Granulation method of sintered NdFeB powder

A technology of neodymium iron boron and powder materials, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of poor fluidity, low bulk density, difficult filling, etc., to reduce production costs, good orientation, filling high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: A kind of granulation method of sintered NdFeB powder comprises the following steps:

[0031] ① Prepare the sintered NdFeB raw material into a fine powder 1 with an average particle size of 2-5 μm;

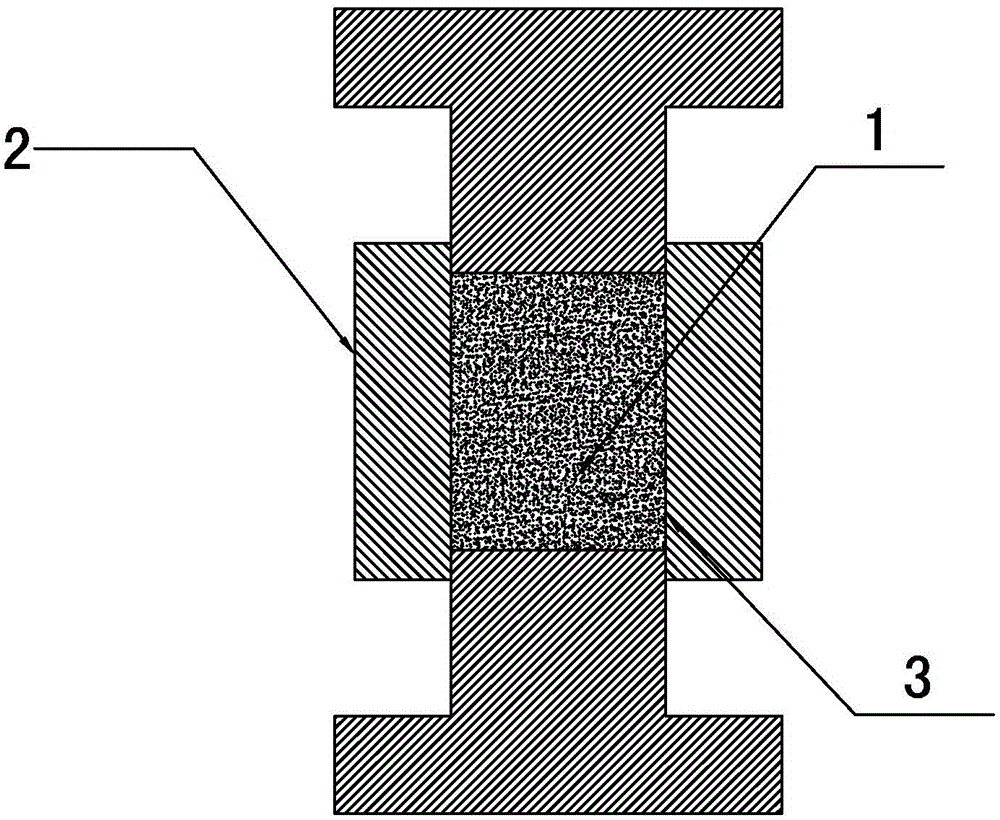

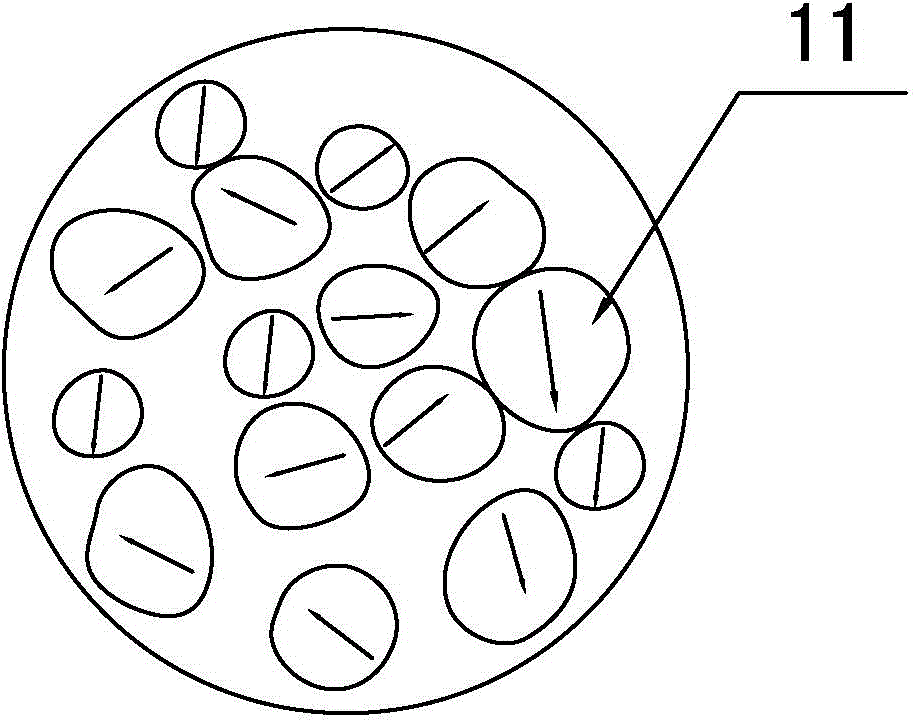

[0032] ②Add the fine powder material 1 into the cavity 3 of the orientation forming mold 2; the charging state is as follows: