Patents

Literature

299results about How to "Uniform and dense structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

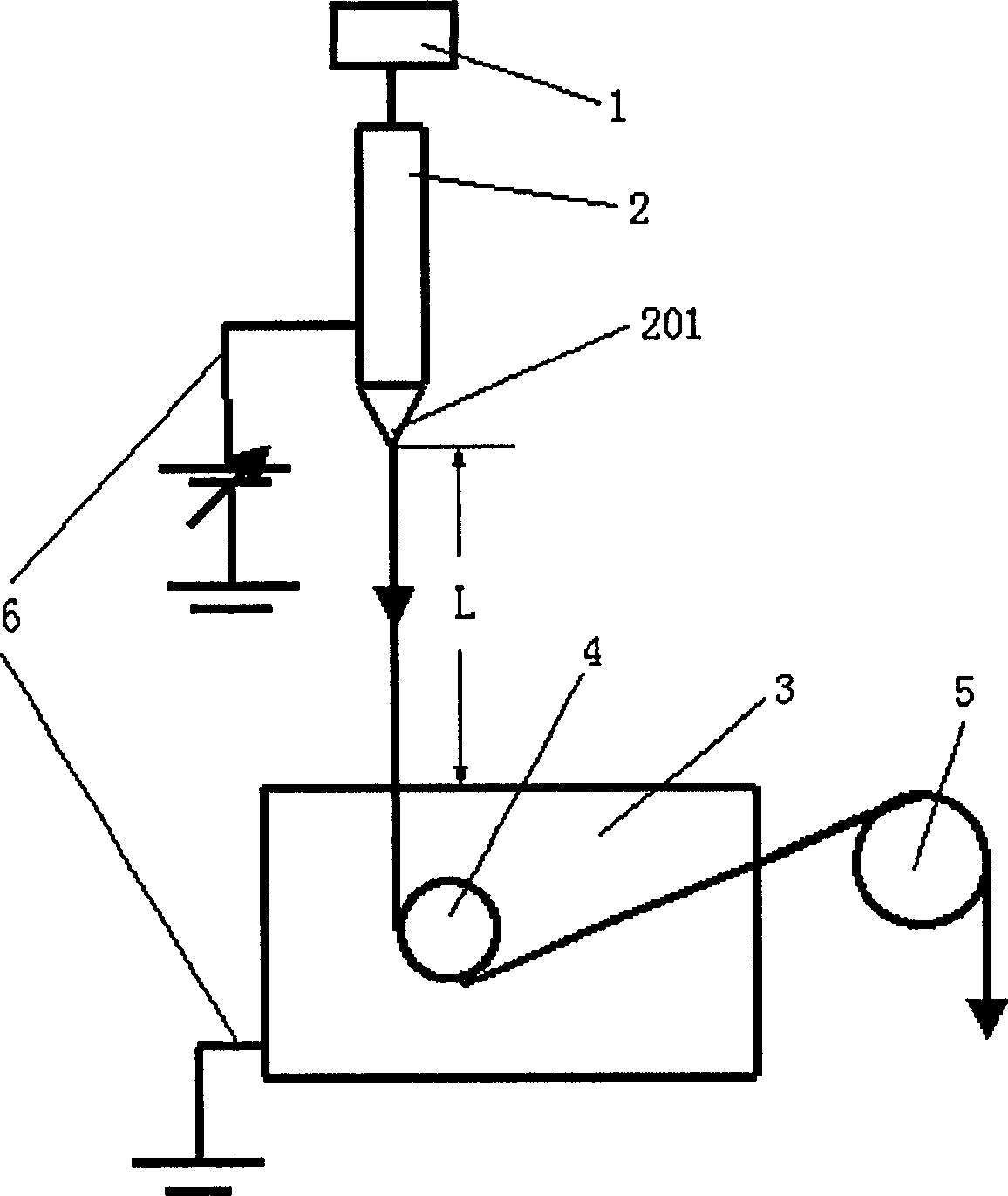

Static spinning device and its industrial use

InactiveCN1715463AHigh speedImprove mechanical propertiesFilament/thread formingElectrospinningMagnification

The present invention provides electrostatic spinning apparatus and its industrial application. The apparatus includes polymer solution conveying machine, spinning nozzle device connected to the outlet of the polymer solution conveying machine, spinning bath below the spinning nozzle device, fiber turning guide roller set inside the spinning bath and electrodes set on the spinning nozzle device and the spinning bath. The apparatus of the present invention is used in spinning polymer, and has greatly raised wet spinning speed, great fiber drafting magnification, well oriented fiber molecule chain, compact fiber structure, greatly raised mechanical performance of fiber, wide solvent selecting range, simplified electrostatic spinning equipment, raised solvent recovering rate and less environmental pollution caused by the solvent.

Owner:DONGHUA UNIV

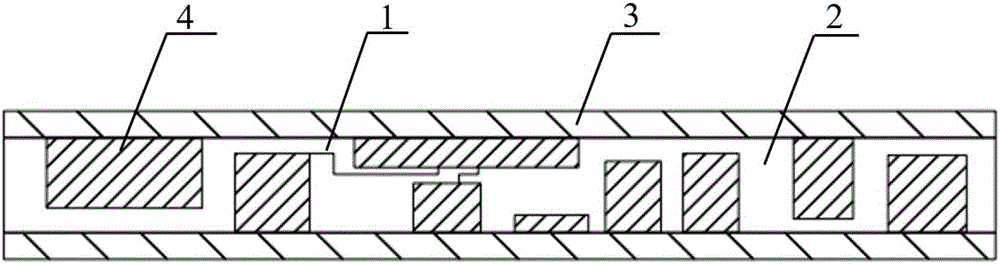

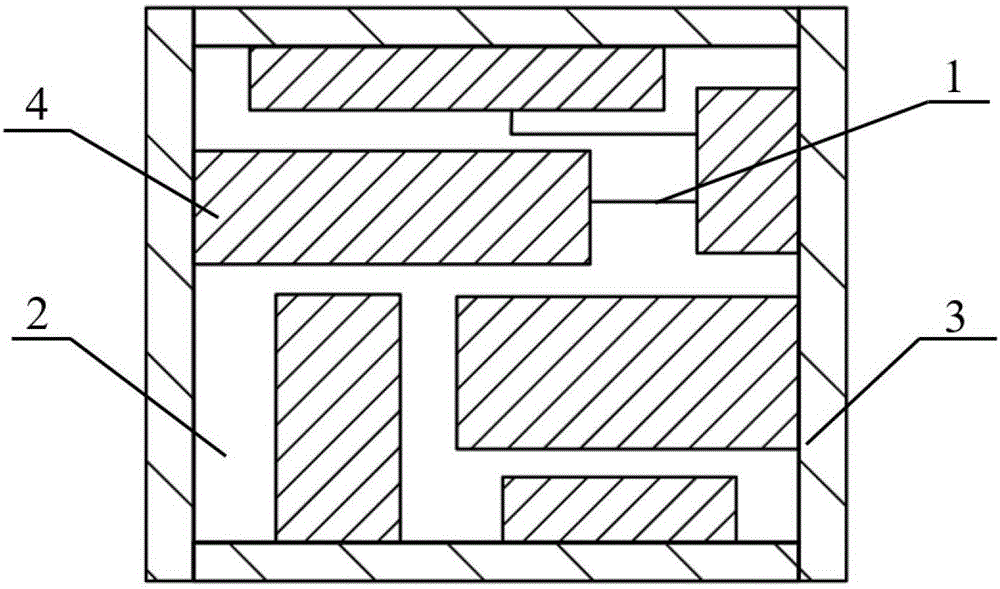

Composite 3D printing method of buried circuit board

ActiveCN106211622ASave the machining processHigh dimensional accuracyPrinted circuit assemblingAdditive manufacturing apparatusMicro structureSelective laser melting

The invention belongs to the technical field of 3D printing, and particularly discloses a composite 3D printing method of a buried circuit board. Two 3D printing modes of selective laser melting (SLM) and selective laser sintering (SLS) are combined, an SLS / SLM forming device is used, selective distribution of insulation nonmetal powder and conductive metal powder in all layers in an insulation substrate area and a conducting circuit area is achieved through powder feeding spray heads and powder suction spray heads, and the groove-machining-free buried circuit board is manufactured through the main forming steps of modeling, slicing, powder spreading, powder suction, powder feeding and laser scanning forming. The advantages of being capable of forming complex shapes and micro structures of the 3D printing technology are utilized, integral manufacturing of the buried circuit board is achieved, the manufacturing process of a traditional buried circuit board is greatly simplified, the manufacturing cost is reduced, the manufacturing period is shortened, and the space utilization rate of the circuit board is remarkably increased.

Owner:HUAZHONG UNIV OF SCI & TECH

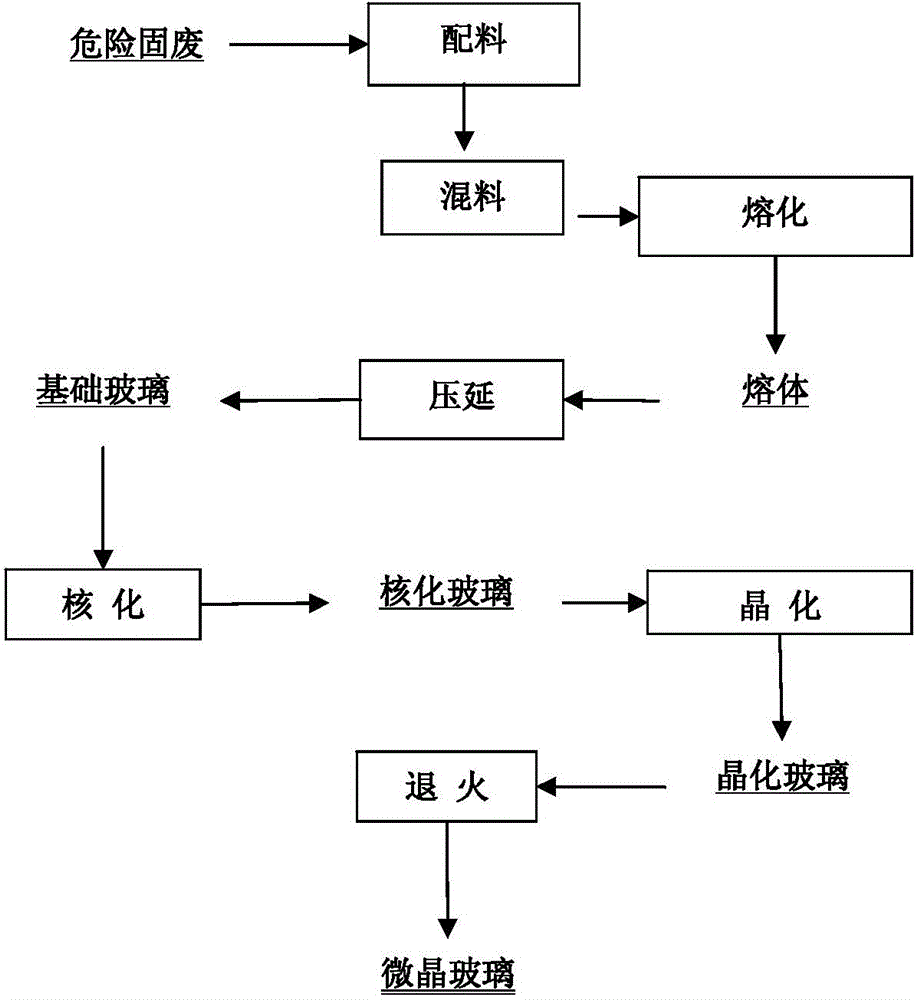

Method for preparing microcrystalline glass from hazardous solid wastes

The invention discloses a method for preparing microcrystalline glass by taking hazardous solid wastes which are hazardous solids for short. The method is characterized by taking heavy metals in the hazardous solids as nucleating agents, mixing, fusing, rolling, nucleating, crystallizing and annealing to obtain the microcrystalline glass. The method has the advantages that the heavy metal elements in waste incineration ash, stainless steel slag, stainless steel acid pickling sludge, electroplating sludge, chromium slag, lead-zinc smelting slag and coal ash can be stably solidified; the pollution is avoided; meanwhile, high-additional-value microcrystalline glass is prepared; the harmless high-value application of the hazardous solids is realized; and the method has remarkable environmental and economic benefits and wide market prospects.

Owner:UNIV OF SCI & TECH BEIJING

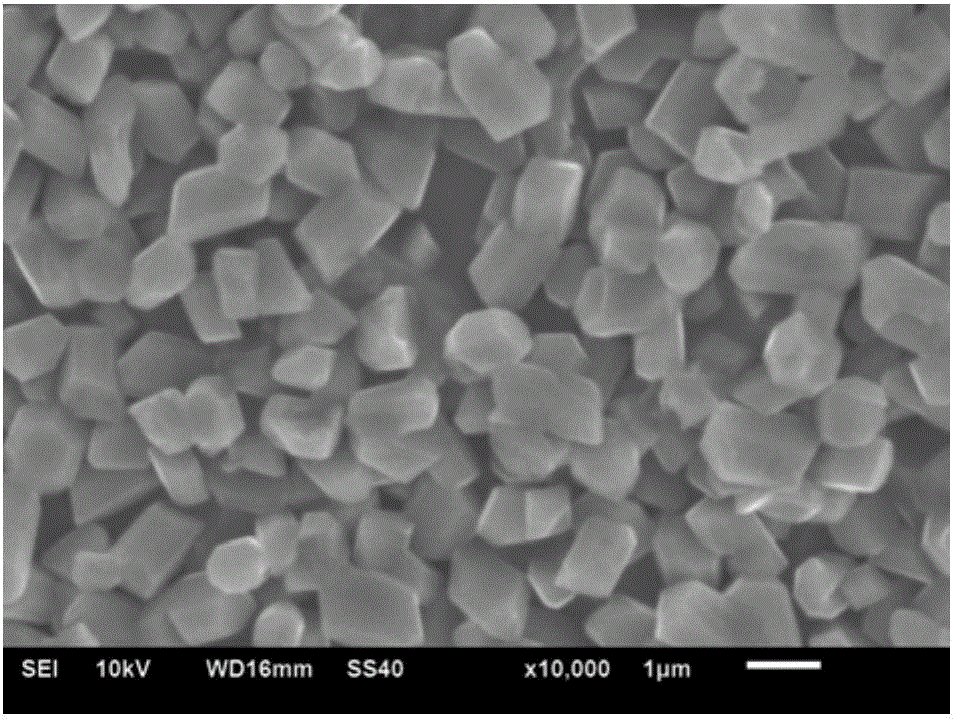

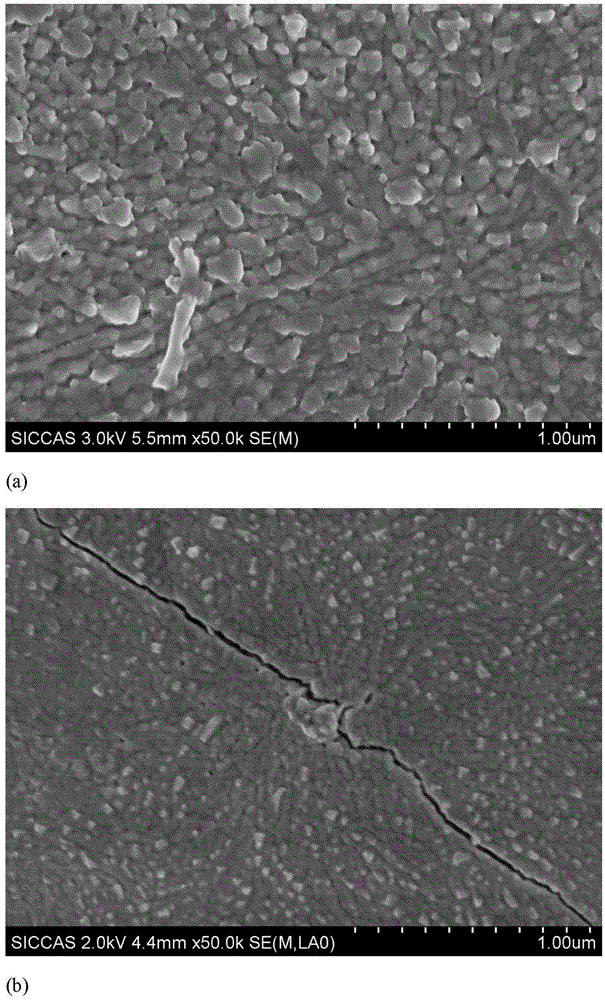

Method for preparing perovskite thin film in perovskite solar cell via solution air extraction and ventilation method

ActiveCN105702871AIncrease supersaturationSpeed up evaporationSolid-state devicesSemiconductor/solid-state device manufacturingSolvent moleculePerovskite solar cell

The invention provides a method for preparing a perovskite thin film in a perovskite solar cell via a solution air extraction and ventilation method. The method comprises the following steps: a perovskite liquid film coated on a surface of a base body is subjected to air extracting and drying operation in an environment where the partial pressure of the solvent is lower than 99% saturated vapor pressure of the solvent at current temperature; during drying processes or after the perovskite liquid film is completely dries, a gas which does not react chemically with a perovskite is let in, and therefore a process that the solvent is evaporated or solvent molecules leave the environment can be accelerated via solvent molecule concentration dilution. Heterogeneous nucleation and growth of the surface of the base body can be realized via control over drying process conditions, and therefore a uniform and compact perovskite thin film can be formed. The method can be used for accelerating liquid film drying processes, making solvent steam molecules leave a surface of the thin film quickly, and obtaining the uniform-structured and compact perovskite thin film; thus current leakage caused by perovskite thin film loopholes can be prevented and the method can help make high-efficiency solar cells; the method is advantaged by simple operation, easy-to-implement property, low cost, high repetition accuracy, convenience for industrialization and the like.

