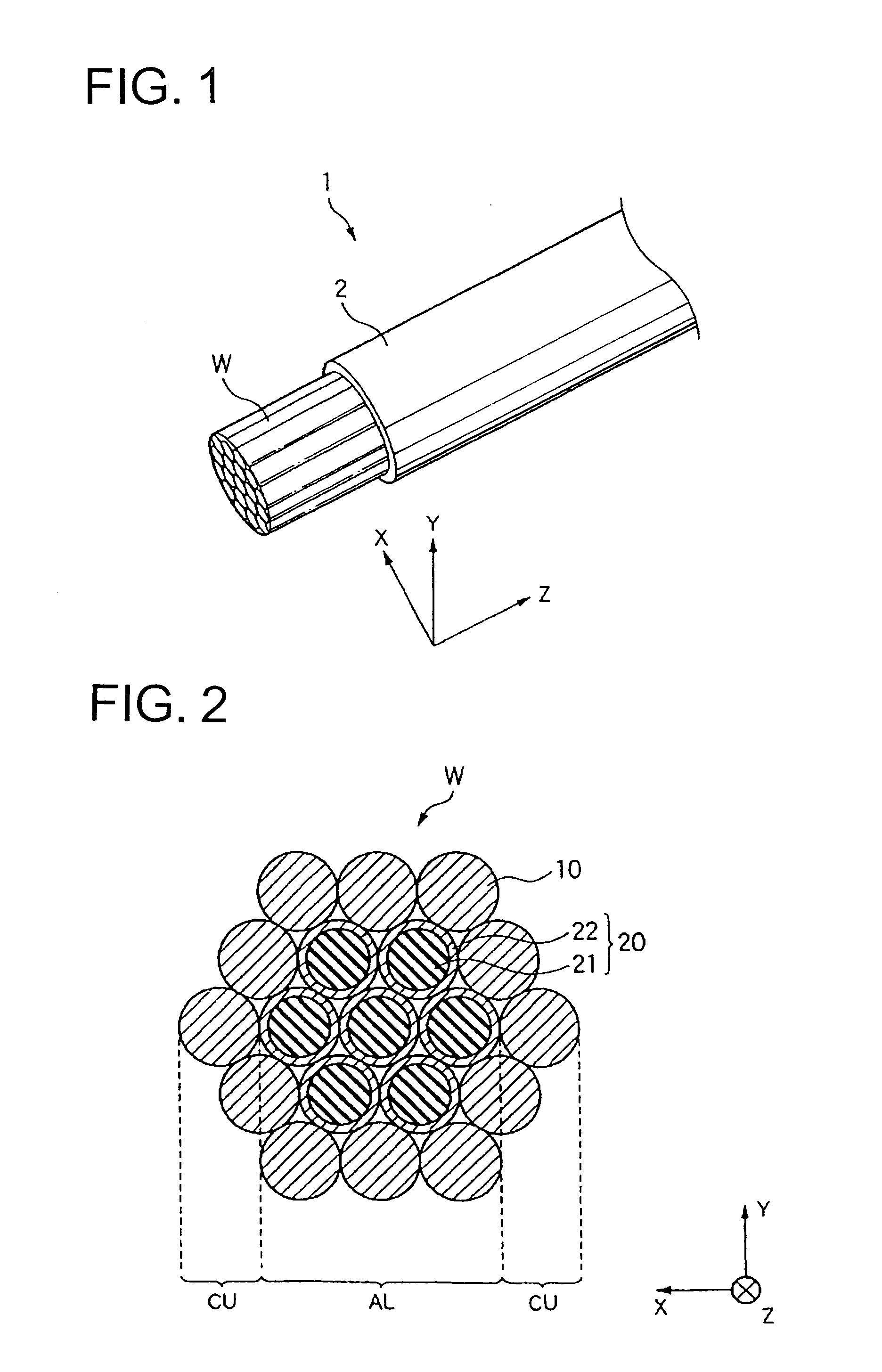

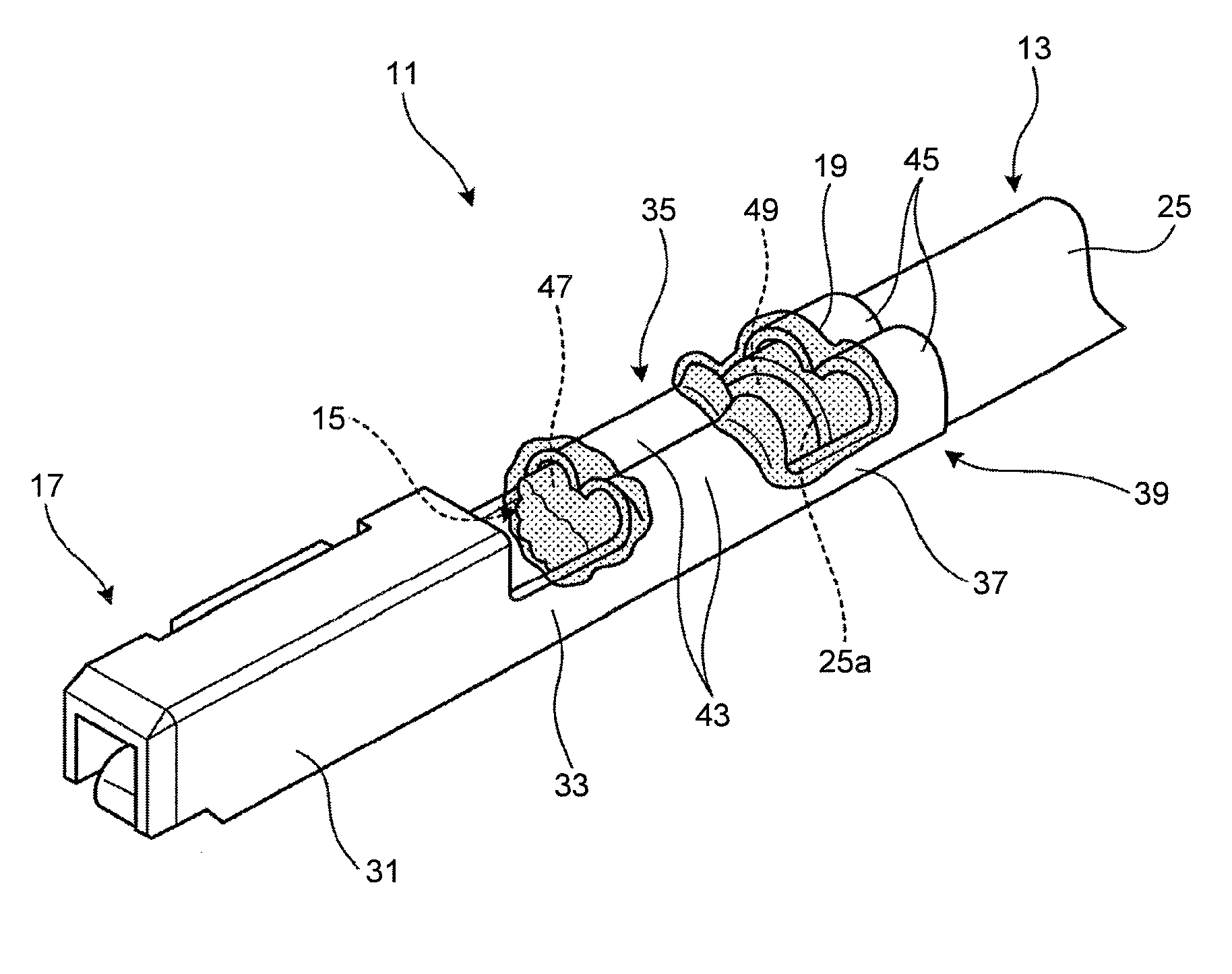

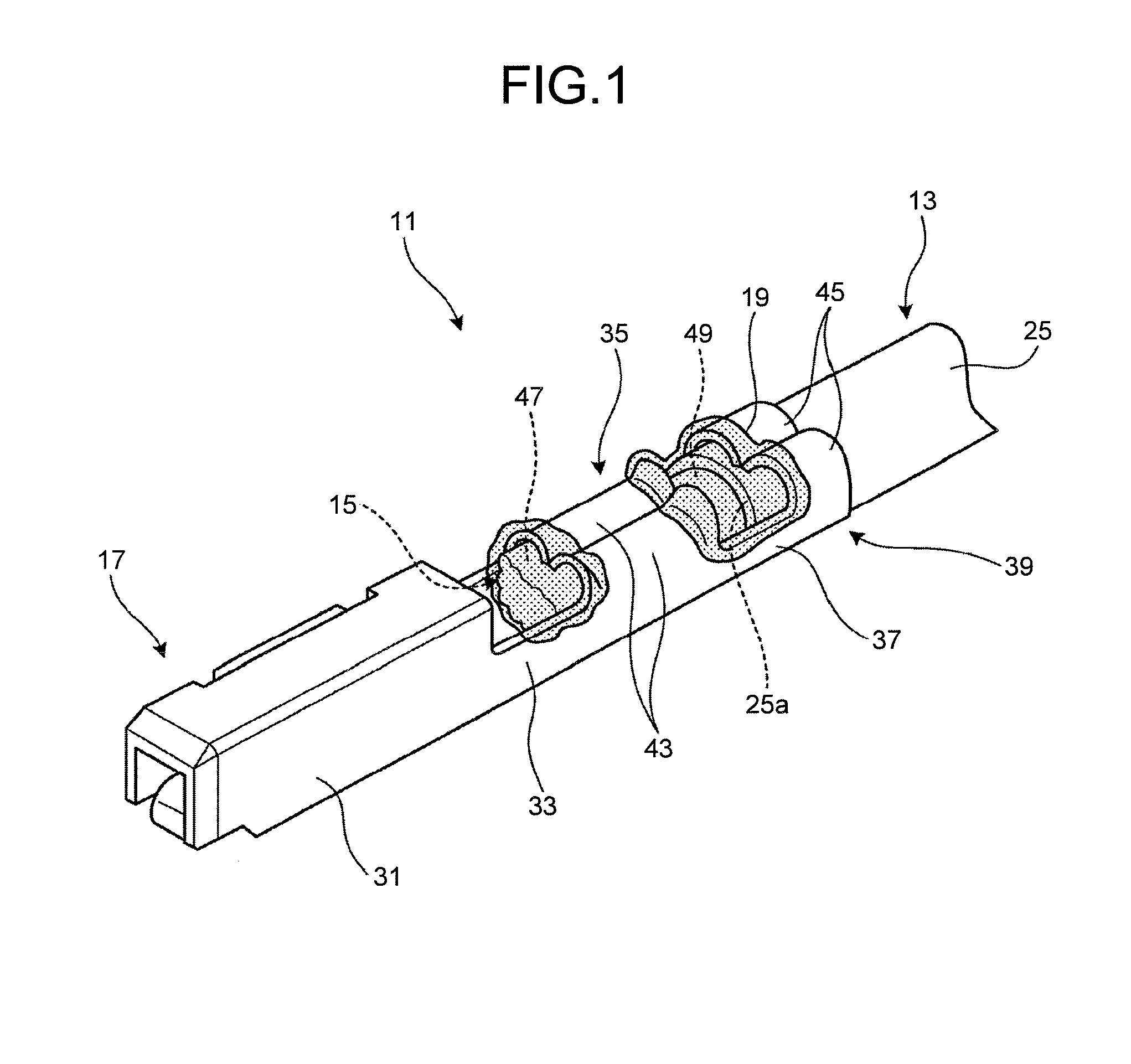

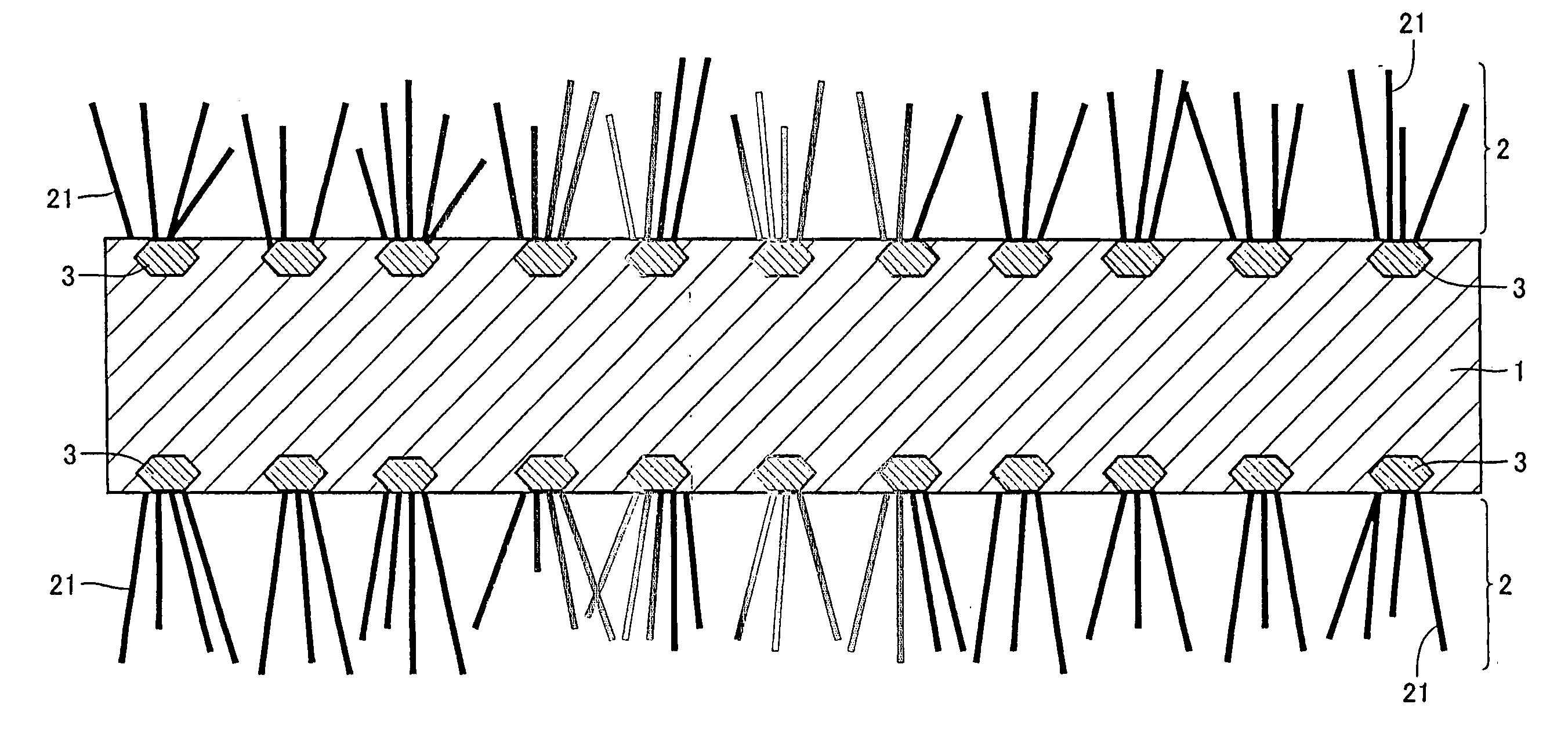

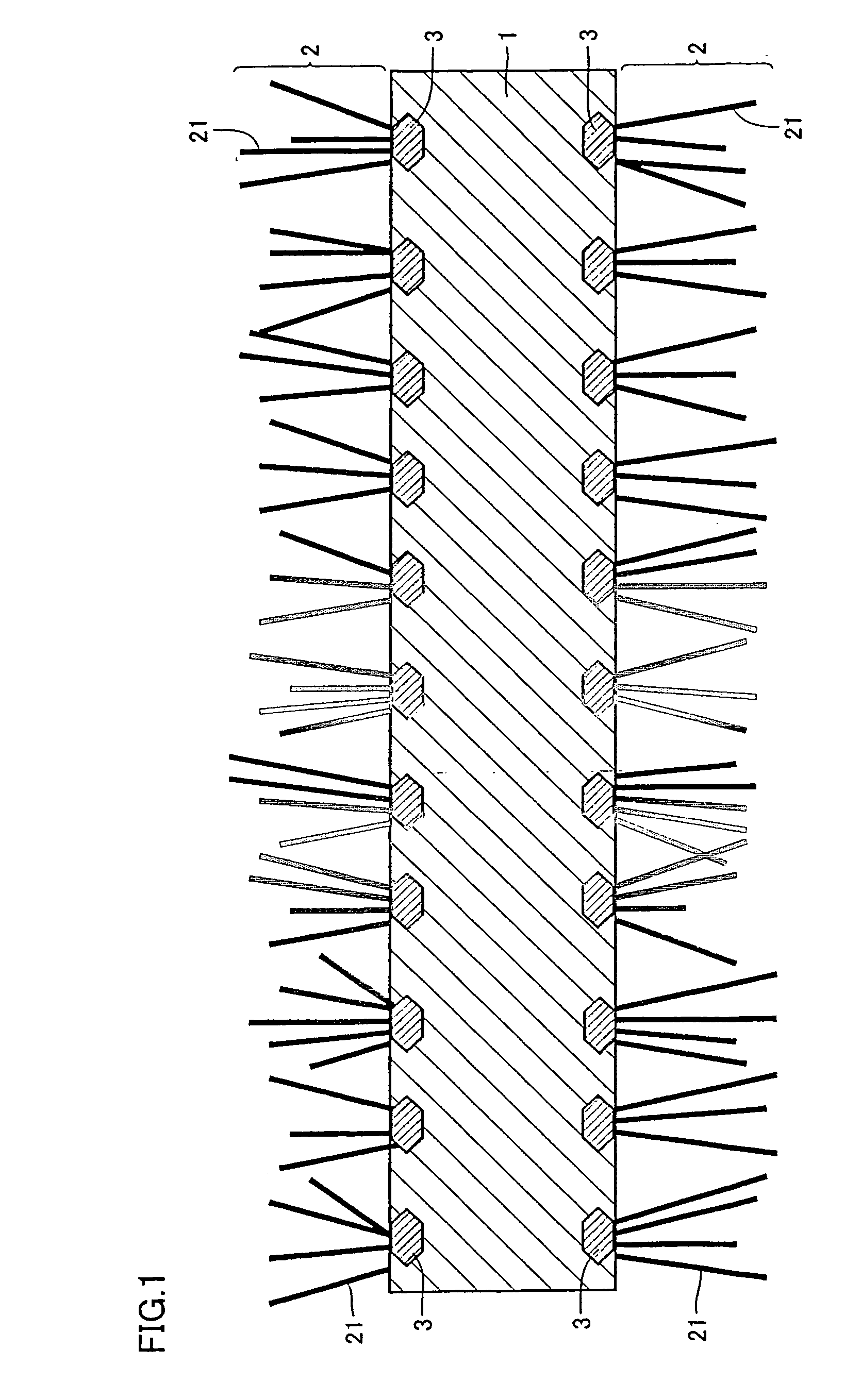

Composite electric wire

InactiveUS20100263911A1Avoid erosionEasy to handleNon-insulated conductorsConductive materialElectrical conductorCopper plating

Provided is a composite electric wire, which is intended to realize a light weight and improve a mechanical strength at the same time and which is enabled to improve the reliability by avoiding the problem of oxide coating or electric erosion so that the electric wire may be easily handled for use as a car-mounted wire harness.The composite electric wire comprises an electric wire body (W) composed of center conductors (AL) and outer-layer conductors (CU) arranged to extend in a Z-direction along the outer circumferences of the center conductors (AL) and to enclose the center conductors (AL). In the electric wire body (W), the center conductors (AL) composed of copper-coated aluminum element wires (20) of a (1+6) number are sectionally positioned at the center portion of the electric wire body (W) in an X-Y plane, and the outer-layer conductors (CU) composed of twelve copper element wires (10) are positioned in the outer circumference portion arranged around the center portion of the X-Y plane. Moreover, the outer-layer conductors (CU) make contact at their outer circumferences with the outer circumferences of the center conductors (AL), thereby to make their electric connections.

Owner:YAZAKI CORP

Heat resistant austenitic stainless steel

InactiveUS6485679B1High creep rupture strengthGood steam oxidation resistanceRigid pipesHeat exchange apparatusAustenitic stainless steelTungsten

A heat resistant austenitic stainless steel with high strength at elevated temperatures, good steam oxidation resistance, good fire side corrosion resistance, and a sufficient structural stability, suitable for use in boilers operating at high temperatures has a composition (by weight) of. 0.04 to 0.10% carbon (C), not more than 0.4% silicon (Si), not more than 0.6% manganese (MN), 20 to 27% chromium (Cr), 22.5 to 32% nickel (Ni), not more than 0.5% molybdenum (Mo), 0,20 to 0.60% niobium (Nb), 0.4 to 4.0% tungsten (W), 0.10 to 0.30% nitrogen (N), 0.002 to 0.008% boron (B), less than 0.05% aluminium (Al), at least one of the elements Mg and Ca in amounts less than 0.010% Mg and less than 0.010% Ca, and the balance being iron and inevitable impuities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

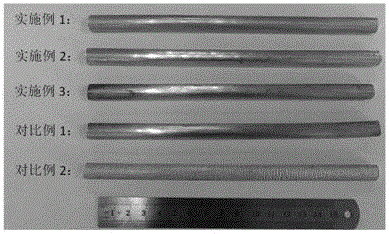

Preparation method of aluminum element doped ternary positive electrode material

InactiveCN104916837AImprove performanceGood physical propertiesCell electrodesSecondary cellsManganeseCobalt

