Patents

Literature

92 results about "Czochralski process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

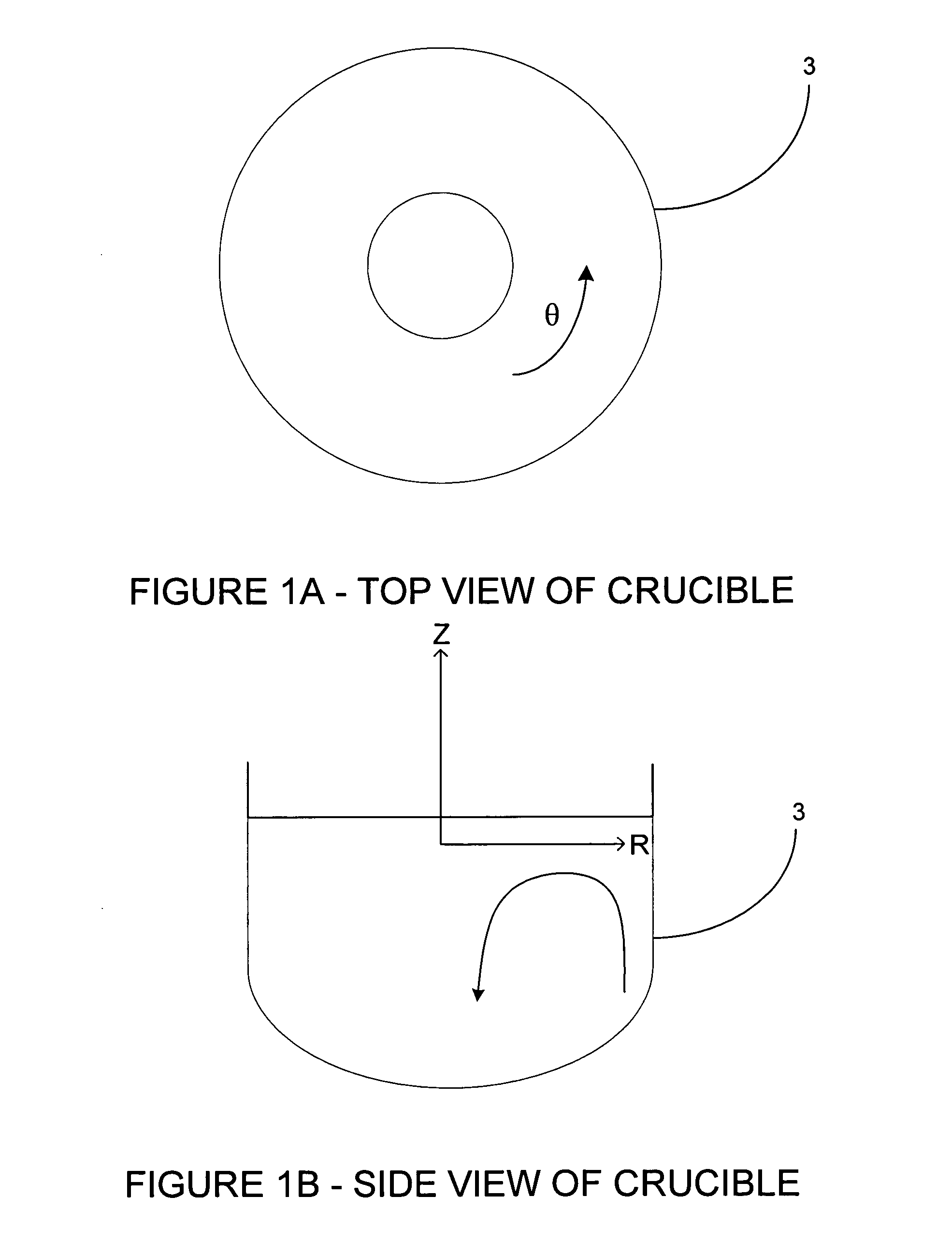

The Czochralski process is a method of crystal growth used to obtain single crystals of semiconductors (e.g. silicon, germanium and gallium arsenide), metals (e.g. palladium, platinum, silver, gold), salts and synthetic gemstones. The process is named after Polish scientist Jan Czochralski, who invented the method in 1915 while investigating the crystallization rates of metals. He made this discovery by accident: instead of dipping his pen into his inkwell, he dipped it in molten tin, and drew a tin filament, which later proved to be a single crystal.

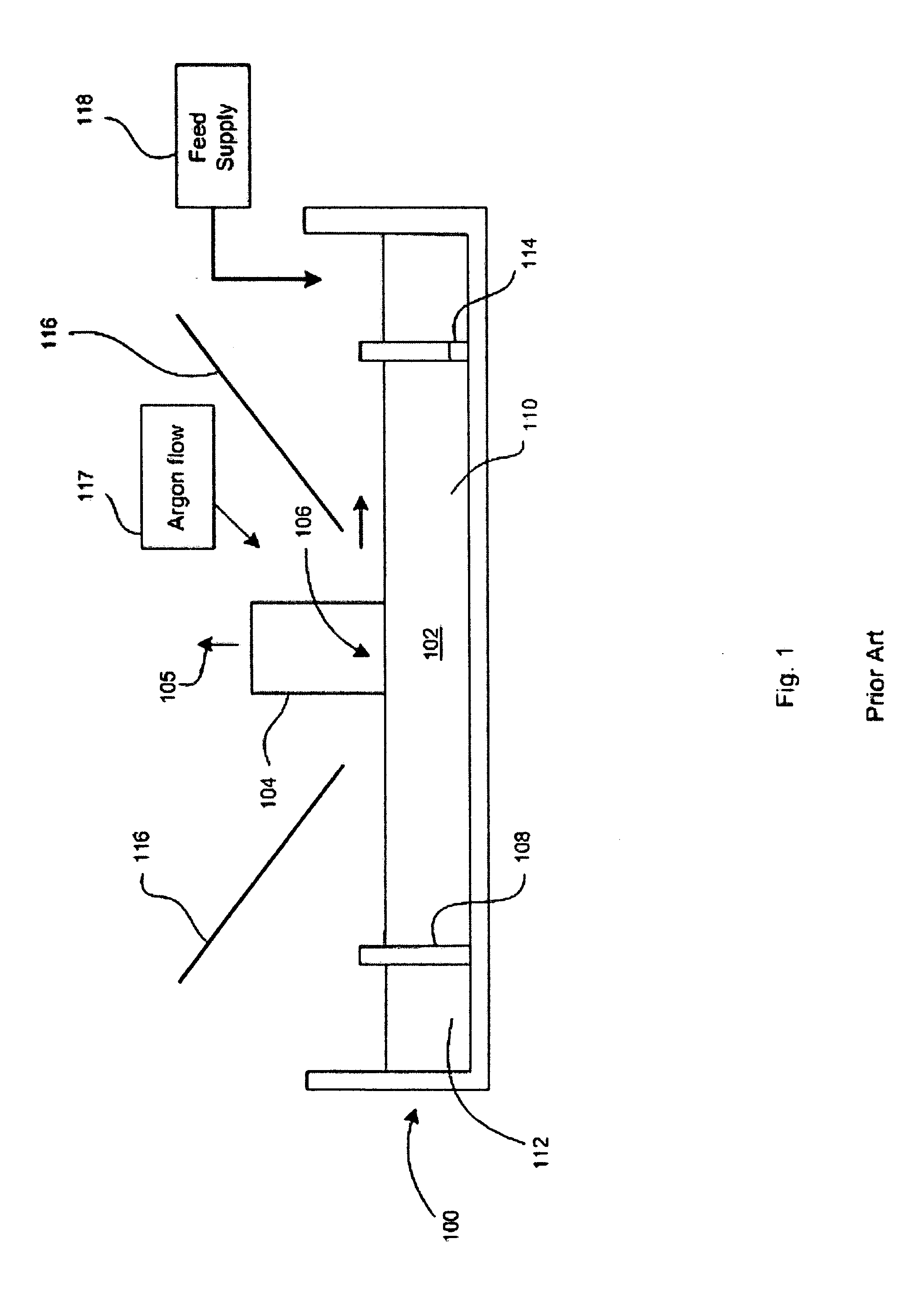

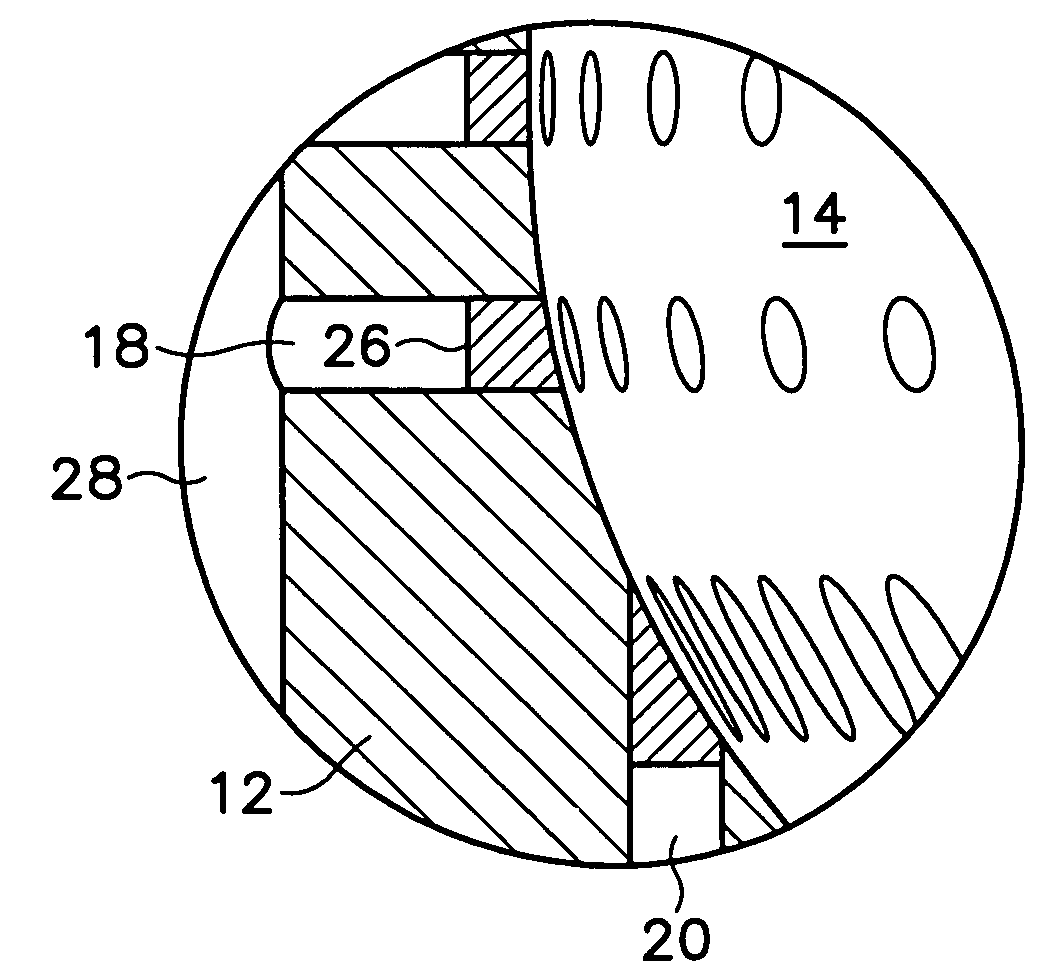

Weir design providing optimal purge gas flow, melt control, and temperature stabilization for improved single crystal growth in a continuous Czochralski process

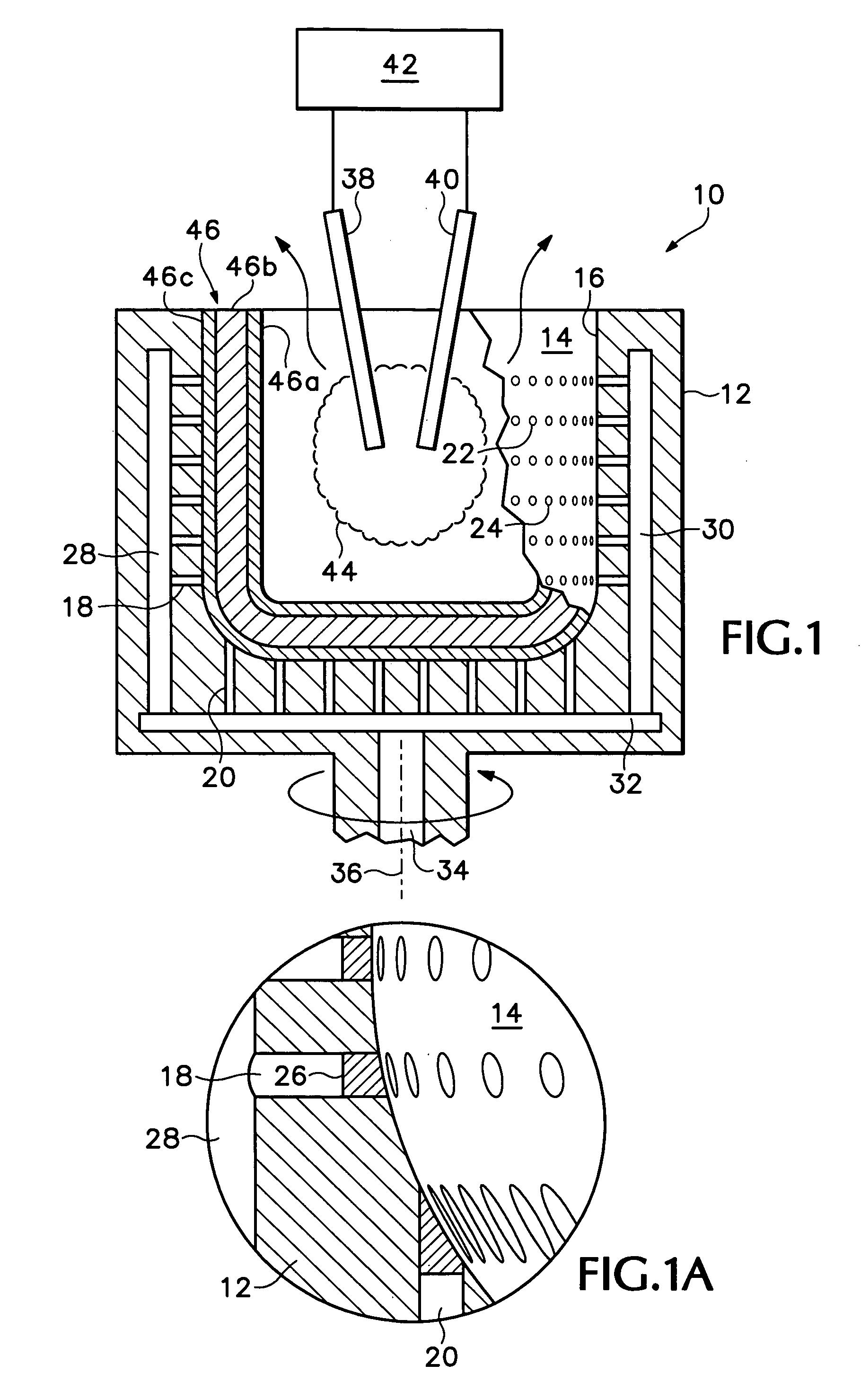

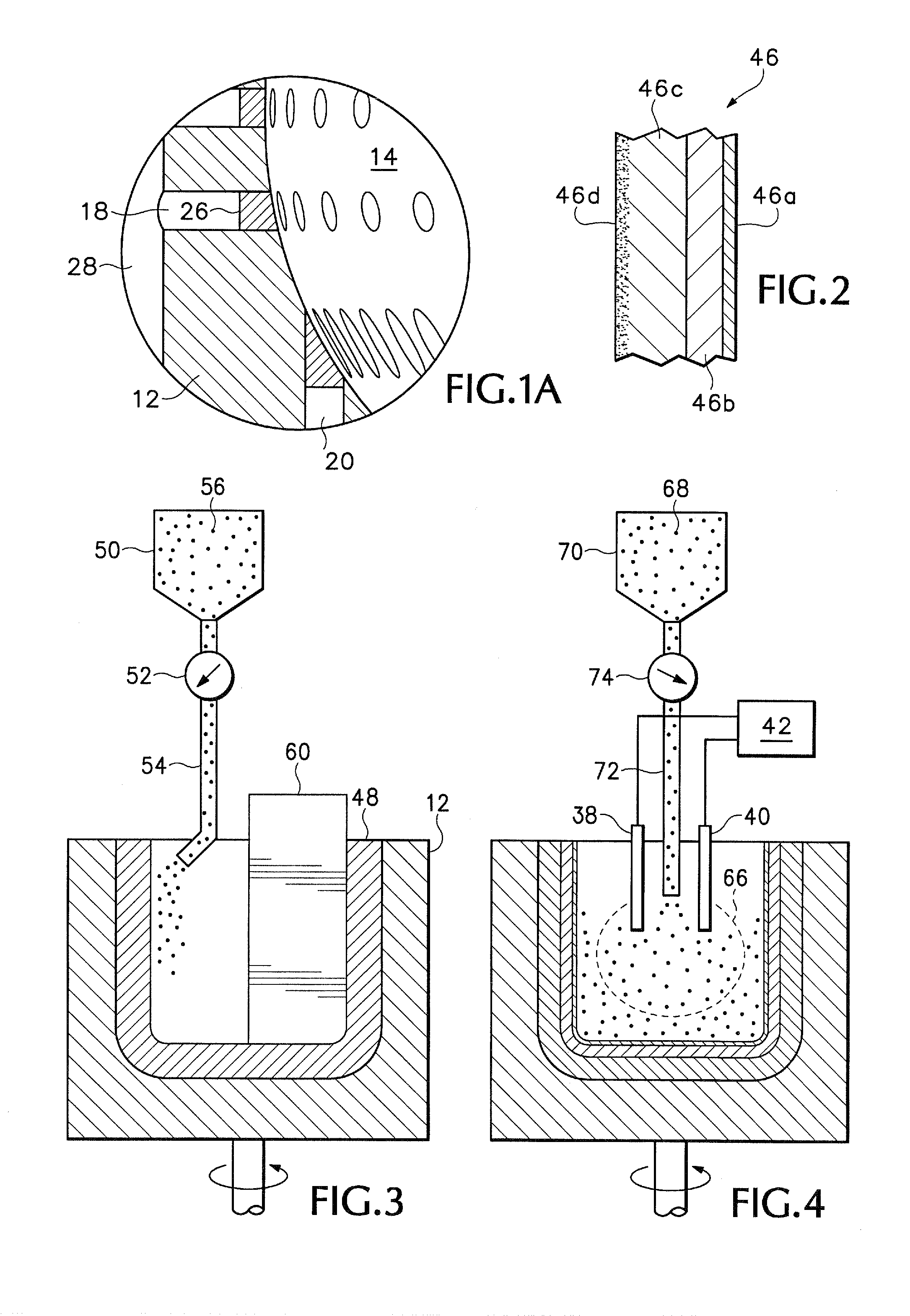

ActiveUS8262797B1Increase path lengthExtended transit timePolycrystalline material growthBy pulling from meltSingle crystalEngineering

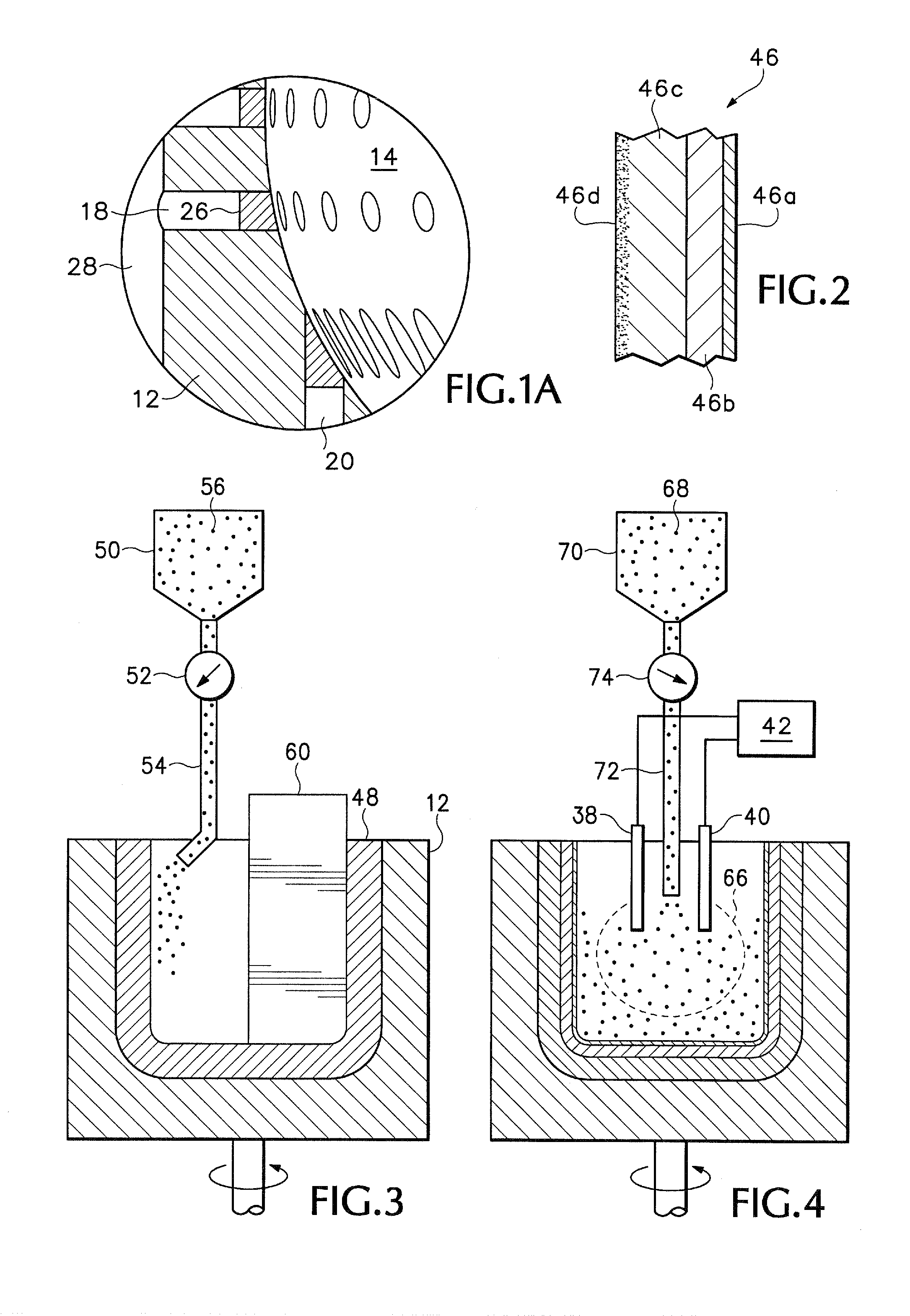

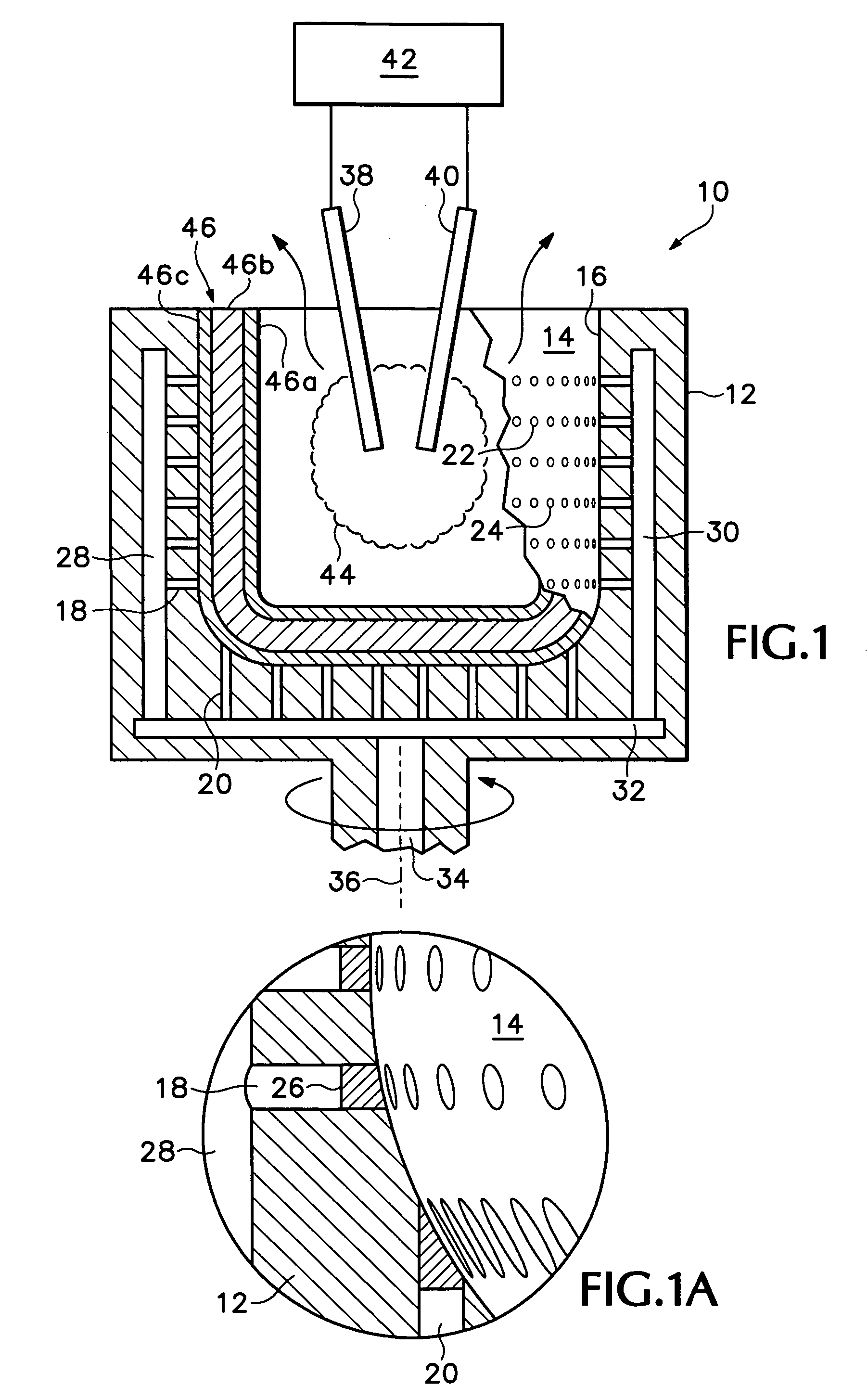

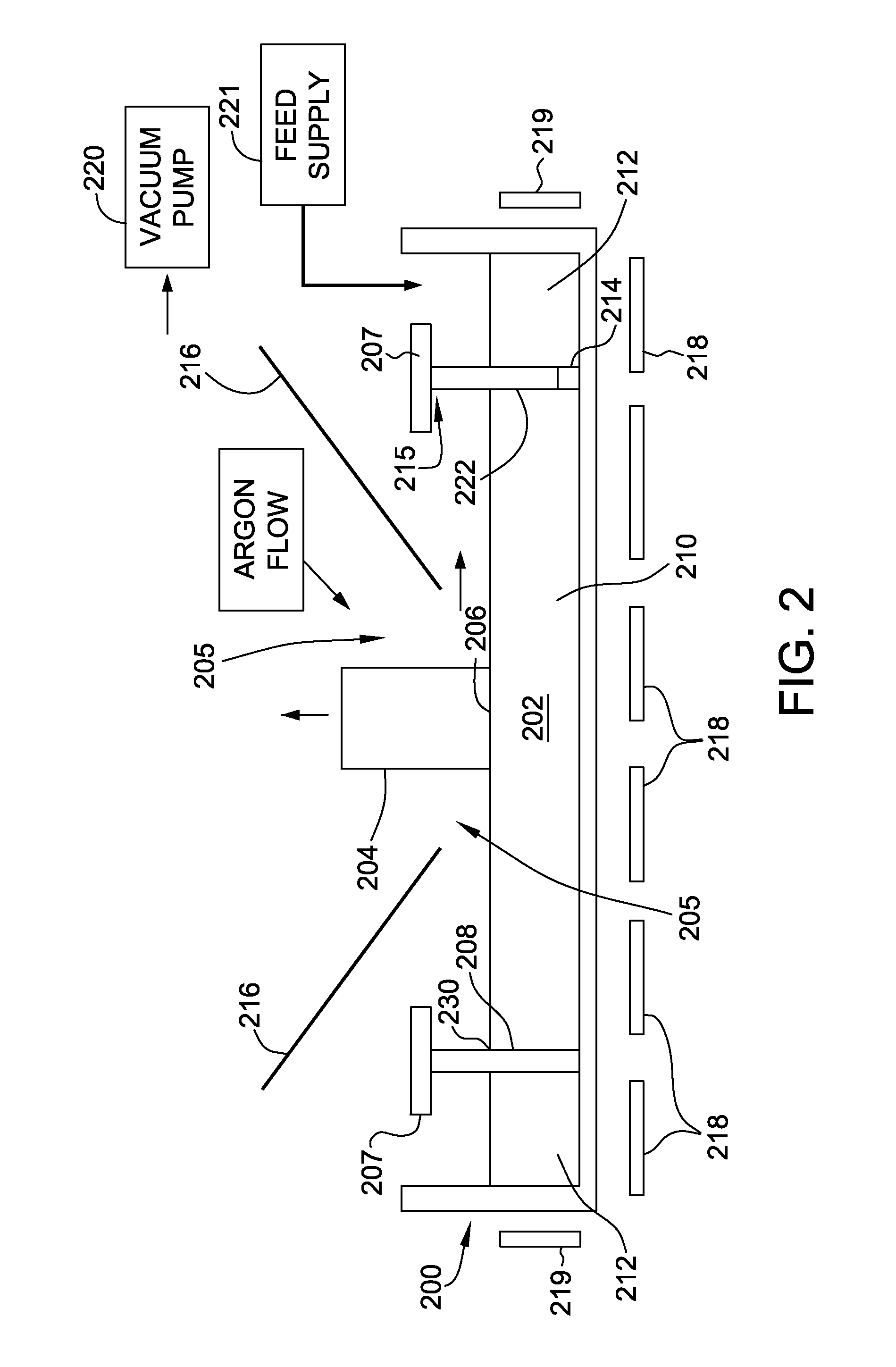

A weir is extended vertically to define an optimal annular gap between the top of the weir and the underside of a super-adjacent heat shield. The annular gap provides a high velocity stream of argon gas to be directed from the growth region to the melt region to substantially eliminate the transport of airborne particles from the melt region to the growth region. The tall weir may be configured as a modular, reusable weir extension supportably engaged with an outer (and / or inner) weir.

