Patents

Literature

36results about How to "Guaranteed shear capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

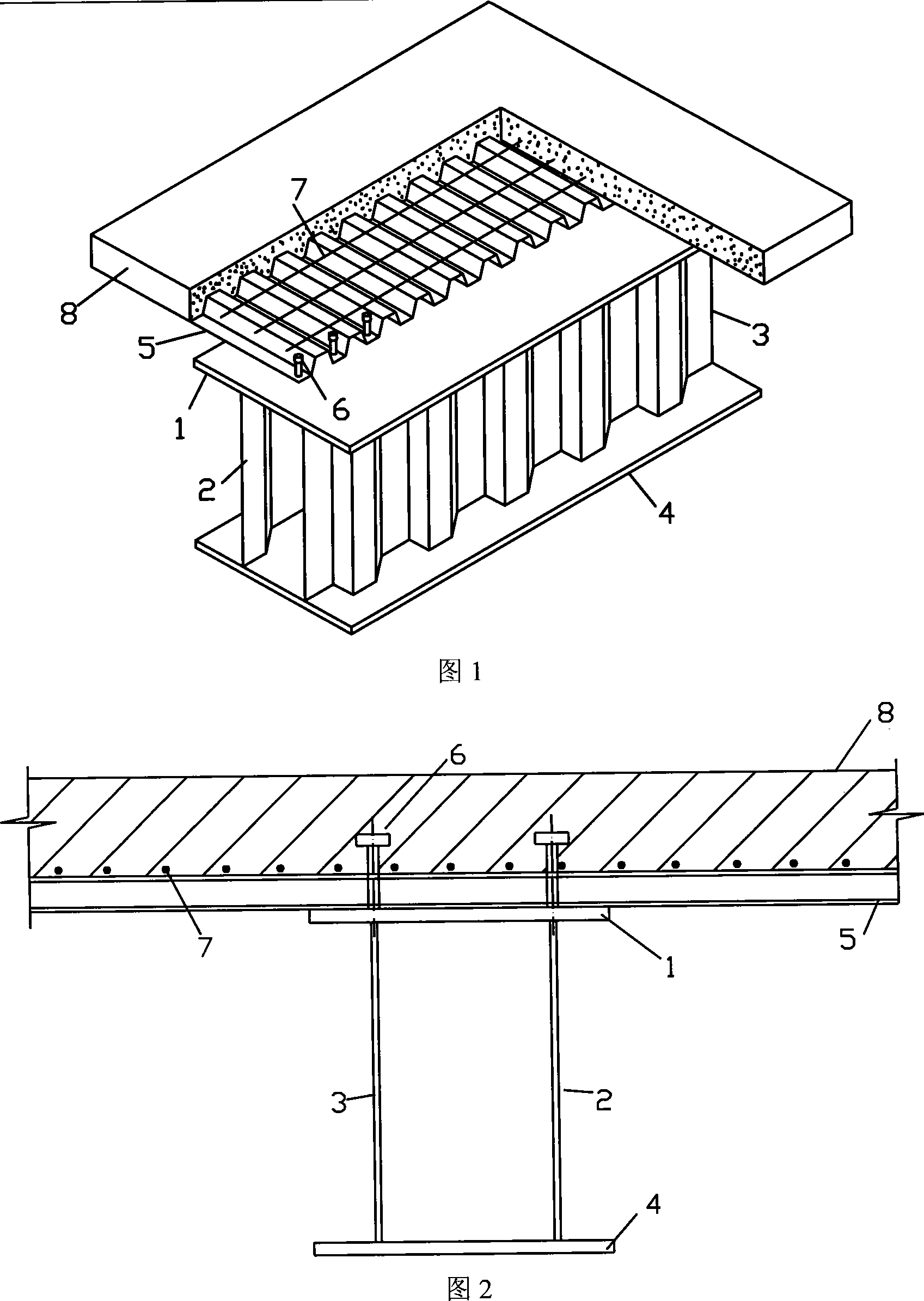

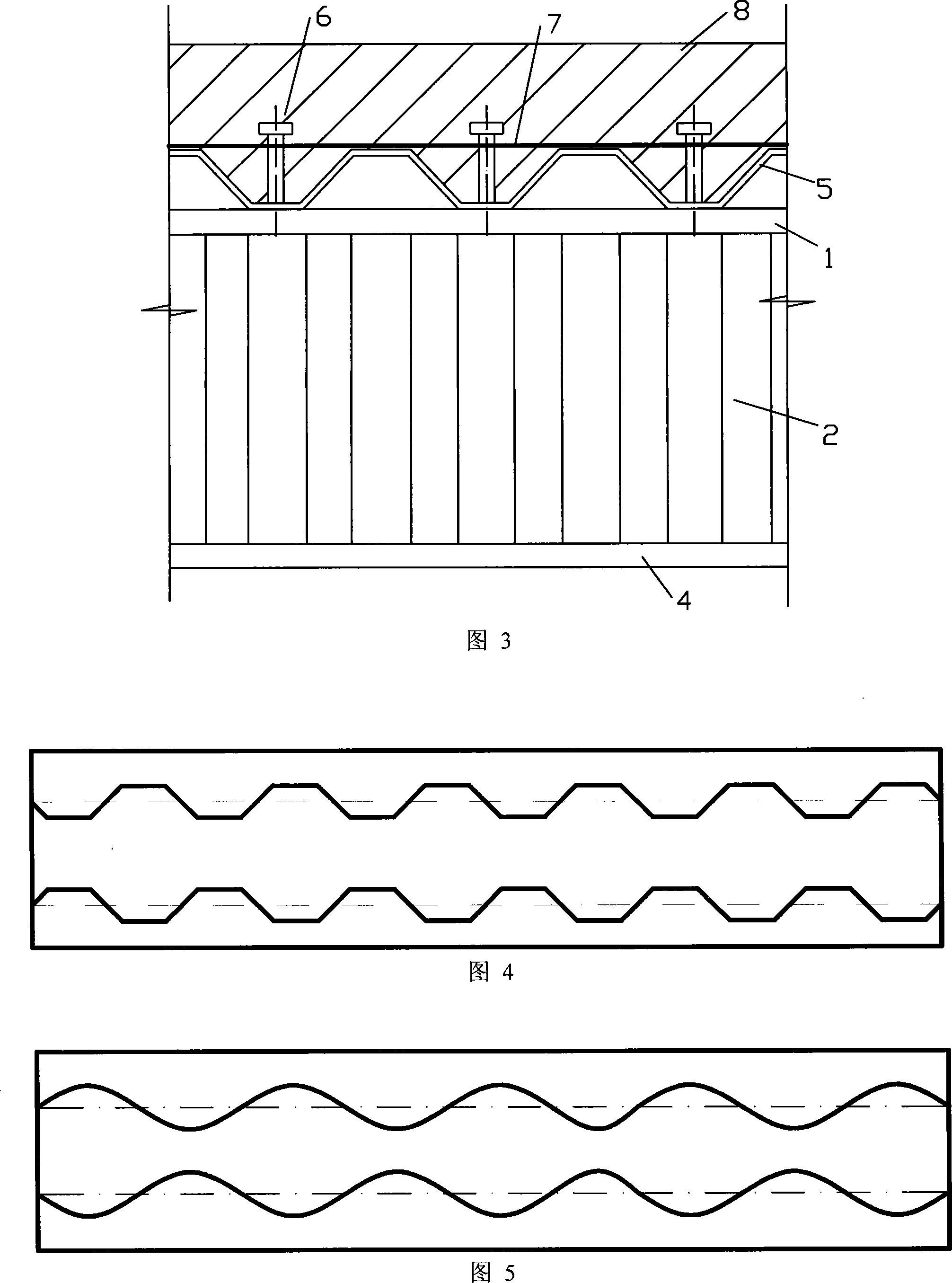

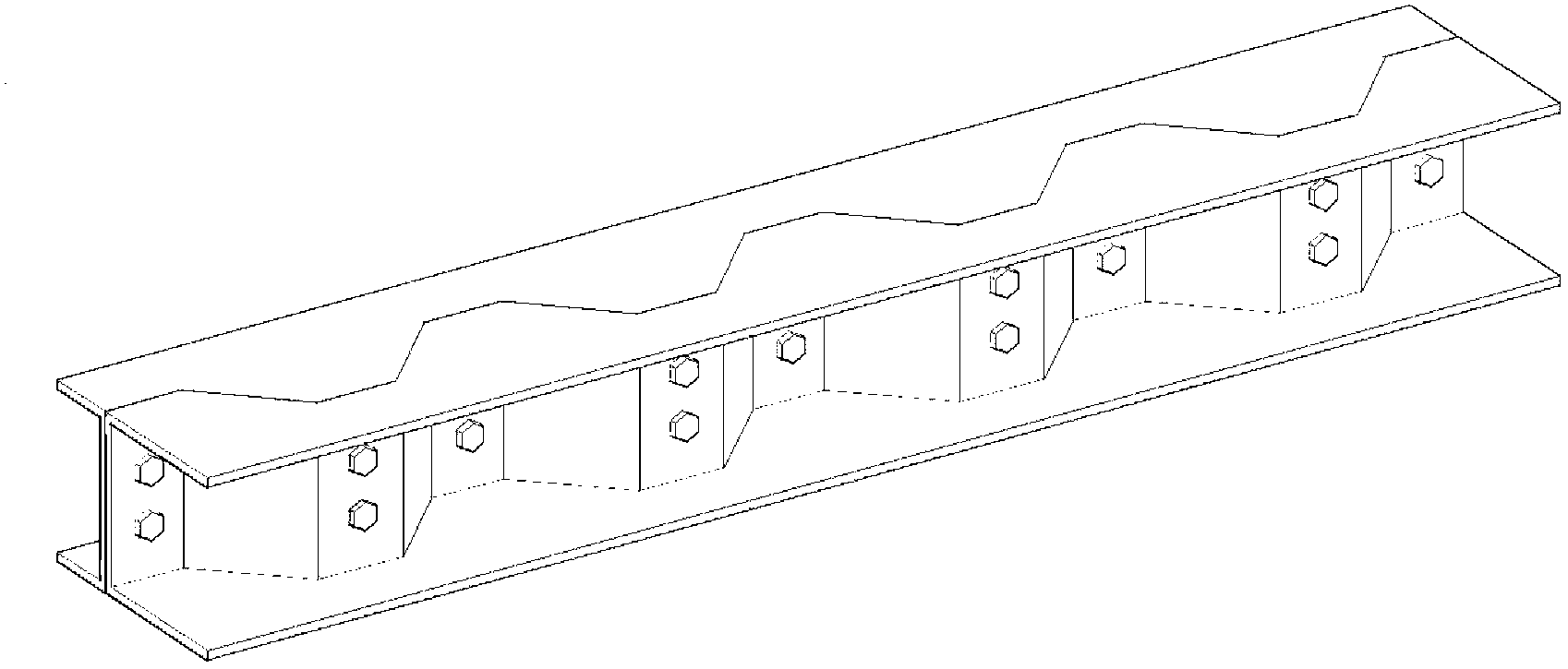

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

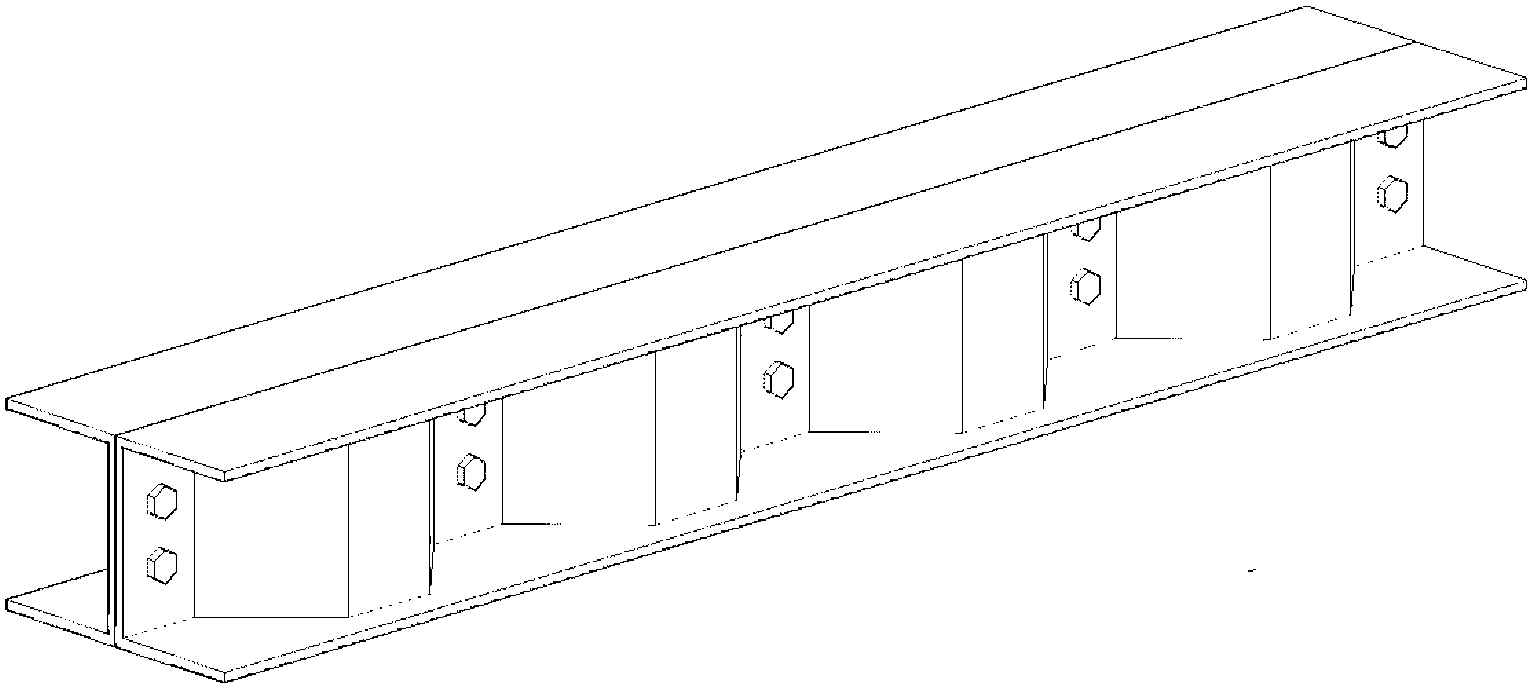

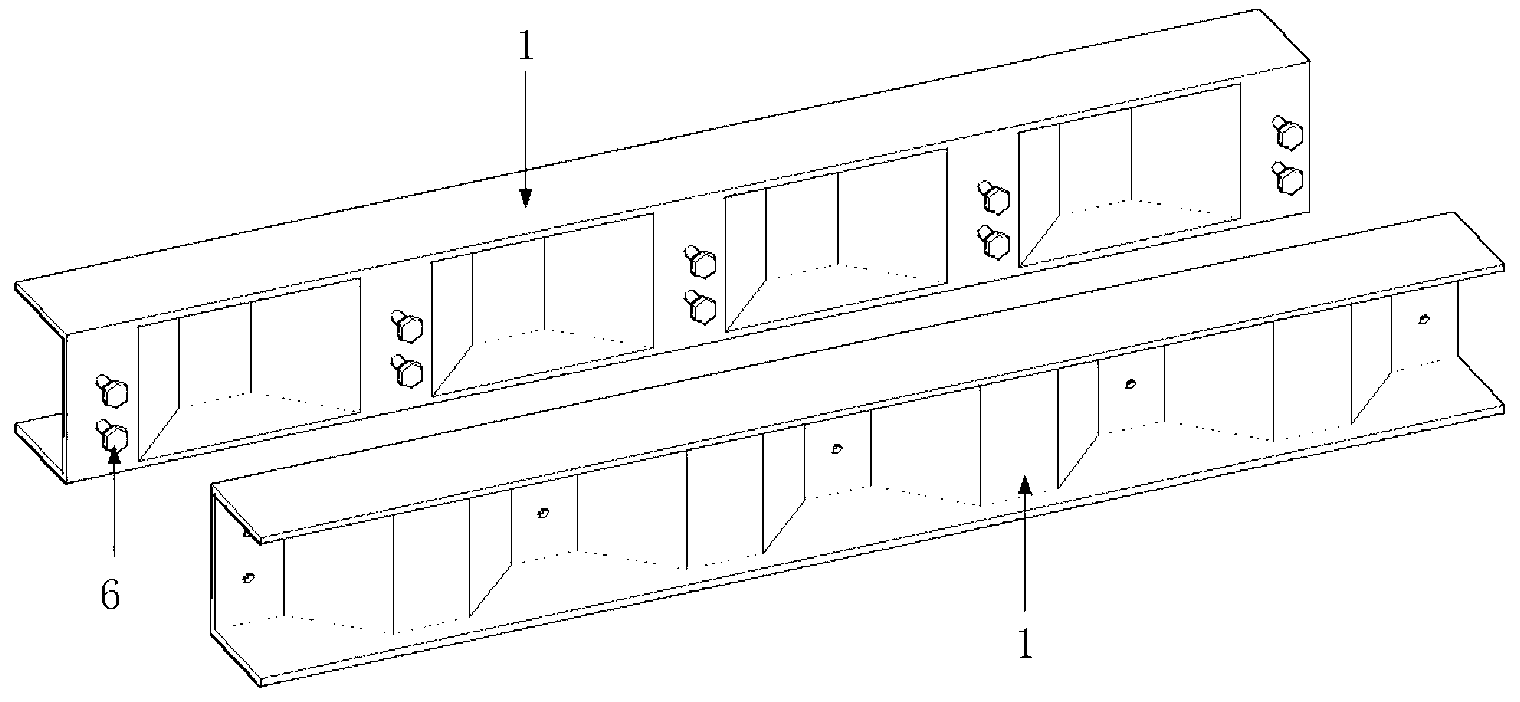

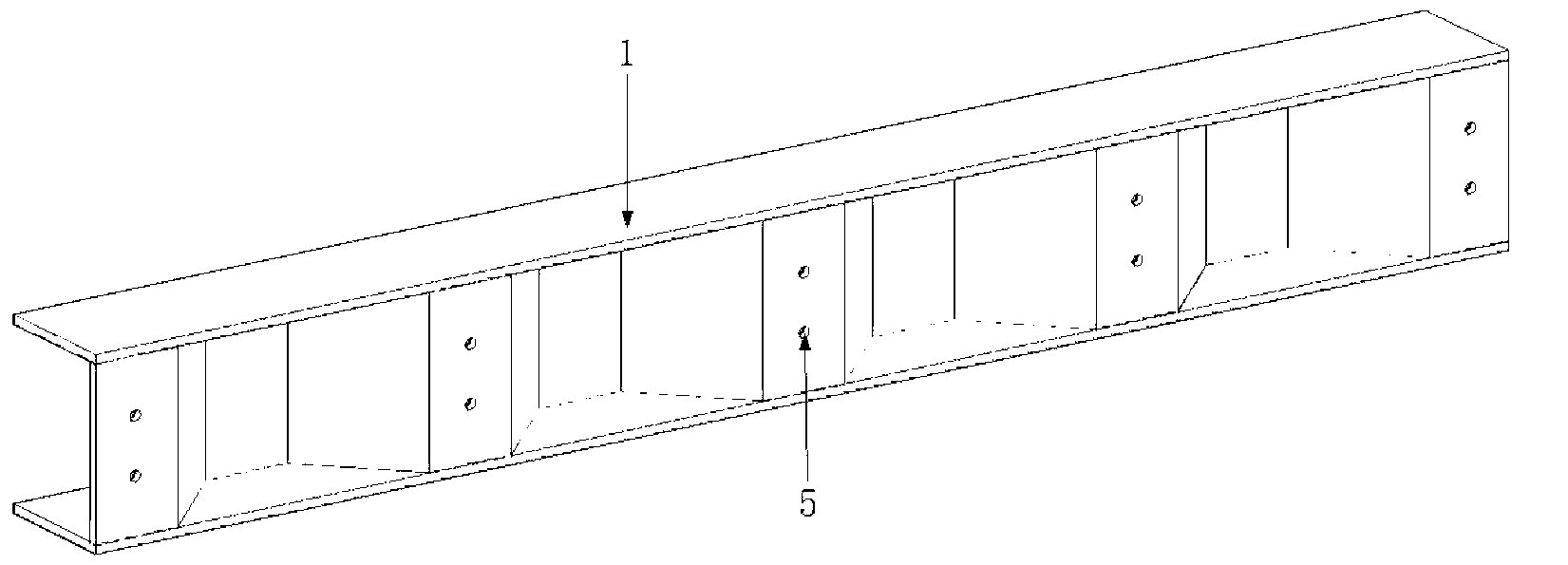

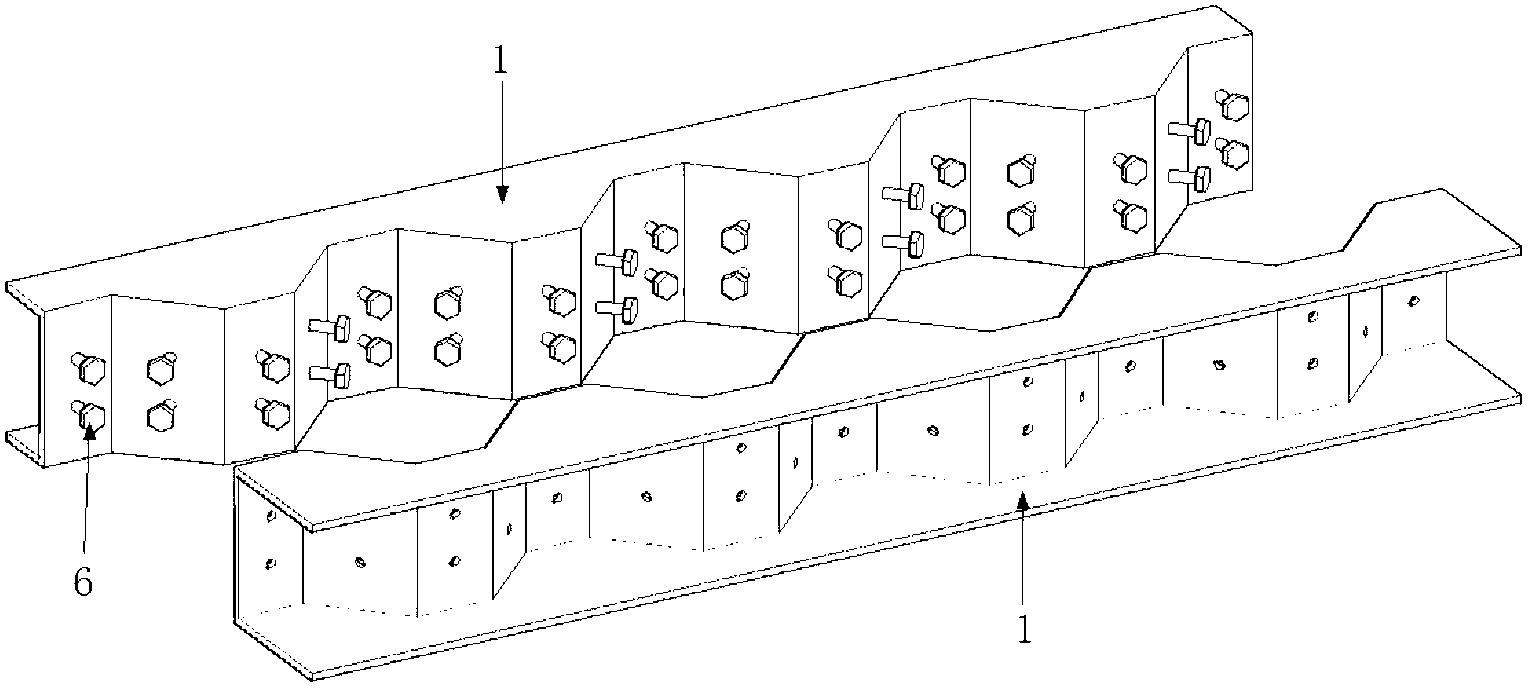

Fabricated honeycomb web steel beam

ActiveCN103233551AImprove mechanical performanceReduce thicknessGirdersJoistsRepeating waveformsSheet steel

The invention relates to a fabricated honeycomb web steel beam, and belongs to the technical field of building profiles. The fabricated honeycomb web steel beam is formed by web plates of two corrugated web steel channel beams, which are butted and assembled through a bolt. The section opening of each corrugated web steel channel beam is formed by an upper flange, a lower flange and a web plate; the sections of the web plates form even or uneven periodic repeated waveforms; the corrugated sections are rectangular curves, or arc angle rectangle curves, or trapezoidal curves or arc angle trapezoidal curves, or wedge curves, or arc angle wedge curves, or sine curves; the flanges are plain plates; each upper flange is parallel to each lower flange; the web plates are vertically located between the flanges as a whole; the outer sides of the corrugated curves of the web plates along the length direction are flush to a side boundary of each flange along the length direction; and the web plates are connected with the flanges by a single-side angle welding line. The fabricated honeycomb web steel beam is an innovation-type steel beam suitable for the fabricated steel structure system. Compared with the traditional fabricated beam, the fabricated honeycomb web steel beam has the advantages of light dead load, high carrying capacity, and good mechanical behavior.

