Patents

Literature

3233 results about "OXALIC ACID DIHYDRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxalic acid is a reducing agent and its conjugate base, known as oxalate (C. 2O2−. 4), is a chelating agent for metal cations. Typically, oxalic acid occurs as the dihydrate with the formula C2H2O4·2H2O.

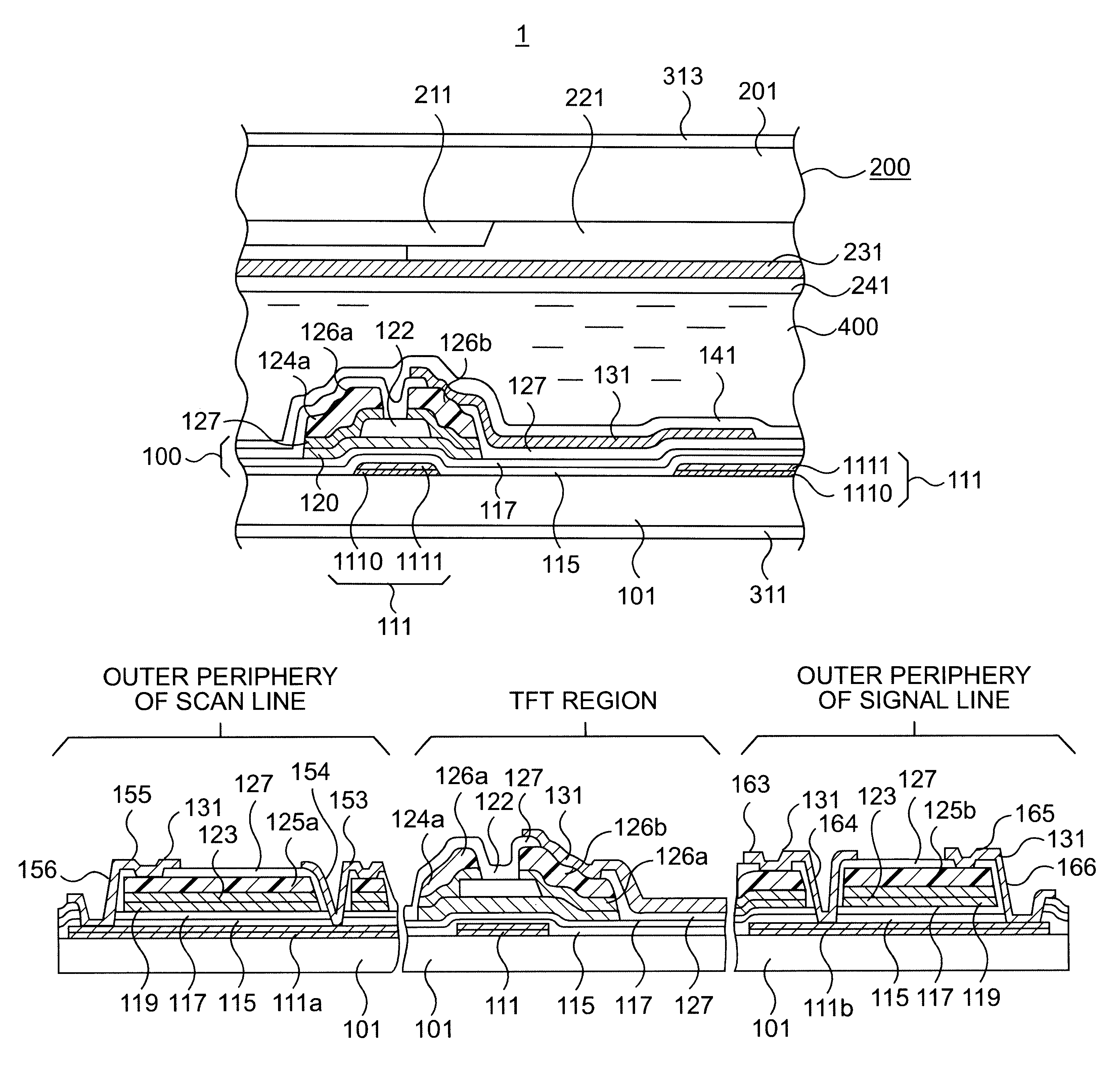

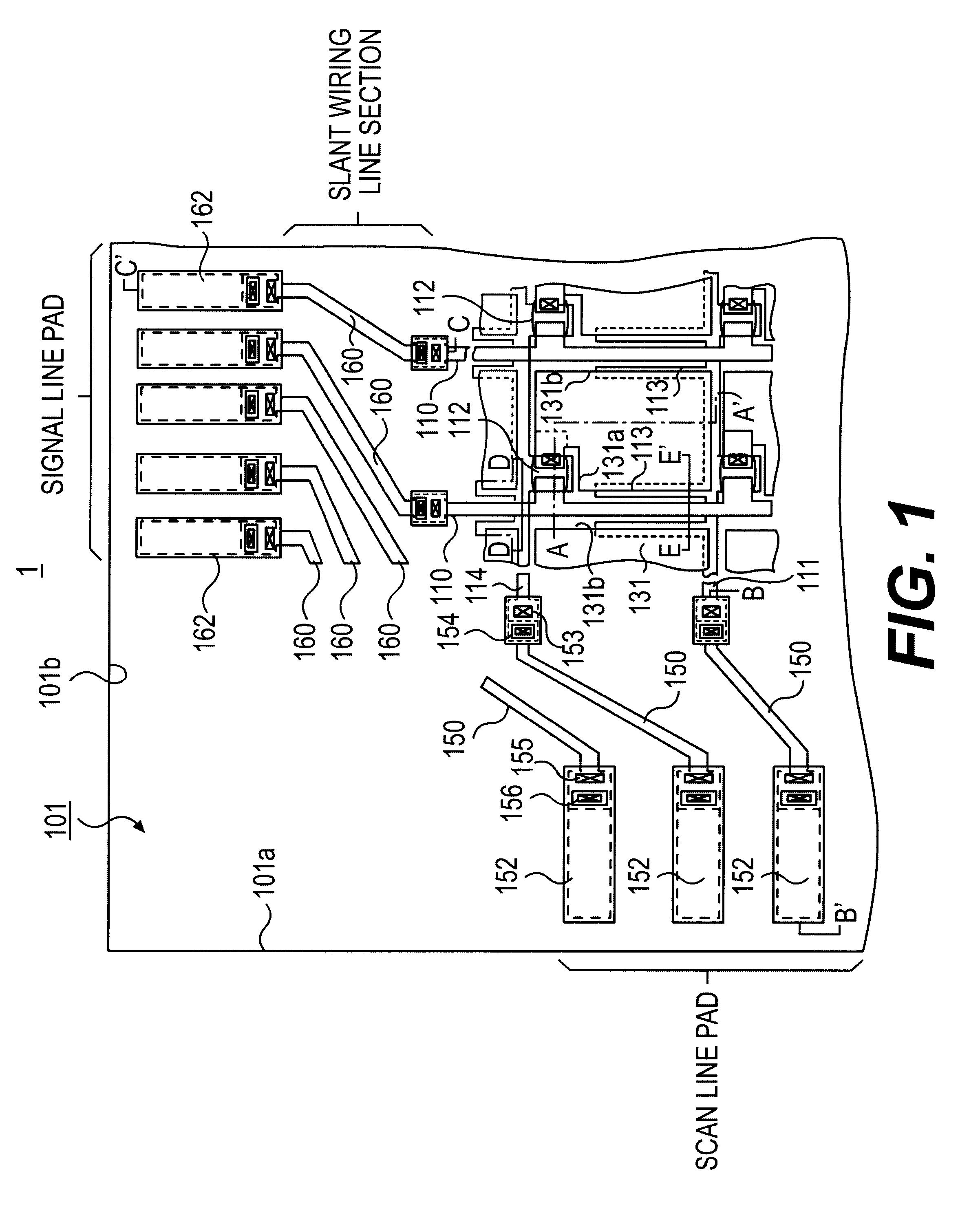

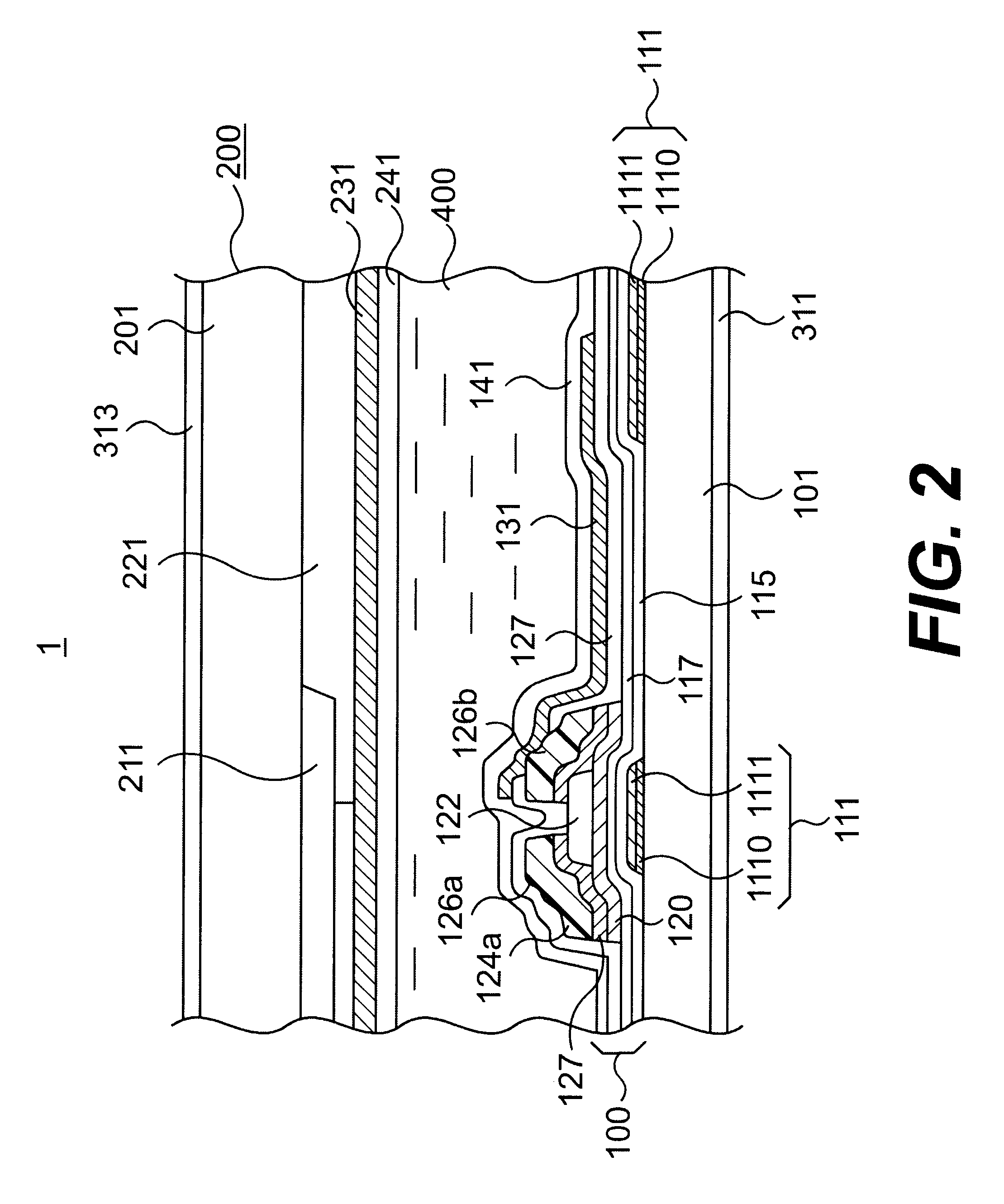

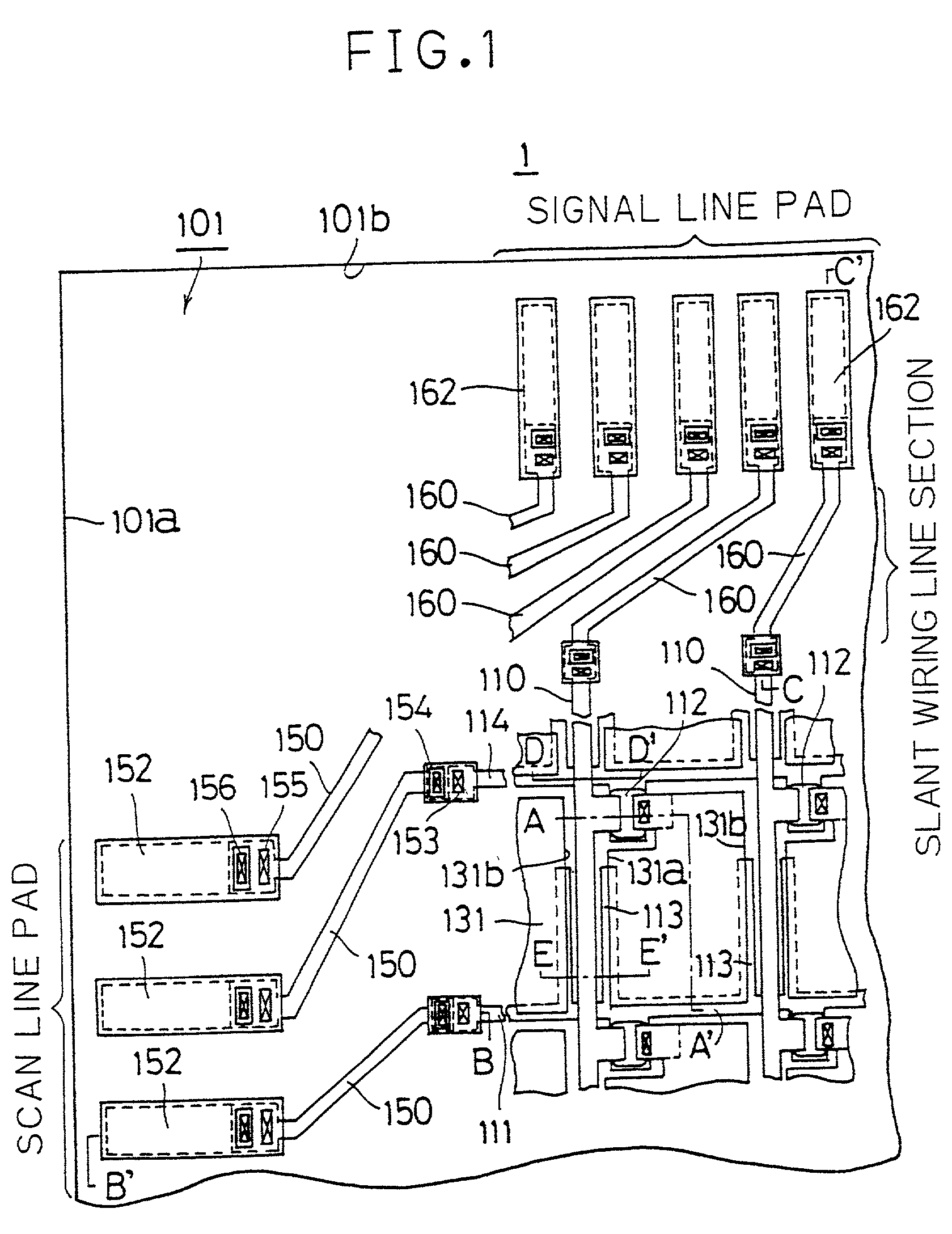

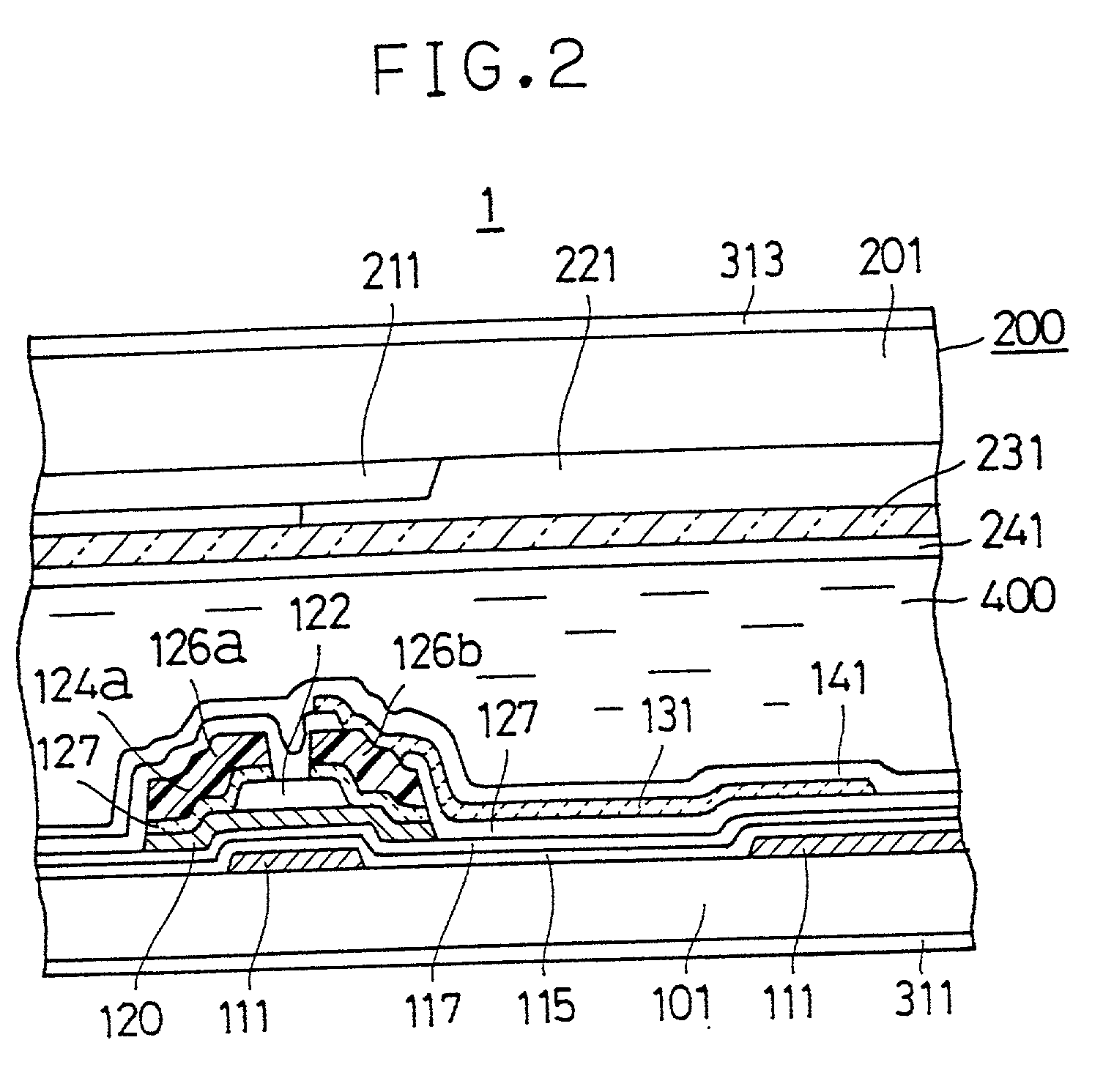

Method of manufacturing array substrate

InactiveUS6528357B2Reduce productionSolid-state devicesSemiconductor/solid-state device manufacturingOXALIC ACID DIHYDRATEDielectric