Owner:CORNER STAR LTD

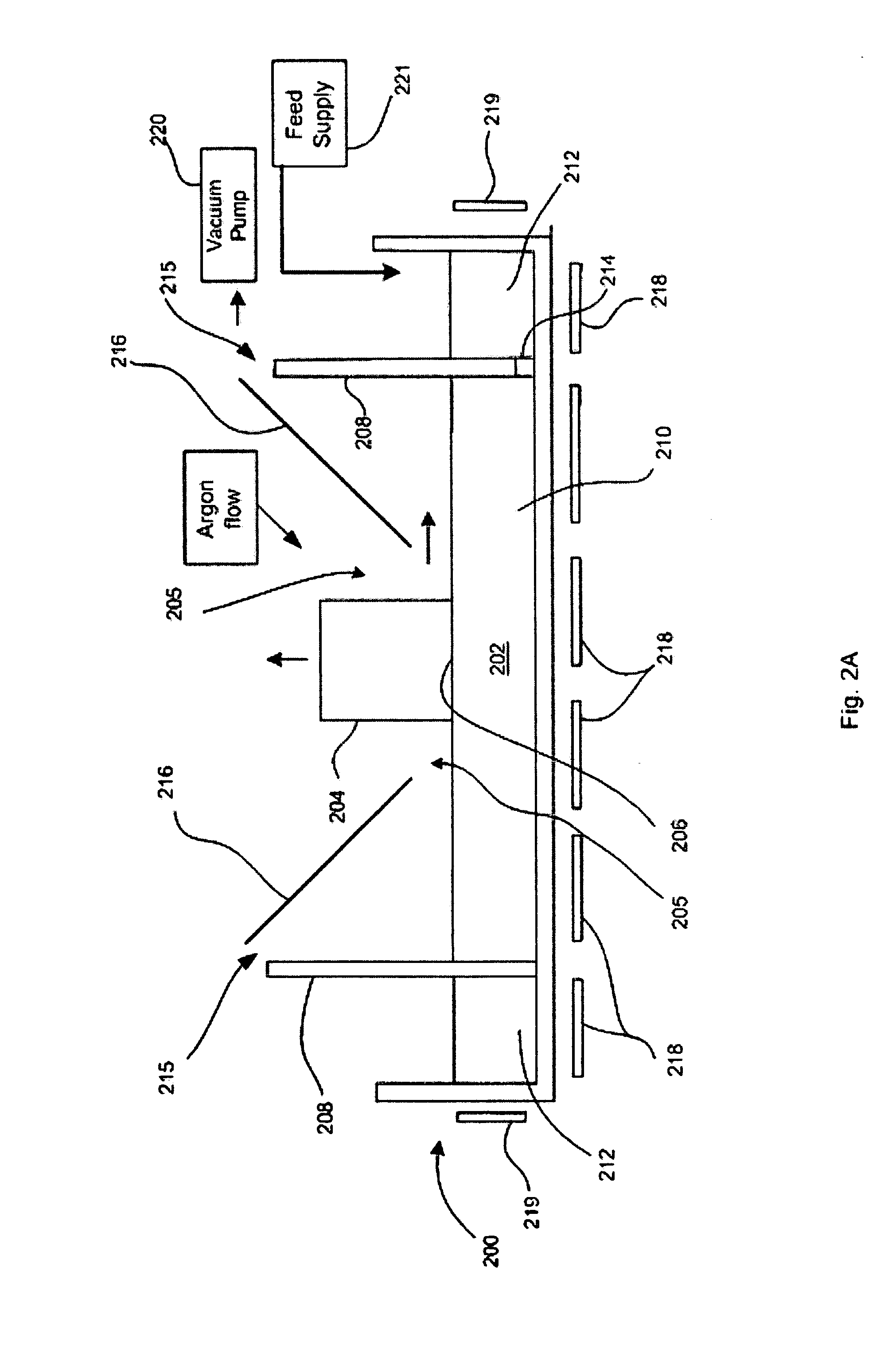

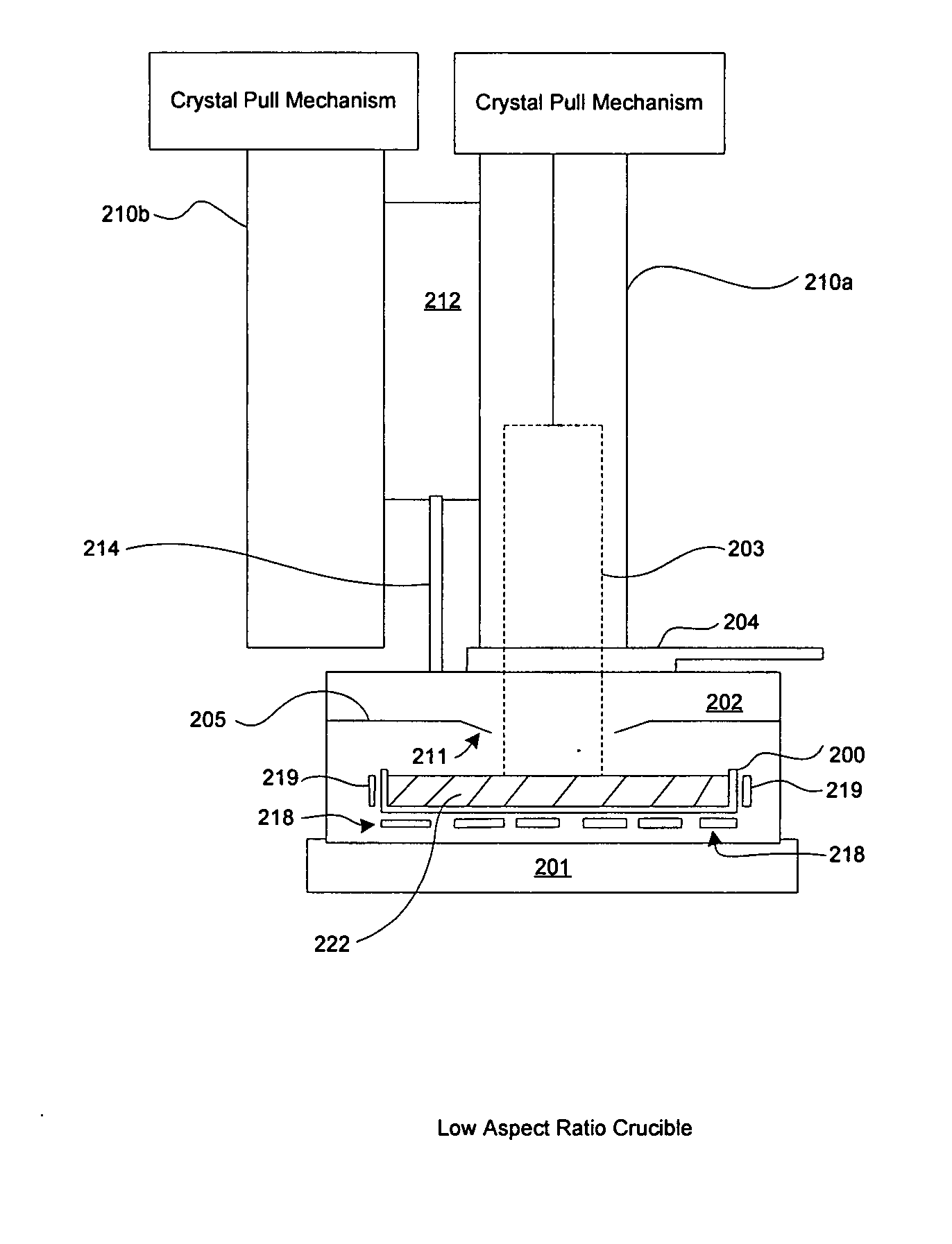

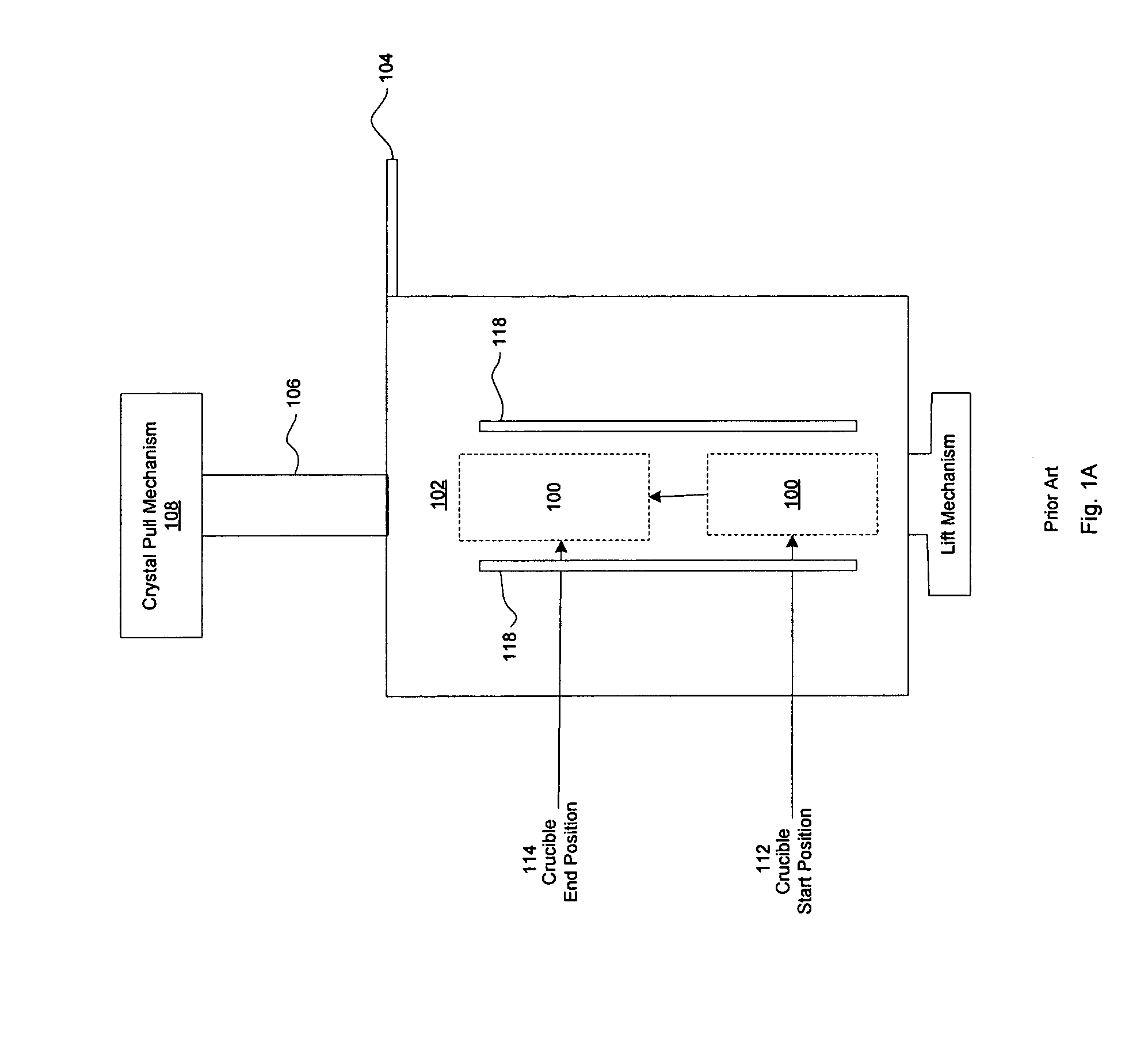

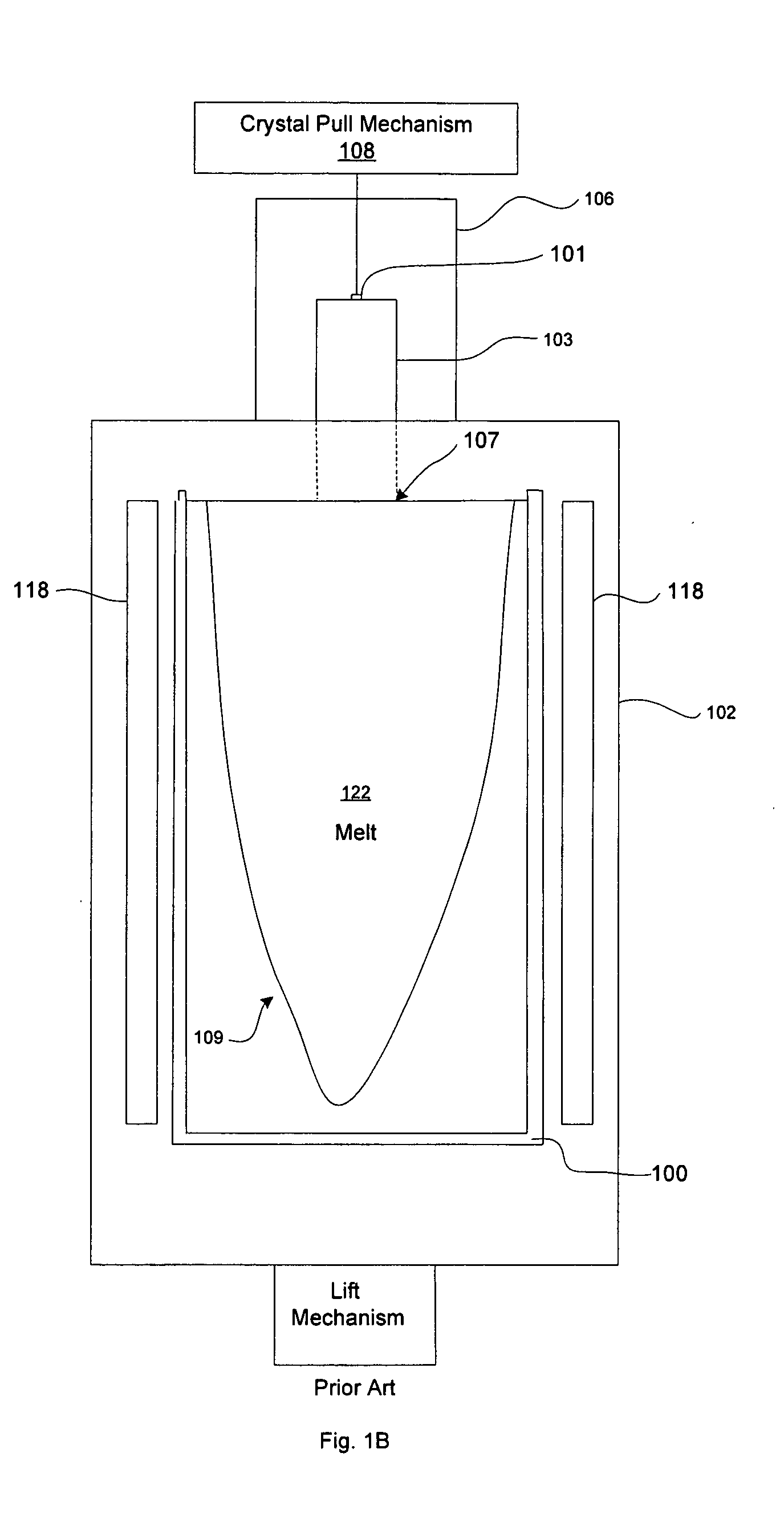

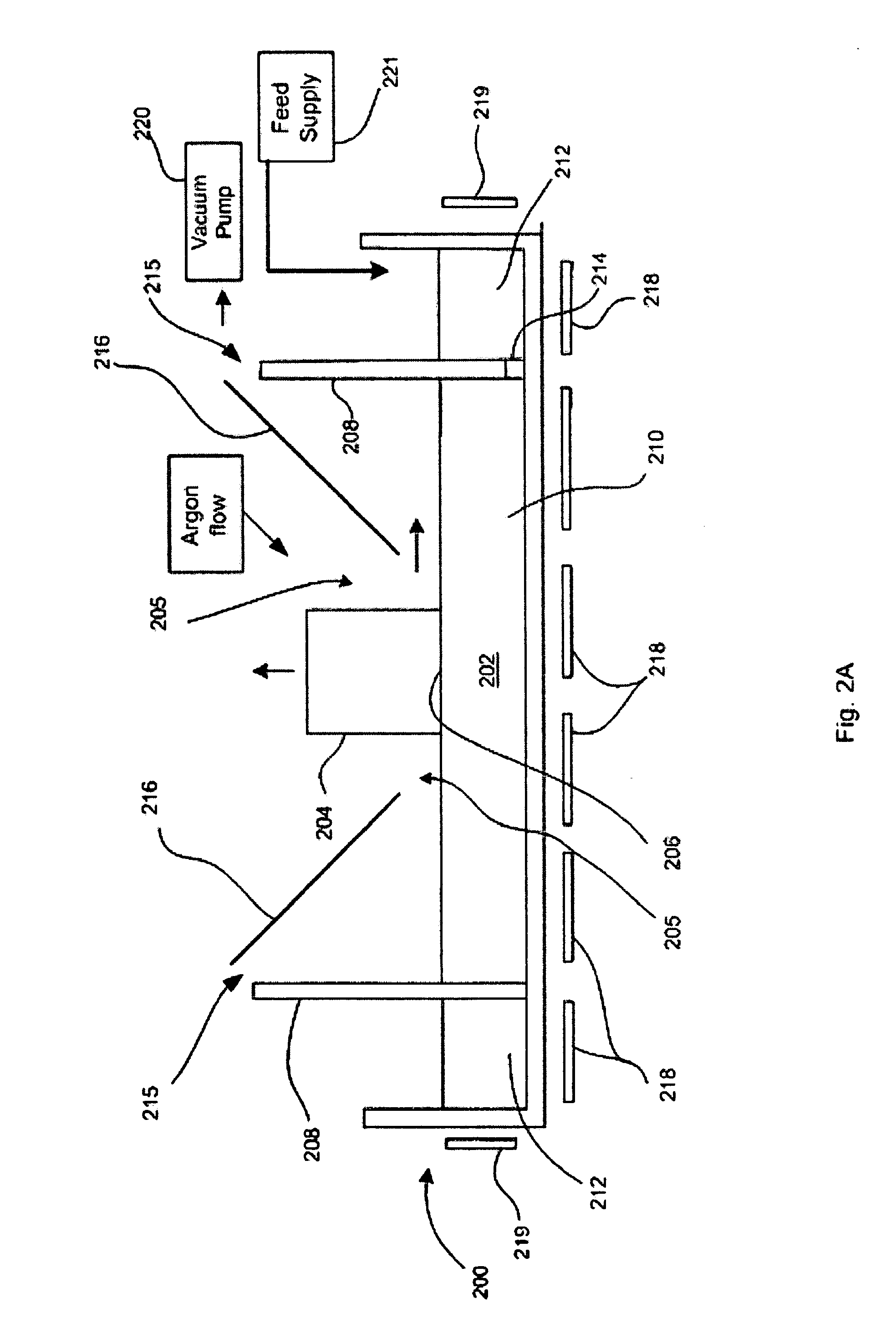

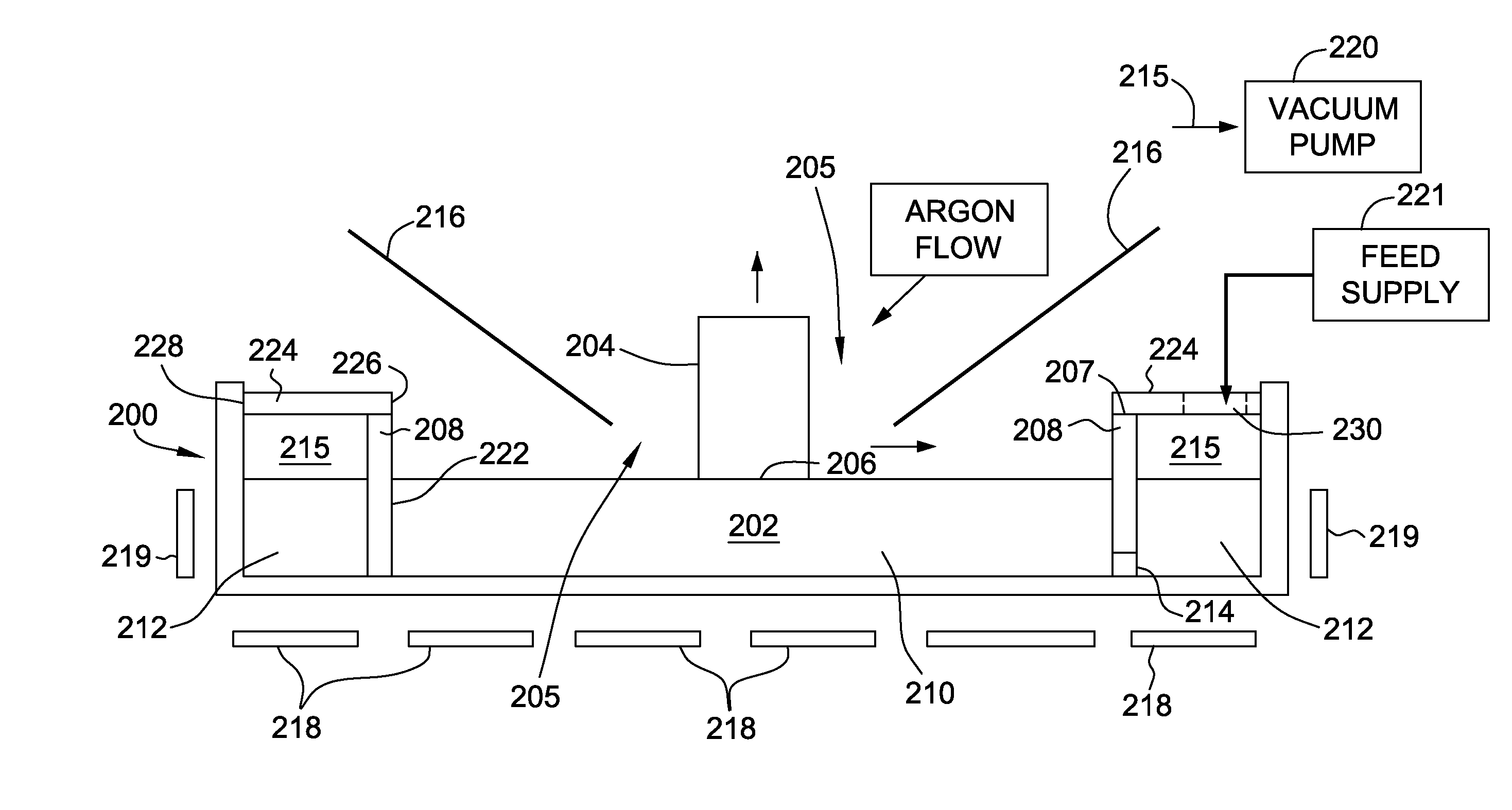

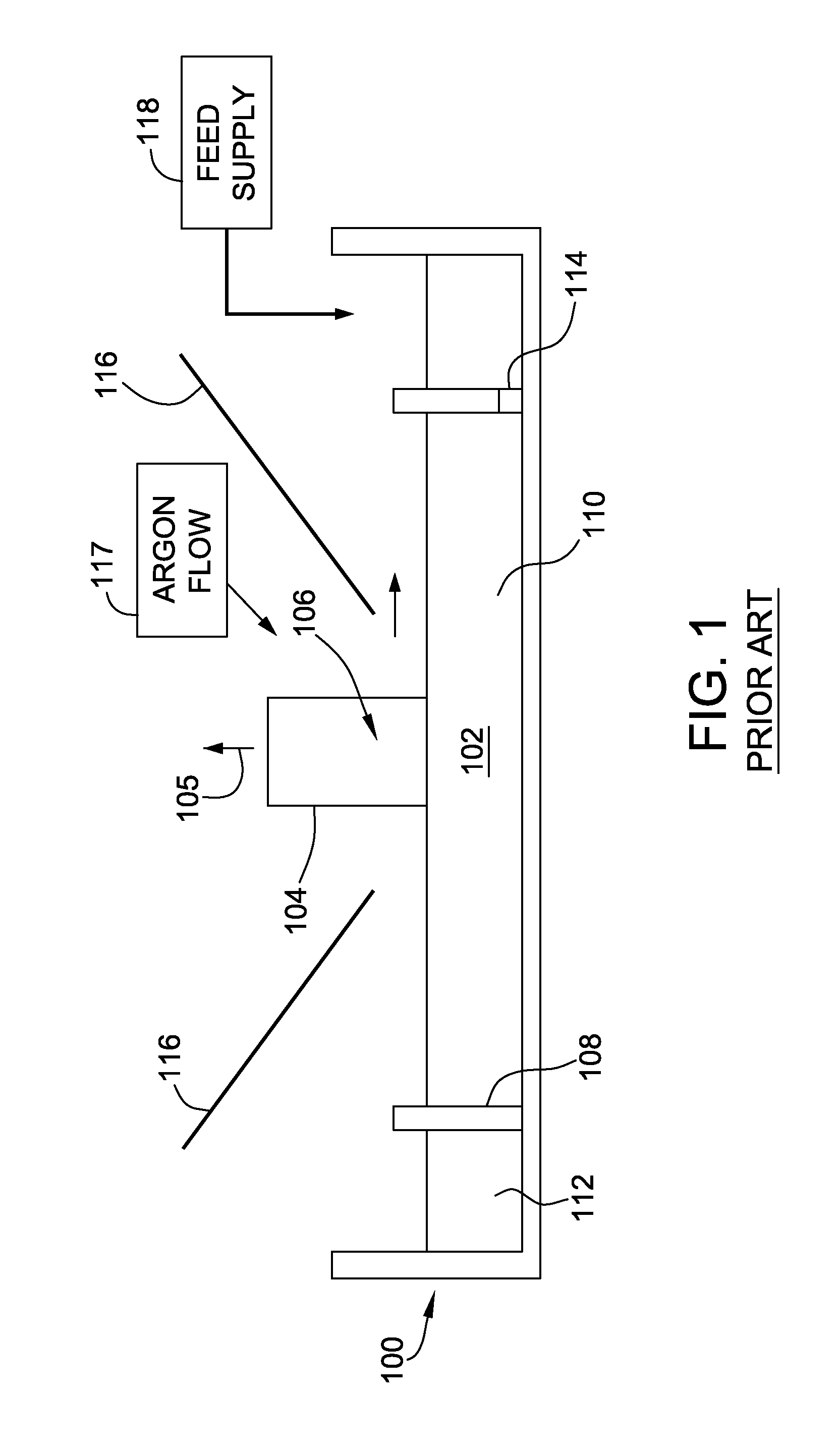

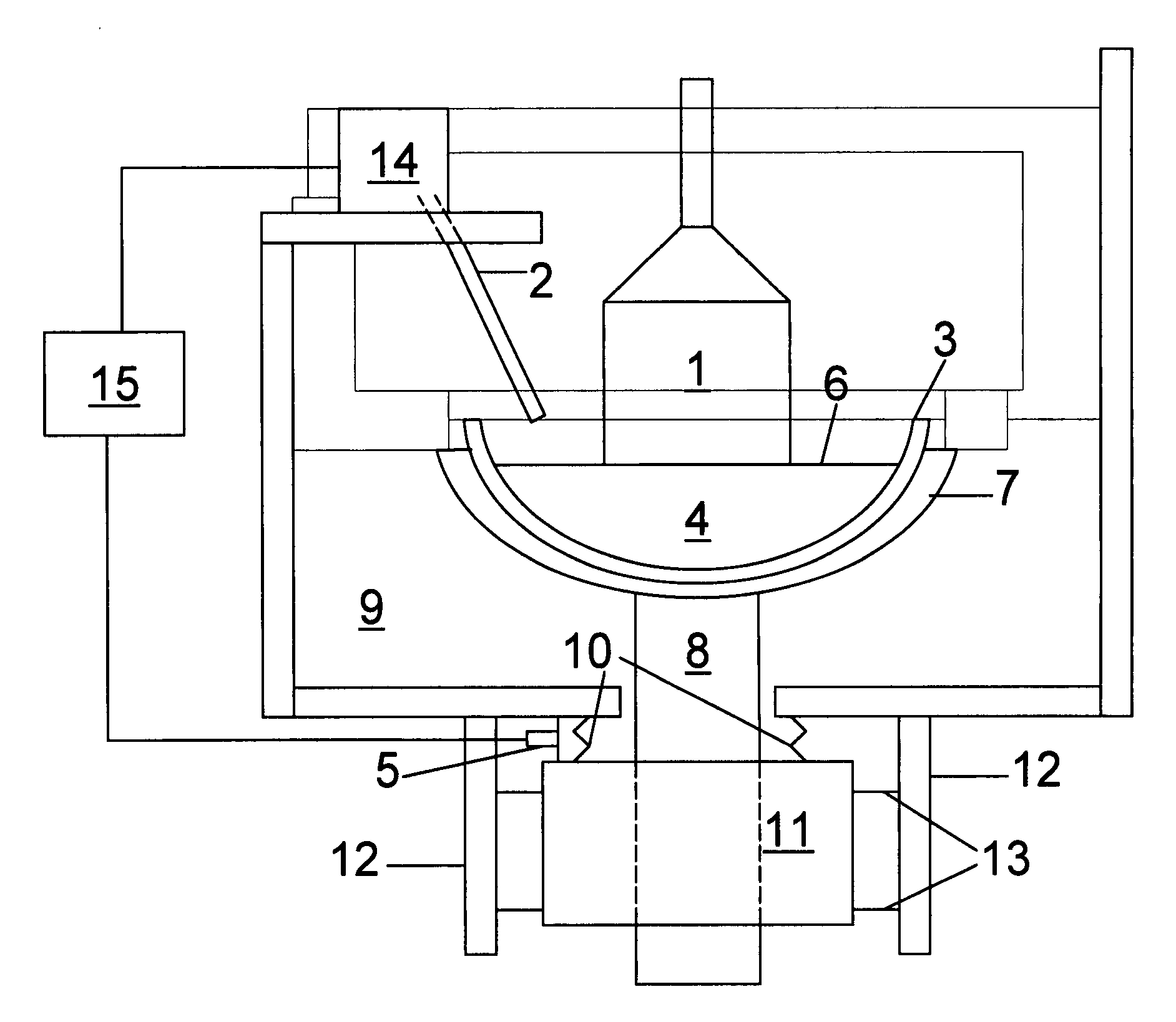

System for continuous growing of monocrystalline silicon

ActiveUS20050092236A1Easy temperature controlAccelerated crystal growthAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

