Patents

Literature

186results about How to "Preventive effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

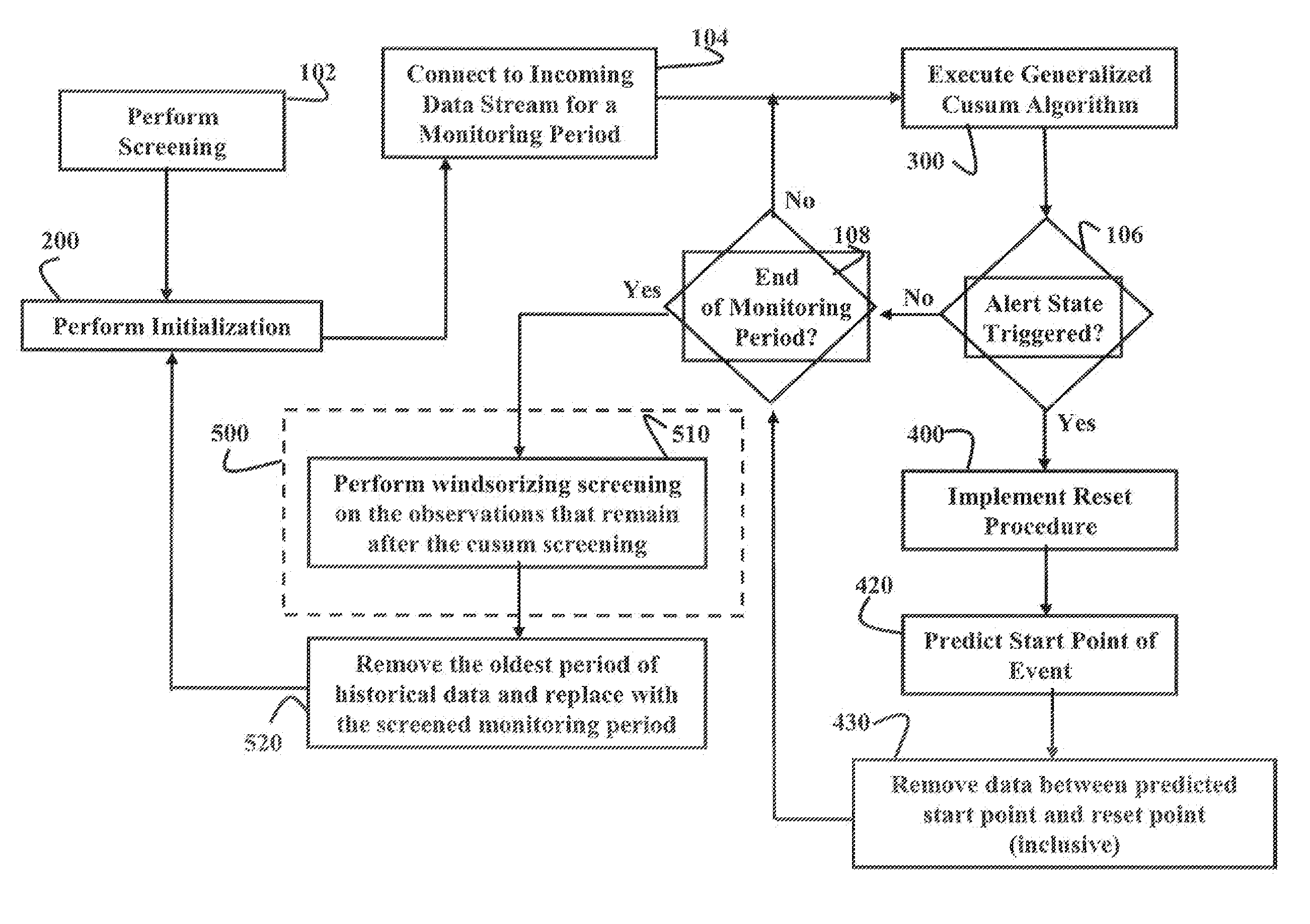

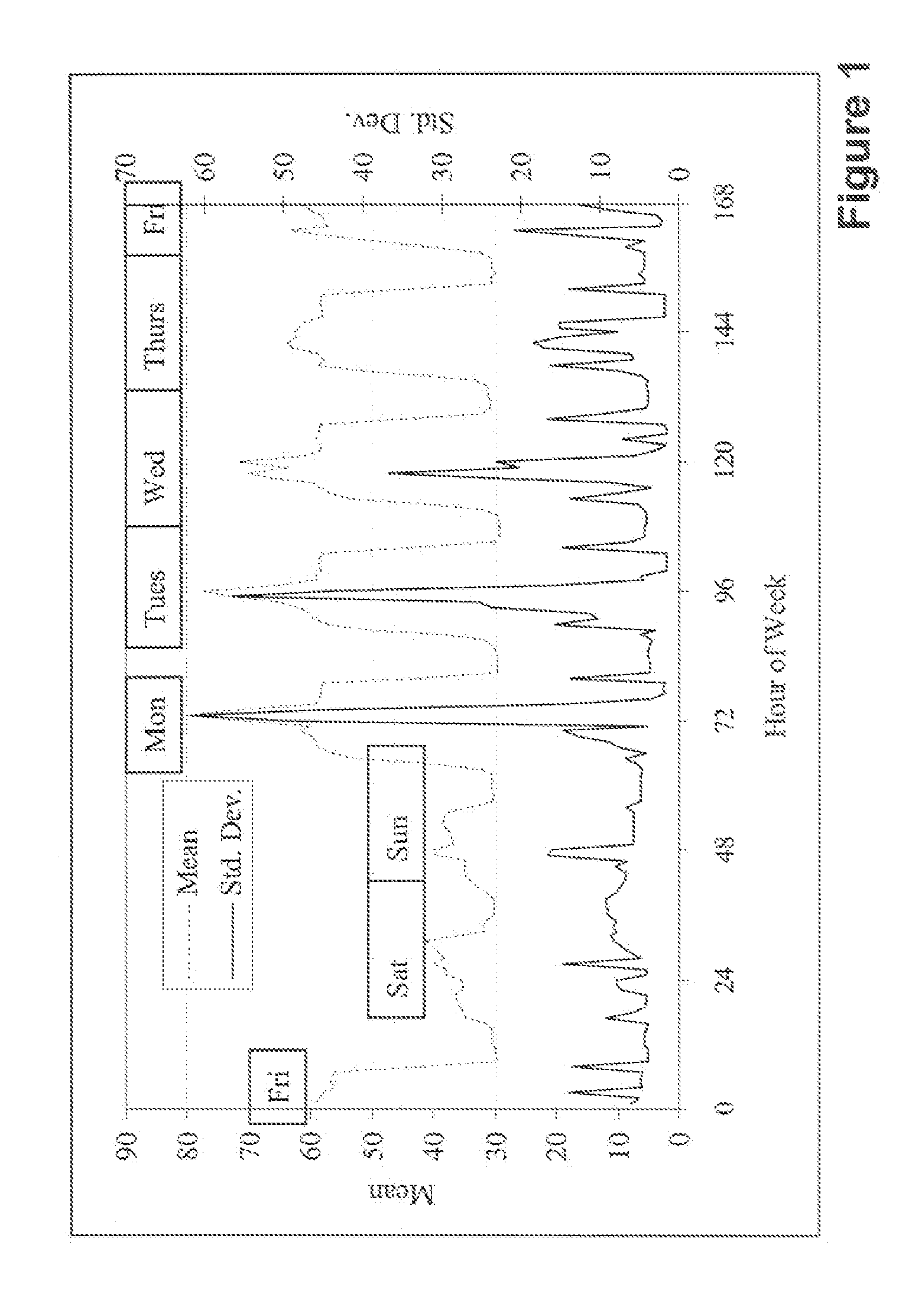

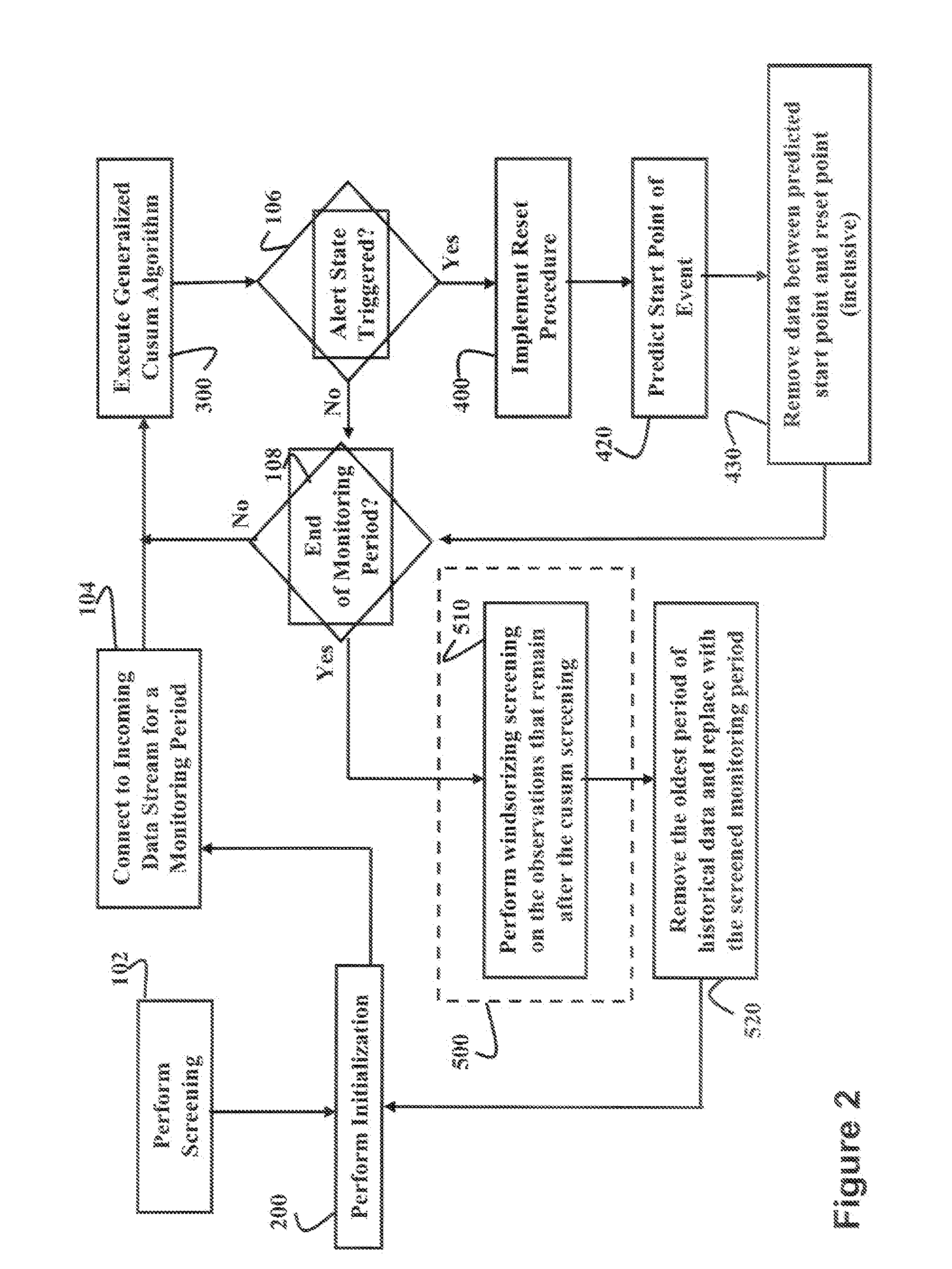

Nonparametric method for determination of anomalous event states in complex systems exhibiting non-stationarity

ActiveUS20080270071A1Preventive effectAmplifier modifications to reduce noise influenceTesting/monitoring control systemsPeak valueNormal behaviour

Owner:VMWARE INC

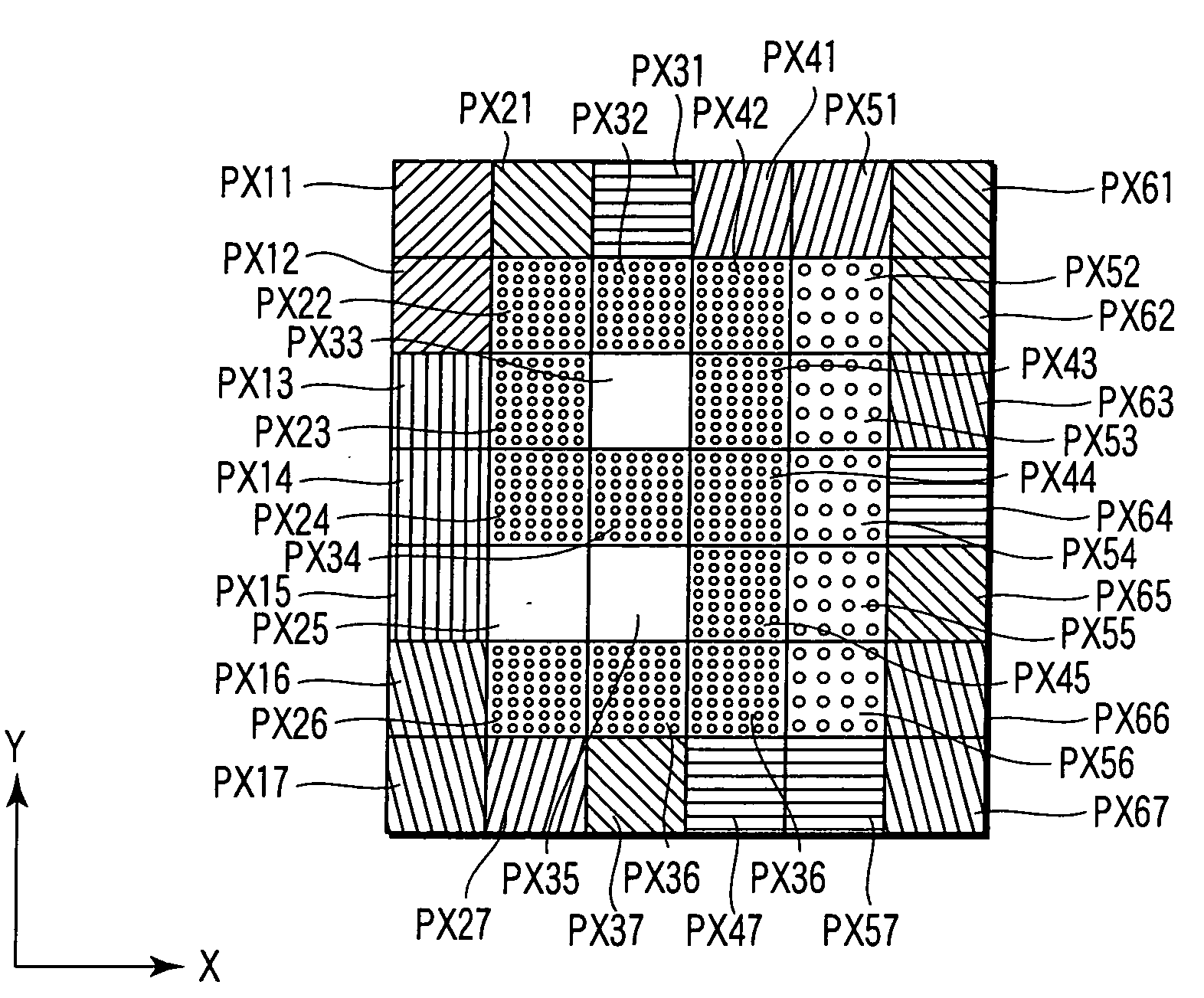

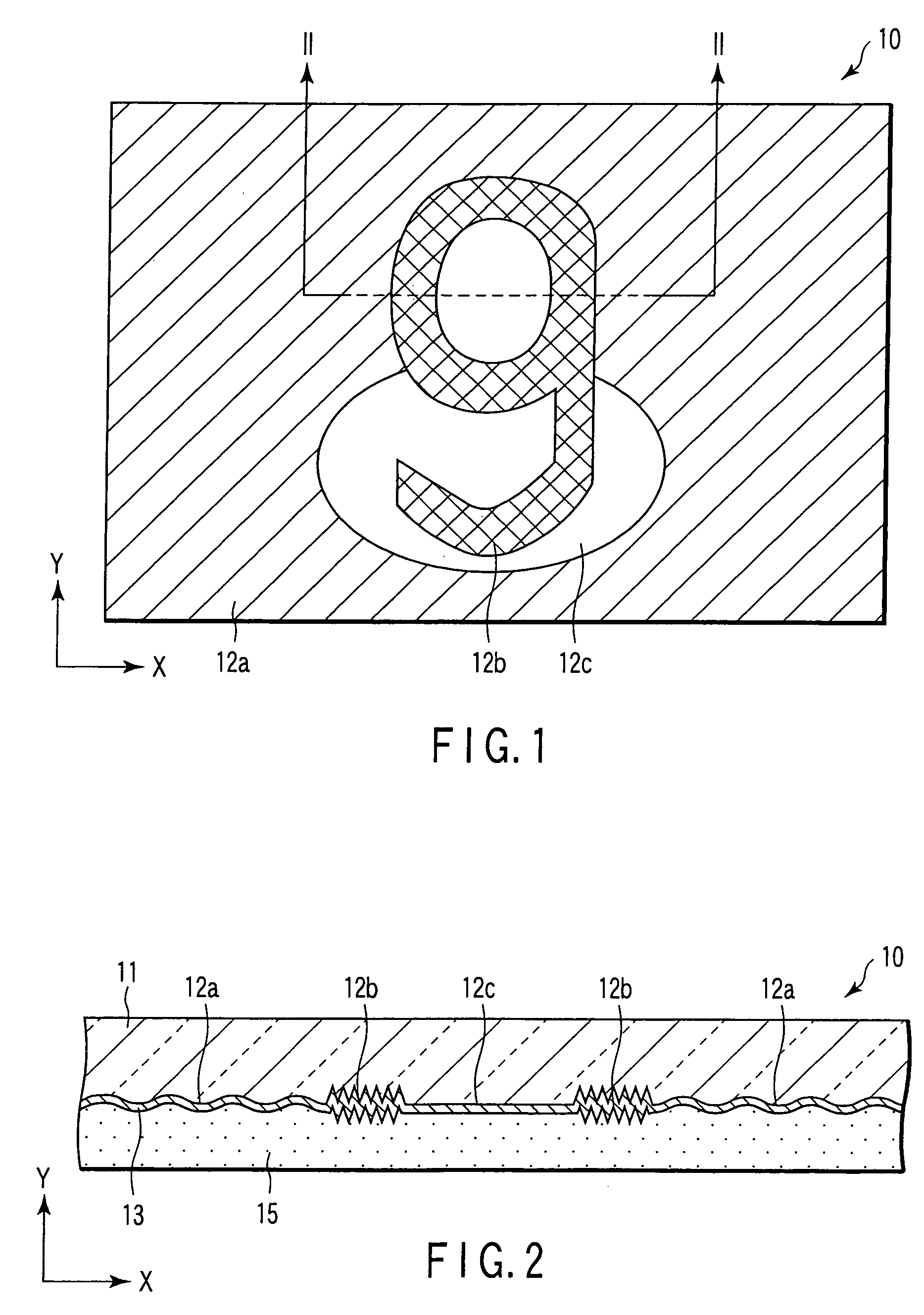

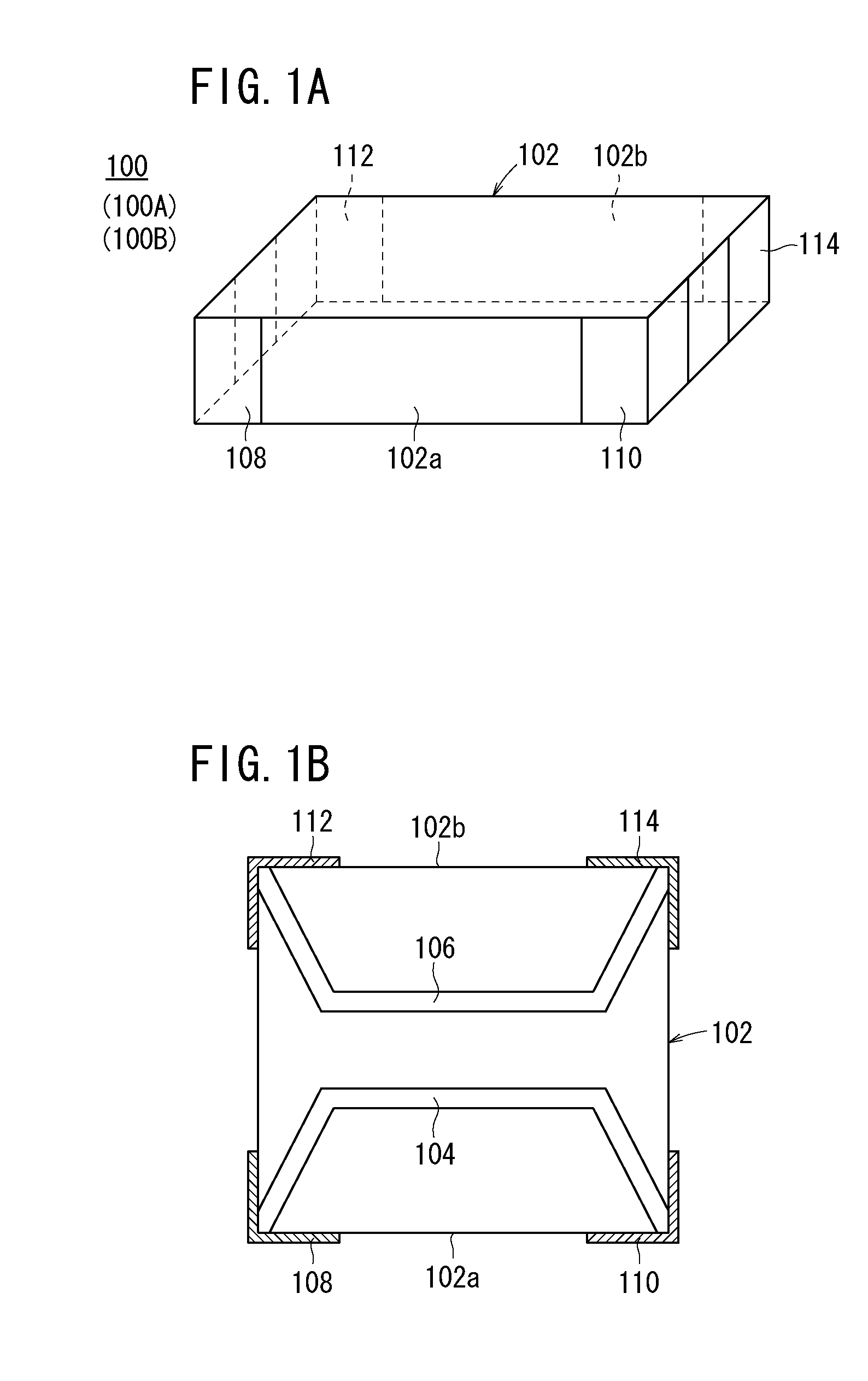

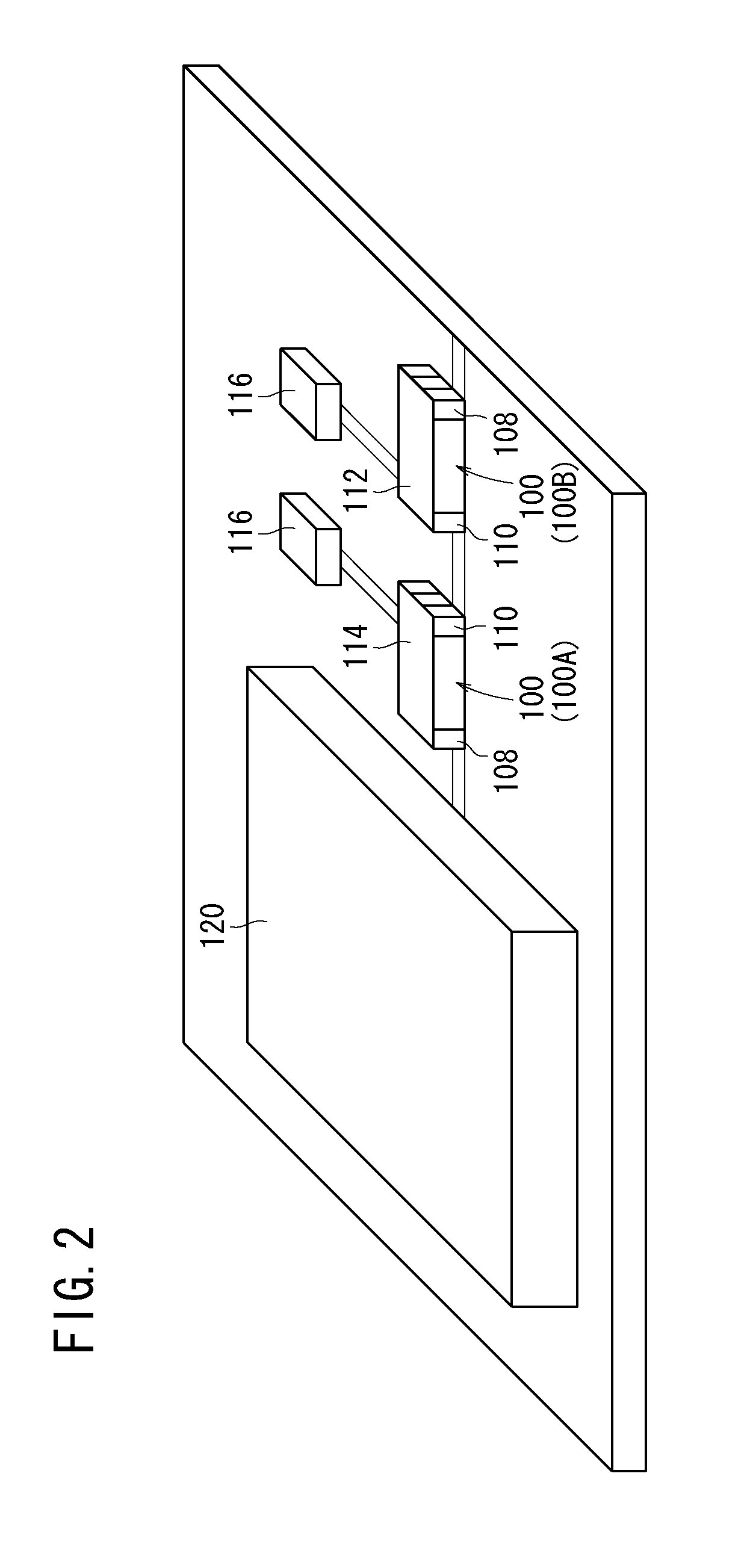

Display and labeled article

ActiveUS20080272883A1Preventive effectHigh prevention effectElectric signal transmission systemsDigital data processing detailsEngineeringDiffraction grating

A higher forgery prevention effect is realized. A display includes a first interface section provided with a relief-type diffraction grating constituted by a plurality of grooves, and a second interface section provided with a plurality of recesses or projections arranged two-dimensionally at a center-to-center distance smaller than the minimum center-to-center distance of the plural grooves, and each having a forward tapered shape.

