Patents

Literature

109results about How to "Guaranteed structural quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

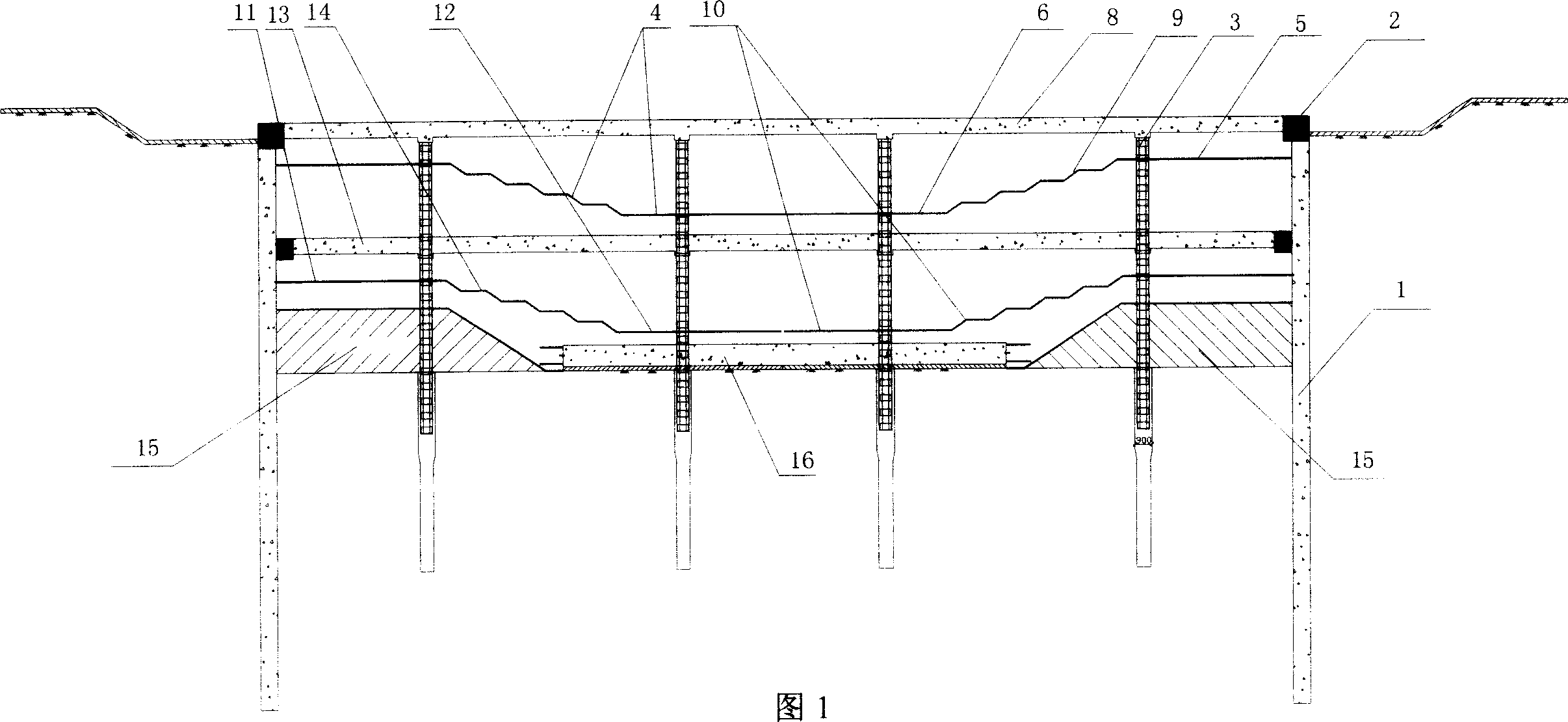

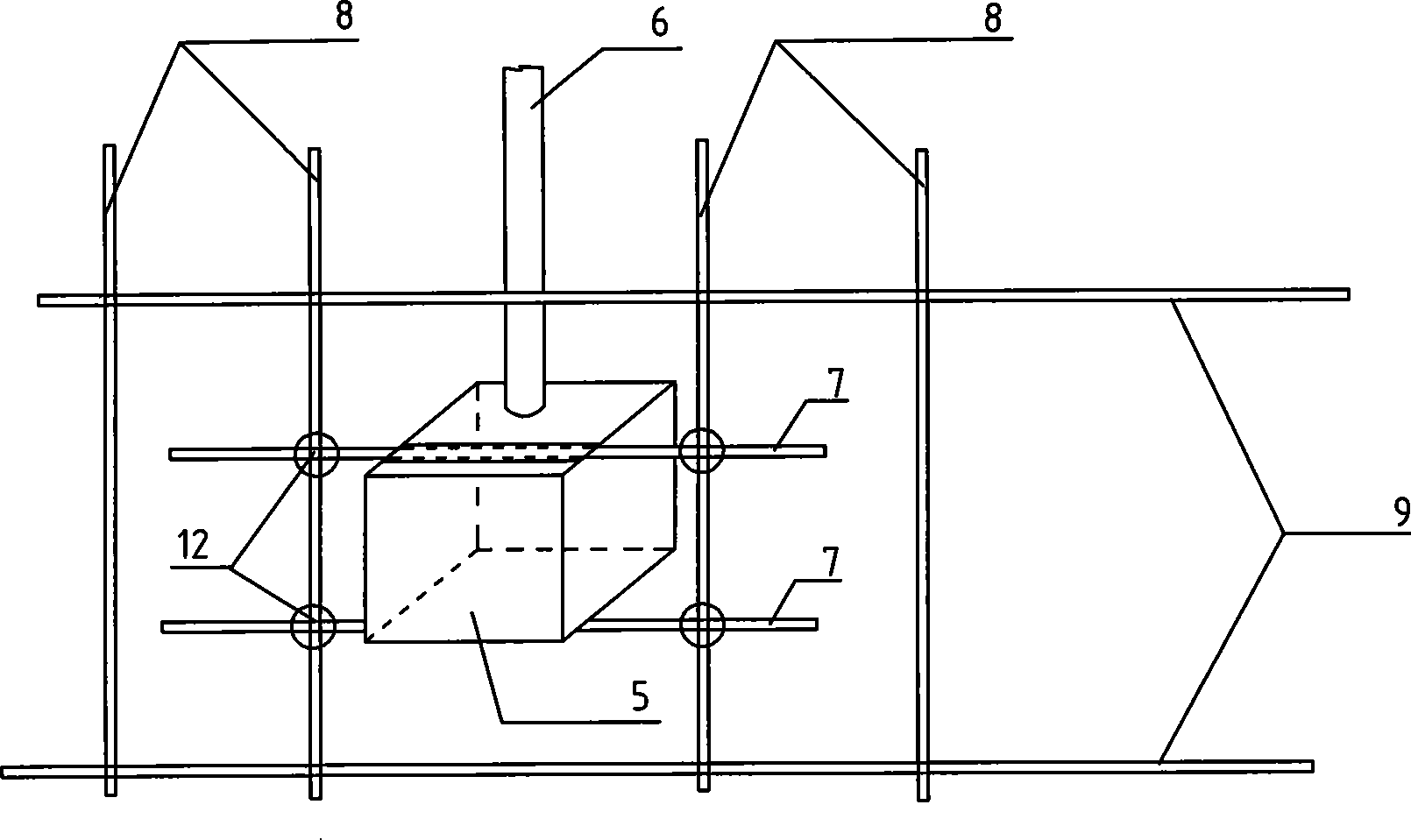

Tray type excarvating contrary construction method

InactiveCN1948633AReduce excavation costsReduce distortionBuilding constructionsExcavationsInverse methodBuilding construction

This invention provides a basin excavation inverse method. Its major construction step is the open excavation in retaining structure edge at the first step , and digs a kind of pot-style structure, and pour the top layer concrete of underground structure, and provides dug holes; then excavates in another way, it is a pot of architecture, and pours the top structure concrete of the underground two-story, and allows dug holes; following mining, and pouring the top three underground structure plate and the top four floors underground structure ; the bottom of base plate structure is divided into two parts ;it excavates scope of the bottom floor firstly, the pit digs to the bottom, pouring concrete, then the envelope around 6 ~ 10 meters pumps the excavation. This construction method is suitable for the large pit area, depth deeper large-scale construction projects, as it constructs conveniently, saves manpower and resources to improve the progress of the project, and shortens the construction periods.

Owner:SHANGHAI NO 7 CONSTR

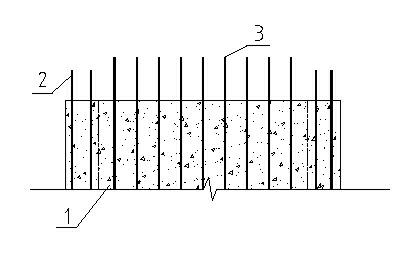

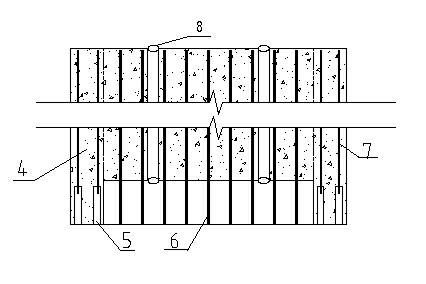

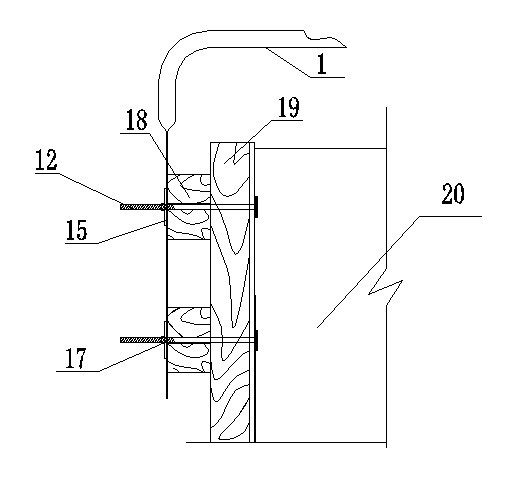

Assembly-type residential shear wall structural wall body vertical connection construction method

ActiveCN102425310AReduce the number of connectionsReduce construction costsBuilding material handlingHigh pressureRebar

The invention relates to a prefabricated shear wall body vertical connection construction method, in particular to an assembly-type residential shear wall structural wall body vertical connection construction method, which is characterized in that: when a prefabricated lower layer wall body is connected with a prefabricated upper layer wall body, supporting leg parts on two ends of the bottom part of a shear wall body are connected with each other through a reinforced bushing anchoring grouting method, and preformed steel reinforced parts on the middle part of the shear wall are connected with each other through a binding and overlapping method. When an upper layer wall body is prefabricated, anchoring connection bushings are respectively embedded on the supporting leg parts on two ends of the shear wall, the middle part of the shear wall is produced into a feeding passage for pouring concrete at a later period by embedding a steel bushing, self-compacting concrete is poured towards the middle part of the shear wall from a feeding port on the top part of the feeding passage, and high-strength grouting materials are fulfilled into the anchoring connection bushing at high pressure through a high-pressure grouting machine. Due to the adoption of the method, the quantity of the connection bushing can be reduced, the cost can be saved, and the connection quality and the connection speed can be improved. The weaknesses of the traditional shear wall vertical connection installation process that the cost is high, the construction speed is slow, the quality is difficult to control, and the like can be overcome.