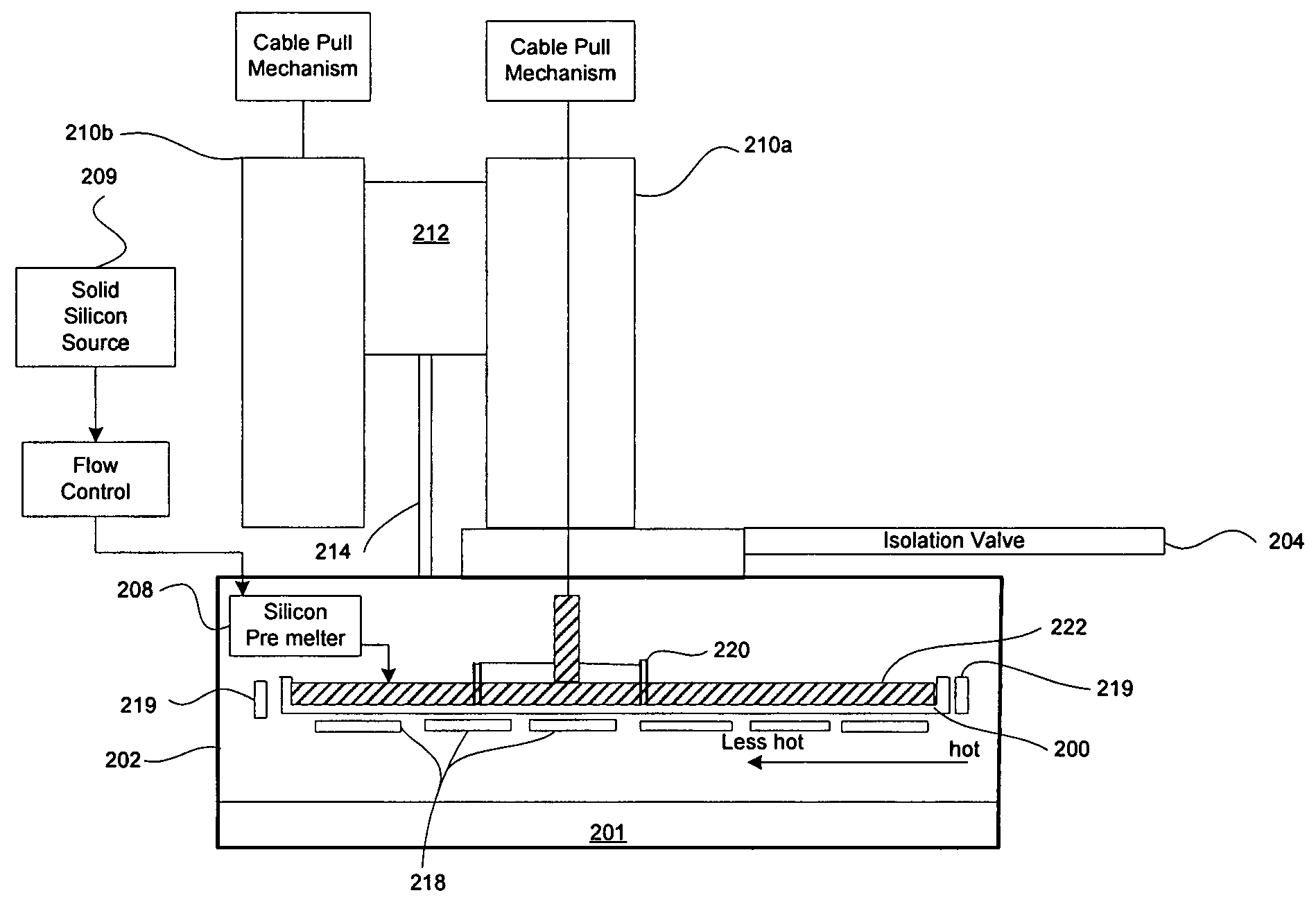

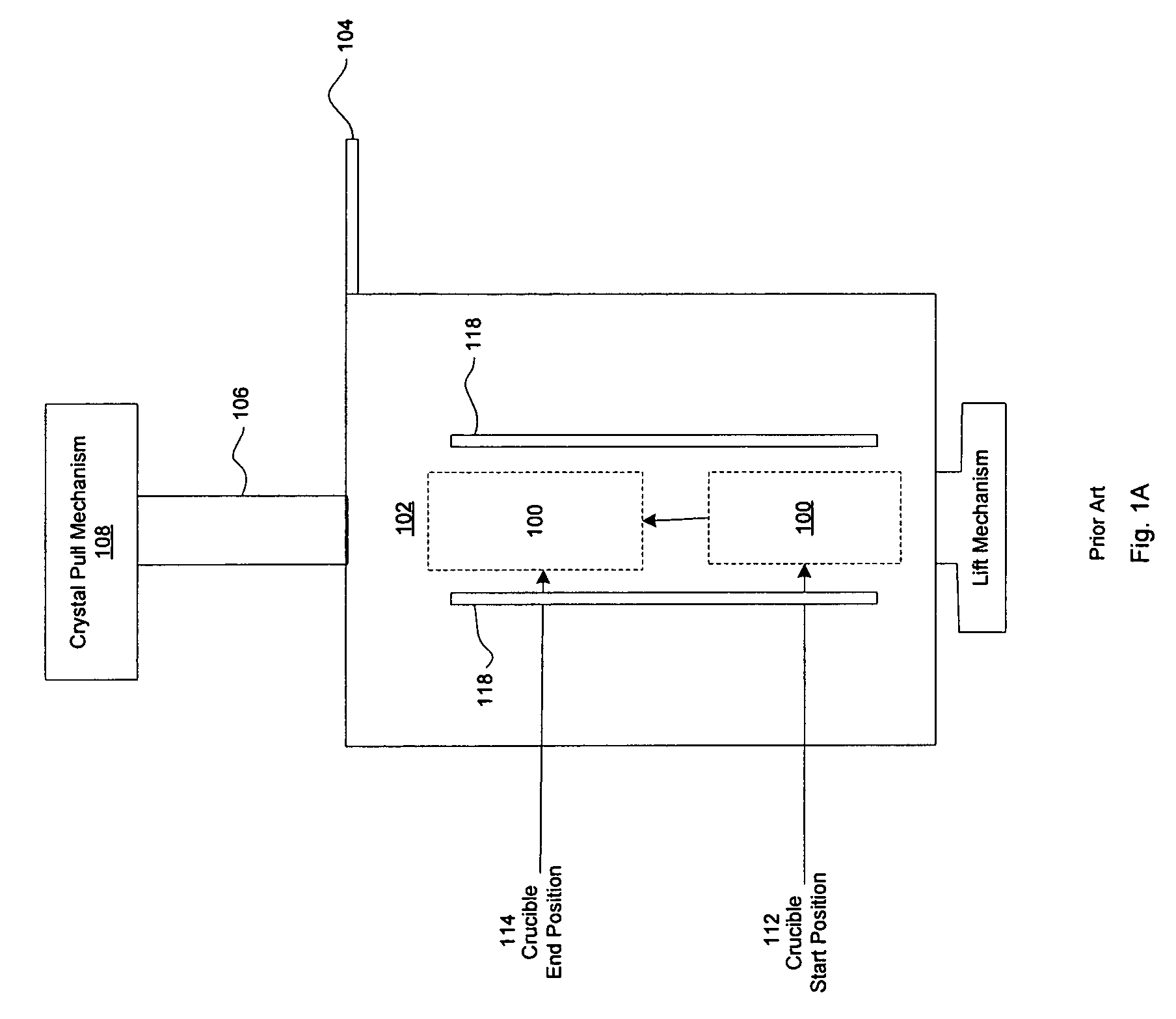

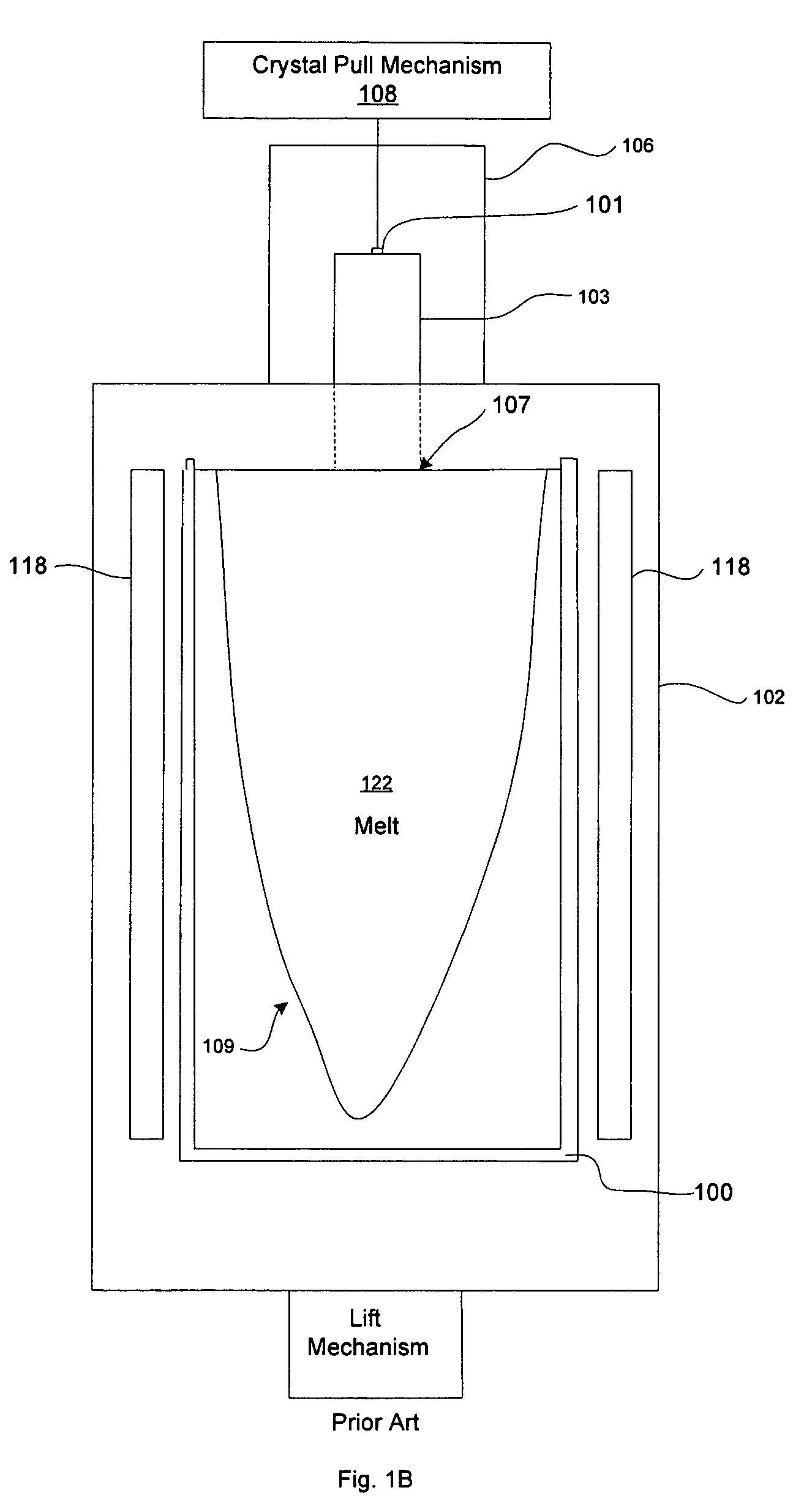

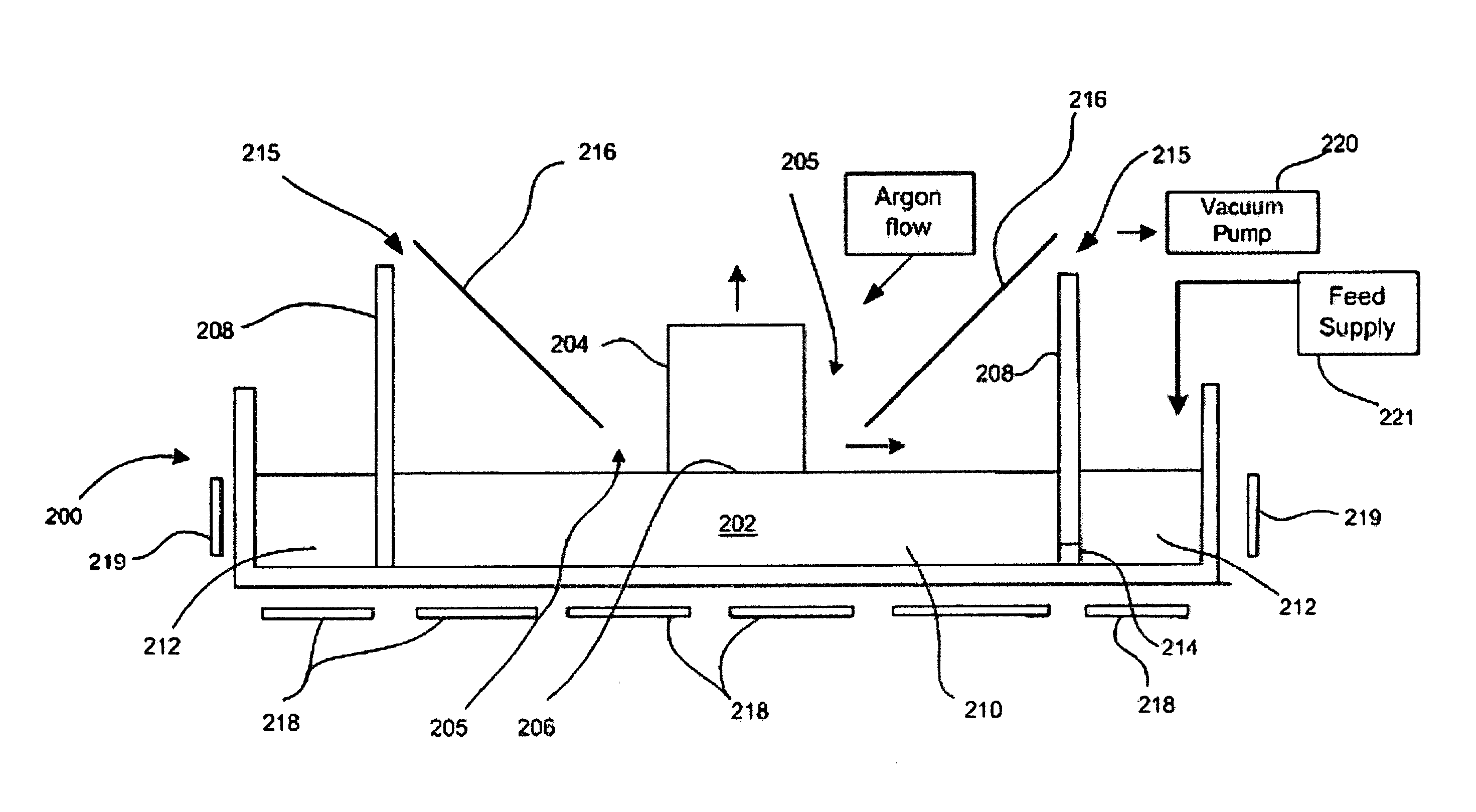

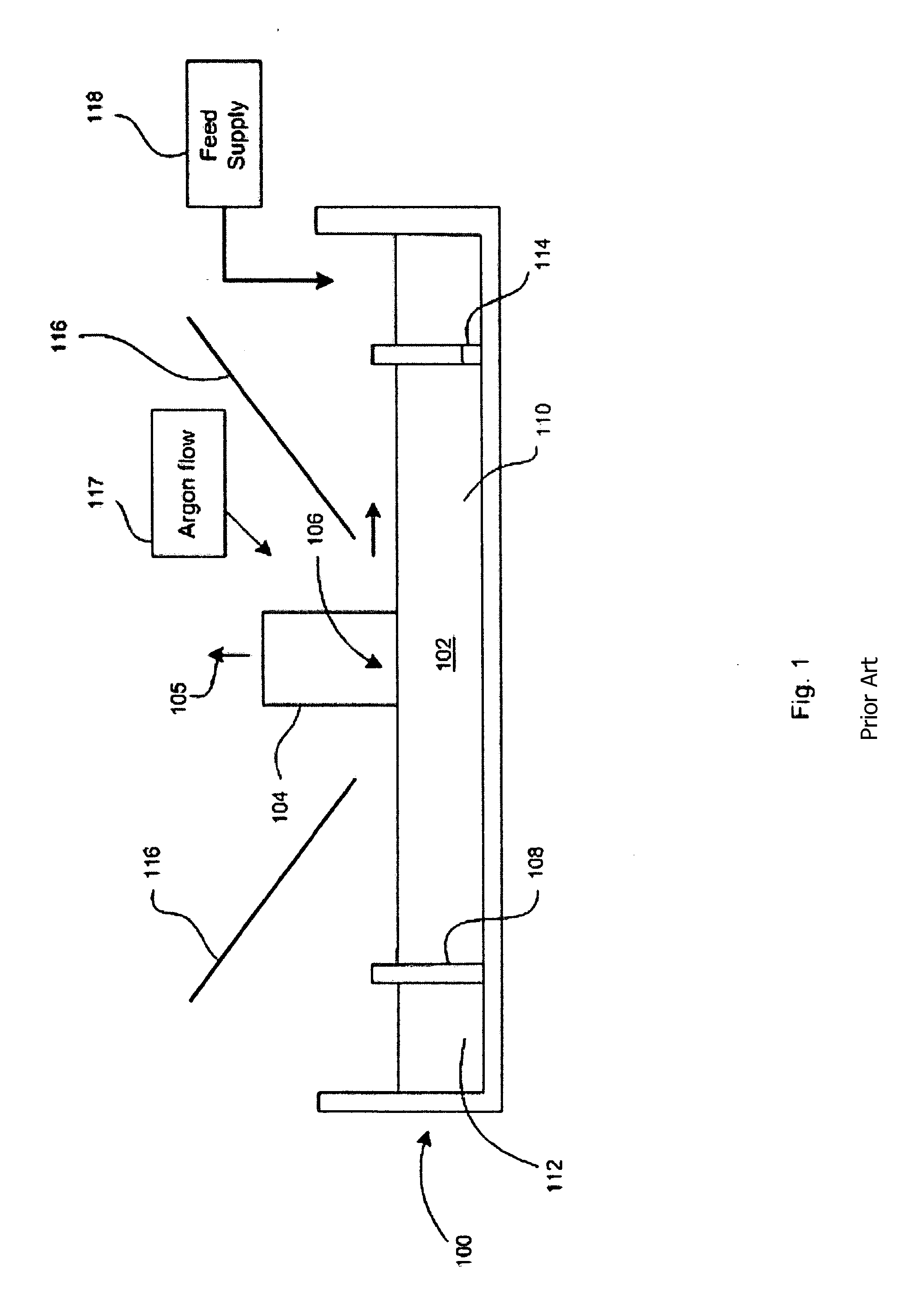

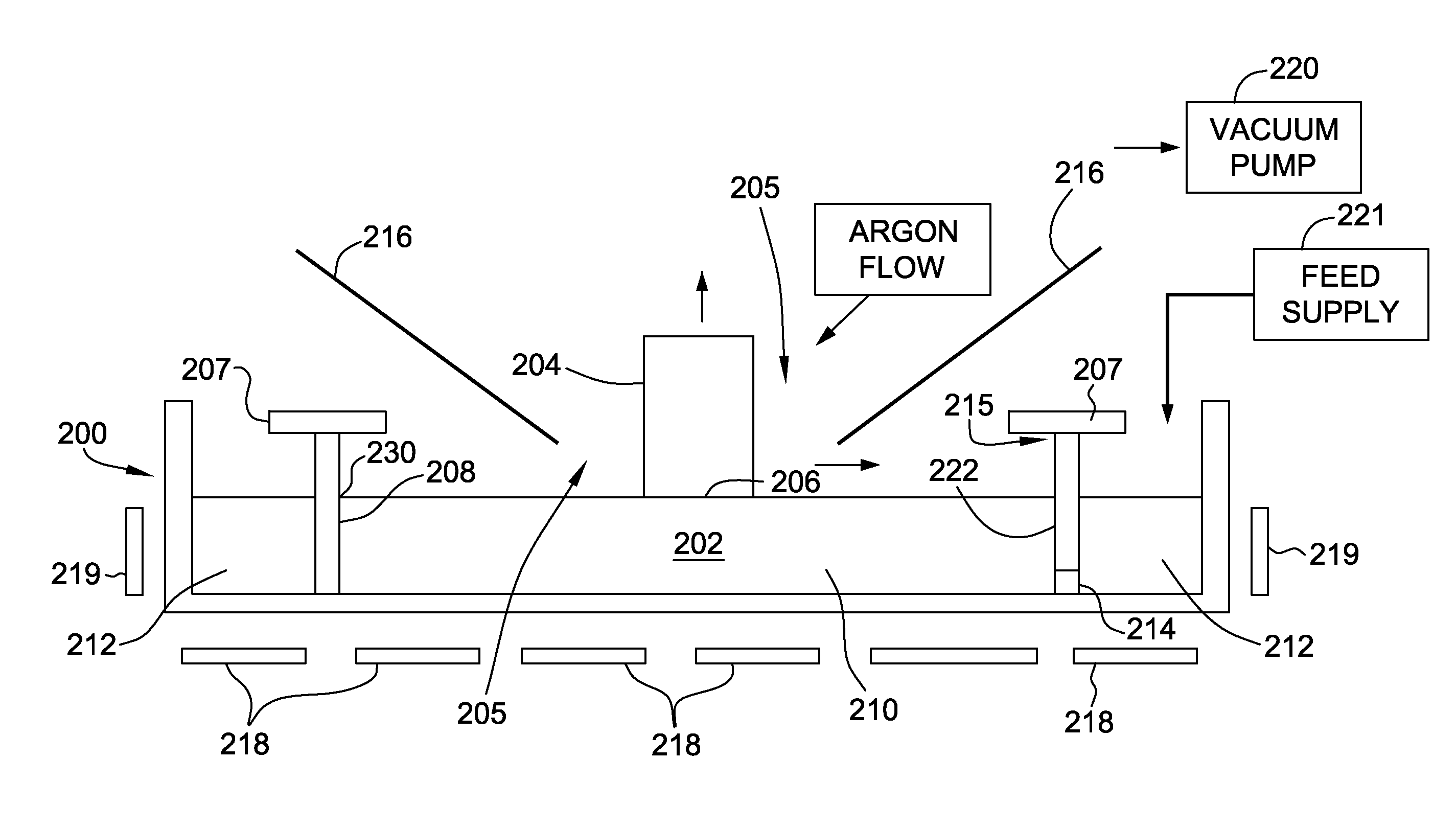

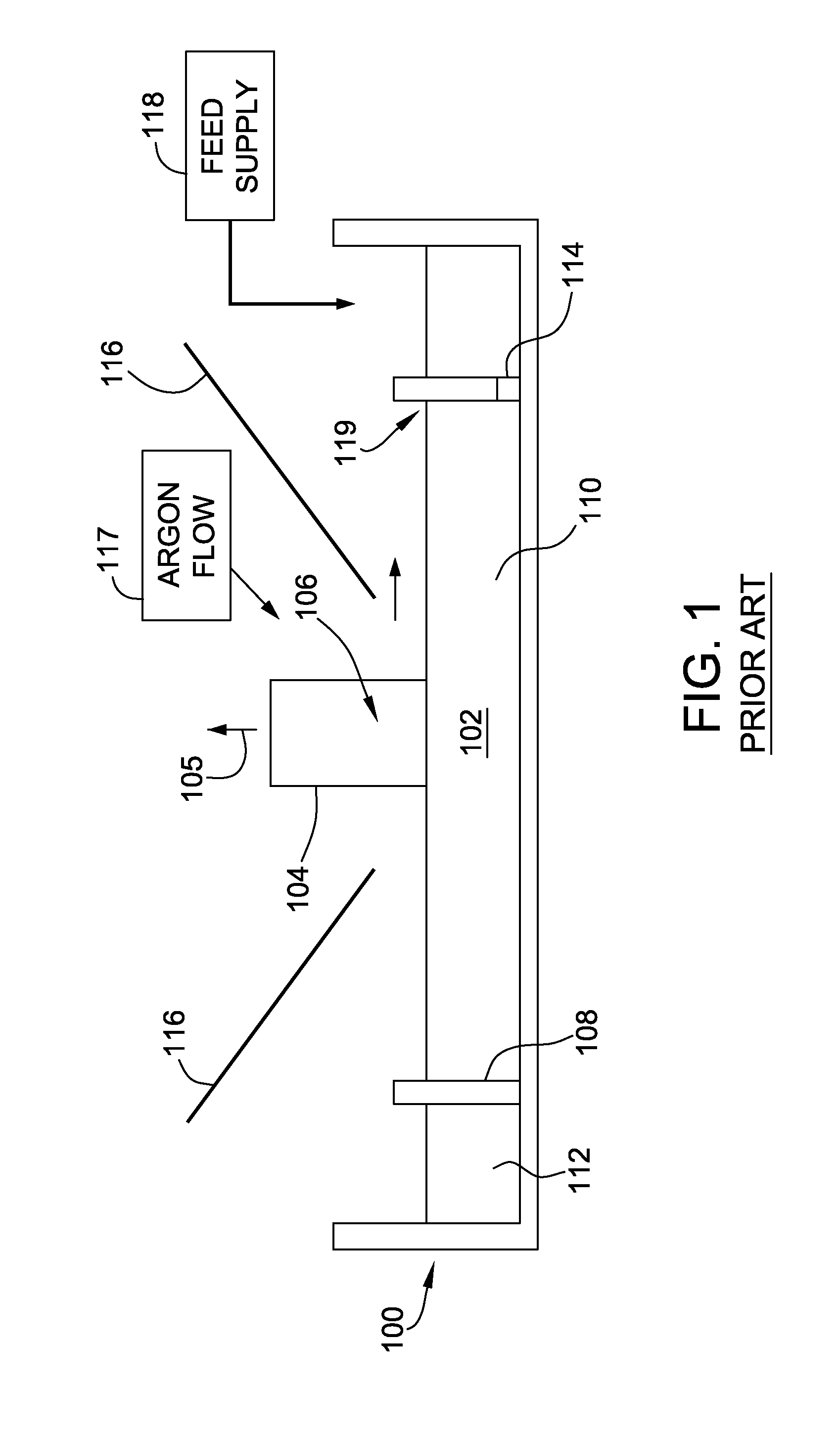

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

Silica glass crucible with barium-doped inner wall

InactiveUS20070051297A1After-treatment apparatusPolycrystalline material growthSolar cellSilicon dioxide

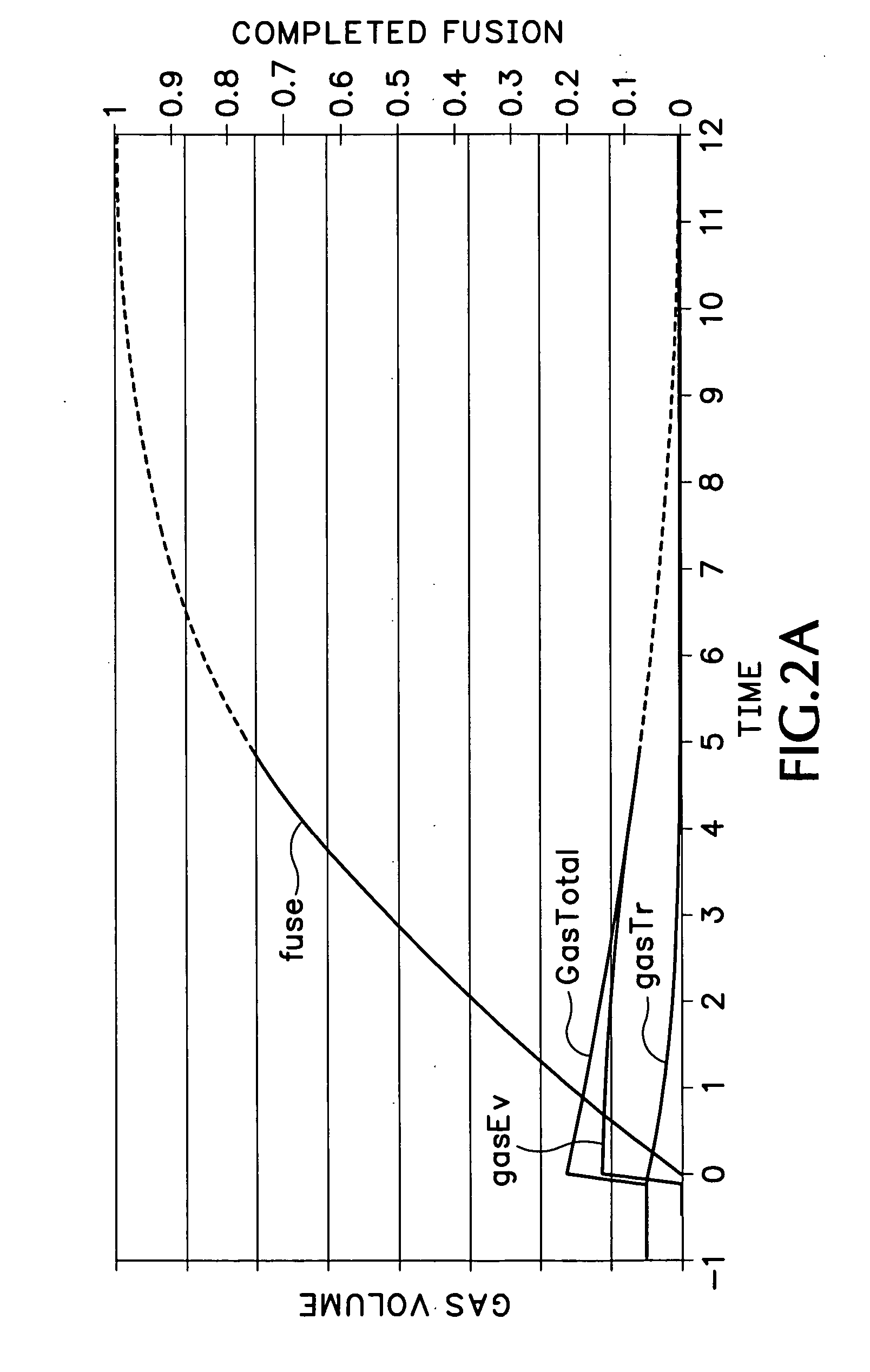

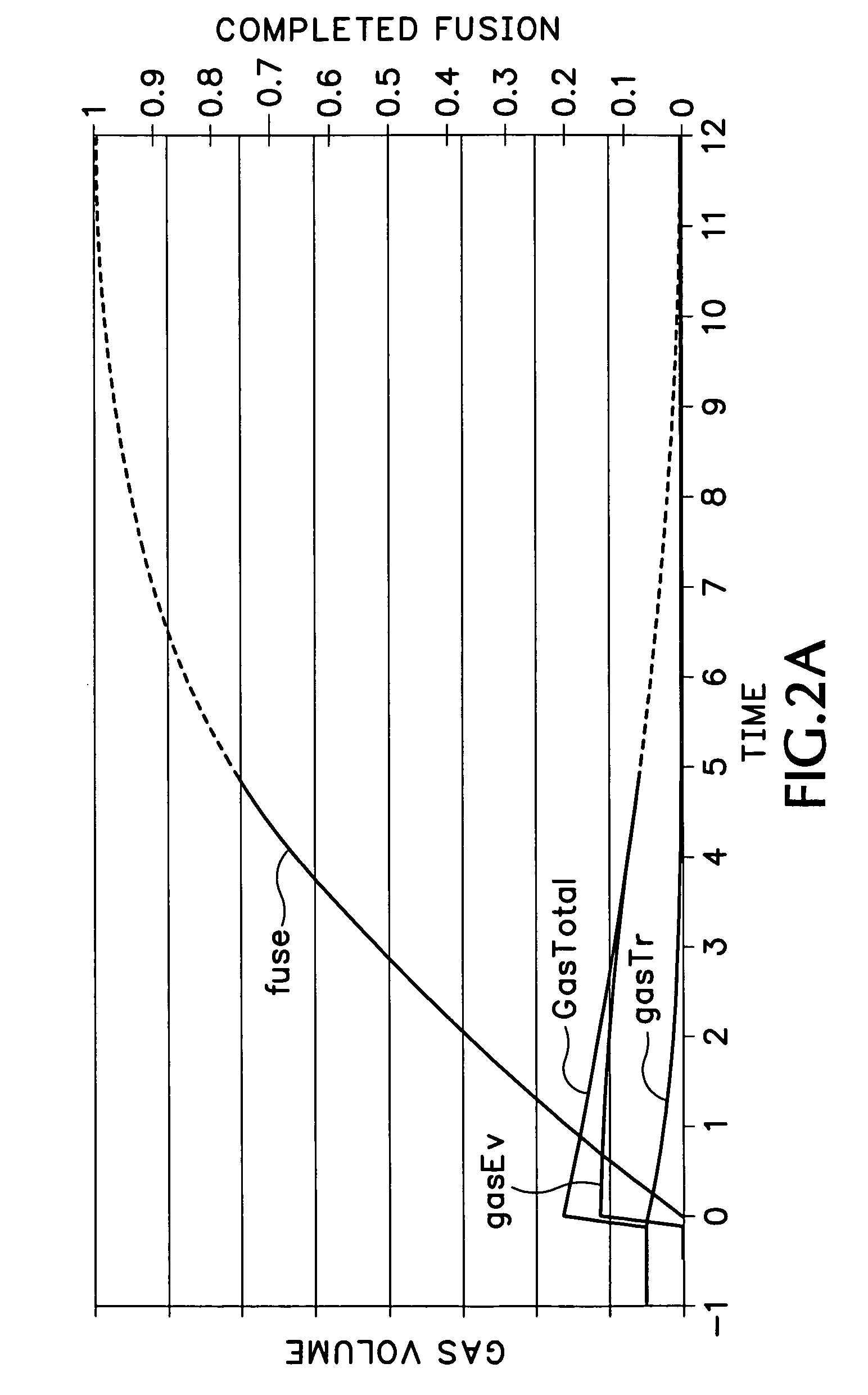

A silica glass crucible includes a thin barium-doped inner layer, a stable, bubble-free intermediate layer, and a stable opaque outer layer. The fusion process of the present invention controls the dynamic gas balance at the fusion front where formed grain is melted to dense fused silica. The crucible demonstrates reduced bubble growth during a Czochralski process. As a result of the thin barium-doped layer and the reduced bubble growth, the inner surface of the crucible is uniformly minimally textured during a CZ process. The present crucible is especially suited for intense CZ processes for manufacturing silicon ingots used for solar cells or with silicon that is heavily doped with antimony, boron, or arsenic.

Owner:SHIN ETABU QUARTZ PRODS

System for continuous growing of monocrystalline silicon

ActiveUS7635414B2Low oxygenEliminate downtimeAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

Lithium niobate substrate and method of producing the same

ActiveUS20050145165A1Color non-uniformityPoor resolutionPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthMaterials scienceHeat treated

In a method of producing a lithium niobate substrate by the use of a lithium niobate crystal grown by the Czochralski process, the lithium niobate crystal is heat-treated at a temperature of from 300° C. or more to less than 500° C. in the state the lithium niobate crystal is buried in a powder constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C, or in the state the lithium niobate crystal is held in a container constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C.

