Patents

Literature

330 results about "Stretch ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The stretch ratio or extension ratio is a measure of the extensional or normal strain of a differential line element, which can be defined at either the undeformed configuration or the deformed configuration. It is defined as the ratio between the final length ℓ and the initial length L of the material line. Related formulas.

Microporous PVDF films and method of manufacturing

Shaped microporous articles are produced from polyvinylidene fluoride (PVDF) and nucleating agents using thermally induced phase separation (TIPS) processes. The shaped microporous article is oriented in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0. The shaped article may also comprise a diluent, glyceryl triacetate. The shaped microporous article may also have the micropores filled with a sufficient quantity of ion conducting electrolyte to allow the membrane to function as an ion conductive membrane. The method of making a microporous article comprises the steps of melt blending polyvinylidene fluoride, nucleating agent and glyceryl triacetate; forming a shaped article of the mixture; cooling the shaped article to cause crystallization of the polyvinylidene fluoride and phase separation of the polyvinylidene fluoride and glyceryl triacetate; and stretching the shaped article in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0.

Owner:3M INNOVATIVE PROPERTIES CO

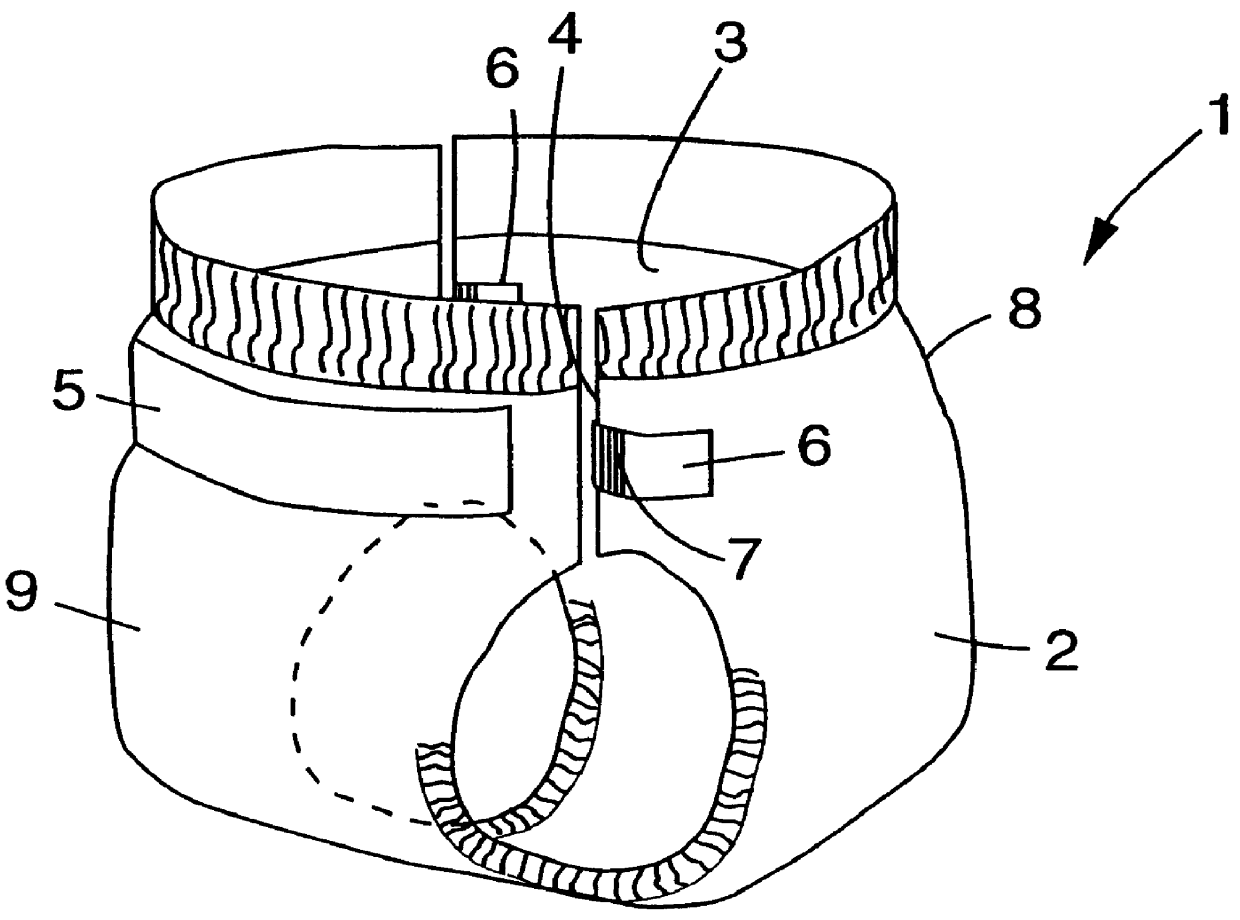

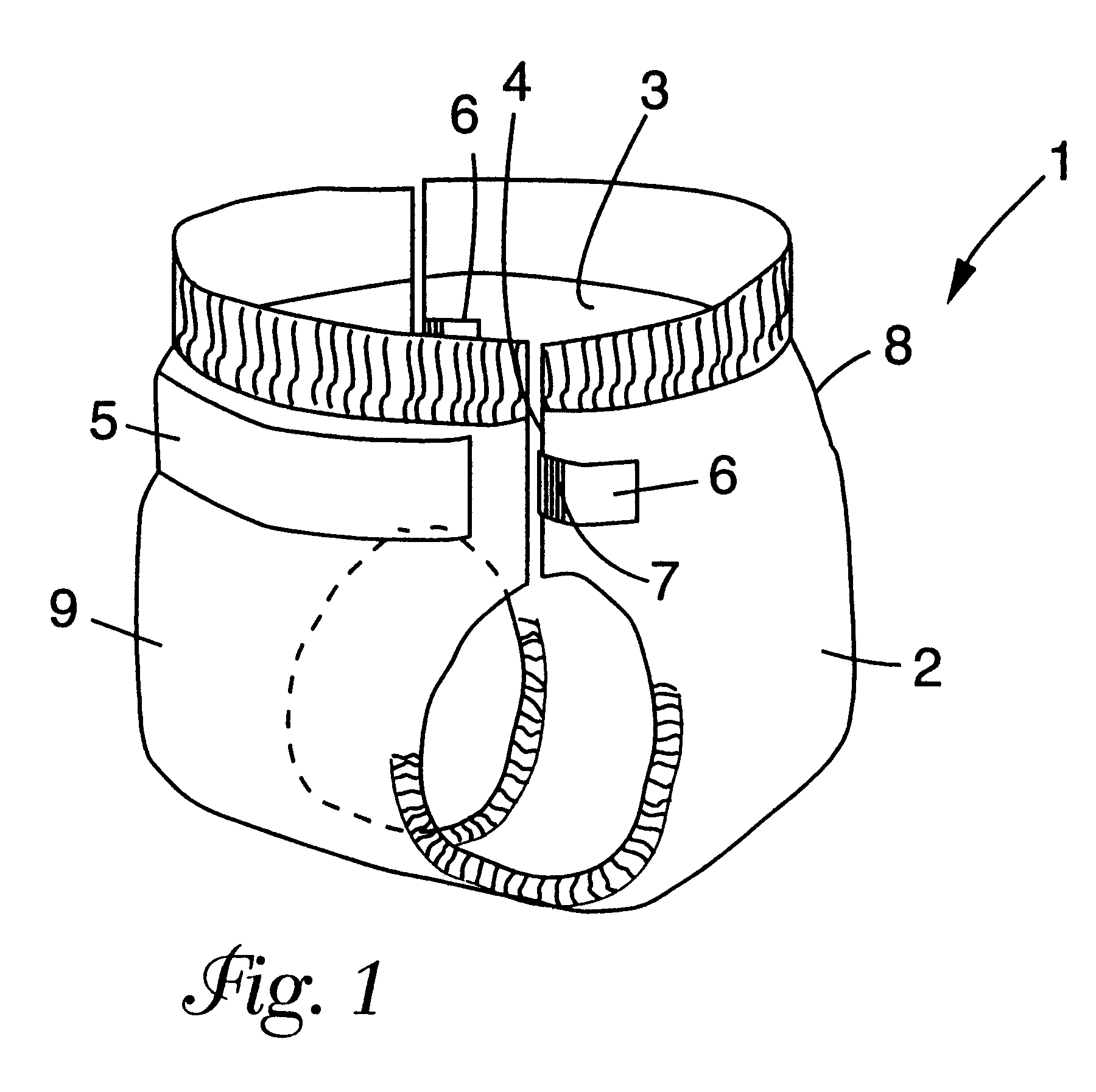

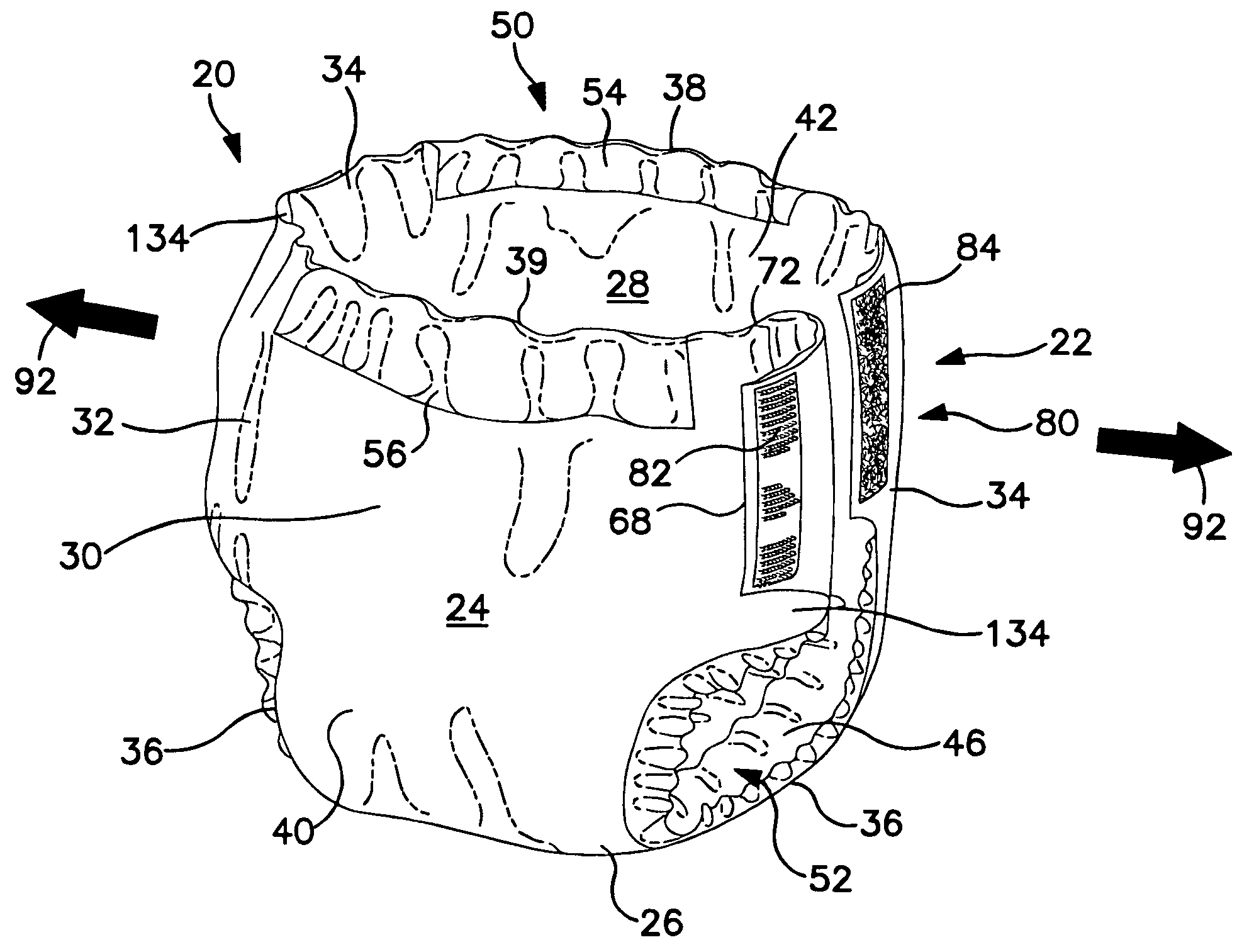

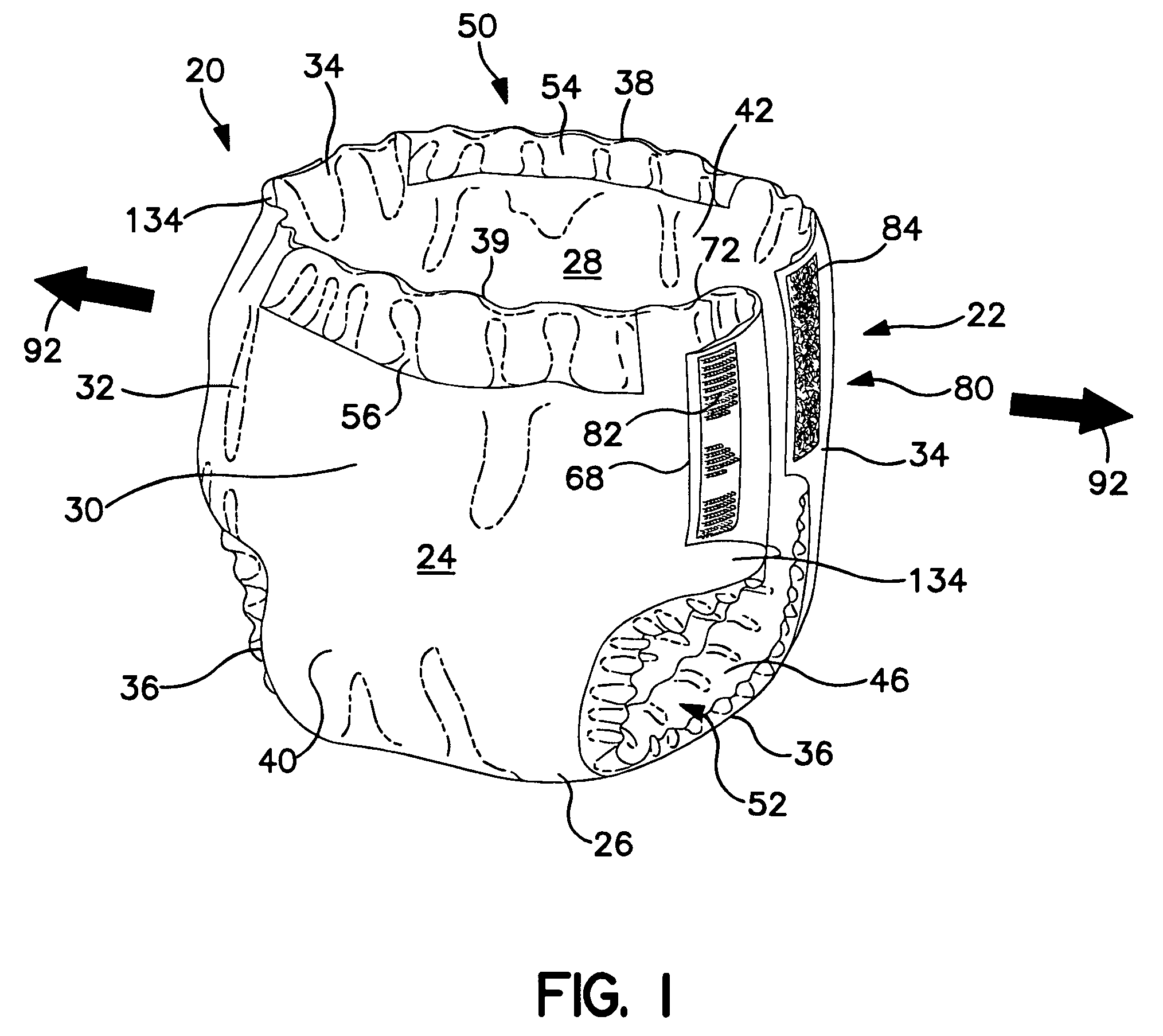

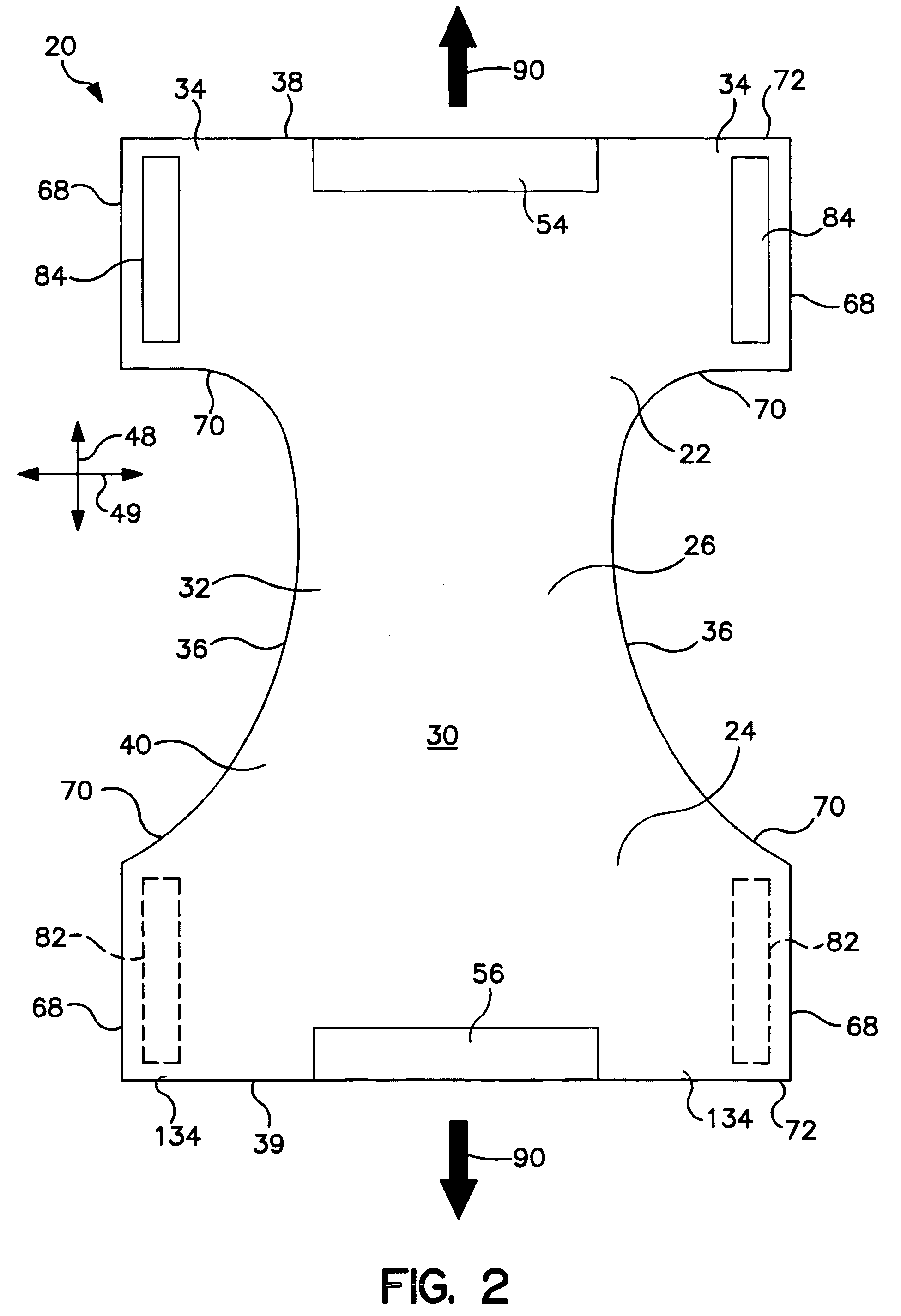

Elastic tab laminate

There is provided an extensible elastic tab designed to be adhered to the edge of an article, formed using a coextruded elastic film comprising at least one elastic layer and at least one second layer on at least a first face of the elastic layer with at least one face of the coextruded elastic film attached to at least a partially extensible nonwoven layer. The partially expandable, or extensible nonwoven layer has at least one first portion with limited extensibility in a first direction and at least one second inextensible portion in the first direction. The extensible elastic tab when stretched to the extension limit of the first portion or portions in the first direction will elastically recover at least 1.0 cm, preferably at least 2 cm providing an elastic tab having a Useful Stretch Ratio (as defined in the Examples) of at least 30 percent. The Useful Stretch Ratio includes the portion of the elastic recovery length having an elastic recovery force of greater than 20 grams / cm force, but below a given extension which generally is 90 percent of the extension limit. Further the elastic tab in the region of the Useful Stretch Ratio preferably has an incremental extension force of less than about 300 grams / cm. The invention tab provides definable predictable elastic performance and is useful as a fastening tab used to join to surfaces requiring elastic engagement, particularly a person or animal. The tab is particularly useful as a diaper fastening tab.

