Patents

Literature

232results about How to "Improve inhalation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

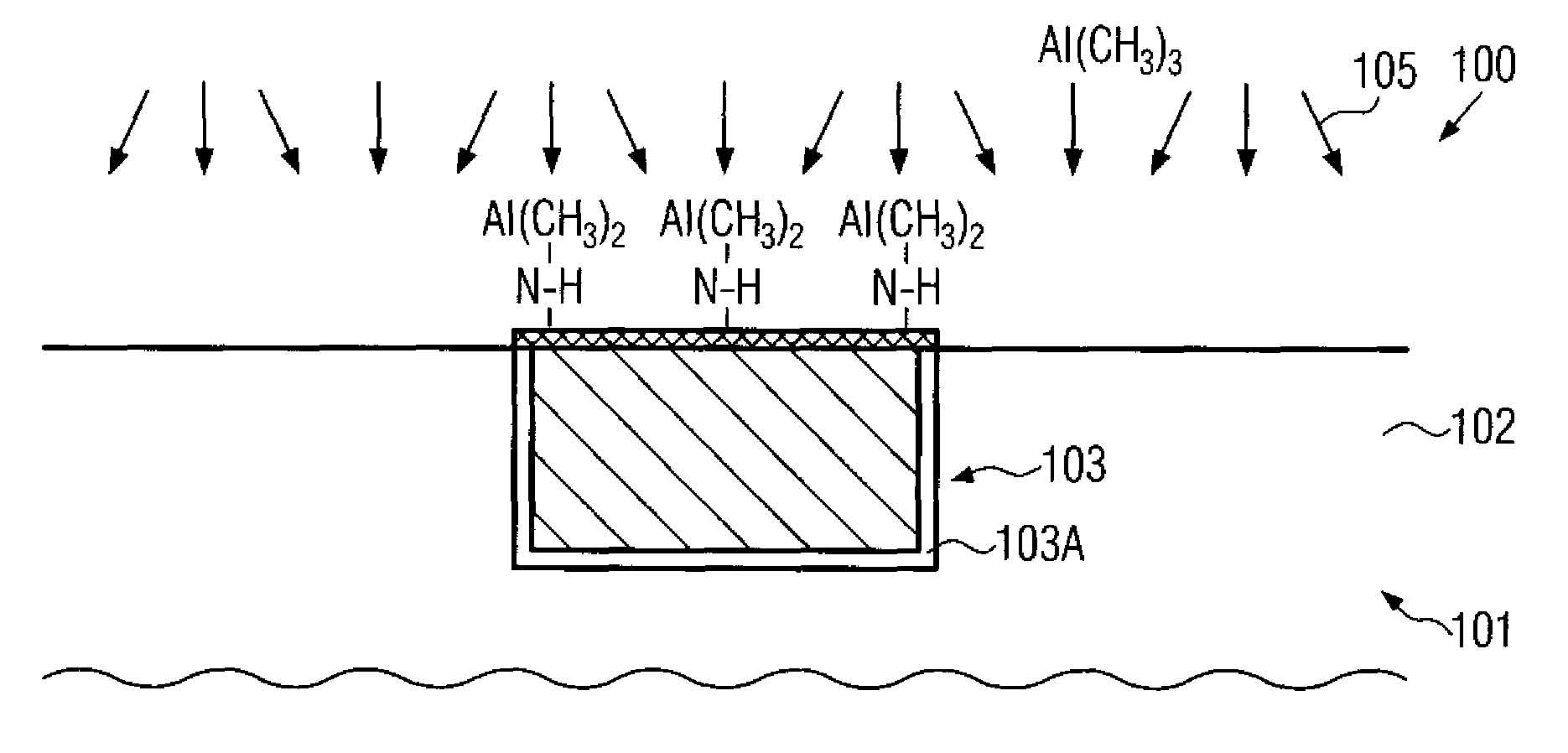

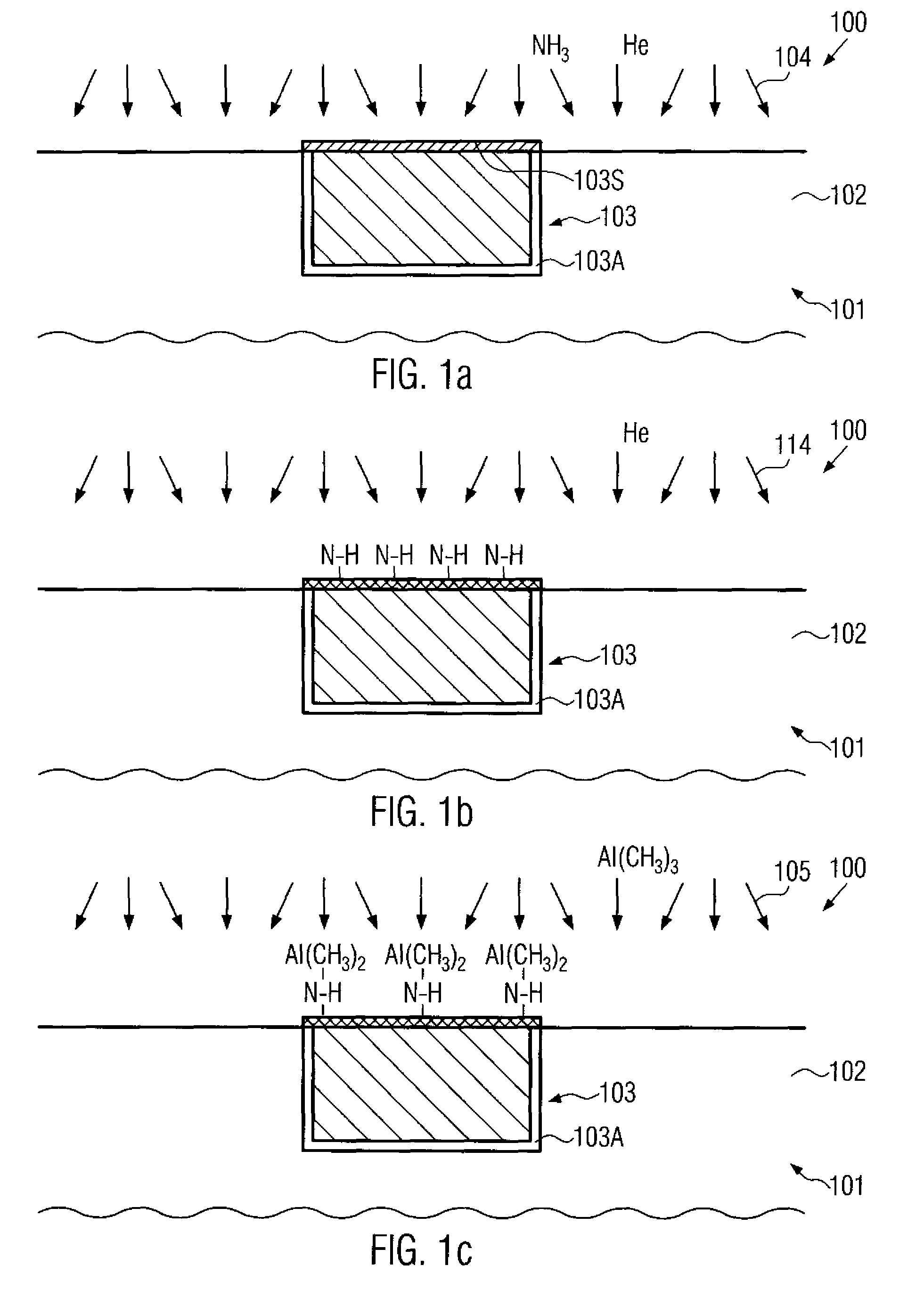

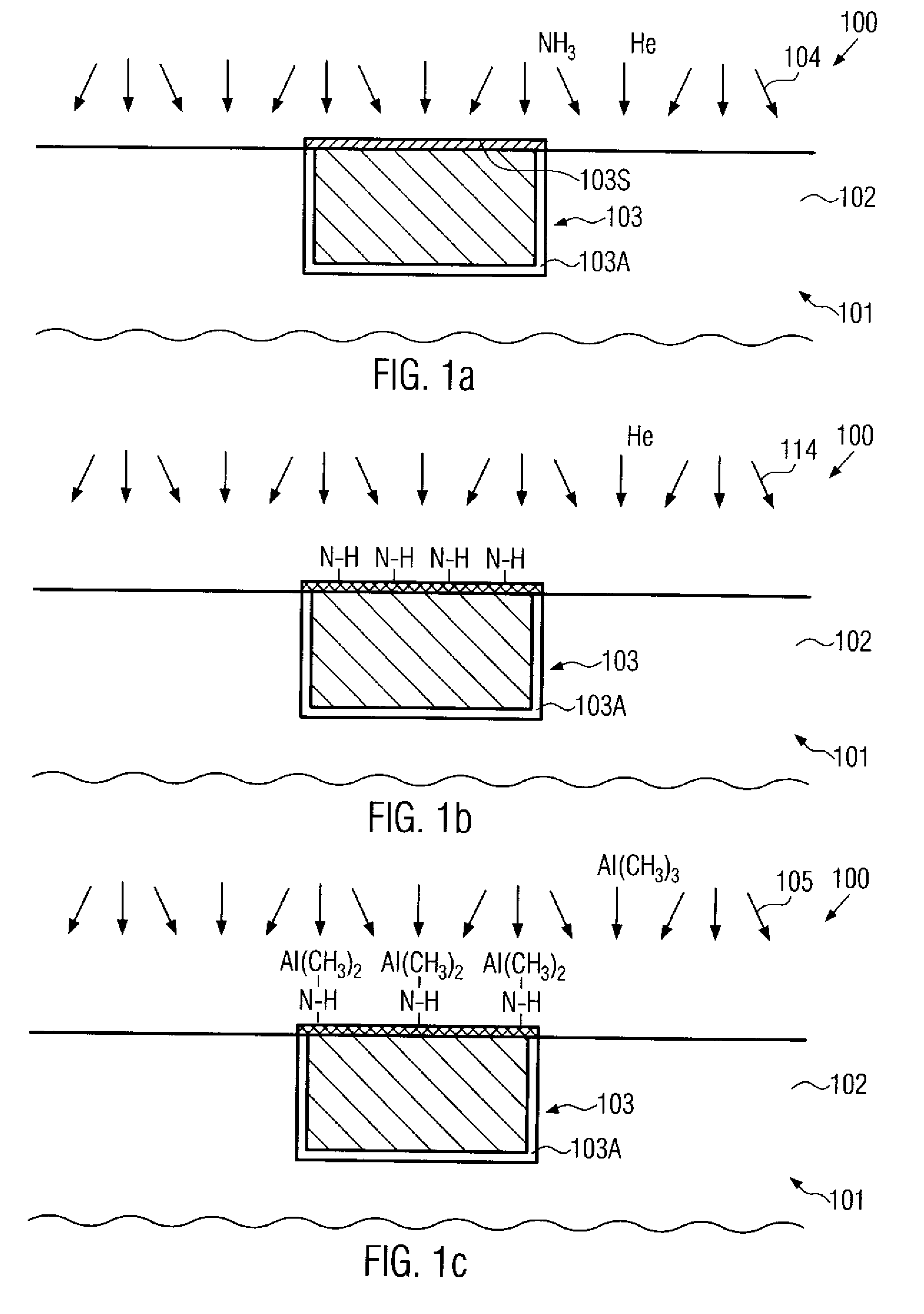

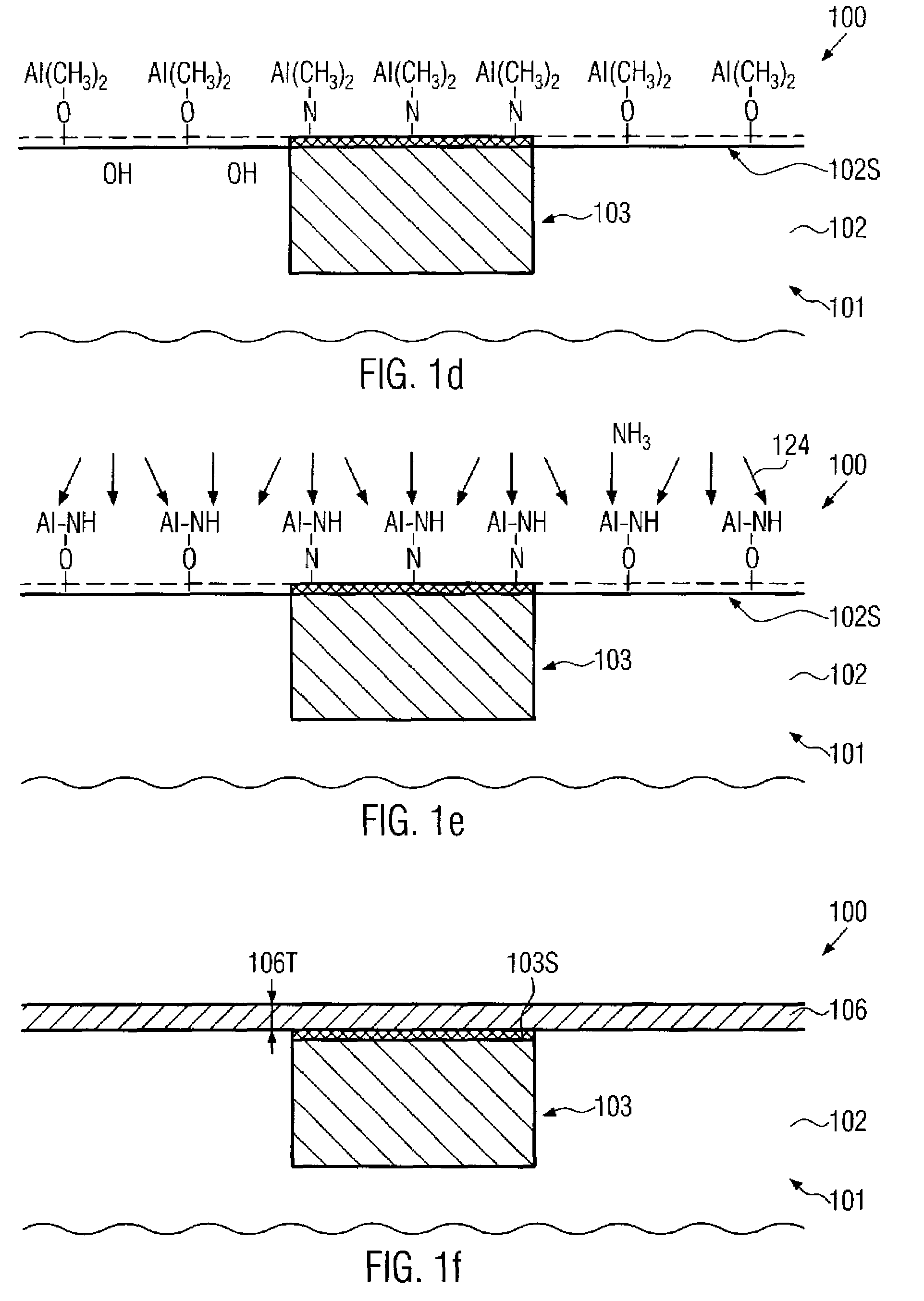

Method of manufracturing increasing reliability of copper-based metallization structures in a microstructure device by using aluminum nitride

ActiveUS7829460B2Reduce parasitic capacitanceEasy to controlSemiconductor/solid-state device detailsSolid-state devicesSelf limitingPermittivity

Owner:GLOBALFOUNDRIES U S INC

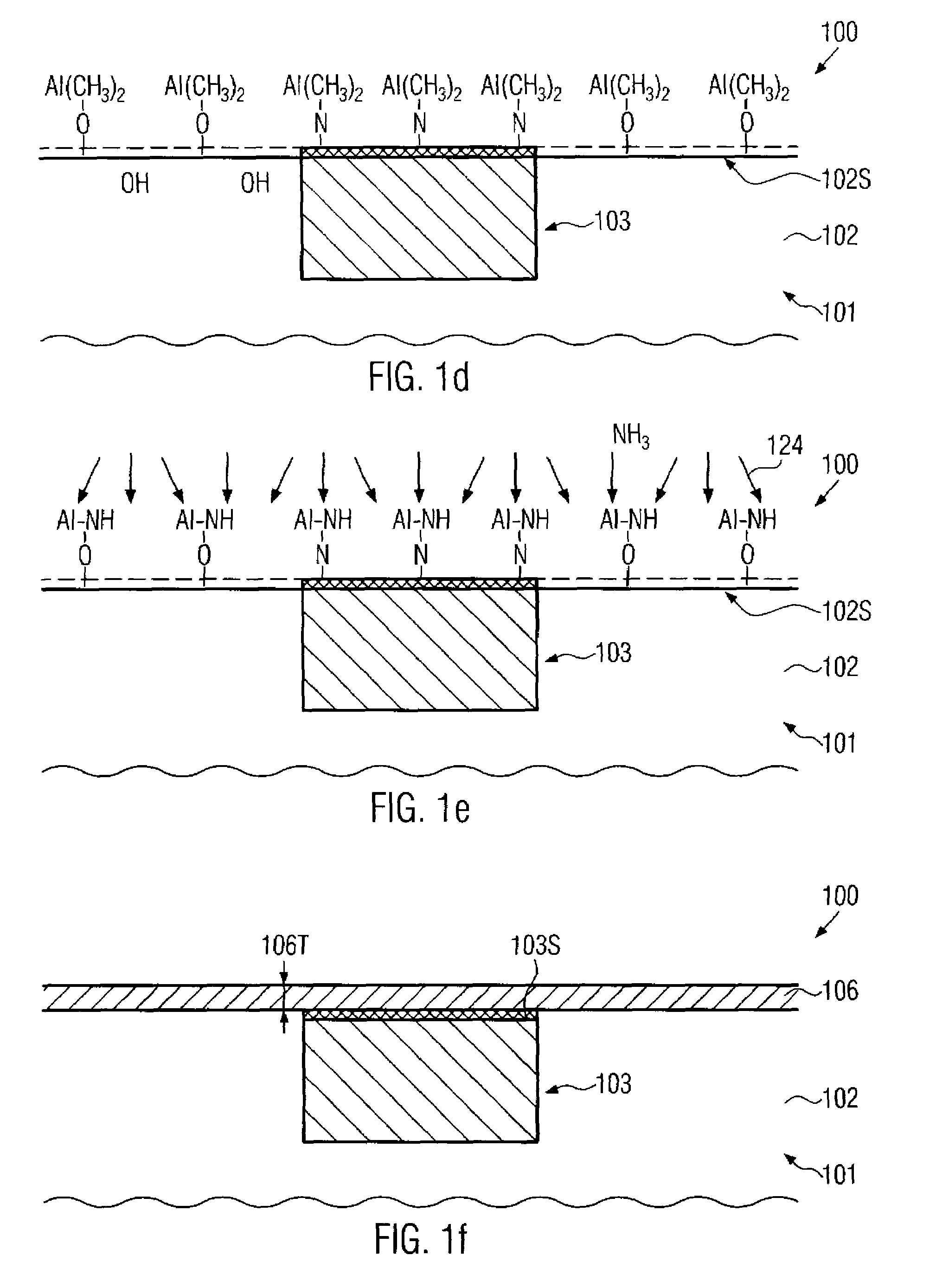

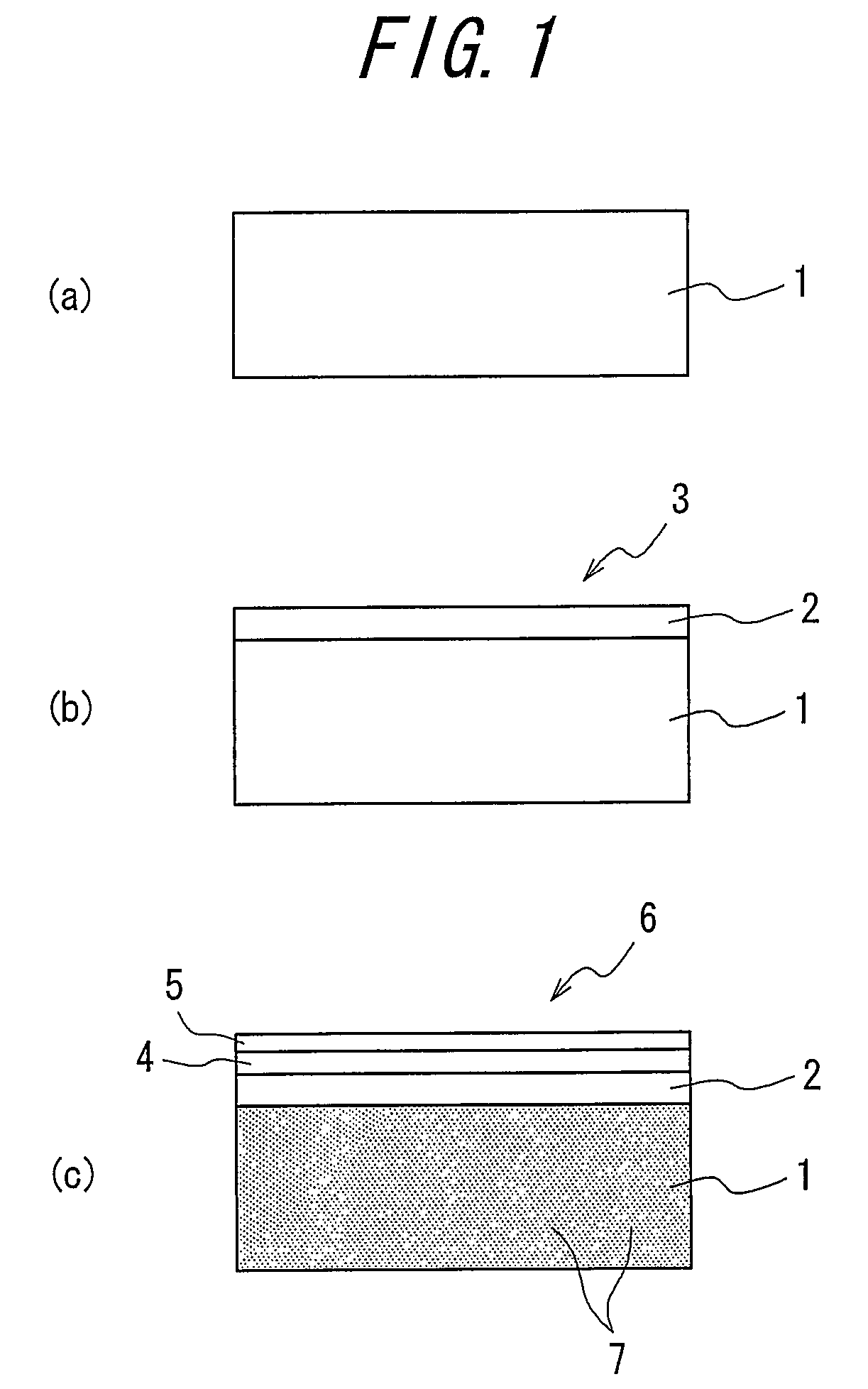

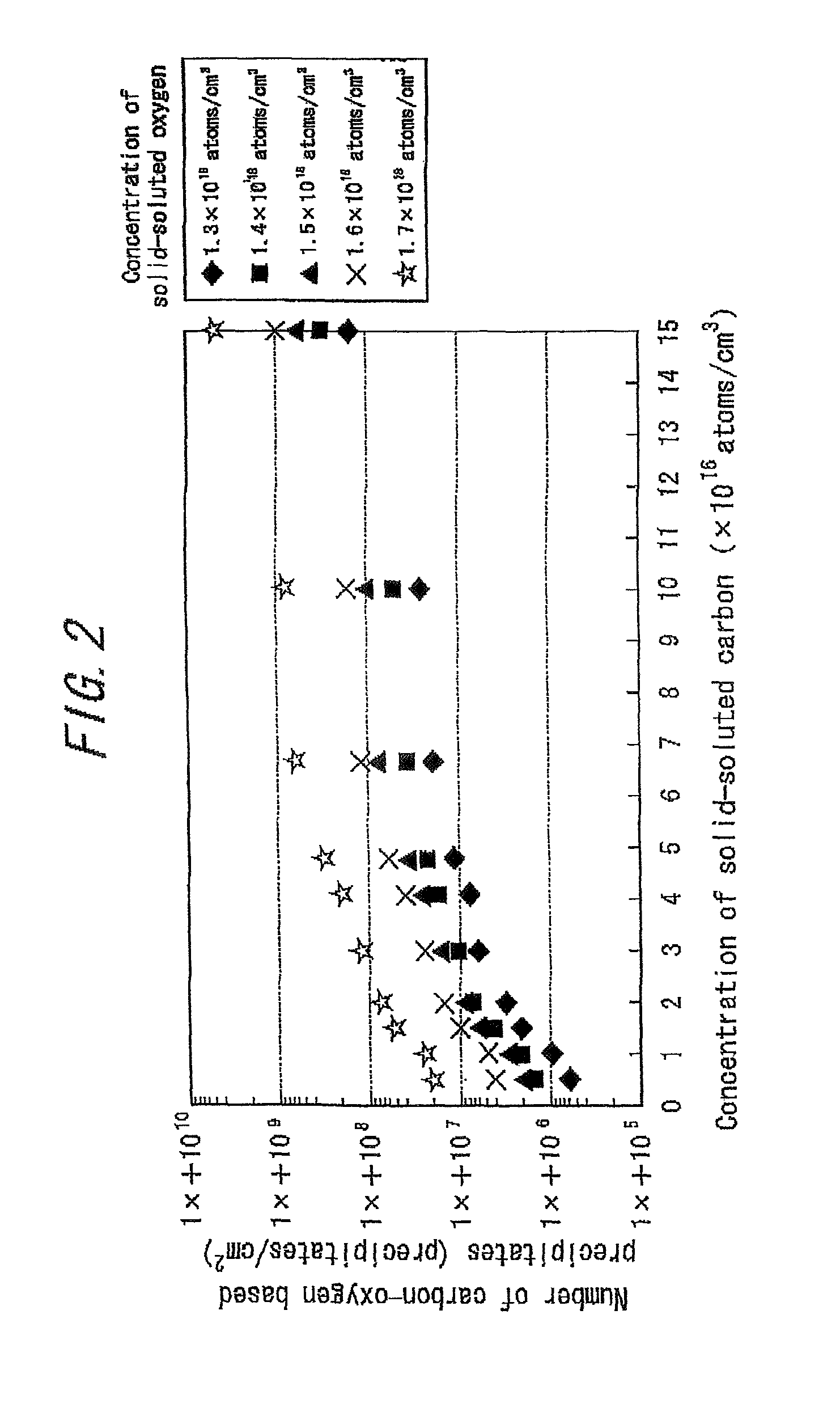

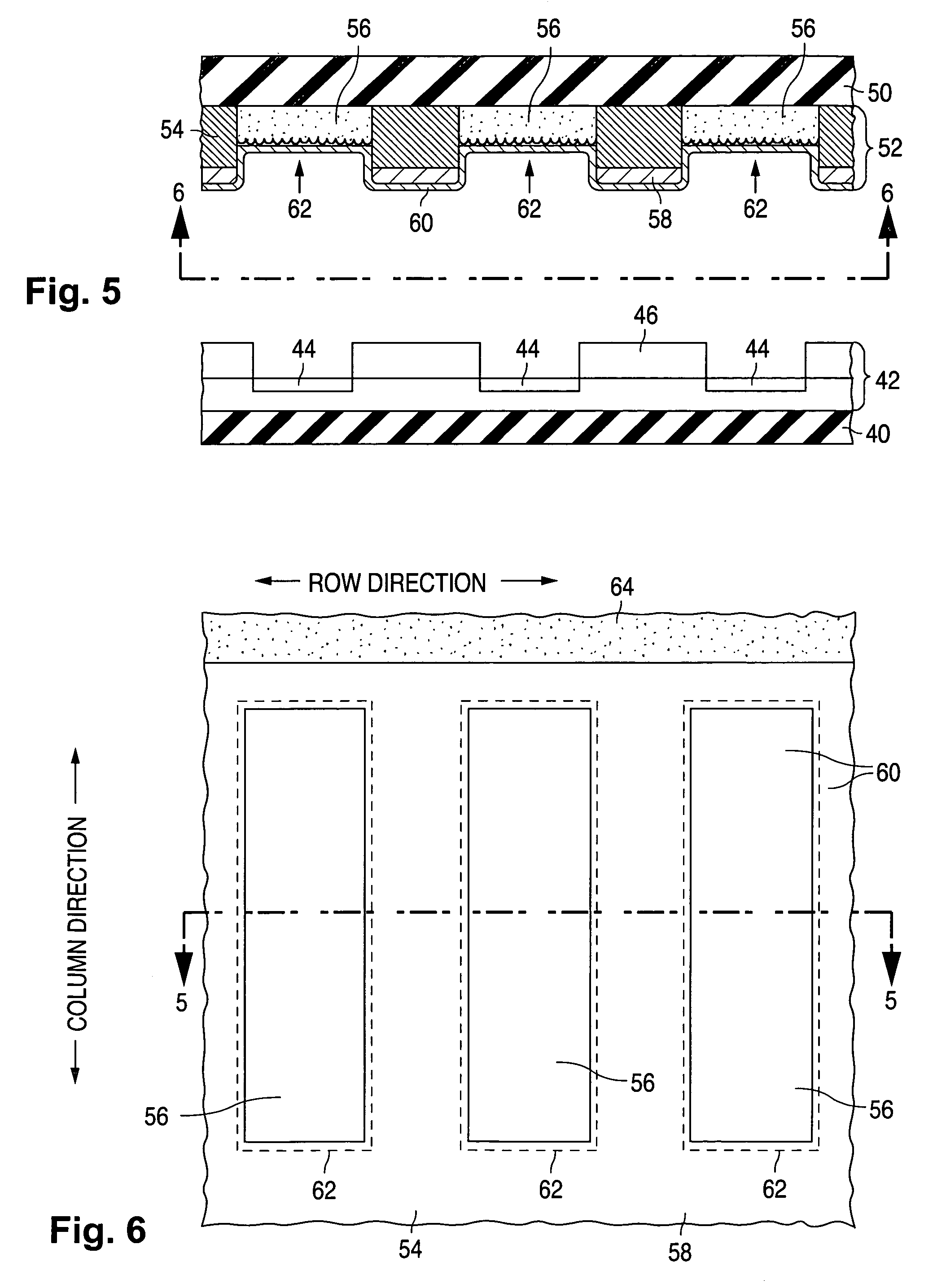

Semiconductor substrate for solid-state image sensing device as well as solid-state image sensing device and method for producing the same

ActiveUS8063466B2Improve inhalation effectGood electric characteristicPolycrystalline material growthAfter-treatment detailsCarbon ionOxygen

There is provided a semiconductor substrate for solid-state image sensing device in which the production cost is lower than that of a gettering method through a carbon ion implantation and problems such as occurrence of particles at a device production step and the like are solved.Silicon substrate contains solid-soluted carbon having a concentration of 1×1016-1×1017 atoms / cm3 and solid-soluted oxygen having a concentration of 1.4×1018-1.6×1018 atoms / cm3.

Owner:SUMCO CORP

Increasing reliability of copper-based metallization structures in a microstructure device by using aluminum nitride

ActiveUS20080179741A1Improve adhesionSuperior performance characteristicSemiconductor/solid-state device detailsSolid-state devicesSelf limitingCopper

By forming an aluminum nitride layer by a self-limiting process sequence, the interface characteristics of a copper-based metallization layer may be significantly enhanced while nevertheless maintaining the overall permittivity of the layer stack at a lower level.

