Patents

Literature

75results about How to "Meet the needs of different fields" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

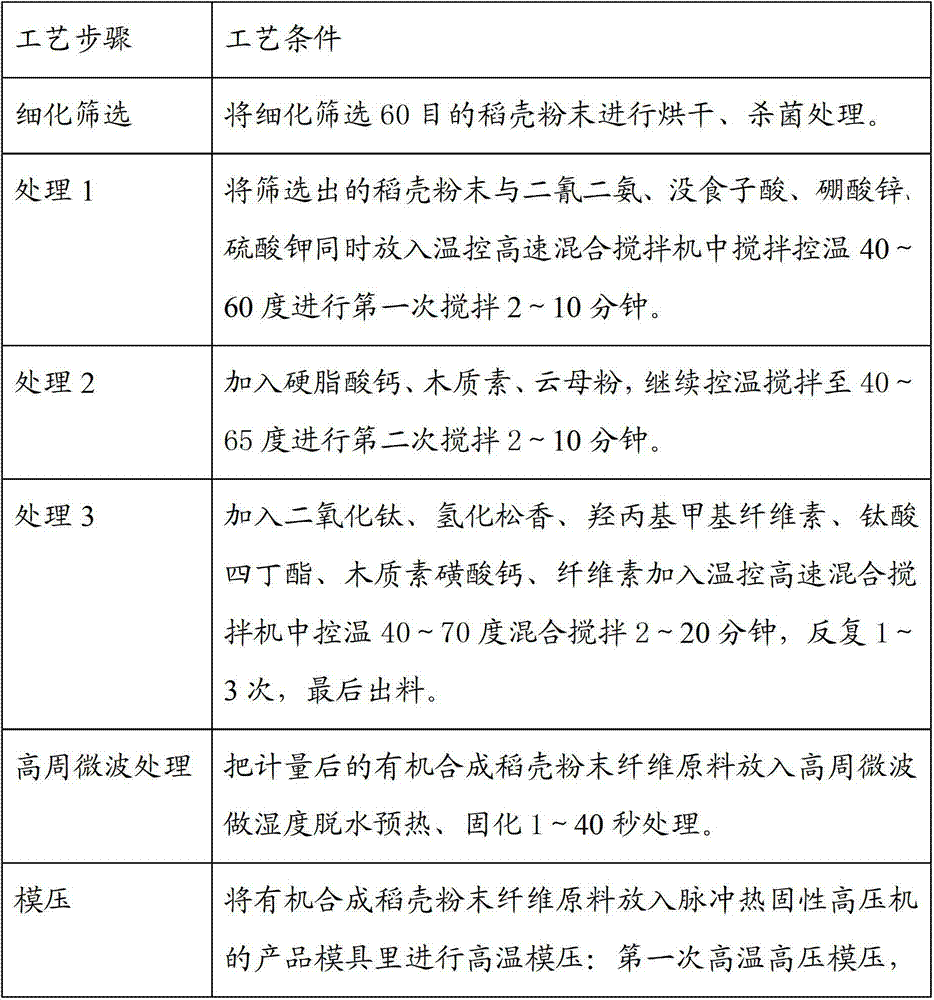

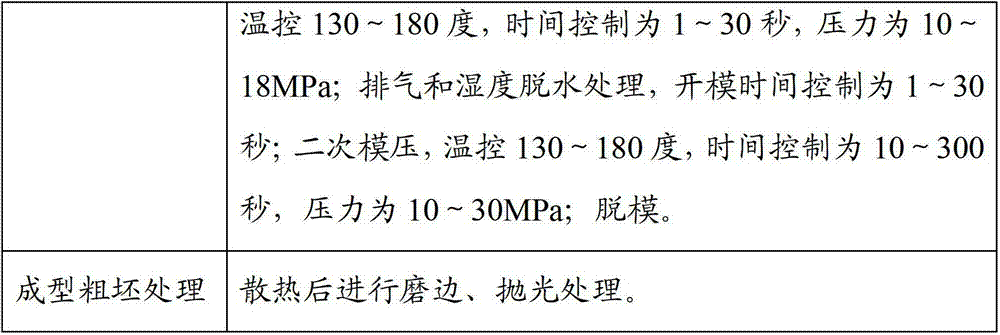

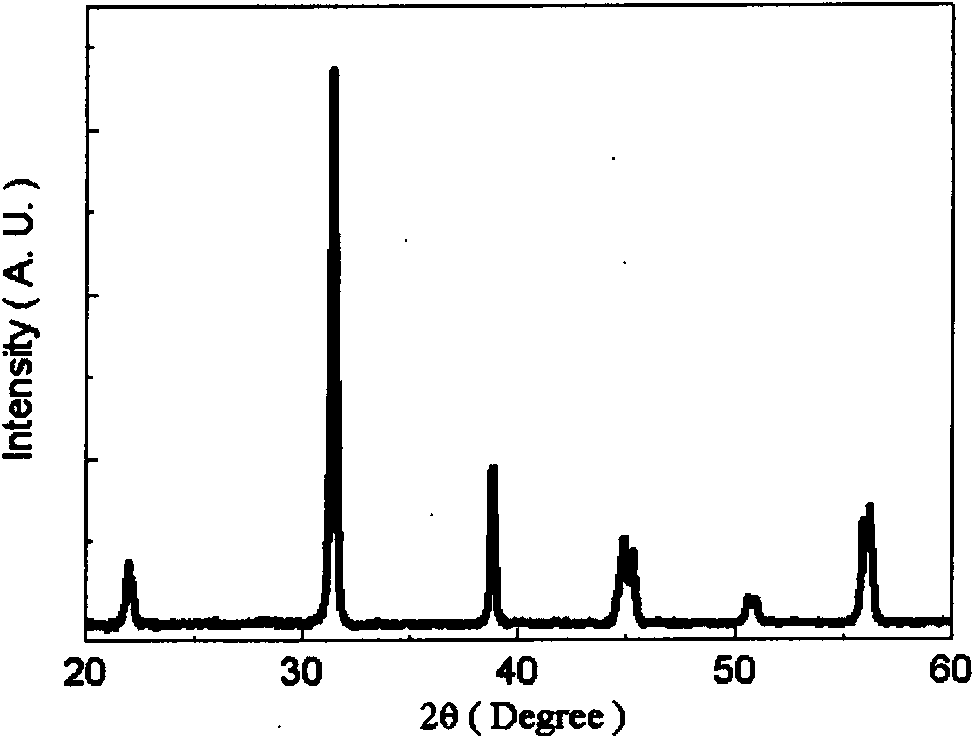

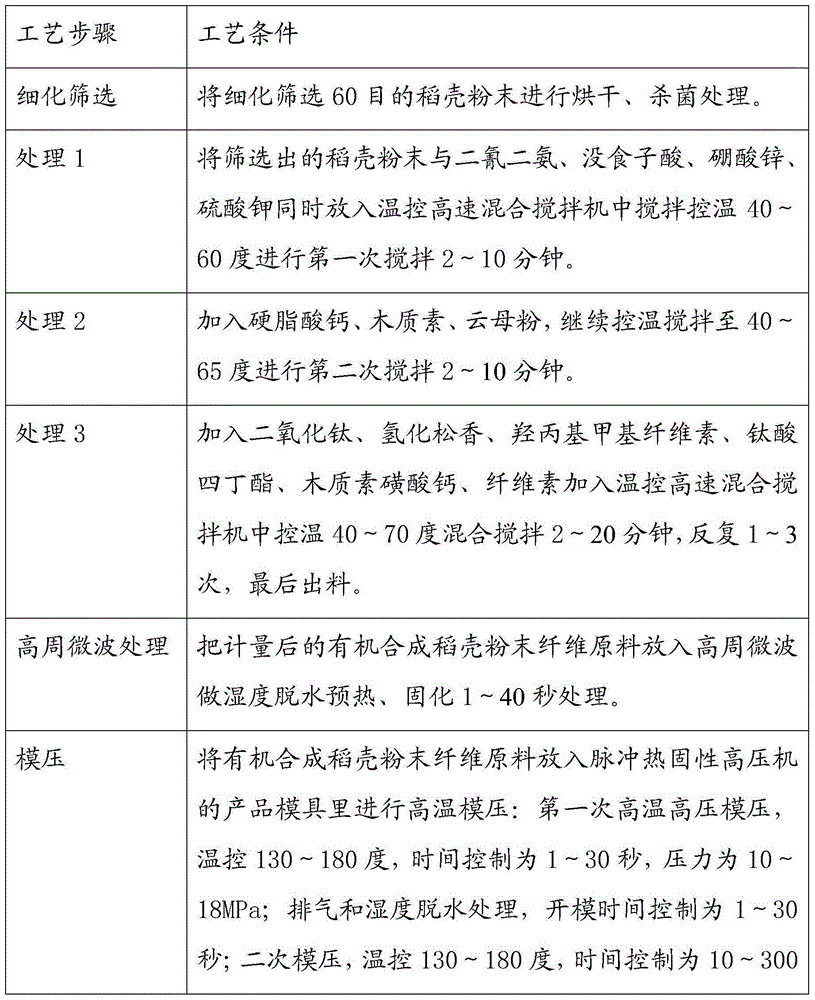

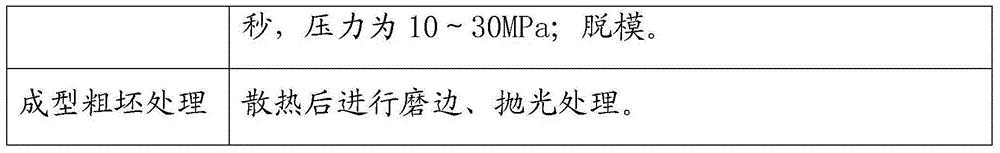

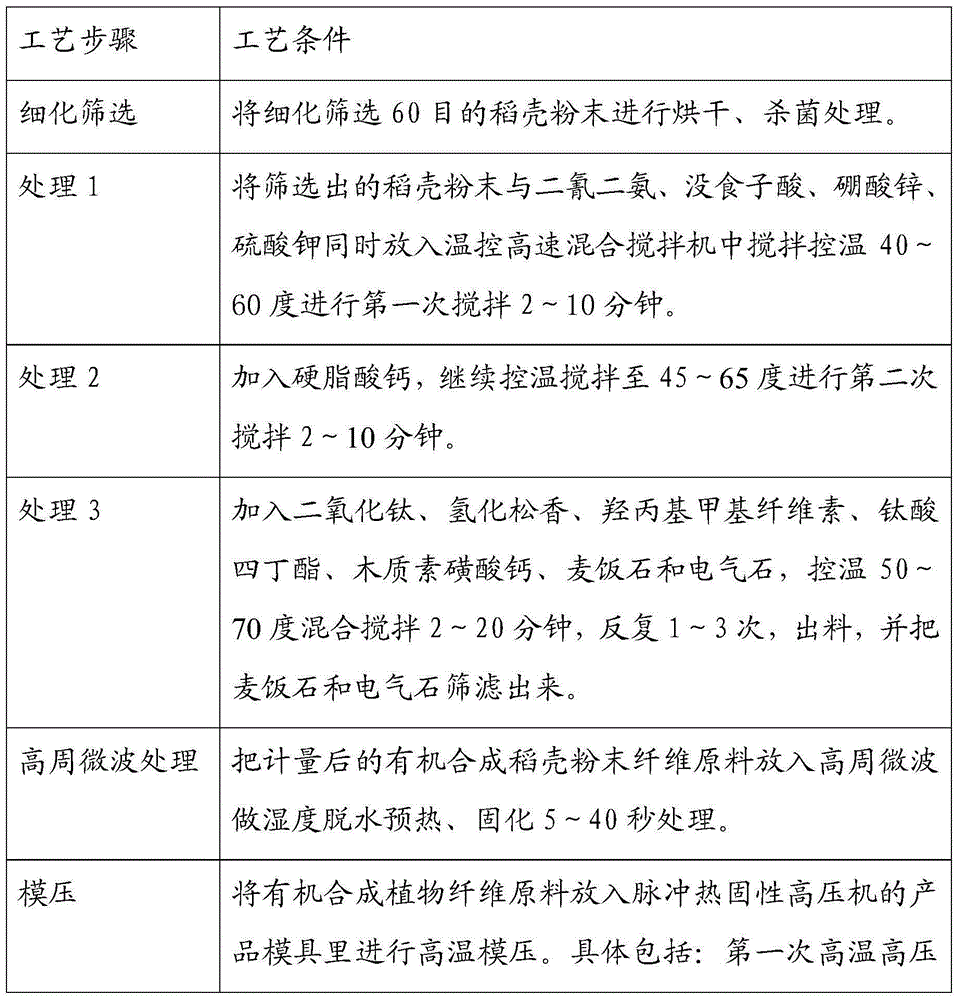

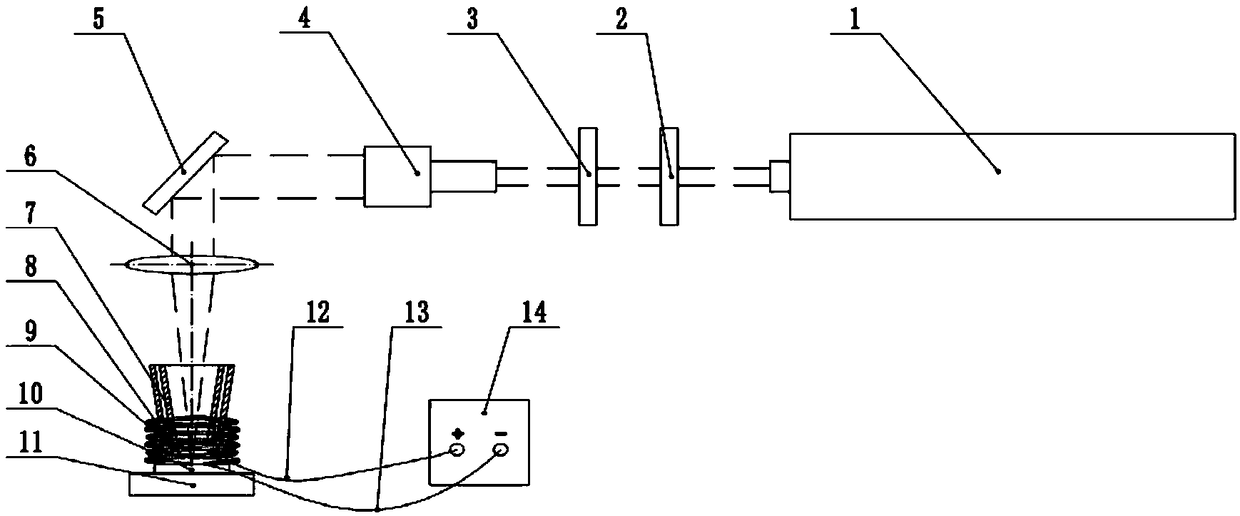

Plant fiber environment-friendly material as well as preparation method and application thereof

InactiveCN103113753AWide variety of sourcesEvenly distributedWood working apparatusFlat articlesFiberWide field

The invention discloses a plant fiber environment-friendly material and a preparation method thereof as well as application of the material in tableware, toys, furniture, decoration or wall. The preparation method comprises the following steps of: pretreating, grinding and screening the plant fiber; mixing the screened plant fiber powder with an adhesive and a modification aid, and stirring at high temperature, wherein the adhesive mainly adopts hydroxypropyl methyl cellulose; filtering with a riddler, and dehydrating and preheating the screened organic synthesis plant fiber raw material; and performing high-temperature die pressing. According to the plant fiber environment-friendly material as well as the preparation method and application thereof, the product has good performance and additional functionality, can be applied to wider fields, conforms to relatively high requirements on using safety, and facilitates environmental protection so as to overcome the shortcomings of the existing plant fiber environment-friendly material and a preparation method and application thereof.

