Patents

Literature

32results about How to "Fully oriented" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

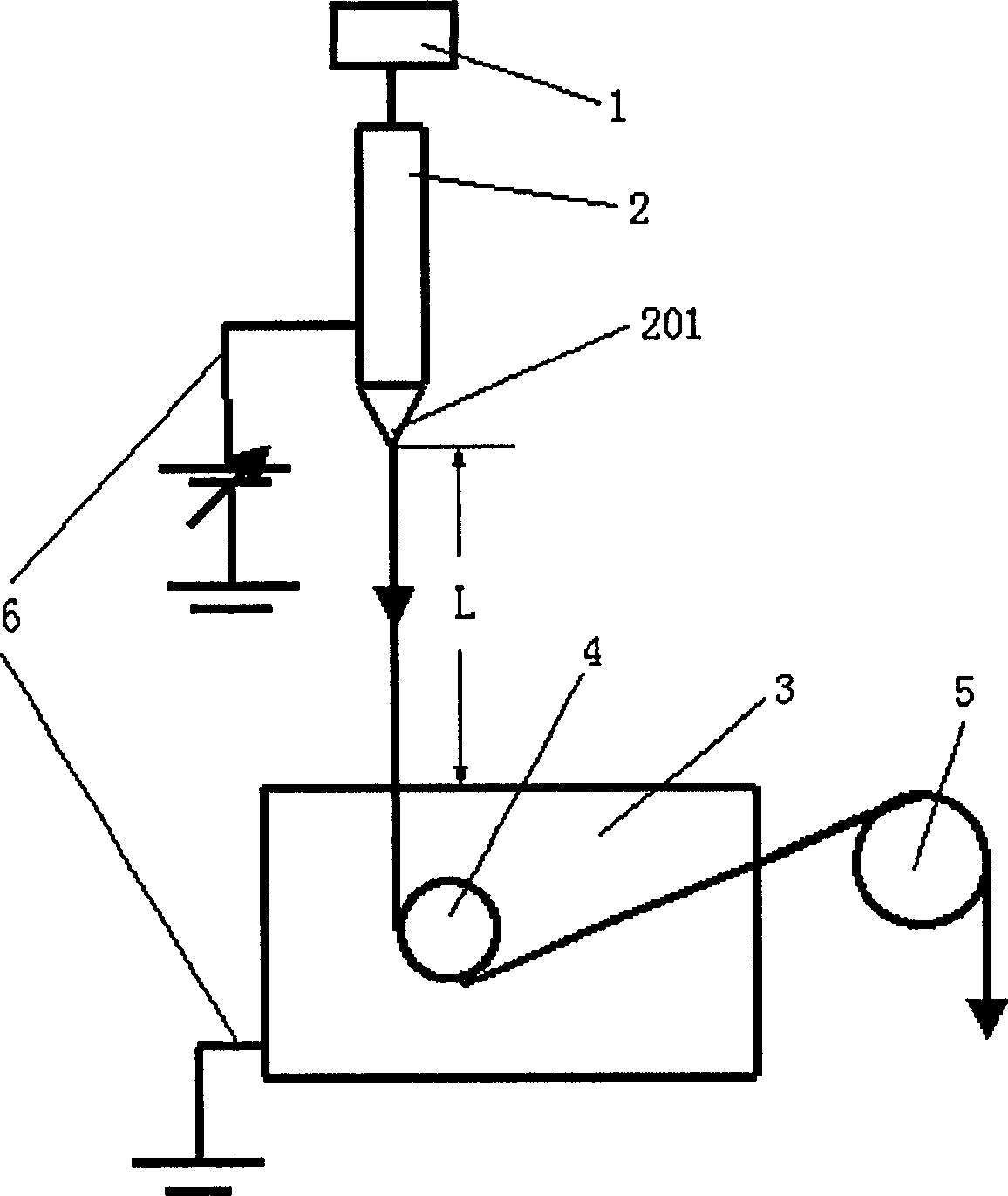

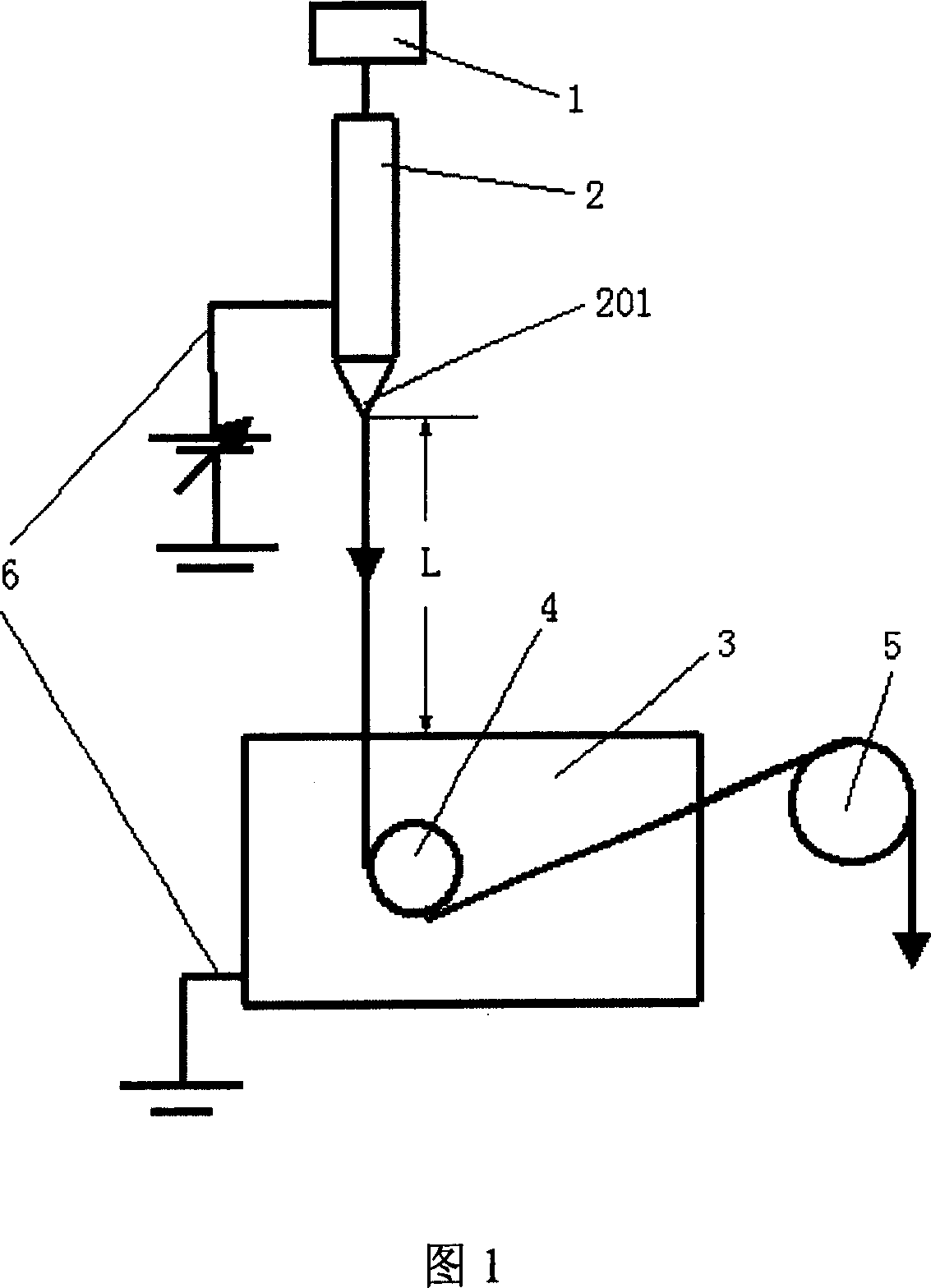

Static spinning device and its industrial use

InactiveCN1715463AHigh speedImprove mechanical propertiesFilament/thread formingElectrospinningMagnification

The present invention provides electrostatic spinning apparatus and its industrial application. The apparatus includes polymer solution conveying machine, spinning nozzle device connected to the outlet of the polymer solution conveying machine, spinning bath below the spinning nozzle device, fiber turning guide roller set inside the spinning bath and electrodes set on the spinning nozzle device and the spinning bath. The apparatus of the present invention is used in spinning polymer, and has greatly raised wet spinning speed, great fiber drafting magnification, well oriented fiber molecule chain, compact fiber structure, greatly raised mechanical performance of fiber, wide solvent selecting range, simplified electrostatic spinning equipment, raised solvent recovering rate and less environmental pollution caused by the solvent.

Owner:DONGHUA UNIV

Method of preparing polyparaphenyl bracing benzdioxazole fibre

ActiveCN1693551AGuaranteed molarityAvoid timeMonocomponent synthetic polymer artificial filamentMelt spinning methodsFiberSlurry

The invention discloses a new method for preparing polyparaphenyl bracing benedioxazole fiber, including the steps: (1) adding 4,6-diamido resorcinol-terephthalate, multipolyphosphoric acid and P2O5 in the ratio of 1 to 1.5-6 to 0.7-3 to a prepolymerization reaction kettle and making prepolymerization reaction in stages at 80-180 deg.C for 8-15 hr; (2) feeding the prepolymer obtained in step (1) into a double spiral extruder to continue reaction so as to obtain pulp with specific concentration logarithmic viscosity of 20-40 dl / g; (3) continuously extruding the pulp obtained in step (2) into spinning component and then adopting an art of first stretching-then solidifying, and then performing alkali washing, water washing, drying and coilding to make it. The advantages are short reaction cycle, high strength and modulus fiber, simple process and low pollution discharge

