Fabricated beam column connection joint and installation method thereof

A beam-column connection and assembly technology, which is applied in the direction of architecture and building structure, can solve problems such as complex steel bar structure, achieve the effects of improving construction efficiency, simplifying construction technology, and avoiding complicated steel bar structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

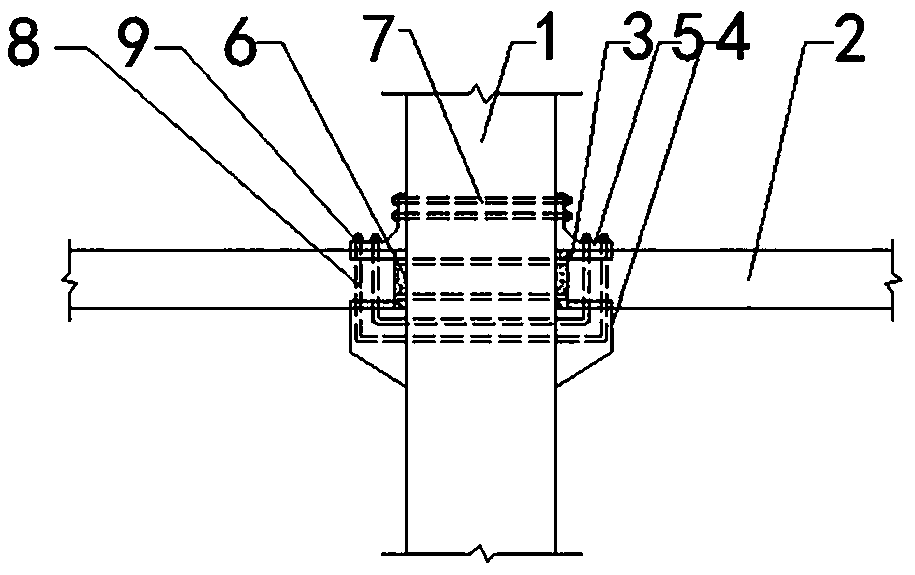

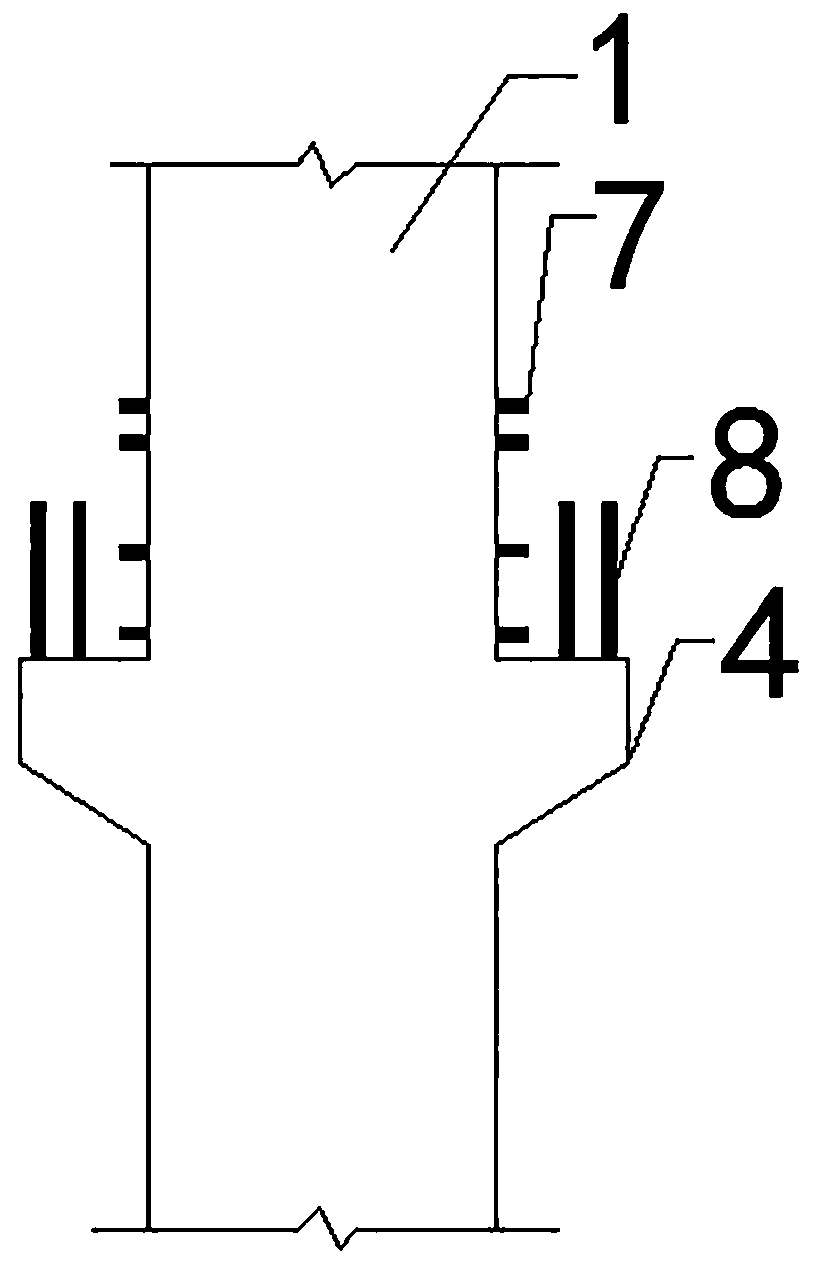

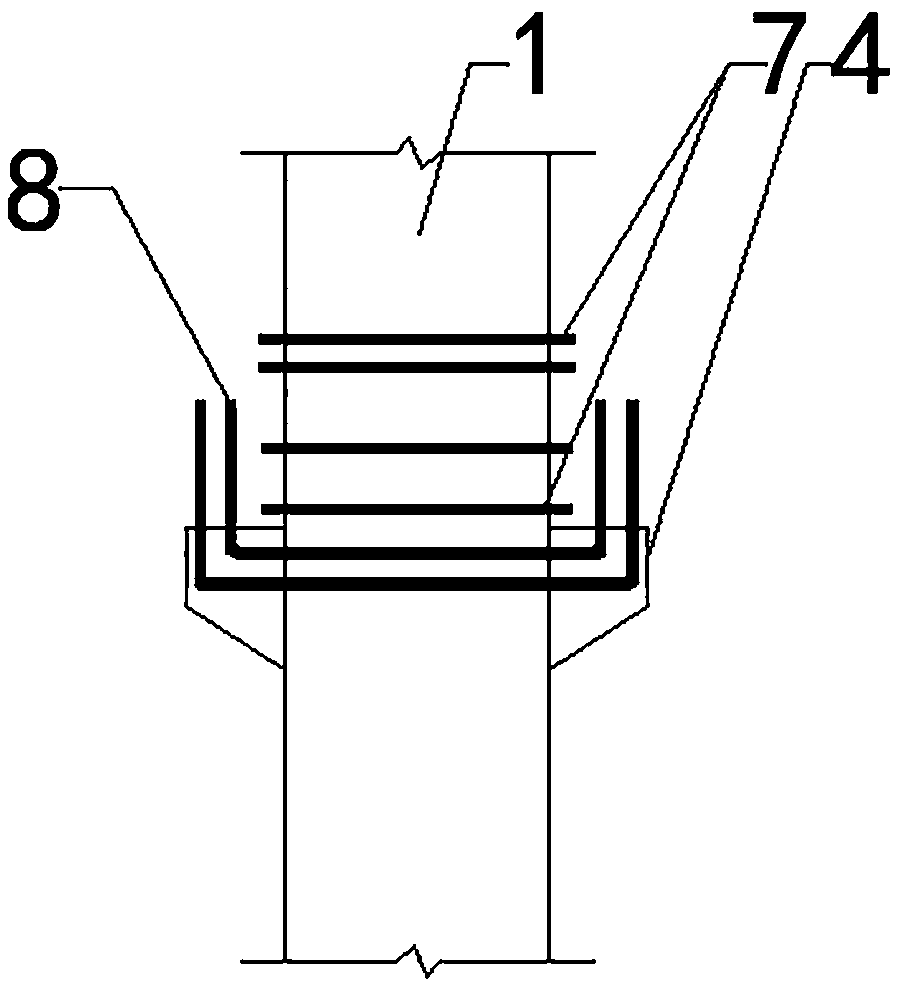

[0027] Example: such as Figure 1~6 As shown, a prefabricated beam-column connection node includes a prefabricated reinforced concrete column 1, a prefabricated reinforced concrete beam 2, a pre-embedded steel plate 3, a corbel 4, an upper fixed angle steel 5, a mortar layer 6, and a pre-embedded column piercing steel bar 7, Pre-buried beam piercing steel bars 8, bolt caps 9, longitudinal steel bars 10 in beams, steel bar sleeves 11, and reserved beam piercing steel bar holes 12; the prefabricated reinforced concrete columns 1 and corbels 4 are respectively provided with four pre-buried piercing bars. Column steel bars 7 and four pre-embedded beam-through steel bars 8, said pre-embedded column-through steel bars 7 and pre-embedded beam-through steel bars 8 are arranged along the horizontal and vertical directions respectively; On the column piercing reinforcement 7, the pre-embedded column piercing reinforcement 7 and the longitudinal reinforcement 10 in the beam are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com