Owner:GLOBALFOUNDRIES US INC

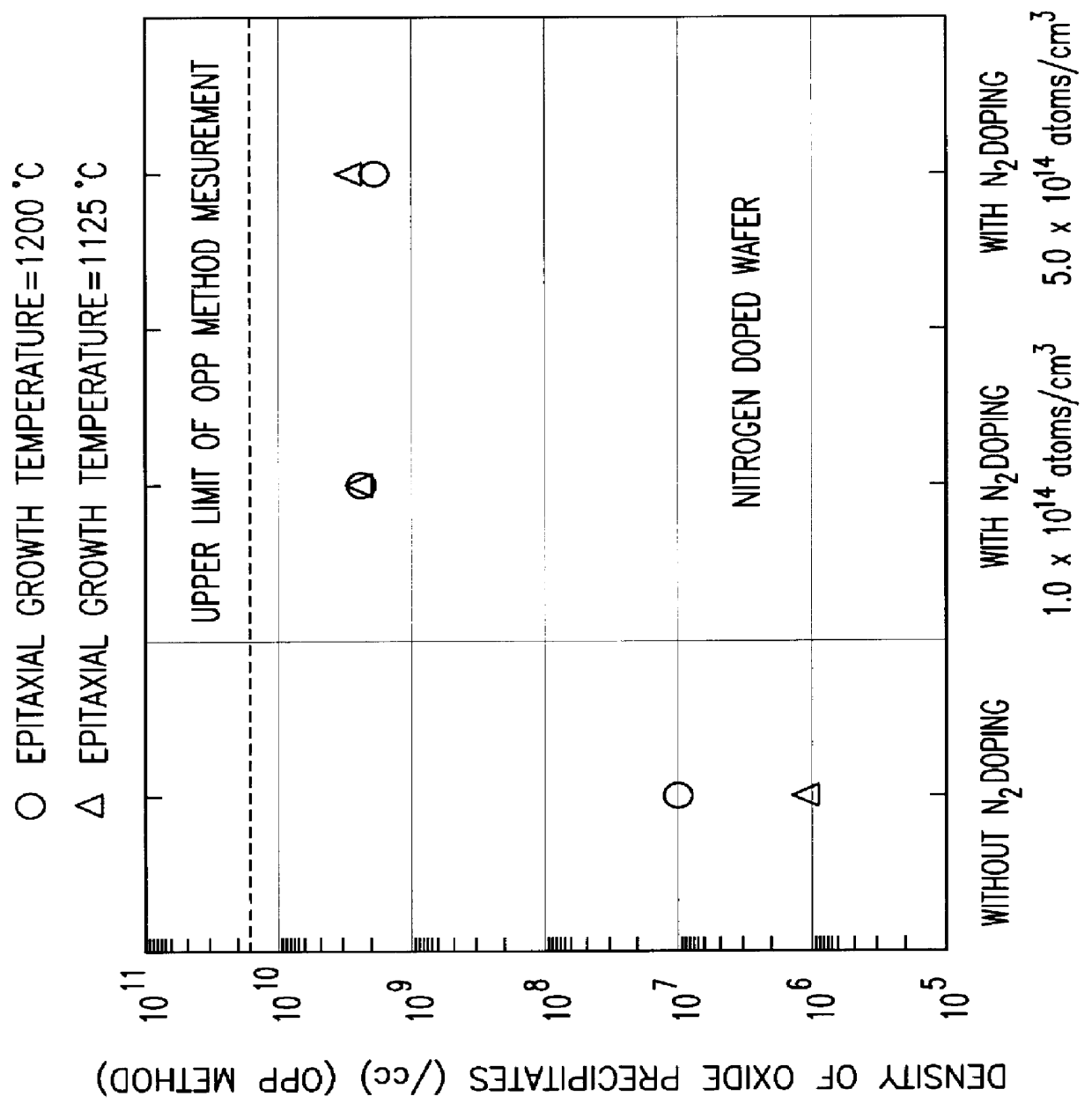

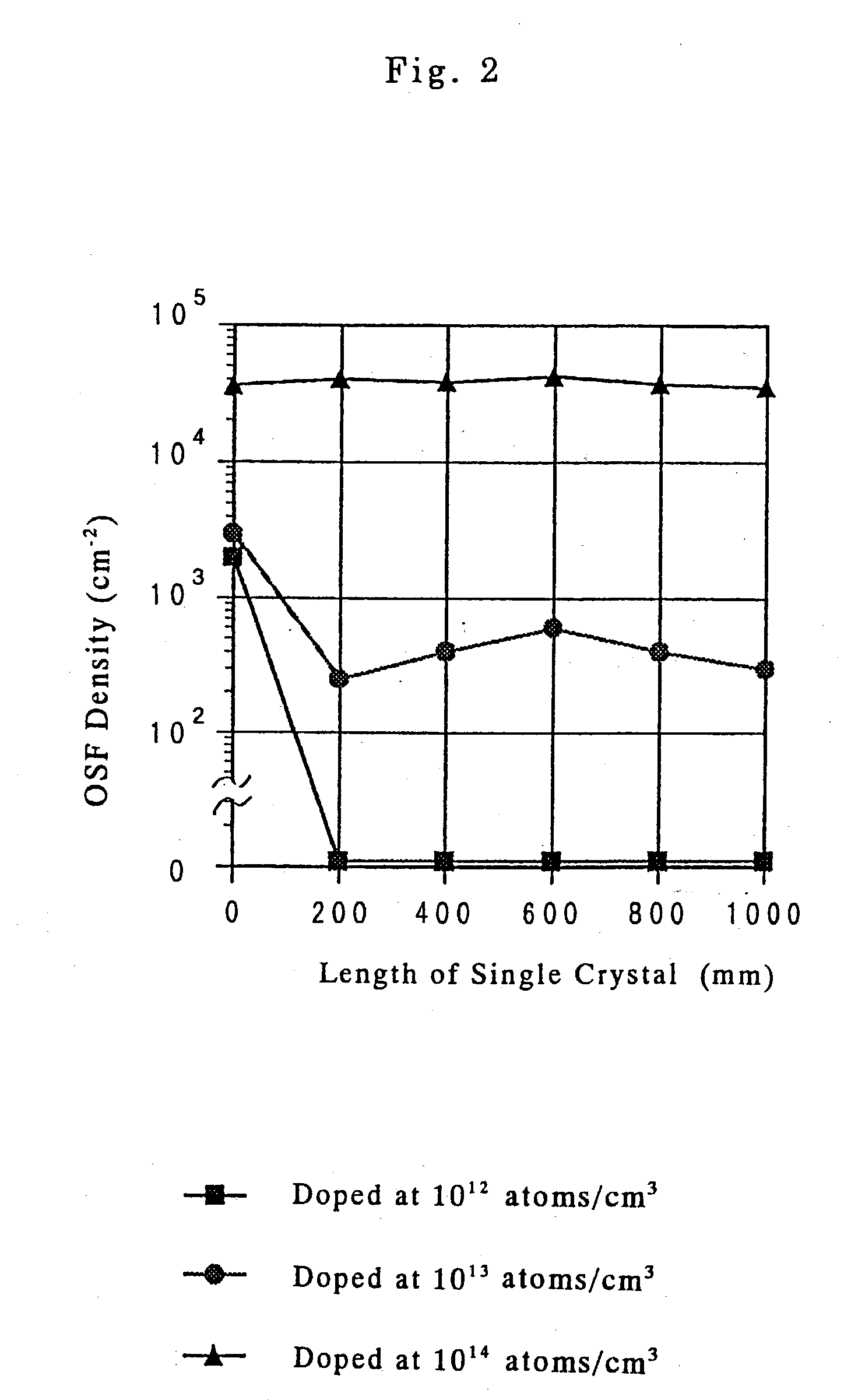

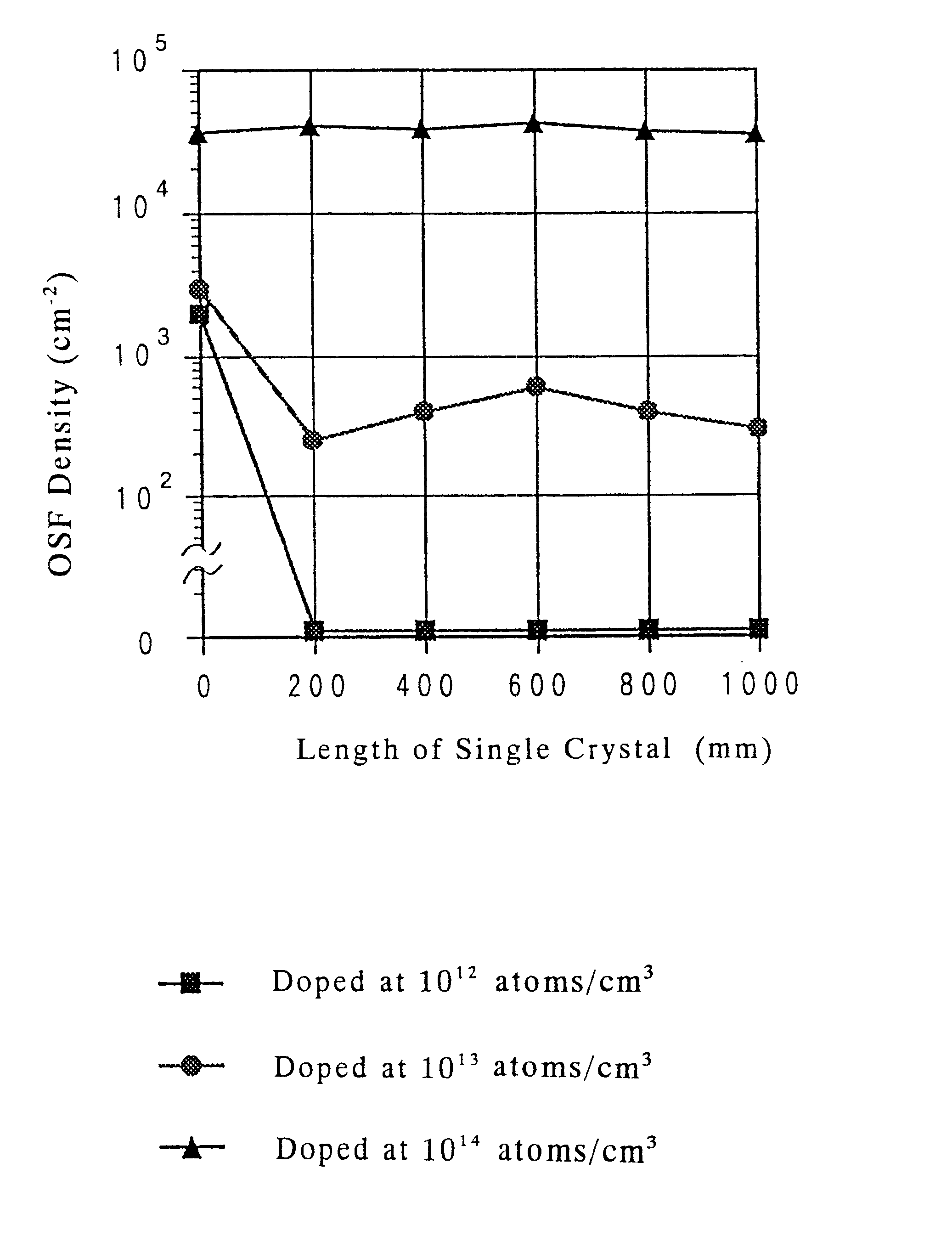

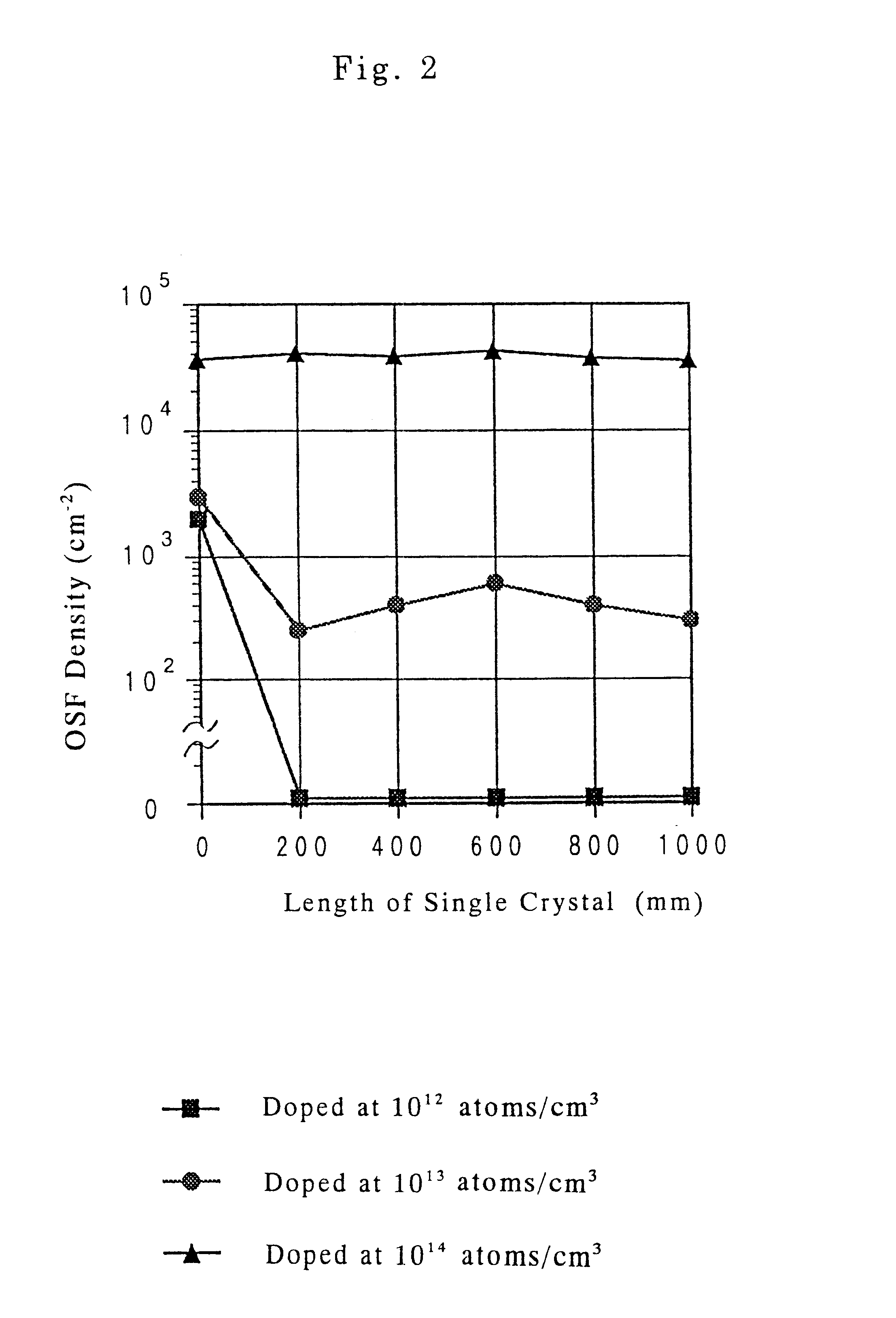

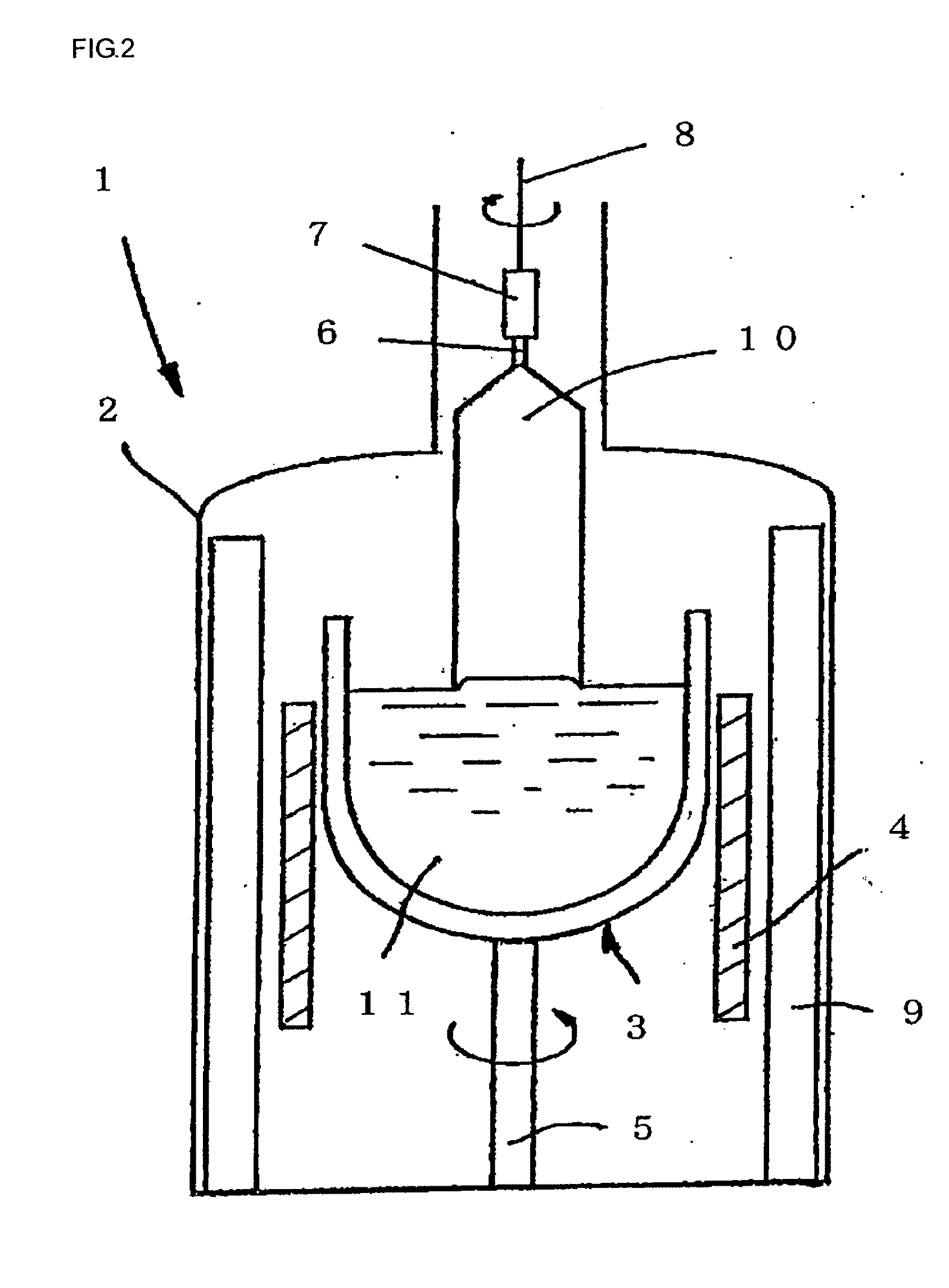

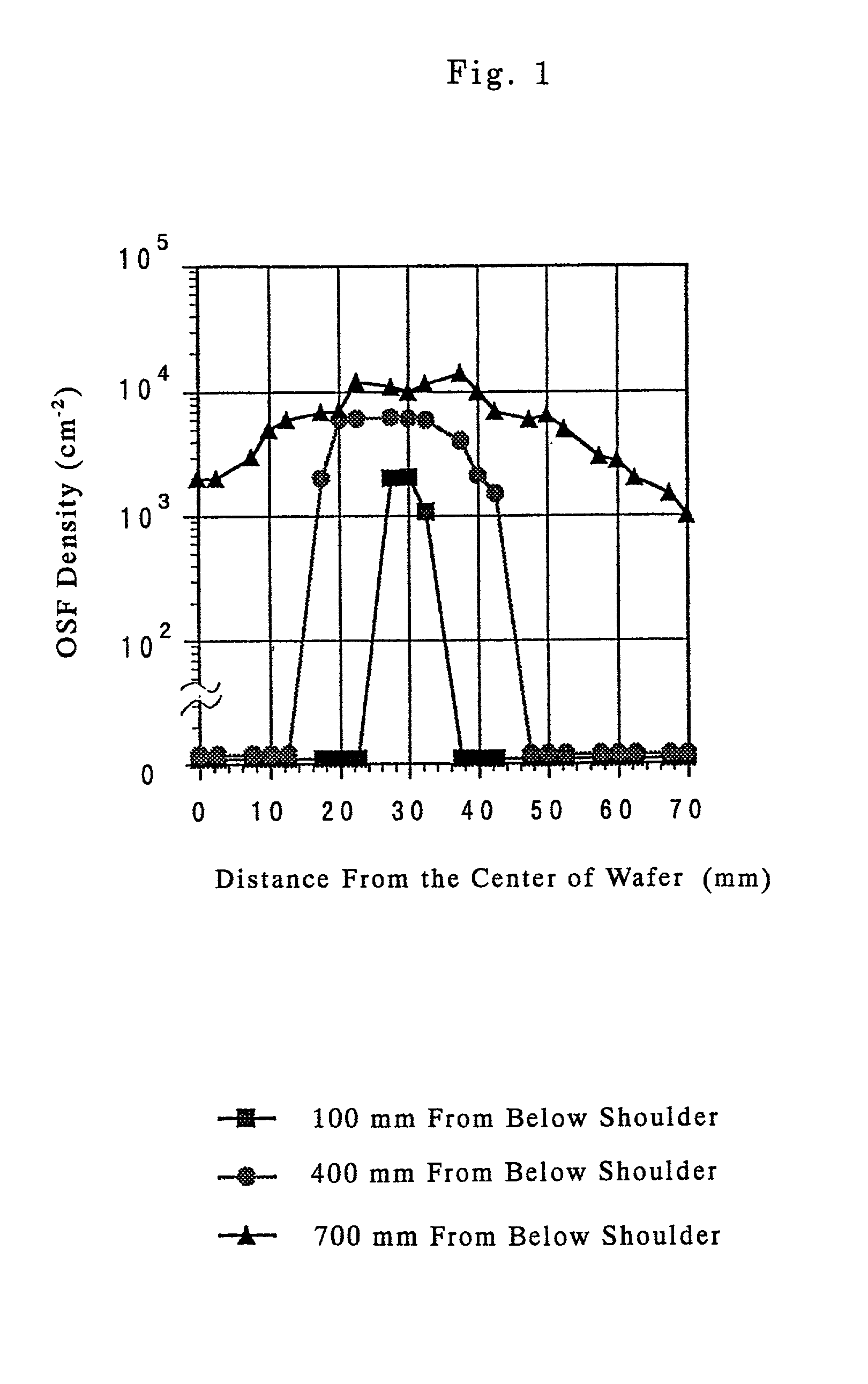

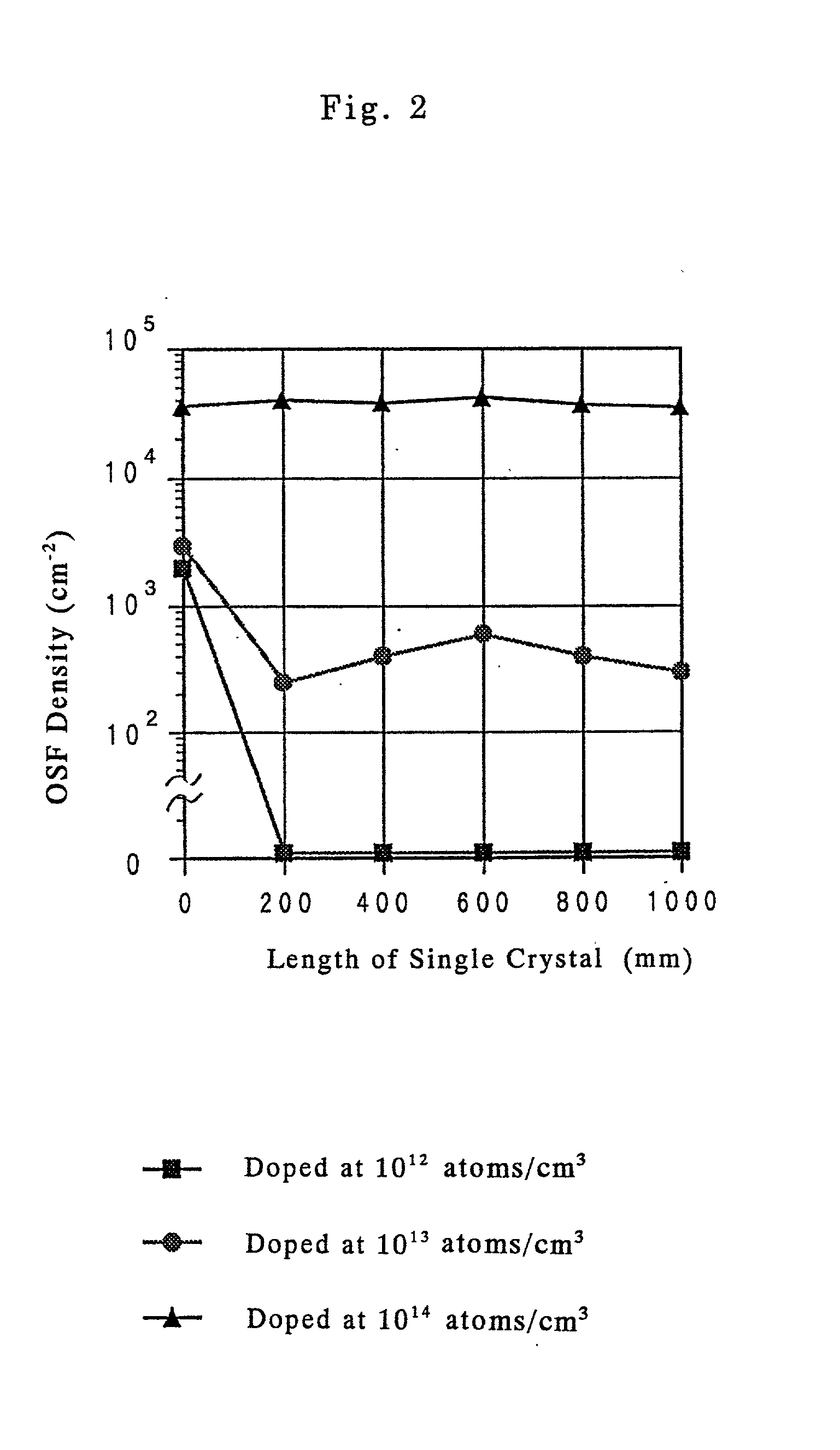

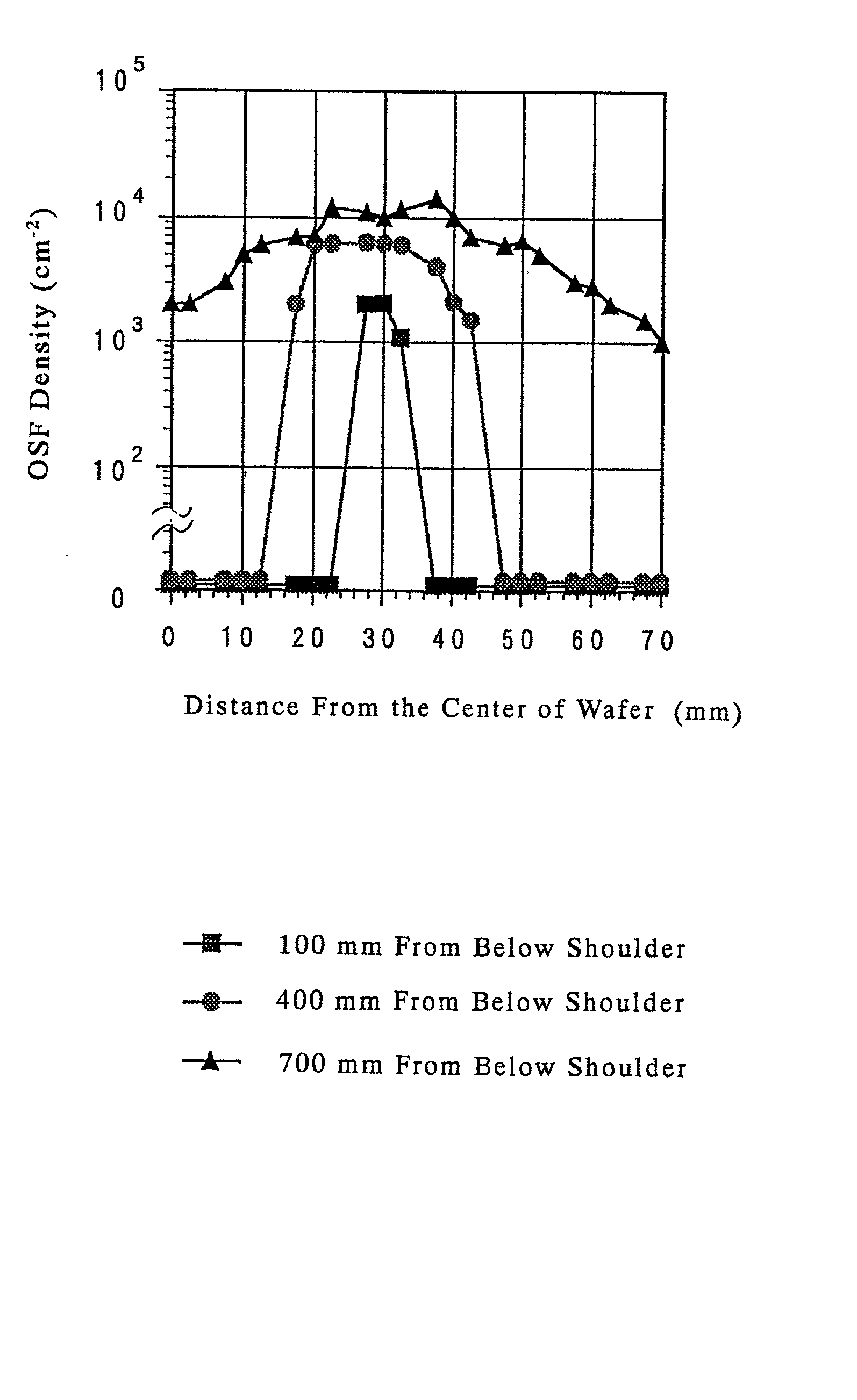

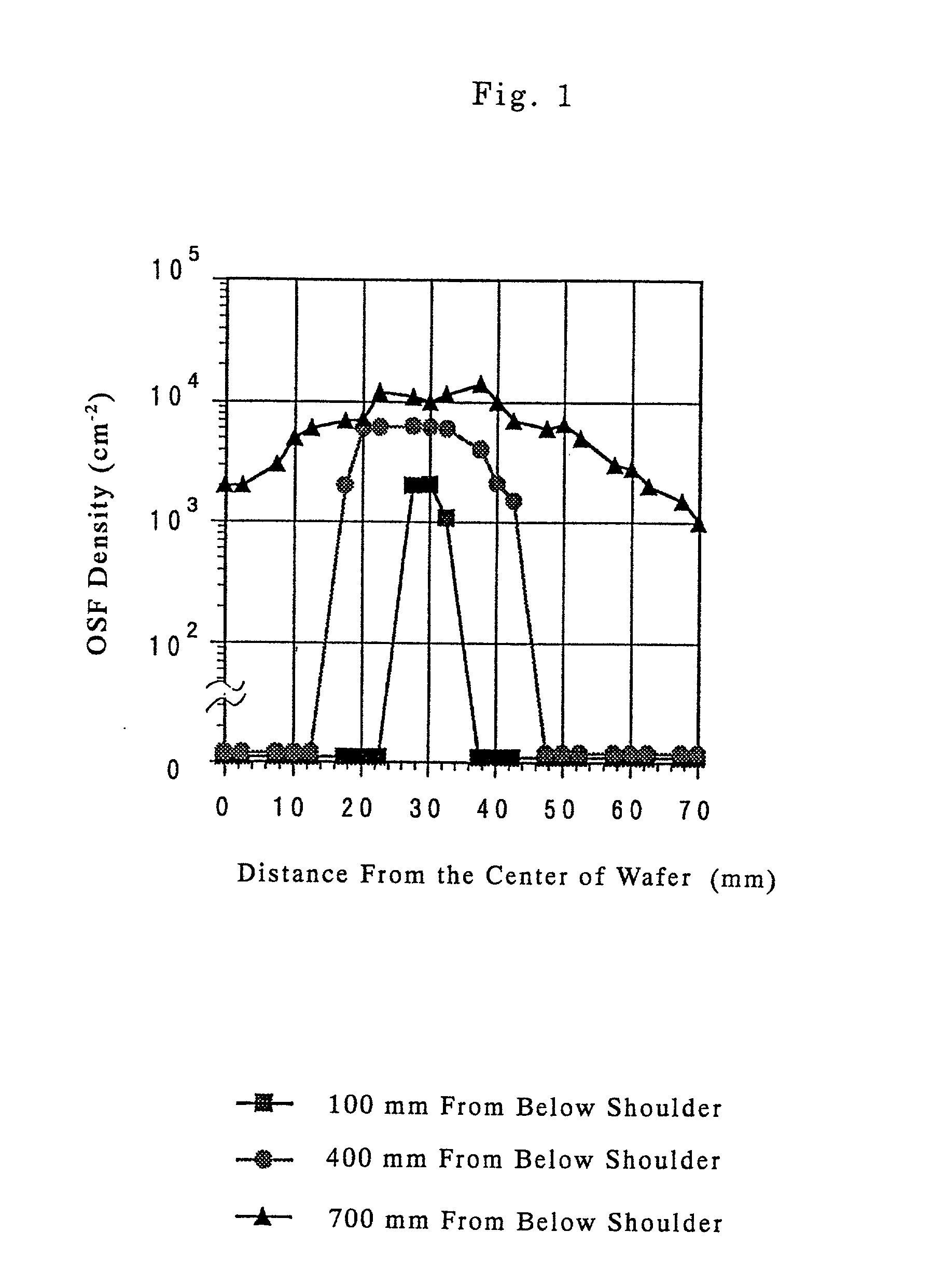

Method for producing an epitaxial silicon single crystal wafer and the epitaxial silicon single crystal wafer

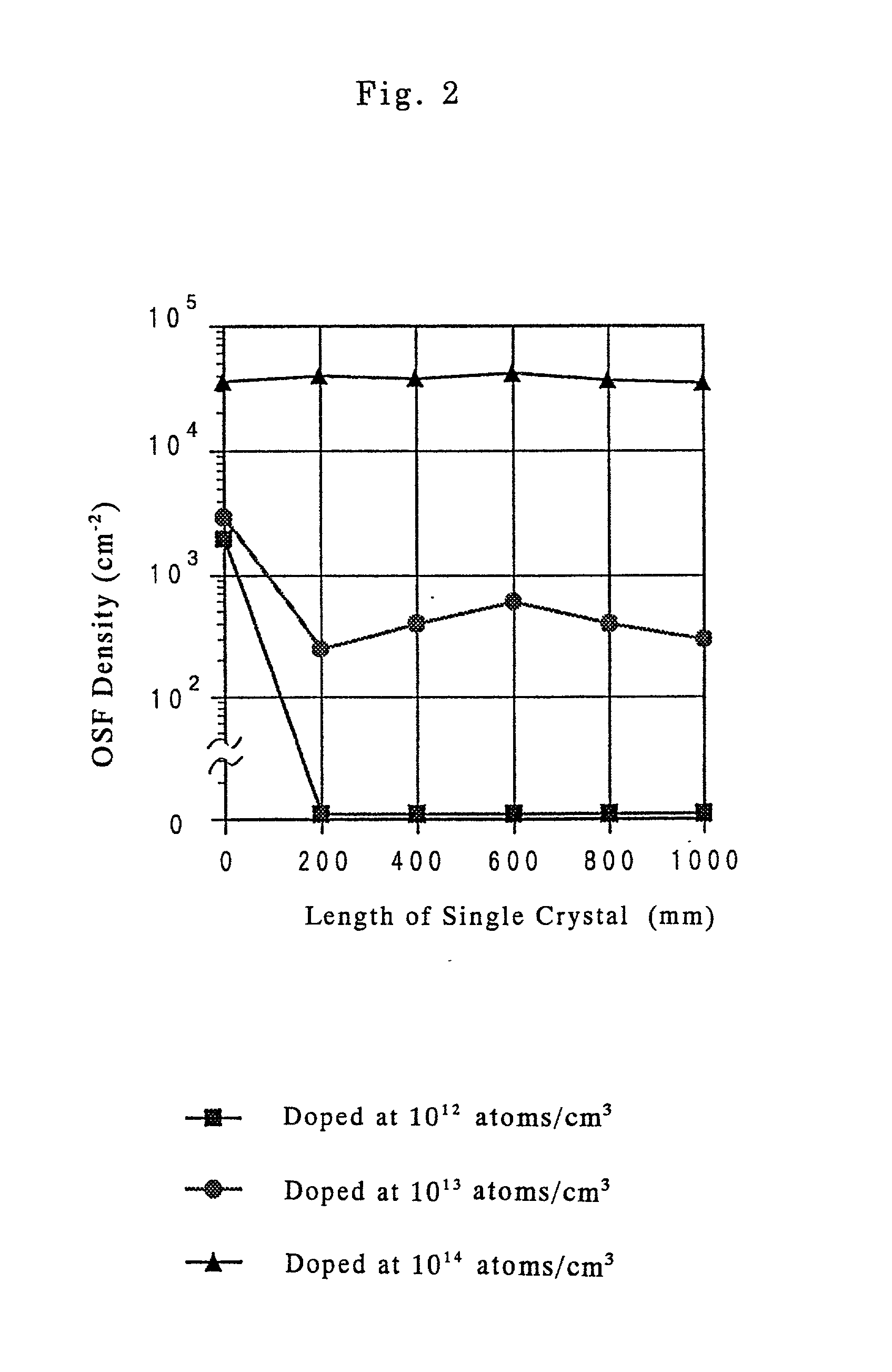

InactiveUS6162708AReduce concentrationEasy to producePolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalCrystallinity

There is disclosed a method for producing an epitaxial silicon single crystal wafer comprising the steps of growing a silicon single crystal ingot wherein nitrogen is doped by Czochralski method, slicing the silicon single crystal ingot to provide a silicon single crystal wafer, and forming an epitaxial layer in the surface layer portion of the silicon single crystal wafer. There can be manufactured easily and in high productivity an epitaxial silicon monocrystal wafer which has high gettering capability when a substrate having a low boron concentration is used, a low concentration of heavy metal impurity, and an excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