Owner:DONGHUA UNIV +2

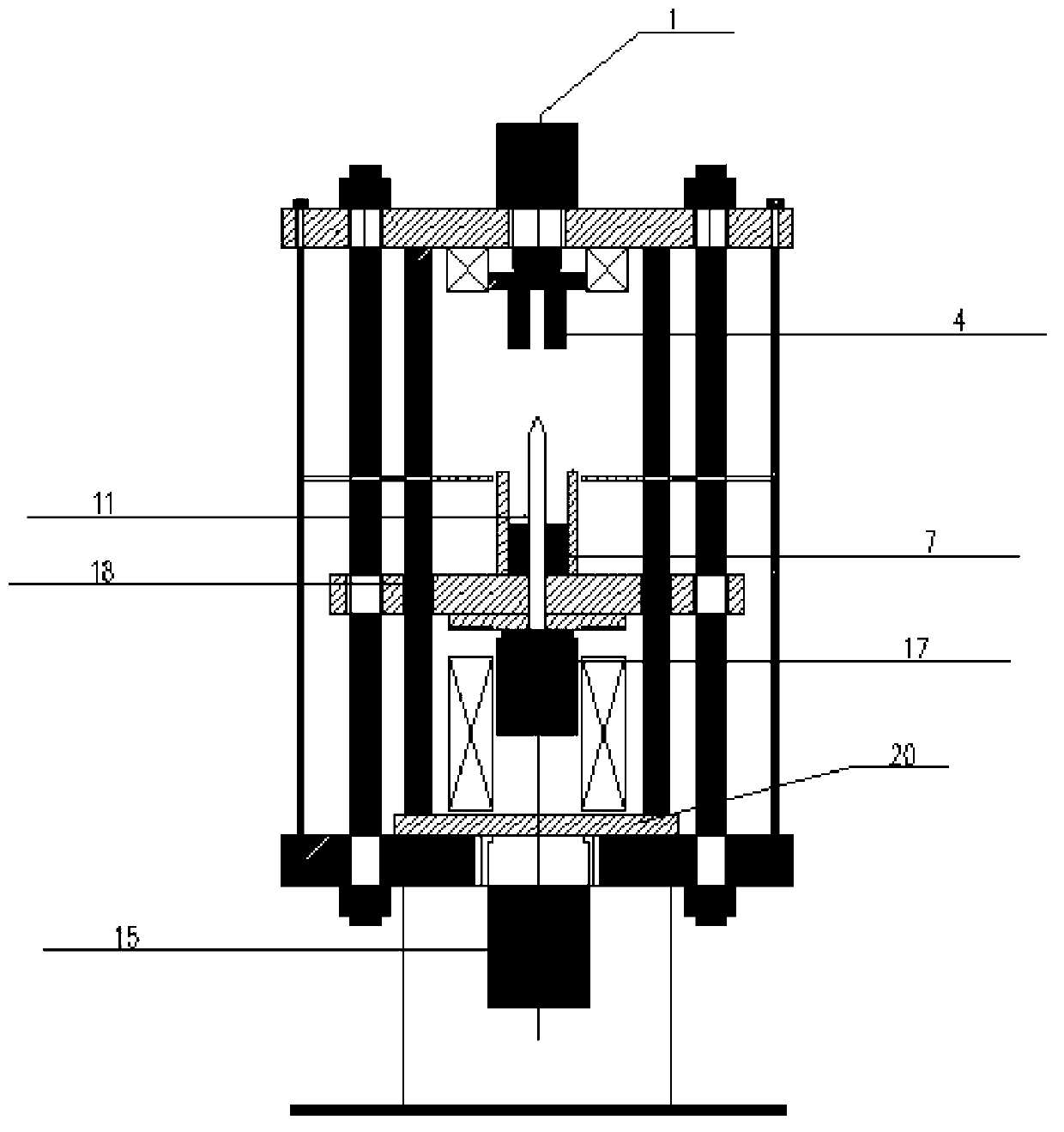

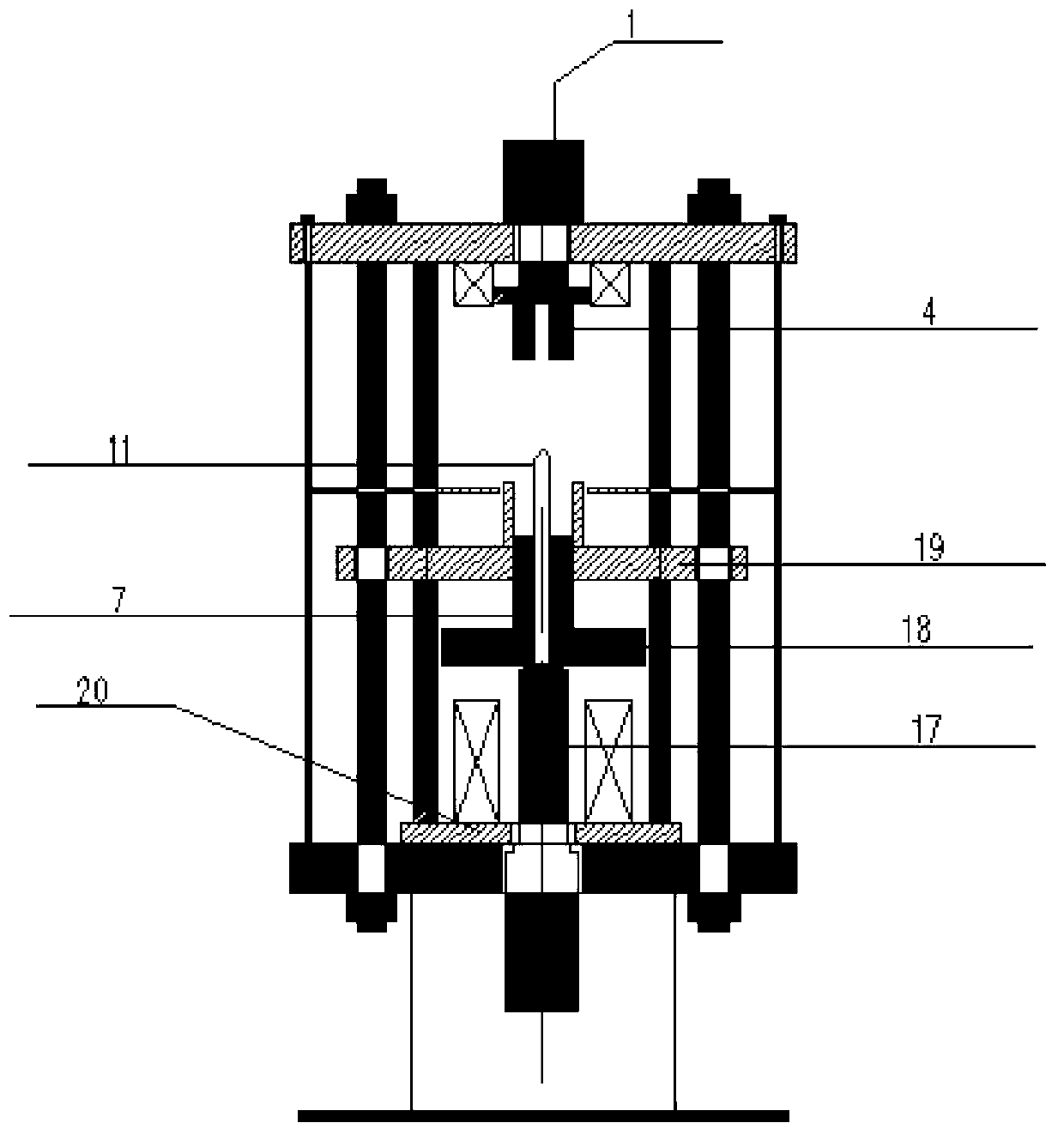

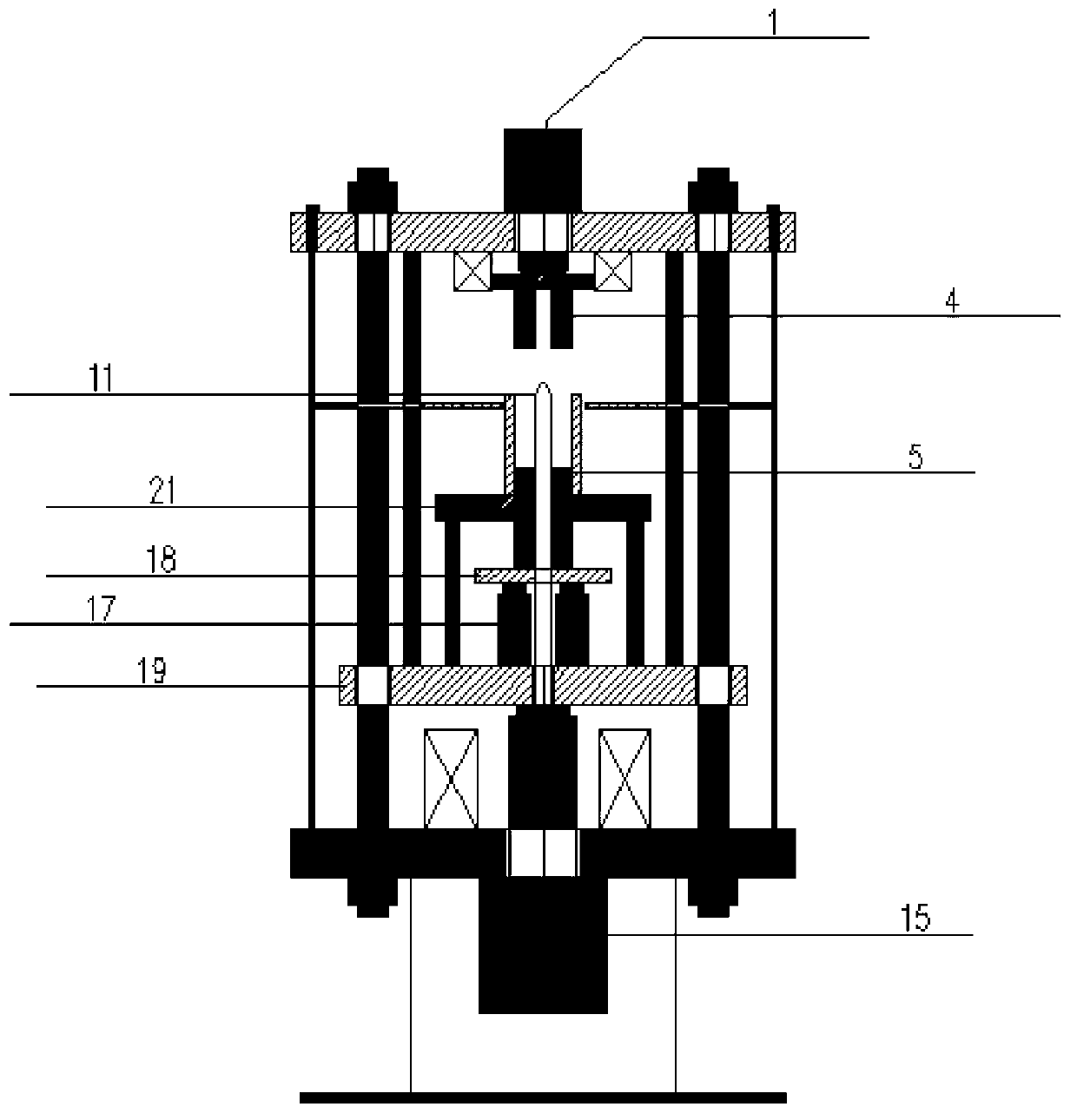

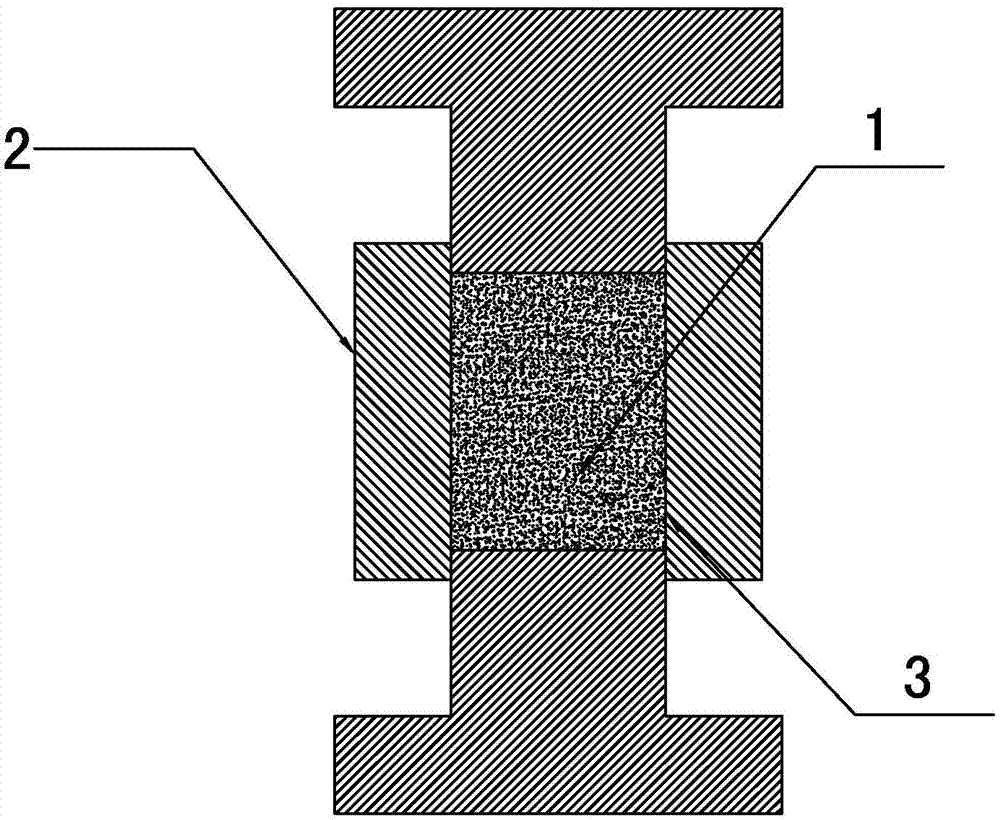

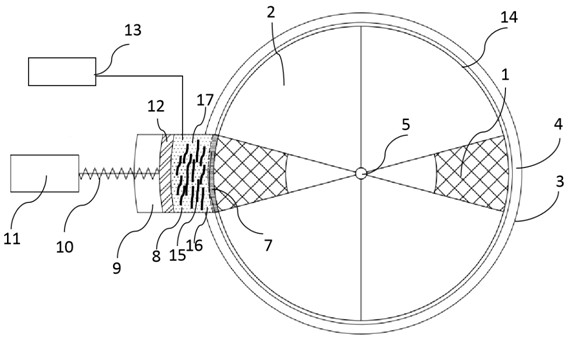

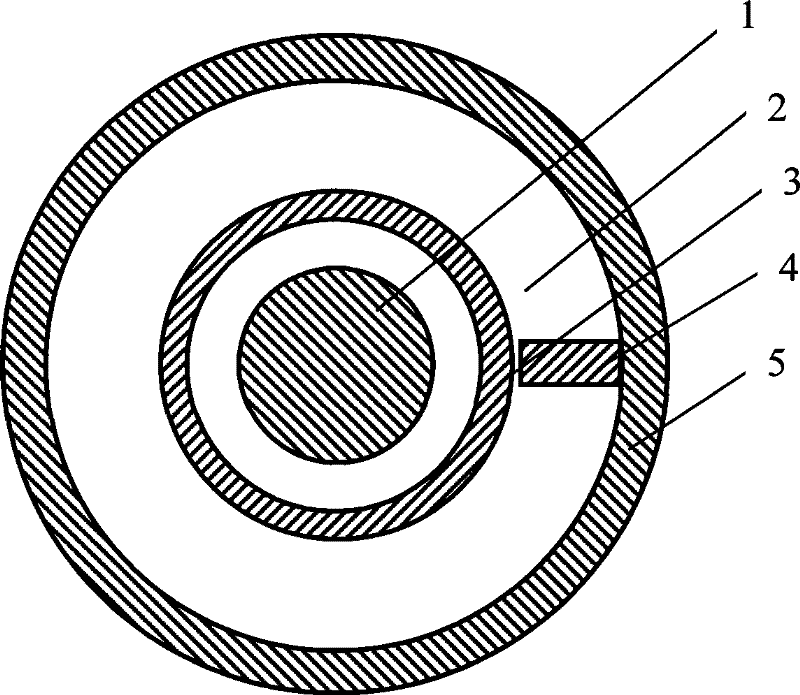

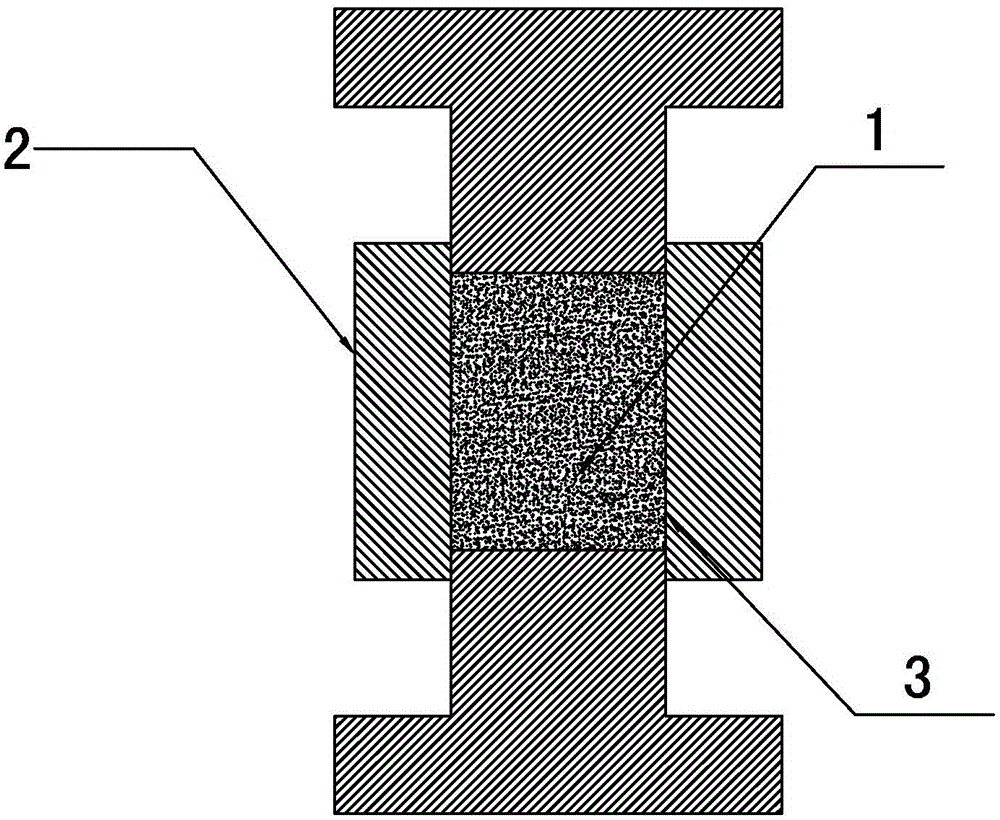

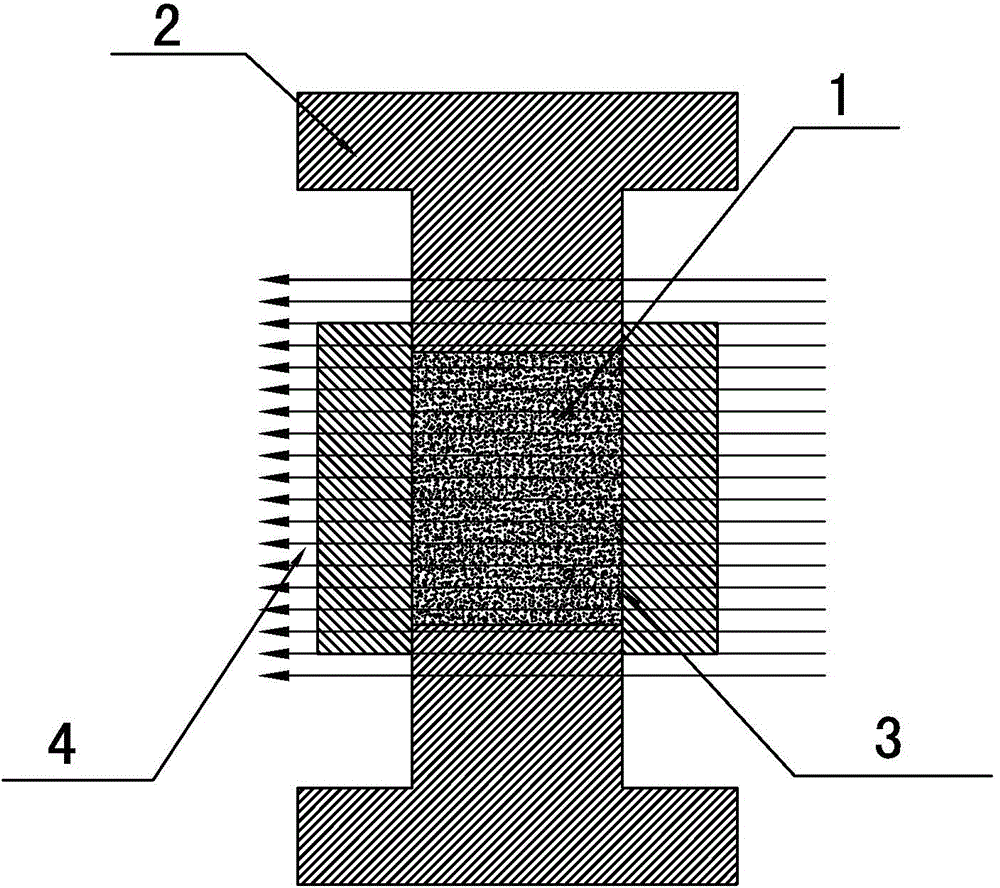

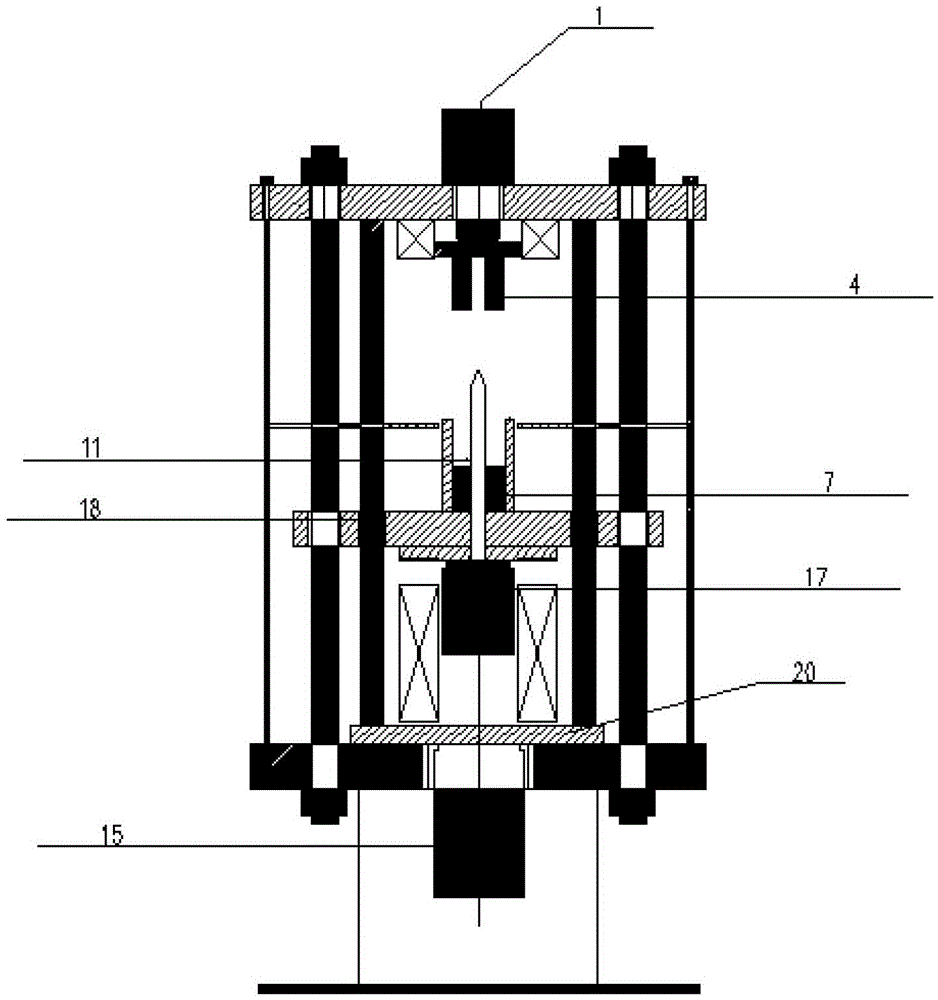

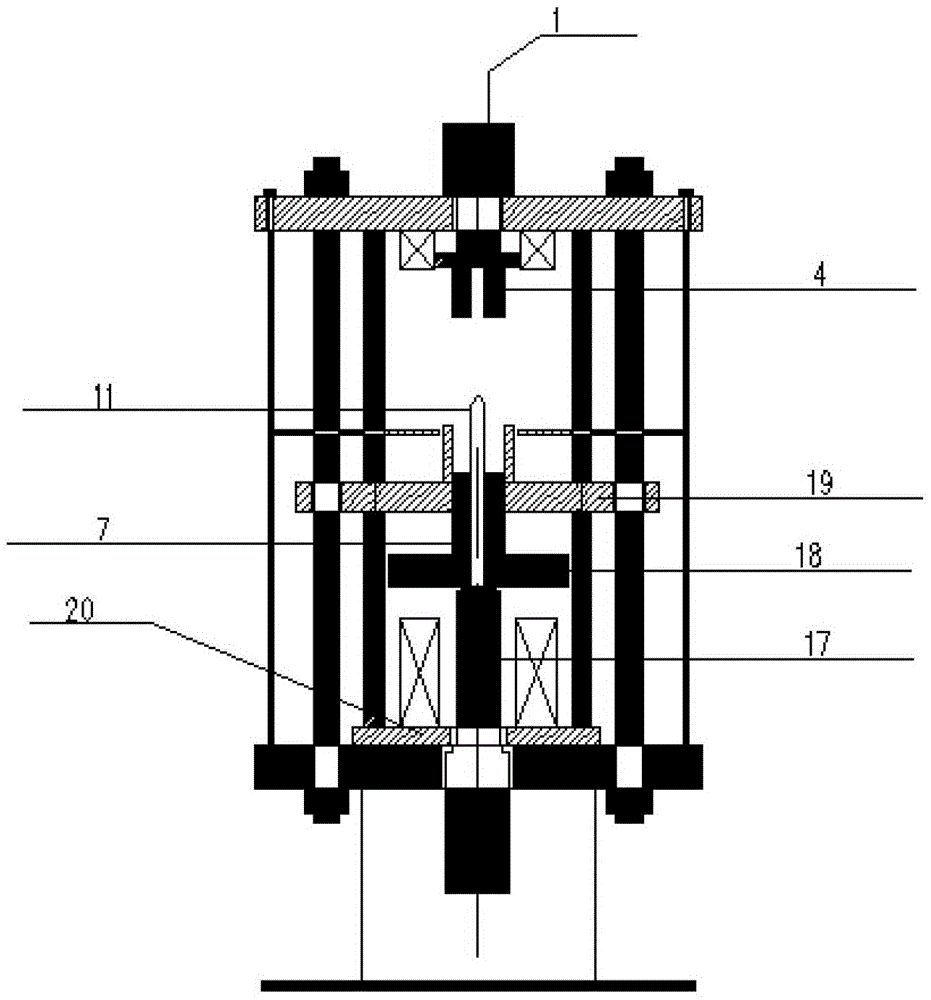

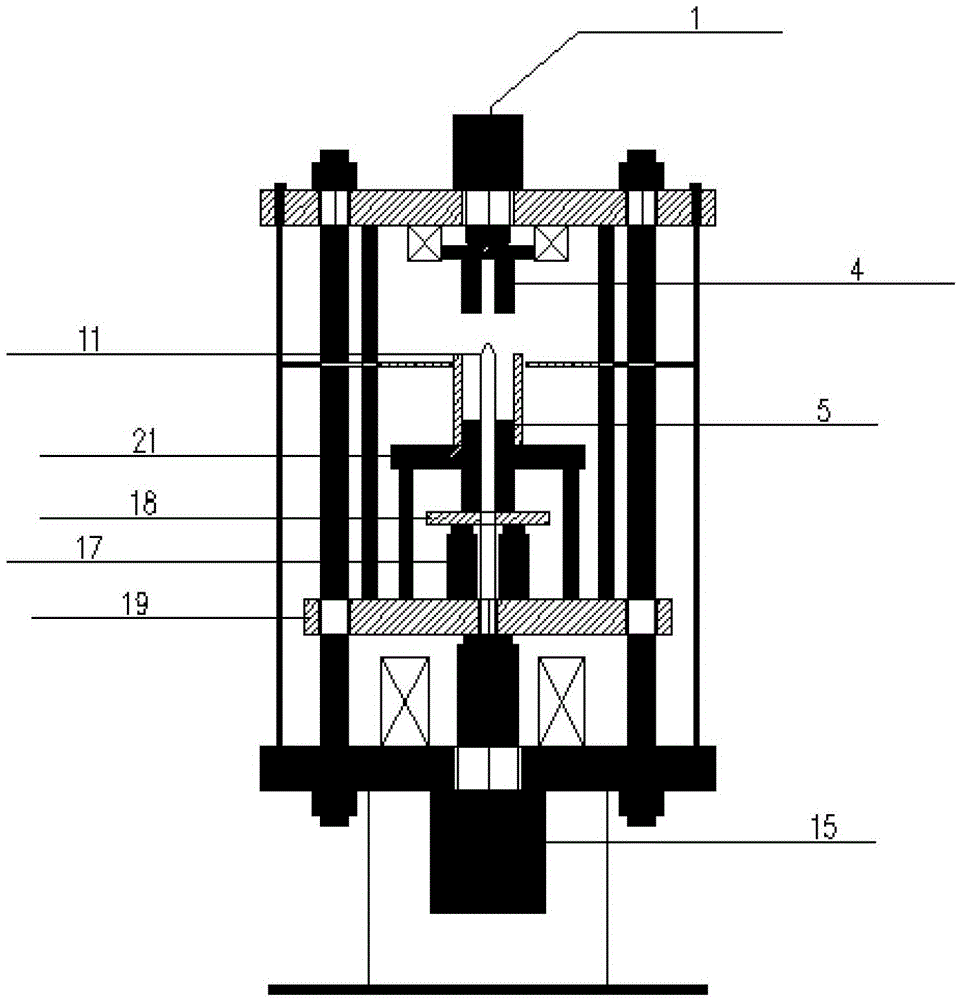

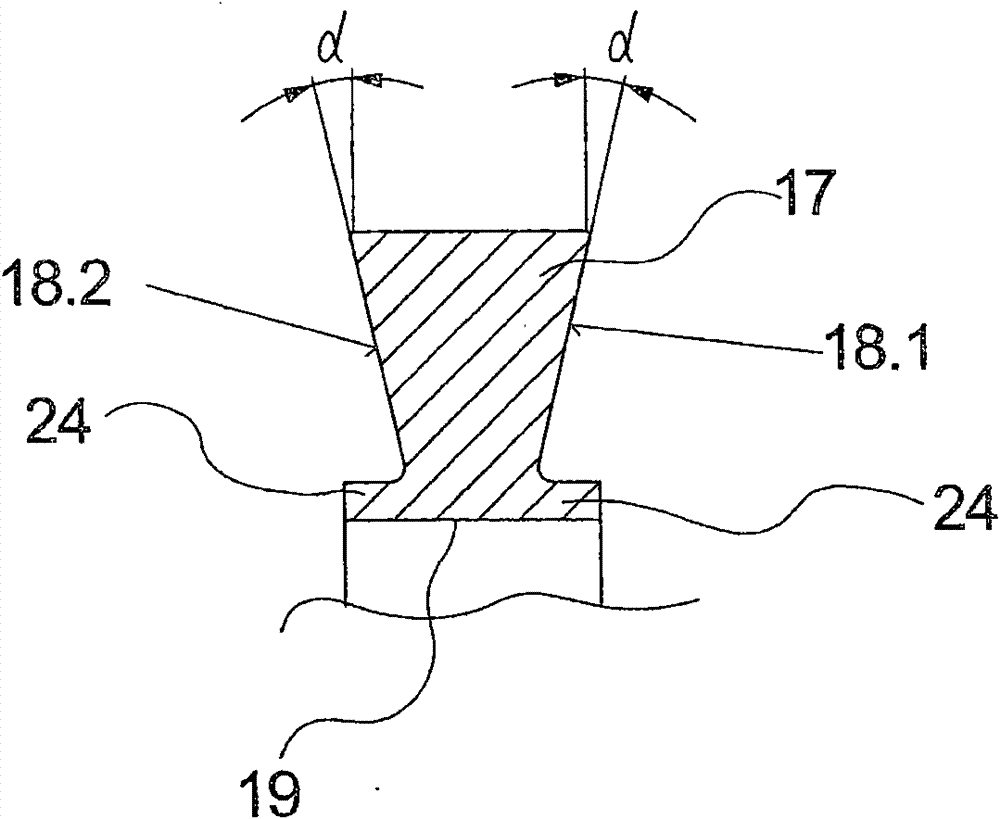

Preparation device for radial orientation permanent magnet ring

ActiveCN103123863AGood orientationFully orientedPermanent magnetsInductances/transformers/magnets manufactureExcitation currentMagnetic poles

The invention relates to a preparation device for a radial orientation permanent magnet ring. An outer magnetic pole is fixed on an outer magnetic pole connection support, and the thickness of the outer magnetic pole is far smaller than the height of a mold cavity. When exciting current passes through a coil, a radial magnetic field is generated in a ranged space of the mold cavity between a core rod and the outer magnetic pole, powder materials in the mold cavity are pushed by an oil cylinder to move vertically in a reciprocating mode, and therefore the power materials sequentially and circularly pass through the plane where the outer magnetic pole is located when the powder materials are pressed. When all the power materials sequentially and repeatedly pass through the plane where the outer magnetic pole is located and are pressed, the powder materials in a whole mold can be fully and uniformly oriented, radial orientation uniformity of the radial permanent magnet ring is greatly improved, meanwhile, axial uniformity of orientation degrees can also be improved, and the advantage is obvious especially for high radial rings. Besides, according to the preparation device for the radial orientation permanent magnet ring, the methods of manual mold release and automatic mold release can be adopted, operation is flexile, and the qualification rate of the pressed radial rings is greatly improved.

