Patents

Literature

33results about How to "Inhibition of scalability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making quench hardening layer of cold roll barrel

ActiveCN1840714AQuality improvementAdd depthIncreasing energy efficiencyProduction rateIntermediate frequency

The related processing method for quench-hardening layer of roller body comprises: processing roller with steel, letting roller body cross in turn the first and second LF sensors and MF sensor for induction electric heating, and spraying water for cool to obtain the target layer with depth more than 50mm. This invention can improve wear and yield, reduces energy consumption, and brings great economic benefits.

Owner:BAOSTEEL ROLL SCI & TECH

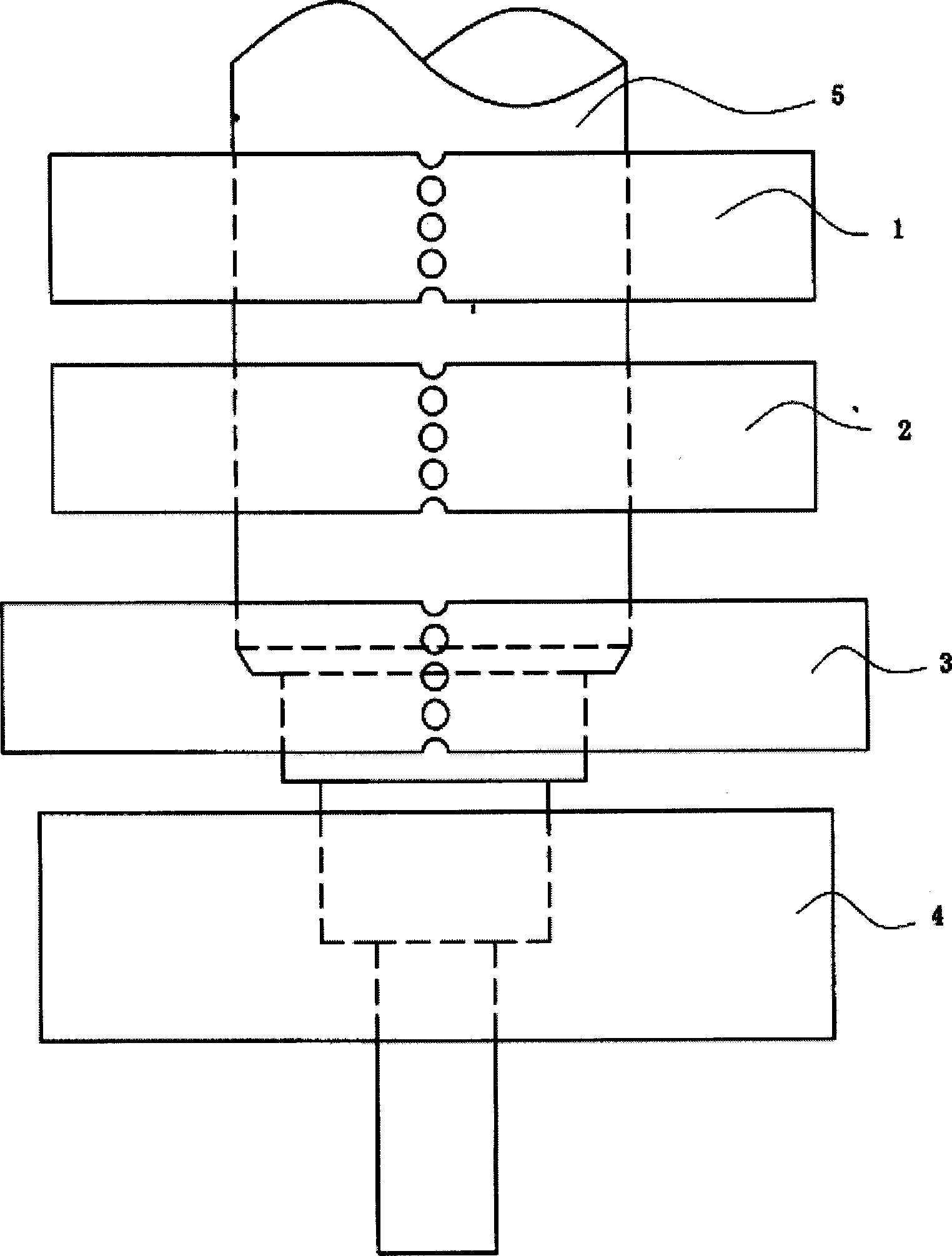

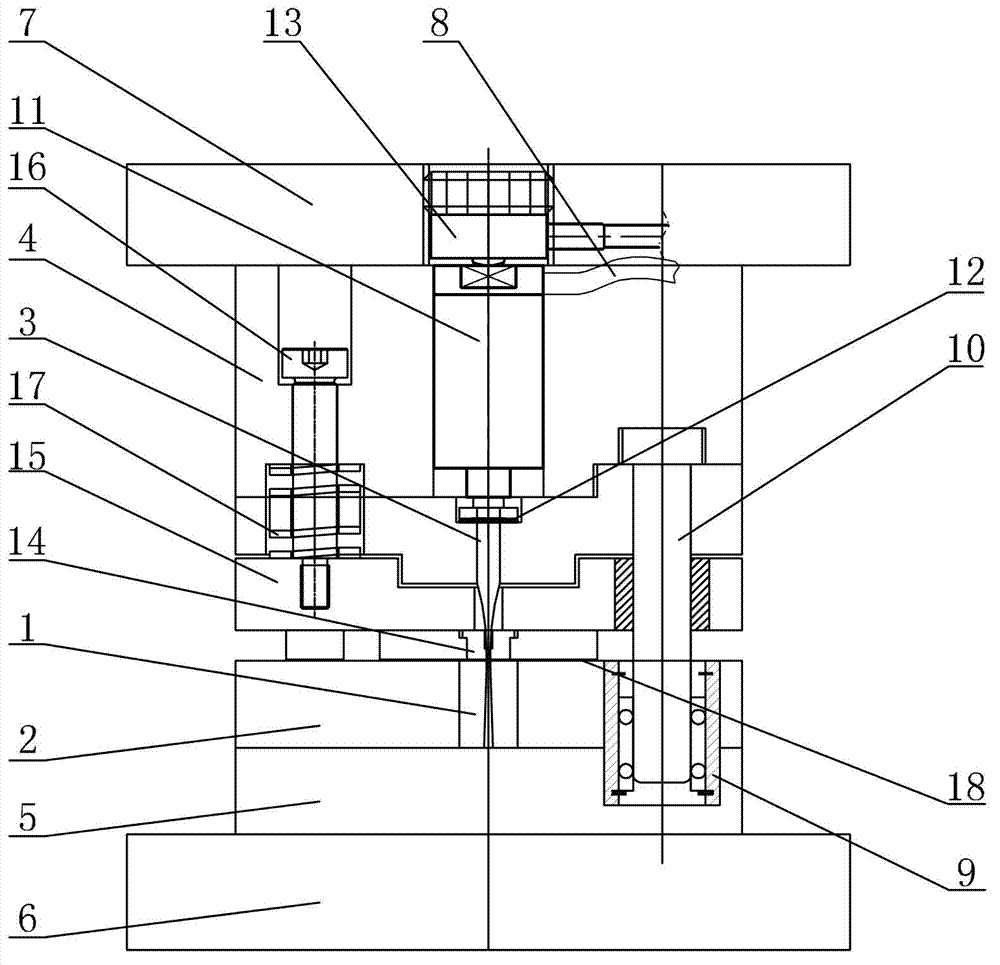

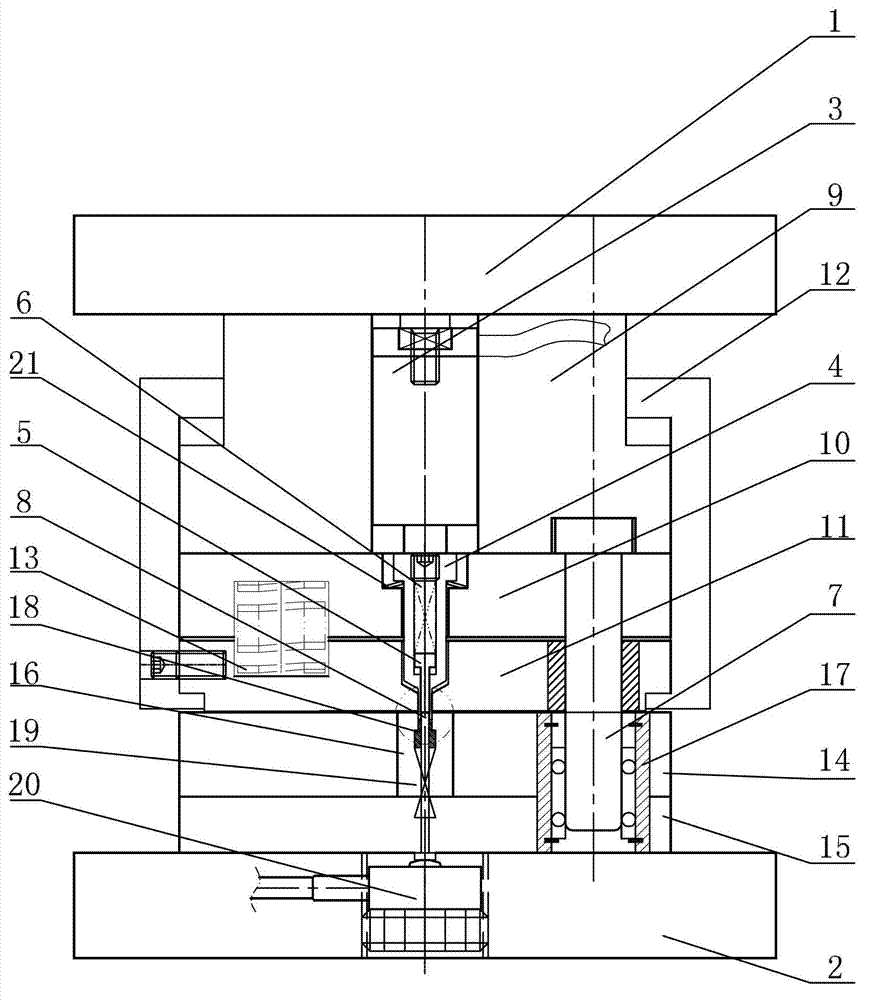

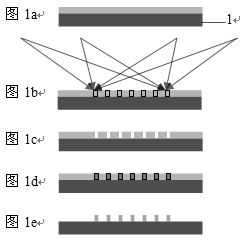

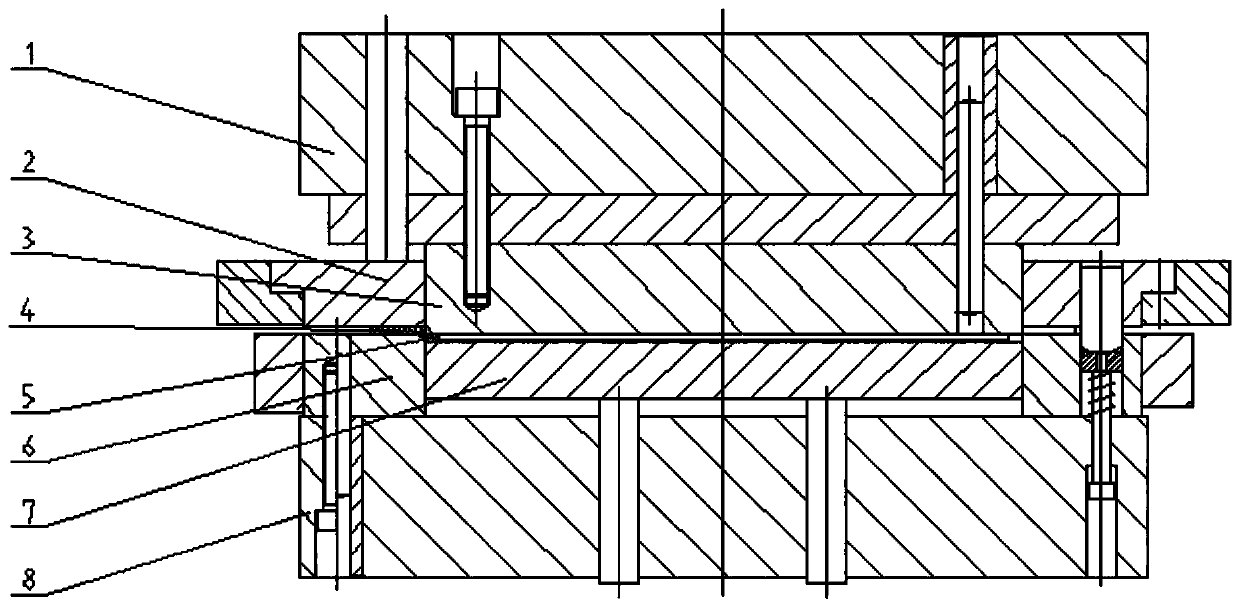

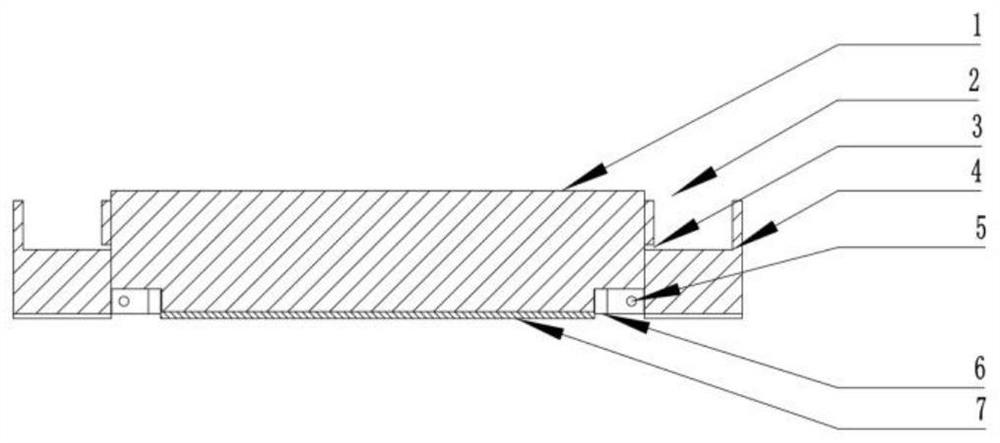

High-frequency vibration auxiliary micro-blanking forming device and method for foil plate

ActiveCN102962331AInhibition of germinationInhibition of scalabilityMechanical vibrations separationEjection devicesHigh frequency powerEngineering

The invention relates to a micro-blanking forming device and a forming method, in particular to a high-frequency auxiliary micro-blanking forming device and a method for a foil plate. The device and the method aim at solving the problems in the existing high-precision blanking forming of the foil plate that an interval between a female die and a male die is small, a blanking force is significantly increased by a size effect, and the dies are badly worn and have short service lives. The device comprises a female die fixing plate, a lower bolster and a lower die plate that are sequentially connected from the top down, wherein an upper die plate and a male die fixing plate are sequentially arranged above the female die fixing plate; a female die is embedded into the middle part of the upper surface of the female die fixing plate; a vibration component and a punch are sequentially mounted in the male die fixing plate from the top down in an inserting manner; a middle line of the punch is coincided with that of the female die; the vibration component is connected with a high-frequency power source; a guide sleeve is mounted on the upper surface of the female die fixing plate in an inserting manner; the upper end of a guide column is mounted in the male die fixing plate in an inserting manner; and the lower end of the guide column is mounted in the guide sleeve in an inserting manner. The device and the method are used for blanking forming of the foil plate.

Owner:HARBIN INST OF TECH

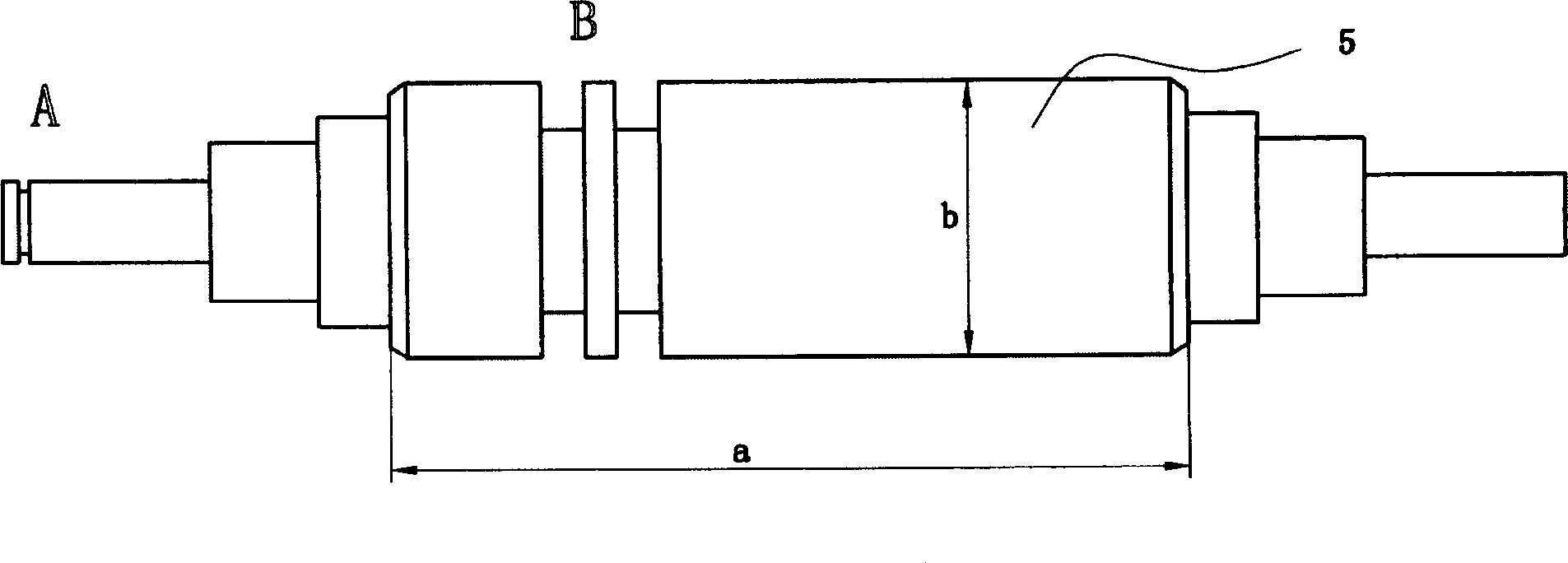

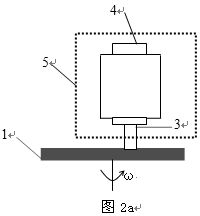

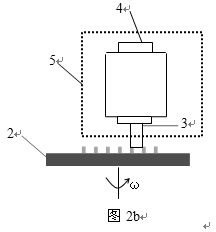

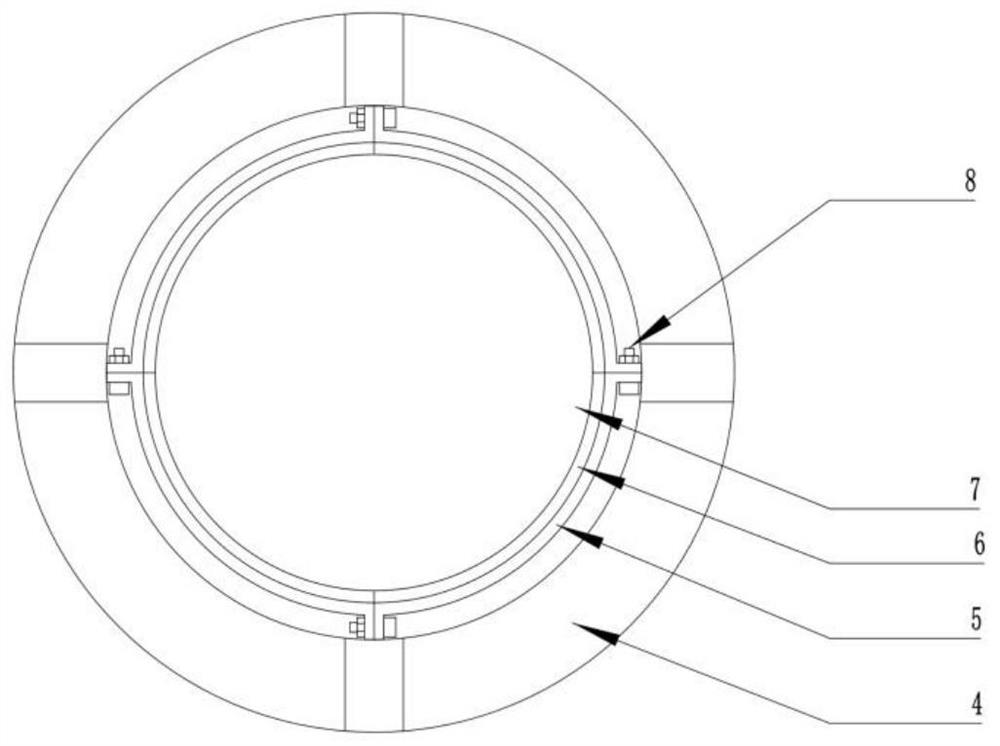

Device and method for high-frequency vibration assisted micro-deep drawing forming of foil boards

ActiveCN103042109AReduce frictionInhibition of germinationShaping toolsHigh frequency powerMicro actuator

The invention relates to a device and a method for micro-deep drawing forming of foil boards, in particular to a method and a device for high-frequency vibration assisted micro-deep drawing forming of foil boards and aims to solve the problem that low-strength foil boards are difficult to form small-diameter cylinder pieces by means of deep drawing. An upper die base, an upper die component, a lower die component and a lower die base of the device are sequentially arranged from top to bottom, the upper end of the upper die component is connected with the lower surface of the upper die base, the lower end of the lower die component is connected with the upper surface of the lower die seat, a magnetic extendable micro-actuator and a male die are arranged in the upper die component sequentially from top to bottom, the magnetic extendable micro-actuator is connected with a high-frequency power supply, a power output end of the magnetic extendable micro-actuator is connected with the upper end of the male die, a back pressure spring and a back pressure ejector rod are arranged in a cavity of the male die sequentially from top to bottom, a deep drawing punch is inserted on the upper surface of the lower die component, and a belleville spring is sleeved on the outer side wall of the upper end of the male die. The device and the method are used for micro-deep drawing forming of the foil boards.