Owner:CHINA 22MCC GROUP CORP +1

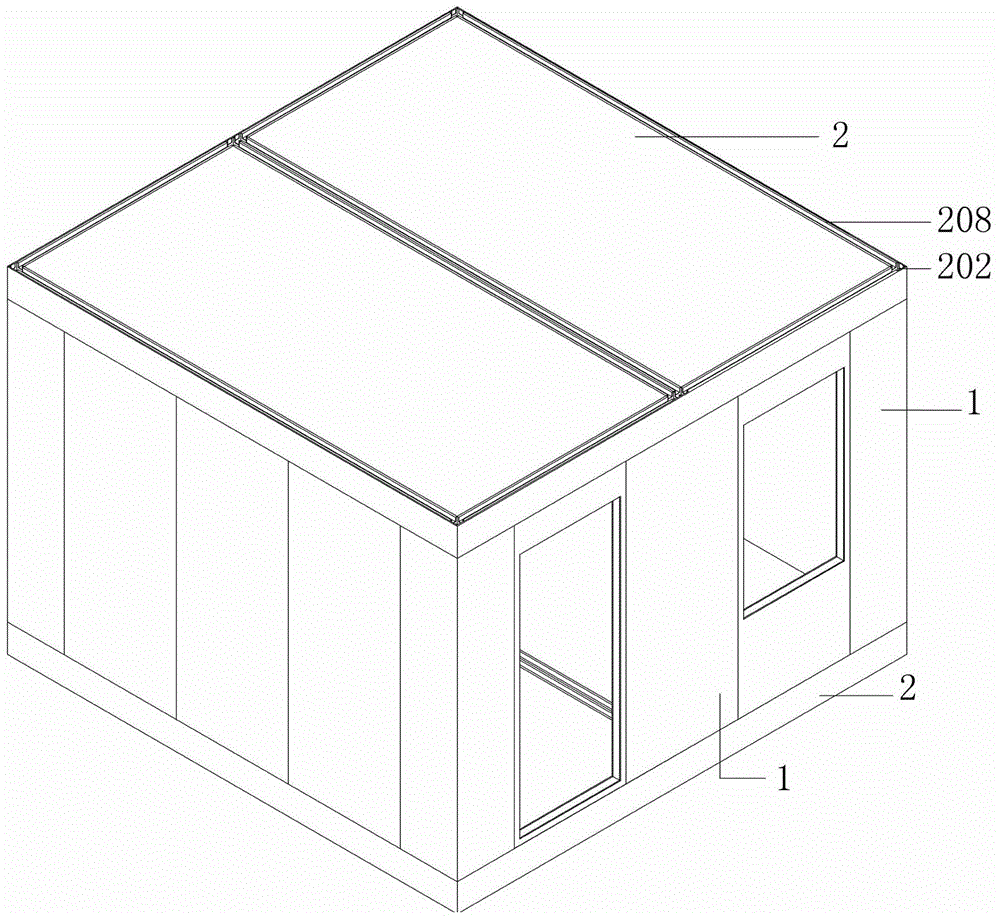

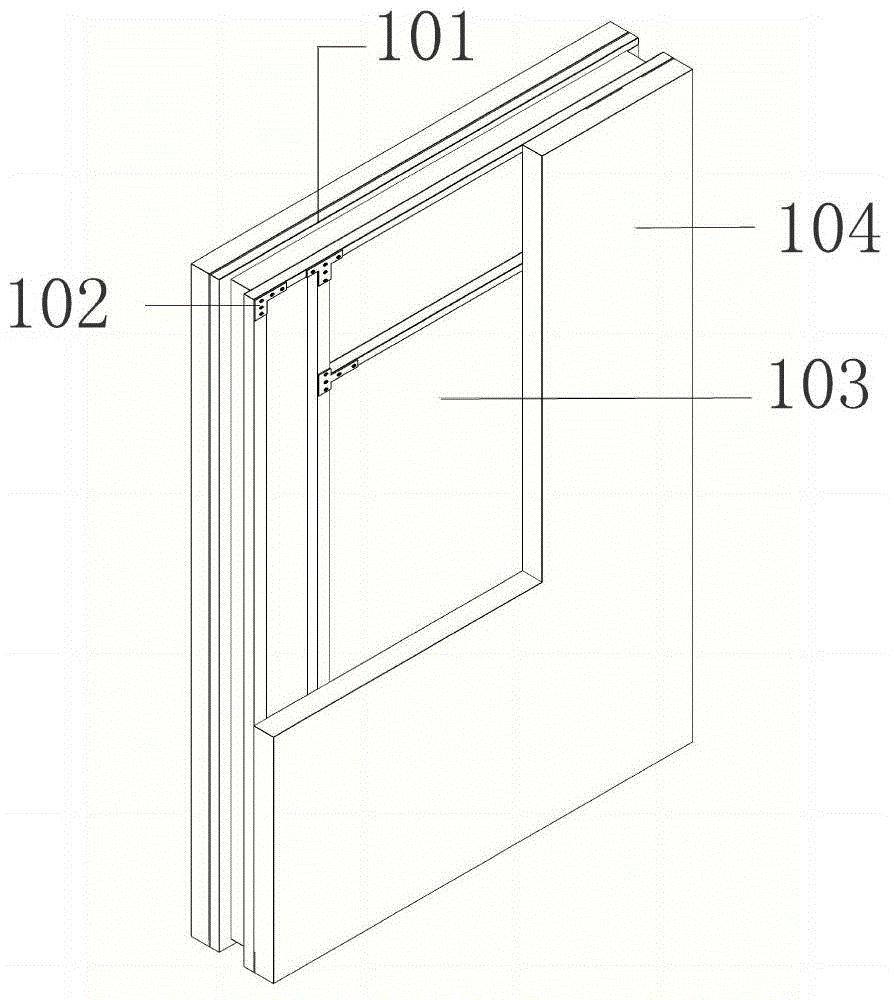

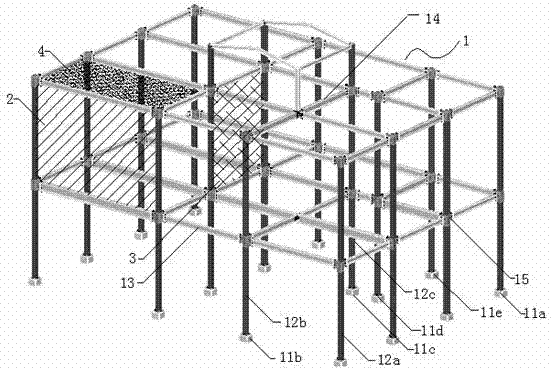

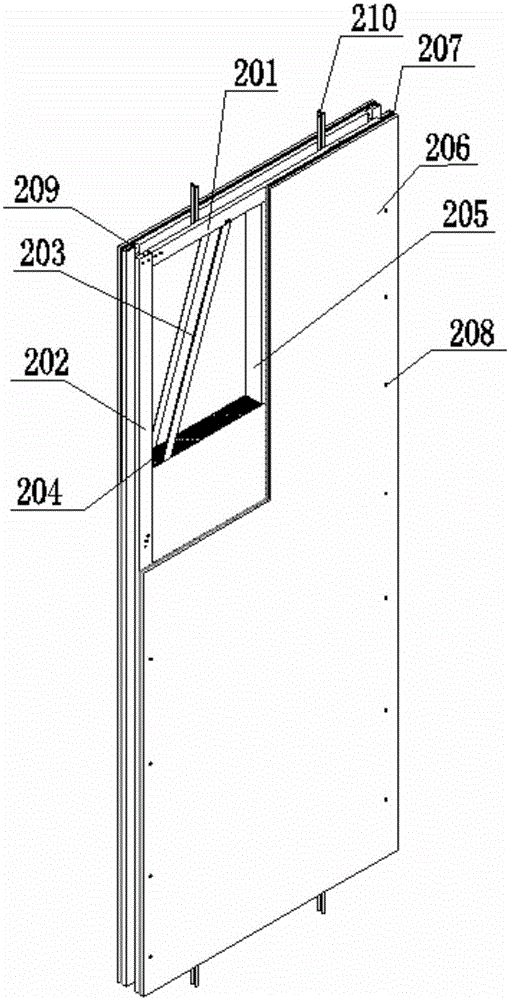

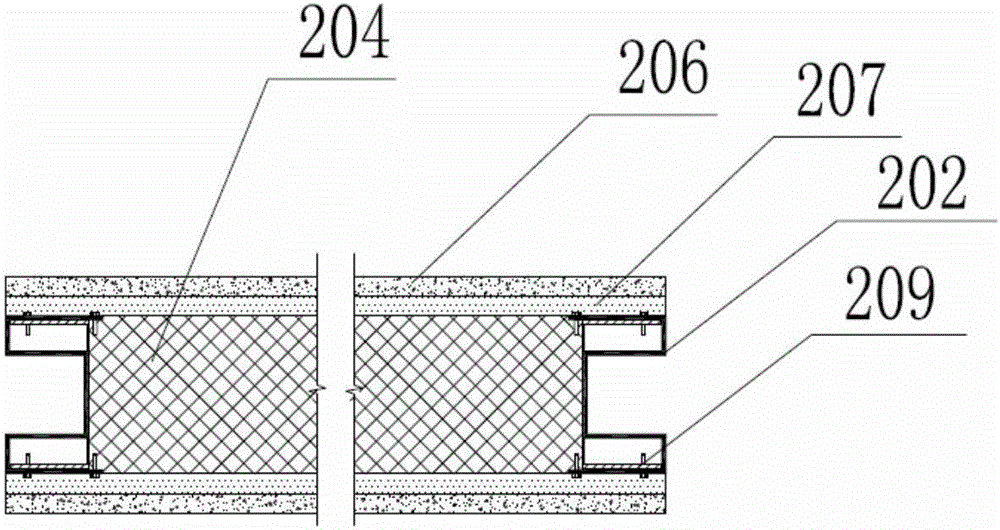

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

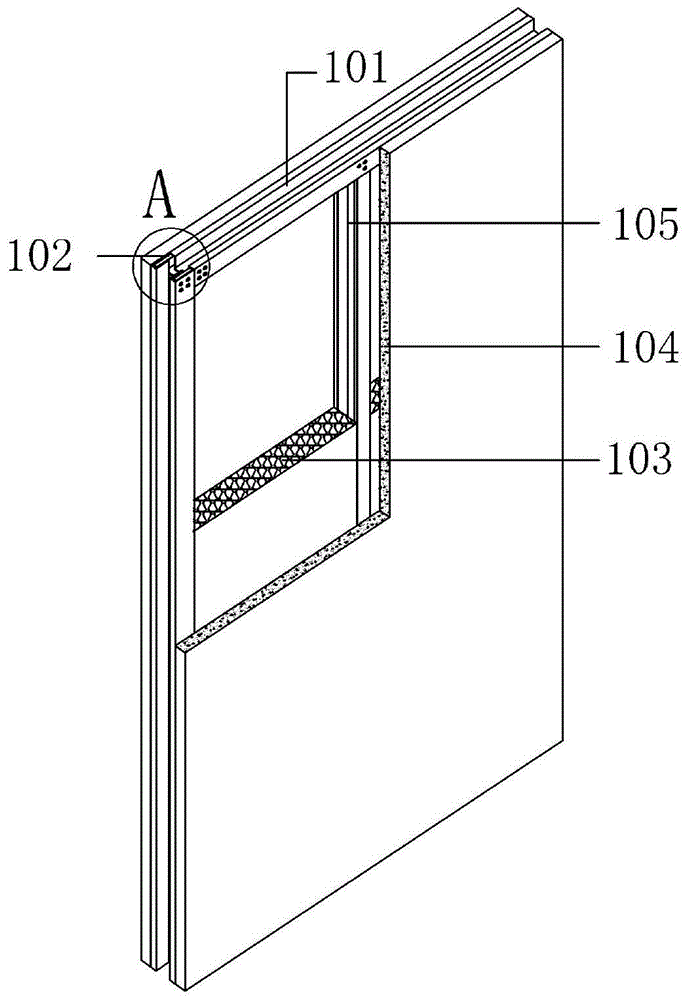

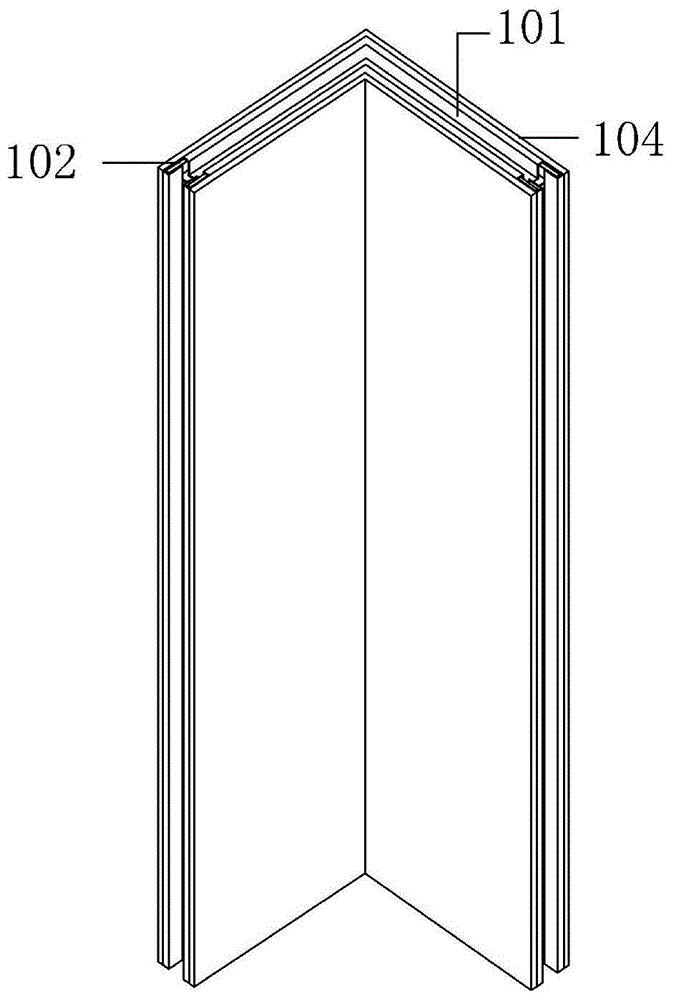

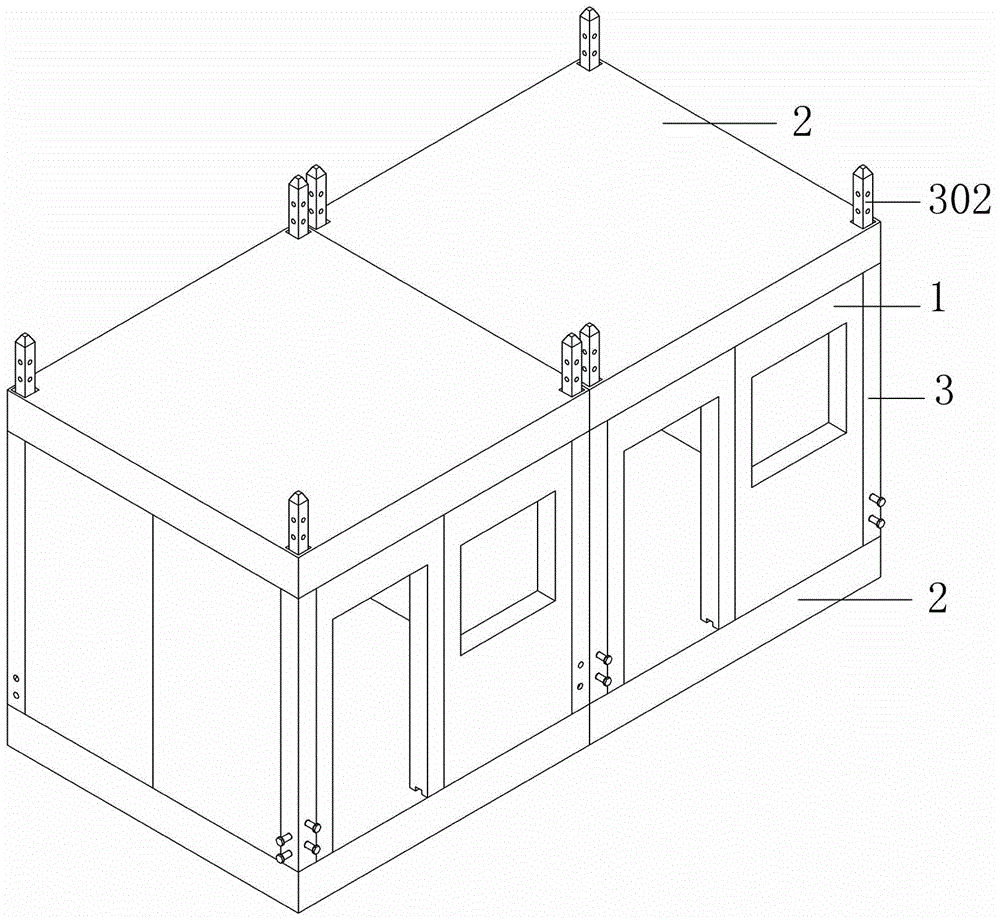

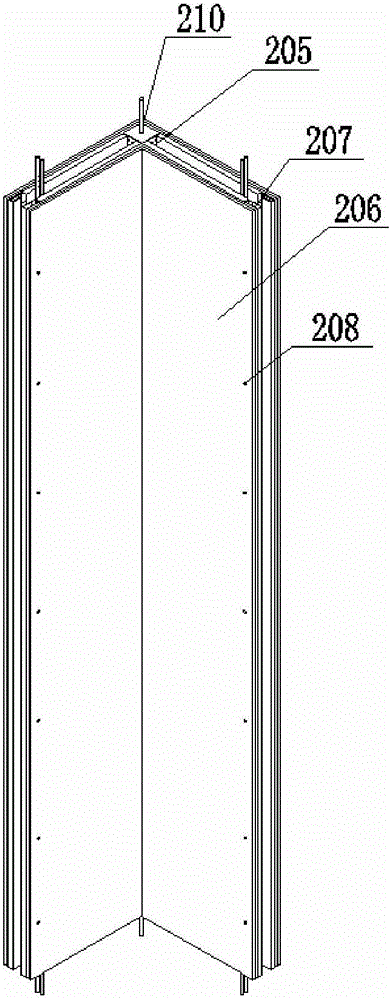

Simply-built green light steel fabricated building and installation method

ActiveCN104947792AImprove prefabrication rateEnsure structural safetyBuilding componentsBuilding material handlingPollutionPrefabrication

The invention provides a simply-built green light steel fabricated building and an installation method. The fabricated building comprises wall plates, main plates, composite frame columns and main connection pieces. The two wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. The composite frame columns and the wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. In the connection process, firstly the main connection pieces abut against the composite frame columns, the self-tapping screws are screwed into the composite frame columns to fix the composite frame columns, the wall plates are then arranged in place, and the main connection pieces are clamped into lateral side grooves of the wall plates. The main boards are connected with the composite frame columns, and body column sleeves of the portions, on the top layers of the main plates, of the composite frame columns are inserted in upwards-exposed tenon columns in a sleeved mode and are then fixed through bolts. By means of the full industrialized prefabrication of the wall plates and the main plates, the prefabrication rate of main components of the building is greatly increased, and therefore the structure safety and quality of the building are better facilitated, site workloads are reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