Owner:王丹 +2

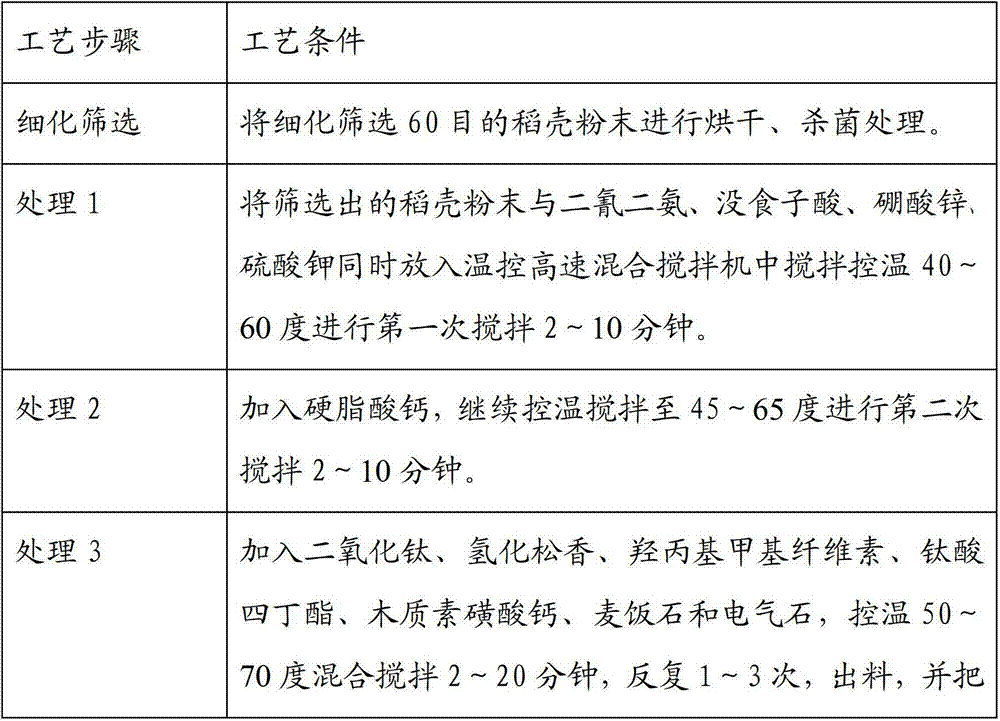

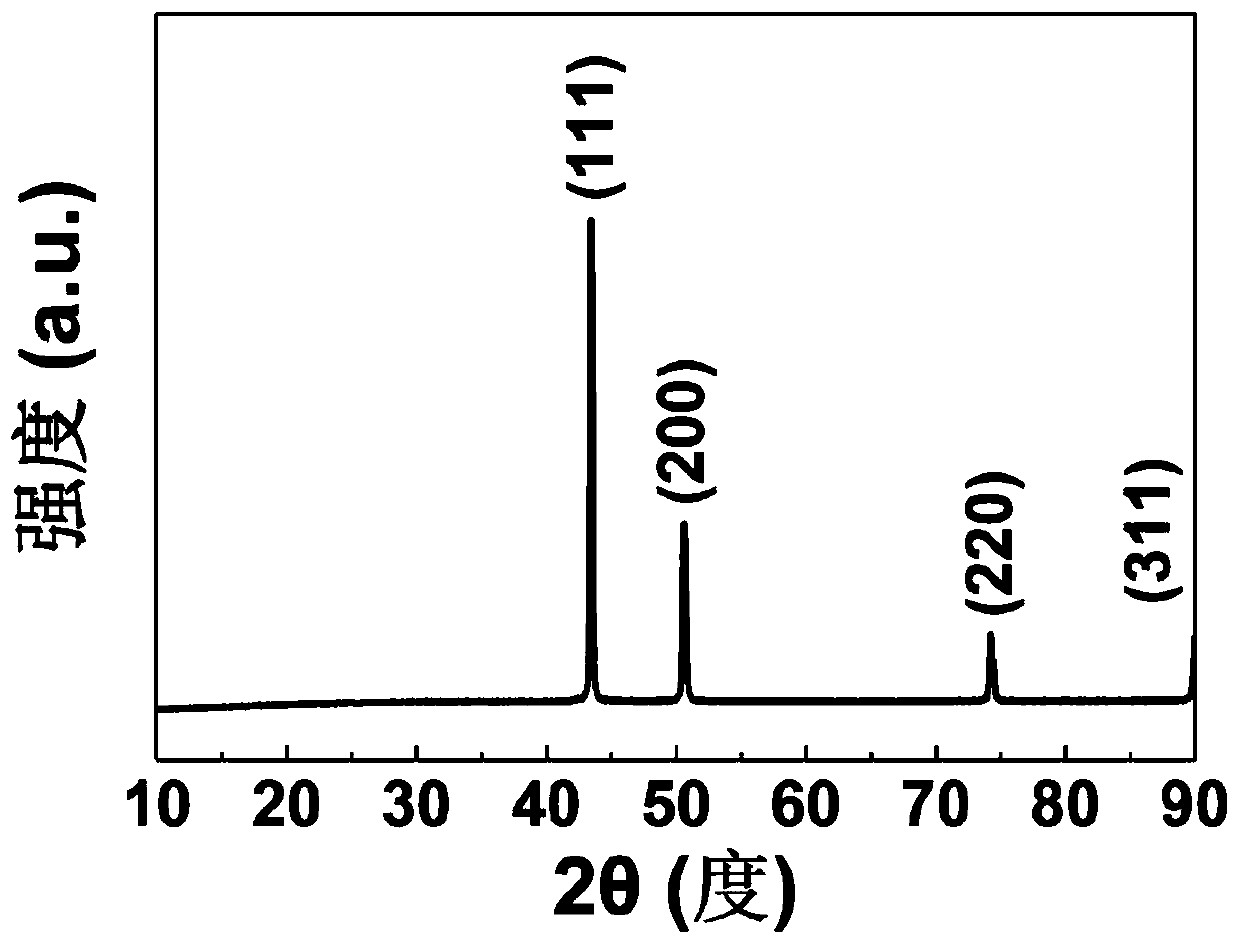

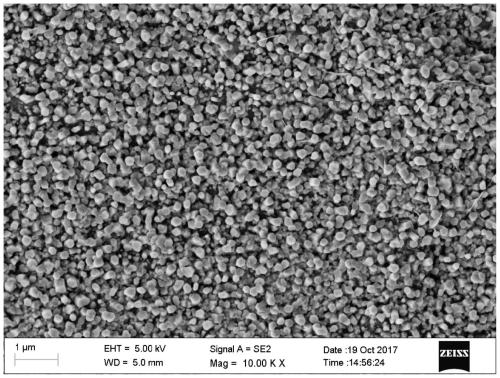

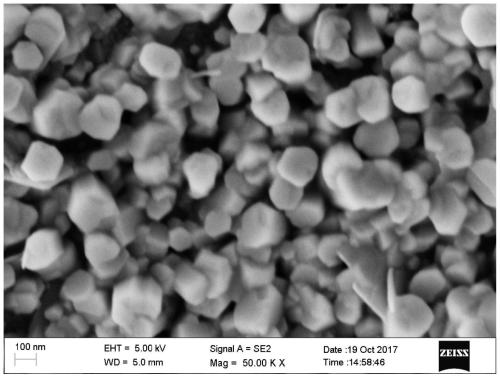

Calcium barium zirconate titanate base piezoceramics and preparation method thereof

InactiveCN101648807ALower coercive fieldLow equipment requirementsPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateZirconium dioxide

The invention discloses calcium barium zirconate titanate base piezoceramics and a preparation method thereof. The chemical formula of the calcium barium zirconate titanate base piezoceramics is (1-x-y)BaTiO3-xCaTiO3-yBaZrO3, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions. The preparation method comprises the following steps: mixing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide according to the stoichiometric proportion (1-x-y)BaTiO3-xCaTiO3-yBaZrO3 (x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions), ball-milling, calcining, ball-milling for the second time, granulating, moulding, removing the binder, high-temperature sintering and the like so as to finally prepare the calcium barium zirconate titanate base piezoceramics with high piezoelectric performance. The method greatly enhances the piezoelectric performance of the lead-free piezoceramic system and the technical stability of the material, so that the lead-free piezoceramics in the barium titanate system achieve the practical level in the aspectsof components and technique.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

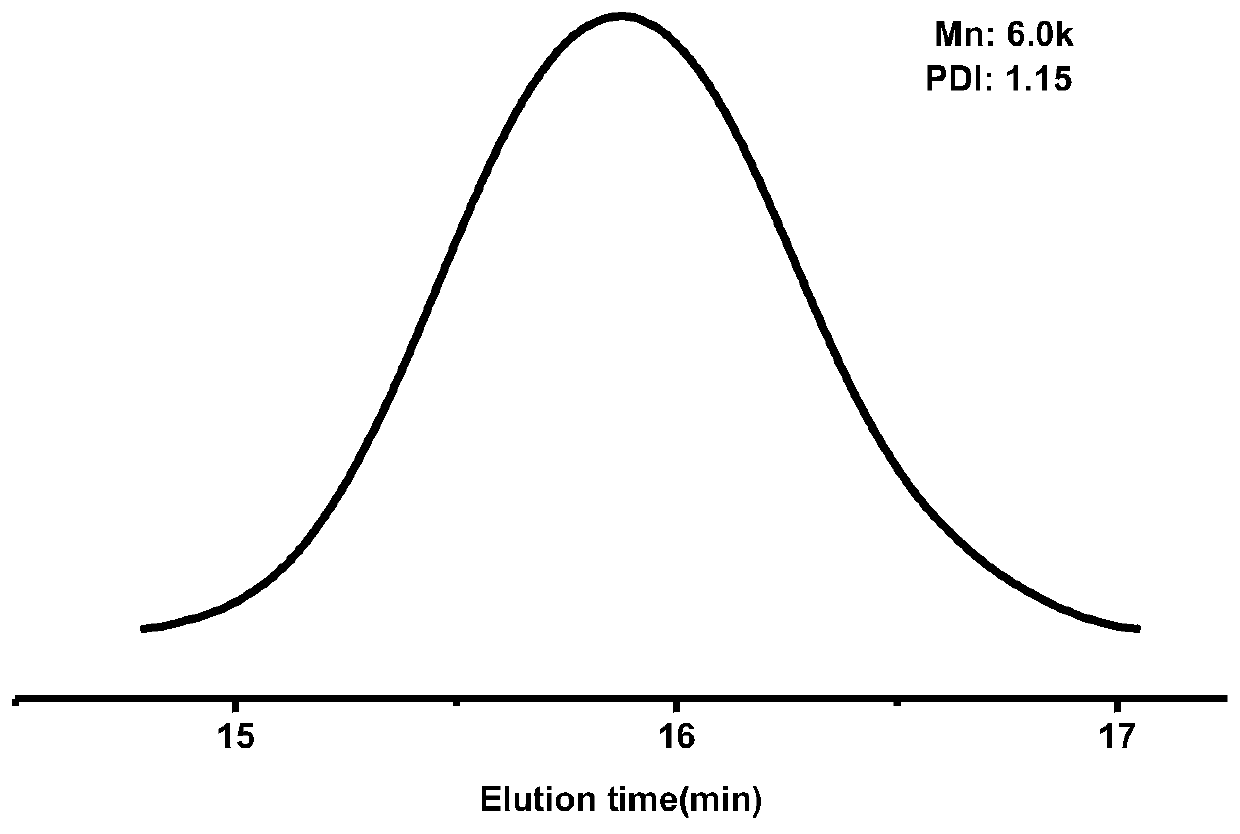

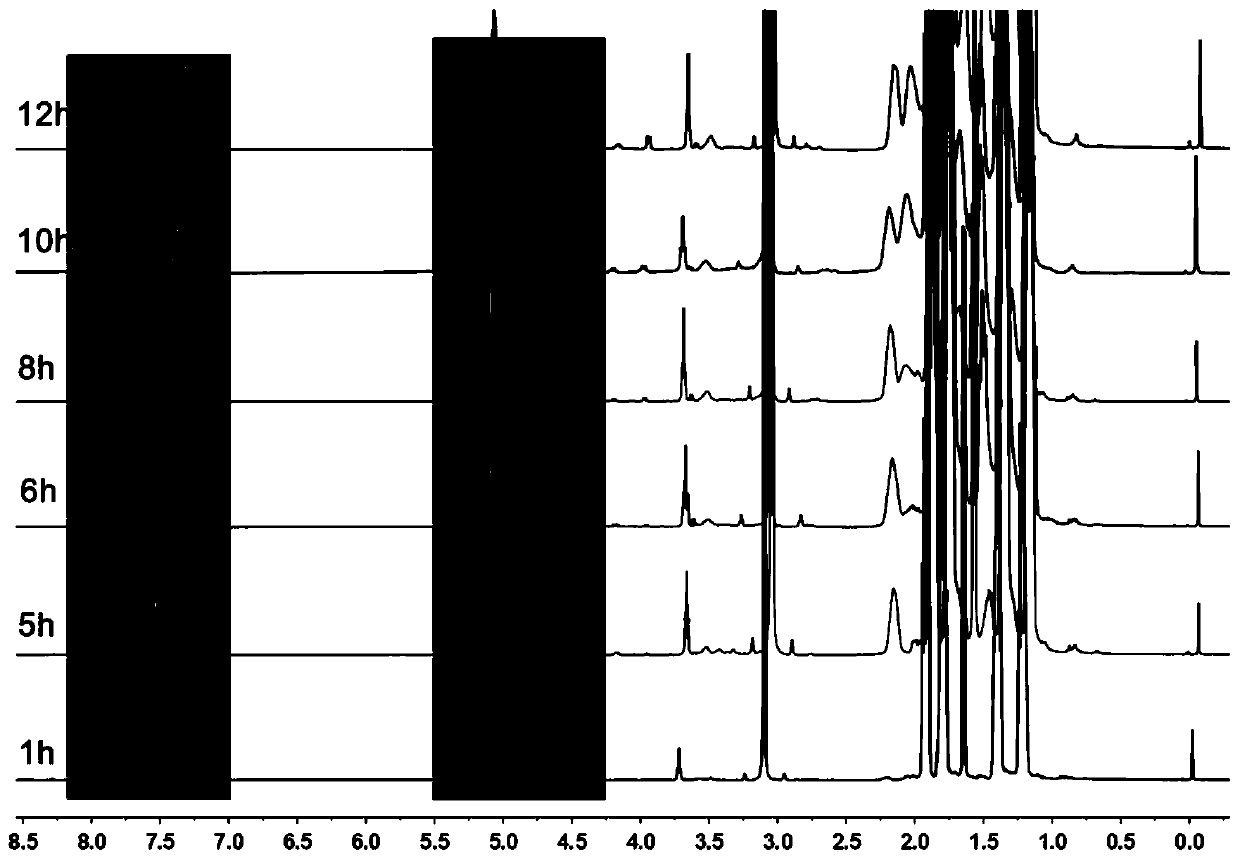

Preparation method of carbon dioxide based block copolymer

The invention belongs to the technical field of polymer synthesis, and more particularly relates to a preparation method of a carbon dioxide-based biodegradable block copolymer. The carbon dioxide-based biodegradable block copolymer is prepared by using a cyclic anhydride monomer, a lactone monomer, an epoxy compound and carbon dioxide as monomers, using an organic Lewis acid and organic Lewis base mixture as a catalyst, and using a terminal hydroxyl compound as an initiator to initiate ring-opening copolymerization of the cyclic anhydride monomer, the lactone monomer, the epoxy compound and the carbon dioxide in one step. The preparation method can effectively utilize the carbon dioxide and convert the carbon dioxide into a practical polymer material. The obtained polymer has no metal residue, and the luster and performance of the polymer can be ensured. One-step feeding is adopted to avoid the problems of complicated steps and purification in the step-by-step synthesis of the block copolymer. Meanwhile, the carbon dioxide-based biodegradable block copolymer has high controllability in molecular weight and block length.