Owner:杨冠军

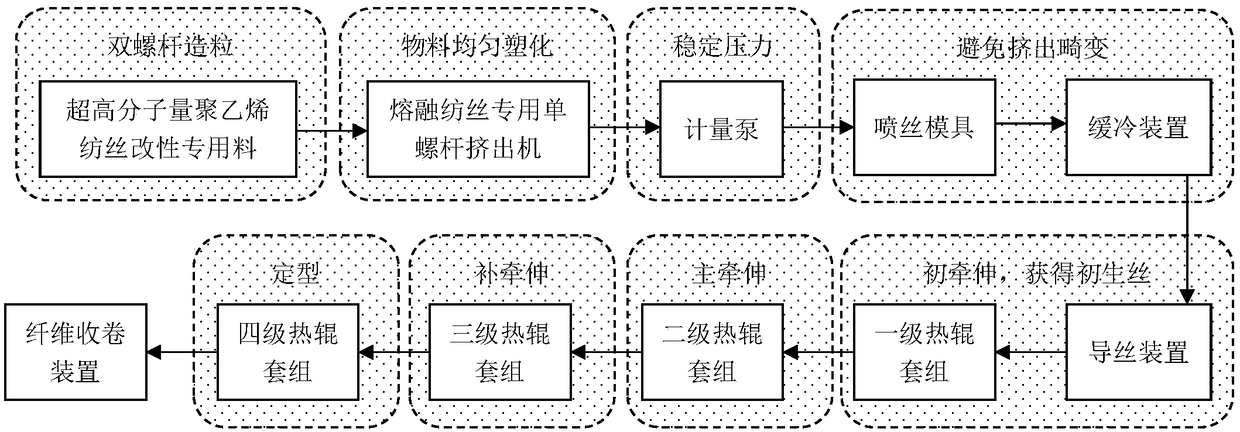

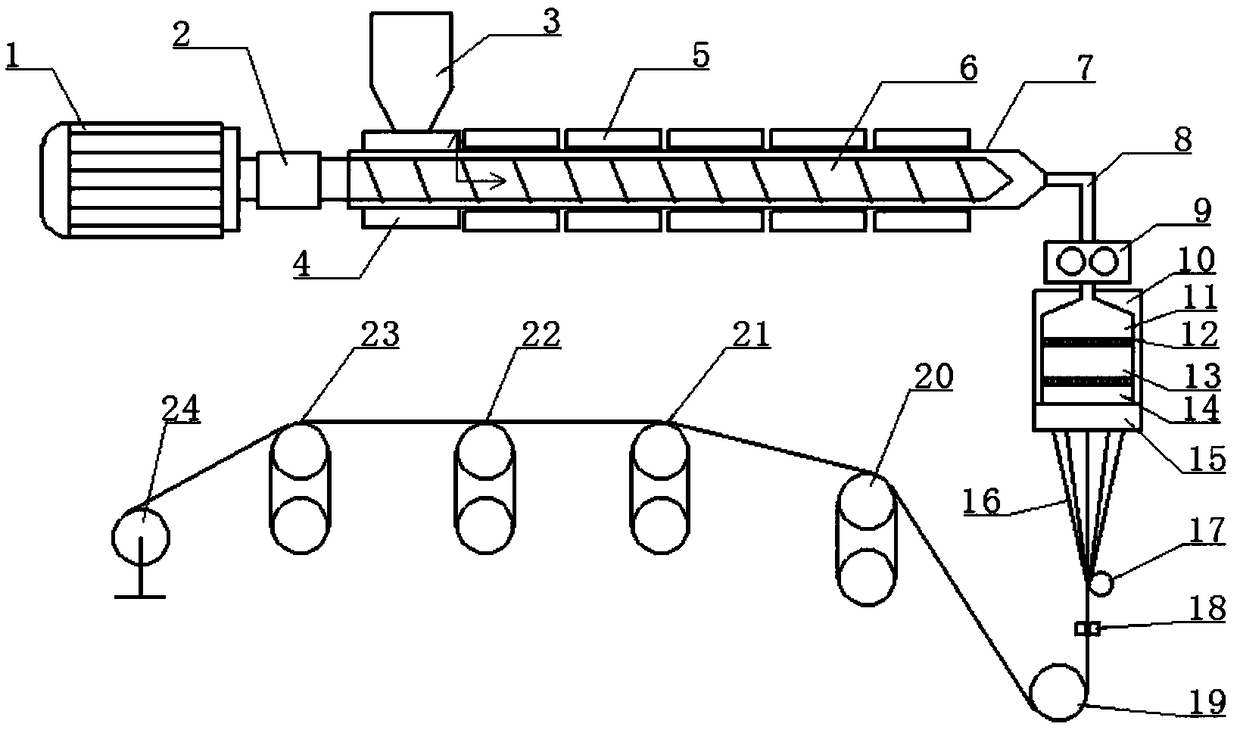

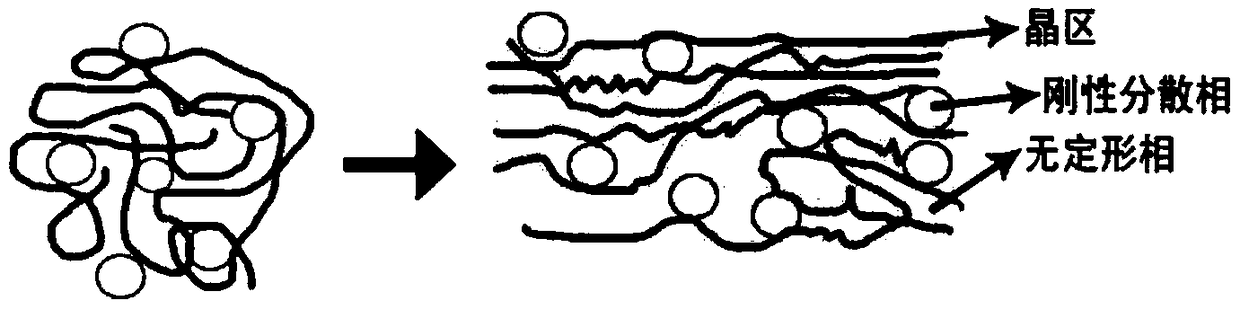

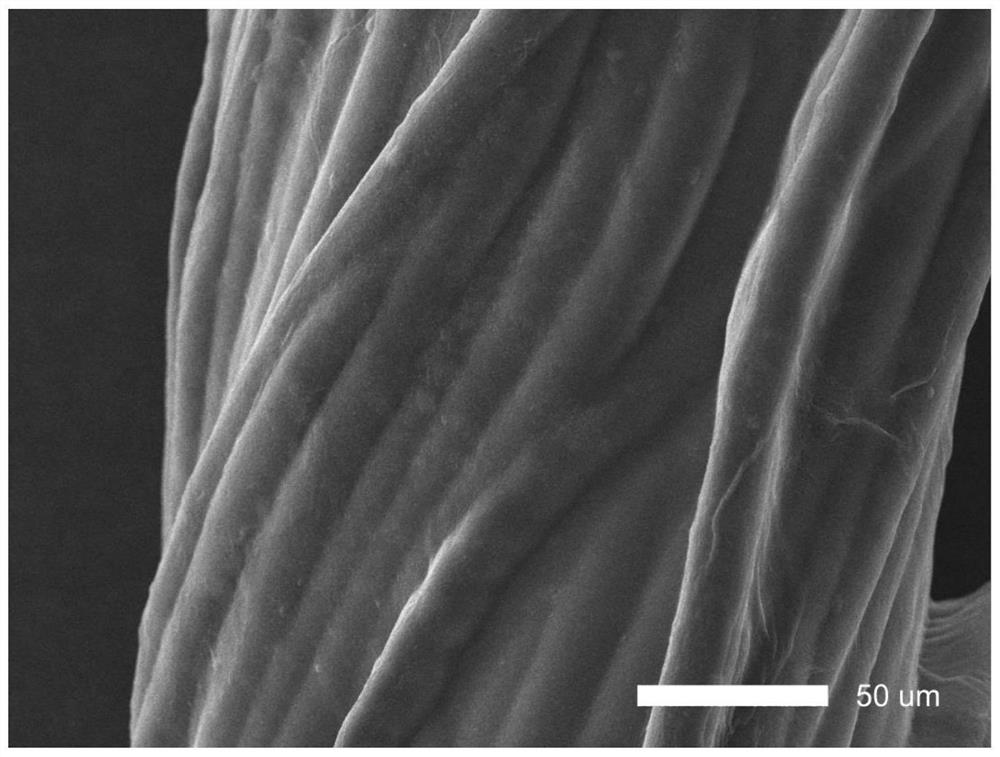

Modified ultra-high molecular weight polyethylene fiber forming special material, and preparation method and melt spinning fiber forming method thereof

ActiveCN108660535AThe internal structure of the fiber is uniform and denseGood mechanical propertiesArtificial filament heat treatmentMelt spinning methodsTraction systemMelt spinning

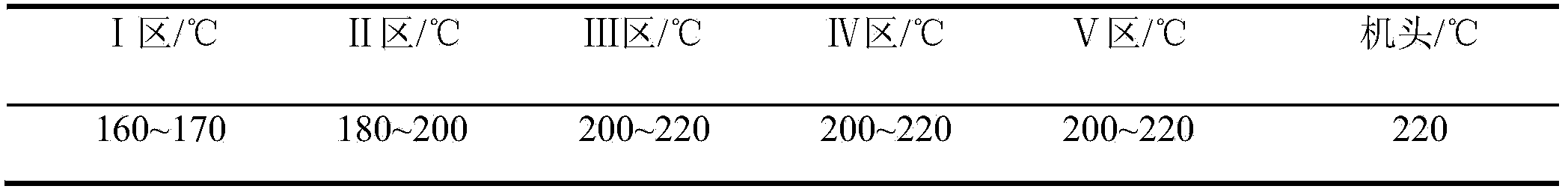

The invention relates to a modified ultra-high molecular weight polyethylene fiber forming special material, and a preparation method and a melt spinning fiber forming method thereof, and belongs to the technical field of high quality fiber materials. The special material is prepared from the following ingredients: ultra-high molecular weight polyethylene, high-density polyethylene, antioxygen andmodified nanometer inorganic filler. The melt spinning fiber forming method for the modified ultra-high molecular weight polyethylene fiber forming special material comprises the following steps: carrying out fusion plasticization on the modified ultra-high molecular weight polyethylene fiber forming special material through a single screw extruder, entering a spinning box body through a meteringpump device, carrying out fusion extrusion by a spinning component, and taking the heating function of a slow cooling device as an auxiliary to prepare a primary filament; S2: carrying out preliminary drawing on the primary filament obtained in S1, entering a four-level hot roller traction system to be subjected to grading drawing and sizing, and rolling through a fiber rolling device, and obtaining a finished product fiber. By use of the melt spinning fiber forming technology, middle and high strength ultra-high molecular weight polyethylene fibers can be produced at low cost, and the application of the middle and high strength ultra-high molecular weight polyethylene fibers in civilian field including labor protection, marine fishery and the like can be widely expanded.

Owner:BEIJING UNIV OF CHEM TECH

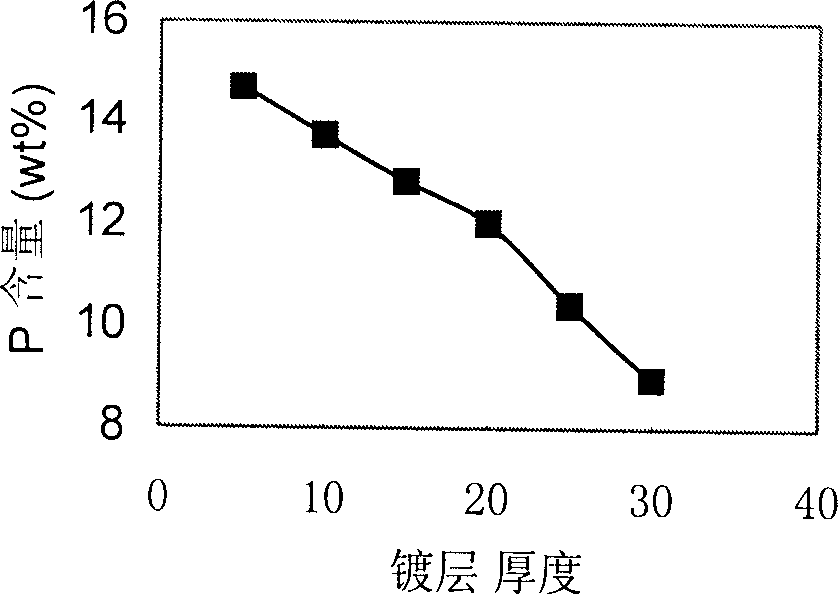

Antiwear nickel phosphor functionalized gradient plate preparation method

The invention discloses a preparation method for wearable nickel phosphate function gradient plating coat, which comprises: with design idea for gradient material, using single-bath electroplating method, preparing the coat with phosphate content gradient varying by boosting current density gradually and controlling deposition time. This product has proper phosphate content gradient and thermal expansion coefficient to release the thermal stress problem and high bond strength and abrasion resistance. This method can replace current used technique.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Zinc-based composite coating for improving corrosion resistance of neodymium-iron-boron magnet

InactiveCN102653643AReduce the impactUniform thicknessLiquid surface applicatorsAnti-corrosive paintsSilicone resinPolytetrafluoroethylene

The invention relates to a zinc-based composite coating for improving corrosion resistance of a neodymium-iron-boron magnet. The zinc-based composite coating is characterized by comprising a zinc-based coating and a reinforced protective coating, wherein the zinc-based coating consists of the following components by mass percent: 65%-95% of flake zinc powder, 1%-30% of flake aluminum powder and 0%-5% of amorphous composite chromic salt compound, the molecular formula of the amorphous composite chromic salt compound is nCrO3.mCr2O3, and n and m are natural numbers; and the reinforced protective coating is one of a wear-resisting organic silicone resin coating, a polytetrafluoroethylene coating and an epoxy resin coating. The zinc-based composite coating provided by the invention has the advantages that the coating is uniform and compact in structure and good in substrate bonding property, is not easy to peel or fall off, is less in magnetic property influence, uniform in thickness, low in porosity and extremely strong in corrosion resistance, is extremely compact and has no corner effect and no hydrogen embrittlement; and the process is environment-friendly.

Owner:BAOTOU RES INST OF RARE EARTHS

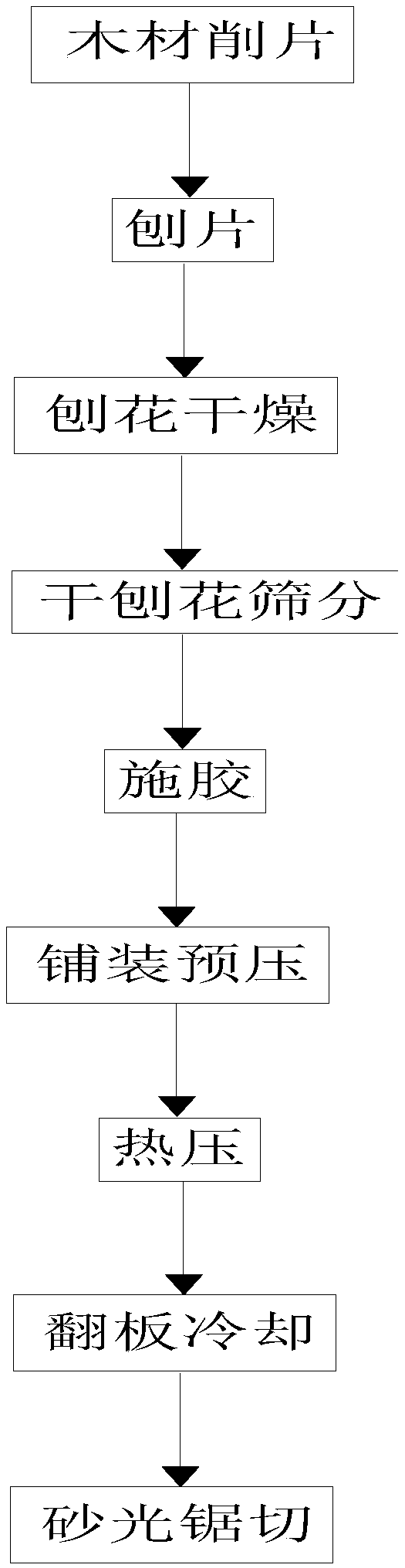

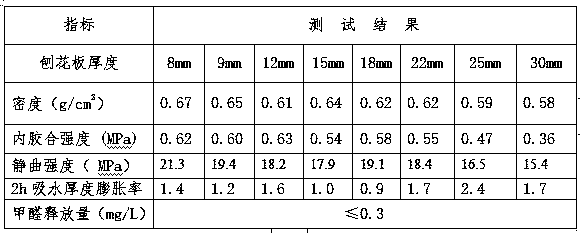

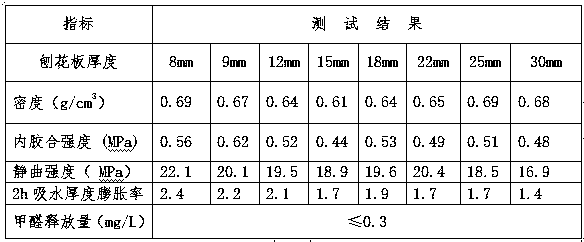

Ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings

InactiveCN109624016ALess squeezeAvoid secondary damageFlat articlesDomestic articlesWood shavingsManufacturing technology

