Patents

Literature

53results about How to "Improve structural ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

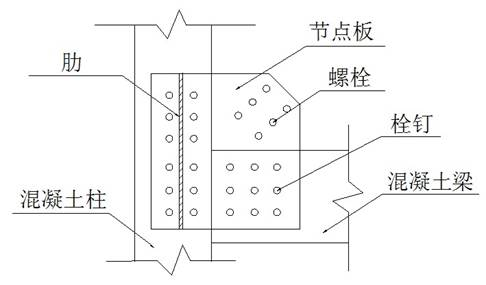

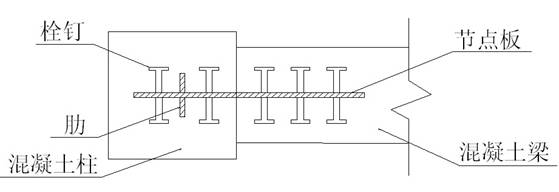

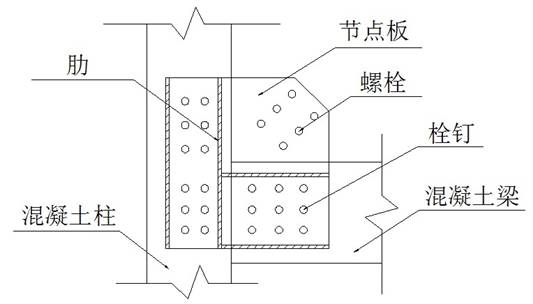

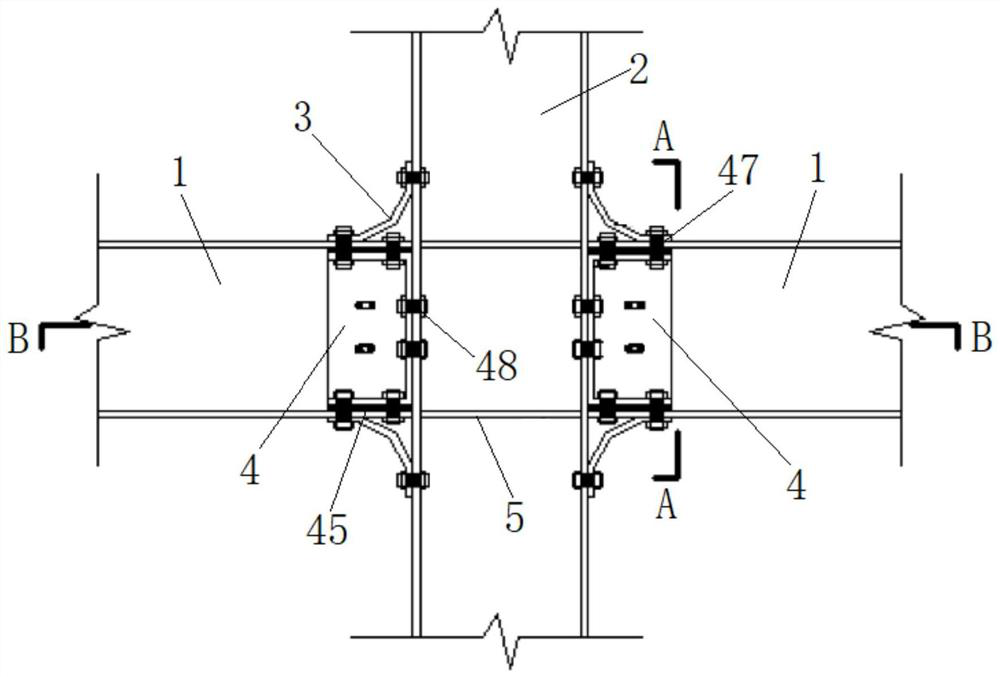

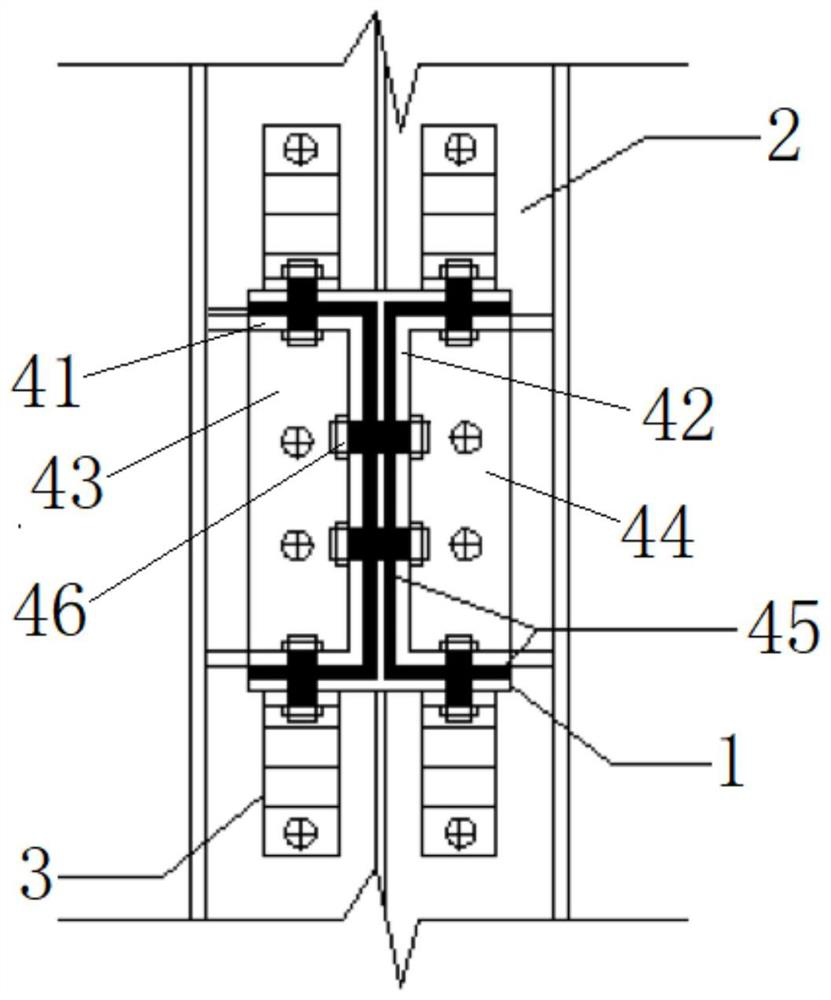

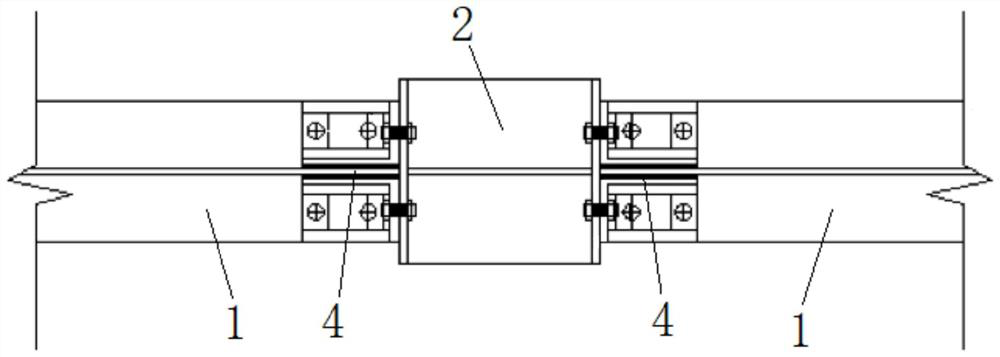

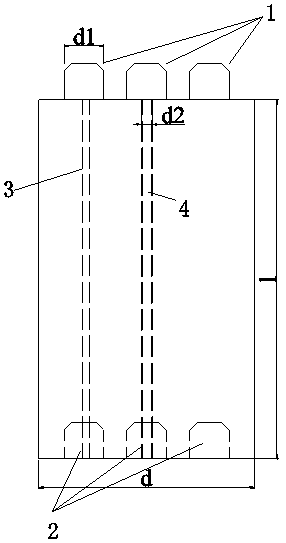

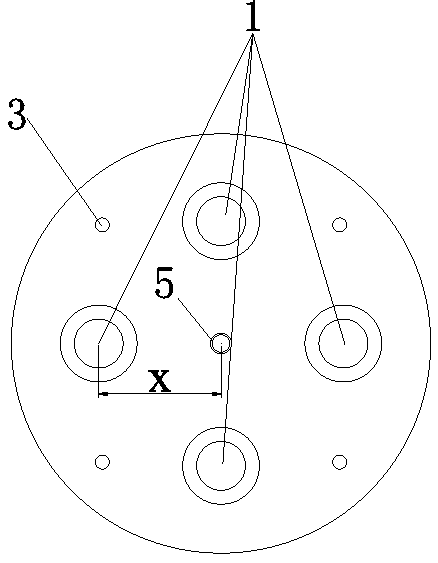

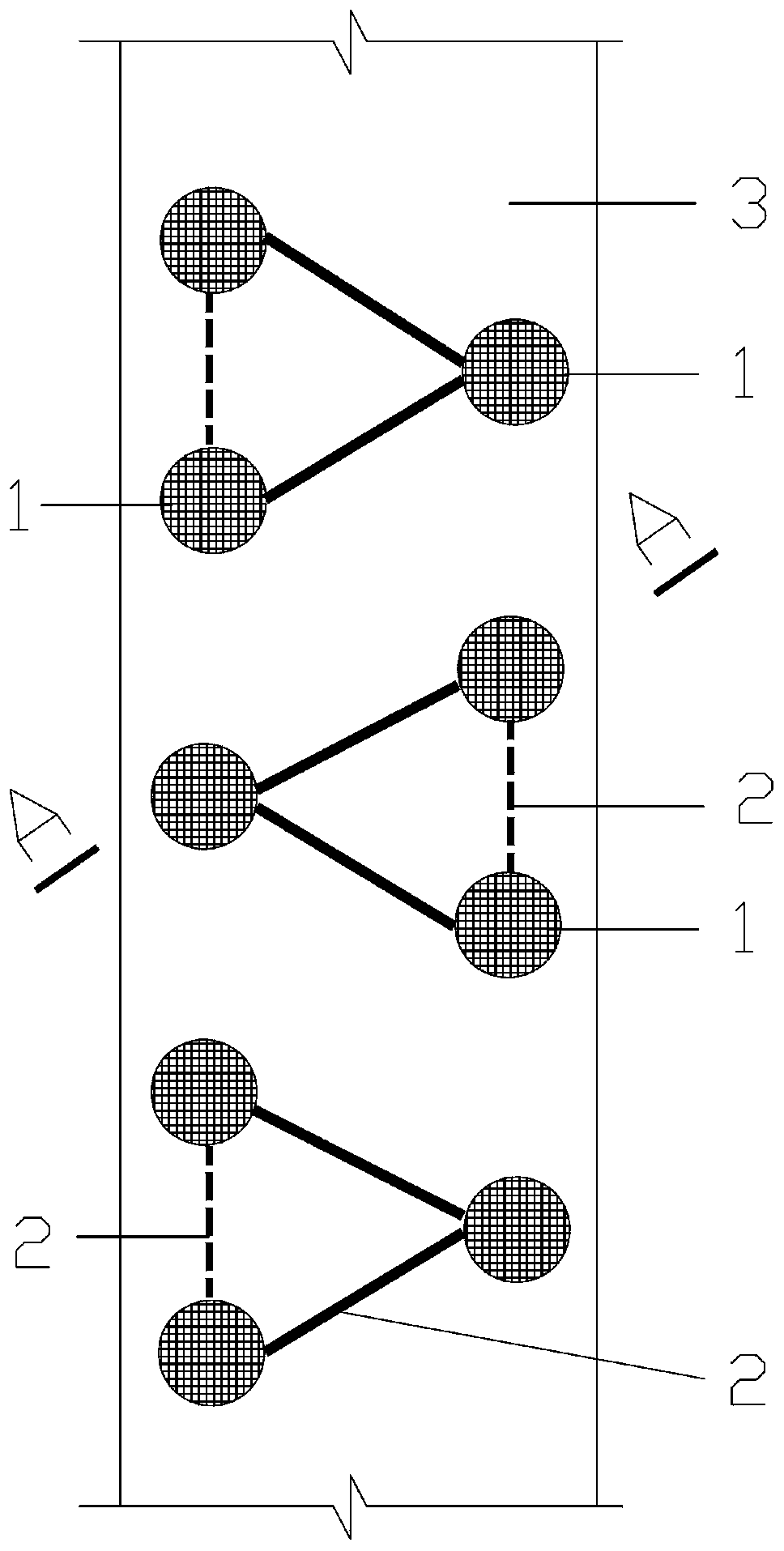

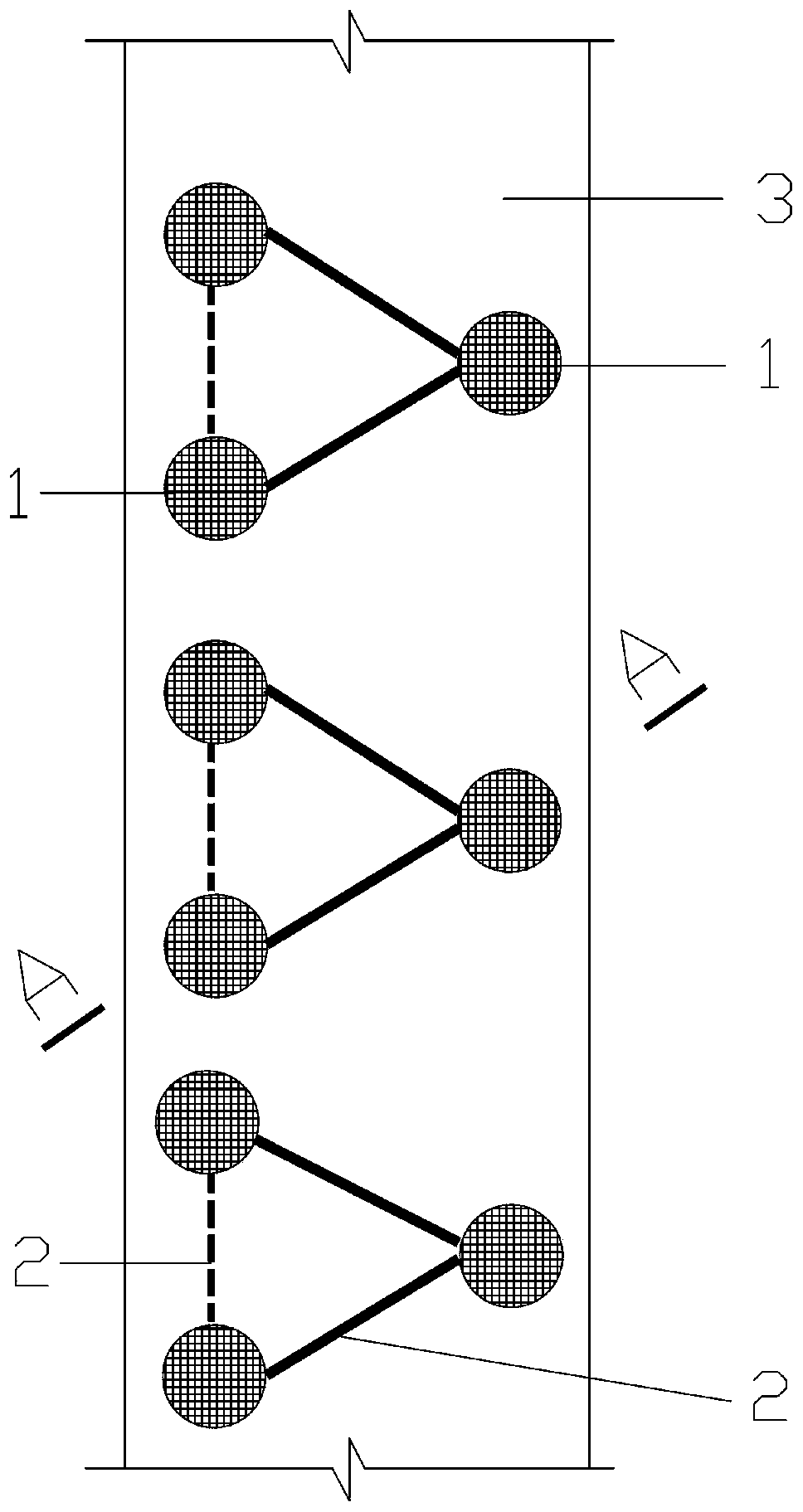

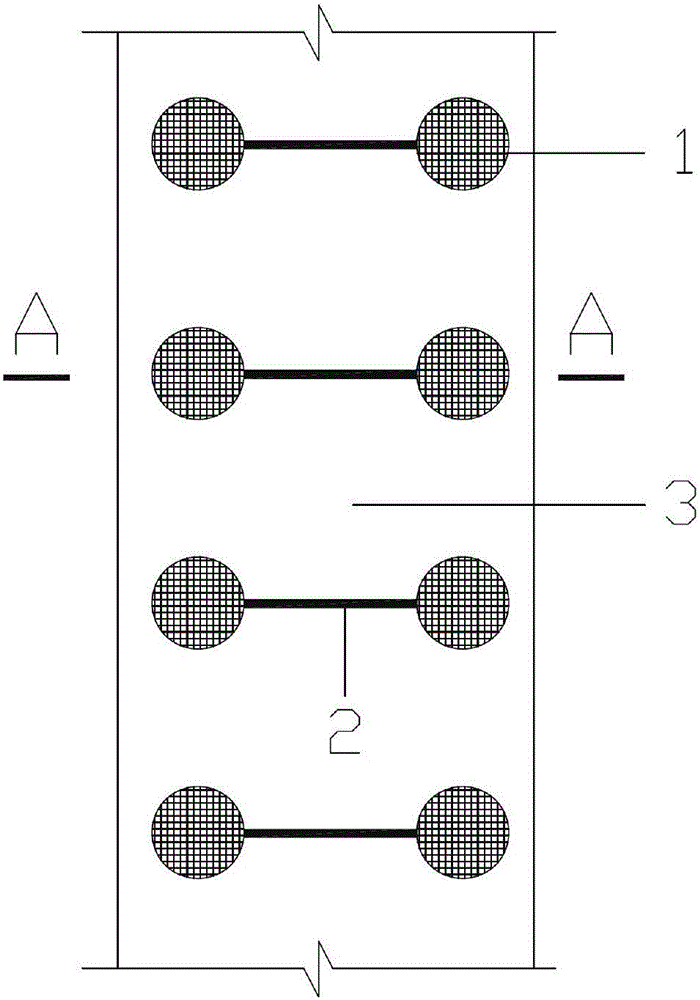

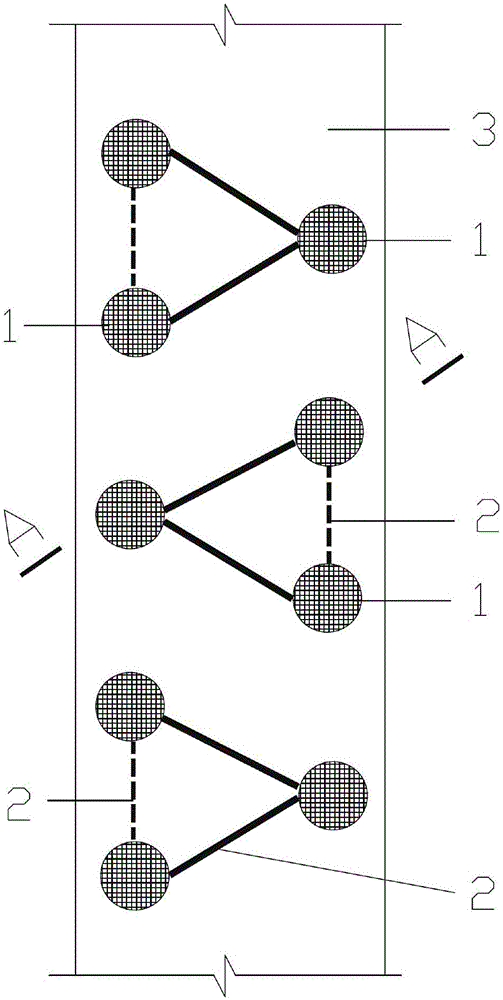

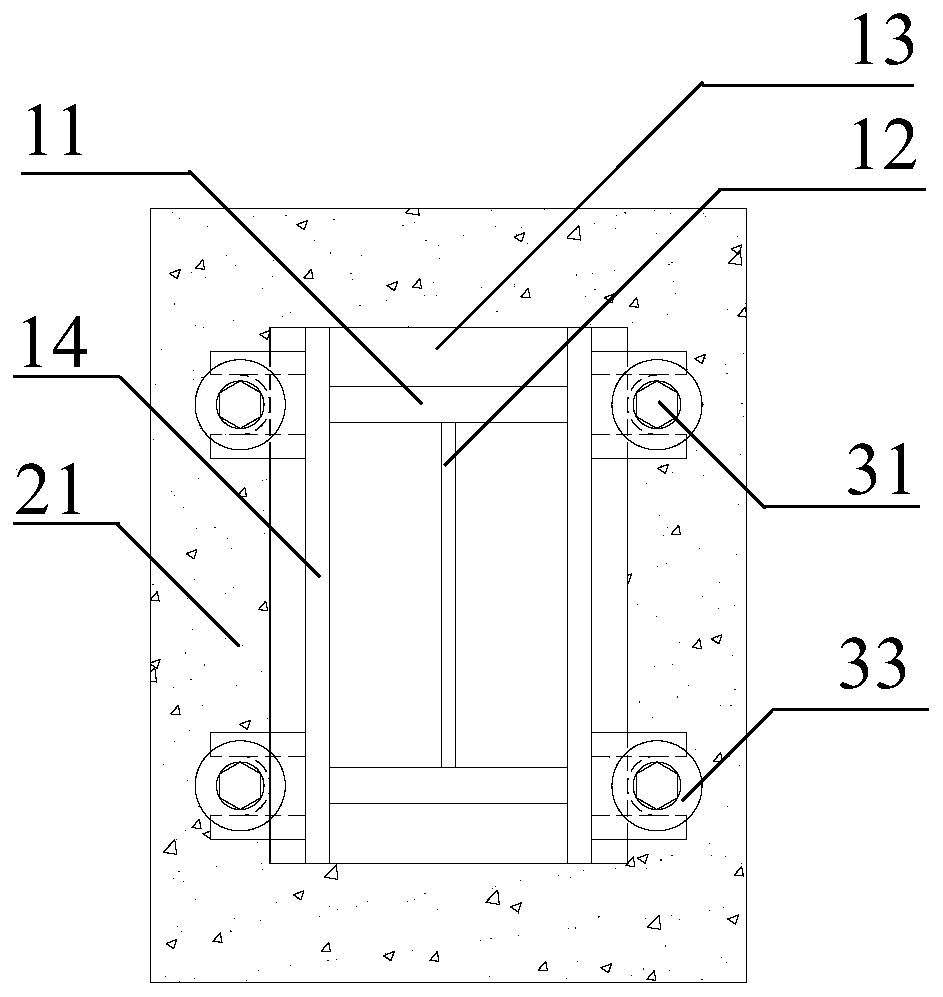

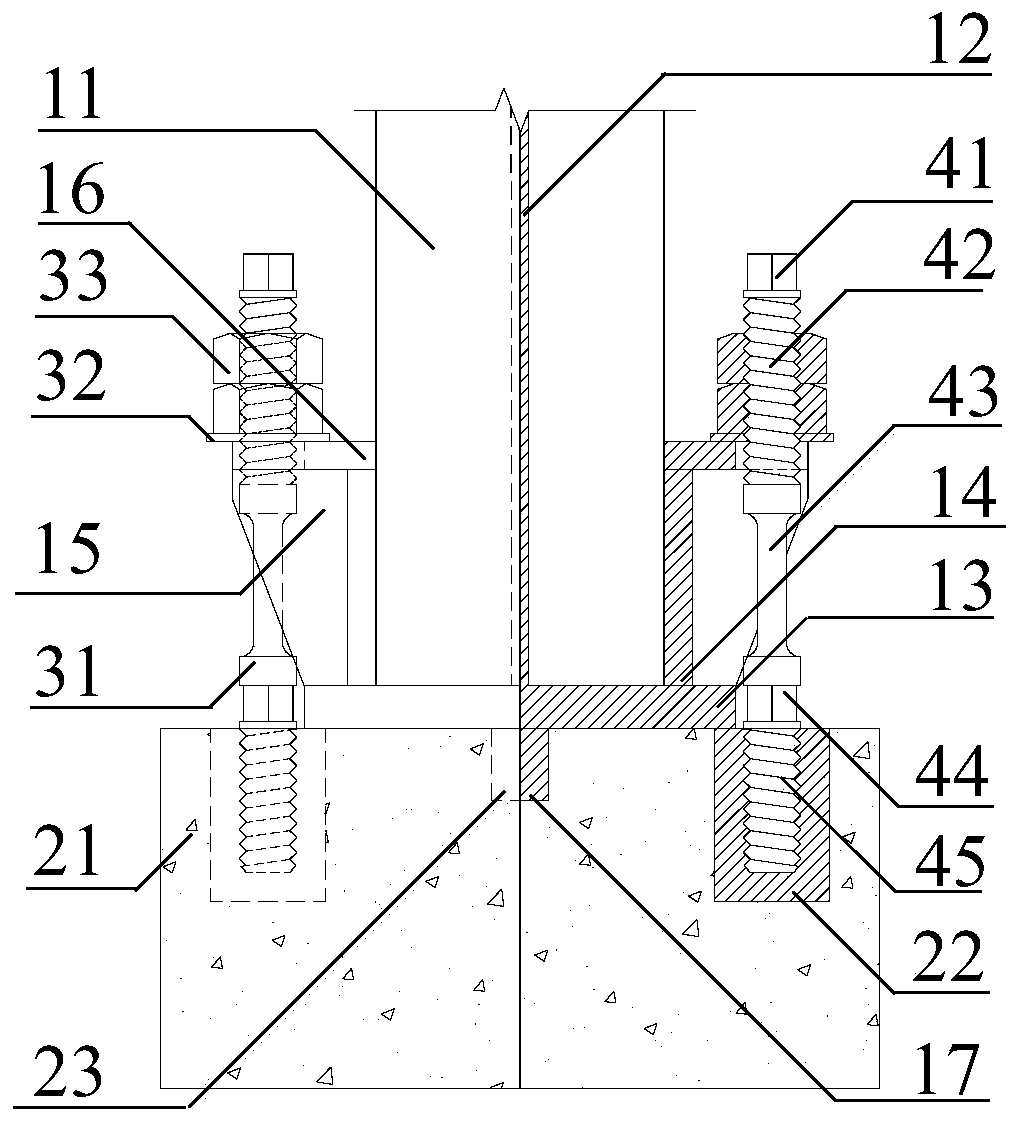

BRB (buckling restrained brace) concrete frame beam-column joint

InactiveCN102011434ALow costImprove structural ductilityShock proofingBuckling-restrained braceConcrete beams

The invention discloses a BRB (buckling-restrained brace) concrete frame beam-column joint, belonging to a building element. The joint disclosed by the invention consists of a buckling restrained brace and a concrete beam-column. The invention is characterized in that the BRB concrete beam-column joint can be a stud-connected joint which is a joint of the beam and column of a BRB concrete frame; the joint is an A-shaped steel joint which is the joint of the beam and column of the BRB concrete frame; the joint can be a combined joint which is the joint of the beam and column of the BRB concrete frame; and the joint is a connecting joint of a BRB and a foundation, and a joint of the BRB of the BRB concrete frame and the foundation. The joint is composed of the BRB and the concrete beam-column, therefore, the anti-seismic capability of the joint is good, and the joint can be applied to large-span and high-rise concrete frames.