Owner:SUMITOMO METAL MINING CO LTD

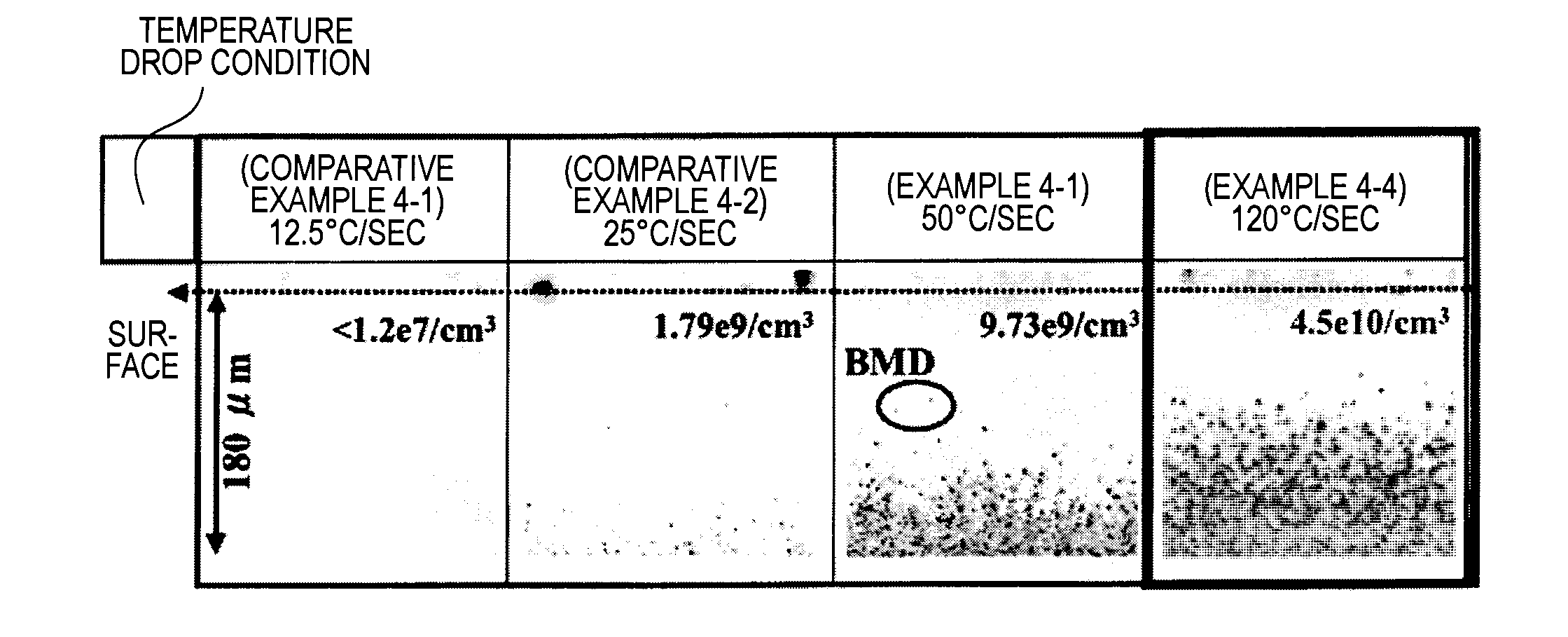

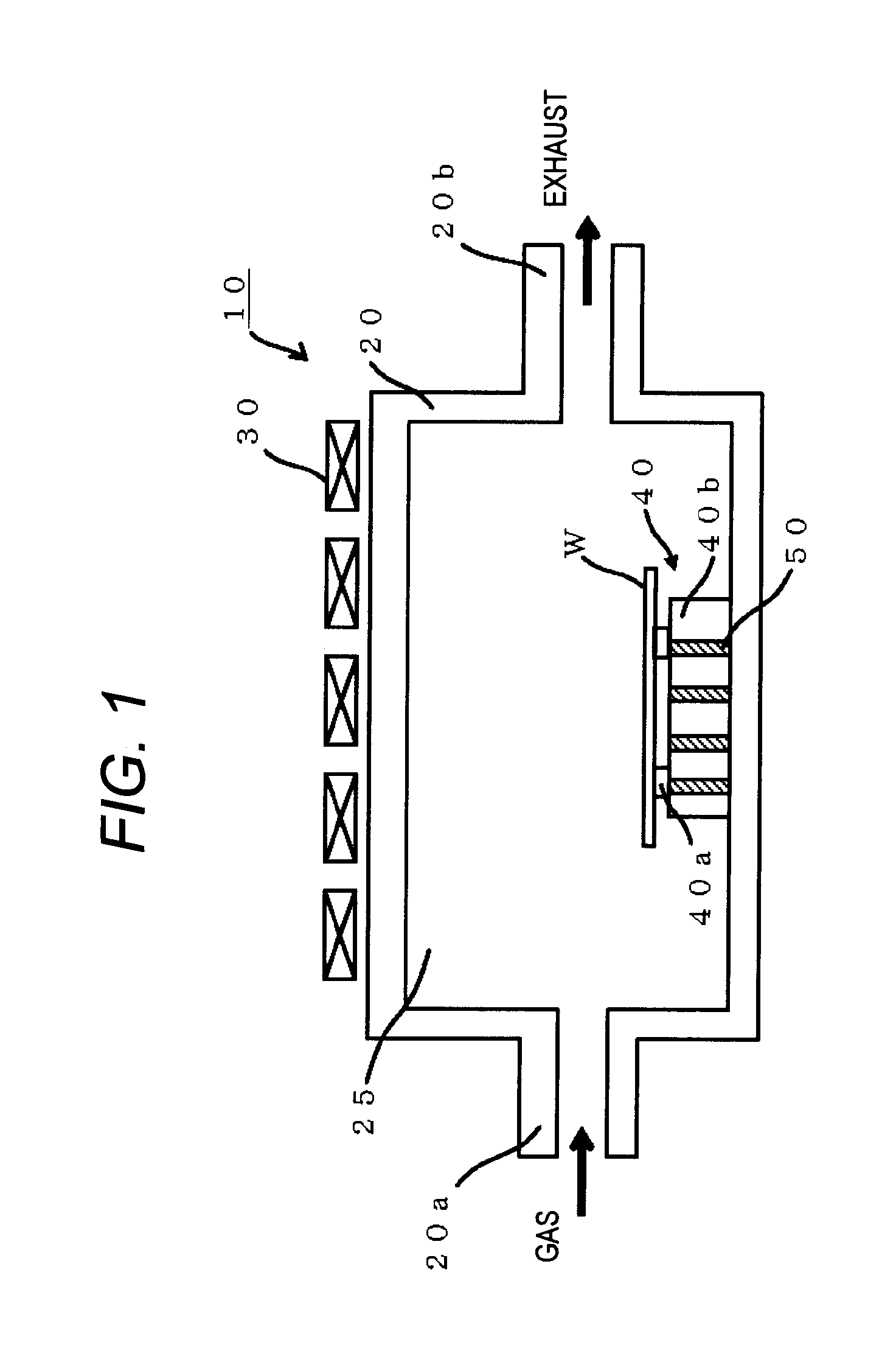

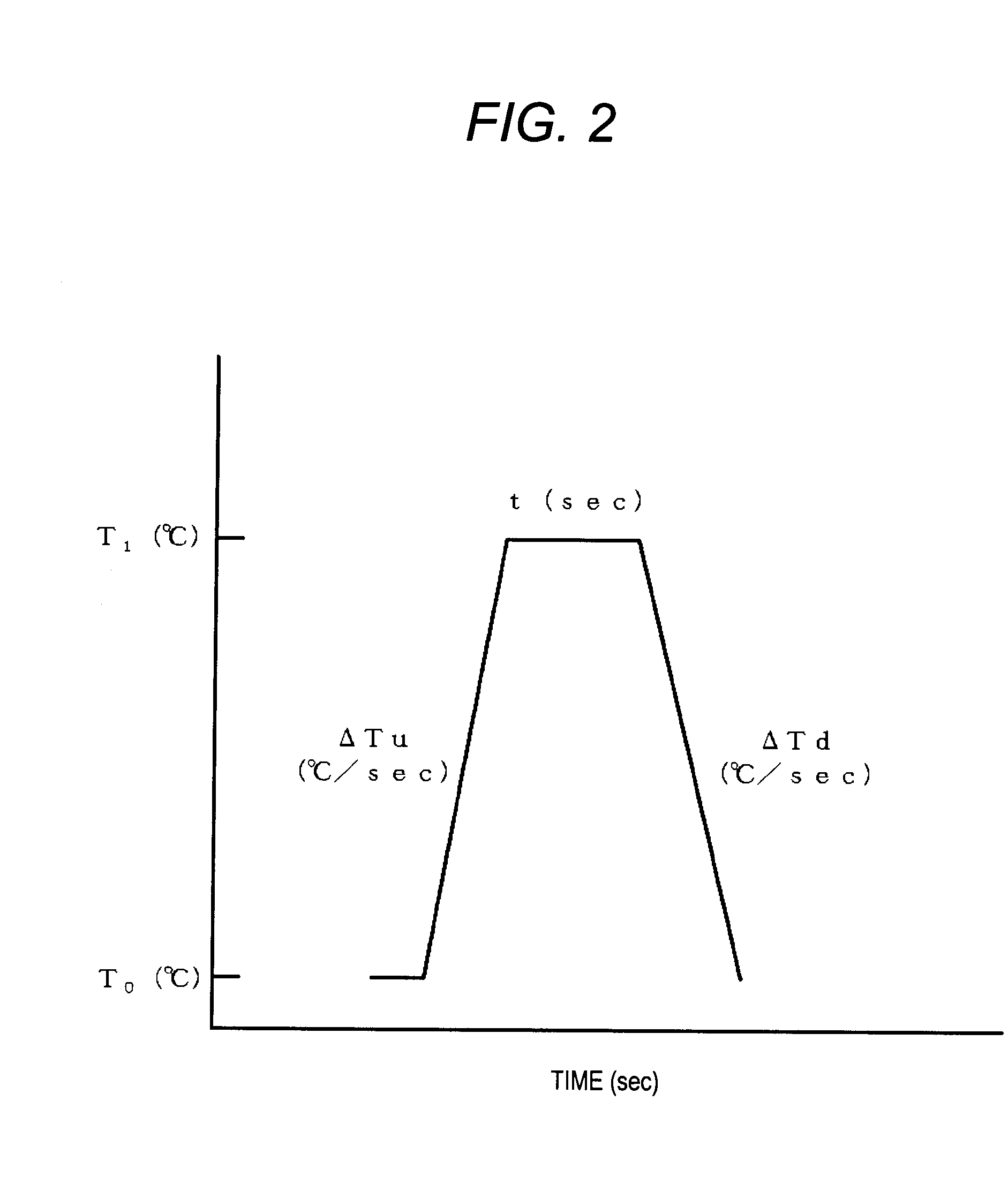

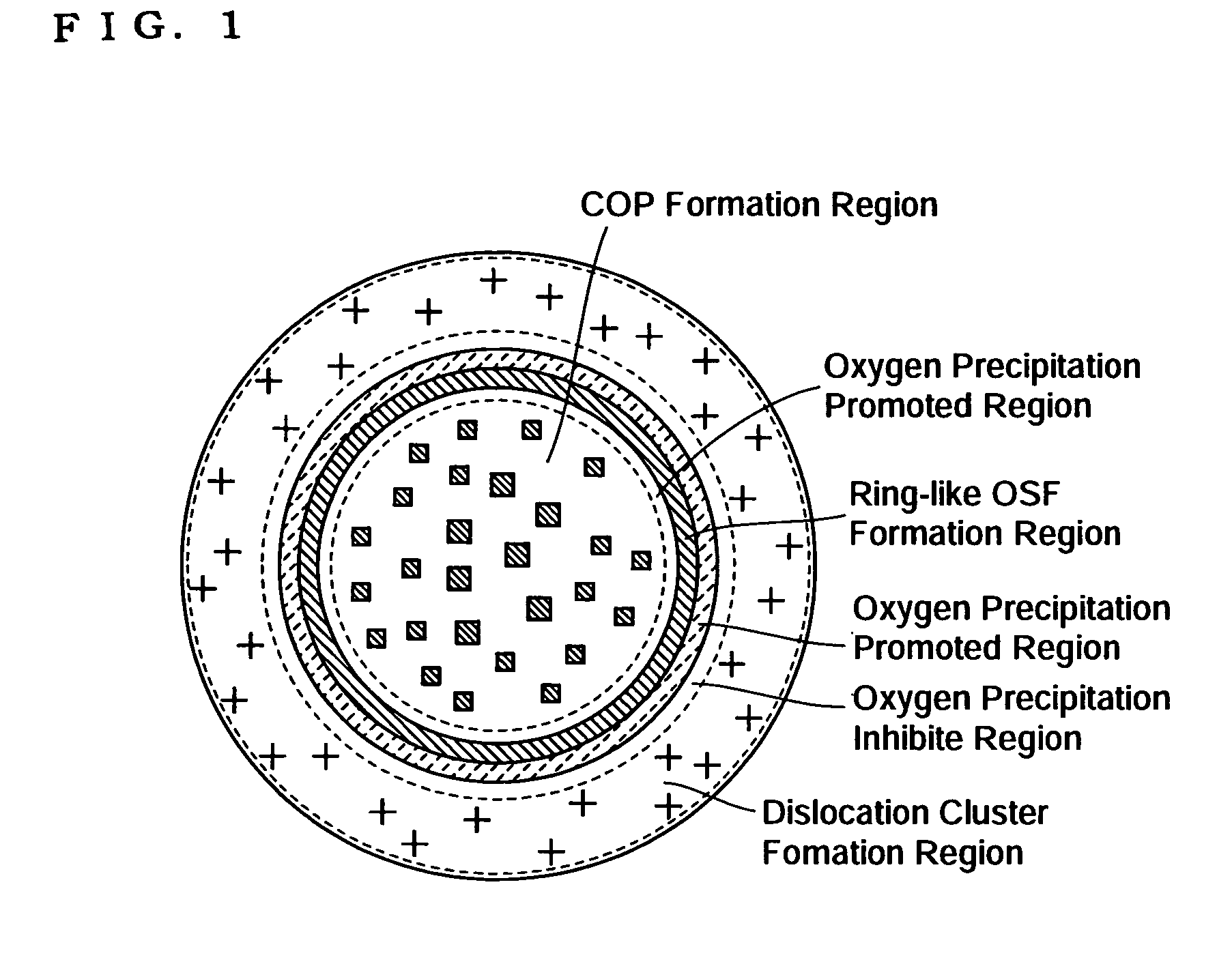

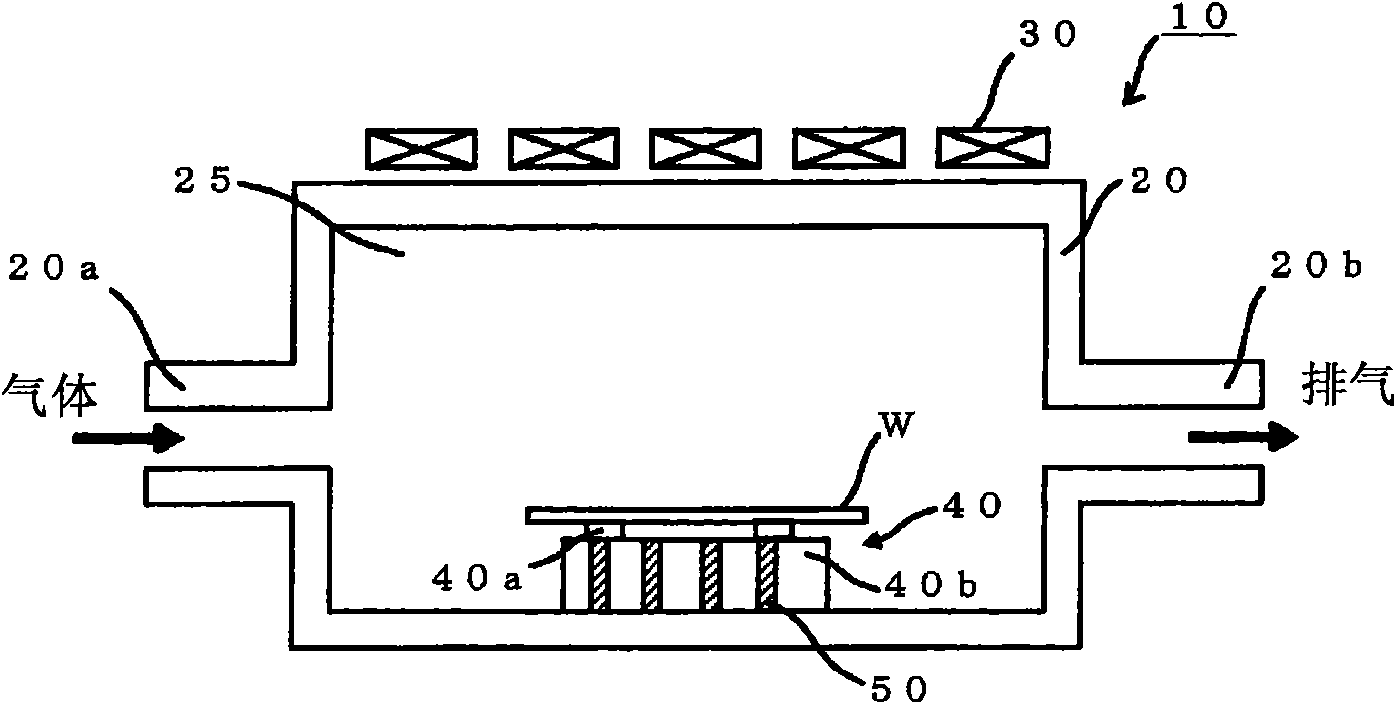

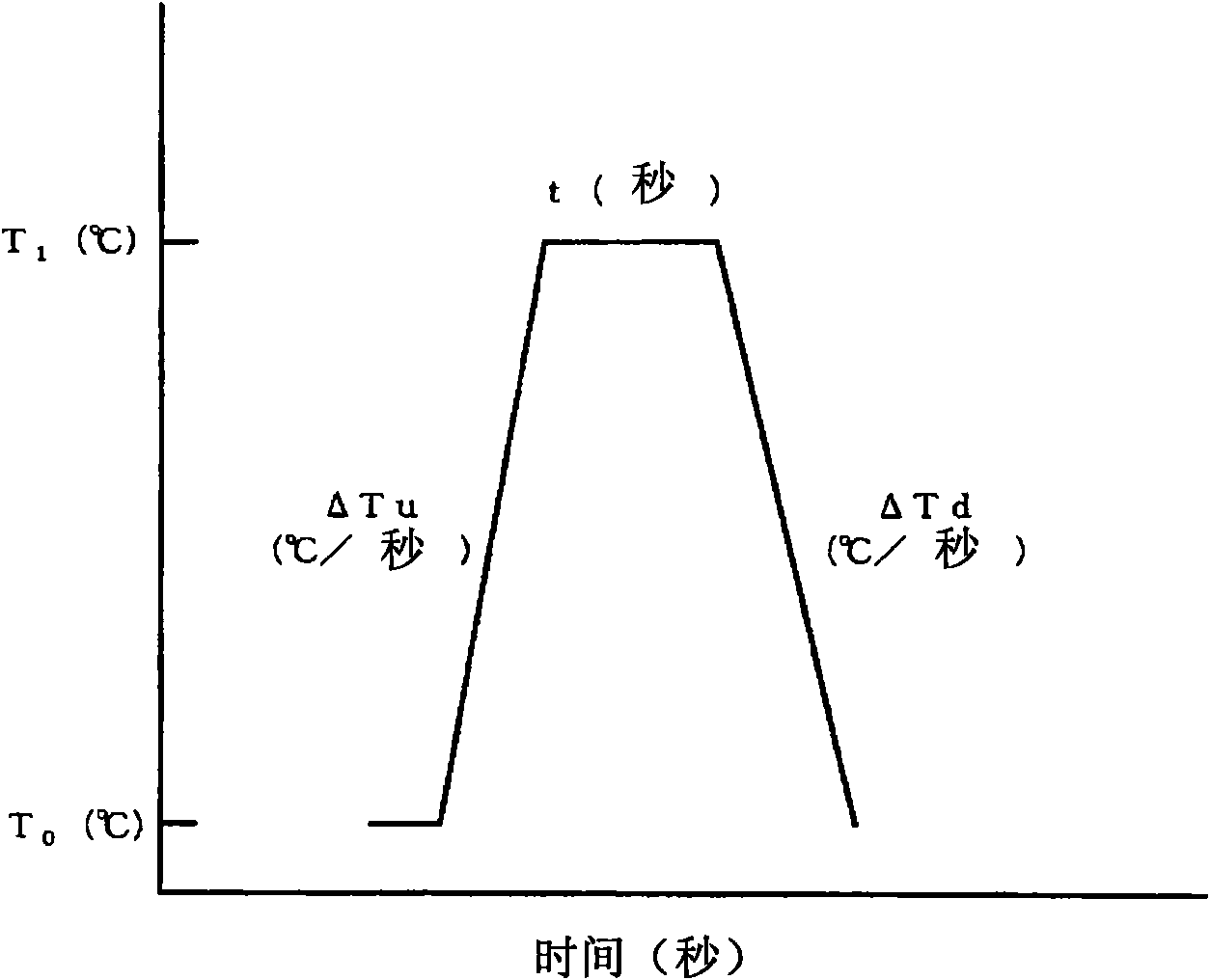

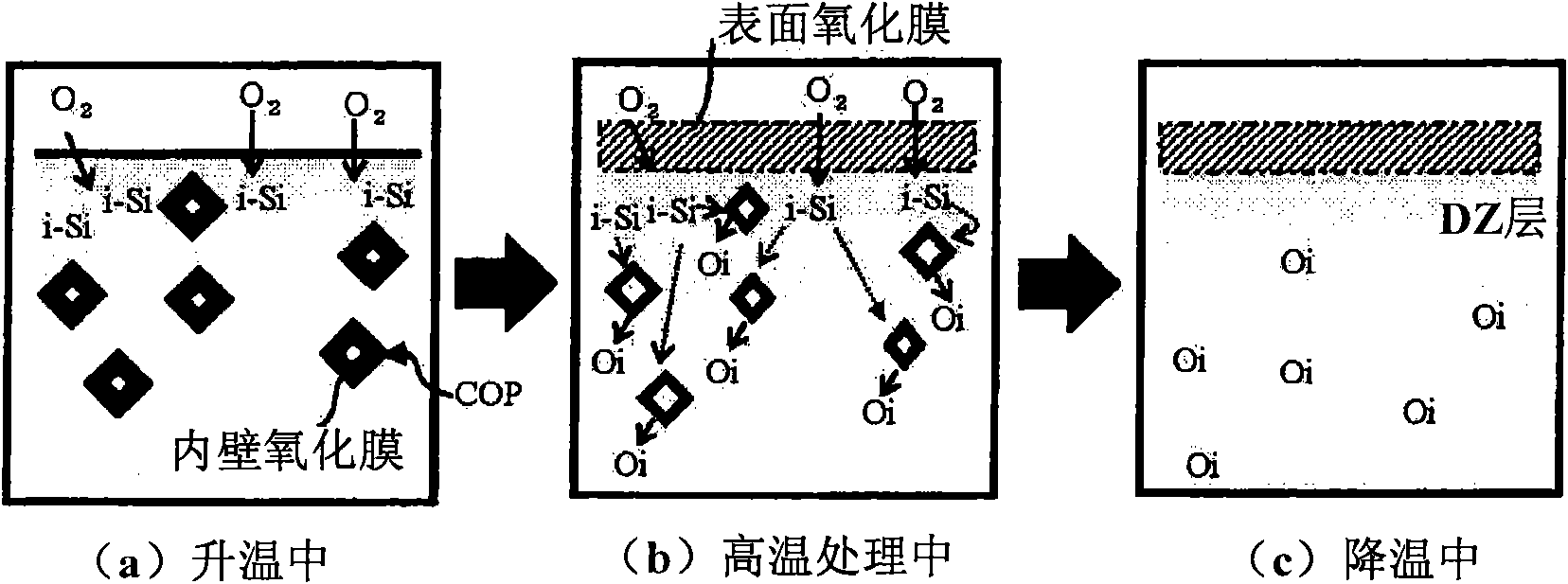

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveUS20100038757A1Reduce capacitySuppress generationPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300° C. or more, but less than 1380° C. in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer according to the invention has, in a defect-free region (DZ layer) including at least a device active region of the silicon wafer, a high oxygen concentration region having a concentration of oxygen solid solution of 0.7×1018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon in supersaturated state.

Owner:GLOBALWAFERS JAPAN

Silica glass crucible with bubble-free and reduced bubble growth wall

A silica glass crucible includes a stable, bubble-free inner layer and an opaque outer layer, both layers demonstrating reduced bubble growth during a Czochralski process. When used in the CZ process, little volume change is observed in the crucible wall, and the crucible has little influence on melt level. The present crucible is especially suited for slow silicon ingot pulling with reduced crystalline defects. The fusion process of the present invention controls the dynamic gas balance at the fusion front where formed grain is melted to dense fused silica.

Owner:SHIN ETABU QUARTZ PRODS

Method for heat treatment of silicon wafers

InactiveUS20060189169A1Promote formationStable formationSemiconductor/solid-state device manufacturingHigh densityOxygen ions

A method is provided for the heat treatment of low oxygen concentration silicon wafers obtained from a silicon single crystal produced by the Czochralski process. The method comprises high-temperature oxidation heat treatment for the formation of a high oxygen concentration region under the wafer surface and the subsequent oxygen precipitation heat treatment. The high-temperature oxidation heat treatment can cause inward diffusion of oxygen from the wafer surface to form a region increased in oxygen concentration under the wafer surface, and the subsequent oxygen precipitation heat treatment can form a DZ layer on the wafer surface and stably form oxygen precipitates optimal in size within the wafer at a high density, so that excellent gettering effects can be produced. Further, in case of using as SOI substrates formed by SIMOX, too, the same effects as mentioned above can be produced by carrying out the high-temperature oxidation heat treatment after oxygen ion implantation in the SIMOX process and then carrying out the oxygen precipitation heat treatment.

Owner:SUMCO CORP

Method For Manufacturing Epitaxial wafer

ActiveUS20080286565A1High IG effectFew epitaxial defectLayered productsSemiconductor/solid-state device manufacturingWaferingSingle crystal