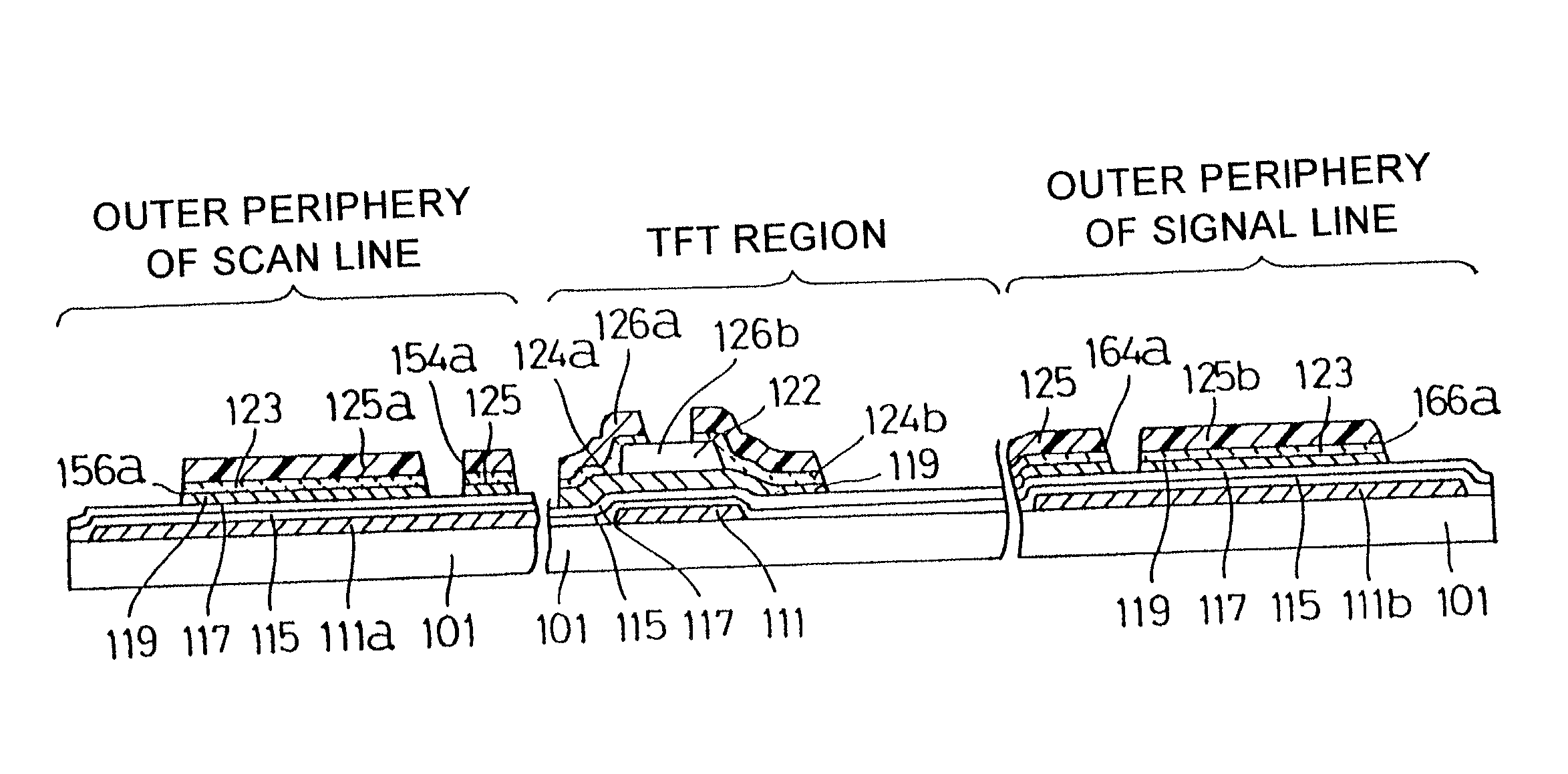

In the manufacturing method of array substrates for use in flat panel display devices including liquid crystal display (LCD) devices, it is aimed to prevent failure of interlayer dielectric film due to wiring deformation or the like while reducing the resistivity of wiring. It is also aimed to prevent corrosion of a metal wiring layer at the etching process and to thereby prevent deterioration of production yield due to corrosion. According to the method of the invention, to form scanning lines (111), an aluminum-neodymium alloy (Al-Nd) film (1110) is deposited in 300 nm thickness on the first hand, and then 50 nm thick Mo film (1110) is deposited thereon. Subsequently, gate insulator films (115 and 117) are formed by CVD processes at a substrate temperature of 350° C. Further, an etching process for forming pixel electrode (131) is carried out by HBr, HI, Oxalic acid or a mixture liquid containing at least one of these acids.

Owner:KK TOSHIBA

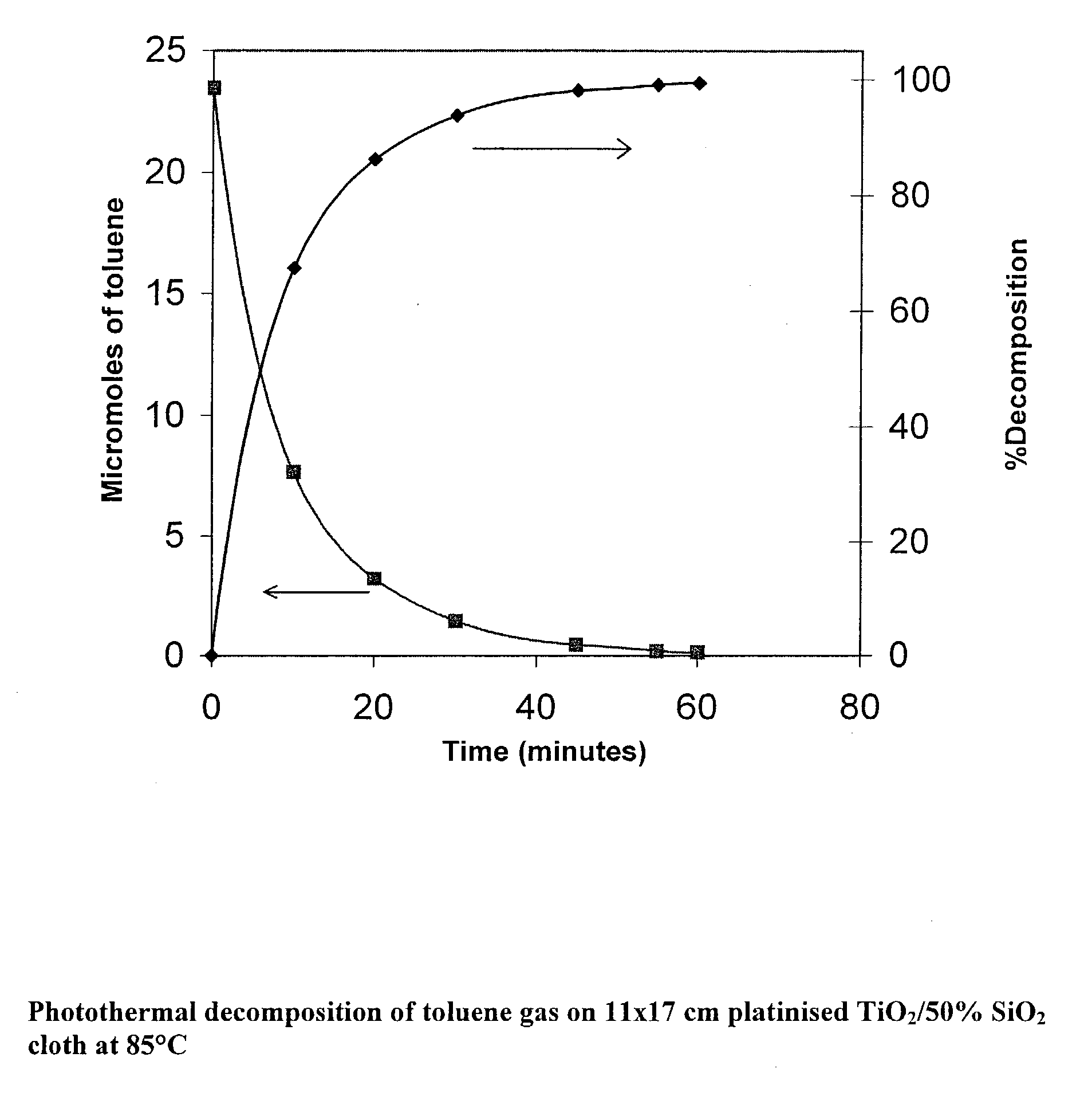

Titanium-containing materials

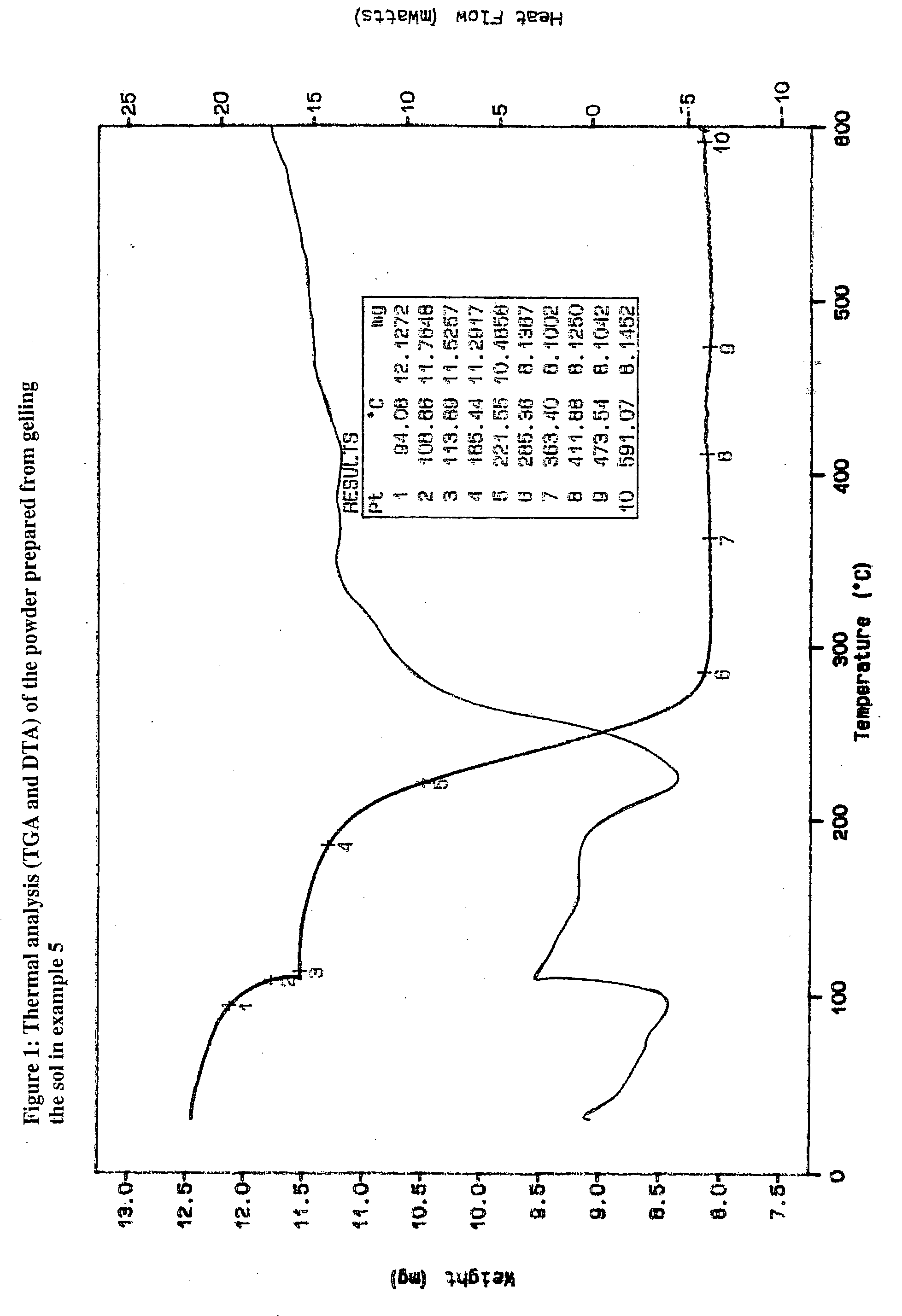

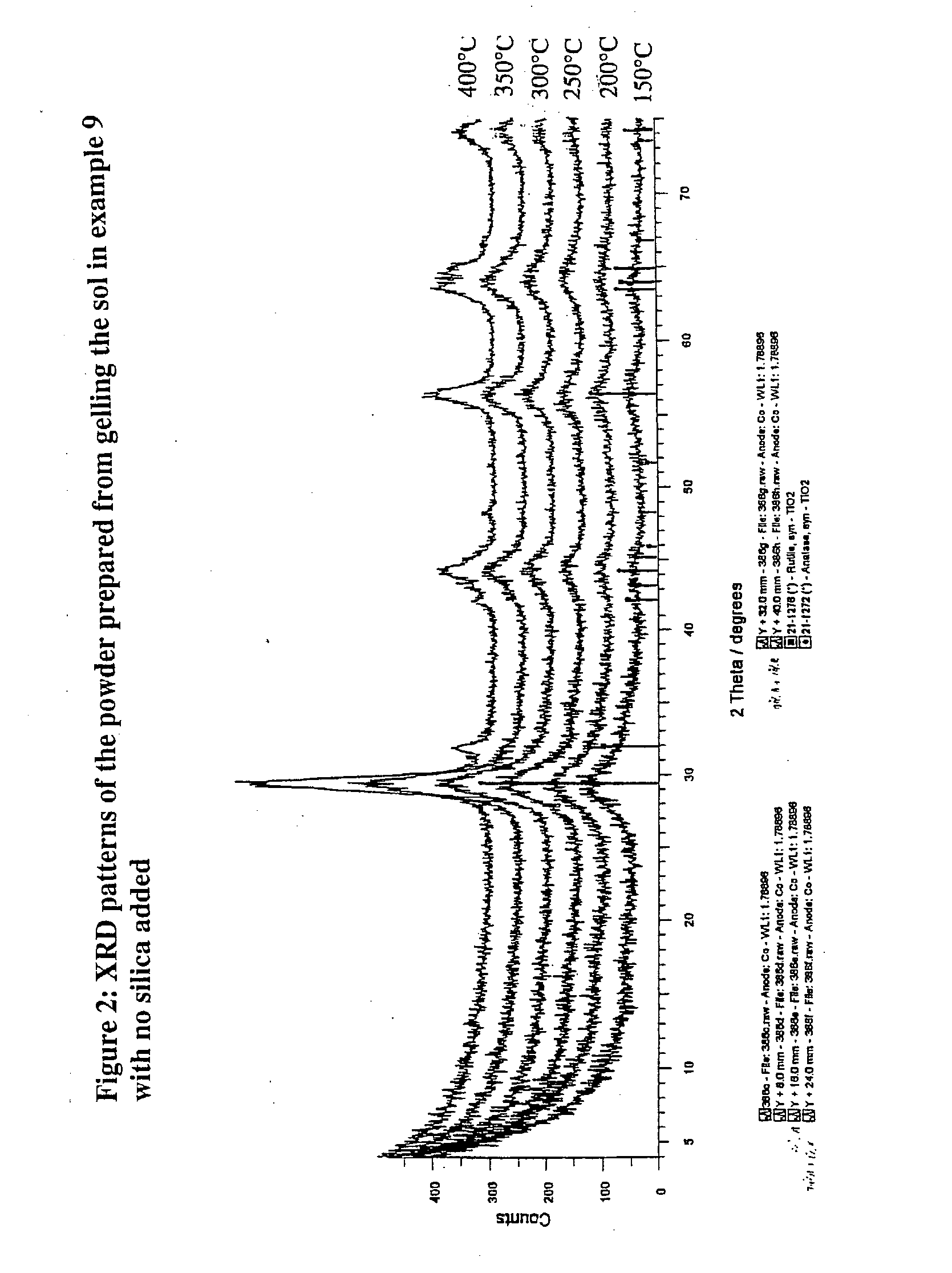

The invention relates to a method of preparing a solution containing colloidal particles which contain crystalline titanium dioxide wherein one or more hydrolysable titanium-containing compound(s) is stabilised by oxalic acid in a reaction medium. The reaction further relates to the preparation of titania materials (including particulate materials, coating solutions and films) which comprise or include anatase phase titania, and so are suitable in photocatalytic applications. The invention also deals with a method of preparing B-phase titania.

