Patents

Literature

49 results about "Glass corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass Corrosion. Definition - What does Glass Corrosion mean? Glass corrosion is the deterioration of glass and its critical properties due to electrochemical reactions of the exposed material's surface with the surrounding environment.

Dishwasher detergent with improved protection against glass corrosion

InactiveUS20050075258A1Organic detergent compounding agentsSurface-active detergent compositionsOXALIC ACID DIHYDRATEOrganic acid

A dishwasher detergent containing a builder and one or more magnesium and / or zinc salt(s) of at least one monomeric and / or polymeric organic acid, excluding zinc ricinoleate, zinc abietate, and zinc oxalate. A method of inhibiting glass corrosion by treatment with one or more salts of magnesium and / or zinc with organic acids, excluding formic acid, acetic acid, gluconic acid, and oxalic acid.

Owner:HENKEL KGAA

Dishwasher detergent with improved protection against glass corrosion

InactiveUS7153816B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGluconic acidGlass corrosion

A dishwasher detergent containing a builder and one or more magnesium and / or zinc salt(s) of at least one monomeric and / or polymeric organic acid, excluding zinc ricinoleate, zinc abietate, and zinc oxalate. A method of inhibiting glass corrosion by treatment with one or more salts of magnesium and / or zinc with organic acids, excluding formic acid, acetic acid, gluconic acid, and oxalic acid.

Owner:HENKEL KGAA

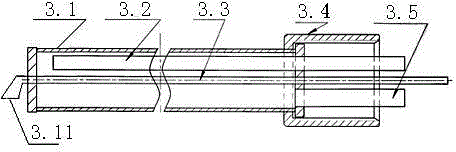

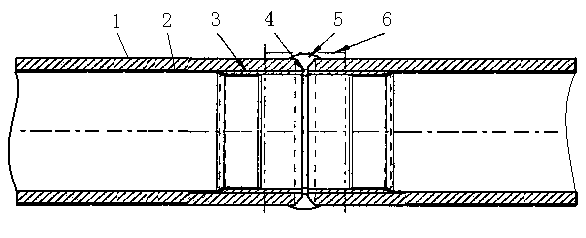

Glass-lined anti-corrosion steel pipe producing and welding processes

InactiveCN103822031AGood chemical stabilitySmooth inner wallLiquid surface applicatorsArc welding apparatusChemical industryGlass corrosion

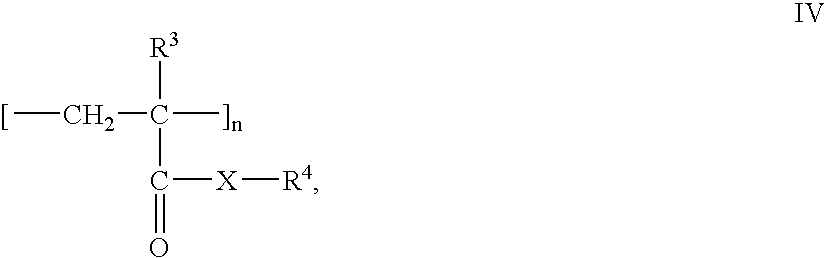

The invention relates to a glass-lined anti-corrosion steel pipe producing and welding processes. The producing process includes pre-overlaying a nickel-based corrosion resistant alloy layer from 1.5 to 2 mm in inner holes with depth of 30 to 50 mm to the end face of a steel pipe, allowing the nickel-based corrosion resistant alloy layer to fuse on the base material; beveling the overlaid-preprocessed end face of the steel pipe, and smoothly polishing the surface of the nickel-based overlaying layer; performing rust removal and dust treatment on the inner wall of the steel pipe; coating glass powder on the inner wall of the steel pipe in a hot spraying manner to melt and form an inner glass corrosion resistant layer. By coating the inner glass corrosion resistant layer on the inner wall of a metal pipe in a hot melting manner, a glass and metal composite corrosion resistant structure is formed, chemical stability is high, the inner wall is smooth, and fluid resistance is small; the glass-lined anti-corrosion steel pipe has special advantages of corrosion resistance, waxing resistance, wear resistance, resistance reduction and energy efficiency, and can be widely applied in various fields of petroleum, chemical industry, natural gas, tap water, sewage, municipal construction and the like.

Owner:胜利油田金岛工程安装有限责任公司

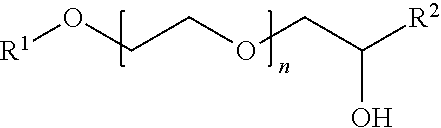

Optical glass detergent

ActiveCN109576077AQuick and effective cleaningQuality is not affectedInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolyethylene glycolTurbidity

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

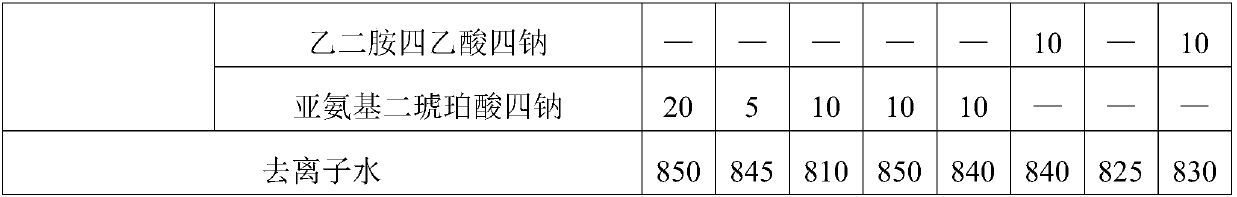

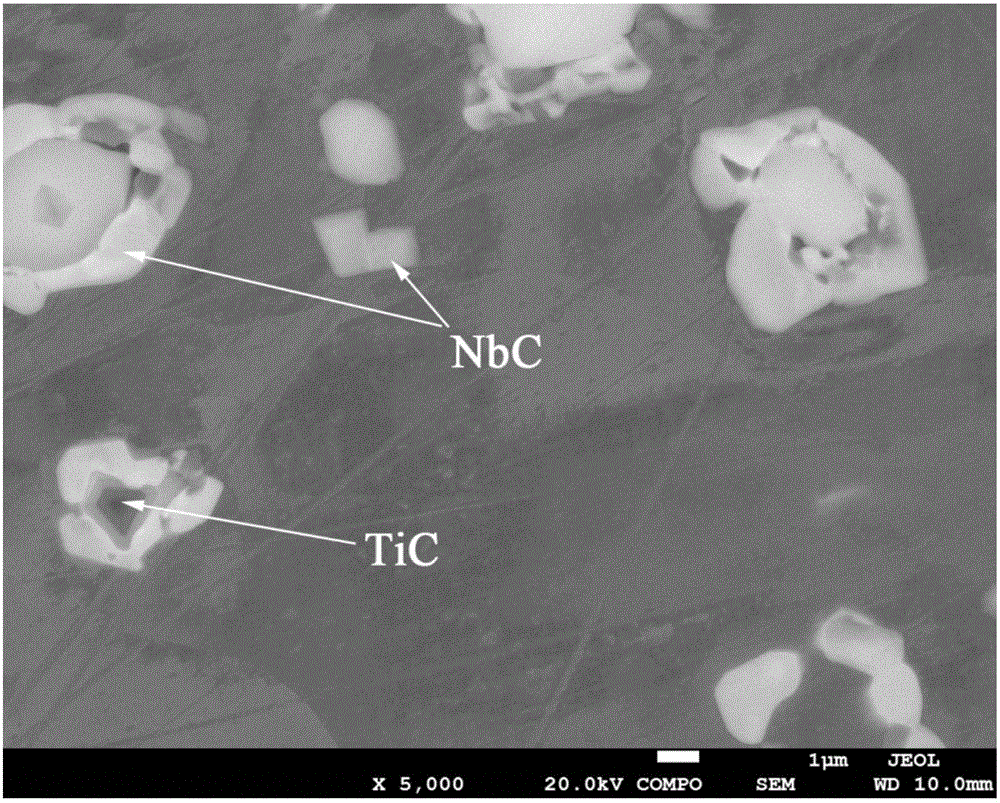

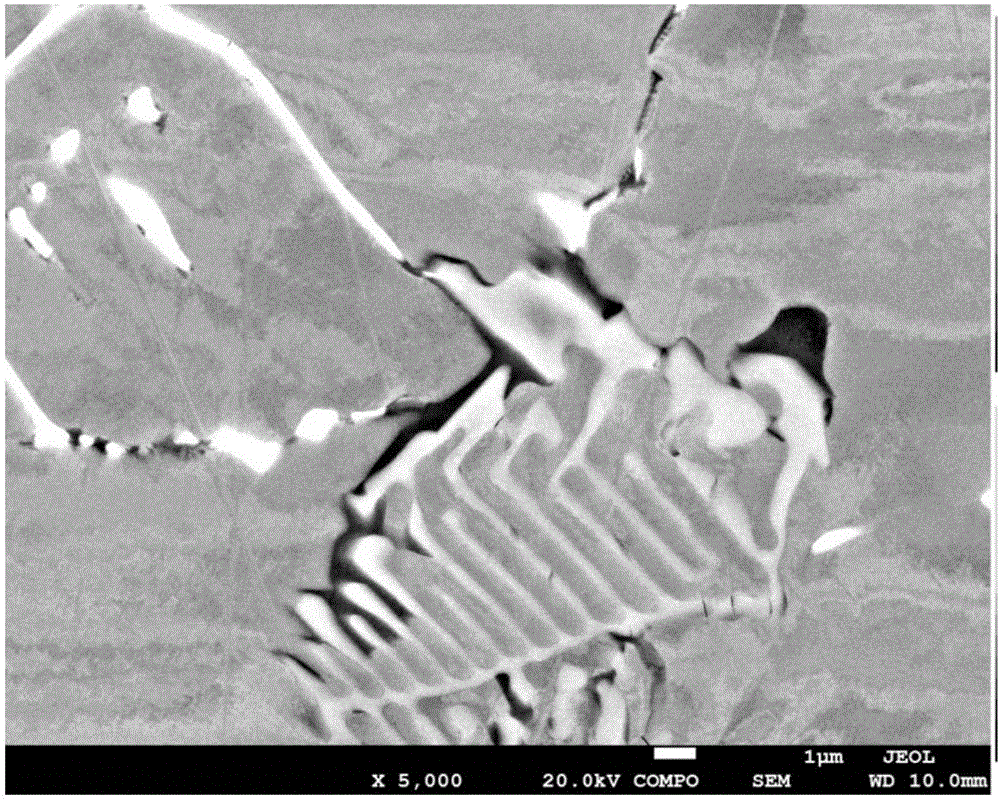

Iron-nickel-based high-temperature alloy

The invention discloses iron-nickel-based high-temperature alloy which is resistant to glass corrosion. The alloy comprises components which satisfies the following range requirement in percentage by mass: 0.7% to 1.0% of C, 24% to 30% of Cr, 48% to 55% of Ni, 0.5% to 3.5% of Co, smaller than or equal to 0.5% of Mn, smaller than or equal to 0.5% of Si, 0.5% to 2.5% of Nb, smaller than or equal to 2.5% of Mo, 5% to 10% of W, 0.1% to 1.2% of Ti, 0.1% to 3.5% of Al and the balance Fe. The alloy can be used in an as-cast condition or in a solid solution state; the compressive yield strength of the alloy at 1000 DEG C and 1100 DEG C is respectively higher than 100MPa and 60MPa; the 500-hour deformation degree of the alloy under a 1050DEG C / 25MPa compression creep condition is not higher than 1.5%; the 180-hour deformation degree of the alloy under a 1050DEG C / 35MPa compression creep condition is not higher than 5.0%.

Owner:HUANENG POWER INTERNATIONAL +1

Glass erosion liquid and preparation method thereof

The invention relates to a vitreous etching bath, which comprises 0.5%-8% microcosmic salt, 0.5%-8% pyrophosphate, 0.01%-0.5% inorganic alkaline, 5%-45% surface activator and 39%-93% water. The preparing method comprises the following steps: adding the microcosmic salt and the pyrophosphate in the water, heating in order to dissolve; adding inorganic alkaline and non-ionic surface activator and mixing. The invention can remove greasy dirt, fingerprint, particles and sio2 for buffed glass base plate, which can removes the impurity and Ceo2 on the glass, achieves the request of the environmental protection.

Owner:天津晶岭电子材料科技有限公司

Lead-free glass powder, lead-free glass powder slurry, large-area dye-sensitized solar cell as well as preparation method and application thereof

InactiveCN106630650AGood dispersionUniform particle sizeLight-sensitive devicesCapacitor housing/encapsulationSlurrySolar cell

The invention discloses lead-free glass powder, lead-free glass powder slurry, a large-area dye-sensitized solar cell as well as a preparation method and application thereof. The lead-free glass powder comprises the following components: 10-20% of SiO2, 5-15% of B2O3, 40-70% of Bi2O3, 1-10% of ZnO, 1-10% of Al2O3, 0.5-5% of Na2O, 1-5% of BaO and 2-7% of CaO. The lead-free glass powder slurry comprises the following components: 70-80% of the lead-free glass powder, 15-25% of an organic carrier and 1-5% of additives. According to the formed dense glass corrosion-resistant protective layer, the corrosion resistance of a conductive silver grid can be improved; and moreover, due to the glass powder around the FTO conductive glass, a photo-anode and a counter electrode are sealed, and by virtue of a whole face printing manner, the quantity of holes is reduced, the packaging technology is simplified, leakage of electrolyte can be slowed down, and the service life of the cell is prolonged.

Owner:KUSN INNOVATION INST OF NANJING UNIV

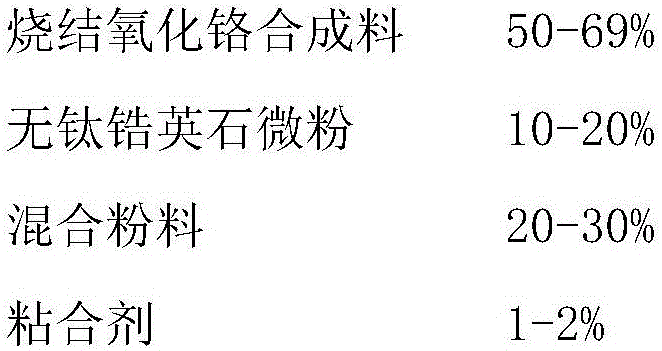

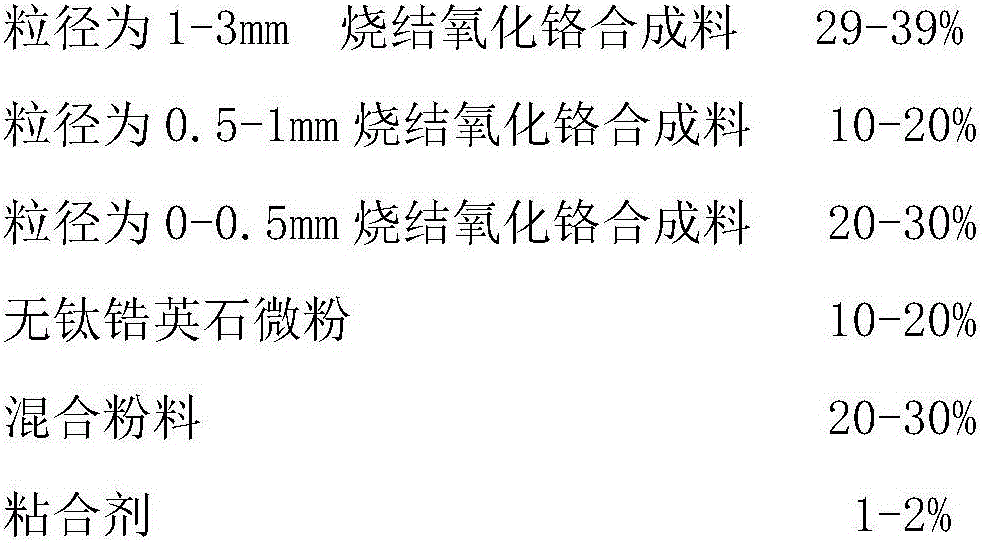

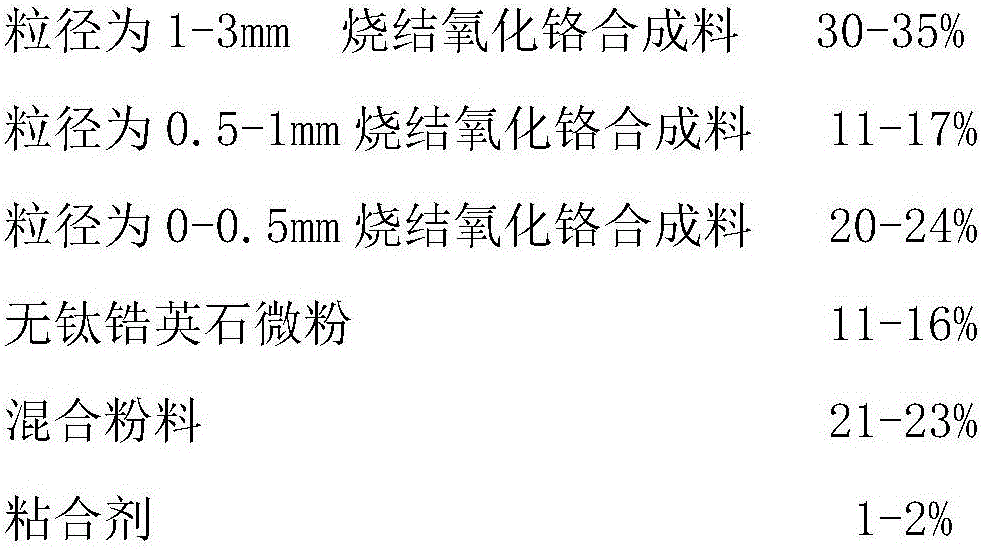

Chromic oxide refractory material and preparation method thereof

The invention discloses a chromic oxide refractory material which is prepared from aggregate, a substrate material and an adhesive. The aggregate is a sintered chromic oxide synthesized particle material with the particle size of 0-3mm; the substrate material comprises titanium-free zirconite micropowder and mixed powder with the particle size of less than 20 mu m; the chromic oxide content in the sintered chromic oxide synthesized particle material is greater than or equal to 85%; the zirconium silicate content in the titanium-free zirconite micropowder is greater than 99%; and the mixed powder comprises chromic oxide, zirconium oxide, silicon oxide or titanium oxide powder. The chromic oxide refractory material cannot be stripped and molten into the glass metal in the use process, and meanwhile, the chromic oxide has very high glass corrosion resistance, and the corrosion resistance of the product is further enhanced.

