Non-evaporable low-temperature activated zirconium getter film and preparation method thereof

A zirconium-based getter and film technology, which is applied in electrical components, vacuum evaporation plating, ion implantation plating, etc., can solve the problems of difficult smelting and processing of alloy targets, short service life of getters, and inability to use them. To achieve the effect of favoring adsorption and internal diffusion, increasing the rate and volume of inhalation, and improving the surface and internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

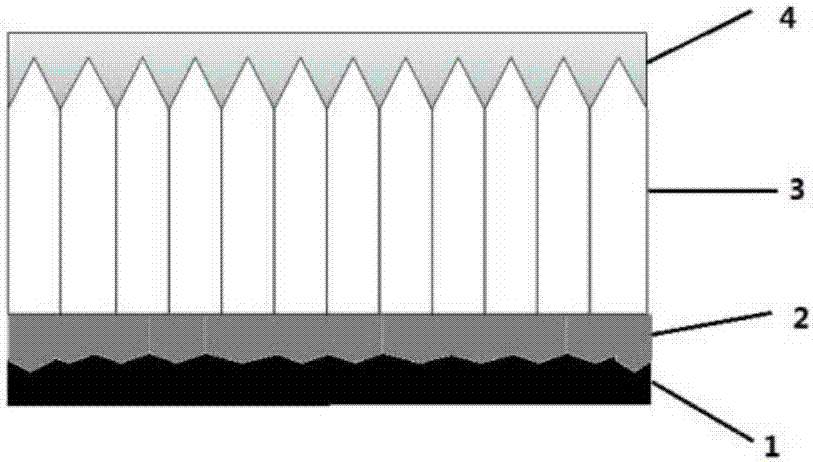

[0045] The preparation method of the getter film of the present invention is to deposit a layer of adjustment layer on the polished single crystal silicon by physical vapor deposition, deposit a getter layer on the surface of the adjustment layer, and deposit a protective layer on the getter layer, and prepare Three-layer structure getter film.

[0046] First, prepare polished single crystal silicon as a deposition substrate. Use acetone, alcohol, and deionized water to ultrasonically clean the single-crystal silicon wafers for 10-20 minutes each, and bake the silicon wafers in a constant temperature oven for 1-2 hours after cleaning.

[0047] Put the silicon wafer to be cleaned into the etching system to etch for 10-30 minutes. After the silicon wafer is taken out, use acetone, alcohol, and deionized water to clean it ultrasonically, and then bake it in a constant temperature oven for 1-2 hours.

[0048] The preparation method of the adjustment layer is the radio frequency m...