Owner:BEIJING UNIV OF TECH +1

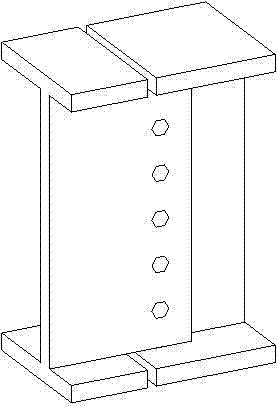

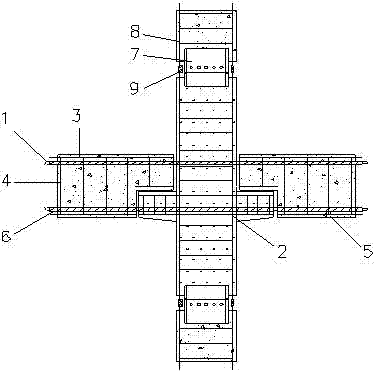

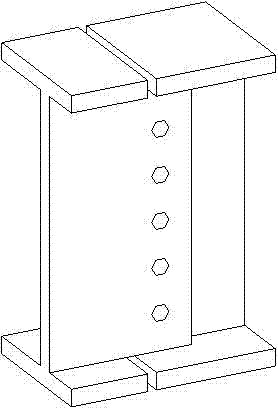

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

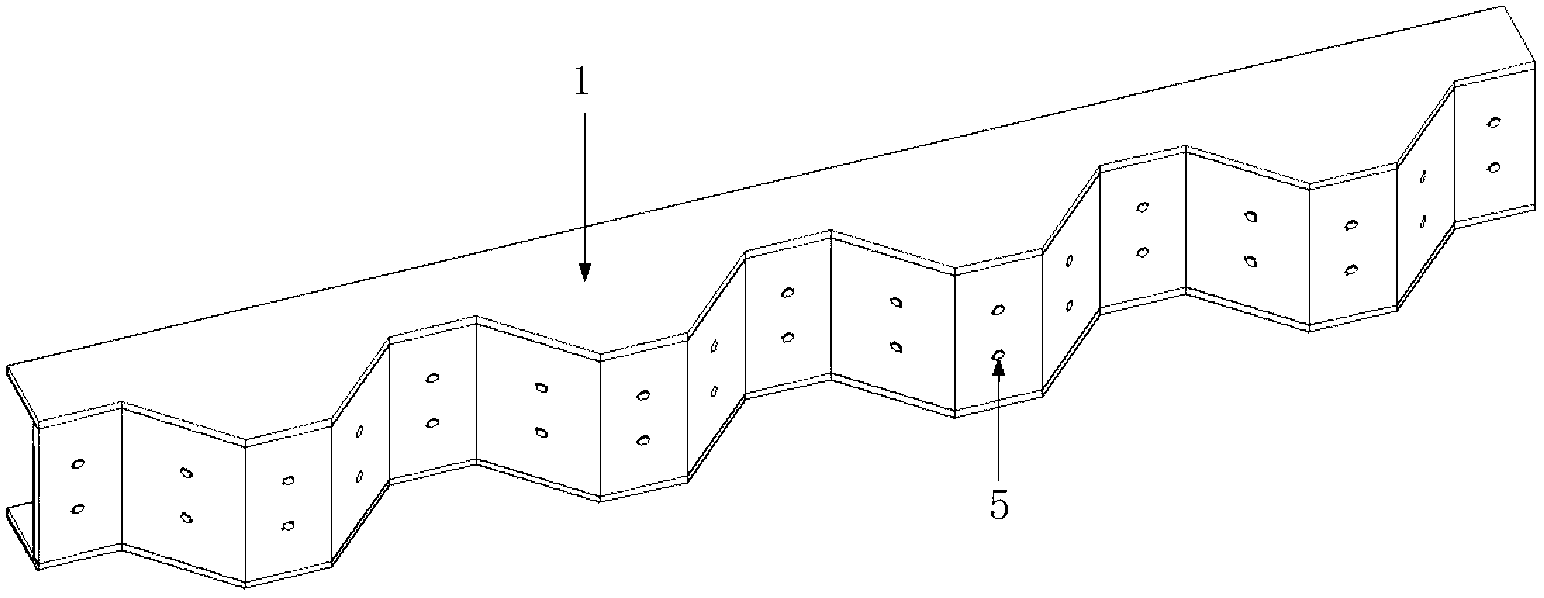

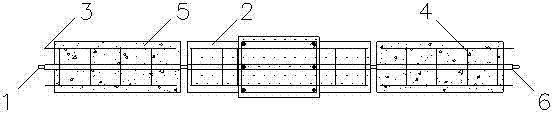

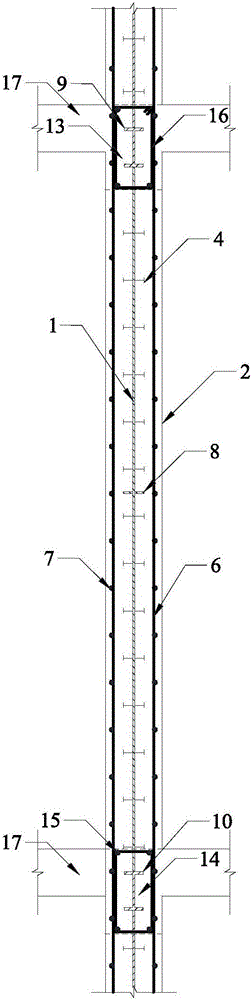

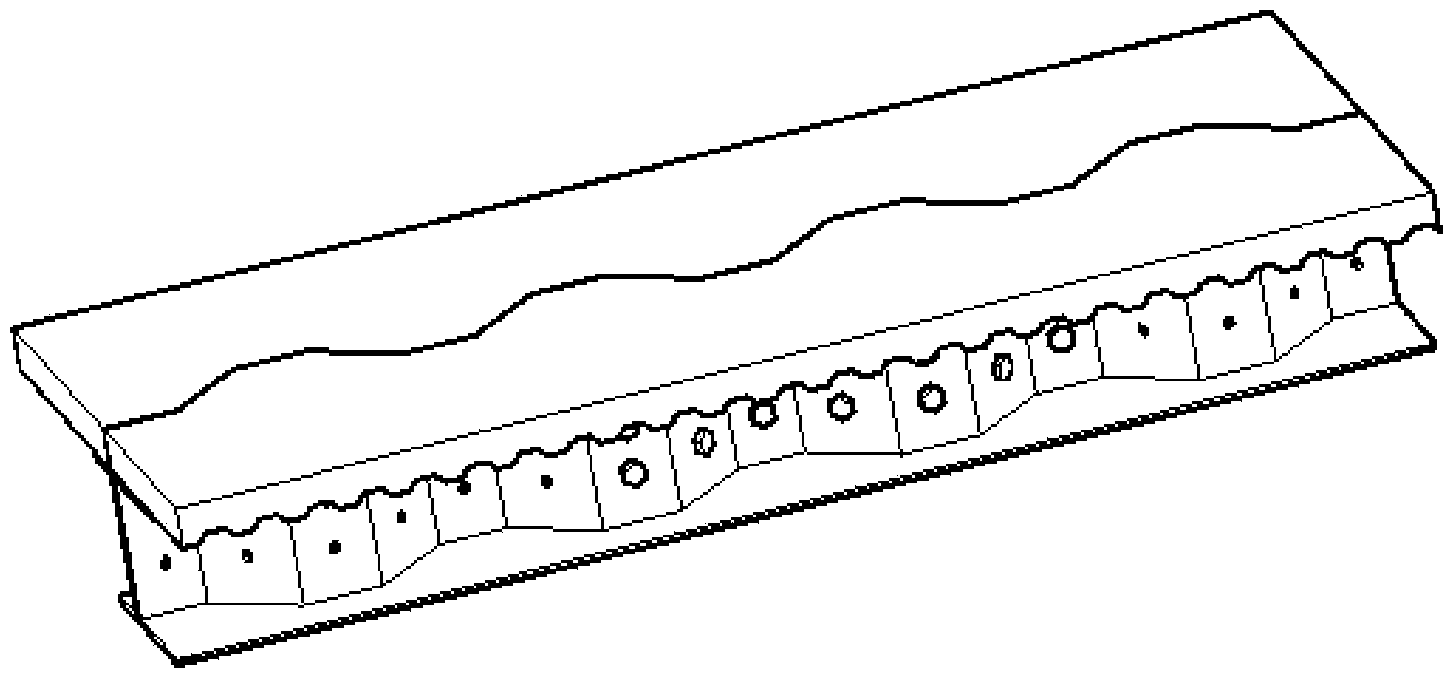

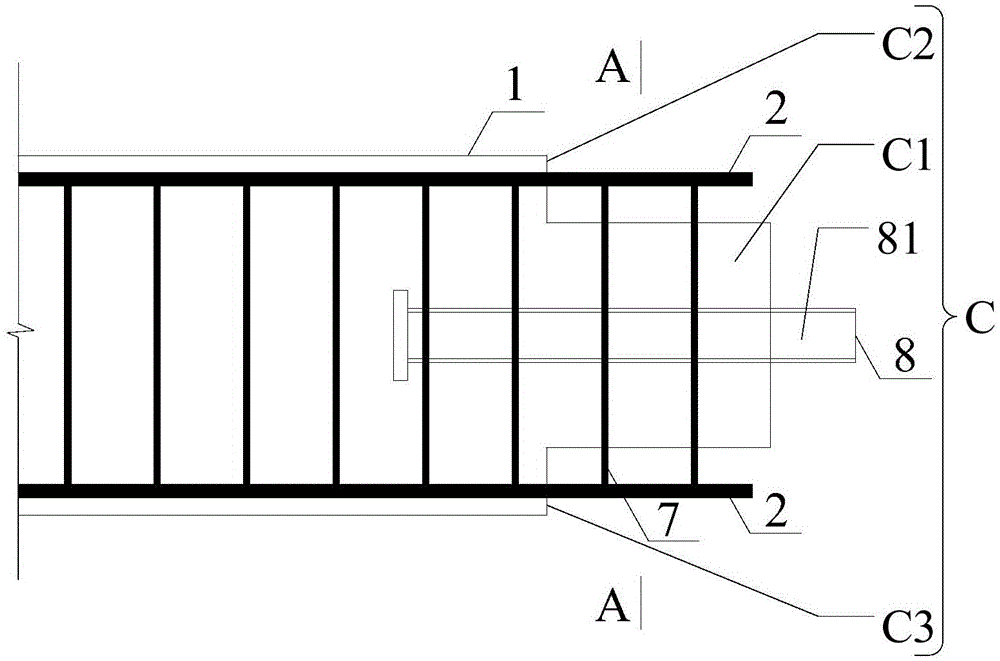

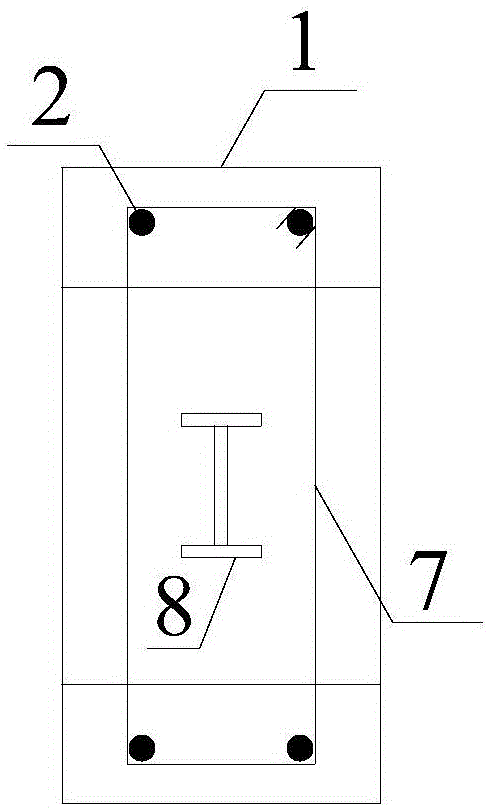

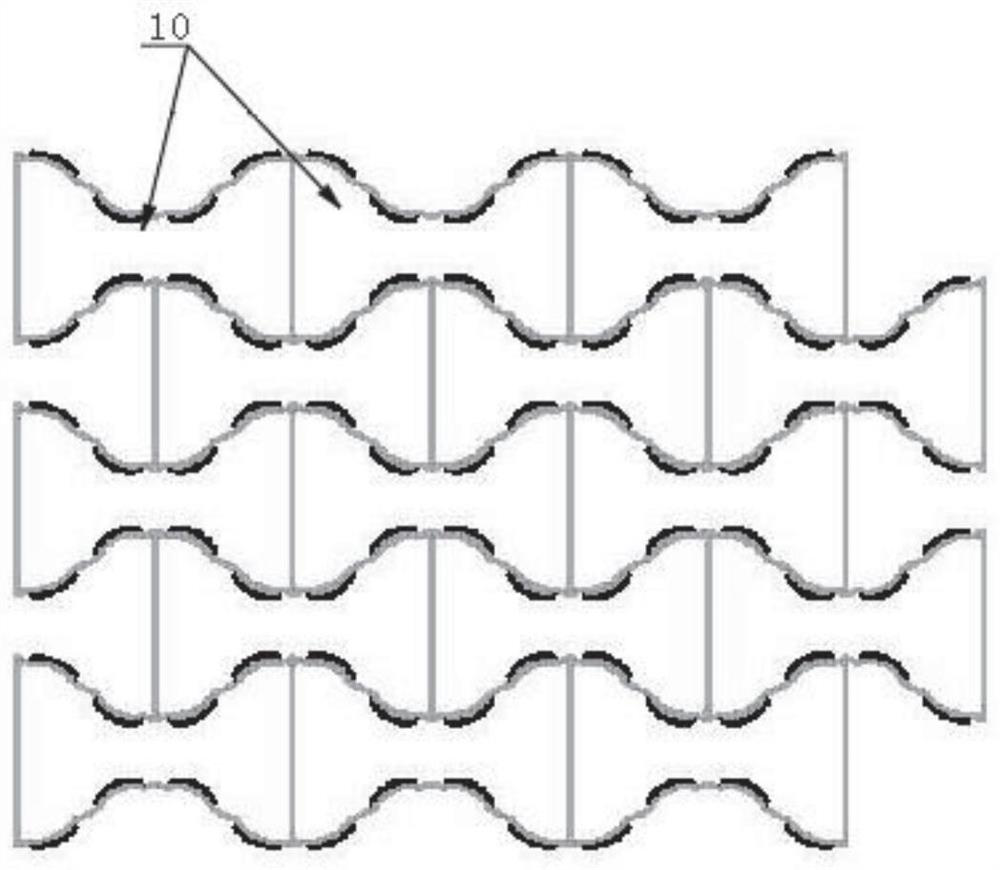

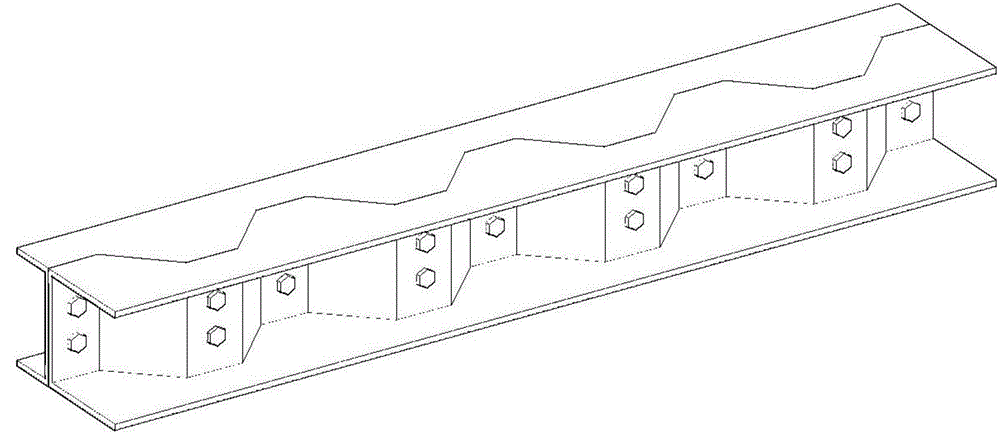

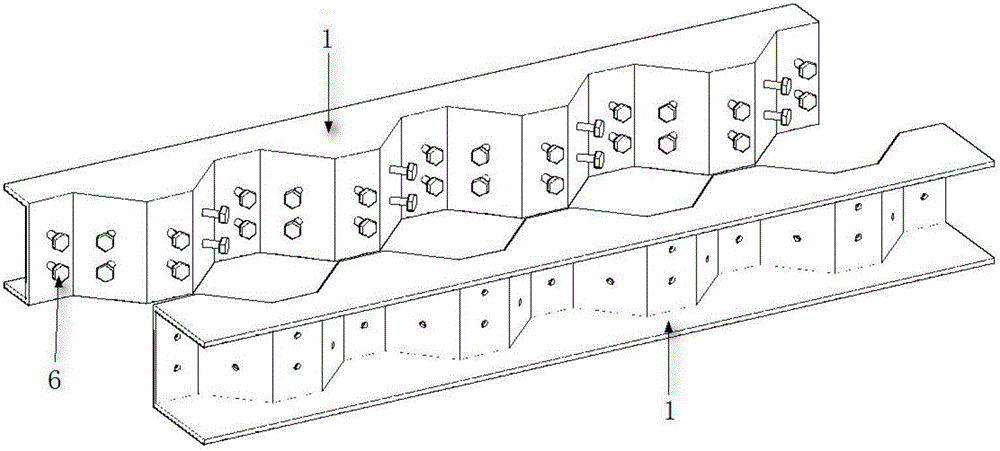

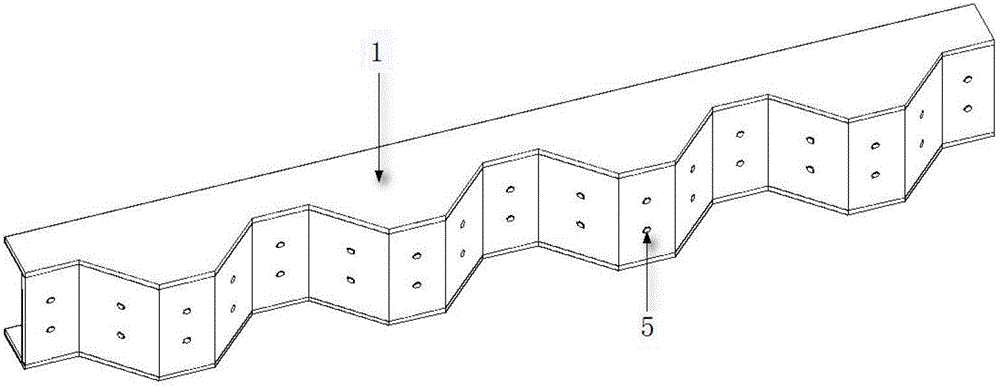

Assembly type ripple web plate occluded steel beam

ActiveCN103290992AImprove mechanical performanceReduce thicknessGirdersJoistsRepeating waveformsButt joint

The invention relates to an assembly type ripple web plate occluded steel beam which is prepared from two ripple steel channel beams assembled together through occlusion and butt joint of web plates and through bolts. A cross section mouth of each ripple steel channel beam is composed of an upper flange, a lower flange and one web plate, wherein the cross sections of the web plate form a uniform or nonuniform periodically-repeating waveform, the cross section of ripples of the web plate is a rectangular curve, an arc angle rectangular curve, a trapezoid curve, an arc angle trapezoid curve, a wedge-form curve, an arc angle wedge-form curve or a sine curve, the flanges are steel plates, one edge of each flange in a length direction is a waveform curve with a shape similar to that of the curve of the cross sections of the web plate, the upper flange is parallel to the lower flange, the web plate is perpendicular to and located between the upper flange and the lower flange, the waveform curve edges of the flanges are connected with the ripple cross sections of the web plate, and the web plate is connected with the flanges through single-sided angle welding. The assembly type ripple web plate occluded steel beam provided by the invention is applicable to innovative steel beams in an assembly type steel structure system; and compared with traditional assembly type steel beams, the assembly type ripple web plate occluded steel beam has the advantages of light weight, high carrying capacity and good bearing performance.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

Prestressed prefabricated ECC-RC combination beam column joint component

InactiveCN103774755AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention relates to a prestressed prefabricated ECC-RC combination beam column joint component which comprises a prestressed rib and a joint with a bracket. The joint with the bracket is composed of an ECC material, longitudinal bars and stirrups. The joint with the bracket comprises an outward-extending column, wherein the length of the outward-extending column is about 1-2 times of the height of the column section. A hole channel is required to be reserved between the joint and a prefabricated RC beam connected with the joint. The prefabricated ECC joint is connected with the prefabricated RC beam through the post-tensioned prestressed rib which penetrates through the hole channel. H-shaped steel is embedded in the end of the outward-extending column and the end of a prefabricated RC column, wherein the embedded depth and the outward-extending length both range from 10 cm to 15 cm, the longitudinal bars at the end of the outward-extending column and the end of the prefabricated RC column respectively extend outwards by 10-15 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of the prefabricated RC column and the embedded H-shaped steel of the prefabricated joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prestressed prefabricated ECC-RC combination beam column joint component, the prestressed prefabricated joint component formed by pouring of the steel bar reinforced ECC material is applied to an assembly type frame structure, so that the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; since prestress is used as an assembly means, residual deformation of the structure after an earthquake can be reduced, the restorable function is achieved, and post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

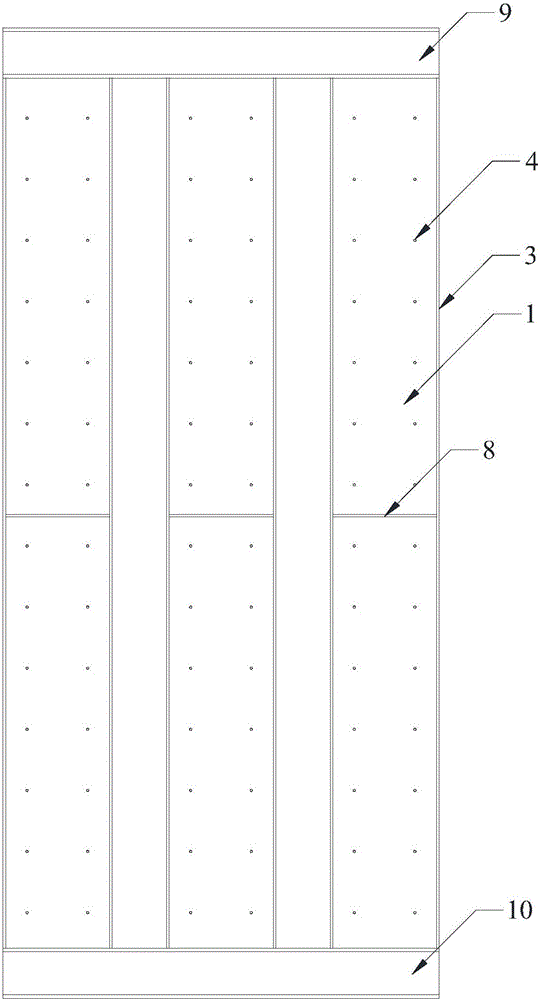

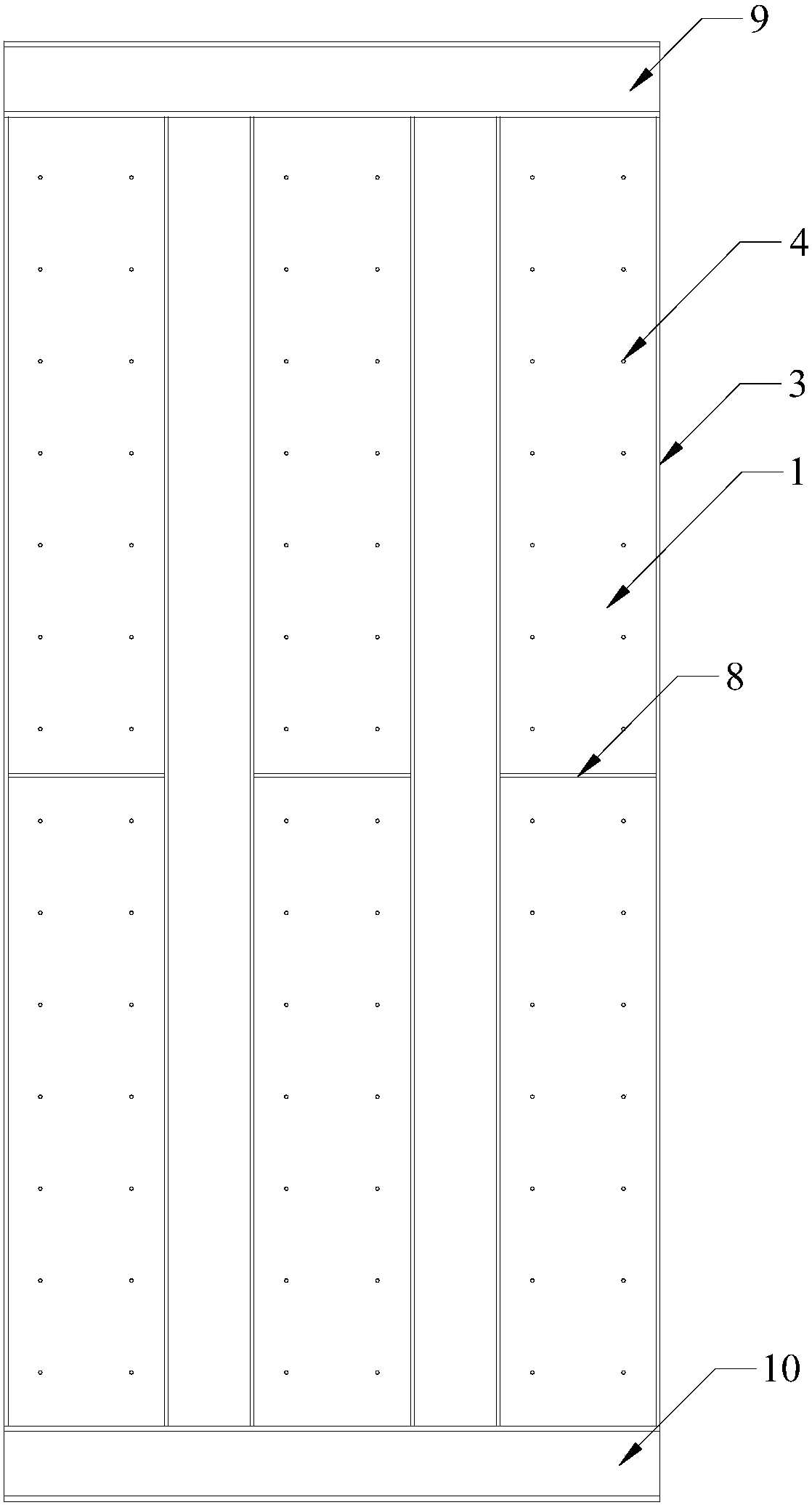

High-strength concrete composite shear wall with built-in segmented steel plates and construction method for same

ActiveCN106049708ALess prone to bucklingWork well togetherWallsHigh strength concreteHigh resistance

The invention belongs to the technical field of structure engineering and relates to a high-strength concrete composite shear wall with built-in segmented steel plates and a construction method for the same. The invention provides the high-strength concrete composite shear wall with the built-in segmented steel plates and further provides the building and construction method for the shear wall. The composite shear wall and the construction method for the same provided by the invention are characterized in that through segmented layout of the steel plate, concrete pouring and binding bar layout become convenient; a cooperative working ability of the steel plates and concrete is enhanced; bearing force is ensured; and deformability and an energy-dissipation capability of the composite shear wall can also be enhanced. In comparison with a composite shear wall covered by steel plates, the composite shear wall provided by the invention has higher resistance to high temperatures and can show better performance when a fire disaster takes place. Meanwhile, in comparison with a concrete composite shear wall with a whole steel plate, the shear wall provided by the invention has the advantages that conversion and transition among layers can be implemented through reduction of the quantity of the segmented steel plates; inter-layer rigidity transition becomes gentler; and the structure is also simpler.

