High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

A technology for high-speed trains and steel casting, applied in heat treatment equipment, casting molding equipment, casting molds, etc., can solve the problems of room temperature strength and toughness, high temperature strength, cold and heat fatigue resistance matching, etc., to reduce casting defects and improve cold and heat resistance Effects of fatigue failure performance and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] On the other hand, the present invention provides a method for preparing cast steel for high-toughness and cold-heat fatigue-resistant high-speed train brake discs, comprising the following steps:

[0039] Step 1: Manufacture resin sand mold;

[0040] Use quartz sand, resin, and curing agent to make resin sand molds, and use three-dimensional geometric entities or 3D printing equipment to prepare resin sand mold components. The part of the sand mold components that contacts molten steel is painted with zircon powder coating for 1-10 times. After the sand mold components are naturally dried and solidified, they are preheated at 100-800°C for 1-8 hours to remove moisture, remove solid particles in the sand mold cavity, and assemble the mold to obtain a resin sand mold for molten steel pouring.

[0041] The particle size of quartz sand is 10-200 mesh, and SiO in quartz sand 2 The mass percentage of the content is greater than 90%, the added amount of the resin is 0.5%-25....

Embodiment 1

[0064] The present invention provides a high-toughness and cold-heat-fatigue-resistant high-speed train brake disc cast steel, and its chemical composition mass percentage is shown in Table 1.

[0065] The invention provides a method for preparing cast steel for brake discs of high-toughness and cold-heat fatigue-resistant high-speed trains, which comprises the following steps:

[0066] Step 1: Make resin sand mold;

[0067] Use quartz sand, phenolic resin, and curing agent to make resin sand molds. The particle size of the quartz sand is 50-80 mesh, and the quartz sand is SiO 2 The mass percentage of the content is greater than 95%, the added amount of the phenolic resin is 2.0% of the total mass of the sand mold, and the added amount of the curing agent is 30% of the added resin mass. After the sand mold is fully dried and solidified naturally, the water is fully removed after preheating at 600°C for 4 hours, and the solid particles in the cavity are sucked out by negative ...

Embodiment 2

[0083] A high-toughness anti-cold and heat fatigue-resistant high-speed train brake disc cast steel and its preparation method are carried out according to the method in Example 1, the difference is that:

[0084] 1. A kind of high-toughness anti-cold and heat fatigue high-speed train brake disc cast steel, its chemical composition mass percentage is as shown in table 4.

[0085] 2. The pouring method is adopted for pouring, the pouring temperature is 1580°C, the pouring time is 40s, and the gate of the sprue is covered with a ceramic filter to filter coarse inclusions in the molten steel.

[0086] 3. After pouring, the casting is protected by an argon atmosphere and left to cool for 30 minutes, during which the casting is accelerated by adding a chilled iron mold. Then, the casting is exposed to air and cooled to 500°C, the casting is taken out of the box, and the riser is cut and then air-cooled to room temperature.