Owner:广州市石基耐火材料厂

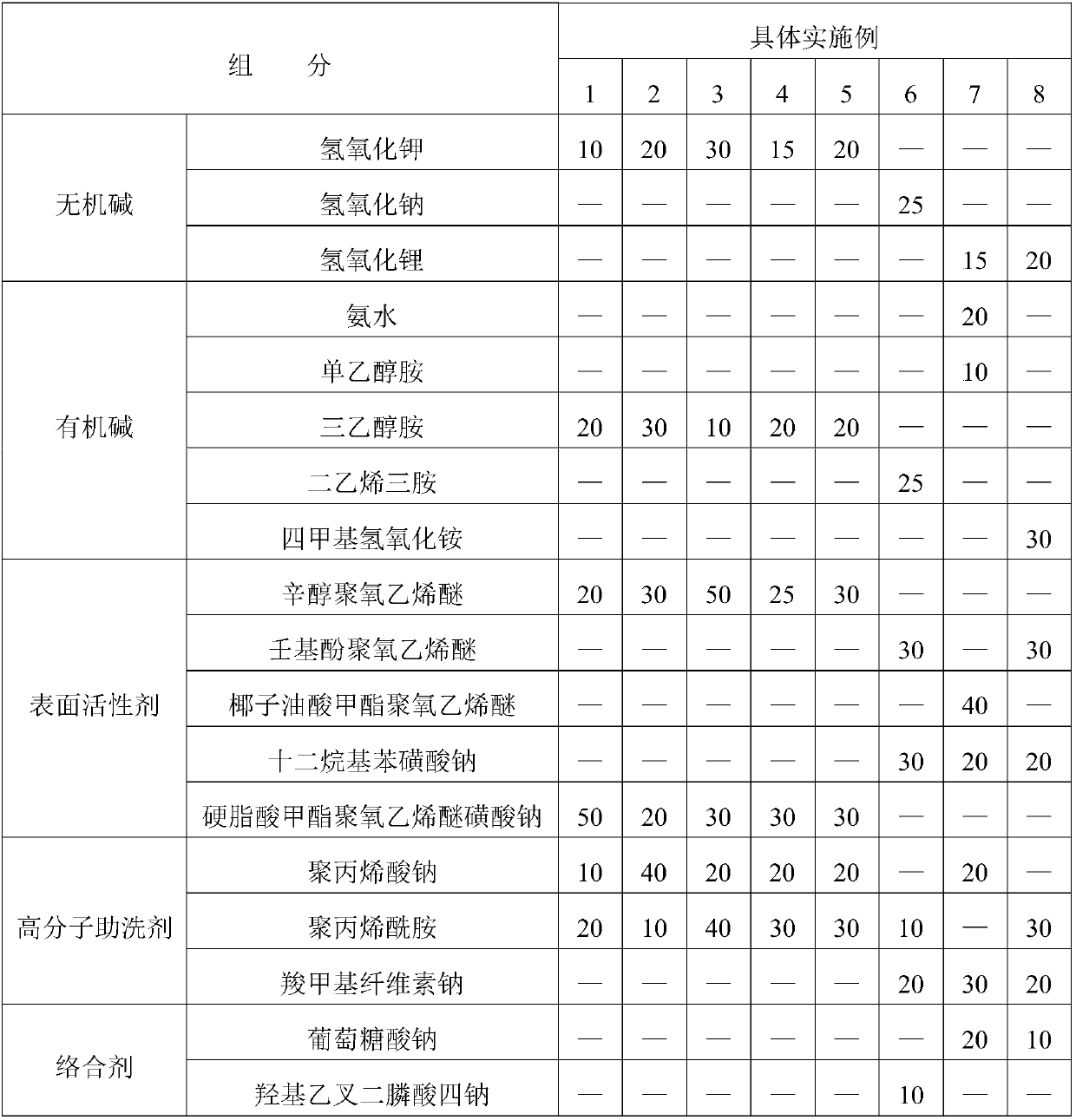

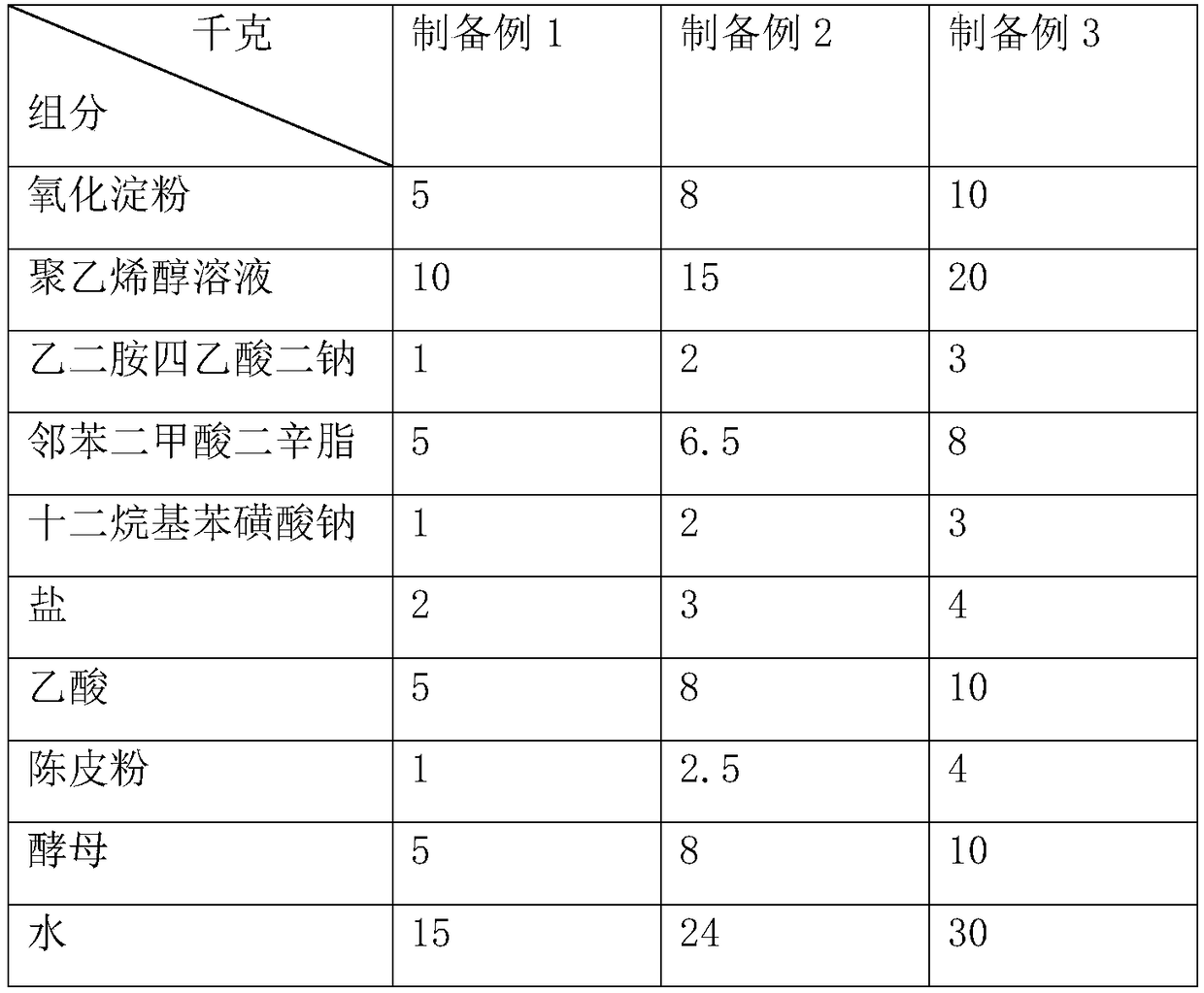

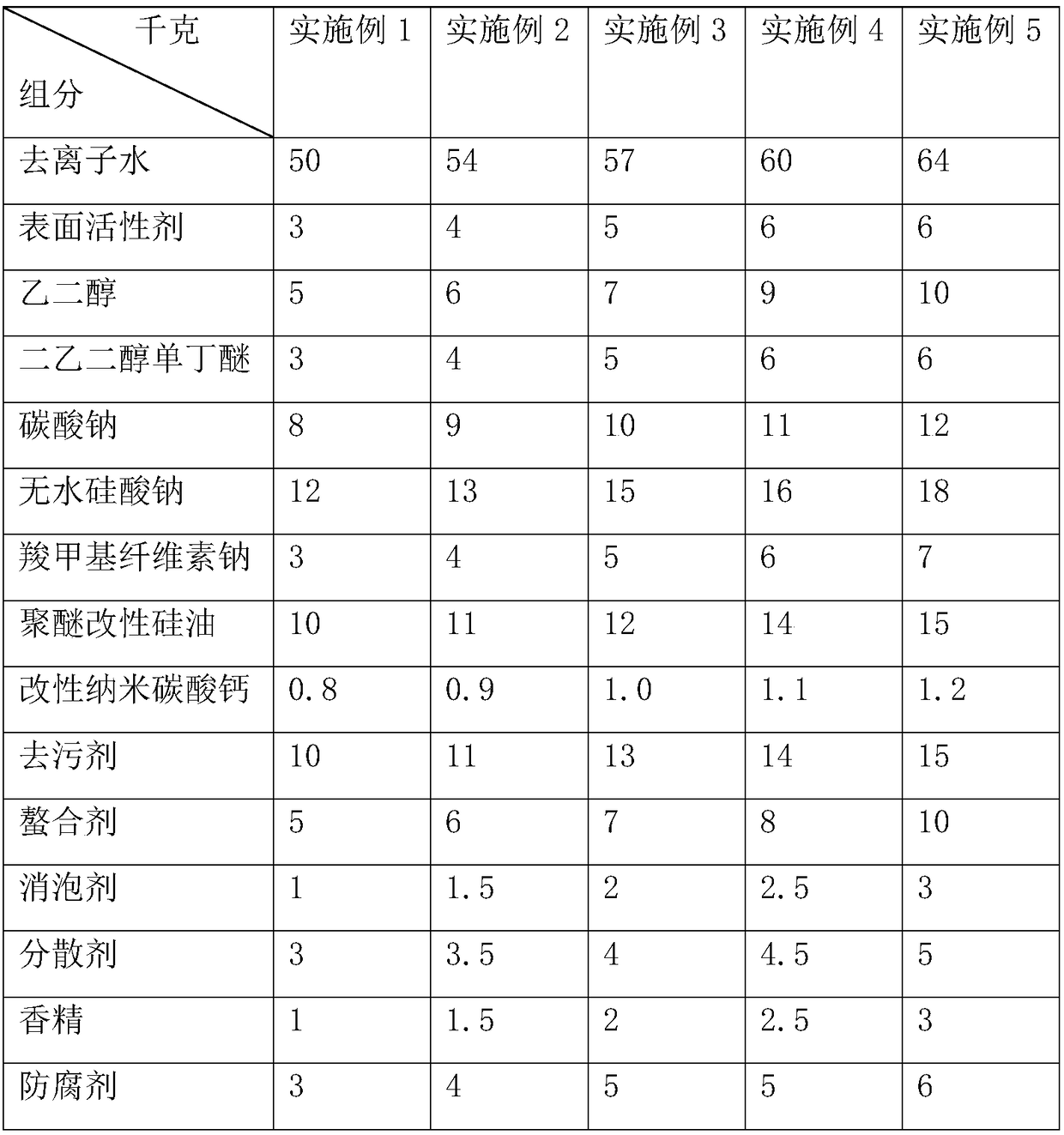

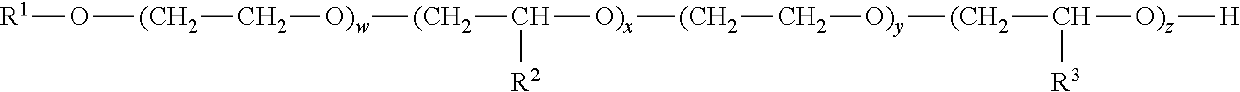

Glass detergent and preparation method thereof

InactiveCN109504554AImprove surface activityImprove decontamination abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleansing AgentsGlass corrosion

The invention discloses a glass detergent and a preparation method thereof. The glass detergent comprises the following components in parts by weight: 50-64 parts of deionized water, 3-6 parts of a surfactant, 5-10 parts of ethylene glycol, 3-6 parts of diethylene glycol ethylene glycol butyl ether, 8-12 parts of sodium carbonate, 13-18 parts of anhydrous sodium silicate, 3-7 parts of sodium carboxymethyl cellulose, 10-15 parts of polyether modified silicon oil, 0.8-1.2 parts of modified nano calcium carbonate, 10-15 parts of a decontaminant, 5-10 parts of a chelating agent, 1-3 parts of a defoaming agent, 3-5 parts of a dispersant, 1-3 parts of an essence and 3-6 parts of a preservative. The glass detergent disclosed by the invention has the advantages that oil stain and dust are effectively removed, glass corrosion is avoided, and the yield of products is increased.

Owner:深圳市天正隆科技有限公司

Corrosion-preventing processing method for pipe end of inner lining glass corrosion-preventing steel pipe

InactiveCN103231148ASolve the problem of surface corrosion protectionReach continuationLaminationArc welding apparatusCorrosion resistant alloyHeat-affected zone

The invention relates to a corrosion-preventing processing method for a pipe end of an inner lining glass corrosion-preventing steel pipe. The corrosion-preventing processing method comprises a first step of performing overlaying welding of a nickel base corrosion-resistant alloy layer in advance from the end face of the steel pipe to an inner hole with a depth of 30-50mm, and enabling the thickness of the nickel base corrosion-resistant alloy layer to be 1.5-2mm; and a second step of cleaning the surface of the nickel base overlaying welding layer surface, depositing a glass inner corrosion-preventing layer after an inner wall of the steel pipe undergoes derusting and blowing, enabling the glass inner corrosion-preventing layer to be covered on the nickel base overlaying welding layer, and reserving a welding heat affected zone of 15-25mm. Compared with the prior art, the continuous nickel base corrosion-resistant alloy protecting layer is formed on the surface of the pipe inner hole of a weld seam, the problem of corrosion of the inner surface of the weld seam is solved, continuation of the inner corrosion-preventing layer is achieved, and generation of repaired openings is avoided.