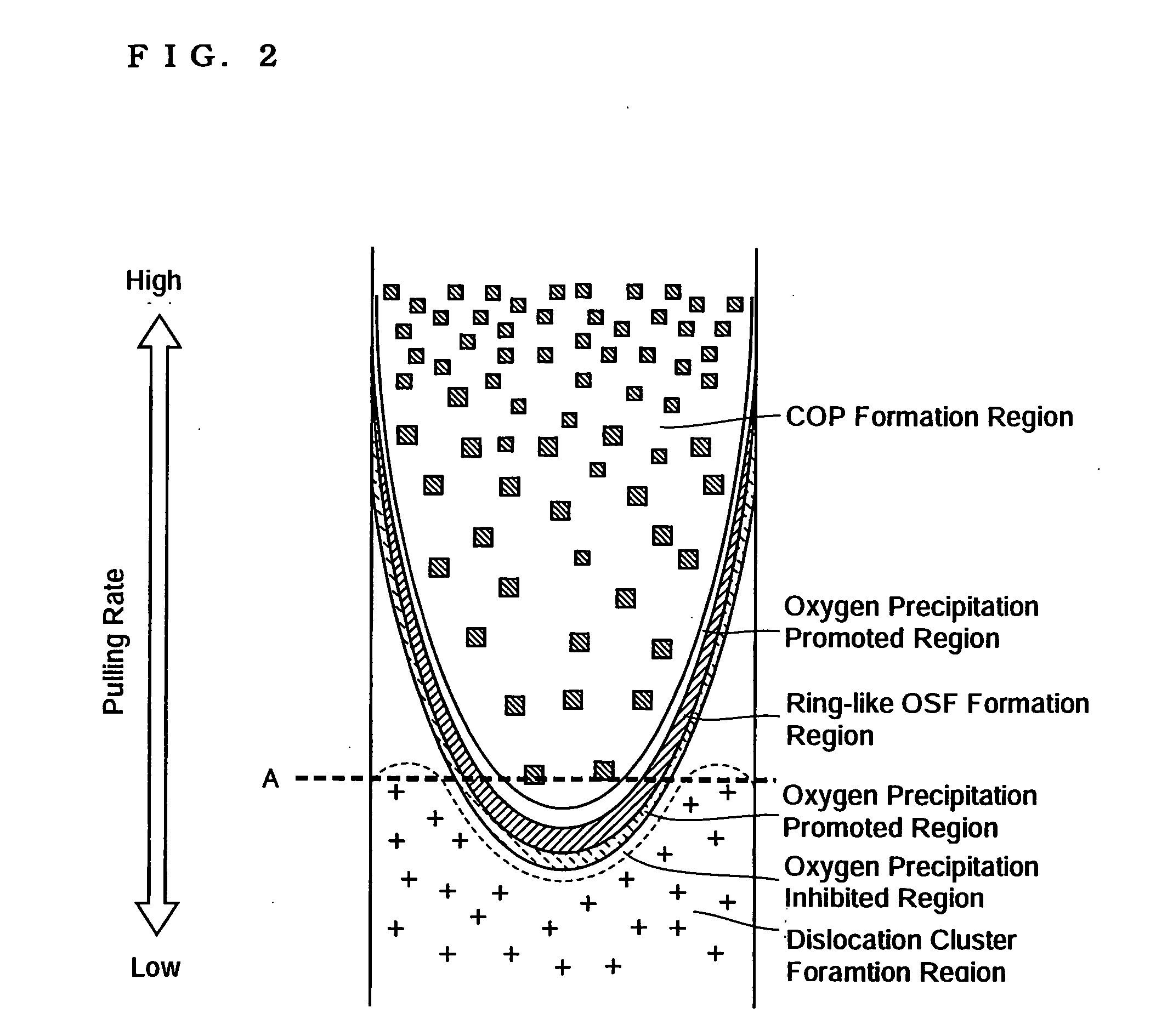

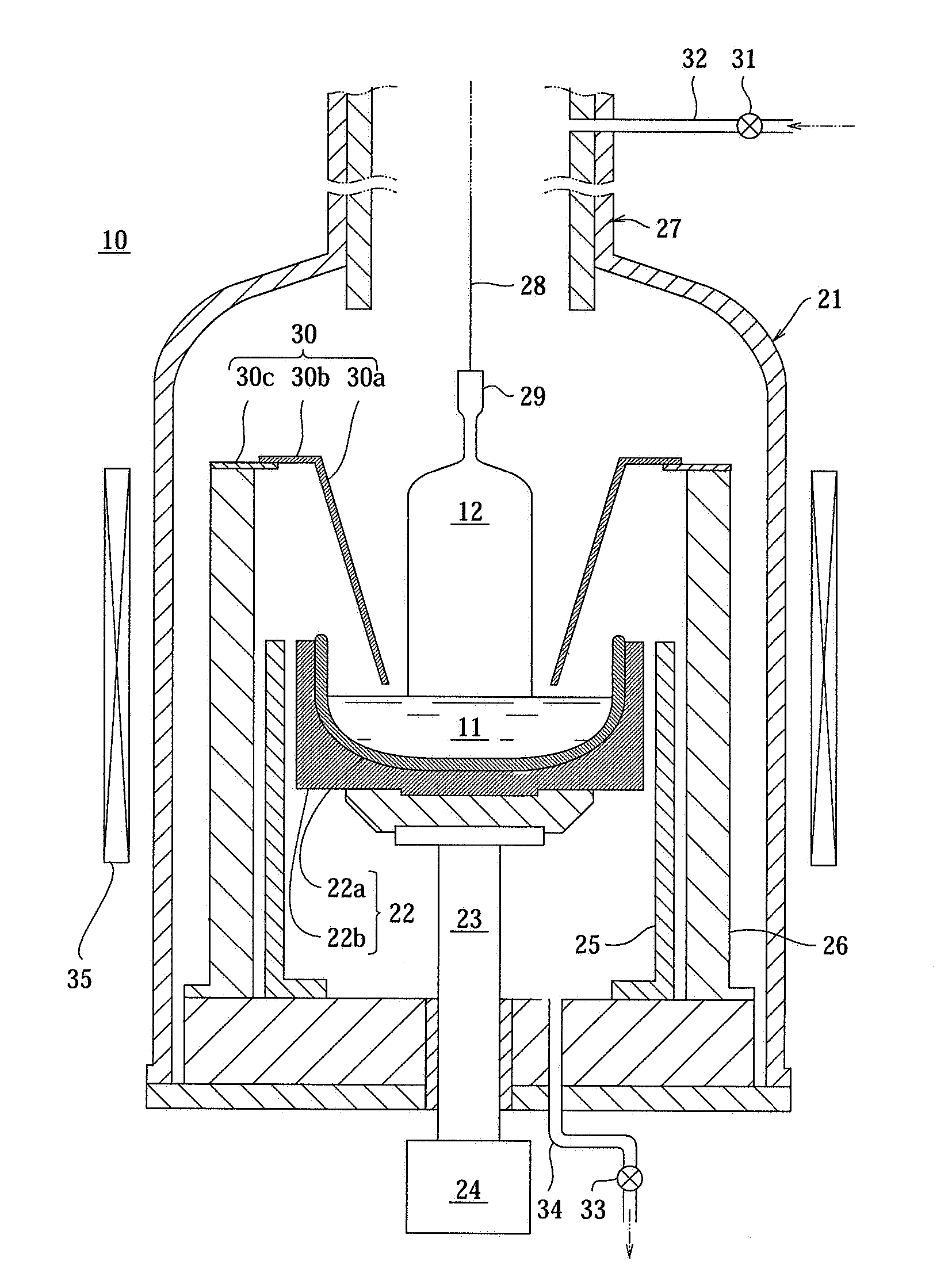

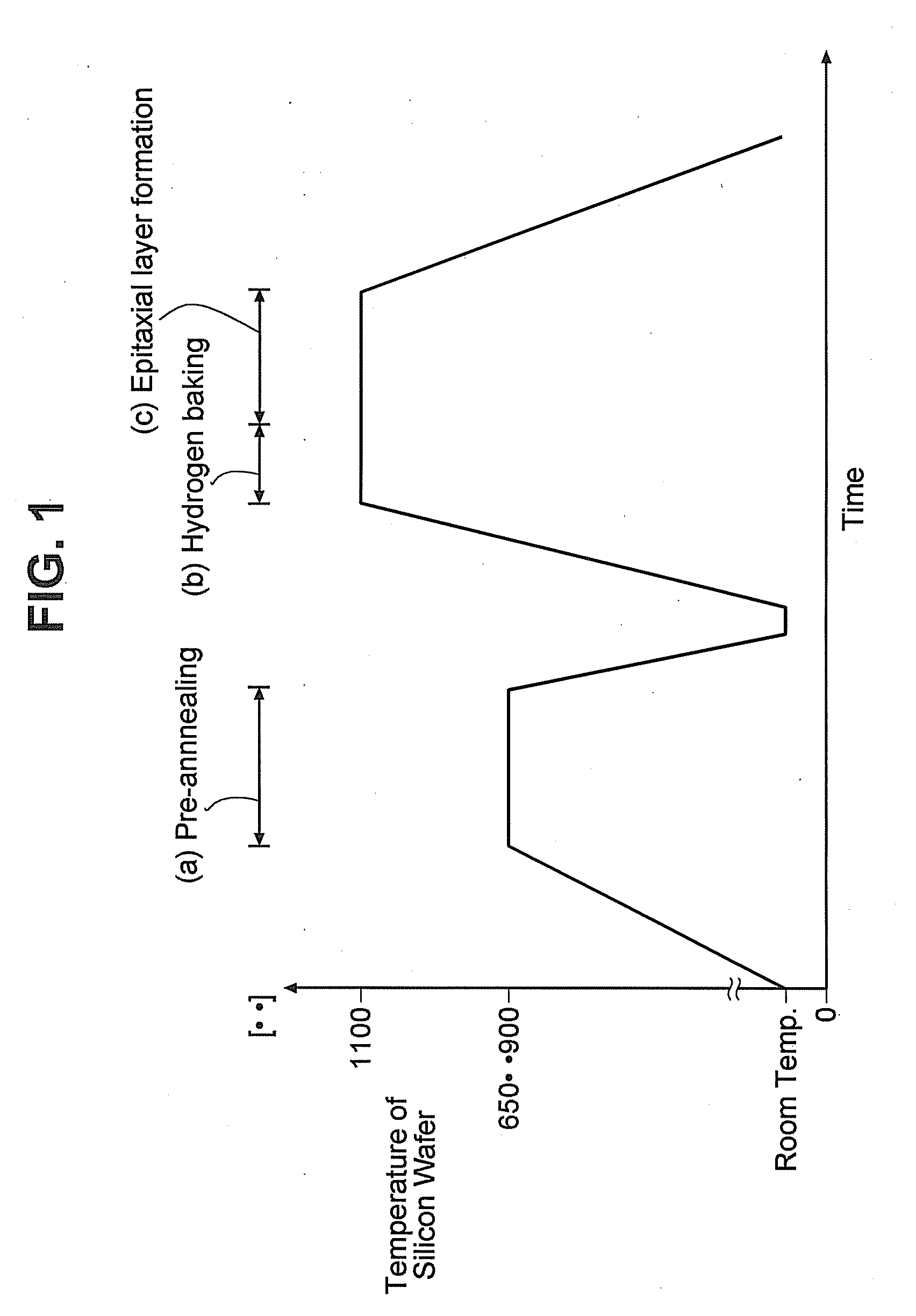

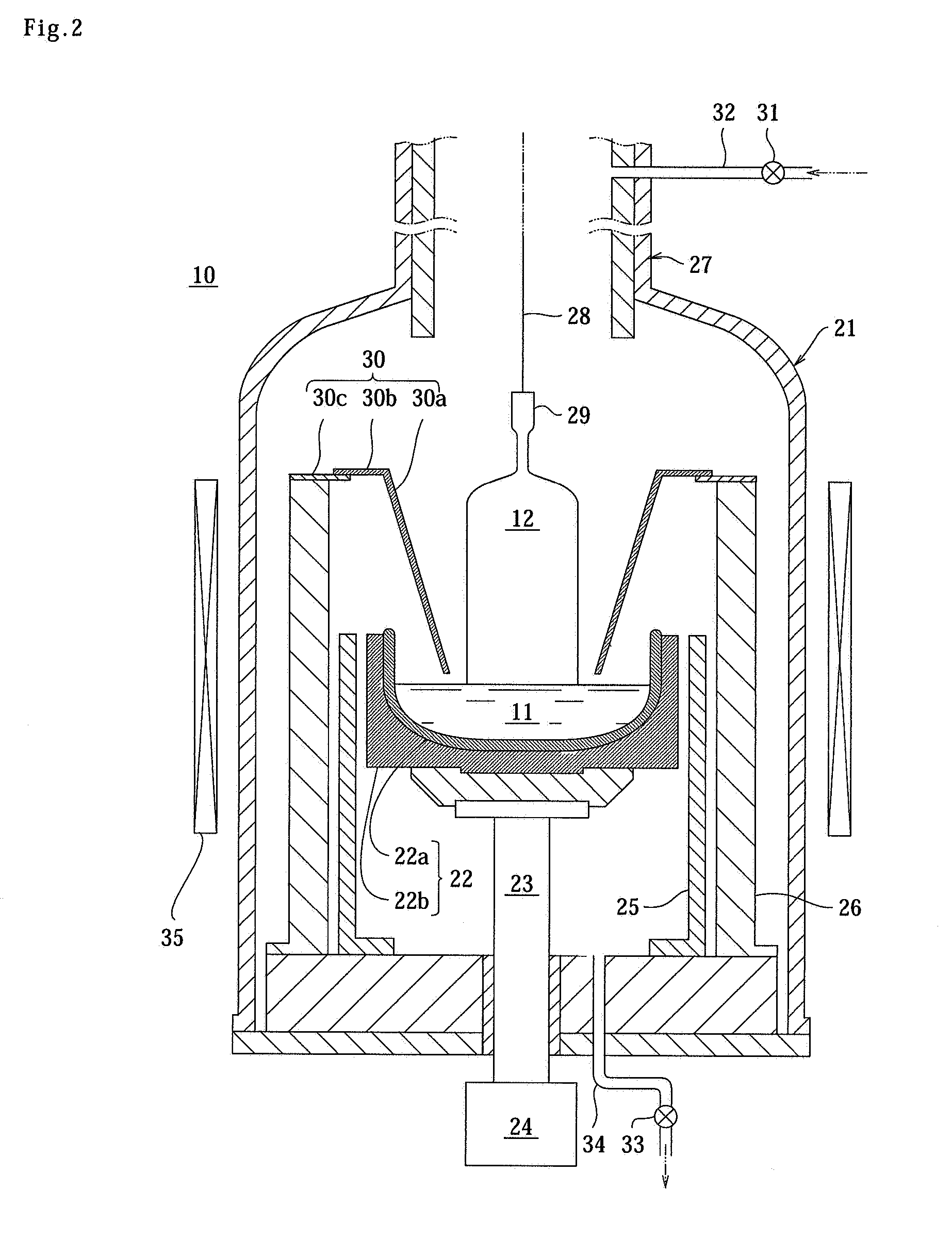

A method for manufacturing an epitaxial wafer includes: a step of pulling a single crystal from a boron-doped silicon melt in a chamber based on a Czochralski process; and a step of forming an epitaxial layer on a surface of a silicon wafer sliced from the single crystal. The single crystal is allowed to grow while passed through a temperature region of 800 to 600° C. in the chamber in 250 to 180 minutes during the pulling step. The grown single crystal has an oxygen concentration of 10×1017 to 12×1017 atoms / cm3 and a resistivity of 0.03 to 0.01 Ωcm. The silicon wafer is subjected to pre-annealing prior to the step of forming the epitaxial layer on the surface of the silicon wafer, for 10 minutes to 4 hours at a predetermined temperature within a temperature region of 650 to 900° C. in an inert gas atmosphere. The method is to fabricate an epitaxial wafer that has a diameter of 300 mm or more, and that attains a high IG effect, and involves few epitaxial defects.

Owner:SUMCO CORP

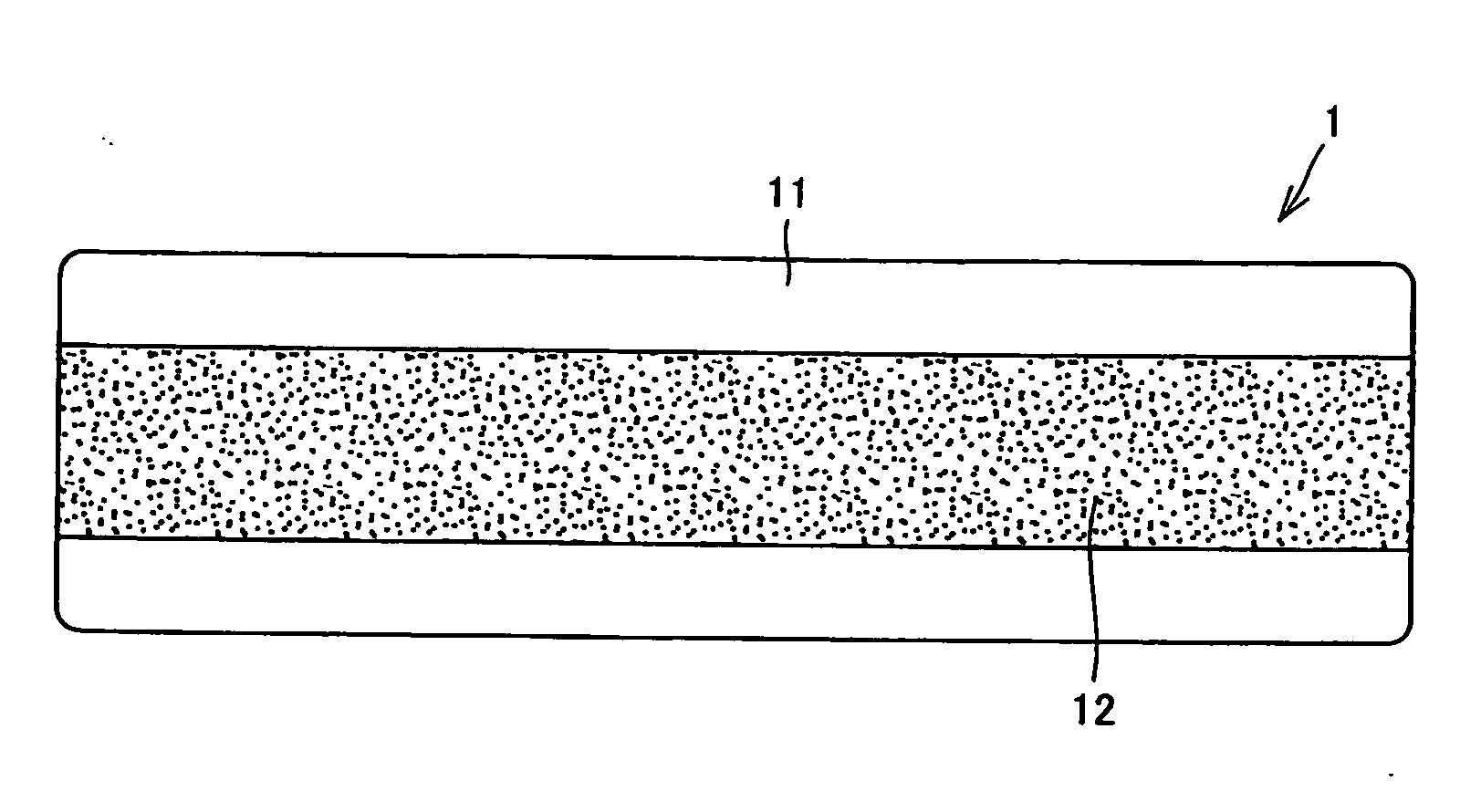

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveCN101638807AThe preparation method is simple and easyImprove productivityPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300 DEG C or more, but less than 1380 DEG C in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer (10) according to the invention has, in a defect-free region (DZ layer) (12) including at least a device active region of the silicon wafer, a high oxygen concentration region (12) having a concentration of oxygen solid solution of 0.71018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon (14) in supersaturated state.