The invention relates to the technical field of artificial plate manufacturing, in particular to an ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings. The ultra-strength shaving board manufacturing technology comprises the processes of wood chipping, flaking, drying, sieving, glue applying, paving and pre-pressing, hot-pressing, board reversingand cooling, sanding and saw cutting, testing and classifying, warehousing and packaging and the like. The quality performance of an ultra-strength shaving board produced and manufactured by the ultra-strength shaving board manufacturing technology is far better than the standards of an European oriented strand board in 'EN300: 2006-OSB' and 'T / CTWPDA03-2017 veneer shaving board', and the strength of the ultra-strength shaving board even reaches the strength level of a hipboard or plywood; the ultra-strength shaving board has the outstanding features of highest mechanical strength compared with a plate with the same density, lowest density compared with a plate with the same strength, and material saving, and the mechanical strength performance of the ultra-strength shaving board is improved greatly due to the fact that the product structure is uniform and compact; and the advantages of a stable size, non-deformation, small thickness tolerance and the like are realized, and the transformation and upgrading of the artificial board industry, especially shaving board industry are facilitated greatly.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

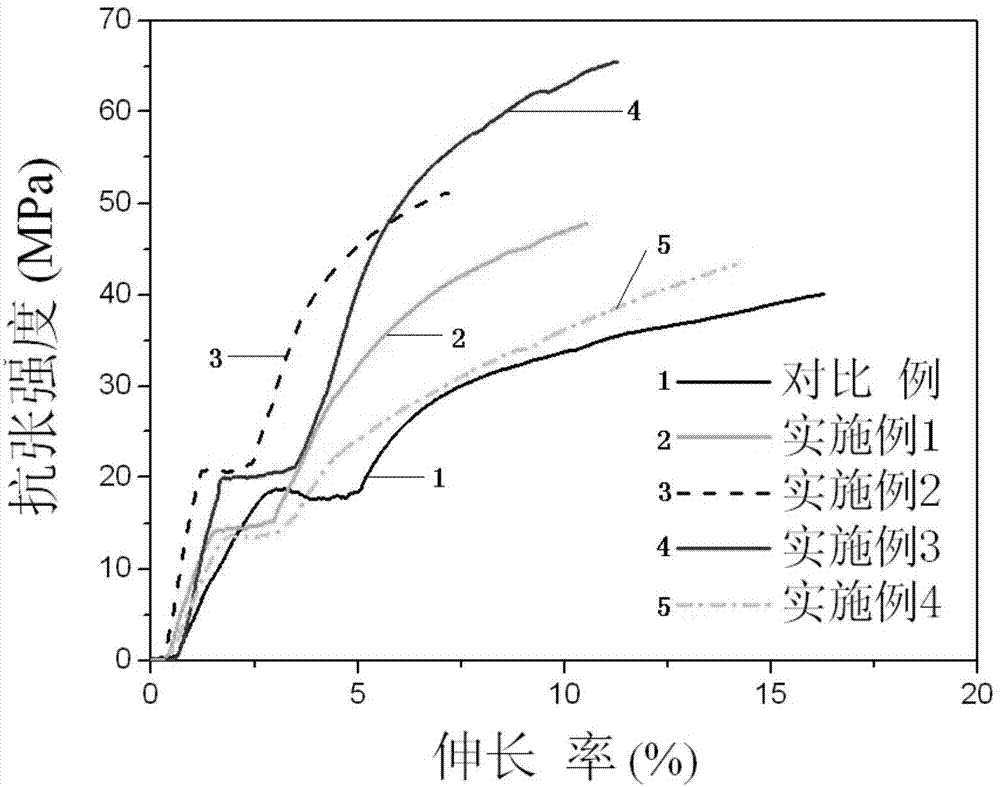

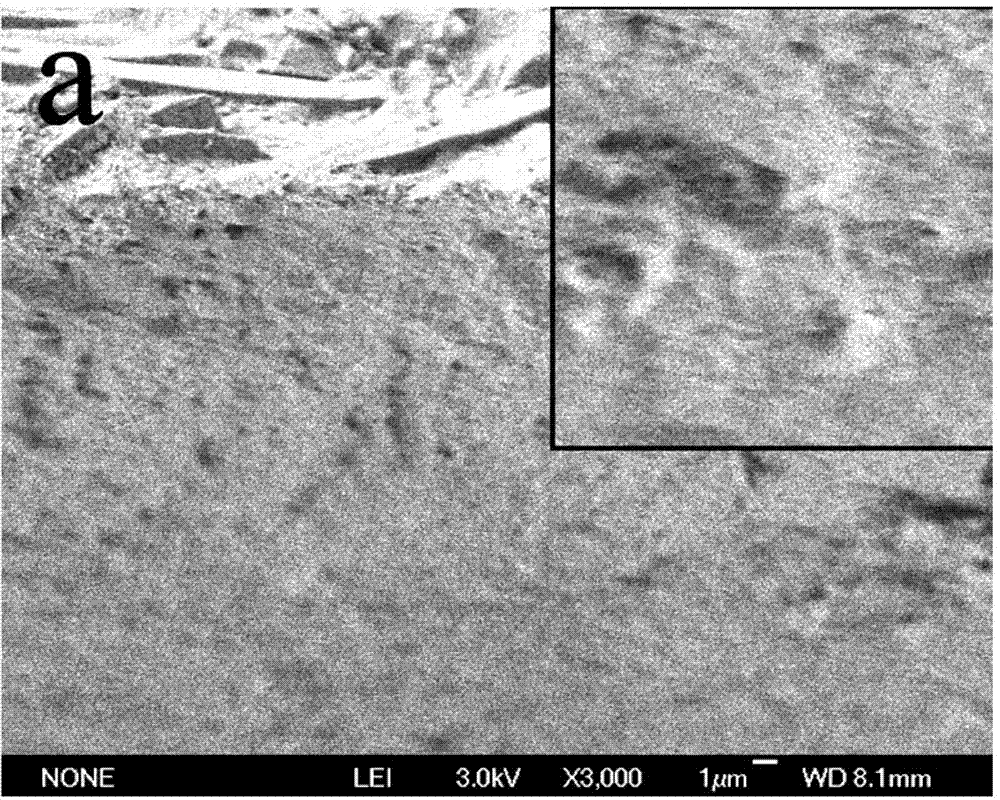

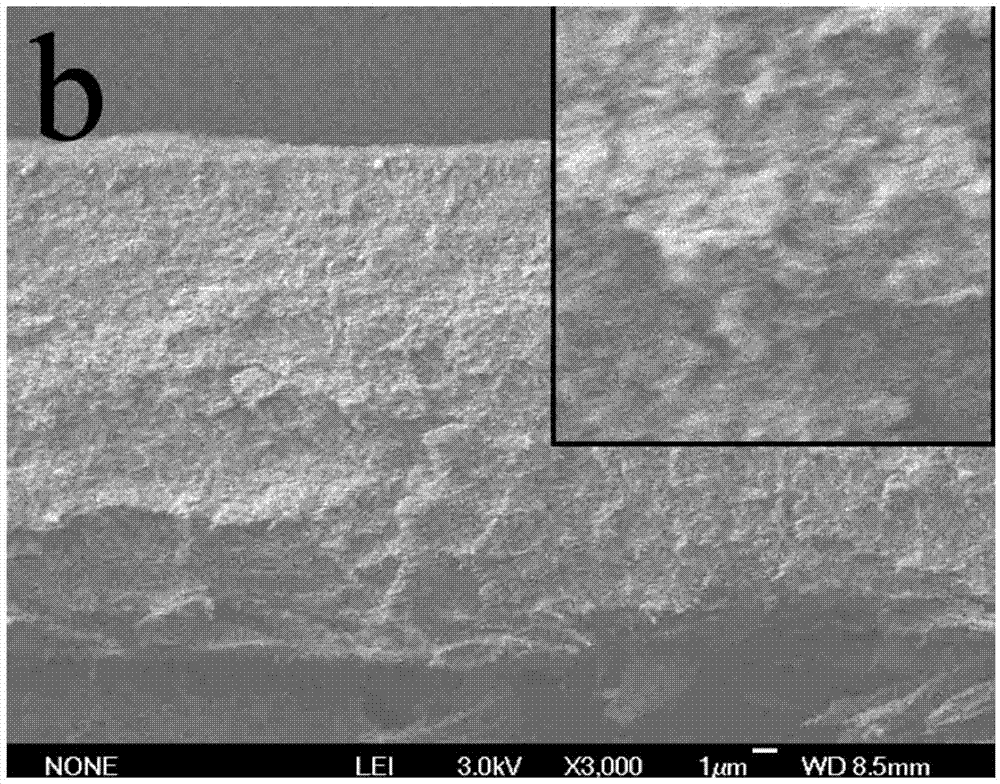

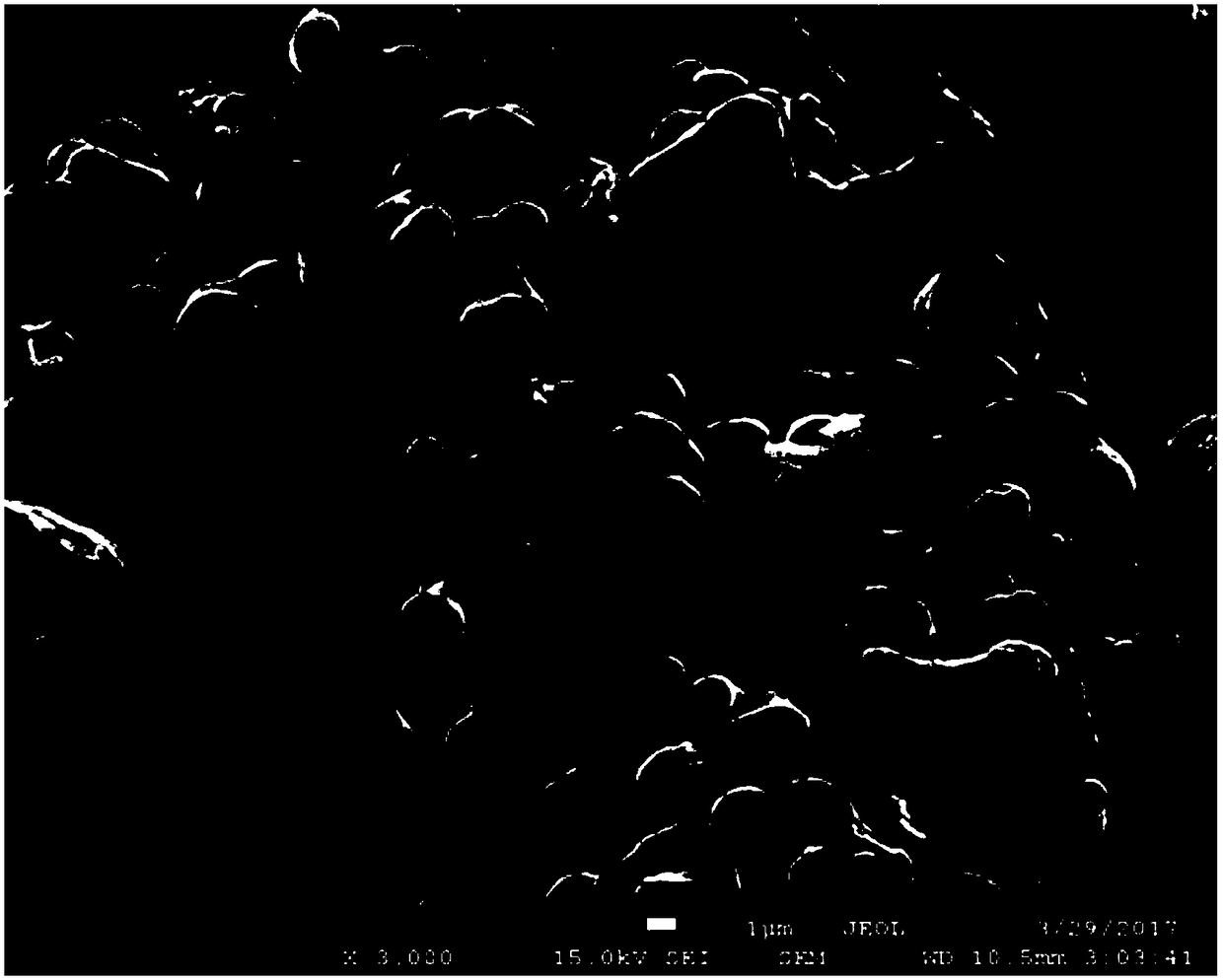

Preparation method of cellulose-based composite material

The invention relates to a preparation method of a cellulose-based composite material. The method comprises the following steps: preparing a cellulose solution and a lithium magnesium silicate solution; mixing the cellulose solution with the lithium magnesium silicate solution; coagulating and regenerating in a coagulating bath; washing and drying to obtain the cellulose-based composite material. According to the preparation method, lithium magnesium silicate can form a stable nanometer flake structure in a water system, so that ultra-fine dispersion of lithium magnesium silicate nano particles in the cellulose solution is realized, and the cellulose-based composite material, which is compact and even in structure, and is significantly improved in the tensile property, is prepared; dispersing is carried out in absence of any surfactant. Therefore, the preparation method is simple in steps, and has good practical application value.

Owner:QILU UNIV OF TECH

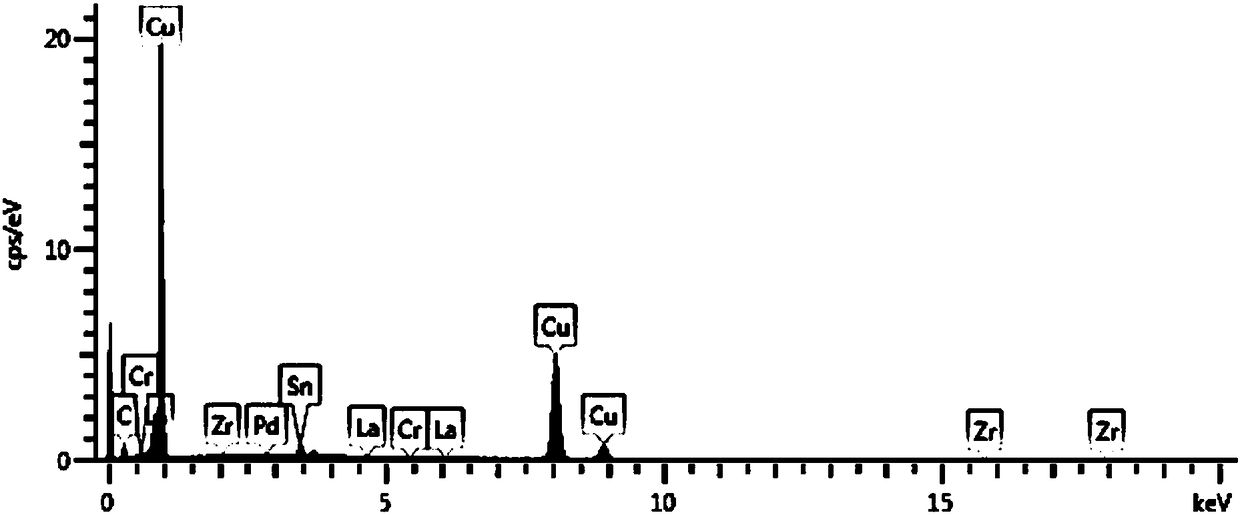

Nanocarbon reinforced copper-based composite material for maglev trains, and preparation method thereof

The invention discloses a nanocarbon reinforced copper-based composite material for maglev trains. The nanocarbon reinforced copper-based composite material is characterized in that the nanocarbon reinforced copper-based composite material comprises 0.1-5% of surface-modified carbon nanotubes, 0.1-5% of surface modified graphene, 2-10% of graphite powder, 1-4% of chromium powder, 1-8% of lead powder, 2-10% of tin powder, 0.1-1% of zirconium powder, 0.01-0.5% of lanthanum powder, and the balance of copper powder, wherein the surface-modified carbon nanotubes are carbon nanotubes obtained by modifying carbon nanotubes with an aqueous solution of gallic acid, and the surface-modified graphene is graphene modified with an aqueous solution of rutin. A copper-based composite material has low impurity content, and maintains the structure of an added reinforcing phase component complete, and various added components have a co-reinforcing effect, and significantly improve the strength, the hardness and the current-carrying friction and wear properties of the copper-based composite material. The invention also discloses a preparation method of the copper-based composite material. The methodhas the advantages of simple process, easiness in production, and broad application prospect.

Owner:SOUTHWEST JIAOTONG UNIV

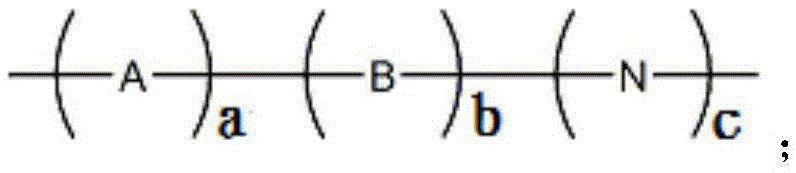

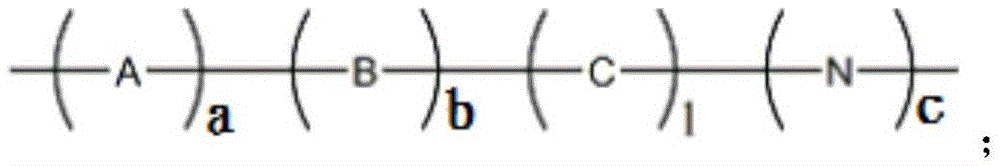

Application of ultra-high early strength polycarboxylic acid water reducer to preparation of precast concrete component

The invention discloses a preparation method of a precast concrete component. The method comprises the following steps: natural curing is carried out for a precast component preliminary body which is formed after concrete pouring, demoulding is carried out when the precast component preliminary body reaches demoulding strength, natural curing is continuously carried out, and the precast concrete component is obtained. The concrete comprises following components: cement, aggregates, an ultra-high early strength polycarboxylic acid water reducer and water; the super early strength polycarboxylic acid water reducer is a compound shown in the formula (I) or the formula (II). The invention also discloses a precast concrete component which is prepared by the preparation method of the precast concrete component. The ultra-high early strength polycarboxylic acid water reducer is used for promoting cement hydration, any activity enhancing admixtures are not added, a concrete mix ratio is optimized, and finally die stripping time of the precast concrete component is shortened from 30-40 hours to 12-15 hours; turnover period of the die is accelerated, and economic benefit is improved.