Owner:胜利油田金岛工程安装有限责任公司

Glass corrosion mask layer method

The invention discloses a glass corrosion mask layer method. The method comprises the following steps: a) a silicon chip having a surface oxide layer and glass are subjected to catalysis bonding through hydroxide; b) removing oxide on the upper surface of the silicon chip; c) thinning the silicon chip; d) photoetching the surface of the silicon chip by a photoresist, forming an image required by glass corrosion; e) using DRIE (deep reactive ion etching) anisotropy etching, etching the silicon chip, wherein the etching depth is to a glass layer; f) removing the photoresist on the silicon chip; g ) corroding the glass; and h) removing silicon and silicon oxide on the glass and cleaning to obtain a required glass structure. According to the intention, glass corrosion depth is not restricted, thermal stress due to anode bonding temperature can be avoided, expensive equipment is not required, and operation is simple.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

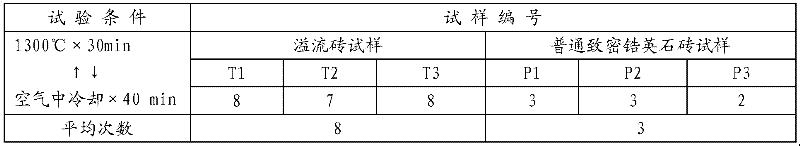

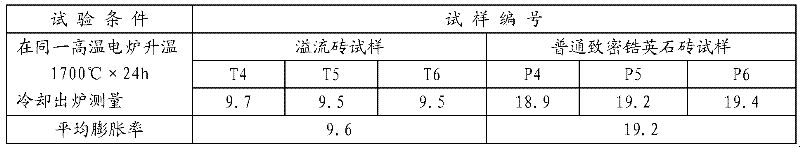

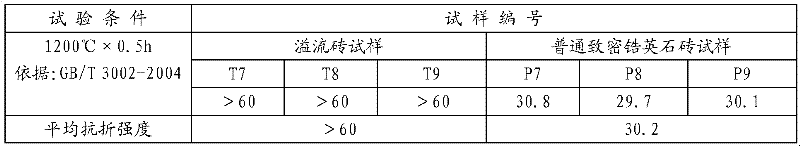

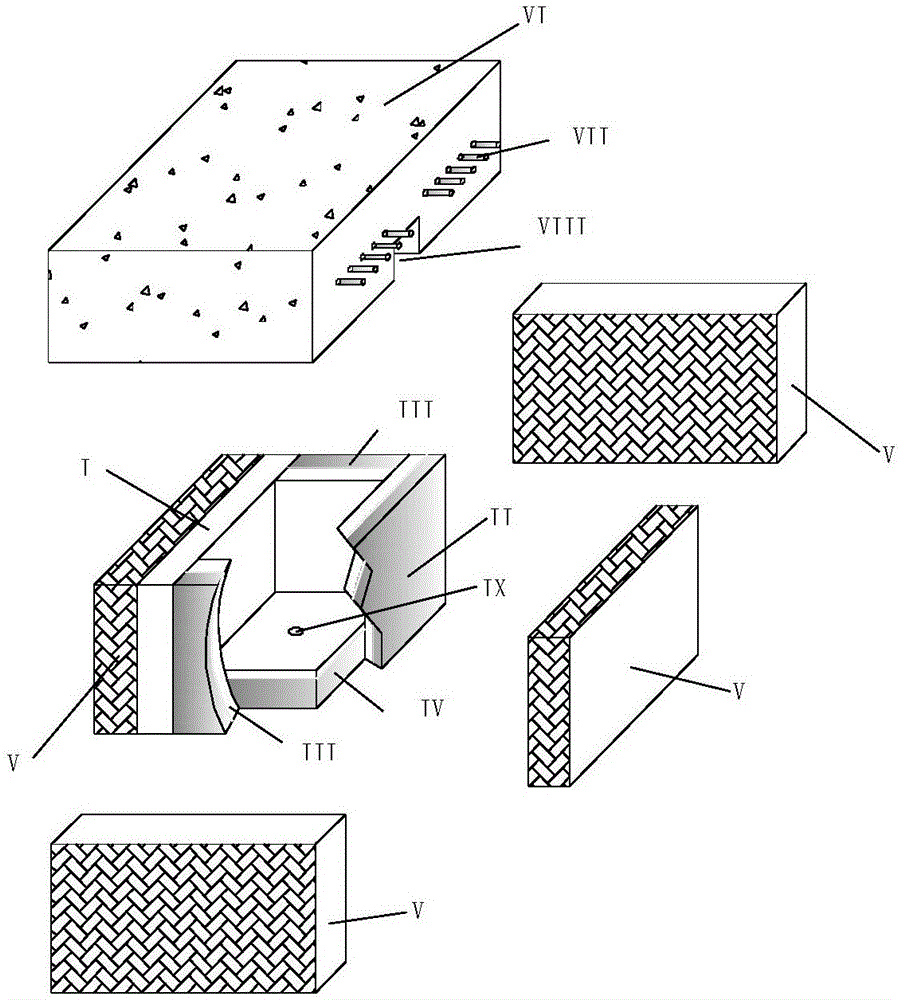

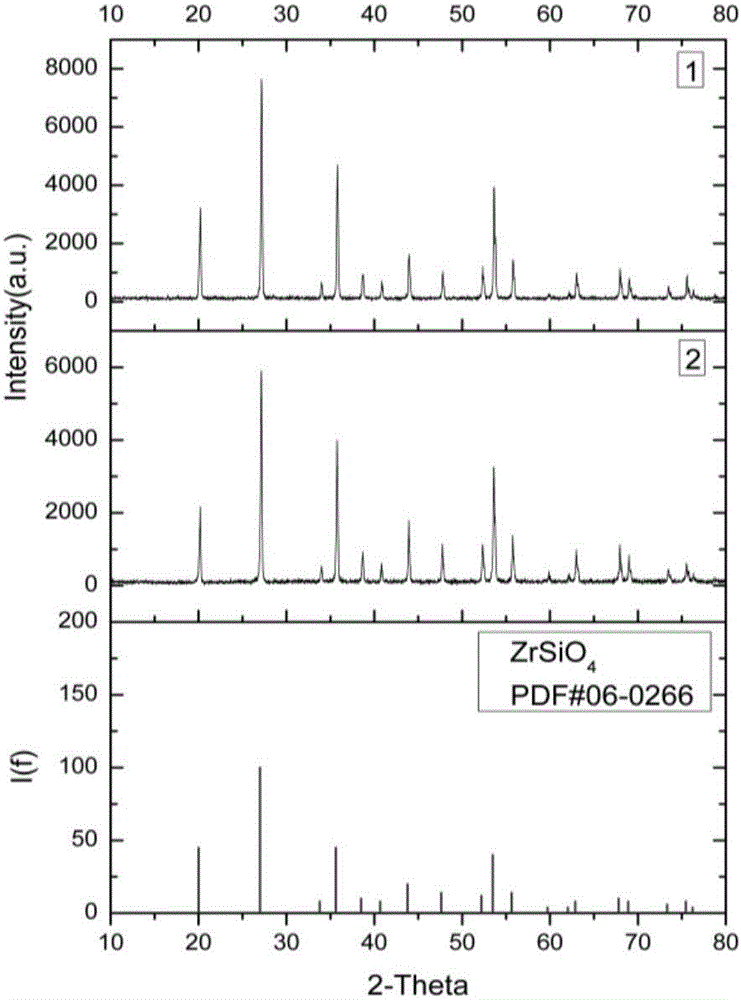

Preparation method for compact zirconite overflow brick with high breaking-resistance and low expansion

The invention provides a preparation method for compact zirconite overflow brick with high breaking-resistance and low expansion. The method comprises the following steps: (1) adopting zircon sand having a ZrSiO4 content more than or equal to 98.5% as a starting raw material; (2) carrying out acid cleaning for the zircon sand: a hydrochloric acid solution is adopted for immersing the zircon sand, followed by washing through water, and atmospheric drying; (3) calcinating the acid cleaned zircon sand; (4) grinding the calcinated zircon sand in a stirring mill according to the following ratio, by weight, 99.0-99.4% of the zircon sand (having a ZrSiO4 content more than or equal to 99.7%), 0.4-0.8% of TiO2, 0.1-0.2% of phosphoric acid; (5) drying the slurry by baking: a screw dehydrator is adopted for drying; (6) crushing the powder, and carrying out screening through a vibrating screen having 30 meshes; (7) carrying out isostatic pressing; (8) carrying out sintering. According to the present invention, due to establishments of a specific forming institution and a specific sintering institution, thermal shock resistance of the products is improved; the overflow brick having characteristics of larger size, no visible blowholes, no melted holes and no slag corrosion is produced successfully; high-temperature breaking-resistance of the overflow brick is raised; refiring cubical expansivity of the overflow brick is reduced; glass corrosion resistance of the overflow brick is improved so as to prolong service life of the overflow brick.