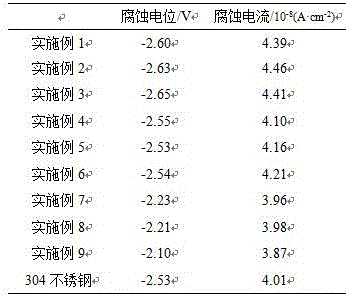

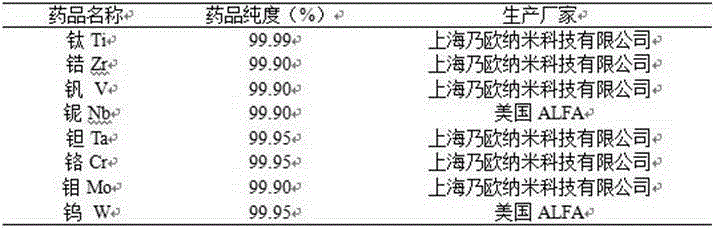

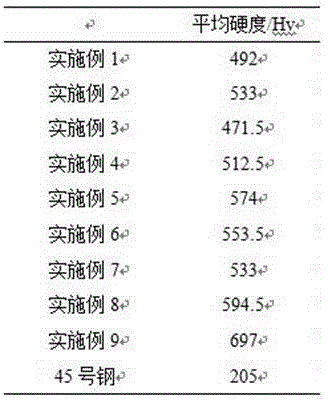

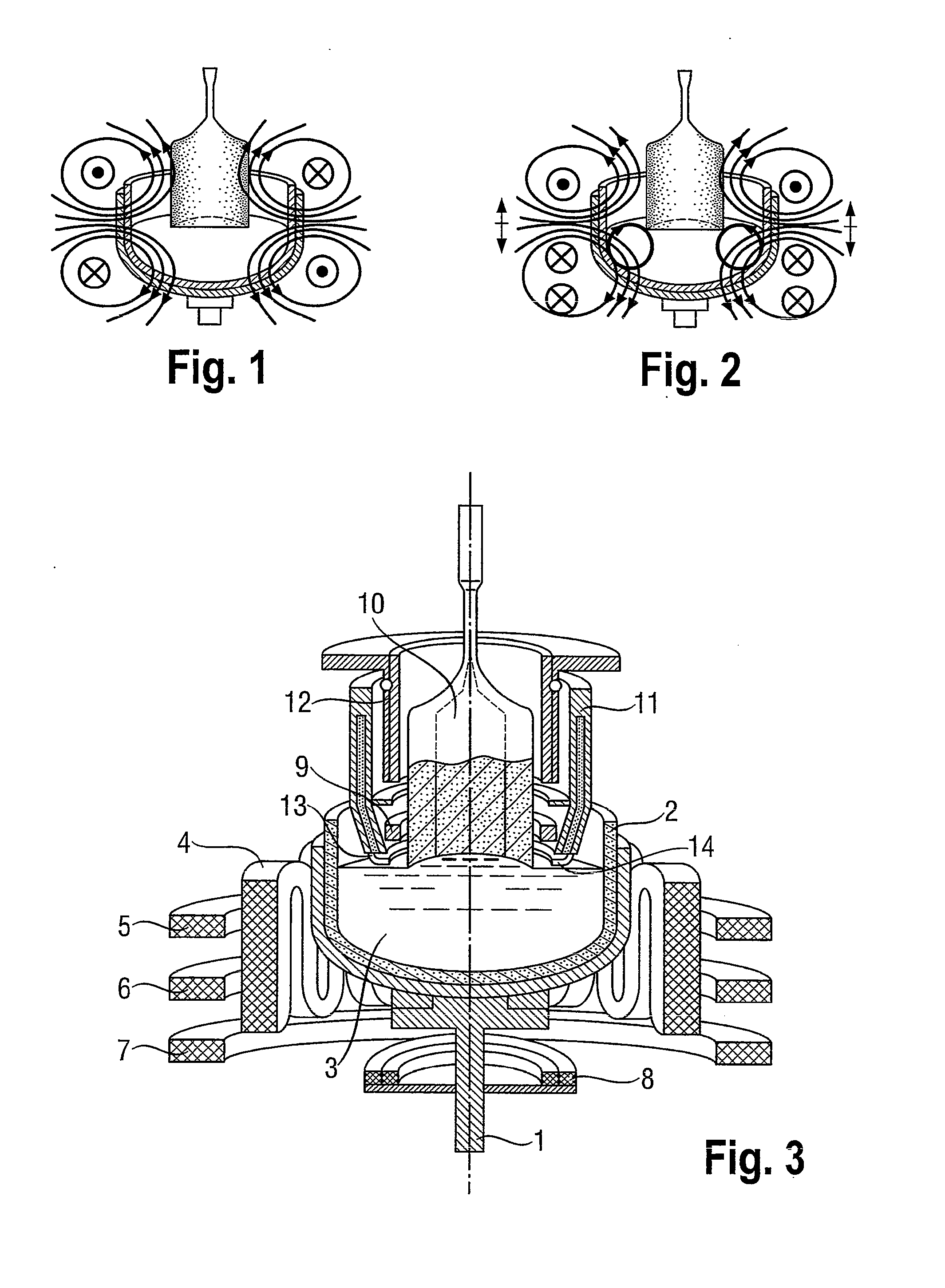

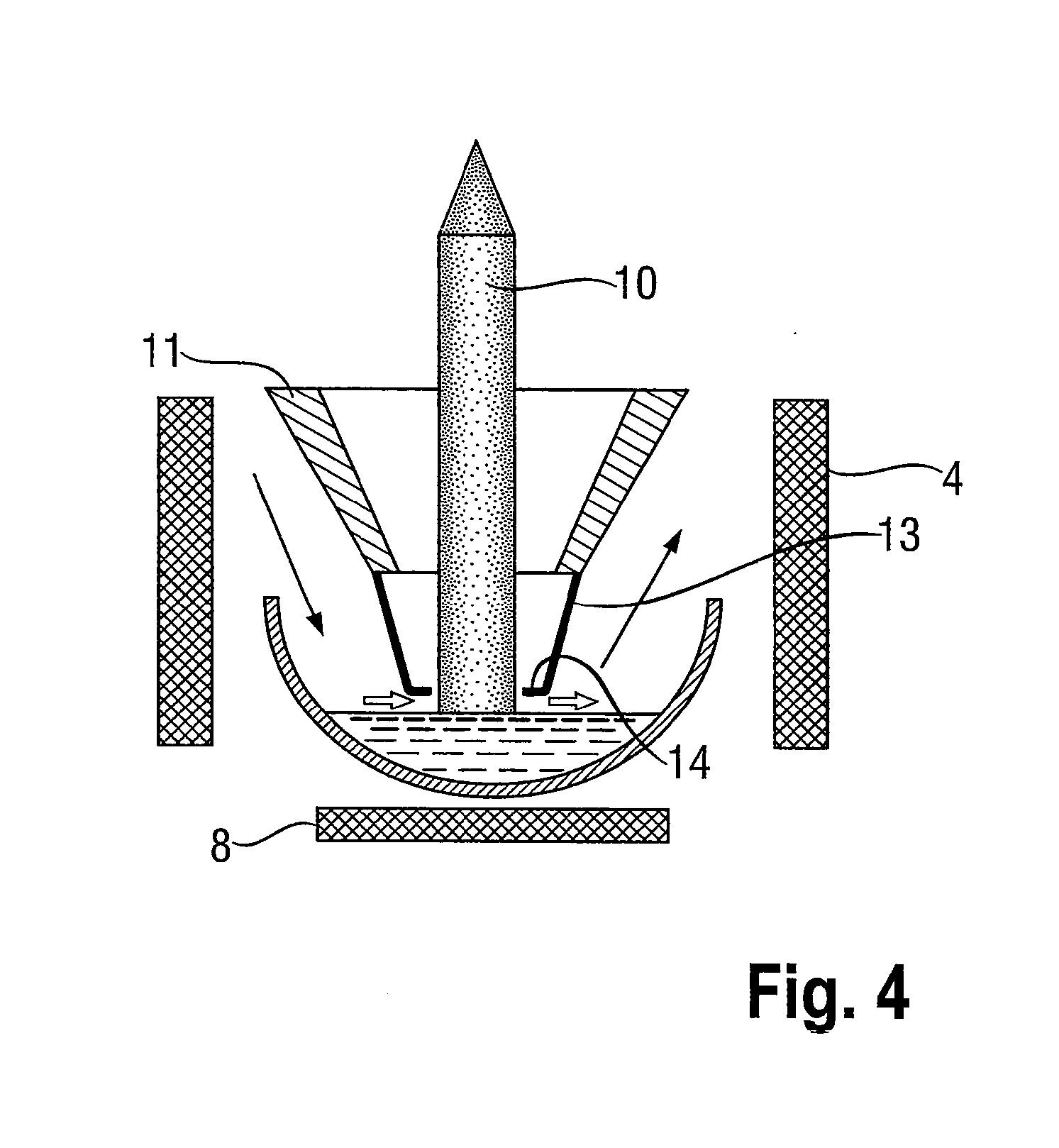

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

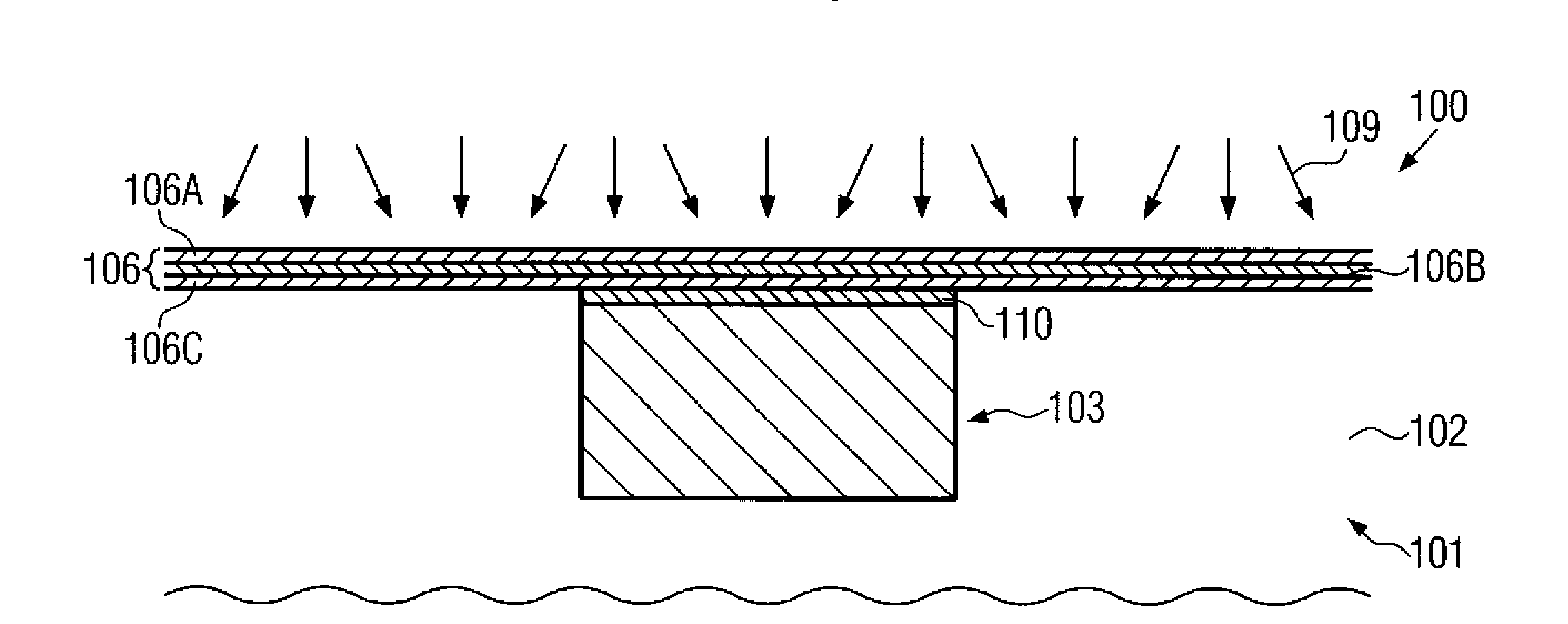

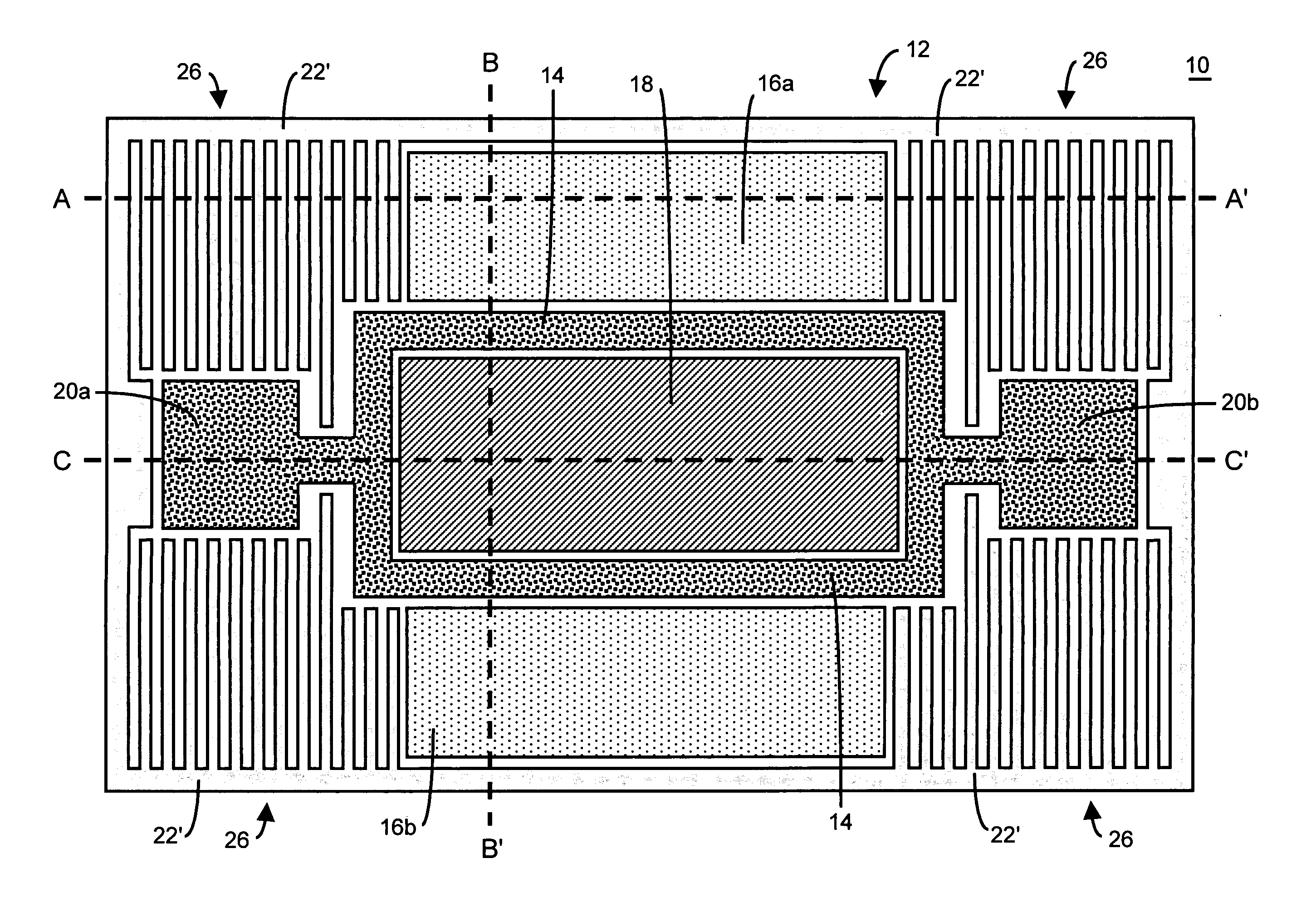

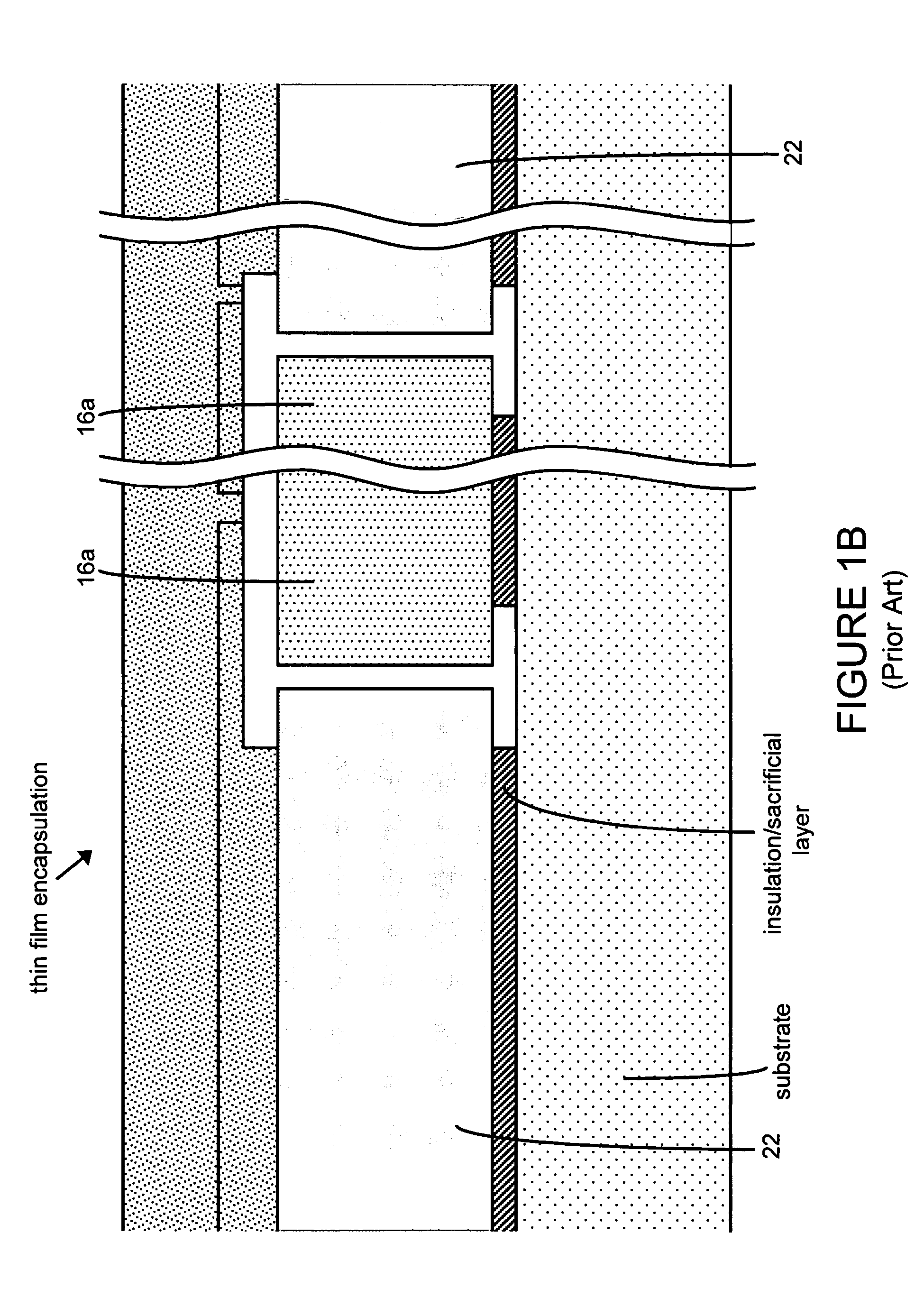

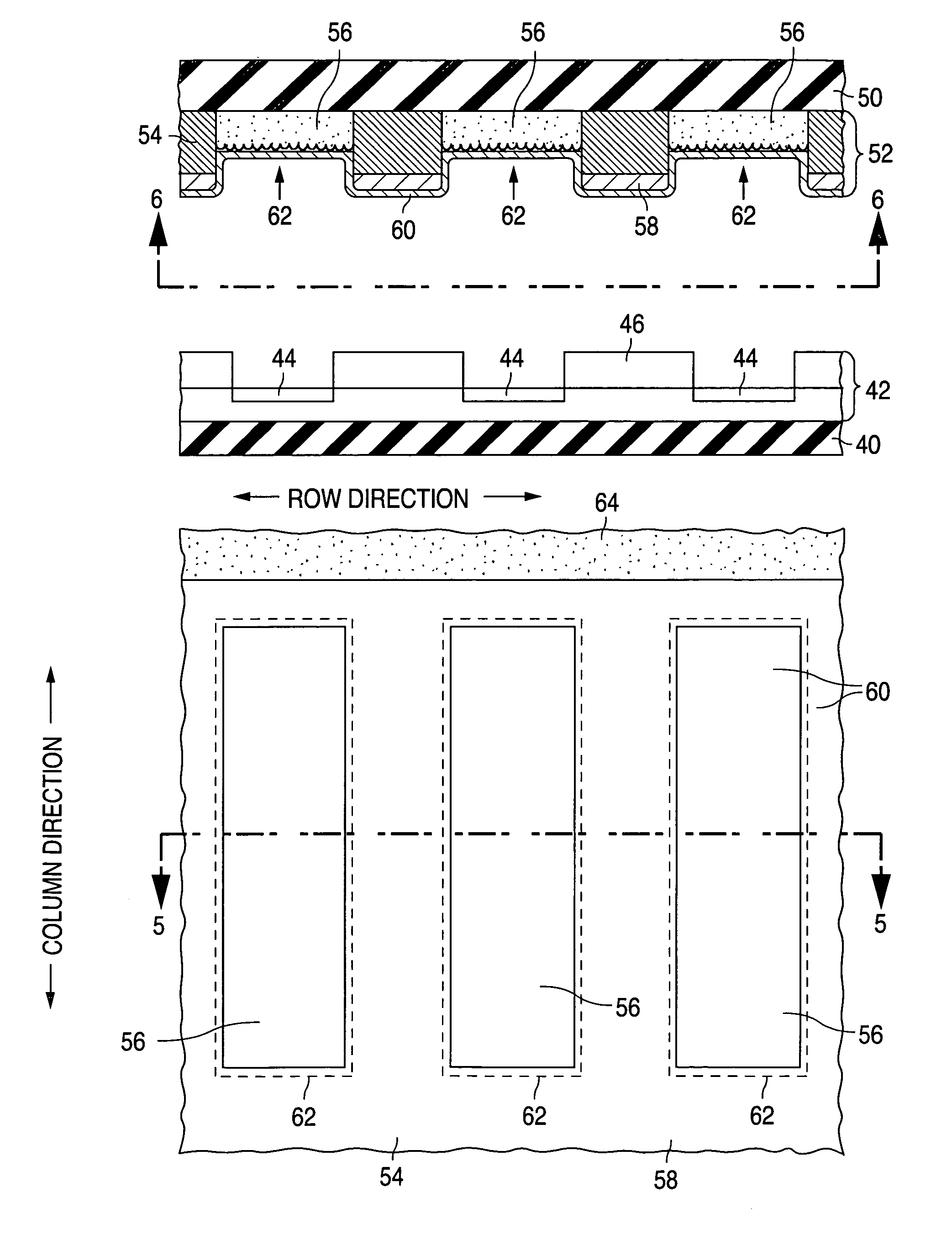

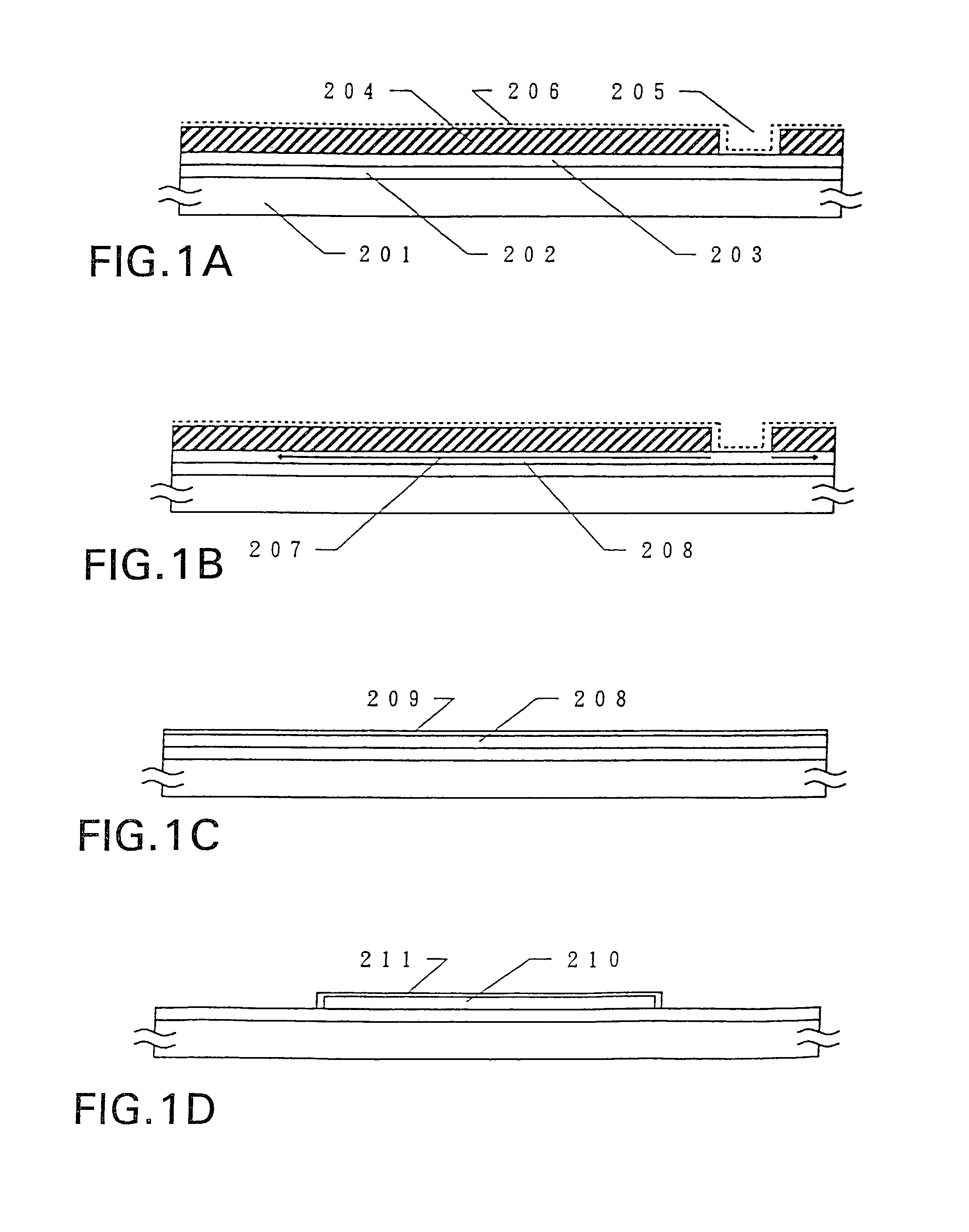

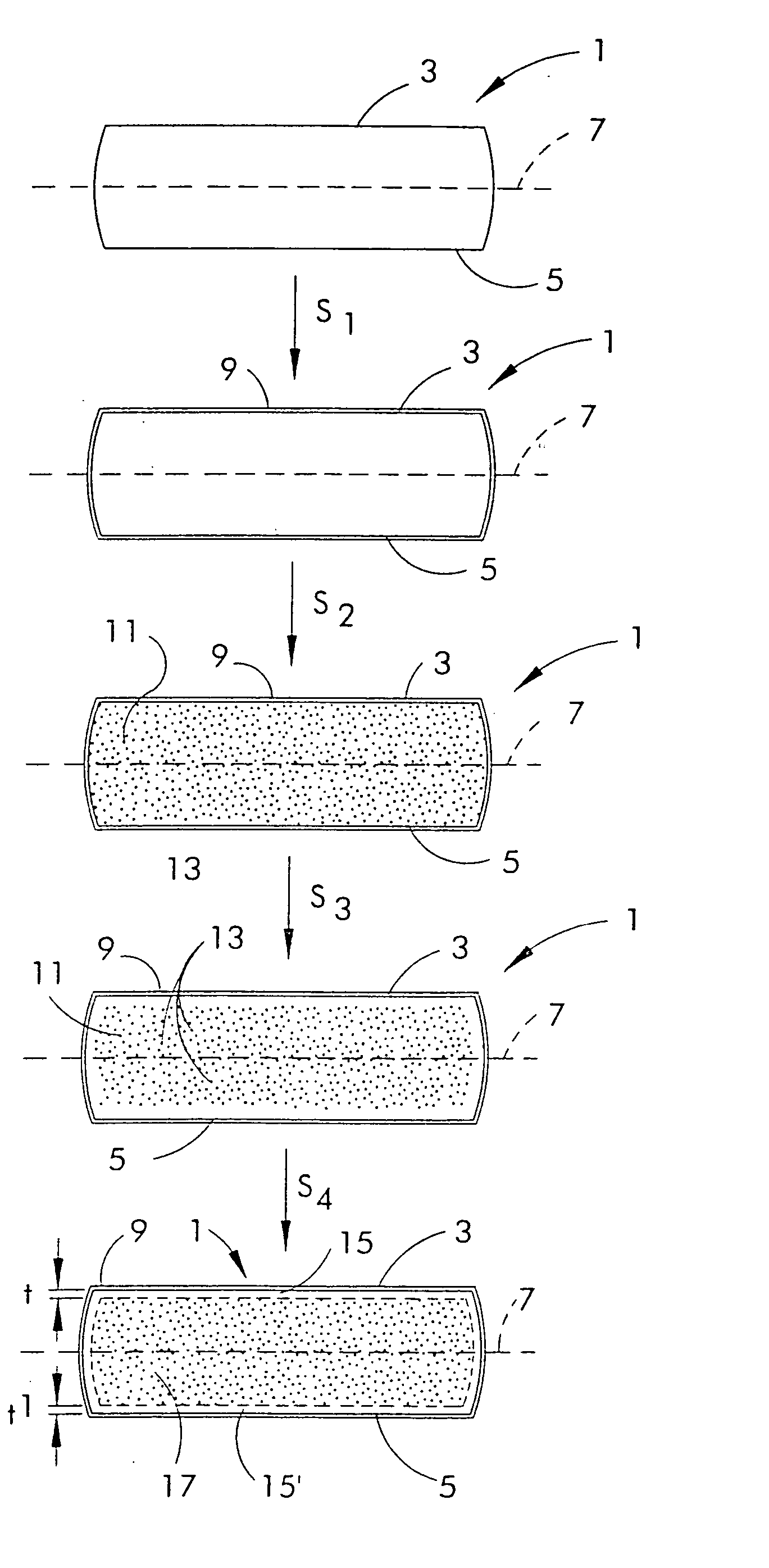

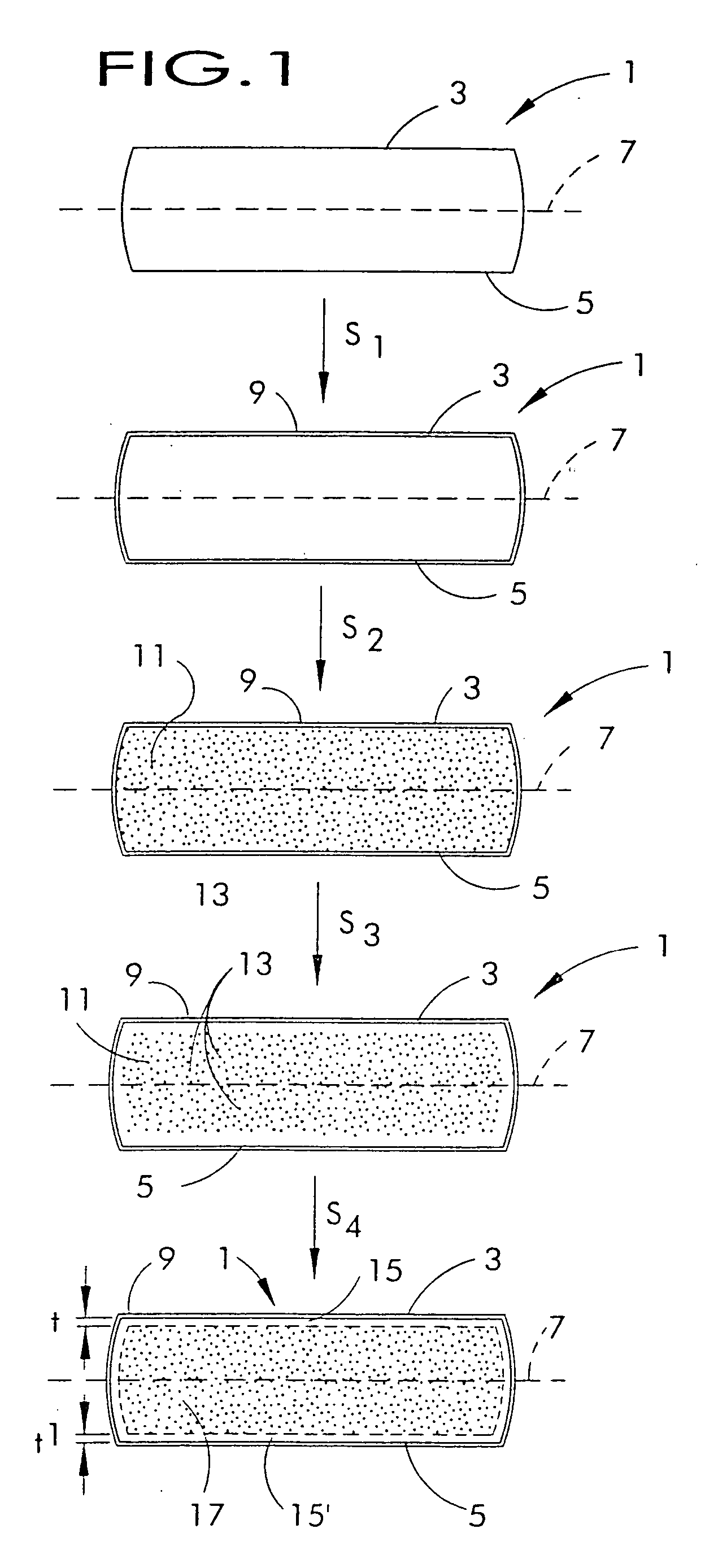

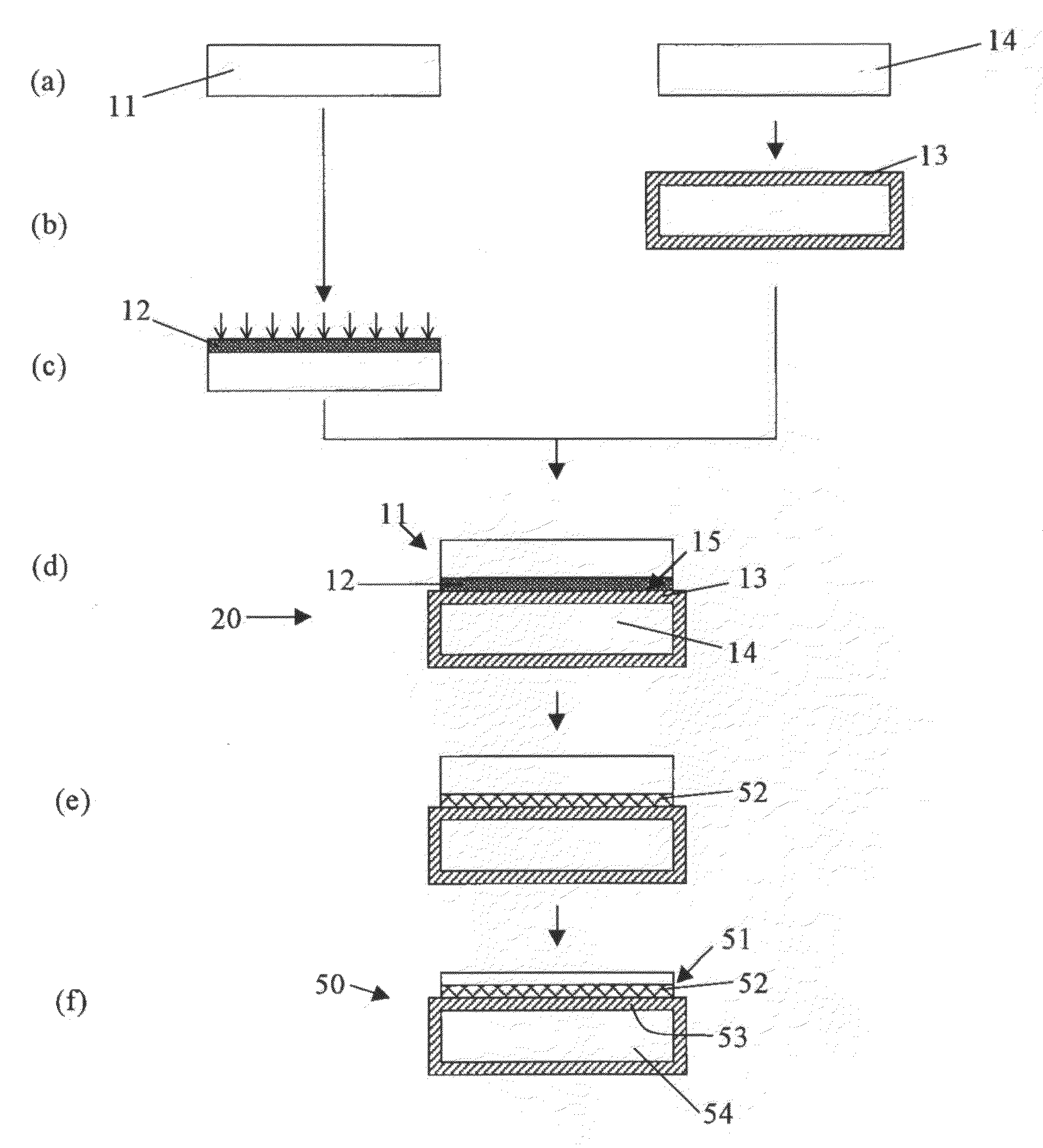

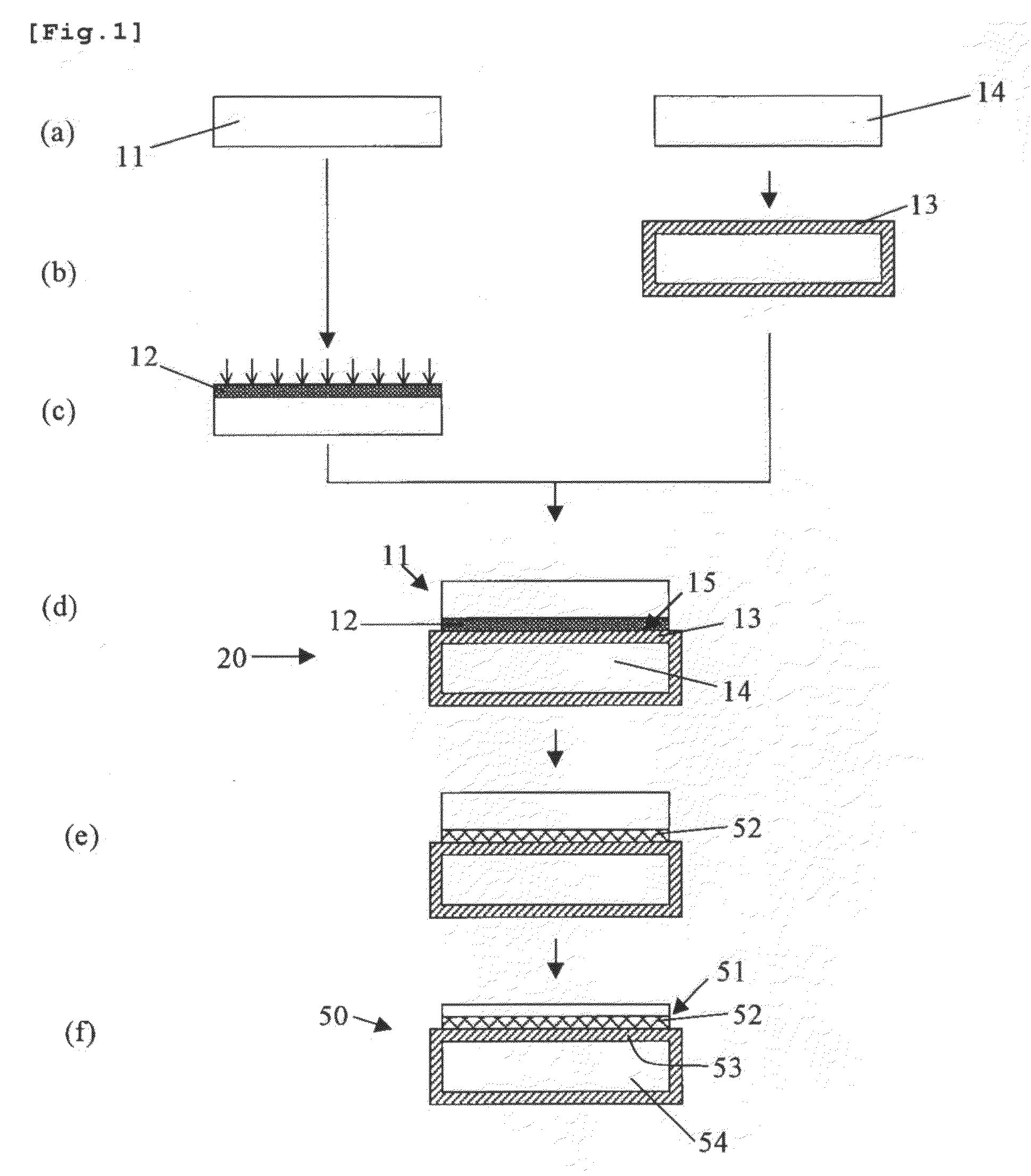

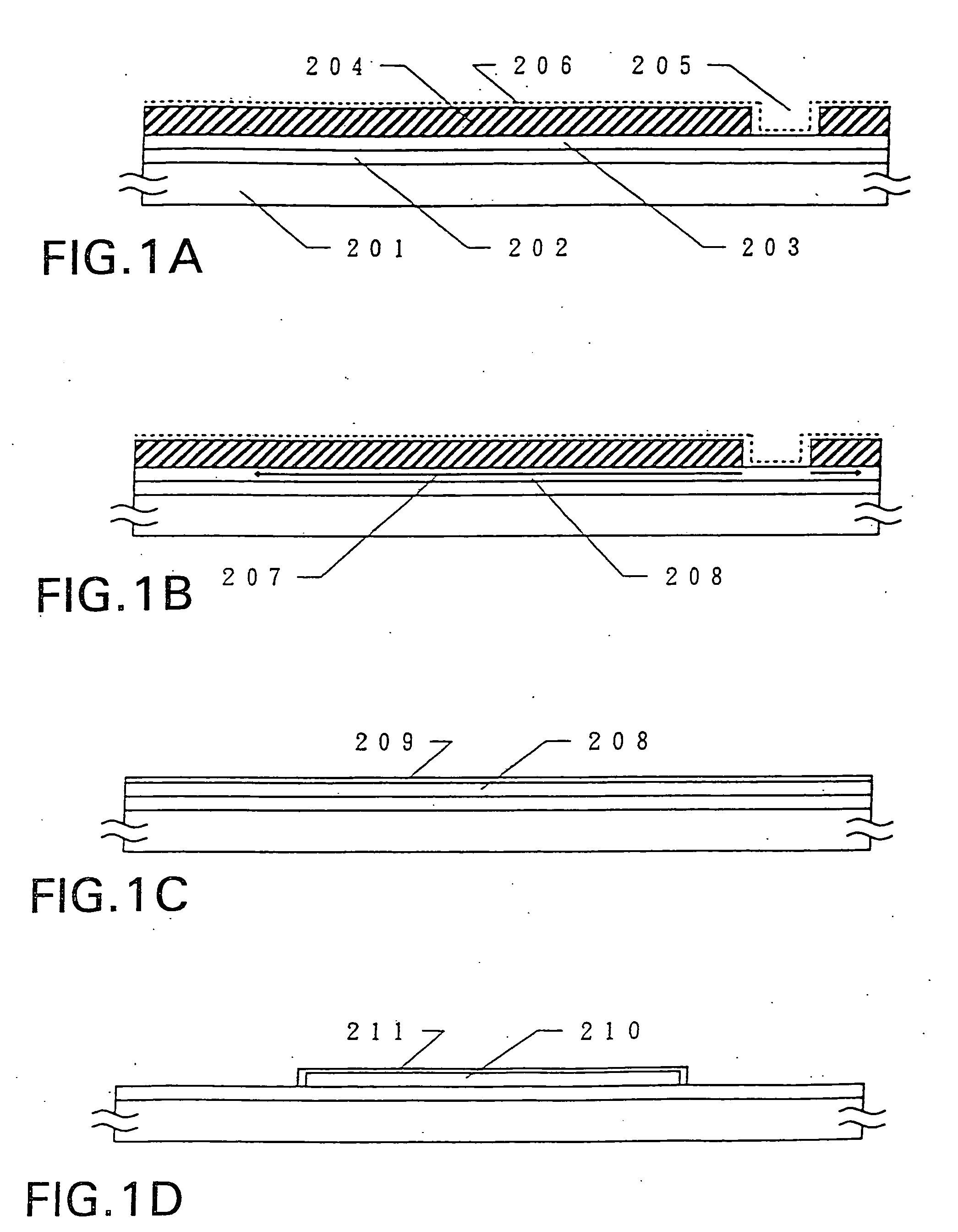

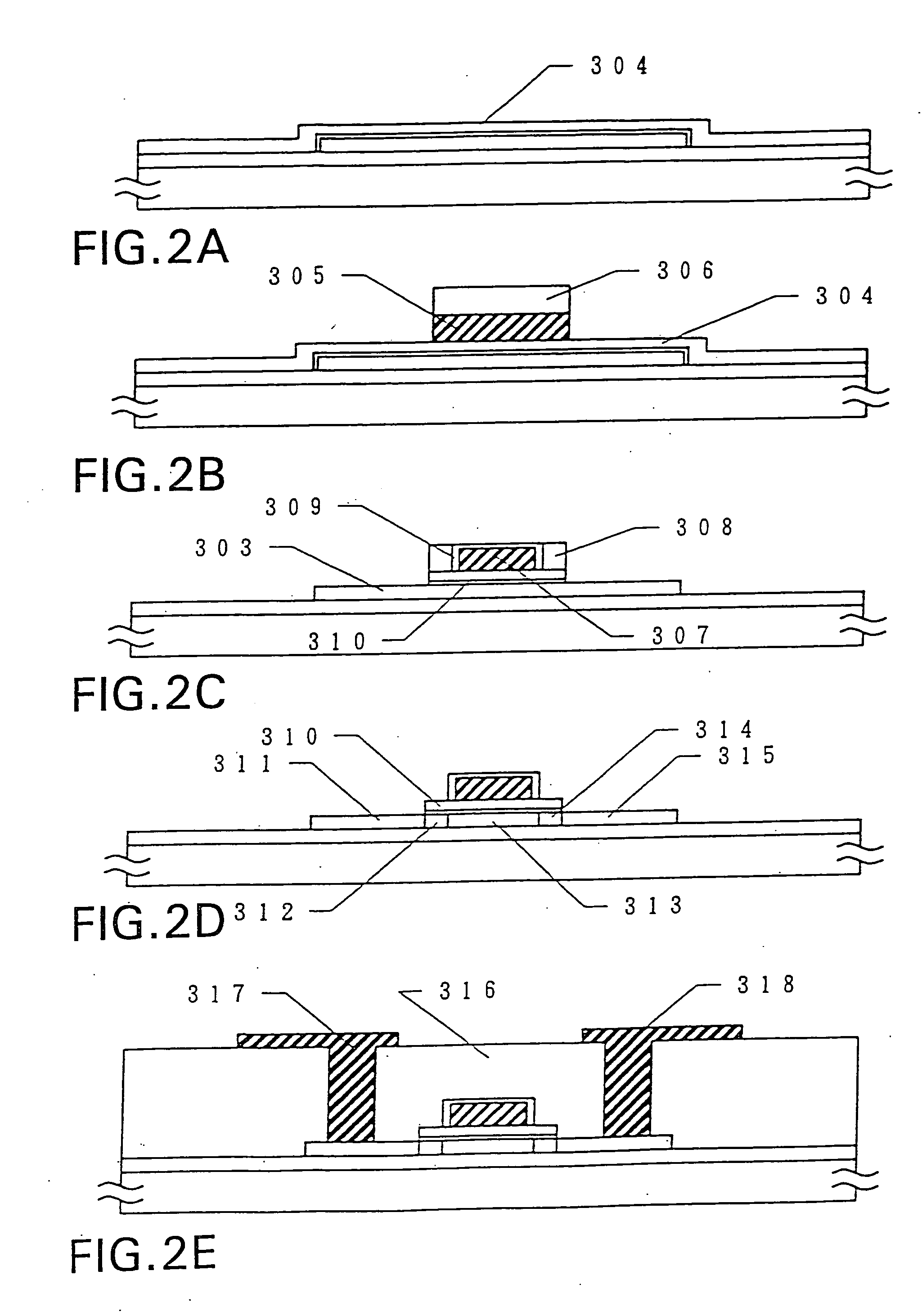

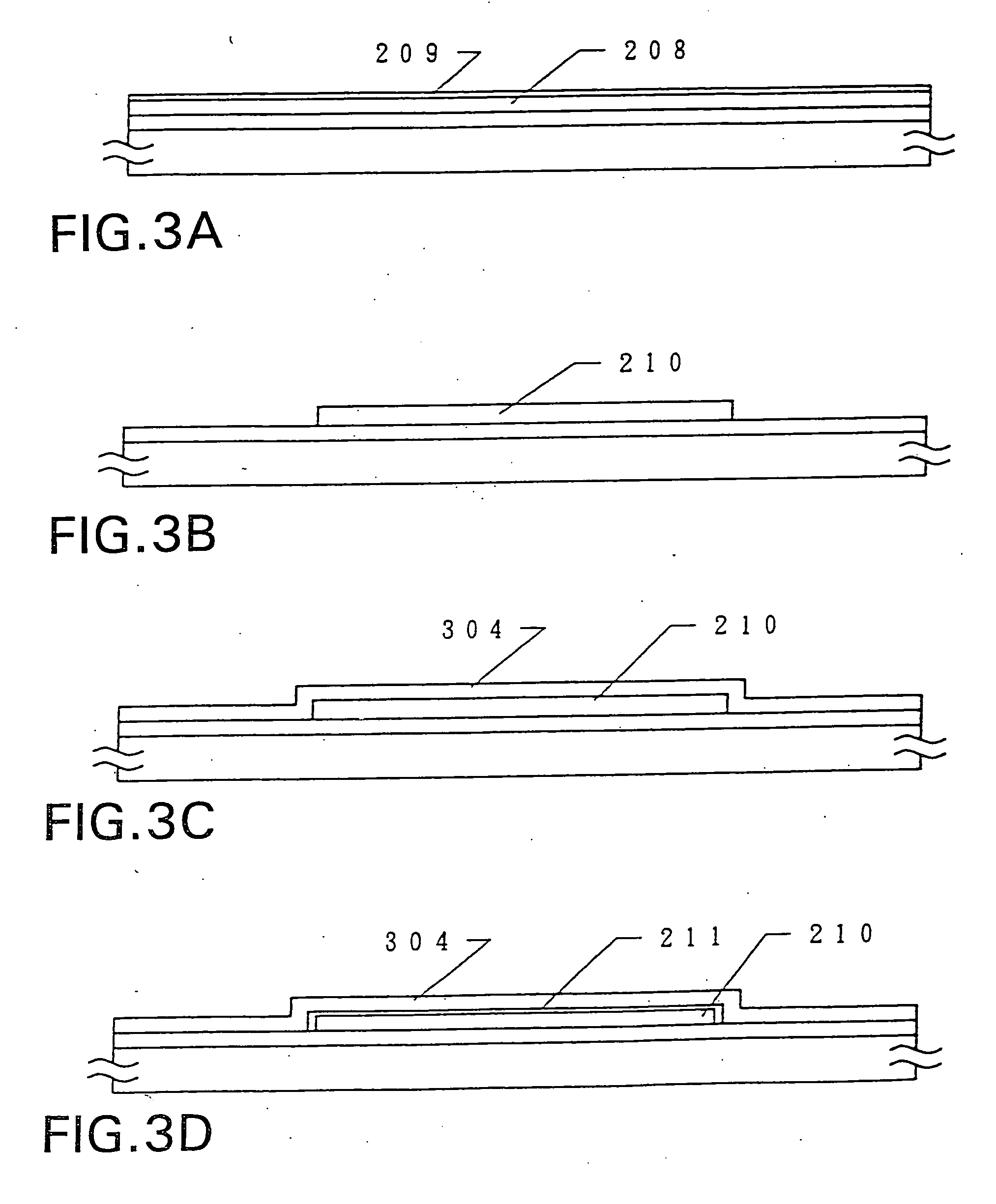

Integrated getter area for wafer level encapsulated microelectromechanical systems

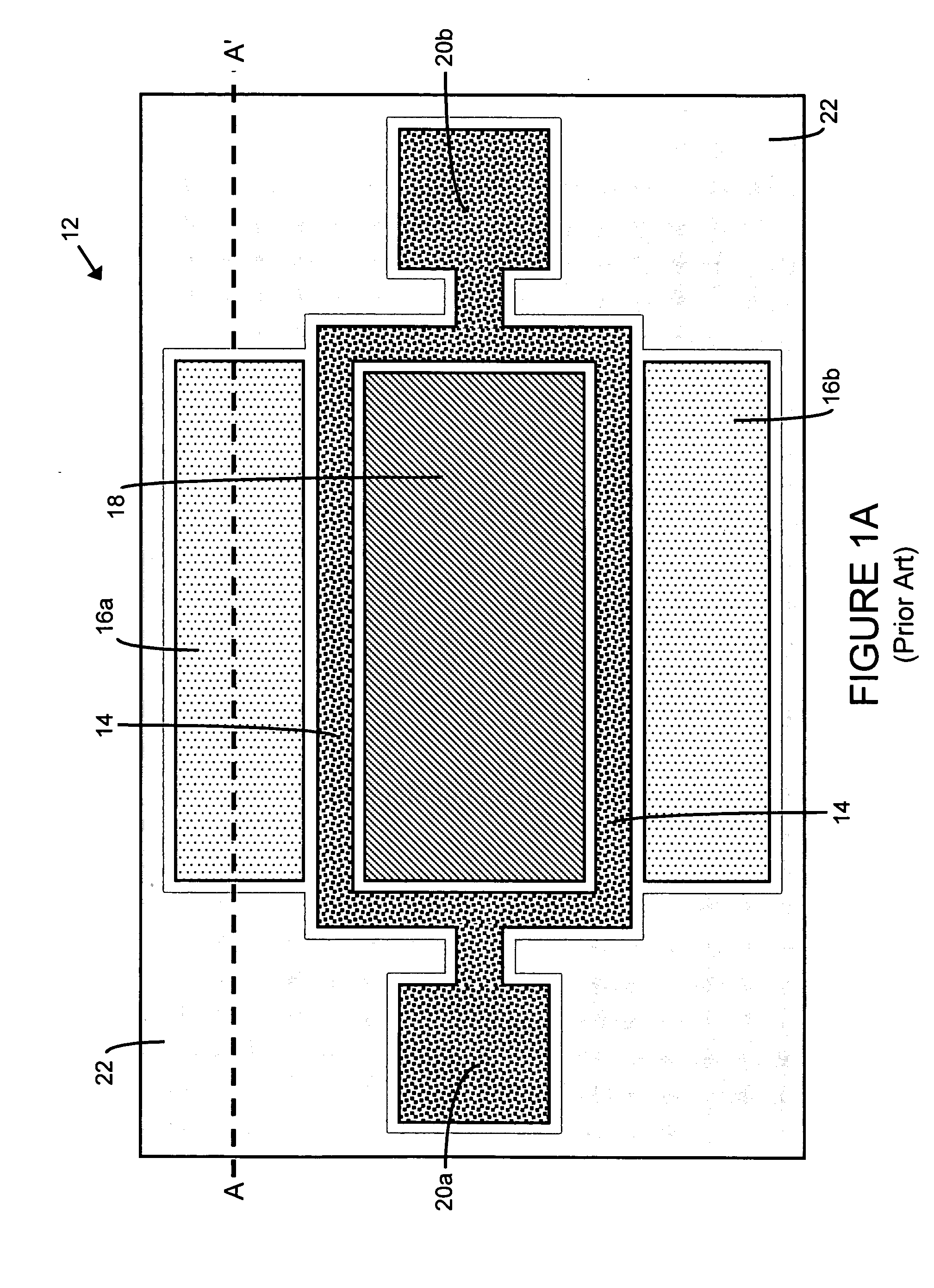

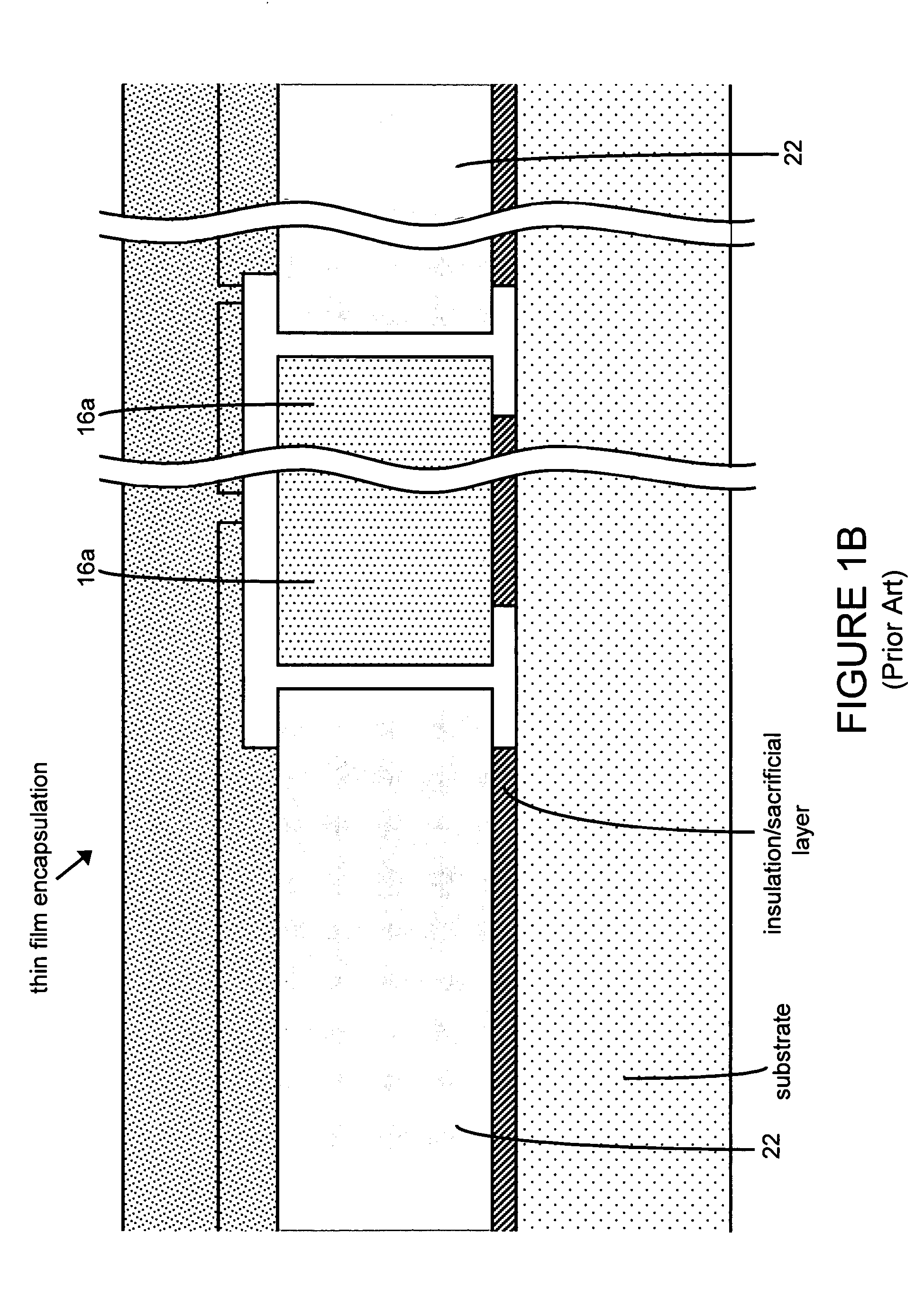

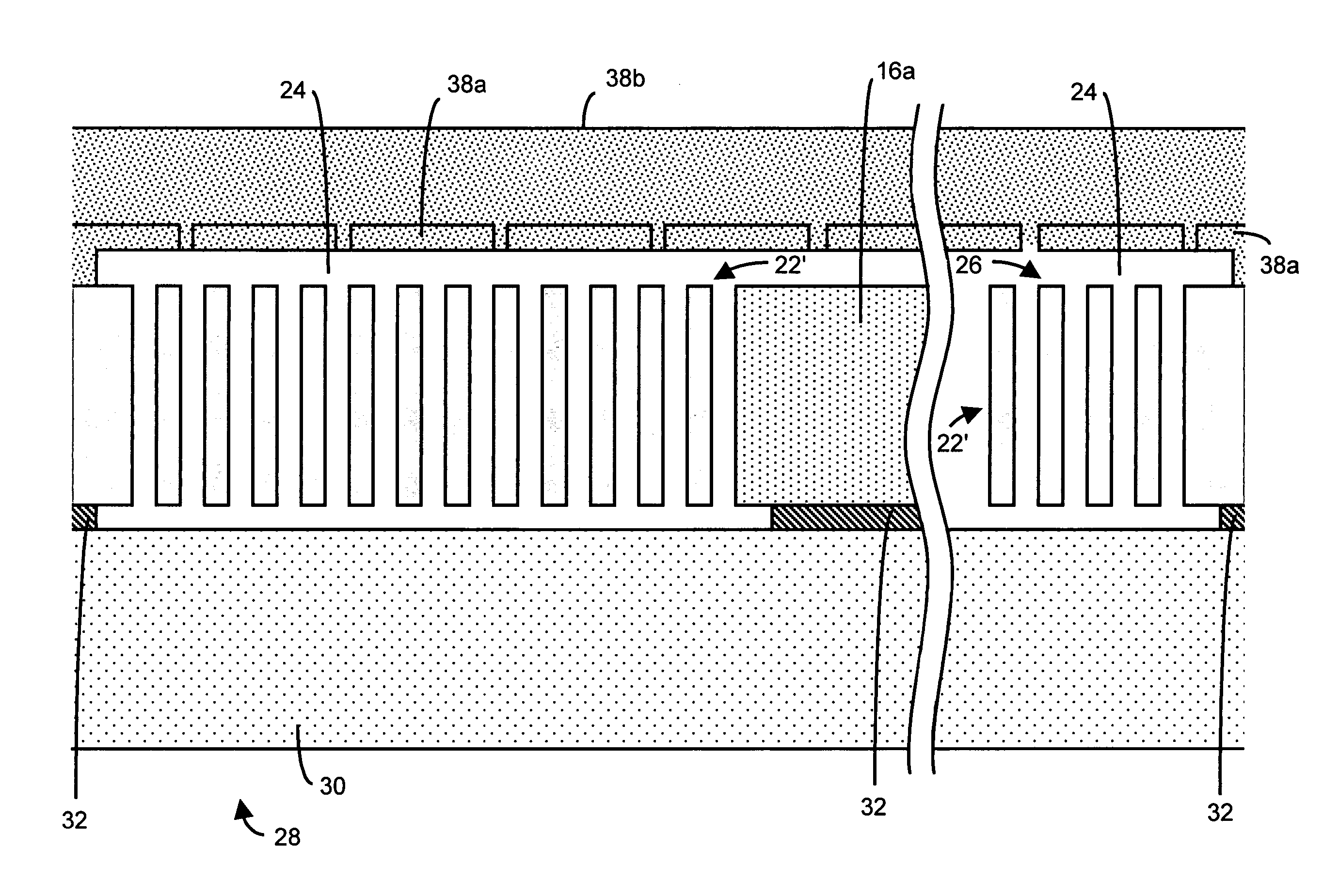

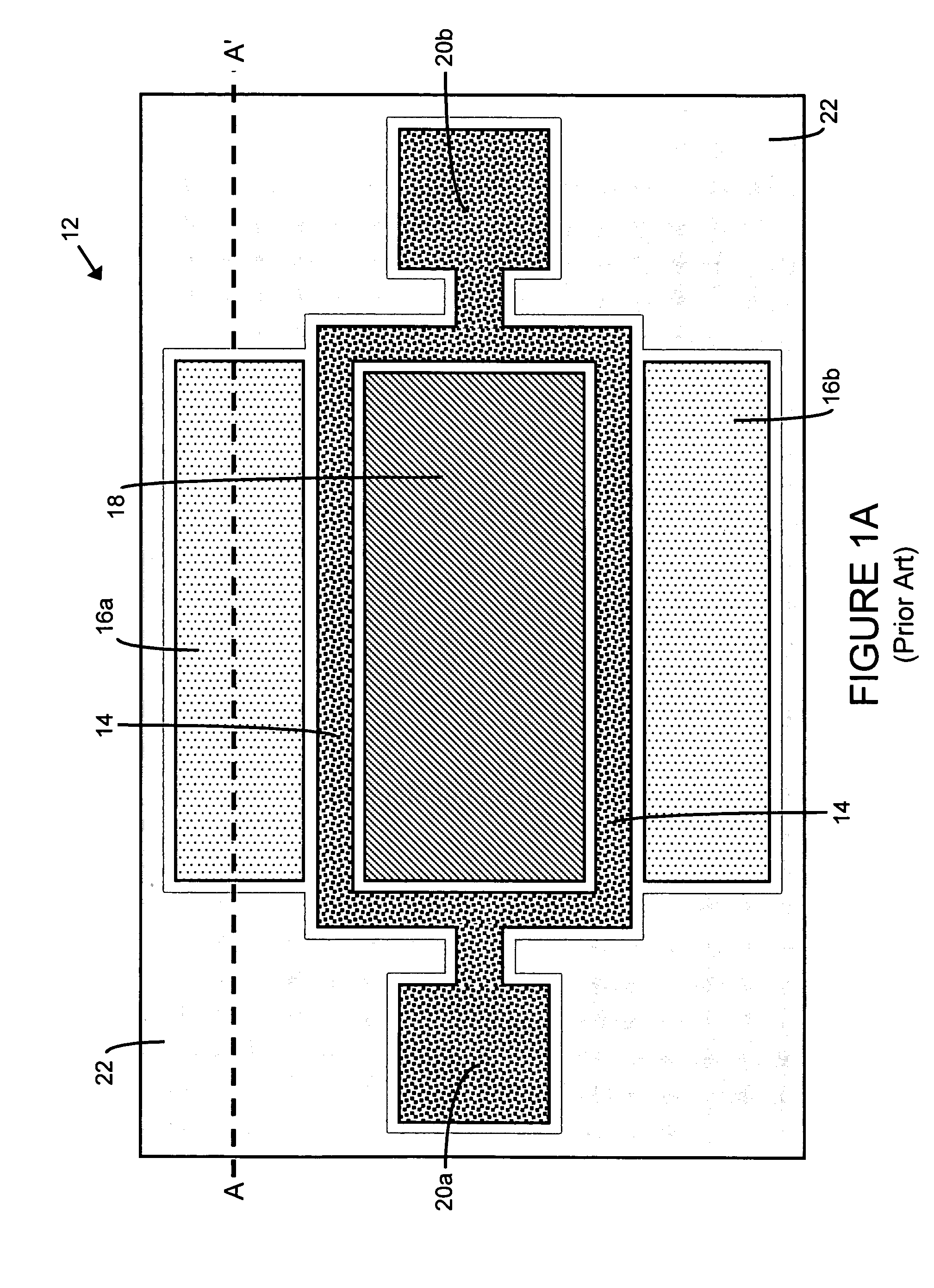

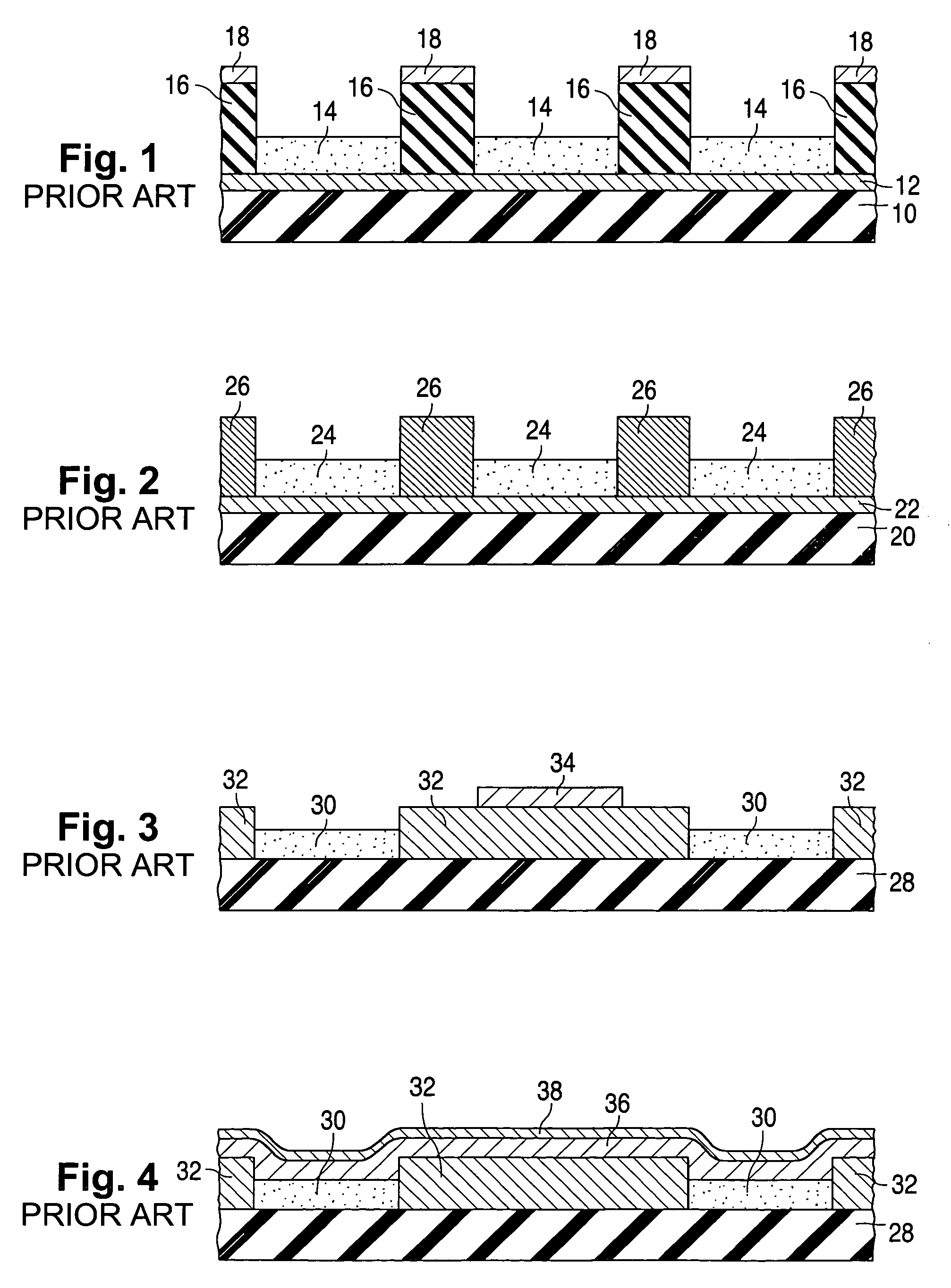

ActiveUS20050179099A1Improve inhalation effectLittle to no increase in overall dimensions of the MEMSAcceleration measurement using interia forcesDecorative surface effectsMicroelectromechanical systemsEngineering

There are many inventions described and illustrated herein. In one aspect, present invention is directed to a thin film encapsulated MEMS, and technique of fabricating or manufacturing a thin film encapsulated MEMS including an integrated getter area and / or an increased chamber volume, which causes little to no increase in overall dimension(s) from the perspective of the mechanical structure and chamber. The integrated getter area is disposed within the chamber and is capable of (i) “capturing” impurities, atoms and / or molecules that are out-gassed from surrounding materials and / or (ii) reducing and / or minimizing the adverse impact of such impurities, atoms and / or molecules (for example, reducing the probability of adding mass to a resonator which would thereby change the resonator's frequency). In this way, the thin film wafer level packaged MEMS of the present invention includes a relatively stable, controlled pressure environment within the chamber to provide, for example, a more stable predetermined, desired and / or selected mechanical damping of the mechanical structure.