Owner:HARBIN INST OF TECH

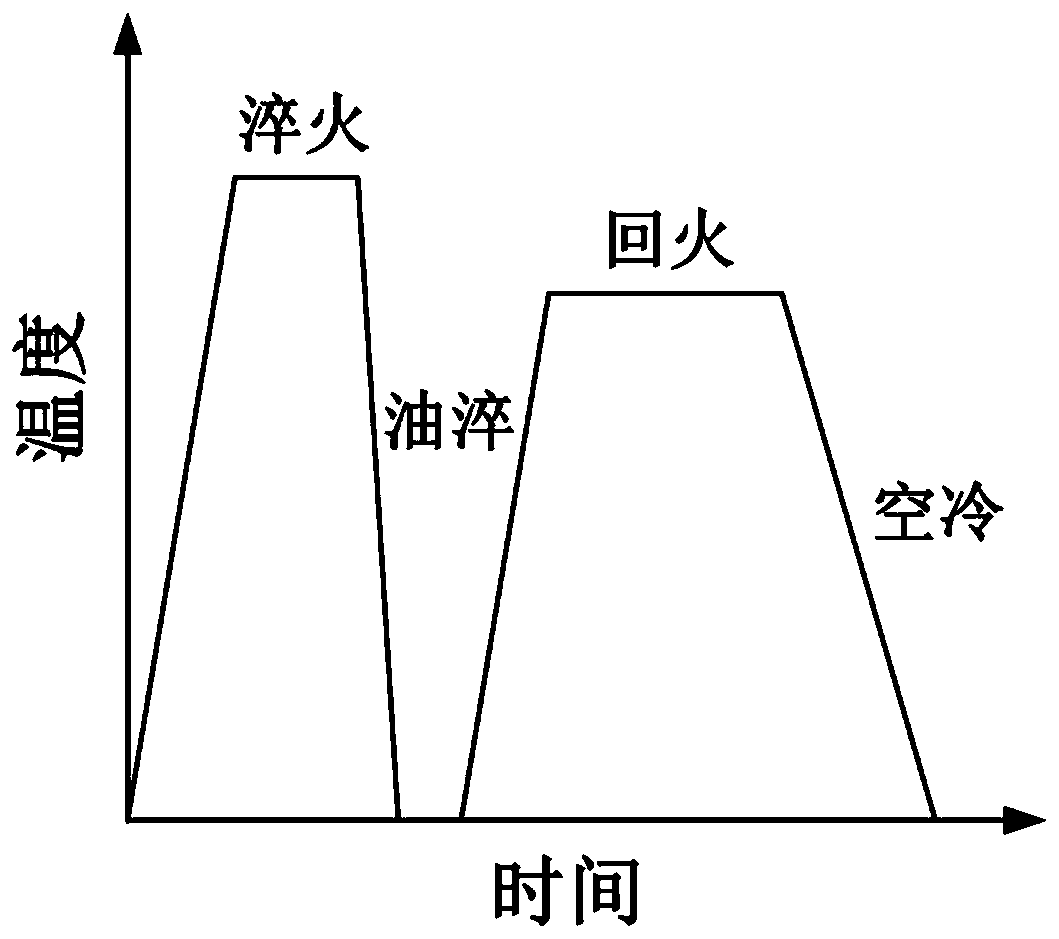

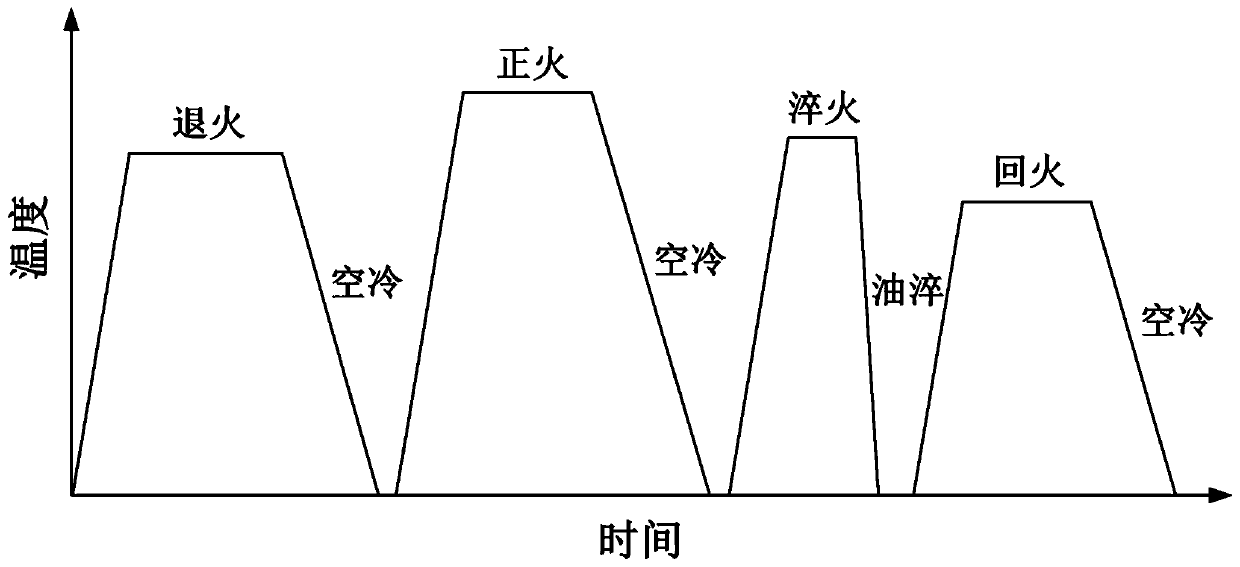

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Quasi-crystal abrasive paste applicable to surface mechanical finishing of soft metals

InactiveCN103242803AImprove smoothnessReduce wearOther chemical processesPolishing compositions with abrasivesSurface finishGranularity

The invention discloses a quasi-crystal abrasive paste applicable to the surface mechanical finishing of soft metals, and the adopted abrasive material thereof is a quasi-crystal alloy powder material. The quasi-crystal abrasive paste comprises a quasi-crystal alloy and related phase materials; the granularity of a powdered abrasive material is less than or equal to 50mu m; the mass percentage of the quasi-crystal powdered abrasive material in the abrasive paste is 1-90%, and the balance of the abrasive paste refers to abradant auxiliary materials such as oil-soluble or water-soluble pastes and the like. According to the invention, based on the unique grinding behavior and mechanism, the abrasive paste has an efficient mechanical finishing and defect repair capacity to the surfaces of soft metals / alloy specimens or workpieces; and compared with traditional abrasive materials, a surface finishing effect required by workpieces can be achieved efficiently, and the erosion amount is low, therefore, the abrasive paste is applicable to the surface finishing of high-precision workpieces, namely, the dimensional accuracy of workpieces can be kept while the surface quality of workpieces is satisfied. The abrasive paste disclosed by the invention has the characteristics of high stability, high liquidity, no adhesiveness and easiness for cleaning, therefore, the abrasive paste is an ideal grinding material for the mechanical finishing of soft materials.

Owner:DALIAN UNIV OF TECH

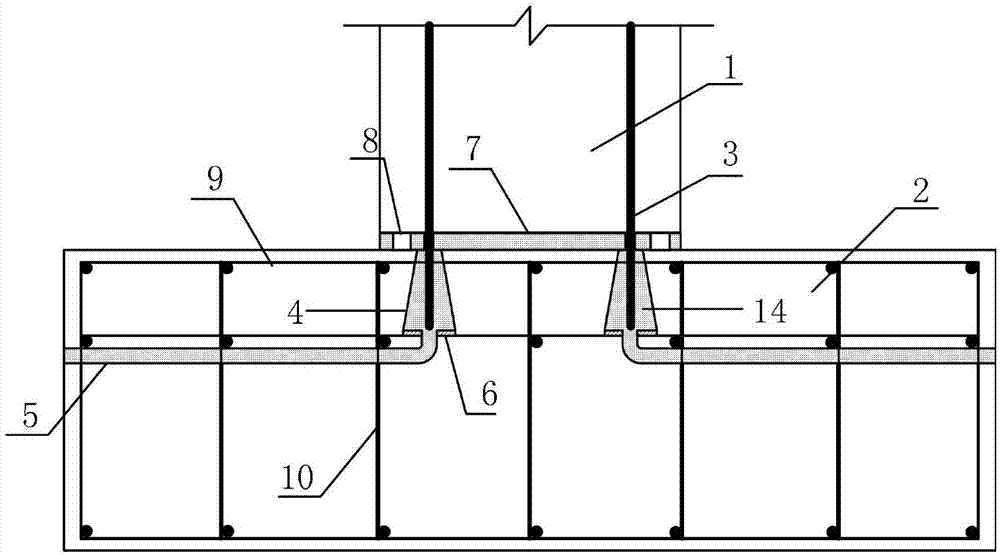

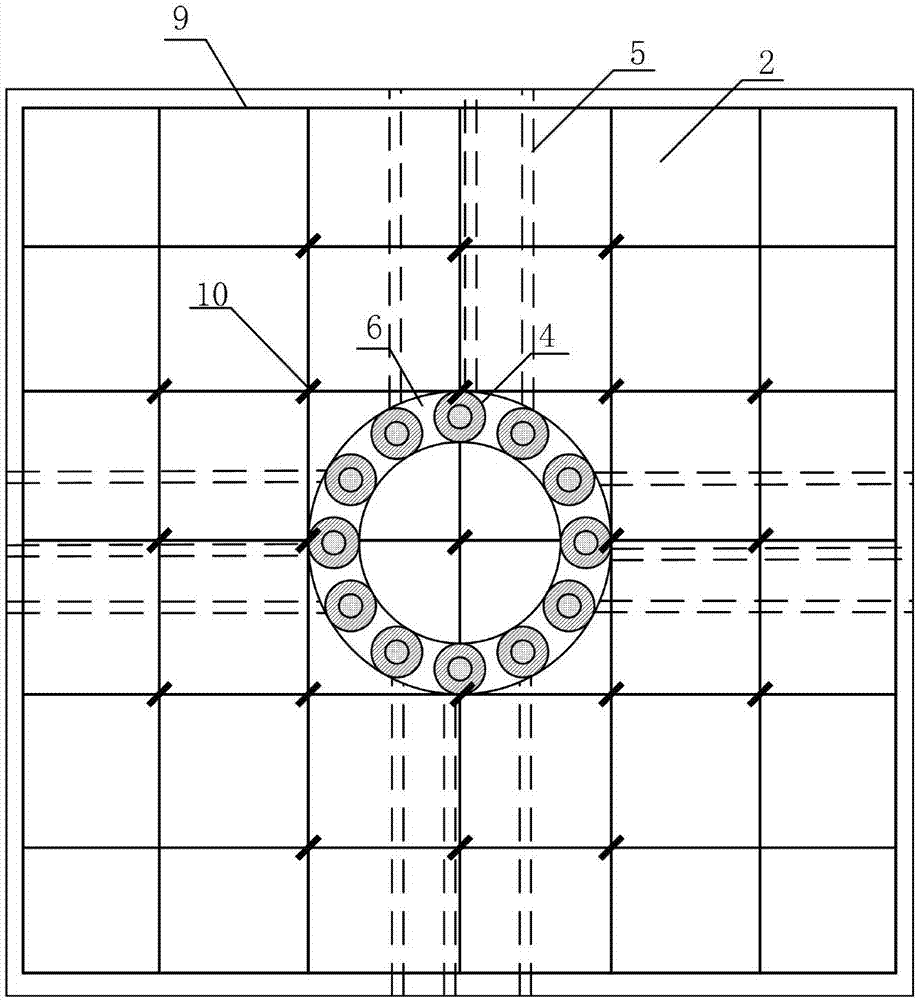

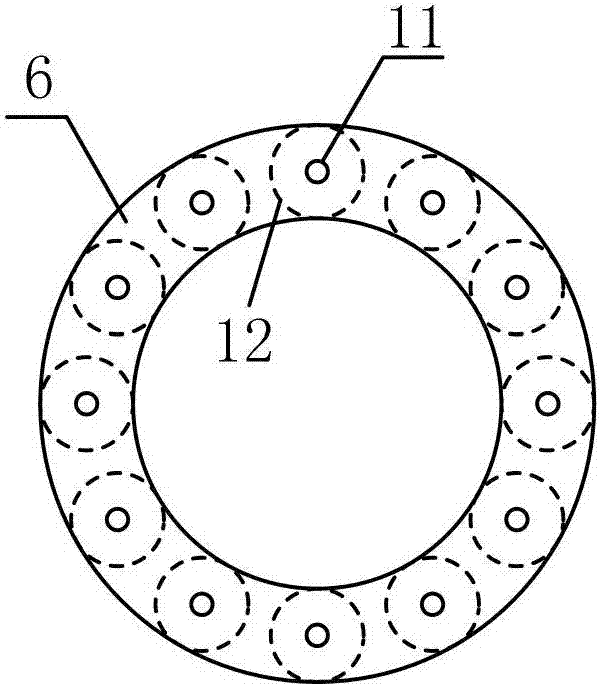

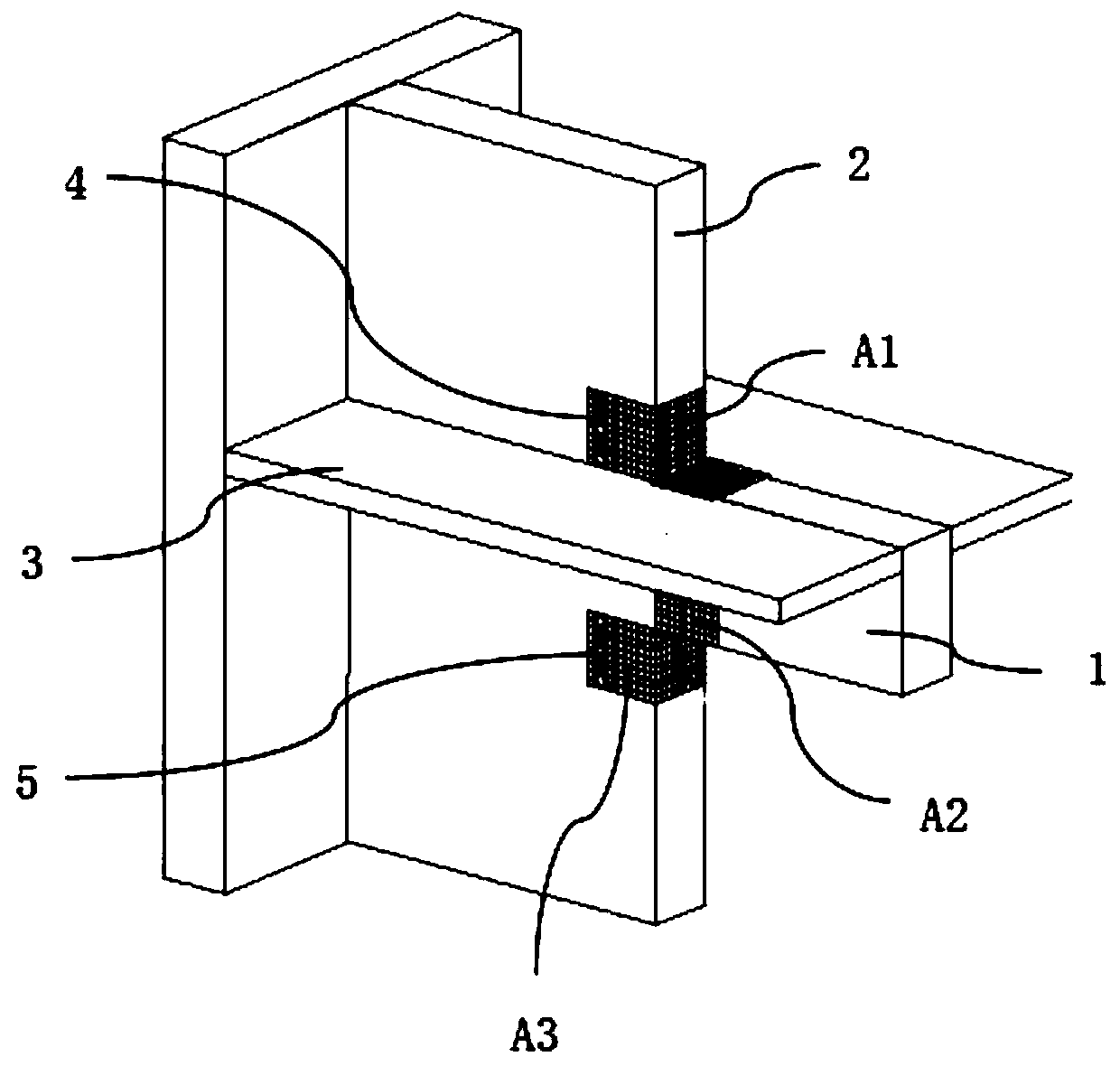

Conical pipe anchor bar connection structure for prefabricated assembly structure

ActiveCN107882051AImprove adhesionImprove binding abilityBridge structural detailsFoundation engineeringReinforced concreteEngineering

The invention discloses a conical pipe anchor bar connection structure for a prefabricated assembly structure, and belongs to the field of prefabricated assembly engineering. The connection structurecomprises a conical pipe, a grouting guide pipe and a fixing circular ring. The conical pipe is of a pre-embedded structure, the conical pipe can achieve a restraint effect on steel bars and groutingmaterials in the conical pipe, and meanwhile the tension capacity of the conical pipe in concrete can be improved. Frame vertical ribs and tie bars in a prefabricated bearing table also achieve a restraint effect on cracking of the bearing table or foundation concrete caused during pulling of the conical pipe. In prefabricated components, a conical pipe group is connected with the surrounding frame vertical ribs and the tie bars, and therefore the anchor performance of the conical pipe group can be improved. The steel bar anchorage length needed by the conical pipe anchor bar connection structure is small, the conical pipe anchor bar connection structure can be used for connection between a reinforced concrete structure prefabricated assembly component and a foundation or the bearing table, and rapid building of the prefabricated assembly reinforced concrete is achieved.

Owner:BEIJING UNIV OF TECH

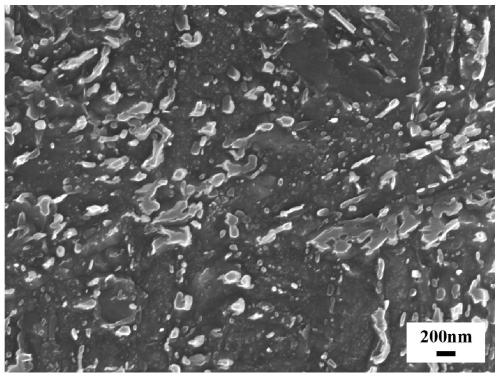

Laser fatigue enhancement method for metallic glass

ActiveCN102618700AAvoid embrittlementInhibition formationMetallic material coating processesErbium lasersCw laser

The invention relates to the technical field of metallic glass surface treatment, in particular to a laser fatigue enhancement method for metallic glass. The laser fatigue enhancement method for the metallic glass comprises the main steps as follows: 1) a metallic glass surface is ground and polished, and is cleaned with alcohol; 2) the metallic glass surface is subjected to heat treatment by adopting a CO2 continuous laser, and the treatment temperature is controlled through adjusting the laser process parameters so as to enable the surface to have an amorphous-nanocrystal composite structure; 3) aluminum foil is attached to the heat-treated metallic glass surface; and 4) flowing water is defined as a constrained layer, and an Nd: Glass nanosecond pulse laser is adopted to impact the metallic glass surface to which the aluminum foil is attached, so as to obtain surface enhancement modified metallic glass. The invention integrates advantages of the laser thermal effect, comprehensively regulates and controls the microstructure and the stress state of the metallic glass surface, and effectively enhances the fatigue performance. The invention has a simple process, is suitable for producing the metallic glass on a large scale, and can prepare the metallic glass with a high anti-fatigue performance.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

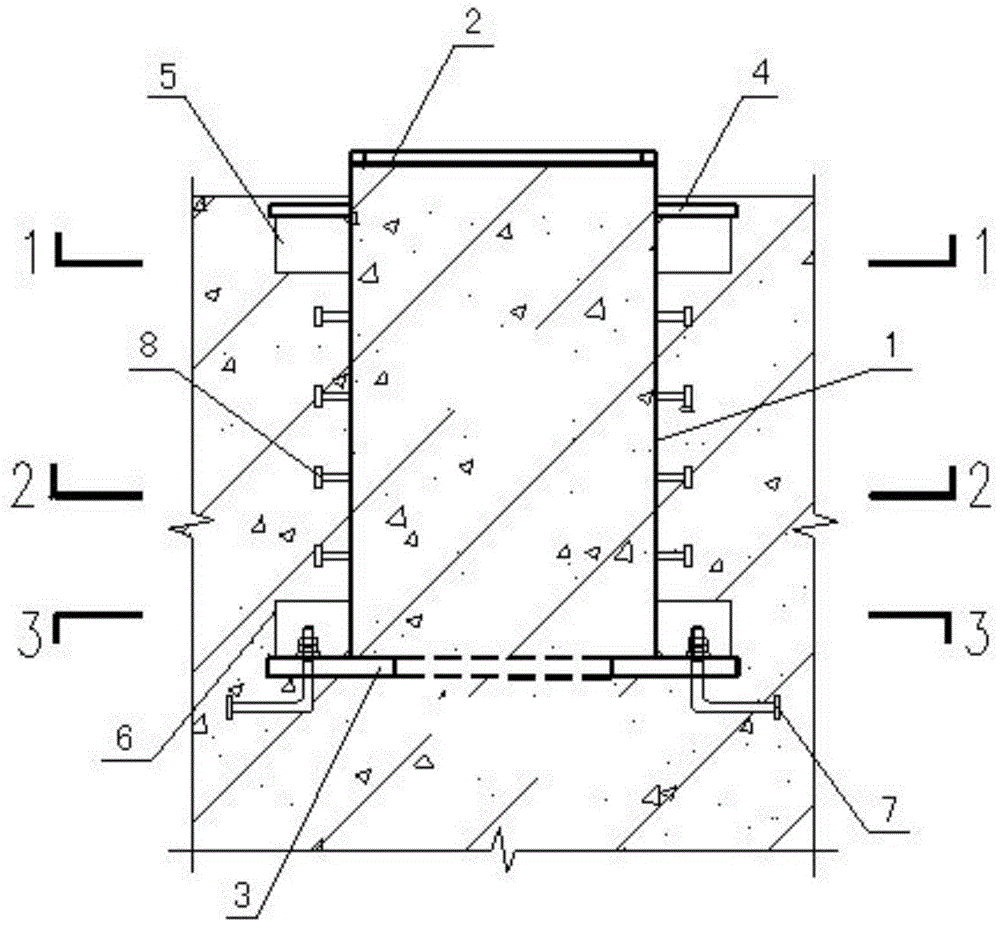

Overturn-preventing wind generating set foundation ring well stressed

ActiveCN104895105AAvoid localized crushingAvoid tearingFoundation engineeringWind energy generationSurface layerBolt connection

The invention discloses an overturn-preventing wind generating set foundation ring well stressed. The overturn-preventing wind generating set foundation ring well stressed comprises a steel cylinder. An upper flange is arranged on the top of the steel cylinder, a lower flange is arranged on the bottom of the steel cylinder, and the part, below the upper flange, of the steel cylinder is buried in concrete. A reinforcing ring is arranged in the part, located inside surface-layer concrete, of the outer wall of the steel cylinder, and a plurality of upper sheet stiffening ribs are uniformly arranged below the reinforcing ring and along the outer wall of the steel cylinder. A plurality of lower sheet stiffening ribs are uniformly arranged above the lower flange and along the outer wall of the steel cylinder. Lower flange anchor bolts are in bolt connection with the lower flange through holes uniformly formed in the lower flange. Cylinder body studs are uniformly arranged on the outer wall of the part, buried in the concrete, of the steel cylinder according to calculation. By arranging the reinforcing ring, the stiffening ribs, the cylinder body studs, the lower flange anchor bolts and the like, the wind generating set foundation ring can well prevent partial failure of the concrete, sliding and overturning.