Owner:3M INNOVATIVE PROPERTIES CO

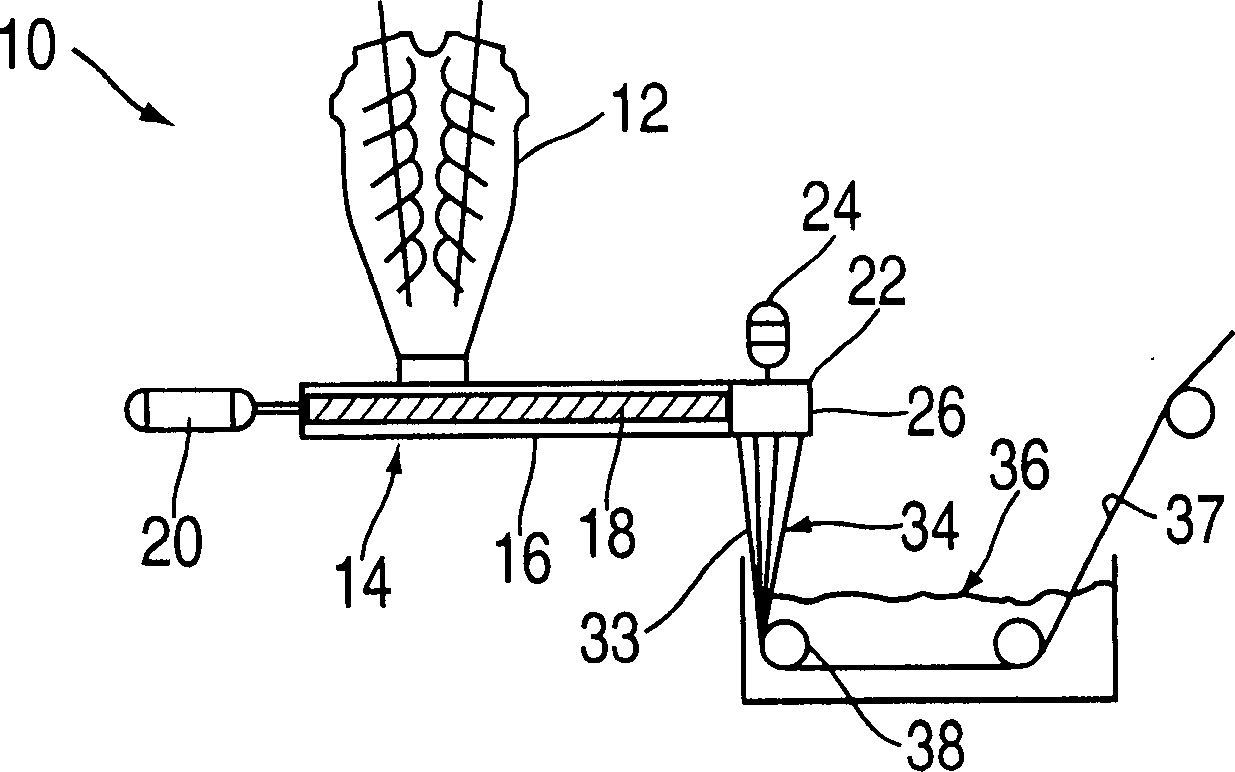

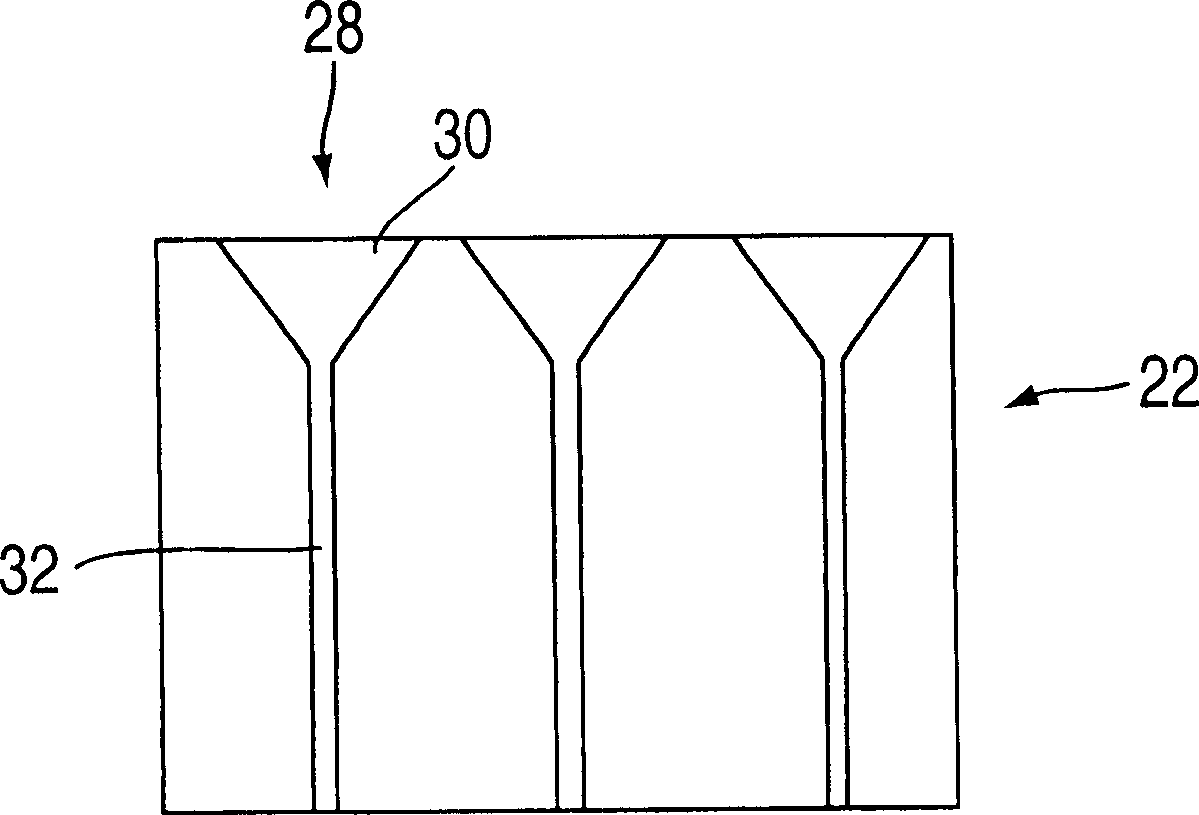

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

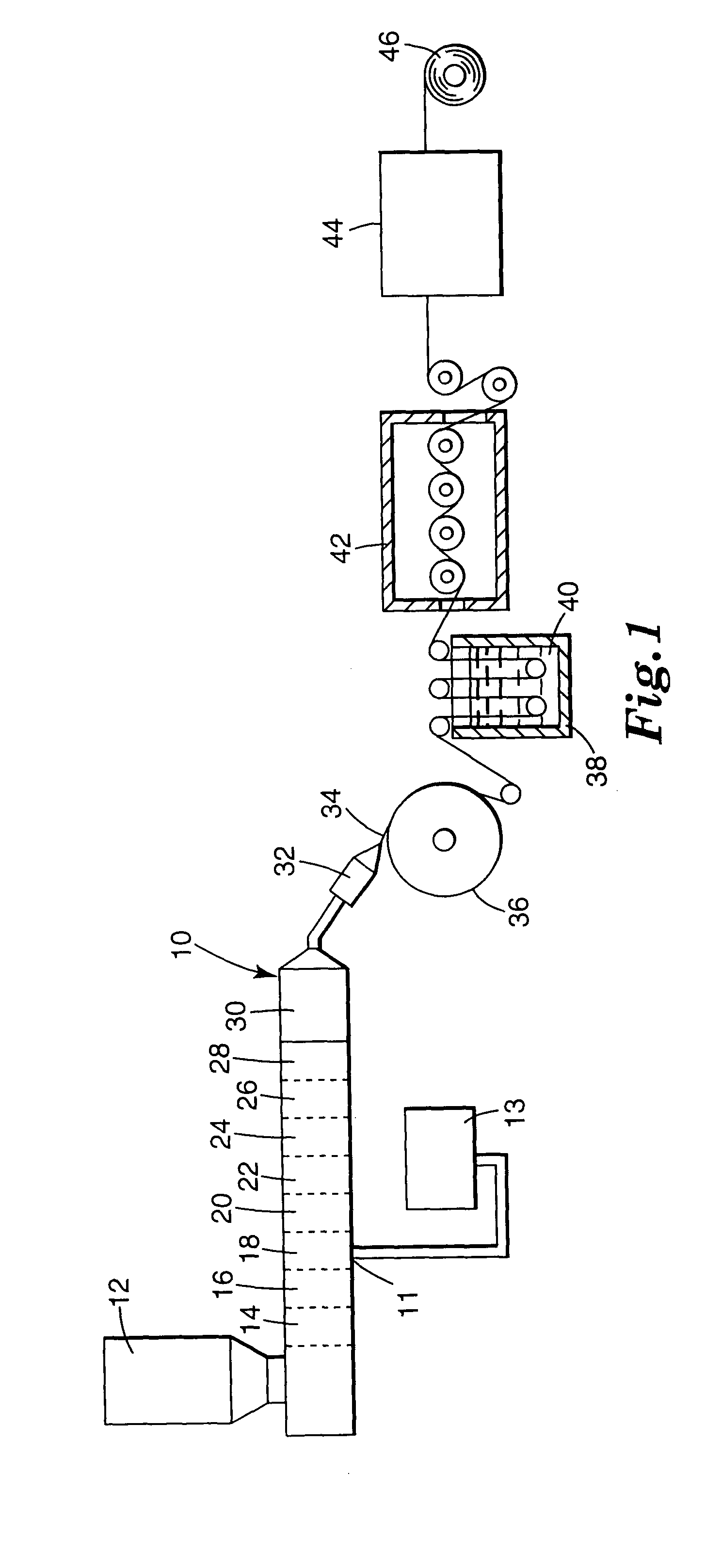

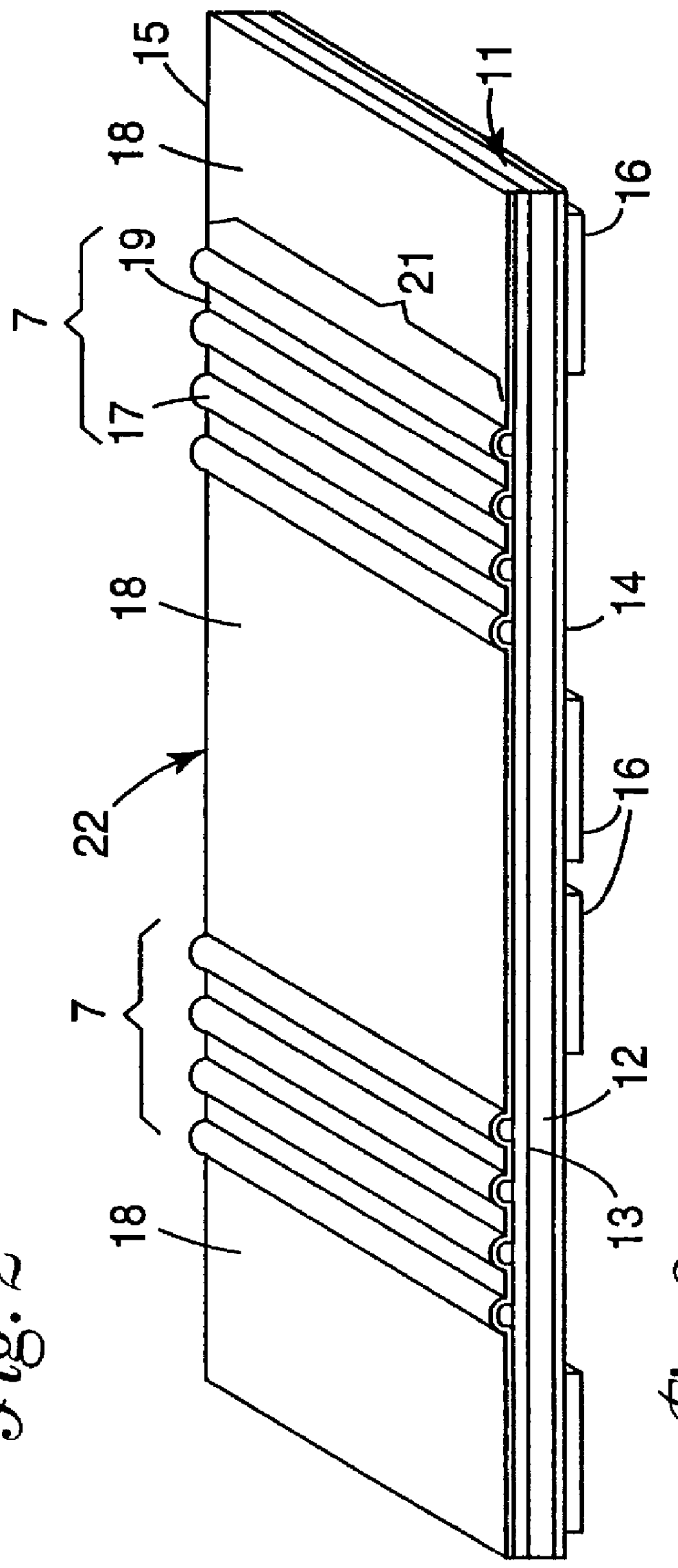

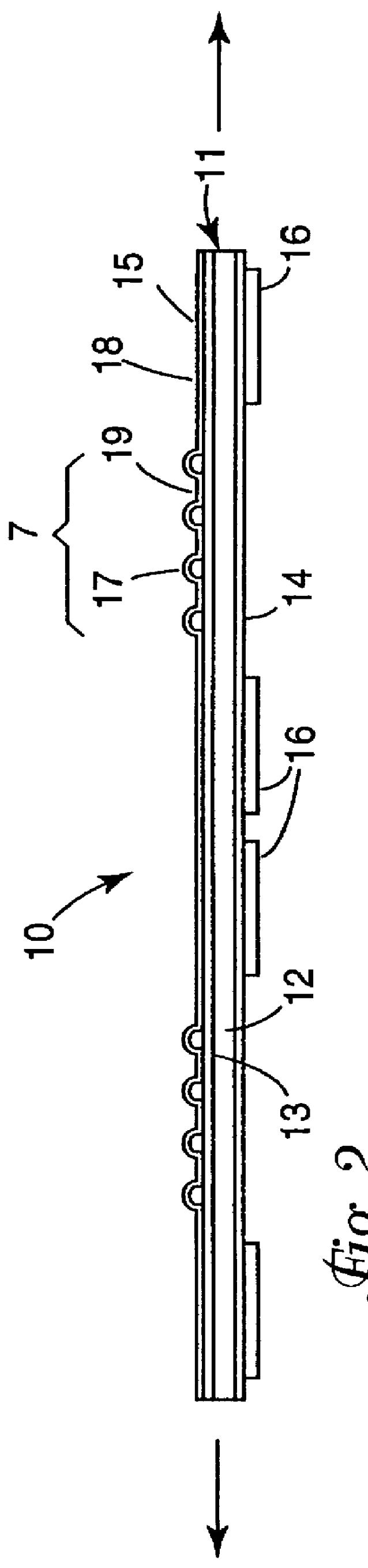

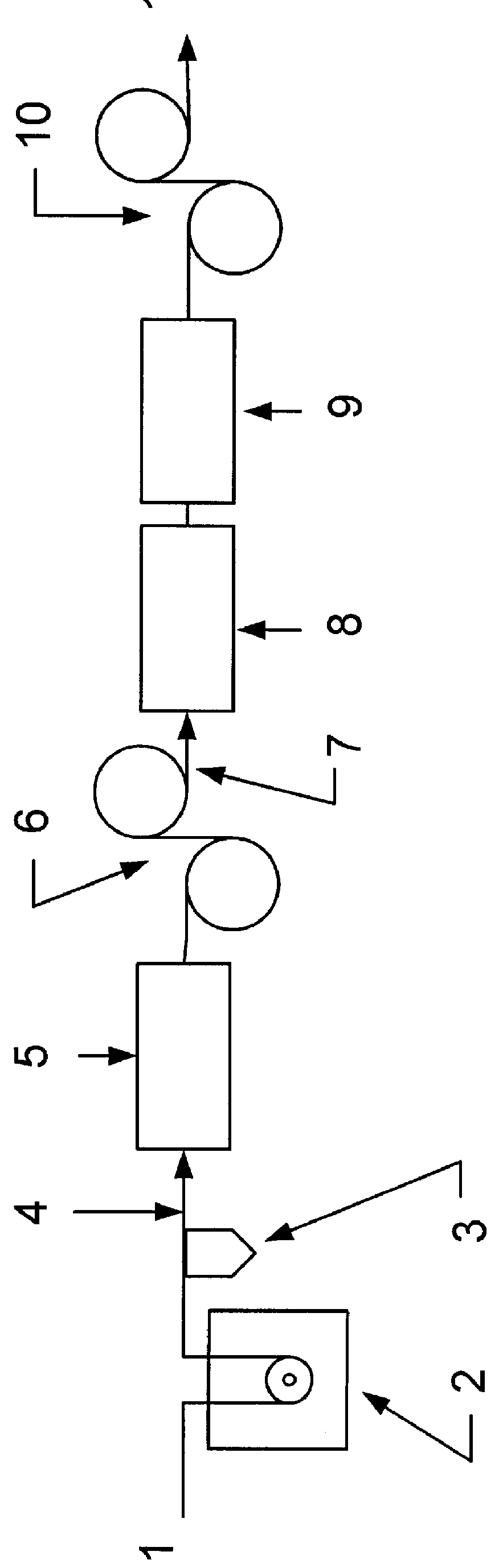

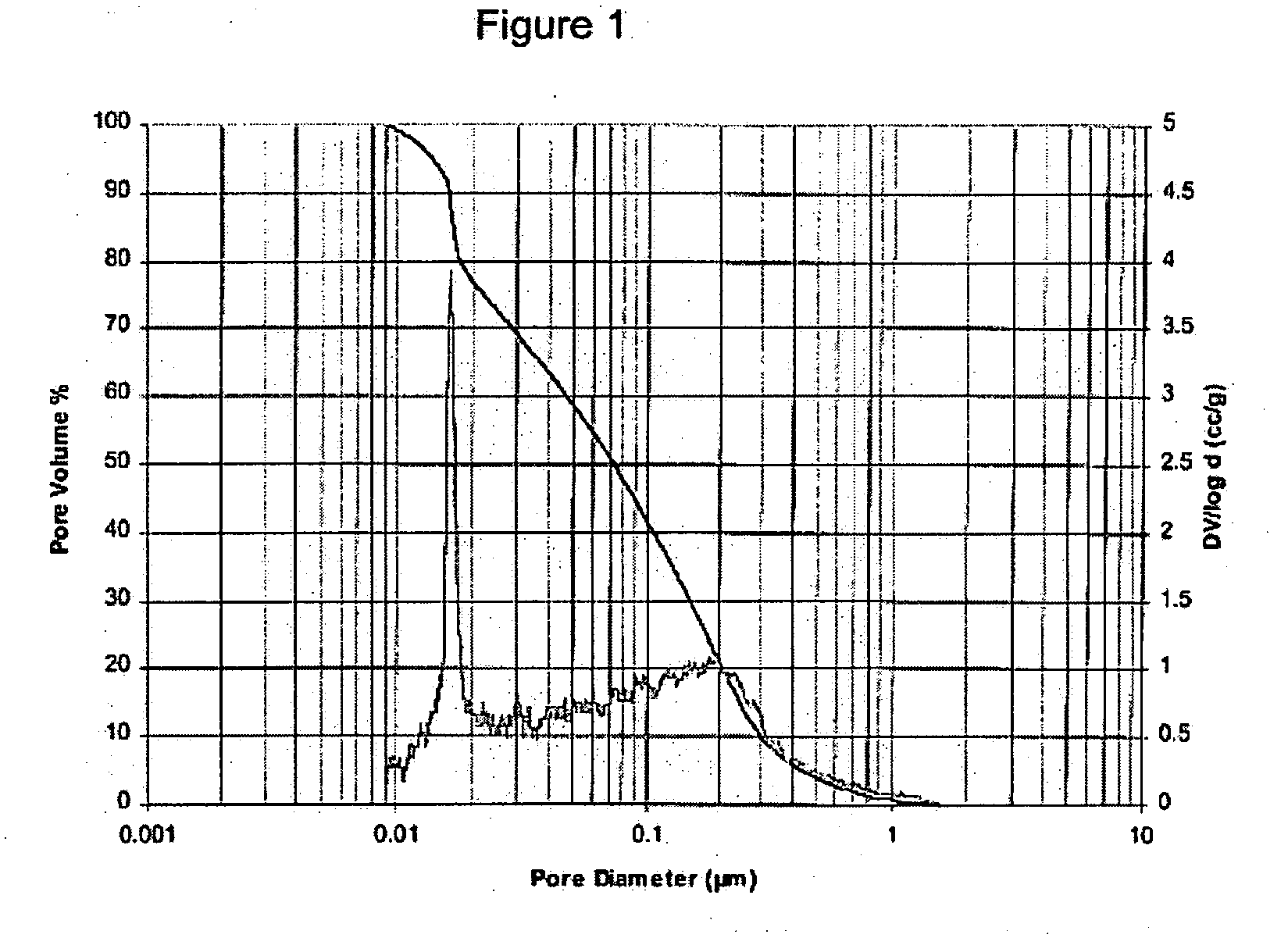

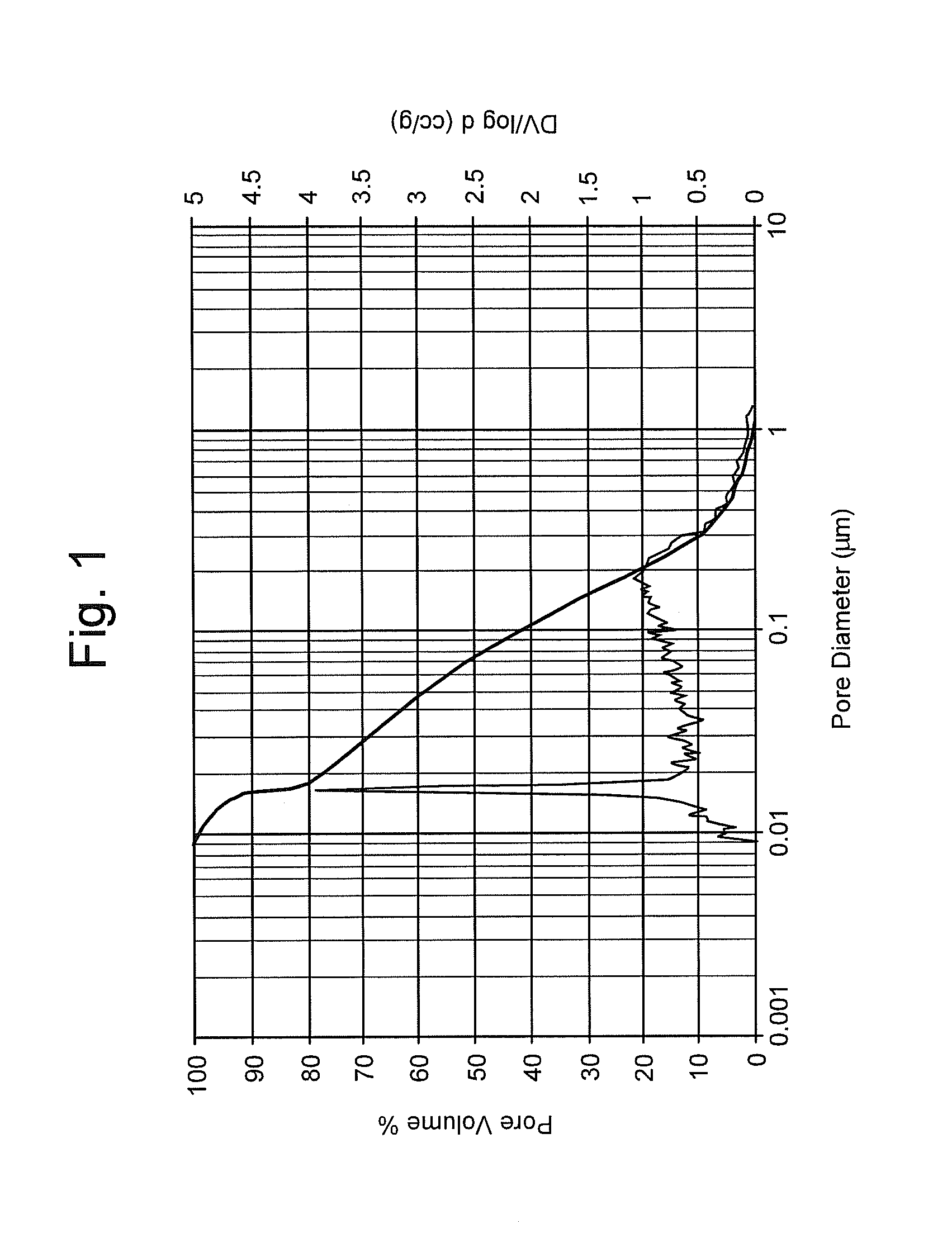

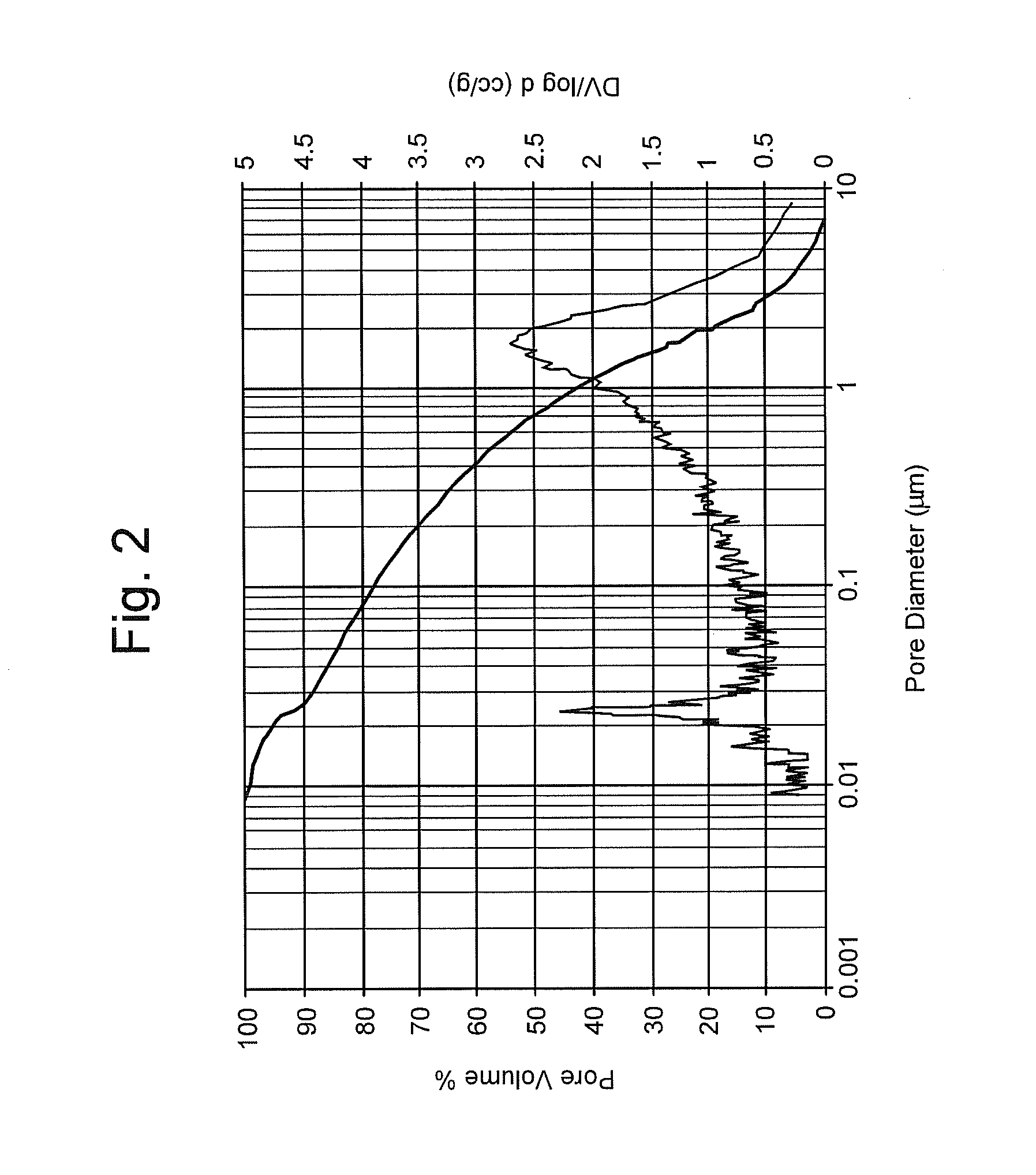

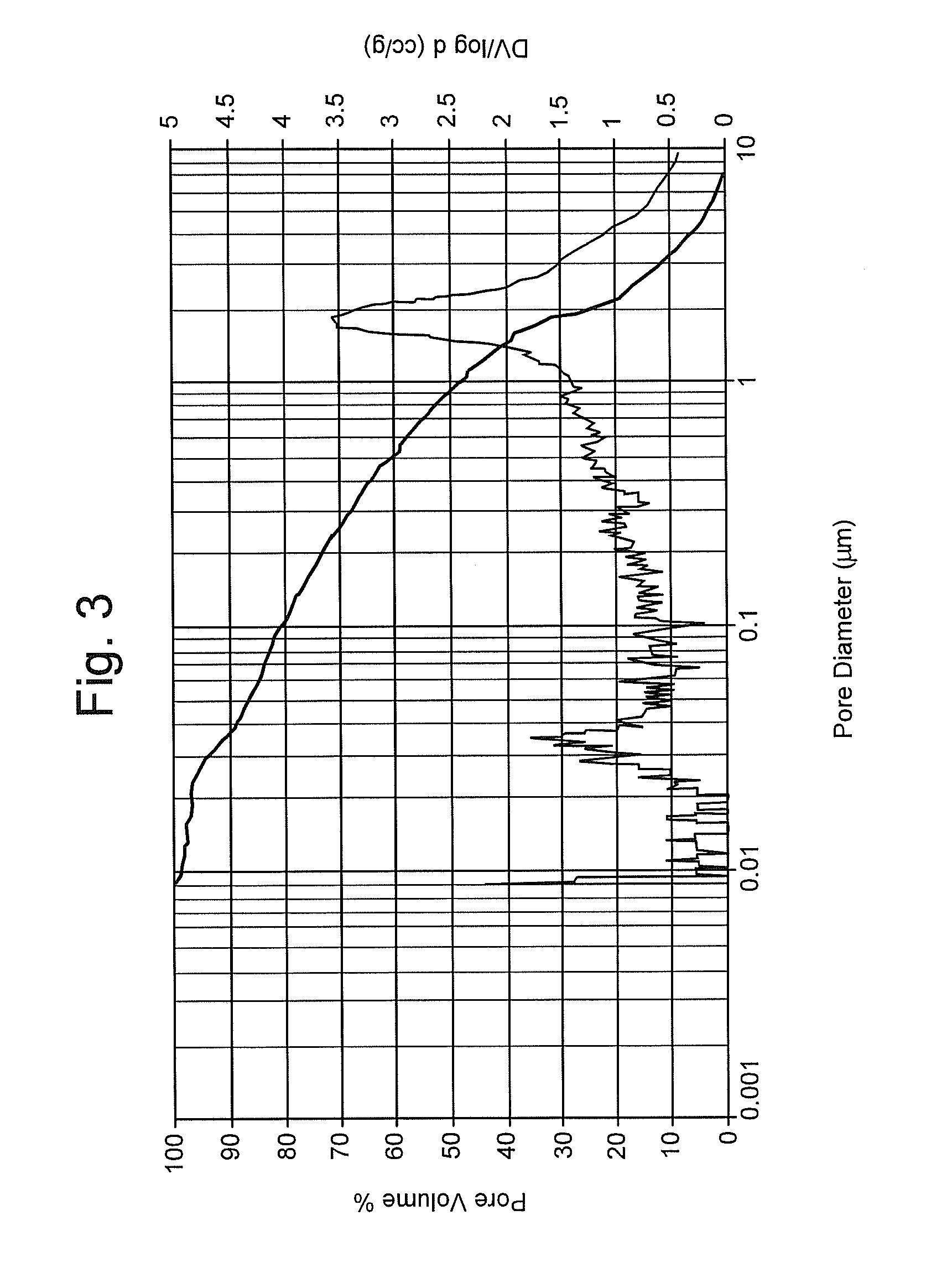

Microporous material and a method of making same

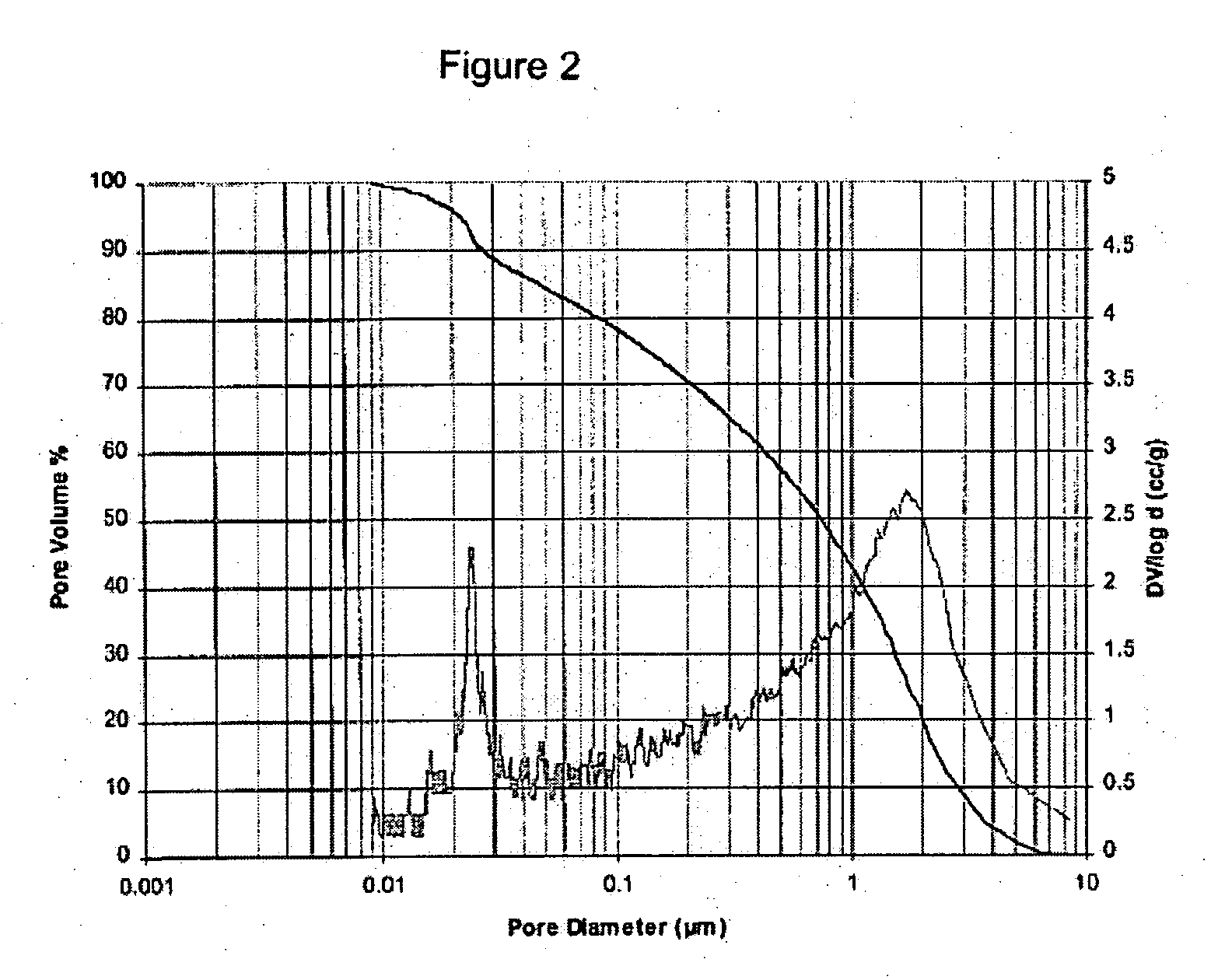

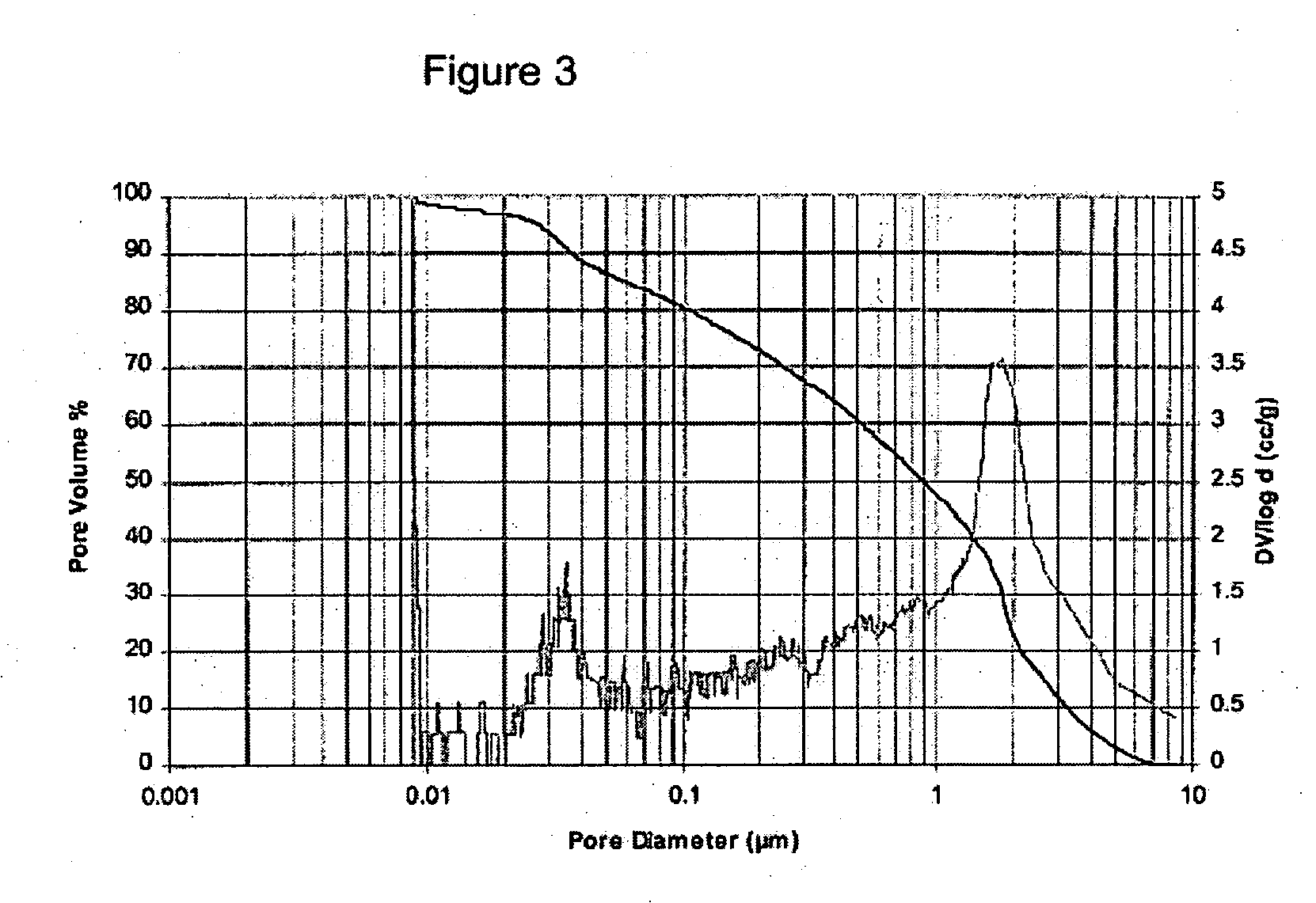

ActiveUS20060121269A1Improved dimensional stability and physical propertyElectrolyte holding meansSemi-permeable membranesPlasticizerStretch ratio

A method for producing a microporous material comprising the steps of: providing an ultrahigh molecular weight polyethylene (UHMWPE); providing a filler; providing a processing plasticizer; adding the filler to the UHMWPE in a mixture being in the range of from about 1:9 to about 15:1 filler to UHMWPE by weight; adding the processing plasticizer to the mixture; extruding the mixture to form a sheet from the mixture; calendering the sheet; extracting the processing plasticizer from the sheet to produce a matrix comprising UHMWPE and the filler distributed throughout the matrix; stretching the microporous material in at least one direction to a stretch ratio of at least about 1.5 to produce a stretched microporous matrix; and subsequently calendering the stretched microporous matrix to produce a microporous material which exhibits improved physical and dimensional stability properties over the stretched microporous matrix.