Owner:IND RES LTD

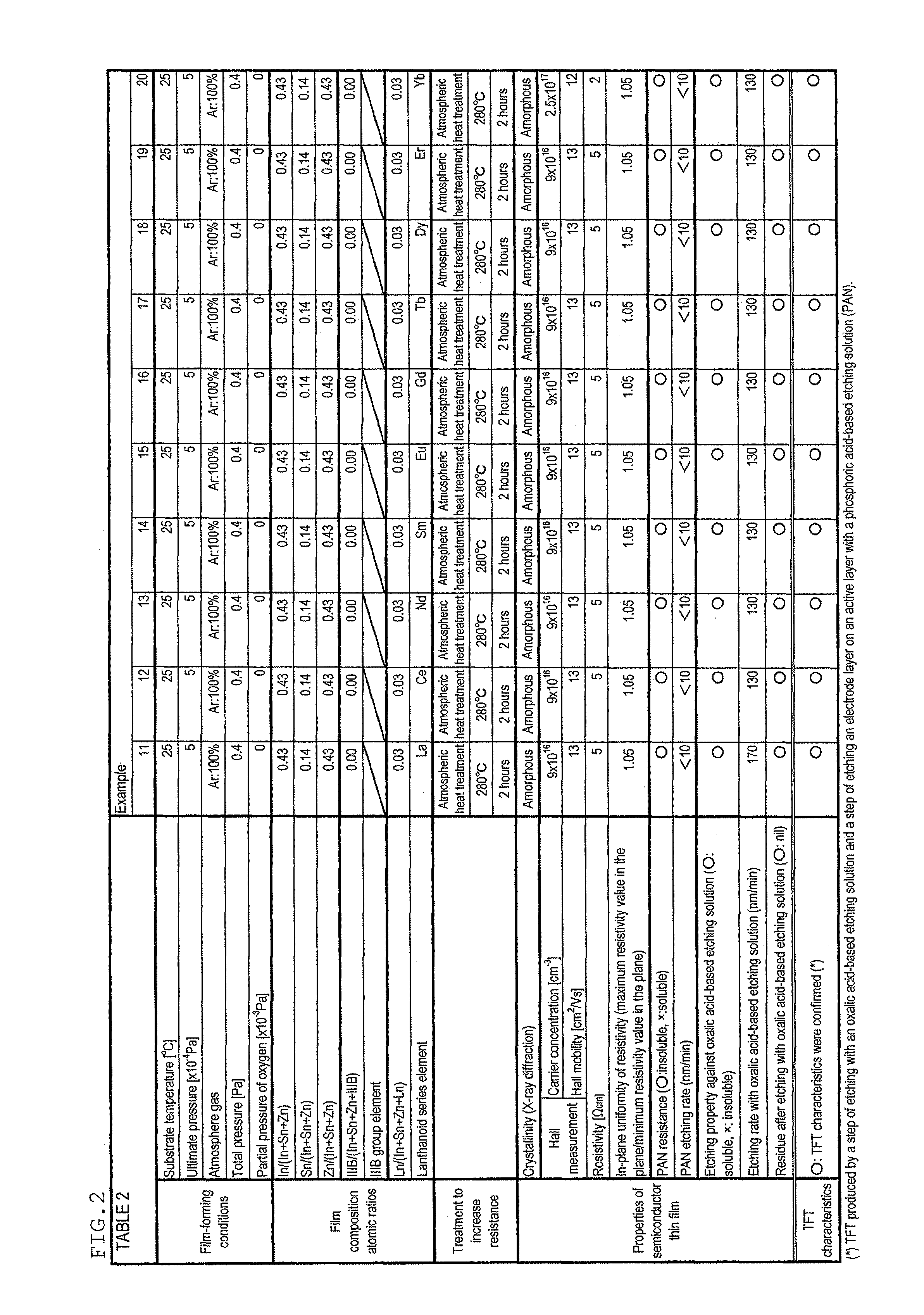

Noncrystalline oxide semiconductor thin film, process for producing the noncrystalline oxide semiconductor thin film, process for producing thin-film transistor, field-effect-transistor, light emitting device, display device, and sputtering target

ActiveUS8232552B2Industrially produced with easeIncrease volumeCellsVacuum evaporation coatingOXALIC ACID DIHYDRATEIndium

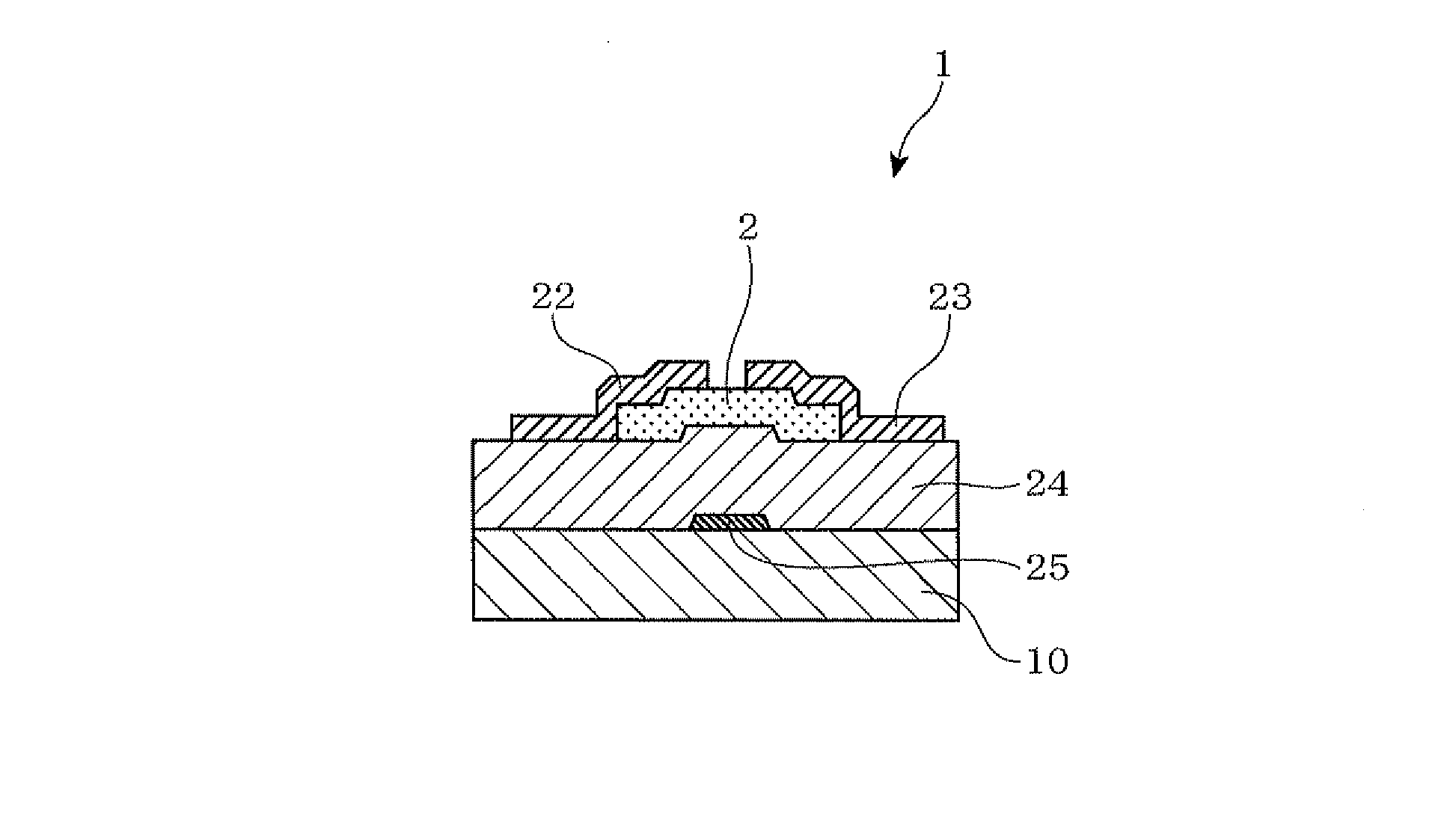

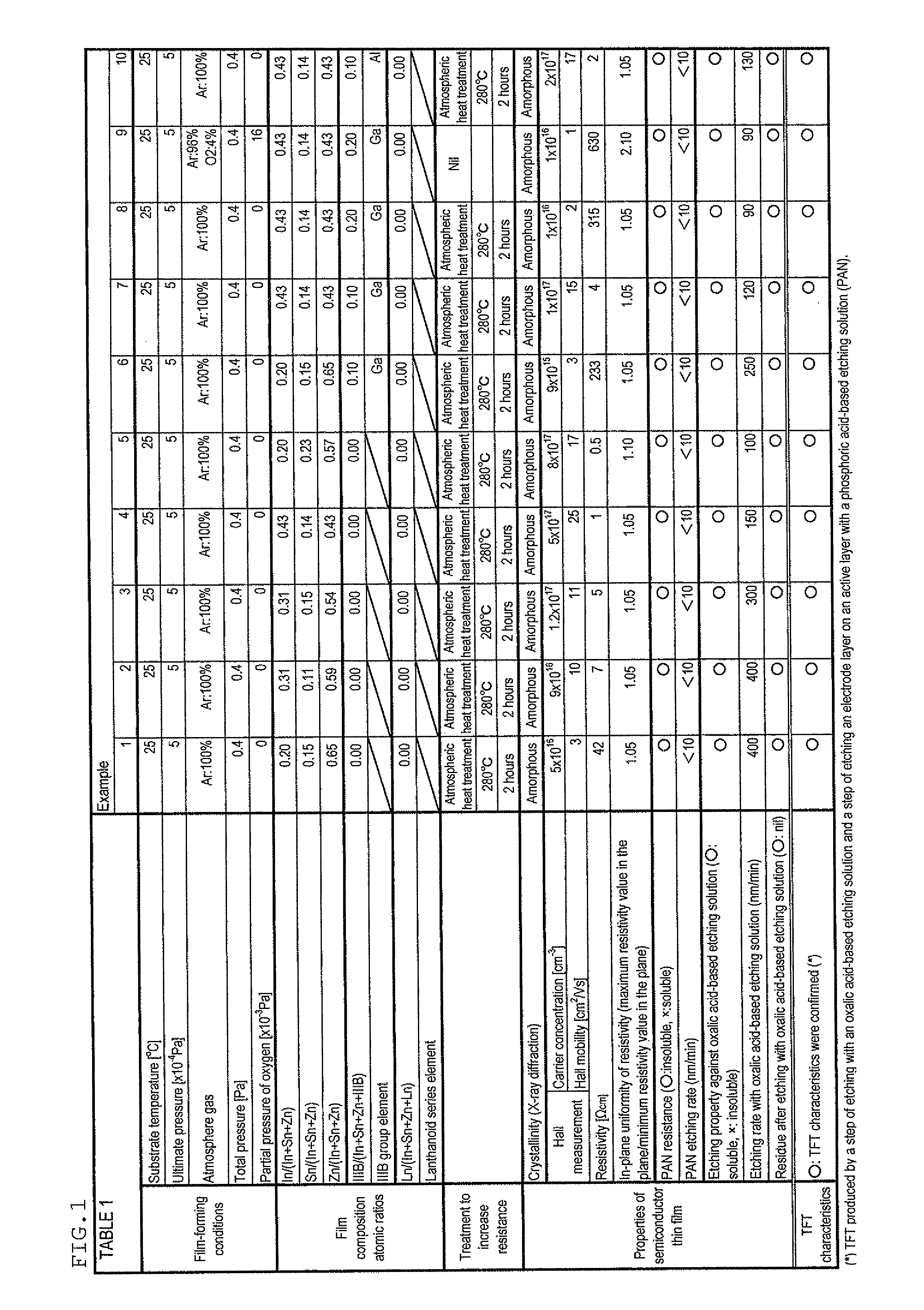

This invention provides an amorphous oxide semiconductor thin film, which is insoluble in a phosphoric acid-based etching solution and is soluble in an oxalic acid-based etching solution by optimizing the amounts of indium, tin, and zinc, a method of producing the amorphous oxide semiconductor thin film, etc. An image display device (1) comprises a glass substrate (10), a liquid crystal (40) as a light control element, a bottom gate-type thin film transistor (1) for driving the liquid crystal (40), a pixel electrode (30), and an opposing electrode (50). The amorphous oxide semiconductor thin film (2) in the bottom gate-type thin film transistor (1) has a carrier density of less than 10+18 cm−3, is insoluble in a phosphoric acid-based etching liquid, and is soluble in an oxalic acid-based etching liquid.

Owner:IDEMITSU KOSAN CO LTD

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Dishwasher detergent with improved protection against glass corrosion

InactiveUS20050075258A1Organic detergent compounding agentsSurface-active detergent compositionsOXALIC ACID DIHYDRATEOrganic acid

A dishwasher detergent containing a builder and one or more magnesium and / or zinc salt(s) of at least one monomeric and / or polymeric organic acid, excluding zinc ricinoleate, zinc abietate, and zinc oxalate. A method of inhibiting glass corrosion by treatment with one or more salts of magnesium and / or zinc with organic acids, excluding formic acid, acetic acid, gluconic acid, and oxalic acid.

Owner:HENKEL KGAA

Non-tea-based, packaged beverages

Provided is a non-tea-based, packaged beverage which includes a sour seasoning, contains catechins at high concentration, and even after stored over along term, can still give a refreshing feeling specific to a sour taste. The non-tea-based, packaged beverage is free of the persistence of a sour taste, which is experienced when taken in sport scenes, and is excellent in mouth refreshment. Even in a form filled in an oxygen-permeable, clear container, the non-tea-based, packaged beverage shows excellent color tone stability. The non-tea-based, packaged beverage contains a purified product of green tea extract added to it. The purified product comprises non-polymer catechins in its solid constituents and has a content weight ratio of (B) oxalic acid to (A) the non-polymer catechins [(B) / (A)] in a range of from 0 to 0.002. The non-tea-based, packaged beverage comprises the following ingredients (A) to (D): (A) from 0.03 to 0.6 wt % of non-polymer catechins, (B) oxalic acid or a salt thereof at an ingredient (B) / ingredient (A) of from 0 to 0.02, (C) caffeine at an ingredient (C) / ingredient (A) weight ratio of from 0 to 0.16, and (D) from 0.03 to 1.0 wt % of a sour seasoning, and has a pH of from 2 to 6.

Owner:KAO CORP

Processes for texturing a surface prior to electroless plating

InactiveUS20090302005A1Improve surface roughnessEasy to understandDecorative surface effectsBlade accessoriesOXALIC ACID DIHYDRATEAqueous solution