The invention relates to the field of electrode materials, and concretely relates to a preparation method of an aluminum element doped ternary positive electrode material. The technical problem of poor cycle performance of nickel-cobalt-aluminum ternary positive electrode materials in the prior art is solved in the invention. An aluminum doped ternary positive electrode material precursor is prepared through a co-precipitation technology, the physical and chemical performances of the ternary positive electrode material precursor are improved to improve the bulk density and the cycle performance of the nickel-cobalt-aluminum ternary positive electrode materials, and the surface of the ternary positive electrode materials are modified through surface coating to improve the performances of the aluminum doped ternary positive electrode materials.

Owner:田东

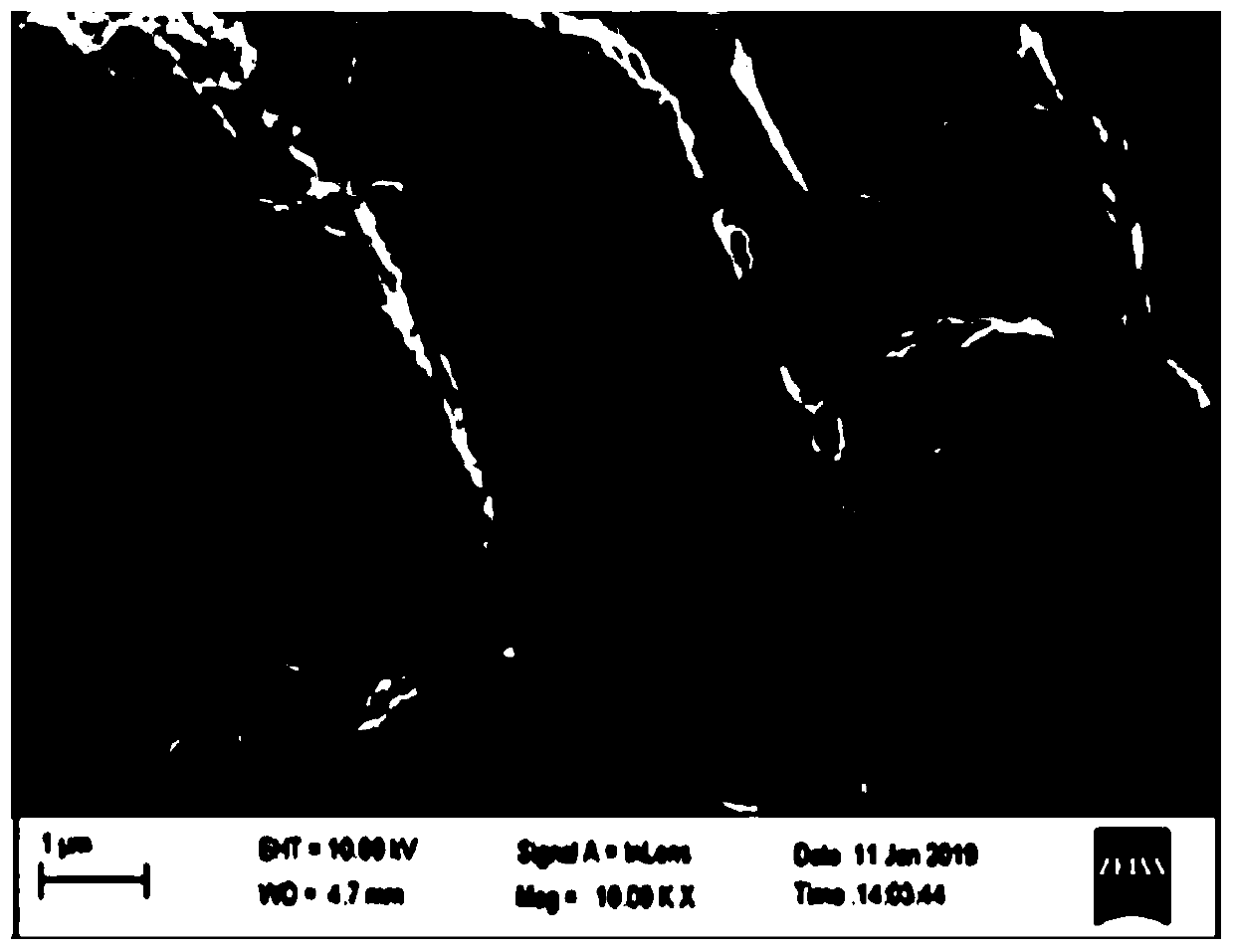

Negative electrode material, electrochemical device comprising negative electrode material and electronic device

The invention relates to a negative electrode material, an electrochemical device comprising the negative electrode material and an electronic device. The negative electrode material comprises a lithiation silica material, an inorganic coating layer and a polymer coating layer, wherein one Si-O-M bond is at least arranged between the inorganic coating layer and the lithiation silicon oxide material, and M includes at least one of an aluminum element, a boron element, and a phosphorus element. The negative electrode material provided by the invention has relatively high stability to water, relatively high initial coulombic efficiency and relatively good cycling stability.

Owner:NINGDE AMPEREX TECH

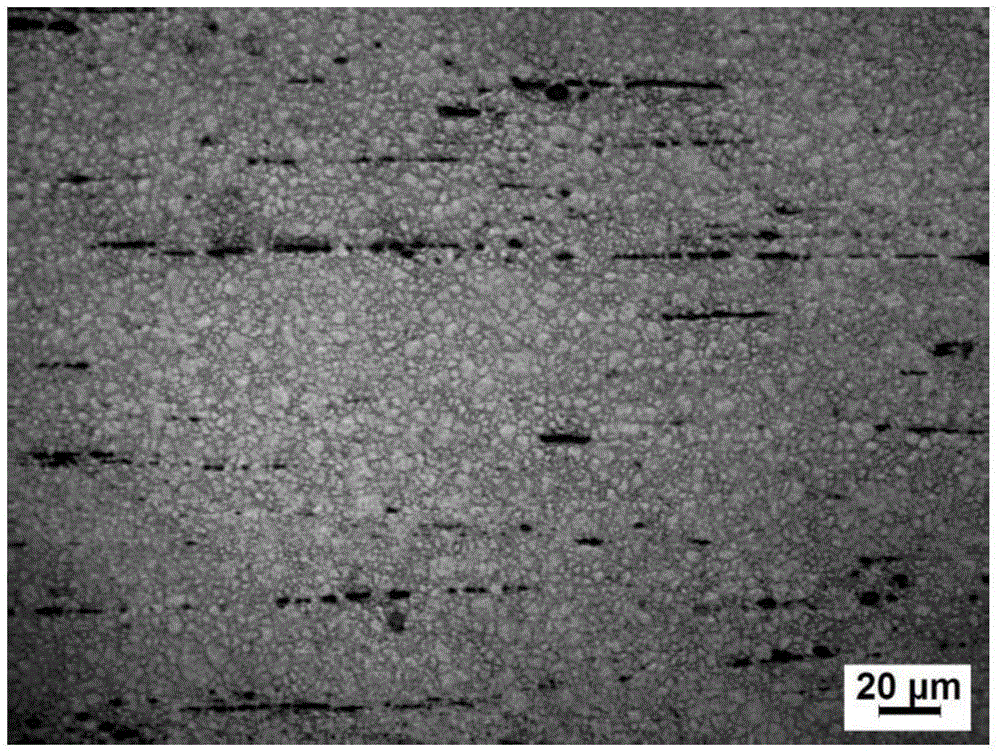

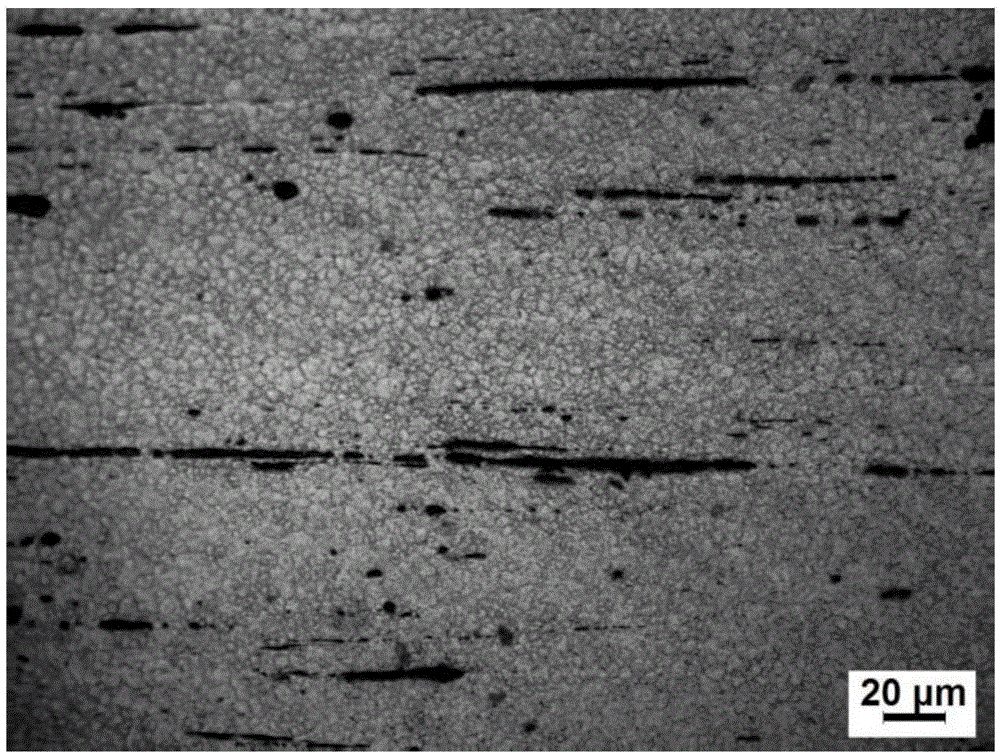

High-speed-extrudable wrought magnesium alloy and preparation method thereof

The invention discloses a high-speed-extrudable wrought magnesium alloy and a preparation method thereof. The high-speed-extrudable wrought magnesium alloy comprises the following components in percentage by mass: 2wt%-10wt% of Bi, 0.5wt%-5wt% of Al, 0.1wt%-2wt% of Zn, 0.1wt%-1.0wt% of Mn and the balance of magnesium. According to the high-speed-extrudable wrought magnesium alloy, the element Bi is taken as a main alloy element, lots of Mg3Bi2 phases are formed by virtue of a simple alloying measure, and a small quantity of aluminum elements and zinc elements are supplemented, so that the plasticity of the alloy is improved; and by combining a manganese element, the corrosion resistance is improved, and the high-speed-extrudable high-strength magnesium alloy is developed from the alloy series and can be applied to high speed extrusion with the extrusion speed which is not less than 20m / min.