Owner:广州市石基耐火材料厂

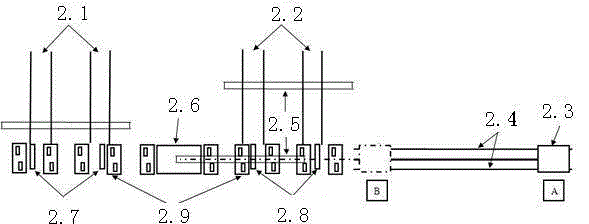

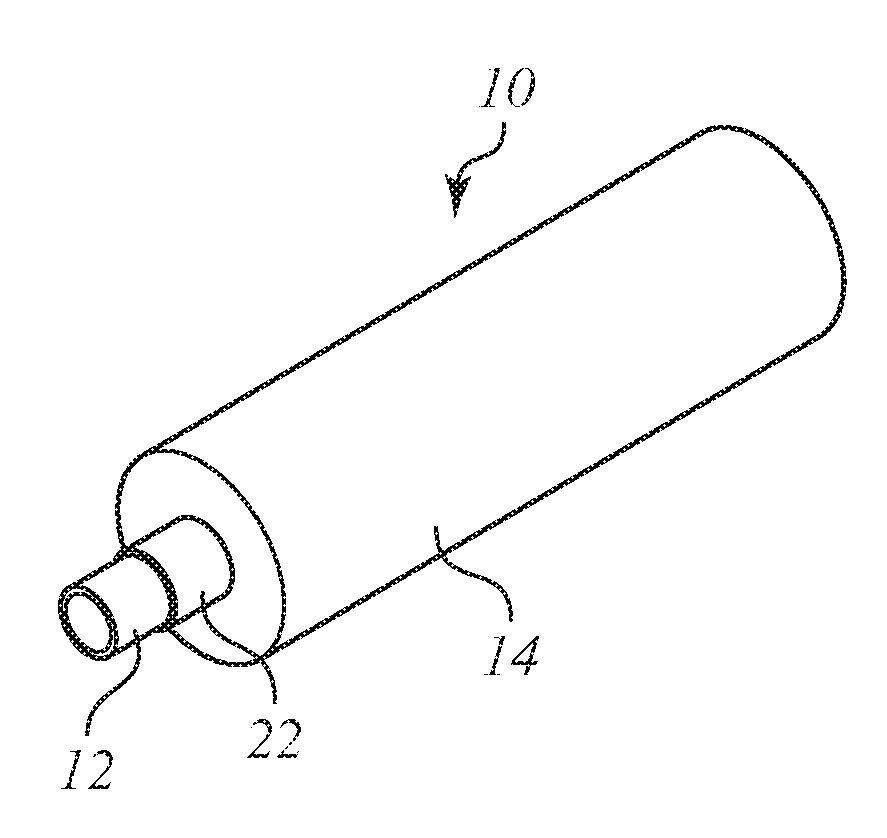

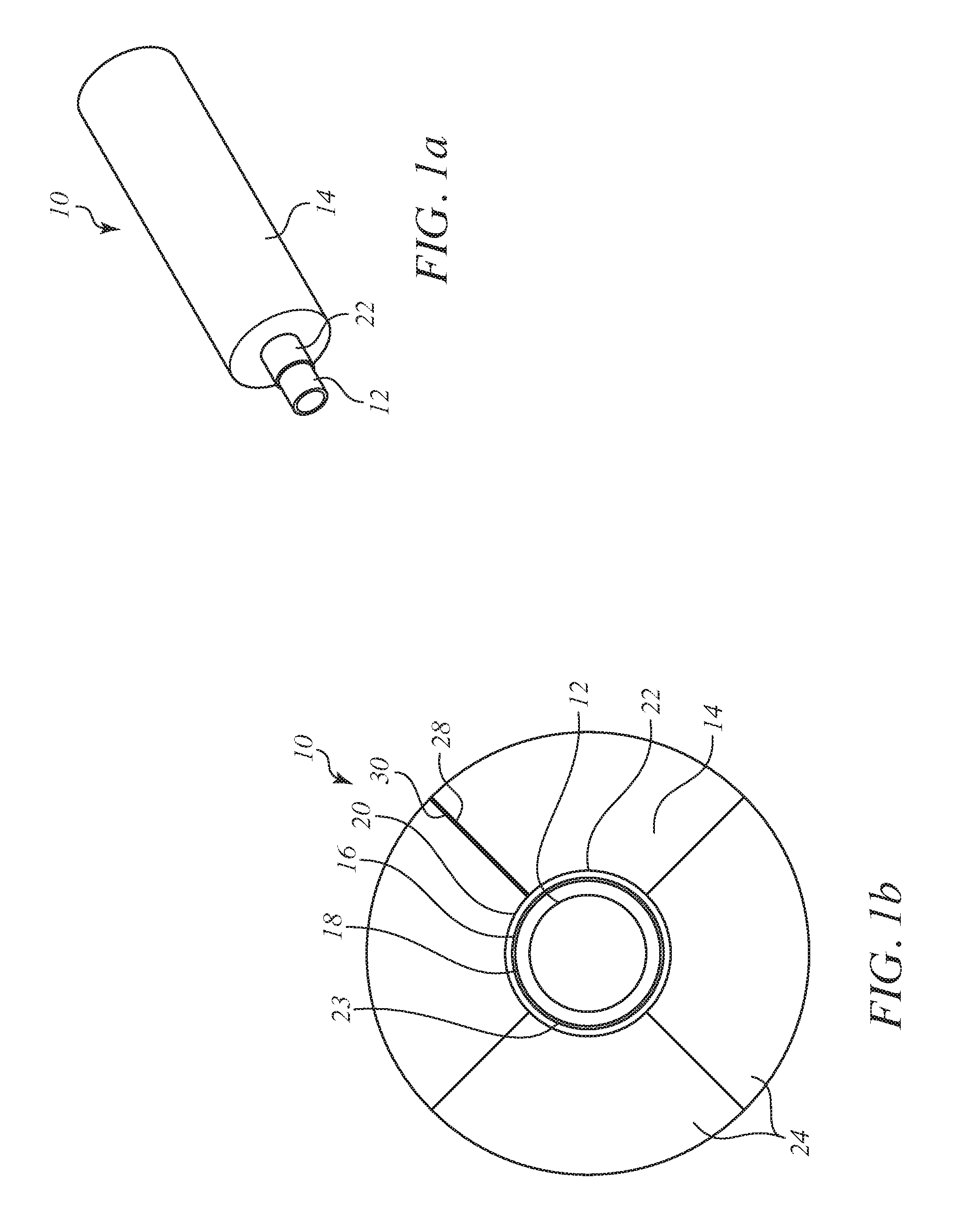

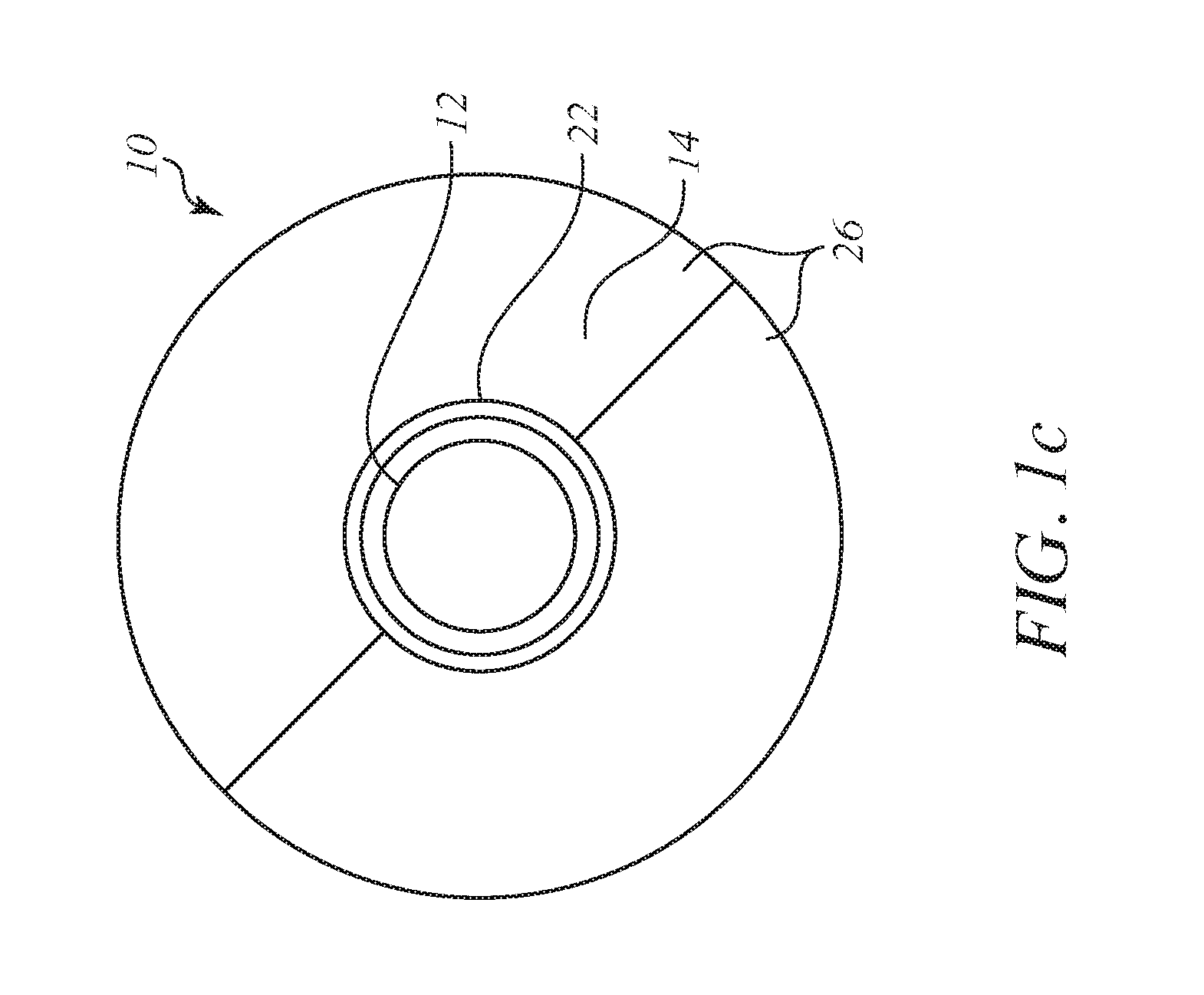

Cellular glass corrosion under insulation system

ActiveUS20170009914A1Eliminating and greatly reducing riskAttenuation of soundThermal insulationPipe elementsInsulation layerEngineering

A cellular glass system for an outer surface of a pipe. An insulation layer surrounds the outer surface of the pipe. The insulation layer has an outer surface and an inner surface and comprises cellular glass. A foam fills an annular space between the outer surface of the pipe and the inner surface of the insulation layer and is configured to limit water intrusion into the annular space and attenuate sound. The system may also include another insulation layer and another foam layer between the two insulation layers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

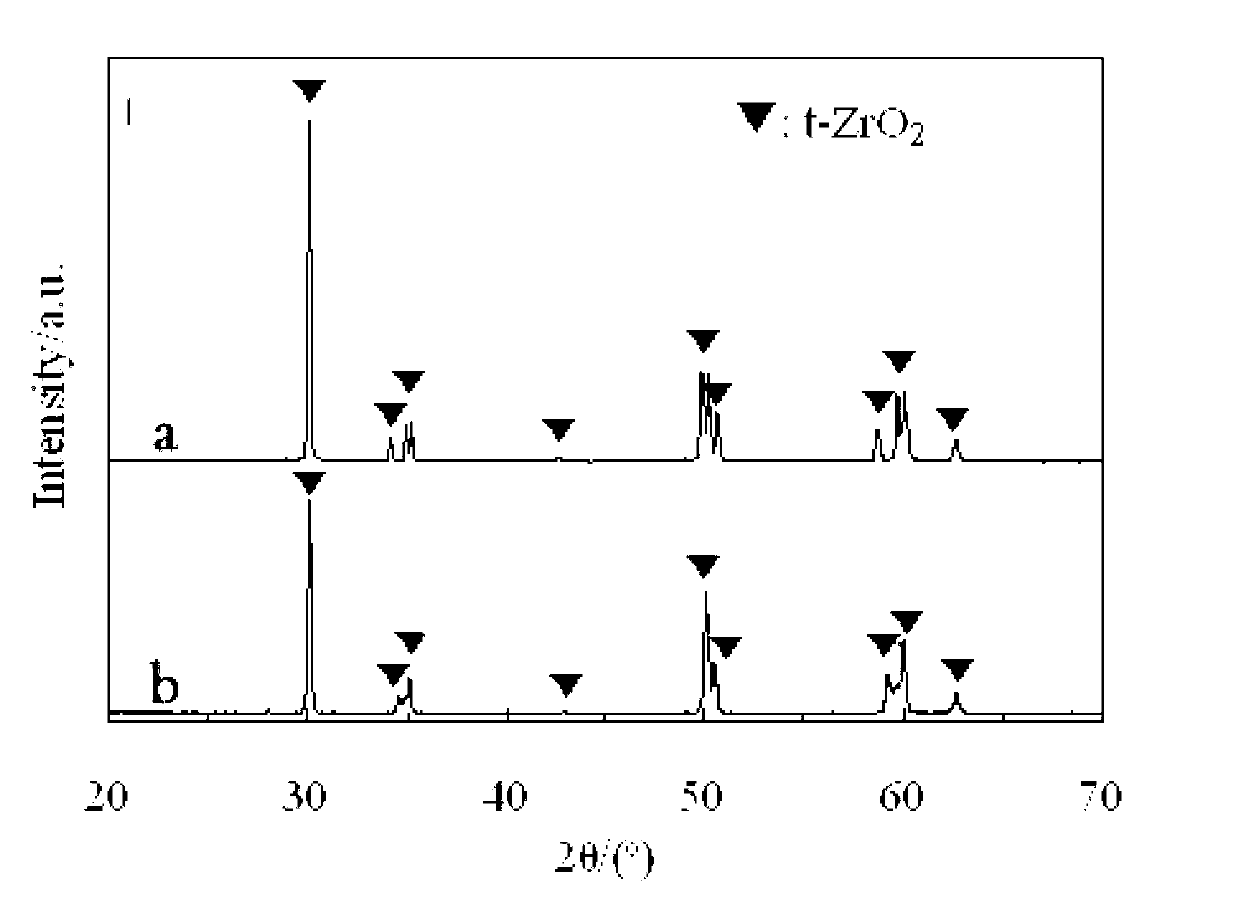

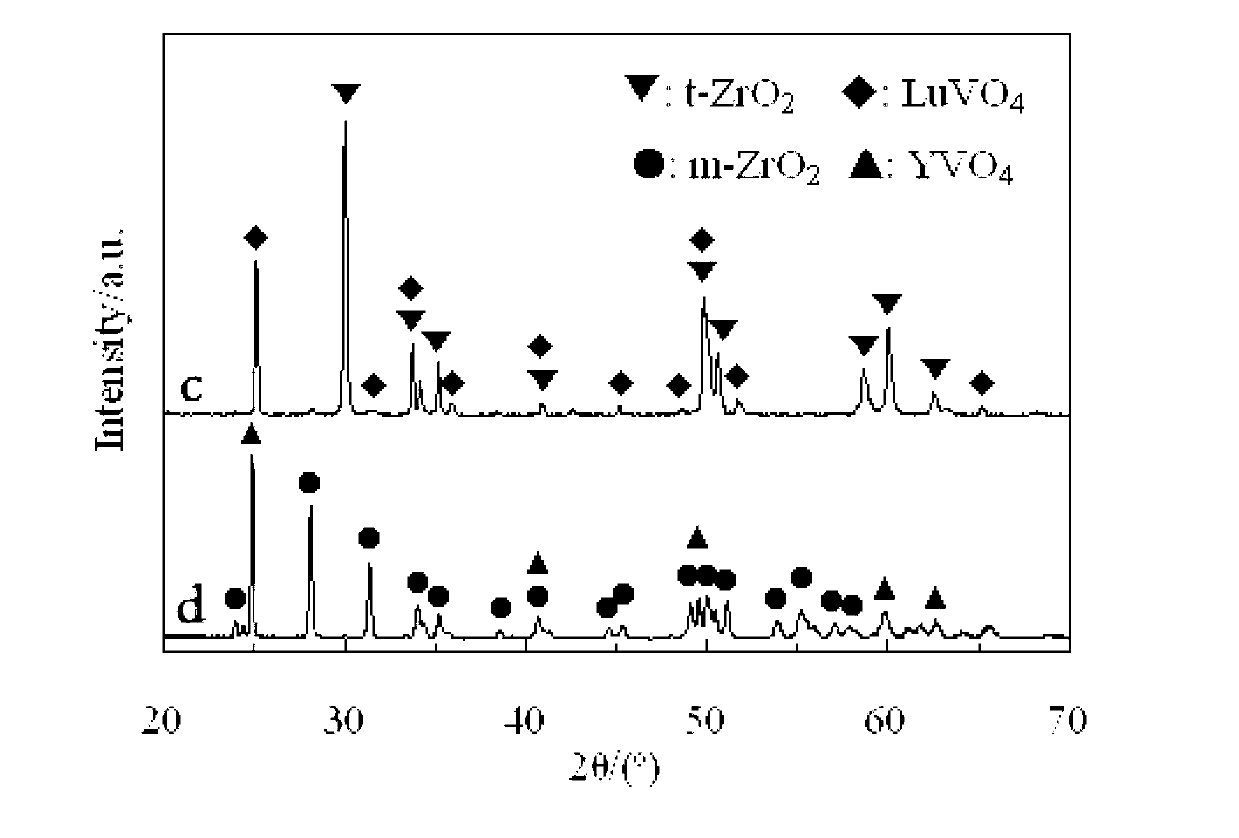

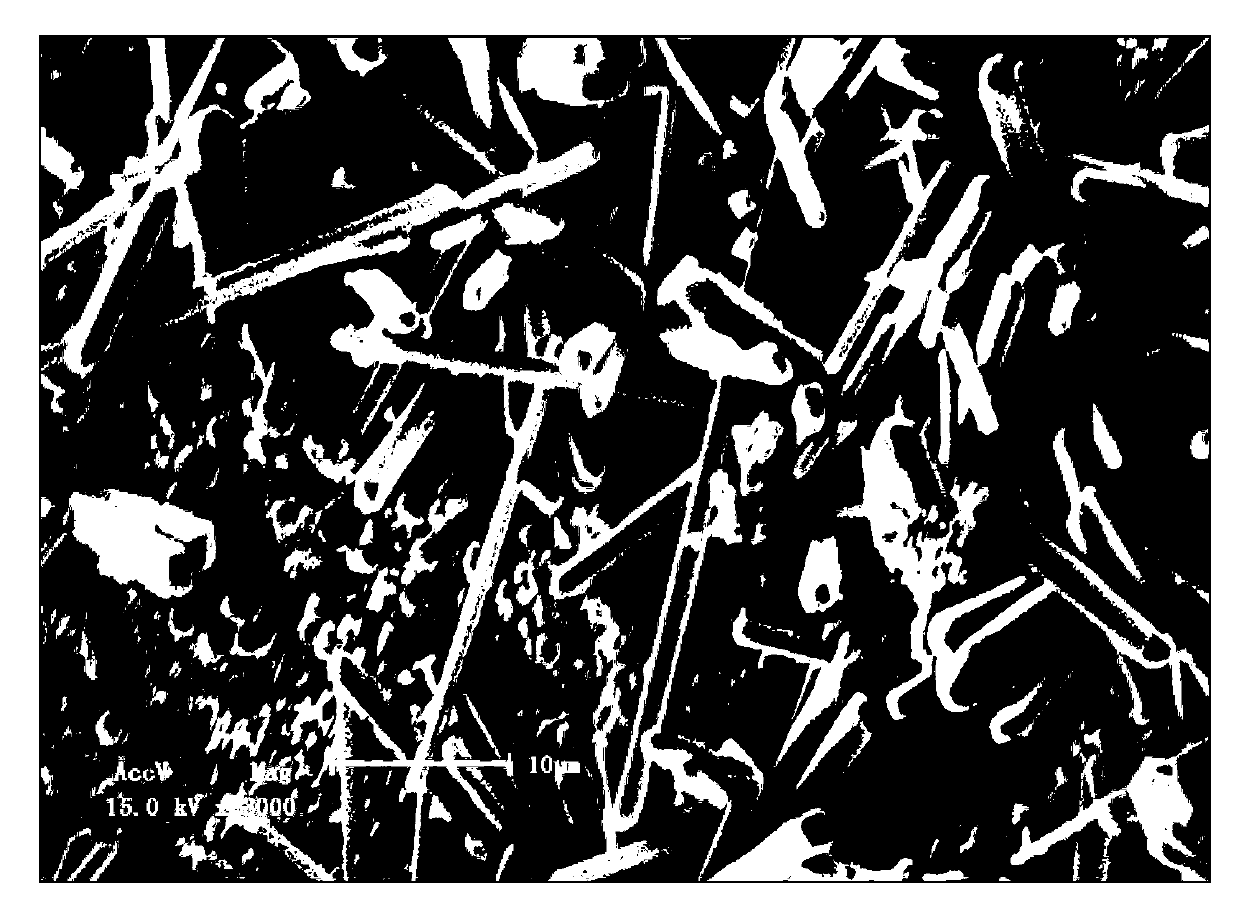

Multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material

ActiveCN103130501AMolten Salt Corrosion Life ImprovementHigh viscosityAluminum silicateGlass corrosion

The invention provides a multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material which is prepared by performing mixed ball milling on a main component and stabilizer, wherein the main component is ZrO2; the stabilizer is a mixture of Nb2O5, TiO2 and rare metal oxide; the mol ratio of the Nb2O5 to the TiO2 to the rare metal oxide to the ZrO2 in the multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material is x:1.5x:x:(100-3.5x), and 3<=x<=7; and the rare metal oxide is Lu2O3 or In2O3. The multi-element stable zirconium oxide corrosion-resistant thermal barrier coating material provided by the invention has excellent Na2SO4-V2O5 molten salt corrosion resistance and excellent calcium / magnesium / aluminum silicate molten glass corrosion resistance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

