Large-scale steel and concrete combined hollow anti-slide pile and its construction method

A concrete and large-scale technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as the inability to realize industrialized production of structures, the inability to adopt prefabricated structures, and the collapse of hole walls to achieve material saving and good structural ductility , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

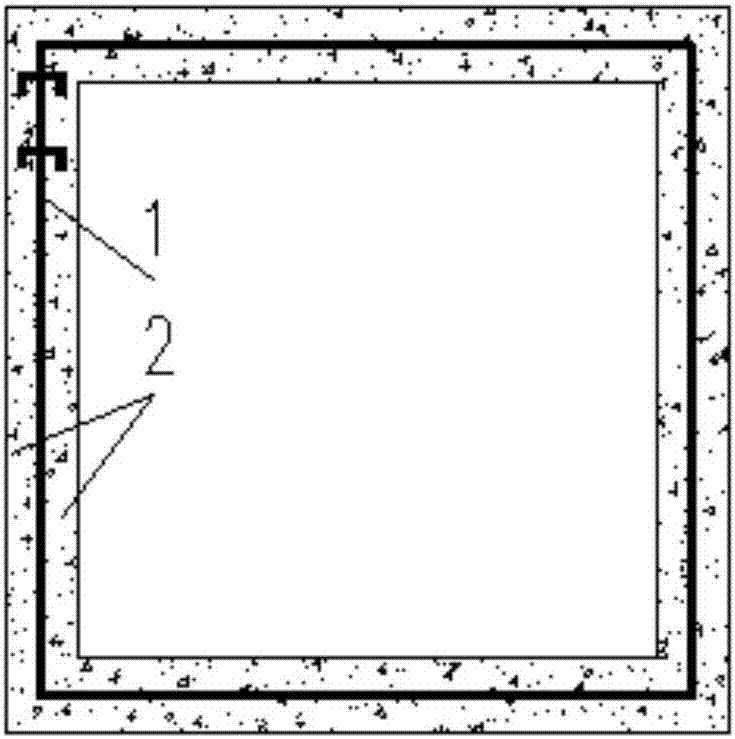

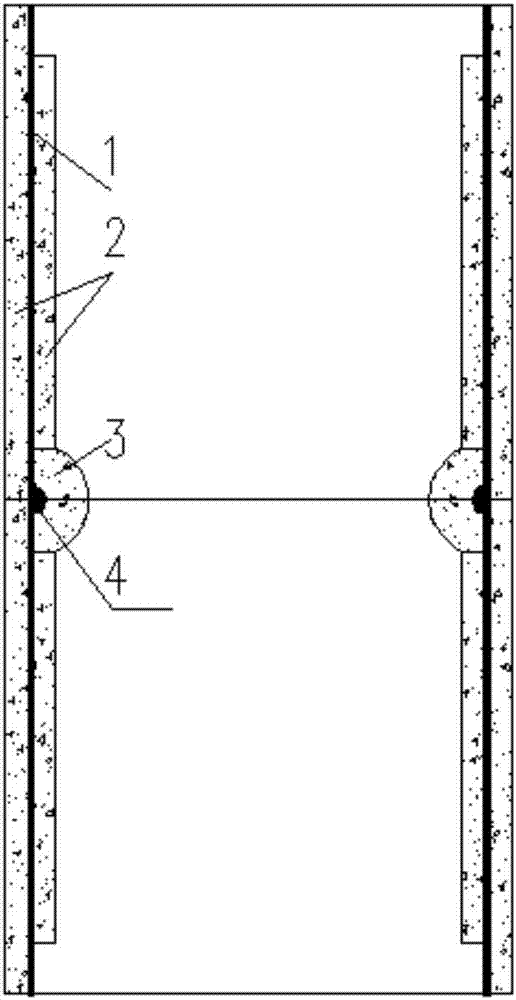

[0019] Large-scale steel and concrete composite hollow anti-slide piles, including a plurality of pile sections, the pile section is formed of a square frame by steel 1, and the inner and outer sides of the square frame are covered with concrete 2; the upper and lower ends of the inner concrete expose steel 1. The pile sections are stacked up and down, and connection points 4 are formed between the steel materials of the upper and lower adjacent pile sections, and there is a secondary concrete pouring layer 3 at the connection point 4.

[0020] The steel is a steel plate or section steel.

[0021] The pile joint is a combined structure composed of built-in steel plate or section steel and outsourced concrete. The thickness of the steel 1 is generally about 2-5mm, and the concrete strength level is generally above C25. The two form a combined structure. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com