Owner:DARAMIC LLC

Peel and stick stretch wrap

Owner:BMIC LLC

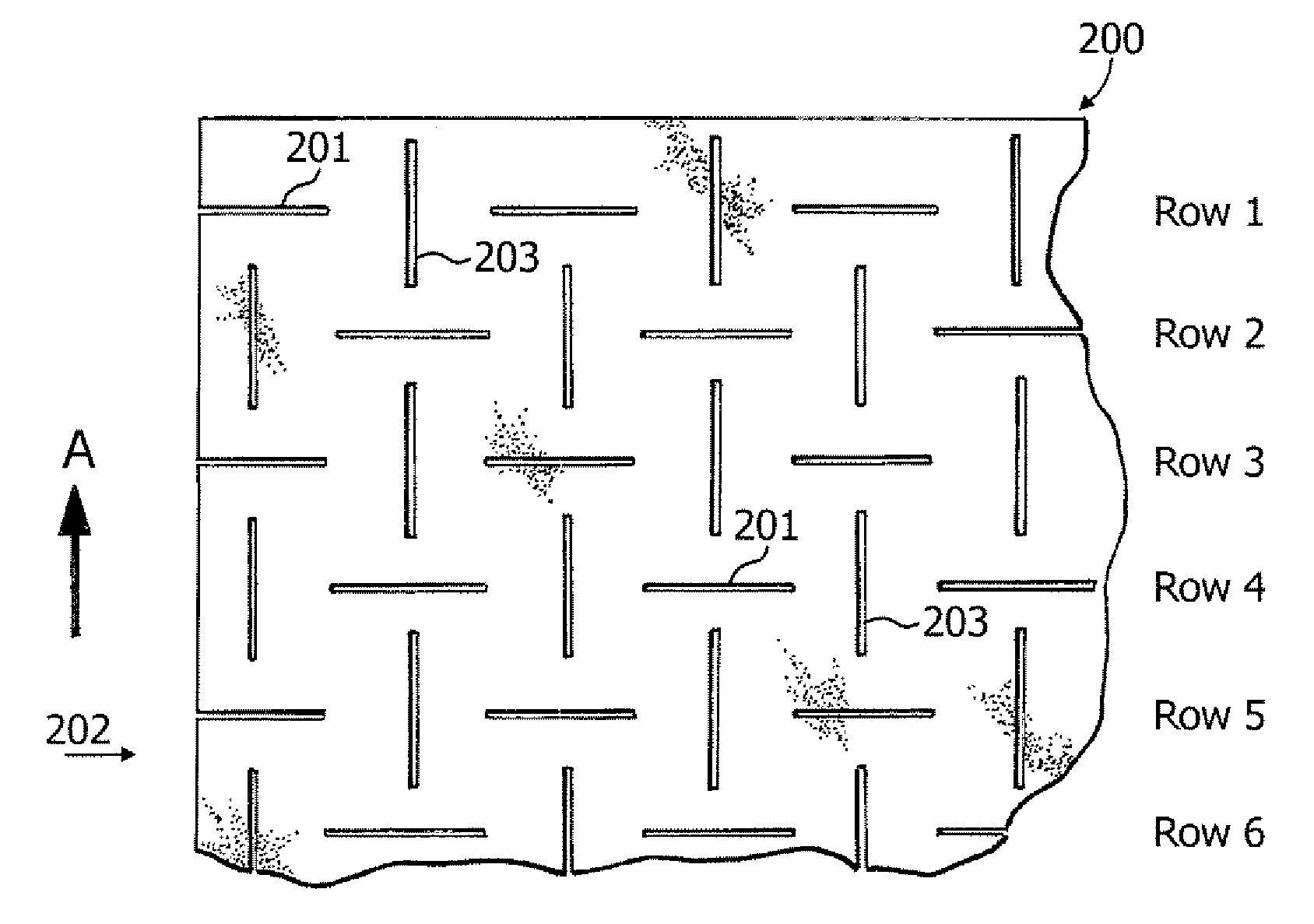

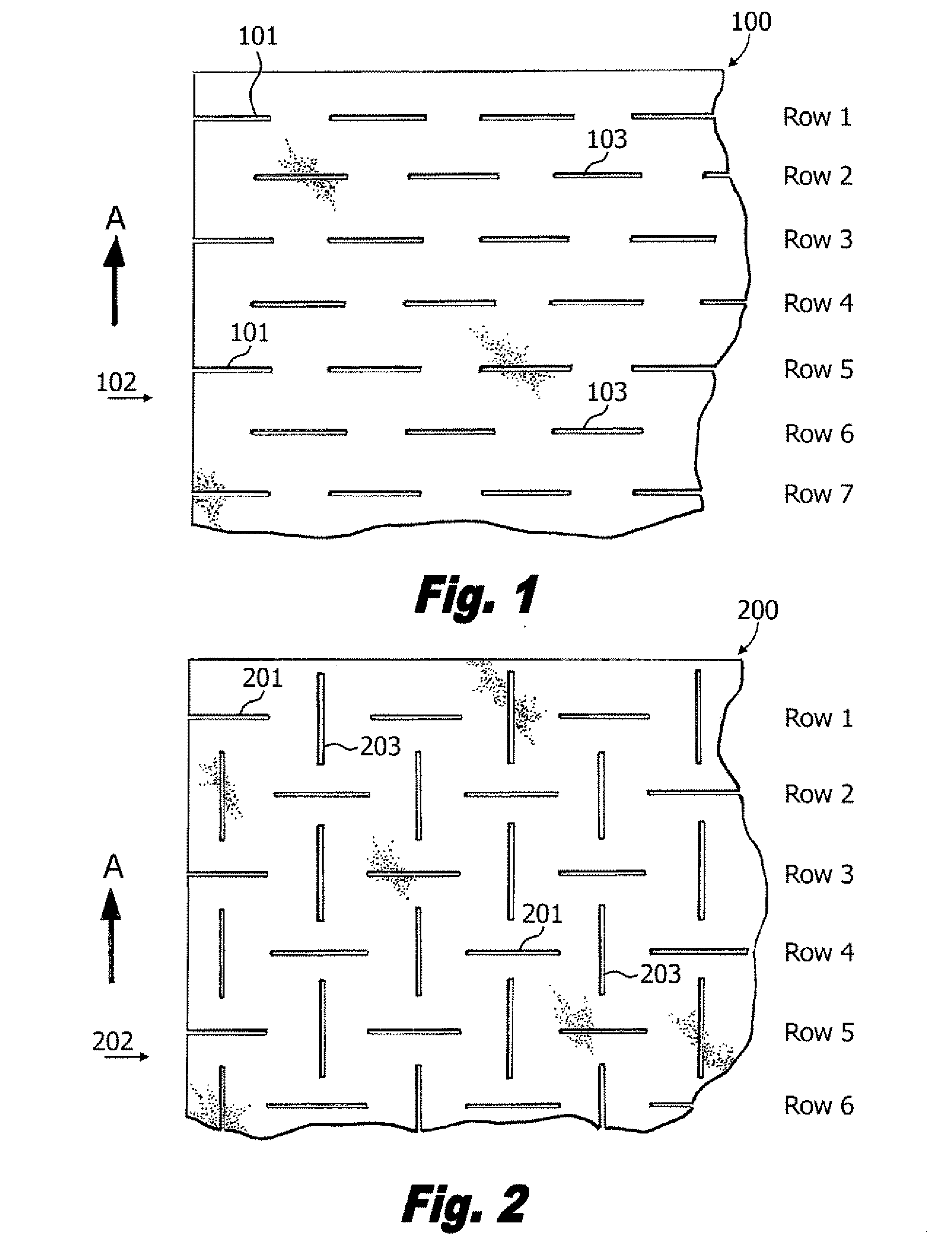

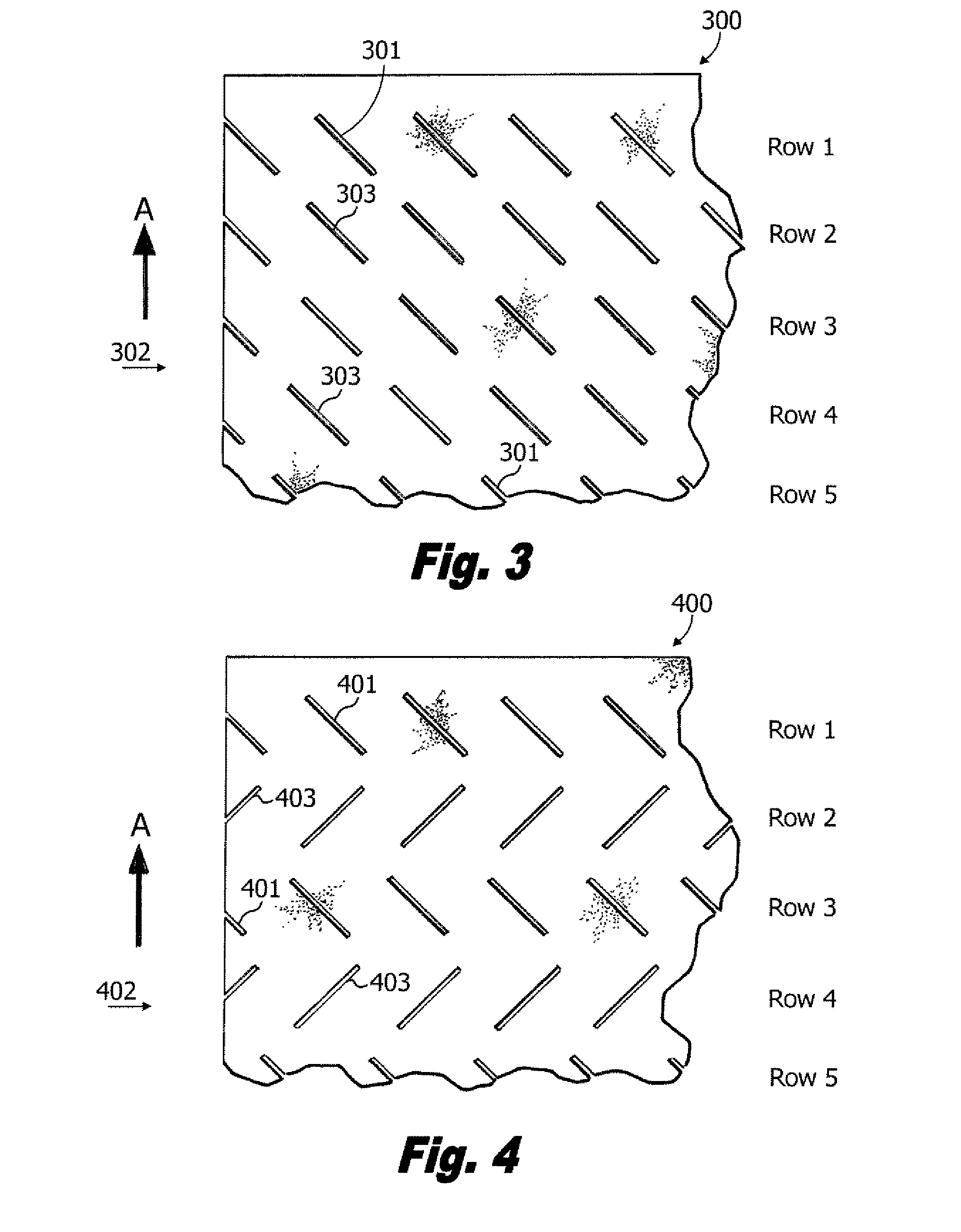

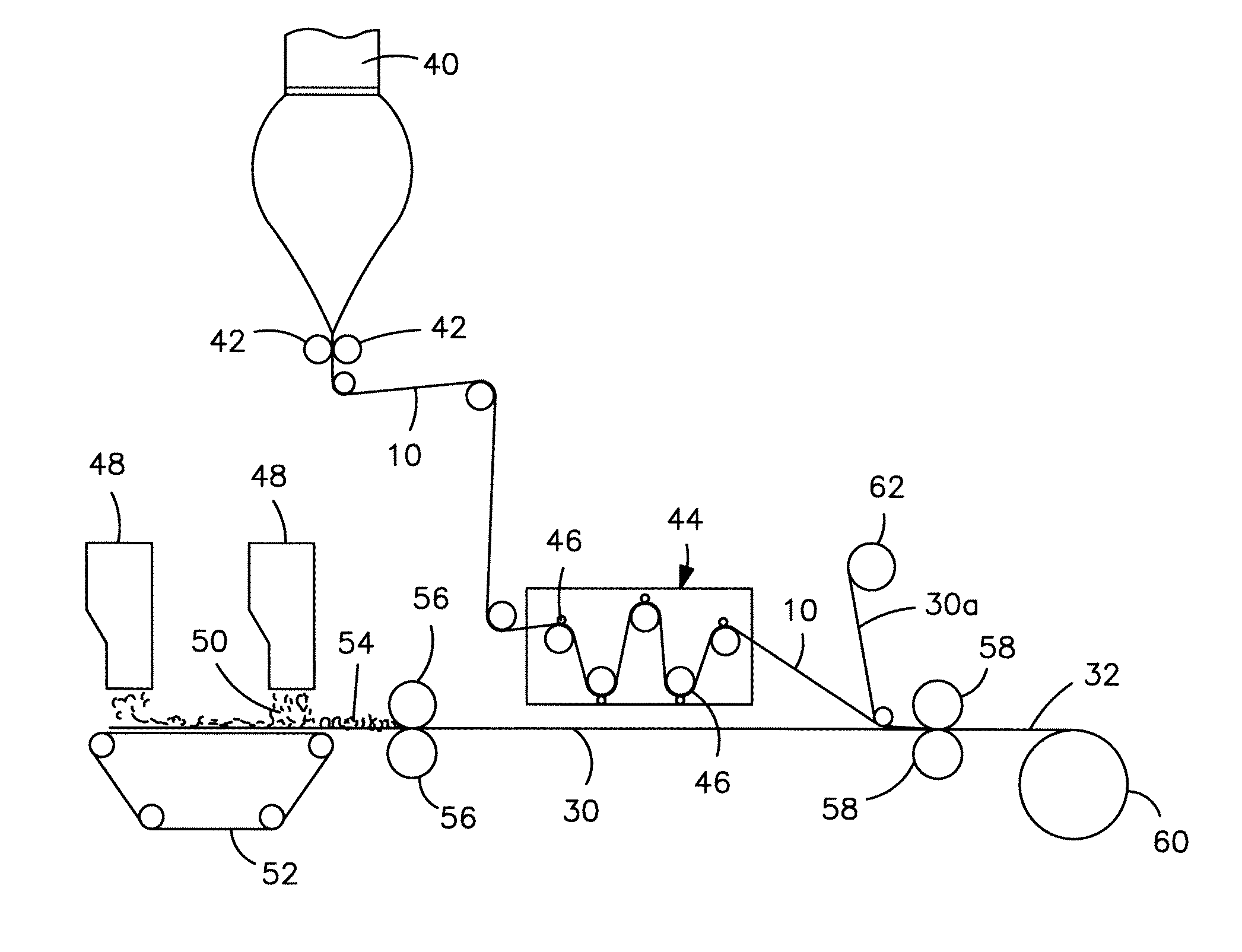

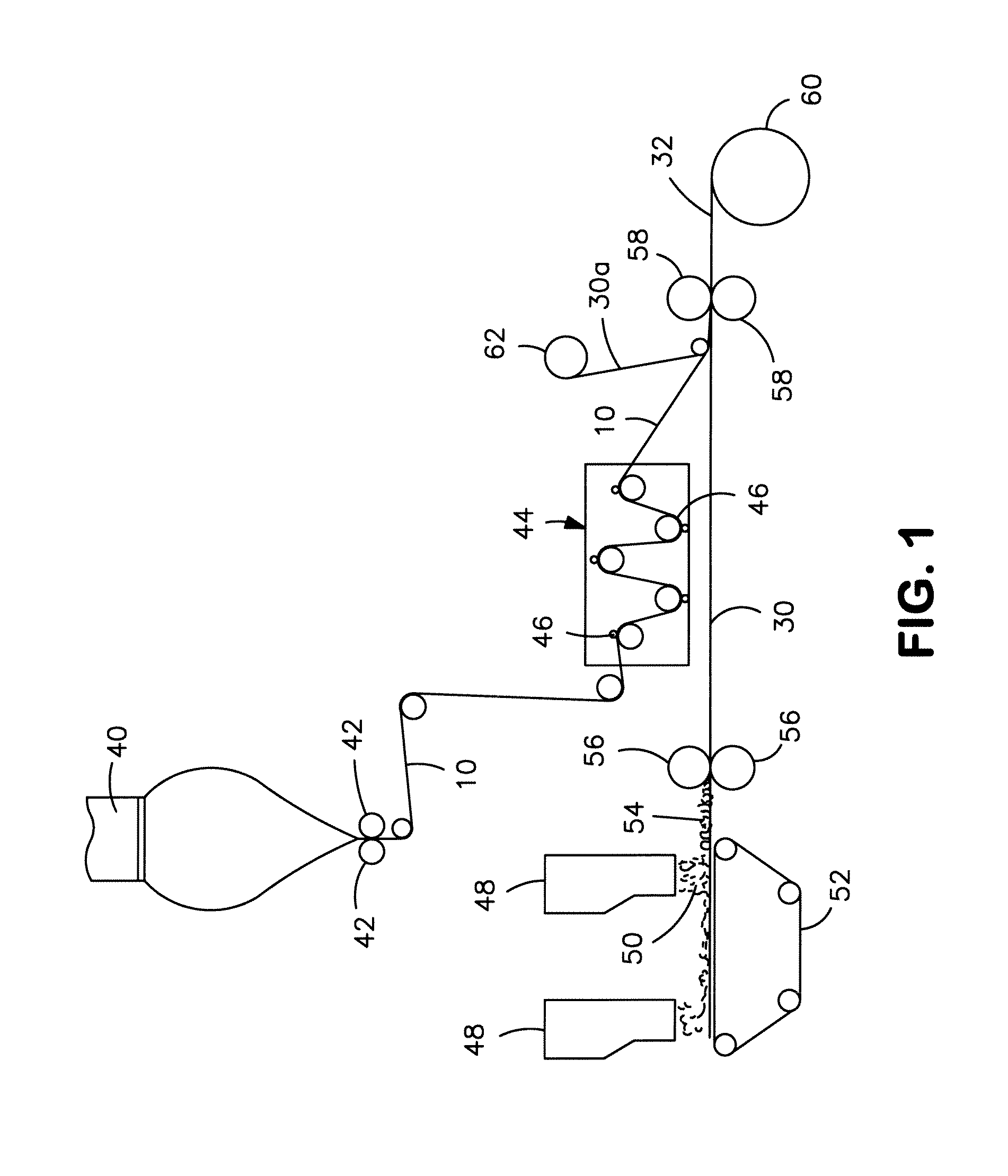

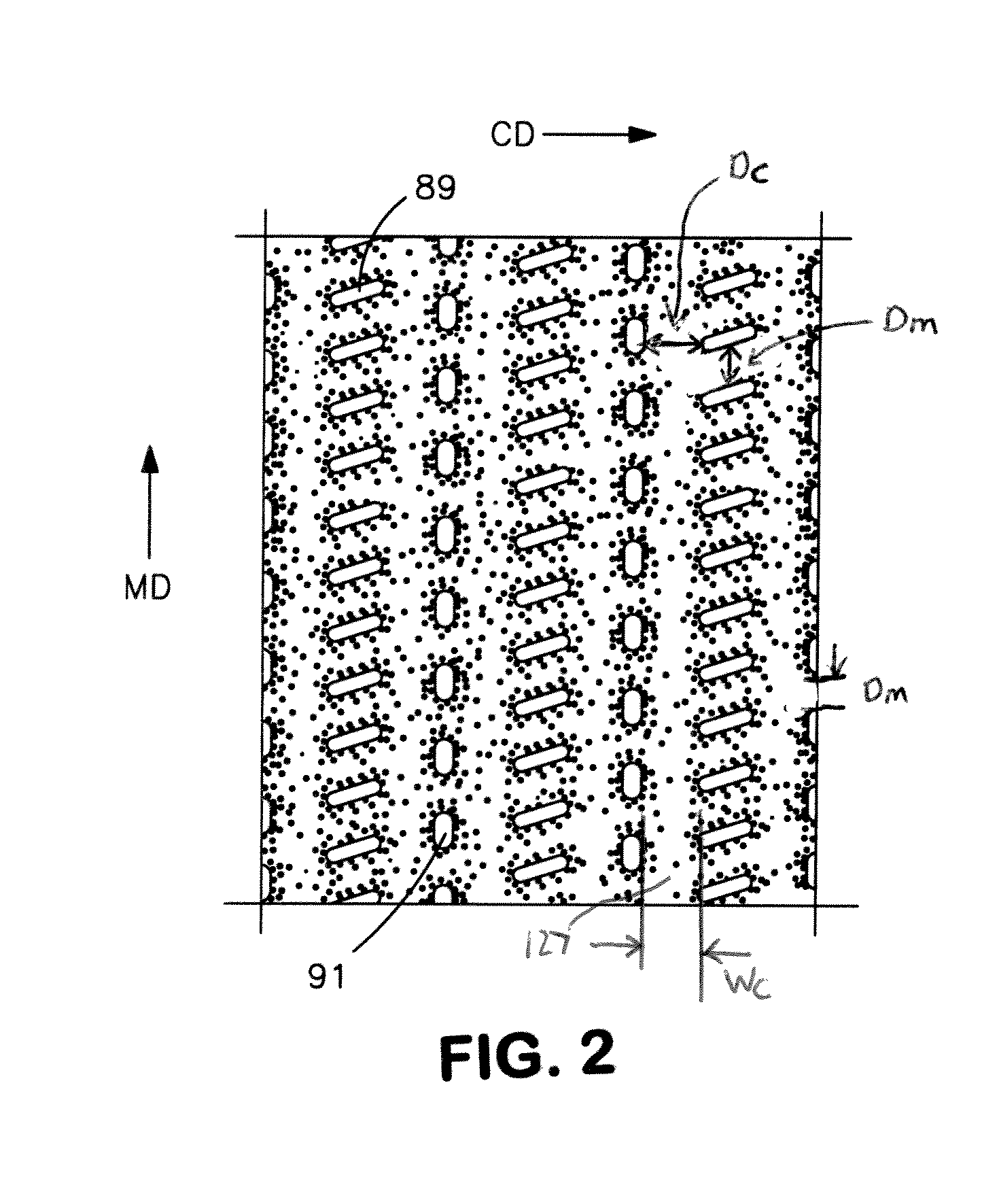

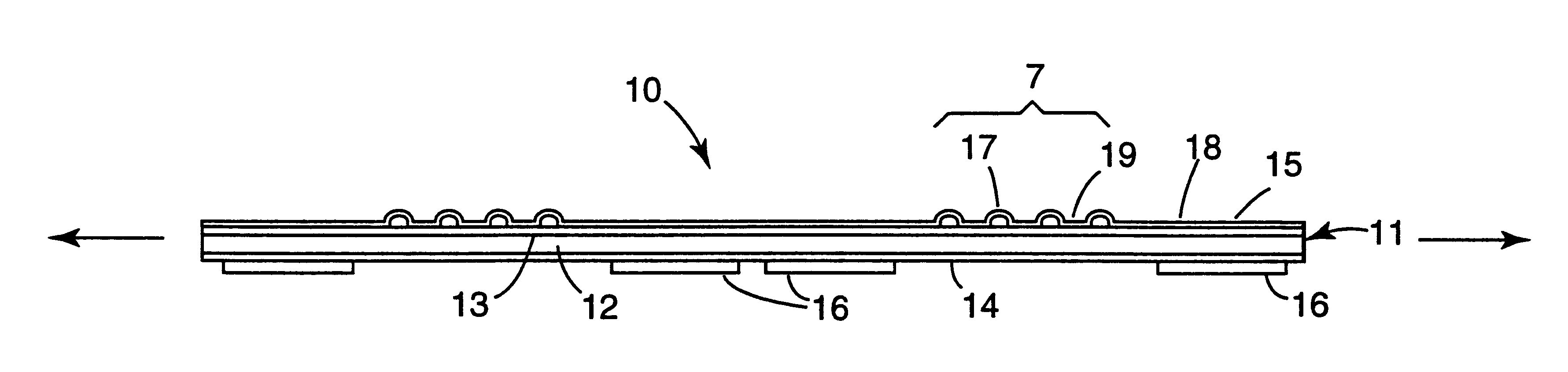

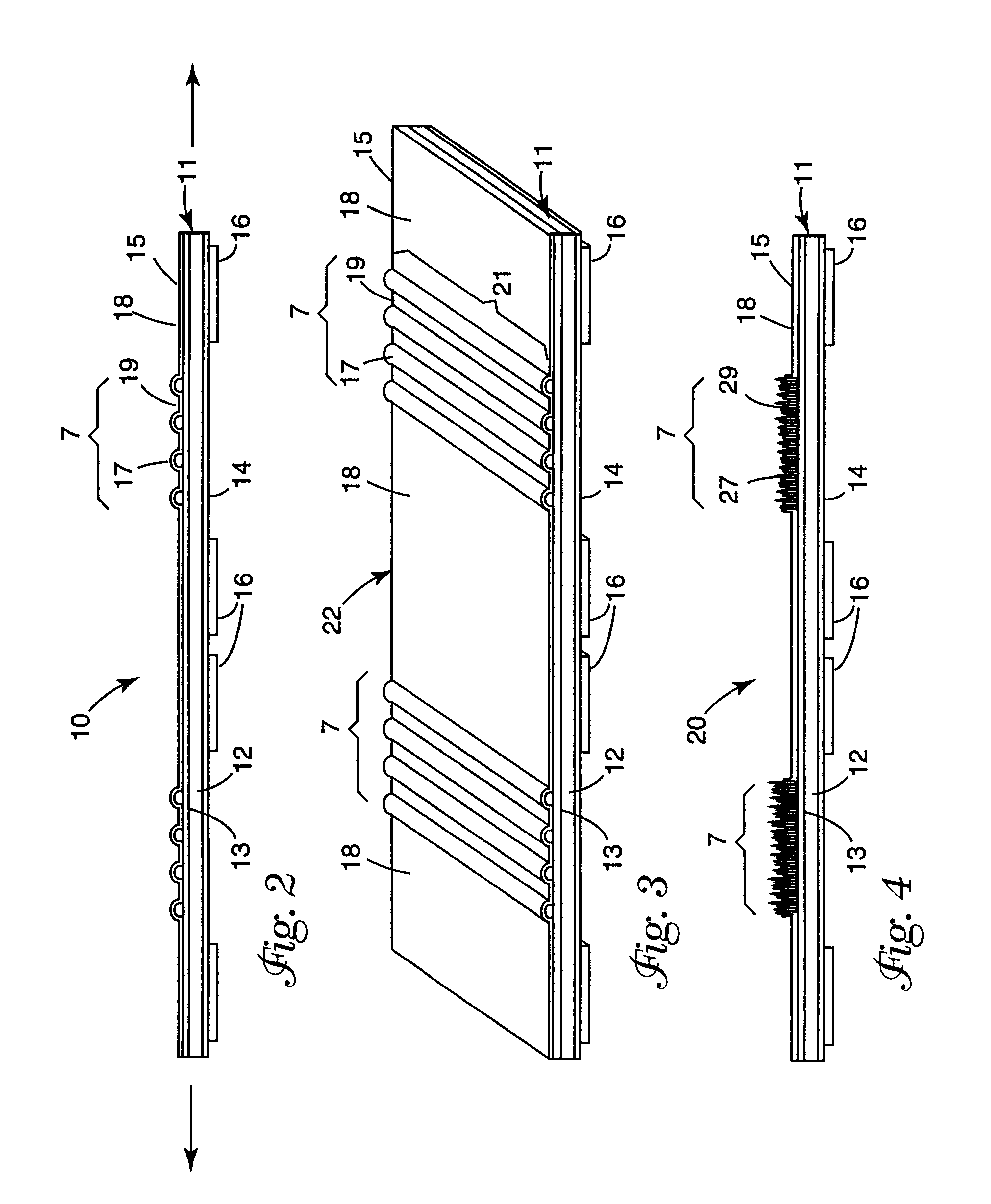

Method of making a smooth elastic nonwoven composite

A method making an elastic nonwoven composite that contains an elastic film laminated to one or more nonwoven web materials is provided. The method includes forming an elastic film from a polymer composition and passing the film and a nonwoven web material, the nonwoven material having a basis weight from about 5 gsm to about 30 gsm, through a nip formed by at least one patterned roll. The patterned roll includes raised bonding elements repeating in the machine direction, the elements being spaced in the machine direction by less than about 760 micrometers. At the nip, the film and the nonwoven web material are concurrently melt fused while the film is under tension at a stretch ratio of about 1.5 or more in the machine direction.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Elastic tab laminate

There is provided an extensible elastic tab designed to be adhered to the edge of an article, formed using a coextruded elastic film comprising at least one elastic layer and at least one second layer on at least a first face of the elastic layer with at least one face of the coextruded elastic film attached to at least a partially extensible nonwoven layer. The partially expandable, or extensible nonwoven layer has at least one first portion with limited extensibility in a first direction and at least one second inextensible portion in the first direction. The extensible elastic tab when stretched to the extension limit of the first portion or portions in the first direction will elastically recover at least 1.0 cm, preferably at least 2 cm providing an elastic tab having a Useful Stretch Ratio (as defined in the Examples) of at least 30 percent. The Useful Stretch Ratio includes the portion of the elastic recovery length having an elastic recovery force of greater than 20 grams / cm force, but below a given extension which generally is 90 percent of the extension limit. Further the elastic tab in the region of the Useful Stretch Ratio preferably has an incremental extension force of less than about 300 grams / cm. The invention tab provides definable predictable elastic performance and is useful as a fastening tab used to join to surfaces requiring elastic engagement, particularly a person or animal. The tab is particularly useful as a diaper fastening tab.