Owner:HUNAN UNIV OF SCI & TECH

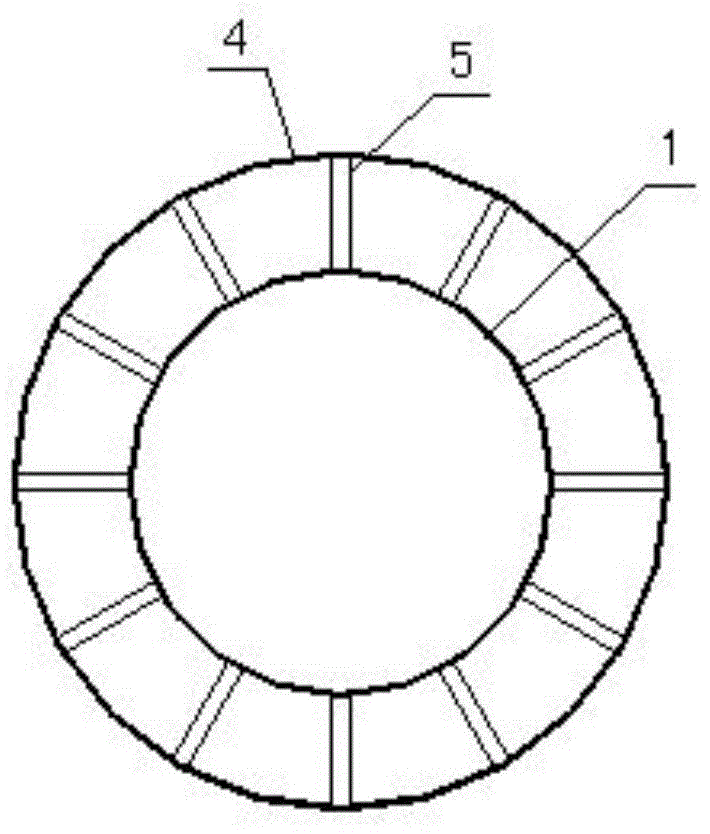

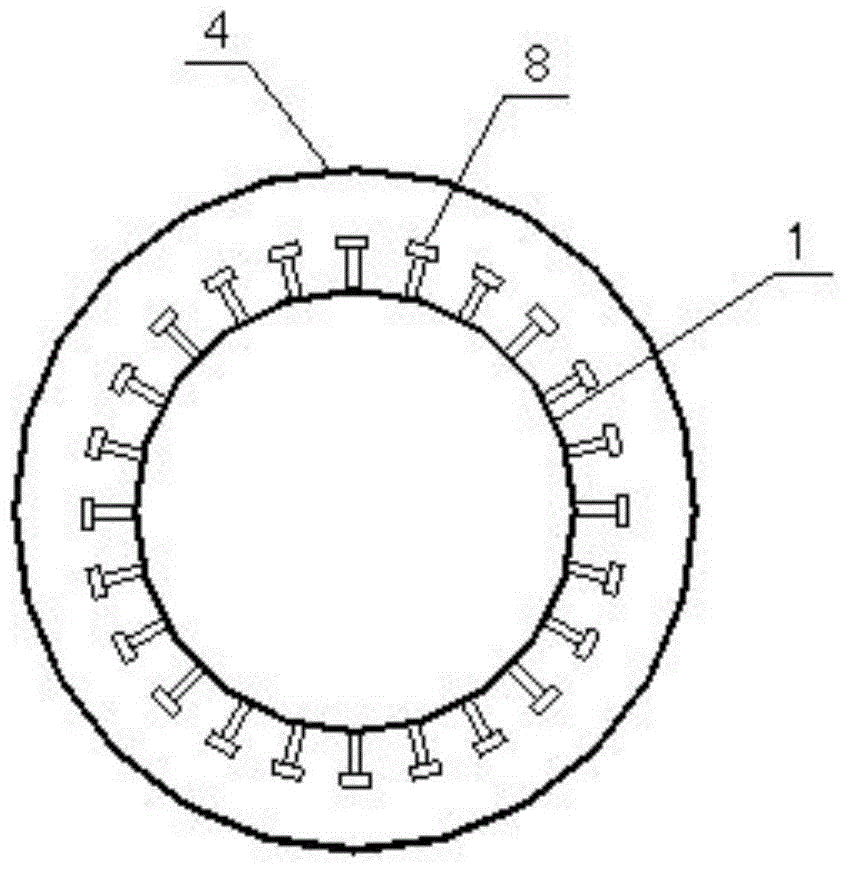

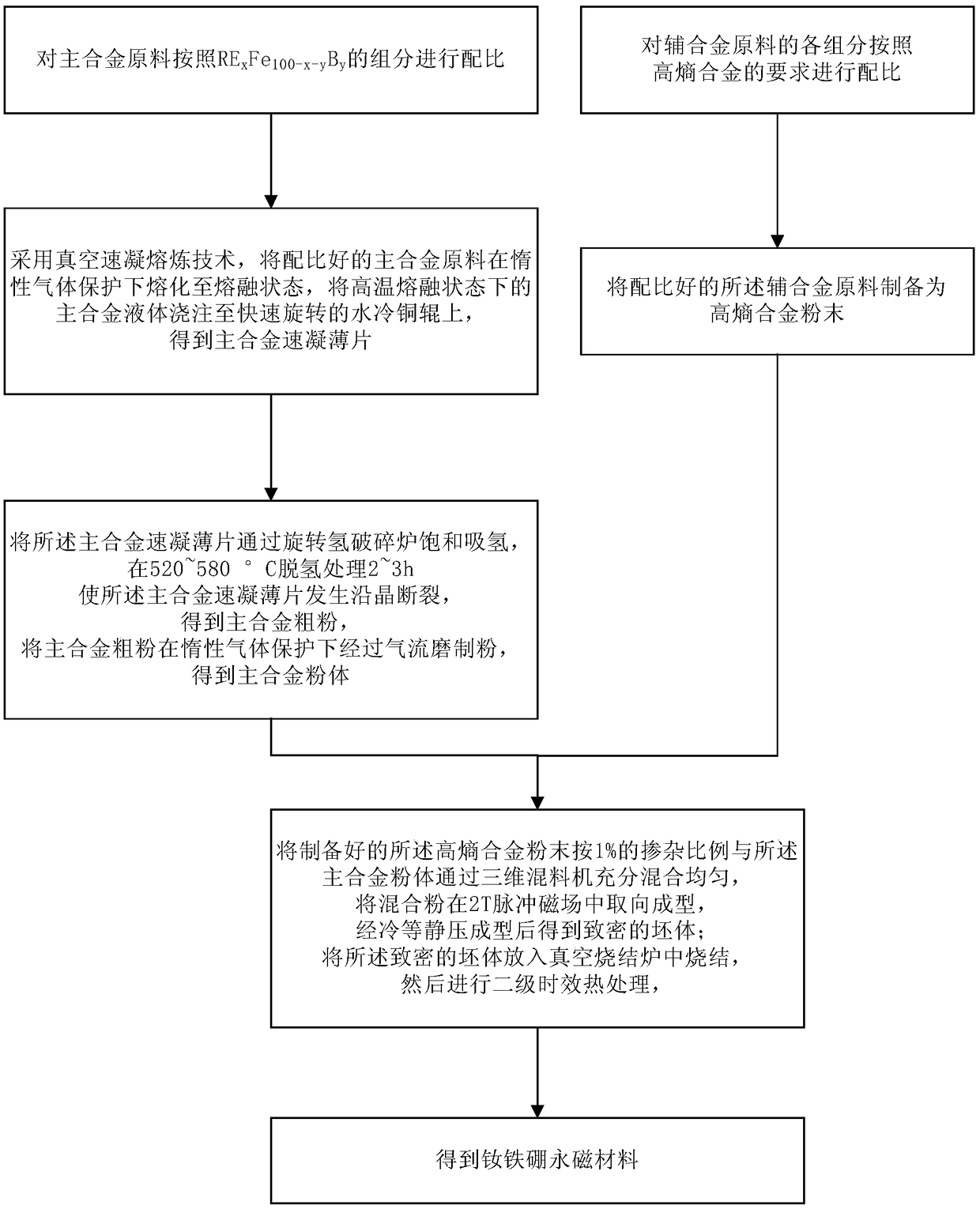

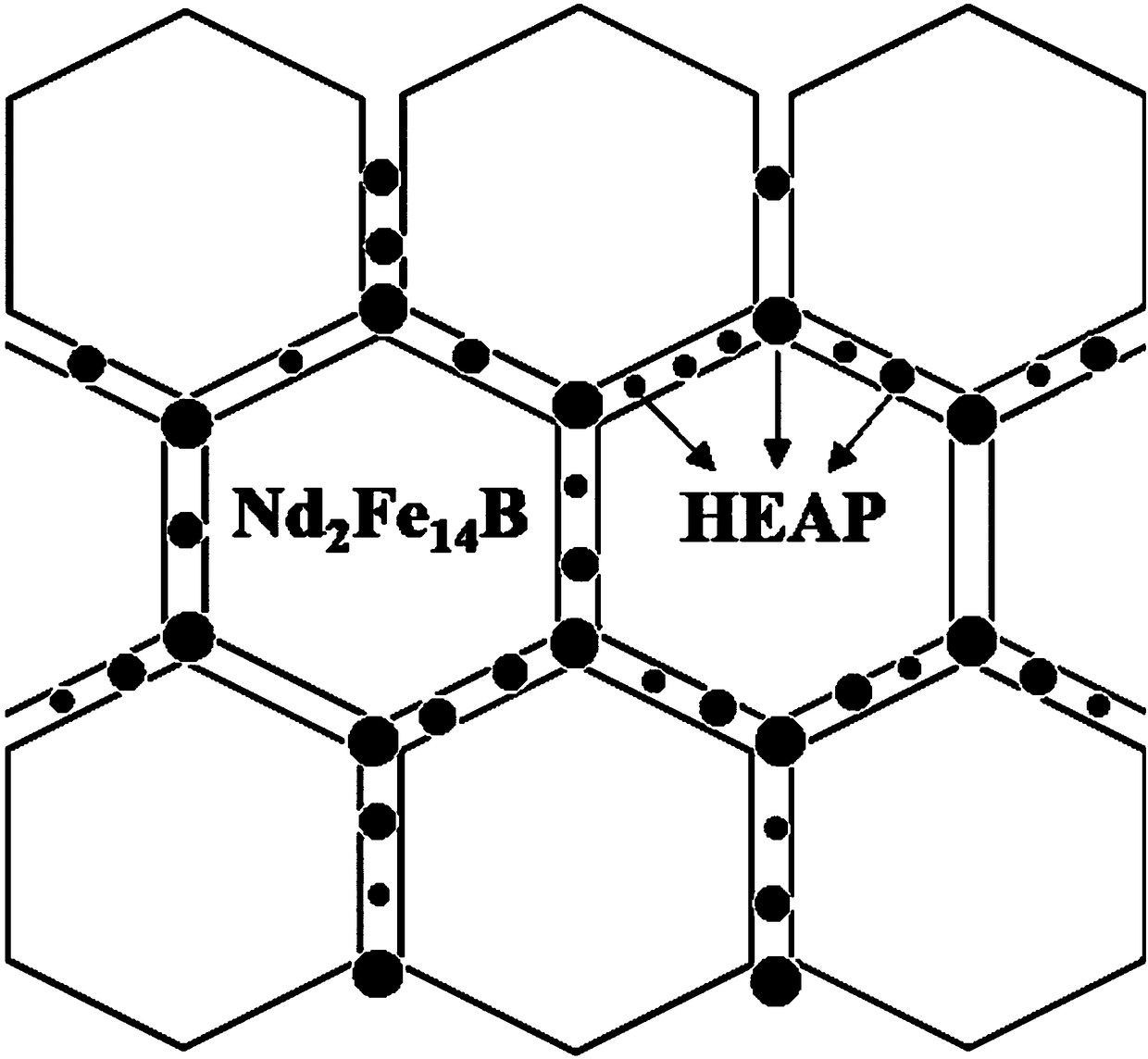

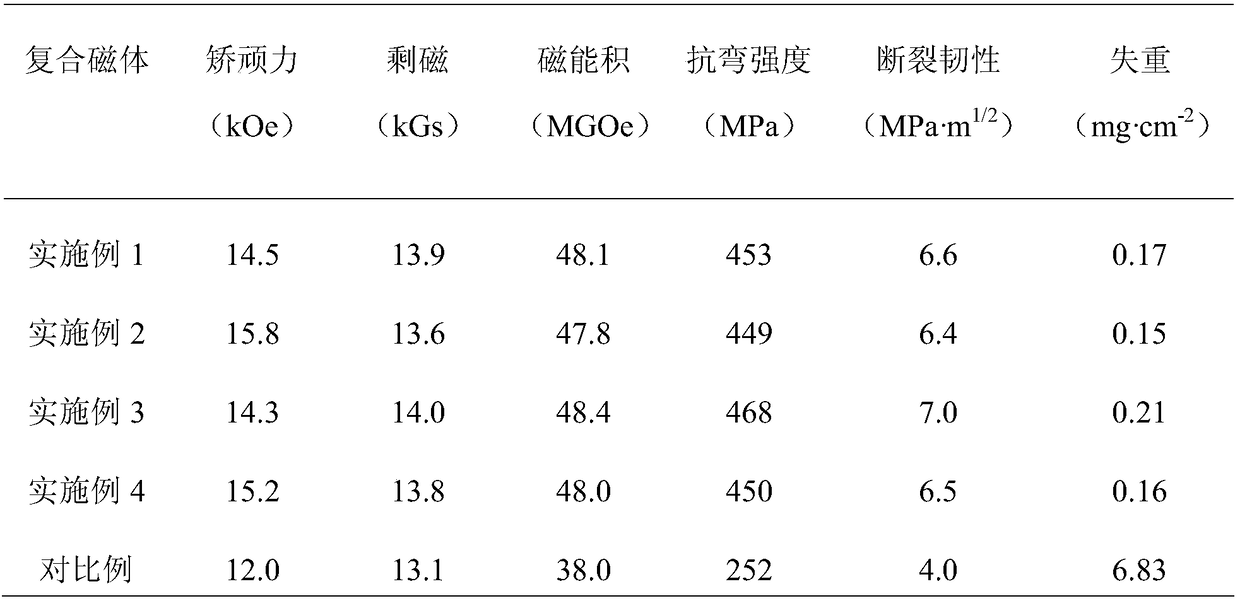

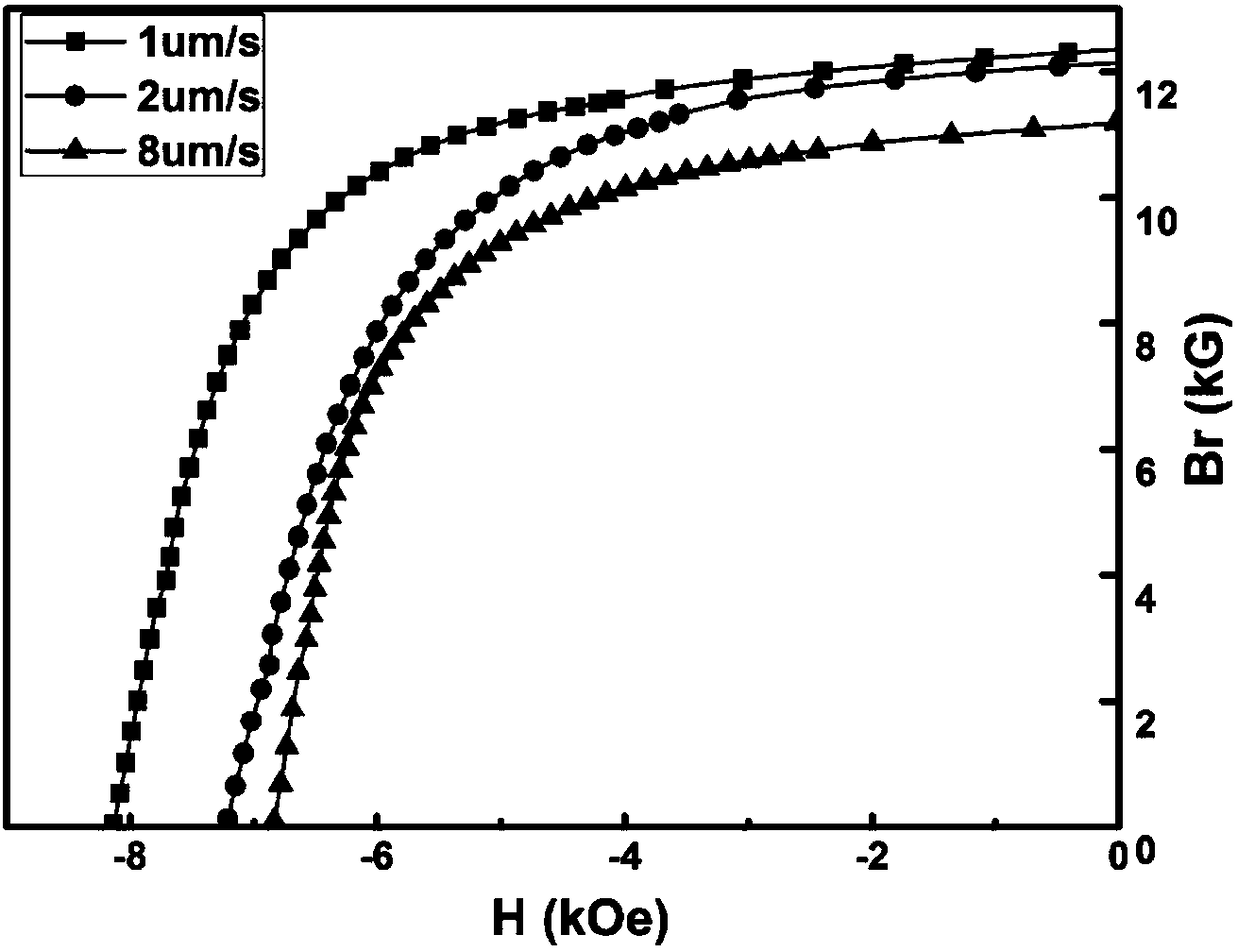

NdFeB permanent magnet material for magnetic suspension system and preparation method thereof

ActiveCN109087768AGrain refinementImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsHigh entropy alloysSolid solution

The invention relates to a NdFeB permanent magnet material suitable for a magnetic suspension system and a preparation method thereof. This material is prepared by adoping of 0.5%-5.0%high entropy alloy in the main alloy of RExFe100-x-yBy, so that the alloy of the invention can realize demagnetization coupling through the high entropy alloy. Moreover, since the high entropy alloy doped in the material has a single solid solution nanostructure, the invention can also restrain the alloy grain growth in the sintering process through the high entropy alloy, refine the grain, make the alloy component structure more uniform and uniform, and effectively improve the comprehensive magnetic properties of the NdFeB permanent magnet material. The magnetic performance of the NdFeB permanent magnet material is improved, and further the strength and toughness, the vibration resistance and the corrosion resistance of the material are improved, so that the material is suitable for application environments such as magnetic levitation and the like, which have more restrictions on the working conditions.