Owner:GUANGDONG REDWALL NEW MATERIALS

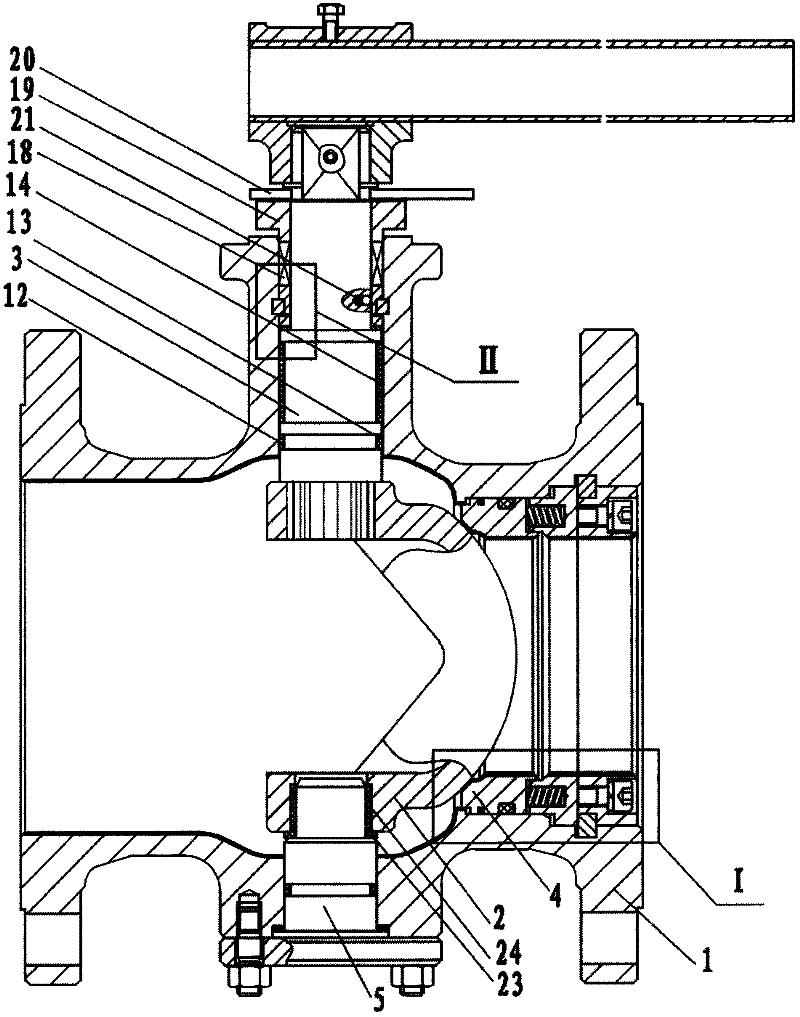

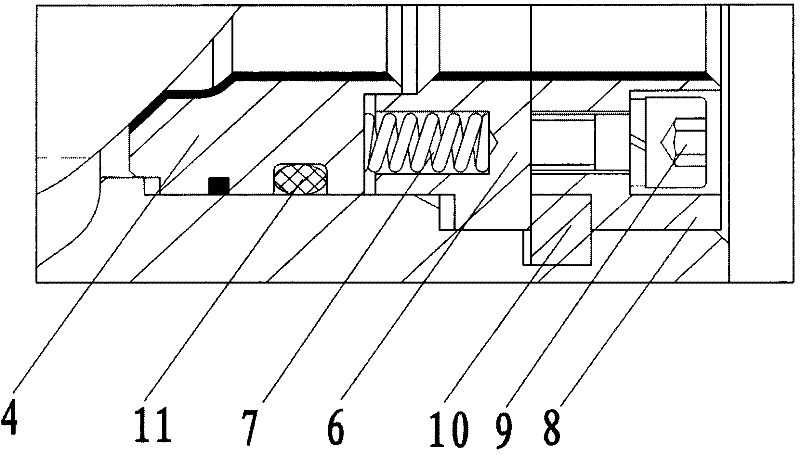

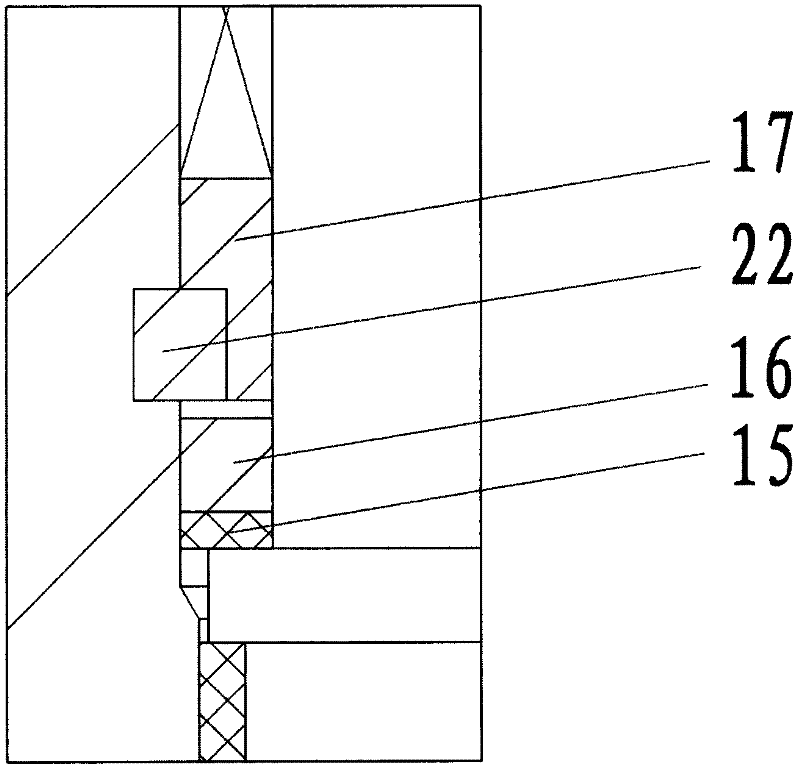

High-temperature metal hard seal ball valve for granular media

ActiveCN102654202AAvoid damageImprove sealingSpindle sealingsPlug valvesMetallic materialsEngineering

The invention provides a high-temperature metal hard seal ball valve for granular media. The high-temperature metal hard seal ball valve comprises a valve body, a ball body, a valve rod, a valve seat and a bottom cover, wherein the ball body is arranged in a cavity in the valve body, the valve rod connected with the ball body extends out of the valve body through a center through hole at the upper part of the valve body, the bottom cover is positioned at the bottom of the valve body and comprises a bottom cover baseplate and a bottom cover shaft, the bottom cover baseplate is movably connected with the valve body, the bottom cover shaft penetrates through a through hole at the lower part of the valve body and is connected with the ball body in the cavity of the valve body, the ball body and the valve seat are made of metal materials, the valve seat is mounted in the valve body and on the inner wall which is in contact with the ball body, a spring seat is arranged on the outer side of the valve seat, a disc spring is mounted in a groove between the spring seat and the valve seat, a pressure ring is arranged on the outer side of the spring seat, the pressure ring is fixedly mounted on the spring seat through a screw, a pendant collet for playing a sealing role is arranged in the contact position of the spring seat, the pressure ring and the valve body, an O ring is arranged in the groove between the valve seat and the valve body, and the O ring is made of fluorine rubber.

Owner:OVIKO GRP CO LTD

Polyamide/acrylonitrile-butadiene-styrene copolymer alloy and its prepn

The present invention relates to one kind of polyamide / acrylonitrile-butadiene-styrene copolymer alloy and its preparation process. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy is prepared with polyamide 35-60 wt%, acrylonitrile-butadiene-styrene copolymer 8-50 wt%, compatilizer 2-10 wt%, flexibilizer 2-15 wt%, antioxidant stabilizer 0.2-2 wt%, lubricant 0.3-3 wt%, and nucleator 0.1-2 wt%. The preparation process includes weighing the materials based on the weight proportion, mixing in a high speed mixer for 1-4 min, mixing, melting and extruding in a double screw extruder, and pelletizing. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy has simple processing and molding process and high performance.

Owner:SHENZHEN KEJU NEW MATERIAL

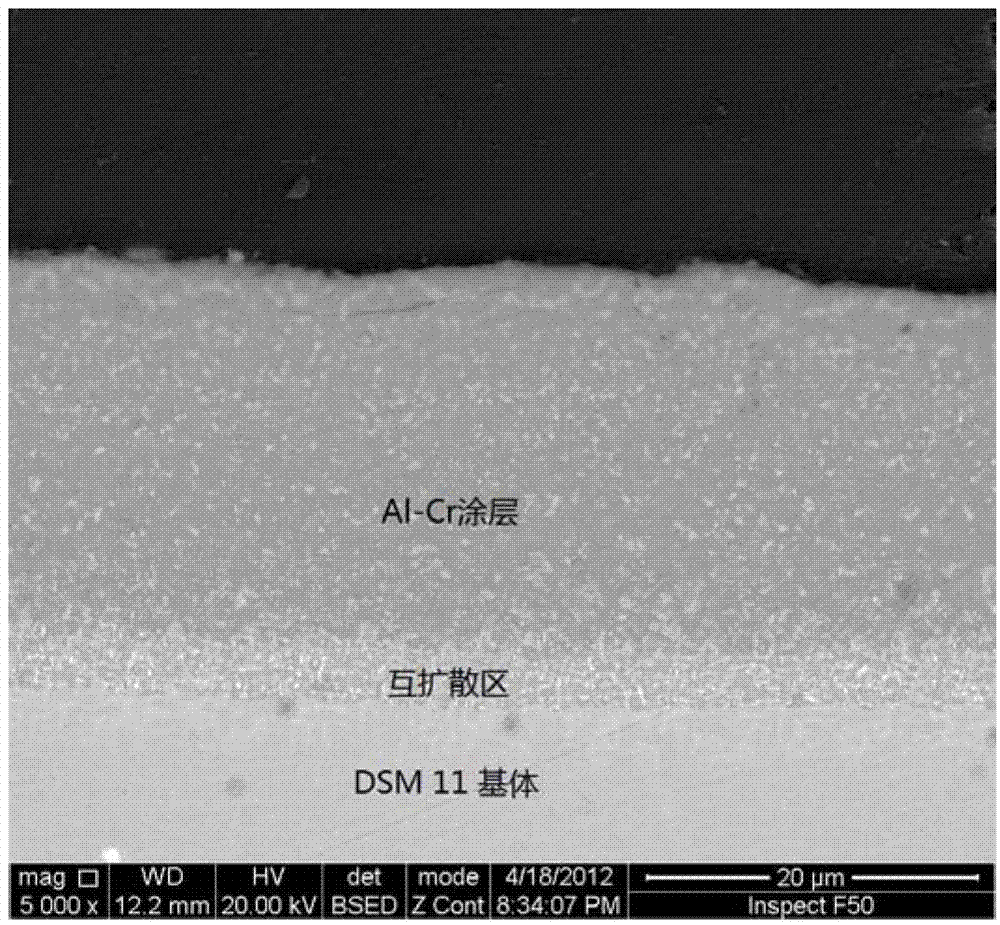

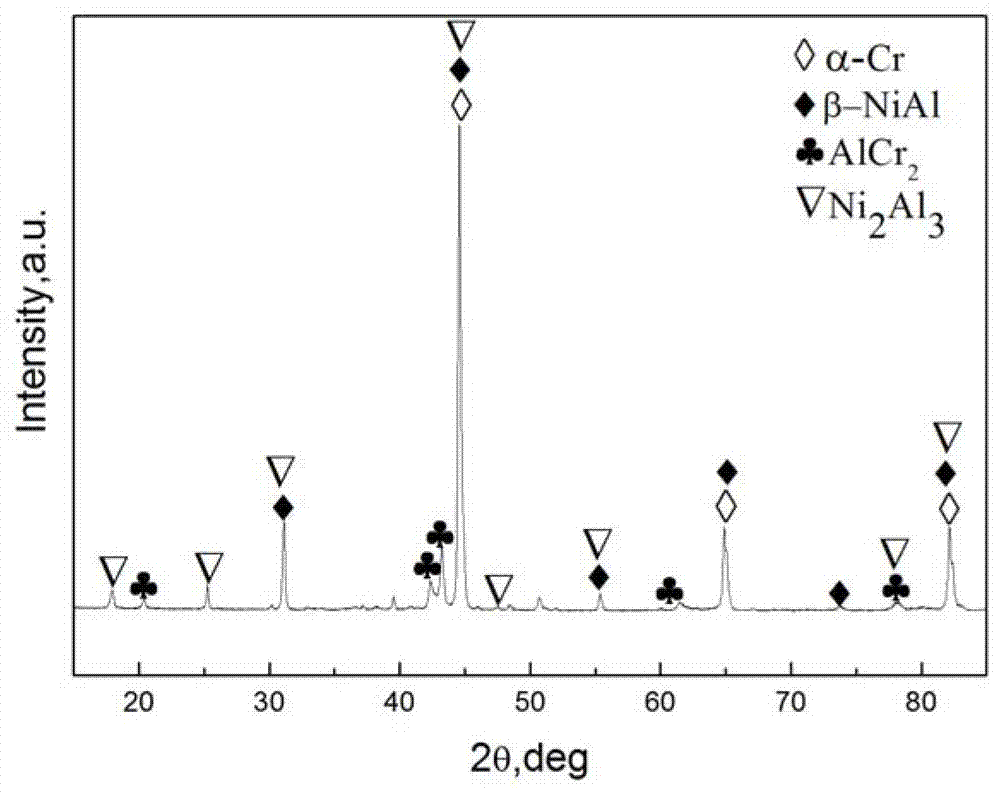

Preparation method for Al-Cr coating on nickel-based superalloy

InactiveCN103590002AExtended service lifeImprove antioxidant capacityVacuum evaporation coatingSputtering coatingPre treatmentMaterials science

The invention discloses a preparation method for an Al-Cr coating on a nickel-based superalloy, which belongs to the technical field of high temperature protection coatings. The method comprises the following steps: pretreating a superalloy matrix; depositing a Cr layer on the surface of the cleaned superalloy by using arc ion plating; and finally, carrying out alumetizing through powder embedding so as to obtain the Al-Cr coating on the superalloy. The preparation method for the Al-Cr coating on the nickel-based superalloy has the advantages of good process repeatability, easy realization of industrial production and the like; the prepared coating has a compact structure, high bonding strength on the matrix and controllable components, the storage phase of Al and the content of Cr in the coating are effectively increased, so antioxidation and anti-thermal etching performance of the raising are improved, and the service life of the coating is effectively prolonged. The coating prepared by the preparation method is applicable to protection of the nickel-based superalloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