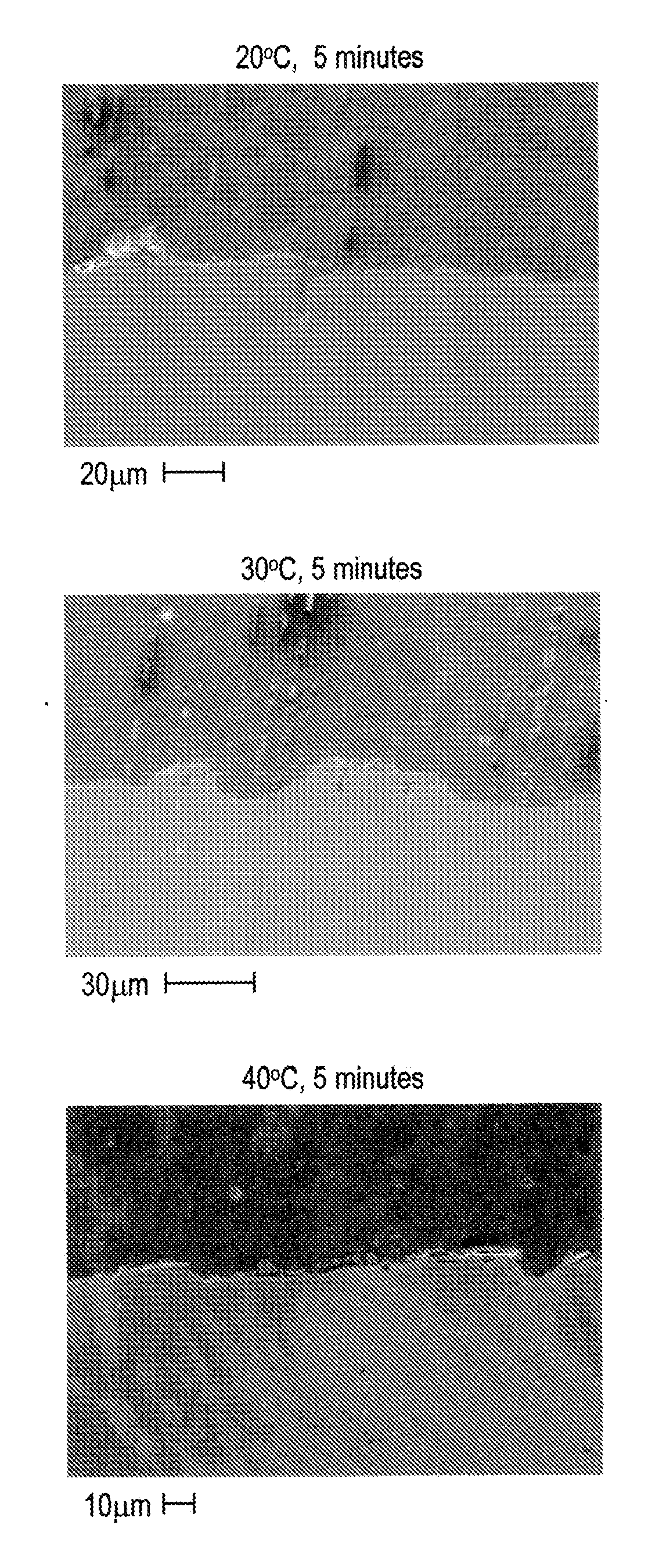

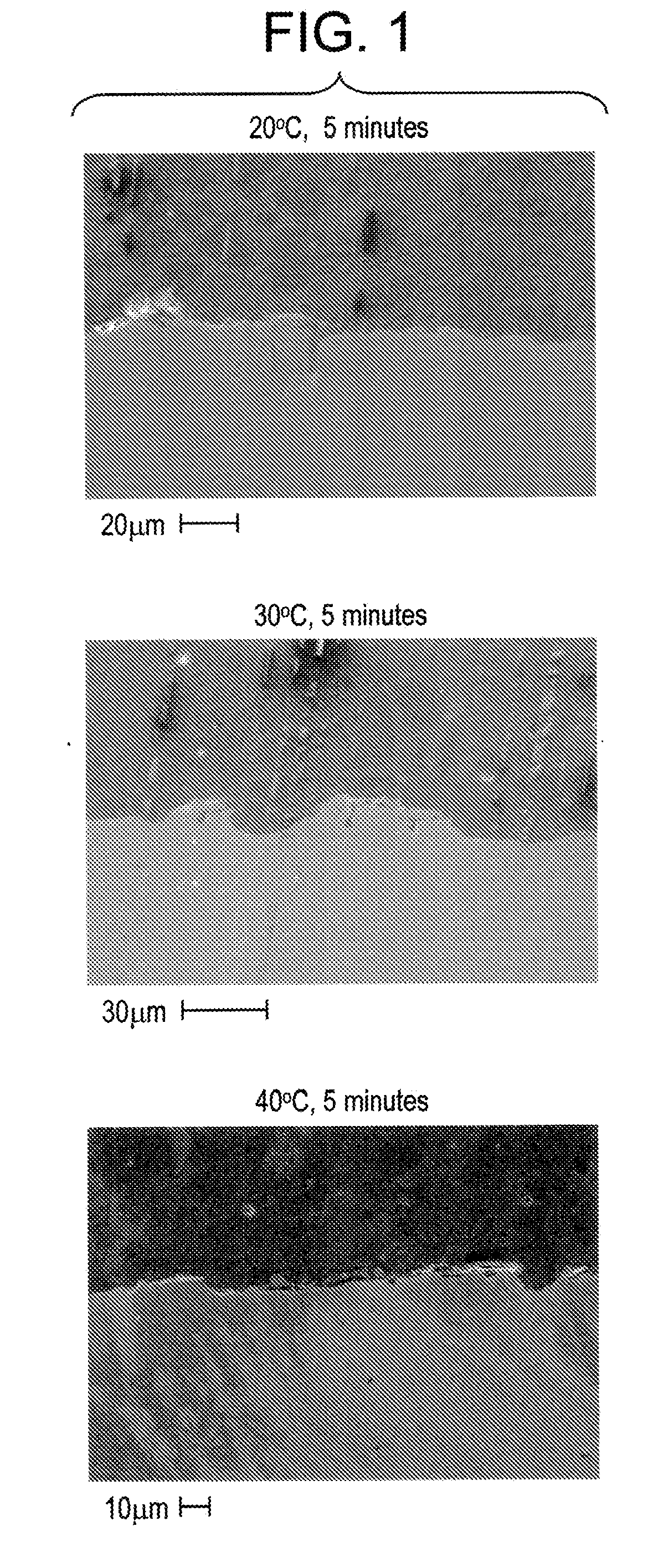

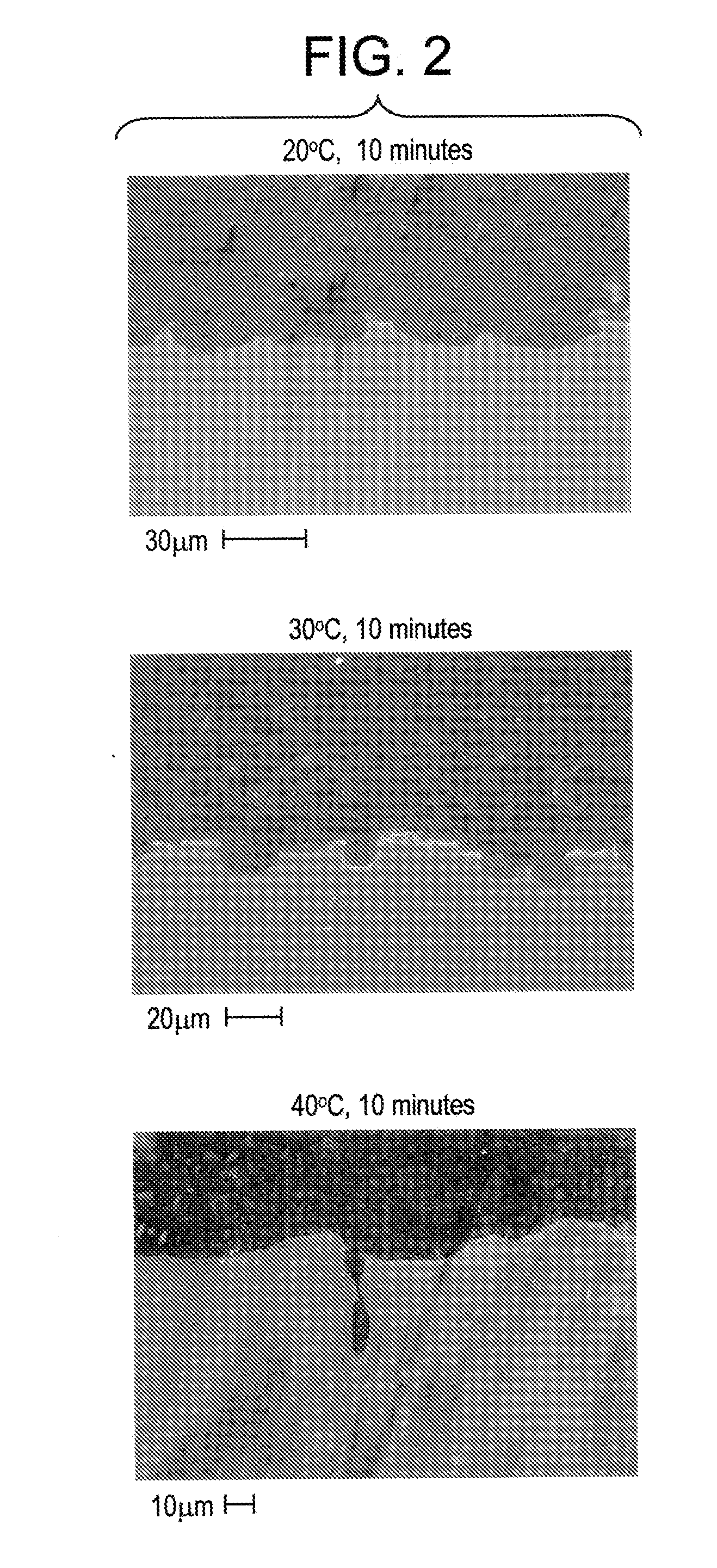

Process for roughening a surface of a base metal substrate includes contacting the surface with an aqueous solution comprising oxalic acid, sulfuric acid, and hydrogen peroxide at a temperature and for a period of time effective to roughen the surface to an average roughness greater than 60 Ra, removing a modest amount of base material, and generating no narrow and deep crevices at all. The surface is roughened prior to application of an electroless coating onto the substrate.

Owner:GENERAL ELECTRIC CO

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

Solid supported noble metal catalyst and its preparing method

InactiveCN1425499ASmall particle sizeIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOXALIC ACID DIHYDRATEAlkaline earth metal

The supported noble metal catalyst has any one of Ru, Rh, Pd, Os, Ir, Pt, Au, Ag, Cu and Ni as the active component; and any one of active carbon, graphite, carbon nanotube, Al2O3, SiO2, molecular sieve, MgO and TiO2 as the carrier. Its active component accounts for 0.1-90 % and metal particle size of 0.5-6 nm. The preparation process includes dispersing the active component, hydroxide or carbonate of alkali metal or alkali earth metal and carrier in solvent separately; mixing in certain proportion, heating the solution, adding nitric acid, sulfuric acid, hydrochloric acid, oxalic acid or acetic acid as precipitation promoter; and stoving. The catalyst is used as catalyst for fuel cell and makes the fuel cell possess high performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

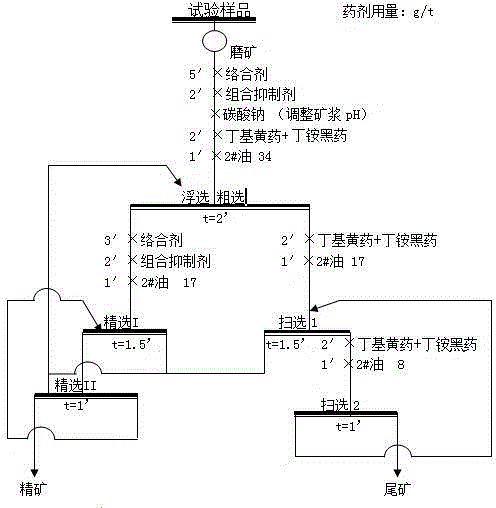

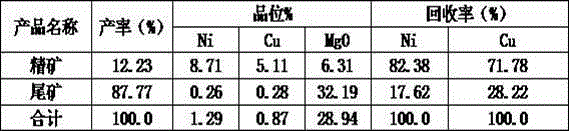

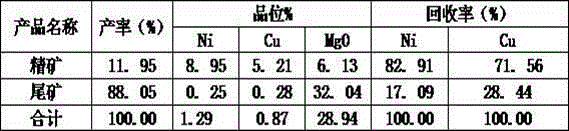

Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

The invention relates to a method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation. The method includes steps of firstly adding complexing agent oxalic acid, citric acid, tartaric acid, quadrol and EDTA (ethylene diamine tetraacetic acid), cleaning active ions of copper and nickel on the surface of magnesium-contained gangue mineral such as serpentine, removing flotation activity of sulfide ore collector such as xanthogenate, and adding composition agent to suppress gangue mineral. Ore pulp is treated by complexing agent, the flotation environment is improved, and floatability difference between copper-nickel sulfide mineral and magnesium-contained gangue mineral is increased. By combined inhibitor, serpentine and talc gangue mineral are suppressed, and magnesium-reducing effect is better; nickel recovery rate is increased to some extent as compared with that of actual production. Meanwhile, content of magnesium oxide in concentrate is reduced, and melting cost is lowered.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Production method of environmental-friendly type low-cost middle and high density fiber board

ActiveCN101791817AReduce formaldehyde contentReduce releaseNon-macromolecular adhesive additivesWood working apparatusOXALIC ACID DIHYDRATEFiber

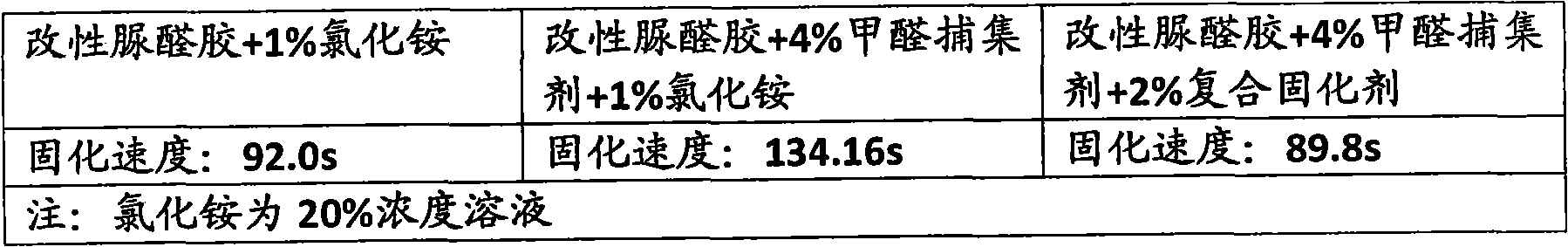

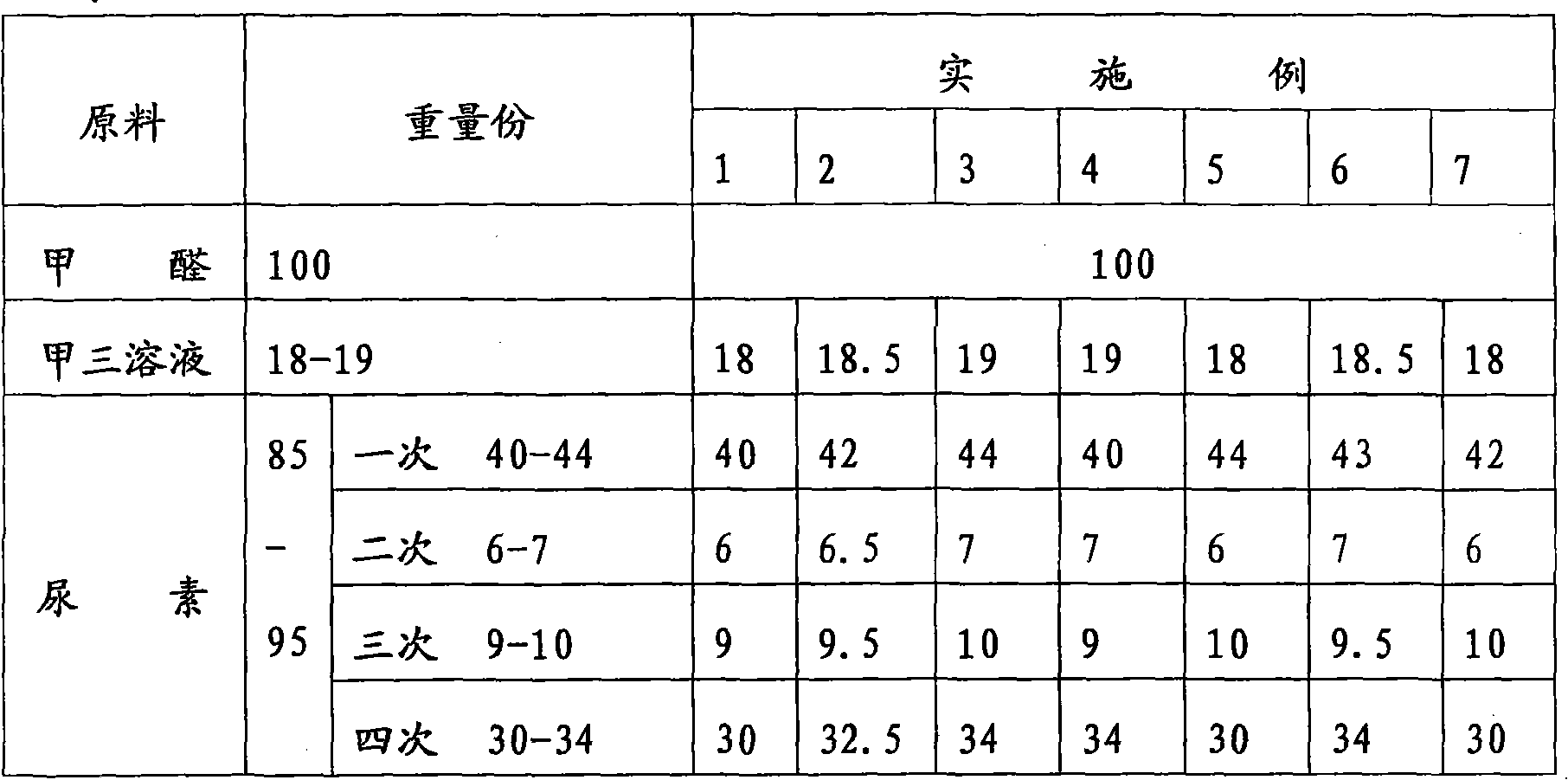

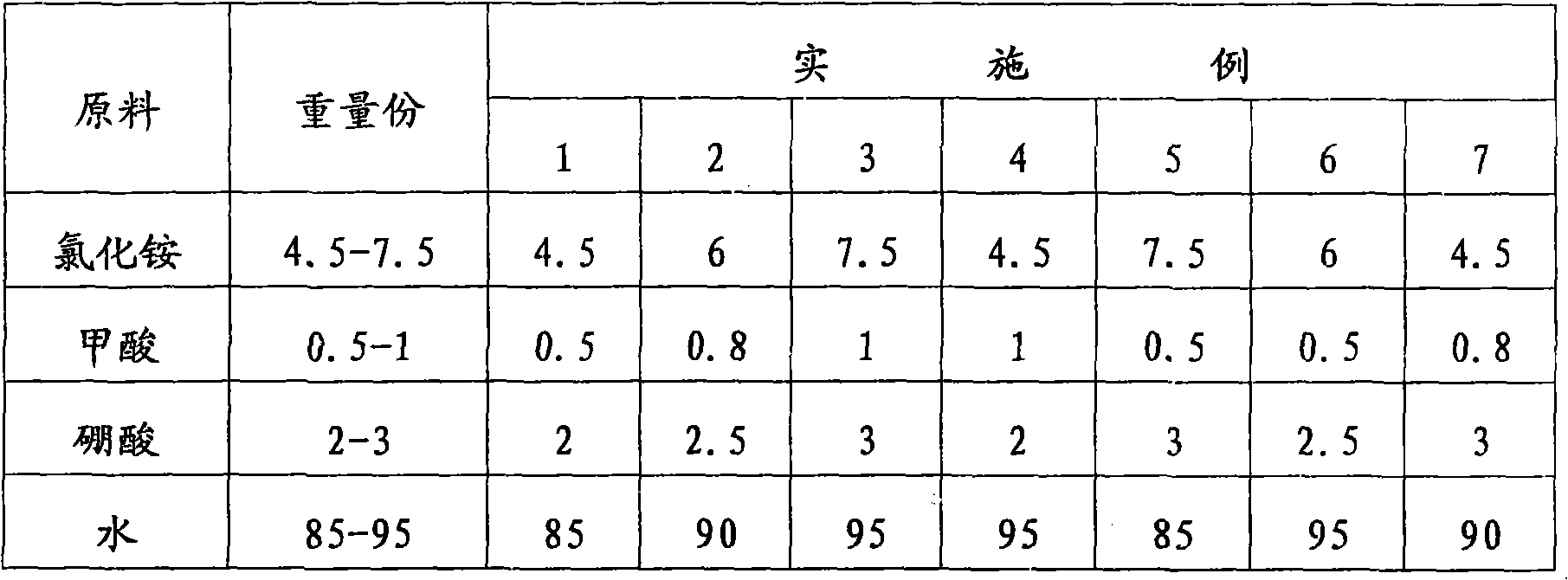

The invention relates to a production method of an environmental-friendly type low-cost middle and high density fiber board. Self-made modified urea-formaldehyde glue, a composite curing agent and a formaldehyde trapping agent are used in a glue blending procedure, wherein the modified urea-formaldehyde glue is prepared by heating formaldehyde, melamine and urea in a reaction kettle through a chemical reaction; the composite curing agent is prepared by mixing ammonium chloride, boric acid, oxalic acid and water; and the formaldehyde trapping agent is prepared from phosphoric acid, urea, a catalyst and water under a certain temperature condition. When the middle and high density fiber is produced, the application amount of the formaldehyde trapping agent is 3 percent or 4 percent of the weight of modified urea-formaldehyde glue solid, the application amount of the modified urea-formaldehyde glue solution is 12.5 percent of the weight of absolute dried fiber, and the application amount of the composite curing agent is 3 percent or 2 percent of the weight of the modified urea-formaldehyde glue solution. The middle and high density fiber board produced using the three ingredients can completely meet Eo level environmental-friendly requirements, has good compatibility and high bonding strength and greatly reduces production cost of the fiber board.

Owner:ZHEJIANG FORESTRY ACAD +1

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475AFlexible adjustment ratioHomogeneous coprecipitationCell electrodesOXALIC ACID DIHYDRATENickel salt

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Method of manufacturing array substrate

InactiveUS20020132385A1Reduce productionSolid-state devicesSemiconductor/solid-state device manufacturingDielectricOXALIC ACID DIHYDRATE

In the manufacturing method of array substrates for use in flat panel display devices including liquid crystal display (LCD) devices, it is aimed to prevent failure of interlayer dielectric film due to wiring deformation or the like while reducing the resistivity of wiring. It is also aimed to prevent corrosion of a metal wiring layer at etching process and to thereby prevent deterioration of production yield due to the corrosion. According to the method of the invention, when to form scanning lines 111, an aluminum-neodymium alloy (Al-Nd) film 1110 is deposited in 300 nm thickness on first hand, and then 50 nm thick Mo film 1110 is deposited thereon. Subsequently, gate insulator films 115,117 are formed by CVD processes at a substrate temperature of 350° C. Further, an etching process for forming pixel electrode 131 is carried out by HBr, HI, oxalic acid or a mixture liquid containing at least one of these acid.

Owner:KK TOSHIBA

Scaling powder for no-clean lead-free low-silver welding paste

ActiveCN104400257AImprove printing qualityEasy to shapeWelding/cutting media/materialsSoldering mediaBenzoic acidOXALIC ACID DIHYDRATE

The invention discloses scaling powder for no-clean lead-free low-silver welding paste. The scaling powder comprises, by weight percentage, 3-13% of active agent, 0.2-1.5% of surface active agent, 0.2-3.0% of emulgator, 3.0-10.0% of thixotropic agent, 3-8% of film-forming agent, 0.1-1% of antioxidant, 0.1-0.5% of corrosion inhibitor and the rest of solvent. The active agent is composed of four or five components in succinic acid, oxalic acid, salicylic acid, glutaric acid, citric acid, adipic acid, lactic acid, benzoic acid, malic acid and triethanolamine. The scaling powder for the no-clean lead-free low silver welding paste does not contain halogen, the corrosion to a circuit board is greatly lowered, the printing quality of the welding paste is good without bridging or turned-down edges, a welding point is good in forming after returning, the brazing connecting defect is greatly lowered, the residue is small without solder balls, the cleaning is not needed, the welding paste is directly used for assembling, the Sn-0.45 Ag-0.68 Cu or Sn-0.3 Ag-0.7 Cu low silver welding paste manufactured by using the scaling powder does not contain the halogen and rosin, the organic chemistry smoke is small, and the pollution to the environment is small.