Owner:SHENYANG JIANZHU UNIVERSITY

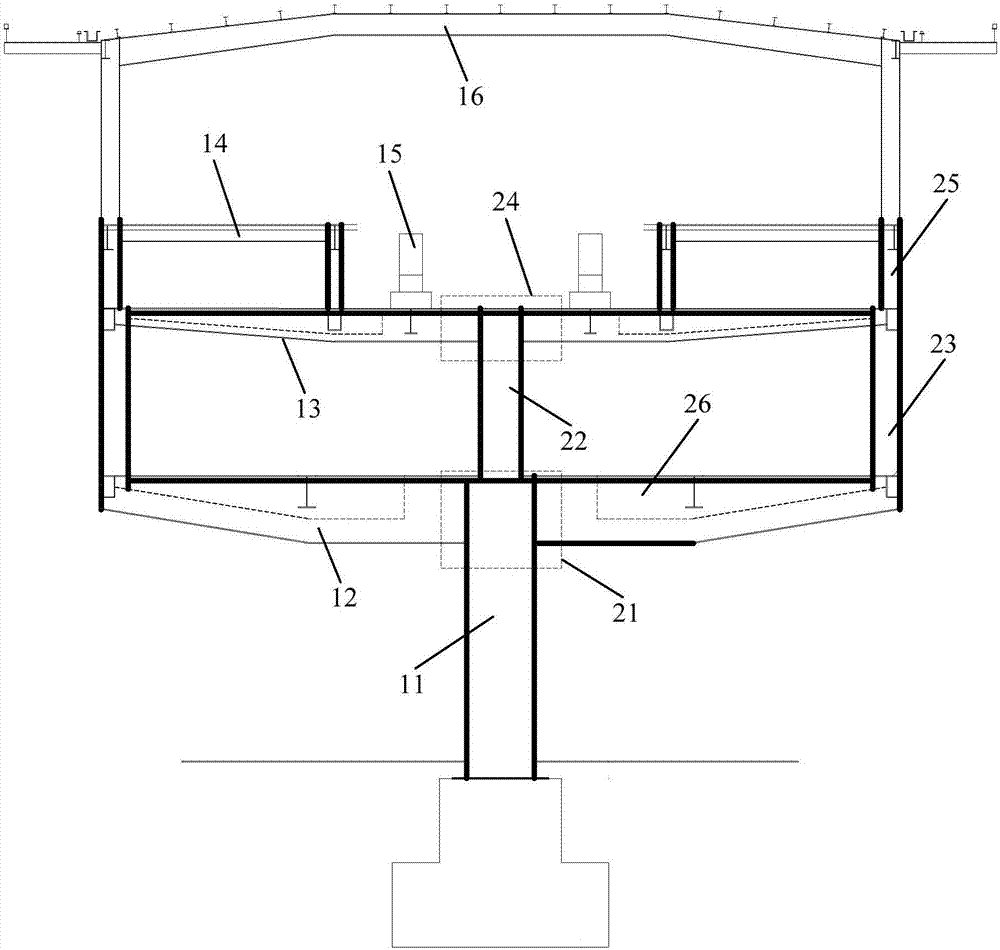

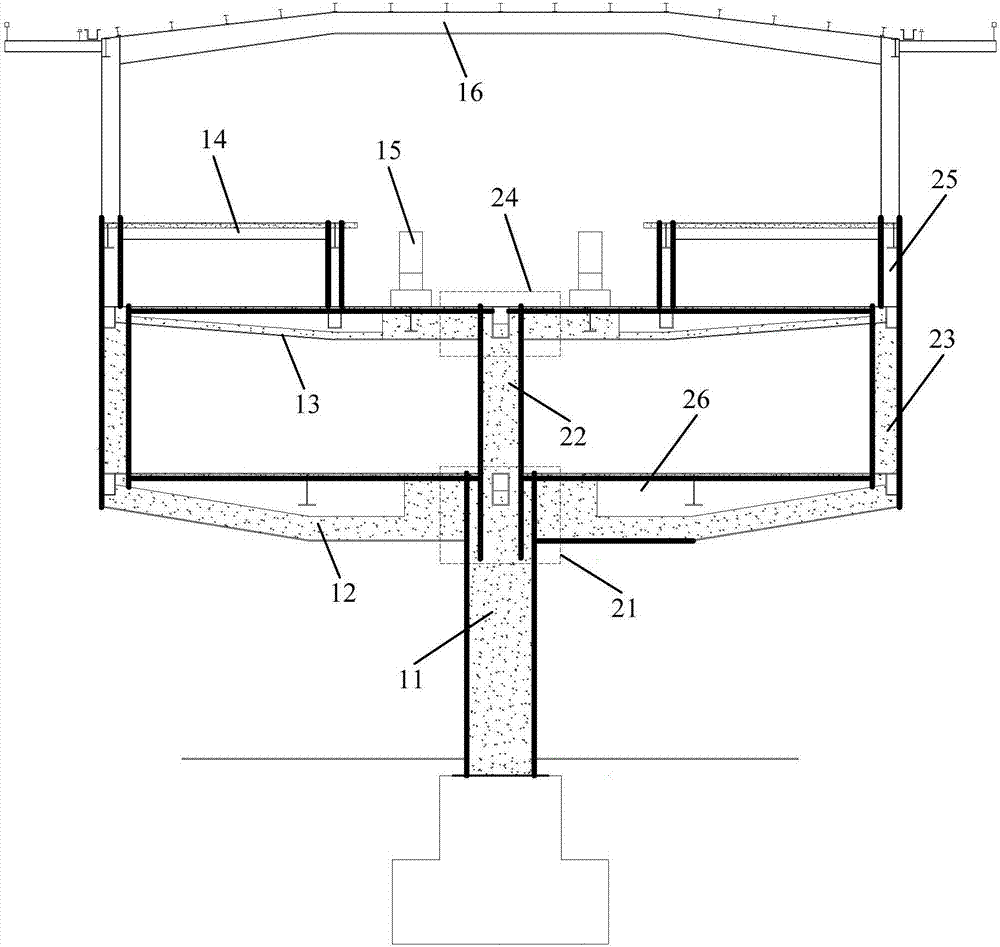

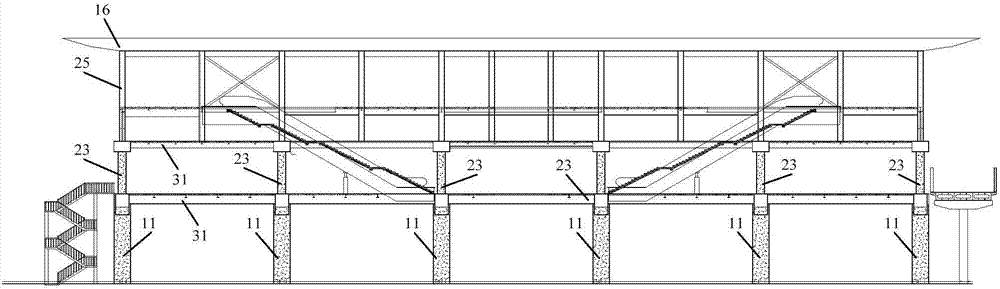

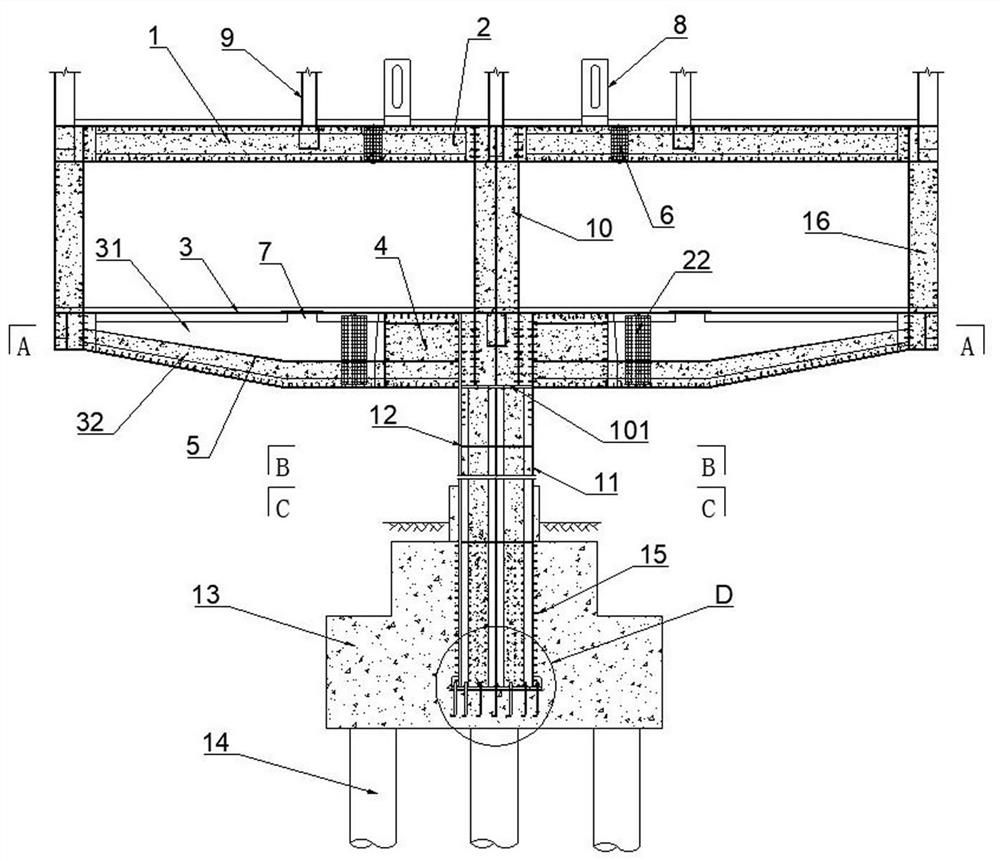

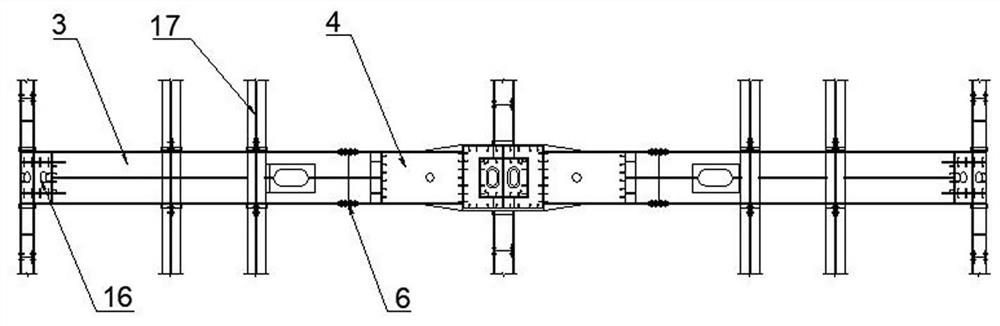

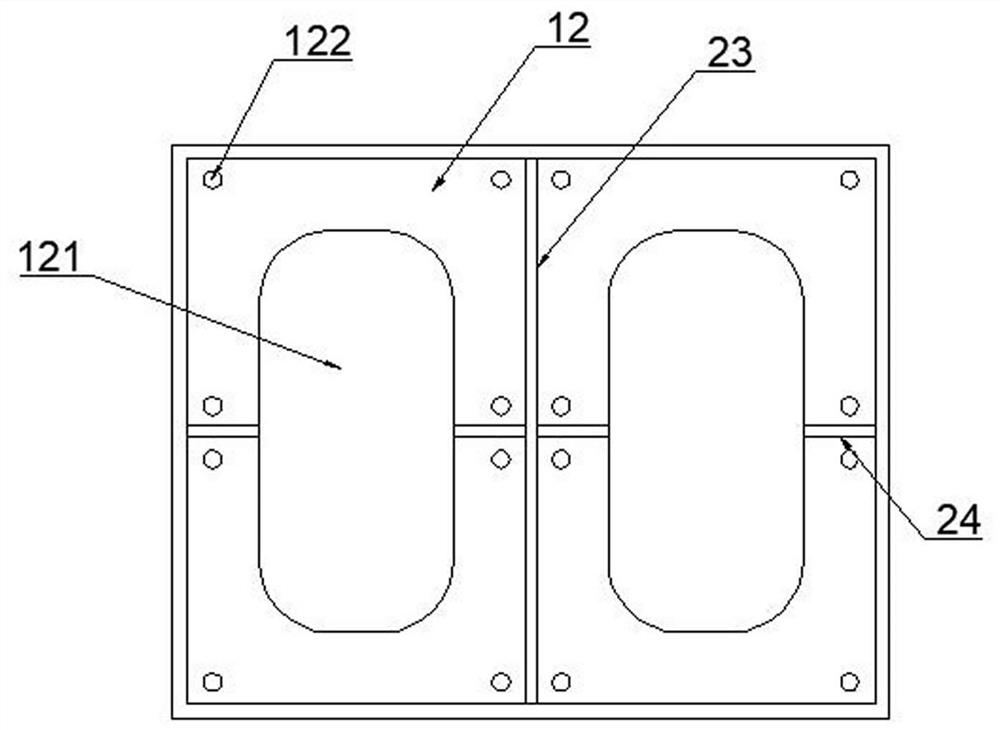

Track traffic overhead station

The invention discloses a track traffic overhead station. The track traffic overhead station comprises a plurality of single-column steel-concrete combined frame structures, and each single-column steel-concrete combined frame structure comprises a pier column, a first steel-concrete combined beam, a second steel-concrete combined beam, platform structures, track beams and a roof canopy; the first steel-concrete combined beams are mounted at the tops of the pier columns through first combined beam column nodes; the second steel-concrete combined beams are mounted at the tops of a middle column and side columns of a station hall layer through second combined beam column nodes; the roof canopies are mounted at the tops of supporting columns of the two ends of the second steel-concrete combined beams; and the first steel-concrete combined beams and the second steel-concrete combined beams are each a square steel pipe combined beam with a containing cavity, and the bottoms of the containing cavities and the connecting positions of the containing cavities and the first combined beam column nodes or the second combined beam column nodes are poured with concrete. By adoption of the track traffic overhead station, the self weights of structural components can be reduced, structural ductility and seismic performance are improved, and the construction period is shortened.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

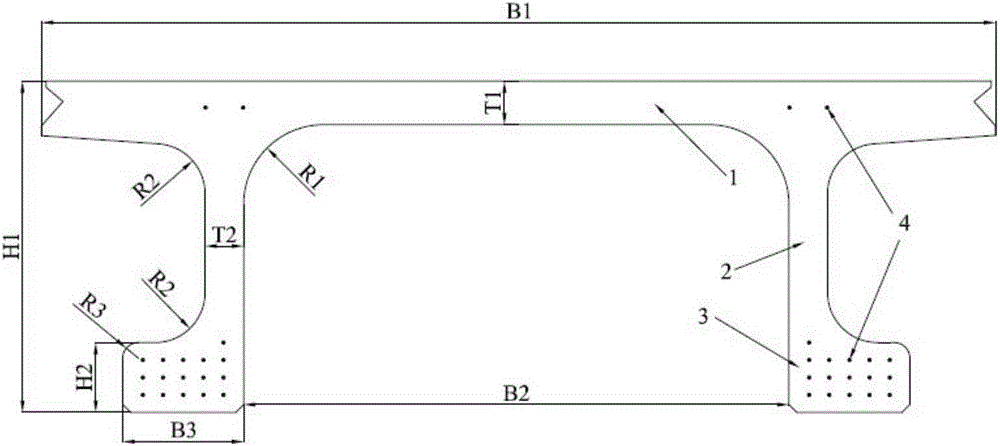

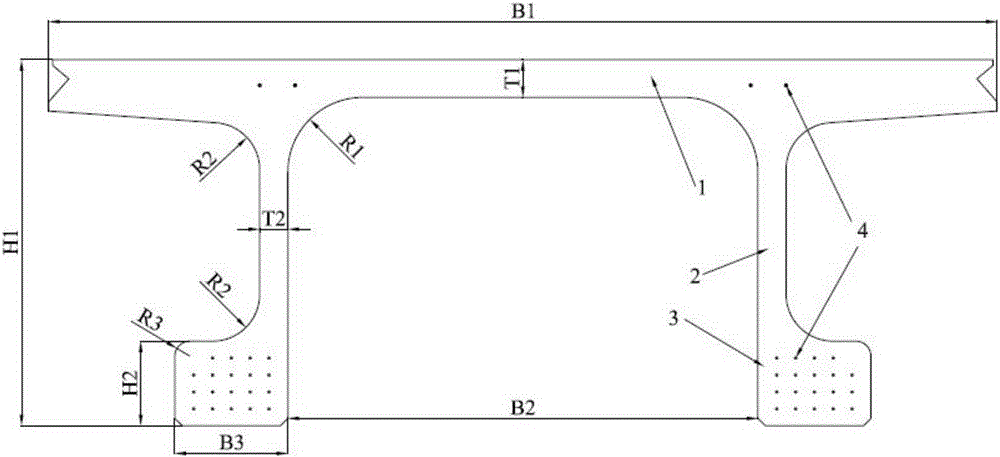

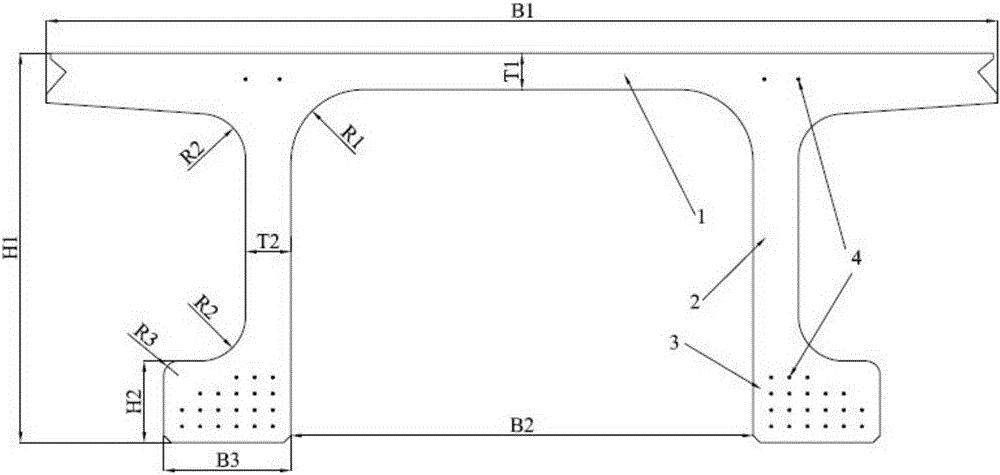

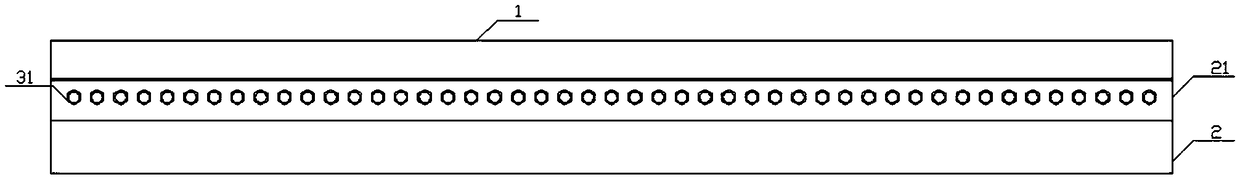

Ultra-high performance cement-based pi-shaped girder poured with ultra-high performance cement-based composite

ActiveCN105256709ASmall sectionLight weightSolid waste managementBridge materialsCompressive strengthUltimate tensile strength

The invention relates to an ultra-high performance cement-based pi-shaped girder poured with an ultra-high performance cement-based composite. The pi-shaped girder meets the following conditions: H1 / B1 is equal to (0.2-1); T1 / H1 is equal to (0.01-0.3); T2 / B3 is equal to (0.1-0.5); B2 / B1 is equal to (0.2-0.8); B3 / B2 is equal to (0.1-0.5); T2 / H1 is equal to (0.02-0.2); R2 / R1 is equal to (0.3-0.8); R3 / R2 is equal to (0.1-0.5); B1 is larger than or equal to 1500 mm and is smaller than or equal to 5000 mm; H1 is larger than or equal to 500 mm and is smaller than or equal to 3000 mm; the span L is equal to (10-200 m). According to the ultra-high performance cement-based pi-shaped girder, the grain composition of multielement cementing materials and grain composition of aggregates are optimized, and a chemical additive is used, so that the compressive strength reaches 170 MPa or above under standard curing for 28 d under the precondition that the material has good fluidity; the ultra high strength cement-based composite and a high strength rib material are adopted, the construction is reasonable, and the design is optimized, so that the whole component has the characteristics that light weight and durability are achieved, the upper structure and the deck slab are integrated, and quick prefabrication and assembly can be achieved, while the bearing capacity is guaranteed; the ultra-high performance cement-based pi-shaped girder can be applicable to quick construction of small-sized and medium-sized bridges in the fields of highways and railways.