Owner:3M INNOVATIVE PROPERTIES CO

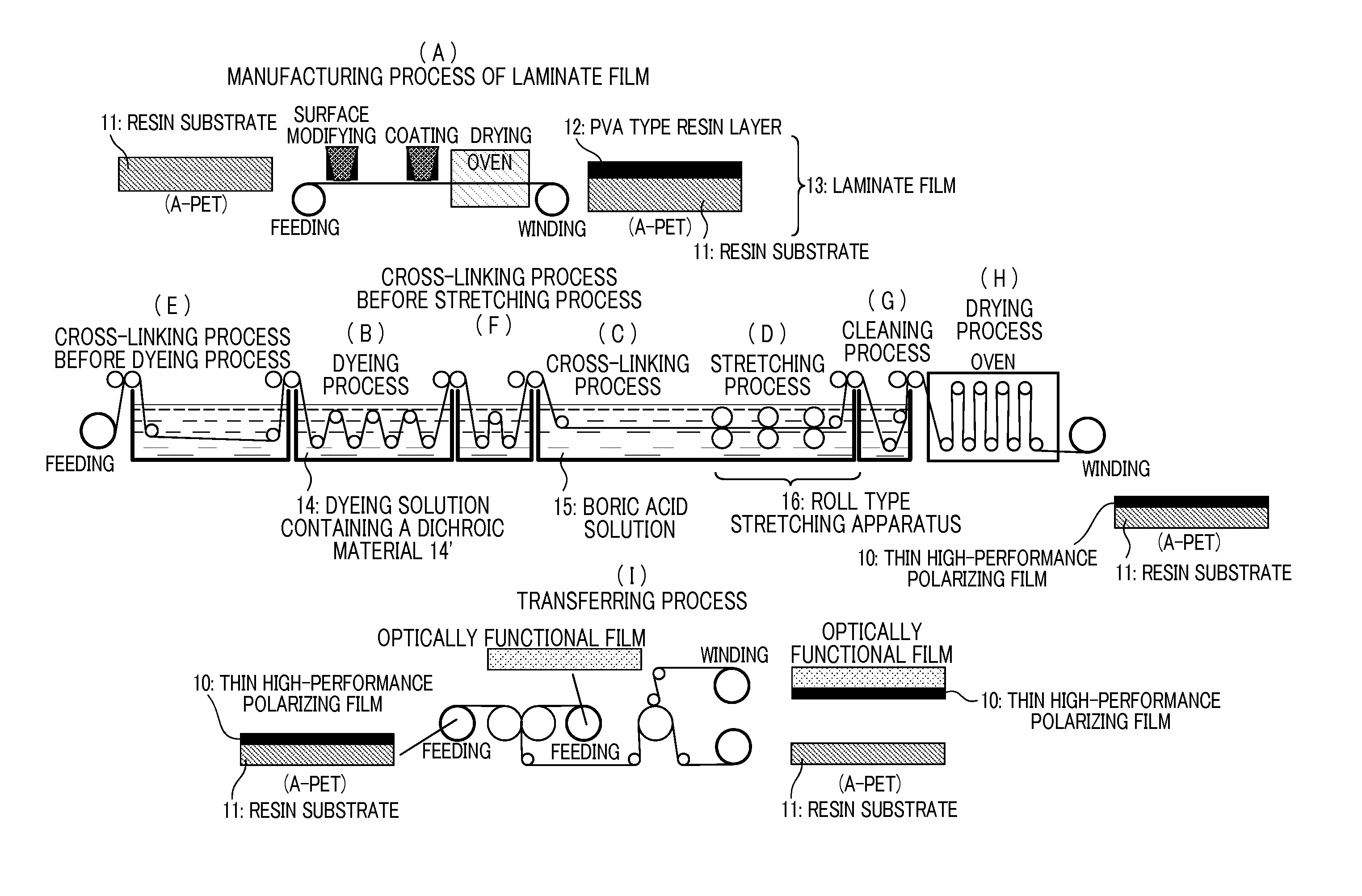

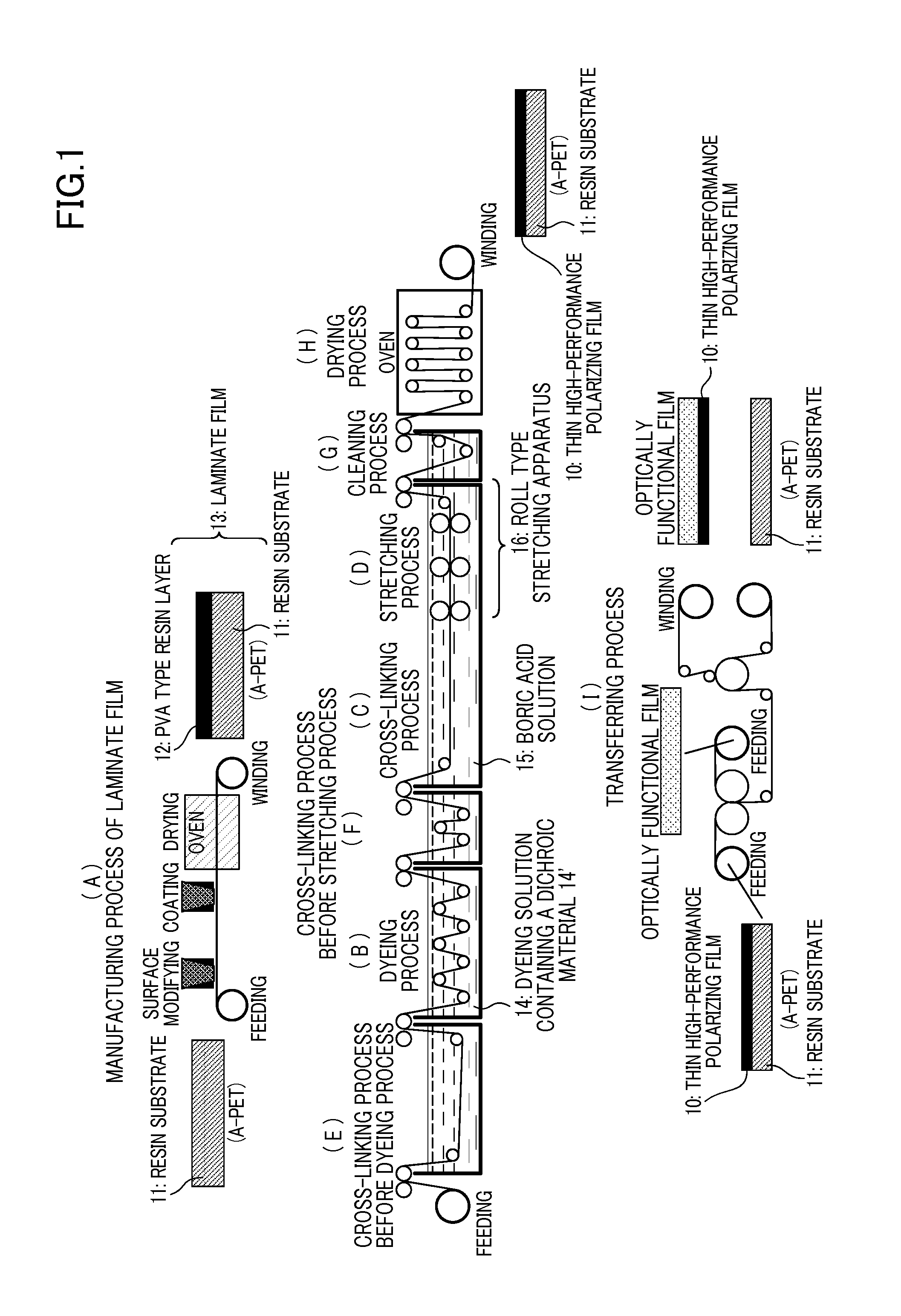

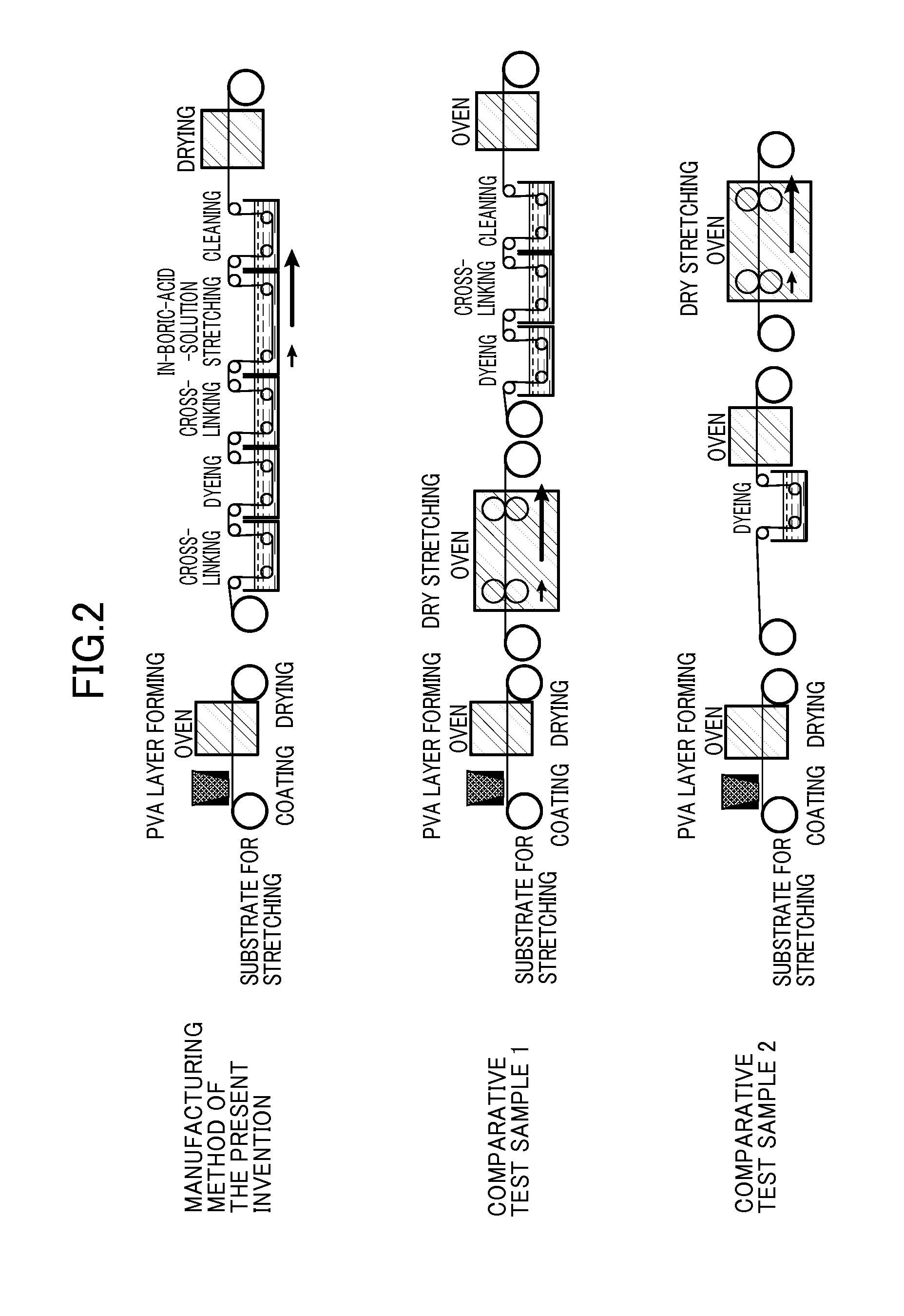

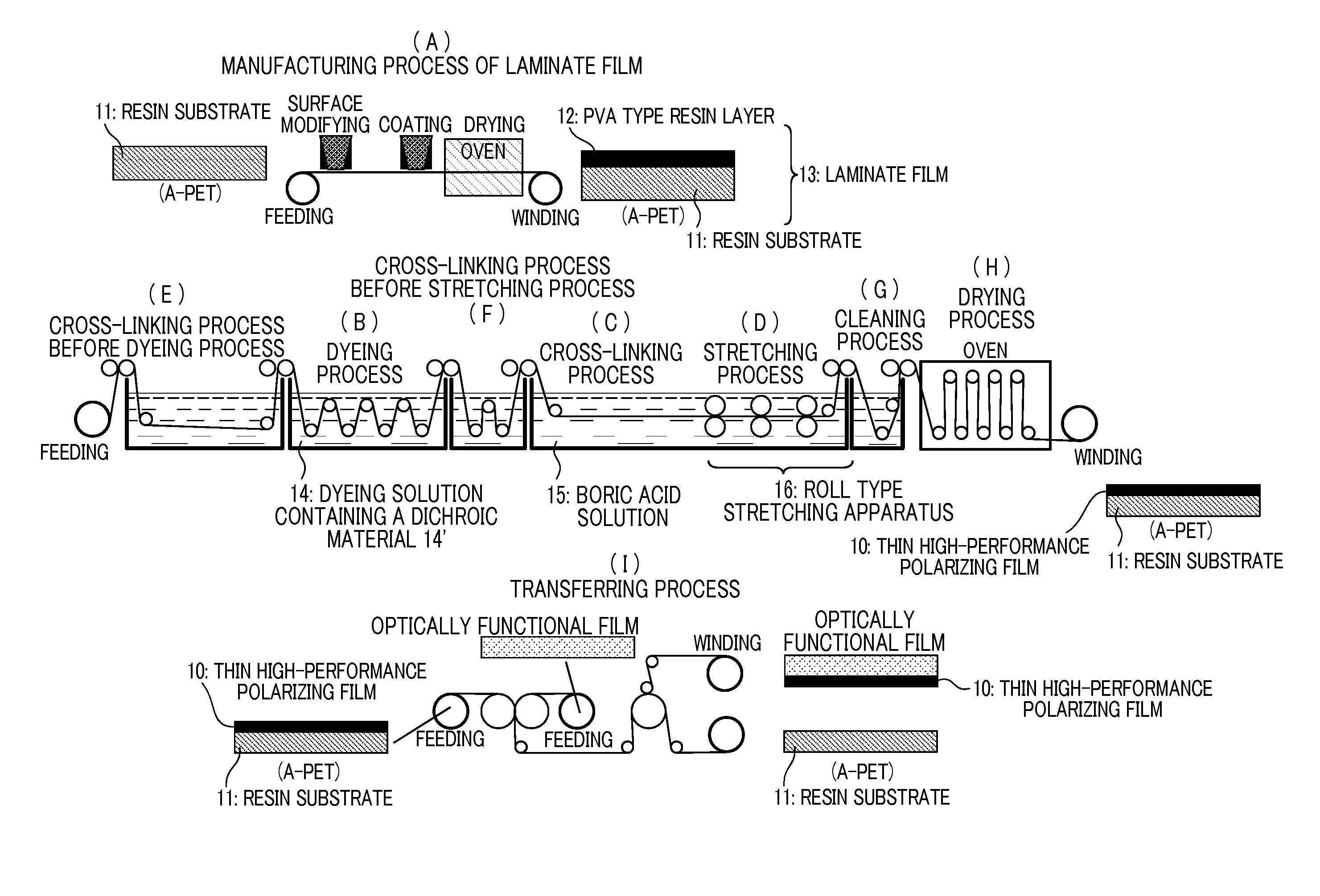

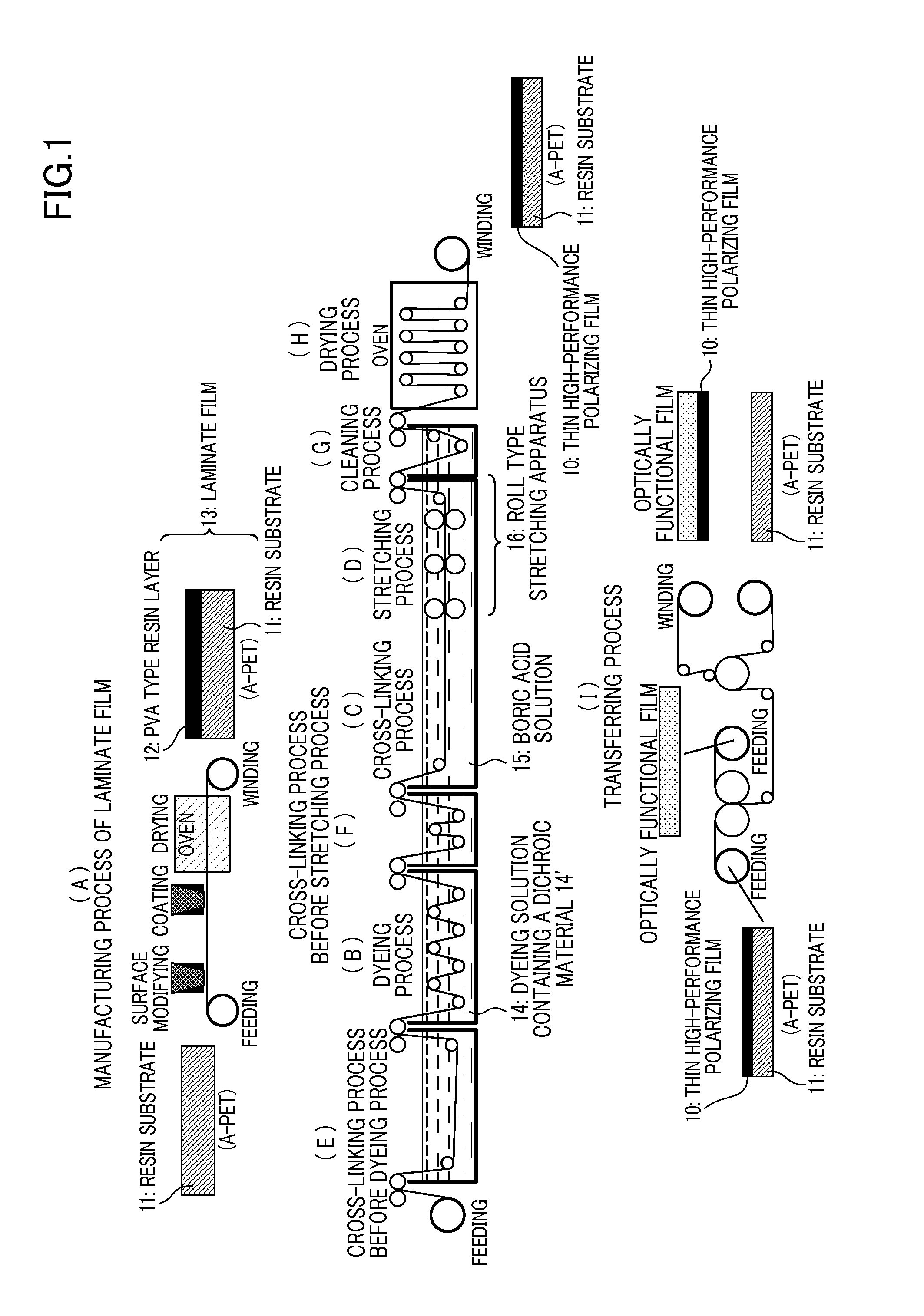

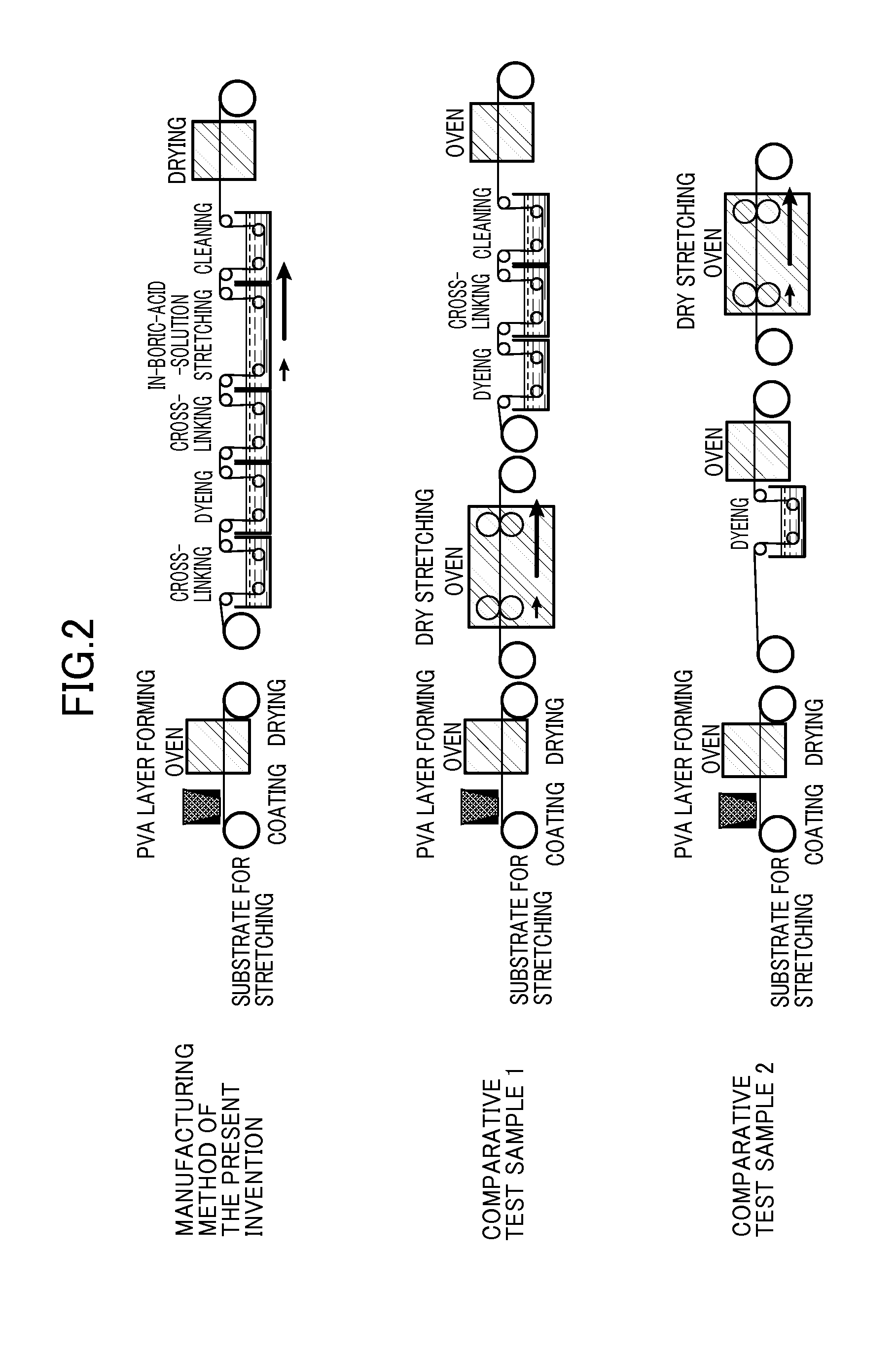

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

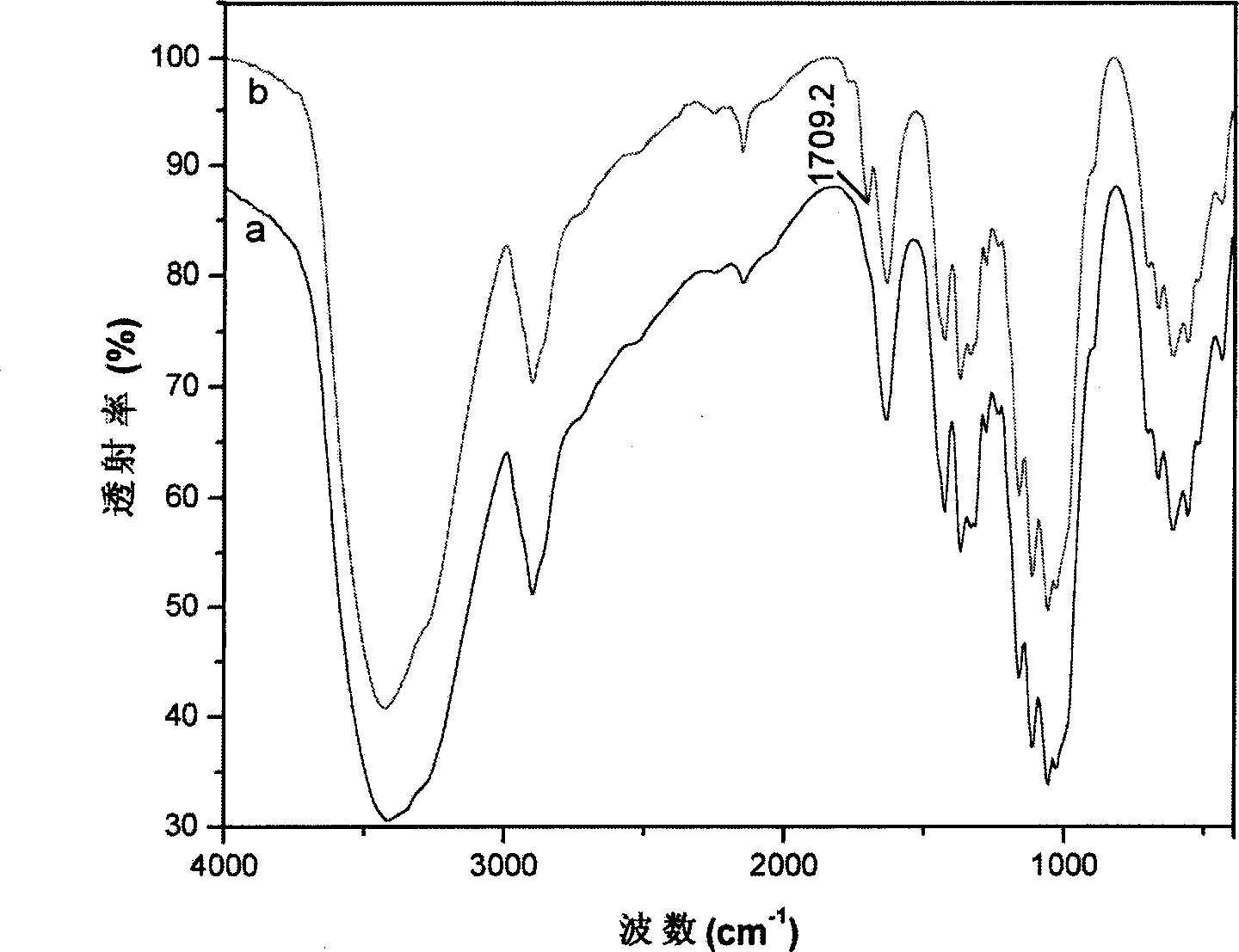

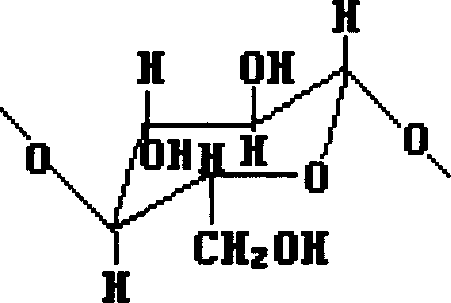

Process for preparing modified cotton fibre

The invention relates to a modified cotton fiber manufacturing method. It belongs to textile fiber material modification technique. It includes the following steps: boiling-off twisted cotton yarn and bleaching; processing selective oxidation reaction by putting the cotton yarn into periodate with 0.1-3g / L concentration at 30-60 centigrade degree for 1-2h; removing the oxidant; washing; dehydrating; drying; gaining oxidation cotton fiber with less than 25% strength stretch ratio; using the matter with -NH2, -OH active group to graft and cross link. Thus the cotton fiber is modified to gain multifunction composite cotton fiber. It can increase its wearability and addition value, expand application area, and solve the cotton fiber function in textile fiber material field.