Owner:HEBEI UNIV OF TECH

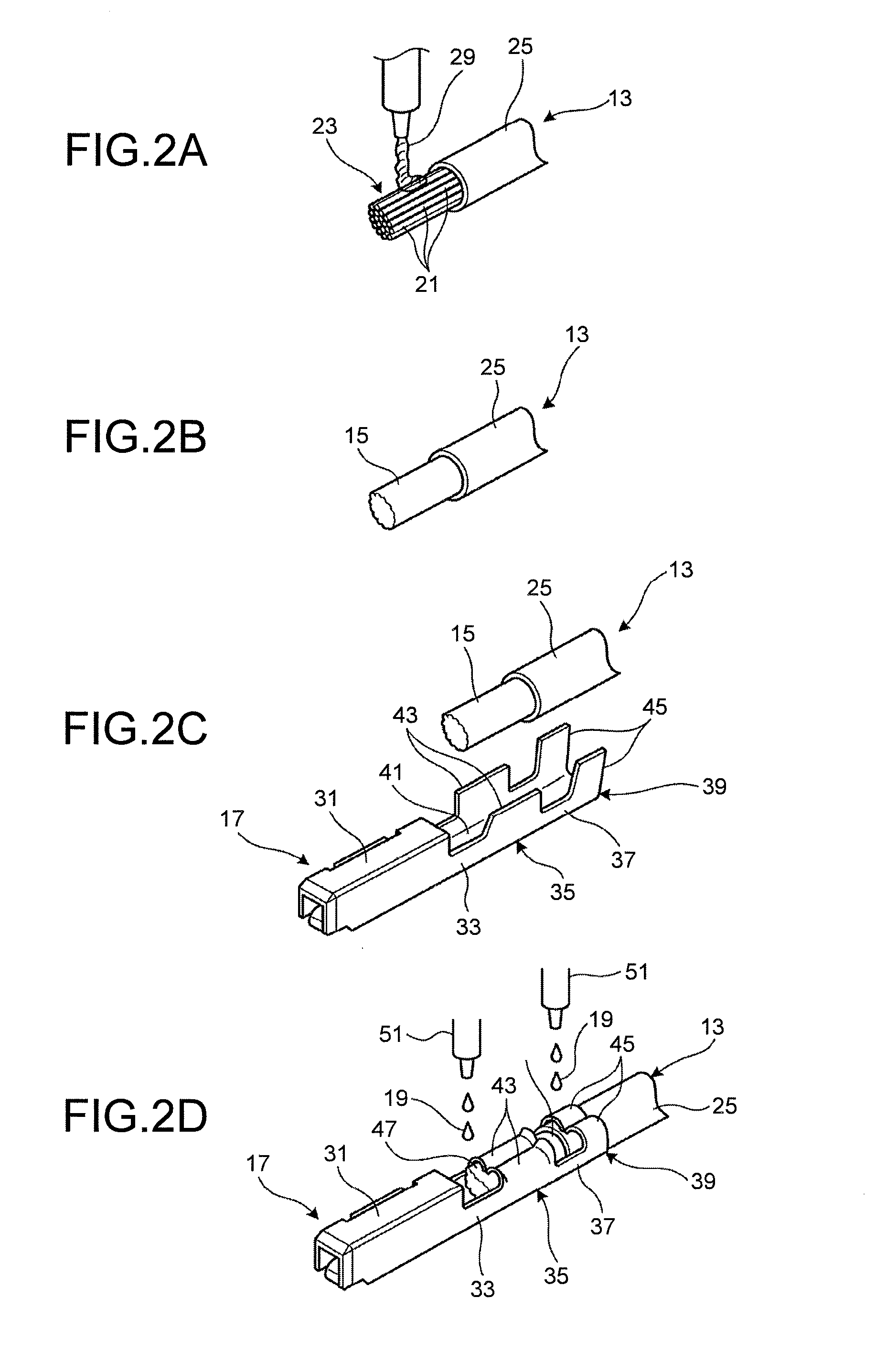

Aluminum electric wire with crimp-type terminal and method of manufacturing the same

InactiveUS20150287496A1Slow down progressEasy to operateBraided wire conductorsConductive materialElectrical conductorWater repellent

An aluminum electric wire with crimp-type terminal includes a coated electric wire including a conductor having a plurality of twisted aluminum element wires made of an aluminum alloy, a conductor portion where the plurality of aluminum element wires exposed by stripping an insulating coating of the coated electric wire are integrally formed into a solid wire, a crimp-type terminal made of a copper alloy having a conductor crimping portion crimped to couple to the conductor portion formed into the solid wire, and a water-repellent agent provided for a front side exposed conductor portion and a rear side exposed conductor portion 49 exposed to outside air without being covered by the conductor crimping portion of the crimp-type terminal.