Owner:TOPPAN PRINTING CO LTD

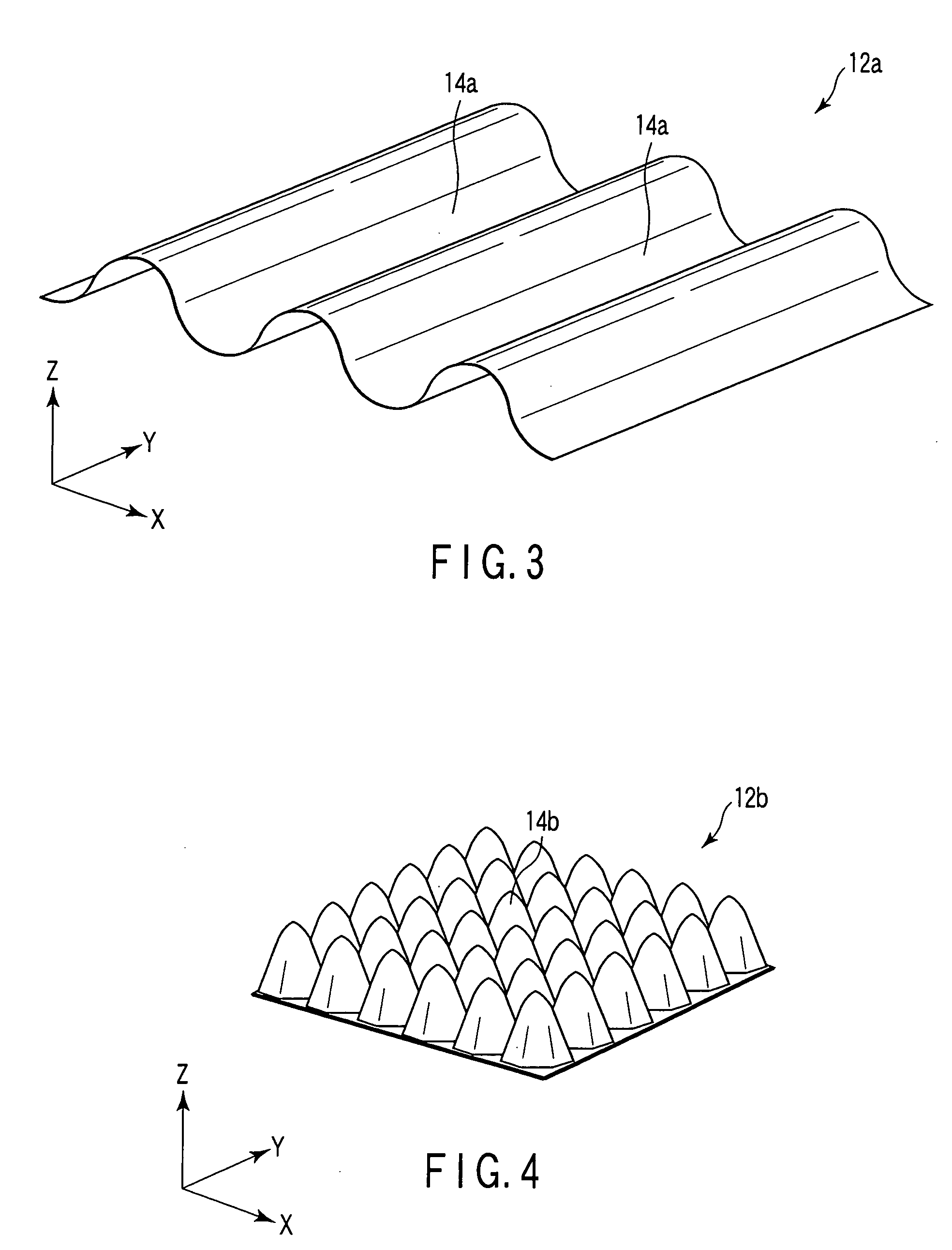

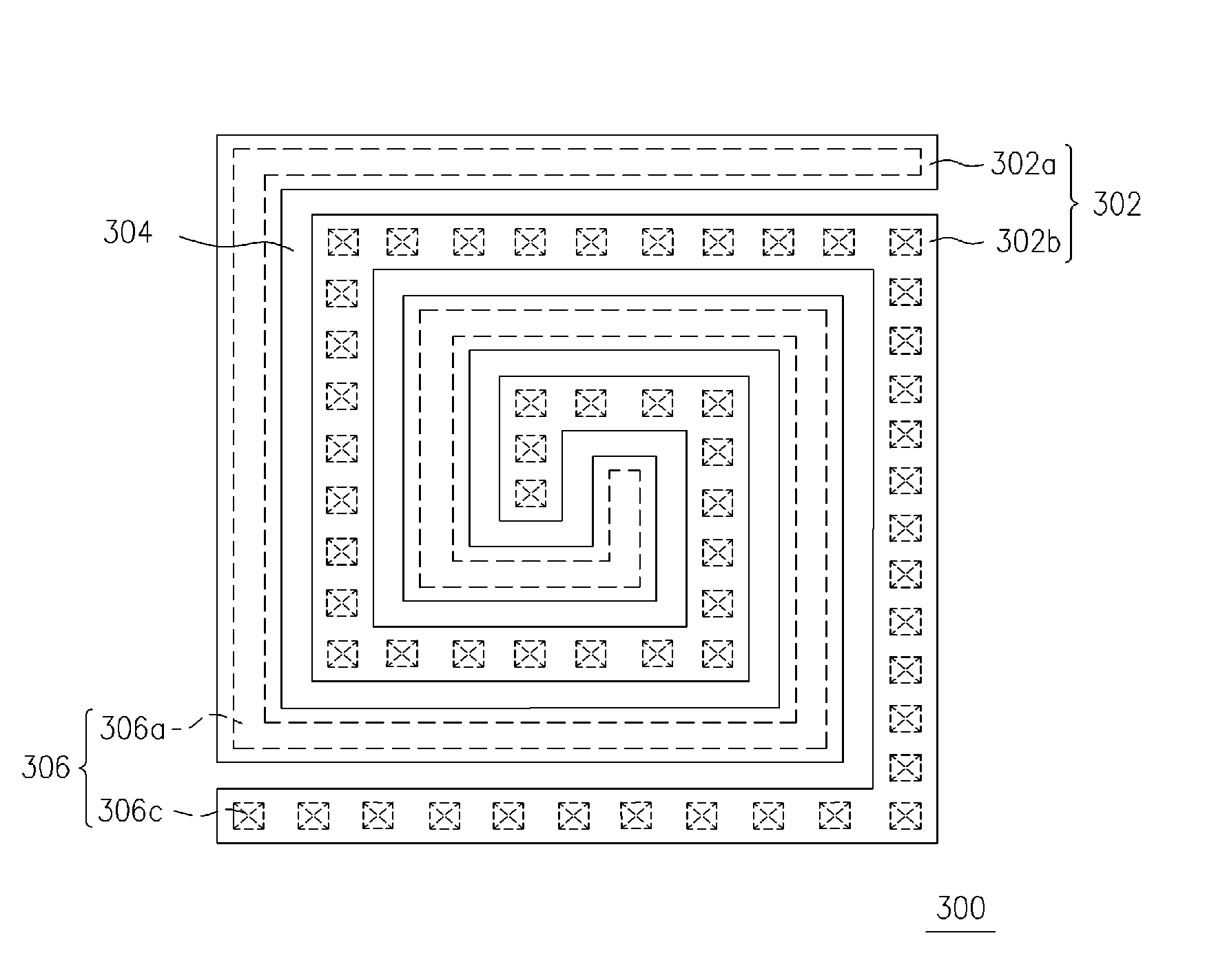

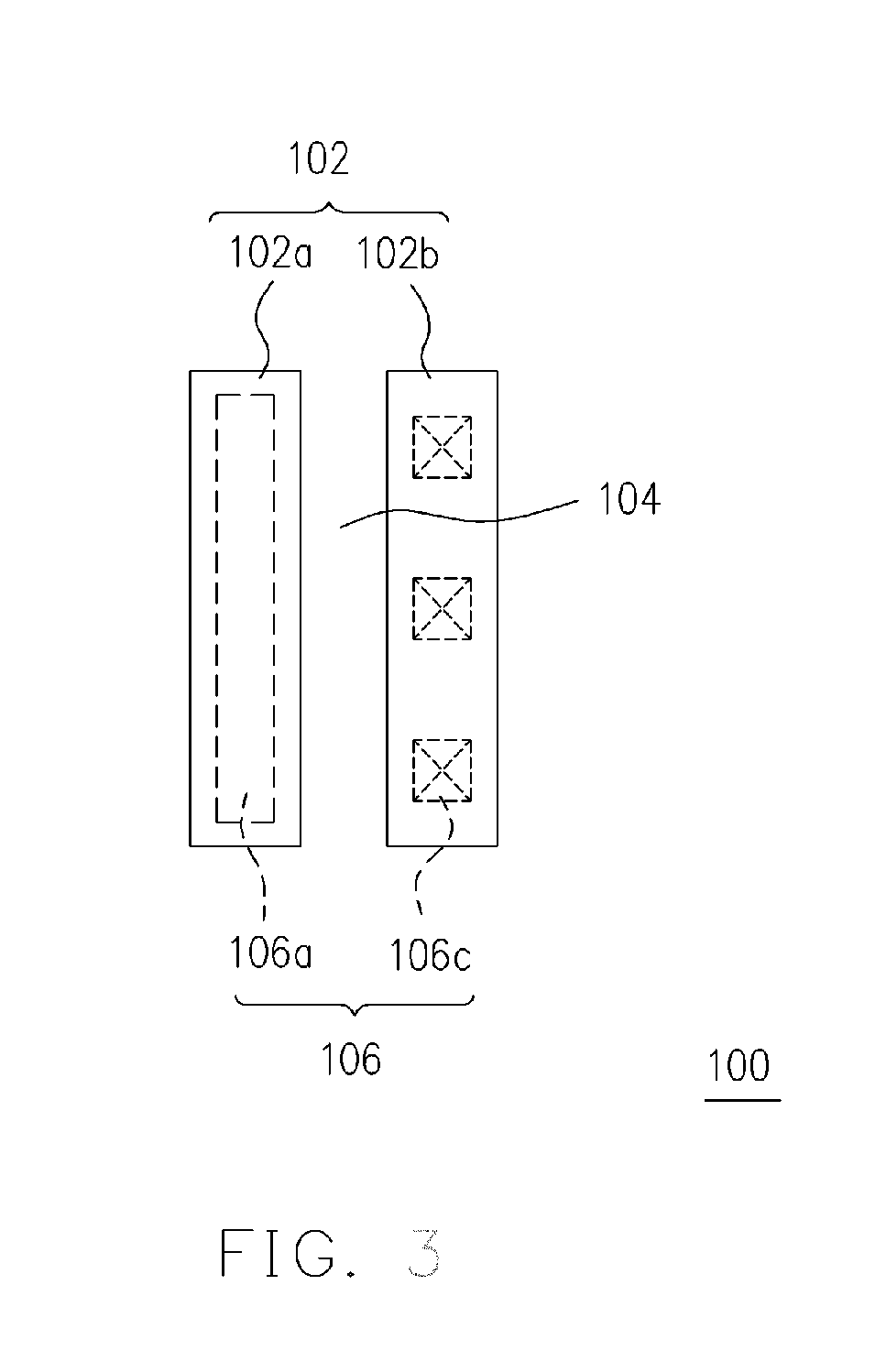

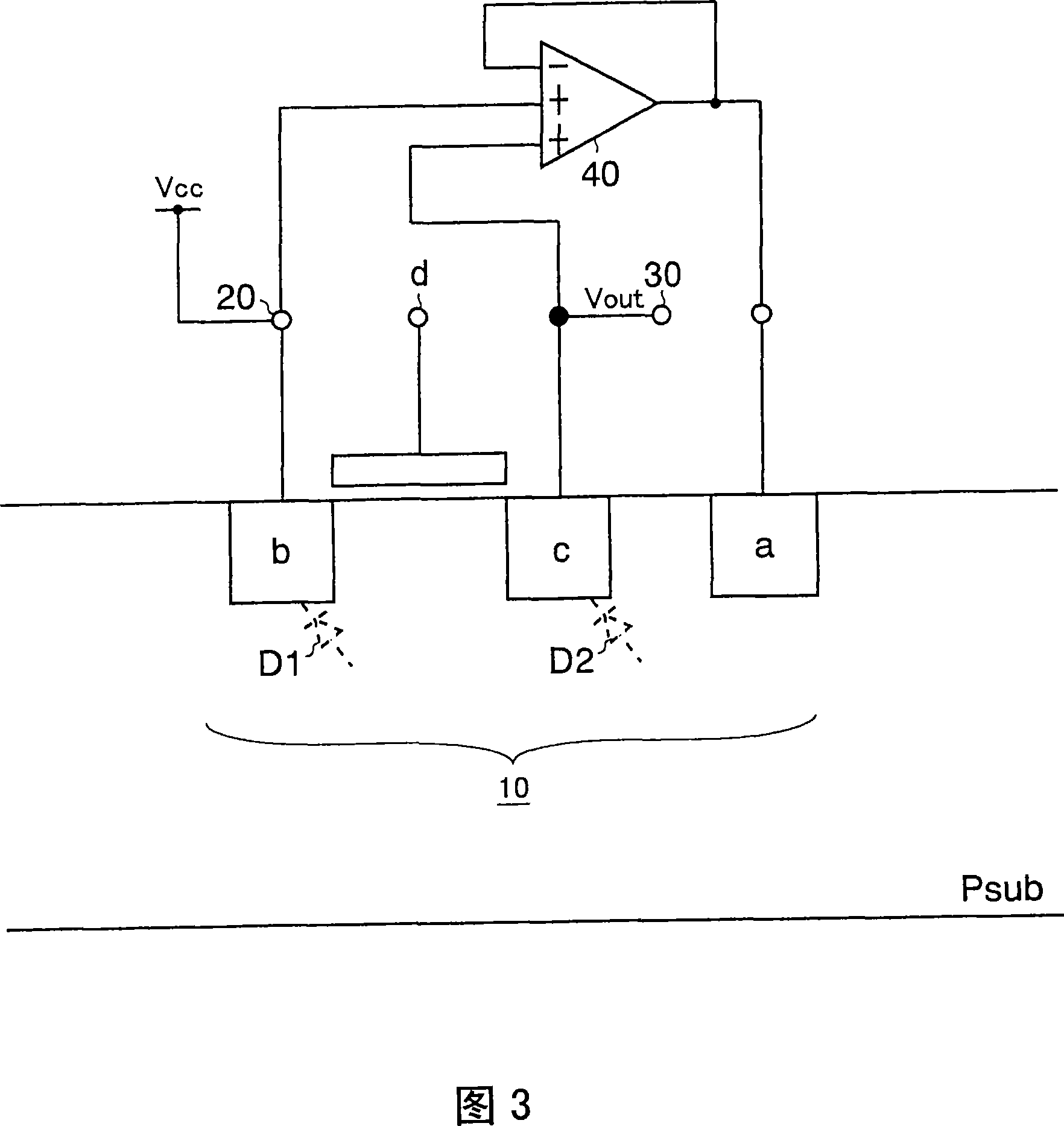

Capacitor structure

InactiveUS20070181973A1Preventive effectGood compatibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringDielectric layer

A capacitor structure including a plurality of conductive layers, a dielectric layer and a plurality of contacts is disclosed. The conductive layers are stacked, and each conductive layer has a first conductive pattern and a second conductive pattern. The dielectric layer is disposed between the first conductive pattern and the second conductive pattern and between two adjacent conductive layers. The contacts are disposed in the dielectric layer, and electrically connected to the first conductive patterns in two adjacent conductive layers and electrically connected to the second conductive patterns in two adjacent conductive layers. Wherein, the contact electrically connecting to the first conductive patterns in two adjacent conducive layers is a first strip contact, which extends between the first conductive patterns in two adjacent conductive layers, and the boundary of the first strip contact is located within the boundary of the first conductive pattern.

Owner:UNITED MICROELECTRONICS CORP

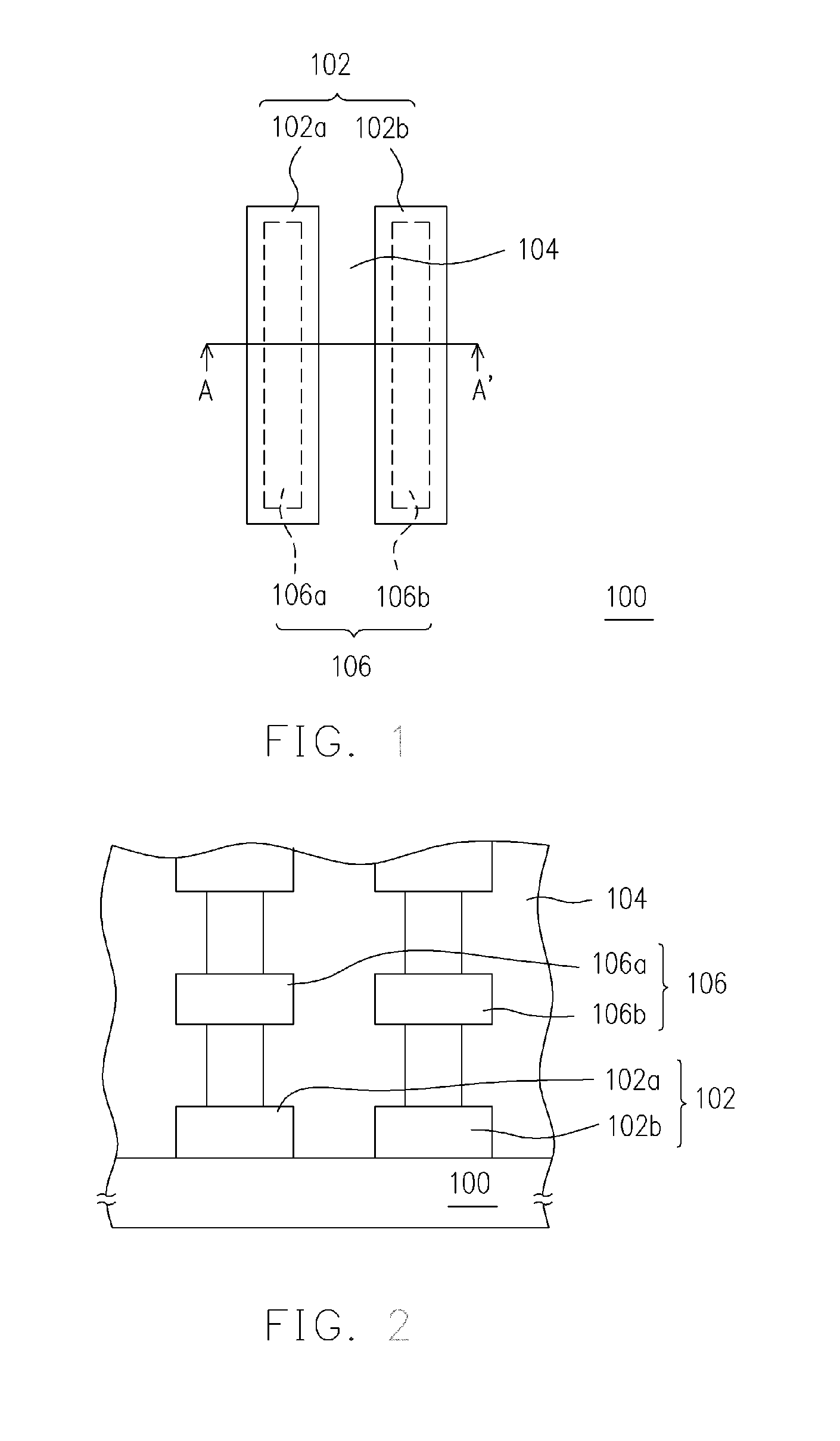

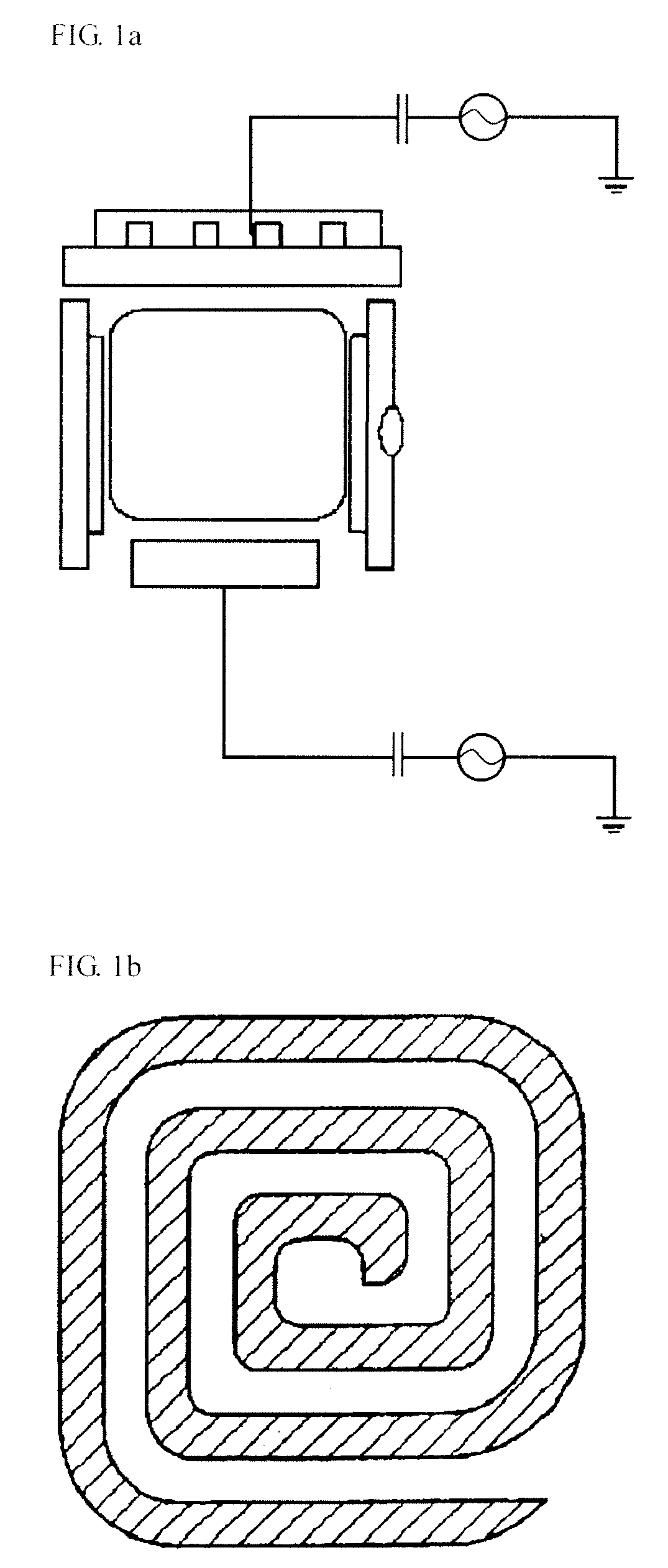

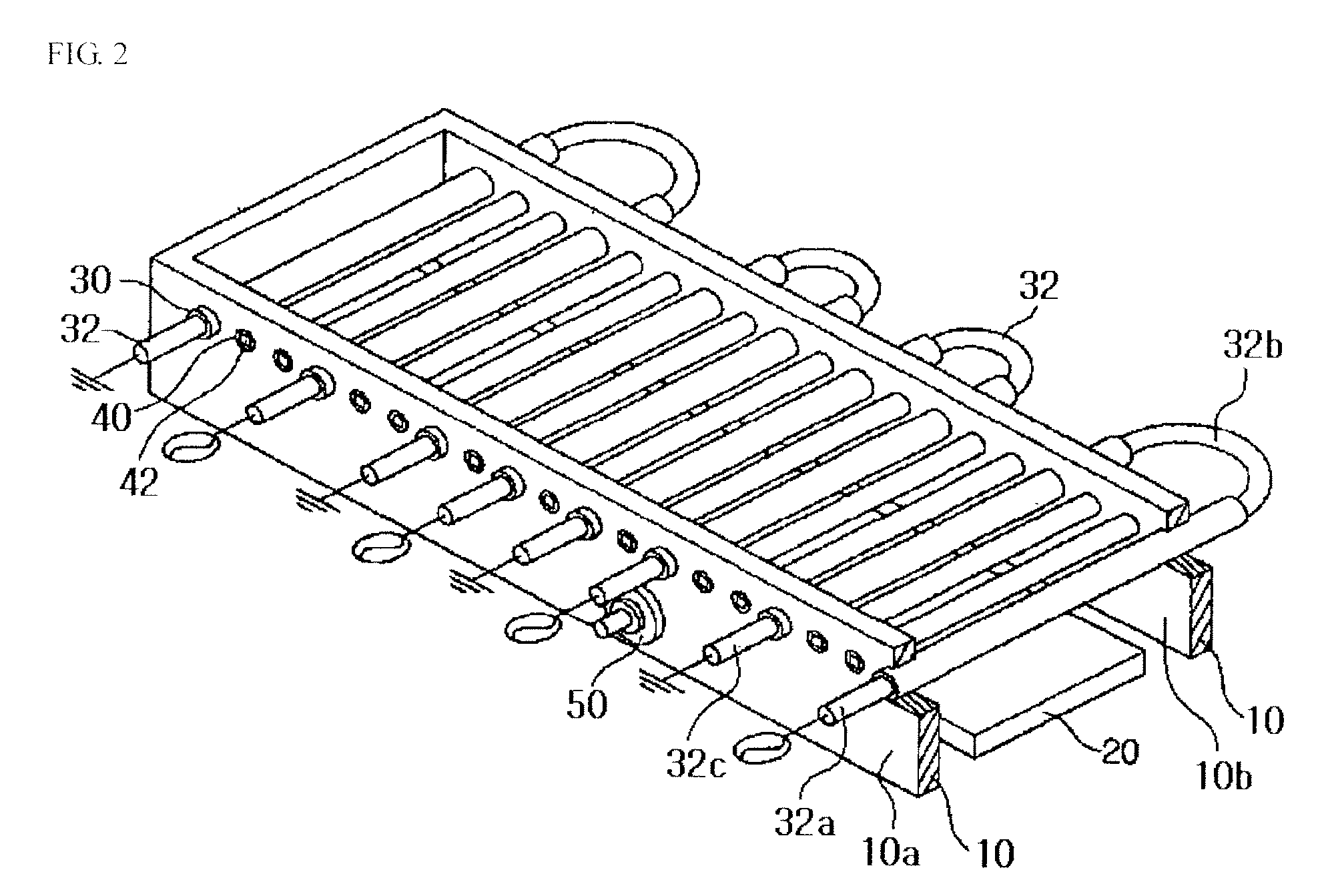

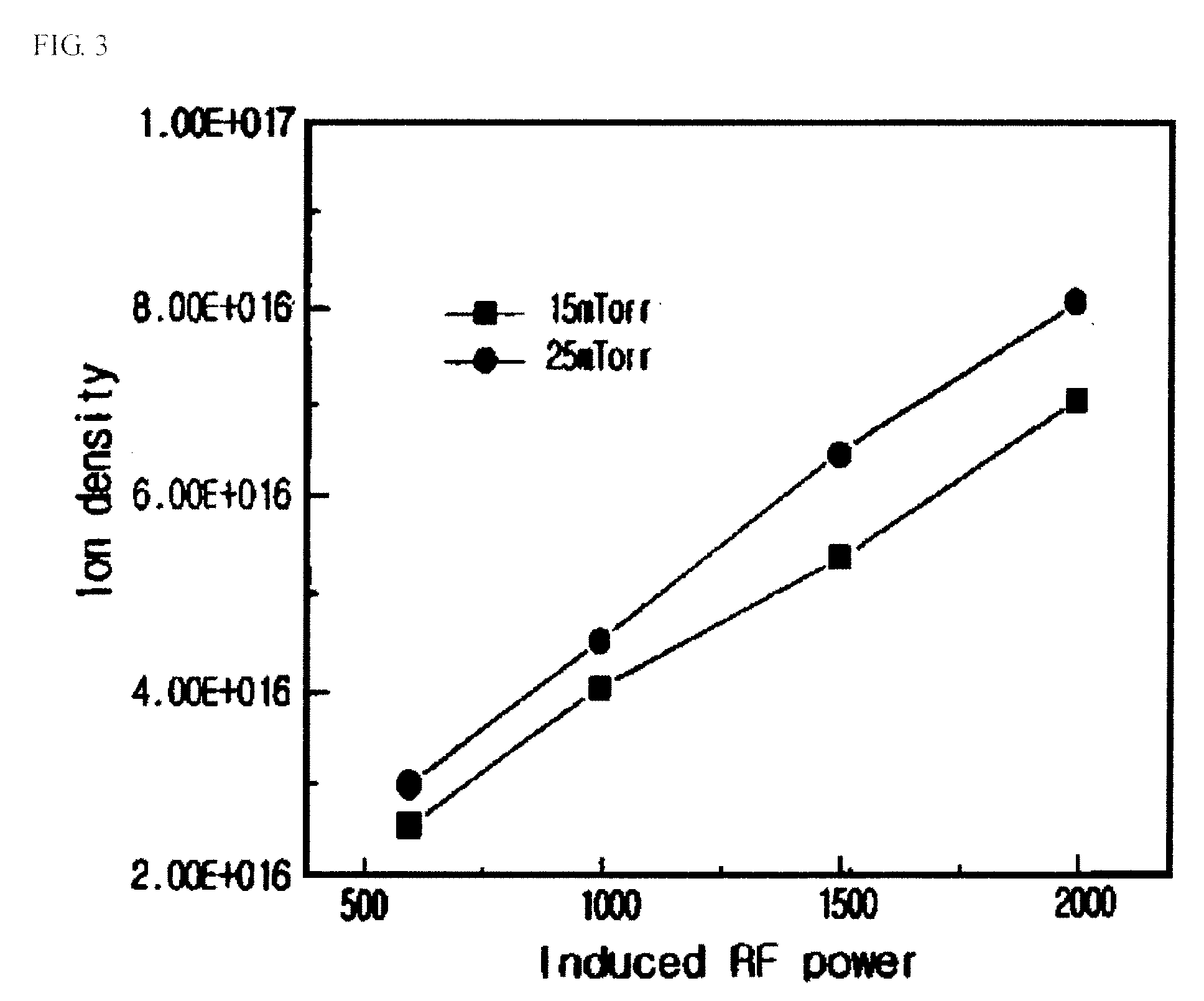

Inductively coupled plasma processing apparatus having internal linear antenna for large are processing

ActiveUS20090173445A1Preventive effectElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringInductively coupled plasma

An inductively coupled plasma processing apparatus for a large area processing includes a reaction chamber and a bending type antenna structure. The bending type antenna structure includes bending type linear antennas. Each of the bending type linear antennas has a first end, a second end and a bended portion. The bending type linear antennas are arranged horizontally in parallel with the substrate to pass through the reaction chamber inside the reaction chamber. The bending type linear antennas are spaced apart from each other. A bended portion of a bending type linear antenna is protruded out of the reaction chamber, a first end of each of the bending type linear antennas is protruded out of the reaction chamber and is coupled to an RF power, and a second end of each of the bending type linear antennas is protruded out of the reaction chamber and is coupled to a ground.