Owner:浙江宏日泰耐克新材料科技有限公司

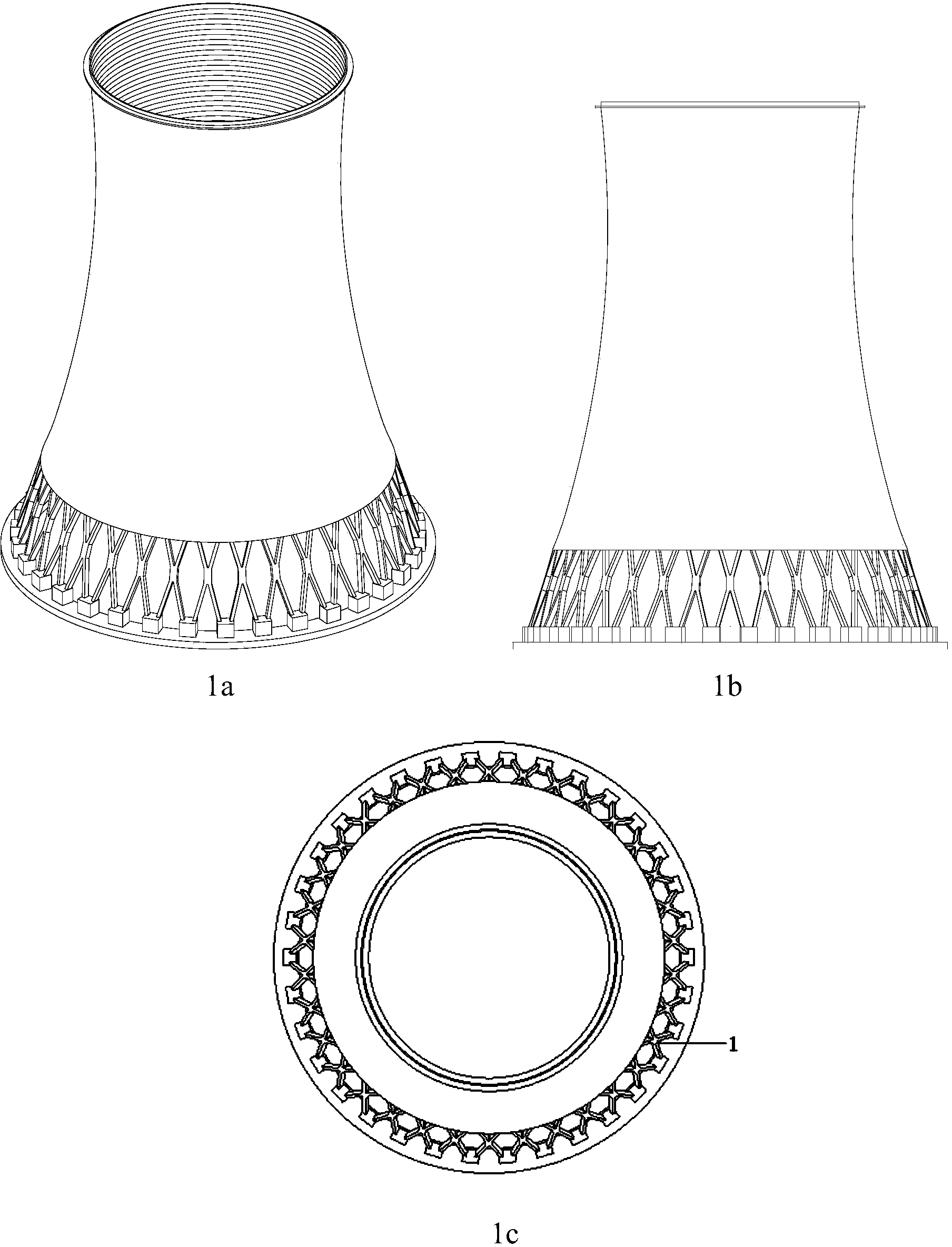

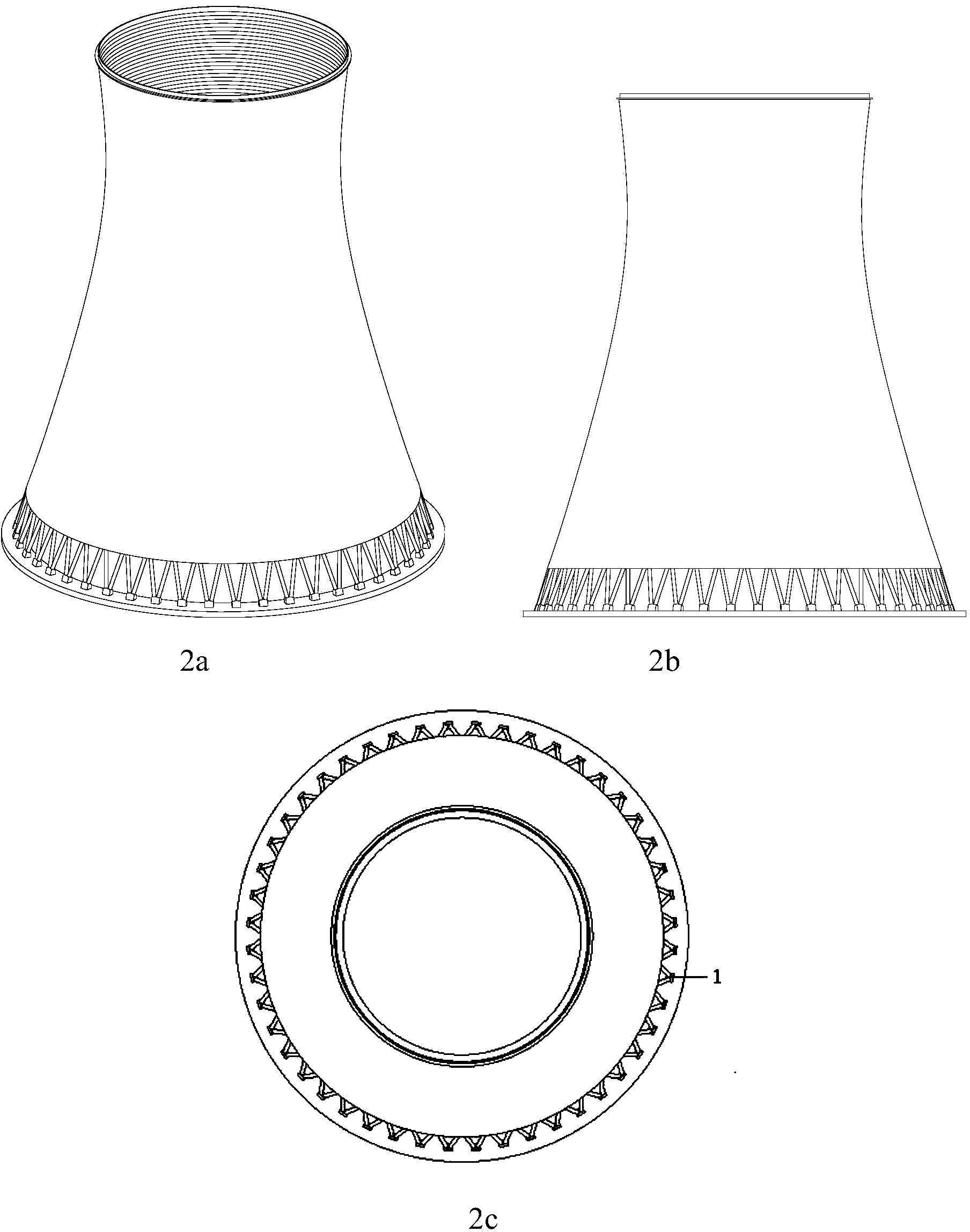

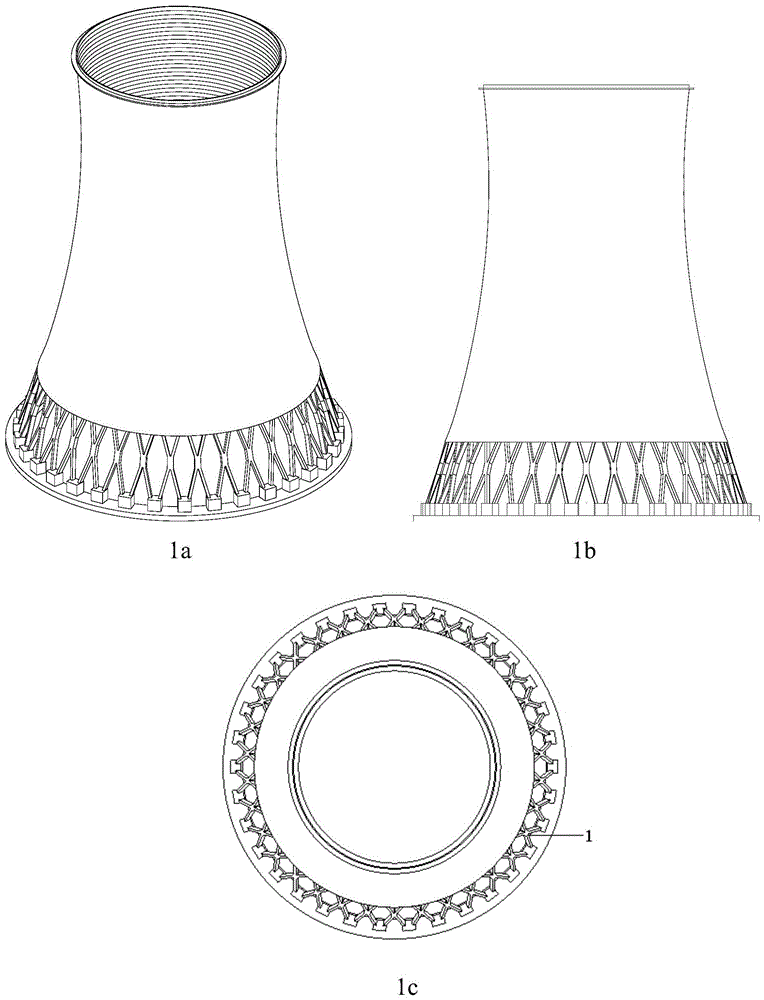

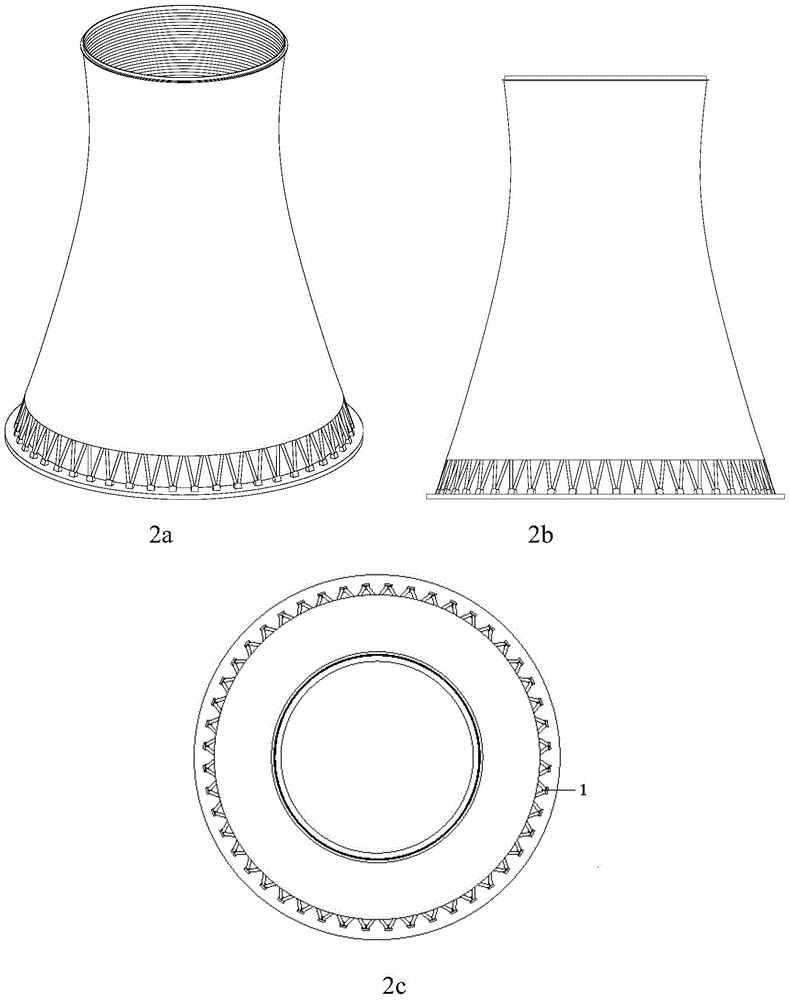

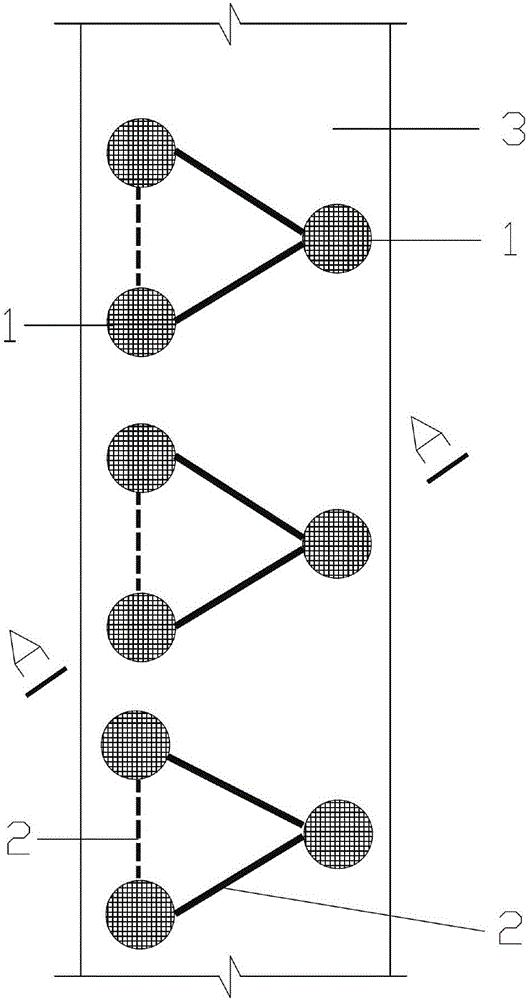

Raking prop structure used for natural draft cooling tower and construction method thereof

ActiveCN104372967AImprove mechanical propertiesSmall cross-sectional sizeStrutsBuilding material handlingNatural ventilationCooling tower

The invention discloses a raking prop structure used for a natural draft cooling tower and a construction method of the raking prop structure. The raking prop structure includes a raking prop structure body which is formed by mutually connecting a plurality of prop house racks to be in an annular structure. The prop house racks are in a steel tube-concrete combination structure composed of steel tubes and concrete with which the steel tubes are filled. The prop house racks comprise ring beams, pier columns and props, wherein the ring beams are connected with the top ends of the props, and bottom ends of the props are connected with the pier columns; the props are X-type props or V-type props. The construction method comprises the steps that concrete in raking props and concrete in the ring beams of the steel tube-concrete combination structure are injected from the bottom, one-off or staged lift-up method pouring is adopted, and the segmented ring beams are assembled through welding to form an integrated ring beam. The raking prop structure has the advantages that the cross-sectional dimension of each raking prop is small, the structural ductility is good, the construction speed is high, service life is long, the construction cost of the whole tower is low, post-maintenance is easy, and the maintenance cost is low.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

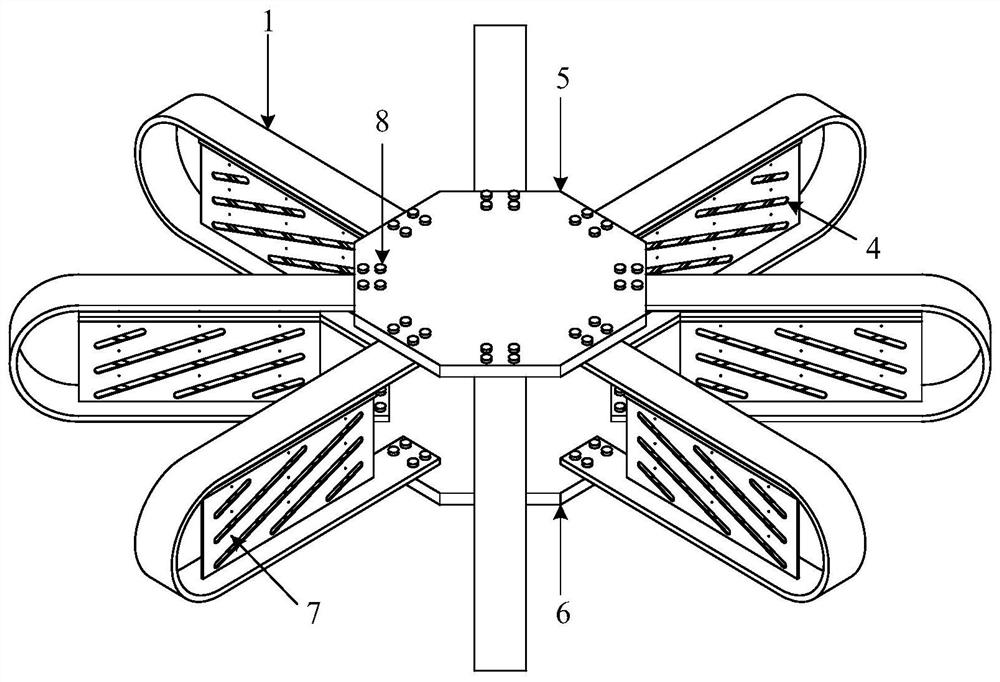

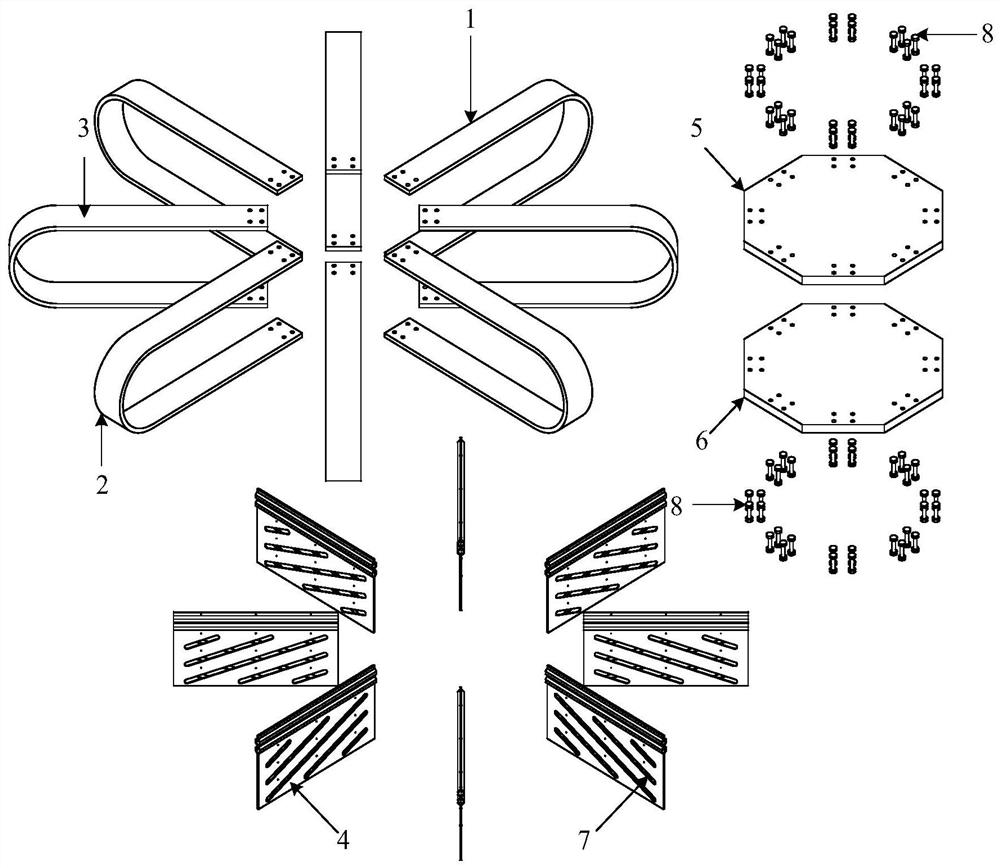

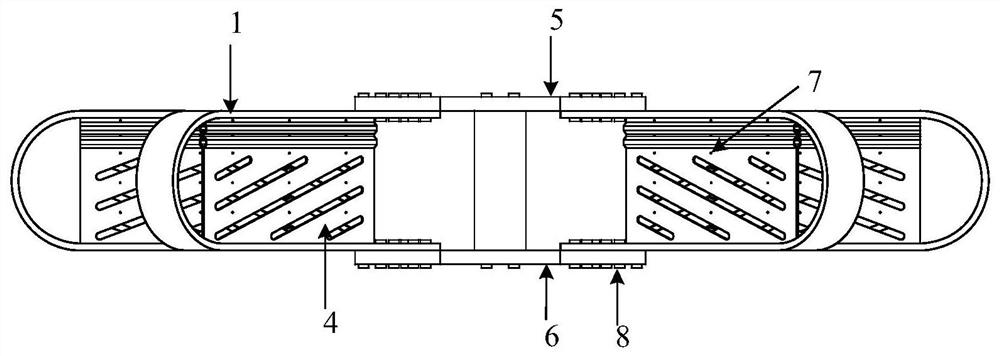

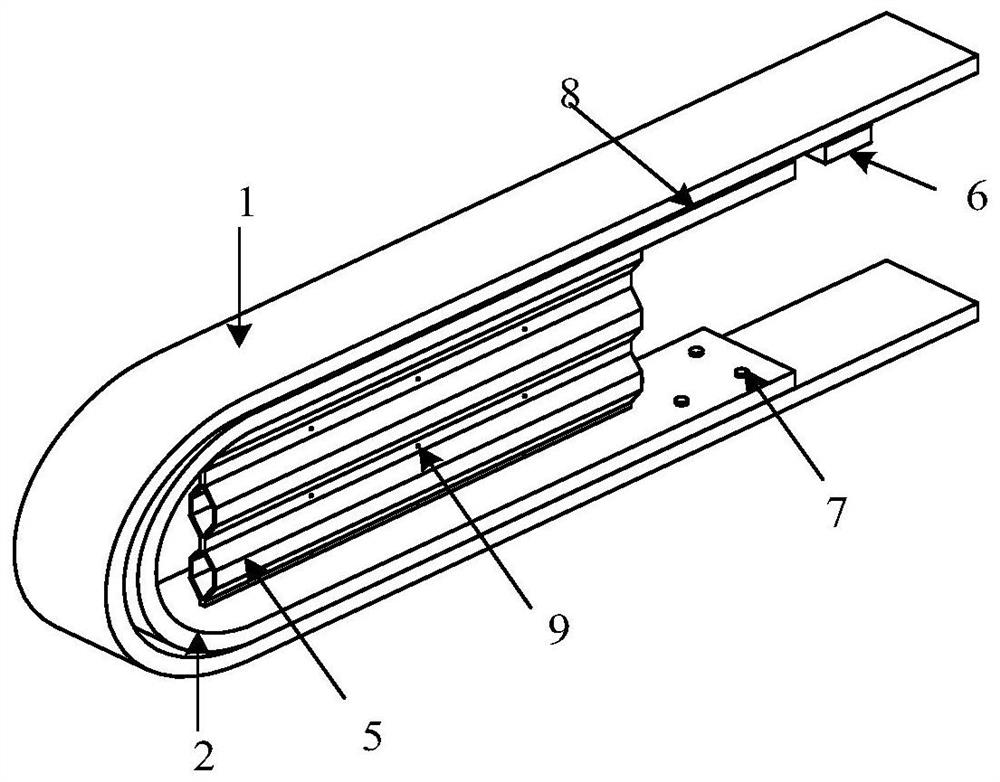

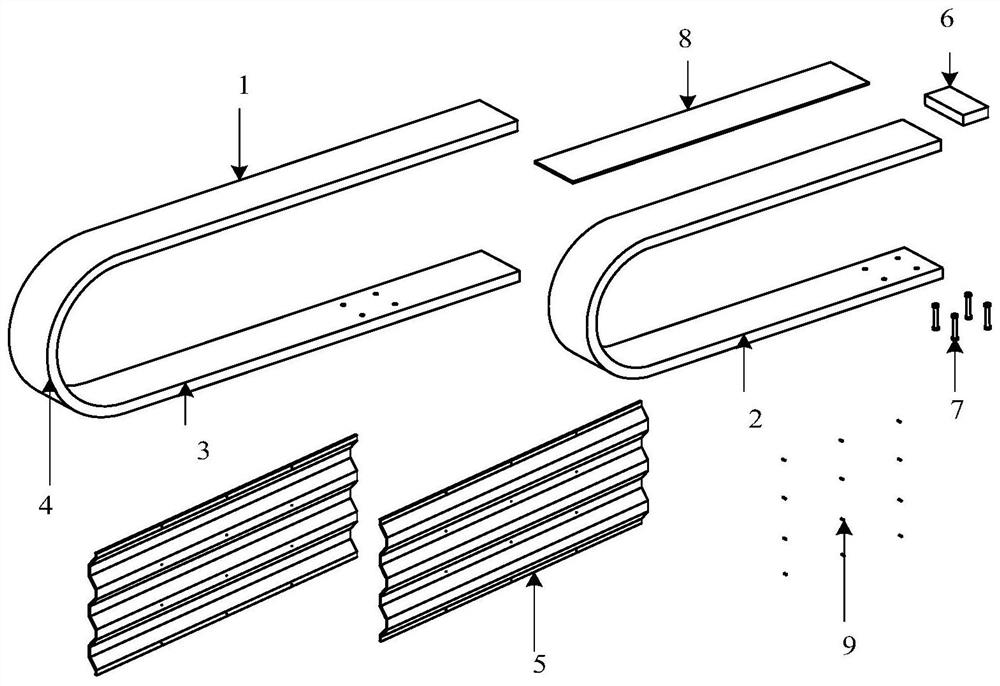

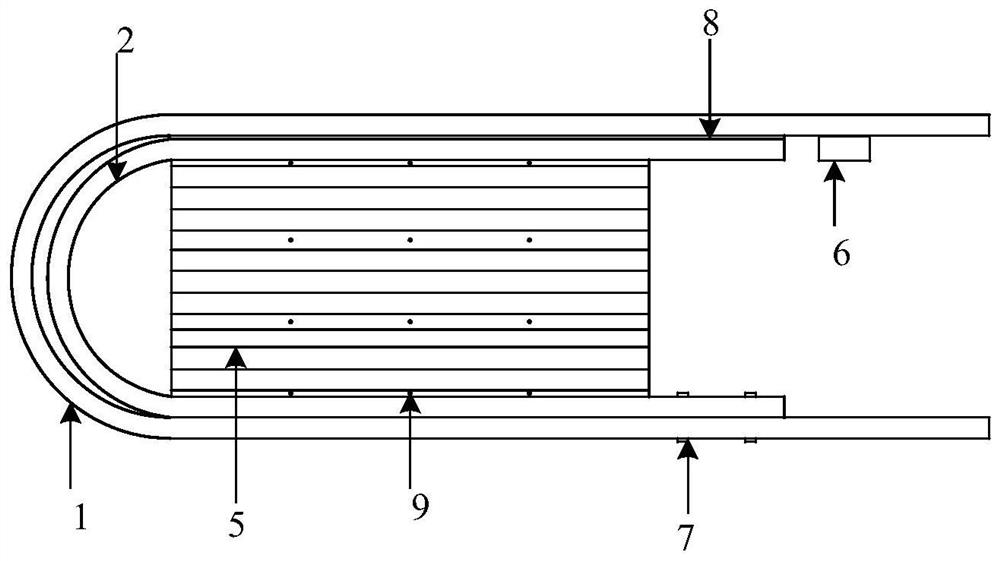

Detachable U-shaped corrugated belt double-layer inclined-slit steel plate damper

ActiveCN111945911AImprove energy consumptionIncrease lateral stiffnessProtective buildings/sheltersShock proofingEconomic benefitsEngineering

The invention relates to a detachable U-shaped corrugated belt double-layer inclined-slit steel plate damper, and belongs to the technical field of civil engineering energy dissipation and shock absorption. The metal damper is composed of a plurality of U-shaped energy dissipation parts, double-layer inclined-slit steel plates, an upper cover plate and a lower cover plate. The metal damper is based on the design concepts that multidirectional energy dissipation is achieved, energy dissipation parts are detachable, the shear bearing capacity is improved, out-of-plane buckling is restrained, multiple shear energy dissipation mechanisms work cooperatively, and a double-insurance mechanism is adopted, and the limitation of a traditional metal damper is broken through. U-shaped energy dissipation units are connected in parallel, so that the multidirectional energy dissipation of the damper is effectively realized. Through a reasonable design, the damper can achieve multi-position yield, theenergy dissipation performance is stable, and the shear bearing capacity is greatly improved. The U-shaped energy dissipation parts and the double-layer inclined-slit steel plates dissipate energy together to form the double-insurance mechanism. After an earthquake, the normal use function can be recovered only by replacing the energy dissipation parts. The metal damper develops towards the assembling direction, is easy and convenient to replace and obvious in economic benefit, can be effectively combined with a support, and provides lateral force for the support.

Owner:BEIJING UNIV OF TECH

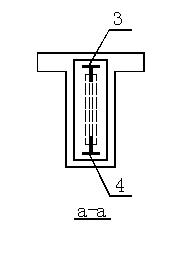

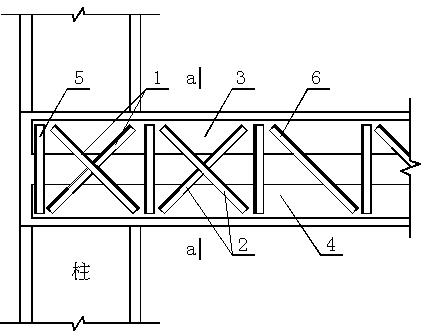

Truss type steel-reinforced concrete framework side node with energy dissipation device

The invention relates to a truss type steel-reinforced concrete framework side node with an energy dissipation device. The steel skeleton in a beam is a truss type steel skeleton, which comprises vertical members, chord members and diagonal members. T-shaped profile steels are arranged on the upper and the lower parts of the beam to serve as the chord members, and are connected through angle irons, so that a truss type steel skeleton concrete beam member is formed. The vertical members and the chord members on the ends of the beam and in the core area of the node form a rectangular structure, the diagonal members are crossed, and are welded between the upper chord members and the lower chord members, the truss type steel skeleton extends into a column, and the length of the extending end is 0.9 times as the width of the section of the column in the direction. The ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of the truss type steel-reinforced concrete framework side node with the energy dissipation device disclosed by the invention are remarkably increased in comparison with the ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of reinforced concrete nodes. The truss type steel-reinforced concrete framework side node with the energy dissipation device has good structural seismic resistance and energy-dissipating capability.