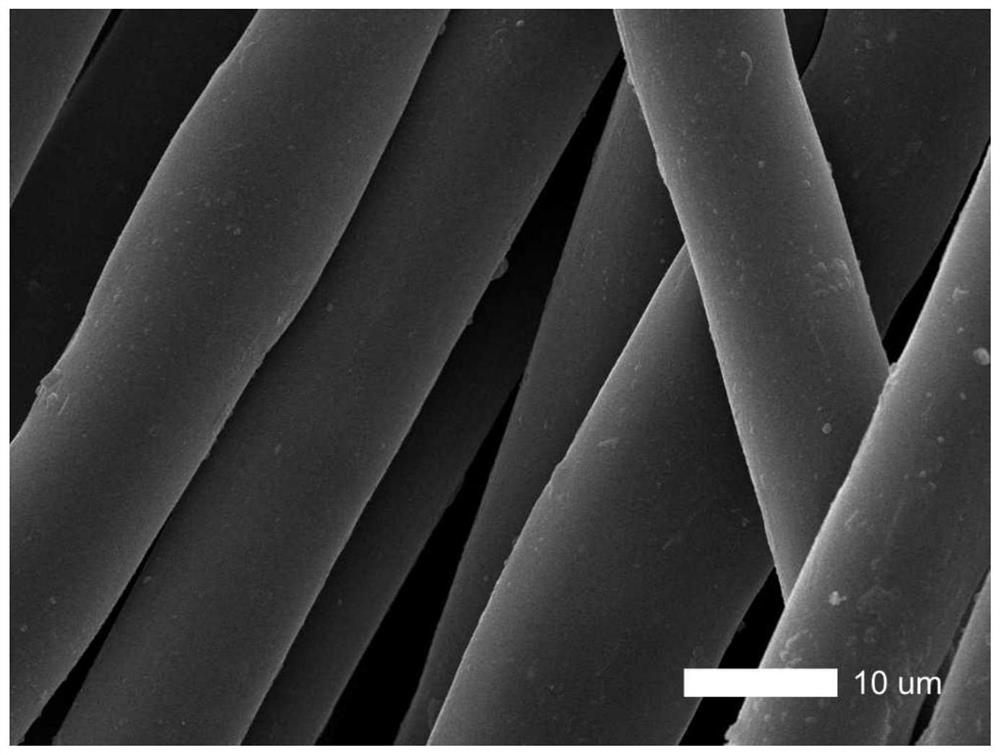

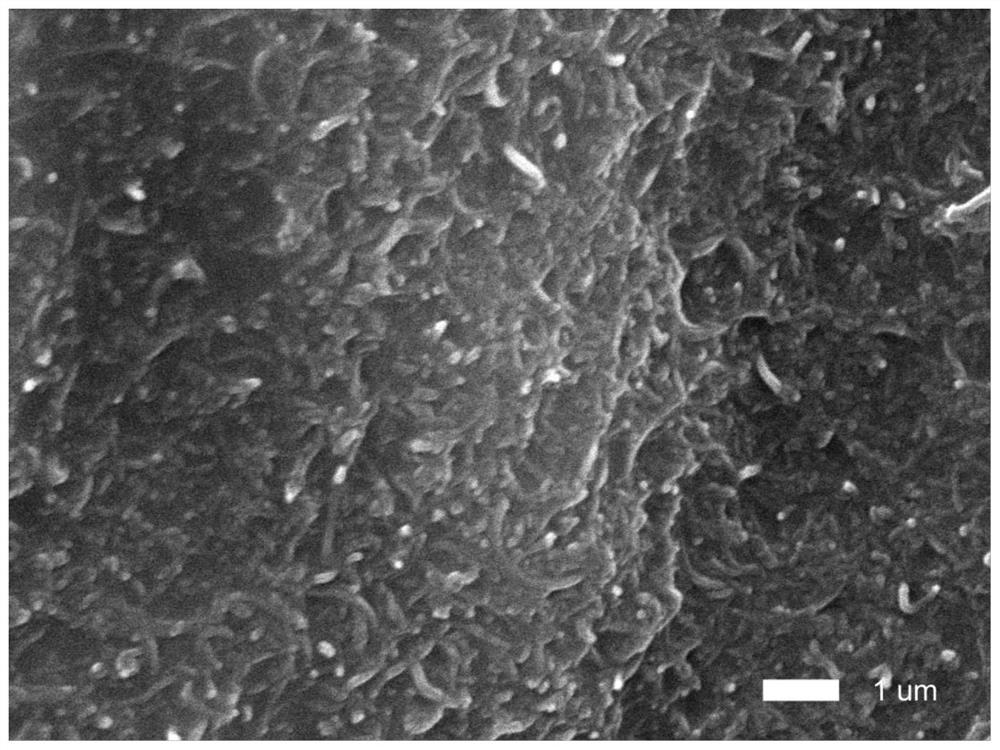

Layer-by-layer self-assembly composite conductive fiber bundle and preparation method thereof

ActiveCN111636195AImprove conductivityHigh specific surface areaPhysical treatmentFiber bundleConductive coating

The invention provides a layer-by-layer self-assembly composite conductive fiber bundle and a preparation method thereof. The method comprises the following steps that firstly, a fiber bundle is subjected to oxygen plasma pretreatment to finish physical modification of fibers, so that the surface of the fiber bundle has a certain active group; and then, through a layer-by-layer self-assembly method, electropositive substances and electronegative substances are alternately deposited on the surface of the fiber bundle through the combination of electrostatic forces of positive charges and negative charges to form a composite conductive coating, in this way, the layer-by-layer self-assembly composite conductive fiber bundle formed by compositing a fiber bundle body and the composite conductive coating deposited on the fiber bundle body is prepared. The preparation method is simple and controllable, and the conductivity of the composite conductive fiber bundle can be regulated and controlled by controlling the self-assembly time, the number of self-assembly layers and the type and concentration of electropositive / electronegative substances; and the conductive coating of the prepared composite conductive fiber bundle is uniform and compact in structure and excellent in conductivity, and can be widely applied to the fields of wearable electronic devices, energy storage, sensing and the like.

Owner:WUHAN TEXTILE UNIV

Crucible and preparation method thereof

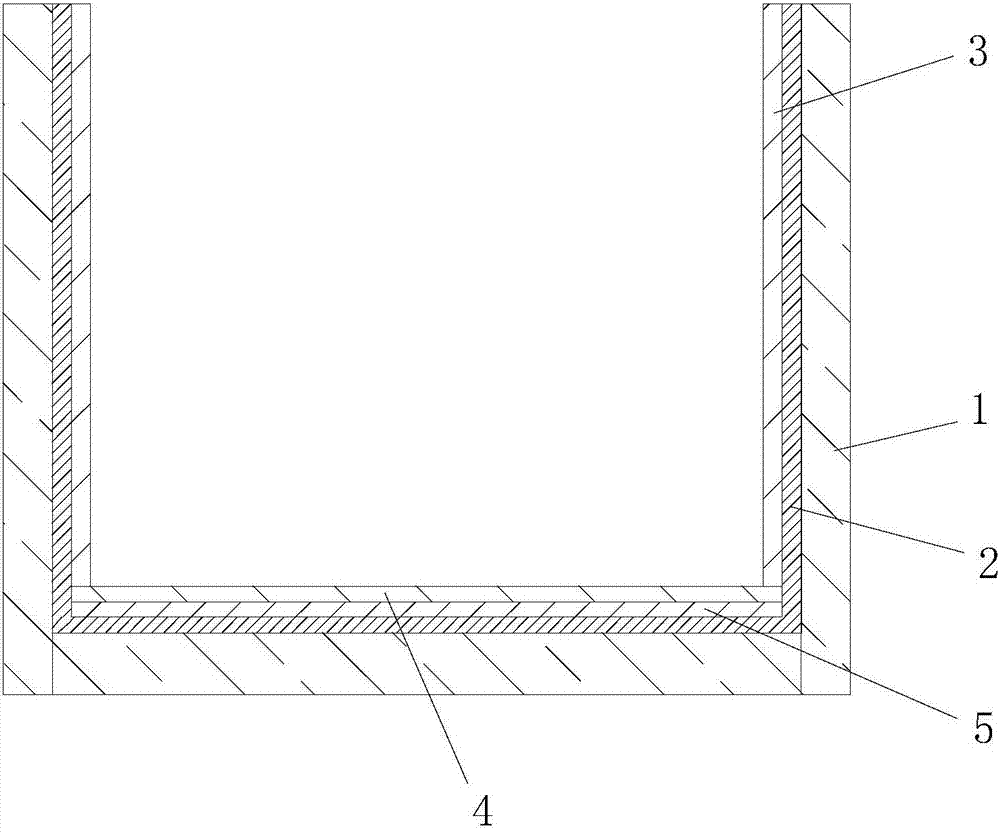

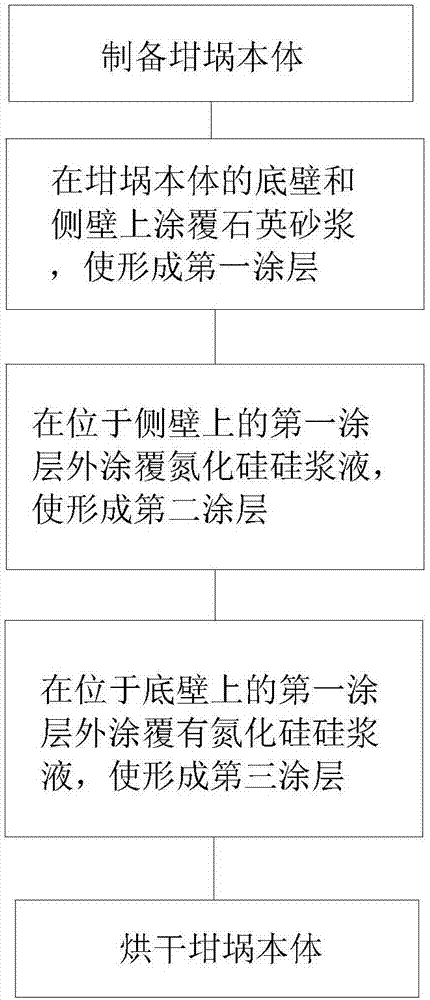

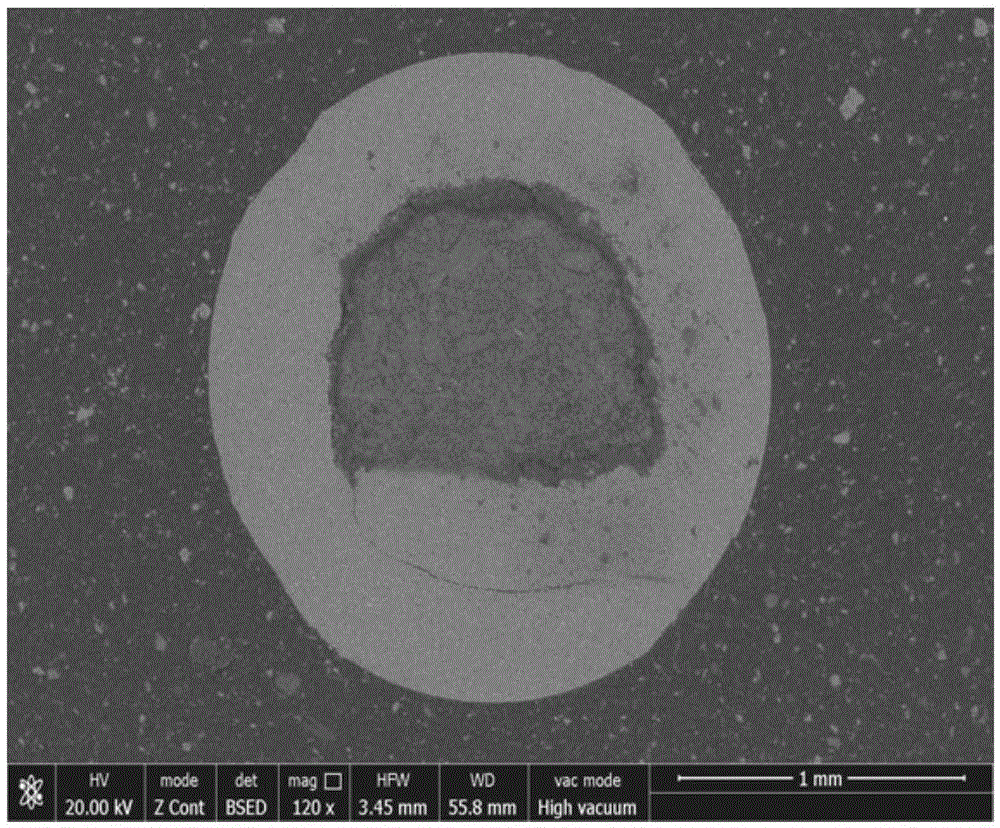

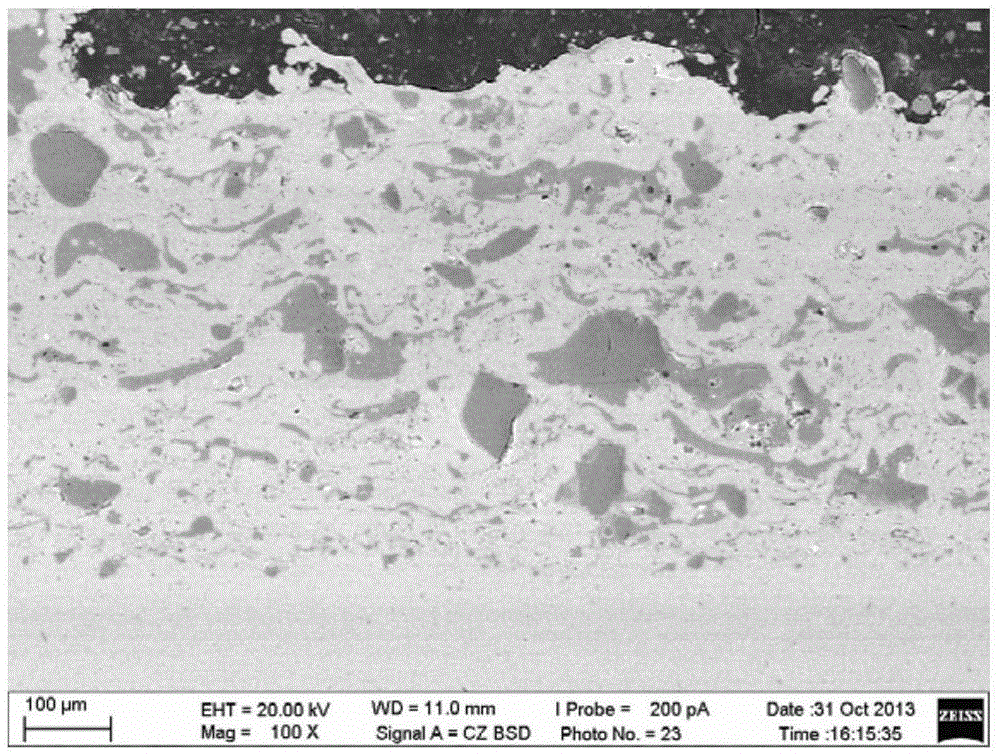

ActiveCN107573101AReduce spreadReduce defect densityPolycrystalline material growthSingle crystal growth detailsCrucibleMetal impurities

The invention provides a crucible and a preparation method thereof. The crucible comprises: a crucible body, a first coating, a second coating and a third coating, wherein the crucible body comprisesa bottom wall and a side wall; the first coating layer is arranged on the bottom wall and the side wall for preventing metal impurities from diffusing to crystalline grains in the crucible body, the second coating is arranged on the outside of the first coating layer on the side wall, the second coating layer is used to assist in nucleating the crystalline grains within the crucible body; the third coating is arranged on the outside of the first coating layer on the bottom wall, the third coating layer is used to assist in separating the crystalline grains within the crucible body from the crucible body. The crucible of the invention can effectively reduce diffusion of the metal impurities in the crucible body into polycrystalline crystals located in the crucible body, so that purity of the prepared polycrystalline silicon is high.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

Electric arc spraying wire as well as preparation and spraying methods thereof

ActiveCN105296912AImprove high temperature resistanceGood heat reflection performanceMolten spray coatingStatic friction coefficientMicron scale

The invention relates to an electric arc spraying wire as well as preparation and spraying methods thereof. A coating layer is prepared by adopting an electric arc spraying process. A spraying material is an aluminum based ceramic powder core wire, and a spraying matrix material is a steel or aluminum material, wherein the spraying material is in an aluminum sheet coated ceramic powder core structure, the outer diameter of the wire is phi 2mm, the ceramic powder core is prepared by mixing micron-scale Al2O3, nano-scale Al2O3, micron-scale SiO2 and nano-scale SiO2, an aluminum strip is folded into a U shape by virtue of a forming mold, then is uniformly filled into the ceramic powder core, coats the powder core closely by virtue of a mold, and is drawn into a spraying wire with the outer diameter of phi 2mm, and the ceramic powder core accounts for 20-38% of the mass content of the wire. A test result satisfy that the static friction coefficient of the coating layer is more than 0.9, the bonding strength is more than or equal to 20MPa, and bubbling failures are avoided by virtue of a 360h salt spray corrosion test, so that application requirements can be well met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

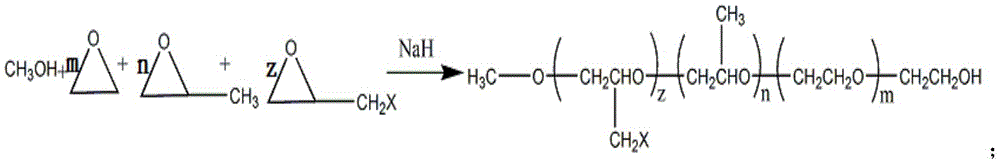

High-slump-loss-resistant synergist and preparation method and application thereof

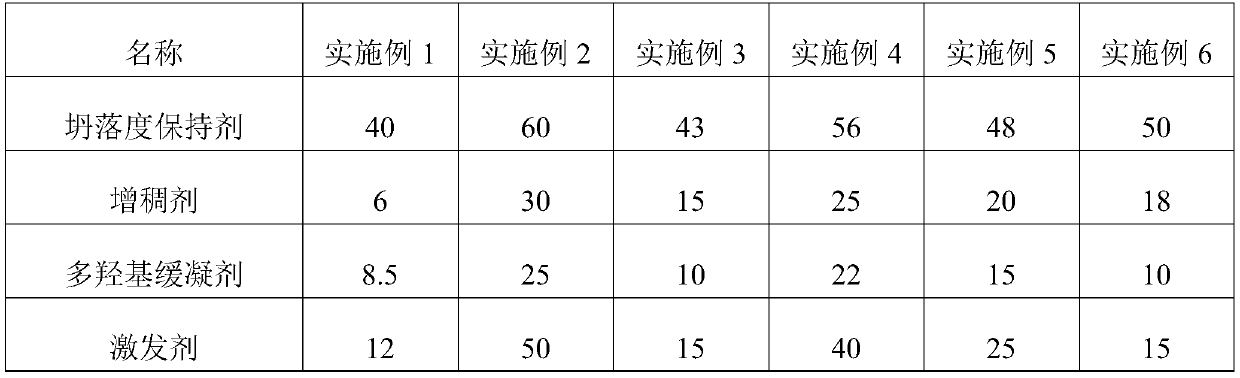

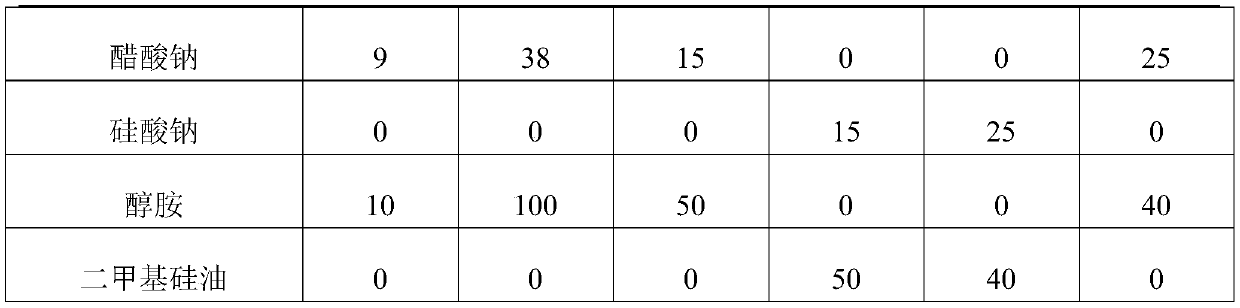

The invention belongs to the technical field of concrete, and provides a high-slump-loss-resistant synergist, which is prepared from 40 to 60 parts of slump maintainers, 6 to 30 parts of thickening agents, 8.5 to 25 parts of polyhydroxyl retarders, 12 to 50 parts of excitants, 9 to 38 parts of sodium acetate or sodium silicate and 10 to 100 parts of hydramine or simethicone, wherein the slump maintainers are prepared from 300 to 450 parts of polyether, 20 to 45 parts of unsaturated acid, 30 to 80 parts of acrylic ester, 1.1 to 3.8 parts of chain transferring agents and 0.5 to 1.5 parts of reducing agents. A preparation method comprises the following steps of adding polyether into water; performing heating dissolution; then, dripping a material A and a material B; performing reaction for one hour to obtain the slump maintainers; adding water into thickening agents for dissolution; sequentially adding the polyhydroxyl retarders, the excitants, sodium acetate or sodium silicate; after thedissolution, adding hydramine or simethicone; adding the slump maintainers; performing uniform mixing to obtain the high-slump-loss-resistant synergist applied to concrete preparation. By using the technical scheme, the high-slump-loss-resistant synergist solves the problem of fast concrete slump loss in the prior art; meanwhile, the intensity is improved.

