Patents

Literature

99 results about "Structure Collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Failure in built environment with loss of functional integrity.

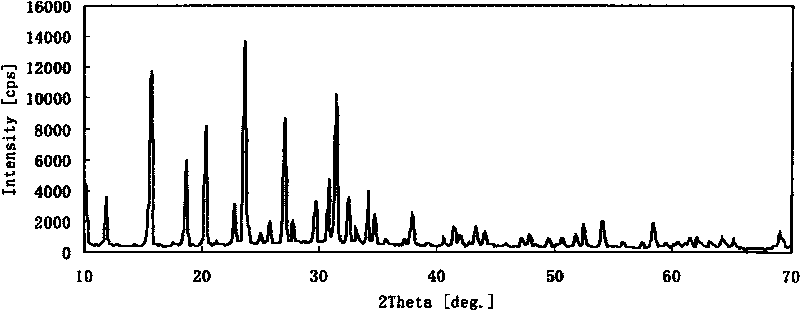

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

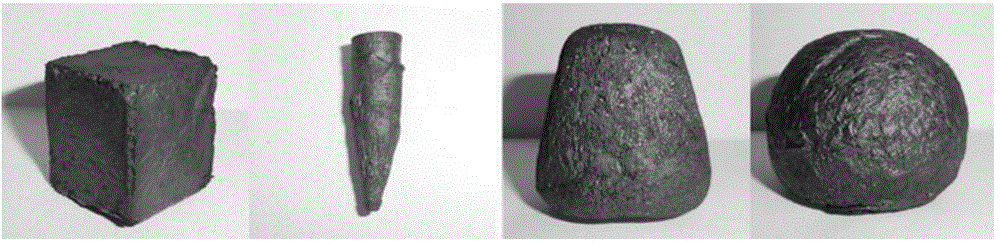

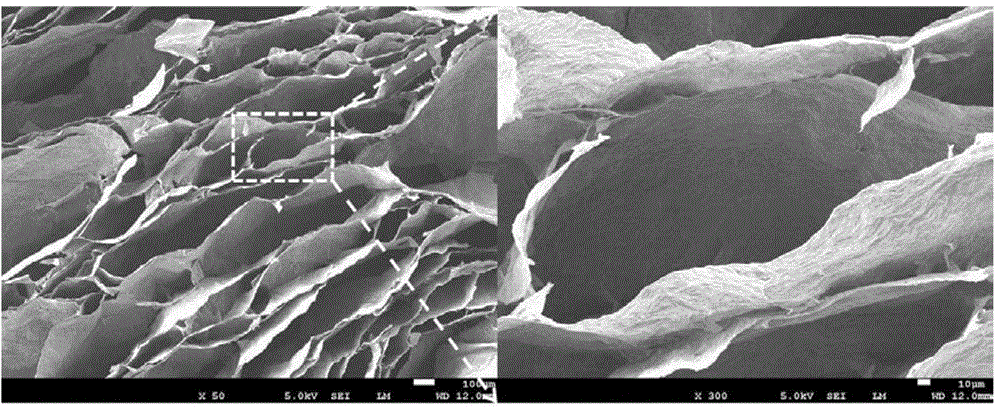

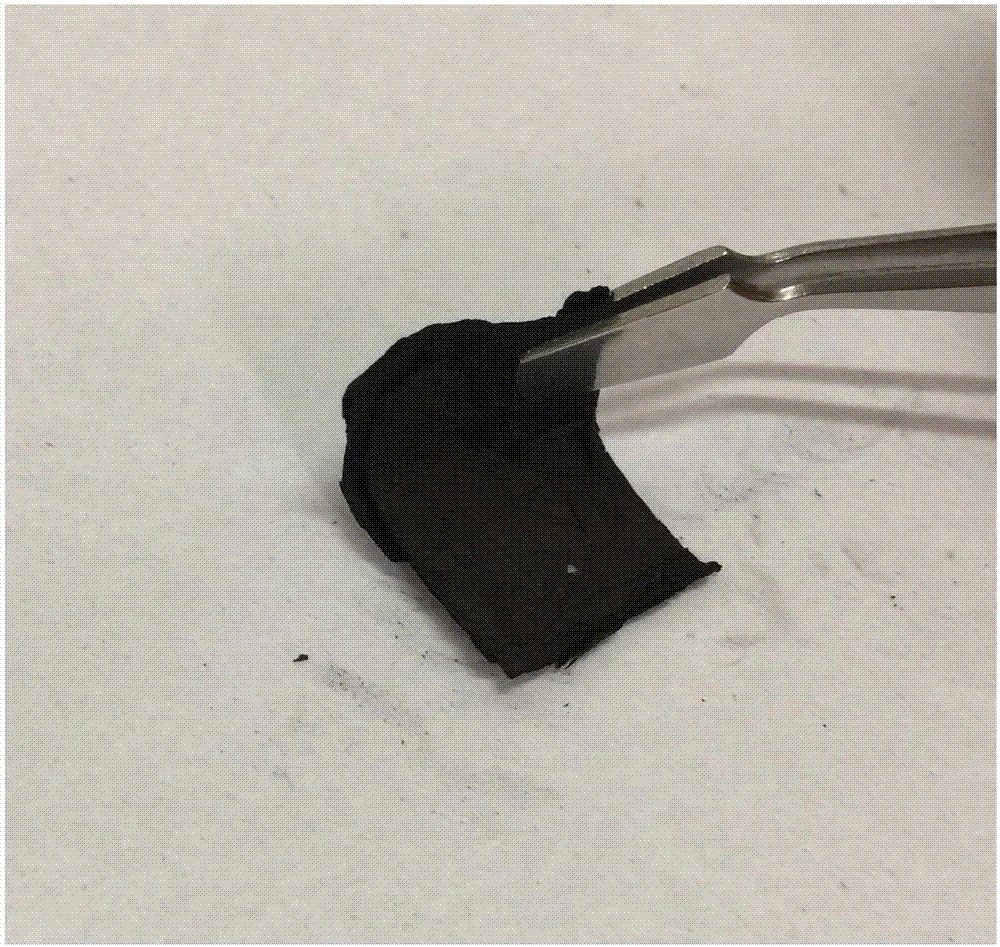

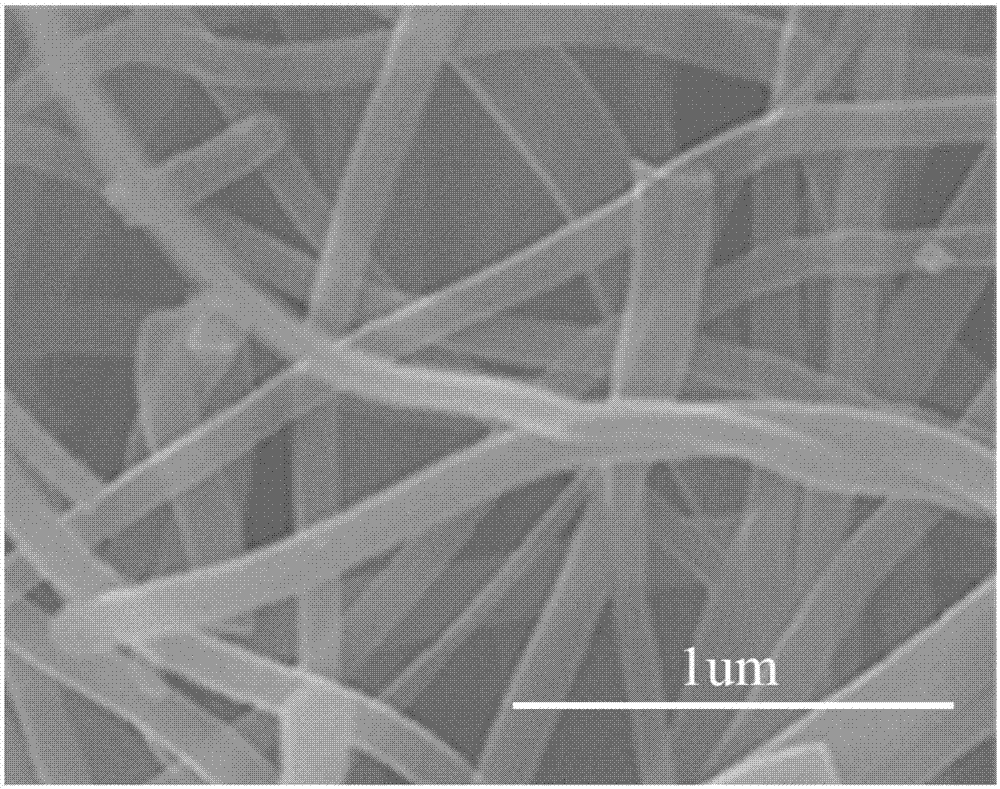

Method for preparing graphene aerogel through constant pressure drying

ActiveCN104925787ASolve the problems of mass productionSimple processSupercritical dryingAir liquid interface

The invention provides a method for preparing a graphene aerogel through constant pressure drying. The method comprises the following steps of: firstly, preparing a hydrogel by using aqueous dispersions of oxidized graphene as raw materials; processing the hydrogel by freezing and melting so as to reassemble the internal structure of the hydrogel, wherein the formed structure is strong enough to resist the structure collapse caused by air-liquid interface tension during constant pressure drying; and finally, realizing the preparation of the graphene aerogel through constant pressure drying. Compared with a freeze drying method and a supercritical drying method, the method disclosed by the invention has the advantages that the efficiency for preparing the graphene aerogel is greatly improved, the production cost is reduced, and the industrialized production of the graphene aerogel is hopeful to realize. In addition, the invention further provides a novel graphene aerogel, and the characteristics of macropores and super resilience, of the graphene aerogel, can be applied in many fields.

Owner:QINGDAO UNIV OF SCI & TECH

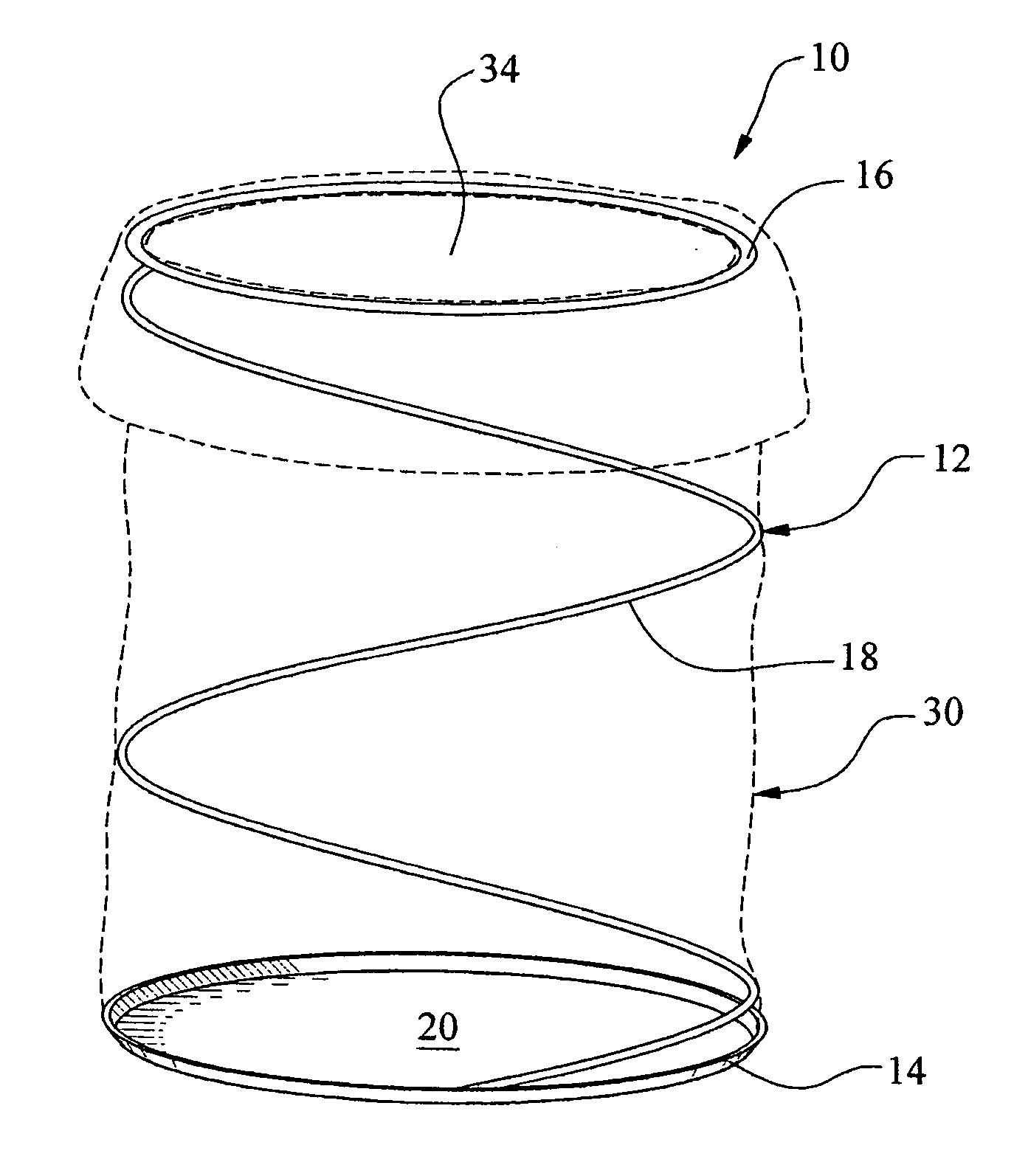

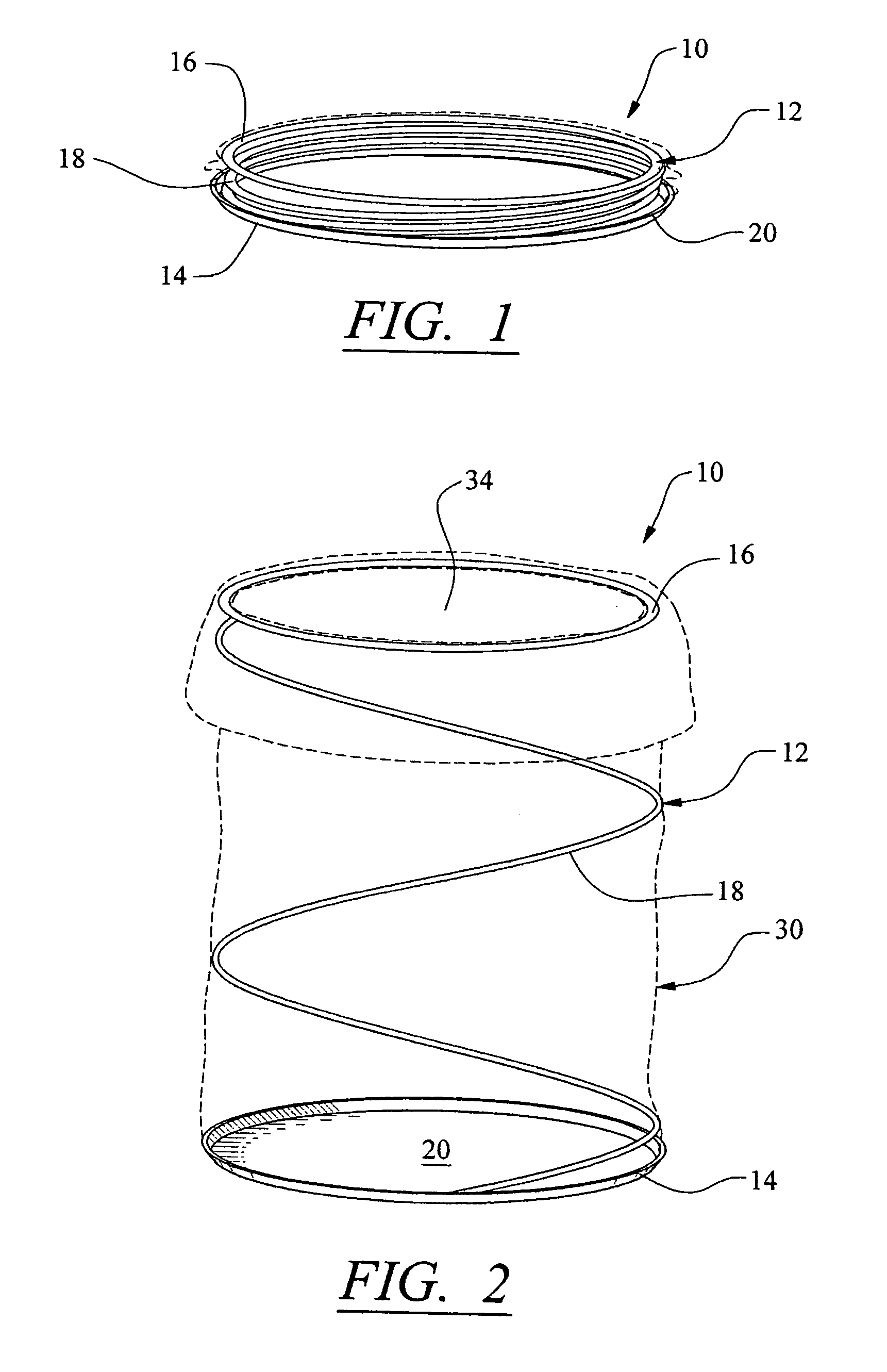

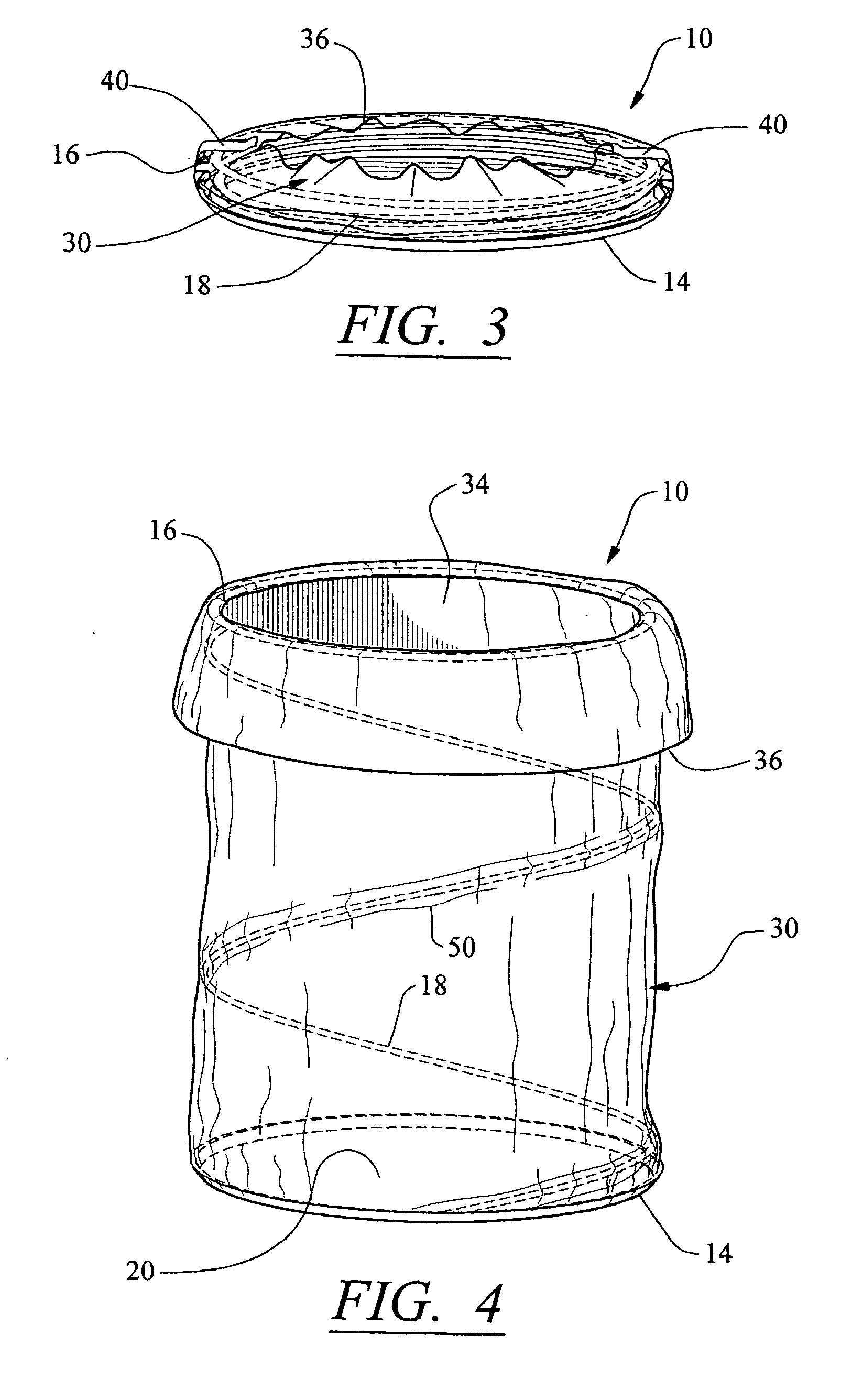

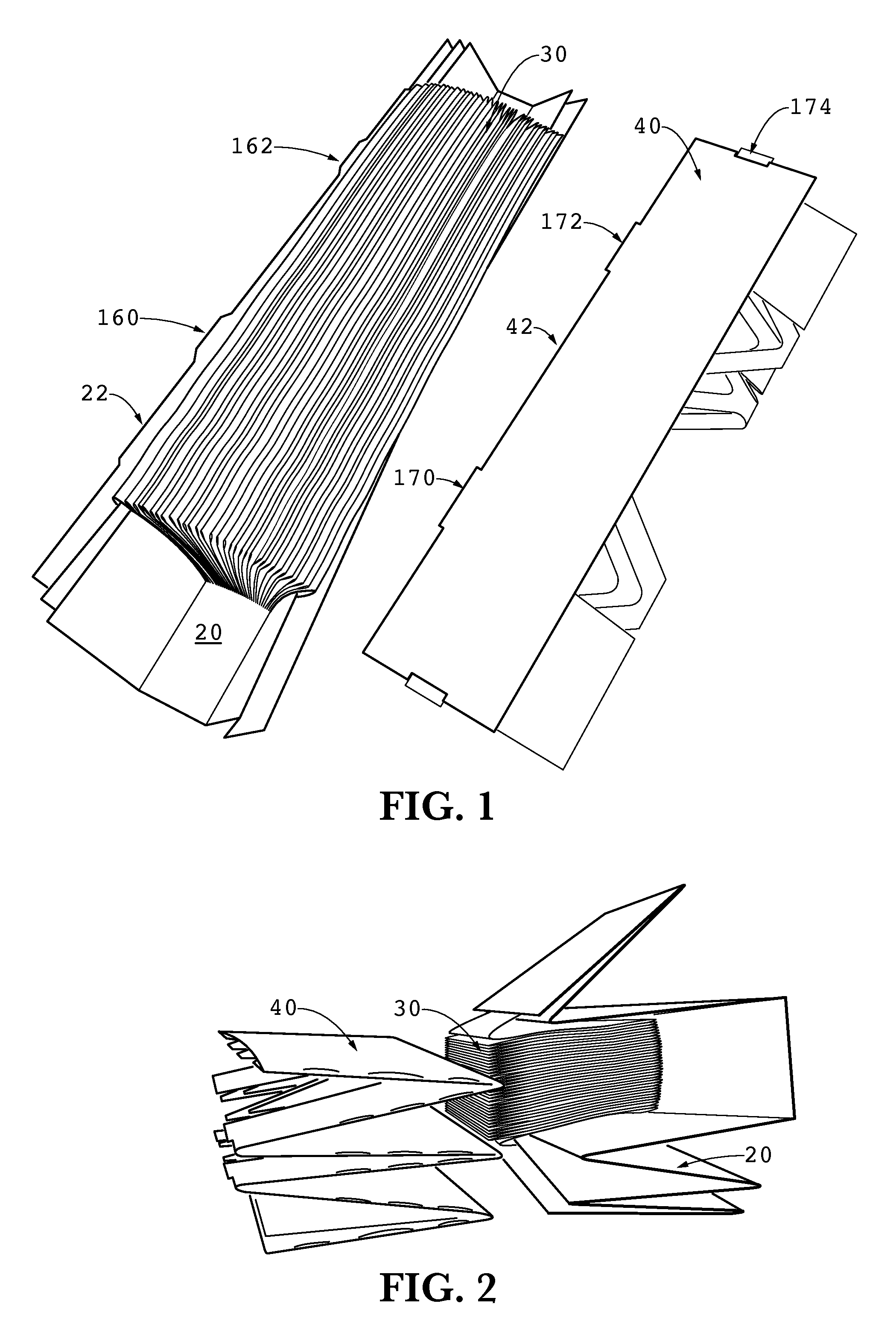

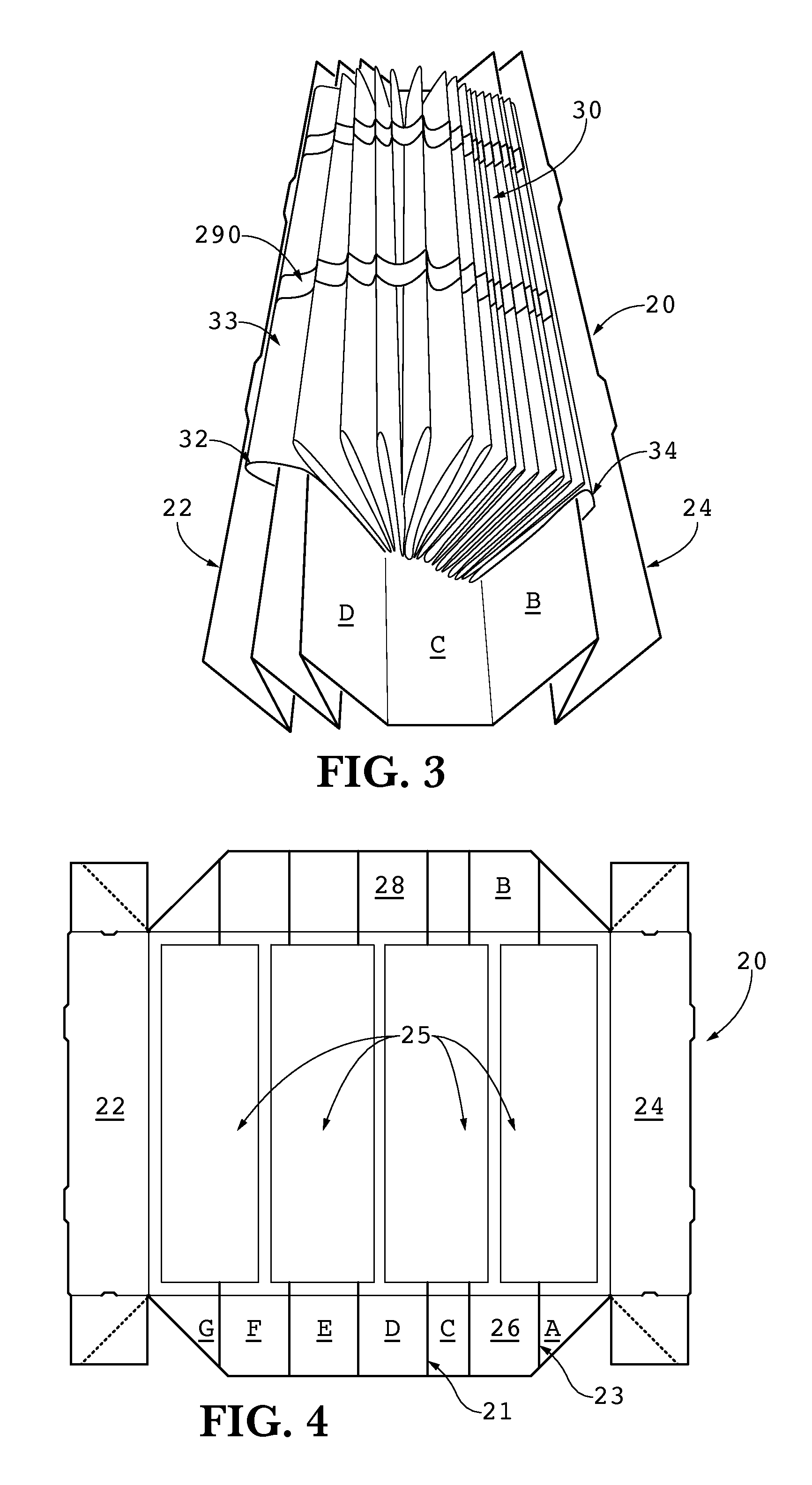

Disposable trash container

InactiveUS20050284866A1Convenient and neat disposalLow profileBagsSacksEngineeringStructure Collapse