Owner:TONGJI UNIV

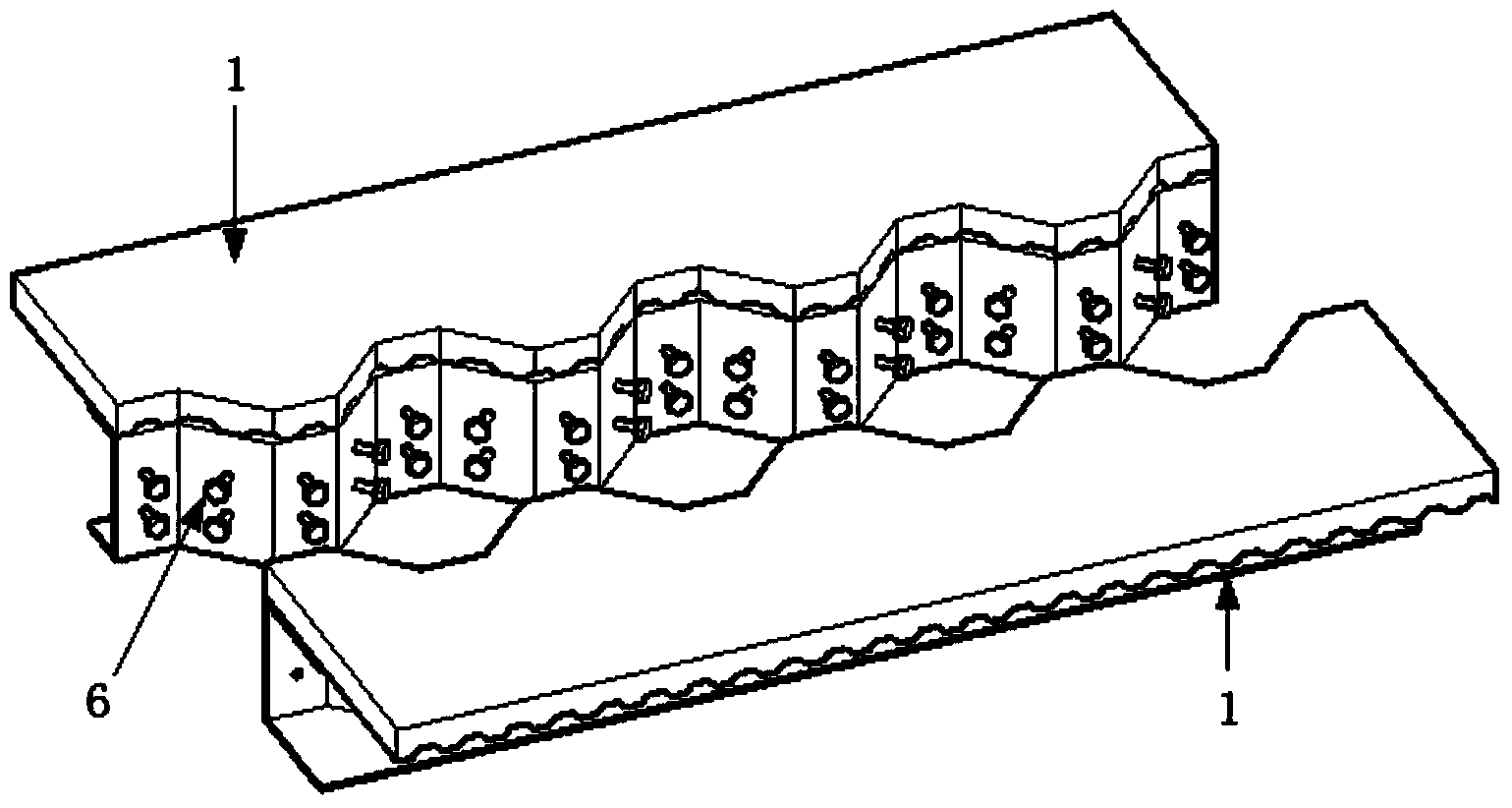

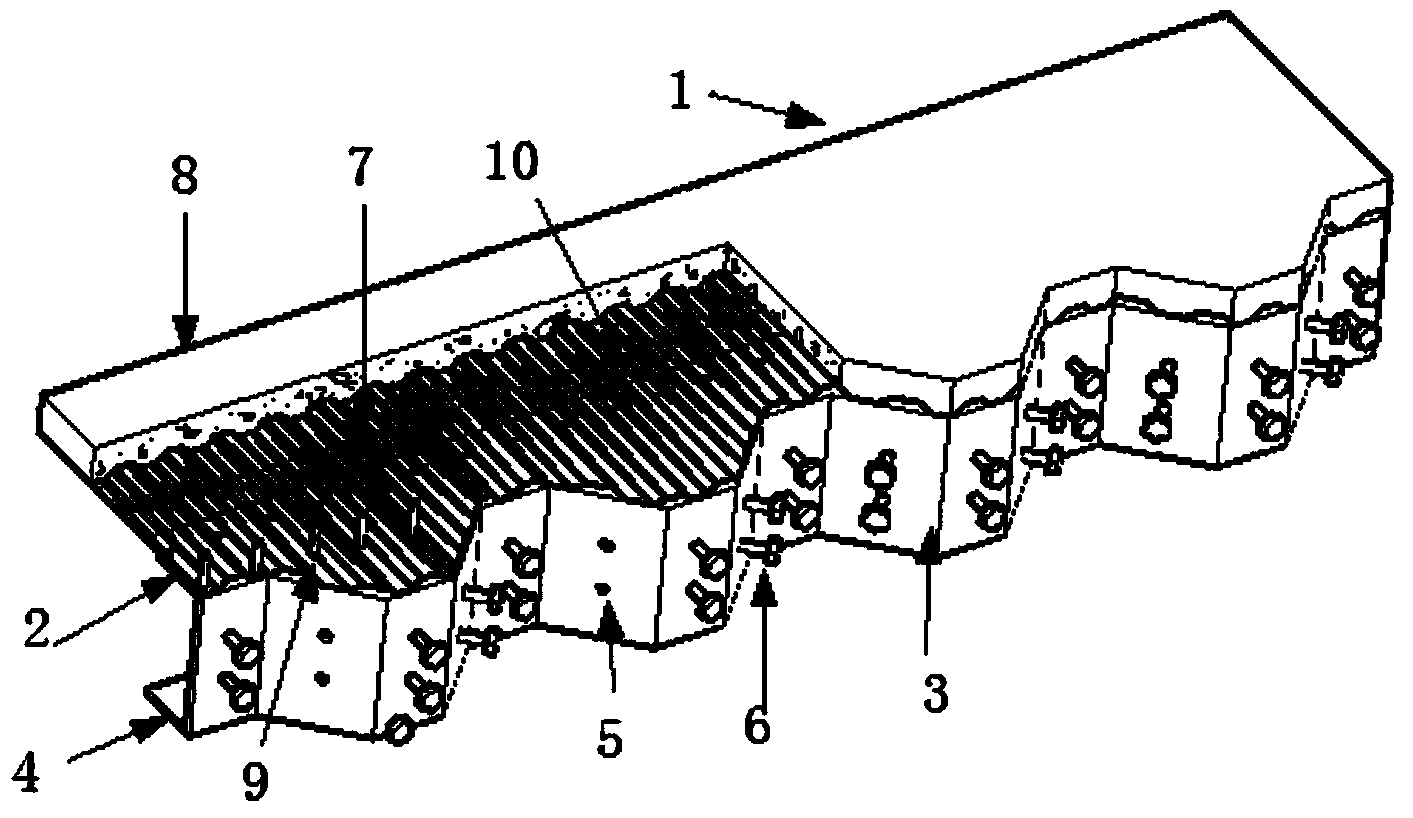

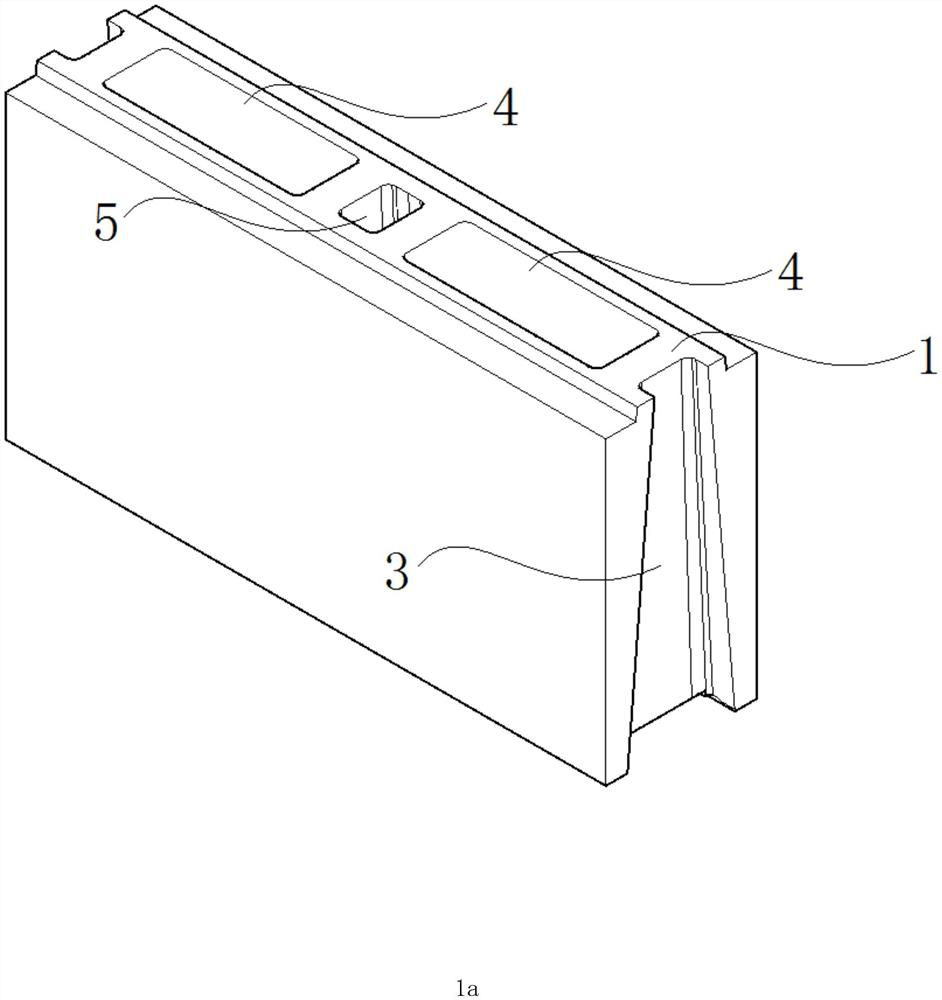

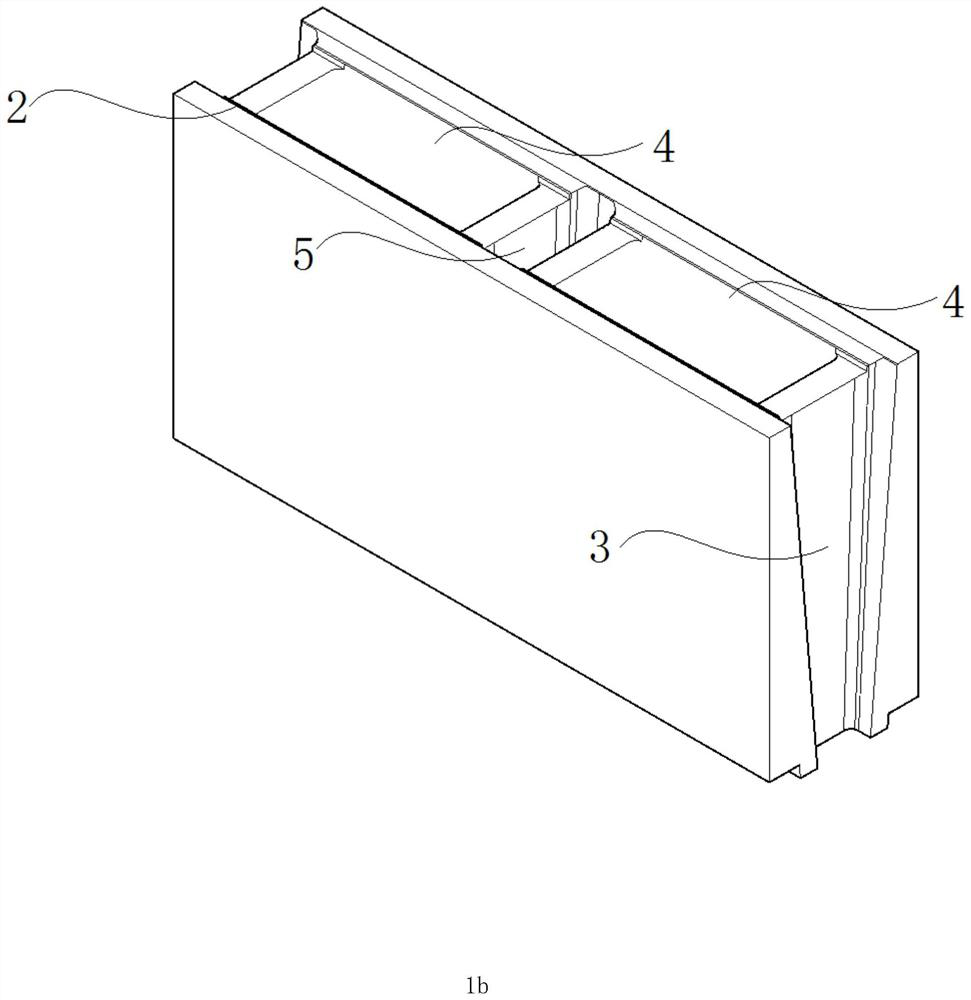

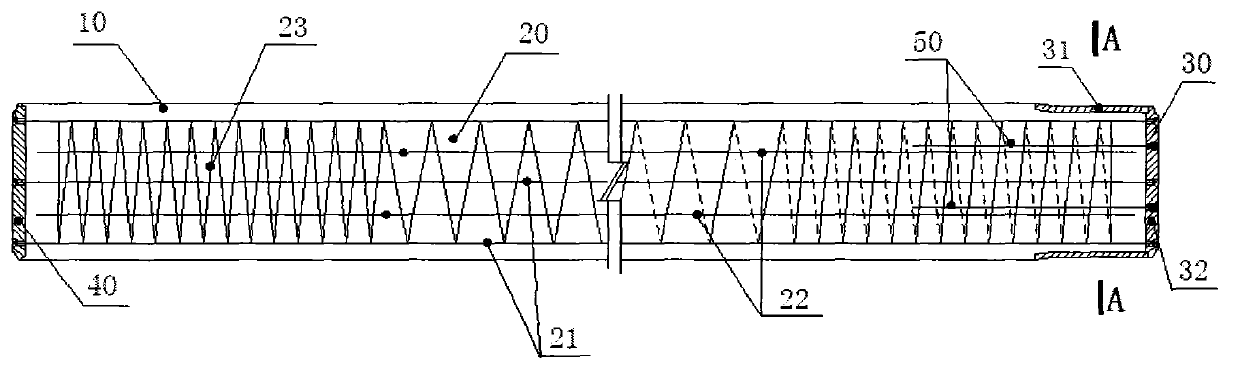

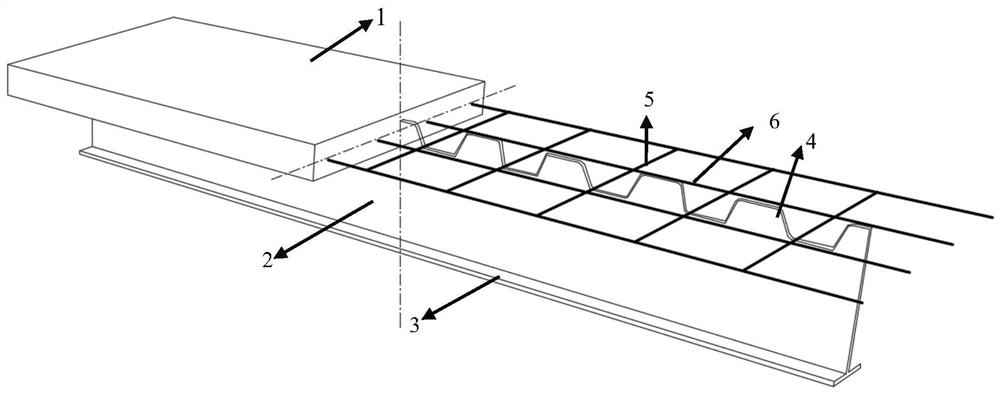

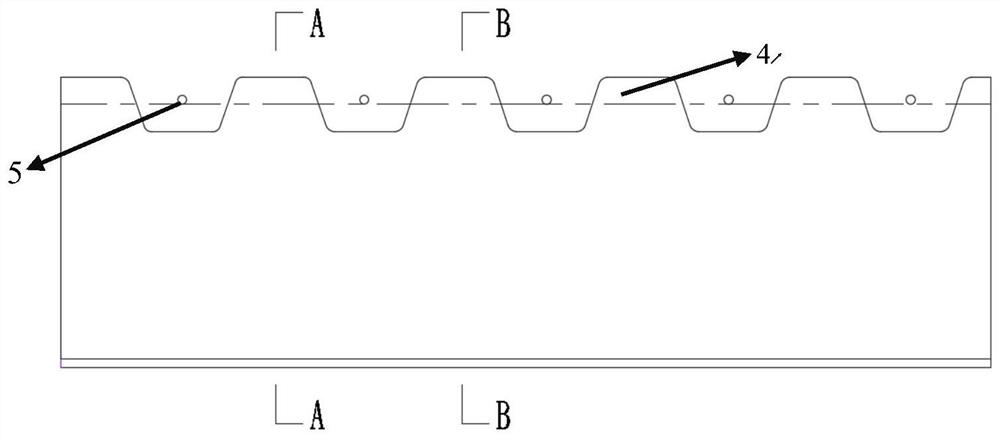

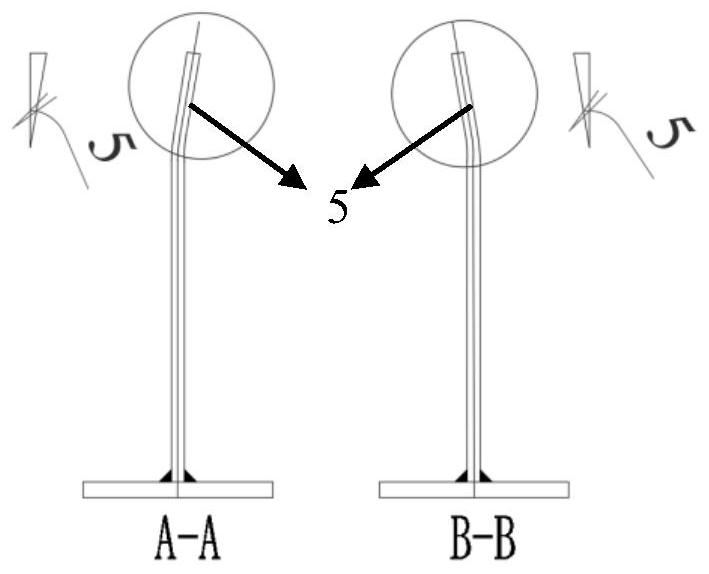

Assembly type corrugated web holding-on H shaped steel composite beam

InactiveCN103485476AExcellent out-of-plane stiffnessExcellent buckling capacityGirdersJoistsFillet weldSheet steel

The invention relates to an assembly type corrugated web holding-on H shaped steel composite beam which is assembled by two corrugated steel channel composite beam webs in a holding-on butt joint mode through bolts. The fracture surface of each corrugated steel channel composite beam is composed of an upper flange, a lower flange, one web, a profiled steel plate and a reinforced concrete plate. The fracture surface of each web is in even or uneven wave shape repeated periodically; the flanges are steel plates, and one side in the length direction of each flange is a corrugated curve which is same as curves of the webs in shape; the upper flange is in parallel with the lower flange, the webs are vertically located between the flanges, the corrugated curve sides of the flanges are connected with the corrugated fracture surfaces of the webs, and the webs and the flanges are connected by the adoption of single-face fillet weld. The reinforced concrete wing plate, the profiled steel plate and the upper flange are fixed through studs. The assembly type corrugated web holding-on H shaped steel composite beam is an innovation-type composite beam which is suitable for a full assembly type steel structural system and has the advantages of saving rolled steel and being high in bearing capacity and good in stress performance compared with a traditional assembly type steel beam and a traditional composite beam.

Owner:BEIJING UNIV OF TECH

Detachable concrete component constructing method

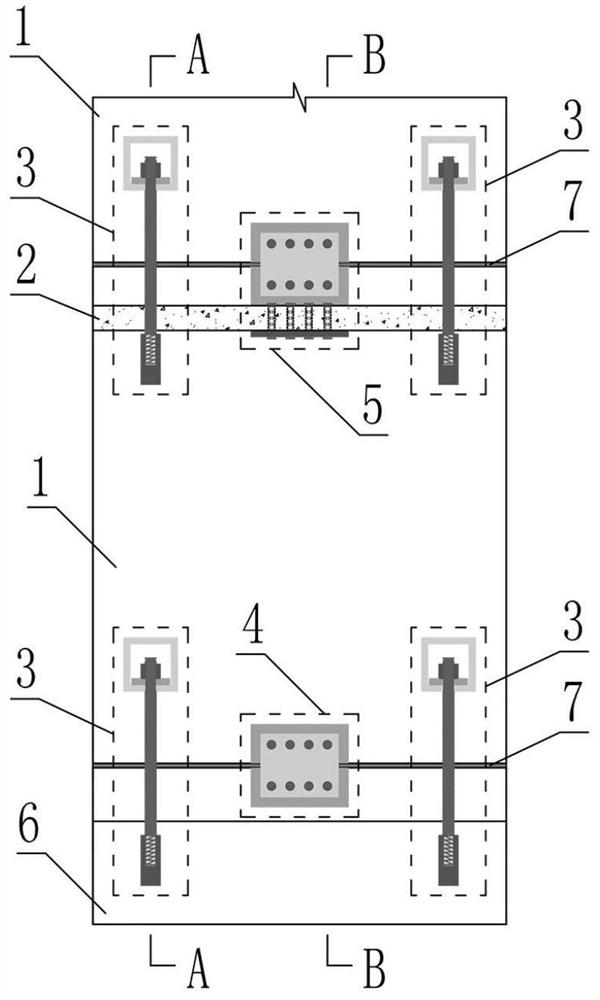

ActiveCN105155773AGuaranteed shear capacityGuaranteed local shear capacityBridge structural detailsGirdersConcrete beamsEngineering

The invention provides a detachable concrete component. The detachable concrete component comprises a concrete frame column section, a first concrete beam section, a second concrete beam section and a longitudinal bar intersection region, wherein one end of the second concrete beam section is perpendicularly connected with the concrete frame column section integrally; the other end of the second concrete beam section is spliced with a tenon type connecting joint at one end of the first concrete beam section through a mortise type connecting joint; and a plurality of first longitudinal bars arranged on the upper side and the lower side of the inside of the first concrete beam section and a plurality of second longitudinal bars arranged on the upper side and the lower side of the inside of the second concrete beam section outwards extend to the longitudinal bar intersection region and then are connected to one another. The invention further provides a constructing method and application of the detachable concrete component. The manufactured first concrete beam section can be detached and then assembled again, the amount of post-poured concrete is small, the detachable concrete component is convenient to mount and detach, the shearing force bearing capability and the repeated bending moment capability of the detachable concrete component are the same with those of an integrally cast concrete beam, and the structure is safe.