Owner:ROBERT BOSCH GMBH

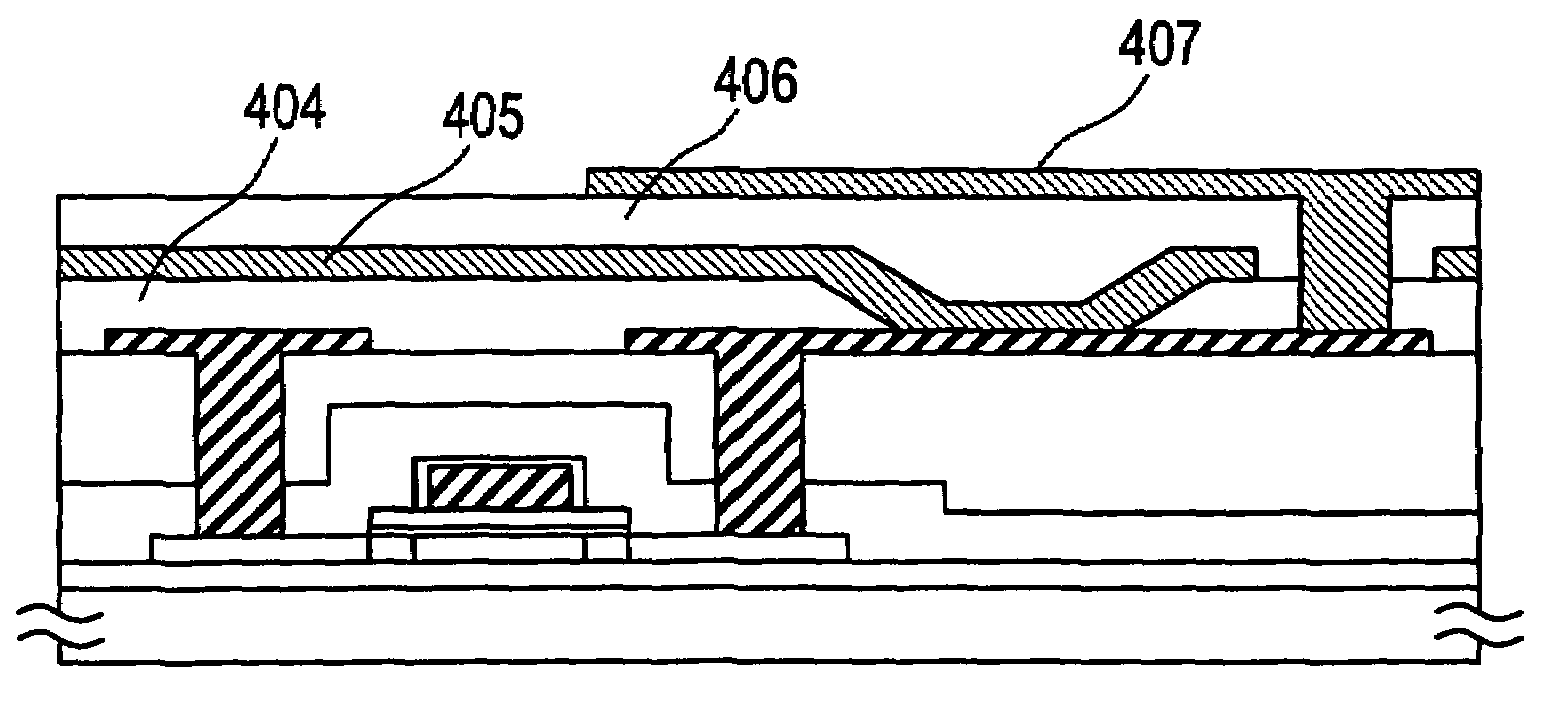

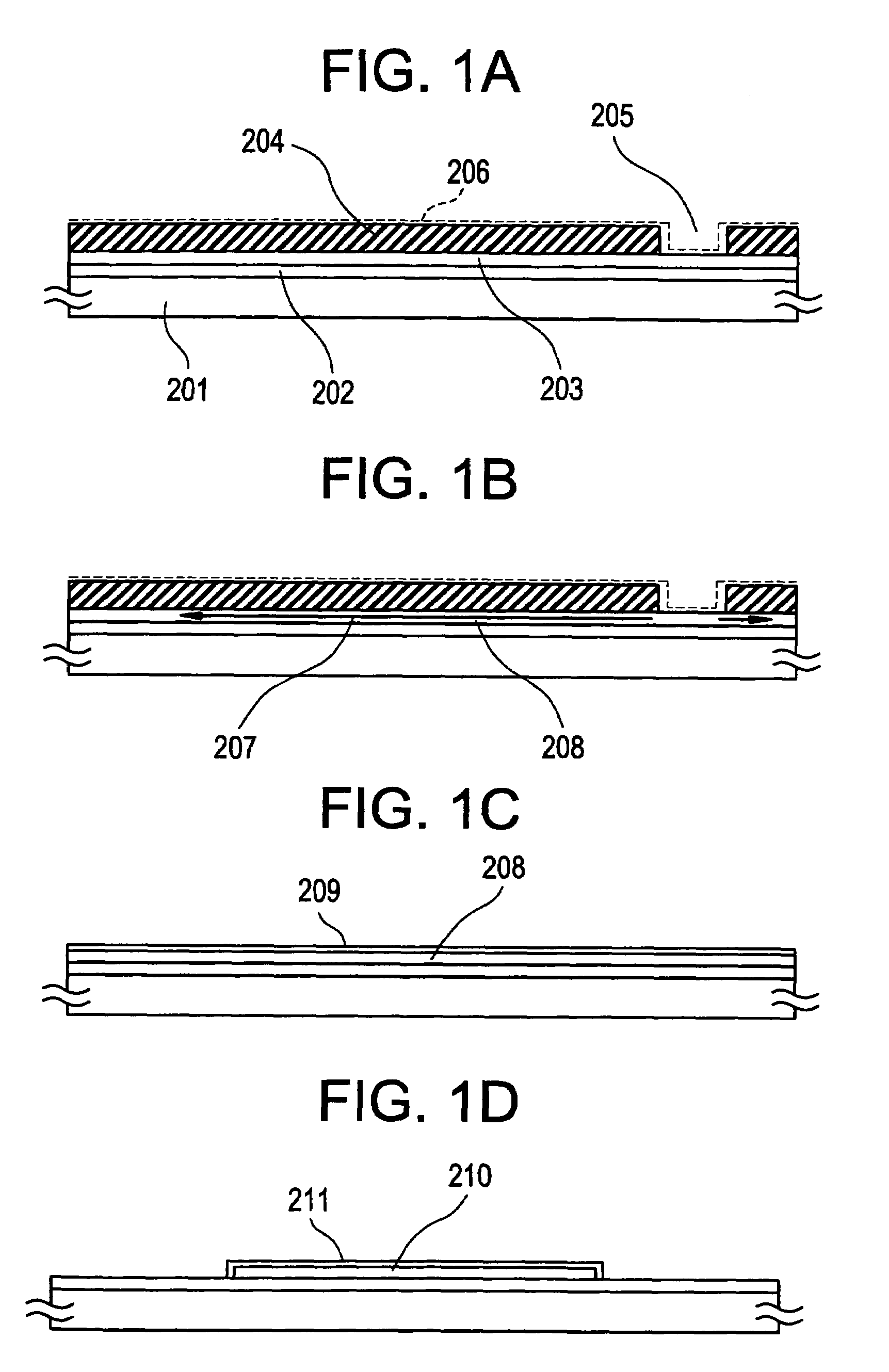

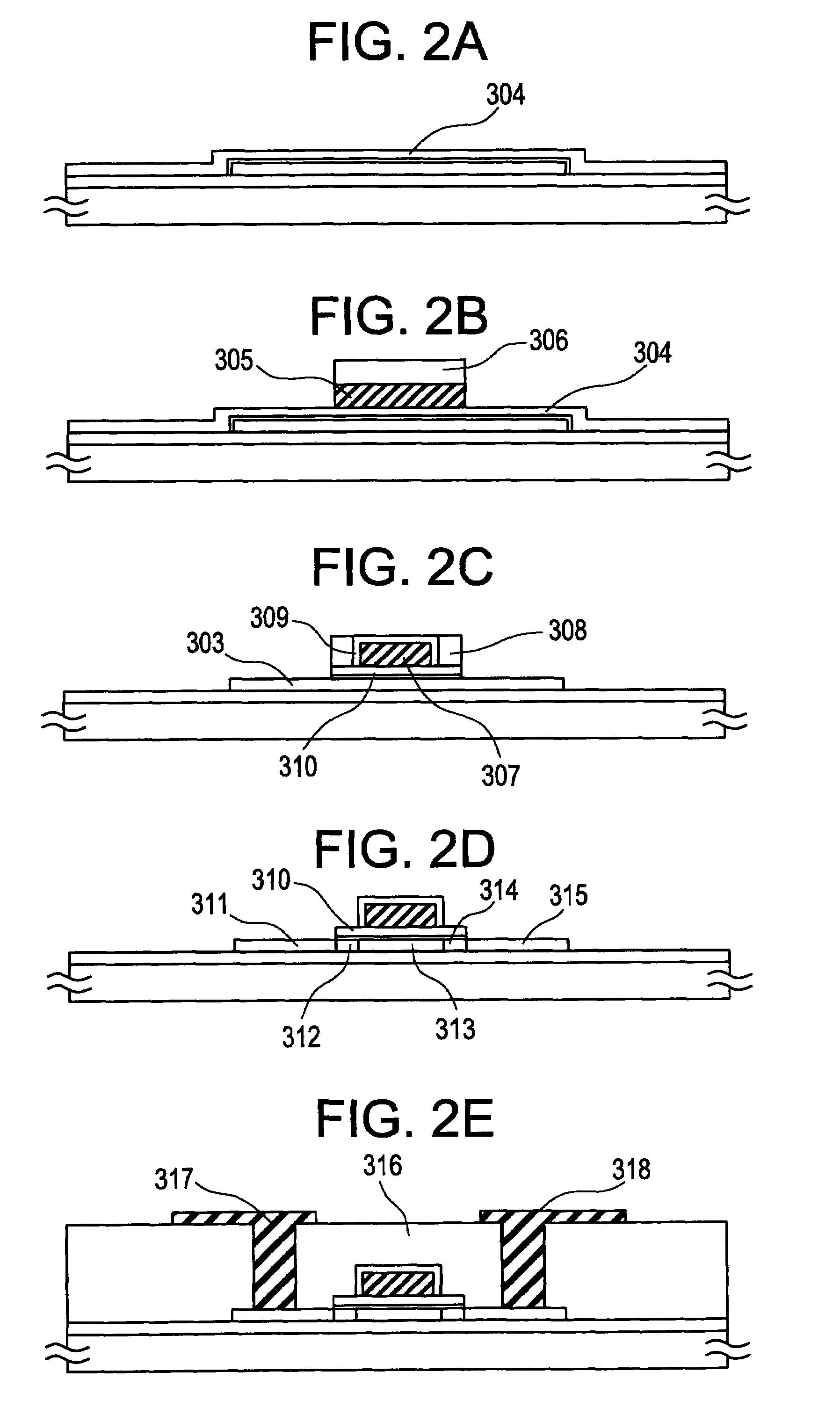

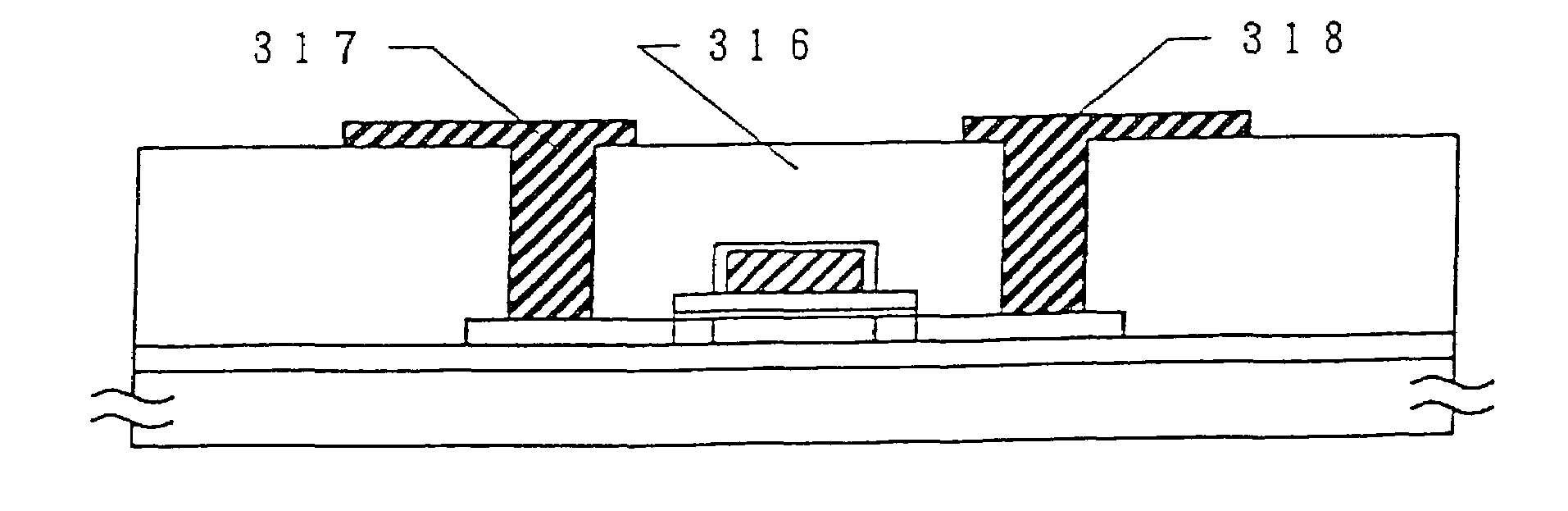

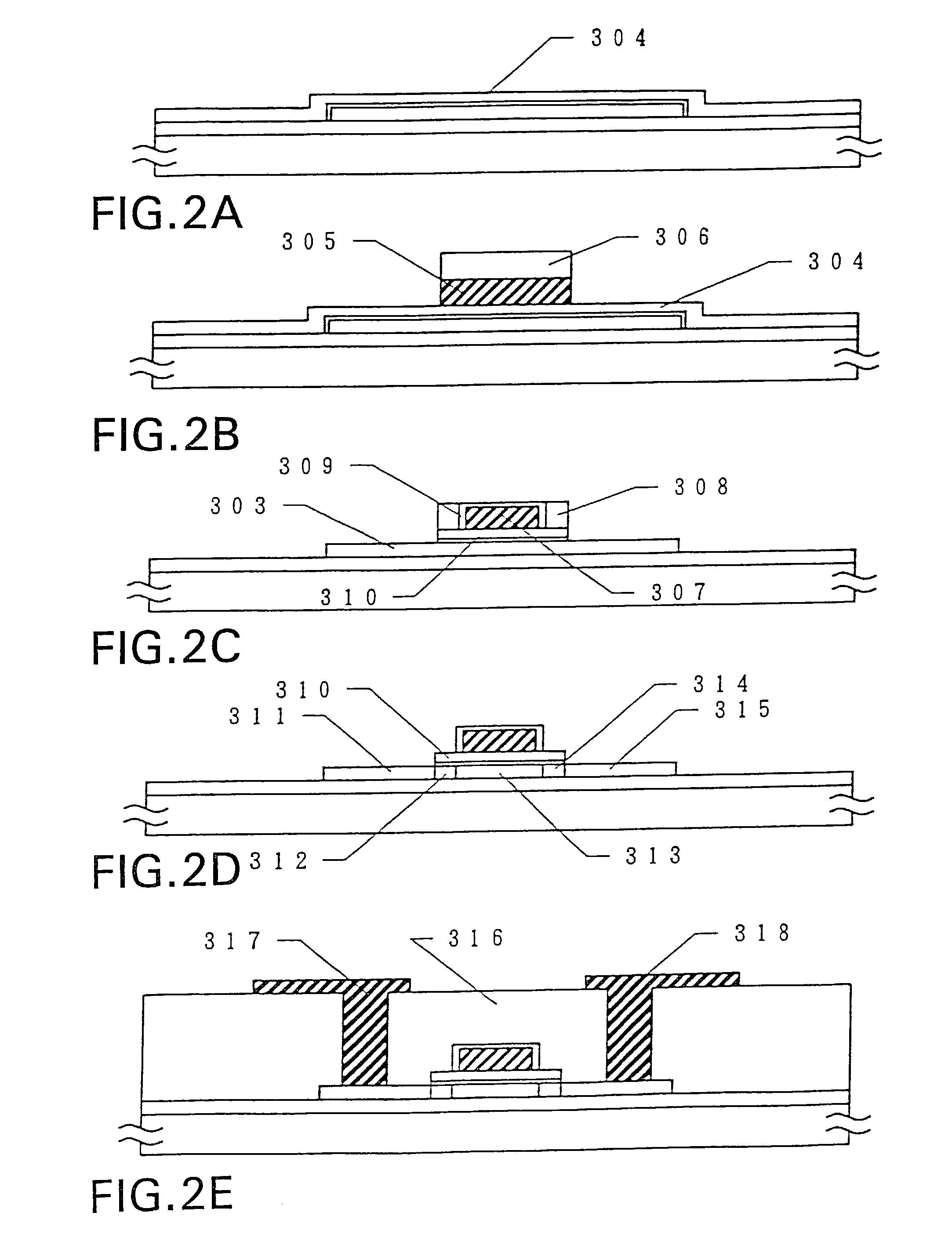

Integrated getter area for wafer level encapsulated microelectromechanical systems

ActiveUS7115436B2Improve inhalation effectLittle to no increase in overall dimensions of the MEMSAcceleration measurement using interia forcesDecorative surface effectsMicroelectromechanical systemsProduct gas

There are many inventions described and illustrated herein. In one aspect, present invention is directed to a thin film encapsulated MEMS, and technique of fabricating or manufacturing a thin film encapsulated MEMS including an integrated getter area and / or an increased chamber volume, which causes little to no increase in overall dimension(s) from the perspective of the mechanical structure and chamber. The integrated getter area is disposed within the chamber and is capable of (i) “capturing” impurities, atoms and / or molecules that are out-gassed from surrounding materials and / or (ii) reducing and / or minimizing the adverse impact of such impurities, atoms and / or molecules (for example, reducing the probability of adding mass to a resonator which would thereby change the resonator's frequency). In this way, the thin film wafer level packaged MEMS of the present invention includes a relatively stable, controlled pressure environment within the chamber to provide, for example, a more stable predetermined, desired and / or selected mechanical damping of the mechanical structure.

Owner:ROBERT BOSCH GMBH

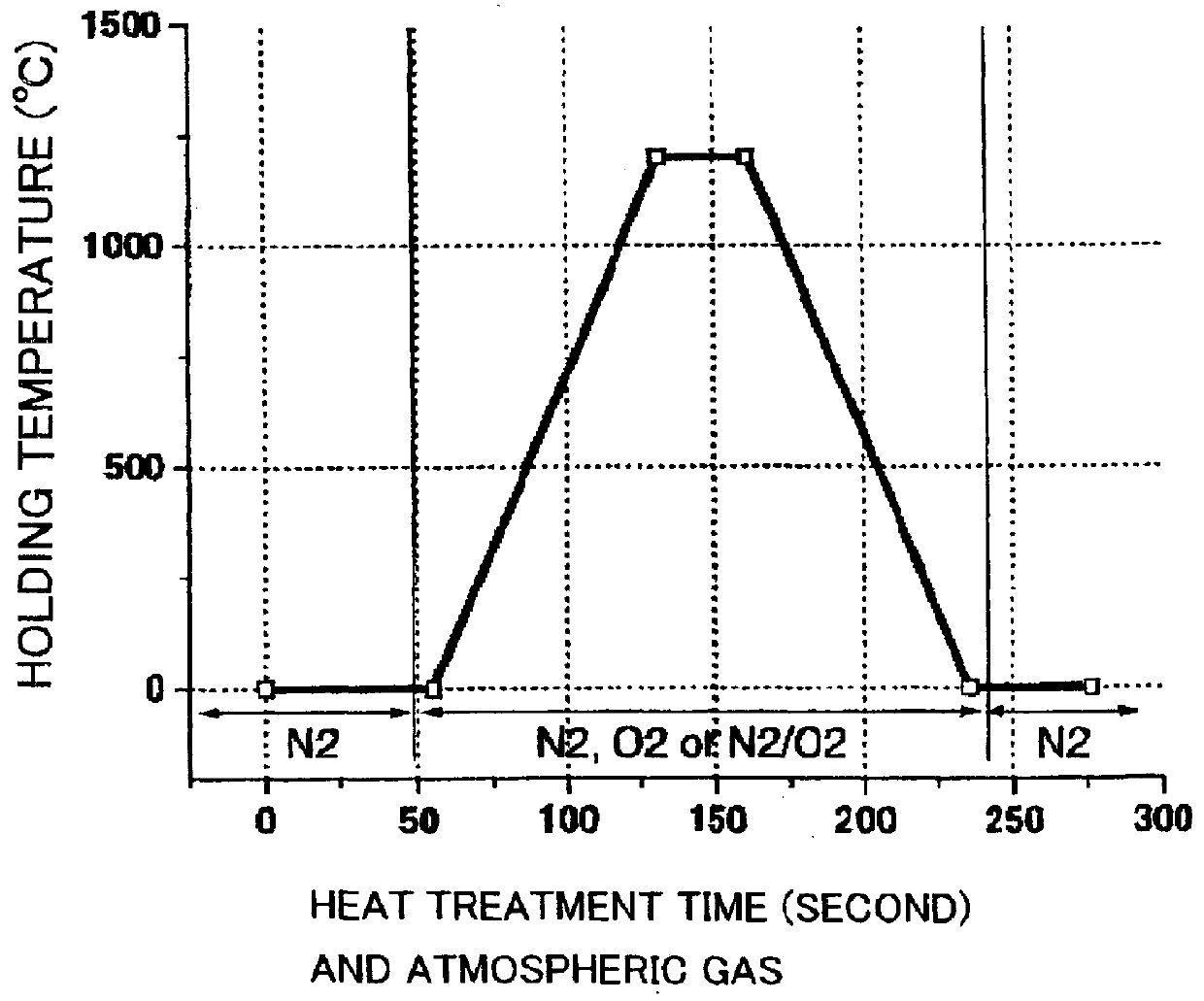

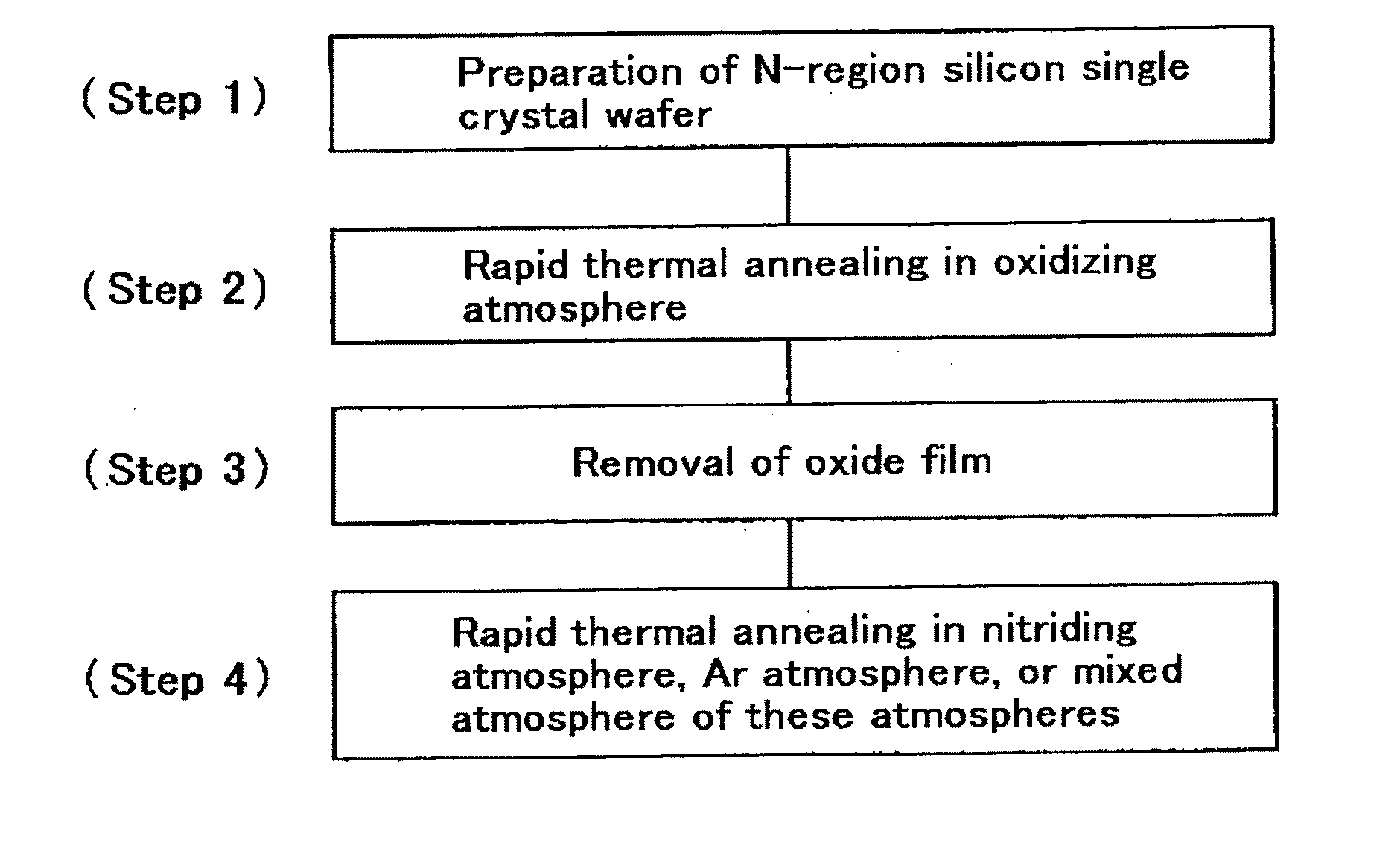

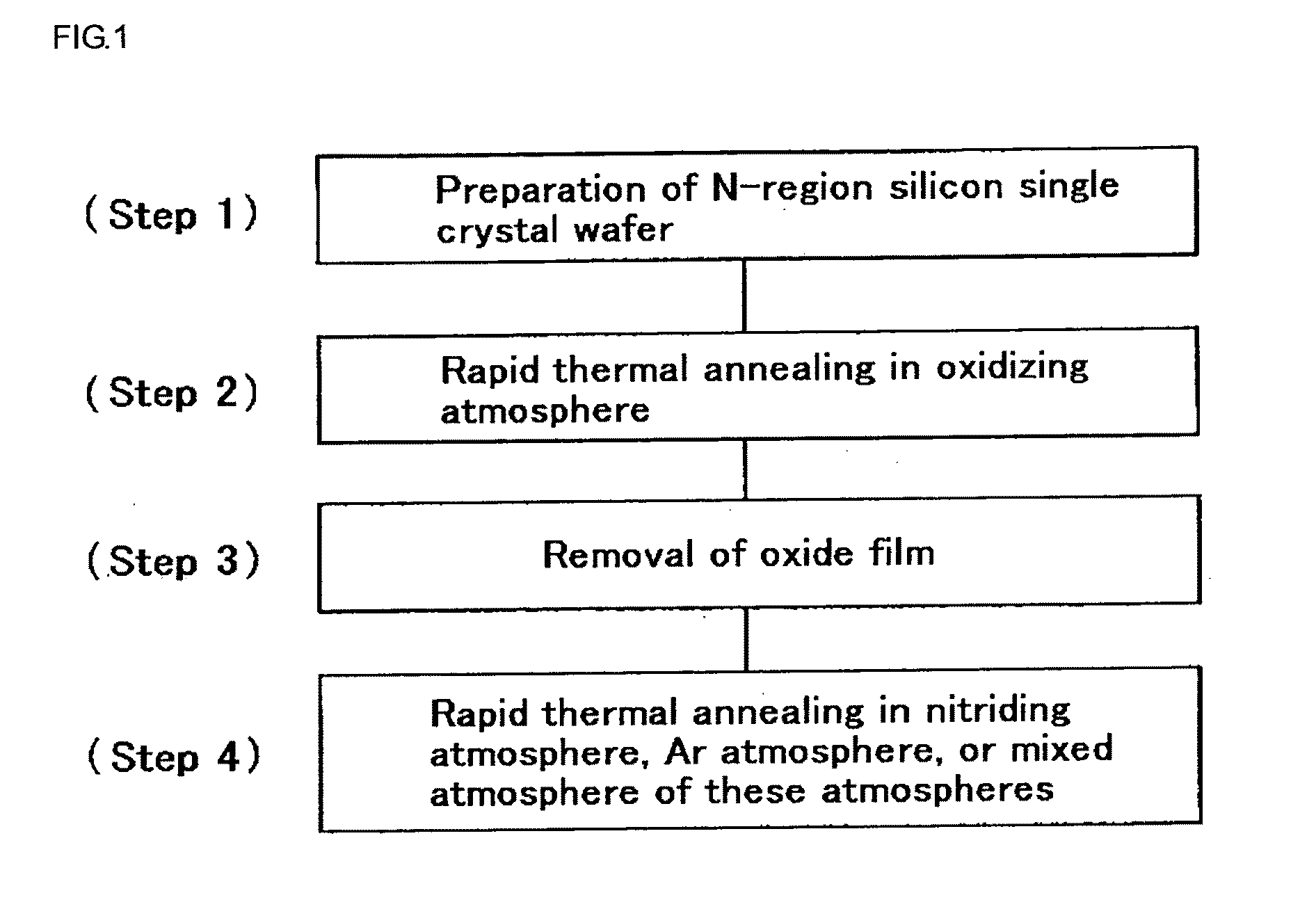

Method for heat treatment of silicon substrate, substrate treated by the method, and epitaxial wafer utilizing the substrate

InactiveUS6143071AImprove productivityEasy to processPolycrystalline material growthAfter-treatment detailsNitrogenNitrogen gas

Owner:SHIN-ETSU HANDOTAI CO LTD

Semiconductor device having a crystalline semiconductor film

InactiveUS7173282B2Easy to moveLow efficiencyTransistorSolid-state devicesAmorphous siliconCrystallinity

Nickel is selectively held in contact with a particular region of an amorphous silicon film. Crystal growth parallel with a substrate is effected by performing a heat treatment. A thermal oxidation film is formed by performing a heat treatment in an oxidizing atmosphere containing a halogen element. During this step, the crystallinity is improved and the gettering of nickel elements proceeds. A thin-film transistor is formed so that the direction connecting source and drain regions coincides with the above crystal growth direction. As a result, a TFT having superior characteristics such as a mobility larger than 200 cm2 / Vs and an S value smaller than 100 mV / dec. can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

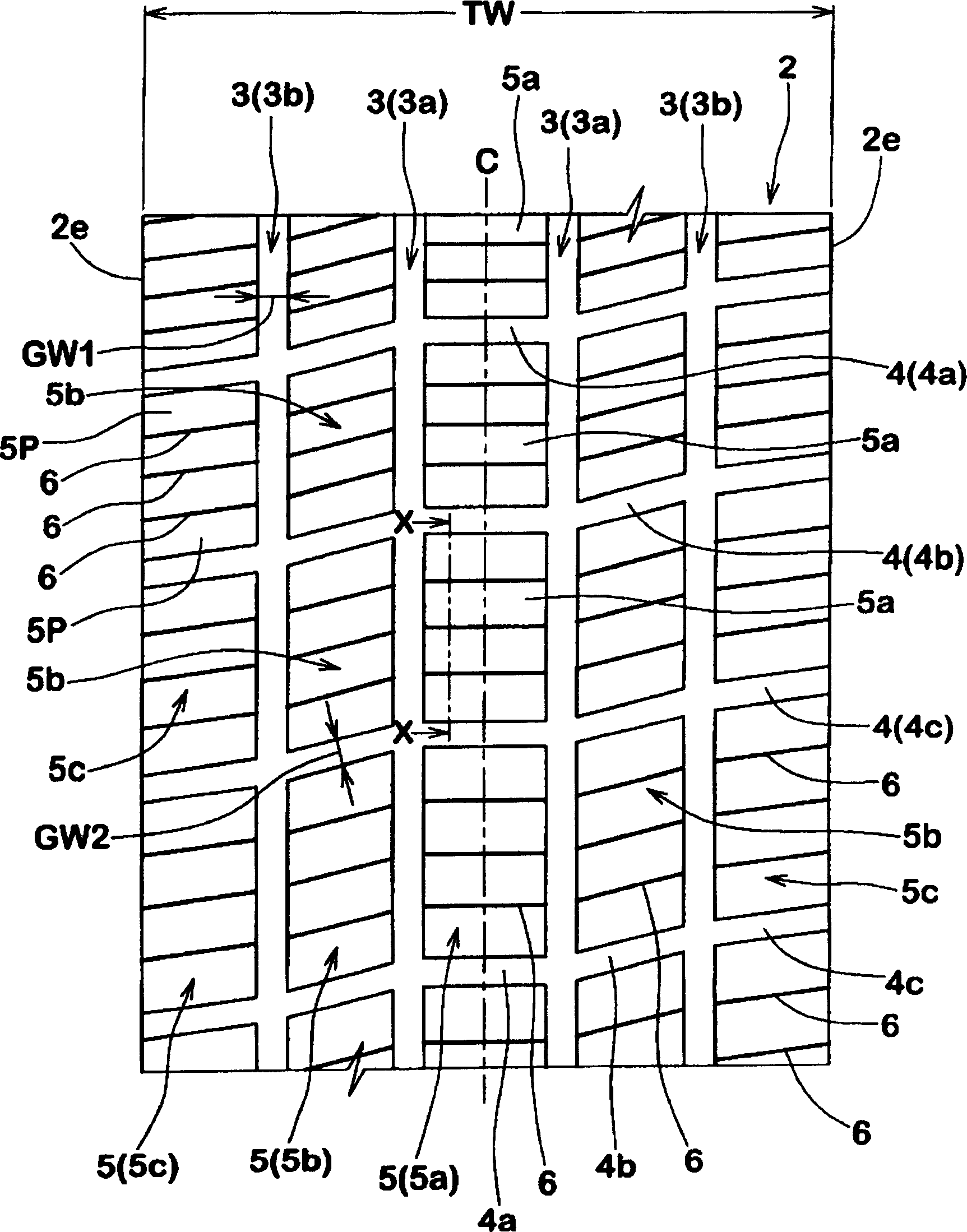

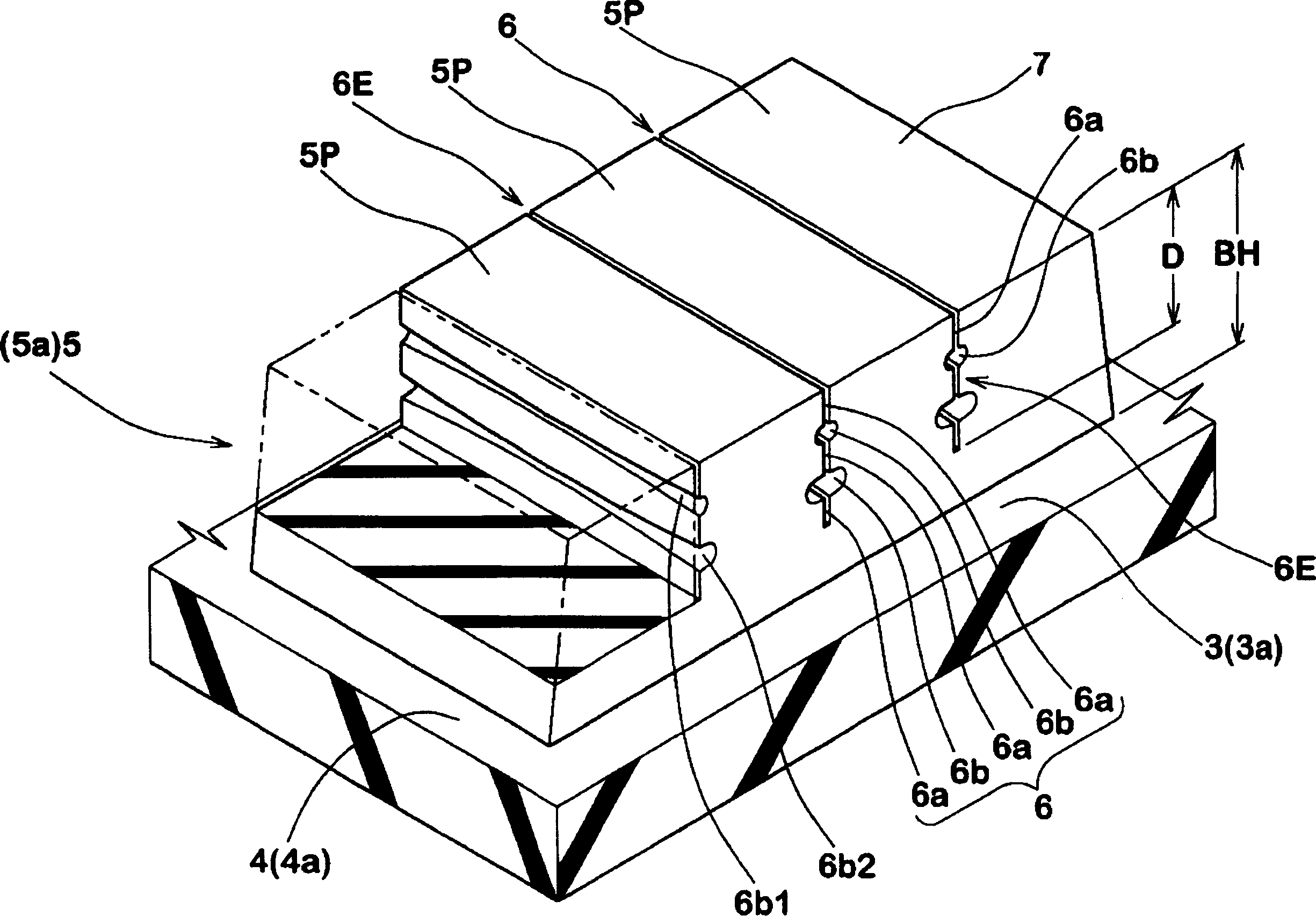

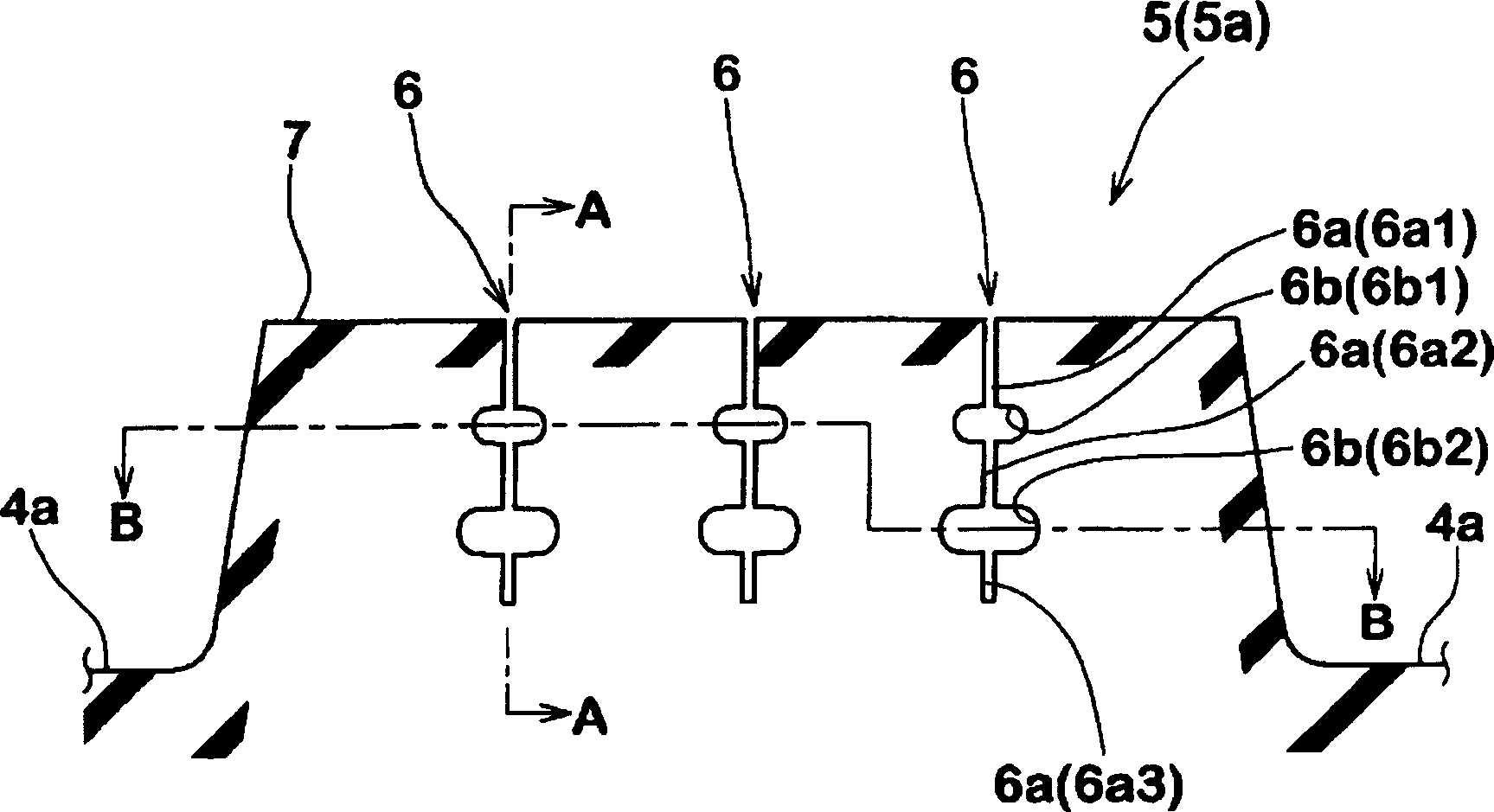

Inflation tire

InactiveCN1853965APrevent occlusionImprove inhalation effectTyre tread bands/patternsStructural engineeringMaximum depth

PROBLEM TO BE SOLVED: To provide a pneumatic tire capable of enhancing water-absorbing effect on an ice road and improving traveling performance. ŽSOLUTION: The pneumatic tire is provided with a plurality of longitudinal grooves 3 extending to the tire circumferential direction on a tread part. The pneumatic tire has land parts 5 between adjacent longitudinal grooves 3, 3 or between the longitudinal groove 3 and the tread end. The land part 5 is provided with a siping shape narrow groove 6 which extends to the direction crossing the land part 5, at least one end 6E is communicated to the longitudinal groove 3 or the tread end, and opens at the ground surface 7. The siping shape narrow groove 6 comprises a sipe part 6a having an incised shape groove width of 2.0 mm or less, and an expanded width part 6b which is continued to the inward radial direction of the sipe part 6a and has the groove width of more than 2.0 mm. The expanded width 6b is provided at the area Y where the maximum depth D of the siping shape narrow groove from the ground surface 7 is not less than 20% and not more than 90%. ŽCOPYRIGHT: (C)2007,JPO&INPIT Ž

Owner:SUMITOMO RUBBER IND LTD

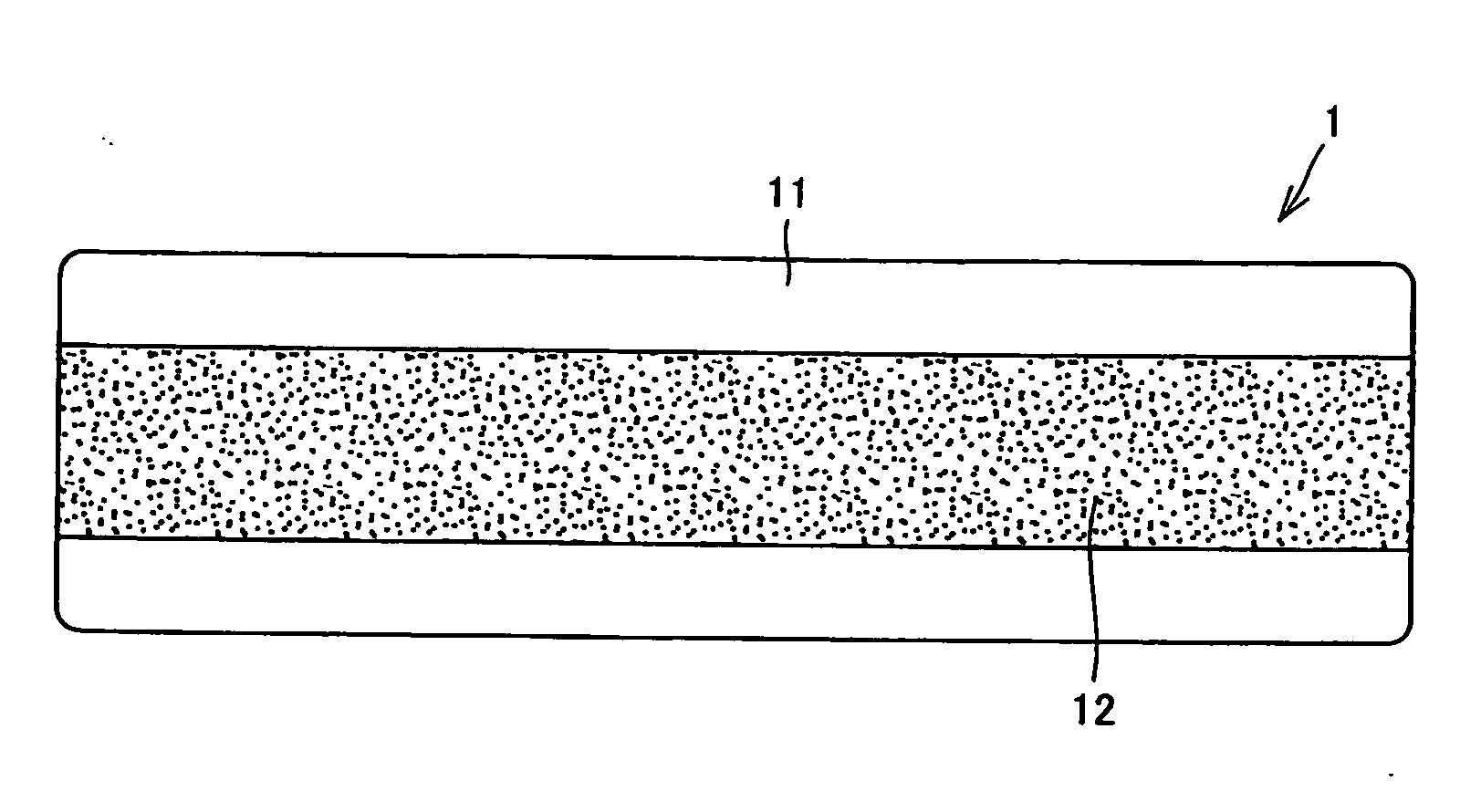

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20030175532A1Increase widthFew surface defectPolycrystalline material growthSiliconWaferingSingle crystal

Owner:SUMITOMO MITSUBISHI SILICON CORP

Silicon single crystal, silicon wafer, and epitaxial wafer.

