Heat shield device for CZ-Si single crystal furnace

A single crystal furnace, Czochralski technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of increasing crystal heat dissipation, and achieve the effect of increasing heat dissipation, easy implementation, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using a 22-inch thermal field and a 135kg feed rate, the 8-inch solar-grade silicon single crystal is drawn. The heat shield device is arranged above the crucible along the same axis as the crucible. The argon flow rate is controlled to be 30-80slm, and the pressure in the furnace is maintained at 15-20 T. The crucible rotation speed is 6-10 rpm, and the crystal rotation speed is 8-12 rpm. According to the conventional Czochralski process, seeding, shouldering, shoulder turning, equal diameter and finishing are carried out. Among them, the position of the seeding crucible controls the guide tube to be 15-35mm away from the molten silicon liquid surface, and the pulling speed of the head is set to 75-80mm / h; as the length of the crystal increases, the pulling speed gradually decreases, and the growth speed in the middle is controlled at 65 -70mm / h. The method can increase the average growth rate of the existing 22-inch thermal field silicon single crystal from 0.9 mm / ...

Embodiment 2

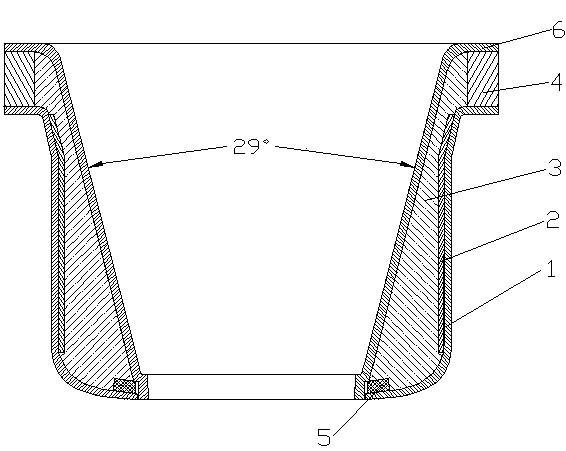

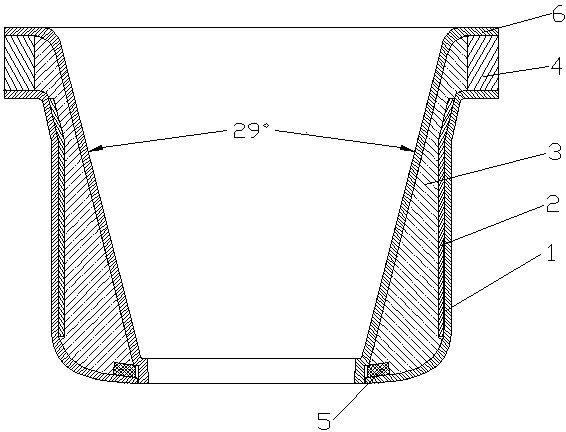

[0027] The outer cylinder is made of isostatic high-purity graphite, and its upper part is about a quarter of its height slightly conical open, and the rest of the lower part is in the shape of a hollow cylinder, with edges extending horizontally outward at the top and horizontally extending inward at the bottom edge.

[0028] Cut the 0.5mm thick cold-rolled molybdenum sheet into several small rectangles with equal width, the length of which is slightly smaller than the height of the outer cylinder. The small rectangular molybdenum sheets are close to the inner wall of the outer cylinder, and the long sides are adjacent, and there is no space between adjacent molybdenum sheets. , forming a heat reflective layer.

[0029] The carbon felt is laid along the inner surface of the heat reflection layer of the molybdenum sheet (the surface opposite to the contact surface of the molybdenum sheet and the outer cylinder), with a certain thickness to form a heat insulation layer.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com