Preparation method of layered high purity zircon refractory material

A technology of refractory materials and zircon, which is applied in the field of preparation of layered high-purity zircon refractory materials, can solve the problems of glass transmittance and light absorption, and it is difficult to meet the low impurity content of high-grade optical glass and laser glass. Ease of design and application, high quality and low, good resistance to erosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

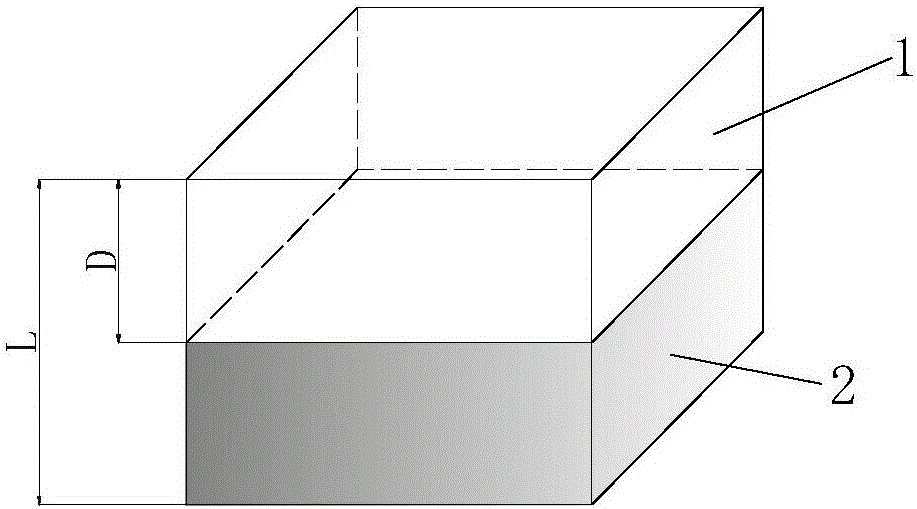

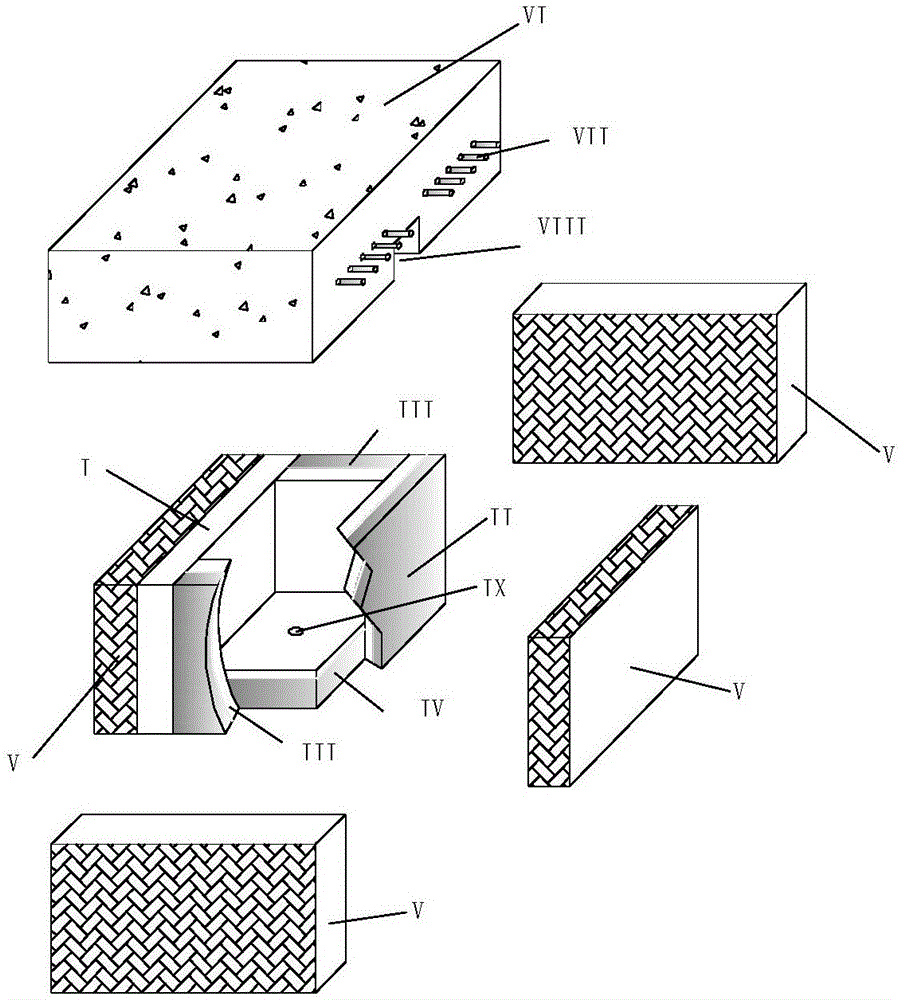

[0030] The preparation method of the layered high-purity zircon refractory material of the present invention comprises the following steps:

[0031] ① Preparation of high-purity zircon raw materials: ZrO with purity ≥ 99.9%, 66-67.7wt% is selected 2 , SiO with purity ≥99.9%, 32-33wt% 2 , purity ≥ 99.5%, 0.3 ~ 2wt% TiO 2 , mixed with zirconia ball milling until the fineness is 0.1~5μm≥95%, and then synthesized by calcination at ≥1100°C for 20~48 hours, adding 0.1~0.2wt% of high-grade pure phosphoric acid, using zirconia The balls are ground into mud, and the fineness requirement is 0.1-6 μm ≥ 95%. The mud-like high-purity zircon is dried, the powder is pulverized, and passed through a 30-mesh vibrating sieve to obtain a high-purity zircon raw material;

[0032] ②Preparation of ordinary zircon raw materials: choose ZrSiO 4 ≥98.5% common zircon raw material, plus 0.3~2wt% TiO 2 , 0.1-0.2wt% phosphoric acid, using zirconia balls to grind into slurry, with a fineness of 0.1-6μm...