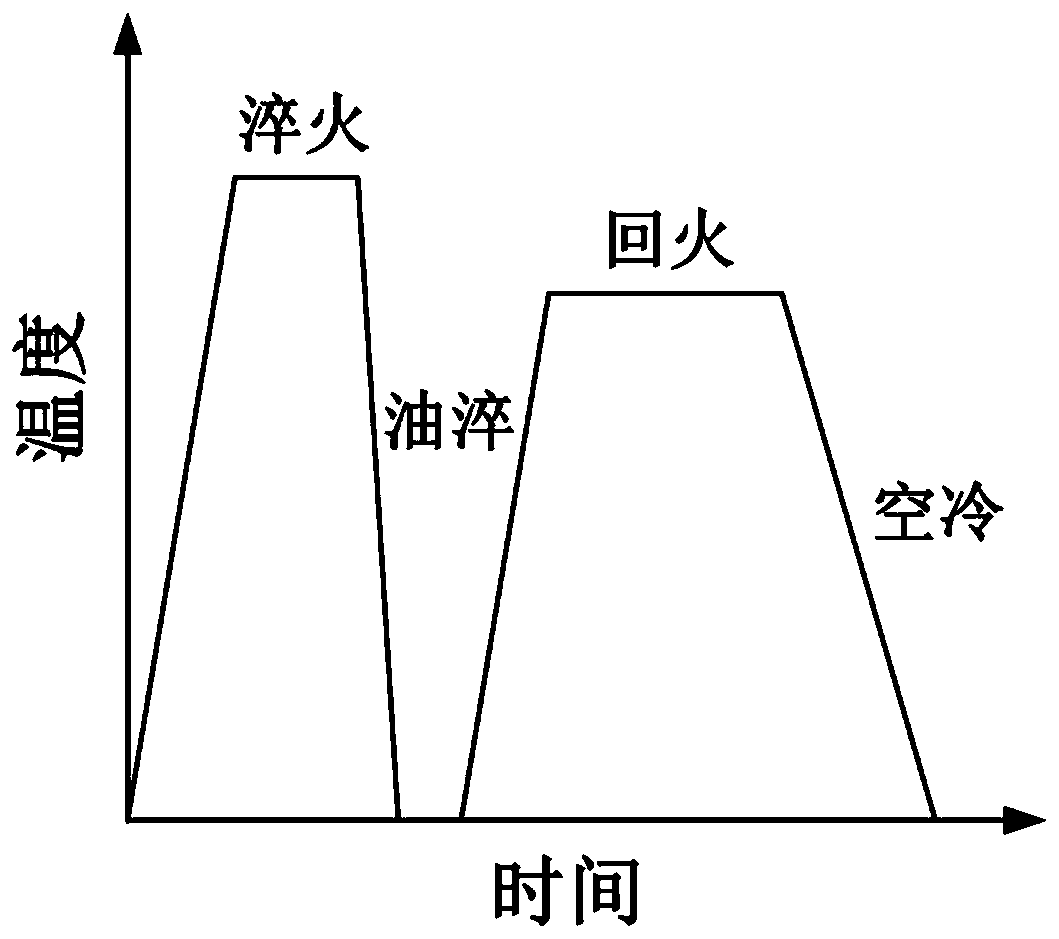

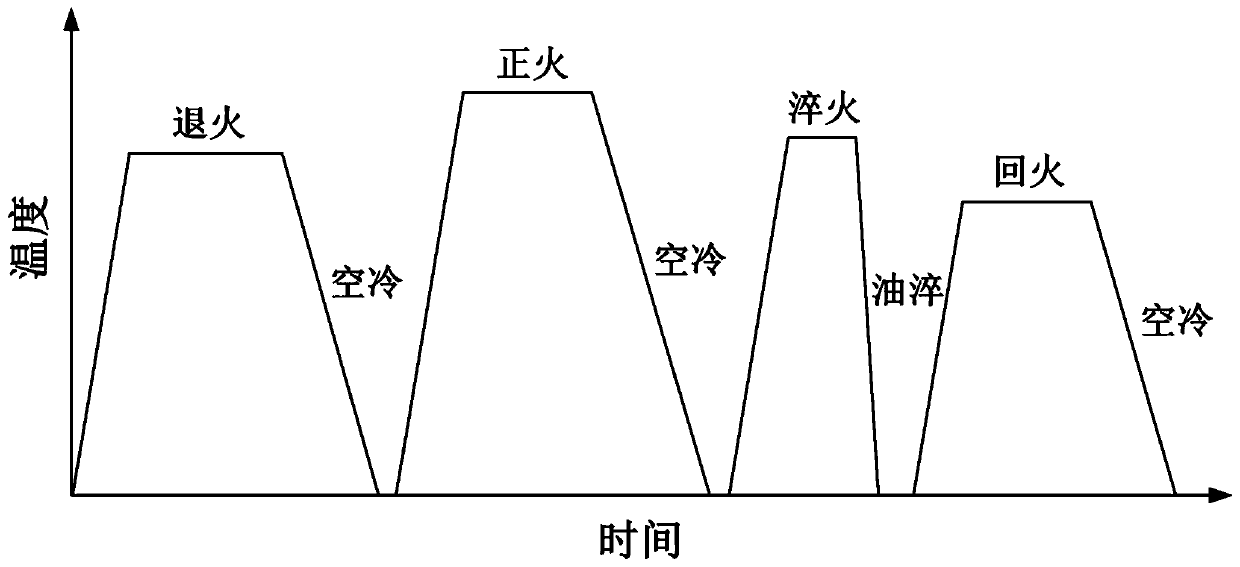

[0087] 4. After the casting is cooled to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com