InactiveUS6641888B2Increase widthEnhance formation rate and growth ratePolycrystalline material growthSiliconSingle crystalMaterials science

Owner:SUMITOMO MITSUBISHI SILICON CORP

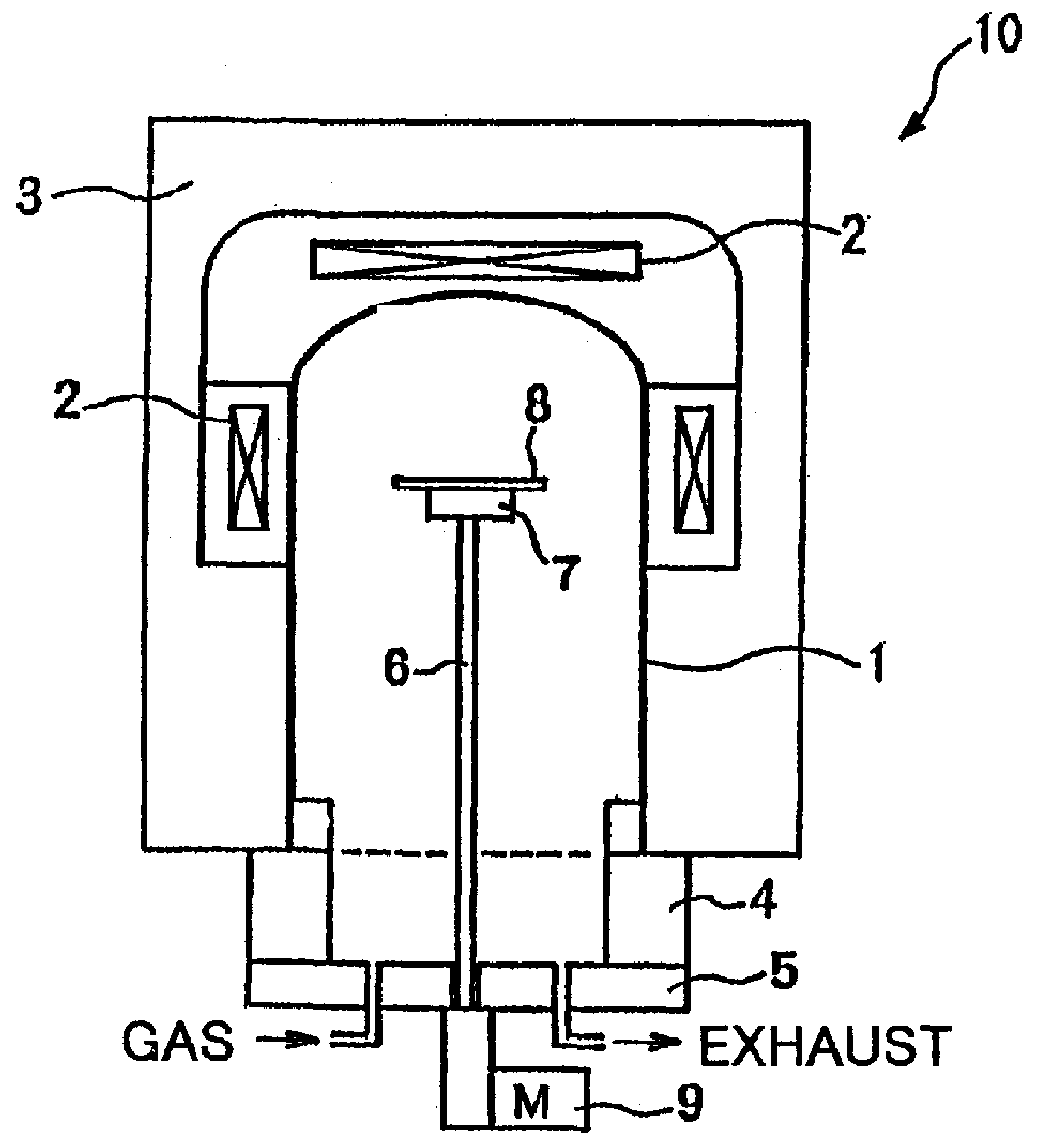

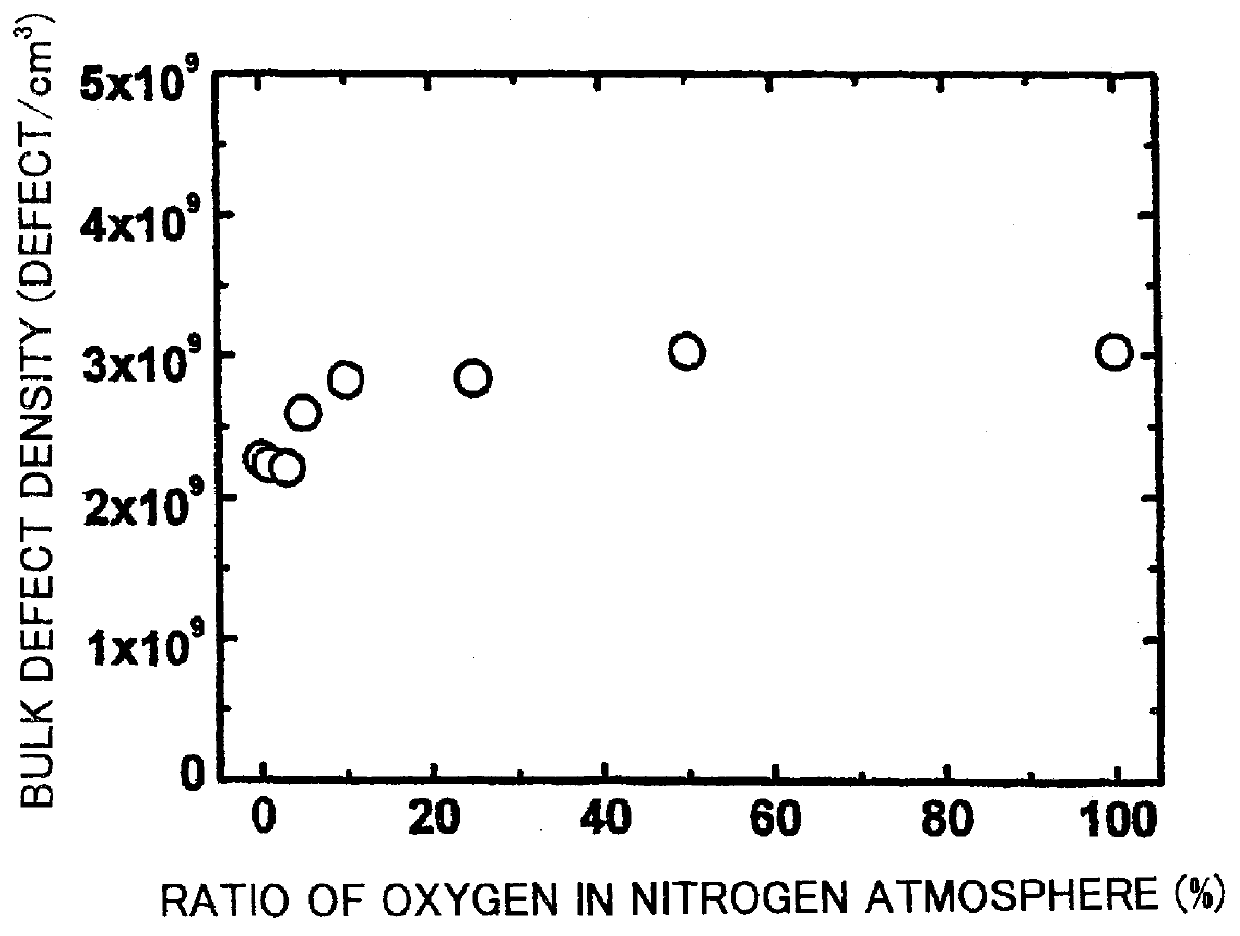

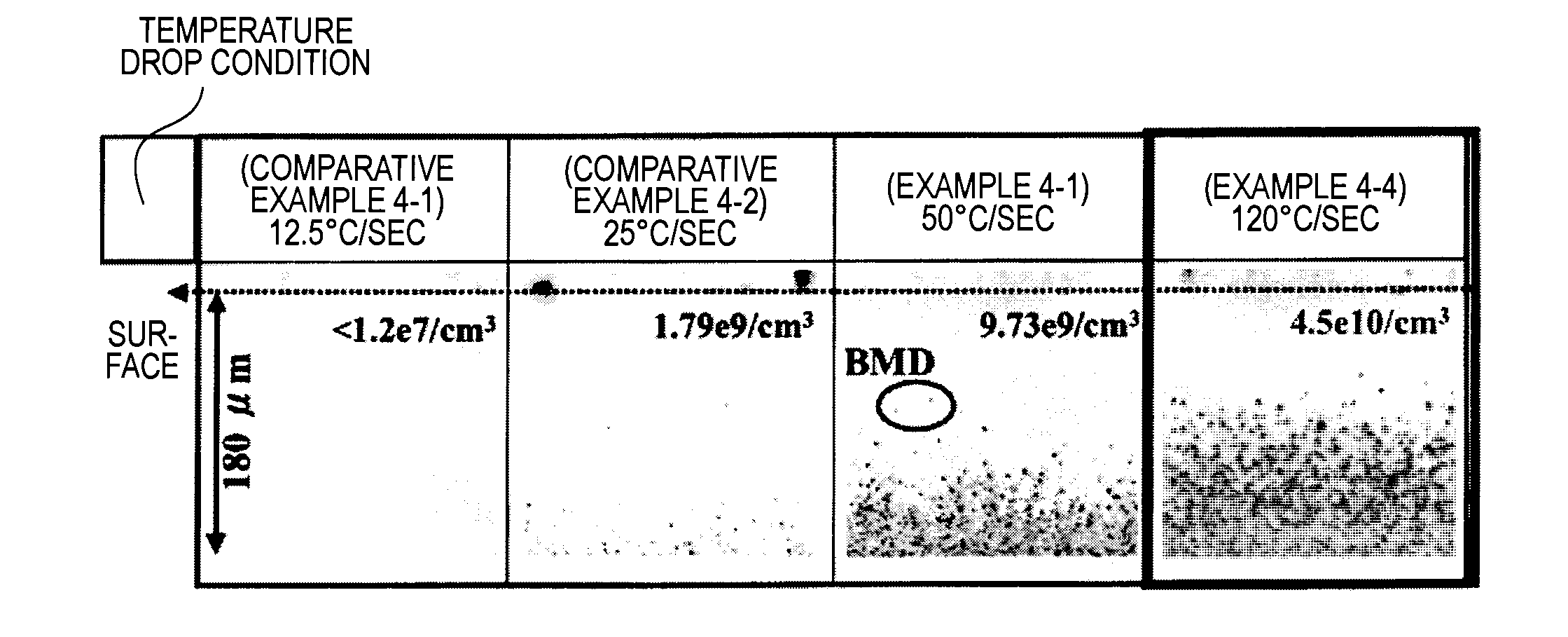

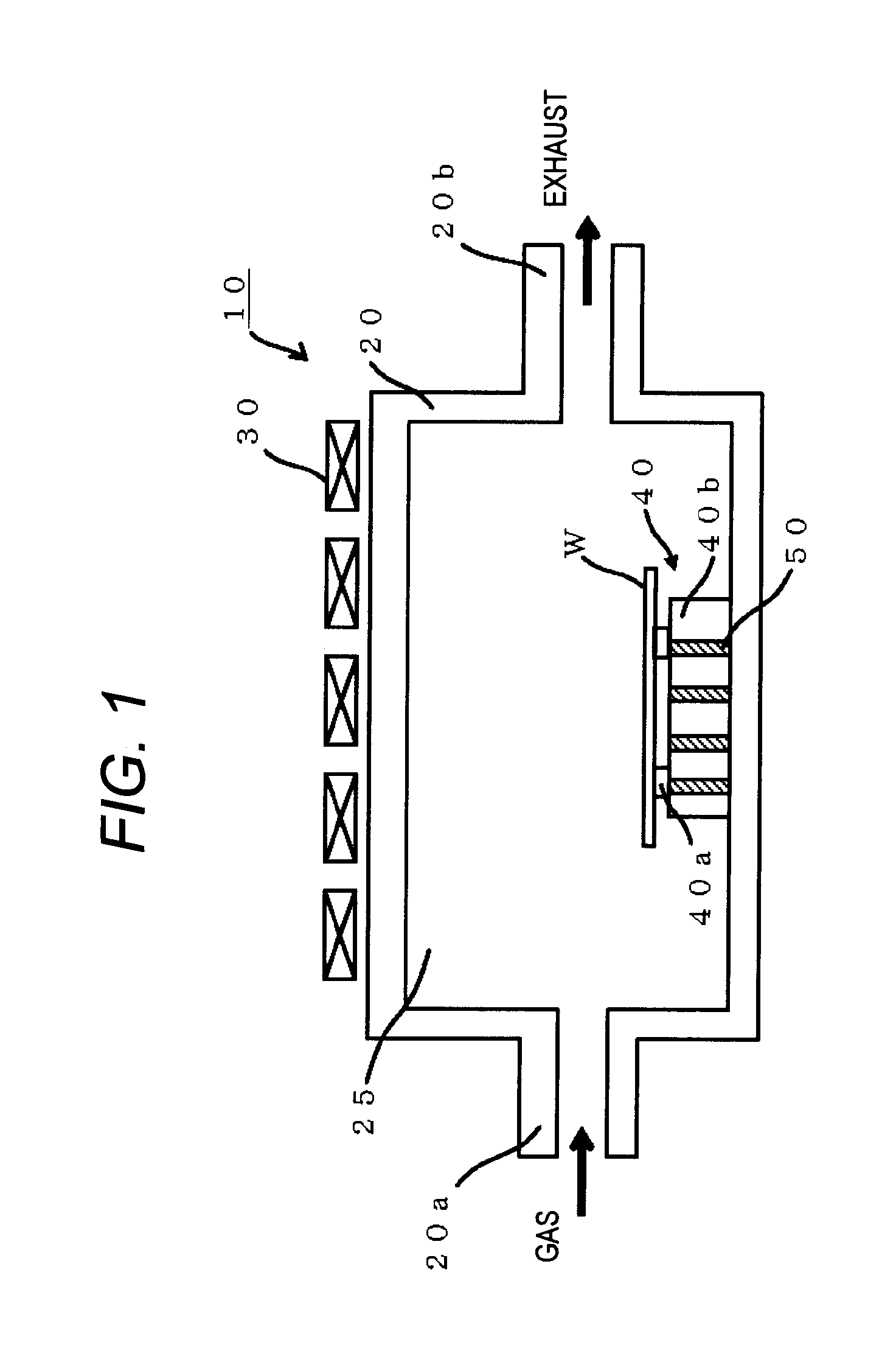

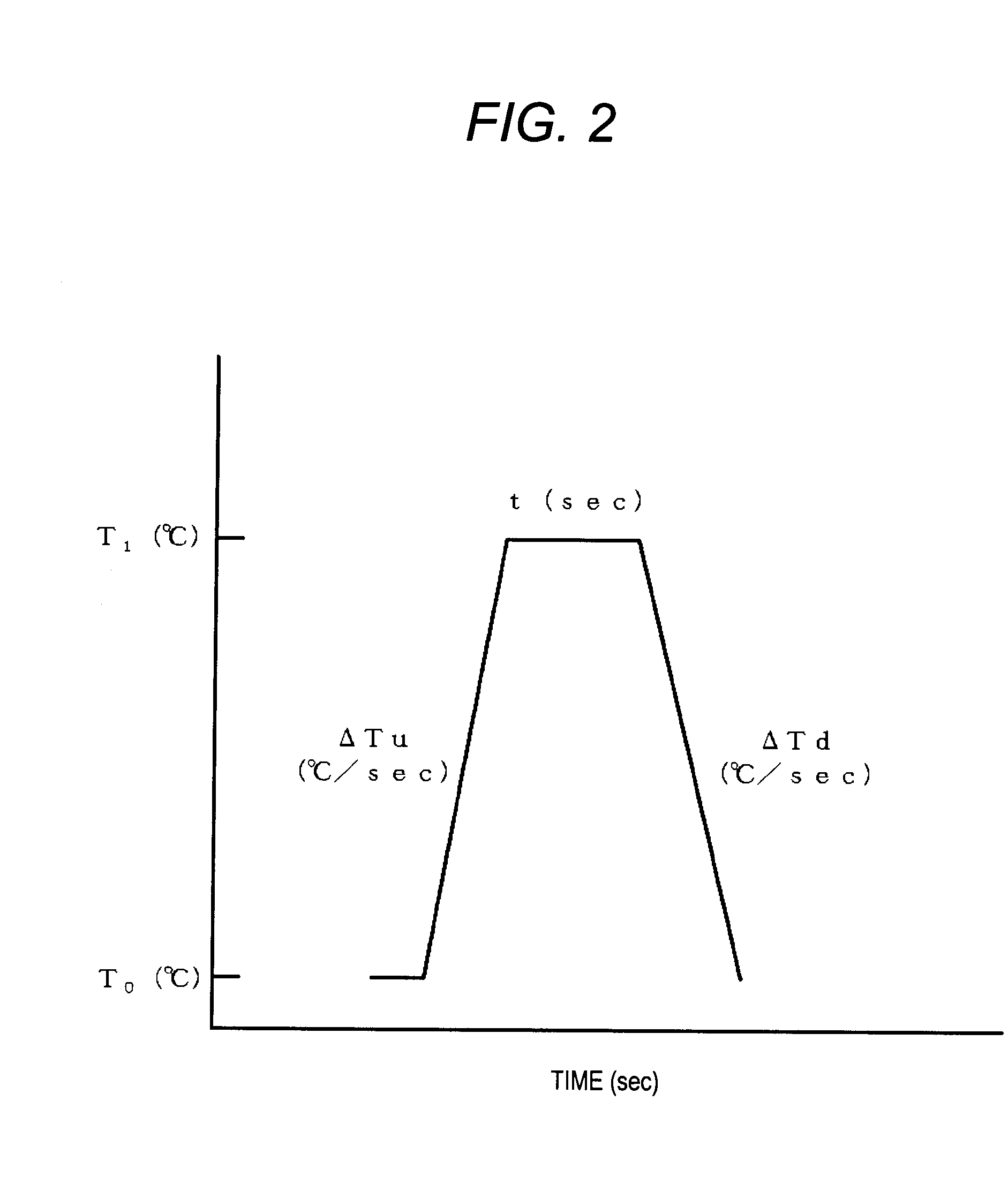

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveUS20100038757A1Reduce capacitySuppress generationPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

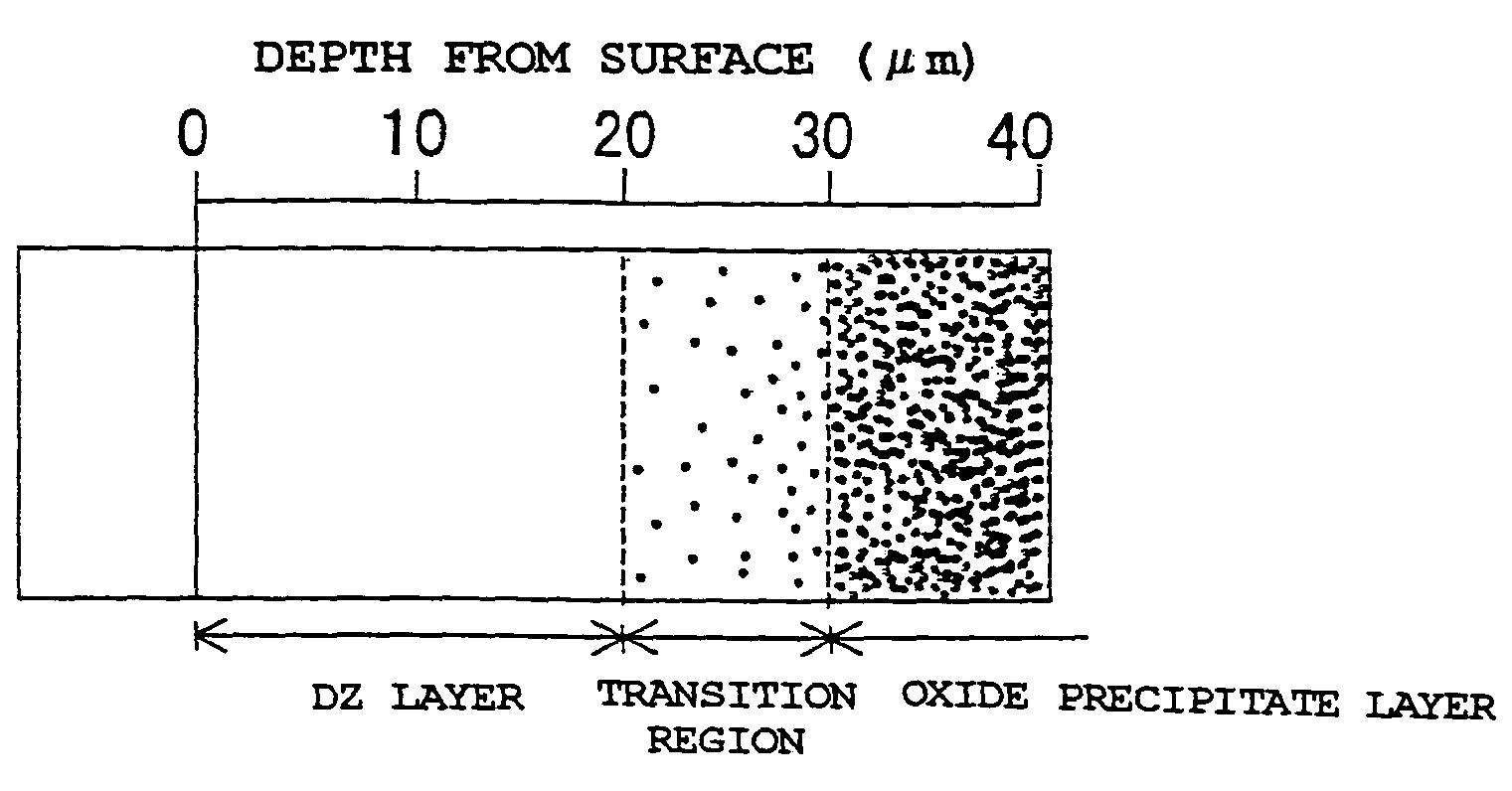

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300° C. or more, but less than 1380° C. in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer according to the invention has, in a defect-free region (DZ layer) including at least a device active region of the silicon wafer, a high oxygen concentration region having a concentration of oxygen solid solution of 0.7×1018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon in supersaturated state.

Owner:GLOBALWAFERS JAPAN

Light-emitting and electron-emitting devices having getter regions

InactiveUS7315115B1Improve performanceEasy to manufactureTube/lamp screens manufactureGetteringLight emitting deviceElectron

A light-emitting device contains getter material (58) typically distributed in a relatively uniform manner across the device's active light-emitting portion. An electron-emitting device similarly contains getter material (112, 110 / 112, 128, 132, and 142) typically distributed relatively uniformly across the active electron-emitting portion of the device.

Owner:CANON KK +1

Method for heat treatment of silicon wafers

InactiveUS20060189169A1Promote formationStable formationSemiconductor/solid-state device manufacturingHigh densityOxygen ions

A method is provided for the heat treatment of low oxygen concentration silicon wafers obtained from a silicon single crystal produced by the Czochralski process. The method comprises high-temperature oxidation heat treatment for the formation of a high oxygen concentration region under the wafer surface and the subsequent oxygen precipitation heat treatment. The high-temperature oxidation heat treatment can cause inward diffusion of oxygen from the wafer surface to form a region increased in oxygen concentration under the wafer surface, and the subsequent oxygen precipitation heat treatment can form a DZ layer on the wafer surface and stably form oxygen precipitates optimal in size within the wafer at a high density, so that excellent gettering effects can be produced. Further, in case of using as SOI substrates formed by SIMOX, too, the same effects as mentioned above can be produced by carrying out the high-temperature oxidation heat treatment after oxygen ion implantation in the SIMOX process and then carrying out the oxygen precipitation heat treatment.

Owner:SUMCO CORP

Semiconductor device and its manufacturing method

InactiveUS7078727B2Superior characteristicEasy to moveTransistorSolid-state devicesCrystallinitySemiconductor

Nickel is selectively held in contact with a particular region of an amorphous silicon film. Crystal growth parallel with a substrate is effected by performing a heat treatment. A thermal oxidation film is formed on the silicon film by performing a heat treatment in an oxidizing atmosphere containing a halogen element. During this step, in the silicon film, impurities included such as oxygen or chlorine, are segregated with extending along the crystal growth, the crystallinity is improved, and the gettering of nickel element proceeds. A thin-film transistor is formed so that the direction connecting source and drain regions coincides with the above crystal growth direction. As a result, a TFT having superior characteristics such as a mobility larger than 200 cm2 / Vs and an S value smaller than 100 mV / dec. can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

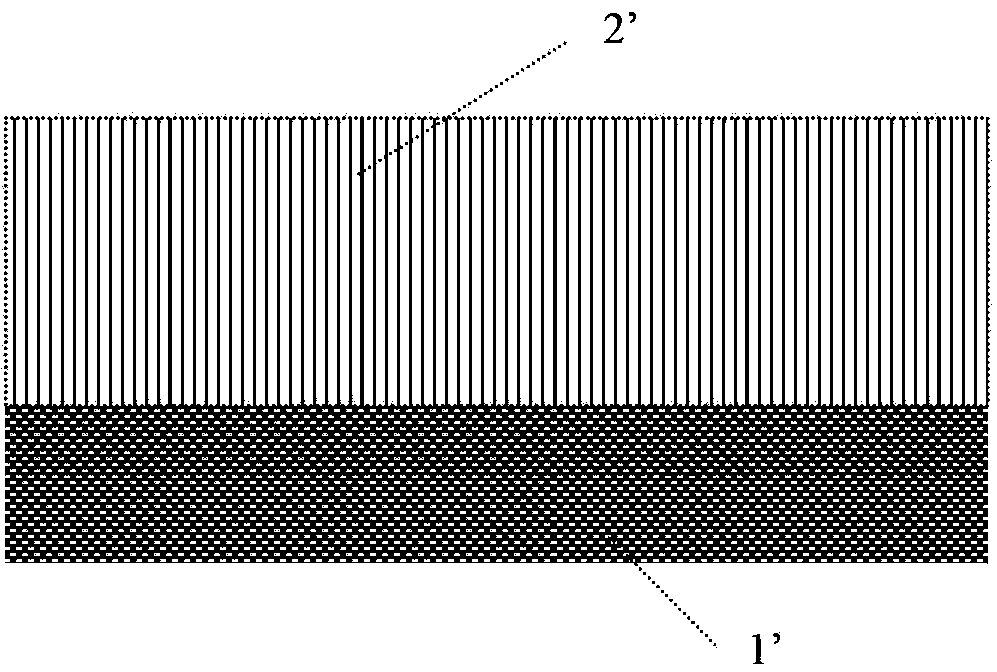

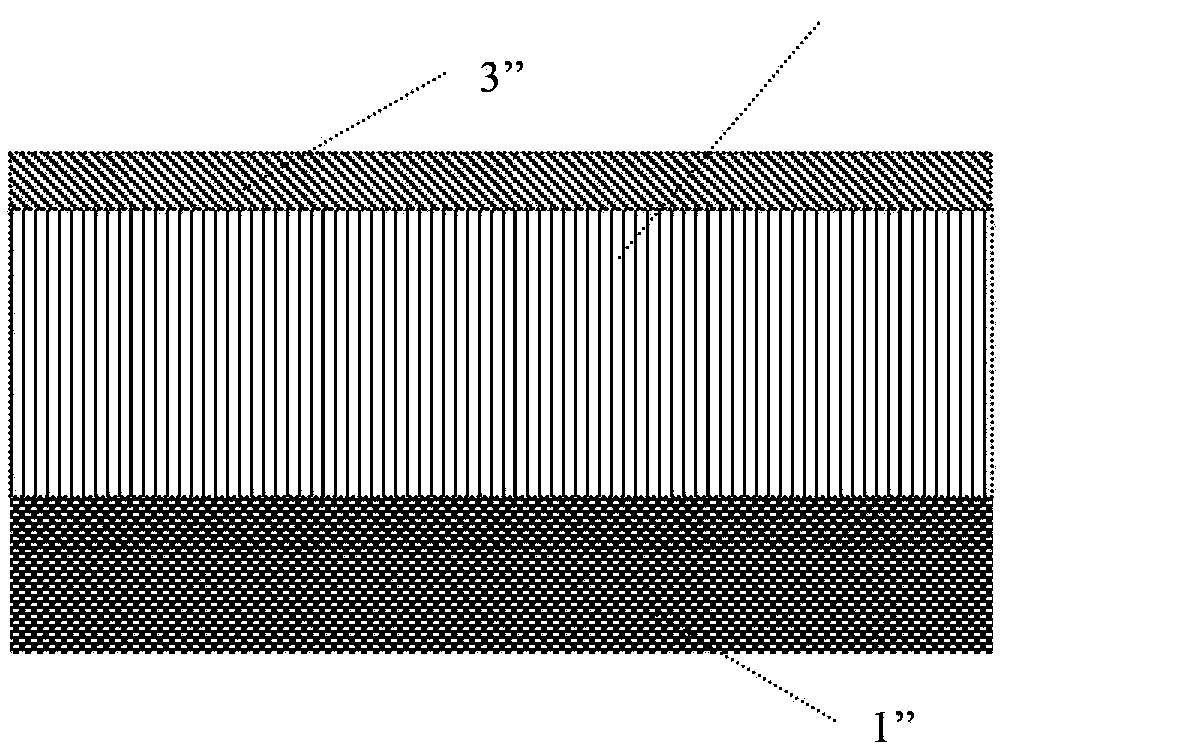

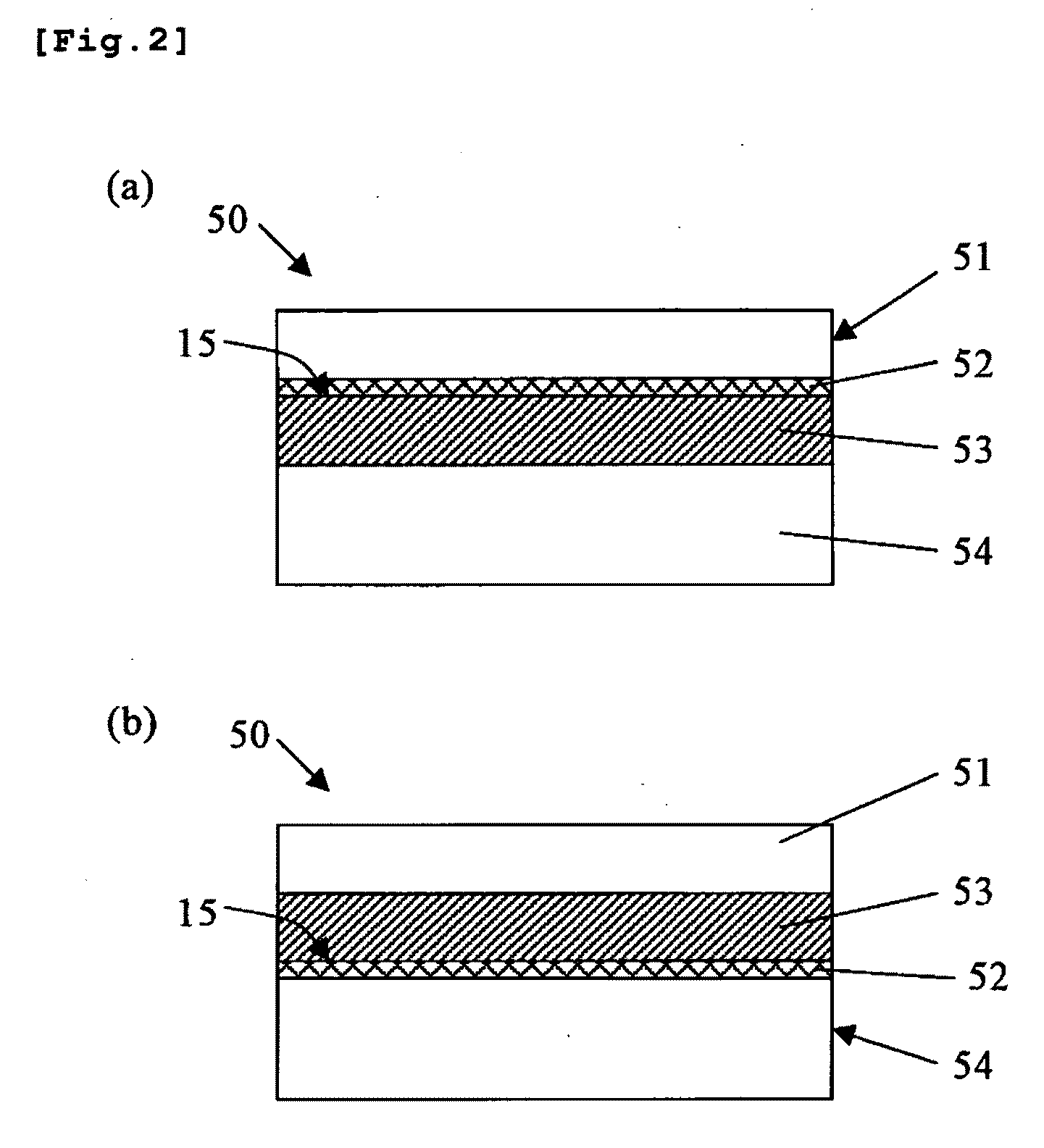

Thin-film getter with high gas absorption performance and preparation method thereof

ActiveCN103182297AImprove adhesionInhibition of poisoningOther chemical processesDispersed particle separationAbsorption capacityRadio frequency magnetron sputtering

The invention provides a thin-film getter with high gas absorption performance and a preparation method thereof. The thin-film getter is formed by depositing a gas absorbing layer on a metal, silicon, ceramic or glass substrate or on the inner wall of a sealed device or is a film with two-layer structure composed by the gas absorbing layer and an adjusting layer, wherein the gas absorbing layer is multi-component alloy formed by Zr, Co and at least one material selected from the group consisting of Y, La, Ce, Pr and Nd, and the adjusting layer is one or alloy of more selected from the group consisting of Ti, Zr, Y, Hf, Mn, Cu, Cr, Al, Fe, Pt and Ru. The preparation method employs radio frequency magnetron sputtering for deposition of films of the gas absorbing layer and the adjusting layer. The thin-film getter provided by the invention is activated at a temperature in a range of 250 to 350 DEG C, has a high gas absorption rate and high gas absorption capacity, overcomes the problems of poor adhesion, low preparation efficiency and easy poisoning during activation of conventional thin-film getters and can meet design requirements for a vacuum working environment needed for realizing high reliability and a long service life of micro-electromechanical systems (MEMS), flat-panel displays (OLED / FED / LCD), solar heat-insulating boards and hydrogen-sensitive microelectronic devices.

