Method for carrying out shear-resistant reinforcement on beam with floor slab

A floor and steel plate technology, which is applied in the field of shear reinforcement of beams with floors, can solve the problems of easy aging, structural adhesives not resistant to high temperatures, and incompatibility of adhesive interfaces, and achieve good impermeability and crack resistance. Easy anchoring, overlapping positioning, soft construction effect

Inactive Publication Date: 2019-11-01

HUNAN UNIV OF TECH

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The traditional shear reinforcement methods of reinforced concrete beams mostly use carbon fiber cloth, carbon fiber plate, steel plate or section steel as the reinforcement layer. Structural adhesives are not resistant to high temperatures and are prone to aging. Inconsistency with inorganic concrete due to their material properties can easily lead to incompatibility on the bonding interface, so that the reliability and durability of reinforcement cannot be guaranteed, and the process is complicated, and the construction quality is not easy to guarantee

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

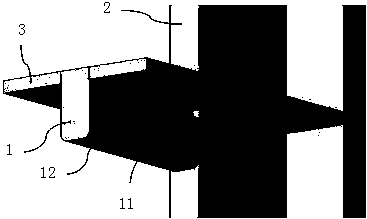

[0066] The difference between this embodiment and Embodiment 1 is that the CFRP mesh is laid at the non-beam end of the beam web, that is, the CFRP mesh is laid at any position on the beam web far away from both ends of the beam, and other setting details are the same as Example 1 is the same.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

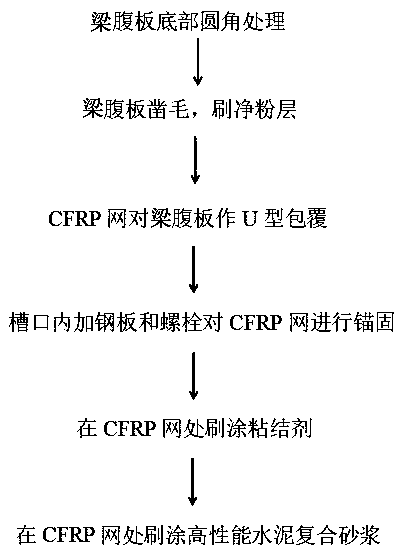

The invention belongs to the technical field of seismic reinforcement and discloses a method for carrying out shear-resistant reinforcement on a beam with a floor slab. The beam with the floor slab comprises a beam, a wall or a column arranged at the end of the beam and the floor slab vertically connected with the beam, the wall or the column. The composite mortar reinforced by CFRP net is used for reinforcing a connecting beam section of the beam with the floor slab which is easy to be sheared and damaged. The CFRP net U-shaped surrounding beam web plate is used, CFRP net lines vertical to the axis of the connecting beam cooperate with original beam stirrups to bear seismic shearing force, CFRP net lines parallel to the axis of the connecting beam play a role in "forming a net" or 'distributing ribs', so that shearing-resistant net lines are stressed more uniformly, steel plates and bolts embedded in the upper end of the beam web plate can firmly fix the shearing-resistant CFRP net, the composite mortar cooperates with concrete to resist shearing, and the CFRP net U-shaped surrounding beam web plate plays a role in resisting compression shearing, bonding, protecting, slope findingand filling and repairing on concrete cracks, and a high-performance cement composite mortar reinforcing layer reinforced by the CFRP net can effectively guarantee the shearing-resistant bearing capacity of a reinforced beam.

Description

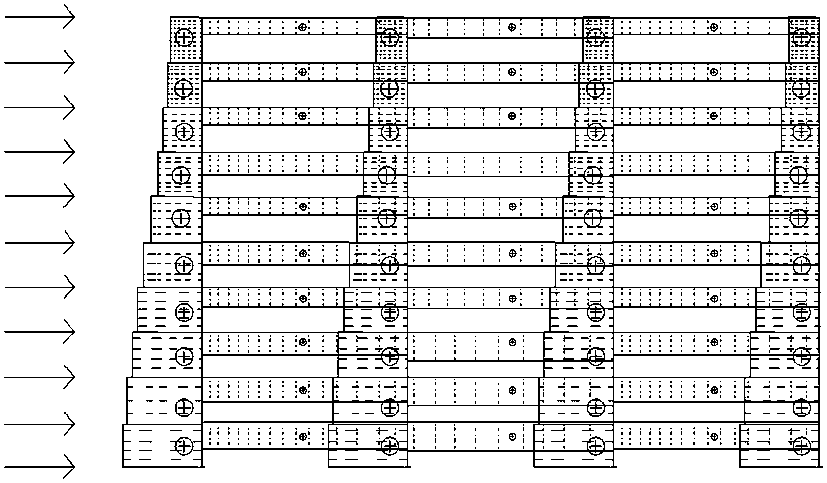

technical field [0001] The invention relates to the field of anti-seismic reinforcement, in particular to a method for performing shear reinforcement on beams with floor slabs. Background technique [0002] Coupling beams in the reinforced concrete short-limb shear wall structure system designed according to my country's existing codes, frame beams in the cast-in-place frame structure system, independent simply supported beams, and reinforced concrete bridges, such with slabs or flanges Beams, due to the influence of design and construction or other factors, may cause insufficient shear stirrups, and are prone to shear failure under horizontal earthquake or wind loads, such as figure 1 shown. [0003] For reinforced concrete beams with slabs or flanges, since the slabs or flanges are integrally cast in-situ with the web, the shear reinforcement layer can only be arranged in the web area, and the reinforcement layer cannot be made into a " Closed enclosure”, the anti-strippi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G23/02

CPCE04G23/0218

Inventor 蒋隆敏王球刘奥

Owner HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com