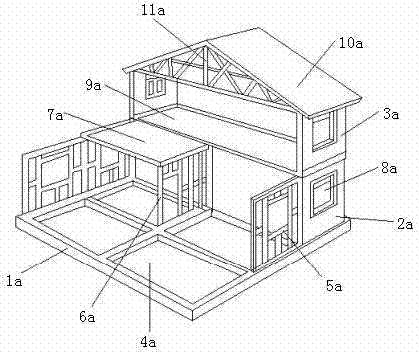

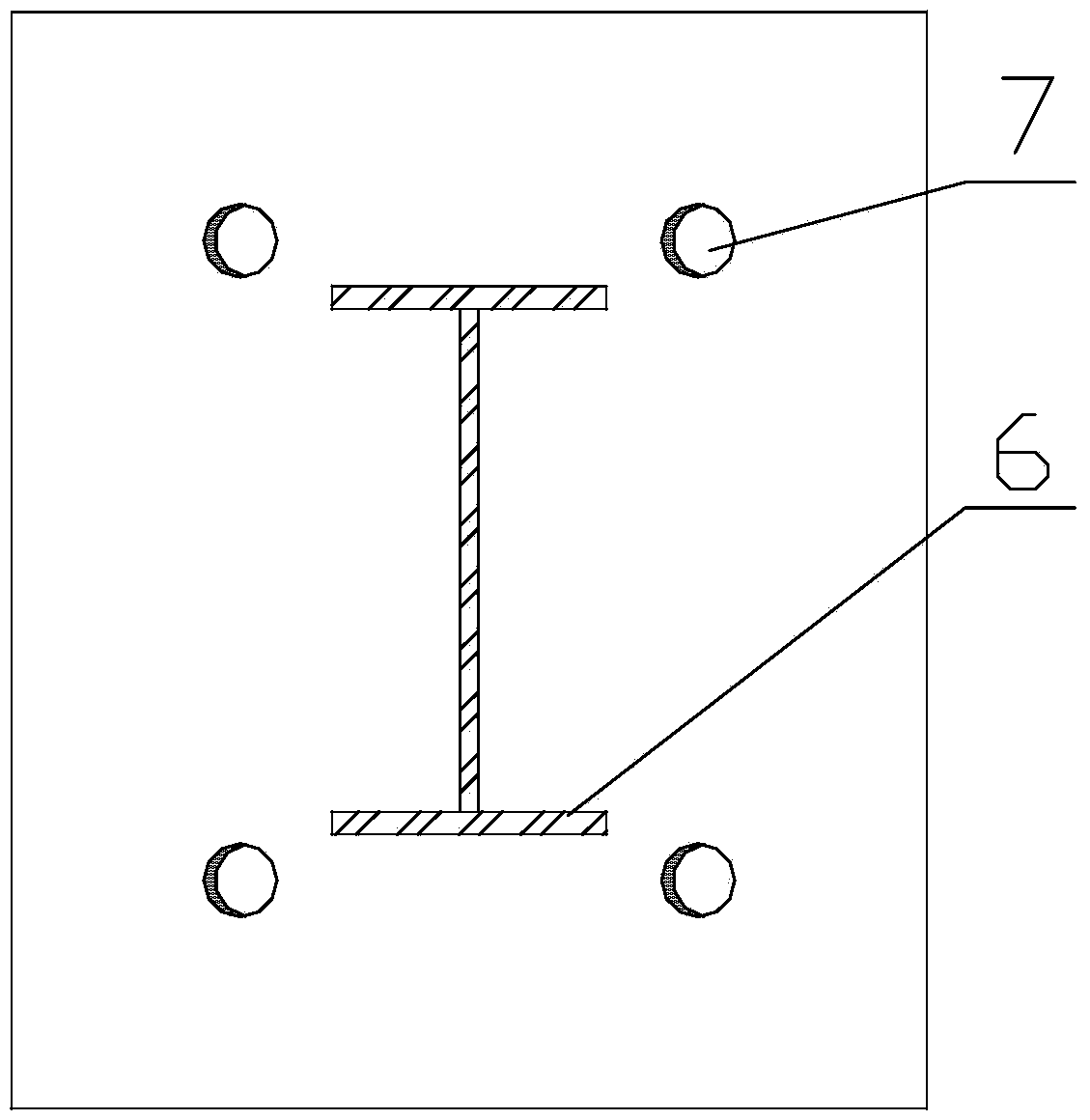

Light-weight steel structure house and construction method thereof

ActiveCN106948472AFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

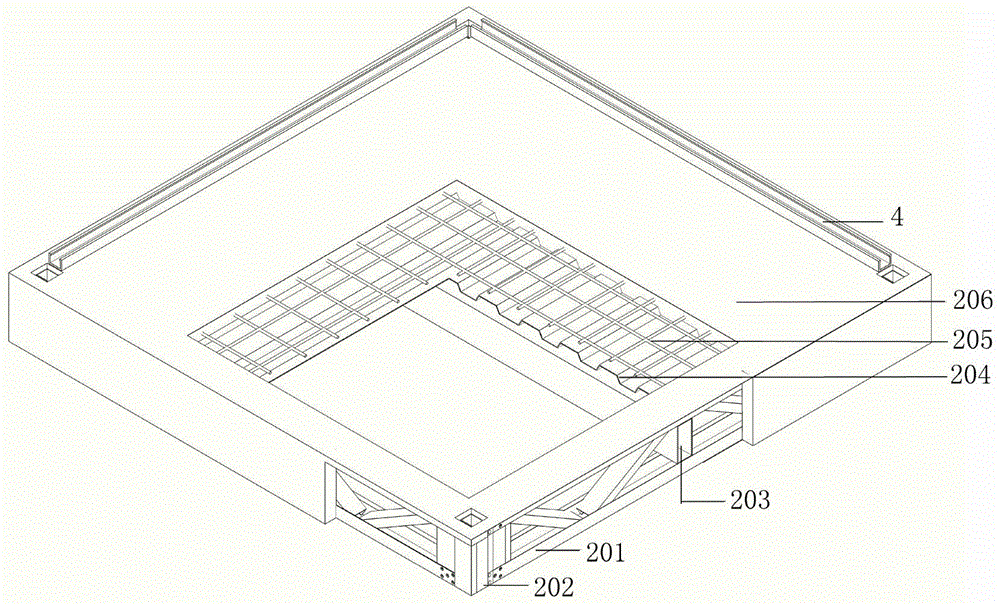

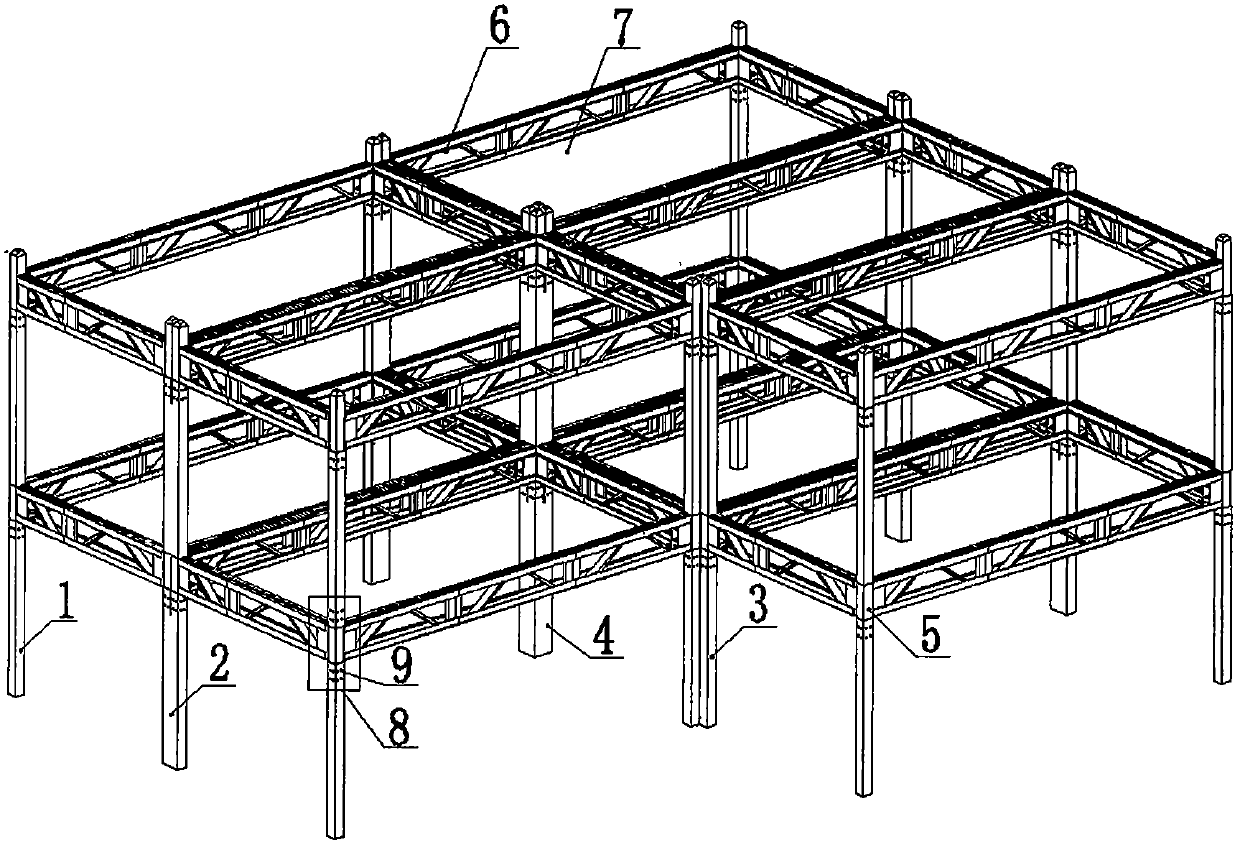

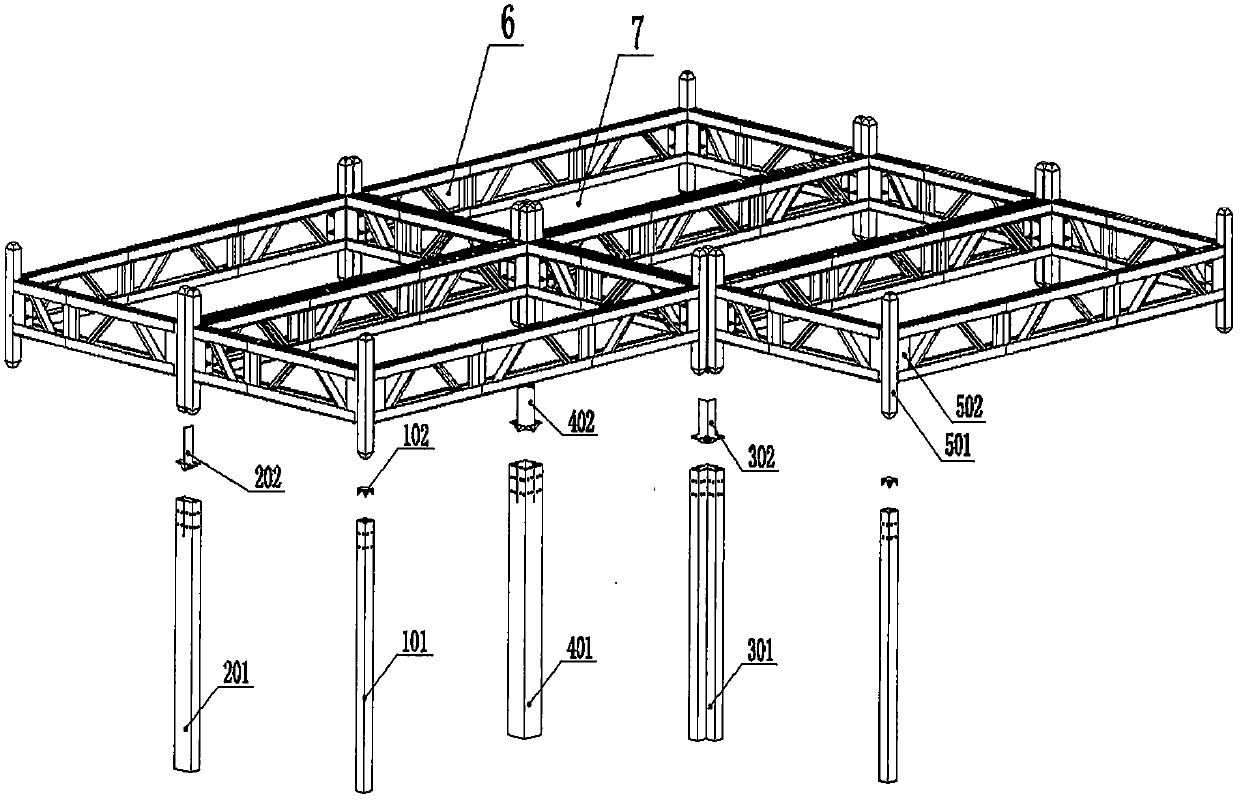

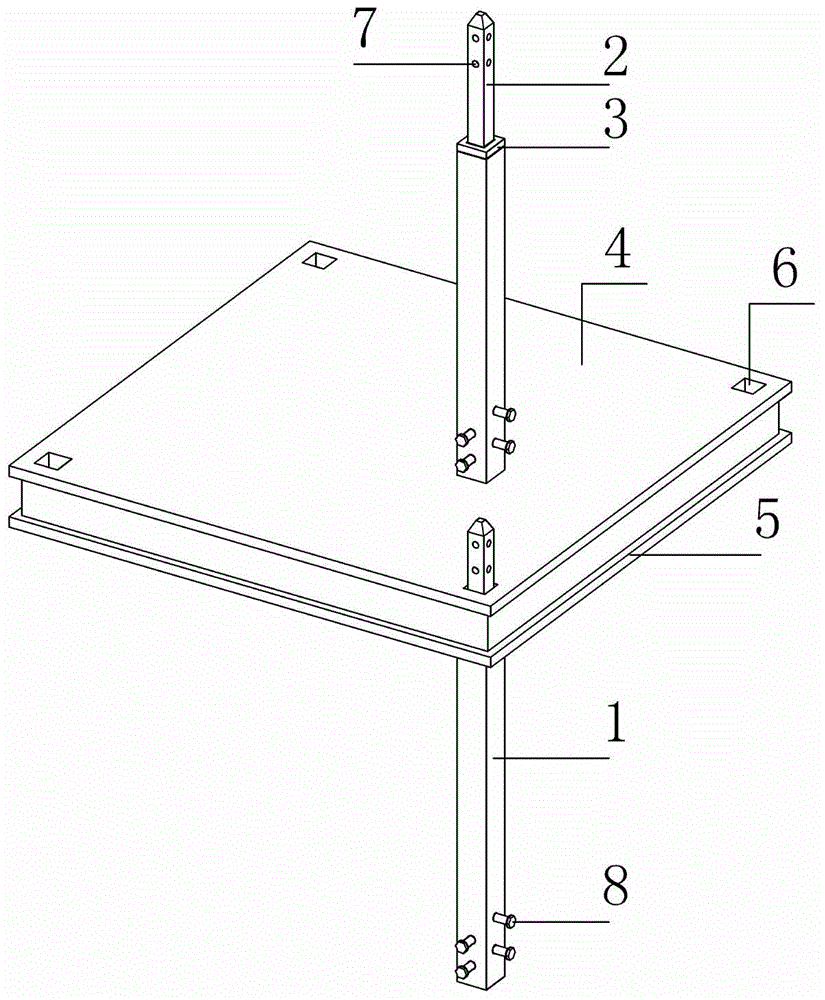

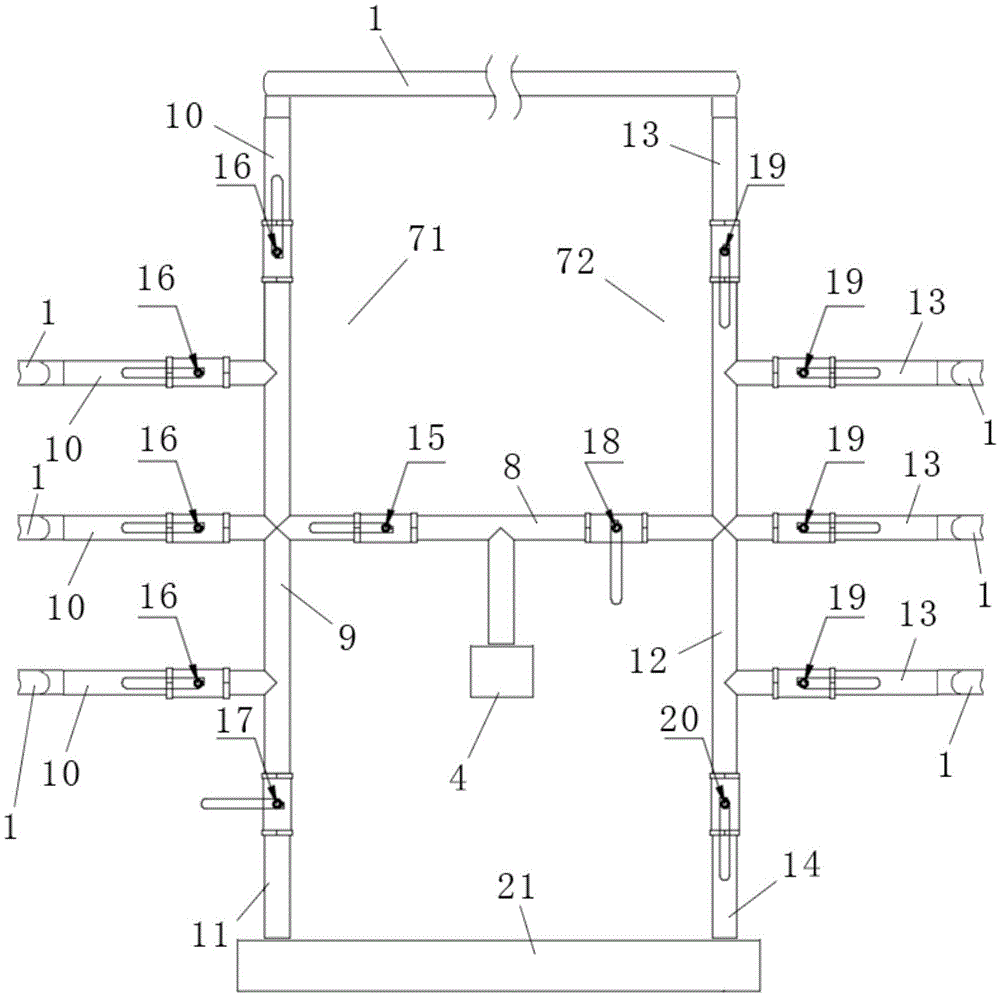

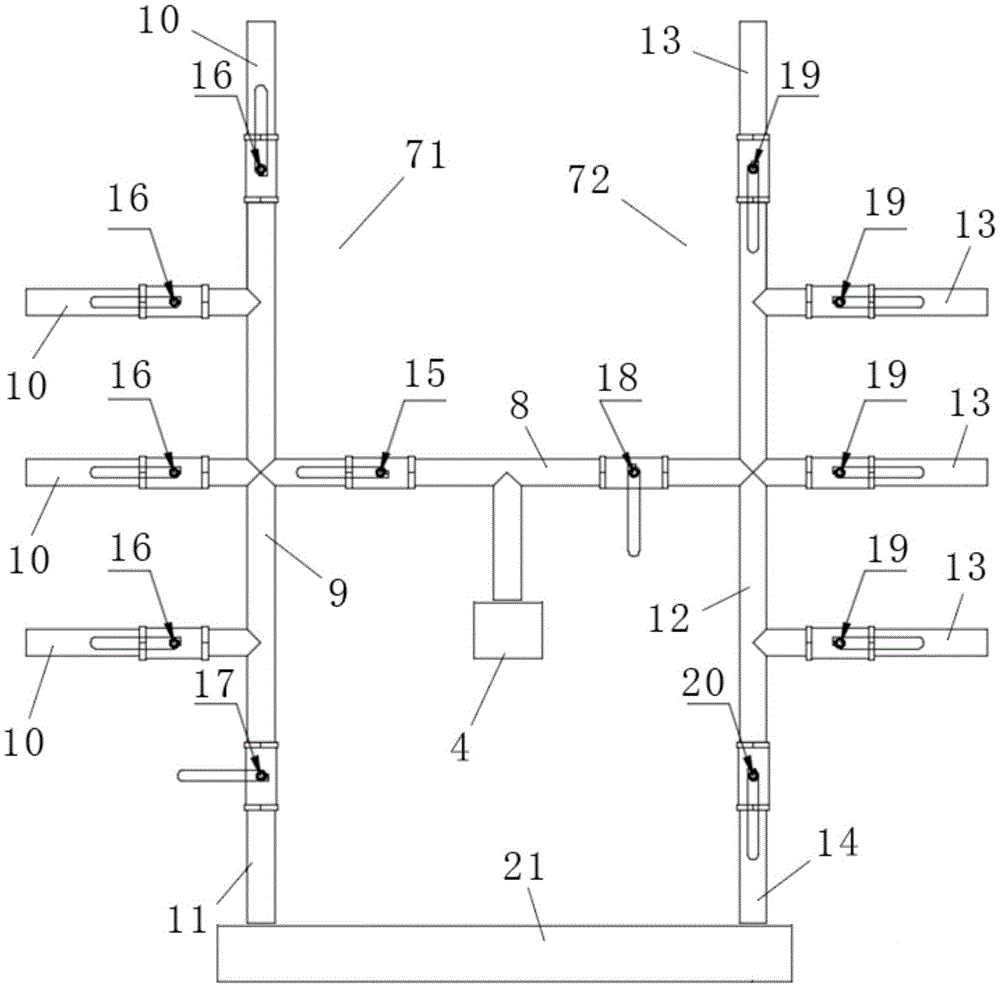

Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

InactiveCN107795013AImprove prefabrication rateEnsure structural safetyStrutsPillarsCold formedHouse building

The invention relates to a prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and a construction method thereof, and belongs to the technical fieldof structural engineering. Single-hole columns, double-hole columns, three-hole columns and four-hole columns are support columns of the system. A floor module is the main structure of the system. Theconnection mode between the floor and the columns is the connection mode between the support columns and the main structure of the system. The single-hole columns and the double-hole columns are respectively arranged at joint connection support parts at the bottom of the floor module. The three-hole columns are arranged at corner support parts at the bottom of the floor module. The four-hole columns are located at center cross support parts at the bottom of the floor module. Through the method of optimizing the light steel plate column structure system by implanting beam-column joints in thefloor, the structure is allowed to bear the force more reasonably, the consumption of building materials and the amount of construction work at a construction site are greatly reduced, and a rapid green construction is truly realized. The whole building is sturdy and durable, thermal-insulating, lightweight, energy-saving, environmentally friendly, suitable for all kinds of housing construction and highly applicable, and will bring good economic and social benefits.