Owner:HUAZHONG UNIV OF SCI & TECH

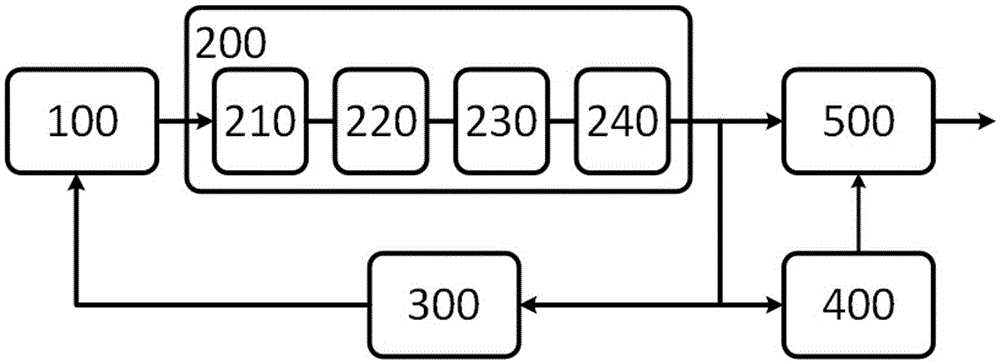

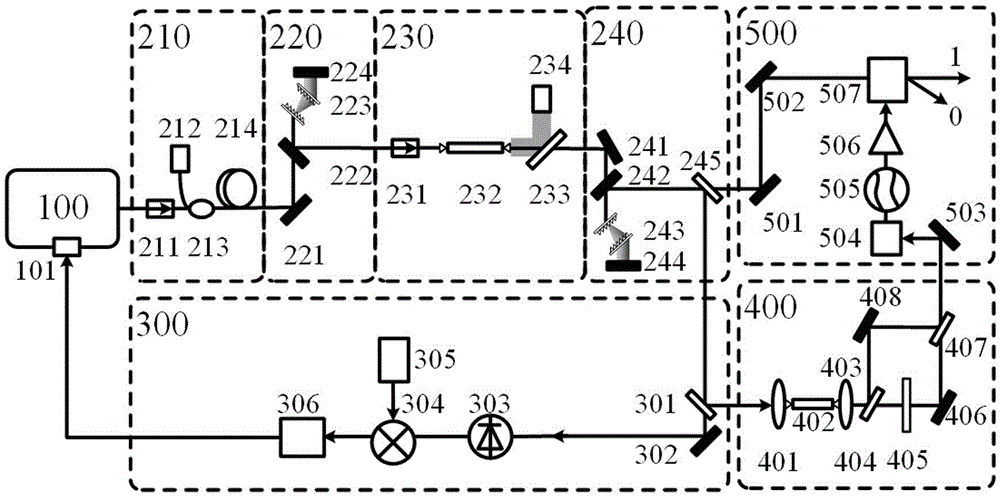

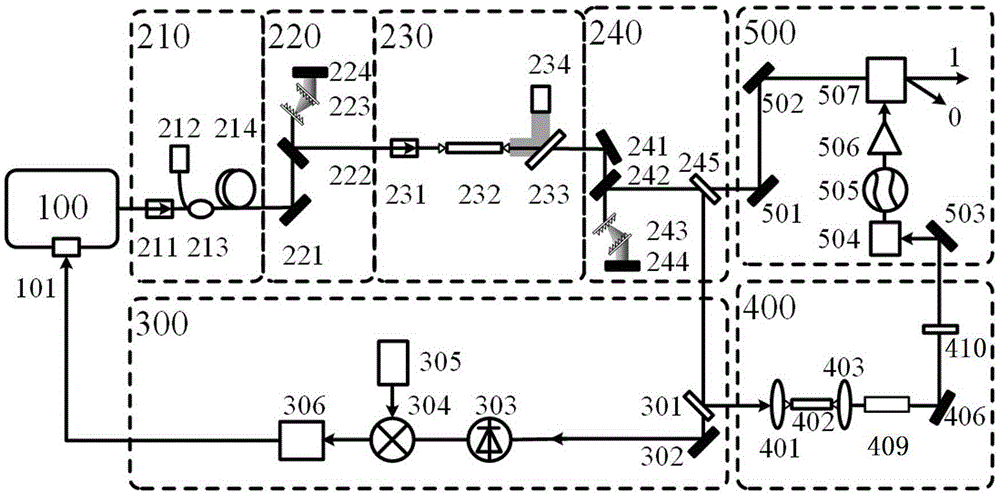

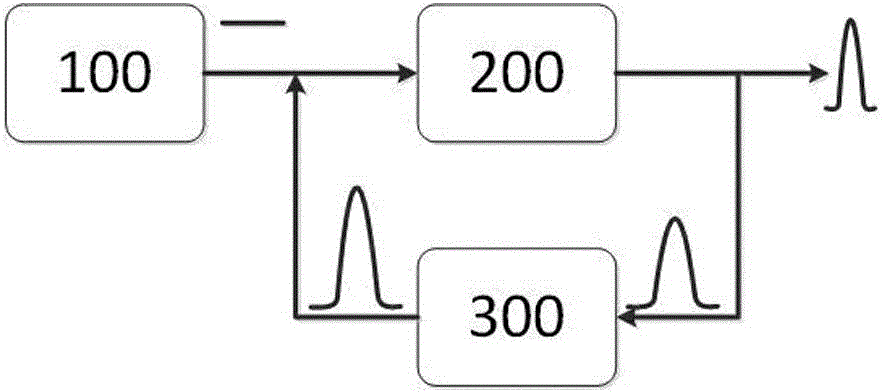

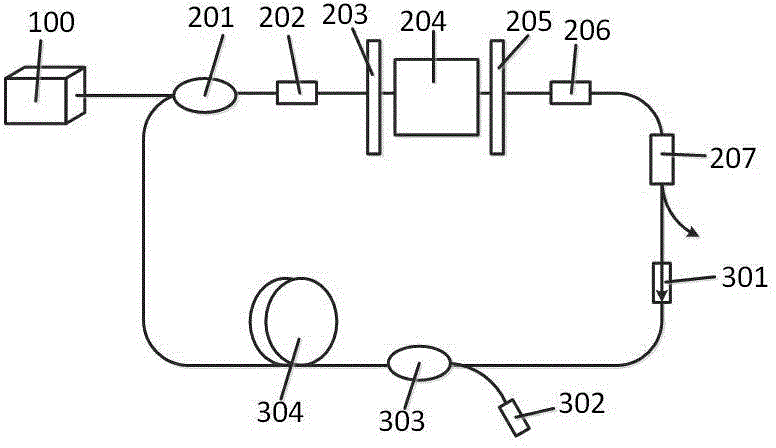

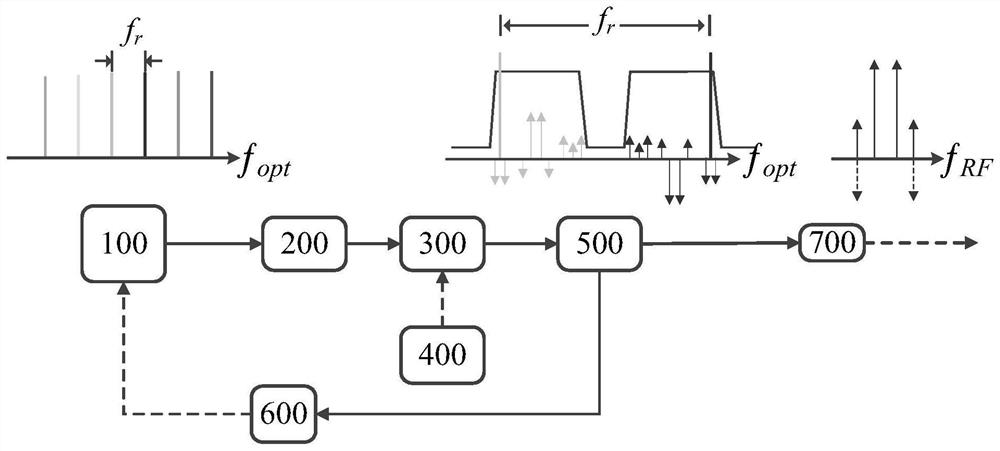

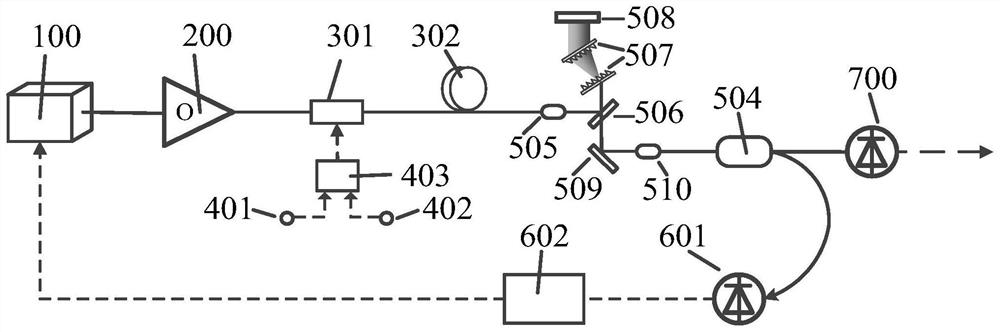

High-power ultrashort-pulse optical frequency comb generation method based on self-similar amplifier

ActiveCN105428987ARealizing Optical Frequency CombsNarrow widthLaser detailsBandwidth limitationCarrier signal

The invention discloses a high-power ultrashort-pulse optical frequency comb generation method based on a self-similar amplifier. The high-power ultrashort-pulse optical frequency comb generation method is based on self-similar amplification technology and effectively overcomes gain narrowing, bandwidth limitation and nonlinear phase distortion in pulse amplification. A light spectrum is effectively expanded, and the bandwidth of an output pulse is reduced. Furthermore the power of a mode-locked pulse is effectively expanded, thereby acquiring a high-power femtosecond pulse and improving carrier envelope phase zero-frequency locking precision. Furthermore carrier envelope phase zero-frequency locking technology based on an acoustic-optical crystal frequency shifter is utilized, thereby realizing large reaction bandwidth and high control precision, and realizing a high-frequency high-power ultrashort-pulse optical frequency comb through real-time control. The high-power ultrashort-pulse optical frequency comb generation method is advantageous in that the high-power ultrashort-pulse optical frequency comb generation method can be directly expanded and applied on femtosecond optical frequency comb control technology for obtaining the stable high-frequency high-power ultrashort-pulse optical frequency comb.

Owner:CHONGQING HUAPU INFORMATION TECH CO LTD

Method for 3D printing of bicomponent composite material with skin-core structure

InactiveCN109203473ARich varietyEasy to separate3D object support structuresApplying layer meansSkin corePolymer

The invention relates to a method for 3D printing of a bicomponent composite material with a skin-core structure. Skin layer polymers and core layer polymers are conveyed to an outer layer and a middle layer of the same nozzle of a 3D printer by different runners for extrusion to prepare the bicomponent composite material with the skin-core structure; the skin layer polymers and the core layer polymers are materials for forming a skin layer and a core layer of the bicomponent composite material with the skin-core structure; the 3D printer mainly consists of a bin I, a bin II, a screw extruderI, a screw extruder II, a metering pump I, a metering pump II, a distribution plate, a nozzle and multiple melt pipes; and the skin layer polymers and the core layer polymers are fed in the screw extruder I and the screw extruder II by the bin I and the bin II for melting, then, are conveyed into the metering pump I and the metering pump II by the melt pipes, are metered into the same distributionplate by the metering pumps, and are distributed into the nozzle by the distribution plate. Products printed by the method can integrate the characteristics of different materials to meet the demandsin different fields.

Owner:DONGHUA UNIV

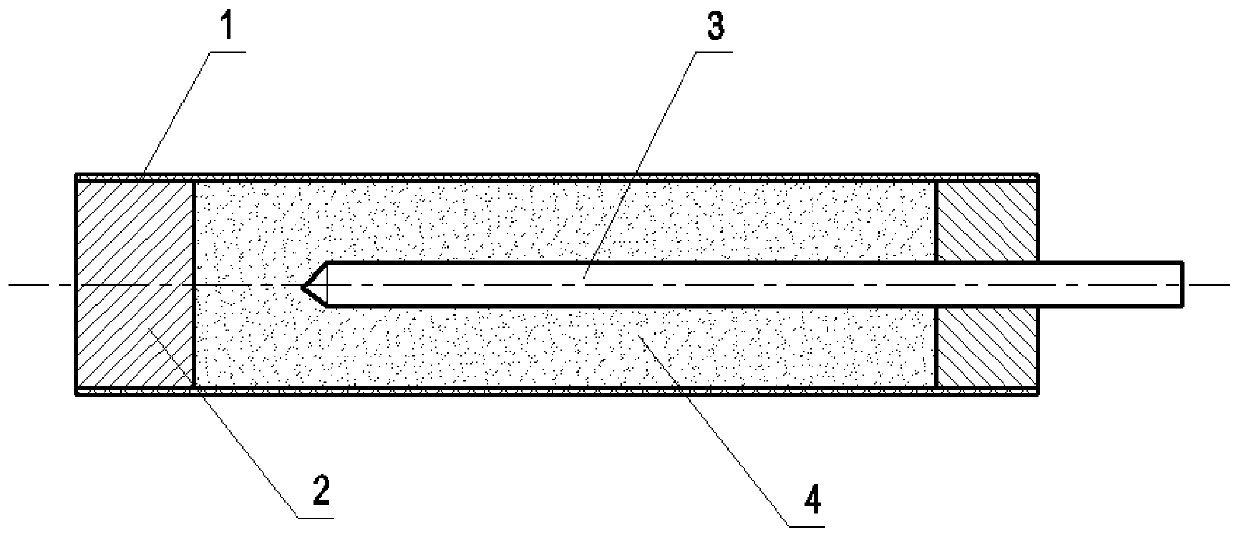

Machining method of capillary wick and assembly method of capillary wick and pipe casing

ActiveCN110303153ASolve the problem of high precision requirements for external dimensionsImprove capillary suctionTransportation and packagingIndirect heat exchangersLoop heat pipeMetal powder

The invention belongs to the technical field of evaporators of loop heat pipes, particularly relates to a machining method of a capillary wick and further discloses an assembly method of the capillarywick and a pipe casing. According to the machining method of the capillary wick, a binding agent is added to an existing metal powder material, a green body is prepared after isostatic compaction, channels are machined in the green body, and the capillary wick is prepared after sintering. According to the assembly method of the capillary wick and the pipe casing, the inner wall of the pipe casingis coated with paste containing the binding agent, so that an adhesive coating is formed; the capillary wick is inserted into the pipe casing, left to stay still until the capillary wick is dried andsintered at a high temperature, then the pipe casing and the capillary wick are closely adhered together, and the problem of high requirements for the accuracy of the overall size of the capillary wick in assembly manners in the prior art is solved; and additionally, the whole process has the advantages of simple machining manner, relatively short machining time and relatively low machining costs.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

Preparation method of highly dispersed NiCo alloy-graphene nanometer composite catalyst

ActiveCN109926054AAvoid accumulationNovel preparationMetal/metal-oxides/metal-hydroxide catalystsAlloyElectrochemistry

The invention belongs to the field of electrochemistry, and relates to a preparation method of a highly dispersed NiCo alloy-graphene nanometer composite catalyst. The preparation method comprises following steps: functionalized nanometer graphene is prepared; oxidized graphene is dispersed in deionized water, the above functionalized nanometer graphene is added with stirring, the pH value is adjusted to 7, a nickel source compound solution and a cobalt source compound solution are added drop by drop, an obtained precipitate is collected, and is washed with deionized water, and dried so as toobtain a nickel cobalt-oxidized graphene compound; calcination is carried out at a gas atmosphere so as to obtain the NiCo alloy-graphene nanometer composite catalyst. According to the preparation method, synthesis process is simplified; small size NiCo alloy nanometer particles are uniformly dispersed on graphene sheet layers; accumulation of nanometer particles is avoided; the NiCo alloy particles are provided with relatively large specific surface area; cost is low; and batch production can be realized.

Owner:禹州市新佳汇新材料科技有限公司

A method for preparing graphene airgel by drying under normal pressure

ActiveCN104925787BSolve the problems of mass productionSimple processGrapheneSupercritical dryingFreeze-drying

The invention provides a method for preparing graphene aerogel by normal pressure drying. The method firstly uses an aqueous dispersion of graphene oxide as a raw material to prepare a hydrogel, and then undergoes freezing and thawing treatment to reassemble its internal structure. The formed structure is sufficient to resist the structure collapse caused by the gas-liquid interfacial tension during atmospheric drying, and finally the graphene aerogel is prepared by atmospheric drying. Compared with freeze drying and supercritical drying methods, the present invention greatly improves the preparation efficiency of graphene aerogel, reduces production cost, and is expected to realize industrialized production of graphene aerogel. In addition, the present invention provides a new graphene aerogel whose macroporous and super-resilient properties will be applied in many fields.

Owner:QINGDAO UNIV OF SCI & TECH

Visible light-sensitive semiconductor composite photocatalytic material and preparation method thereof