Owner:SUNGKYUNKWAN UNIVERSITY

Method for extracting effective constituents from maca

InactiveCN103463123AReduce loss rateGuaranteed withdrawalOrganic active ingredientsNervous disorderAlcohol ethylPhysical chemistry

The invention provides a method for extracting effective constituents from maca. The method includes the following steps that fresh or dry maca roots are taken as raw materials, the maca roots are washed, impurities are removed, an ethyl alcohol-water solution is used as homogenate liquid, the maca roots are homogenized, crushed and extracted, so that a homogenate extracting solution is obtained, filtering is conducted, filtering residues are mixed with an extraction solvent, negative pressure cavitation solid-liquid mixing cyclone extraction is conducted to obtain the extracting solution, the extraction solutions are combined and concentrated, a concentrated solution and a low-level solvent are mixed, then negative pressure cavitation liquid-liquid extraction is conducted, an extracting liquor is obtained, an extract is obtained after concentration, ethyl alcohol is added for redissolving, and thus a solution 1 is obtained; the extracted maca filtering residues are extracted again through hot water, an extracting solution is obtained after filtering, and a solution 2 is obtained after concentration; the solution 1 and the solution 2 are combined and dried, and extractives of the effective constituents of the maca are obtained. The method for extracting the effective constituents from the maca has the advantages that the technological process is simple, the production cycle is short, the effective constituents can be efficiently extracted, products can maintain the original flavor of the maca, used equipment is conventional equipment, production cost is low, and industrial production is easy to achieve.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

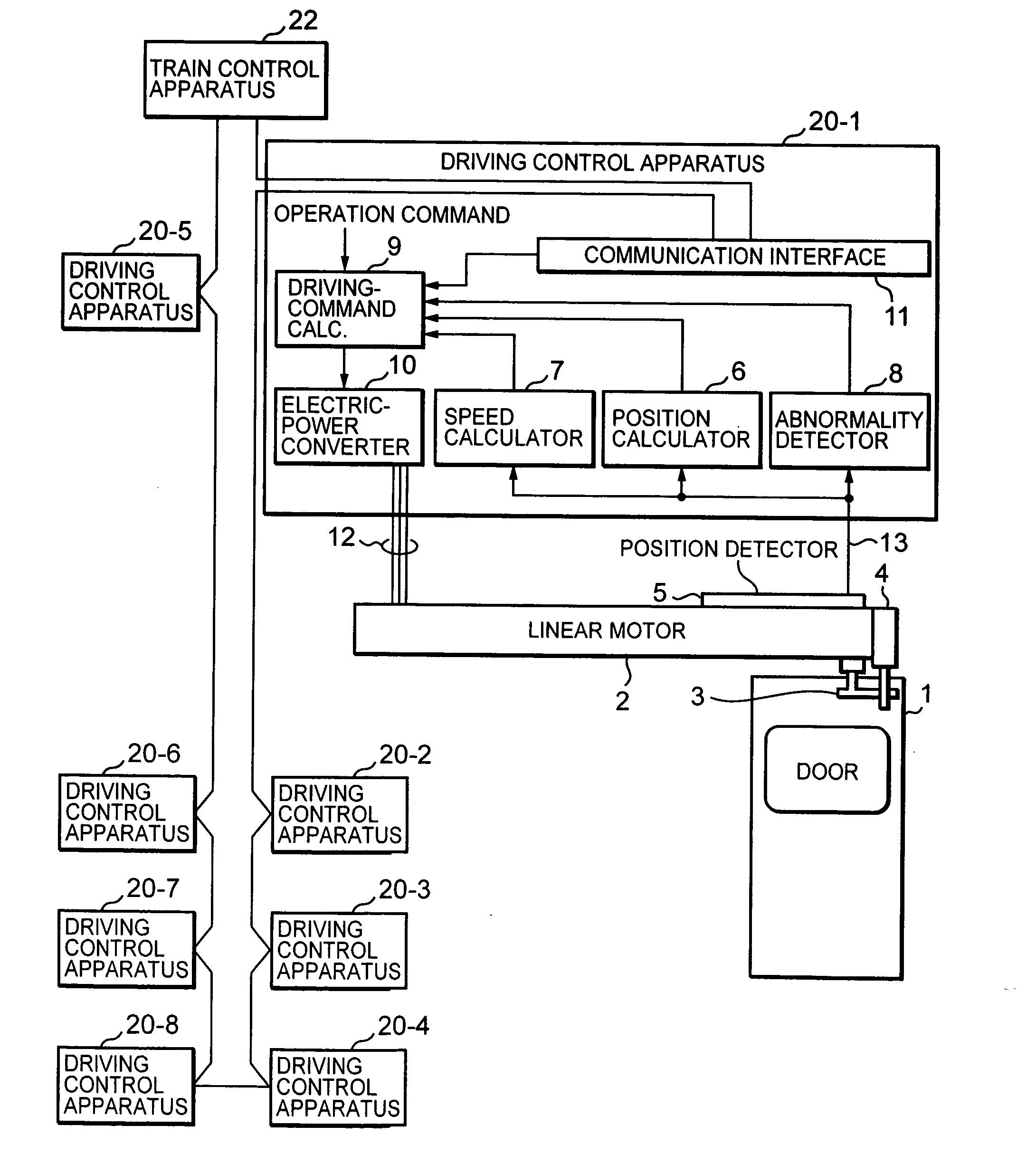

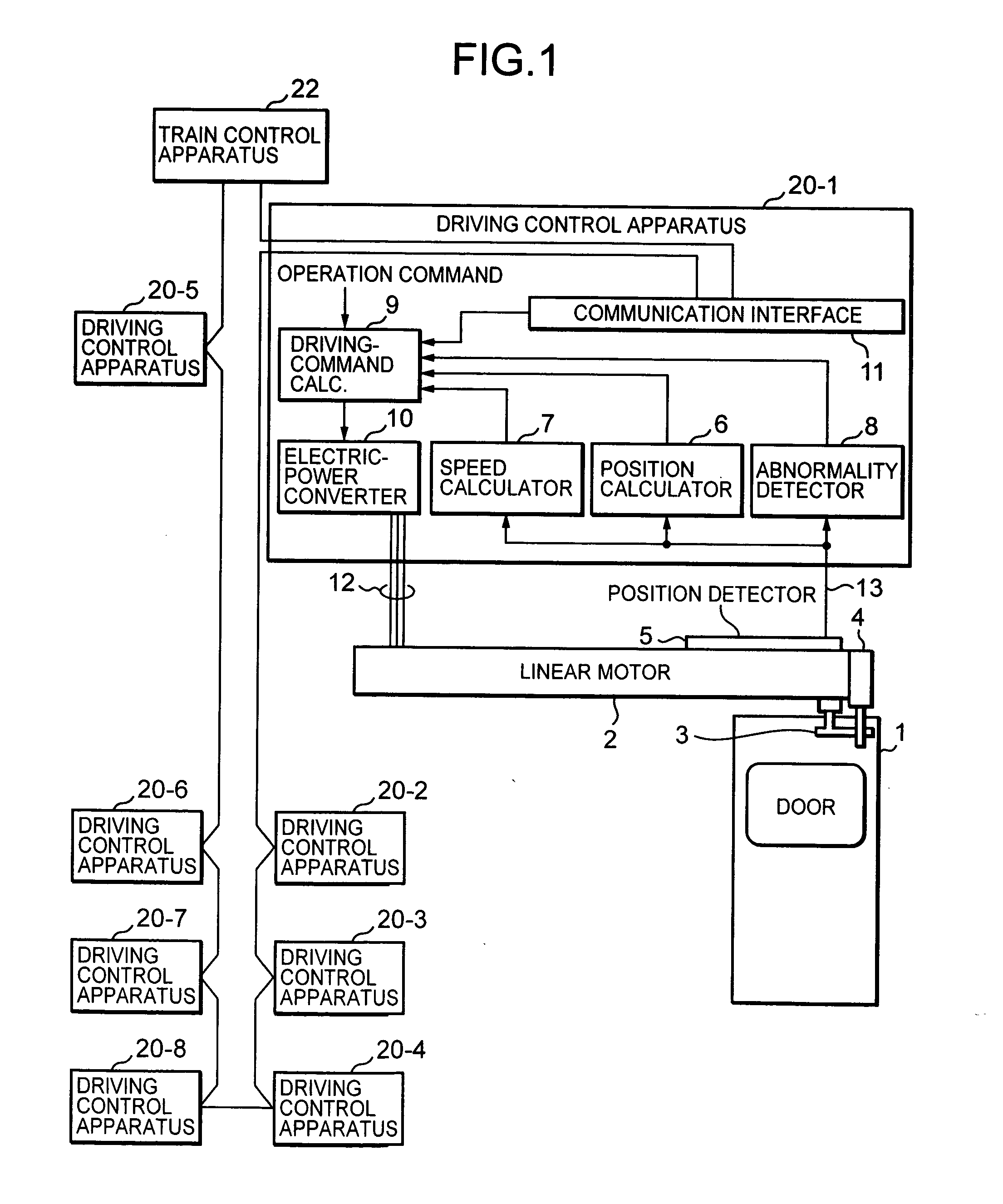

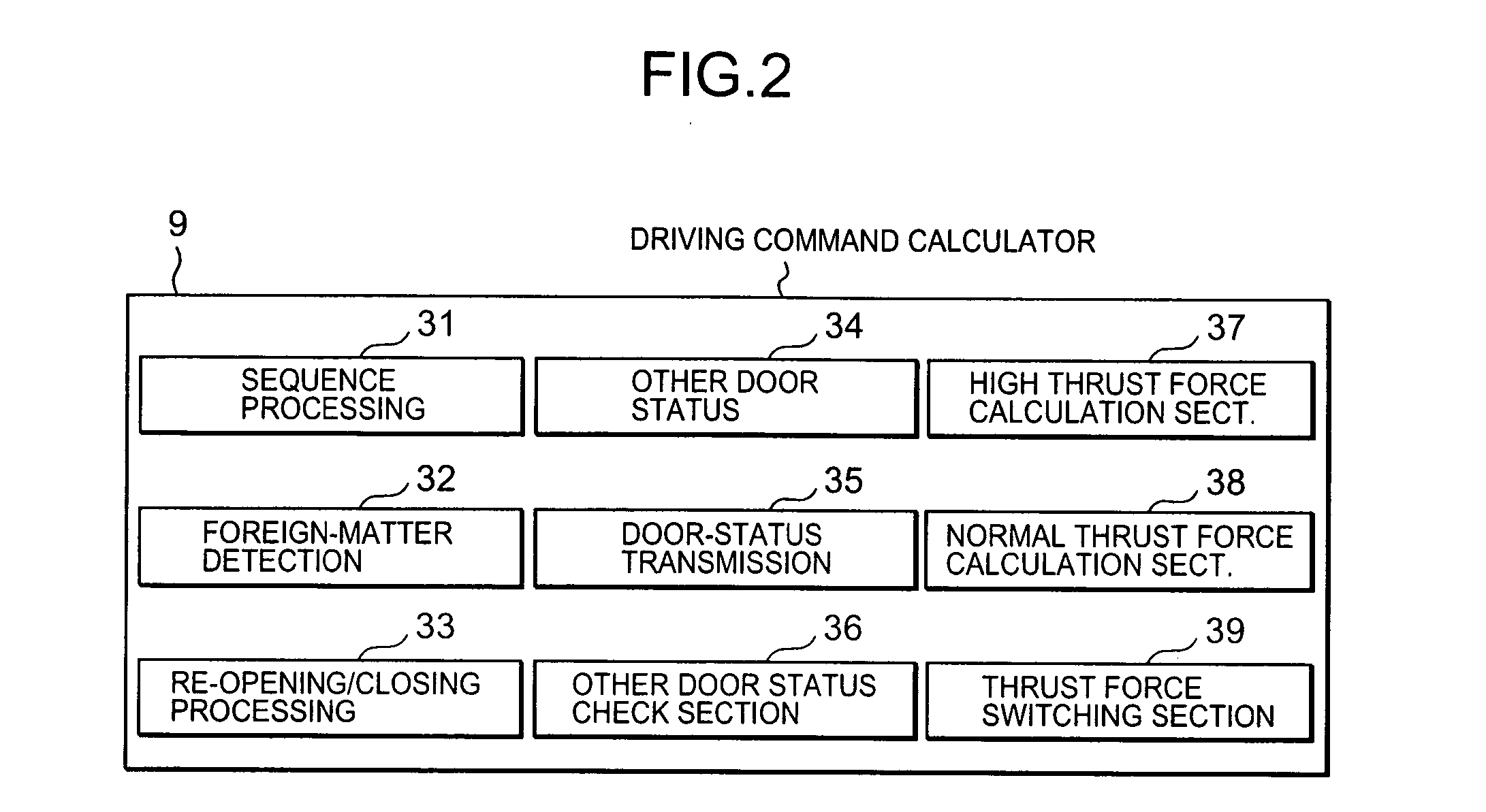

Door driving control apparatus

InactiveUS20050102903A1Preventive effectPrevent operationMotor/generator/converter stoppersElectric motor controlAdverse effectVoltage

An apparatus allowing proper compartment door closure, which prevents reduction in voltage of a power source and adverse effects on the operation of other electrical apparatus provided in a same compartment, when trash or deformation of rubber or the like of limited size attached to the end of the door makes the door difficult to close. A door driving control apparatus controls opening and closing of the door by an electric motor. When small foreign matter no larger than a predetermined size is detected to be trapped in the door, a thrust force for driving the door open and closed is switched to high-output thrust force. When a driving-command calculator detects the trapped small foreign matter, the door status data of other doors transmitted from the other doors' driving control apparatus is received. When the door status data shows other doors are not driven to re-opened and close with high-output thrust force, a command for switching to high-output thrust force is provided.

Owner:FUJI ELECTRIC SYST CO LTD

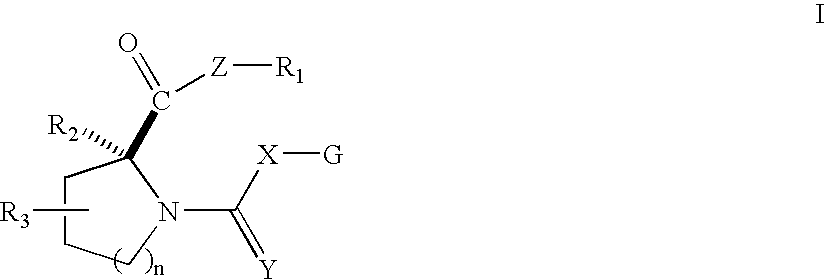

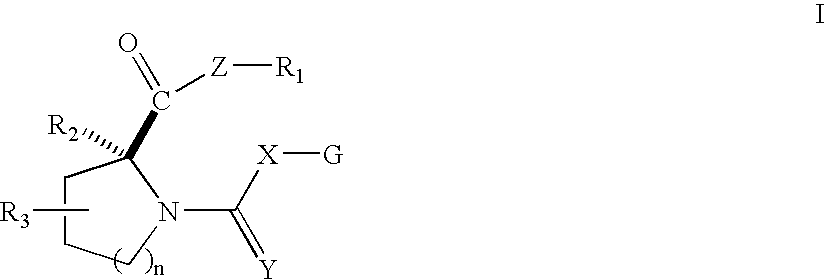

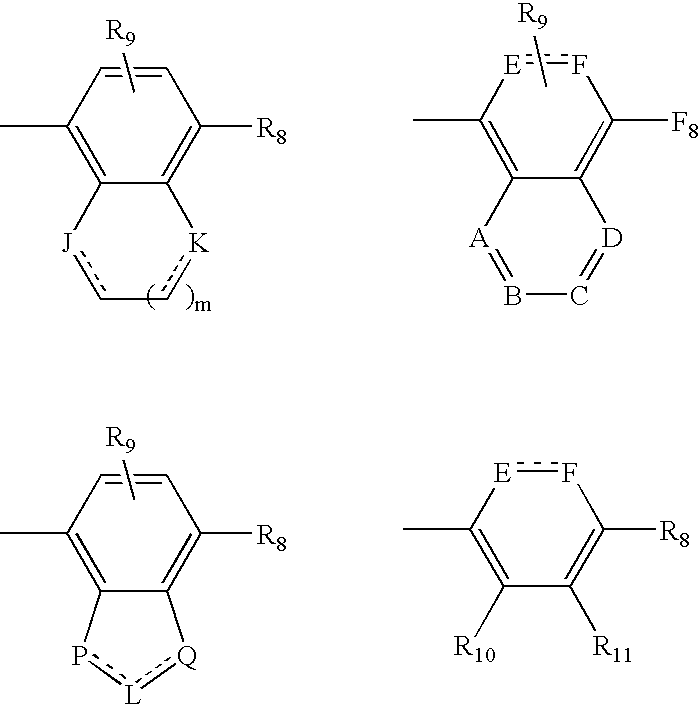

Open chain prolyl urea-related modulators of androgen receptor function

ActiveUS20050059652A1Preventive effectReduce bone density or growthBiocideNervous disorderDrugSarcopenia

The invention provides for a pharmaceutical composition capable of modulating the androgen receptor comprising a compound of formula I wherein R1, R2, R3, X, Y, Z and G are as described herein. Further provided are methods of using such compounds for the treatment of nuclear hormone receptor-associated conditions, such as age related diseases, for example sarcopenia, and also provided are pharmaceutical compositions containing such compounds.

Owner:BRISTOL MYERS SQUIBB CO

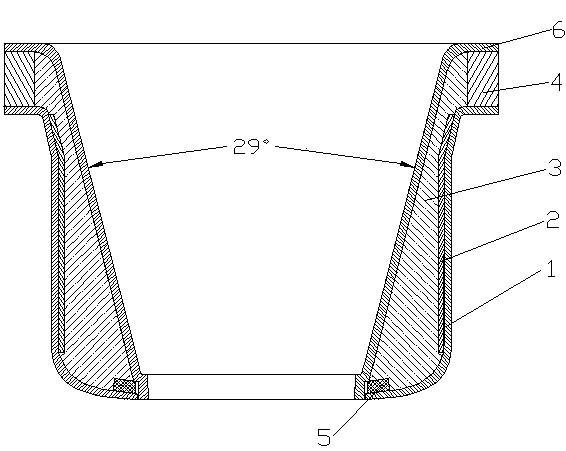

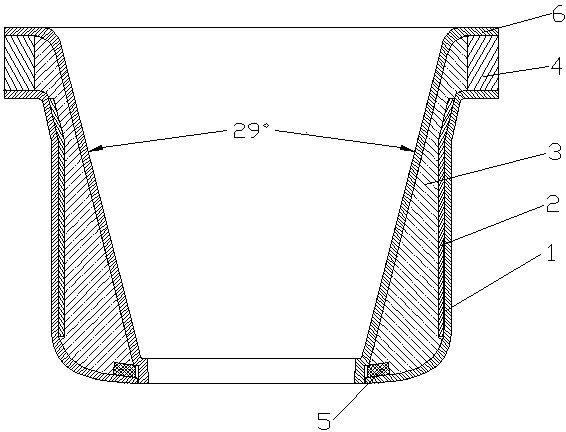

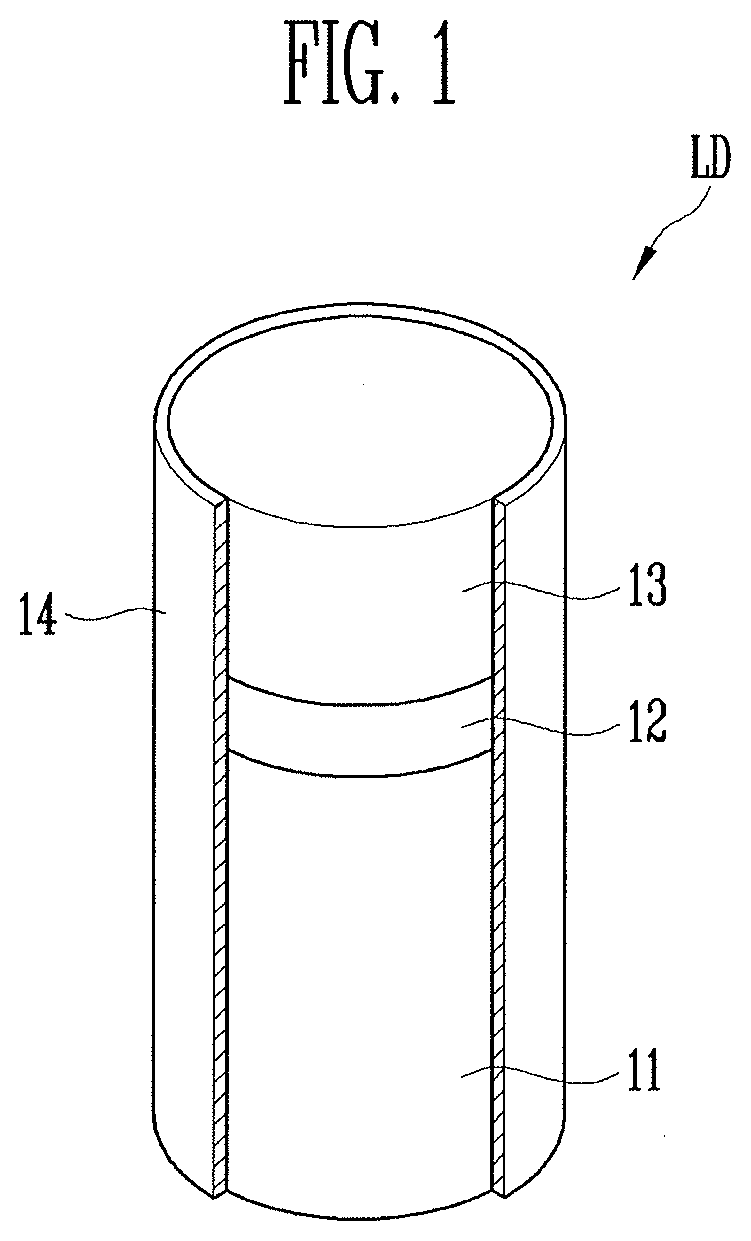

Heat shield device for CZ-Si single crystal furnace

ActiveCN102352530APreventive effectImprove cooling effectPolycrystalline material growthBy pulling from meltSingle crystalEngineering

The invention relates to a heat shield device for a CZ-Si single crystal furnace and the device comprises an outer barrel, a heat protective layer, an inner barrel, a heat reflecting layer, a heat insulation pad I and a heat insulation pad II, wherein the heat reflecting layer is arranged between the outer barrel and the heat protective layer; the heat protective layer is arranged between the heat reflecting layer and the inner barrel; the heat insulation pad I is arranged between the outer barrel and the inner barrel at the upper end of the heat shield device; one end of the heat insulation pad I is tightly matched with the heat protective layer; the heat insulation pad II is arranged between the outer barrel and the inner barrel at the bottom end of the heat shield device; and one end of the heat insulation pad II is tightly matched with the heat protective layer. The heat shield device is characterized in that the action of the reflected heat radiation of a molybdenum sheet heat reflecting layer on crystals can be effectively prevented, the heat dissipation of crystals can be increased greatly and the crystal growth speed can be improved. A better heat preservation effect on the fused silica can be realized, the blow-in power consumption can be further reduced, and the production cost is saved. The heat shield device has low cost and is easy to realize.

