Method for preparing graphene aerogel through constant pressure drying

A technology of graphene airgel and graphene hydrogel, which is applied in the field of drying and preparing graphene aerogels under normal pressure, can solve the problems of large differences in performance aerogels, and achieve low cost, good mechanical properties and electrical conductivity The effect of simple performance and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

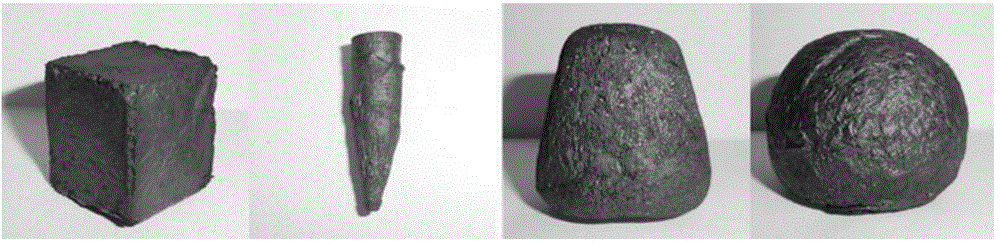

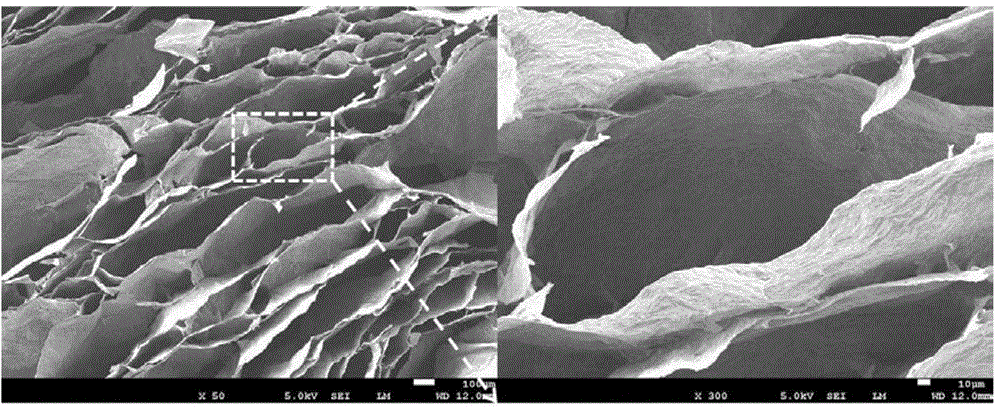

Embodiment 1

[0045] Use 325 mesh flake graphite as raw material, prepare graphene oxide by improved Hummer's chemical method, obtain the graphene oxide (GO) solution of 10 mg per milliliter, get 5 milliliters of GO solution and join in the cylindrical glass bottle, add 5 milliliters to go Ionized water, adjust the concentration of GO solution to 5 mg / ml, then take 100 microliters of hydrazine hydrate solution with a mass fraction of 35%, add it to the GO solution, and ultrasonicate for 5 minutes to disperse the hydrazine hydrate evenly. Seal it with a stopper, and react at 95 degrees Celsius for 0.5 hour to form a gel. Then stop the reaction. After the gel drops to room temperature, put the gel in the refrigerator to freeze. The temperature of the refrigerator is about -18 degrees Celsius. Two hours later, after the gel is completely frozen, take the gel to room temperature , after completely thawing, freeze and thaw again under the same conditions, and then place the hydrogel at 95 degree...

Embodiment 2

[0047] The process flow is the same as in Example 1, except that the concentration of the GO solution is adjusted to 4 mg / ml, the total amount is 10 ml, 80 microliters of hydrazine hydrate is added, and the reaction time is 1 hour. After the gel is formed, the freezing temperature is -30 degrees Celsius. After freezing and thawing, react for another 1.5 hours.

Embodiment 3

[0049] The process flow is the same as in Example 1, except that the concentration of the GO solution is adjusted to 3 mg / ml, the total amount is 10 ml, and the amount of hydrazine hydrate added is 90 microliters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com