Embodiment 1

[0043] According to the size of the refractory material, estimate the raw material consumption of high-purity zircon and common commercial zircon. High-purity zircon raw materials need to be artificially synthesized.

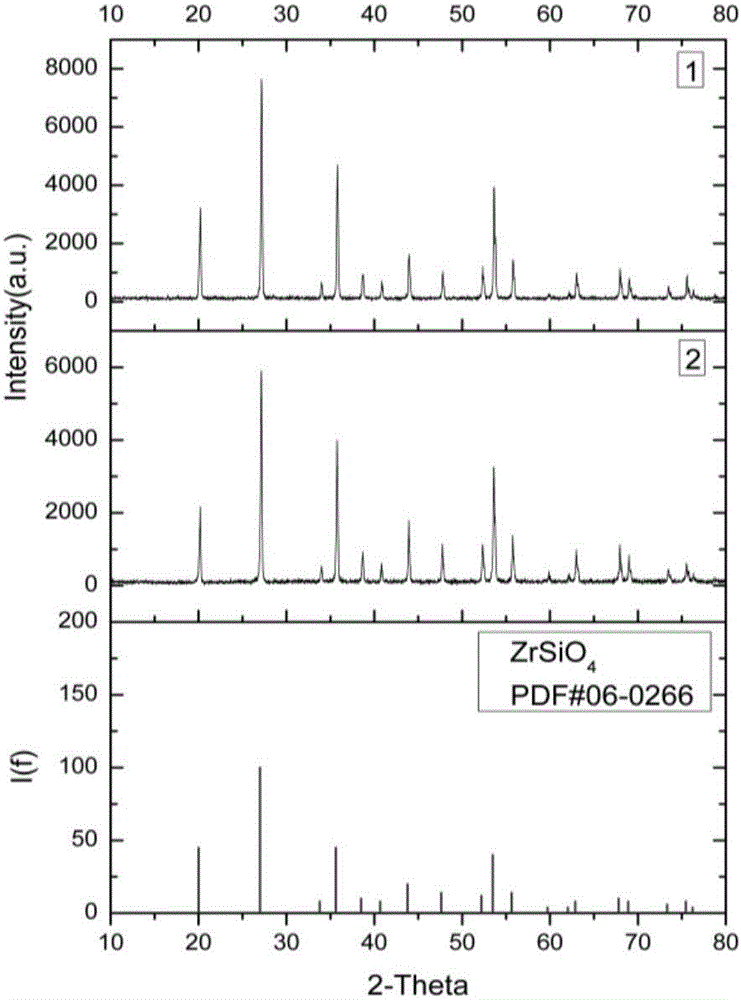

[0044] 125 kg of high-purity zircon raw materials are required, and a balance of 30wt% needs to be reserved for production and subsequent processing, according to the following ratio: high-purity ZrO 2 66.2wt%, high-purity SiO 2 33wt%, 0.8wt% high-purity TiO 2 , equipped with 162 kg of raw materials. All raw material purity ≥99.9%, and CuO content ≤5ppmw, CuO+Co 2 o 3 +NiO+Cr 2 o 3 ≤10ppmw, Fe 2 o 3 Content ≤ 50ppmw. Ball mill the zirconia and silica mixture for 36 hours until the fineness requirement is 0.1~6μm≥95%1μm, put it into a clean mold, calcinate at 1350℃ for 30 hours, and then generate high-purity zircon raw material by solid state reaction. use.

[0045] 54 kg of ordinary commercial zircon raw materials are required, and 30 wt% of productio...

Embodiment 2

[0049] According to the size of the refractory material, estimate the raw material consumption of high-purity zircon and common commercial zircon. High-purity zircon raw materials need to be artificially synthesized.

[0050] 53.5 kg of high-purity zircon raw materials are required, and a balance of 30wt% needs to be reserved for production and subsequent processing, according to the following ratio: high-purity ZrO 2 66wt%, high purity SiO 2 32wt%, 2wt% high purity TiO 2 , configure 70 kg of raw materials. All raw material purity ≥99.9%, and CuO content ≤5ppmw, CuO+Co 2 o 3 +NiO+Cr 2 o 3 ≤10ppmw, Fe 2 o 3 Content ≤ 50ppmw. Ball mill the zirconia and silica mixture for 36 hours until the fineness requirement is 0.1~6μm≥95%1μm, put it into a clean mold, calcinate at 1100°C for 20 hours, and then generate high-purity zircon raw material by solid state reaction. use.

[0051] 53.5 kg of common commercial zircon raw materials are required, and 30wt% production and proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com