Owner:江西永磁磁浮科技有限责任公司

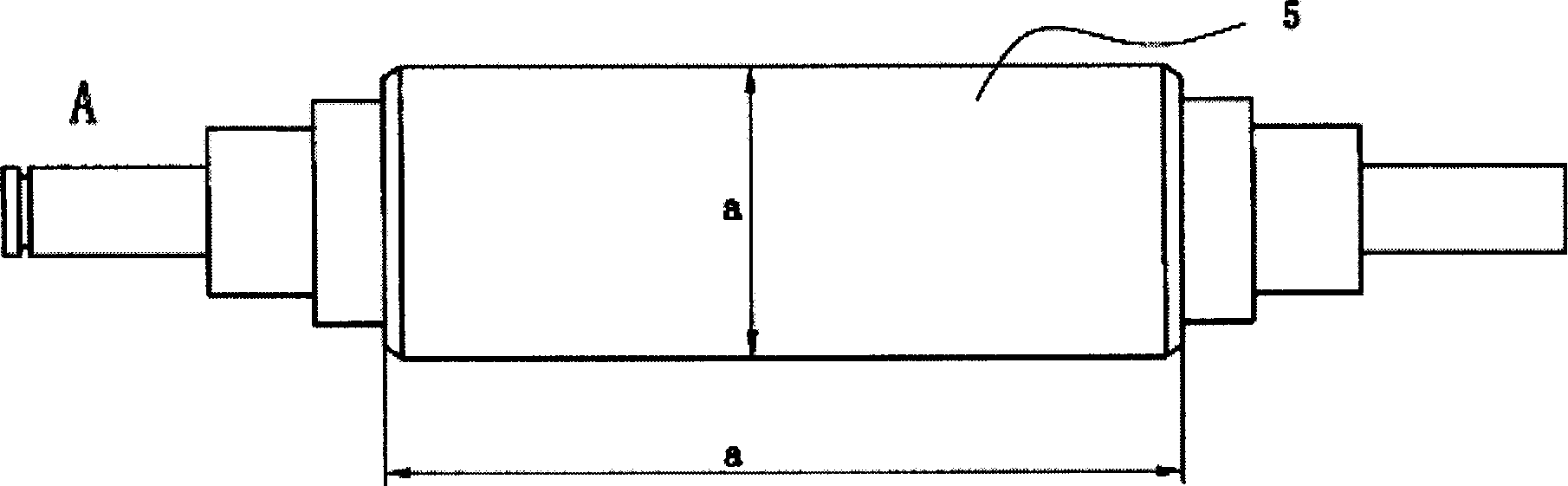

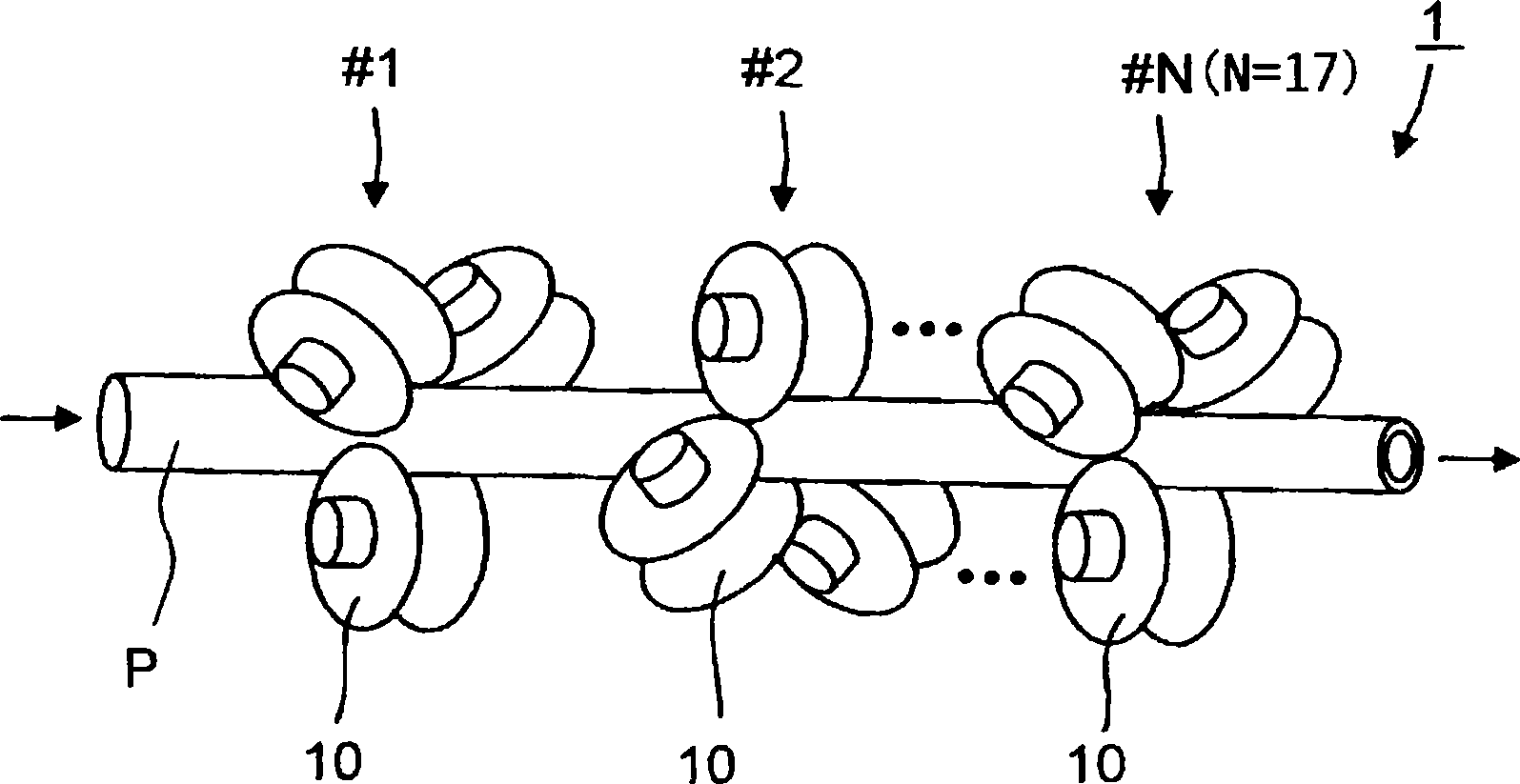

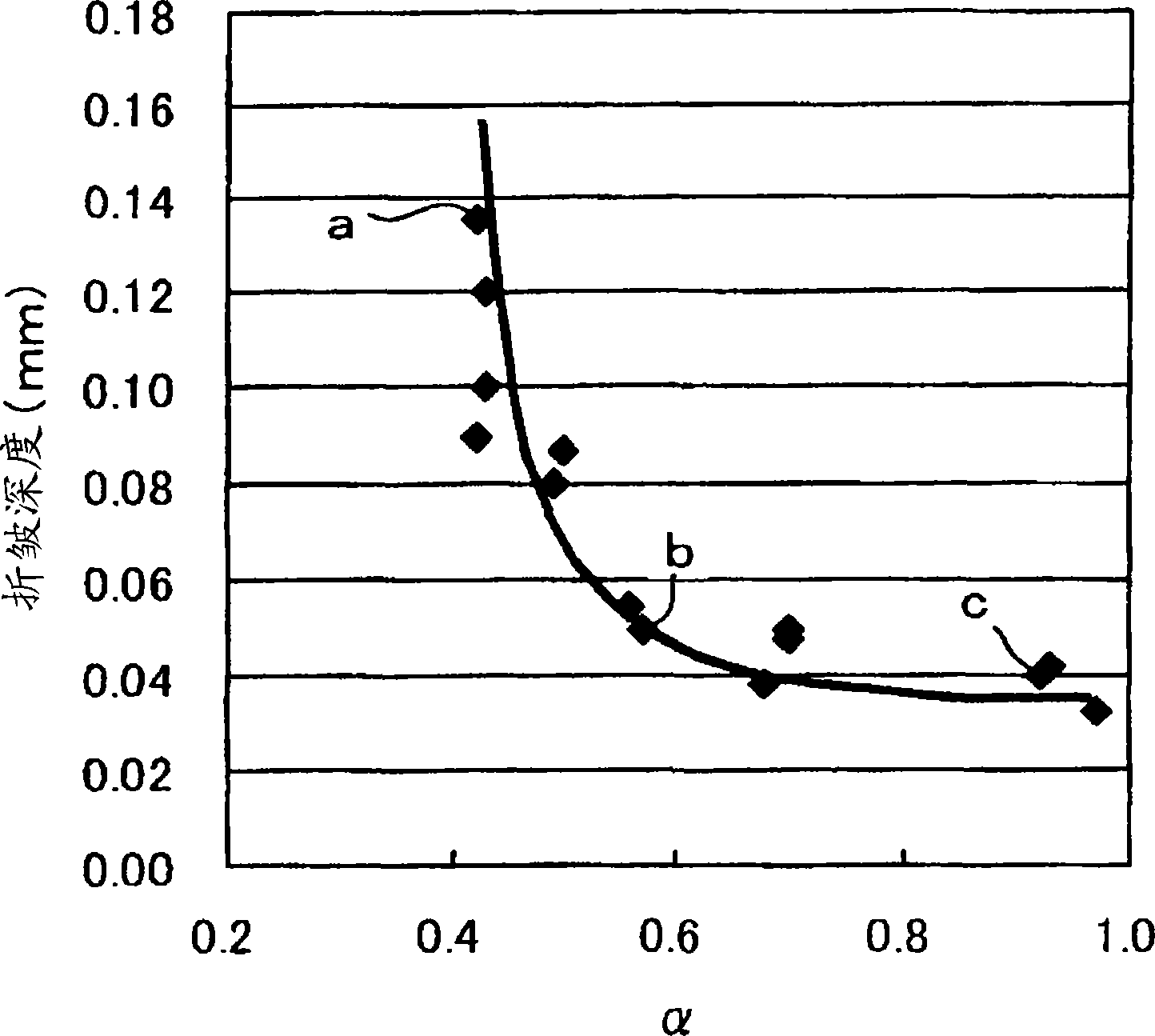

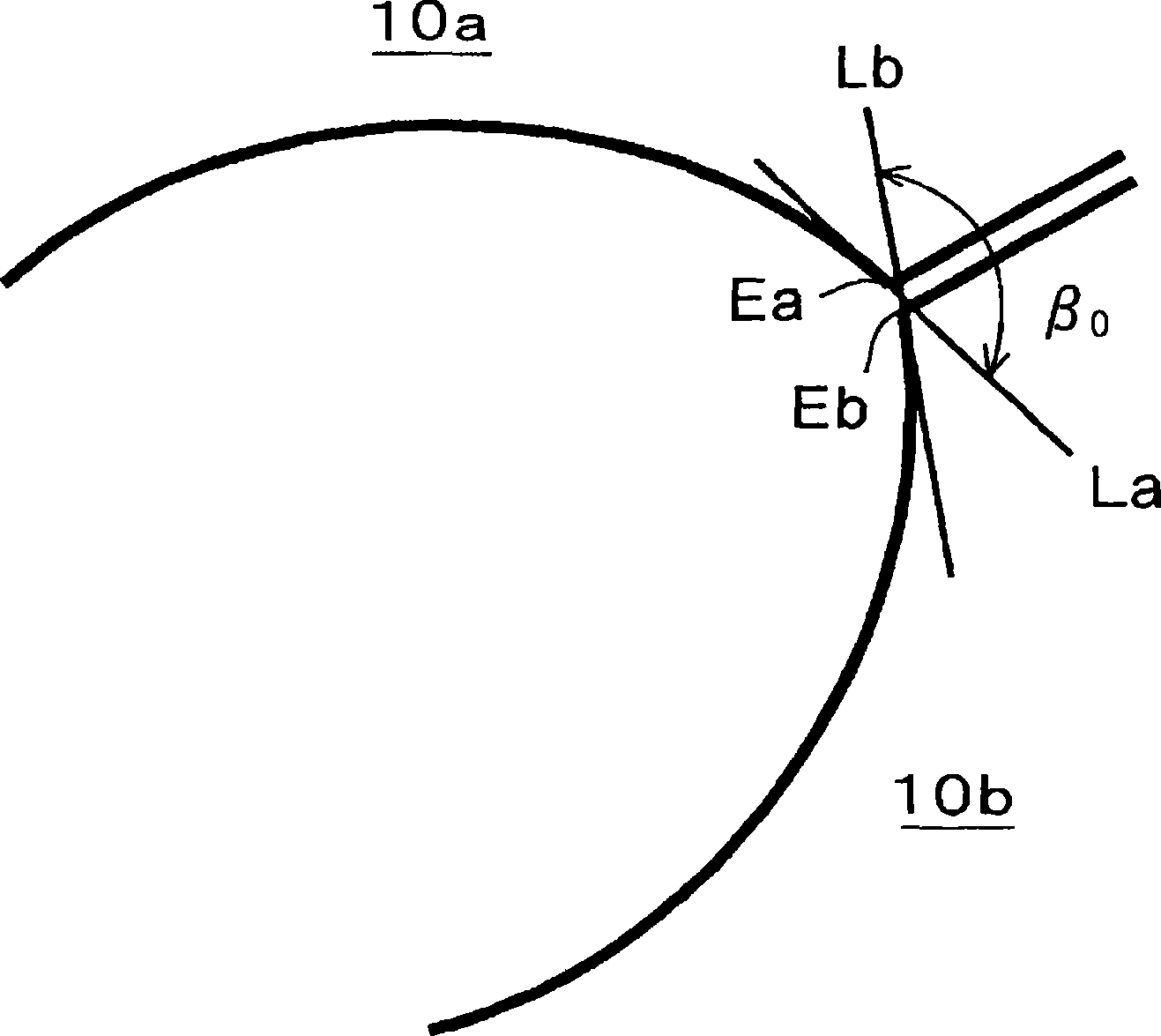

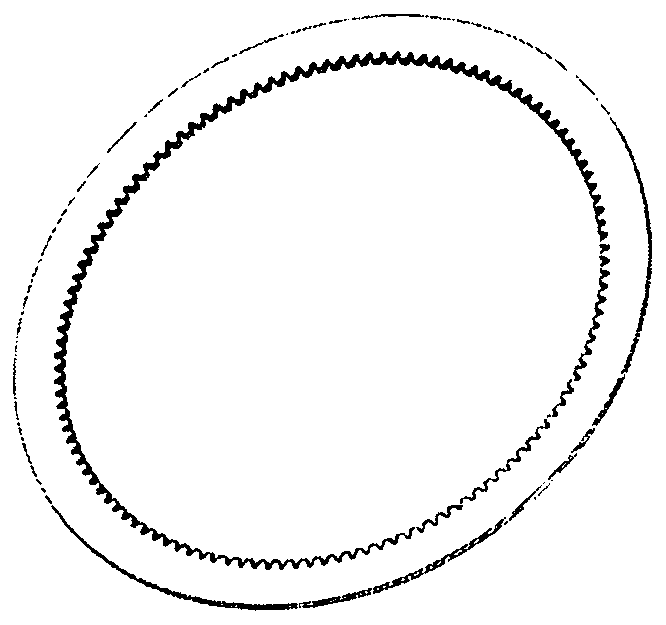

Tube manufacturing method and apparatus for fixed diameter rolling

InactiveCN1905958AInhibits the occurrence of wrinklesInhibition of scalabilityRollsMetal rolling arrangementsGreek letter betaMechanical engineering

A tube manufacturing method, comprising a step for rolling a tube at a fixed diameter by using an apparatus for fixed diameter rolling formed of a plurality of stands having a plurality of hole type rolling rolls. The method is characterized in that, where the minimum value of angles formed by the tangents drawn on the opposed edge parts of the hole type rolling rolls adjacent to each other in all stands is beta (deg), the outer diameter of the tube on the out-side of the apparatus for fixed diameter rolling is D (mm), and the wall thickness of the tube on the out-side of the apparatus for fixed diameter rolling is t (mm), such a hole type rolling roll that the angle beta can fulfill the requirement of the following expression (1) is used. beta >= 1.13 x 10 x Ln (t / D x 100) + 1.37 x 10<2> ... (1).

Owner:NIPPON STEEL CORP

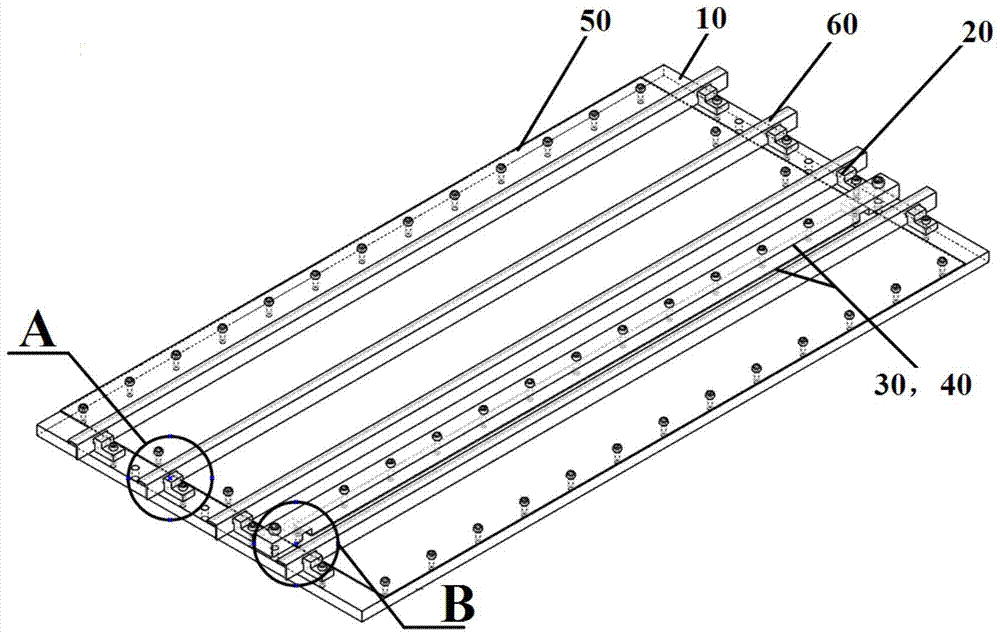

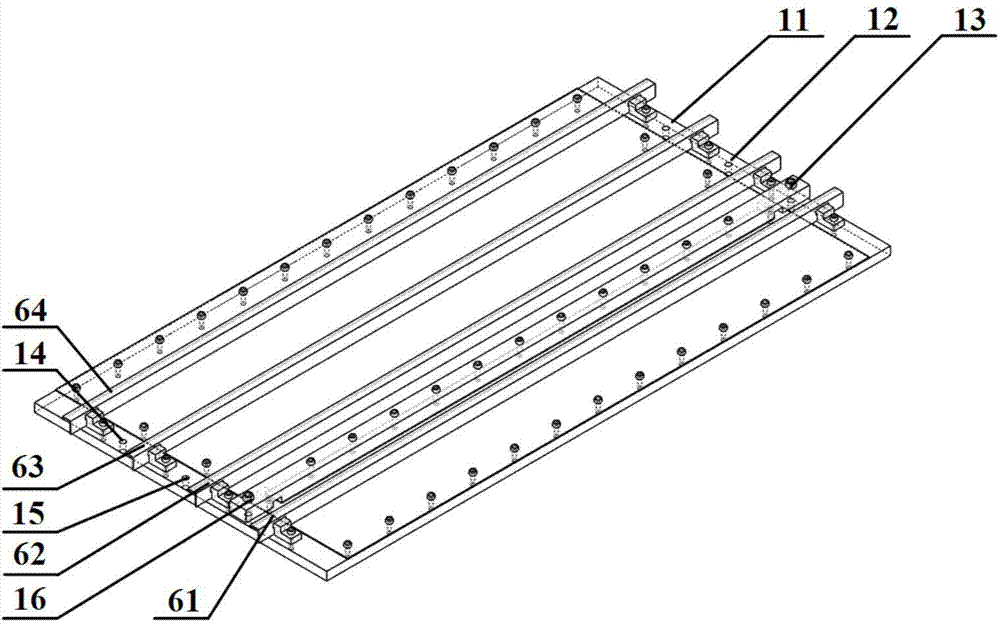

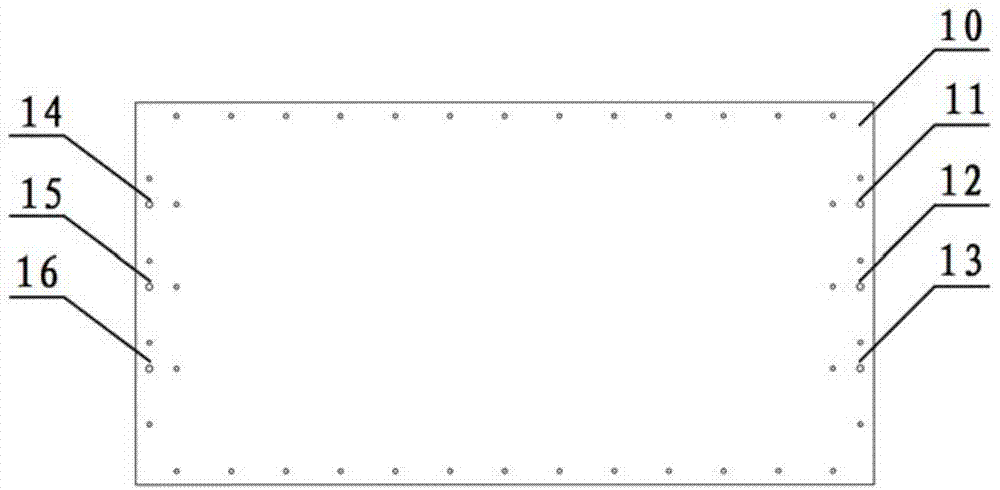

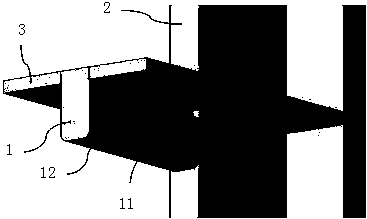

Laser welding clamp for T-shaped structural component

ActiveCN104259661AControl deflectionInhibition of crystallization cracksWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a laser welding clamp for a T-shaped structural component, and the T-shaped structural component comprises an envelope and a stringer, the laser welding clamp comprises a bottom plate for supporting the envelope; a pressing bar which is used to press the envelope such that the envelope is tightly close to the bottom plate; a corner-bending pressing block which is respectively arranged on both ends of each stringer, one end of the corner-bending pressing block is connected with the stringer while the other end thereof is connected with the bottom plate. The laser welding clamp can effectively control deflection deformation of the stringer and restrain generation and extension of solidification cracks at laser welding end points.

Owner:SHANGHAI AIRCRAFT MFG +1

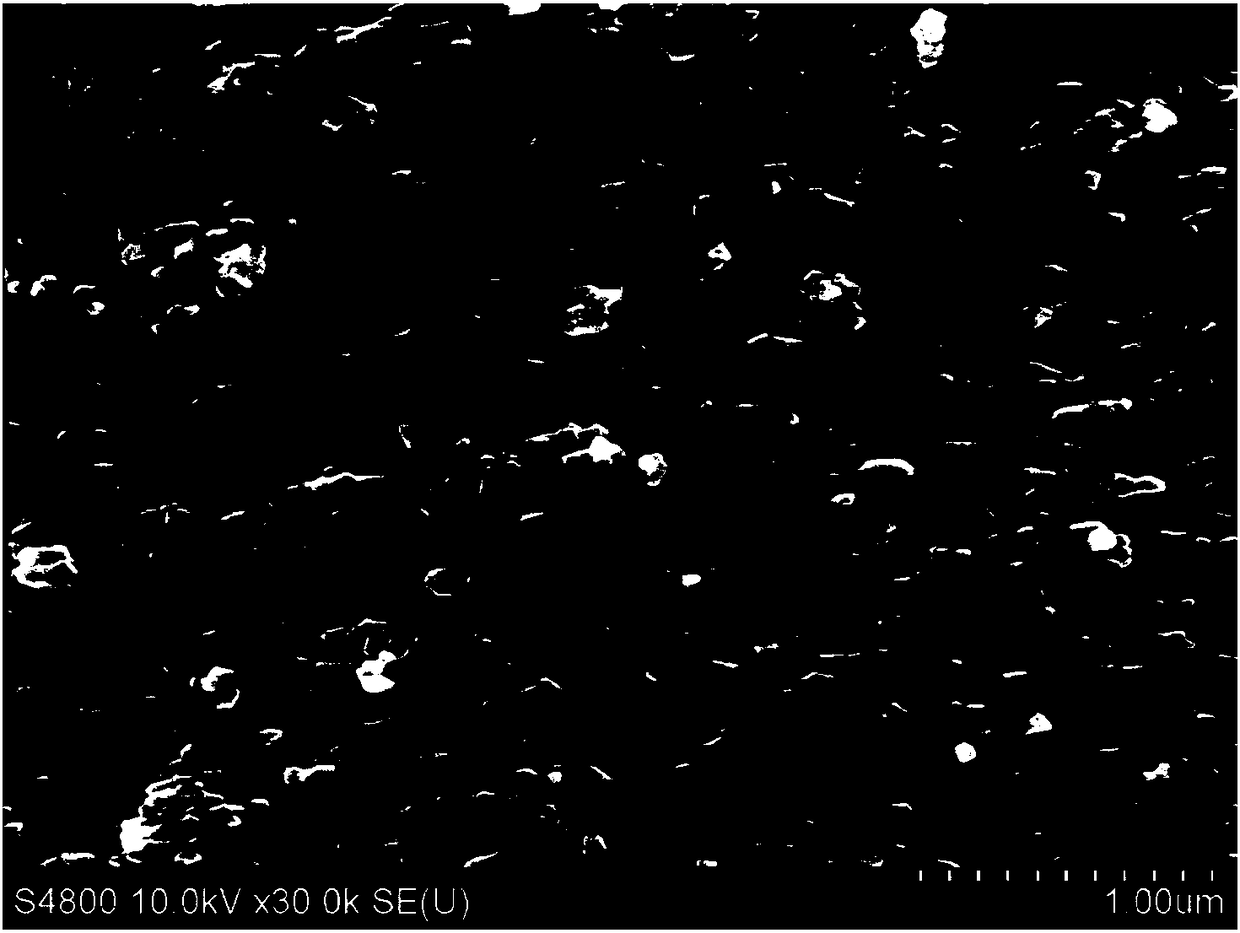

Nanocrystalline complex phase neodymium iron boron permanent magnet texturing enhancement preparation method

ActiveCN108346508AImprove compactnessImprove magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMagnetic phaseThermal deformation

The invention provides a nanocrystalline complex phase neodymium iron boron permanent magnet texturing enhancement preparation method. According to the method, an NdFeB complex green body obtained bythermal pressing treatment is subjected to thermal deformation treatment at a low temperature and low rate to obtain a total-compact anisotropic NdFeB complex phase permanent magnet. Compared with theconventional process, the permanent magnet is subjected to deformation and orientation at a low temperature, so that grain growth can be suppressed effectively; and meanwhile, grain boundary phase uniform distribution at a low temperature can be facilitated by thermal deformation at low rate, so that hard magnetic phase texturing can be reinforced, crack formation and expansion in the deformationprocess can be suppressed, and the compaction and magnetic performance of the block body can be improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

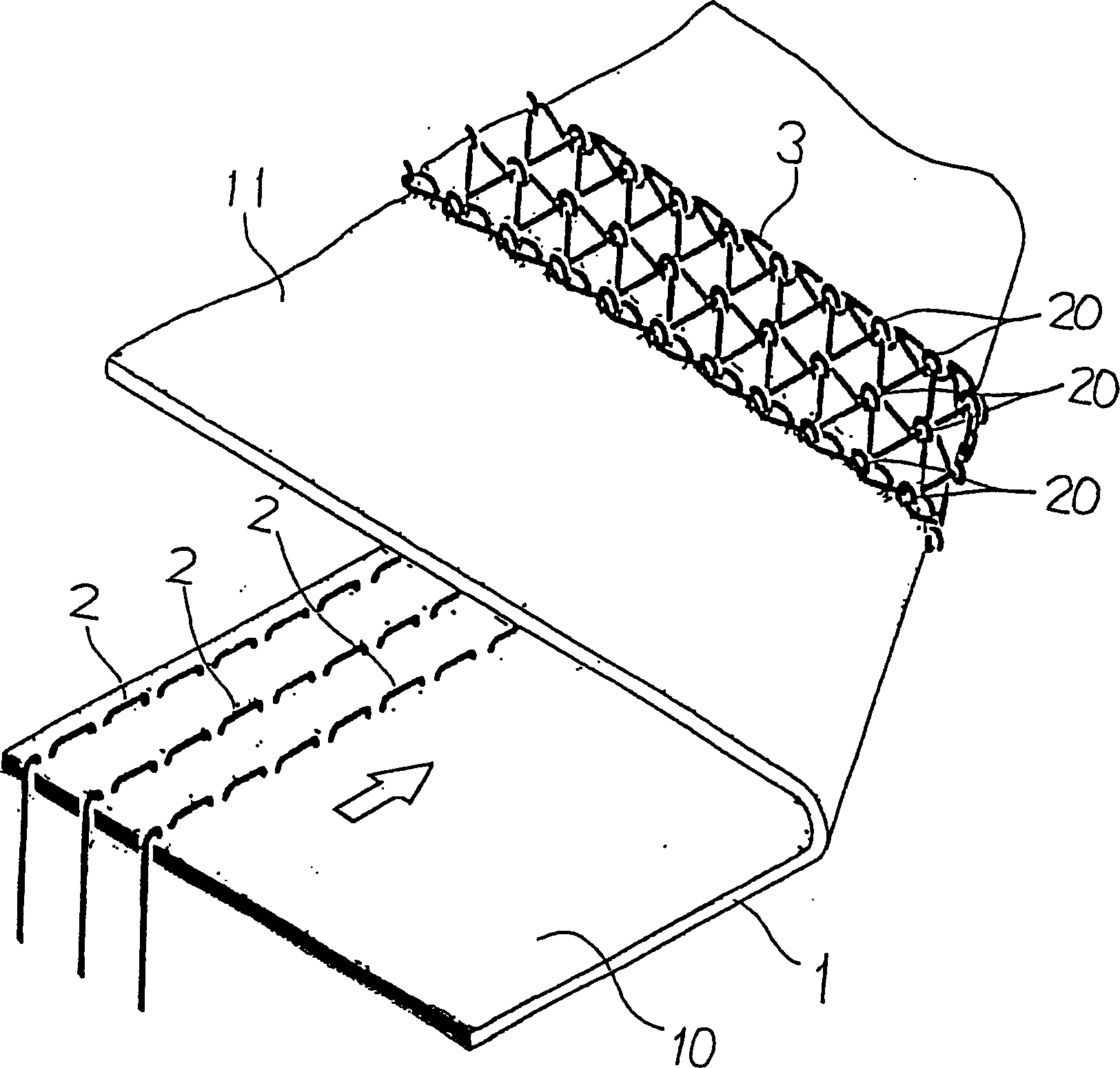

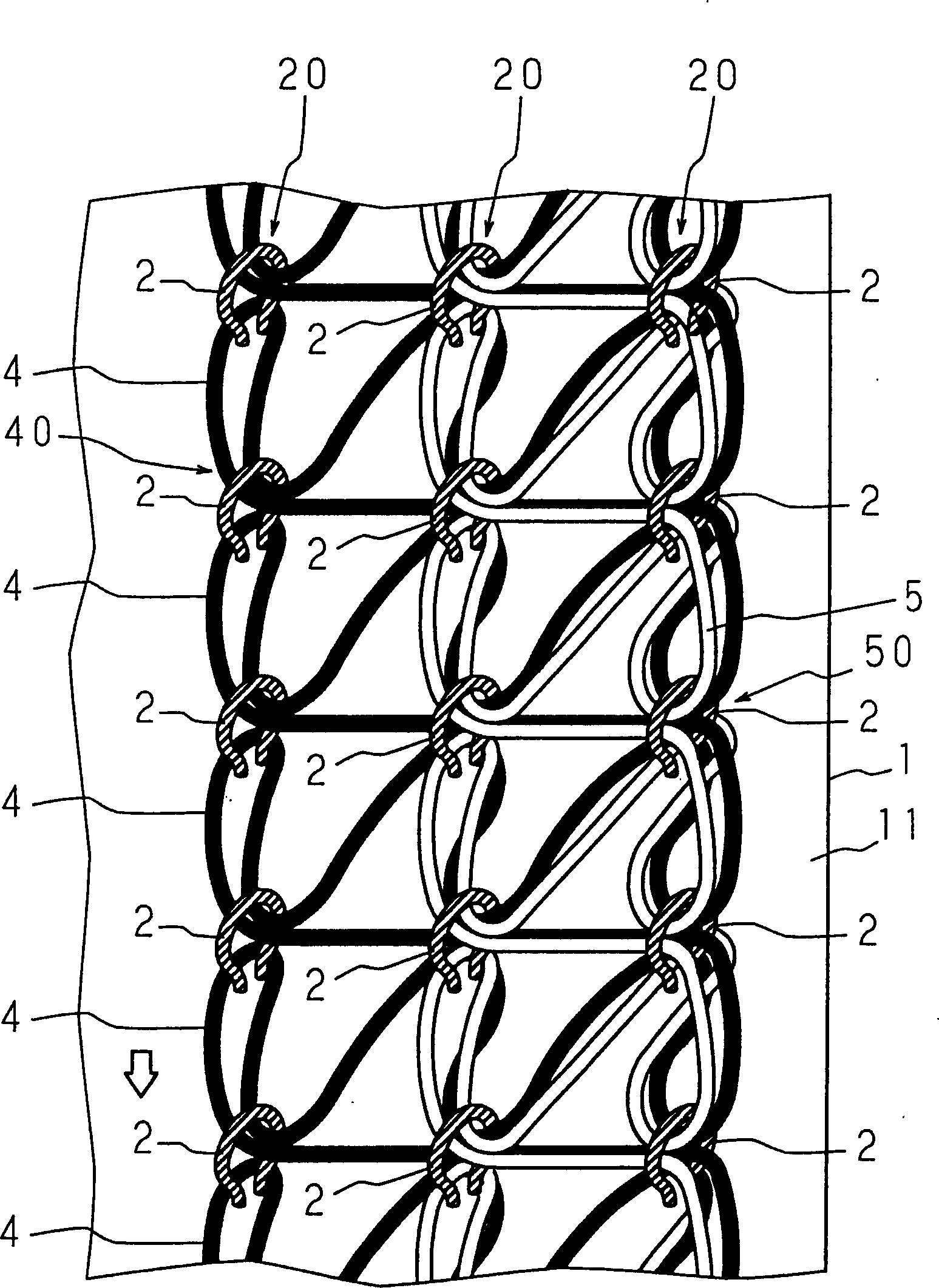

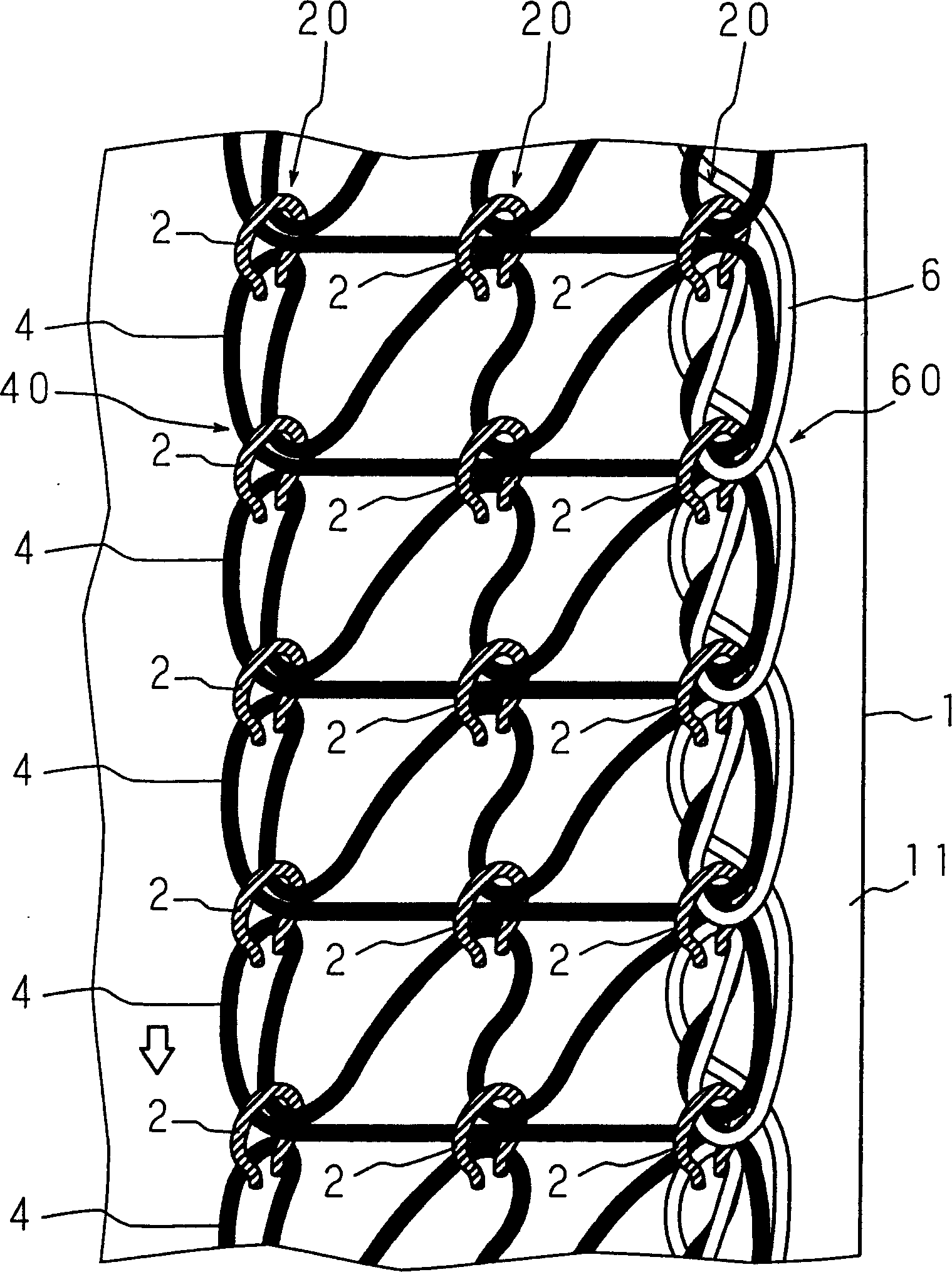

Stitching structure

InactiveCN1590621APrevent dismantlingStop sheddingSewing apparatusEngineeringUltimate tensile strength

In the stitch structure of the present invention, several rows of loops are arranged on the back of the fabric to be sewn, the first double-thread overlock portion formed by winding the first set of threads around all the rows of loops, and The second double-thread lock seam part formed by the second set of threads being entangled with a part of the above-mentioned several loop rows is combined, so in addition to improving the sewing strength, it can moderately suppress the stretchability and prevent cutting Unnecessary disassembly caused by wires.