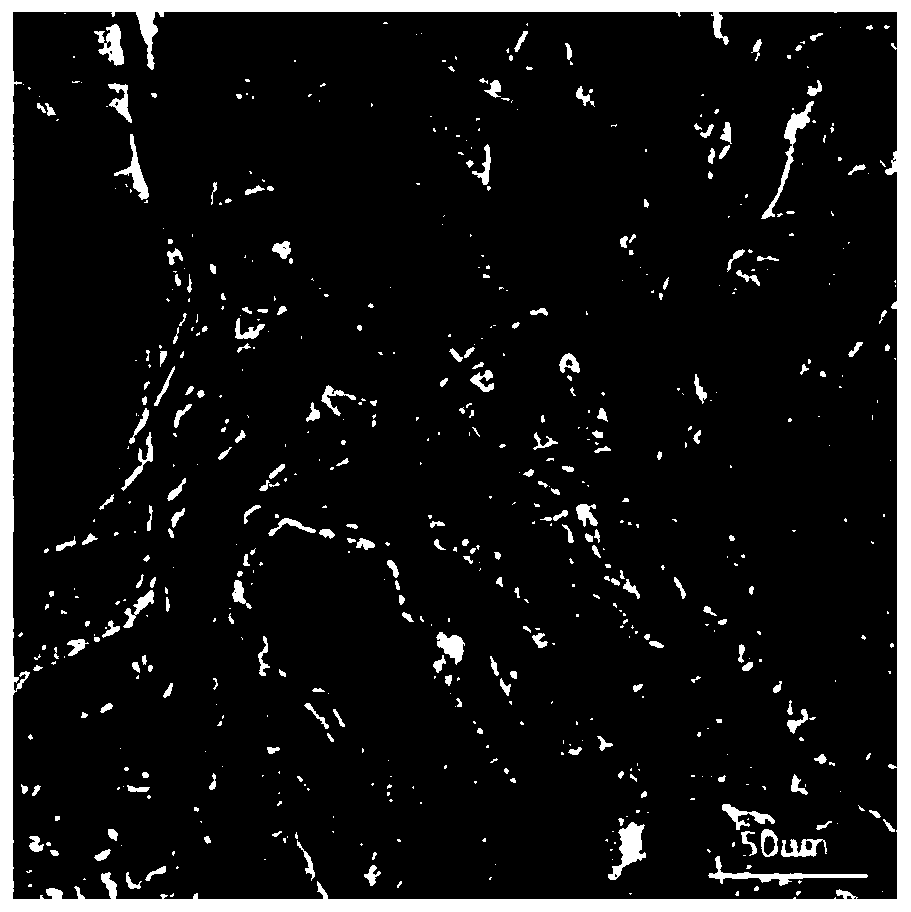

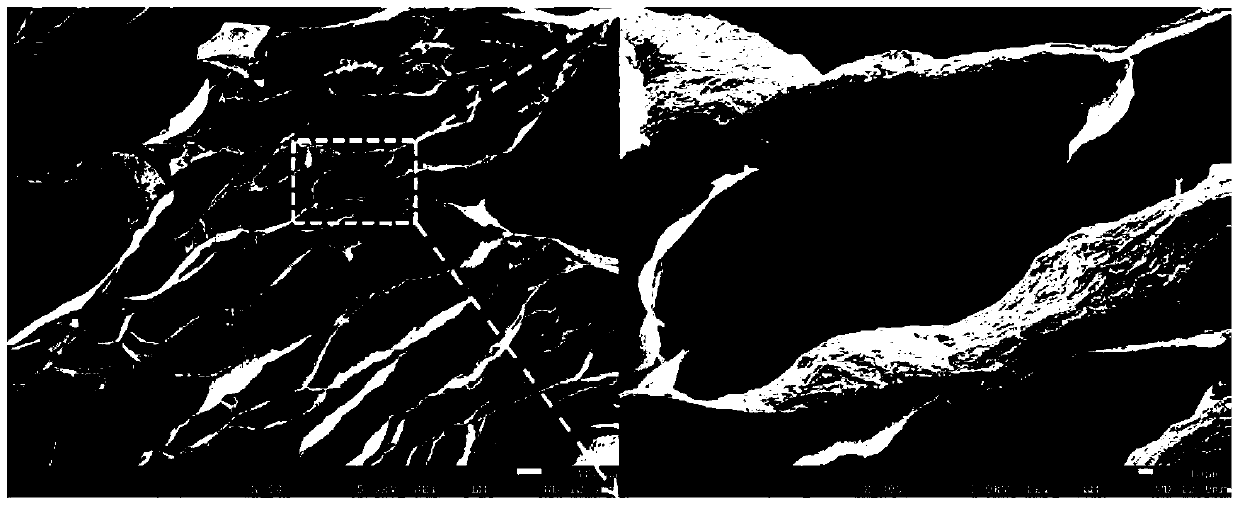

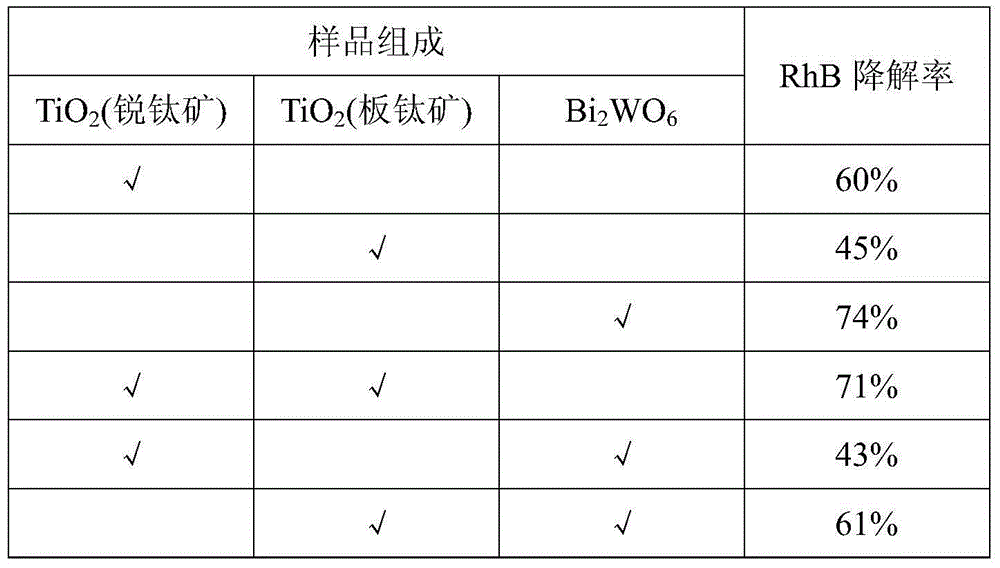

InactiveCN103331155ABroaden the photoresponse rangeHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionSolvent

The invention discloses a visible light-sensitive semiconductor composite photocatalytic material. The visible light-sensitive semiconductor composite photocatalytic material is characterized in that the visible light-sensitive semiconductor composite photocatalytic material is a TiO2 / Bi2WO6 composite crystal material having a multistage heterojunction structure and is prepared from 1-30 parts by mole of TiO2 nanocrystals, 1 part by mole of a tungsten salt and 1.8 to 2.2 parts by mole of a bismuth salt. The invention also discloses a preparation method of the visible light-sensitive semiconductor composite photocatalytic material. The TiO2 / Bi2WO6 composite crystal material has the multistage heterojunction structure so that photon-generated carrier separation is promoted. Through optimization of composition and a ratio of a reaction solvent, a particle size of a Bi2WO6 phase in the composite system is controlled so that a nanoscale TiO2 / Bi2WO6 composite photocatalyst is obtained. The visible light-sensitive semiconductor composite photocatalytic material has good photocatalysis effects in visible-light photocatalysis of RhB.

Owner:东莞上海大学纳米技术研究院 +1

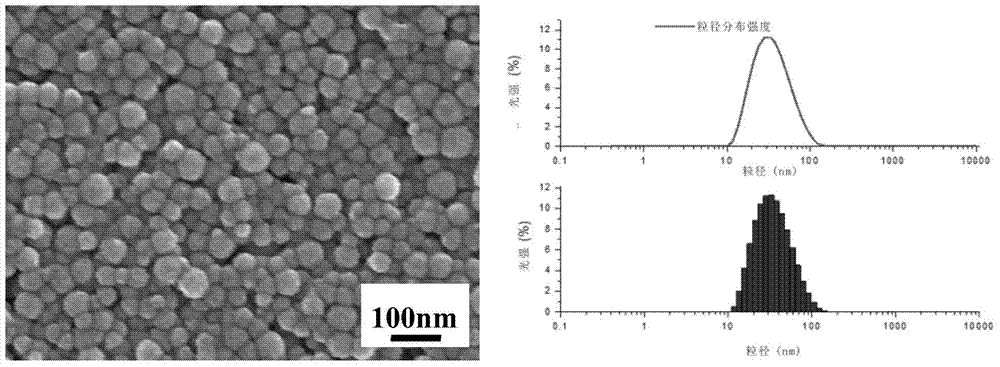

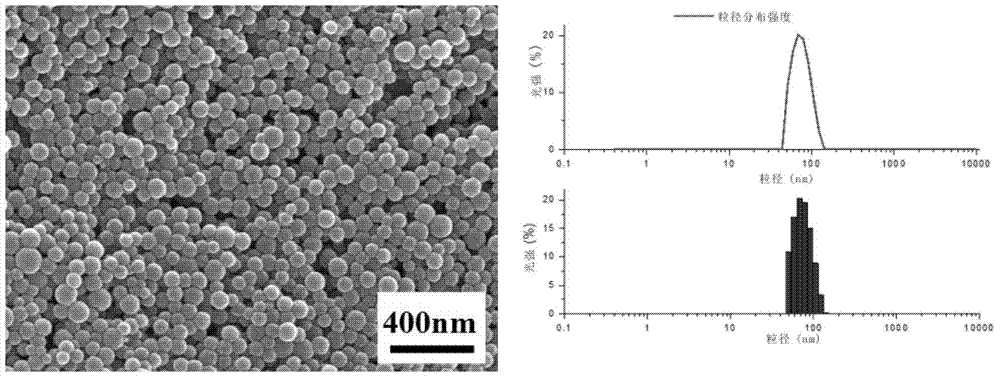

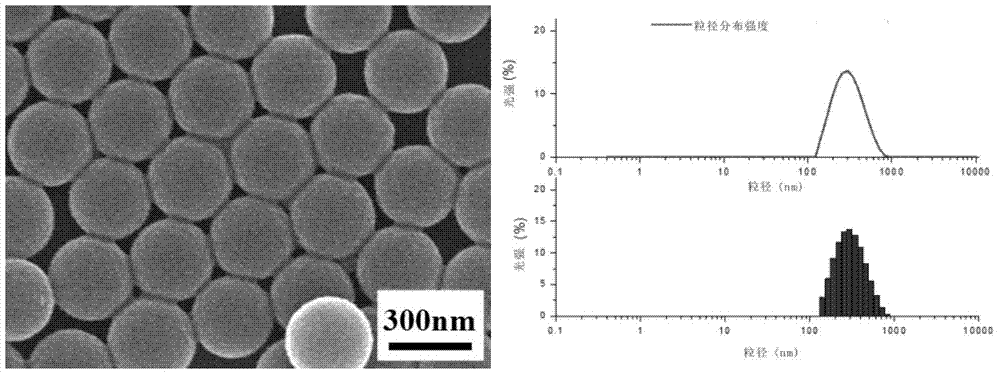

Method for preparing granularity controllable narrow range polymer micro-nano spheres

The invention discloses a method for preparing granularity controllable narrow range polymer micro-nano spheres. The granularity controllable narrow range polymer micro-nano spheres can be efficiently and continuously produced at normal temperature by using industrial grade polydisperse polymer products, recovered polymer materials, homopolymers and copolymers which are wide in source as raw materials by virtue of a two-step production process of mechanical stirring-micro jet flow. In a preparation process, the proportion of a dispersed phase to a continuous phase, the type and use level of surfactants and compounding schemes of types of organic solvents and high pressure chamber of the device are adjusted without high-temperature time-consuming polymerization reaction and cockamamie post-treatment as well as purification of raw materials, so that the grain size and grain size distribution of the micro-nano spheres can be controlled. The diameters are adjustable from 30nm to 3mu m, the polydispersity index is less than 0.2, and the micro-nano spheres are smooth and non-adhesive on the surfaces and can be re-dispersed in a solvent. The obtained polymer micro-nano spheres have a wide application range in the fields of standard metering, food industry, medicines, bioengineering, coating and plastic processing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

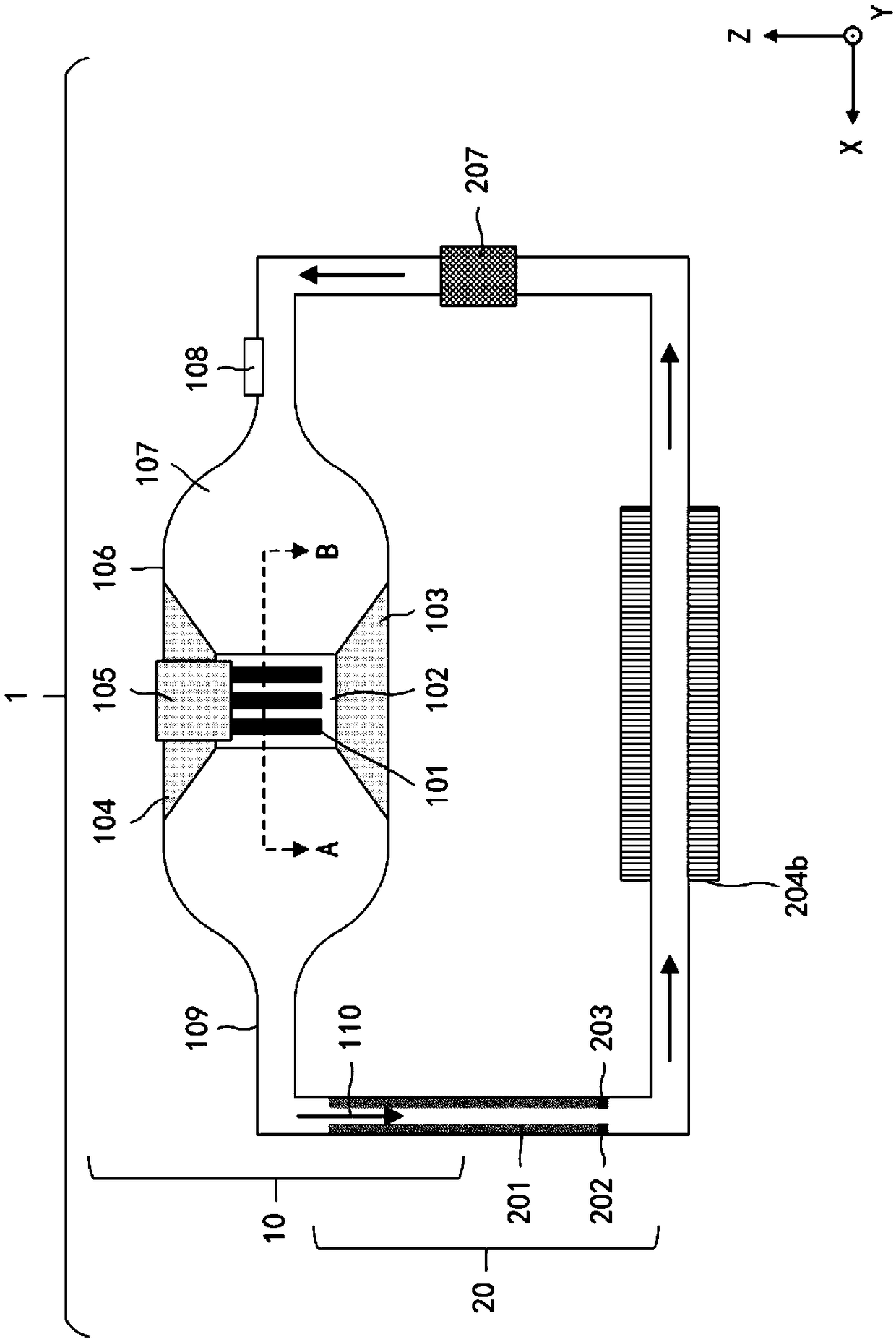

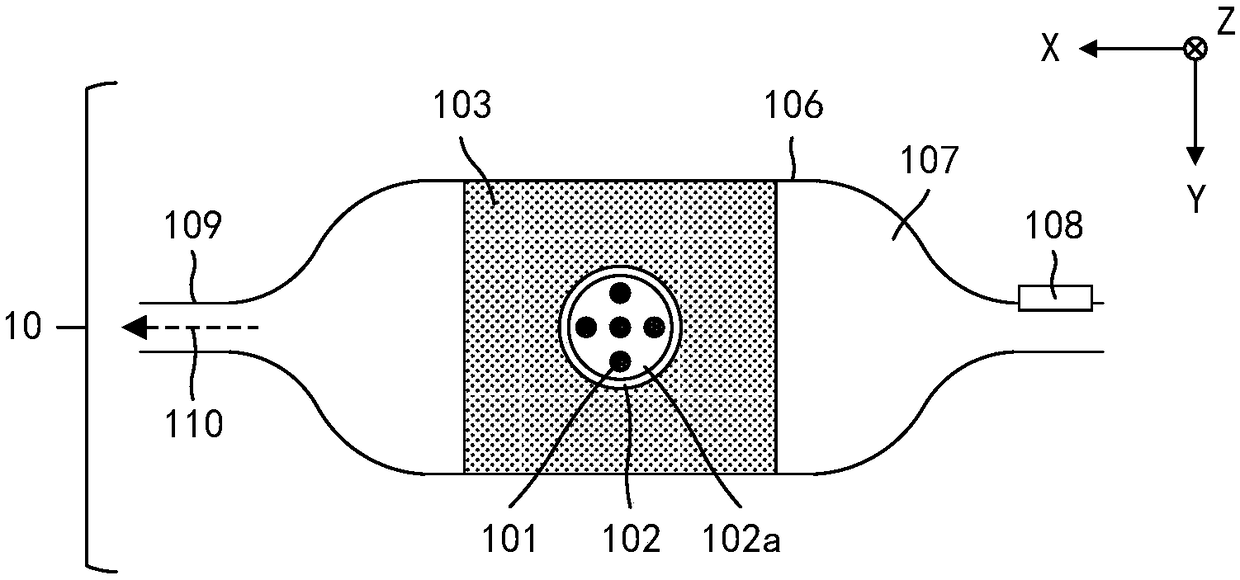

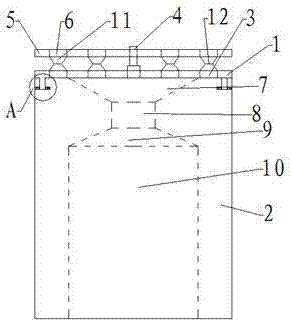

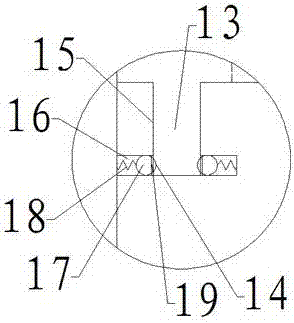

Piezoelectric thermoelectric dynamic isotope cell

ActiveCN108550412ASolve technical bottlenecksImprove energy conversion efficiencyRadiation electrical energyThermoelectric energy conversionGas pipeline

The invention provides a piezoelectric thermoelectric dynamic isotope cell. The cell comprises a gas pipeline, a heat source cavity covering case, a fuel box, a radioactive source, a gas state workingmedium, a thermoelectric energy conversion assembly and a single-cavity compressor. The opposite two ends of the heat source cavity cover communicate with the two ends of the gas pipeline so that a closed circulation pipeline is formed. A unidirectional gas charging valve is arranged on the heat source cavity covering case. The fuel box is fixedly arranged in the heat source cavity covering case.The radioactive source is arranged in the fuel box. The gas state working medium fills the circulation pipeline. The piezoelectric energy conversion assembly is arranged on the inner surface of the gas pipeline. The piezoelectric energy conversion assembly is arranged on the outer surface of the gas pipeline and separated from the piezoelectric energy conversion assembly. The single-cavity compressor is arranged on the gas pipeline and used for driving the gas state working medium to flow in a circulation manner. Thus, the cell is highly stable, high in energy conversion efficiency, high in working stability, and quite long in service lifetime and the output power is adjustable.