Owner:CHONGQING UNIV OF TECH

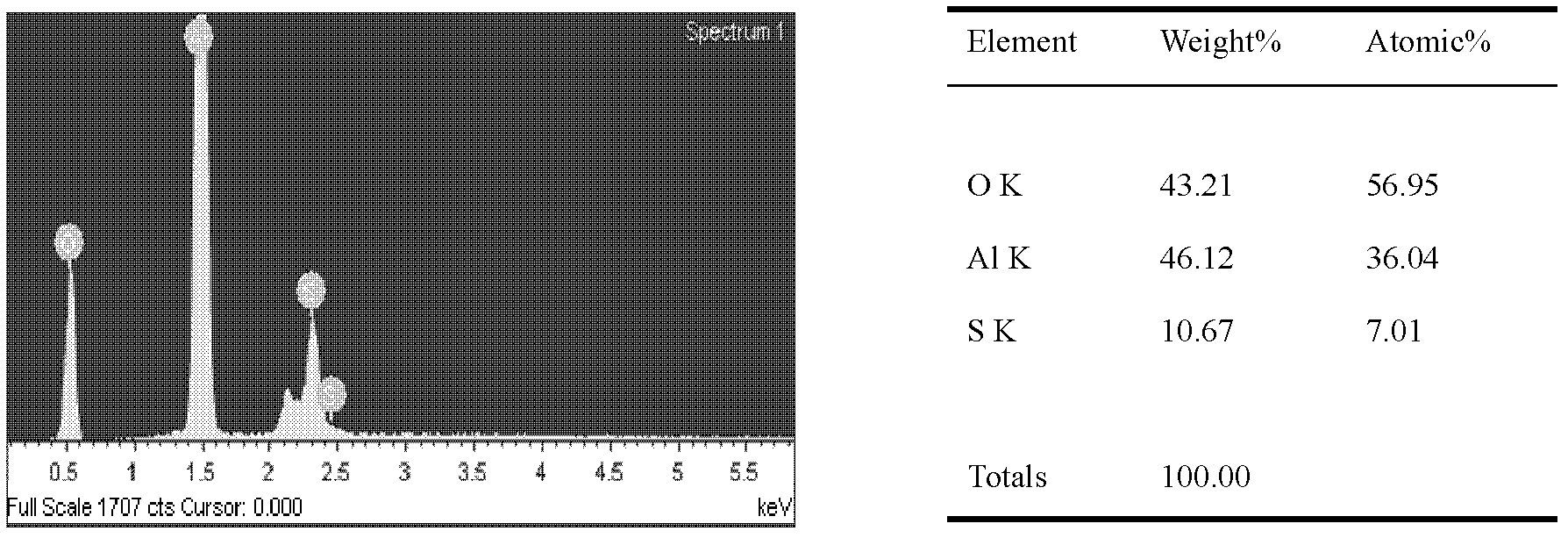

Process for producing flue gas denitration catalyst and flue gas denitration catalyst produced with the process

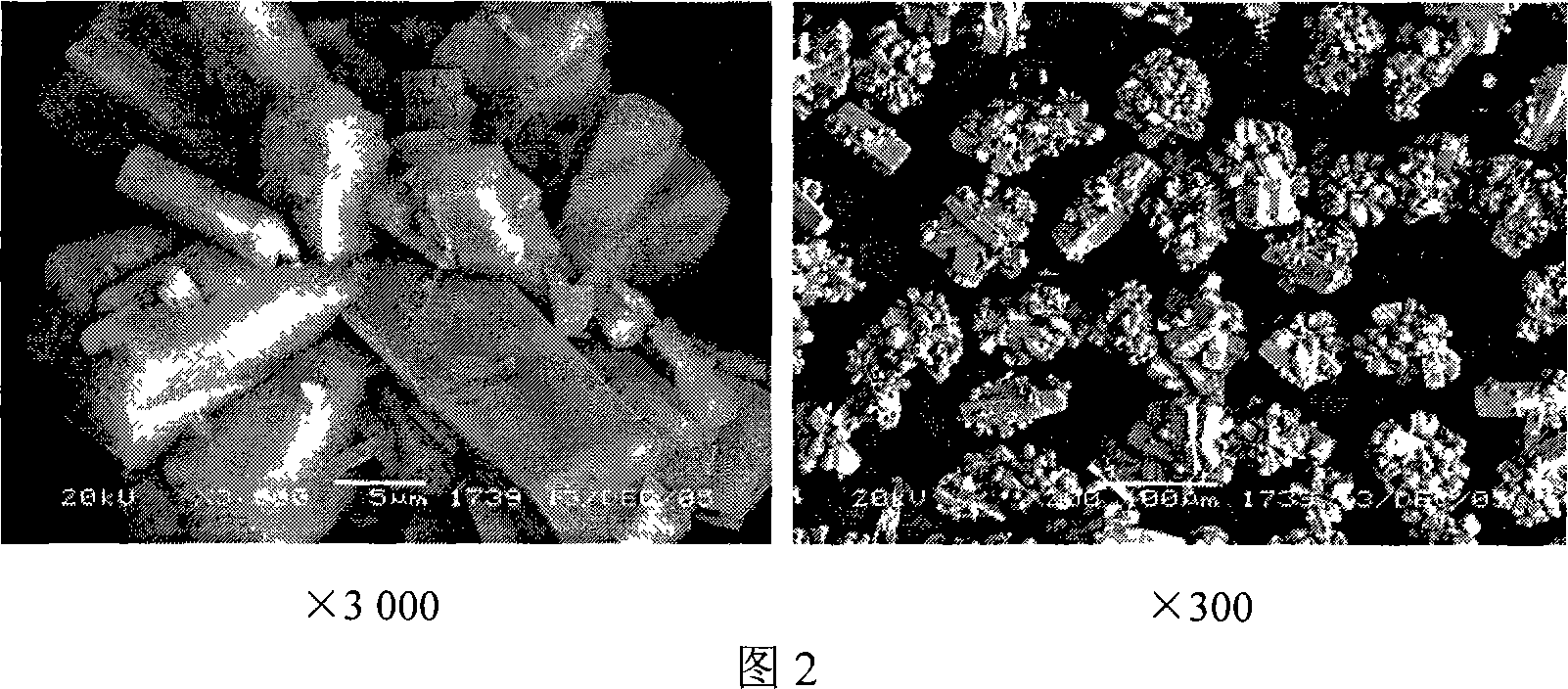

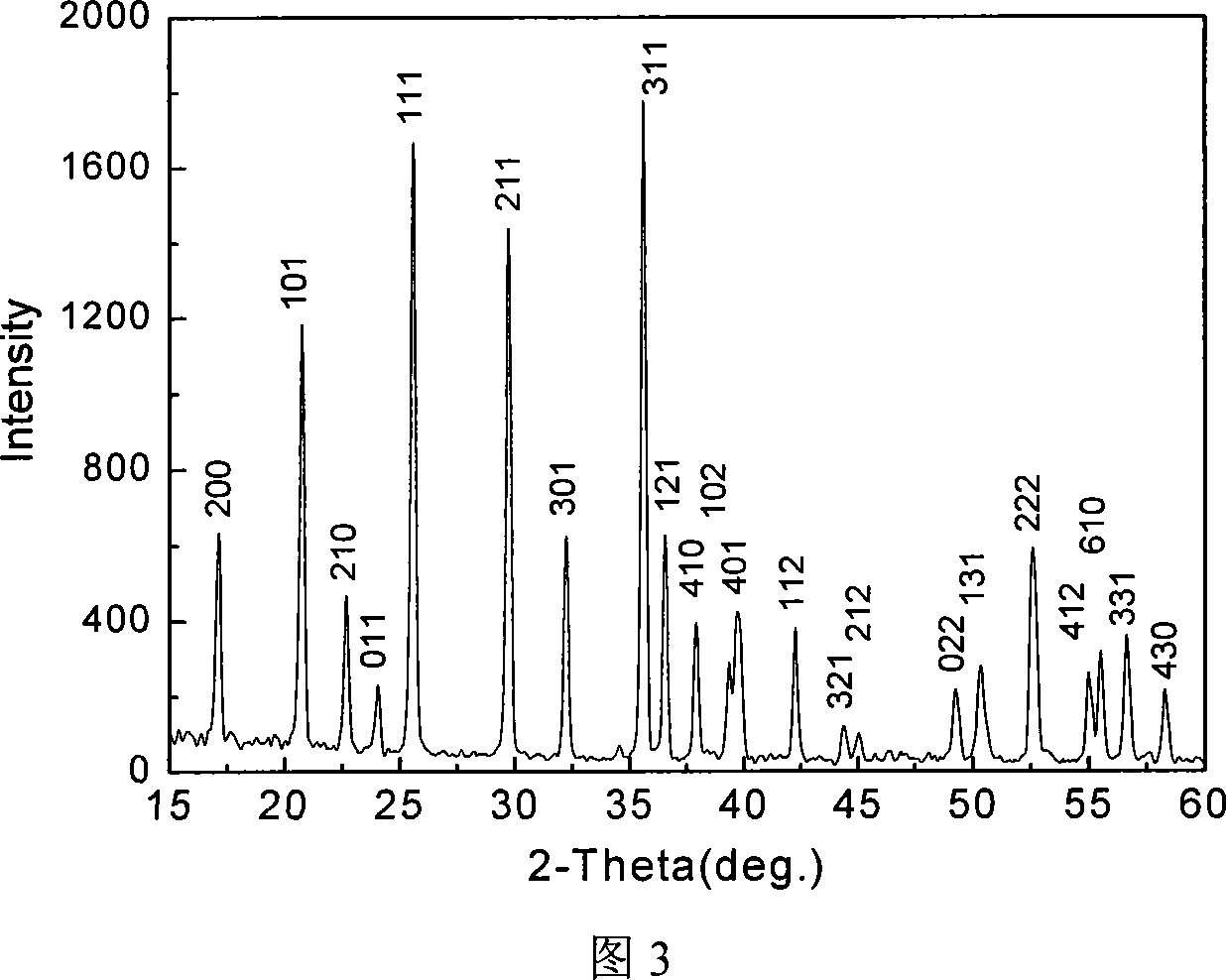

InactiveCN101428215AEasy to shapeHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPowder mixtureFlue gas

The invention relates to a method for preparing a catalyst for flue gas denitrification. The method comprises the following steps: step 1: preparing a powder mixture of titanium dioxide nanoparticles, binders and auxiliaries; step 2: preparing an oxalic acid solution of tungsten and vanadium; step 3: mixing the powder mixture produced in the step 1 and the solution produced in the step 2 to obtain a catalyst slurry; and step 4: uniformly spreading the catalyst slurry produced in the step 3 on a surface-treated stainless steel net, rolling and molding, drying and calcining to obtain the final catalyst. Furthermore, the invention also relates to a catalyst for flue gas denitrification, which is prepared by the method. The catalyst with high mechanical strength and excellent catalytic activity overcomes the problem that the prior catalyst for flue gas denitrification has poor mechanical strength after molding.

Owner:HARBIN INST OF TECH

Aqueous dispersion for chemical mechanical polishing

InactiveUS20010039766A1Improve balanceImprove accuracyPigmenting treatmentOther chemical processesOXALIC ACID DIHYDRATEColloidal silica