Owner:TONGJI UNIV

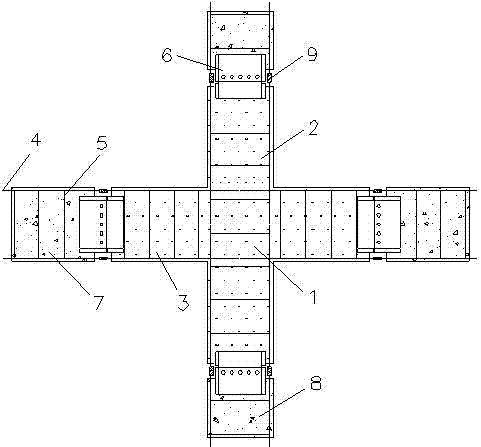

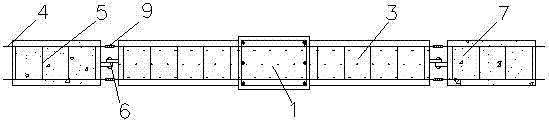

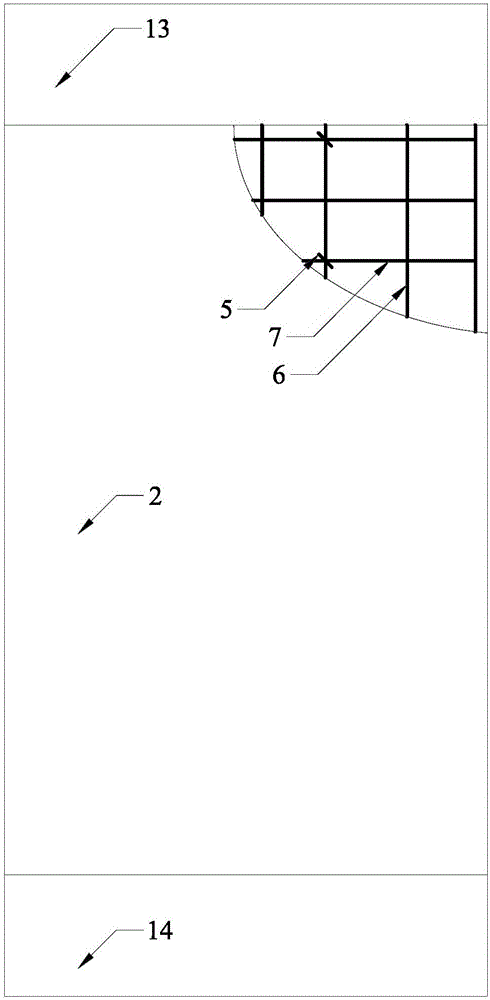

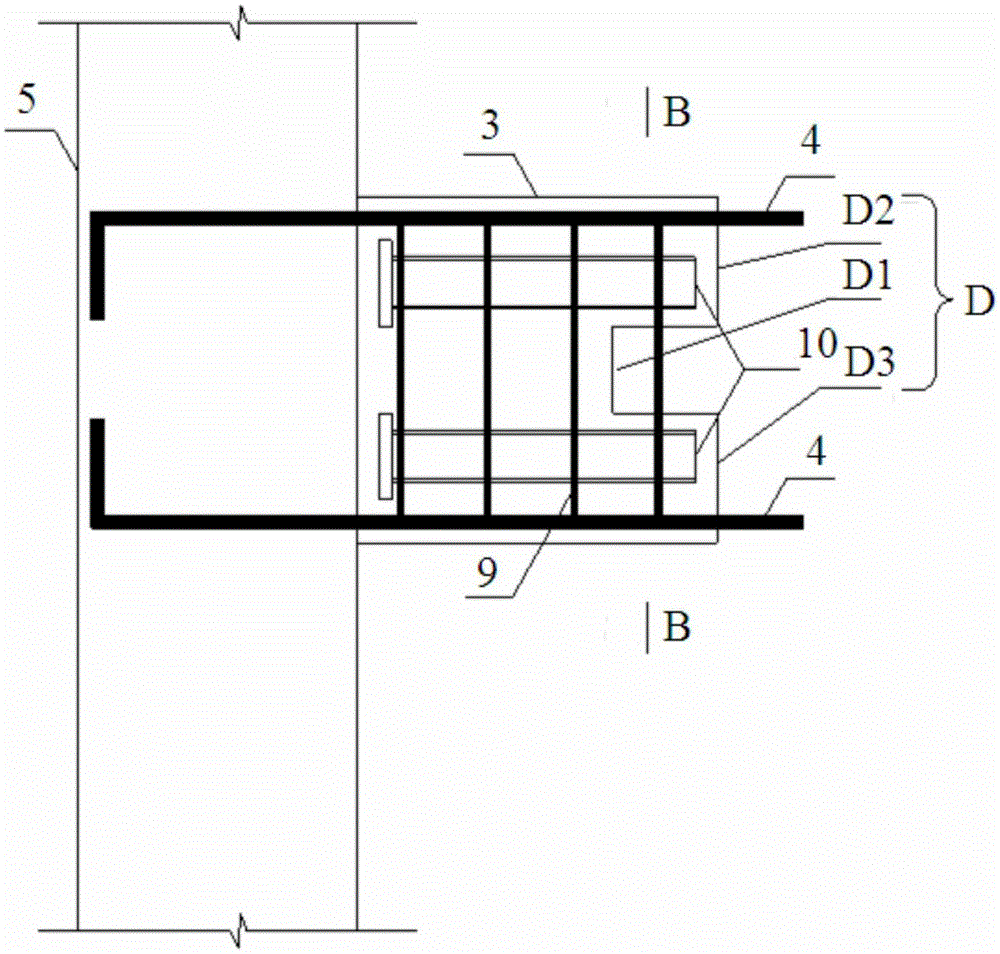

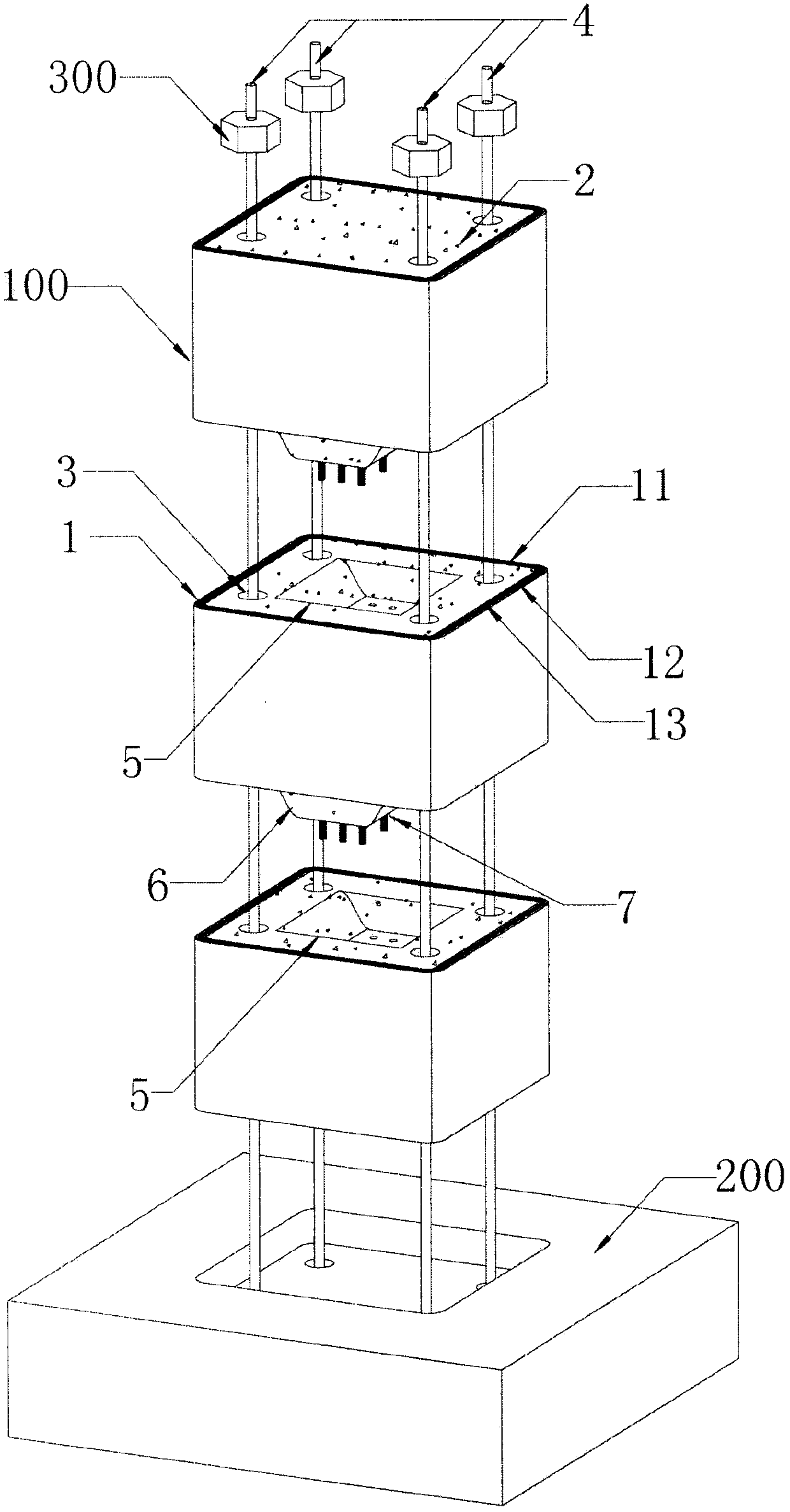

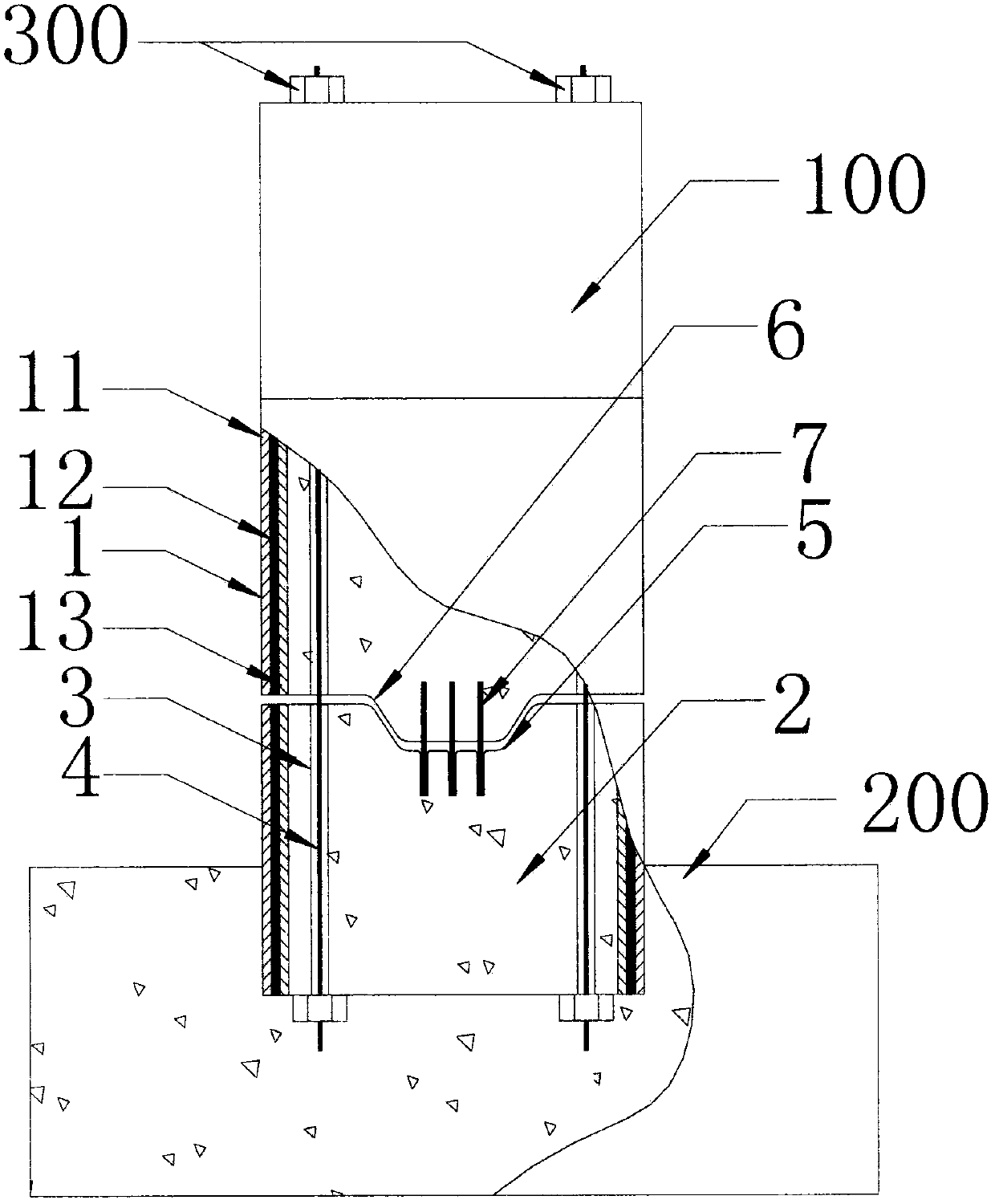

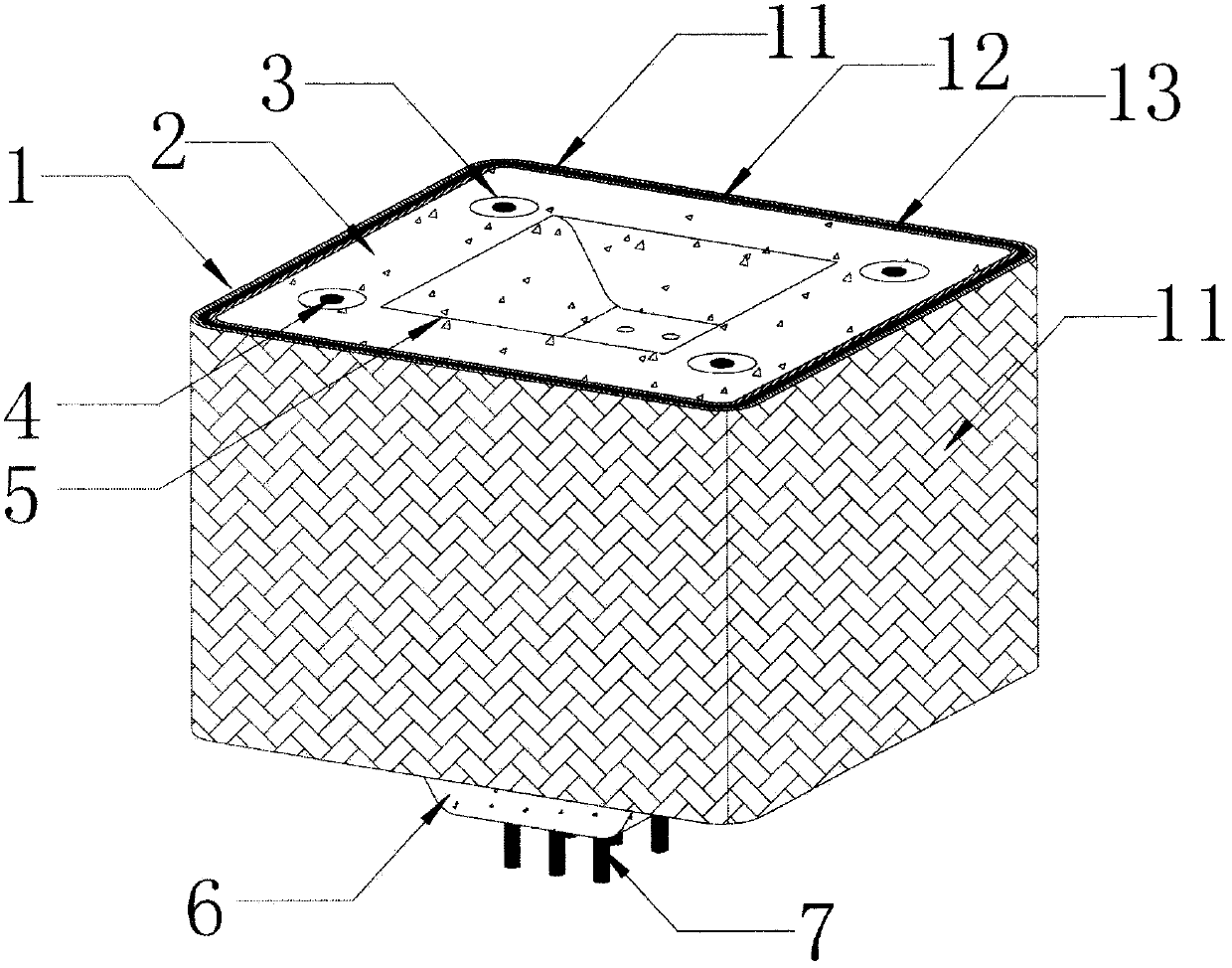

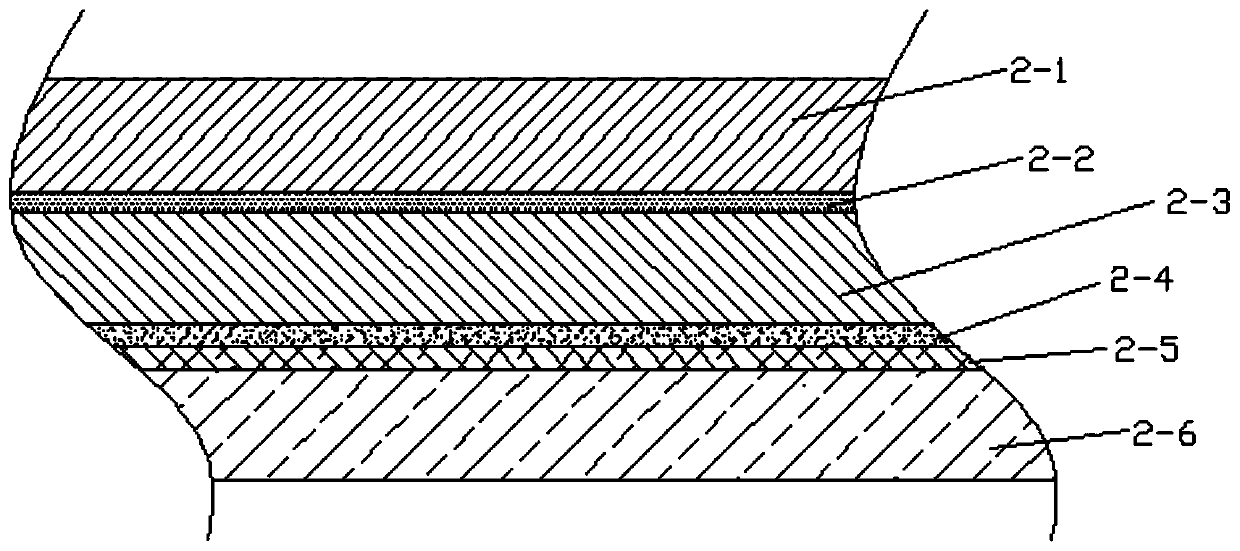

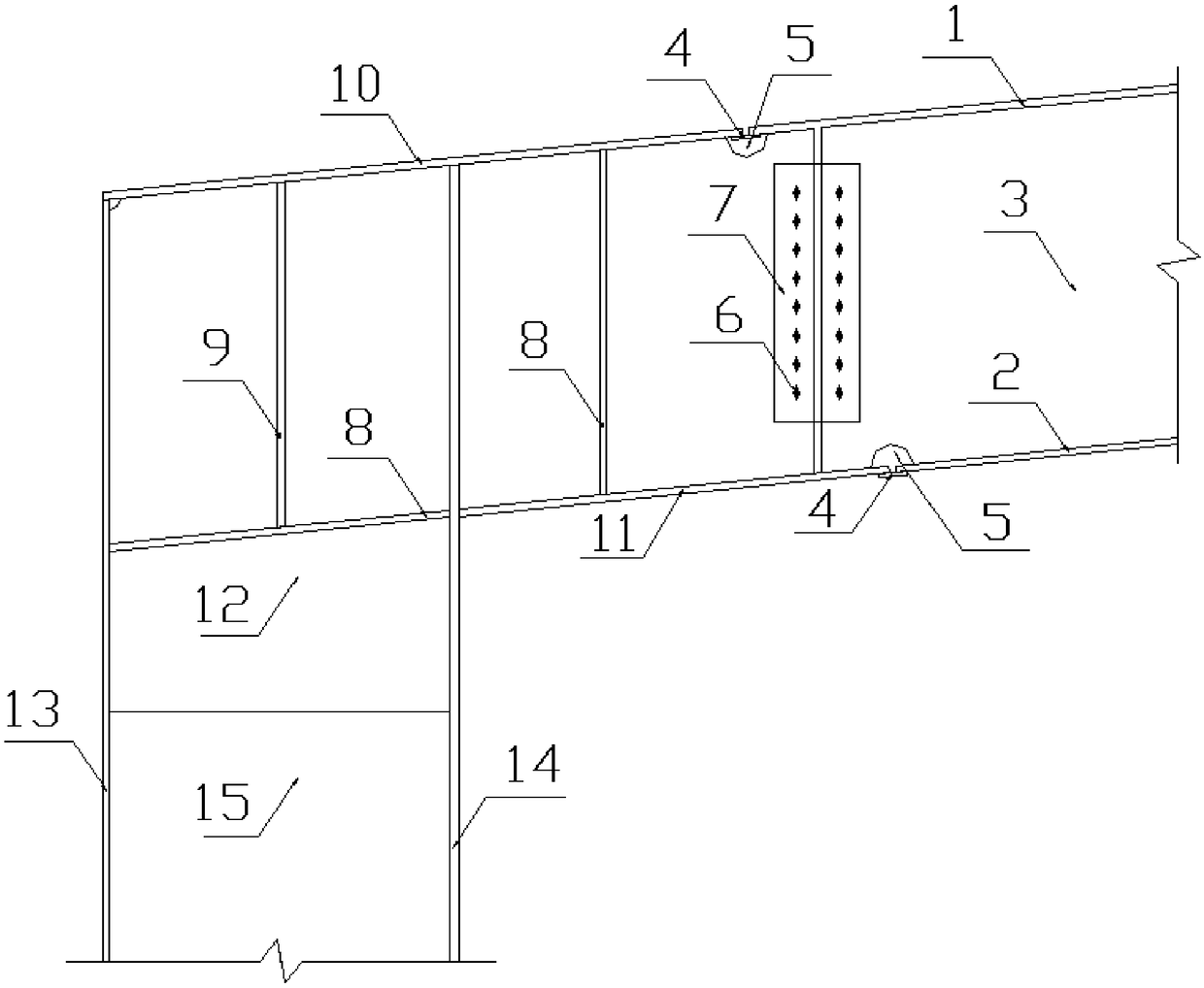

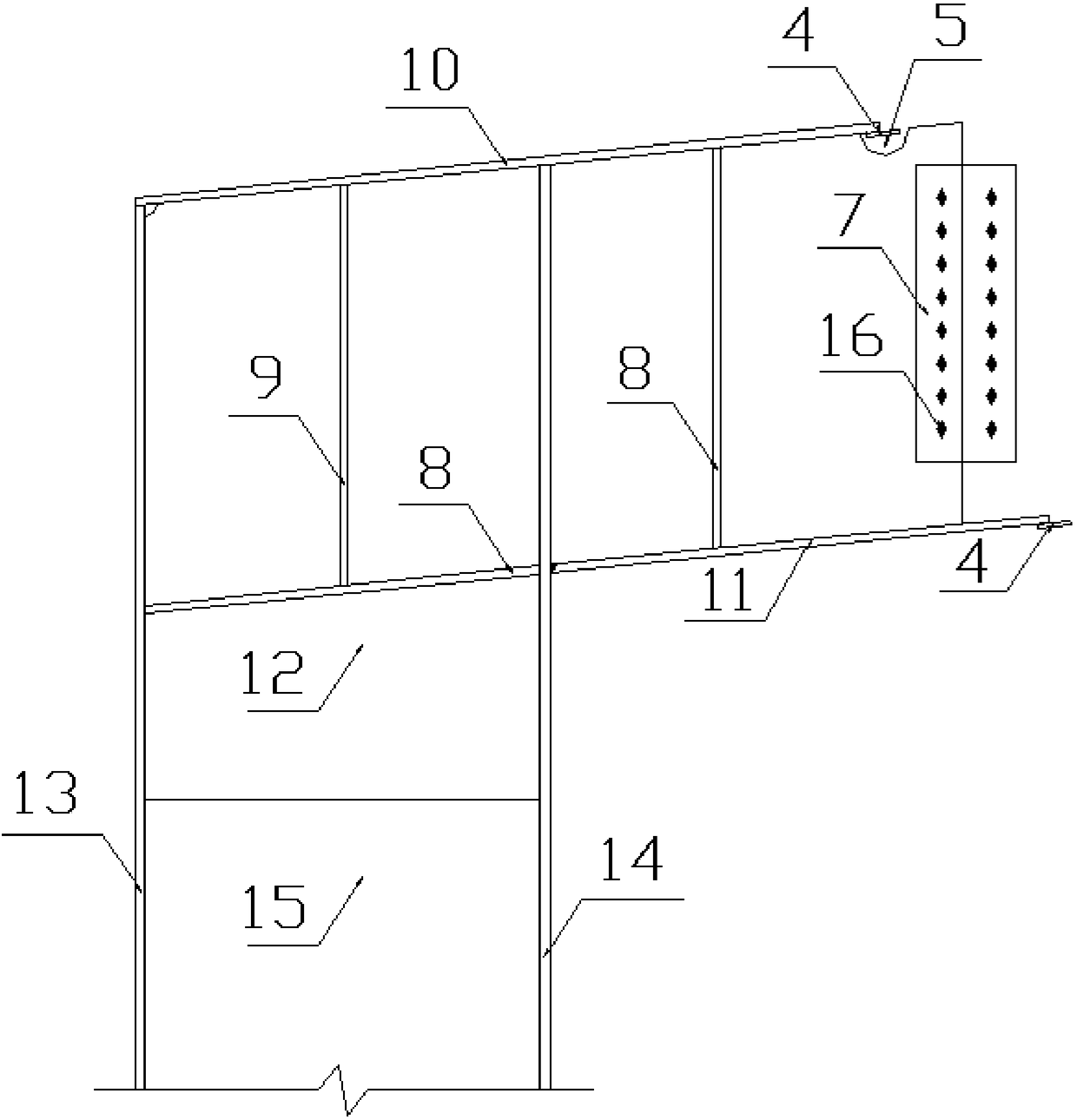

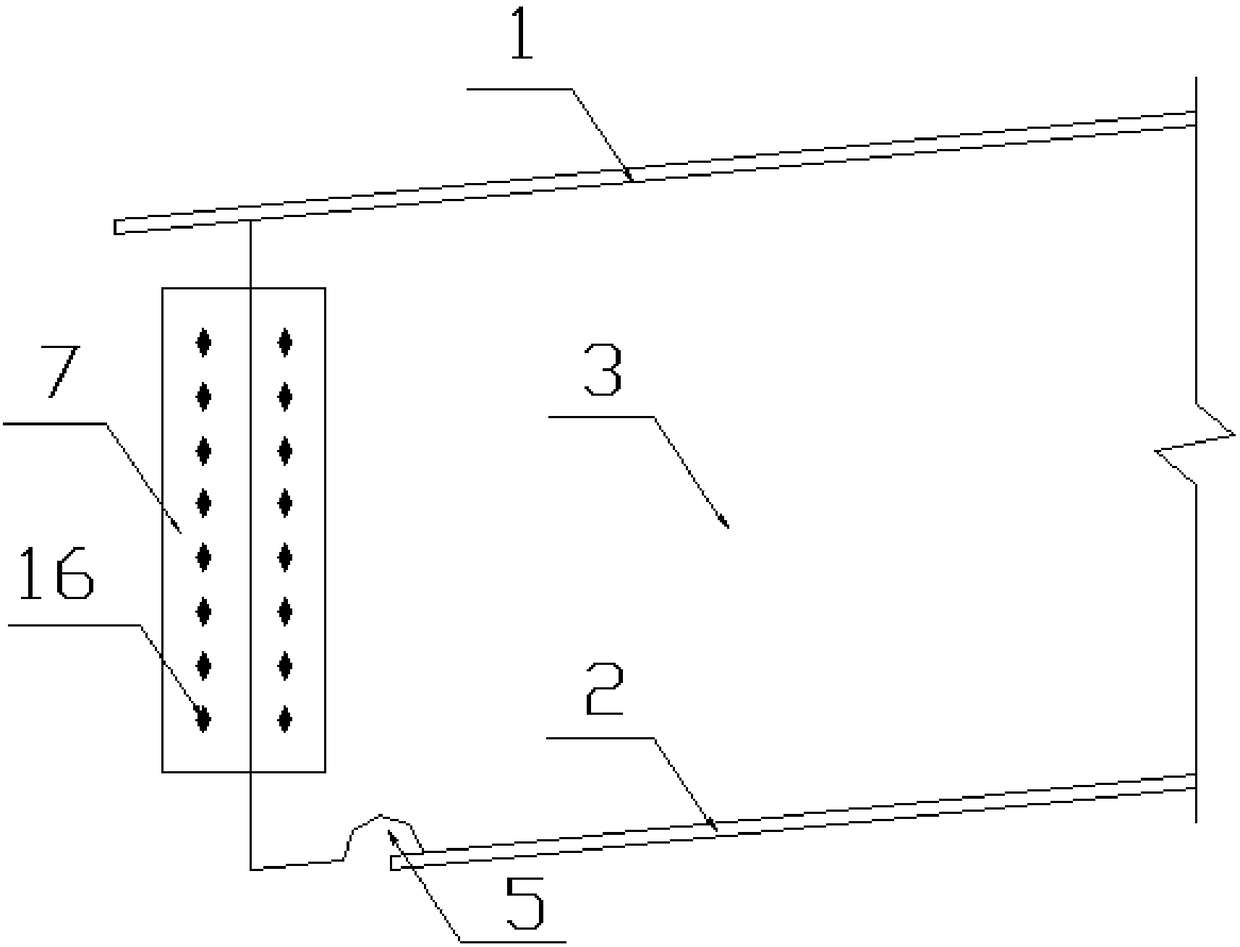

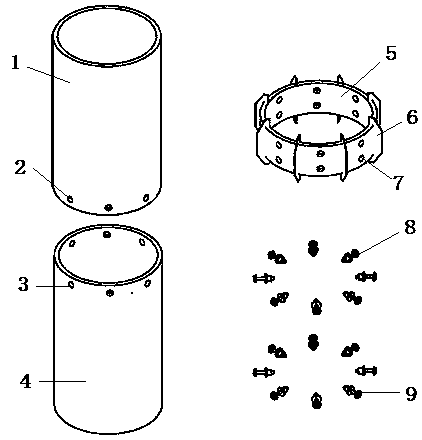

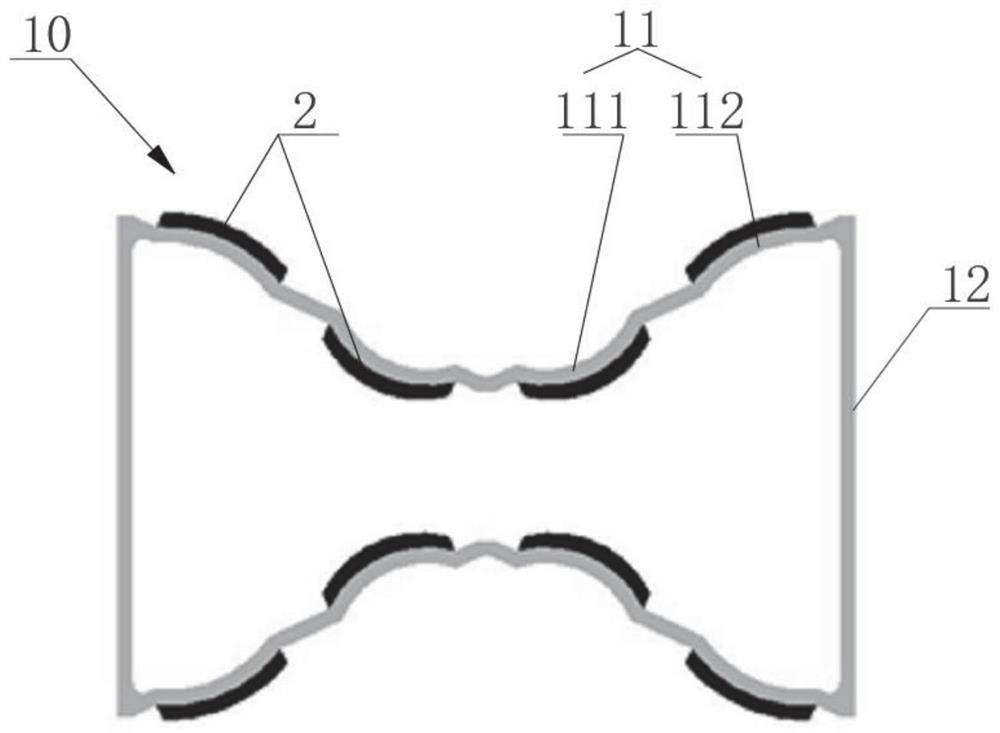

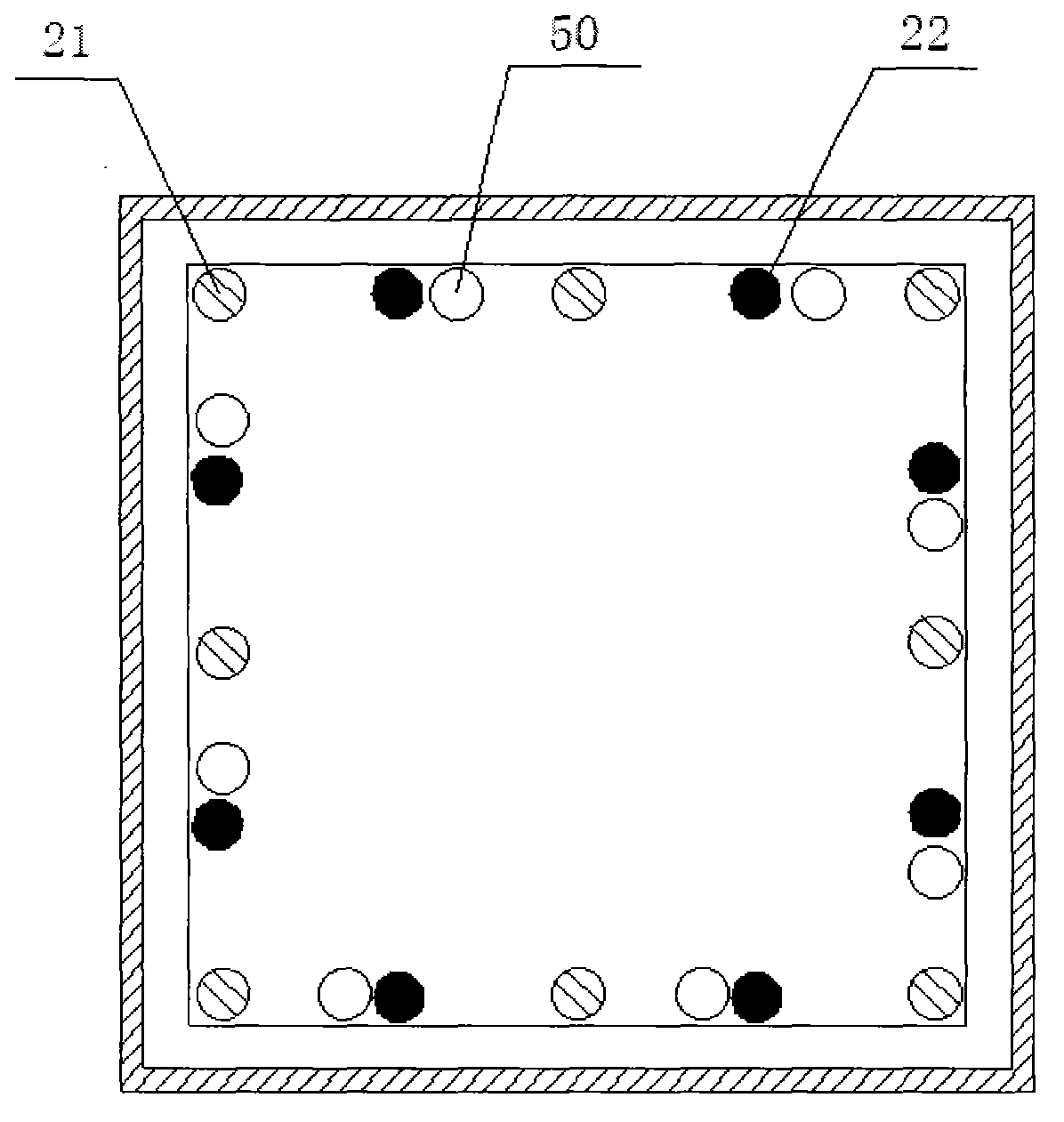

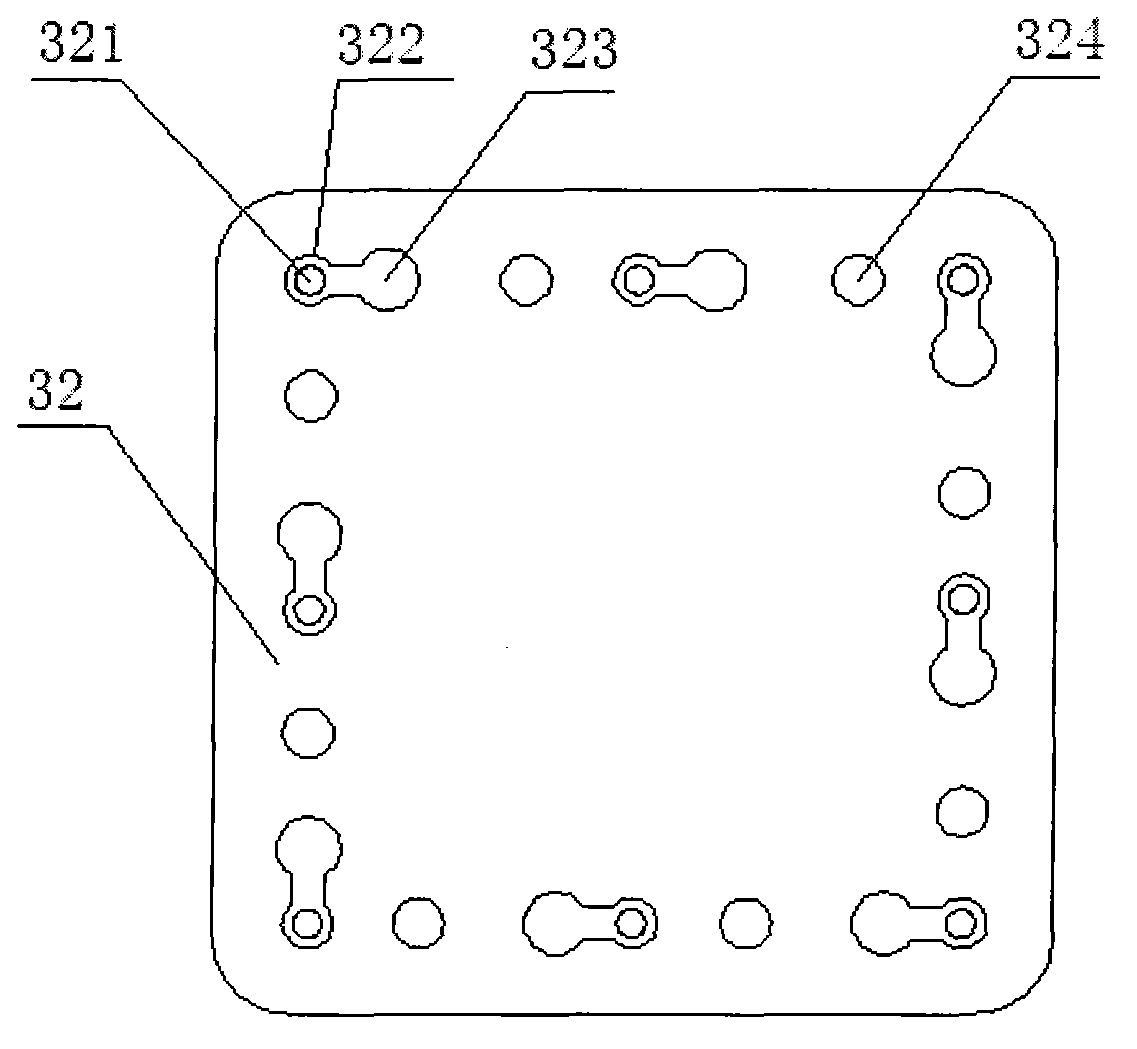

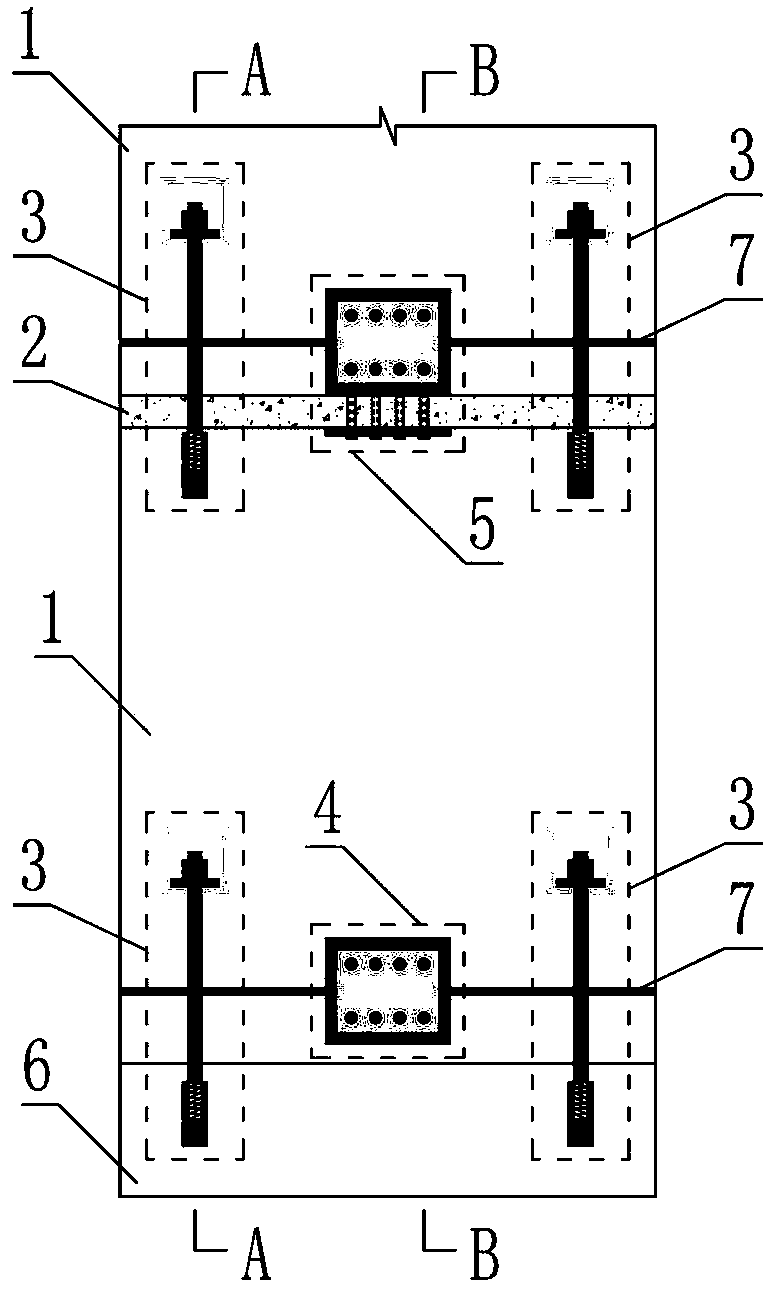

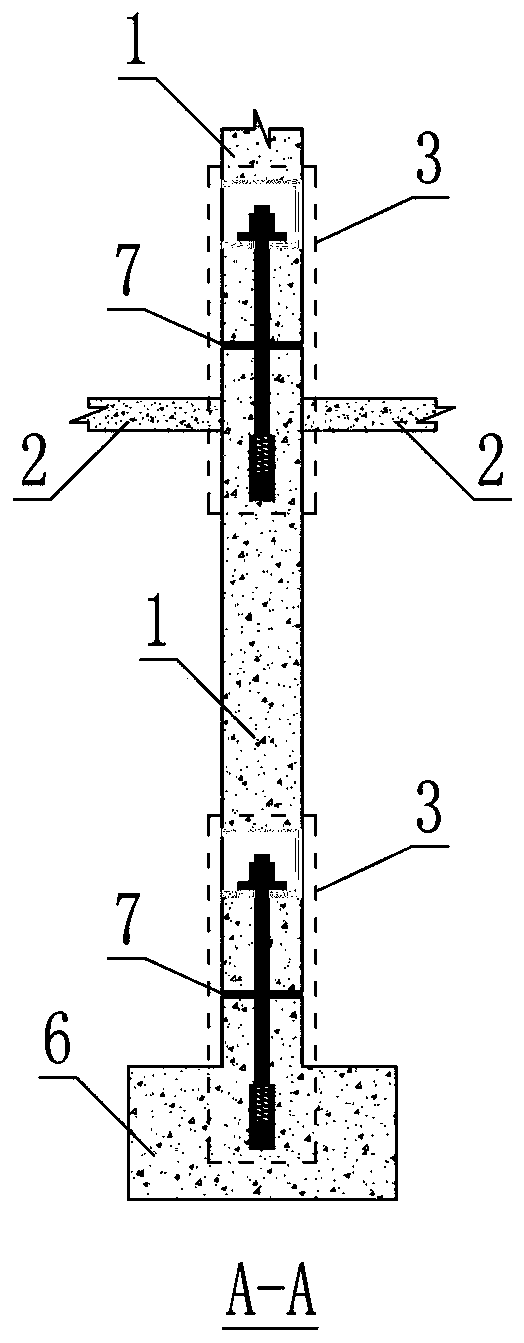

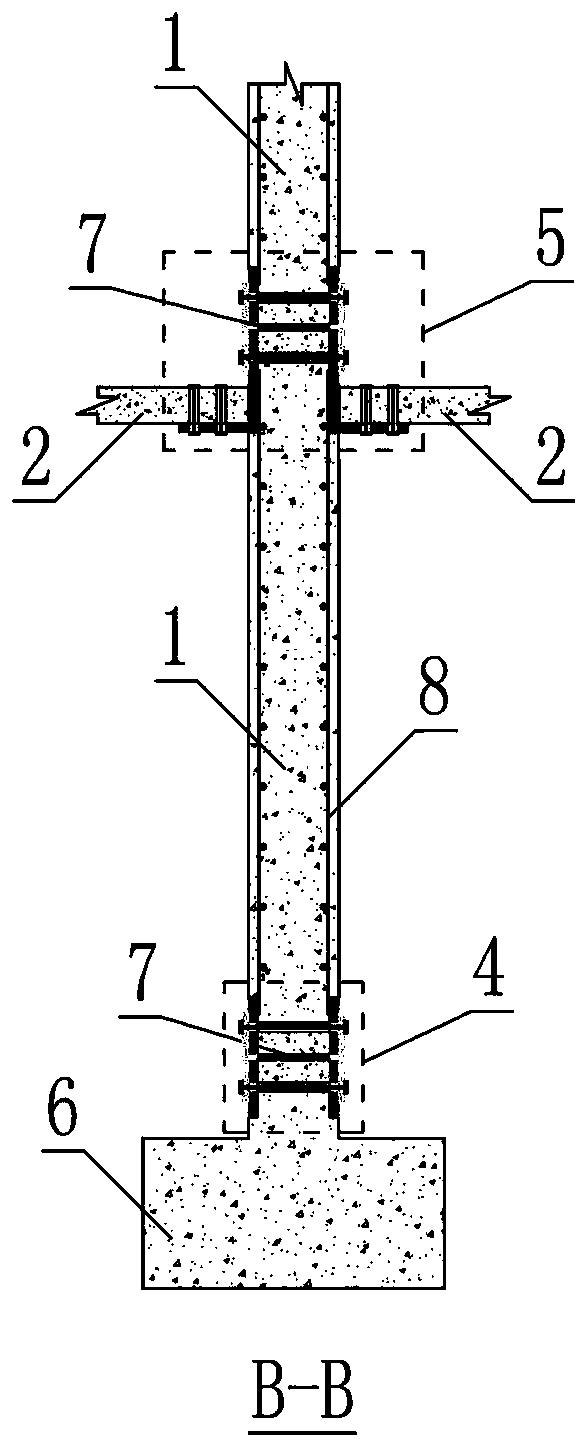

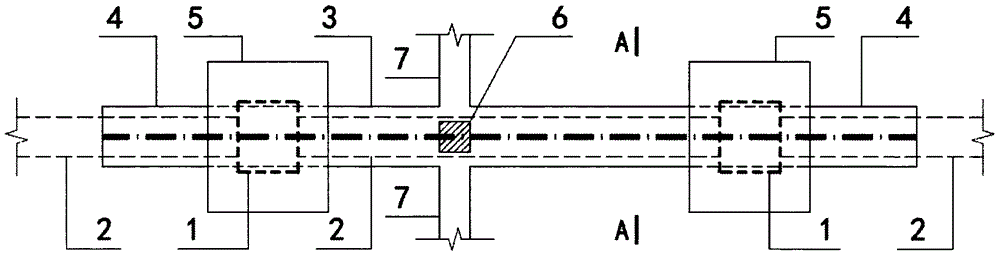

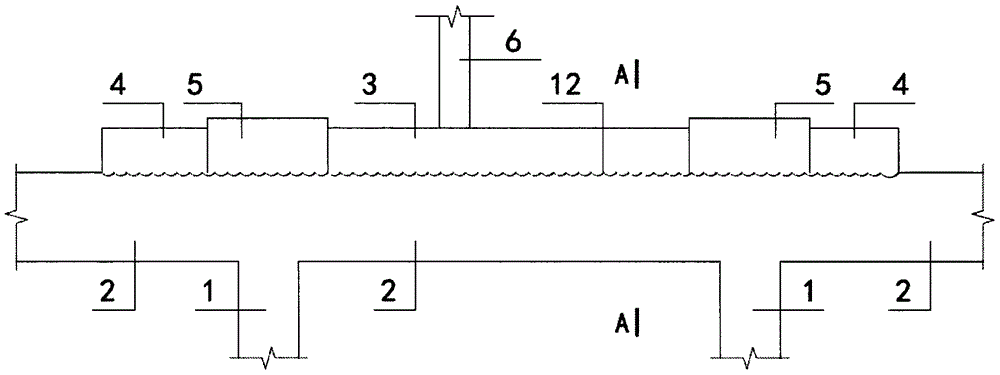

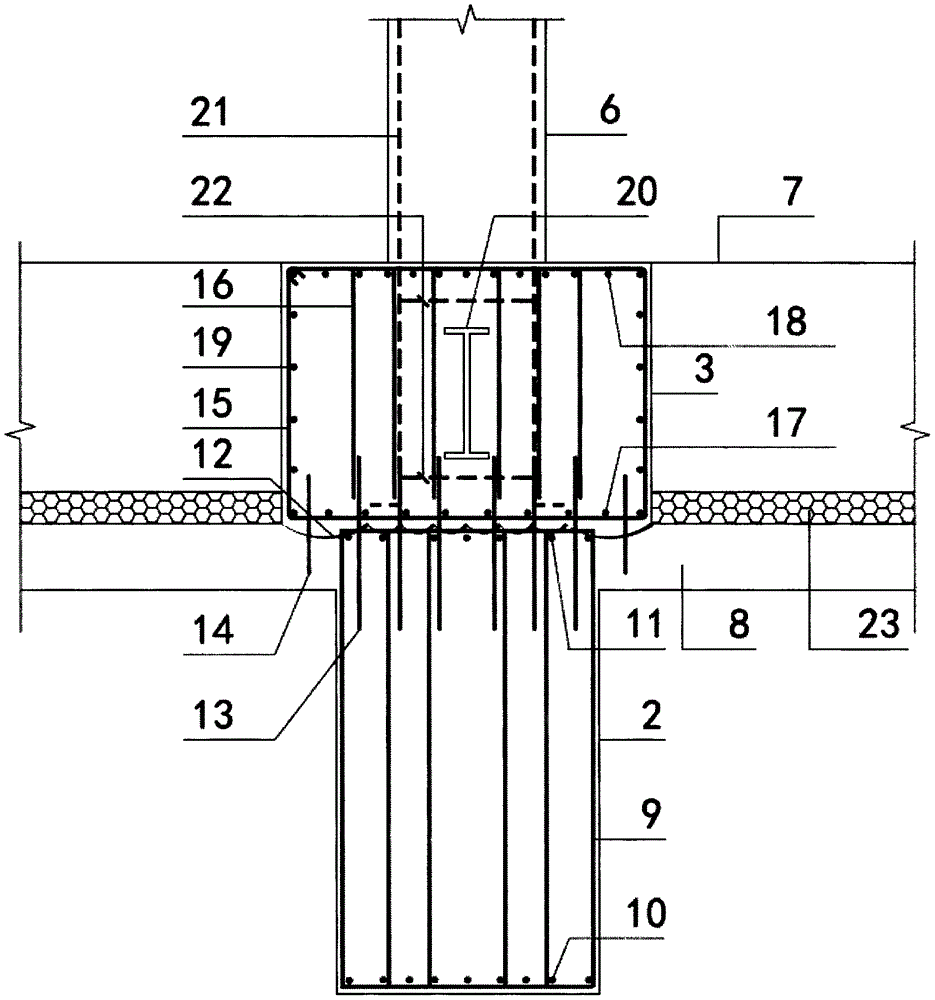

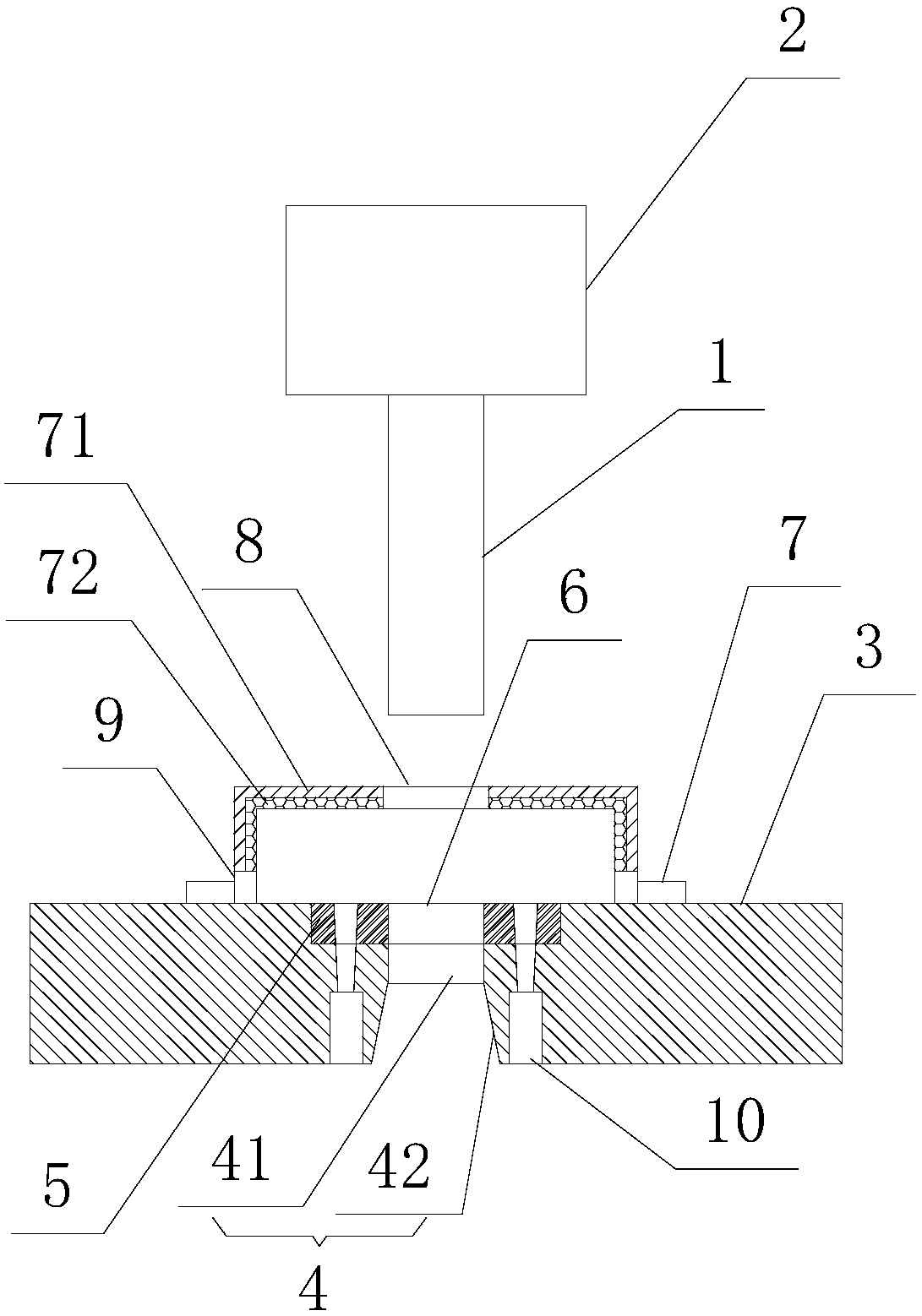

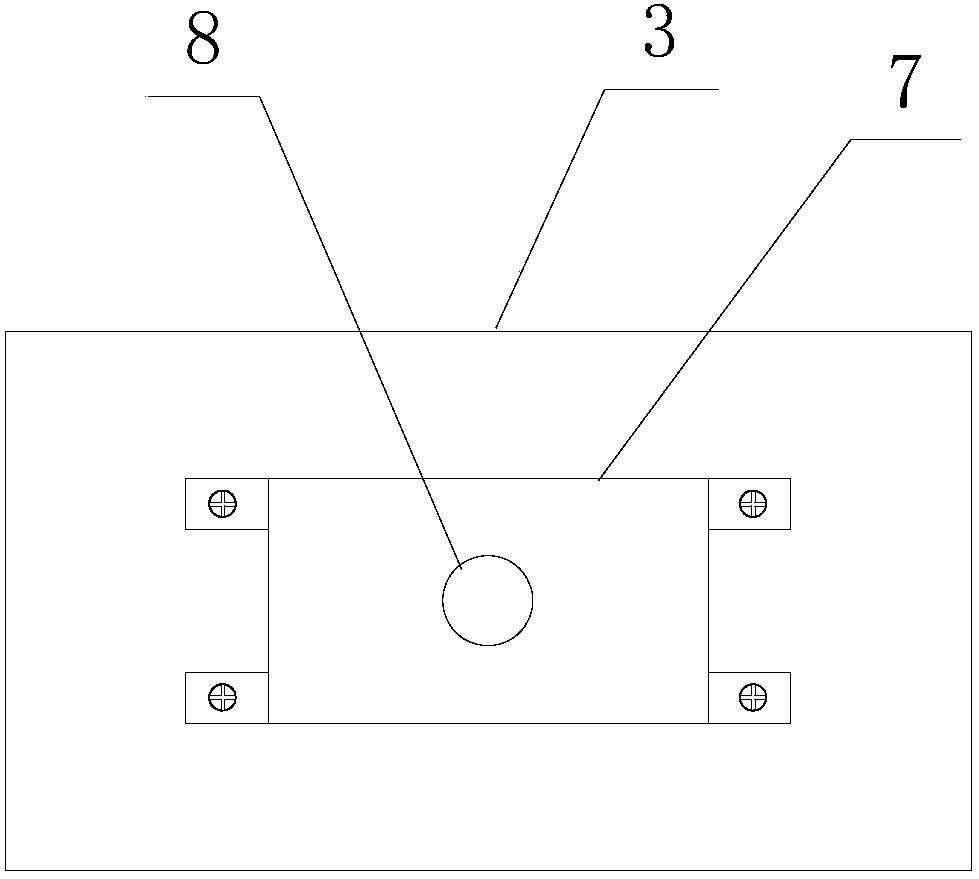

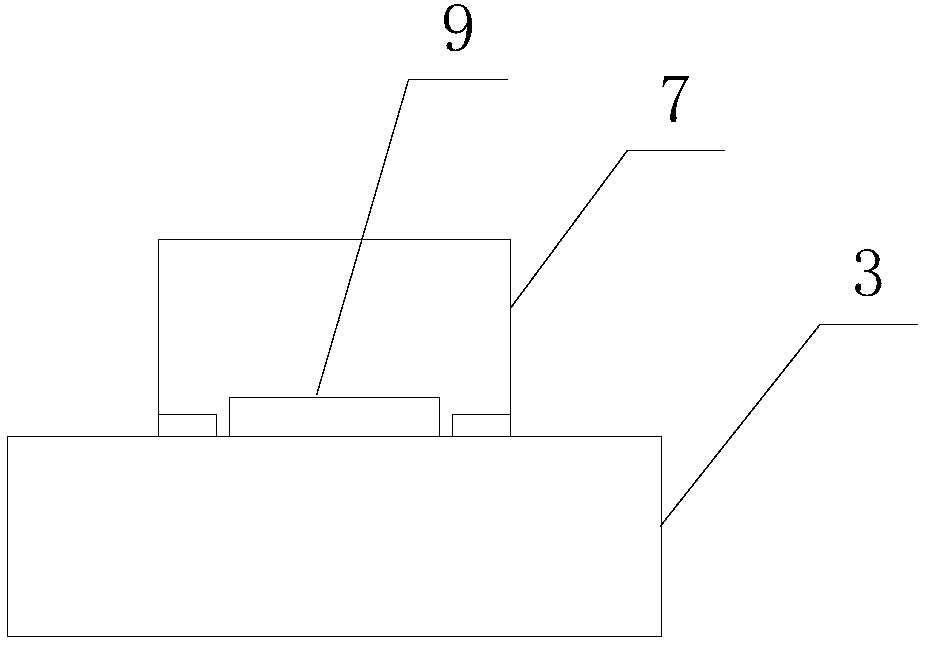

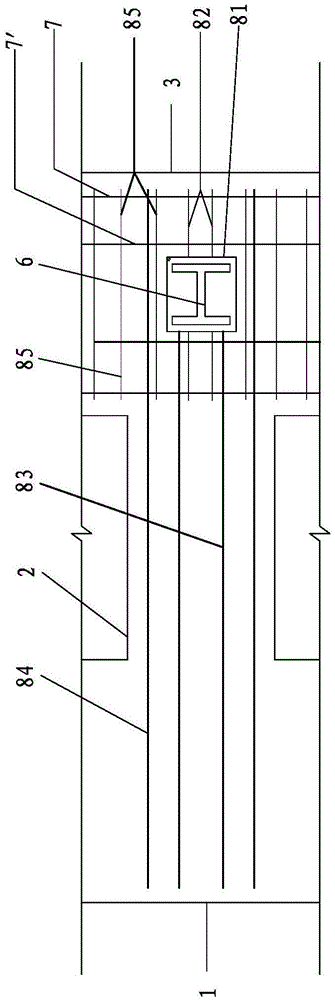

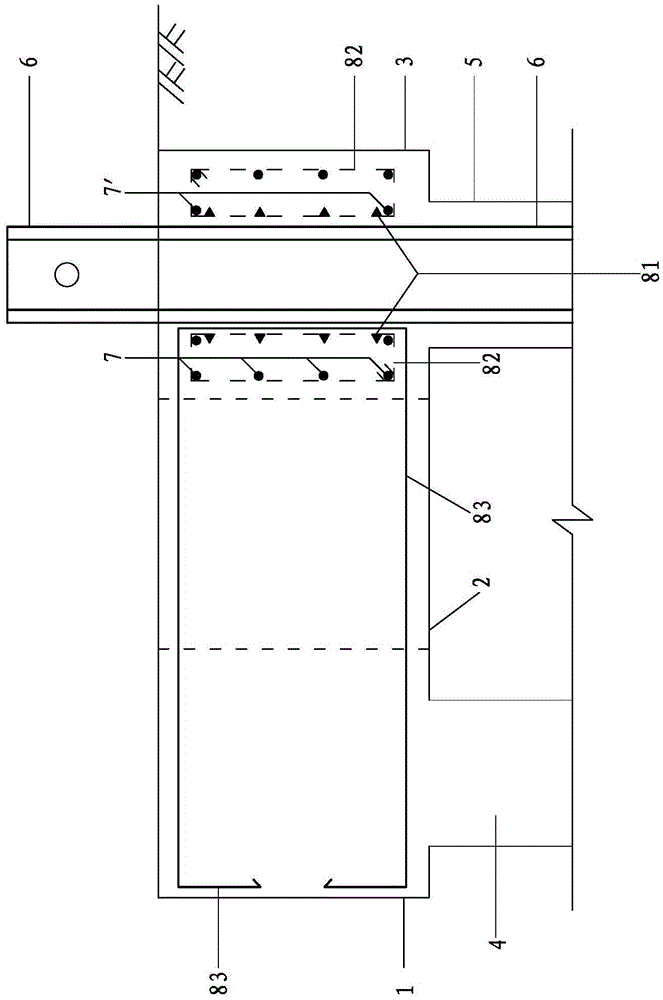

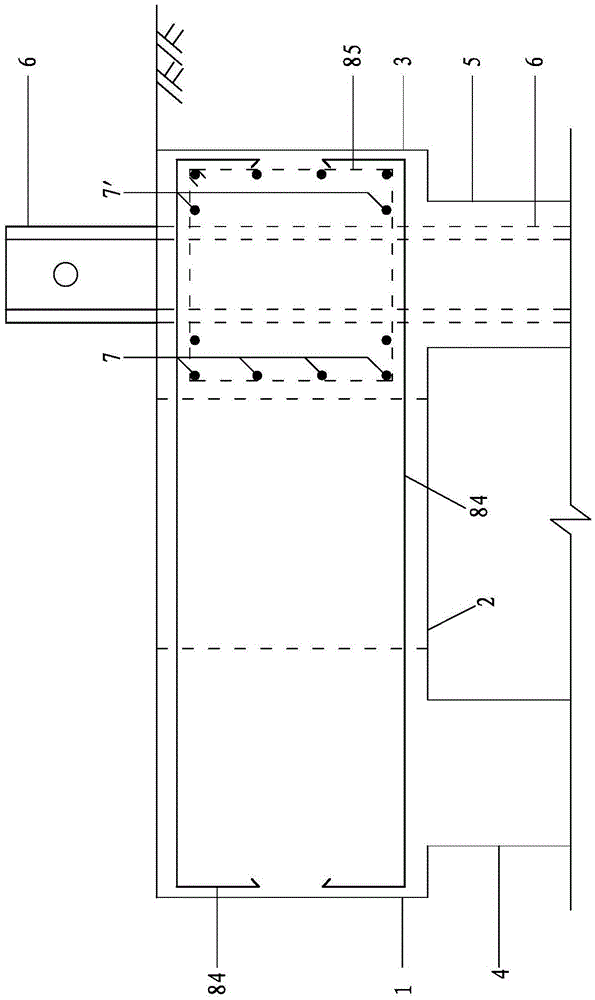

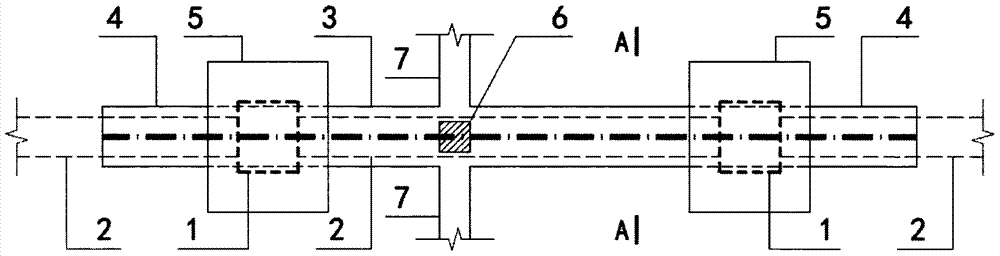