Owner:YAZAKI CORP

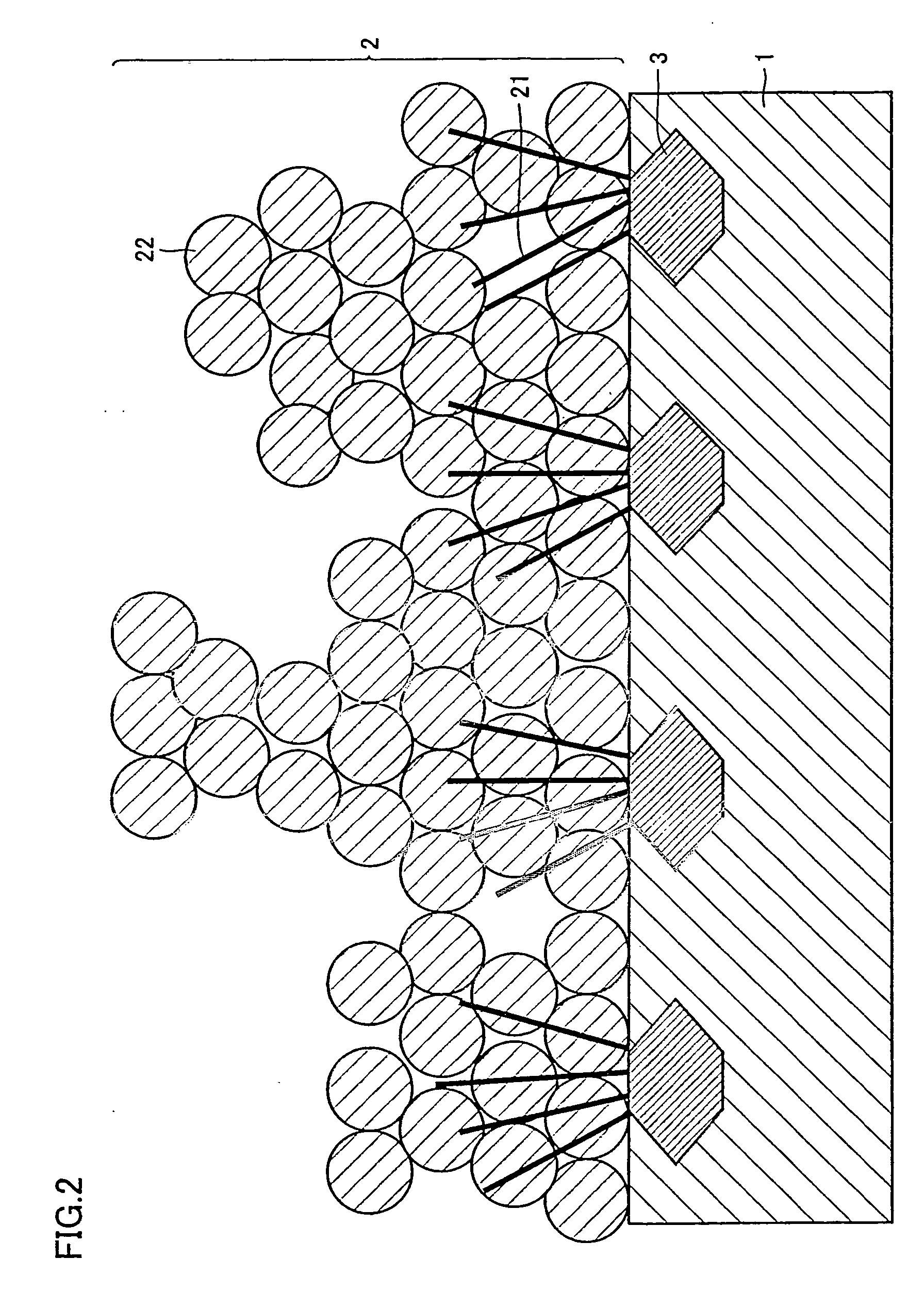

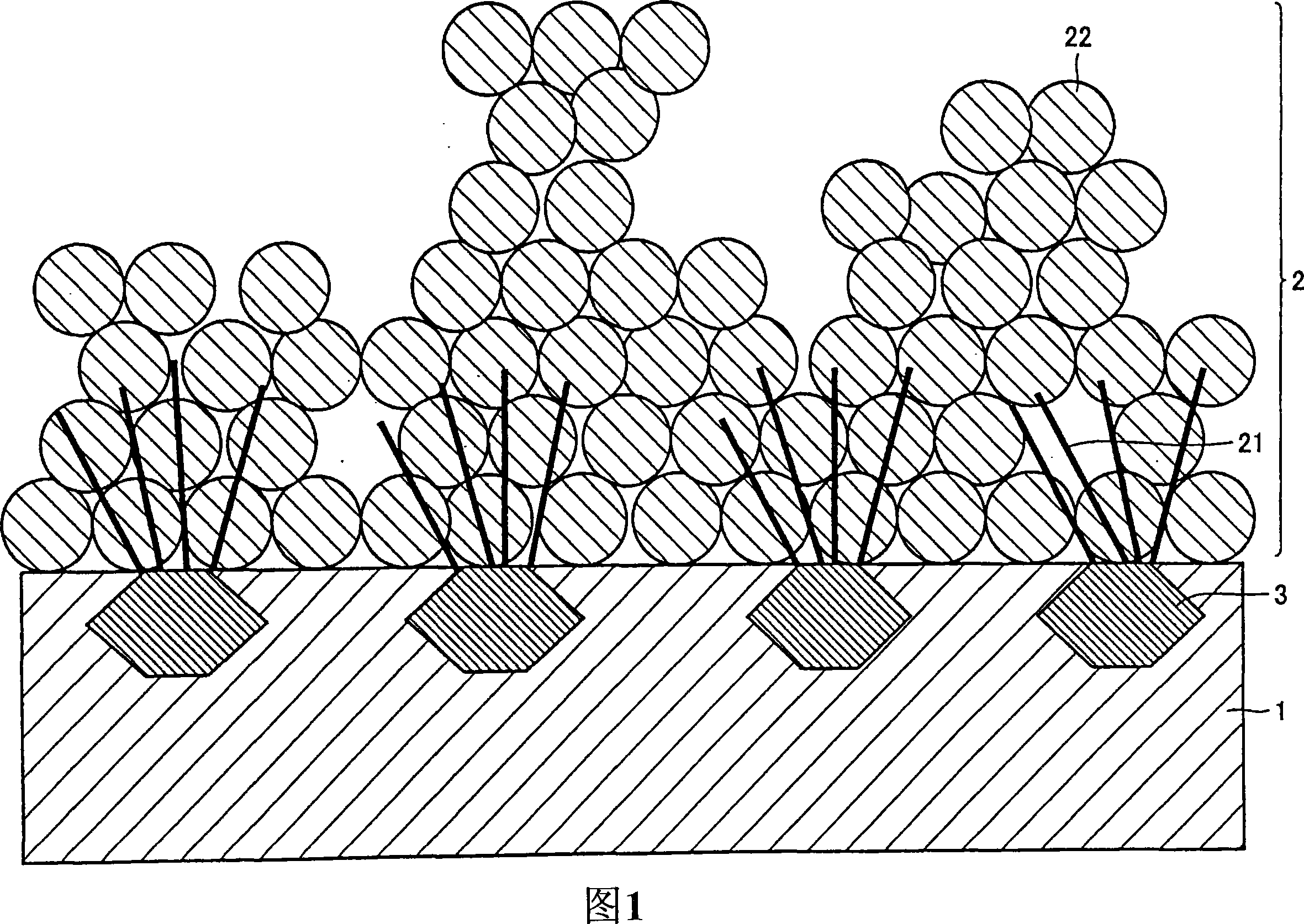

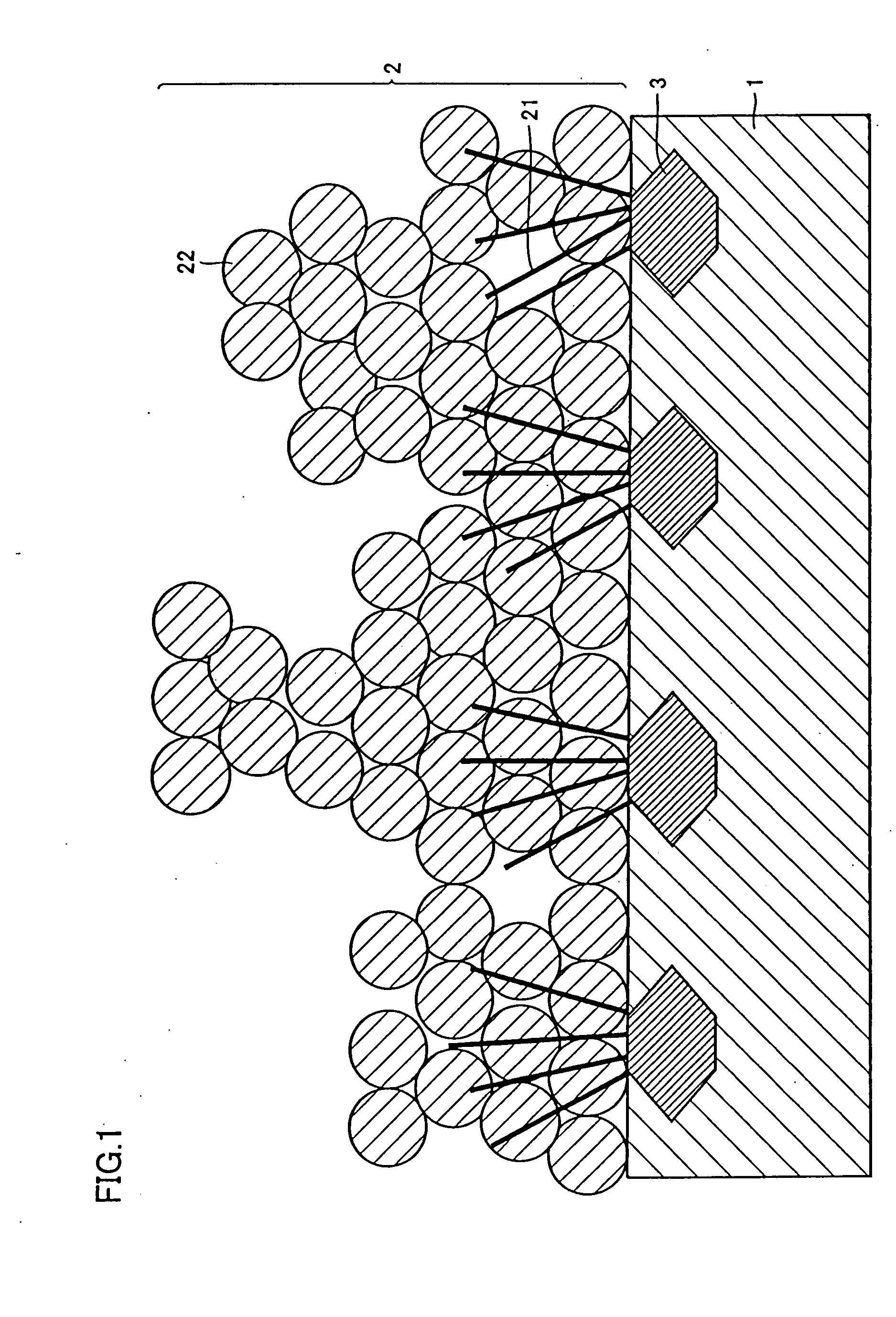

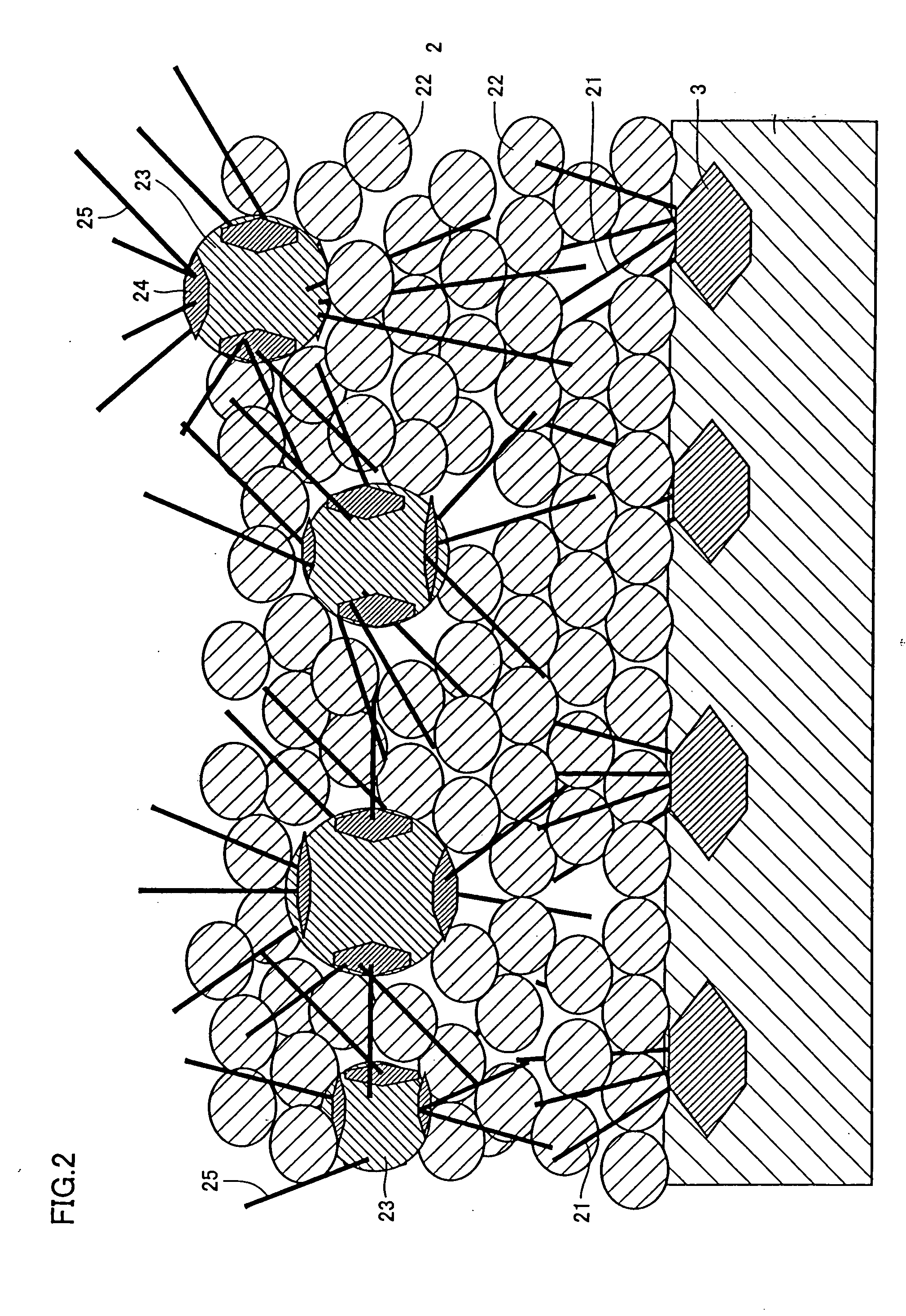

Carbon-coated aluminum and method for producing same

ActiveUS20060172134A1AdhesionImprove adhesionHybrid capacitor electrodesElectrode carriers/collectorsCarbon coatedHydrocarbon