Owner:GRIMAT ENG INST CO LTD

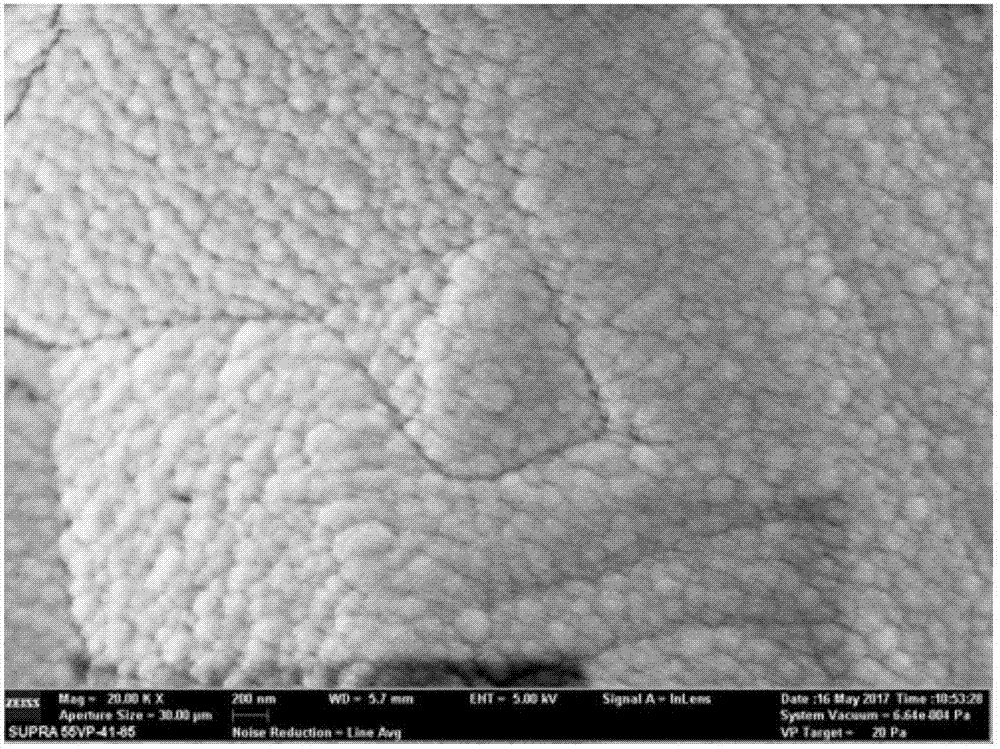

Zr-Co-Re thin film getter provided with protection layer, and preparation method thereof

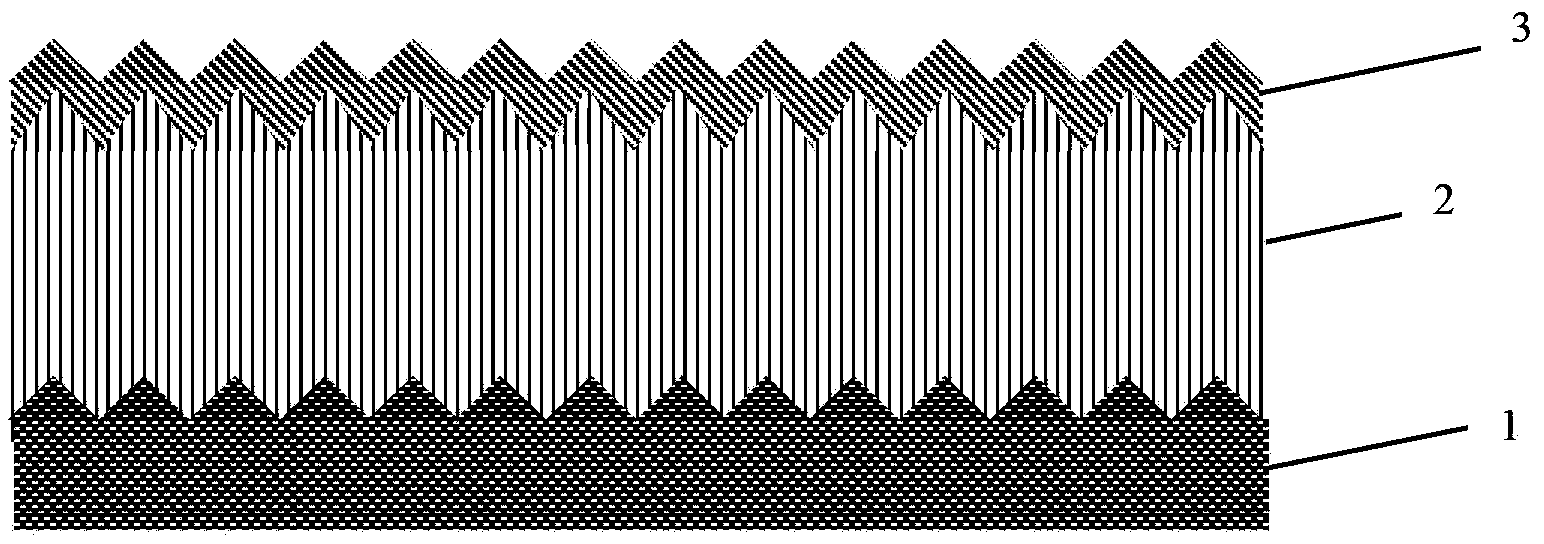

InactiveCN103849835AIncrease speedIncrease inspiratory capacityVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

The invention relates to a Zr-Co-Re thin film getter provided with a protection layer, and a preparation method thereof. The Zr-Co-Re thin film getter is composed of a getter layer and the protection layer; main components of the getter layer are Zr, Co, and one or more selected form rare earth elements La, Ce, Pr, and Nd; and main component of the protection layer is Ni. Pulsed laser deposition film plating is adopted, and deposition of the double-layer structured thin film getter containing the protection layer and the getter layer on texture monocrystalline silicon is carried out. The texture substrate is capable of increasing effective area of the getter thin film, and so that inspiratory flow rate and inspiratory capacity are increased. The surface of the getter layer is plated with a Ni protection layer; Ni is capable of realizing dissociation of hydrogen, and increasing absorption amount of hydrogen; and the Ni protection layer is capable of inhibiting absorption of oxygen and reducing activation temperature. Activation of the Zr-Co-Re thin film getter can be realized in roasting processes at a temperature of 180 to 350 DEG C; after roasting, the Zr-Co-Re thin film getter possesses excellent inspiration performance at room temperature, can be used for internal gas residue removing of high vacuum microelectronic devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

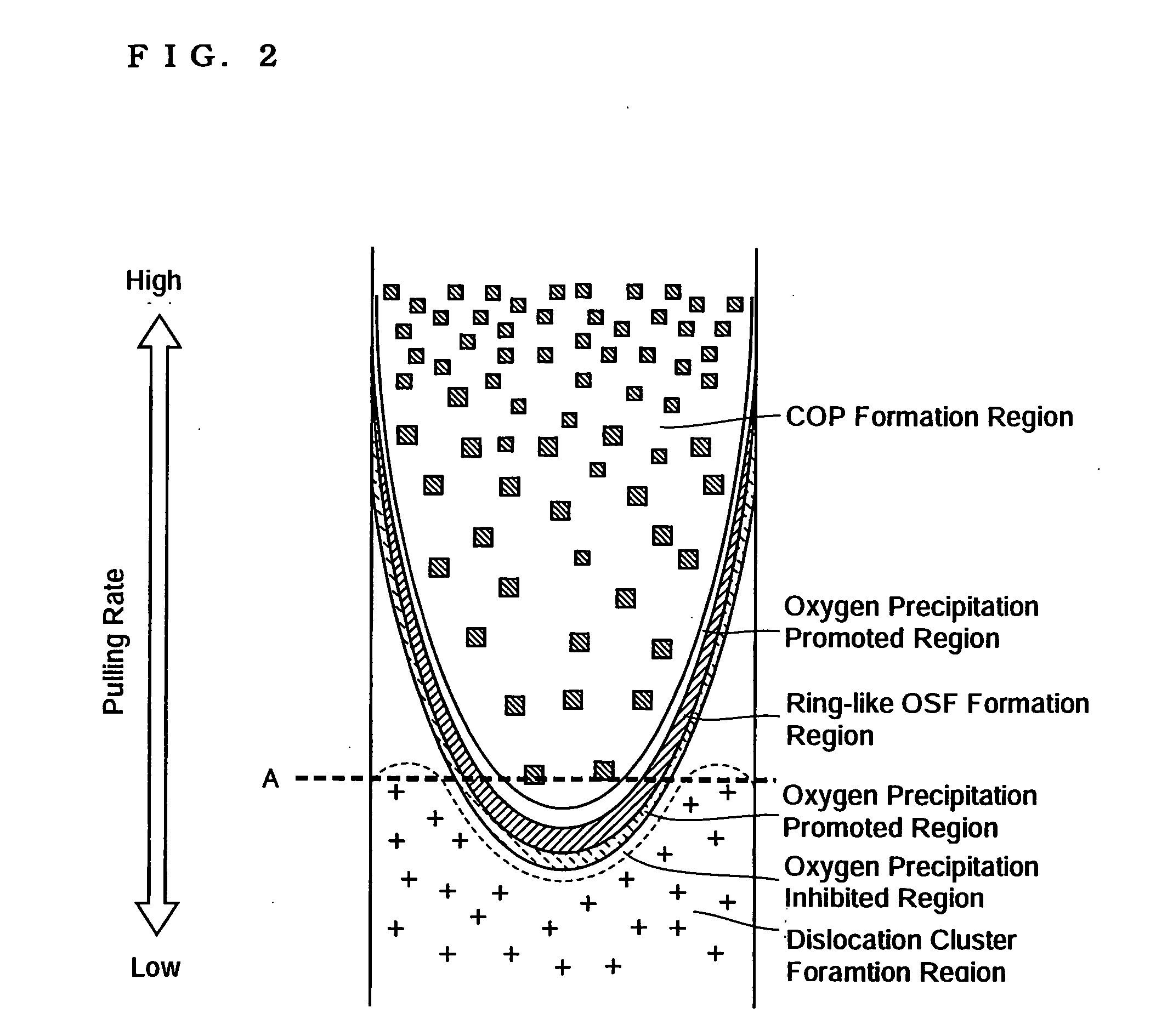

Process for implementing oxygen into a silicon wafer having a region which is free of agglomerated intrinsic point defects

InactiveUS20050130394A1Improve inhalation effectPolycrystalline material growthSemiconductor/solid-state device testing/measurementSilicon on insulatorSingle crystal silicon wafer

The present invention relates to a process for the preparation of a silicon on insulator wafer. The process includes implanting oxygen into a single crystal silicon wafer which is substantially free of agglomerated vacancy-type defects. The present invention further relates to a process for the preparation of a silicon on insulator wafer wherein oxygen is implanted into a single crystal silicon wafer having an axially symmetric region in which there is a predominant intrinsic point defect which is substantially free of agglomerated intrinsic point defects. Additionally, the present invention relates to a silicon on insulator (“SOI”) structure in which the device layer is substantially free of agglomerated intrinsic point defects.

Owner:MEMC ELECTONIC MATERIALS INC

Method for manufacturing silicon single crystal wafer

ActiveUS20100105191A1High gettering capabilityLarge manufacture marginPolycrystalline material growthAfter-treatment detailsOxideSurface layer

Owner:SHIN-ETSU HANDOTAI CO LTD

Method of producing silicon wafer and silicon wafer

InactiveUS7147711B2High gettering abilityHigh resistivityPolycrystalline material growthAfter-treatment detailsHigh resistivityOxide

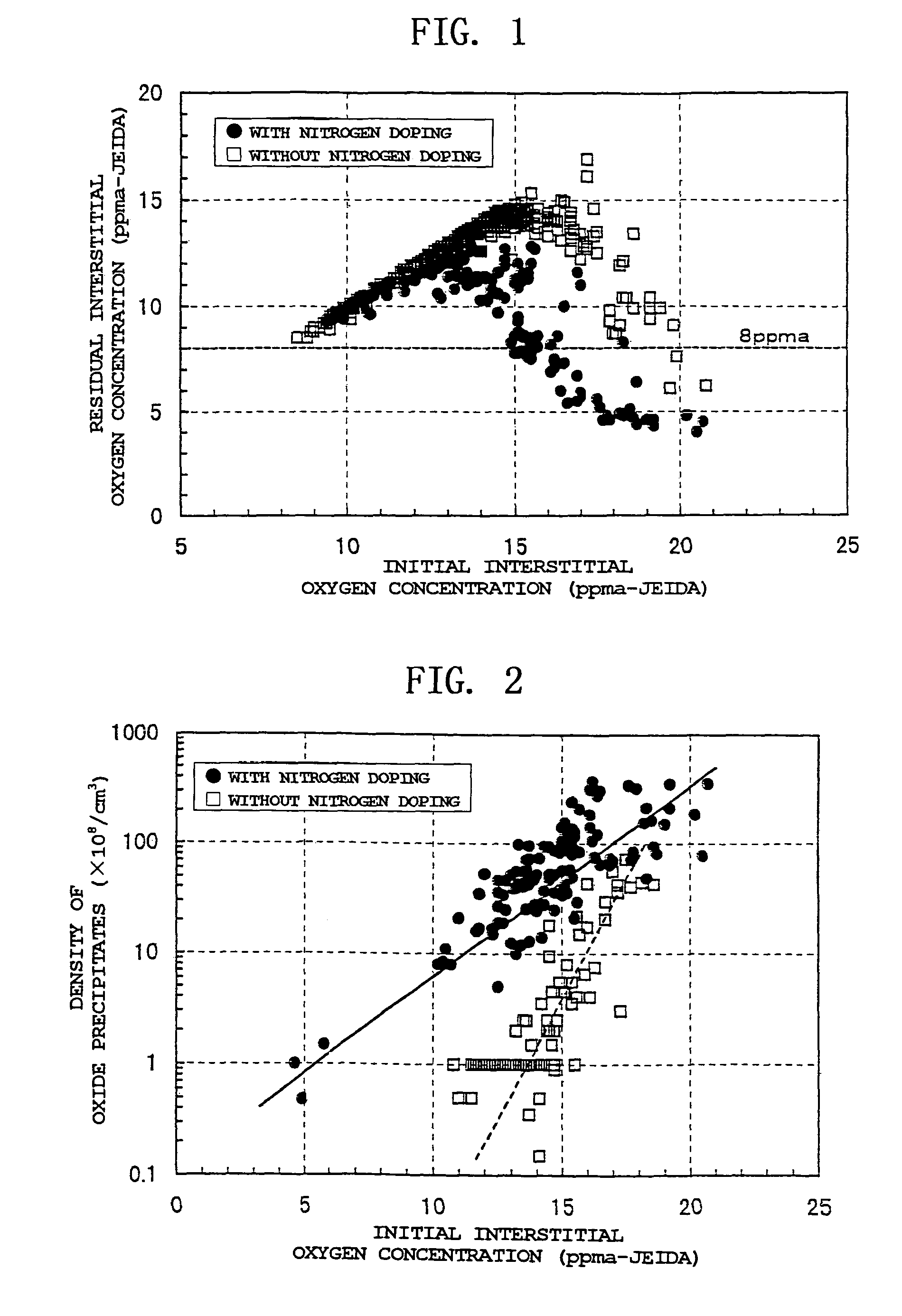

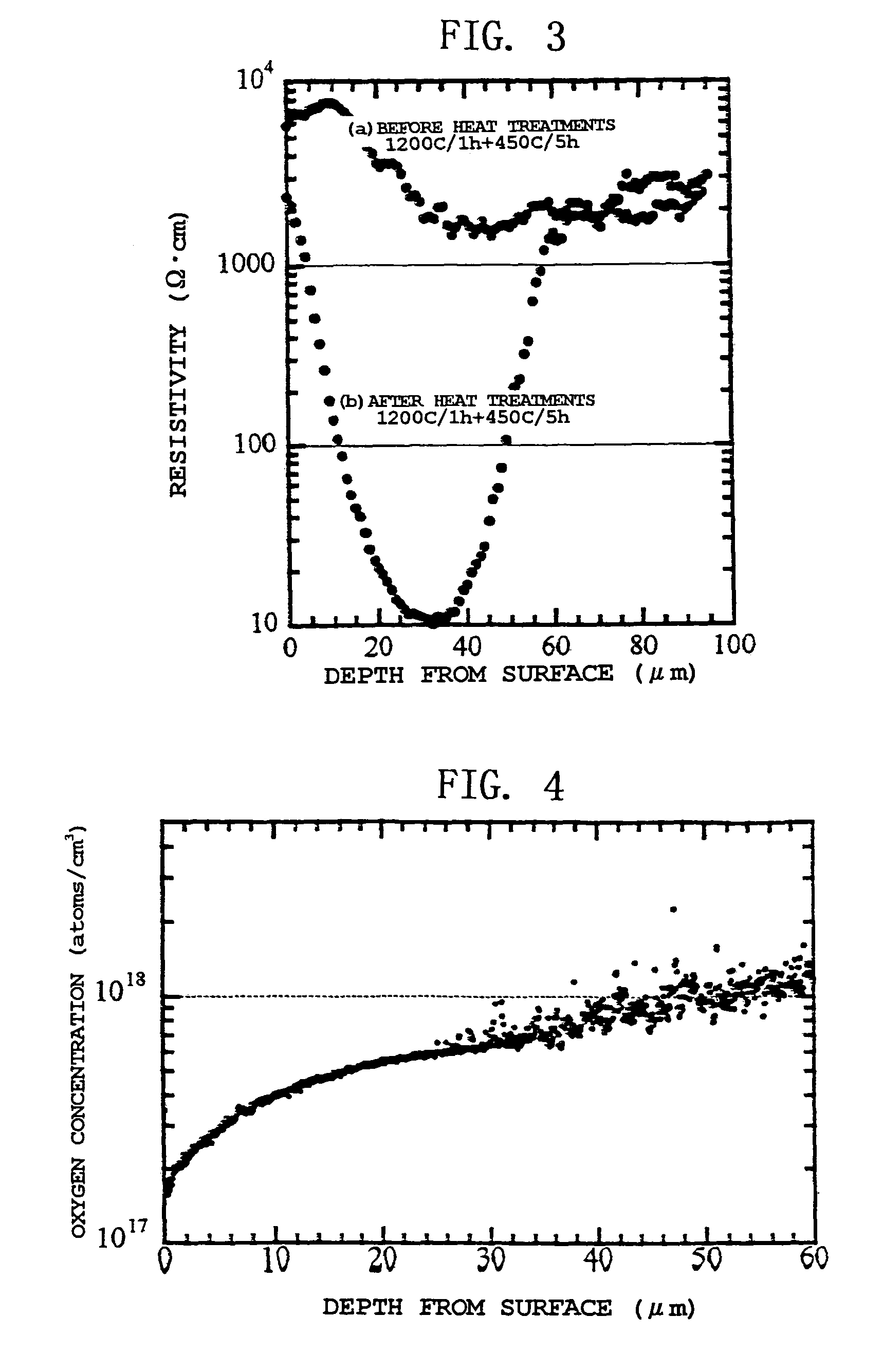

The present invention provides a method for producing a silicon wafer, which comprises growing a silicon single crystal ingot having a resistivity of 100 Ω·cm or more and an initial interstitial oxygen concentration of 10 to 25 ppma and doped with nitrogen by the Czochralski method, processing the silicon single crystal ingot into a wafer, and subjecting the wafer to a heat treatment so that a residual interstitial oxygen concentration in the wafer should become 8 ppma or less, and a method for producing a silicon wafer, which comprises growing a silicon single crystal ingot having a resistivity of 100 Ω·cm or more and an initial interstitial oxygen concentration of 8 ppma or less and doped with nitrogen by the Czochralski method, processing the silicon single crystal ingot into a wafer, and subjecting the wafer to a heat treatment to form an oxide precipitate layer in a bulk portion of the wafer, as well as silicon wafers produced by these production methods. Thus, there is provided a DZ-IG silicon wafer in which a DZ layer of high quality is formed, and which can maintain high resistivity even if the wafer is subjected to a heat treatment for device production.

Owner:SHIN-ETSU HANDOTAI CO LTD

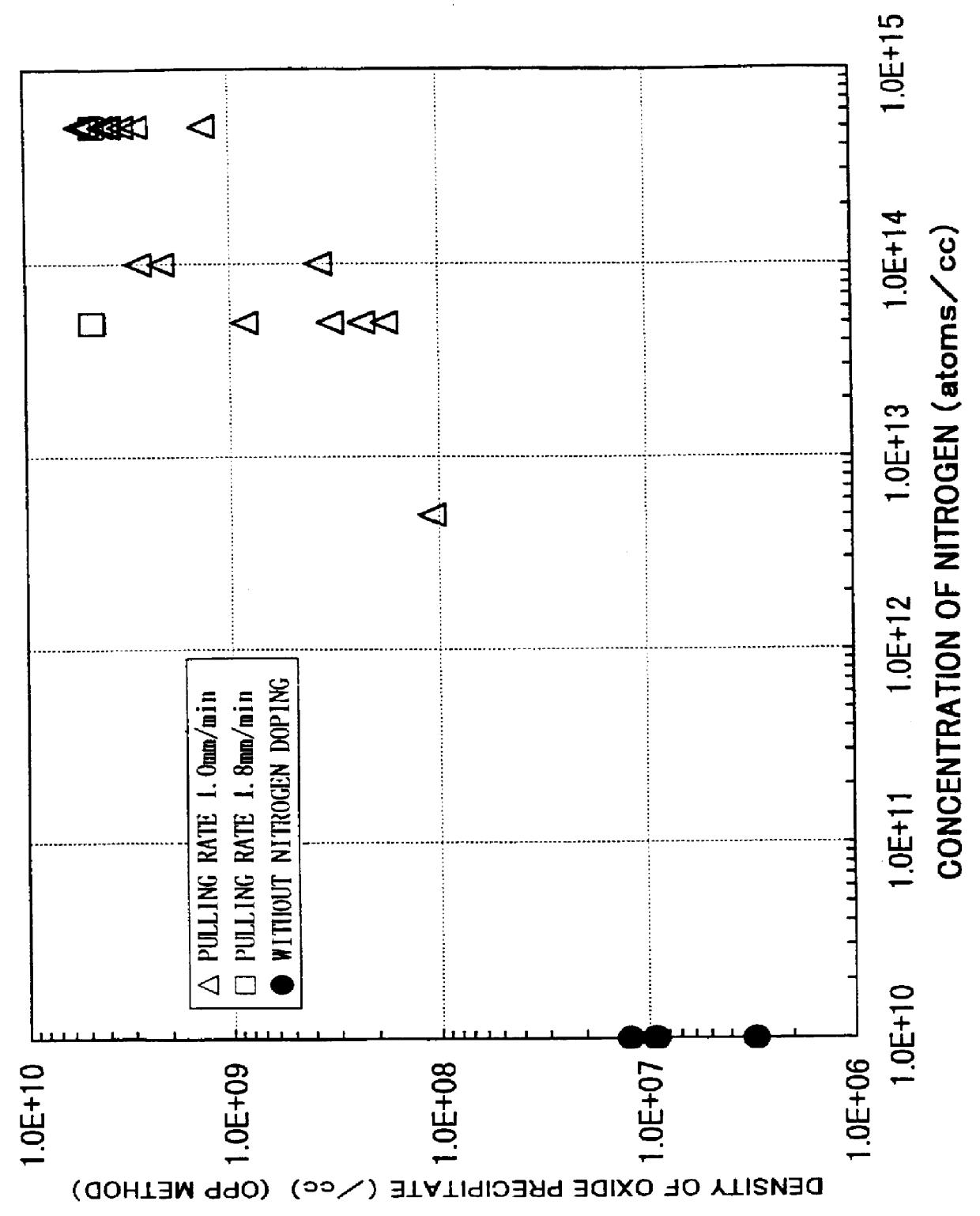

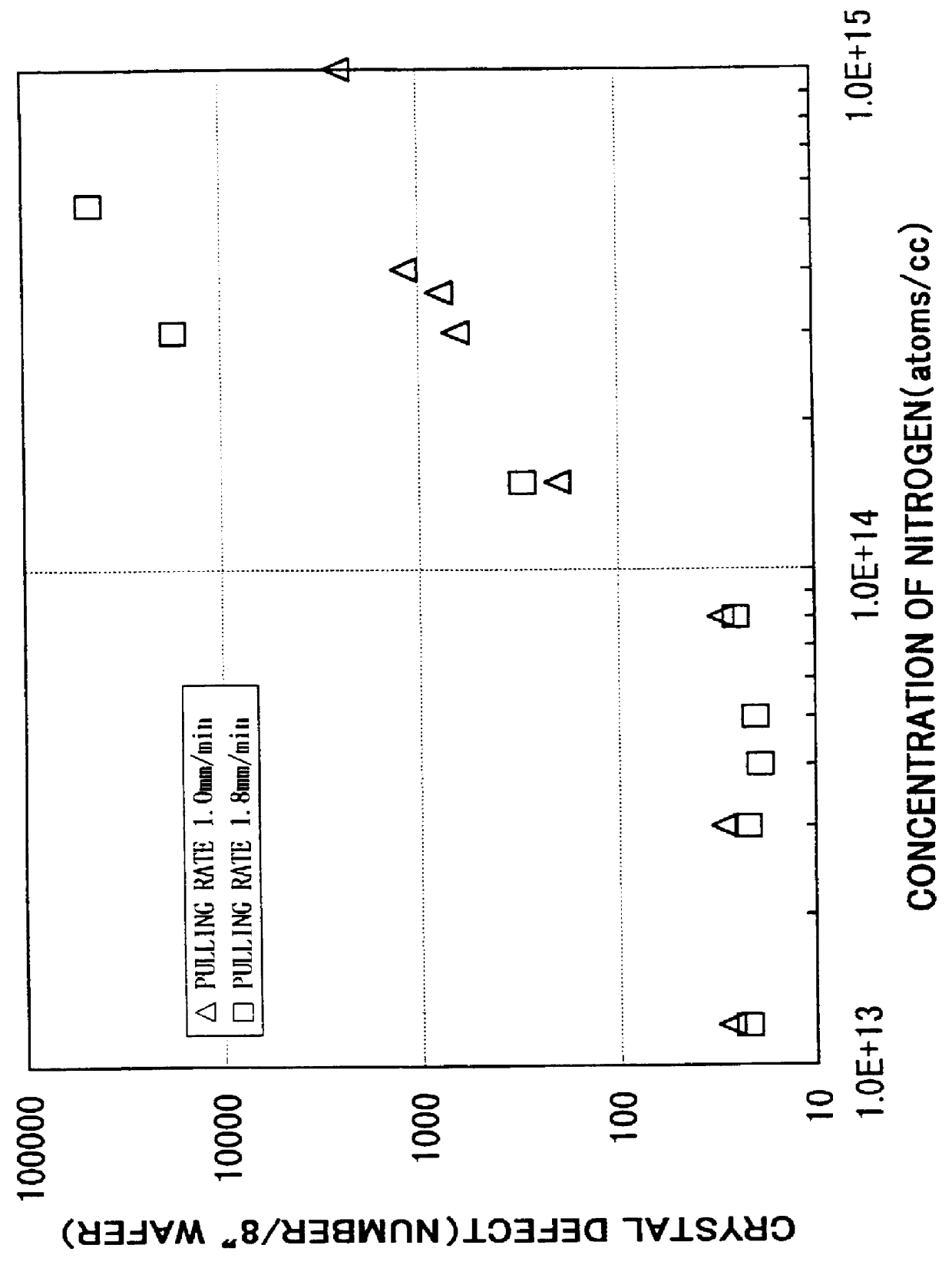

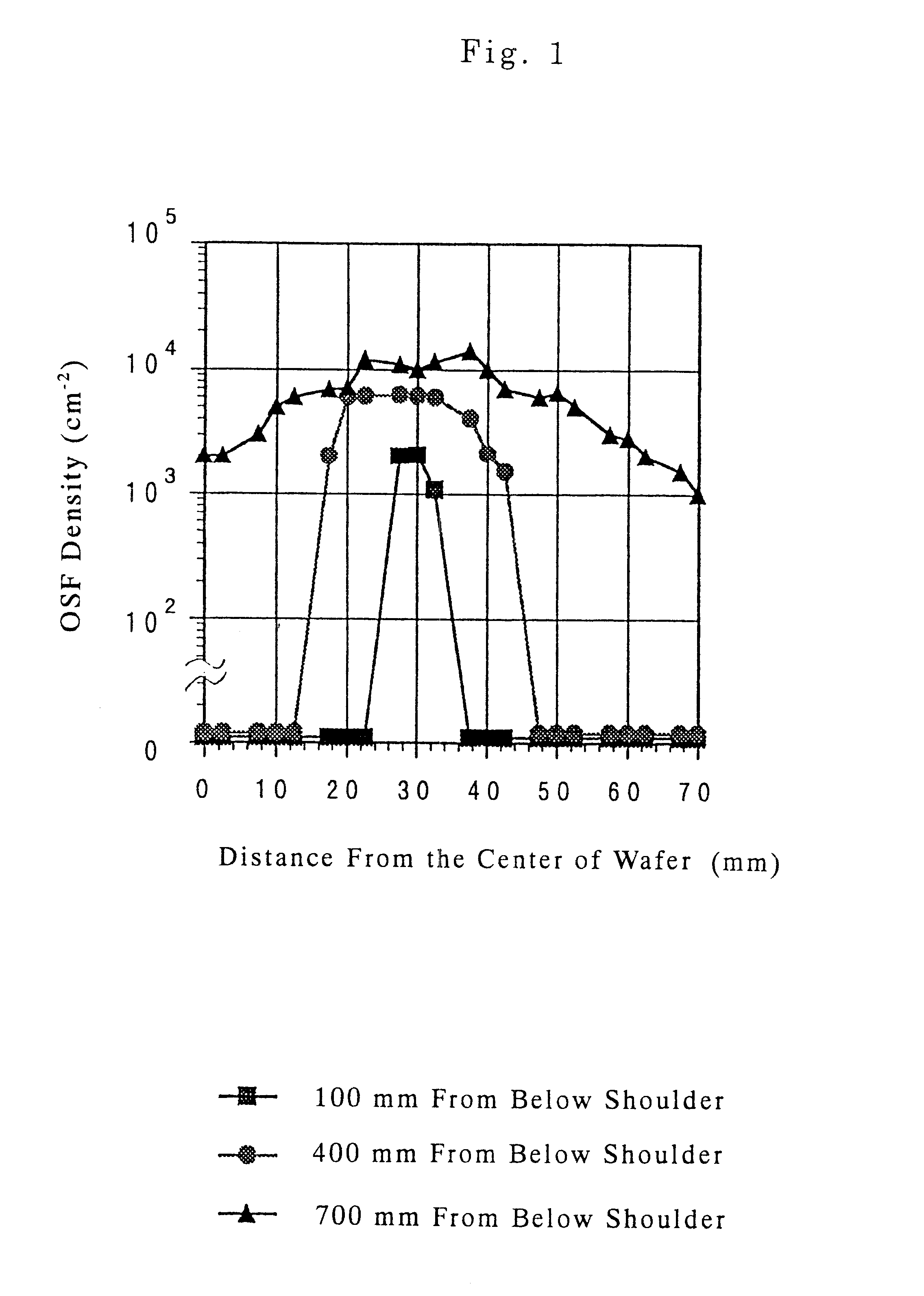

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20020142171A1Increase widthFew surface defectPolycrystalline material growthSiliconSingle crystalBoron doping

There are provided silicon single crystal, silicon wafer, and epitaxial wafer having a sufficient gettering effect suitable for a large-scale integrated device. The silicon single crystal which is suitable for an epitaxial wafer is grown with nitrogen doping at a concentration of 1x1013 atoms / cm3 or more, or with nitrogen doping at a concentration of 1x1012 atoms / cm3 and carbon doping at a concentration of 0.1x1016-5x1016 atoms / cm3 and / or boron doping at a concentration of 1x1017 atoms / cm3 or more. The silicon wafer is produced by slicing from the silicon single crystal, and an epitaxial layer is grown on a surface of the silicon wafer to produce the epitaxial wafer. The present invention provides an epitaxial wafer for a large-scale integrated device having no defects in a device-active region and having an excellent gettering effect without performance of an extrinsic or intrinsic gettering treatment, which is a factor for increasing the number of production steps and production costs.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20020142170A1Increase widthFew surface defectPolycrystalline material growthBy pulling from meltWaferingSingle crystal

There are provided silicon single crystal, silicon wafer, and epitaxial wafer having a sufficient gettering effect suitable for a large-scale integrated device. The silicon single crystal which is suitable for an epitaxial wafer is grown with nitrogen doping at a concentration of 1x1013 atoms / cm3 or more, or with nitrogen doping at a concentration of 1x1012 atoms / cm3 and carbon doping at a concentration of 0.1x1016-5x1016 atoms / cm3 and / or boron doping at a concentration of 1x1017 atoms / cm3 or more. The silicon wafer is produced by slicing from the silicon single crystal, and an epitaxial layer is grown on a surface of the silicon wafer to produce the epitaxial wafer. The present invention provides an epitaxial wafer for a large-scale integrated device having no defects in a device-active region and having an excellent gettering effect without performance of an extrinsic or intrinsic gettering treatment, which is a factor for increasing the number of production steps and production costs.

Owner:SUMITOMO MITSUBISHI SILICON CORP

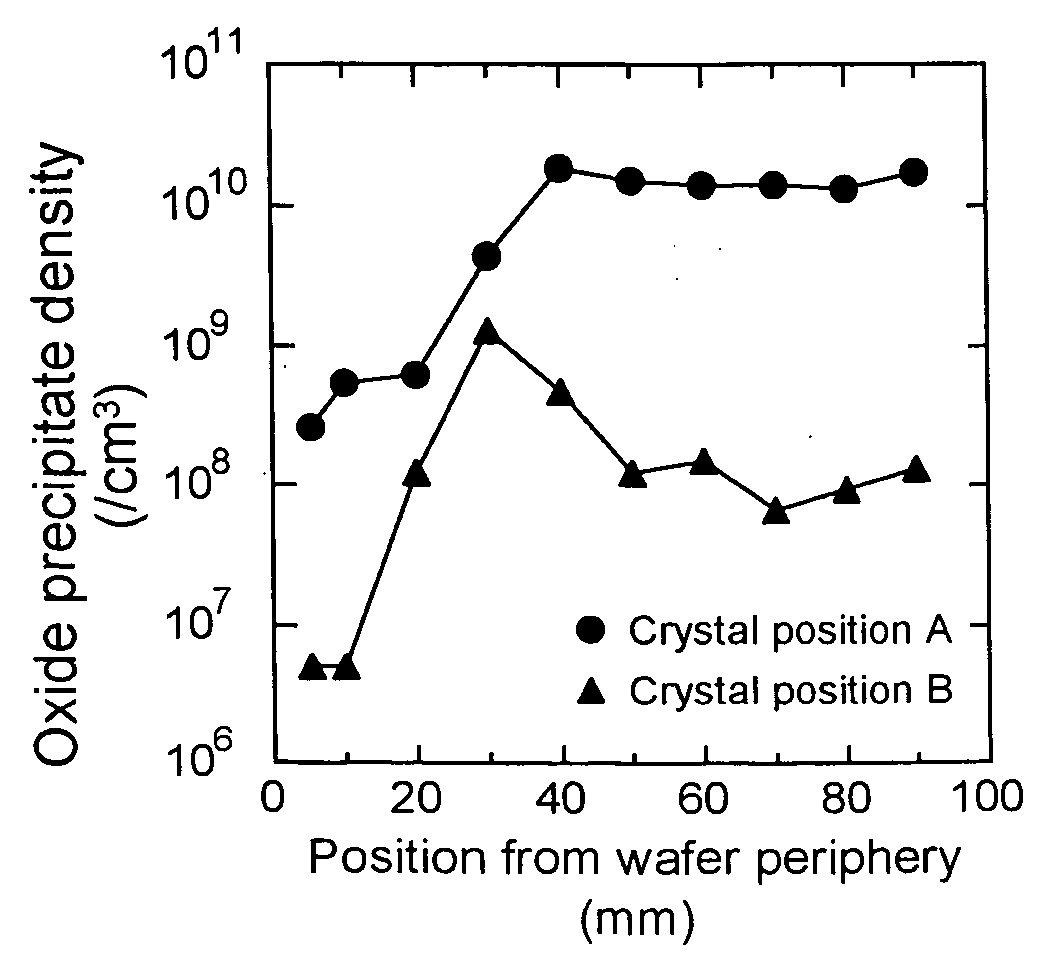

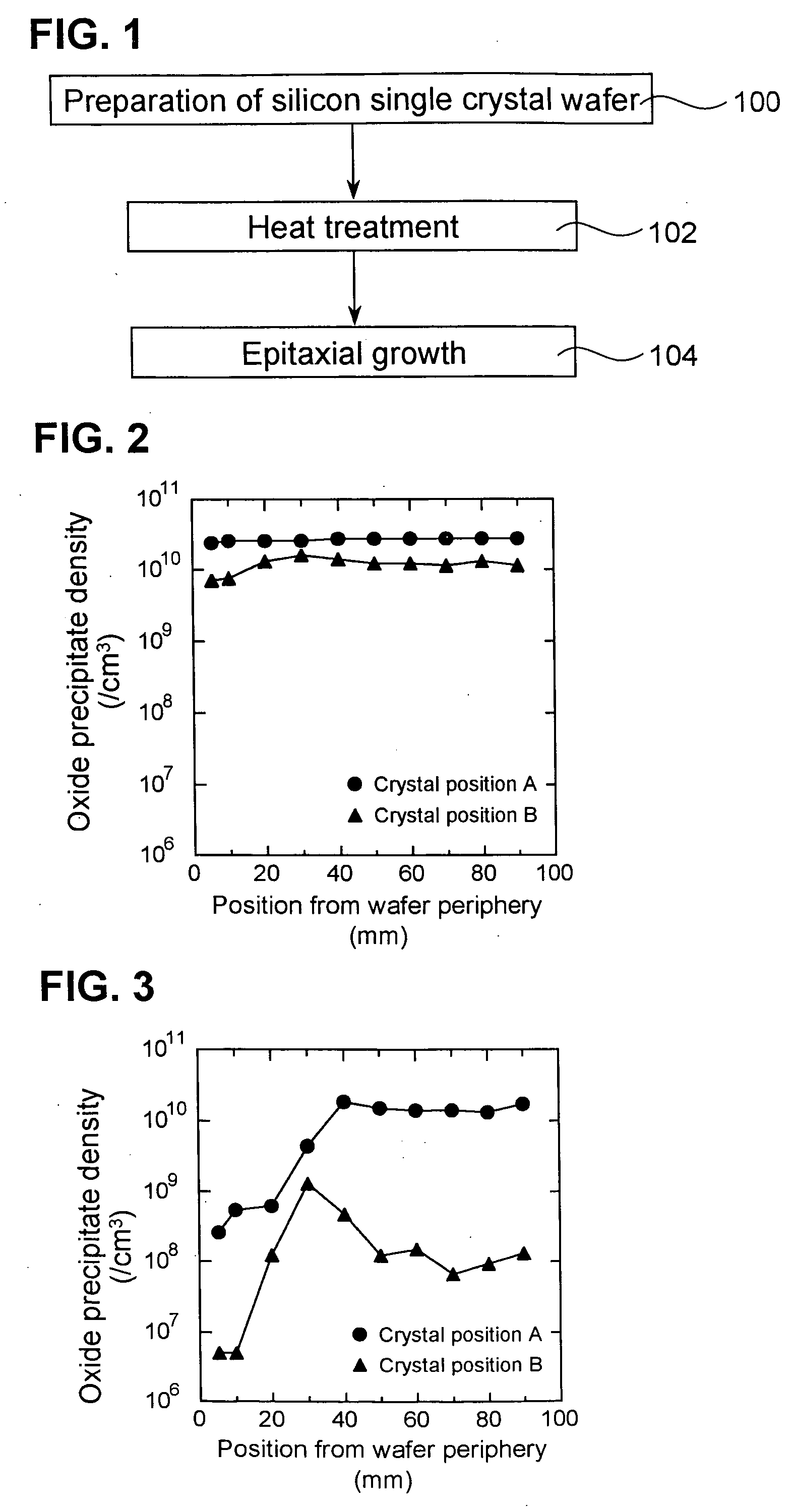

Silicon epitaxial wafer and its production method

InactiveUS20050087830A1Improve the immunitySufficient effectPolycrystalline material growthSemiconductor/solid-state device detailsSingle crystal substrateVolumetric Mass Density

The present invention provides a silicon epitaxial wafer having an excellent IG capability all over the radial direction thereof and a process for manufacturing the same. The present invention is directed to a silicon epitaxial wafer having an excellent gettering capability all over the radial direction thereof, wherein density of oxide precipitates detectable in the interior of a silicon single crystal substrate after epitaxial growth is 1×109 / cm3 or higher at any position in the radial direction.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method for Producing Soi Wafer

ActiveUS20090104752A1Efficient productionImprove inhalation effectSemiconductor/solid-state device manufacturingOptoelectronicsMetal contamination

The present invention relates to a method for producing an SOI wafer, having at least a step of a bonding heat treatment for increasing bonding strength by heat-treating a bonded wafer obtained by bonding a base wafer and a bond wafer, in which argon is ion-implanted from a surface of either the base wafer or the bond wafer at a dosage of 1×1015 atoms / cm2 or more at least before the bonding step, the surface ion-implanted with argon is used as a bonding surface in the bonding step, and an increase rate of temperature to a treatment temperature of the bonding heat treatment is 5° C. / minute or higher. Thus the present invention provides a method for producing an SOI wafer facilitating the efficient production of an SOI wafer having in the neighborhood of a buried insulator layer thereof a polycrystalline silicon layer uniform in thickness introduced and having high gettering ability toward metal contaminations in the SOI layer by a simple and low-cost method.

Owner:SHIN-ETSU HANDOTAI CO LTD

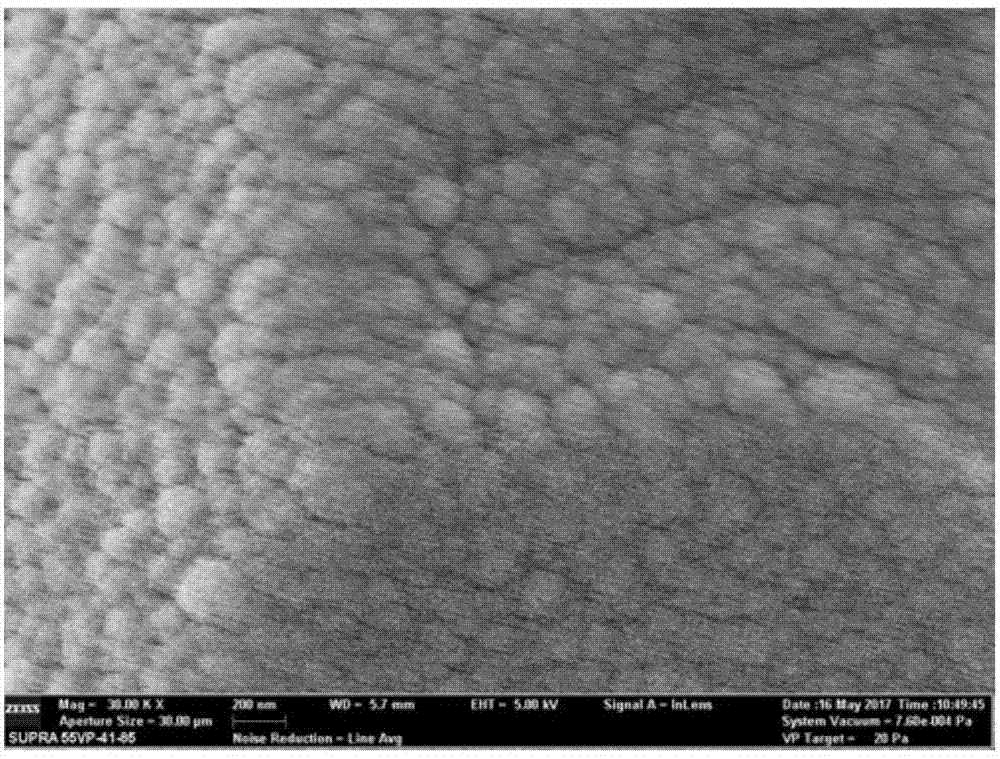

Non-evaporable low-temperature activated zirconium getter film and preparation method thereof

InactiveCN107400854AIncreased active surfaceImprove inhalation effectSemiconductor/solid-state device detailsVacuum evaporation coatingAdhesion forceChemical composition

The invention discloses a non-evaporable low-temperature activated zirconium getter film and a preparation method thereof. The non-evaporable low-temperature activated zirconium getter film comprises an adjusting layer, a gettering layer and a protecting layer which grow on a rough monocrystalline silicon wafer sequentially, wherein in terms of chemical composition, the gettering layer contains 75%-77% by mass of zirconium, 18%-22% by mass of cobalt, 2%-5% by mass of yttrium and the balance of other inevitable impurities; in terms of a microstructure, the gettering layer is formed by densely arranged columnar grains, and the height of columnar tissue is 100-300 nm. The prepared getter film has the advantages of being environment-friendly, high in gettering capacity, low in activation temperature, high in adhesion force, long in service life, easy to prepare, low in cost and the like and is applicable to packaging of mini vacuum devices in the industrial field of microelectronics.