Owner:OAKNER STUART P +2

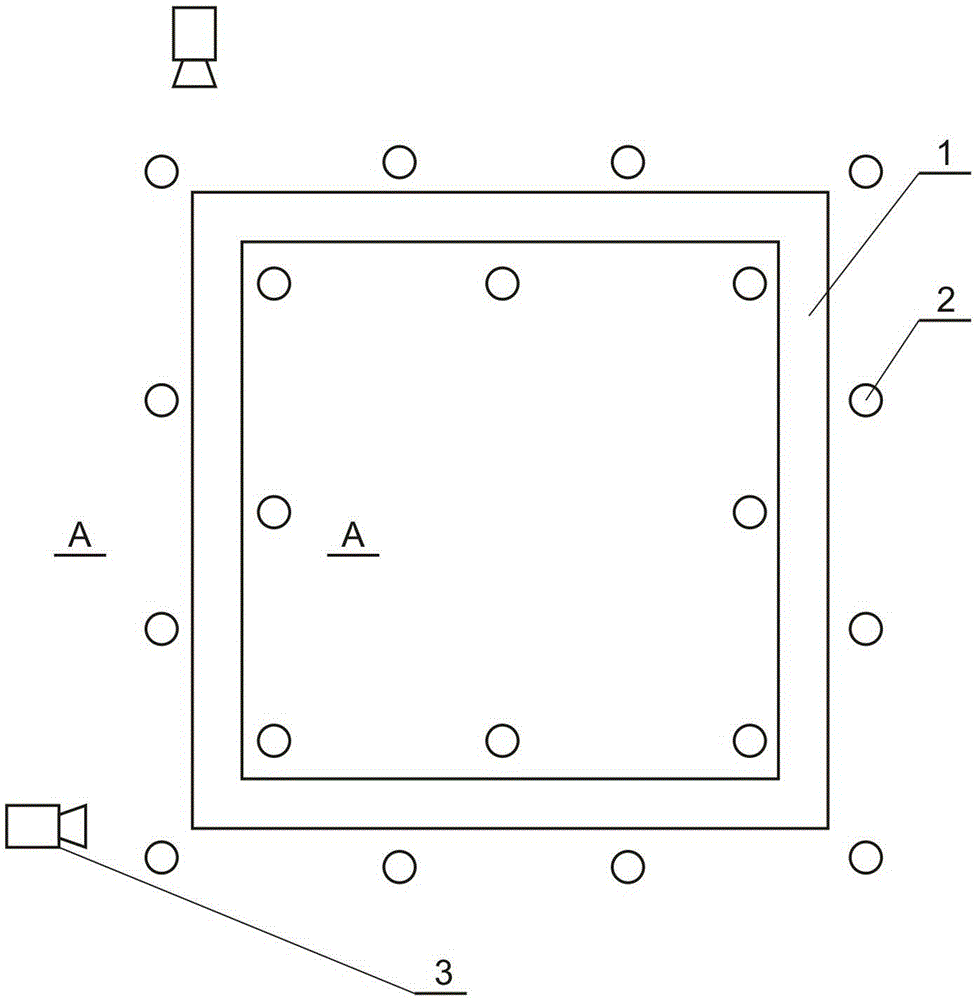

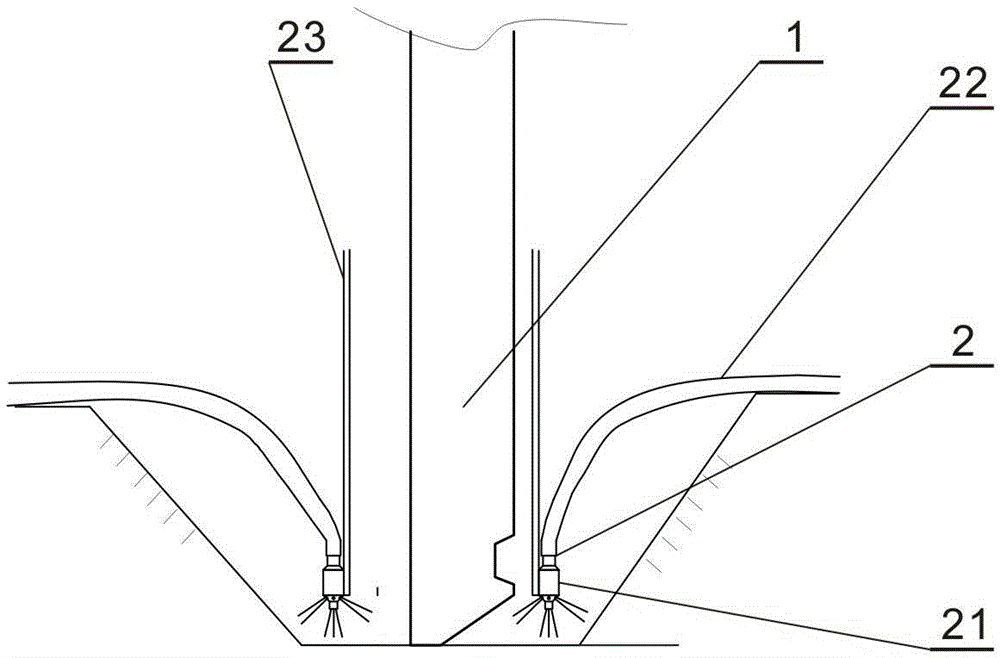

Three-dimensional treatment method of subway deep foundation pit in karst intense development region

InactiveCN105862722AEnsure construction safetyGuaranteed operational safetyExcavationsSoil preservationKarstEngineering

The invention discloses a three-dimensional treatment method of a subway deep foundation pit in a karst intense development region. The three-dimensional treatment method comprises the steps of karst cave / soil cave treatment; waterproof curtain construction; divisional grouting; and bottom sealing grouting. According to the three-dimensional stereo construction method, the foundation pit constriction safety and subway operation safety are guaranteed, the difficulty is low, the cost is low, the construction period is short, the method is the first one at home and abroad, the construction is convenient to organize, the construction procedure is scientific, the method is safe and reliable, the risks that a retaining structure collapses during construction and inrushing occurs in the foundation pit under the action of high-water head pressure confined karstic water are avoided, the capacity of the foundation pit for preventing partial karst collapse, the safety of a station structure, and the safety of subway operation are improved, and the method is applicable to karst treatment construction of the subway deep foundation pit.

Owner:CHINA CONSTR COMM ENG GRP UNITED

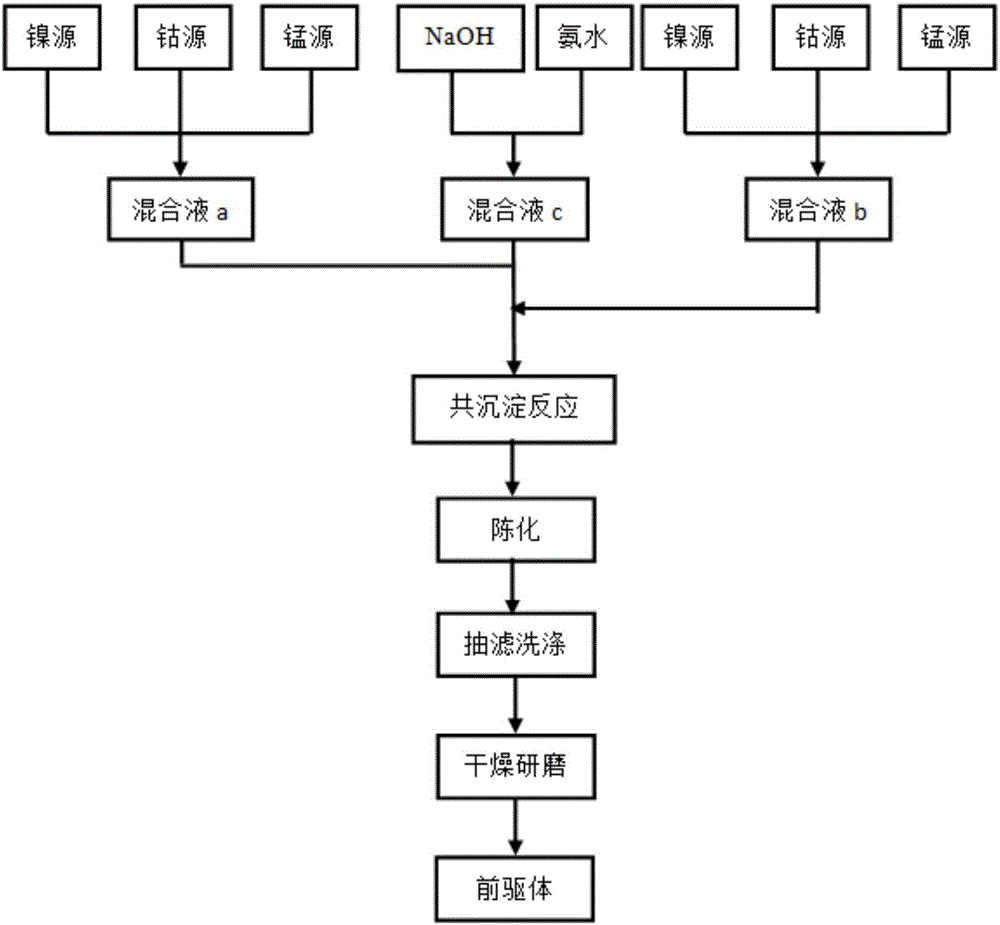

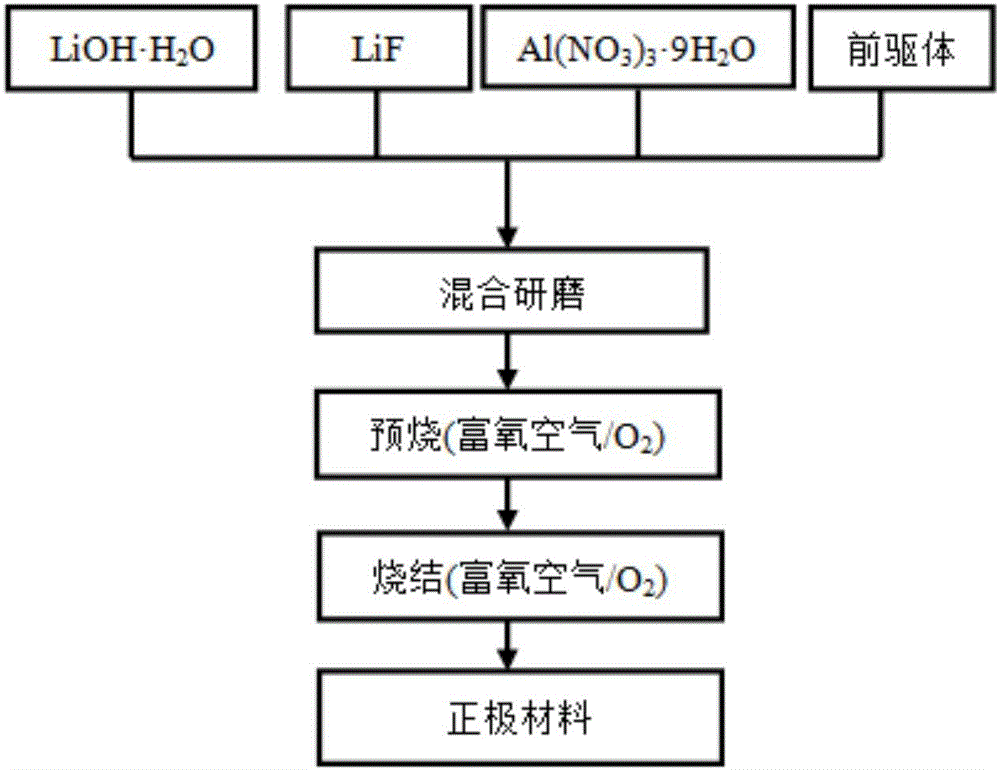

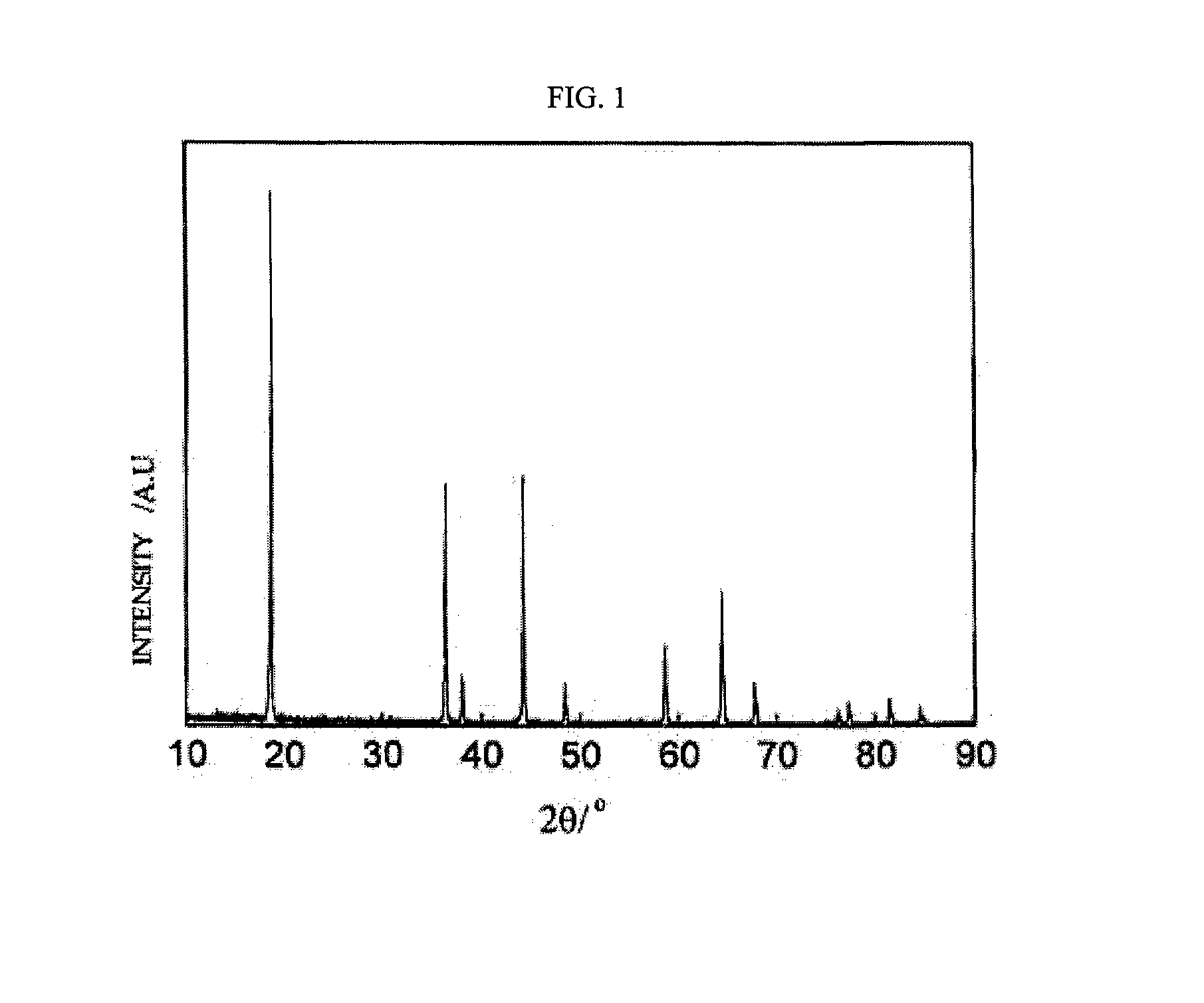

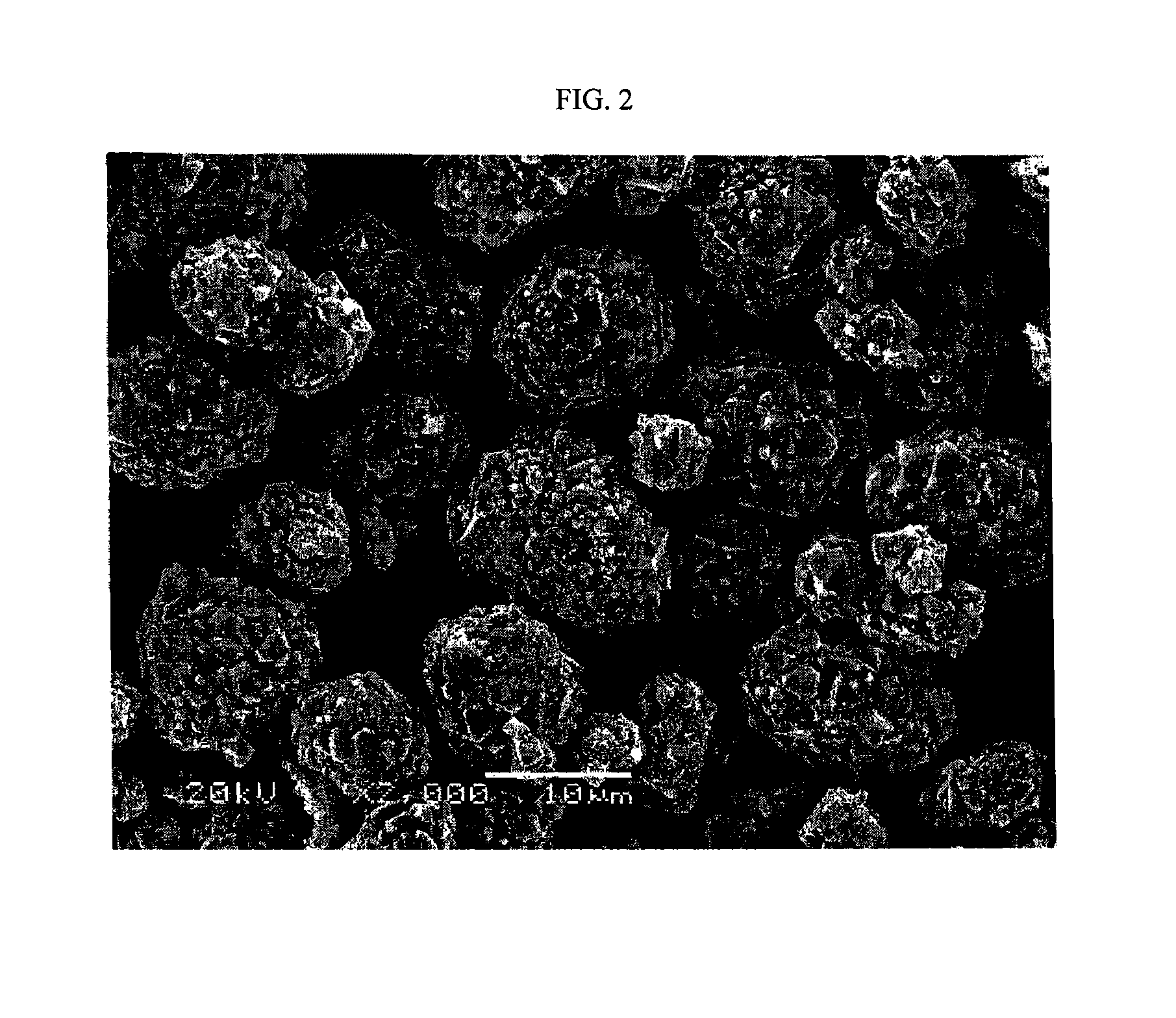

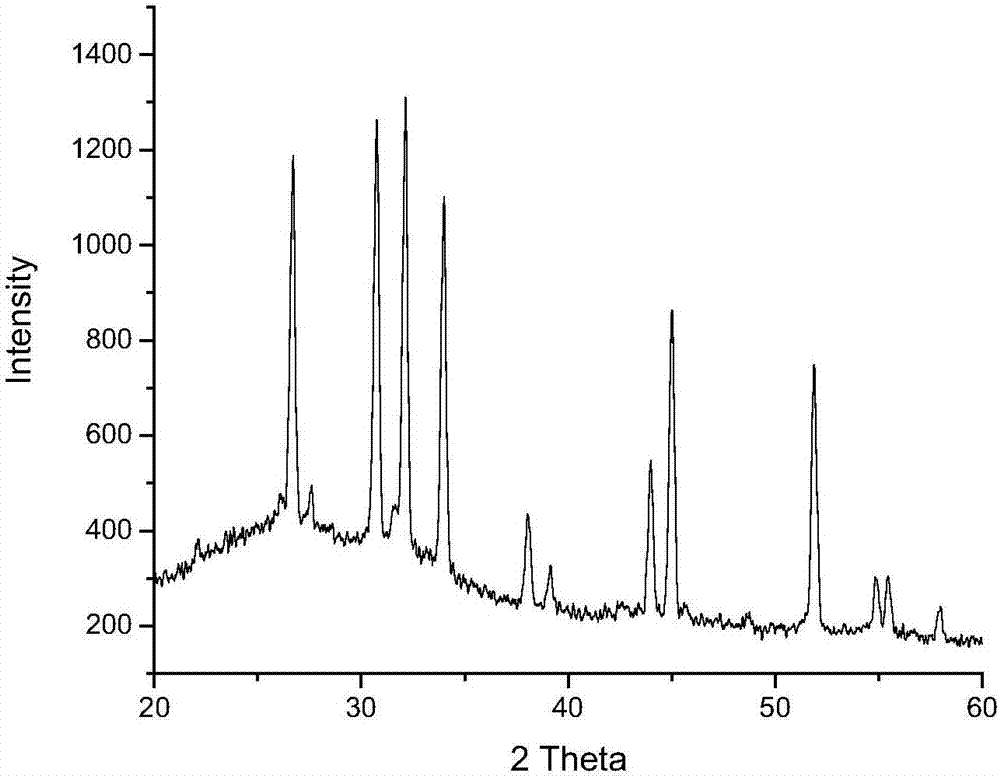

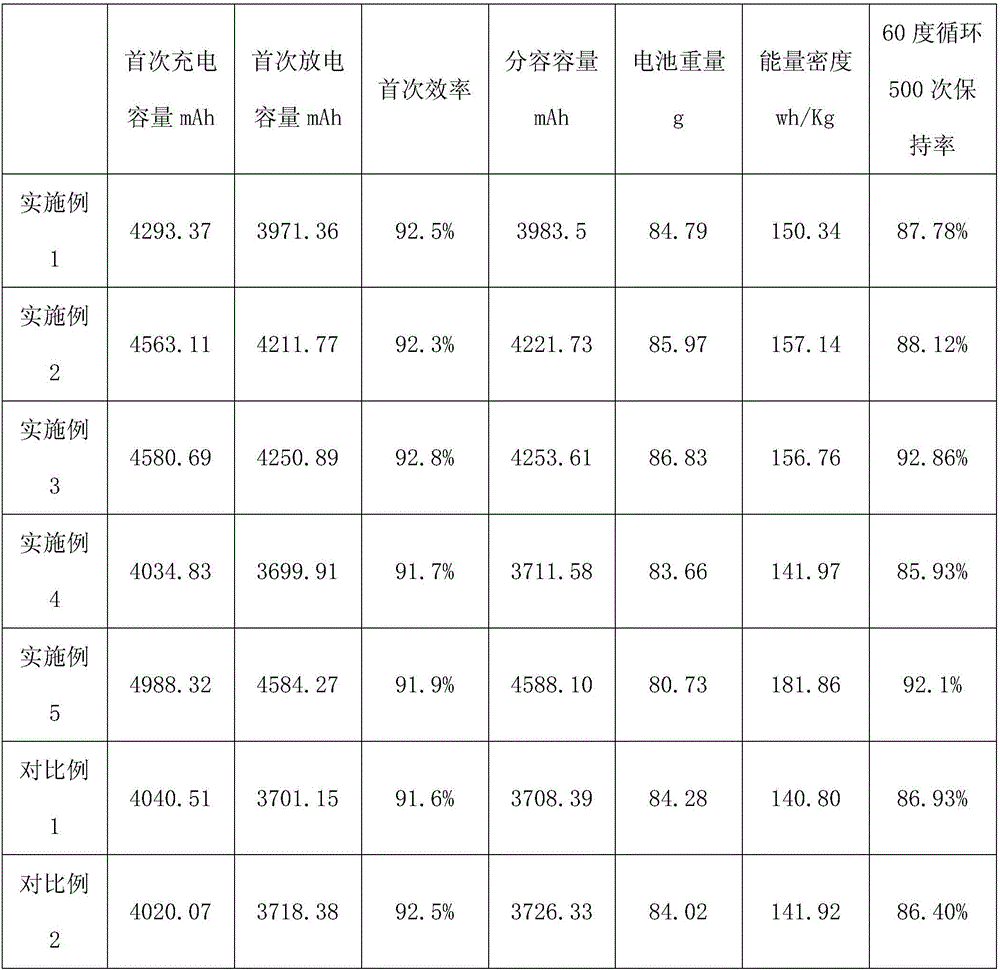

Lithium ion battery positive electrode material with ultrahigh energy density and preparation method of lithium ion battery positive electrode material with ultrahigh energy density