Embodiment 2

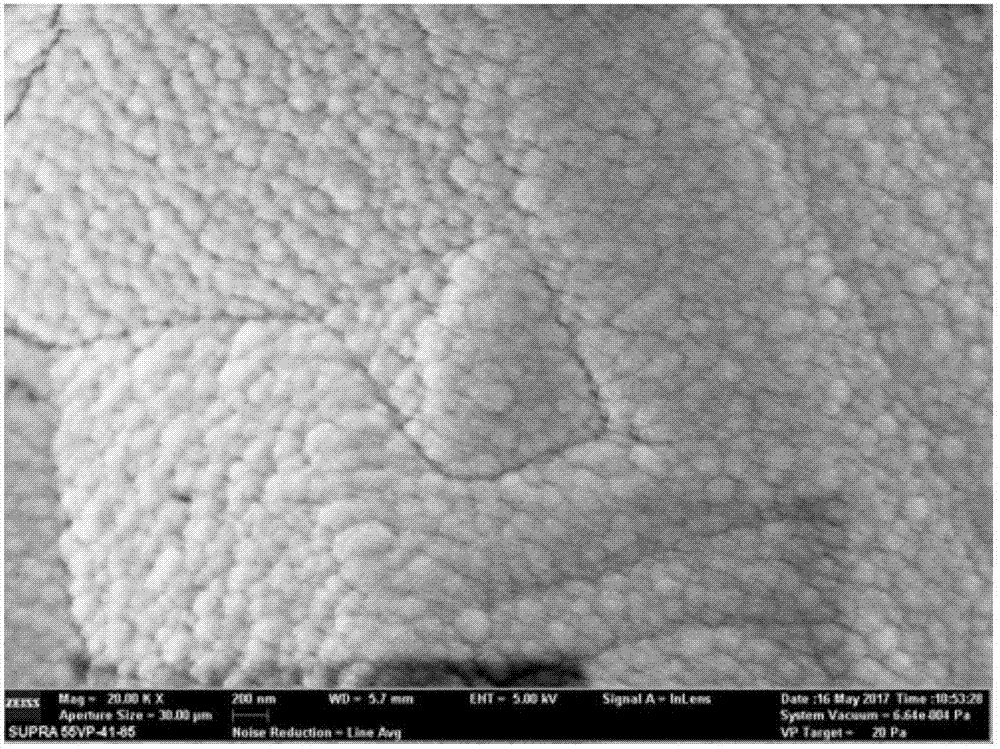

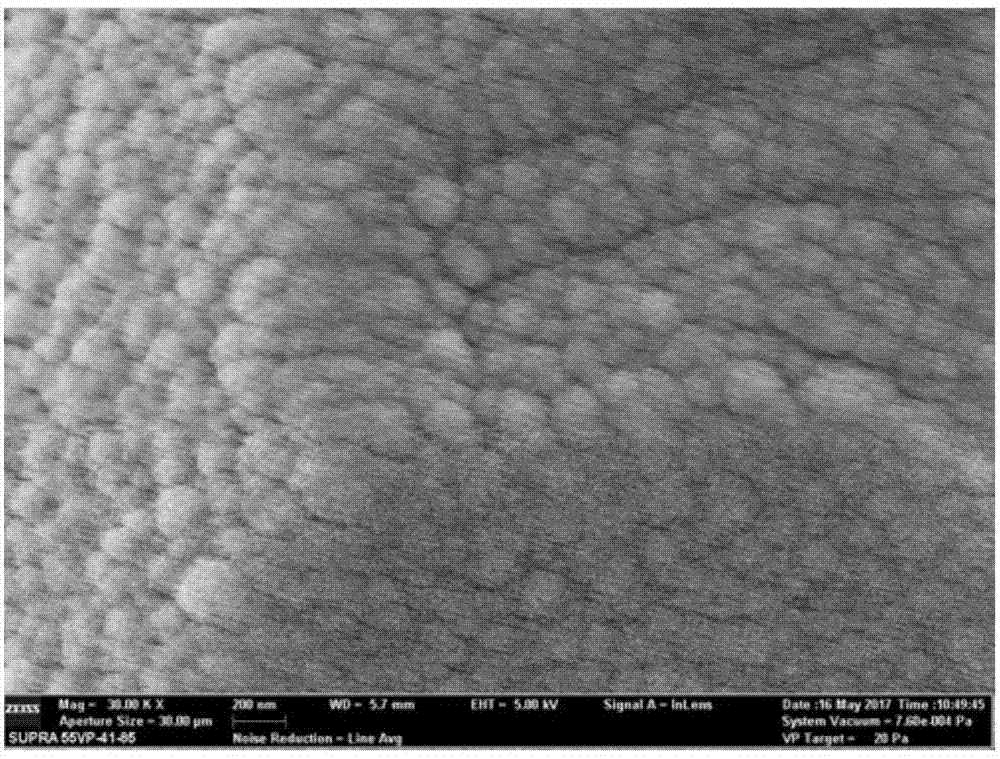

[0053] The operation method and process conditions of its thin film preparation are basically the same as in Example 1, the only difference is that the substrate is first polished with sandpaper, the surface roughness is 150nm, and the cleaning process is the same as in Example 1. Under this condition, the average thickness of the adjustment layer is 150nm, the thickness of the gas absorption layer is 500nm-3μm, the particle diameter of the gas absorption layer is about 10-40nm, the columnar height is about 200nm, and the surface of the film is rough.

Embodiment 3

[0055] The operation method and process conditions of the thin film preparation are basically the same as in Example 1, the only difference is that the substrate is ultrasonically cleaned with acetone, alcohol, and deionized water for 10-20 minutes each, and the silicon wafer is baked in a constant temperature oven after cleaning. Baking for 1 to 2 hours; prepare a silicon wafer etching solution, the etching solution is an aqueous solution of NaOH and isopropanol, of which the NaOH content is 7wt.%. Put the silicon wafer in the solution and corrode it for 5 minutes, take it out and clean it with distilled water, then ultrasonically clean the single crystal silicon wafer with acetone, alcohol, and deionized water for 10-20 minutes each, and bake the silicon wafer in a constant temperature oven for 1 ~2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com