Owner:深圳热电新能源科技有限公司

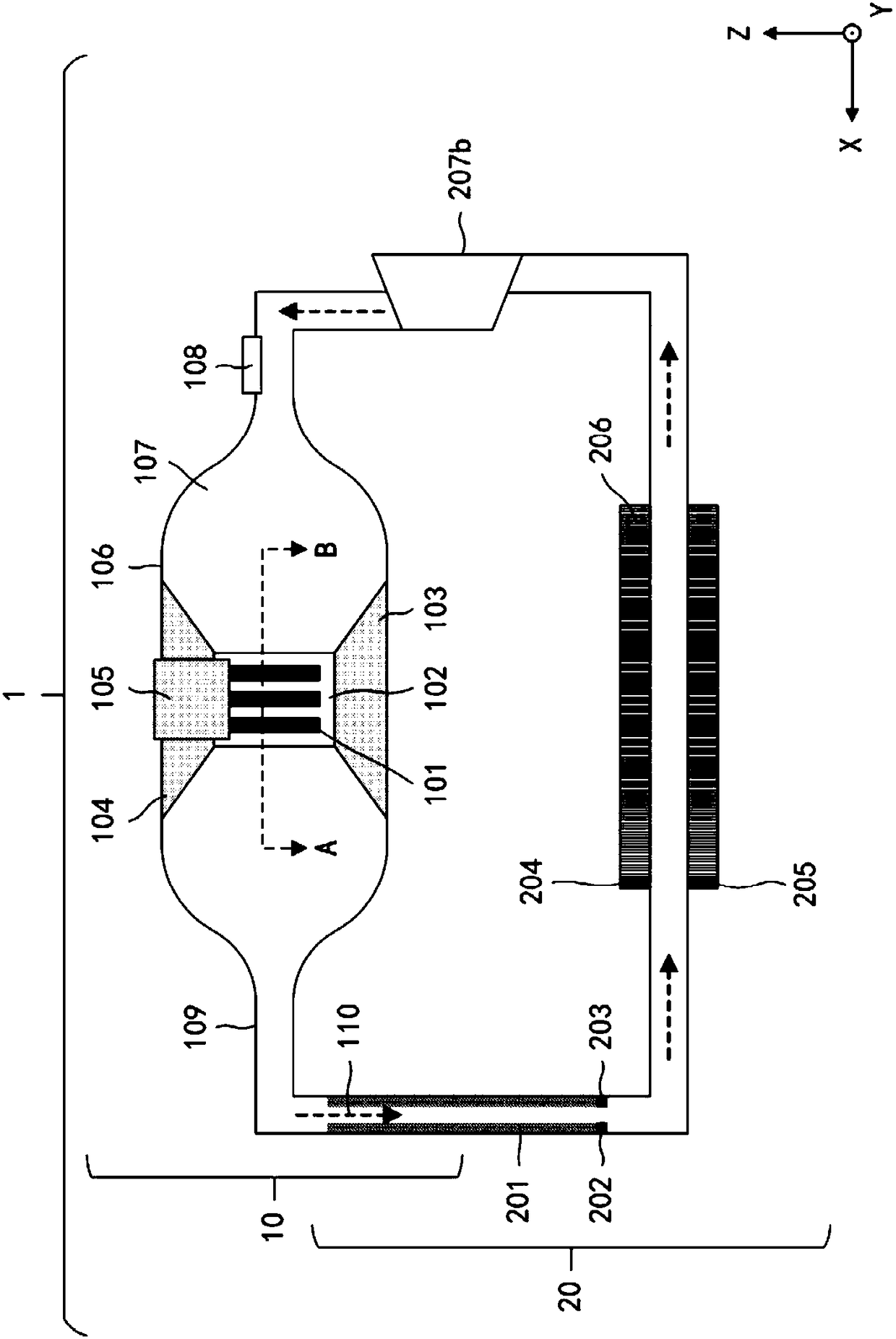

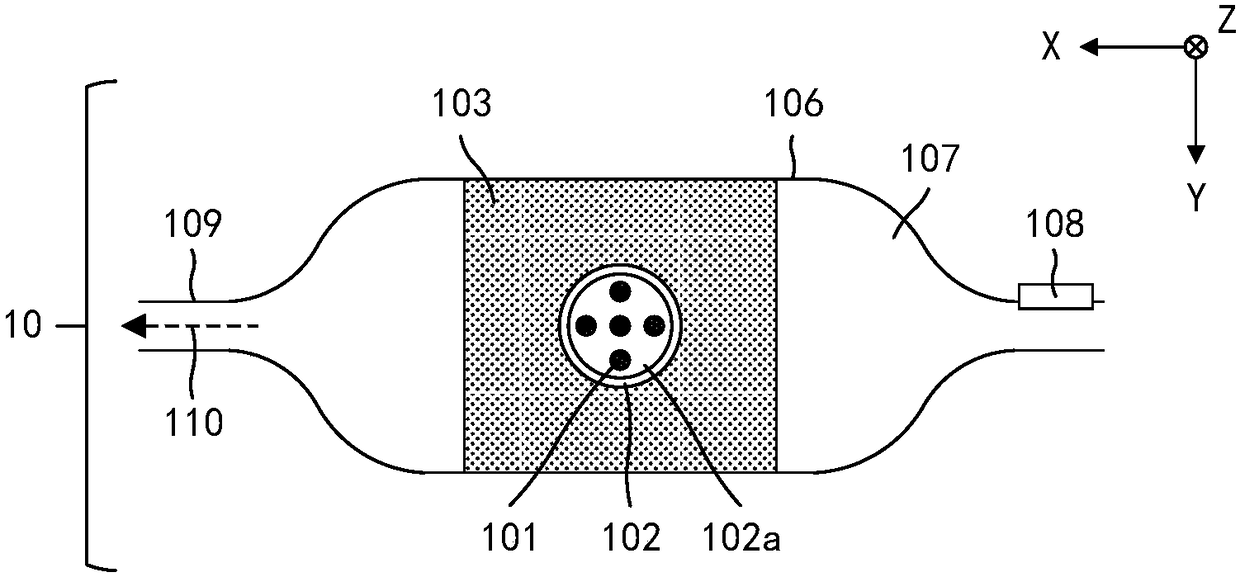

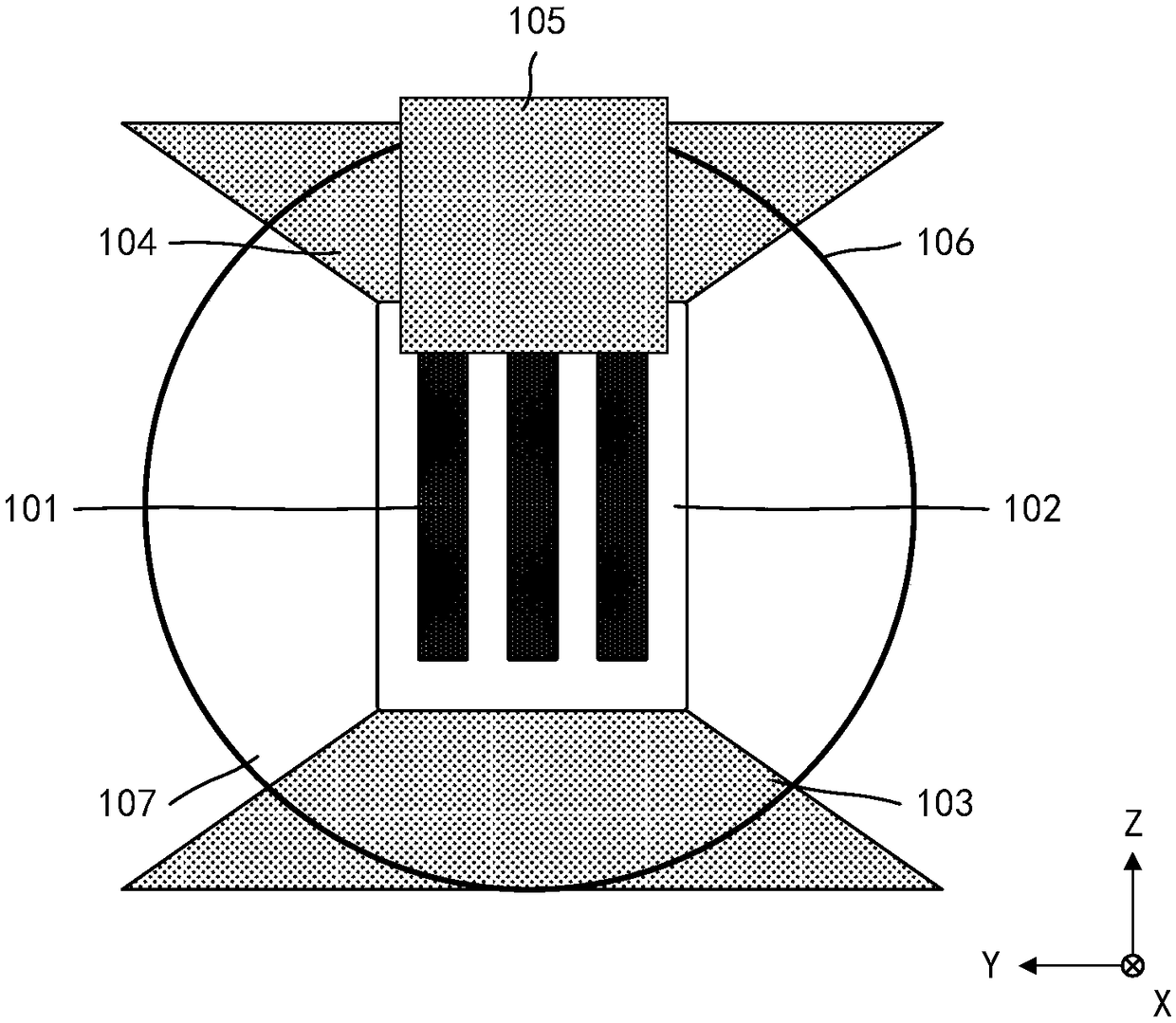

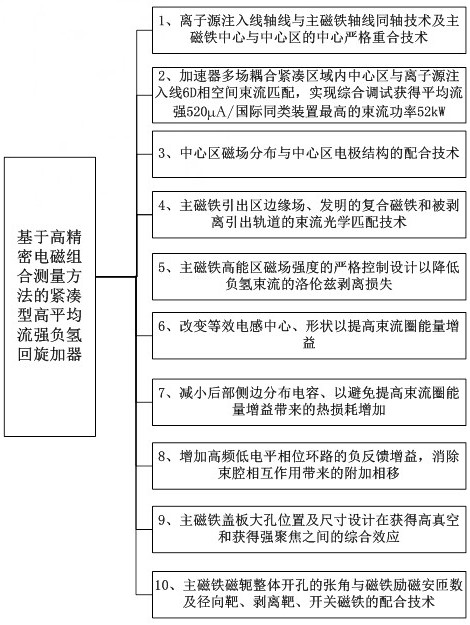

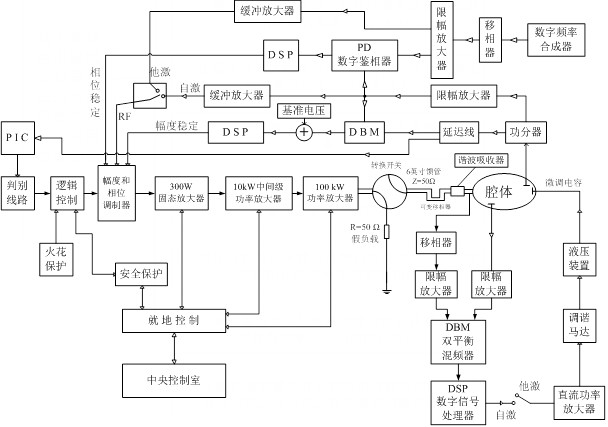

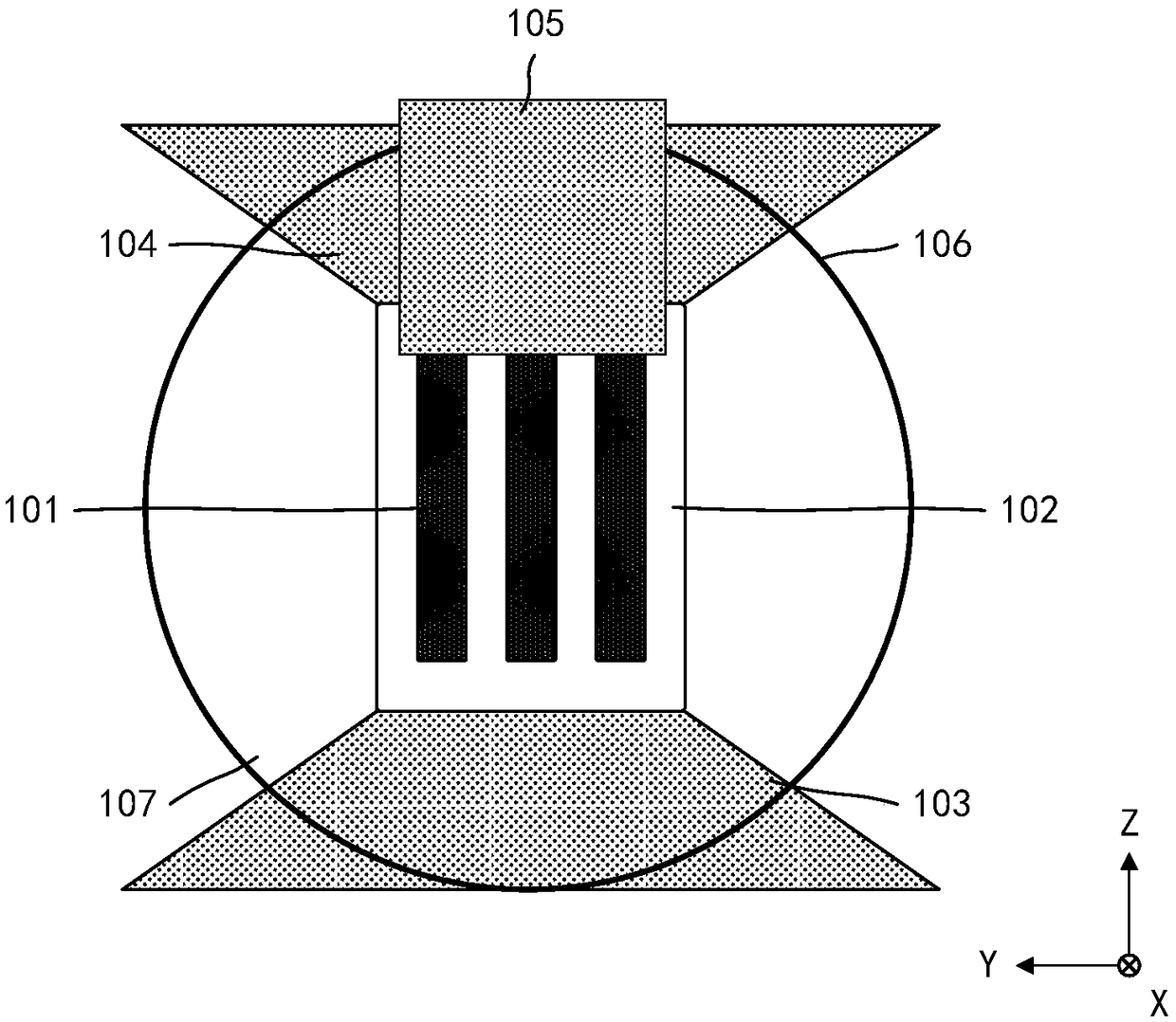

High-precision electromagnetic combined measurement method and negative hydrogen cyclotron based on method

ActiveCN112098734AGood effectSolve the errorMagnetic resonance acceleratorsElectromagentic field characteristicsIon beamParticle physics

The invention discloses a high-precision electromagnetic combined measurement method and a negative hydrogen cyclotron based on the method, and belongs to the technical field of high-current proton cyclotron electromagnetic field characteristic and electric field distribution measurement. The measurement method comprises the following steps: measuring a strong-current negative hydrogen ion beam generation process; measuring a high-current negative hydrogen ion beam transmission process; measuring a high-current negative hydrogen ion beam injection process; measuring a high-current negative hydrogen ion beam acceleration process; and measuring a high-current negative hydrogen ion beam extraction process; The invention further discloses the compact high-average-flow-intensity negative hydrogen cyclotron based on the high-precision electromagnetic combined measurement method; the measurement method runs through the whole process of generation, transmission, strong injection, accelerationand extraction of strong-flow negative hydrogen ions; through the cooperation technology of all links of installation, combination and debugging in the overall integration process of a main magnet assembly, a high-frequency subsystem, an injection and extraction subsystem, a double-layer sealed vacuum chamber and other systems, the problem of beam loss in all links of beam injection, accelerationand extraction is solved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for preparing granite decorative plate from granite sawing mud

ActiveCN111003989AEliminate the effects ofLow costSolid waste managementLaminationStructural deformationMaterials preparation

The invention discloses a preparation method for preparing a granite decorative plate from granite sawing mud. The method comprises the steps of surface layer material preparation, surface layer material forming, base layer material preparation, base layer material forming, composite material secondary forming and product maintenance. The machine-made fine sand and stone powder produced by processing granite solid waste are adopted to replace quartz sand and quartz powder, and the product cost can be effectively reduced on the basis that granite sawing mud is massively applied and the environmental influence is eliminated; after the product is formed at a time, the product is free of cracks in appearance and deformation in structure, and is excellent in stability, and has the advantages ofhigh strength, high bending resistance, low water absorption, acid and alkali resistance, fire resistance, weather resistance and the like of an RPC composite material, all indexes are superior to those of natural stone, and the product service life reaches 50 years or longer.