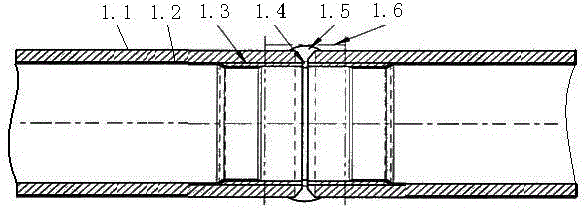

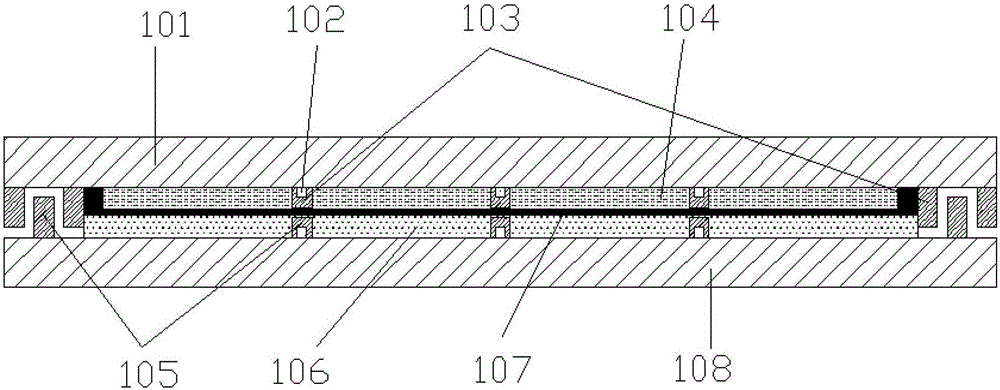

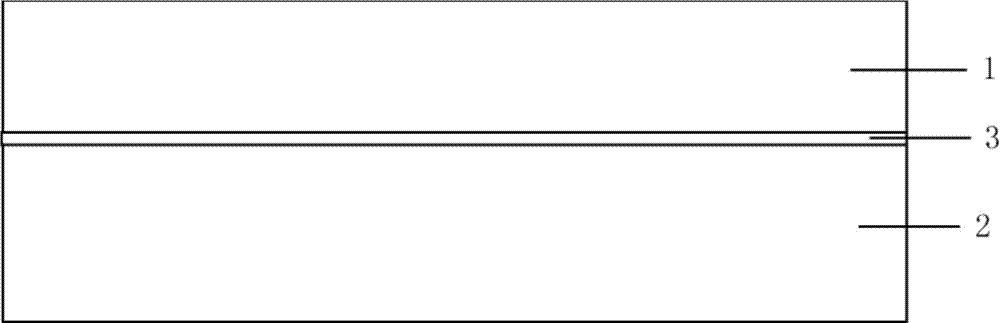

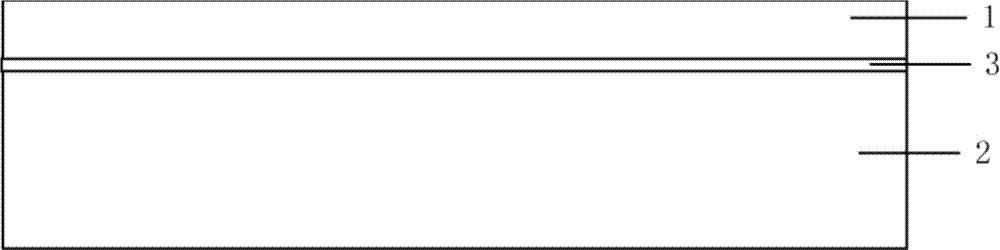

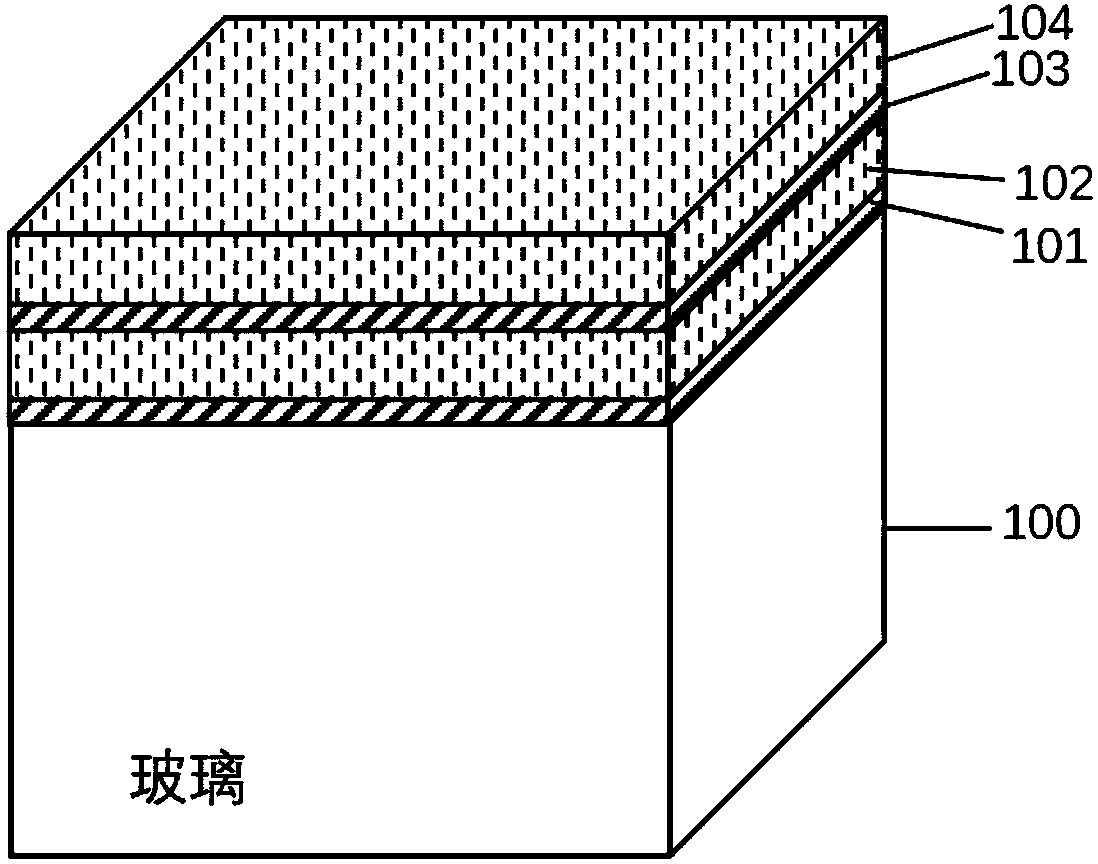

Glass corrosion composite mask structure and glass corrosion method

The invention provides a glass corrosion composite mask structure and a glass corrosion method. The glass corrosion composite mask structure comprises a first metal priming coat layer, a first metal layer, a second metal priming coat layer, a second metal layer and a photoresist layer which are sequentially arranged from a glass substrate, wherein the first metal priming coat layer and the secondmetal priming coat layer are metal Cr layers; the first metal layer and the second metal layer are made of metal Au or metal Cu. According to the composite mask structure for glass corrosion, the glass corrosion depth can be increased, the bonding performance of masks and glass is good, and meanwhile the complex stress control problem of polycrystalline silicon and monocrystalline silicon can be avoided.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

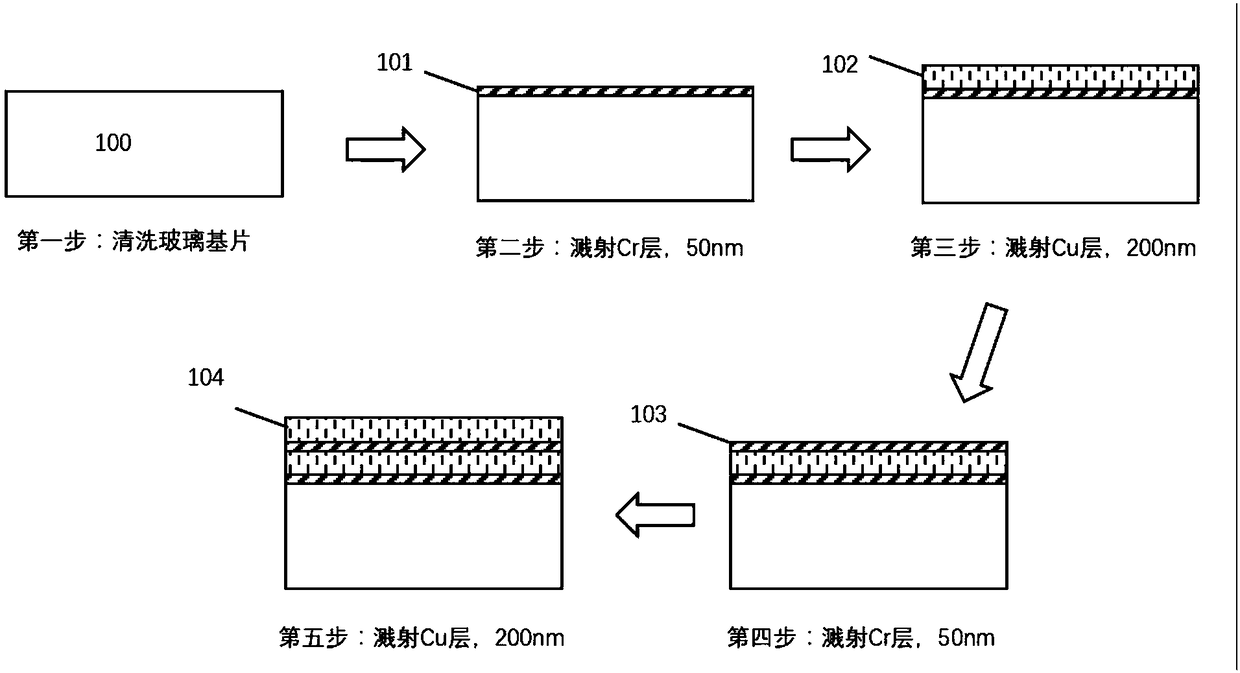

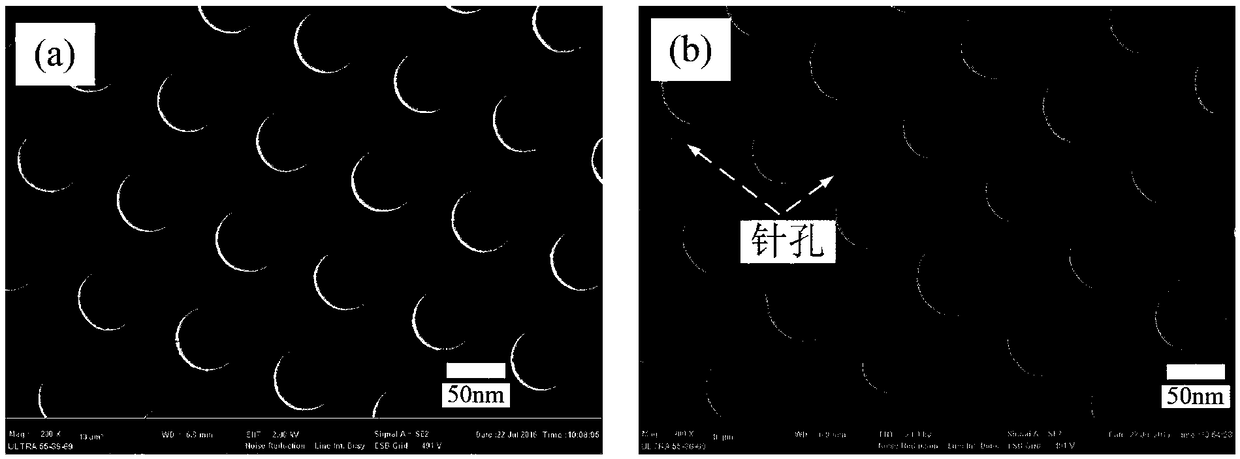

Multilayer metal mask seed layer for glass HF etching and manufacturing method thereof

The invention discloses a multilayer metal mask seed layer for glass HF etching and a manufacturing method thereof. The multilayer metal mask seed layer uses a magnetron sputtering method to sputter multiple metal films on a clean glass surface so that a complex mask layer structure of Cr / Cu / Cr / Cu is orderly formed from the glass substrate to top. The first and third Cr layers have thickness of 10to 100 nm, and the second and fourth Cu layers have thickness of 100 to 300 nm. The structure of the multi-layer metal mask seed layer can play a good masking role in the process of glass HF corrosion, minimize the occurrence of pinhole phenomenon in the glass corrosion process, prevent the occurrence of undercutting phenomenon and achieve good corrosion effects.

Owner:SHENZHEN UNIV

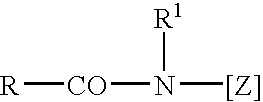

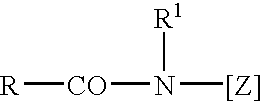

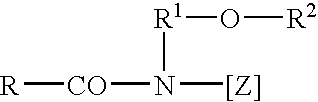

Cleaning compositions for glass surfaces

InactiveUS7897554B2Improves drying behaviorReduce formationDetergent mixture composition preparationDetergent materialsSilyleneGlass corrosion

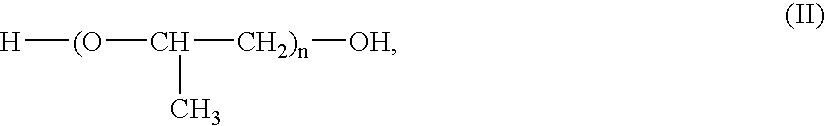

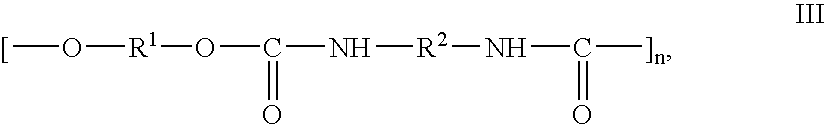

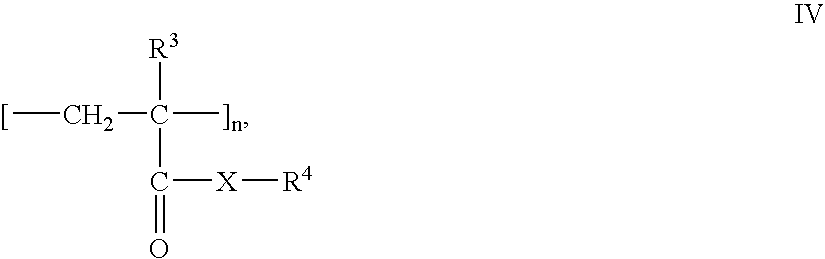

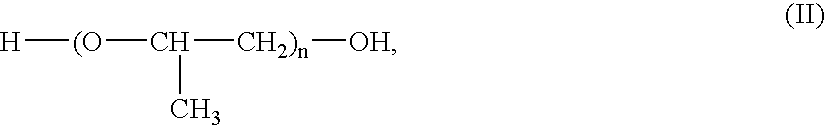

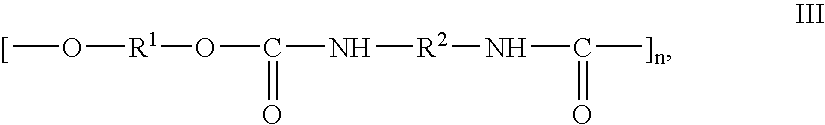

Multi-armed silyl polyalkoxylates of the formula (I), (H-A)n-Z-[A-B—Si(OR1)r(R2)3−r]m (I), where Z is an (m+n)-valent radical having at least three carbon atoms, A is a divalent polyoxyalkylene radical, B is a chemical bond or a divalent organic radical having 1 to 50 carbon atoms, OR1 is a hydrolysable group, R1 and R2 independently of one another are a linear or branched alkyl group having 1 to 6 carbon atoms and r is an integer from 1 to 3, and m is an integer ≈1 and n is 0 or an integer ≈1, and m+n has a value from 3 to 100, for reducing glass corrosion and / or for improving the drying performance during mechanical cleaning of a glass surface. Also compositions, in particular for the cleaning of glass surfaces, which compositions contain compounds of the formula (I).