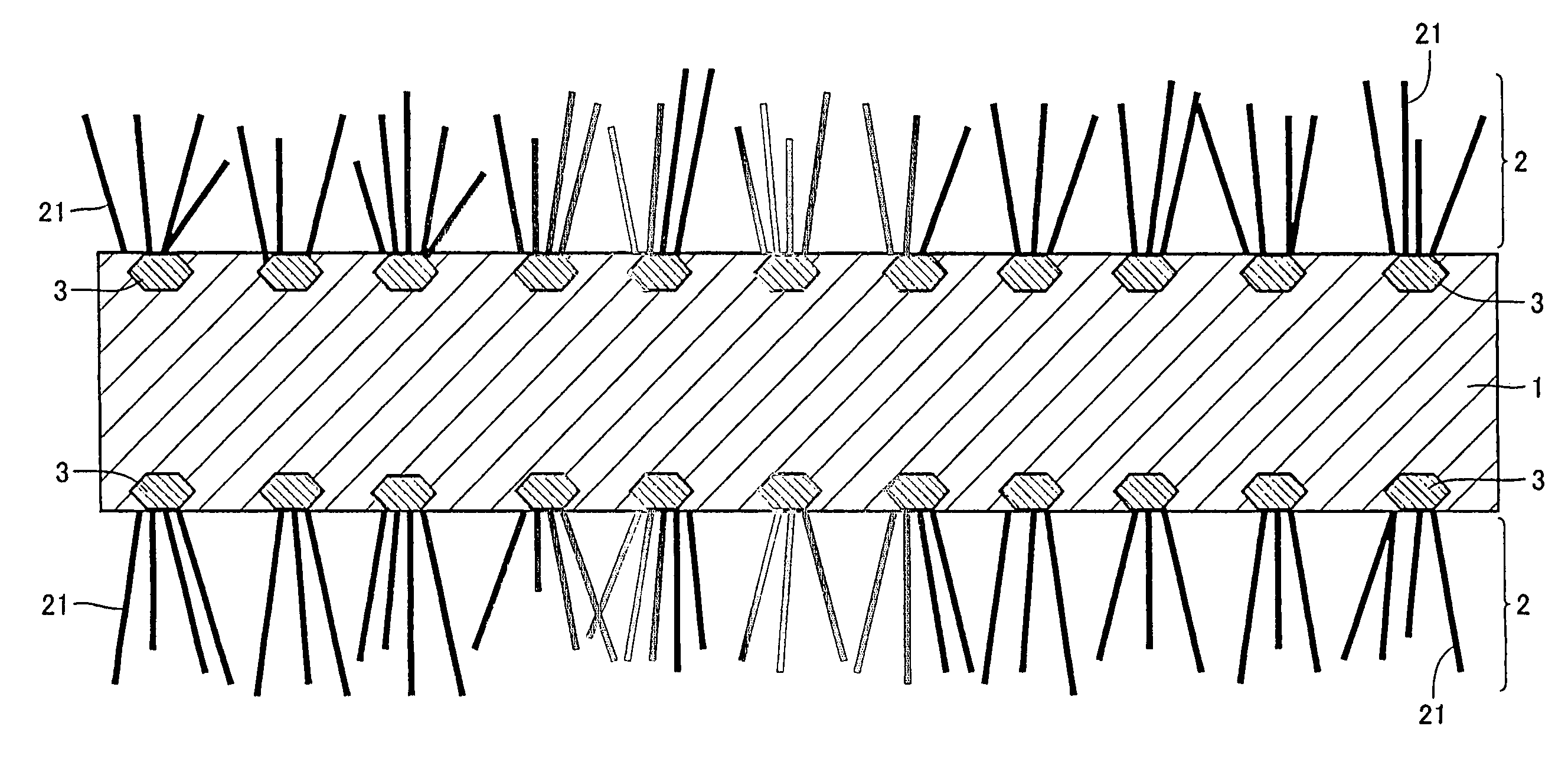

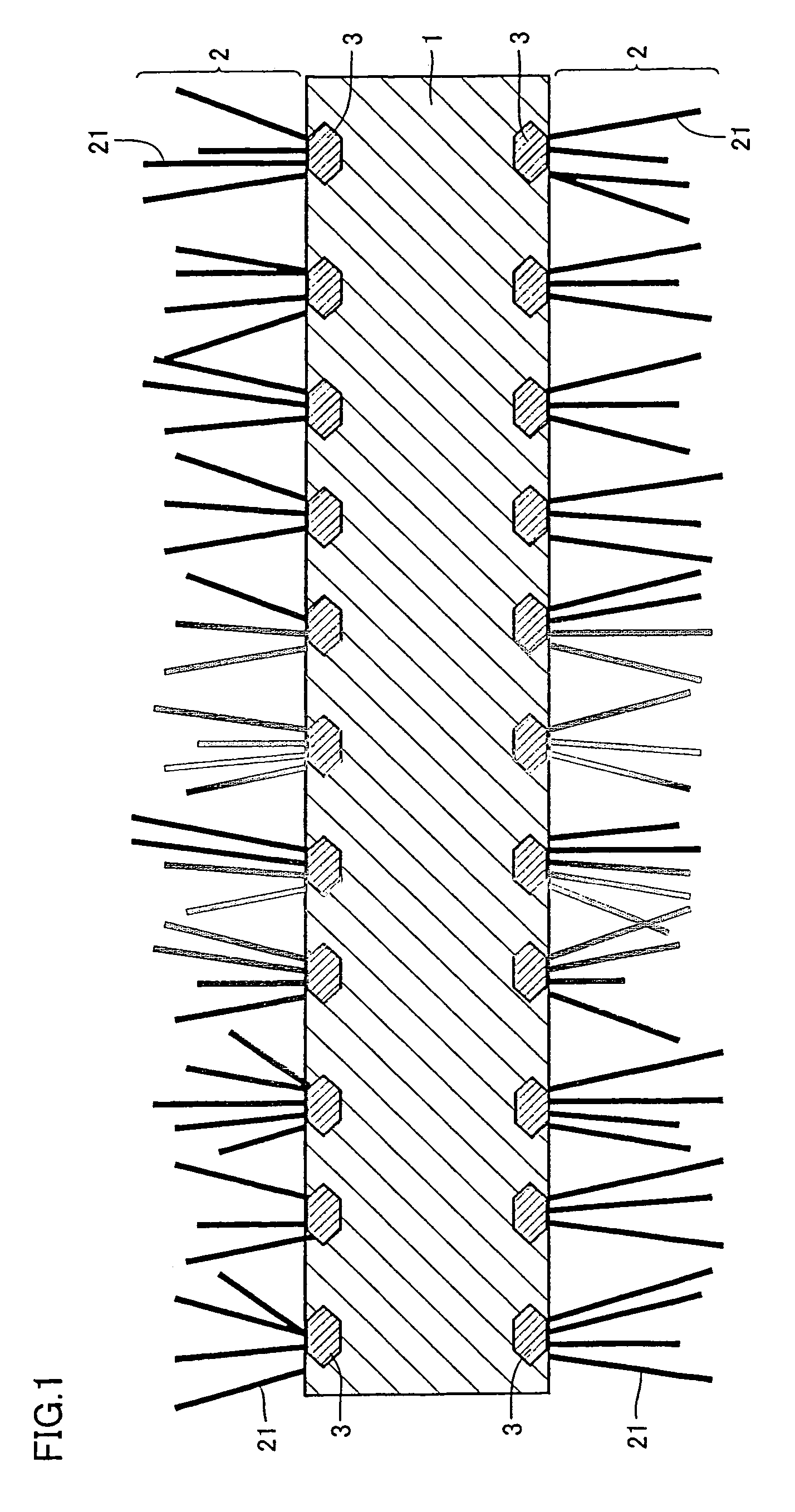

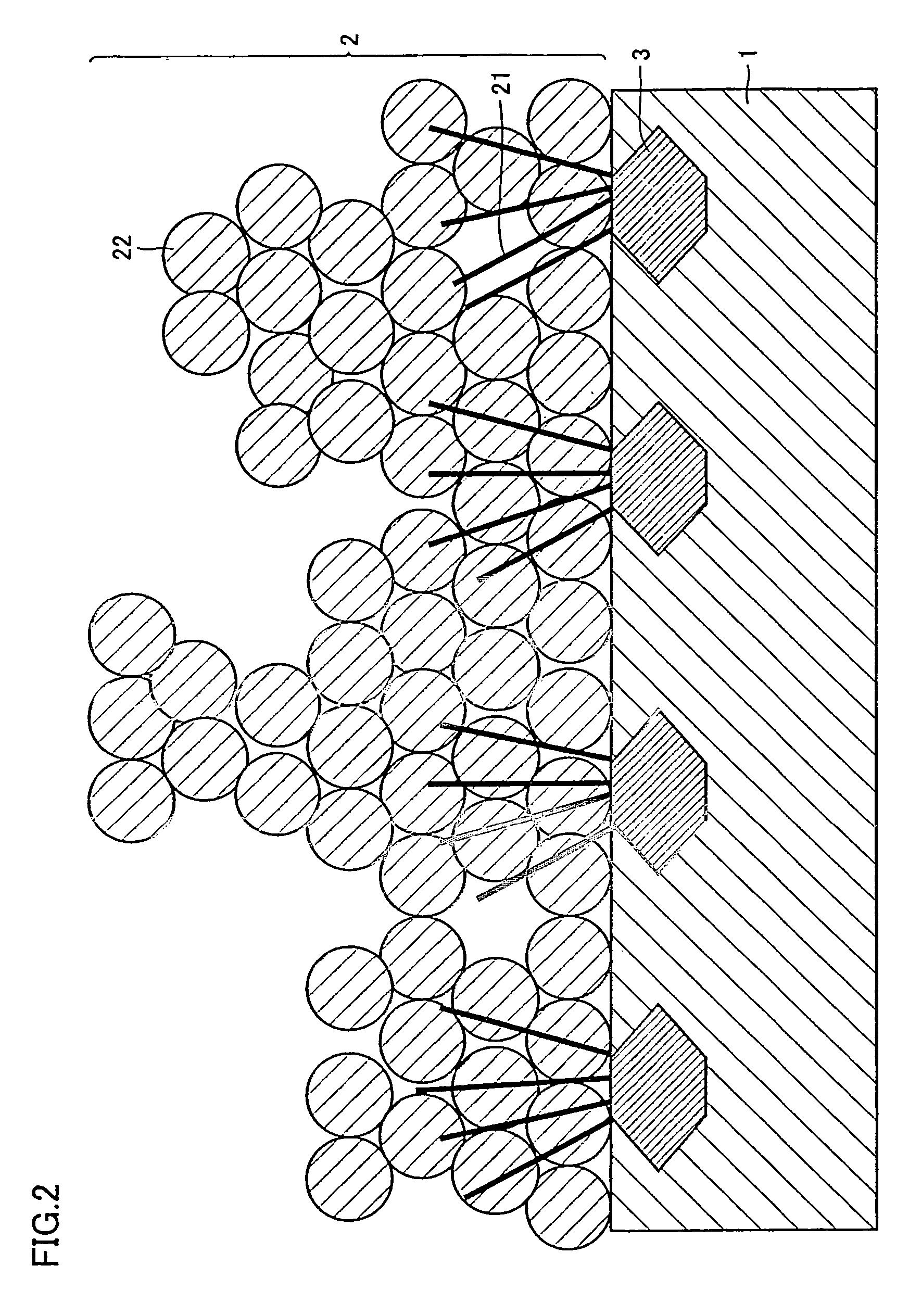

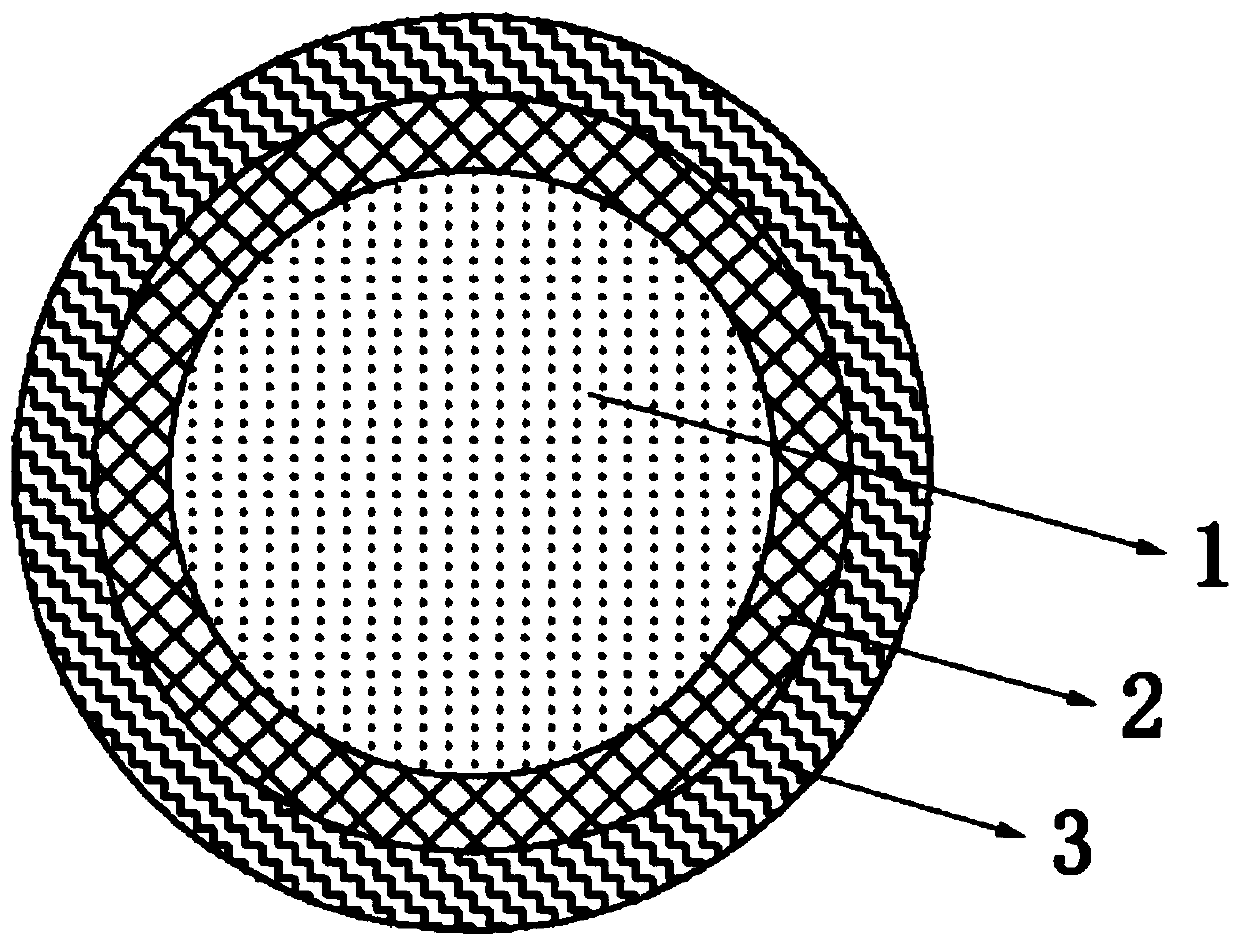

Provided are an aluminum material coated with carbon which can improve the adhesion between an aluminum material and an active substance layer, and a manufacturing method thereof. The aluminum material coated with carbon includes an aluminum material (1) and a carbon-containing layer (2) formed on the surface of the aluminum material (1), and also includes an interposition layer (3) that is formed between the aluminum material (1) and the carbon-containing layer (2) and contains an aluminum element and a carbon element. The manufacturing method of an aluminum material coated with carbon includes a step of arranging an aluminum material in a space containing a hydrocarbon-containing substance and a step of heating in the state where the aluminum material is arranged in the space containing the hydrocarbon-containing substance.

Owner:TOYO ALUMINIUM KK

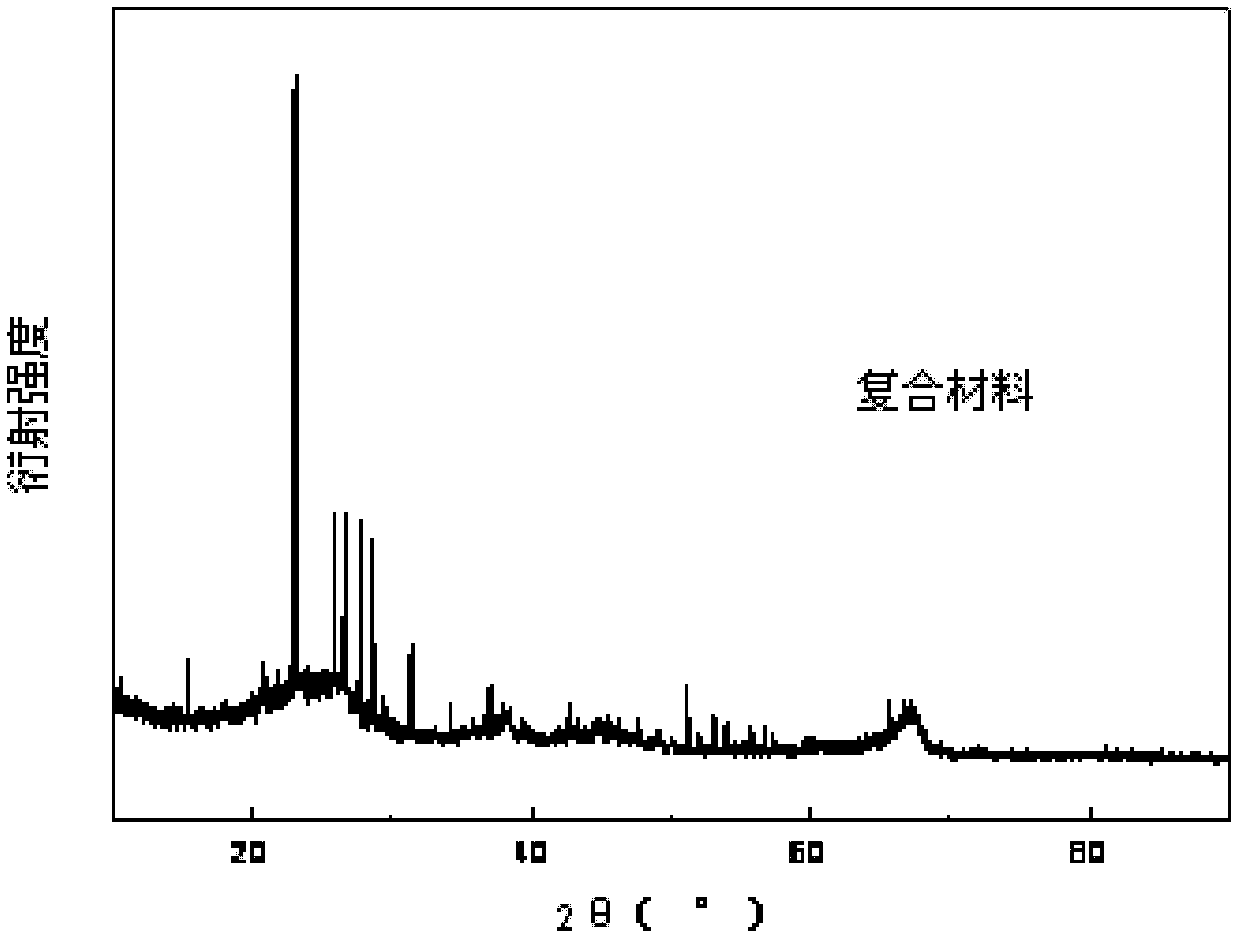

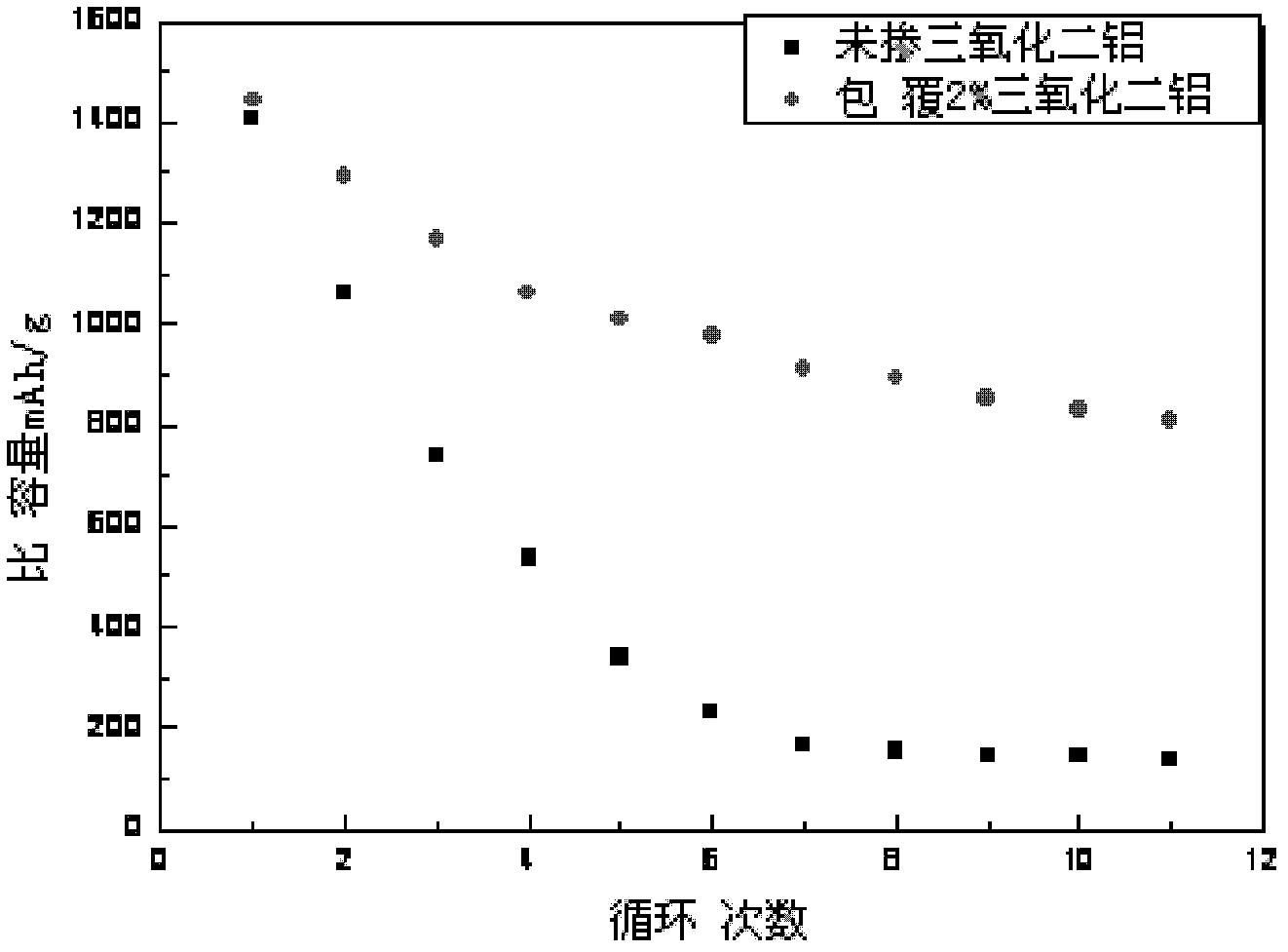

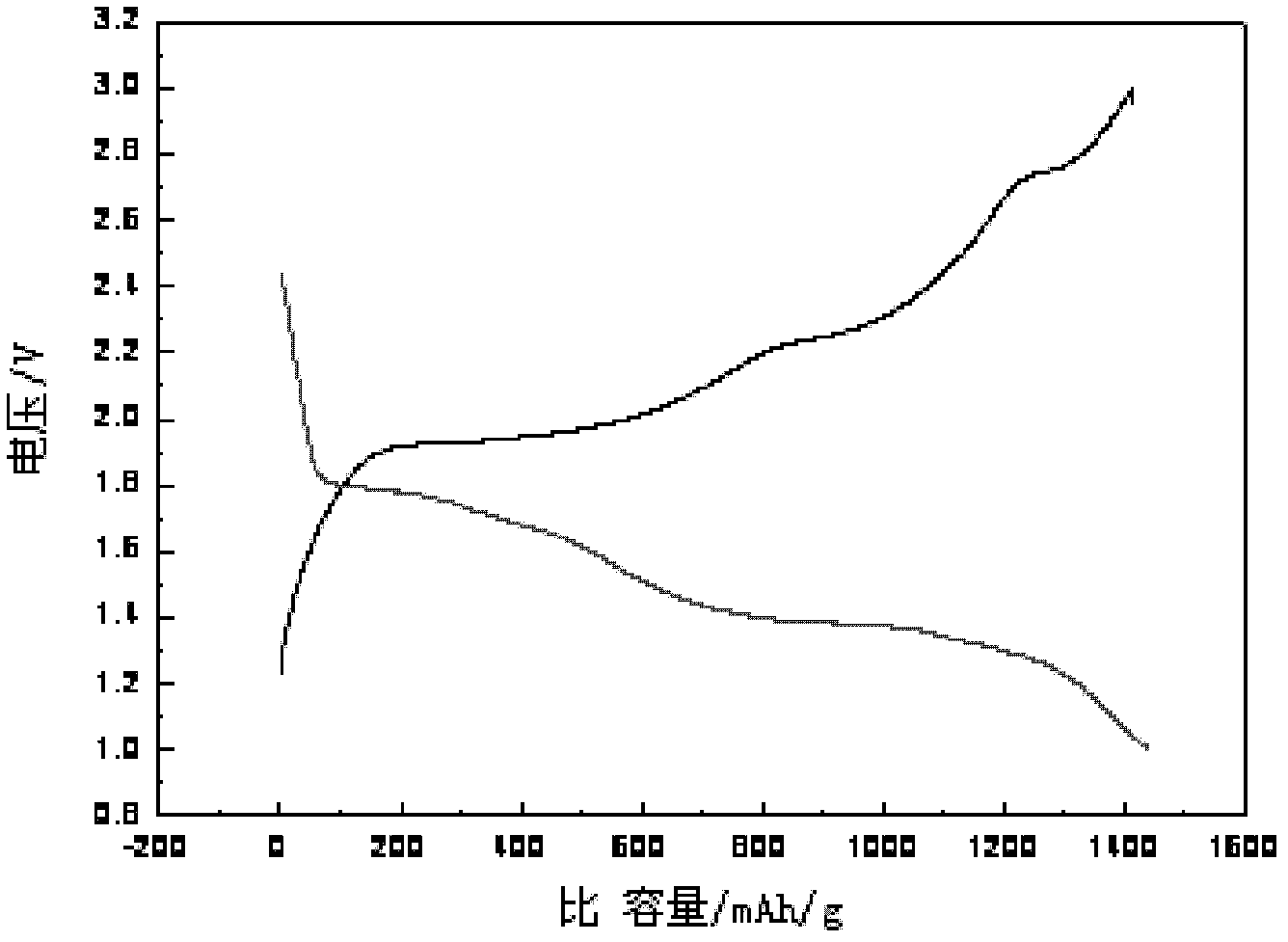

A kind of preparation method of sulfur positive electrode of lithium-sulfur battery