Owner:SISHUI HUIFENG AGRI DEV ENG CO LTD

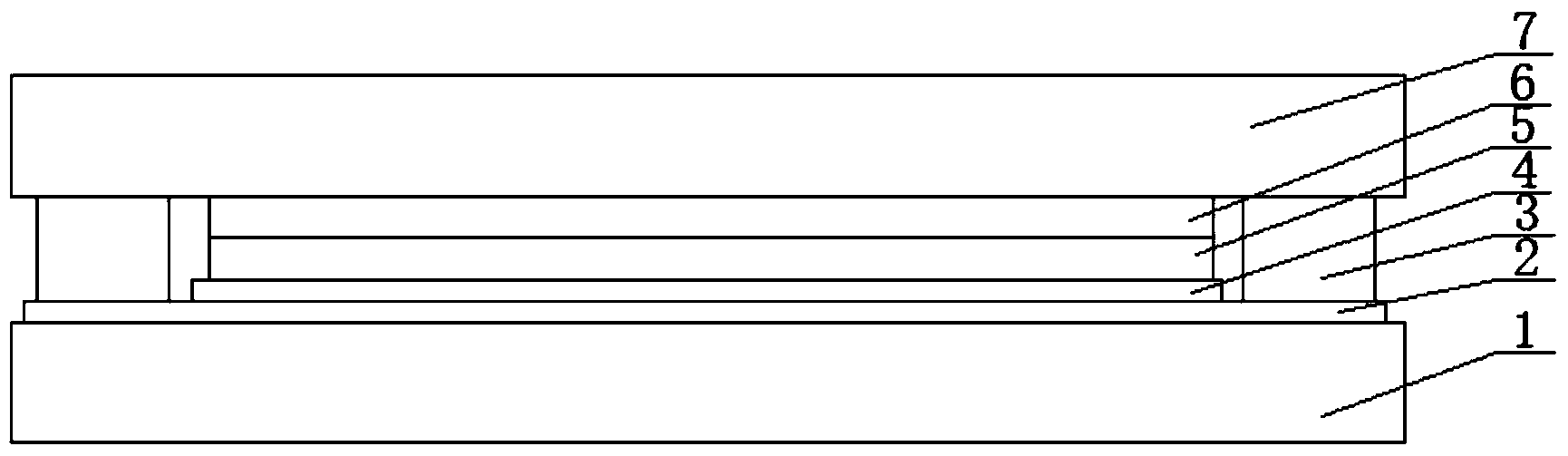

Flexible substrate CdTe thin-film solar cell and preparing method thereof

InactiveCN104319298ALow costImprove efficiencyFinal product manufacturePhotovoltaic energy generationContact layerMetal

The invention discloses a flexible substrate CdTe thin-film solar cell and a preparing method thereof. The flexible substrate CdTe thin-film solar cell is composed of the following seven parts including a transparent flexible substrate thin-film material layer, a transparent conducting thin film layer, a negative electrode, a CdS thin-film window layer, a CdTe thin-film absorbing layer, a back electrode metal contact layer and a flexible thin-film material packaging layer, wherein the transparent conducting thin film layer is formed in the manner that ZnxCd1-xO deposits on the flexible substrate thin-film material layer, the negative electrode is formed on the transparent conducting thin film layer, the CdS thin-film window layer is arranged on the transparent conducting thin film layer, the CdTe thin-film absorbing layer is arranged on the CdS thin-film window layer, the back electrode metal contact layer is arranged on the CdTe thin-film absorbing layer, and the flexible thin-film material packaging layer is arranged on the back electrode metal contact layer. The flexible substrate CdTe thin-film solar cell has the advantages of being low in cost, high in efficiency and capable of meeting requirements of different fields, and the preparing method can be applied to mass preparing of low-temperature technology flexible substrate CdTe thin-film solar cells.

Owner:上海联孚新能源科技集团有限公司

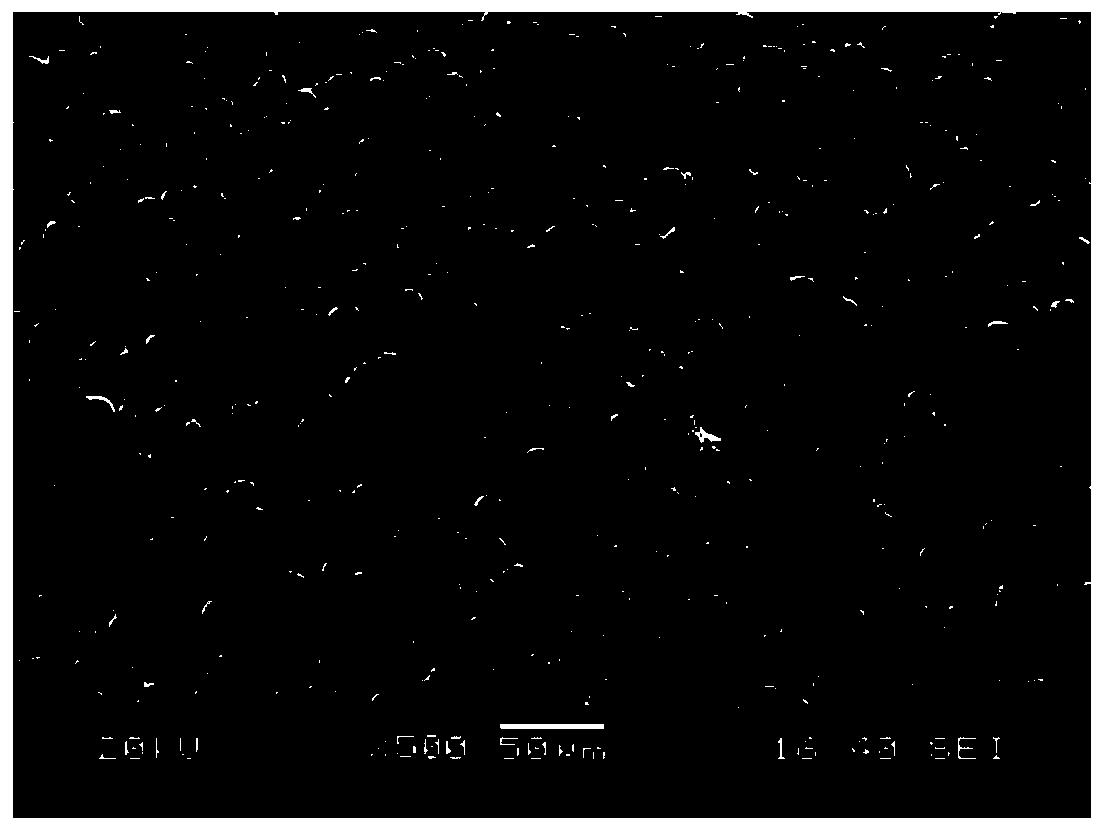

Porous metal foil as well as preparation method and application thereof

The invention relates to a porous metal foil as well as a preparation method and an application thereof. The method comprises the following steps of introducing a metal foil into an electroplating solution, and electrifying to form an electroplating layer on the surface of the metal foil; placing the metal foil loaded with the electroplating layer in a vacuum furnace, and sequentially carrying outtwo-stage heating treatment on the metal foil loaded with the electroplating layer under the condition of vacuum to obtain the porous metal foil. The pore size structure of the prepared porous metalfoil is controllable. The preparation method is simple, feasible, low in cost and small in pollution. The pore size distribution of the porous metal foil can be adjusted conveniently. The obtained metal foil has a thickness of 5 to 200 [mu]m and an average pore size of 100 nm to 10 [mu]m.

Owner:SHANDONG UNIV

Preparation method of ventilating metal

InactiveCN104451234AScientific and reasonable production processQuality controllablePore distributionMechanical property

The invention relates to a preparation method of ventilating metal. The preparation method is characterized by comprising the following steps: selecting materials; compressing a shrinkage cavity and compressing; sintering at high temperature; compressing for the second time; cutting to prepare a finished product and the like. By taking foamed metal as a raw material, the finished product is prepared by the following steps: compressing a shrinkage cavity and compressing; sintering at high temperature; compressing for the second time; cutting and the like. The preparation method of the ventilating metal has the advantages that scientific and reasonable production flow is adopted, the method is suitable for producing various ventilating metals, simplicityand feasibility are realized, the quality can be controlled easily and pollution in the production process can be avoided, and the ventilating metal which is directly obtained by the method has the advantages of being high in cost performance, good in mechanical property, uniform in pore distribution and wide in application and having diversified products and the like. The open-cell rate of the prepared metal reaches 97-99%.

Owner:吉林省正大新型材料科技有限公司

Dynamic isotope cell based on liquid metal

ActiveCN108648847AImprove cycle stabilityImprove energy conversion efficiencyRadiation electrical energyCell basedNuclear engineering

The present invention provides a dynamic isotope cell based on liquid metal. The dynamic isotope cell comprises: a metallic conduit; a heat source cavity cladding, wherein two opposite ends of the heat source cavity cladding respectively communicate with two ends of the metallic conduit to form a closed circulation line, and the heat source cavity cladding is provided with a one-way inflation valve; a fuel box fixedly arranged at the internal portion of the heat source cavity cladding; a radioactive source arranged in the fuel box; liquid metal stored in the circulation line; a piezoelectric transduction module arranged at the inner surface of the metallic conduit; a heat radiation structure arranged at the outer surface of the metallic conduit and arranged at intervals with the piezoelectric transduction module; and an electromagnetic pump arranged on the metallic conduit and configured to drive the circulation flow of the liquid metal. The dynamic isotope cell is good in reliability,high in energy conversion efficiency, good in work stability, adjustable in output power and long in service life.

Owner:深圳热电新能源科技有限公司

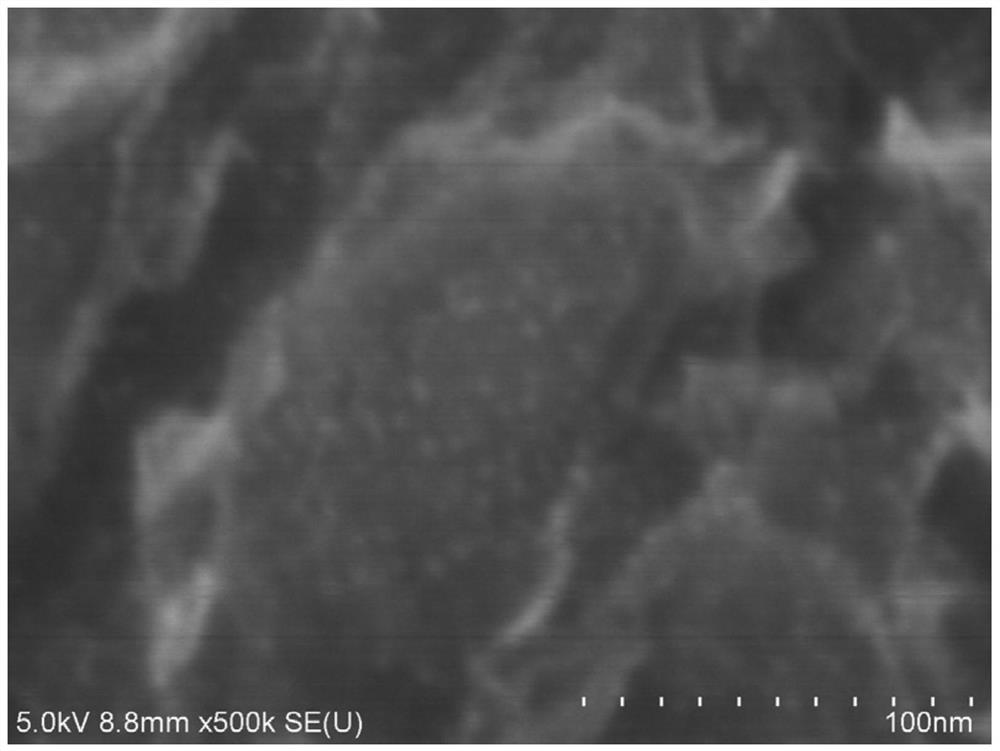

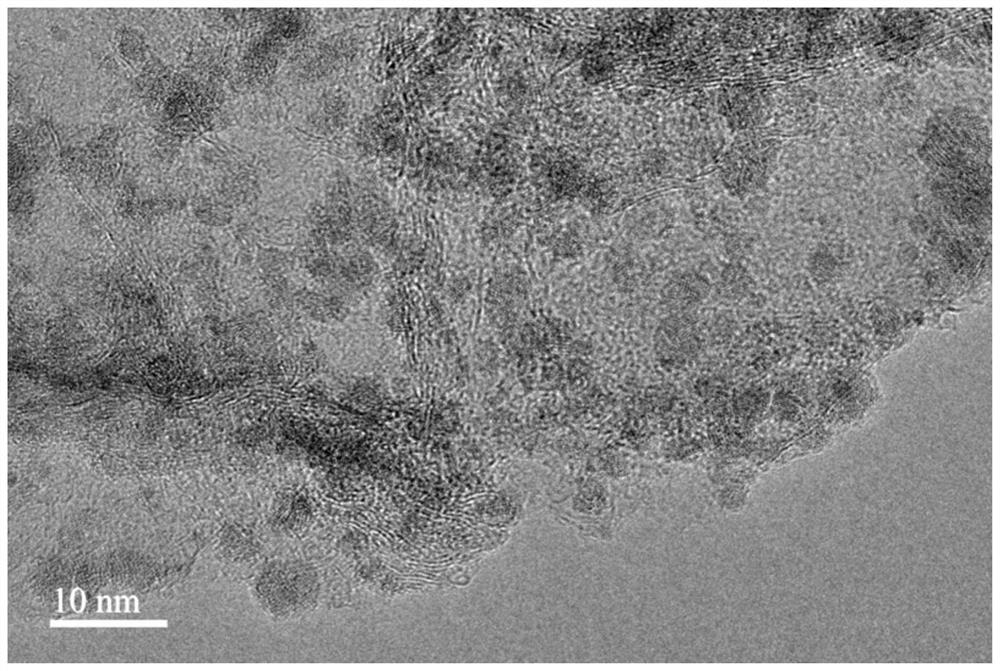

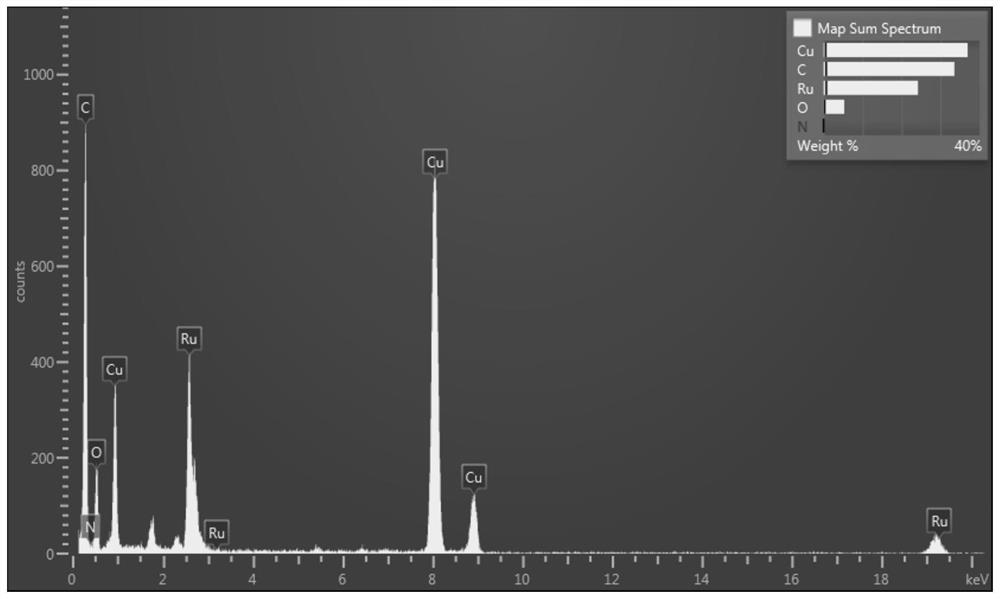

Preparation method of high-dispersion graphene-ruthenium oxide nano composite material

InactiveCN111696790ALarge specific surface areaAvoid accumulationMaterial nanotechnologyHybrid capacitor electrodesAir atmosphereGraphene nanocomposites

The invention discloses a preparation method of a high-dispersion graphene-ruthenium oxide nano composite material and belongs to the field of electrochemistry. The preparation method comprises the following steps of preparing graphene quantum dots; dispersing graphene oxide into deionized water, adding the graphene quantum dot solution while stirring, adjusting a pH value to be neutral, dropwiseadding ruthenium source solution, collecting precipitate, washing with the deionized water, and drying to obtain a ruthenium-graphene oxide compound; calcining in a gas atmosphere to obtain a ruthenium-graphene nano composite material; and carrying out low-temperature heat treatment under an air atmosphere condition to obtain the graphene-ruthenium oxide nano composite material. The method is advantaged in that the synthesis process is simplified, small-size ruthenium oxide nanoparticles are formed and uniformly dispersed on the graphene sheet layer, and accumulation of the nanoparticles is avoided, so ruthenium oxide has a large specific surface area.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Coating for metal film resistors

InactiveCN104164160AGood film formingExcellent adhesionPolyamide coatingsEpoxy resin coatingsEpoxySilanes

A disclosed is coating for metal film resistors composed of the following raw materials in parts by weight: 40-60 parts of high-temperature-resistant epoxy resin, 20-30 parts of polyamide resin, 10-20 parts of ethylene oxide, 1-5 parts of an adhesion promoter, 2-5 parts of a binder, 5-10 parts of nanometer silicon dioxide, and 0.1-0.5 parts of polyurethane. The adhesion promoter is one of chlorinated resin, sulfonyl amine, silane and titanates, and the binder is propylene polyurethaneacrylate glue. The provided coating for metal film resistors is good in film forming property and excellent in adhesive force, is resistant to high temperature and moisture environment, and is capable of satisfying demands of different fields.