Owner:GUANGXI UNIV

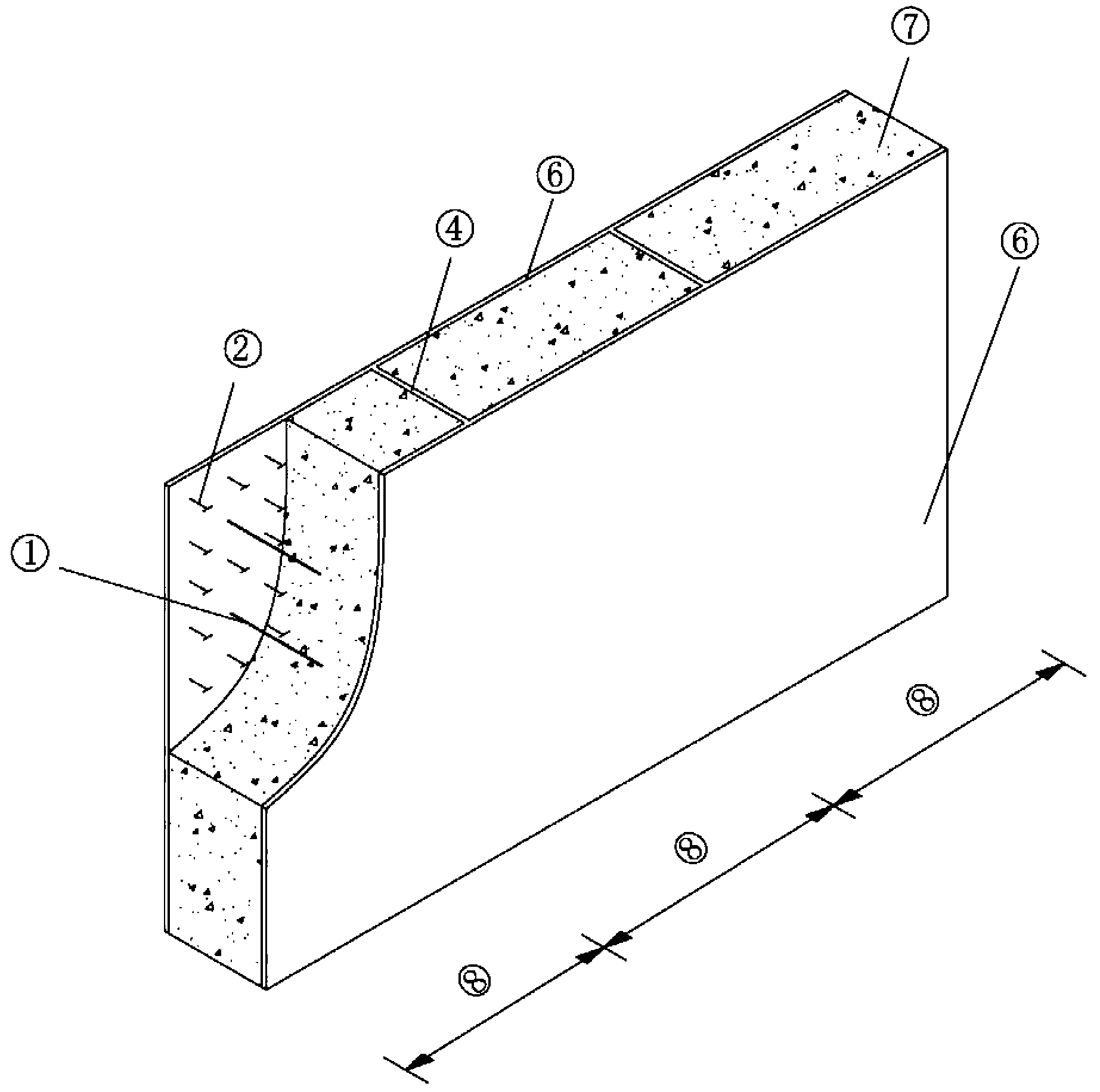

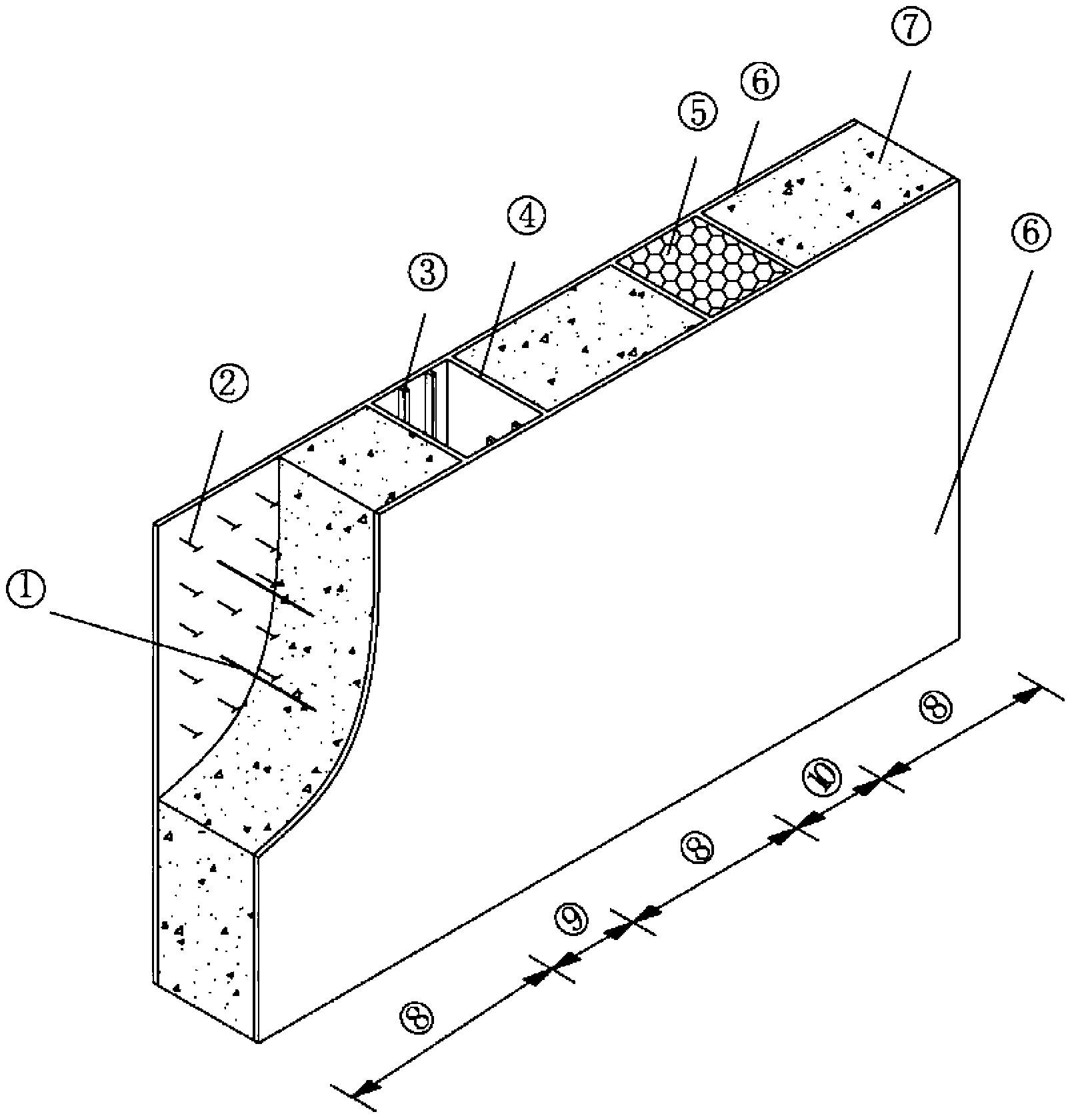

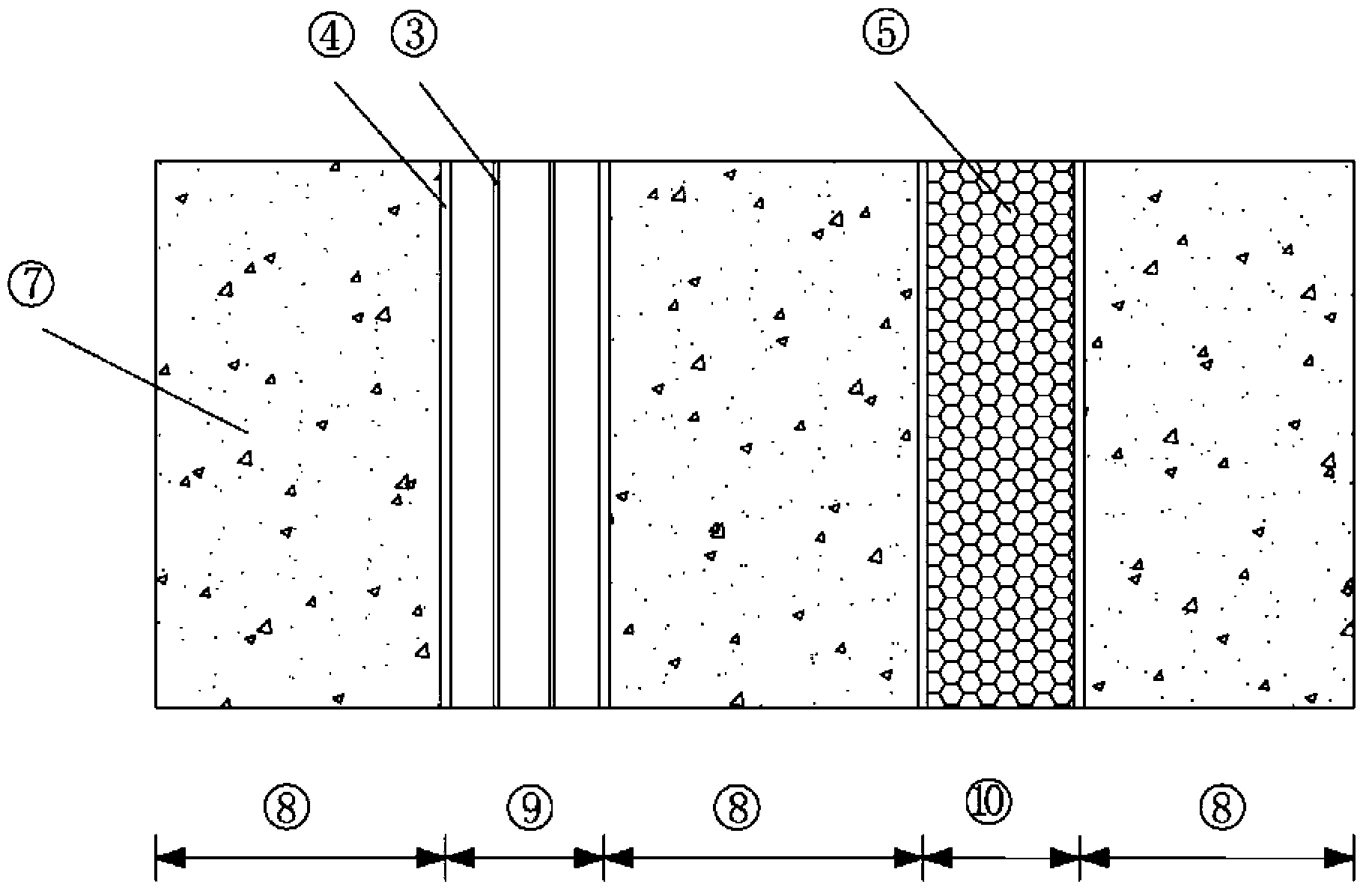

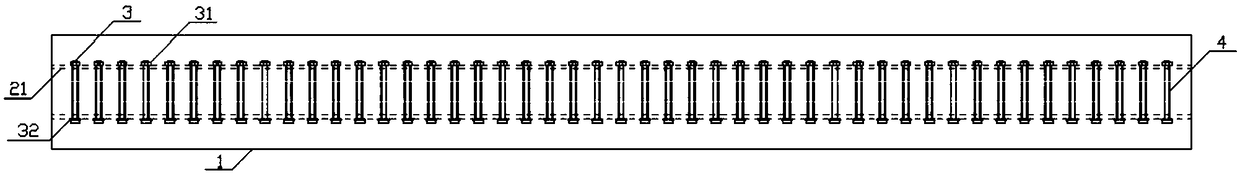

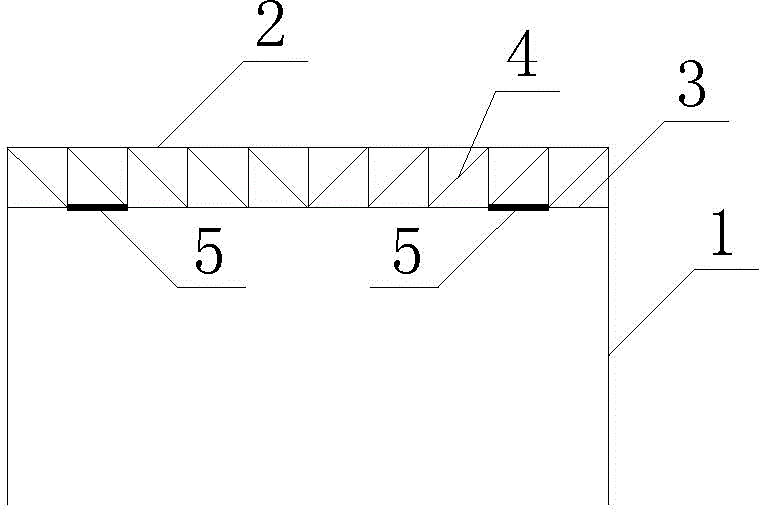

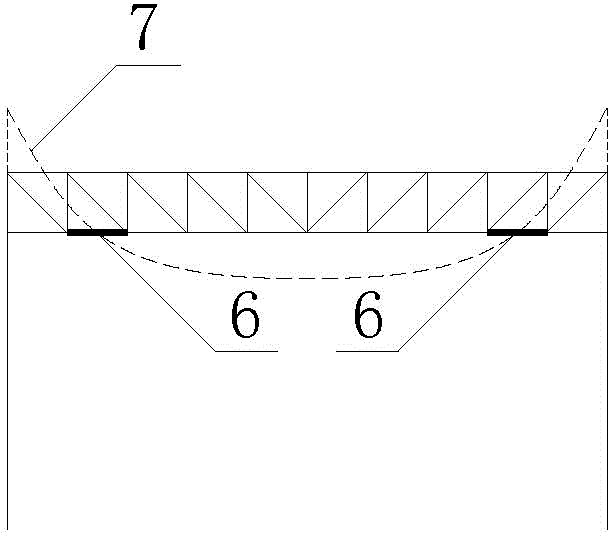

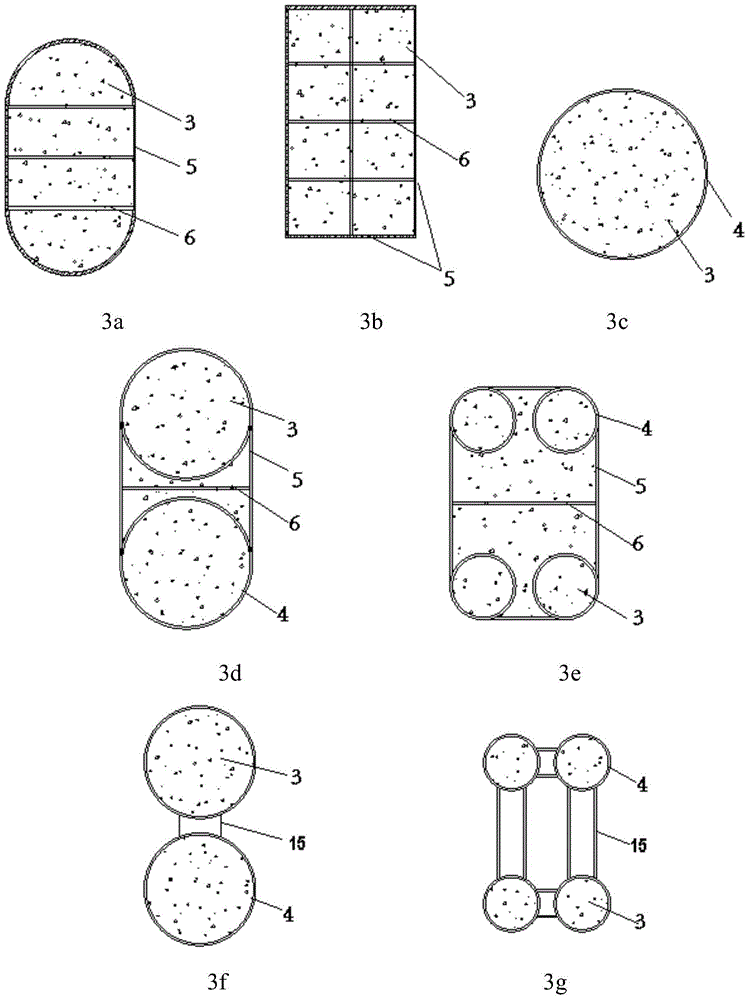

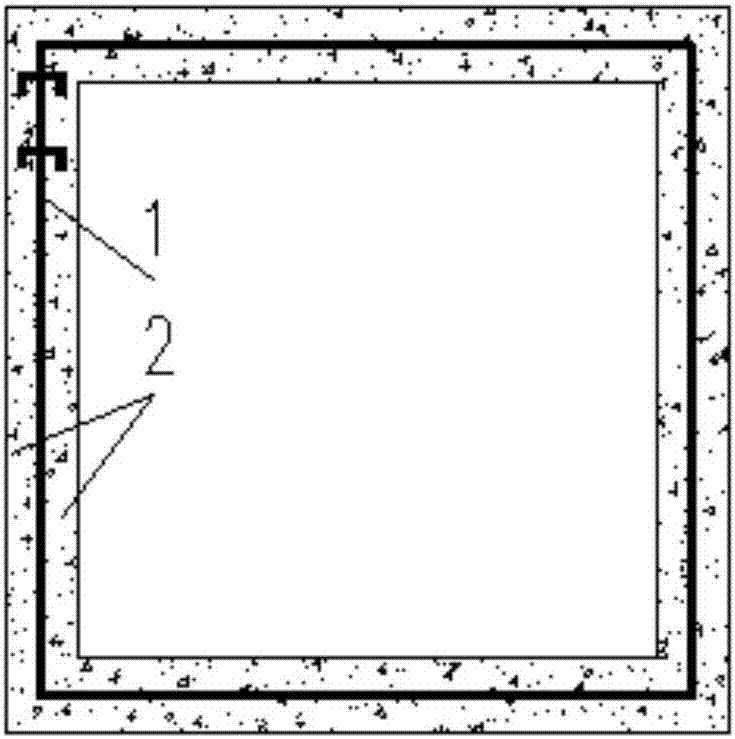

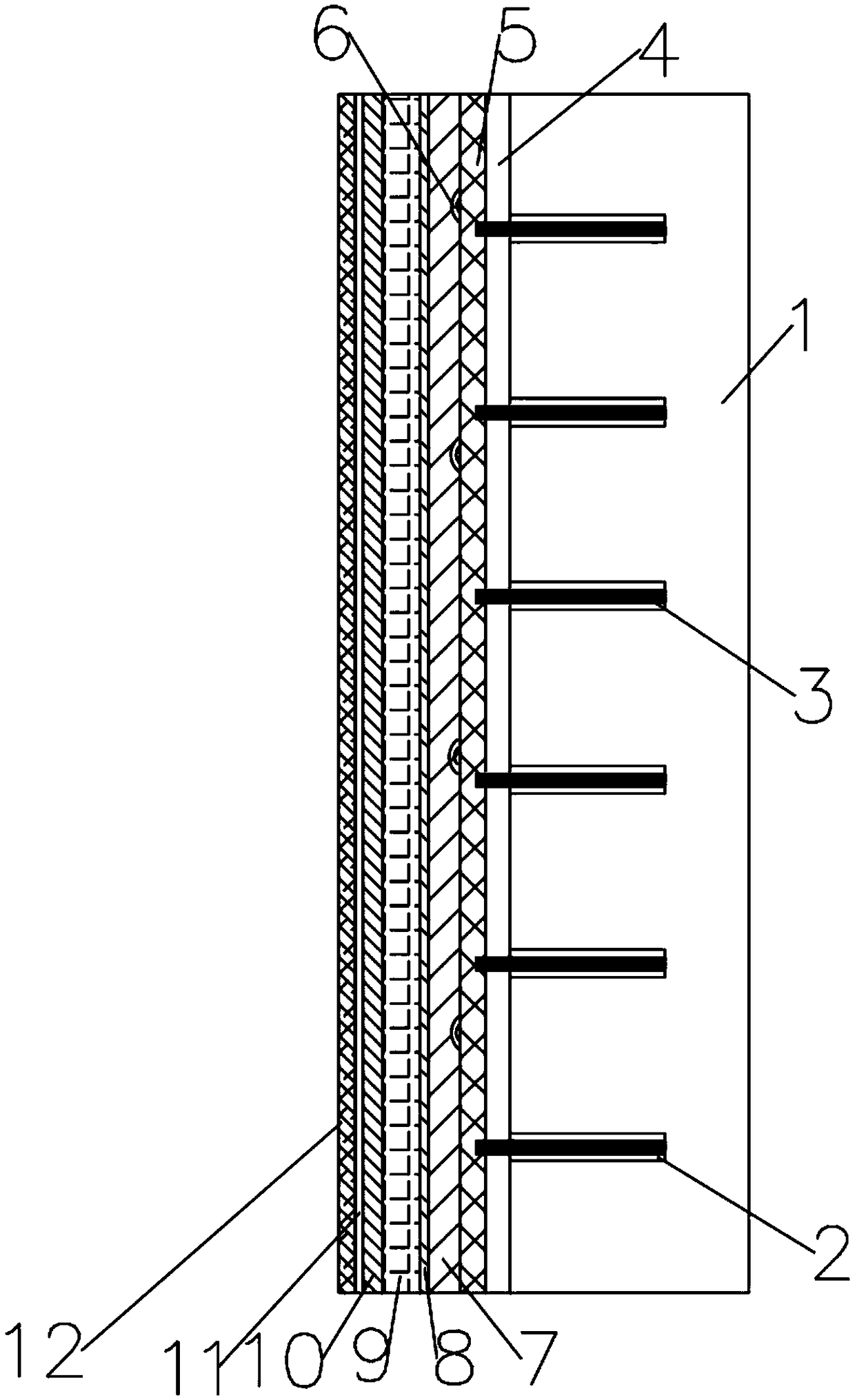

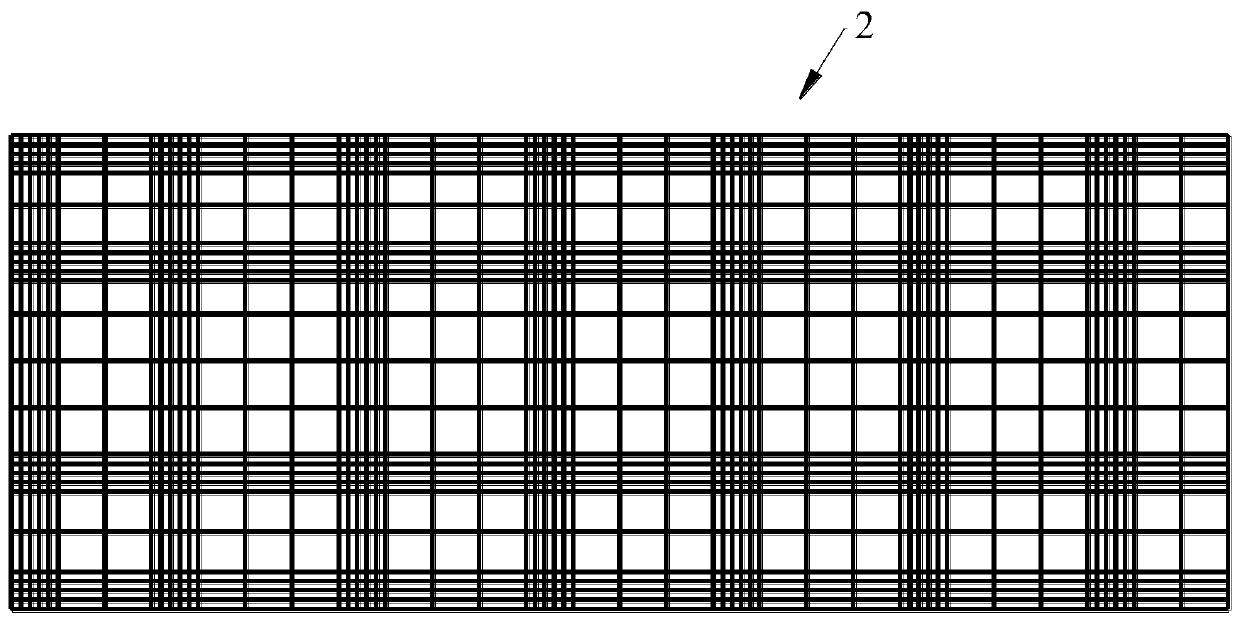

Multiple-chamber type double steel plate concrete combined shear wall

The invention relates to a multiple-chamber type double steel plate concrete combined shear wall, which integrally consists of two wall body surface steel plates (6) and a wall inner plain concrete (7), wherein the wall body surface steel plates (6) and the wall inner neat concrete (7) are connected by bolt screws (2), split reinforced bars (1) and vertical separating plates (4) to ensure the cooperated work, the bolt screws (2), the split reinforced bars (1) and the vertical separating plates (4) are welded on the steel plates, the wall body space between the two steel plates is separated into bin chambers by the vertical separating plates (4), the inside of one part of bin chambers is cast with concrete to form concrete bin chambers (8), the other part of bin chambers is kept empty and is filled with a foam aluminum porous energy dissipating material to form an empty bin chamber (9) and an energy dissipating material filling bin chamber (10), and then the alternative distribution of the concrete bin chambers (8), the empty bin chamber (9) and the energy dissipating material filling bin chamber (10) is realized. The multiple-chamber type double steel plate concrete combined shear wall has the advantage that the rigidity is reduced, and the extensibility is increased, so the suitability is further improved.

Owner:BEIHANG UNIV

Assembly type steel reinforced concrete framework spatial module structure and system and construction method

PendingCN107605038AImprove prefabrication rateImprove hoisting efficiencyBuilding material handlingReinforced concreteFloor slab

The invention provides an assembly type steel reinforced concrete framework spatial module structure and system and a construction method. The spatial module structure comprises a bell-shaped five-face spatial modular structure composed of four prefabricated walls, section steel columns, section steel beams, section steel longitudinal beams and a steel concrete composite floor slab; the prefabricated wall comprises a rectangular wall panel main body and section steel rods which are detachably connected to two sides of the wall panel main body; the section steel columns are detachably connectedwith two adjacent prefabricated walls; the section steel beams are detachably connected to tops of the transverse prefabricated walls; the section steel longitudinal beams are detachably connected totops of longitudinal prefabricated walls; shear resistant connecting members are connected with intervals to tops of the section steel longitudinal beams in the long axis direction; the steel concrete composite floor slab is detachably connected to the section steel beams and the section steel longitudinal beams. The invention solves the technical problems that the prior assembled building structural system has the problems of low assembly rate, poor anti-seismic performance, large workload of hoisting on site and complex site construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