Owner:SUZHOU UNIV

Method of making microporous material

ActiveUS7445735B2Improved dimensional stability and physical propertyElectrolyte holding meansSemi-permeable membranesPlasticizerStretch ratio

Owner:DARAMIC LLC

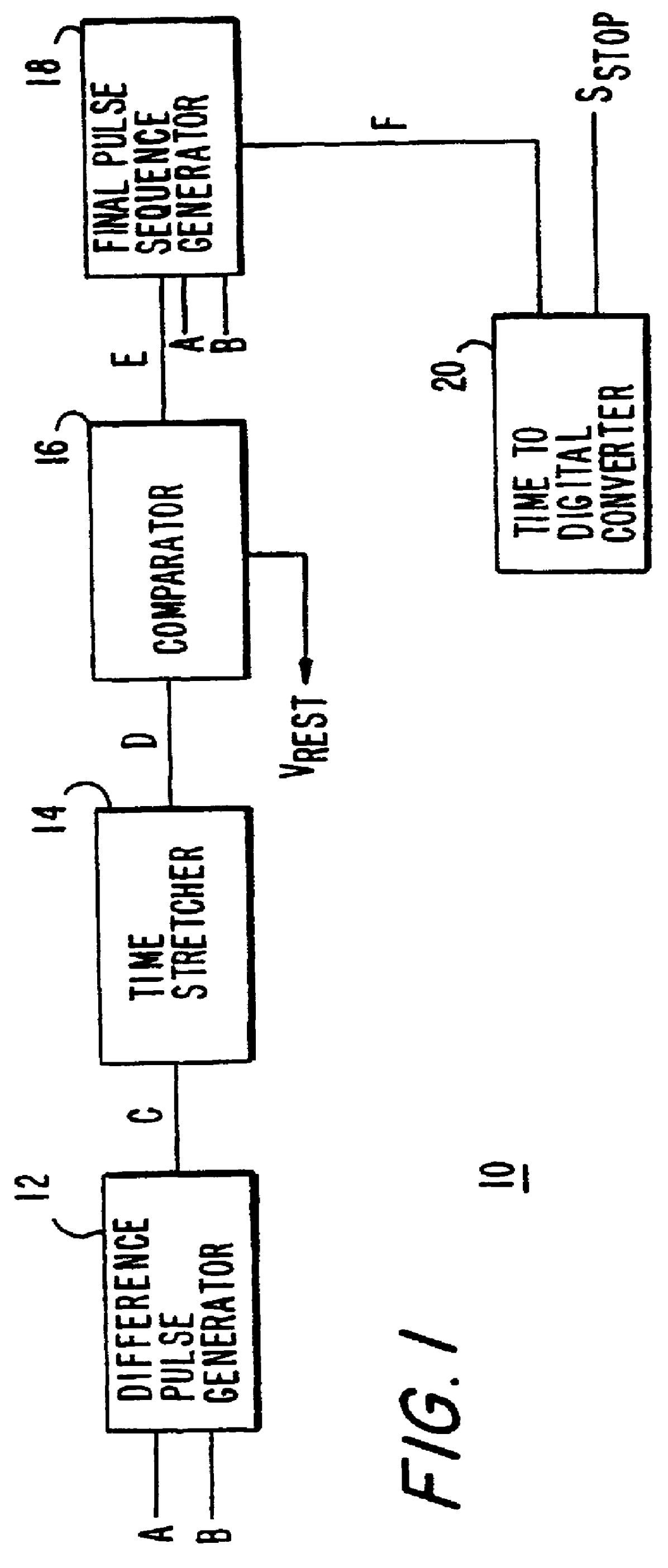

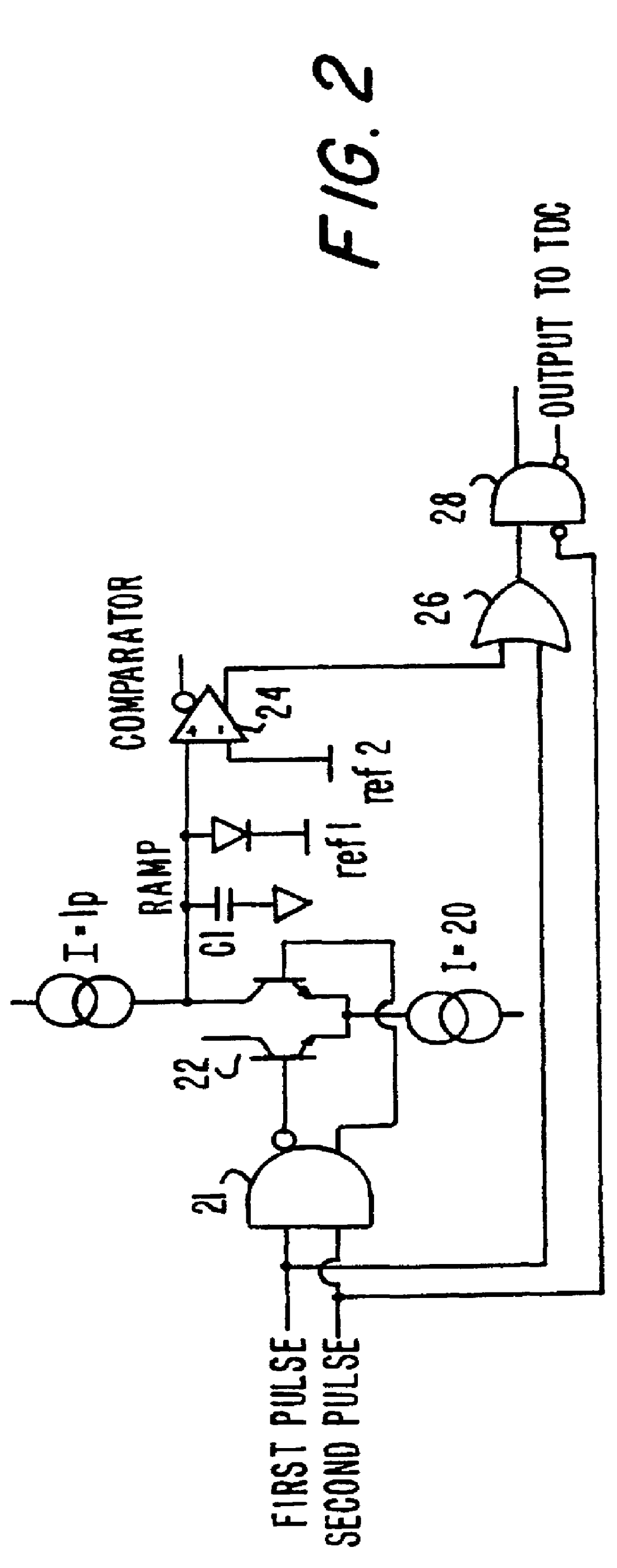

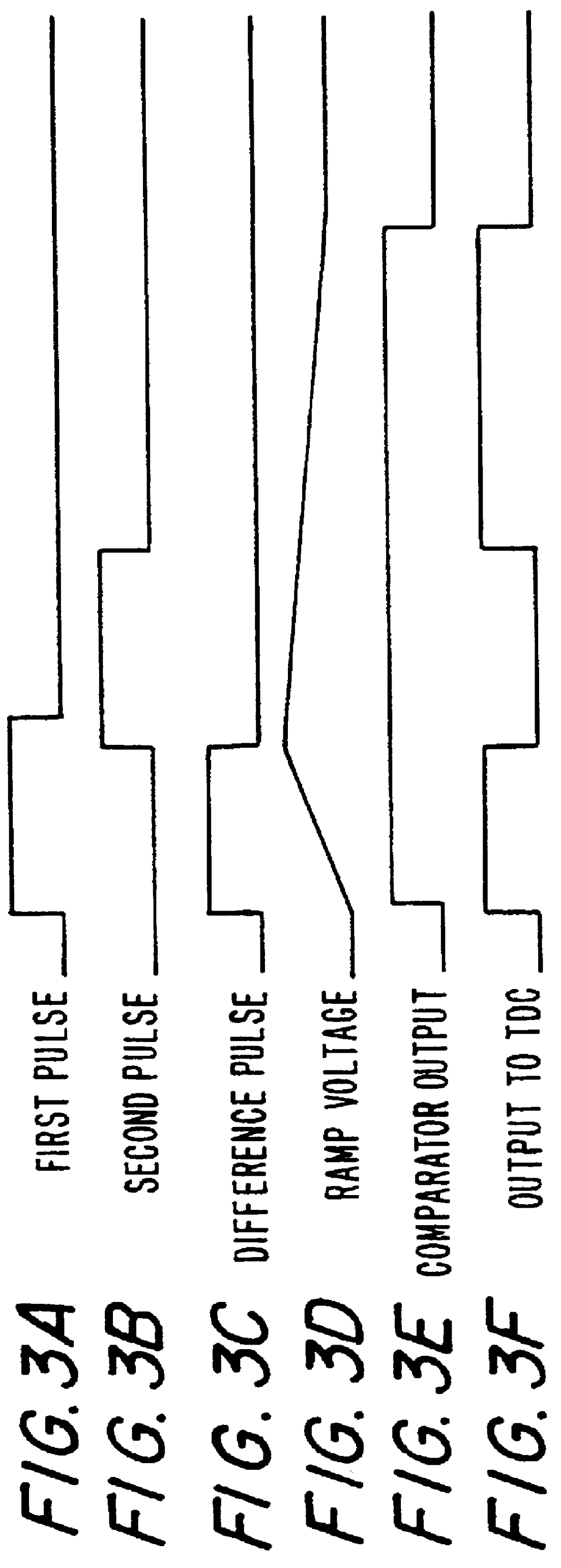

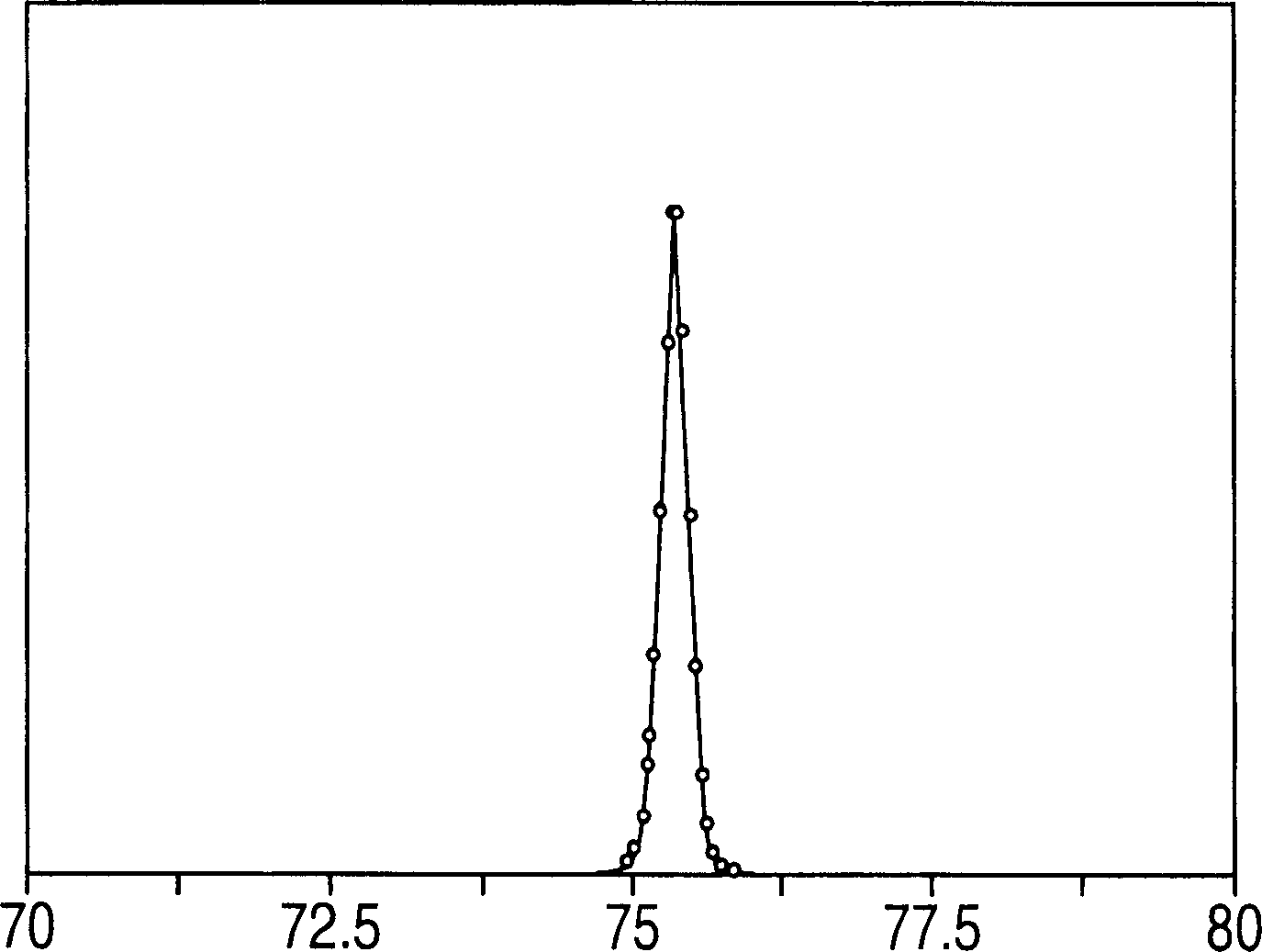

Apparatus and method for measuring time intervals with very high resolution

InactiveUS6137749AHigh resolutionSimple designElectromechanical unknown time interval measurementPulse characteristics measurementsImage resolutionStretch ratio

PCT No. PCT / US97 / 05299 Sec. 371 Date Dec. 18, 1998 Sec. 102(e) Date Dec. 18, 1998 PCT Filed Apr. 1, 1997 PCT Pub. No. WO97 / 39360 PCT Pub. Date Oct. 23, 1997To measure relatively long time intervals with very high resolution, apparatus and method operate to receive a first pulse and a clock signal that has a known period, synchronize the first pulse with the clock signal, stretch the first synchronized pulse in accordance with a first stretch ratio, produce a first compared output pulse corresponding to the first stretched signal, synchronize the first compared output pulse with the clock signal, generate a first pulse sequence from the first synchronized pulse and the first synchronized compared output pulse, convert times of occurrences of the edges of the first pulse sequence to respective time values, receive a second pulse and generate a second pulse sequence in a manner similar to that of the first pulse sequence, convert times of occurrences of the edges of the second pulse sequence to respective time values, count the elapsed number of clock periods between the first and second synchronized pulses, derive the time interval between the received pulses from the time values, the first and second stretch ratios, the period of the clock and the elapsed number of clock periods, and calibrate the first and second stretch ratios from the time values.