ActiveCN106299326AImprove discharge specific capacityImprove electrochemical performanceCell electrodesAluminium-ion batterySodium-ion battery

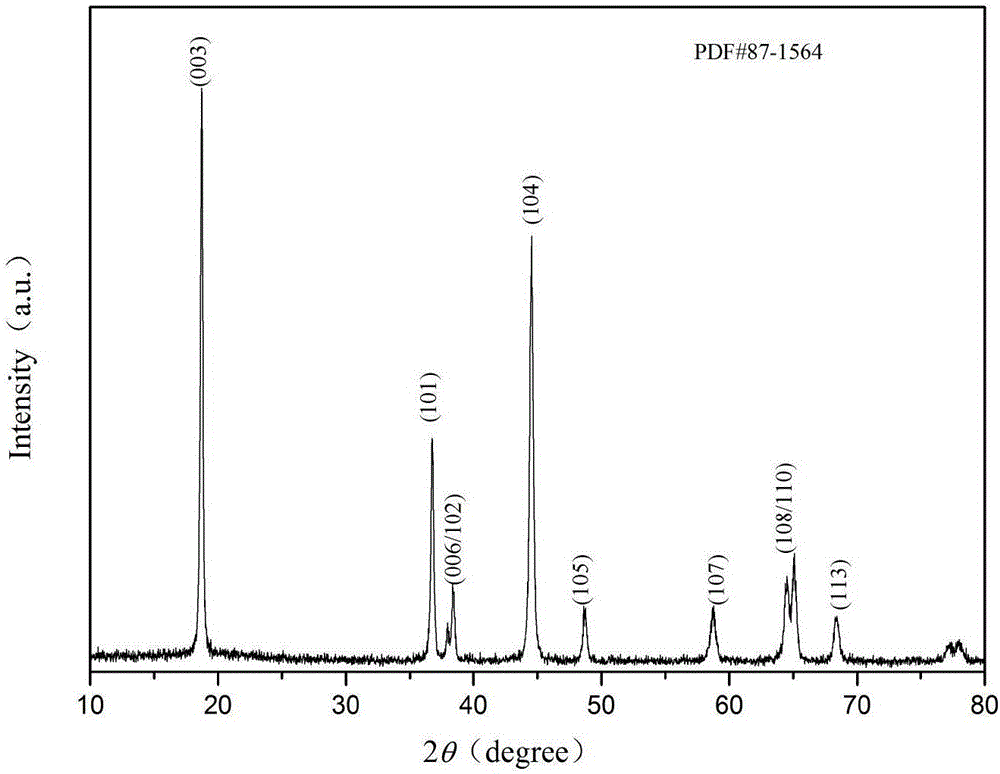

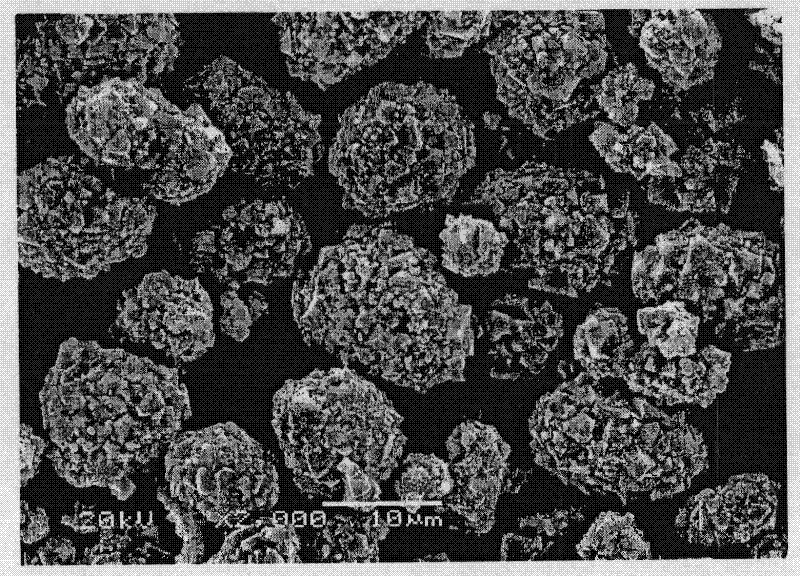

The invention belongs to the field of lithium ion batteries, provides a lithium ion battery positive electrode material with ultrahigh energy density, and aims to overcome the defects that nickel cobalt lithium manganite is poor in electrochemical performance and low in specific capacity and energy density. A molecular expression of the lithium ion battery positive electrode material is Li(Ni0.6Co0.2Mn0.2)1-xAlxO2-yFy, wherein x is greater than 0, and y is smaller than or equal to 0.05; a small amount of aluminum element replaces part of nickel element, and a fluorine element partially replaces an oxygen element, so that an internal structure of the material is stabilized, and structure collapse under a high-proportion lithium-removing state is inhibited; by co-doping aluminum with fluorine, specific discharge capacity and comprehensive electrochemical properties of the material are greatly improved; energy density is remarkably improved; besides, according to the lithium ion battery positive electrode material disclosed by the invention, a precursor material of which nickel elements are gradually distributed is prepared by adopting a gradient coprecipitation method; the concentration of the precursor material is gradually increased from inside to outside, so that the specific discharge capacity of the positive electrode material is favorably improved; a prepared product is high in purity, high in chemical uniformity and high in crystallization quality; products are small in particles, uniform in distribution, excellent in electrochemical performance and lower in manufacturing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

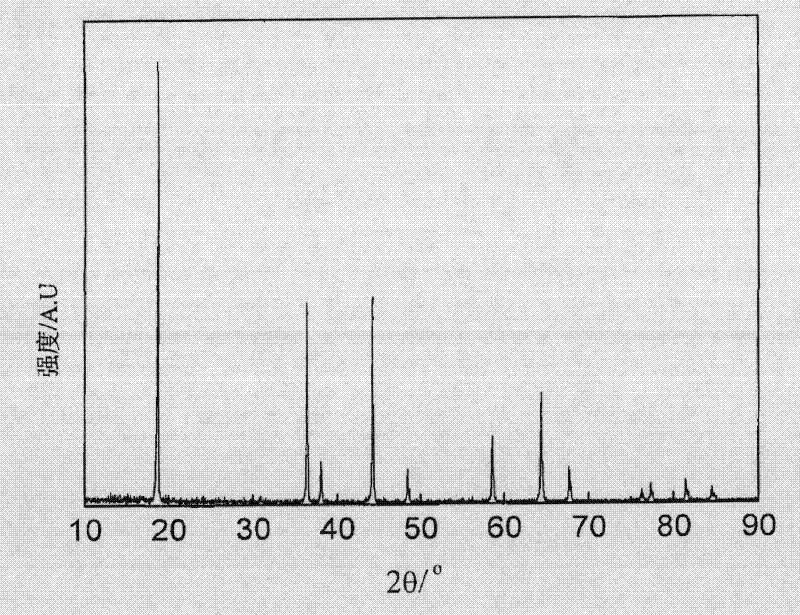

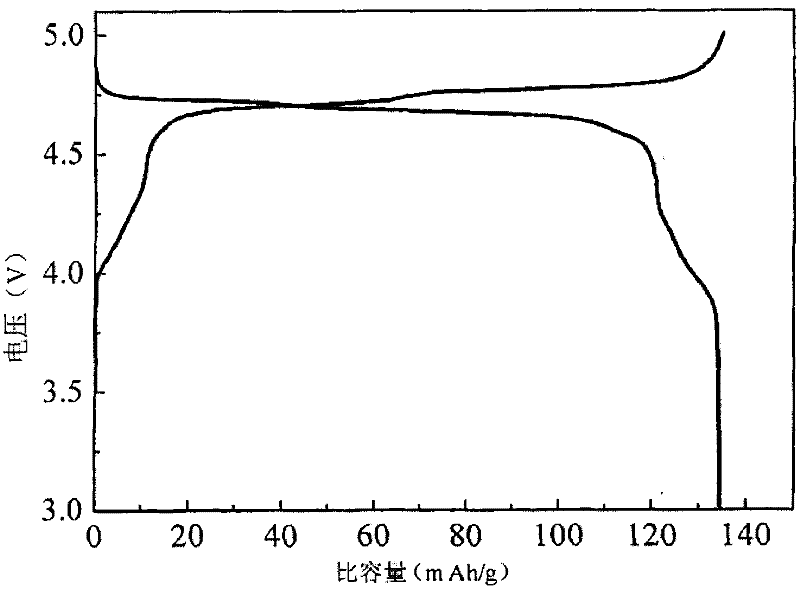

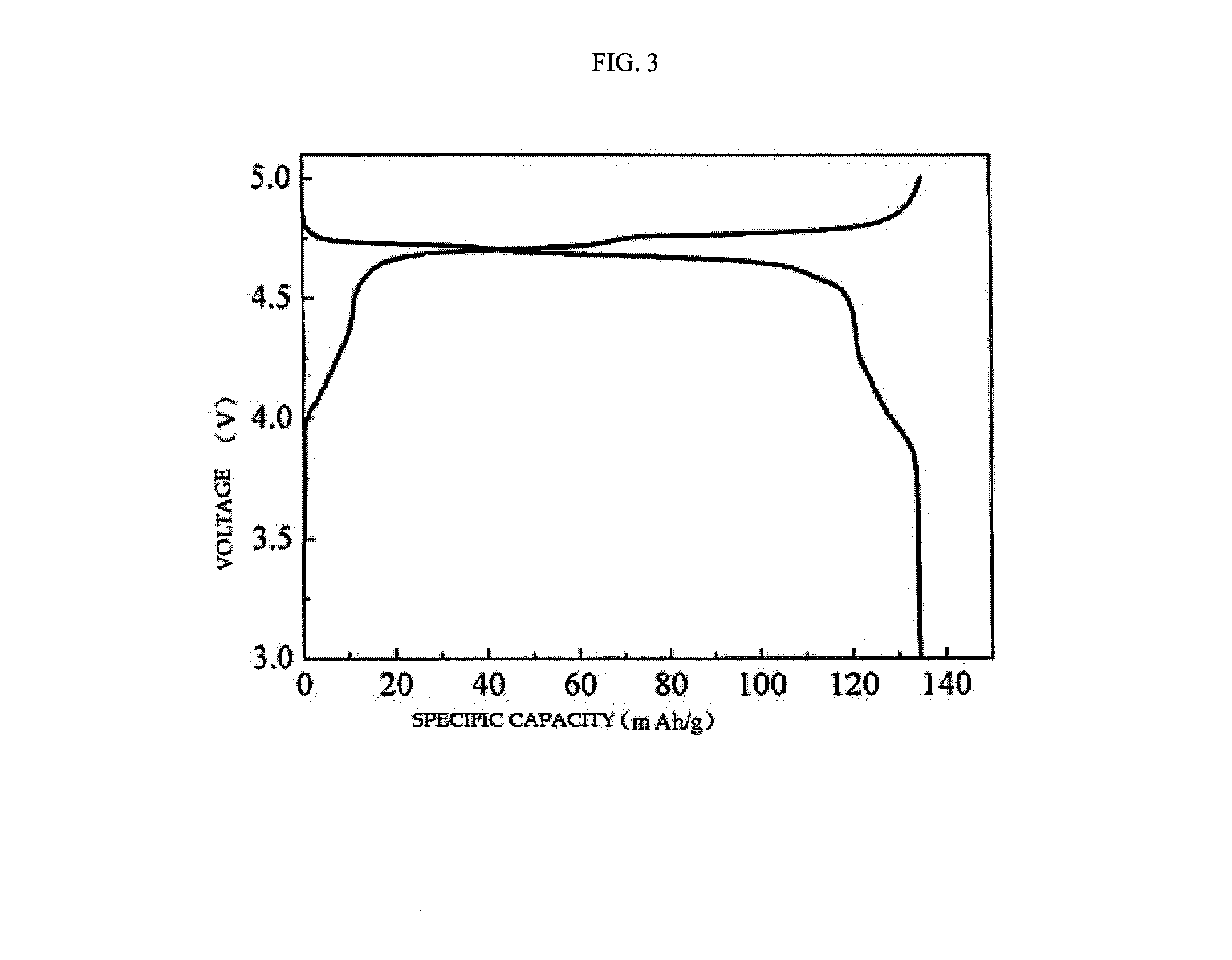

Cathode material for high voltage lithium battery

InactiveCN102263258AStable structureAvoid damageCell electrodesLi-accumulatorsCyclic processSynthesis methods

The present invention advantageously provides a high-voltage lithium battery cathode material and its general formula for the composition of the high-voltage lithium battery cathode material presented in this invention: €ƒ€ƒ€ƒ€ƒ€ƒ€ƒ€ƒ€ƒLiMn 1.5 Ni 0 . 5-X M X O 4 Of which: 0 <X ‰¤ 0.2, M represents one or several elements comprised by copper, zinc, magnesium, aluminum, cadmium, zirconium, and titanium. The present invention relates to a high-voltage lithium battery cathode material, which utilizes the liquid-phase co-precipitation method to dope transition metal elements, so that all elements could be mixed at the atomic level and obtain a relatively uniform product, stabilizing the crystal structure, avoiding the capacity attenuation caused by structure collapse in the material cyclic process; in addition, this invention has also increased the conductivity, improved the capacity of 5V platform, thereby avoiding the substantial damage to the battery system resulted from the decomposition of the electrolyte. Thus, a newly high-voltage lithium battery cathode material featured with good electrochemical properties and cycle performance has been proposed in the present invention; moreover, the utilization of liquid-phase co-precipitation has the advantages of simple synthesis method, convenient operation process, easier to control, high yield coefficient, low energy consumption, and easy-to-industrial production.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

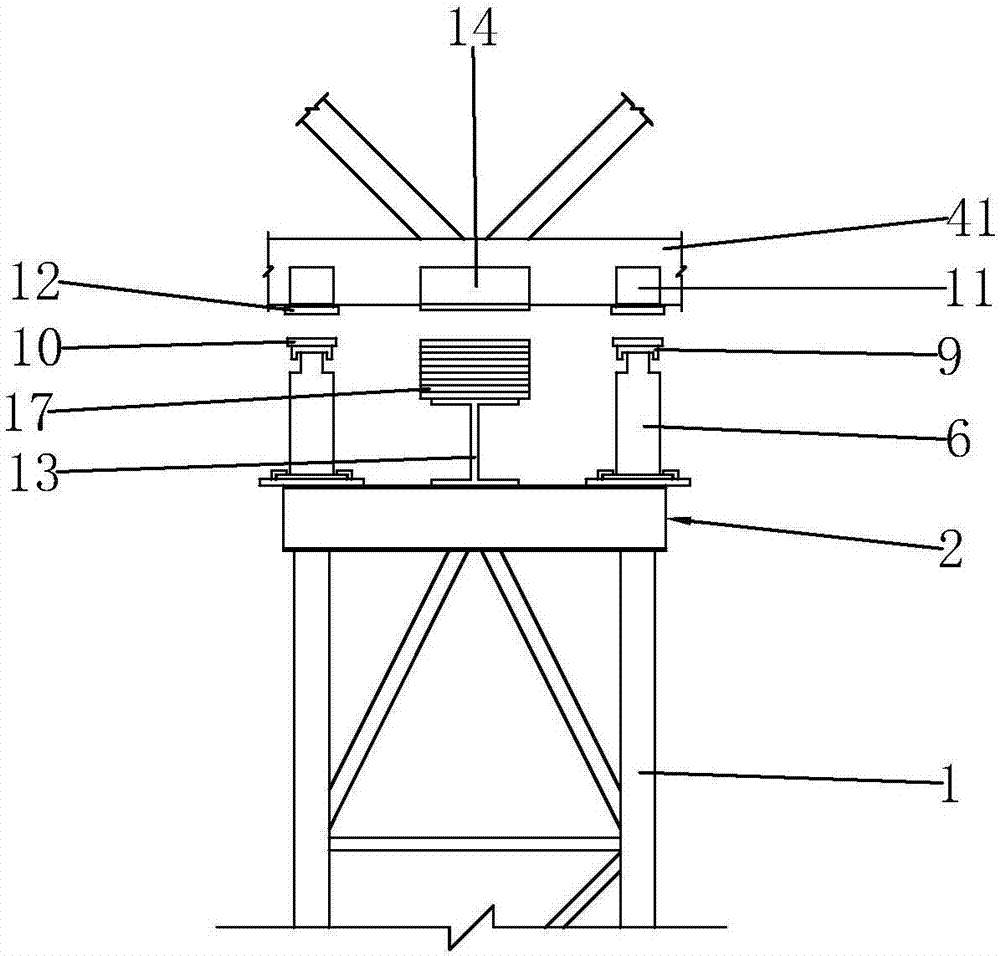

Method for butting and synchronously unloading segments of steel truss structure in air

ActiveCN107143145ASolve problems that are difficult to control qualityRelease local internal forceBuilding material handlingShoresEngineeringStructure Collapse

The invention discloses a method for butting and synchronously unloading segments of a steel truss structure in the air. The method comprises the following steps: (1) manufacturing and mounting a temporary supporting frame; (2) manufacturing and mounting an operating platform; (3) manufacturing and mounting a scaffold; (4) hoisting a truss in position; (5) butting truss segments in the air and permanently fixing; (6) enabling a jack to be in position; (7) mounting a first U-shaped sleeve groove; (8) removing the scaffold, and mounting a lower bearing beam; (9) mounting a second U-shaped sleeve groove; (10) mounting a limiting steel pin rod and a limiting plate; and (11) unloading step by step. The method disclosed by the invention has the advantages that the problem that the quality is difficult to control when a long-span plane truss adopts a segmental mounting method is effectively solved, an unloading process is steady and controllable, the phenomena that the original structure produces larger deflection, local rod pieces are over-stressed, node connection is destroyed and even structure collapse is caused due to an improper unloading scheme can be avoided, and synchronous unloading of the truss structure is realized.