Owner:YAMATO SEWING MASCH MFG CO LTD

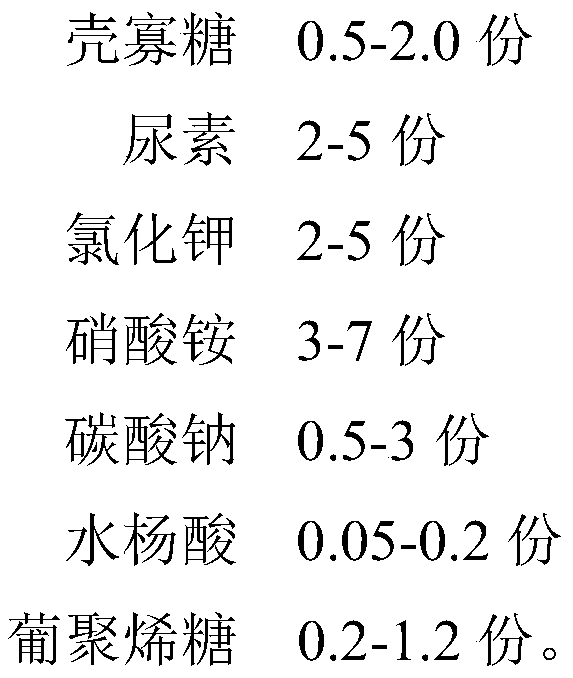

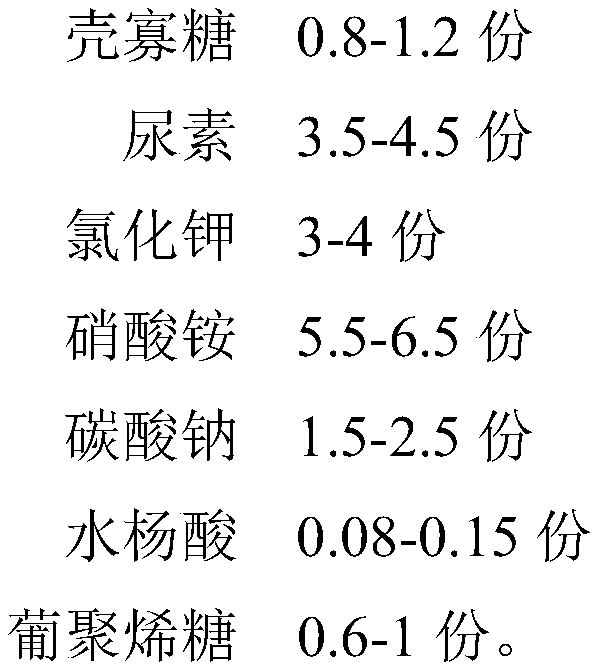

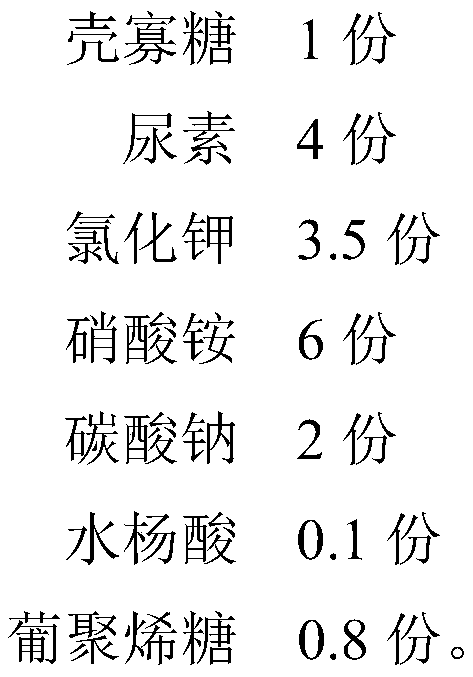

Special anti-stress foliar fertilizer for Brassica chinensis L., and using method thereof

InactiveCN110105133AEnhance plant growthHigh in proteinAmmonium nitrate fertilisersOrganic fertilisersAnti stressPotassium

The invention discloses a special anti-stress foliar fertilizer for Brassica chinensis L., and a using method thereof. The special anti-stress foliar fertilizer for Brassica chinensis L. comprises, bymass, 0.5-2.0 parts of chitooligosaccharide, 2-5 parts of urea, 2-5 parts of potassium chloride, 3-7 parts of ammonium nitrate, 0.5-3 parts of sodium carbonate, 0.05-0.2 part of salicylic acid and 0.2-1.2 parts of glucosan. The anti-stress foliar fertilizer can significantly improve the resistance of the Brassica chinensis L. to drought, ponding and saline soil, and significantly improves the plant growth, the protein content and the yield.

Owner:HUBEI ENG UNIV

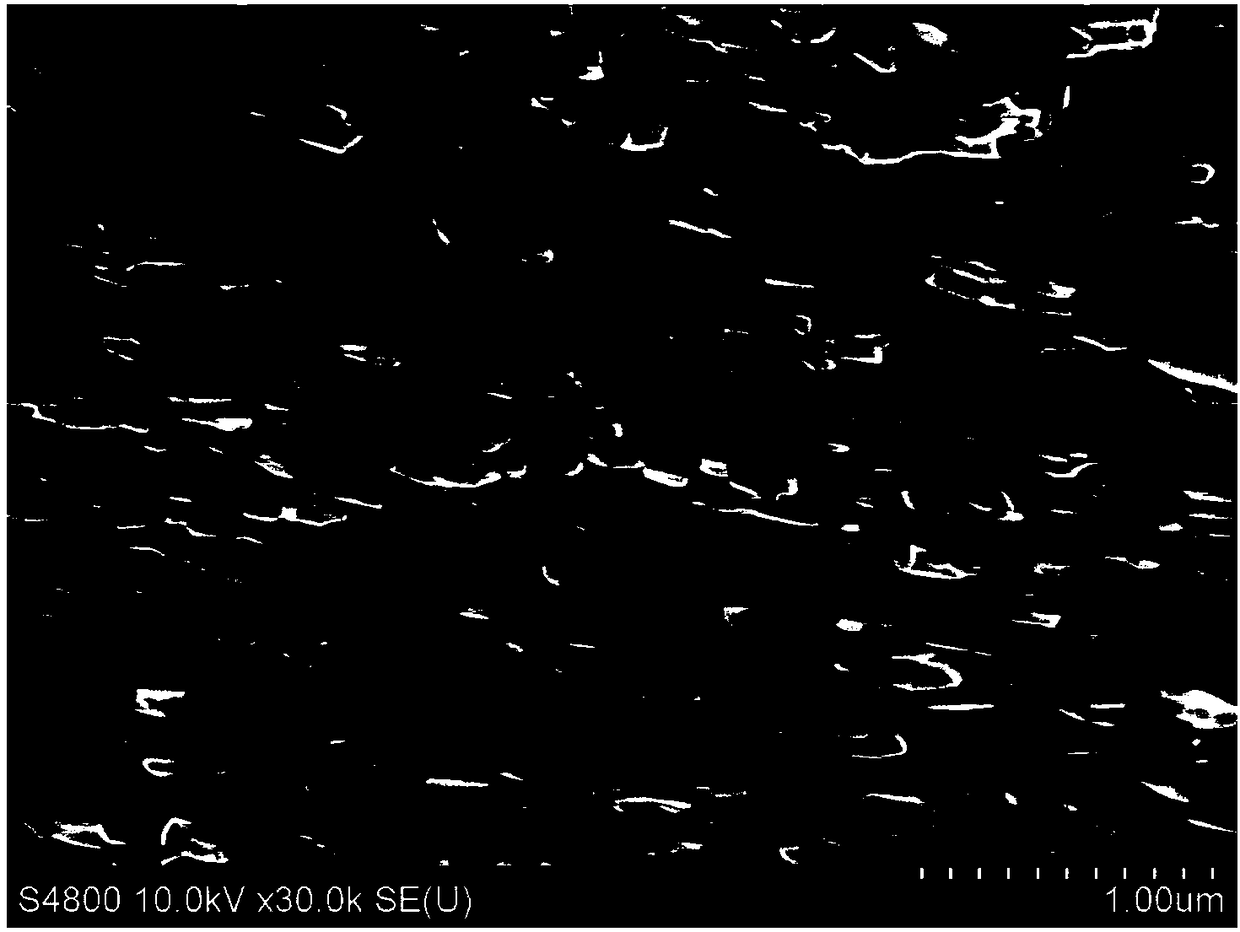

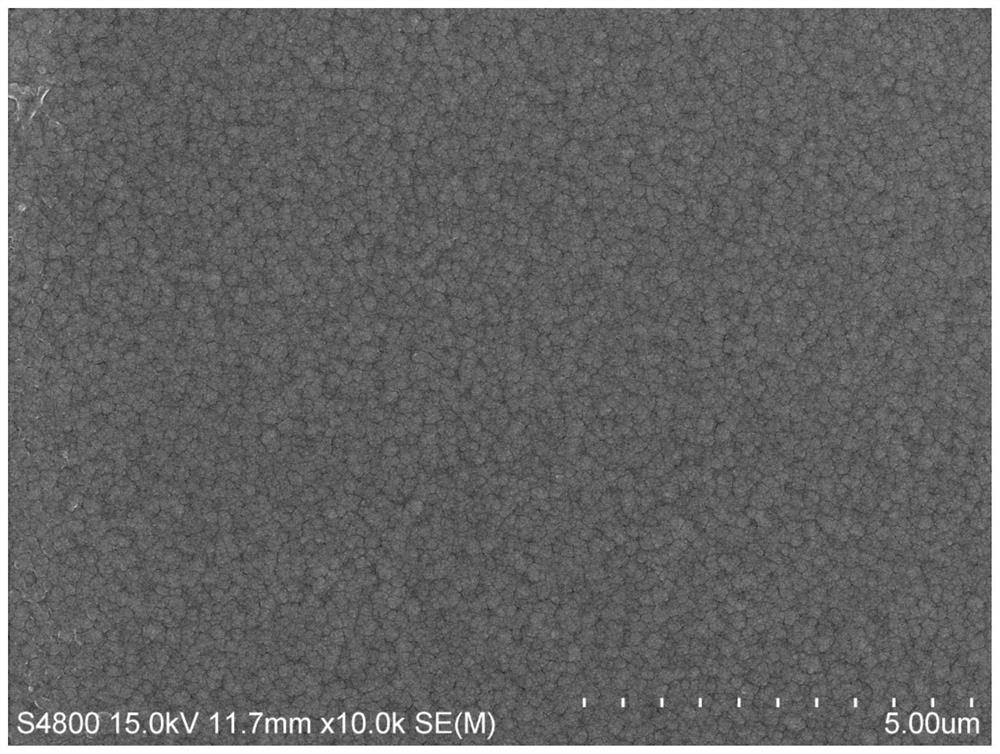

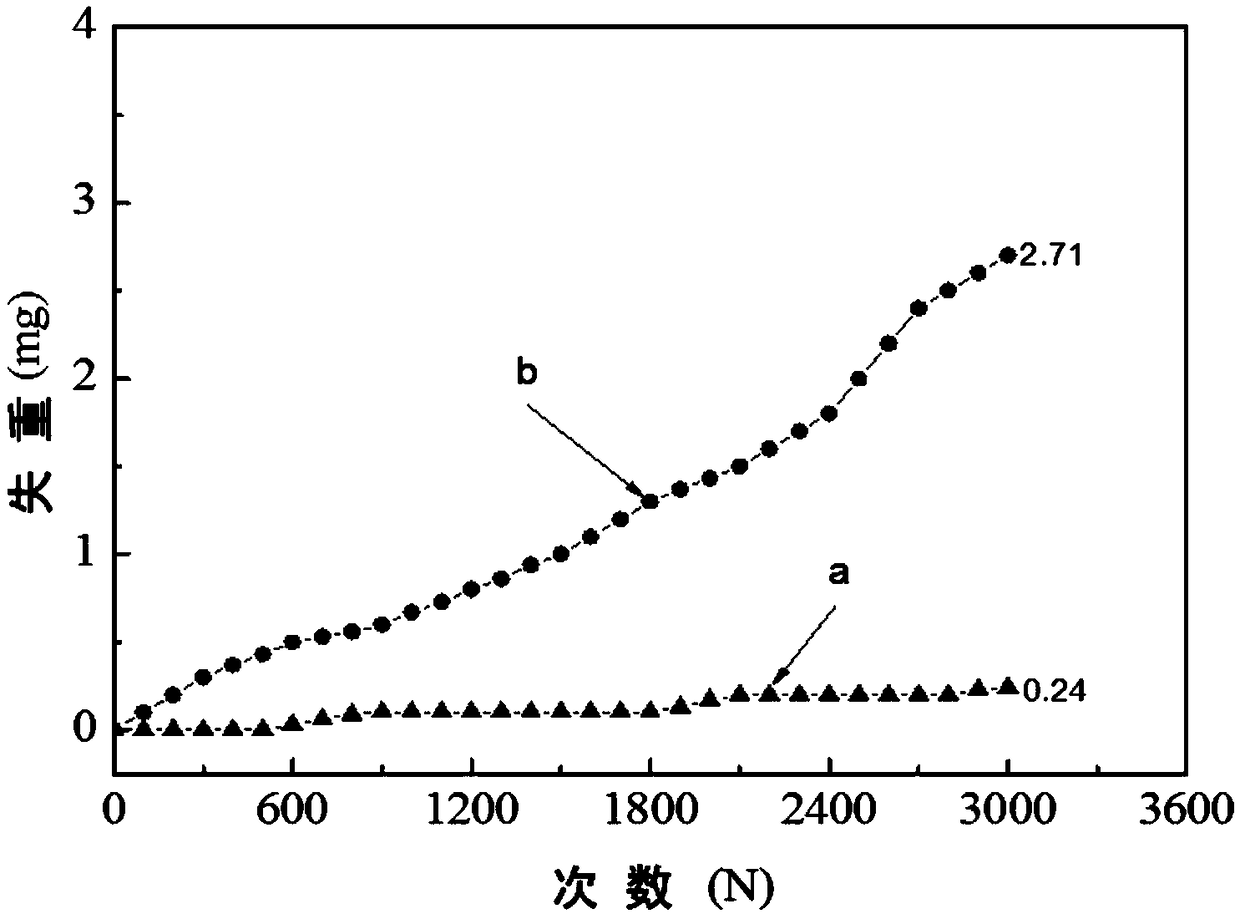

Friction control method of magnetic micro-nano texture surface and device

InactiveCN102636429ATo achieve the purpose of real-time controlOptimizing Tribological PropertiesPreparing sample for investigationUsing mechanical meansMicro nanoWear testing

The invention relates to a friction control method of magnetic micro-nano texture surface and a device, and belongs to the field of surface texture frictional wear control. The friction control method comprises the following steps of: firstly, preparing a surface with the micro-nano texture: implementing laser photoetching on a sample and carrying out electrochemical deposition on the sample after finishing the laser photoetching so as to prepare a regular plating layer with the micro-nano texture, wherein the laser power parameter is arranged in the range of 5-100 mW, the electrochemical deposition parameter is that the forward and reverse impulse working time is 5 ms-1 s, the frequency is 0-200 Hz, the current density is 10-50 mA / cm<2>, the keeping plating solution temperature is 30 DEG C-60 DEG C, the ph value is 3-5, and the stirring rate is 30-90r / min; secondly, carrying out magnetization treatment: carrying out magnetization treatment on the sample, wherein the magnetic field intensity is 2.25*104-4.5*104A / m; and thirdly, carrying out a frictional wear test: fixing the sample on a friction wear testing machine so as to applying a magnetic field to the sample for magnetization, and meanwhile, starting the friction wear testing machine for the frictional wear test, thus obtaining a friction factor. The friction control method and the device provided by the invention have the advantages that the structure and constituent of the composite plating layer are controllable, the device can carry out real-time regulation and control on the magnetic field intensity, and the application range is wide.

Owner:CHINA UNIV OF MINING & TECH

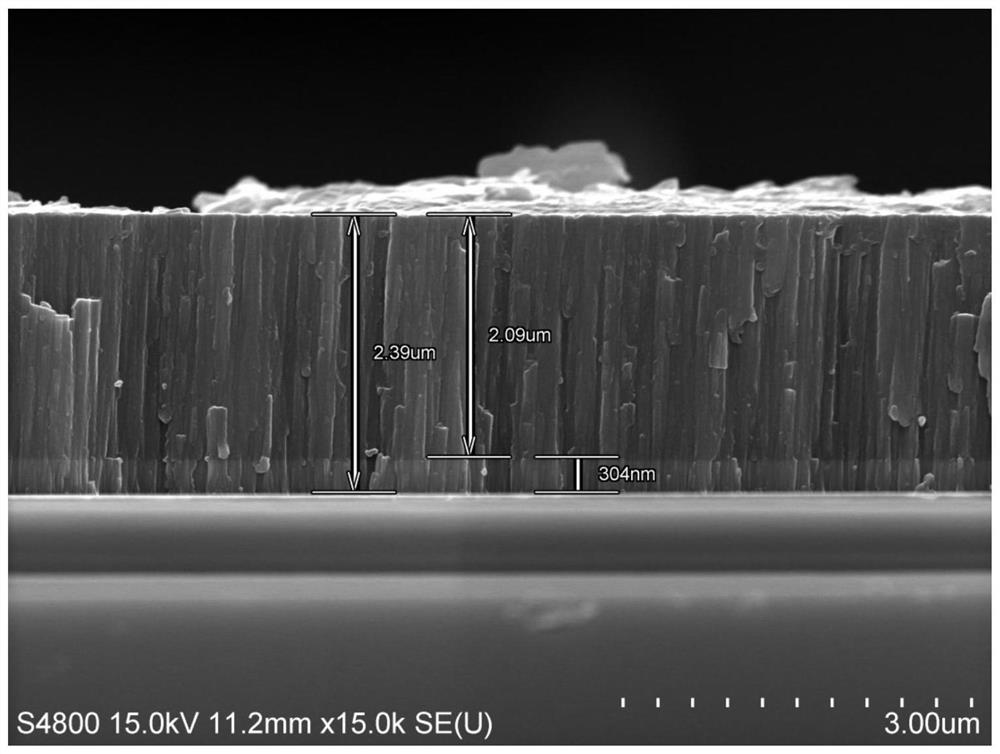

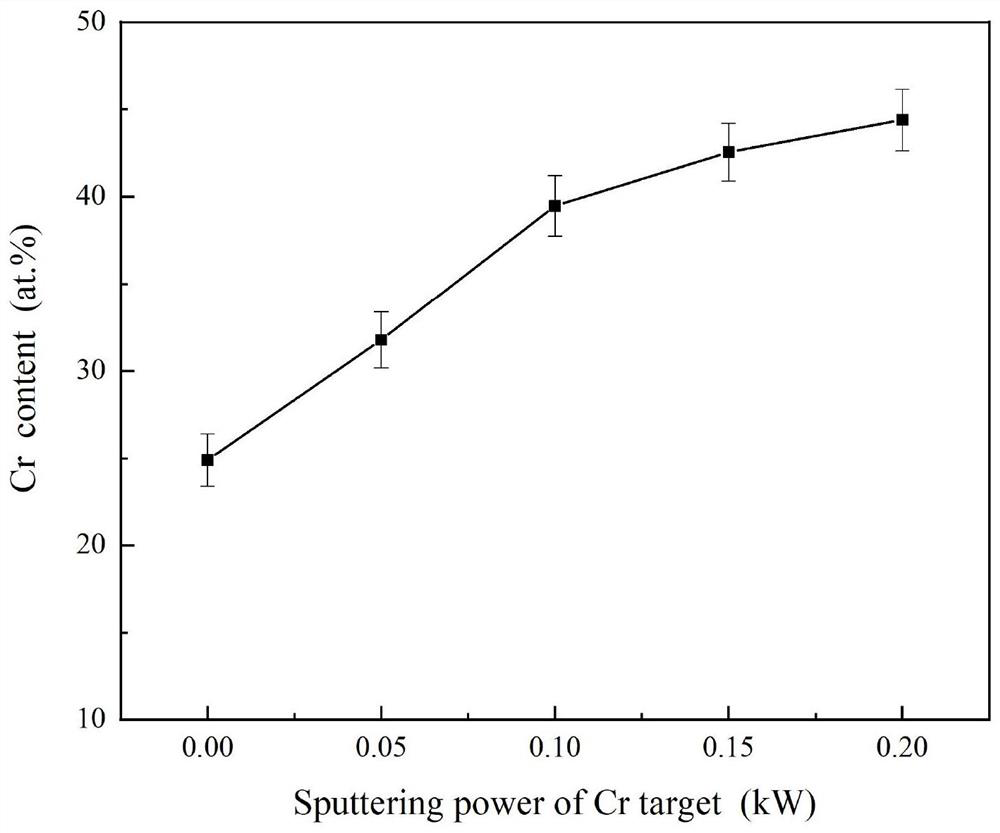

Preparation process of CrB2-Cr coating with high Cr content

ActiveCN112410728AIncrease ionization rateAchieve resilienceVacuum evaporation coatingSputtering coatingArgon atmosphereHeat stability

