Optimum design method of non-bearing frame structure of light vehicle

A frame structure and optimization design technology, applied in computing, special data processing applications, instruments, etc., to achieve optimal design effects, improve bending stiffness, and good design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

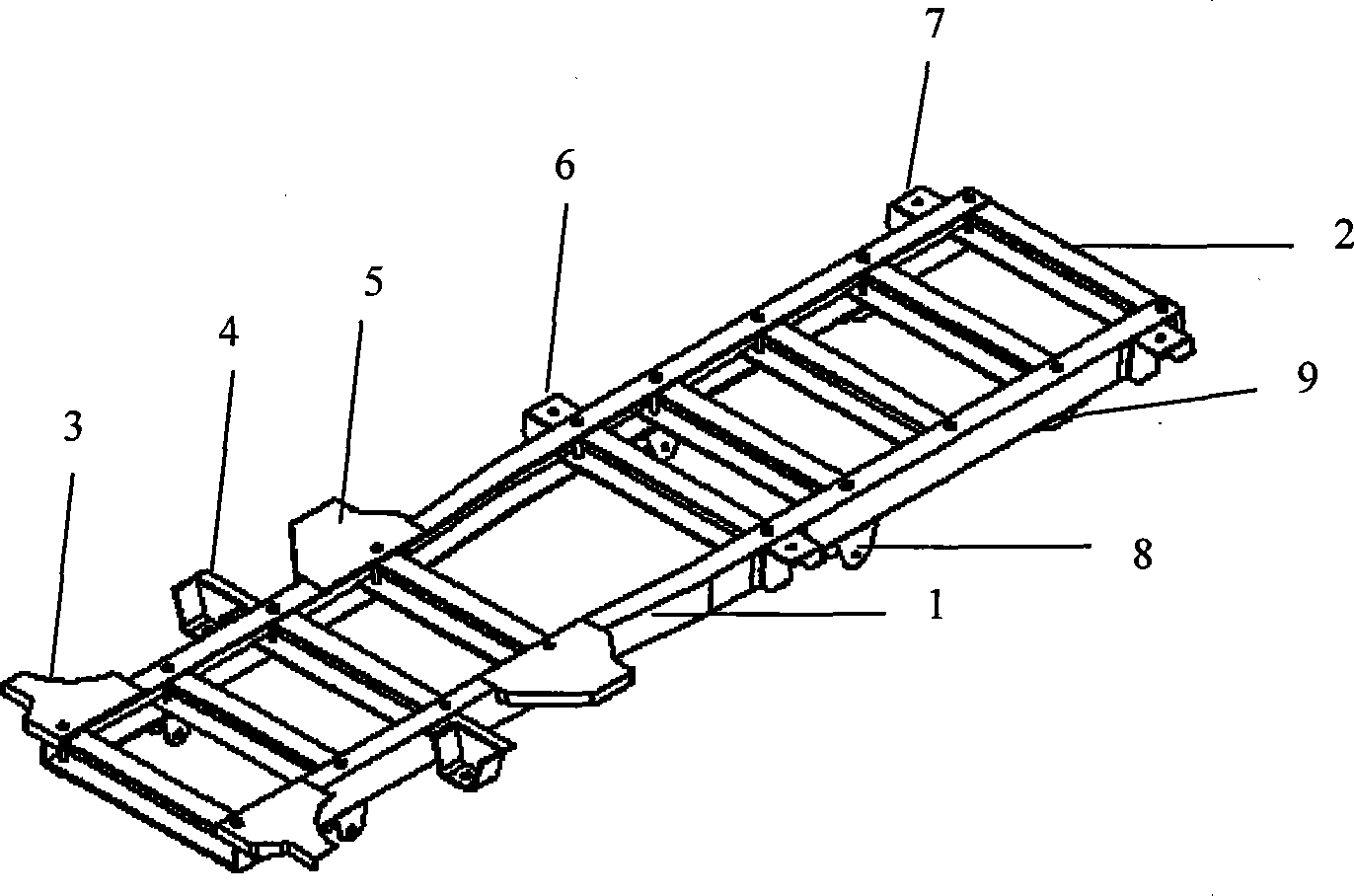

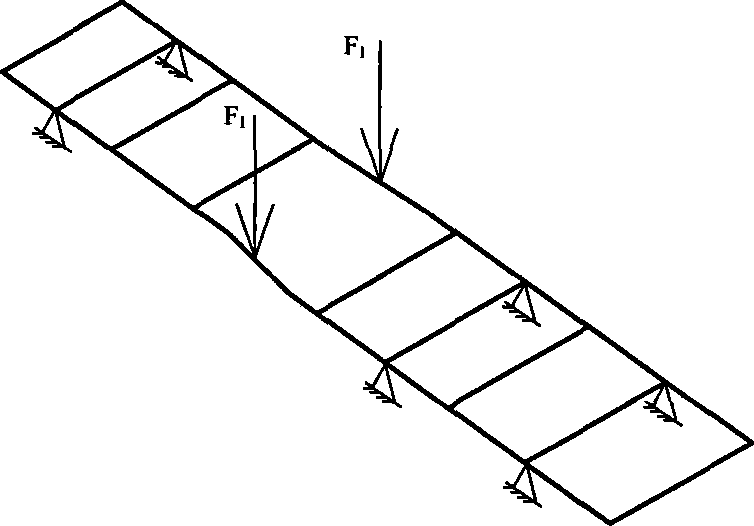

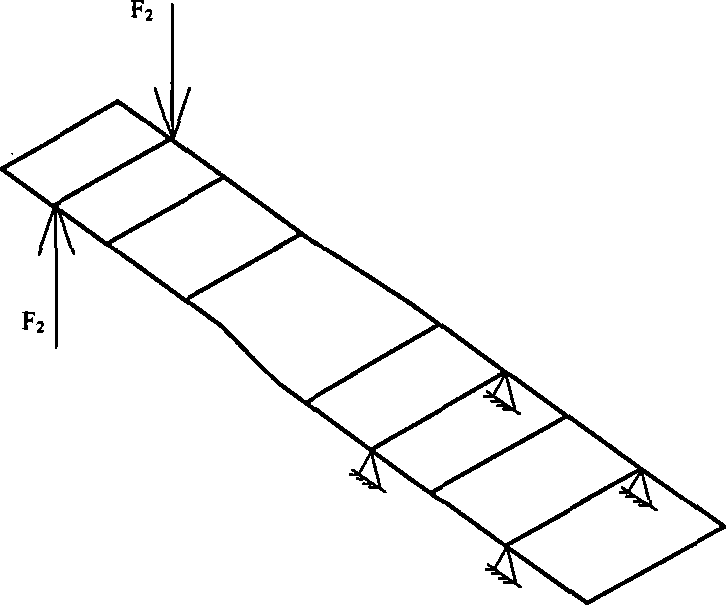

[0027] The invention discloses an optimal design method for a non-load-bearing frame structure of a light vehicle. The invention mainly includes establishing a geometric model of the frame structure, establishing a simplified equivalent finite element model of the frame structure, loading the frame load and boundary conditions, defining Implementation steps such as optimizing the design area and design variables, defining the optimization objective function, structural topology optimization design, reconstruction of the geometric model of the frame structure, and structural verification.

[0028] The present invention provides a method for optimizing the design of a non-load-bearing frame structure of a light vehicle, comprising the following steps:

[0029] (1) Use SolidWorks software to establish a three-dimensional geometric model of the original frame structure of the light vehicle, and output it into an IGES data file format to obtain the IGES model of the frame structure;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com