Owner:兰州同邦建材有限公司

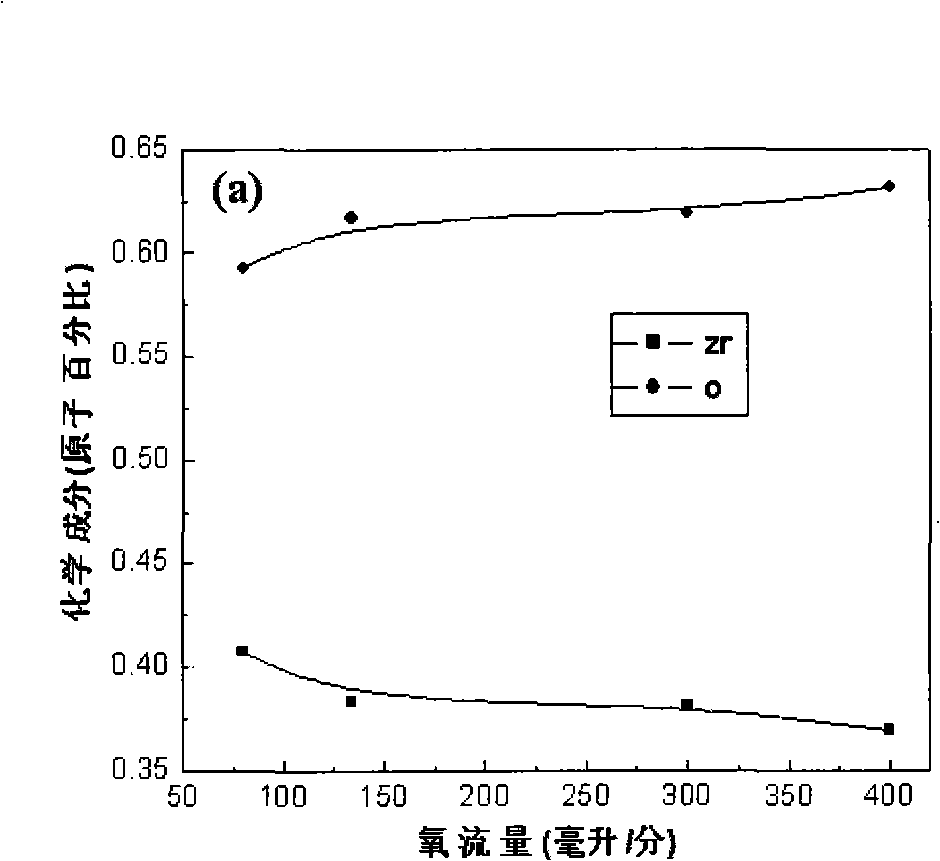

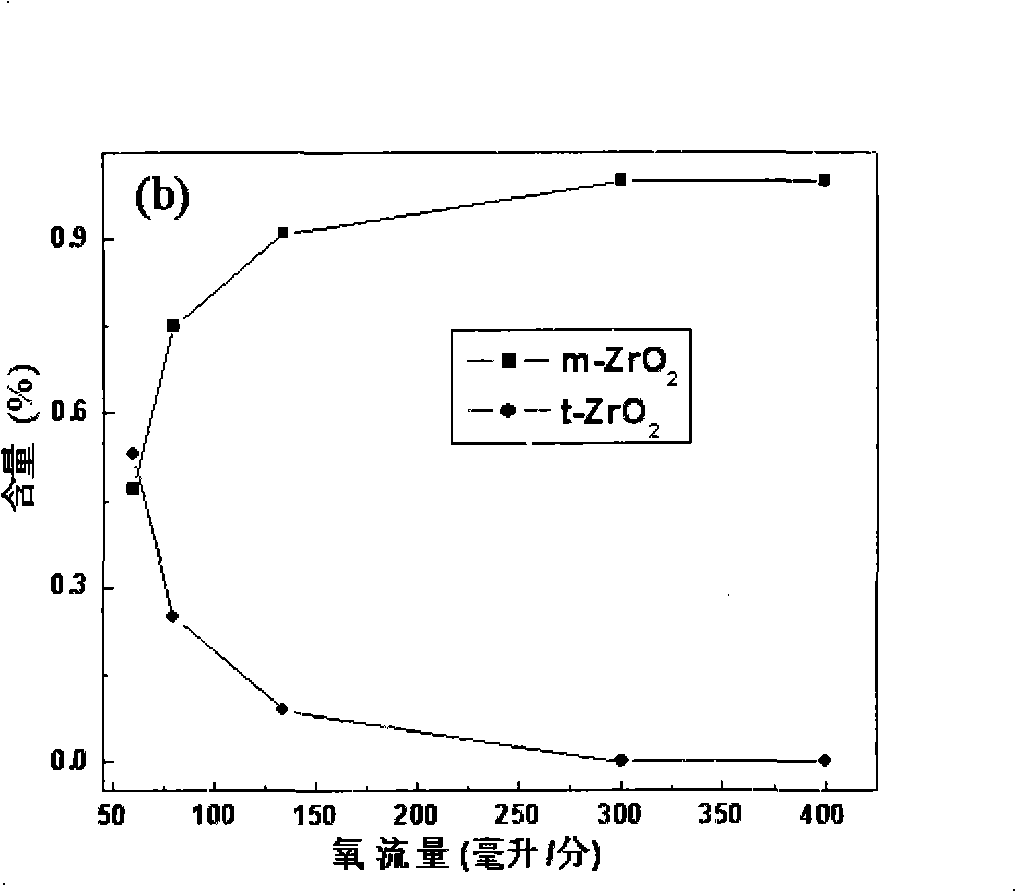

Process for preparing zirconia coating

InactiveCN101307424AGood process repeatabilityLarge adjustment rangeVacuum evaporation coatingSputtering coatingAlloy substrateCrystal structure

The invention relates to a coating preparation technology, in particular to a technique for preparing a zirconia coating, which is to adopt the arc ion plating technology and utilize pure Zr or ZrY alloy target materials for deposition reaction of a ZrO2 coating or a Zr(Y)O2 coating on an alloy substrate or an arc ion plating MCrAlY coating in O2 atmosphere. The technique for preparing the zirconia coating has the advantages of good technical repeatability, easy realization of industrial production and so on; the ZrO2 coating or the Zr(Y)O2 coating prepared has uniform and compact texture, is a cylindrical crystal structure, and has good bonding strength; and the Zr(Y)O2 coating has good thermal shock resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

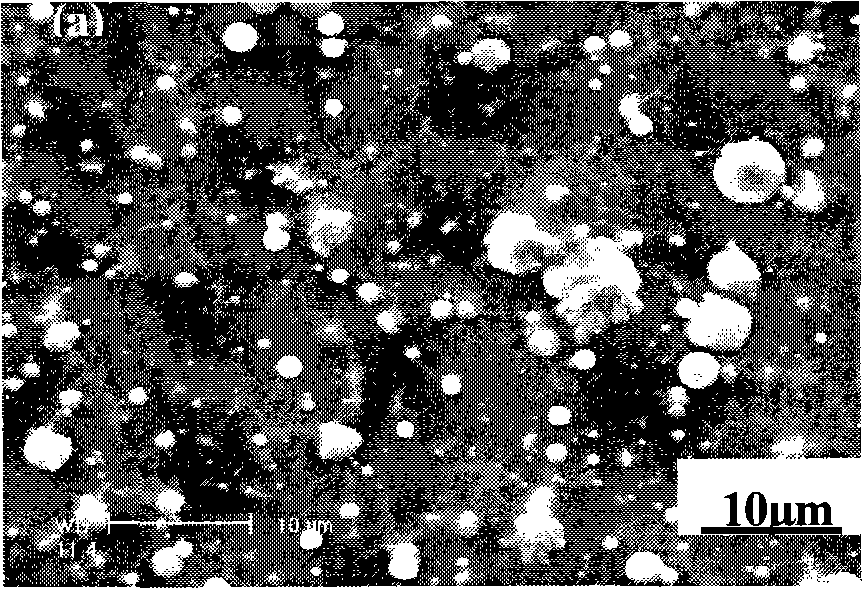

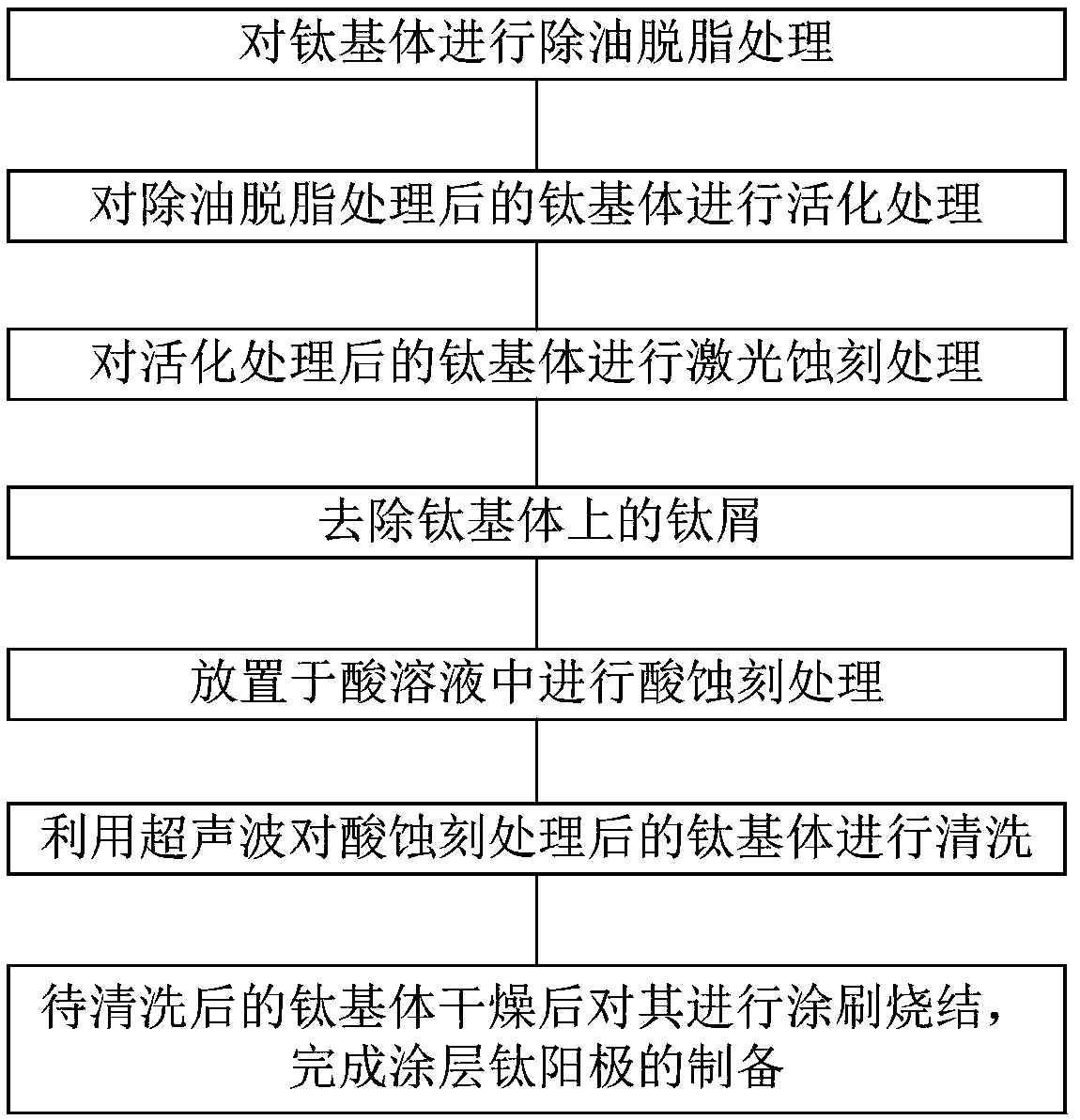

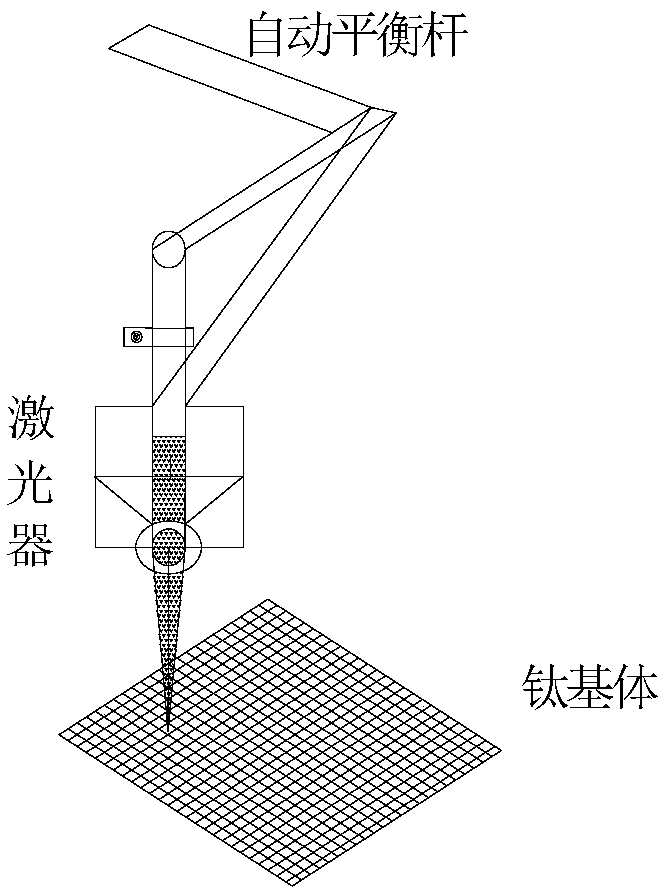

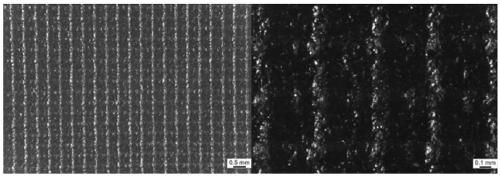

Preparing method for titanium-based coating titanium anode

The invention belongs to the technical field of electrochemistry industry titanium electrode preparing, and relates to a preparing method for a titanium-based coating titanium anode. The preparing method specifically comprises the following steps including titanium base body pretreatment, namely oil removal and degreasing, activating treatment, laser etching, titanium scrap removal, acid treatment, ultrasonic cleaning, drying, coating sintering and finished product obtaining. According to the preparing method, roughening treatment is conducted on the surface of a titanium base body through a laser etching method, the method is simple in usage and free of pollution, oxide skin generated by the titanium base body can be rapidly treated, and long-time treatment through an acid solution is notneeded any more; any regular roughening arrangement can be obtained, grid gaps are easily fully filled with coatings, a uniform and dense structure is obtained, meanwhile, the large-current work intensity can be borne, and corrosion resistance is high.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

Lithium-ion battery separator prepared by polyethylene mixture and preparation method of lithium-ion battery separator

ActiveCN103887465AExpand the range of raw materialsHigh porositySecondary cellsCell component detailsFilm materialLithium electrode

The invention discloses a lithium-ion battery separator prepared by a polyethylene mixture and a preparation method of the lithium-ion battery separator. The invention relates to a polyolefin microporous film material for the lithium-ion battery separator and a preparation method of the polyolefin microporous film material. The method comprises the following steps: fully swelling ultrahigh molecular weight polyethylene (UHMWPE) and a certain types of diluents to form UHMWPE jell; performing melt blending on a certain amount of UHMWPE jell and high-density polyethylene (HDPE) on a double-screw extruder, performing extrusion casting on a blending resin on casting equipment, and preparing a casting base film with a perfect oriented lamellar crystal structure; and performing heat treatment on the casting base film to perform cold drawing and hot drawing, and performing heat setting to prepare the polyethylene microporous film. The limitation on the range of raw material resin melt flow rate (molecular weight) range in the process of preparing the polyethylene microporous film in a conventional uniaxial stretching process is broken, the casting base film with the perfect oriented lamellar crystal structure is prepared by using polyethylene resin with wide melt flow rate range, and the polyethylene resin raw material range suitable for preparing the polyethylene microporous film in the uniaxial stretching method is widened.

