Cu-Cr alloy and ultrasonic-assisted smelting method thereof

An ultrasonic-assisted, cu-cr technology, applied in the field of Cu-Cr alloy, can solve the problems of unrealized modification of chromium crystals, and achieve the effect of reducing casting defects and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

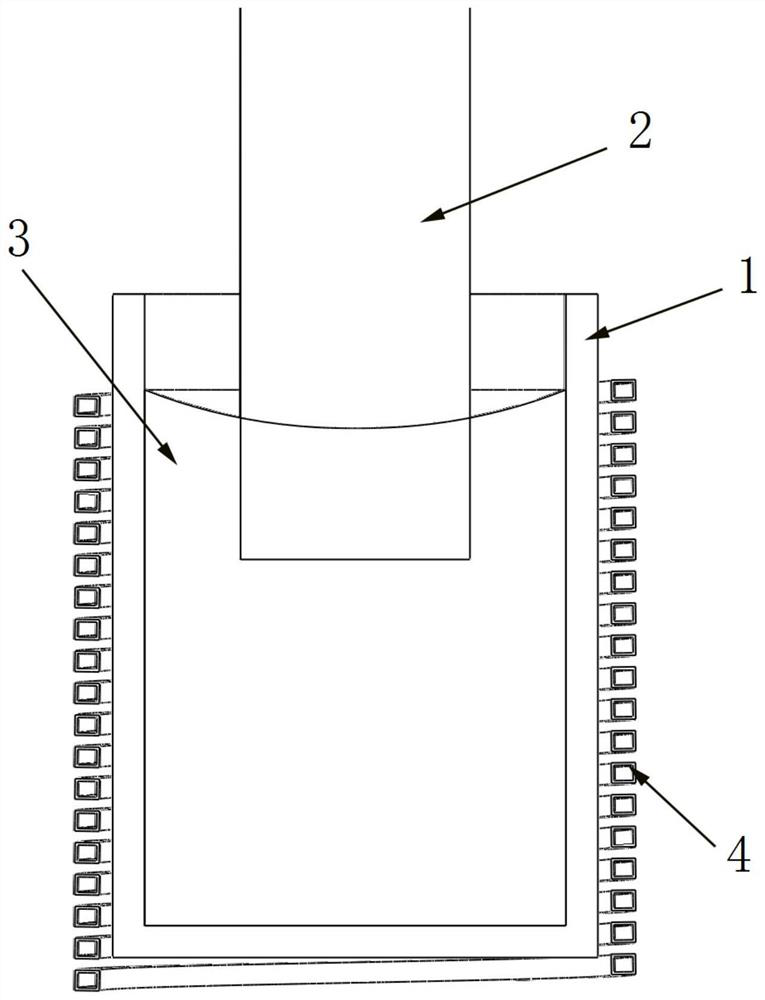

Method used

Image

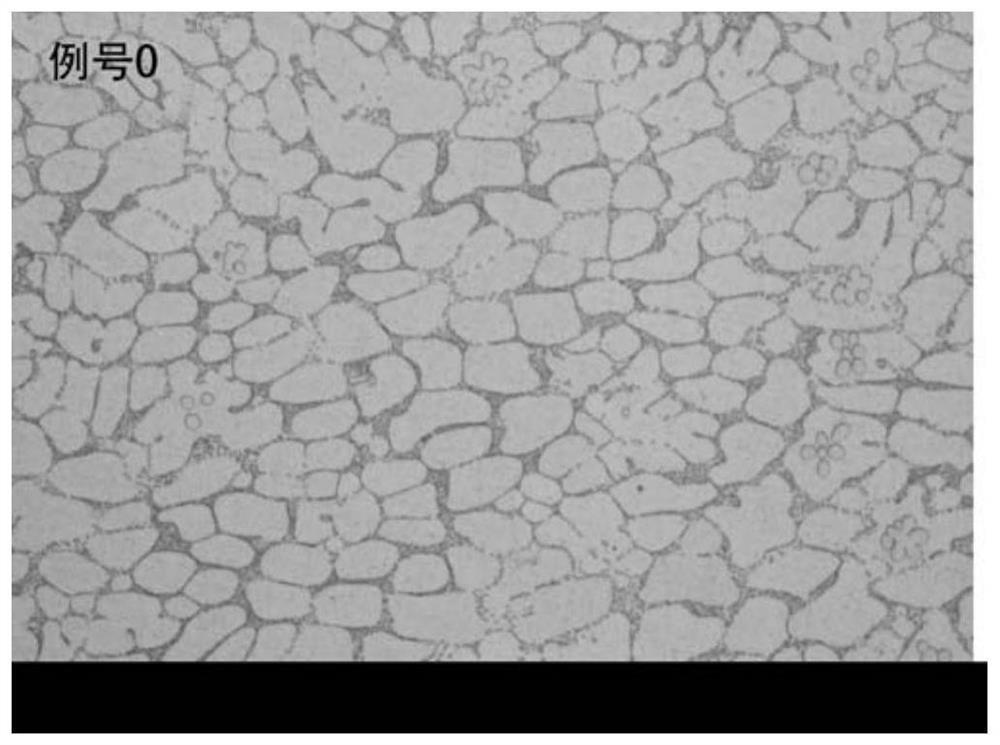

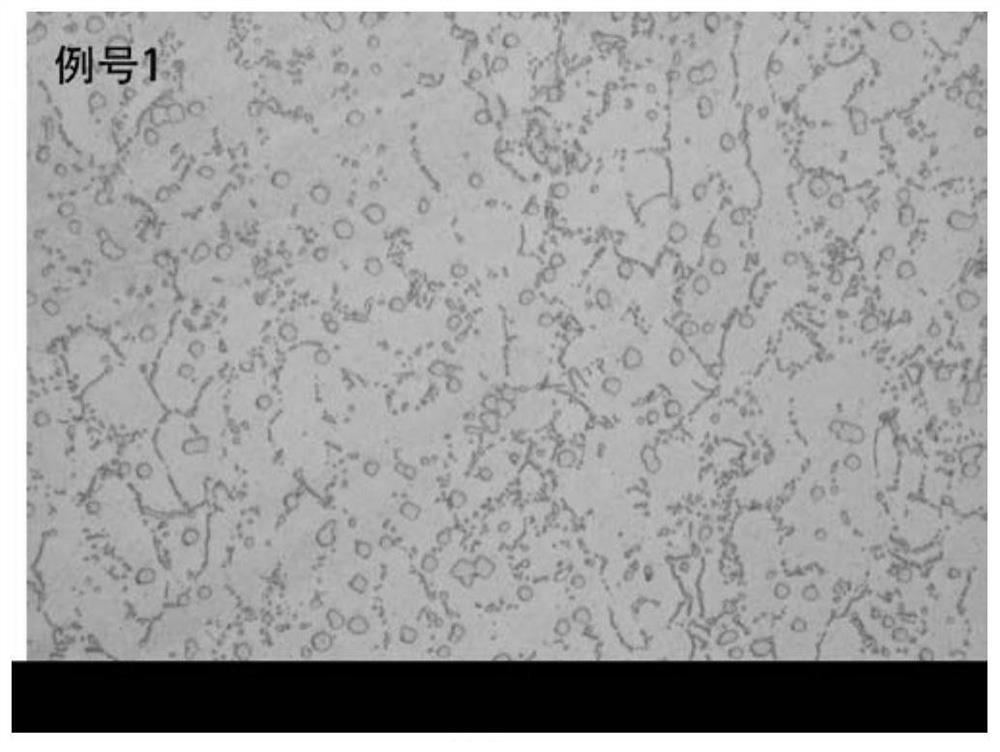

Examples

Embodiment 1

[0035] This embodiment discloses a Cu-Cr alloy ultrasonic assisted melting method, comprising the following steps:

[0036] Step 1: Preparation of copper-chromium master alloy raw materials. According to the mass fraction ratio: Cr: 20%, Cu: 80%, put 75g of high-purity copper particles and 15g of high-purity electrolytic chromium into the boron nitride crucible 1 And put it in a drying oven at 60°C for 1 hour, the purpose is to remove the residual moisture on the raw materials and the crucible;

[0037] The second step: prepare the master alloy: put the dried raw materials into the vacuum high-frequency induction furnace with the crucible (the copper particles are pressed on the chromium sheet), turn on the mechanical pump to vacuum to 130pa, turn on the molecular pump to vacuum to 10pa, Turn off the molecular pump and the mechanical pump in turn to stop vacuuming; open the protective gas valve to feed argon protective gas until the gauge pressure in the furnace is 0.5 atmosph...

Embodiment 2

[0049] This embodiment discloses a Cu-Cr alloy ultrasonic assisted melting method, comprising the following steps:

[0050] The first step: Copper-chromium master alloy raw material preparation: According to the mass fraction ratio: Cr: 20%, Cu: 80%, put 75g of high-purity copper particles and 15g of high-purity electrolytic chromium into the boron nitride crucible and mix Put it in a drying oven at 60°C for 1 hour to remove the residual moisture on the raw materials and the crucible;

[0051] The second step: prepare the master alloy: put the dried raw materials into the vacuum high-frequency induction furnace with the crucible (the copper particles are pressed on the chromium sheet), turn on the mechanical pump to vacuum to 130pa, turn on the molecular pump to vacuum to 10pa, Turn off the molecular pump and the mechanical pump in turn to stop vacuuming; open the protective gas valve to feed argon protective gas until the gauge pressure in the furnace is 0.5 atmospheres, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com