Owner:浙江中南绿建科技集团有限公司

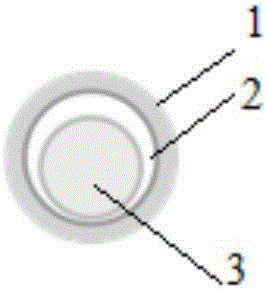

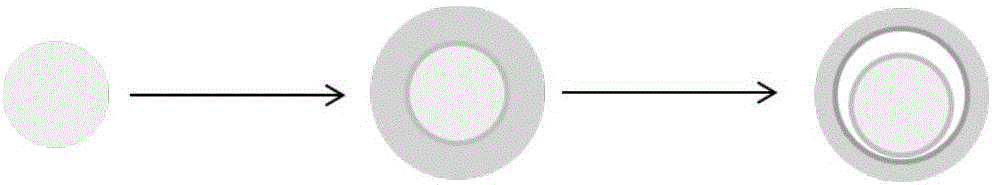

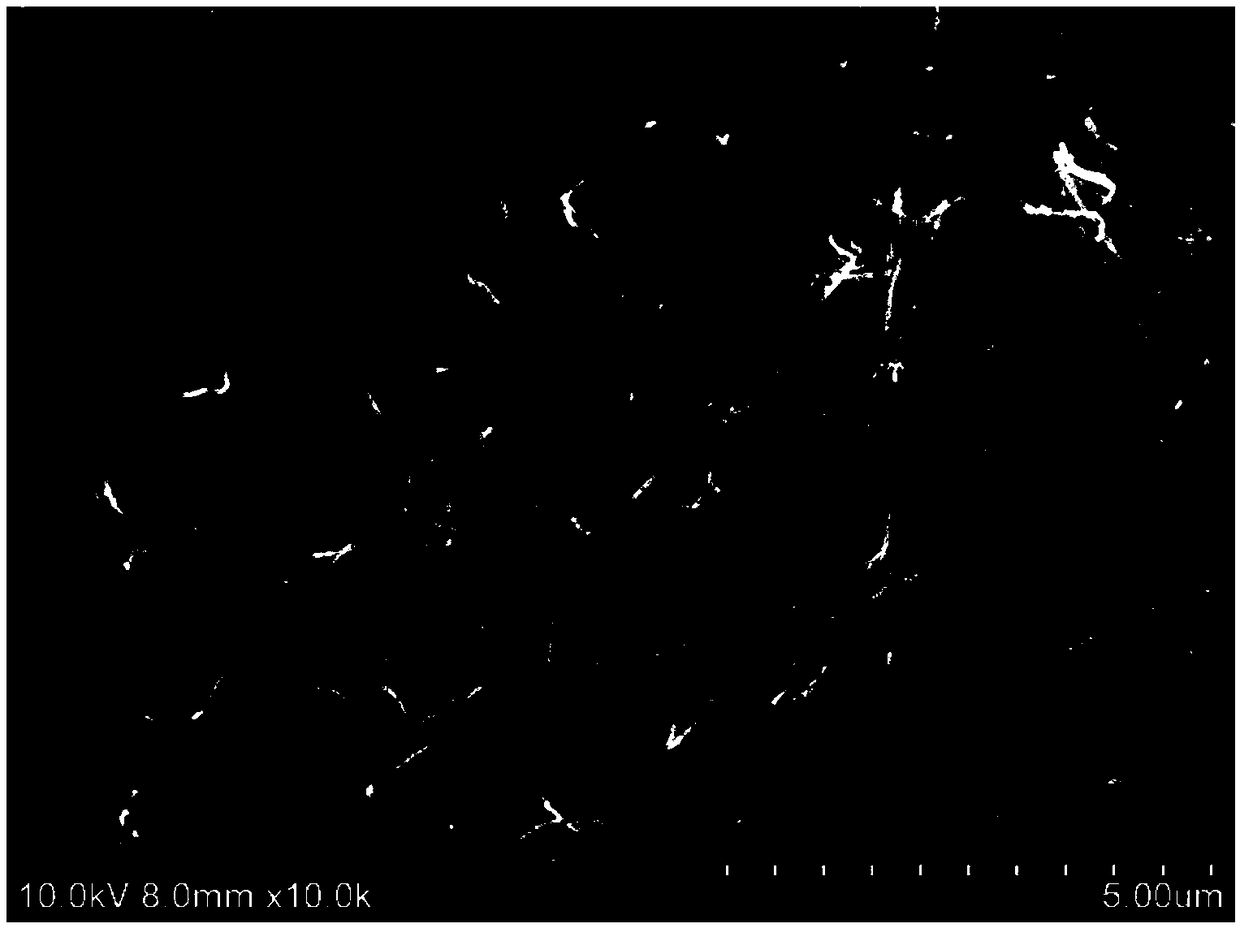

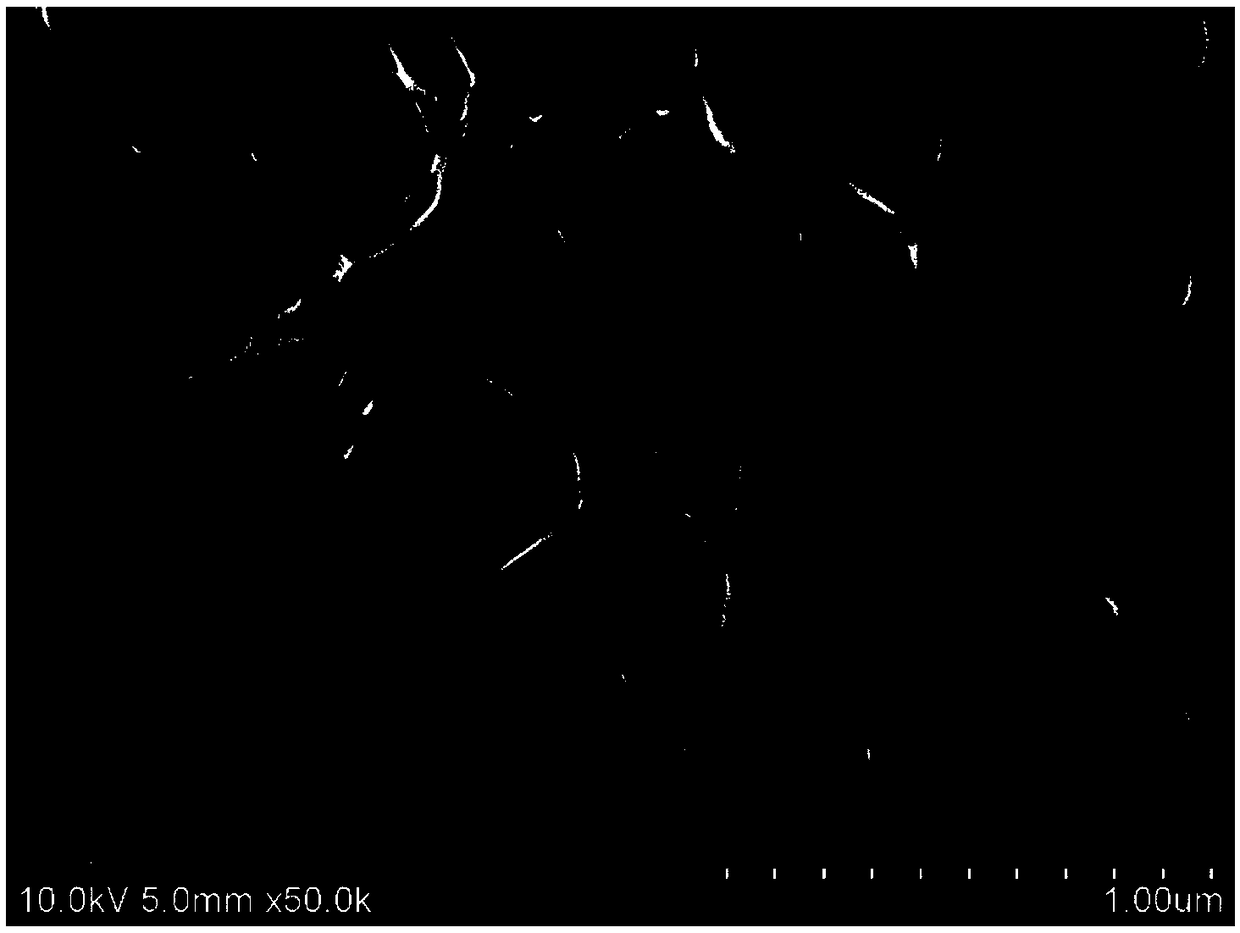

Polymer and nanometer sulfur composite material with shell and egg yolk structure and preparation method

ActiveCN106602019AShorten the transmission distanceAvoid reunionMaterial nanotechnologyCell electrodesLithium–sulfur batterySulfur

The invention relates to a polymer and nanometer sulfur composite material with a shell and egg yolk structure and a preparation method of the composite material. The composite material is provided with the shell and egg yolk double-layer structure, a central nucleus is formed by sulfur particles, an outer shell is formed by a polymer, a gap is preserved between the central nucleus and the shell, so that the double-layer structure like an egg shell and an egg yolk is formed; elemental sulfur is shrunk in the process that the temperature is quickly changed by using the change of crystal form and the change of density in different temperatures, and the elemental sulfur is partially dissolved and separated out by using a solvent, so that the composite material of the shell and egg yolk structure is formed. The composite material of the structure is applicable to cathodes of lithium sulfur batteries, structure collapse caused by volume expansion in the discharge process of the elemental sulfur is relieved, the dissolution and loss of discharge products are inhibited, and the electrical conductivity and circularity of the material are improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

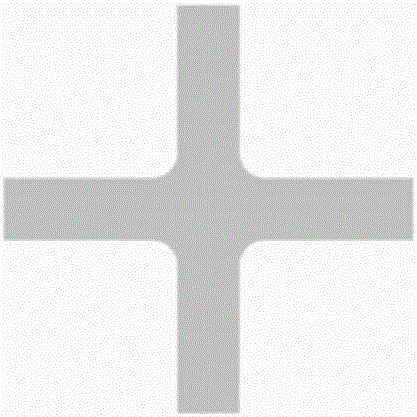

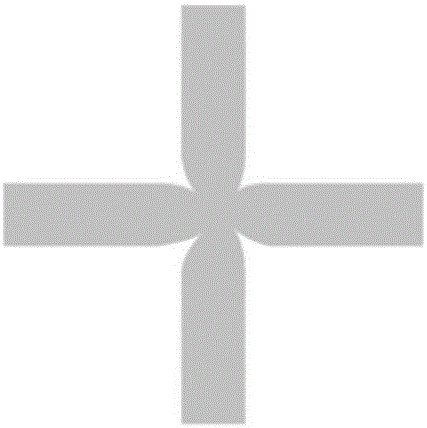

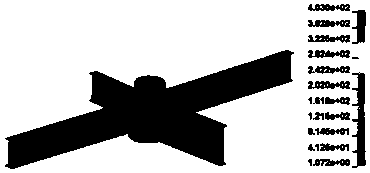

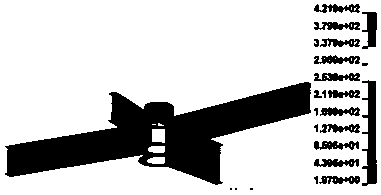

Additive manufacturing method of electric arc fuse wire with cross structure

ActiveCN106513930AMeet processing needsMeet the needs of useArc welding apparatusMultiple formsElectric arc furnace

The invention provides an additive manufacturing method of an electric arc fuse wire with a cross structure. With adoption of the additive manufacturing method, two types of forming layer paths intersect to form grids, and the forming layer paths do not mutually cross each other, so that the defects that the cross structure collapses, necks down and protrudes are avoided and grid shaped reinforcing ribs without structural defects are formed to meet the follow-up machining and using demands; and in addition, the grid cross structure is controllable in angle, is suitable for the machining demands of the grid shaped reinforcing ribs of multiple forms, high in applicability, simple in forming technology and easy to realize.

Owner:CAPITAL AEROSPACE MACHINERY +1

High-voltage lithium battery cathode material

InactiveUS20130126802A1Stable crystal structureImprove conductivityCell electrodesConductive materialCyclic processDecomposition

The present invention advantageously provides a high-voltage lithium battery cathode material and its general formula for the composition of the high-voltage lithium battery cathode material presented in this invention:LiMn1.5Ni0.5-XMXO4 Of which: 0<X≦0.2, M represents one or several elements comprised by copper, zinc, magnesium, aluminum, cadmium, zirconium, and titanium.The present invention relates to a high-voltage lithium battery cathode material, which utilizes the liquid-phase co-precipitation method to dope transition metal elements, so that all elements could be mixed at the atomic level and obtain a relatively uniform product, stabilizing the crystal structure, avoiding the capacity attenuation caused by structure collapse in the material cyclic process; in addition, this invention has also increased the conductivity, improved the capacity of 5 V platform, thereby avoiding the substantial damage to the battery system resulted from the decomposition of the electrolyte. Thus, a newly high-voltage lithium battery cathode material featured with good electrochemical properties and cycle performance has been proposed in the present invention; moreover, the utilization of liquid-phase co-precipitation has the advantages of simple synthesis method, convenient operation process, easier to control, high yield coefficient, low energy consumption, and easy-to-industrial production.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