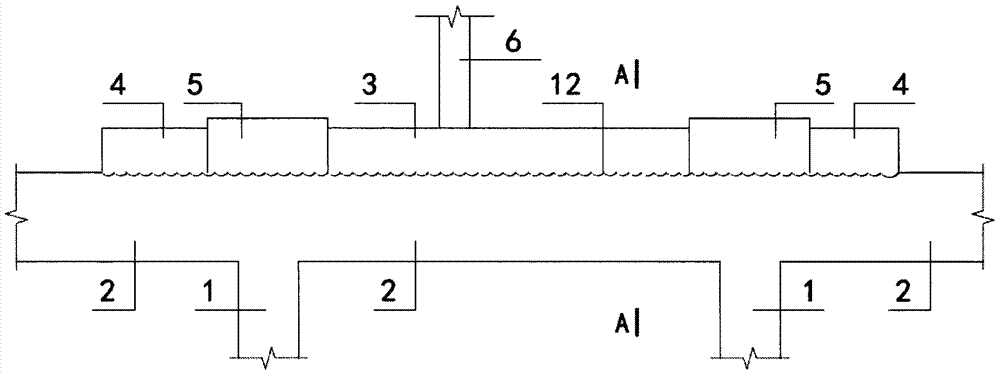

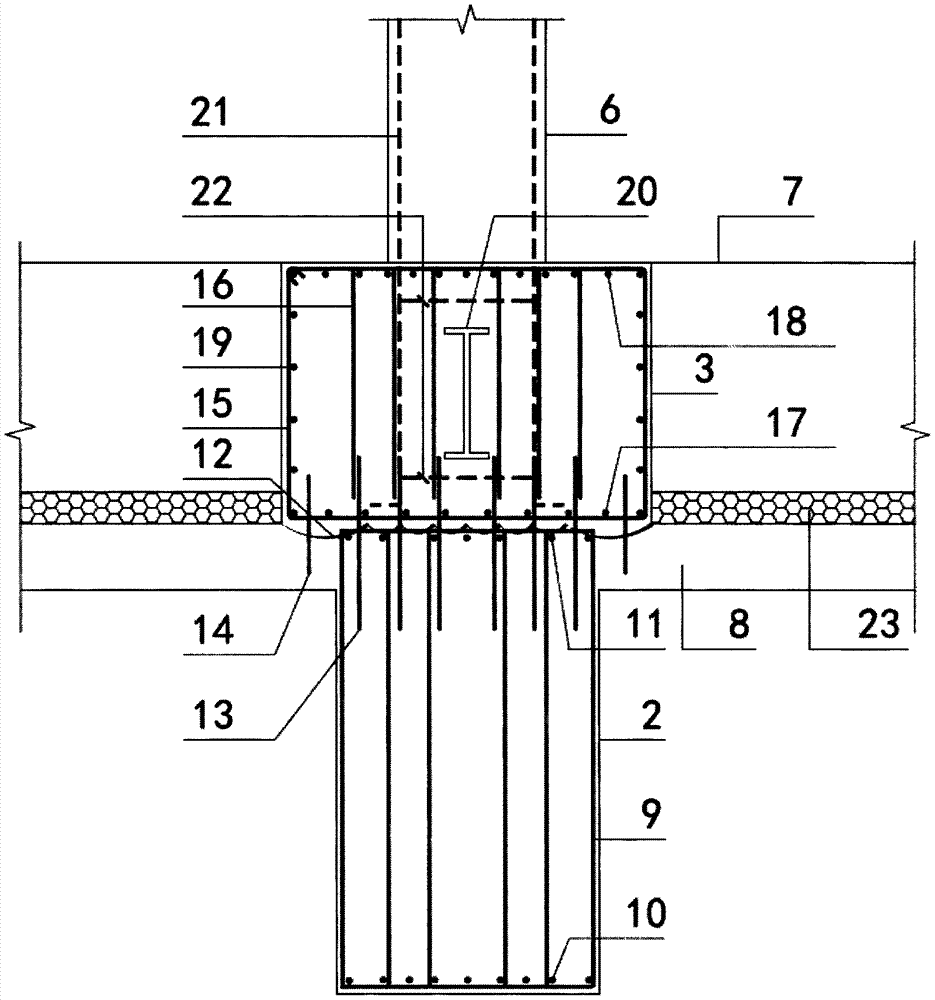

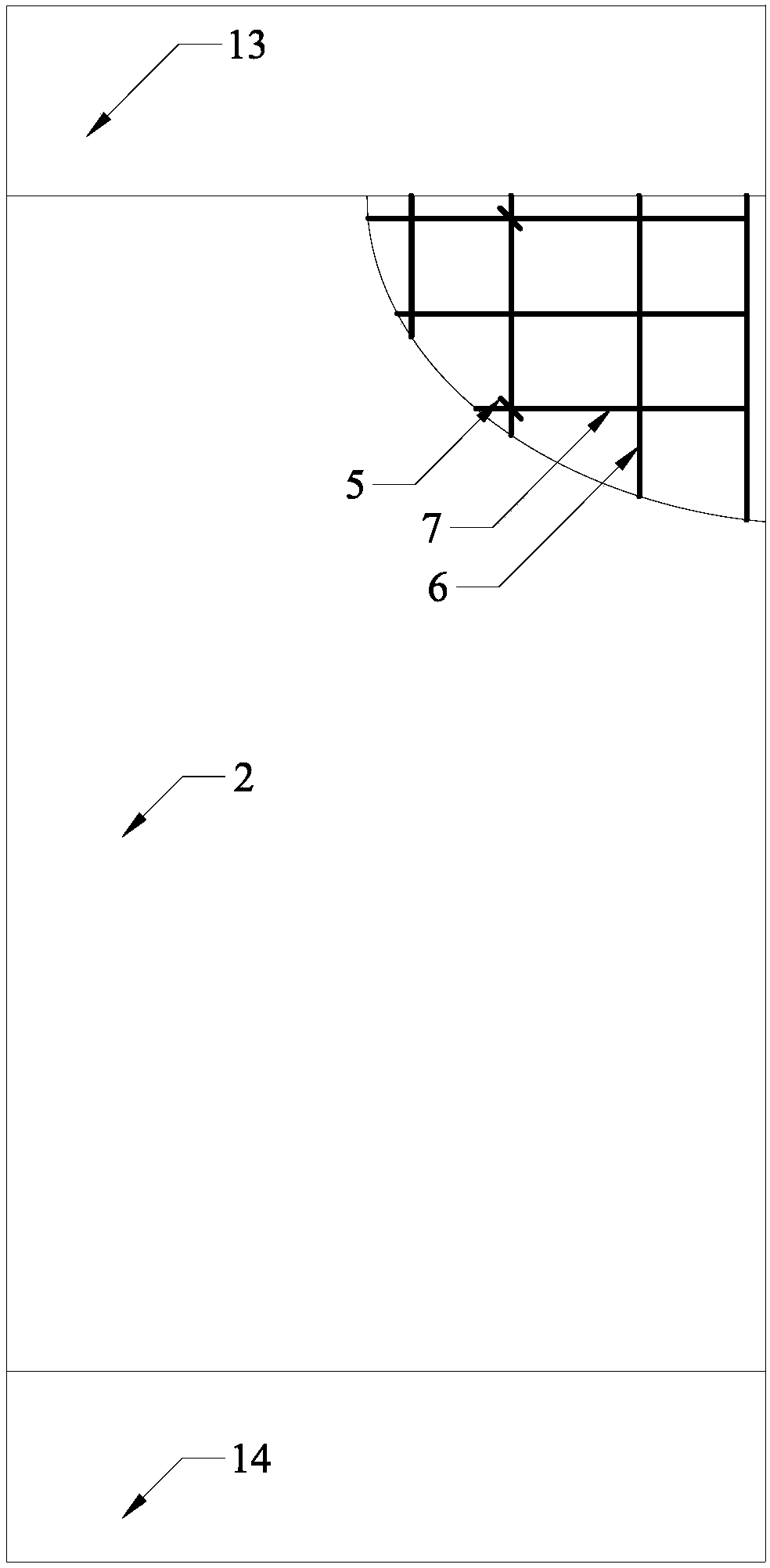

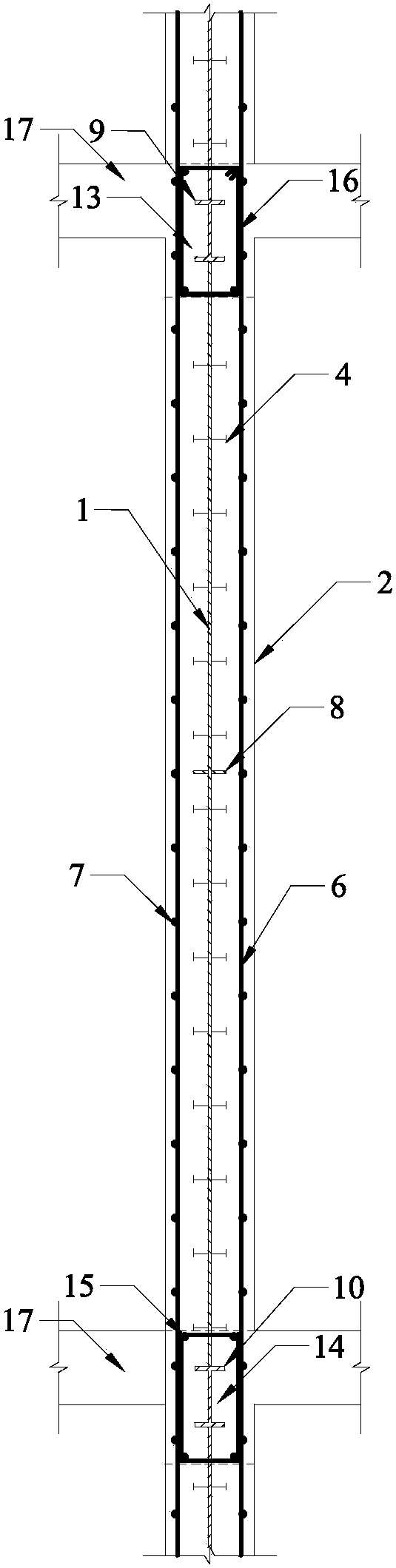

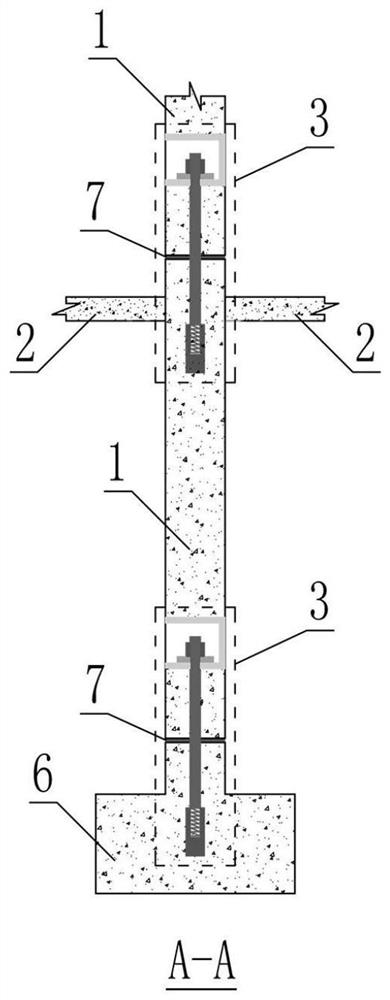

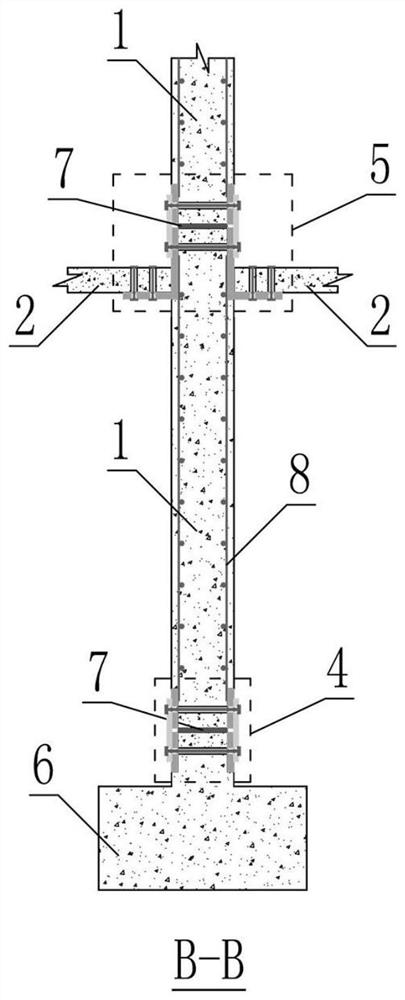

Assembly-type composite tube sea-water sea-sand concrete bridge pier and manufacturing method

PendingCN107806010AImprove restraintGuaranteed shear capacityBridge structural detailsBridge erection/assemblyPre stressSeawater

The invention discloses an assembly-type composite tube sea-water sea-sand concrete bridge pier. The structure of the bridge pier is composed of multiple composite tube sea-water sea-sand concrete column segments (100) which can be stacked, and the composite tube sea-water sea-sand concrete column segments (100) are connected into an entirety through back-tension prestressing force. The assembly-type composite tube sea-water sea-sand concrete bridge pier is characterized in that the composite tube sea-water sea-sand concrete bridge pier column segments are formed by composite tubes (1), sea-water sea-sand concrete (2), corrugated pipes (3), prestressing ribs (4) and anti-shear ribs (7), one or more pairs of protruding ribs (6) and grooves (5) are arranged between seams of every two composite tube sea-water sea-sand concrete bridge pier column segments, and the protruding ribs (6) and the grooves (5) are glued through a cementing material; each composite tube sea-water sea-sand concretebridge pier column segment (100) is provided with the corresponding corrugated pipe (3) in the height direction, and one or more prestressing ribs (4) penetrate through the corrugated pipes (3) of each column segment. The assembly-type composite tube sea-water sea-sand concrete bridge pier has the advantages that the bridge pier is good in durability, high in bearing capacity and good in corrosion resistance, the materials are easy to take, and the bridge pier is beneficial to sustainable development; meanwhile, the structure of the assembly-type composite tube sea-water sea-sand concrete bridge pier has the advantages that the structure can be prefabricated and transported in a large scale, is convenient to mount, short in construction period, low in energy consumption and little in environmental pollution, and can be suitable for marine engineering structural construction.