Owner:谢志强 +1

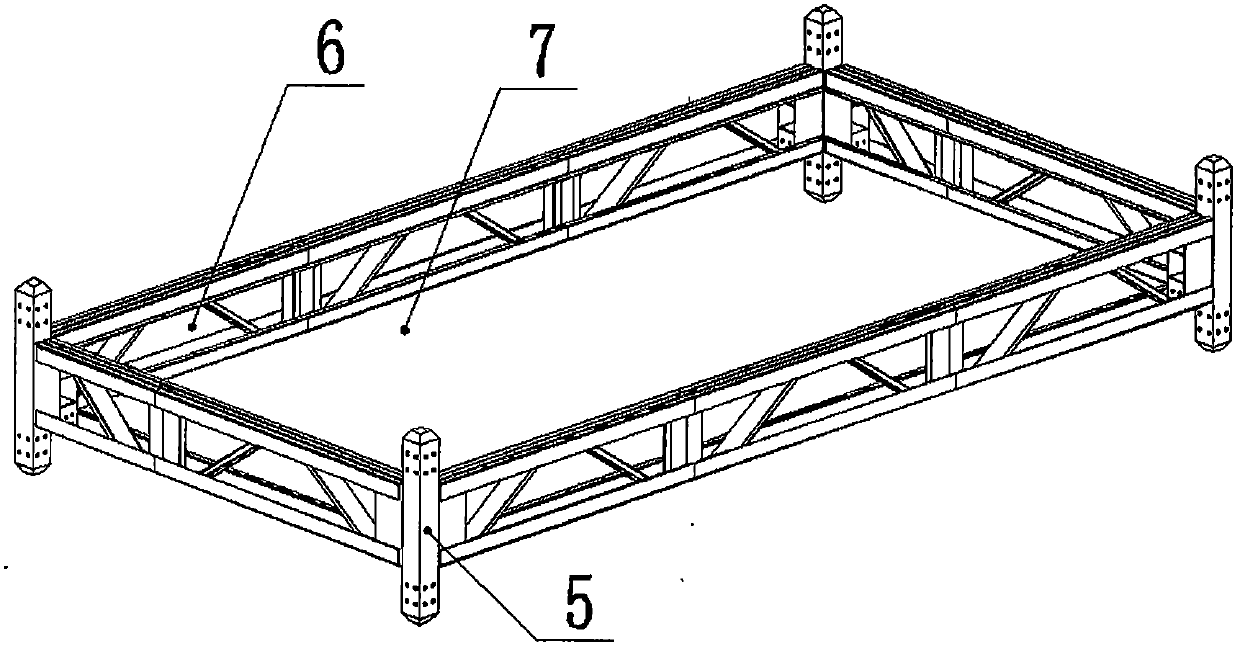

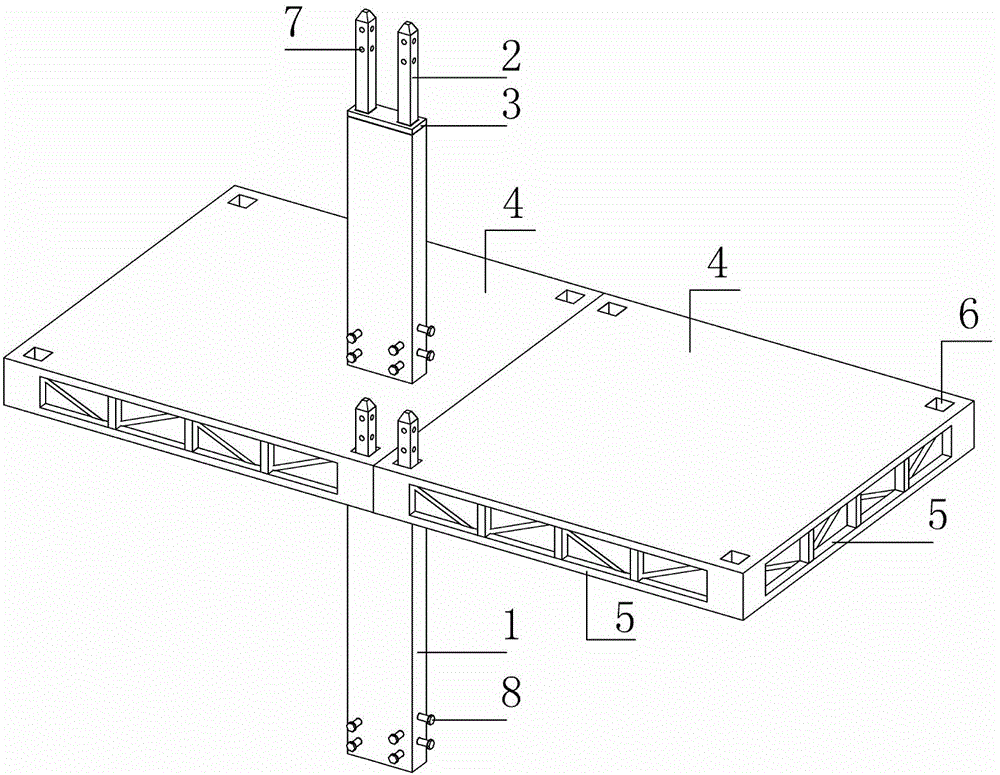

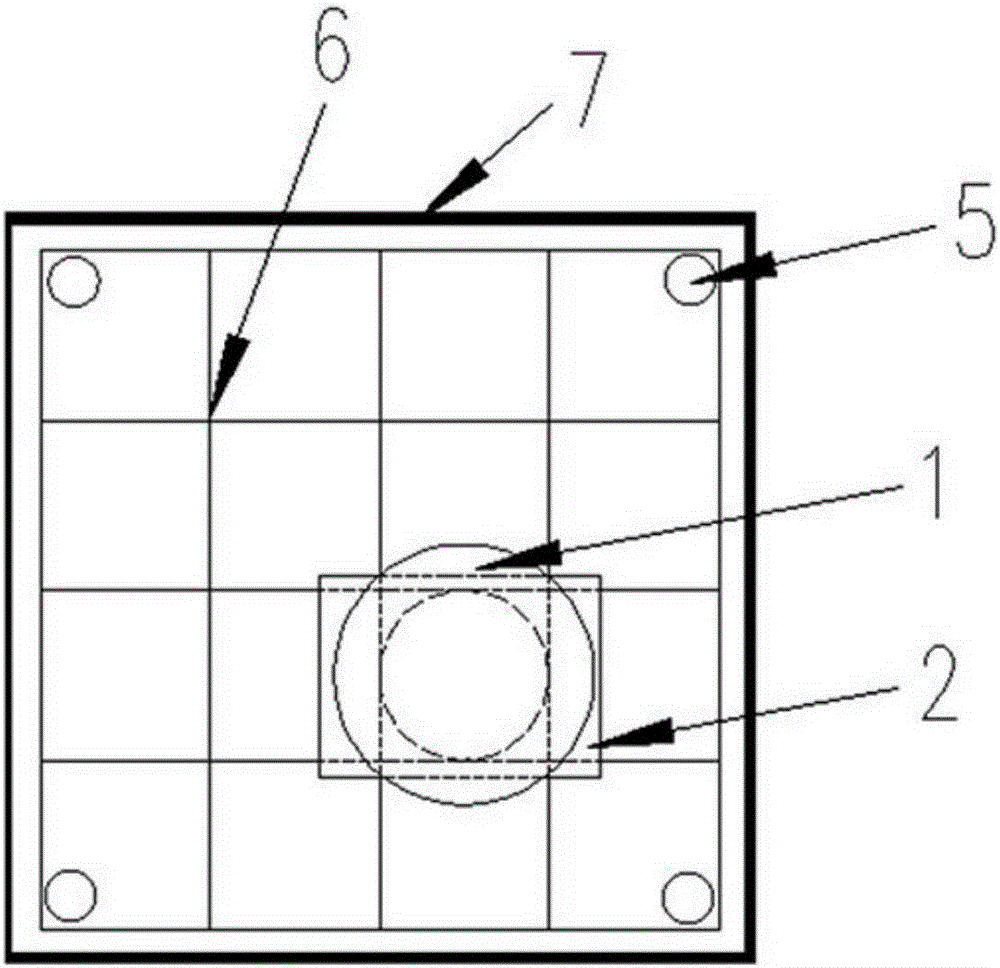

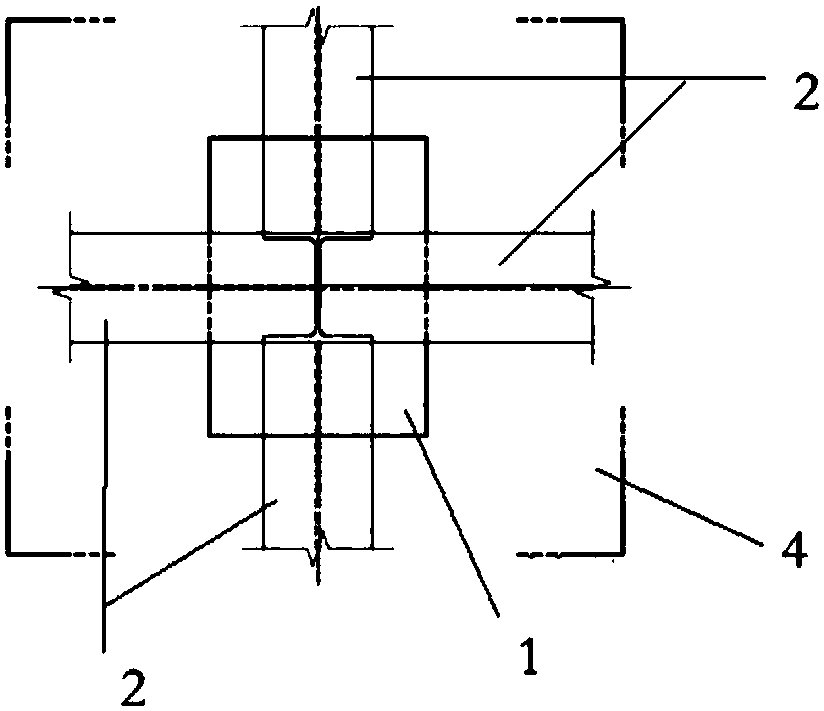

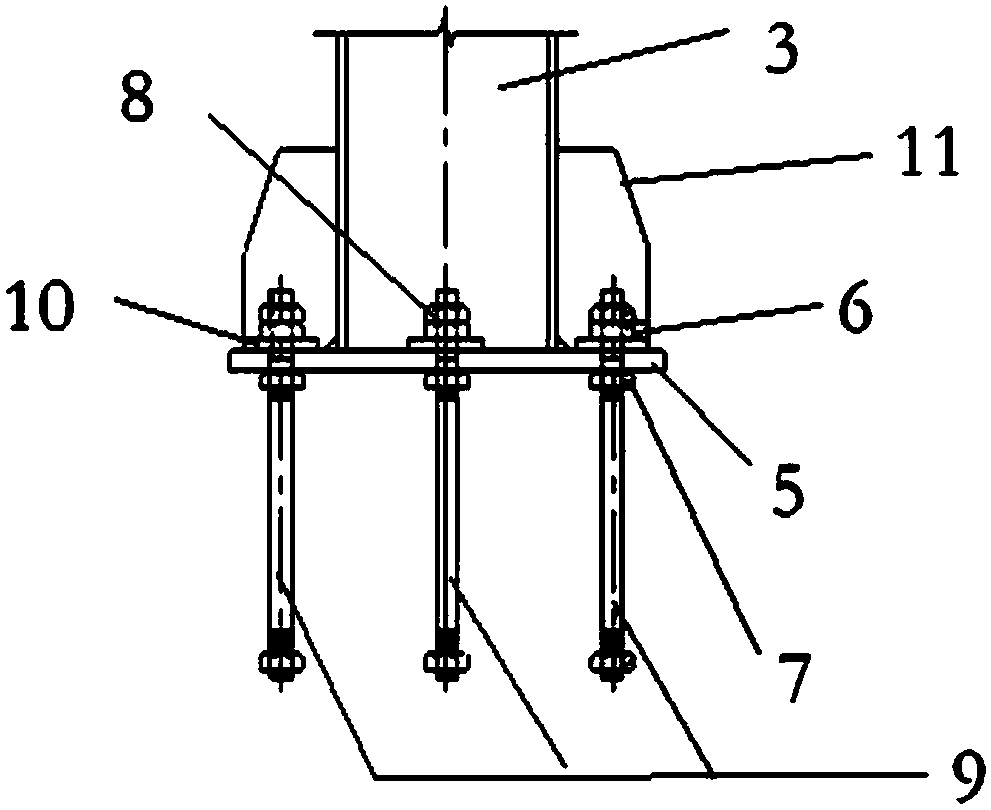

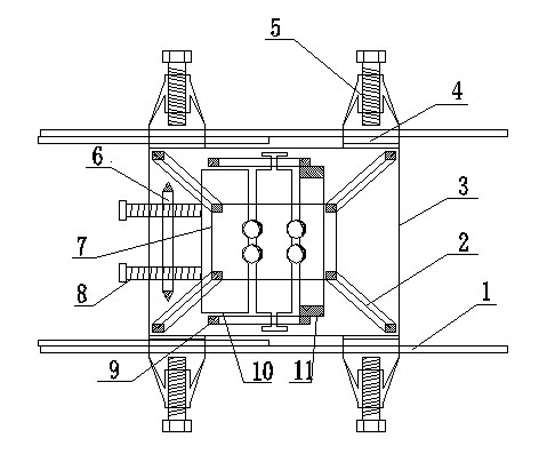

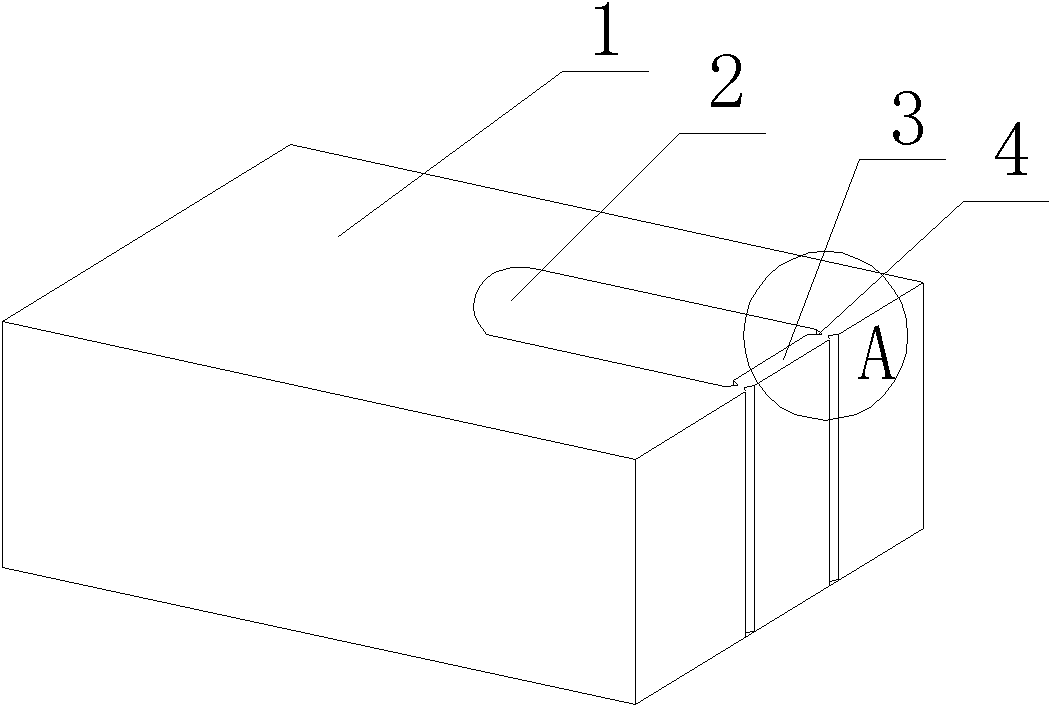

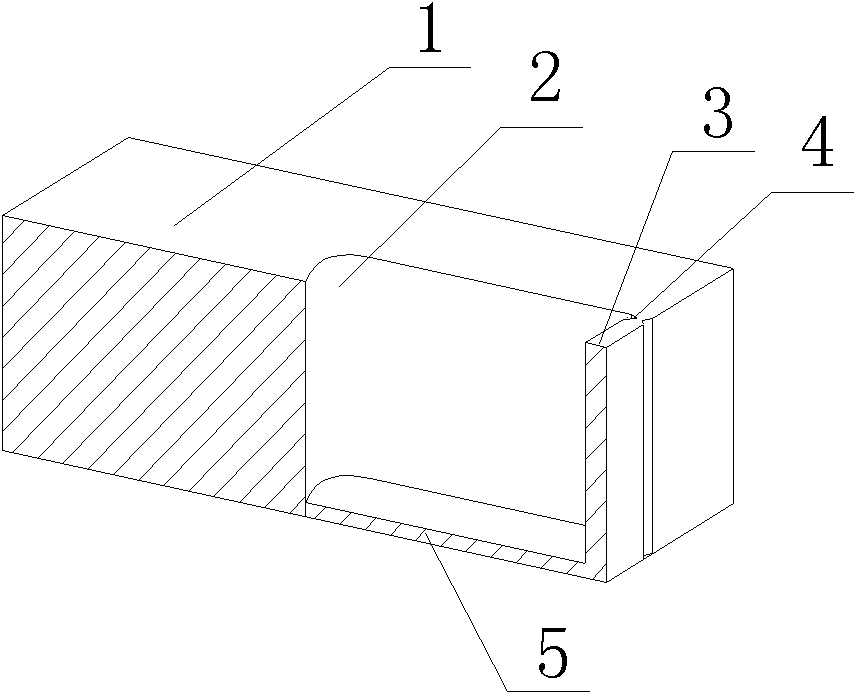

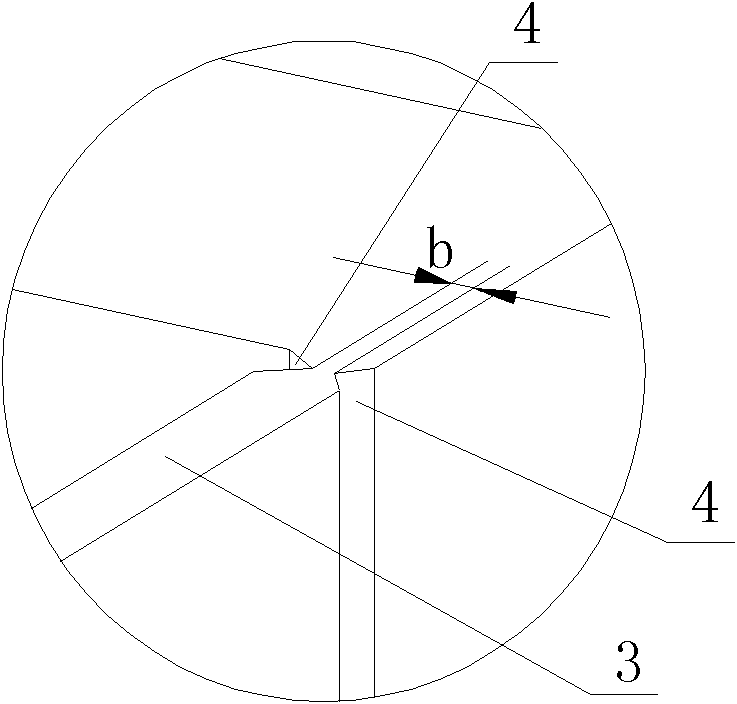

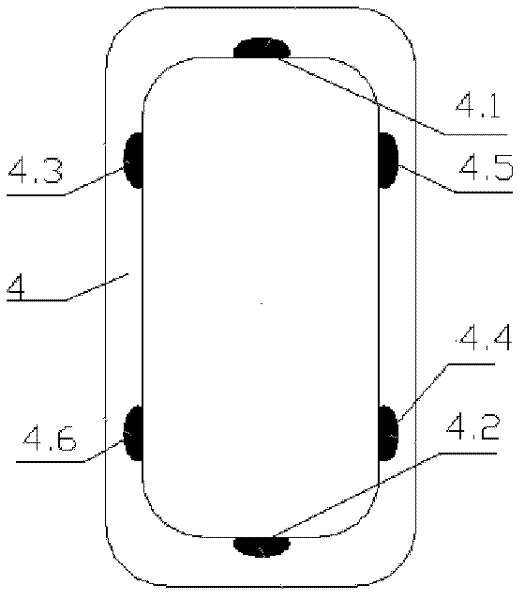

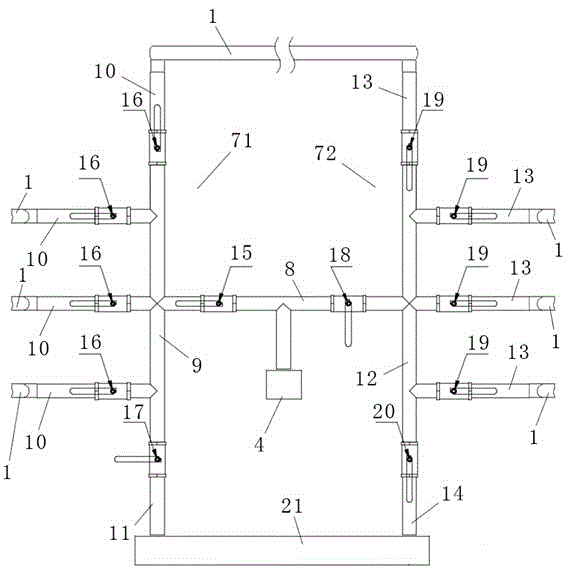

Prefabricated slab and column mortise and tenon type connecting joint and installation method

ActiveCN104947803AEnsure structural safetyGuaranteed structural qualityBuilding material handlingFloor slabMortise and tenon

The invention discloses a prefabricated slab and column mortise and tenon type connecting joint and an installation method. The connecting joint comprises a composite frame column, a floor slab and a high-strength bolt. A column end sealing plate is welded to the top end of a column body, and the bottom end of a column tenon is welded to the column end sealing plate. Frame beams on the periphery are structural steel or structural steel combination trusses. Tenon holes are hollow steel members connected with the frame beams, the cross section shape of the tenon holes is the same as that of the column tenon, and the cross sections of the tenon holes are larger than the cross section of the column tenon but small than the cross section of a body of the composite frame column. Composite frame columns and floor slabs are sequentially connected and fixed through bolt holes and high-strength bolts. By means of tenon and mortise type connection of slabs and columns prefabricated in a factory, the structure form and the installation mode are greatly simplified, the structural safety and quality of a building can be guaranteed better, the field workload is reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

Construction method for installing wire pipe and wire box on the wall

ActiveCN101247029AEasy to fixReduce quality problemsCable installation apparatusHuman powerBuilding construction

The present invention discloses a method for constructing the distributing pipe and wire box on the wall body. The wire box with depth for 80mm is adopted, and in construction the wire box is installed properly firstly and then the civil construction of the wall body is executed. The method has the advantages of convenient installing to the wire pipe and wire box and construction to the wall body, accelerating the construction progress of the civil construction and installation, reducing the quality common fault of wall cracking and environment pollution, eliminating the secondary trenching, holing and compensating the plaster, and evidently reducing the costs of human power, material, machinery and the like. After the construction the wire box and the surface of the wall body is smooth and specious, the fixing of the wire box is firm and the wall body at the circumference of the wire box is not easily crack.

Owner:CHENGDU CONSTR ENG GROUP CORP

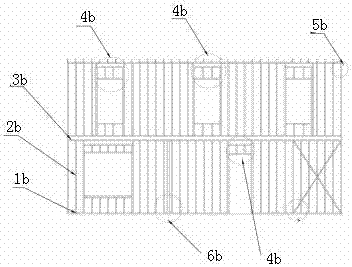

DGC board-type assembled house system and construction method and manufacturing method thereof

InactiveCN105804233AImprove prefabrication rateEnsure structural safetyWallsFloorsModular compositionInsulation layer

The invention discloses a DGC board-type assembled house system and a construction and a manufacturing method thereof. A basic unit of the system is formed by floor slabs and wallboards which are combined and assembled in a modularized manner; the wallboards are prefabricated composite boards, each wallboard mainly consists of a light-steel frame, a peripheral guard board, a sandwich insulation layer, a heat insulating layer and turnbuckles, and different wallboard standard modules such as in-line wallboards, L-shaped wallboards, T-shaped wallboards and cross-shaped wallboards are adopted and freely combined; the floor slabs are prefabricated composite boards, the floor slabs are used as foundation slabs, floor slabs or roof slabs of the DGC board-type assembled house system, and vertical connection between the floor slabs and the wallboards in the system consists of combined connection of lateral connection of horizontal M-shaped steel, M-shaped chord members and square steel pipes through tapping screws and vertical connection of the turnbuckles in trusses. According to the DGC board-type assembled house system and the construction method and the manufacturing method thereof, the structure is simple, the construction speed is fast, the construction period is reduced, the cost is low, and the defects of single structure, complex installation process and high labor cost of the existing assembled house structure can be overcome.

Owner:江苏保力自动化科技有限公司

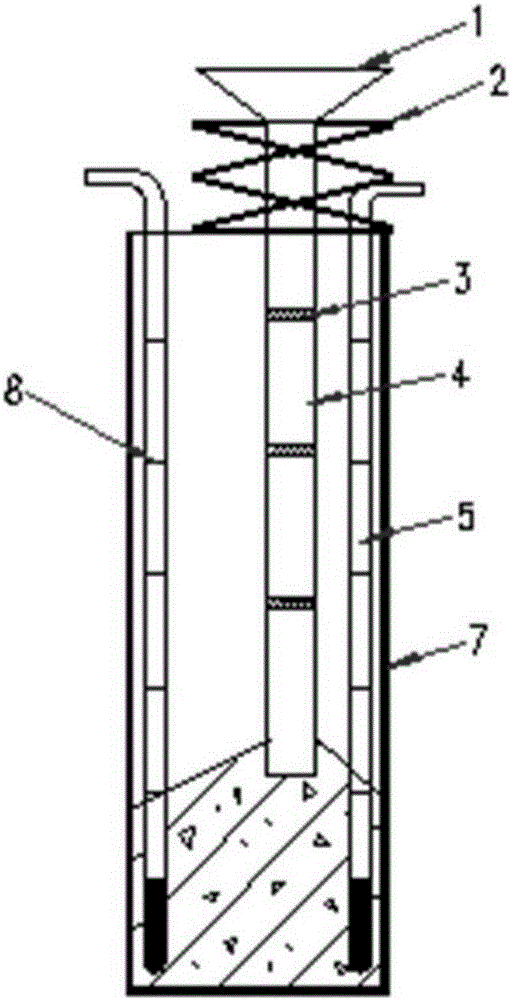

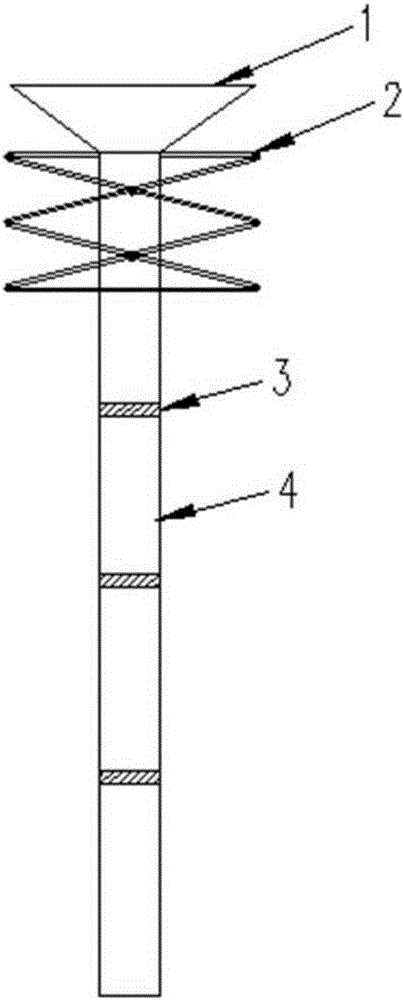

Device and method for one-time pouring molding of ultra-high concrete column

InactiveCN105350777AEnsure structural safetyGuaranteed structural qualityBuilding material handlingReinforced concreteHoneycomb

The invention discloses a device and method for one-time pouring molding of an ultra-high concrete column. The device comprises a guiding device arranged in an ultra-high concrete column formwork. The guiding device comprises a collecting hopper, a scissor fork lifting mechanism, guiding pipe connecting mechanisms and a guiding pipe. The collecting hopper is arranged on the top of the guiding pipe, the guiding pipe is divided into multiple sections with the equal length, the sections are connected through the guiding pipe connecting mechanisms, the lower portion of the collecting hopper is sleeved with the scissor fork type lifting mechanism for lifting the guiding pipe, multiple vibrating rods for vibrating and densifying concrete are arranged between hoops on the edges of the formwork, multiple sections of scale marks are arranged on the vibrating rods, and the length of each section of scale mark is equal to that of each section of guiding pipe. Coincidence and integrity with the concrete are guaranteed, the honeycomb and scale phenomenon caused by the fact that vibration is not in place is avoided, the structural safety and appearance quality of one-time molding of the ultra-high reinforced concrete structure column are guaranteed accordingly, appearance attractiveness is improved, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

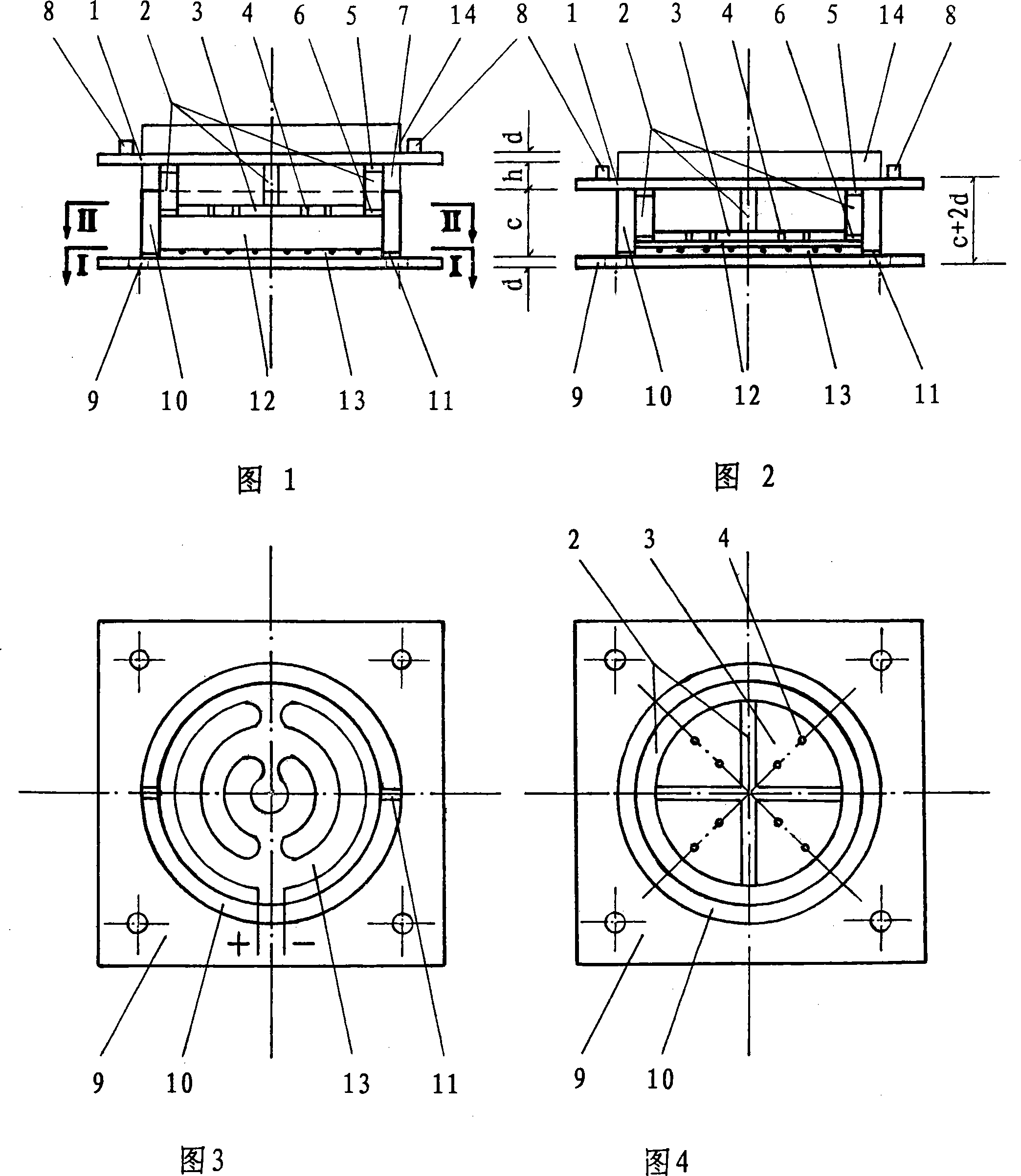

Sedimentation support for bridge

InactiveCN101250850ANo need to expand the disposal areaRestoration Flatness IndexBridge structural detailsCompression deviceEngineering

The invention relates to a bridge settlement support, which comprises a product support, further comprises an upper settlement compression device which is located on the bottom portion of the product support, the device comprises an upper settlement body and a lower bottom basin, the upper settlement body comprises a top plate, an inner support plate and a middle carrier plate, the top plate is located at the lever direction, the middle carrier plate is fixed on the lower portion of the top plate and is parallel to the top plate through the inner support plate, the middle carrier plate is equipped with a plurality of rheological channels, the inner support plate comprises a ring plate and a baffle which is fixed in the ring plate to form a plurality of cavities, and the upper portion of the ring plate is equipped with a plurality of vent holes. The lower bottom basin comprises a bottom plate and an outer support plate which is fixed on the upper portion of the bottom plate, an overflow orifice is arranged between the bottom plate and the outer support plate, the outer support plate is a ring cylinder which is tightly sleeved on the outer side of the inner support plate, an electric heating disk is laid on the bottom plate, and a compression body is filled between the electric heating disk and the middle carrier plate. The bridge settlement support has the beneficial effects that the disease of bumping at bridge-head is effectively eliminated through that the self settlement drives the floor elevation reduce.

Owner:郝贤成

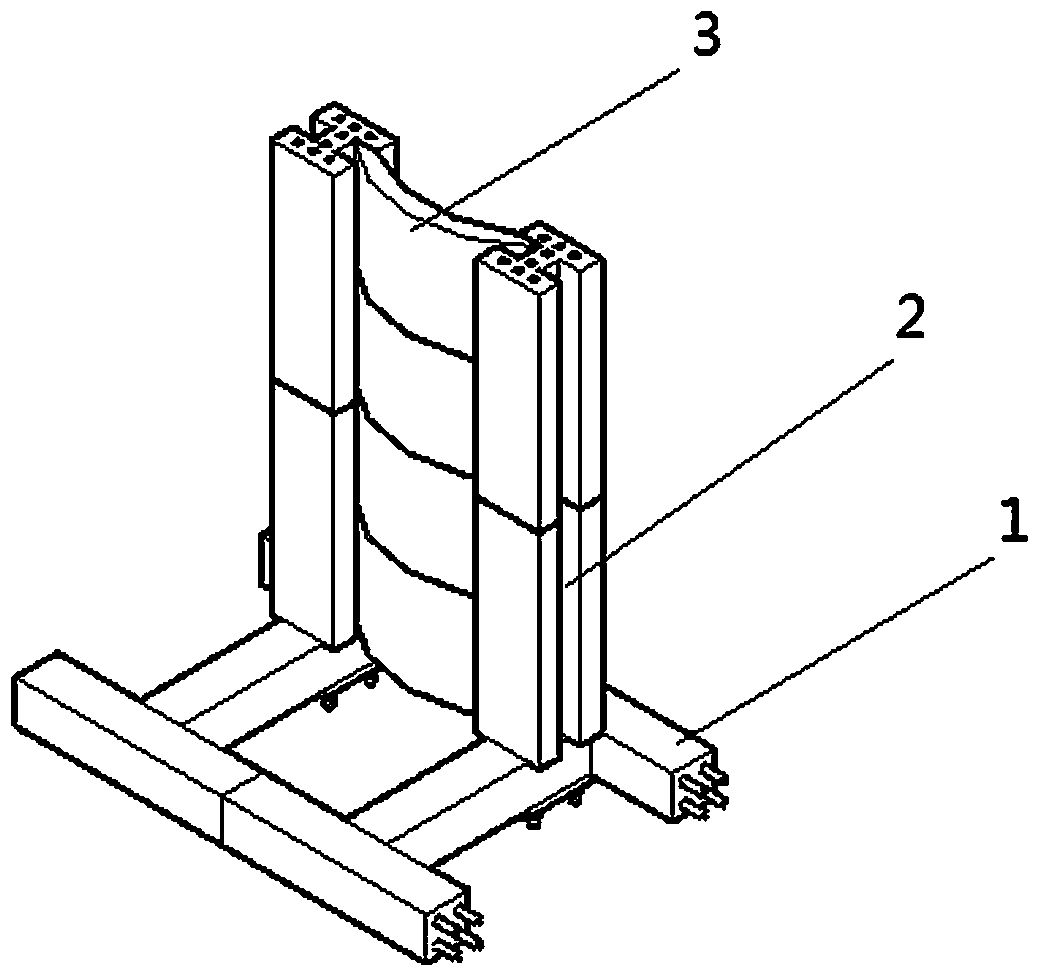

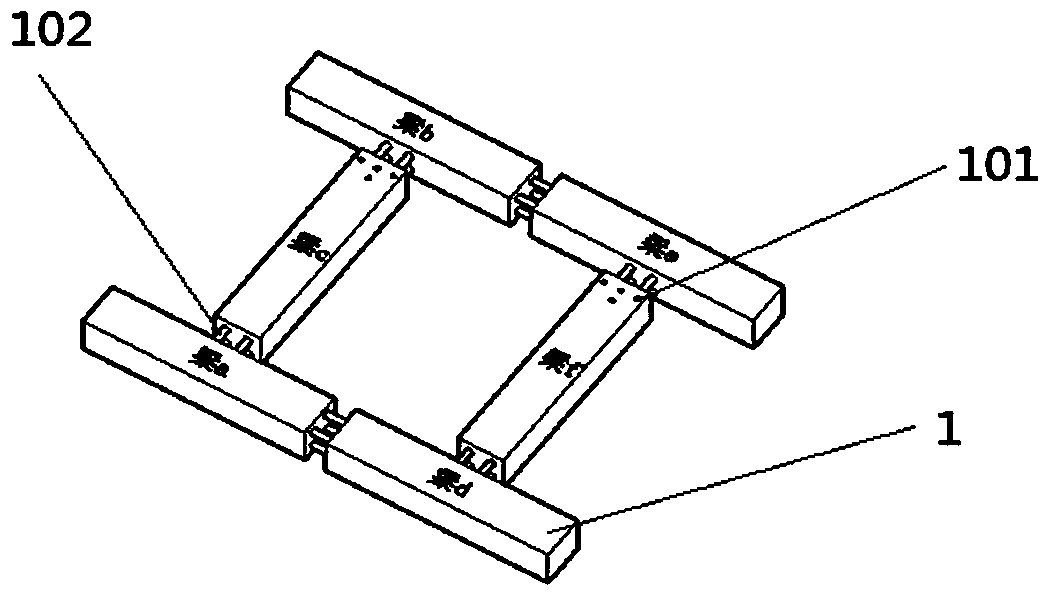

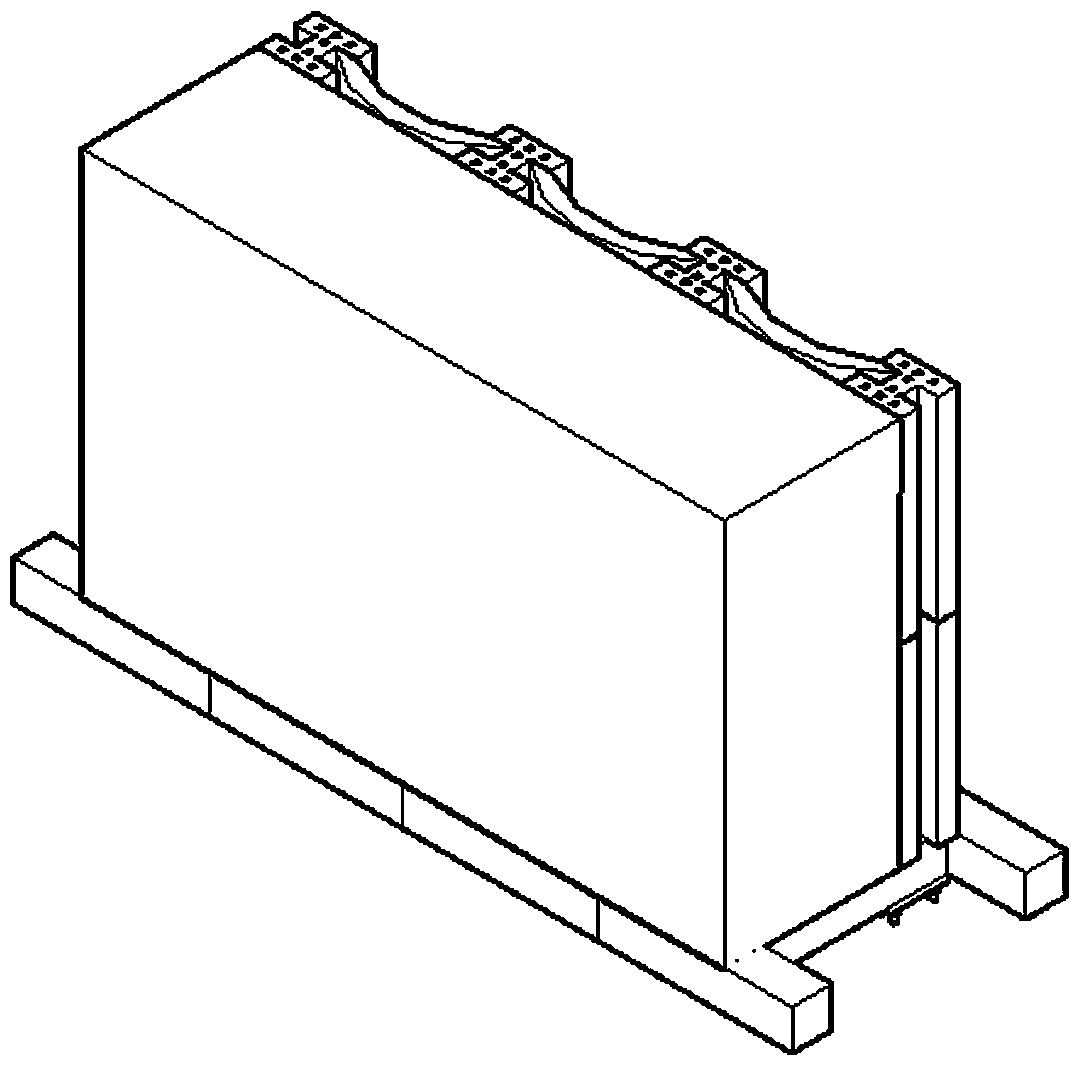

Module prestress fabricated retaining wall and assembly method thereof

InactiveCN107905251AReduce laborReduce the impactArtificial islandsUnderwater structuresPre stressRebar