InactiveCN102280614AImprove electrochemical performanceHigh initial discharge specific capacityCell electrodesSodium bicarbonateMass ratio

The invention provides a preparation method of a sulfur positive electrode of a lithium sulfur battery. The preparation method comprises the following steps: a) preparing a mixed slurry according to the condition that the mass ratio of a sublimed sulfur to an active carbon is (4-9):2; b) drying and grinding the mixed slurry; c) dispersing the mixture in a sodium bicarbonate or ammonia solution, and performing the ultrasonic oscillation; d) adding an aluminum sulfate, aluminum chloride or aluminum potassium sulfate solution according to the condition that the mol ratio of a sulfur carbon mixture to an aluminum element in aluminum salt is 100:(0.5-3) so as to prepare a composite material covered by the aluminum hydroxide; e) filtering and drying the composite material, warming to 140-300 DEG C within 6-11 hours under the protection of inert gas, and grinding to obtain the sulfur carbon positive electrode material covered by the aluminum oxide for the lithium sulfur battery; and f) preparing the positive electrode of the lithium sulfur battery, assembling and testing the performance of the battery. The initial discharging specific capacity of the sulfur positive electrode composite material for the lithium sulfur battery prepared by the invention can achieve 1441.7.8 mAh / g, the battery discharging specific capacity is still maintained at 808.1mAh / g at room temperature after ten times of circulation, and the capacity retention rate can achieve 56.52%.

Owner:TIANJIN UNIV +1

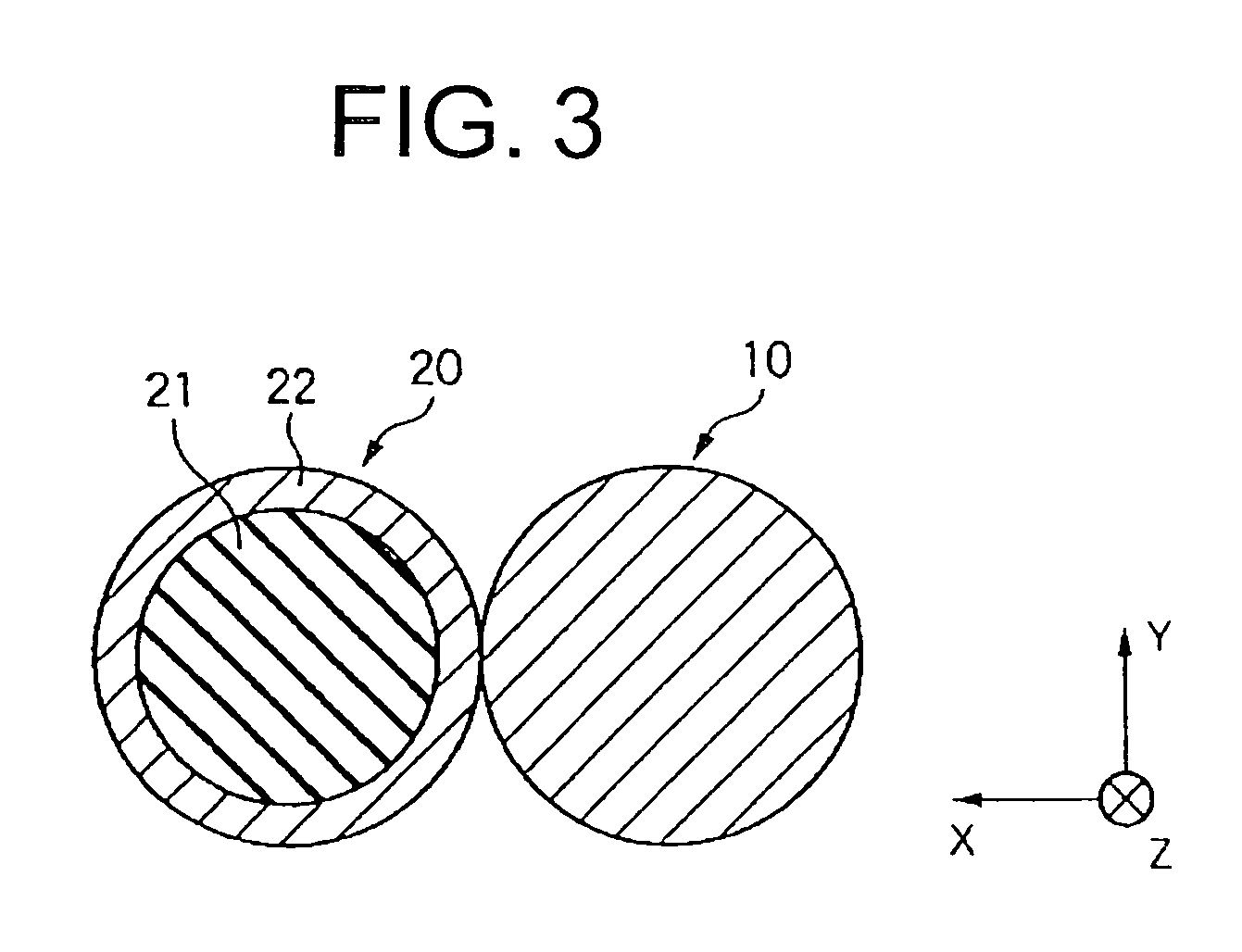

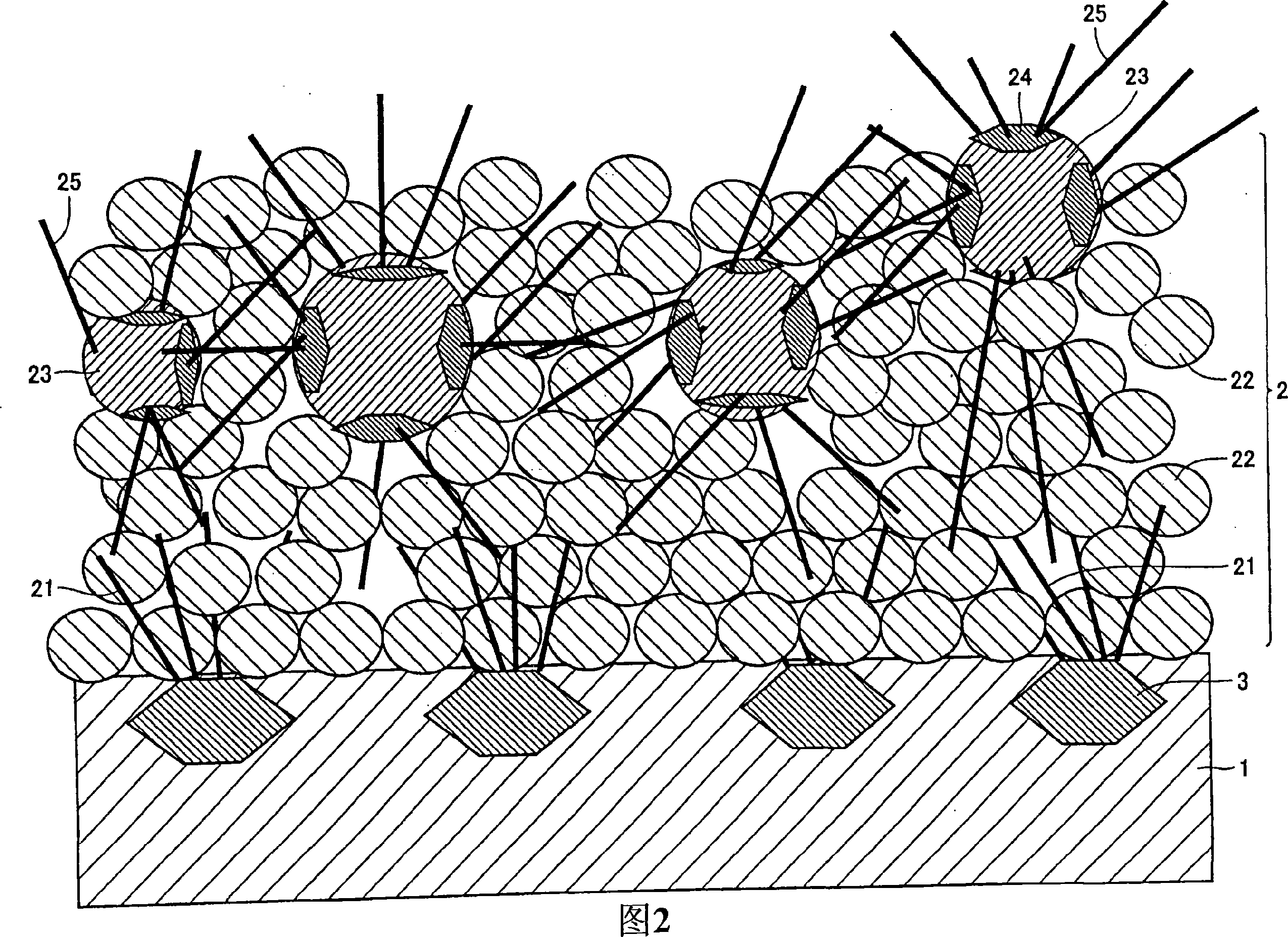

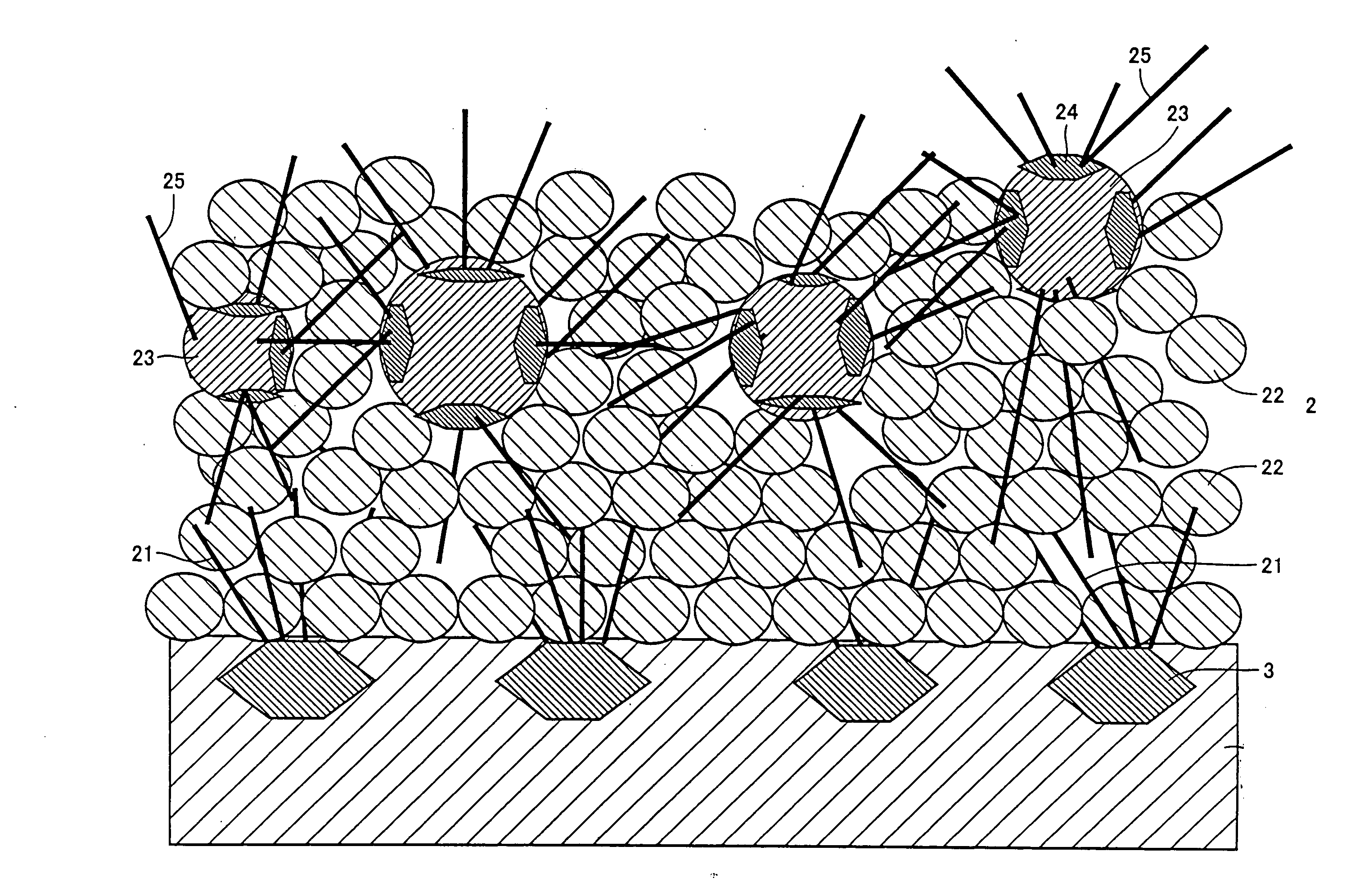

Capacitor electrode member, its manufacturing method and capacitor with same

ActiveCN101027736AExcellent adhesionLarge capacityHybrid capacitor electrodesDouble layer capacitorsCarbideCarbon particle

The invention provides a capacitor electrode member in which layers constituting the electrode member are highly adhesive. The capacitor electrode member comprises aluminum material (1), a carbon-containing layer (2) formed on the surface of the aluminum material (1), and further an interposition layer (3) containing an aluminum element and a carbon element, the interposition layer being formed between the aluminum material (1) and the carbon-containing layer (2). The interposition layer (3) constitutes a first surface portion which is formed on at least a part of the region of the surface of the aluminum material (1) and contains a carbide of aluminum. The carbon-containing layer (2) constitutes a second surface portion (21) formed so as to extend outward from the first surface portion (3). The carbon-containing layer (2) further contains carbon particles (22) and the second surface portion (21) is formed between the first surface portion (3) and the carbon particles (22) and contains a carbide of aluminum.