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

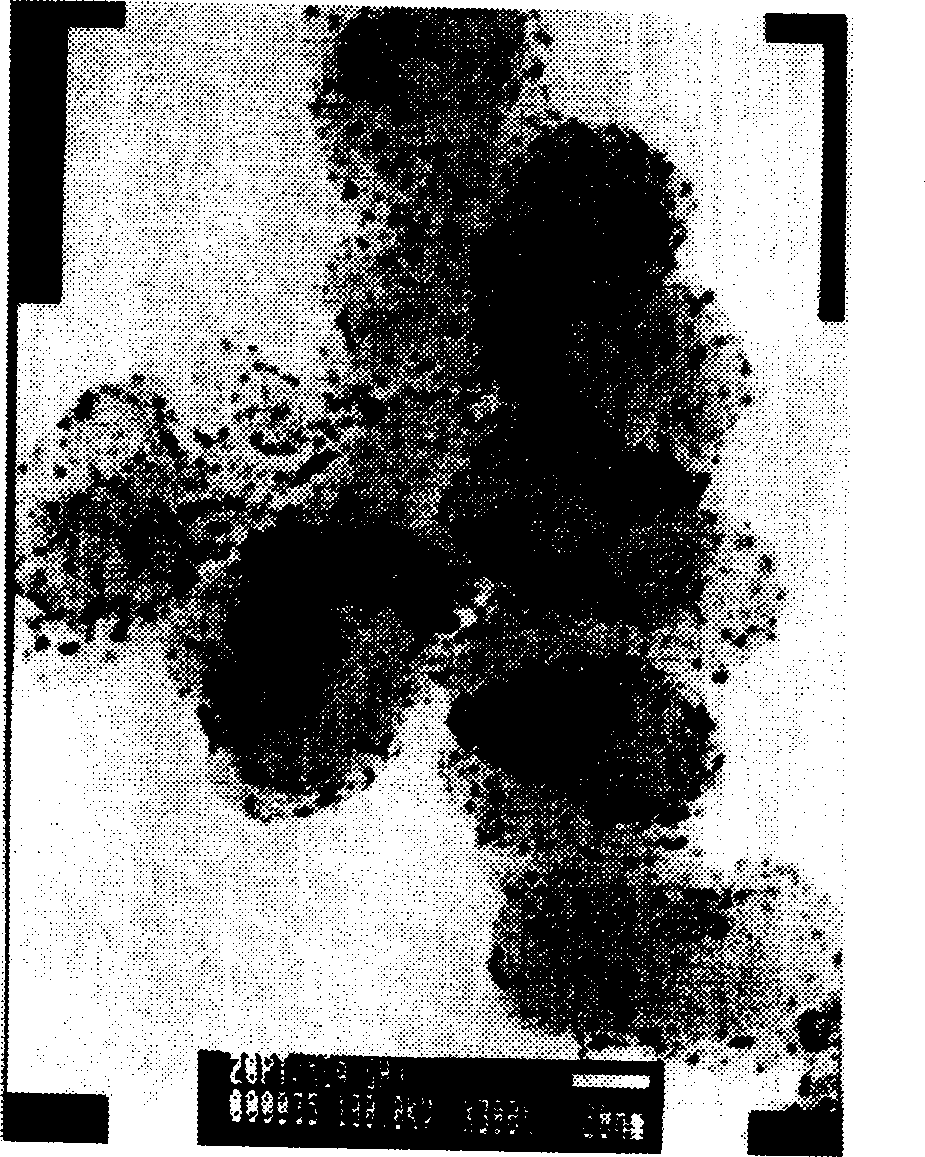

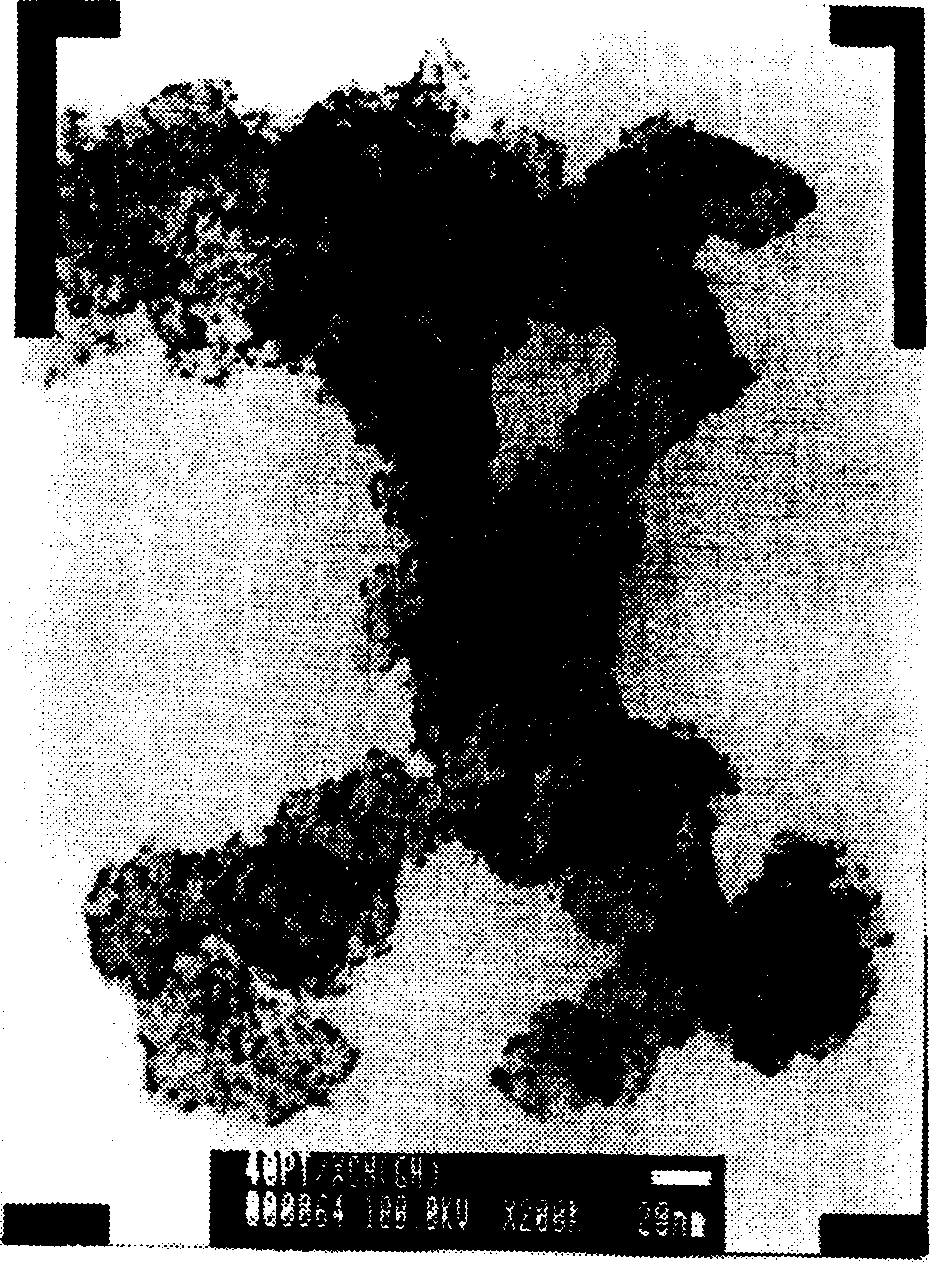

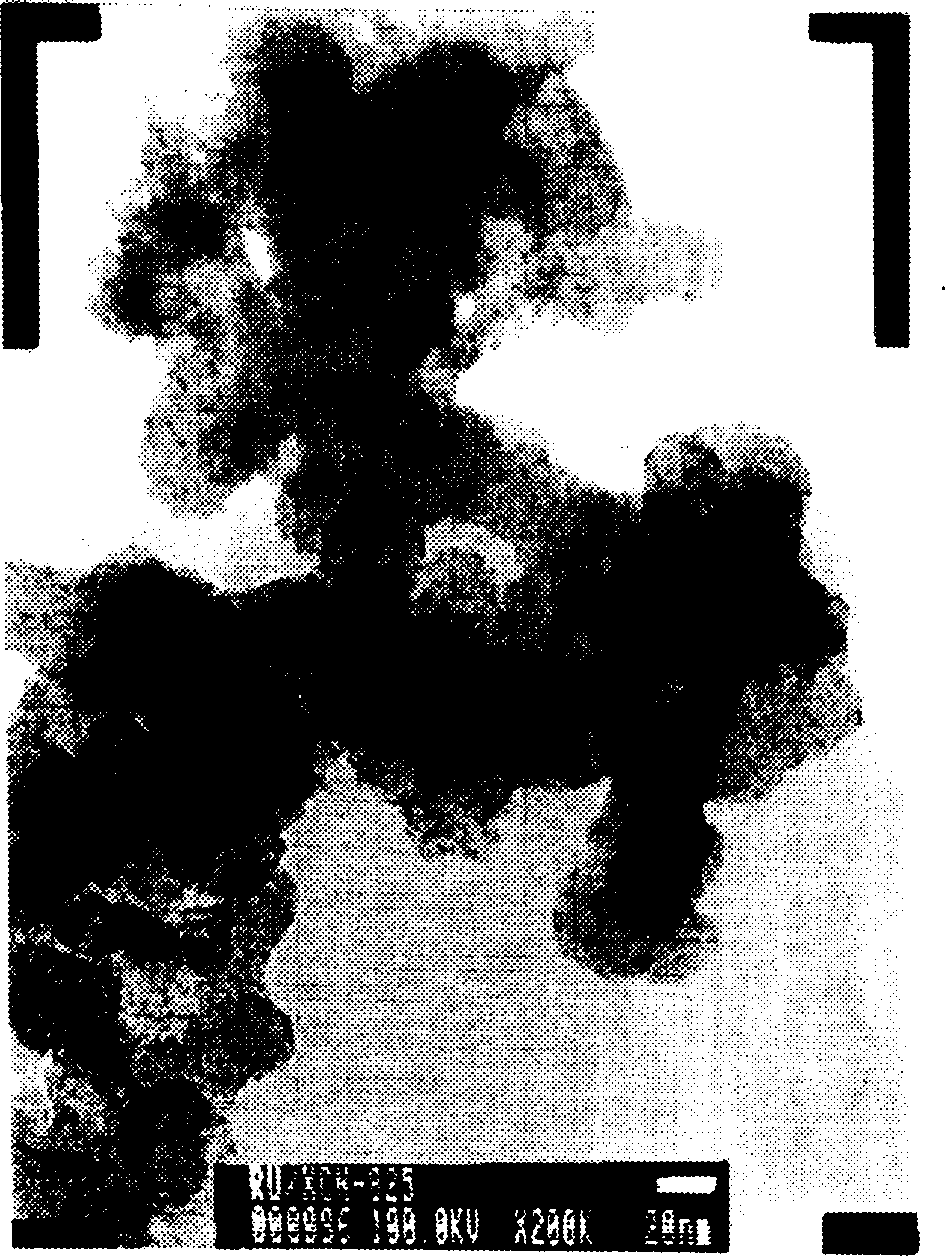

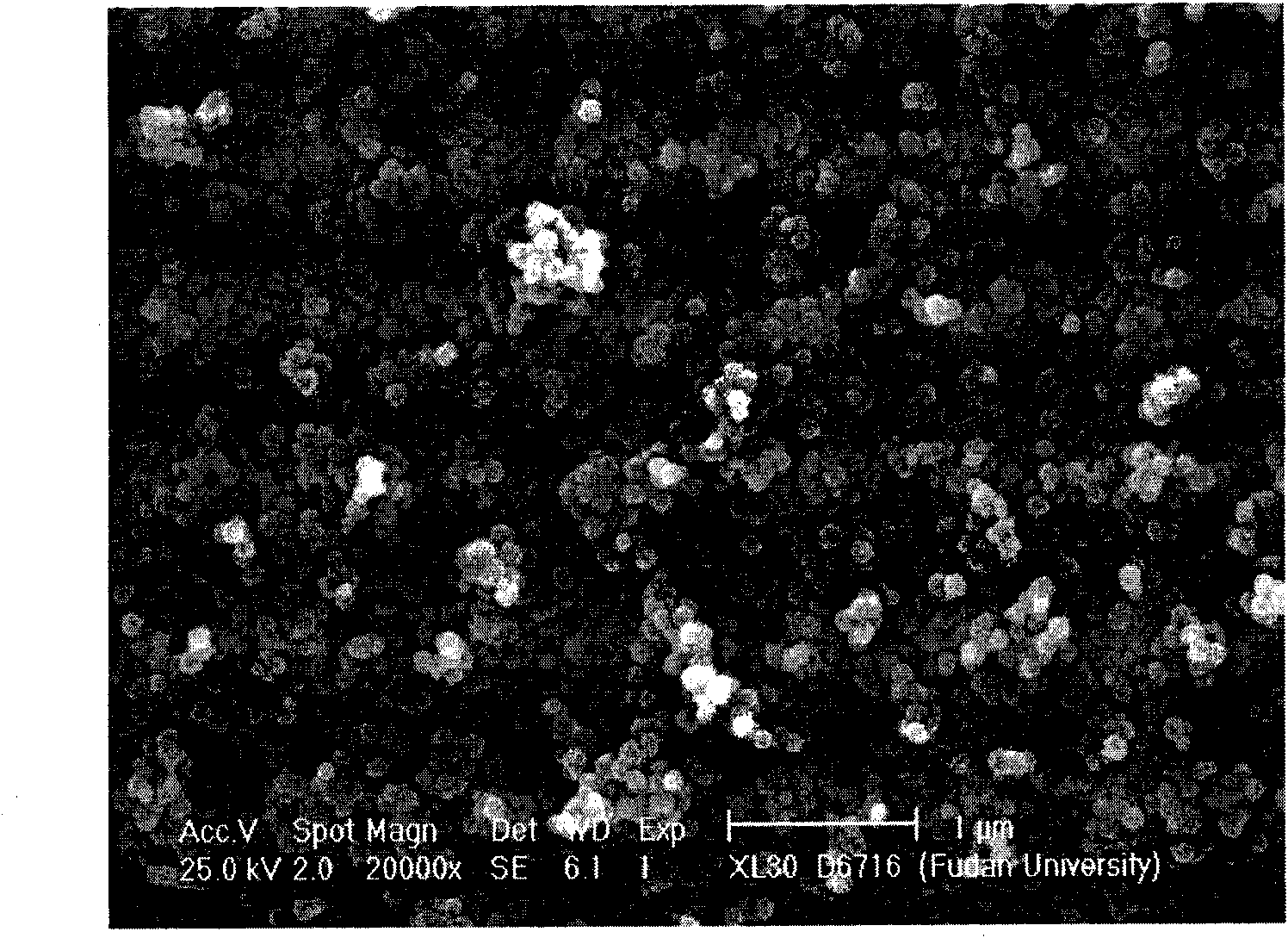

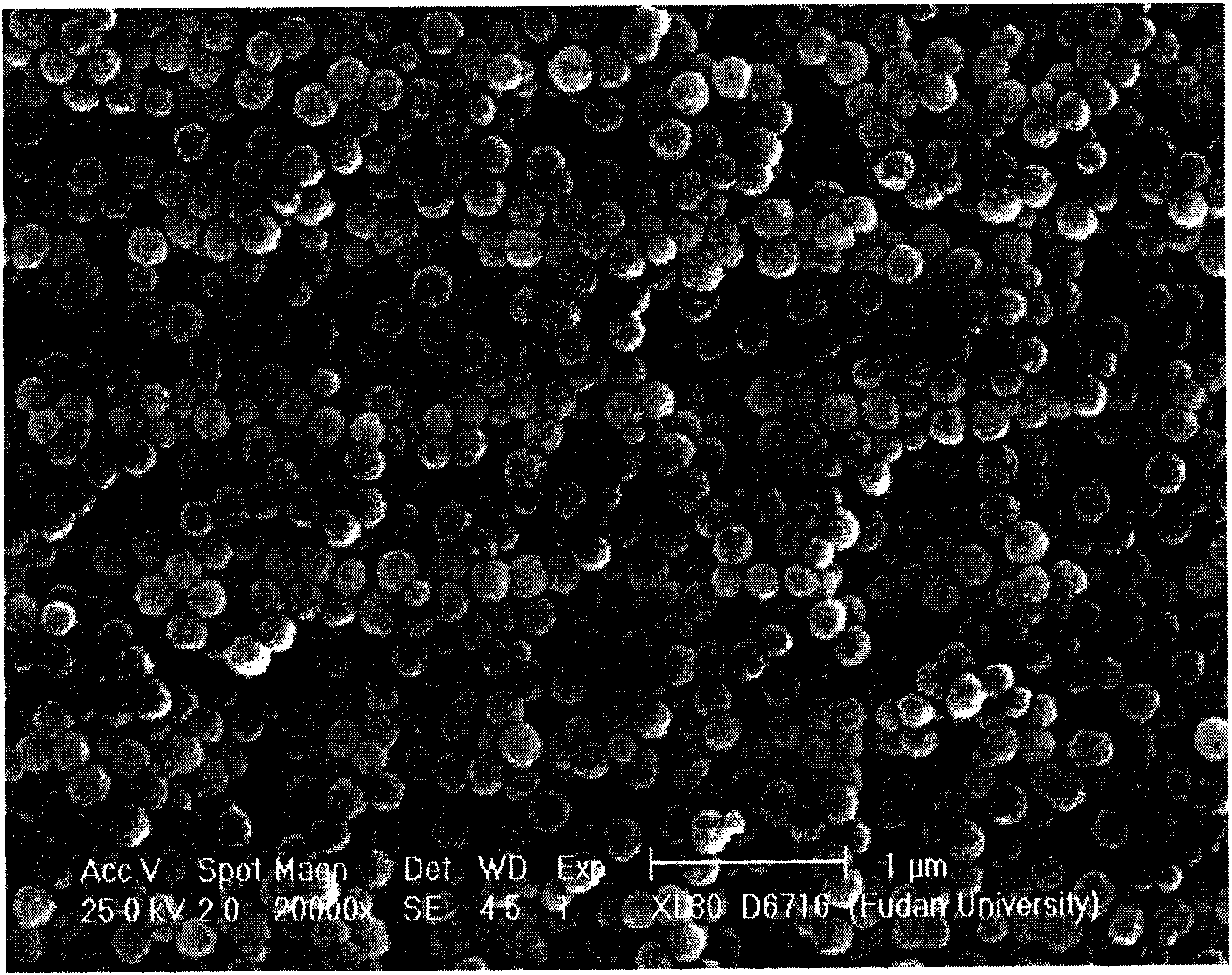

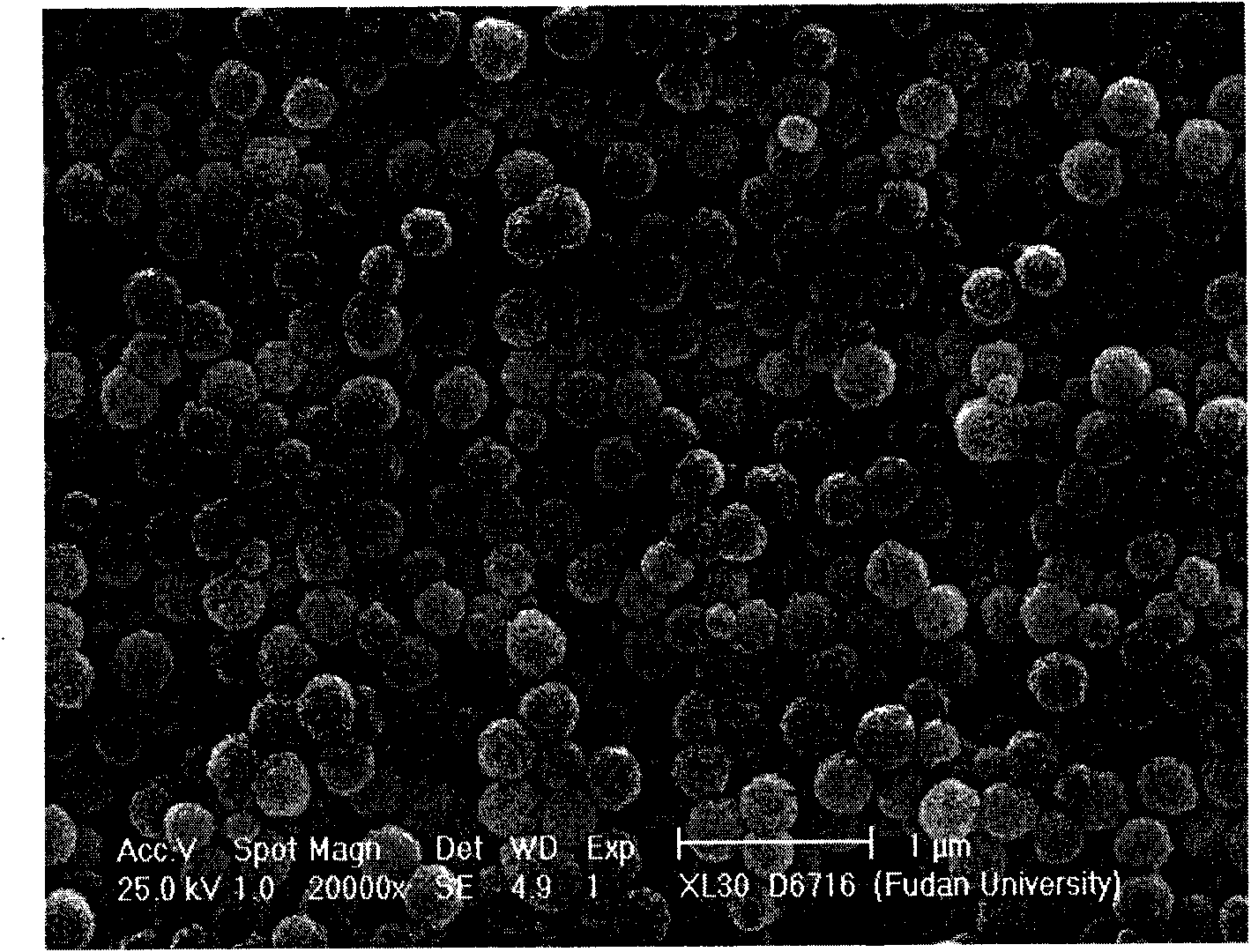

Super paramagnetism inorganic nanometer microballoon and preparation method thereof

InactiveCN101640089ALarge particle sizeResponsiveness to strong external magnetic fieldInorganic material magnetismSuperparamagnetismExternal field

The invention belongs to advanced nanometer material and nanotechnology field, in particular to a super paramagnetism inorganic nanometer microballoon and a preparation method thereof. The super paramagnetism inorganic nanometer microballoon has grain diameters of 80-410nm and hydrophilic surfaces, wherein the magnetism inorganic nanometer microballoon is formed by nano particles with grain diameters of 6-10nm; the nano particles are one or more than one of Fe3O4, Gamma-Fe2O3, MnFe2O4, NiFe2O4 and CuFe2O4; and the surface of the magnetism nanometer microballoon is coated by organic hydrophilicmicromolecule which is one or more than one of oxalic acid, citric acid, dihydroxysuccinic acid, and malic acid. The microballoon has bigger grain diameter and strong external field responsibility, and simultaneously keeps the super paramagnetism character; as the microballon has hydrophilic surface, the microballon can well disperse in water solution. Cell experiments show that the microballon has very low cytotoxicity and is particularly suitable for use in biomedicine, such as cell marks, separation and magnetic resonance imaging, etc.

Owner:FUDAN UNIV

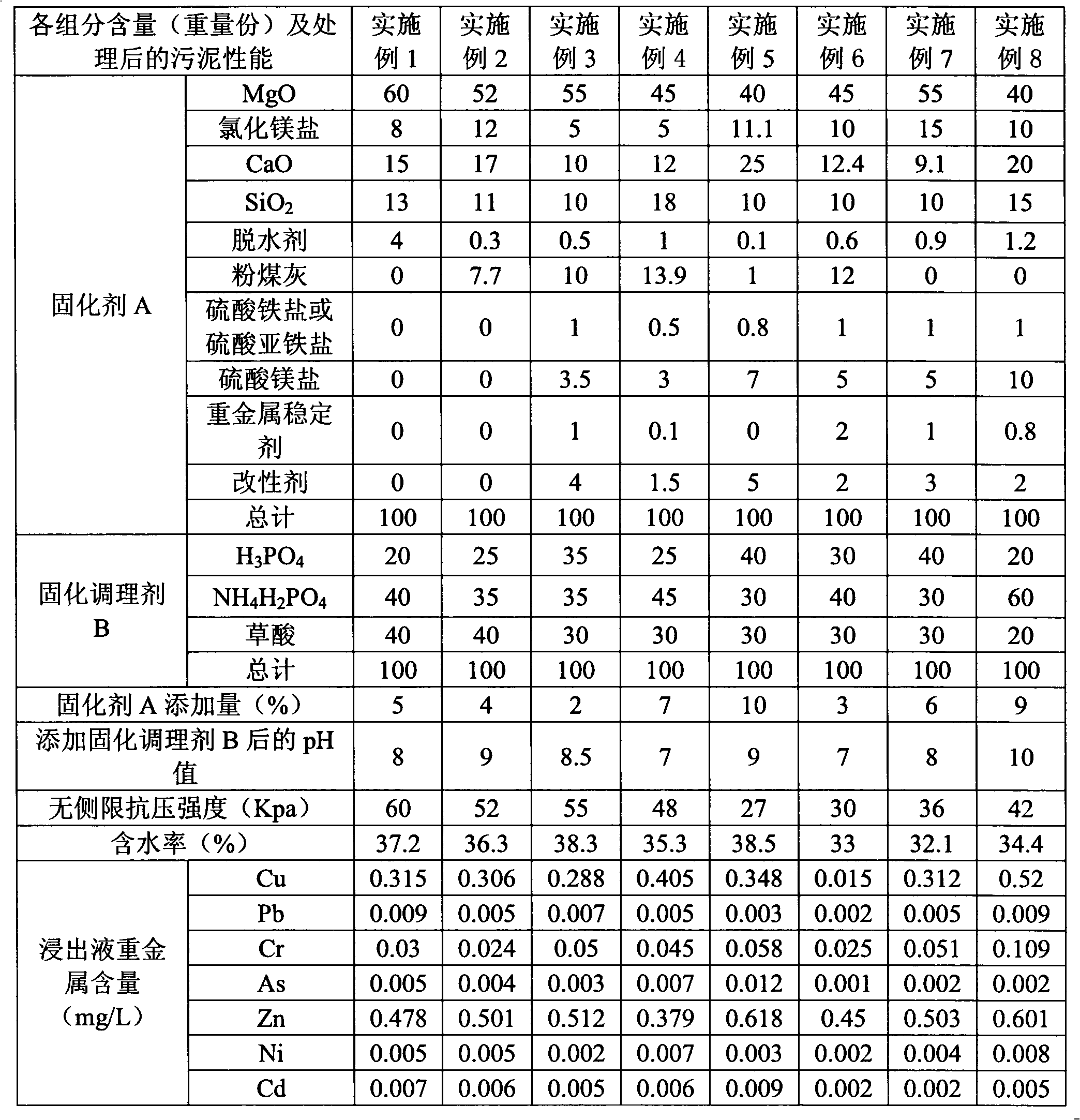

Sludge curing treatment agent and method for treating sludge by use of curing treatment agent