Owner:ORIENT MAGNET TECH OMT

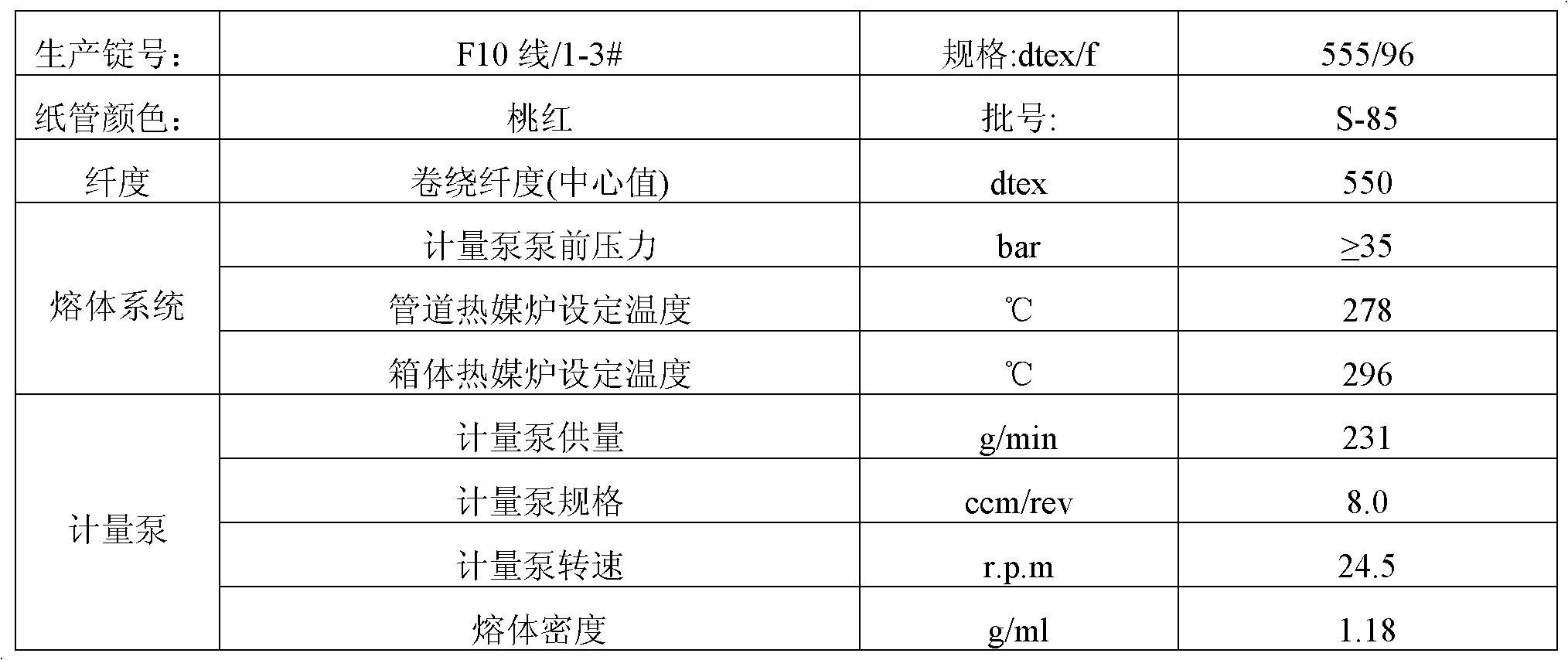

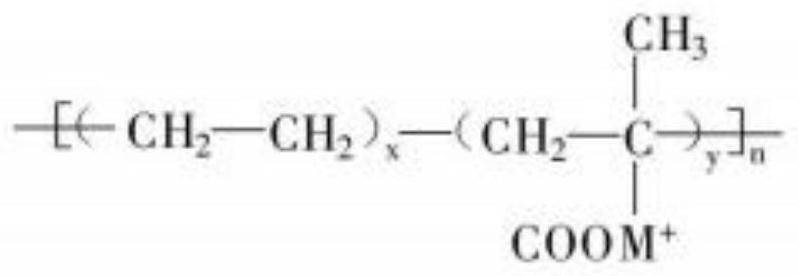

Intermediate-strength coarse-denier dacron FDY (Fully drawn yarn) and method for producing same

InactiveCN102443861AFully stretchedFully orientedStretch-spinning methodsYarnPolyethylene terephthalate

The invention discloses an intermediate-strength coarse-denier dacron FDY (Fully drawn yarn) and a method for producing the same. The method for preparing the dacron FDY includes the steps of enabling a PET (polyethylene terephthalate) melt to be extruded from spinneret orifices of an elliptical spinneret plate for spinning according to a direct spinning FDY process route prior to being cooled through cross air blowing and being solidified to a sliver sequentially, then being oiled by an oil wheel prior to being rolled by two pairs of heat rollers, and finally being placed in a major net to be wound into a FDY spinning cake. The acquired dacron FDY is of a coarse-denier yarn variety with the fineness degree ranging from 400D to 600D. The method breaks the convention that coarse-denier yarns with the fineness degree higher than 300D are produced by means of double-strand combination, so that production capacity of the coarse-denier yarns with one machine is improved, and production and processing cost is greatly reduced.

Owner:JIANGSU HUAYA FIBER

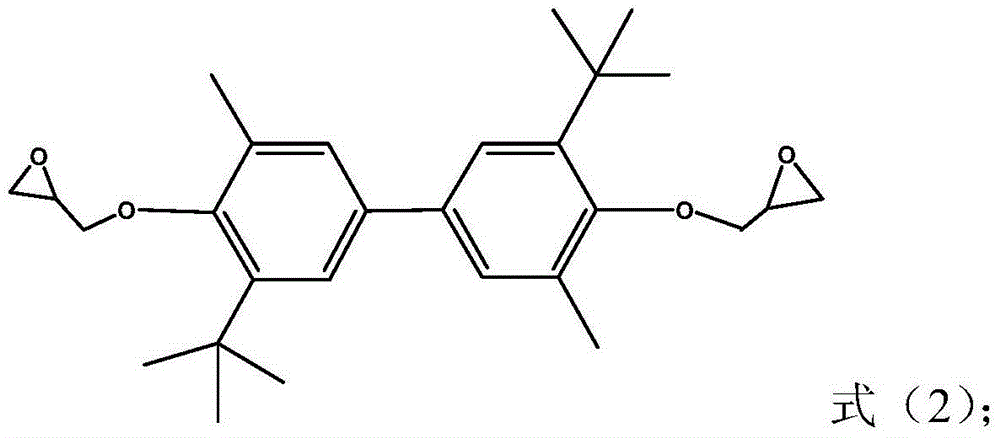

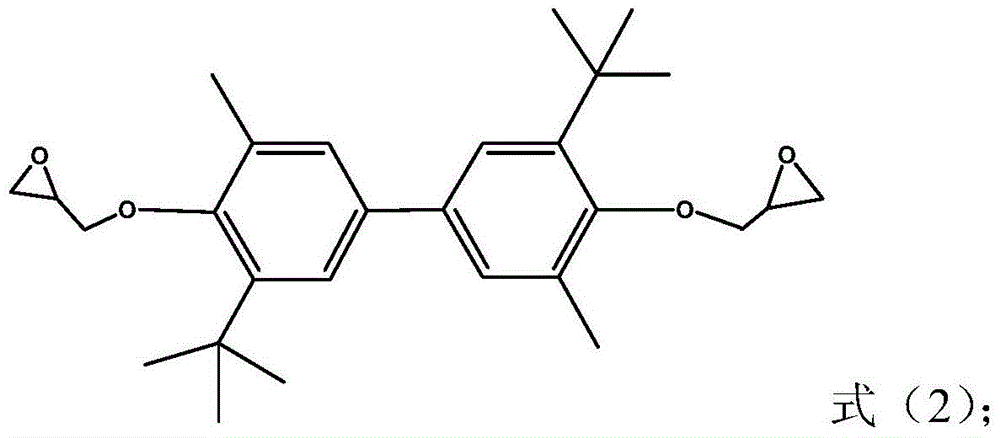

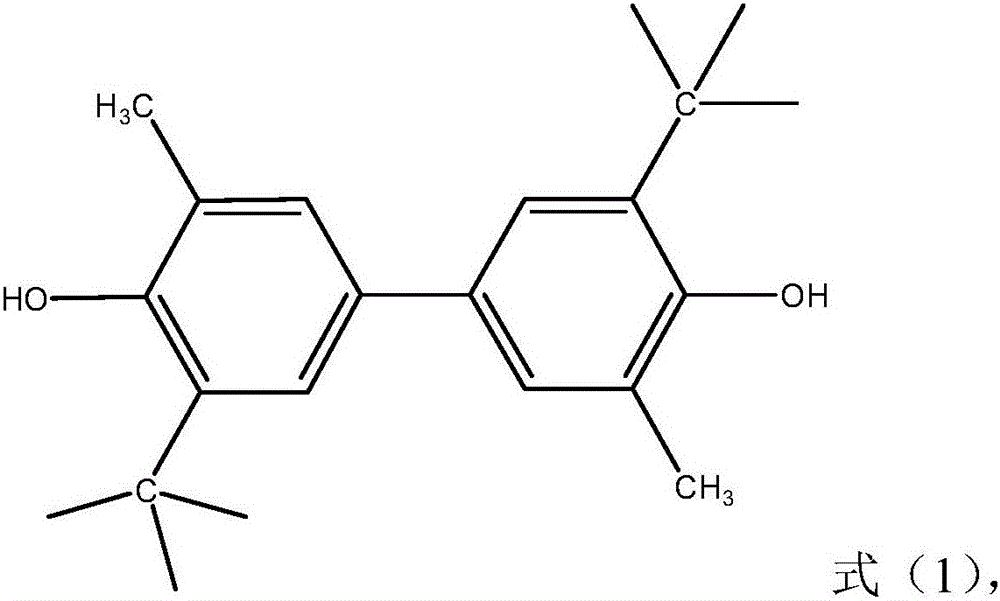

Liquid crystal epoxy resin as well as preparation method and application thereof

The invention discloses liquid crystal epoxy resin as well as a preparation method and an application thereof. The preparation method comprises the following steps: reacting 3,5'-di-tert-butyl-5,3'-dimethyl biphenol with excessive epichlorohydrin in the presence of a phase transfer catalyst, thereby obtaining 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether, wherein the softening point of 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is measured to be 10 DEG C through DSC, and the 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is a thick non-solid product at the room temperature; then, selecting a proper curing agent to pre-cure at a low temperature, enabling a biphenyl rid-rod-shaped structure to orientate and arrange with enough time, curing and cross-linking at a high temperature, thereby obtaining a liquid crystal structure. Compared with the conventional preparation method for the rigid-rod-shaped epoxy resin, the preparation method disclosed by the invention is low in curing cost.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