Owner:TOYO ALUMINIUM KK

Method for secondary aluminum ash harmless use

InactiveCN109052445AHigh alumina contentIncrease contentAluminium chloridesCeramic materials productionBrickAluminium chlorohydrate

The invention discloses a method for secondary aluminum ash harmless use. The method comprises the following steps: mixing water with secondary aluminum ash, heating, stirring, leaching, and carryingout solid-liquid separation after water leaching so as to obtain primary filtrate and primary filter residues; heating and evaporating the primary filtrate so as to obtain a soluble salt; mixing the primary filter residues with an acid, heating and stirring to achieve leaching; after acid leaching, and carrying out solid-liquid separation so as to obtain secondary filtrate and secondary filter residues; manufacturing bricks with the secondary filter residues; adjusting the pH value of the secondary filtrate within 2.5-3.0; heating and aging the secondary filtrate after the pH value is adjusted, thereby obtaining aluminum polychlorid. By adopting the method, the aluminum element in secondary aluminum ash can be utilized to the maximum extent, aluminum nitride which is hard to react with theacid can be converted into aluminum hydroxide which is easy to react with the acid through high-temperature water leaching, dissolution of the aluminum element in the secondary aluminum ash can be improved, and the content of aluminum oxide in a prepared aluminum polychlorid product can be increased; in addition, a salt solvent and a nitrogen element in the secondary aluminum ash can be recycled,and damage of leaching residues upon the environment can be reduced.

Owner:CENT SOUTH UNIV

In-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material and preparation method thereof

ActiveCN103614601AAvoid problems caused by non-degradableGood biocompatibilityProsthesisRare earthBiocompatibility Testing

The invention provides an in-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material and a preparation method thereof. The material has an in-situ bacteriostasis function and comprises the following components in percentage by weight: 0.05-8.0% of Ag, 0.005-6.5% of Zn, 0.1-2.0% of Mn and the balance of Mg. The in-vivo controlled degradable bacteriostatic Mg-Ag-Zn-Mn magnesium alloy implant material not only can be used for solving the problem that the current clinic titanium and stainless steel metal implant materials are non-degradable in vivo, but also can be used for solving the problem that potential toxic elements such as rare earth or an aluminum element and the like exist in the traditional degradable biomedical magnesium alloy technology, has favorable biocompatibility and the mechanics and corrosion degradation matching performance, and also has a remarkable in-situ bacteriostasis effect so that the infection probability of an implanted part is effectively reduced.

Owner:SUZHOU ORIGIN MEDICAL TECH

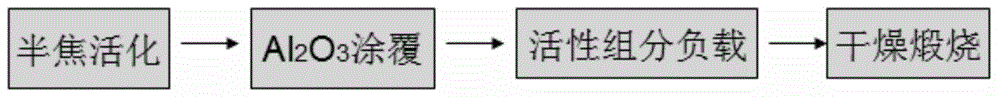

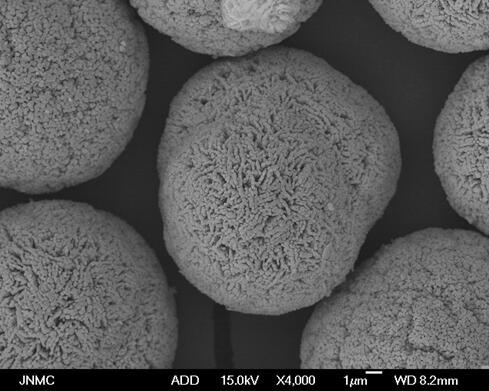

Low-temperature high-activity flue gas denitrification catalyst and preparation thereof

ActiveCN104941630ALow denitrification catalytic efficiencyHigh denitrification catalytic efficiency of flue gas at low temperature (90-120°C)Dispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementSinter Plant

The invention relates to a low-temperature high-activity flue gas denitrification catalyst and preparation thereof. According to the catalyst, a carbon-base material serves as a carrier and carries one or more metal active components of active Al2O3, Mn, Cu and Fe and one or two of rare earth active components of Ce and La. The content of the carbon-base carrier ranges from 35% to 65%, the carrying content of the Al2O3 ranges from 2% to 5% by the content of the aluminum element, the content of the metal active components ranges from 13% to 26% by the content of the metal elements, and the carrying content of the rare earth active components ranges from 20% to 39% by the content of the rare earth elements. According to the catalyst, the carbon-base material is activated through dilute nitric acid and then is coated with aluminum oxide sol, the metal active components and the rare earth active components are carried, then drying and sintering are carried out in the inert atmosphere, and the catalyst is obtained. The catalyst high in flue gas denitrification catalytic efficiently at the low temperature (90-120 DEG C) and not likely to cause poisoning and failures is obtained. The catalyst is low in production cost, simple in production technology and especially suitable for thermal power plants, steel plants, sintering plants and other enterprises with heavy fuel gas emission.

Owner:北京大学包头创新研究院

Preparation method of large-particle narrow-distribution aluminum doped tricobalt tetroxide

ActiveCN110217832AEvenly distributedHigh solid contentCell electrodesCobalt oxides/hydroxidesSynthesis methodsSynthesis Phase

The invention relates to the technical field of lithium ion batteries, in particular to a preparation method of large-particle narrow-distribution aluminum doped tricobalt tetroxide. The method includes a stage of continuously synthesizing large-particle narrow-distribution aluminum doped cobalt carbonate, and a stage of calcining the large-particle narrow-distribution aluminum doped cobalt carbonate. A large-particle cobalt carbonate precursor prepared by continuous centrifugation to improve the solid content, the continuous synthesis method and a special aluminum salt method in the cobalt carbonate wet-process synthesis stage is dense, narrow in particle size distribution, good in sphericity and uniform in aluminum element distribution. Through a three-step calcination method, the temperature in the first step is 180-250 DEG C and the cobalt carbonate is partially decomposed to form a micropore channel; the cobalt carbonate is completely decomposed in the second step in which the temperature is 300-500 DEG C; in the third step, the temperature is 650-800 DEG C, particle surfaces are densified, the content of the cobaltous phase is lower, the crystal form is more complete, and thelarge-particle narrow-distribution aluminum doped tricobalt tetroxide is formed. .

Owner:JINCHUAN GROUP LIMITED +1

Liquid quick-setting admixture, shotcreting material and method for shotcreting using them

InactiveUS20070056473A1Good storage stabilityMaintain good propertiesUnderground chambersAlkali metal silicate coatingsShotcreteSulfur

To provide a liquid quick-setting admixture and a spraying material and a spraying method using it, which make spraying excellent in quick-setting property possible and which may improve the storage stability of the liquid quick-setting admixture. A liquid quick-setting admixture characterized by comprising sulfur, aluminum and alkali metal element components, and a complexing agent. Said liquid quick-setting admixture preferably contains per 100 parts of the sulfur element component as SO3, from 25 to 110 parts of the aluminum element component as Al2O3, from 2.5 to 50 parts of the alkali metal element component as R2O (in which R is an alkali metal atom) and from 2.5 to 75 parts of the complexing agent.

Owner:DENKA CO LTD

Aluminum elements and processes for the preparation of the same and chemical agents therefor

InactiveUS20050194574A1Not to damageImprove corrosion resistanceLiquid surface applicatorsDispersed particle filtrationTitaniumChromium Hexavalent Compound

There are provided aluminum elements covered on their surfaces with a coating film free from harmful hexavalent chromium compounds and fluorine compounds. Particularly, aluminum dicast and aluminum cast materials having excellent paint adherence and corrosion resistance are provided. The coating film for aluminum elements comprises (i) chromium, (ii) zinc and (iii) cobalt and / or titanium with 95% by mass or more of said chromium being a trivalent chromium.

Owner:NIPPON HYOMEN KAGAKU KK

Lithium-manganese-aluminum oxygen anode material and preparation method thereof

ActiveCN102683667AReduce solubilityIncrease the amount of participationCell electrodesLithiumLattice defects

The invention provides a lithium-manganese-aluminum oxygen anode material, which has the atomic ratio of LiaMn2-x-yAlxMyO4; the concentration of A1 is in a gradient distribution presenting gradually risen from the inner part of the lithium-manganese-aluminum oxygen anode material to the surface; the concentration of Mn is in a gradient distribution presenting gradually decreased from the inner part of the lithium-manganese-aluminum oxygen anode to the surface. The invention further provides a preparation method of lithium-manganese-aluminum oxygen anode material. By adding solution or turbid liquid of aluminum source compound in the precipitation process, the aluminum element replaces the position of a manganese element in the formed lithium-manganese-aluminum material, so that the spinel structure of the lithium-manganese-aluminum material is stabilized, the forming of the lattice defect is avoided and the well high-temperature circulating performance of the lithium-manganese-aluminum material is guaranteed, the dissolution of manganese in the electrolyte is reduced and the high-temperature circulating performance of the lithium-manganese-aluminum oxygen anode material is further improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Capacitor Electode Member, Method for Manufacturing the Same, and Capacitor Provided with the Electrode Member

ActiveUS20080218945A1Improved layer adhesionImprove adhesionHybrid capacitor electrolytesElectrolytic capacitorsCarbideOptoelectronics

The invention provides a capacitor electrode member in which layers constituting the electrode member are highly adhesive. The capacitor electrode member comprises aluminum material (1), a carbon-containing layer (2) formed on the surface of the aluminum material (1), and further an interposition layer (3) containing an aluminum element and a carbon element, the interposition layer being formed between the aluminum material (1) and the carbon-containing layer (2). The interposition layer (3) constitutes a first surface portion which is formed on at least a part of the region of the surface of the aluminum material (1) and contains a carbide of aluminum. The carbon-containing layer (2) constitutes a second surface portion (21) formed so as to extend outward from the first surface portion (3). The carbon-containing layer (2) further contains carbon particles (22) and the second surface portion (21) is formed between the first surface portion (3) and the carbon particles (22) and contains a carbide of aluminum.

Owner:TOYO ALUMINIUM KK

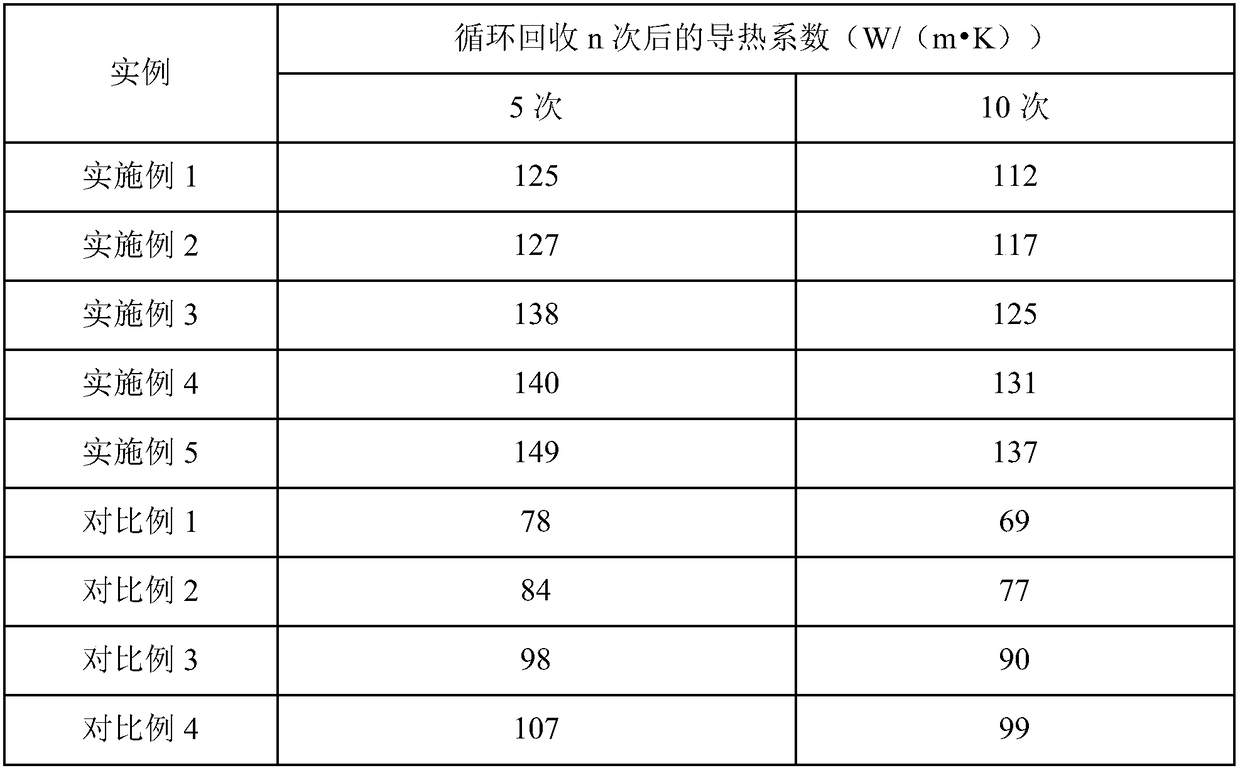

Heat-conducting aluminum alloy and application thereof

ActiveCN108085541AImprove mechanical propertiesGood flow forming performanceHeat exchange apparatusHeat conductingMechanical property

The invention discloses a heat-conducting aluminum alloy and application thereof. The heat-conducting aluminum alloy comprises alloying elements, unavoidable impurities and the balance aluminum element. By taking the total weight of the heat-conducting aluminum alloy as a benchmark, the alloying elements comprise 5.0-11.0% of Si, 0.4-1.0% of Fe, 0.2-1.0% of Mg, less than 0.1% of Zn, less than 0.1%of Mn, less than 0.1% of Sr and less than 0.1% of Cu. According to the prepared heat-conducting aluminum alloy, the tensile strength is not less than 250 MPa, the yield strength is not less than 150MPa, the ductility is not less than 3.5%, and the heat conducting coefficient is not less than 150 W / (m.K); and the mechanical property is high, the flow forming performance is good, and good heat conductivity can further be maintained through repeated recycling.