Owner:内蒙古中环晶体材料有限公司

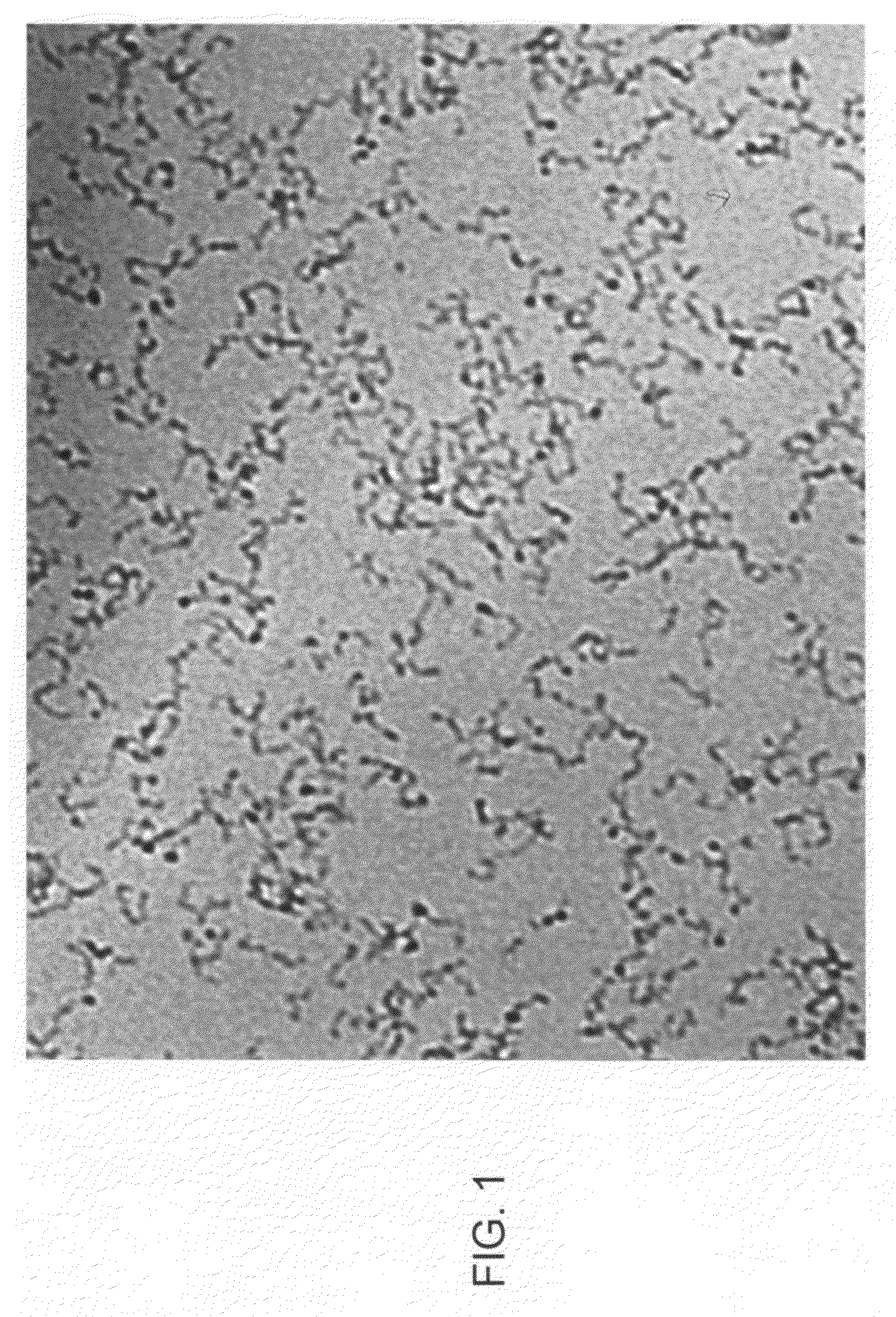

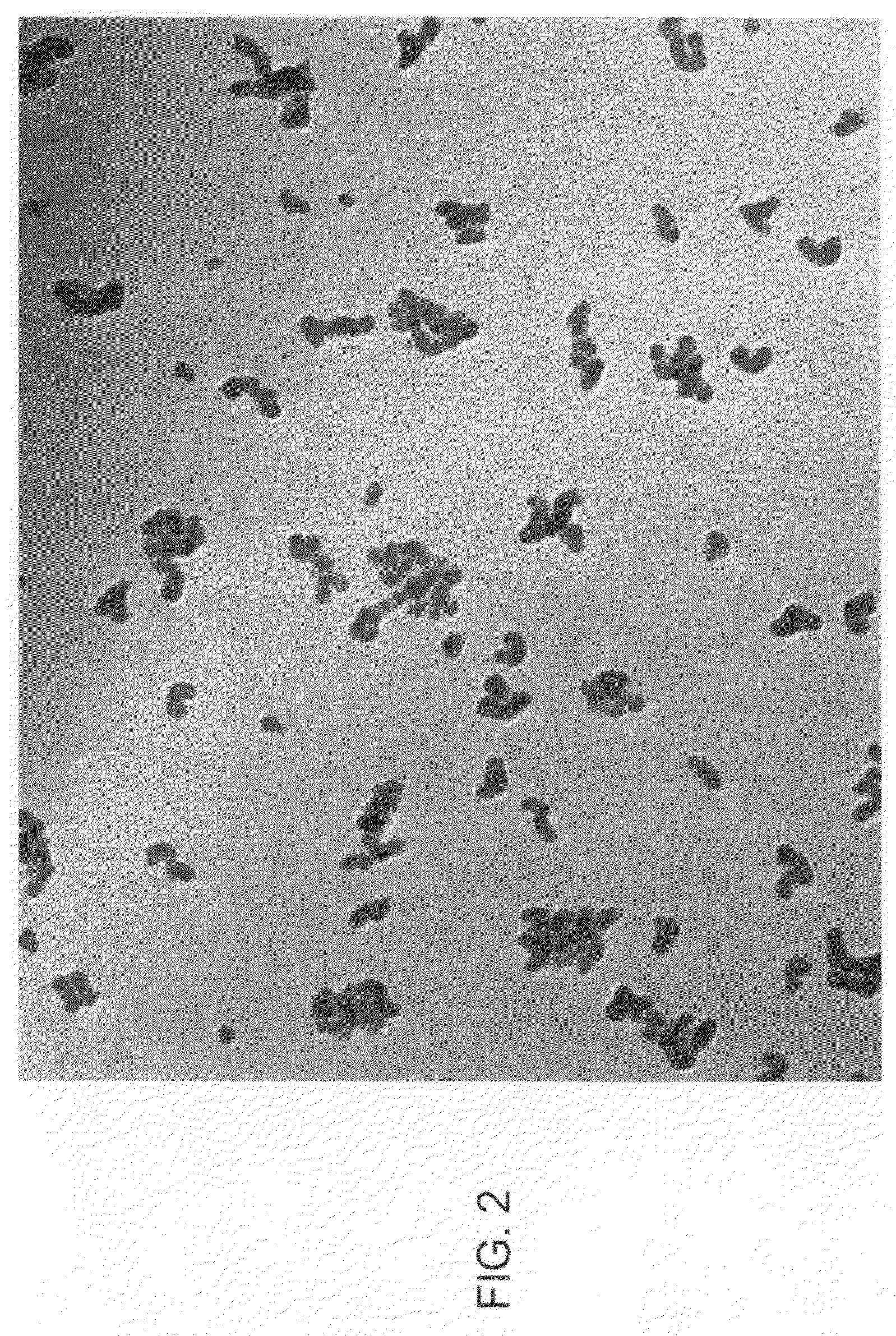

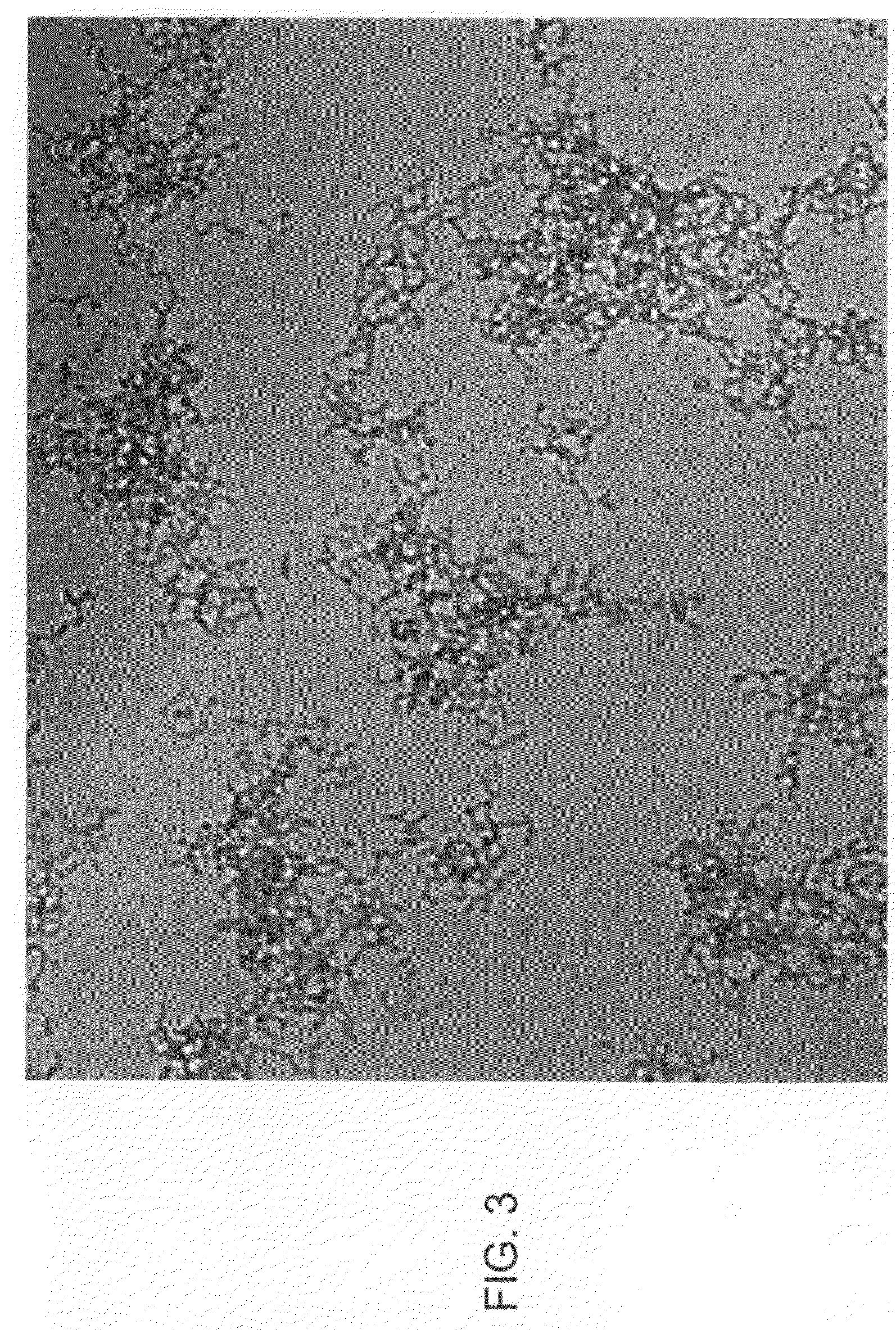

Colloidal silica for semiconductor wafer polishing and production method thereof

InactiveUS20090267021A1Excellent polish abilityPreventive effectMaterial nanotechnologyOther chemical processesColloidal silicaChemistry

Colloidal silica forming nonspherical particles cluster, whose long axis / short axis ratio of silica particles is of 1.2 to 20, and average long axis / short axis ratio of 3 to 15. This colloidal silica can be produced by forming particles by adding basic nitrogen compounds to an active silicic acid aqueous solution, the solution which produced by hydrolysis of tetraalkoxysilane, while heating, then growing particles by using a build up method.

Owner:NIPPON CHECMICAL IND CO LTD +1

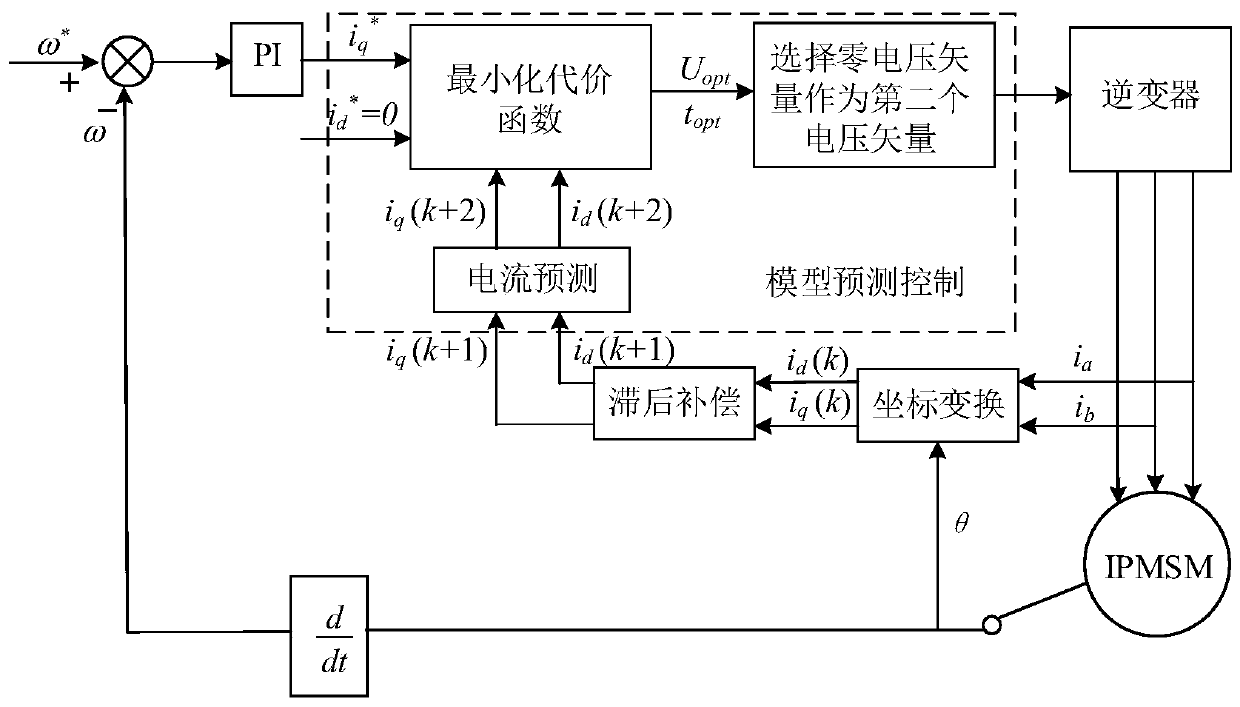

Permanent magnet synchronous motor model prediction current control method

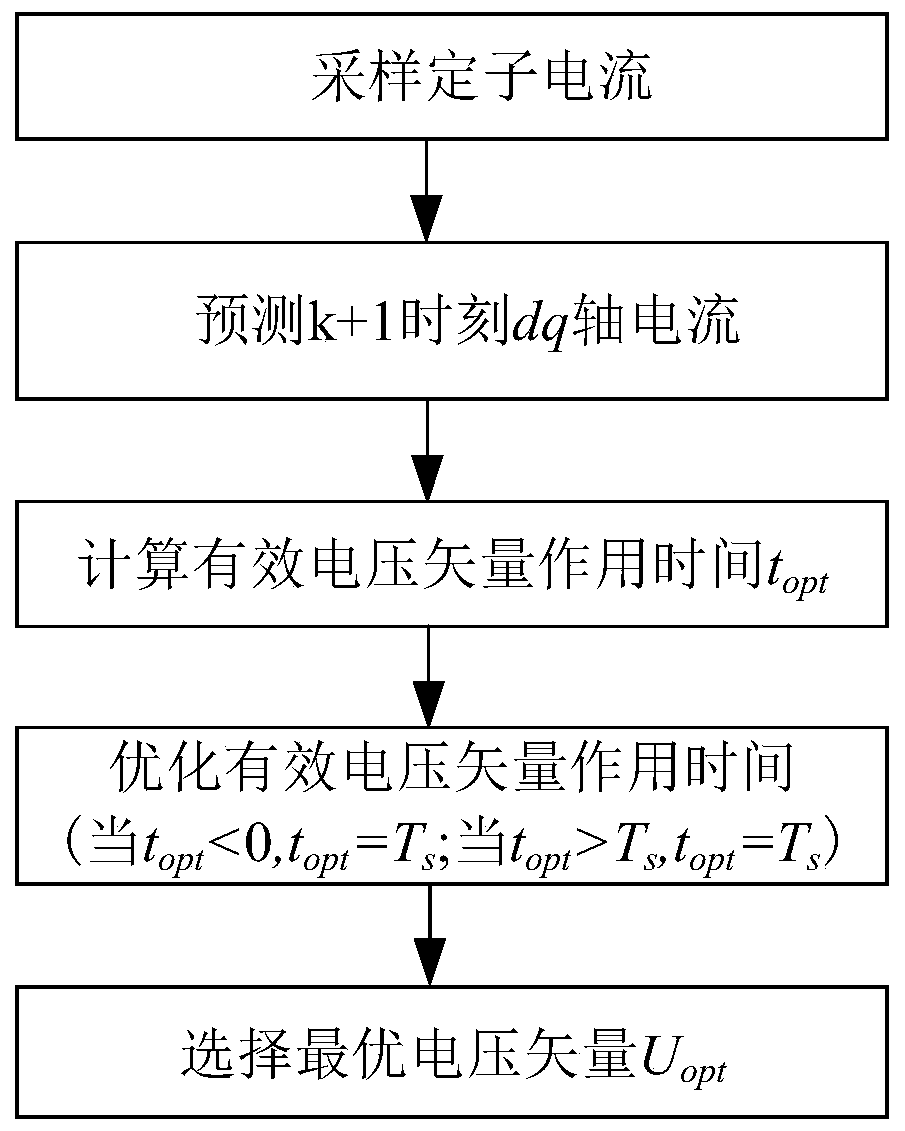

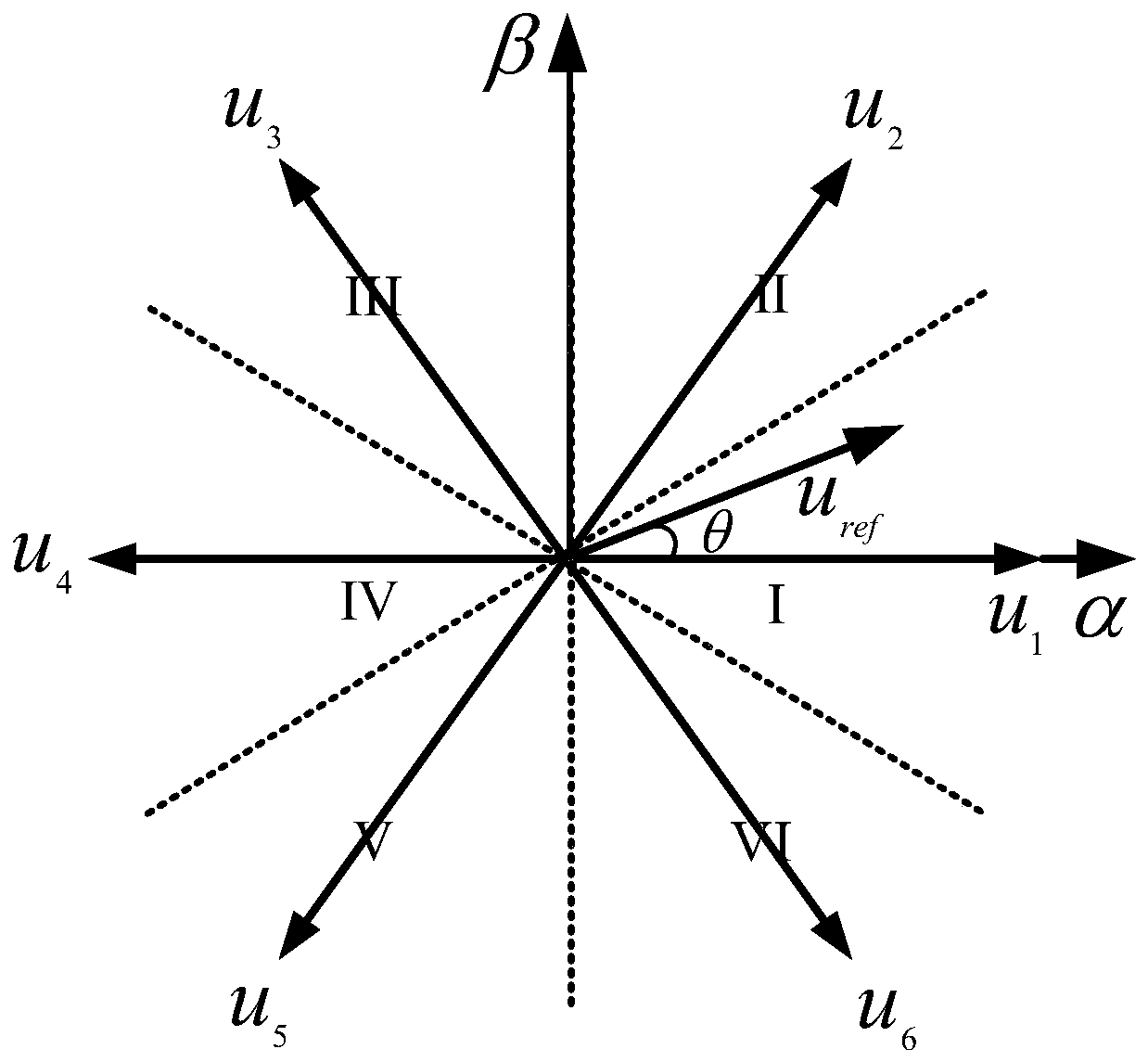

InactiveCN110995076ASmall rippleImprove steady state performanceAC motor controlElectric motor controlVoltage vectorPermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor model prediction current control method. The method comprises the following steps: the step S1, sampling stator current; the step S2, predicting a dq-axis current at a k+1 moment; the step S3, calculating effective voltage vector action time top<t>; the step S4, optimizing the effective voltage vector action time; and the step S5, selecting an optimal voltage vector Uopt. According to the control method, the voltage vector and the action time of the voltage vector are optimized together, so that the additional calculation amount is not increased, the quadrature-direct axis current ripples are remarkably reduced, and the finally selected voltage vector is globally optimal.

Owner:HUNAN UNIV

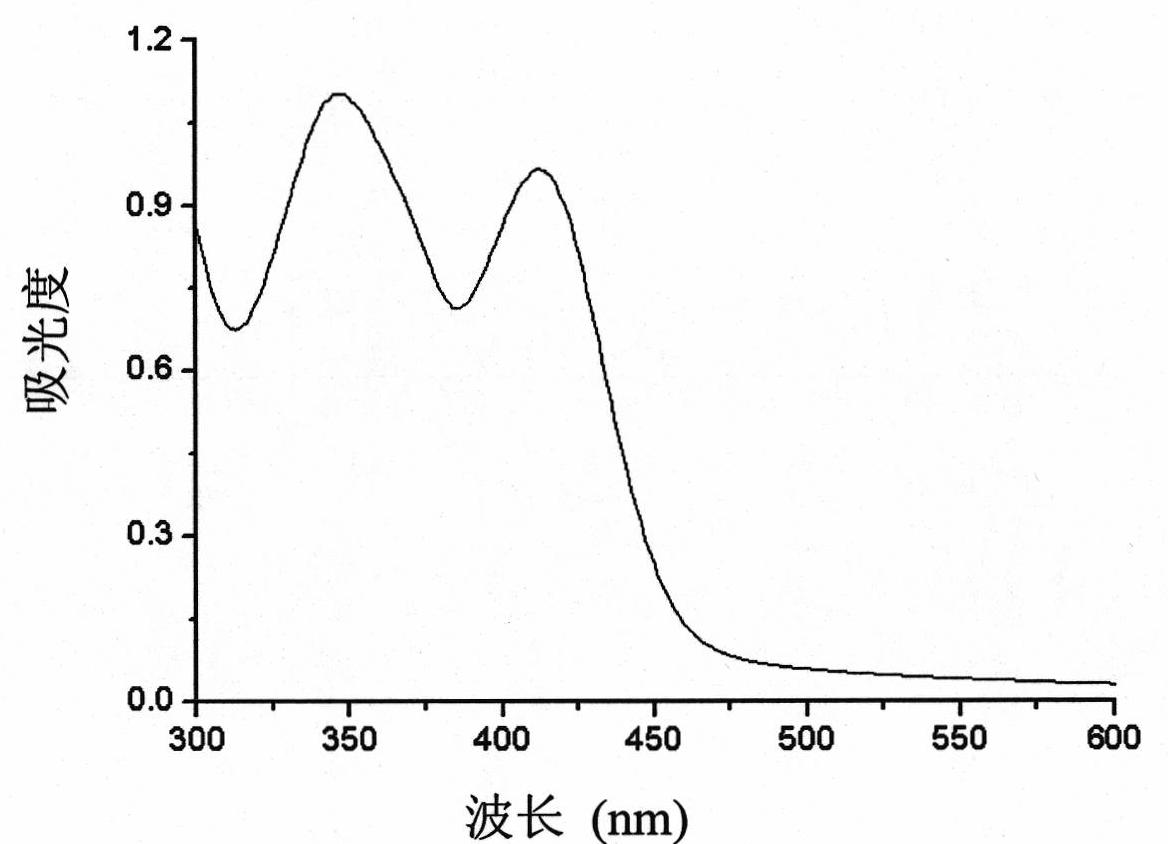

Photoluminescent nano particle as well as preparation method and application thereof

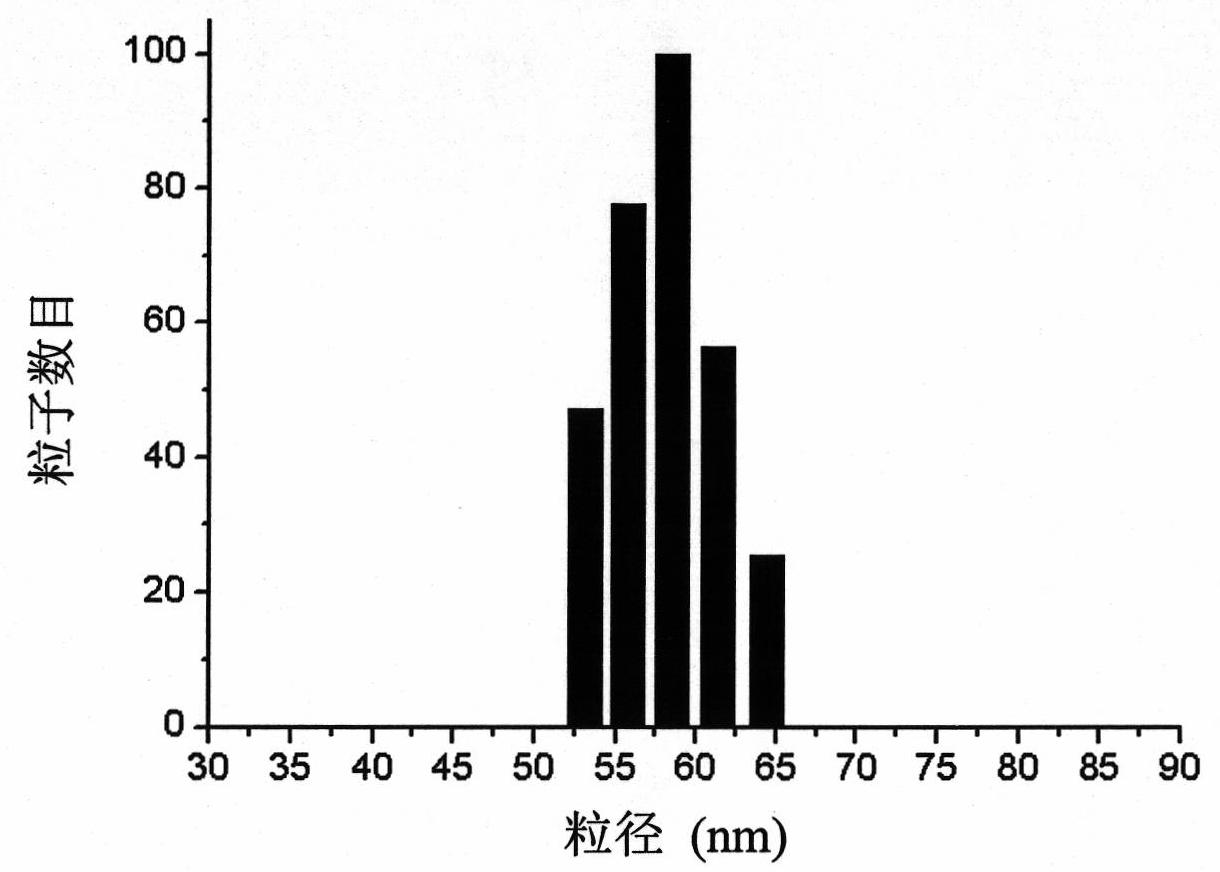

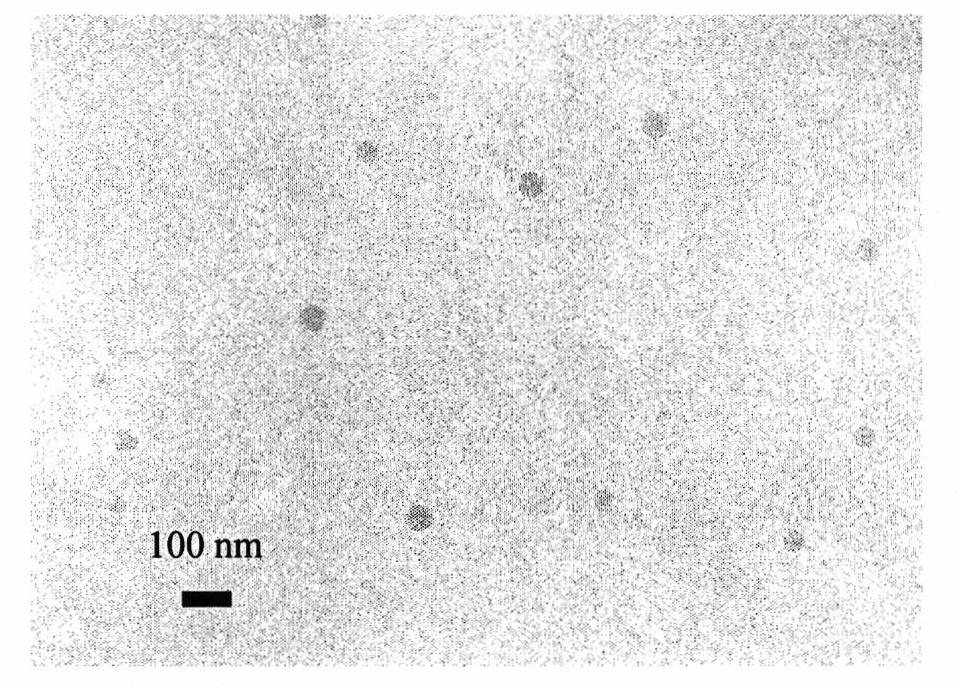

InactiveCN102134253ANarrow emission peakStocks displacement is largeGroup 3/13 organic compounds without C-metal linkagesBiological testingOrganic solventPhotoluminescence

The invention discloses a photoluminescent nano particle as well as a preparation method and an application thereof. The photoluminescent nano particle is composed of a carboxyl-containing copolymer matrix material and a rare earth fluorescent dye dispersed in the matrix material. The preparation method of the fluorescent nano particle comprises the following steps: dissolving the rare earth compound fluorescent dye and the copolymer in an organic solvent which is capable of being miscible with water; and adding the solution in water, so that the fluorescent nano particle is formed by utilizing a coprecipitation-self assembly process. The fluorescent nano particle has the advantages of excellent long wave excitation luminescence property and good stability, and has a surface carboxyl group for coupling biomolecules. A biological probe based on the fluorescent nano particle has a wide application prospect in the aspects of high-sensitivity fluorescent immunoassay, biological imaging and the like.