The invention discloses a module prestress fabricated retaining wall and an assembly method thereof. The module prestress fabricated retaining wall comprises retaining wall basic units, each retaining wall basic unit is composed of a basic module, rib column modules and an arc-shaped plate, wherein the two rib column modules and the basic module are vertical and are connected through reinforcingsteel bar grouting, and the arc-shaped plate is inserted between the two rib column modules; and the multiple retaining wall basic units are connected through the reinforcing steel bar grouting to form the module type prestress fabricated retaining wall. Modularization, prefabrication and assembling of the retaining wall are achieved, the retaining wall basic units are prefabricated and molded outside a construction site, the structure quality of the retaining wall is guaranteed, the construction efficiency is improved, and the labor amount of a construction worker is reduced. Meanwhile, mountain cutting and quarrying are avoided during construction, influences on the environment are reduced, and construction is not limited by the environment.

Owner:HUNAN UNIV OF SCI & TECH

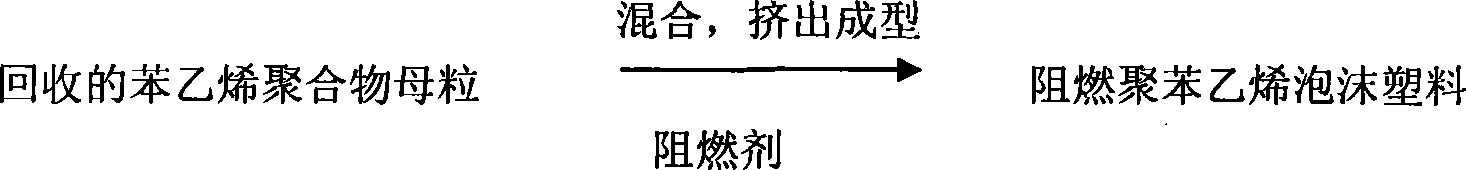

Flame-resistant vinyl benzene polymer foam plastic

The invention relates to a flame-retardant styrene polymer foam plastics, which comprises styrene polymer and flame-retardant agent compound. The weight of phosphorus-containing compound takes up 2 percent to 4 percent of the total weight of the styrene polymer. The weight of HBCD takes up at least 5 percent to 8 percent of the total weight of the styrene polymer. The weight of antimony oxide compound takes up at least 2 percent of the total weight of the styrene polymer; the weight of expansion flame-retardant compound takes up at least 6 percent to 12 percent of the total weight of the styrene polymer. The invention, by recycling the styrene polymer foam plastics and through the extrusion production technique of common styrene polymer foam plastics, gets the styrene polymer foam plastics with good flame-retardant performance (the flame-retardant performance meets the requirement on heat insulation foam plastics of GB8624). The extruded type flame-retardant styrene polymer foam plastics the invention gets has low coefficient of thermal conductivity ( high energy saving efficiency), high intensity, and the flame retardance which can meet the requirement of national building fireproof standard, replaces molded type styrene polymer foam plastics and has good prospect on building insulation and pipe sandwich heat thermal insulation, etc.

Owner:TIANJIN FIRE RES INST

Method for constructing steel column and column head sizing steel model of profile steel

InactiveCN107869195AImprove bearing capacityIncrease stiffnessFoundation engineeringBuilding constructionsEngineeringBinding profile

The invention discloses a method for constructing a steel column and column head sizing steel model of profile steel. The method comprises the following steps: pre-embedding multiple groups of foundation bolts into a stand foundation, and screwing an adjusting nut onto each foundation bolt; hoisting a profile steel column, enabling a column base plate of the profile steel column to be supported onthe adjusting nuts of a group of foundation bolts which are correspondingly arranged, inserting one base plate on each foundation bolt, sequentially screwing fastening nuts and non-stop nuts, and then adjusting the scale height of the adjusting nuts on each group of foundation bolts; correcting the size of the profile steel column arranged at the lowest layer; carrying out secondary grouting on the bottom part of the column base plate; then sequentially connecting steel main beams or steel secondary beams, binding profile steel column reinforcing steel bars, and installing a column mold of the layer; fixing the profile steel column in the upper layer to each profile steel column; then sequentially connecting the steel main beams or the steel secondary beams, binding the profile steel column reinforcing steel bars, and installing the column mold of the layer; finally pouring concrete in the column mold. By adopting the method disclosed by the invention, the bearing capacity, the rigidity, the fire resistance and the seismic resistance of a structure are greatly increased.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

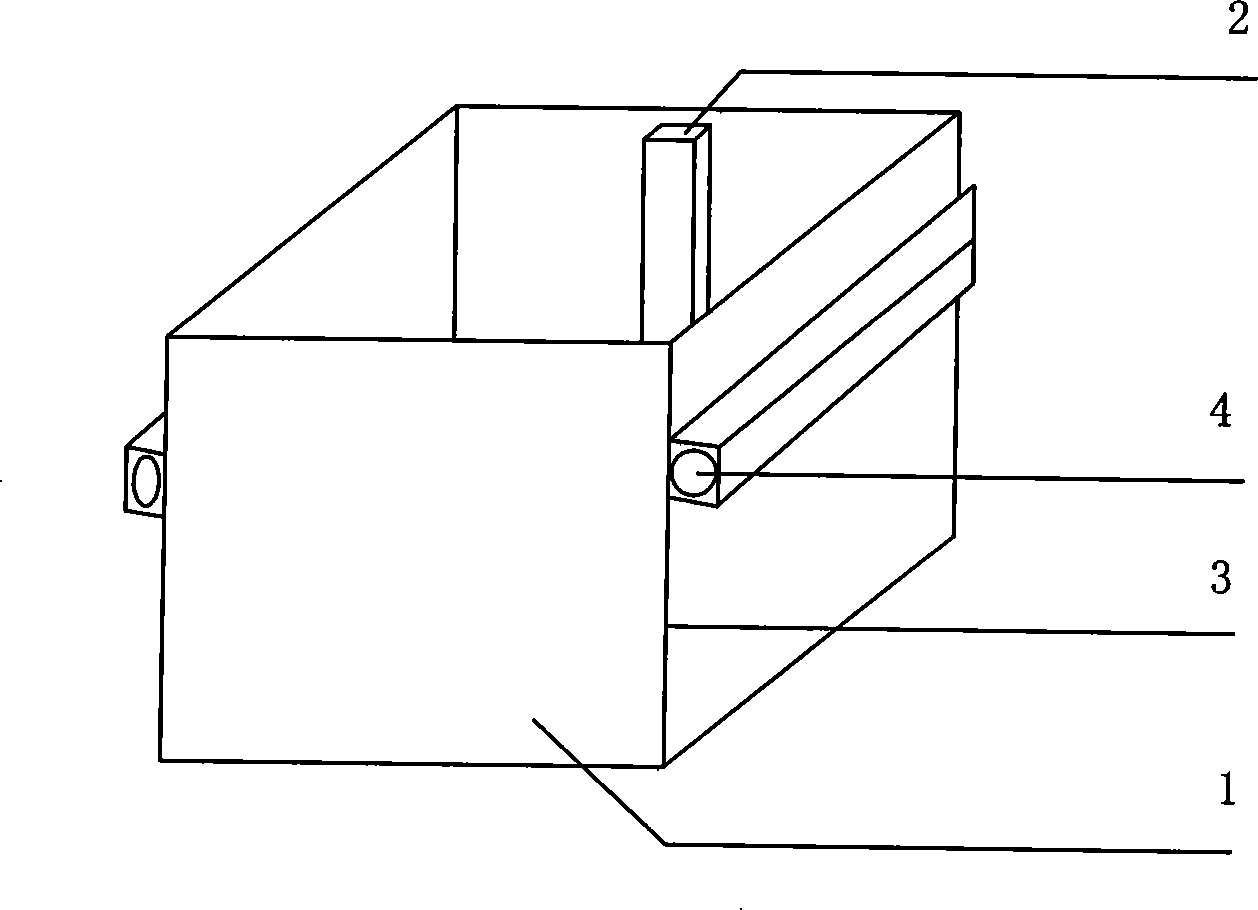

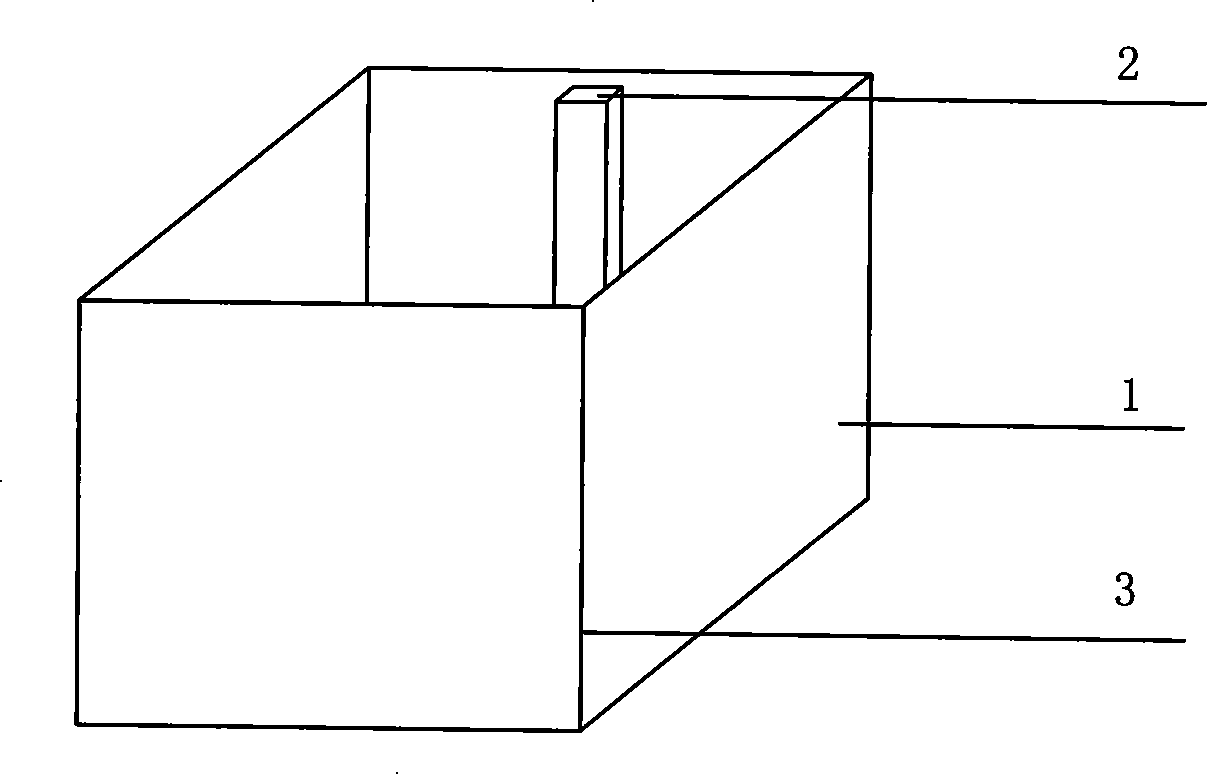

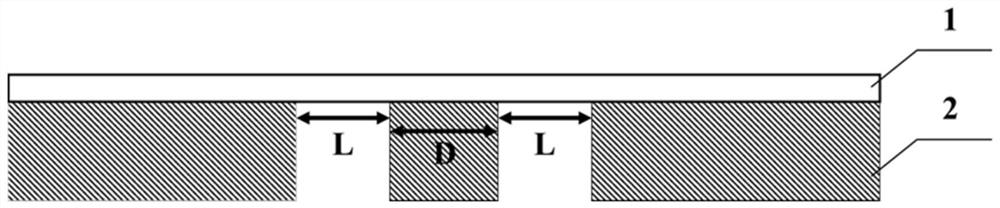

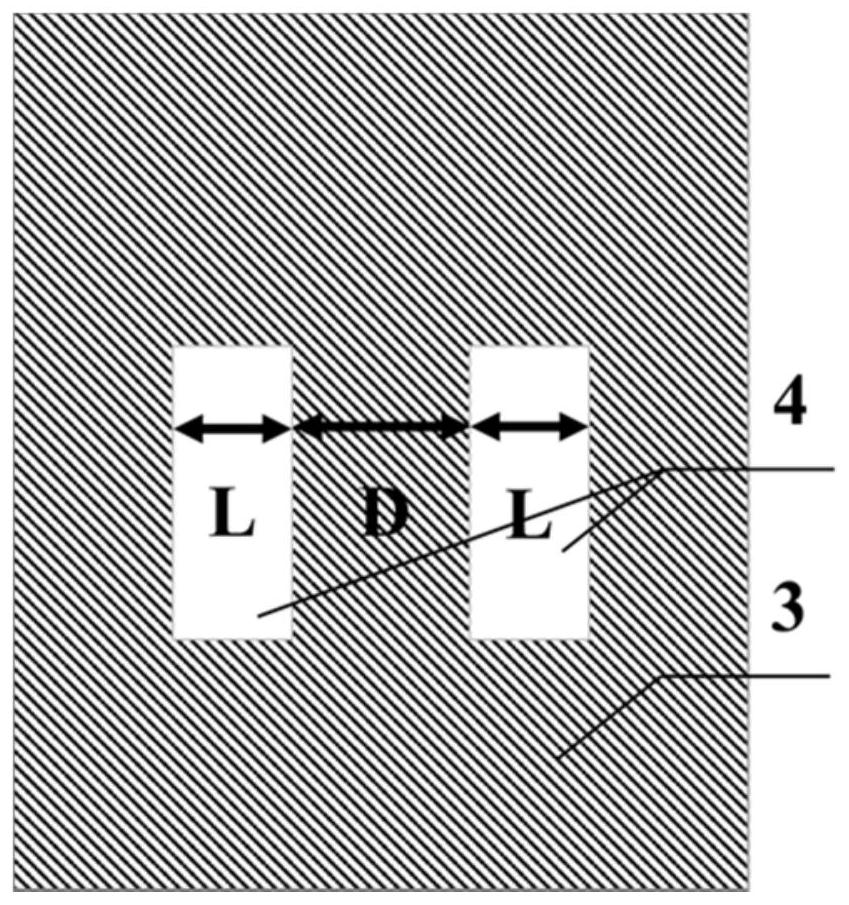

Suspension type embedded part and hole reserved template fixing method

ActiveCN102080383AAvoid wastingGuaranteed structural qualityFoundation engineeringFixed frameEngineering

The invention relates to a method for constructing an equipment foundation in an industrial factory building, in particular to a suspension type embedded part and hole reserved template fixing method. The method comprises the following steps of: connecting and firming a fixing frame; connecting an embedded part or a hole reserved template with the fixing frame, wherein the fixing frame consists of two parallel monolithic frames and an intermediate platform assembly; allowing the two monolithic frames to pass through openings on the two sides of a bottom platform respectively; screwing four monolithic frame fastening bolts on the two sides of the bottom platform; fixing the platform assembly on the monolithic frames; anchoring the two ends of each monolithic frame with templates on the two sides of the equipment foundation; allowing an embedded part connecting reinforcement exposed out of the upper part of the embedded part to pass through a hole on a high plate to be connected with the fixing frame, wherein the position of the embedded part or the hole reserved template is offset; and adjusting the position of the platform assembly by adjusting the monolithic frame fastening bolts. The invention has the advantages that: by the method, construction efficiency and construction quality are improved, unnecessary material waste is avoided and the structural quality of a constructed position is guaranteed.

Owner:CHINA 22MCC GROUP CORP +1

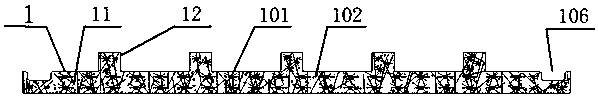

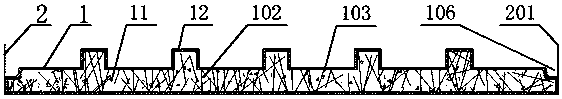

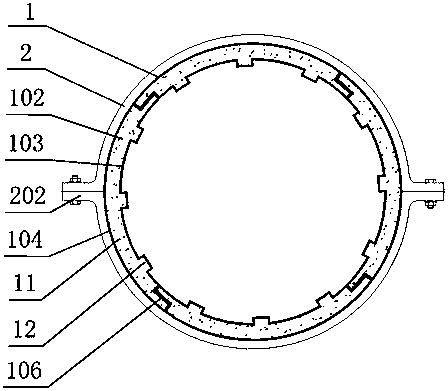

Building waste residue sintering-free embedded pipeline groove brick and using method thereof

ActiveCN102071771AImprove construction efficiencyBuild walls fastBuilding componentsBuilding material handlingBrickArchitectural engineering

The invention discloses a building waste residue sintering-free embedded pipeline groove brick and a using method thereof, which belong to the technical field of wall body bricks and installation technology thereof. The pipeline groove brick comprises a brick body, wherein the brick body is provided with a groove; the end part of the groove is provided with a preserved layer; and the thickness of the preserved layer does not surpass 8 millimeters. Moreover, a method for installing a conduit on the brick body by using the groove brick is provided. The pipeline groove brick can be taken as an ordinary wall building brick as well as the building waste residue sintering-free embedded pipeline groove brick which is matched with a pipeline; simultaneously, the pipeline groove brick is convenient to transport, a small number of building wastes is produced, a small amount of flying dust is produced, construction efficiency is high, energy is saved and environment is protected; and the pipeline groove brick is particularly suitable for wall body construction occasions for assembling pipelines.