Owner:GLOBALWAFERS JAPAN

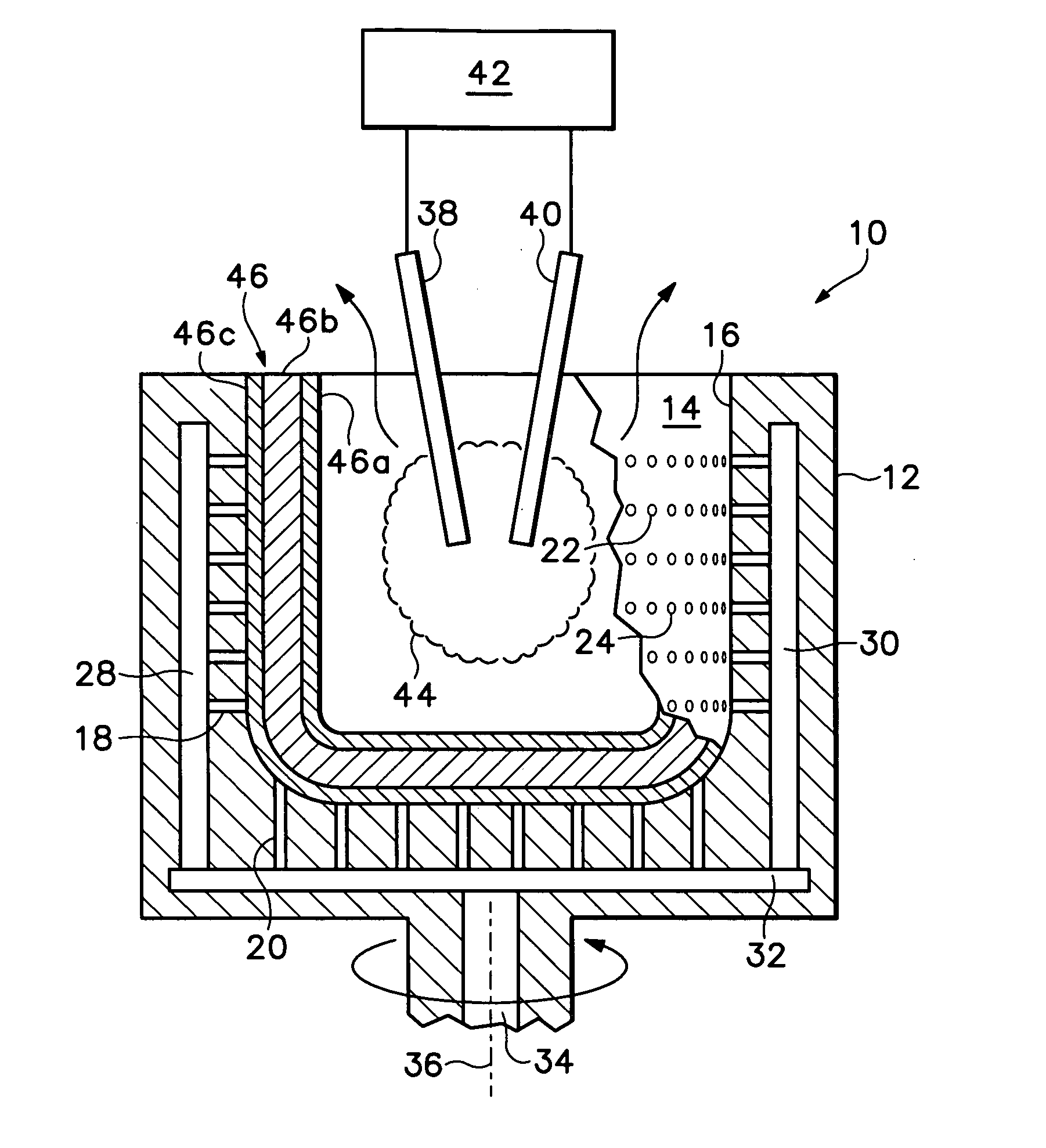

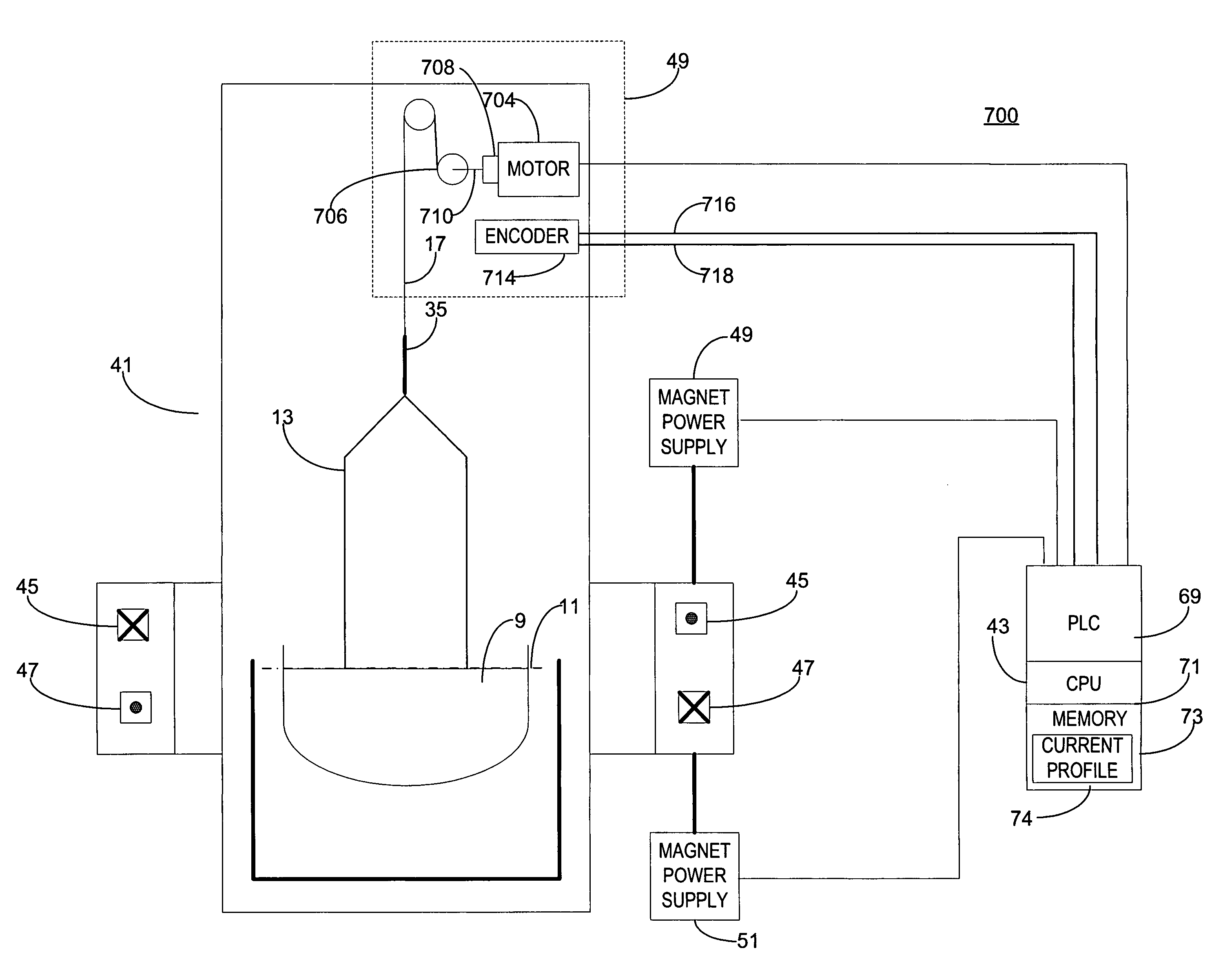

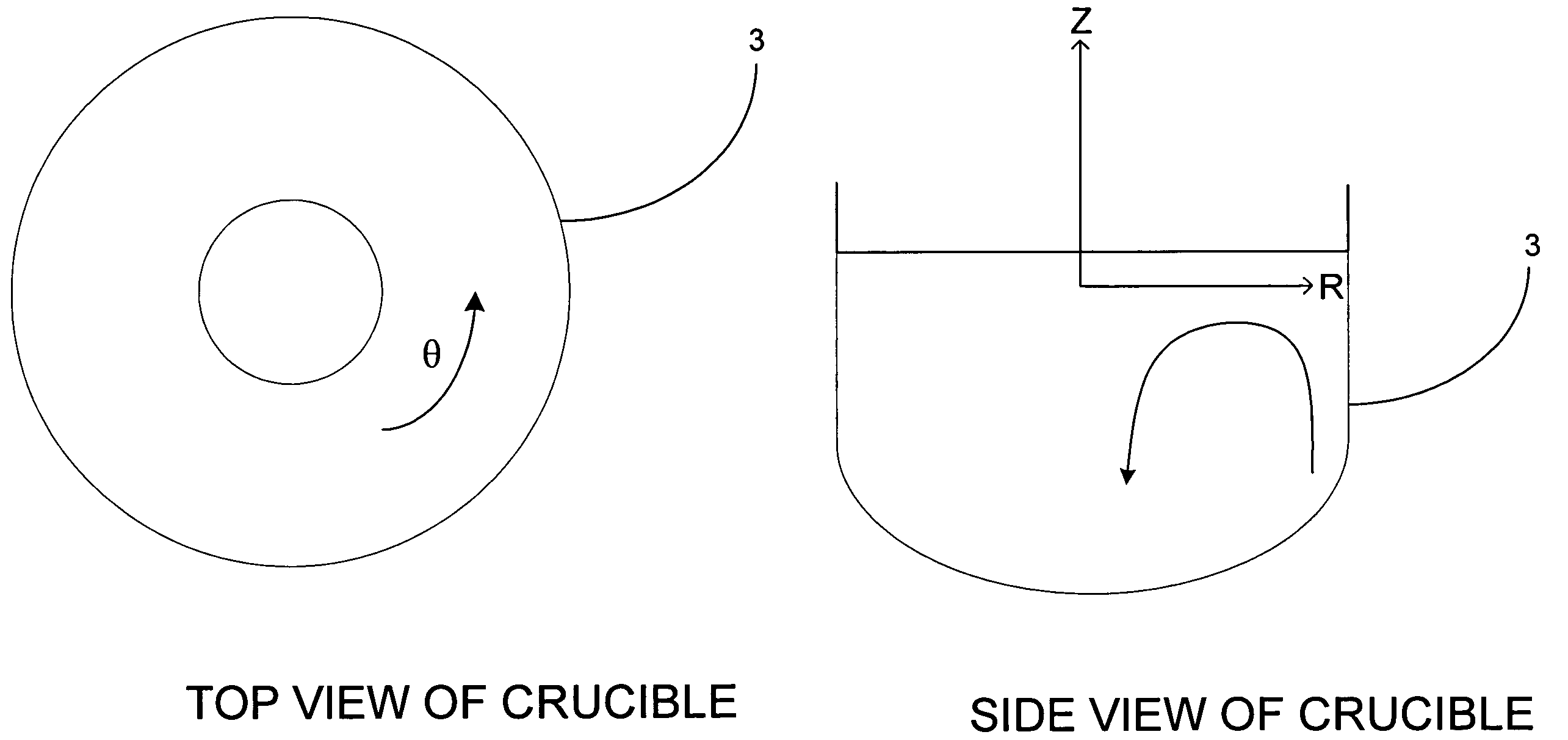

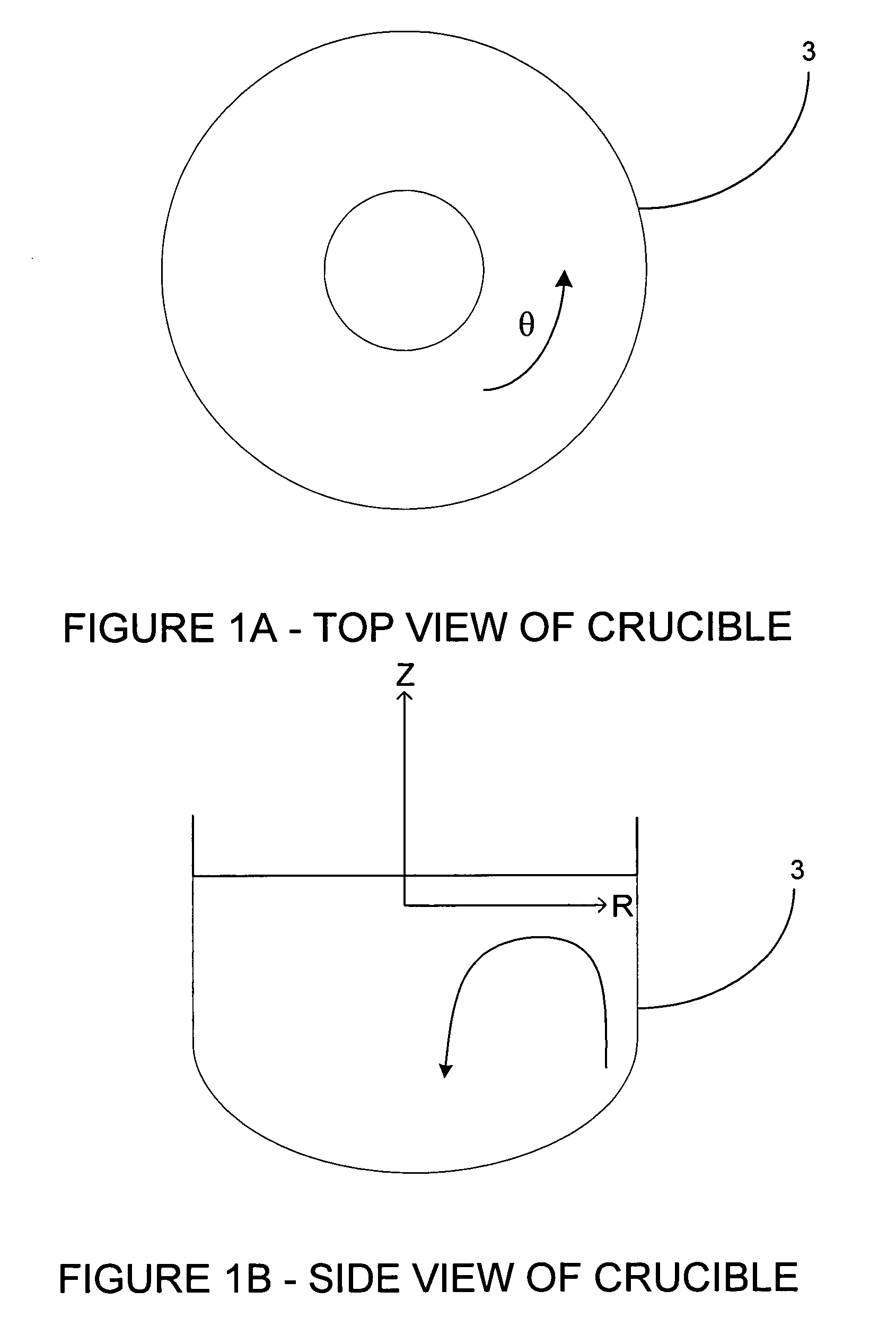

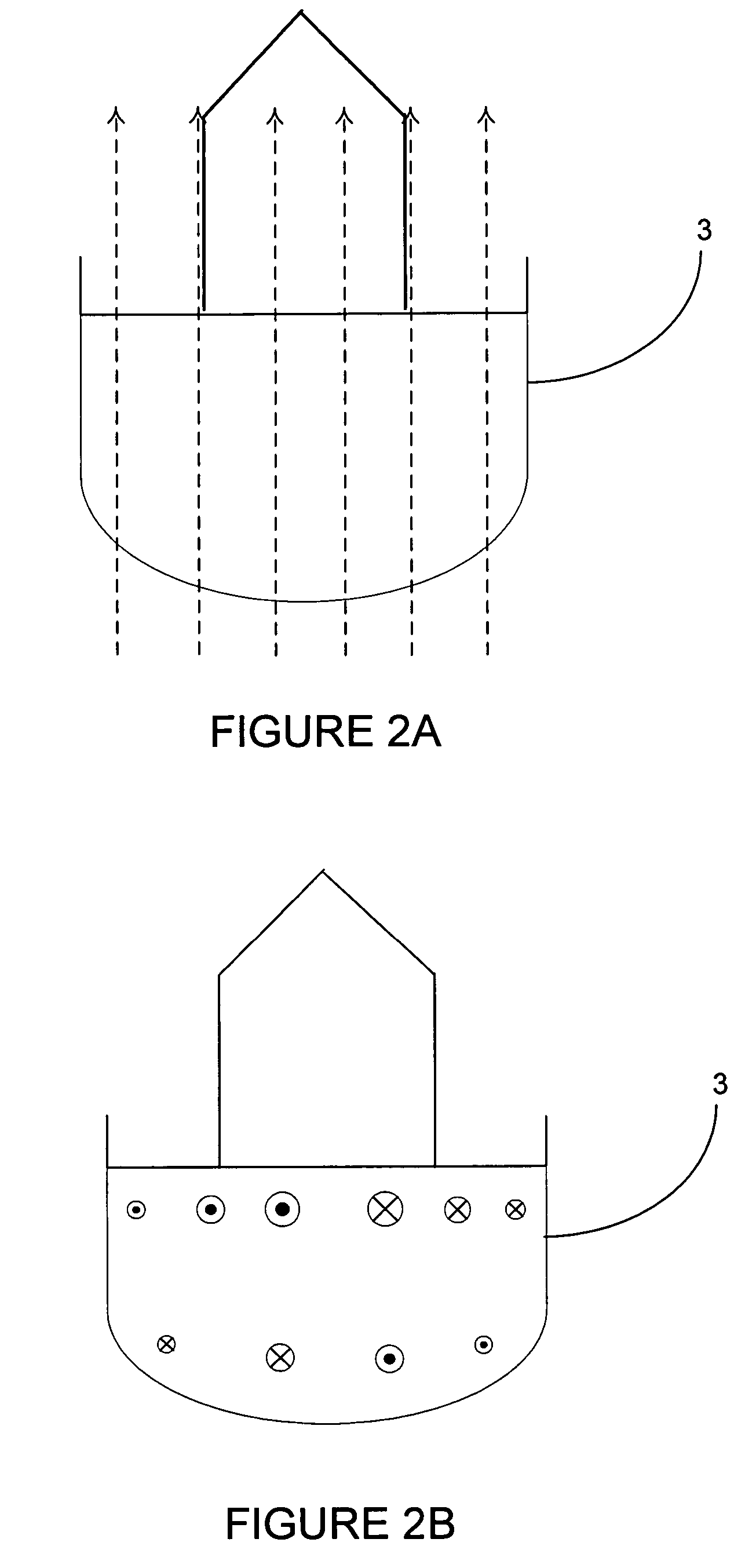

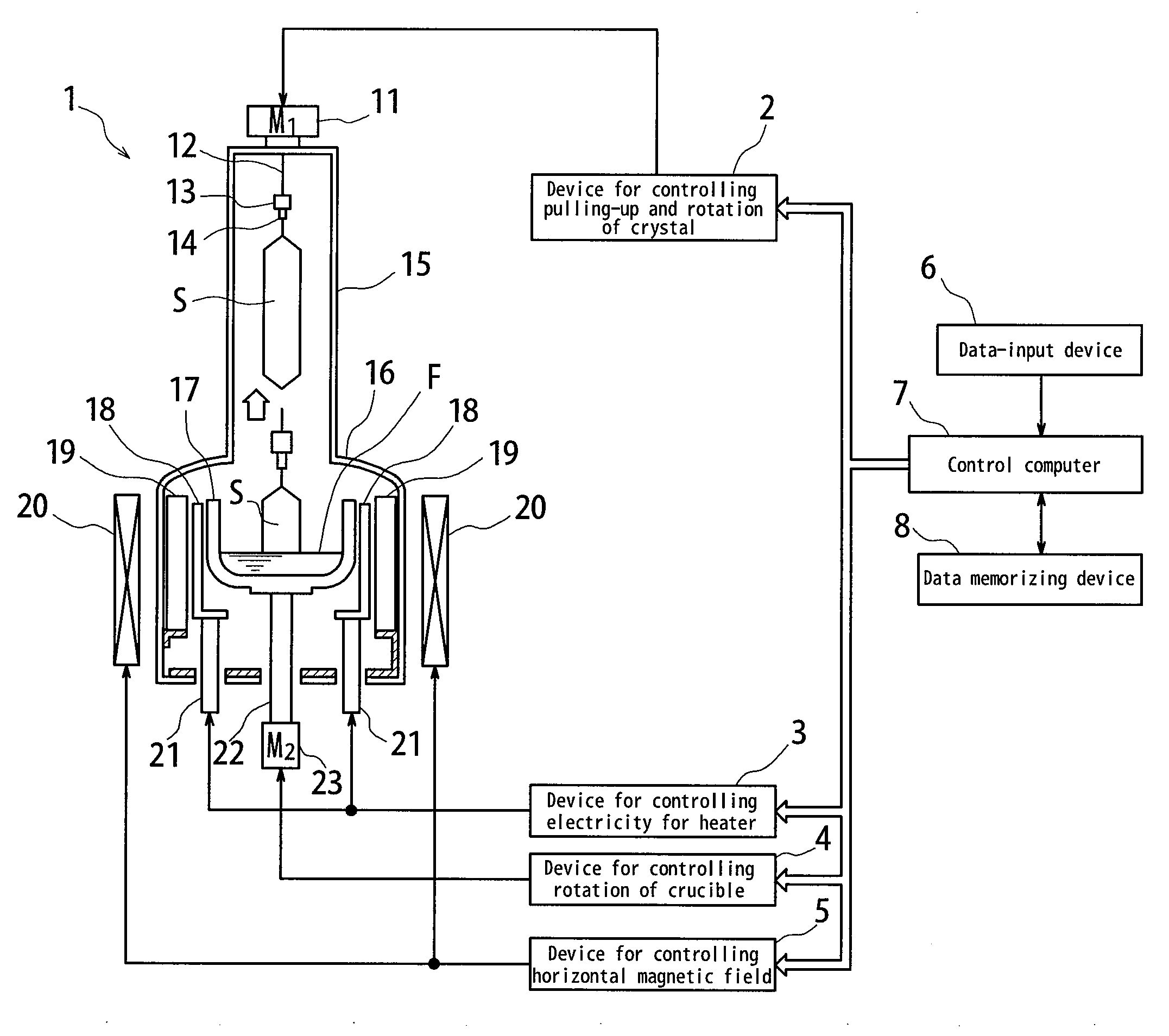

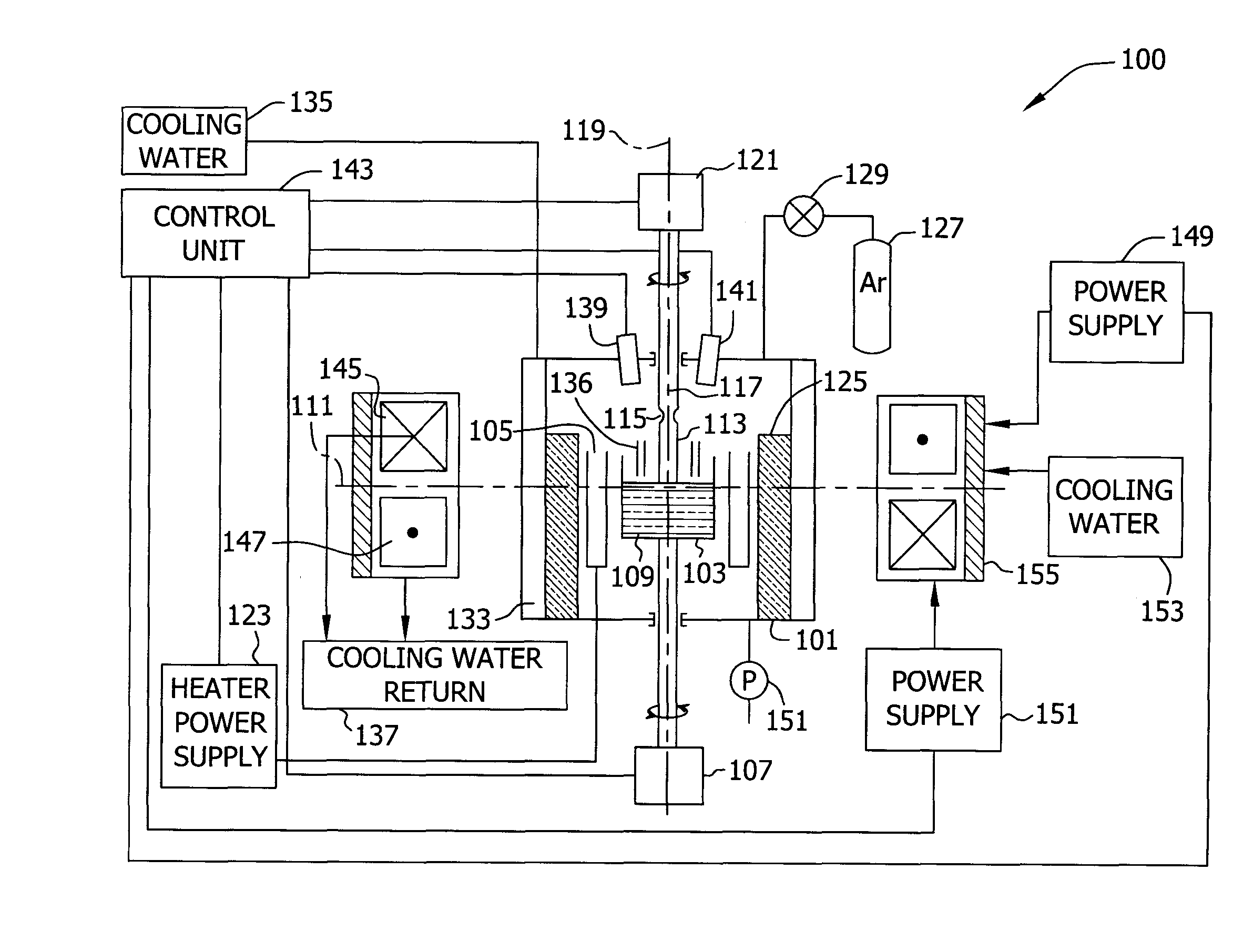

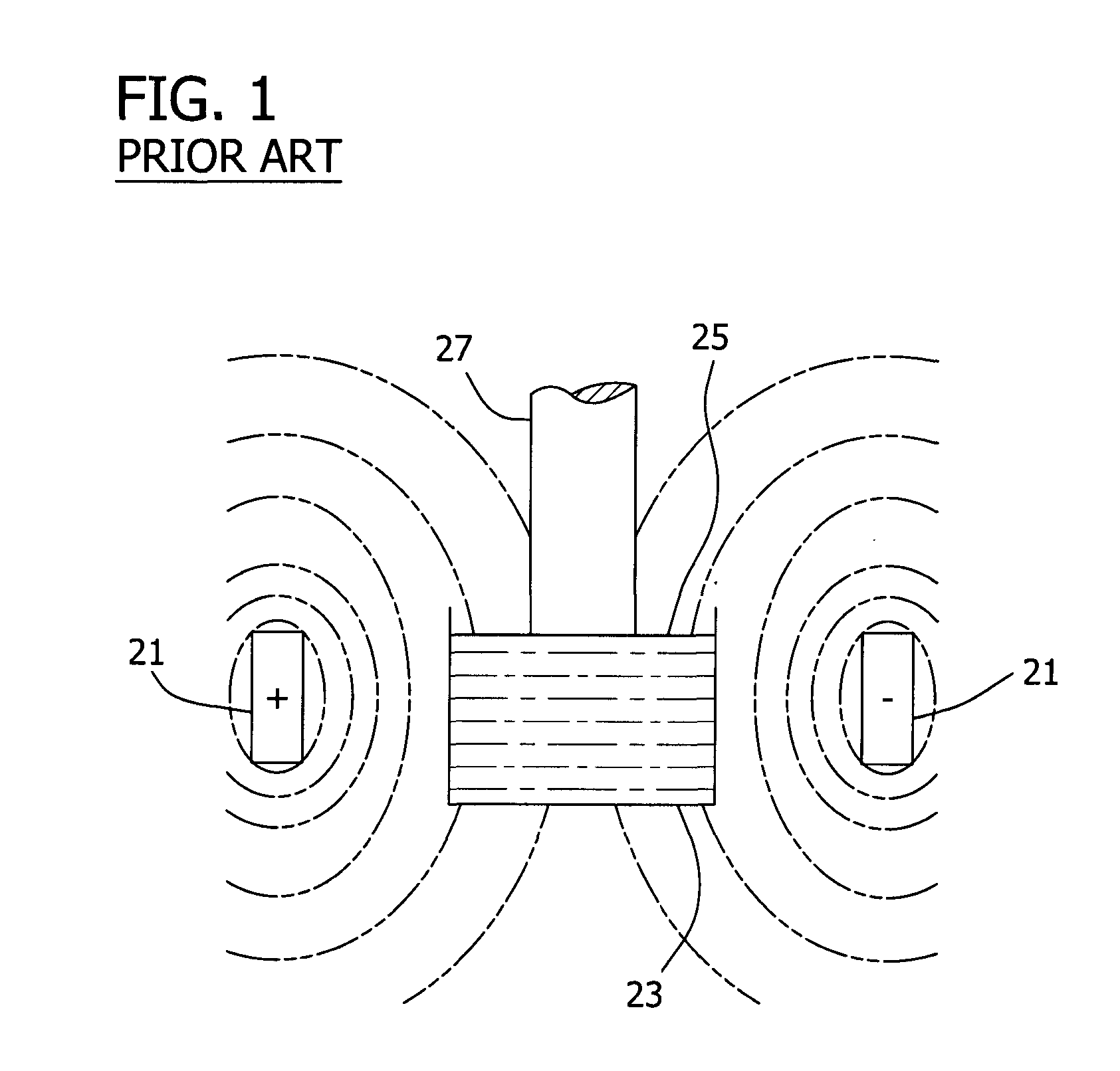

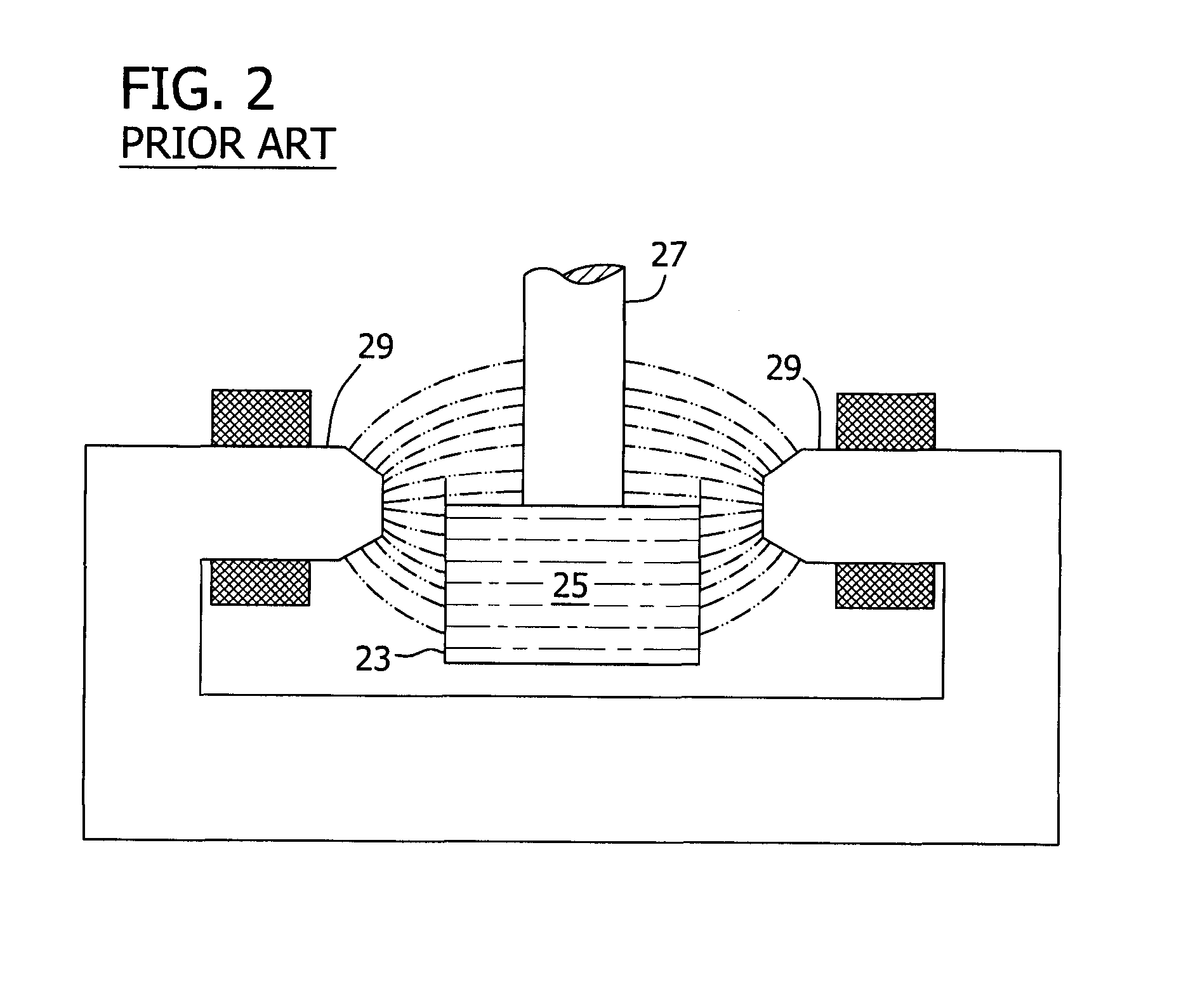

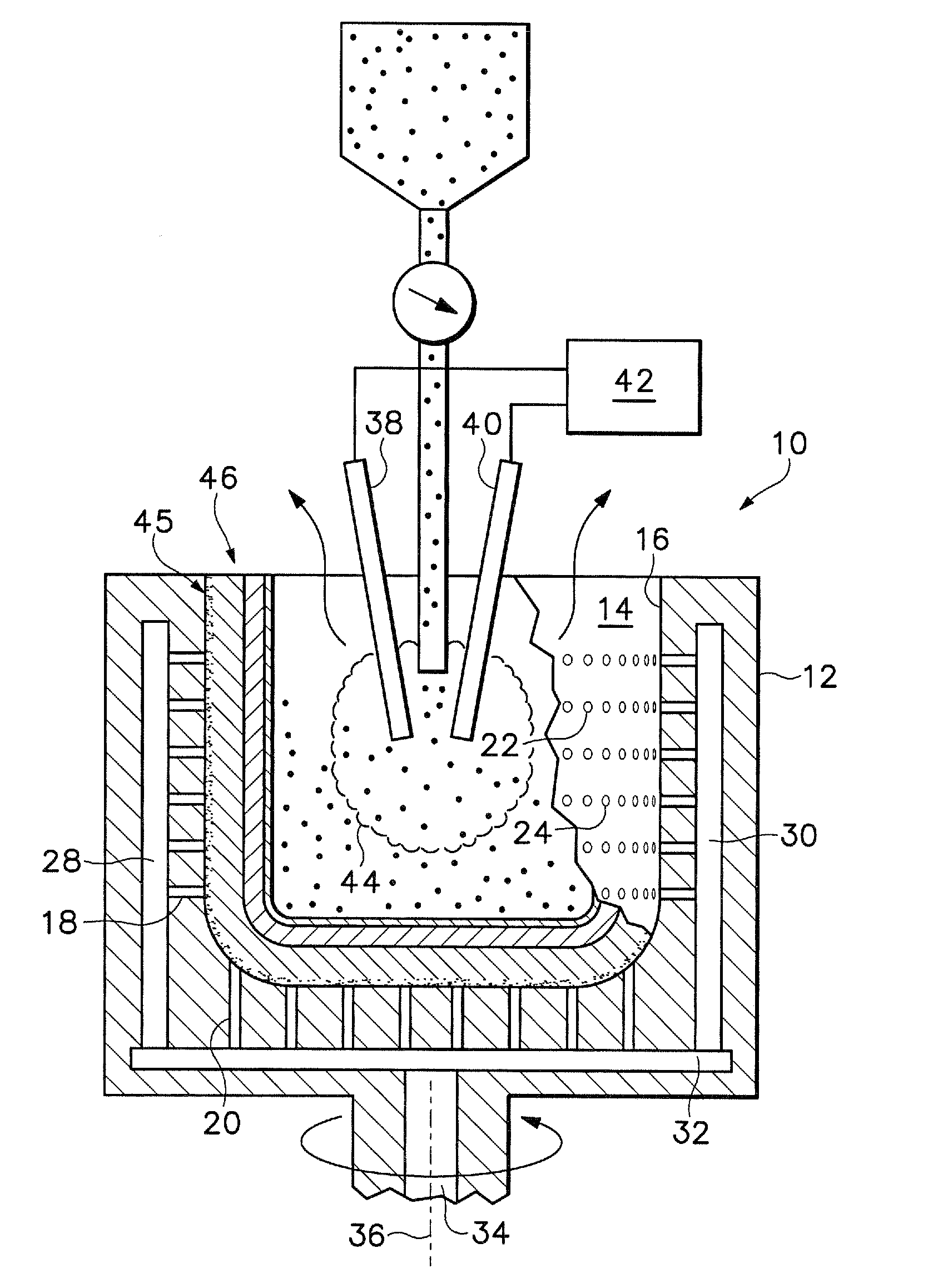

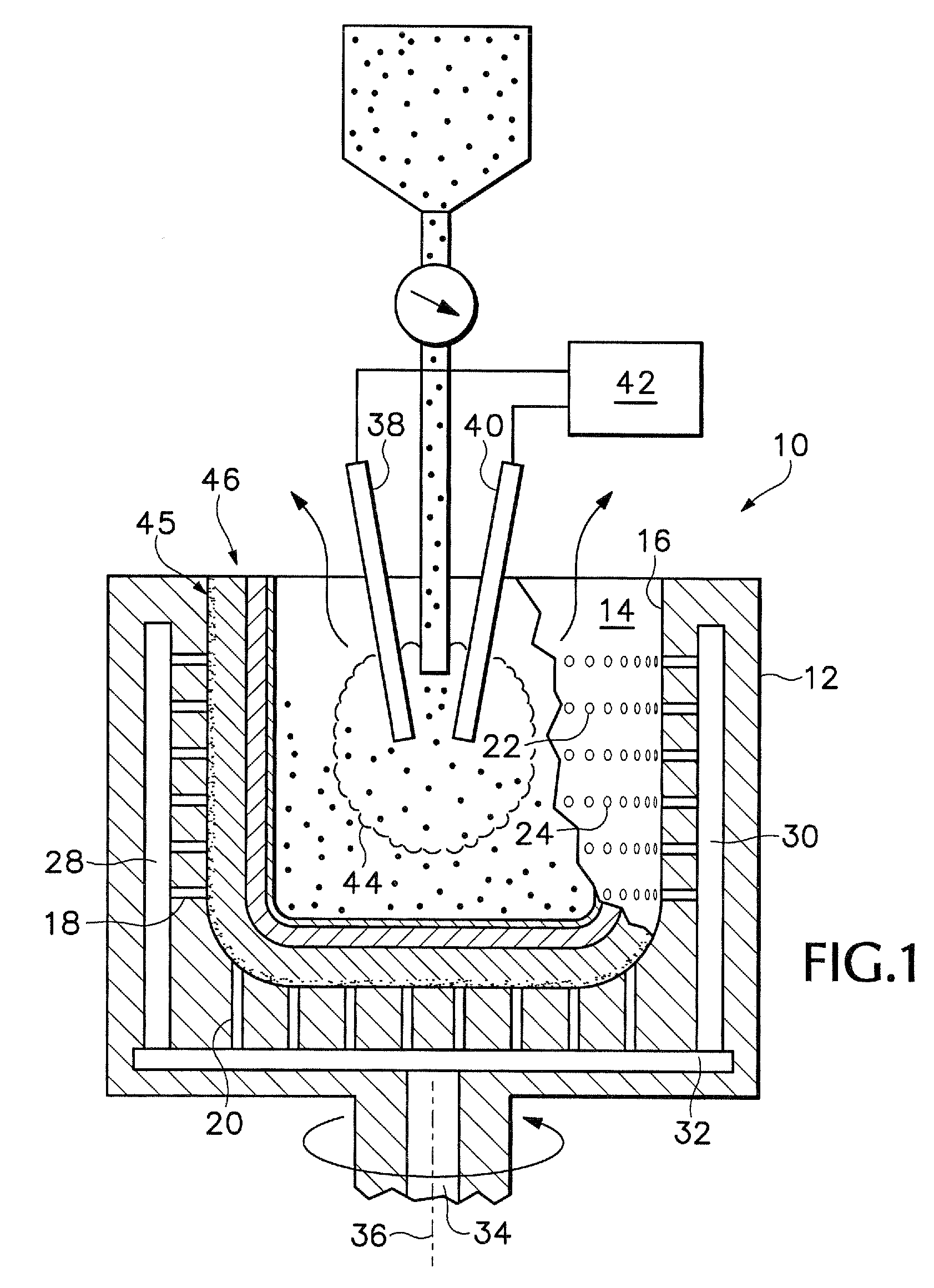

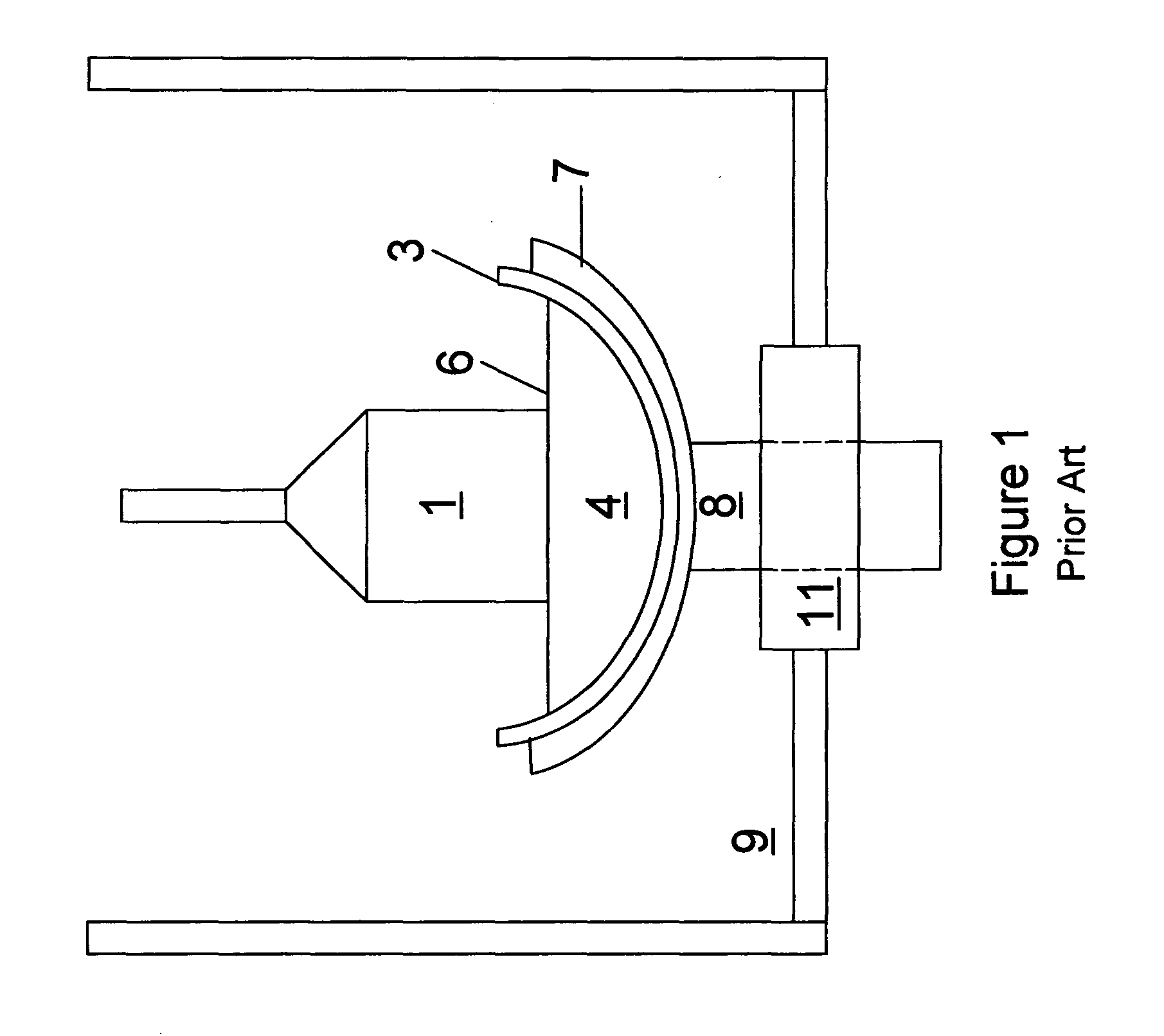

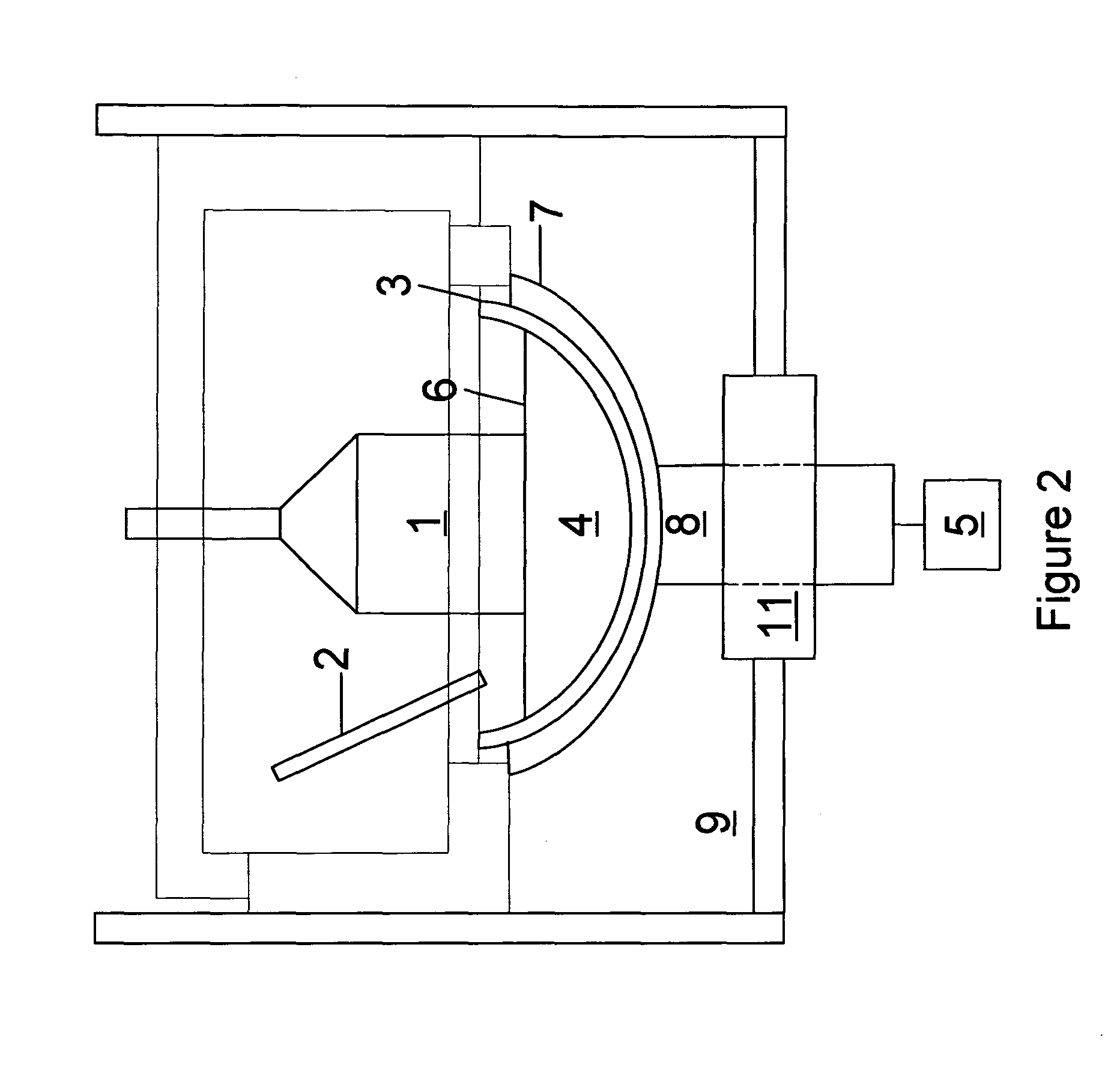

Electromagnetic pumping of liquid silicon in a crystal growing process

ActiveUS20060144320A1Improve efficiencyIncrease flexibilityPolycrystalline material growthBy pulling from meltCrucibleCombined use

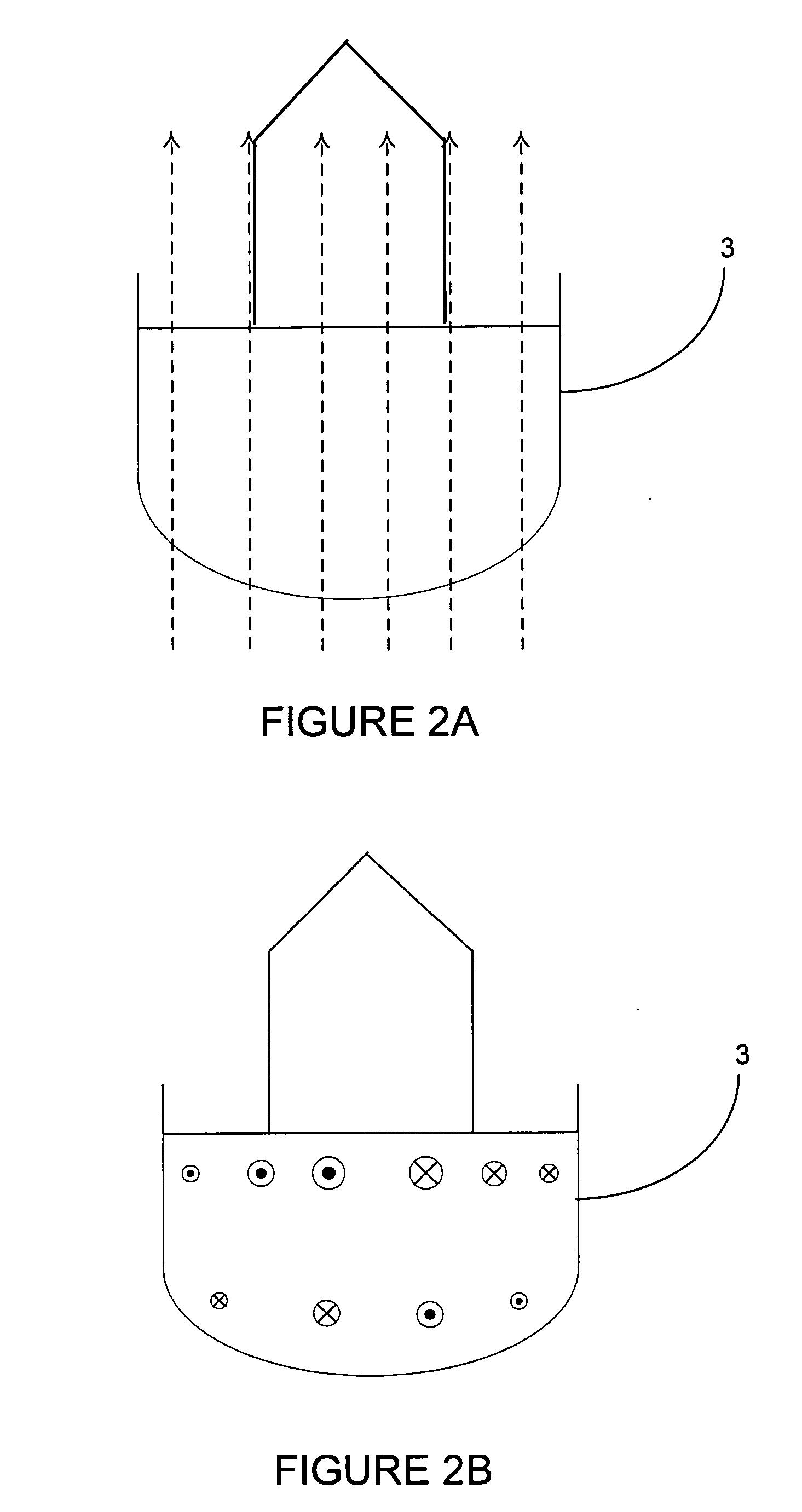

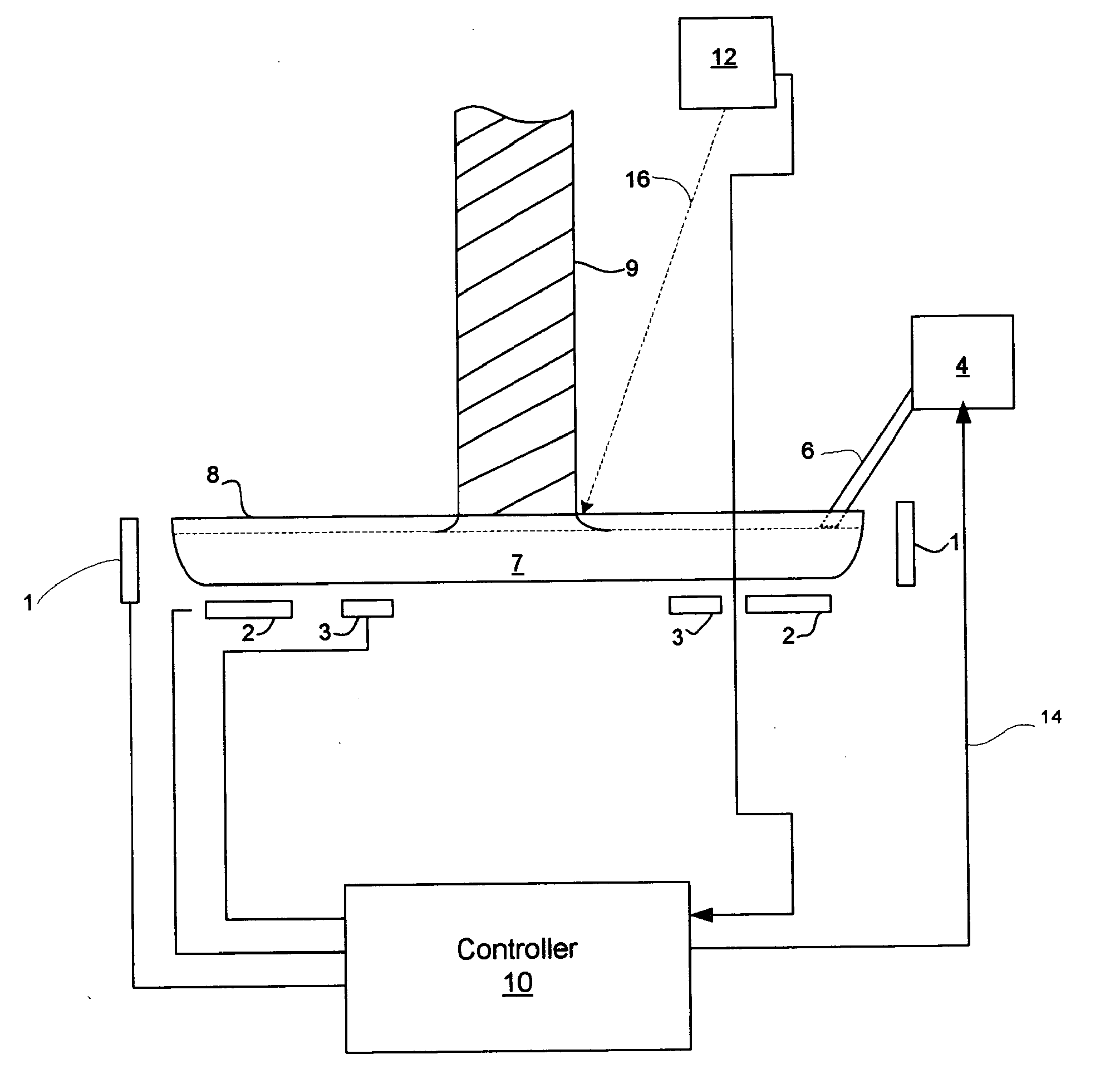

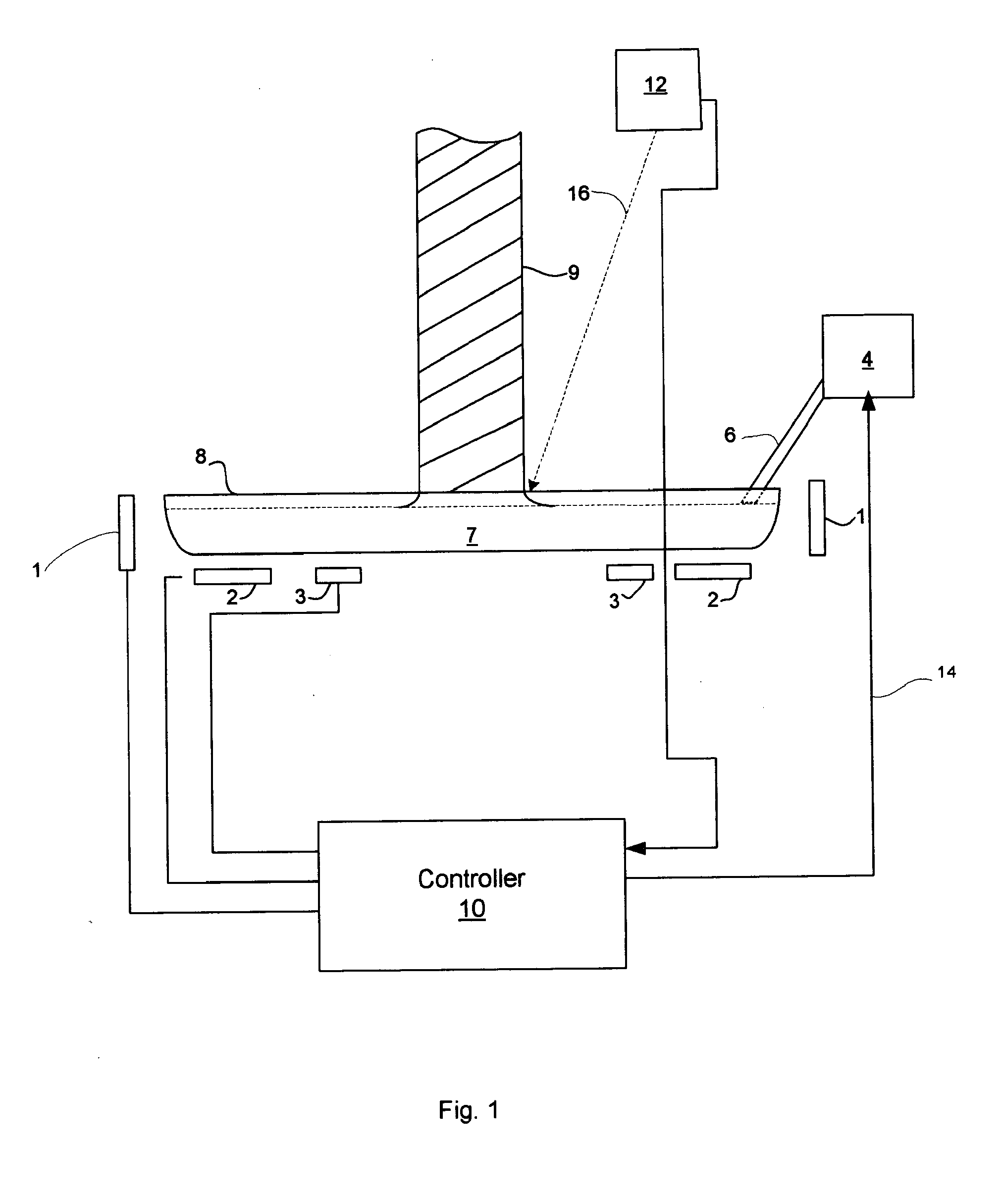

A method and system for use in combination with a crystal growing apparatus for growing a monocrystalline ingot according to a Czochralski process. The crystal growing apparatus has a heated crucible including a semiconductor melt from which the ingot is pulled. The ingot is grown on a seed crystal pulled from the melt. A time varying external magnetic field is imposed on the melt during pulling of the ingot. The magnetic field is selectively adjusted to produce pumping forces in the melt to control a melt flow velocity while the ingot is being pulled from the melt.