Owner:CHANGZHOU UNIV

High-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and preparation method thereof

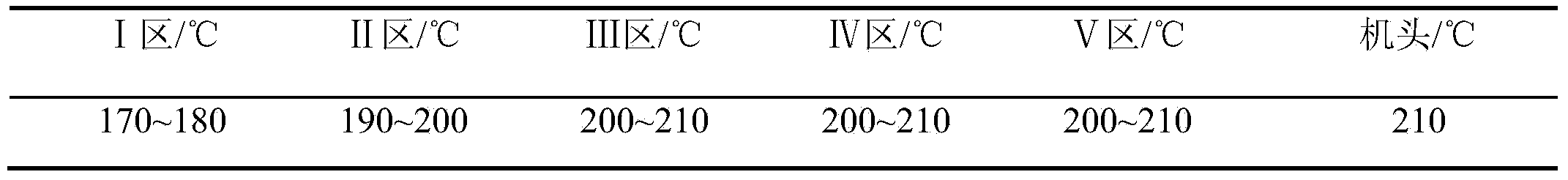

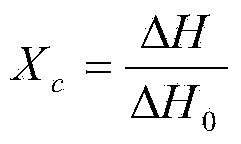

The invention discloses high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and a preparation method thereof. The high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete comprises cement, fly ash, silicon powder, steel slag powder, boron nitride, graphene oxide flake powder, sand, gravel, high-strength polyvinyl alcohol fiber, a polycarboxylic acid water reducing agent, a dispersion activator, a modified graphene oxide dispersion and water. The obtained concrete has the initial and 28-day-old heat conductivity of 6.26-7.53W / (m.K) and 9.58-12.73W / (m.K) respectively and has the capability of dispersing and conducting cement hydration heat and resisting temperature cracks caused by environment temperature change; 28-day-old concrete has the compressive strength of 87.6-116.7MPa, the rupture strength of 17.6-19.5MPa, the splitting tensile strength of 11.7-12.6MPa, the bending tensile strength of 12.4-13.8MPa and the bending tensile modulus of 45.7-52.5GPa; the water permeability resistance, the chloride ion permeability resistance, the freeze-thaw resistance and the carbonation resistance reachthe highest levels; and the prepared concrete has good social and economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

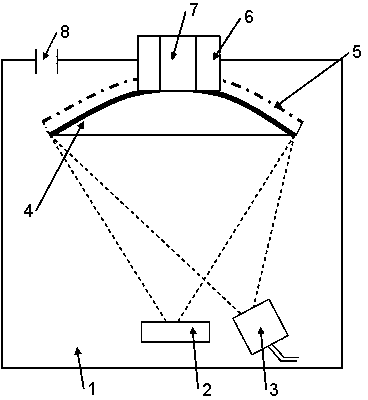

Vacuum coating machine

InactiveCN103469163AImprove efficiencySimple structureVacuum evaporation coatingSputtering coatingIon beamEngineering

The invention discloses a vacuum coating machine. The vacuum coating machine comprises a vacuum chamber (1), wherein an electronic gun (2) and an auxiliary ion source (3) are arranged at the lower part of a cavity of the vacuum chamber (1), a substrate frame over against the electronic gun (2) and the auxiliary ion source (3) are arranged above the electronic gun (2) and the auxiliary ion source (3), a substrate heater (5) is arranged at the outer side of the substrate frame (4); a light-operated system (6) and a crystal-operated system (7) are arranged at a connecting part of the top of the substrate frame (4) and the cavity top of the vacuum chamber (1), the electronic gun (2), the auxiliary ion source (3), the light-operated system (6) and the crystal-operated system (7) are connected with a monitoring device through signal lines. The substrate heater is used for stably and uniformly heating the substrate before coating film so as to improve the compactness and the uniformity of the film; an ion beam is used for bombarding the growing film to form a film structure with uniform compactness, the stability and quality of the coated film are improved so that the aim of improving the optical and mechanical performances of the coated film is achieved.

Owner:无锡启晖光电科技有限公司

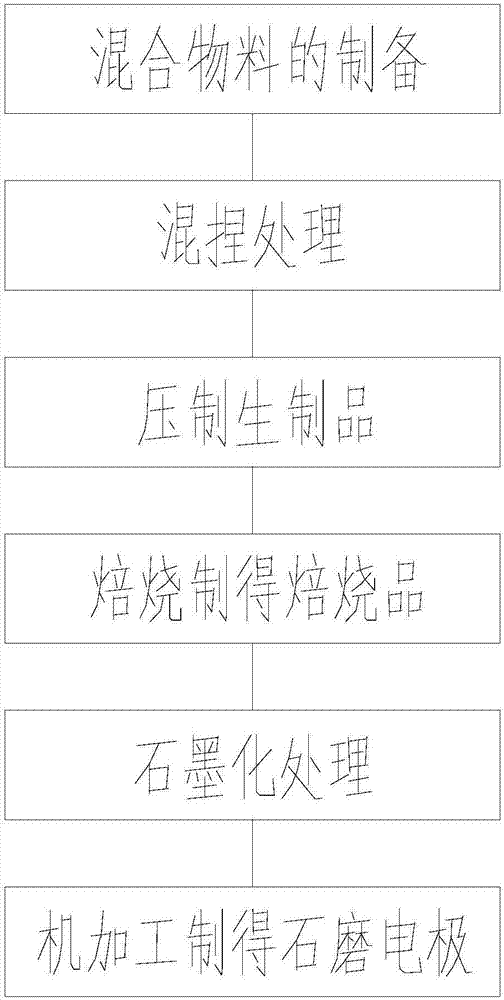

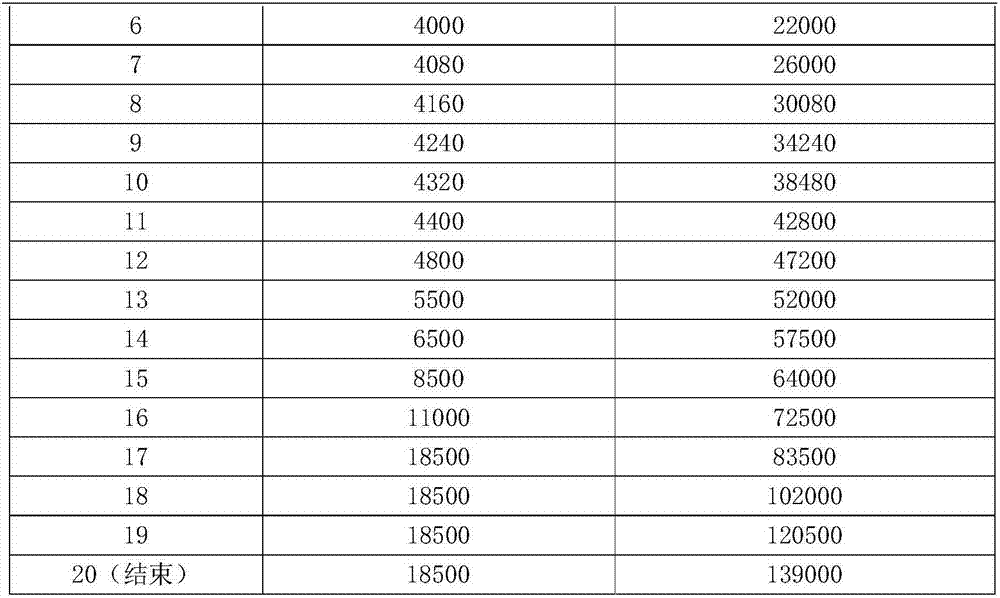

Large-sized high-power graphite electrode and manufacturing method thereof

The invention relates to a large-sized high-power graphite electrode and a manufacturing method thereof. The manufacturing method includes: using calcined petroleum coke and needle coke as the dry materials, crushing and sieving the dry materials to obtain multi-granularity granules and powder, coordinately using graphite scraps and raw graphite scraps, mixing according to a certain proportion to form a mixed material, using high-coking-value medium-temperature improved asphalt as the binder in a mixing and kneading pot, adding stearic acid additives to perform mixing and kneading to obtain a paste material, cooling the paste material in an even-cooling cooling system, extruding in a 41MN extruding machine to obtain a raw product, calcining, graphitizing, and machining to obtain the graphite electrode. The manufacturing method has the advantages that the high-coking-value medium-temperature improved asphalt is used as the binder, the overall system temperature is matched and regulated, a traditional impregnation procedure and a secondary calcination procedure are omitted, the manufactured high-power graphite electrode is even and compact in structure, and the quality index and use performance of the graphite electrode can meet national standards.

Owner:介休市志尧碳素有限公司

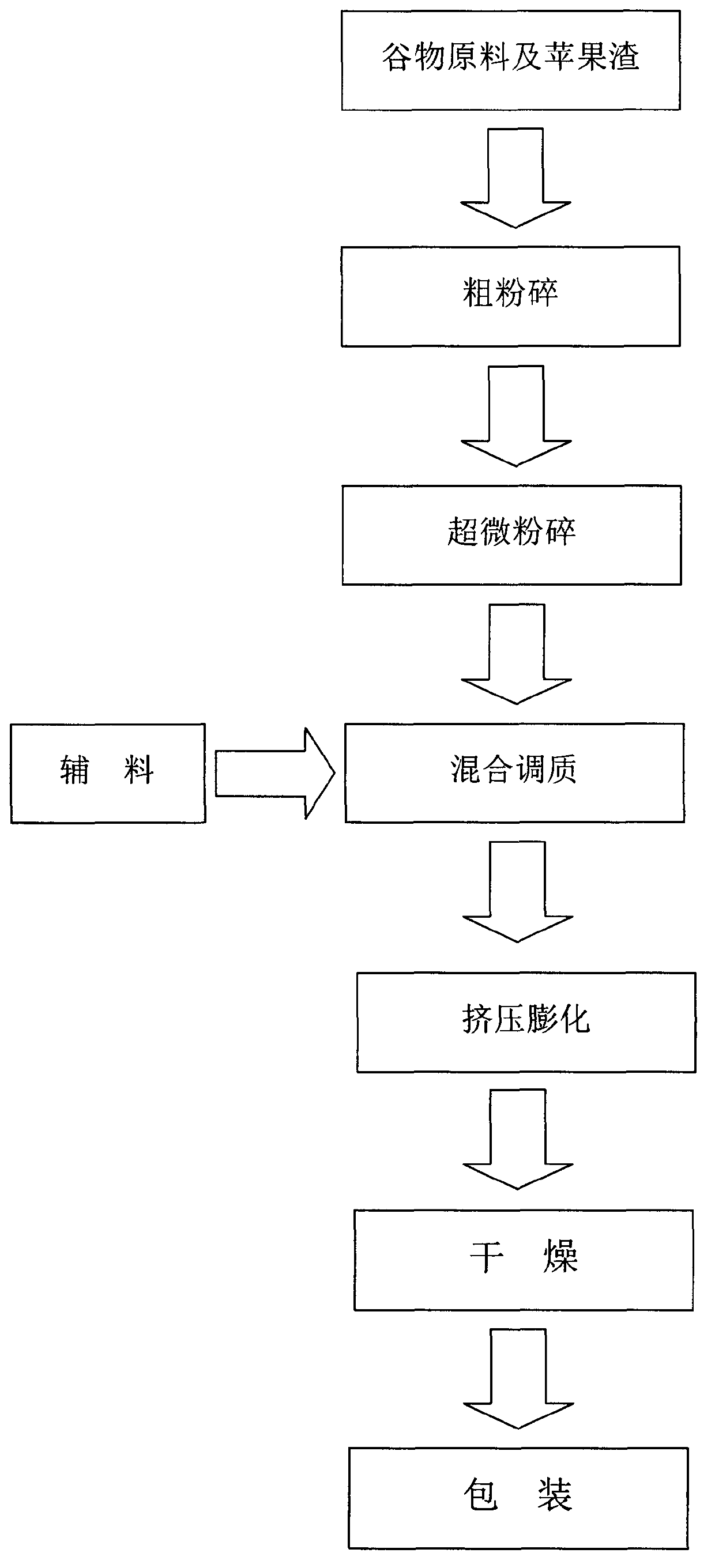

Method for preparing nutrient grain breakfast with high crispness in hot milk

ActiveCN102960630ARealize comprehensive utilizationCrispy tasteFood preparationProtein moleculesAbsorption index

The invention provides a method for preparing nutrient grain breakfast with high crispness in hot milk. The nutrient grain breakfast is rich in nutrition and tastes crisp. The nutrient grain breakfast is formed by mixing corns, wheat, oat, jumble beads, apple pomace and whole grains, so the product is comprehensive and balanced in nutrition; the apple pomace is rich in dietary fiber and vitamins; waste is used; and the nutrient grain breakfast is good for the heath. By superfine grinding smashing and a dual-screw extrusion swelling technology, the product tastes fine and smooth and is easy to absorb. In consideration of a dietary habit of the Chinese who get used to eat hot food and hot beverage; and in the market at present, most grain breakfast foods are designed for cold milk and are quickly softened in the hot milk and lose the crispness. Micro air holes are formed in the product due to the addition of egg shell powder or shell powder; the structure is uniform and fine; cream and diacetyl tartaric acid monoglyceride can form a layer of hydrophobic oil film outside starch and protein molecules to stop water absorption; the water absorption index of a final product can be greatly reduced; and in the hot milk (with the temperature of 50 to 60 DEG C), the nutrient grain breakfast can keep the original shape and relatively high crispness for a long time. The method is scientific and rational in design and has important significance for comprehensive development and utilization of grains.

Owner:JIANGNAN UNIV

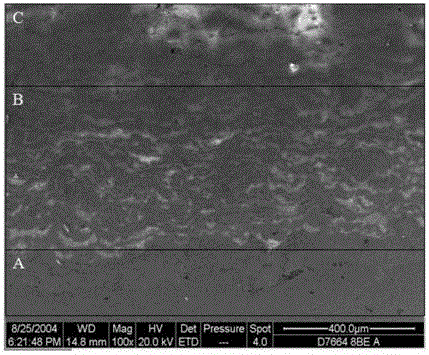

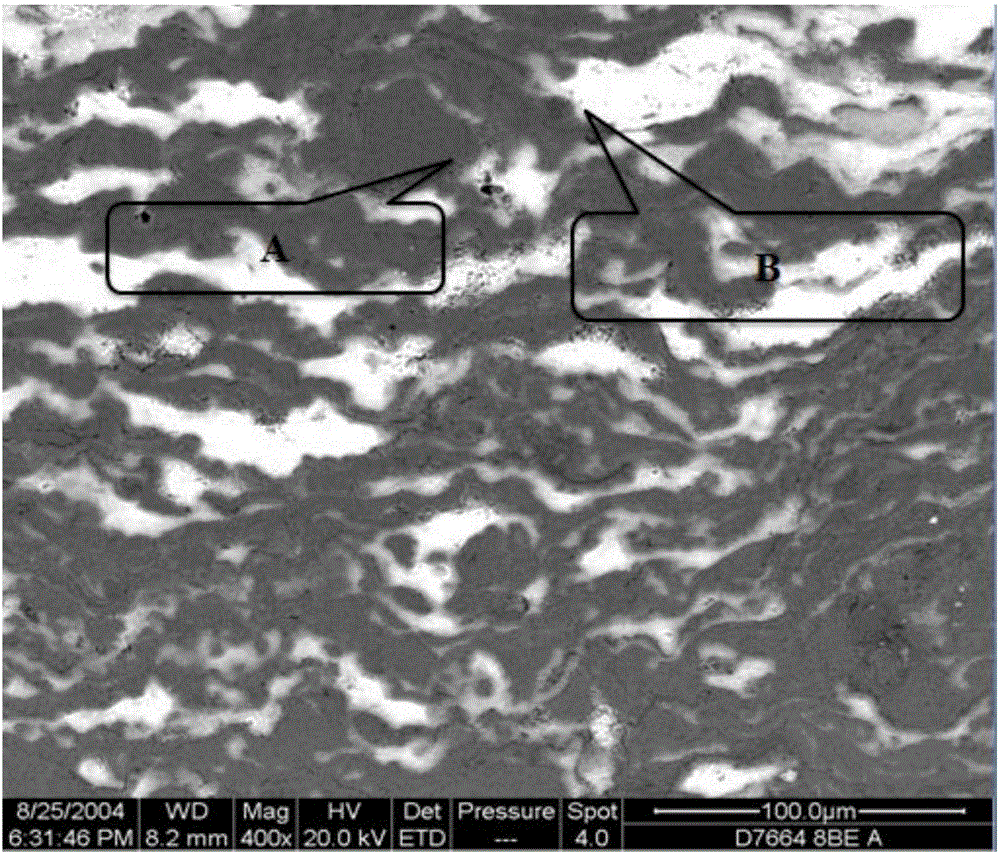

High-heat-conductivity tungsten-copper heat sink and electronic packaging material, and preparation method thereof