Owner:TELEDYNE LECROY

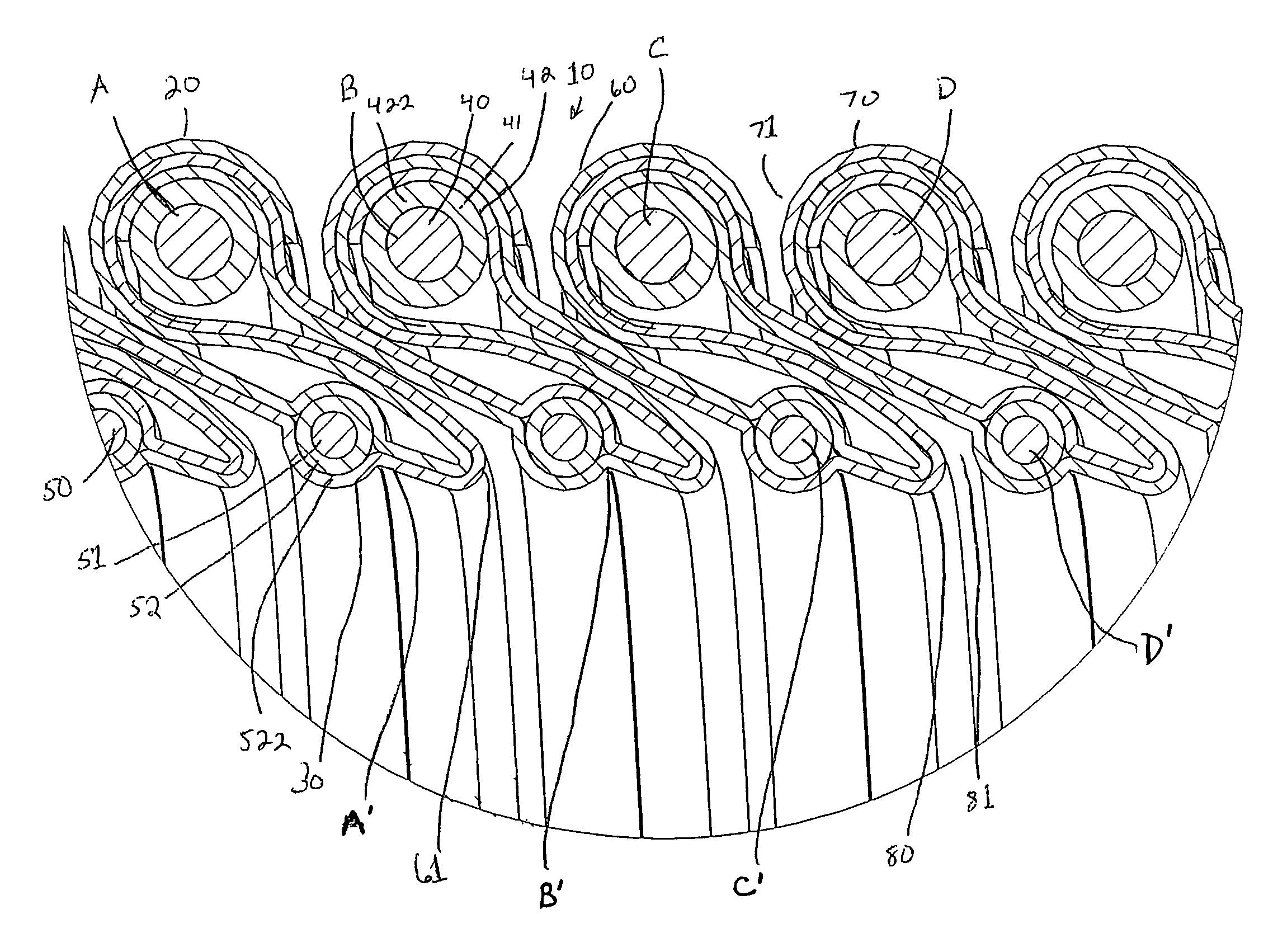

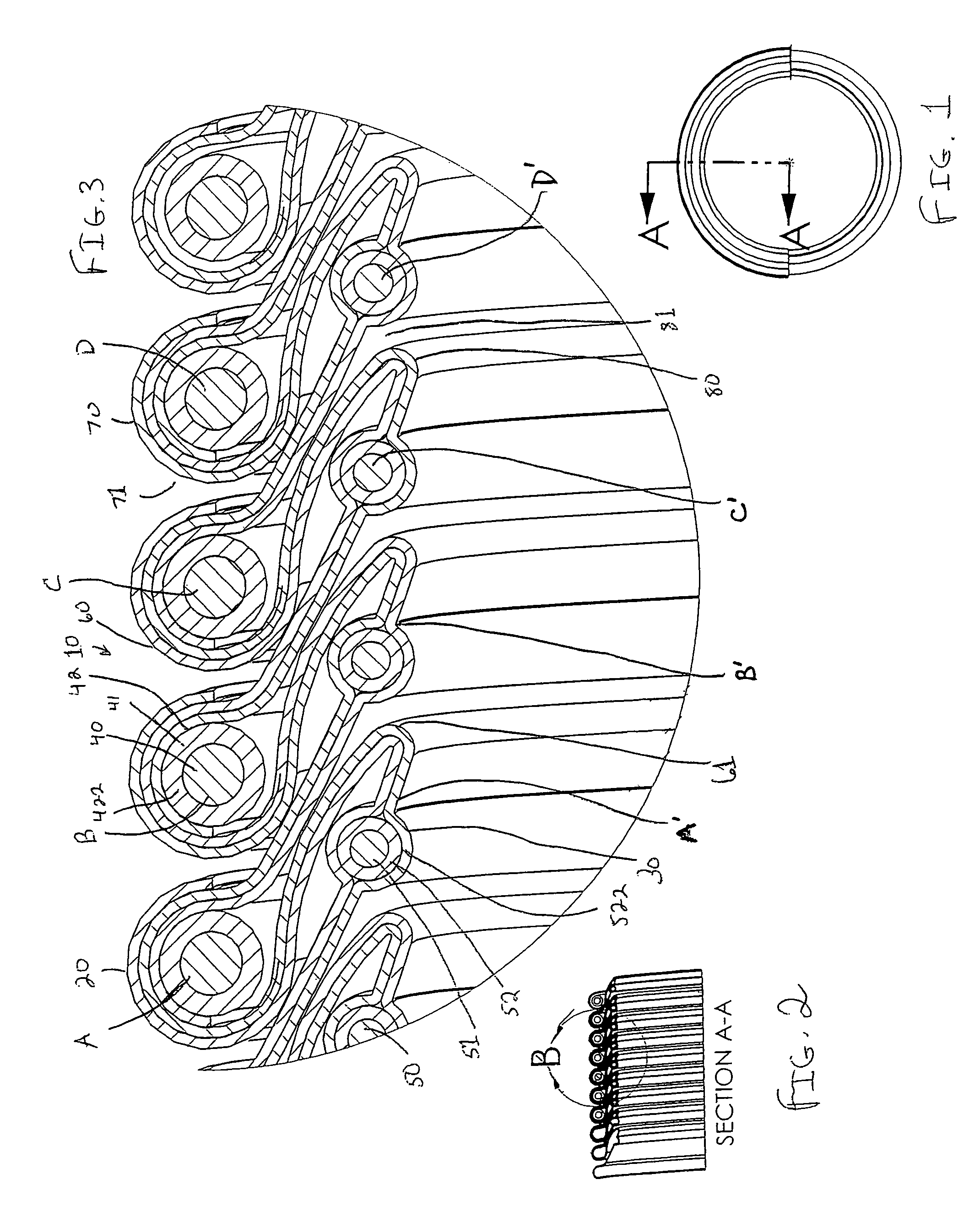

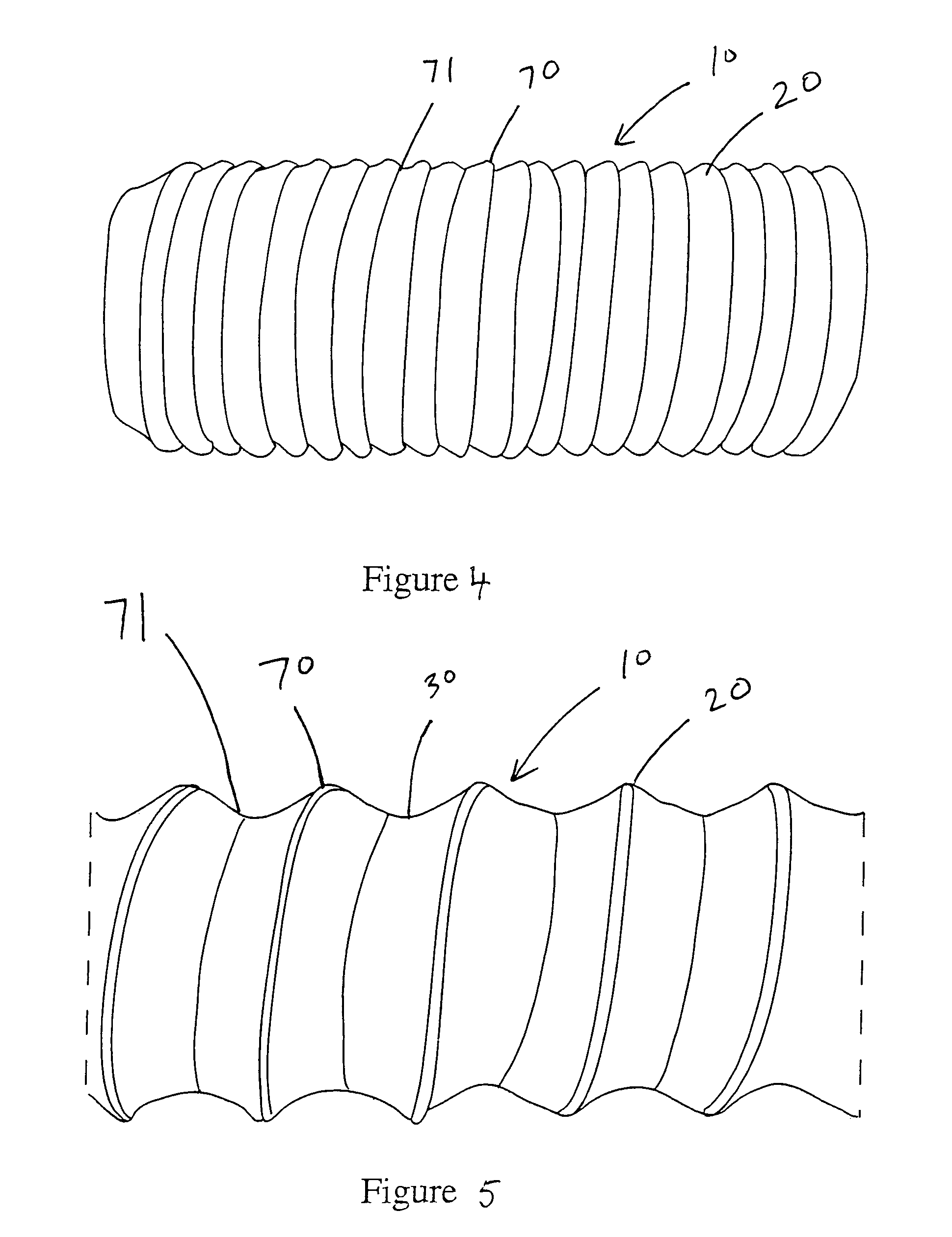

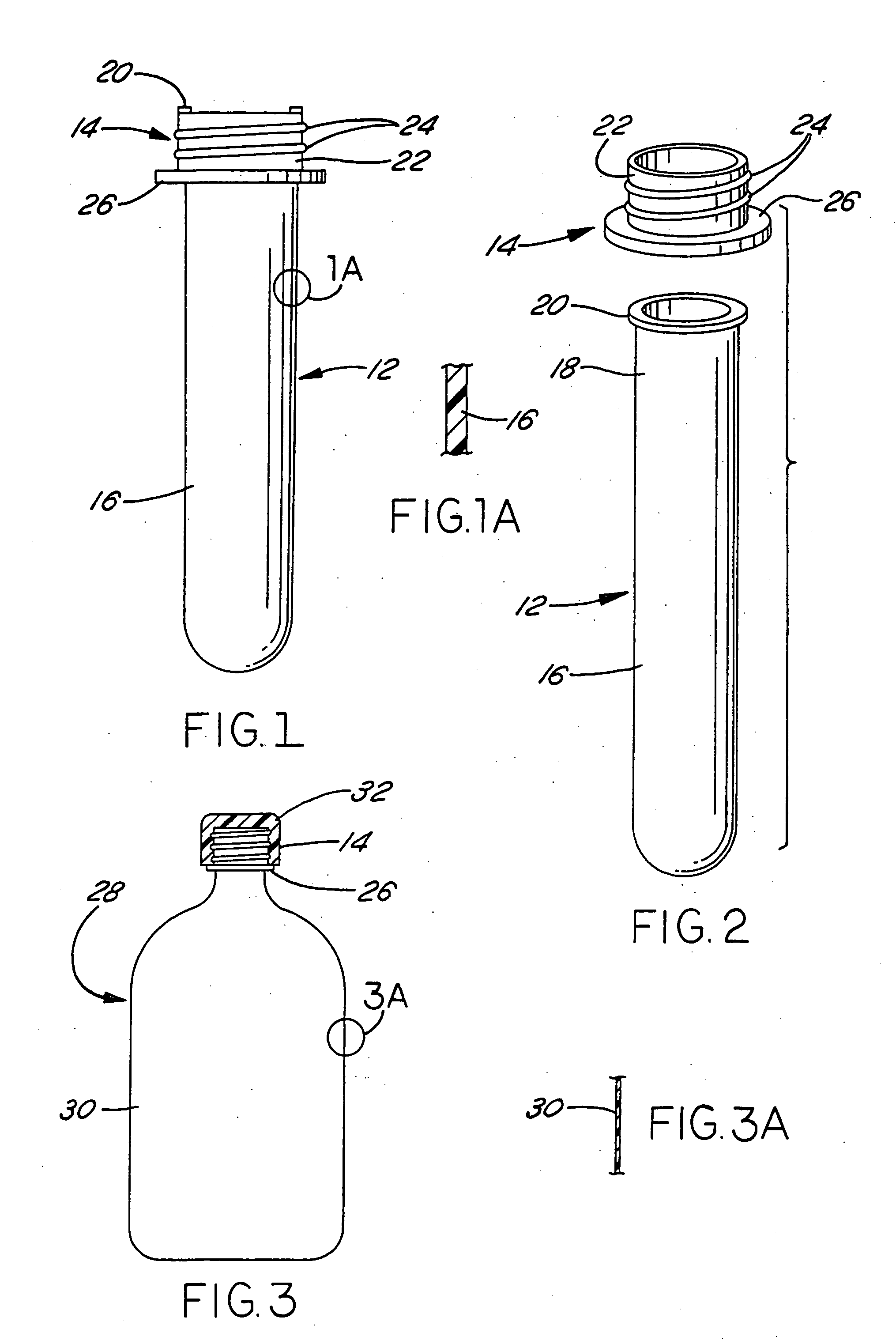

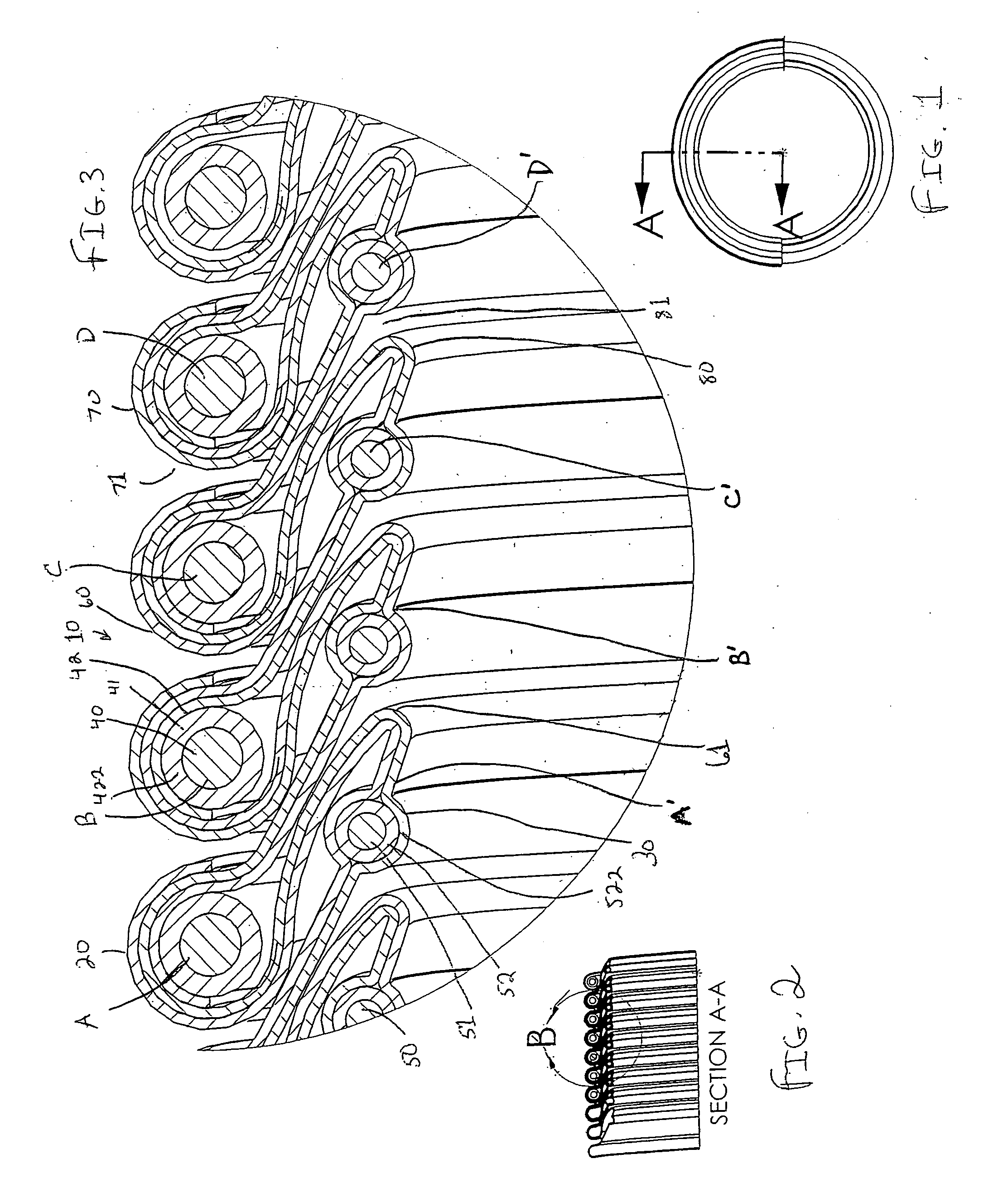

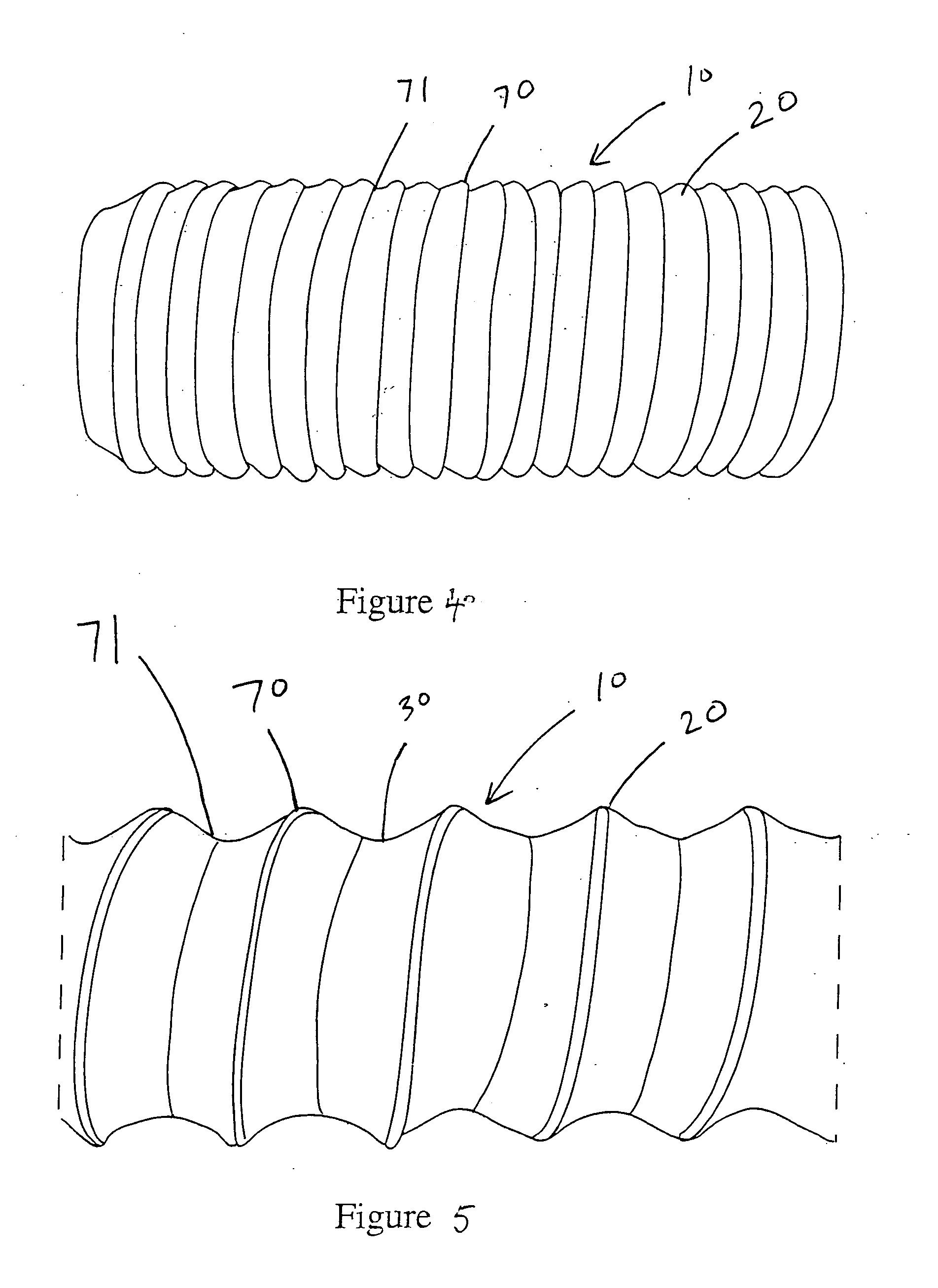

Electrical stretch hose

InactiveUS7520302B2Low costEasy to manufactureSuction cleanersInsulated cablesElectricityEngineering

The present invention is an electrical extensible hose that includes an outer shell, an inner core and at least one helical wire, which acts like a skeleton. In the present invention one implemented an additional wire that was conductive. The outer shell and inner core of the present invention may be bonded together via heat fusion. The helical wire is attached to the inner core via heat fusion. The helical wire supports the outer shell and inner core so as to form a tube. The outer shell and the inner core have a portion that forms an angular fold and have a portion that remains fixed. The second wire is attached at a point below the fixed portion of the electrical stretch hose so as to allow for maximum constriction caused by the shrinkable force created by the helical wire, thus increasing the stretch ratio of the hose.

Owner:FLEXIBLE TECH INC

Stretchable absorbent article having lateral and longitudinal stretch properties

Absorbent articles with carefully controlled stretch properties are disclosed. In particular, the articles exhibit stretch not only in the lateral direction but also in the longitudinal direction. Specifically, the articles have a biaxial stretch ratio, which refers to a ratio of stretch along the hip circumference of the article to the amount of stretch in the longitudinal direction, that is from about 1.0 to about 2.5, and particularly from about 1.1 to about 1.5. Absorbent articles made in accordance with the present invention are capable of accommodating a relatively large size range of wearers. The articles also exhibit improved fit and prevent sagging or drooping of the crotch region, even after the crotch region has been wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Thin high-performance polarizing film and method for manufacturing the same

ActiveUS20120327512A1Improve solubilityThin polarizingOptical articlesPolarising elementsBoric acidStretch ratio

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

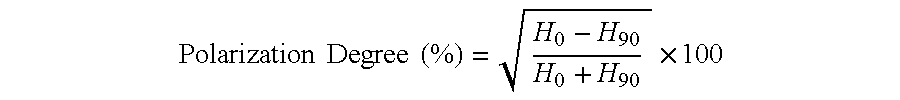

Polarizing plate, optical element, and liquid crystal display

InactiveUS6897916B2Convenient lightingRaise the draw ratioPhotomechanical apparatusPolarising elementsVisibilityLiquid-crystal display

A polyvinyl alcohol-based polarizing film is provided, and the polarizing film has excellent surface smoothness while the light transmittance and the polarization degree are improved due to the high stretch ratio. The polarizing film is obtained from a polyvinyl alcohol film having a thickness ranging from 85 μm to 150 μm by dyeing the film with a dichroic substance and stretching it to 4-7 times its original length. The polarizing film has a light transmittance ranging from 35% to 50% and a polarization degree of at least 80%, and the surface roughness in a direction perpendicular to the stretching axis is at most 0.04 μm based on a centerline average roughness. A transparent protective layer or a transparent protective plate comprising the transparent protective layer is formed on at least one surface of the polarizing film in order to provide a polarizing plate. The transparent protective layer can be subject to a pre-treatment selected from a hard-coat treatment and an anti-glare treatment. Additional optical layers are laminated on the polarizing plate in order to provide an optical element. A polarizing plate or an optical element comprising the above-mentioned polarizing film has an excellent light transmittance and polarization degree, so that stripe-shaped streaks inhibiting visibility will not be observed substantially even in a reflection mode.

Owner:NITTO DENKO CORP

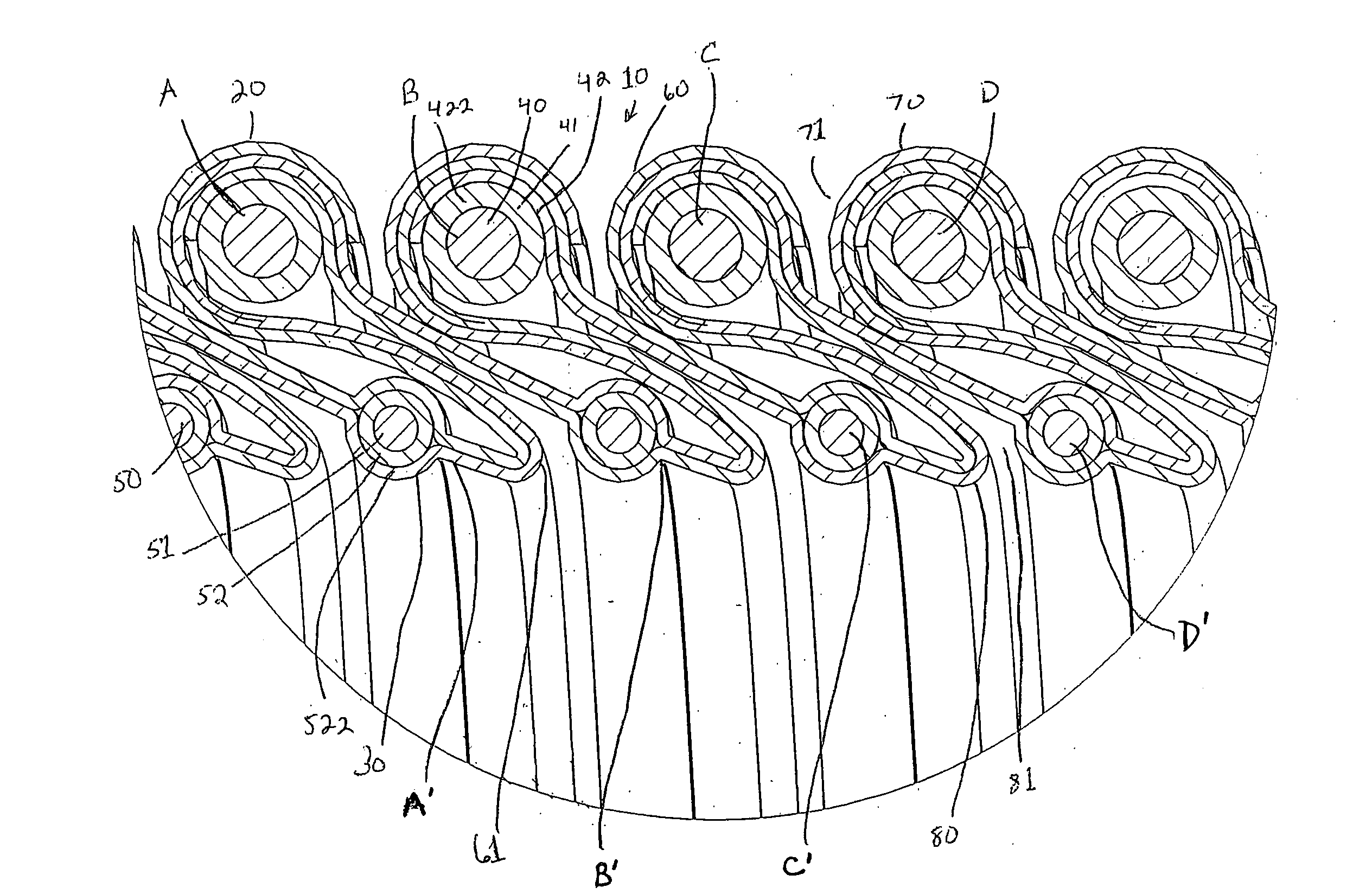

High tenacity, high modulus filament

Polyethylene solutions are extruded through a multi-orifice spinneret into a cross-flow gas stream to form a fluid product. The fluid product is stretched at a temperature at which a gel will form at a stretch ratio of at least 5:1 over a length of less than about 25 mm with the cross-flow gas stream velocity at less than about 3m / min. The fluid product is quenched in a quench bath consisting of an immiscible liquid to form a gel. The gel is stretched. The solvent is removed from the gel to form a xerogel and the xerogel product is stretched in at least two stages to produce a polyethylene yarn characterized by a tenacity of at least 35g / d, a modulus of at least 1600 g / d and a work to break of at least 65 J / g. The yarn is further characterized by having greater than about 60 % of a high strain orthorhombic crystalline component and, optionally, a monoclinic crystalline component greater than about 2 % of the crystalline content. Composite panels made with these yarns exhibit excellent ballistic resistance, e.g., SEAC of 300J-m<2> / Kg or higher against .38 caliber bullets using test procedure NILECJ-STD-0101.01. A ballistic resistant composite panel is provided comprising a polyethylene multi-filament yarn having a tenacity of at least about 35 g / d, a modulus of at least 1600 g / d, a work-to-break of at least about 65 J / g wherein the yarn has greater than about 60 % of a high strain orthorhombic crystalline component and the yarn has a monoclinic crystalline component greater than about 2 % of the crystalline content.

Owner:HONEYWELL INT INC

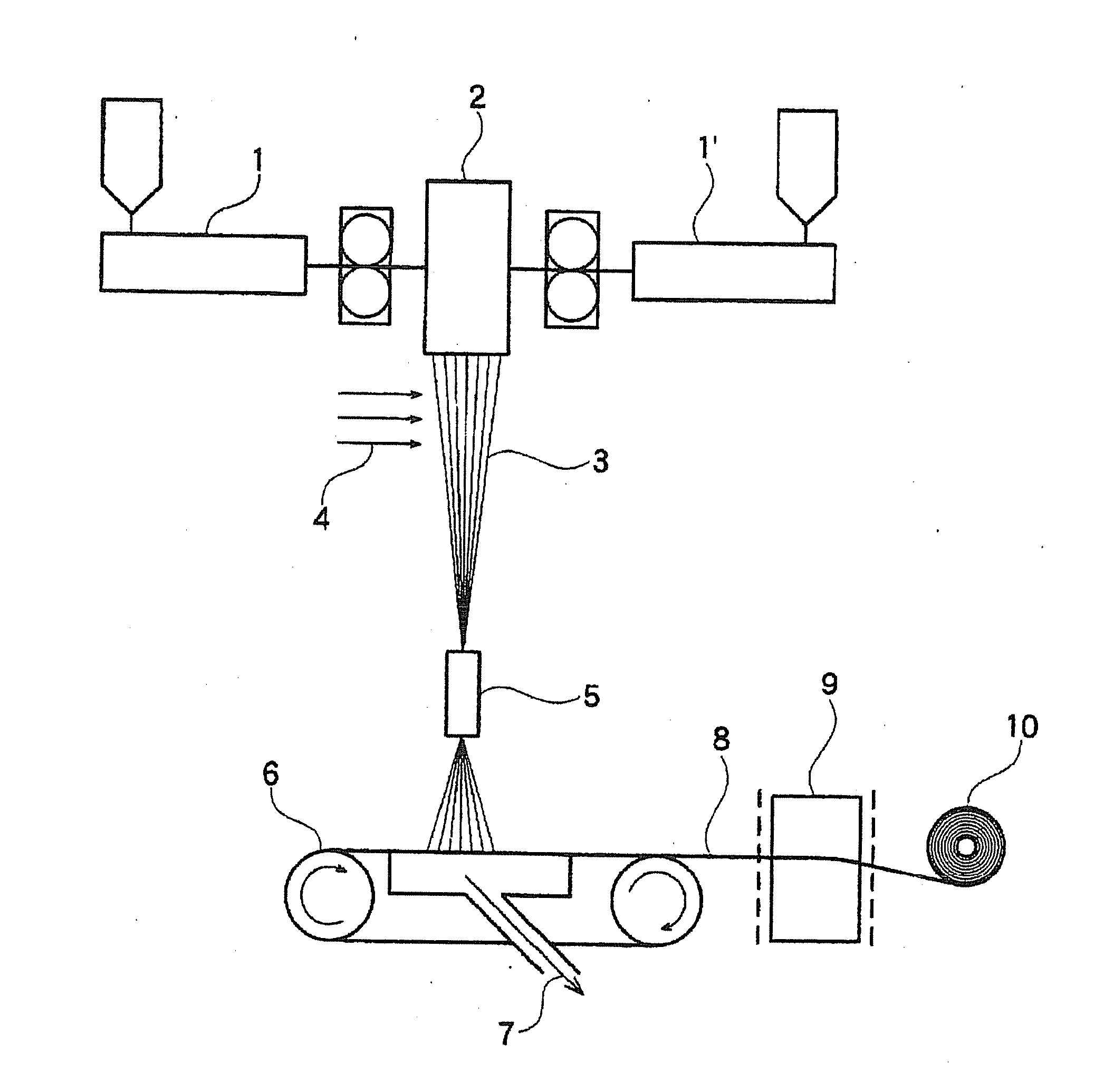

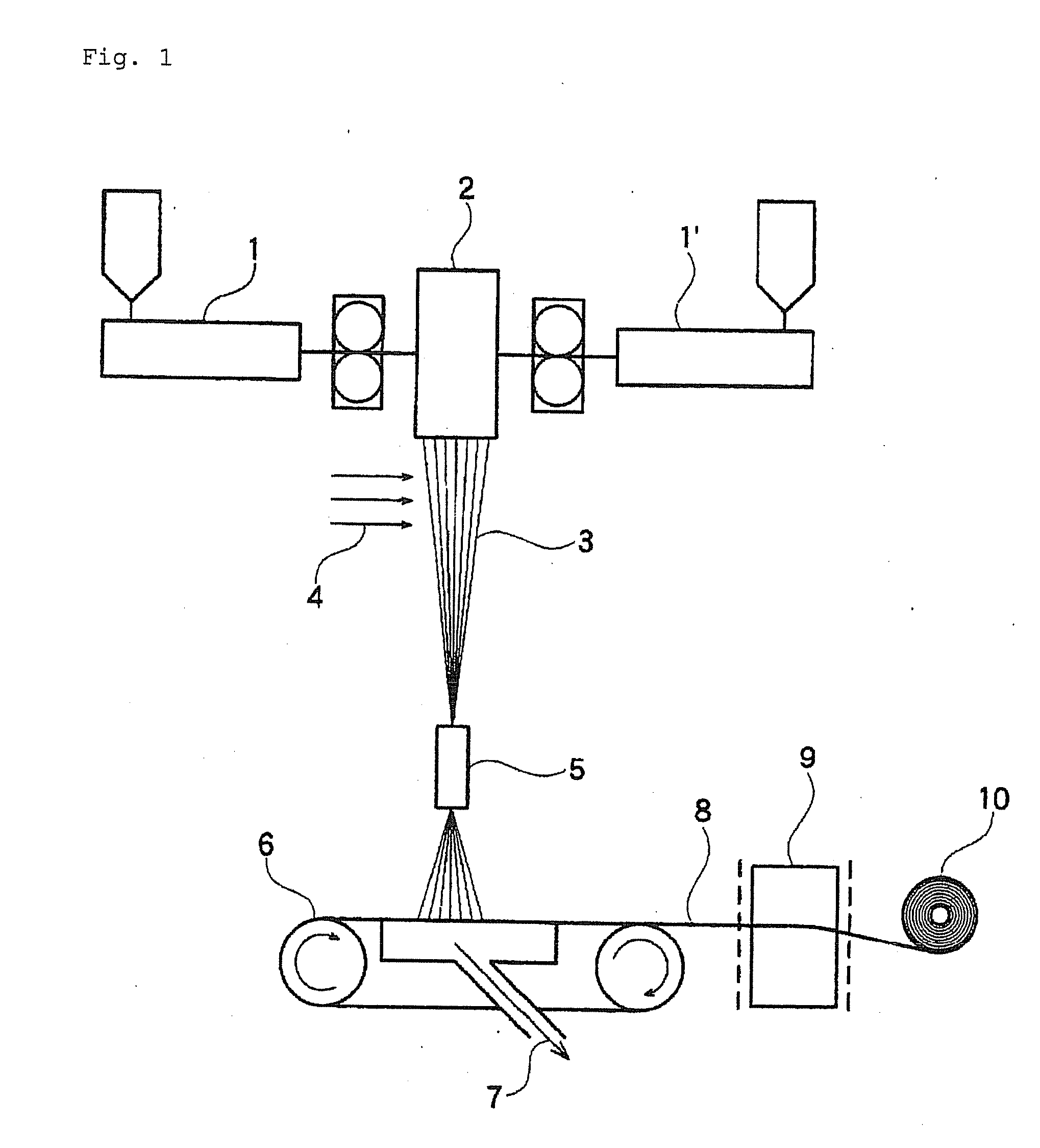

Method for preparing low-titer high-strength high-modulus polyethylene fibre

The present invention discloses a process for producing low-titer, high-strength and high-modulus polyethylene fibers, comprising the following steps: dissolving the ultra-high molecular weight polyethylene into paraffin oil with a low viscosity to form a spinning solution with a concentration of 3ˆ¼15%; extruding the spinning solution through a thin spinneret with at least 10 orifices having a diameter ¦ of 0.7ˆ¼0.8mm and a length / diameter ratio of 10ˆ¼12, by applying a high pressure in the range of 2.5±1.0MPa to the spinning solution, such that the fluid in the orifices is extruded at a shear rate of 200ˆ¼3 500sec -1 ; and then performing a jet stretch at a deformation rate of 200ˆ¼5 000min -1 within an air-gap of 10ˆ¼15mm between the spinneret and the quench bath surface; feeding the jet-stretched fluid into the quench bath to form gel filaments; extracting and drying the gel filaments; and performing a multistage ultrahigh post stretch on the dried gel filaments with a stretch ratio of 15 or less. In this process, the solution is extruded at a high rate by using a spinneret with small orifice diameter, thereby achieving a high shear rate and a high deformation rate, so the present process is a novel and effective spinning process.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

Polyester film and production method thereof

InactiveUS6517762B1Stretching ratioImprove productivitySynthetic resin layered productsRecord information storagePolyesterEngineering

The object of the present invention is to provide a method for producing a polyester film excellent in rigidity, toughness, dimensional stability, electric properties, etc. and less in thickness fluctuation and surface defects, hence very suitable as a film for various industrial materials such as magnetic recording media, capacitors, heat transfer ribbons and thermal mimeographic stencil paper. The first method of the present invention is a method for producing a polyester film, in which a film made of a resin mainly composed of a polyester is simultaneously biaxially stretched by a simultaneously biaxially stretching tenter oven, comprising the step of effecting small-ratio stretching at an area stretching ratio of 1.0005 to 3.0 times three times or more, to achieve a total area stretching ratio of 25 to 150 times, and the second method of the present invention is a method for producing a polyester film, in which a film made of a resin mainly composed of a polyester is stretched using a simultaneously biaxially stretching tenter oven, comprising the step of effecting a series of operation consisting of stretching and subsequent relaxation twice to less than 10000 times, to achieve a total area stretching ratio of 25 to 150 times.

Owner:TORAY IND INC

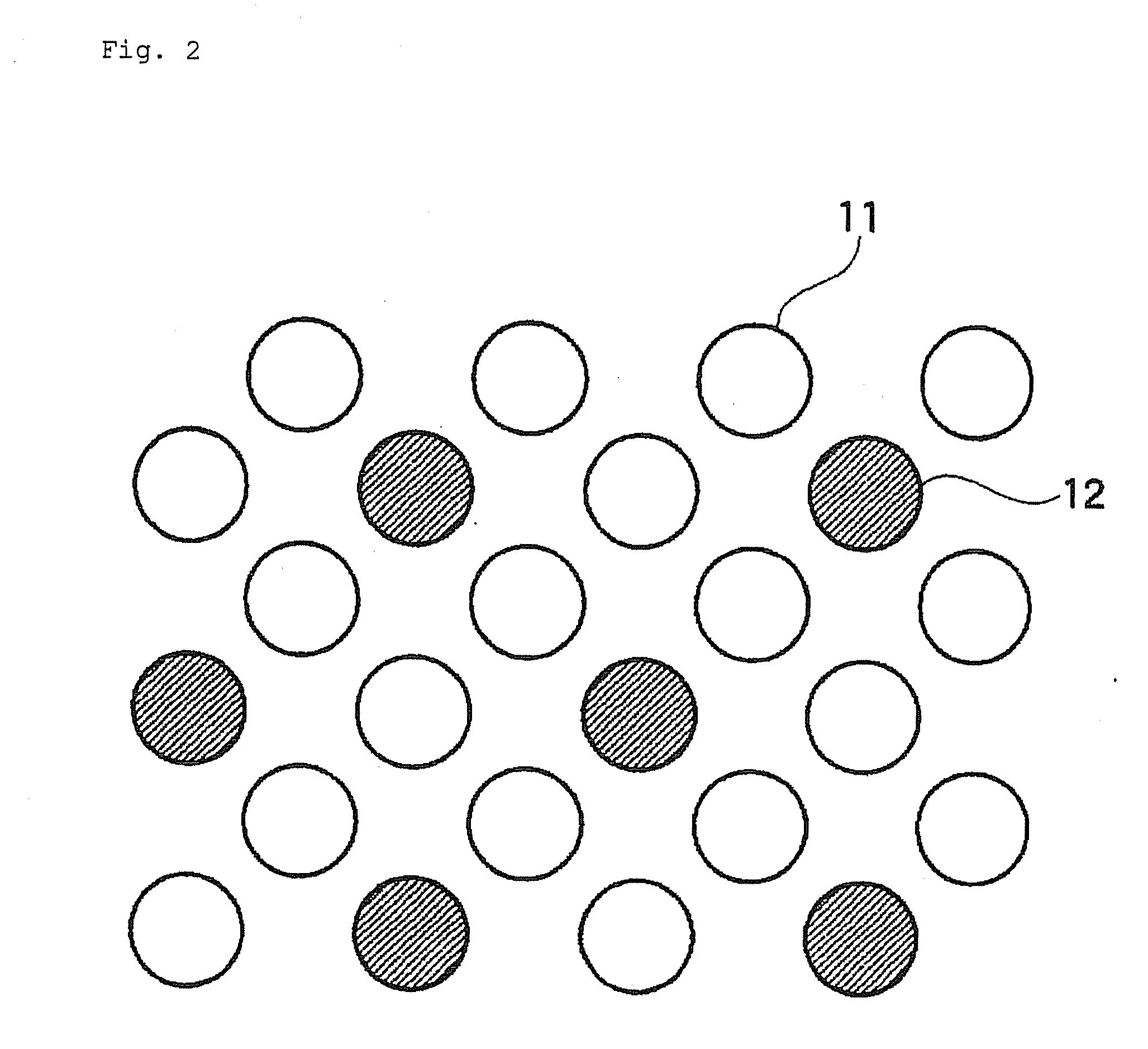

Polypropylene Nonwoven Fabric and Use Thereof

ActiveUS20080014819A1Excellent in appearance propertyExcellent in stretch propertyFilament/thread formingAdhesive dressingsResidual strainPolymer science

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

Sequentially Biaxially-Oriented Polyglycolic Acid Film, Production Process Thereof and Multi-Layer Film

InactiveUS20110027590A1Improve the heating effectMaintain good propertiesSynthetic resin layered productsMedical devicesStretch ratioOrganic chemistry

A production process of a sequentially biaxially-oriented polyglycolic acid film, which includes Step 1 of stretching an amorphous polyglycolic acid sheet in one direction at a stretching temperature within a range of from 40 to 70° C. and a primary draw ratio of 2.5 to 7.0 times, thereby forming a uniaxially oriented film; Step 2 of causing the uniaxially oriented film to pass through within a temperature environment controlled to a temperature within a range of from 5 to 40° C. and lower by at least 5° C. than the stretching temperature in Step 1; Step 3 of stretching the uniaxially oriented film in a direction perpendicular to the stretching direction in Step 1 at a stretching temperature within a range of from 35 to 60° C. and higher by at least 3° C. than the temperature in Step 2, thereby forming a biaxially oriented film, the area stretch ratio of which is 11 to 30 times; and Step 4 of subjecting the biaxially oriented film to a heat treatment at 70 to 200° C.