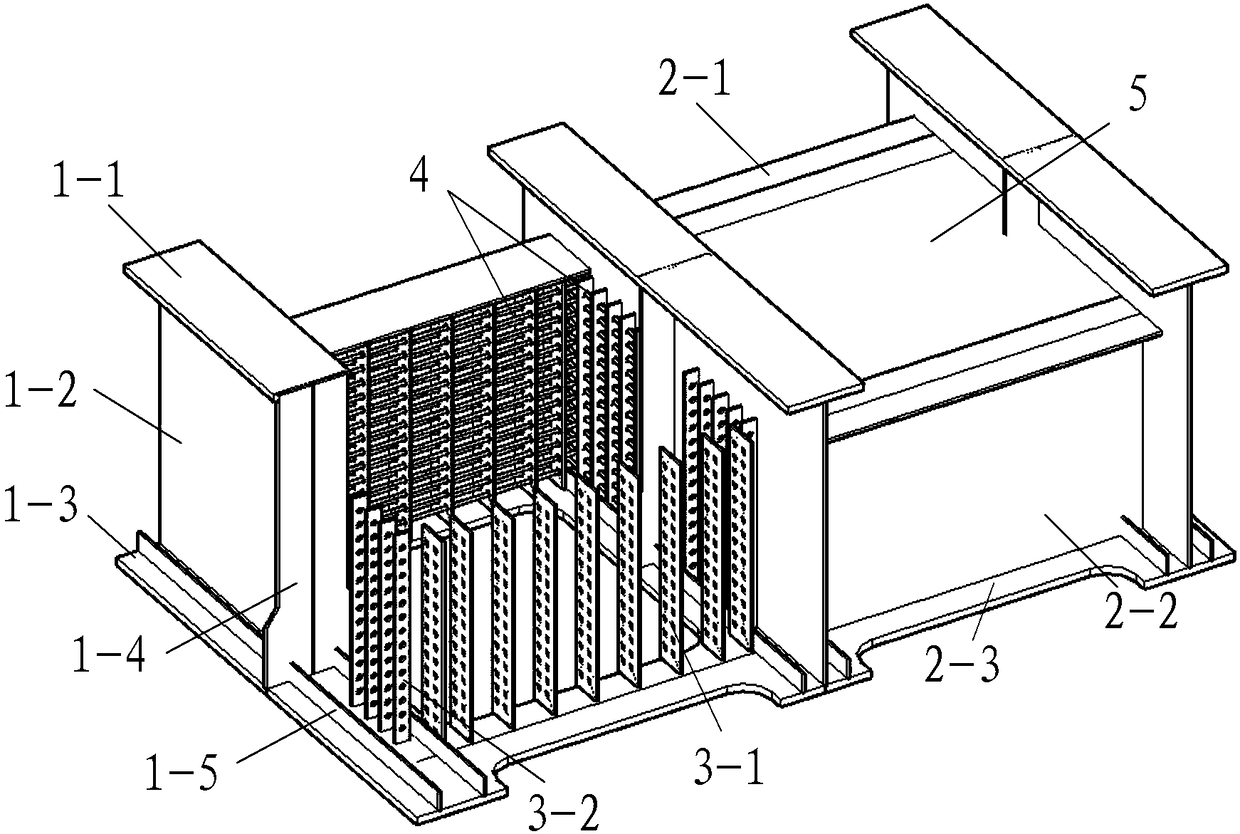

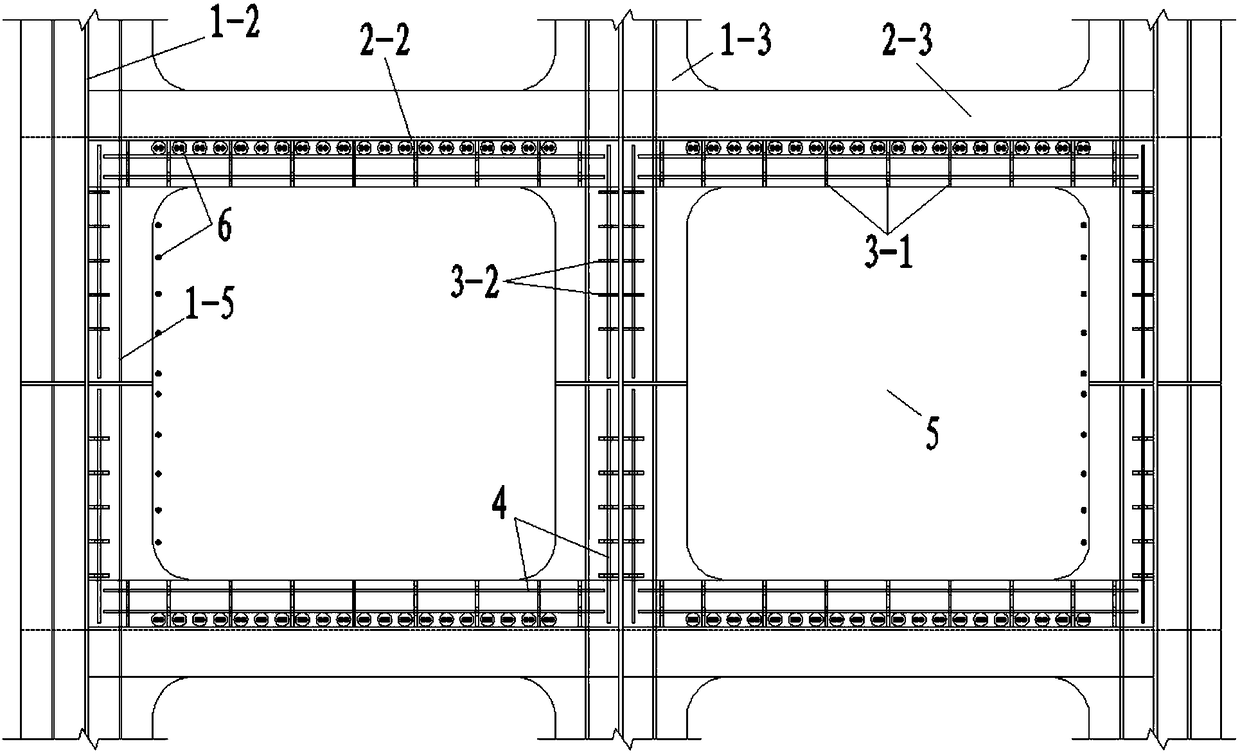

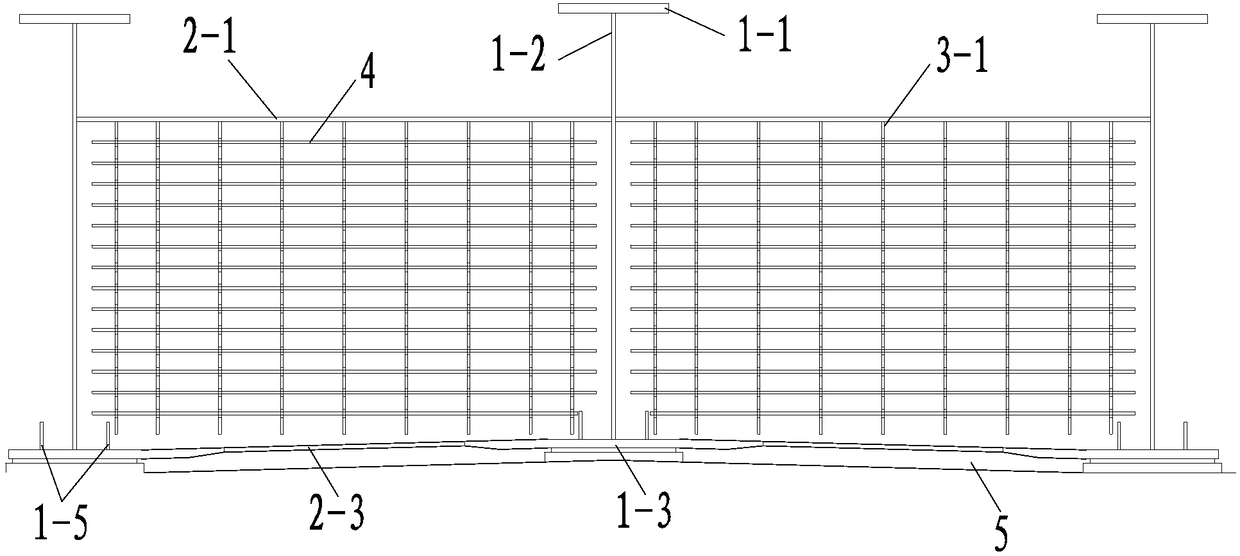

Combined rigid frame steel plate girder-pier girder solid structure

The invention discloses a combined rigid frame steel plate girder-pier girder solid structure. According to the structure, an I-shaped steel main girder and a crossbeam form a box-shaped grid room, perforated plate connection pieces are arranged inside web plates of the box-shaped grid room and penetrate through reinforcing bars and pour concrete, so as to solidify the pier girder. To ensure thatthe load born by the main girder is transmitted to the pier effectively, perforated plate connection pieces are arranged inside web plats of the steel main girder and the crossbeam of the box-shaped grid room, the perforated plates penetrate through common reinforcing bars and then concrete is cast so as to resist shear force, shaft force and bending moment of the pier girder solidified part; thesteel plate girder and the concrete pier are connected through the perforated plates, so that the structure is simple, bears forces reasonably and transmits force reliably, can meet various requirements of normal use and limit loading, improves the crossover capability of the bridge while the dead weight is reduced, is convenient and quick in construction, and solves main problems that the web plate concrete cracks, the middle span warps downwards and the anti-seismic performance is reduced in the existing concrete rigid frame bridge due to long-term load.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Energy dissipation type coupled anti-seismic wall with reinforcing bars, grouting holes, building blocks and combined coupling beam and manufacturing method

InactiveCN104775544AAvoid instant collapseGood for load bearingWallsBuilding material handlingEarthquake resistanceEngineering

The invention belongs to the technical field of earthquake resistance of building structures, and particularly relates to an energy dissipation type coupled anti-seismic wall with reinforcing bars, grouting holes, building blocks and a combined coupling beam and a manufacturing method. The energy dissipation type coupled anti-seismic wall is adopted by a bearing wall of a multi-storey building in a town. The energy dissipation type coupled anti-seismic wall comprises a building block wall body, a coupling beam, soft steel dampers, single-reinforcement core columns, construction core columns and horizontal pull connecting ribs. According to the invention, due to the combined action of the core columns and the horizontal pull connecting ribs, the building block wall body is effectively constrained, and the integrity and the anti-seismic performance of a coupling wall column are improved. The coupling beam and a constraint building block wall beam on the top of the coupling beam are combined to form the shear type combined coupling beam, and the soft steel dampers are arranged on the portions of connection between the coupling beam and the coupling wall column, so that multiple energy dissipation and seismic resistance defense lines of the coupled anti-seismic wall are formed, and the ductility and the energy dissipation capacity of the wall body are enhanced.

Owner:ANHUI XINHUA UNIV

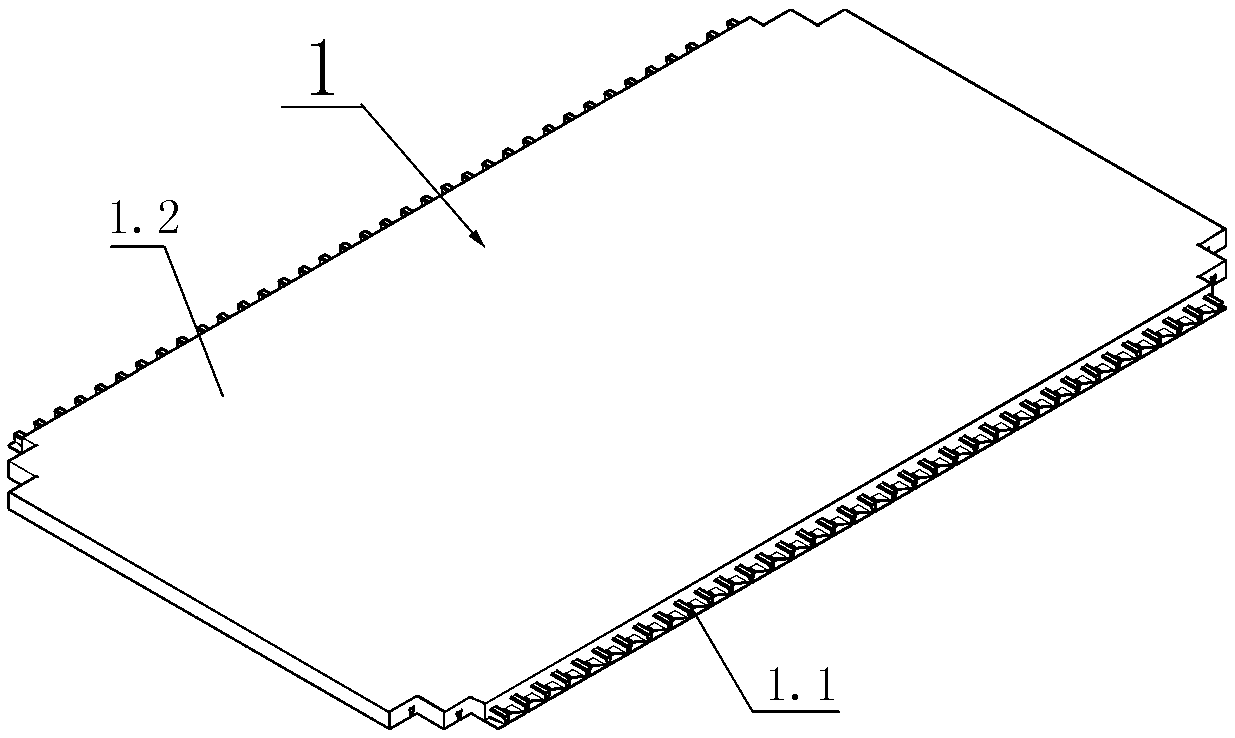

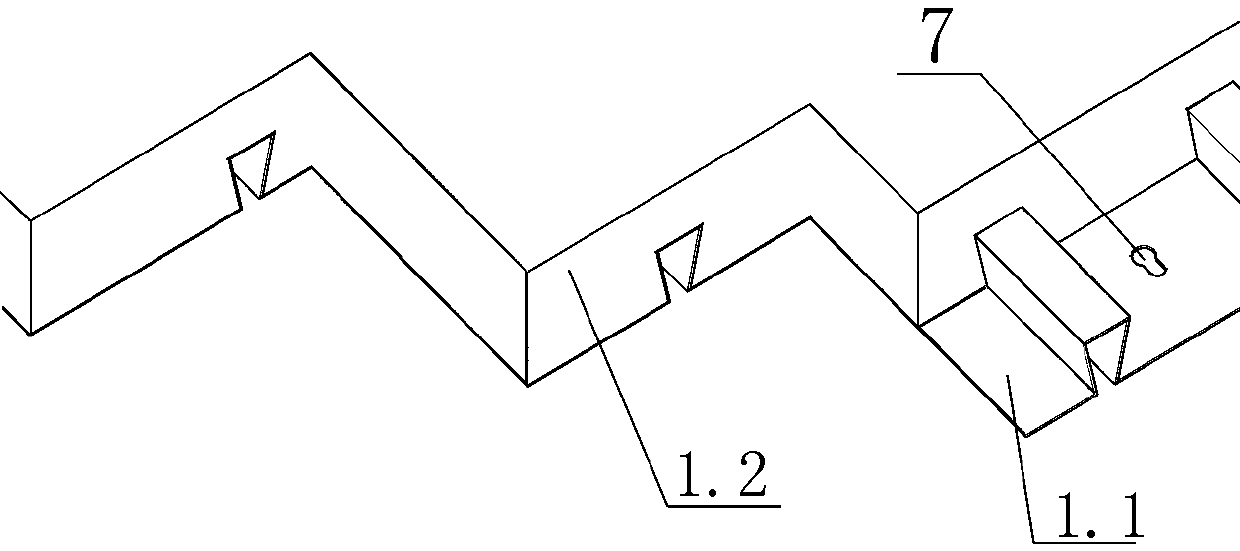

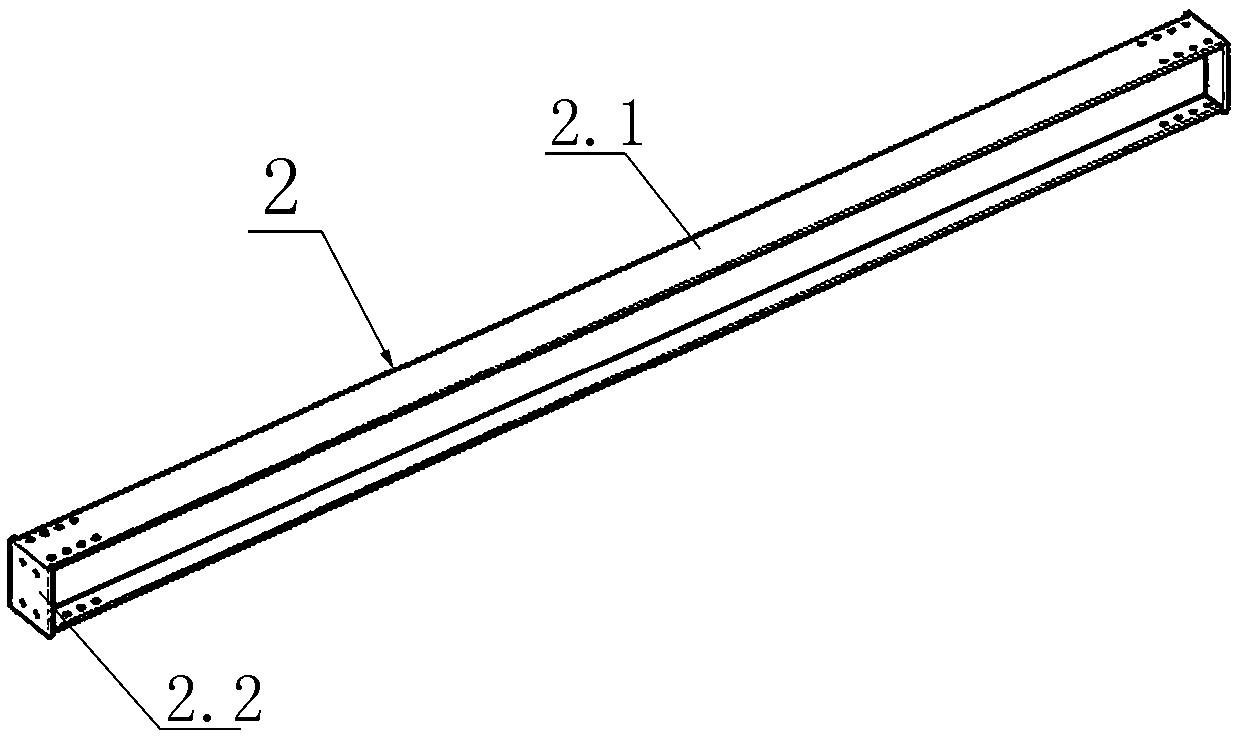

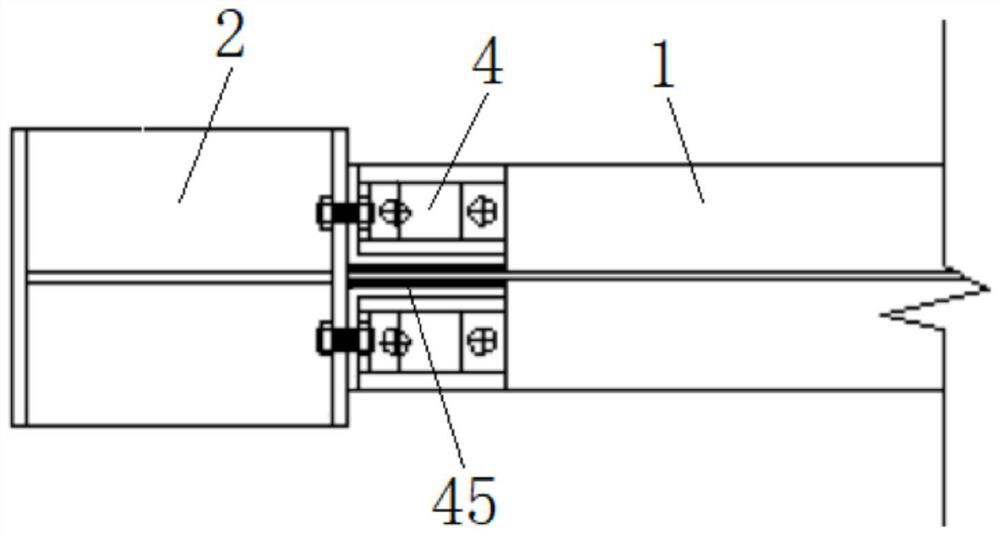

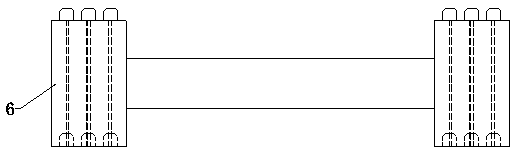

Detachable prefabricated steel-concrete combined beam structure and manufacturing technique thereof

PendingCN108643449AIncreased shear capacitySolve the lack of shear resistanceLoad-supporting elementsConcrete beamsPrecast concrete

The invention discloses a detachable prefabricated steel-concrete combined beam structure. The detachable prefabricated steel-concrete combined beam structure comprises an I-shaped steel beam, a prefabricated concrete plate, a concrete plate support and a fixing member. An upper flange of the I-shaped steel beam is folded upwards to form a groove-channel-type upper flange; the concrete plate support is arranged at the bottom of the prefabricated concrete plate, and a concrete beam of a T-shaped structure is composed of the prefabricated concrete plate and the concrete plate support and is embedded into the groove-channel-type upper flange of the steel beam; connecting holes are evenly formed in the concrete plate support, the groove-channel-type upper flange is provided with evenly-formedreserved holes, the reserved holes of the groove-channel-type upper flange of the steel beam and the connecting holes of the concrete plate support part are aligned; and the fixing member enables theconcrete beam and the steel beam to be spliced through the reserved holes and the connecting holes. The prefabricated type is adopted, thus rapid construction can be conducted, a deck slab can be replaced, and the cost can be lowered. Through the connecting effect of shear-resistant connecting pieces, the concrete deck slab plays a role in restraining the pressed flange of the steel beam, and accordingly the stability of the steel beam is improved.

Owner:ZHEJIANG INST OF COMM

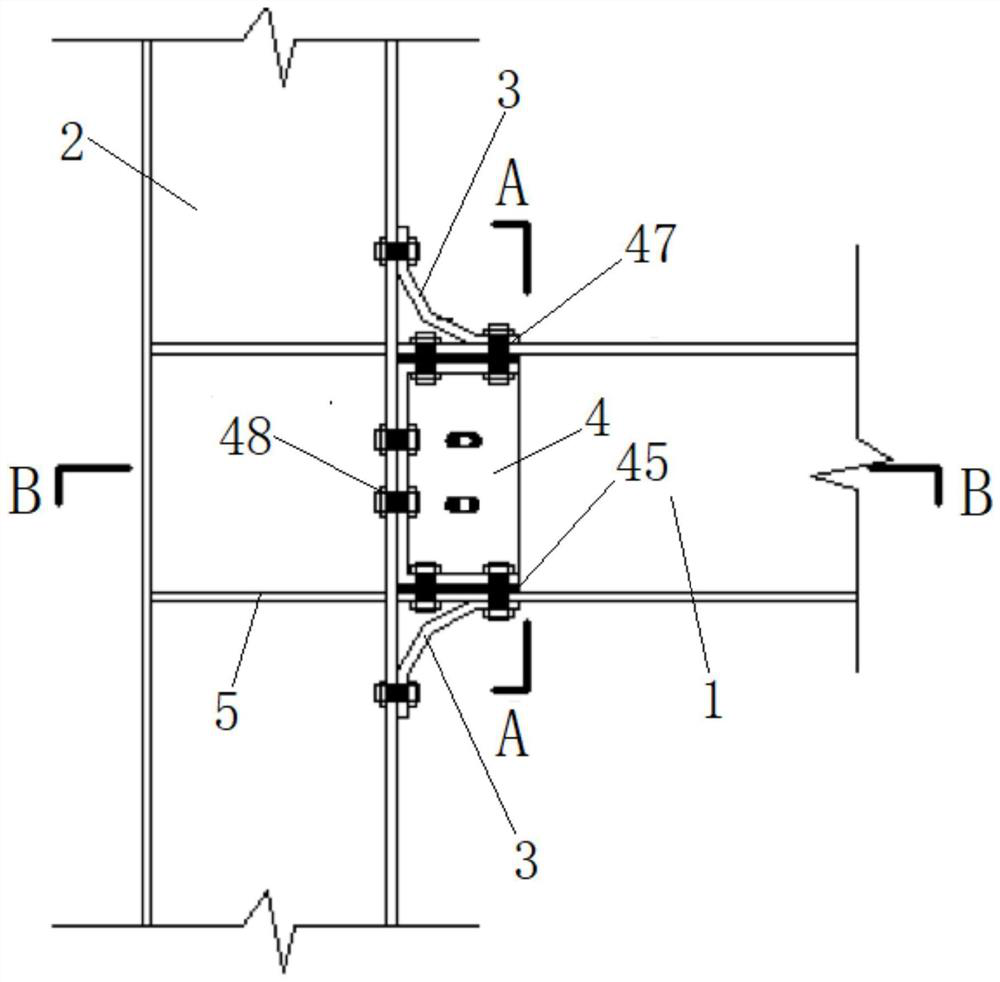

Self-resetting steel frame beam-side column joint and construction method thereof

PendingCN112177174ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingClassical mechanicsShape-memory alloy

The invention provides a self-resetting steel frame beam-side column joint and a construction method thereof. The self-resetting steel frame beam-side column joint comprises a steel beam, wherein thesteel beam is horizontally arranged on one side of a steel column; a shape memory alloy plate is arranged between a flange of the steel beam and a flange of the steel column, and the shape memory alloy plate is arranged on the outer side of the flange of the steel beam; one end of the shape memory alloy plate is connected with the flange of the steel beam, and the other end of the shape memory alloy plate is connected with the flange of the steel column; and friction energy dissipaters are symmetrically arranged on the two sides of a web of the steel beam, one end of each friction energy dissipater is connected with the steel beam, and the other end of each friction energy dissipater is connected with the flange of the steel column. According to the self-resetting steel frame beam-side column joint and the construction method thereof, the shape memory alloy plate is arranged, and the self-resetting function of the joint is achieved by utilizing the plastic deformation of the shape memory alloy plate; and friction energy dissipation can be achieved between the friction energy dissipaters and the flange and the web of the steel beam, and the friction energy dissipaters and the shapememory alloy plate generate a synergistic effect to jointly absorb seismic energy at the joint, so that the structural ductility and energy dissipation capacity of the steel frame beam-side column joint are effectively improved, and the post-earthquake repair cost of the structure is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

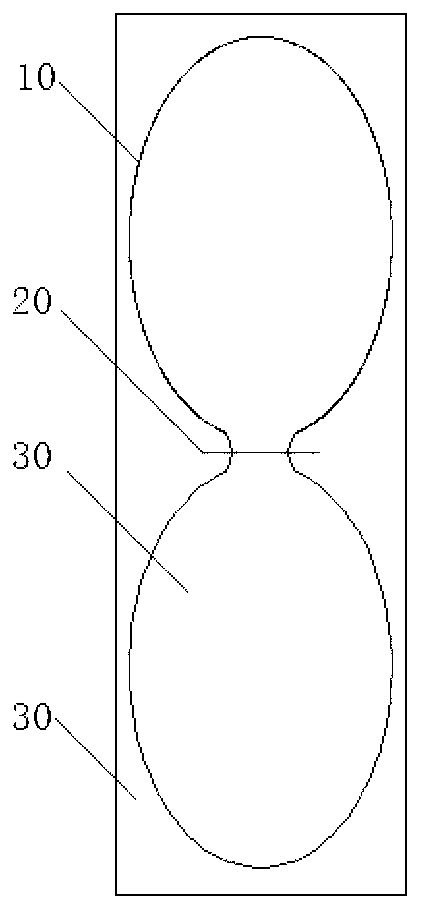

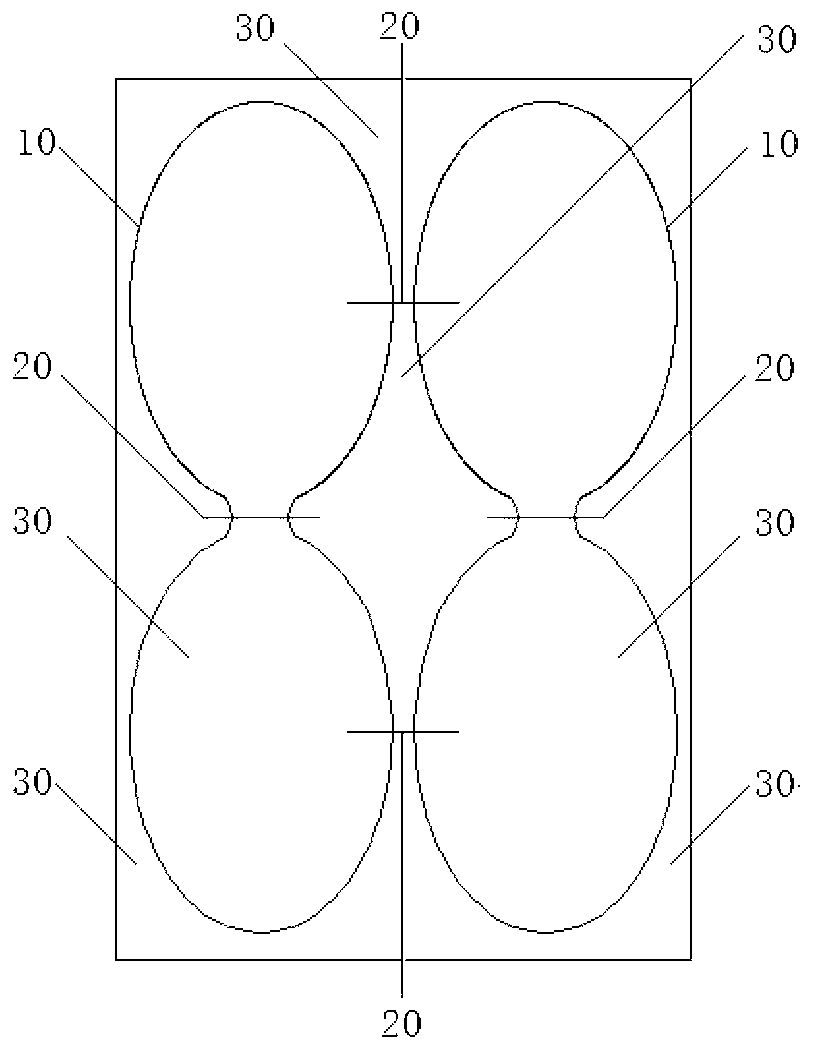

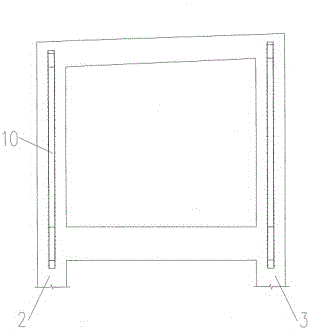

Flexible reinforced earth structure based on 8-shaped tyre

InactiveCN103276718AReduce horizontal thrustPassive drag reductionSoil preservationEarth materialsEngineering

The invention discloses a flexible reinforced earth structure based on an 8-shaped tyre and relates to a reinforced earth structure. A basic unit structurally comprises 8-shaped waste tyres (10), high-strength plastic bolt nuts (20) and building padding (30). The high-strength plastic bolt nuts (20) are connected among the 8-shaped waste tyres (10), and the building padding (30) is paved at holes inside and outside the 8-shaped waste tyres (10). The 8-shaped waste tyres (10) are arranged in a plane transversely and longitudinally to form a planar net structure. A three-dimensional net structure is composed of a plurality of layers of vertical planar net structures. The flexible reinforced earth structure is easy to compact and avoids damage caused by too much deformation. The reinforced earth structure is good in ductility and durability, low in modulus of deformation, high in damp and good in seismic resistance and has good deformation adaptation and long-term stability. The reinforced earth structure is simple, convenient to construct and low in cost, fully uses waste and earth materials on the field and reduces environment pollution and covering area.