Owner:GLOBALWAFERS CO LTD

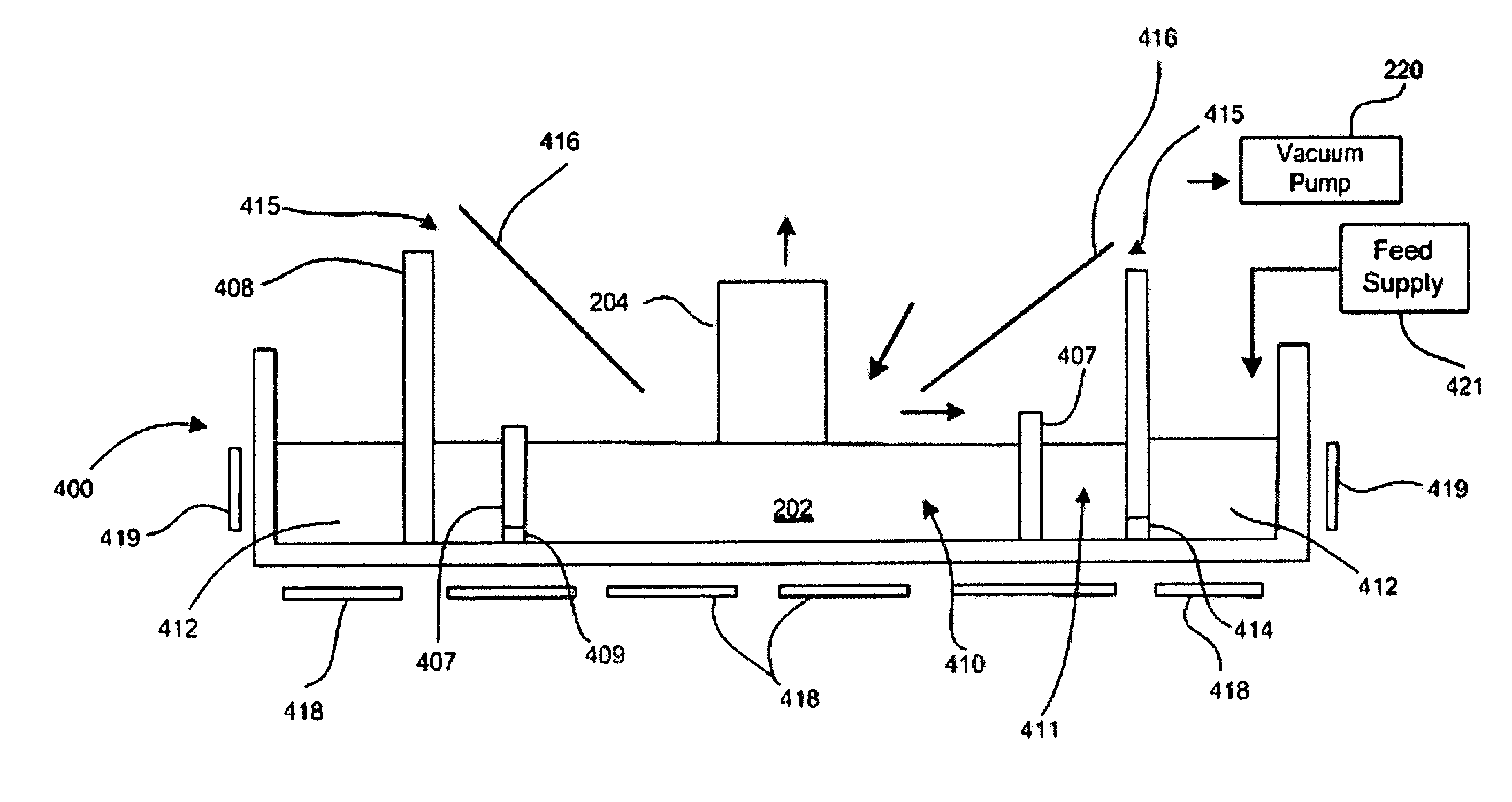

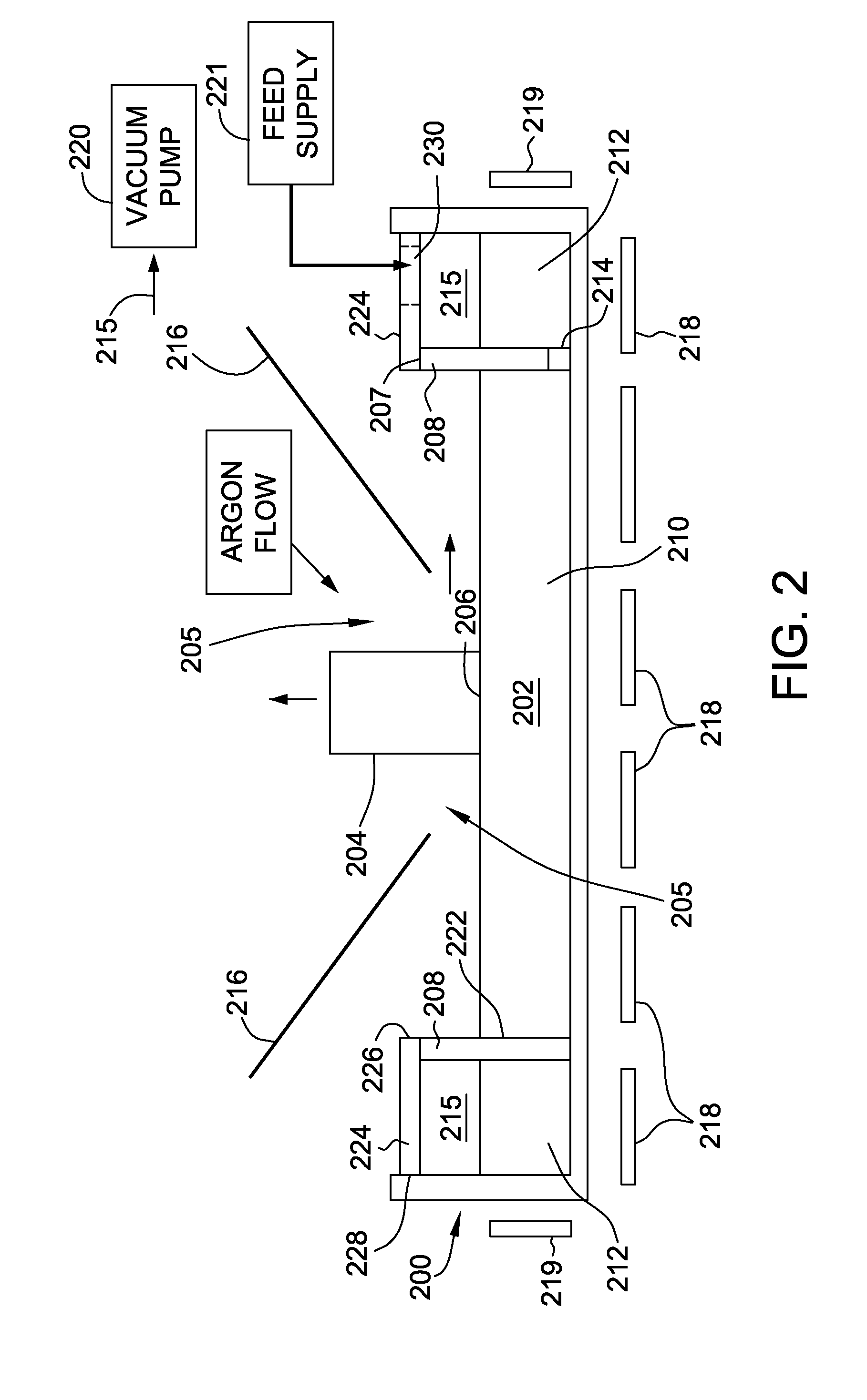

Weir method for improved single crystal growth in a continuous czochralski process

ActiveUS20130233237A1Rule out the possibilitySufficient volumePolycrystalline material growthBy pulling from meltCrucibleCrystalline materials

A method is disclosed for continuous CZ crystal growing wherein one or more crystal ingots are pulled into a growth chamber from a crystal / melt interface defined in a crucible containing molten crystalline material that is continuously replenished by crystalline feedstock. The method includes separating the molten crystalline material, controlling the flow of the molten crystalline material and defining an annular space with respect to sidewalls of a heat shield in the chamber.

Owner:CORNER STAR LTD

Electromagnetic pumping of liquid silicon in a crystal growing process

ActiveUS7291221B2Improve rendering capabilitiesImprove efficiencyPolycrystalline material growthBy pulling from meltCrucibleCombined use

A method and system for use in combination with a crystal growing apparatus for growing a monocrystalline ingot according to a Czochralski process. The crystal growing apparatus has a heated crucible including a semiconductor melt from which the ingot is pulled. The ingot is grown on a seed crystal pulled from the melt. A time varying external magnetic field is imposed on the melt during pulling of the ingot. The magnetic field is selectively adjusted to produce pumping forces in the melt to control a melt flow velocity while the ingot is being pulled from the melt.

Owner:GLOBALWAFERS CO LTD

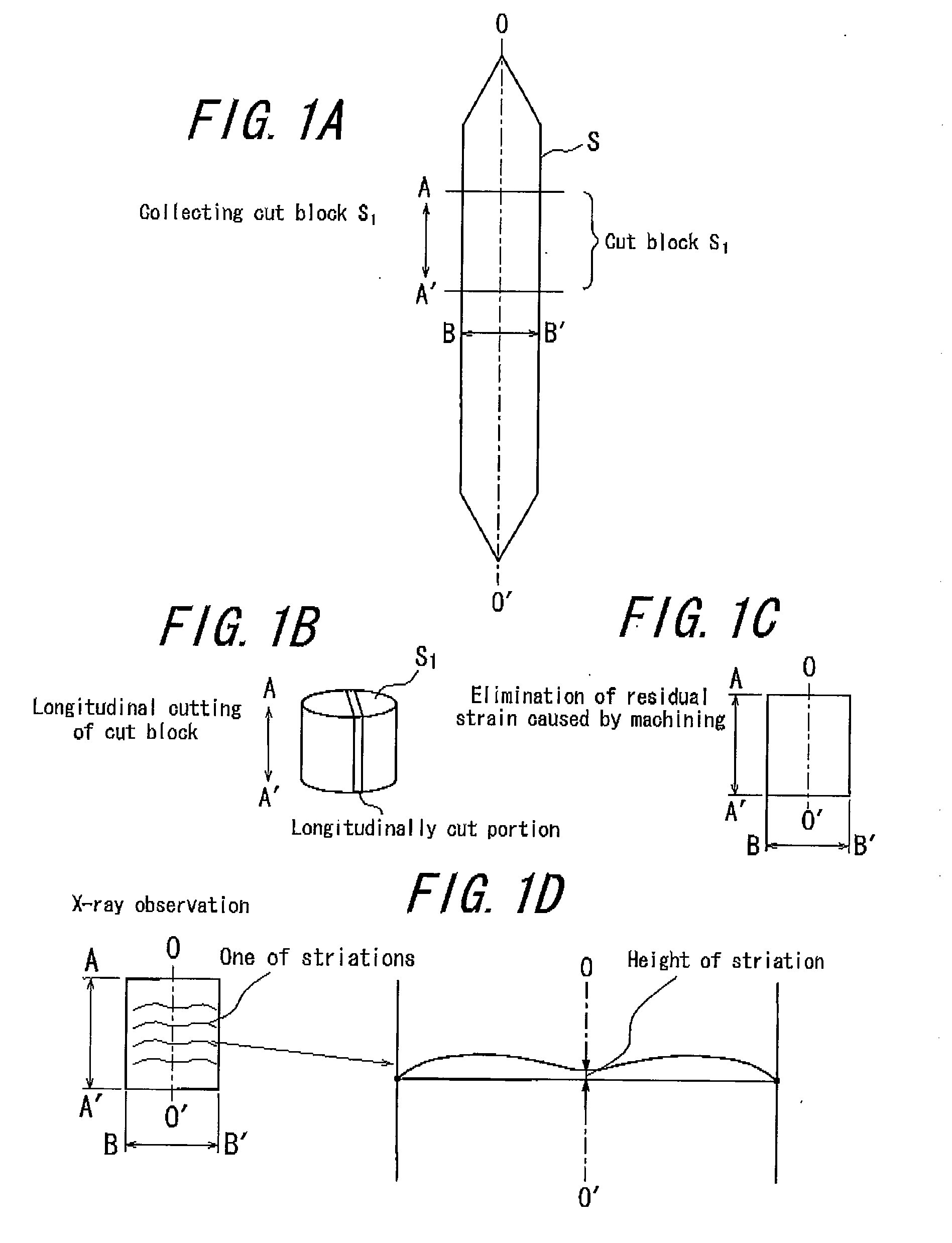

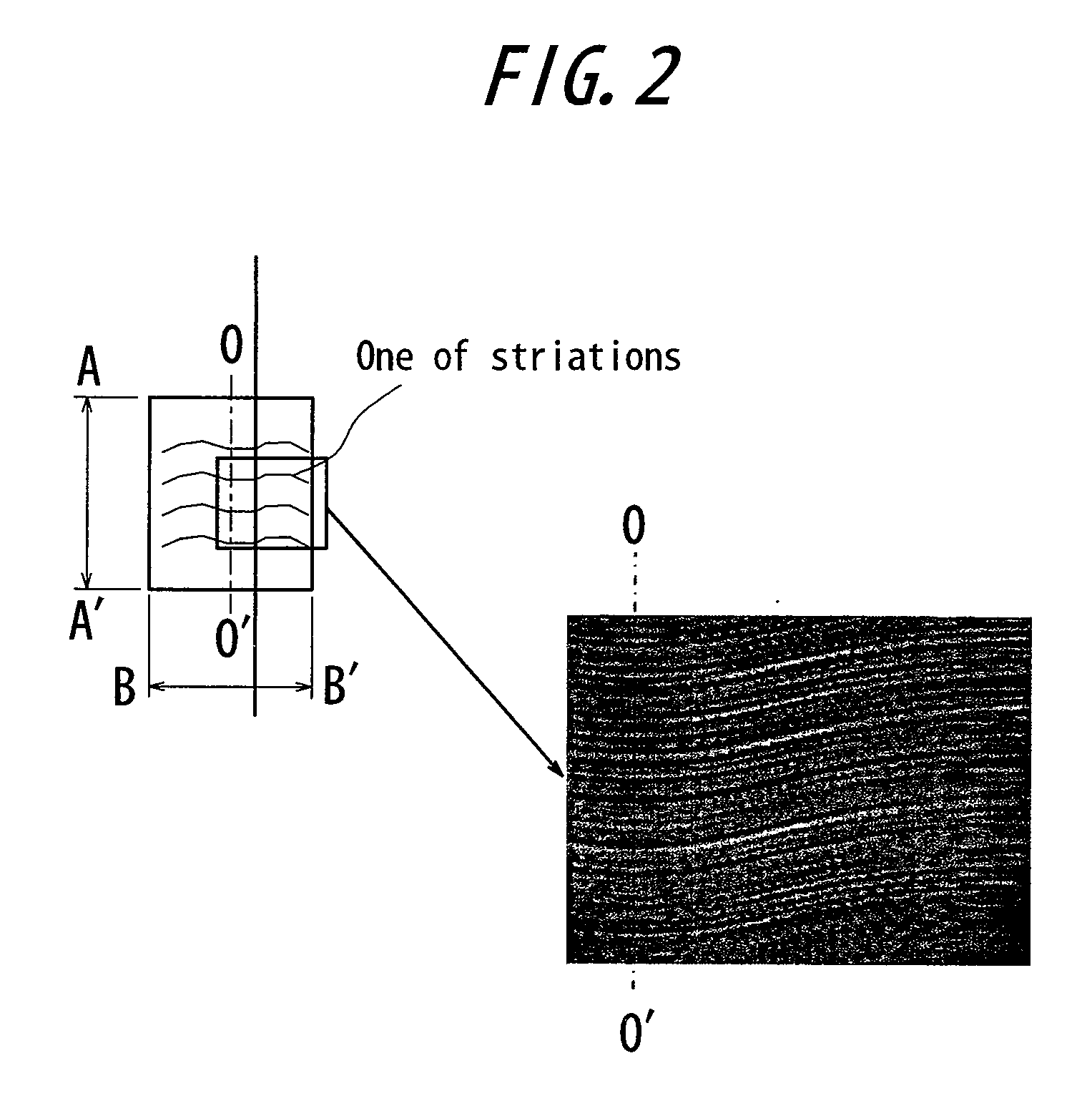

Method of producing single crystal silicon

ActiveUS20110056428A1Increase battery capacityReduce power consumptionPolycrystalline material growthBy pulling from meltDopantMetallurgy

The present invention provides a technique which enables production of single crystal silicon having relatively low resistivity by preventing cell growth during crystal growth from occurring, especially in a case where a relatively large amount of dopant is added to a molten silicon raw material. Specifically, the present invention provides a method of producing single crystal silicon by the Czochralski process, comprising producing single crystal silicon having relatively low resistivity by controlling a height of a solid-liquid interface when the single crystal silicon is pulled up.

Owner:SUMCO TECHXIV

Silica glass crucible with bubble-free and reduced bubble growth wall

A silica glass crucible includes a stable, bubble-free inner layer and an opaque outer layer, both layers demonstrating reduced bubble growth during a Czochralski process. When used in the CZ process, little volume change is observed in the crucible wall, and the crucible has little influence on melt level. The present crucible is especially suited for slow silicon ingot pulling with reduced crystalline defects. The fusion process of the present invention controls the dynamic gas balance at the fusion front where formed grain is melted to dense fused silica.

Owner:SHIN ETABU QUARTZ PRODS

Non-linear optical crystal calcium niobate

InactiveCN1847470APolycrystalline material growthBy pulling from meltNonlinear optical crystalSingle crystal

The non-linear optical crystal calcium niobate as one new type of photoelectronic functional material has the molecular formula of Ca2Nb2O7 and abbreviation of CN. It may be used in doubling frequency of Nd:YAG laser. It is prepared through high temperature sintering to obtain compound for growing CN monocrystal, and subsequent Czochralski process to grow CN monocrystal in the conditions of growing temperature 1600 deg.c, pulling speed 0.5-2 mm / hr, rotation speed 5-20 rpm and nitrogen, argon or other inert gas atmosphere. CN may find its wide application in various non-linear optical fields.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

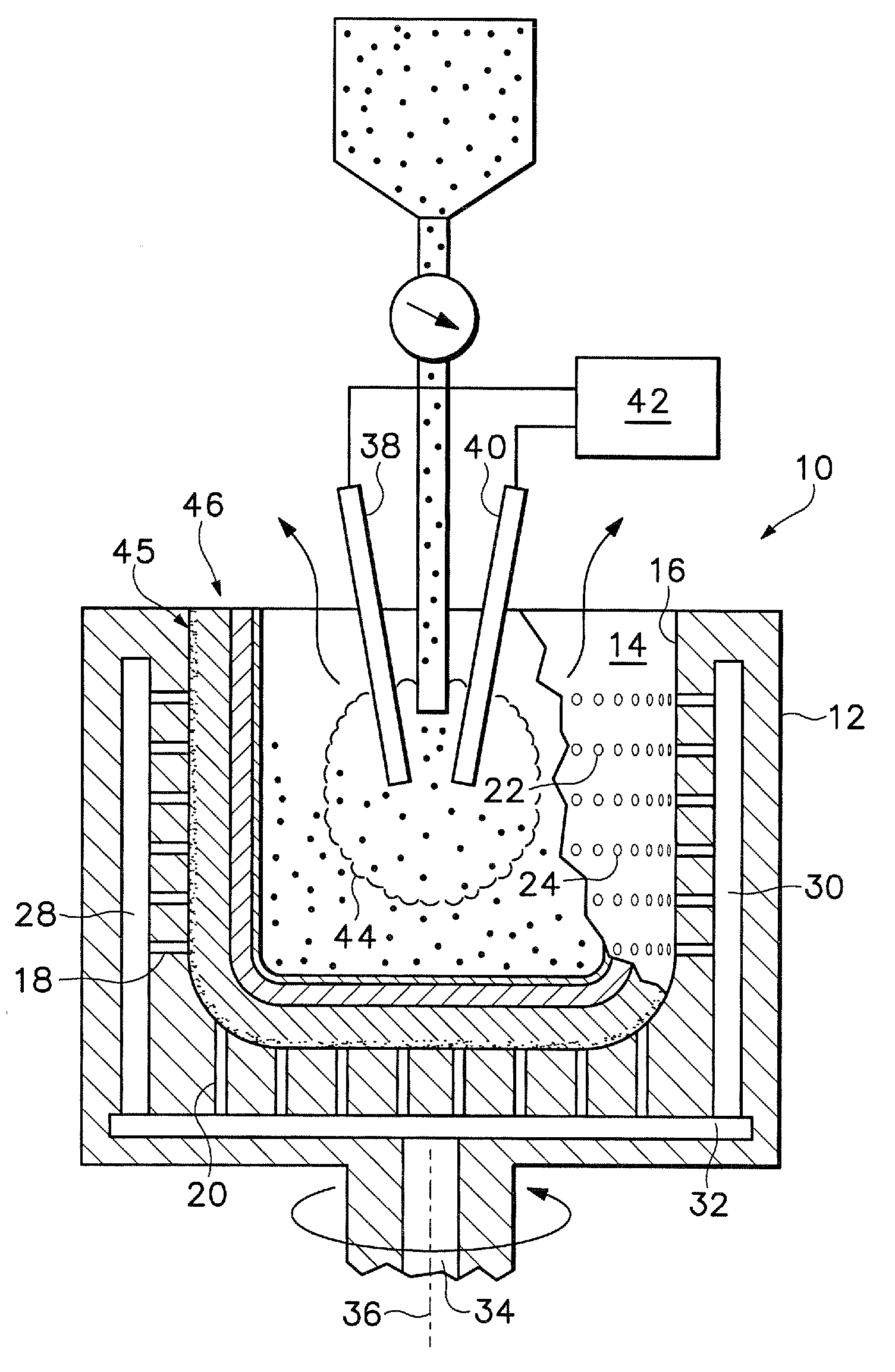

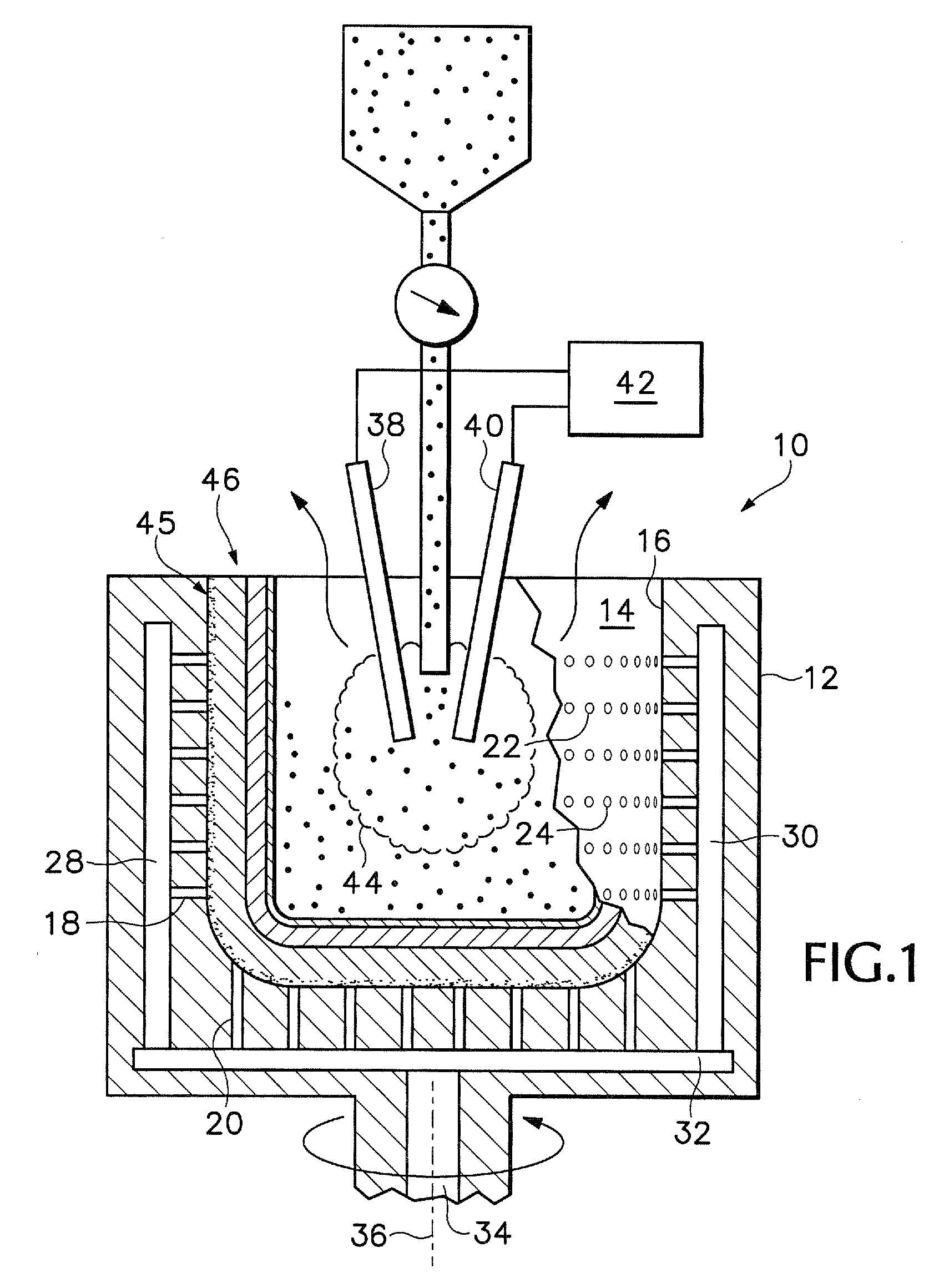

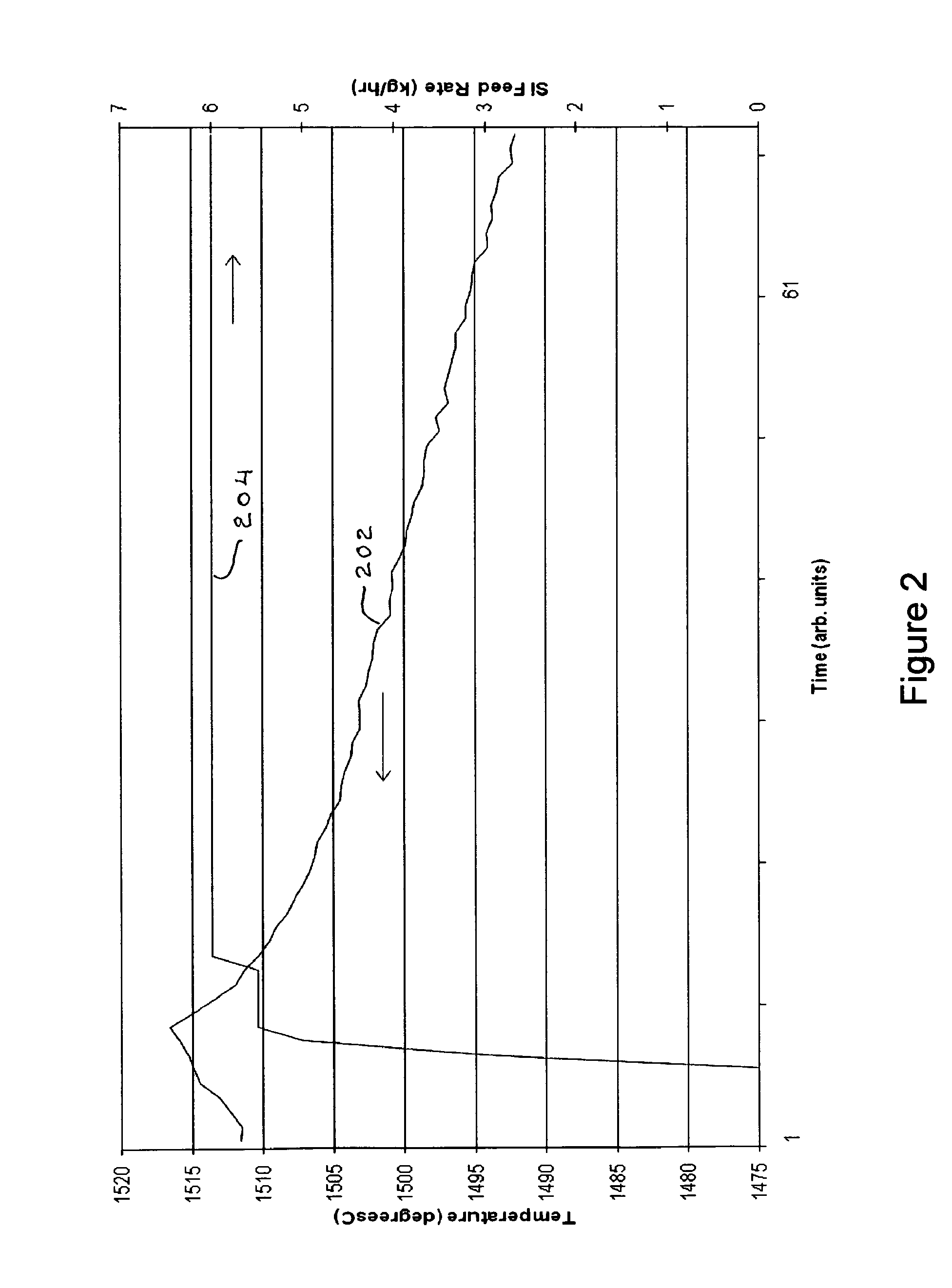

Methods for controlling melt temperature in a czochralski grower

InactiveUS20120210931A1Improve insulation performanceReducing heater powerPolycrystalline material growthBy pulling from meltControl mannerElectric power

In a Czochralski process for growing single crystal silicon ingots, a system is provided for adding solid material to the liquid silicon during crystal growth for the purpose of directly controlling the latent heat of fusion with respect to a crystal melt interface. In contrast to the standard method for controlling power to the crucible heater, the present system has been found to be much more effective for controlling melt temperature in the crucible, especially in heavily insulated systems. The system provides the advantage of reducing the electric power required to operate a Czochralski grower, while increasing the speed with which the melt temperature can be raised or lowered in a controlled manner.