The invention discloses a preparation process of a CrB2-Cr coating with high Cr content, and belongs to the technical field of coating preparation. The CrB2-Cr nano composite coating is prepared on ametal or hard alloy matrix by adopting a high-power pulse and pulse direct-current composite magnetron sputtering technology. In order to better control the content of Cr in the coating, a CrB2 targetand two metal Cr targets are selected and used as target materials at the same time, a metal Cr transition layer is deposited after glow discharge cleaning and ion bombardment cleaning are conductedon the surface of a base material, finally, the Cr targets and the CrB2 target are started at the same time, the CrB2-Cr coating is deposited, and the coating process is conducted in the argon atmosphere all the time. The process is simple and good in repeatability; and the Cr element content in the prepared CrB2-Cr coating is remarkably increased, the coating has high hardness, a high melting point and excellent high-temperature thermal stability and corrosion resistance, the toughness of the coating is also improved to a certain extent, and the coating is compact in structure and high in binding force with the matrix.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

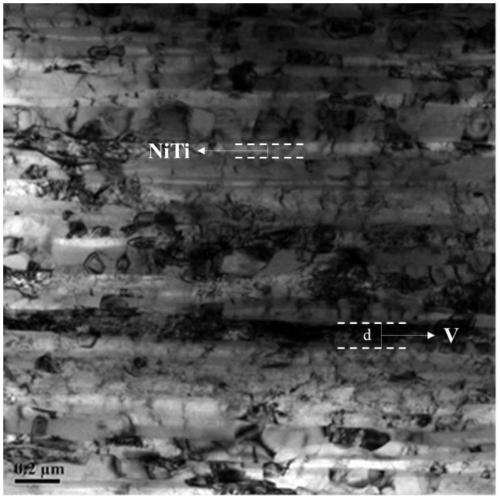

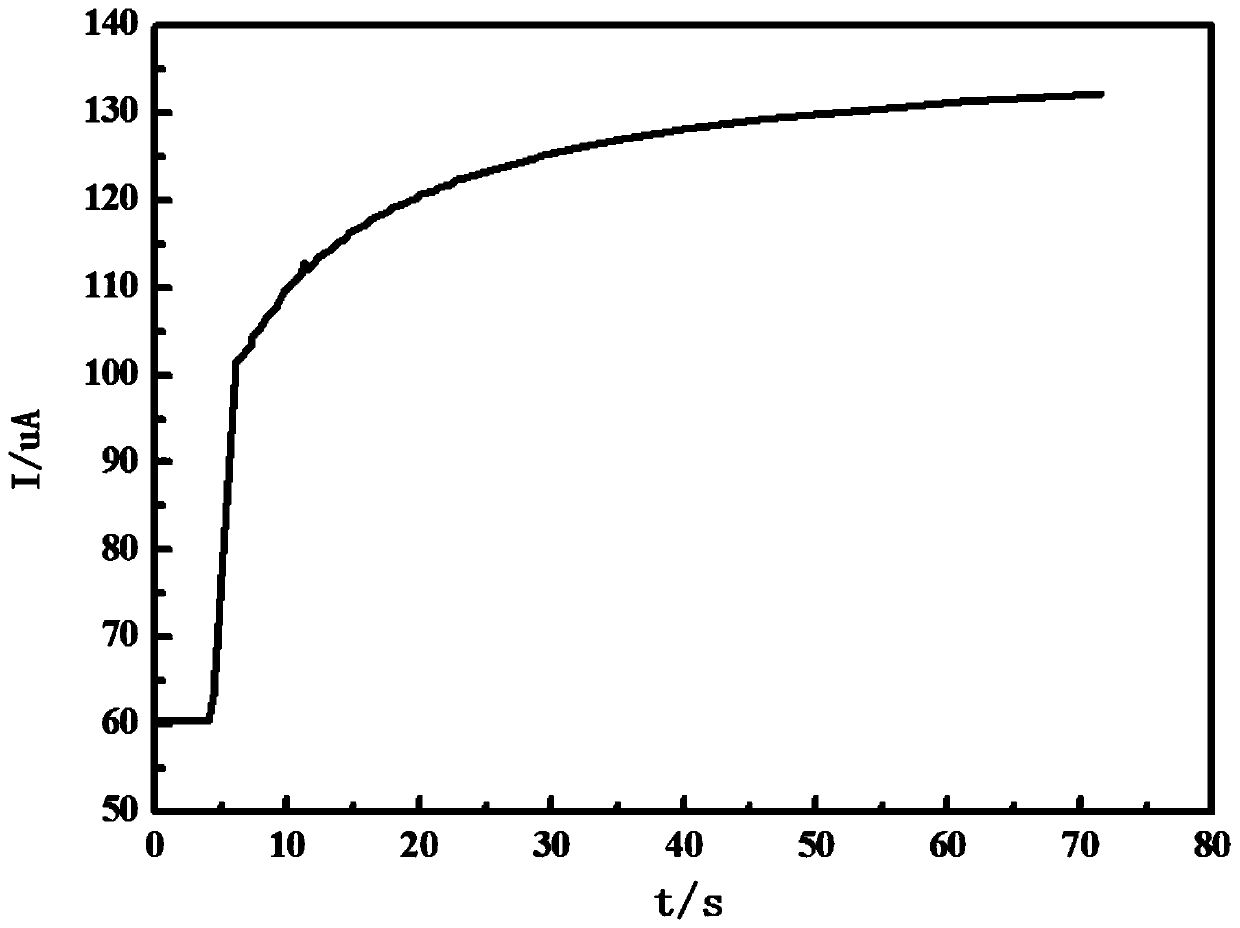

Nickel/titanium/vanadium nanowire alloy hydrogen permeability membrane and preparing method and application

InactiveCN110306096AImprove hydrogen permeabilityImprove plastic toughnessSemi-permeable membranesNanowireIngot casting

The invention discloses a nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane and a preparing method and application. The method comprises the following steps that nickel, titaniumand vanadium particles are taken and evenly mixed to obtain mixed metal powder; the mixed metal powder is put into a smelting device to be smelted, and a nickel / titanium / vanadium alloy ingot casting is obtained; the nickel / titanium / vanadium alloy ingot casting is subjected to heat preservation for 30 min at the temperature of 900 DEG C, furnace cooling to the room temperature is carried out, and annealing is finished; the annealed nickel / titanium / vanadium alloy ingot casting is forged, the forging temperature is 750 to 850 DEG C, forging starting temperature is 780 DEG C, and rod-like nickel / titanium / vanadium alloy is obtained; the nickel / titanium / vanadium alloy is subjected to drawing at the temperature of 450 to 550 DEG C, and the filamentous nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane is obtained. The prepared nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane has the higher hydrogen permeability rate, higher plasticity and toughness and lower hydrogen embrittlement susceptibility.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

4D printing crack-free special substrate made of titanium-nickel shape memory alloy and preparation method thereof

ActiveCN109112362AInhibitionInhibition of scalabilityAdditive manufacturing apparatusCrack freeShape-memory alloy

The invention discloses a 4D printing crack-free special substrate made of a titanium-nickel shape memory alloy and a preparation method thereof. The substrate is prepared from 40 to 80 percent by mass of Ni, 10 to 60 percent by mass of Ti and 2 to 10 percent by mass of Zr. The prepared 4D printing crack-free special substrate made of the titanium-nickel shape memory alloy has high hardness, highstrength, high toughness and insusceptibility to cracking.

Owner:CENT SOUTH UNIV

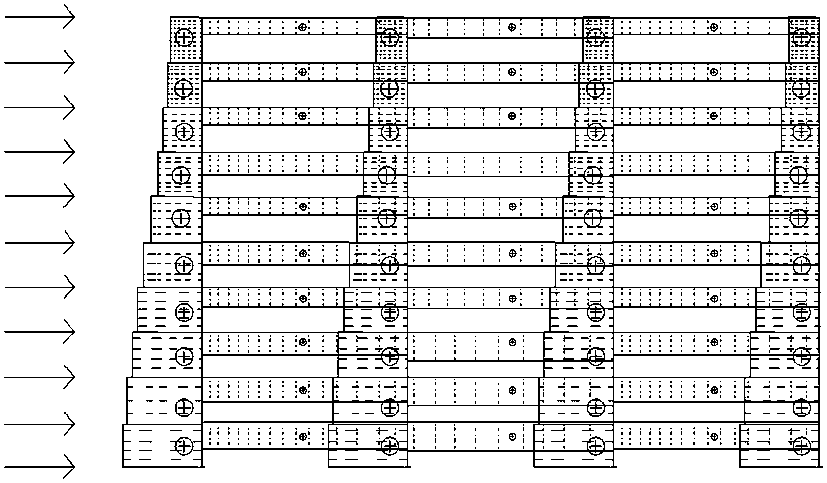

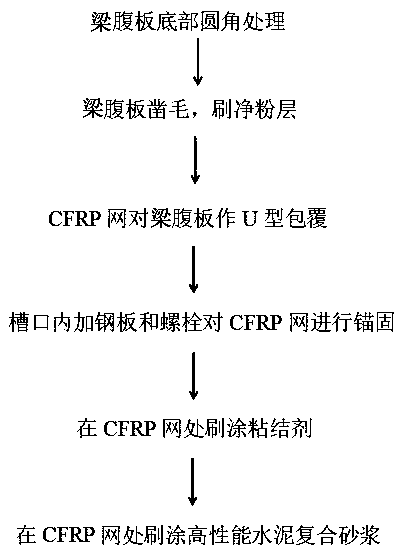

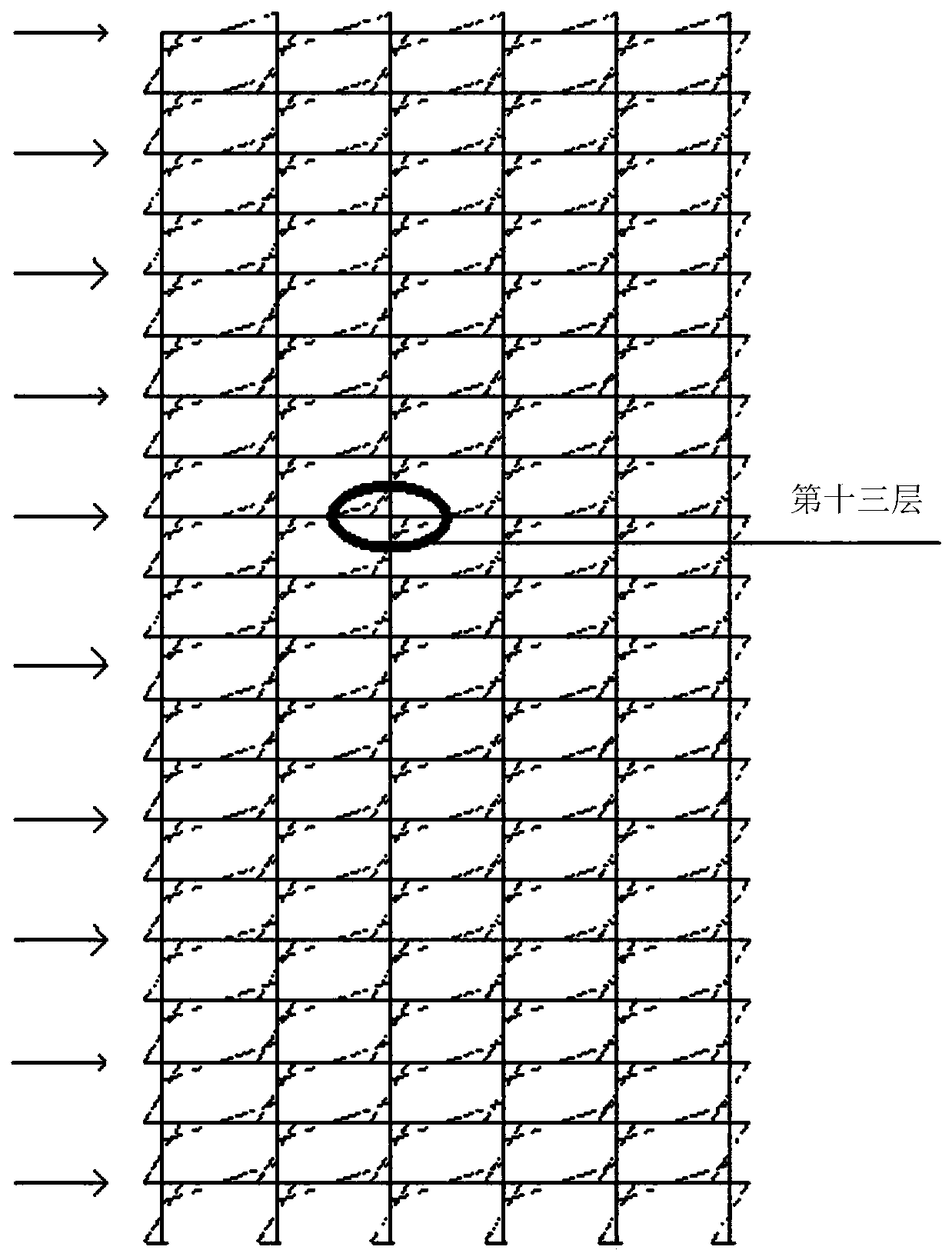

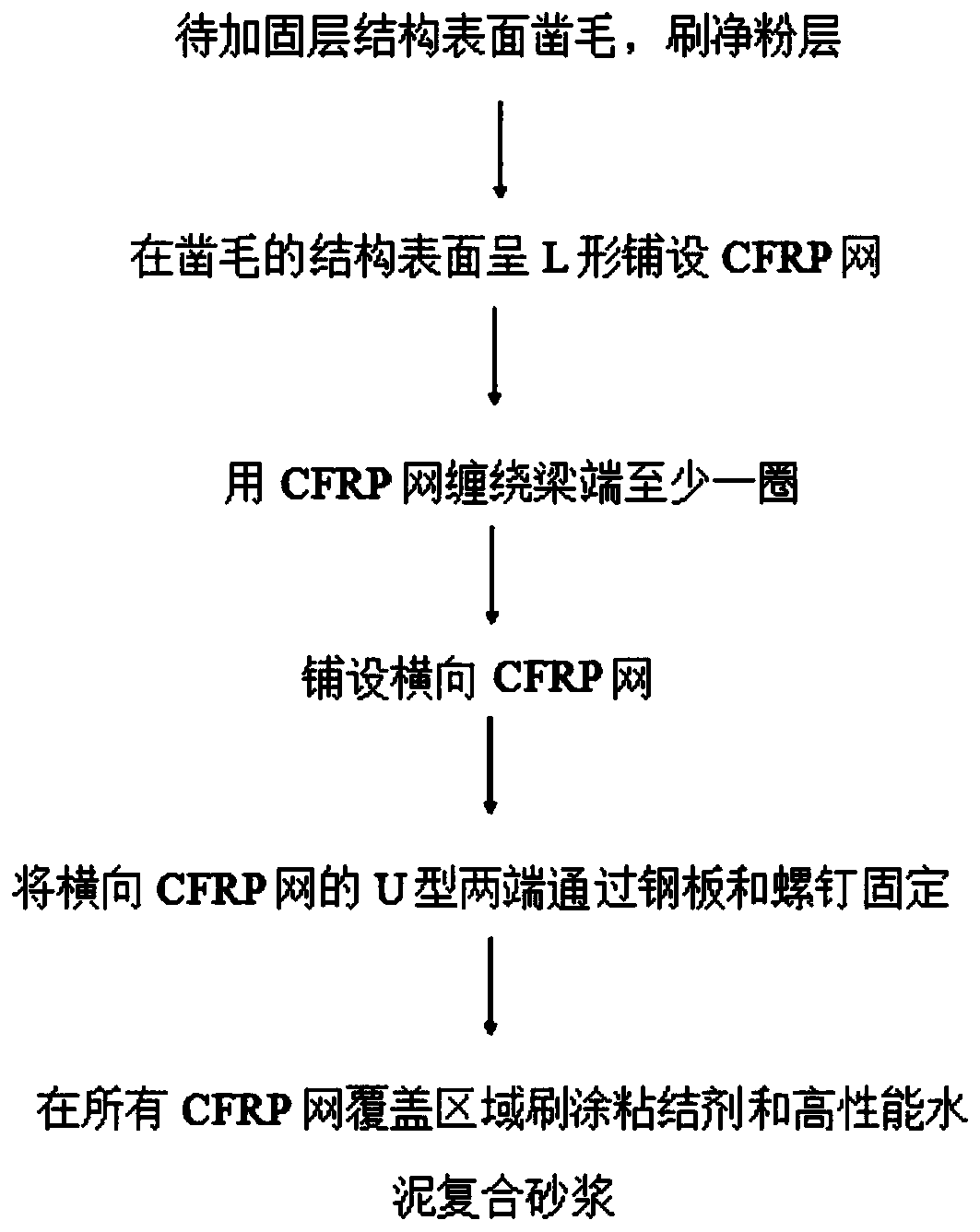

Method for carrying out shear-resistant reinforcement on beam with floor slab

InactiveCN110397300AReduce thicknessGuaranteed shear capacityBuilding repairsCement compositesFloor slab

The invention belongs to the technical field of seismic reinforcement and discloses a method for carrying out shear-resistant reinforcement on a beam with a floor slab. The beam with the floor slab comprises a beam, a wall or a column arranged at the end of the beam and the floor slab vertically connected with the beam, the wall or the column. The composite mortar reinforced by CFRP net is used for reinforcing a connecting beam section of the beam with the floor slab which is easy to be sheared and damaged. The CFRP net U-shaped surrounding beam web plate is used, CFRP net lines vertical to the axis of the connecting beam cooperate with original beam stirrups to bear seismic shearing force, CFRP net lines parallel to the axis of the connecting beam play a role in "forming a net" or 'distributing ribs', so that shearing-resistant net lines are stressed more uniformly, steel plates and bolts embedded in the upper end of the beam web plate can firmly fix the shearing-resistant CFRP net, the composite mortar cooperates with concrete to resist shearing, and the CFRP net U-shaped surrounding beam web plate plays a role in resisting compression shearing, bonding, protecting, slope findingand filling and repairing on concrete cracks, and a high-performance cement composite mortar reinforcing layer reinforced by the CFRP net can effectively guarantee the shearing-resistant bearing capacity of a reinforced beam.

Owner:HUNAN UNIV OF TECH

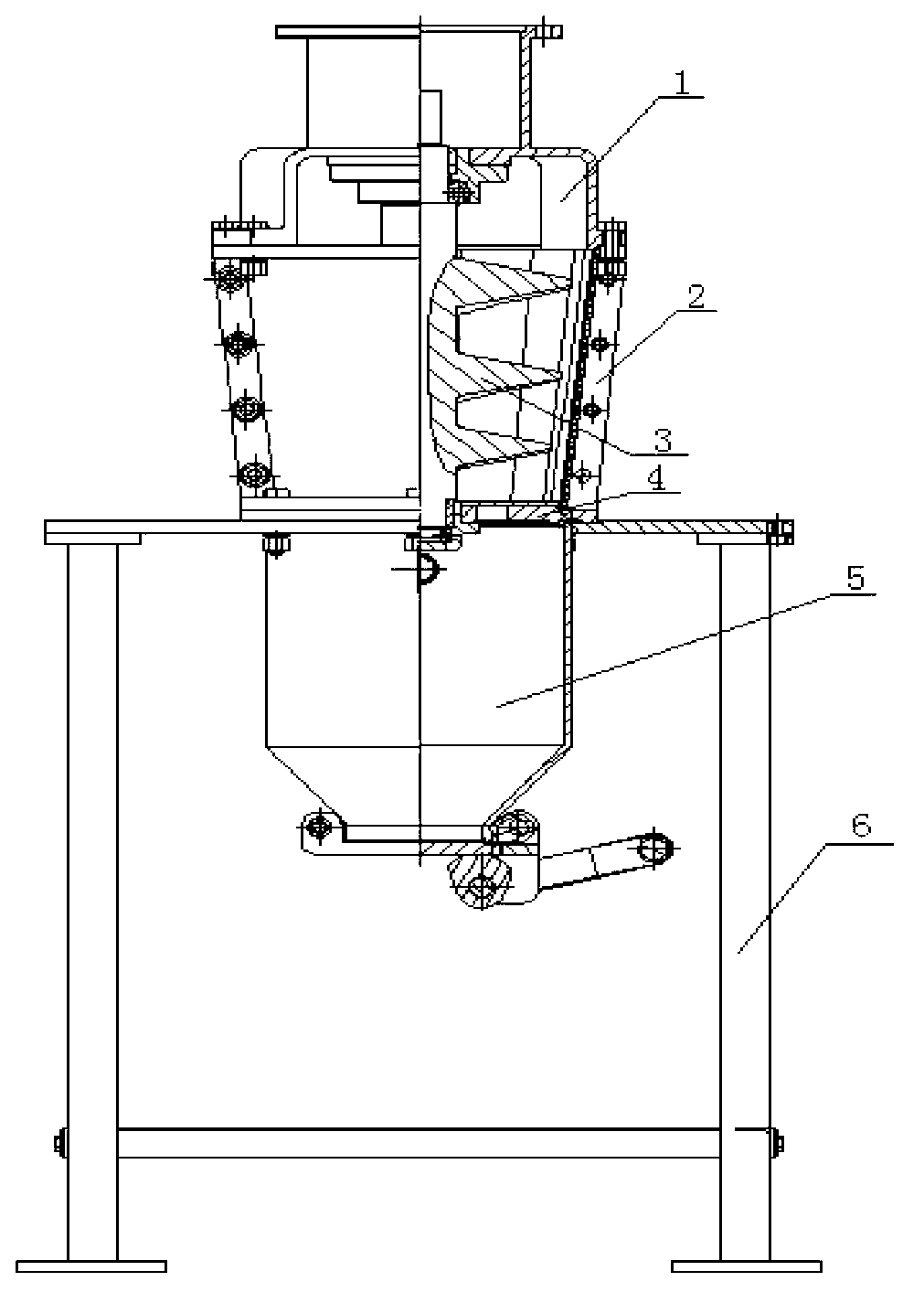

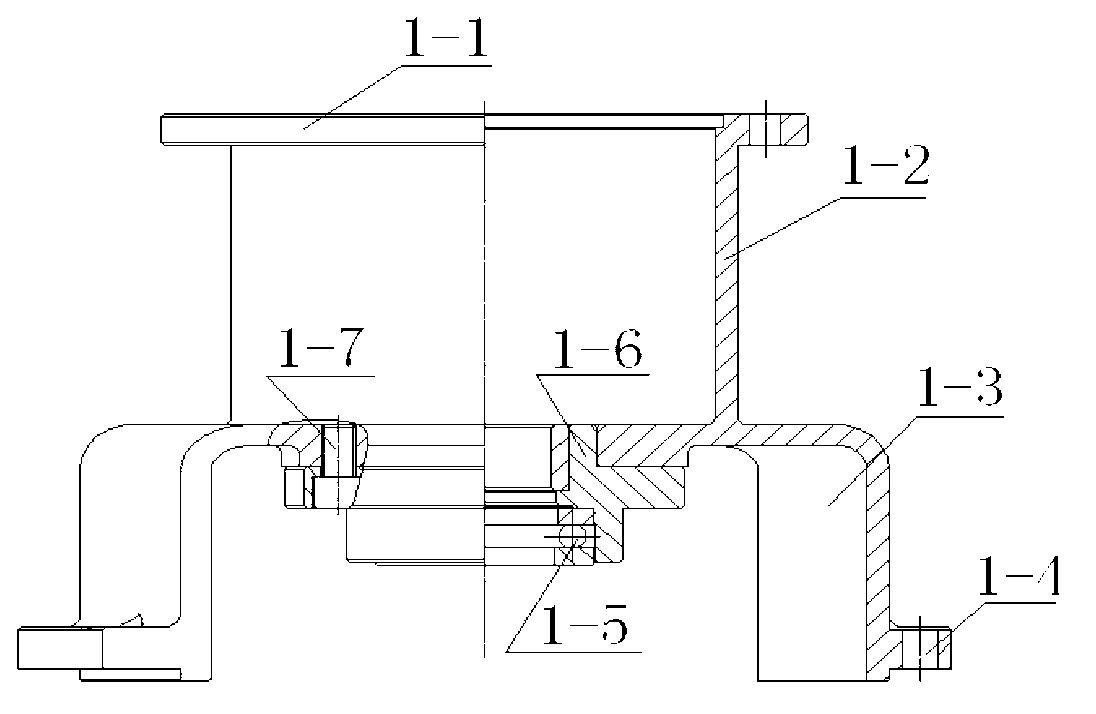

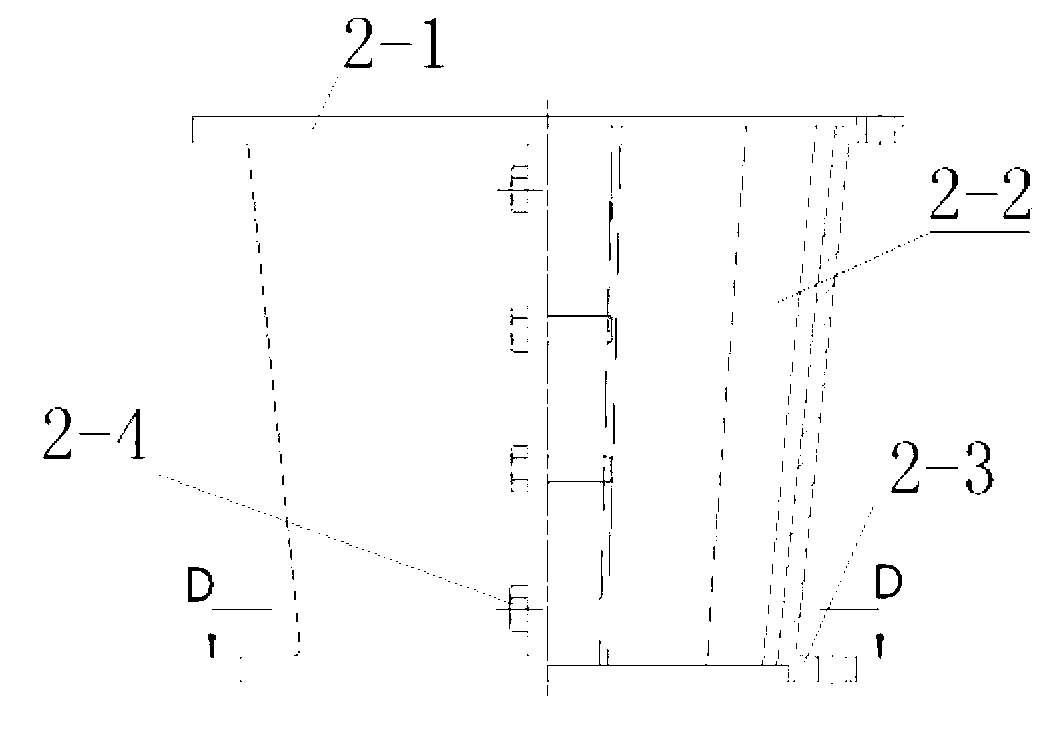

Forming explosive column/block mechanical disruption device

The invention discloses a forming explosive column / block mechanical disruption device which mainly comprises a charge-in barrel, a disruption barrel, a distance-changeable worm, a sieve plate, a material-collecting barrel and a support, when a disruption explosive column / block is completely immerged in the water environment, a speed-regulating motor is used for driving the distance-changeable worm to slowly rotate. Pressure capable of ensuring that the explosive column / block reaches the disruption intensity is acted on the explosive column / block according to the squeezing and conveying principle of a screw, and accordingly the explosive column / block is crumbled. Rotating of the distance-changeable can gradually disrupt an explosive block into small uniform explosive partials from above down in a gradation mode, the small explosive partials are conveyed to the sieve plate connected with the low end of the disruption barrel, and the sizes of the finally obtained explosive partials are about 2mm-4mm by sieving of the sieve plate. The sizes of the explosive partials after being disrupted can be controlled through replacement of sieve plate s with different sizes of hole space, and control of particle size after cracking of the disruption partials and uniformity of granularity of the explosive column / block are achieved.