Owner:NANJING FORESTRY UNIV

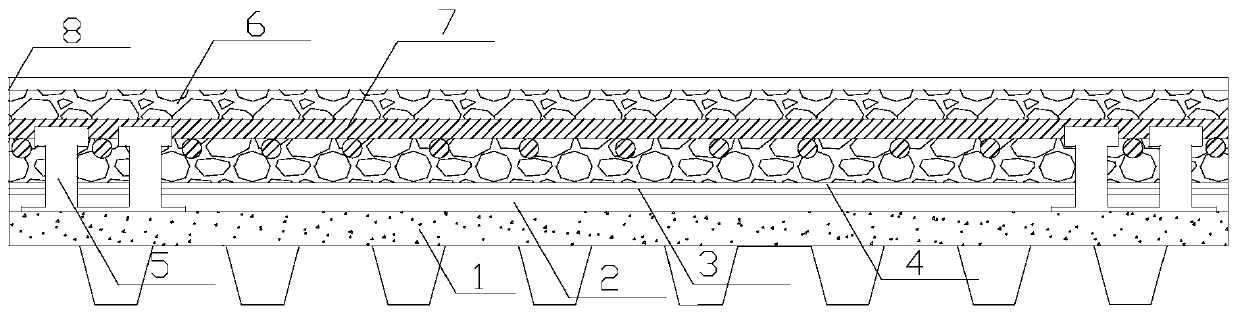

A normal-temperature health-preserving type steel bridge deck pavement structure and a construction method thereof

InactiveCN109695203AGuaranteed shear capacityReduce welding workloadBridge structural detailsBridge erection/assemblyEpoxyCrushed stone

The invention discloses a normal-temperature health-preserving type steel bridge deck pavement structure and a construction method thereof. The upper surface of a steel plate is provided with a shear-resistant stud that has a strip steel bottom plate; an epoxy resin macadam anti-shearing layer is arranged on the anti-shearing studs with the strip steel bottom plates; wherein a double-layer reinforcing mesh is arranged on the upper surface of the epoxy resin macadam shear-resistant layer, a wet joint interface agent layer and a normal-temperature health-preserving type ultrahigh-toughness cement concrete layer are arranged on the double-layer reinforcing mesh, and a resin macadam wearing layer is arranged on the upper surface of the normal-temperature health-preserving type ultrahigh-toughness cement concrete layer. The novel interlayer connection mode in which the shear-resistant studs with the marked line position pasted with the strip steel bottom plate are matched with the epoxy resin macadam shear-resistant layer is adopted to replace a traditional connection mode in which the shear-resistant studs are welded, so later maintenance is facilitated. The invention further providesa mixed proportion design and preparation method of the low-shrinkage, pumpable and normal-temperature health-preserving type ultrahigh-toughness cement concrete, the stress state of the steel bridgedeck can be improved under the cooperation of the stress absorption layer, and the occurrence probability of fatigue cracking of the steel bridge deck slab and pavement is reduced.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

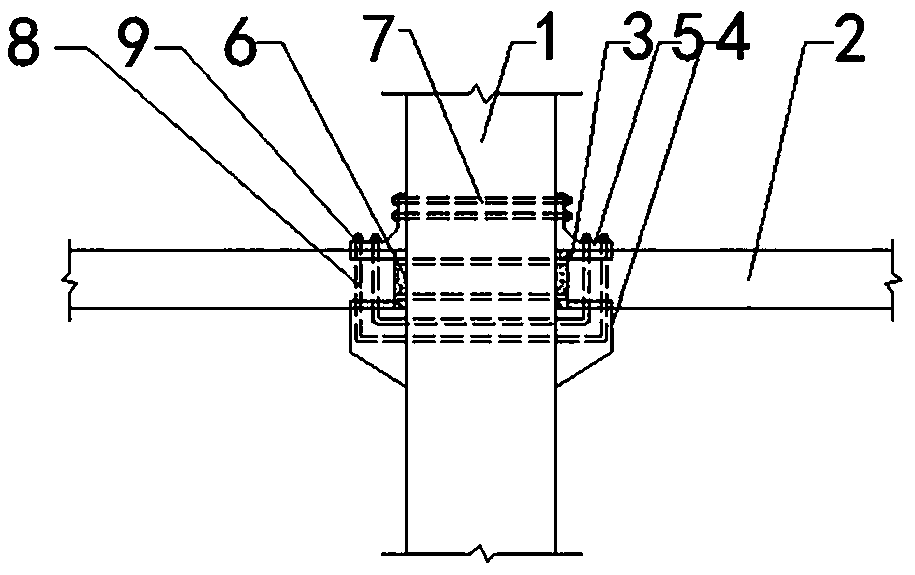

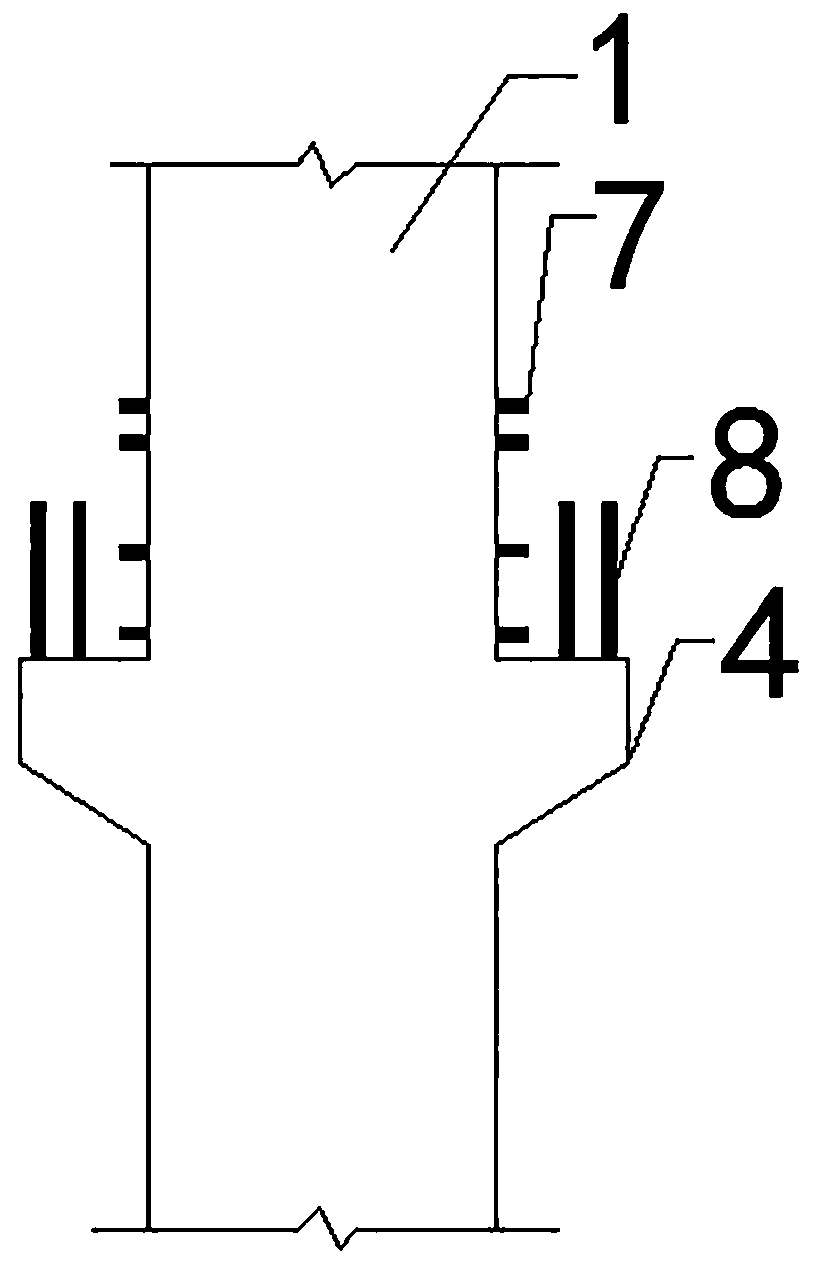

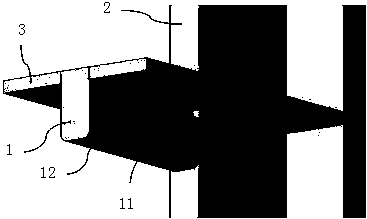

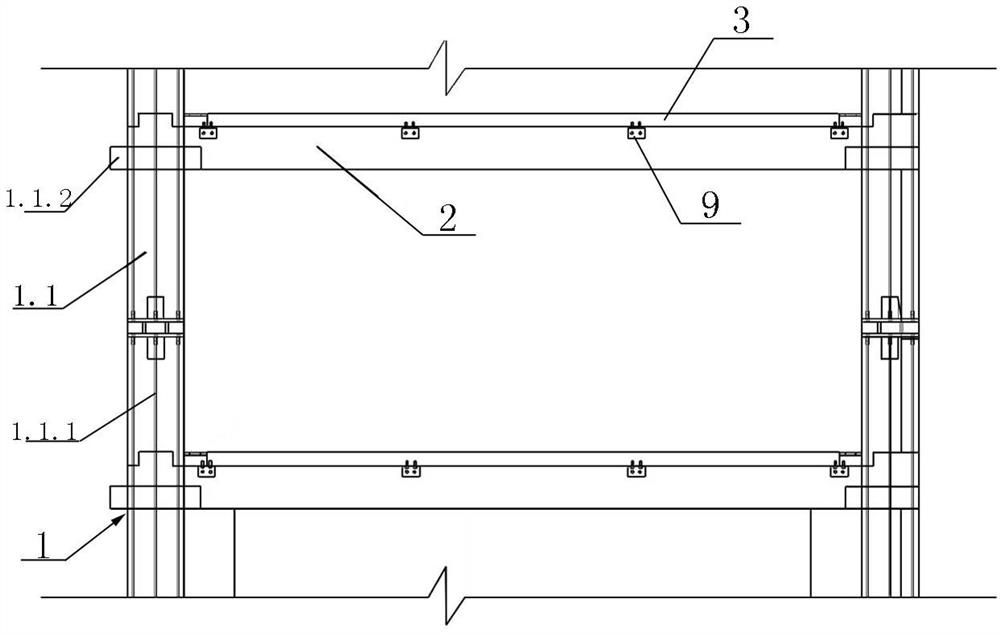

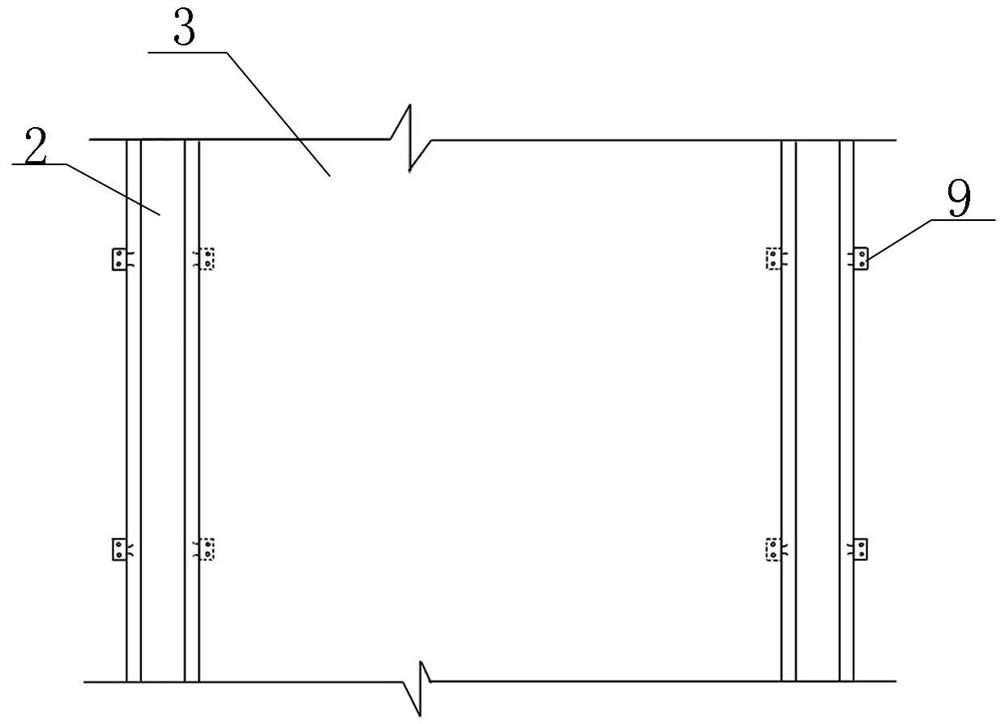

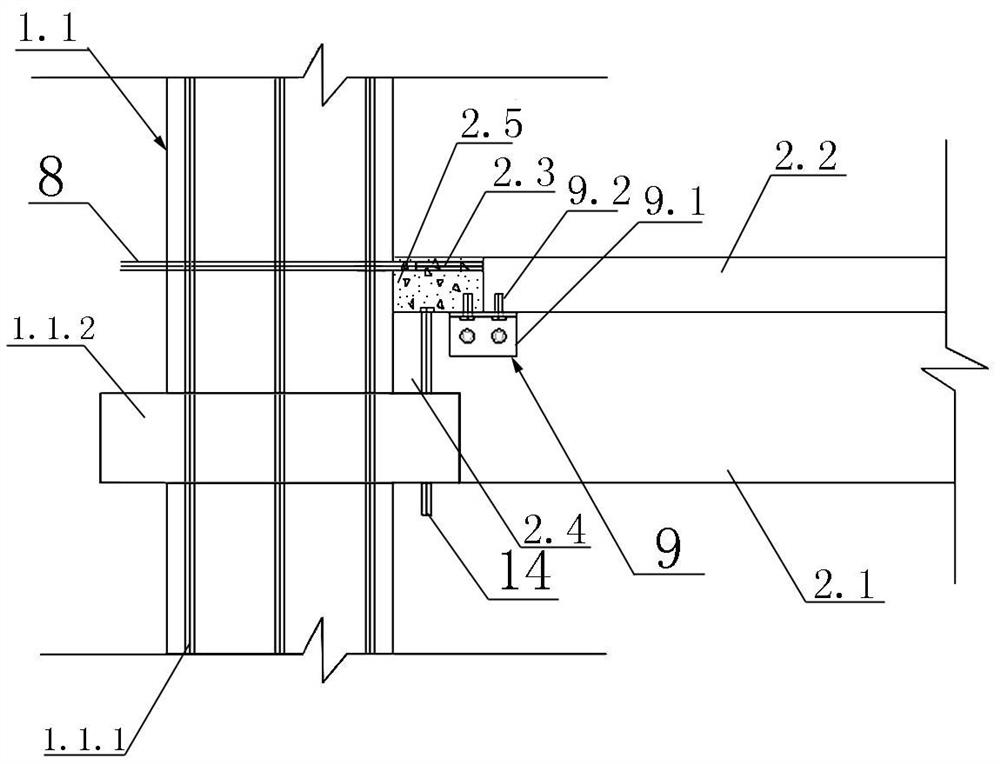

Beam-column connecting joint structure

InactiveCN108331162AGuaranteed shear capacityReduce deflectionBuilding constructionsSteel columnsCantilever

The invention relates to a beam-column connecting joint structure, and belongs to the technical field of building steel structures. Steel columns are provided with cantilever beams each of an integralstructures, the steel columns and steel beams form Z-shaped butting joint, and the steel beams and the steel columns are connected at webs through the mode that two clamping plates are matched with high-strength bolts while the steel beams and the steel columns are welded at flange plates. According to the beam-column connecting joint structure, the shear bearing capacity of the splicing positions of steel column cantilevered parts and the steel beam can be ensured, the lateral resisting stiffness of a steel frame structure is improved, the deflection of the steel beams is decreased, accurateposition during high altitude hoisting of the steel beams in a construction site can also be ensured, on-site construction is facilitated, and the construction quality is ensured; and the joint structure form has the advantages of safety, reliability, clear force transmission and the like.

Owner:CHINA 19TH METALLURGICAL CORP

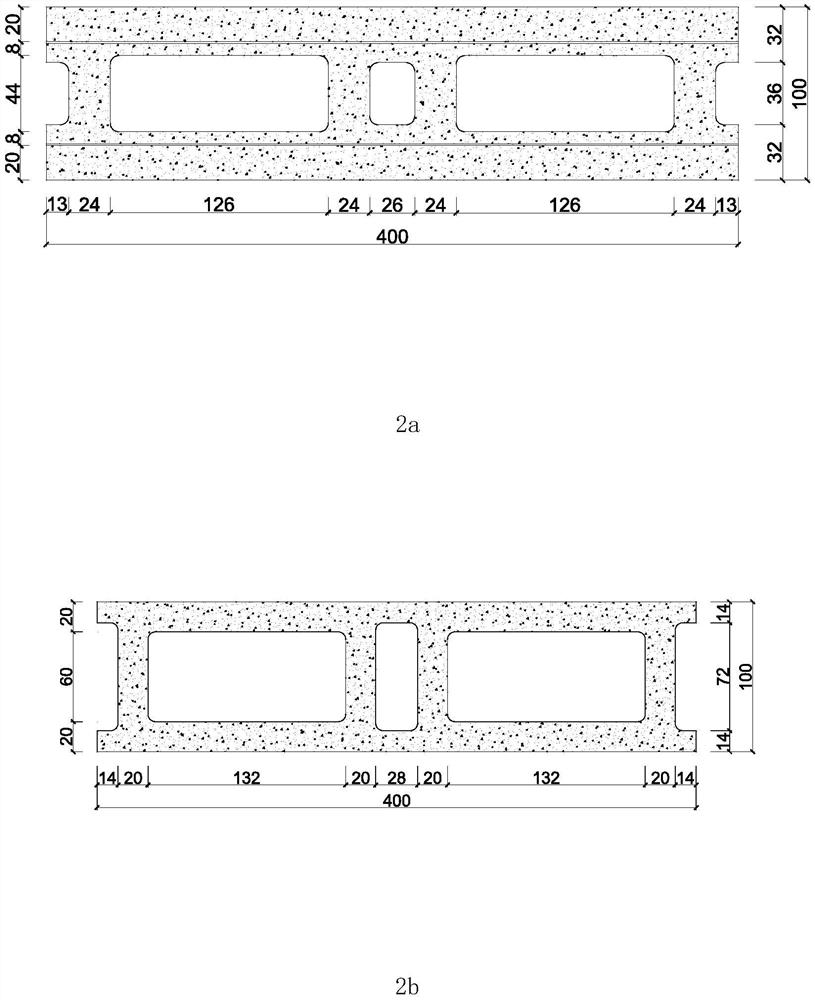

Tenon-and-mortise hollow building block and laying method thereof

InactiveCN112177233AHigh hollow rateImprove thermal insulationConstruction materialWallsEarthquake resistanceBrick

Owner:SOUTHEAST UNIV

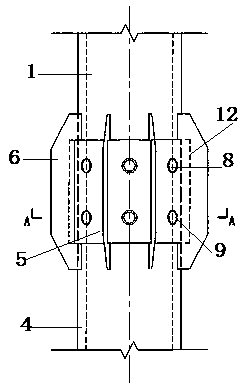

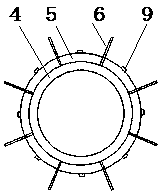

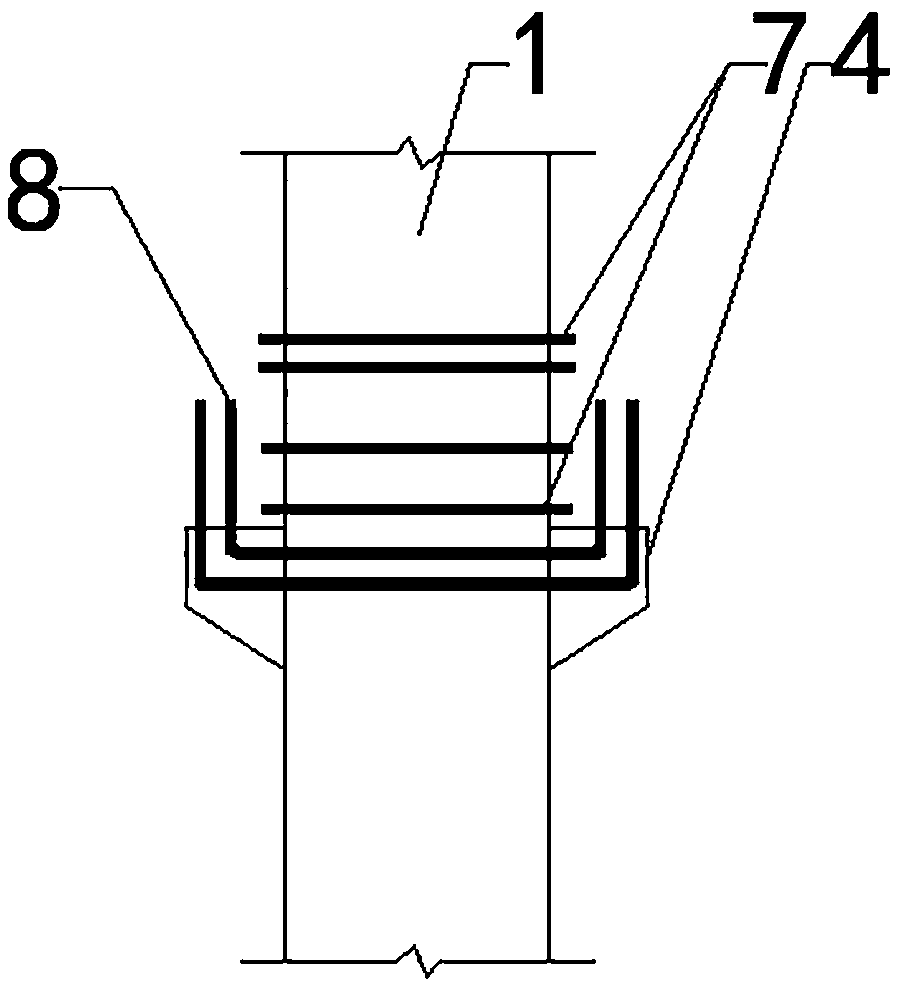

Assembly type steel pipe tower outer sleeve type node

PendingCN110939305AAvoid destructionImprove the level of assemblyBuilding constructionsTowersTowerSteel tube

The invention relates to an assembly type steel pipe tower outer sleeve type node. The assembly type steel pipe tower outer sleeve type node comprises an upper main pipe and a lower main pipe which are connected, and further comprises an outer sleeve and a plurality of stiffening ribs. The outer sleeve is arranged at the periphery of the connecting end of the upper main pipe and the lower main pipe and is fixedly connected with the upper main pipe and the lower main pipe through rivets. The plurality of stiffening ribs are uniformly distributed and fixedly connected to the outer surface of theouter sleeve and the upper and lower end surfaces of the outer sleeve. For a node needing to be connected with a supporting rod or a supporting pipe, the stiffening ribs are used as inserting platesand are provided with connecting holes, and a high-strength bolt penetrates through the connecting holes to fixedly connect the supporting rod or the supporting pipe to the stiffening ribs. During field assembly, the upper main pipe is hoisted, the stiffening ribs and the upper end surface of the lower main pipe are jointly used as temporary supports when the upper main pipe is assembled, and an LMB type single-sided pulling rivet is connected with the outer sleeve. The assembly type steel pipe tower outer sleeve type node is simple in structure and clear in stress, the pulling rivet is sheared, the design of the node is facilitated, the construction is convenient, and the assembly level of a power transmission line steel pipe tower can be improved.

Owner:GANSU ELECTRIC POWER DESIGN INST

Fabricated beam column connection joint and installation method thereof

InactiveCN108018944AImprove construction efficiencyAvoid problems such as complex structuresBuilding constructionsReinforced concrete columnEngineering

The invention belongs to the field of prefabricated structures in civil engineering, and particularly relates to a fabricated beam column connection joint and an installation method thereof. The fabricated beam column connection joint comprises a prefabricated reinforced concrete column, prefabricated reinforced concrete beams, pre-buried steel plates, brackets, upper end fixed angle irons, mortarlayers, pre-buried prick post steel bars, pre-buried beam-passing steel bars, bolted caps, longitudinal steel bars in beam, a reinforcement sleeve, and reserved beam-passing reinforced holes; four pre-buried prick post steel bars and four pre-buried beam-passing steel bars are respectively arranged in the prefabricated reinforced concrete column and the brackets; two beam-passing reinforced holesare respectively reserved at the left side and the right side of the prefabricated reinforced concrete beams; and the side walls of the prefabricated reinforced concrete column are provided with thebrackets and the upper end fixed angle irons. The fabricated beam column connection joint and the installation method thereof is simple in structure, the construction efficiency of beam column structure is effectively improved, the construction technology is simplified, and the problems of complex reinforcement structure in the beam column joint area while ensuring the bending and shear bearing capacity of the joints are avoided.

Owner:SHENYANG JIANZHU UNIVERSITY

Metamaterial structure with negative Poisson ratio and thermal expansion capable of being regulated simultaneously

ActiveCN112682681AGuaranteed shear capacityGuaranteed fracture resistanceSheets/panelsThermal dilatationHigh stiffness

The invention provides a metamaterial structure with negative Poisson ratio and thermal expansion capable of being regulated simultaneously. The metamaterial structure comprises at least one honeycomb unit; the honeycomb unit comprises a concave honeycomb base structure made of a material I and fitting parts made of a material II; the concave honeycomb base structure comprises a group of concave bent rods which are arranged at intervals, the concave bent rods are connected into a whole through straight rods, each concave bent rod comprises a repeating unit formed by connecting at least one convex arc section and at least one concave arc section, and the repeating units extend reversely and symmetrically to form a concave shape; the fitting parts are fitted along the outer side contours of the convex arc sections and the concave arc sections; and the thermal expansion coefficient of the material II is larger than that of the material I. According to the metamaterial structure, the shear capacity, fracture resistance, energy absorption, indentation resistance and other properties of the structure are ensured, and the characteristic of being capable of regulating the thermal expansion of the whole structural member is improved. The whole honeycomb unit is of an antisymmetric deformation bent structure, and the performance requirement for high rigidity is met.

Owner:SOUTHEAST UNIV

Partially-prestressed reinforced concrete solid square pile upper segment and manufacturing method thereof

InactiveCN103103978AGuaranteed shear capacityIncreased shearing capacityCeramic shaping apparatusBulkheads/pilesReinforced concretePre stress

The invention provides a partially-prestressed reinforced concrete solid square pile upper segment and a manufacturing method thereof. The partially-prestressed reinforced concrete solid square pile upper segment and the manufacturing method thereof are used for solving the problems that in the prior art, in the process of pile cutting of an upper segment of a prefabricated pile, a pile body is damaged, or pile cutting is not convenient, so that the phenomenon that the pile body can not meet requirements for mechanical performance and pile sinking construction is caused. The upper segment of the square pile comprises concrete, a reinforcement cage, a pile cap and a fixed end plate, wherein the reinforcement cage is of a square combined type whole structure, the pile cap is arranged at one end of the reinforcement cage and fixedly connected with the reinforcement cage, and the fixed end plate is arranged at the other end of the reinforcement cage and is fixedly connected with the reinforcement cage. By the adoption of the technical scheme, the square pile upper segment facilitates pile cutting under the premise that the pile body is not damaged, is beneficial to improving mechanical performance of the upper segment of the prefabricated pile, and improves bearing force of tension of the pile body.

Owner:江苏固丰管桩集团有限公司

Detachable assembled shear wall structure with replaceable component and assembling method

The invention provides a detachable assembled shear wall structure with replaceable components and an assembling method. Precast shear walls and a foundation and upper and lower layers of precast shear walls are both connected with each other through the replaceable components; and the precast shear walls and a precast floor slab are connected with each other through common bolts. According to thedetachable assembled shear wall structure with the replaceable components, each member and the replaceable components can be all precast in a factory and can be mounted after being transported to thesite. The precast shear walls are reinforced concrete shear walls which are industrially made and produced in a prefabrication factory. The precast floor slab is a reinforced concrete floor slab which is industrially made and produced in the prefabrication factory. According to the detachable assembled shear wall structure with the replaceable components, the detachability of the shear wall and the quick recovery of the structure after earthquake are realized, and requirements of structure assembled construction and building industrialization are satisfied.