Owner:HENKEL KGAA

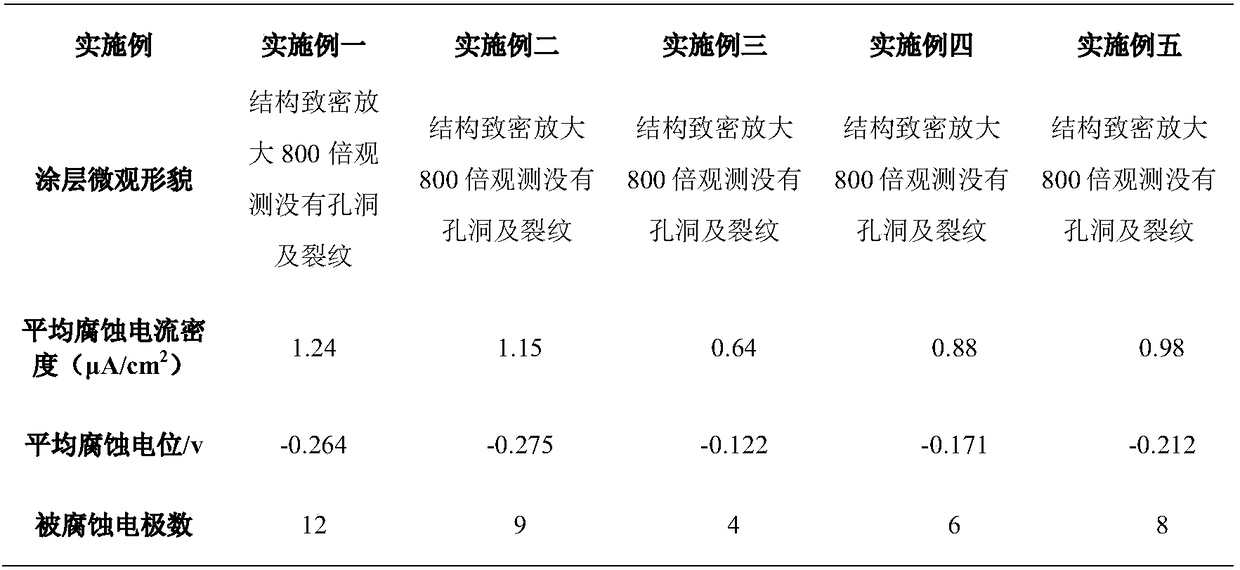

Method for characterizing surface micro-corrosion characteristics of low carbon steel coated with enamel layer by using wire beam electrode

ActiveCN108827866AHigh measurement accuracyImprove measurement reliabilityWeather/light/corrosion resistancePreparing sample for investigationElectrochemistryGlass corrosion

The invention discloses a method for characterizing surface micro-corrosion characteristics of low carbon steel coated with an enamel layer by using a wire beam electrode. The wire beam electrode is used to characterize the surface micro-corrosion condition of low carbon steel coated with the enamel layer and the inhibition effect of the coating itself on a corrosion solution. The method adopts amulti-electrode coupling system, all the wires are short-circuited together, the electrochemical behavior is regarded as an integral electrode, and an open circuit potential is called the integral potential which is the coupling potential of all the single electrodes. On this basis, the corrosion of materials at different times is characterized. The surface potential and current scanning of the wire beam electrode can better characterize the occurrence and development of local corrosion of carbon steel in the corrosion solution in time and space; at the same time, local corrosion factors can quantitatively characterize the uneven characteristics of WBE surface corrosion and the ability of corrosion inhibitors to repair the local corrosion, and the wire beam electrode can be used to effectively characterize the corrosion of the material micro-region and the protection effect of the coating on a substrate and the inhibition of corrosive ions.

Owner:SHANGHAI UNIV

Supporting brick for glass kiln

The present invention provides a supporting brick for a glass kiln, wherein the raw materials comprise, by mass, 50-60% of tabular corundum, 10-20% of alpha-Al2O3 micro-powder, 5-6% of zirconite, 10-15% of mullite, 2-5% of aluminium dihydrogen phosphate, 1-4% of clay, and 2-3% of zirconium dioxide. The supporting brick preparation method comprises: mixing tabular corundum, mullite, zirconite and aluminium dihydrogen phosphate, adding other raw materials and water, carrying out high speed mixing to obtain a mixed material, reducing the pressure in a vacuum box to achieve 140-120 Pa, pressing to obtain a high-density semi-finished product, drying and sintering the semi-finished product, and discharging out from the kiln. According to the present invention, high temperature rapid transformation resistance and chemical component corrosion and wear resistance in a glass liquid are substantially increased, the use age is significantly prolonged, the bubble exhaust time of the glass product is reduced, and the glass corrosion resistance time is prolonged.

Owner:浙江立鑫高温耐火材料有限公司

Cleaning Compositions For Glass Surfaces

InactiveUS20090298736A1Improves drying behaviorReduce formationOrganic detergent compounding agentsDetergent mixture composition preparationSilyleneGlass corrosion

Multi-armed silyl polyalkoxylates of the formula (I), (H-A)n-Z-[A-B—Si(OR1)r(R2)3−r]m (I), where Z is an (m+n)-valent radical having at least three carbon atoms, A is a divalent polyoxyalkylene radical, B is a chemical bond or a divalent organic radical having 1 to 50 carbon atoms, OR1 is a hydrolysable group, R1 and R2 independently of one another are a linear or branched alkyl group having 1 to 6 carbon atoms and r is an integer from 1 to 3, and m is an integer ≈1 and n is 0 or an integer ≈1, and m+n has a value from 3 to 100, for reducing glass corrosion and / or for improving the drying performance during mechanical cleaning of a glass surface. Also compositions, in particular for the cleaning of glass surfaces, which compositions contain compounds of the formula (I).

Owner:HENKEL KGAA

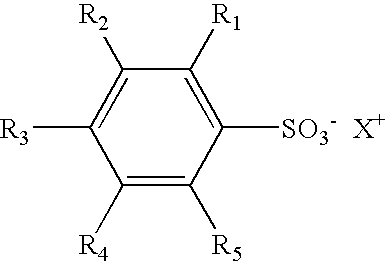

Cleaning Agents With Protection Against Glass Corrosion

ActiveUS20200024549A1Easy to useNegatively alter solidification timeOrganic detergent compounding agentsSurface-active detergent compositionsSulfate zincAcetic acid

Cleaning agents, preferably dishwashing detergents, in particular the automatic dishwashing detergent, having at least one low-water, preferably substantially anhydrous gel-like phase which contains at least one water-soluble zinc salt, preferably zinc sulfate and / or zinc acetate, particularly preferably zinc acetate.

Owner:HENKEL KGAA

Preparation method of layered high purity zircon refractory material

The invention relates to a preparation method of a layered high purity zircon refractory material. The method includes the steps of: preparation of a high-purity zircon raw material, preparation of a common zircon raw material, layered isostatic pressing and high temperature solid phase sintering. Experiments show that very little transition metal impurity ion contamination is introduced in a glass smelting process of the layered high purity zircon refractory material prepared by the method provided by the invention, a layered molding technology can be employed to control the cost, and also can achieve good anti-glass corrosion effect.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