Owner:CHENGDU NO 4 CONSTR ENG

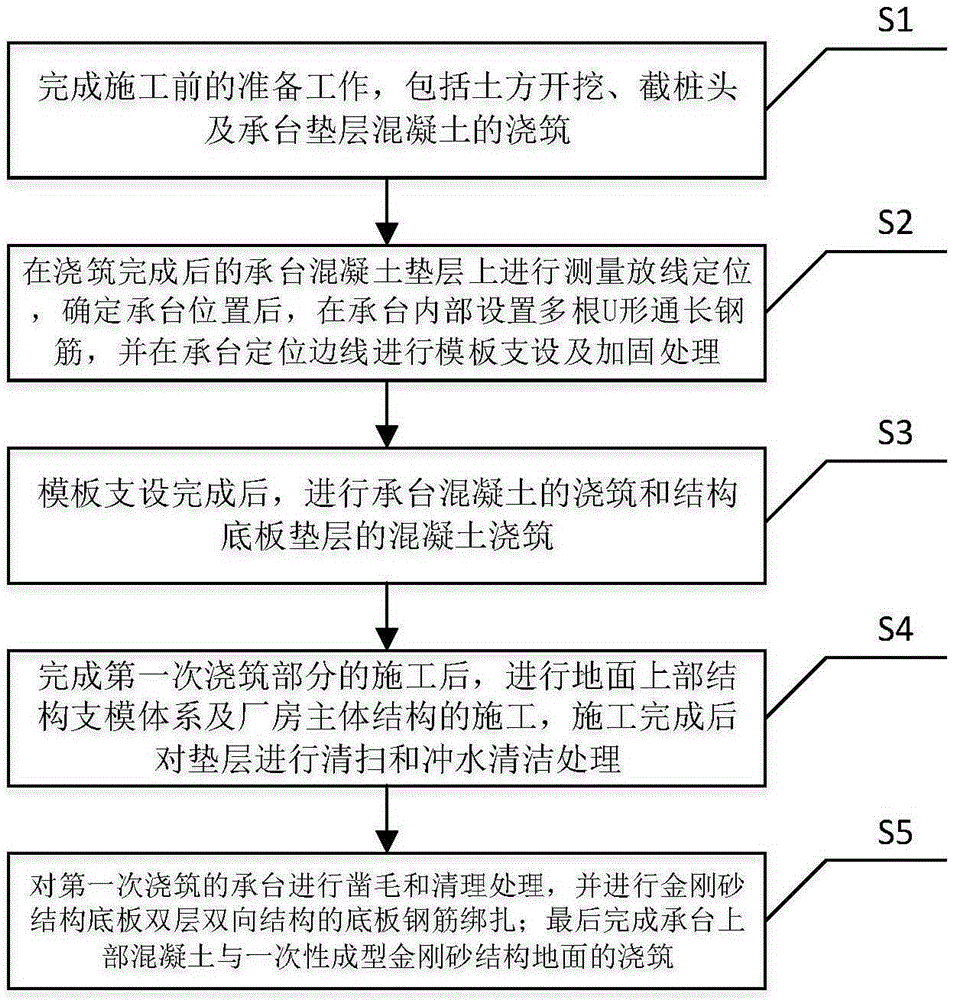

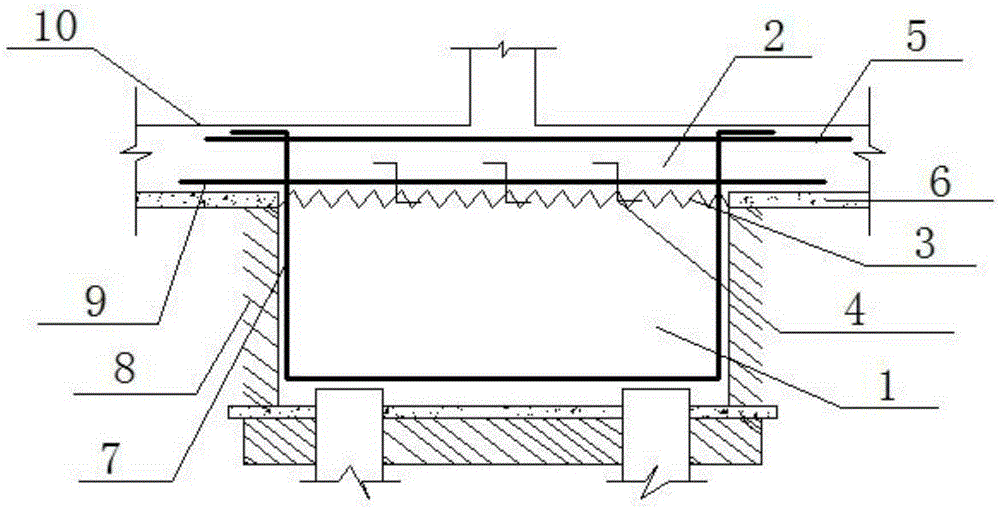

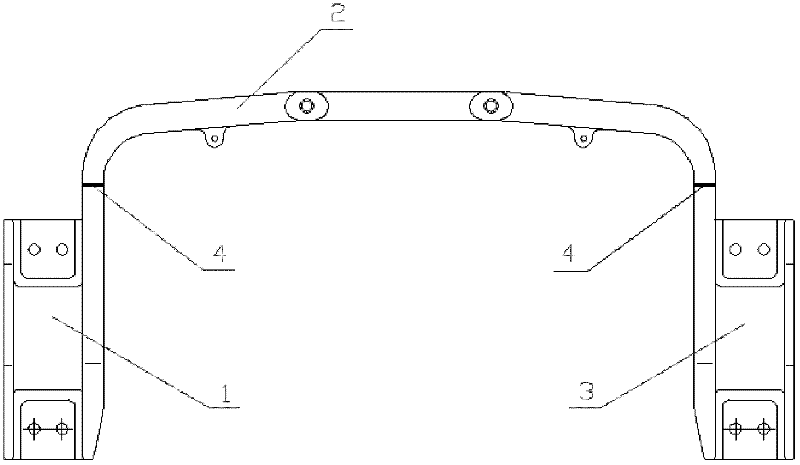

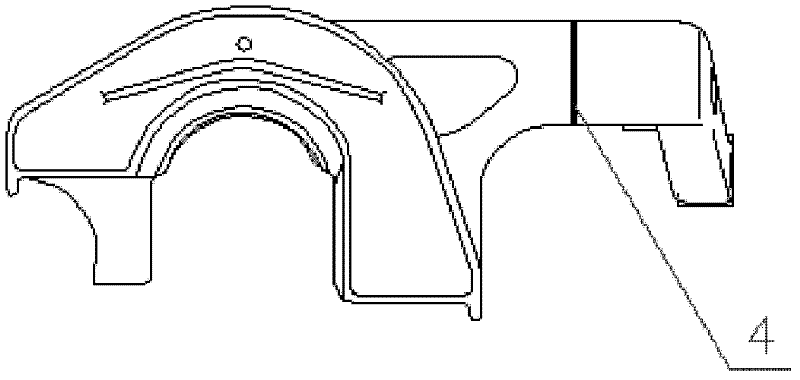

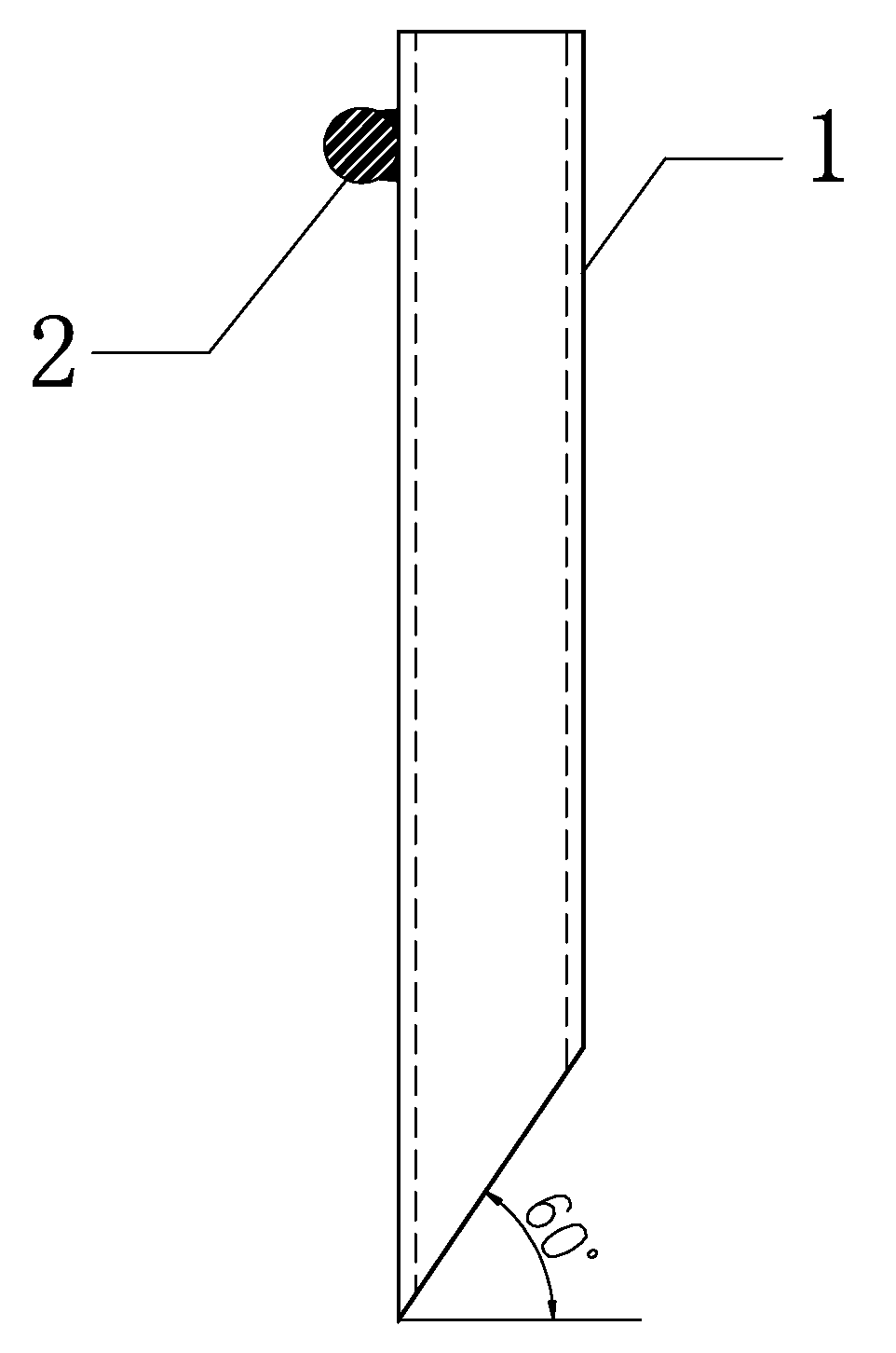

Construction method suitable for emery structural ground of large factory building

ActiveCN105350559AGuaranteed structural strengthGuaranteed structural qualityArtificial islandsUnderwater structuresOperational costsRebar

The invention discloses a construction method suitable for an emery structural ground of a large factory building. The construction method comprises the following steps: S1) the preparatory work before construction is finished; S2) the surveying and the positioning are performed on a concrete cushion layer of a bearing platform; multiple U-shaped long reinforcements are arranged in the bearing platform; and the template supporting and the reinforcement treatment are performed on a positioning sideline of the bearing platform; S3) after the template supporting is finished, the concrete casting of the bearing platform and the concrete casting of a structural baseplate cushion layer are performed; S4) a ground upper structure formwork system and a factory building main structure are constructed; and S5) the deburring and the cleaning are performed for the bearing platform; the baseplate reinforcement binding of a two-layer and two-direction structure of an emery structural baseplate is performed; and finally, the casting of concrete at the upper part of the bearing platform and a once-molded emery structural ground is finished. The construction method not only can guarantee the structure strength and quality of the bearing platform, but also can largely shorten the construction period, can guarantee the surface of the bearing platform to be not damaged by later construction, and reduces the management cost and the operation cost.

Owner:CHINA FIRST METALLURGICAL GROUP

Bogie auxiliary framework of railway wagon and production technology thereof

InactiveCN102501872AGuarantee the quality of castingsGuaranteed weld qualityArc welding apparatusBogiesTruckEngineering

The invention discloses a bogie auxiliary framework of a railway wagon and production technology thereof. The bogie auxiliary framework is formed by split structures including a left saddle, a right saddle and an arm for connecting the left saddle and the right saddle. The left saddle, the right saddle and the arm are connected into a whole through welding, and welding connection positions are respectively located at a left saddle connection rod straight line section and a right saddle connection rod straight line section. The production technology comprises the following steps of respectively performing casting processing on the left saddle, the right saddle and the arm; performing welding groove processing on the left saddle, the right saddle and the arm; assembling the left saddle and the arm, and assembling the right saddle and the arm; performing positioned welding; performing layered welding; polishing welding joints, performing flaw detection and removing stress; integrally processing a saddle surface, drilling holes and reaming holes; and pressing a sleeve. The bogie auxiliary framework of the railway wagon and the production technology of the bogie auxiliary framework utilize combination of the split structures, spin-off structures are scientific, a combination welding method can effectively guarantee quality requirements of all portions of the auxiliary framework and reduce casting manufacture difficulty, machining difficulty and machining cost, and the quality of the butt welding technology of the saddles and the arm of the auxiliary framework is excellent.

Owner:CRRC MEISHAN

Method for repairing pavement by using plain concrete and reinforced concrete

PendingCN108316089ASimple construction methodGuarantee the construction qualityIn situ pavingsPaving detailsRebarReinforced concrete

Owner:HUALAN DESIGN GRP CO LTD

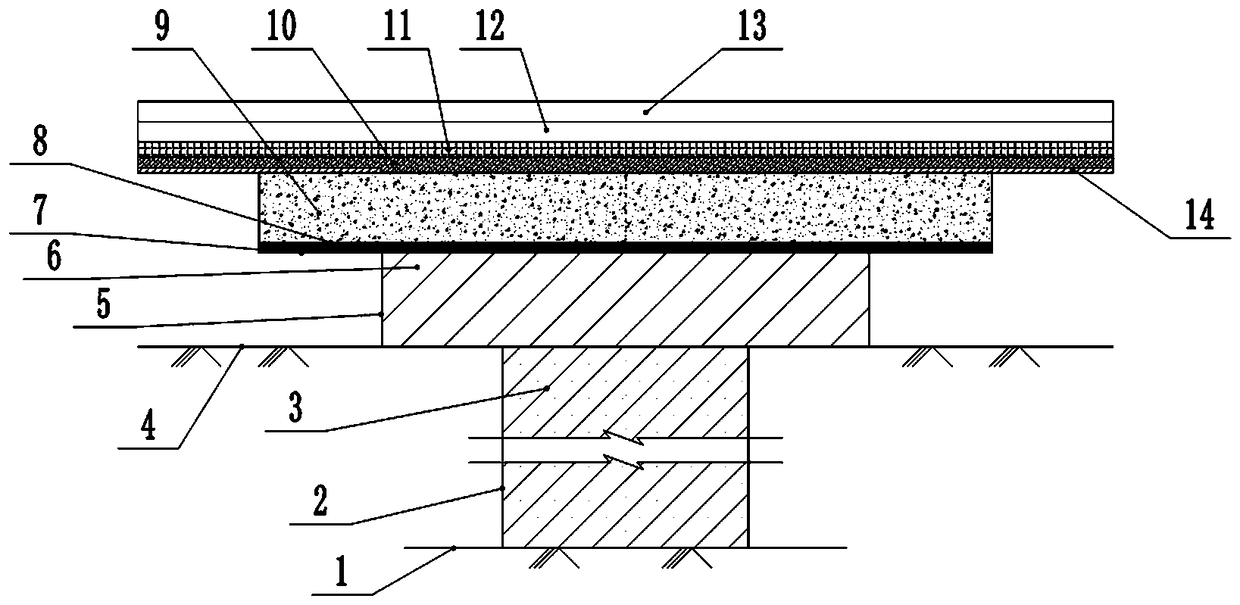

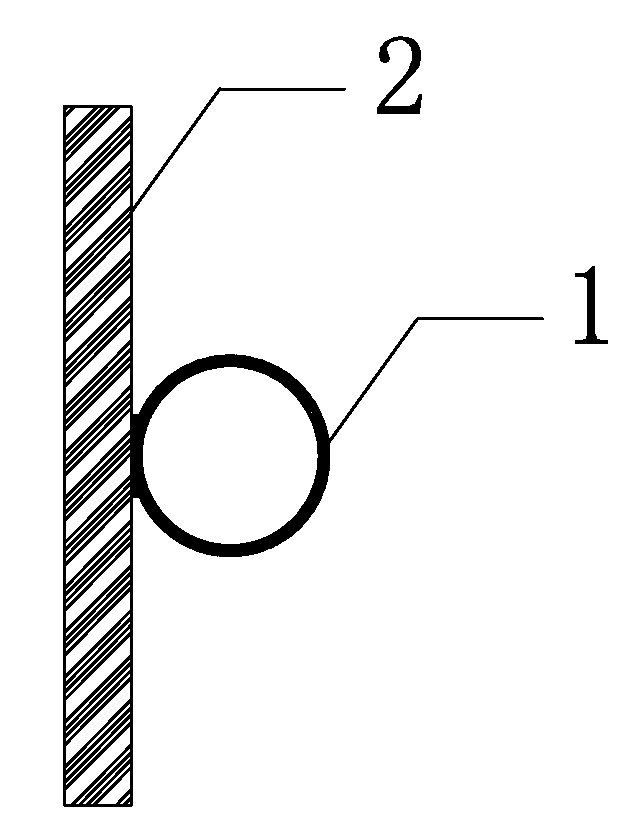

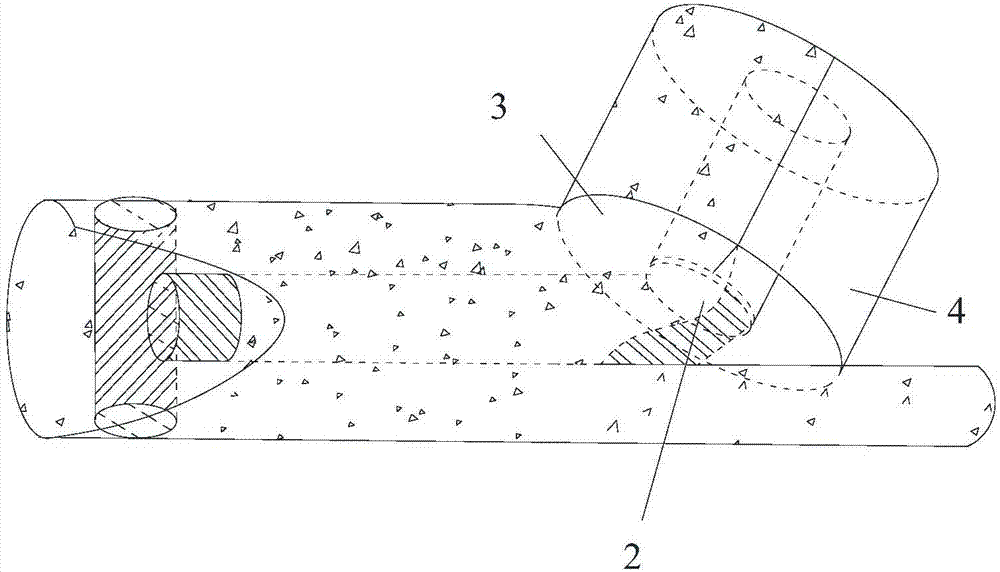

Tamping assist device for concrete pouring and manufacture method thereof

ActiveCN103669875AImprove vibrationEasy to operateBuilding material handlingRebarUltimate tensile strength

A tamping assist device used for concrete pouring of intensive steel bar frame columns and nodes is matched with a vibration tamping rod for vibration tamping construction, comprises a tamping assist cylinder and a handle, and is characterized in that the tamping assist cylinder (1) is a steel tube with the diameter 20mm or more larger than the diameter of the vibration tamping rod, the diameter of the tamping assist cylinder (1) is 50-60mm, the wall thickness of the tamping assist cylinder (1) is 3.6-5mm, the length of the tamping assist cylinder (1) is 200mm larger than the thickness of a platform to be formed by pouring, the upper end of the tamping assist cylinder is a flat mouth, an oblique pointed end with an angle less than 30 degrees is arranged at the lower end of the tamping assist cylinder, the handle (2) is a steel rod with the length of 300-400mm and with the diameter of 20-25mm, and the middle of the handle (2) and the upper portion of the tamping assist cylinder (1) are fixed together by welding. The tamping assist device used for the concrete pouring of the intensive steel bar frame columns and the intensive steel bar frame nodes and a manufacture method thereof have the advantages of coordinating with vibration tamping, facilitating the vibration tamping, being convenient to operate, reducing operation procedures and labor intensity of field operation staff, and improving production efficiency.