InactiveCN103664126AReduce moisture contentCause secondary pollutionSludge treatment by de-watering/drying/thickeningOXALIC ACID DIHYDRATEChloride salt

The invention provides a novel sludge curing treatment agent. The curing treatment agent comprises a curing agent A and a curing conditioner B, wherein the curing agent A comprises the following components in percentage by weight: 40-60% of MgO, 5-20% of magnesium chloride salt, 10-20% of SiO2, 10-30% of CaO, 0.1-4% of dehydrating agent and 0-20% of fly ash; the curing conditioner B comprises the following components in percentage by weight: 20-40% of H3PO4, 30-50% of NH4H2PO4 and 20-40% of oxalic acid; the curing agent A accounts for 0.5-10% of the total amount of sludge in treatment by mass; and the curing conditioner B accounts for 0-5% of the total amount of sludge in treatment by mass. By adopting the sludge curing treatment agent provided by the invention to treat the sludge with relatively high water content and particularly water content over 80%, the sludge can be cured generally in 1-2 days, the curing time is short, and the water content is reduced to about 30% 7 days later; after the curing, the water content of the sludge is low; and the sludge after the curing treatment can be subjected to landfill on site or applied to roadbed, greening, earthing, ecological restoration and the like, thereby avoiding secondary pollution to environment.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Oxide solid solution, preparation method of oxide solid solution, lithium ion battery anode material and preparation method of lithium ion battery anode material

ActiveCN102627332AThe composition is determined and reliableImprove stabilityCell electrodesManganese oxides/hydroxidesOXALIC ACID DIHYDRATENickel salt

The invention relates to oxide solid solution, a preparation method of the oxide solid solution, a lithium ion battery anode material and a preparation method of the lithium ion battery anode material. The oxide anode material is prepared by using the oxide solid solution as precursors. The preparation method of the oxide anode material comprises the steps of adding mixed water solution of nickel salt, cobalt salt and manganese salt into oxalic acid or oxalate water solution to produce nickel, cobalt and manganese oxalate co-precipitated products, separating solid from liquid, washing, drying, calcining in an atmosphere of air and decomposing to obtain the oxide solid solution; and mixing and grinding the solid solution and lithium salt, drying and roasting at high temperature to obtain the oxide anode material. The solid solution is an ideal raw material for preparing the oxide anode material, the process stability and the product consistency are improved and the material performance is improved; and the oxide anode material is a high-voltage and high-capacity anode material. The preparation methods are suitable for the large-scale, economic, stable and reliable production of the solid solution and the oxide anode material.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Preparation of aluminum or aluminum alloy dual-layer anodic oxide film and preparation of multi-color coloring film thereof

The invention provides preparation of an aluminum or aluminum alloy dual-layer anodic oxide film and preparation of a multi-color coloring film thereof, and particularly provides a preparation method of a high-decoration multi-color alumina coloring film by forming a dual-layer oxide film on the surface of aluminum or aluminum alloy by adopting a twice anodic oxidation method in the same medium, and performing electrolytic coloring treatment. The preparation method comprises the following steps: oxidizing an aluminum sample which is subjected to mechanical pre-treatment, deoiling and polishing in sulfuric acid or oxalic acid containing electrolyte with current density between 0.5 and 2A / dm<2>by adopting power waveform; and keeping on oxidization for 8 to 20 minutes with current density of between 0.5 and 2A / dm<2> by adopting a second type of power waveform in the same oxidation tank. A dual-layer anodic oxide film with different structures and compositions is prepared by controlling changes of two types of power waveforms and changes of electrolytic parameter oxidation time and current density related to the power waveforms, and the dual-layer anodic oxide film is subjected to electrolytic coloring by adopting a conventional electrolytic coloring method. The structures and compositions of the dual-layer film can be regulated by the power waveform and electrolytic parameters of twice anodic oxidations, so that colors and tones of the film can be regulated and changed in a large range after the electrolytic coloring, and an alumina coloring film which is more colorful than that by conventional oxidation-electrolytic coloring can be acquired.

Owner:HUNAN UNIV

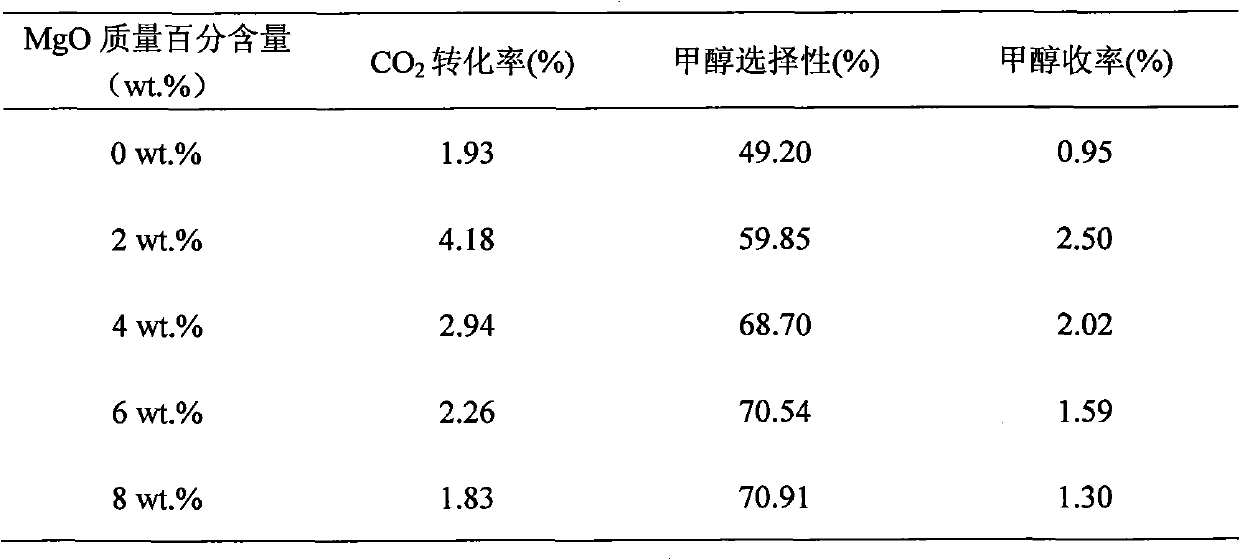

Catalyst for preparing methyl alcohol by carbon dioxide catalytic hydrogenation and preparing method thereof

InactiveCN102000578AHigh activityMeet environmental protection requirementsOrganic compound preparationHydroxy compound preparationEfficient catalystMethanol

The invention provides a catalyst for preparing methyl alcohol by carbon dioxide catalytic hydrogenation and a preparing method thereof, belonging to the technical field of catalysts. The catalyst is characterized in that: the catalyst for preparing the methyl alcohol by the carbon dioxide catalytic hydrogenation comprises components in mass ratio of CuO: ZnO: Al2O3: MgO being 3: 6: 1:X (wherein X is in the range of 0.001-0.2) and is prepared by a coprecipitation method. The preparing method comprises the following steps of: (1) dissolving weighed nitrate solutions of copper, zinc, aluminum and magnesium in absolute ethyl alcohol or water, dropping oxalic acid ethanol solution or oxalic acid water solution into the mixed solution, heating, and stirring to obtain the precursor of the catalyst; (2) drying the precursor of the catalyst, roasting for a period of time at certain temperature, cooling and then grinding, tabletting, crushing and sieving the precursor of the catalyst to obtain the catalyst for preparing the methyl alcohol by the carbon dioxide catalytic hydrogenation. Compared with the MgO-free catalyst with the same component mass ratio of CuO to ZnO to Al2O3, the catalyst has better activity, stability and methyl alcohol selectivity; the preparing method is simple, and has low cost and less pollution; and the catalyst is an effective catalyst for preparing the methyl alcohol by the carbon dioxide catalytic hydrogenation.

Owner:DALIAN UNIV OF TECH

Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

InactiveCN101396656ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateSlurry

The invention belongs to the chemical material field, in particular to an SO3 poisoning resisting power plant flue gas SCR denitrification catalyst and a preparation method thereof. Tungsten doped titanium pigment which is synthesized from domestic metatitanic acid slurry and ammonium paratungstate oxalic acid solution is adopted by the catalyst as a carrier. Vanadium is used as a main catalyst, and oxide of germanium or zinc is added as additive for lowering the oxidization of the vanadium on SO2. Through drying, calcining and sieving, the catalyst is obtained. The catalyst comprises 80-95wt percent of TiO2, 3-15wt percent of WO3, 1-8wt percent of V2O5 and 1-8wt percent of GeO2 or ZnO2. The preparation method has the advantages of simple preparation process, easy operation, low cost and good denitrification effect. The SCR catalyst prepared by the method is tested to prove high denitrification efficiency and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

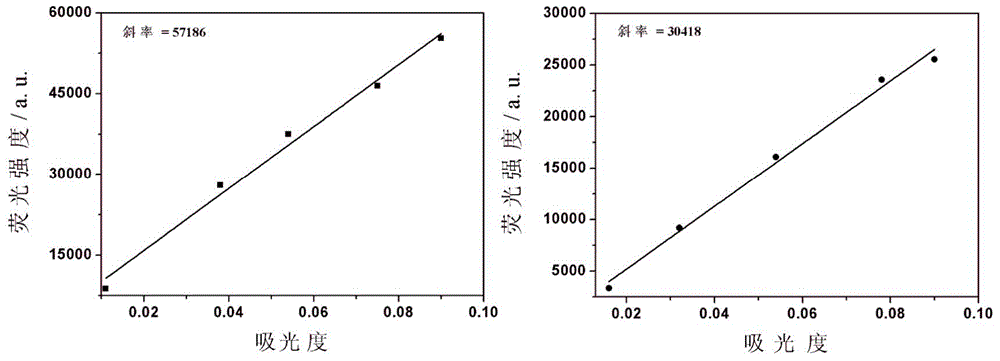

Tea polyphenol detecting test paper, standard color comparison card and usage thereof

InactiveCN101294912AEasy to detectLong storage timeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPhenolic content in teaPotassium sodium tartrate

The invention provides tea polyphenol test paper, which is prepared by using transition metal, such as iron, as a color development agent; using tartaric acid, citric acid, oxalic acid, hydrofluoric acid and salicylsulfonic acid, or any of sylvite, sodium salt and potassium sodium tartrate thereof as a complexing agent; and using soluble starch, polyvinyl alcohol, agaragar, polyacrylamide gel or gelatin as a bonding agent. Meanwhile, a standard tea polyphenol concentration color card is prepared. The tea polyphenol content can be quickly and visually observed according to the contrast between the color development of a sample to be tested on the detecting test paper and the standard color card. The test paper is suitable for quickly measuring the tea polyphenol content in plants or plant products, particularly suitable for the measurement of tea polyphenol content in tea. The test paper has the advantages of simple method, convenience, rapidness, low cost and easy popularization.

Owner:SHANXI UNIV

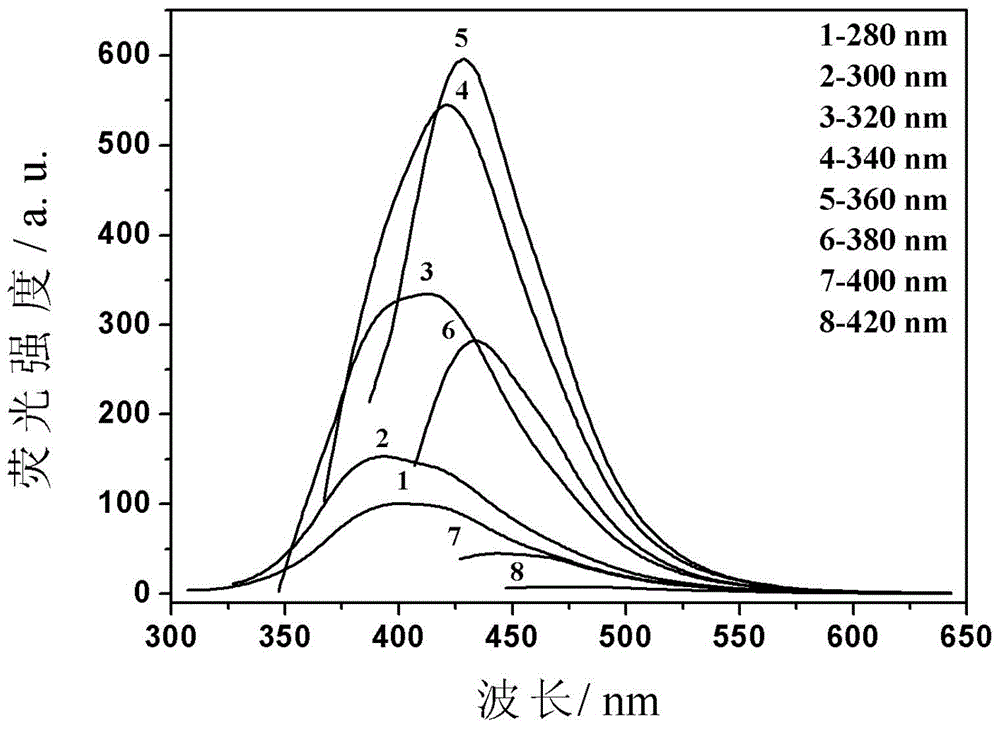

Fluorescent carbon quantum dot as well as preparation method and application thereof

InactiveCN104357049AEasy to operateWide variety of sourcesStampsFluorescence/phosphorescenceUreaQuantum yield

The invention provides a fluorescent carbon quantum dot which is high in fluorescent quantum yield and a preparation method of the fluorescent carbon quantum dot. The preparation method of the fluorescent carbon quantum dot comprises the following steps: by taking oxalic acid as a carbon source and urea as a nitrogen source, adding secondary water to perform ultrasonic treatment to obtain a clear solution; putting the clear solution in a microwave oven to react to finally obtain light yellow solids; taking out the light yellow solids to be naturally cooled, then, adding a certain amount of secondary water, and stirring and dissolving to obtain a light yellow solution, removing insoluble substances to obtain a clear light yellow solution, dialyzing to remove impurities to obtain a carbon quantum dot solution, and freezing and drying to obtain a carbon quantum dot. The preparation method disclosed by the invention is simple in process, wide in raw material source, low in price, low in requirements of preparation conditions, and relatively high in quantum yield of the obtained quantum dot. The carbon quantum dot obtained by the preparation method disclosed by the invention can be used for detecting Fe<3+> and Ag<+> in water, can be applied to living cell fluorescence imaging and also can be used as a false proof mark.