figure 1 As shown, the magnetic pole direction of the fine powder powder after charging is as follows figure 2 as shown, figure 2 The direction of the middle arrow indicates the magnetic pole direction of each fine powder 11 in the fine powder material 1, and at this time, the magnetic pole direction of the fine powder 11 is chaotic;

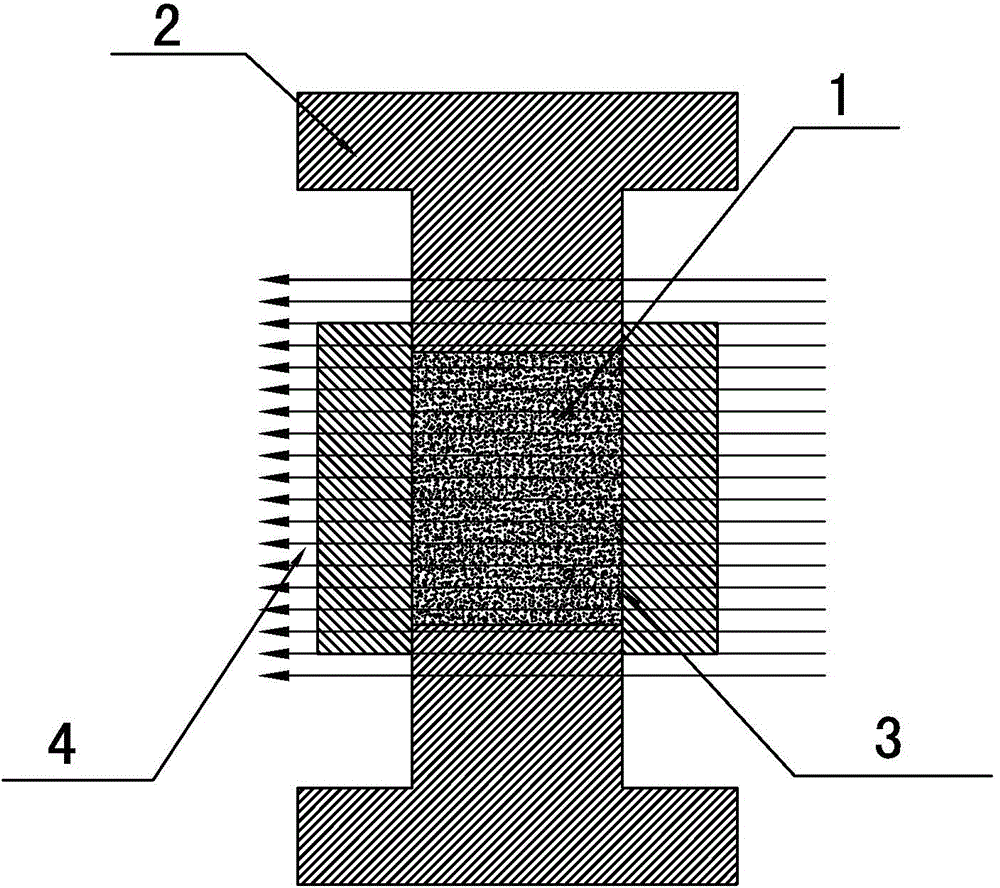

[0033] ③ Use magnetic field 4 to orient the fine powder, where the magnetic field is 1-2T, and the orientation time is >2S; the orientation state of fine powder 1 is as follows: image 3 Shown, the magnetic pole direction of each fine powder 11 in the fine powder material 1 after orientation is as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com