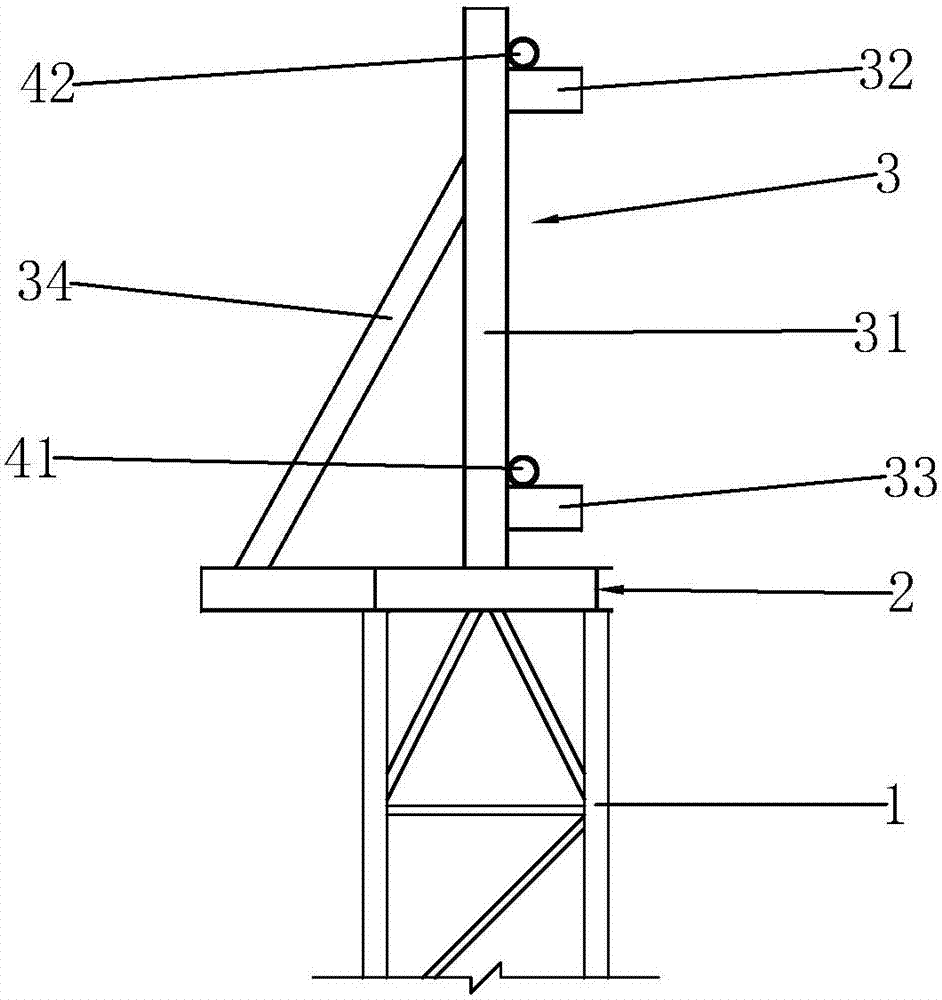

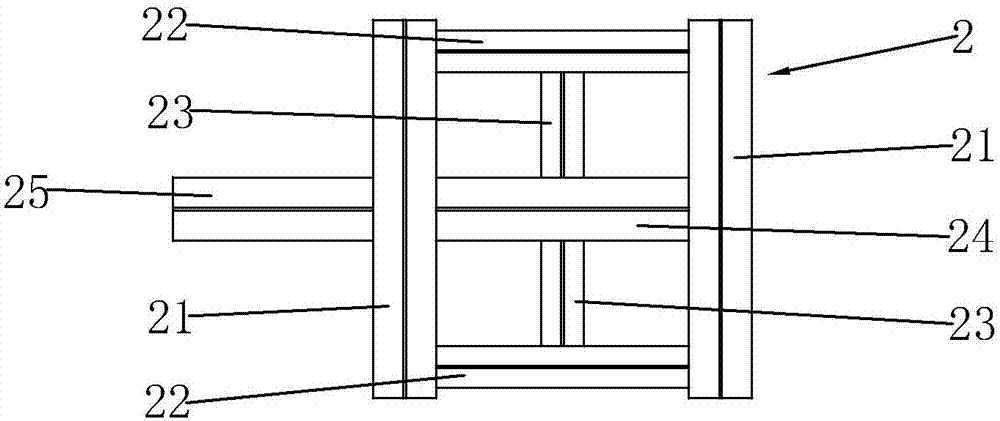

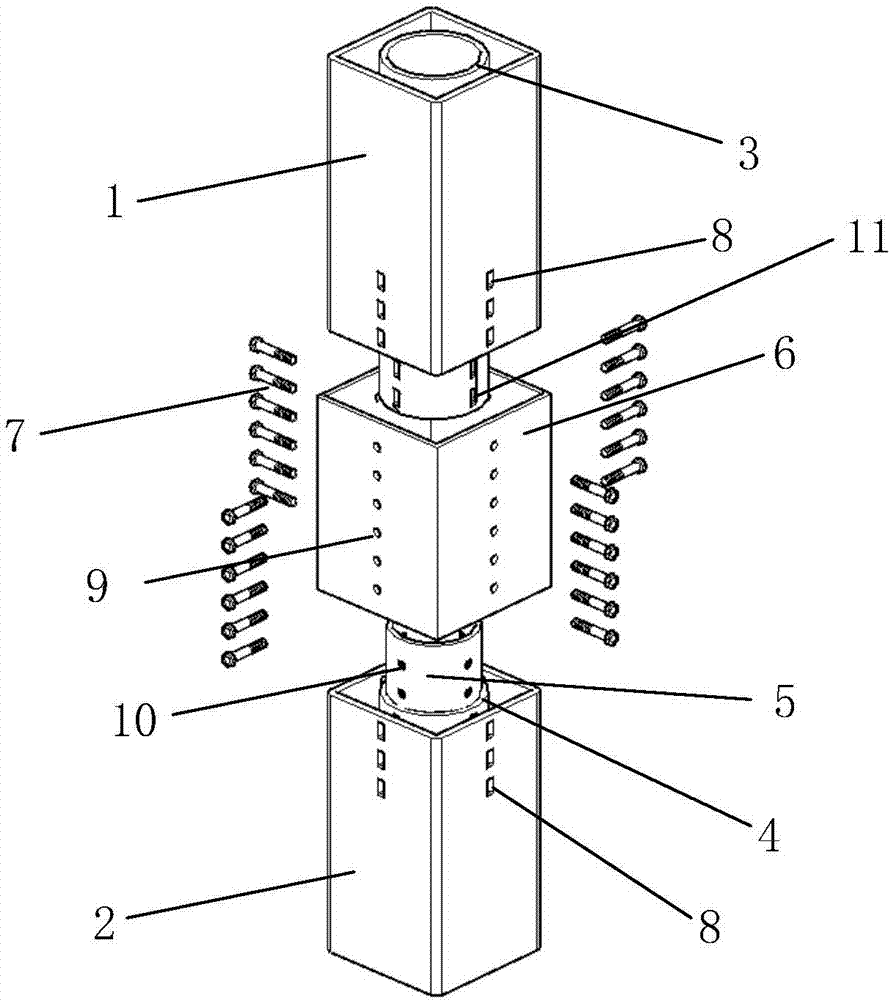

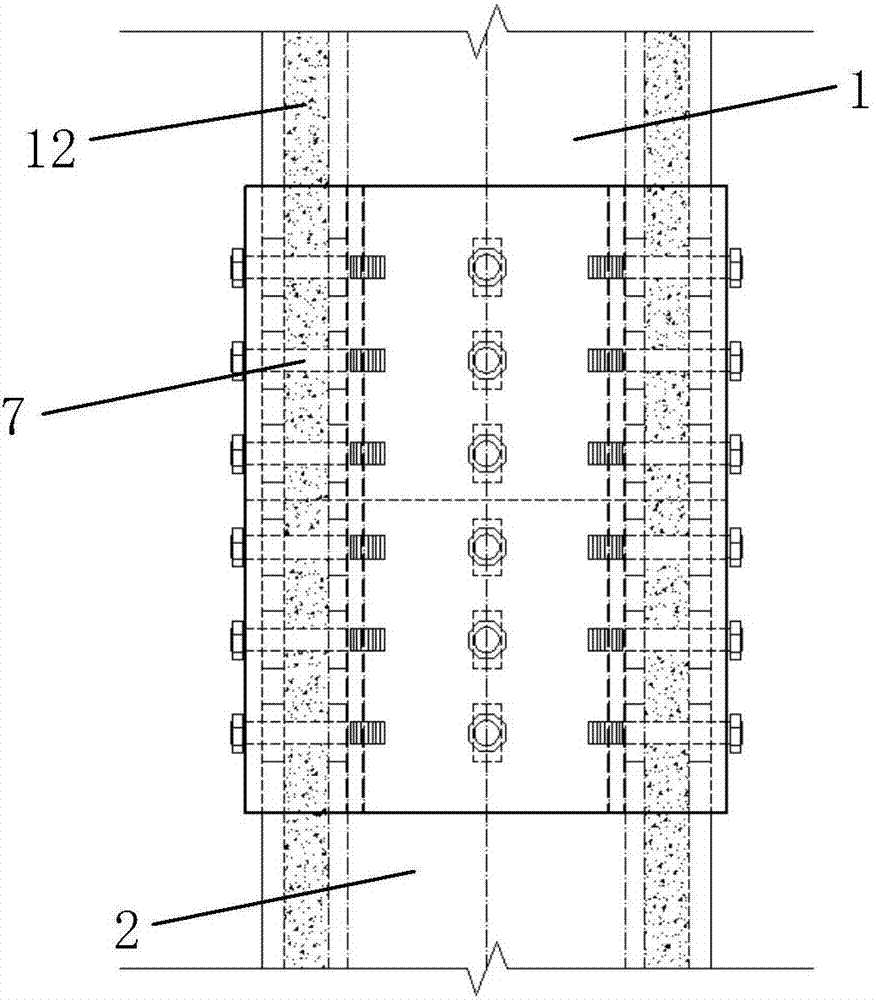

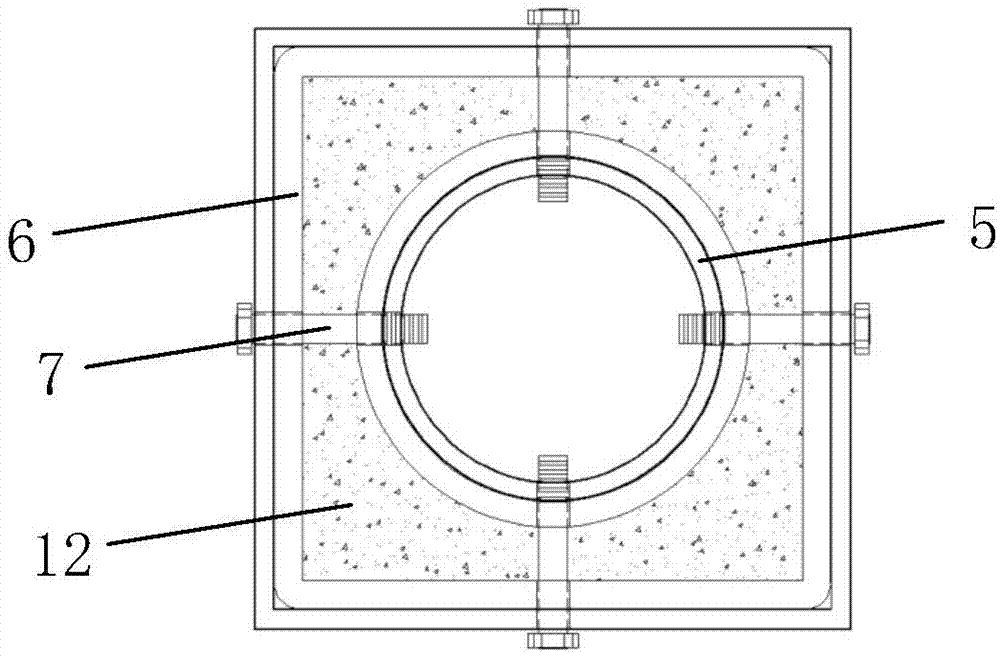

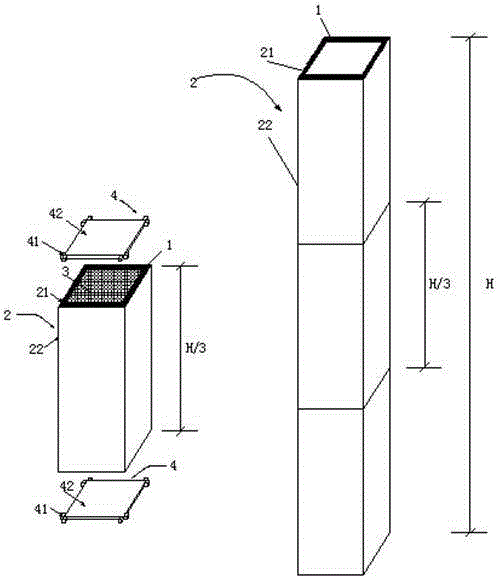

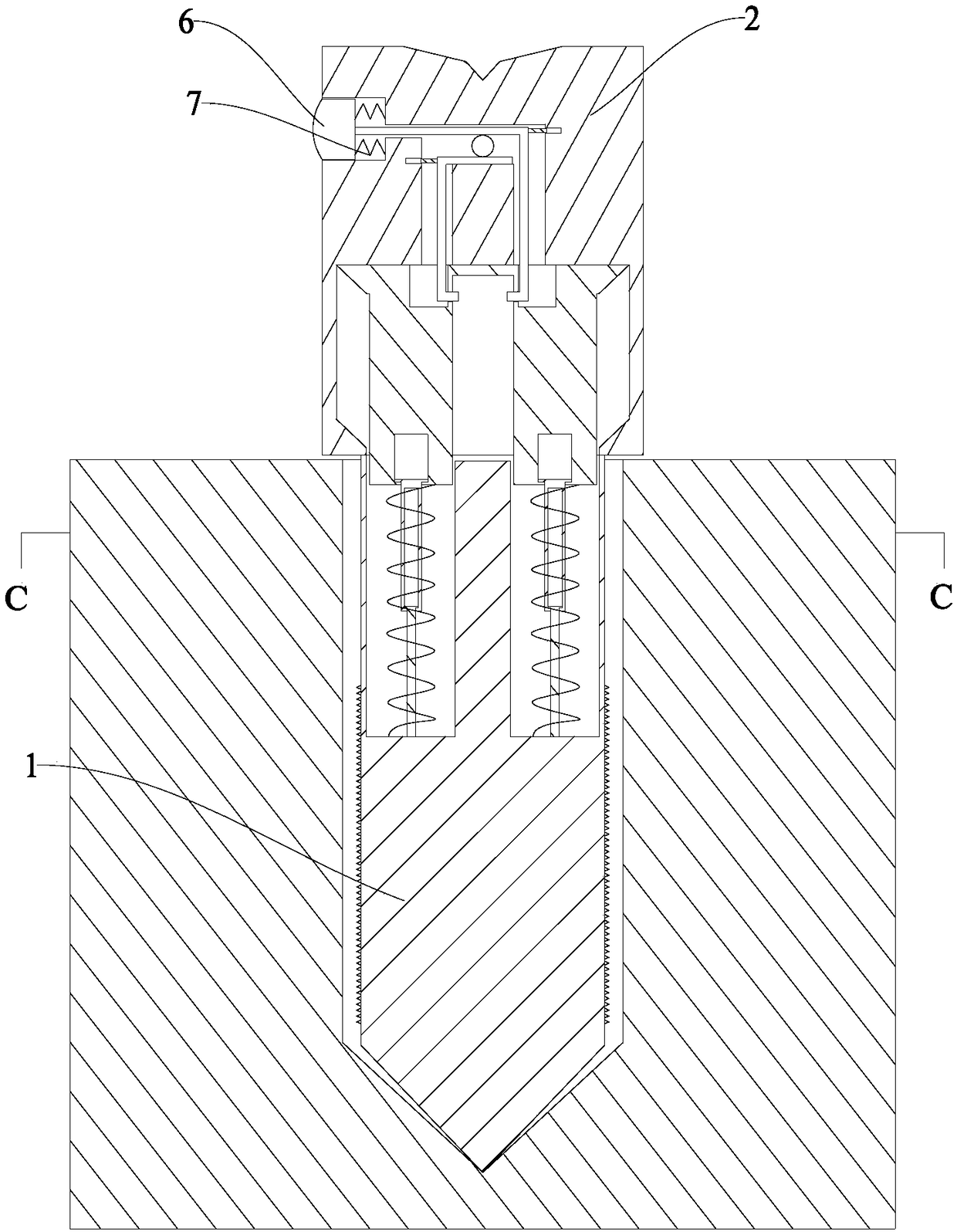

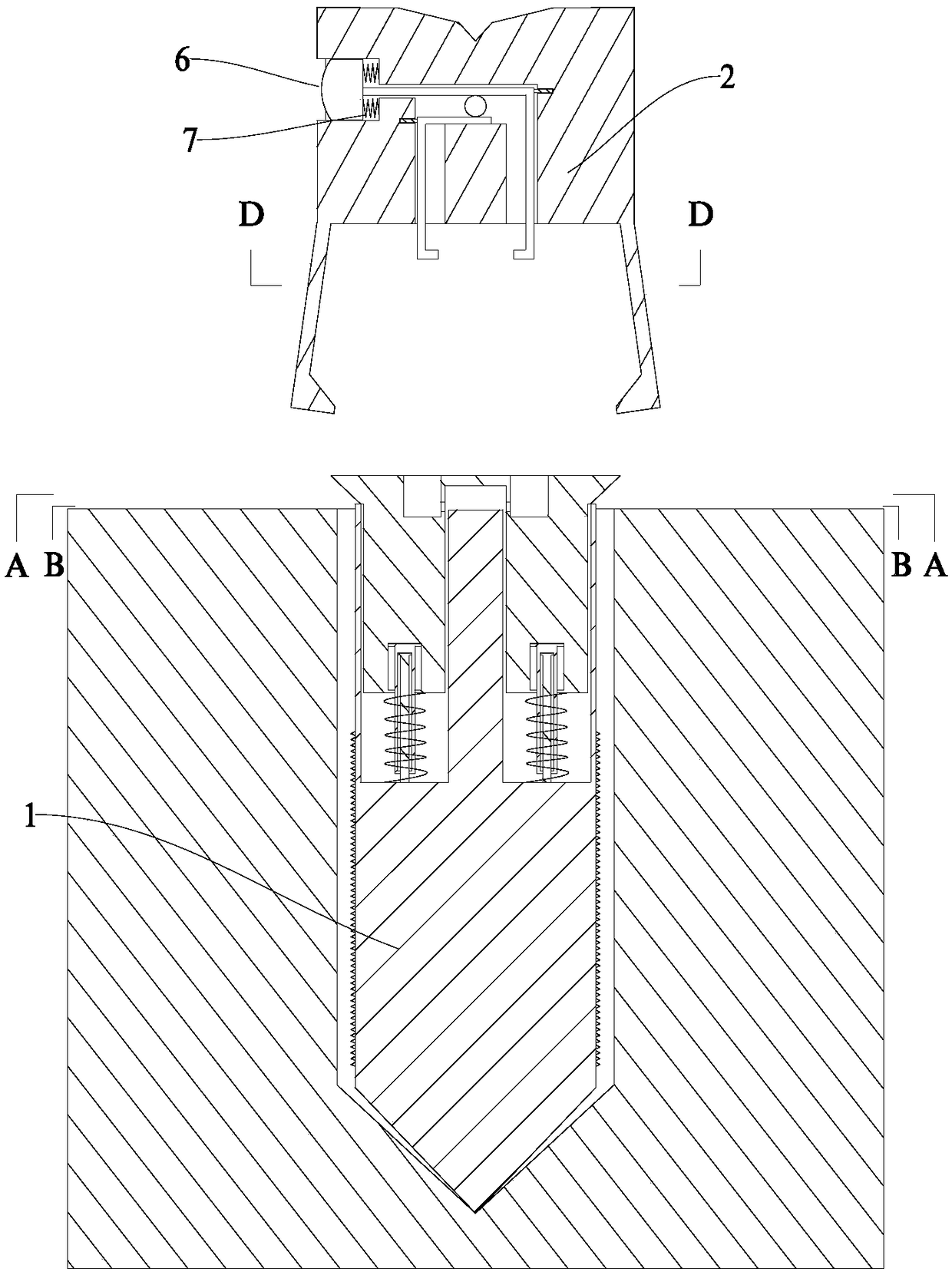

Outer-square and inner-circular steel pipe double-sleeve splicing joint and construction method thereof

InactiveCN107514061ATroubleshoot technical issues with structural collapseImprove vertical load carrying capacityBuilding constructionsStructure CollapseVertical load

The invention relates to the technical field of building steel structure construction, in particular to an outer-square and inner-circular steel pipe double-sleeve splicing joint and a construction method thereof. The outer-square and inner-circular steel pipe double-sleeve splicing joint comprises an upper-section square steel pipe column, a lower-section square steel pipe column, an upper-section circular steel pipe column and a lower-section circular steel pipe column. The square steel pipe columns comprise the upper-section square steel pipe column and the lower-section square steel pipe column, and the circular steel pipe columns comprise the upper-section circular steel pipe column and the lower-section circular steel pipe column. The joint further comprises a square outer sleeve connected between the upper-section square steel pipe column and the lower-section square steel pipe column, a circular inner sleeve connected between the upper-section circular steel pipe column and the lower-section circular steel pipe column and a long bolt. According to the outer-square and inner-circular steel pipe double-sleeve splicing joint and the construction method thereof, the problems that as for an existing outer-square and inner-circular steel pipe core cylinder joint connecting mode, on-site construction operation is inconvenient, connecting components are complex in design and construction, the rigidity of a joint is insufficient, and how a current core cylinder joint is spliced through sleeves is not determined are solved; and the technical problem that when the vertical load of a column is over large, a bolt fractures, and thus a structure collapses is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Explosionproof energy-consumption lightweight steel construction column

ActiveCN105201142AIncreased bending stiffnessAvoid buckling failureStrutsPillarsSteel columnsStructure Collapse

The invention aims at overcoming the defects existing in the prior art and aims at providing an explosionproof energy-consumption lightweight steel construction column which has the capabilities of improving the explosionproof capability of a lightweight steel column, reducing the bearing capacity reduction caused by buckling failure of the lightweight steel column and preventing whole structure collapse caused by toppling of the lightweight steel column, thus avoiding person casualty accidents. A technical solution adopted by the invention is an explosionproof energy-consumption lightweight steel structure column which comprises the lightweight column, a foamed aluminum layer enclosed by steel plates, and a lightweight steel cover plate, wherein the steel column is positioned in an intermediate layer of the explosionproof energy-consumption lightweight steel structure column; the foamed aluminum layer enclosed by the steel plates comprises a first foamed aluminum filling layer and a steel sleeve, wherein the steel sleeve consists of mutually connected steel plates which encircle a steel column; the first foamed aluminum filling layer is arranged between the steel sleeve and the steel column.

Owner:HUAIAN YANGZI STEEL STRUCTURAL ENG CO LTD

Preparation method and application of self-support flexible electrode

InactiveCN107394118AStable supportImprove mechanical propertiesMaterial nanotechnologyCell electrodesFiberPorosity

The invention discloses a preparation method and an application of a self-support flexible electrode. The self-support flexible electrode has the advantages of environment friendliness, mild reaction condition, no conductive agent or binding agent addition, self-support film and excellent mechanical property. Compared with the existing SnO2 flexible electrode, the obtained flexible electrode comprises a carbon-clad nanofiber; a carbon-clad layer can protect an active material against corrosion of an electrolyte, and can inhibit structure collapse caused by volume expansion in charging and discharging processes; the flexible electrode is high in porosity; permeation of the electrolyte is facilitated; the flexible electrode can bear repeated bending without breaking; the electrochemical property basically remains constant; the flexible electrode can be directly cut for mounting a battery; and shape design and assembling of the battery are facilitated. The characteristics facilitate further improving the electrochemical property of the flexible electrode; and the flexible electrode is expected to become an excellent-property flexible electrode material of a lithium ion battery.

Owner:XIANGTAN UNIV

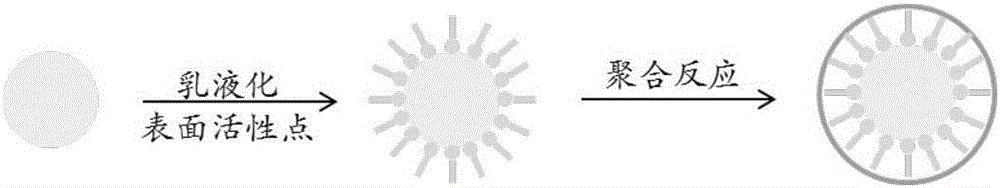

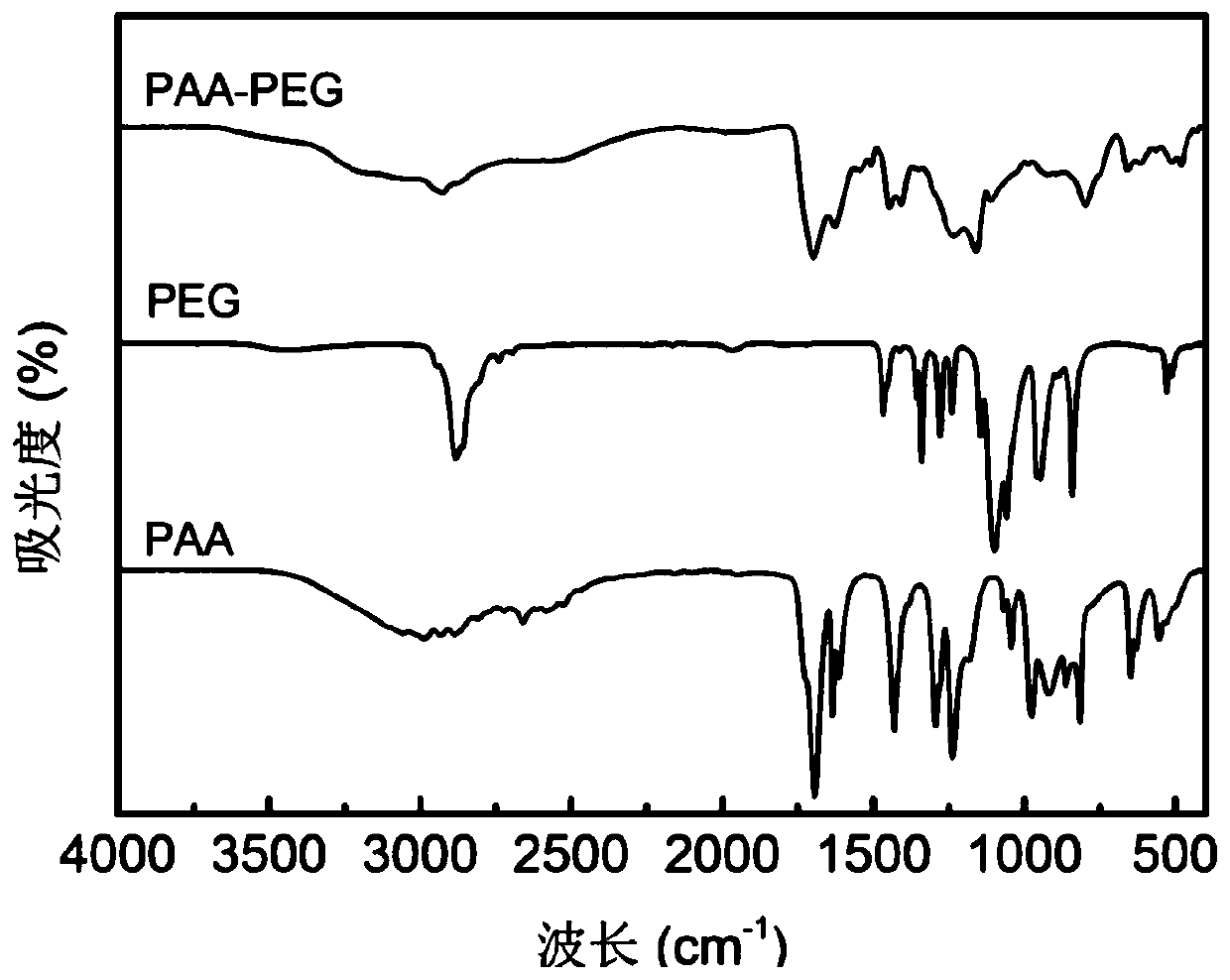

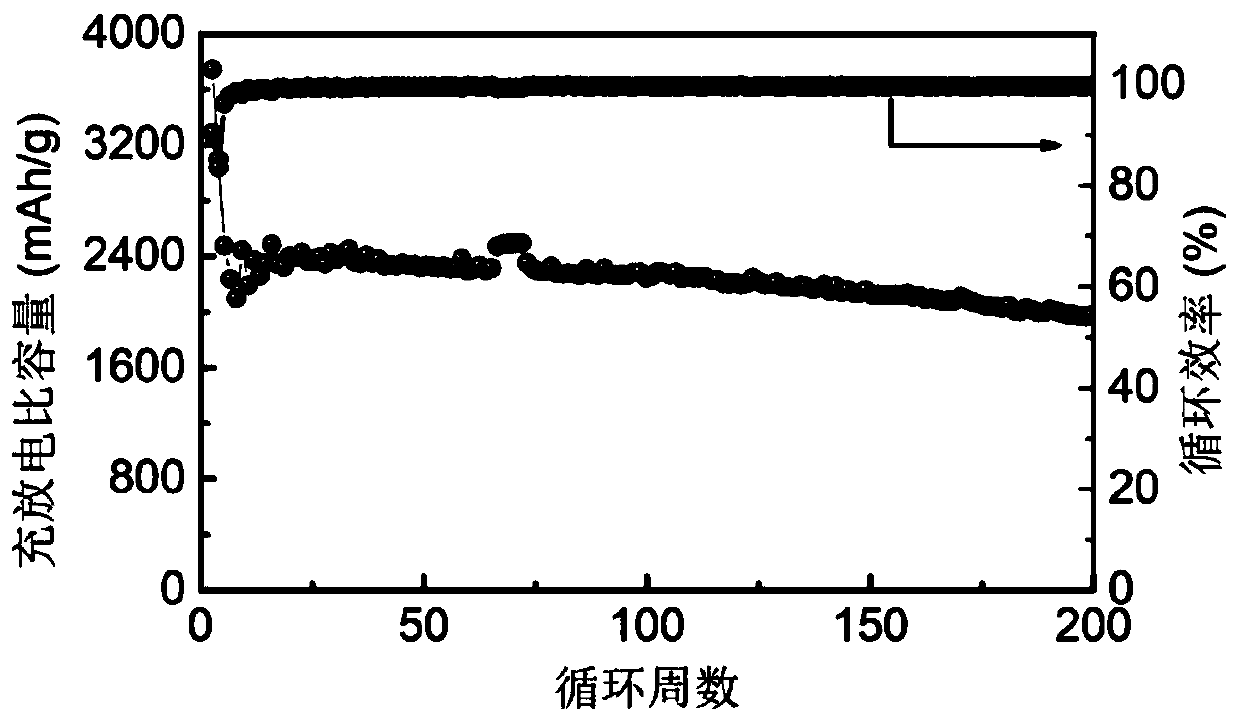

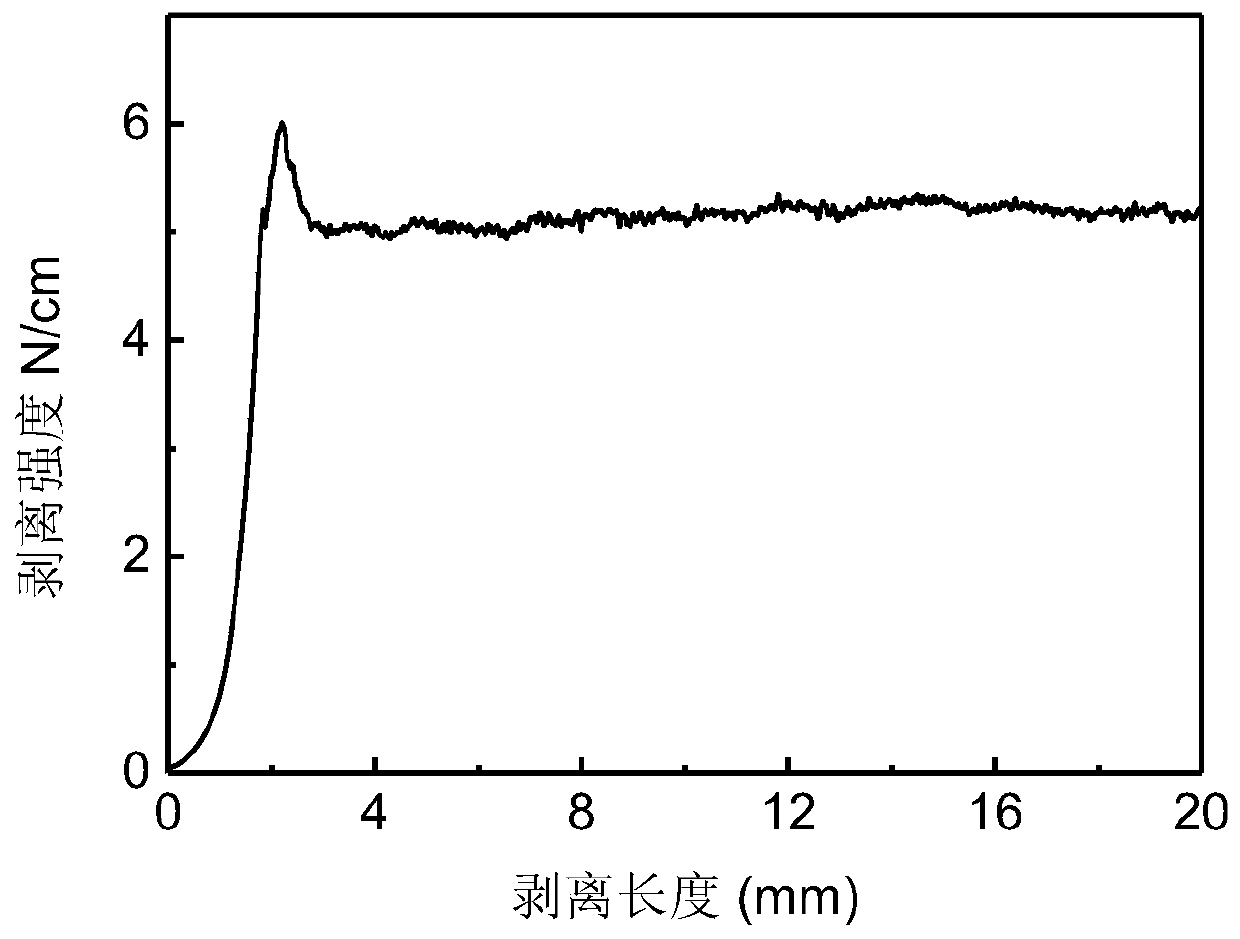

Three-dimensional network adhesive for secondary battery and preparation method thereof, negative electrode slurry and negative electrode material

ActiveCN109888170AStable structureImprove mechanical propertiesElectrode manufacturing processesAdhesiveSlurry

The invention discloses a three-dimensional network adhesive for a secondary battery and a preparation method thereof, a negative electrode slurry and a negative electrode material. The adhesive is apolyacrylic acid-polyethylene glycol hydrogel polymeric adhesive having a three-dimensional network structure; the three-dimensional network structure is stable and has excellent mechanical properties, so that the irreversible slip does not occur between a polymer molecular chain and active particles when the three-dimensional network structure is applied to the battery, and the stress generated by the volume expansion of the active material can be effectively borne. In the preparation method of the three-dimensional network adhesive, the raw materials are easy to obtain, the cost is low, andthe repeatability is good, therefore, the preparation method of the three-dimensional network adhesive can be widely applied in actual production; by using the negative electrode slurry and the negative electrode material prepared through the adhesive, the problem of material powdering and electrode structure collapse due to volume expansion and contraction of the active material in the battery electrode during charging and discharging processes is solved; therefore, the capacity attenuation of the battery is relieved, and the cycle stability of the battery is improved.

Owner:XI AN JIAOTONG UNIV

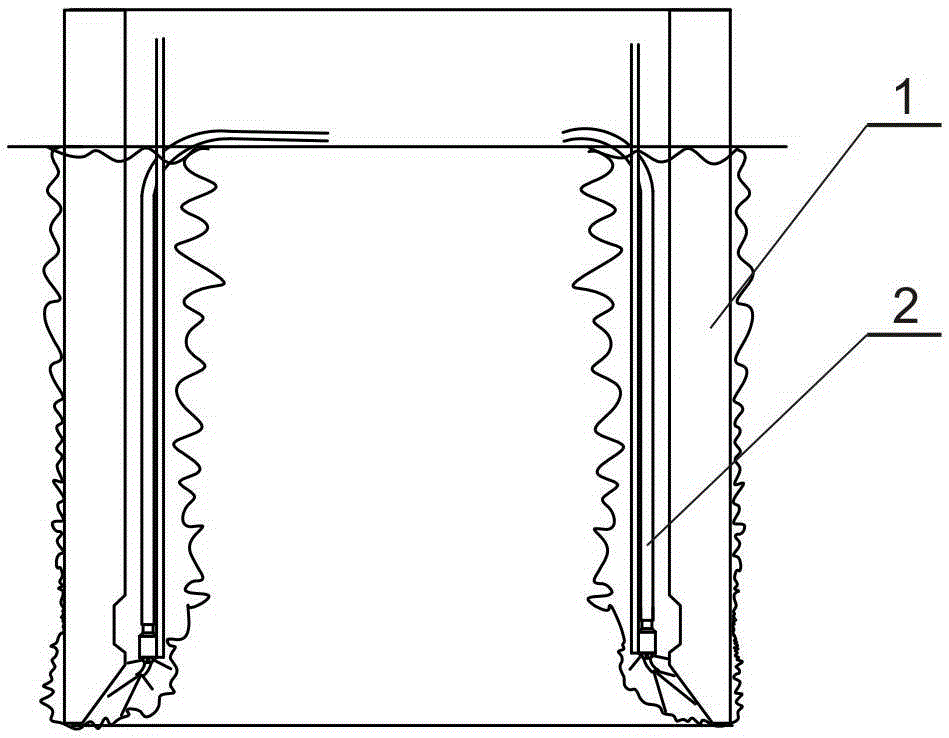

Method for carrying out settlement of underground wall structure by means of high-pressure water guns

InactiveCN105239577AImprove work efficiencyFast constructionFoundation engineeringSlurryTotal station

The invention discloses a method for carrying out settlement of an underground wall structure by means of high-pressure water guns. The method for carrying out the settlement of the underground wall structure by means of the high-pressure water guns comprises the following steps that (a) a field is leveled, and setting-out is conducted for positioning; (b) the underground wall structure is poured in place; (c) a total station is installed; (d) pre-preparation for the settlement of the underground wall structure is conducted; (e) the high-pressure water guns are arranged; (f) settlement of the first stage of the underground wall structure is conducted by means of the high-pressure water guns; (g) the second stage of the underground wall structure is poured in place; and (h) the underground wall structure is reinforced through grouting. According to the method for carrying out the settlement of the underground wall structure by means of the high-pressure water guns, an annular slurry groove is formed in the periphery of the underground wall structure, so that a soil body supporting the underground wall structure collapses in order, and accordingly the underground wall structure sinks slowly under the action of the self-weight, and construction of an underground building wall and a building enclosure is achieved; the method for carrying out the settlement of the underground wall structure by means of the high-pressure water guns has the advantages of being high in construction speed and high in working efficiency.

Owner:冯克俊

Preparation method of aerosil composite material

The invention relates to the technical field of aerogel, in particular to a preparation method of an aerosil composite material. The method includes: weighing a silane coupling agent and adding it into a beaker, adding methanol and an acetic acid solution in a volume ratio of 1:4, performing stirring to dissolve the silane coupling agent, then adding glass fibre subjected to aerosol and surface treatment, letting the glass fiber and silicone sol fully integrate and disperse evenly, after gel forms, conducting aging, adding an alcohol solution and alkane for replacement modification respectively, and performing drying, thus obtaining the fiber reinforced aerosil composite material. Through introduction of a reinforcement body, the method provided by the invention effectively reduces the surface tension between holes, reinforces the strength of aerogel skeleton, overcomes the shortcomings of low strength and high brittleness of pure aerosil, avoids excessive volume contraction, structure collapse and other problems at the aging and drying stage, reduces surface cracks, and acquires the composite aerogel material with good blocking performance.