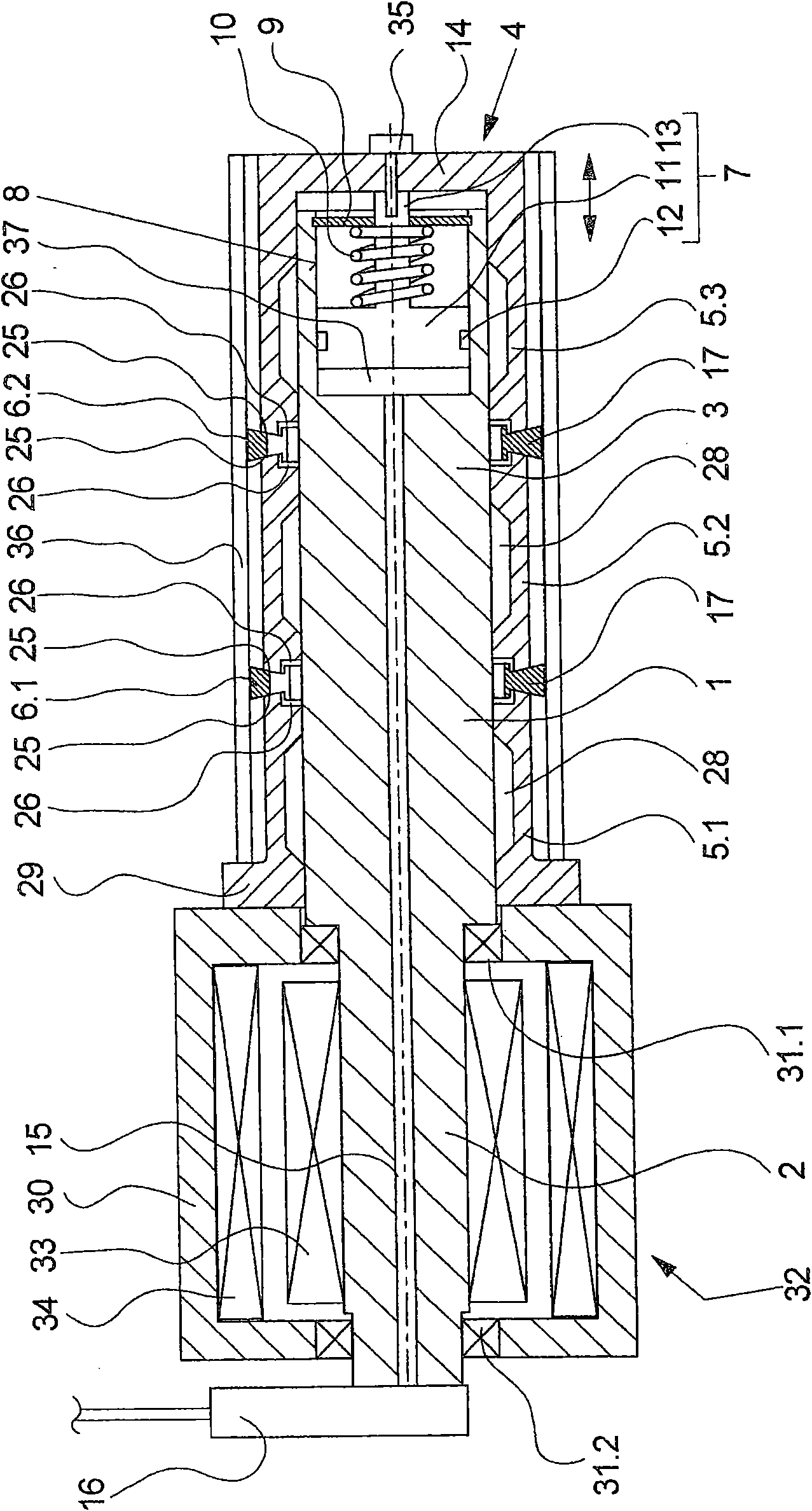

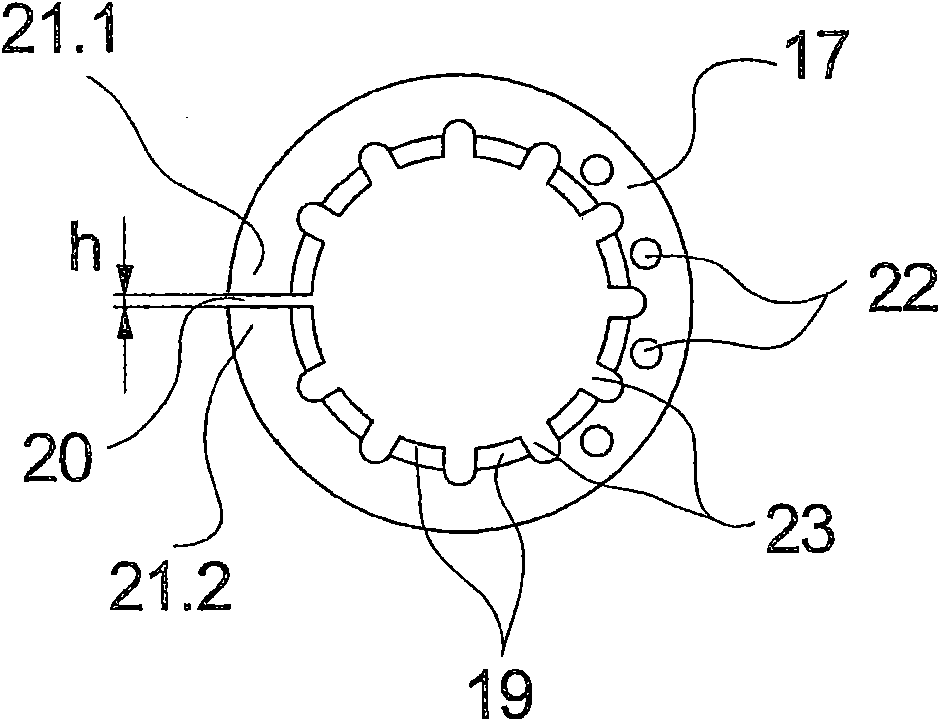

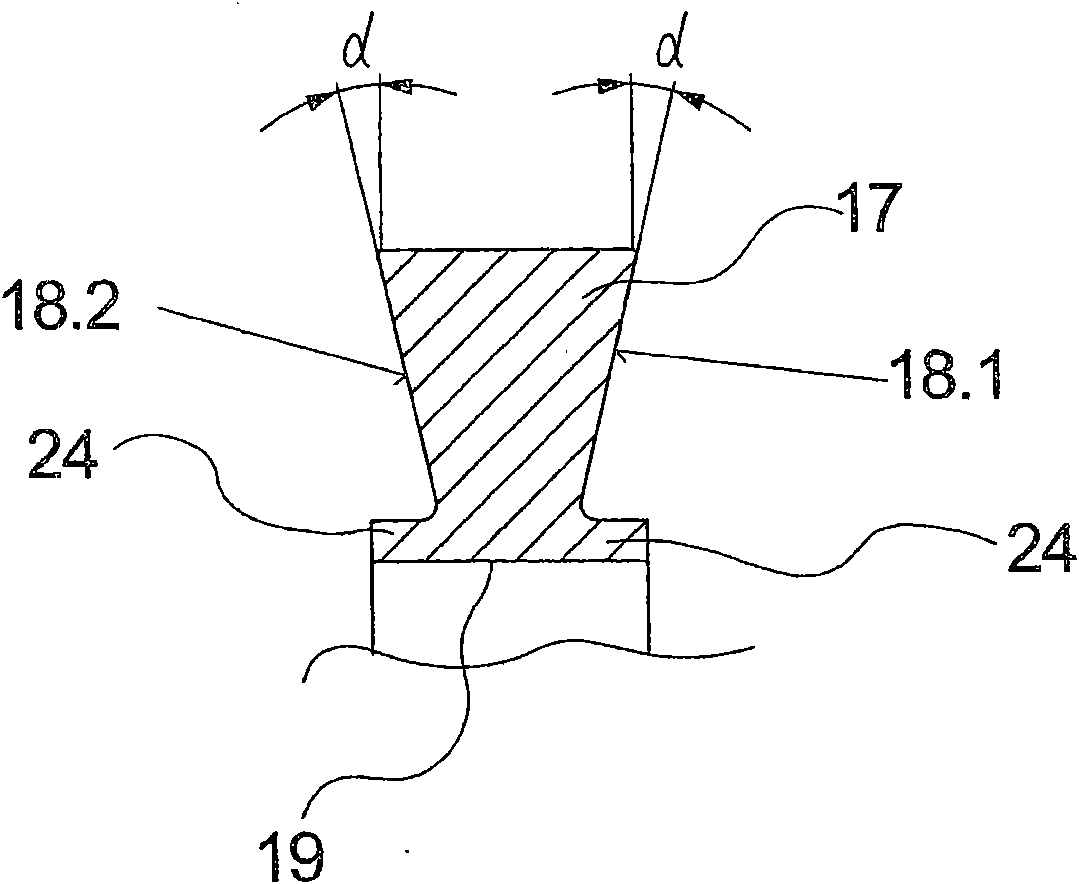

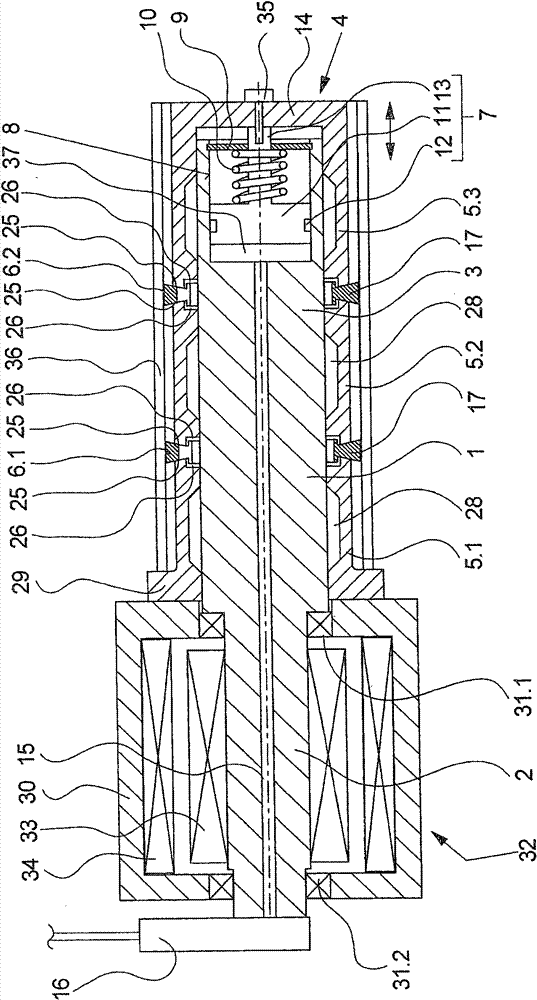

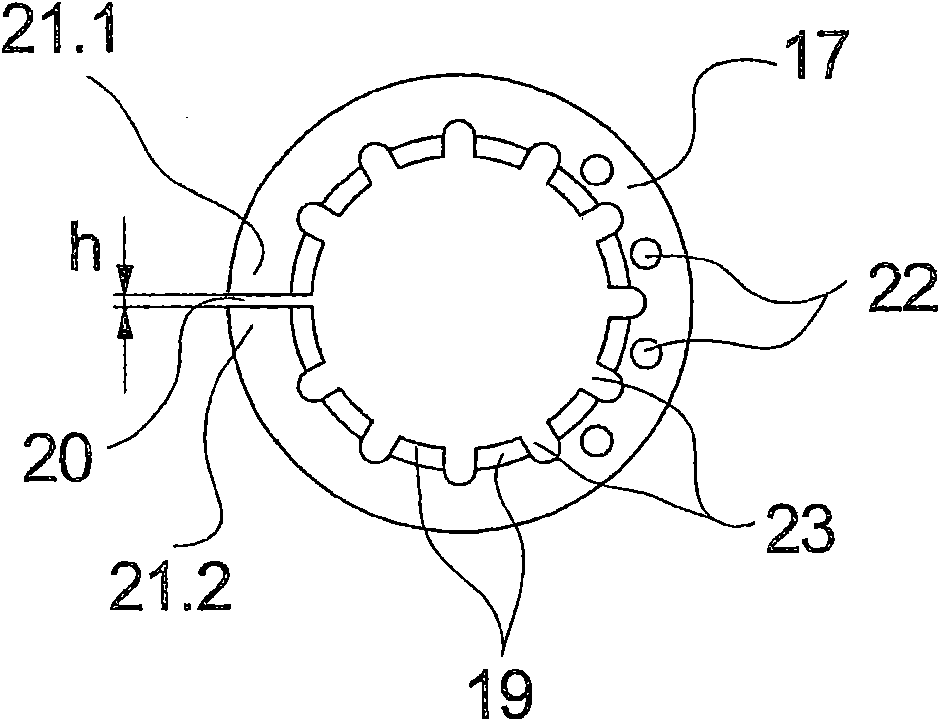

Bobbin holder

The invention relates to a bobbin holder for tensioning a bobbin tube (36) and receiving a wound thread bobbin. The bobbin holder comprises a rotatable drive shaft (1) that is connected to a drive (32) with a bearing end thereof and that has a tensioning device (4) for tensioning a bobbin tube on a tensioning end. The tensioning device (4) comprises a plurality of bobbin tubes (5.2, 5.3) on the periphery of the drive shaft (1) and interposed tensioning rings (6.1). A tensioning piston (7) guided on the free end (2) of the drive shaft acts upon at least one of the bobbin tubes to deform the tensioning rings. In order to allow the use of high fatigue strength materials for the tensioning ring, the tensioning ring comprises a continuous separating slot (20) on the periphery, which extends between two opposite ring ends (21.1, 21.2) of the tensioning ring, deformation being essentially achieved by an expansion of the tensioning ring.

Owner:OERLIKON TEXTILE GMBH & CO KG

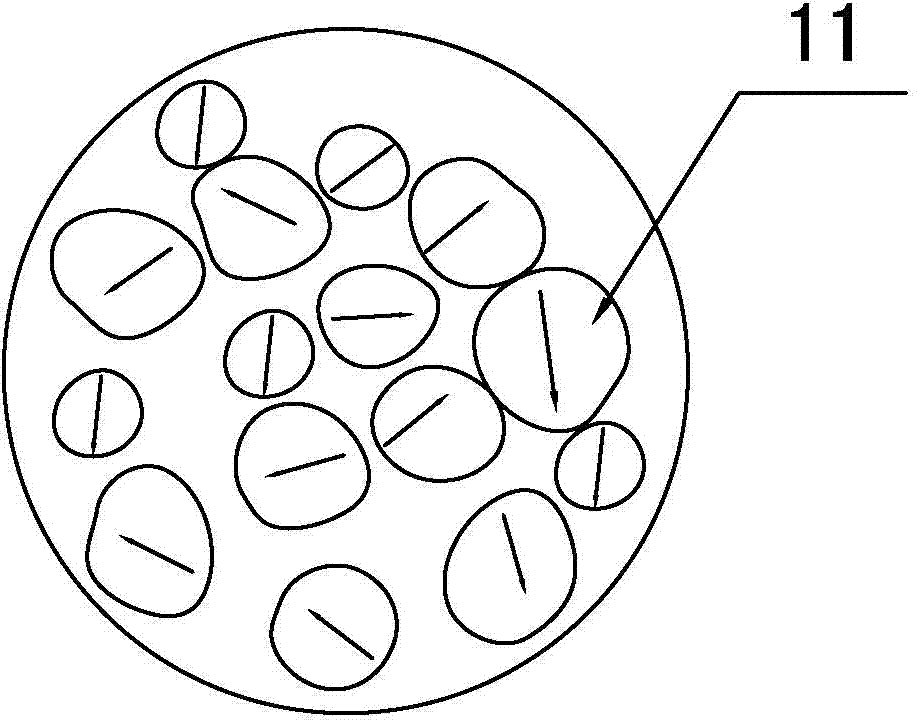

Preparation method for high-orientation-degree sintered neodymium iron boron permanent magnetic material

ActiveCN105931833AImprove liquidityLow densityInductances/transformers/magnets manufactureMagnetic materialsCrazingOrganic solvent

The invention discloses a preparation method for a high-orientation-degree sintered neodymium iron boron permanent magnetic material, and belongs to the field of the rare earth permanent magnetic material. The preparation method is characterized by comprising the steps of mixing neodymium iron boron powder granules and an organic solvent to prepare paste, and pouring the paste into a die; then carrying out non-pressure orientation in a magnetic field to obtain a high orientation degree; next, obtaining a blank with certain density through isostatic cool pressing; and finally, carrying out sintering, densifying, tempering and thermal treatment to obtain the magnet. According to the preparation method provided by the invention, the paste formed by the neodymium iron boron powder and the organic solvent is high in fluidity, and is not pressed by the pressure in the magnetic field orientation process, so that complete orientation and no damage to the paste can be ensured; then certain density and uniform density distribution of the blank can be obtained through the step of isostatic cool pressing; and therefore, sintering densification can be realized, and cracks and falling off of edges and corners caused by uneven density in the sintering process can be avoided as well, so that the high-orientation-degree sintered neodymium iron boron permanent magnetic material can be obtained finally.

Owner:UNIV OF SCI & TECH BEIJING

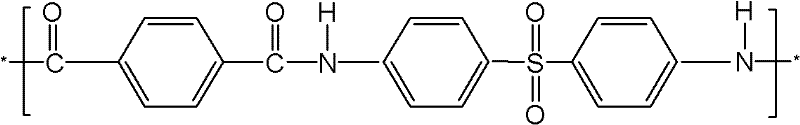

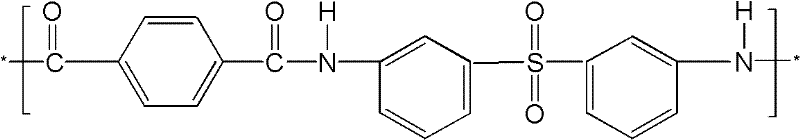

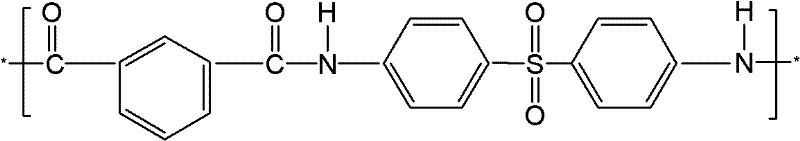

Method for preparing aromatic polysulphonamide fibers

InactiveCN102358958AFully orientedIncrease spinning speedMonocomponent synthetic polymer artificial filamentStretch-spinning methodsBreaking strengthFiber

The invention relates to a method for preparing aromatic polysulphonamide fibers. The method comprises the following steps of: extruding a solution of aromatic polysulfonamide with the apparent viscosity of 20-200Pa.s at the temperature of between 60 and 160DEG C by using spinneret orifices, and making the extruded silk pass through an air layer and enter a coagulating bath, wherein a ratio of a drawing rate for coagulating bath outlet to a spinneret orifice extrusion rate is 1.2-5; and performing at least two stages of plasticizing draw and wash draw, and performing dry draw and further high temperature hot draw to obtain aromatic polysulphonamide fibers with the filament number of 1.0-5.0dtex and the breaking strength of more than 3.8cN / dtex. In the method for preparing the aromatic polysulphonamide fibers, a dry jet wet spinning process is adopted, the height orientation of as-spun fibers is ensured through the forward draw of a spinning jet and the drawing process in the plasticizing, washing and drying stage by stage, macromolecular orientation and crystallization are improved by high temperature draw with lower draw multiple, and the strength of the fibers is improved.

Owner:DONGHUA UNIV

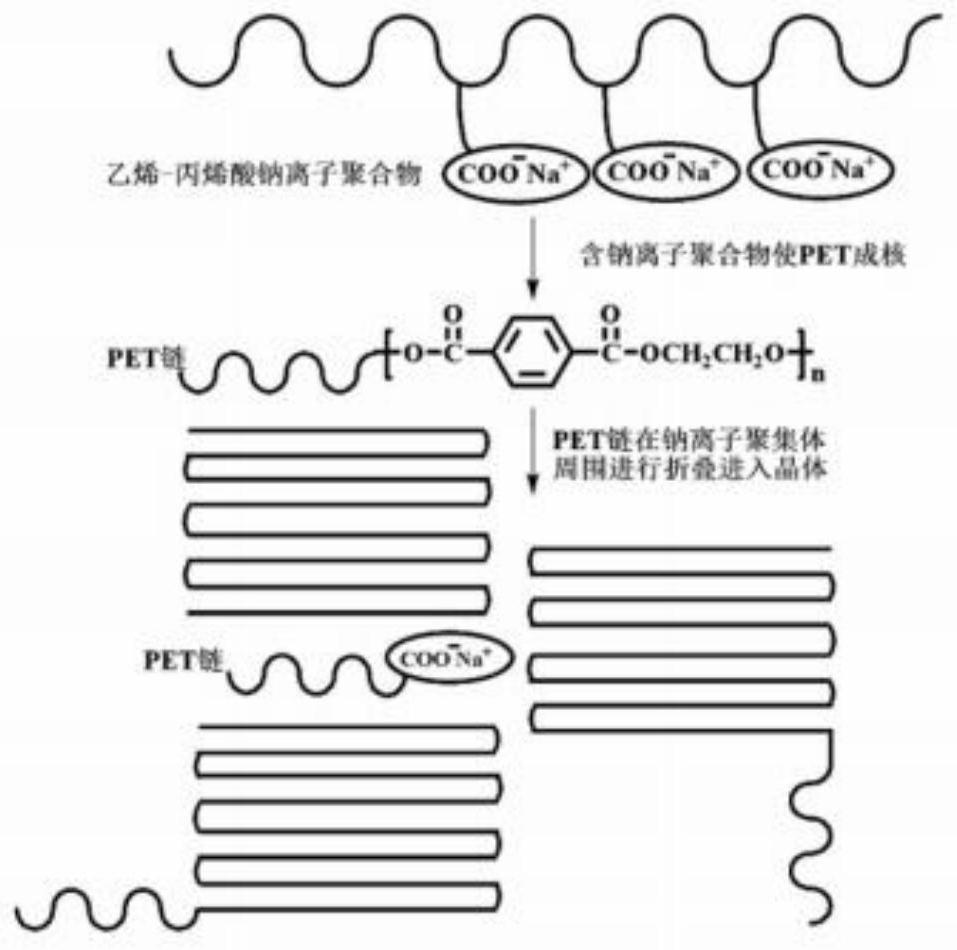

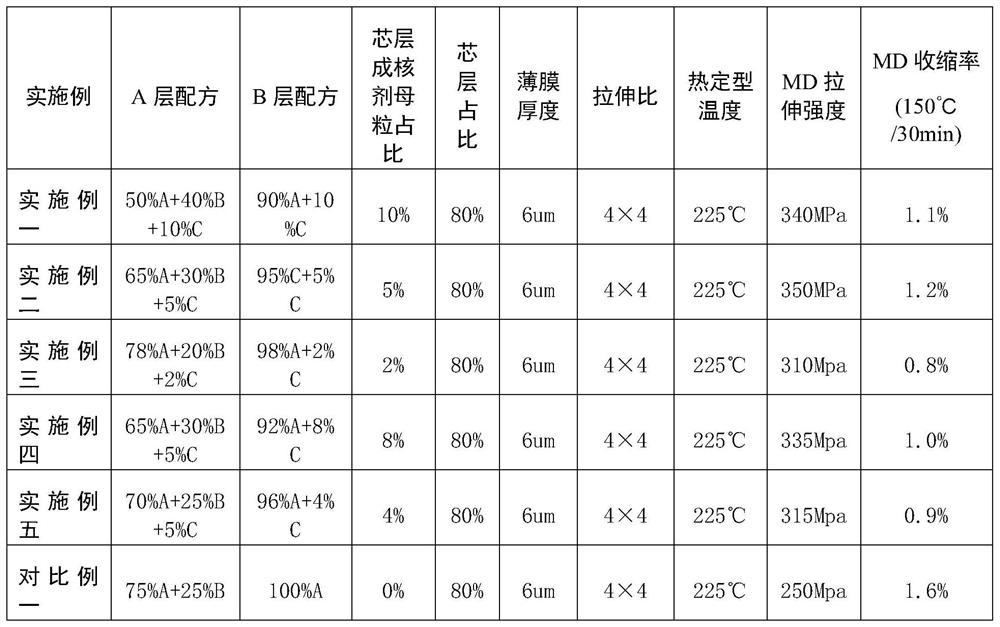

High-tensile-strength polyester film for lithium battery current collector and preparation method thereof

ActiveCN113524830AFully orientedFully crystallizedSynthetic resin layered productsPolyesterPolymer science

The invention discloses a high-tensile-strength polyester film for a lithium battery current collector. The longitudinal tensile strength of the high-tensile-strength polyester film is greater than 300MPa, and the static longitudinal thermal shrinkage at the temperature of 150 DEG C is less than 1.5%. The high-tensile-strength polyester film is characterized by comprising a surface layer A, wherein the surface layer A is prepared from the following raw materials in percentage by mass: 50-78% of a raw material A, 20-40% of a raw material B and 2-10% of a raw material C; and a core layer B which is prepared from the following raw materials in percentage by mass: 90 to 98 percent of raw material A and 2 to 10 percent of raw material C, wherein the surface layer A is of a two-layer structure and is respectively compounded on two surfaces of the core layer; the raw material A is high-viscosity polyethylene glycol terephthalate, the raw material B is polyethylene glycol terephthalate containing a nanoscale SiO2 additive, and the raw material C is high-viscosity polyethylene glycol terephthalate containing a macromolecular crystallization improver. The inventionis suitable for the technical field of polyester film manufacturing.