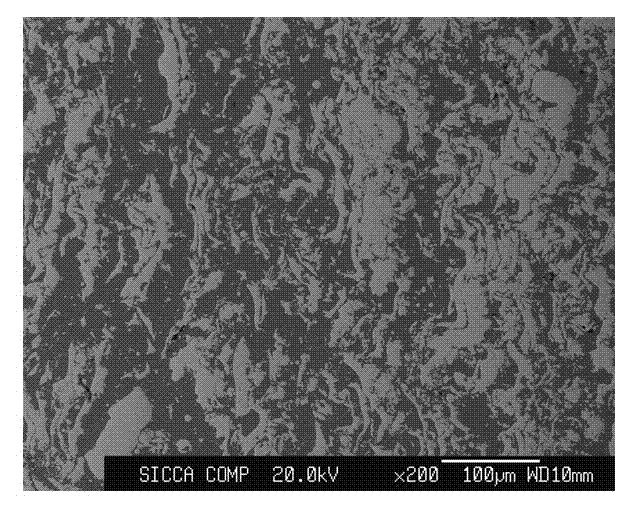

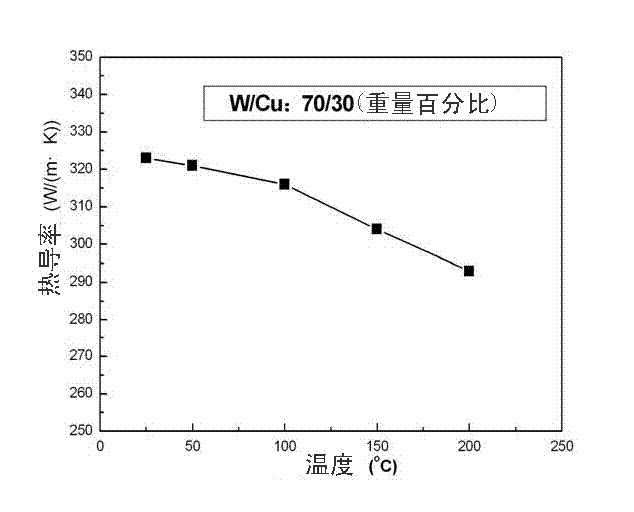

ActiveCN103194712AUniform structureUniform and dense structureMolten spray coatingSemiconductor/solid-state device detailsPorosityRoom temperature

The invention relates to a high-heat-conductivity tungsten-copper heat sink and electronic packaging material. The tungsten-copper heat sink and electronic packaging material is composed of copper or a copper alloy matrix, and a tungsten-copper composite coat formed on copper or the copper alloy matrix through a vacuum plasma spraying technology, wherein the room-temperature heat conduction coefficient of the tungsten-copper heat sink and electronic packaging material is greater than 300W / (m.K), the porosity of the tungsten-copper composite coat is lower than 3%, the thickness of the tungsten-copper composite coat is 100-2000mum, and the weight percent content of copper in the tungsten-copper composite coat is 10-40%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

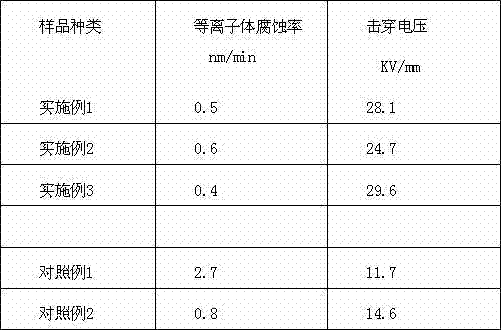

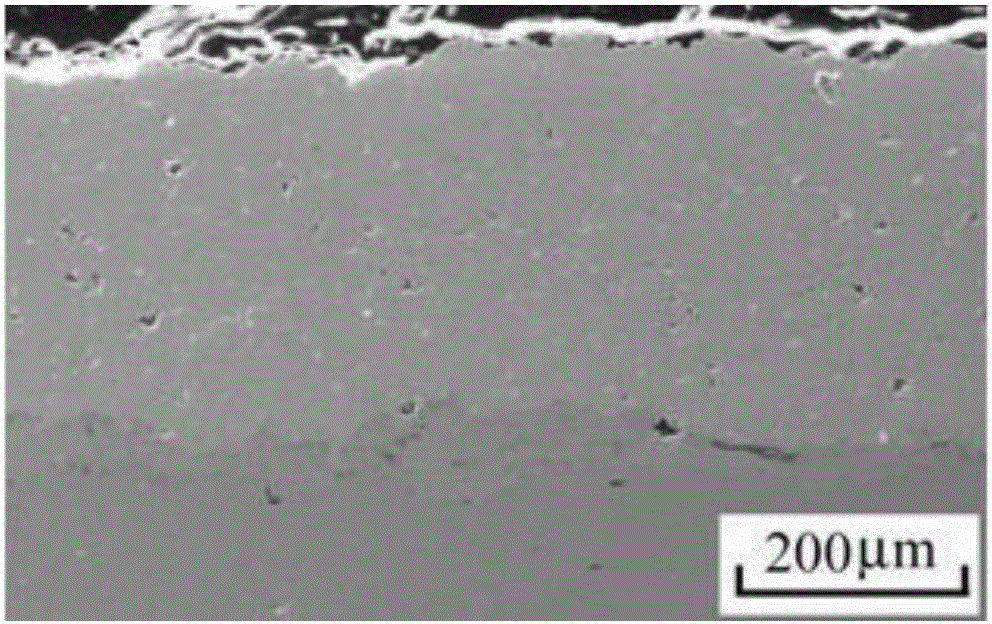

Application of nanometer aluminum oxide-based composite ceramic coating

InactiveCN102443753AImprove insulation performanceReduce intrinsic internal stressMolten spray coatingNano structuringCeramic coating

The invention relates to a nanometer aluminum oxide-based coating technology, in particular to a nanometer aluminum oxide-based composite ceramic coating for resisting corrosion of plasma gas in a high-voltage environment. The nanometer aluminum oxide-based composite ceramic coating is prepared by a hot spraying method and has the thickness being 50mum to 2mm; and the nanometer aluminum oxide-based composite ceramic coating comprises the following components of 20-75 percent by weight of aluminum oxide, 10-40 percent by weight of zirconium oxide and 10-60 percent by weight of rare earth oxide, wherein the rare earth oxide is any one or a combination of more than two of yttrium oxide, lanthanum oxide, gadolinium oxide, cerium oxide, dysprosium oxide, neodymium oxide and europium oxide. Thenanometer aluminum oxide-based composite ceramic coating has a compact nanometer structure, the capability of resisting electric breakdown of 24-29KV / MM and the function of resisting corrosion of fluorine-containing plasma. In various plasma devices, the ceramic coating is used on the surfaces of related parts, so that the conditions of frequent maintenance, cleaning and replacement can be avoided.

Owner:安徽禹恒材料技术有限公司

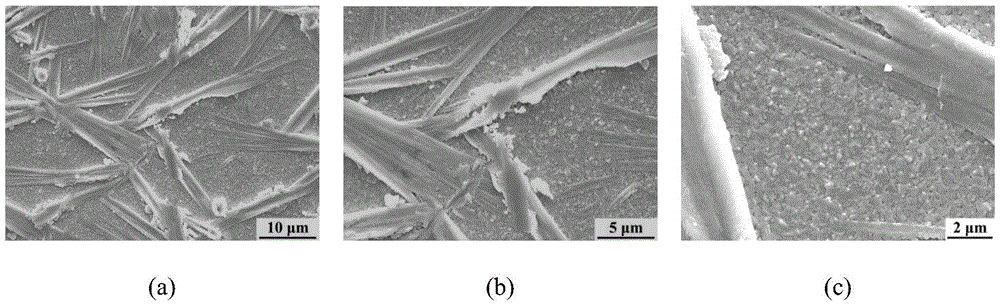

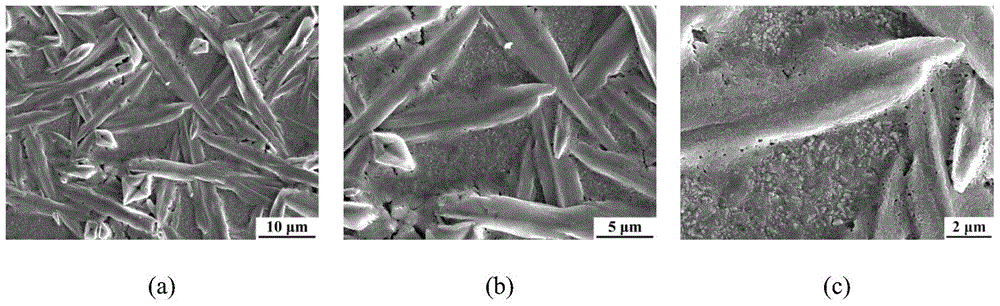

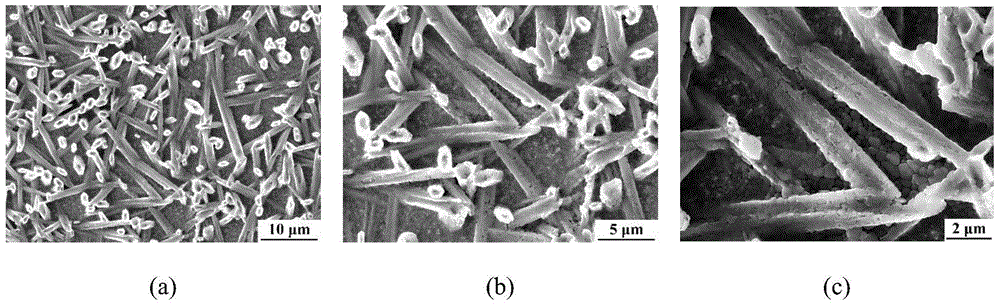

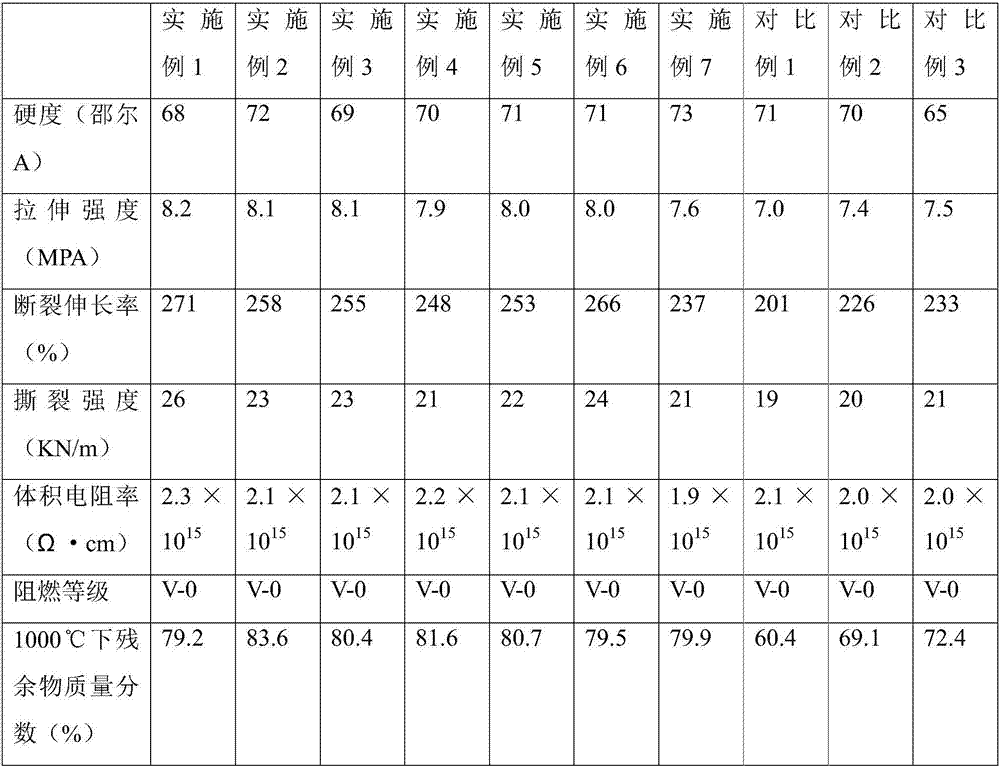

Ceramic silicone rubber composite with excellent burning resistance

The invention belongs to the field of macromolecular rubber materials, and relates to a silicone rubber composition, in particular to a ceramic silicone rubber composite with excellent burning resistance. The ceramic silicone rubber composite is prepared from, by weight, 100 parts of silicone rubber, 20-60 parts of formed ceramic filling, 5-15 parts of fluxing agent and 2-4 parts of vulcanizing agent, wherein the formed ceramic filling is the mixture of alumina silicate fibers and needle-like wollastonite, and the mass ratio of the alumina silicate fibers to the needle-like wollastonite is (15-25):(30-40). According to the ceramic silicone rubber composite with the excellent burning resistance, the compound of the alumina silicate fibers and the needle-like wollastonite is adopted as the formed ceramic filling to improve the thermal stability and burning resistance of the ceramic silicone rubber.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

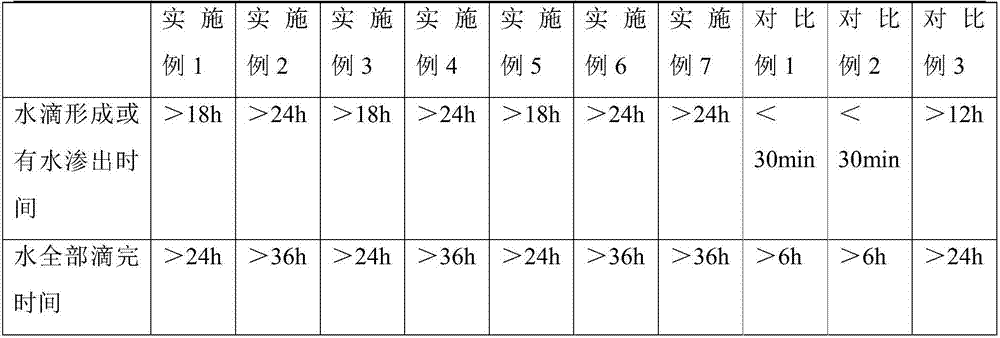

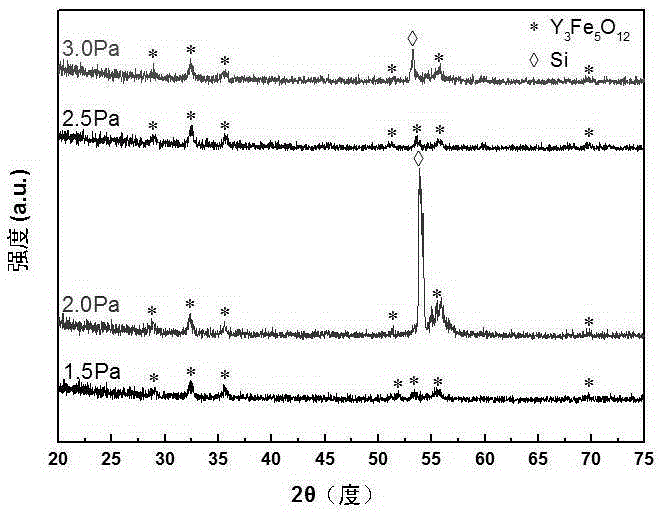

Yttrium iron garnet film material and preparing method thereof

ActiveCN105331942AThe method is simpleLow dielectric lossVacuum evaporation coatingSputtering coatingDielectric lossFilm material

The invention relates to an yttrium iron garnet film material and a preparing method thereof. The preparing method includes the following steps that firstly, the surface of an Si / SiO2 substrate is cleaned; secondly, an yttrium iron garnet film is sputtered on the surface of the cleaned substrate through a radio frequency magnetron sputtering method, Y3Fe5O12 is adopted as the target material, background vacuum is smaller than 4.0*10-4 pa, sputtering gas is at least one of O2, N2 and Ar, sputtering pressure is 1.5-3.0 Pa, the temperature of the substrate ranges from room temperature to 600 DEG C, and sputtering power is 60-150 W; and thirdly, the yttrium iron garnet film prepared in the second step is subjected to post annealing. The film material prepared through the method has the beneficial effects that the structure is compact and is not cracked, saturation magnetization can be comparable to that of ceramic, the dielectric loss is low, coercive force is low, and the Curie temperature is far higher than the room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method and device for preparing gradient metal ceramic composite coating on surface of bias current plate

ActiveCN105755422AAdhesive hasThermal conductivity hasMolten spray coatingEfficient propulsion technologiesSurface layerHigh-temperature corrosion

The invention discloses a method for preparing a gradient metal ceramic composite coating on the surface of a bias current plate.The method comprises the steps that bottom layer raw material powder is introduced into a supersonic plasma spraying system, and under the effect of spraying current, the bottom layer raw material powder is sprayed to a matrix through primary airflow; middle layer raw material powder is introduced into the supersonic plasma spraying system, and under the effect of the spraying current, the middle layer raw material powder is sprayed to the matrix through the primary airflow; surface layer raw material powder is introduced into the supersonic plasma spraying system, and under the effect of the spraying current, the surface raw material powder is sprayed to the matrix through the primary airflow.The invention further discloses a device for preparing the gradient metal ceramic composite coating on the surface of the bias current plate.The method and device have the properties such as high temperature corrosion resistance, thermal shock resistance, high temperature erosion resistance, normal temperature salt-spray corrosion resistance and abrasion resistance, and have the advantages that the bonding strength of a bottom layer in the coating is high, and the heat conductivity is good.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com