Owner:HUBEI UNIV OF TECH

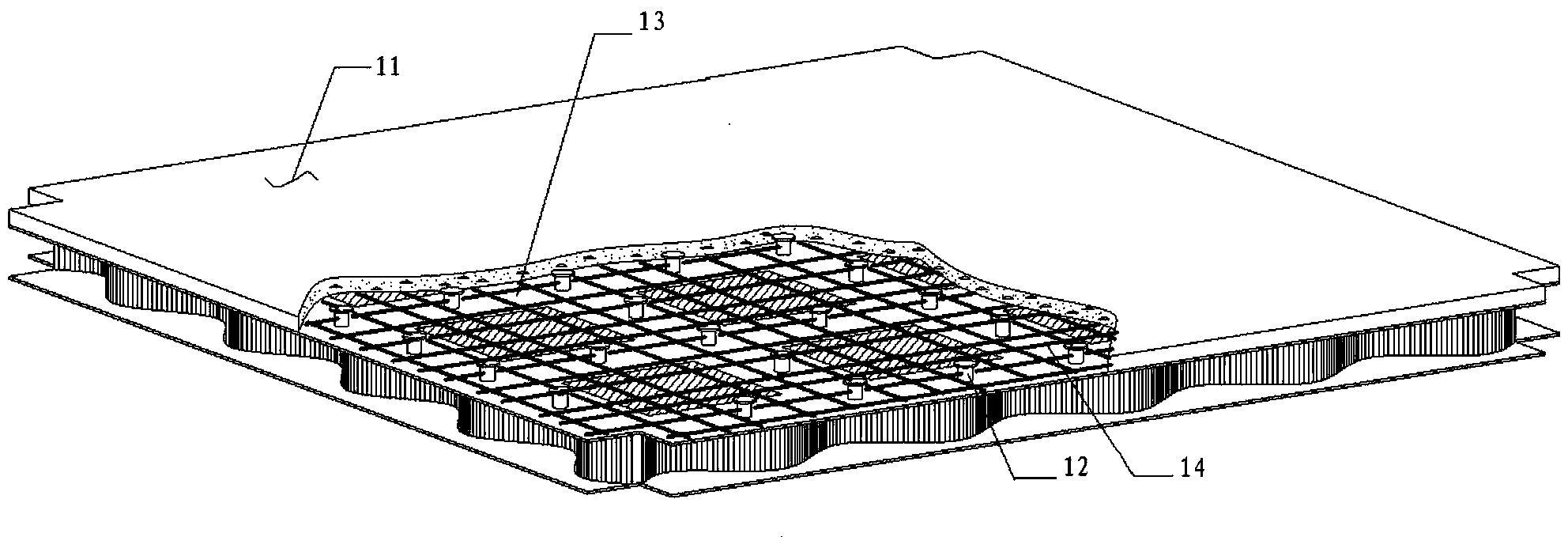

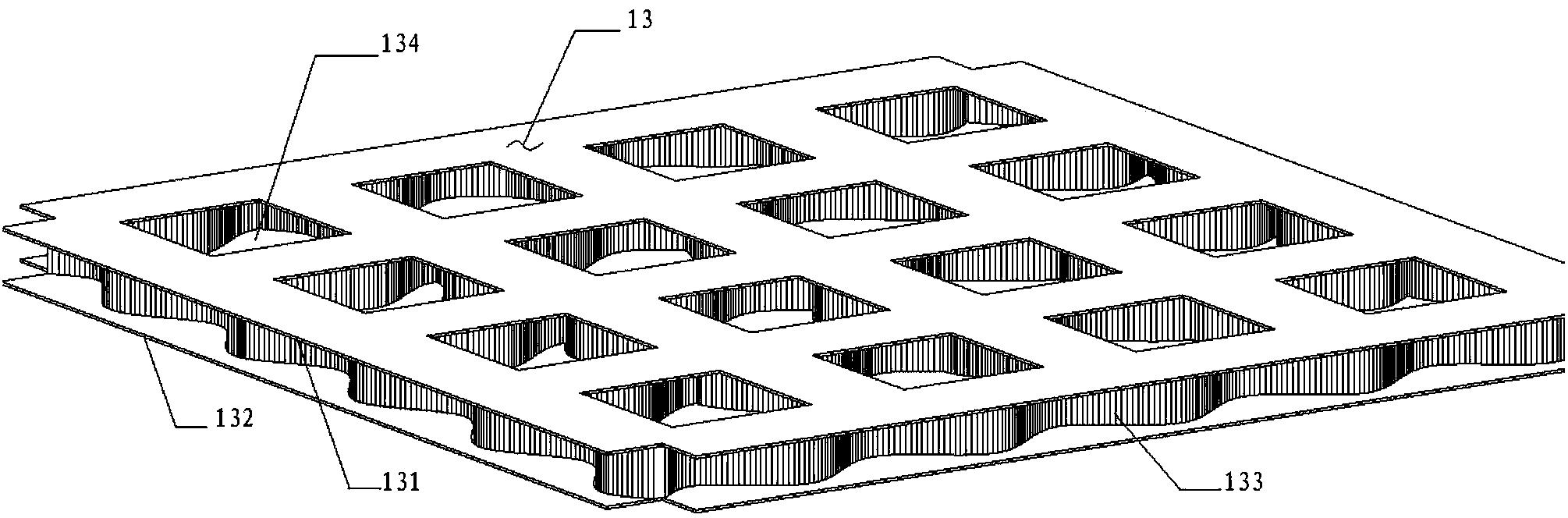

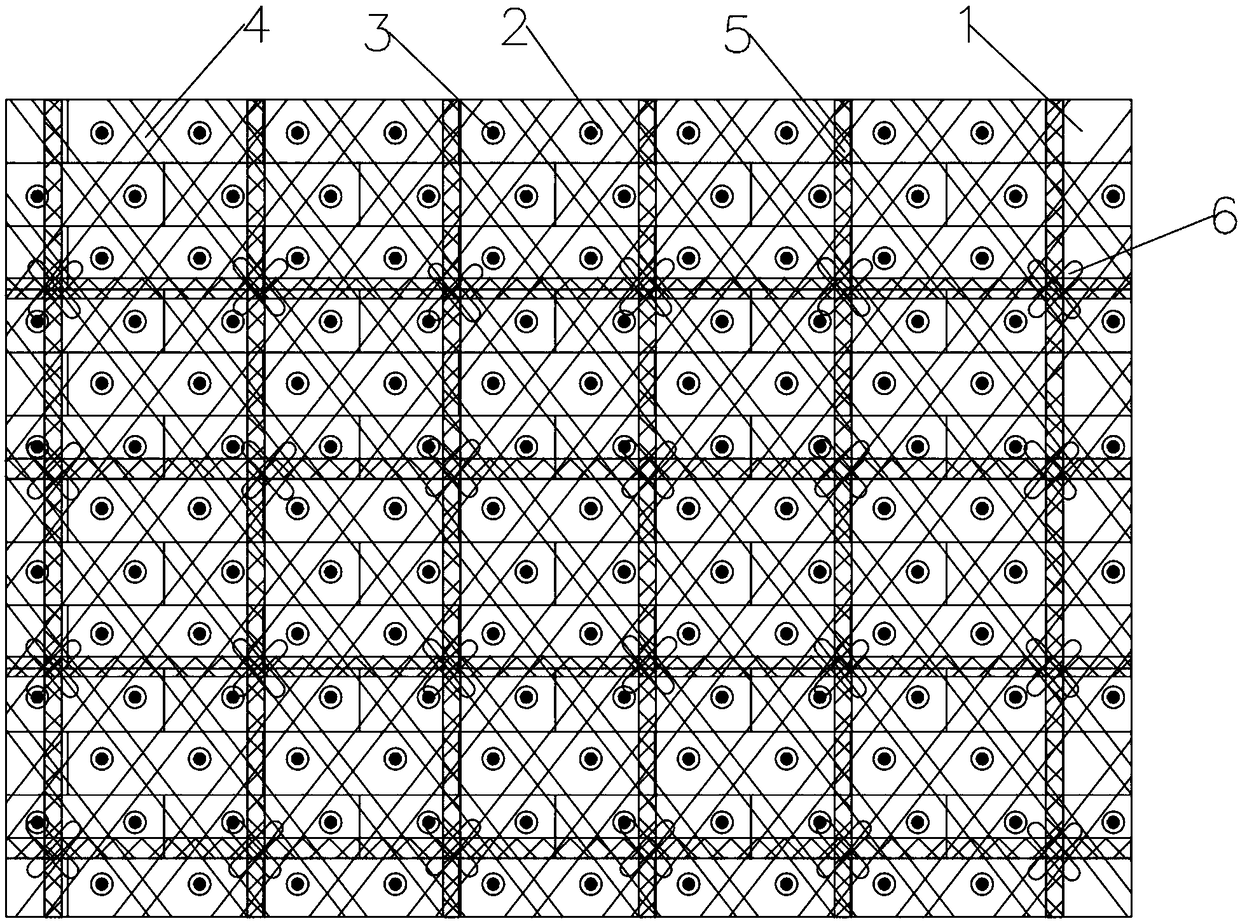

Combined dense rib plate as well as manufacturing method and assembled type plate-column structure thereof

ActiveCN104389374AImprove seismic performanceImprove impact resistanceFloorsPlate columnShock resistance

The invention discloses a combined dense rib plate as well as a manufacturing method and an assembled type plate-column structure thereof, for improving the shock resistance and the impact resistance of combined dense rib plates. The combined dense rib plate comprises concrete wing plates, anti-shearing connecting parts and steel beams, wherein the upper wing edges of the steel beams are connected with the anti-shearing connecting parts; the concrete wing plates are positioned above the steam beams and are connected with the steel beams through the anti-shearing connecting parts; the steel beams comprise transverse beams and longitudinal beams; the transverse beams are in orthogonal connection with the longitudinal beams; grids are formed between every two adjacent transverse beams and between every two adjacent longitudinal beams which are in orthogonal connection with the two adjacent transverse beams; each transverse beam and each longitudinal beam comprise upper wing edges, lower wing edges which are positioned below the upper wing edges, and webs which are positioned between the upper wing edges and the lower wing edges and are connected with the upper wing edges and the lower wing edges. The combined dense rib plate is applicable to the technical field of building structures.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Large-dimension steel and concrete combined hollow anti-slide pile and construction method thereof

InactiveCN105908738AIncreased bending stiffnessImprove structural ductilityBulkheads/pilesForming processesConcrete cover

The invention relates to geotechnical engineering, in particular to a large-dimension steel and concrete combined hollow anti-slide pile and a construction method thereof. The large-dimension steel and concrete combined hollow anti-slide pile comprises a plurality of pile sections which form a square framework by virtue of steel products, wherein concrete covers the inner side and the outer side of the square framework; the steel products are exposed from the upper end and the lower end of the concrete at the inner side; the pile sections are stacked up and down; a connecting point is formed between the steel products of upper and lower adjacent pile sections; and the connecting point is provided with a secondary concrete layer. The large-dimension steel and concrete combined hollow anti-slide pile provided by the invention is mounted in stages in a hole forming process, the mounted pile sections can be used as a protective structure, and are also used as one part of an anti-slide engineering pile, so that the construction speed is shortened, and the materials are saved; and the large-dimension steel and concrete combined hollow anti-slide pile has greater bending rigidity and better structure ductility, so that greater anti-slide bearing capacity can be obtained when the wall thickness is relatively small.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

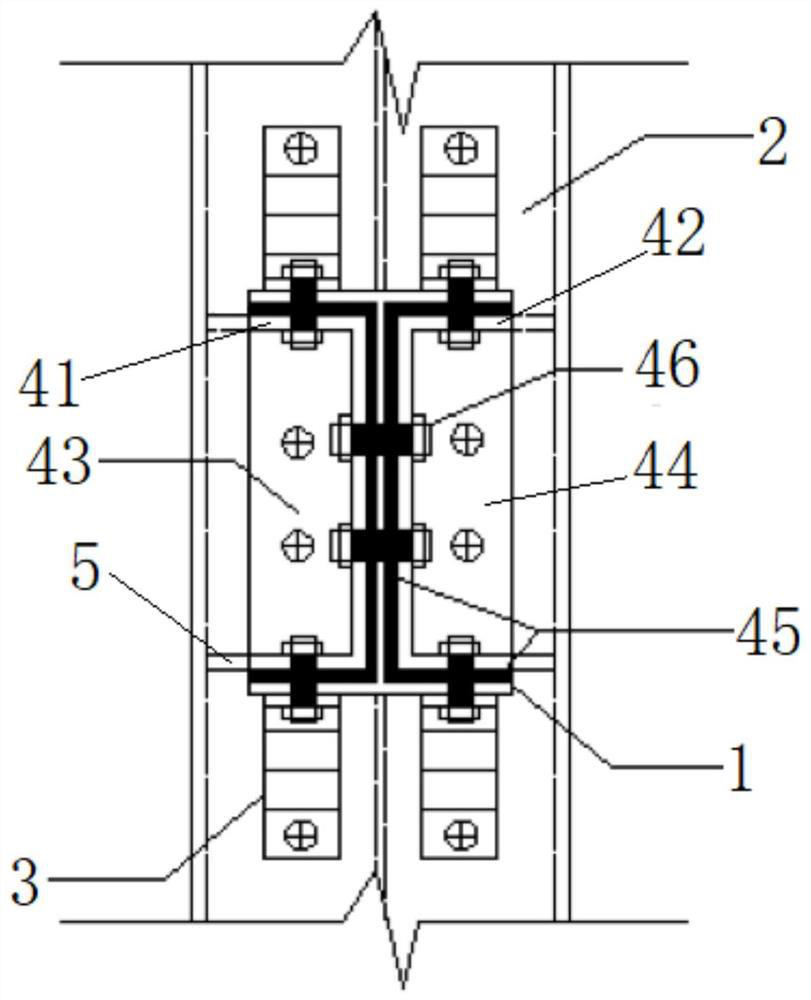

Self-resetting steel frame beam-middle column joint and construction method thereof

PendingCN112144672ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingShape-memory alloyEngineering

The invention provides a self-resetting steel frame beam-middle column joint and a construction method thereof. The self-resetting steel frame beam-middle column joint comprises two steel beams; the two steel beams are horizontally arranged on two sides of a middle column; a shape memory alloy bent steel plate is arranged between the flange of each of the steel beams and the flange of the middle column; the shape memory alloy bent steel plates are arranged on the outer sides of the flanges of the steel beams; one ends of the shape memory alloy bent steel plates are connected with the flanges of the steel beam, and the other ends are connected with the flange of the middle column; friction energy dissipaters are symmetrically arranged on two sides of webs of the steel beams; and one ends ofthe friction energy dissipaters are connected with the steel beams, and the other ends are connected with the flange of the middle column. The self-resetting function of the joint is achieved throughplastic deformation of the shape memory alloy bent steel plates; and friction energy dissipation can be achieved between the friction energy dissipaters and the flanges and webs of the steel beams, the friction energy dissipaters and the shape memory alloy bent steel plates generate a synergistic effect to jointly absorb earthquake energy at the joint, the structural ductility and energy dissipation capacity of the steel frame beam-middle column joint are effectively improved, and the post-earthquake repair cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Pier prefabricated and assembled segment, pier and construction method thereof

PendingCN110004837AImprove integrityStrong self-resetting abilityBridge structural detailsBridge erection/assemblySteel barEngineering

The invention discloses a pier prefabricated and assemble segment. The pier prefabricated and assemble segment comprises a segment body, a plurality of joints are arranged at the upper end of the segment body, a plurality of joint holes matched with the joints in an adapted and inserted mode are formed in the upper end of the segment body, and reserved common steel bar holes and prestressing steelbundle holes are further formed in the segment body in the longitudinal direction. The invention further discloses a pier including the pier prefabricated and assembled segment and a construction method of the pier. The prefabricated and assembled pier segment is adopted, hoisting, splicing and prestressed post-tensioning can be completed on site, and the prefabricated and assembled pier segmentcan be widely used in alpine or high altitude areas.

Owner:BEIJING JIAOTONG UNIV

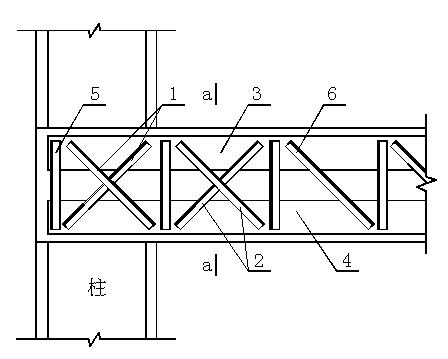

Bending-resistant ductile truss frame

InactiveCN104532950AEnsure safetyEasy to implement yield mechanismShock proofingEarthquake resistanceArchitectural engineering

The invention provides a bending-resistant ductile truss frame, and belongs to the field of earthquake proofing of building structures. According to the technical scheme, the bending-resistant ductile truss frame is that a yielding energy dissipating rod is arranged at the span of a bending moment infection point of the truss under the vertical load effect; two ends of the yielding energy dissipating rod are respectively hinged to adjacent lower chord members; the bearing capacity of the yielding energy dissipating rod is less than that of the lower chord members, so that the yielding energy dissipating rod can be yielded earlier than the lower chord members under earthquake; the yielding energy dissipating rod is mounted after the vertical load is loaded. The equivalent damping ratio of the bending-resistant ductile truss frame under fortification and rare occurrence earthquake is obviously increased and more than that of the common truss frame, the shearing force of the base and interlayer displacement are obviously less than those of the common truss frame, and the energy dissipating effect and earthquake absorption effect are obvious; compared with the common truss frame, a frame column of the bending-resistant ductile truss frame is difficultly avoided plastic hinge, so that the strong column and weak beam yielding mechanism is easily achieved, and as a result, the ductility of the structure is improved, and the preset earthquake proofing performance target is achieved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

A kind of oblique pillar structure for natural draft cooling tower and its construction method

ActiveCN104372967BImprove mechanical propertiesSmall cross-sectional sizeStrutsBuilding material handlingCooling towerNatural ventilation

The invention discloses an oblique pillar structure for a natural ventilation cooling tower and a construction method thereof. The structure includes a slanted strut structure, wherein the slanted strut structure consists of a plurality of strut frames interconnected to form a ring structure, and the strut frame is a steel pipe-concrete composite structure composed of steel pipes and concrete filled in the steel pipes; the strut frame includes a ring beam , piers and pillars, wherein the top of the pillars is connected to the ring beam, and the bottom end is connected to the piers; the pillars are X-shaped pillars or V-shaped pillars. The construction method is that the concrete in the inclined pillars and the concrete in the ring beam of the steel tube-concrete composite structure are poured from the bottom, and the one-time or segmented jacking method is poured, and the segmented ring beams are assembled into an integral ring beam by welding. The invention has the advantages of small cross-sectional size of the inclined pillar, good structural ductility, fast construction speed, long service life, relatively cheap construction cost of the whole tower, easy and low maintenance cost in the later period, and the like.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

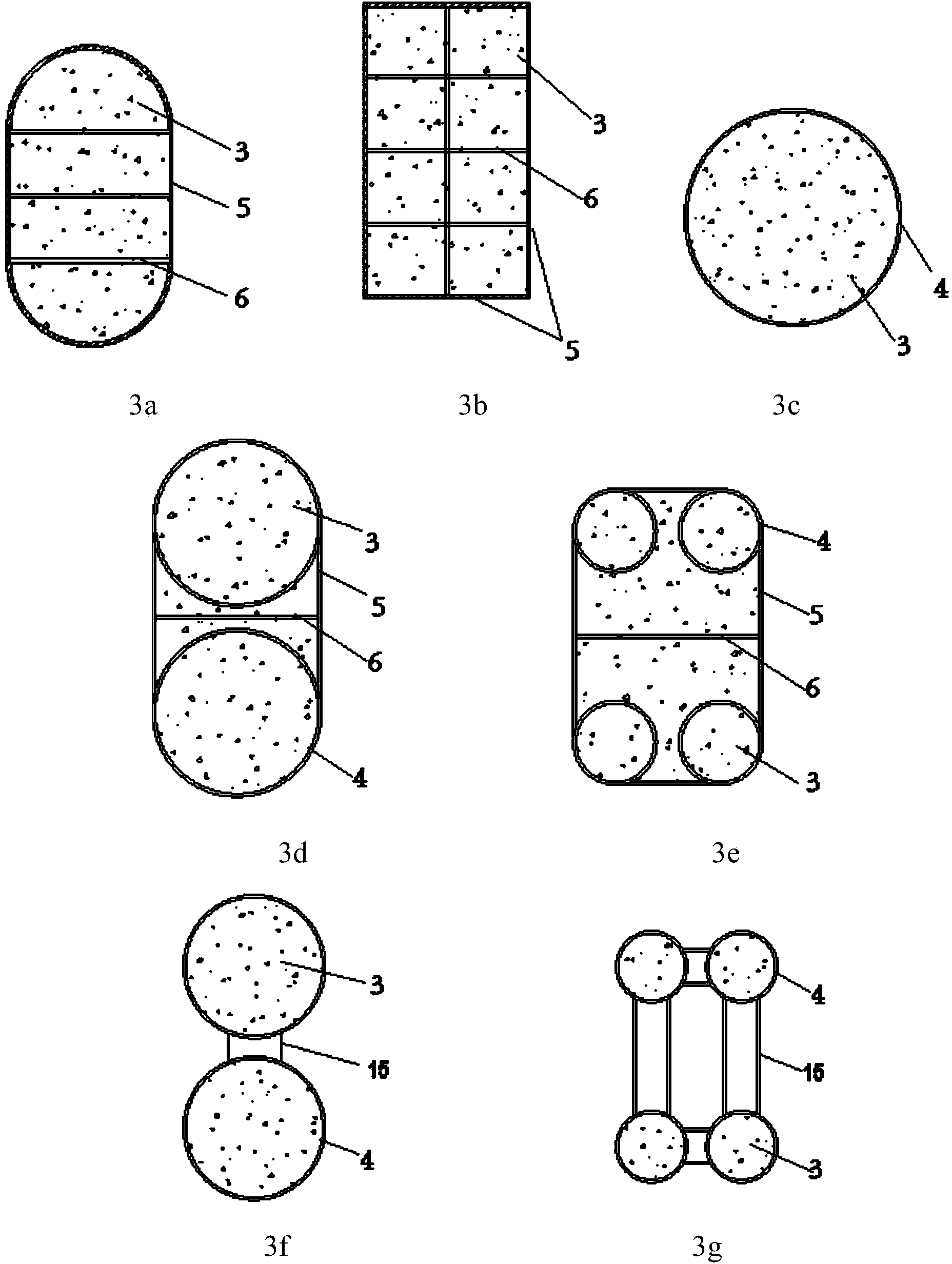

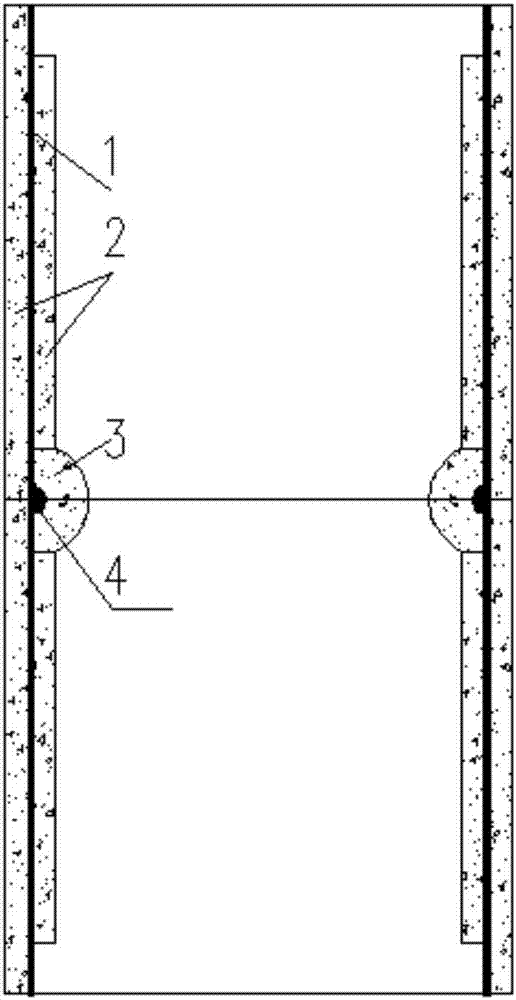

Composite reinforced diaphragm wall and its construction method

ActiveCN106759266BImprove construction conditionsReduce engineering costsExcavationsBulkheads/pilesStructural engineering

The invention relates to a combined reinforcement continuous wall and belongs to the technical field of foundation pit support in civil engineering. The combined reinforcement continuous wall can replace a concrete underground continuous wall support mode and a bored concrete pile support mode. The combined reinforcement continuous wall is composed of vertical reinforcements, connection bodies, multifunctional crowns, inner charged materials and outer auxiliary materials. Each vertical reinforcement is composed of a pipe body or formed after the pipe body is combined with a linear body, wherein the linear body is located in the pipe body. Each connecting body is composed of a horizontal component or a vertical component or an inclined component or a plate provided with holes. The crowns are located on the tops of the vertical reinforcements and can be assembled, detached and repeatedly used. After the connecting bodies and the crowns are connected with the vertical reinforcements, a combined reinforcement is formed. The inner charged materials are located in the pipe bodies. The outer auxiliary materials are located outside the pipe bodies. The invention further relates to a construction method of the combined reinforcement continuous wall. When applied to foundation pit support, the combined reinforcement continuous wall and a construction method of the combined reinforcement continuous wall have the advantages that cost can be reduced, the work efficiency can be improved, the safety can be improved, and environmental friendliness can be achieved.