Owner:PEKING UNIV

Method for preparing coating carrying growth factor on surface of bone injury repair material

InactiveCN103191469AAvoid rapid degradationImprove bindingCoatingsProsthesisMetallic materialsLayer by layer self assembly

The invention discloses a method for preparing a coating carrying out a growth factor on the surface of a bone injury repair material. According to the method, 5 to 100 unit films are formed on the surface of the material through a layer-by-layer self-assembly process; four layers of unit films comprise a polyelectrolyte layer (polycation layer with amino) with positive charges, a polysaccharide oxide layer (with negative charges), a growth factor embedding micro and nano particle layer with positive charges and a polysaccharide oxide layer (with negative charges) from inside to outside. Micro and nano particles with negative charges in the unit films are sandwiched between the two polysaccharide oxide layers with the negative charges through electrostatic adsorption, and the amino carried by the micro and nano particles can be covalently bound with the aldehyde group of polysaccharide oxides, so that the micro and nano particles are well immobilized in the unit films. The unit films can be covalently bound and crosslinked with each other through the polycation with the amino and the polysaccharide oxide with the aldehyde group, achieve an electrostatic adsorption effect due to opposite electric properties, and have strong binding force; and the coating is high in stability, slow in degradation, long and controllable in bone induction acting time and good in bone induction effect.

Owner:SOUTHWEST JIAOTONG UNIV

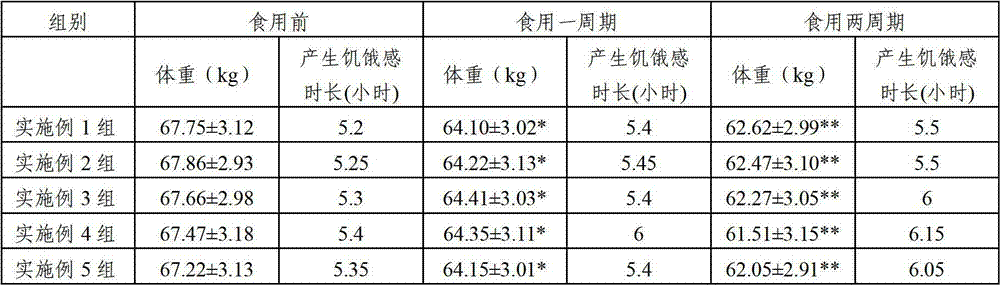

Meal replacement jelly powder and preparation method thereof

ActiveCN102871011AImprove freshnessGreat tasteFood preparationMeal replacementGamma-Aminobutyric acid

The invention relates to meal replacement jelly powder and a preparation method thereof. The meal replacement jelly powder comprises the following components in parts by weight: 20-35% of polydextrose, 1-8% of isomaltulose, 5-15% of konjac glucomannan, 4-10% of carageenan, 0.1-1% of gamma aminobutyric acid and 0.3-1.4% of collagen. According to the meal replacement jelly powder and the preparation method, a jelly form is adopted, so that the product has a good taste and an attractive appearance. Satiety is improved by adding a substance with a meal replacement effect into the meal replacement jelly powder, so that the purpose of slimming is achieved.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

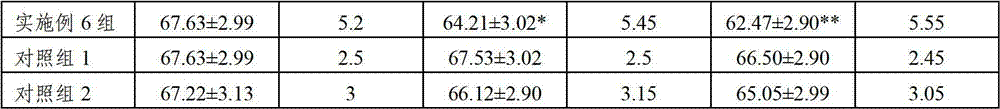

Pretreatment method of epoxy type plasticizer production wastewater

The invention provides a pretreatment method of epoxy type plasticizer production wastewater. The pretreatment method is characterized by comprising the following specific steps: step one, conducting acidification and demulsification on the epoxy type plasticizer production wastewater, conducting microporous aeration and oil removal firstly, removing oil by utilizing a full-automatic oil scraper, and adjusting the pH value of wastewater to be 4.5-5.5; and step two, pumping the wastewater treated by the step one into an air floatation device for air floatation treatment, wherein the chemical adding sequence in the operation of the air floatation device is as follows: adding polymeric aluminum firstly, then adding alkali liquor to adjust the pH value to be 7.5-8.5, and finally adding anionic polyacrylamide, and water discharged from the air floatation device is filtered by quartz sand; and step three, filling the wastewater treated in the step two to be full of a natural manganese sand filter tank by a mode of feeding from the lower part and the discharging from the upper part so as to remove residual hydrogen peroxide in the wastewater to obtain the pre-treated epoxy type plasticizer production wastewater. The pretreatment method has the advantages that the oil can be removed thoroughly, floatation slag generated by air floatation is obvious, the volume of the floatation slag is small after the floatation slag is discharged into a sludge drying bed to be concentrated, the treatment is easy and the like.

Owner:浙江嘉澳环保科技股份有限公司

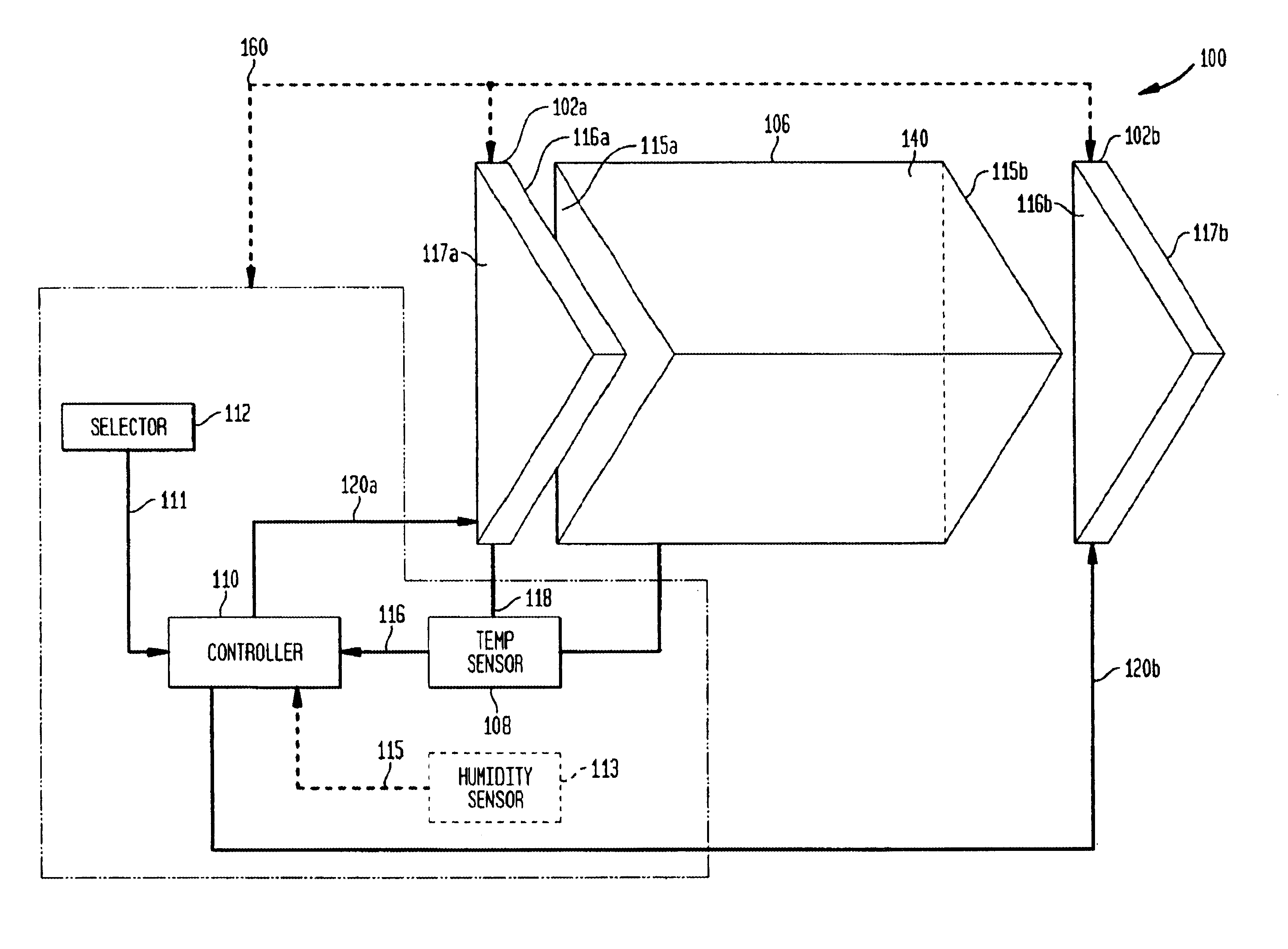

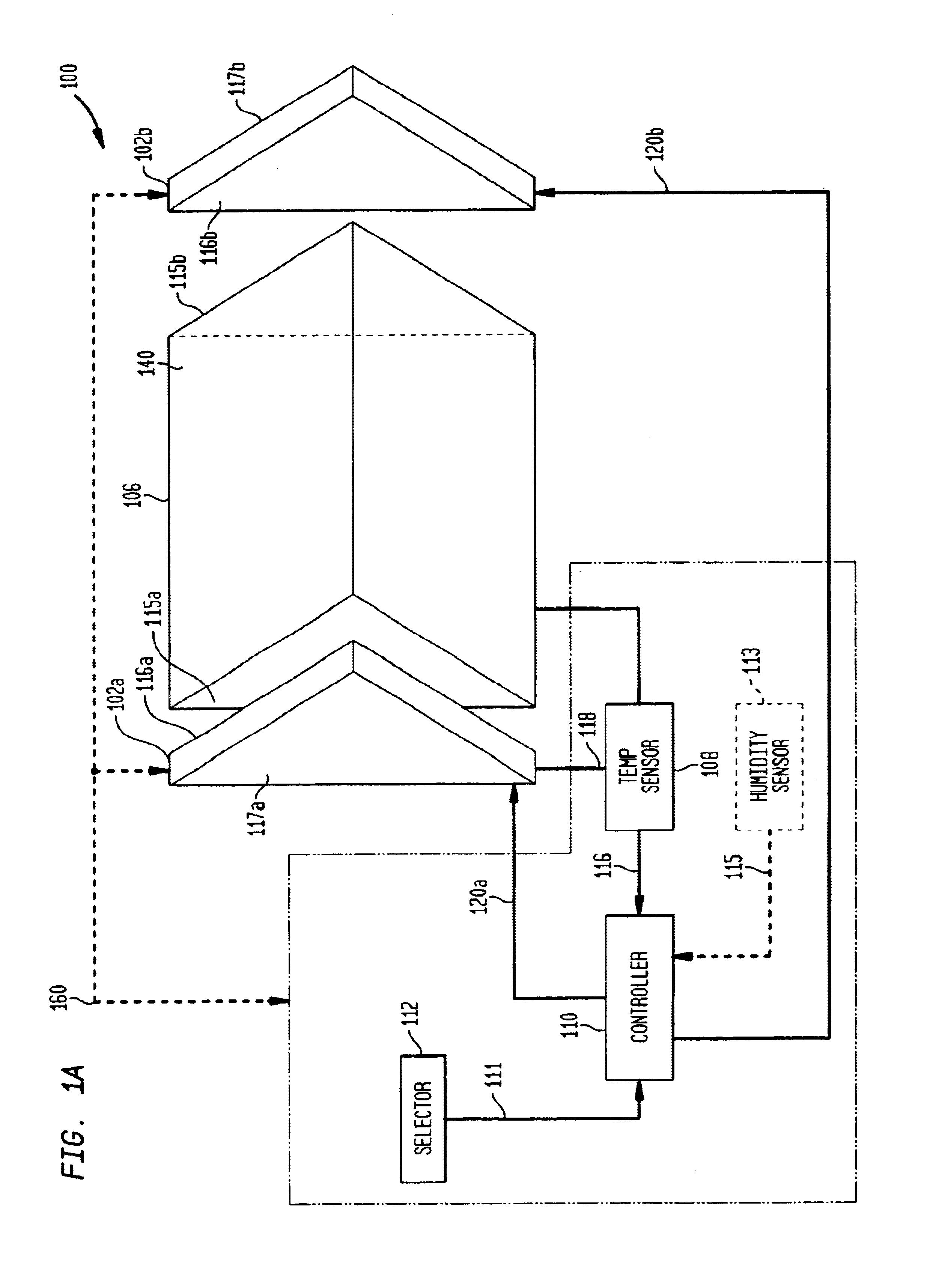

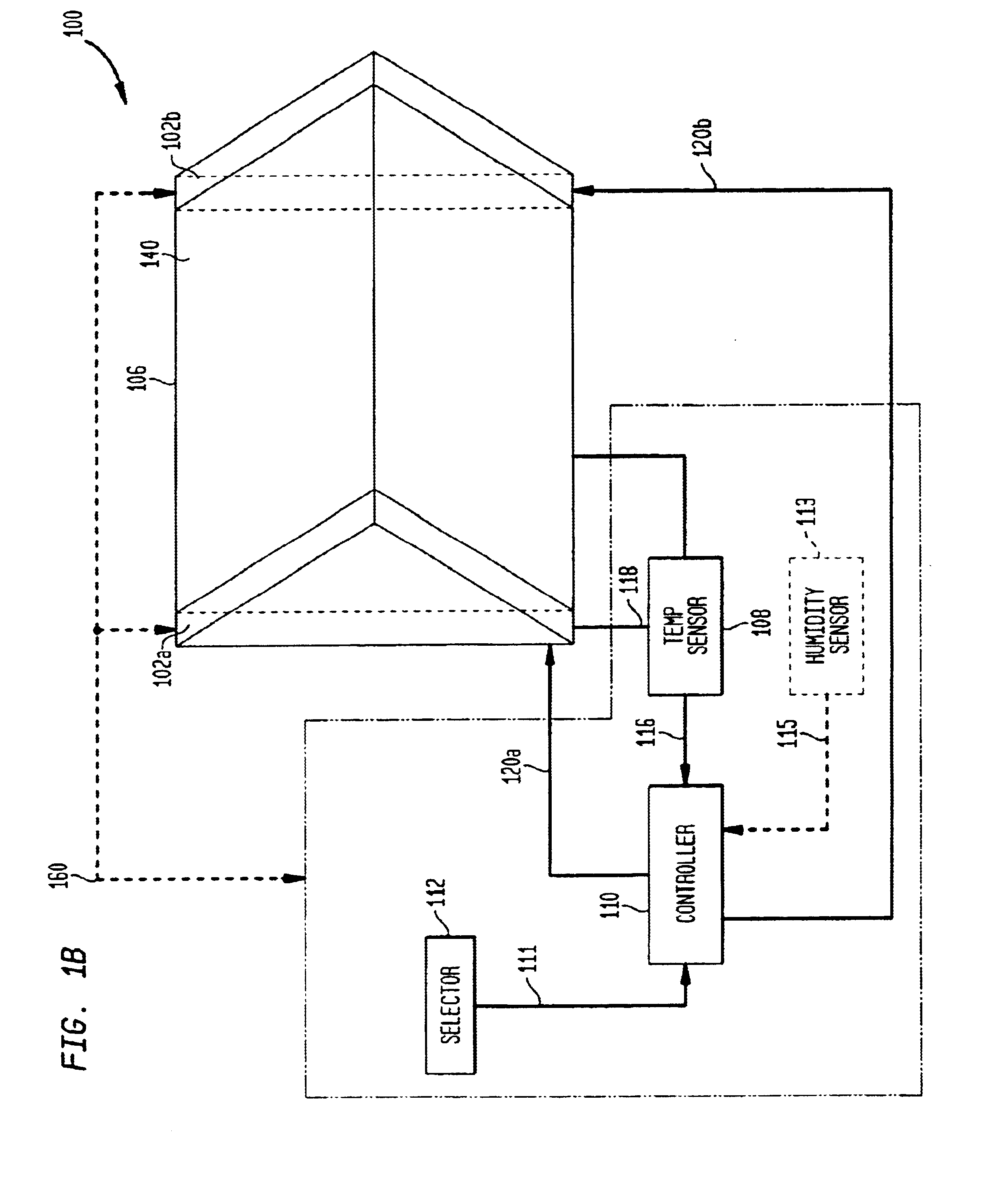

System and method for biometric image capturing

InactiveUS6872916B2High qualityPreventive effectHeater elementsCharacter and pattern recognitionPrismTotal internal reflection

Biometric object image capturing systems and methods prevent undesirable interruptions of total internal reflection of a prism that result in improper biometric images. A thermal assembly comprising a plurality of thermal elements is placed adjacent to the image capturing device. The thermal elements upon supply of a current are capable of either heating or cooling the image capturing device or a platen of the image capturing device. If cooling of the biometric object receiving surface is required, the thermal elements can be controlled to decrease temperature of an area where a biometric object is placed, or an area adjacent to where the biometric object is placed. If heating of the biometric object receiving surface is required, the thermal elements can be controlled to increase temperature of an area where a biometric object is placed, or an area adjacent to where the biometric object is placed, to remove and prevent accumulation of moisture.

Owner:CROSS MATCH TECH

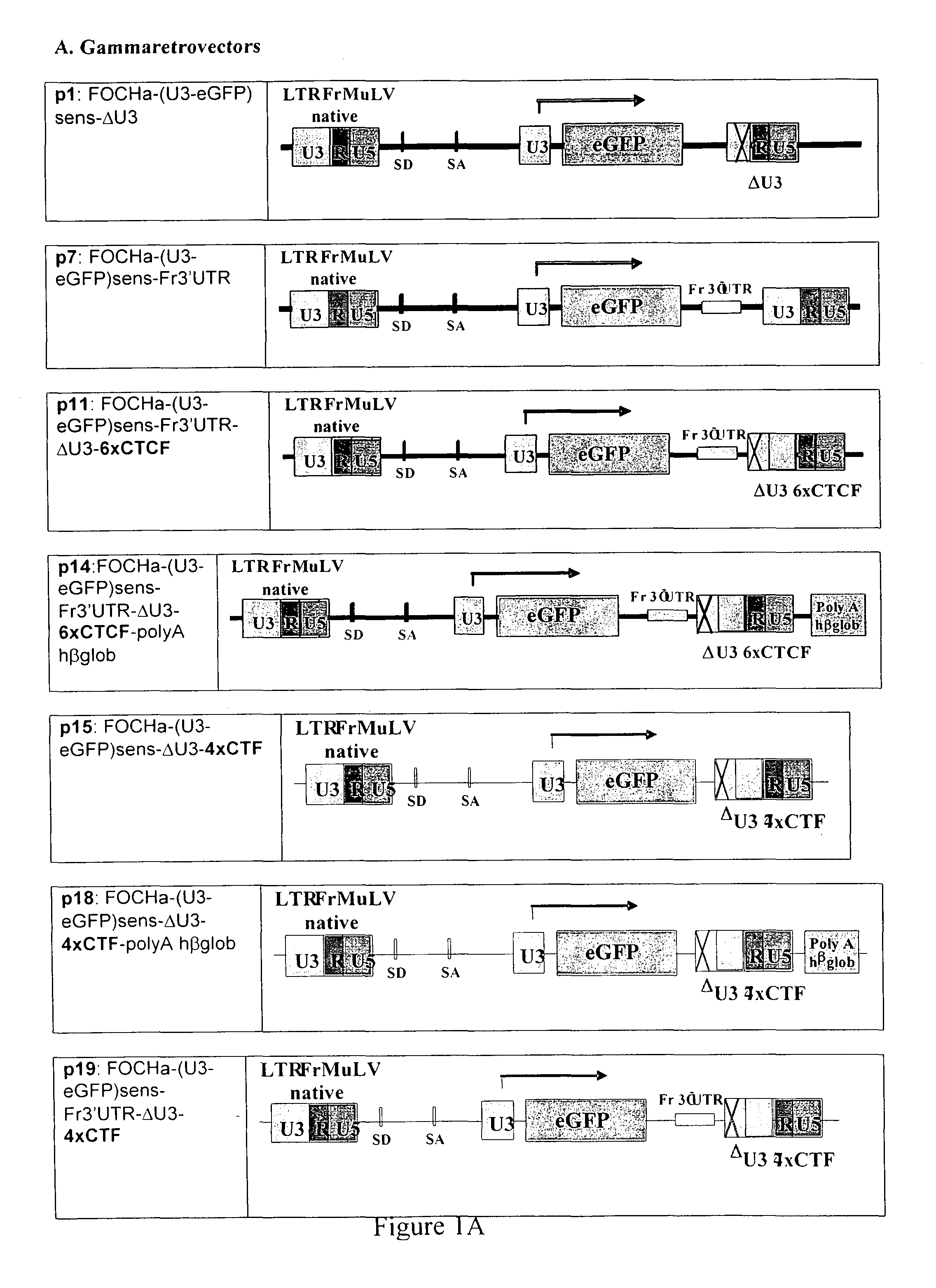

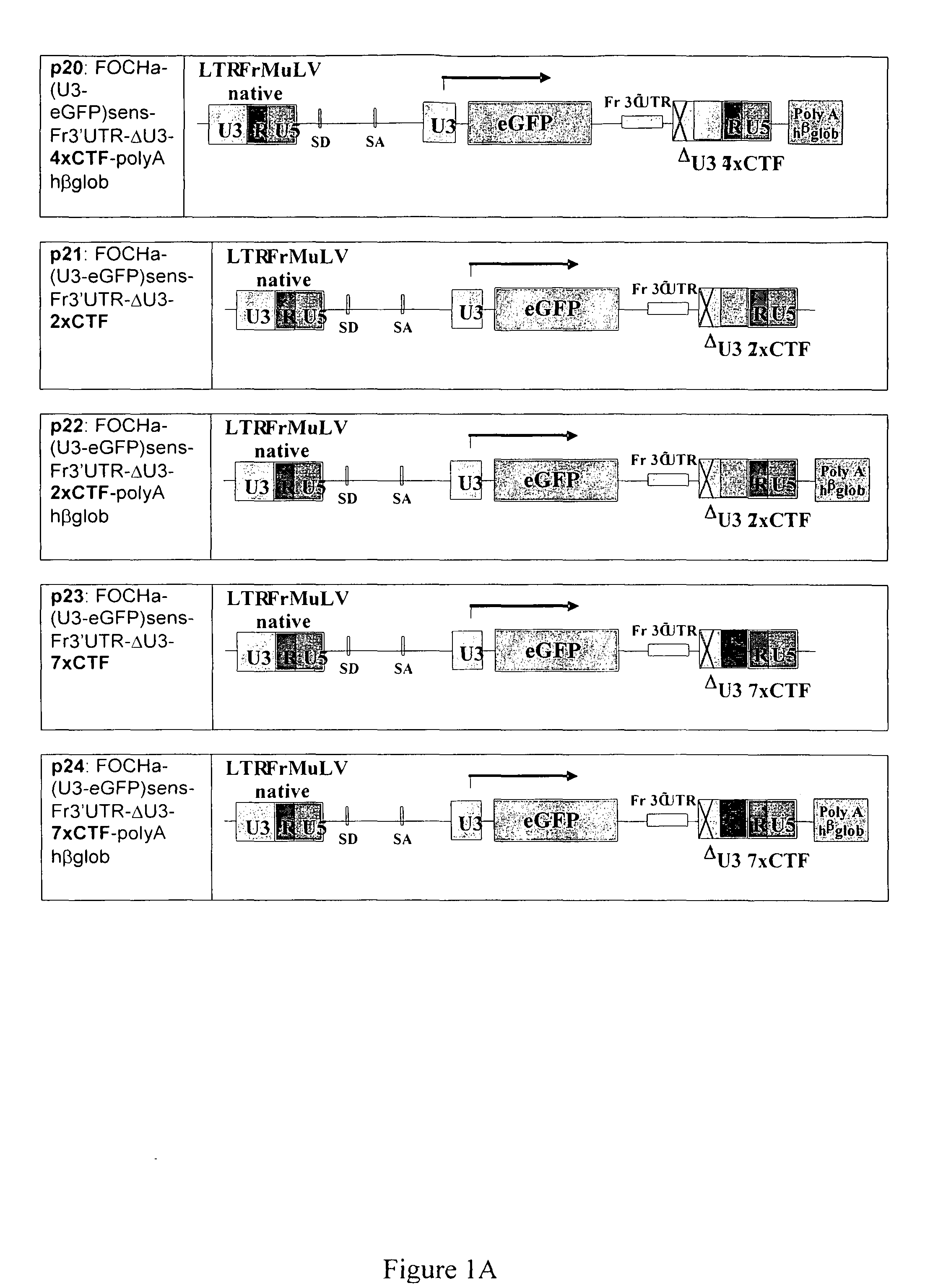

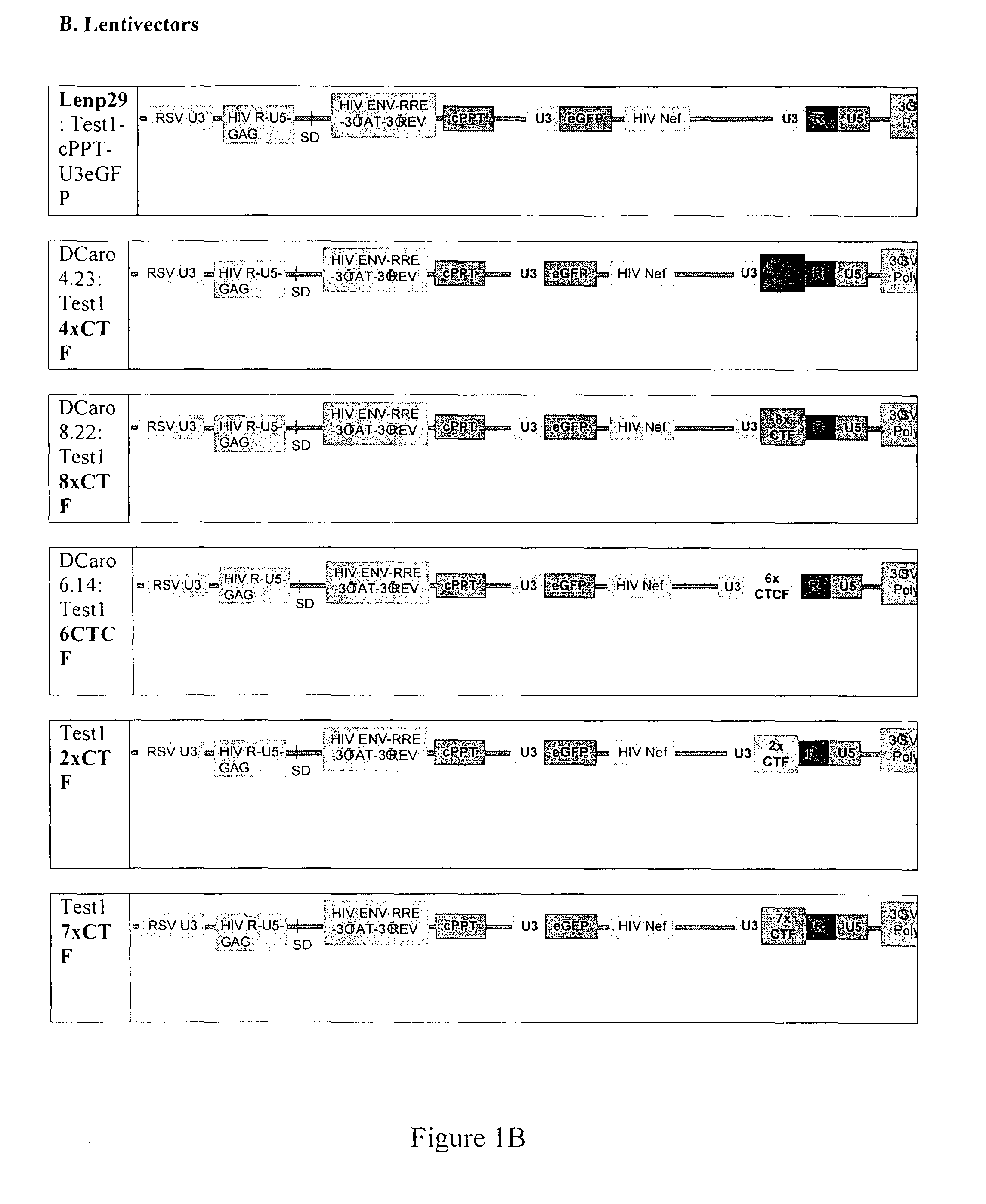

Gene transfer vectors comprising genetic insulator elements and methods to identify genetic insulator elements

ActiveUS20120115227A1Preventive effectReduced expression levelVectorsGenetic material ingredientsRegulatory sequenceGene transfer

The present invention relates to a gene transfer vector (GTV) and in particular to an integrating gene transfer vector (IGTV), which comprises at least one genetic insulator element (GIE), wherein the each comprises at least two copies of an element selected from the group consisting of: a CTF binding site; a first CTCF binding site and a second CTCF binding site, wherein the first and the second CTCF binding sites are derived from the regulatory sequences of different genes.