Owner:SOLAICX

Heat Shield For Improved Continuous Czochralski Process

An apparatus for growing ingots by the Czochralski method is described. The ingots are drawn from a melt / crystal interface in a quantity of molten silicon replenished by crystalline feedstock. The apparatus includes a crucible configured to hold the molten silicon and a weir supported in the crucible. The weir is configured to separate the molten silicon into an inner growth region from an outer region configured to receive the crystalline feedstock. The weir includes a sidewall extending vertically and a top wall. An annular heat shield is disposed on the top wall of the weir that covers at least about 70% of the outer region.

Owner:SOLAICX

Method for controlling sapphire seeding form of Kyropoulos method

InactiveCN102758251AAvoid the phenomenon of "long unilateral"Easy to observePolycrystalline material growthUsing seed in meltStable stateCrucible

The invention discloses a method for controlling a sapphire seeding form of a Kyropoulos method. The method comprises that an aluminum oxide raw material is placed in a mono-crystal furnace crucible, seed crystal is installed on a seed crystal rod, a vacuum system and a heating system are started, the voltage of the heating system is adjusted, so that the aluminum oxide raw material is melted completely, a convectional stable state of a melt surface is achieved, and the deviation distance of a cold core of a liquid level and a geometric centre of the crucible is less than 20mm; the seed crystal position is adjusted slowly, then the seed crystal is close to the melt liquid surface gradually, simultaneously, the working voltage of the heating system is adjusted, and the melting of the seed crystal is avoided; preheating is performed for 30 minutes at a position of 2-5mm from the lower end portion of the seed crystal to the melt liquid surface; and the seed crystal is rotated through a traditional Czochralski process, the working voltage of the heating system is adjusted, the diameter of the end portion of crystallization is controlled to be less than 50mm and shouldering is started to be performed after the cold core is coated by the end portion of the crystallization. By the aid of the method, the form of the end portion of the crystallization can be well controlled, the operation is simple, and the success ratio and the yield of the seed crystal are improved.

Owner:无锡鼎晶光电科技有限公司

Controlling a Melt-Solid Interface Shape of a Growing Silicon Crystal Using an Unbalanced Magnetic Field and Iso-Rotation

ActiveUS20090320743A1Increased process windowEasy to controlPolycrystalline material growthBy pulling from meltCrucibleIngot

A system for growing silicon crystals that facilitates controlling a shape of a melt-solid interface is described. The crystal growing system includes a heated crucible including a semiconductor melt from which a monocrystalline ingot is grown according to a Czochralski process. The ingot is grown on a seed crystal pulled from the melt. The method includes applying an unbalanced cusped magnetic field to the melt, and rotating the ingot and the crucible in the same direction while the ingot is being pulled from the melt.

Owner:GLOBALWAFERS CO LTD

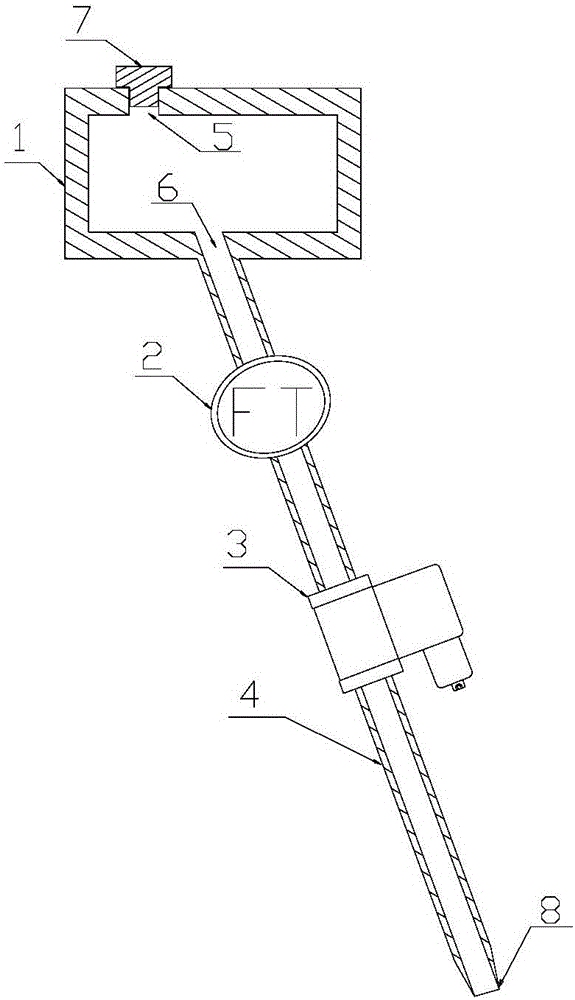

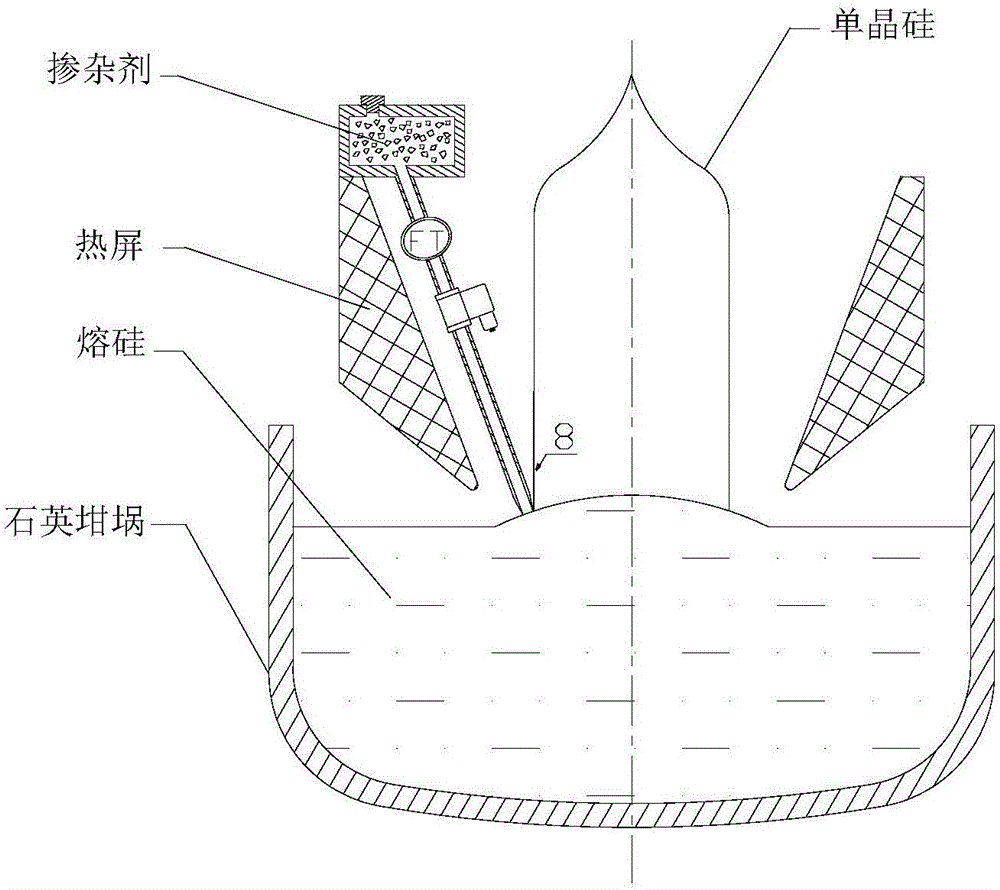

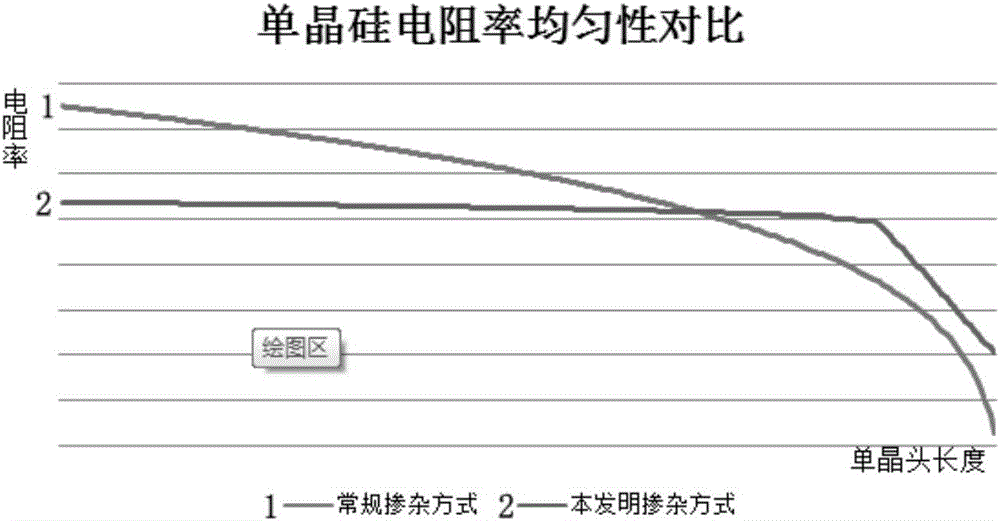

Method and device for improving uniformity of axial resistivity of czochralski monocrystalline silicon

ActiveCN106400106AImprove uniformitySimple structurePolycrystalline material growthBy pulling from meltElectric resistivityElectromagnetic valve

The invention discloses a method and a device for improving the uniformity of the axial resistivity of czochralski monocrystalline silicon. The device comprises a doping agent container, a mass flowmeter, an electromagnetic valve and a conveying pipe. The method comprises the following steps of (1), preparation before the start of the pulling of monocrystalline silicon; (2), melting of a polycrystalline-silicon raw material; (3), seeding; (4), shouldering; (5), shoulder rotation; (6), diameter equaling; (7), ending. The method and the device for improving the uniformity of the axial resistivity of the czochralski monocrystalline silicon have the advantages that (1), a conventional doping way in a czochralski process is changed, the uniformity of an axial doping element in the monocrystalline silicon is improved, and further, the uniformity of the axial resistivity is improved; (2), the device provided by the invention is simple in structure and is convenient to operate.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Processing process for preparing single crystal silicon through Czochralski method

InactiveCN107794563ALow oxygenInhibit entryPolycrystalline material growthBy pulling from meltCrystal rotationCzochralski method

The invention discloses a processing technology for preparing single crystal silicon by the Czochralski method, which comprises the following steps: necking growth: when the temperature of the silicon melt is stabilized to a certain temperature, the seed crystal is immersed in the silicon melt, and the seed crystal is Increase the pulling speed at a certain rate to reduce the diameter of the seed crystal to 3-7mm; shoulder growth: after the necking growth is completed, reduce the crucible temperature and pulling speed, adjust the crucible rotation speed and crystal rotation speed, and increase the crystal to the required diameter; equal-diameter growth: after the shoulder growth is completed, adjust the crucible temperature, pulling speed, crucible rotation speed and crystal rotation speed, so that the diameter of the ingot is maintained between plus and minus 2mm; the present invention adds pure boron to the single crystal silicon raw material, The mass ratio of pure boron to monocrystalline silicon raw materials is 5%-15%, so that the resistivity of monocrystalline silicon can reach 300Ω / CM, and the radial uniformity of resistivity is within 3%; reduce the oxygen content in silicon melt It effectively inhibits the entry of oxygen from the silicon melt into the silicon crystal, improves work efficiency, and reduces the oxygen content of the silicon crystal.

Owner:JIANGSU YONGJIA ELECTRONICS MATERIALS

Self-frequency doubling laser crystal Nd-doped calcium niobate

InactiveCN1847471AExcellent optical propertiesStable growth processPolycrystalline material growthBy pulling from meltSpectroscopyRefractive index

The present invention relates to artificial crystal, and is especially one kind of self-frequency doubling laser crystal, Nd:Ca2Nb2O7 crystal, and its preparation process. By means of Czochralski process in the conditions of growing temperature 1600 deg.c, pulling speed 0.5-2 mm / hr and rotation speed 5-20 rpm, high quality and large size Nd:Ca2Nb2O7 crystal may be obtained. As one new kind of laser crystal, the Nd:Ca2Nb2O7 crystal can output laser beam of wavelength or self-frequency doubling green laser beam of wavelength 534 nm. The laser of Nd:Ca2Nb2O7 crystal may find its wide application in spectroscopy, biomedicine, military and other fields.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Silica glass crucible with barium-doped inner wall

InactiveUS7427327B2After-treatment apparatusPolycrystalline material growthSolar cellSilicon dioxide

A silica glass crucible includes a thin barium-doped inner layer, a stable, bubble-free intermediate layer, and a stable opaque outer layer. The fusion process of the present invention controls the dynamic gas balance at the fusion front where formed grain is melted to dense fused silica. The crucible demonstrates reduced bubble growth during a Czochralski process. As a result of the thin barium-doped layer and the reduced bubble growth, the inner surface of the crucible is uniformly minimally textured during a CZ process. The present crucible is especially suited for intense CZ processes for manufacturing silicon ingots used for solar cells or with silicon that is heavily doped with antimony, boron, or arsenic.

Owner:SHIN ETABU QUARTZ PRODS

Crucible weight measurement system for controlling feedstock introduction in Czochralski crystal growth

ActiveUS8257496B1Weight approximately constantAfter-treatment apparatusPolycrystalline material growthCrucibleIngot

A weighing system is provided for a continuous Czochralski process that accurately measures the weight of the crucible and melt during crystal growth to control the introduction of feedstock in order to keep the weight approximately constant. The system can measure the weight of the crucible while the crucible is rotating, and is insensitive to vibrations of the melt surface as well as variable torques on the crucible shaft induced by the rotation. The system also measures the weight of the crucible and its contents in order to control the amount of feedstock recharged after an ingot is withdrawn.

Owner:CORNER STAR LTD

Lithium niobate substrate and method of producing the same

ActiveUS7309392B2Color non-uniformityLess coloringPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyHeat treatedMaterials science

In a method of producing a lithium niobate substrate by the use of a lithium niobate crystal grown by the Czochralski process, the lithium niobate crystal is heat-treated at a temperature of from 300° C. or more to less than 500° C. in the state the lithium niobate crystal is buried in a powder constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C, or in the state the lithium niobate crystal is held in a container constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C.

Owner:SUMITOMO METAL MINING CO LTD

Compound R2MB10O10 as non-linear optical crystal and its preparation and use

InactiveCN1084399CImprove mechanical propertiesUnbreakablePolycrystalline material growthActive medium materialRare-earth elementCongruent melting

The present invention provides one compound with chemical expression of R2MB10O10, (where R is one or several elements selected from rare earth elements and Y and M is Ca, Sr or Ba); and one monocrystal and their preparation and application. The compound has the feature of congruent melting. the R2MB10O10 monocrystal may be prepared through the melt process, especially czochralski process or the pulling method, has non-linear optical effect similar to LBO but low cost, large size, good mechanical performance and no slaking, and suits the need of laser frequency change in blue and green light band. The monocrystal may be used in producing non-linear optical devices and that with doped rare earth laser activating ion may be used in producing non-linear composite laser function device.

Owner:UNIV OF SCI & TECH OF CHINA

Weir For Improved Crystal Growth in A Continuous Czochralski Process

ActiveUS20140144372A1Prevent thermal and mechanical disturbancesReduce erosionPolycrystalline material growthBy pulling from meltCzochralski methodIngot

An apparatus for growing ingots by the Czochralski method includes a growth chamber defining an enclosure configured to circulate a purge gas about the growing ingot and a crucible provided in the growth chamber configured to hold the molten silicon. A weir is supported in the crucible and is configured to separate the molten silicon into an inner growth region surrounding the melt / crystal interface from an outer region configured to receive the crystalline feedstock. The weir comprises at least one sidewall extending vertically and a cap extending substantially perpendicularly to the sidewall.

Owner:CORNER STAR LTD

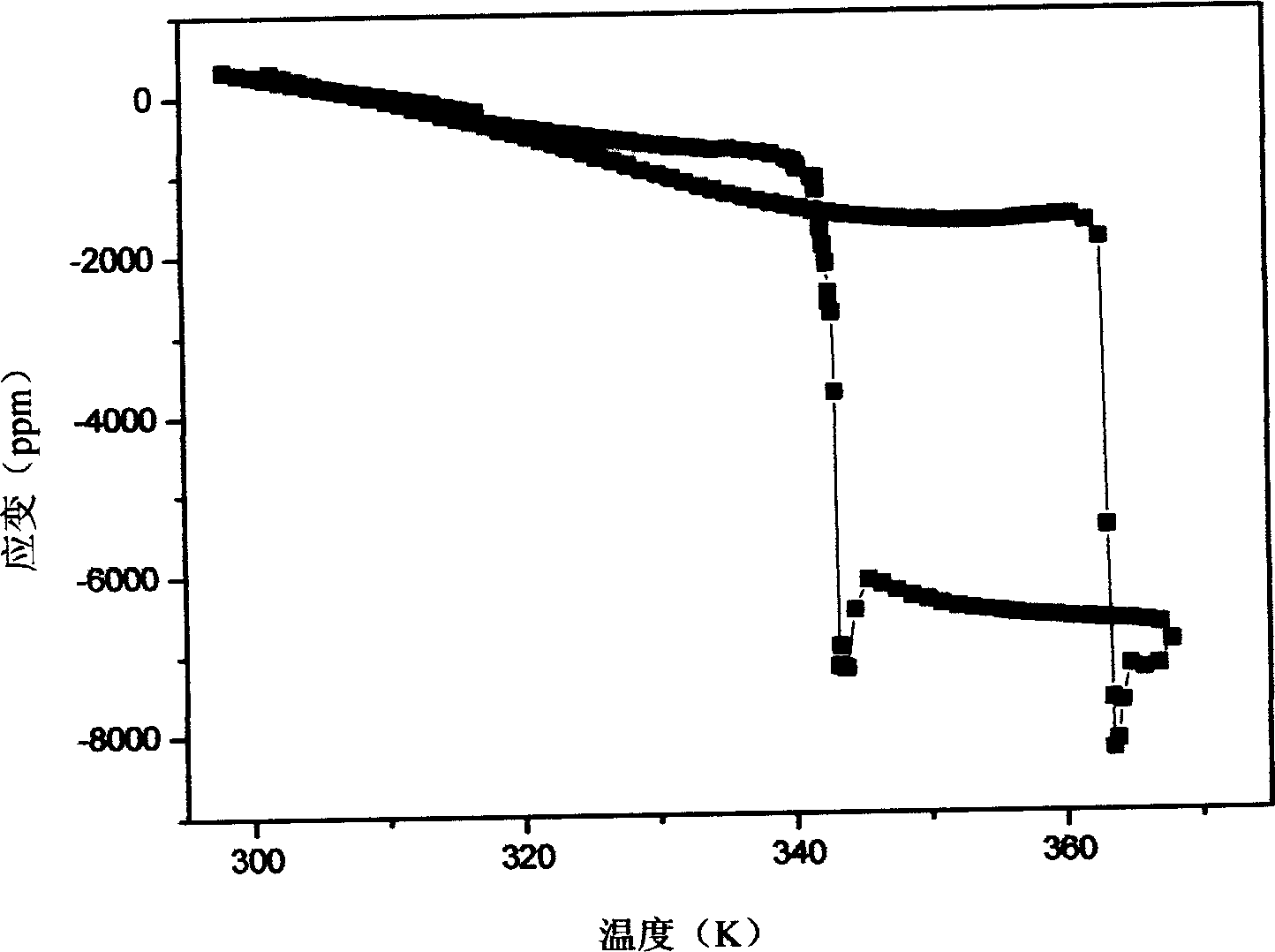

Magnetic material with bidirectional shape memory effect and single-crystal producing method thereof

InactiveCN1610020AWide range of usesLow costPolycrystalline material growthBy pulling from meltMartensite transformationMemory effect

The present invention discloses one kind of magnetic material with bi-directional shape memory effect and its monocrystal preparing process. The magnetic monocrystal material has the chemical expression of MnxNiyGaz, where x is 37-55, y is 20-38, z is 20-30, x+y+z=100, x, y and z are atom percentage content. The monocrystal preparing process includes setting prepared material in crucible and Czochralski process of growing the magnet MnxNiyGaz monocrystal. The magnetic monocrystal material has its martensitic transformation temperature regulated via altering the Mn, Ni and Ga ratio, and may have martensitic starting point regulated in 36-350 K and Curie temperature in 140-330 deg.c as requirement. In addition, the present invention uses conventional equipment, has low cost and is easy industrial application.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

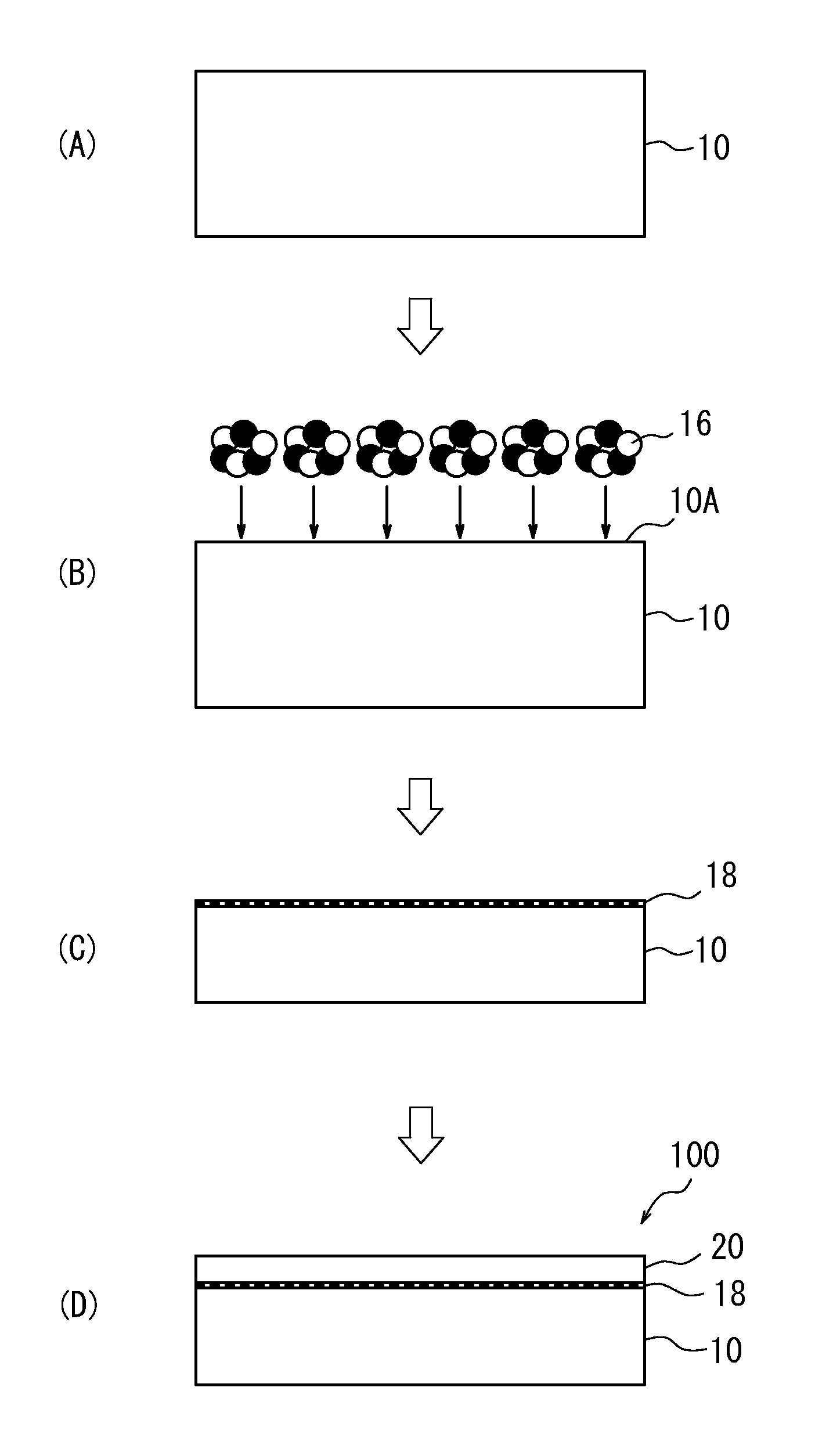

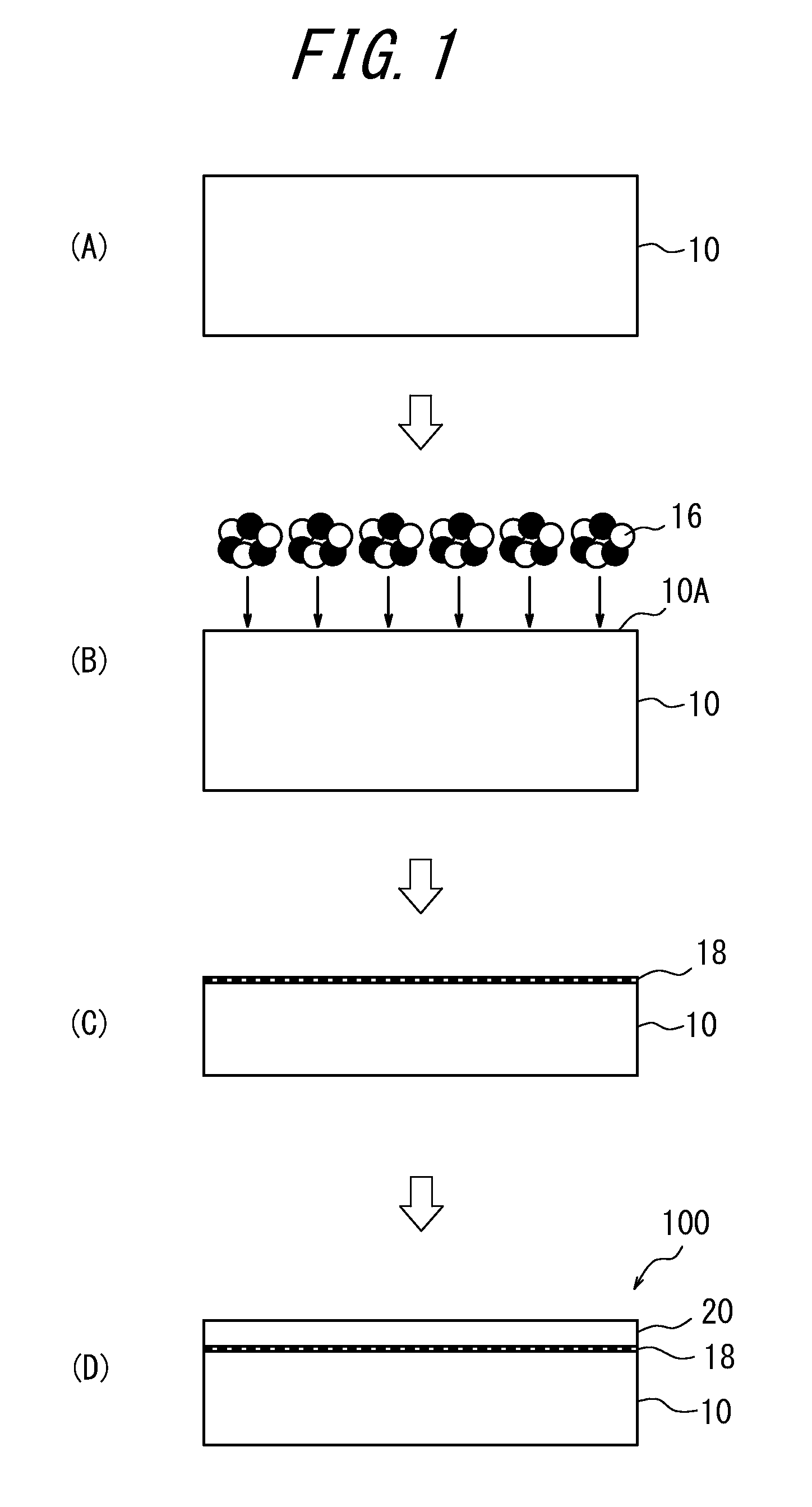

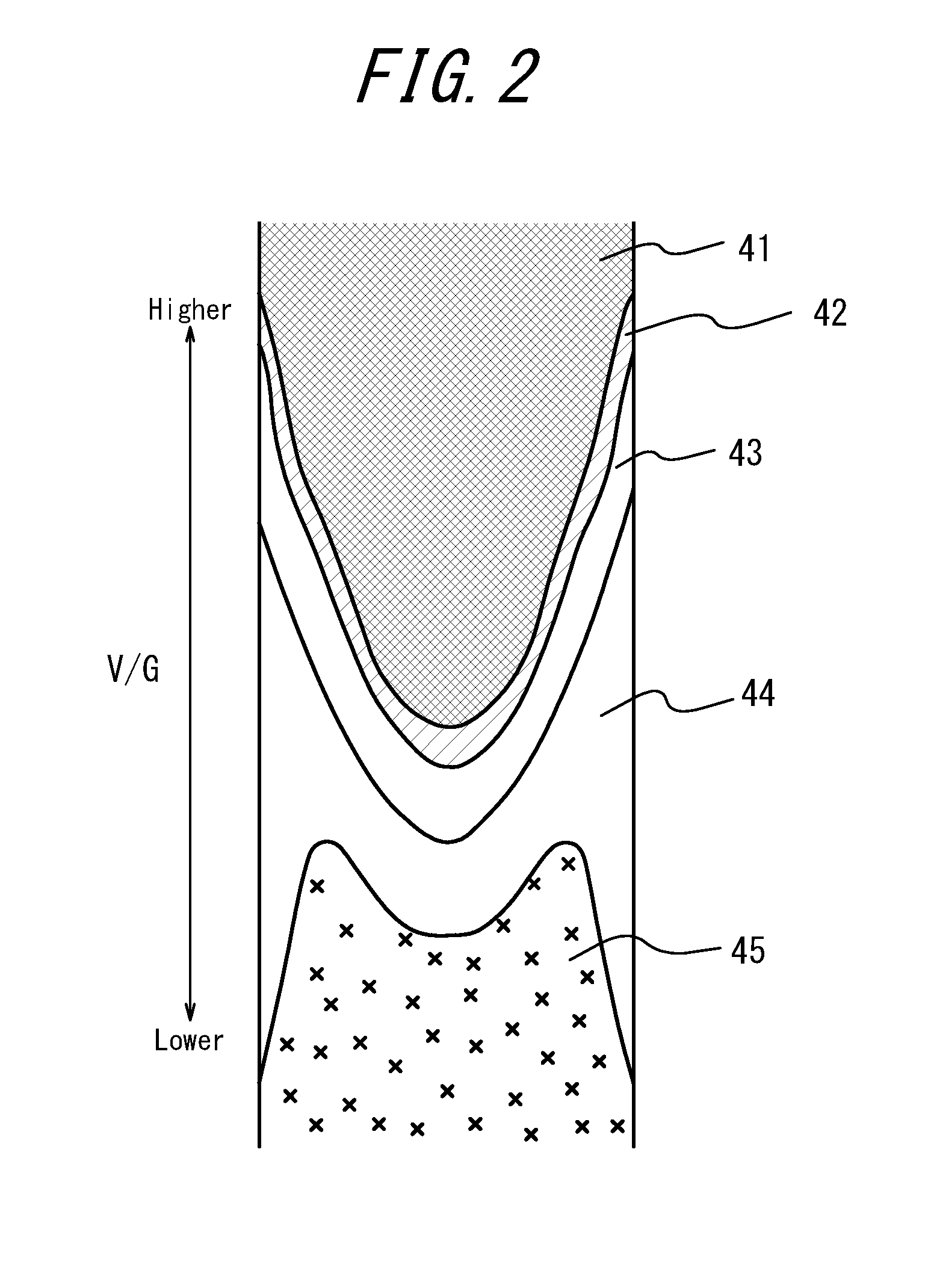

Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device

ActiveUS9117676B2Improve inhalation effectSuppress metal contaminationSolid-state devicesSemiconductor/solid-state device manufacturingMetal contaminationEpitaxial silicon

Provided is an epitaxial silicon wafer with reduced metal contamination achieved by higher gettering capability and a method of efficiently producing the same.The method of producing an epitaxial wafer includes a wafer production step of pulling a single crystal silicon ingot having a COP formation region by Czochralski process, and subjecting the obtained single crystal silicon ingot to slicing, thereby producing a silicon wafer 10 including COPs; a cluster ion irradiation step of irradiating the produced silicon wafer 10 with cluster ions 16 to form a modifying layer 18 formed from a constituent element of the cluster ions 16, contained as a solid solution in a surface portion 10A of the silicon wafer 10; and an epitaxial layer formation step of forming an epitaxial layer 20 on the modifying layer 18 of the silicon wafer 10.

Owner:SUMCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com