Owner:王立明

Combined reinforcement continuous wall and construction method thereof

ActiveCN106759266AImprove construction conditions and construction impactsReduce engineering costsExcavationsBulkheads/pilesEngineeringStructural engineering

The invention relates to a combined reinforcement continuous wall and belongs to the technical field of foundation pit support in civil engineering. The combined reinforcement continuous wall can replace a concrete underground continuous wall support mode and a bored concrete pile support mode. The combined reinforcement continuous wall is composed of vertical reinforcements, connection bodies, multifunctional crowns, inner charged materials and outer auxiliary materials. Each vertical reinforcement is composed of a pipe body or formed after the pipe body is combined with a linear body, wherein the linear body is located in the pipe body. Each connecting body is composed of a horizontal component or a vertical component or an inclined component or a plate provided with holes. The crowns are located on the tops of the vertical reinforcements and can be assembled, detached and repeatedly used. After the connecting bodies and the crowns are connected with the vertical reinforcements, a combined reinforcement is formed. The inner charged materials are located in the pipe bodies. The outer auxiliary materials are located outside the pipe bodies. The invention further relates to a construction method of the combined reinforcement continuous wall. When applied to foundation pit support, the combined reinforcement continuous wall and a construction method of the combined reinforcement continuous wall have the advantages that cost can be reduced, the work efficiency can be improved, the safety can be improved, and environmental friendliness can be achieved.

Owner:王立明

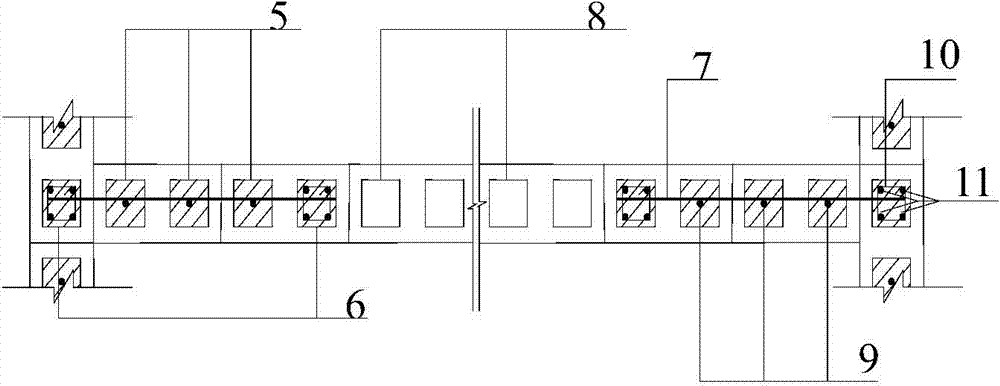

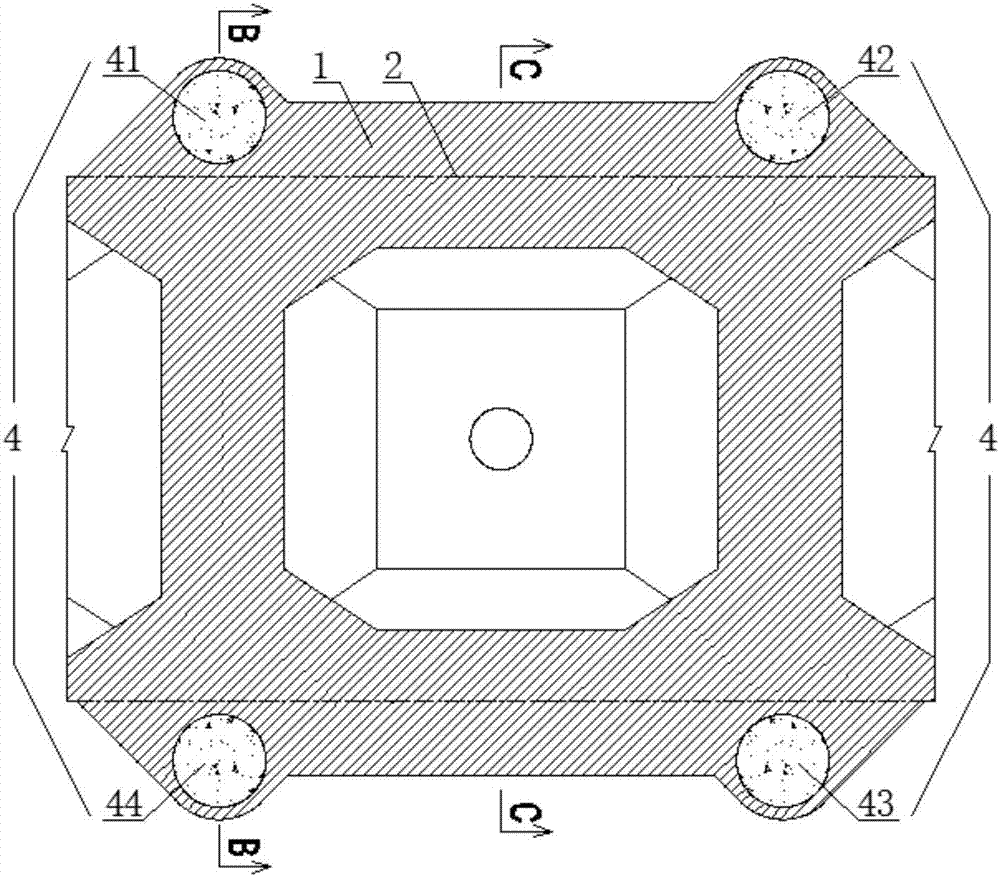

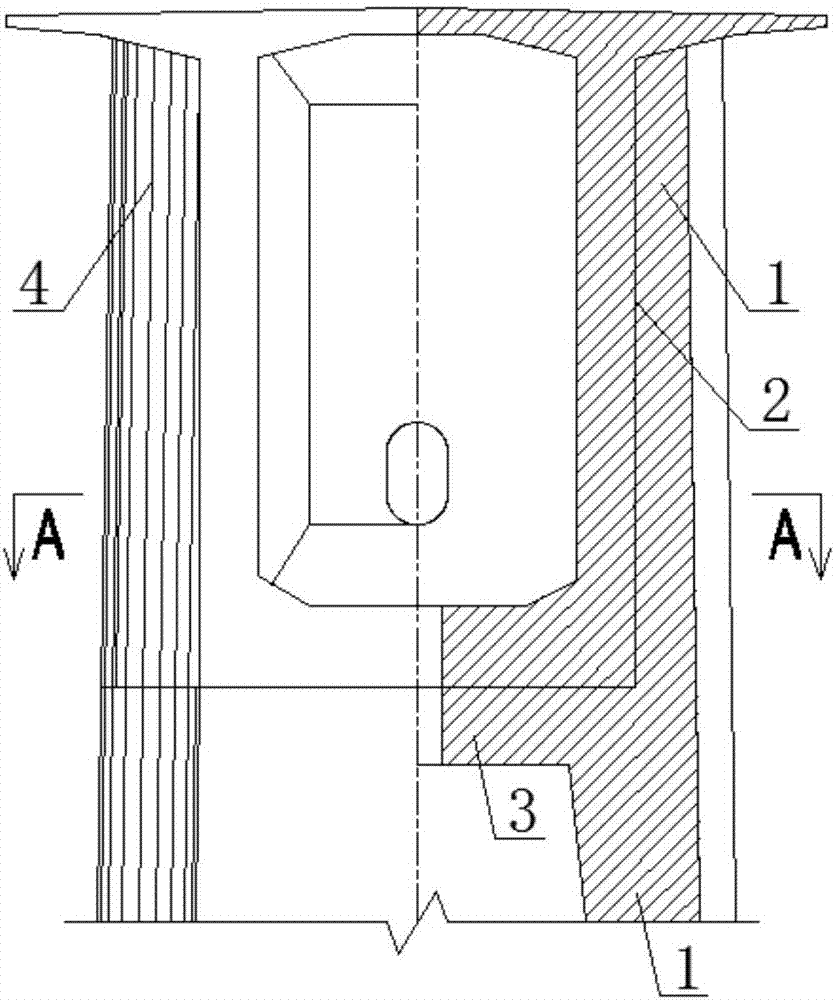

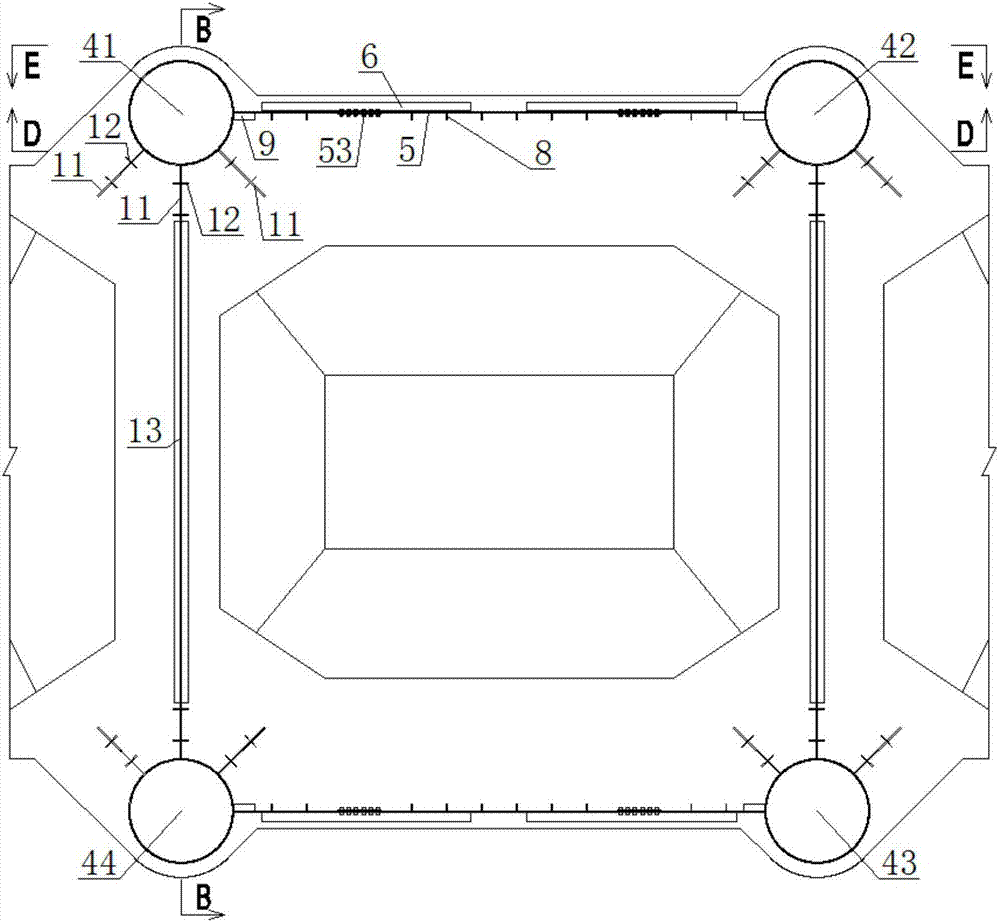

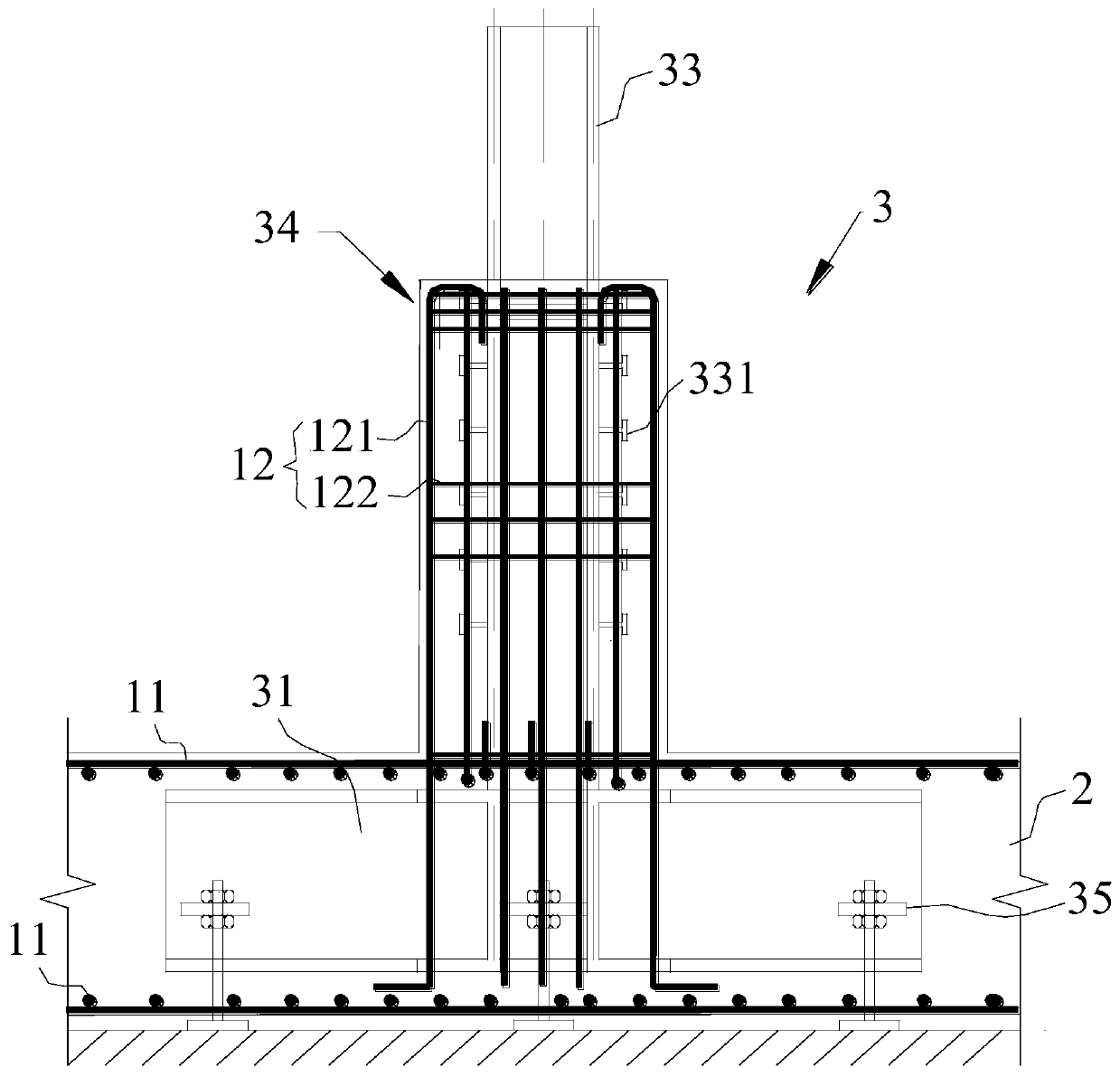

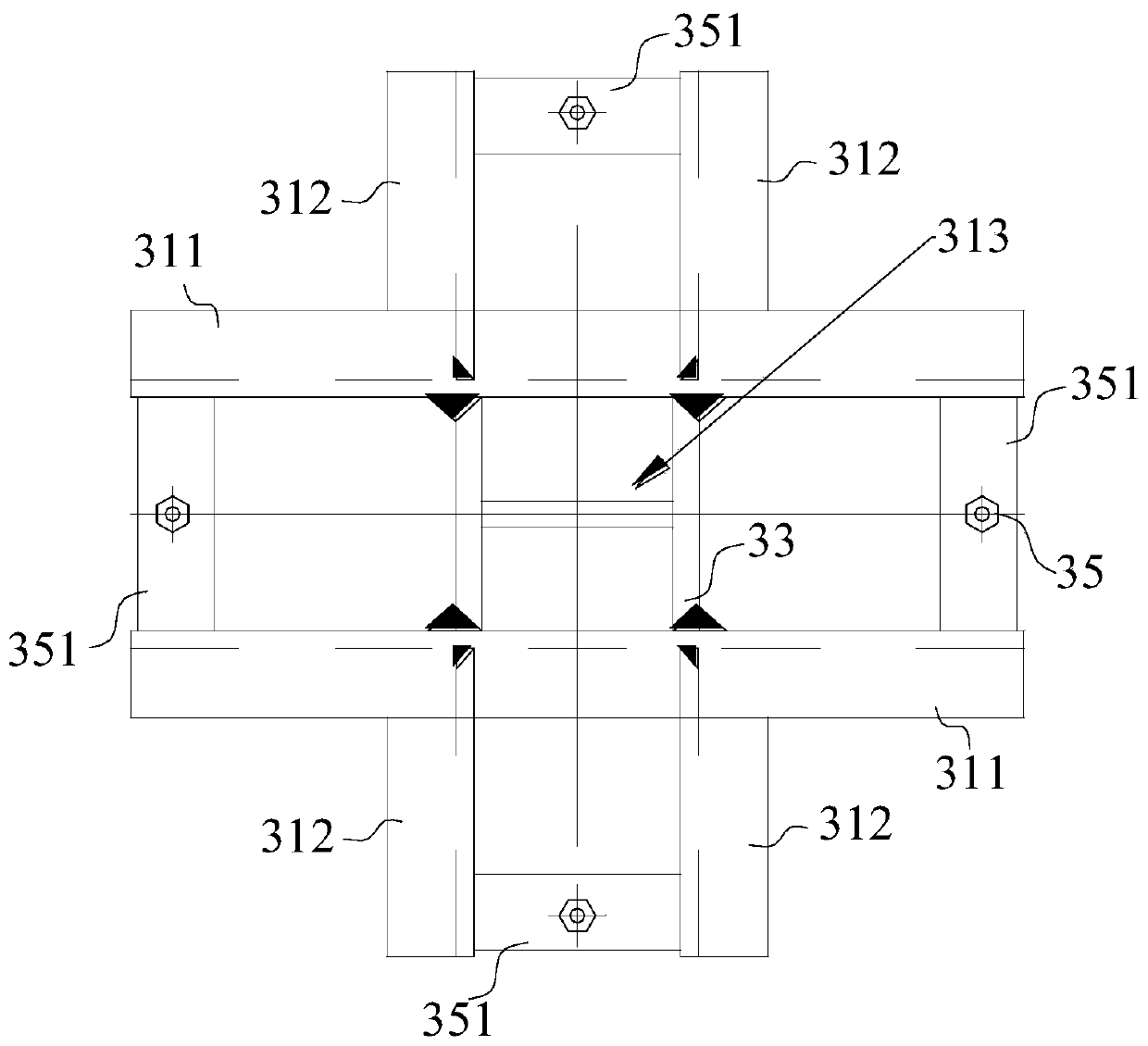

Overall pier and beam built-in connecting structure and construction method thereof

ActiveCN107254835AImprove integrityIncrease stiffnessClimate change adaptationBridge structural detailsPre stressEngineering

The invention relates to an overall pier and beam built-in connecting structure and a construction method thereof. The connecting structure comprises a main beam and concrete-filled steel tube combined pier. The built-in section of the pier and a main beam are integrally formed in an integral pouring mode, the main beam is arranged between main steel tubes of four corner points of the pier, steel frameworks are connected between the adjacent main steel tubes, and prestress steel strands are arranged between the main steel tubes and on the box walls of the steel frameworks and the main beam. Aiming at the problems that the ultimate bearing capacity of a pier and beam connecting position is lower than other positions of the structure, and the pier beam connecting position is firstly damaged under the earthquake load effect, through structure overall rigidity demonstration and system rigidity matching demonstration, the transverse size of the top face of the pier is increased, a beam body of the main beam is embedded between the main steel tubes of the pier in an overall width mode, the steel frameworks are arranged to be connected with the main steel tubes of the pier, the longitudinal and transverse prestress steel strands are tensioned, finally rebar pouring concrete is arranged, the connecting intensity of the pier and the main beam is improved, the ultimate bearing capacity of the pier and beam fixed connecting position is effectively improved, and then the pier and beam connecting position is not a weak link of a structural system any more.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE OF COMM

Elevated single-column station in high-intensity area and construction method thereof

ActiveCN111963203AReduce construction costsReduce earthquake responseUnderground chambersTunnel liningStructural systemRail traffic

The invention relates to the technical field of railway station construction, in particular to an elevated single-column station in a high-intensity area and a construction method thereof. Through thedesign that the lower layer is a station hall layer and the upper layer is a platform layer, the station hall layer of a high-speed rail station is directly arranged below the platform layer, and meanwhile, the station hall layer and the platform layer do not occupy too much land area, so that the arrangement of the high-speed rail station is not limited by land any more, the construction cost ofa high-speed rail is reduced, and the development of high-speed rail traffic is promoted. And meanwhile, a steel pipe-concrete combined structure system greatly reduces the dead weight of the structure and reduces the earthquake response. Due to the fact that the dead weight of the structure is reduced, the built height of the elevated single-column station can be effectively increased, and the elevated single-column station has good road landscape.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

