Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

A technology of cold-formed thin-walled steel and slab-column structures, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of light steel dense rib keel composite structure with heavy workload, self-heavy concrete material, single installation method, etc., to achieve The effect of rapid green construction, reduction of building material consumption, and improvement of the degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments of the description.

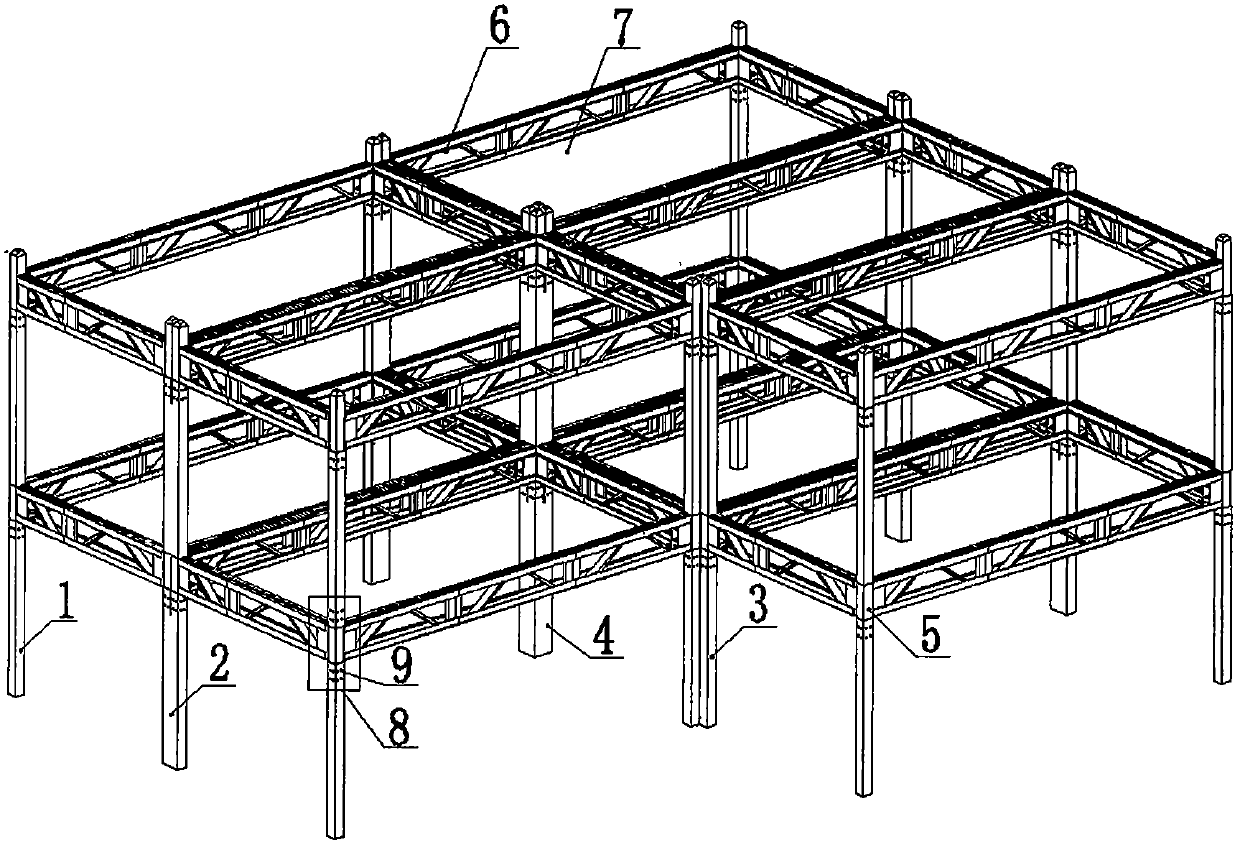

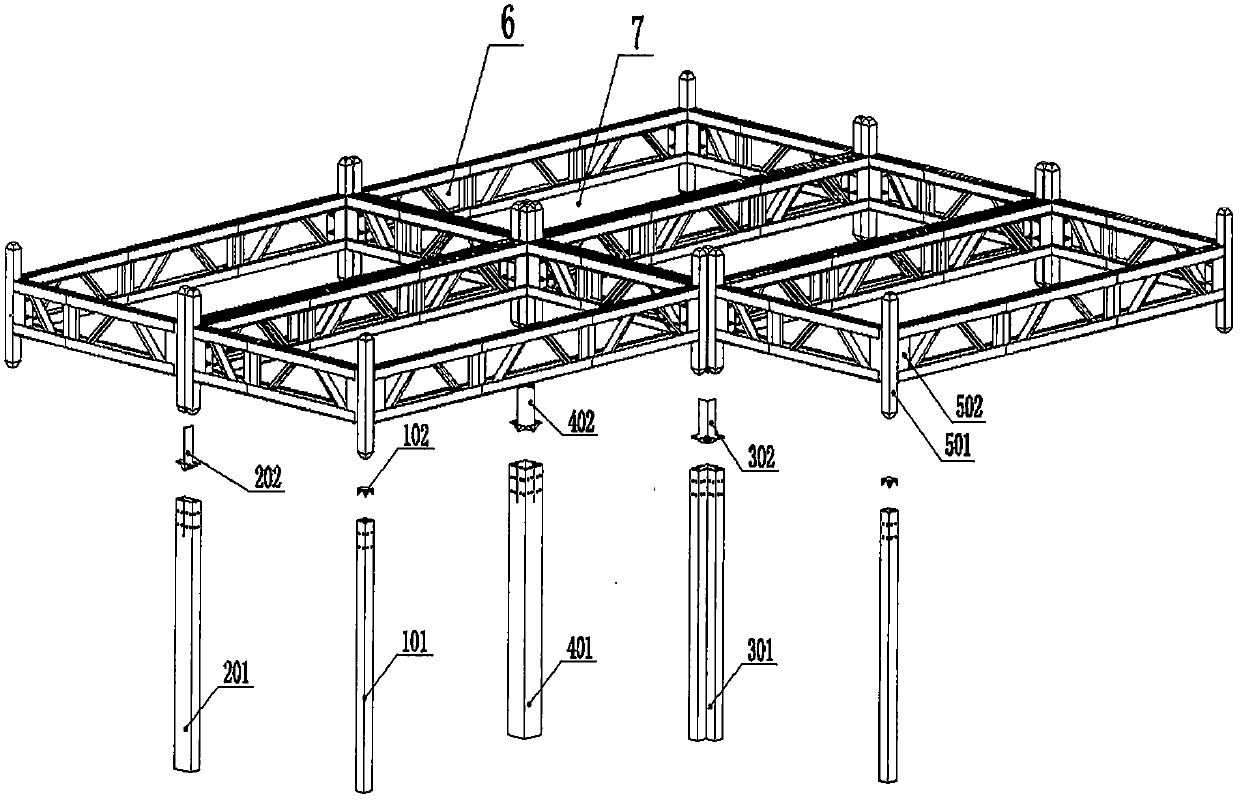

[0042] An assembled cold-formed thin-walled steel plate column structure mortise and tenon joint system, the system includes a single-hole column (1), a double-hole column (2), a three-hole column (3), a four-hole column (4), tenon (5), light steel truss beam (6), floor module (7) and the connection method between floor and column (8).

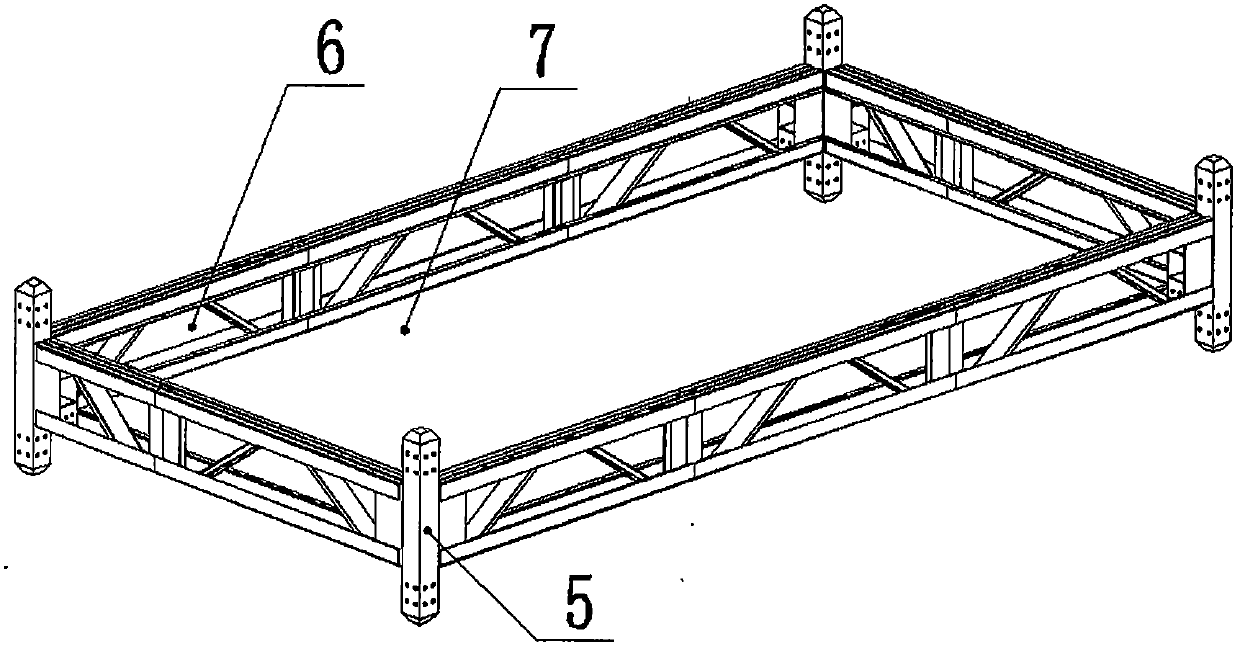

[0043] refer to figure 2 As shown, the floor module (7) is a floor slab prefabricated in the factory according to the building modulus, and the floor module (7) includes a tenon (5) and a light steel truss beam (6); the light steel truss beam (6) is composed of a chord (601 ) and the diagonal rod (602) are connected by self-tapping screws, the chord (601) is a U-shaped section form with grooves and outer curling, the diagonal rod (602) is C-shaped steel; the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com