Owner:CENT NAT DE LA RECHERCHE SCI

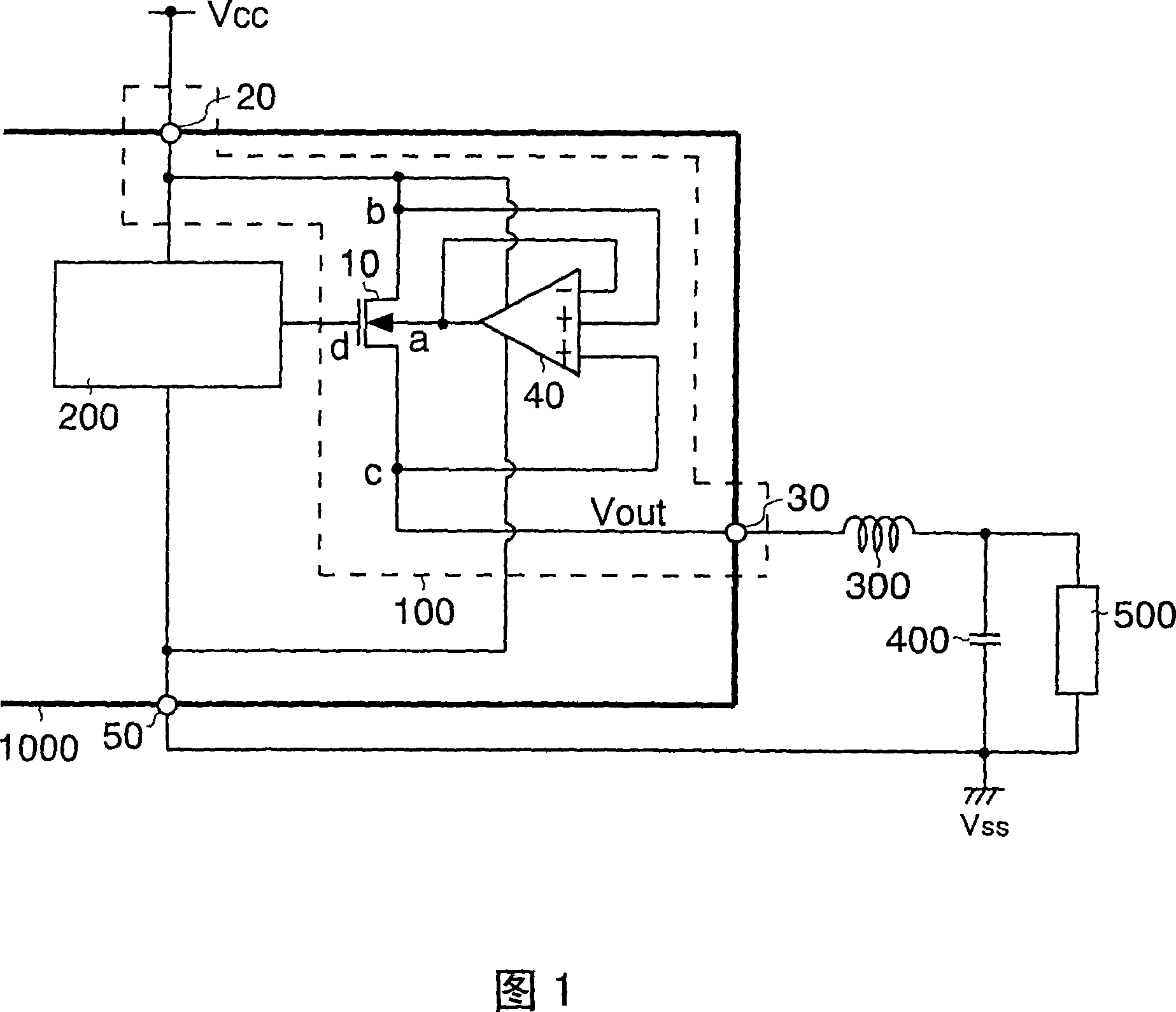

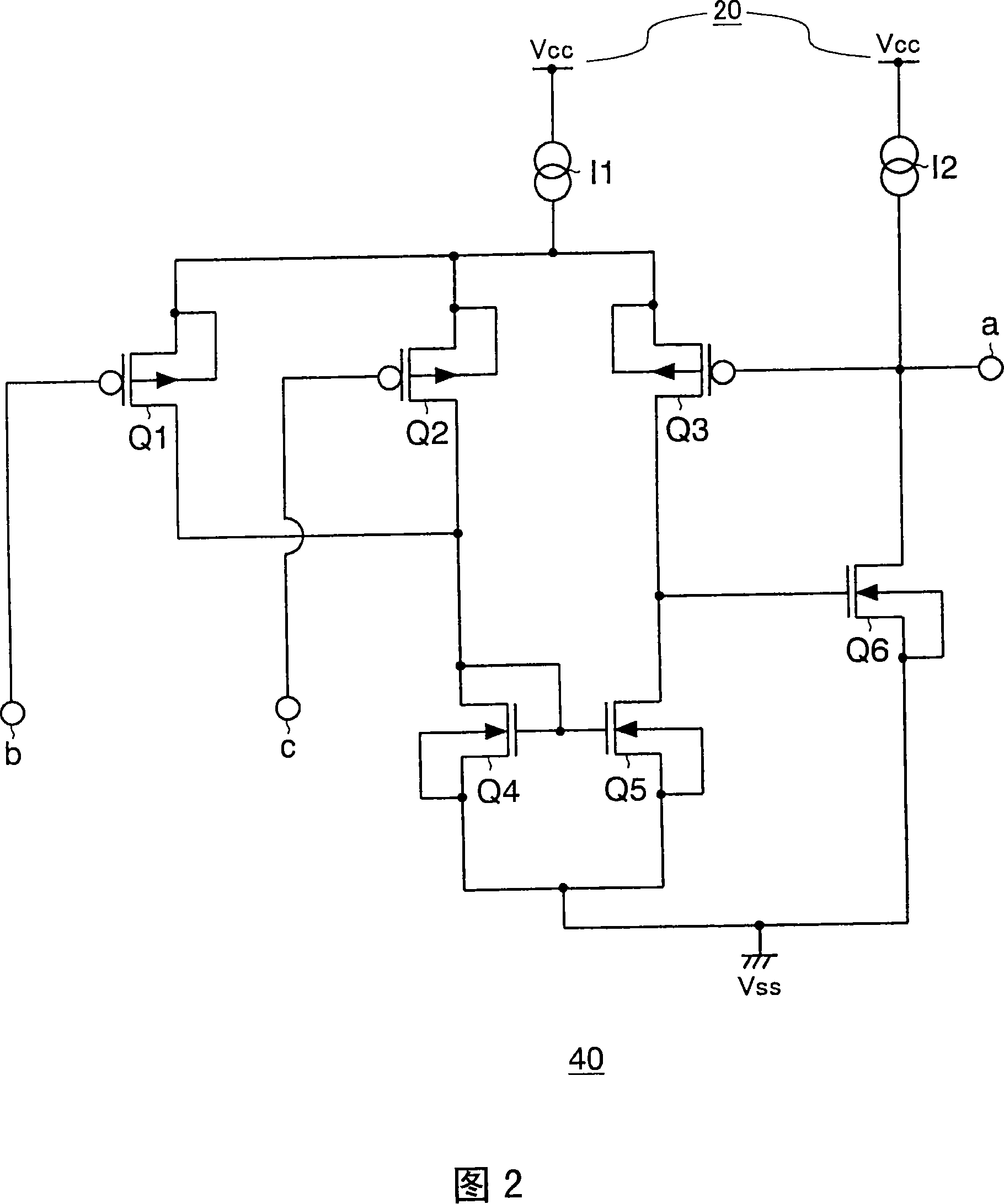

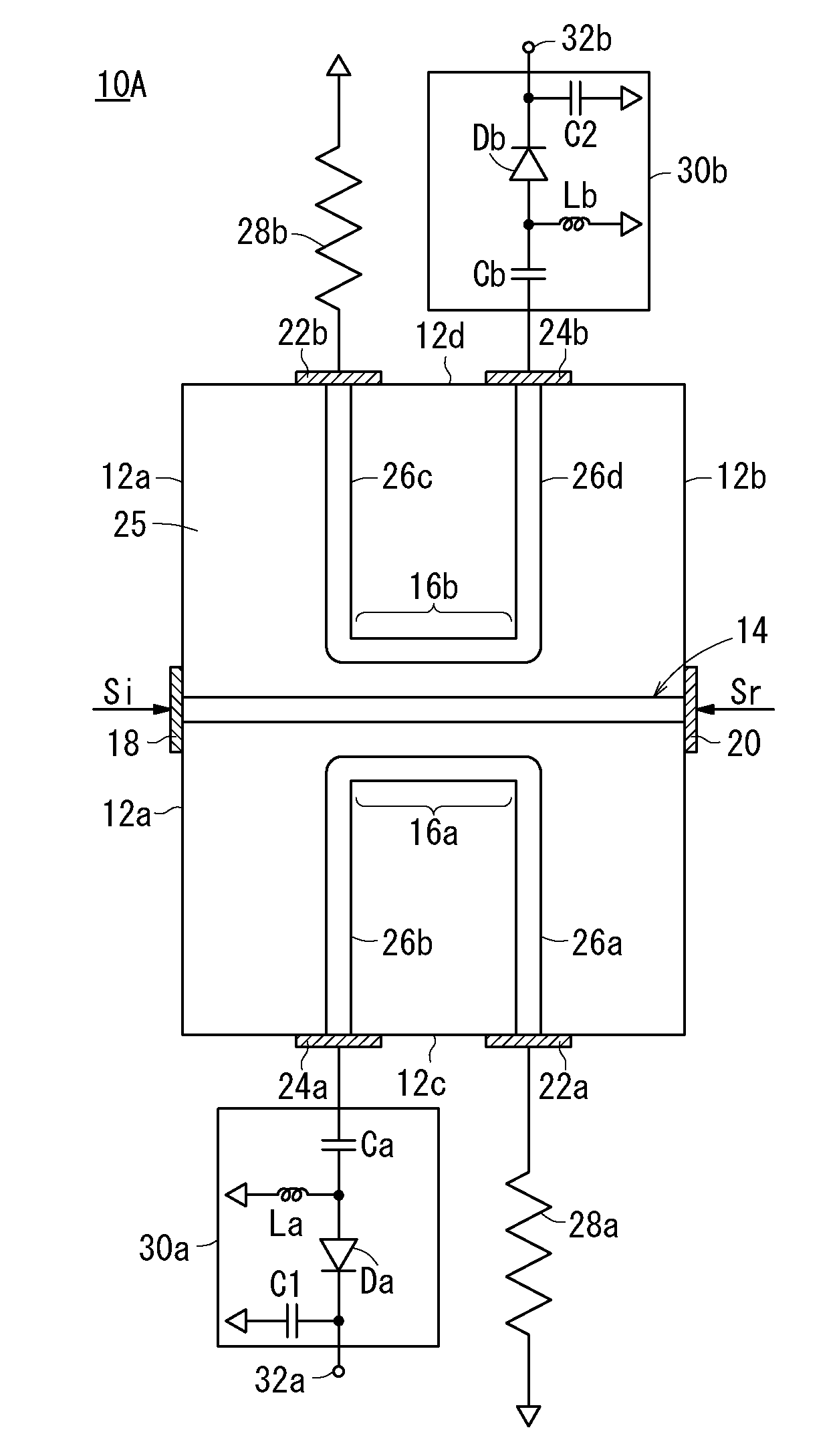

Semiconductor device, power supply device, and information processing device

InactiveCN101171678APreventive effectAvoid reverse currentTransistorDc-dc conversionInformation processingDrain current

Owner:ROHM CO LTD

Directional coupler

InactiveUS20110148544A1Preventive effectMultiple-port networksWaveguidesDielectric substrateDirectional coupling

A directional coupler includes a dielectric substrate having at least an input terminal and an output terminal on a surface thereof, a main line disposed in the dielectric substrate and extending between the input terminal and the output terminal, a first coupling line for monitoring a level of an input signal which is input through the input terminal, the first coupling line being disposed in the dielectric substrate and having an end electrically connected to a first terminating resistor, and a second coupling line for monitoring a level of a reflected signal which is input through the output terminal, the second coupling line being disposed in the dielectric substrate and having an end electrically connected to a second terminating resistor.

Owner:NGK INSULATORS LTD

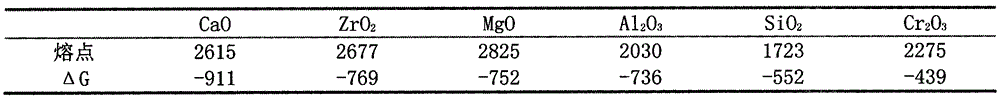

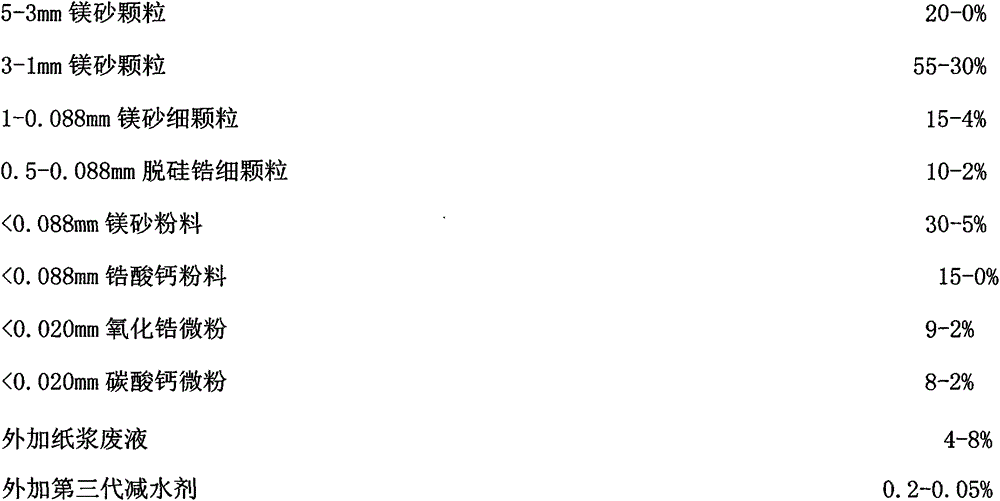

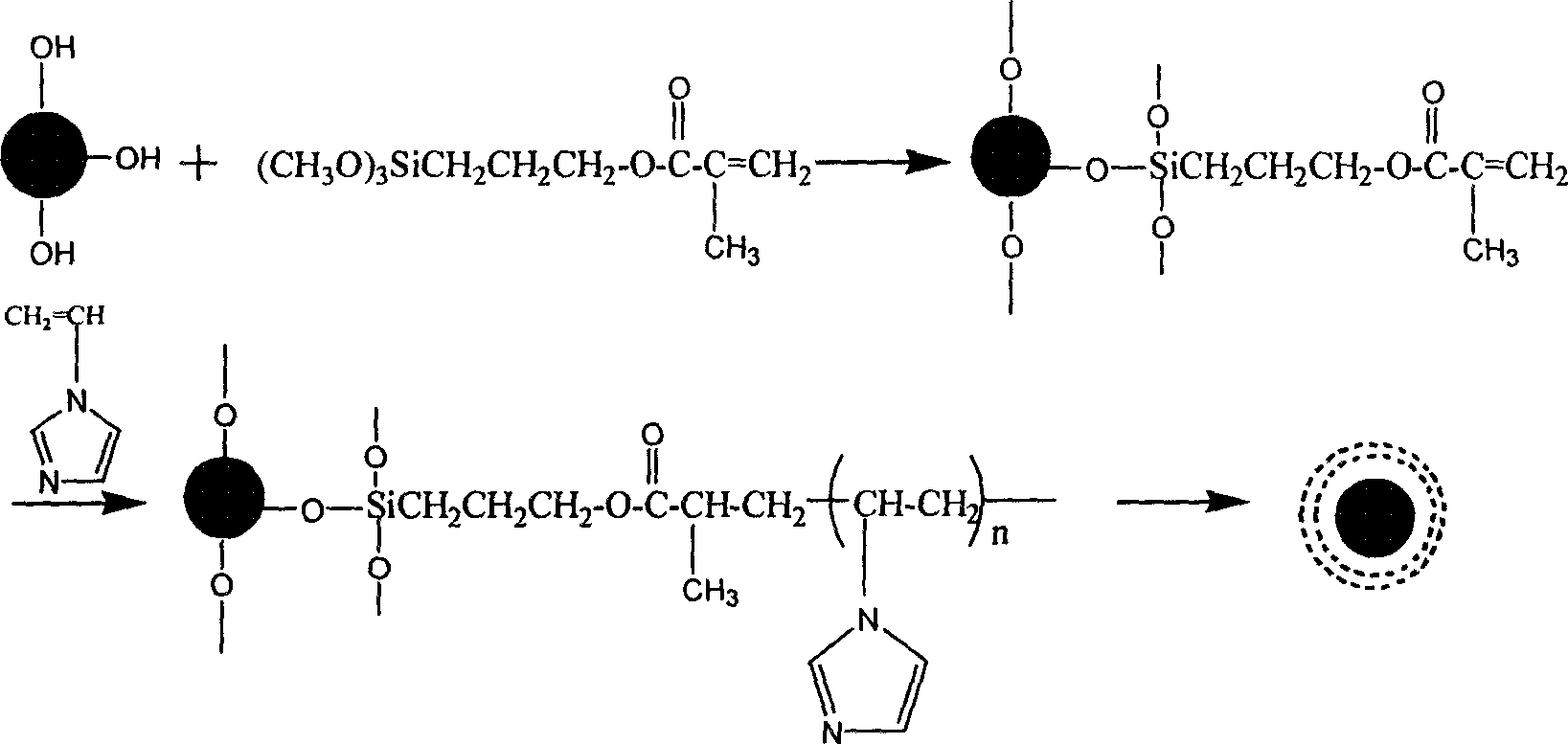

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Preparation method of high-boiling point salt type perfluor sulfoacid resin solution

ActiveCN101759858AConducive to the industrialization of preparationSimple processSolid electrolyte fuel cellsFuel cell detailsBoiling pointSolvent

The invention relates to a preparation method of high-boiling point salt type perfluor sulfoacid resin solution, which comprises the following steps: adopting strong base for processing the perfluor sulfoacid resin so that resin functional groups are converted into form-R types with alkali metal ions; then, placing the R type perfluor sulfoacid resin into a container to be maintained for 2 to 24 hours at 110 DEG C to 250 DEG C under the protection of inert gas; and obtaining the R type perfluor sulfoacid resin solution. The invention adopts a high-boiling point solvent, the obtained solution can be directly used for preparing fuel battery membranes, in addition, the technology in the solution preparation process is simple, the equipment requirement is low, and the operation is simple.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

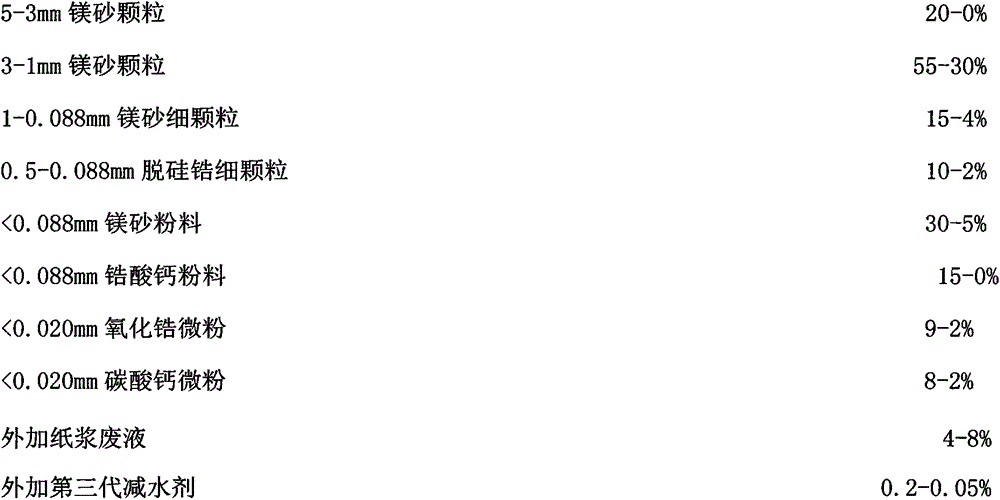

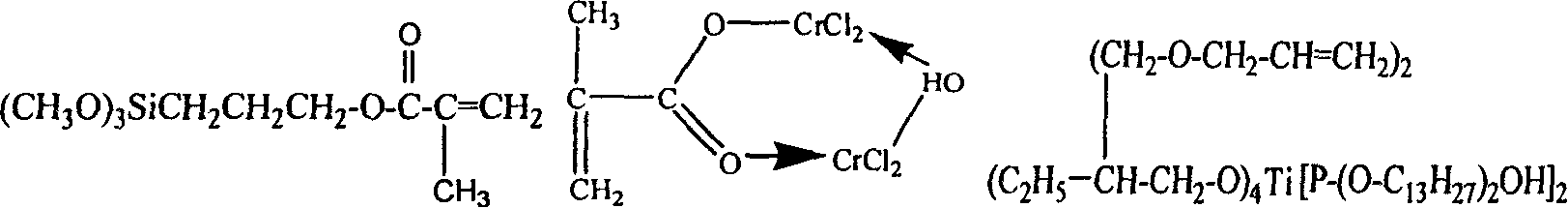

Tungsten trioxide/polymer nano core-shell microsphere and preparing process thereof

InactiveCN1634647AChange optical propertiesChange thermal propertiesMicroballoon preparationMicrocapsule preparationOrganic solventMicrosphere

This invention relates to a tungsten trioxide and polymer nanometer shell micro ball and the process method, which belongs to organic and inorganic, compound materials technique field and are processed by emulsion polymerization on the surface of tungsten trioxide particles. It covers macromolecule materials on the tungsten trioxide nanometer particles to avoid the reaction between outer environments with the particles and to alter the particles optics properties and it together with other organic semi-conductor makes effective compound to improve its photoelectricity property or process property.