Owner:浙江南洋科技有限公司

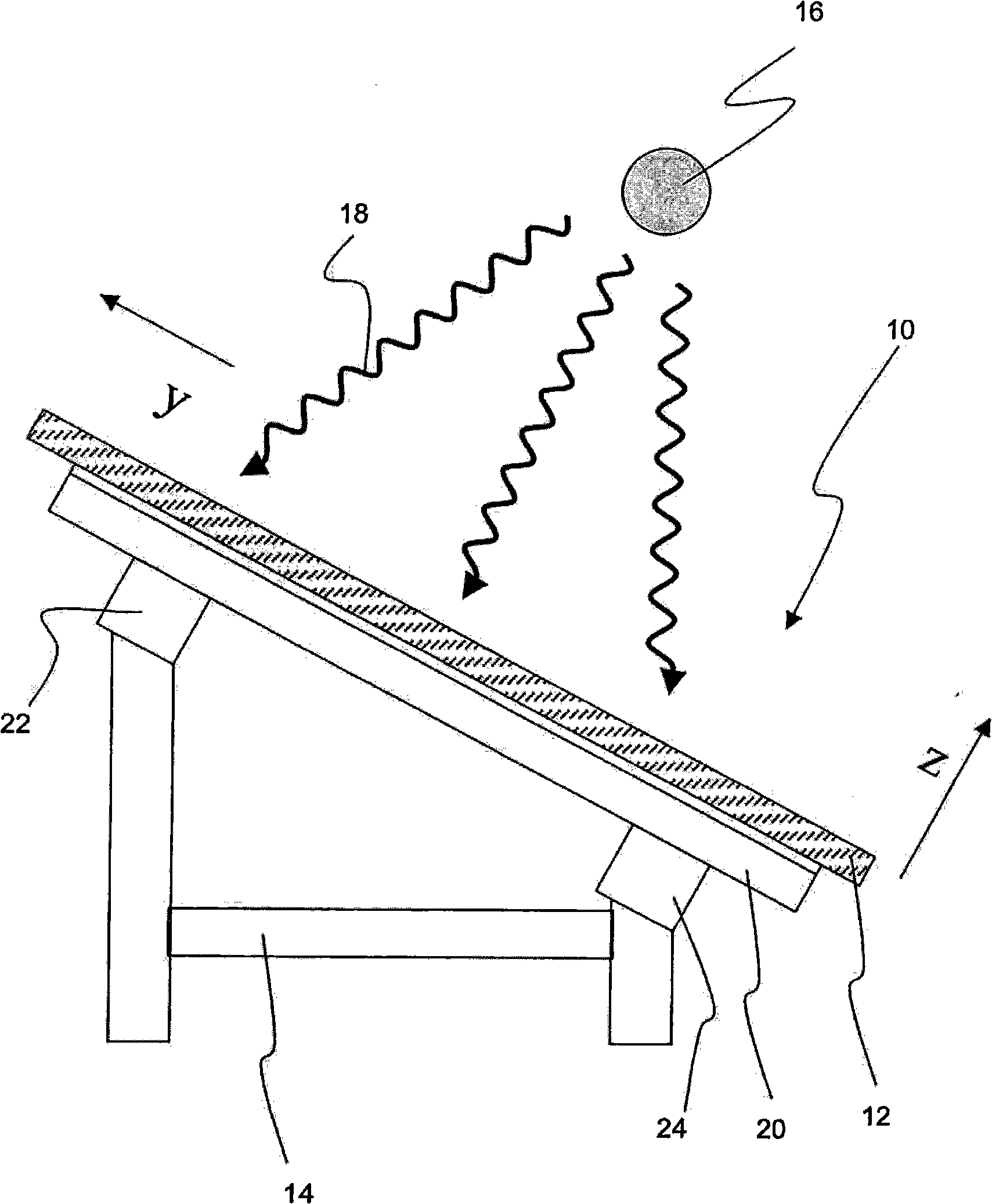

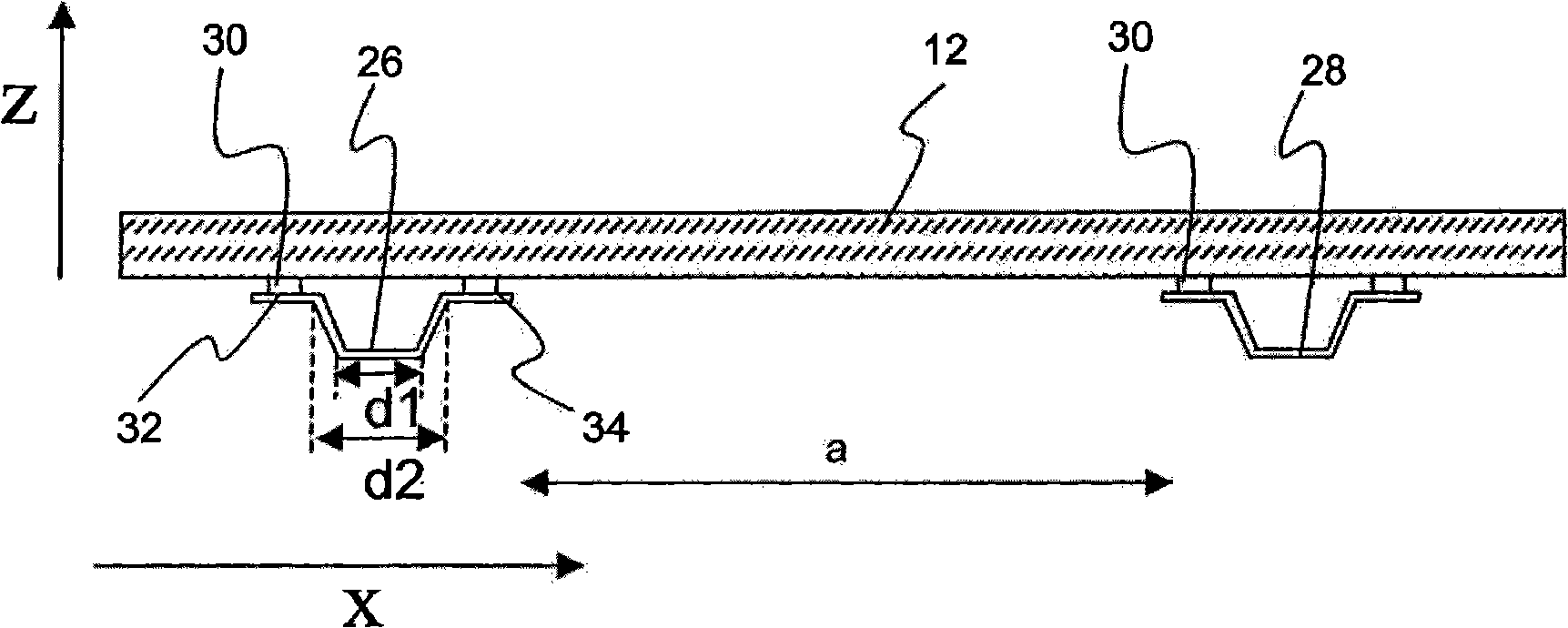

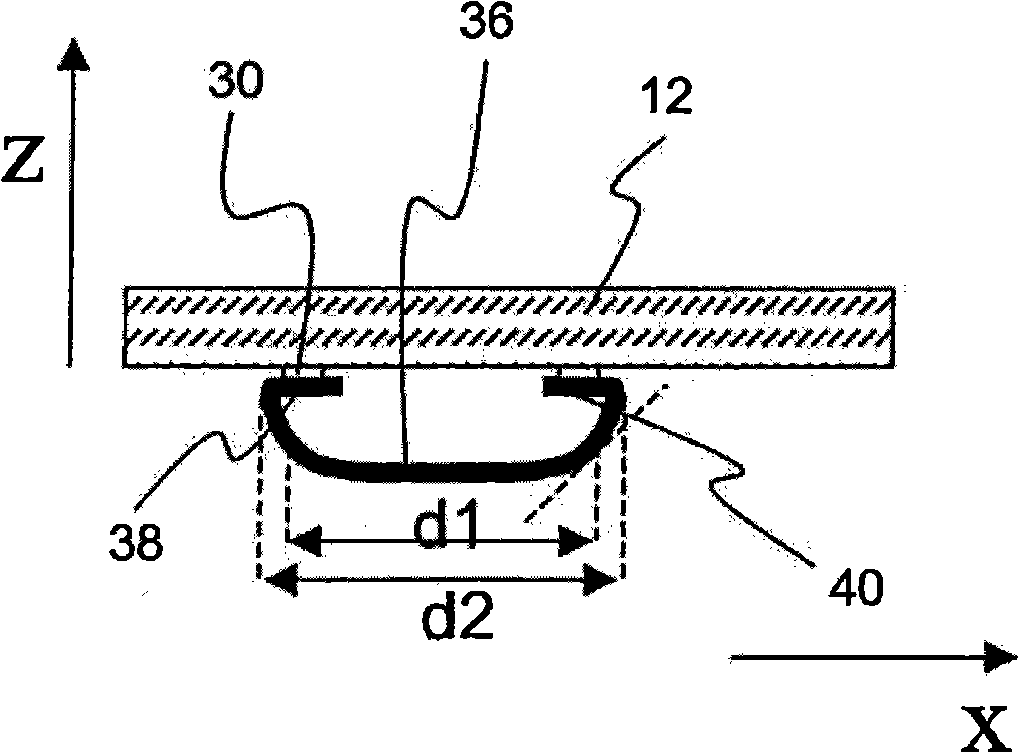

Fastening structure for a large solar module, and solar module

InactiveCN102119305AReliable interlockingSufficient immobilizationPhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

A fastening structure for fastening a large solar module (12) to a substructure (14), with at least two holding profiles (26) which are fastenable on the rear side to one component of the solar module (12) and substructure (14), characterized by at least two receiving profiles (60) which are each fastenable to the other component of the solar module (12) and substructure (14) in a relative position to each other corresponding to the relative position of the holding profiles (26), wherein the holding profile (26) and the receiving profile (60) have a mutually complementary profile shape such that the holding profile (26) is receivable in the receiving profile (60) in a substantially form-fitting manner, wherein mutually corresponding engagement formations are provided on at least one intermeshing holding profile (26) and receiving profile (60); pair and are used to engage together the holding profile (26) and the receiving profile (60) in a locking manner.

Owner:GEHRLICHER SOLAR

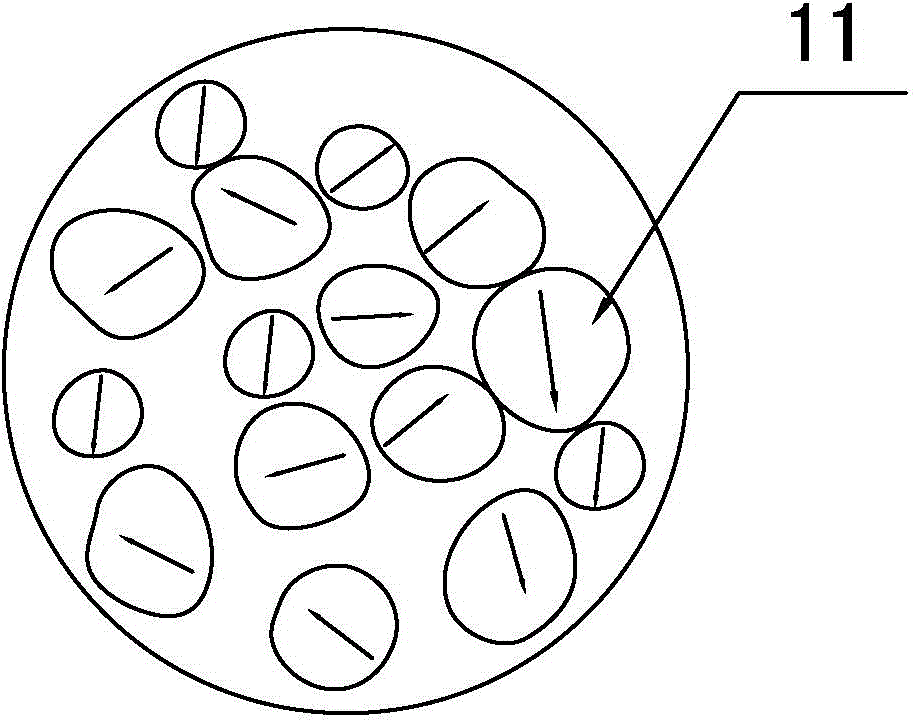

Granulation method of sintered neodymium iron boron powder materials

ActiveCN103480836AGood orientationImprove liquidityInorganic material magnetismApparent densityMetallurgy

The invention discloses a granulation method of sintered neodymium iron boron powder materials. The granulation method comprises the following steps of producing sintered neodymium iron boron materials into fine powder materials, wherein the average particle size of the fine powder materials is 2 to 5 microns; adding the fine powder materials into a mold chamber; performing orientation on the fine powder materials through the magnetic field, wherein the magnetic field is larger than 0.8 teslas and the orientation time is larger than 2 seconds; performing compression forming on the fine powder materials to obtain a green body; performing granulation on the green body to obtain the sintered neodymium iron boron powder materials, wherein the average particle size of the sintered neodymium iron boron powder materials is 15 to 100 microns. According to the granulation method of the sintered neodymium iron boron powder materials, the orientation of the sintered neodymium iron boron powder materials is sufficient; the apparent density is high; the liquidity is good; the sintered neodymium iron boron powder materials can be applied to production of products which are thin in wall and high in filled height directly, regular large pieces of blanks do not need to be produced first, and accordingly the production cost is reduced.

Owner:NINGBO YUNSHENG +6

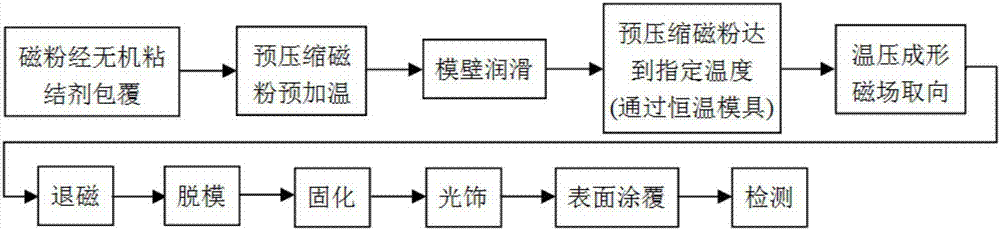

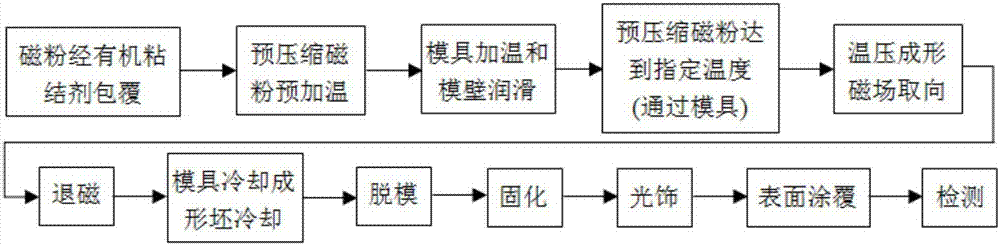

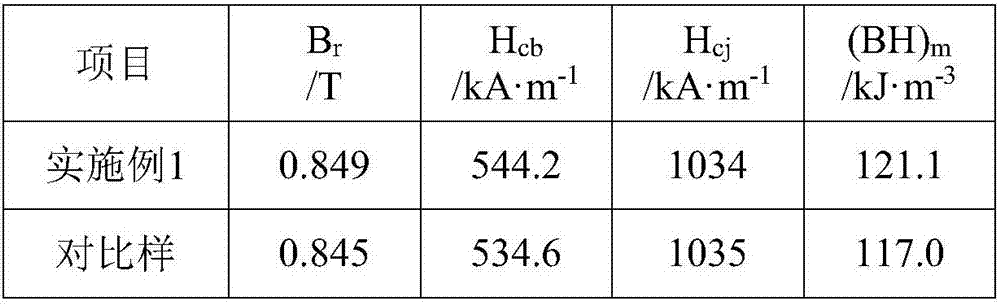

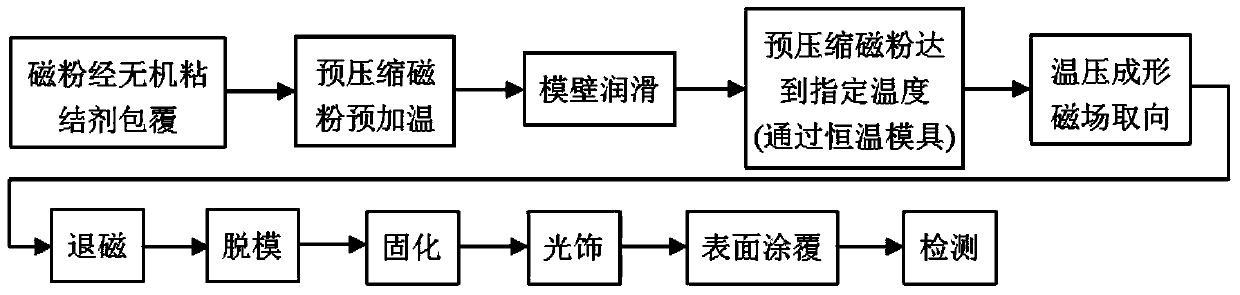

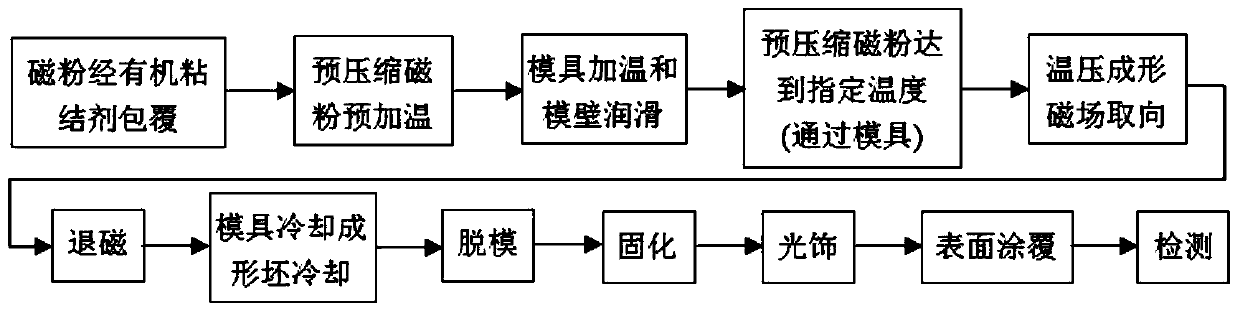

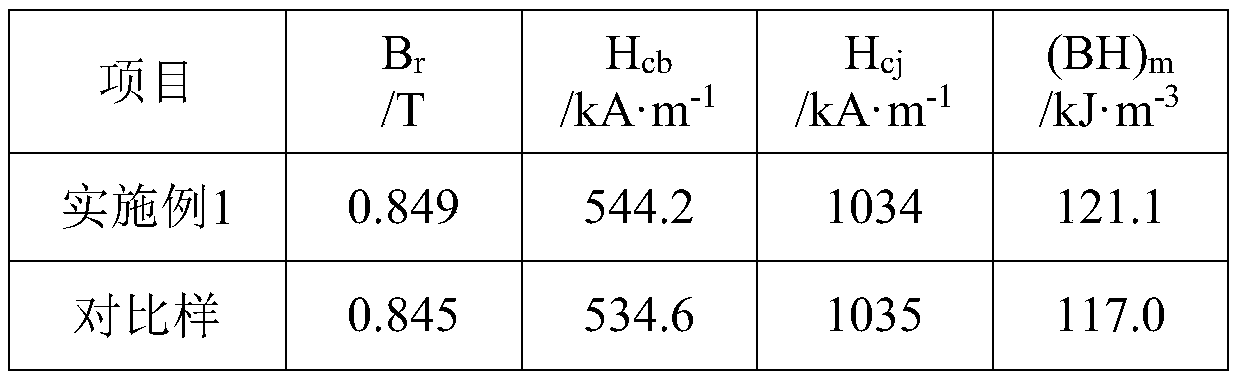

Bonded magnet and preparation method thereof

ActiveCN107359036AStrong shape retentionIncrease productivityInorganic material magnetismInductances/transformers/magnets manufactureAl powderPhosphate

The invention discloses a bonded magnet and a preparation method thereof. The magnet includes magnetic powder, an inorganic binder, a lubricant and metallic powder. The preparation method of the bonded magnet includes: mixing the magnetic powder, the inorganic binder, and a solvent to form a magnetic powder mixture. The inorganic binder is any of silicate, phosphate, sulfate and borate, or a mixture of two or more than two of the silicate, phosphate, sulfate and borate; the metallic powder is any of Cu powder, Al powder, Zn powder, copper alloy powder, aluminum alloy powder, and zinc alloy powder, or a mixture of two or more than two of the Cu powder, Al powder, Zn powder, copper alloy powder, aluminum alloy powder, and zinc alloy powder. According to the method, magnetic powder covering is performed through the inorganic binder, and then the problem that the magnetic powder covered by an organic binder is poor in fluidity at a high temperature, so the pre-compressed magnetic powder cannot be evenly and stably filled in a die cavity, and cannot be filled in a thin wall die cavity even can be solved; and the inorganic binder can allow high shape preserving ability of a formed blank at the high temperature, and the formed blank can be directly released from the die when the formed blank is not cooled, and the production efficiency is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

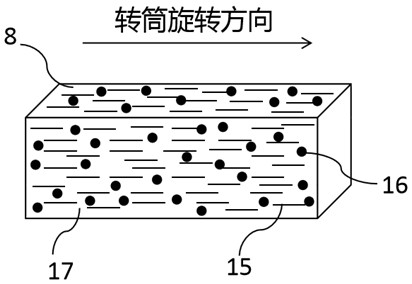

Directional heat-conducting fin and preparation method thereof, and semiconductor heat dissipation device

ActiveCN113150558AGood orientationImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringSemiconductor

The invention belongs to the field of heat-conducting fin preparation technologies and semiconductor heat dissipation, and particularly discloses a preparation method of a directional heat-conducting fin, which comprises the following steps: S1, preparing a fluid composition for the heat-conducting fin; S2, placing the fluid composition obtained in the step S1 in an orientation forming device, applying high-speed shearing force of circular motion to the fluid composition layer by layer, orienting the heat-conducting filler in the fluid composition in the shearing direction, forming oriented thin-layer compositions, collecting the thin-layer compositions in a mold layer by layer, forming a continuous multi-layer collection body, S3, carrying out thermocuring on the multi-layer convergence body to obtain an oriented composition block; and S4, slicing the oriented composition block along a direction vertical to the orientation to obtain the oriented heat-conducting sheet. The convergence body prepared by the method is good in orientation, few in defect and high in efficiency, the heat-conducting fin obtained by slicing treatment has high orientation, high heat conductivity and uniformity, and meanwhile, the heat-conducting fin can be well applied to a semiconductor heat dissipation device.