Owner:KUREHA KAGAKU KOGYO KK

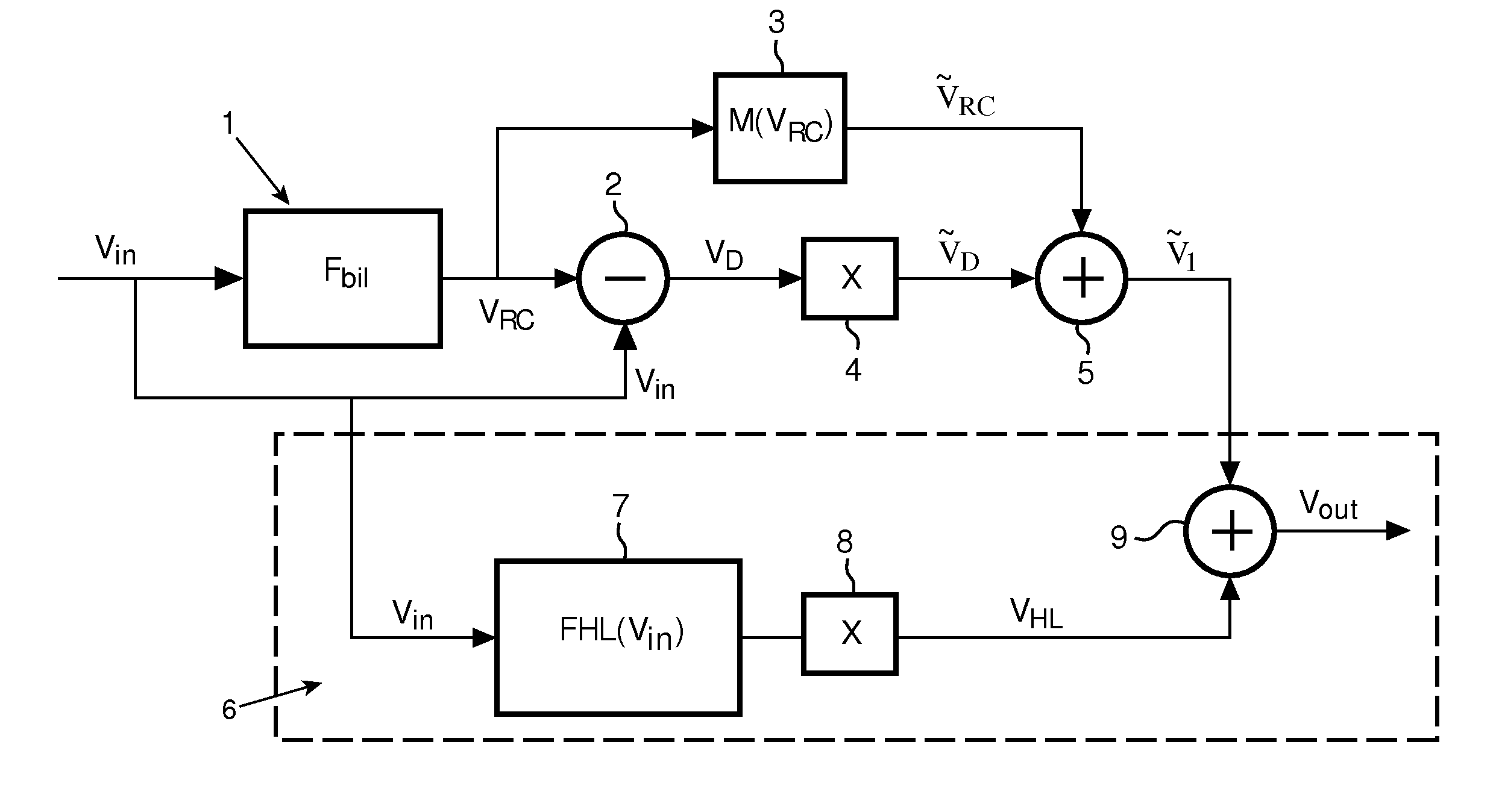

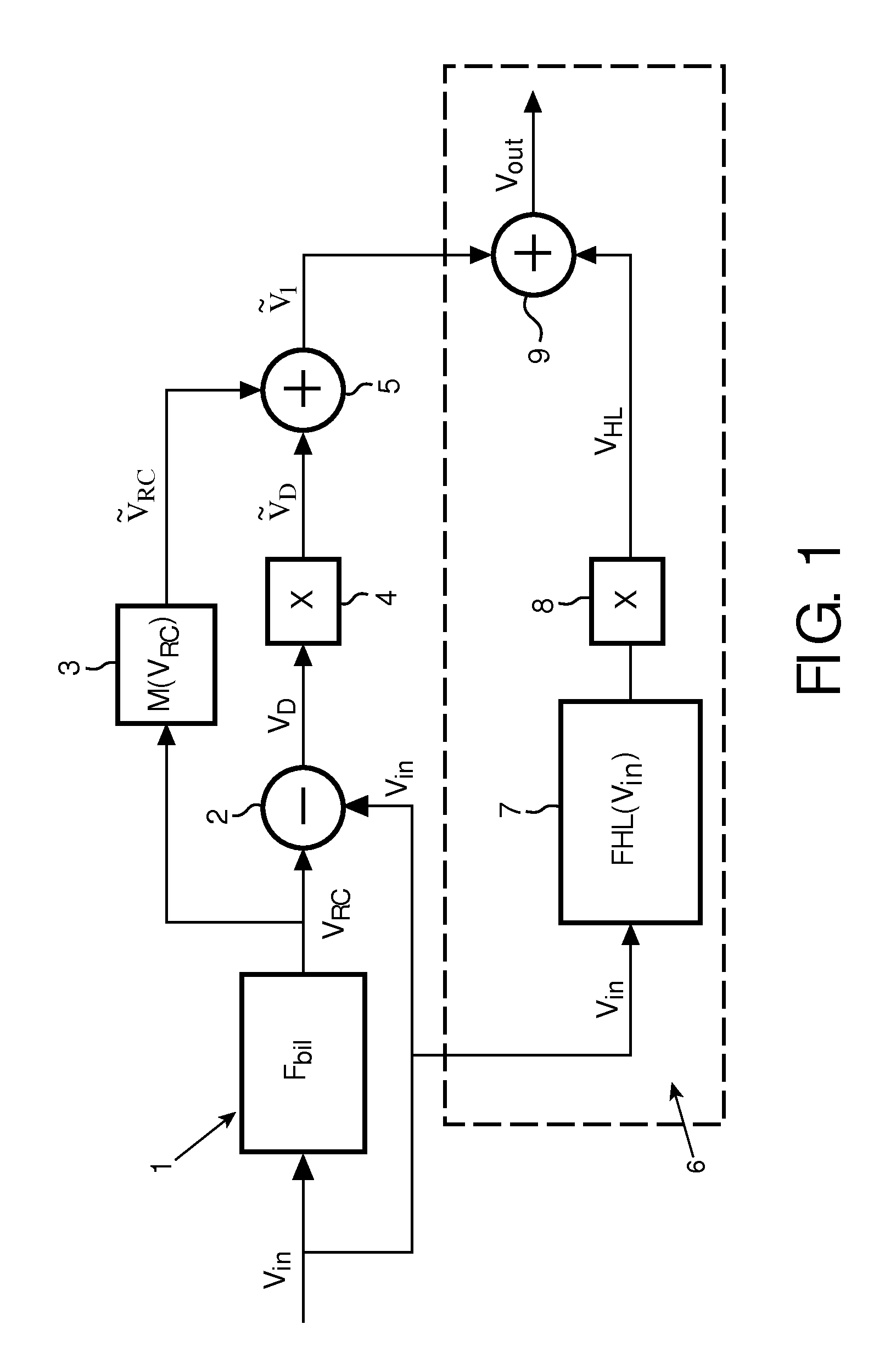

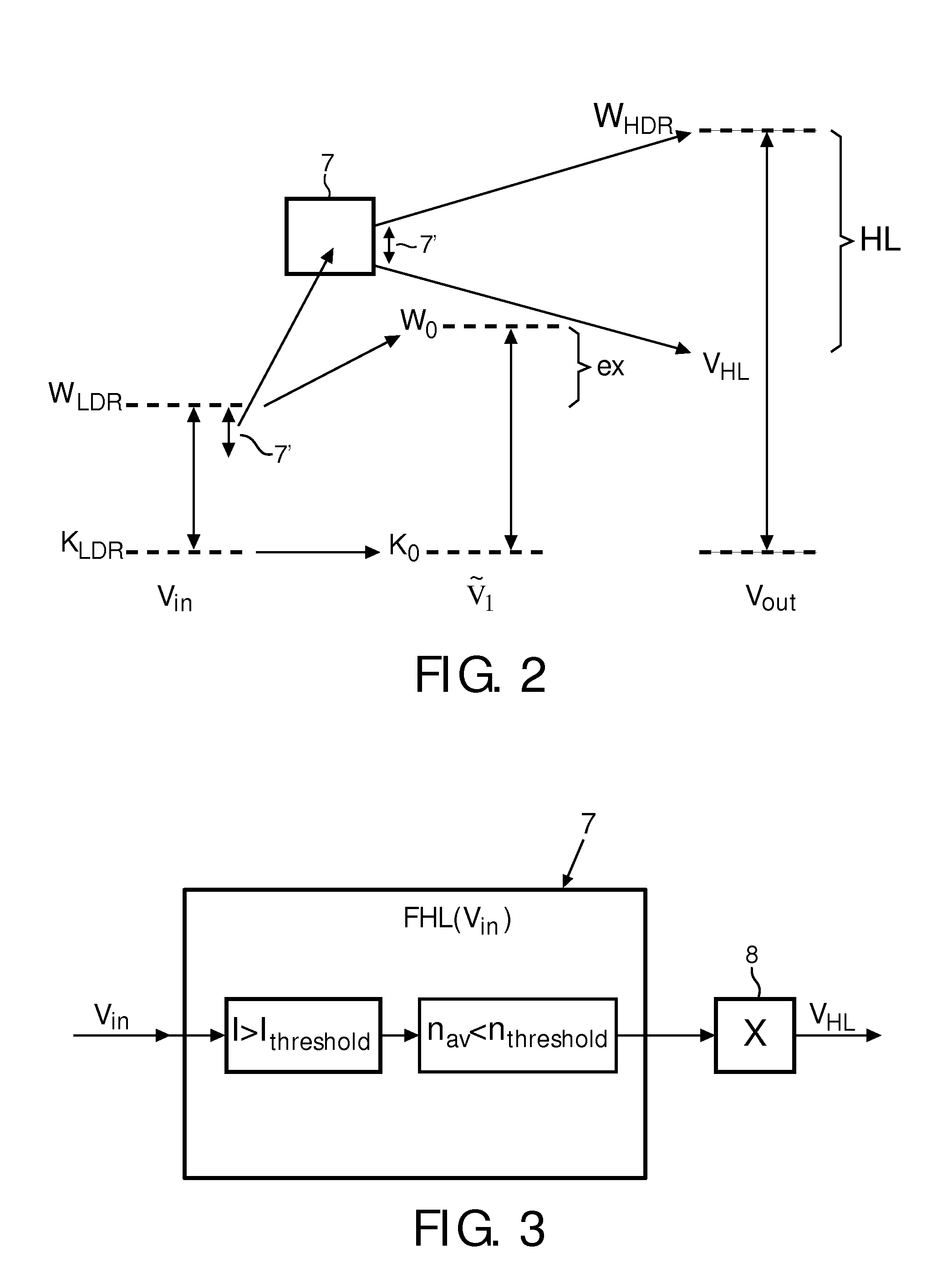

Method for converting input image data into output image data, image conversion unit for converting input image data into output image data, image processing apparatus, display device

InactiveUS20110310116A1High reproduction qualityPleasant and natural appearanceTelevision system detailsImage enhancementDisplay deviceStretch ratio

In a method, unit and display device the input image signal is split into a regional contrast signal (VRC) and a detail signal (VD), followed by stretching separately the dynamic ranges for both signals, wherein the dynamic range for the regional contrast signal is stretched with a higher stretch ratio than the dynamic range for the detail signal. Preferably the stretch ratio for the detail signal is near 1 or preferably 1. In preferred embodiment highlights are identified and for the highlights the dynamic range is stretched to an even higher degree than for the regional contrast signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

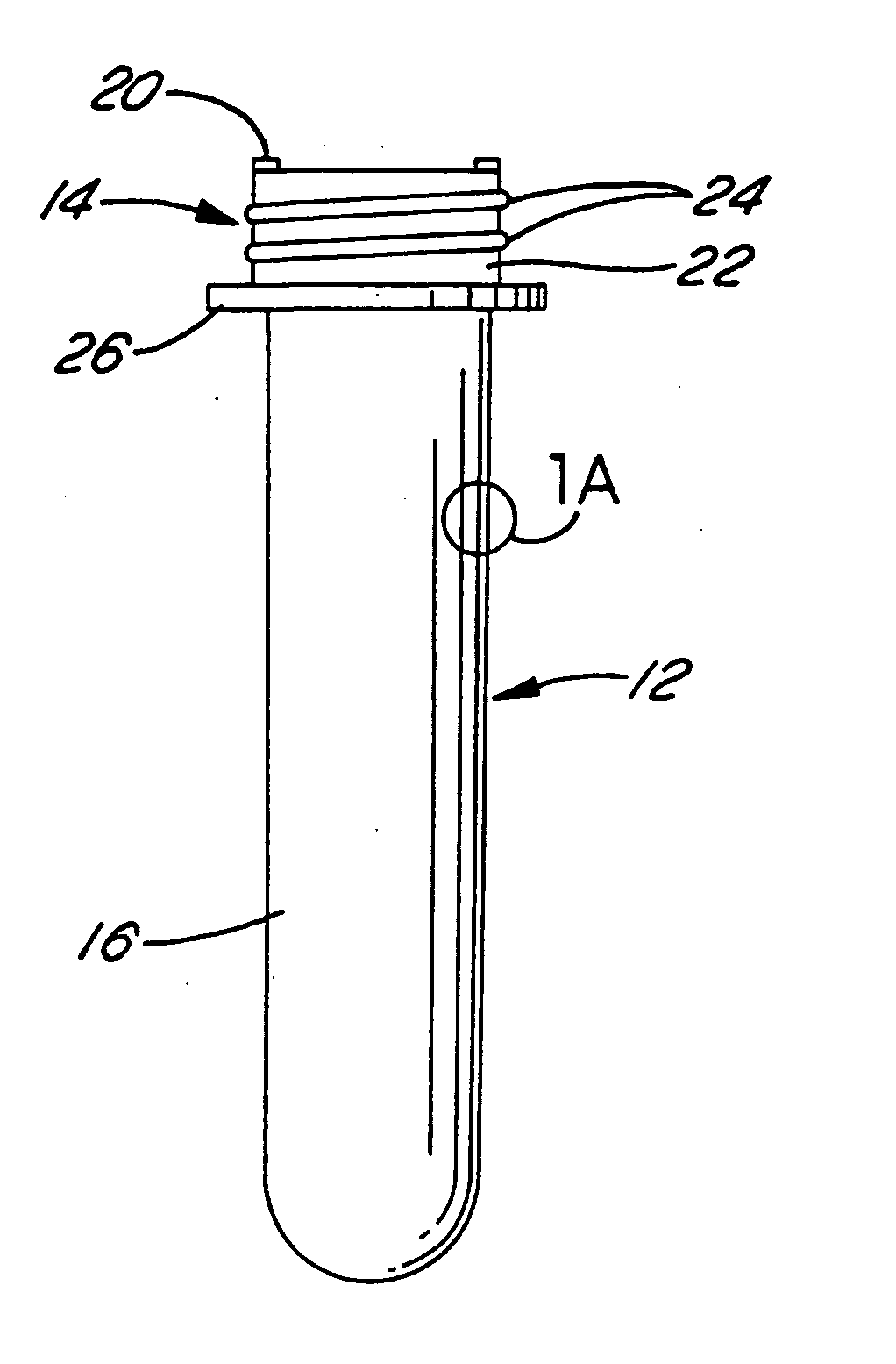

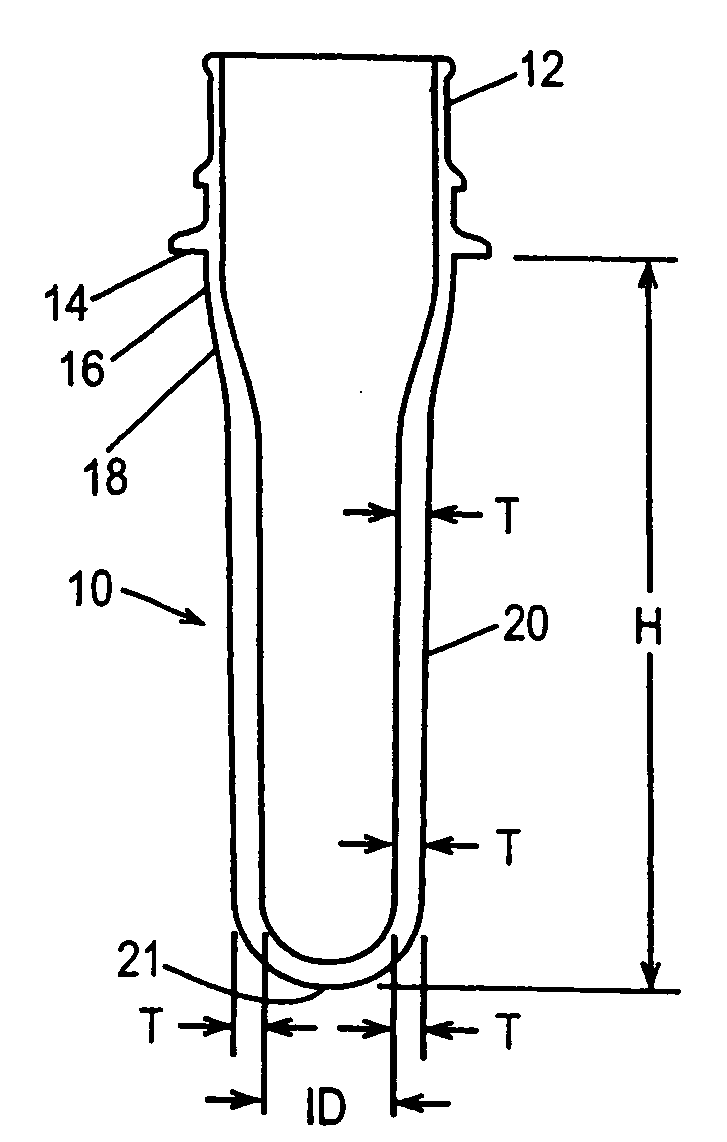

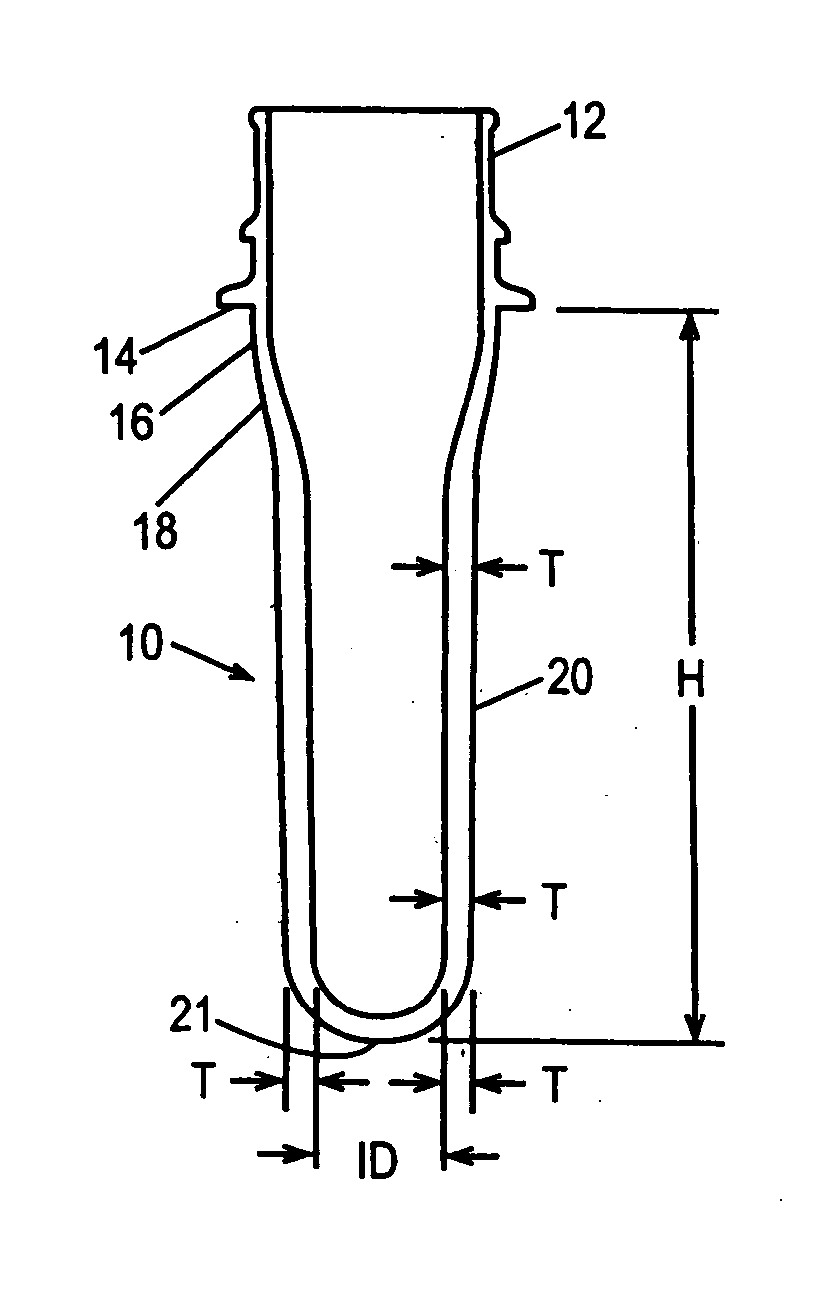

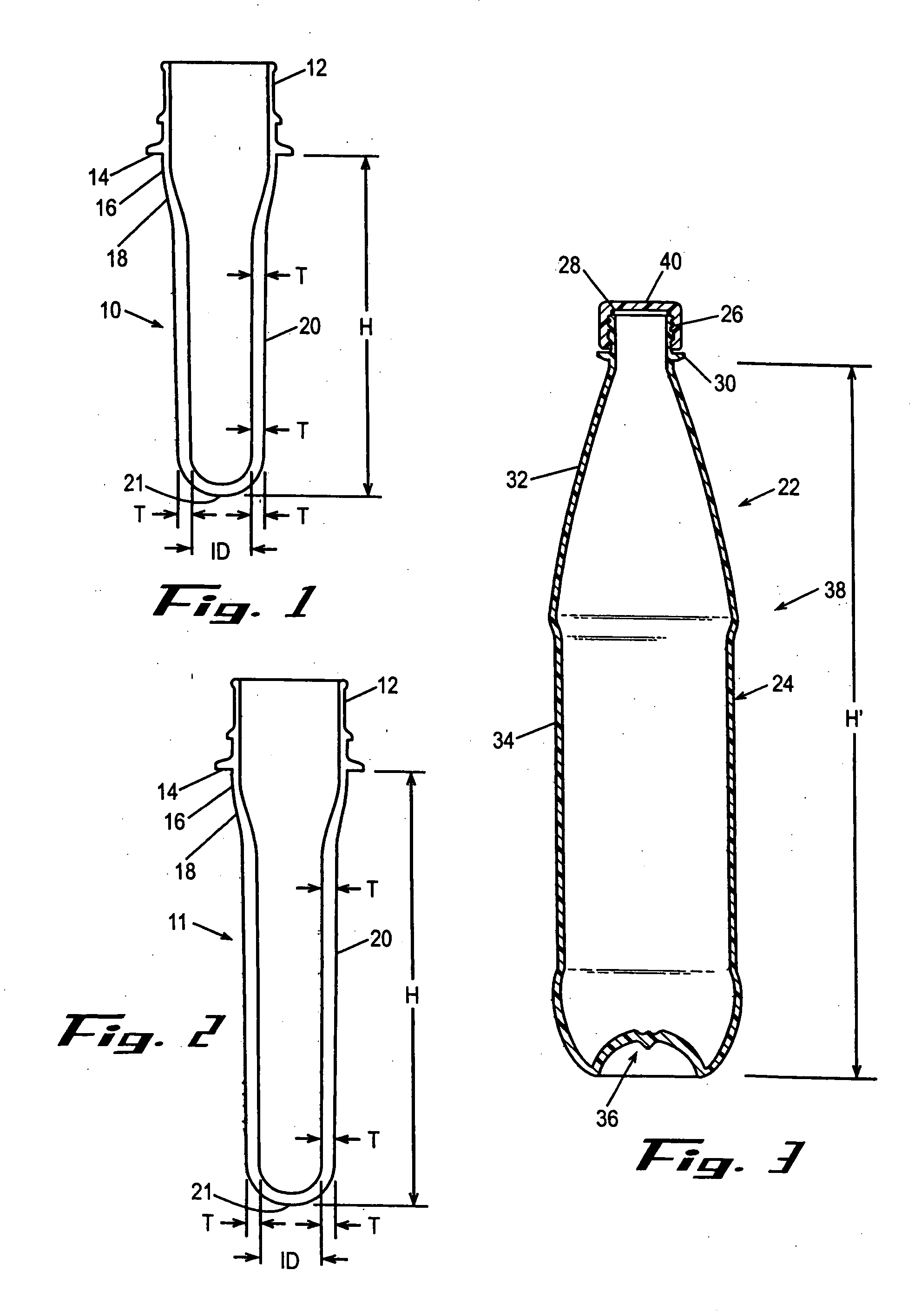

Lightweight container and method of manufacture

InactiveUS20050158495A1Accurate and stable dimensioningLimit cycle timeBottlesSynthetic resin layered productsBlow moldingEngineering

A hollow plastic container includes an open finish, a closed bottom and a sidewall connecting the finish to the bottom. The sidewall is ultra thin, having a radial wall thickness of not more than 0.008 inch, preferably in the range of about 0.003 to 0.004 inch. The container preferably is blow molded from a preform having a wall thickness such that a stretch ratio of eight to ten is obtained during the blowing operation. The preform may be heated prior to blow molding to achieve sidewall crystallization at a level of 28% to 35%.

Owner:GRAHAM PACKAGING PET TECH

Electrical stretch hose

InactiveUS20090050227A1Tight limitGreat stretch ratioSuction cleanersInsulated cablesHelical lineEngineering

The present invention is an electrical extensible hose that includes an outer shell, an inner core and at least one helical wire, which acts like a skeleton. In the present invention one implemented an additional wire that was conductive. The outer shell and inner core of the present invention may be bonded together via heat fusion. The helical wire is attached to the inner core via heat fusion. The helical wire supports the outer shell and inner core so as to form a tube. The outer shell and the inner core have a portion that forms an angular fold and have a portion that remains fixed. The second wire is attached at a point below the fixed portion of the electrical stretch hose so as to allow for maximum constriction caused by the shrinkable force created by the helical wire, thus increasing the stretch ratio of the hose.

Owner:FLEXIBLE TECH INC

Preforms for preparing lightweight stretch blow molded pet copolymer containers and methods for making and using same

ActiveUS20060257603A1Improve mechanical propertiesGood thermal propertiesSynthetic resin layered productsDomestic articlesGramMaximum diameter

An injection molded preform for making a stretch blow molded container having an overall stretch ratio of from about 12 to about 16, wherein the overall stretch ratio is a product of a hoop stretch ratio and an axial stretch ratio, wherein the hoop stretch ratio is from about 5.6 to about 6.5, wherein the axial stretch ratio is from about 2.4 to about 2.7, and wherein the preform comprises a CG PET Copolymer having a free blow volume of from about 650 to about 800 ml measured at 100° C. and 90 psi using a 25 gram weight preform designed for a 500 ml container with a maximum diameter of 65 mm and a height of 200 mm from below the container finish and having a hoop stretch ratio of 5.5 and an axial stretch ratio of 2.6. This invention also relates to a method of making such preforms and stretch blow molded containers and methods of making the same.

Owner:THE COCA-COLA CO

PET copolymer composition with enhanced mechanical properties and stretch ratio, articles made therewith, and methods

InactiveUS20050118371A1Shorten cycle timeImprove mechanical propertiesBottlesSynthetic resin layered productsDiolStretch ratio

A container is made from a preform comprising a PET Copolymer comprising a diol component having repeat units from ethylene glycol and a non-ethylene glycol diol component and a diacid component having repeat units from terephthalic acid and a non-terephthalic acid diacid component. The total amount of non-ethylene glycol diol component and non-terephthalic acid diacid component is present in the poly(ethylene terephthalate) copolymer in an amount from about 0.2 mole percent to less than 2.2 mole percent. The container is useful in packaging beverages and corresponding methods are disclosed.