Owner:SOUTHWEAT UNIV OF SCI & TECH

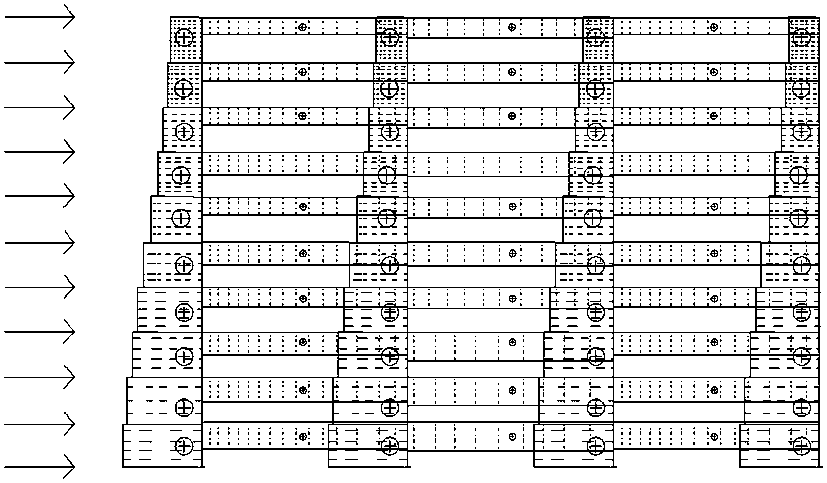

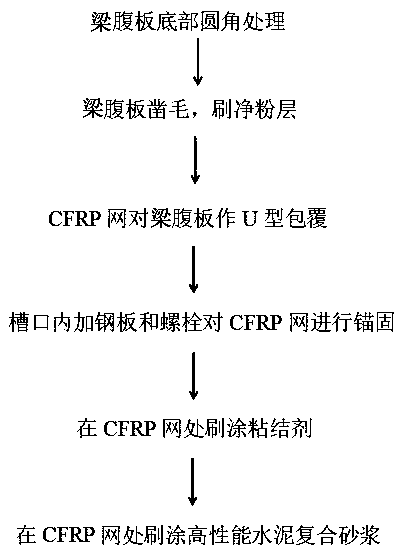

Method for carrying out shear-resistant reinforcement on beam with floor slab

InactiveCN110397300AReduce thicknessGuaranteed shear capacityBuilding repairsCement compositesFloor slab

The invention belongs to the technical field of seismic reinforcement and discloses a method for carrying out shear-resistant reinforcement on a beam with a floor slab. The beam with the floor slab comprises a beam, a wall or a column arranged at the end of the beam and the floor slab vertically connected with the beam, the wall or the column. The composite mortar reinforced by CFRP net is used for reinforcing a connecting beam section of the beam with the floor slab which is easy to be sheared and damaged. The CFRP net U-shaped surrounding beam web plate is used, CFRP net lines vertical to the axis of the connecting beam cooperate with original beam stirrups to bear seismic shearing force, CFRP net lines parallel to the axis of the connecting beam play a role in "forming a net" or 'distributing ribs', so that shearing-resistant net lines are stressed more uniformly, steel plates and bolts embedded in the upper end of the beam web plate can firmly fix the shearing-resistant CFRP net, the composite mortar cooperates with concrete to resist shearing, and the CFRP net U-shaped surrounding beam web plate plays a role in resisting compression shearing, bonding, protecting, slope findingand filling and repairing on concrete cracks, and a high-performance cement composite mortar reinforcing layer reinforced by the CFRP net can effectively guarantee the shearing-resistant bearing capacity of a reinforced beam.

Owner:HUNAN UNIV OF TECH

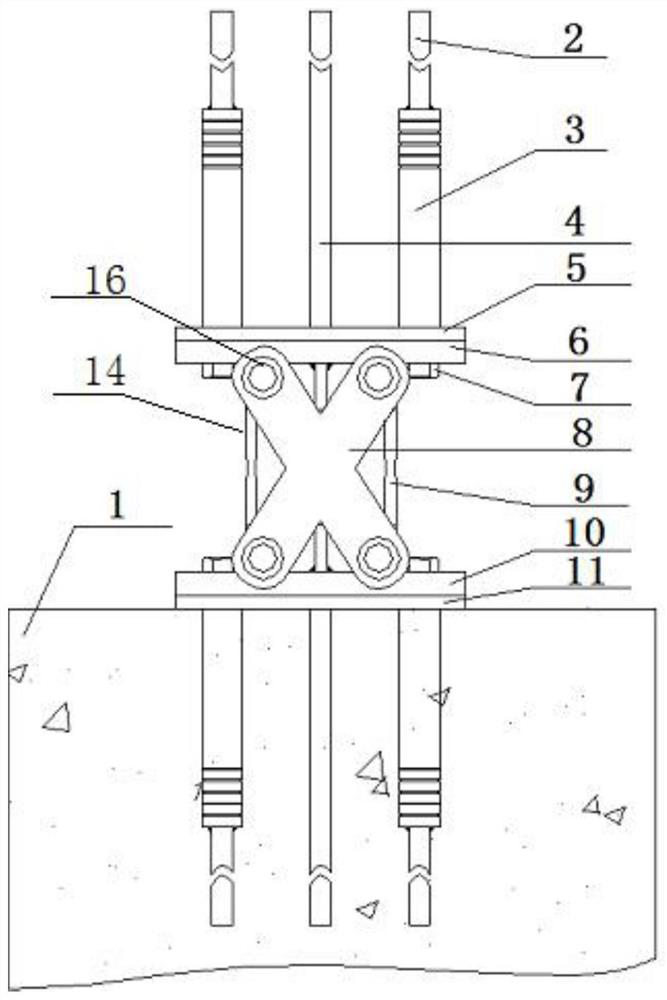

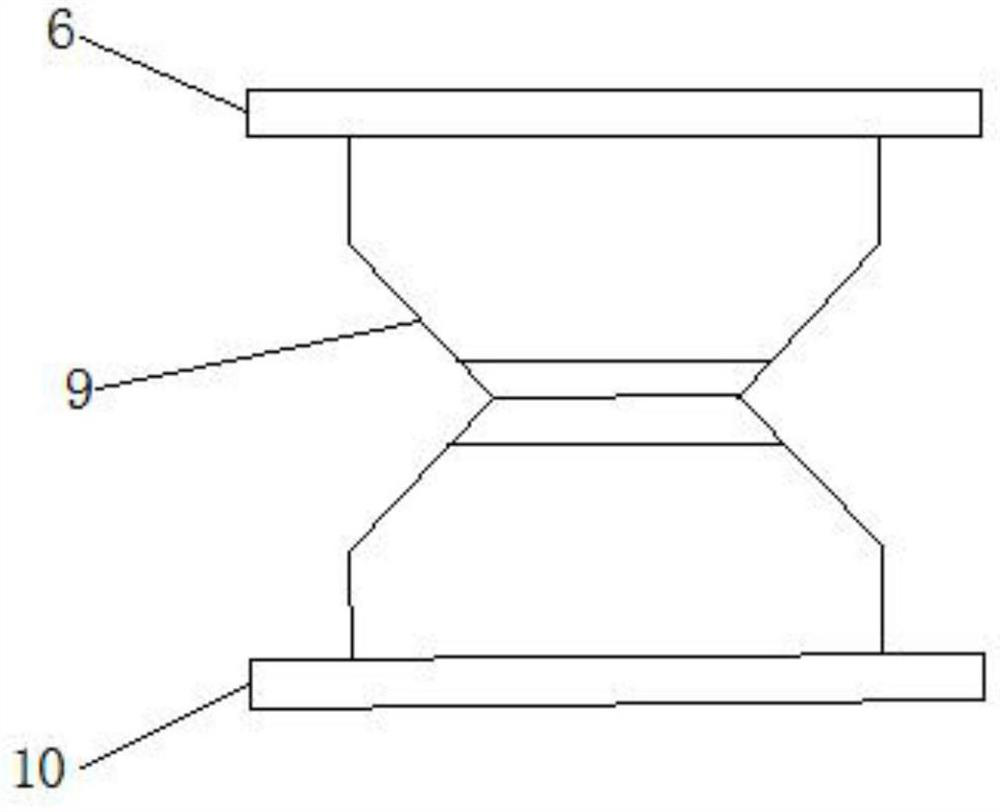

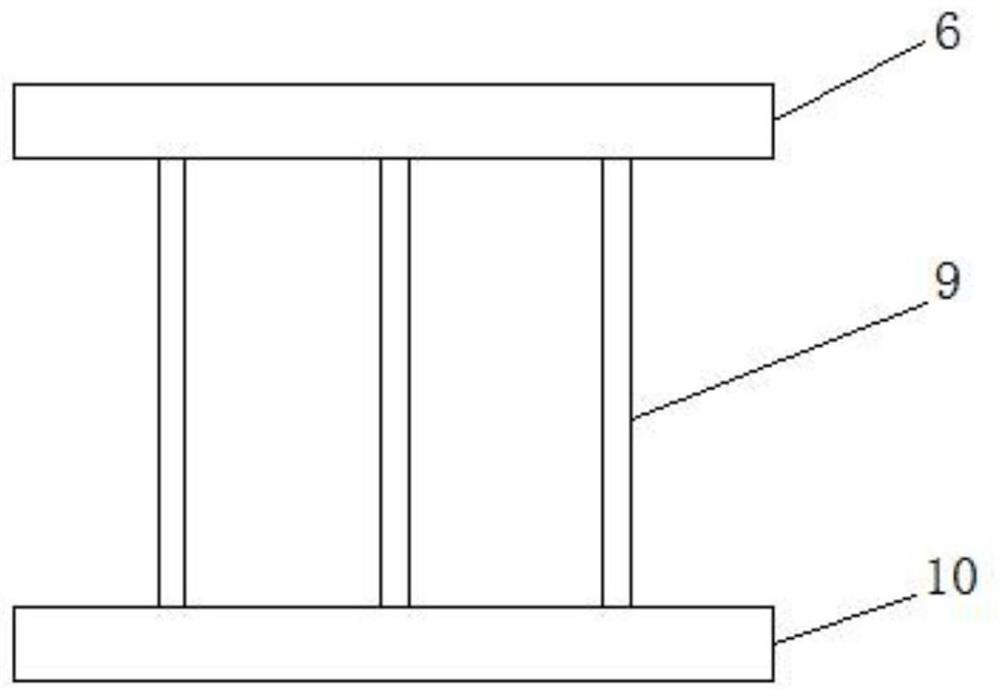

Special wind-resistant device in building seismic isolation engineering and using method thereof

InactiveCN112359996AMake sure the middle thicknessReduce in quantityProtective buildings/sheltersShock proofingArchitectural engineeringRebar

The invention discloses a special wind-resistant device in building seismic isolation engineering and a using method thereof, the special wind-resistant device comprises a wind-resistant support, thewind-resistant support comprises an upper connecting plate, a wind-resistant steel plate and a lower connecting plate, one end of the wind-resistant steel plate is welded at the bottom of the upper connecting plate, and the other end of the wind-resistant steel plate is welded with the top of the lower connecting plate. The wind-resistant device is machined and manufactured in a factory-like mode,the weld joint quality of the wind-resistant support is strictly controlled, and the precision of the sizes of all parts of the wind-resistant steel plate is strictly controlled. An X-shaped temporary supporting frame is additionally arranged on the wind-resistant support, temporary vertical and lateral bearing force is provided for the wind-resistant support, lateral out-of-plane deformation ofthe wind-resistant support due to construction load is avoided, shear capacity of the wind-resistant support is guaranteed, sleeves of bolts are fully used for lengthening anchor bars, and the wind-resistant support is simple in structure and convenient to assemble and disassemble. The number of anchor bars is reduced, the number of crossed reinforcing steel bars in a joint area is reduced, and the compactness of concrete pouring at the embedded plate is guaranteed.

Owner:周力

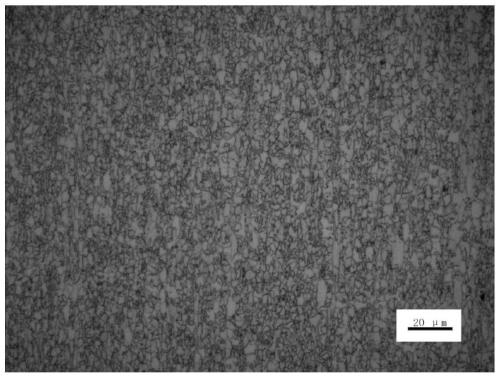

High-wear-resistance high-frequency induction welded steel pipe raw material steel and preparation method and application thereof

ActiveCN111455270AImprove wear resistanceSignificant work hardening rateProcess efficiency improvementHigh wear resistancePipe

The invention provides high-wear-resistance high-frequency induction welded steel pipe raw material steel and a preparation method thereof. The high-wear-resistance high-frequency induction welded steel pipe raw material steel comprises the following components in percentage by mass: 0.15-0.20% of C, 0-0.05% of Si, 0.5-1.3% of Mn, not greater than 0.008% of P, not greater than 0.005% of S, 0.03-0.04% of Al, 0.03-0.08% of Nb, 0.03-0.10% of V, and the balance Fe and inevitable impurities. The high-wear-resistance high-frequency induction welded steel pipe raw material steel has such advantages as easy formation, easy welding and high machining hardening degree; and in addition, the wear resistance of a welded steel pipe and a carrier roller prepared by the high-wear-resistance high-frequencyinduction welded steel pipe raw material steel in service is further improved.

Owner:SHOUGANG CORPORATION +1

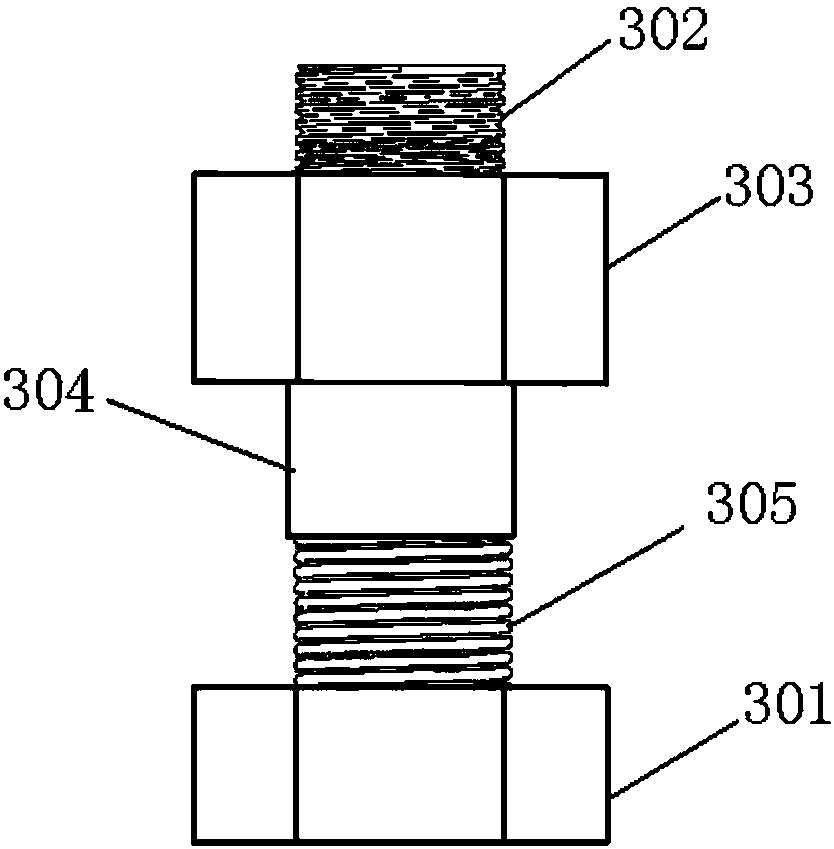

Friction type high-strength bolt capable of monitoring and controlling pretension force, connecting piece and construction method thereof

InactiveCN107588079AHigh degree of prefabricationReduce labor costsNutsScrewsHemt circuitsEngineering

The invention discloses a friction type high-strength bolt capable of monitoring and controlling pretension force, a connecting piece and a construction method thereof. The high-strength bolt comprises a nut, a thread section, a nut, an outer sleeve and a semiconductor spring; a clamping groove is formed in the top face of the nut, the nut, the outer sleeve and the semiconductor spring are sequentially connected into a whole in a preset mode during prefabrication, the nut is screwed from one end of the thread section, the semiconductor spring, the outer sleeve and the nut are sleeved from theother end of the thread section, the semiconductor spring and the clamping groove in the top face of the nut are clamped, and the nut and the thread section are in threaded connection; different subregions are arranged on the thread section to primarily control pretension force, and a built-in circuit is arranged to accurately control pretension force. A traditional force transmission mode is changed by the bolt, the pretension force can be monitored and controlled, the bolt can be adjusted in real time according to change of the pretension force, and shear capacity and rigidity of the connecting position and connection reliability are ensured.

Owner:HOHAI UNIV

Superimposed reinforcement structure and method for additionally arranging column grid on existing long-span structure

The invention belongs to the field of constructional engineering and particularly relates to a superimposed reinforcement structure for additionally arranging a column grid on an existing long-span structure. The superimposed reinforcement structure comprises existing structure columns and an existing long-span structure beam which is supported on the existing structure columns. An additional beam superimposed layer is arranged on the existing long-span structure beam, profile steel is arranged inside the additional beam superimposed layer, and the existing long-span structure beam and the additional beam superimposed layer are provided with shear-resistant connection steel bars and junction surface constructional steel bars in the position of an old and new concrete junction surface. By means of the superimposed reinforcement structure, components of the existing structure do not need to be dismantled, the damage to the existing structure is small, and normal functional application of an existing building does not need to be interrupted; the characteristic that the existing structure possesses certain bearing capacity is fully utilized, and temporary construction safety supporting measures are not needed, so that the construction cost is reduced and the construction efficiency is improved; and the shear-resistant bearing capacity of the superimposed structure in the position of the junction surface is guaranteed, and finally, the overall anti-bending bearing capacity of the superimposed structure is guaranteed.

Owner:ZHEJIANG GAD

Fabricated corrugated web occlusal steel girders

ActiveCN103290992BImprove mechanical performanceExcellent out-of-plane stiffnessGirdersJoistsRepeating waveformsSheet steel

The invention relates to an assembly type ripple web plate occluded steel beam which is prepared from two ripple steel channel beams assembled together through occlusion and butt joint of web plates and through bolts. A cross section mouth of each ripple steel channel beam is composed of an upper flange, a lower flange and one web plate, wherein the cross sections of the web plate form a uniform or nonuniform periodically-repeating waveform, the cross section of ripples of the web plate is a rectangular curve, an arc angle rectangular curve, a trapezoid curve, an arc angle trapezoid curve, a wedge-form curve, an arc angle wedge-form curve or a sine curve, the flanges are steel plates, one edge of each flange in a length direction is a waveform curve with a shape similar to that of the curve of the cross sections of the web plate, the upper flange is parallel to the lower flange, the web plate is perpendicular to and located between the upper flange and the lower flange, the waveform curve edges of the flanges are connected with the ripple cross sections of the web plate, and the web plate is connected with the flanges through single-sided angle welding. The assembly type ripple web plate occluded steel beam provided by the invention is applicable to innovative steel beams in an assembly type steel structure system; and compared with traditional assembly type steel beams, the assembly type ripple web plate occluded steel beam has the advantages of light weight, high carrying capacity and good bearing performance.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

Stamping die

The invention discloses a stamping die, comprising a stamping head, a head mounting block and a stamping die plate. The stamping head is arranged right above the stamping die plate; the stamping die plate is provided with a mounting groove in which leaks are arranged, each mounting groove is provided with an edge part, the edge part is provided with an edge hole; the edge hole is arranged correspondingly right above the leak holes; the stamping die plate is fitted with a soundproof cover that covers the edge part, the part of a soundproof cover right above the edge hole is provided with a through hole that admits the punch head, and each left and right of the soundproof cover is provided with a plate passing groove. The stamping die is simple in structure and reasonable in design, can decrease nose pollution, allows the edge part on the stamping die to removed, and helps ensure the shearing capacity of the edge portion of the die.

Owner:CHENGDU RUIDA ZHIXIANG TECH CO LTD

Steel-concrete shear connector and preparation method thereof

InactiveCN112359707AGuaranteed shear capacityGuaranteed ductilityBridge structural detailsNumerical controlClassical mechanics

The invention provides a steel-concrete shear connector and a preparation method thereof. The steel-concrete shear connector comprises a zigzag tooth-shaped shear connector (4) and shear reinforcements (5), the zigzag tooth-shaped shear connector (4) is located at the top of a steel beam web (6), and the zigzag tooth-shaped shear connector (4) is used for connecting a concrete slab (1) and a steelbeam; the zigzag tooth-shaped anti-shearing connecting pieces are alternately bent towards the left side and the right side by a certain angle so as to resist lifting between concrete and a steel beam. And the zigzag tooth-shaped shear connector (4) is obtained by cutting a steel plate by a numerical control machine tool and then alternately rolling folded angles towards the left side and the right side on a rolling machine. Compared with a traditional anti-shearing connecting piece, the steel-concrete shear connector has the advantages that the construction process is greatly simplified on the basis that effective anti-shearing connection of the steel concrete is guaranteed, and the steel-concrete shear connector has excellent economical efficiency.

Owner:TONGJI UNIV

A prefabricated assembly dry-type connection frame structure system and its construction method

ActiveCN110965639BNode connection is reliableEnsure safetyProtective buildings/sheltersShock proofingEarthquake resistanceFloor slab

The invention discloses a prefabricated dry-type connecting frame structure system and a construction method thereof. The prefabricated dry-type connecting frame structure system comprises a structural column, a frame beam and a prefabricated hollow floor. The structural column is formed by splicing a set of column assembling units, and the column assembling units are connected through inter-column connecting parts. Embedded parts are respectively embedded in the top and the bottom of the column assembly units; each embedded part comprises an embedded plate, a shear-resistant insertion cylinder and a steel bar connector; a cross-shaped hole is formed in the middle of each embedded plate; each inter-column connecting part comprises a top plate, a bottom plate, a vertical supporting plate and a shear key, wherein the shape of the shear key is matched with that of the corresponding cross-shaped hole; the frame beam comprises a concrete beam body, and concrete protrusions are arranged on the top face of the concrete beam body. Beam main reinforcements are arranged in the concrete bulges, and the two ends of the beam main reinforcements exceed the end surfaces of the concrete bulges; connecting ribs are arranged in the column assembly units; and the connecting ribs are welded with the beam main ribs. The technical problems that wet operation exists in construction of a traditional fabricated structure system, on-site formwork erecting is needed, the structural anti-seismic property is poor, joint connection is unreliable, construction is complex, and safety is low are solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Beam-type connecting node for special-shaped double-row piles

InactiveCN105544560AGuarantee continuityReduced shear and flexural strengthExcavationsBulkheads/pilesRebarRigid frame

The invention belongs to retaining and protection of foundation excavation, and discloses a beam-type connecting node for special-shaped double-row piles. The beam-type connecting node comprises a rigid-frame beam, a back-row wall crown beam and structural steel. The structural steel is built in the back-row wall crown beam. The two ends of the rigid-frame beam are connected with a cast-in-place pile of the front-row piles and the structural steel inside the back-row wall. Back-row wall crown beam longitudinal bars inside the back-row wall crown beam are arranged on the two sides of flanges of the structural steel and connected through built-in reinforcing steel bars. The built-in reinforcing steel bars include small stirrups, U-shaped main reinforcing bars and structural steel sleeve stirrups. The small stirrups are bound to the back-row wall crown beam longitudinal bars on the same side of the structural steel, the open ends of the U-shaped main reinforcing bars are anchored into a front-row pile crown beam, the closed ends of the U-shaped reinforcing steel bars are close to the flanges of the structural steel, and the structural steel sleeve stirrups are sleeved with the small stirrups on the two sides of the structural steel and the closed ends of the U-shaped main reinforcing bars. By adopting the beam-type connecting node, the difficult problem that main reinforcing bars inside a rigid-frame beam cannot penetrate through the back-row wall crown beam due to the fact that the structural steel penetrates through the rigid-frame beam can be avoided, and meanwhile the problem that the anti-shearing capacity and the anti-bending bearing capacity of the rigid-frame beam are greatly weakened due to the fact that the structural steel penetrates through the rigid-frame beam can be solved.

Owner:HUAQIAO UNIVERSITY

A construction method of superimposed reinforcement structure with newly added column network on the existing long-span structure

ActiveCN106401208BAvoid damageNo need to interrupt normal functional useBuilding repairsRebarLong span

The invention belongs to the field of constructional engineering and particularly relates to a superimposed reinforcement structure for additionally arranging a column grid on an existing long-span structure. The superimposed reinforcement structure comprises existing structure columns and an existing long-span structure beam which is supported on the existing structure columns. An additional beam superimposed layer is arranged on the existing long-span structure beam, profile steel is arranged inside the additional beam superimposed layer, and the existing long-span structure beam and the additional beam superimposed layer are provided with shear-resistant connection steel bars and junction surface constructional steel bars in the position of an old and new concrete junction surface. By means of the superimposed reinforcement structure, components of the existing structure do not need to be dismantled, the damage to the existing structure is small, and normal functional application of an existing building does not need to be interrupted; the characteristic that the existing structure possesses certain bearing capacity is fully utilized, and temporary construction safety supporting measures are not needed, so that the construction cost is reduced and the construction efficiency is improved; and the shear-resistant bearing capacity of the superimposed structure in the position of the junction surface is guaranteed, and finally, the overall anti-bending bearing capacity of the superimposed structure is guaranteed.

Owner:ZHEJIANG GAD

A built-in segmented steel plate-high-strength concrete composite shear wall and its construction method

ActiveCN106049708BLess prone to bucklingWork well togetherWallsHigh strength concreteHigh resistance

The invention belongs to the technical field of structure engineering and relates to a high-strength concrete composite shear wall with built-in segmented steel plates and a construction method for the same. The invention provides the high-strength concrete composite shear wall with the built-in segmented steel plates and further provides the building and construction method for the shear wall. The composite shear wall and the construction method for the same provided by the invention are characterized in that through segmented layout of the steel plate, concrete pouring and binding bar layout become convenient; a cooperative working ability of the steel plates and concrete is enhanced; bearing force is ensured; and deformability and an energy-dissipation capability of the composite shear wall can also be enhanced. In comparison with a composite shear wall covered by steel plates, the composite shear wall provided by the invention has higher resistance to high temperatures and can show better performance when a fire disaster takes place. Meanwhile, in comparison with a concrete composite shear wall with a whole steel plate, the shear wall provided by the invention has the advantages that conversion and transition among layers can be implemented through reduction of the quantity of the segmented steel plates; inter-layer rigidity transition becomes gentler; and the structure is also simpler.

Owner:TONGJI UNIV

A detachable assembly shear wall structure and assembly method with replaceable components

The invention provides a detachable assembled shear wall structure with replaceable components and an assembly method, which means that the connection between the prefabricated shear wall and the foundation and between the prefabricated shear walls on the upper and lower floors are all completed by replaceable components, and the prefabricated The connection between the shear wall and the prefabricated floor is completed by ordinary bolts. All components and replaceable components in the detachable assembled shear wall structure with replaceable components can be prefabricated in the factory and installed after being transported to the site. Prefabricated shear walls are reinforced concrete shear walls industrially manufactured and produced in prefabricated factories. The prefabricated floor slab is a reinforced concrete floor slab manufactured and produced industrially by a prefabricated factory. The invention realizes the detachability of the shear wall and the rapid recovery of the structure after an earthquake, and meets the requirements of structural assembly construction and building industrialization.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com