Owner:BYD CO LTD

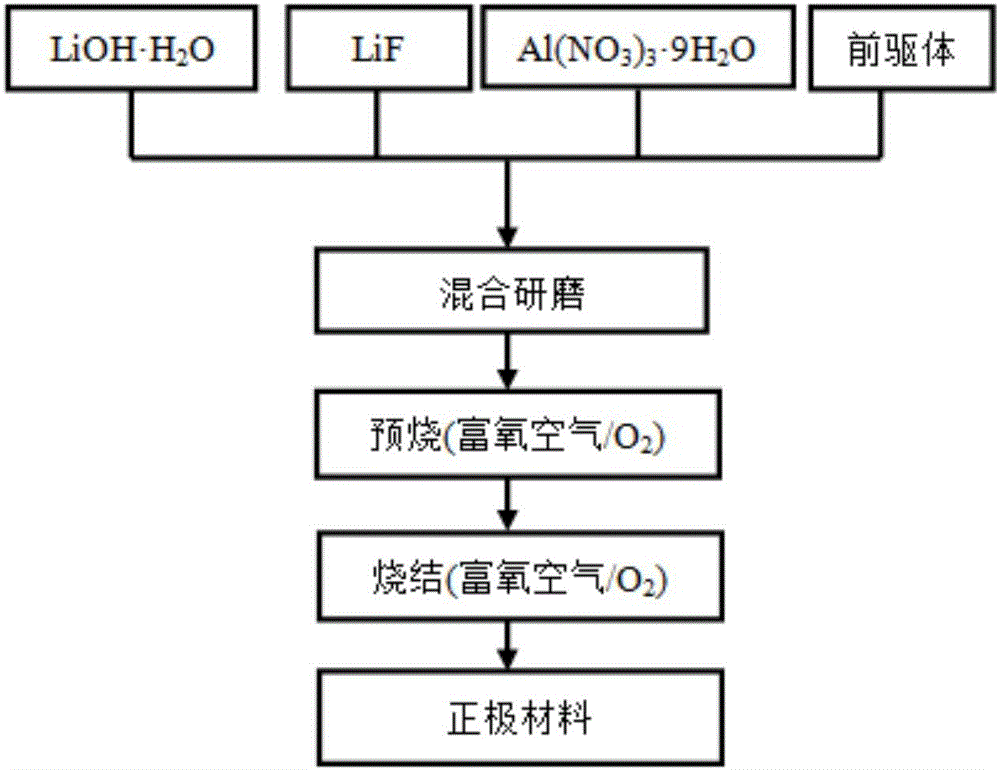

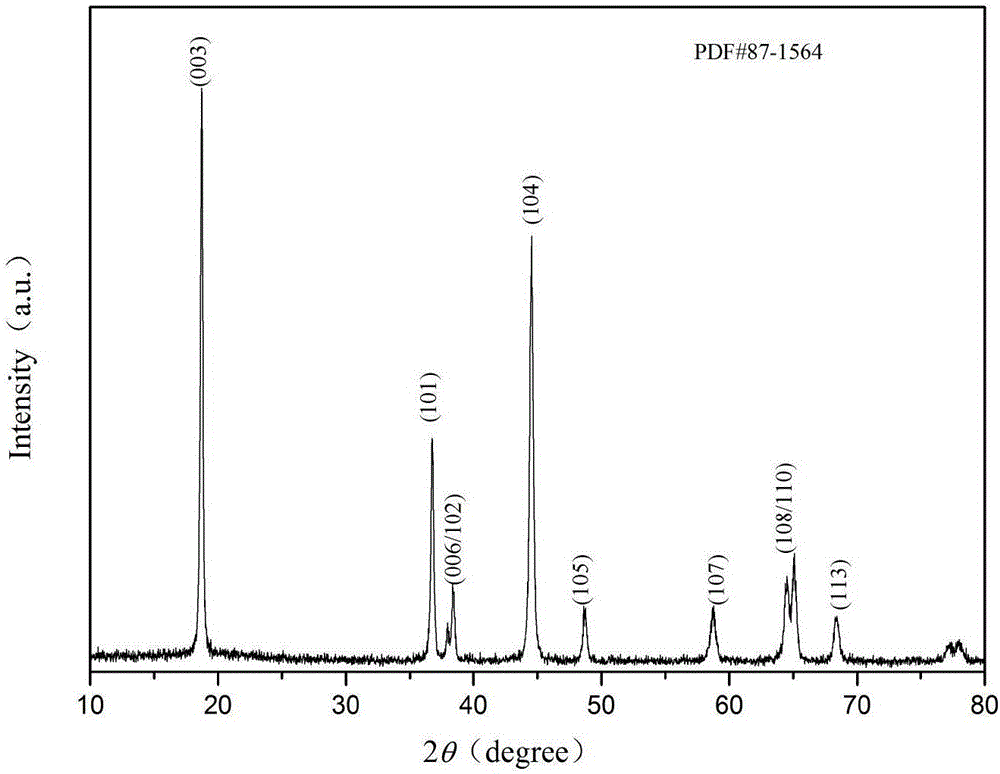

Lithium ion battery positive electrode material with ultrahigh energy density and preparation method of lithium ion battery positive electrode material with ultrahigh energy density

ActiveCN106299326AImprove discharge specific capacityImprove electrochemical performanceCell electrodesAluminium-ion batterySodium-ion battery

The invention belongs to the field of lithium ion batteries, provides a lithium ion battery positive electrode material with ultrahigh energy density, and aims to overcome the defects that nickel cobalt lithium manganite is poor in electrochemical performance and low in specific capacity and energy density. A molecular expression of the lithium ion battery positive electrode material is Li(Ni0.6Co0.2Mn0.2)1-xAlxO2-yFy, wherein x is greater than 0, and y is smaller than or equal to 0.05; a small amount of aluminum element replaces part of nickel element, and a fluorine element partially replaces an oxygen element, so that an internal structure of the material is stabilized, and structure collapse under a high-proportion lithium-removing state is inhibited; by co-doping aluminum with fluorine, specific discharge capacity and comprehensive electrochemical properties of the material are greatly improved; energy density is remarkably improved; besides, according to the lithium ion battery positive electrode material disclosed by the invention, a precursor material of which nickel elements are gradually distributed is prepared by adopting a gradient coprecipitation method; the concentration of the precursor material is gradually increased from inside to outside, so that the specific discharge capacity of the positive electrode material is favorably improved; a prepared product is high in purity, high in chemical uniformity and high in crystallization quality; products are small in particles, uniform in distribution, excellent in electrochemical performance and lower in manufacturing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

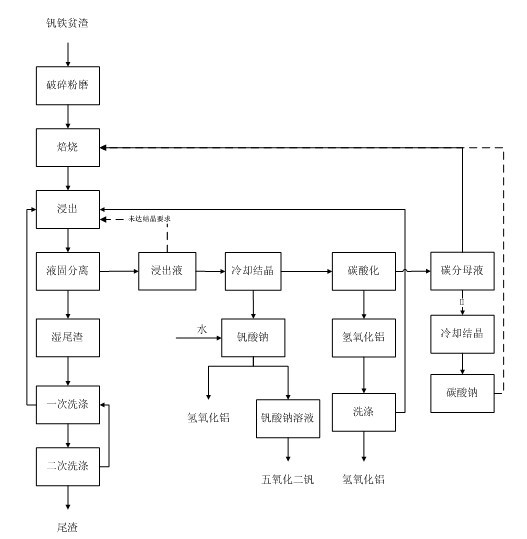

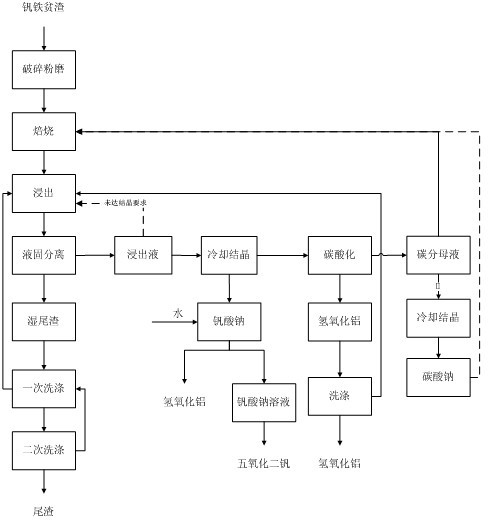

Cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag

ActiveCN102586610ARealize co-existenceAchieve separationProcess efficiency improvementSlagAluminium hydroxide

The invention relates to a cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag, and belongs to the technical field of metallurgy. The technical scheme is that: the vanadium iron slag is subjected to sodium oxide roasting by using high-proportion Na2CO3 as a roasting transforming agent, vanadium and aluminum of a clinker obtained after sodium oxide roasting are synchronously dissolved out by using an aqueous solution, sodium vanadate crystals containing aluminum hydroxide are crystallized, the purity of the obtained Al(OH)3 is over 95 percent, the purity of vanadium pentoxide is over 98 percent, the co-extraction of the vanadium and the aluminum, the separation of the vanadium and the aluminum and the cyclic utilization of sodium salt are realized, the recovery rate of the vanadium is over 85 percent, the recovery rate of the aluminum is over 60 percent, the weight of tailings is reduced by 40 to 50 percent after leaching, and the tailings can be used for preparing an aluminum-magnesium flocculant by an acid method. The high-efficiency extraction of the vanadium is realized, the resource reutilization of an aluminum element in the slag is also realized, wastewater discharge is avoided in the whole production process, CO2 gas for carbonation can be replaced by roasting flue gas, the proportion of carbon emission isreduced, and the process has remarkable economic and environmental benefits, and can be effectively applied to the treatment of the aluminothermic vanadium iron slag and related materials.

Owner:HEBEI IRON AND STEEL

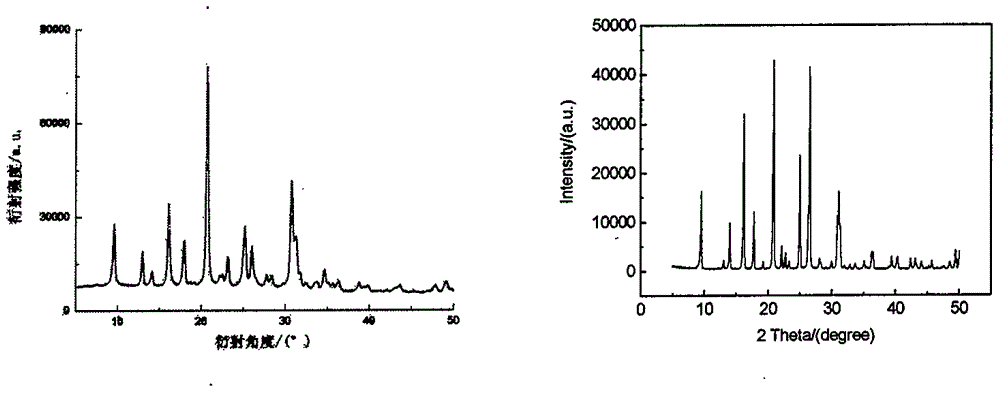

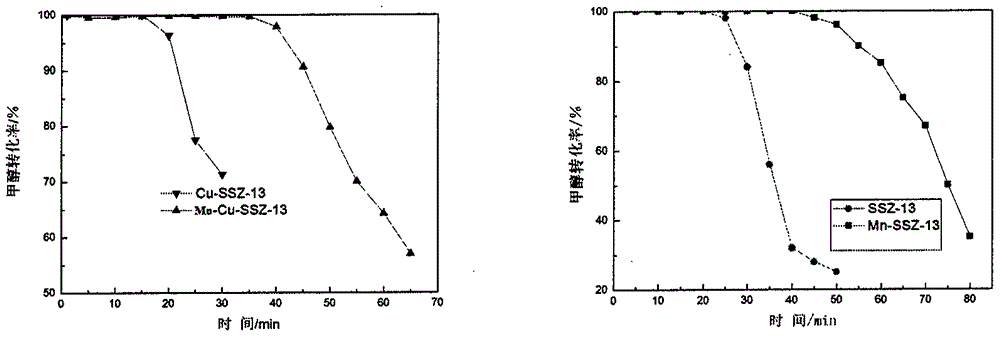

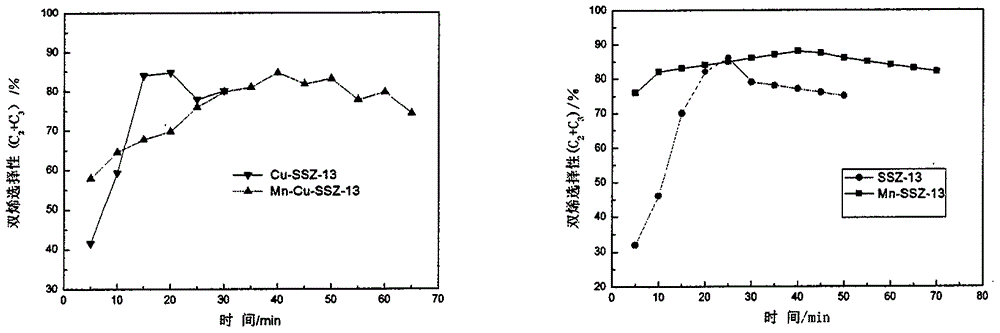

Preparation of a metal manganese modified silicon-aluminum molecular sieve material Mn-SSZ-13, and applications of the material in alkene preparation from methanol and denitration

A metal manganese modified silicon-aluminum molecular sieve material Mn-SSZ-13 is provided. The material comprises 0.1-10% of manganese, 0-15% of aluminum, 75-100% of silicon and 0-25% of copper. Two materials have CHA type topological structures, and the specific surface area measured by a BET process after calcination at 600 DEG C for 4 h is not less than 500 m<2> / g. A preparing process includes fully mixing a copper source (may be none), a template, an aluminum source, sodium hydroxide, a silicon source and water according to a certain sequence to obtain an initial gel solution, crystallizing, performing ammonium chloride ion exchange, calcinating and performing manganese ion exchange to obtain a product. The prepared molecular sieve material has advantages of high MTO diolefin selectivity and long catalytic service lifetime, and can be used for nitrogen oxide selective reduction (SCR catalysts).

Owner:TIANJIN POLYTECHNIC UNIV

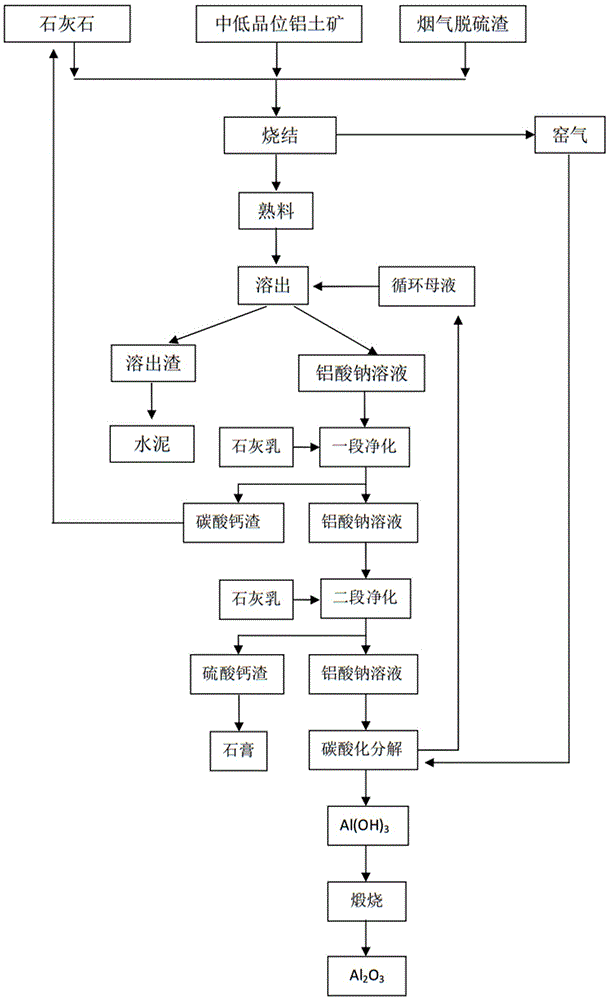

Method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime

ActiveCN105540628AAvoid the effect of dissolution rateAvoid corrosionAluminium oxides/hydroxidesSocial benefitsSlag

The invention relates to the technical field of aluminum oxide, and in particular relates to a method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime. According to the method, through properly adding a small amount of flue gas desulfurization slag and the lime into sulfur-containing monohydrallite for sintering, the aluminum oxide is produced, enabling aluminum element and sulphur element in a raw material to form a 4Cao.3Al2O3.SO3 phase, and by enabling silicon element to form a gamma-2CaO.SiO2 phase, and then adopting a low-temperature dissolution technology to perform aluminum oxide production, the deleterious effect of the sulphur element is reduced, the aluminum oxide dissolution performance of clinker is improved, and better market application value and social benefit are realized.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-strength porous ceramics and low-temperature preparation method thereof

InactiveCN108546143ALow densityHigh porosityCeramic materials productionCeramicwarePhosphatePorous ceramics

The invention belongs to the technical field of porous ceramics, and discloses high-strength porous ceramics and a low-temperature preparation method thereof. The method comprises the steps: (1) mixing raw materials, wherein the raw materials include solid waste, low-grade minerals and an additive, and the raw materials also include an aluminum source when an aluminum element in the raw materialsis insufficient; (2) molding the mixed raw materials into green bodies; (3) firing the green bodies at the temperature of 800-1300 DEG C to obtain the high-strength porous ceramics, wherein the additive is one or more of alumina, nitrate, carbonate, sulfate, phosphate, fluoride and borax. The solid waste and the low-grade minerals are used as a part of the raw materials, the recovery and utilization of resources are realized, and the method is environmentally friendly and economical; the method has the advantages of wide range of the raw materials, simple process (one-step in-situ preparationof a whisker skeleton structure), and low production cost, and is suitable for industrial production. At the same time, the method has less energy consumption, and the prepared porous ceramics have the whisker skeleton structure and have the advantages of high porosity, low density and high mechanical strength.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com