Owner:ZHEJIANG CHANGE ORGANIC SILICON MATERIAL

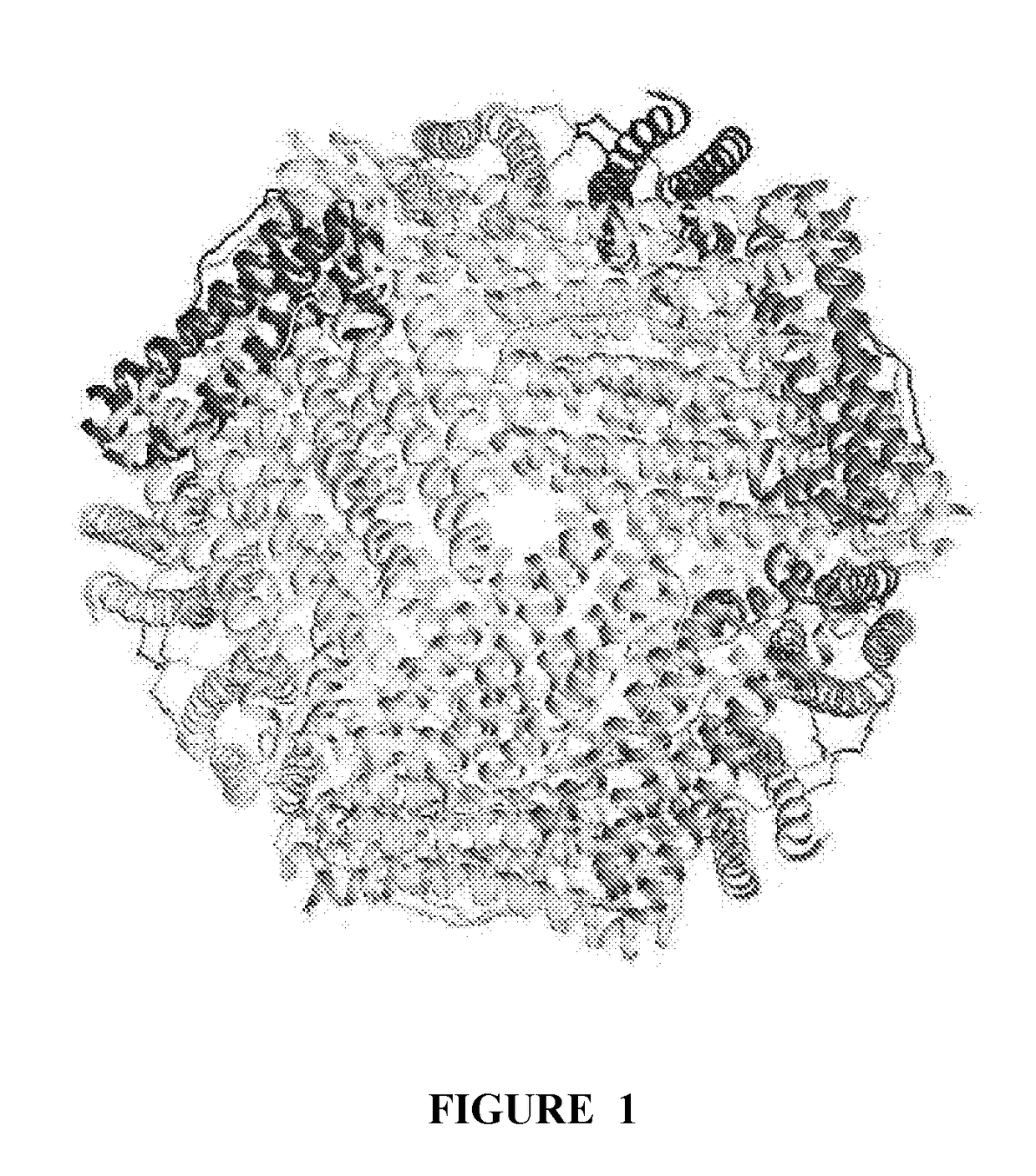

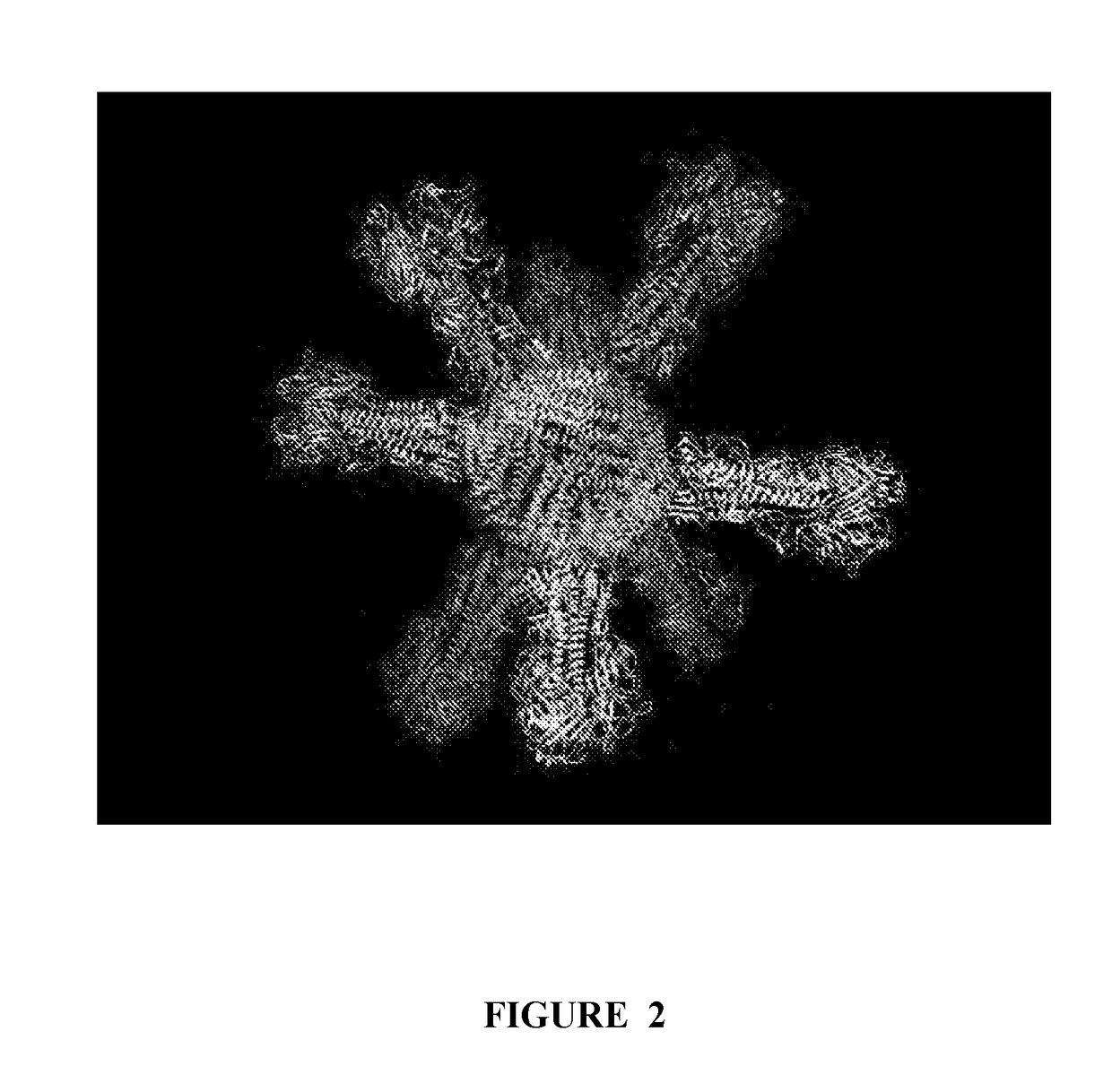

Nsp10 self-assembling fusion proteins for vaccines, therapeutics, diagnostics and other nanomaterial applications

ActiveUS20180326044A1Undesirable effectPreventive effectSsRNA viruses negative-senseSsRNA viruses positive-senseAntibodyBiophysics

A fusion protein is provided which is based on a self-assembling gene-regulatory NSP10 protein and a protein or peptide capable of being fused to NSP10 without interfering with the assembly or aggregation of the resulting fusion protein. The disclosure also relates to any nanoparticle formed thereby whether complete or not, and methods for the use of the NSP10 fusion protein are also disclosed, including use as vaccines for any indication in humans or animals, therapeutic methods involving the use of the fusion proteins such as using the protein to targeted an antibody or receptor, such as for treating or diagnosing cancer, bio-sensors using the fusion protein, or the use of the fusion proteins in cell sorting or any imaging application.

Owner:CARTER DANIEL C

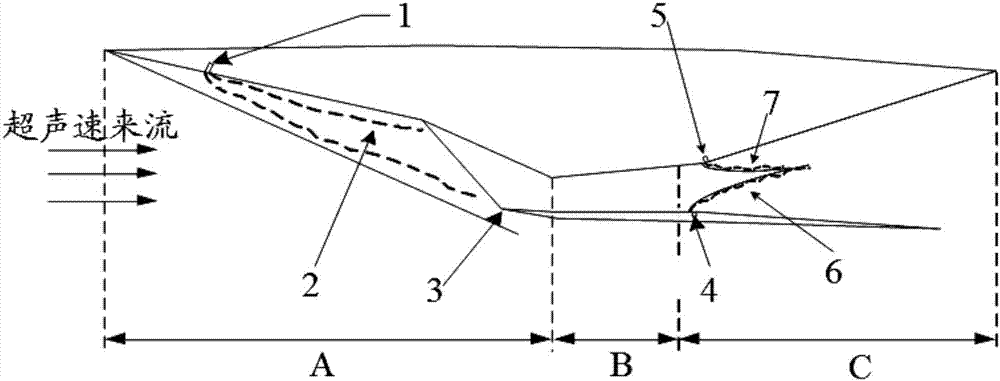

Supersonic velocity detonation engine and propulsion system thereof

ActiveCN106930864APreventive effectBurn fullyTurbine/propulsion fuel supply systemsContinuous combustion chamberInlet channelCombustion chamber

The invention discloses a propulsion system which comprises an air inlet channel, a combustion chamber and an expansion spraying pipe connected with the combustion chamber. A first hot jet flow spout allowing spraying of a hot jet flow is formed in the upper wall surface of the combustion chamber, a second hot jet flow spout allowing spraying of the hot jet flow is formed in the lower wall surface of the combustion chamber, after spraying the hot jet flows, the first hot jet flow spout and the second hot jet flow spout can induce a supersonic velocity incoming flow to form two strands of oblique detonation waves, and the two strands of oblique detonation waves can intersect in the middle of the expansion spraying pipe. According to the propulsion system provided by the invention, the first hot jet flow spout and the second hot jet flow spout are formed in the combustion chamber, the hot jet flows sprayed from the two hot jet flow spout induces the incoming flow to form the stable oblique detonation waves, and the oblique detonation waves produce regular reflection, so that the action of the detonation waves and a boundary layer is avoided, meanwhile, full combustion of incoming flow premixed gas is guaranteed, after combustion through the double oblique detonation waves, heat is released rapidly, expansion occurs to produce thrust, and the combustion efficiency is improved. The invention further discloses a supersonic velocity detonation engine comprising the propulsion system.

Owner:NAT UNIV OF DEFENSE TECH

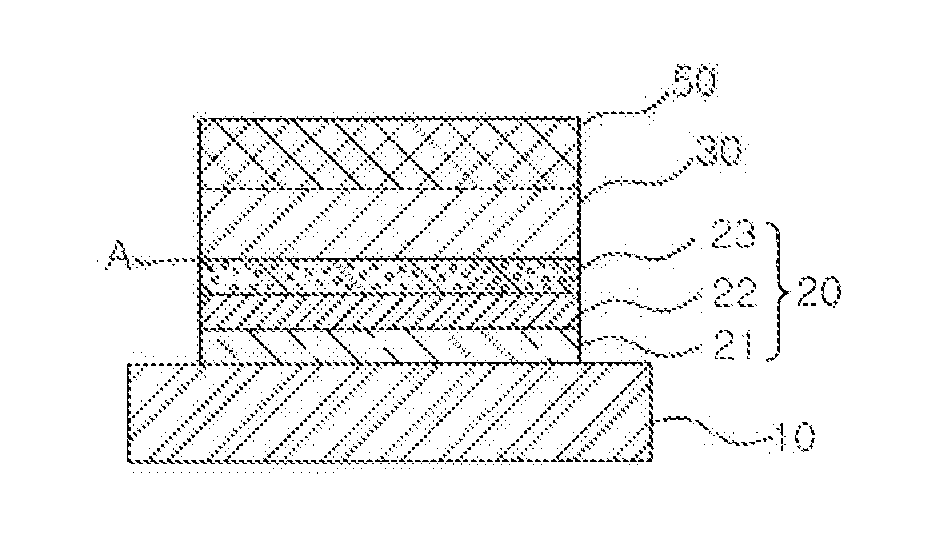

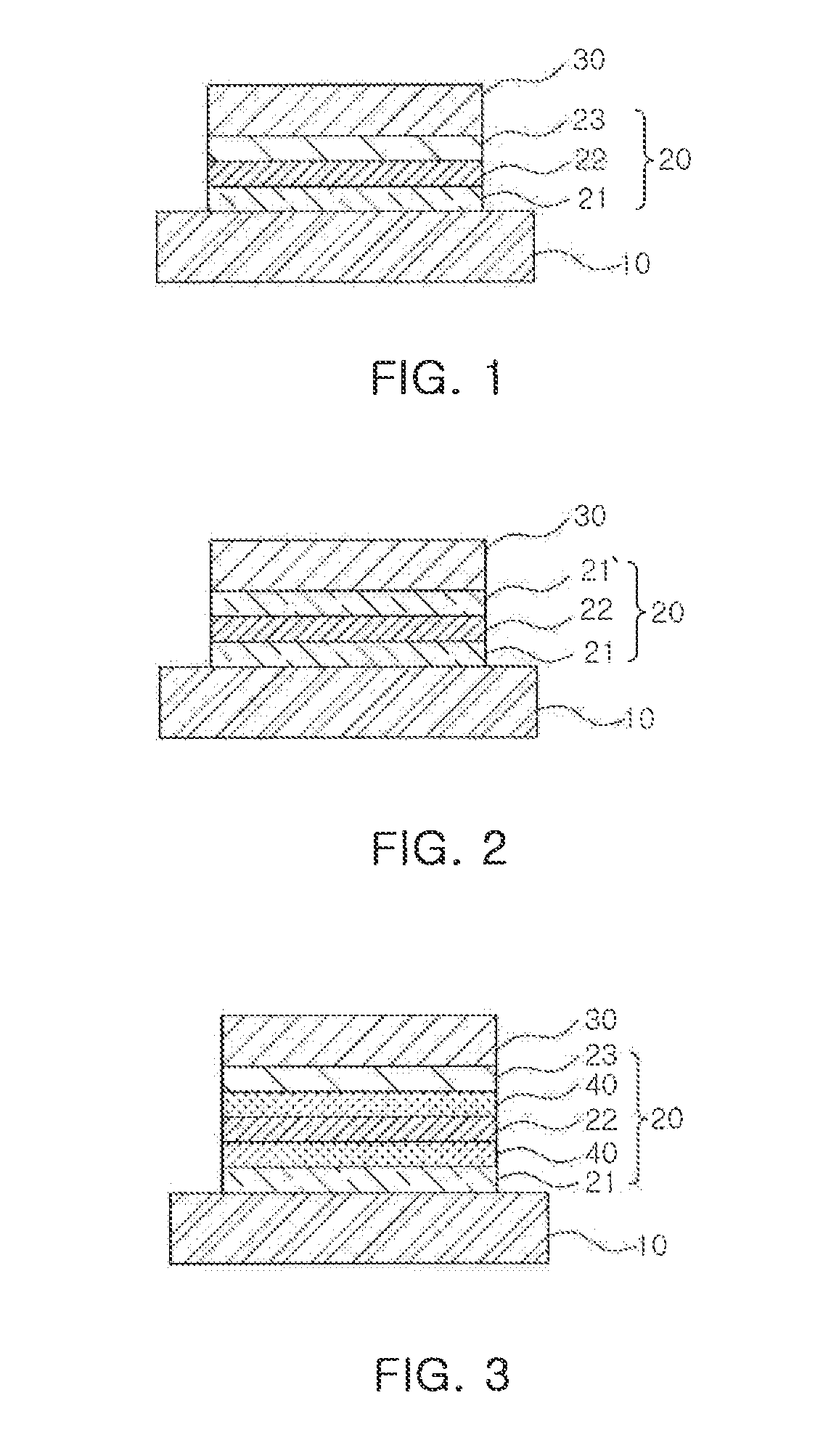

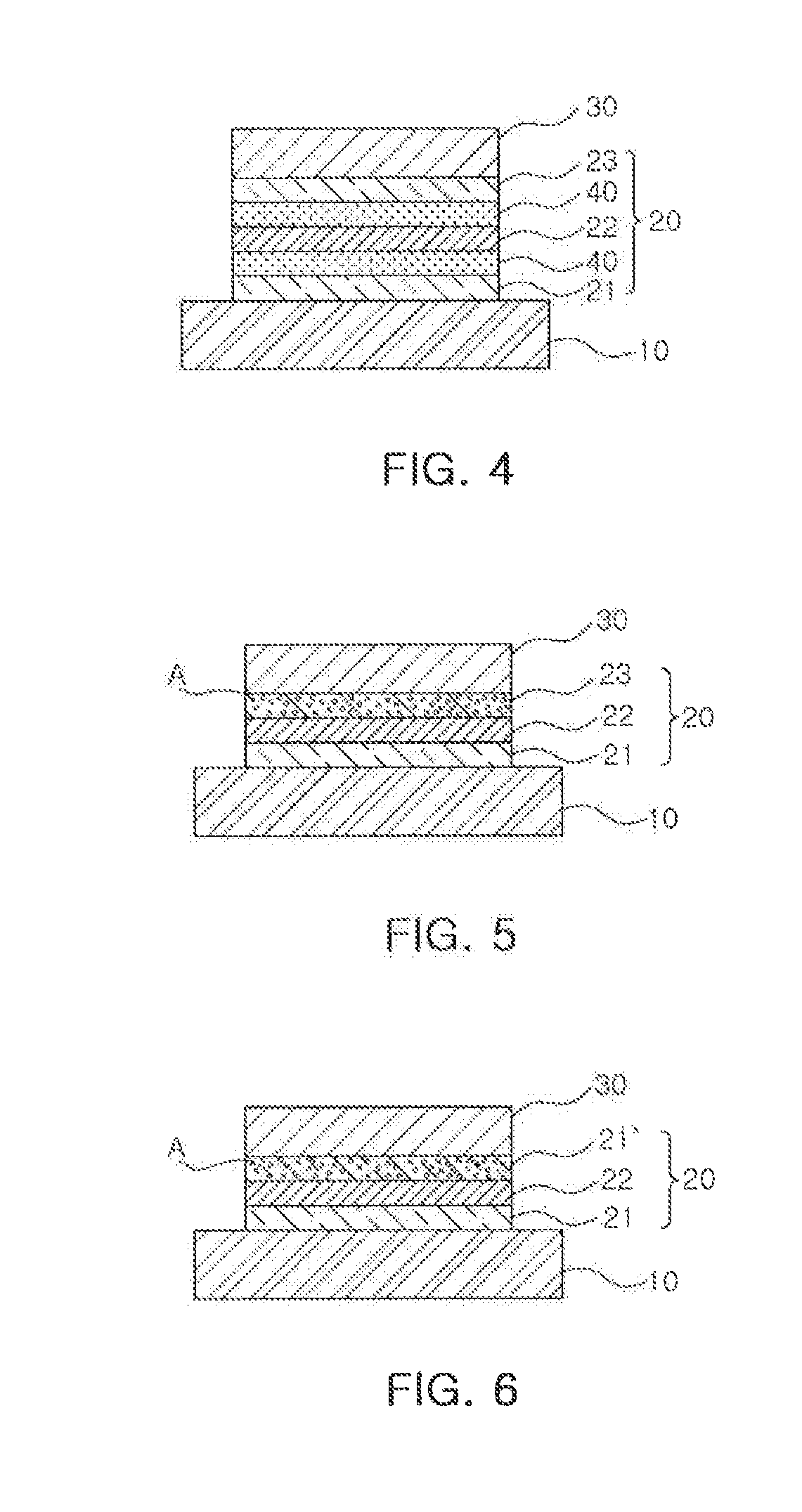

Solar cell substrate, method for manufacturing same, and solar cell using same

InactiveUS20140124028A1Superior diffusion prevent effectPreventive effectElectrolytic coatingsFinal product manufactureSolar cellMetal

One aspect of the present invention is a solar cell substrate, comprising: a lower substrate; and a lower electrode that is formed on the upper part of said lower substrate, wherein a metal diffusion-preventing film having at least one or two or more metal layers is included between said lower substrate and said lower electrode, and if two or more metal layers are formed, the metal layers adjoining each other can be different metals. Additionally, a solar cell, which is another aspect of the present invention, comprises: a lower substrate; and a lower electrode that is formed on the upper part of said lower substrate, wherein a metal diffusion-preventing film having at least one or two or more metal layers is included between said lower substrate and said lower electrode, and if two or more metal layers are formed, the metal layers adjoining each other comprise solar cell substrates which are of different metals; p-type light absorption layers formed on said solar cell substrates; n-type buffer layers formed on said light absorption layers; transparent windows formed on said buffer layers; and upper electrodes formed on said transparent windows.

Owner:POSCO

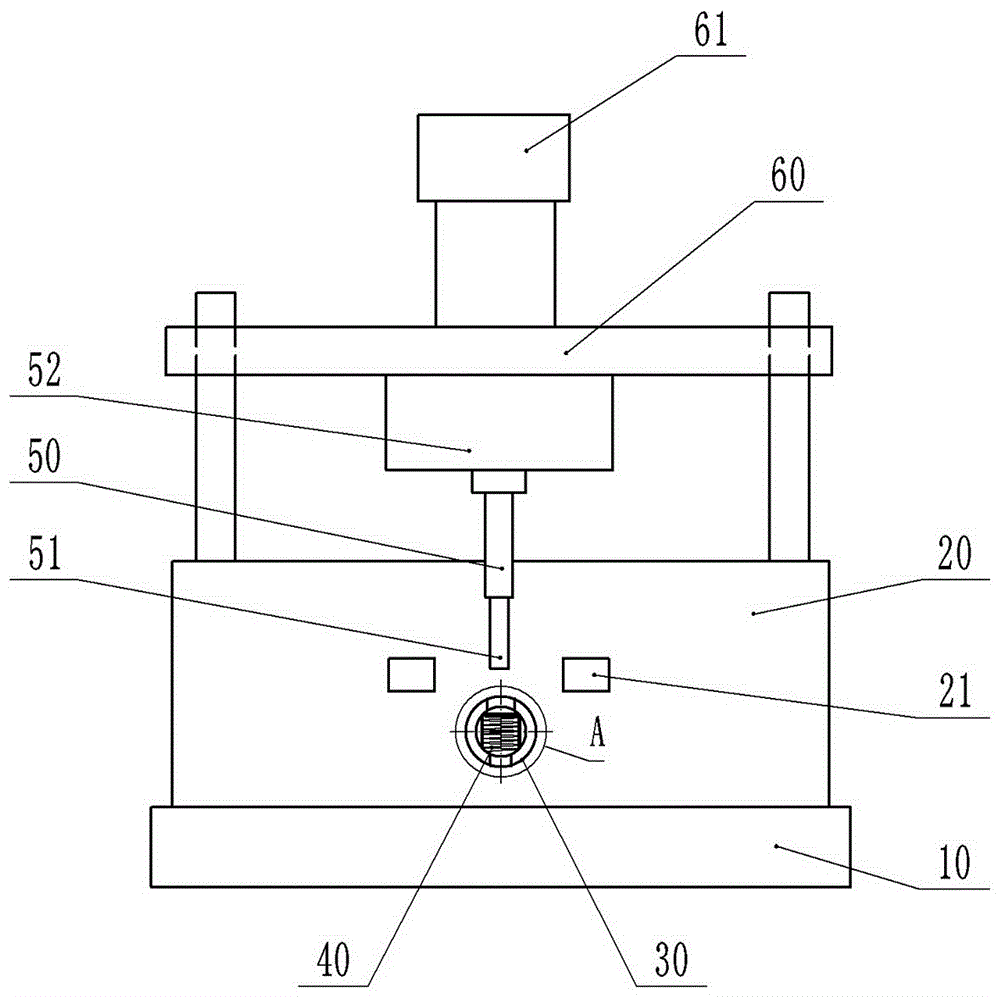

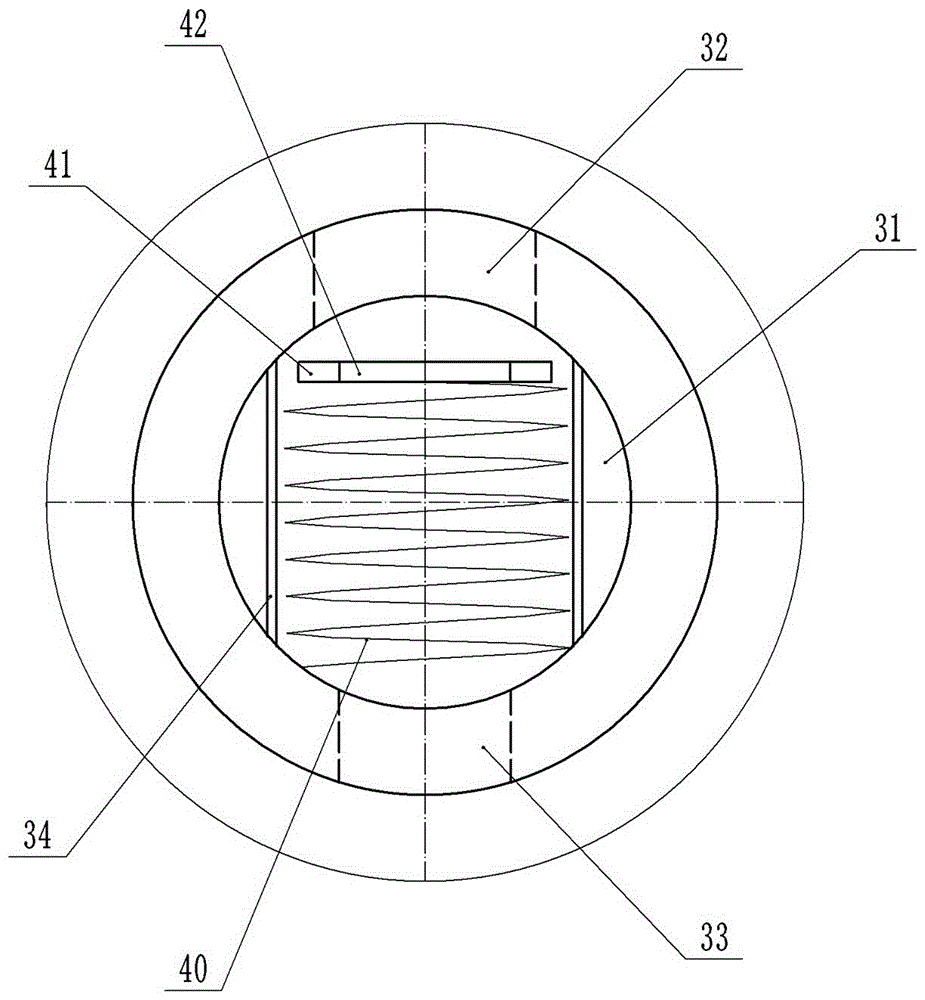

Tube piercing device

ActiveCN106734539AImprove work efficiencyImprove processing efficiencyPerforating toolsMetal-working feeding devicesEngineering

The invention discloses a tube piercing device. The tube piercing device comprises a base, a fixed plate, a mandrel, a punch and a pressure plate, wherein the fixed plate is perpendicularly fixed on the base; the mandrel is fixed on the fixed plate; limiting blocks are arranged on the fixed plate; guide pillars are also arranged on the fixed plate; the pressure plate penetrates through the guide pillars and is slidably connected with the guide pillars; a die shank is fixed at the upper end of the pressure plate; a punch seat is arranged at the lower end of the pressure plate; the punch comprises a small punch and a large punch; a hollow cavity is formed in the mandrel; a through hole is formed in a position, which corresponds to the punch, of the mandrel and comprises a large through hole and a small through hole; an elastic piece is arranged in the hollow cavity and positioned at the through hole; the elastic piece is fixed on the mandrel and positioned on one side close to the small through hole; and a straight hole capable of allowing the small punch to penetrate through is formed in the elastic piece. Compared with the prior art, the tube piercing device has the characteristics that holes with different sizes and diameters can be formed in a tube by punching at a time, meanwhile, wastes generated by piercing can further be discharged out of the tube and the mandrel, and therefore, the tube piercing efficiency is greatly improved.