Owner:XIAN MODERN CHEM RES INST

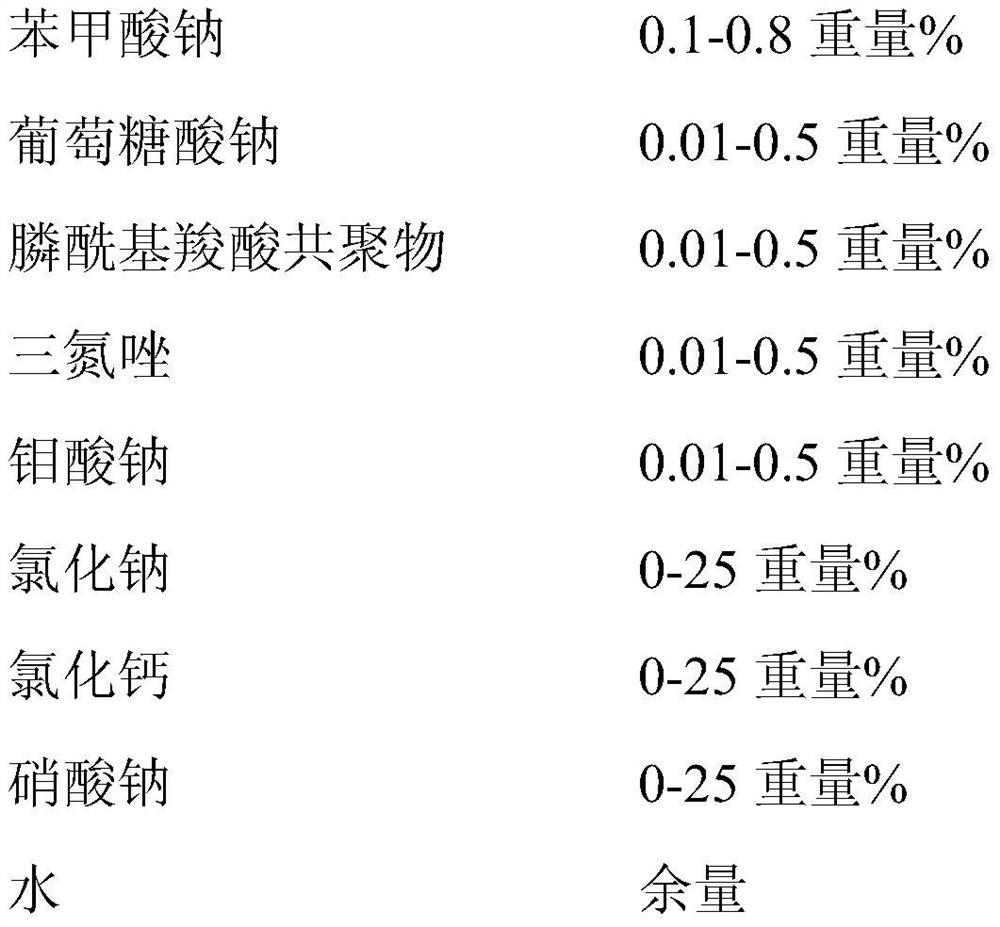

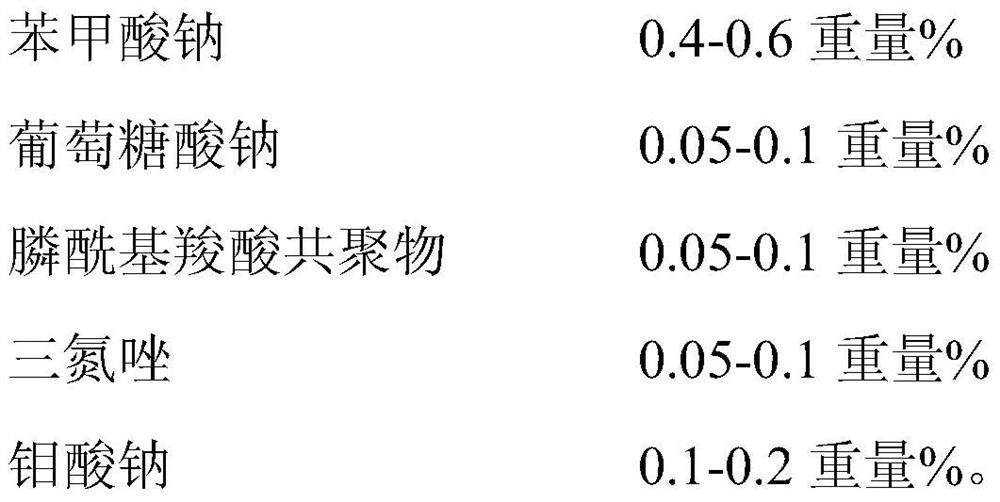

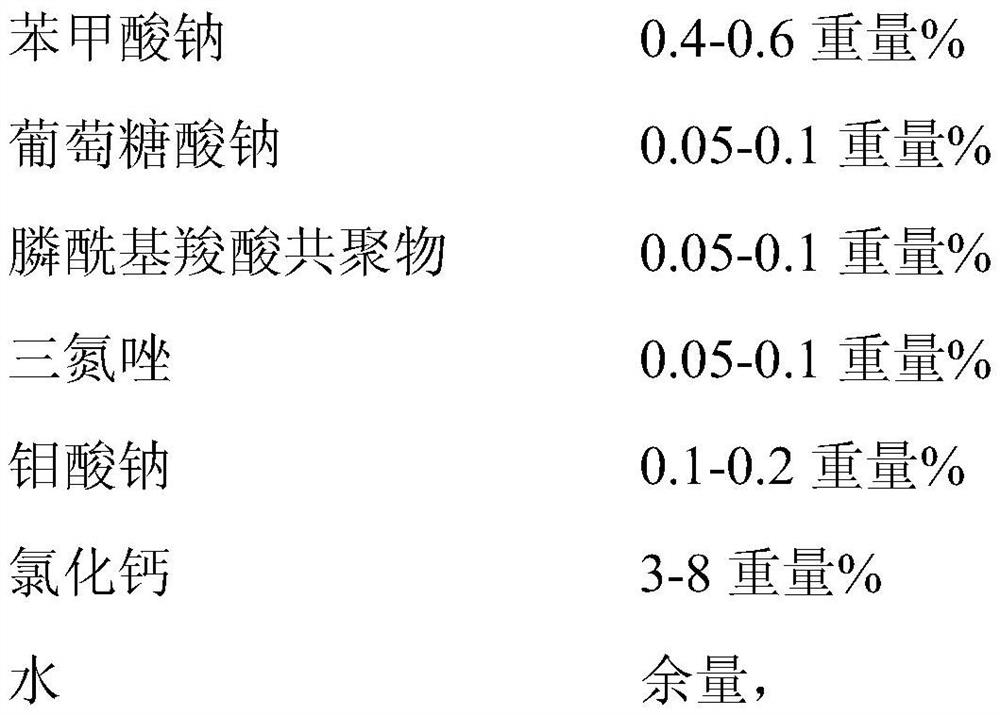

Water-based quenching liquid, preparation method thereof and application of water-based quenching liquid in quenching of elastic strip

PendingCN113278771AFast quenchingImprove product qualityFurnace typesQuenching agentsAcyl groupCarboxylic acid

The invention relates to the technical field of railway engineering product manufacturing, in particular to water-based quenching liquid, a preparation method thereof and application of the water-based quenching liquid in quenching of an elastic strip. The water-based quenching liquid comprises the following components in percentage by weight: 0.1 to 0.8 percent of sodium benzoate, 0.01 to 0.5 percent of sodium gluconate, 0.01 to 0.5 percent of phosphono carboxylic acid copolymer, 0.01 to 0.5 percent of triazole, 0.01 to 0.5 percent of sodium molybdate, 0 to 25 percent of sodium chloride, 0 to 25 percent of calcium chloride, 0 to 25 percent of sodium nitrate and the balance of water, wherein the contents of sodium chloride, calcium chloride and sodium nitrate are not 0 at the same time. By the adoption of the water-based quenching liquid, the quenching speed of the elastic strip can be increased, the hardness uniformity of a quenching core part is guaranteed, residual compressive stress is generated on the surface of the quenched elastic strip, generation and extension of hardening cracks are inhibited, and the water-based quenching liquid has the advantages of being safe and environmentally friendly.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

Method for anti-bending reinforcement of beam end with floor

The invention belongs to the technical field of seismic reinforcement and discloses a method for anti-bending reinforcement of a beam end with a floor, wherein a wall or a pillar is disposed at the beam end; the floor is in perpendicular connection to a beam, the wall or the pillar; and composite mortar reinforced by a CFRP mesh is paved to an L-shaped connecting surface between the beam and the wall or the pillar for reinforcement. The method disclosed by the invention has the beneficial effects that based on characteristics of the CFRP mesh that the mesh is light, high in strength and modulus, flexible and easy in construction, easy in anchoring, overlapping and positioning, durable, anti-corrosion, anti-fatigue, anti-magnetic, anti-shielding, and anti-stripping and can reduce thicknessof a reinforcement layer, the CFRP mesh is built in the high-performance cement composite mortar for reinforcement of parts with complicated structures, so various adverse factors of reinforcement with various composite materials which take a traditional rebar mesh as a reinforcement phase can be remedied. The high-strength CFRP mesh is paved to the L-shaped connecting surface between the beam andthe wall or the pillar in an L-shaped manner, so the reinforcement layer formed through combination of the CFRP mesh and the subsequent cement composite mortar can give full play to an anti-tension effect.

Owner:HUNAN UNIV OF TECH

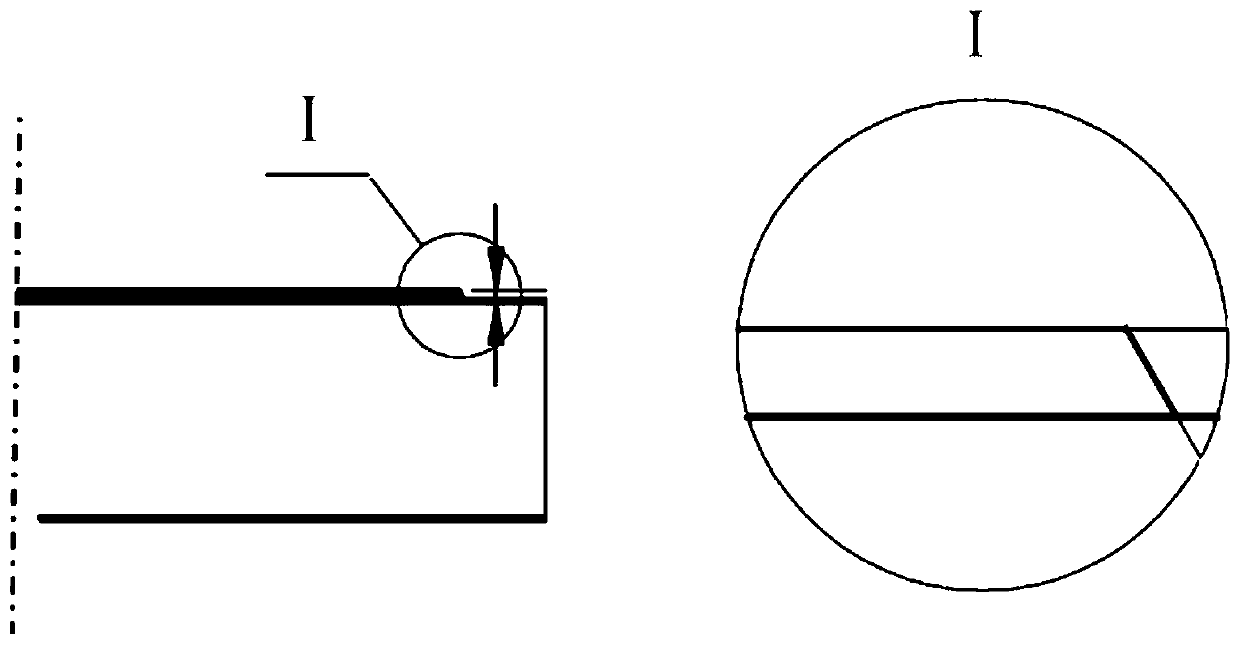

High-strength steel sheet multi-teeth structure precision stamping forming die and method

The invention provides a high-strength steel sheet multi-teeth structure precision stamping forming die and a high-strength steel sheet multi-teeth structure precision stamping forming method. The high-strength steel sheet multi-teeth structure precision stamping forming method includes applying a precision stamping technology to processing of a multi-teeth structure of a high-strength steel sheet, enabling the multi-teeth structure of the high-strength steel sheet to efficiently and rapidly form, and obtaining high residual compressive stress and low roughness at bottoms of teeth, does need surface strengthening for tooth profiles, obtains products good in consistency, and can significantly prolong structure fatigue life. The high-strength steel sheet multi-teeth structure precision stamping forming die particularly comprises an upper die portion and a lower die portion, wherein the upper die portion comprises an upper die seat, a blank holder and a male die, the lower die portion comprises a female die, a reverse pressing plate and a lower die seat, the reverse pressing plate is specially designed, material in a shearing area of the part is under three-dimensional pressure, a three-dimensional pressure stress state is formed, and therefore generation and extension of cracks are effectively inhibited. Due to the fact that the female die adopts tiny annular bulge contact stamping, stress in the inner tooth shearing area of the multi-teeth structure of the high-strength steel sheet can be improved, the shape of the material along a cutting edge of the female die is punched in pure shear mode, surface smoothness of inner teeth of the multi-teeth structure is greatly improved, and part quality is guaranteed.

Owner:CHINA NORTH VEHICLE RES INST

Fixture for inhibiting initiation and expansion of grinding and polishing cracks of diamond film and use method

ActiveCN112792735AImprove the whole film rateInhibition of germinationLapping machinesGrinding feedersCrazingMechanical engineering

The invention discloses a clamp for inhibiting initiation and expansion of grinding and polishing cracks of a diamond film and a use method. The clamp comprises a base, a water tank, water tank drainage holes, a base limiting ring, a tensioning ring, a buffering cushion and a tensioning bolt, the upper top surface of the base of the clamp is a load applying surface, the lower bottom surface is a surface adhered with the diamond film after heating, stress is prefabricated between the surface and the diamond film through cooling, the base limiting ring is placed outside the base, the water tank is placed at the top of the base limiting ring, a water source is provided for a gap between the base and the base limiting ring through the water tank drainage holes evenly distributed in the bottom of the water tank, the buffering cushion is placed on the bottom surface of the base, and the tensioning ring covers the outer edge of the buffering cushion. After the flattening treatment is completed, rapidly heating treatment is directly carried out on the whole clamp until a binder loses efficacy, and the leveling treatment process is completed. According to the clamp for inhibiting initiation and expansion of the grinding and polishing cracks of the diamond film and the use method, the whole film rate and the machining efficiency of the diamond film are improved, the powder blocking problem is solved, and environmental pollution is reduced; and the method can further be used for flattening treatment of the diamond film with the cracks, crack expansion is inhibited, and the usable area of the diamond film is increased.

Owner:UNIV OF SCI & TECH BEIJING +1

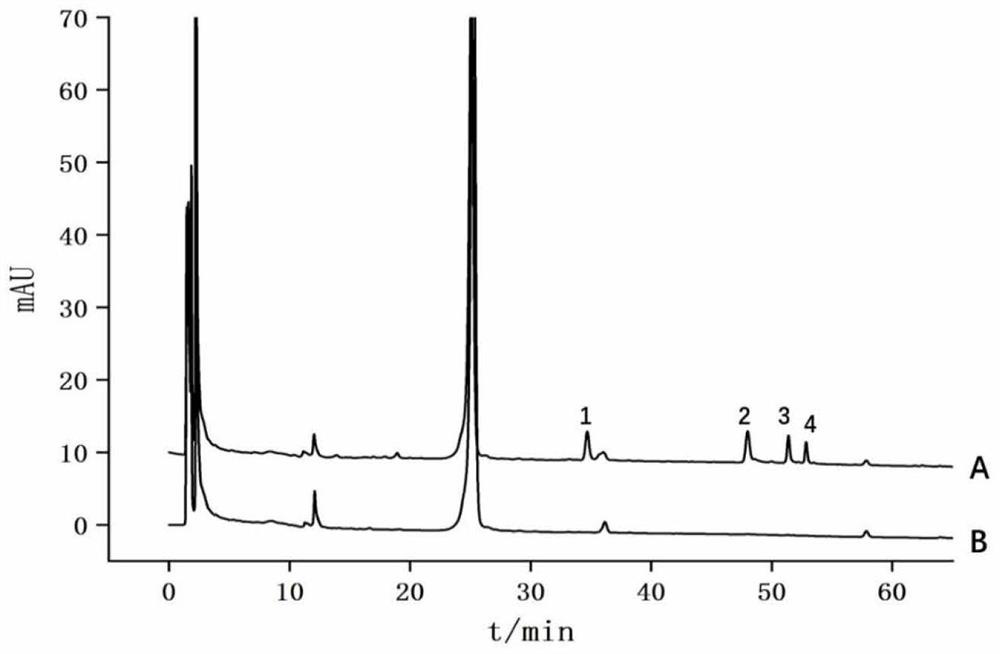

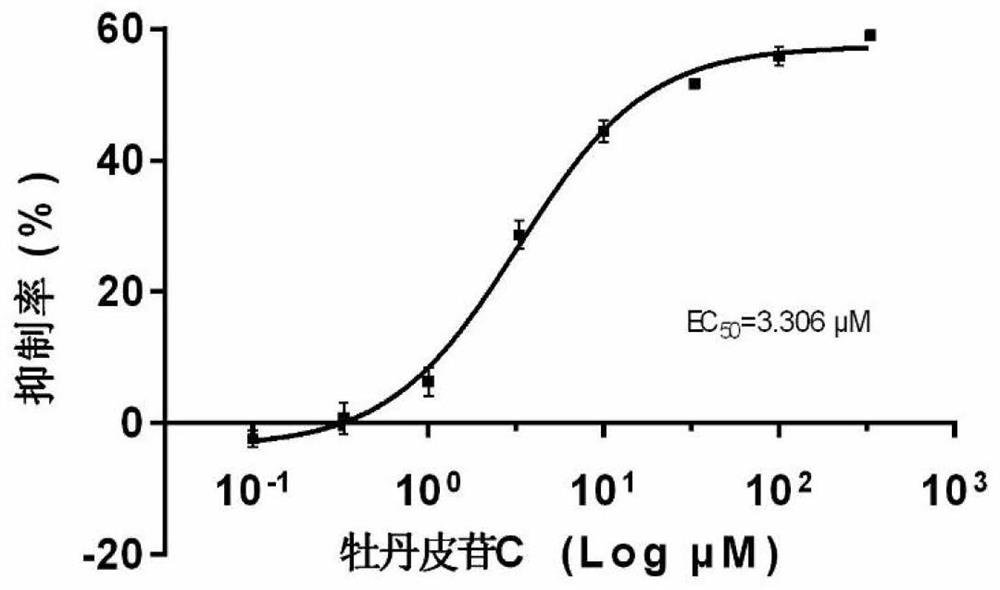

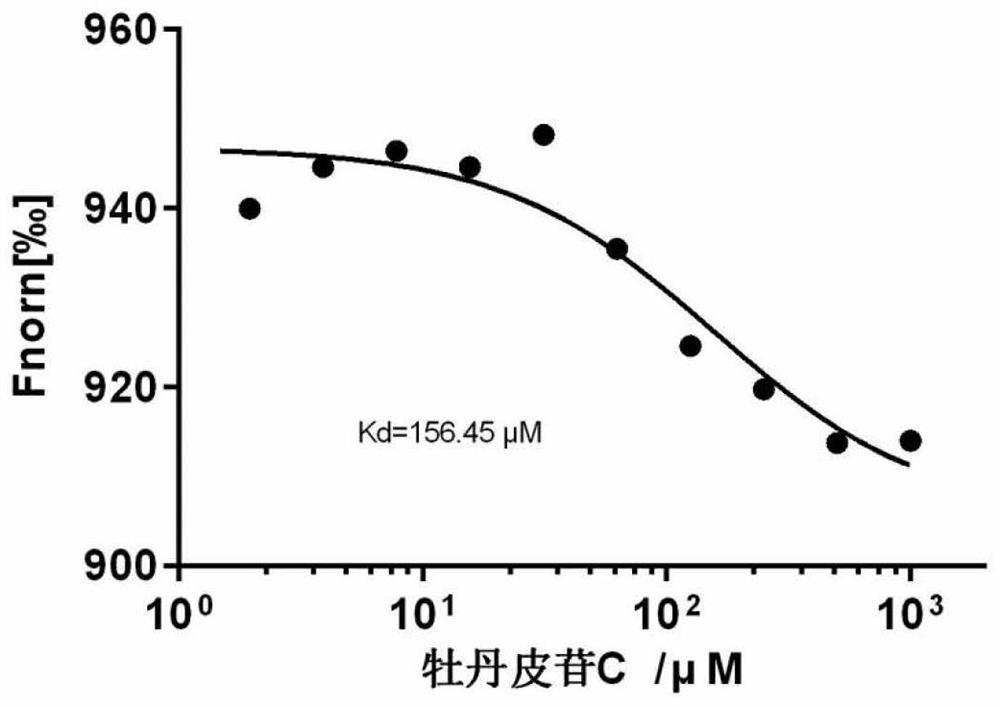

Application of moutan bark glycoside C in preparation of protein disulfide bond isomerase inhibitor

PendingCN114469975AInhibit aggregationInhibition of adhesionOrganic active ingredientsBlood disorderIsomeraseAntithrombotic

The invention belongs to the technical field of biological medicine, and discloses application of moutan bark glycoside C in preparation of a protein disulfide isomerase inhibitor. A protein disulfide bond isomerase binding component is obtained through affinity chromatography, and activity determination finds that moutan glycoside C can specifically inhibit protein disulfide bond isomerase (EC50lt; the antithrombotic peptide has the advantages that the antithrombotic peptide has a potential antithrombotic effect and is expected to be developed into drugs for preventing thrombotic diseases, and the effect of inhibiting platelet aggregation is achieved by interfering adhesion and expansion of platelets.