Owner:MCC5 GROUP CORP SHANGHAI

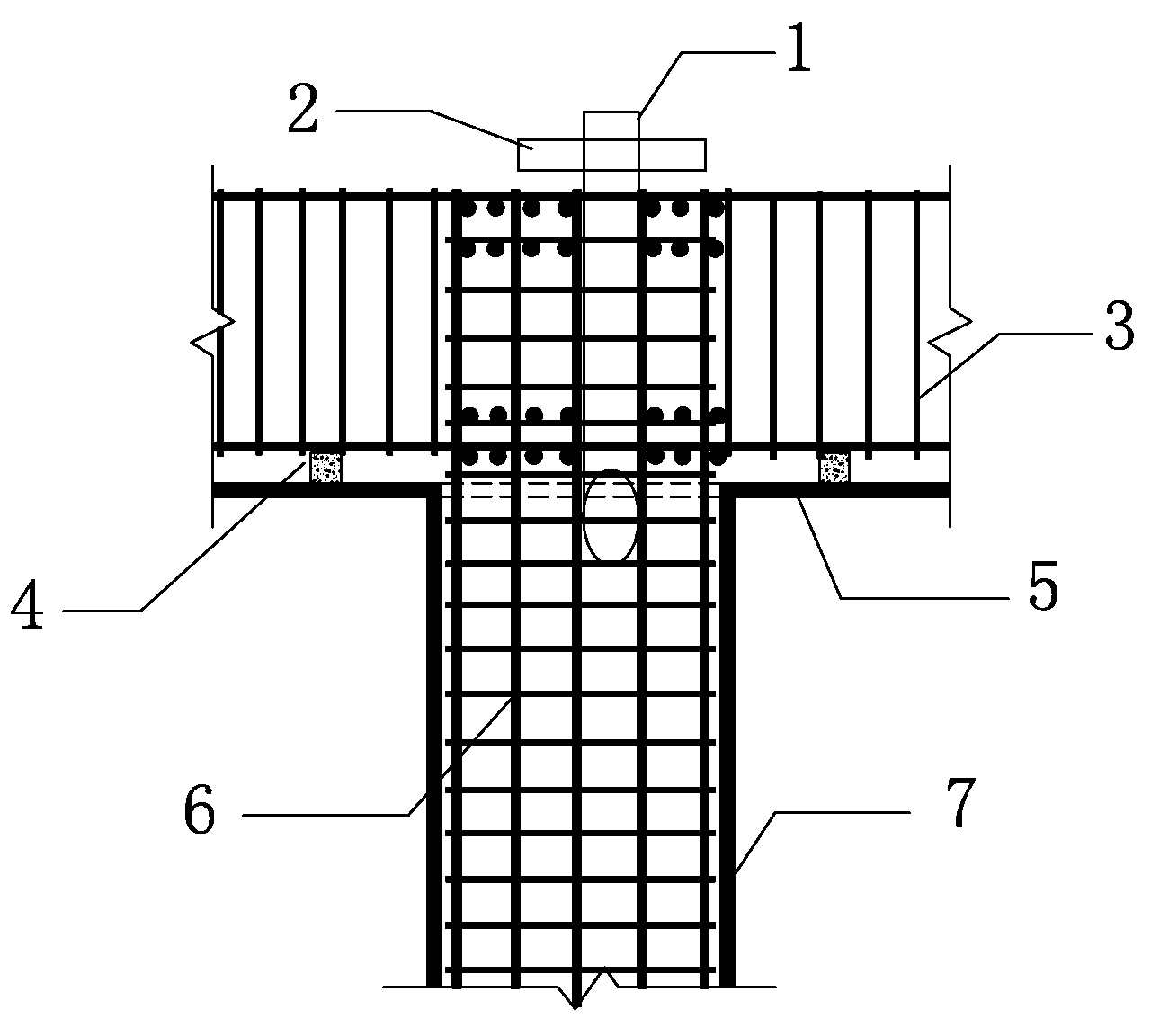

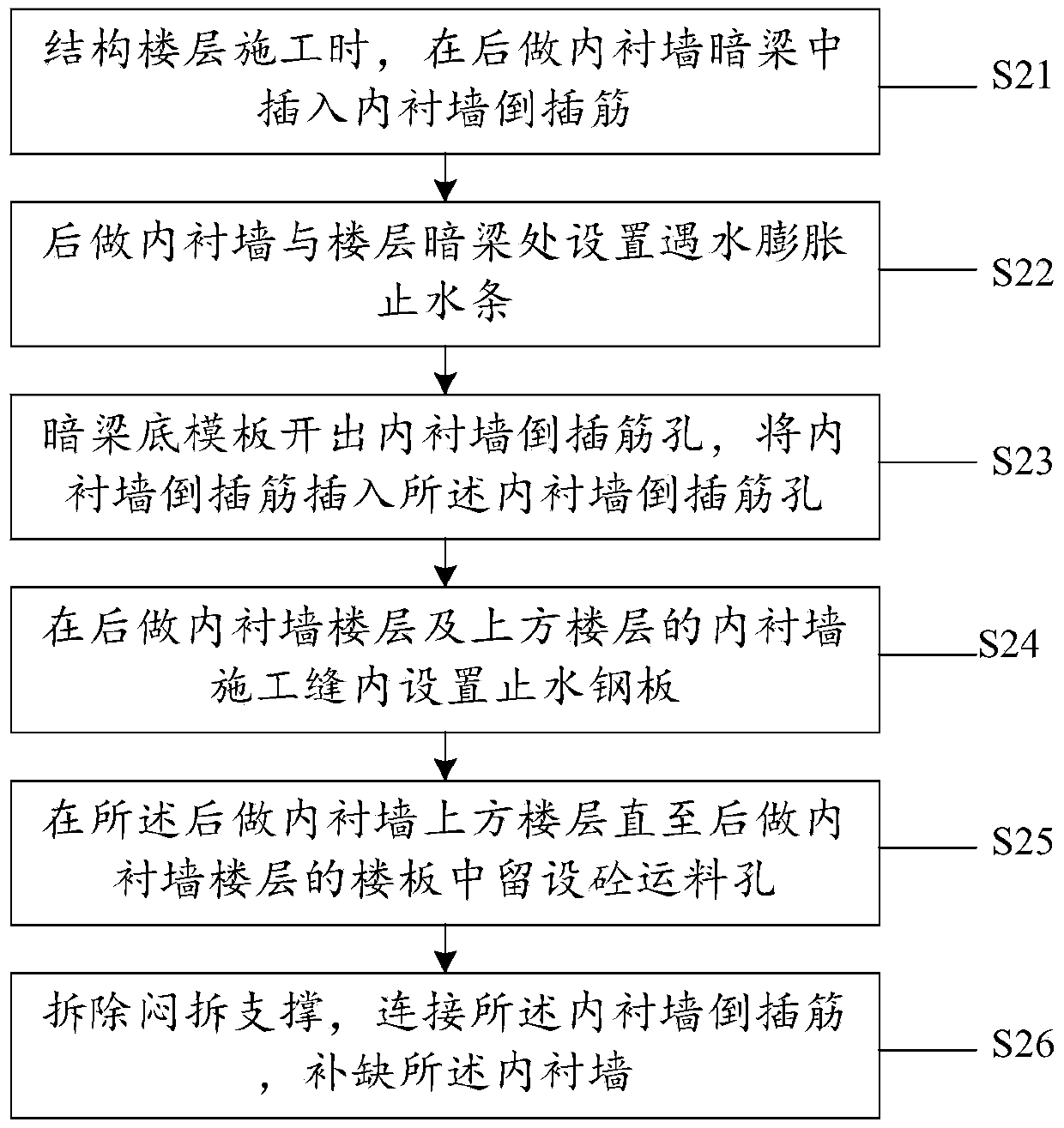

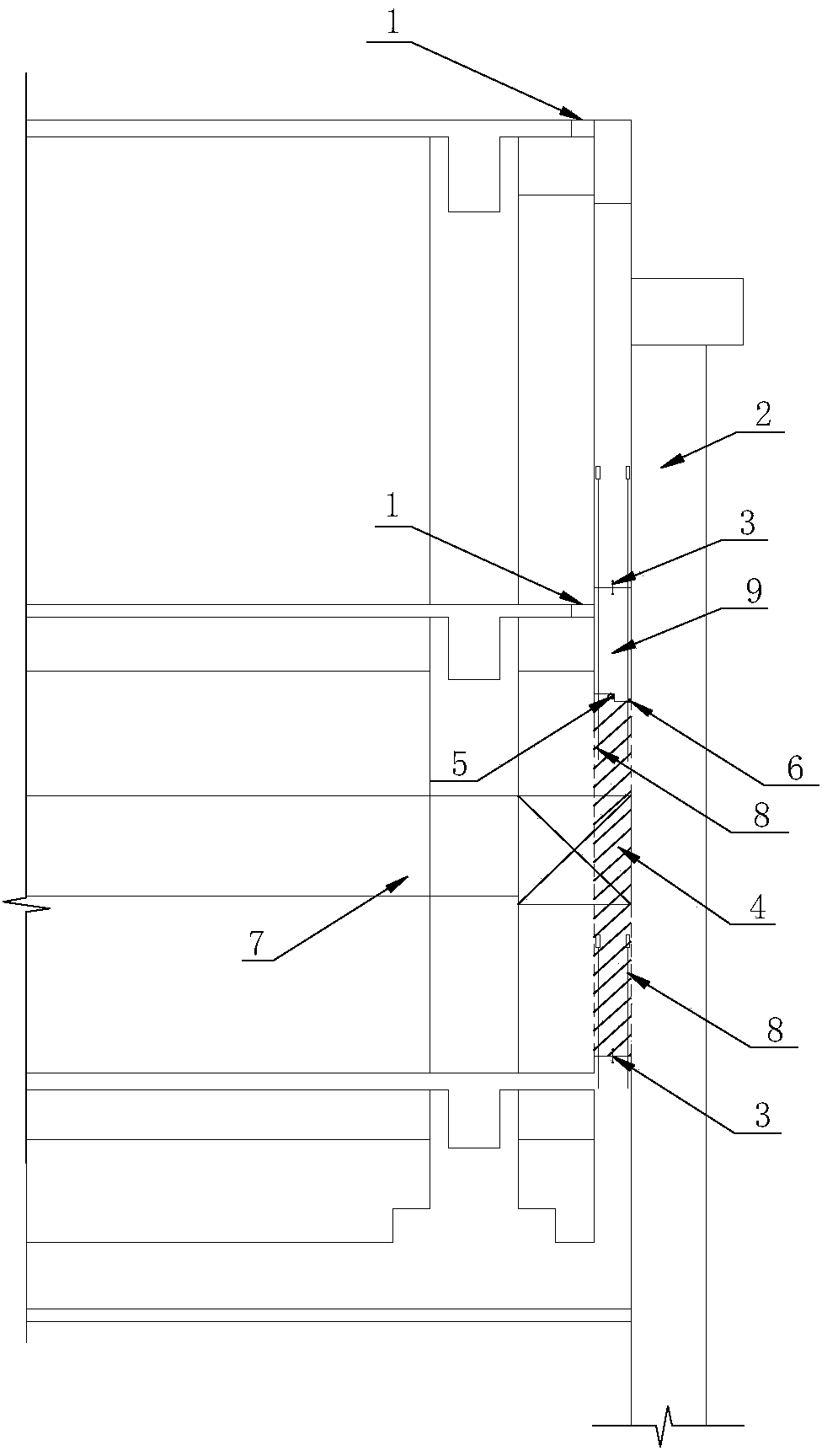

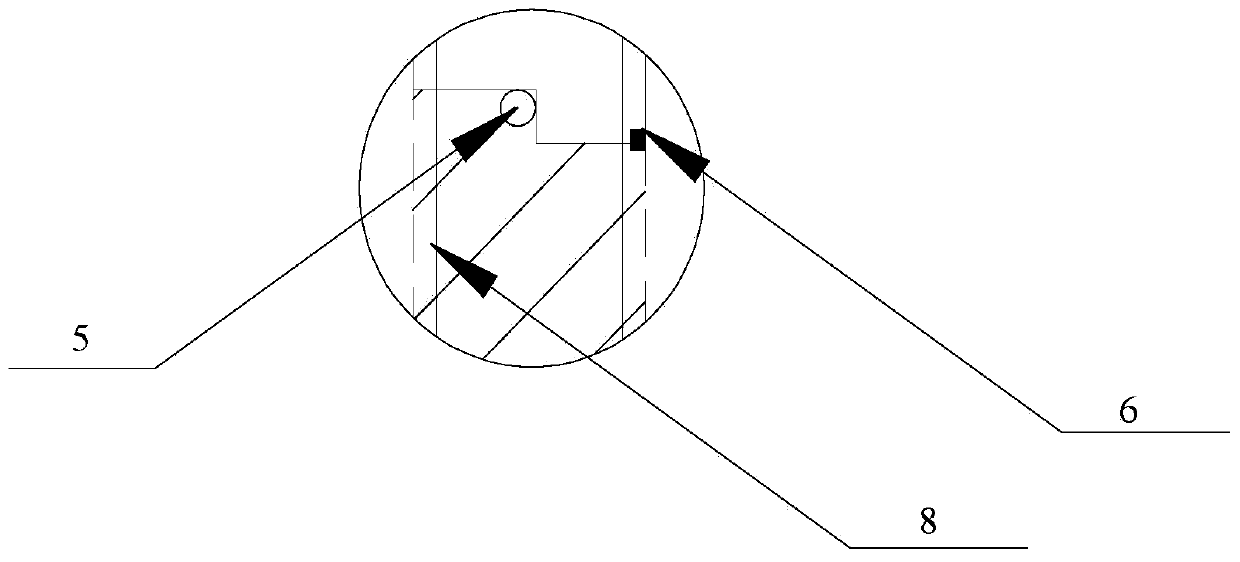

Later-construction method for inner wall of basement

ActiveCN103628486AImprove construction qualityShorten the construction periodExcavationsBasementFloor slab

The invention provides a later-construction method for an inner wall of a basement. The later-construction method comprises the steps that during structure storey construction, inner wall inverse-inserting ribs are inserted into hidden beams of the later-made inner wall; the later-made inner wall and the hidden beams of floors are provided with water stopping strips which swell with water; bottom templates of the hidden beams are provided with inner wall inverse-inserting rib holes, and the inverse-inserting ribs are inserted into the inner wall inverse-inserting rib holes; water stopping steel boards are arranged in inner wall construction gaps in the floor where the later-made inner wall is located and the floor above the later-made inner wall; concrete conveying holes are formed from a floor plate of the floor above the later-made inner wall to a floor plate of the floor where the later-made inner wall is located; stuffy demolition supports are disassembled, the inner wall inverse-inserting ribs are connected, and lack supply is conducted on the inner wall. By means of the method, construction quality of the inner wall is effectively improved, and a construction period is shortened.

Owner:SHANGHAI NO 7 CONSTR

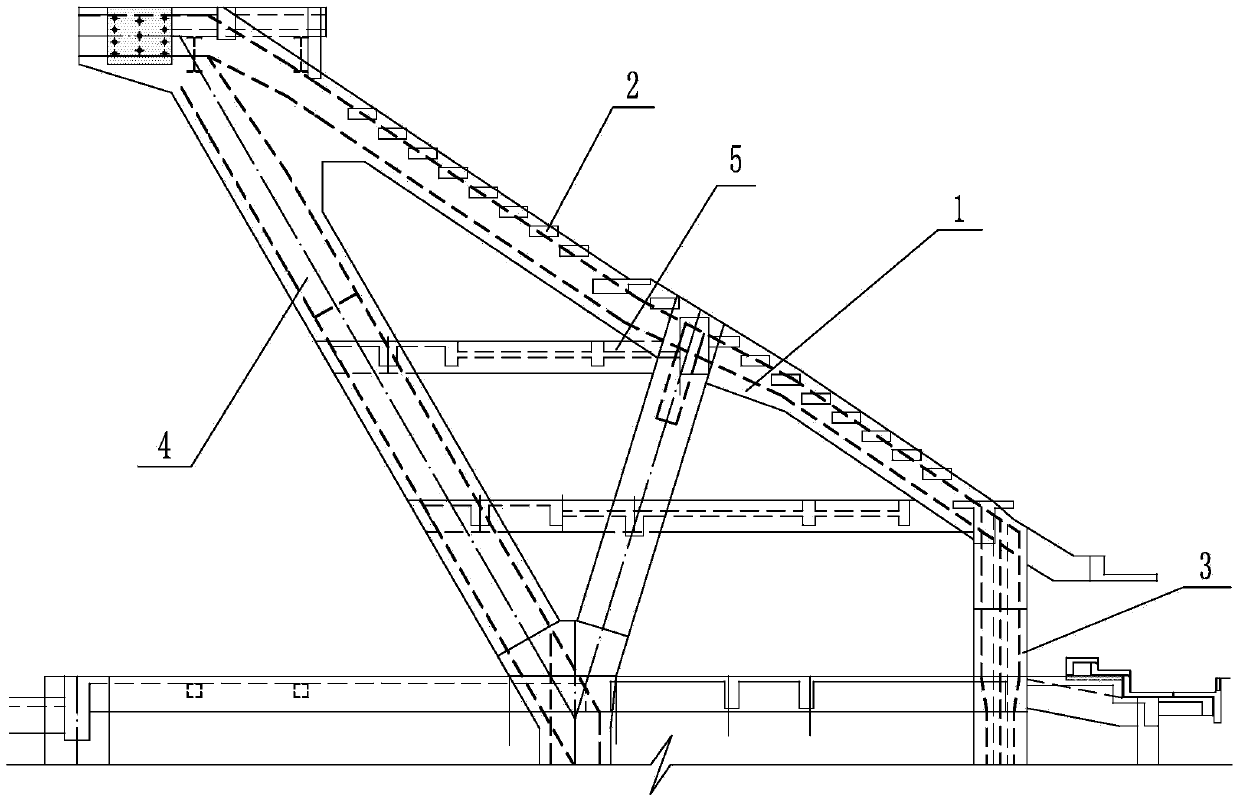

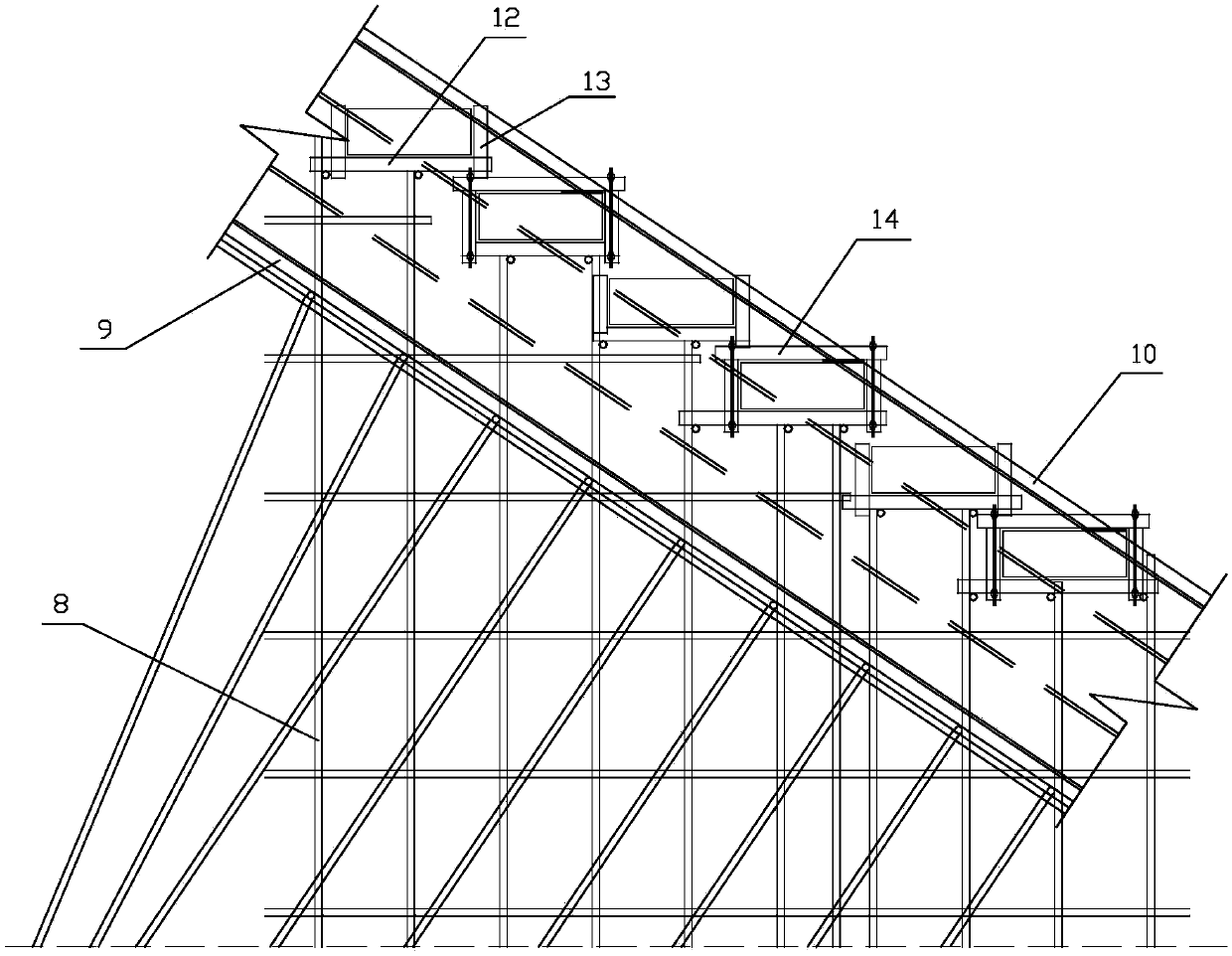

Oblique beam for grandstand of stadium and construction process for oblique beam

ActiveCN104213728AGuaranteed viewing effectSolve the problem of excessive horizontal thrustGrandstandsBuilding constructionsUpper floorPhysics

The invention belongs to the technical field of construction for oblique beams for grandstands of stadiums, and particularly relates to an oblique beam for a grandstand of a stadium and a construction process for the oblique beam. The oblique beam for the grandstand of the stadium is characterized by mainly comprising an oblique beam body; the lower end of the oblique beam body is connected with the upper end of a first-layer column through casting; the middle and the upper end of the oblique beam body are connected with a Y-shaped column through casting; two sides of the oblique beam body and the oblique beam body are provided with lugs through casting; the lugs are higher than the upper surface of the oblique beam body. The oblique beam can ensure the visual effect of upper-layer spectators under the condition of a certain inclination angle.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

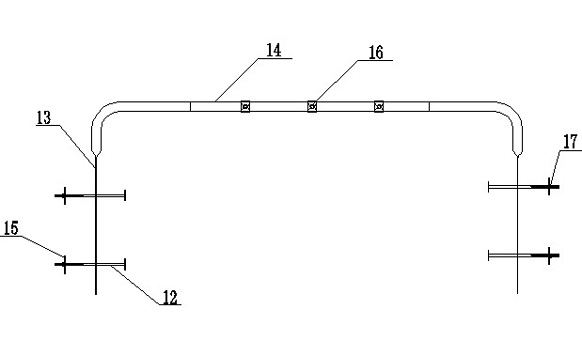

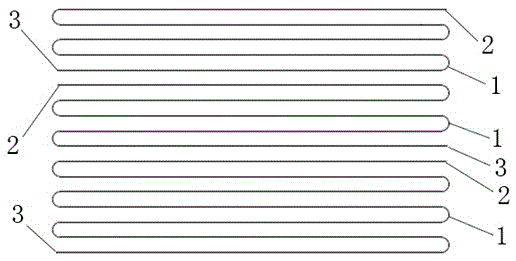

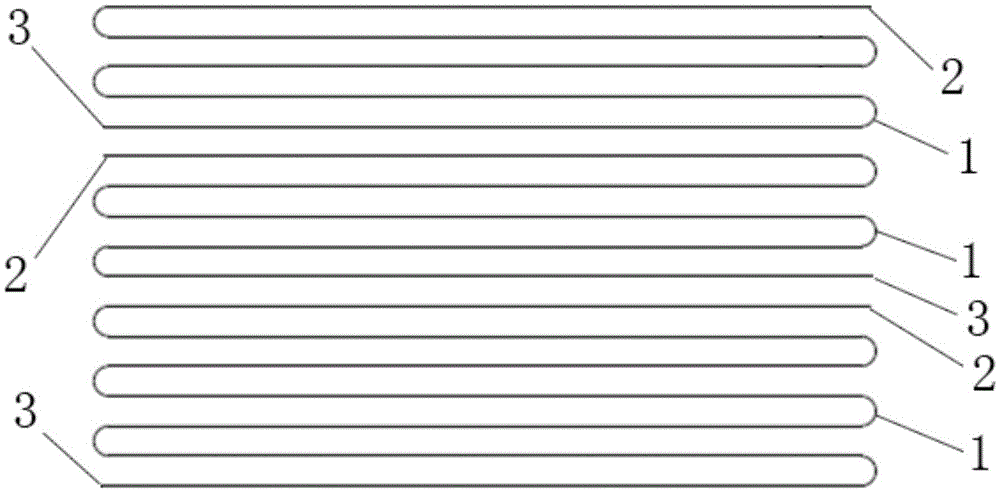

Cooling system for construction of mass concrete structure

InactiveCN105485995AUse less materialCooling effectDomestic cooling apparatusLighting and heating apparatusWater sourceCooling pipe

The invention relates to the technical field of bridge building construction, in particular to a cooling system for construction of a mass concrete structure. The cooling system comprises a plurality of cooling pipes arranged in concrete, wherein a water inlet is formed in one end of each cooling pipe; a water outlet is formed in the other end of each cooling pipe; the water inlet communicates with a water source; and the cooling system further comprises a pumping device which is used for pumping water from the water source into the cooling pipes. According to the scheme, during the casting process of the mass concrete structure, the cooling pipes are arranged in the concrete, the pumping device is started, cooling water from the water source enters the cooling pipes via the water inlets and then are drained via the water outlets, and the cooling water takes away heat of hydration in the concrete, so that the temperature difference between different parts of the mass concrete structure is reduced, and then the thermal stress in the mass concrete structure, the residual stress after hardening of the concrete construction and the risk of cracking of the concrete construction are reduced. Therefore, the structural quality of the mass concrete structure is guaranteed.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

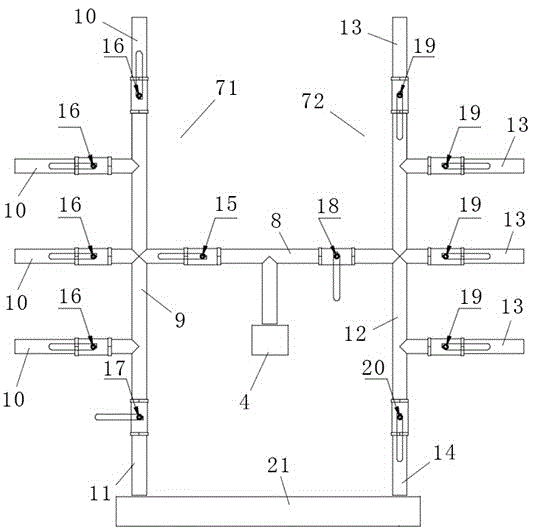

3D printing reinforced concrete structure integrated implementing device and method thereof

ActiveCN107575028ASimple structureIncrease flexibilityAdditive manufacturing apparatusBuilding material handlingReinforced concrete3D printing

The invention discloses a 3D printing reinforced concrete structure integrated implementing device. The integrated implementing device comprises a reinforcing head for conducting reinforcing on to-be-poured concrete, and a concrete spray head for pouring the concrete, and the concrete spray head sleeves the reinforcing head. According to the 3D printing reinforced concrete structure integrated implementing device disclosed by the invention, the effect that building structure reinforcing and concrete pouring are conducted at the same time is achieved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

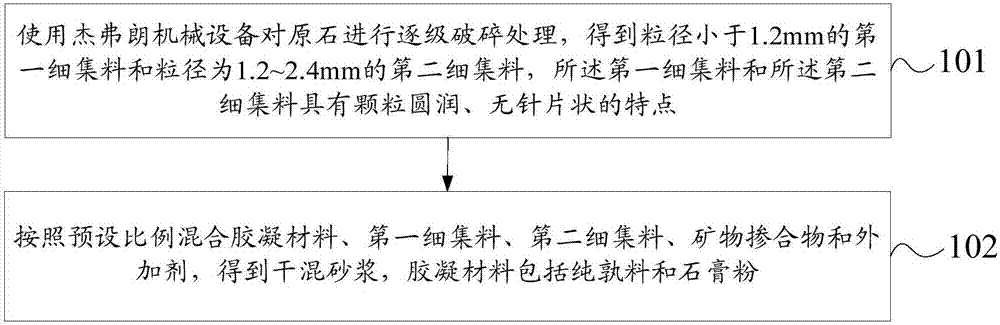

Dry-mixed mortar and preparation method thereof

The invention provides dry-mixed mortar and a preparation method of the dry-mixed mortar. The dry-mixed mortar comprises the following components in parts by weight: 10-50 parts of a binding material, 50-70 parts of a first fine aggregate with the grain size less than 1.2 mm, 20-30 parts of a second fine aggregate with the grain size of 1.2-2.4 mm, 50-60 parts of a mineral admixture, and 2-5 parts of an additive; the binding material comprises 95-96 parts by weight of a pure clinker and 4-5 parts by weight of gypsum powder; the additive comprises one or more of a latex powder, a water repellent, a stabilizer, cellulose, a wood fiber, starch ether, a thixotropic lubricant and an air entraining agent; the first fine aggregate and the second fine aggregate are obtained by crushing and shaping a raw stone step by step, and have the characteristics that the particle is round and is not elongated or flaky, and the obtained dry-mixed mortar is higher in workability, flows conveniently, is easy to level in the construction, is high in construction efficiency and high in adhesive property, and has the special functions of waterproofness, thermal insulation and the like.