Owner:江苏国科新材料科技有限公司

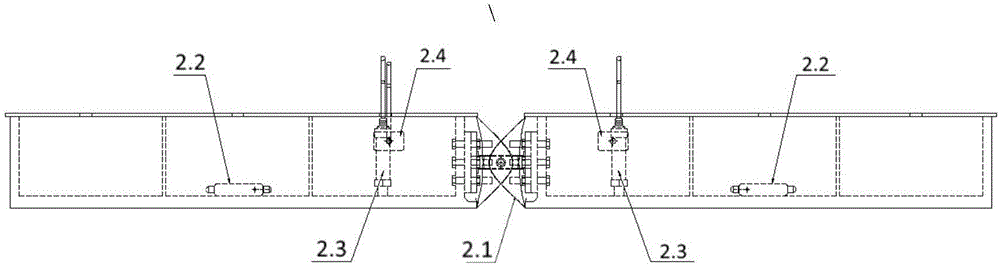

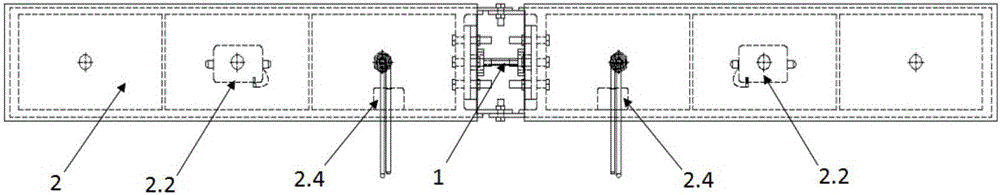

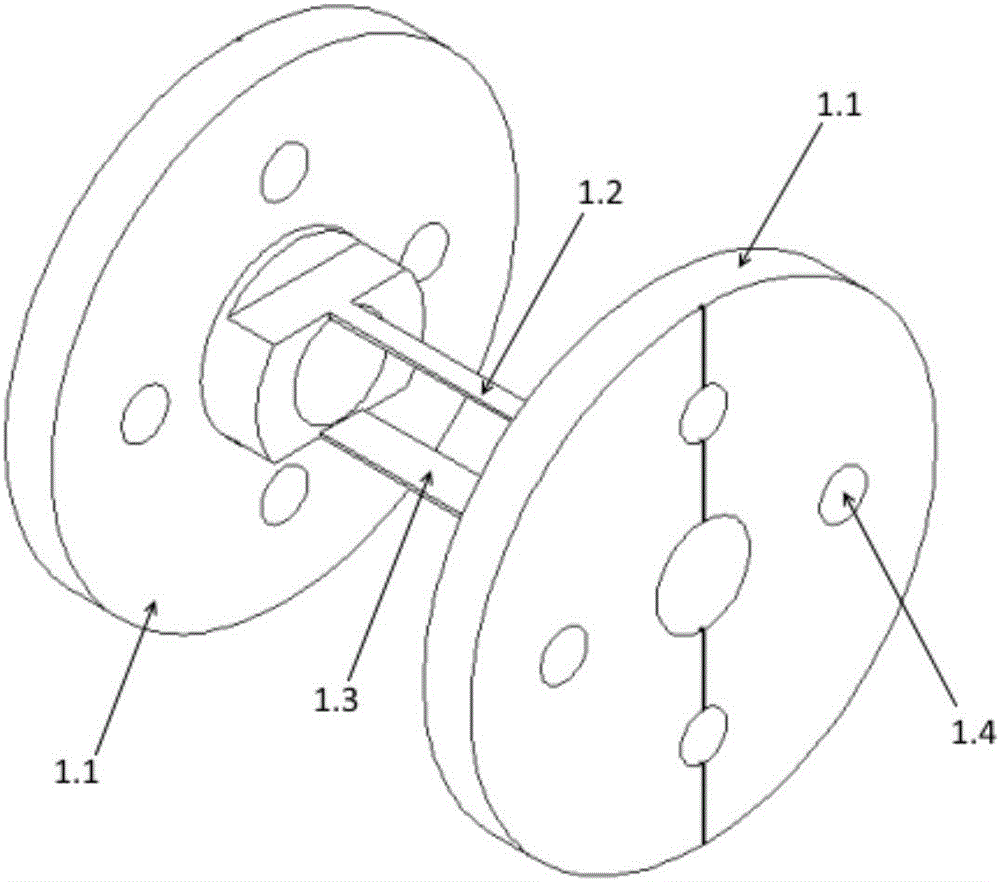

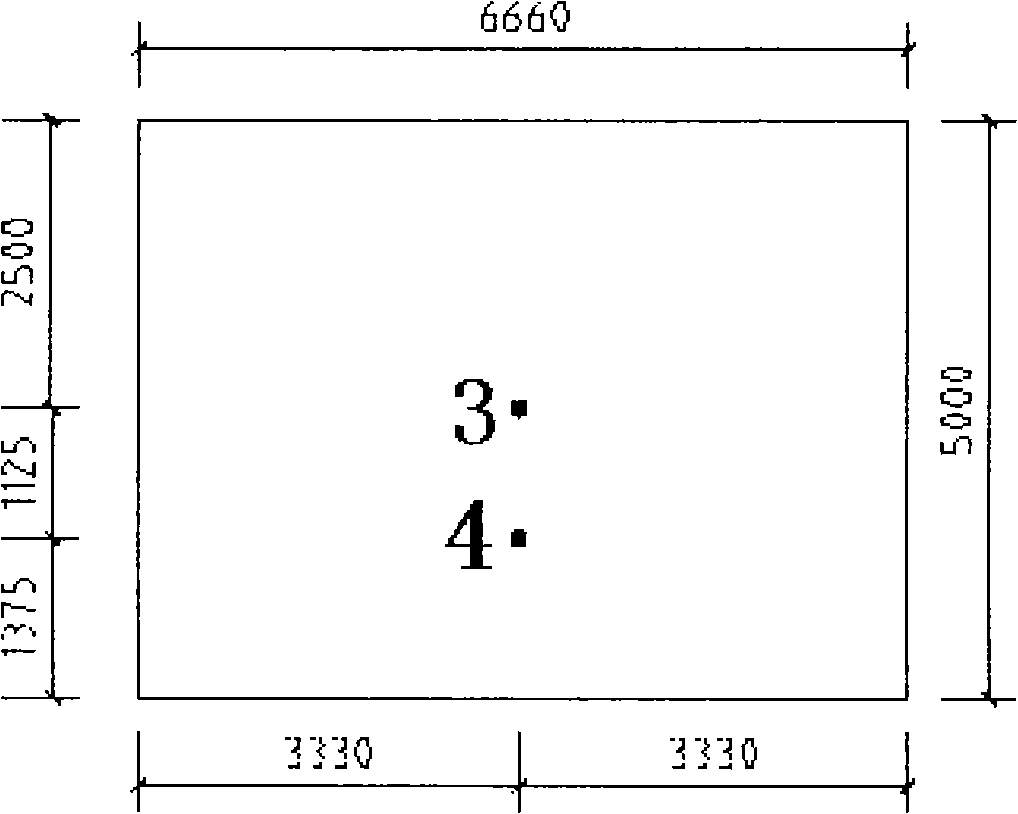

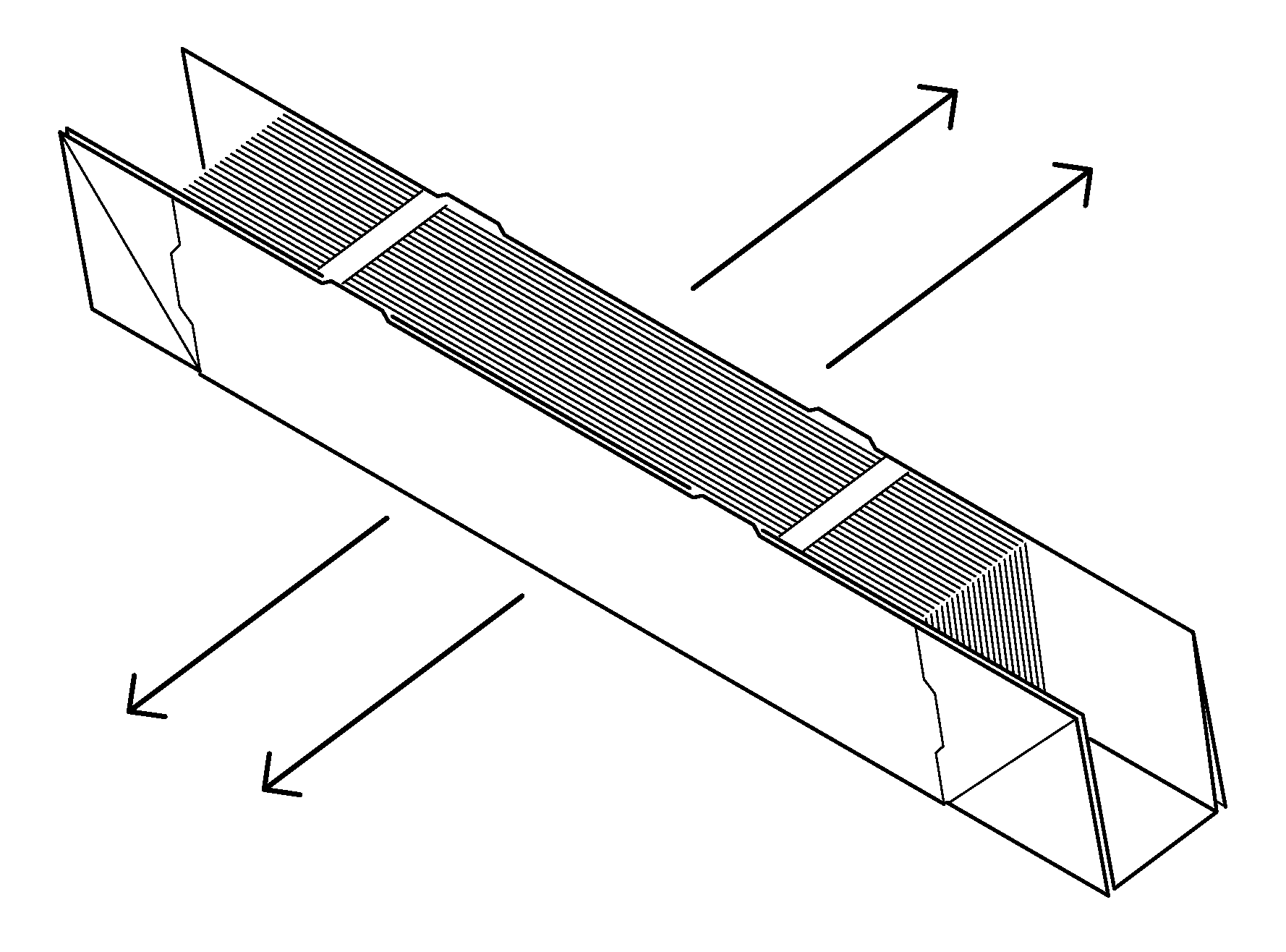

Method and device for testing structural collapse response of ship hull girder under waves

ActiveCN106768853AConforms to nonlinear ultimate strength characteristicsFacilitate the study of structural failure mechanismsHydrodynamic testingRotational deformationMarine engineering

The invention discloses a method and a device for testing the structural collapse response of a ship hull girder under waves. The device comprises a buckling hinge and a ship hull model, wherein the ship hull model is divided into two ship hull sections from the middle part; the two ship hull sections are hinged together, thus being capable of making relative rotation along the vertical direction; the buckling hinge comprises an upper hinge piece, a lower hinge piece and two ship hull connecting plates; the upper hinge piece and the lower hinge piece are long-strip-shaped sheet metals, and the thickness and width of the upper hinge piece are smaller than those of the lower hinge piece; the upper hinge piece and the lower hinge piece are parallel to a waterline plane of the ship hull model, and the two ends of the upper hinge piece and the lower hinge piece are respectively and fixedly connected with the two ship hull connecting plates; the two ship hull connecting plates are respectively and fixedly connected with the two ship hull sections. The method adopts the device for testing the structural collapse response for testing; two wireless inclinometers are used for recording the longitudinal inclination motions of the ship hull sections in real time, so that the rotational deformation of the buckling hinge in the middle of a test model under the condition of different wave heights can be obtained.

Owner:WUHAN UNIV OF TECH

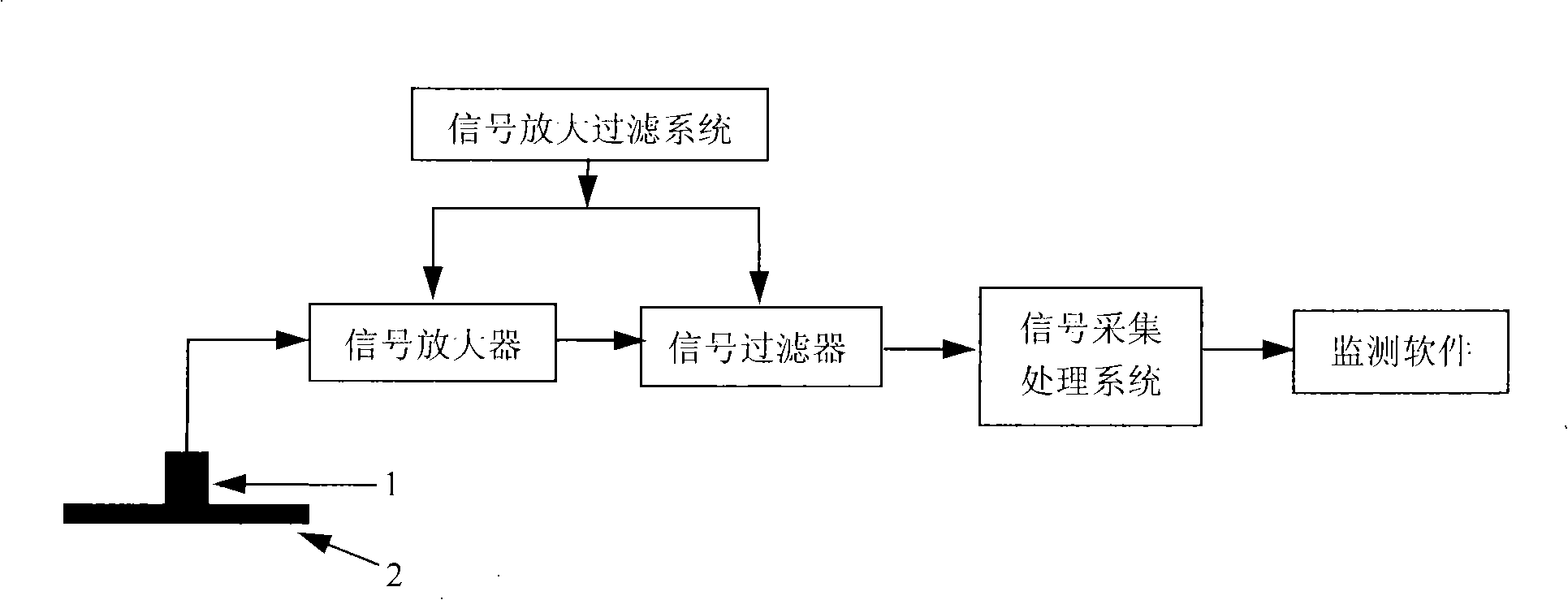

Method and system for monitoring building structure collapse vibration when fire hazard occurs

InactiveCN101354305AMonitor working statusTimely evacuationVibration testingAudio power amplifierMonitoring system

The invention provides a system and a method for monitoring the collapse vibration of a building structure in a fire. The monitoring system essentially consists of a system for testing vibration characters and relevant software for monitoring the collapse. The system for testing the vibration characters consists of a high-temperature-resistance vibration sensor, a matched signal amplifier and a matched smart signal collecting and processing analyzer. The monitoring software is utility software independently researched and developed and based on C++ Language, which can forecast the functional mode of the building structure according to the parameters of the vibration characters input to the system for testing the vibration characters. Therefore, when a fire happens, the functional mode of the building structure can be know well so that fire-fighting time can be accurately seized for avoiding heavy casualties and property losses. The development of the system can help to know well of the vibration characters of the building structure, caused by the fire, forecast and monitor the collapse of the building and provide important bases for fire-fighting.

Owner:HARBIN INST OF TECH

Carbon three-dimensional structural electrode of secondary battery and preparation method and application of carbon three-dimensional structural electrode

InactiveCN109411756AAvoid it happening againImprove Coulombic efficiencyMaterial nanotechnologyFuel and secondary cellsDendriteThree dimensional electrode

The invention provides a carbon three-dimensional structural electrode and a preparation method and application thereof. When the carbon three-dimensional structural electrode provided by the invention is adopted as an anode of a battery, active metal is deposited on or dissolved out of a carbon material three-dimensional skeleton, corresponding metallic dendrites are not generated, and the phenomenon that the dendrites puncture an electrolyte and consequently the battery is subjected to short circuit is avoided; rich holes in the three-dimensional electrode can accommodate the active metal deposited on a skeleton electrode and volume-expanded active metal, and the problems that the electrode structure collapses due to dissolving out of the active metal, consequently the size and shape ofthe battery are changed, the cycle life is shortened, and energy density is decreased are avoided through the rigid structure of the three-dimensional skeleton; and a carbon material can provide a space or a channel for embedding and stripping metal ions, and the storage capacity of the battery is increased. When the carbon three-dimensional structural electrode provided by the invention is used as the anode of the battery, the original assembly process of the battery does not need to be changed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

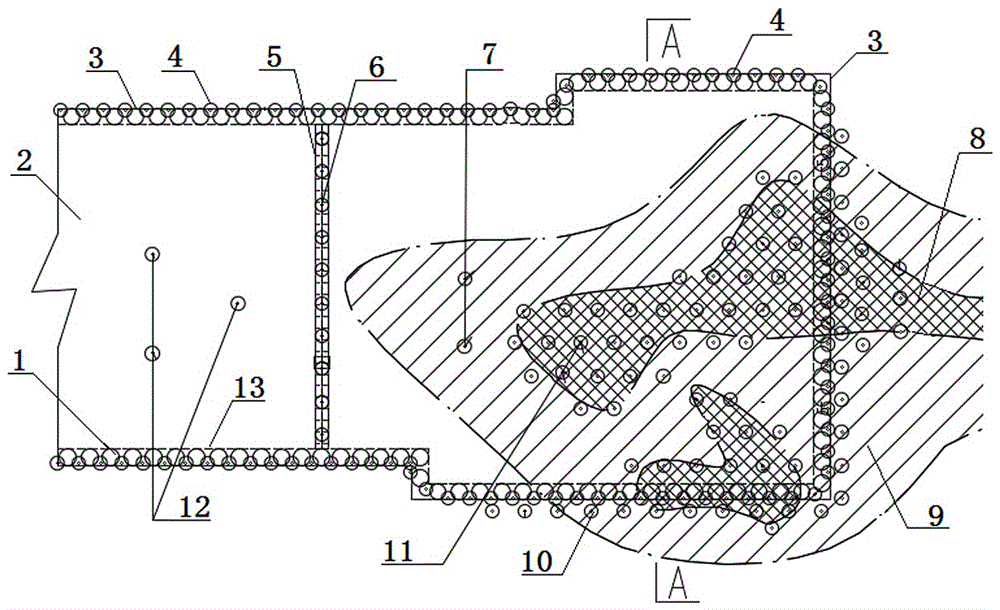

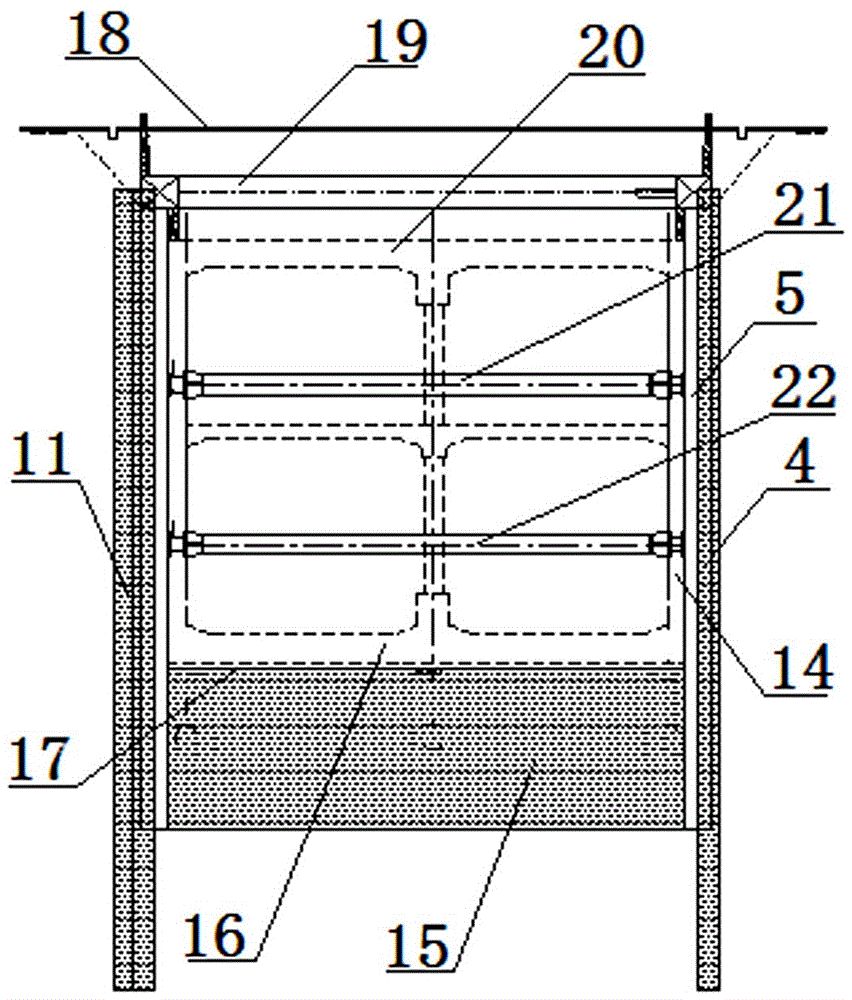

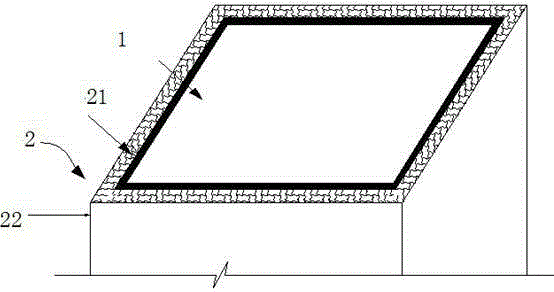

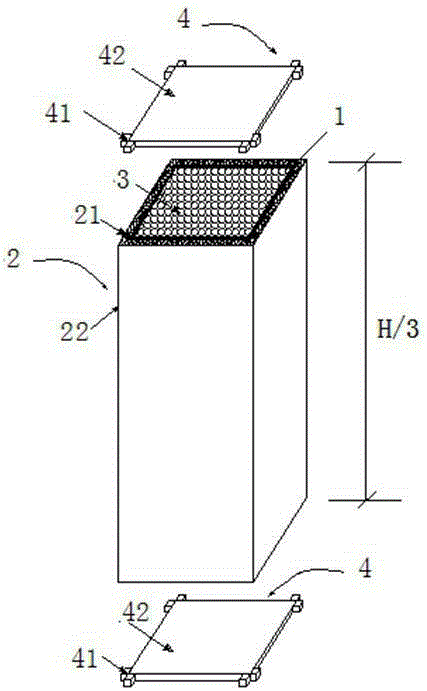

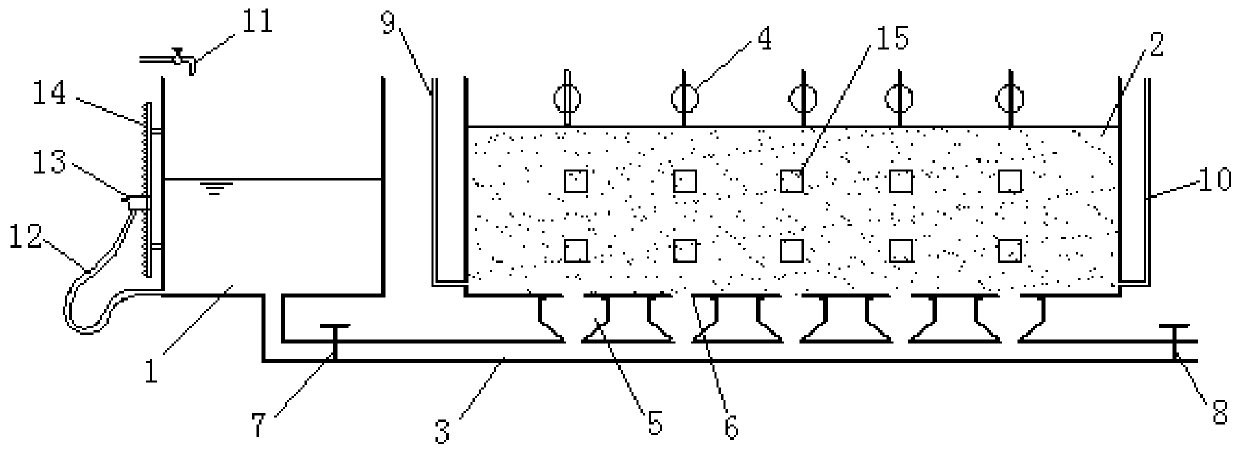

Coverage type karst collapse simulation test device and operation method thereof

ActiveCN111122830AMeet the simulation test requirementsEasy to operateEarth material testingCoverage TypeKarst

The invention discloses a coverage type karst collapse simulation test device and an operation method thereof. The problems that in the prior art, an opening of a karst structure cannot be adjusted, the interaction mode and the influence rule of multi-structure collapse are difficult to analyze, and operation is complex are solved. The catastrophe evolution process of covered karst surface collapse can be effectively simulated, and meanwhile, key influence factors such as the size, number and position of karst structures, the thickness of a covered soil layer and underground water level changecan be conveniently adjusted. According to the technical scheme, the device comprises a water level control box and a collapse simulation box, wherein an overflow device for adjusting the water levelin the water level control box is mounted on one side of the water level control box; the collapse simulation box is used for filling a soil body, a plurality of karst structure openings are formed in the bottom of the collapse simulation box in the length direction at equal intervals, and control valves used for adjusting the sizes of the openings are installed on the karst structure openings; wherein the water level control box is connected with the karst structure opening through a water passing pipeline, and the water passing pipeline can supply water to the collapse simulation box.