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD

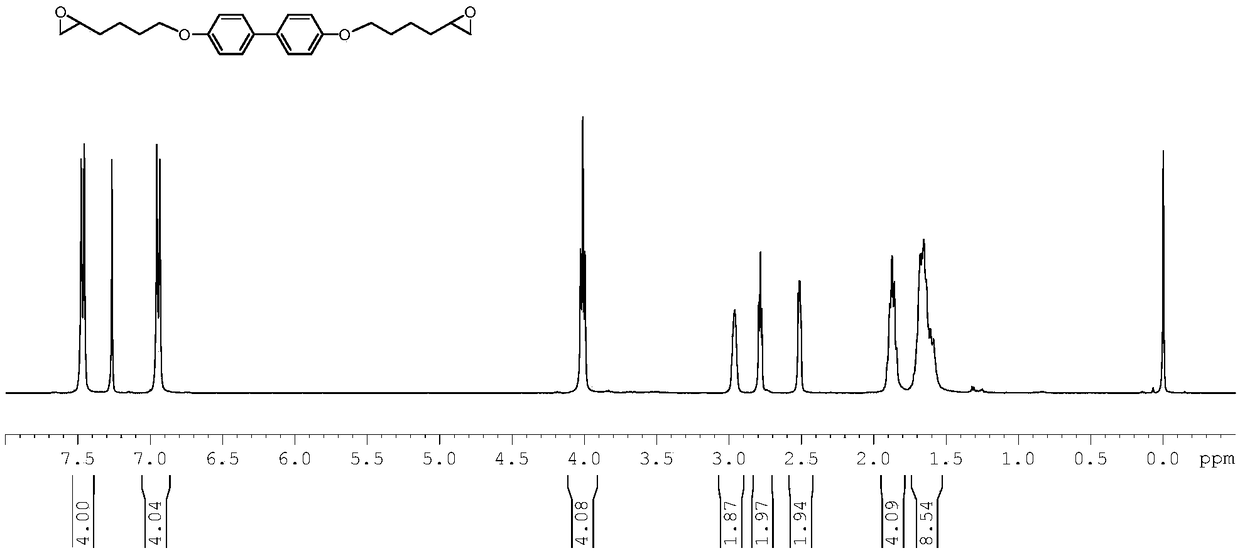

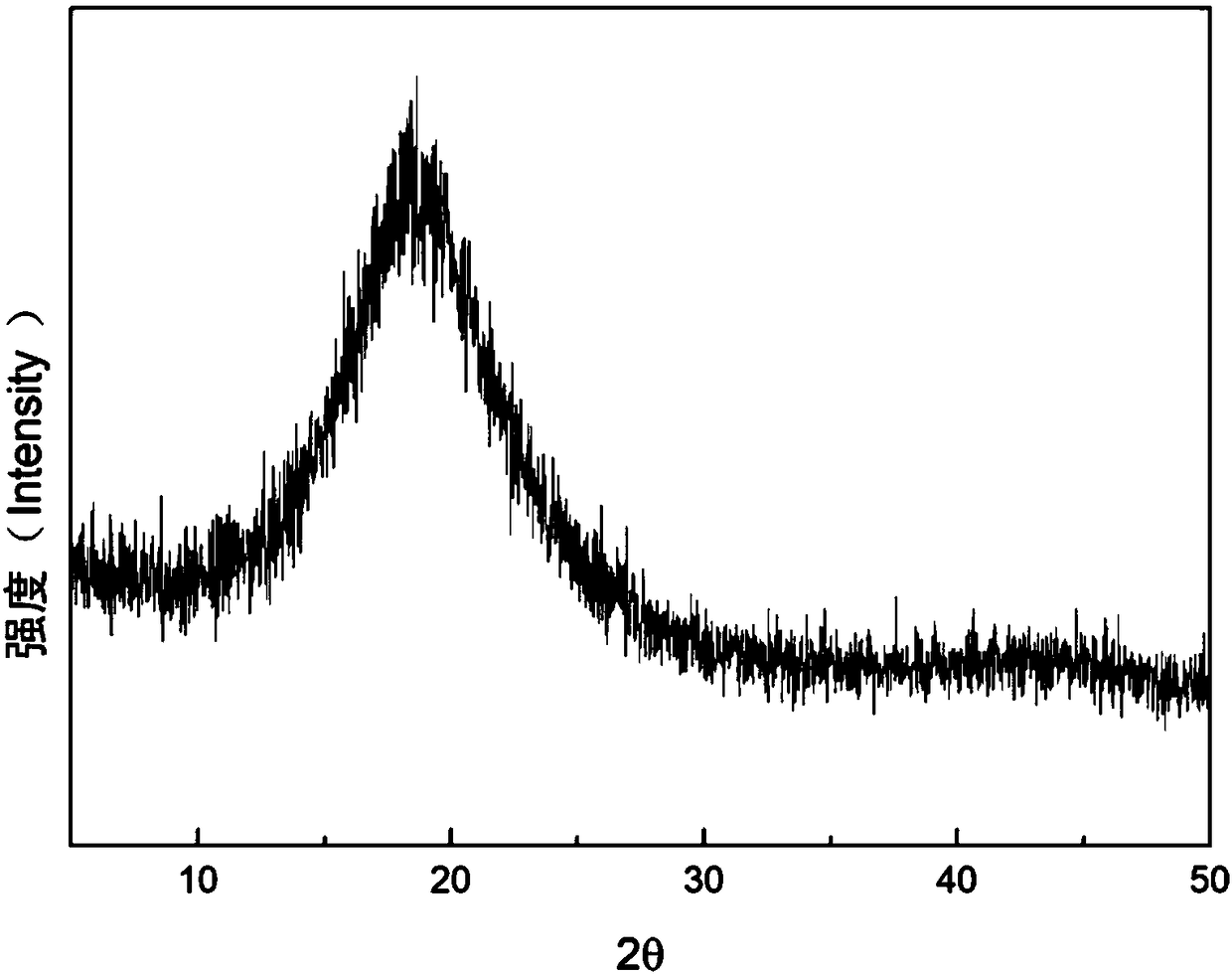

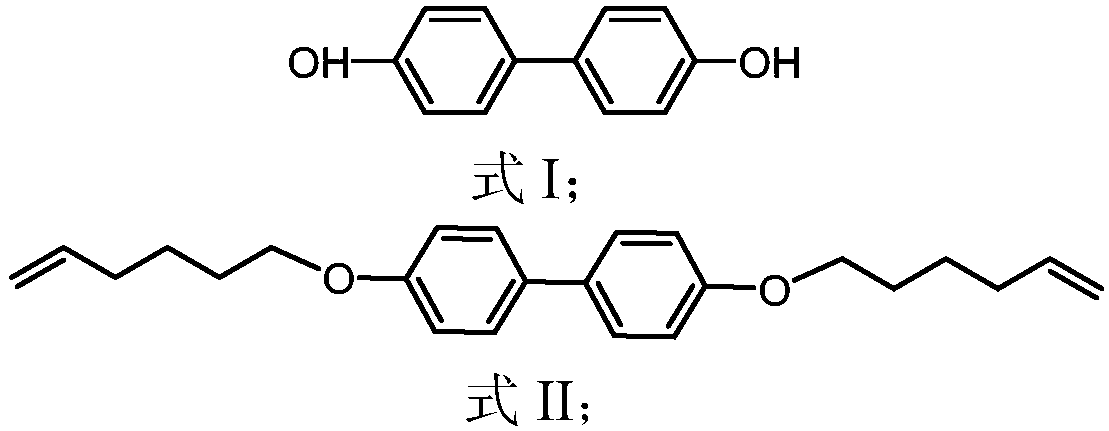

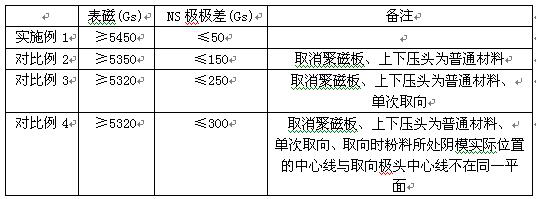

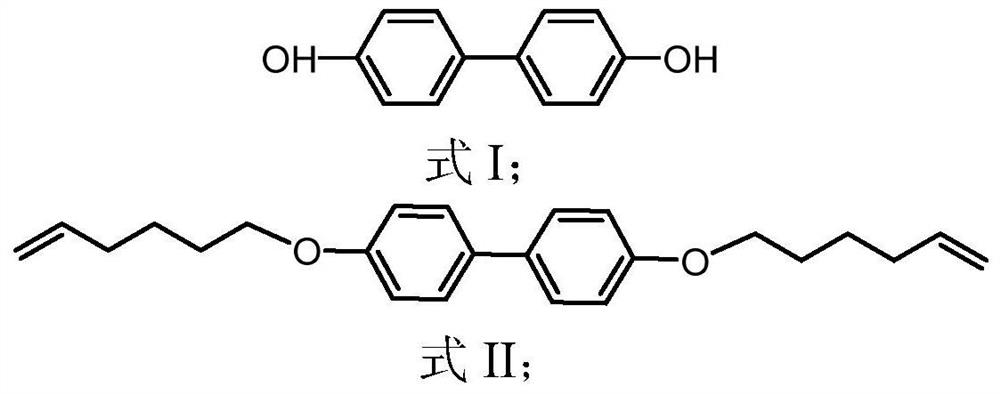

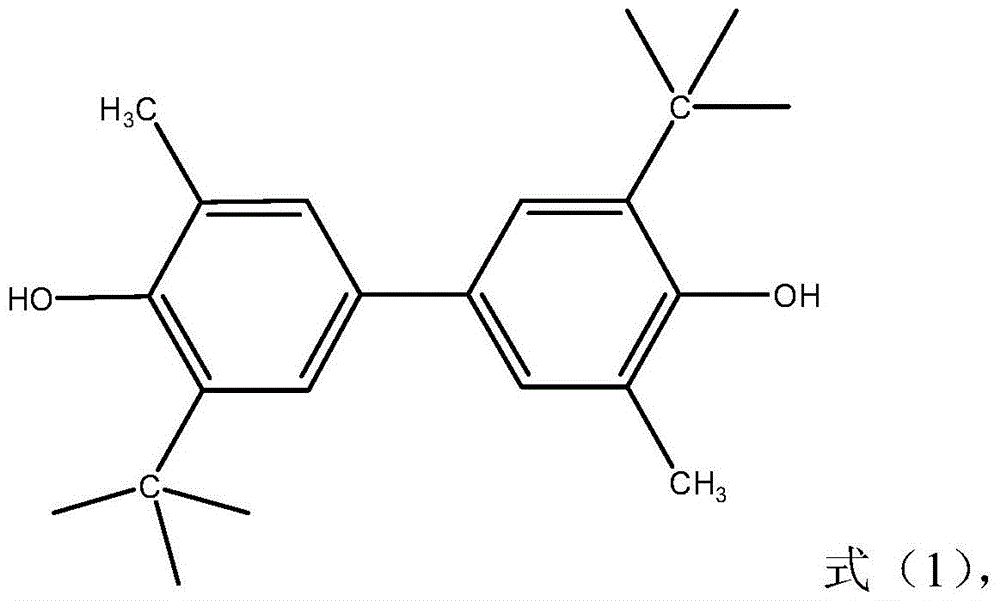

Diphenyl liquid-crystal epoxy resin as well as preparation method and application thereof

ActiveCN108409689ALow curing difficultyReduce curing costsLiquid crystal compositionsOrganic chemistryEpoxyBenzene

The invention discloses diphenyl liquid-crystal epoxy resin as well as a preparation method and application thereof. The preparation method of the diphenyl liquid-crystal epoxy resin comprises the following steps of: (1) dissolving diphenyl diphenol in acetone, rising the temperature to 60-80 DEG C, adding potassium carbonate, stirring with 6-bromo-1-hexene for reaction, and obtaining 4,4'-di(5-hexenyloxo)diphenyl; (2) dissolving the 4,4'-di(5-hexenyloxo)diphenyl in dichloromethane, then rising the temperature to 40-50 DEG C, adding peroxide for reaction, and obtaining 4,4'-di(5,6-epoxyhexyloxy)diphenyl; (3) dissolving the 4,4'-di(5,6-epoxyhexyloxy)diphenyl and a curing agent in an organic solvent to obtain mixed liquid; then vacuumizing the mixed liquid till to be constant weight, and after the solvent is volatilized, carrying out sectional curing to obtain the diphenyl liquid-crystal epoxy resin. The diphenyl liquid-crystal epoxy resin, the preparation method and the application disclosed by the invention have the beneficial effects that the curing difficulty is low, the curing cost is low, and the obtained diphenyl liquid-crystal epoxy resin is good in heat-conducting property.

Owner:中科广化(重庆)新材料研究院有限公司 +3

Method of preparing polyparaphenyl bracing benzdioxazole fibre

ActiveCN1285778CGuaranteed molarityIncreased Relative Inherent ViscosityMonocomponent synthetic polymer artificial filamentMelt spinning methodsFiberPolymer science

The invention discloses a new method for preparing poly-p-phenylene benzobisoxazole fibers, which comprises the following steps: (1) The ratio of adding components to a precondensation reactor is: 1:1.5~6:0.7~3 4,6-diaminoresorcinol-terephthalate, polyphosphoric acid and P 2 o 5 , at 80-180°C, carry out the pre-condensation reaction in stages for 8-15 hours; (2) The pre-condensation polymer obtained in step (1) enters the twin-screw extruder to continue the reaction to obtain an inherent viscosity of 20-20. 40dl / g poly-p-phenylene benzobisoxazole slurry; (3) After the slurry obtained in step (2) is continuously squeezed into the spinning assembly, the coagulation process is first stretched, and then washed with alkali, washed with water, dried, Wind spinning poly-p-phenylene benzodiaxazole fiber. The invention has the advantages of low equipment requirements, short reaction period, high strength and modulus of the prepared fiber, simple process and controlled sewage discharge.

Owner:DONGHUA UNIV +2

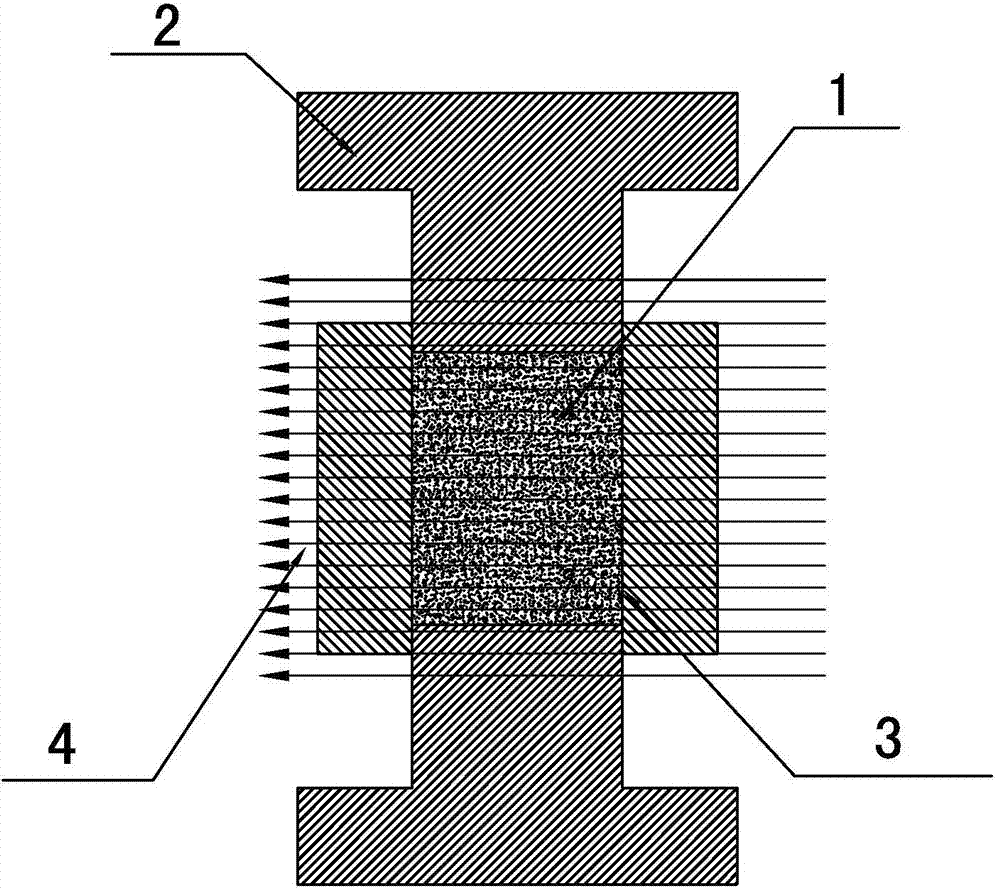

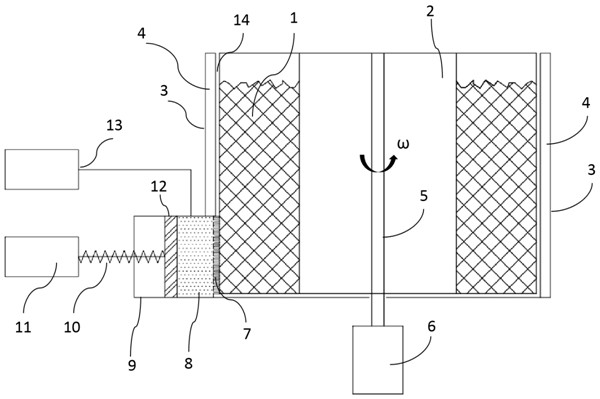

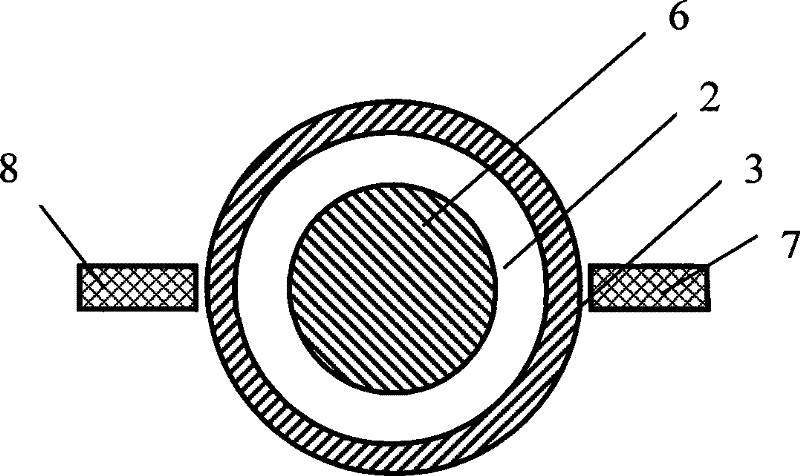

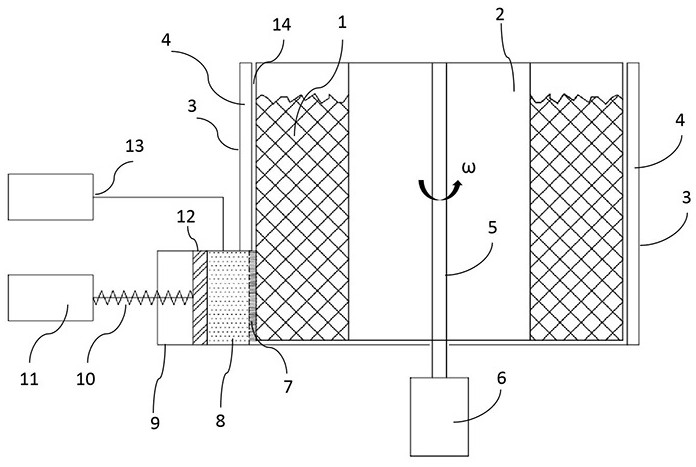

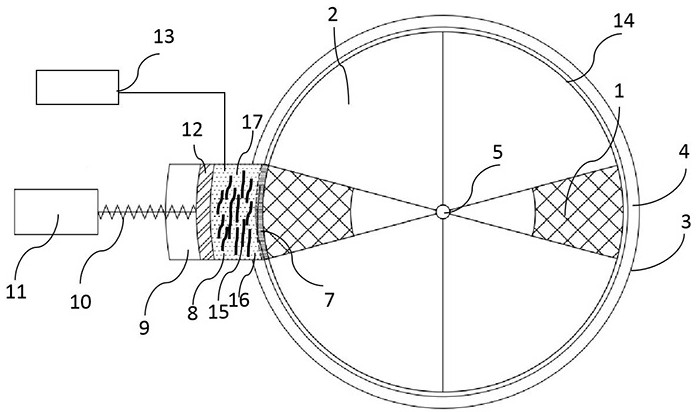

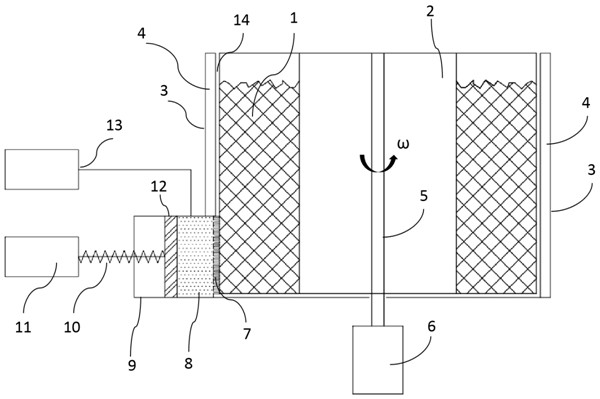

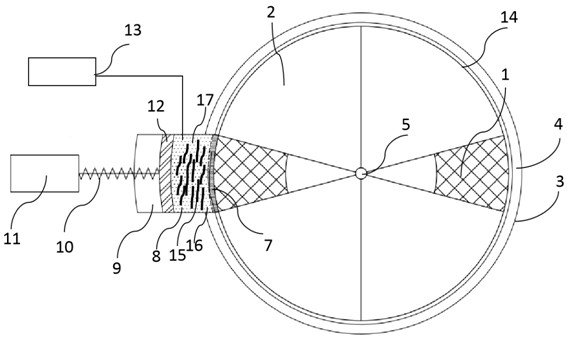

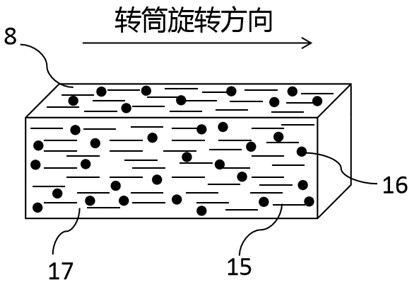

Method and apparatus for forming of radiation orientating round ring-shaped magnetic body

ActiveCN101256898BFully orientedConsistent orientationPermanent magnet manufactureMagnetic polesCondensed matter physics

The present invention discloses a molding method and apparatus for circular ring magnetic body in radiating way to resolve the technical problems which make magnetic powder uniform. Methods of the invention are that: orientation magnetic field is disconnected setting at circular ring magnetic body with 360 degrees in forming process, the forming process has relative rotation movement between orientation magnetic field and magnetic powder; the equipment of the invention is equipped with ring shaped molding chamber in the orientation magnetic field, and the orientation magnetic field is disconnected at circular ring magnetic body with 360 degrees, a moving structure with relative rotation is formed between one magnetic pole and another magnetic pole in orientation magnetic field, or betweenthe ring shaped mold form and the orientation magnetic field, The present invention has more complete orientation to the magnetic powder compared with the present technology, because the orientation magnetic field at 360 degree is same with the magnetic field, the degree of orientation of radiating ring at different angle is identical, so the present invention can be used for producing sintered radiating ring magnetic body, bonding radiating ring magnetic body and bonding injection molding radiating ring magnetic body.

Owner:SHENZHEN RADIMAG TECH CO LTD

Granulation method of sintered NdFeB powder

ActiveCN103480836BGood orientationImprove liquidityInorganic material magnetismApparent densityMetallurgy

The invention discloses a granulation method of sintered neodymium iron boron powder materials. The granulation method comprises the following steps of producing sintered neodymium iron boron materials into fine powder materials, wherein the average particle size of the fine powder materials is 2 to 5 microns; adding the fine powder materials into a mold chamber; performing orientation on the fine powder materials through the magnetic field, wherein the magnetic field is larger than 0.8 teslas and the orientation time is larger than 2 seconds; performing compression forming on the fine powder materials to obtain a green body; performing granulation on the green body to obtain the sintered neodymium iron boron powder materials, wherein the average particle size of the sintered neodymium iron boron powder materials is 15 to 100 microns. According to the granulation method of the sintered neodymium iron boron powder materials, the orientation of the sintered neodymium iron boron powder materials is sufficient; the apparent density is high; the liquidity is good; the sintered neodymium iron boron powder materials can be applied to production of products which are thin in wall and high in filled height directly, regular large pieces of blanks do not need to be produced first, and accordingly the production cost is reduced.

