A method for preparing graphene airgel by drying under normal pressure

A graphene aerogel, graphene hydrogel technology, applied in the directions of graphene, nano-carbon, etc., can solve problems such as large differences in performance of aerogels, and achieve the effects of low cost, industrialized production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

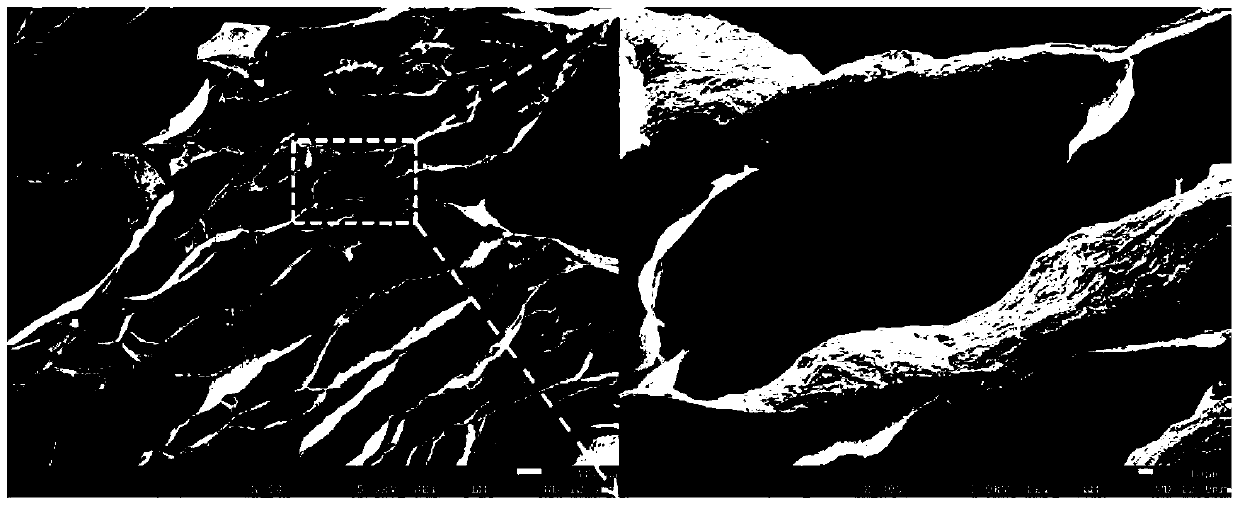

Image

Examples

Embodiment 1

[0045] Use 325 mesh flake graphite as raw material, prepare graphene oxide by improved Hummer's chemical method, obtain the graphene oxide (GO) solution of 10 mg per milliliter, get 5 milliliters of GO solution and join in the cylindrical glass bottle, add 5 milliliters to go Ionized water, adjust the concentration of GO solution to 5 mg / ml, then take 100 microliters of hydrazine hydrate solution with a mass fraction of 35%, add it to the GO solution, and ultrasonicate for 5 minutes to disperse the hydrazine hydrate evenly. Seal it with a stopper, and react at 95 degrees Celsius for 0.5 hour to form a gel. Then stop the reaction. After the gel drops to room temperature, put the gel in the refrigerator to freeze. The temperature of the refrigerator is about -18 degrees Celsius. Two hours later, after the gel is completely frozen, take the gel to room temperature , after completely thawing, freeze and thaw again under the same conditions, and then place the hydrogel at 95 degree...

Embodiment 2

[0047] The process flow is the same as in Example 1, except that the concentration of the GO solution is adjusted to 4 mg / ml, the total amount is 10 ml, 80 microliters of hydrazine hydrate is added, and the reaction time is 1 hour. After the gel is formed, the freezing temperature is -30 degrees Celsius. After freezing and thawing, react for another 1.5 hours.

Embodiment 3

[0049] The process flow is the same as in Example 1, except that the concentration of the GO solution is adjusted to 3 mg / ml, the total amount is 10 ml, and the amount of hydrazine hydrate added is 90 microliters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com