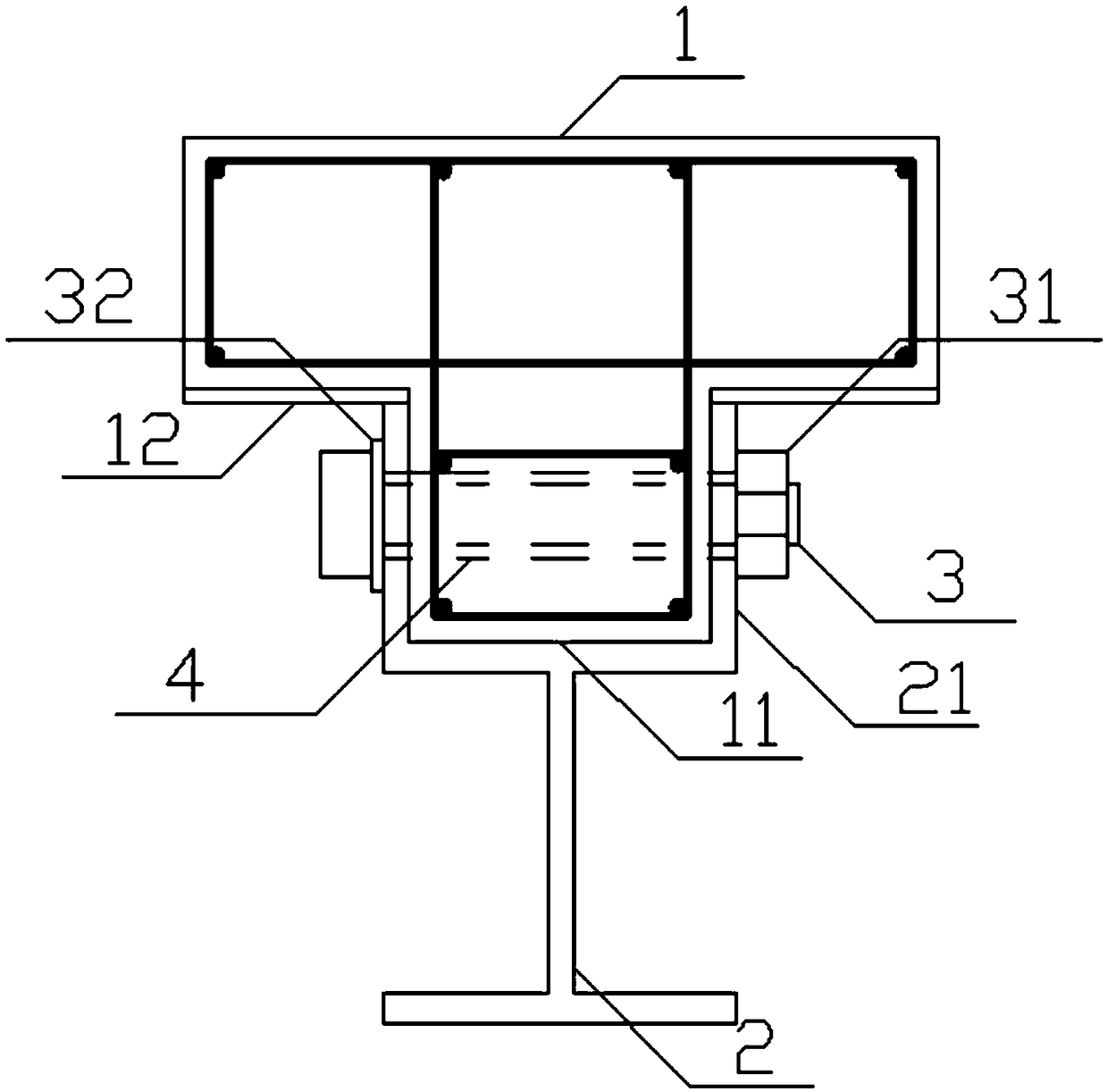

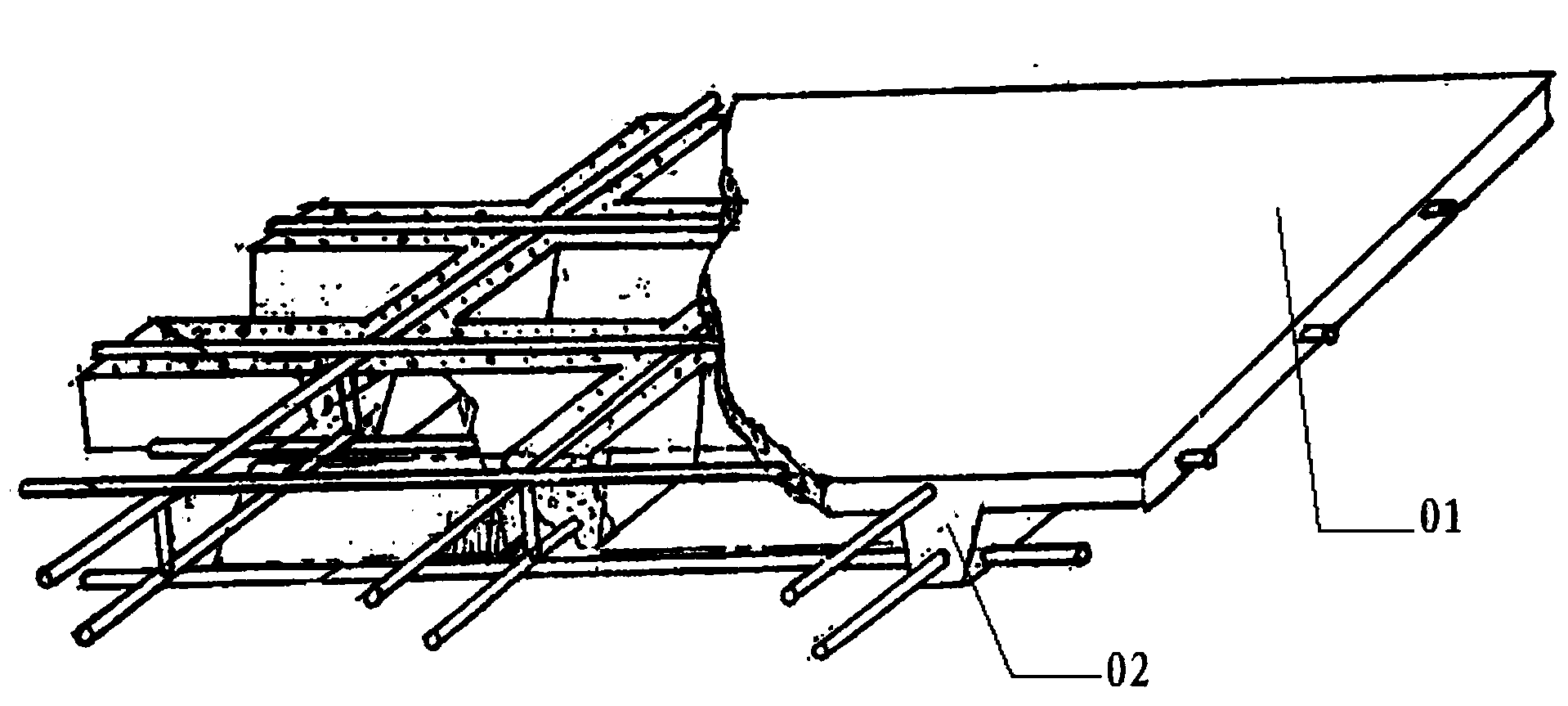

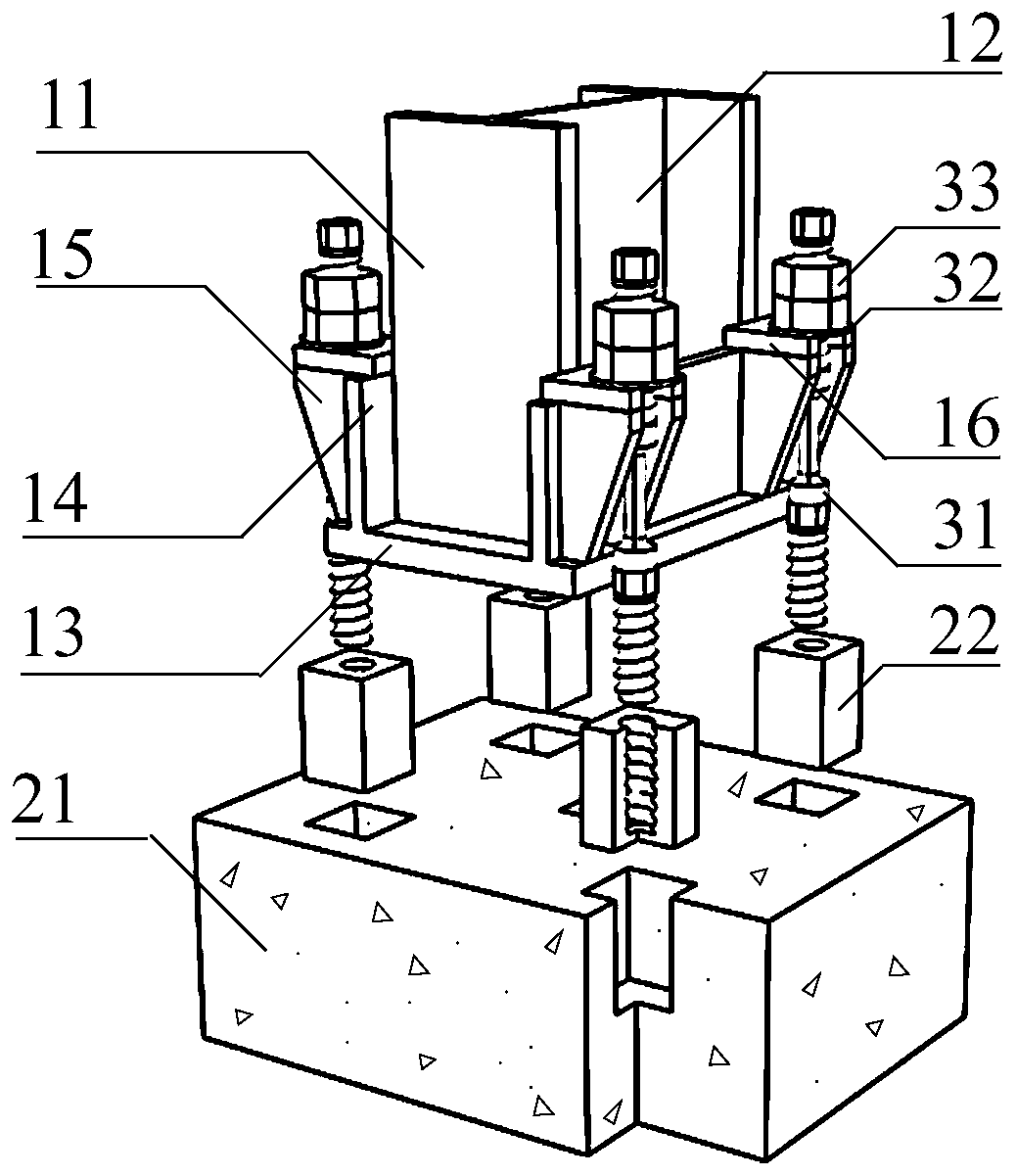

Replaceable column base for recoverable functional structure

ActiveCN111075113ASimple structureEasy to maintain laterStrutsFoundation engineeringArchitectural engineeringSteel columns

The invention belongs to the technical field of structural engineering steel structures, and particularly relates to a replaceable column base for a recoverable functional structure. The replaceable column base comprises a bottom layer steel column and a foundation 21, wherein the bottom layer steel column comprises a flange 11, a web 12, a bottom plate 13, a reinforcing part and a replaceable anchor bolt; the flange 11 and the web 12 are connected with the bottom plate 13 through welding; the bottom plate 13 of the bottom layer steel column is placed on the top surface of the foundation 21; and a threaded sleeve 22 is pre-buried in the foundation 21, and the threaded sleeve 22 and the foundation 21 are reliably anchored and connected. The replaceable column base can achieve yield energy dissipation under the earthquake effect so as to protect the bottom layer steel column against bending yield failure, and after an earthquake, rapid recovery of the structure function can be achieved by replacing the anchor bolt.

Owner:TSINGHUA UNIV

Nested U-shaped staged yield damper

PendingCN111945915AOvercoming the drawbacks of yield point concentrationReduce frictionProtective buildings/sheltersShock proofingEconomic benefitsIndustrial engineering

The invention relates to a nested U-shaped staged yield damper, and belongs to the technical field of structural engineering energy dissipation and shock absorption. The metal damper is composed of two U-shaped energy dissipation parts which are nested in the same direction in the horizontal direction, a double-layer corrugated energy dissipation part, a brass base plate and a steel cushion block.According to the nested U-shaped staged yield damper, the design concepts that staged yield is adopted, energy dissipation parts can be replaced, the shear bearing capacity of the damper is improved,out-of-plane buckling is restrained, the structural rigidity is improved, and various energy dissipation mechanisms work together and the like are applied, and the limitation of a traditional metal damper is broken through. Staged yield is achieved through the nesting design of the U-shaped energy dissipation parts and the arrangement of the steel cushion block. Meanwhile, the reasonably designeddamper has good shear bearing capacity and energy dissipation performance, the normal use function can be recovered only by replacing the energy dissipation parts after an earthquake, and the economic benefit is obvious. The metal damper develops towards the assembling direction, replacement is convenient, arrangement modes are various, and the number of the metal dampers can be flexibly increased or decreased according to actual conditions.

Owner:BEIJING UNIV OF TECH

Large-scale steel and concrete combined hollow anti-slide pile and its construction method

InactiveCN105908738BIncreased bending stiffnessImprove structural ductilityBulkheads/pilesForming processesConcrete cover

The invention relates to geotechnical engineering, in particular to a large-dimension steel and concrete combined hollow anti-slide pile and a construction method thereof. The large-dimension steel and concrete combined hollow anti-slide pile comprises a plurality of pile sections which form a square framework by virtue of steel products, wherein concrete covers the inner side and the outer side of the square framework; the steel products are exposed from the upper end and the lower end of the concrete at the inner side; the pile sections are stacked up and down; a connecting point is formed between the steel products of upper and lower adjacent pile sections; and the connecting point is provided with a secondary concrete layer. The large-dimension steel and concrete combined hollow anti-slide pile provided by the invention is mounted in stages in a hole forming process, the mounted pile sections can be used as a protective structure, and are also used as one part of an anti-slide engineering pile, so that the construction speed is shortened, and the materials are saved; and the large-dimension steel and concrete combined hollow anti-slide pile has greater bending rigidity and better structure ductility, so that greater anti-slide bearing capacity can be obtained when the wall thickness is relatively small.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

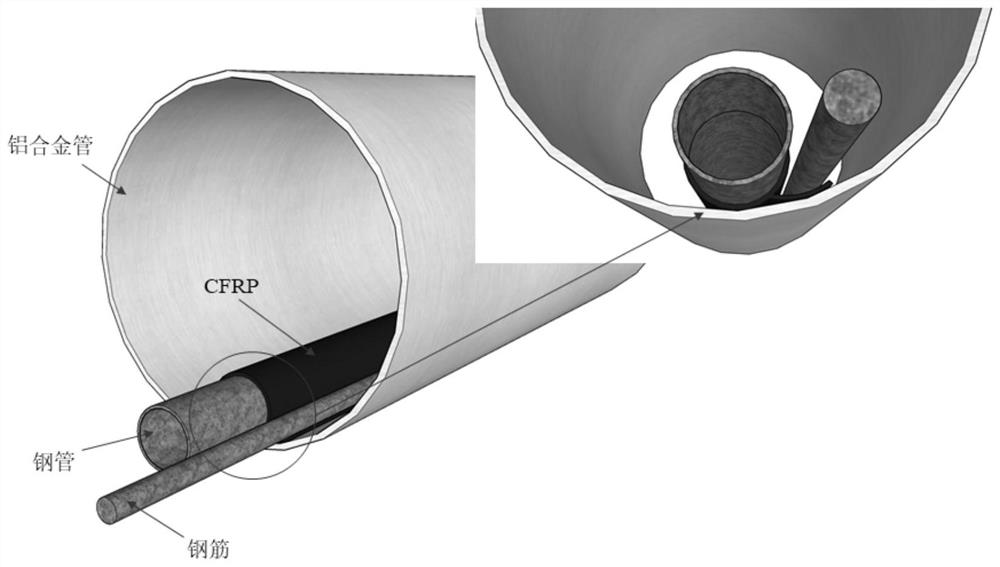

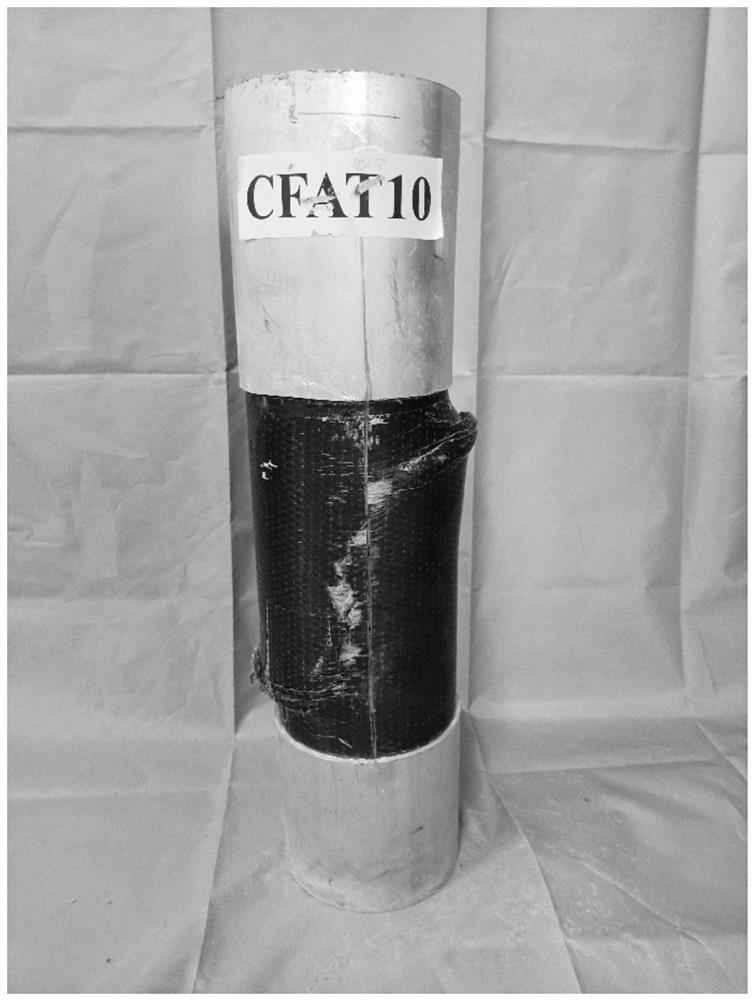

Aluminum alloy composite seawater concrete column with CFRP attached inside

PendingCN113585622ALight in massHigh tensile strengthStrutsPillarsMarine architectureAlloy composite

The invention discloses an aluminum alloy composite seawater concrete column with CFRP attached inside, and belongs to the technical field of marine building engineering structures. The aluminum alloy composite seawater concrete column with the CFRP attached inside is composed of seawater concrete, an aluminum alloy pipe and CFRP cloth; and the CFRP cloth is adhered to the inner wall of the aluminum alloy pipe to form a CFRP-aluminum alloy composite pipe, and the CFRP-aluminum alloy composite pipe is filled with the seawater concrete. According to the composite column, the aluminum alloy pipe and the CFRP are used as an external structure, and the use performance such as corrosion resistance, bearing capacity and shock resistance of the composite column structure can be remarkably improved through the restraining effect on internal concrete.

Owner:GUANGXI UNIV

Wall anti-seismic mortar

InactiveCN108868034AHigh affinityImprove seismic performanceCovering/liningsShear capacityEngineering

The invention provides wall anti-seismic mortar, comprising a wall body and a reinforcing mesh, wherein the wall surface of the wall body is uniformly provided with a plurality of holes, the hole diameter is 20-30 mm, the hole spacing is 100-120 mm, the hole depth is 120-180 mm, tie bars with diameter of 4-8 mm are inserted into the holes and are fixed by the mortar poured in the holes, the reinforcing mesh is tied on a wall surface by the tie bars and comprises a plurality of steel bars arranged in an X shape, and the wall surface and the reinforcing mesh are coated with a mortar layer with thickness of 30-80 mm. The wall anti-seismic mortar has strong structural shear capacity and good structure ductility.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

Universal base structure for power distribution device building of transformer substation

PendingCN110644519AImprove integrityReduce settlementFoundation engineeringTransformerArchitectural engineering

The invention discloses a universal base structure for a power distribution device building of a transformer substation. The universal base structure comprises a plurality of first steel bars, a raftpoured from concrete, and a column pier arranged on the raft, wherein the column pier comprises a #-shaped steel frame, a support column and a column leg reinforcing pier; the #-shaped steel frame isflatly laid and embedded into the raft, and welded and fixed to the adjacent first steel bar in the raft; the support column is vertically connected into the central area of the #-shaped steel frame in an insertion manner, a receiving groove used for receiving a part of the support column is arranged in the central area of the #-shaped steel frame, the support column is welded and fixed to the groove wall of the receiving groove, and a plurality of studs are welded to the outer circumferential surface of the support column; and the column leg reinforcing pier is poured from a plurality of second steel bars and concrete, and wrapped at the bottom of the support column, and the second steel bars comprise a plurality of longitudinal bars which are arranged at the periphery of the support column and a plurality of stirrups connected with the plurality of longitudinal bars.

Owner:ZHEJIANG UNIV +3

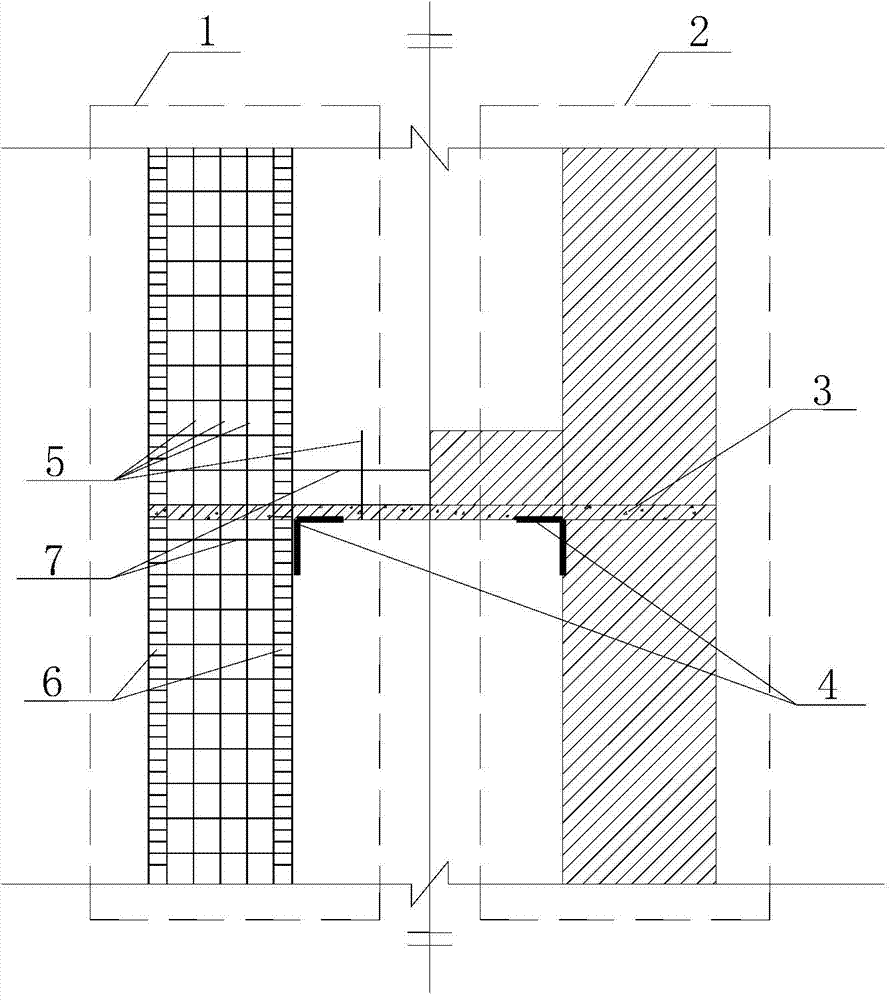

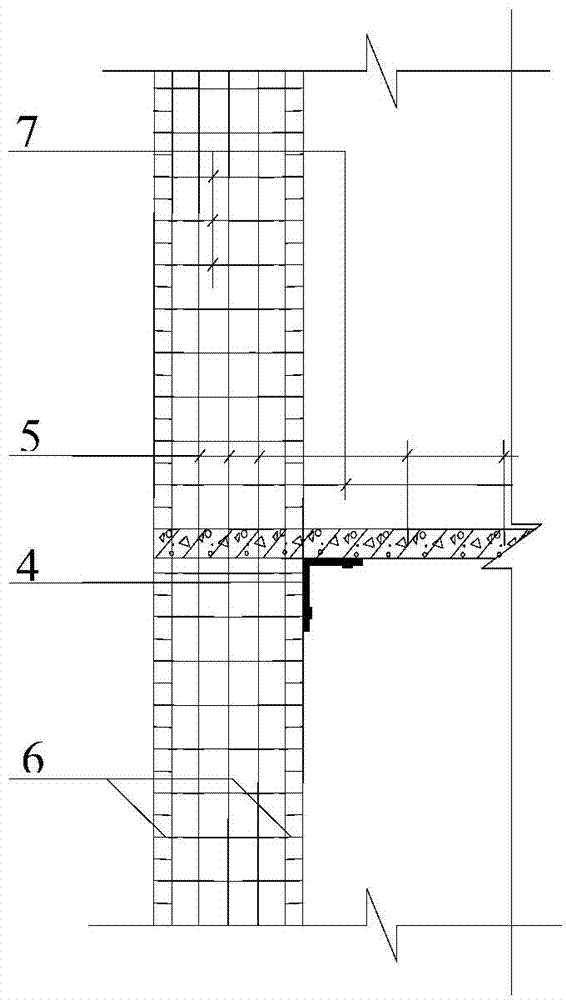

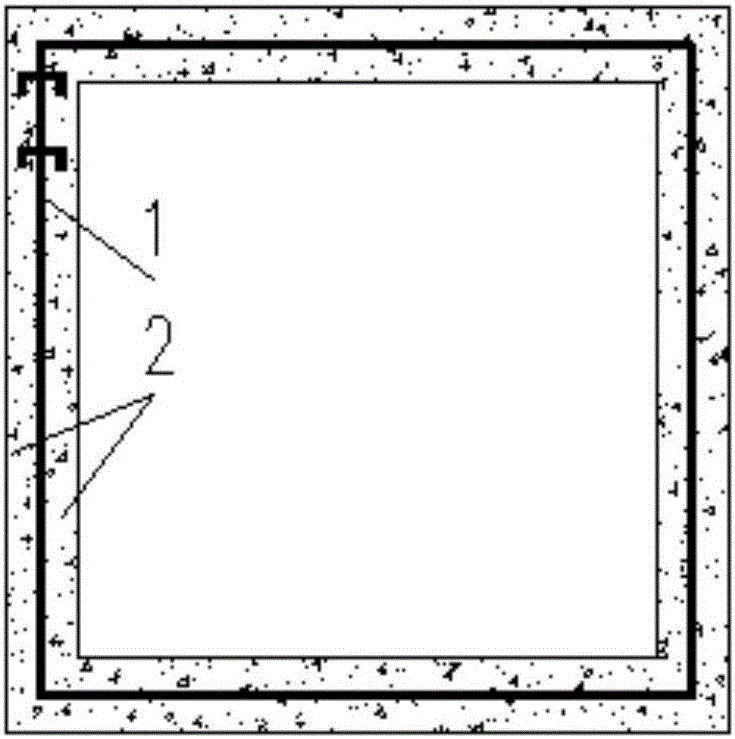

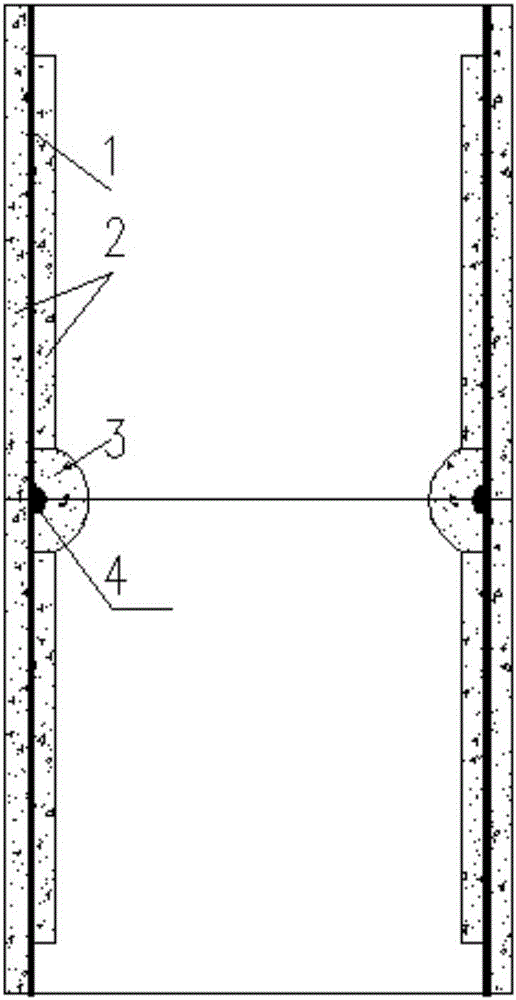

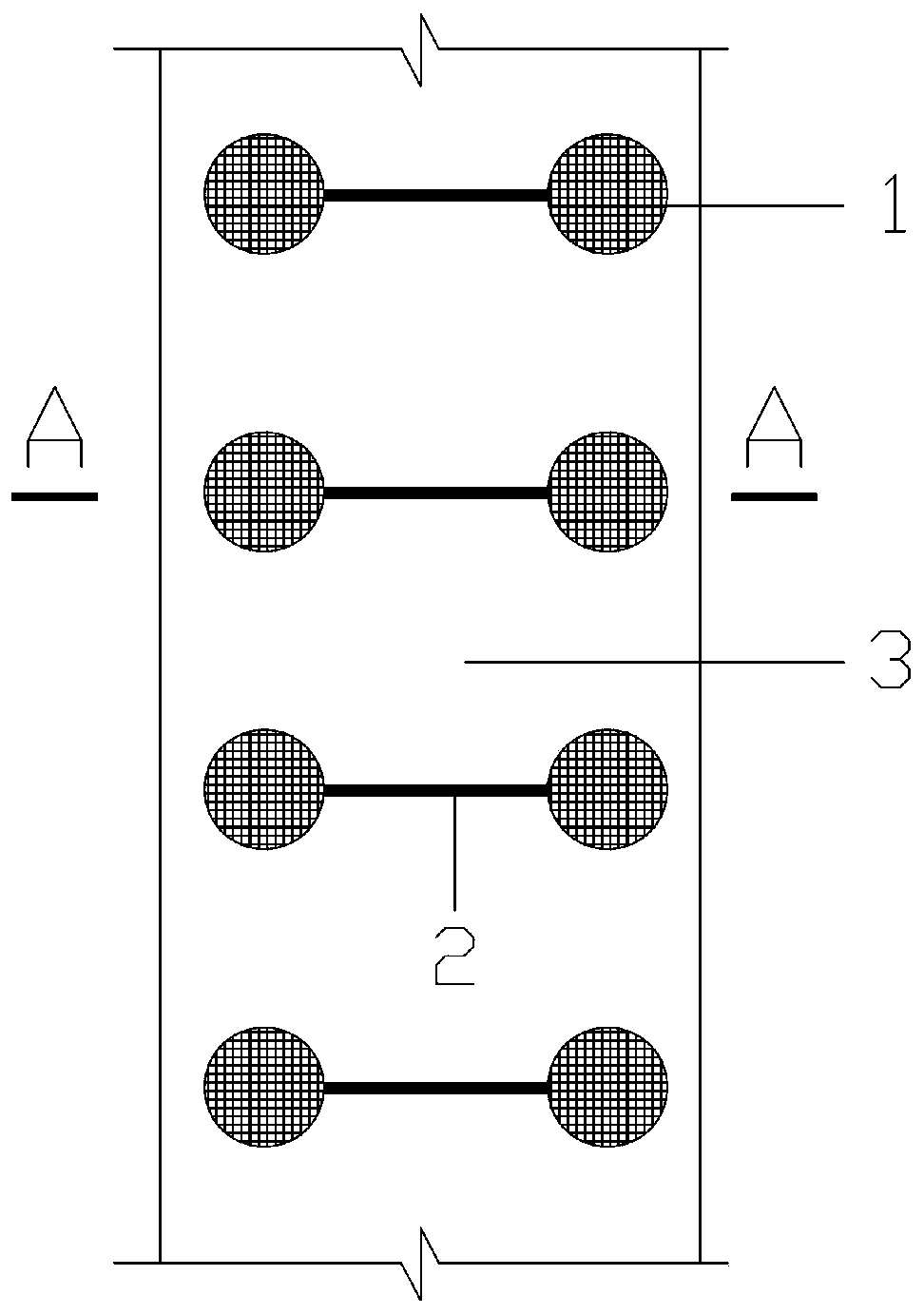

Anti-earthquake thermal power plant main plant house reinforced concrete frame bent and construction method thereof

InactiveCN105696703AImprove shear resistanceImprove structural ductilityShock proofingReinforced concrete columnRebar

The invention discloses an anti-seismic reinforced concrete frame bent frame of a main factory building of a thermal power plant and a construction method thereof, which solves the problem that the existing reinforced concrete frame bent frame of a main factory building of a thermal power plant has weak seismic capacity. Including the reinforced concrete column of bent frame A column (1), the reinforced concrete column of frame B column (2) and the reinforced concrete column of frame C column (3), the reinforced concrete column of frame B column (2) and the frame C column of reinforced concrete ( 3) A frame grid (4) is arranged between them, and channel steel shear keys (8) and horizontal bars (9) are respectively arranged at the connection between the turbine platform (7) and the reinforced concrete column (2) of the frame column B, The herringbone steel support (5) is set in the frame grid (4), and the stiff type steel bar (10) is set at the top of the reinforced concrete column (2) of column B of the frame and the reinforced concrete column (3) of column C of the frame. . The invention improves the structural ductility of the reinforced concrete frame bent frame of the main factory building of the thermal power plant under a large earthquake.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com