Owner:重庆鼎汉巅宏汽车零部件有限公司

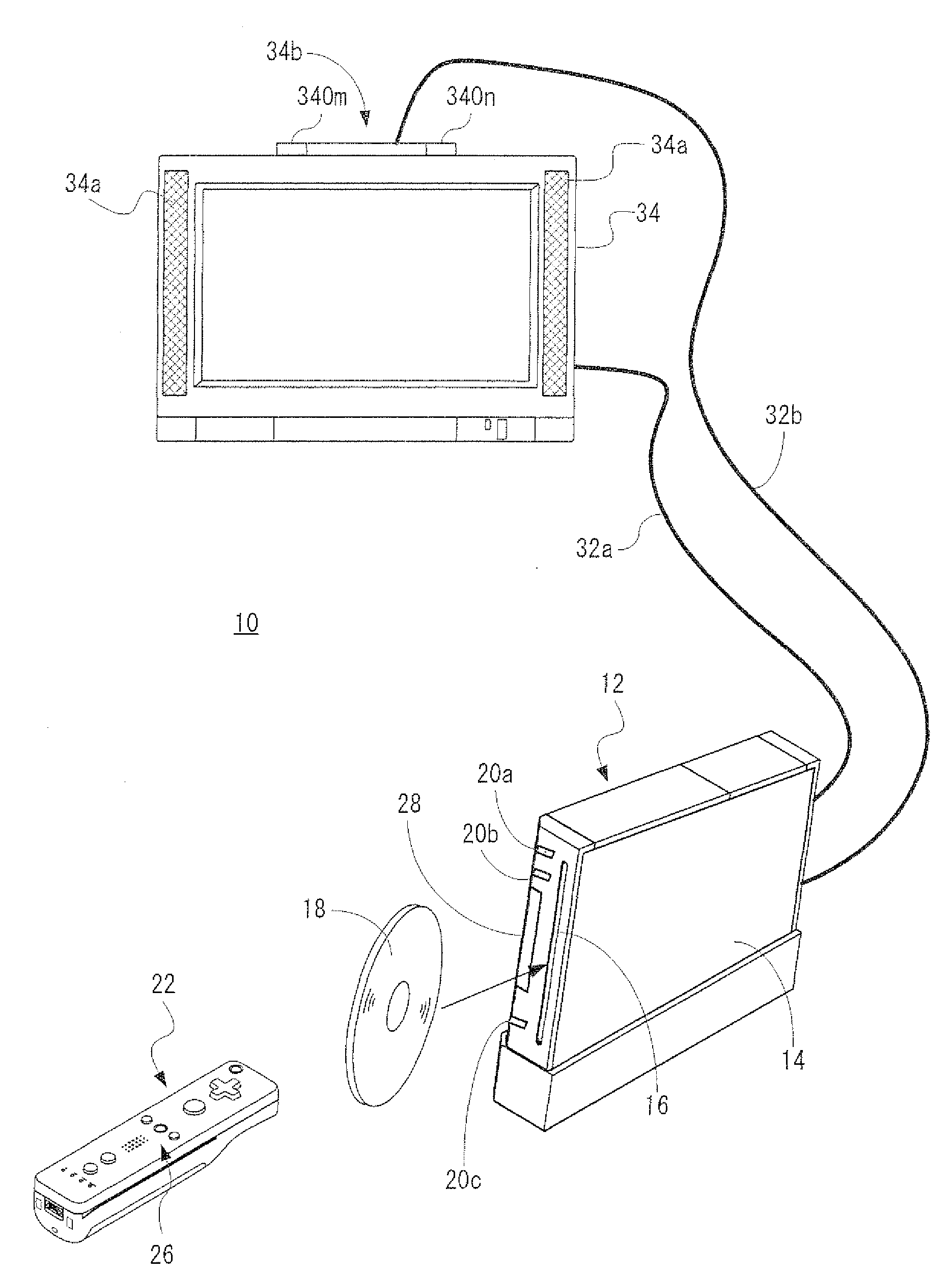

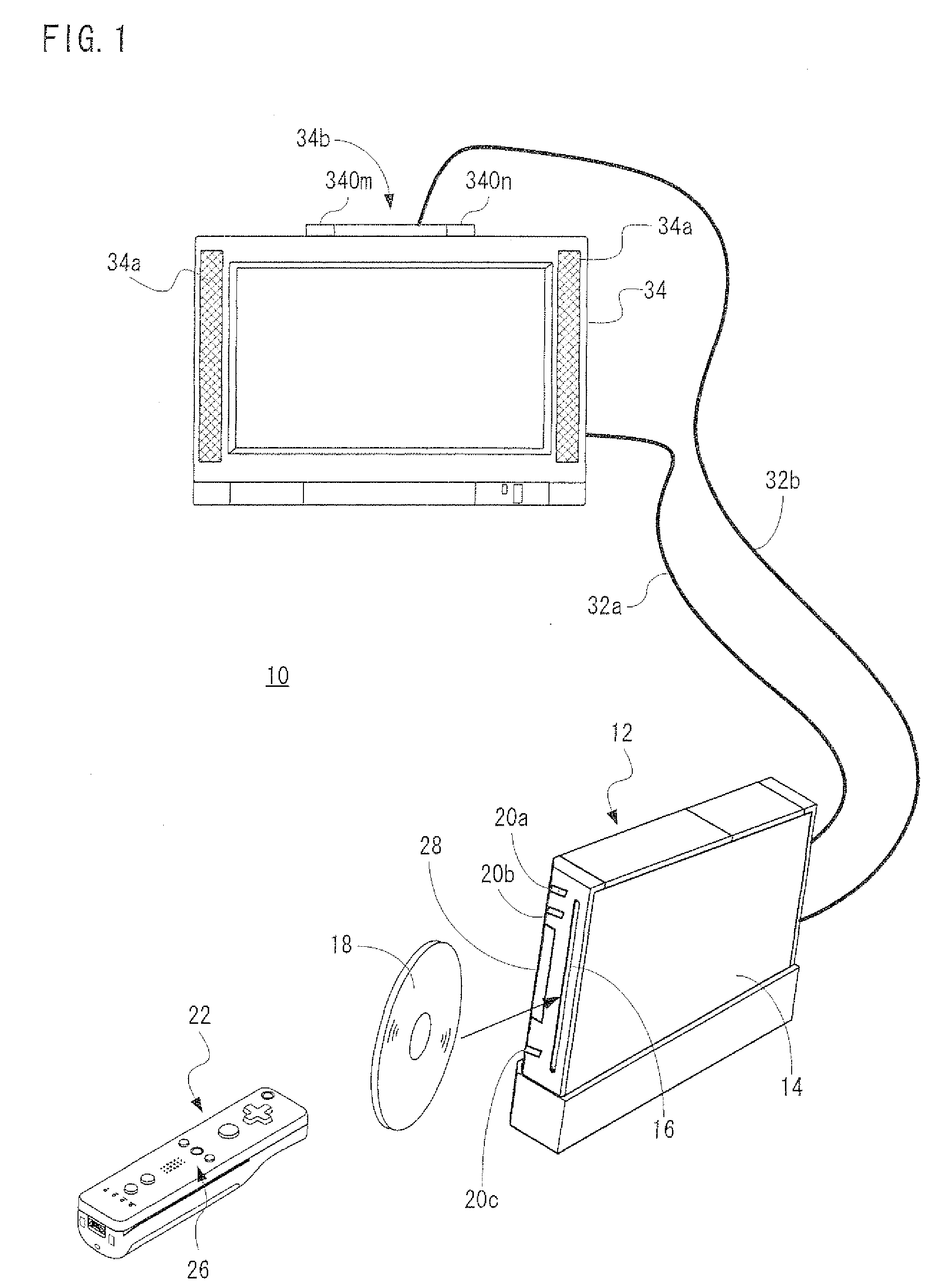

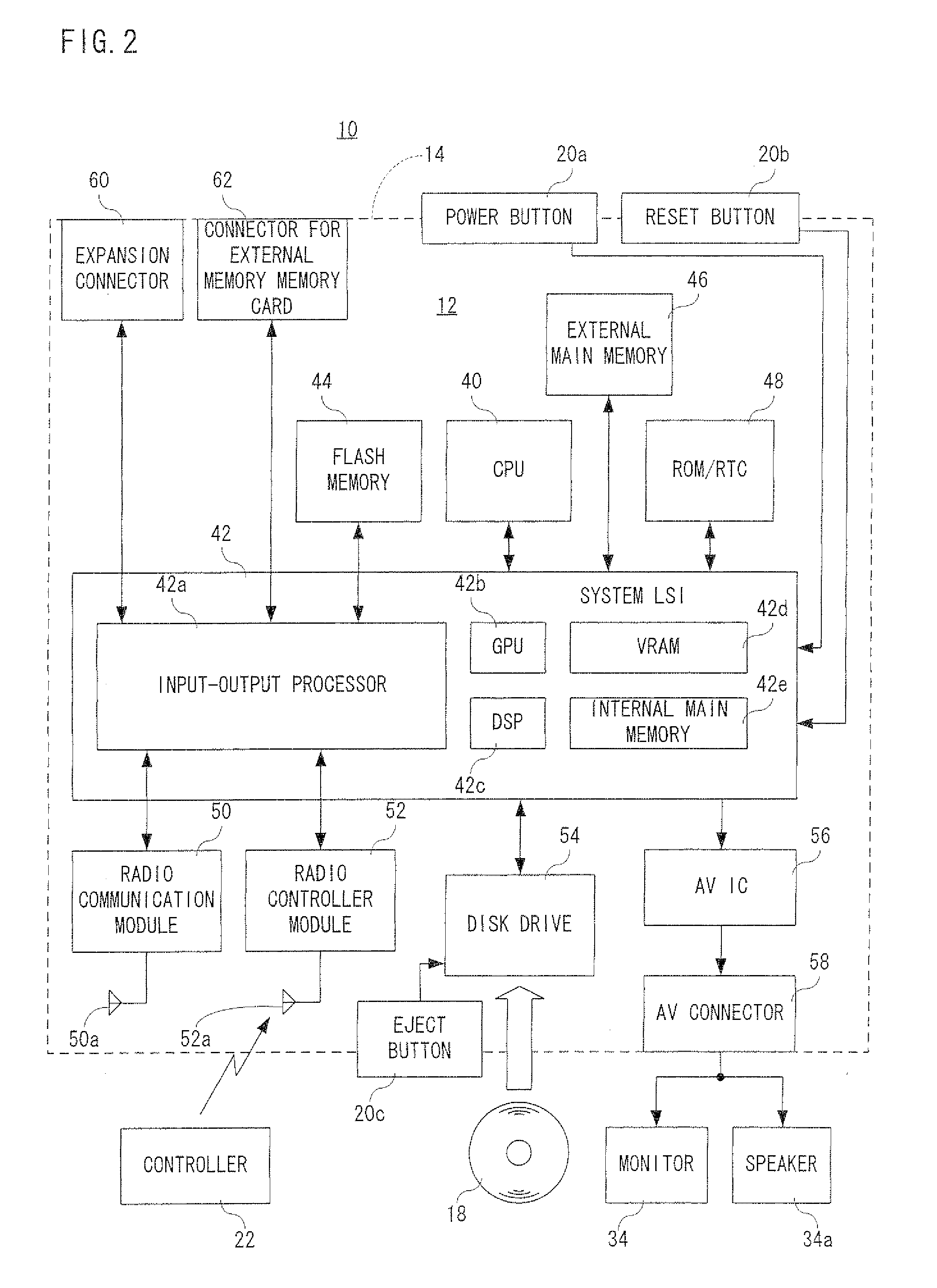

Storage medium storing game program, game apparatus, and game controlling method

ActiveUS20100292010A1Preventive effectVideo gamesSpecial data processing applicationsOperating instructionImaging data

A game apparatus includes a CPU, and when a virtual game is started, the CPU generates game image data and displays a corresponding game screen on a monitor. In the game screen, an operating instruction describing operation procedure is displayed and contents of the instruction changes according to a progress of the game. For example, as the game advances, an operating instruction including how to perform a new operation is displayed when a player object learns a new attack, or when a level (experience) of the player object increases or an operation level of the player increases. However, if the virtual game has not been played for a relatively long period of time, the operating instruction is displayed regardless of the progress of the game.

Owner:NINTENDO CO LTD +1

Method for grafting maleic anhydride with ethylene propylene terpolymer

The invention relates to a method for grafting maleic anhydride by ethylene propylene diene monomers. The method is characterized in that the ethylene propylene diene monomers are taken as raw materials, maleic anhydride is taken as a grafting monomer, a plasticizer, a reinforcing agent and a vulcanization retarder are added, the obtained mixture is evenly mixed and then put into an extruder to be fused and blended so as to granulate and obtain the graft of ethylene propylene diene monomers and maleic anhydride, i.e., EPDM-g-MAH; before the fusion and extrusion of the mixture, high-energy rayradiation is carried out to the mixture by a radiant point; and during granulation, the length-diameter ratio of the screw of the extruder is 15 to 33:1, the rotation speed of the extruder is 30 r / min to 180 r / min and the temperature of the die orifice of the extruder is 60 DEG C to 180 DEG C. The method does not cause the ethylene propylene diene monomers (EPDM) to gel, which is conducive to thecompatibility of the ethylene propylene diene monomer with a polar polymer (engineering plastics); the grafting rate of the grafting product is high and can reach up to 1.2 percent to 3.6 percent; and radiation grafting adopted does not pollute the environment, saves energy and reduces production cost by about 30 percent.

Owner:张万鹏

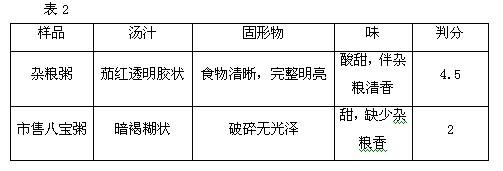

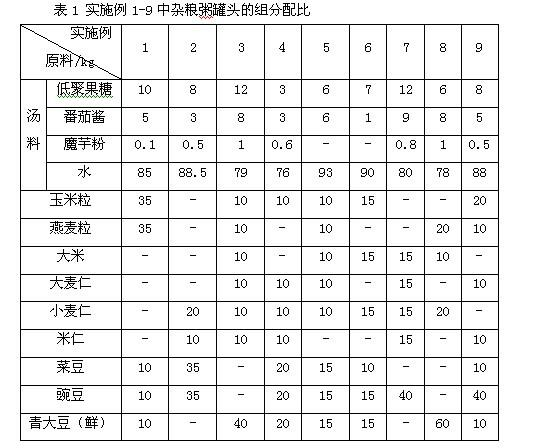

Minor cereal porridge can

InactiveCN102318796ANaturally NutritiousWith health functionFood preparationFood additiveNatural food

The invention belongs to the technical field of foods, in particular to a minor cereal porridge can which contains fructo-oligosaccharide (FOS) and tomato paste. The minor cereal porridge can is formed by sealing a metal can or a plastic cup filled with a minor cereal porridge food, wherein the minor cereal porridge food is mainly prepared from the following components in parts by weight: 3-15 parts of FOS, 1-9 parts of tomato paste, 76-93 parts of water, 0-1 part of konjaku flour, 30-70 parts of bean and 30-70 parts of minor cereals, wherein the bean is one or more of kidney bean, garden peaand green soybean; and the minor cereal is one or more of shelled corn, shelled oat, rice, barley and wheat kernel and rice kernel. In the invention, porridge is prepared by making soup in a way of diluting FOS and tomato paste with water, mixing the soup with minor cereals and curing, so that a fully natural food which keeps a natural color and does not contain any chemical additive is obtained,and the defects of monotonous mouthfeel, small quantity of soybean cereals and large quantity of food additives existing in the conventional eight-treasure porridge food are overcome.

Owner:余世明

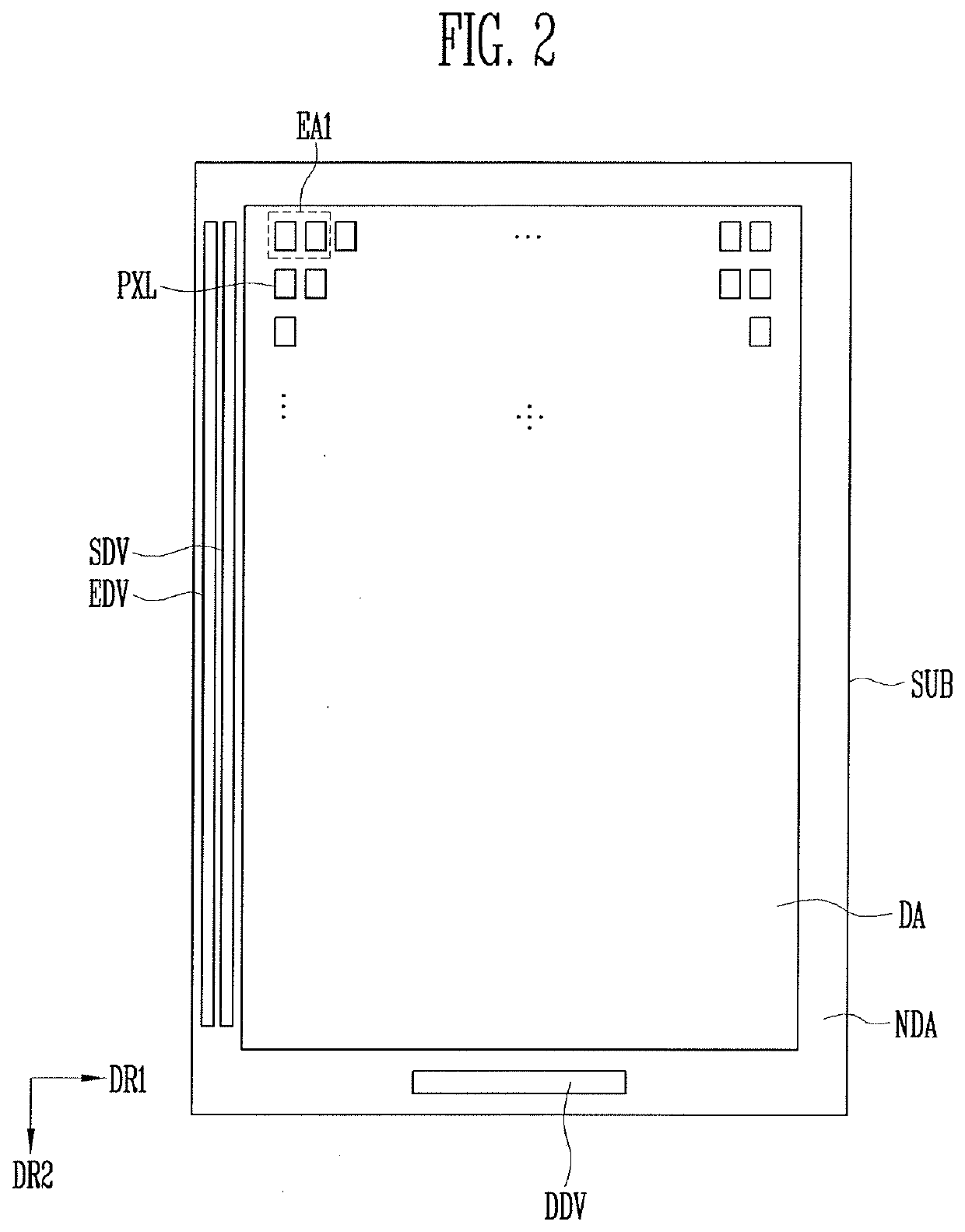

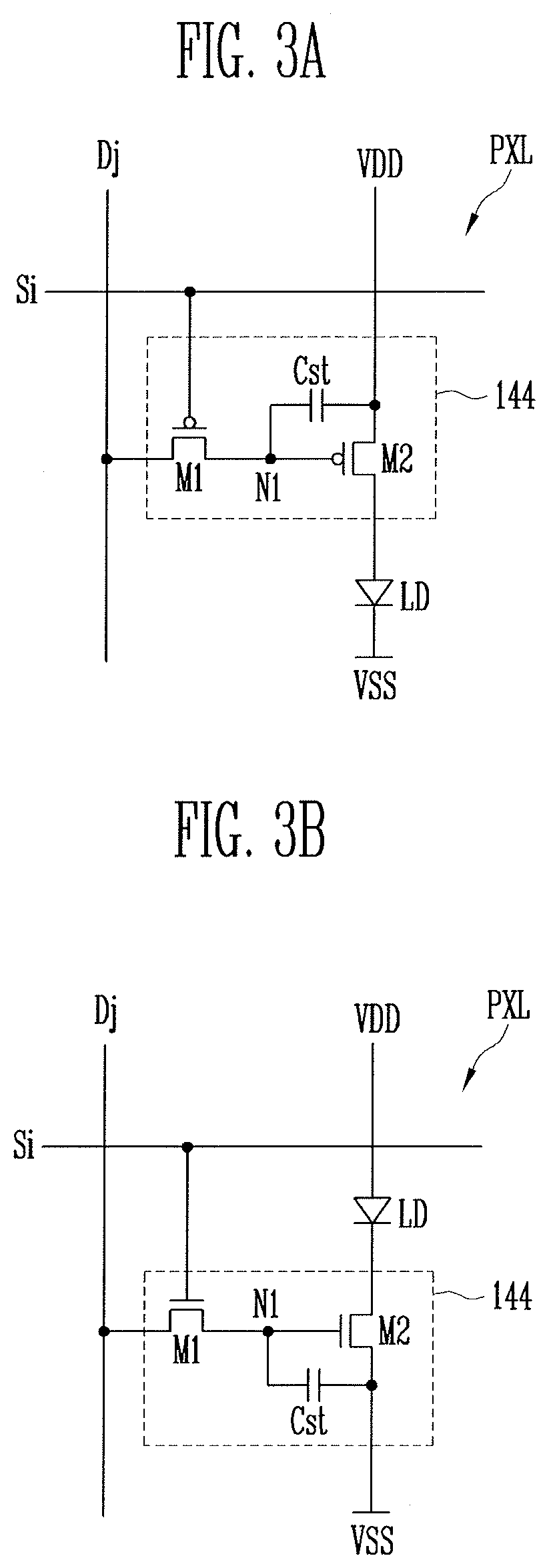

Display device

ActiveUS20200203587A1Preventive effectSolid-state devicesSemiconductor devicesDisplay deviceLight emitting device

A display device includes a substrate including a plurality of pixels; an electrode part including a first electrode in each pixel of the plurality of pixels on the substrate and a second electrode spaced apart from the first electrode on a same plane; a plurality of light emitting devices spaced apart from each other between the first electrode and the second electrode; a power line part including a first power line between the substrate and the first electrode, the first power line to receive a first driving power source, and a second power line between the substrate and the second electrode, the second power line to receive a second driving power source; and a shielding electrode line between the power line part and the first electrode, the shielding electrode line to receive the first driving power source.

Owner:SAMSUNG DISPLAY CO LTD

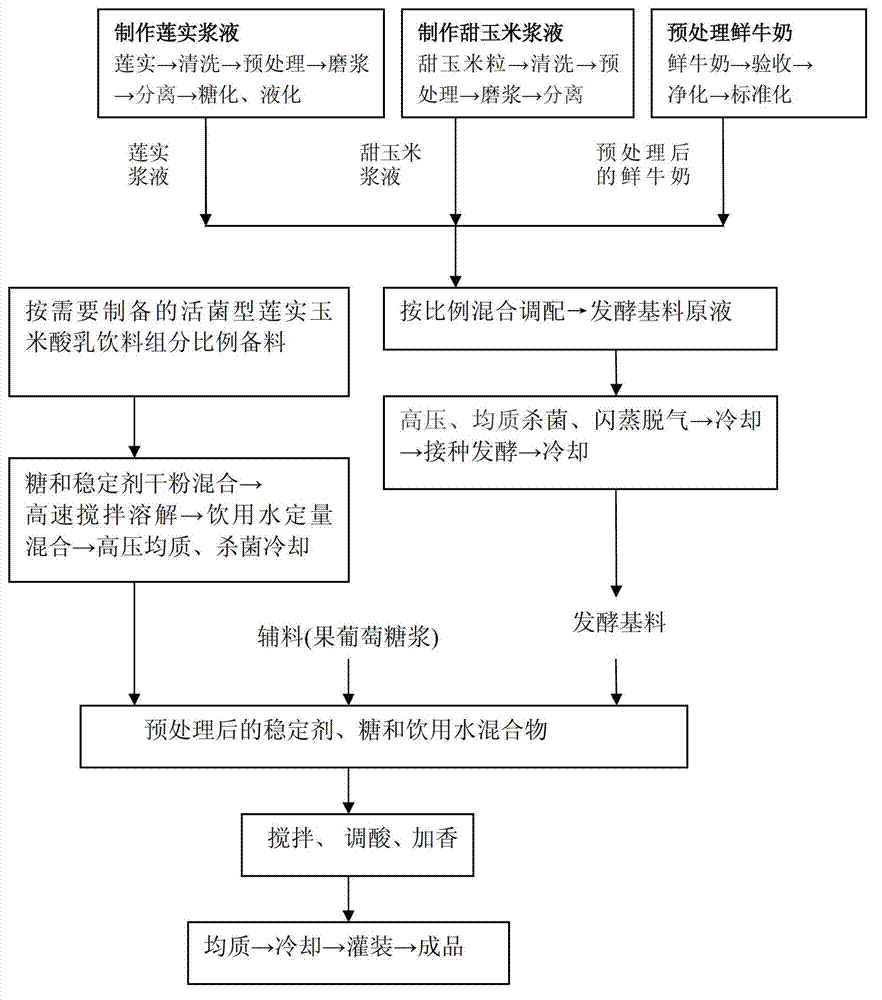

Live bacteria type lotus seed and corn yoghurt beverage and preparation method thereof

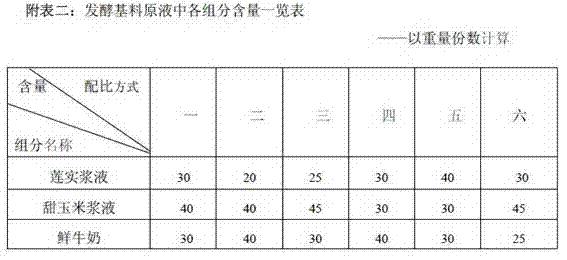

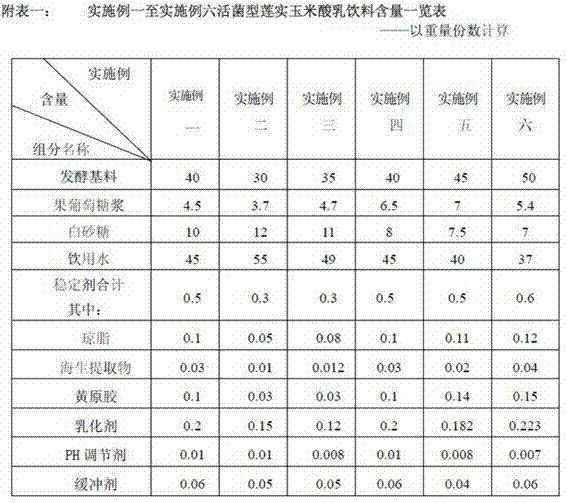

InactiveCN102805150AEnsure health and safetyEnsure food safetyMilk preparationBiotechnologyGlucose-Fructose Syrup

The invention provides a live bacteria type lotus seed and corn yoghurt beverage which is a mixture prepared by using base fermentation material, and the like, wherein the mixture comprises following components by weight parts: 30 to 50 parts of base fermentation material, 3 to 8 parts of glucose syrup, 7 to 12 parts of white granulated sugar, 35 to 55 parts of drinking water, 0.3 to 0.6 parts of stabilizing agents, and a small amount of food flavors, wherein the base fermentation material is prepared by fermenting a stock solution of the base fermentation material, which is formed by mixing lotus seed slurry, sweet corn slurry and pretreated fresh milk; and the stock solution of the base fermentation material comprises following components by weight parts: 20 to 40 parts of lotus seed slurry, 30 to 45 parts of sweet corn slurry and 20 to 40 parts of fresh milk. A preparation method of the live bacteria type lotus seed and corn yoghurt beverage comprises the steps that the lotus seed slurry, the sweet corn slurry and the pretreated fresh milk are mixed to be homogenized, sterilized, and the like at high pressure, and then inoculated to be fermented; and then the base fermentation material, the glucose syrup, the white granulated sugar, the drinking water and the stabilizing agents are prepared to obtain the live bacteria type lotus seed and corn yoghurt beverage. The beverage is rich in nutrition and performs a certain health care function; and the preparation method is reasonable.

Owner:LIUZHOU SHENYING SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com