Owner:SUQIAN RONGJIN INFORMATION TECH

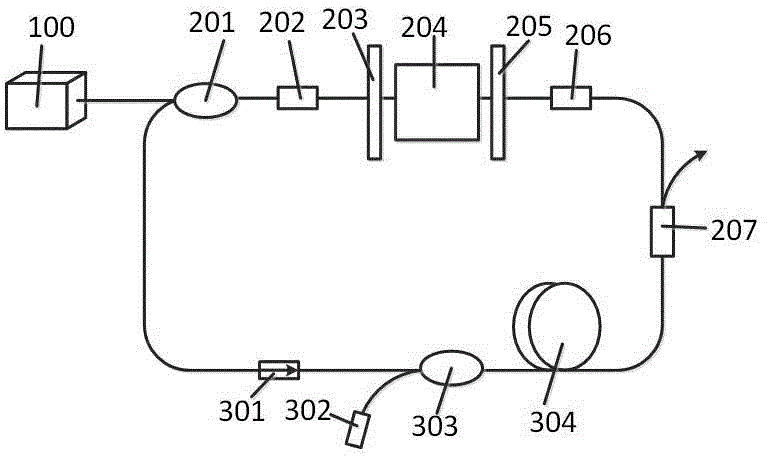

Broadband optical frequency comb and implement method thereof

ActiveCN104319612ALow mode-locking thresholdSimple structureOptical resonator shape and constructionOptoelectronicsWideband

The invention discloses a broadband optical frequency comb and an implement method thereof. The broadband optical frequency comb is characterized by comprising a continuous laser source, a pulse generation module and an amplification control module, wherein the continuous laser source is connected to the input end of the pulse generation module, and the output end of the pulse generation module is connected to the input end of the pulse generation module by the amplification control module to form a closed loop cavity. The broadband optical frequency comb has the advantages that, laser is continuously injected based on single-longitudinal-mode narrow-linewidth, an F-P cavity-cavity enhanced structure is adopted, the pulse is repeatedly modulated, the spectrum can be effectively broadened, and thereby the broadband optical frequency comb can be directly expansively applied to the control technology of femtosecond optical frequency combs to obtain the stable broadband femtosecond optical frequency comb.

Owner:华东师范大学重庆研究院

Plant fiber environmental protection material and its manufacturing method and application

InactiveCN103113753BWide variety of sourcesEvenly distributedWood working apparatusDomestic articlesBiotechnologyCellulose

The invention discloses a plant fiber environment-friendly material and a preparation method thereof as well as application of the material in tableware, toys, furniture, decoration or wall. The preparation method comprises the following steps of: pretreating, grinding and screening the plant fiber; mixing the screened plant fiber powder with an adhesive and a modification aid, and stirring at high temperature, wherein the adhesive mainly adopts hydroxypropyl methyl cellulose; filtering with a riddler, and dehydrating and preheating the screened organic synthesis plant fiber raw material; and performing high-temperature die pressing. According to the plant fiber environment-friendly material as well as the preparation method and application thereof, the product has good performance and additional functionality, can be applied to wider fields, conforms to relatively high requirements on using safety, and facilitates environmental protection so as to overcome the shortcomings of the existing plant fiber environment-friendly material and a preparation method and application thereof.

Owner:王丹 +2

Porous platinum preparation method and application of porous platinum

ActiveCN111235422AHigh purityPrevent oxidationMetal/metal-oxides/metal-hydroxide catalystsPore diameterAlloy

The invention relates to a porous platinum preparation method and application of porous platinum. The preparation method provided by the invention comprises the following steps that metal platinum andmetal low in melting and boiling point are put into a vacuum furnace, a vacuum condition is kept, after heating at the low temperature is conducted for a period of time, the temperature is increased,vacuum is kept, and then the porous platinum can be obtained. According to the method, platinum alloy smelting and porous platinum preparing are integrated, no pilot process is needed, the operationcan be completed on the same equipment, thus, the cost can be reduced, in addition, metal oxidization can be avoided, and the platinum purity is improved; the porosity of the porous platinum can be changed by adjusting and controlling the temperature and time, the prepared porous platinum is uniform in pore diameter distribution, controllable in size and high in porosity, and accordingly, requirements in different fields are met; and elements which are low in melting and boiling point and are obtained through high temperature evaporation can be recycled, accordingly, wasting and polluting areavoided, and the material utilization rate is increased.

Owner:SHANDONG UNIV

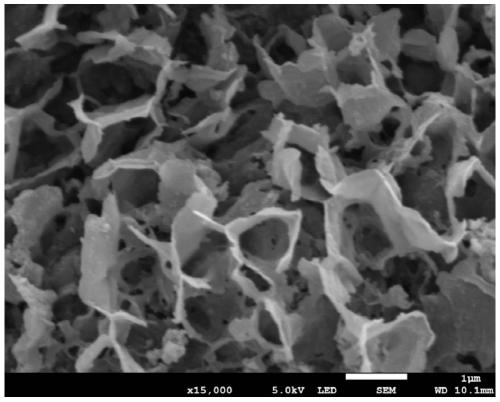

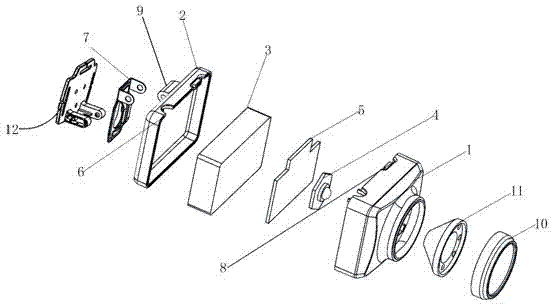

Double vortex electric field assisted ultrafast laser machining system and machining method thereof

ActiveCN108723581AReduce energy lossReduce thermal effectsLaser beam welding apparatusMicro nanoMovement control

The invention relates to a double vortex electric field assisted ultrafast laser machining system and a machining method thereof. The system comprises an ultrafast laser, a polarization modulation lens, a beam amplifier, a focusing lens, a coaxial air suction device, a double helix electrode and a five-axis displacement platform. The machining method comprises the following steps that firstly, a workpiece is clamped on the five-axis displacement platform where the double helix electrode is fixed; then a power supply is connected with the double-helix electrode, and the double-helix electrode is enabled to generate a double vortex electric field of 0-10<5>V / m by controlling the voltage of the power supply; and the ultrafast laser is started, polarization modulation, light beam amplificationand reflect focalization are carried out on laser beams, then the laser beams pass through the double vortex electric field to act on the surface of the workpiece, and meanwhile, coaxial air suctionis carried out above the workpiece so as to remove plasma. According to the double vortex electric field assisted ultrafast laser machining system and the machining method thereof, movement control over the plasma is achieved by utilizing the double vortex electric field, and the coaxial air suction is combined, so that high-efficiency and high-quality laser micro-nano machining and laser drillingare achieved.

Owner:HUNAN UNIV

Preparation method of spherical active carbon with controllable pore size and product and applications thereof

ActiveCN108946722ALow costAperture adjustableGas treatmentOther chemical processesActivated carbonFood industry

The invention belongs to the technical field of adsorption materials, and provides a preparation method of a spherical active carbon and a product and applications thereof. The inventor surprisingly finds that in the preparation method, by regulating the activation processing atmosphere and processing temperature, spherical active carbon with a controllable pore size can be prepared, the yield ishigh, and the cost is low. The mass percentage of spherical active carbon with a pore size of 3-8 nm is 95% or more. By selecting different technologies, spherical active carbon with different pore sizes can be prepared, the requirements of different fields can be satisfied; and moreover, the active carbon has an excellent adsorbing property, is capable of efficiently adsorbing harmful gas such asCO, H2S, HCl, SO2, NOx, and the like, and is applied to food industry for food preparation and / or food discoloring.

Owner:SHENZHEN GLOBAL GREENLAND NEW MATERIALS CO LTD

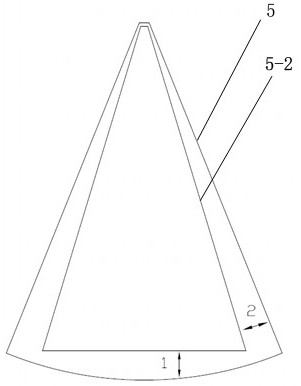

Combined nozzle

InactiveCN106944273AEasy to repair and replaceChange atomization rateSpray nozzlesEngineeringPlenum chamber

The invention discloses a combined nozzle, comprising: a spray head and a pipe body, the spray head is installed on the top of the pipe body; a boss is provided at the bottom of the spray head; a groove is provided at the top of the pipe body; the spray head There are a number of first atomization holes, and a telescopic rod is installed in the middle of the nozzle; a nozzle board is installed outside the nozzle, and the nozzle and the nozzle board are connected by a telescopic rod. Several second atomization holes; the number and distribution of the first atomization holes and the second atomization holes are the same; the corresponding first atomization holes and the second atomization holes are connected by rubber The pipes are connected; the pipe body is sequentially provided with an injection chamber, a pressurization chamber, a diversion chamber and a water inlet chamber from top to bottom, and the ejection chamber and the diversion chamber are both tapered. Through the above method, the present invention provides a combined nozzle. The nozzle adopts a combined structure, which makes maintenance and replacement more convenient, and the atomization rate can be changed according to requirements to meet the needs of different fields.

Owner:SUZHOU HUICHENG PRECISION MOLD

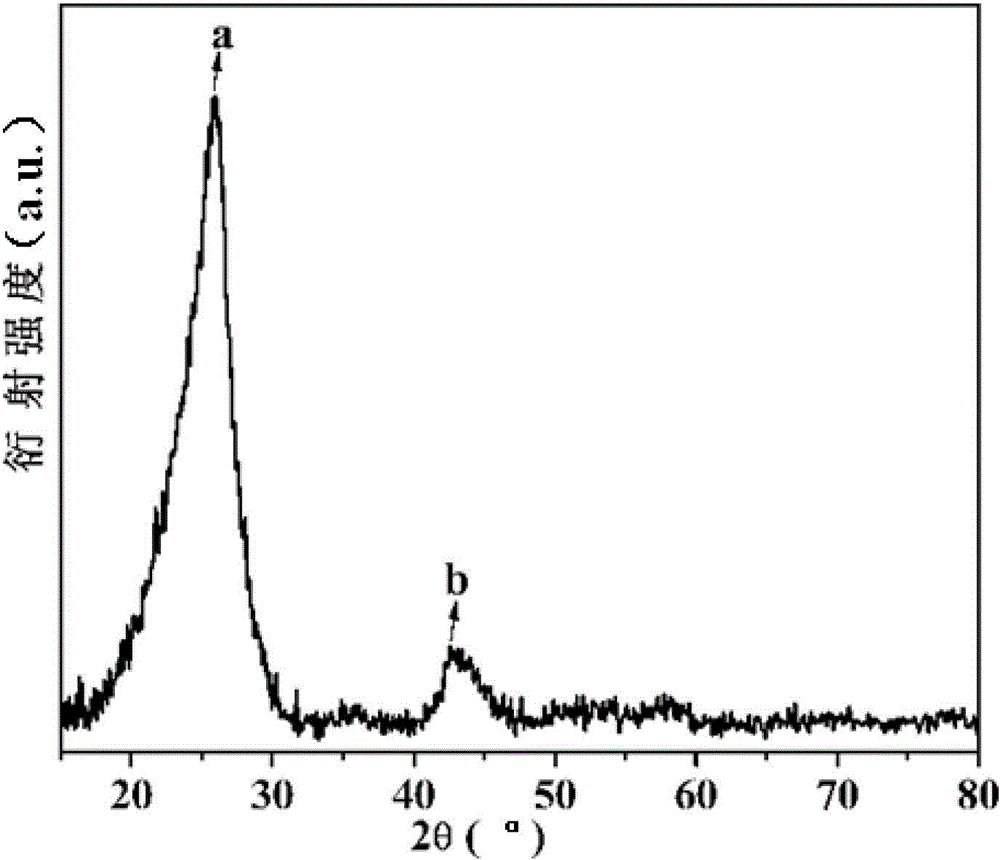

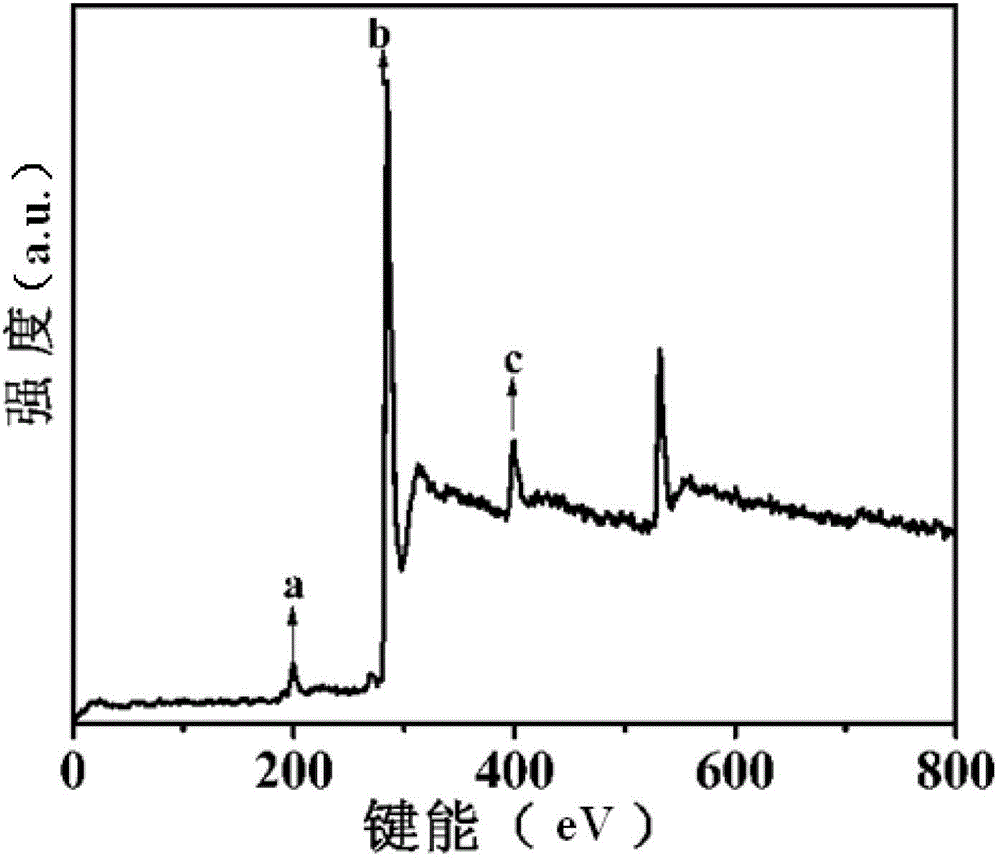

A method for preparing boron-nitrogen co-doped graphitized nano-carbon with biomass as carbon source

ActiveCN103332687BUniform compositionLower synthesis costMaterial nanotechnologyGrapheneCarbonizationChemistry

The invention discloses a method for preparing boron and nitrogen codoped graphitized nano carbon by taking biomass as a carbon source, and relates to a synthetic method of boron and nitrogen codoped graphitized nano carbon. The method aims at solving the problem that industrial production is difficult to achieve due to the fact that the existing preparation technology of boron and nitrogen codoped graphitized nano carbon is complicated, reaction conditions are harsh, the contents of boron and nitrogen are low, the yield is low, and the cost is high. The method comprises the steps of 1, pretreatment, 2, precursor preparation, 3, carbonization treatment and 4, acid treatment. The method adopts the rich biomass in nature as the carbon source, so that a preparation technology is simple, and the synthetic cost of a material is lowered; by changing a material ratio of raw materials, the contents of nitrogen and boron in a finished product and graphitization degrees of nitrogen and boron can be adjusted and controlled, and requirements of different fields can be met; and the biomass is uniform in component, so that functionalization ions can be dispersed in the biomass very well, and a pattern and the property of the product are uniform. The method is used for preparing boron and nitrogen codoped graphitized nano carbon by taking the biomass as the carbon source.