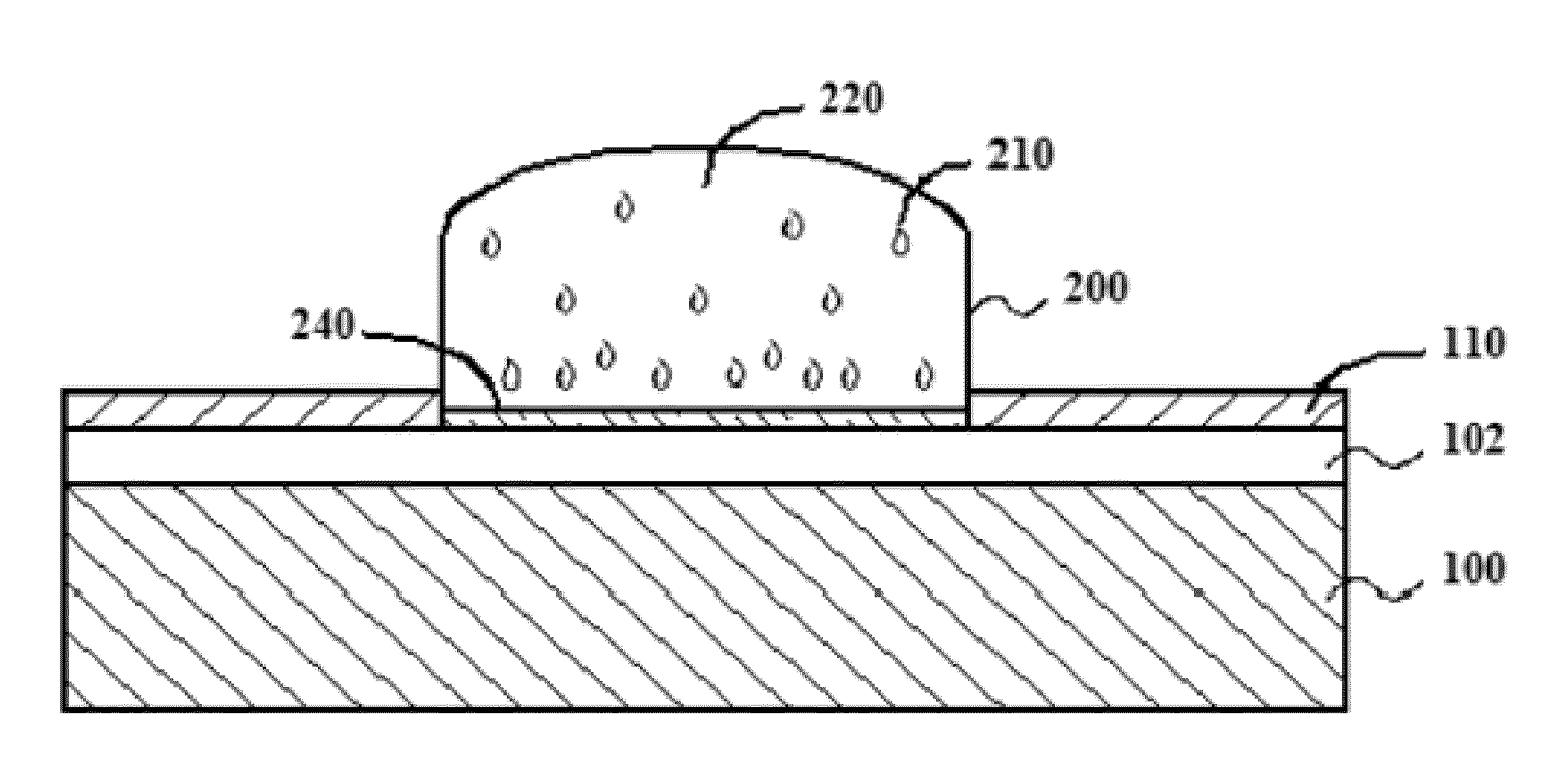

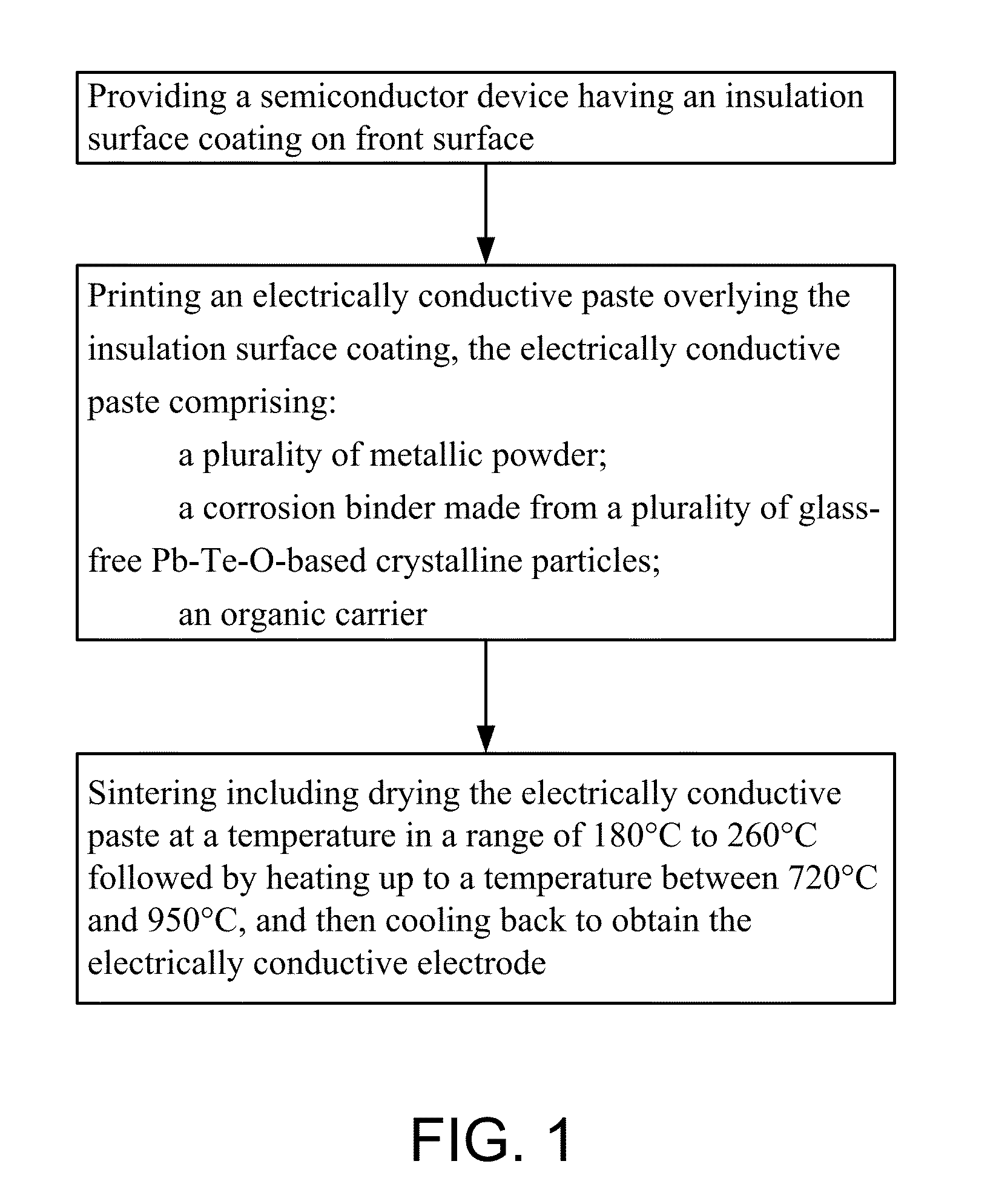

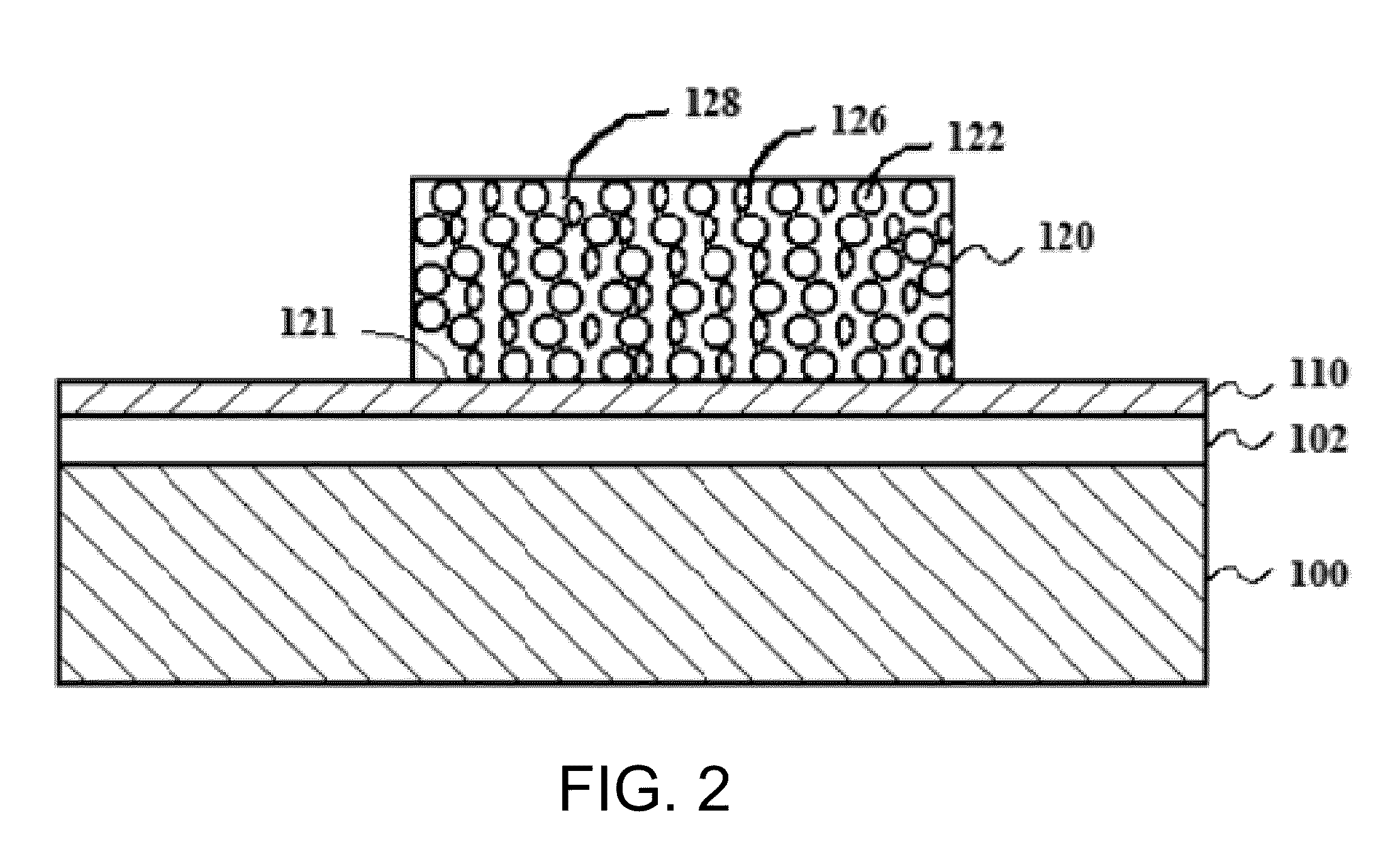

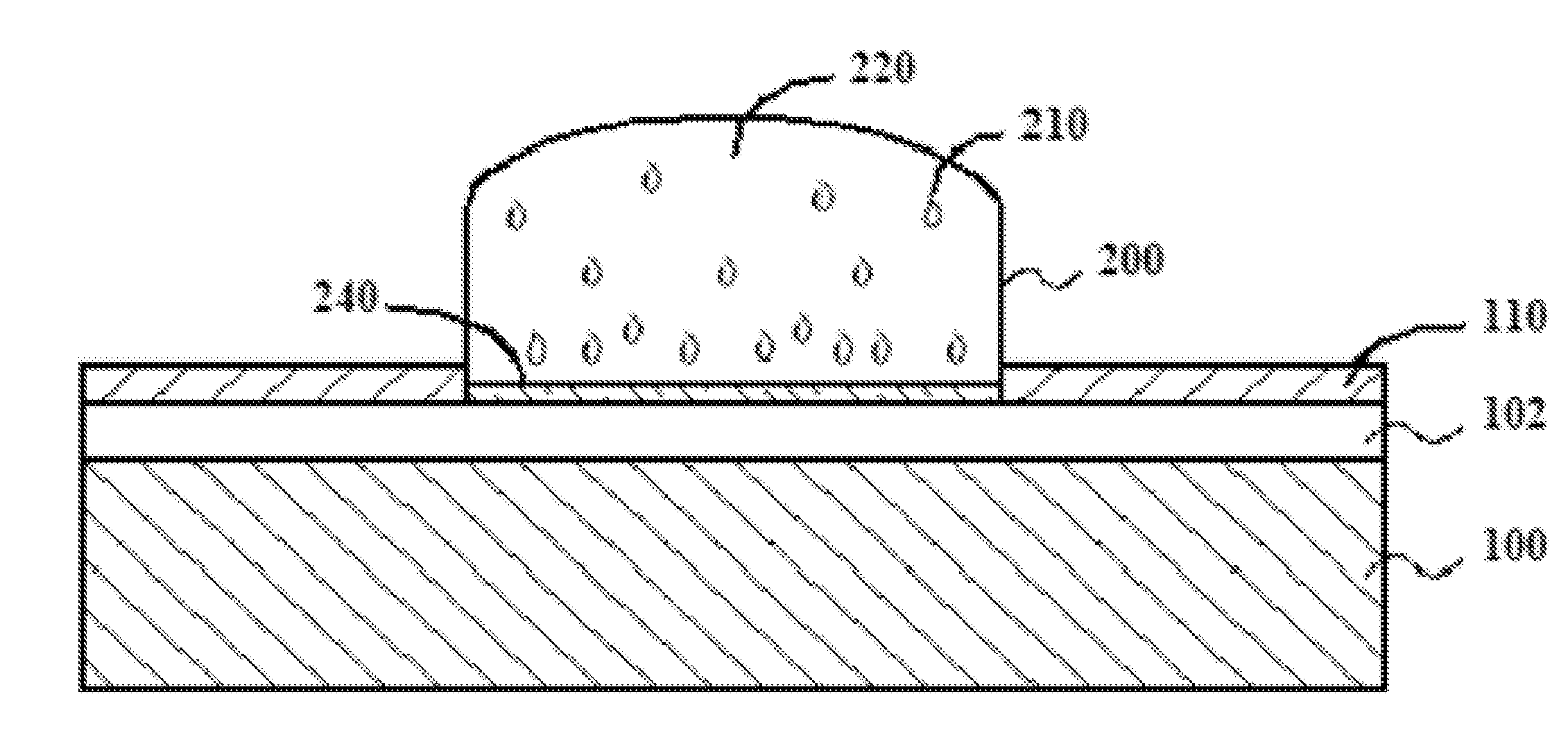

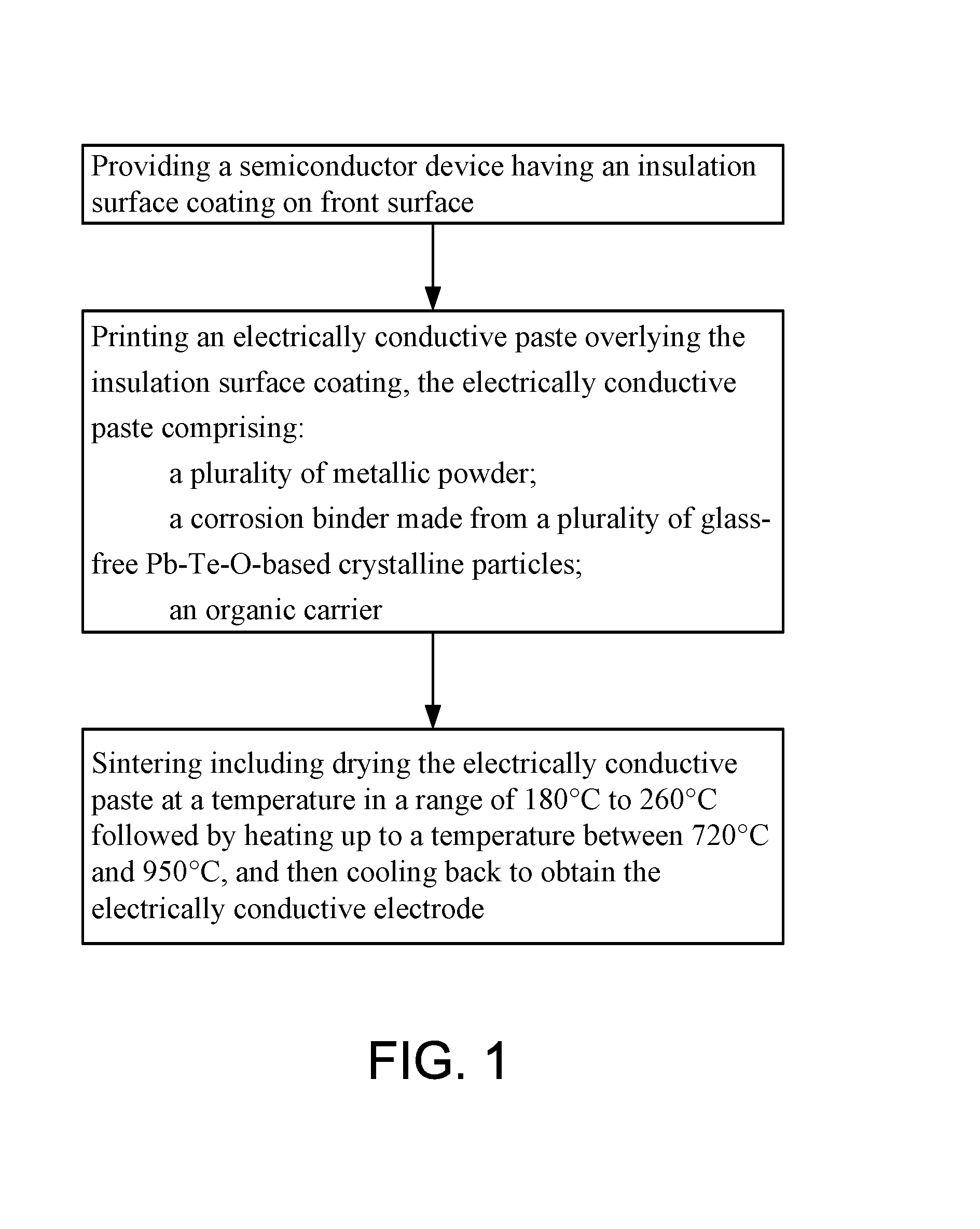

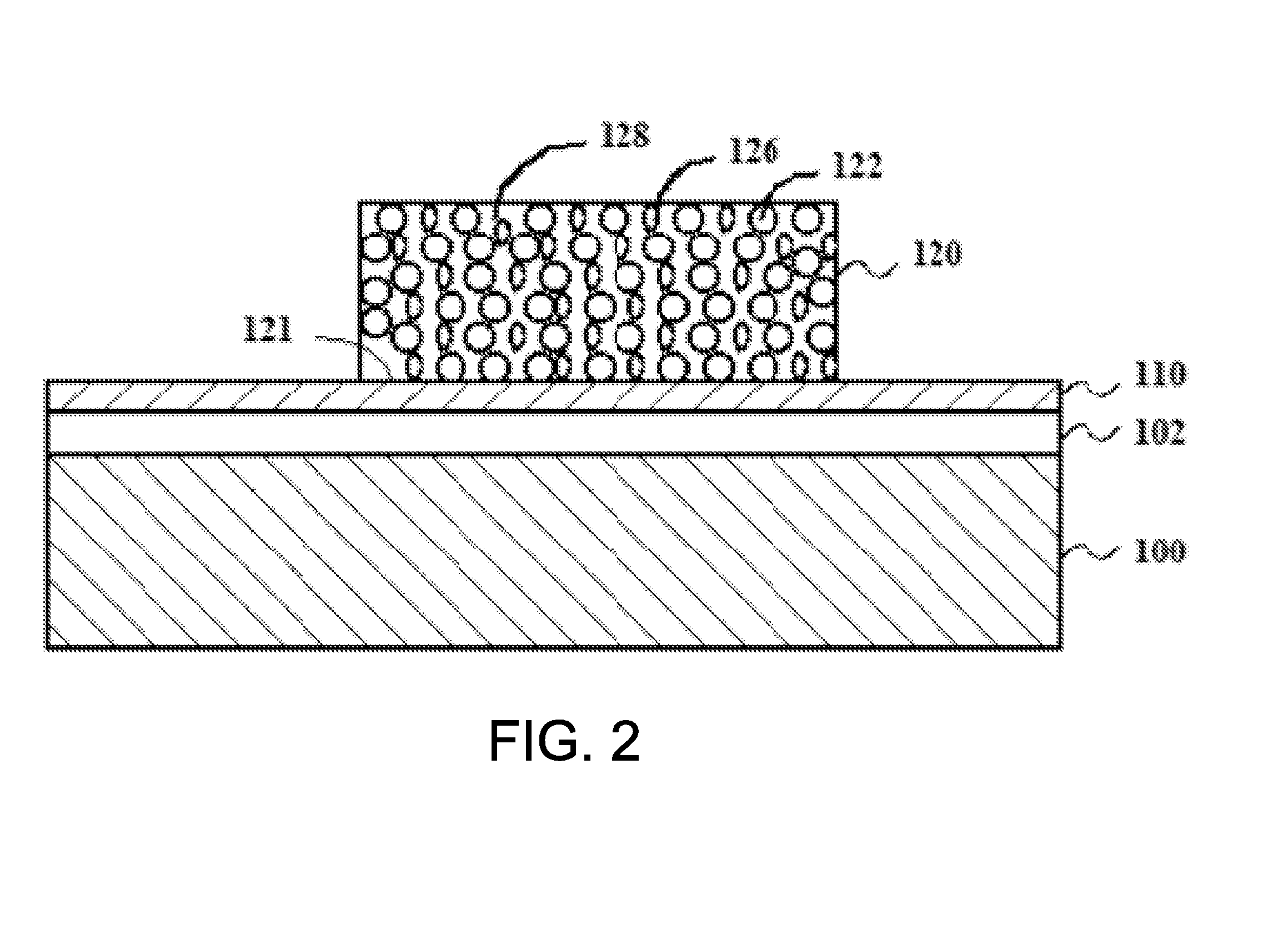

Electrically conductive paste for front electrode of solar cell and preparation method thereof

InactiveUS20160260850A1Strong stickinessExcellent metal-semiconductor electrical contactNon-conductive material with dispersed conductive materialPhotovoltaic energy generationElectrical batteryOhmic contact

The present invention provides an electrically conductive paste for a front electrode of a solar cell and a preparation method thereof. The electrically conductive paste is composed of a glass-free corrosion binder, a metallic powder and an organic carrier. The corrosion binder is one or more Pb—Te based crystalline compounds having a fixed melting temperature in a range of 440° C. to 760° C. During a sintering process of the electrically conductive paste for forming an electrode, the glass-free corrosion binder is converted into a liquid for easily corroding and penetrating an antireflective insulating layer on a front side of the solar cell, so that a good ohmic contact is formed. At the same time, the electrically conductive metallic powder is wetted, and the combination of the metallic powder is promoted. As a result, a high-conductivity front electrode of a crystalline silicon solar cell is formed.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

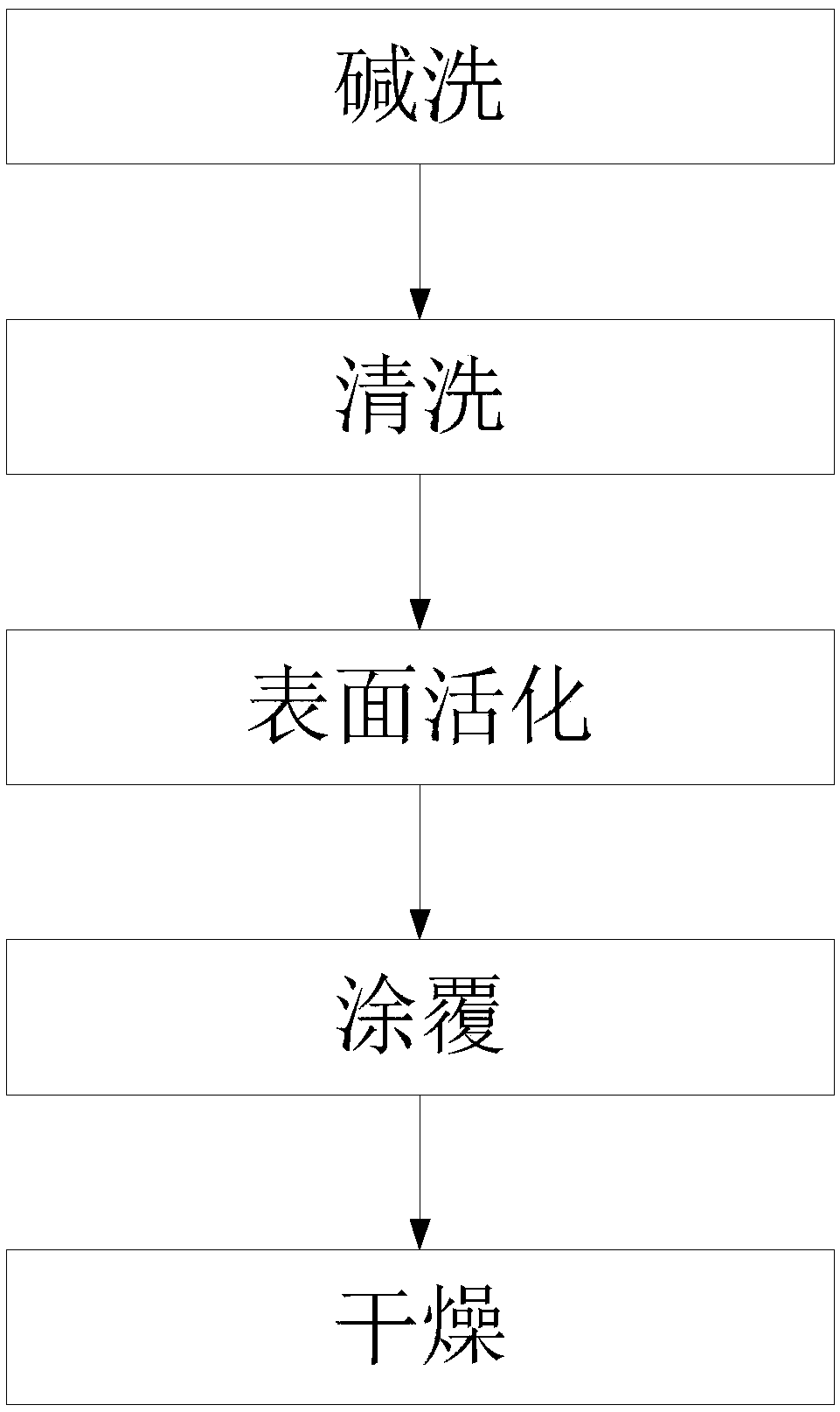

Method of preventing hydrogen fluoride corrosion for glass in aluminum electrolysis industry

ActiveCN108970944ANo reduction in physical and chemical propertiesDoes not reduce light transmittanceLiquid surface applicatorsCoatingsHydrogen fluorideOptical transmittance

The invention discloses a method of preventing hydrogen fluoride corrosion in aluminum electrolysis industry and belongs to the field of glass corrosion prevention. The method includes the sequentialsteps of alkali washing of glass, cleaning, surface activation, coating, and drying. The method allows a coating and glass to be combined better; mechanical properties of the glass coating can be improved; whole mechanical and chemical properties and light transmittance of glass are not lowered. In addition, the method helps effectively prevent hydrogen fluoride corrosion and improve tolerance ofglass to acids and bases, attraction of dust to glass surface is greatly reduced, and light transmittance of the glass is greatly improved. The method allows coating precision to be improved on the whole, adaptability of machine batch treatment is improved, and it is guaranteed that anticorrosion performance of glass meets the standard at the premise of improved efficiency; as the whole coating step is applicable to automation on equipment, the method has better control convenience than the prior art.