Owner:YUNNAN NORMAL UNIV

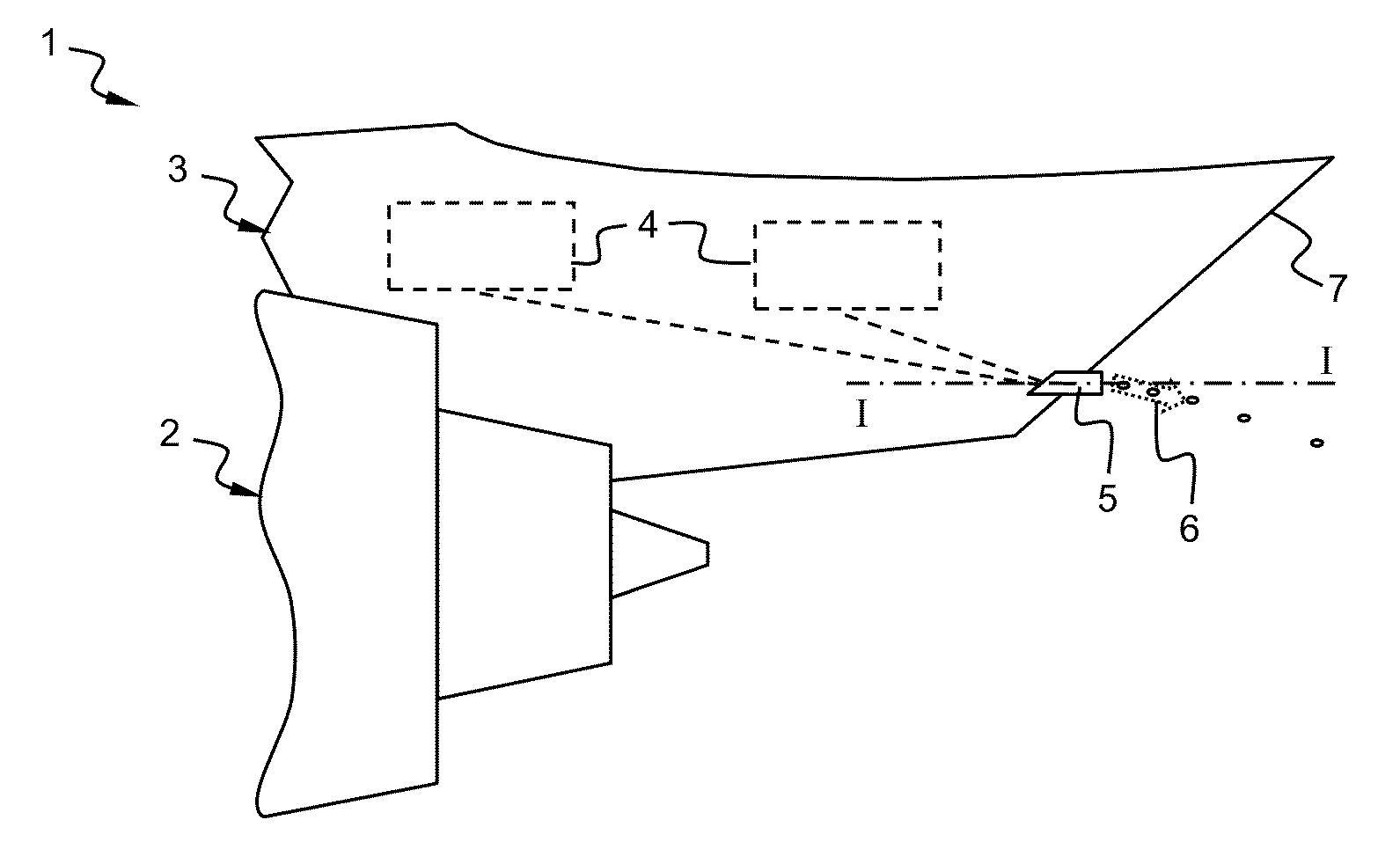

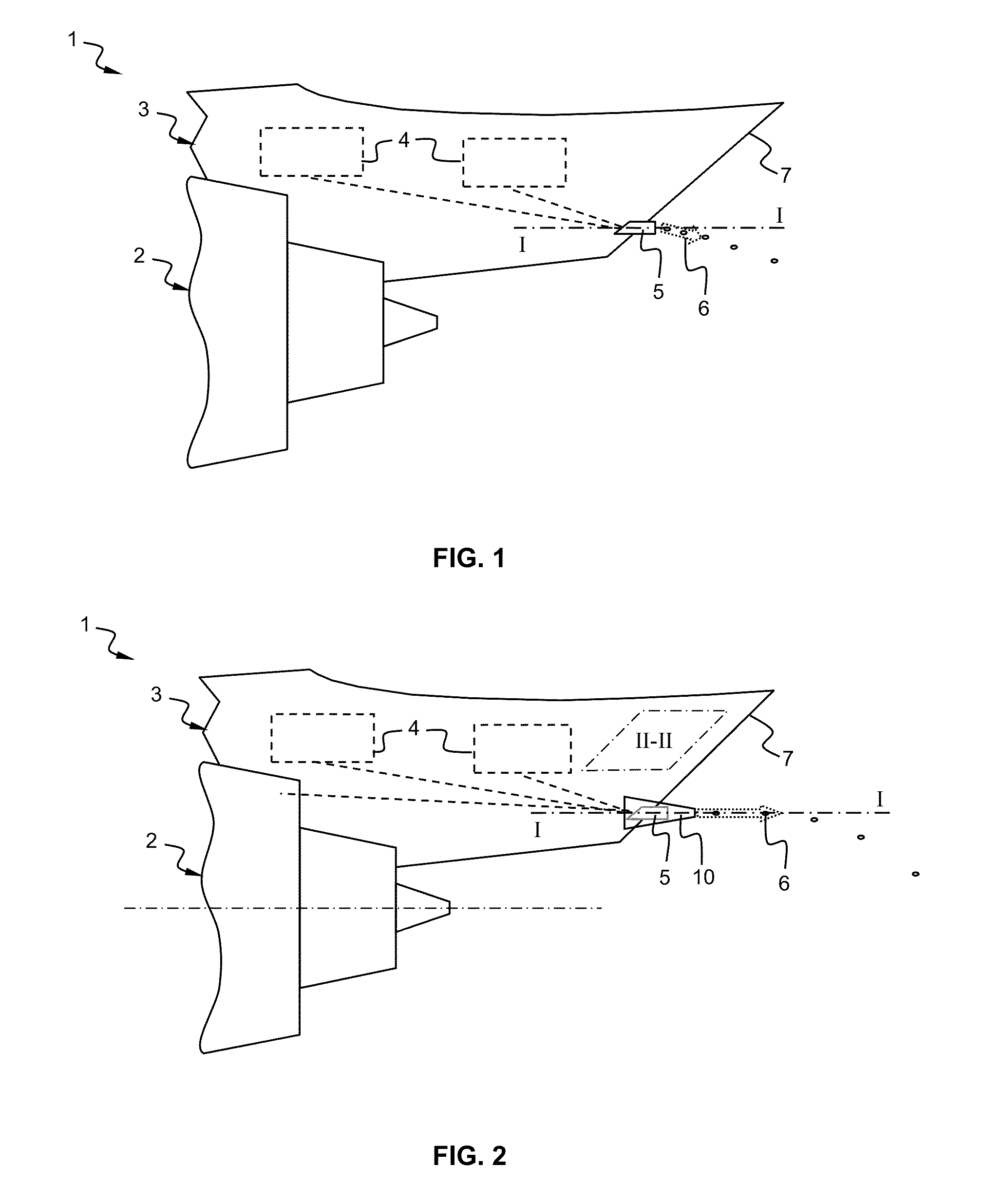

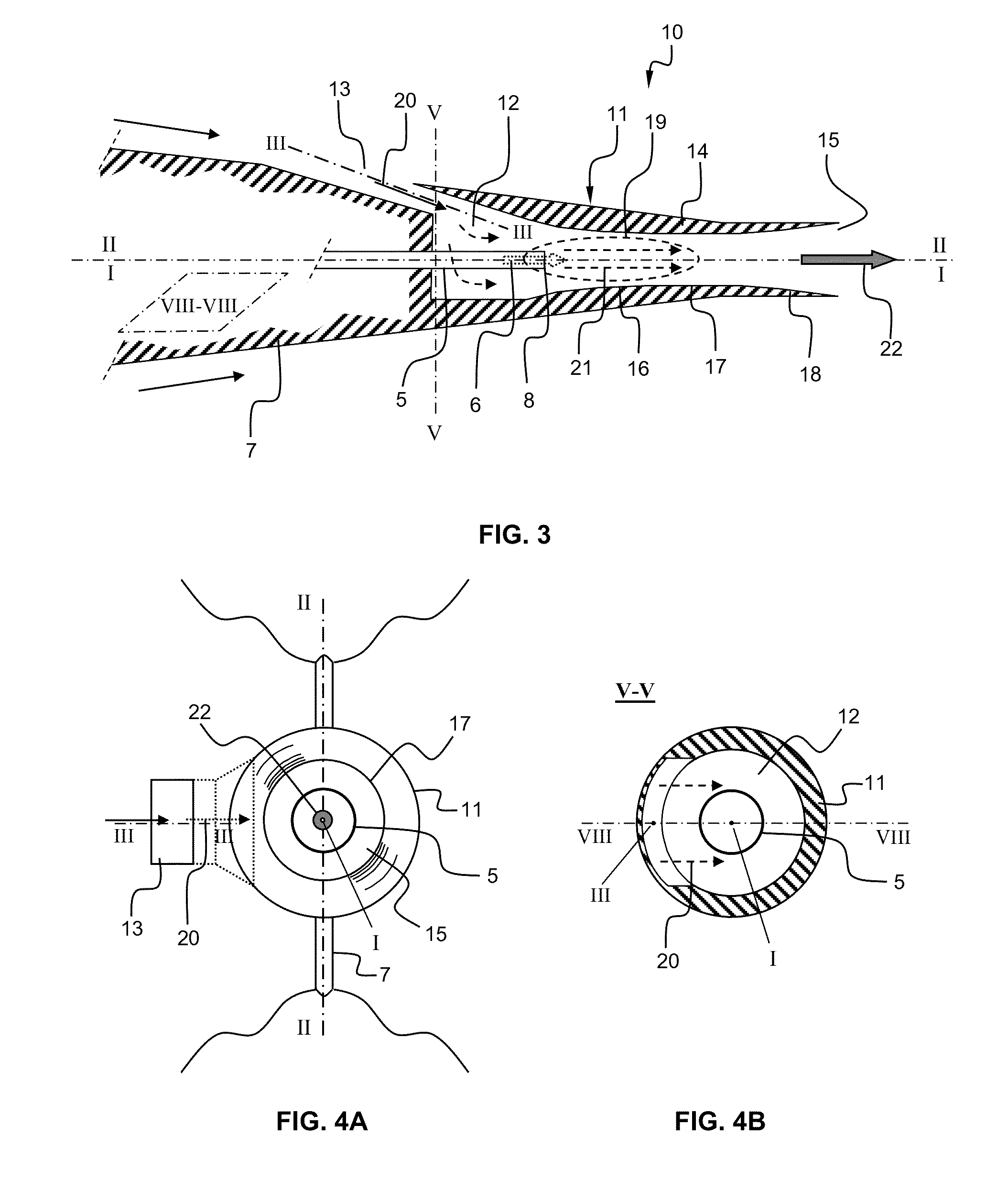

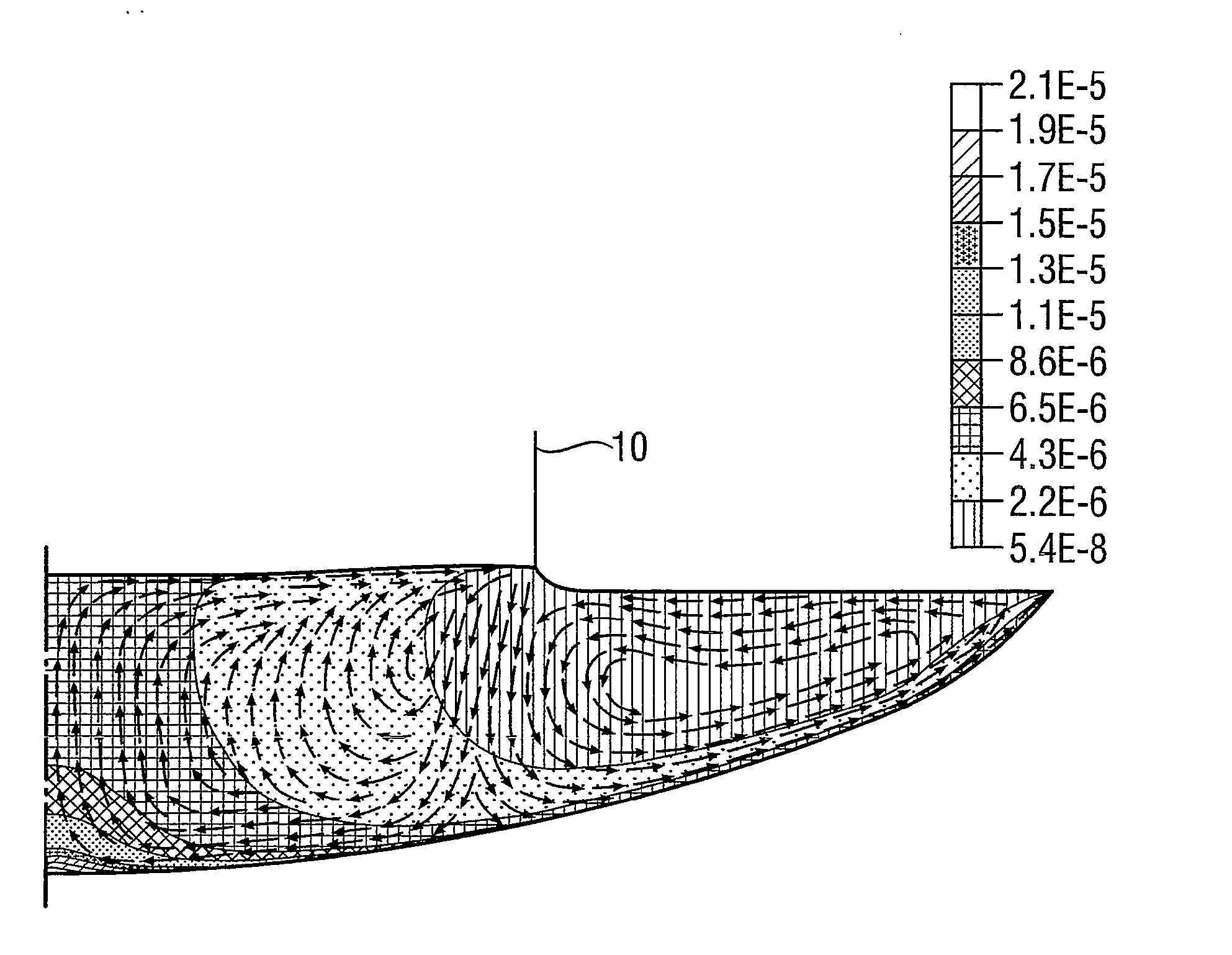

Draining device

InactiveUS20130327059A1Improve drainage capacityDrawback mentionedPressure pumpsGas turbine plantsPlenum chamberDrain tube

A draining device for draining a fluid from an aircraft engine support strut includes a suction arrangement having an inlet and extending along a longitudinal main axis to form a plenum chamber and a drain tube fluidly connected to the aircraft engine support strut and extending along the longitudinal main axis, the drain tube ending by an outlet, the outlet of the drain tube terminating within the plenum chamber of the suction arrangement. An air flow entering the inlet of the suction arrangement causes a low-pressure region to be created within the plenum chamber, substantially downstream the outlet of the drain tube.

Owner:SHORT BROTHERS

Non-evaporable type low-temperature activating zirconium-based getter alloy and preparation process thereof

ActiveCN102758101ALow activation temperatureImprove inhalation effectOther chemical processesLanthanideAlloy

The invention relates to a getter alloy, a non-evaporable type low-temperature activating zirconium-based getter alloy and a preparation process thereof. The getter alloy comprises, by mass, 75-77% of zirconium, 17-19% of cobalt, 6%-7% of lanthanide series rear earth and 0%-0.5% of other inevitable impurities, and the lanthanide series rear earth comprises, by mass, 60%+ / -5% of lanthanum, 30%+ / -3% of neodymium and 10%+ / -1% of other lanthanide series elements. The getter alloy has the advantages of low-temperature activating, simultaneously, the hydrogen gettering ability of the getter alloy is higher than that of traditional zirconium-based getters, and the low activation temperature and the high gettering performance are guaranteed.

Owner:NANJING GETTERS & ELECTRONICS

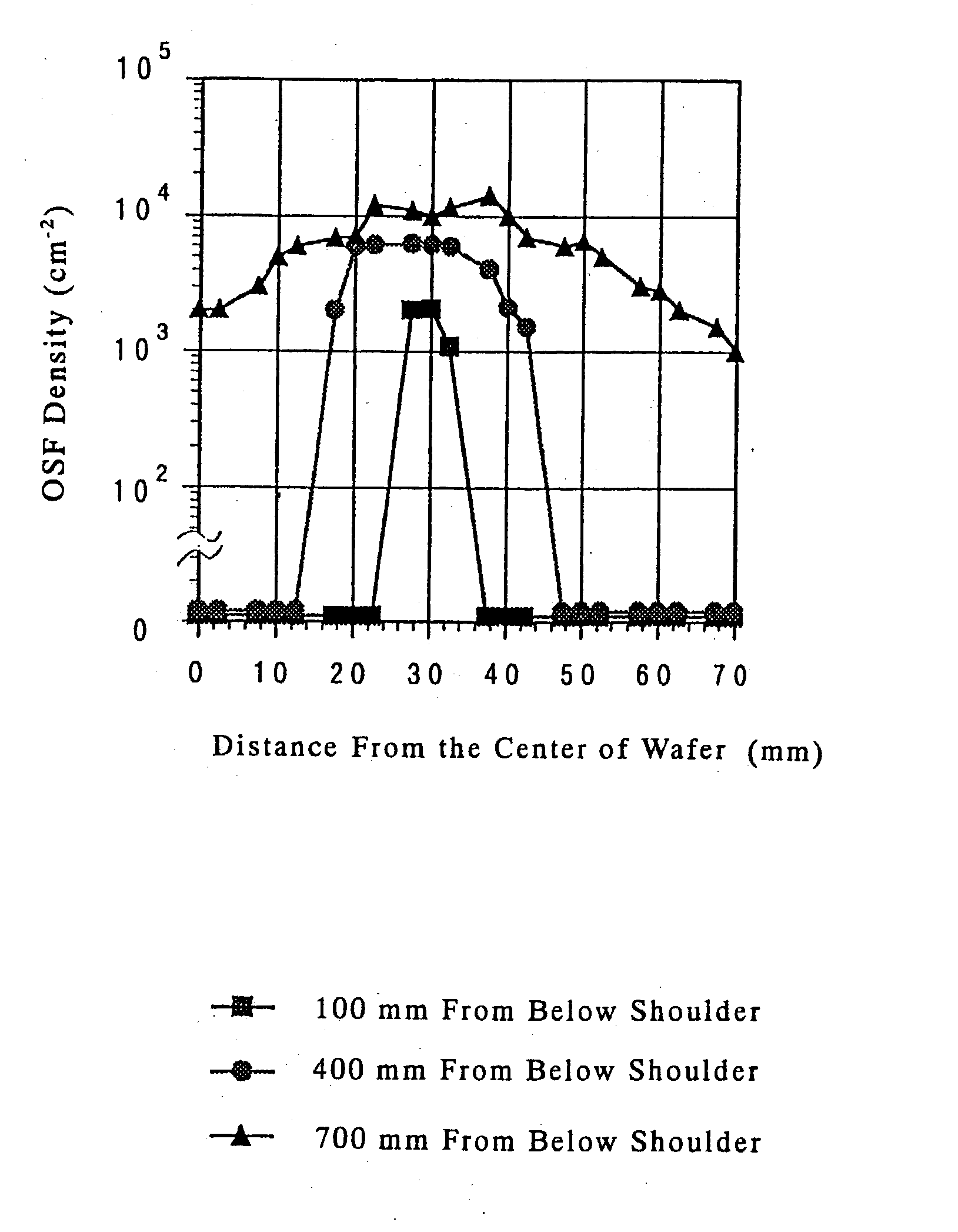

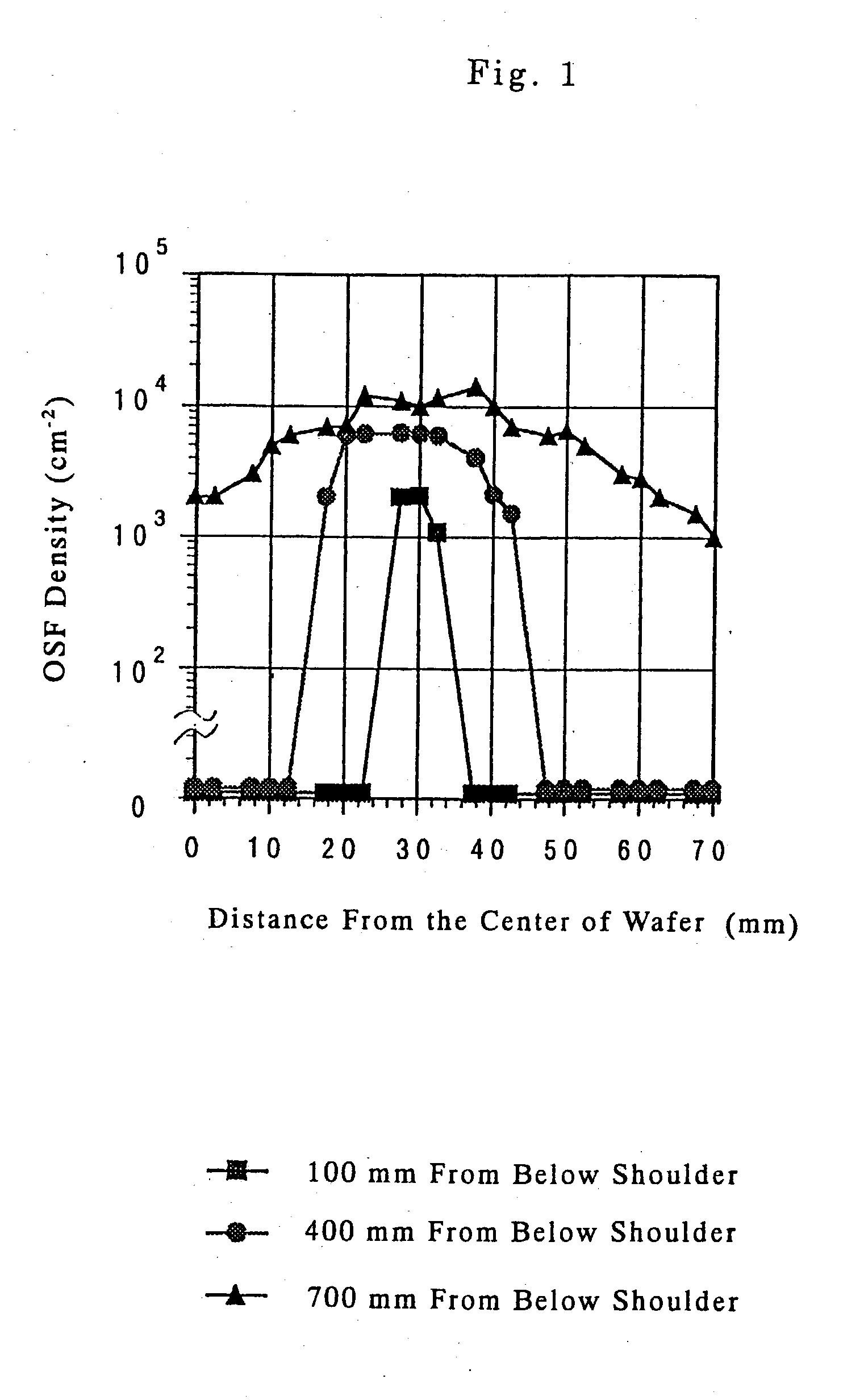

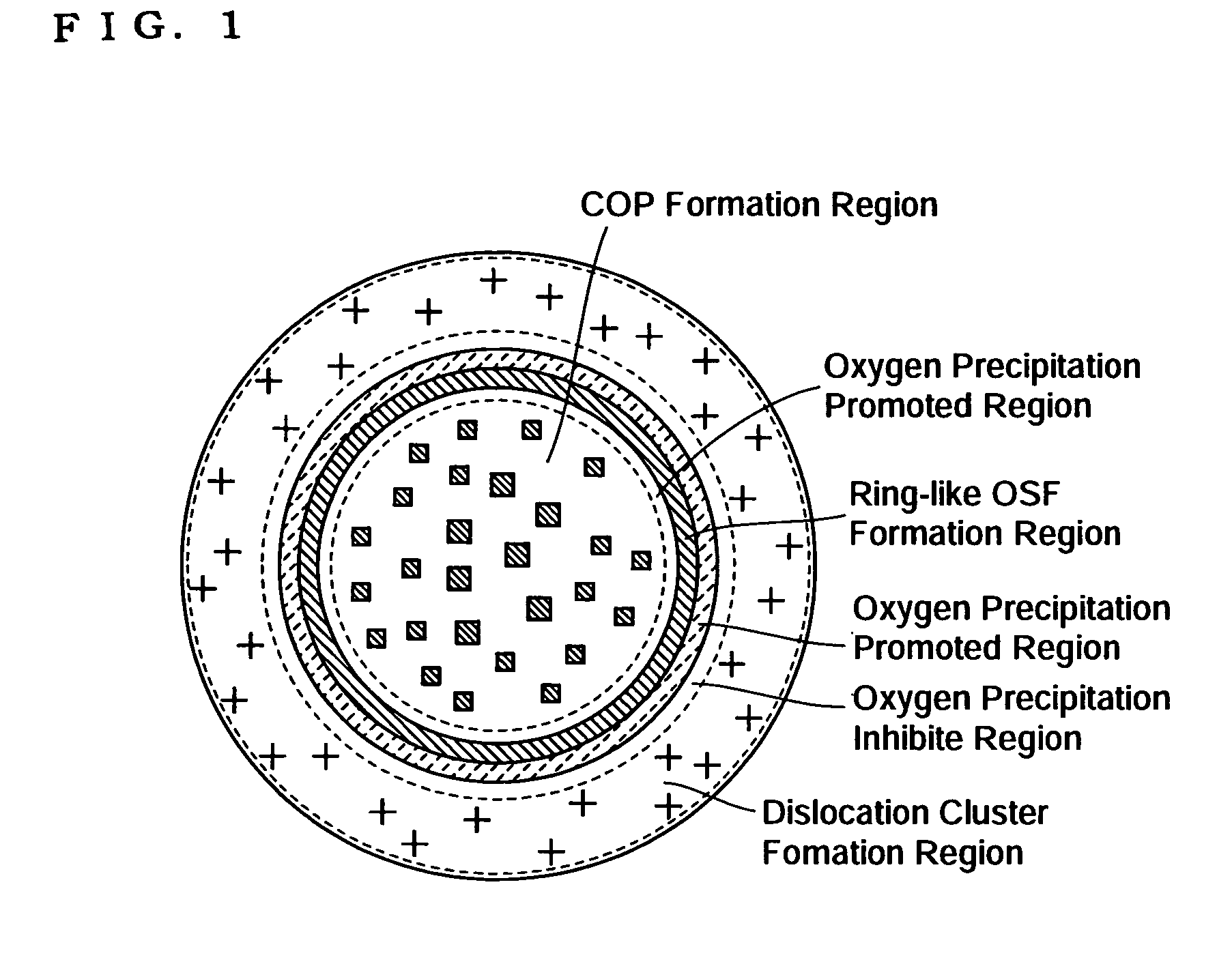

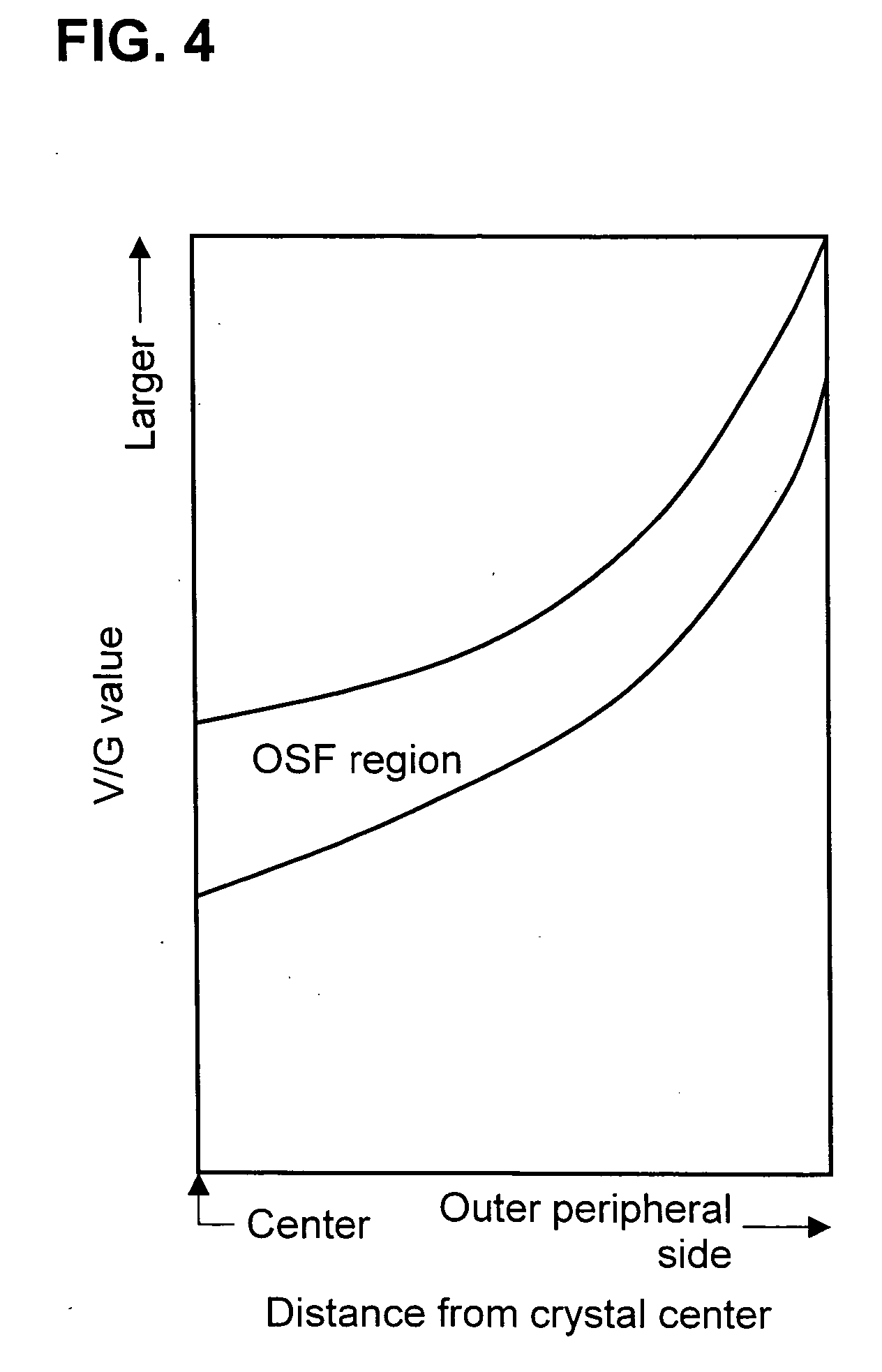

Semiconductor wafer composed of monocrystalline silicon and method for producing itö

ActiveUS20100059861A1Improve inhalation effectFree from defectPolycrystalline material growthAfter-treatment detailsNitrogenOxygen

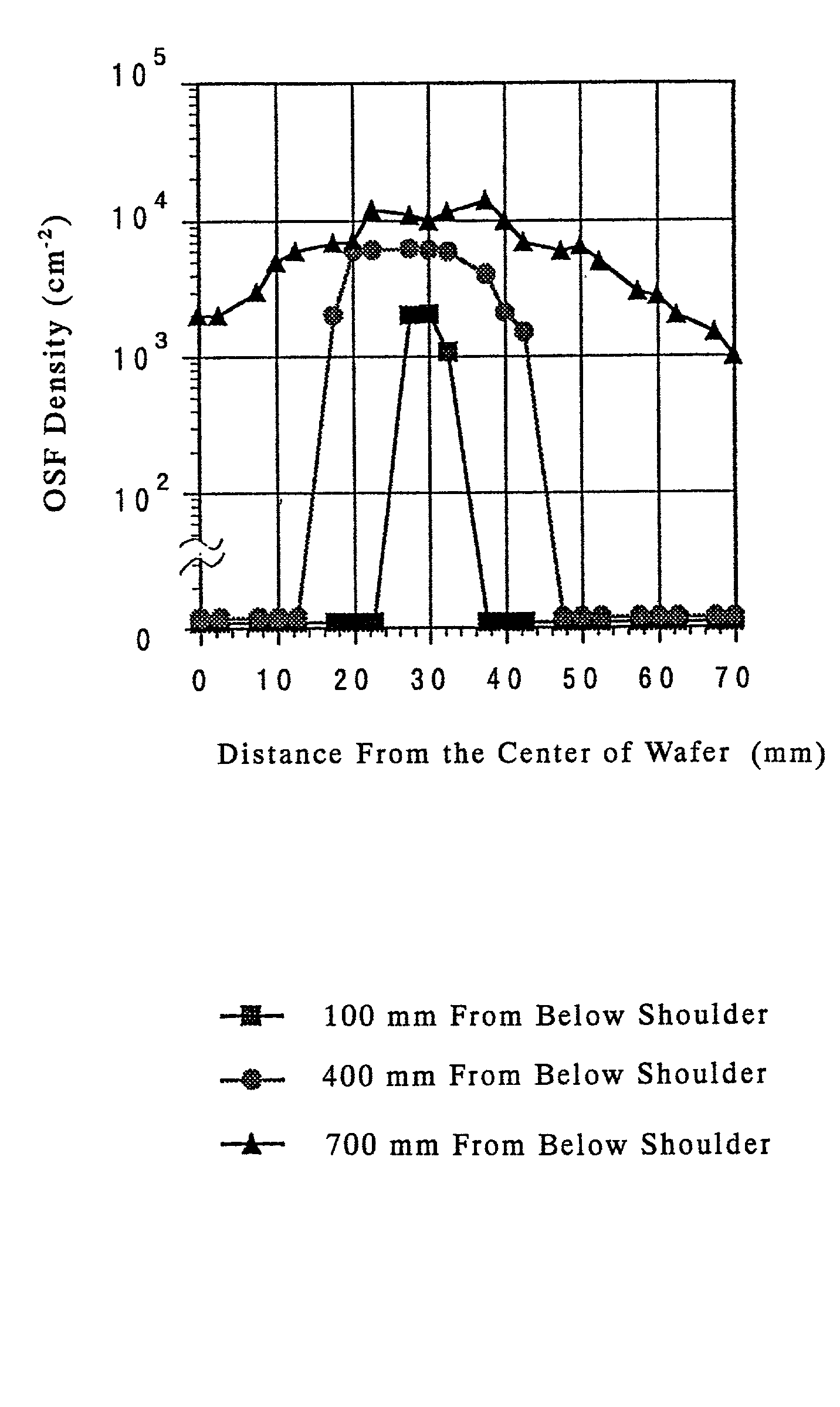

Semiconductor wafers composed of monocrystalline silicon and doped with nitrogen contain an OSF region and a PV region, wherein the OSF region extends from the center radially toward the edge of the wafer as far as the Pv region; the wafer has an OSF density of less than 10 cm−2, a BMD density in the bulk of at least 3.5×108 cm−3, and a radial distribution of the BMD density with a fluctuation range BMDmax / BMDmim of not more than 3. The wafers are produced by controlling initial nitrogen content and maintaining oxygen within a narrow window, followed by a heat treatment.

Owner:SILTRONIC AG

Semiconductor device and its manufacturing method

InactiveUS20060249730A1Improve featuresEasy to moveTransistorSolid-state devicesDevice materialCrystallinity

Nickel is selectively held in contact with a particular region of an amorphous silicon film. Crystal growth parallel with a substrate is effected by performing a heat treatment. A thermal oxidation film is formed on the silicon film by performing a heat treatment in an oxidizing atmosphere containing a halogen element. During this step, in the silicon film, impurities included such as oxygen or chlorine, are segregated with extending along the crystal growth, the crystallinity is improved, and the gettering of nickel element proceeds. A thin-film transistor is formed so that the direction connecting source and drain regions coincides with the above crystal growth direction. As a result, a TFT having superior characteristics such as a mobility larger than 200 cm2 / Vs and an S value smaller than 100 mV / dec. can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com