Owner:CHINA PHARM UNIV

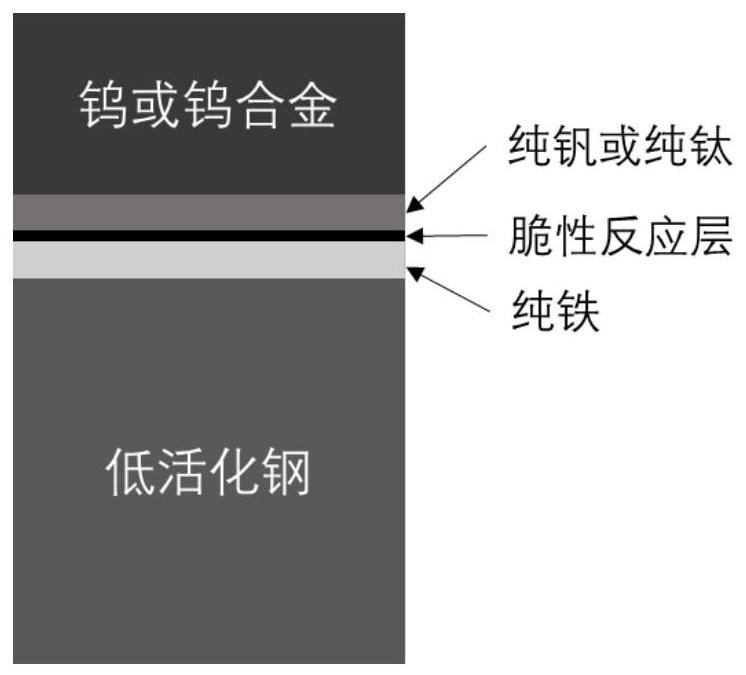

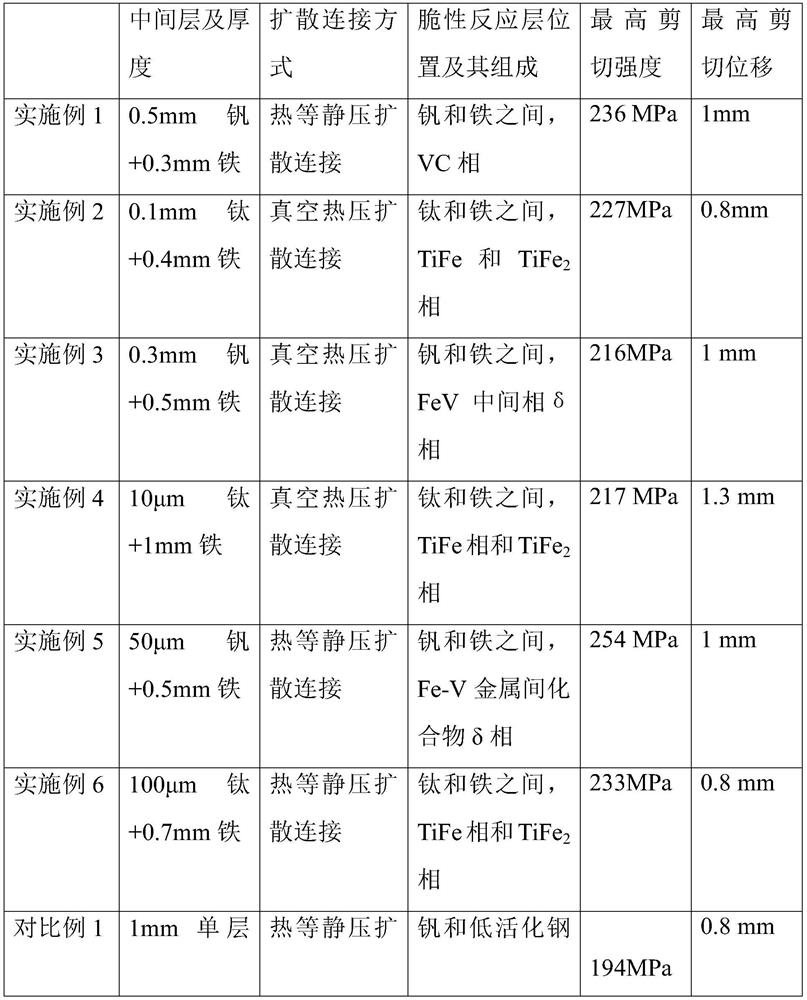

A Diffusion Bonding Method of Tungsten and Low-Activation Steel

ActiveCN112496518BImprove connection strengthInhibition of germinationWelding/soldering/cutting articlesNon-electric welding apparatusReaction layerPlastic property

The invention belongs to the field of metal diffusion welding, and in particular relates to a diffusion connection method of tungsten and low-activation steel. The structure of vanadium (or titanium) / iron / low activation steel is combined, and vacuum hot pressing or hot isostatic pressing is used for diffusion bonding of the combination. The temperature of diffusion bonding is controlled at 700‑1000℃, and the time of diffusion bonding is controlled at 0.5‑4 Hour. The invention controls the brittle reaction layer between the soft intermediate layers, forming a hard / soft / hard / soft / hard interface structure, and the interface stress can be fully released through the plastic deformation or viscoplastic deformation of the soft intermediate layer. , which inhibits the initiation and propagation of cracks in the brittle tungsten and reactive layers, resulting in the as-prepared tungsten / low activation steel joints with high connection strength, good plasticity and excellent thermal fatigue resistance.

Owner:SOUTHWESTERN INST OF PHYSICS

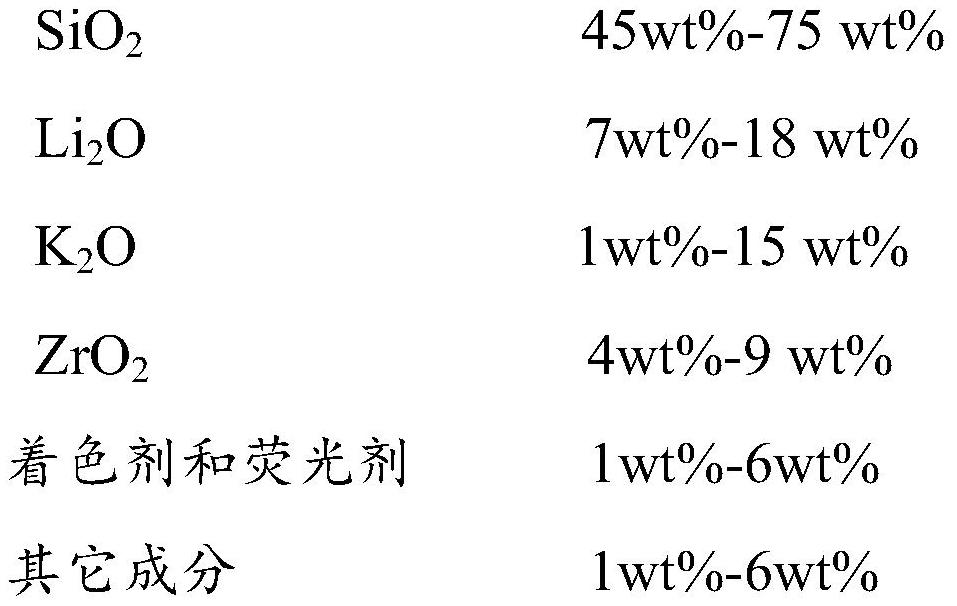

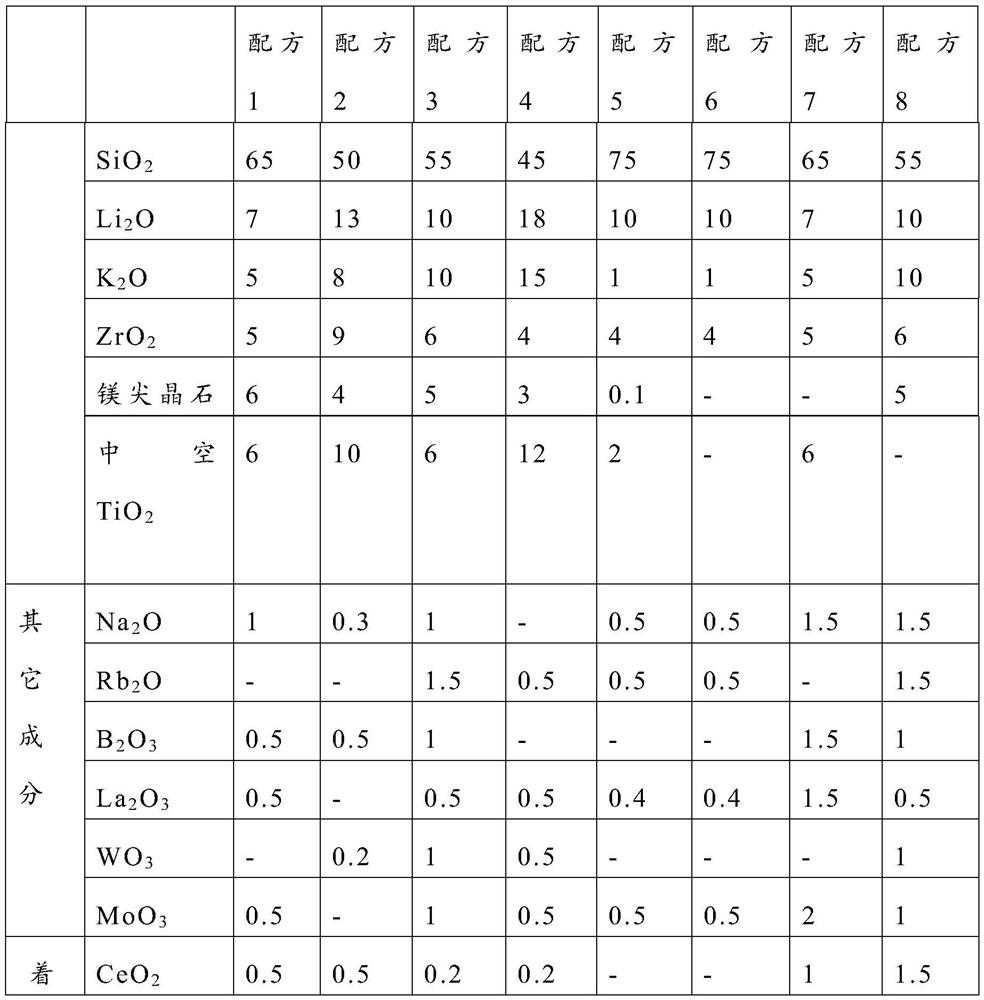

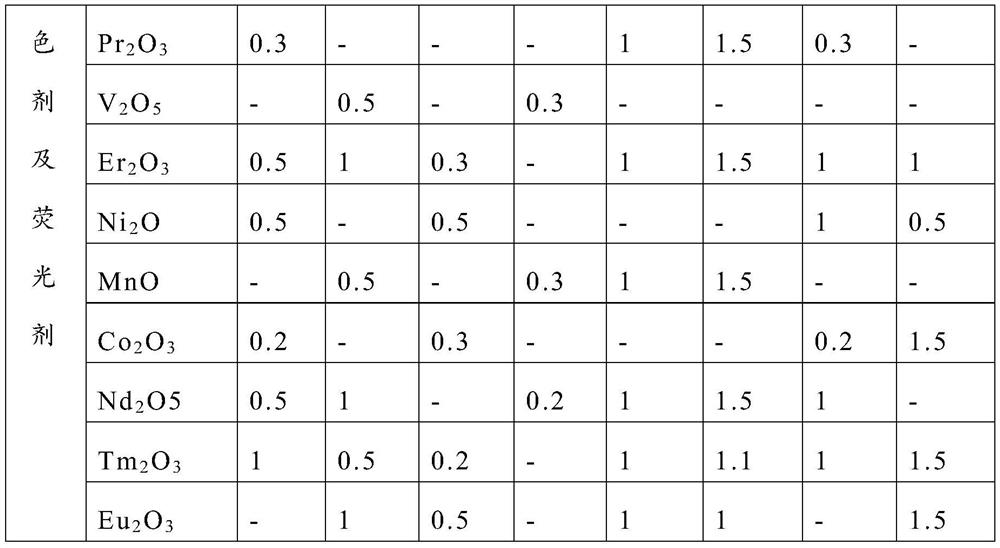

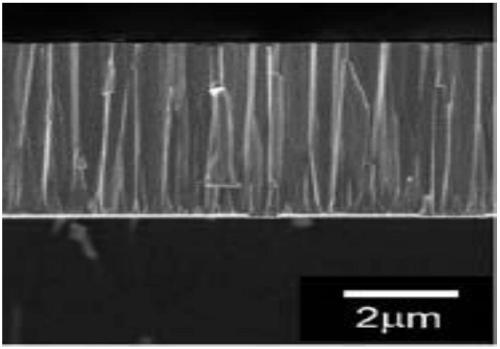

Lithium silicate glass ceramic, preparation method thereof and obtained prosthesis

PendingCN114644459AImprove yield rateLow softening temperatureImpression capsGlass furnace apparatusSilicate glassPhysical chemistry

The invention provides lithium silicate glass ceramic, a preparation method thereof and an obtained prosthesis, and belongs to the technical field of dental materials. The lithium silicate glass ceramic provided by the invention is prepared from the following components in percentage by weight: 59wt%-97.9 wt% of a basic glass component, 22wt%-12wt% of hollow TiO2 and 0.1 wt%-6wt% of magnesium spinel. The magnesium spinel and the hollow titanium oxide are added into the lithium silicate glass ceramic provided by the invention, the generation and expansion of cracks in the preparation process can be effectively inhibited by utilizing the hollow structure of the hollow titanium oxide, and the reduction of the cracks plays an important role in improving the yield in the preparation process of the lithium silicate glass ceramic. Meanwhile, the magnesium spinel component is added into the original components, so that the softening temperature and the die-casting temperature of the lithium silicate glass ceramic can be effectively reduced, and the requirements of the dental restoration material on corresponding performance can be met.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

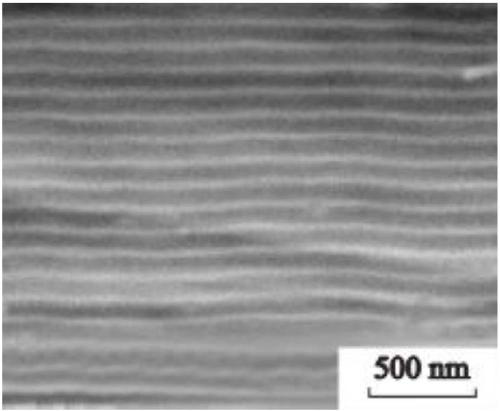

Ion plating Ni-P nanometer laminated membrane and preparation method thereof

ActiveCN109457220AHighlight substantiveSignificant progressVacuum evaporation coatingSputtering coatingChemical platingTotal thickness

The invention discloses an ion plating Ni-P nanometer laminated membrane. The nanometer laminated Ni-P membrane of a laminated structure is acquired in a sedimentation manner through an ion plating technology with ferrous metal as a substrate material, the total thickness of the nanometer laminated Ni-P membrane is adjustable within the range of 2 microns-80 microns, and the self-corrosion potential of the nanometer laminated Ni-P membrane is 230 mV or above. The microstructure of the nanometer laminated Ni-P membrane is more compact, and the abrasion resisting performance and the corrosion resisting performance of the plating membrane are remarkably improved. The invention further discloses a preparation method of the ion plating Ni-P nanometer laminated membrane. By adopting the ion plating technology for sedimentation, it does not need to use any chemical plating solution, no waste liquid is generated, and environmental friendliness is achieved.

Owner:于志明

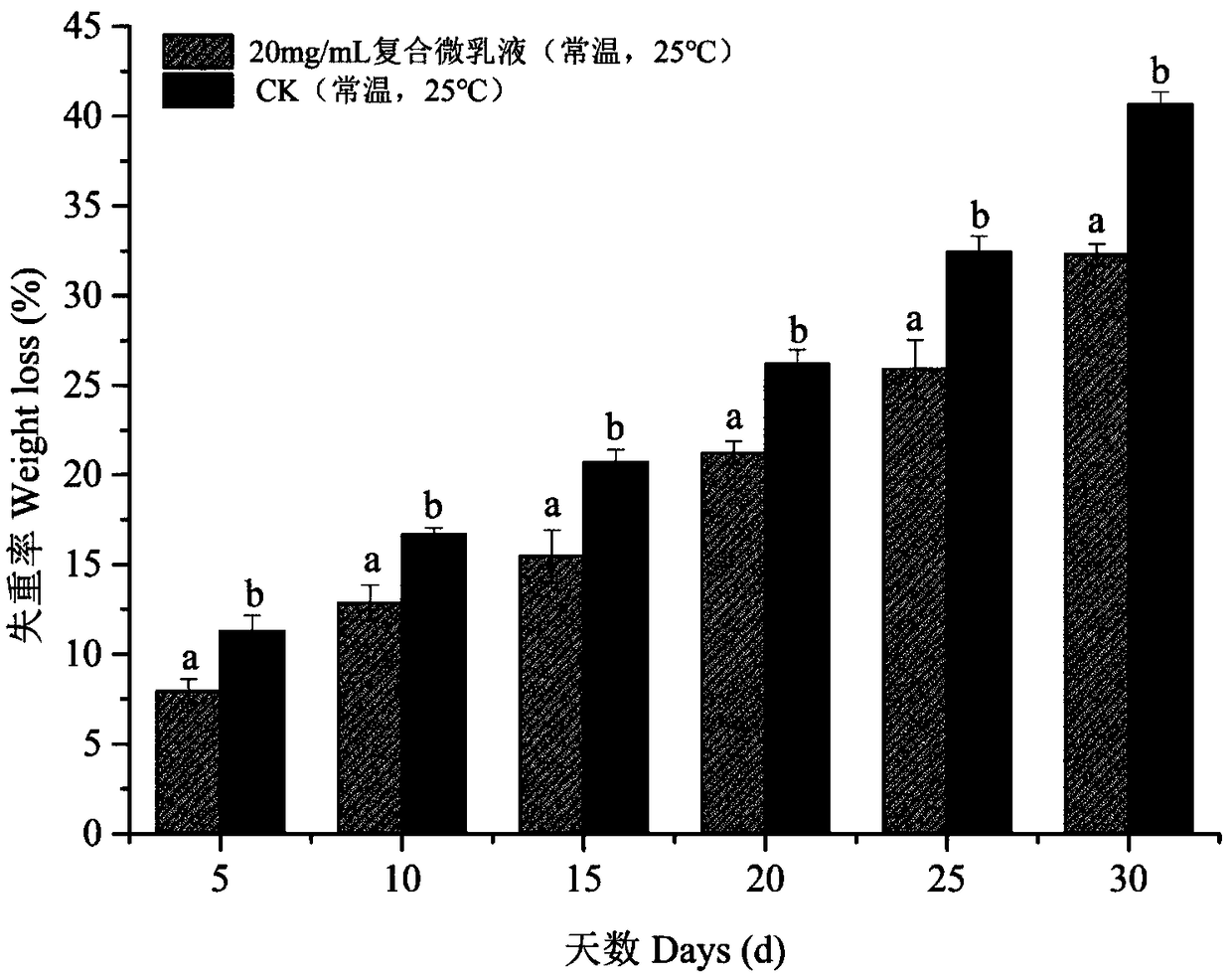

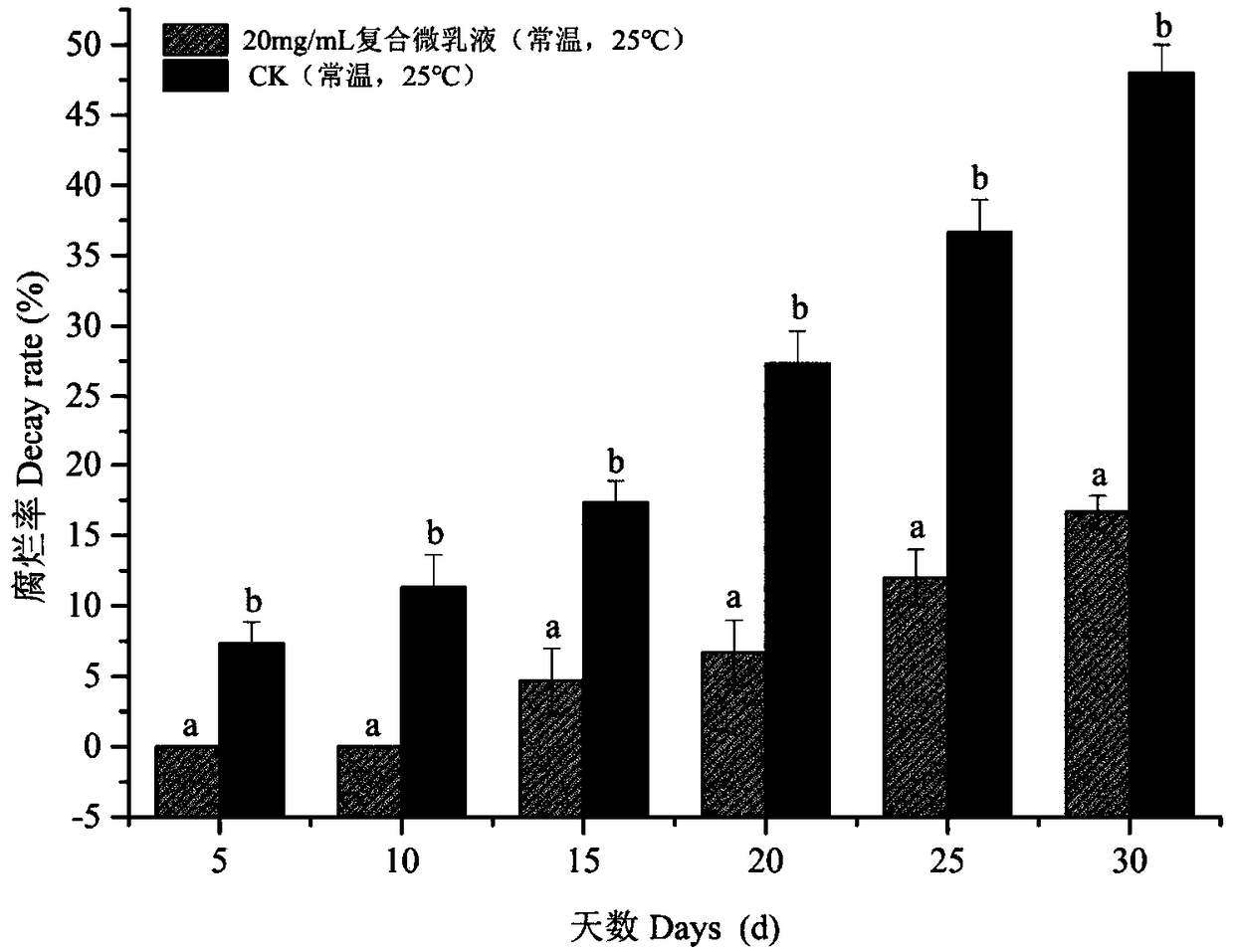

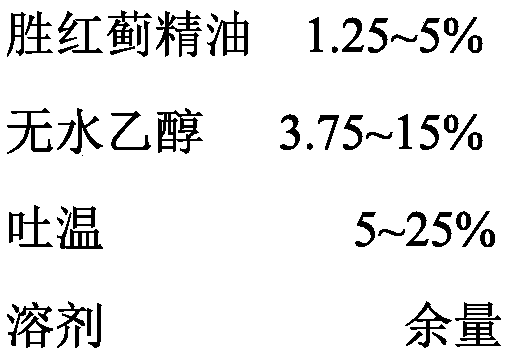

Fresh keeping agent composition for mandarins and preparation method of fresh keeping agent composition

ActiveCN108719455AReduce water lossReduce decay rateFruit and vegetables preservationBiotechnologyLoss rate

The invention discloses a fresh keeping agent composition for mandarins and a preparation method of the fresh keeping agent composition. The fresh keeping agent composition consists of the following components in percentage by weight: 1.25-5% of tropic ageratum essential oil, 3.75-15% of anhydrous alcohol, 5-25% of tween and the balance of solvents. Through adoption of the fresh keeping agent composition for mandarins, the growth of penicillium italicum, penicillium digitatum and penicillium expansum can be significantly restrained; and when fresh keeping agents are used for performing fruit immersion treatment on the mandarins, the water loss rate and the rotting rate of the mandarins in the storage process can be significantly reduced. The fresh keeping agent composition for mandarins disclosed by the invention is simple in formula components, simple in compounding technology, natural, environmentally-friendly, and non-toxic, conforms to green, environmental protection and ecologicalcivilization construction ideas at present, and has favorable development and application prospects.

Owner:HUAQIAO UNIVERSITY +1

Method for preparing thermal insulation material by utilizing silica gel wastewater

InactiveCN107500714ARealize resource utilizationReduce pollutionMagnesium phosphateThermal insulation

The invention discloses a method for preparing a thermal insulation material by utilizing silica gel wastewater, and belongs to the field of heat insulation materials. The method comprises the following steps: putting the silica gel wastewater, calcium oxide and aluminum chloride into a reaction kettle for reaction to obtain reactants; cooling and collecting the reactants; putting the reactants into a container and electrifying the container, filtering and collecting filter residues; calcinating the filter residues at temperature of 500 to 550 DEG C; cooling and collecting calcined materials; putting the calcined materials into a ball mill; then adding surfactant into the ball mill and carrying out ball milling to obtain a ball mill material; putting water, the ball mill material, magnesium phosphate, dispersants, hydroxypropyl methylcellulose and sodium carbonate into the container, and mixing, standing and stirring to obtain a stirred mixture; pouring the stirred mixture into a mould; squeezing and screeding the stirred mixture; then putting the mould into a drying oven and drying the mould; cooling the mould; collecting a dried material to obtain the thermal insulation material prepared by utilizing the silica gel wastewater. The method disclosed by the invention has the beneficial effects that the thermal insulation material disclosed by the invention has a good thermal insulation effect, is strong in stability and is worthy of being popularized.

Owner:常州鼎众冷暖设备工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com