Owner:山东大学(齐河)新材料与智能装备研究院 +1

Collapsible pleated filter and frame

ActiveUS9320998B2Easy to assembleEasy disposalDispersed particle filtrationFiltration separationFilter mediaEngineering

A collapsible HVAC filter that includes a pleated filter media pack with ends that attach to ends of a planar filter frame member. The structure collapses by folding the filter frame member along score lines and compressing the pleated filter media while the media and frame member are attached. The collapsed components occupy little space relative to the expanded filter, and can be expanded to form a completed filter with little effort required by the end user. Most of the filter media is collapsed in a generally U-shaped channel formed from the folded filter frame member.

Owner:COLUMBUS INDS

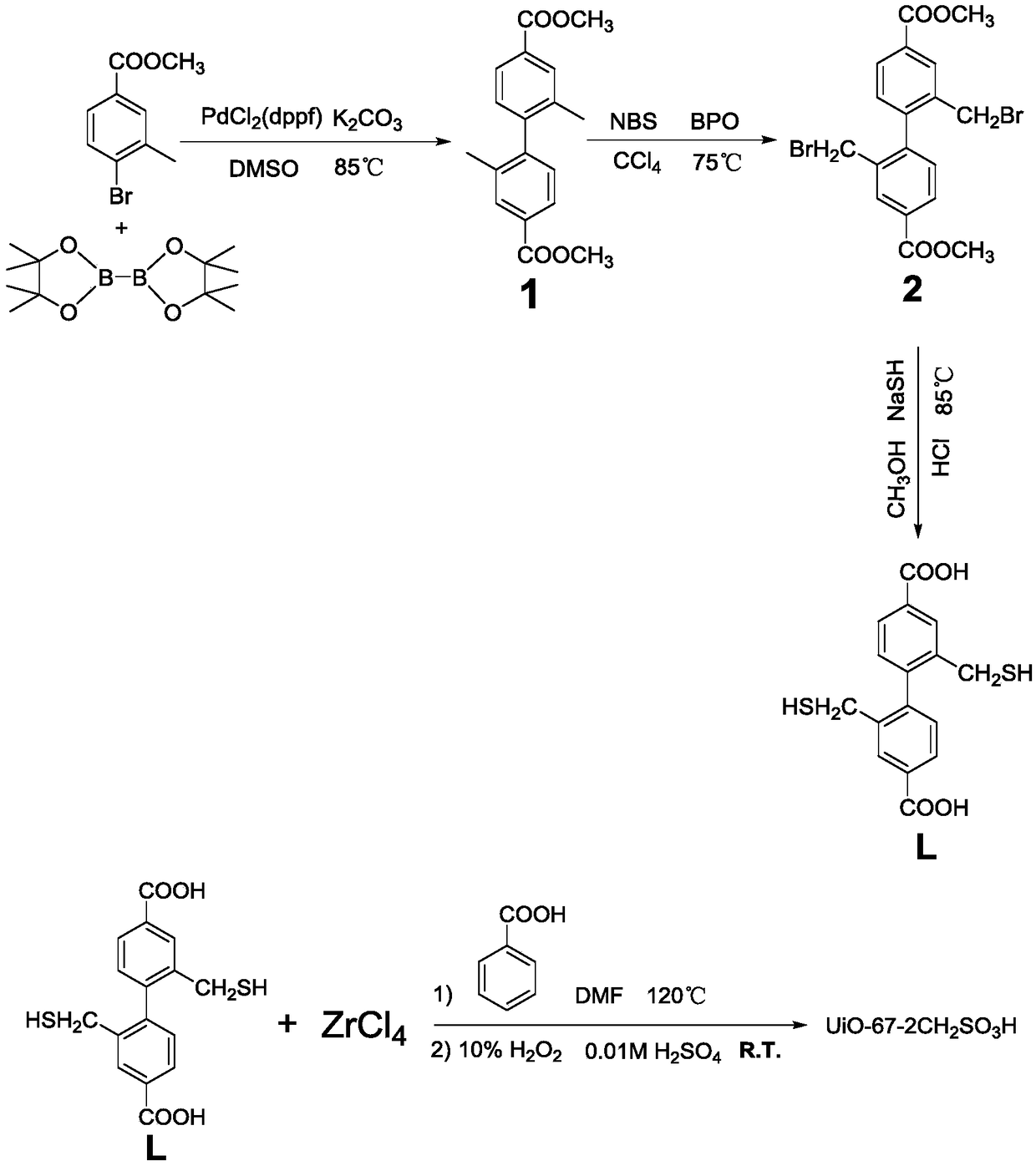

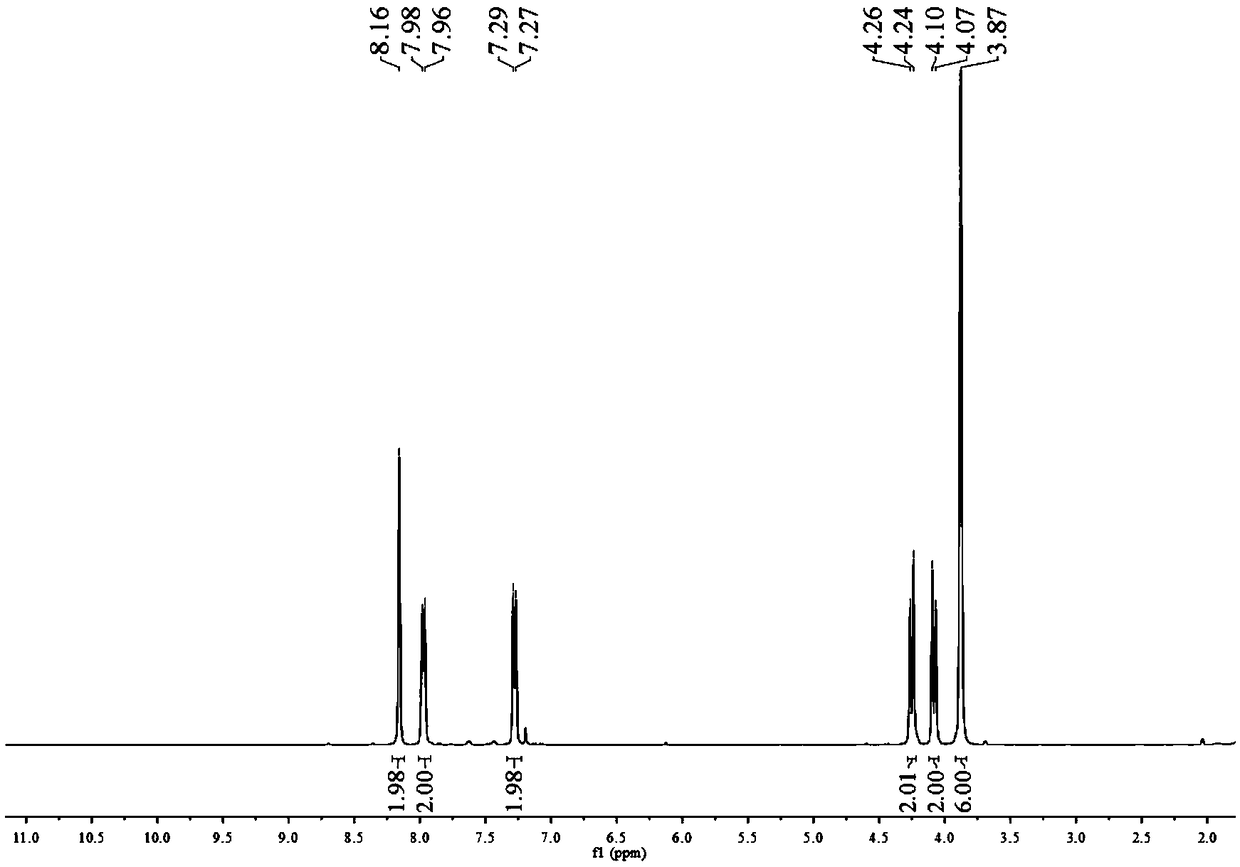

Sulfonic acid functionalized zirconium-based metal organic framework material and preparation method and application thereof

ActiveCN109265702AImprove proton conductivityCation exchangersMetal-organic frameworkCarboxylic acid

The invention provides a sulfonic acid functionalized zirconium-based metal organic framework material and a preparation method and application thereof. The chemical formula of the metal organic framework material is Zr6O4(OH)4(C16H12O10S2)6. An aromatic carboxylic acid organic ligand containing sulfonic acid functional groups in the metal organic matrix material makes the metal organic frameworkmaterial have higher proton conductivity and better thermal stability. The preparation method comprises the steps that 2,2'-dimercaptopyl-4,4'-dicarboxylic acid is utilized as a sulfhydryl functionalized aromatic carboxylic acid ligand, the sulfhydryl groups are oxidized into sulfonic acid groups by utilizing a post-synthesis oxidation method, and a polysulfonic acid group functionalized zirconium-based metal organic framework material is obtained. Under the temperature of 80 DEG C and the relative humidity of 70% or below, the proton conductivity of the material is 1.11 * 10<-5> to 1.48 * 10<-5>S cm<-1>; and thermal analysis and varying temperature XRD indicate that the material shows obvious weightlessness and structure collapse at 450 DEG C or above and can keep structural stability at200 DEG C or below.

Owner:GUANGDONG UNIV OF TECH

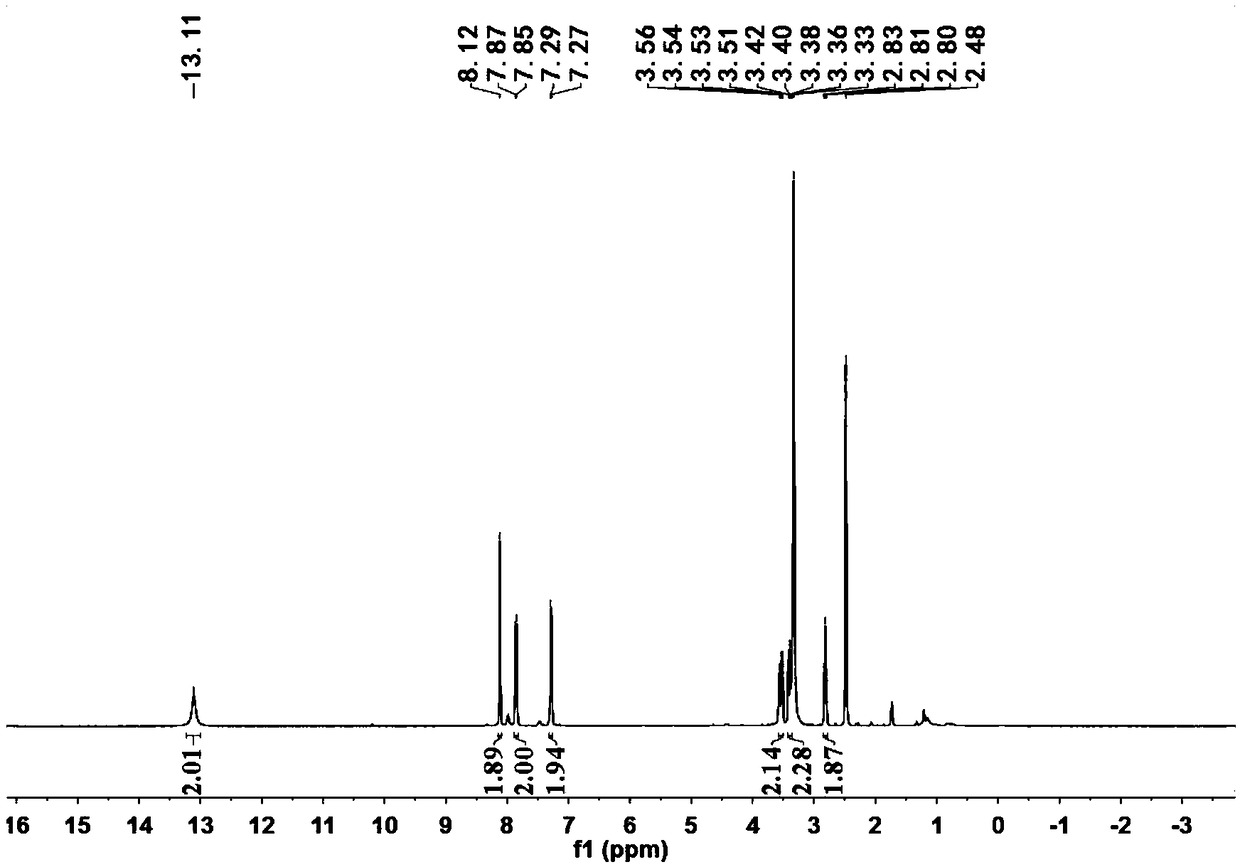

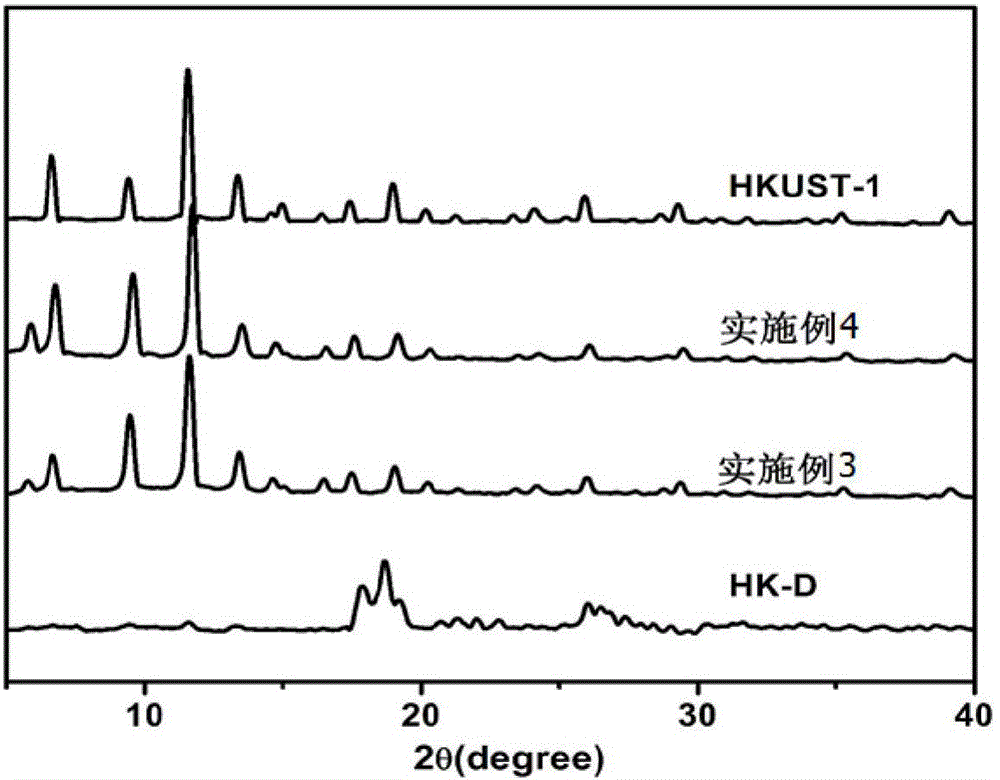

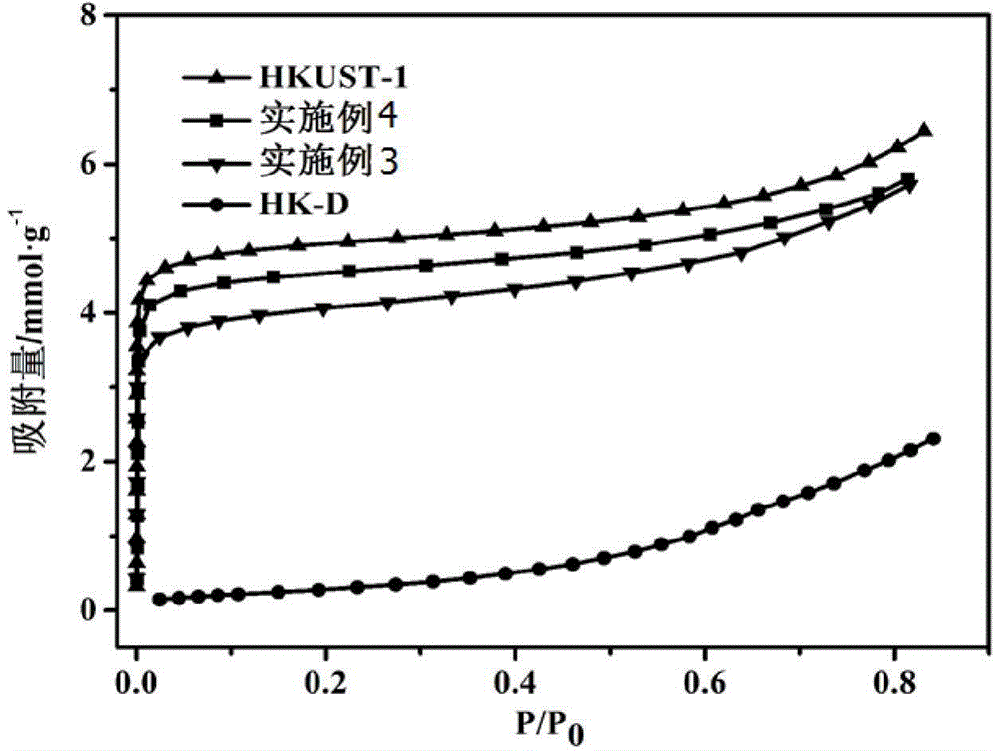

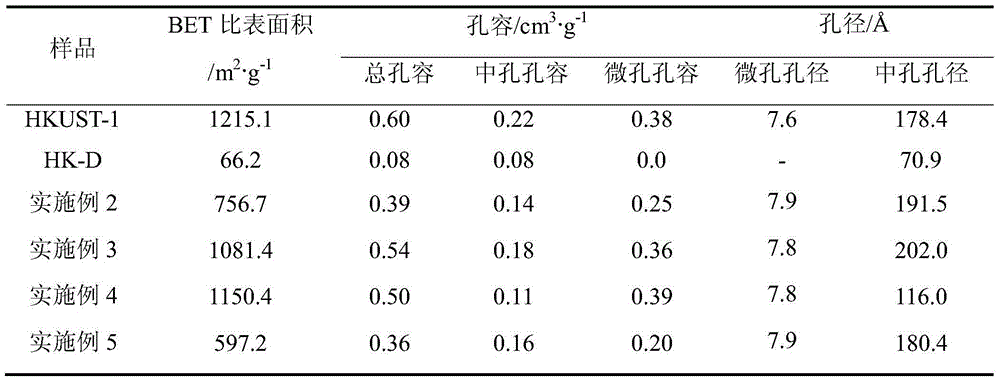

Method for repairing copper base-metal organic framework porous material

ActiveCN104592255AReduce pollutionRealize resource reuseOther chemical processesCopper organic compoundsMetal-organic frameworkCopper

Belonging to the technical field of metal organic skeleton materials, the invention discloses a method for repairing a copper base-metal organic framework porous material. The method includes the steps of: putting a structure collapsed copper base-metal organic framework porous material into a ball mill, and adding a repair solvent to conduct ball milling; after ball milling, taking out the solid material and performing drying, thus obtaining the repaired copper base-metal organic framework porous material. The copper base-metal organic framework porous material obtained by the repairing method provided by the invention has a BET specific surface area restored to 95% of a new HKUST-1 material, and adsorption capacity restored to 92% of the new HKUST-1 material. The repairing process of the method provided by the invention only needs adding of trace solvent, and has the characteristics of rapid repairing and simple operation, thus being an efficient and economical novel green repairing method.

Owner:SOUTH CHINA UNIV OF TECH

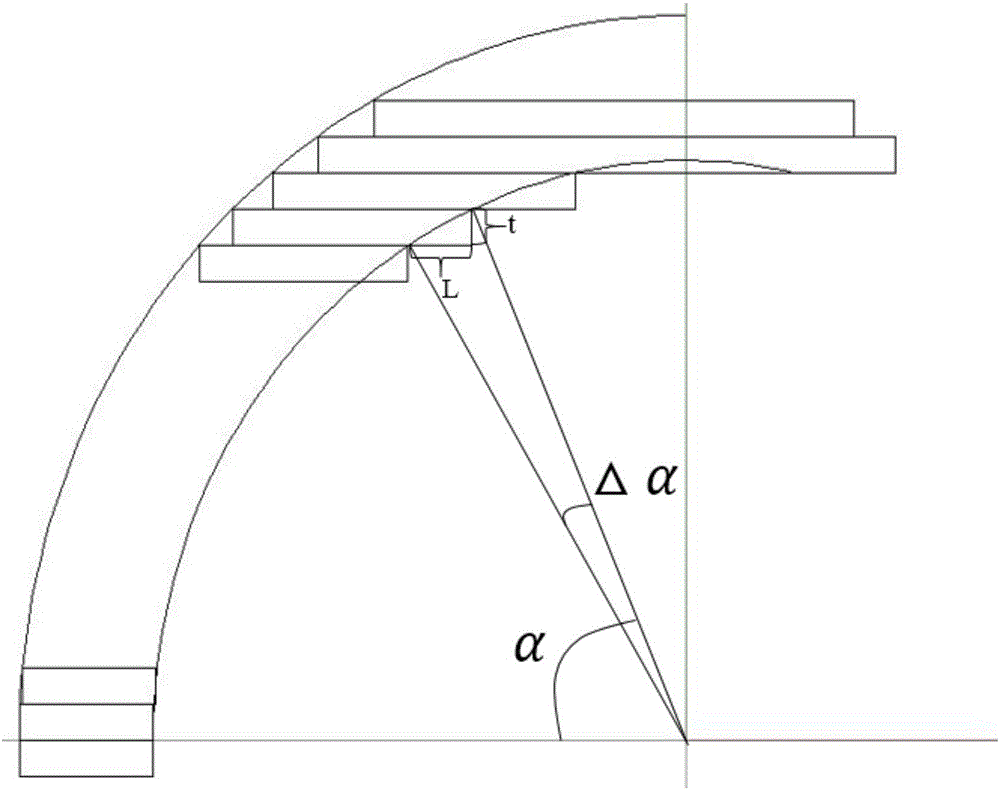

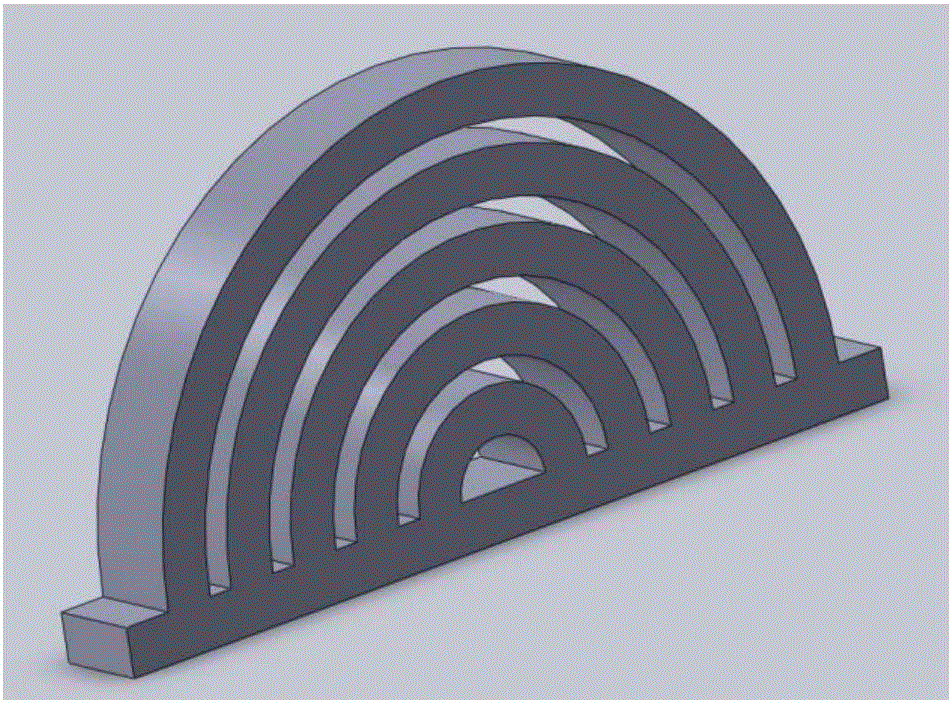

Method for obtaining structural design parameters

InactiveCN106671399AEfficiently calculate and verifyEasy to operateAdditive manufacturing apparatusIncreasing energy efficiencyDesign standardEngineering