Owner:HEILONGJIANG UNIV

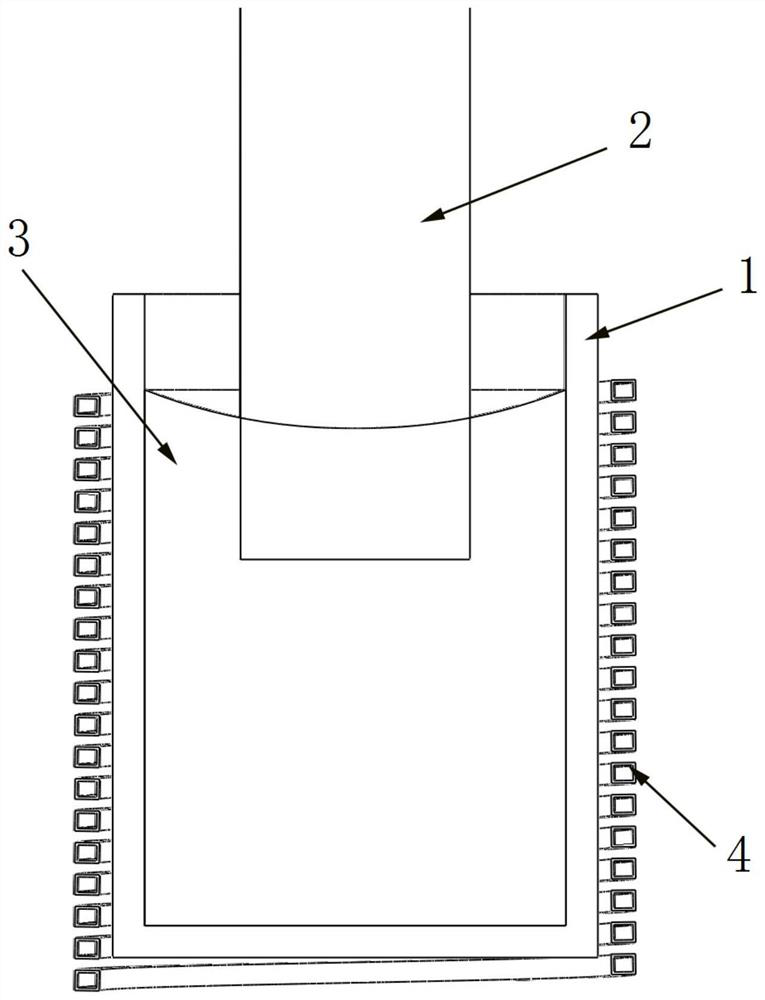

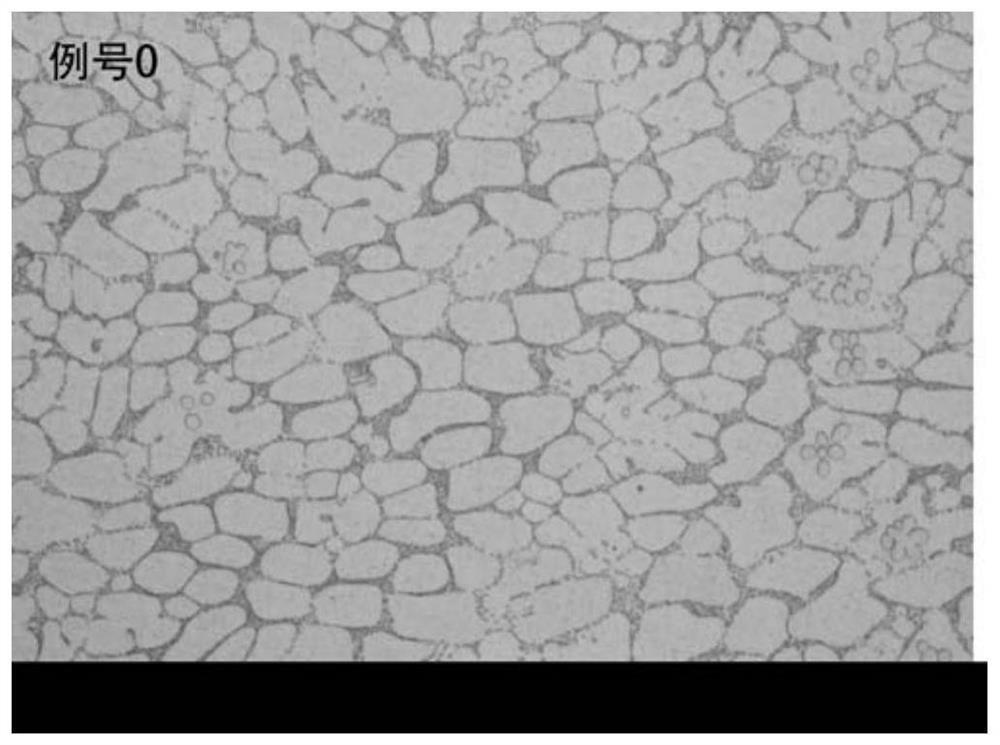

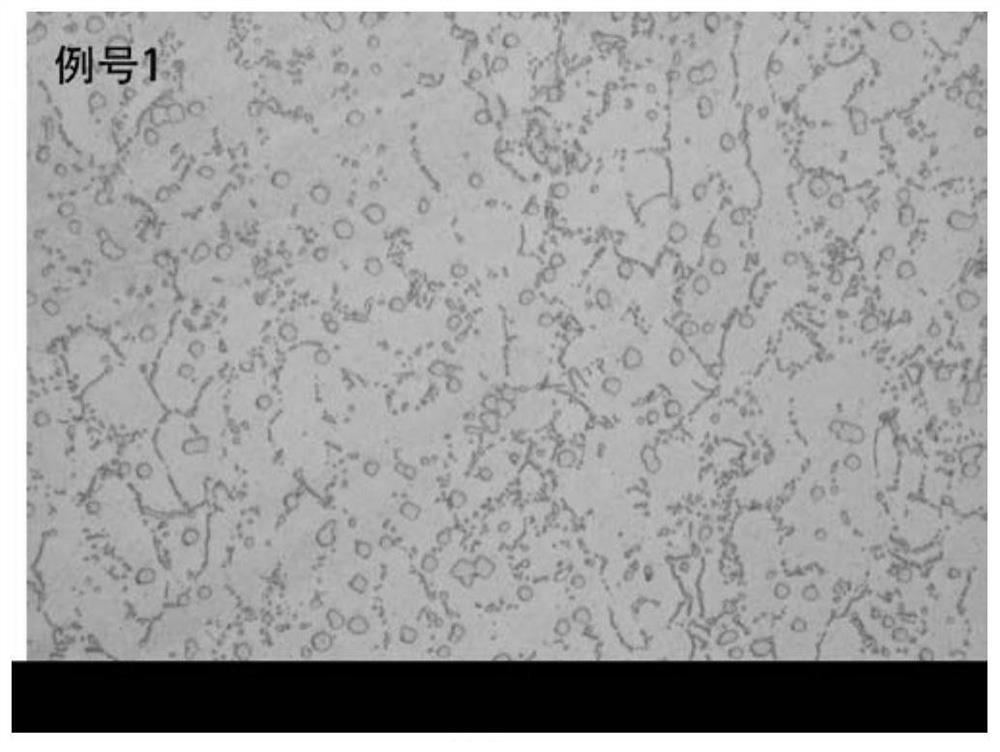

Cu-Cr alloy and ultrasonic-assisted smelting method thereof

The invention provides a Cu-Cr alloy and an ultrasonic-assisted smelting method thereof. The ultrasonic-assisted smelting method of the Cu-Cr alloy comprises the following steps: mixing copper particles with high-purity electrolytic chromium sheets, preparing a Cu-Cr intermediate alloy in a vacuum high-frequency induction furnace, mixing the obtained intermediate alloy with electrolytic copper blocks, and carrying out dilution in a medium-frequency induction furnace; and after the intermediate alloy is molten and is completely mixed with a melt, carrying out ultrasonic treatment on the metal melt for 0.5-5 min, and after the ultrasonic treatment is completed, pouring the alloy liquid into a water cooling mold to obtain a Cu-Cr alloy material. The whole process is carried out under non-vacuum standard atmospheric pressure. The smelting method is applied to a copper-based pseudo alloy for the first time, the quality of a cast ingot is improved, the microstructure of the as-cast alloy is improved, and the mechanical property of the alloy is improved.

Owner:DALIAN UNIV OF TECH

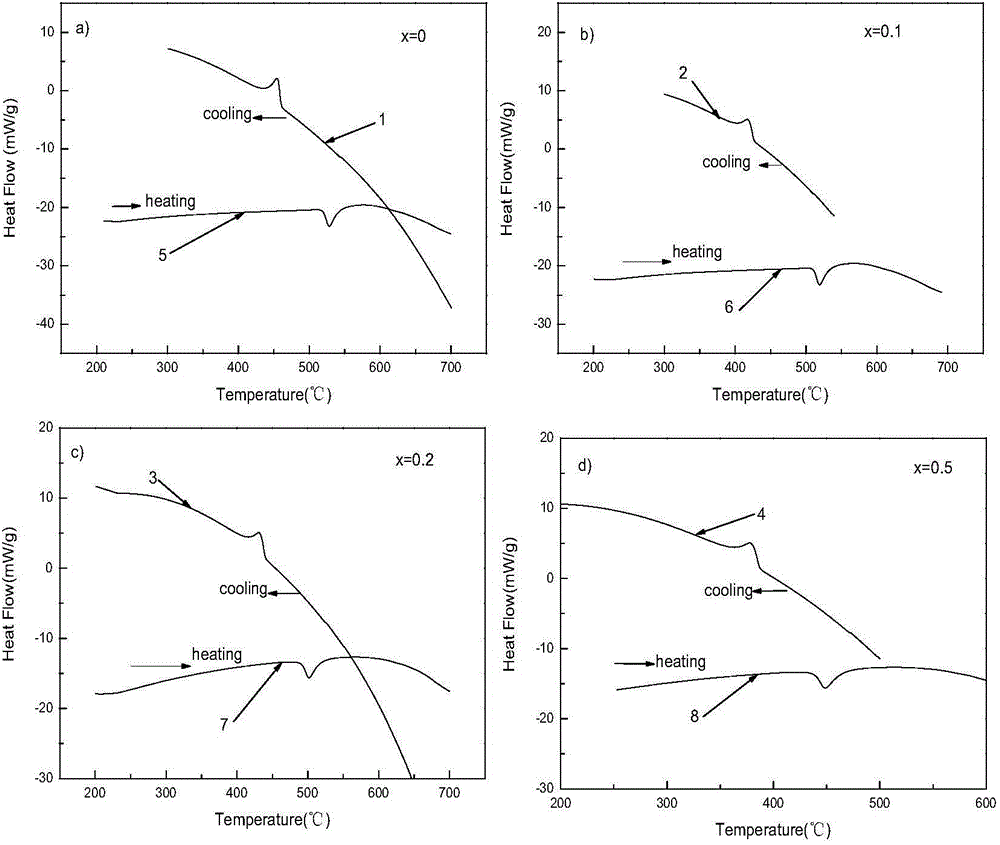

Gamma phase-inhibited high temperature double-phase Ni-Mn-Ga-Gd alloy and preparation method thereof

InactiveCN104962780AGamma phase reductionWide temperature rangeMartensite transformationDouble phase

The invention concretely relates to a gamma phase-inhibited high temperature double-phase Ni-Mn-Ga-Gd alloy and a preparation method thereof. The structural general formula of the alloy is represented by Ni58Mn25Ga17-xGdx, and x in the general formula is 0.1-0.5. The gamma phase of the Ni58Mn25Ga17-xGdx alloy obtained through material taking, arc melting, cleaning, heat insulation and quenching in water is obviously reduced, and is about 80-40% lower than that of present Ni58Mn25Ga17 alloy; and the martensite phase transition temperature of the Ni58Mn25Ga17-xGdx alloy is 387.5-461.4DEG C, and the temperature range is wide, so demands of different fields are met. Raw materials required in the invention are cheap and have abundant reserves, the alloy material prepared in the invention has the advantages of good toughness, large strength and good processing property, and can be processed to form various shapes as needed, and the preparation method has the advantages of simple process, easy industrial production, and development of a new idea for application of high-temperature and high-plasticity shape memory alloys.

Owner:DALIAN UNIV

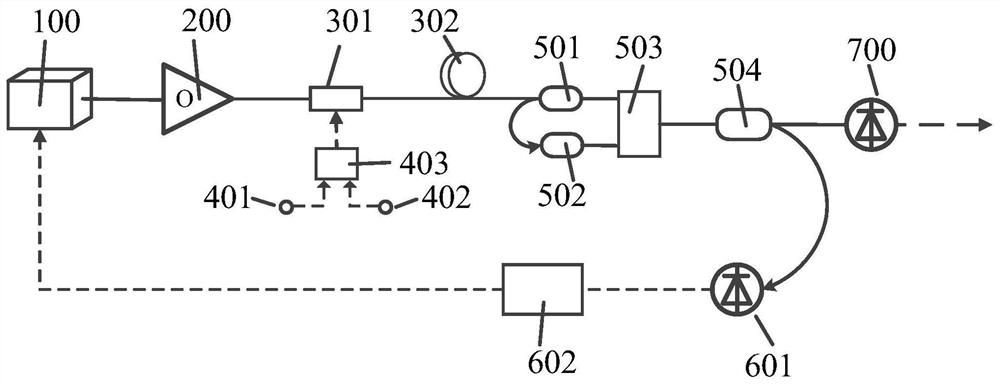

Large dynamic signal demodulation model device based on phase modulation

ActiveCN111901041ANo need for bias point controlPrecise Amplitude Control of Radio Frequency Third-Order Spurious SignalsPhotonic quantum communicationRadio-over-fibreSoftware engineeringMechanical engineering

The invention belongs to the technical field of microwave photons, and particularly relates to a large dynamic signal demodulation model device based on phase modulation. The demodulation model devicecomprises an optical frequency comb source, an optical amplification module, a phase modulation module, a radio frequency source module, an optical filtering module, a frequency locking control module and a photoelectric detection module. The optical frequency comb source is connected with an optical input port of the phase modulation module after passing through the optical amplification module;meanwhile, a radio frequency signal output by the radio frequency source module is connected with a radio frequency input port of the phase modulation module, and an optical signal output by the phase modulation module is divided into two paths after being processed by the optical filtering module: a first path is connected with the frequency locking control module to generate a feedback signal and output the feedback signal to the optical frequency comb source to control and adjust the absolute comb tooth frequency of the optical frequency comb source; a second path is connected with the photoelectric detection module to generate and output a radio frequency signal; the optical frequency comb source is used for providing phase-locked dual-wavelength laser, accurate adjustment and suppression of high-order spurious signals are achieved, and therefore the third-order intermodulation value and the dynamic range of a link are improved.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP +1

Safe and anti-explosion air energy lithium battery highlight LED multipurpose head lamp

InactiveCN103925475AReduce volumeReduce weightLighting support devicesElectric circuit arrangementsUltrasonic weldingLight beam

A safe and anti-explosion air energy lithium battery highlight LED multipurpose head lamp comprises a main front cover shell and a rear cover bottom shell. A highlight LED head lamp body is mounted inside the main front cover shell and the rear cover bottom shell. The safe and anti-explosion air energy lithium battery highlight LED multipurpose head lamp is characterized in that the main front cover shell comprises a high-efficiency highlight focusing lens with four auxiliary lamp positioning holes and used for containing a highlight-type energy-saving environment-friendly high-power LED light source, light beams emitted by the LED light source are ejected from a lens through hole end, the LED light source is in power supply connection with a lithium battery through an aluminum alloy heat-radiation driving complex circuit board, the lens is provided with four phi5 LEDs, a front cover and a rear cover are matched and encapsulated through an ultrasonic welding machine, the LED light source, the driving circuit board and the lithium battery are contained in the front cover and the rear cover, and a two-layer elastic band head pasting board is mounted on the rear cover bottom shell, so that the head lamp can be conveniently and comfortably worn on the head of a human body to realize light emitting and lighting. The safe and anti-explosion air energy lithium battery highlight LED multipurpose head lamp has the advantages of being small in size, light in weight, long in lighting time, safe and anti-explosion, energy saving and environment friendly, convenient and comfortable, high in light emitting efficiency, long in service life and the like.

Owner:刘成雷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com