Assembly type steel reinforced concrete framework spatial module structure and system and construction method

A modular structure and prefabricated technology, applied in building construction, construction, and building materials processing, etc., can solve the problems of complex construction of node parts, large workload of on-site hoisting, poor seismic performance, etc., to achieve easy construction and installation, The effect of improving hoisting efficiency and improving prefabrication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

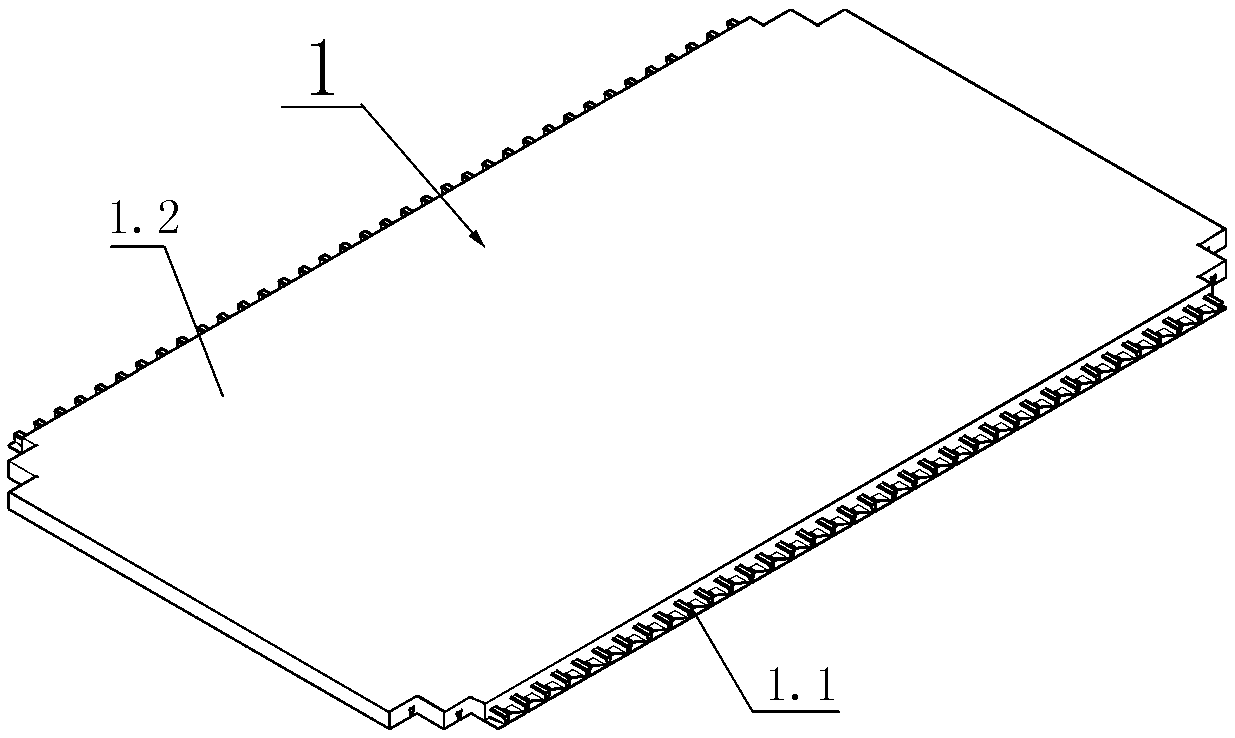

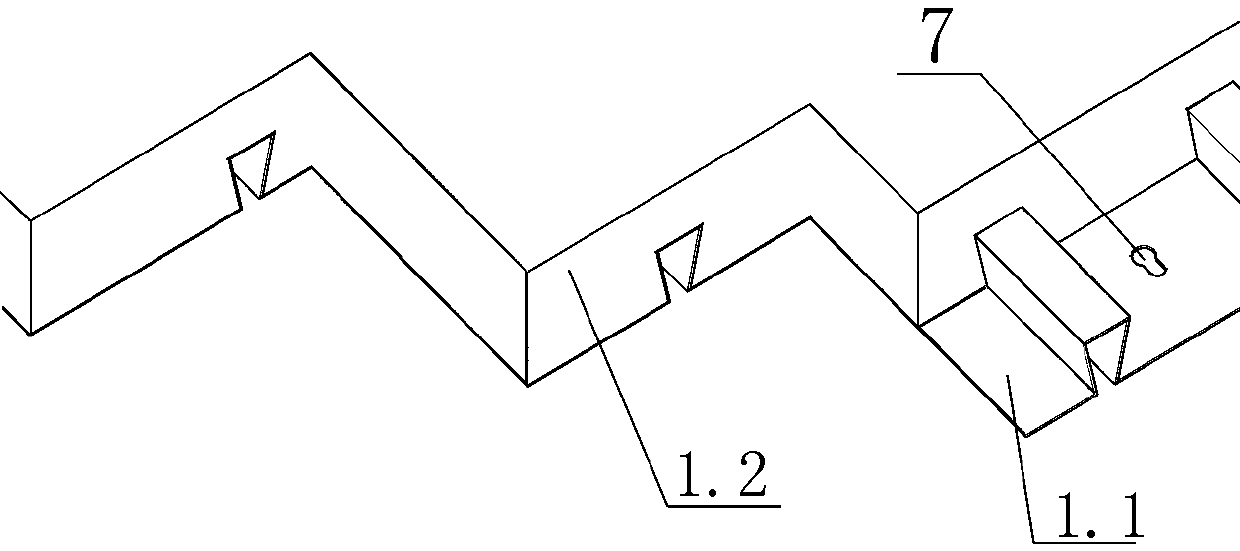

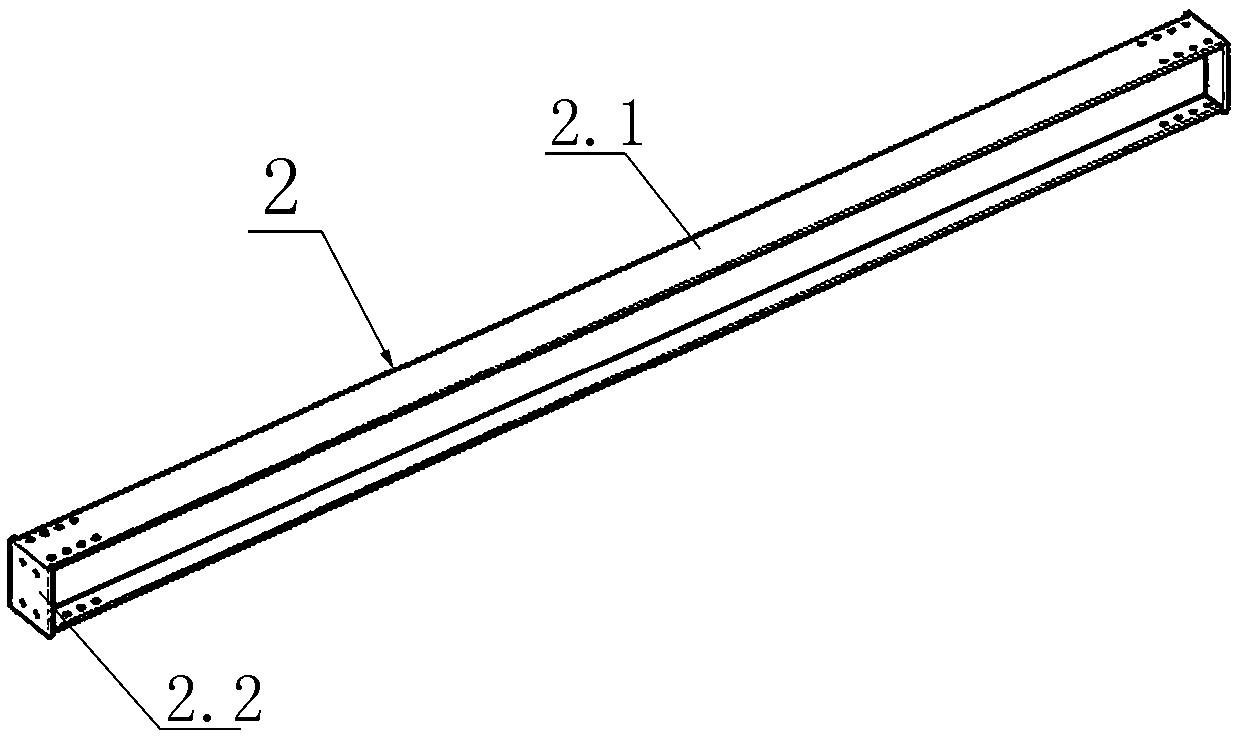

[0055] like Figure 1-14 As shown, this prefabricated steel concrete frame space module structure includes a bell jar-shaped five-sided space spliced by four prefabricated walls 5, steel columns 4, steel beams 2, steel longitudinal beams 3 and a steel-concrete composite floor 1 Modular structure; the prefabricated wall body 5 includes a rectangular wall panel body 5.1 and profile steel rods 5.2 detachably connected to both sides of the wall panel body 5.1; the top of the profile steel rod 5.2 is connected to the top surface of the wall panel body 5.1 flush, the bottom of the shaped steel rod 5.2 exceeds the bottom surface of the wall panel main body 5.1, and the length of the excess part is adapted to the thickness of the steel-concrete composite floor 1; At the corner position, and each steel column 4 is detachably connected with two adjacent prefabricated walls 5; the top of the steel column 4 exceeds the top of the prefabricated wall 5, and the length of the excess part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com