Owner:SHANXI UNIV

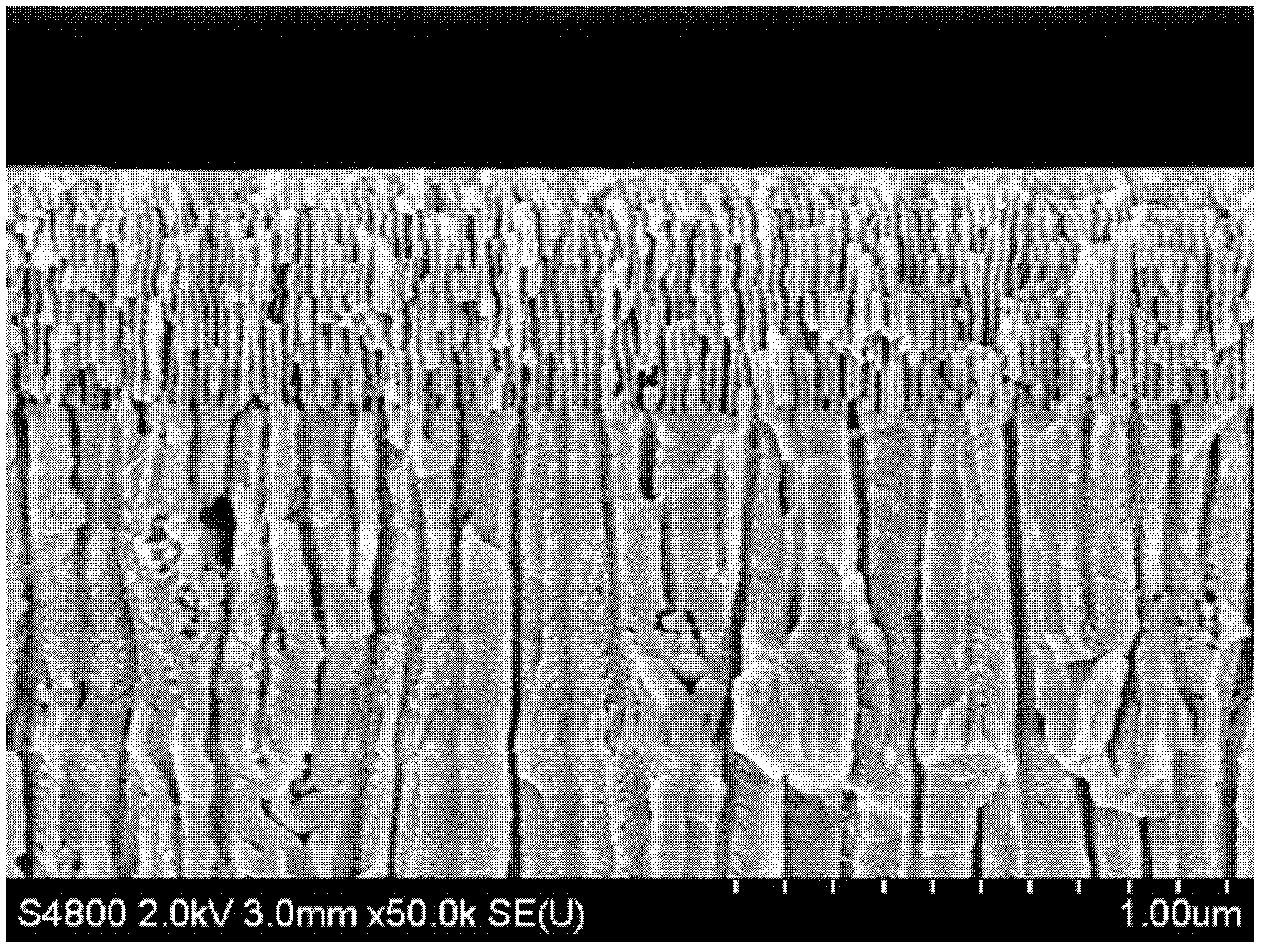

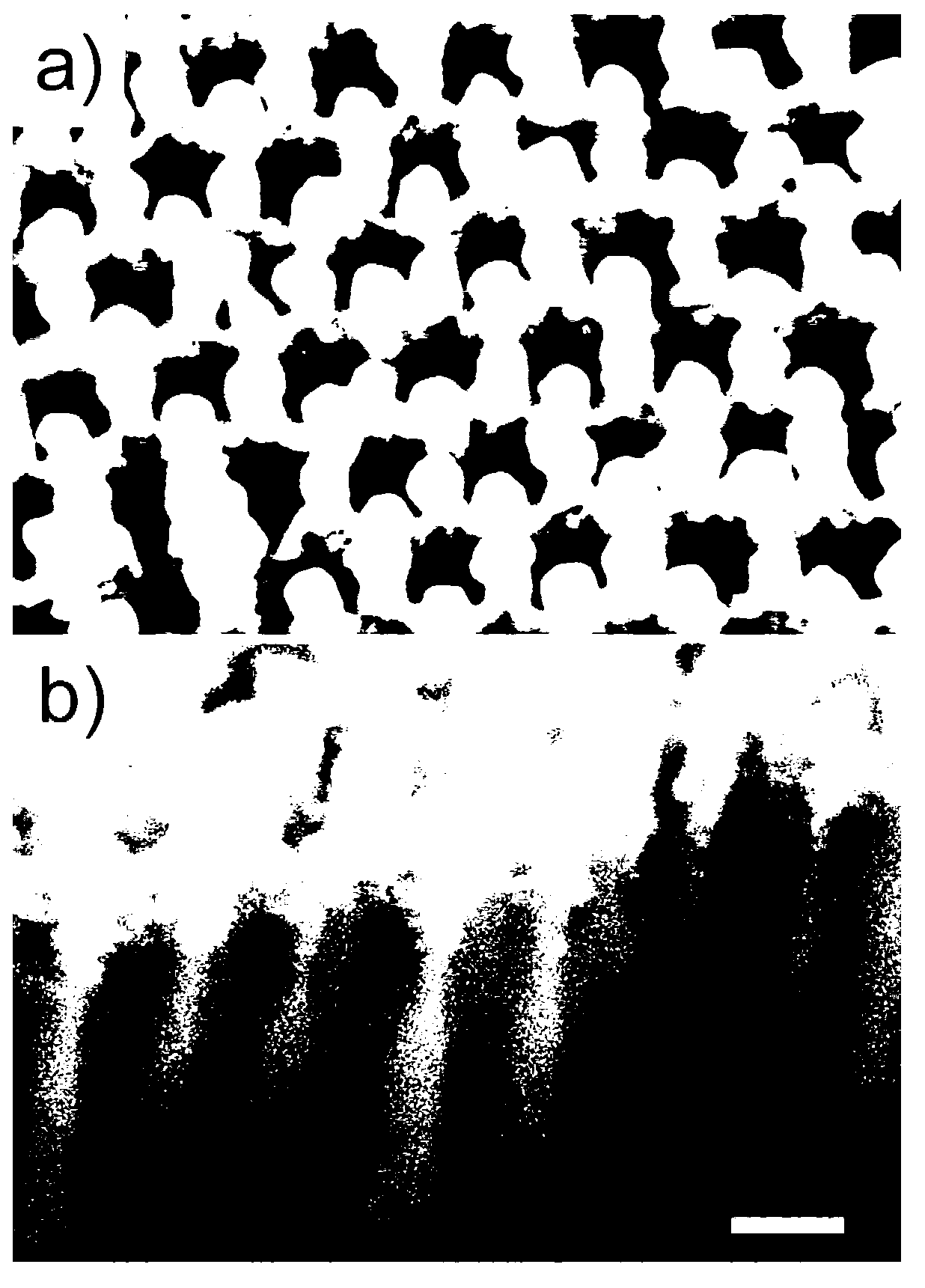

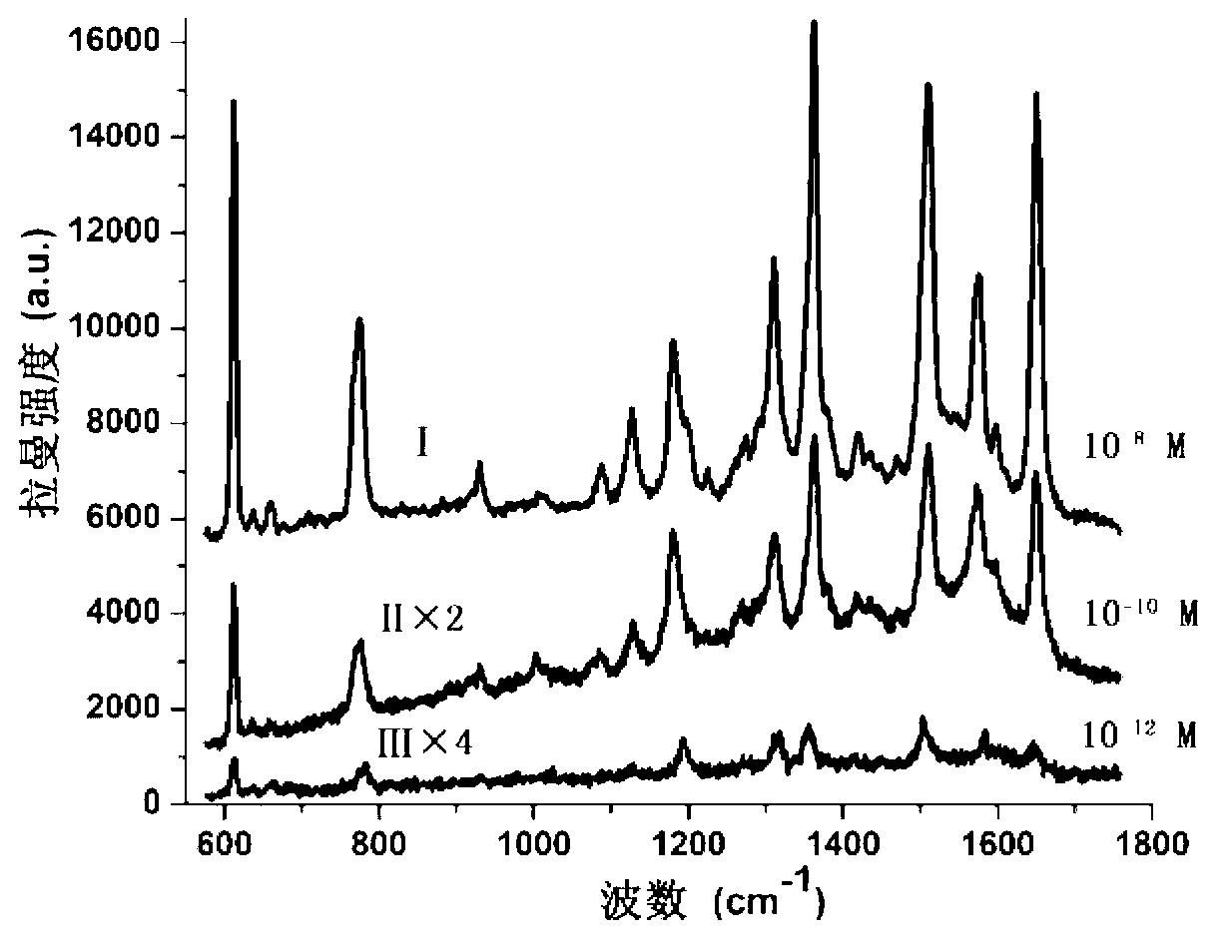

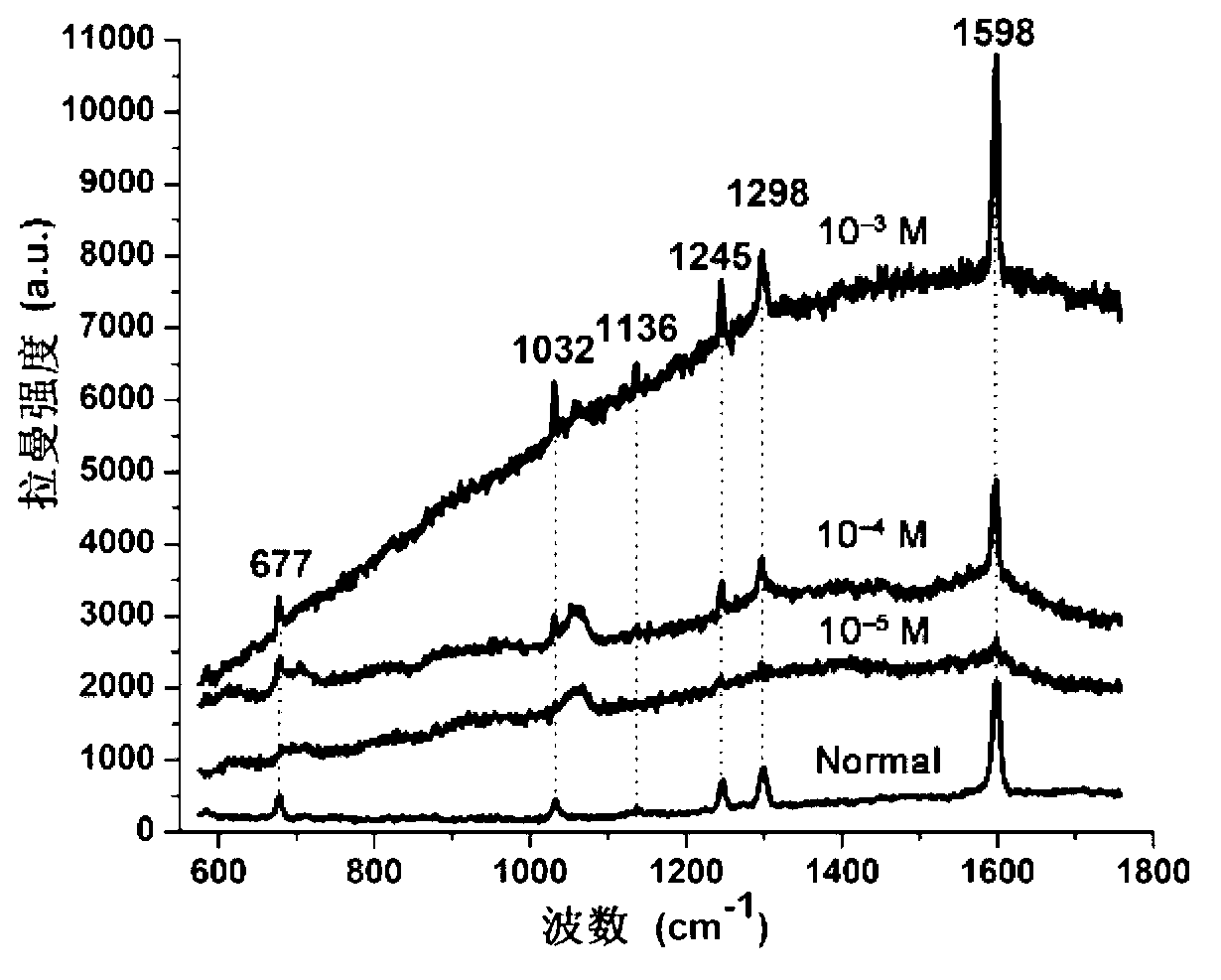

Silver nanometer column array erected on orifice of porous alumina template and preparation method and application thereof

InactiveCN103060878AMaintain propertiesHigh SERS activityVacuum evaporation coatingSurface reaction electrolytic coatingOXALIC ACID DIHYDRATEPhosphorus acid

The invention discloses a silver nanometer column array erected on the orifice of a porous alumina template and a preparation method and application thereof. The silver nanometer column array is characterized in that silver nanometer columns with the heights of 30-200 nanometers and the diameters of 30-60 nanometers are sequentially hexagonally arrayed on the periphery of the orifice of the porous anodic alumina template with taper holes; and silver nanometer particles with the particle size of 5-40 nanometers are attached to the walls of the taper holes. The preparation method comprises the following steps of: firstly placing an aluminum sheet into an oxalic acid solution, and carrying out anodization at direct-current voltage for at least 2 hours; then placing into a phosphorus-chromium acid mixed solution, and soaking for at least 3 hours to obtain an intermediate product; then firstly placing the intermediate product into the oxalic acid solution, carrying out the anodization at the direct-current voltage for at least 20 seconds, then placing the intermediate product into a phosphorus acid solution, and soaking for at least 1 minute; repeating the process for at least 10 times to obtain the alumina template with the holes in the shape of the taper holes; and then placing the alumina template into an ion sputter for silver sputtering so as to prepare a target product. The silver nanometer column array disclosed by the invention can be used as an active base of surface-enhanced Raman scattering; and the content of rhodamine or tetrachlorobiphenyl which is attached to the silver nanometer column array is measured by using a laser Raman spectrometer.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Technique for preparing high-hardness large-aperture thick film by mixed acid anode oxidation

The invention relates to a technology of mixed acid anodizing high hardness wide-bore thick-film, first the anodizing solution is mixed with the phosphoric acid and the oxalic acid preparation; then the alkaline solution removes the oxide layer of specimen surface; and then acidic solution neutralizes the surface residue, followed by electrochemical polishing treatment; more the anode is oxidized to prepare the porous alumina, finally the specimen of anodization in the phosphoric acid solution process the reaming. The invention relates to a method of the mixed acid with the phosphoric acid and the oxalic acid as the electrolyte to form 20-45um porous alumina film; the anode is oxidized by the phosphoric acid to reaming, the aperture increased to 80-140nm; the temperature of the anodization mixed the oxalic acid is higher greatly, to save the energy; the micromesh of the mixed acid anodic alumina film fills in the PTFE, MoS2, carbon nano fibers, zinc stearate, and other solid lubricants, prepared to self-lubricating materials, the invention is worthy of spreading to application.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

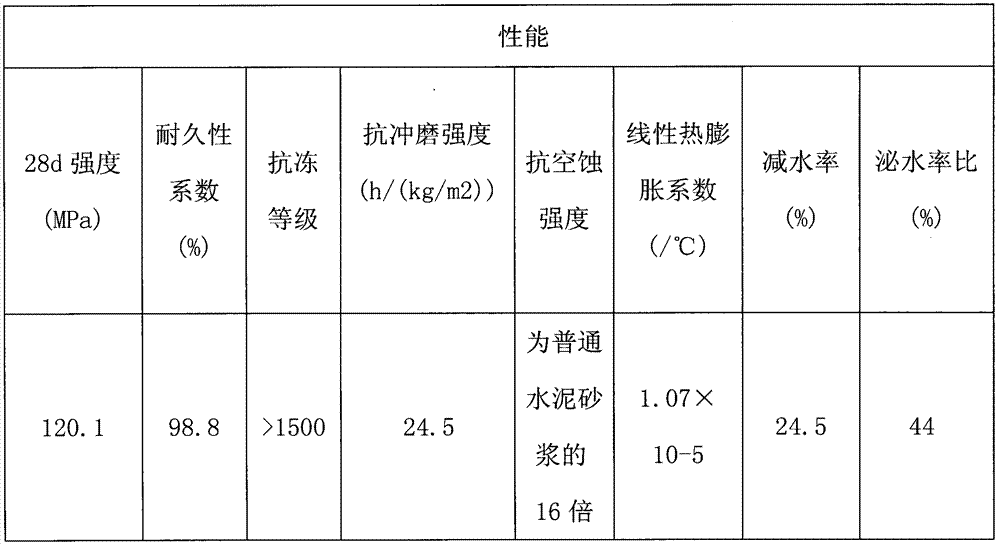

Concrete material and preparation method thereof

The invention provides a concrete material, comprising the following components with corresponding proportions: cement, fine aggregate, coarse aggregate, fly ash, silica fume, carbon nanotube, nano silica, ceramsite, polyphenyl particles, steel fibers, nano kaolin particles, ultrafine natural zeolite powder, gypsum, polymer emulsion, a diol compound, modified lignosulfonate, a layered silicate mineral material, polysiloxane, oxalic acid, styrene acrylic emulsion, crystalline hydrated magnesium aluminum silicate minerals, water, a super plasticizer, a barium-containing naphthalene superplasticizer, an organic polymer plastic retaining agent, a composite retarder and an air entraining agent. The invention further relates to a preparation method of the concrete material. Compared with the existing concrete, various properties of the concrete material provided by the invention are greatly improved. The concrete material has a wide application range, a significant practical engineering value and remarkable technical and economic significance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for preparing a catalyst for partial oxidation of propylene

InactiveCN1564709AHigh activityHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsOXALIC ACID DIHYDRATEOxalate

The present invention relates to a method for preparing a catalyst for partial oxidation of propylene, particularly a method for preparing a catalyst for preparing an acrylic acid, using an organic acid such as a citric acid, maleic acid and oxalic acid. The complex oxide catalyst according to the invention, when used in the gas phase catalytic oxidation of propylene, may produce acrolein in high yield.

Owner:LG CHEM LTD

Process for recovering rare earth oxide from waste liquid containing rare earth element, and process for producing rare earth oxide using same

InactiveCN1675131AImprove efficiencySolid waste disposalRare earth metal compoundsDicarbonateOxalate

ABSTRACT Rare earth oxides capable of being re-used as an abrasive are recovered from an abrasive waste liquid by a process comprising the steps of (1) mixing and heating a rare earth element-containing waste liquid with an acid, to dissolve rare earth elements contained in the liquid; (2) removing insoluble matter from the rare earth element solution; (3) incorporating a soluble carbonate salt or a soluble hydrogencarbonate salt, or an oxalic acid in the rare earth element solution, to convert the rare earth elements to rare earth carbonates or rare earth oxalates; (4) separating the rare earth carbonates or rare earth oxalates from a slurry of the rare earth carbonates or rare earth oxalates; (5) baking the separated rare earth carbonate or rare earth oxalate to produce rare earth oxides; and (6) recovering the rare earth oxides.

Owner:SHOWA DENKO KK

Preformed soldering terminal with halogen-free soldering fluxes coated on surfaces

ActiveCN103056556AEasy to storeEasy to useWelding/cutting media/materialsSoldering mediaOXALIC ACID DIHYDRATEActive agent

The invention provides a preformed soldering terminal with halogen-free soldering fluxes coated on the surfaces, and the performed soldering terminal is good in soldering performance, and the quantity of the soldering fluxes can be controlled easily. A soldering flux coating is formed by the method that the preformed soldering terminal is wetted by halogen-free liquid soldering fluxes and then dried, the halogen-free liquid soldering fluxes are composed of the following components by weight: 35-42% of carrier, 1.0-1.4% of surface wetting agent, 0.5-1.2% of leveling agent, 0.3-0.5% of active agent, 0.1-1.0% of resin film-forming agent, 0.15-1.2% of thickening agent, and the balance is organic solvents. The carrier is rosin, the surface wetting agent is T-80, TX-100 and Span60, the leveling agent is OP-10, the active agent is oxalic acid, salicylic acid and malic acid, the resin film-forming agent is polybutadiene and polyurethane, the thickening agent is hydrogenated castor oil, and the organic solvent is alcohol or ketone which is lower than 110 DEG C in boiling point. The weight of the preformed soldering terminal with the halogen-free soldering fluxes coated on the surfaces is regarded as a standard, the content of the soldering flux coating is 0.2-5.0%, and the preformed soldering terminal with the halogen-free soldering fluxes coated on the surfaces is suitable for soldering of packaging of electronic components.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com