Owner:THE COCA-COLA CO +1

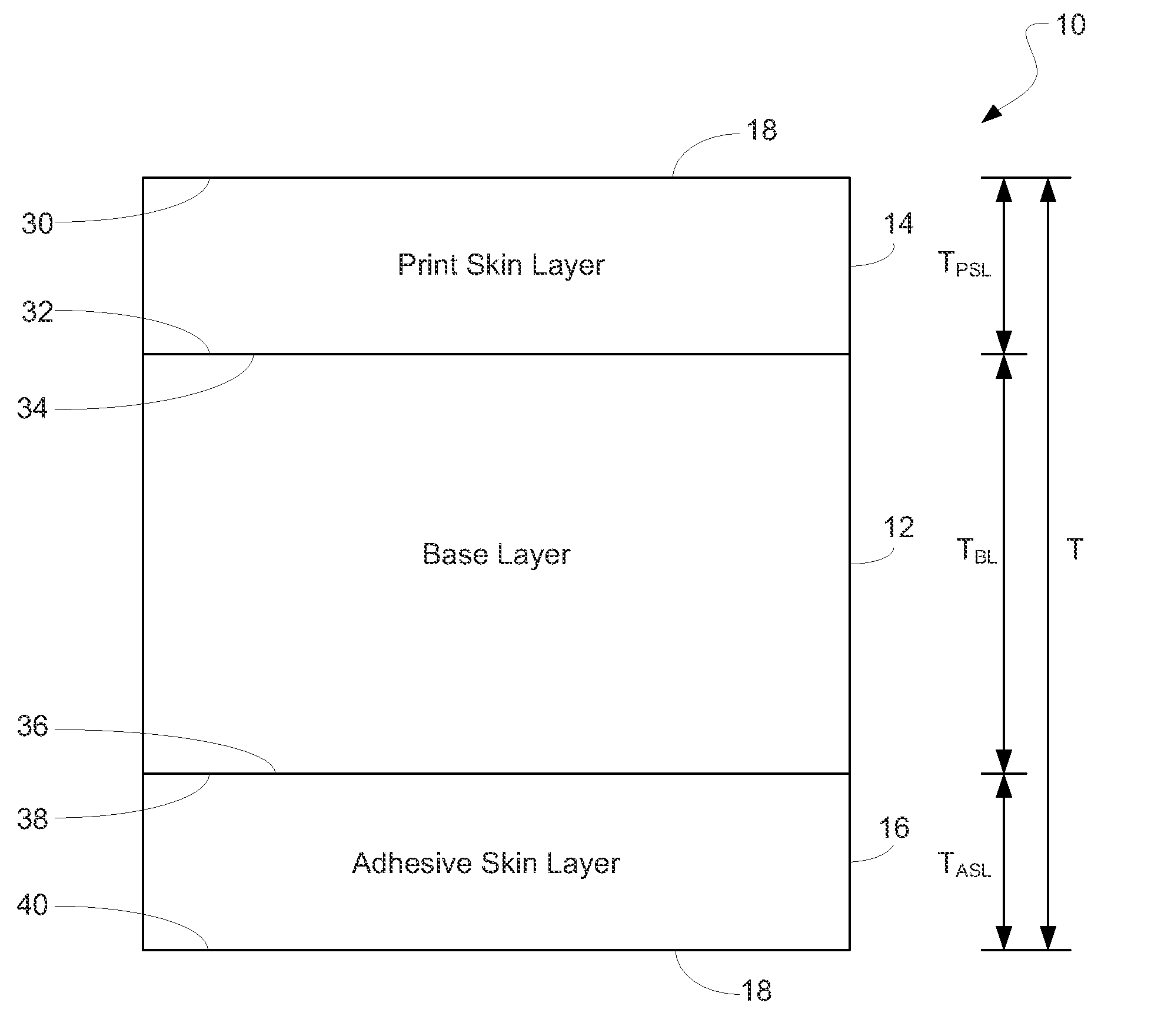

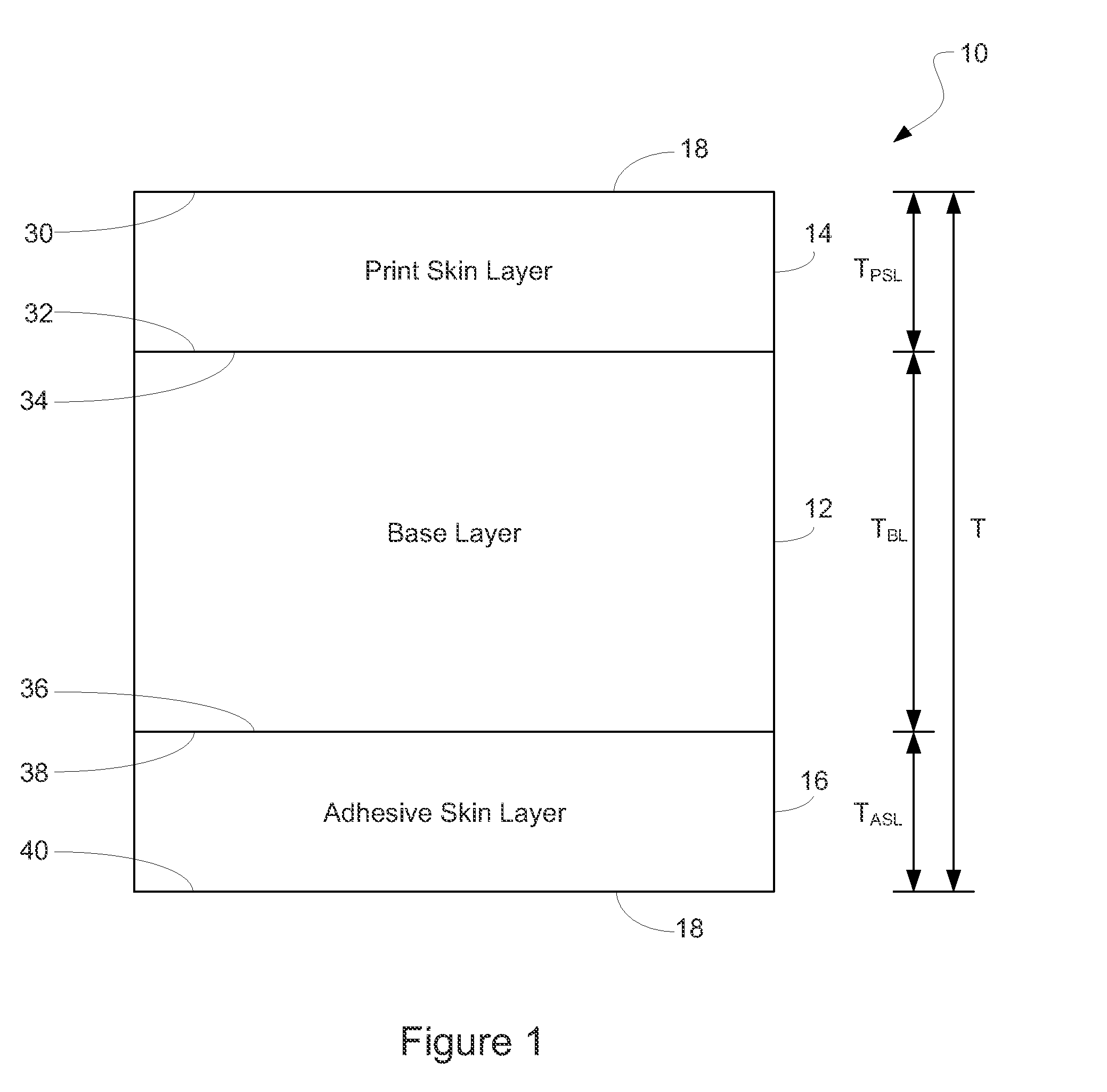

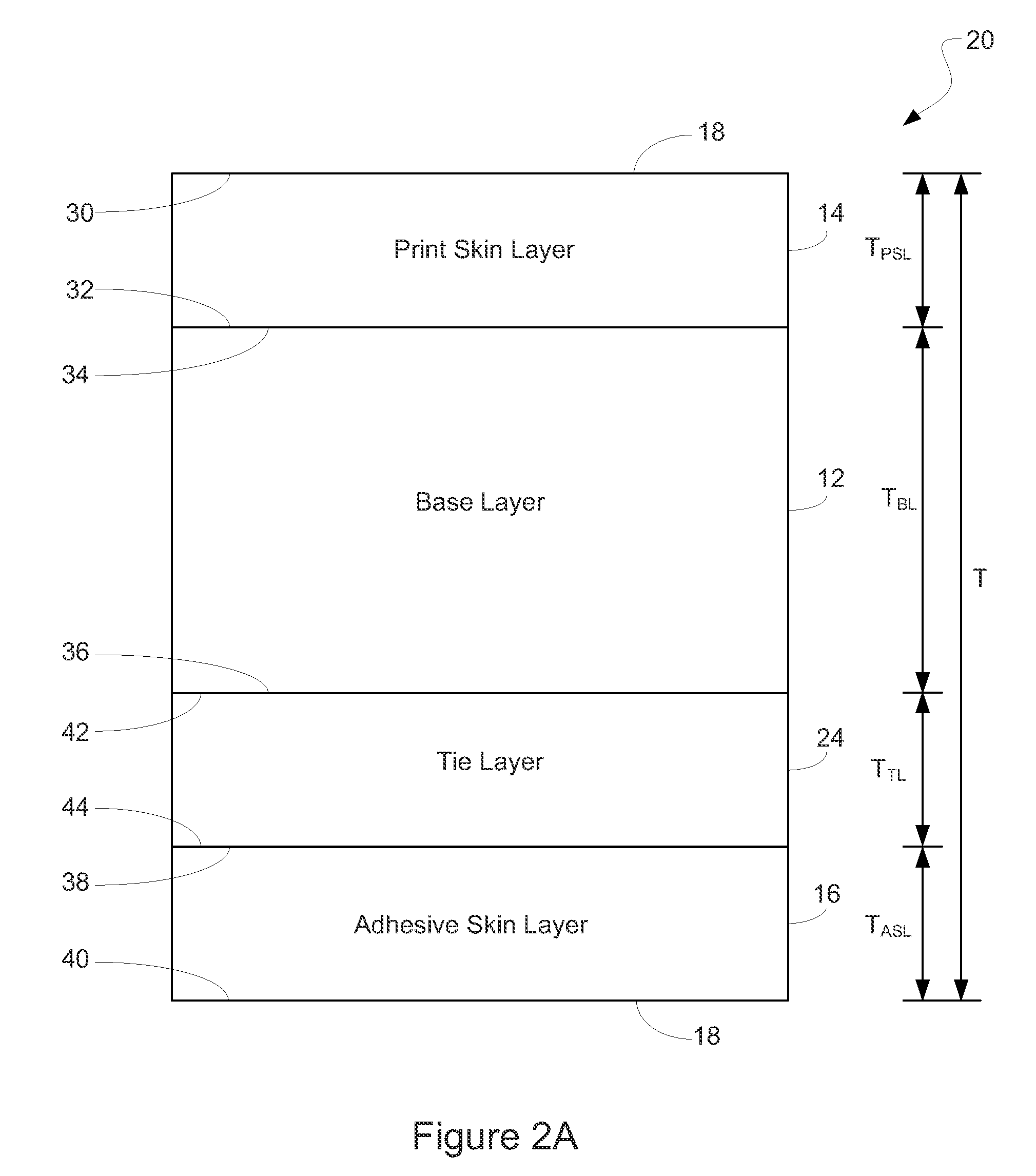

Biaxially stretched multilayered film and related label and method

A film, for use in a label and a related method, including a print skin layer, a base layer, and an adhesive skin layer having at least one heat-activated thermoplastic polymer. The film is stretched biaxially in both a machine direction and a transverse direction. The stretch ratio in a first direction is greater than 2:1 to 10:1, the stretch ratio in a second direction ranges in value from 1.02:1 to 1.8:1, the film has an ASTM D1204 shrinkage at 100° C. of at least 0.5% in both the machine and transverse directions, and the film has an ASTM D882 2% secant modulus of at least 679,134 kPa (98,500 psi) in the first direction.

Owner:AVERY DENNISON CORP

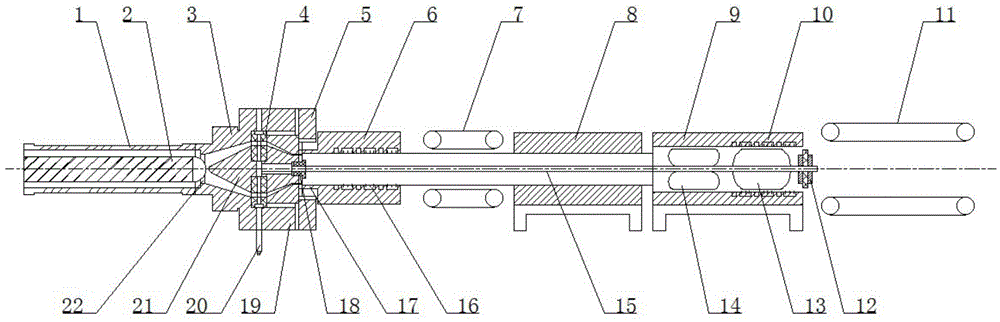

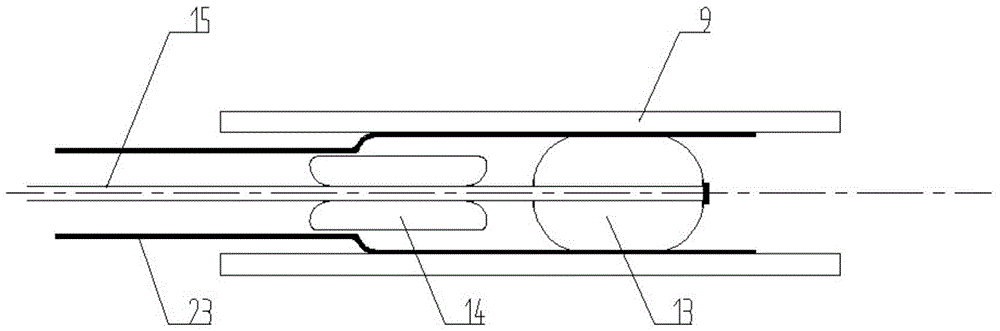

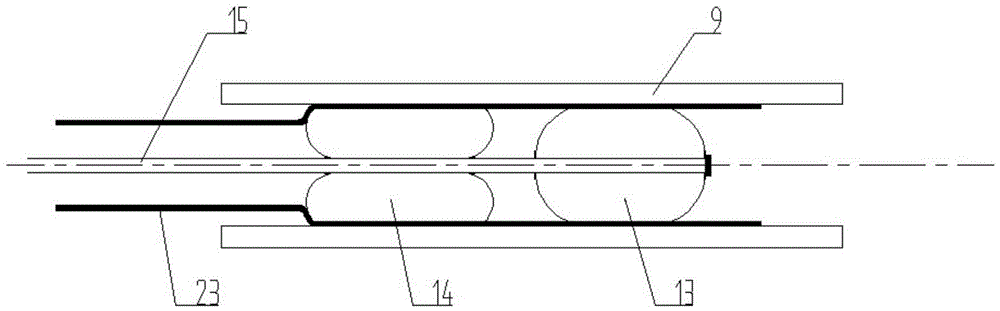

Production equipment and process for large-diameter biaxial-stretching PVC pipe fitting

ActiveCN104149354ARealize continuous productionEnhanced axial mechanical propertiesTubular articlesProduction linePipe fitting

The invention discloses production equipment and process for a large-diameter biaxial-stretching PVC pipe fitting. The equipment mainly comprises a tapered double-screw extruder, an extruder head, a vacuum sizing device A, a first traction device, a reheating device, a stretching and diameter expanding molding device, a vacuum sizing device B and a second traction device which are sequentially and linearly arrayed to form a production line; the stretching and diameter expanding molding device is composed of an inflation rod, an expansion bag, an expansion sizing mould and a shaping bag; each of the expansion bag and the shaping bag is of an annular bag-shaped structure; the expansion bag is continuously expanded and retracted under the action of the inflation rod; a pipe fitting to be expanded moves by a certain distance through the action of an outer ring circular-arc surface of the expansion bag when the expansion bag is expanded once, so that each point of the pipe fitting can be subjected to annular expansion; the stretching is generated in the axial direction of the pipe fitting through a stretching ratio between the first traction device and the second traction device. By adopting the production equipment and process, the continuous production of the diameter-expanded pipe fitting is successfully realized, the thermal contraction of the pipe fitting is small and the axial mechanical property can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

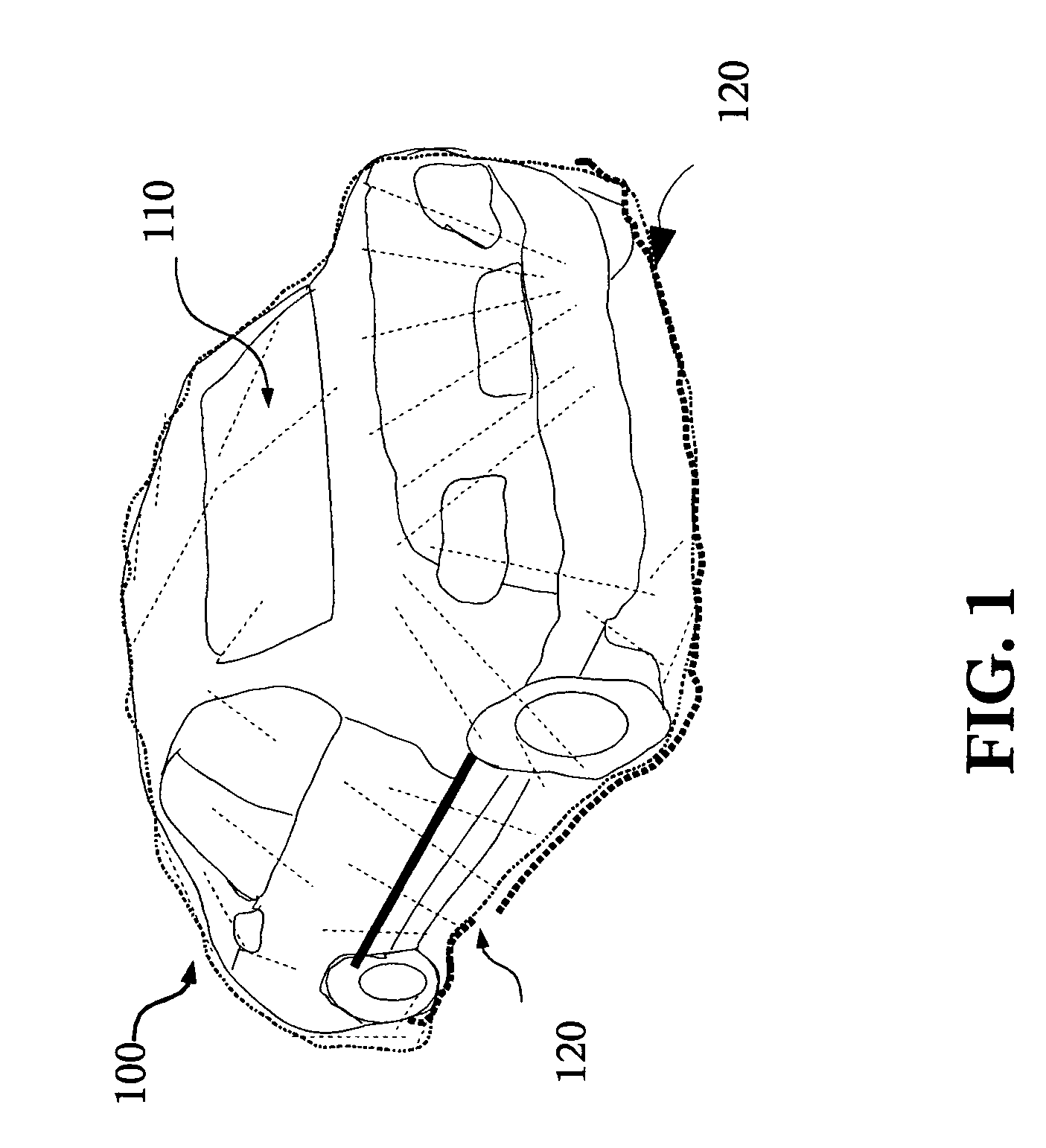

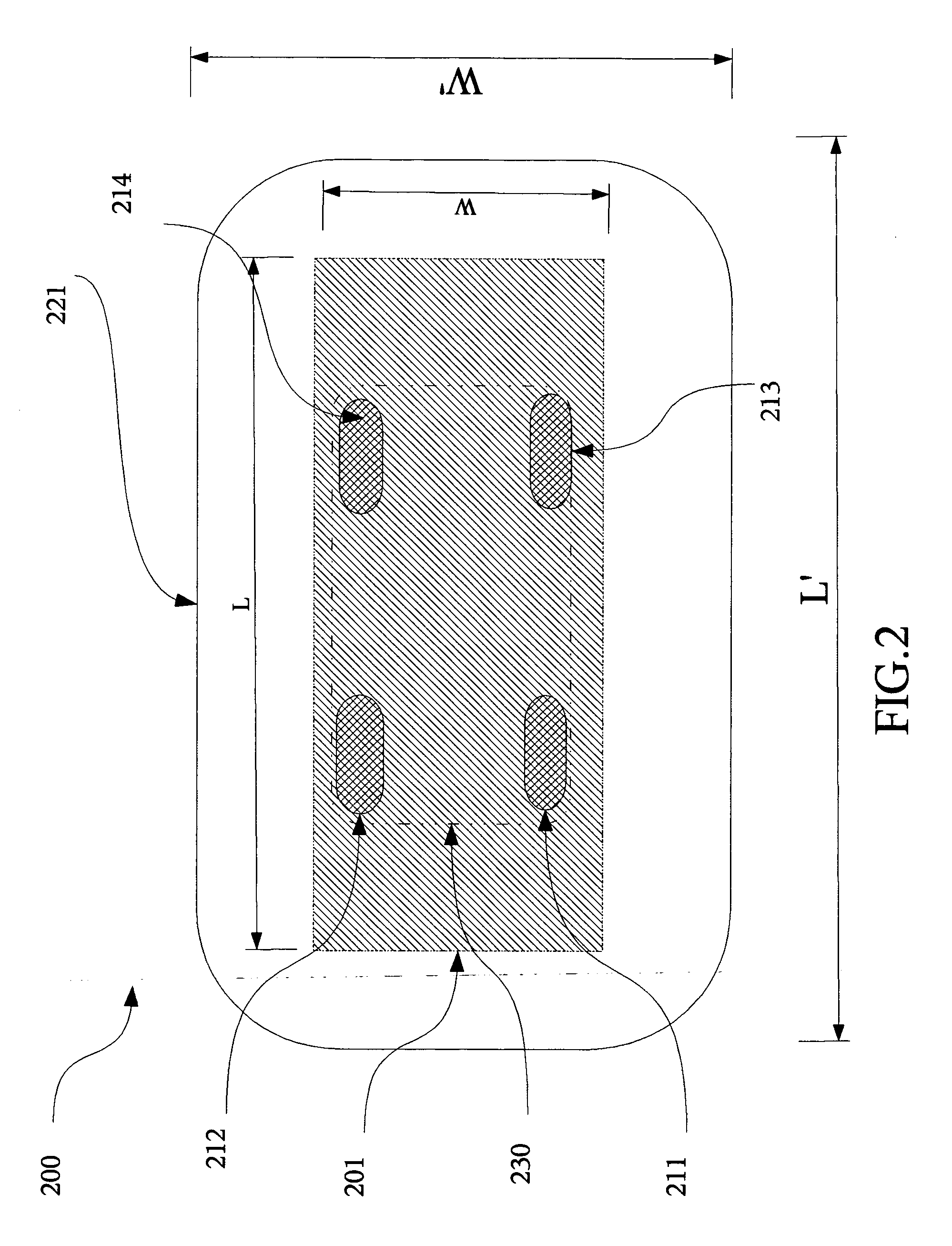

Protective vehicle cover

InactiveUS20050151391A1Easy to installMinimize the numberSuperstructure subunitsRemovable external protective coveringsEngineeringStretch ratio

A protective cover for vehicles is configured to fully protect a vehicle from paint overspray, yet avoids surfaces scratches induced by existing debris. An elastic band having a high stretch ratio aids in both cover placement and reduce movement to further minimize risk of damage to painted surface. The protective cover is preferably fabricated from thin gauge transparent plastic sheeting; such that the low cost makes the product desirable as it can be disposed of after being contaminated by a single use.

Owner:BRYD RANDALL R

Method for preparing optical reflective film

ActiveCN102093676AImprove efficiencyCoatingsOptical elementsOptical reflectionPolyethylene terephthalate glycol

The invention discloses a method for preparing an optical reflective film. Spherical microbubbles are uniformly distributed in the optical reflective film. The preparation method comprises the following steps of: A, blending a chain extender, an organic foaming agent and a nanometer granular inorganic filler into polyethylene terephthalate (PET) serving as a master batch, and mixing uniformly; B, performing blending granulation on a mixture obtained in step A to obtain masterbatches; C, melting and plasticizing the masterbatches, and then performing tape casting to obtain a cast piece; and D, longitudinally stretching the glassy cast piece prepared in step C by adopting a longitudinal stretching machine in a heating state, and then performing transverse stretching by adopting a widening machine in a heating state, wherein the longitudinal stretching ratio is between 3 and 4, and the transverse stretching ratio and the longitudinal stretching ratio are consistent. The microbubbles are uniformly distributed in the prepared optical film, each microbubble can be used as a reflective unit, and reflective units which are distributed in high density form total reflection on rays to achieve the aims of high efficiency and ray reflection without loss.

Owner:NINGBO DXC NEW MATERIAL TECH

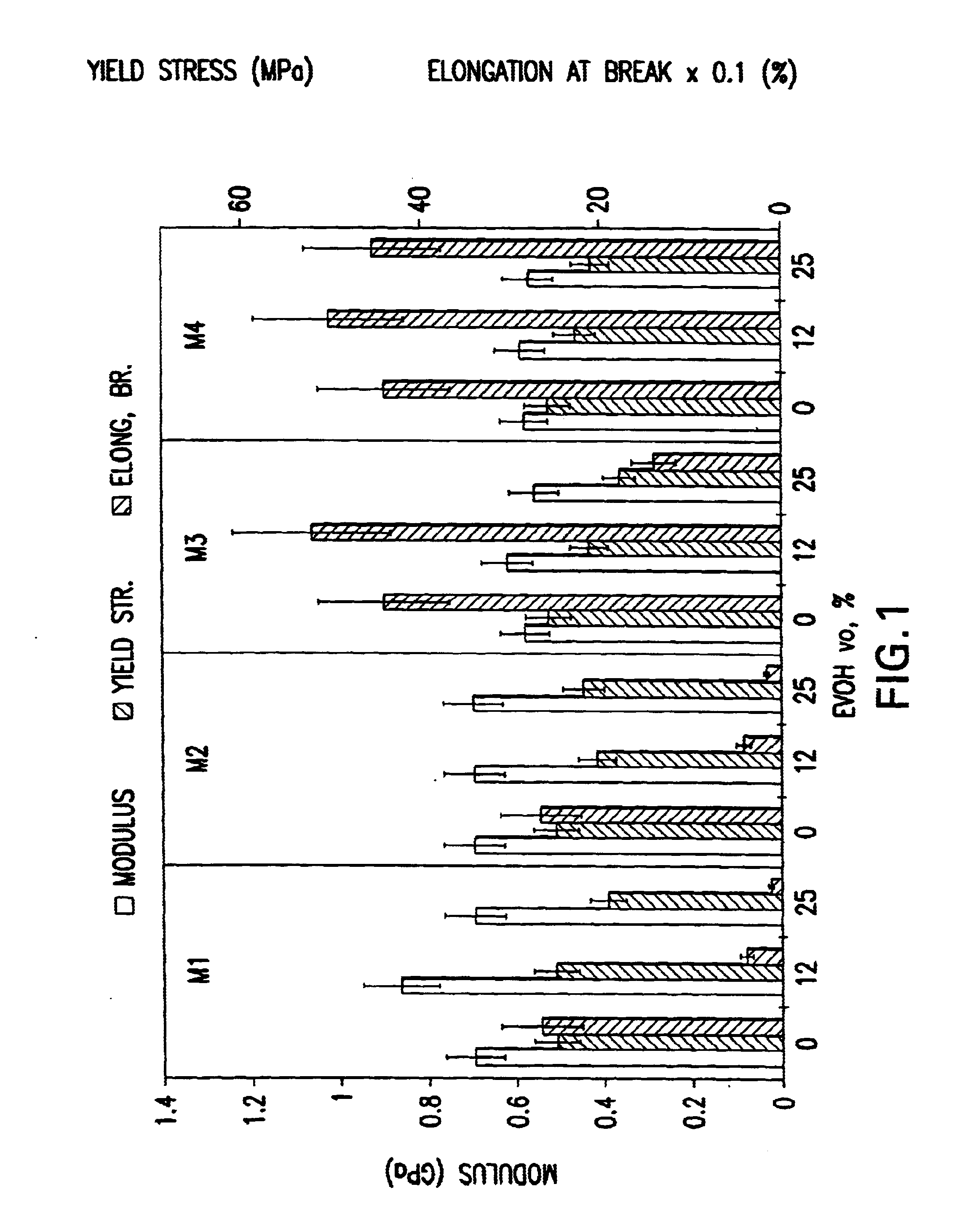

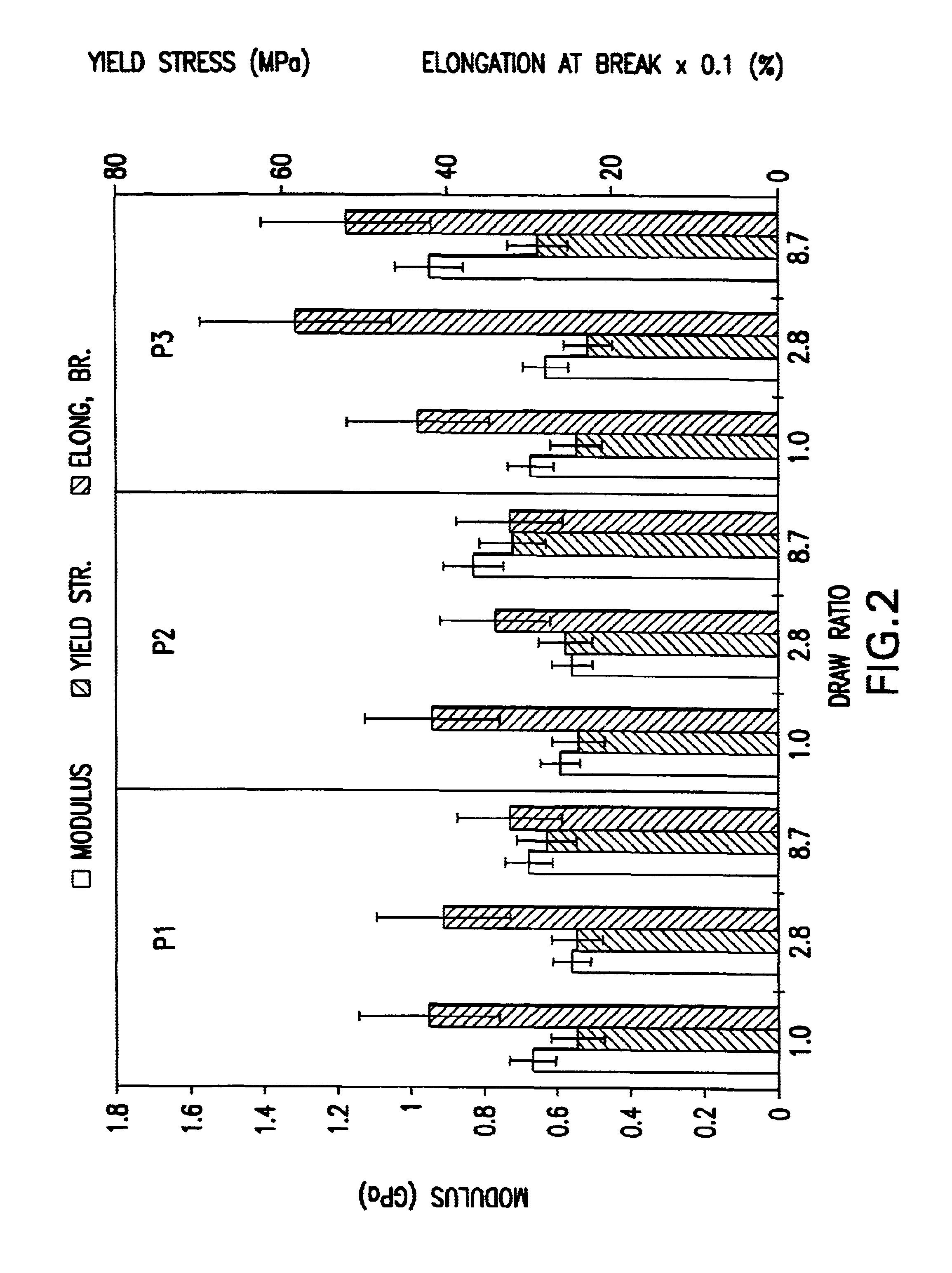

Process for making multiphase polymeric film having a lamellar structure with controlled permeability and/or controlled mechanical properties

InactiveUS6649103B1Improve mechanical propertiesDiminished barrier propertyLaminationLamination apparatusStretch ratioMechanical property

A process for making a multiphase polymeric film having a lamellar structure with controlled permeability and / or controlled mechanical properties, comprising the steps of:preparing a molten blend made of a first polymer phase dispersed in a second polymer phase which is a matrix polymer phase incompatible with the said first phase and of a compatibilizer selected from the group consisting of DEM, MAH, DEM-g-SEBS, MAH-g-SEBS, DEM-g-PP and MAH-g-PP;extruding the molten blend through a flat die provided with an exit and stretching the so extruded blend downwards said exit at a preselected stretching ratio to produce the said multiphase polymeric film, andsolidifying the extruded film sufficiently rapidly to preserve the lamellar structure and the multiphase polymeric films thereby obtained.Granules with a lamellar structure are obtained by grinding the so obtained multiphase polymeric film and are useful for preparing shaped articles with improved physical properties.

Owner:UNIV LAVAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com