Owner:NINGBO YUNSHENG +6

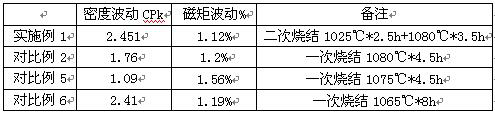

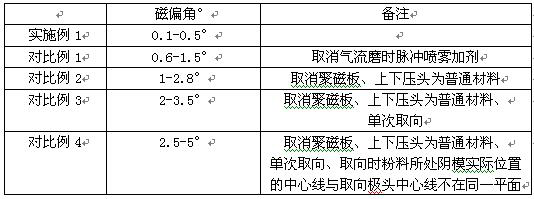

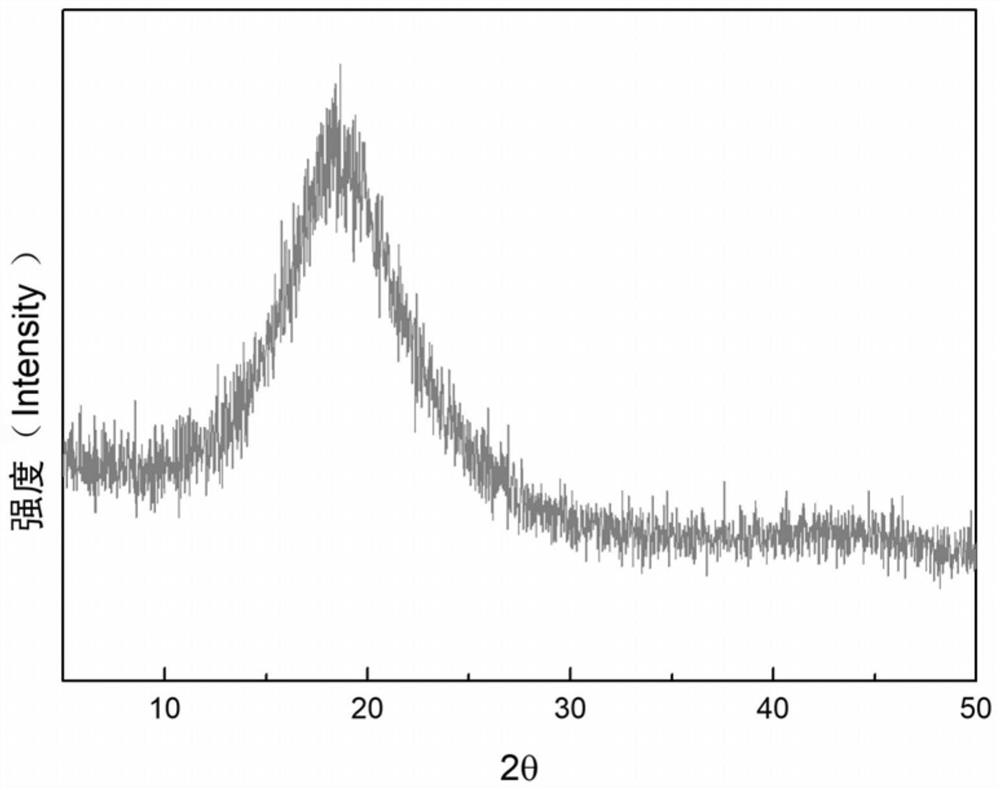

A kind of preparation method of rare earth permanent magnet with high homogeneity and high performance

ActiveCN111489889BAvoid distributingFully orientedInductances/transformers/magnets manufactureMagnetic materialsMagnetic fluxMaterials science

The invention discloses a preparation method of a high-homogeneity and high-performance rare earth permanent magnet. The distribution of magnetic lines of force is optimized by adding a magnetic concentrating plate inside the female mold and selecting materials with near magnetic permeability for the upper and lower pressure heads; and by controlling the orientation of the product. At this time, the position of the powder is on the same plane as the centerline of the orientation pole head, so that the powder in the mold cavity can be fully oriented, and the magnetic declination angle and NS pole surface magnetic difference of the final magnet can be reduced and improved. When passing through the jet mill, the pulse spray method is adopted, and the mixed liquid additive is evenly added to improve the fluidity of the powder for preparing the magnet, and improve the density of the green body and the uniformity of the orientation of the local magnetic domain; it adopts the progressive pre-pressing process of multiple magnetization opposite directions , Repeated multiple times of orientation, step by step two-way preloading method, so that the consistency of density, surface magnetism, magnetic flux and magnetic moment of the final magnet is improved. The secondary sintering process is adopted, combined with liquid-phase sintering of nano-rare earth hydrides, to increase the coercive force of the magnet.

Owner:浙江凯文磁业有限公司

A kind of biphenyl type liquid crystal epoxy resin and its preparation method and application

ActiveCN108409689BImprove toughnessHigh activityLiquid crystal compositionsOrganic chemistryOrganosolvFirming agent

The invention discloses diphenyl liquid-crystal epoxy resin as well as a preparation method and application thereof. The preparation method of the diphenyl liquid-crystal epoxy resin comprises the following steps of: (1) dissolving diphenyl diphenol in acetone, rising the temperature to 60-80 DEG C, adding potassium carbonate, stirring with 6-bromo-1-hexene for reaction, and obtaining 4,4'-di(5-hexenyloxo)diphenyl; (2) dissolving the 4,4'-di(5-hexenyloxo)diphenyl in dichloromethane, then rising the temperature to 40-50 DEG C, adding peroxide for reaction, and obtaining 4,4'-di(5,6-epoxyhexyloxy)diphenyl; (3) dissolving the 4,4'-di(5,6-epoxyhexyloxy)diphenyl and a curing agent in an organic solvent to obtain mixed liquid; then vacuumizing the mixed liquid till to be constant weight, and after the solvent is volatilized, carrying out sectional curing to obtain the diphenyl liquid-crystal epoxy resin. The diphenyl liquid-crystal epoxy resin, the preparation method and the application disclosed by the invention have the beneficial effects that the curing difficulty is low, the curing cost is low, and the obtained diphenyl liquid-crystal epoxy resin is good in heat-conducting property.

Owner:中科广化(重庆)新材料研究院有限公司 +3

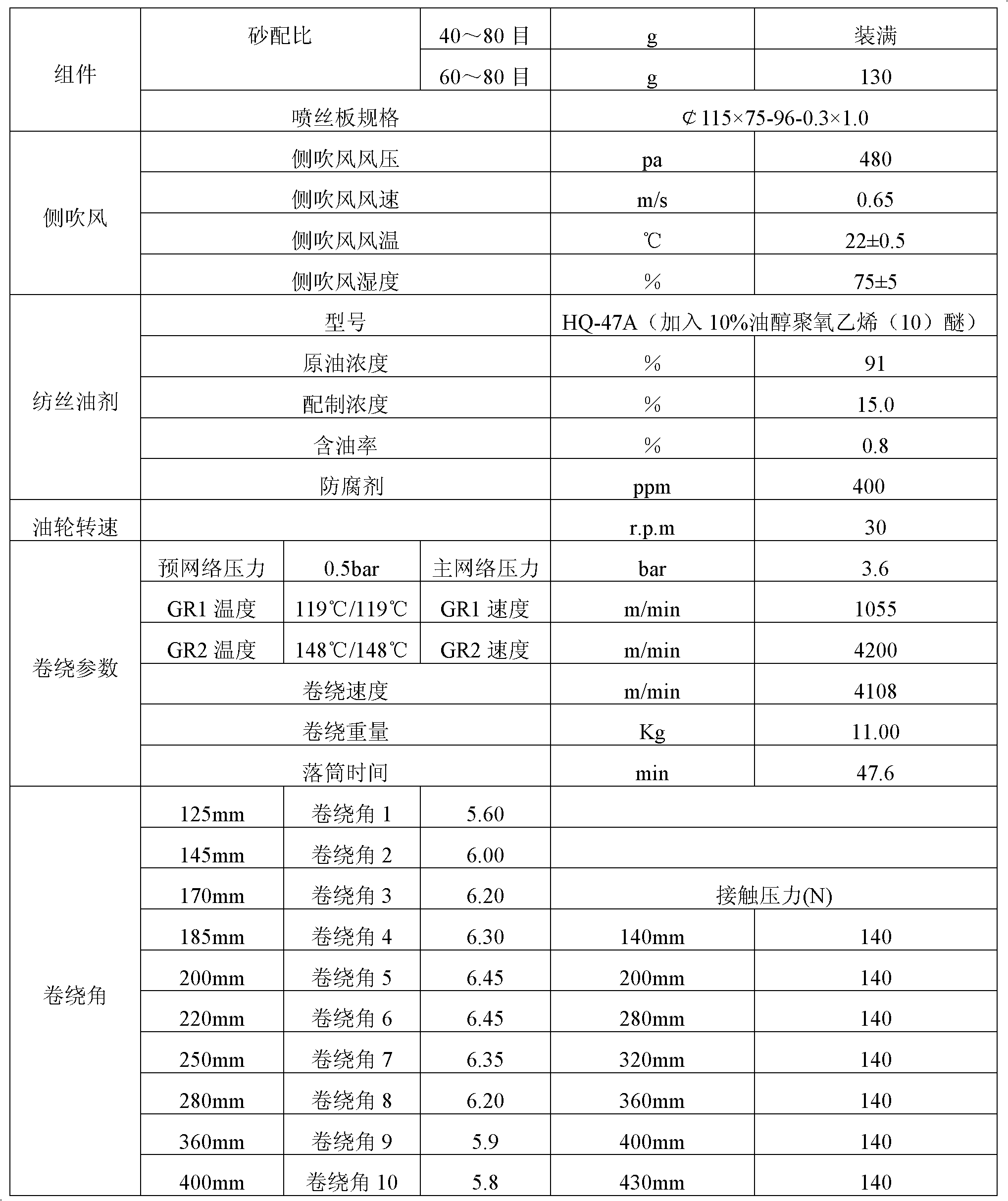

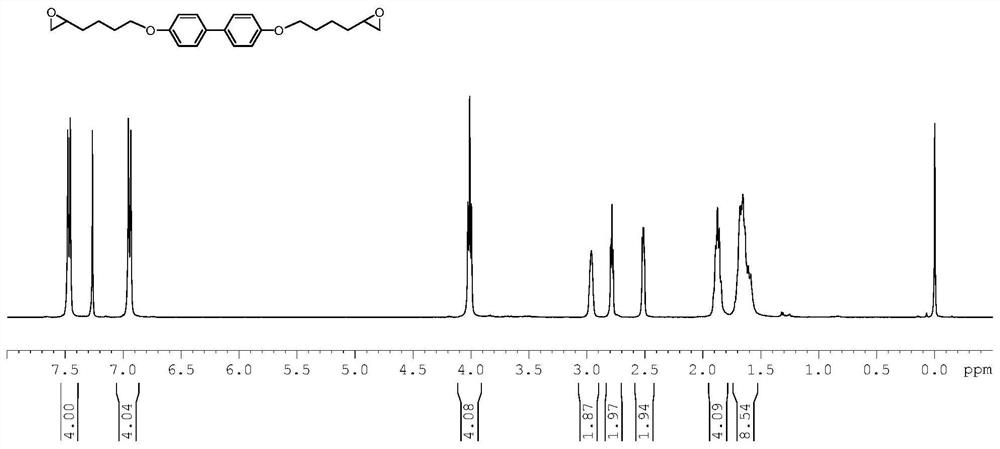

A kind of liquid crystal epoxy resin and its preparation method and application

The invention discloses liquid crystal epoxy resin as well as a preparation method and an application thereof. The preparation method comprises the following steps: reacting 3,5'-di-tert-butyl-5,3'-dimethyl biphenol with excessive epichlorohydrin in the presence of a phase transfer catalyst, thereby obtaining 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether, wherein the softening point of 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is measured to be 10 DEG C through DSC, and the 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is a thick non-solid product at the room temperature; then, selecting a proper curing agent to pre-cure at a low temperature, enabling a biphenyl rid-rod-shaped structure to orientate and arrange with enough time, curing and cross-linking at a high temperature, thereby obtaining a liquid crystal structure. Compared with the conventional preparation method for the rigid-rod-shaped epoxy resin, the preparation method disclosed by the invention is low in curing cost.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Directional heat-conducting fin and preparation method thereof, and semiconductor heat dissipation device

PendingCN114133744AWide viscosity rangeGood orientationSemiconductor/solid-state device detailsSolid-state devicesPhysicsEngineering

The invention belongs to the field of heat-conducting fin preparation technologies and semiconductor heat dissipation, and particularly discloses a preparation method of a directional heat-conducting fin, which comprises the following steps: S1, preparing a fluid composition for the heat-conducting fin; s2, the fluid composition obtained in the step S1 is placed in an orientation forming device, high-speed shearing force of circular motion is applied to the fluid composition layer by layer, so that the heat-conducting filler in the fluid composition is oriented in the shearing direction, oriented thin-layer compositions are formed, the thin-layer compositions are collected in a mold layer by layer, a continuous multi-layer collection body is formed, and the multi-layer collection body is obtained. S3, carrying out thermocuring on the multi-layer convergence body to obtain an oriented composition block; and S4, slicing the oriented composition block along a direction vertical to the orientation to obtain the oriented heat-conducting sheet. The convergence body prepared by the method is good in orientation, few in defect and high in efficiency, the heat-conducting fin obtained by slicing treatment has high orientation, high heat conductivity and uniformity, and meanwhile, the heat-conducting fin can be well applied to a semiconductor heat dissipation device.

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD

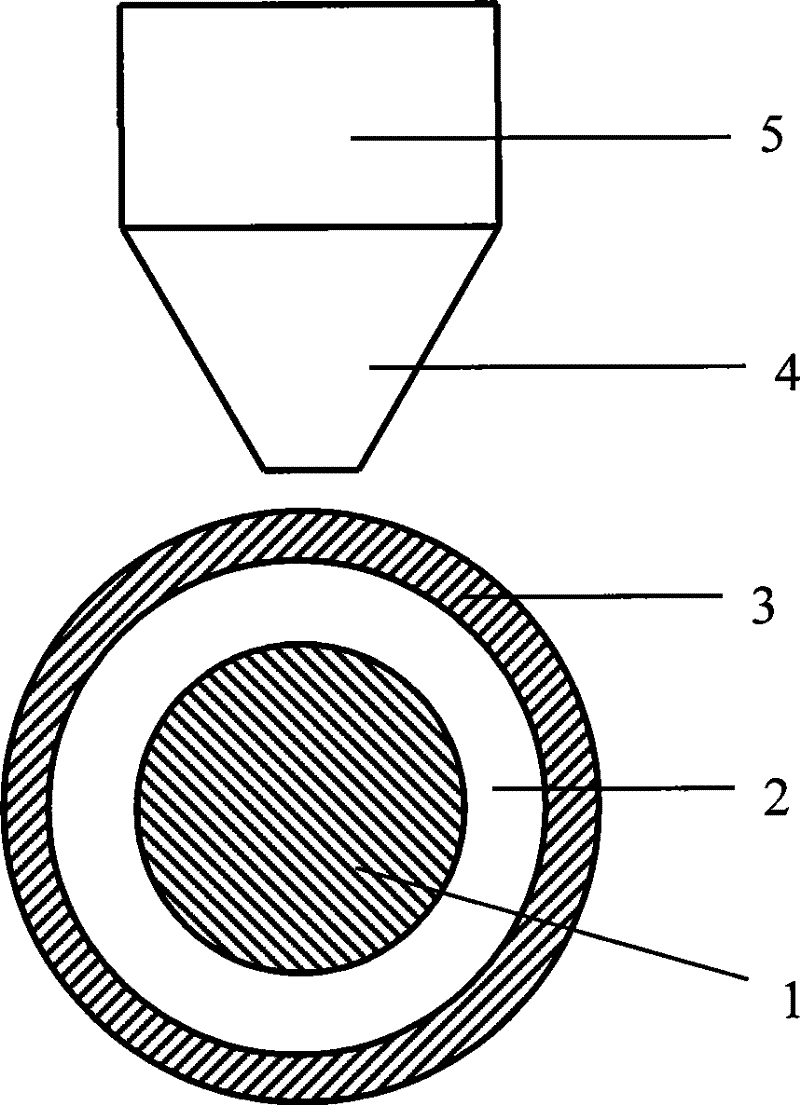

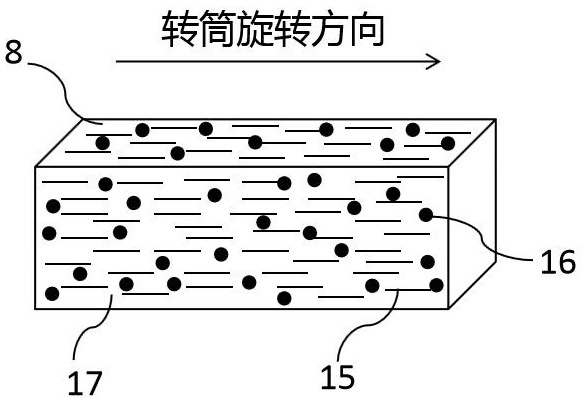

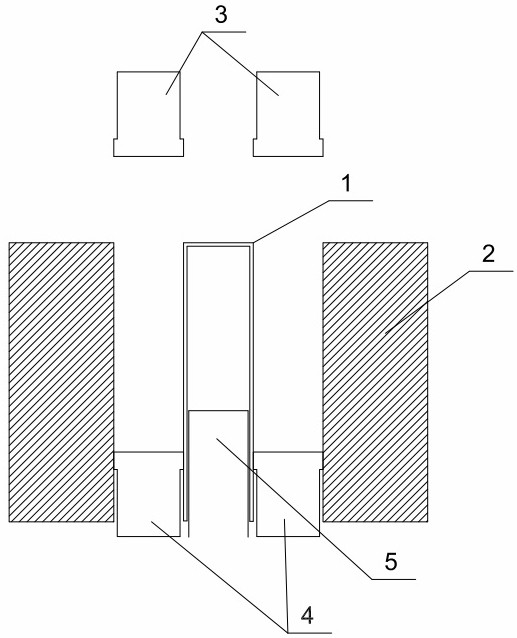

A progressive orientation mold for a multi-pole magnetic ring and its orientation method

ActiveCN114042916BNarrow down the upper and lower rangesEasy to useInductances/transformers/magnets manufactureLower poleMechanical engineering

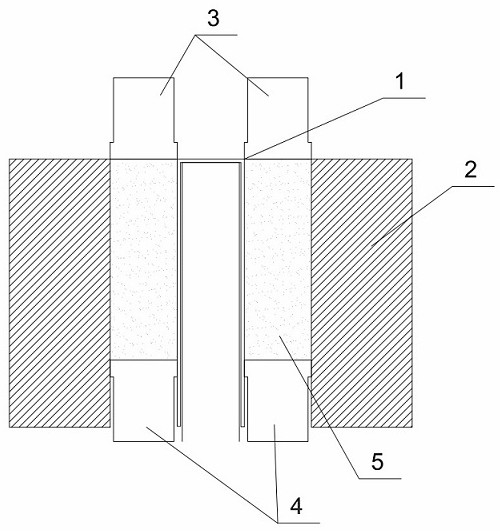

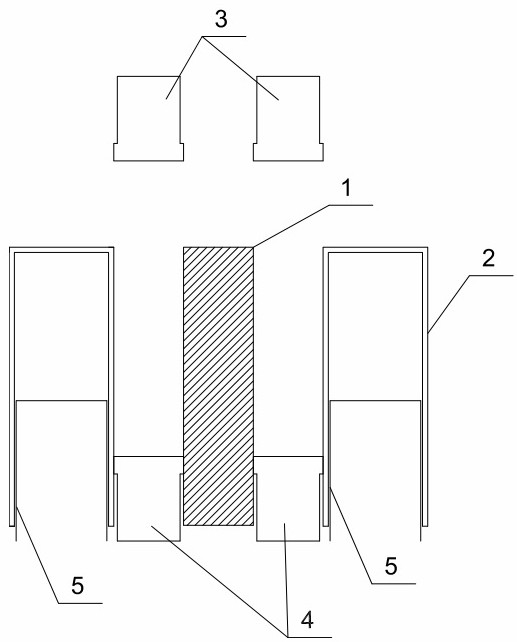

The invention discloses a progressive orientation mold for multi-pole magnetic rings and an orientation method thereof, which solves the technical problems that the products prepared by the orientation mold and the orientation method in the prior art have large upper and lower extreme differences and differences in surface magnetism. It includes a mold core (1) and a mold sleeve (2) arranged outside the mold core (1), and there is an annular gap between the mold core (1) and the mold sleeve (2); the mold core (1) and the mold At least one of the sleeves (2) is provided with a cavity inside, and a movable orienter (5) is provided in the cavity, and the orienter (5) is connected to the controller; the upper end of the annular gap is provided with a size The matching upper pressing head (3), the lower end of the annular gap is provided with the matching lower pressing head (4). The invention is used in the preparation of the multi-pole magnetic ring, can effectively reduce the upper and lower pole difference of the multi-pole magnetic ring, and improve the working performance of the multi-pole magnetic ring.