Owner:CHONGQING UNIV

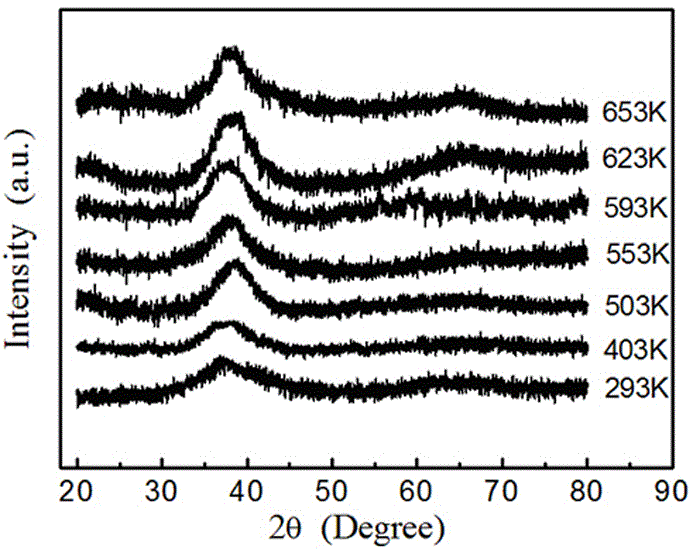

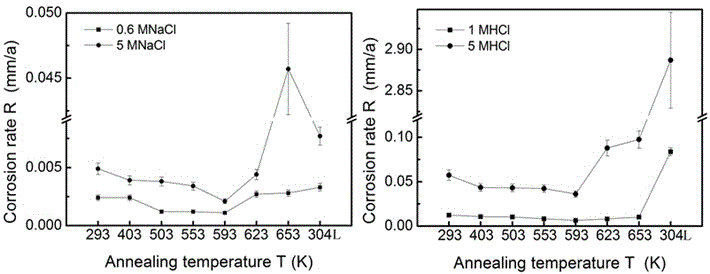

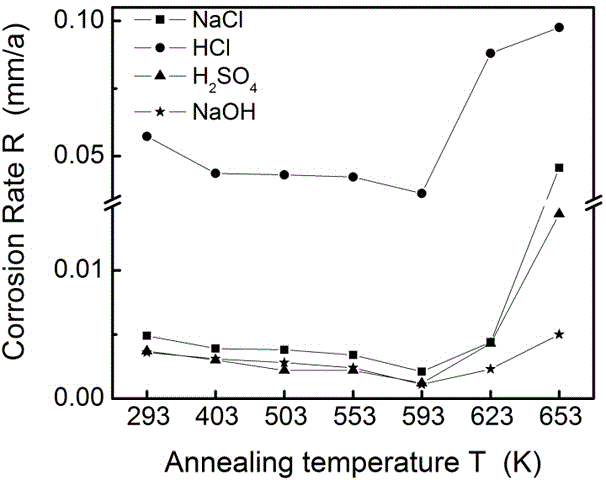

An optimized process for improving the corrosion resistance of Zrcunialti bulk metallic glasses

The invention belongs to the research on improving the corrosion resistance of new structural materials, specifically an optimization process for improving the corrosion resistance of ZrCuNiAlTi bulk metallic glass, which is characterized in that: the atomic percentage is Zr 52.5 Cu 17.9 Ni 14.6 al 10 Ti 5 The alloy composition metal glass is used as the substrate, and the best corrosion resistance is achieved by annealing at 593K for 15 minutes. The present invention selects Vit105 bulk metallic glass as the research object, through the T g The following annealing at different temperatures obtains samples in different degrees of relaxation state. Combined with the corrosion performance test in different solutions, the influence of annealing temperature on the corrosion resistance is obtained, and the corrosion resistance of Vit105 bulk metallic glass is optimized, which is helpful for in-depth understanding of bulk metallic glass. And the scientific and rational application of this new type of functional material has high practical value.

Owner:ZHENGZHOU UNIV

Cleaning agent for removing residual film glue from car glass and preparation method of cleaning agent

InactiveCN106675795AQuick washReduce corrosionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsAcetic acidOrganic solvent

The invention belongs to the field of technical production of cleaning agents, and discloses a cleaning agent for removing residual film glue from car glass. The cleaning agent comprises the following components in parts by weight: 200-300 parts of isopropanol, 0.5-2 parts of sodium dodecyl sulfate, 5-15 parts of ethylene glycol n-butyl ether, 1-10 parts of acetic acid, 30-50 parts of hydrochloric acid and 600-700 parts of deionized water. The preparation method of the cleaning agent comprises the following steps: sequentially adding isopropanol, acetic acid, hydrochloric acid and the deionized water in parts by weight into a stirrer, mixing for 10-20min by stirring, then proportionally adding sodium dodecyl sulfate and ethylene glycol n-butyl ether, further mixing for 15-30min by stirring, and performing standing to obtain the cleaning agent for removing the residual film glue from car glass. The cleaning agent adopts a neutral organic solvent formula, can quickly clean the residual film glue on the car glass, can quicken the glue removing speed, and is small in car glass corrosion, low in using cost and mild in reaction conditions.

Owner:广州红路实业有限公司

Preparation method of fireproof hollow glass

InactiveCN108689621AImprove stabilityReduce internal stressGlass tempering apparatusIon exchangePotassium ions

The invention relates to a preparation method of glass, in particular to a preparation method of fireproof hollow glass. The preparation method comprises the steps that firstly, a groove is corroded on the back face of the glass through a photolithography technique and a glass corrosion technique, then surface ion exchange is conducted, sodium ions on the surface of the glass are substituted withcesium ions and potassium ions, then the back faces of two pieces of tempered cesium-potassium glass are opposite, the position between the two pieces of the tempered cesium-potassium glass is filledwith boronic silicon modified polyvinyl butyral resin, the tempered cesium-potassium laminated glass is obtained, the position between the two pieces of tempered cesium-potassium laminated glass is aerated with dry fire extinguishing gas and sealed with a sealing strip, and the fireproof hollow glass is obtained. The fireproof hollow glass has the following beneficial effects that (1) the internalstress on the glass surface is small, the binding strength of the laminated glass is higher, and the stability of the glass is good; (2) the fireproof property, the flame retardant property and the heat insulation property are outstanding, and the safety is high; and (3) automatic fire extinguishing can be conducted.

Owner:ZHEJIANG XIXI GLASS

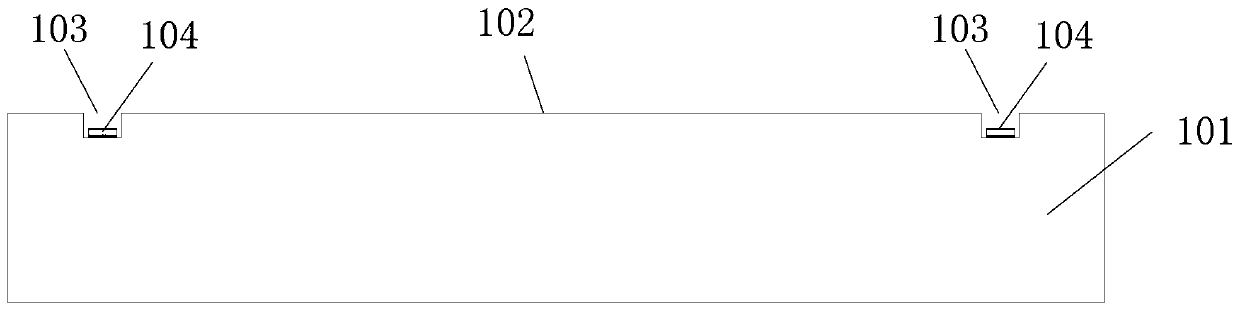

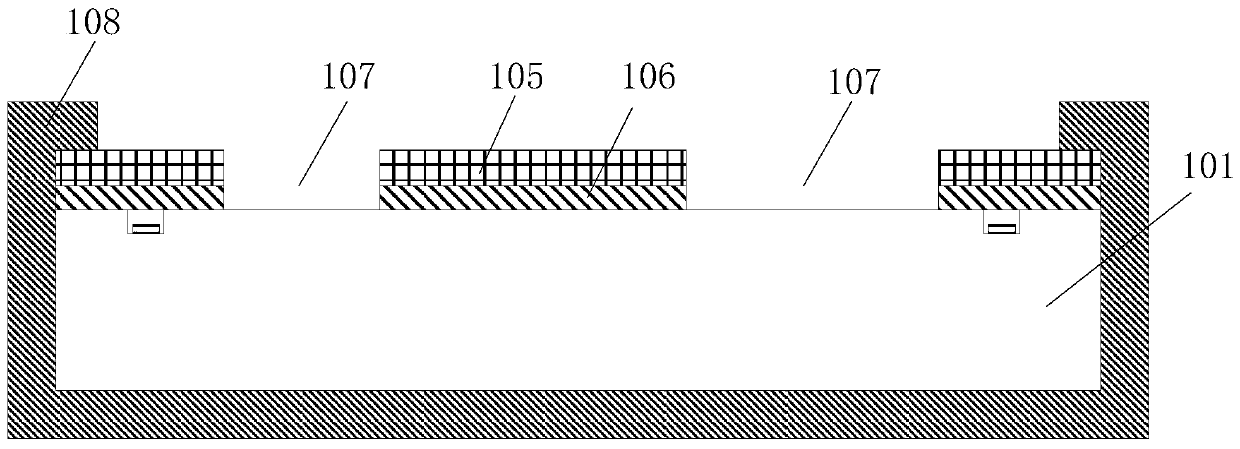

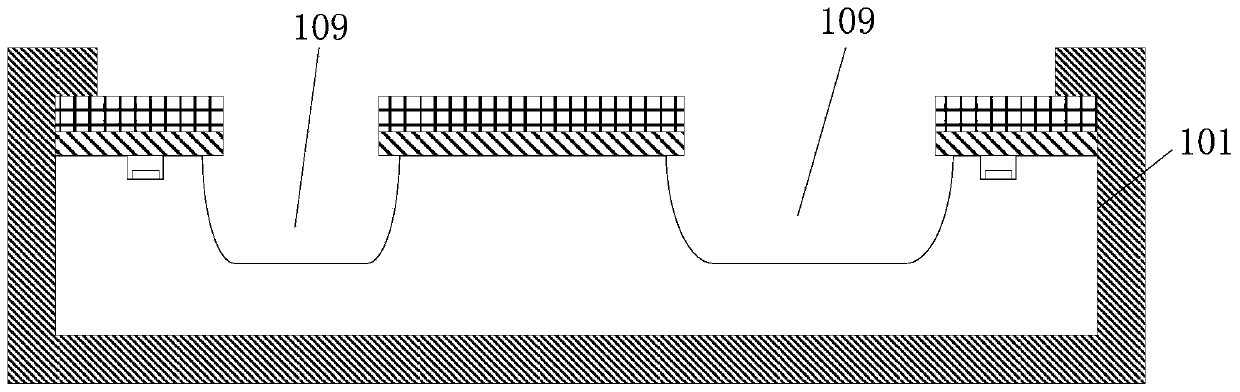

Manufacturing method of glass cavity suitable for wafer-level vacuum packaging

ActiveCN111099555AReduce lateral undercuttingReduce surface undercuttingDecorative surface effectsChemical vapor deposition coatingGlass chipThin membrane

The invention relates to a manufacturing method of a glass cavity suitable for wafer-level vacuum packaging. The manufacturing method comprises the following steps: carrying out primary cleaning on aglass sheet; etching the surface of the glass to form a first pattern; carrying out secondary cleaning on the glass sheet; depositing a metal tungsten film on the surface of the glass; forming a second pattern on the tungsten film in the shallow groove formed by the first pattern in the second step; depositing a composite gold film on the surface of the glass; the composite gold film is coated with photoresist, photoetching is conducted on the gold film, and a cavity pattern is formed; protecting the edges of the gold-film-free surface and the gold-film-containing surface of the glass sheet byusing a blue film; and aligning the silicon wafer with the hollow pattern with the glass sheet with the glass sheet cavity according to the second pattern to form the glass sheet with the getter filmin the cavity for wafer-level vacuum packaging. The thick photoresist and the metal film are adopted to form the composite mask, the influence of defects and pinholes on the surface of the single-layer mask on corrosion can be eliminated, and surface undercutting in the glass corrosion process is reduced.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Method for manufacturing a front electrode of a semiconductor device

InactiveUS20160260851A1Strong stickinessExcellent metal-semiconductor electrical contactNon-conductive material with dispersed conductive materialPhotovoltaic energy generationOhmic contactSilicon solar cell

The present invention provides a method for manufacturing a front electrode of a semiconductor device. The method includes using an electrically conductive paste composed of a glass-free corrosion binder, a metallic powder and an organic carrier. The corrosion binder is one or more Pb—Te based crystalline compounds having a fixed melting temperature in a range of 440° C. to 760° C. During a sintering process of the electrically conductive paste for forming an electrode, the glass-free corrosion binder is converted into a liquid for easily corroding and penetrating an antireflective insulating layer on a front side of the solar cell, so that a good ohmic contact is formed. At the same time, the electrically conductive metallic powder is wetted, and the combination of the metallic powder is promoted. As a result, a high-conductivity front electrode of a crystalline silicon solar cell is formed.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

Rotating pipe and manufacturing method thereof

The invention relates to a rotary tube and a production method thereof, belonging to the field of special mechanical techniques for producing tubular products. The rotary tube comprises a matrix, wherein in the chemical components of the matrix, the ratio of Al2O3 and SiO2 is over 2.5, and the content of Al2O3 in the chemical components of the matrix is over 60%. Aiming to the shortcomings of the prior art, in the inventive rotary tube, a dense surface layer is sprayed or glazed on the blank surface, the surface layer contains lanthanum and cerium rare earths, and the surface of the rotary tube after high-temperature calcination is dense and has high mechanical strength of internal structure, so as to improve the glass corrosion resistance and service life of the rotary tube.

Owner:SHANDONG JIATENG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com