Owner:辽宁煜梽新型建材有限公司

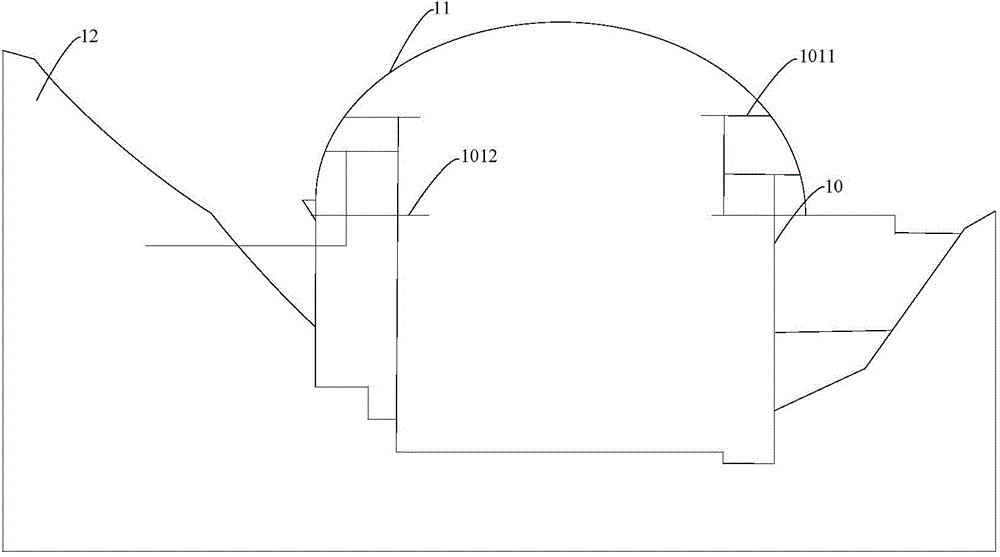

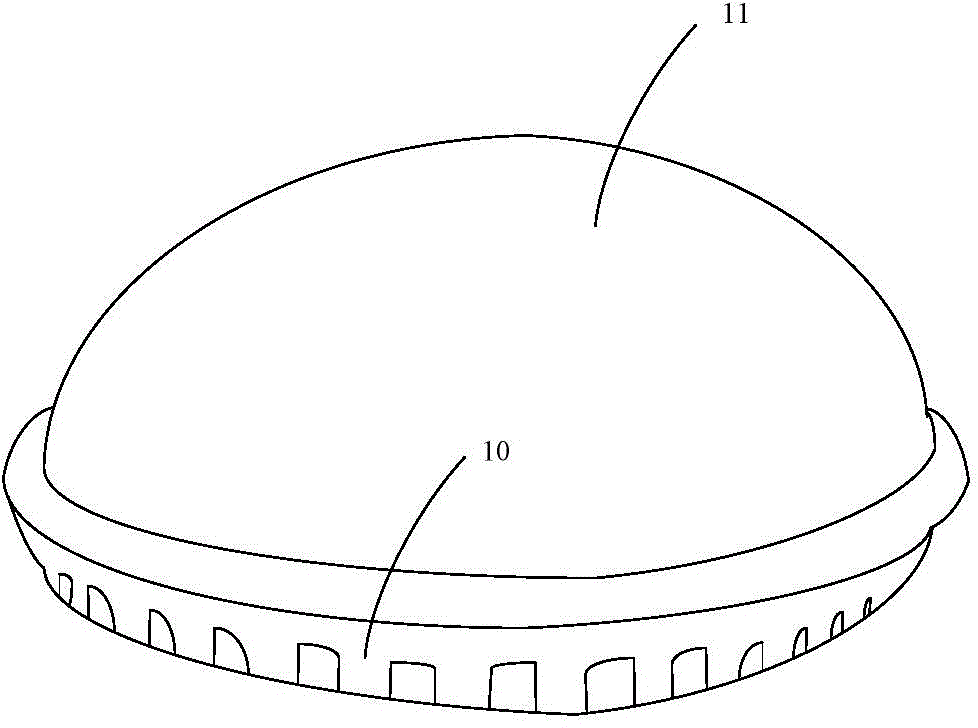

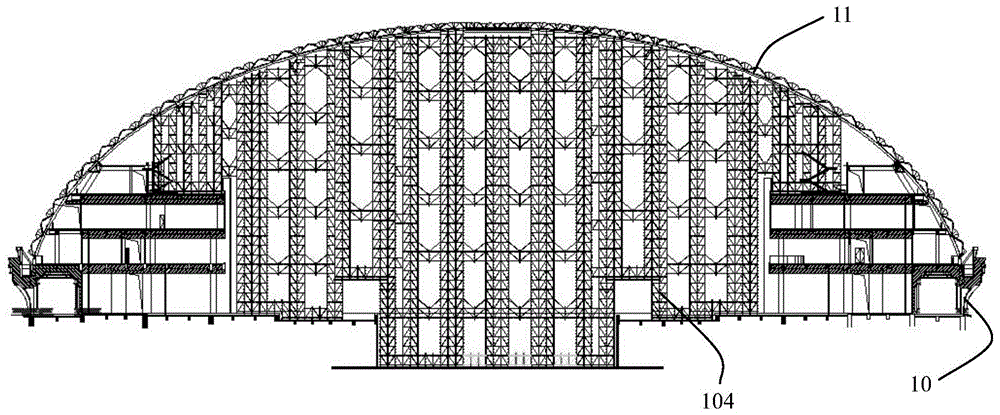

Construction method of large-span ellipsoidal aluminum alloy dome structure

ActiveCN104314169ASolve the problem of constructing ellipsoidal aluminum alloy dome structureLarge bearing capacityArched structuresVaulted structuresSpandrelAluminium alloy

The invention relates to a construction method of a large-span ellipsoidal aluminum alloy dome structure. The construction method includes pouring to form an annular supporting structure at the top of a building main structure; fixing a support on the annular supporting structure; assembling aluminium alloy rod members on the support to form an aluminum alloy net shell structure, measuring curvature in the process of assembling the aluminum alloy rod members, adjusting deviation through connecting joints of the support and the aluminium alloy rod members, and forming the ellipsoidal aluminum alloy net shell structure at the top of the building main structure; hermetically connecting waterproof aluminium plates on the aluminum alloy net shell structure. The aluminum alloy net shell structure is formed by assembling the aluminum alloy rod members, and ellipsoidal curvature is realized through the connecting joints of the support and the aluminum alloy rod members, so that the aluminum alloy net shell structure has stability higher than that of an existing polygonal structure unit; assembling operation is simple, construction efficiency is high, and the formed aluminum alloy net shell structure is stable in structure and high in load bearing capacity.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

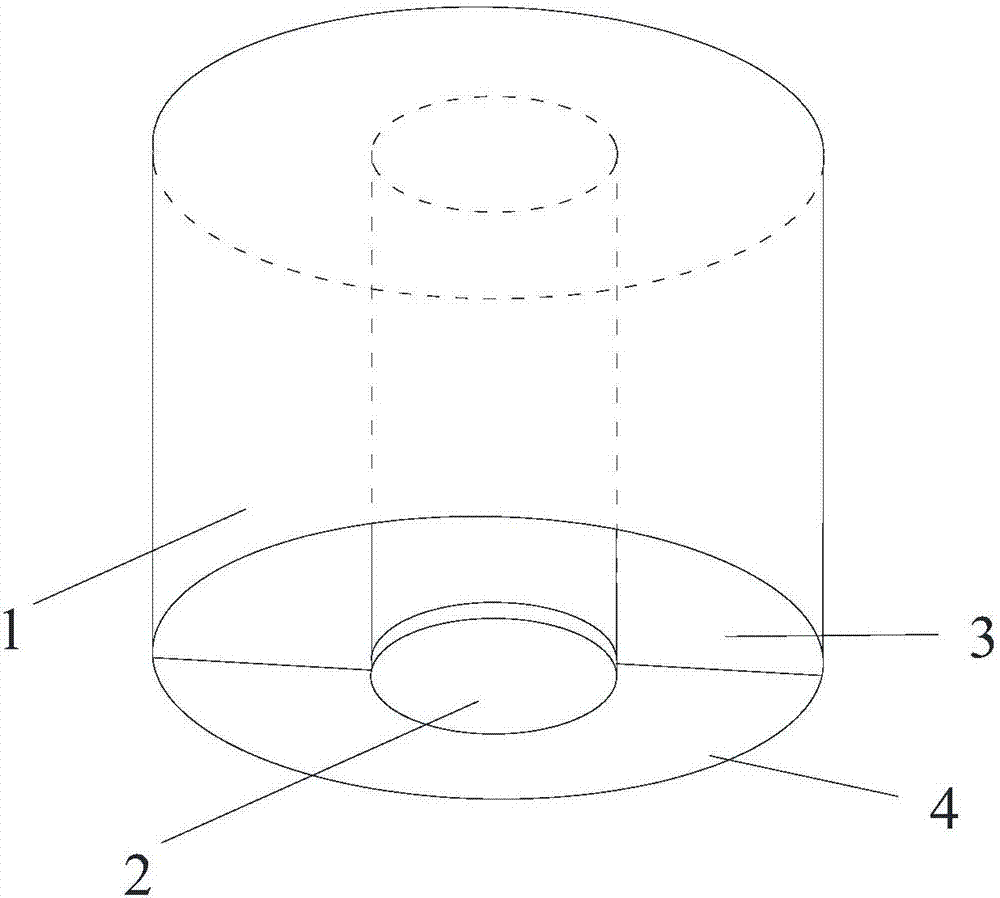

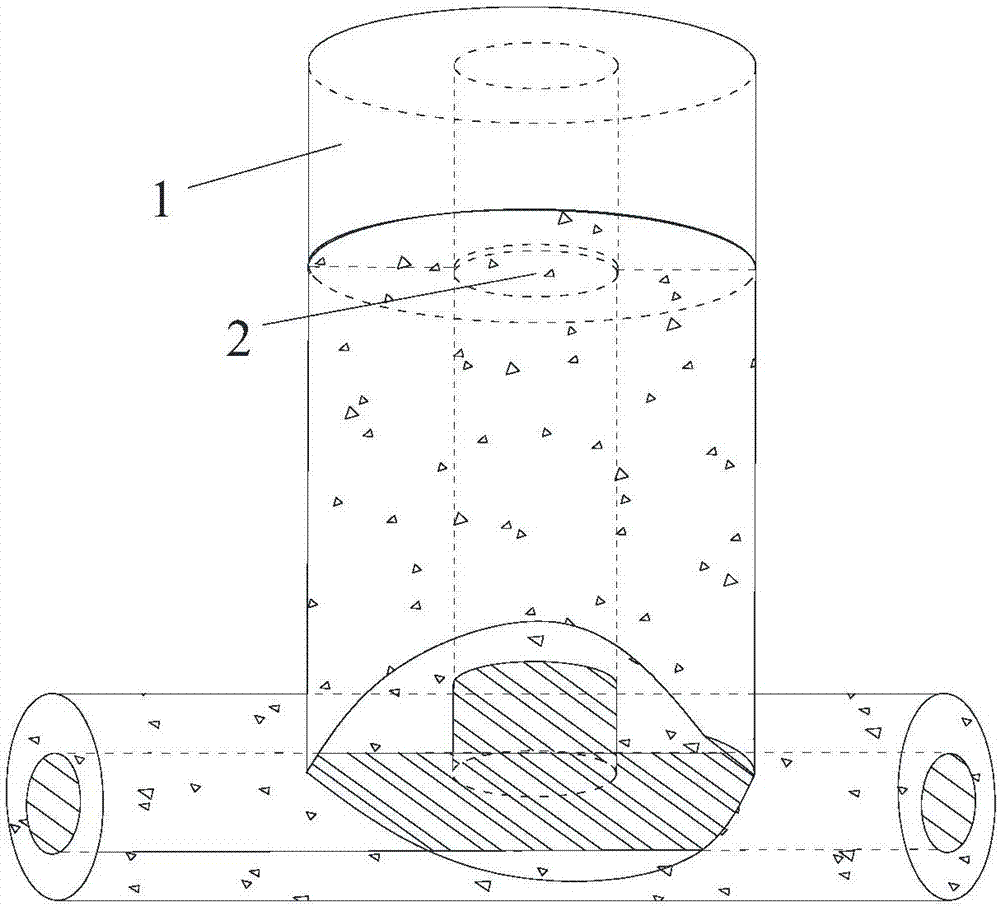

Construction method of bridge bearing platform

ActiveCN105544583AUse less materialCooling effectFoundation engineeringArchitectural engineeringBuilding construction

The invention relates to the technical field of bridge construction, in particular to a construction method of a bridge bearing platform. The construction method sequentially includes the following steps that A, the bridge bearing platform to be cast is layered in the vertical direction; B, according to layering in the step A, concrete of the bottommost layer is poured; and C, after the concrete poured in the step B is solidified, a concrete pouring method in the step B is repeated, and concrete is poured layer by layer until casting of the bearing platform is completed. According to the scheme of the invention, when casting construction of the bridge bearing platform is carried out, the bridge bearing platform is layered firstly; besides, cooling devices are arranged to cool the interior of the concrete, temperature differences between various positions in a concrete structure are reduced, and thus the thermal stress in the concrete structure is reduced, the residual stress after the concrete structure is hardened is reduced, and the risk that cracks occur in the concrete structure is reduced; and in this way, the structural quality of the concrete structure is guaranteed.

Owner:广西长兴工程建设有限公司 +1

Protective reinforced rib template for construction

PendingCN107893506AEconomicalGuaranteed structural qualityStrutsConstruction materialMoistureCement mortar

A protective reinforced rib template for construction mainly comprises a rigid fiber mortar reinforced rib template body, the rigid fiber mortar reinforced rib template body comprises a rib plate anda rib strip. The rib strip is fixed to the inner plate face of the rib plate, the rib plate and the rib strip are prepared from cement mortar or fiber cement mortar, or prepared from that rib ropes transversely and / or longitudinally arranged in the cement mortar or the fiber cement mortar at intervals, or prepared from the cement mortar or the fiber cement mortar and fiber cloth and / or fiber meshes, or prepared from the cement mortar or the fiber cement mortar and the fiber cloth and / or the fiber meshes and / or fiber ropes. The protective reinforced rib template for construction has theadvantages of being low in weight, high in anti-cracking and anti-impact strength, simple in structure, convenient to manufacture, convenient to transport, low in cost, economical and practicable andthe like. Form removing is not needed, acceleration of the construction schedule is facilitated, and the construction quality is improved. Evaporating of moisture in cast-in-place concrete slurry canbe prevented, and the protective reinforced rib template can be individually and accurately customized, and is convenient to construct and install.

Owner:长沙紫宸科技开发有限公司

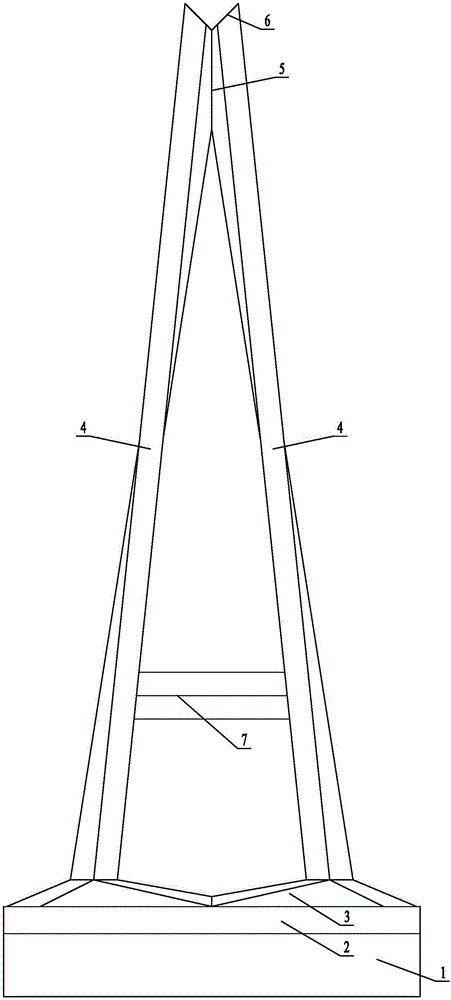

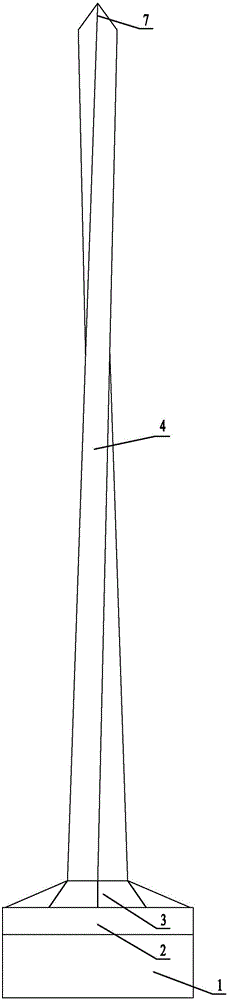

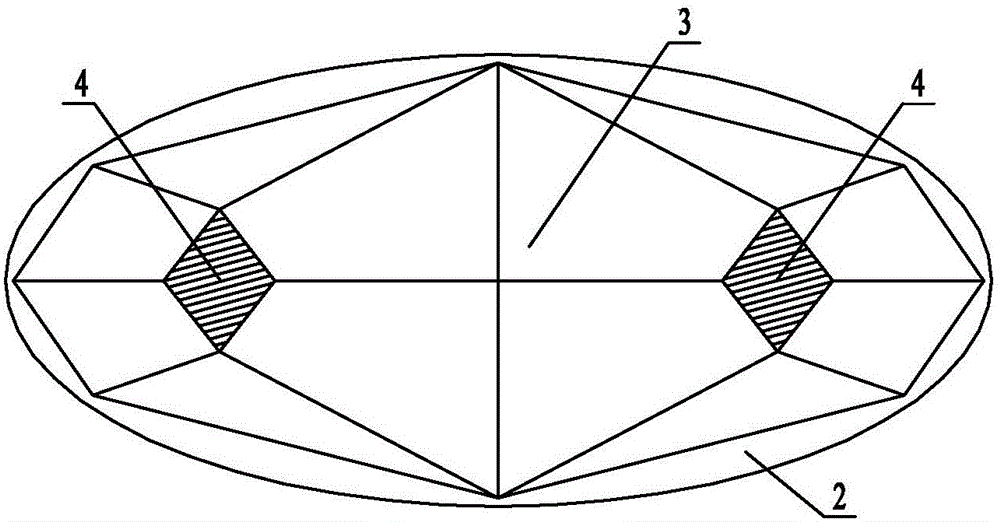

Space twisting curved surface A type bridge cable tower and construction method thereof

ActiveCN105887679AImprove the landscape effectNovel shapeBridge structural detailsBridge erection/assemblyEngineeringTransverse beam

The invention discloses a space twisting curved surface A type bridge cable tower and a construction method thereof. The cable tower comprises a foundation, a bearing platform, a tower seat, tower columns, an inclined top tower crown and a lower transverse beam, wherein two tower columns are arranged; the two tower columns are inclined toward the inside and are symmetrically arranged to form two inclined edges of an A shape; the twisting directions of the two tower columns are different; a continuous twisting shape is formed from each tower column to the tower bottom and from each tower column to the tower top; the twisting angle, relative to the tower bottom, of the tower top is 90 degrees; the horizontal cross section of each tower column is a rhombus section and each rhombus edge of the rhombus section is a straight line; four edges of any one horizontal cross section of each tower column are straight lines before and after twisting; the surface of the periphery of each tower column is a curved surface composed of a plurality of space straight lines; the crossed line formed by crossing of the surface of the periphery of each tower column and any vertical plane is the straight line; the tower tops of the two tower columns are fused at the tower top to form a tower top fusion section; and the lower transverse beam is a transverse edge of the A shape and the whole body of the cable tower is A-shaped and is of a uniform straight-line twisted shape. The invention also discloses the construction method of the space twisting curved surface A type bridge cable tower.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

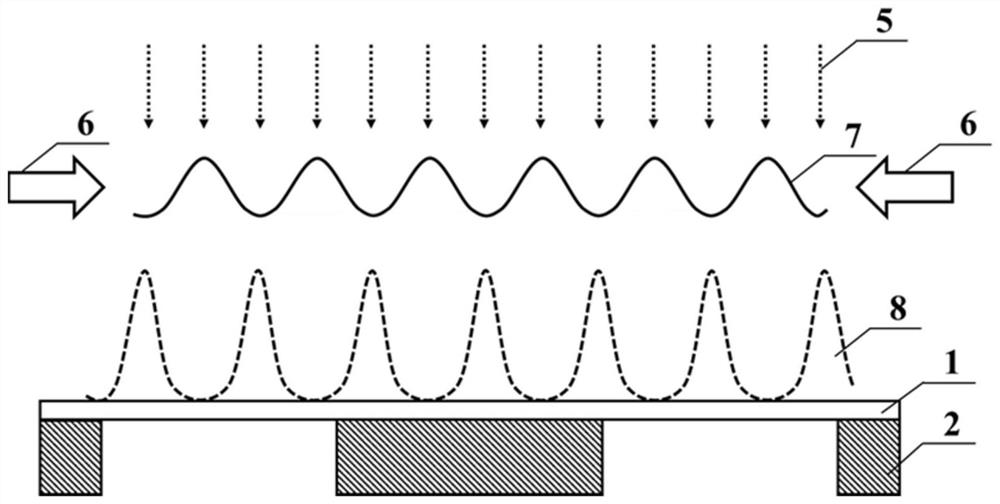

Preparation method of self-tracing grating standard substance capable of accurately shortening pitch value

The invention relates to a preparation method of a self-tracing grating standard substance capable of accurately shortening a pitch value, which is used for preparing a hundred-nanometer-scale and below small-pitch tracing standard substance on the basis of a laser convergence atomic deposition technology and a soft X-ray interference photoetching technology, and comprises the following steps of:(1) obtaining a mask substrate; (2) adopting a laser convergence atomic deposition technology to deposit and prepare a mask on the mask substrate; (3) obtaining a photoresist sample which comprises photoresist and a second underlayment, exposing and developing the photoresist by adopting the mask through a soft X-ray interference photoetching technology to obtain a photoresist grating structure; and (4) transferring the photoresist grating structure to the second underlayment to obtain the self-tracing grating standard substance. Compared with the prior art, the self-tracing grating standard substance prepared by the method has the advantages of high precision, traceability, accurate shortening of the pitch value and the like.

Owner:TONGJI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com