Owner:绵阳和一磁电有限公司

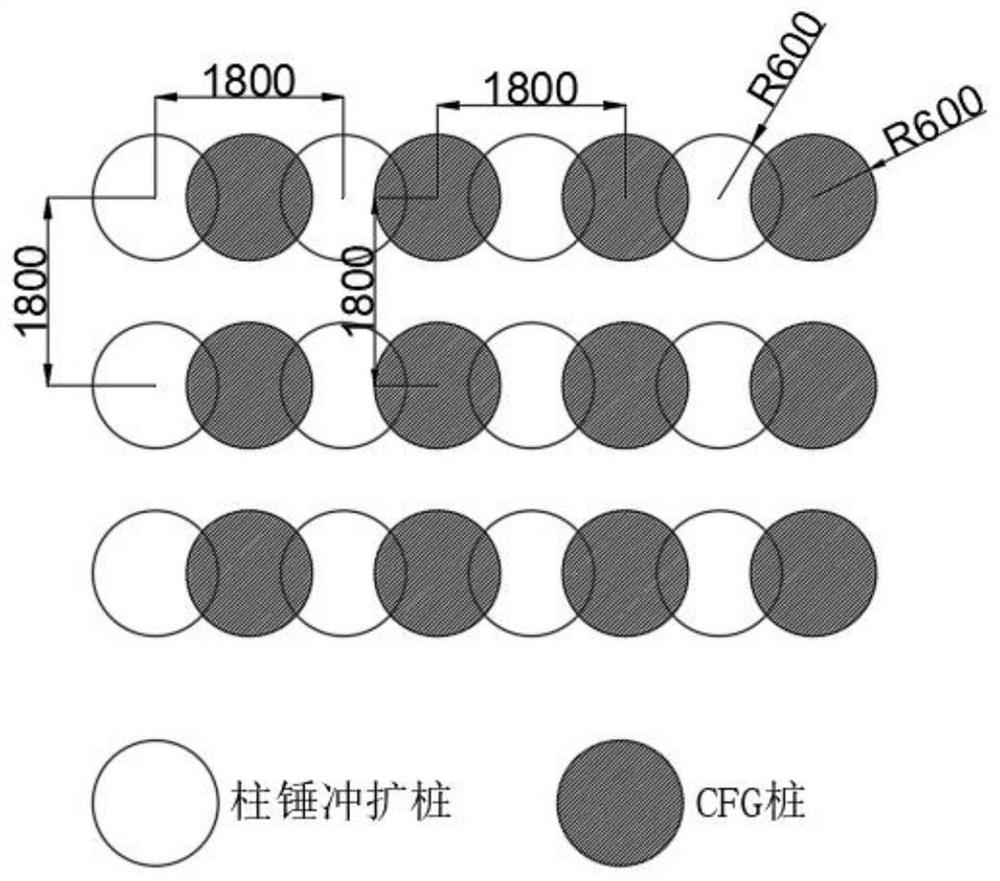

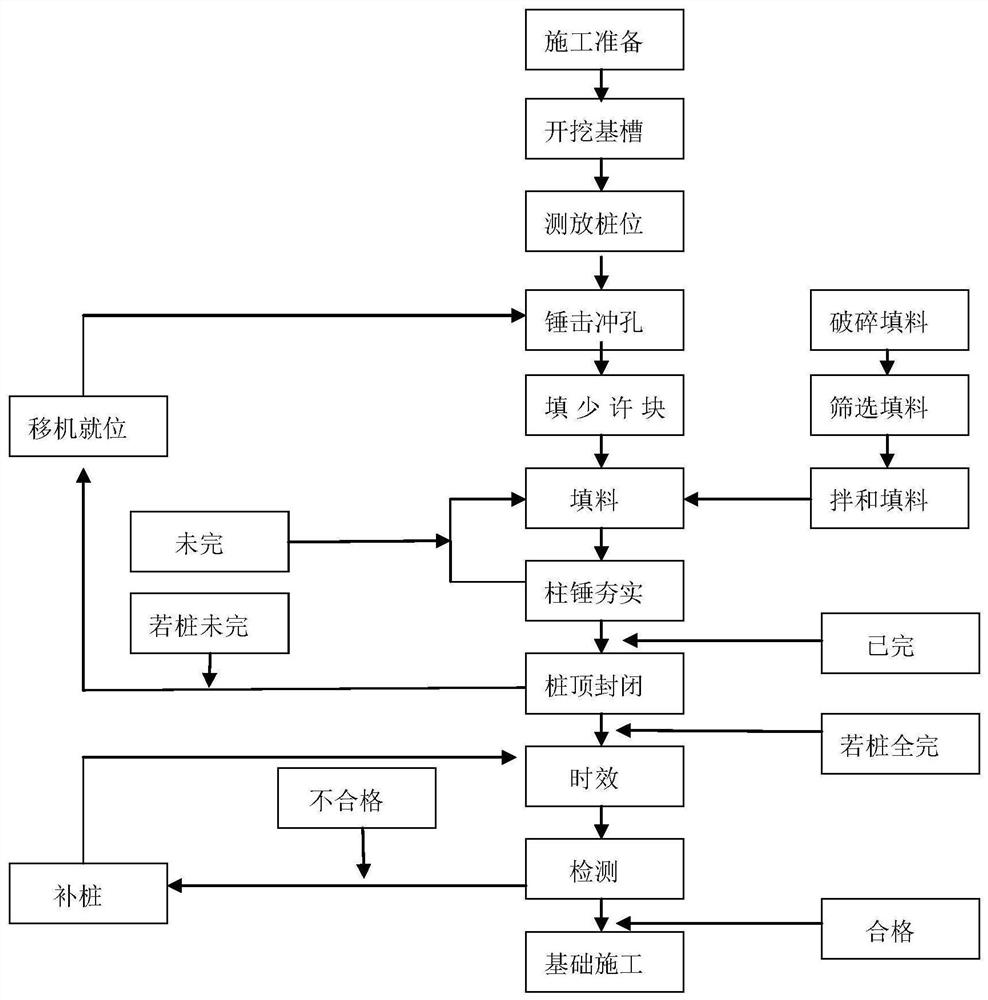

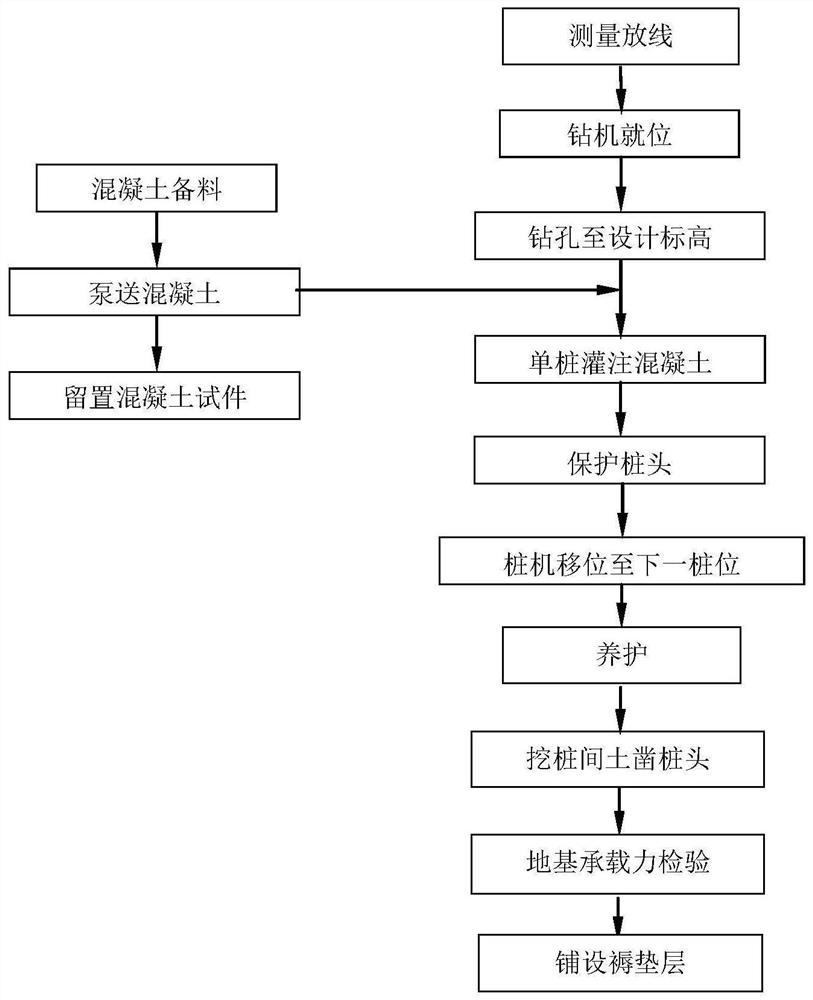

Construction technology for foundation reinforcement of large-scale hydraulic structures in construction waste soil layer

ActiveCN113006042BEasy to useNo pollution in the processReciprocating drilling machinesBulkheads/pilesFree fallingPunching

The invention discloses a foundation reinforcement construction process for a large-scale hydraulic structure in the ground layer of construction waste. The steps are as follows: S1. Punching and expanding pile construction with a column hammer: 1) measuring and setting out the line; 2) measuring and placing the pile position; , so that the column hammer is aligned with the pile position; 4) punching through the column hammer; 5) filling; 6) forming a pile; 8) After the excavation of the foundation pit, the soil between the piles and the pile head are manually removed, and after meeting the requirements, the owner, supervisor, and survey are invited to inspect the trench; S2. CFG pile construction; the present invention Through the combination of column hammer punching expansion pile construction and CFG pile construction, the two complement each other and have a good application prospect; there is a column hammer, and the column hammer includes a door-shaped support frame, a base, a column hammer body and a column hammer body for lifting The unique lifting unit fully guides the entire column hammer body in multiple positions during the free fall process, improving stability and accuracy.

Owner:BEIJING MUNICIPAL CONSTR

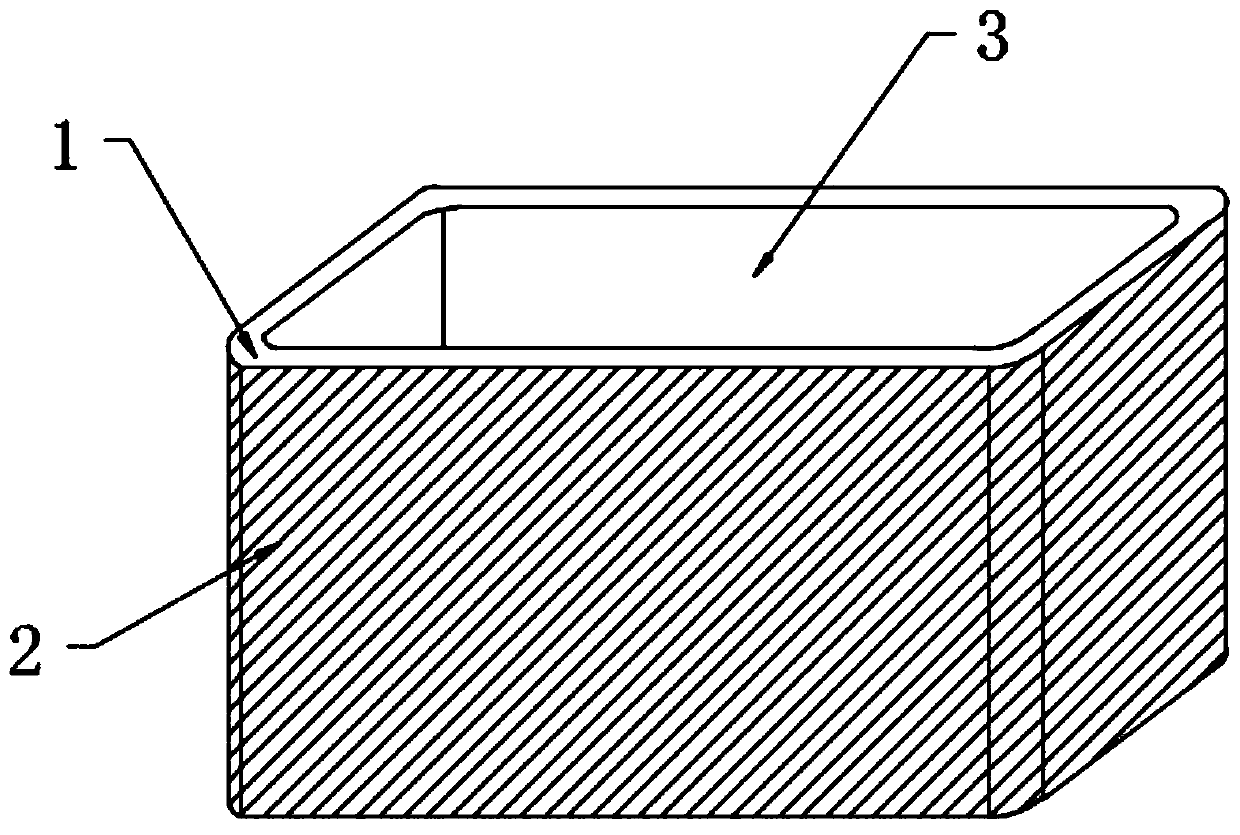

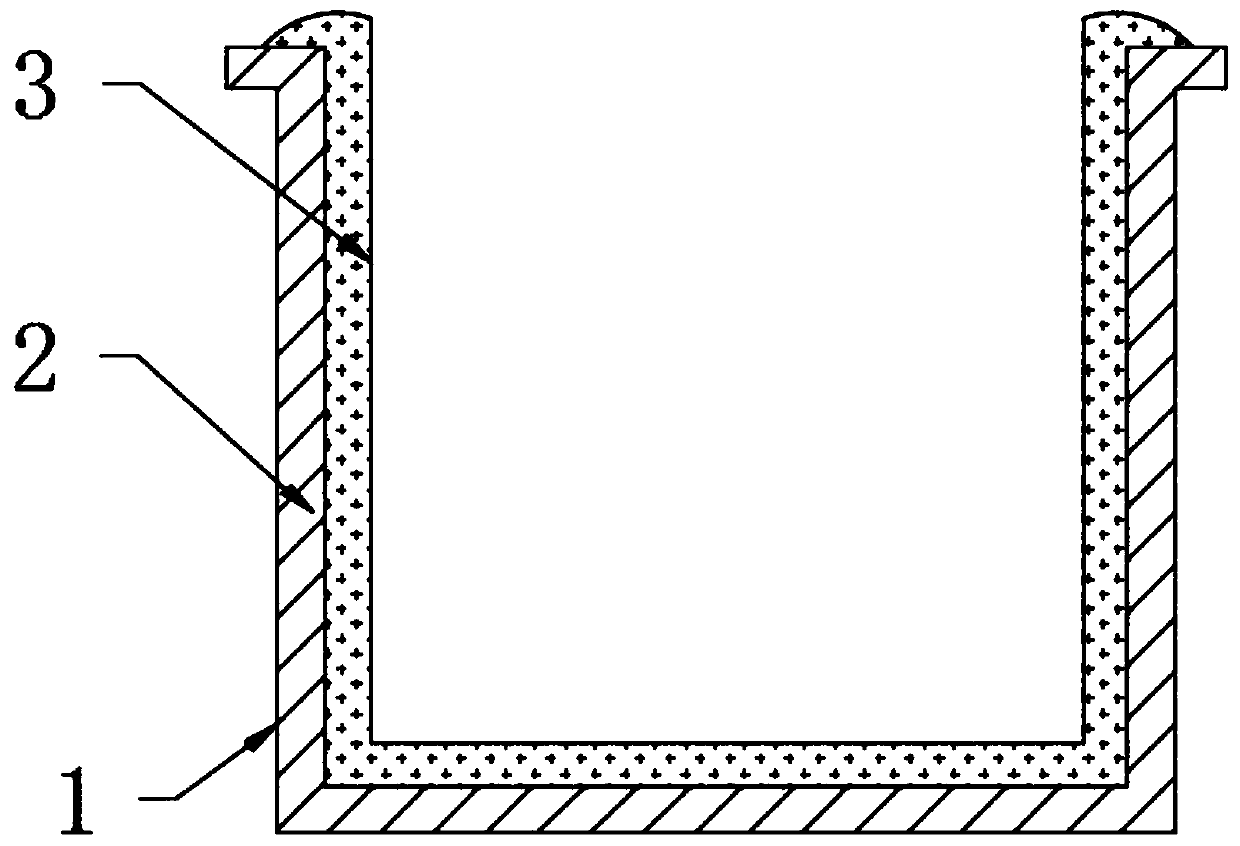

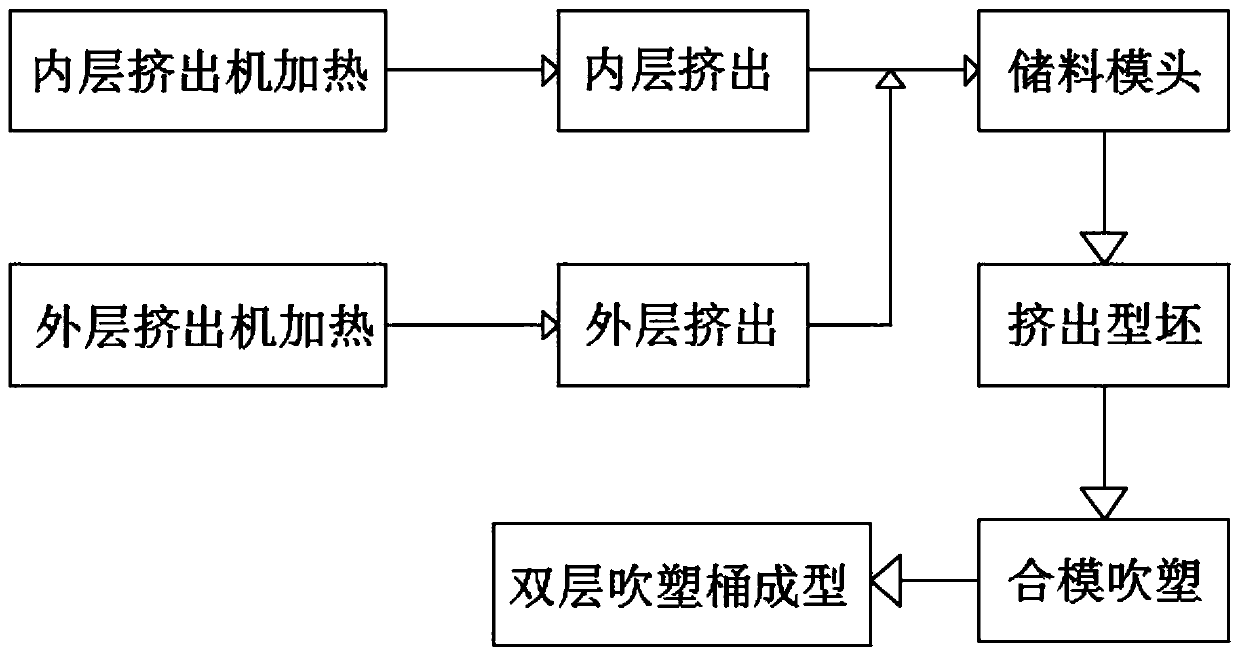

Double-layer PE large-scale hollow blow molding barrel and production process thereof

PendingCN110303663AQuality is not affectedNo migrationCans/barrels/drumsDomestic articlesBlow moldingEngineering

The invention discloses a double-layer PE large-scale hollow blow molding barrel and a production process thereof. The double-layer PE large-scale hollow blow molding barrel comprises a blow molding barrel body, the blowing barrel body comprises an outer coloring layer and an inner raw material natural color layer, the inner raw material natural color layer is located inside the outer coloring layer, the outer coloring layer and the inner raw material natural color layer form a double-layer type blank in a material storage die head, the outer coloring layer and the inner raw material natural color layer are connected in an extruding and hot melting mode in an extrusion die head to form a whole, and the outer coloring layer and the inner raw material natural color layer form an integral layer. According to the double-layer PE large-scale hollow blow molding barrel and the production process, a hollow blow molding mode is adopted, plastic molecules are stretched in two directions duringmolding, the orientation is sufficient, so that the product performance is greatly improved on the basis of injection molding, the durability of the product is improved, the using cost of a user is reduced, the product forming mold is designed in a two-blank simultaneous injecting symmetry mode, the large-gas-quantity double-needle side blowing is adopted, top blowing is used for cooperating auxiliary molding in process at the same time, so that the production efficiency is improved by one time while the product performance is ensured compared with that of a single-cavity mold.

Owner:汕头市永安塑胶实业有限公司

A preparation device for radially oriented permanent magnet rings

ActiveCN103123863BGood orientationFully orientedPermanent magnetsInductances/transformers/magnets manufacturePower flowMagnetic poles

The invention relates to a preparation device for a radial orientation permanent magnet ring. An outer magnetic pole is fixed on an outer magnetic pole connection support, and the thickness of the outer magnetic pole is far smaller than the height of a mold cavity. When exciting current passes through a coil, a radial magnetic field is generated in a ranged space of the mold cavity between a core rod and the outer magnetic pole, powder materials in the mold cavity are pushed by an oil cylinder to move vertically in a reciprocating mode, and therefore the power materials sequentially and circularly pass through the plane where the outer magnetic pole is located when the powder materials are pressed. When all the power materials sequentially and repeatedly pass through the plane where the outer magnetic pole is located and are pressed, the powder materials in a whole mold can be fully and uniformly oriented, radial orientation uniformity of the radial permanent magnet ring is greatly improved, meanwhile, axial uniformity of orientation degrees can also be improved, and the advantage is obvious especially for high radial rings. Besides, according to the preparation device for the radial orientation permanent magnet ring, the methods of manual mold release and automatic mold release can be adopted, operation is flexile, and the qualification rate of the pressed radial rings is greatly improved.

Owner:ORIENT MAGNET TECH OMT

A kind of directional heat conduction sheet and its preparation method, and semiconductor cooling device

ActiveCN113150558BGood orientationImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesHeat conductingPhysical chemistry

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD

Bobbin holder

A bobbin holder for tensioning a bobbin tube and receiving a wound thread bobbin is presented. The bobbin holder includes a rotatable drive shaft that is connected to a drive with a bearing end thereof and that has a tensioning device for tensioning a bobbin tube on a tensioning end. The tensioning device includes a plurality of bobbin tubes on the periphery of the drive shaft and interposed tensioning rings. A tensioning piston guided on the free end of the drive shaft acts upon at least one of the bobbin tubes to deform the tensioning rings. In order to allow the use of high fatigue strength materials for the tensioning ring, the tensioning ring includes a continuous separating slot on the periphery, which extends between two opposite ring ends of the tensioning ring, deformation being essentially achieved by an expansion of the tensioning ring.

Owner:OERLIKON TEXTILE GMBH & CO KG

A bonded magnet and its preparation method

ActiveCN107359036BStrong shape retentionIncrease productivityInorganic material magnetismInductances/transformers/magnets manufactureAl powderPhosphate

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

A preparation method of high orientation degree sintered NdFeB permanent magnet material

ActiveCN105931833BImprove liquidityLow densityInductances/transformers/magnets manufactureMagnetic materialsOrganic solventMetallurgy

Owner:UNIV OF SCI & TECH BEIJING

Static spinning device and its industrial use

InactiveCN100347348CHigh speedImprove mechanical propertiesFilament/thread formingElectrospinningEngineering

The present invention provides electrostatic spinning apparatus and its industrial application. The apparatus includes polymer solution conveying machine, spinning nozzle device connected to the outlet of the polymer solution conveying machine, spinning bath below the spinning nozzle device, fiber turning guide roller set inside the spinning bath and electrodes set on the spinning nozzle device and the spinning bath. The apparatus of the present invention is used in spinning polymer, and has greatly raised wet spinning speed, great fiber drafting magnification, well oriented fiber molecule chain, compact fiber structure, greatly raised mechanical performance of fiber, wide solvent selecting range, simplified electrostatic spinning equipment, raised solvent recovering rate and less environmental pollution caused by the solvent.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com