The invention relates to a method for obtaining structural design parameters in the layer-by-layer manufacturing process. The method for obtaining the structural design parameters comprises the following steps that firstly, an arc structure with the radius greater than the critical collapse radius is manufactured layer by layer until a dangling structure collapses; and secondly, the collapsing position is observed, and the included angle alpha 0 between the line connecting the collapsing position and the circle center of the arc structure and the horizontal direction is obtained, wherein the critical collapse radius is the maximum radius of the arc structure before the collapse occurs when the arc structure is printed. According to the method for obtaining the structural design parameters in the layer-by-layer manufacturing process, operation and implementation are easy, and the maximum dangling structure capable of being printed without a support can be effectively calculated and verified through the printed arc structure. Through the method, a series of design standards and support additional arranging standards can be set, so that the blank of design standards for the 3D printing process can be filled.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

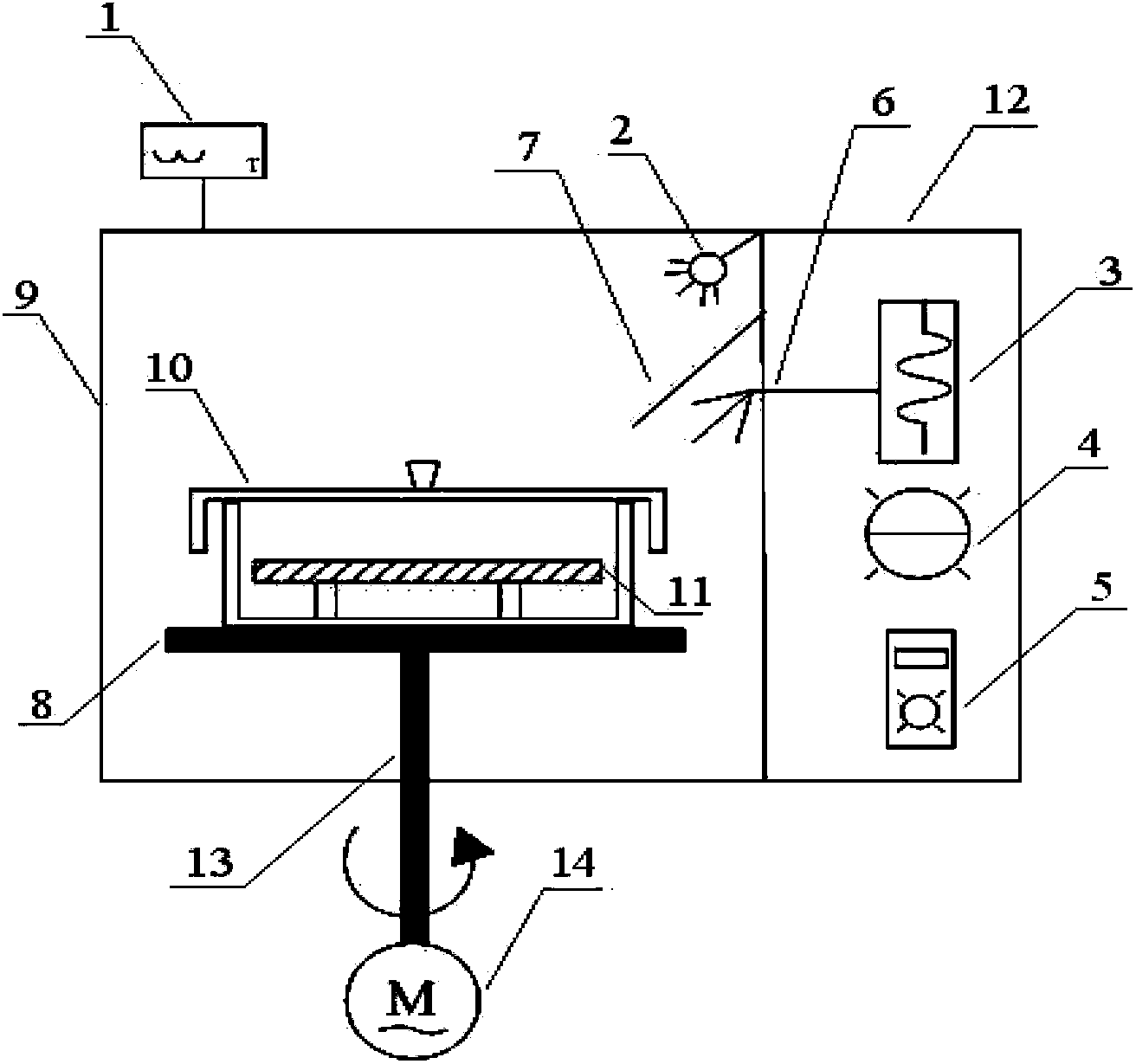

Method and apparatus for drying nanometer pattern by using microwave

InactiveCN103420333AReduce usageReduce consumptionMicrostructural devicesHeating arrangementStructure CollapseNanometre

The present invention relates to the technical field of semiconductor drying processes, and discloses a method and an apparatus for drying a nanometer pattern by using microwave. The method comprises: cleaning a nanometer sample sheet requiring a treatment; and carrying out a drying treatment on the cleaned nanometer sample sheet by using microwave. The apparatus comprises a fluorescent lamp, a microwave generator, a microwave resonance cavity, a magnetron, a quartz cleaning box, a rotation table, a frequency converter, a rotation rod, a motor and a power supply. According to the present invention, the problem of structure collapsing during a drying process can be effectively solved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for increasing energy density of lithium ion battery and prolonging cycle life of lithium ion battery

ActiveCN106299502ASimple processEasy to operateSecondary cells charging/dischargingCyclic processLithium iron phosphate

The invention relates to the field of lithium ion batteries, in particular to a high-energy lithium ion phosphate battery, and aims at providing a method for increasing the capacity of a lithium ion phosphate battery, actually achieving the gram capacity of a lithium ion phosphate cathode material, enabling the capacity not to be reduced in the cyclic process, increasing the energy density of the lithium ion phosphate battery and prolonging the cycle life of the lithium ion phosphate battery. In the manufacturing process of the lithium ion battery, an active lithium material is added and supplemented into an active cathode material to form a mixed material, the gram capacity of the mixed material is improved, and the effective active lithium amount supplied by the supplemented active lithium material accounts for 1%-25% of the active lithium amount of the anode capacity; the supplemented active lithium material needs to be subjected to lithium removal, and the structure collapses after lithium removal, that is to say, the initial charge cut-off voltage is set as the voltage needed when the material is completely subjected to lithium removal until the material is in an irreversible state. The method has the advantages of being simple in process, convenient to operate and the like.

Owner:桐乡市众胜能源科技有限公司

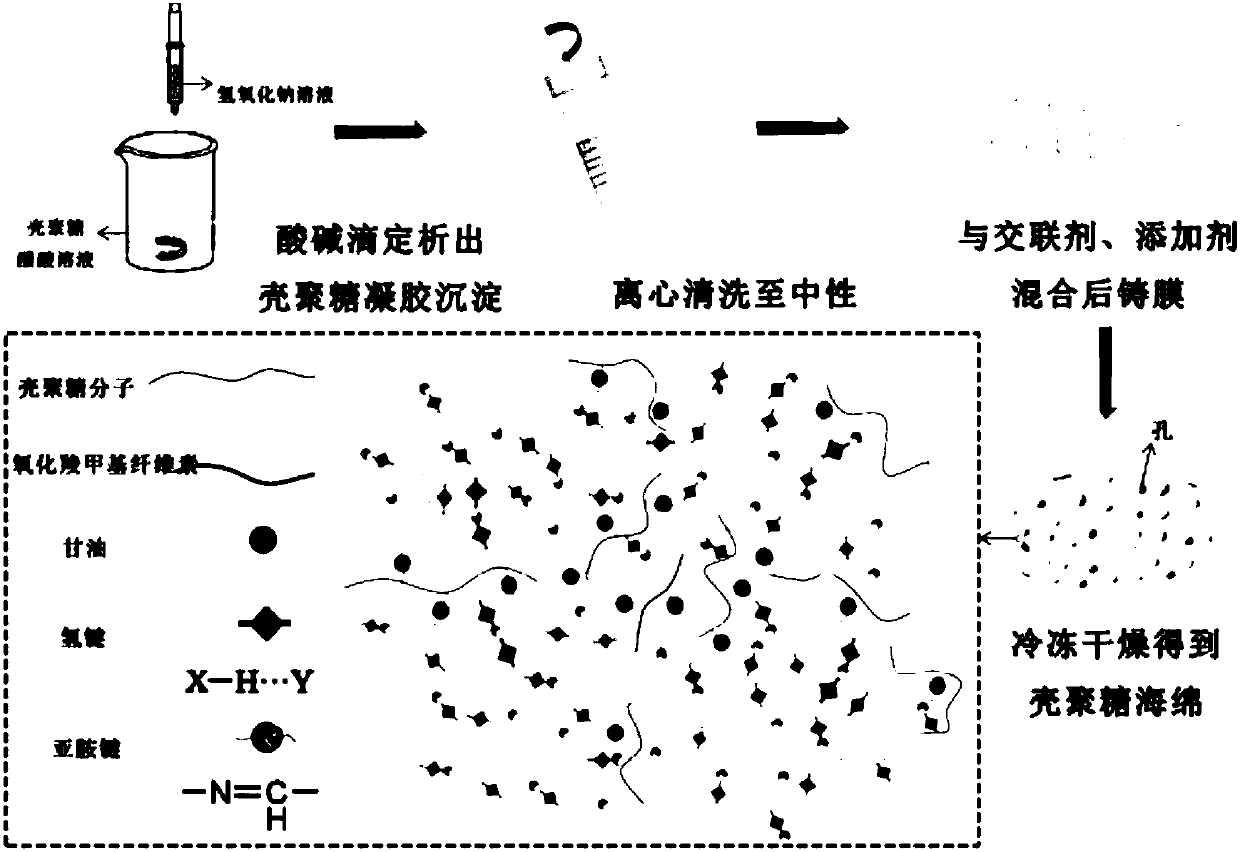

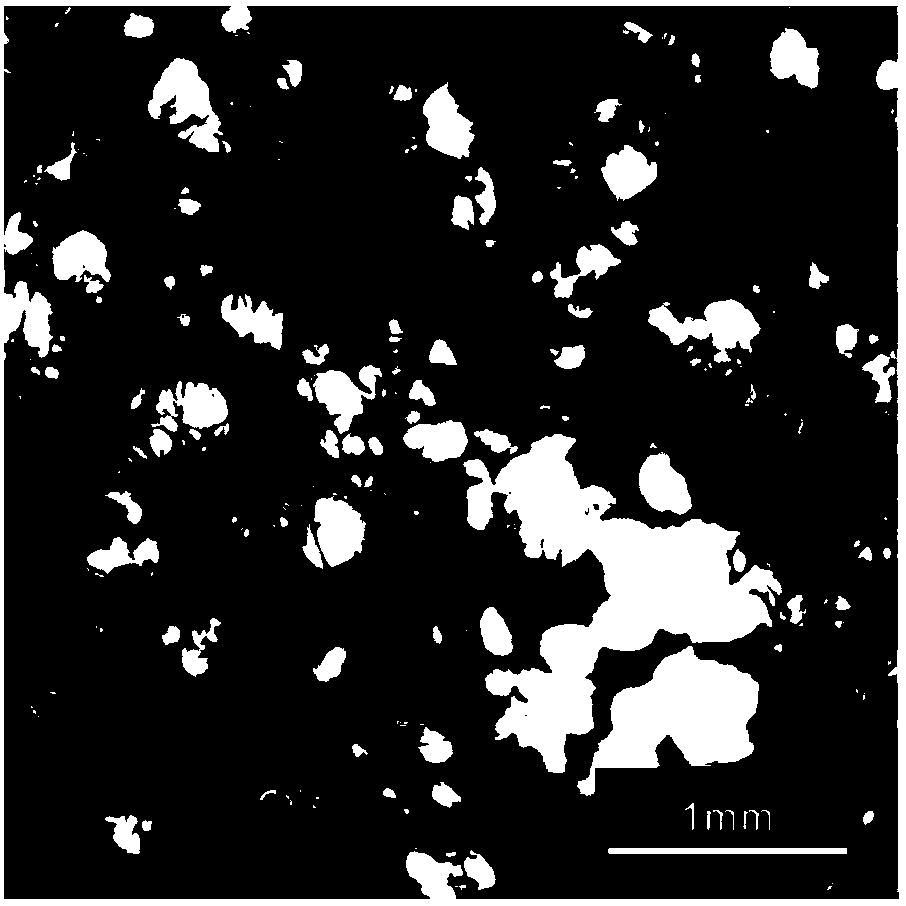

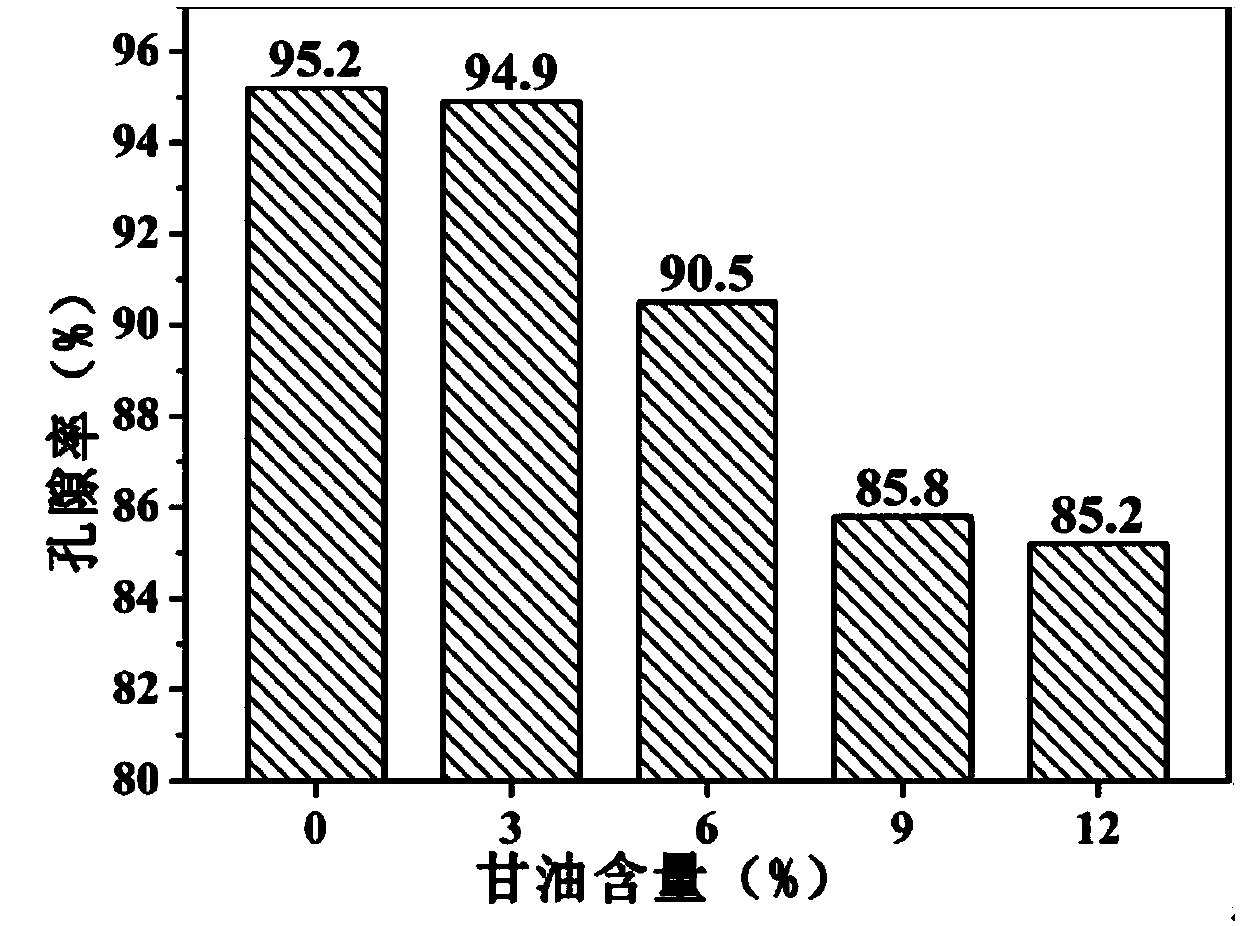

Preparation method of chitosan-based medicine-carrying flexible sponge

InactiveCN109745577AImprove stabilityPrevent structural collapseAbsorbent padsBandagesCross-linkFreeze-drying

The invention discloses a preparation method of chitosan-based medicine-carrying flexible sponge. The method comprises the following steps: taking chitosan as raw material, dropwisely adding a precipitant sodium hydroxide to obtain chitosan gel precipitate in the process of continuously stirring an acetic acid solution of chitosan, centrifugally cleaning the chitosan gel precipitate, and then mixing the chitosan gel precipitate with a cross-linking agent of oxidizing carboxymethyl cellulose, a plasticizer glycerol and an antibacterial drug tetracycline hydrochloride, and freeze-drying the castfilm to obtain the medicine-carrying flexible sponge body. According to the invention, the chitosan gel precipitate prepared by acid-base titration is used for preparing the sponge body, and the stability of the sponge obtained by freeze-drying is good, and the structure is not damaged when swelling is caused, and one-step molding is carried out, and the structure collapse caused by alkali washing and secondary freeze-drying is avoided, and because of the one-step molding, the chitosan-based medicine-carrying flexible sponge is convenient to carry medicine. According to the invention, glycerol is added as a plasticizer, so that the sponge is soft and elastic. The method has the advantages of short process period, simple and convenient process, low cost and suitability for commercial production.

Owner:NANJING UNIV OF SCI & TECH

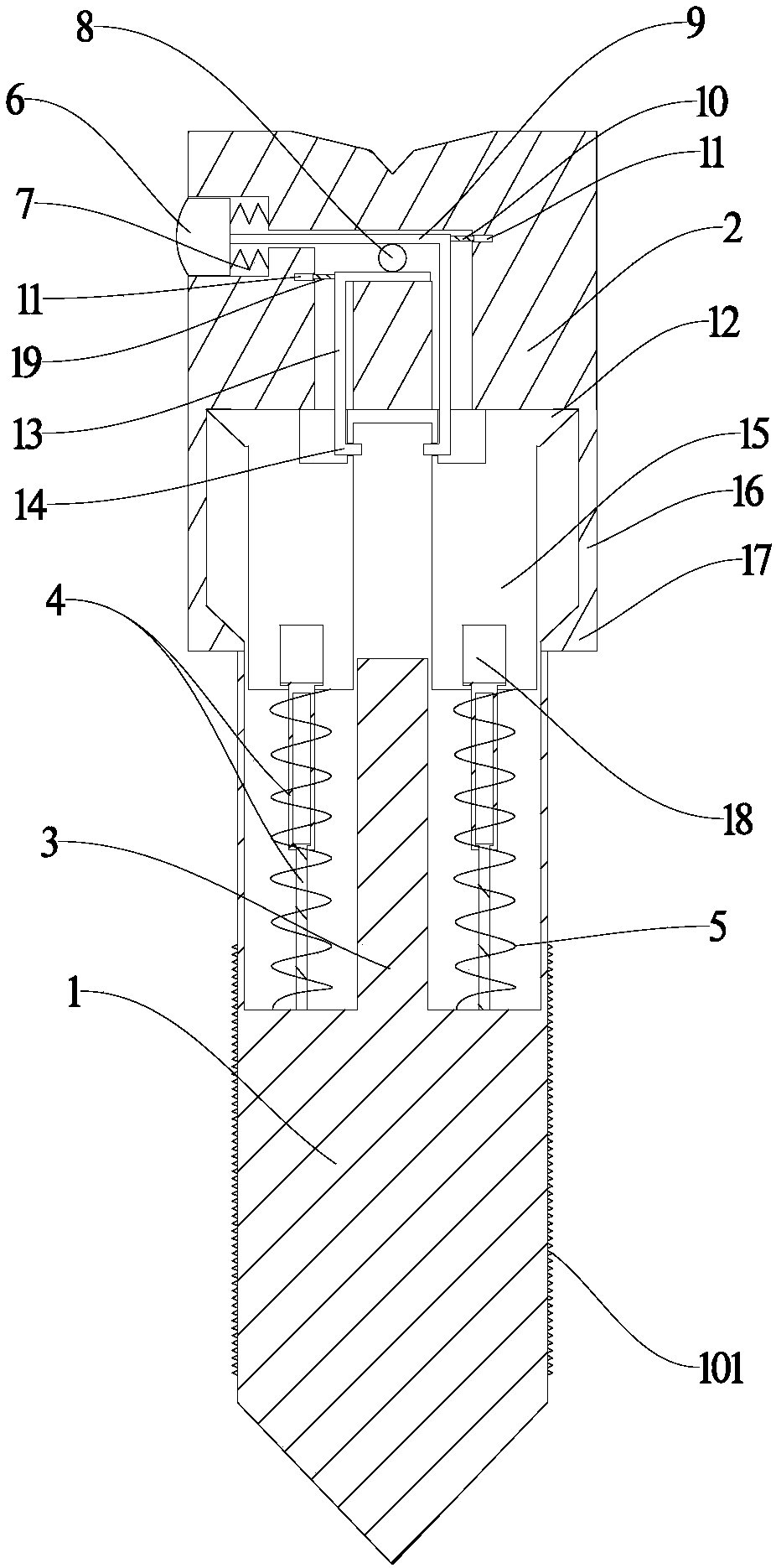

Anti-derotation screw capable of cooperating with hole depth

ActiveCN108167300ASolve the problem of structural collapse with serious adverse consequencesAddress serious adverse outcomesPinsNutsEngineeringStructure Collapse

The invention discloses an anti-derotation screw capable of cooperating with the hole depth. The anti-derotation screw comprises a screw body, a screw head assembly and a return stroke block assembly.The screw head assembly is arranged on the top of the screw body. The return stroke block assembly is arranged in the screw body. The screw head assembly comprises a screw head, a button, a spring A,a gear, a limiting rod A, a guide column A, an inner wall hole, a limiting rod B, a positioning protrusion, a connecting rod, a lug B and a guide column B. The return stroke block assembly comprisesa cylindrical guide rod, a telescopic rod, a spring B, an annular lug A, a return stroke block and a return stroke block bottom hole. Through the joint effect of the screw body, the screw head assembly and the return stroke block assembly, the problem of serious adverse consequences caused by structure collapse caused by screw derotation is solved; and the problem that when threads are located below a hole, the hole is deep, and a screw head is not long enough, a screw is not easily stabilized by hand when the screw is just screwed in is further solved.

Owner:NINGBO QUNLI FASTENER MFG CO LTD

Method for assembling and folding lifting frame structure of self-elevating wind power installation platform

InactiveCN107662059AShorten the closing cycleReduce tooling costsWelding/cutting auxillary devicesAuxillary welding devicesElectricityThick plate

The invention discloses a method for the general assembly and closing of a lifting frame structure of a self-elevating wind power installation platform. The hoisting and positioning of the side box structure, the hoisting and positioning of the upper guide structure, the welding of the lifting frame structure and the surrounding well, the welding of the lifting frame structure and the upper guide, and the post-welding dimension inspection steps complete the assembly and closing of the lifting frame structure of the self-elevating wind power installation platform; The invention optimizes and controls the precision of the final assembly and closing process of the lifting frame structure, overcomes the welding process that is difficult to control the size of the thick plate welding shrinkage assembly, shortens the closing cycle of the lifting frame structure, and realizes precision closing. To achieve the company's goal of reducing labor costs, tooling costs and management costs, improving economic benefits, and increasing the company's technical background.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

High-speed train station concrete-filled steel tube column-steel reinforced concrete beam node structure

PendingCN108625476AImprove impact resistanceGuaranteed to workBuilding constructionsConcrete beamsButt joint

The invention discloses a high-speed train station concrete-filled steel tube column-steel reinforced concrete beam node structure. The high-speed train station concrete-filled steel tube column-steelreinforced concrete beam node structure comprises a concrete-filled steel tube column, a steel reinforced concrete beam and a ring beam and is characterized in that the concrete-filled steel tube column comprises an upper concrete-filled steel tube column, a lower concrete-filled steel tube column and a concrete-filled steel tube node column, and a cross plate and an eight-section plate are arranged in the bottom area of the upper concrete-filled steel tube column; an outer ring plate is arranged on the outer wall of the concrete-filled steel tube node column, and the upper flange and the lower flange of the steel reinforced concrete beam are in butt joint with the outer ring plate; the web of the steel reinforced concrete beam is connected with the concrete-filled steel tube node column;an inner ring plate, an inner partition and an inner rib plate are arranged in the concrete-filled steel tube node column. The node structure has the advantages that by the inner ring plate, the inner partition and the inner rib plate, axial force, transmitting to the upper column, in the column and shear force, transmitting to a frame girder, in the beam can be reduced effectively; after structural column stability loss, the inner ring plate, the inner partition and the inner rib plate can effectively transmit the axial force and bending moment in the beam, and structure collapse resistanceis increased effectively.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com